Lennox XP16-024-230-01, XP16-024-230-05, XP16-024-230-03, XP16-036-230-01, XP16-024-230-04 Unit Information

...Page 1

Corp. 0626−L5

Service Literature

Revised October 21, 2010

XP16 (HFC−410A) SERIES UNITS

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause personal injury, loss of life, or

damage to property.

Installation and service must be performed by a licensed

professional installer (or equivalent) or a service agency.

CAUTION

Physical contact with metal edges and corners while

applying excessive force or rapid motion can result in

personal injury. Be aware of, and use caution when

working near these areas during installation or while

servicing this equipment.

XP16

TABLE OF CONTENTS

Model Number Identification 2. . . . . . . . . . . . . . . . . . . .

Typical Serial Number Identification 2. . . . . . . . . . . . . .

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Data 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Dimensions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Parts Arrangement 5. . . . . . . . . . . . . . . . . . . . . . . .

Operating Gauge Set and Service Valves 7. . . . . . . . .

Recovering Refrigerant from System 9. . . . . . . . . . . . .

Unit Placement 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and Installing Panels 12. . . . . . . . . . . . . . . . .

New or Replacement Line Set 14. . . . . . . . . . . . . . . . . .

Brazing Connections 16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing Line Set and Indoor Coil 19. . . . . . . . . . . . . . .

Installing Indoor Metering Device 20. . . . . . . . . . . . . . . .

Leak Test Line Set and Indoor Coil 21. . . . . . . . . . . . . .

Evacuating Line Set and Indoor Coil 22. . . . . . . . . . . . .

Electrical 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing Units Void of Charge 24. . . . . . . . . . . . . . . . . .

Unit Start−Up 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Refrigerant 24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Operation 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defrost System 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Wiring Diagram and Sequence of

Operations 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checklists 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The XP16 is a high efficiency residential split−system

two−stage heat pump unit, which features a scroll

compressor and HFC−410A refrigerant. XP16 units are

available in 2, 3, 4 and 5 tons. tons. XP16 units are rated for

230 volts only. Applications where supply voltage is less

requires a hard start kit. The series is designed for use with

an indoor unit with an expansion valve approved for

HFC−410A.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of

refrigerant (CFCs, HCFCs and HFCs) as of July 1, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for noncompliance.

Page 1

WARNING

Electric Shock Hazard. Can cause injury or

death. Unit must be grounded in

accordance with national and local codes.

Line voltage is present at all components

when unit is not in operation on units with

single-pole contactors. Disconnect all

remote electric power supplies before

opening access panel. Unit may have

multiple power supplies.

2006 Lennox Industries Inc.

Page 2

Model Number Identification

Refrigerant Type

X = HFC−410A

Unit Type

P = Heat Pump

− −

P 16 036

X 5

Nominal Cooling Capacity

230

−

Minor Revision Number

Voltage

230 = 208/230V−1ph−60hz

024 = 2 tons

Series

036 = 3 tons

048 = 4 tons

060 = 5 tons

Typical Serial Number Identification

Location Code

19 = Saltillo, Mexico

58 = Marshalltown, IA

Year Code

08 = 2008

09 = 2009

10 = 2010

19 09 C

05716

5 (or 6) Digit Unique Number

Month Code

A = January

B = February

C = March

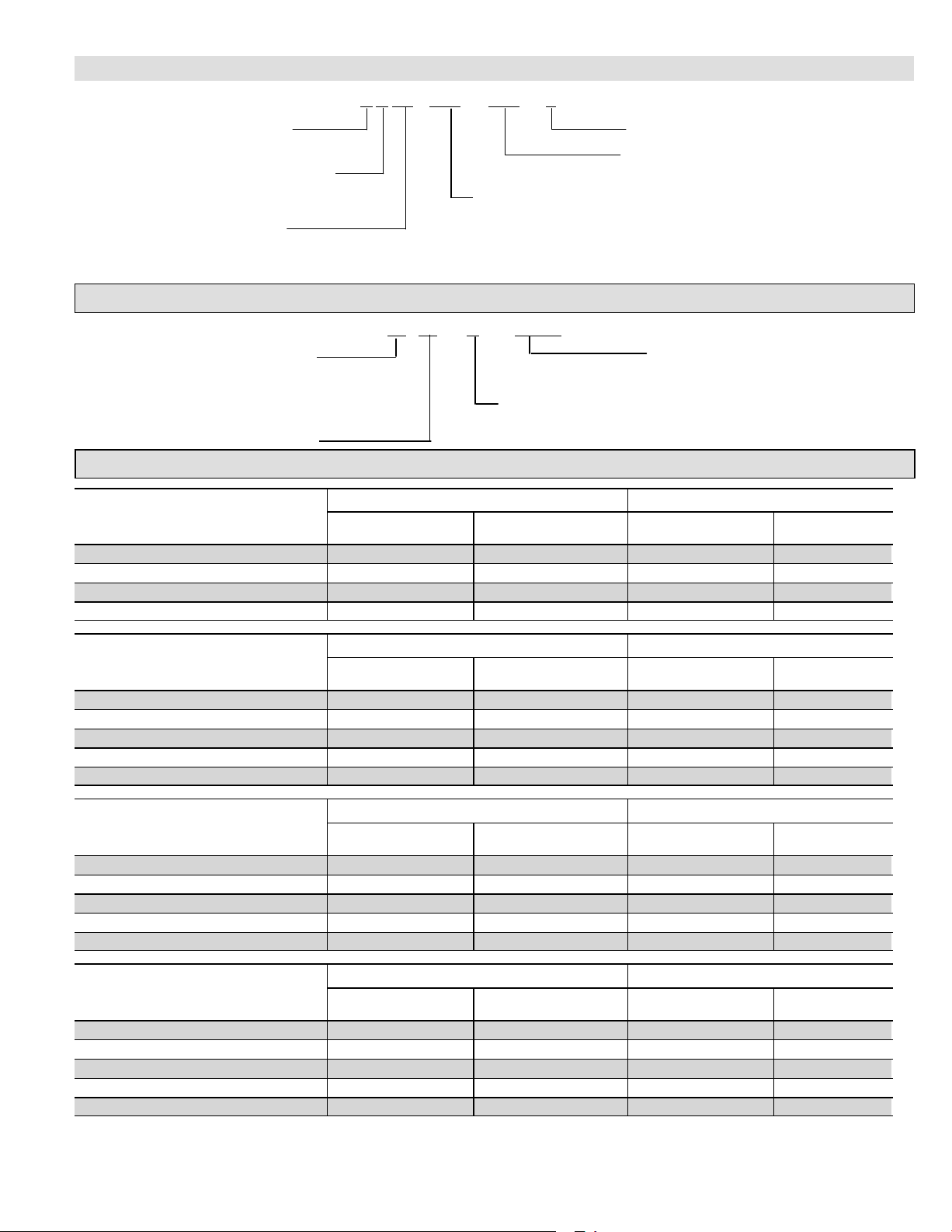

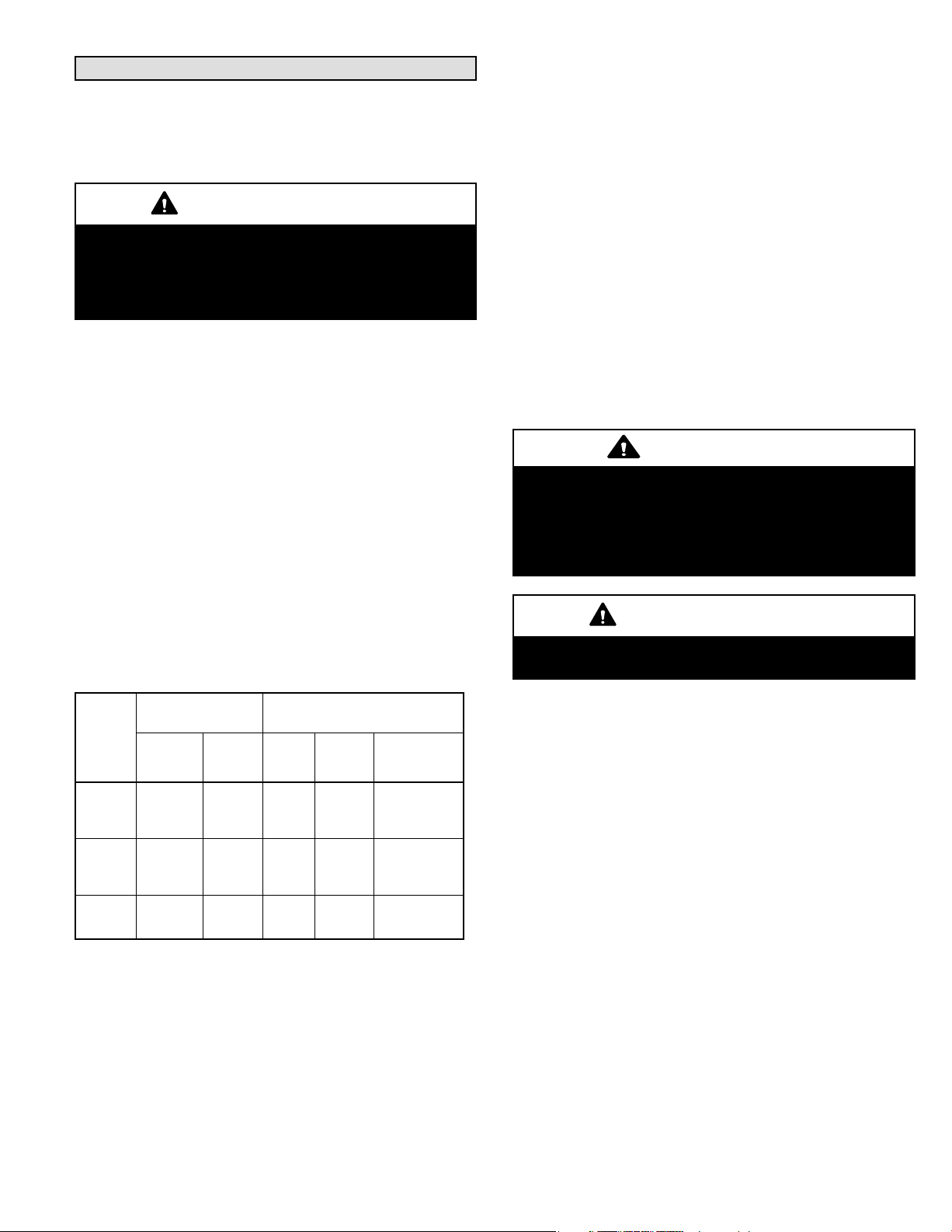

Specifications

Unit Outdoor Fan

Model Number

XP16−024−230−01 74 9 lbs. 9 oz. 3 18

XP16−024−230−03 74 7 lbs. 13 oz. 3 18

XP16−024−230−04 74 7 lbs. 13 oz. 3 18

XP16−024−230−05 74 8 lbs. 13 oz. 3 18

Sound Rating Number

(dB)

1

Factory Refrigerant

Charge

2

Number of Blades Diameter − inches.

Unit Outdoor Fan

Model Number

XP16−036−230−01 76 12 lbs. 8 oz. 4 22

XP16−036−230−02 76 12 lbs. 8 oz. 4 22

XP16−036−230−03 76 10 lbs. 4 oz. 4 22

XP16−036−230−04 76 10 lbs. 4 oz. 4 22

XP16−036−230−05 76 10 lbs. 9 oz. 4 22

Model Number

XP16−048−230−01 76 15 lbs. 7 oz. 4 22

XP16−048−230−02 76 15 lbs. 7 oz. 4 22

XP16−048−230−03 76 15 lbs. 7 oz. 4 22

XP16−048−230−04 76 15 lbs. 7 oz. 4 22

XP16−048−230−05 76 11 lbs. 12 oz. 3 26

Model Number

XP16−060−230−01 78 13 lbs. 8 oz. 3 26

XP16−060−230−02 78 13 lbs. 8 oz. 3 26

XP16−060−230−03 78 11 lbs. 7 oz. 3 26

XP16−060−230−04 78 11 lbs. 7 oz. 3 26

XP16−060−230−05 78 12 lbs. 15 oz. 3 26

1

Tested according to AHRI Standard 270−2008 test conditions.

2

Refrigerant charge sufficient for 15 feet length of refrigerant lines.

Sound Rating Number

Sound Rating Number

Sound Rating Number

(dB)

(dB)

(dB)

1

1

1

Factory Refrigerant

Unit Outdoor Fan

Factory Refrigerant

Unit Outdoor Fan

Factory Refrigerant

Charge

Charge

Charge

2

2

2

Number of Blades Diameter − inches.

Number of Blades Diameter − inches.

Number of Blades Diameter − inches.

Page 2

XP16

Page 3

Electrical Data

208/230V−60 Hz−1 Ph

Unit Compressor Condenser Fan

Model Number

Over−

current

Protection

(amps)

1

Minimum

Circuity

Ampacity

Rated Load

Amps (RLA)

2

Maximum

XP16−024−230−01 20 14.0 10.25 52.0 1/10 PSC 1075 0.7 1.4

XP16−024−230−03 20 14.0 10.25 52.0 1/10 PSC 1075 0.7 1.4

XP16−024−230−04 20 14.0 10.25 52.0 1/10 PSC 1075 0.7 1.4

XP16−024−230−05 20 14.0 10.25 52.0 1/10 PSC 1075 0.7 1.4

Unit Compressor Condenser Fan

Model Number

Over−

current

Protection

(amps)

1

Minimum

Circuity

Ampacity

Rated Load

Amps (RLA)

2

Maximum

XP16−036−230−01 35 22.0 16.67 82.0 1/6 PSC 825 1.1 2.1

XP16−036−230−02 35 22.0 16.67 82.0 1/6 PSC 825 1.1 2.1

XP16−036−230−03 35 22.0 16.67 82.0 1/6 PSC 825 1.1 2.1

XP16−036−230−04 35 22.0 16.67 82.0 1/6 PSC 825 1.1 1.87

XP16−036−230−05 35 22.5 16.67 82.0 1/4 PSC 825 1.7 3.1

Locked

Rotor

Amps

(LRA)

Motor

HP

208/230V−60 Hz−1 Ph

Locked

Rotor

Amps

(LRA)

Motor

HP

Motor

Type

Motor Type

Nominal

RPM

Nominal

RPM

Full Load

Amps (FLA)

Full Load

Amps (FLA)

Locked Rotor

Amps (LRA)

Locked Rotor

Amps (LRA)

208/230V−60 Hz−1 Ph

Unit Compressor Condenser Fan

Model Number

Maximum

Over−

current

Protection

(amps)

1

Minimum

Circuity

Ampacity

Rated Load

Amps (RLA)

2

Locked

Rotor

Amps

(LRA)

Motor

HP

Motor Type

Nominal

RPM

Full Load

Amps (FLA)

Locked Rotor

Amps (LRA)

XP16−048−230−01 45 28.2 21.15 96.0 1/4 PSC 825 1.7 3.1

XP16−048−230−02 45 28.2 21.15 96.0 1/4 PSC 825 1.7 3.1

XP16−048−230−03 45 28.2 21.15 96.0 1/4 PSC 825 1.7 3.1

XP16−048−230−04 45 28.2 21.15 96.0 1/4 PSC 825 1.7 3.1

XP16−048−230−05 45 28.2 21.15 96.0 1/3 PSC 825 1.8 2.9

208/230V−60 Hz−1 Ph

Unit Compressor Condenser Fan

Model Number

Maximum

Over−

current

Protection

(amps)

1

Minimum

Circuity

Ampacity

Rated Load

Amps (RLA)

2

Locked

Rotor

Amps

(LRA)

Motor

HP

Motor Type

Nominal

3

RPM

Full Load

Amps (FLA)

Locked Rotor

Amps (LRA)

XP16−060−230−01 55 33.9 25.64 118.0 1/3 PSC 825 1.8 2.9

XP16−060−230−02 60 33.9 25.87 118.0 1/3 PSC 825 1.8 2.9

XP16−060−230−03 60 33.9 25.87 118.0 1/3 PSC 825 1.8 2.9

XP16−060−230−04 60 33.9 25.87 118.0 1/3 PSC 825 1.8 2.9

700

XP16−060−230−05 60 35.1 25.87 118.0 1/3 VS

1

HACR type circuit breaker or fuse.

2

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

3

PSC = permanent split capacitor motor (single speed); VS = variable speed.

(1st Stage)

820

(2nd Stage)

2.8 N/A

XP16

Page 3

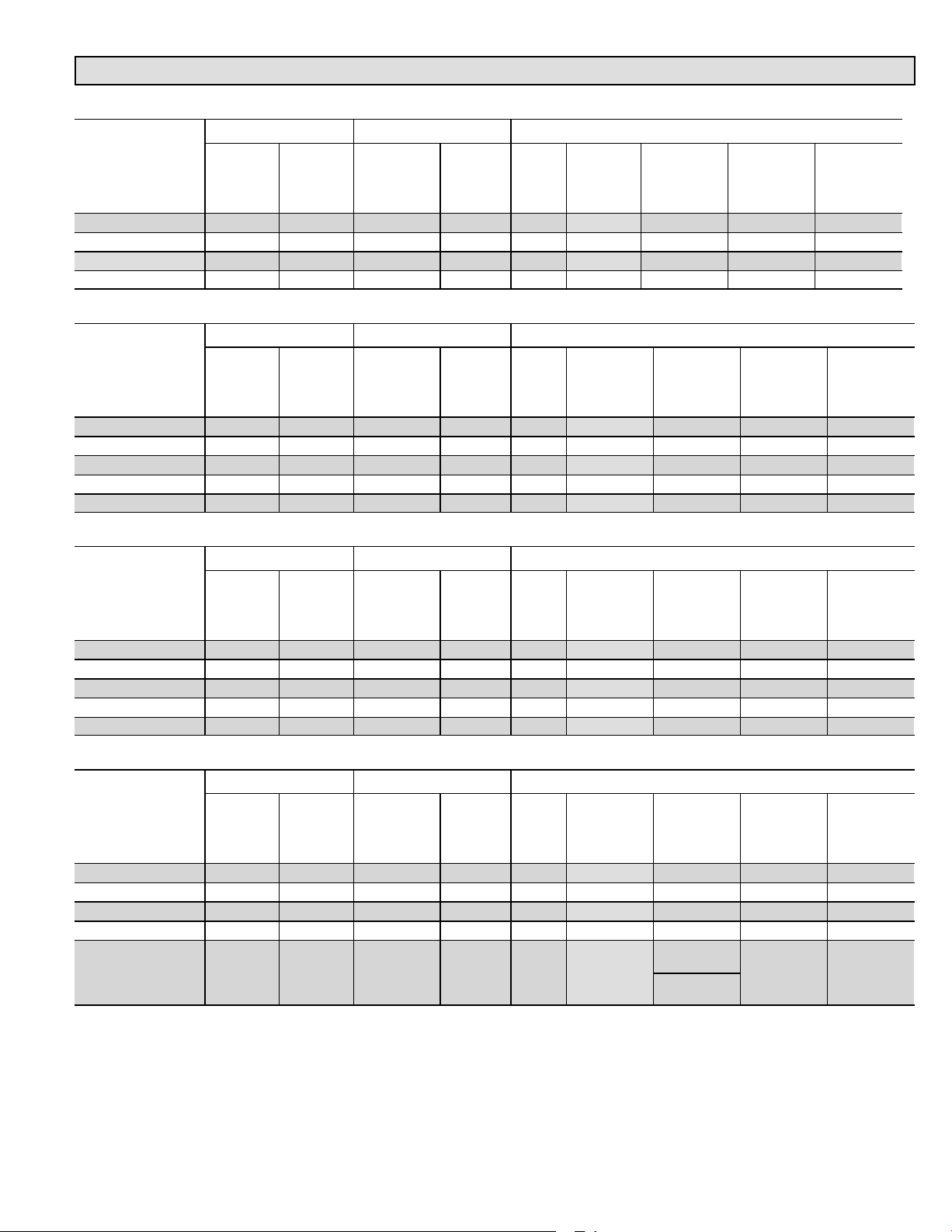

Page 4

Unit Dimensions − Inches (mm)

A

LIQUID LINE

CONNECTION

ELECTRICAL INLETS

SUCTION LINE

CONNECTION

C

9−1/2

(241)

8−1/4

(210)

4−3/4"

(121)

UNIT SUPPORT FEET

B

TOP VIEW

D

E

F

G

XP16−036 to −060 BASE WITH LEGS

K

J

H

UNIT SUPPORT

FEET

8−1/2

(216)

8−3/4

(222)

SIDE VIEW

5−1/2

(140)

13−1/2

(343)

XP16−024 BASE SECTION

4−1/2"

(108)

Model Number A B C D E F G H J K

XP16−024−01,

−02, −03, −04

31 (889) 27 (686) 28 (711) − − − − − − −

XP16−024−05 35 (889) 27 (686) 28 (711) − − − − − − −

XP16−036−01,

−02, −03, −04

35 (889) 30−1/2 (775) 35 (889) 13−7/8 (352) 7−3/4 (197) 3−1/4 (83) 27−1/8 (689) 3−5/8 (92) 4−1/2 (114) 20−5/8 (524)

XP16−036−05 39 (991) 30−1/2 (775) 35 (889) 13−7/8 (352) 7−3/4 (197) 3−1/4 (83) 27−1/8 (689) 3−5/8 (92) 4−1/2 (114) 20−5/8 (524)

XP16−048−01,

−02, −03, −04

XP16−048−05 35 (889) 35−1/2 (902)

XP16−060−01,

−02, −03, −04

XP16−060−05 45 (1143 35−1/2 (902)

45 (1143) 30−1/2 (775) 35 (889)) 16−7/8 (429) 8−3/4 (222) 3−1/8 (79) 30−3/4 (781) 4−5/8 (117) 3−3/4 (95) 26−7/8 (683)

39 (991) 35−1/2 (902)

39−1/2

(1003)

39−1/2

(1003)

39−1/2

(1003)

16−7/8 (429) 8−3/4 (222) 3−1/8 (79) 30−3/4 (781) 4−5/8 (117) 3−3/4 (95) 26−7/8 (683)

16−7/8 (429) 8−3/4 (222) 3−1/8 (79) 30−3/4 (781) 4−5/8 (117) 3−3/4 (95) 26−7/8 (683)

16−7/8 (429) 8−3/4 (222) 3−1/8 (79) 30−3/4 (781) 4−5/8 (117) 3−3/4 (95) 26−7/8 (683)

Page 4

XP16

Page 5

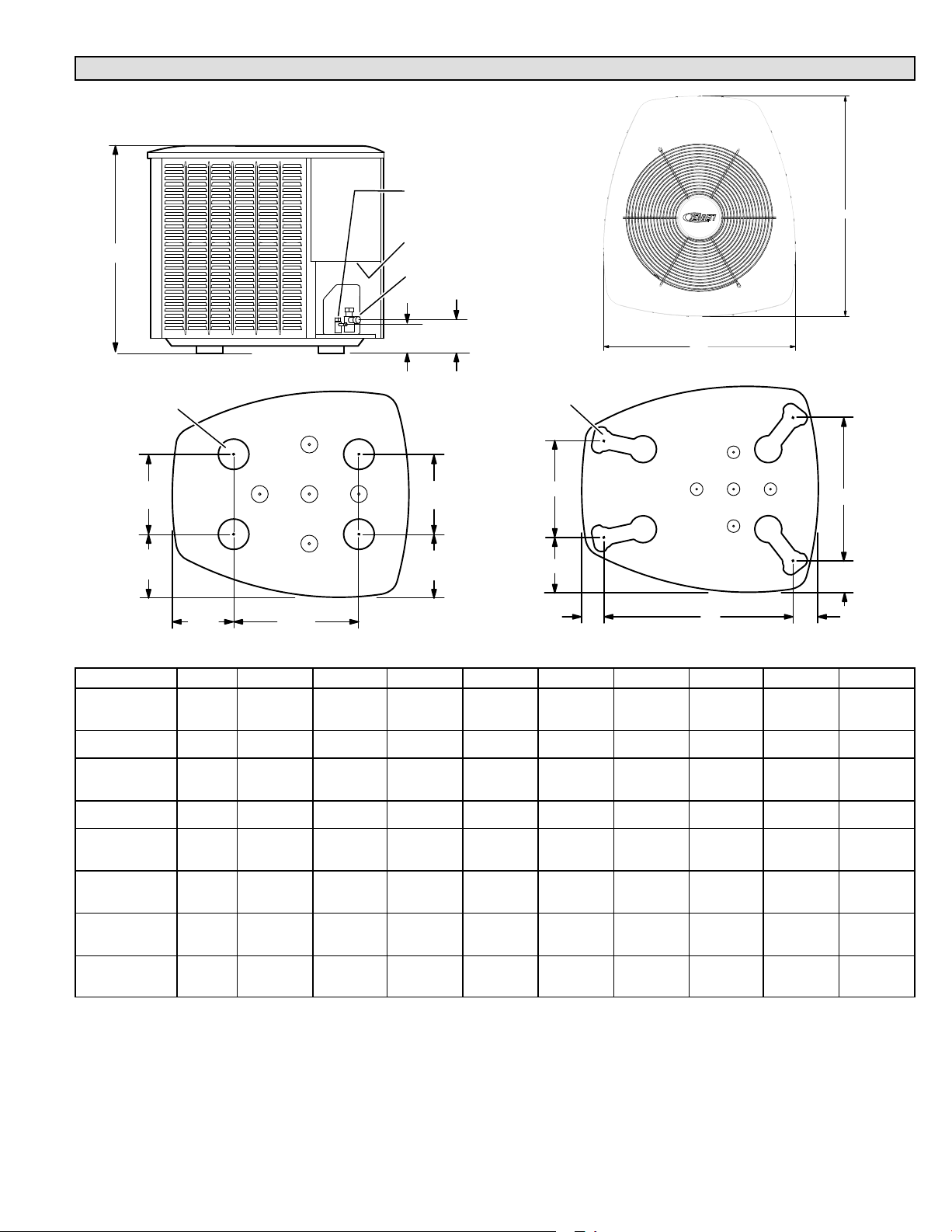

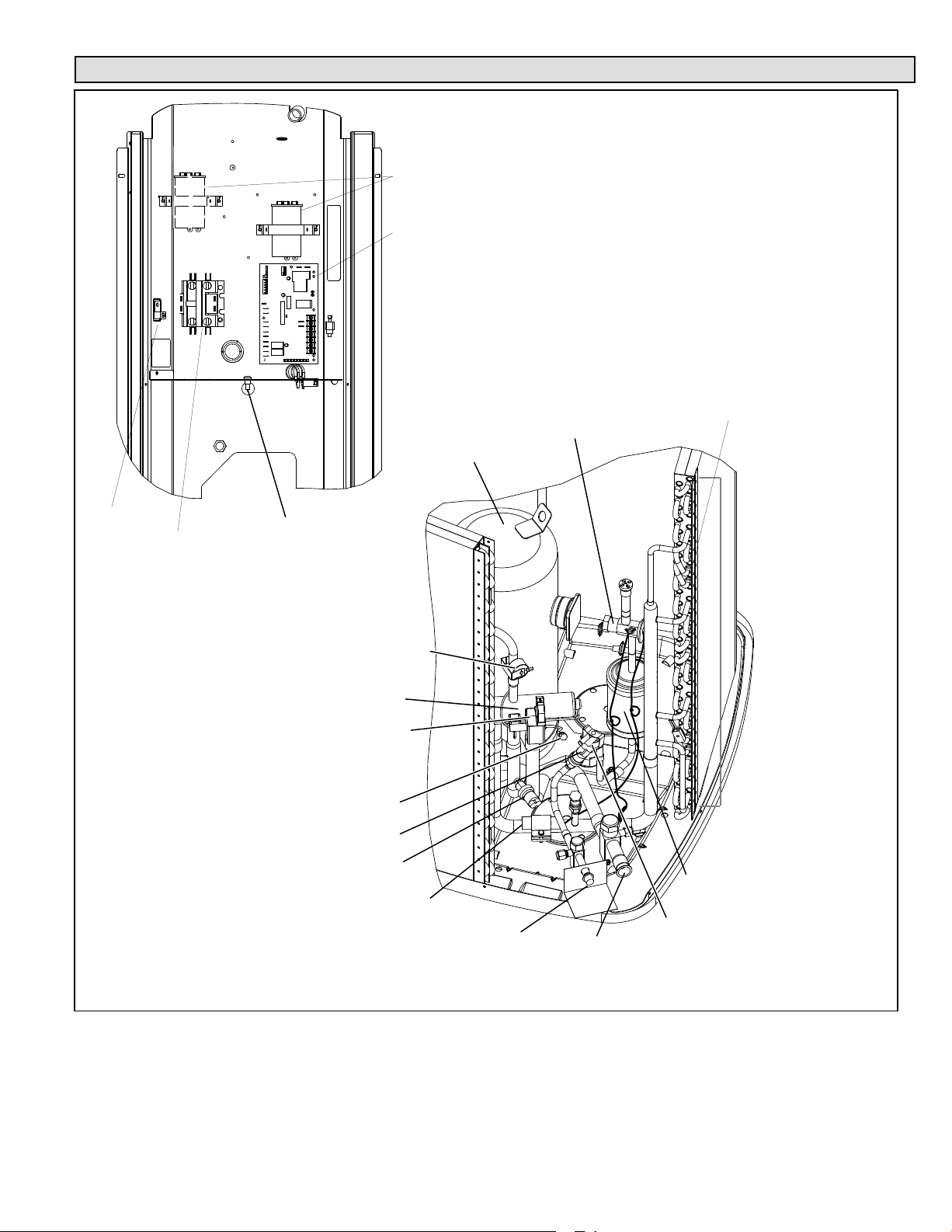

Typical Unit Parts Arrangement

CAPACITOR (LOCATION OF

CAPACITOR VARIES.)

DEFROST CONTROL (A108)

GROUND

LUG

CONTACTOR

(K−1)

AMBIENT

TEMPERATURE

SENSOR (RT13)

DISCHARGE LINE SENSOR (RT28)

REVERSING VALVE

REVERSING VALVE SOLENOID

TRUE SUCTION PORT

HIGH PRESSURE SWITCH (S4)

COMPRESSOR

CHECK

EXPANSION VALVE

FOR COIL SENSOR (RT21) LOCATION

SEE FIGURE 2.

XP16

LOW PRESSURE SWITCH (S87)

EXPANSION VALVE SENSING BULB

LIQUID VALVE AND GAUGE PORT / LIQUID LINE CONNECTIONS

Figure 1. Typical Parts Arrangements

Page 5

CRANKCASE HEATER THERMOSTAT (S40)

VAPOR VALVE AND GAUGE

PORT / SUCTION LINE

CONNECTIONS

LIQUID LINE BI−FLOW FILTER DRIER

Page 6

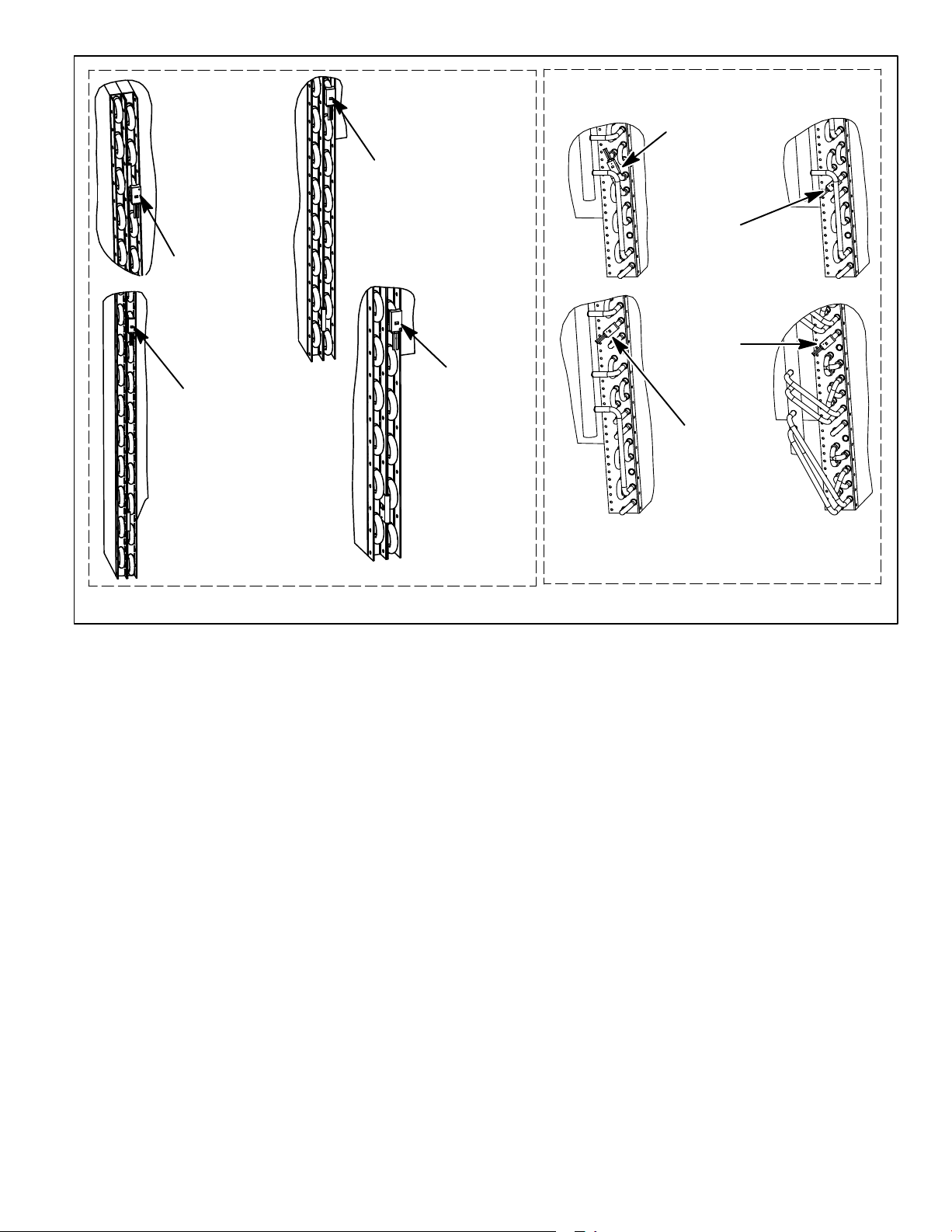

XP16−024

COIL SENSOR −THIRD

HAIRPIN DOWN FROM

THE TOP ON INSIDE

ROW.

XP16−036

COIL SENSOR − NINTH

HAIRPIN UP FROM THE

BOTTOM ON INSIDE

ROW.

XP16−048

COIL SENSOR − EIGHT HAIRPIN

UP FROM THE BOTTOM ON

INSIDE ROW.

XP16−060

COIL SENSOR −

SIXTH HAIRPIN UP

FROM THE BOTTOM

ON INSIDE ROW.

XP16−024

COIL SENSOR

7 tubes up from

bottom (7−1/2")

XP16−036

COIL SENSOR

17 tubes up

from bottom

(17−1/2")

XP16−060

COIL SENSOR

12 tubes up from

bottom (11−1/2")

XP16−048

COIL SENSOR

13 tubes up from

bottom (12−1/2")

(XP16−XXX−230−05)

(XP16−XXX−230−01 through 04)

CLIP COIL TEMPERATURE SENSOR FROM THE DEFROST BOARD ON THE RETURN BEND SHOWN.

Figure 2. Coil Sensor (RT21) Locations

Page 6

XP16

Page 7

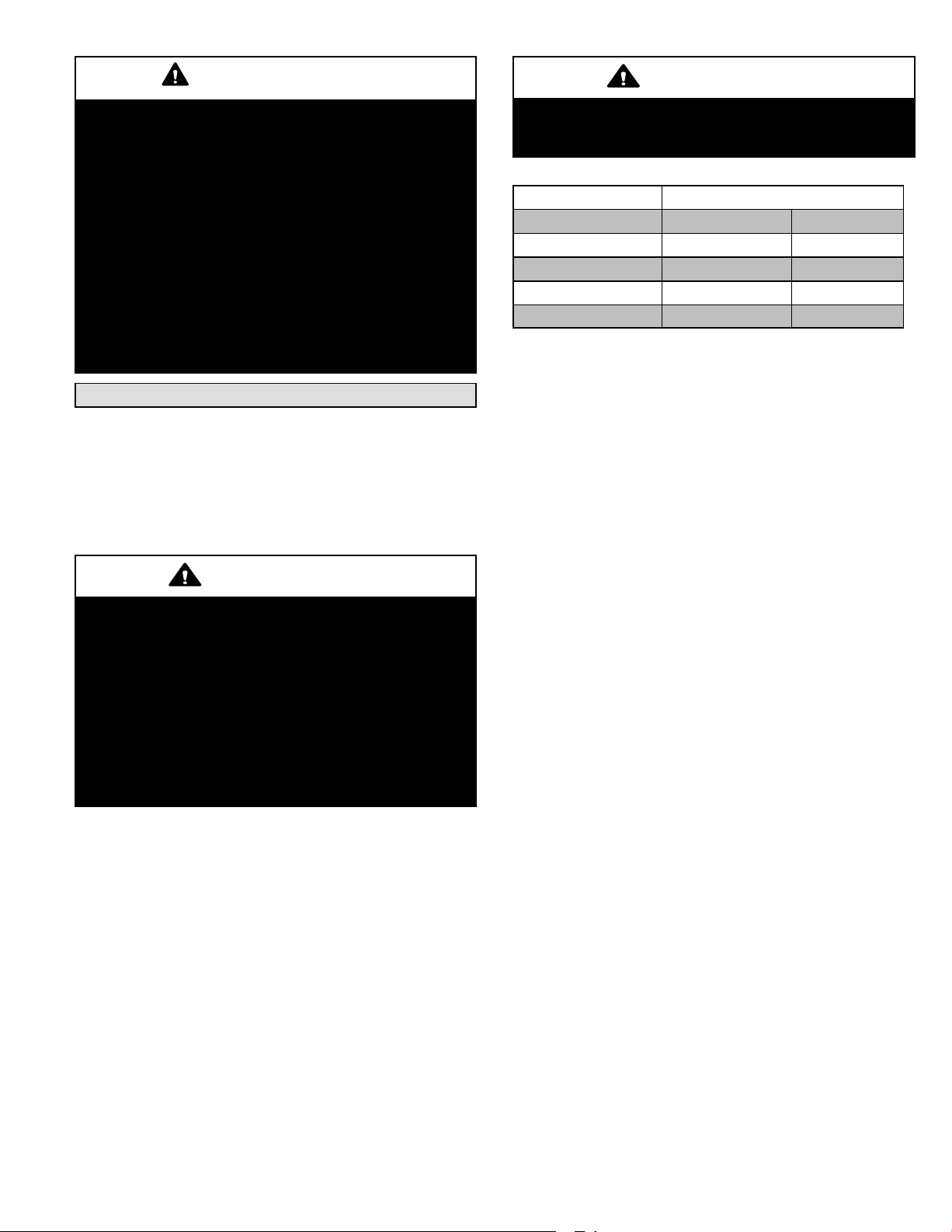

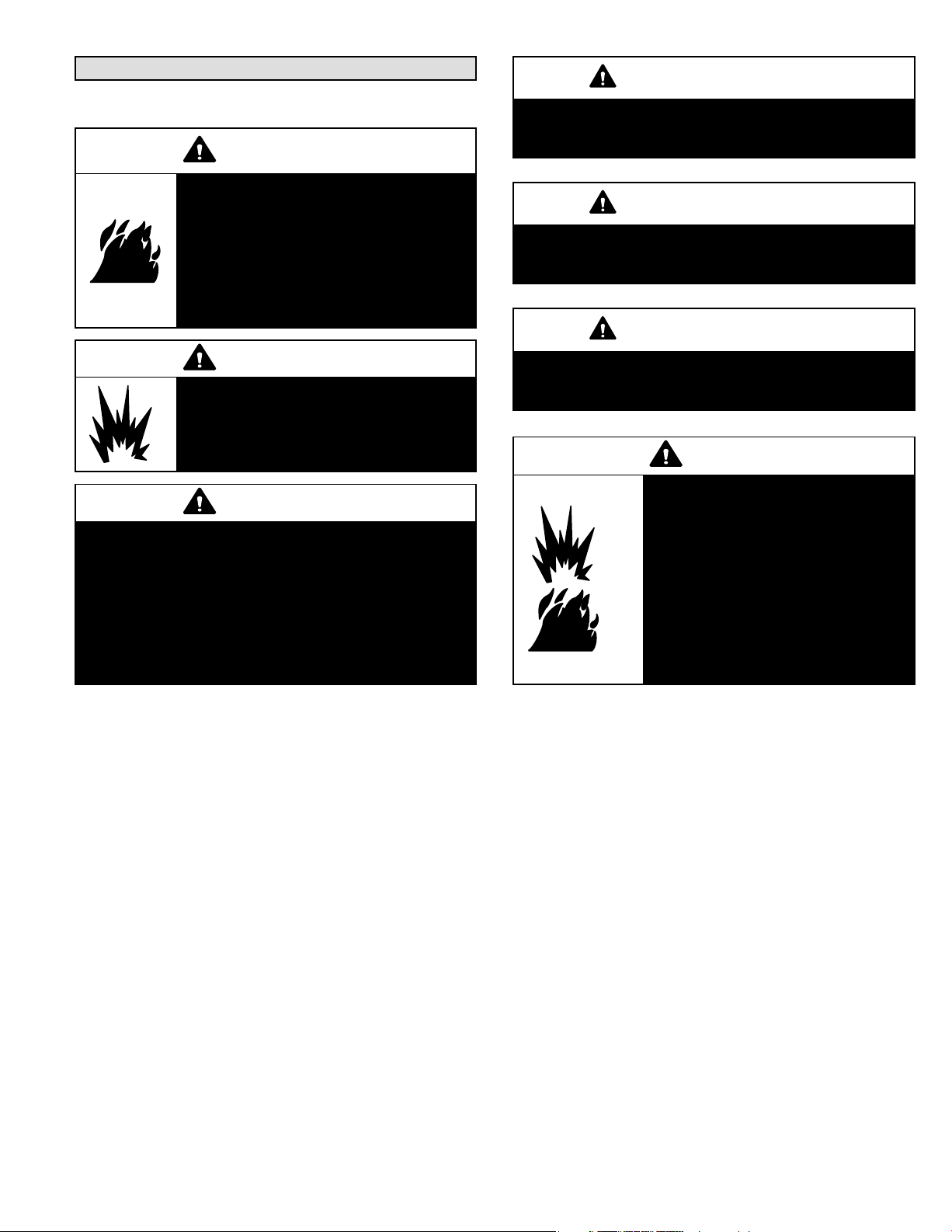

WARNING

IMPORTANT

This product and/or the indoor unit it is matched with may

contain fiberglass wool.

Disturbing the insulation during installation, maintenance,

or repair will expose you to fiberglass wool dust. Breathing

this may cause lung cancer. (Fiberglass wool is known to

the State of California to cause cancer.)

Fiberglass wool may also cause respiratory, skin, and eye

irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets available

from address shown below, or contact your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

Operating Gauge Set and Service Valves

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

TORQUE REQUIREMENTS

When servicing or repairing heating, ventilating, and air

conditioning components, ensure the fasteners are

appropriately tightened. Table 1 lists torque values for

fasteners.

IMPORTANT

Only use Allen wrenches of sufficient hardness (50Rc −

Rockwell Harness Scale minimum). Fully insert the

wrench into the valve stem recess.

Service valve stems are factory−torqued (from 9 ft−lbs for

small valves, to 25 ft−lbs for large valves) to prevent

refrigerant loss during shipping and handling. Using an

Allen wrench rated at less than 50Rc risks rounding or

breaking off the wrench, or stripping the valve stem

recess.

See the Lennox Service and Application Notes #C−08−1 for

further details and information.

To prevent stripping of the various caps used, the

appropriately sized wrench should be used and fitted

snugly over the cap before tightening.

Table 1. Torque Requirements

Parts Recommended Torque

Service valve cap 8 ft.− lb. 11 NM

Sheet metal screws 16 in.− lb. 2 NM

Machine screws #10 28 in.− lb. 3 NM

Compressor bolts 90 in.− lb. 10 NM

Gauge port seal cap 8 ft.− lb. 11 NM

USING MANIFOLD GAUGE SET

When checking the system charge, only use a manifold

gauge set that features low loss anti−blow back fittings.

Manifold gauge set used with HFC−410A refrigerant

systems must be capable of handling the higher system

operating pressures. The gauges should be rated for use

with pressures of 0 − 800 psig on the high side and a low side

of 30" vacuum to 250 psig with dampened speed to 500 psi.

Gauge hoses must be rated for use at up to 800 psig of

pressure with a 4000 psig burst rating.

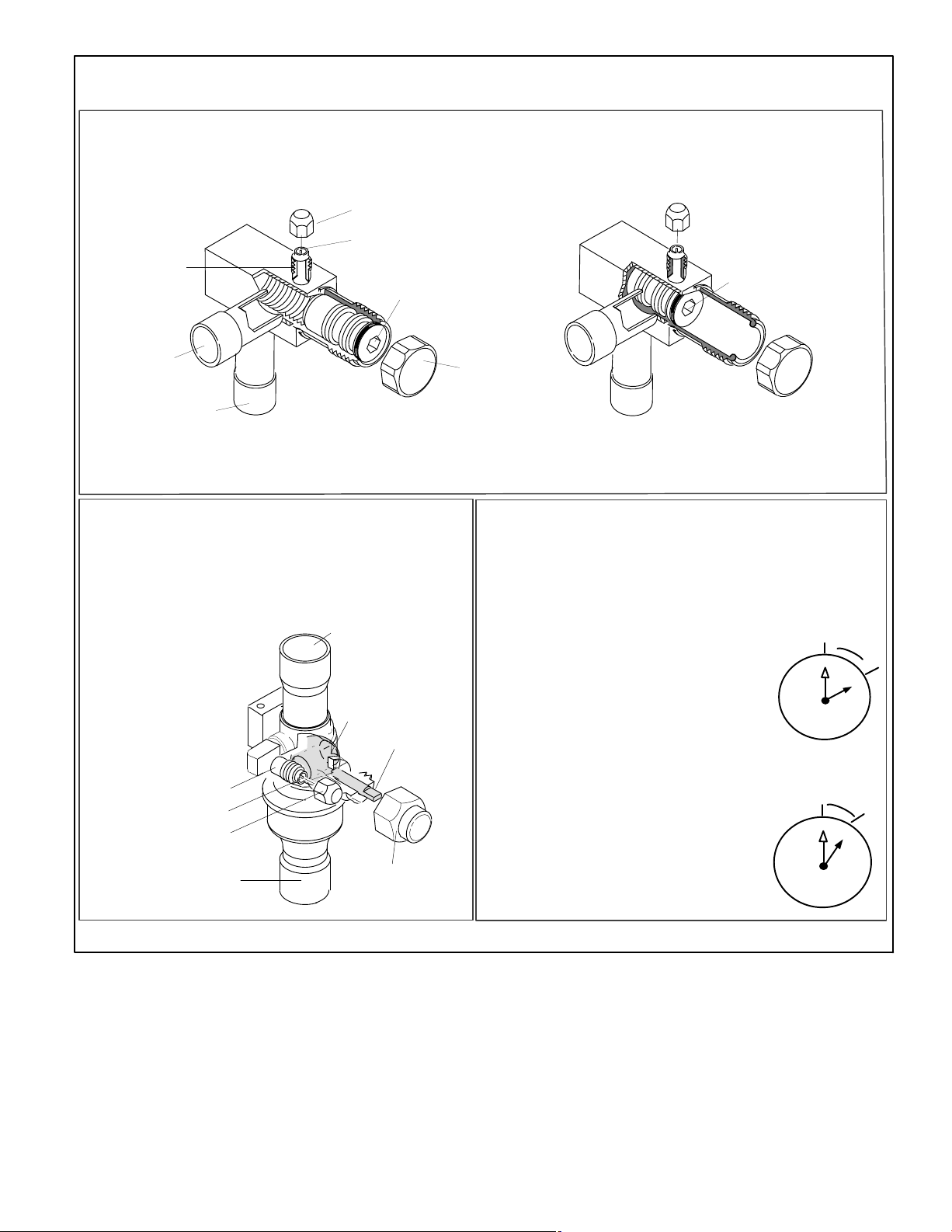

OPERATING SERVICE VALVES

The liquid and vapor line service valves are used for

removing refrigerant, flushing, leak testing, evacuating,

checking charge and charging.

Each valve is equipped with a service port which has a

factory−installed valve stem. Figure 3 provides information

on how to access and operating both angle and ball service

valves.

XP16

Page 7

Page 8

SERVICE VALVES

ANGLE AND BALL

Operating Angle Type Service Valve:

1. Remove stem cap with an appropriately sized wrench.

2. Use a service wrench with a hex−head extension (3/16" for liquid line valve sizes and 5/16" for vapor line valve sizes) to back

the stem out counterclockwise as far as it will go.

SERVICE PORT CAP

SERVICE PORT CORE

(VALVE STEM SHOWN

TO INDOOR

UNIT

(VALVE STEM SHOWN OPEN)

INSERT HEX WRENCH HERE

CLOSED) INSERT HEX

WRENCH HERE

SERVICE PORT

CORE

TO OUTDOOR UNIT

ANGLE−TYPE SERVICE VALVE

(BACK−SEATED OPENED)

When service valve is OPEN, the service port is

open to linE set, indoor and outdoor unit.

Operating Ball Type Service Valve:

1. Remove stem cap with an appropriately sized wrench.

2. Use an appropriately sized wrenched to open. To open valve,

roate stem counterclockwise 90°. To close rotate stem clockwise 90°.

TO INDOOR UNIT

TO OPEN ROTATE STEM

COUNTERCLOCKWISE 90°.

TO CLOSE ROTATE STEM

CLOCKWISE 90°.

SERVICE PORT

SERVICE PORT

SERVICE PORT

CORE

CAP

TO OUTDOOR

UNIT

BALL (SHOWN

CLOSED)

VALV E

STEM

STEM CAP

STEM CAP

ANGLE−TYPE SERVICE VALVE

(FRONT−SEATED CLOSED)

WHEN SERVICE VALV E IS CLOSED, THE SERVICE PORT IS

OPEN

TO THE LINE SET AND INDOOR UNIT.

To Access Service Port:

A service port cap protects the service port core from contamination and

serves as the primary leak seal.

1. Remove service port cap with an appropriately sized wrench.

2. Connect gauge set to service port.

3. When testing is completed, replace service port cap and tighten as

follows:

D With torque wrench: Finger tighten and

torque cap per table 1.

D Without torque wrench: Finger tighten and

use an appropriately sized wrench to turn

an additional 1/6 turn clockwise.

Reinstall Stem Cap:

Stem cap protects the valve stem from damage and serves as the

primary seal. Replace the stem cap and tighten as follows:

D With Torque Wrench: Finger tighten and

then torque cap per table 1.

D Without Torque Wrench: Finger

tighten and use an appropriately

sized wrench to turn an additional

1/12 turn clockwise.

9

10

9

10

8

12

11

8

7

6

12

11

7

6

1/6 TURN

1

2

3

4

5

1/12 TURN

1

2

3

4

5

NOTE A label with specific torque requirements may be affixed to the stem cap. If the label is present, use the specified torque.

Figure 3. Angle and Ball Service Valves

Page 8

XP16

Page 9

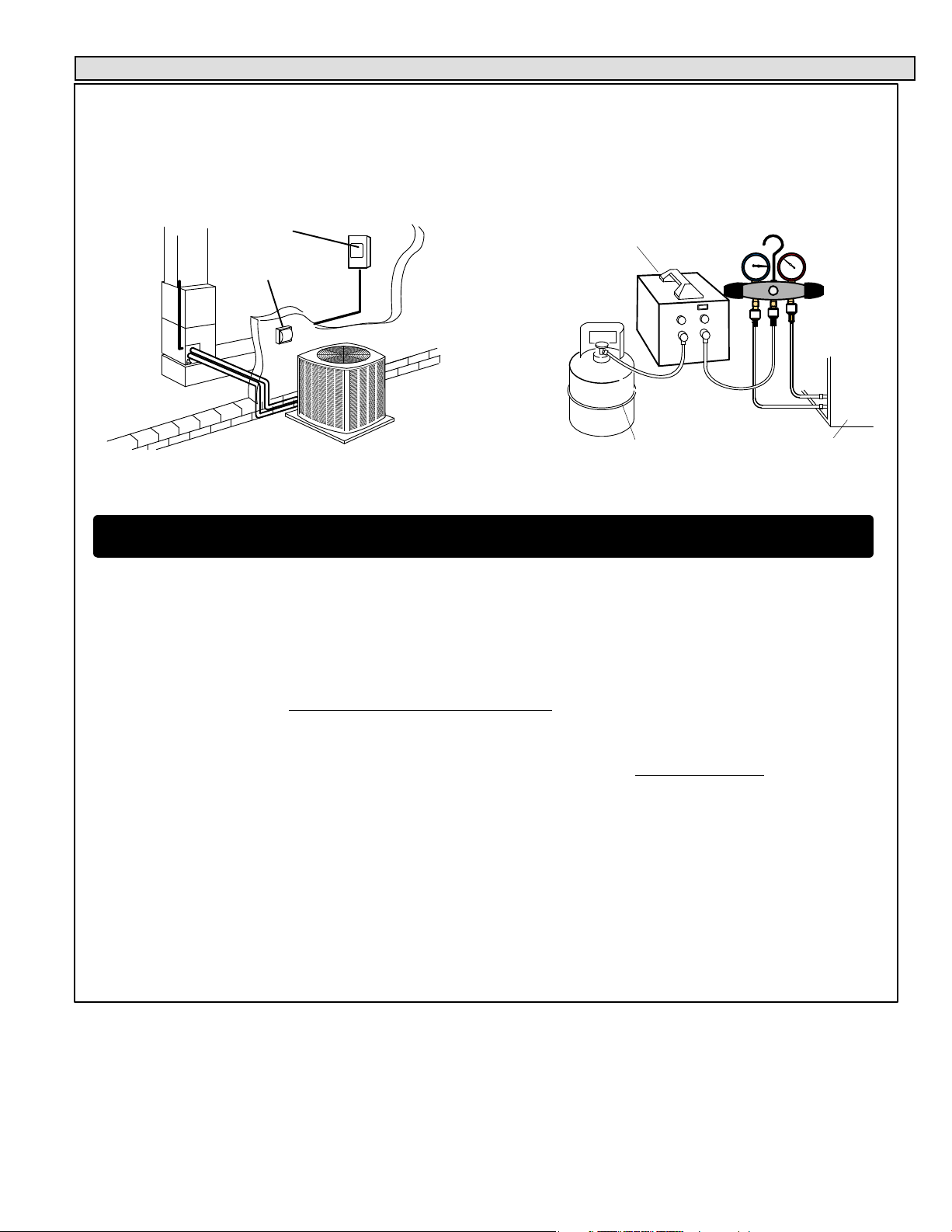

Recovering Refrigerant from System

DISCONNECT POWER

Disconnect all power to the existing outdoor unit at the disconnect

1

switch or main fuse box/breaker panel.

MAIN FUSE BOX/BREAKER PANEL

MAIN FUSE

BOX/BREAKER

PANEL

DISCONNECT

SWITCH

RECOVERING REFRIGERANT

Remove existing HCFC−22 refrigerant using one of the following procedures:

3

IMPORTANT Some system configurations may contain higher than normal refrigerant charge due to either large internal coil vol-

umes, and/or long line sets.

CONNECT MANIFOLD GAUGE SET

Connect a gauge set, clean recovery cylinder and a recovery

2

machine to the service ports of the existing unit. Use the

instructions provided with the recovery machine to make the

connections.

MANIFOLD GAUGES

RECOVERY MACHINE

LOW

CLEAN RECOVERY

CYLINDER

OUTDOOR UNIT

HIGH

METHOD 1:

Us this method if the existing outdoor unit is not equipped with shut−off valves, or if the unit is not operational and you plan to use the existing

HCFC−22 to flush the system.

Remove all HCFC−22 refrigerant from the existing system. Check gauges after shutdown to confirm that the entire system is completely void of

refrigerant.

METHOD 2:

Use this method if the existing outdoor unit is equipped with manual shut−off valves, and you plan to use new HCFC−22 refrigerant to flush the

system.

The following devices could prevent full system charge recovery into the outdoor unit

D Outdoor unit’s high or low−pressure switches (if applicable) when tripped can cycle the compressor OFF.

D Compressor can stop pumping due to tripped internal pressure relief valve.

D Compressor has internal vacuum protection that is designed to unload the scrolls (compressor stops pumping) when the pressure ratio meets

a certain value or when the suction pressure is as high as 20 psig. (Compressor suction pressures should never be allowed

Prolonged operation at low suction pressures will result in overheating of the scrolls and permanent damage to the scroll tips, drive bearings

and internal seals.)

Once the compressor can not pump down to a lower pressure due to one of the above system conditions, shut off the vapor valve. Turn OFF the

main power to unit and use a recovery machine to recover any refrigerant left in the indoor coil and line set.

Perform the following task:

A Start the existing HCFC−22 system in the cooling mode and close the liquid line valve.

B Use the compressor to pump as much of the existing HCFC−22 refrigerant into the outdoor unit until the outdoor system is full. Turn the outdoor

unit main power OFF and use a recovery machine to remove the remaining refrigerant from the system.

NOTE It may be necessary to bypass the low pressure switches (if equipped) to ensure complete refrigerant evacuation.

C When the low side system pressures reach 0 psig, close the vapor line valve.

D Check gauges after shutdown to confirm that the valves are not allowing refrigerant to flow back into the low side of the system.

:

to go into a vacuum.

Figure 4. Refrigerant Recovery

XP16

Page 9

Page 10

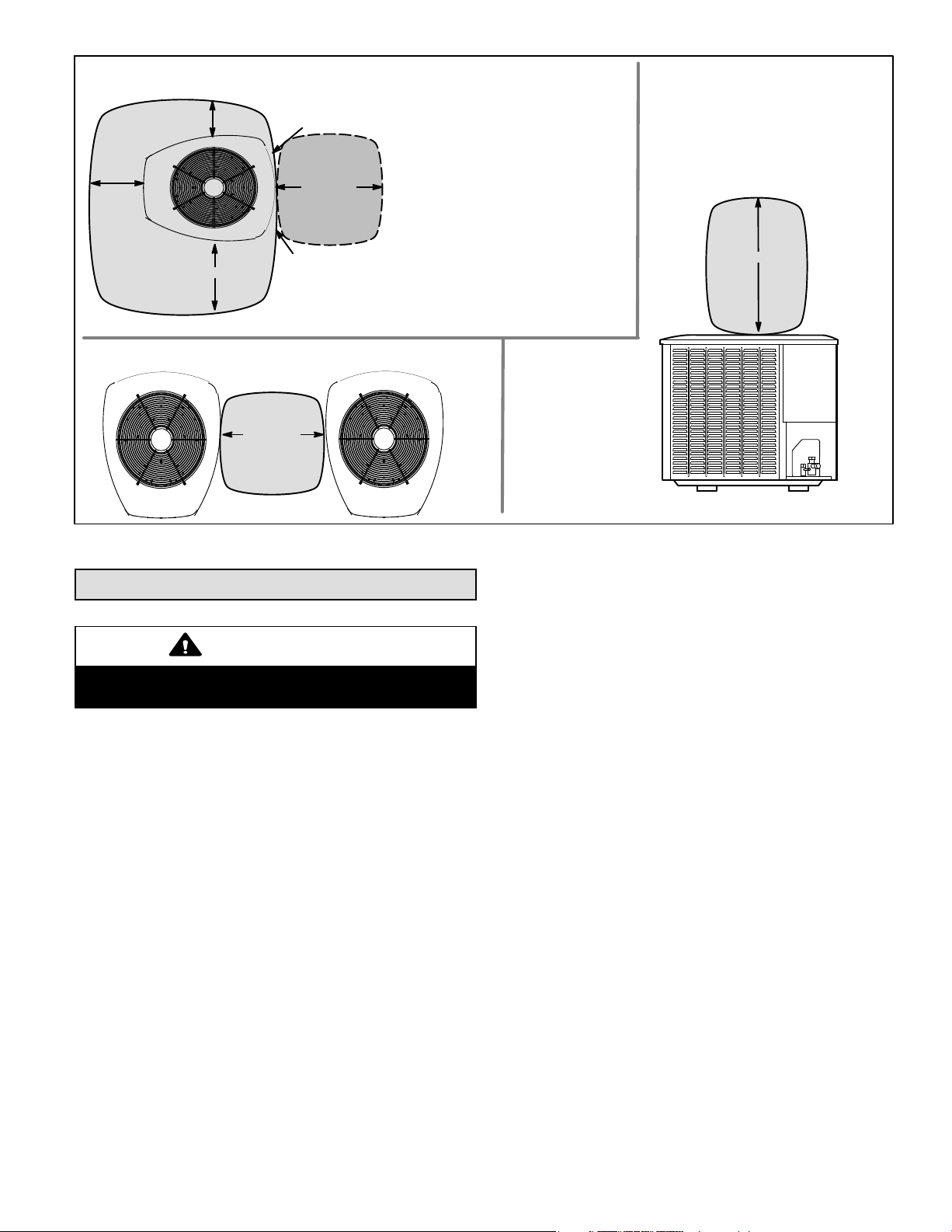

CLEARANCE ON ALL SIDES INCHES (MILLIMETERS)

12 (305)

6 (152)

36 (914)

ACCESS PANEL

CONTROL PANEL

ACCESS

LOCATION

30 (762)

LINE SET

CONNECTIONS

MINIMUM CLEARANCE BETWEEN

TWO UNITS

24 (610)

Figure 5. Installation Clearances

NOTES:

D Clearance to one of the other three

sides must be 36 inches (914mm).

D Clearance to one of the remaining

two sides may be 12 inches

(305mm) and the final side may be

6 inches (152mm).

MINIMUM CLEARANCE

ABOVE UNIT

48 (1219)

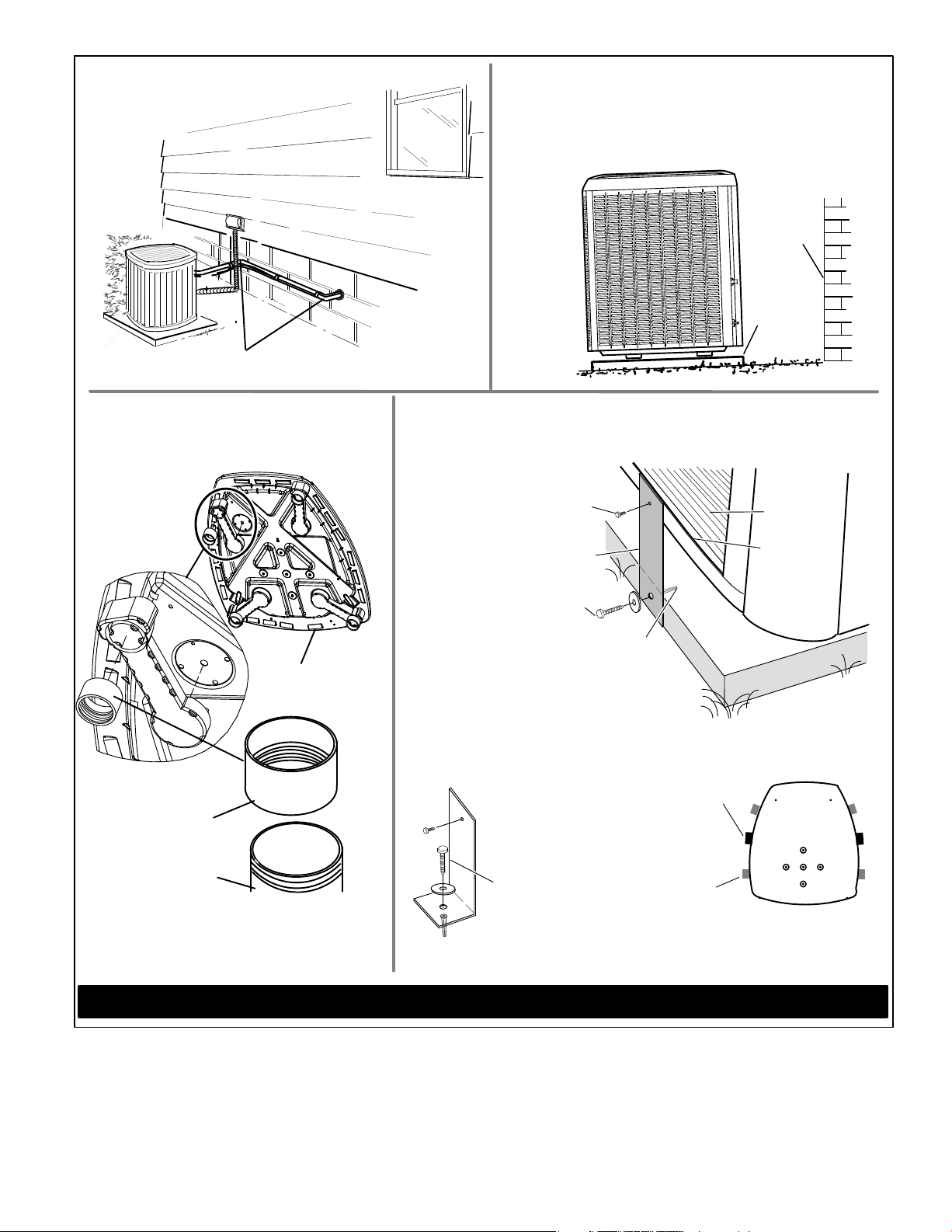

Unit Placement

CAUTION

In order to avoid injury, take proper precaution when lifting

heavy objects.

See Unit Dimensions on page 3 for sizing mounting slab,

platforms or supports. Refer to figure 5 for mandatory

installation clearance requirements.

POSITIONING CONSIDERATIONS

Consider the following when positioning the unit:

D Some localities are adopting sound ordinances based

on the unit’s sound level registered from the adjacent

property, not from the installation property. Install the

unit as far as possible from the property line.

D When possible, do not install the unit directly outside a

window. Glass has a very high level of sound

transmission. For proper placement of unit in relation to

a window see the provided illustration in figure 6, detail

A.

PLACING UNIT ON SLAB

When installing unit at grade level, the top of the slab should

be high enough above grade so that water from higher

ground will not collect around the unit. The slab should have

a slope tolerance as described in figure 6, detail B.

NOTE If necessary for stability, anchor unit to slab as

described in figure 6, detail D.

ELEVATING THE UNIT

Units are outfitted with elongated support feet as illustrated

in figure 6, detail C.

If additional elevation is necessary, raise the unit by

extending the height of the unit support feet. This may be

achieved by using a 2 inch (50.8mm) Schedule 40 female

threaded adapter.

The specified coupling will fit snuggly into the recessed

portion of the feet. Use additional 2 inch (50.8mm) Schedule

40 male threaded adaptors which can be threaded into the

female threaded adaptors to make additional adjustments to

the level of the unit.

NOTE Keep the height of extenders short enough to

ensure a sturdy installation. If it is necessary to extend

further, consider a different type of field−fabricated

framework that is sturdy enough for greater heights.

Page 10

XP16

Page 11

DETAIL A

Install unit away from windows.

Outside Unit Placement

DETAIL B

Install unit level or, if on a slope, maintain slope tolerance of two

(2) degrees (or two inches per five feet [50 mm per 1.5 m]) away

from building structure.

Slab Mounting at Ground Level

BUILDING

STRUCTURE

MOUNTING

SLAB

TWO 90° ELBOWS INSTALLED IN LINE SET WILL

REDUCE LINE SET VIBRATION.

DETAIL C

Elevated Slab Mounting

using Feet Extenders

LEG DETAIL

2" (50.8MM) SCH 40

FEMALE THREADED

ADAPTER

BASE

GROUND LEVEL

STABILIZING UNIT ON UNEVEN SURFACES

DETAIL D

#10 1/2" LONG SELF−DRILLING

SHEET METAL SCREWS

STABILIZING BRACKET (18 GAUGE

METAL 2" WIDTH; HEIGHT AS

#10 1−1/4" LONG HEX HD SCREW

Concrete slab use two plastic anchors (hole

drill 1/4")

Wood or plastic slab no plastic anchor (hole

drill 1/8")

DETAIL E

Stabilizing bracket (18 gauge metal 2" (50.8mm) width; height as required); bend to form

right angle as exampled below.

Slab Side Mounting

REQUIRED)

AND FLAT WASHER

Deck Top Mounting

MINIMUM ONE

PER SIDE

COIL

BASE PAN

CORNER POST

2" (50.8MM) SCH 40

MALE THREADED

ADAPTER

Use additional 2" SCH 40 male threaded adapters

which can be threaded into the female threaded

adapters to make additional adjustments to the level

of the unit.

IMPORTANT To help stabilize an outdoor unit, some installations may require strapping the unit to the pad using brackets and anchors

commonly available in the marketplace.

One bracket per side (minimum). For extra stability, two brackets per side, two inches

(51mm) from each corner.

SAME FASTENERS AS

SLAB SIDE MOUNTING.

FOR EXTRA

STABILITY

Figure 6. Placement, Slab Mounting and Stabilizing Unit

XP16

Page 11

Page 12

STABILIZING UNIT ON UNEVEN SURFACES

IMPORTANT

Unit Stabilizer Bracket Use (field−provided):

Always use stabilizers when unit is raised above the

factory height. (Elevated units could become unstable in

gusty wind conditions).

Stabilizers may be used on factory height units when

mounted on unstable an uneven surface.

With unit positioned at installation site, perform the

following

1. Remove two side louvered panels to expose the unit

2. Install the brackets as illustrated in figure 6, detail D or

3. Replace the panels after installation is complete.

ROOF MOUNTING

Install the unit a minimum of 6 inches (152 mm) above the

roof surface to avoid ice build−up around the unit. Locate the

unit above a load bearing wall or area of the roof that can

adequately support the unit. Consult local codes for rooftop

applications.

If unit coil cannot be mounted away from prevailing winter

winds, a wind barrier should be constructed. Size barrier at

least the same height and width as outdoor unit. Mount

barrier 24 inches (610 mm) from the sides of the unit in the

direction of prevailing winds.

:

base.

E using conventional practices.

Removing and Installing Panels

IMPORTANT

Do not allow panels to hang on unit by top tab. Tab is for

alignment and not designed to support weight of panel.

IMPORTANT

To help stabilize an outdoor unit, some installations may

require strapping the unit to the pad using brackets and

anchors commonly available in the marketplace.

WARNING

To prevent personal injury, or damage to panels, unit or

structure, be sure to observe the following:

While installing or servicing this unit, carefully stow all

removed panels out of the way, so that the panels will not

cause injury to personnel, nor cause damage to objects or

structures nearby, nor will the panels be subjected to

damage (e.g., being bent or scratched).

While handling or stowing the panels, consider any

weather conditions, especially windy conditions, that may

cause panels to be blown around and battered.

NOTICE

Roof Damage!

This system contains both refrigerant and oil. Some

rubber roofing material may absorb oil and cause the

rubber to swell when it comes into contact with oil. The

rubber will then bubble and could cause leaks. Protect the

roof surface to avoid exposure to refrigerant and oil

during service and installation. Failure to follow this

notice could result in damage to roof surface.

Page 12

XP16

Page 13

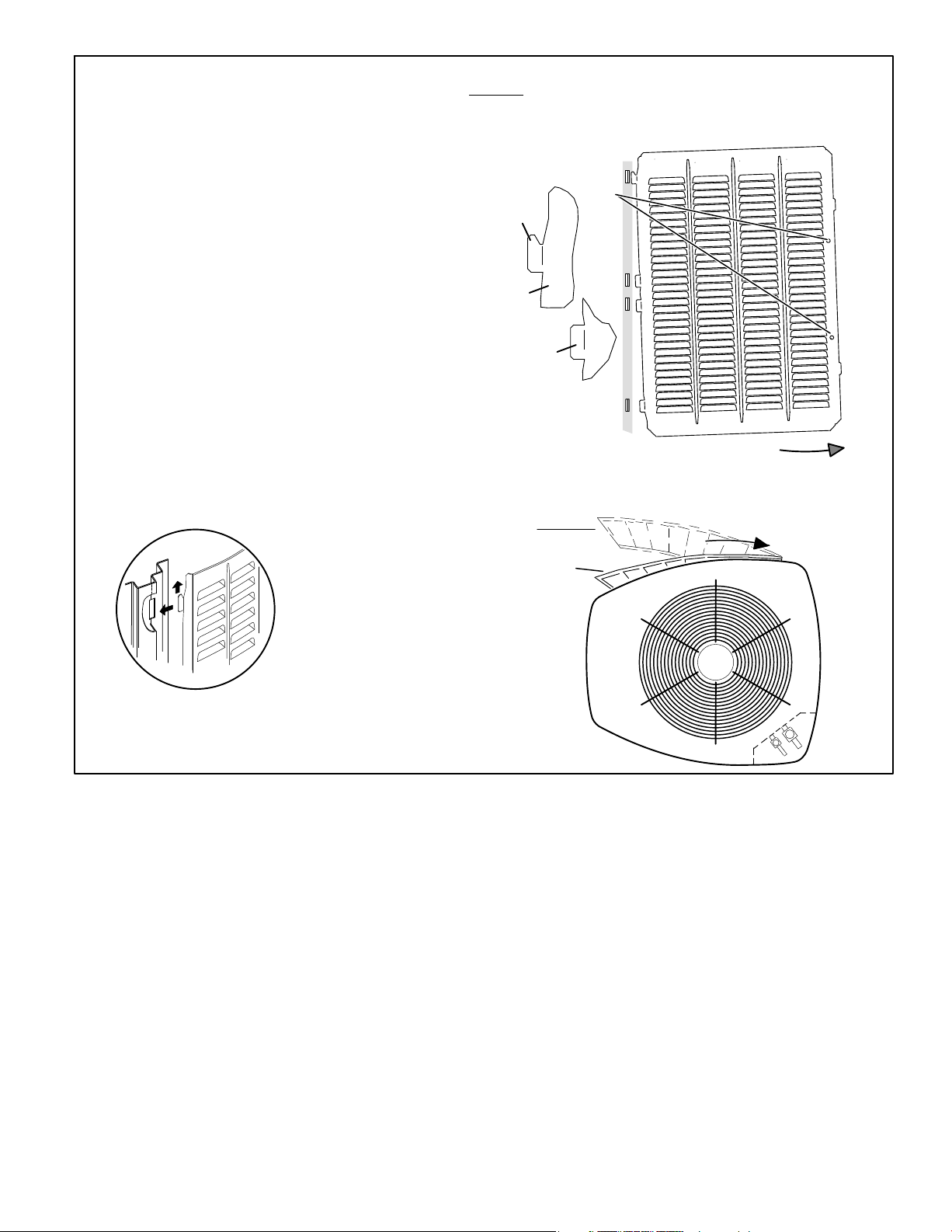

LOUVERED PANEL REMOVAL

Remove the louvered panels as follows:

1. Remove two screws, allowing the panel to swing open

slightly.

2. Hold the panel firmly throughout this procedure. Rotate bot-

tom corner of panel away from hinged corner post until lower three tabs clear the slots as illustrated in detail B.

3. Move panel down until lip of upper tab clears the top slot in

corner post as illustrated in detail A.

LOUVERED PANEL INSTALLATION

Position the panel almost parallel with the unit as illustrated

in detail D with the screw side as close to the unit as possible. Then, in a continuous motion:

1. Slightly rotate and guide the lip of top tab inward as illustrated in detail A and C; then upward into the top

slot of the hinge corner post.

2. Rotate panel to vertical to fully engage all tabs.

3. Holding the panel’s hinged side firmly in place, close

the right−hand side of the panel, aligning the screw

holes.

4. When panel is correctly positioned and aligned, insert

the screws and tighten.

Detail C

MAINTAIN MINIMUM PANEL ANGLE (AS CLOSE TO PARALLEL WITH THE UNIT

AS POSSIBLE) WHILE INSTALLING PANEL.

IMPORTANT

ALIGNMENT AND NOT DESIGNED TO SUPPORT WEIGHT OF PANEL.

PANEL SHOWN SLIGHTLY ROTATED TO ALLOW TOP TAB TO EXIT (OR

ENTER) TOP SLOT FOR REMOVING (OR INSTALLING) PANEL.

! DO NOT ALLOW PANELS TO HANG ON UNIT BY TOP TAB. TAB IS FOR

SCREW

LIP

DETAIL A

DETAIL B

ANGLE MAY BE TOO

EXTREME

HOLES

ROTATE IN THIS DIRECTION;

THEN DOWN TO REMOVE

HOLD DOOR FIRMLY TO THE HINGED

PANEL

SIDE TO MAINTAIN

FULLY−ENGAGED TABS

PREFERRED ANGLE

FOR INSTALLATION

Figure 7. Removing and Installing Panels

XP16

Page 13

Page 14

New or Replacement Line Set

REFRIGERANT LINE SET

This section provides information on installation or

replacement of existing line set. If new or replacement line

set is not being installed then proceed to Brazing

Connections on page 16.

IMPORTANT

Lennox highly recommends changing line set when

converting the existing system from HCFC−22 to

HFC−410A. If that is not possible and the line set is the

proper size as reference in table 2, use the procedure

outlined under Flushing the System on page 13.

If refrigerant lines are routed through a wall, then seal and

isolate the opening so vibration is not transmitted to the

building. Pay close attention to line set isolation during

installation of any HVAC system. When properly isolated

from building structures (walls, ceilings. floors), the

refrigerant lines will not create unnecessary vibration and

subsequent sounds. See figure 8 for recommended

installation practices. Also, consider the following when

placing and installing a high−efficiency outdoor unit.

Liquid lines that meter the refrigerant, such as RFC1 liquid

lines, must not be used in this application. Existing line set of

proper size as listed in table 2 may be reused. If system was

previously charged with HCFC−22 refrigerant, then existing

line set must be flushed (see Flushing the System on page

19).

Field refrigerant piping consists of liquid and vapor lines from

the outdoor unit to the indoor unit coil (braze connections).

Use Lennox L15 (sweat, non−flare) series line set, or

field−fabricated refrigerant line sizes as listed in table 2.

Table 2. Refrigerant Line Set Inches (mm)

Model

−018

−024

−030

−036

−042

−048

−060

Valve Field

Connections

Liquid

Line

3/8 in.

(10 mm)

3/8 in.

(10 mm)

3/8 in.

(10 mm)

Vapor

Line

3/4 in

(19 mm)

7/8 in

(22 mm)

1−1/8 in.

(29 mm)

Recommended Line Set

Liqui

d

Line

3/8 in.

(10

mm)

3/8 in.

(10

mm)

3/8 in.

(10

mm)

Vapor

Line

3/4 in

(19 mm)

7/8 in

(22 mm)

1−1/8 in.

(29 mm)

L15

Line Sets

L15−41

15 ft. − 50 ft.

(4.6 m − 15

m)

L15−65

15 ft. − 50 ft.

(4.6 m − 15

m)

Field

Fabricated

NOTE When installing refrigerant lines longer than 50

feet, see the Lennox Refrigerant Piping Design and

Fabrication Guidelines, CORP. 9351−L9, or contact Lennox

Technical Support Product Applications for assistance.

To obtain the correct information from Lennox, be sure to

communicate the following information:

D Model (XP16) and size of unit (e.g. −036).

D Line set diameters for the unit being installed as listed

in table 2 and total length of installation.

D Number of elbows vertical rise or drop in the piping.

The compressor is charged with sufficient Polyol ester oil for

line set lengths up to 50 feet. Recommend adding oil to

system based on the amount of refrigerant charge in the

system. No need to add oil in system with 20 pounds of

refrigerant or less. For systems over 20 pounds − add one

ounce of every five pounds of refrigerant.

Recommended topping−off POE oils are Mobil EAL ARCTIC

22 CC or ICI EMKARATEt RL32CF.

WARNING

Polyol Ester (POE) oils used with HFC−410A

refrigerant absorb moisture very quickly. It is very

important that the refrigerant system be kept closed as

much as possible. DO NOT remove line set caps or

service valve stub caps until you are ready to make

connections.

IMPORTANT

Mineral oils are not compatible with HFC−410A. If oil must

be added, it must be a Polyol Ester oil.

Page 14

XP16

Page 15

Line Set Isolation The following illustrations are examples of proper refrigerant line set isolation:

REFRIGERANT LINE SET TRANSITION

FROM VERTICAL TO HORIZONTAL

ANCHORED HEAVY NYLON

WIRE TIE OR AUTOMOTIVE

MUFFLER-TYPE HANGER

WALL

STUD

NON−CORROSIVE

METAL SLEEVE

AUTOMOTIVE

MUFFLER-TYPE HANGER

STRAP LIQUID LINE TO

VAPOR LINE

LIQUID LINE

VAPOR LINE − WRAPPED

IN ARMAFLEX

REFRIGERANT LINE SET INSTALLING

HORIZONTAL RUNS

To hang line set from joist or rafter, use either metal strapping material or anchored heavy nylon wire ties.

WIRE TIE (AROUND

VAPOR LINE ONLY)

8 FEET (2.43 METERS)

STRAPPING

MATERIAL (AROUND

VAPOR LINE ONLY)

TAPE OR

WIRE TIE

FLOOR JOIST OR

ROOF RAFTER

8 FEET (2.43 METERS)

NON−CORROSIVE

METAL SLEEVE

STRAP THE VAPOR LINE TO THE

JOIST OR RAFTER AT 8 FEET (2.43

METERS) INTERVALS THEN STRAP

THE LIQUID LINE TO THE VAPOR LINE.

TAPE OR

WIRE TIE

REFRIGERANT LINE SET INSTALLING

VERTICAL RUNS (NEW CONSTRUCTION SHOWN)

NOTE Insulate liquid line when it is routed through areas where the

surrounding ambient temperature could become higher than the

temperature of the liquid line or when pressure drop is equal to or

greater than 20 psig.

OUTSIDE WALL

WOOD BLOCK

BETWEEN STUDS

VAPOR LINE WRAPPED

WITH ARMAFLEX

OUTSIDE

WALL

PVC

PIPE

FIBERGLASS

INSULATION

VAPOR LINE

SLEEVE

CAULK

LIQUID

LINE

NOTE Similar installation practices should be used if line set

is to be installed on exterior of outside wall.

LIQUID LINE

WIRE TIE

INSIDE WALL

STRAP

NON−CORROSIVE

METAL SLEEVE

WIRE TIE

WOOD BLOCK

WIRE TIE

STRAP

FLOOR JOIST OR

XP16

ROOF RAFTER

Figure 8. Line Set Installation

Page 15

Page 16

Brazing Connections

Use the procedures outline in figures 9 and 10 for brazing

line set connections to service valves.

WARNING

Danger of fire. Bleeding the refrigerant

charge from only the high side may result

in pressurization of the low side shell and

suction tubing. Application of a brazing

torch to a pressurized system may result in

ignition of the refrigerant and oil mixture −

Check the high and low pressures before

applying heat.

IMPORTANT

Connect gauge set low pressure side to vapor line

service valve and repeat procedure starting at paragraph

4 for brazing the liquid line to service port valve.

IMPORTANT

Allow braze joint to cool before removing the wet rag from

the service valve. Temperatures above 250ºF can

damage valve seals.

IMPORTANT

WARNING

When using a high pressure gas such as

dry nitrogen to pressurize a refrigeration or

air conditioning system, use a regulator

that can control the pressure down to 1 or

2 psig (6.9 to 13.8 kPa).

CAUTION

Brazing alloys and flux contain materials which are

hazardous to your health.

Avoid breathing vapors or fumes from brazing operations.

Perform operations only in well−ventilated areas.

Wear gloves and protective goggles or face shield to

protect against burns.

Wash hands with soap and water after handling brazing

alloys and flux.

Use silver alloy brazing rods with 5% minimum silver alloy

for copper−to−copper brazing. Use 45% minimum alloy for

copper−to−brass and copper−to−steel brazing.

WARNING

Fire, Explosion and Personal Safety

Hazard.

Failure to follow this warning could result in damage, personal injury or

death.

Never use oxygen to pressurize or

purge refrigeration lines. Oxygen,

when exposed to a spark or open

flame, can cause fire and/or an explosion, that could result in property

damage, personal injury or death.

Page 16

XP16

Page 17

CUT AND DEBUR

Cut ends of the refrigerant lines square (free from nicks or dents)

1

and debur the ends. The pipe must remain round. Do not crimp end

of the line.

CUT AND DEBUR

LINE SET SIZE MATCHES

SERVICE VALVE CONNECTION

SERVICE VALVE

COPPER TUBE

REDUCER

CONNECTION

STUB

CAP AND CORE REMOVAL

Remove service cap and core from

2

both the suction / vapor and liquid line

service ports.

SERVICE PORT

CAP

SERVICE

PORT

CORE

LIQUID LINE SERVICE

VALV E

SERVICE

PORT

CORE

SERVICE

PORT CAP

SUCTION / VAPOR LINE

SERVICE VALVE

LINE SET SIZE IS SMALLER

THAN CONNECTION

REFRIGERANT LINE

DO NOT CRIMP SERVICE

VALVE CONNECTOR WHEN

PIPE IS SMALLER THAN

CONNECTION

ATTACH THE MANIFOLD GAUGE SET FOR BRAZING LIQUID AND SUCTION / VAPOR LINE SERVICE

VALVES

3

Flow regulated nitrogen (at 1 to 2 psig) through the low−side refrigeration gauge set into the liquid line service port valve, and out of the suction

/ vapor line service port valve.

A Connect gauge set low pressure side to

liquid line service valve (service port).

B Connect gauge set center port to bottle of

nitrogen with regulator.

C Remove core from valve in suction / vapor

line service port to allow nitrogen to

escape.

SUCTION / VAPOR SERVICE PORT MUST BE

OPEN TO ALLOW EXIT POINT FOR NITROGEN

VAPOR LINE

INDOOR

UNIT

LIQUID LINE

ATTACH

GAUGES

C

LIQUID LINE SERVICE

SUCTION /

VAPOR LINE

SERVICE

VALV E

VALV E

LOW

HIGH

B

OUTDOOR

UNIT

WHEN BRAZING LINE SET TO

A

SERVICE VALVES, POINT FLAME

AWAY FROM SERVICE VALVE.

USE REGULATOR TO FLOW

NITROGEN AT 1 TO 2 PSIG.

NITROGEN

XP16

Figure 9. Brazing Procedures

Page 17

Page 18

WRAP SERVICE VALVES

To help protect service valve seals during brazing, wrap water saturated cloths around service valve bodies and copper tube stubs. Use

4

additional water saturated cloths underneath the valve body to protect the base paint.

FLOW NITROGEN

Flow regulated nitrogen (at 1 to 2 psig) through the refrigeration gauge set into the valve stem port connection on the liquid service valve

5

and out of the suction / vapor valve stem port. See steps 3A, 3B and 3C on manifold gauge set connections

BRAZE LINE SET

Wrap both service valves with water saturated cloths as illustrated here and as mentioned in step 4, before brazing to line set. Water

6

saturated cloths must remain water saturated throughout the brazing and cool−down process.

LIQUID LINE SERVICE VALVE

WHEN BRAZING LINE SET TO

SERVICE VALVES, POINT FLAME

AWAY FROM SERVICE VALVE.

IMPORTANT Allow braze joint to cool. Apply

additional water saturated cloths to help cool brazed

joint. Do not remove water saturated cloths until piping

has cooled. Temperatures above 250ºF will damage

valve seals.

LIQUID LINE

WATER SATURATED

CLOTH

WARNING

1. FIRE, PERSONAL INJURY, OR PROPERTY

DAMAGE will result if you do not wrap a water

saturated cloth around both liquid and suction line

service valve bodies and copper tube stub while

brazing in the line set! The braze, when complete,

must be quenched with water to absorb any

residual heat.

2. Do not open service valves until refrigerant lines

and indoor coil have been leak−tested and

evacuated. Refer to procedures provided in this

supplement.

SUCTION / VAPOR LINE

PREPARATION FOR NEXT STEP

After all connections have been brazed, disconnect manifold gauge set from service ports. Apply additional water saturated cloths to both

7

services valves to cool piping. Once piping is cool, remove all water saturated cloths. Refer to the unit installation instructions for the next

step in preparing the unit.

SUCTION / VAPOR LINE

SERVICE VALVE

WATER SATURATED

CLOTH

WHEN BRAZING LINE SET TO

SERVICE VALVES, POINT FLAME

AWAY FROM SERVICE VALVE.

Figure 10. Brazing Procedures (continued)

Page 18

XP16

Page 19

Flushing Line Set and Indoor Coil

TYPICAL EXISTING FIXED ORIFICE

1A

DISTRIBUTOR

ASSEMBLY

A On fully cased coils, remove the coil access and plumbing panels.

B Remove any shipping clamps holding the liquid line and distributor

assembly.

C Using two wrenches, disconnect liquid line from liquid line orifice

housing. Take care not to twist or damage distributor tubes during this

process.

D Remove and discard fixed orifice, valve stem assembly if present and

Teflon

E Use a field−provided fitting to temporary reconnect the liquid line to

the indoor unit’s liquid line orifice housing.

COIL SHOWN)

DISTRIBUTOR TUBES

LIQUID LINE ORIFICE HOUSING

TEFLON® RING

REMOVE AND DISCARD

WHITE TEFLON

(IF PRESENT)

®

washer as illustrated above.

®

SEAL

FIXED ORIFICE

LIQUID LINE ASSEMBLY

(INCLUDES STRAINER)

REMOVAL PROCEDURE (UNCASED

OR

BRASS NUT

1B

TWO PIECE PATCH PLATE

(UNCASED COIL ONLY)

CONNECT GAUGES AND EQUIPMENT FOR

FLUSHING PROCEDURE

2

INV ERTED HCFC−22

CYLINDER CONTAINS

CLE AN HCFC−22 TO BE

USED FOR FLUSHING.

A

1

VAPOR LINE

SERVICE VALVE

EXISTING

INDOOR

UNIT

LIQUID LINE SERVICE

VALV E

VAPOR

LIQUID

D

RECOVERY

CYLINDER

A Inverted HCFC−22 cylinder with clean refrigerant to the vapor service

valve.

B HCFC−22 gauge set (low side) to the liquid line valve.

C HCFC−22 gauge set center port to inlet on the recovery machine with

an empty recovery tank to the gauge set.

D Connect recovery tank to recovery machines per machine instructions.

OUTDOOR

B

NEW

UNIT

OPENED

C

RECOVERY MACHINE

MANIFOLD

LOW

TANK

RETURN

INLET

DISCHARGE

GAUGE

HIGH

CLOSED

TYPICAL EXISTING EXPANSION VALVE REMOVAL

PROCEDURE (UNCASED COIL SHOWN)

ORIFICE

HOUSING

EQUALIZER

LINE

STUB END

TEFLON

RING

VAPOR

CHECK

EXPANSION

VALV E

®

LIQUID LINE

ASSEMBLY WITH

BRASS NUT

LINE

TEFLON

RING

®

SENSING

LINE

LIQUID

LINE

LIQUID LINE

DISTRIBUTOR

TUBES

DISTRIBUTOR

ASSEMBLY

MALE EQUALIZER

LINE FITTING

SENSING BULB

A On fully cased coils, remove the coil access and plumbing panels.

B Remove any shipping clamps holding the liquid line and distributor

assembly.

C Disconnect the equalizer line from the check expansion valve

equalizer line fitting on the vapor line.

D Remove the vapor line sensing bulb.

E Disconnect the liquid line from the check expansion valve at the liquid

line assembly.

F Disconnect the check expansion valve from the liquid line orifice

housing. Take care not to twist or damage distributor tubes during this

process.

G Remove and discard check expansion valve and the two Teflon

rings.

H Use a field−provided fitting to temporary reconnect the liquid line to

the indoor unit’s liquid line orifice housing.

FLUSHING LINE SET

The line set and indoor unit coil must be flushed with at least the

3

same amount of clean refrigerant that previously charged the

system. Check the charge in the flushing cylinder before

proceeding.

A Set the recovery machine for liquid recovery and start the

recovery machine. Open the gauge set valves to allow the

recovery machine to pull a vacuum on the existing system line

B

set and indoor unit coil.

B Invert the cylinder of clean HCFC−22 and open its valve to allow

liquid refrigerant to flow into the system through the vapor line

valve. Allow the refrigerant to pass from the cylinder and

through the line set and the indoor unit coil before it enters the

recovery machine.

C After all of the liquid refrigerant has been recovered, switch the

recovery machine to vapor recovery so that all of the HCFC−22

vapor is recovered. Allow the recovery machine to pull down to

0 the system.

D Close the valve on the inverted HCFC−22 drum and the gauge

set valves. Pump the remaining refrigerant out of the recovery

machine and turn the machine off.

®

XP16

Figure 11. Installing Indoor Expansion Valve

Page 19

Page 20

Installing Indoor Metering Device

This outdoor unit is designed for use in systems that use

check expansion valve metering devices at the indoor coil.

See the Lennox XP16 Engineering Handbook for approved

expansion valve kit match−ups. The expansion valve unit

can be installed internal or external to the indoor coil. In

INDOOR EXPANSION VALVE INSTALLATION

TWO PIECE

PATCH PLATE

(UNCASED

COIL ONLY)

DISTRIBUTOR

TUBES

DISTRIBUTOR

ASSEMBLY

MALE EQUALIZER LINE

FITTING (SEE

EQUALIZER LINE

INSTALLATION FOR

FURTHER DETAILS)

Sensing bulb insulation is required if

mounted external to the coil casing. sensing

bulb installation for bulb positioning.

EQUALIZER LINE INSTALLATION

A Remove and discard either the flare seal cap or flare nut

with copper flare seal bonnet from the equalizer line port

on the vapor line as illustrated in the figure to the right.

B Remove and discard either the flare seal cap or flare nut

with copper flare seal bonnet from the equalizer line port

on the vapor line as illustrated in the figure to the right.

(Uncased Coil Shown)

LIQUID LINE

ORIFICE

HOUSING

STUB

END

TEFLON

RING

EQUALIZER

LINE

VAPOR

CHECK

EXPANSION

VALV E

®

ASSEMBLY WITH

LINE

TEFLON

LIQUID LINE

BRASS NUT

®

RING

SENSING

LINE

LIQUID LINE

SENSING BULB INSTALLATION

applications where an uncased coil is being installed in a

field−provided plenum, install the expansion valve in a

manner that will provide access for field servicing of the

expansion valve. Refer to below illustration for reference

during installation of expansion valve unit.

A Remove the field−provided fitting that temporary

reconnected the liquid line to the indoor unit’s distributor

assembly.

B Install one of the provided Teflon

®

rings around the

stubbed end of the expansion valve and lightly lubricate

the connector threads and expose surface of the

®

Teflon

ring with refrigerant oil.

C Attach the stubbed end of the expansion valve to the

liquid line orifice housing. Finger tighten and use an

appropriately sized wrench to turn an additional 1/2 turn

clockwise as illustrated in the figure above, or 20 ft−lb.

D Place the remaining Teflon

end of the expansion valve. Lightly lubricate connector

threads and expose surface of the Teflon

®

washer around the other

®

ring with

refrigerant oil.

E Attach the liquid line assembly to the expansion valve.

Finger tighten and use an appropriately sized wrench to

turn an additional 1/2 turn clockwise as illustrated in the

figure above or 20 ft−lb.

A Attach the vapor line sensing bulb in the proper

orientation as illustrated to the right using the clamp and

screws provided.

NOTE Confirm proper thermal contact between vapor line

and expansion bulb before insulating the sensing bulb once

installed.

B Connect the equalizer line from the expansion valve to

the equalizer vapor port on the vapor line. Finger tighten

the flare nut plus 1/8 turn (7 ft−lbs) as illustrated below.

VAPOR LINE

BULB

12

ON LINES SMALLER THAN

7/8", MOUNT SENSING

BULB AT EITHER THE 3 OR

9 O’CLOCK POSITION.

BULB

1/2 Turn

10

9

8

10

9

8

12

11

7

6

1/8 Turn

12

11

7

6

1

2

3

4

5

1

2

3

4

5

FLARE SEAL CAP

OR

FLARE NUT

COPPER FLARE

SEAL BONNET

MALE BRASS EQUALIZER

LINE FITTING

VAPOR LINE

VAPOR LINE

12

BULB

NOTE NEVER MOUNT ON BOTTOM OF LINE.

Figure 12. Installing Indoor Expansion Valve

Page 20

ON 7/8" AND LARGER LINES,

MOUNT SENSING BULB AT

EITHER THE 4 OR 8 O’CLOCK

POSITION. NEVER MOUNT ON

BOTTOM OF LINE.

BULB

XP16

Page 21

IMPORTANT

The Environmental Protection Agency (EPA) prohibits the

intentional venting of HFC refrigerants during

maintenance, service, repair and disposal of appliance.

Approved methods of recovery, recycling or reclaiming

must be followed.

IMPORTANT

If this unit is being matched with an approved line set or

indoor unit coil which was previously charged with

mineral oil, or if it is being matched with a coil which was

manufactured before January of 1999, the coil and line

set must be flushed prior to installation. Take care to

empty all existing traps. Polyol ester (POE) oils are used

in Lennox units charged with HFC−410A refrigerant.

Residual mineral oil can act as an insulator, preventing

proper heat transfer. It can also clog the expansion

device, and reduce the system performance and

capacity.

Failure to properly flush the system per the instructions

below will void the warranty.

CONNECT GAUGE SET

A Connect an HFC−410A manifold gauge set high pressure

1

hose to the vapor valve service port.

NOTE Normally, the high pressure hose is connected to

the liquid line port. However, connecting it to the vapor port

better protects the manifold gauge set from high pressure

damage.

B With both manifold valves closed, connect the cylinder of

HFC−410A refrigerant to the center port of the manifold

gauge set.

NOTE Later in the procedure,

the HFC−410A container will be

replaced by the nitrogen

container.

Leak Test Line Set and Indoor Coil

WARNING

When using a high pressure gas such as

dry nitrogen to pressurize a refrigeration or

air conditioning system, use a regulator

that can control the pressure down to 1 or

2 psig (6.9 to 13.8 kPa).

IMPORTANT

Leak detector must be capable of sensing HFC

refrigerant.

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in personal injury

or death.

HIGHLOW

MANIFOLD GAUGE SET

OUTDOOR UNIT

B

A

2

XP16

TO VAPOR

SERVICE VALVE

NITROGEN

HFC−410A

TEST FOR LEAKS

After the line set has been connected to the indoor and outdoor units, check the line set connections and indoor unit for leaks. Use

the following procedure to test for leaks:

A With both manifold valves closed, connect the cylinder of HFC−410A refrigerant to the center port of the manifold gauge set. Open the

valve on the HFC−410A cylinder (vapor only).

B Open the high pressure side of the manifold to allow HFC−410A into the line set and indoor unit. Weigh in a trace amount of HFC−410A.

[A trace amount is a maximum of two ounces (57 g) refrigerant or three pounds (31 kPa) pressure]. Close the valve on the HFC−410A

cylinder and the valve on the high pressure side of the manifold gauge set. Disconnect the HFC−410A cylinder.

C Connect a cylinder of dry nitrogen with a pressure regulating valve to the center port of the manifold gauge set.

D Adjust dry nitrogen pressure to 150 psig (1034 kPa). Open the valve on the high side of the manifold gauge set in order to pressurize the line set

and the indoor unit.

E After a few minutes, open one of the service valve ports and verify that the refrigerant added to the system earlier is measurable with a

leak detector.

F After leak testing disconnect gauges from service ports.

Figure 13. Leak Test

Page 21

Page 22

Evacuating Line Set and Indoor Coil

CONNECT GAUGE SET

NOTE Remove cores from service valves (if not already done).

1

A

Connect low side of manifold gauge set

with 1/4 SAE in−line tee to vapor line

service valve

B

Connect high side of manifold gauge

set to liquid line service valve

C

Connect micron gauge available

connector on the 1/4 SAE in−line tee.

D

Connect the vacuum pump (with

vacuum gauge) to the center port of

NITROGEN

the manifold gauge set. The center

port line will be used later for both the

HFC−410A and nitrogen containers.

HFC−410A

VACUUM PUMP

OUTDOOR

UNIT

A

B

A34000 1/4 SAE TEE WITH

SWIVEL COUPLER

500

C

MICRON

GAUGE

GAUGE SET

TO VAPOR

SERVICE VALVE

TO LIQUID LINE

SERVICE VALVE

LOW

MANIFOLD

D

EVACUATE THE SYSTEM

A Open both manifold valves and start the vacuum pump.

2

B Evacuate the line set and indoor unit to an absolute pressure of 23,000 microns (29.01 inches of mercury).

NOTE During the early stages of evacuation, it is desirable to close the manifold gauge valve at least once. A rapid rise in pressure

indicates a relatively large leak. If this occurs, repeat the leak testing procedure.

NOTE The term absolute pressure means the total actual pressure within a given volume or system, above the absolute zero of

pressure. Absolute pressure in a vacuum is equal to atmospheric pressure minus vacuum pressure.

C When the absolute pressure reaches 23,000 microns (29.01 inches of mercury), perform the following:

D Close manifold gauge valves

D Close valve on vacuum pump

D Turn off vacuum pump

D Disconnect manifold gauge center port hose from vacuum pump

D Attach manifold center port hose to a dry nitrogen cylinder with pressure regulator set to 150 psig (1034 kPa) and purge the hose.

D Open manifold gauge valves to break the vacuum in the line set and indoor unit.

D Close manifold gauge valves.

D Shut off the dry nitrogen cylinder and remove the manifold gauge hose from the cylinder. Open the manifold gauge valves to release the

dry nitrogen from the line set and indoor unit.

E Reconnect the manifold gauge to the vacuum pump, turn the pump on, and continue to evacuate the line set and indoor unit until the

absolute pressure does not rise above 500 microns (29.9 inches of mercury) within a 20−minute period after shutting off the vacuum

pump and closing the manifold gauge valves.

F When the absolute pressure requirement above has been met, disconnect the manifold hose from the vacuum pump and connect it to an

upright cylinder of HFC−410A refrigerant. Open the manifold gauge valve 1 to 2 psig in order to release the vacuum in the line set and indoor

unit.

G Perform the following:

RECOMMEND

MINIMUM 3/8" HOSE

HIGH

D Close manifold gauge valves.

D Shut off HFC−410A cylinder.

D Reinstall service valve cores by removing manifold hose from service valve. Quickly install cores with core

tool while maintaining a positive system pressure.

D Replace stem caps and secure finger tight, then tighten an additional one−sixth (1/6) of a turn as illustrated.

Figure 14. Evacuating System

Page 22

10

9

8

1/6 TURN

12

11

7

6

1

2

3

4

5

XP16

Page 23

IMPORTANT

Use a thermocouple or thermistor electronic vacuum

gauge that is calibrated in microns. Use an instrument

capable of accurately measuring down to 50 microns.

WARNING

Danger of Equipment Damage. Avoid deep vacuum

operation. Do not use compressors to evacuate a

system. Extremely low vacuums can cause internal

arcing and compressor failure. Damage caused by deep

vacuum operation will void warranty.

Evacuating the system of non−condensables is critical for

proper operation of the unit. Non−condensables are defined

as any gas that will not condense under temperatures and

pressures present during operation of an air conditioning

system. Non−condensables and water suction combine with

refrigerant to produce substances that corrode copper

piping and compressor parts.

Electrical

In the U.S.A., wiring must conform with current local codes and

the current National Electric Code (NEC). In Canada, wiring

must conform with current local codes and the current

Canadian Electrical Code (CEC).

Refer to the furnace or air handler installation instructions for

additional wiring application diagrams and refer to unit

nameplate for minimum circuit ampacity and maximum

overcurrent protection size.

24VAC TRANSFORMER

Use the transformer provided with the furnace or air handler

for low-voltage control power (24VAC − 40 VA minimum)

SIZE CIRCUIT AND INSTALL DISCONNECT

SWITCH

1

Refer to the unit nameplate for minimum circuit ampacity, and

maximum fuse or circuit breaker (HACR per NEC). Install power

wiring and properly sized disconnect switch.

NOTE Units are approved for use only with copper conductors.

Ground unit at disconnect switch or to an earth ground.

MAIN FUSE

BOX/BREAKER

PANEL

DISCONNECT

SWITCH

UNIT LOW VOLTAGE CONNECTIONS

3

INSTALL THERMOSTAT

Install room thermostat (ordered separately) on an inside wall

2

approximately in the center of the conditioned area and 5 feet

(1.5m) from the floor. It should not be installed on an outside wall

or where it can be affected by sunlight or drafts.

THERMOSTAT

5 FEET

(1.5M)

NOTE 24VAC, Class II circuit connections are made in the control

panel.

HIGH VOLTAGE FIELD WIRING

FACTORY WIRING

LOW VOLTAGE (24V) FIELD WIRING

WIRE RUN LENGTH AWG# INSULATION TYPE

LESS THAN 100’ (30 METERS) 18 TEMPERATURE RATING

MORE THAN 100’ (30 METERS) 16 35ºC MINIMUM.

XP16

A

D

B

C

TERMINAL STRIP

Page 23

A Run 24VAC control wires through cutout with grommet.

B Run 24VAC control wires through wire tie.

C Make 24VAC control wire connections defrost control terminal

strip.

D Tighten wire tie to security 24V control wiring.

NOTE − FOR PROPER VOLTAGES, SELECT THERMOSTAT WIRE (CONTROL WIRES)

GAUGE PER TABLE ABOVE.

NOTE − WIRE TIE PROVIDES LOW VOLTAGE WIRE STRAIN RELIEF AND TO MAINTAIN

SEPARATION OF FIELD INSTALLED LOW AND HIGH VOLTAGE CIRCUITS.

NOTE − DO NOT BUNDLE ANY EXCESS 24VAC CONTROL WIRES INSIDE CONTROL

BOX.

Page 24

Servicing Units Void of Charge

If the outdoor unit is void of refrigerant, clean the system

using the procedure described below.

1. Leak check system using procedure outlined on page

21.

2. Evacuate the system using procedure outlined on page

22.

3. Use nitrogen to break the vacuum and install a new filter

drier in the system.

4. Evacuate the system again using procedure outlined on

page 22.

5. Weigh in refrigerant using procedure outlined in figure

18.

6. Monitor the system to determine the amount of moisture

remaining in the oil. It may be necessary to replace the

filter drier several times to achieve the required dryness

level. If system dryness is not verified, the

compressor will fail in the future.

Unit Start−Up

2. Inspect all factory− and field−installed wiring for loose

connections.

3. After evacuation is complete, open both the liquid and

vapor line service valves to release the refrigerant

charge contained in outdoor unit into the system.

4. Replace the stem caps and tighten to the value listed in

table 1.

5. Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit’s

nameplate. If not, do not start the equipment until you

have consulted with the power company and the voltage

condition has been corrected.

6. Set the thermostat for a cooling demand. Turn on power

to the indoor indoor unit and close the outdoor unit

disconnect switch to start the unit.

7. Recheck voltage while the unit is running. Power must

be within range shown on the nameplate.

8. Check system for sufficient refrigerant by using the

procedures listed under System Charge.

IMPORTANT

If unit is equipped with a crankcase heater, it should be

energized 24 hours before unit start−up to prevent

compressor damage as a result of slugging.

1. Rotate fan to check for binding.

GAUGE SET

CONNECTIONS FOR TESTING AND CHARGING

TRUE SUCTION PORT

B

CONNECTION

REFRIGERANT TANK

CHARGE IN

LIQUID PHASE

DIGITAL SCALE

INSIDE OUTDOOR UNIT

TEMPERATURE

D

SENSOR

System Refrigerant

This section outlines procedures for:

1. Connecting gauge set for testing and charging;

2. Checking and adjusting indoor airflow;

3. Adding or removing refrigerant.

MANIFOLD GAUGE SET

LOW

HIGH

OUTDOOR UNIT

A

C

TO LIQUID

LINE SERVICE

VALV E

TEMPERATURE SENSOR

(LIQUID LINE)

A Close manifold gauge set valves and connect the center hose to a cylinder of HFC−410A. Set for liquid phase charging.

B Connect the manifold gauge set’s low pressure side to the true suction port. See figure 1 for approximate location of the true suction port.

C Connect the manifold gauge set’s high pressure side to the liquid line service port.

D Position temperature sensor on liquid line near liquid line service port.

Figure 15. Gauge Set Setup and Connections

Page 24

XP16

Page 25

CHARGING INFORMATION FOR MODEL XP16−XXX−230−01 AND XP16−XXX−230−02

Unit Charging Sticker − 401193S, dated 02/06

If the system is low on charge, follow the appropriate

procedure outlined below. Charging should be done with unit

operating in the cooling mode, if possible.

Charge Using The Weigh−in MethodOutdoor

Temperature < 65ºF (18ºC(

If the system is void of refrigerant, or if the outdoor ambient

temperature is cool, the refrigerant charge should be

weighed into the unit. Do this after any leaks have been

repaired.

1. Recover the refrigerant from the unit.

2. Conduct a leak check, then evacuate as previously

outlined.

3. Weigh in the unit nameplate charge. If weighing facilities

are not available or if you are charging the unit during

warm weather, follow one of the other procedures

outlined below.

Charge Using The Subcooling MethodOutdoor

Temperature < 65ºF (18ºC)

When the outdoor ambient temperature is below 65ºF

(18ºC), use the subcooling method to charge the unit. It may

be necessary to restrict the air flow through the outdoor coil

to achieve pressures in the 325−375 psig (2240−2585 kPa)

range. These higher pressures are necessary for checking

the charge. Block equal sections of air intake panels and

move obstructions sideways until the liquid pressure is in the

325−375 psig (2240−2585 kPa) range. See figure 16.

Block coil one side at a time with cardboard/plastic until

proper testing pressures are reached.

CARDBOARD OR

PLASTIC SHEET

Figure 16. Blocking Outdoor Coil

1. With manifold gauge hose still on the liquid service port

and unit operating stably, use a digital thermometer to

record the liquid line temperature. At the same time,

record the liquid line pressure reading.

2. Use a temperature/pressure chart for HFC−410A to

determine the saturation temperature for the liquid line

pressure reading.

3. Subtract the liquid line temperature from the saturation

temperature (according to the chart) to determine

subcooling. (Saturation temperature − Liquid line

temperature = Subcooling)

4. Compare subcooling values with those in table 1; if

subcooling is greater than shown, recover some

refrigerant. If subcooling is less than shown, add some

refrigerant.

Charge Using Normal Operating

Pressures/Approach Method

>

65ºF (18ºC)

When outdoor ambient temperature is above 65_F (18_C),

use approach charge method. For best results, indoor

temperature should be 70°F (21°C) to 80°F (26°C). Monitor

system pressures while charging.

1. Record outdoor ambient temperature using a digital

thermometer.

2. Attach high pressure gauge set; operate unit for several

minutes; allow system pressures to stabilize.

3. Compare stabilized pressures with those provided in

table 3. Minor variations in these pressures may be

expected due to differences in installations. Significant

differences could mean that the system is not properly

charged or that a problem exists with some component

in the system. Pressures higher than those listed

indicate that the system is overcharged. Pressures

lower than those listed indicate that the system is

undercharged. Verify adjusted charge using the

approach method.

Use the same digital thermometer to check both outdoor

ambient temperature and liquid line temperature. Verify the

unit charge using the approach method.

4. The difference between the ambient and liquid

temperatures should match values given in table 2. If

values do not agree with the those in table 2, add

refrigerant to lower the approach temperature or

recover refrigerant from the system to increase the

approach temperature.

Outdoor Temperature

Using the Normal Operating Pressures Table

Use table 3 as a general guide when performing

maintenance checks. This is not a procedure for charging

the unit (see Charging/Checking Charge section). Minor

variations in normal operating pressures may be expected

due to differences in installations. Significant differences

could mean that the system is not properly charged or that a

problem exists with some component in the system.

XP16

Page 25

Page 26

Table 3 − Indoor Units Matchups and Subcooling Charge Levels (XP16−XXX−230−05)

XP16 Model −024 −036 −048 −060

Charging Temperatures and Pressures

Table 1 − Subcooling Values

Saturation Temperature minus Liquid Line Temperature °F (ºC) + 1ºF (0.5ºC)

Temp. °F

(°C)

Table 2 − Approach Values

Liquid Line Temperature minus Outdoor Ambient Temperature ºF (ºC) + 1ºF (0.5ºC)

Temp. °F

(°C)

Table 3 − Normal Operating Pressures (Liq. +10 & Vap. +5 psig) **

Temp. °F

(°C)*

Liquid Vapor Liquid Vapor Liquid Vapor Liquid Vapor

Cooling − First Stage (Low Capacity)

65 (18.3) 232 146 225 144 235 144 225 138

75 (23.9) 264 148 261 147 268 145 264 141

85 (29.4) 307 149 302 149 310 147 305 142

95 (35.0) 353 151 349 151 356 148 352 146

105 (40.6) 403 153 397 153 407 150 405 148

115 (46.1) 460 155 461 157 466 152 459 150

Cooling − Second Stage (High Capacity)

65 (18.3) 240 143 239 139 244 140 241 134

75 (23.9) 279 145 278 141 283 141 280 136

85 (29.4) 322 147 322 143 326 144 324 137

95 (35.0) 371 149 367 146 374 147 373 138

105 (40.6) 423 151 426 148 427 148 425 142

115 (46.1) 485 154 489 151 491 151 486 146

Heating − First Stage (Low Capacity)

40 (4.4) 337 93 328 98 369 75 351 63

50 (10) 322 117 333 118 366 114 335 92

Heating − Second Stage (High Capacity)

20 (−7.0) 279 62 296 62 311 58 308 59

30 (−1.0) 288 76 309 75 334 72 323 70

40 (4.4) 302 93 322 92 354 89 318 69

50 (10) 306 112 336 113 381 108 329 82

* Outdoor Coil Entering Air Temp. F (C)

** These are most−popular−match−up pressures. Indoor match up, indoor air quality, and indoor load cause pressures to vary.

8 (4.4)

7 (3.9)

9 (5) 8 (4.4)

8 (4.4) 9 (5) 8 (4.4) 8 (4.4)

Page 26

XP16

Page 27

CHARGING INFORMATION FOR MODEL XP16−XXX−230−03, XP16−XXX−230−04 and XP16−XXX−230−05

ADDING OR REMOVING REFRIGERANT

This system uses HFC−410A refrigerant which operates at

much higher pressures than HCFC−22. The pre−installed

liquid line filter drier is approved for use with HFC−410A only.

Do not replace it with components designed for use with

HCFC−22.

COOLING MODE INDOOR AIRFLOW CHECK

Check airflow using the Delta−T (

DT) process using the

illustration in Figure 17.

HEATING MODE INDOOR AIRFLOW CHECK

Blower airflow (CFM) may be calculated by energizing

electric heat and measuring:

AIRFLOW

INDOOR COIL

Temperature of air

entering indoor

coil ºF

A

Wet−bulb ºF

D Temperature rise between the return air and supply air

temperatures at the indoor coil blower unit,

D Measuring voltage supplied to the unit,

D Measuring amperage being drawn by the heat unit(s).

Then, apply the measurements taken in following formula to

determine CFM:

CFM =

Amps x Volts x 3.41

1.08 x Temperature rise (F)

DT

80 24 24 24 23 23 22 22 22 20 19 18 17 16 15

78 23 23 23 22 22 21 21 20 19 18 17 16 15 14

76 22 22 22 21 21 20 19 19 18 17 16 15 14 13

Dry−bulb

74 21 21 21 20 19 19 18 17 16 16 15 14 13 12

72 20 20 19 18 17 17 16 15 15 14 13 12 11 10

70 19 19 18 18 17 17 16 15 15 14 13 12 11 10

57 58 59 60 61 62 63 64 65 66 67 68 69 70

DRY

BULB

C

53º

T

19º

Drop

air flow

air flow

B

A

72º

B

64º

DRY BULB

WET BULB

All temperatures are expressed in ºF

INDOOR COIL

Use the following procedure to adjust for optimal air flow across the indoor coil:

1. Determine the desired DT Measure entering air temperature using dry bulb (A) and wet bulb (B). DT is the intersecting value of A and B in the table (see triangle).

2. Find temperature drop across coil Measure the coil’s dry bulb entering and leaving air temperatures (A and C).

Temperature Drop Formula: (T

3. Determine if fan needs adjustment If the difference between the measured T

is within +

3º, no adjustment is needed. See example below:

) = A minus C.

Drop

and the desired DT (T

Drop

Drop

–DT)

Assume DT = 15 and A temp. = 72º, these C temperatures would necessitate stated actions:

Cº T

53º 19 – 15 = 4 Increase the airflow

58º 14 – 15 = −1 (within +3º range) no change

62º 10 – 15 = −5 Decrease the airflow

– DT = ºF ACTION

Drop

Changing air flow affects all temperatures; recheck temperatures to confirm that the temperature drop and DT

are within +

3º.

4. Adjust the fan speed See indoor unit instructions to increase/decrease fan speed.

Figure 17. Checking Indoor Airflow over Evaporator Coil using Delta−T Chart Formula

XP16

Page 27

Page 28

Use WEIGH IN method for adding initial refrigerant charge, and then use SUBCOOLING method for verifying

refrigerant charge.

WEIGH IN

CHARGING METHOD

CALCULATING SYSTEM CHARGE FOR OUTDOOR UNIT VOID OF CHARGE

If the system is void of refrigerant, first, locate and repair any leaks and then weigh in the refrigerant charge into the

unit. To calculate the total refrigerant charge:

Amount specified on

nameplate

NOTE Insulate liquid line when it is routed through areas where the surrounding ambient

temperature could become higher than the temperature of the liquid line or when pressure drop is equal

to or greater than 20 psig.

NOTE The above nameplate is for illustration purposes only. Go to actual nameplate on outdoor unit

for charge information.

Adjust amount. for variation

in line set length listed on

line set length table below.

+

Refrigerant Charge per Line Set Length

Liquid Line

Set Diameter

3/8" (9.5 mm)

*If line length is greater than 15 ft. (4.6 m), add this amount.

If line length is less than 15 ft. (4.6 m), subtract this amount.

Additional charge

specified per indoor unit

match−ups

+

Ounces per 5 feet (g per 1.5 m)