Lenovo x3840 X6, x3950 X6 Planning Manual

System x x3850 X6 and x3950 X6 Data Center Planning

v1.0.3

FAST, AGILE, RESILIENT CHOICE & FLEXIBILITY SUPERIOR COOLING

The sixth generation of

Enterprise X-Architecture

technology, the X6 servers

are fast in application

performance, has an agile

design and is a

resilient platform that

maximizes up time.

The x3850 X6 server

supports up to four

redundant power supplies,

and the x3950 X6 up to eight

redundant power supplies,

offering 750W, 900W or

1400W capacities to meet

your environmental needs.

The systems provide

Calibrated Vectored

Cooling™, with up to ten

redundant hot-swap fan

packs and five fan zones with

N+1 fan redundancy per

node. Each fan pack includes

two counter-rotated dualmotor fans.

.

Author:

Rani Doughty

rdoughty@lenovo.com

Questions / Comments: power@lenovo.com

Data Center Services, Enterprise Business Group

Revision History

1.0.0 – Feb 24th, 2014 Initial Release

1.0.1 – October 1st, 2014 Updates to format, contacts, webpage, and email.

1.0.2 – April 21st, 2015 Update to template

1.0.3 May 22nd, 2015 Convert to Lenovo logo IMM2

Contributors:

Jerrod Buterbaugh, System x Data Center Services

Reviewers:

Matthew Archibald, System x Data Center Services

2

.

Table of Contents

INTRODUCTION.............................................................................................................5

About This Guide....................................................................................................5

SYSTEM X X6 SYSTEM POWER OVERVIEW.........................................................................6

SYSTEM X X6 SYSTEM POWER SUPPLY UNIT (PSU)..........................................................6

900W AC PSU – Rating & Part Number Information..............................................6

1400W AC PSU – Rating & Part Number Information............................................6

750W DC PSU – Rating & Part Number Information..............................................6

80 PLUS.................................................................................................................8

X6 POWER SUPPLIES....................................................................................................9

X3850 X6 POWER SUPPLY PLACEMENT...........................................................................9

X3950 X6 POWER SUPPLY PLACEMENT.........................................................................10

POWER SUPPLY INSTALLATION AND ORDERING...............................................................11

POWER SUPPLY INPUT FEED WIRING FOR REDUNDANCY..................................................12

IMM2 POWER POLICIES..............................................................................................14

Setting a Power Policy.........................................................................................15

IMM2 POWER CAPPING AND POWER MONITORING.........................................................16

Enabling Power Capping.......................................................................................16

Power Monitoring and Power Allocation..............................................................17

Power History......................................................................................................18

SYSTEM X POWER MAXIMIZER......................................................................................19

SYSTEM X POWER CONFIGURATOR................................................................................20

SYSTEM X X6 PDU AND LINE CORD SELECTION...............................................................21

Switched and Monitored PDUs - North America..................................................21

Switched and Monitored PDUs - International.....................................................22

Enterprise PDUs - North America........................................................................23

Enterprise PDUs - International..........................................................................24

Front-end PDUs - North America........................................................................26

Front-end PDUs - International...........................................................................26

Universal Rack PDUs............................................................................................27

0U Basic PDUs - North America...........................................................................30

0U Basic PDUs - International.............................................................................30

SYSTEM X X6 POWER CORDS.......................................................................................31

System x x3850 X6 and x3950 X6 Worldwide PDU Power Cords..........................31

System x x3850 X6 and x3950 X6 North American Power Cords.........................32

System x x3850 X6 and x3950 X6 International Power Cords..............................33

TYPICAL POWER FOR COMMON X3850 X6 CONFIGURATIONS............................................34

CUSTOMIZED PDU CONFIGURATIONS............................................................................37

TYPICAL PDU CONFIGURATIONS...................................................................................37

1400W PSU Configuration Diagrams....................................................................37

900W PSU Configuration Diagrams......................................................................59

900W & 1400W PSU Combination Configuration Diagrams..................................80

System x North American PDUs Line Cords.........................................................85

System x International PDUs Line Cords..............................................................90

REFERENCE MATERIAL................................................................................................96

What is N+N and N+1 PSU Redundancy...............................................................96

3

.

N+N and N+1 Examples........................................................................................96

IEC 320 CONNECTORS................................................................................................97

IEC 320 CONNECTORS................................................................................................98

IEC 309 PIN & SLEEVE PLUG DECODE.........................................................................99

INGRESS PROTECTION (IP) DECODE...........................................................................100

60A THREE PHASE DELTA POWER CALCULATIONS........................................................100

50A THREE PHASE DELTA POWER CALCULATIONS........................................................101

30A THREE PHASE DELTA POWER CALCULATIONS........................................................101

32A THREE PHASE DELTA POWER CALCULATIONS........................................................102

16A THREE PHASE DELTA POWER CALCULATIONS........................................................102

SYSTEM X6 DOCUMENTS............................................................................................103

Helpful Links.......................................................................................................103

Support..............................................................................................................104

4

.

Introduction

The System x X6 servers are the sixth generation of servers built upon the System x

Enterprise X-Architecture. Enterprise X-Architecture is the culmination of bringing

generations of System x technology and innovation derived from our experience in

high-end enterprise servers.

The System x X6 generation server pack numerous fault-tolerant and high-availability

features into a high-density, rack-optimized, chassis-like package where all

serviceable components are front and rear accessible, significantly reducing the

space needed to support massive network computing operations and simplify

servicing.

The X6 product portfolio is based on the Intel Xeon processor E7-8800/4800 v2

product families which comprises of a 4U, 4 socket x3850 X6 server that is scalable

to an 8U, 8 socket x3950 X6 server. The X6 systems offer the new “bookshelf”

design concept that is based on a fix chassis mounted in a standard rack cabinet. The

modular components that can be installed in the chassis called “Books”, comprises of

a Compute Book, Storage Book, and I/O Book.

The x3850 X6 server contains five fan zones with space for up to two fans per zone

totaling ten hot swap fans with N+1 fan redundancy. Up to four redundant hot-swap

900W AC, 1400W AC, or 750W DC power supplies can be installed supporting N+N,

N+1, and N configurations.

The x3950 X6 server contains ten fan zones with space for up to two fans per zone

totaling twenty hot swap fans with N+1 fan redundancy. Up to eight redundant hotswap 900W AC, 1400W AC, or 750W DC power supplies can be installed supporting

N+N, N+1, and N configurations.

The System x x3850 X6 enclosure covered in this guide is currently marketed

worldwide. The intent of this guide is to provide power information for installation

planning of System x X6 System. This guide contains examples of the System x x3850

X6 enclosure connected to various PDUs and circuits.

About This Guide

When using this guide keep in mind that power connections to the System x X6

system(s) must be wired to comply with local and/or national electrical codes. Consult

your local AHJ (Authority Having Jurisdiction) to ensure compliance.

Each example covered in this guide gives System x PDU option information.

5

.

System x X6 System Power Overview

Use the Power Configurator at the link below to estimate power consumption and

heat load for System x X6 configurations.

http://www.ibm.com/support/entry/portal/docdisplay?lndocid=LNVO-PWRCONF

System x X6 System Power Supply Unit (PSU)

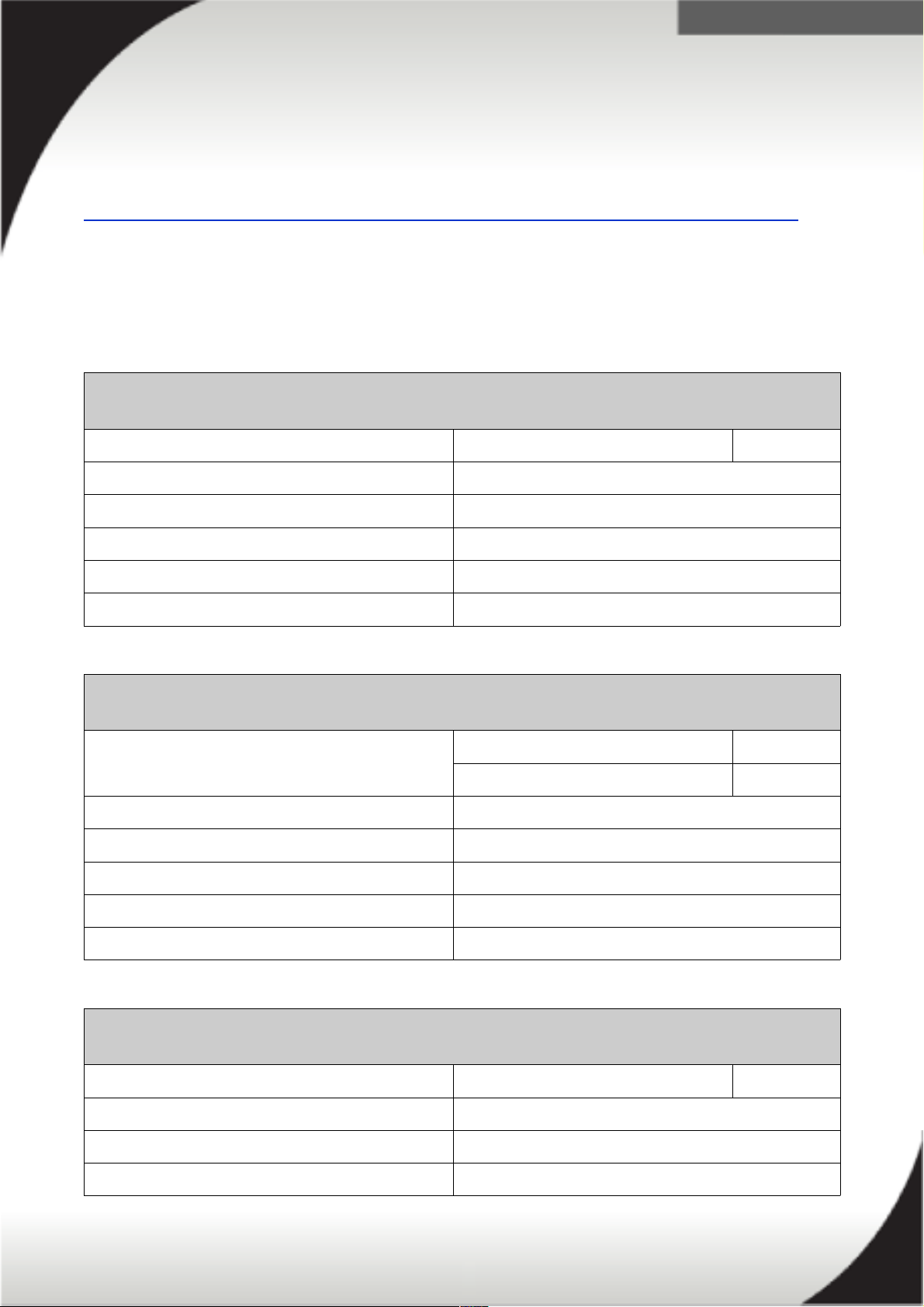

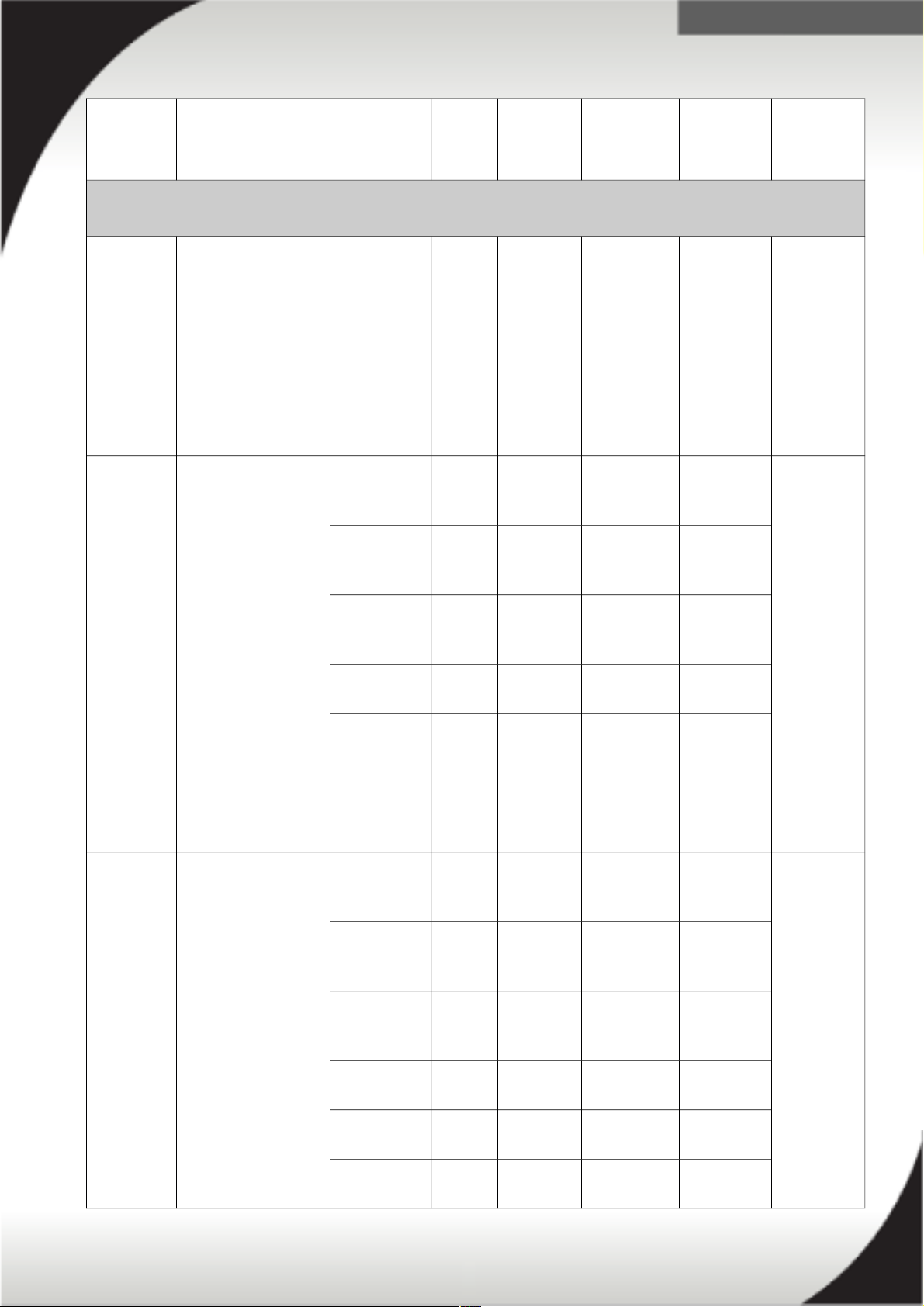

The following tables represent the technical specifications of the compatible PSUs for

the x3850 X6 and x3950 X6 servers.

900W AC PSU – Rating & Part Number Information

Power Supply Unit Part Numbers PN: 44X4132 FC: A4R0

DC Output Wattage @ 200-240V AC 900W

Max Input Amps @ 200-240V: 5A

DC Output Wattage @ 100-127V AC 900W

Max Input Amps @ 100-127V 10A

Nominal Input Voltage Range 100-127V AC & 200-240V AC @ 50-60 Hz.

1400W AC PSU – Rating & Part Number Information

Power Supply Unit Part Numbers PN: 44X4152 < 5000 altitude FC: A54E

PN: 44X4150 > 5000 altitude FC: A45D

DC Output Wattage @ 200-240V AC 1400W

Max Input Amps @ 200-240V: 8A

DC Output Wattage @ 100-127V AC 900W

Max Input Amps @ 100-127V 10A

Nominal Input Voltage Range 100-127V AC & 200-240V AC @ 50-60 Hz.

750W DC PSU – Rating & Part Number Information

Power Supply Unit Part Numbers PN: 88Y7433 FC: A2EA

DC Output Wattage @ -36V DC 750W

PSU Max Input Amps @ -36V 24A

Nominal Input Voltage Range -48V (-30V to -60V)

6

.

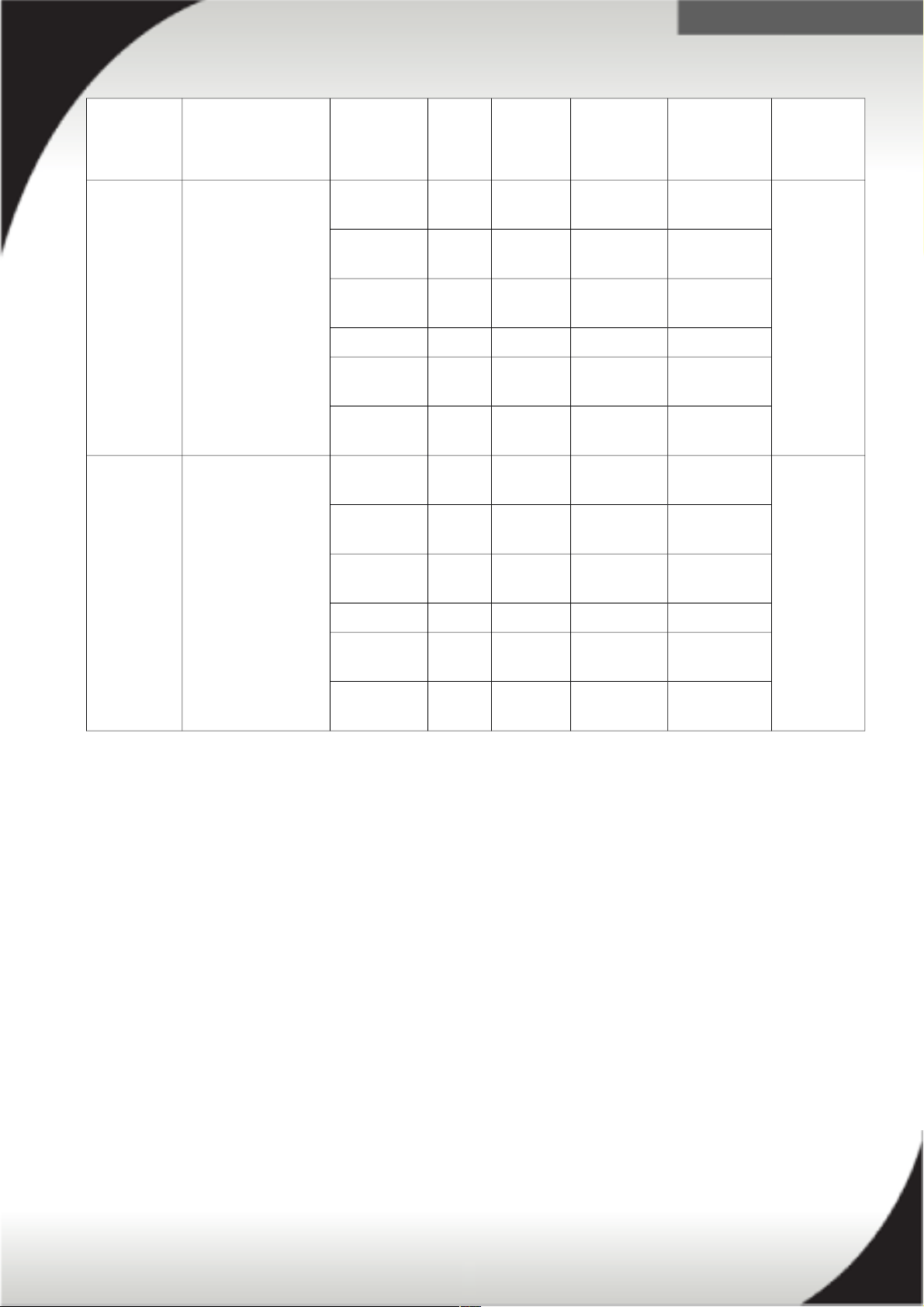

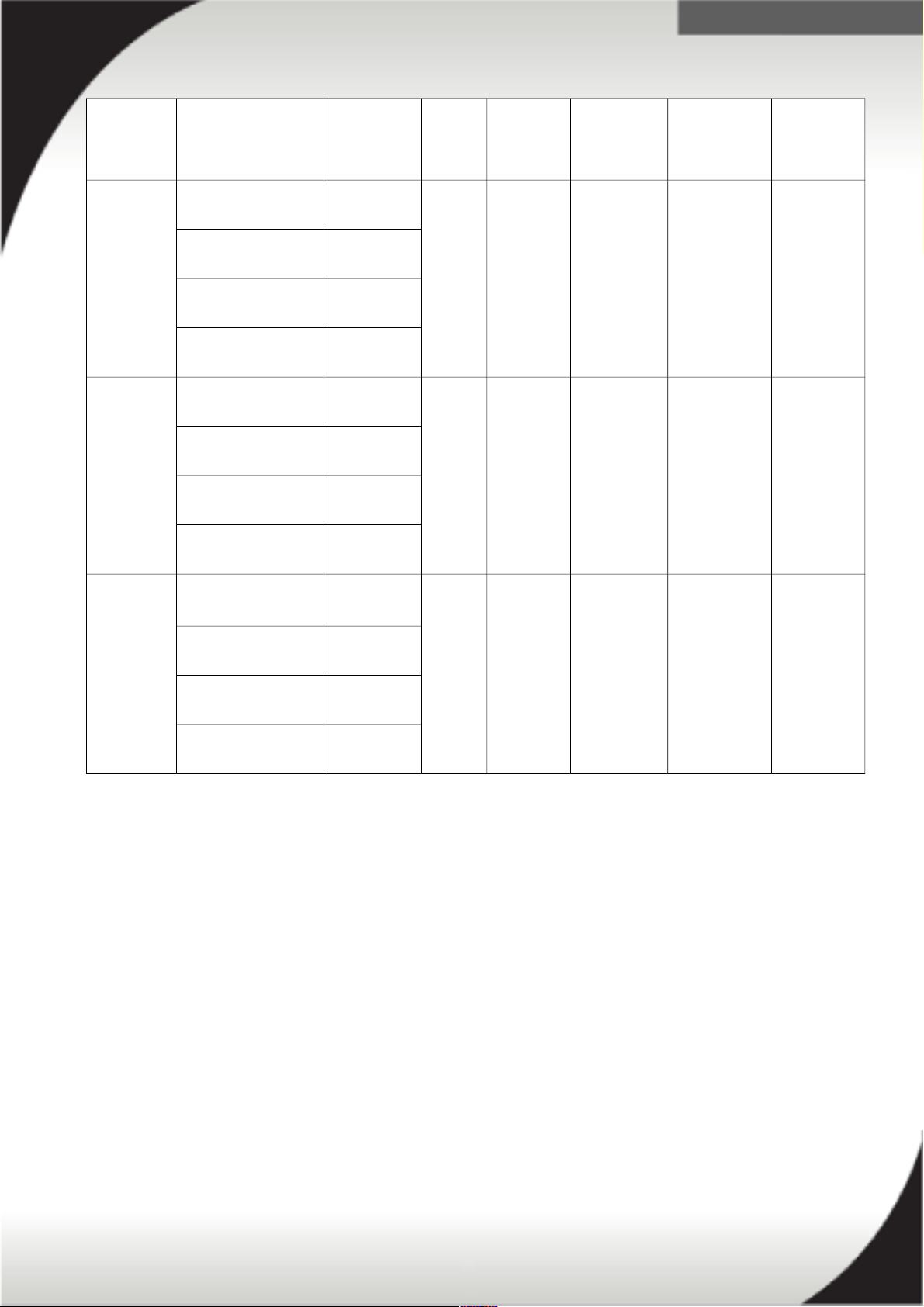

Depending on your load and power requirements, the x3850 X6 supports the

following power supply installation:

One 900W

One 1400W

Two 900W

Two 1400W

Two 900W and two 1400W

Four 900W

Four 1400W

Four 750W DC

7

Figure 1: x6 hot swap power supply

.

80 PLUS

80 PLUS is a performance specification for power supplies used within servers and

computers. To meet the 80 PLUS standard, the power supply must have an efficiency

of 80% or greater, at 20%, 50%, and 100% of rated load with PF of 0.9 or greater.

The standard has several grades, such as Bronze, Silver, Gold, Platinum, and

Titanium. More information on 80 PLUS is available at http://www.80PLUS.org.

The power supplies used in System x X6 Systems are hot-swap high efficiency 80

PLUS Platinum power supplies operating at 94% efficiency. The efficiency varies by

load as shown in the table below.

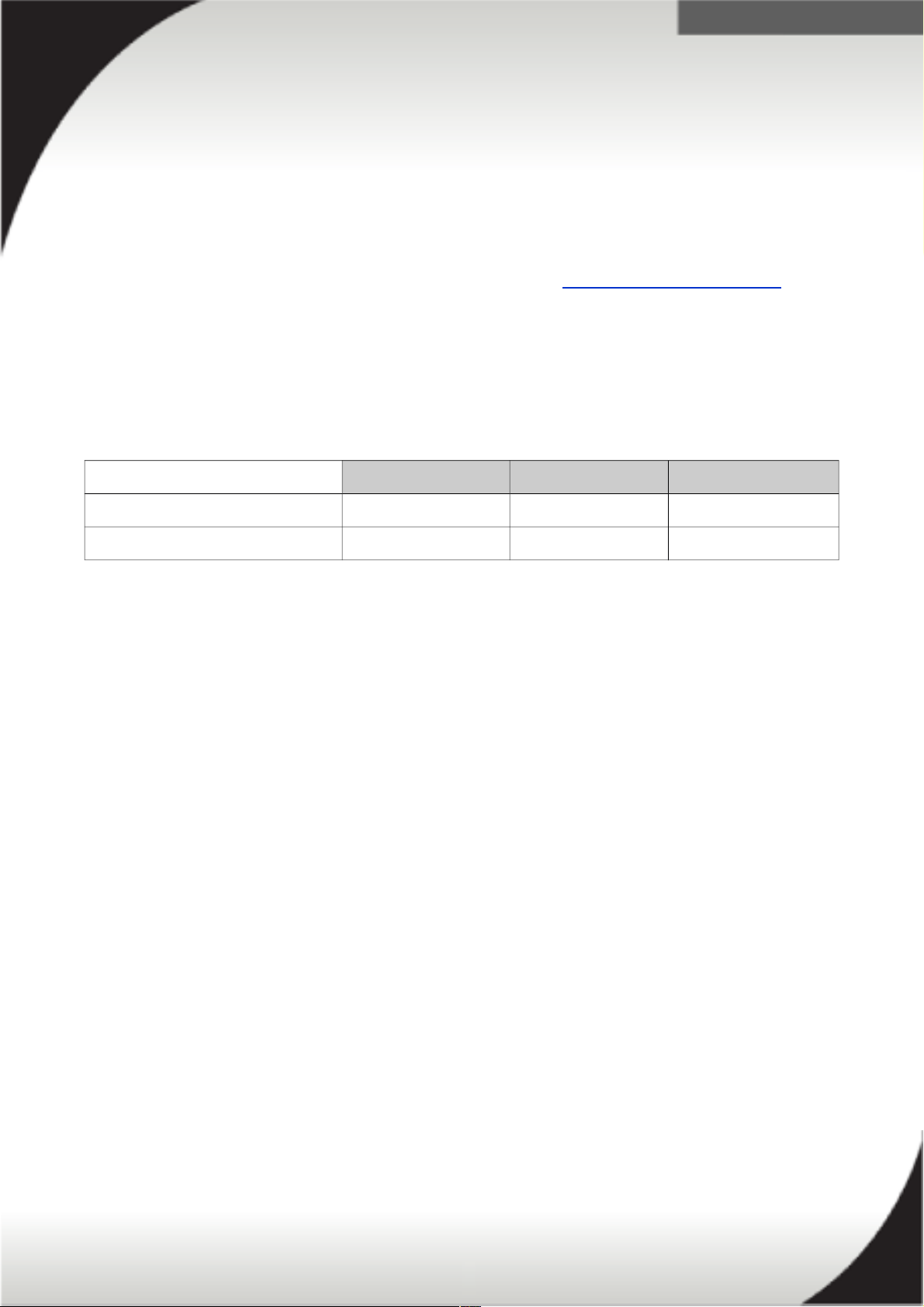

Power Efficiencies at Different Load Levels

20% load 50% load 100% load

80 PLUS Platinum standard 90.00% 94.00% 91.00%

System x X6 1400W PSU 93.62% 94.21% 91.85%

8

.

X6 Power Supplies

The following section covers the x3850 X6 and x3950 X6 power supplies unit (PSU)

installation order and placement rules. Input feed wiring for redundancy is also

discussed.

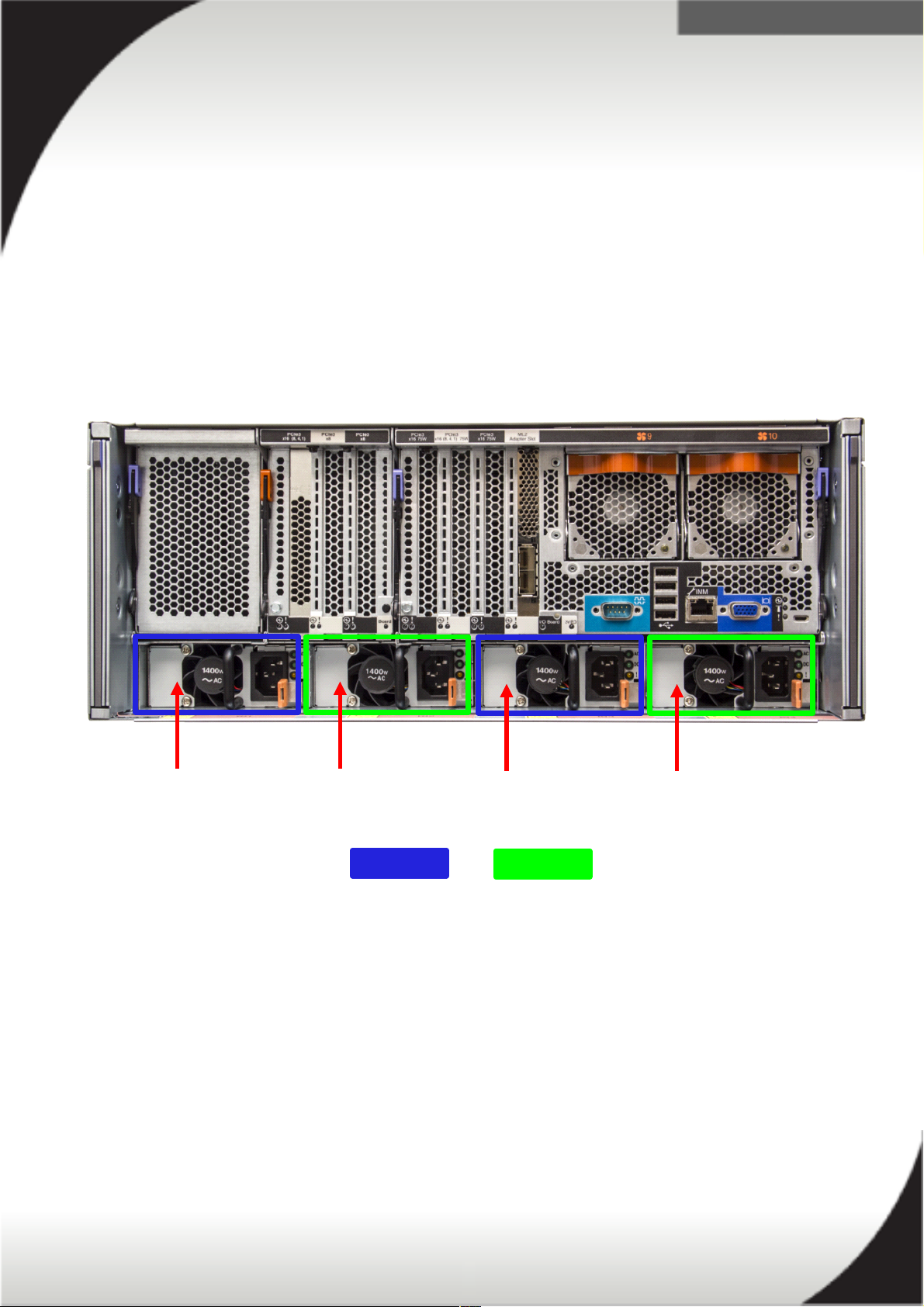

x3850 X6 Power Supply Placement

The power supplies are labeled from left to right when viewed from the rear of the

server and are grouped in pairs as seen in the following picture. Group A (blue)

consists of PSU bay 1 and 3 and Group B (green) consists of PSU bay 2 and 4.

PSU Bay 1 PSU Bay 2 PSU Bay 3 PSU Bay 4

Group A Group B

9

.

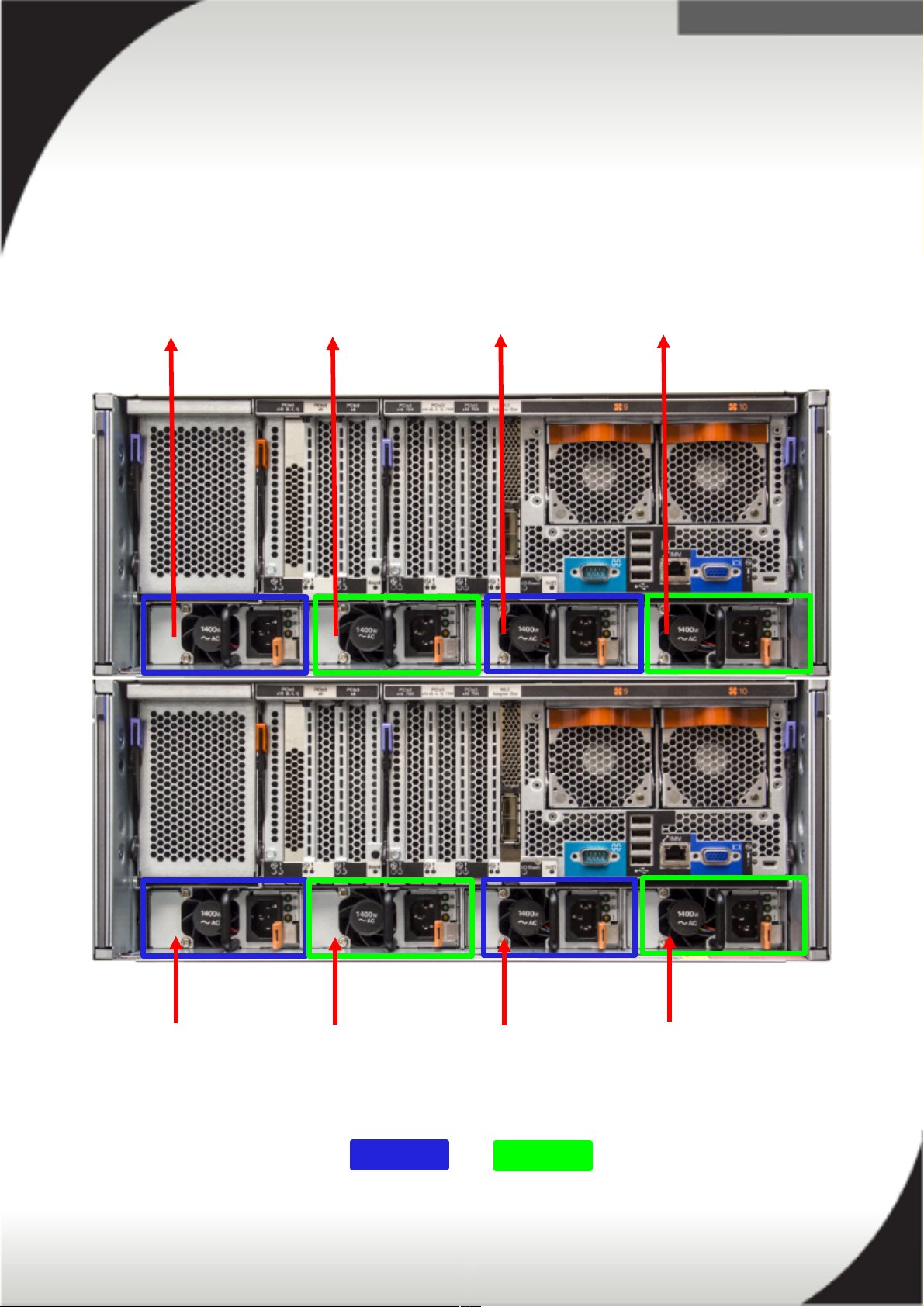

x3950 X6 Power Supply Placement

The power supplies are labeled from left to right when viewed from the rear of the

server and are grouped in pairs as seen in the following picture. Group A (blue)

consists of PSU bay 1, 3, 5 and 7 and Group B (green) consists of PSU bay 2, 4, 6

and 8.

PSU Bay 5 PSU Bay 6 PSU Bay 7 PSU Bay 8

PSU Bay 1 PSU Bay 2 PSU Bay 3 PSU Bay 4

Group A Group B

10

.

Power Supply Installation and Ordering

The following rules apply when installing 1, 2, and 4 AC and DC PSUs in the x3850 X6

system.

For a 1 PSU installation, install the PSU in bay 3. Fillers must be installed in

bays 1, 2, and 4.

For a 2 PSU installation, install the PSU in bay 2 and 3. Fillers must be installed

in bays 1 and 4. Ensure both PSUs are of the same wattage (both 900W or

both 1400W only). Install each supply on separate power feeds for power

redundancy.

For a 4 PSU installation, install the PSUs in all bays.

The 750W DC power supply requires all 4 PSUs to be installed together.

Due to the smaller size of the 900W and 750W PSUs a mechanical filler is

installed in the bay along with the PSU.

Mixing of AC and DC power supplies is not supported.

The suggested power installation order for a x3850 X6 is as follows:

PS Bay 3 – 1st power supply to be installed

PS Bay 2 – 2nd power supply to be installed

PS Bay 1 – 3rd power supply to be installed

PS Bay 4 – 4th power supply to be installed

Note: 1, 2 or 4 PSU configurations are supported. 3 PSU configurations are not

supported.

The suggested power installation order for a x3950 X6 is as follows:

PS Bay 3 – 1st power supply to be installed

PS Bay 2 – 2nd power supply to be installed

PS Bay 7 – 3rd power supply to be installed

PS Bay 6 – 4th power supply to be installed

PS Bay 1 – 5th power supply to be installed

PS Bay 4 – 6th power supply to be installed

PS Bay 5 – 7th power supply to be installed

PS Bay 8 – 8th power supply to be installed

Note: 4 or 8 PSU configurations are supported. All other combinations (1, 2, 3, 5, 6,

and 7) are not supported.

Use the System x Power Configurator tool to calculate your total power draw and

assist you in determining the type and number of PSUs required.

11

.

In a 4 PSU configuration, mixing of 900W PSUs and 1400W PSUs is allowed. The

following rules apply when mixing PSUs.

A mixture of 900W and 1400W PSUs must be installed in group A and group B.

Example:

Bay 1 (group A) = 900W

Bay 2 (group B) = 1400W

Bay 3 (group A) = 1400W

Bay 4 (group B) = 900W

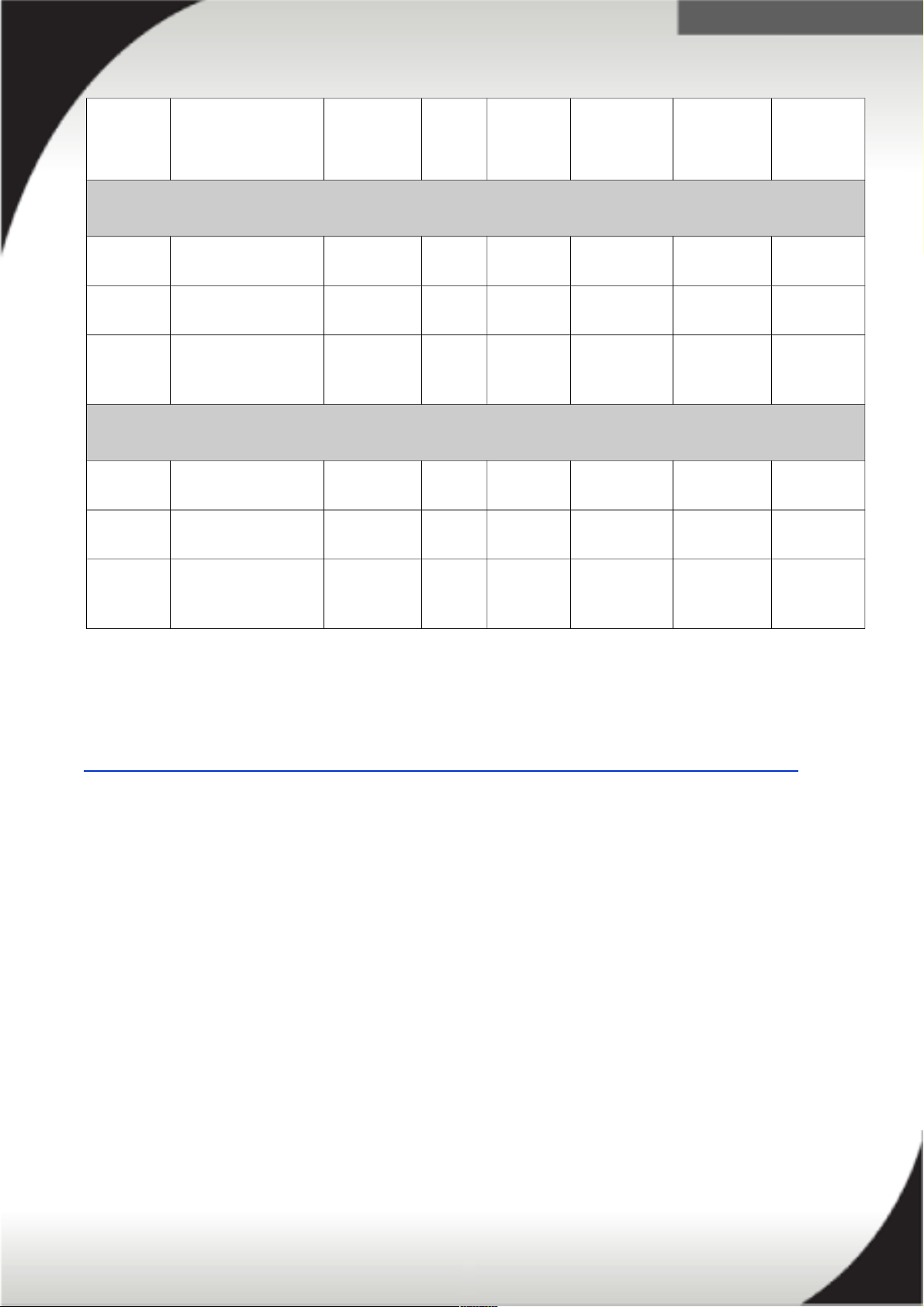

Power Supply Input Feed Wiring for Redundancy

The IMM2 Code for the x3850 X6 server requires power supplies in bays 1 and 3 to

be wired to feed 1, and power supplies in bays 2 and 4 to be wired to feed 2.

This is due to how the power supplies are internally connected and how the IMM2

determines if the system is redundant based on the

power policy

selected. If the

power supplies are not correctly connected, the selected IMM2 power policy may not

function as intended. Power policies are discussed in the next section.

The following rules apply when connecting the server to input feeds for redundancy.

PSUs in group A and PSUs in group B must be balanced in both quantity and

power output (A=B). If the groups are not balanced, the system will not boot.

As an example, mixed wattages must be balanced:

Feed 1 (group A) = 900W and 1400W PSUs

Feed 2 (group B) = 900W and 1400W PSUs

Input power feeds for both group A and group B must be different for

redundancy. Example of a 2 PSU installation.

PSU 1 (group A) = Feed 1

PSU 2 (group B) = Feed 2

Input power feeds for both group A and group B must be different for

redundancy. Example of a 4 PSU installation.

PSU 1 (group A) = Feed 1

PSU 2 (group B) = Feed 2

PSU 3 (group A) = Feed 1

PSU 4 (group B) = Feed 2

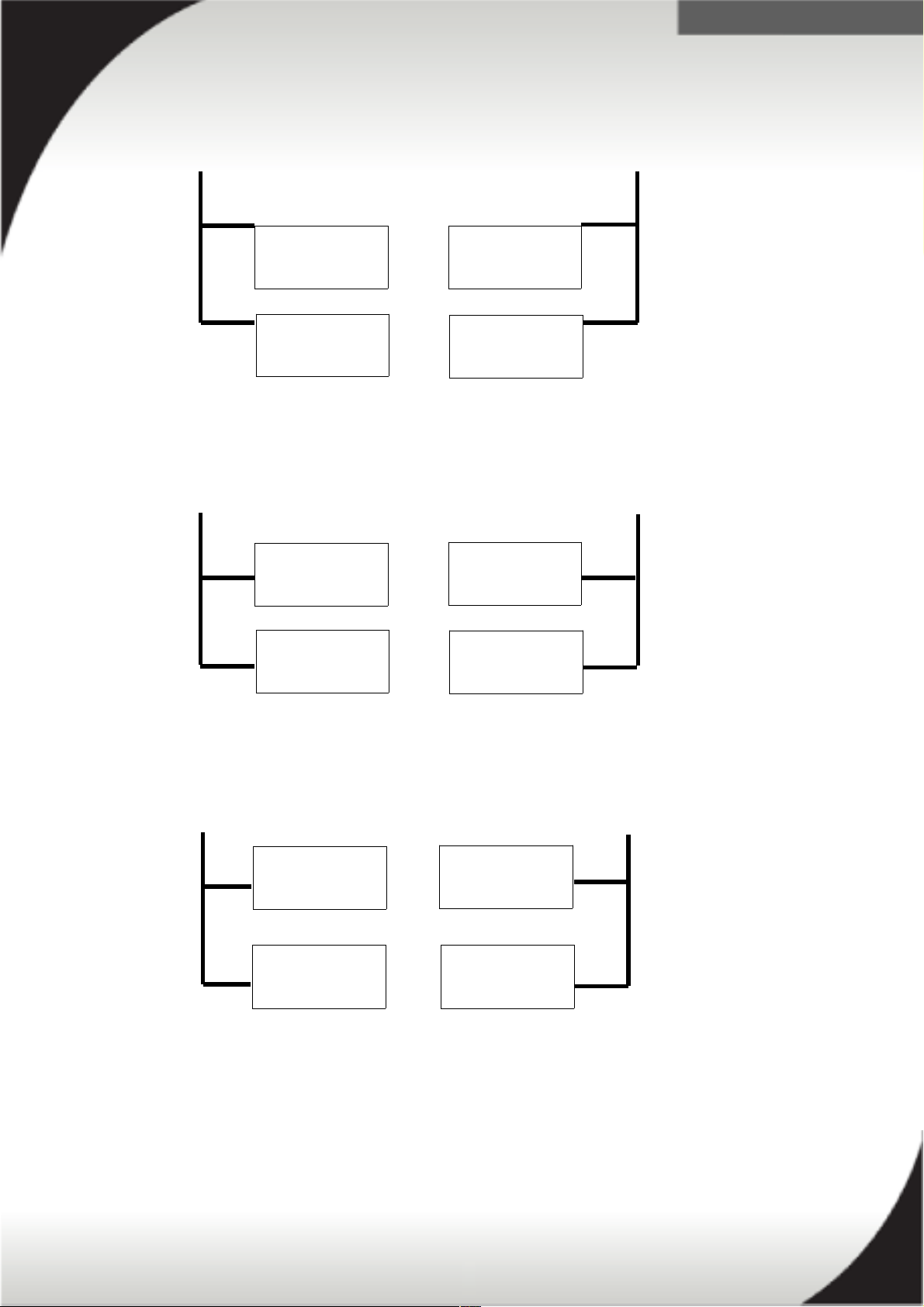

The following illustrations depict how a x3850 X6 server should be wired for

redundancy in a 2 PSU configuration, a 4 PSU configuration, and a mixed wattage

configuration.

12

.

Example of input feed wiring for 2 x 1400W PSUs:

Feed 1 Feed 2

Group A Group B

Example of input feed wiring for 4 x 900W PSUs:

Feed 1 Feed 2

Group A Group B

Example of input feed wiring for 2 x 900W and 2 x 1400W PSUs:

Feed 1 Feed 2

Group A Group B

13

PS 1, Bay 3

1400W

PS 3, Bay 1

Empty

PS 2, Bay 2

1400W

PS 4, Bay 4

Empty

PS 1, Bay 3

900W

PS 3, Bay 1

900W

PS 2, Bay 2

900W

PS 4, Bay 4

900W

PS 1, Bay 3

1400W

PS 3, Bay 1

900W

PS 2, Bay 2

1400W

PS 4, Bay 4

900W

.

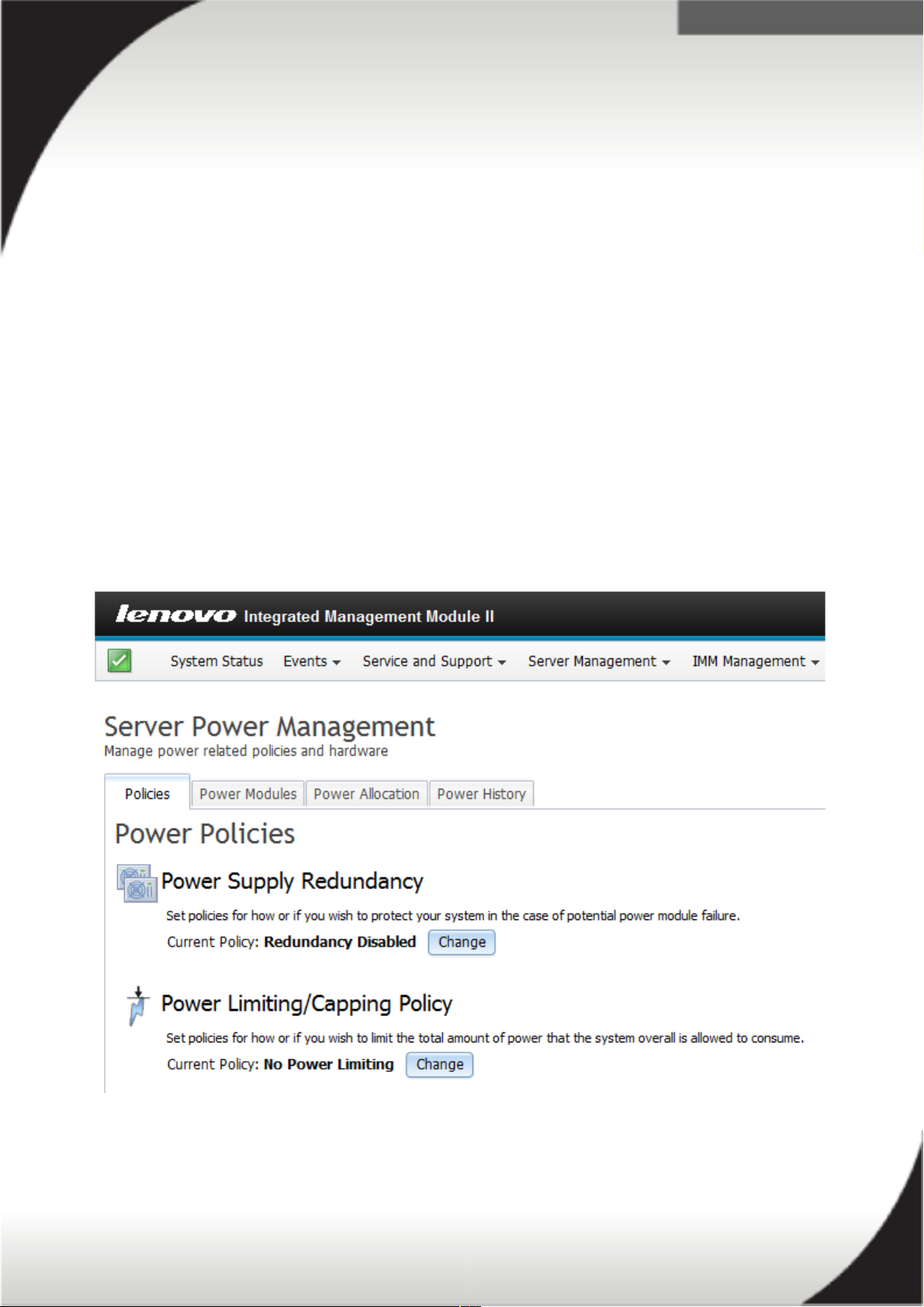

IMM2 Power Policies

As previously mentioned, the IMM2 code controls the x3850 X6 and x3950 X6 power

policy. The servers support three modes of redundancy based on the power supply

configuration, system load and the Power Policy configuration controlled by the

IMM2:

Non-redundant

Fully system redundant

Redundant with reduced performance (throttling)

When the server is booting,

Power Maximizer

runs in the background to verify the

available power in the system. If Power Maximizer determines the available power in

the system does not meet the systems power load based on the hardware installed,

and does not meet the Power Policy chosen in the IMM2, the system will not be

allowed to boot. Power Maximizer is discussed further in the following sections.

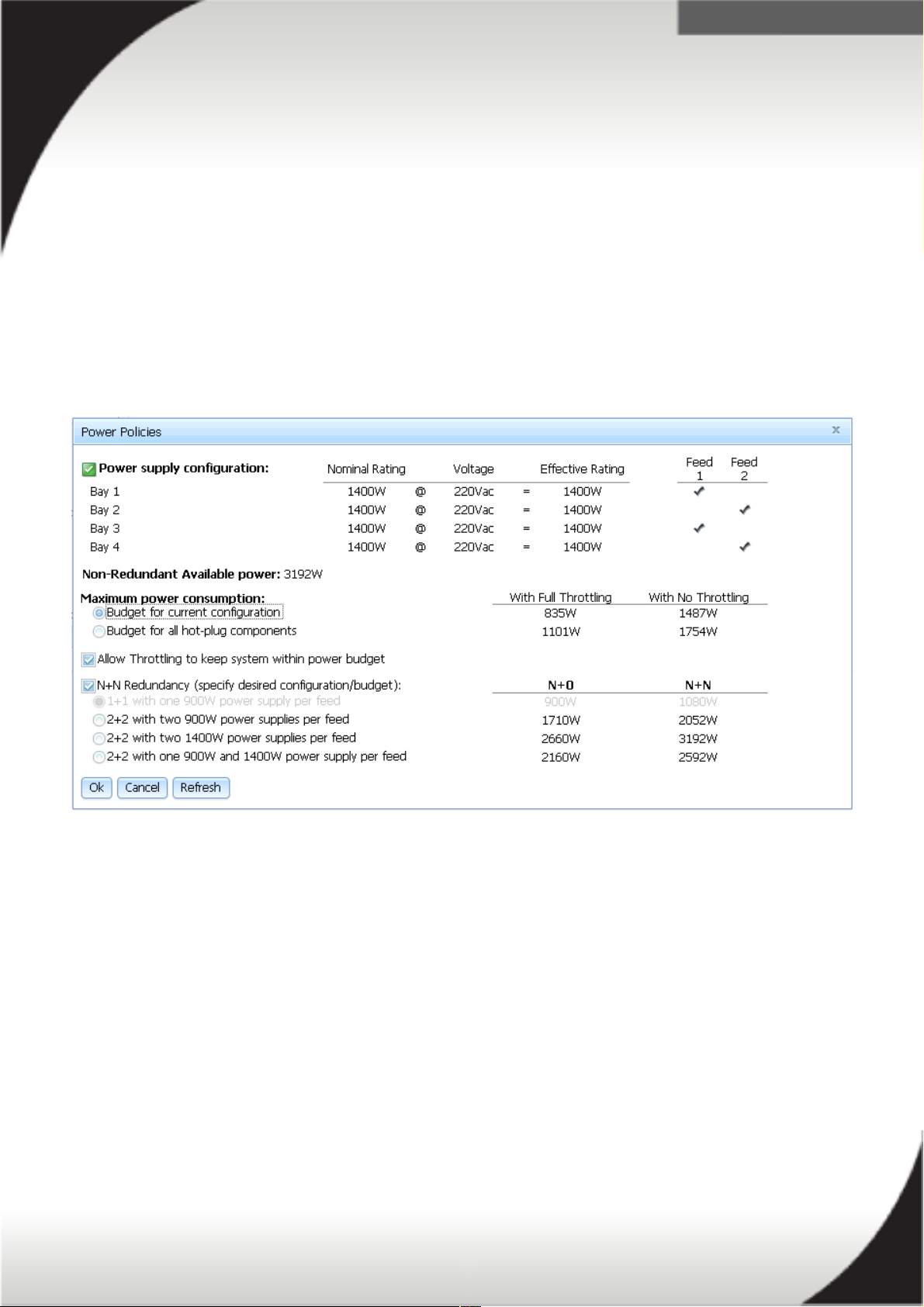

The below image is a screenshot of the IMM2 Server Power Management page where

you can change the servers power policies.

14

.

Setting a Power Policy

The default power policy configuration setting for both AC and DC models is NonRedundant with Throttling enabled. This is to ensure the server will boot the first time

regardless of the installed hardware or if you have not yet implemented a power

policy.

You can set and change the Power Policy and System Power Configurations using the

IMM2 web interface. The power configurations and policies can be changed via the

web, CIM and ASU interfaces. These settings cannot be changed by UEFI. The

following figure is the IMM2 power policy page.

15

.

IMM2 Power Capping and Power Monitoring

The 'Server Management Power' page in the IMM2 settings allows for power capping

(throttling) and power allocation and monitoring of the X6 hardware to help manage

the systems power usage and consumption. The following sections discusses both of

these features of the IMM2.

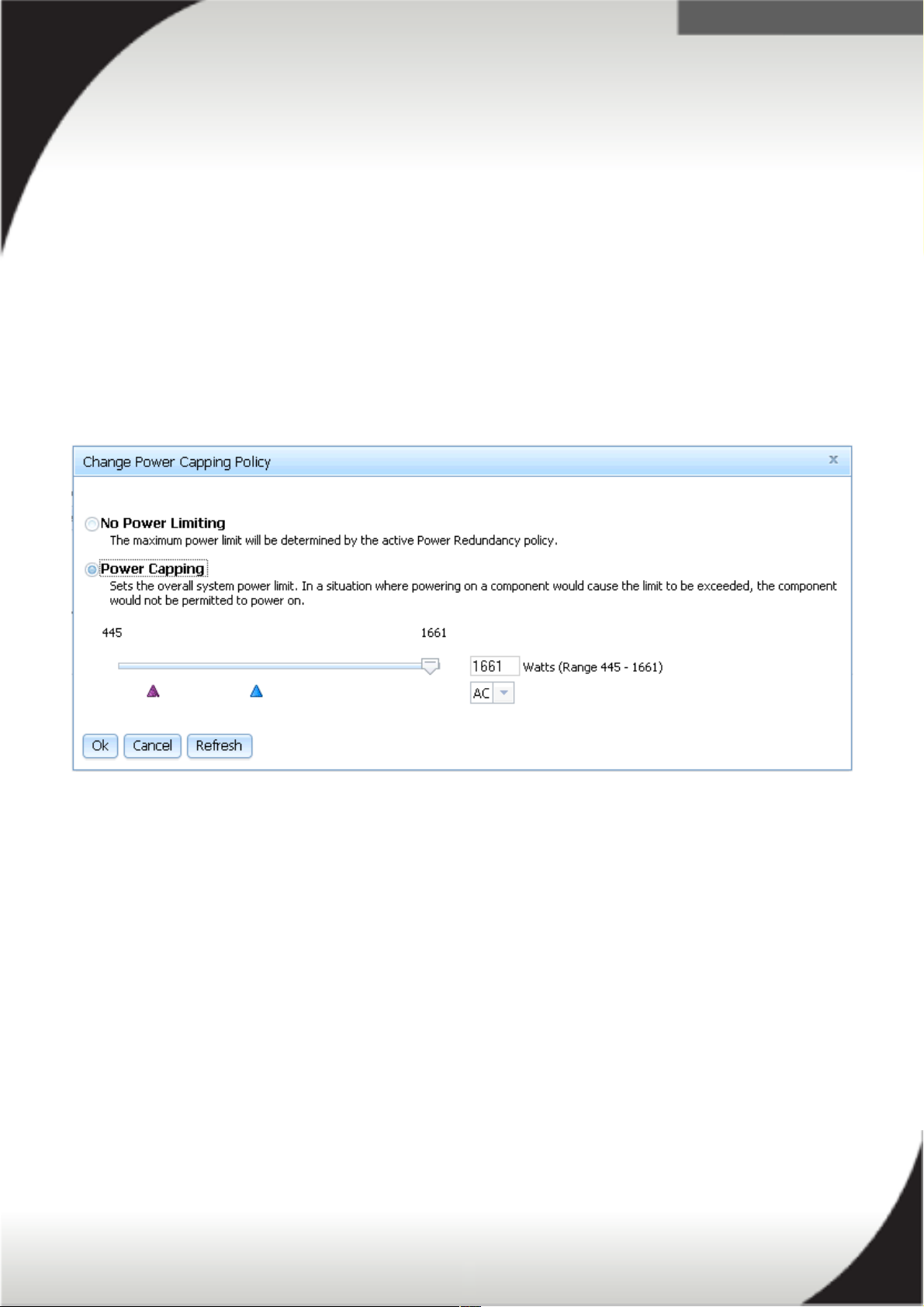

Enabling Power Capping

From the IMM2 'Server Power Management' page, under the 'Policies' tab, you can

set 'Power Limiting/Power Capping'. The below image is a screenshot of the power

capping policy page. Note that setting a power capacity limit works by throttling the

hardware's performance (such as the CPU) so it will produce less power.

Ensure you confirm your servers power consumption via the power monitoring tools

in the IMM2. The power monitoring and allocation tool is discussed in the next

section. You do not want to set the power capacity limit too low and risk exceeding the

power capacity limit. In the event you exceed the power capacity limit the server

and/or some of its components may not power on.

16

.

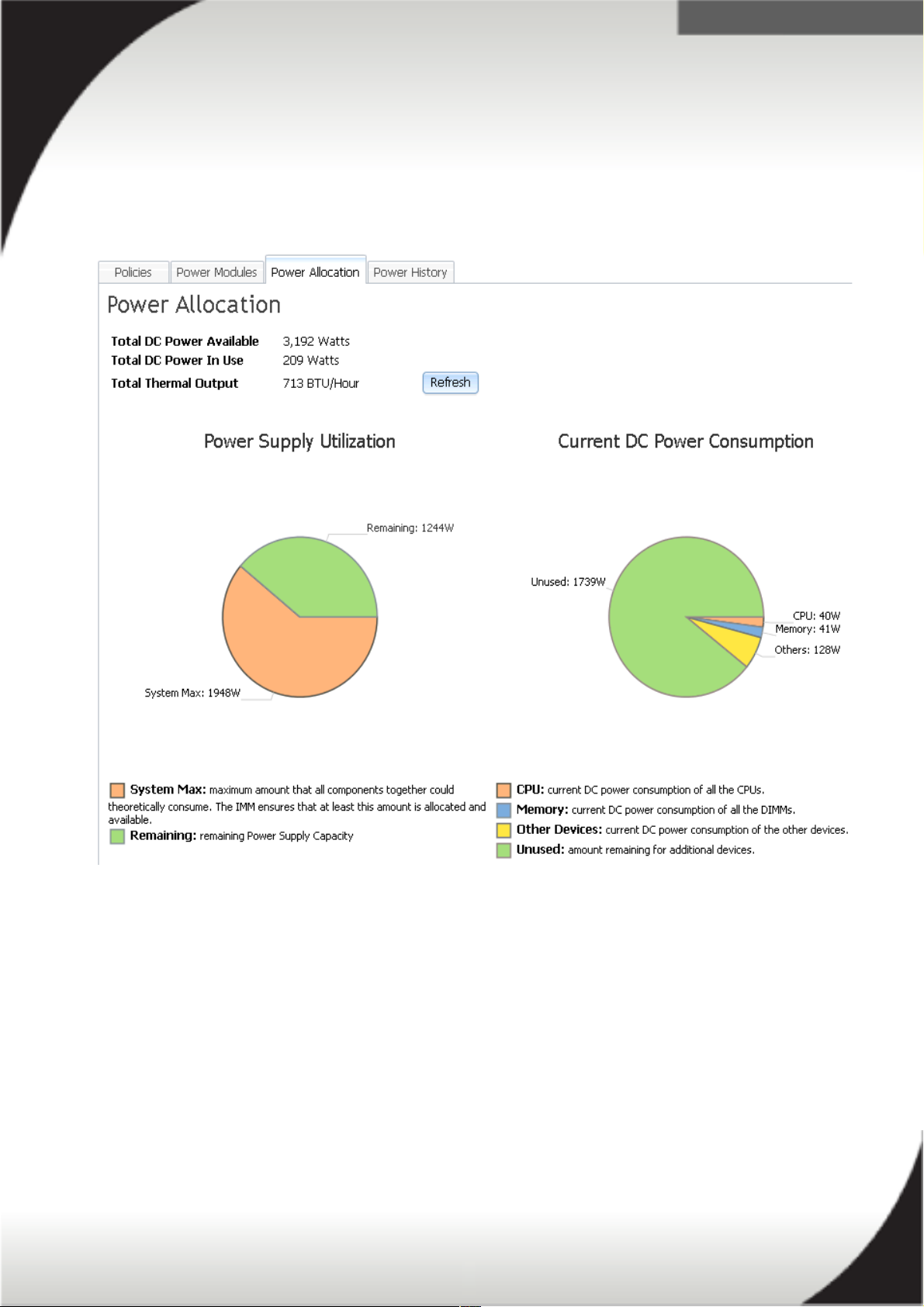

Power Monitoring and Power Allocation

The 'Server Power Management' page contains information on the power supply

utilization and the DC power consumption of your server. The below image is a screen

shot of this page from the IMM2.

The wattage calculated for the power supply utilization and the DC power

consumption is only the theoretically amount of power that all components installed in

your server could potentially consume. It is not a picture of the servers real-time

power usage. For real-time AC power usage use the 'Power History' tab, which is

discussed in the next section.

The IMM2 will use the power supply utilization information and the DC power

consumption information to ensure the server has enough power source(s) installed

to power all of the hardware. If the IMM2 detects insufficient power source(s)

available it may not turn all of the servers components on or the server itself may not

turn on at all.

17

.

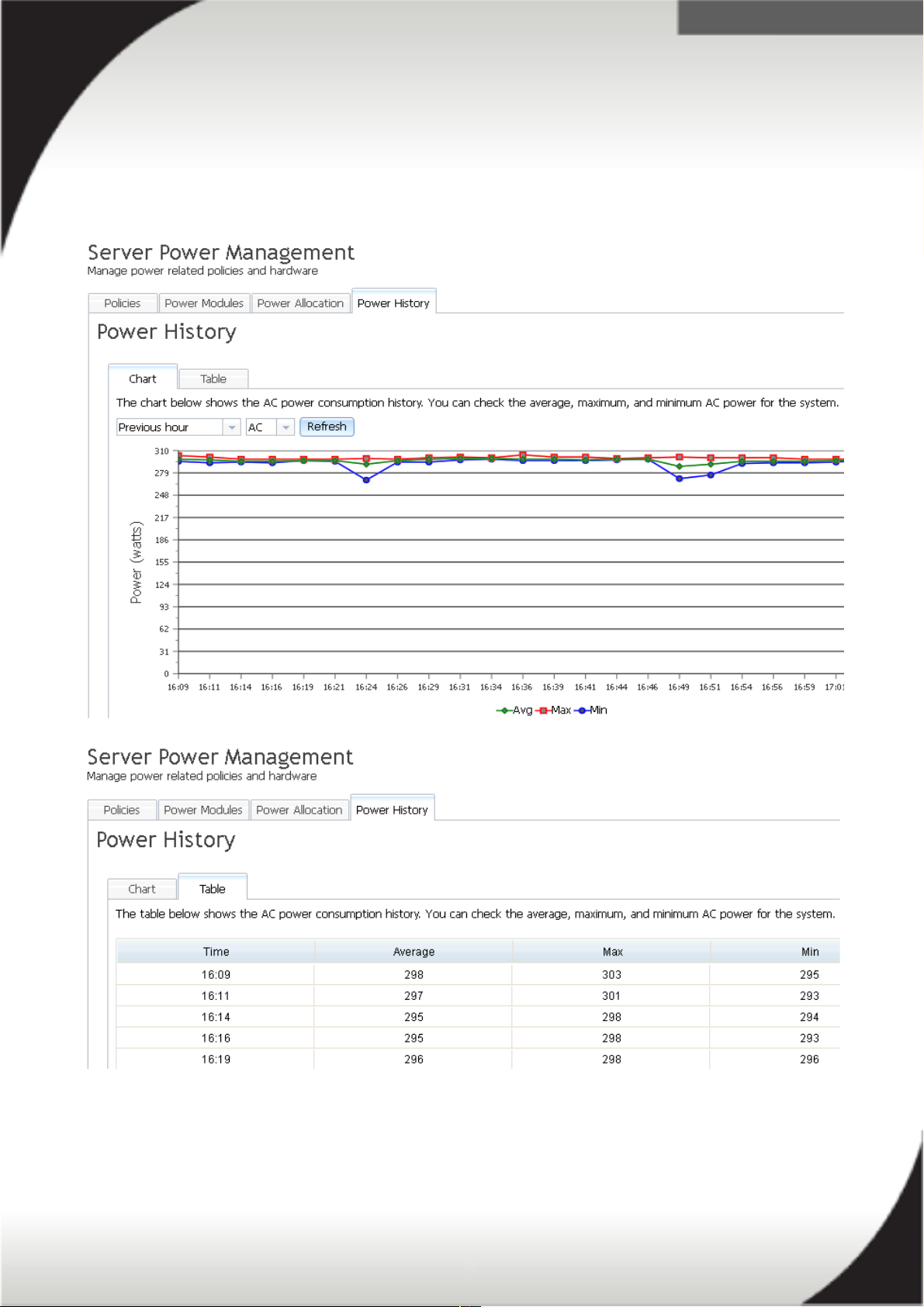

Power History

The 'Server Power Management' page contains information on the history of your

power consumption. This is found under the 'Power History' tab. The below images

are screen shots of a servers power history in chart and table format. You can view

the history of the servers AC or DC power consumption in minutes, hours or days.

18

.

System x Power Maximizer

System x Power Maximizer is an integrated software tool for determining the asconfigured total power budget for all new System x, Pure Flex, iDataPlex, and

NeXtScale systems. This technology takes a more granular approach of determining

system and chassis power budget than using look-up tables in system management

devices. The benefits of this allow power policies to be set based on actual

component power consumption under any supported operating condition or workload.

Power policies are able to be more accurately maintained without unnecessary overbudgeting to ensure as much available power is provisioned by the system as the

policies allow. This prevents resiliency and performance impacts such as unexpected

throttling and system nodes powering off unexpectedly.

The System x Power Maximizer functions by running separate, sub-system specific

workloads and then calculates a total worst-case power consumption estimate. The

result of the System x Power Maximizer is reported to the respective management

interhttp://www.Systemx.com/systems/bladecenter/resources/powerconfig.htmlfac

e for determining power-on support and redundancy policy of the supported systems.

The System x Power Maximizer result is not directly reported to any user interface,

but the power policies are managed by this configuration specific power budget. This

means that as the configurations change, the enclosure will automatically manage the

provisioned power according to the power policy set by the end user.

19

.

System x Power Configurator

The System x Power Configurator is a software tool designed to assist with

calculating System x Systems environmental information. The data in the System x

Power Configurator tool is derived from running real-world workloads across a

number of configurations to properly characterize component power consumption

under various conditions. The current workloads are a combination of Floating Point

and Small FFT Processor workloads as well as running configuration-tuned versions

of HPL (Portable Implementation of the High-Performance Linpack Benchmark) and

Stream to exercise multiple sub-systems of the IT systems. The two highest power

consuming sub-systems in a non-HPC (High Performance Computing) IT system are

processor and memory, so focus is given to exercising those sub-systems to correctly

model power consumption under traditional and virtual workloads. For HPC type IT

systems, some configurations contain GPGPU (General Purpose Graphical

Processing Unit) or MIC (Many Integrated Core) I/O adapters. These adapters are

characterized by running highly parallel graphic rendering workloads for complete

characterization. All tests are conducted using default uEFI/BIOS settings.

The System x Power Configurator provides three groups of environmental

information. The first represents Idle or minimum power consumption, the second is

Maximum power consumption, and the third is Load Factor. Load Factor is a scale

factor between Idle and Max that can represent any configurations total aggregate

system utilization for a specific workload.

The data reported by System x Power Configurator can be used in certain cases to

determine electrical wiring and levels of redundancy. The data reported by System x

Power Configurator represents a worst-case power consumption value under normal

operating conditions and may not model power consumption under component failure

conditions. Final determinations should be made by persons skilled in the art or by

contacting power@us.System x.com for assistance.

System x Power Configurator tool:

http://www.ibm.com/support/entry/portal/docdisplay?lndocid=LNVO-PWRCONF

20

.

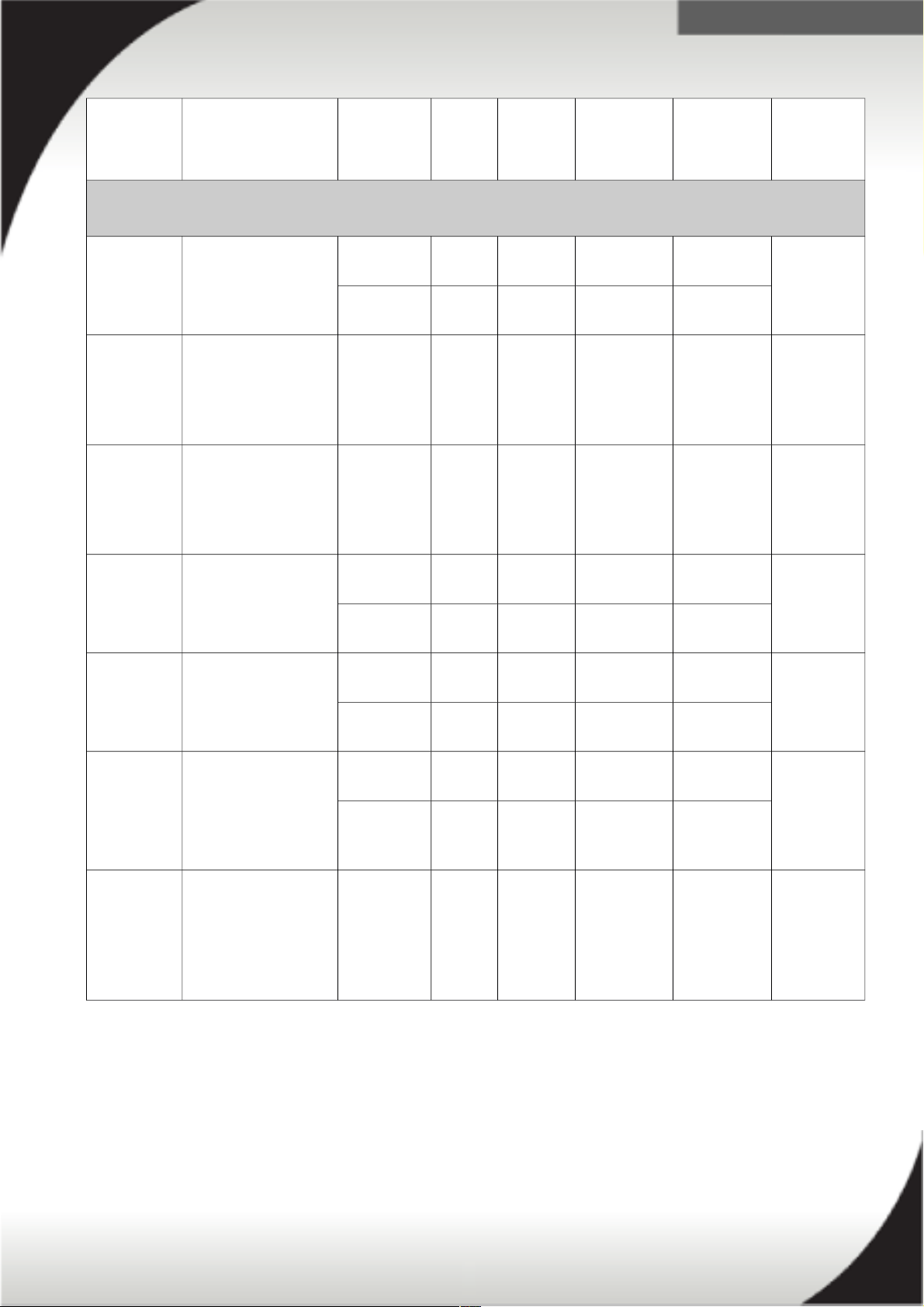

System x X6 PDU and line cord selection

Some PDUs have attached line cords while others require a line cord to be ordered

separately based on your requirement of Three-phase power or Single-phase power.

Refer to the following table for line cord and phase options for both North America

and International PDUs.

Part

Number

Description Line cord

part

number

Phase

(ph)

Voltage

(V)

Line cord

rating

(Derated)

Line cord

plug

Number /

Type of

outlet

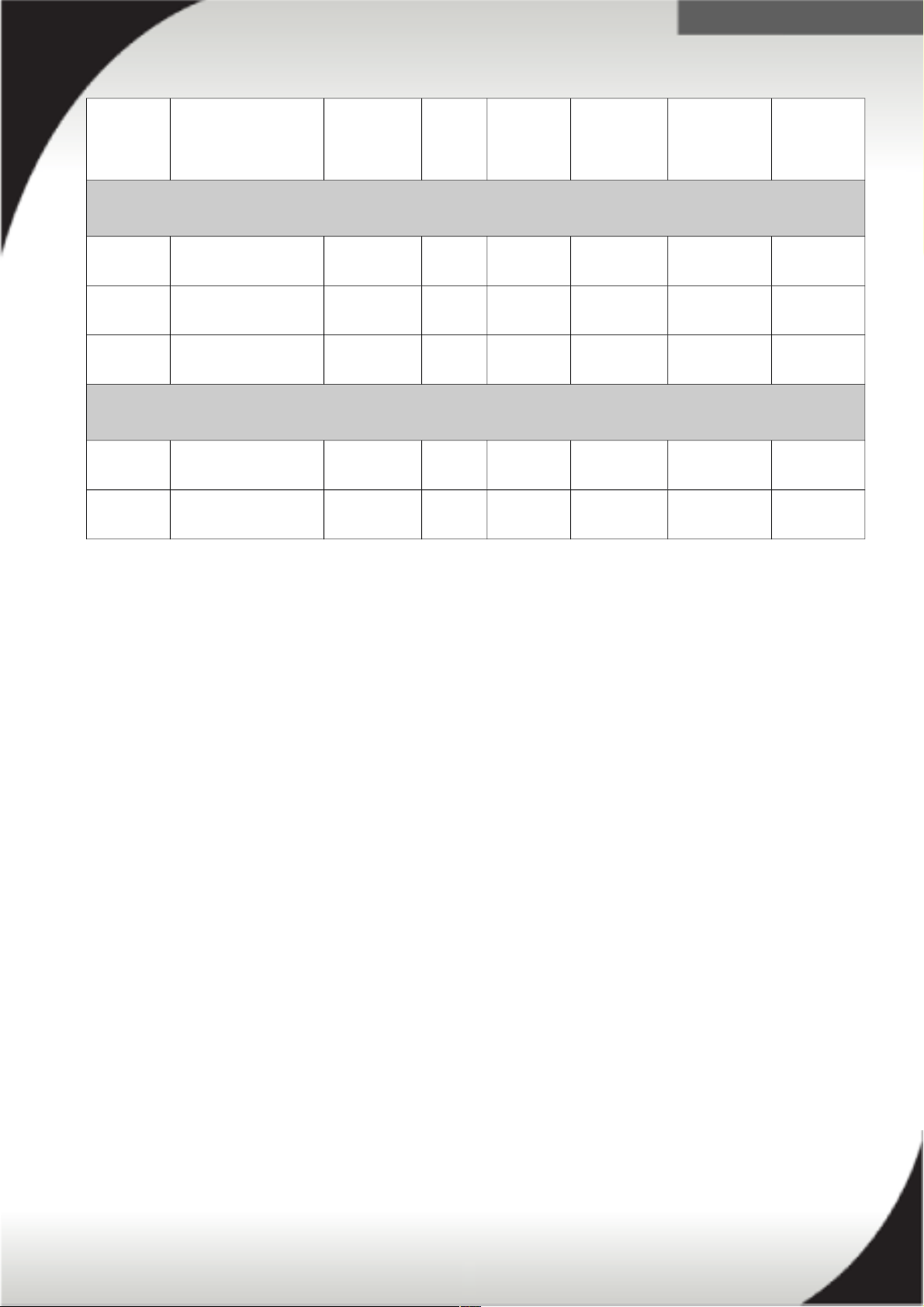

Switched and Monitored PDUs - North America

46M4002 System x 1U 9 C19/3

C13 Active Energy

Manager (AEM) DPI

PDU

40K9614 1ph 200V-

240V

30A (24A) NEMA L6

30P

9 / C19

3 / C13

40K9615 1ph 200V-

240V

60A (48A) IEC 309

2P+G

46M4003 System x 1U 9 C19/3

C13 AEM 60A 3

Phase PDU

Attached 3ph Δ 208V 60A

(27.7A/ph)

IEC 309

3P+G

9 / C19

3 / C13

46M4004 System x 1U 12 C13

AEM DPI PDU

40K9614 1ph 200V-

240V

30A (24A) NEMA L6

30P

12 / C13

40K9615 1ph 200V-

240V

60A (48A) IEC 309

2P+G

46M4005 System x 1U 12 C13

AEM 60A 3 Phase

PDU

Attached 3ph Δ 208V 60A

(27.7A/ph)

IEC 309

3P+G

12 / C13

46M4167 System x 1U 9 C19/3

C13 Switched and

Monitored 30A 3

Phase PDU

Attached 3ph Δ 208V 30A

(13.85A/ph)

NEMA

L21-30P

9 / C19

3 / C13

46M4116 System x 0U 24 C13

Switched and

Monitored 30A PDU

Attached 1ph 200V-

240V

30A (24A) NEMA L6

30P

24 / C13

46M4134 System x 0U 12

C19/12, C13

Switched and

Monitored 50A 3

Phase PDU

Attached 3ph Δ 208V 50A

(23.09A/ph)

CS8365L 12 / C19

12 / C13

21

.

Part

Number

Description Line cord

part

number

Phase

(ph)

Voltage

(V)

Line cord

rating

(Derated)

Line cord

plug

Number /

Type of

outlet

Switched and Monitored PDUs - International

46M4119 System x 0U 24 C13

Switched and

Monitored 32A PDU

Attached 1ph 220V-

240V

32A IEC 309

P+N+G

24 / C13

46M4137 System x 0U 12

C19/12

C13 Switched and

Monitored 32A 3

Phase PDU

Attached 3ph Y 380V-

415V

32A

(32A/ph)

IEC 309

3P+N+G

12 / C19

12 / C13

46M4002 System x 1U 9

C19/3 C13 Active

Energy Manager

DPI PDU

40K9612 1ph 220V-

240V

32A IEC 309

P+N+G

9 / C19

3 / C13

40K9613 1ph 220V-

240V

63A IEC 309

P+N+G

40K9617 1ph 230V-

240V

32A AUS/NZ

3112

40K9618 1ph 220V 30A KSC 8305

40K9611 3ph Y 380V-

415V

32A

(32A/ph)

IEC 309

3P+N+G

47C2495 3ph Y 380V-

415V

16A

(16A/ph)

IEC 309

3P+N+G

46M4004 System x 1U 12 C13

AEM DPI PDU

40K9612 1ph 220V-

240V

32A IEC 309

P+N+G

12 / C13

40K9613 1ph 220V-

240V

63A IEC 309

P+N+G

40K9617 1ph 230V-

240V

32A AUS/NZ

3112

40K9618 1ph 220V 30A KSC 8305

40K9611 3ph Y 380V-

415V

32A

(32A/ph)

IEC 309

3P+N+G

47C2495 3ph Y 380V-

415V

16A

(16A/ph)

IEC 309

3P+N+G

22

.

Part

Number

Description Line cord

part

number

Phase

(ph)

Voltage

(V)

Line cord

rating

(Derated)

Line cord

plug

Number /

Type of

outlet

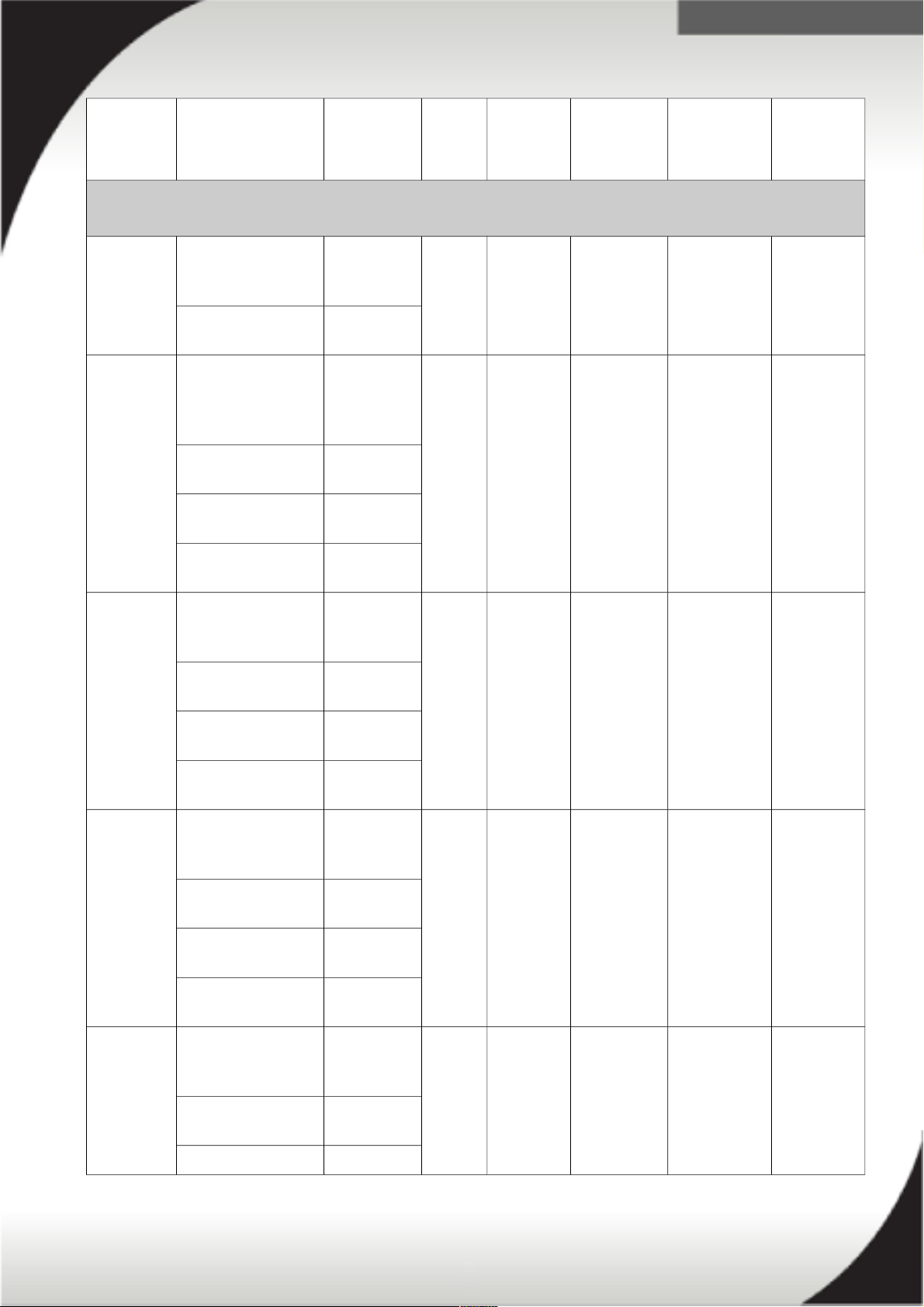

Enterprise PDUs - North America

71762NX System x Ultra

Density

Enterprise 1U PDU

C19 PDU

40K9614 1ph 200V-

240V

30A (24A) NEMA

L6-30P

9 / C19

3 / C13

40K9615 1ph 200V-

240V

60A (48A) IEC 309

2P+G

71763MU System x Ultra

Density

Enterprise 1U PDU

C19 3 Phase 60A

PDU+ Monitored

Attached 3ph 208V 60A

(27.7A/ph)

IEC 309

2P+G

9 / C19

3 / C13

71763NU System x Ultra

Density

Enterprise 1U PDU

C19 3 Phase 60A

PDU Basic

Attached 3ph Δ 208V 60A

(27.7A/ph)

IEC 309

2P+G

9 / C19

3 / C13

39M2816 System x DPI C13

Enterprise 1U PDU+

without line cord

Monitored

40K9614 1ph 200V-

240V

30A (24A) NEMA

L6-30P

12 / C13

40K9615 1ph 200V-

240V

60A (48A) IEC 309

2P+G

39Y8941 DPI Single Phase

C13 Enterprise 1U

PDU without line

cord

40K9614 1ph 200V-

240V

30A (24A) NEMA

L6-30P

12 / C13

40K9615 1ph 200V-

240V

60A (48A) IEC 309

2P+G

39Y8948 DPI Single Phase

C19 Enterprise 1U

PDU without line

cord

40K9614 1ph 200V-

240V

30A (24A) NEMA

L6-30P

6 / C19

40K9615 1ph 200V-

240V

60A (48A) IEC 309

2P+G

39Y8923 DPI 60A Three

Phase C19

Enterprise 1U PDU

with IEC309 3P+G

(208 V) fixed line

cord

Attached 3ph Δ 208V 60A

(27.7A/ph)

IEC 309

3P+G

6 / C19

23

.

Part

Number

Description Line cord

part

number

Phase

(ph)

Voltage

(V)

Line cord

rating

(Derated)

Line cord

plug

Number /

Type of

outlet

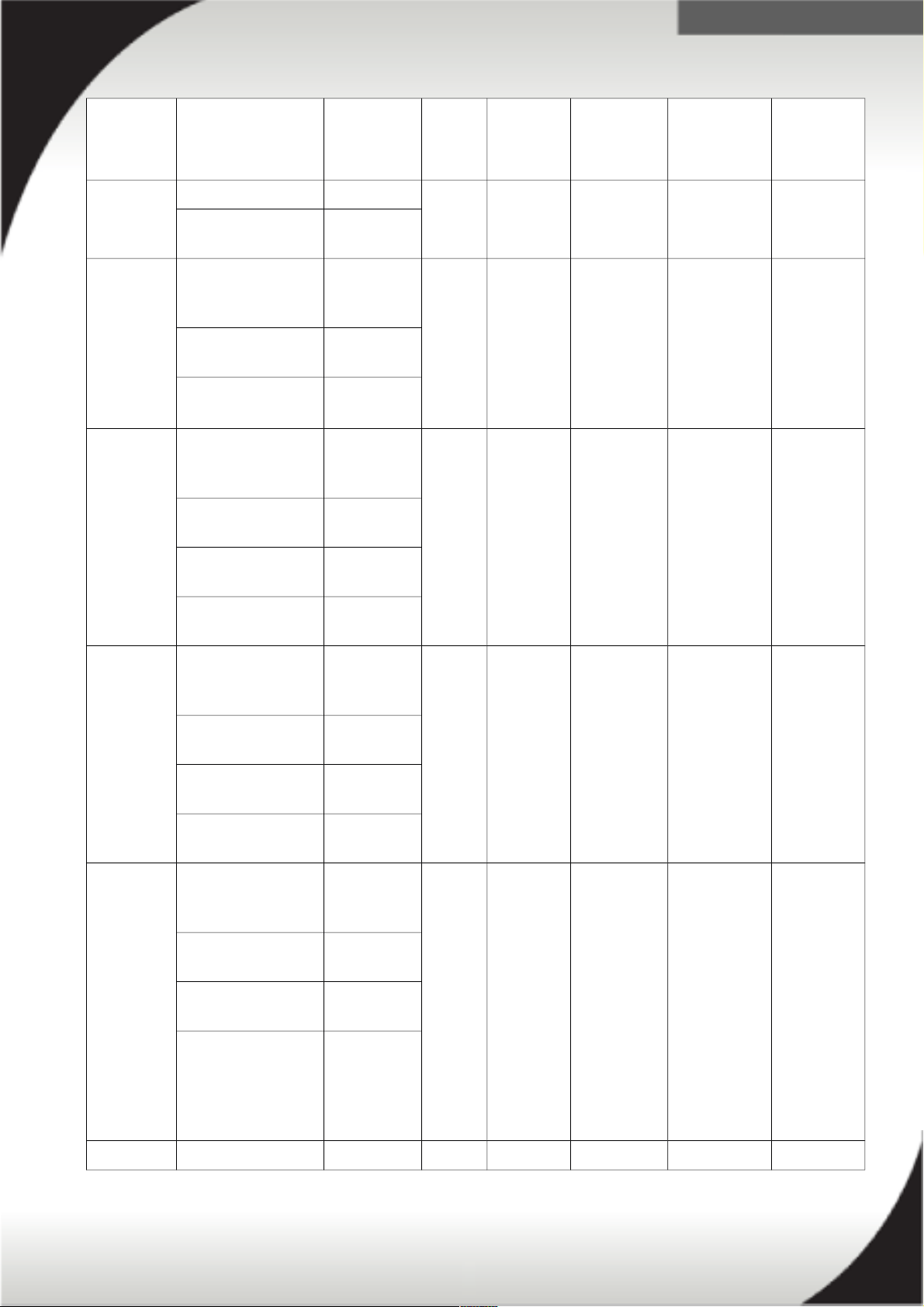

Enterprise PDUs - International

71762NX System x Ultra

Density

Enterprise 1U PDU

C19 PDU (WW)

40K9612 1ph 220V-

240V

32A IEC 309

P+N+G

9 / C19

3 / C13

40K9613 1ph 220V-

240V

63A IEC 309

P+N+G

40K9617 1ph 230V-

240V

32A AUS/NZ

3112

40K9618 1ph 220V 30A KSC 8305

40K9611 3ph Y 380V-

415V

32A

(32A/ph)

IEC 309

3P+N+G

47C2495 3ph Y 380V-

415V

16A

(16A/ph)

IEC 309

3P+N+G

71762MX System x Ultra

Density

Enterprise PDU

C19 1U PDU+ (WW)

40K9612 1ph 220V-

240V

32A IEC 309

P+N+G

9 / C19

3 / C13

40K9613 1ph 220V-

240V

63A IEC 309

P+N+G

40K9617 1ph 230V-

240V

32A AUS/NZ

3112

40K9618 1ph 220V 30A KSC 8305

40K9611 3ph Y 380V-

415V

32A

(32A/ph)

IEC 309

3P+N+G

47C2495 3ph Y 380V-

415V

16A

(16A/ph)

IEC 309

3P+N+G

39M2816 System x DPI C13

Enterprise 1U PDU

without line cord

Monitored

40K9612 1ph 220V-

240V

32A IEC 309

P+N+G

12 / C13

40K9613 1ph 220V-

240V

63A IEC 309

P+N+G

40K9617 1ph 230V-

240V

32A AUS/NZ

3112

40K9618 1ph 220V 30A KSC 8305

40K9611 3ph Y 380V-

415V

32A

(32A/ph)

IEC 309

3P+N+G

47C2495 3ph Y 380V-

415V

16A

(16A/ph)

IEC 309

3P+N+G

24

.

Part

Number

Description Line cord

part

number

Phase

(ph)

Voltage

(V)

Line cord

rating

(Derated)

Line cord

plug

Number /

Type of

outlet

39Y8941 DPI Single Phase

C13 Enterprise 1U

PDU without line

cord

40K9612 1ph 220V-

240V

32A IEC 309

P+N+G

12 / C13

40K9613 1ph 220V-

240V

63A IEC 309

P+N+G

40K9617 1ph 230V-

240V

32A AUS/NZ

3112

40K9618 1ph 220V 30A KSC 8305

40K9611 3ph Y 380V-

415V

32A

(32A/ph)

IEC 309

3P+N+G

47C2495 3ph Y 380V-

415V

16A

(16A/ph)

IEC 309

3P+N+G

39Y8948 DPI Single Phase

C19 Enterprise 1U

PDU

without line cord

40K9612 1ph 220V-

240V

32A IEC 309

P+N+G

6 / C19

40K9613 1ph 220V-

240V

63A IEC 309

P+N+G

40K9617 1ph 230V-

240V

32A AUS/NZ

3112

40K9618 1ph 220V 30A KSC 8305

40K9611 3ph Y 380V-

415V

32A

(32A/ph)

IEC 309

3P+N+G

47C2495 3ph Y 380V-

415V

16A

(16A/ph)

IEC 309

3P+N+G

25

.

Part

Number

Description Line cord

part

number

Phase

(ph)

Voltage

(V)

Line cord

rating

(Derated)

Line cord

plug

Number /

Type of

outlet

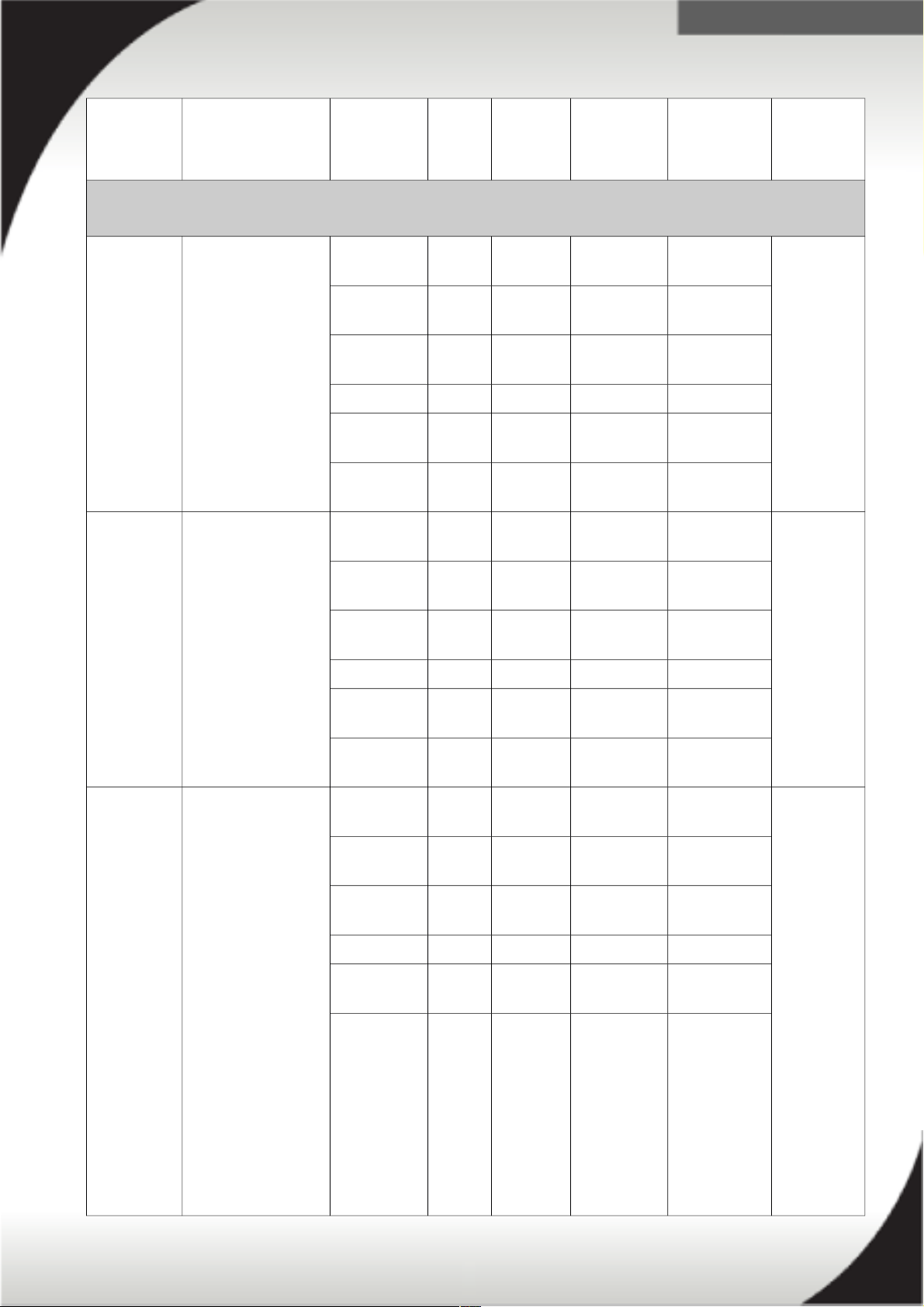

Front-end PDUs - North America

39Y8938 30 amp/125V

Front-end PDU

Included 1ph 125V 30A (24A) NEMA

L5-30P

3 / C19

39Y8939 30 amp/240V

Front-end ½ U PDU

Included 1ph 200V-

240V

30A (24A) NEMA

L6-30P

3 / C19

39Y8940 60 amp Front-end

½ U PDU

Included 1ph 200V-

240V

60A (48A) IEC 309

2P+G

3 / C19

Front-end PDUs - International

39Y8934 DPI 32 amp Front-

end ½ U PDU

Included 1ph 200V-

240V

32A IEC 309

P+N+G

3 / C19

39Y8935 DPI 63 amp Front-

end ½ U PDU

Included 1ph 200V-

240V

63A IEC 309

P+N+G

3 / C19

26

.

Part

Number

Description Line cord

part

number

Phase

(ph)

Voltage

(V)

Line cord

rating

(Derated)

Line cord

plug

Number /

Type of

outlet

Universal Rack PDUs

39Y8951 DPI Universal Rack

PDU with US LV

and HV LC

Included 1ph 200V-

240V

20A IEC 320

C19 to

C20

7 / C13

Optional line cord

2.0m

39M5388

39Y8952 DPI Universal Rack

1U PDU with

CEE7-VII Europe

LC

1

Included 1ph 230V 16A CEE7-VII

Europe

7 / C13

Optional line cord

1.8m

39M5281

Optional line cord

2.5m

39M5282

Optional line cord

4.3m

39M5283

39Y8953 DPI Universal Rack

1U PDU with

Denmark LC

Included 1ph 230V 16A 309 P+N+G 7 / C13

Optional line cord

1.8m

39M5321

Optional line cord

2.5m

39M5322

Optional line cord

4.3m

39M5323

39Y8954 DPI Universal Rack

1U PDU with Israel

LC

Included 1ph 220V 16A Israel SI-32 7 / C13

Optional line cord

1.8m

39M5309

Optional line cord

2.5m

39M5310

Optional line cord

4.3m

39M5311

39Y8955 DPI Universal Rack

1U PDU with Italy

LC

Included 1ph 230V 16A Italy CEI 23-167 / C13

Optional line cord

1.8m

39M5297

Optional line cord 39M5298

1. While line cord Amperage (A) varies from country to country the Universial Rack PDU has a 15A internal breaker and

is limited to 15A.

27

.

Part

Number

Description Line cord

part

number

Phase

(ph)

Voltage

(V)

Line cord

rating

(Derated)

Line cord

plug

Number /

Type of

outlet

2.5m

Optional line cord

4.3m

39M529

39Y8956 DPI Universal Rack

1U PDU with South

Africa LC

Included 1ph 220V-

250V

16A South Africa

SABS 164

7 / C13

Optional line cord

2.5m

39M5290

Optional line cord

4.3m

39M5291

39Y8957 DPI Universal Rack

1U PDU with UK

LC

2

Included 1ph 230V 13A UK BS

1363/A

7 / C13

Optional line cord

1.8m

39M5293

Optional line cord

2.5m

39M5294

Optional line cord

4.3m

39M5294

39Y8958 DPI Universal Rack

1U PDU with

AUS/NZ LC

Included 1ph 230V-

240V

15A Aus/NZ

3112

Australia/NZ

7 / C13

Optional line cord

1.8m

39M5329

Optional line cord

2.5m

39M5330

Optional line cord

4.3m

39M5331

39Y8959 DPI Universal Rack

1U PDU with China

LC

Included 1ph 220V 16A China GB

2099.1

7 / C13

Optional line cord

1.8m

39M5353

Optional line cord

2.5m

39M5354

Optional line cord

4.3m

39M5355

39Y8962 DPI Universal Rack Included 1ph 220V 16A Argentina 7 / C13

2. The Universal Rack PDU is limited to 13A total capacity due to the line cord current capacity of 13A.

28

.

Part

Number

Description Line cord

part

number

Phase

(ph)

Voltage

(V)

Line cord

rating

(Derated)

Line cord

plug

Number /

Type of

outlet

1U

PDU (Argentina)

IRAM 2073

Optional line cord

1.8m

39M5341

Optional line cord

2.5m

39M5342

Optional line cord

4.3m

39M5343

39Y8960 DPI Universal Rack

1U PDU (Brazil)

Included 1ph 220V-

240V

15A Brazil NBR

14136

7 / C13

Optional line cord

1.8m

39M5357

Optional line cord

2.5m

39M5358

Optional line cord

4.3m

39M5359

39Y8961 DPI Universal Rack

1U PDU (India)

Included 1ph 230V 16A India IS

6538

7 / C13

Optional line cord

1.8m

39M5444

Optional line cord

2.5m

39M5445

Optional line cord

4.3m

39M5446

29

.

Part

Number

Description Line cord

part

number

Phase

(ph)

Voltage

(V)

Line cord

rating

(Derated)

Line cord

plug

Number /

Type of

outlet

0U Basic PDUs - North America

46M4128 System x 0U 24 C13

30A PDU

Attached 1ph 200V-

240V

30A (24A) NEMA L6-

30P

24 / C13

46M4125 System x 0U 24 C13

30A 3ph PDU

Attached 3ph Δ 208V 30A

(13.85A/ph)

NEMA

L21-30P

24 / C13

46M4140 System x 0U 12

C19/12

C13 60A 3ph PDU

Attached 3ph Δ 208V 50A

(23.09A/ph)

CS8365L 12 / C19

12 / C13

0U Basic PDUs - International

46M4131 System x 0U 24 C13

32A PDU

Attached 1ph 200V-

240V

32A IEC 309

P+N+G

24 / C13

46M4122 System x 0U 24 C13

16A 3ph PDU

Attached 3ph Y 380V-

415V

16A

(16A/ph)

IEC 309

3P+N+G

24 / C13

46M4143 System x 0U 12

C19/12

C13 32A 3ph PDU

Attached 3ph Y 380V-

415V

32A

(32A/ph)

IEC 309

3P+N+G

12 / C19

12 / C13

See the “System x PDU Technical Reference – North America” and the “System x

PDU Technical Reference – International”, for more information on System x’s

System x PDUs.

http://www.ibm.com/support/entry/portal/docdisplay?lndocid=LNVO-PWRCONF

30

Loading...

Loading...