Page 1

Litho U.S.A.

2015

INSTALLATION

INSTRUCTIONS

WARNING

Improper installation, adjustment, alteration, ser

vice or maintenance can cause property damage,

personal injury or loss of life. Installation and ser

vice must be performed by a licensed professional

HVAC installer or equivalent or service agency.

CAUTION

Danger of sharp metallic edges. Can cause injury.

Take care and wear protective clothing when

servicing unit to avoid accidental contact with

sharp edges.

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Table Of Contents

Dimensions Page 2.................................

Shipping and Packing List Page 3....................

General Page 3....................................

Requirements Page 3...............................

Unit Support Page 4................................

Duct Connection Page 4............................

ZHA036 (3 TON)

ZHB036 (3 TON)

ZHA048 (4 TON)

ZHB048 (4 TON)

ZHA060 (5 TON)

ZHB060 (5 TON)

HEAT PUMP PACKAGED UNITS

507111-02

2/2015

Supersedes 507111-01

Rigging Unit For Lifting Page 4.......................

Horizontal Air Discharge Page 5......................

Condensate Drains Page 5..........................

Electrical Connections Page 6.......................

Blower Operation and Adjustments Page 7............

Start-Up Page 16....................................

Defrost Control Board Page 22........................

Service Page 23....................................

ZH 036, 048, 060 PARTS ARRANGEMENT

CONTROL

PANEL

OUTDOOR

COIL FAN

COMPRESSOR

OUTDOOR

COIL

SIDE POWER

ENTRY

EVAPORATOR

COIL

BLOWER

MOTOR

BLOWER

HOUSING

ELECTRIC HEAT

(OPTIONAL)

TB2 UNIT

TERMINAL

STRIP

UNIT FUSE

BOTTOM POWER

ENTRY

Page 2

ZH 036, 048, 060, DIMENSIONS in (mm)

Holes required for Optional Bottom Power Entry Kit

BOTTOM POWER ENTRY

Conduit Fittings

(Provided in Kit)

A

B

C

Threaded

1/2

1/2

3/4

Wire

Use

ACC.

24V

POWER

47-1/4

(1200)

BASE

Hole Diameter

Required in

Unit Base (Max.)

7/8 (23)

7/8 (23)

1-1/8 (29)

16-1/8

(410)

13-5/8

(346)

11-1/8

(283)

24-9/16

(624)

BOTTOM

RETURN

AIR OPENING

A

B

C

BOTTOM

POWER

ENTRY

(See Table)

75-7/8

(1927)

12-1/8

(308)

TOP VIEW (Base)

25-5/8

(651)

BOTTOM

SUPPLY

OPENING

AIR

5-1/8

(130)

17-3/4

(451)

5-3/4

(146)

5-1/8

(130)

10-7/8

(276)

29

(737)

45-1/4

(1149)

44-7/8 (1140) ZH 060

ZHB036, 048

36-7/8 (937) ZHA036, 046

1

(25)

47-1/4

(1200)

(25)

BASE

POWER

ENTRY

1

(25)

Either

side

3-1/2

(89)

1

END VIEW

ZH 036, 048, 060

LIFTING HOLES

(For rigging)

73-3/4

(1873)

FRONT VIEW

Page 2

3-1/2 (89)

TYP.

11-7/8

(302)

5-3/4

(146)

6-1/2

(165)

CONDENSATE

OUTLET

HORIZONTAL

SUPPLY

17-3/8

(441)

27

(686)

31

(787)

END VIEW

6-1/4

(159)

RETURN

HORIZONTAL

5-9/16

(141)

8-3/8

(213)

10-7/8

(276)

25-3/4

(654)

5-3/4

(146)

Page 3

Shipping and Packing List

Package 1 of 1 contains:

1 - Assembled unit

Check unit for shipping damage. Receiving party should

contact last carrier immediately if shipping damage is

found.

General

These instructions are intended as a general guide and

do not supersede local codes in any way. Authorities

having jurisdiction should be consulted before

installation.

Availability of units and options varies by brand.

Requirements

NOTICE

Roof Damage!

This system contains both refrigerant and oil.

Some rubber roofing material may absorb oil,

causing the rubber to swell. Bubbles in the rubber

roofing material can cause leaks. Protect the roof

surface to avoid exposure to refrigerant and oil

during service and installation. Failure to follow

this notice could result in damage to roof surface.

The National Electric Code (ANSI/NFPA No. 70-1984) is

available from:

National Fire Protection Association

1 Batterymarch Park

PO Box 9101

Quincy, MA 02269-9101

The ZH unit is CSA certified as a heat pump with cooling

and with or without auxiliary electric heat for

non-residential use only at the clearances to combustible

materials as listed on the unit nameplate and in figure 1.

Installation of ZH heat pumps must conform with standards

in National Fire Protection Association (NFPA) “Standard

for Installation of Air Conditioning and Ventilating Systems

NFPA No. 90A,” “Standard for Installation of Residence

Type Warm Air Heating and Air conditioning Systems NFPA

No. 90B,” local municipal building codes and

manufacturer's installation instructions.

UNIT CLEARANCES

HORIZONTAL

OUTDOOR

AIR HOOD

C

D

A

OUTDOOR

AIR HOOD

B

Installation of CSA certified units must also conform with

current standard C273.5 “Installation Requirements for

Heat Pumps” and applicable local codes. Authorities

having jurisdiction should be consulted before

installation.

Use of this unit as a construction heater or air conditioner

is not recommended during any phase of construction.

Very low return air temperatures, harmful vapors and

operation of the unit with clogged or misplaced filters will

damage the unit.

If this unit has been used for heating or cooling of

buildings or structures under construction, the following

conditions must be met or the warranty will be void:

A room thermostat must control the unit. The use of

fixed jumpers that will provide continuous heating or

cooling is not allowed.

A pre-filter must be installed at the entry to the return

air duct.

The return air duct must be provided and sealed to

the unit.

FIGURE 1

1

Unit

Clearance

Service

Clearance

Minimum Opera

tion Clearance36(914)36(914)

*Clearance is 60 in. (1524mm) in horizontal air flow applications.

Note - Entire perimeter of unit base requires support when elevated above

mounting surface.

1

Service Clearance - Required for removal of serviceable parts.

Minimum Operation Clearance - Required clearance for proper unit operation.

A

in.(mm)Bin.(mm

36

(914)36(914)

C

in.(mm)Din.(mm)

)

36*

(914)36(914)

36*

(914)36(914)

To p

Clearance

Unob

structed

Unob

structed

Return air temperature range between 55°F (13°C)

and 80°F (27°C) must be maintained.

Air filters must be replaced and pre-filter must be

removed upon construction completion.

The unit components, duct system, air filters and

evaporator coil must be thoroughly cleaned following

final construction clean-up.

The unit operating conditions (including airflow,

cooling operation, and heating operation) must be

verified according to these installation instructions.

Page 3

507111-02 2/2015

Page 4

WARNING

Electric shock hazard and danger of

explosion. Can cause injury, death or

product or property damage. Turn off

electrical power to unit before

performing any maintenance or

servicing operations on the unit.

IMPORTANT

The Clean Air Act of 1990 bans the intentional vent

ing of refrigerant (CFC's and HCFC's) as of July 1,

1992. Approved methods of recovery, recycling or

reclaiming must be followed. Fines and/or incar

ceration may be levied for non-compliance.

Unit Support

NOTE - Securely fasten roof frame to roof per local codes.

NOTE-When installing unit on a combustible surface for

downflow discharge applications, the Z1CURB roof

mounting frame is required.

B - Horizontal Discharge Applications

1- Specified installation clearances must be maintained

when installing units. Refer to figure 1.

2- Top of support slab should be at least 4” (102mm)

above the finished grade and located so no run-off

water from higher ground can collect around the unit.

3- Units require support along all four sides of unit base.

Supports must be constructed of steel or suitably

treated wood materials.

Duct Connection

All exterior ducts, joints, and openings in roof or building

walls must be insulated and weatherproofed with flashing

and sealing compounds in accordance with applicable

codes. Any duct passing through an unconditioned space

must be insulated.

ZH 036, 048, 060 units are installed on Z1CURB frames.

A - Downflow Discharge Application

Roof Mounting with Z1CURB

1- The Z1CURB roof mounting frame must be installed,

flashed and sealed in accordance with the

instructions provided with the frame.

2- The Z1CURB roof mounting frame should be square

and level to 1/16” per linear foot (5mm per linear

meter) in any direction.

3- Duct must be attached to the roof mounting frame

and not to the unit; supply and return plenums must

be installed before setting the unit.

Installer's Roof Mounting Frame

Many types of roof frames can be used to install the unit,

depending upon different roof structures. Items to keep

in mind when using the building frame or supports are:

1- The unit base is fully enclosed and not insulated, so

an enclosed, insulated frame is required.

2- The frames or supports must be constructed with

non-combustible materials and should be square and

level to 1/16” per linear foot (5mm per linear meter)

in any direction.

3- Frame or supports must be high enough to prevent

any form of moisture from entering unit.

Recommended minimum frame height is 14”

(356mm).

4- Duct must be attached to the roof mounting frame

and not to the unit. Supply and return plenums must

be installed before setting the unit.

5- Units require support along all four sides of unit base.

Supports must be constructed of steel or suitably

treated wood materials.

ZH 036, 048, 060

Page 4

!

CAUTION

In downflow applications, do not drill or punch

holes in base of unit. Leaking in roof may occur if

unit base is punctured.

Rigging Unit For Lifting

1- Connect rigging to the unit base using both holes in

each corner. See figure 2.

2- All panels must be in place for rigging.

3- Place field‐provided H‐style pick in place just above

top edge of unit. Frame must be of adequate

strength and length. (H-style pick prevents damage

to unit.)

UNIT

ZH

*Maximum weight with all available

installed accessories.

CAUTION: DO NOT

WALK ON UNIT.

WEIGHT*

LBS. KG.

664 301

Lifting Point Should

Be Directly Above

Center Of Gravity.

FIGURE 2

Page 5

Horizontal Air Discharge

Unit is shipped with panels covering the horizontal supply

and return air openings. See figure 3.

UNIT SUPPLY AND RETURN AIR OPENINGS

HORIZONTAL

HORIZONTAL

SUPPLY AIR

OPENING

RETURN AIR

OPENING

4- Install return air duct on the intake air side of the

horizontal economizer. See figure 5.

5- Horizontal economizer and return air duct must be

field-supported.

HORIZONTAL RETURN AIR DUCTWORK

WITH ECONOMIZER

HOOD

PROVIDED

WITH

ECONOMIZER

This opening not used

in horizontal applica

tions with economizer

OPTIONAL

HORIZONTAL

ECONOMIZER

UNIT

DOWNFLOW

SUPPLY AIR

OPENING

DOWNFLOW

RETURN AIR

OPENING

FIGURE 3

1- Remove horizontal covers and place a bead of silicone

sealant on the underside of the duct cover flanges. See

figure 4.

2- Position covers over downflow openings. Secure

covers with self-drilling screws in at least two places on

each cover. Drill through duct cover side into flange of

base pan.

3- Place a bead of silicone between insulation and duct

cover to seal in insulation edges. Let silicone dry before

running gas or electric heat.

Units Equipped With An Optional Horizontal Economizer

1- Install the horizontal supply air cover over the down

flow supply air opening as described above.

2- Leave the horizontal return air cover in place.

3- Locate the extra horizontal return cover that is

included with the horizontal economizer kit. Install as

described in previous section.

INSTALL DUCT COVERS - SIDE VIEW

APPLY SILICONE

SEALANT TO

FLANGES

NOT TO

SCALE

FLANGE AND UNIT INSULATION

DUCT COVER

FLANGES

UNIT BASE

FLANGES

APPLY SILICONE SEALANT

BETWEEN DUCT COVER

INSULATION

HORIZONTAL

SUPPLY AIR DUCT

(FIELD-PROVIDED)

HORIZONTAL

RETURN AIR DUCT

(FIELD-PROVIDED)

FIGURE 5

Condensate Drains

Make drain connection to the drain coupling provided

on unit.

Note - The drain pan is made with a glass reinforced

engineered plastic capable of withstanding typical joint

torque but can be damaged with excessive force. Tighten

pipe nipple hand tight and turn an additional quarter turn.

A trap must be installed between drain connection and an

open vent for proper condensate removal. See figure 6. It is

sometimes acceptable to drain condensate onto the roof or

grade; however, a tee should be fitted to the trap to direct

condensate downward. The condensate line must be

vented. Check local codes concerning condensate disposal.

Refer to pages 1 and 2 for condensate drain location.

CONDENSATE SIDE DRAIN CONNECTION

CAULK AROUND CONDENSATE COUPLING

NOTE - Allow clearance to

open doors when installing

condensate piping.

Minimum Pitch

1” (25 mm) per

10' (3 m) of line

OPEN VENT

UNIT

MOUNTING

FRAME

FIGURE 4

FIGURE 6

Page 5

507111-02 2/2015

Page 6

Electrical Connections

POWER SUPPLY

Do not apply power or close disconnect switch until

installation is complete. Refer to start-up directions. Refer

closely to unit wiring diagram.

Refer to unit nameplate for minimum circuit ampacity

and maximum fuse size.

1- Units are factory-wired for 240, 460, or 575 volt supply.

For 208V supply

from the 208V terminal on the control transformer. Move

the wire from the transformer 240V terminal to the 208V

terminal. Place the insulated terminal cover on the

unused 240V terminal.

2- Route power through the side or bottom power

entry area. For bottom power entry, a bottom

power entry kit must be used. Connect power

wiring to K1/K3 contactors in control box. See

figure 7. On units equipped with electric heat, route

power wiring to TB2; see parts arrangement for

location. See unit wiring diagram.

, remove the insulated terminal cover

POWER WIRING

IMPORTANT - Unless field thermostat wires are rated

for maximum unit voltage, they must be routed away

from line voltage wiring.

B - Control Wiring

1- Route thermostat cable or wires from subbase to

control panel (refer to unit dimensions to locate

bottom and side power entry).

Use18 AWG wire for all applications using remotely

installed electro-mechanical and electronic

thermostats.

2- Install thermostat assembly in accordance with

instructions provided with thermostat.

3- Connect thermostat wiring to low voltage leads in

control box. Wire as shown in figure 8 for

electro-mechanical and electronic thermostats. If

using other temperature control devices or energy

management systems see instructions and wiring

diagram provided by manufacturer.

IMPORTANT-Terminal connections at the wall plate or

subbase must be made securely. Loose control wire

connections may allow unit to operate but not with proper

response to room demand.

Y, G, J, M

VOLT ONLY

K1

CONNECT FIELD-

SUPPLIED WIRING

TO K1/K3

K3

FIGURE 7

CONTROL WIRING

A - Thermostat Location

Room thermostat mounts vertically on a standard 2” X 4”

handy box or on any non-conductive flat surface.

Locate thermostat approximately 5 feet (1524 mm)

above the floor in an area with good air circulation at

average temperature. Avoid locating the room

thermostat where it might be affected by:

-drafts or dead spots behind doors and in corners

-hot or cold air from ducts

-radiant heat from sun or appliances

-concealed pipes and chimneys

ZH 036, 048, 060

Page 6

24 VOLT FIELD WIRING WITH ELECTRONIC AND

ELECTRO-MECHANICAL THERMOSTATS

UNIT CONTROL AREA

A2 THERMOSTAT

Note - On electro-mechanical thermo

stats set anticipator at 0.1 amps.

TO CMC1; DO NOT

REMOVE FACTORY

INSTALLED WIRES

NOT ALL TERMINALS

ARE FOUND ON ALL

THERMOSTATS

Jumper terminals R and

OC when thermostat has

no night setback terminals.

FIGURE 8

Page 7

Blower Operation and Adjustments

Units are equipped with belt drive blowers; available

drive varies by model.

Blower performance data is based on static pressure

readings taken in locations shown in figure 9.

Note - Static pressure readings can vary if not taken

where shown.

IMPORTANT

Three phase scroll compressors must be phased

sequentially for correct compressor and blower

rotation. Follow “COOLING START-UP” section of

installation instructions to ensure proper compres

sor and blower operation.

A - Blower Operation

Initiate blower demand at thermostat according to

instructions provided with thermostat. Unit will cycle on

thermostat demand. The following steps apply to

applications using a typical electro-mechanical

thermostat.

1- Set thermostat or temperature control device fan

switch to AUTO or ON. With fan switch in ON position,

blower will operate continuously. With fan switch in

AUTO position, the blower will cycle with demand.

2- Blower and entire unit will be off when thermostat or

temperature control device system switch is in OFF

position.

B - Determining Unit CFM

1- The following measurements must be made with air

filters in place.

2- With all access panels in place, measure static

pressure external to unit (from supply to return).

3- Measure the indoor blower wheel RPM.

4- Referring to pages 9-14, use static pressure and

RPM readings to determine unit CFM. Use

option/accessory air resistance table on page 15

when installing units with any of the options or

accessories listed. Refer to table 3 for minimum

airflow when electric heat is installed.

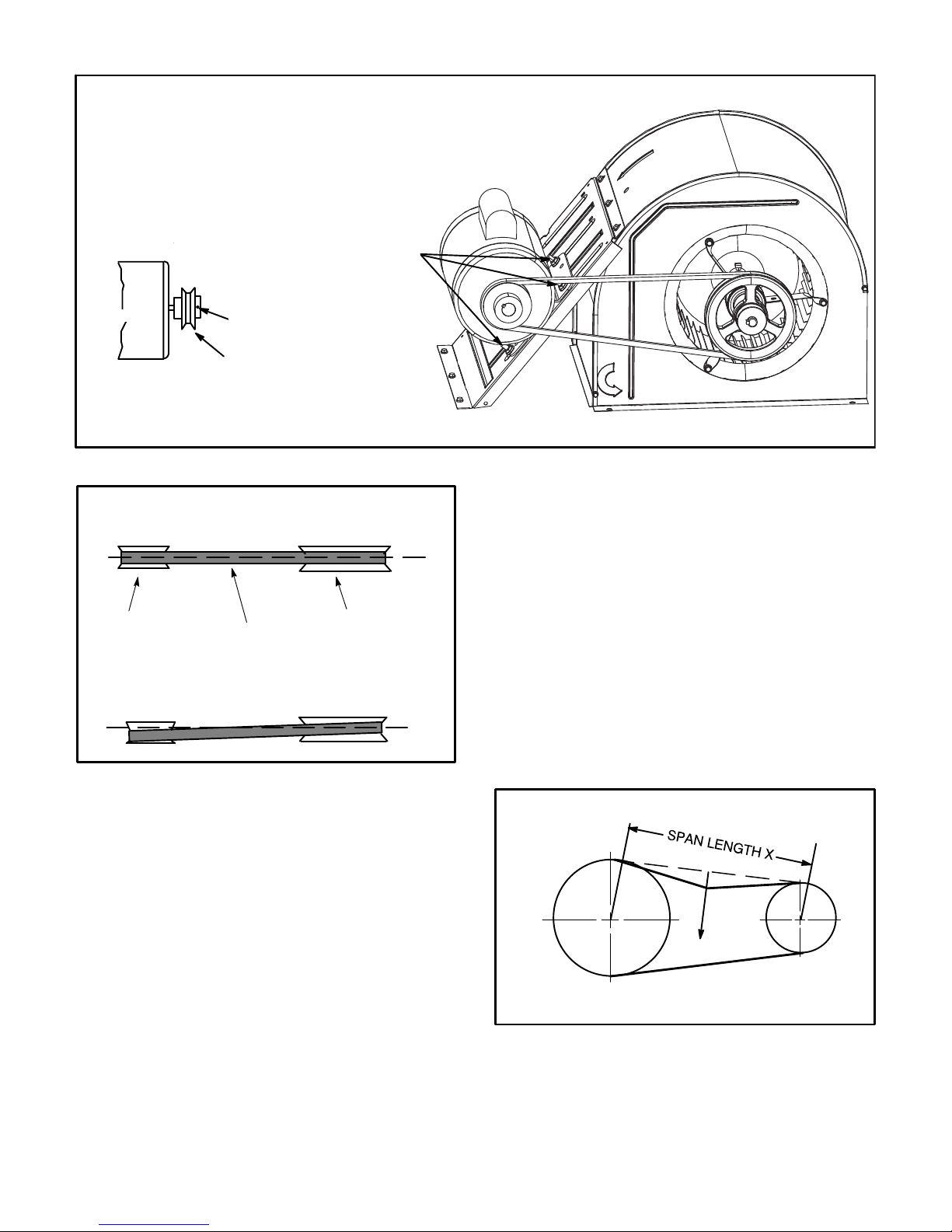

5- The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley

clockwise to increase CFM. Turn counterclockwise to

decrease CFM. See figure 10. Do not exceed

minimum and maximum number of pulley turns as

shown in table 1.

TABLE 1

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt Min. Turns Open Maxi. Turns Open

A Section No minimum 5

C - Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are maintained.

Tension new belts after a 24-48 hour period of operation.

This will allow belt to stretch and seat grooves. Make sure

blower and motor pulley are aligned as shown in figure 11.

INSTALLATIONS WITH DUCTWORK

ROOFTOP UNIT

READING LOCATION

SUPPLY

MAIN

RE

TURN

OFF OF MAIN RUN

DUCT RUN

LOCATION OF STATIC PRESSURE READINGS

INSTALLATIONS WITH CEILING DIFFUSERS

ROOFTOP UNIT

RETURN AIR

SUPPLY

FIRST BRANCH

SUPPLY AIR

READING

LOCATION

SUPPLY AIR

READING

LOCATION

DIFFUSER

FIGURE 9

Page 7

RETURN AIR

READING

RE

TURN

LOCATION

507111-02 2/2015

Page 8

BLOWER ASSEMBLY

TO INCREASE BELT TENSION

1-Loosen four bolts securing motor base to mounting frame.

2-Slide the motor downward to tighten the belt.

3-Tighten four bolts on motor base.

LOOSEN FOUR BOLTS

AND SLIDE BLOWER

MOTOR DOWNWARD

SIDE VIEW

TO TIGHTEN BELT

MOTOR

TO INCREASE CFM

LOOSEN ALLEN SCREW &

TURN PULLEY CLOCKWISE

ALLEN

SCREW

PULLEY

TO DECREASE CFM

TURN PULLEY

COUNTERCLOCKWISE

FIGURE 10

PULLEY ALIGNMENT

ALIGNED

MOTOR

PULLEY

BELT

NOT ALIGNED

BLOWER

PULLEY

FIGURE 11

1- Loosen four bolts securing motor base to mounting

frame. See figure 10.

2- Apply perpendicular force to center of span (X) with

enough pressure to deflect belt 1/64” for every inch

of span length or 1.5mm per 100mm of span length.

Example: Deflection distance of a 40” span would be

40/64” or 5/8”.

Example: Deflection distance of a 400mm span

would be 6mm.

3- Measure belt deflection force. For a used belt, the

deflection force should be 5 lbs. (35kPa). A new belt

deflection force should be 7 lbs. (48kPa).

A force below these values indicates an

undertensioned belt. A force above these values

indicates an overtensioned belt.

MEASURE BELT TENSION

2- To increase belt tension -

Slide blower motor downward to tighten the belt. This

increases the distance between the blower motor and

the blower housing.

To loosen belt tension -

Slide blower motor upward to loosen the belt. This

decreases the distance between the blower motor

and the blower housing.

3- Tighten four bolts securing motor base to the

mounting frame.

D - Check Belt Tension

Overtensioning belts shortens belt and bearing life.

Check belt tension as follows:

1- Measure span length X. See figure 12.

ZH 036, 048, 060

FORCE

DEFLECTION 1/64” PER INCH OF SPAN

OR 1.5mm PER 100mm OF SPAN

FIGURE 12

E-Field-Furnished Blower Drives

For field-furnished blower drives, use pages 9-14 to

determine BHP and RPM required. Reference page 15

for additional air resistance and drive kit numbers. See

table 2 for drive component manufacturer's numbers.

Page 8

Page 9

BLOWER DATA - BELT DRIVE - ZHA036

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 15 for blower motors and drives and wet coil and options/accessory air resistance data.

DOWNFLOW

Air

Volume

cfm

900 562 0.16 629 0.18 699 0.19 771 0.2 840 0.22 904 0.24 962 0.26 1015 0.29

1000 586 0.18 654 0.2 725 0.21 796 0.23 864 0.25 927 0.27 983 0.3 1034 0.33

1100 612 0.2 681 0.22 752 0.24 823 0.26 890 0.28 950 0.31 1004 0.34 1054 0.37

1200 641 0.23 711 0.25 783 0.27 852 0.29 917 0.32 975 0.35 1027 0.39 1074 0.42

1300 673 0.25 744 0.28 815 0.3 882 0.33 944 0.36 1000 0.4 1050 0.44 1096 0.48

1400 709 0.29 779 0.32 849 0.34 914 0.37 973 0.41 1026 0.45 1074 0.49 111 8 0.53

1500 747 0.33 816 0.36 883 0.39 945 0.42 1001 0.46 1052 0.51 1098 0.55 1141 0.59

Air

Volume

cfm

900 1065 0.32 1112 0.35 1158 0.38 1202 0.41 1243 0.44 1284 0.48 1323 0.52 1364 0.55

1000 1082 0.36 1128 0.39 1173 0.42 1216 0.45 1257 0.49 1297 0.53 1336 0.57 1375 0.6

1100 1100 0.4 1145 0.44 1189 0.47 1231 0.51 1272 0.54 1311 0.58 1349 0.62 1388 0.66

1200 111 9 0.45 1163 0.49 1206 0.52 1247 0.56 1287 0.6 1326 0.64 1364 0.68 1402 0.72

1300 1139 0.51 1182 0.55 1224 0.58 1265 0.62 1304 0.66 1342 0.71 1379 0.75 1416 0.79

1400 1160 0.57 1202 0.61 1243 0.65 1283 0.69 1322 0.73 1359 0.78 1396 0.82 1432 0.87

1500 1182 0.64 1223 0.68 1263 0.72 1303 0.76 1341 0.81 1378 0.85 1414 0.9 1449 0.94

HORIZONTAL

Air

Volume

cfm

900 580 0.14 649 0.17 721 0.19 794 0.22 868 0.24 938 0.27 998 0.3 1045 0.33

1000 612 0.17 681 0.19 752 0.22 825 0.25 897 0.27 963 0.3 1017 0.33 1061 0.37

1100 647 0.2 717 0.23 788 0.26 858 0.28 926 0.31 986 0.34 1036 0.38 1077 0.41

1200 687 0.23 757 0.26 826 0.29 893 0.32 955 0.35 1008 0.39 1054 0.42 1095 0.46

1300 730 0.27 798 0.3 864 0.33 926 0.37 982 0.4 1030 0.44 1073 0.47 1116 0.51

1400

1500 820 0.36 881 0.4 939 0.44 993 0.49 1039 0.53 1082 0.56 1124 0.59 1168 0.62

Air

Volume

cfm

900 1091 0.36 1140 0.38 1188 0.4 1232 0.43 1272 0.46 1309 0.49 1346 0.53 1383 0.57

1000 1105 0.4 1154 0.42 1201 0.45 1245 0.47 1284 0.5 1321 0.54 1357 0.58 1394 0.62

1100 1121 0.44 1169 0.47 1216 0.49 1259 0.52 1298 0.56 1335 0.6 1370 0.64 1406 0.69

1200 1139 0.49 1187 0.52 1234 0.54 1276 0.58 1314 0.62 1350 0.66 1385 0.71 1421 0.75

1300 1161 0.54 1208 0.57 1254 0.6 1295 0.64 1332 0.69 1366 0.73 1401 0.78 1436 0.83

1400 1185 0.59 1232 0.63 1276 0.67 1315 0.71 1351 0.76 1384 0.81 1419 0.86 1454 0.9

1500 1212 0.66 1257 0.7 1299 0.74 1337 0.79 1371 0.84 1404 0.89 1438 0.94 1473 0.99

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Furnished Kit ZA01

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Furnished Kit ZA01 Kit ZA04

775 0.31 840 0.34 902 0.38 959 0.42 1009 0.46 1054 0.5 1096 0.53 1140 0.56

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

External Static - in. w.g.

External Static - in. w.g.

Kit ZA04

External Static - in. w.g.

External Static - in. w.g.

Kit ZA04

Page 9

Page 10

BLOWER DATA - BELT DRIVE - ZHA048

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 15 for blower motors and drives and wet coil and options/accessory air resistance data.

DOWNFLOW

Air

Volume

cfm

1200 641 0.23 711 0.25 783 0.27 852 0.29 917 0.32 975 0.35 1027 0.39 1074 0.42

1300 673 0.25 744 0.28 815 0.30 882 0.33 944 0.36 1000 0.40 1050 0.44 1096 0.48

1400 709 0.29 779 0.32 849 0.34 914 0.37 973 0.41 1026 0.45 1074 0.49 111 8 0.53

1500 747 0.33 816 0.36 883 0.39 945 0.42 1001 0.46 1052 0.51 1098 0.55 1141 0.59

1600 787 0.38 854 0.41 918 0.44 976 0.48 1030 0.52 1078 0.56 1123 0.61 1164 0.66

1700 827 0.43 892 0.46 952 0.49 1007 0.53 1058 0.58 1105 0.63 1148 0.68 1189 0.73

1800 868 0.48 929 0.52 986 0.55 1038 0.59 1087 0.64 1132 0.69 1174 0.75 1214 0.80

1900 907 0.54 966 0.58 1019 0.62 1069 0.66 111 6 0.71 1160 0.77 1200 0.82 1240 0.88

2000 946 0.60 1001 0.65 1053 0.69 1101 0.74 1146 0.79 1188 0.85 1228 0.91 1267 0.98

Air

Volume

cfm

1200 111 9 0.45 1163 0.49 1206 0.52 1247 0.56 1287 0.60 1326 0.64 1364 0.68 1402 0.72

1300 1139 0.51 1182 0.55 1224 0.58 1265 0.62 1304 0.66 1342 0.71 1379 0.75 1416 0.79

1400 1160 0.57 1202 0.61 1243 0.65 1283 0.69 1322 0.73 1359 0.78 1396 0.82 1432 0.87

1500 1182 0.64 1223 0.68 1263 0.72 1303 0.76 1341 0.81 1378 0.85 1414 0.90 1449 0.94

1600 1205 0.70 1245 0.75 1284 0.79 1323 0.84 1361 0.88 1397 0.93 1432 0.98 1467 1.03

1700 1228 0.78 1268 0.82 1307 0.87 1345 0.92 1382 0.97 1417 1.02 1452 1.07 1486 1.11

1800 1253 0.85 1292 0.91 1331 0.96 1368 1.01 1404 1.06 1439 1.11 1473 1.16 1506 1.21

1900 1279 0.94 1317 1.00 1355 1.05 1392 1.10 1427 1.16 1461 1.21 1494 1.26 1527 1.31

2000 1305 1.04 1343 1.10 1380 1.15 1416 1.21 1450 1.26 1484 1.32 1516 1.37 1549 1.42

HORIZONTAL

Air

Volume

cfm

1200 687 0.23 757 0.26 826 0.29 893 0.32 955 0.35 1008 0.39 1054 0.42 1095 0.46

1300 730 0.27 798 0.30 864 0.33 926 0.37 982 0.40 1030 0.44 1073 0.47 111 6 0.51

1400

1500 820 0.36 881 0.40 939 0.44 993 0.49 1039 0.53 1082 0.56 1124 0.59 1168 0.62

1600 864 0.42 921 0.46 976 0.51 1027 0.56 1072 0.60 111 3 0.63 1155 0.66 1198 0.69

1700 907 0.48 961 0.53 1013 0.58 1061 0.63 1105 0.67 1146 0.70 1187 0.73 1230 0.77

1800 948 0.56 999 0.61 1049 0.66 1096 0.71 1139 0.75 1180 0.78 1221 0.82 1262 0.86

1900 987 0.64 1037 0.69 1086 0.74 1132 0.79 1174 0.83 1214 0.86 1255 0.90 1295 0.95

2000 1028 0.73 1076 0.78 1123 0.83 1168 0.87 1210 0.91 1250 0.96 1289 1.00 1328 1.06

Air

Volume

cfm

1200 1139 0.49 1187 0.52 1234 0.54 1276 0.58 1314 0.62 1350 0.66 1385 0.71 1421 0.75

1300 1161 0.54 1208 0.57 1254 0.60 1295 0.64 1332 0.69 1366 0.73 1401 0.78 1436 0.83

1400 1185 0.59 1232 0.63 1276 0.67 1315 0.71 1351 0.76 1384 0.81 1419 0.86 1454 0.90

1500 1212 0.66 1257 0.70 1299 0.74 1337 0.79 1371 0.84 1404 0.89 1438 0.94 1473 0.99

1600 1242 0.73 1284 0.77 1324 0.82 1360 0.88 1394 0.93 1426 0.99 1460 1.04 1495 1.08

1700 1272 0.81 1312 0.86 1350 0.92 1385 0.98 1418 1.04 1451 1.09 1485 1.14 1519 1.19

1800 1302 0.90 1341 0.96 1377 1.02 1411 1.08 1444 1.15 1477 1.20 1510 1.25 1544 1.30

1900 1334 1.01 1371 1.07 1406 1.13 1439 1.20 1471 1.26 1504 1.32 1537 1.37 1571 1.41

2000 1365 1.12 1401 1.19 1435 1.25 1468 1.32 1500 1.38 1532 1.44 1565 1.49 1598 1.53

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Furnished Kit ZA02

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Kit ZA02 Kit ZA05

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP

Field Furnished Kit ZA02

775 0.31 840 0.34 902 0.38 959 0.42 1009 0.46 1054 0.50 1096 0.53 1140 0.56

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Kit ZA02 Kit ZA05

External Static - in. w.g.

External Static - in. w.g.

External Static - in. w.g.

RPM BHP RPM BHP RPM BHP RPM BHP

External Static - in. w.g.

Page 10

Page 11

BLOWER DATA - BELT DRIVE - ZHA060

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 15 for blower motors and drives and wet coil and options/accessory air resistance data.

DOWNFLOW

Air

Volume

cfm

1600 764 0.35 822 0.39 880 0.42 936 0.46 991 0.51 1042 0.55 1091 0.60 1136 0.64

1700 801 0.40 857 0.44 913 0.48 968 0.52 1020 0.57 1070 0.61 111 7 0.66 1162 0.71

1800 838 0.46 893 0.50 947 0.54 1000 0.58 1051 0.63 1099 0.68 1145 0.73 1188 0.78

1900 876 0.52 929 0.56 982 0.61 1033 0.65 1082 0.70 1129 0.75 1173 0.80 1215 0.85

2000 914 0.59 966 0.63 1017 0.68 1067 0.72 111 5 0.77 1160 0.83 1203 0.88 1244 0.94

2100 953 0.66 1004 0.71 1054 0.76 1102 0.81 1148 0.86 1192 0.92 1233 0.98 1273 1.04

2200 993 0.74 1042 0.79 1090 0.85 1137 0.90 1181 0.96 1224 1.02 1264 1.09 1303 1.15

2300 1033 0.83 1081 0.89 1128 0.94 1173 1.01 1216 1.07 1257 1.14 1296 1.20 1334 1.27

2400 1074 0.93 1120 0.99 1166 1.05 1209 1.12 1251 1.19 1291 1.26 1329 1.33 1366 1.41

Air

Volume

cfm

1600 1180 0.68 1222 0.72 1263 0.76 1303 0.80 1341 0.85 1378 0.90 1414 0.94 1449 0.99

1700 1204 0.75 1245 0.79 1285 0.84 1325 0.88 1362 0.93 1398 0.98 1434 1.03 1468 1.08

1800 1229 0.83 1270 0.87 1309 0.92 1347 0.97 1384 1.02 1420 1.07 1454 1.12 1488 1.17

1900 1256 0.91 1296 0.96 1334 1.01 1371 1.07 1407 1.12 1442 1.17 1476 1.23 1509 1.28

2000 1284 1.00 1322 1.06 1360 1.11 1396 1.17 1431 1.23 1465 1.28 1498 1.33 1531 1.38

2100 1312 1.10 1350 1.16 1386 1.22 1422 1.28 1456 1.34 1489 1.40 1521 1.45 1554 1.50

2200 1341 1.22 1378 1.28 1414 1.34 1448 1.41 1481 1.46 1513 1.52 1546 1.57 1578 1.62

2300 1371 1.34 1407 1.41 1442 1.47 1475 1.54 1507 1.59 1539 1.65 1571 1.70 1602 1.75

2400 1402 1.48 1436 1.55 1470 1.61 1503 1.67 1535 1.73 1566 1.79 1597 1.84 1628 1.89

HORIZONTAL

Air

Volume

cfm

1600 783 0.38 844 0.41 902 0.44 957 0.48 1008 0.52 1056 0.56 1100

1700 825 0.44 882 0.47 938 0.50 989 0.54 1038 0.57 1083 0.62 1126 0.66 1166 0.71

1800 866 0.50 921 0.53 973 0.56 1021 0.60 1067 0.64 1111 0.68 1152 0.73 1191 0.78

1900 907 0.56 959 0.59 1008 0.63 1054 0.66 1098 0.71 1139 0.75 1179 0.80 1217 0.86

2000 948 0.63 996 0.66 1042 0.70 1086 0.74 1128 0.78 1168 0.83 1207 0.89 1244 0.94

2100 987 0.70 1033 0.74 1077 0.78 111 9 0.82 1159 0.87 1198 0.93 1235 0.99 1272 1.05

2200 1026 0.78 1070 0.82 111 2 0.87 1152 0.92 1191 0.98 1228 1.03 1265 1.10 1301 1.16

2300 1064 0.88 1106 0.92 1147 0.97 1186 1.03 1223 1.09 1260 1.15 1295 1.22 1331 1.28

2400 1102 0.98 1143 1.03 1182 1.08 1220 1.15 1256 1.21 1292 1.28 1327 1.35 1362 1.42

Air

Volume

cfm

1600 1183 0.68 1223 0.72 1263 0.76 1302 0.81 1340 0.86 1377 0.91 1413 0.95 1448 1.00

1700 1205 0.75 1245 0.79 1284 0.84 1322 0.89 1360 0.94 1396 0.99 1431 1.04 1465 1.09

1800 1230 0.83 1268 0.87 1306 0.92 1344 0.98 1380 1.03 1416 1.08 1450 1.13 1483 1.19

1900 1255 0.91 1292 0.96 1330 1.02 1367 1.07 1402 1.13 1437 1.18 1470 1.24 1503 1.29

2000 1281 1.00 1318 1.06 1355 1.12 1391 1.18 1425 1.23 1459 1.29 1492 1.35 1524 1.40

2100 1308 1.11 1345 1.17 1381 1.23 1416 1.29 1450 1.35 1482 1.41 1514 1.46 1546 1.52

2200 1337 1.23 1372 1.29 1408 1.35 1442 1.42 1475 1.47 1507 1.53 1538 1.59 1569 1.64

2300 1366 1.35 1401 1.42 1435 1.49 1469 1.55 1501 1.61 1532 1.67 1563 1.72 1594 1.77

2400 1396 1.49 1431 1.56 1464 1.63 1496 1.69 1528 1.75 1559 1.81 1589 1.86 1619 1.91

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Furnished Kit ZA03

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP

Field Furnished Kit ZA03

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

External Static - in. w.g.

External Static - in. w.g.

Kit ZA03 Kit ZA06

External Static - in. w.g.

RPM BHP RPM BHP RPM BHP RPM BHP

0.60 1142 0.64

External Static - in. w.g.

Kit ZA03 Kit ZA06

Page 11

Page 12

BLOWER DATA - BELT DRIVE - ZHB036

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 15 for blower motors and drives and wet coil and options/accessory air resistance data.

DOWNFLOW

Air

Volume

cfm

900 562 0.11 621 0.13 685 0.16 752 0.18 818 0.21 883 0.24 944 0.27 1001 0.30

1000 584 0.13 644 0.16 707 0.18 773 0.21 838 0.24 901 0.27 960 0.3 1015 0.33

1100 609 0.16 669 0.18 732 0.21 796 0.24 860 0.27 921 0.30 978 0.34 1031 0.37

1200 635 0.19 696 0.21 758 0.24 821 0.27 883 0.31 942 0.34 997 0.38 1049 0.42

1300 664 0.22 725 0.25 786 0.28 848 0.31 908 0.35 965 0.39 1018 0.43 1068 0.47

1400 696 0.26 756 0.29 816 0.32 876 0.36 935 0.40 989 0.44 1041 0.48 1089 0.52

1500 729 0.30 788 0.33 848 0.37 906 0.41 962 0.45 1015 0.50 1065 0.54 111 2 0.58

Air

Volume

cfm

900 1053 0.32 1103 0.35 1149 0.38 1193 0.41 1234 0.43 1274 0.47 1312 0.50 1351 0.53

1000 1066 0.36 1114 0.39 1160 0.42 1204 0.45 1245 0.48 1284 0.51 1322 0.54 1361 0.58

1100 1081 0.40 1128 0.43 1173 0.46 1216 0.49 1257 0.53 1296 0.56 1334 0.60 1372 0.63

1200 1097 0.45 1144 0.48 1188 0.51 1231 0.54 1271 0.58 1310 0.62 1347 0.66 1385 0.69

1300 111 5 0.50 1161 0.53 1204 0.56 1246 0.60 1286 0.64 1325 0.68 1362 0.72 1399 0.76

1400 1135 0.56 1179 0.59 1222 0.62 1264 0.66 1303 0.70 1341 0.75 1378 0.79 1415 0.83

1500 1157 0.62 1200 0.65 1242 0.69 1282 0.73 1321 0.77 1359 0.82 1396 0.86 1431 0.91

HORIZONTAL

Air

Volume

cfm

900 560 0.16 624 0.18 692 0.20 761 0.21 830 0.23 896 0.25 956 0.27 1012 0.29

1000 583 0.18 647 0.20 715 0.22 783 0.24 850 0.25 914 0.27 972 0.30 1025 0.33

1100 609 0.20 673 0.22 740 0.24 808 0.26 873 0.28 934 0.31 990 0.34 1041 0.37

1200 637 0.23 702 0.25 769 0.27 835 0.29 898 0.32 956 0.35 1009 0.38 1058 0.41

1300 669 0.26 734 0.28 800 0.30 863 0.33 924 0.36 979 0.39 1030 0.43 1077 0.46

1400 704 0.29 768 0.32 832 0.35 894 0.37 951 0.41 1004 0.44 1052 0.48 1097 0.52

1500 742 0.33 805 0.36 867 0.39 925 0.42 980 0.46 1030 0.50 1076 0.54 111 9 0.58

Air

olume

V

cfm

900 1064 0.32 111 4 0.35 1162 0.38 1208 0.41 1251 0.45 1293 0.49 1333 0.52 1373 0.56

1000 1076 0.36 1124 0.39 1170 0.42 1216 0.46 1259 0.49 1300 0.53 1340 0.57 1379 0.61

1100 1089 0.40 1136 0.43 1181 0.46 1225 0.50 1268 0.54 1308 0.58 1347 0.62 1386 0.66

1200 1104 0.45 1150 0.48 1194 0.51 1237 0.55 1279 0.59 1319 0.63 1357 0.67 1394 0.71

1300 1121 0.5 1165 0.53 1209 0.57 1251 0.61 1292 0.65 1331 0.69 1368 0.73 1405 0.78

1400 1140 0.56 1183 0.59 1225 0.63 1266 0.67 1306 0.71 1345 0.76 1382 0.8 1417 0.85

1500 1161 0.62 1202 0.65 1243 0.69 1284 0.73 1323 0.78 1360 0.83 1396 0.87 1432 0.92

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Furnished Kit ZA01

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Furnished Kit ZA01

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

External Static - in. w.g.

External Static - in. w.g.

Kit ZA04

External Static - in. w.g.

External Static - in. w.g.

Kit ZA04

Page 12

Page 13

BLOWER DATA - BELT DRIVE - ZHB048

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 15 for blower motors and drives and wet coil and options/accessory air resistance data.

DOWNFLOW

Air

Volume

cfm

1200 620 0.23 681 0.29 744 0.34 809 0.39 875 0.43 941 0.47 1004 0.51 1060 0.54

1300 652 0.28 713 0.34 775 0.39 839 0.44 903 0.48 967 0.51 1025 0.55 1078 0.59

1400 687 0.33 747 0.39 809 0.44 871 0.49 934 0.53 994 0.57 1048 0.61 1098 0.64

1500 724 0.40 784 0.45 844 0.50 905 0.54 965 0.59 1021 0.62 1071 0.66 111 8 0.70

1600 764 0.46 823 0.51 882 0.56 940 0.60 997 0.65 1048 0.69 1094 0.72 1140 0.75

1700 806 0.53 863 0.58 919 0.62 975 0.67 1028 0.71 1075 0.75 111 9 0.78 1164 0.81

1800 849 0.60 903 0.65 957 0.69 1010 0.74 1058 0.78 1102 0.82 1145 0.85 1189 0.88

1900 892 0.68 944 0.72 995 0.77 1045 0.82 1089 0.86 1131 0.89 1174 0.92 1217 0.95

2000 935 0.76 984 0.81 1033 0.86 1079 0.91 1122 0.95 1163 0.97 1204 1.00 1247 1.03

Air

Volume

cfm

1200 1111 0.58 1156 0.60 1199 0.62 1241 0.63 1284 0.65 1326 0.67 1367 0.71 1408 0.74

1300 1127 0.62 1172 0.65 1214 0.66 1256 0.68 1299 0.70 1341 0.73 1381 0.77 1421 0.81

1400 1145 0.68 1189 0.70 1231 0.72 1274 0.74 1316 0.76 1357 0.79 1397 0.83 1436 0.88

1500 1164 0.73 1208 0.75 1251 0.78 1293 0.80 1334 0.83 1374 0.86 1413 0.91 1451 0.95

1600 1185 0.79 1229 0.81 1271 0.84 1313 0.86 1354 0.90 1393 0.94 1431 0.98 1468 1.03

1700 1208 0.84 1252 0.87 1294 0.90 1335 0.94 1375 0.98 1413 1.02 1449 1.07 1485 1.12

1800 1233 0.91 1276 0.94 1318 0.98 1358 1.02 1397 1.06 1434 1.11 1469 1.16 1504 1.21

1900 1261 0.98 1303 1.02 1343 1.06 1382 1.11 1420 1.16 1455 1.21 1490 1.26 1525 1.31

2000 1289 1.07 1330 1.11 1370 1.16 1407 1.21 1444 1.27 1478 1.32 1513 1.37 1547 1.42

HORIZONTAL

Air

Volume

cfm

1200 614 0.21 681 0.25 752 0.30 821 0.34 888 0.39 950 0.43 1006 0.46 1057 0.49

1300 644 0.24 712 0.29 782 0.34 850 0.39 915 0.43 974 0.47 1027 0.51 1076 0.53

1400 677 0.29 746 0.34 814 0.39 880 0.44 942 0.48 998 0.52 1049 0.55 1097 0.58

1500 714 0.34 781 0.40 848 0.45 911 0.49

1600 752 0.40 818 0.45 882 0.50 943 0.55 999 0.59 1050 0.62 1097 0.66 1142 0.69

1700 792 0.46 855 0.52 917 0.56 975 0.61 1028 0.64 1077 0.68 1123 0.72 1166 0.75

1800 832 0.53 894 0.58 952 0.63 1007 0.67 1058 0.70 1105 0.74 1149 0.78 1192 0.82

1900 873 0.60 932 0.65 988 0.69 1040 0.73 1088 0.77 1134 0.81 1177 0.85 1219 0.90

2000 914 0.67 970 0.72 1023 0.76 1073 0.80 1120 0.85 1163 0.89 1205 0.94 1246 0.99

Air

Volume

cfm

1200 1105 0.51 1152 0.53 1197 0.55 1240 0.58 1280 0.61 1320 0.64 1358 0.68 1395 0.72

1300 1123 0.55 1169 0.57 1213 0.60 1255 0.63 1295 0.67 1334 0.70 1372 0.74 1409 0.79

1400 1142 0.60 1187 0.63 1230 0.66 1272 0.69 1312 0.73 1350 0.77 1388 0.82 1424 0.86

1500 1163 0.66 1207 0.69 1249 0.72 1290 0.76 1330 0.80 1368 0.85 1405 0.90 1441 0.94

1600 1185 0.72 1228 0.75 1270 0.79 1310 0.83 1349 0.88 1387 0.93 1423 0.98 1459 1.03

1700 1209 0.78 1251 0.82 1292 0.87 1331 0.92 1370 0.97 1407 1.02 1443 1.07 1478 1.12

1800 1234 0.86 1275 0.91 1315 0.96 1354 1.01 1391 1.06 1428 1.11 1463 1.17 1498 1.22

1900 1260 0.95 1300 1.00 1340 1.05 1377 1.11 1414 1.16 1450 1.22 1485 1.27 1519 1.32

2000 1287 1.04 1326 1.10 1365 1.16 1402 1.21 1437 1.27 1472 1.33 1507 1.38 1541 1.43

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Field Furnished Kit ZA02

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Kit ZA02 Kit ZA05

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP

Field Furnished Kit ZA02

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Kit ZA02 Kit ZA05

External Static - in. w.g.

External Static - in. w.g.

External Static - in. w.g.

RPM BHP RPM BHP RPM BHP RPM BHP

970 0.53 1023 0.57 1072 0.60 111 9 0.63

External Static - in. w.g.

Page 13

Page 14

BLOWER DATA - BELT DRIVE - ZHB060

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 15 for blower motors and drives and wet coil and options/accessory air resistance data.

DOWNFLOW

Air

Volume

cfm

1600 522 0.27 552 0.32 585 0.37 619 0.43 656 0.48 693 0.53 732 0.59 771 0.64

1700 539 0.32 570 0.37 603 0.43 638 0.48 674 0.53 711 0.59 749 0.64 787 0.69

1800 558 0.38 589 0.43 623 0.48 658 0.54 694 0.59 730 0.64 767 0.70 803 0.75

1900 578 0.44 610 0.49 643 0.54 678 0.60 714 0.65 749 0.70 785 0.76 819 0.82

2000 600 0.50 632 0.56 665 0.61 699 0.66 734 0.71 769 0.77 803 0.83 837 0.90

2100 623 0.57 655 0.62 688 0.68 721 0.73 755 0.79 789 0.84 822 0.91 854 0.98

2200 647 0.65 678 0.70 711 0.75 743 0.81 776 0.86 809 0.93 841 1.00 872 1.06

2300 671 0.73 702 0.78 734 0.83 766 0.89 798 0.95 829 1.02 860 1.09 890 1.16

2400 696 0.81 726 0.87 757 0.92 788 0.98 819 1.04 850 1.11 880 1.19 909 1.26

Air

Volume

cfm

1600 809 0.69 844 0.74 877 0.80 908 0.85 936 0.91 963 0.97 989 1.02 1014 1.08

1700 823 0.75 857 0.80 889 0.86 919 0.92 947 0.97 973 1.03 999 1.09 1024 1.14

1800 838 0.81 870 0.87 901 0.92 931 0.98 958 1.04 984 1.10 1009 1.16 1034 1.22

1900 853 0.88 885 0.94 915 0.99 944 1.05 971 1.11 996 1.17 1021 1.23 1045 1.29

2000 869 0.96 899 1.01 929 1.07 957 1.13 984 1.19 1009 1.25 1033 1.31 1058 1.38

2100 885 1.04 915 1.10 944 1.15 971 1.22 997 1.28 1022 1.34 1046 1.40 1070 1.46

2200 902 1.13 931 1.19 959 1.24 986 1.31 1012 1.37 1036 1.43 1060 1.50 1084 1.56

2300 920 1.23 948 1.29 975 1.35 1001 1.41 1027 1.47 1051 1.53 1075 1.60 1098 1.66

2400 938 1.33 965 1.39 992 1.45 1017 1.52 1042 1.58 1066 1.64 1090 1.70 111 3 1.77

HORIZONTAL

Air

Volume

cfm

1600 525 0.30 561 0.34 597 0.39 635 0.43 673 0.47 711 0.51 748

1700 543 0.34 578 0.39 615 0.43 653 0.48 691 0.52 728 0.57 765 0.62 800 0.67

1800 561 0.39 597 0.44 635 0.49 672 0.53 710 0.58 746 0.63 782 0.68 816 0.73

1900 581 0.44 618 0.49 655 0.54 692 0.59 729 0.64 765 0.69 800 0.75 833 0.80

2000 602 0.50 639 0.55 676 0.61 713 0.66 749 0.71 784 0.76 818 0.82 850 0.88

2100 625 0.57 661 0.62 698 0.67 735 0.73 770 0.78 804 0.84 837 0.90 868 0.96

2200 648 0.64 685 0.69 721 0.75 757 0.80 791 0.86 824 0.92 856 0.98 886 1.05

2300 673 0.71 709 0.77 745 0.83 780 0.88 813 0.94 845 1.01 876 1.08 905 1.15

2400 699 0.79 734 0.85 769 0.91 803 0.97 835 1.04 866 1.11 896 1.18 924 1.25

Air

Volume

cfm

1600 819 0.66 851 0.72 883 0.77 913 0.83 943 0.89 971 0.95 998 1.01 1024 1.07

1700 833 0.72 865 0.78 896 0.84 926 0.90 954 0.96 982 1.02 1009 1.08 1034 1.14

1800 848 0.79 880 0.85 910 0.92 939 0.98 967 1.04 994 1.10 1020 1.16 1045 1.23

1900 864 0.87 895 0.93 924 0.99 953 1.06 980 1.12 1007 1.18 1032 1.25 1056 1.31

2000 881 0.95 911 1.01 940 1.08 967 1.14 994 1.21 1020 1.27 1044 1.34 1068 1.40

2100 898 1.03 927 1.10 955 1.17 982 1.23 1008 1.30 1033 1.37 1057 1.43 1080 1.50

2200 916 1.12 944 1.19 971 1.26 998 1.33 1023 1.40 1047 1.47 1071 1.54 1093 1.60

2300 934 1.22 961 1.29 988 1.36 1014 1.43 1038 1.50 1062 1.58 1085 1.65 1107 1.71

2400 952 1.32 979 1.40 1005 1.47 1030 1.54 1054 1.62 1077 1.69 1099 1.76 1121 1.83

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Kit ZAA01 Kit ZAA02

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Kit ZAA02 Kit ZAA03

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP

Kit ZAA01 Kit ZAA02

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Kit ZAA02 Kit ZAA03

External Static - in. w.g.

External Static - in. w.g.

External Static - in. w.g.

RPM BHP RPM BHP RPM BHP RPM BHP

0.56 784 0.61

External Static - in. w.g.

Page 14

Page 15

BLOWER DATA

DRIVE KIT SPECIFICATIONS

Model No.

ZHA/ZHB036

ZHA/ZHB048

ZHA060

ZHB060

NOTE - Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor hp required. Maximum usable hp of

motors furnished are shown. In Canada, nominal motor hp is also maximum usable motor hp. If motors of comparable hp are used, be sure to keep within the service

factor limitations outlined on the motor nameplate.

1

1 hp blower motor is not available for 208/230V-1ph applications. 2 1.5 hp motor is required with ZA05, ZA06 and ZAA03 drive kits.

POWER EXHAUST FAN PERFORMANCE

Return Air System Static Pressure - in. w.g.

OPTIONS / ACCESSORIES AIR RESISTANCE - in. w.g.

Air Volume

cfm

900 0.01 0.01 - - - 0.05 0.03 0.04

1000 0.02 0.01 - - - 0.06 0.03 0.05

1100 0.02 0.02 - - - 0.08 0.04 0.05

1200 0.02 0.02 0.01 0.09 0.05 0.06

1300 0.03 0.02 0.02 0.12 0.05 0.07

1400 0.03 0.03 0.02 0.17 0.06 0.08

1500 0.04 0.03 0.02 0.22 0.07 0.08

1600 0.04 0.03 0.03 0.26 0.08 0.09

1700 0.05 0.04 0.03 0.30 0.09 0.10

1800 0.05 0.04 0.03 0.33 0.10 0.11

1900 0.06 0.05 0.04 0.33 0.11 0.12

2000 0.06 0.05 0.04 0.31 0.12 0.13

2100 - - - 0.06 0.05 0.27 0.13 0.14

2200 - - - 0.06 0.05 0.29 0.14 0.15

2300 - - - 0.07 0.05 0.31 0.15 0.16

2400 - - - 0.07 0.06 0.32 0.16 0.18

CEILING DIFFUSERS AIR RESISTANCE (in. w.g.)

Air Volume

cfm

800 0.15 0.13 0.11 0.11

1000 0.19 0.16 0.14 0.14

1200 0.25 0.20 0.17 0.17

1400 0.33 0.26 0.20 0.20

1600 0.43 0.32 0.20 0.24

1800 0.56 0.40 0.30 0.30

2000 0.73 0.50 0.36 0.36

2200 0.95 0.63 0.44 0.44

Nominal Maximum Nominal Maximum

1

1

1

1

1

1

1

1

0.00 1865

0.05 1785

0.10 1710

0.15 1630

0.20 1545

0.25 1450

0.30 1350

0.35 1240

ZHA036, ZHA048 ZHA060, ZHB036 ZHB048, ZHB060 Downow Horizontal

RTD9-65 Step-Down Diffuser

2 Ends

Open

1 Side &

2 Ends Open

Blower Motor Choice (HP)

1

1.15 1.5 1.7

1

1.15 1.5 1.7

1

1.15 1.5 1.7

1

1.15 1.5 1.7

Wet Indoor Coil

CEILING DIFFUSER AIR THROW DATA

FD9-65

All Ends &

Sides Open

Flush

Diffuser

Page 15

Drive Kit No. RPM Range

ZA01 678 - 1035

ZA04 964 - 1471

ZA02 803 - 1226

2

ZA05 1098 - 1490

ZA03 906-1383

2

ZA06 1262-1634

ZAA01 522 - 784

ZAA02 632 - 875

2

ZAA03 798 - 1105

Air Volume Exhausted

cfm

Electric

Economizer

Heat

1

Air Volume - cfm

Effective Throw - ft.

Model No. RTD9-65 FD9-65

800 10 - 17 14 - 18

1000 10 - 17 15 - 20

1200 11 - 18 16 - 22

1400 12 - 19 17 - 24

1600 12 - 20 18 - 25

1800 13 - 21 20 - 28

2000 14 - 23 21 - 29

2200 16 - 25 22 - 30

1

Effective throw based on terminal velocities of 75 ft. per minute.

Page 16

TABLE 2

DRIVE COMPONENT MANUFACTURER'S NUMBERS

DRIVE COMPONENT PART NUMBERS

Drive No.

Z01 1VP34 X 7/8 31K6901 AK54 X 5/8 10024430 A40 10024517

Z02 1VP34 X 7/8 31K6901 AK46 X 5/8 10024431 A39 10024516

Z03 1VP34 X 7/8 31K6901 AK41 X 5/8 10024428 A39 10024516

Z04 1VP34 X 7/8 31K6901 AK39 X 5/8 10024432 A38 10024515

Z05 1VP44 X 7/8 P81488 AK49 X 5/8 10024426 A41 10024518

Z06 1VP50 X 7/8 53J1501 AK51 X 5/8 10024429 A42 10024519

ZAA01 1VP34 X 7/8 31K69 AK69 X 1 37L47 AX51 13H01

ZAA02 1VP40 X 7/8 79J03 BK80H 100788-03 A53 100245-40

ZAA03 1VP40 X 7/8 79J03 AK59 X 1 31K68 A50 100245-29

MINIMUM AIRFLOW - UNITS WITH ELECTRIC HEAT

kW

CFM - Downflow and Horizontal

ZHA036-060, ZHB036-048 ZHB060

5 960 1750

7.5 960 1750

10 960 1750

Motor Pulley Blower Pulley Belts

Browning OEM Browning OEM Browning OEM

TABLE 3

A first-stage Y1 cooling demand will energize L1

reversing valve solenoid and compressor 1.

Units With Optional Economizer The optional economizer will start on a first stage (Y1)

cooling demand when outdoor air is suitable. An

increased cooling demand (Y2) will energize

compressor 1.

15 960 1750

22.5 1280 1750

Units with electric heat (5-22.5kW) can operate up to 1.6”w.g. maximum static pressure.

2- Refrigerant circuits are factory charged with R-410A

refrigerant. See unit rating plate for correct amount of

charge.

Start-Up

B-Three Phase Scroll Compressor Voltage Phasing

IMPORTANT

This unit is equipped with a crankcase heater. Make

sure heater is energized 24 hours before unit startup to prevent compressor damage as a result of

slugging.

A-Start-Up

Heating

1- Set thermostat or temperature control device to

initiate a first-stage heating demand.

2- A first-stage heating demand (W1) will energize

compressors 1 and the outdoor fan.

Note - L1 reversing valve is de-energized in the

heating mode.

ZH Units With Optional Electric Heat -

An increased heating demand (W2) will energize

electric heat. Electric heat is also energized during

the defrost cycle (W1) to maintain discharge air

temperature.

Cooling

1- Set thermostat or temperature control device fan

switch to AUTO or ON. Set thermostat or

temperature control device to initiate a first-stage

cooling demand.

ZH 036, 048, 060

Three phase scroll compressors must be phased

sequentially to ensure correct compressor and blower

rotation and operation. Compressor and blower are

wired in phase at the factory. Power wires are

color-coded as follows: line 1-red, line 2-yellow, line

3-blue.

1- Observe suction and discharge pressures and

blower rotation on unit start-up.

2- Suction pressure must drop, discharge pressure

must rise, and blower rotation must match rotation

marking.

If pressure differential is not observed or blower rotation is

not correct:

3- Disconnect all remote electrical power supplies.

4- Reverse any two field-installed wires connected to

the line side of K1 contactor. Do not reverse wires at

blower contactor.

Make sure the connections are tight.

Discharge and suction pressures should operate at

their normal start‐up ranges.

Page 16

Page 17

C - Refrigerant Charge and Check

WARNING-Do not exceed nameplate charge under

any condition.

This unit is factory charged and should require no further

adjustment. If the system requires additional refrigerant,

reclaim the charge,

evacuate the system, and add

required nameplate charge.

NOTE - System charging is not recommended below

60°F (15°C). In temperatures below 60°F (15°C), the

charge must be weighed into the system.

If weighing facilities are not available, or to check the

charge, use the following procedure:

6- Continue the process until measured liquid

temperature agrees with the target liquid

temperature. Do not go below the target liquid

temperature when adjusting charge. Note that

suction pressure can change as charge is adjusted.

7- Example ZHA036: At 95°F outdoor ambient and a

measured suction pressure of 130psig, the target

liquid temperature is 105.5°F. For a measured liquid

temperature of 106°F, add charge in increments until

measured liquid temperature agrees with the target

liquid temperature.

D - Compressor Controls

IMPORTANT - Charge unit in standard cooling mode

high stage only

.

1- Make sure outdoor coil is clean. Attach gauge

manifolds and operate unit at full CFM in cooling mode

with economizer disabled until system stabilizes

(approximately five minutes). Make sure all outdoor air

dampers are closed.

2- Compare the normal operating pressures (see tables

4 - 9) to the pressures obtained from the gauges.

Check unit components if there are significant

differences.

3- Measure the outdoor ambient temperature and the

suction pressure. Refer to the appropriate circuit

charging curve to determine a target liquid

temperature.

Note - Pressures are listed for sea level applications.

See unit wiring diagram to determine which controls are

used in each unit. Optional controls are identified on

wiring diagrams by arrows at junction points.

1- Defrost Switch (S6)

Defrost switch closes to initiate defrost when liquid

line temperature falls to 42F (5.6C). Defrost switch

opens when liquid line temperature reaches 70F

(21C) to terminate defrost. If the liquid line

temperature does not rise above 70F (21C), the

CMC1 will terminate defrost after 14 minutes. The

defrost switch is located on the liquid line between the

outdoor expansion valve and the distributor

2- Defrost Control (CMC1)

Defrost is liquid line temperature initiated and

operates for 14 minutes unless terminated by liquid

line temperature.

4- Use the same thermometer to accurately measure the

liquid temperature (in the outdoor section).

When the liquid line temperature drops below 42°F

(5.6C), the defrost switch closes and signals the

If measured liquid temperature is higher than

the target liquid temperature, add refrigerant to

the system.

If measured liquid temperature is lower than

the target liquid temperature, recover some

refrigerant from the system.

defrost control that a defrost cycle is needed. If

the defrost switch is still closed after 90 minutes

(default), a defrost cycle begins and operates for

up to 14 minutes. The defrost switch can terminate

the defrost cycle before the 14 minutes elapses if

liquid line temperature reaches 70F (21C)

5- Add or remove charge in increments. Allow the

system to stabilize each time refrigerant is added or

removed.

Electric heat is energized during defrost to maintain

discharge air temperature.

TABLE 4

ZHA036 NORMAL OPERATING PRESSURES

Outdoor Coil Entering Air Temperature

65 F 75 F 85 F 95 F 105 F 115 F

Suct

(psig)

119 235 122 272 124 314 126 359 129 409 132 461

128 241 130 279 132 319 136 364 146 421 140 470

139 245 146 285 151 331 155 377 155 428 159 482

145 248 154 290 163 335 170 384 174 438 179 498

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Page 17

507111-02 2/2015

Disc

(psig)

Page 18

TABLE 5

ZHA048 NORMAL OPERATING PRESSURES

Outdoor Coil Entering Air Temperature

65 F 75 F 85 F 95 F 105 F 115 F

Suct

(psig)

113 253 116 293 119 336 122 383 125 435 128 492

121 258 123 297 126 341 129 387 133 440 137 498

133 267 138 308 143 354 146 401 151 459 154 516

140 273 148 317 155 366 161 418 167 475 172 536

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

TABLE 6

ZHA060 NORMAL OPERATING PRESSURES

Outdoor Coil Entering Air Temperature

65 F 75 F 85 F 95 F 105 F 115 F

Suct

(psig)

113 254 115 292 119 335 122 380 125 430 128 487

121 260 123 299 126 343 130 391 134 440 137 496

130 265 138 308 143 354 147 404 151 456 154 513

136 270 145 315 153 364 160 414 167 471 172 529

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

TABLE 7

ZHB036 NORMAL OPERATING PRESSURES

Outdoor Coil Entering Air Temperature

65 F 75 F 85 F 95 F 105 F 115 F

Suct

(psig)

119 236 122 274 125 315 128 361 130 410 133 464

126 239 128 278 132 320 136 366 138 416 141 471

135 245 144 285 151 330 153 380 158 429 161 487

140 250 151 290 159 335 167 385 174 440 178 498

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

TABLE 8

ZHB048 NORMAL OPERATING PRESSURES

Outdoor Coil Entering Air Temperature

65 F 75 F 85 F 95 F 105 F 115 F

Suct

(psig)

116 248 119 287 121 328 123 374 126 423 128 477

123 252 127 292 129 336 132 382 135 433 137 487

133 260 140 302 145 347 148 395 152 451 156 505

137 264 146 308 154 357 162 409 168 464 173 523

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

TABLE 9

ZHB060 NORMAL OPERATING PRESSURES

Outdoor Coil Entering Air Temperature

65 F 75 F 85 F 95 F 105 F 115 F

Suct

(psig)

114 255 118 297 120 338 123 387 126 433 130 487

121 257 125 298 131 350 131 389 134 443 137 504

131 267 138 311 144 362 148 410 152 457 153 524

137 269 143 315 154 364 162 417 167 474 169 534

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Page 18

ZH 036, 048, 060

Disc

(psig)

Disc

(psig)

Disc

(psig)

Page 19

130

120

110

100

90

80

ZHA 036 CHARGING CURVE

Outdoor Temperature (°F)

115°

105°

95°

85°

75°

70

110 120 130 140 150 160 170

Suction Pressure (psig)

65°

130

120

110

ZHA048 CHARGING CURVE

95°

100

85°

180

Outdoor Temperature (°F)

115°

105°

90

80

70

110 120 130 140 150 160 170

75°

65°

180

Suction Pressure (psig)

Page 19

507111-02 2/2015

Page 20

ZHA060 CHARGING CURVE

130

120

110

95°

100

85°

90

75°

80

65°

70

110 120 130 140 150 160 170

Suction Pressure (psig)

Outdoor Temperature (°F)

115°

105°

180

130

ZHB 036 CHARGING CURVE

120

110

100

90

80

70

60

110 120 130 140 150 160 170

65°

75°

Suction Pressure (psig)

85°

Outdoor Temperature (°F)

115°

105°

95°

180

ZH 036, 048, 060

Page 20

Page 21

130

120

110

ZHB048 CHARGING CURVE

Outdoor Temperature (°F)

115°

105°

100

90

80

70

60

110 120 130 140 150 160 170

65°

75°

85°

Suction Pressure (psig)

95°

130

120

ZHB060 CHARGING CURVE

180

Outdoor Temperature (°F)

115°

105°

110

95°

100

85°

90

75°

80

65°

70

110 120 130 140 150 160 170

Suction Pressure (psig)

Page 21

507111-02 2/2015

Page 22

Defrost Control Board

The defrost thermostat and the defrost control work

together to ensure that the heat pump outdoor coil does

not ice excessively during the heating mode.

Compressor Accumulated Run-Time Interval

The defrost control will not energize a defrost cycle

unless the unit has been operating in heating mode for

an accumulated 90 minutes (default). The run time

interval can be changed by moving the jumper on the

CMC board timing pins. See figure 13.

DEFROST CONTROL BOARD CMC1

TIMING JUMPER

90 MINUTES

DIAGNOSTIC

LEDS

REMOVED AT THE

FACTORY TO DISABLE

COMPRESSOR DELAY

The defrost interval can be adjusted to 30, 60, or 90

minutes. The defrost timing jumper is factory-installed to

provide a 90-minute defrost interval. If the timing selector

jumper is not in place, the control defaults to a 90-minute

defrost interval.

Defrost Test Option

A TEST option is provided for troubleshooting. The TEST

mode may be started any time the unit is in the heating

mode and the defrost thermostat is closed or jumpered. If

the timing jumper is in the TEST position at power‐up, the

defrost control will ignore the test pins. When the jumper

is placed across the TEST pins for two seconds, the

control will enter the defrost mode. If the jumper is

removed before an additional 5-second period has

elapsed (7 seconds total), the unit will remain in defrost

mode until the defrost switch opens or 14 minutes have

passed. If the jumper is not removed until after the

additional 5-second period has elapsed, the defrost will

terminate and the test option will not function again until

the jumper is removed and re-applied.

Diagnostic LEDs

The defrost board uses two LEDs for diagnostics. The

LEDs flash a sequence according to the condition.

TABLE 10

Defrost Control Board Diagnostic LED

Mode

No power to control OFF OFF

Normal operation /

power to control

Anti‐short cycle

lockout

High pressure switch

fault

High pressure switch

lockout

Green LED

(DS2)

Simultaneous Slow FLASH

Alternating Slow FLASH

Slow FLASH OFF

ON OFF

Red LED (DS1)

FIGURE 13

ZH 036, 048, 060

Page 22

Page 23

Service

The unit should be inspected once a year by a qualified

service technician.

CAUTION

Label all wires prior to disconnection when servic

ing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

TABLE 11

UNIT FILTERS

Unit Qty Filter Size - inches (mm)

ZHA036, 048 4 14 X 20 X 2 (352 X 508 X 51)

ZHA060, ZHB036 4 16 X 20 X 2 (406 X 508 X 51)

2

ZHB048, 060

NOTE-Filters must be U.L.C. certified or equivalent for

use in Canada.

Each

16 X 20 X 2 (406 X 508 X 51)

20 X 20 X 2 (508 X 508 X 51)

WARNING

The State of California has determined that this

product may contain or produce a chemical or

chemicals, in very low doses, which may cause se

rious illness or death. It may also cause cancer,

birth defects, or reproductive harm.

A - Lubrication

All motors are lubricated at the factory. No further

lubrication is required.

B-Compressor

If Interlink compressor replacement is necessary, call

1-800-4-LENNOX (1-800-453-6669).

IMPORTANT

Some scroll compressors have an internal vacu

um protector that will unload scrolls when suc

tion pressure goes below 20 psig. A hissing

sound will be heard when the compressor is run

ning unloaded. Protector will reset when low

pressure in system rises above 40 psig. DO NOT

REPLACE COMPRESSOR.

C - Filters

Units are equipped with temporary filters which must be

replaced prior to building occupation. See table 11 for

correct filter size. Refer to local codes or appropriate

jurisdiction for approved filters.

BACK OF UNIT

LIFT UP AND PULL

OUT (TOOLLESS)

FILTER ACCESS PANEL

FIGURE 14

REMOVE FILTERS

SLIDE FILTER STOP UP

TO REMOVE FILTERS

To change filters, open filter access panel on back side

of unit. See figure 14. Lift filter stop to remove filters.

See figure 15.

WARNING

Units are shipped from the factory with temporary

filters. Replace filters before building is occupied.

Damage to unit could result if filters are not re

placed with approved filters. Refer to appropriate

codes.

Approved filters should be checked monthly and

replaced when necessary. Take note of air flow direction

marking on filter frame when reinstalling filters. See

figure 15.

FIGURE 15

Page 23

507111-02 2/2015

Page 24

D - Supply Air Blower Wheel

Annually inspect supply air blower wheel for accumulated

dirt or dust. Turn off power before attempting to remove

access panel or to clean blower wheel.

E - Indoor Coil

Inspect and clean coil at beginning of each cooling and

heating season. Clean using mild detergent or

commercial coil cleanser. Flush coil and condensate

drain with water taking care not to get insulation, filters

and return air ducts wet.

CLEAN OUTDOOR COIL

ENDPLATE IS SECURED TO MULLION

OUTDOOR

COILS

TOP VIEW

SUPPLY

AIR

RETURN

AIR

F - Outdoor Coil

Clean outdoor coil annually with detergent or commercial

coil cleaner and inspect monthly during the cooling

season.

Outdoor coils are made of single and two formed slabs.

On units with two slabs, dirt and debris may become

trapped between the slabs. To clean between slabs,

carefully separate coil slabs and wash them thoroughly.

See figure 16. Flush coils with water following cleaning.

Note - Remove all screws and gaskets prior to cleaning

procedure and replace upon completion.

G - Filter Drier

The unit is equipped with a biflow filter drier. if

replacement is necessary, order another of like design.

1- Remove screws securing coil end plate to mullion.

2- Remove wire ties connecting coils slabs and separate

slabs 3-4” (76-102mm).

3- Clean coils with detergent or commercial coil cleaner.

4- Rinse thoroughly with water and reassemble

5- Secure coil slabs together using field-provided wire

ties.

.

FIGURE 16

ZH 036, 048, 060

Page 24

Loading...

Loading...