Page 1

LENNDX

INSTALLATION

,1,_2000 Lennox Industries Inc.

Dallas, Texas, USA

HS40 condensing units use R407C which is an ozone

friendly HFC refrigerant. This unit must be installed with a

matching indoor coil and line set as outlined in the Lennox

Engineering Handbook. HS40 condensing units are de-

signed for use in expansion valve systems only. They are

not designed to be used in RFC systems. An expansion

valve and filter drier approved for use with R407C have

been shipped with the unit. These components must be

installed prior to unit operation.

A, WARNING

INSTRUCTIONS

HS40 S UNITS

CONDENSING UNITS lIE_ :.)

504,186M .LU_ Publications

11/2002 Lithe U.S.A.

Supersedes 4/2000

HS40 Condensing Unit ......................... 1

Shipping & Packing List ........................ 1

Unit Dimensions ............................... 2

General Information ............................ 3

Setting the Unit ................................ 3

Electrical ..................................... 3

Plumbing ..................................... 4

Flushing Existing Line Set and Indoor Coil ........ 4

Liquid & Suction Line Service Valves ............. 6

Leak Testing .................................. 7

Evacuation & Dehydration ...................... 7

Start-Up ...................................... 8

Charging ..................................... 8

System Operation ............................. 10

Maintenance .................................. 10

Start-Up & Performance Check List .............. 11

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

1 - Assembled HS40 condensing unit

1 - Bag assembly:

1 - Sight glass

1 - 5/16-3/8 inch adapter

1 - 45° elbow

1 - Expansion valve (approved for use with R407C)

1 - Drier (approved for use with R407C systems)

Check equipment for shipping damage. If you find any

damage, immediately contact the last carrier.

Technical

WARNING

11/02

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIll

Page 1

A, WARNING

504,186M

IIlIIIIIIIIIIIIIIIIIIIIIIIHIIIIIIIIIIIII

Page 2

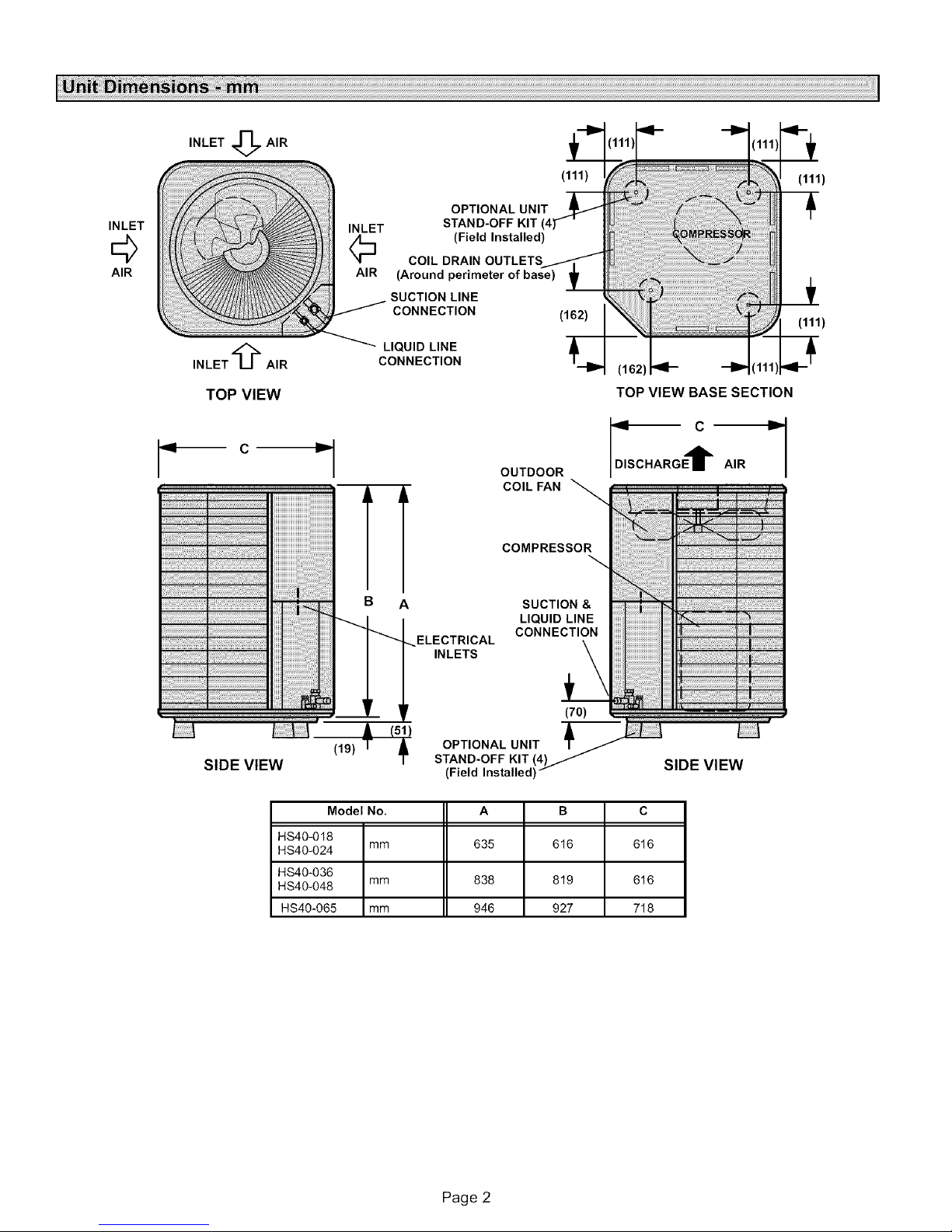

INLET

©

AIR

INLET _AIR

OPTIONAL UNIT

INLET

©

AIR

SUCTION LINE

CONNECTION (162)

STAND-OFF KIT (4)_ "

(Field Installed)

COIL DRAIN OUTLETS_""_I

(Around perimeter of base)

(111)

/

INLET'_AIR

TOP VIEW

=_ C ,v

SIDE VIEW

HS40-018

HS40-024 mm 635 616 616

HS40-036

HS40-048 mm 838 819 616

HS40-065 mm 946 927 718

LIQUID LINECONNECTION

h._l

OUTDOOR

COIL FAN

COMPRESSOR

SUCTION &

LIQUID LINE

ELECTRICAL

INLETS

(19)

Model No, A B C

OPTIONAL UNIT

STAND-OFF KIT (4)_

(Field Installed) /

CONNECTION

(70)

TOP VIEW BASE SECTION

SIDE VIEW

Page 2

Page 3

Theseinstructionsareintendedasageneralguideanddo

notsupersedenationalorlocalcodesinanyway,Authorities

havingjurisdictionshouldbeconsultedbeforeinstallation,

TheHS40unitis "CEmarked"inaccordancewiththere-

quirementsd the latest European Directives for Electrical

and Machinery Safety and Electromagnetic Compatibility. In

addition HS40 units have type Approval Certification with

the Gas Appliance Directive.

A - Slab Mounting

When installing the unit at grade level, install it on a level

slab that is high enough above the grade to allow water to

drain adequately. The top of slab should be located so run-

off water from higher ground will not collect around the unit,

B - Roof Mounting

Install the unit at a minimum of 101 mm above the roof's sur-

face. Ensure that the weight of the unit is properly distributed

over roof joists and rafters. Either redwood or steel supports

are recommended.

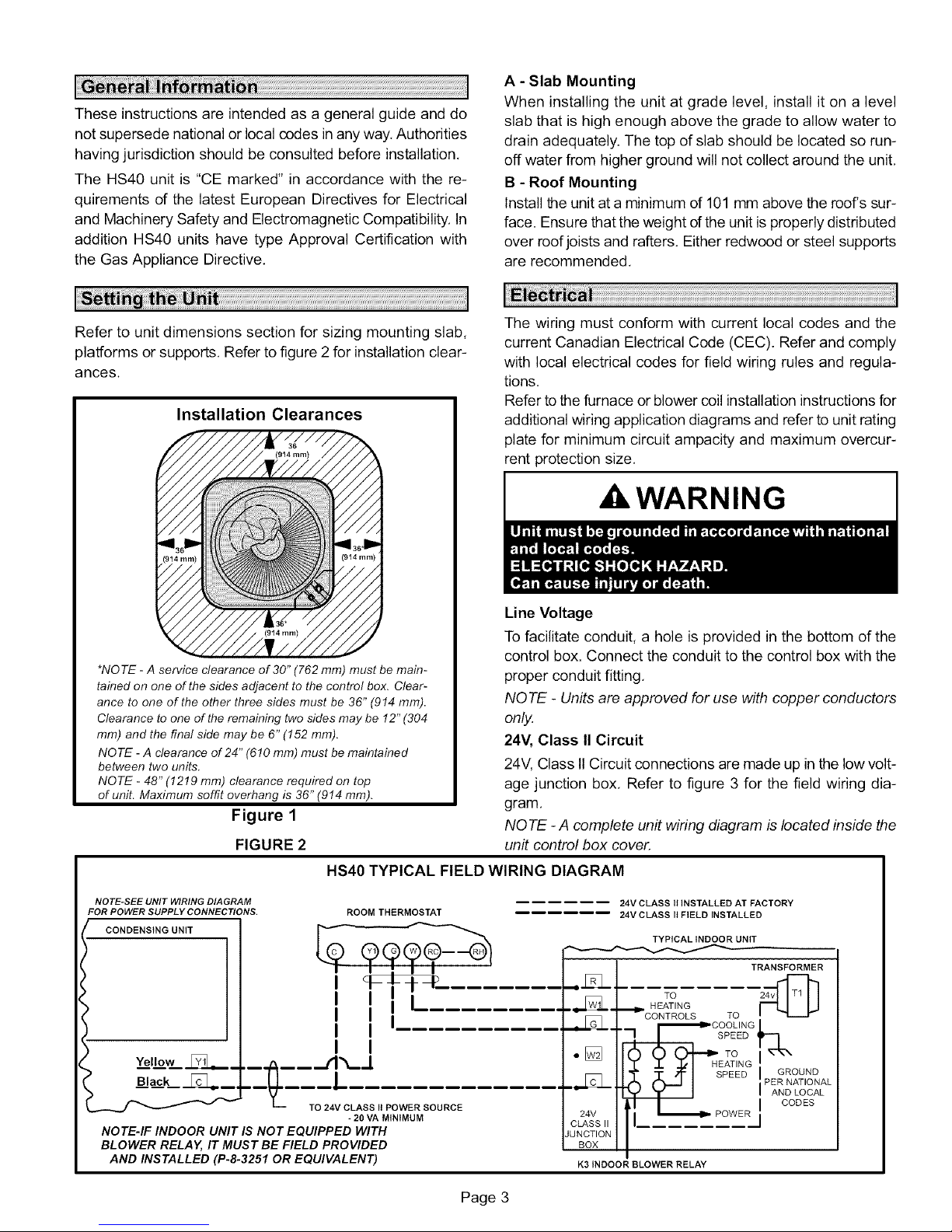

Refer to unit dimensions section for sizing mounting slab,

platforms or supports. Refer to figure 2 for installation clear-

ances.

Installation Clearances

(914 mm)

*NO TE - A service clearance of 30" (762 mm) must be main-

tained on one of the sides adjacent to the control box. Clear-

ance to one of the other three sides must be 36" (914 mm).

Clearance to one of the remaining two sides may be 12" (304

mm) and the final side may be 6" (152 mm).

NOTE - A clearance of 24" (610 mm) must be maintained

between two units.

NOTE - 48" (1219 mm) clearance required on top

of unit. Maximum soffit overhang is 36" (914 mm).

Figure 1

FIGURE 2

HS40 TYPICAL FIELD WIRING DIAGRAM

The wiring must conform with current local codes and the

current Canadian Electrical Code (CEC). Refer and comply

with local electrical codes for field wiring rules and regula-

tions.

Refer to the furnace or blower coil installation instructions for

additional wiring application diagrams and refer to unit rating

plate for minimum circuit ampacity and maximum overcur-

rent protection size.

WARNING

Line Voltage

To facilitate conduit, a hole is provided in the bottom of the

control box. Connect the conduit to the control box with the

proper conduit fitting,

NOTE- Units are approved for use with copper conductors

only,

24V, Class II Circuit

24V, Class II Circuit connections are made up in the low volt-

age junction box, Refer to figure 3 for the field wiring dia-

gram,

NOTE -A complete unit wiring diagram is located inside the

unit control box cover,

NOTE-SEE UNIT WIRING DIAGRAM

FOR POWER SUPPLY CONNECTIONS.

CONDENSING UNIT

Yellow

Black

NOTE-IF INDOOR UNIT IS NOT EQUIPPED WITH

BLOWER RELAY, IT MUST BE FIELD PROVIDED

AND INSTALLED (P-8-3251 OR EQUIVALENT)

'=_'= _124vLc_A_S It POWER SOURCE

ROOM THERMOSTAT

'

I

- 20 VA MINIMUM

Page 3

24V CLASS II INSTALLED AT FACTORY

24V CLASS It FIELD INSTALLED

TYPICAL INDOOR UNIT

TOHEATING

24V

CLASS II

JUNCTION

BOX

K3 INDOOR BLOWER RELAY

TRANSFORMER

TO

SPEED

TO I

HEATING

SPEED PER NATIONAL

GROUND

AND LOCAL

I CODES

Page 4

FIGURE 3

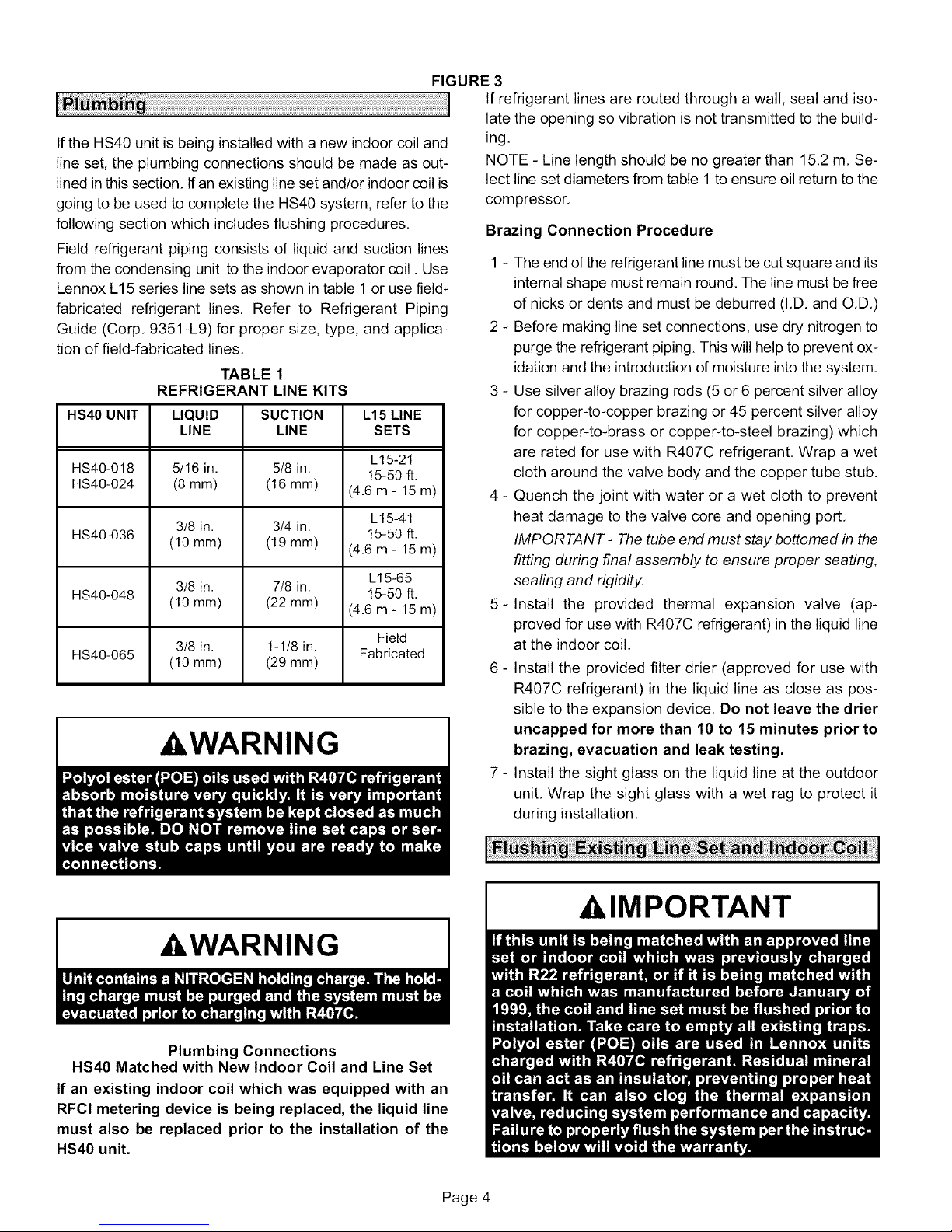

IftheHS40unitisbeinginstalledwithanewindoorcoiland

lineset,theplumbingconnectionsshouldbemadeasout-

linedinthissection.Ifanexistinglinesetand/orindoorcoilis

goingtobeusedtocompletetheHS40system,refertothe

followingsectionwhichincludesflushingprocedures.

Fieldrefrigerantpipingconsistsofliquidandsuctionlines

fromthecondensingunittotheindoorevaporatorcoil.Use

LennoxL15serieslinesetsasshownintable1orusefield-

fabricatedrefrigerantlines.Referto RefrigerantPiping

Guide(Corp.9351-L9)forpropersize,type,andapplica-

tionoffield-fabricatedlines.

TABLE 1

REFRIGERANT LINE KITS

HS40 UNIT LIQUID SUCTION L15 LINE

LINE LINE SETS

HS40-018 5/16 in. 5/8 in.

HS40-024 (8 mm) (16 mm) (4.6 m - 15 m)

3/8 in. 3t4 in.

HS40-036 (10 mm) (19 mm) (4.6 m - 15 m)

318in. 7/8 in. 15-50 ft.

HS40-048 (10 mm) (22 mm) (4.6 m - 15 m)

318in. 1-1/8 in.

HS40-065 (10 mm) (29 mm) Fabricated

L15-21

15-50 ft.

L15-41

15-50 ft.

L15-65

Field

AWARNING

If refrigerant lines are routed through a wall, seal and iso-

late the opening so vibration is not transmitted to the build-

ing.

NOTE - Line length should be no greater than 15.2 m. Se-

lect line set diameters from table 1 to ensure oil return to the

compressor.

Brazing Connection Procedure

1 - The end of the refrigerant line must be cut square and its

internal shape must remain round. The line must be free

of nicks or dents and must be deburred (I.D. and O.D.)

2 - Before making line set connections, use dry nitrogen to

purge the refrigerant piping. This will help to prevent ox-

idation and the introduction d moisture into the system.

3 - Use silver alloy brazing rods (5 or 6 percent silver alloy

for copper-to-copper brazing or 45 percent silver alloy

for copper-to-brass or copper-to-steel brazing) which

are rated for use with R407C refrigerant. Wrap a wet

cloth around the valve body and the copper tube stub.

4 - Quench the joint with water or a wet cloth to prevent

heat damage to the valve core and opening port.

IMPORTANT - The tube end must stay bottomed in the

fitting during final assembly to ensure proper seating,

sealing and rigidity.

5-Install the provided thermal expansion valve (ap-

proved for use with R407C refrigerant) in the liquid line

at the indoor coil.

6 - Install the provided filter drier (approved for use with

R407C refrigerant) in the liquid line as close as pos-

sible to the expansion device. Do not leave the drier

uncapped for more than 10 to 15 minutes prior to

brazing, evacuation and leak testing.

7 - Install the sight glass on the liquid line at the outdoor

unit. Wrap the sight glass with a wet rag to protect it

during installation.

&WARNING

Plumbing Connections

HS40 Matched with New Indoor Coil and Line Set

If an existing indoor coil which was equipped with an

RFCI metering device is being replaced, the liquid line

must also be replaced prior to the installation of the

HS40 unit.

&IMPORTANT

Page 4

Page 5

,CAUTION

Required Equipment

You will need the following equipment in order to flush the

existing line set and indoor coil: two clean R22 recovery

bottles, an oilless recovery machine with a pump down fea-

ture, and two sets of gauges (one for use with R22 and one

for use with the R407C).

3 - Remove the existing refrigerant flow control orifice or

thermal expansion valve before continuing with flush-

ing procedures. The existing devices are not approved

for use with R407C refrigerant and may prevent prop-

er flushing. Use a field-provided fitting to reconnect the

lines.

,IMPORTANT

Flushing Procedure

1 - Remove existing R22 refrigerant using the appropri-

ate procedure below.

If the existing outdoor unit is not equipped with

shut-off valves, or if the unit is not operational

AND you plan to use the existing R22 refrigerant to

flush the system -- Disconnect all power to the exist-

ing outdoor unit. Connect the existing unit, a clean re-

covery cylinder and the recovery machine according

to the instructions provided with the recovery ma-

chine. Remove all R22 refrigerant from the existing

system. Refer to gauges after shutdown to confirm

that the entire system is completely void of refrigerant.

Disconnect the liquid and suction lines from the exist-

ing outdoor unit.

If the existing outdoor unit is equipped with manu-

al shut-off valves AND you plan to use NEW R22

refrigerant to flush the system -- Start the existing

R22 system in the cooling mode and close the liquid

line valve. Pump all of the existing R22 refrigerant

back into the outdoor unit. (It may be necessary to by-

pass the low pressure switches to ensure complete re-

frigerant evacuation.) When the low side system pres-

sures reach 0 psig, close the suction line valve. Dis-

connect all power to the existing outdoor unit. Refer to

gauges after shutdown to confirm that the valves are

not allowing refrigerant to flow back into the low side d

the system. Disconnect the liquid and vapor lines from

the existing outdoor unit.

2 - Remove the existing outdoor unit. Set the new R407C

unit and follow the brazing connection procedure

which begins on the previous page to make line set

connections, DO NOT install provided R407C ex-

pansion valve at this time.

Make low voltage and line voltage connections to the

new outdoor unit. DO NOT turn on power to the unit

or open the outdoor unit service valves at this

time.

4 - Remove the pressure tap valve cores from the HS40

unit's service valves. Connect an R22 cylinder with

clean refrigerant to the suction service valve. Con-

nect the R22 gauge set to the liquid line valve and

connect a recovery machine with an empty recovery

tank to the gauge set.

5 - Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to

allow the recovery machine to pull a vacuum on the ex-

isting system line set and indoor coil.

6 - Invert the cylinder of clean R22 and open its valve to

allow liquid refrigerant to flow into the system through

the suction line valve. Allow the refrigerant to pass

from the cylinder and through the line set and the in-

door coil before it enters the recovery machine.

7 - After all of the liquid refrigerant has been recovered,

switch the recovery machine to vapor recovery so that

all of the R22 vapor is recovered. All the recovery ma-

chine to pull a vacuum on the system.

NOTE - A single system flush should remove all of the

mineral oil from the existing refrigerant lines and in-

door coil. A second flushing may be done (using clean

refrigerant) if insufficient amounts of mineral oil were

removed during the first flush. Each time the system

is flushed, you must allow the recovery machine

to pull a vacuum on the system at the end of the

procedure.

8- Close the valve on the inverted R22 drum and the

gauge set valves. Pump the remaining refrigerant out

of the recovery machine and turn the machine off.

9 - Use nitrogen to break the vacuum on the refrigerant

lines and indoor coil before removing the recovery ma-

chine, gauges and R22 refrigerant drum. Reinstall

pressure tap valve cores into HS40 service valves.

10 -Install the provided expansion valve (approved for use

with R407C refrigerant) in the liquid line at the indoor

coil.

Page 5

Page 6

FLUSHING CONNECTIONS

INVERTED R22

CYLINDER

(Contains clean

R22 to be used for

flushing)

HS40 UNIT

LOW HIGH

PRESSURE PRESSURE

CYLINDER

RECOVER_

EXISTING

INDOOR COIL

EXISTING SUCTION LINE

EXISTING LIQUID LINE

i IO TANK RETURN

_INLET

RECOVERY MACHINE

SERVICE VALVE

FIGURE 4

The liquid line and suction line service valves (figures 5 and

6) and gauge ports are accessible from outside the unit.

The service ports are used for leak testing, evacuating,

charging and checking charge.

The valves are equipped with a service port. A Schrader

valve is factory-installed. A service port cap is supplied to

protect the Schrader valve from contamination and to

serve as the primary leak seal.

To Access Schrader Port:

1 - Remove the service port cap with an adjustable wrench.

2 - Connect gauge to the service port.

3 - When testing is completed, replace the service port cap.

Tighten finger tight, then an additional 1/6 turn.

To Open Liquid or Suction Line Service Valve:

1 - Remove the stem cap with an adjustable wrench.

2 - Use a service wrench with a hex-head extension to

back the stem out counterclockwise until the valve

stem just touches the retaining ring,

SERVICE VALVE

LIQUID LINE t

OP_ENIE: AUGE MAN::I_Oo:: _

NOTE- The inverted R22 cylin-

der must contain at least the

same amount of refrigerant as

was recovered from the existing

system.

LIQUID AND SUCTION LINE SERVICE VALVES

(VALVE OPEN)

INSERT HEX

WRENCH

SERVICE

PORT

STEM CAP

©

X

UNIT SIDE

SERVICE'

PORT

CAP

SCHRADER

VALVE

FIELD SIDE

(VALVE CLOSED)

RETAINING RING

SERVICE

STEM CAP

©

INSERT HEX

,DANGER

3 - Replace the stem cap. Tighten finger tight, then tighten

an additional 1/6 turn.

Page 6

UNIT SIDE

SERVICE

PORT CAF

SCHRADER VALVE OPEP

TO LINE SET WHEN VALVE IS

CLOSED (FRONT SEATED)

FIGURE 5

FIELD SIDE

(VALVE FRONT SEATED)

Page 7

To Close Liquid or Suction Line Service Valve:

1 - Remove stem cap with an adjustable wrench,

2 - Use a service wrench with a hex-head extension to

turn the stem clockwise to seat the valve, Tighten firm-

ly,

3 - Replace the stem cap, Tighten finger tight, then tighten

an additional 1/6 turn,

Five Ton Suction Line (Bali-Type) Service Valve

A ball-type full-service valve is used on five-ton HS40-065

units only, These suction line service valves function the

same way, the differences are in the valve's construction,

Valves are not rebuildable, If a valve has failed, it must be

replaced. A ball valve valve is illustrated in figure 6.

The ball valve is equipped with a service port, A Schrader

valve is factory installed. A service port cap is supplied to

protect the Schrader valve from contamination and assure

a leak free seal,

SUCTION LINE (BALL TYPE) SERVICE VALVE

(VALVE OPEN)

USE ADJUSTABLE WRENCH

ROTATE STEM CLOCKWISE 90 _'TO CLOSE

ROTATE STEM COUNTER-CLOCKWISE 90" TO OPEN

TO OUTDOOR COIL

@ STEM CAP

STEM

BALL

SHOWN OPEN)

TO INDOOR COIL

SERVICE

PORT

CAP SERVICE

SCHRADER VALVE

FIGURE 6

After the line set has been connected to the indoor and out-

door units, the line set connections and indoor unit must be

checked for leaks.

,WARNING

Using an Electronic Leak Detector

&IMPORTANT

1 - Connect the high pressure hose of the manifold gauge

set to the suction valve service port. (Normally, the high

pressure hose is connected to the liquid line port, how-

ever, connecting it to the suction port helps to protect

the manifold gauge set from damage caused by high

pressure.)

2 - With both manifold valves closed, connect the cylinder

of R407C refrigerant, Open the valve on the R407C

cylinder (vapor only).

3 - Open the high pressure side of the manifold to allow

R407C into the line set and indoor unit, Weigh in a trace

amount of R407C, [A trace amount is a maximum of 2

ounces (57 g) refrigerant or 3 pounds (31 kPa) pres-

sure]. Close the valve on the R407C cylinder and the

valve on the high pressure side of the manifold gauge

set. Disconnect R407C cylinder.

4 - Connect a cylinder of nitrogen with a pressure regulat-

ing valve to the center port of the manifold gauge set,

5 - Adjust nitrogen pressure to 150 psig (1034 kPa), Open

the valve on the high side of the manifold gauge set in

order to pressurize the line set and the indoor coil,

6 - After a short period of time, open a refrigerant port to

make sure that an adequate amount of refrigerant has

been added for detection (refrigerant requirements

will vary with line lengths). Check all joints for leaks,

Purge nitrogen and R407C mixture, Correct any leaks

and recheck,

Evacuating the system of non-condensables is critical for

proper operation of the unit. Non-condensables are defined

as any gas that will not condense under temperatures and

pressures present during operation of an air conditioning

system. Non-condensables and water vapor combine with

refrigerant to produce substances that corrode copper pip-

ing and compressor parts.

1 -Connect the manifold gauge set to the service valve

ports as follows: low pressure gauge to suction line

service valve; high pressure gauge to liquid line ser-

vice valve.

IMPORTANT- Compliant scroll compressors (as with

any refrigerant compressor) should never be used to

evacuate a refrigeration or air conditioning system.

NOTE - A temperature vacuum gauge, mercury vacu-

um or thermocouple gauge should be used. The usual

Bourdon tube gauges are inaccurate in the vacuum

range.

Page 7

Page 8

2-The nitrogenholdingchargeintheunitmustbere-

leased.Openbothmanifoldvalvestoreleasethenitro-

genfromtheunit.Seepage5forservicevalveopera-

tion.

3-Connectthevacuumpump(withvacuumgauge)tothe

centerportofthemanifoldgaugeset.

4-Openbothmanifoldvalvesandstartvacuumpump.

5-Evacuatethelineset,condensingunit,andindoorunit

toanabsolutepressureof23mm(23,000microns)of

mercury.Duringtheearlystagesofevacuation,itisde-

sirabletoclosethemanifoldgaugevalveatleastonce

todetermineifthereisarapidriseinabsolutepres-

sure.A rapidrisein pressureindicatesa relatively

largeleak.If thisoccurs,theleaktestingprocedure

mustberepeated.

NOTE - The term absolute pressure means the total

actual pressure within a given volume or system,

above the absolute zero of pressure. Absolute pres-

sure in a vacuum is equal to atmospheric pressure mi-

nus vacuum pressure.

6 -When the absolute pressure reaches 23 mm (23,000

microns) of mercury, close the manifold gauge valves,

turn offthe vacuum pump and disconnect the manifold

gauge center port hose from vacuum pump. Attach the

manifold center port hose to a nitrogen cylinder with

pressure regulator set to 150 psig (1034 kPa) and

purge the hose. Open the manifold gauge valves to

break the vacuum in the system. Close the manifold

gauge valves.

Refer to the unit nameplate for the correct liquid charge.

If you can not measure in the total amount, refer to the

start-up section and set the final system charge accord-

ing to the charging instructions. The R407C refrigerant

cylinder should be chocolate brown.

1 - Rotate the fan to check for frozen bearings or binding.

2 - Inspect all factory and field-installed wiring for loose

connections.

3 - Check voltage supply at the disconnect switch. The

voltage must be within range listed on unit nameplate.

If not, do not start equipment until the power company

has been consulted and the voltage condition cor-

rected.

4 - Set thermostat for a cooling demand, turn on power to

blower and close condensing unit disconnect switch to

start.

5 - Recheck unit voltage with unit running. Power must be

within range shown on unit nameplate. Check amper-

age draw of unit. Refer to unit nameplate for correct

running amps.

Charge the unit with the amount of liquid R407C refrigerant

that is indicated on the unit namplate. This charge is based

on a matching indoor coil and outdoor coil with 4.6 m line

set. For varying lengths d line set, refer to table 2 for refrig-

erant charge adjustment.

TABLE 2

&WARNING

7 -Shut off the nitrogen cylinder and remove the manifold

gauge hose from the cylinder. Open the manifold

gauge valves to release the nitrogen from the system.

8-Reconnect the manifold gauge to the vacuum pump,

turn the pump on and continue to evacuate the system

until the absolute pressure does not rise above .5 mm

(500 microns) of mercury within a20-minute period after

shutting off the vacuum pump and closing the manifold

gauge valves.

9 -When the absolute pressure requirement from step 9

has been met, disconnect the manifold gauge hose

from the vacuum pump. Then, weigh in a LIQUID

charge of R407C through the liquid and suction service

valves.

Liquid Line Set Diameter

5/16 in. (8 mm)

3/8 in. (10 mm)

*If line length is greater than 4.6 m, add this amount. If line

length is less than 4.6 m, subtract this amount.

Grams per 1.5 m adjust

from 4.6 m line set*

57 g per 1.5 m

85 g per 1.5 m

&IMPORTANT

The compressor is charged with sufficient polyol ester

oil for line set lengths up to 15 m. If line set lengths lon-

ger than 15 m will be required, add I ounce (28 gm) of oil

for every additional 3 m of line set. Do not add any more

than 207 ml of oil. Copeland has approved Mobil EAL '"

Arctic 22CC and ICI EMKARATE'" RL32CF for use with

these compressors when oil must be added in the field.

The following procedure is intended as a general guide and

is for use on expansion valve systems only. For best results,

the indoor temperature must range from 21°C to 26°C. Be

sure to monitor system pressures while charging.

Page 8

Page 9

TABLE 3

R407C Saturated Liquid Temperature and Pressure Chart

Use this chart for subcooling only, not superheat

SaturatedLiquid

Temperature°C

15

16

16

17

17

18

18

19

20

20

21

21

22

22

23

23

24

25

25

26

26

27

27

28

28

29

30

30

31

31

32

32

Liquid Line Pressure Liquid Line Pressure

iii/iiiiii_i_i iiiiiil_iliii!iiiiiiii;iiiii_JJJ;_;_iii_;!_i!_i!_i_!!i!_i_i_i_i!i_ii;ili_!_i!_i_i;i¸i_!_;i_iiiiiiii!!iiiiiiiiiiii_i_!_;;¸i

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_ii_iiiiiiiiiiiiiii_Ji_iJi'i'i'i'i'i'iiiii_iiiiiiiiiiiiiiiiii_;.................................,i_ii!!!i!!i!!i!!i!!i!!i!!i!i__ii__i__i_i_iii_iii_ii_i!i_!_i_ii_ii_iii_iil;ii_i!_i;_iililiiIil!!!i_!i_,:_!_ii!_i_ii_i_i_ill_i_!i_i_i_i_ii!i_ii_i_iii_ii!_!ii!_i_iiliiiiiililiiii_ii_ii_i_ii!i_i_!_i_i_ii_il_il_il_ii_il_i_!

53; (

_(_

Saturated Liquid

Temperature °C

33

33

34

35

35

36

36

37

37

38

38

39

40

40

41

41

42

42

43

43

44

45

45

46

47

47

47

48

48

51

54

57

ii/iiiiii_i_ii_i(_ i_ i _iii_!!i!!!i!iiiiiiiiiiiiii_iiii_i_iii!_!i!i;!i;ii!ii_iii_:ii_:_}_i_iiiiiiiiii_i

iiiili!_iiiiiiii_iiiliiii_!ii!!!_illiiii;!!!!!ii_i_iiiiiiiiii_ii_ii_i_i_!i_i_i_i_:;i_i_!iiii_i_i_,!:_@_i_i_iiiiii_

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_ii_i_i_ '................................................iiiiiiiiiiiiiiii!_ii_i_!_!ii_!_i_i_!_i_ii_i_!_!i_!_!i_!_!ii_!_i_!_iii_!_i_!_i!!ii!ii_i_i_i_i_i_i_i_i_i_i_i_i_i_i_ili

ii!!!liliiii!iii_ii_@__ iiii!iii!!liiiiiiiiiiiiiiiii_!i_i1_:_;_ii_@i_i_i_i_i_!;_i!_i!_i!_i!_i!_!i_i_iii_ii

....

Page 9

Page 10

Checking Unit Charge Using Subcooling when

Outdoor Temperature is >_16°C

1 - After the pressures have stabilized, attach the man-

ifold gauge hose to the liquid service port, and record

the liquid pressure. At the same time, use a digital ther-

mometer to record the liquid line temperature,

2 - Use table 3 to determine the saturation temperature

that corresponds with the liquid line pressure reading.

3 - To determine subcooling, subtract the liquid line tem-

perature from the saturation temperature (table 3):

Saturation Temperature

-Liquid Line Temperature

=Subcooling

4 - If the system is operating at subcooling values higher

than 4,4 - 5,5°C, recover refrigerant,

5 - If the system is operating at subcooling values lower

than 4,4 - 5,5°C, add refrigerant through the suction

valve in the liquid state. Some R407C cylinders are

equipped with a dip tube which allows you to draw

liquid refrigerant from the bottom of the cylinder

without turning the cylinder upside-down. The

cylinder will be marked if it is equipped with a dip

tube.

The condensing unit and the indoor blower cycle on de-

mand from room thermostat. When the thermostat blower

switch is switched to the ON position, the indoor blower op-

erates continuously,

Timed-Off Control

Units include a timed-off control which helps equalize sys-

tem pressures. The timed-off control delays compressor

start-up for five minutes on thermostat demand, This allows

the compressor to start in an unloaded condition and pre-

vents compressor short-cycling, The control is located in

the control box and is wired between thermostat terminal

"Y" and the compressor contactor,

High Pressure and Low Pressure Switches

Units include a high pressure switch and a low pressure

switch. The pressure switches are located on valve cores

in the liquid line to allow for easy access, The manually re-

set high pressure switch protects the system from high

pressure conditions which result from a fan failure or a

blocked or dirty coil. The low pressure switch (SPST, NO)

protects the system compressor from damage due to a

loss of charge. The loss of charge switch trips at 25 + 5

psig (172+ 34 kPa) and automatically resets at 55+ 5 psig

(379 + 34 kPa).

Refrigerant Sight Glass

A refrigerant sight glass is provided (in the bag assembly)

with the unit, The sight glass should be field-installed in the

liquid line to monitor the system refrigerant,

_WARNING

At the beginning of each cooling season, the system

should be checked as follows:

1- Clean and inspect condenser coil, Coil may be

flushed with a water hose. Make sure power is off be-

fore cleaning,

2 - Visually inspect connecting lines and coils for evidence

of oil leaks,

3 - Check wiring for loose connections.

4 - Check for correct voltage at unit (unit operating),

5 - Check condenser fan motor amp-draw.

Unit nameplate Actual

NOTE _If owner complains of insufficient cooling, the unit

should be gauged and refrigerant charge checked, Refer to

section on refrigerant charging in this instruction,

Evaporator Coil

1 - If necessary, clean coil.

2 - Check connecting lines and coils for evidence of oil

leaks,

3 - Check condensate line and clean, if necessary.

Indoor Unit

1 - Clean or change filters,

2 - Adjust blower speed for cooling. The pressure drop

over the coil should be measured to determine the cor-

rect blower CFM, Refer to the unit information service

manual for pressure drop tables and procedure,

3 - Belt Drive Blowers -- Check belt for wear and proper

tension,

4 - Check all wiring for loose connections

5 - Check for correct voltage at unit (blower operating).

6 - Check amp-draw on blower motor

Unit nameplate Actual

Page 10

Page 11

Job Name Job No. Date

Job Location City State

Installer

City State

Unit Model No. Serial No.

Nameplate Voltage Amps: __

Minimum Circuit Ampacity

Supply Condenser Fan

Maximum Overcurrent Protection Size

Electrical Connections Tight? I--1

Indoor Filter Clean? E1

Indoor Blower CFM

Supply Voltage (Unit Off)

s.P. Drop Over Evaporator (Dry)

COOLING SECTION

Refrigerant Lines:

Service technician

Compressor

Leak Checked? E]

Service Valves Fully Opened? I--1

Properly Insulated? [--]

Service Valve Caps Tight? [--1

Voltage With Compressor Operating

THERMOSTAT

Properly Set? [_ Level? _--_

Condenser Entering Air Temperature

Discharge Pressure _ Suction Pressure B

Refrigerant Charge Checked? [--_

Condenser Fan Checked? [_

Calibrated? [--_

Page 11

Page 12

LENNOX

Lennox Industries

RO. Box 174, Westgate Interchange,

Northampton NN5 5AG

Telephone: 01604 591159

Facsimile: 01604 587536

Page 12

Loading...

Loading...