Page 1

INSTALLATION

,1,_2008LennoxindustriesInc,

®

Dallas,Texas,USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

X_ WARNING

_, CAUTION

INSTRUCTIONS

Dave Lennox Signature ®

Collection XP15 Units

HEAT PUMP UNITS _-_Technical

505,328M U£[ Publications

04/08 Litho U.S.A.

Supersedes 03/08

XP15 Outdoor Unit ............................ 1

Shipping and Packing List ...................... 1

Unit Dimensions ............................... 2

General Information ........................... 2

Recovering Refrigerant from Existing System ..... 4

Positioning New Outdoor Unit .................. 5

Removing Panel .............................. 6

Electrical Connections ......................... 7

New or Replacement Line Set ................... 9

Brazing Line Set Connections ................... 11

Removing Existing Refrigerant Metering Device . .. 11

Testing for Leaks .............................. 11

Removing Service Valve Port Core .............. 12

Flushing Existing System ....................... 12

Installing New Refrigerant Metering Device ....... 13

Installing Service Valve Port Core ............... 14

Evacuating the System ......................... 14

Start-Up Procedures ........................... 15

System Operations ............................ 19

Lennox System Operation Monitor (LSOM) ....... 19

Defrost System ............................... 21

Maintenance .................................. 26

Homeowner Information ........................ 26

Start-Up and Performance Checklist ............. 28

A IMPORTANT

IMPORTANT

04/08

IIIHIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

The Lennox XP15 outdoor units use HFC-410A

refrigerant, This unit must be installed with a matching

indoor coil and line set as outlined in the Lennox

Engineering Handbook, XP15 series outdoor units are

designed for use in check expansion valve (CTXV)

systems only, and are not designed to be used with other

refrigerant flow control devices. The Lennox Engineering

Handbook lists compatible indoor CTXV kits which are

ordered separately.

1 - Assembled XP15 outdoor unit

1 - Bushing (for low voltage wiring)

2 - Grommets (for liquid and vapor lines)

Check equipment for shipping damage. If you find any

damage, immediately contact the last carrier.

Page 1

505,328M

IIIIIIIIIIIIIIIIIIIIIIHIIIIIIIIIIIIIIIIIIIIIIII

Page 2

39-1/2 DISCHARGE AIR

(1003) t

35-1/2

(902)

ELECTRICAL IN_ETS __

37 (94O)

[-024 thru -042]

47 (1194)

[-048 and -060]

UNIT SUPPORT

FEET \

Y

16-7/8

(429)

8 -3/4

(2_2)

3-1/8

(79) "-_

BASE WITH ELONGATED LEGS

SIDE VIEW

® ® ®

VAPOR LINE

INLET

LIQUID LINE

/INLET

DEFROST CONTROL

& CONTACTOR

OPERATION MONITOR

VAPOR VALVE AND

26-7/8 GAUGE PORT ..

(6_3) DISCHARGE LINE

3-3/4 (95) VAPOR

_' FILTER

4-5/8

(117)

18!1/2

(470)

SYSTEM

4-7/16.__

(113)

7--

8 (203)

1 (25)

XP15 Parts Arrangement

ACCESS VIEW

FAN

CAPACITOR

COMPRESSOR

DOME

COMPRESSOR

PLUG

LOW PRESSURE

HIGH PRESSURE

SWITCH

WARNING

505328M 04/08

I

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

When servicing or repairing HVAC components, ensure

caps and fasteners are appropriately tightened. Table 1

lists torque values for typical service and repair items.

Table 1. Torque Requirements

Part Recommended Torque

Service valve cap 8 ft.- lb. 11 NM

Sheet metal screws 16 in.- lb. 2 NM

Machine screws #10 28 in.- lb. 3 NM

Compressor bolts 90 in.- lb. 10 NM

Gauge port seal cap 8 ft.- lb. 11 NM

Page 2

Page 3

USINGMANIFOLD GAUGE SETS

HFC-410A refrigerant manifold gauge sets must be

capable of handling higher system operating pressures.

The gauge set shall be rated for use with pressures of 0 -

800 psig on the high side, and a low side of 30 inches of

vacuum (Hg) to 250 psig, which retards when opened to

500 psig. Gauge hoses must be rated for use up to 800 psig

of pressure with a 4000 psig burst rating,

OPERATING SERVICE VALVES

IMPORTANT

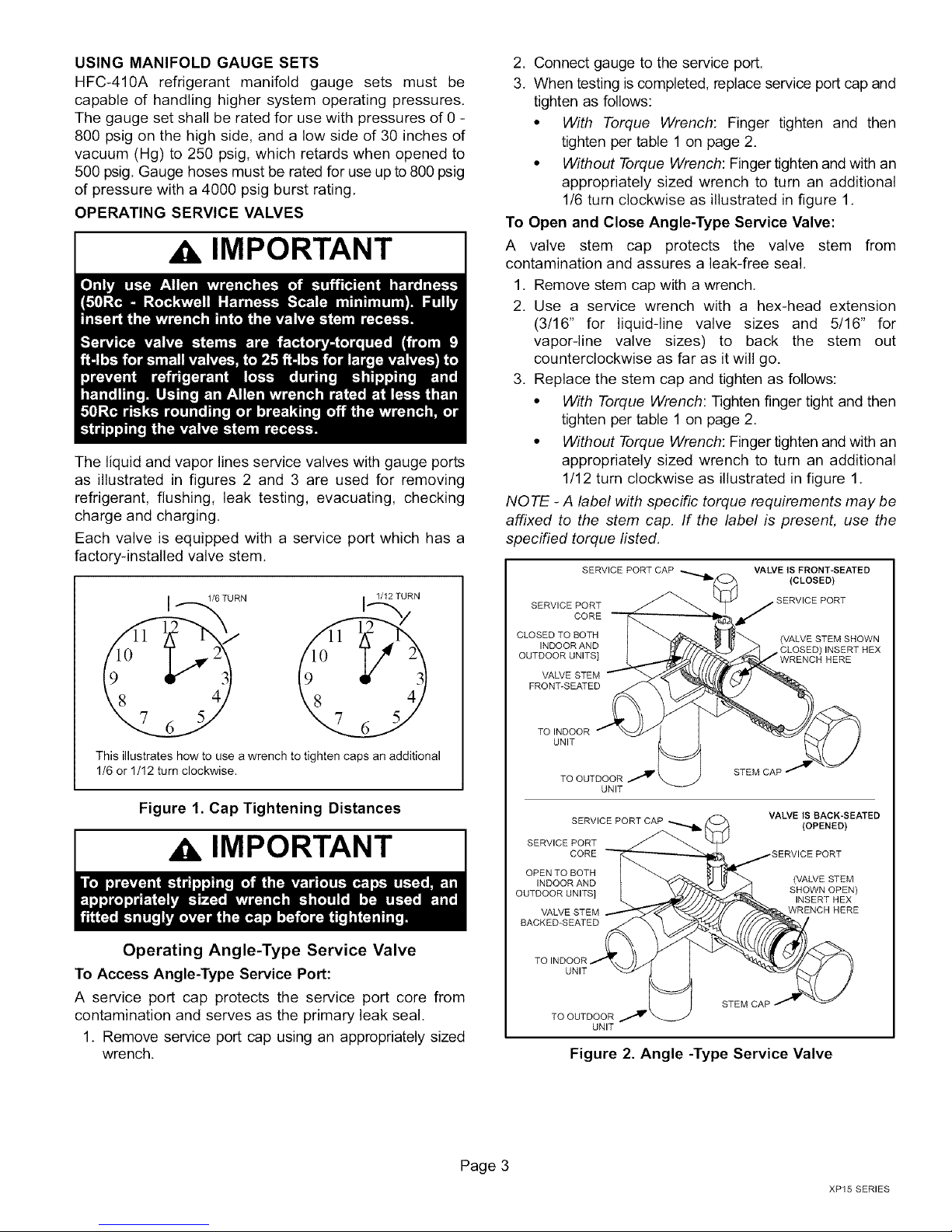

The liquid and vapor lines service valves with gauge ports

as illustrated in figures 2 and 3 are used for removing

refrigerant, flushing, leak testing, evacuating, checking

charge and charging,

Each valve is equipped with a service port which has a

factory-installed valve stem.

1/6 TURN

1/12 TURN

2. Connect gauge to the service port.

3. When testing is completed, replace service port cap and

tighten as follows:

• With Torque Wrench: Finger tighten and then

tighten per table 1 on page 2.

• Without Torque Wrench: Finger tighten and with an

appropriately sized wrench to turn an additional

1/6 turn clockwise as illustrated in figure 1.

To Open and Close Angle-Type Service Valve:

A valve stem cap protects the valve stem from

contamination and assures a leak-free seal.

1, Remove stem cap with a wrench,

2. Use a service wrench with a hex-head extension

(3/16" for liquid-line valve sizes and 5/16" for

vapor-line valve sizes) to back the stem out

counterclockwise as far as it will go.

3. Replace the stem cap and tighten as follows:

• With Torque Wrench: Tighten finger tight and then

tighten per table 1 on page 2.

• Without Torque Wrench: Finger tighten and with an

appropriately sized wrench to turn an additional

1/12 turn clockwise as illustrated in figure 1,

NOTE -A label with specific torque requirements may be

affixed to the stem cap, If the label is present, use the

specified torque listed,

SERVICE PORT CAP

SERVICE PORT _

CLOSED TO BOTH

INDOOR AND

OUTDOOR UNITS]

VALVE STEM

VALVE IS FRONT-SEATED

o

(CLOSED)

jSERV,CEPORT

,, HHERE

This illustrates how to use a wrench to tighten caps an additional

1/6 or 1/12 turn clockwise.

Figure 1. Cap Tightening Distances

IMPORTANT

Operating Angle-Type Service Valve

To Access Angle-Type Service Port:

A service port cap protects the service port core from

contamination and serves as the primary leak seal.

1. Remove service port cap using an appropriately sized

wrench.

Page 3

FRON%SEATEI_

TO INDOOR

CORE _ _ "i

UNIT

TO OUTDOOR _

UNIT

SERVICE PORT CAP _ _:_ VALVE IS(oPENED)BACK=SEATED

CORE SERVICE PORT

SERVICE PORT _

OPEN TO BOTH

INDOOR AND (VALVE STEM

OUTDOOR UNITS] L _ _ SHOWNOPEN)INSERTHEX

VALVE STEM WRENCH HERE

TO INDOOR

UNIT

BACKED-SEATE_ __

TO OUT

UNIT

Figure 2. Angle -Type Service Valve

XP15 SERIES

Page 4

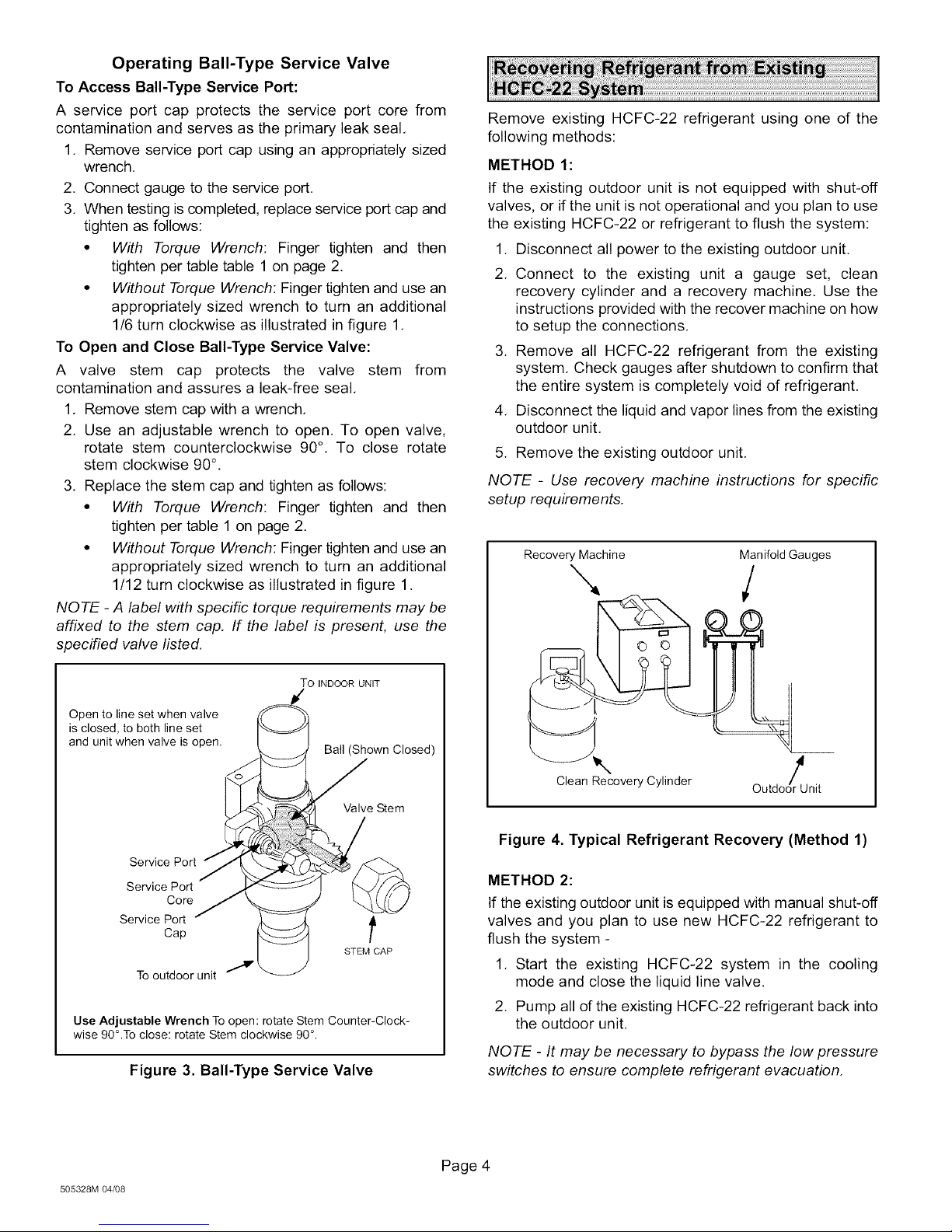

Operating Bali-Type Service Valve

To Access Bali-Type Service Port:

A service port cap protects the service port core from

contamination and serves as the primary leak seal,

1, Remove service port cap using an appropriately sized

wrench,

2. Connect gauge to the service port.

3, When testing is completed, replace service port cap and

tighten as follows:

• With Torque Wrench: Finger tighten and then

tighten per table table 1 on page 2.

• Without Torque Wrench: Finger tighten and use an

appropriately sized wrench to turn an additional

1/6 turn clockwise as illustrated in figure 1,

To Open and Close Bali-Type Service Valve:

A valve stem cap protects the valve stem from

contamination and assures a leak-free seal,

1, Remove stem cap with a wrench,

2, Use an adjustable wrench to open, To open valve,

rotate stem counterclockwise 90°, To close rotate

stem clockwise 90°.

3, Replace the stem cap and tighten as follows:

• With Torque Wrench: Finger tighten and then

tighten per table 1 on page 2.

• Without Torque Wrench: Finger tighten and use an

appropriately sized wrench to turn an additional

1/12 turn clockwise as illustrated in figure 1.

NOTE - A label with specific torque requirements may be

affixed to the stem cap. If the label is present, use the

specified valve listed.

Remove existing HCFC-22 refrigerant using one of the

following methods:

METHOD 1:

If the existing outdoor unit is not equipped with shut-off

valves, or if the unit is not operational and you plan to use

the existing HCFC-22 or refrigerant to flush the system:

1, Disconnect all power to the existing outdoor unit,

2, Connect to the existing unit a gauge set, clean

recovery cylinder and a recovery machine. Use the

instructions provided with the recover machine on how

to setup the connections,

3, Remove all HCFC-22 refrigerant from the existing

system, Check gauges after shutdown to confirm that

the entire system is completely void of refrigerant,

4, Disconnect the liquid and vapor lines from the existing

outdoor unit,

5, Remove the existing outdoor unit,

NOTE - Use recovery machine instructions for specific

setup requirements.

Recovery Machine

\

Manifold Gauges

/

To INDOOR UNIT

Open to line set when valve

is closed, to both line set

and unit when valve is open.

Service Port

Service Port

Core

Service Port

Cap

To outdoor unit

Use Adjustable Wrench To open: rotate Stem Counter-Clock-

wise 90°.To close: rotate Stem clockwise 90°.

Figure 3. Bali-Type Service Valve

Ball (Shown Closed)

Valve Stem

t

STEM CAP

Clean Recovery Cylinder

Figure 4. Typical Refrigerant Recovery (Method 1)

METHOD 2:

If the existing outdoor unit is equipped with manual shut-off

valves and you plan to use new HCFC-22 refrigerant to

flush the system -

1, Start the existing HCFC-22 system in the cooling

mode and close the liquid line valve,

2, Pump all of the existing HCFC-22 refrigerant back into

the outdoor unit,

NOTE - It may be necessary to bypass the low pressure

switches to ensure complete refrigerant evacuation.

Outdoor/_Unit

505328M 04/08

Page 4

Page 5

3.Whenthelowsidesystempressuresreach0 psig,

closethevaporlinevalve,

4. Disconnectall powerto the existingoutdoorunit.

Checkgaugesaftershutdownto confirmthat the

valvesarenotallowingrefrigeranttoflowbackintothe

lowsideofthesystem,

5. Disconnecttheliquidandvaporlinesfromtheexisting

outdoorunit.

6. Removetheexistingoutdoorunit,

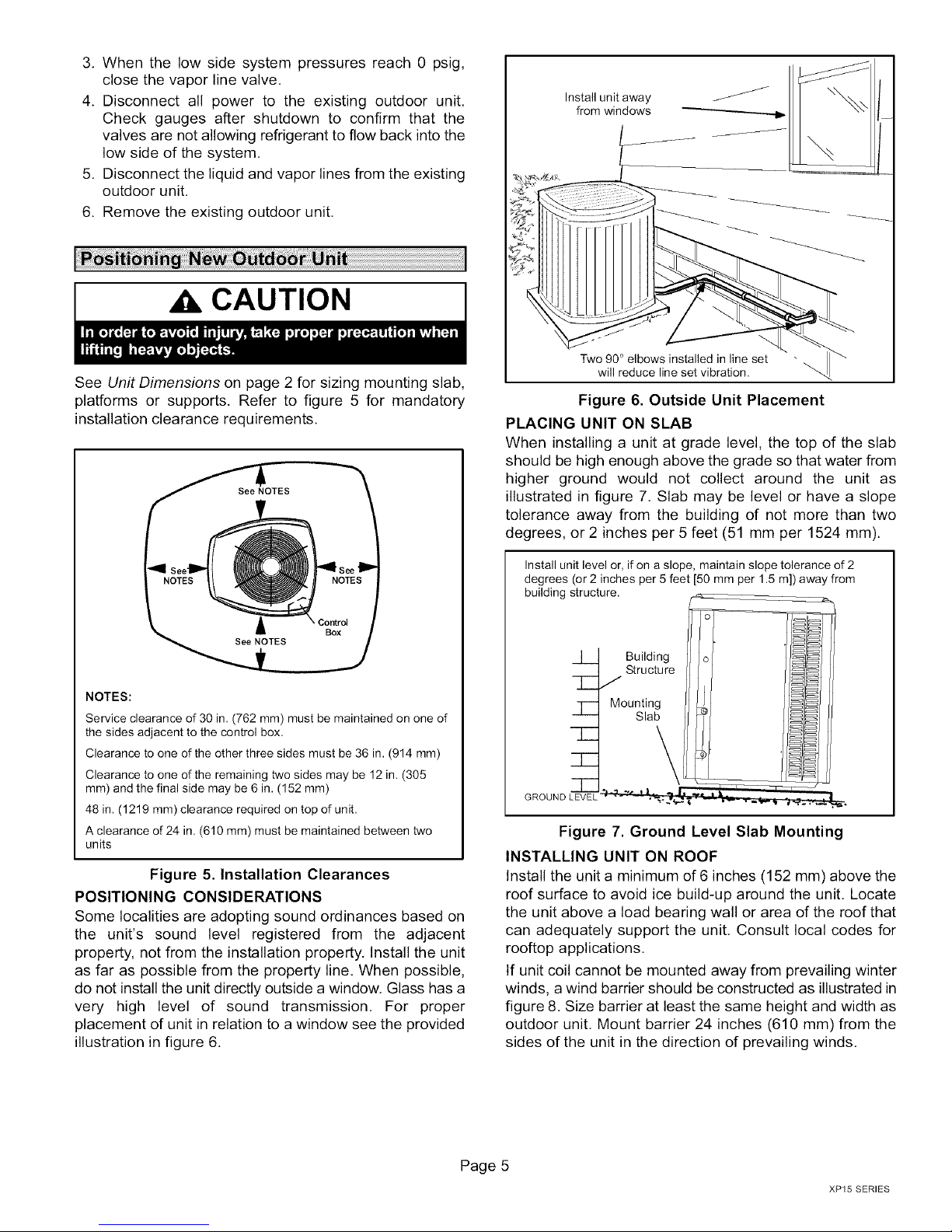

CAUTION

See Unit Dimensions on page 2 for sizing mounting slab,

platforms or supports, Refer to figure 5 for mandatory

installation clearance requirements.

Install unit away

from windows

Two 90° elbows installed inline set -

will reduce line set vibration.

Figure 6. Outside Unit Placement

PLACING UNIT ON SLAB

When installing a unit at grade level, the top of the slab

should be high enough above the grade so that water from

higher ground would not collect around the unit as

illustrated in figure 7. Slab may be level or have a slope

tolerance away from the building of not more than two

degrees, or 2 inches per 5 feet (51 mm per 1524 mm).

NOTES:

Service clearance of 30 in, (762 mm) must be maintained on one of

the sides adjacent to the control box,

Clearance to one of the other three sides must be 36 in, (914 mm)

Clearance to one of the remaining two sides may be 12 in. (305

mm) and the final side may be 6 in, (152 mm)

48 in, (1219 ram) clearance required on top of unit,

A clearance of 24 in, (610 mm) must be maintained between two

units

Figure 5. Installation Clearances

POSITIONING CONSIDERATIONS

Some localities are adopting sound ordinances based on

the unit's sound level registered from the adjacent

property, not from the installation property, Install the unit

as far as possible from the property line. When possible,

do not install the unit directly outside a window, Glass has a

very high level of sound transmission. For proper

placement of unit in relation to a window see the provided

illustration in figure 6.

Install unit level or, if on a slope, maintain slope tolerance of 2

degrees (or 2 inches per 5 feet [50 mm per 1.5 m]) away from

building structure.

Building

Structure

J

7/ Mounting

-T--

Slab

Figure 7. Ground Level Slab Mounting

INSTALLING UNIT ON ROOF

Install the unit a minimum of 6 inches (152 mm) above the

roof surface to avoid ice build-up around the unit. Locate

the unit above a load bearing wall or area of the roof that

can adequately support the unit, Consult local codes for

rooftop applications.

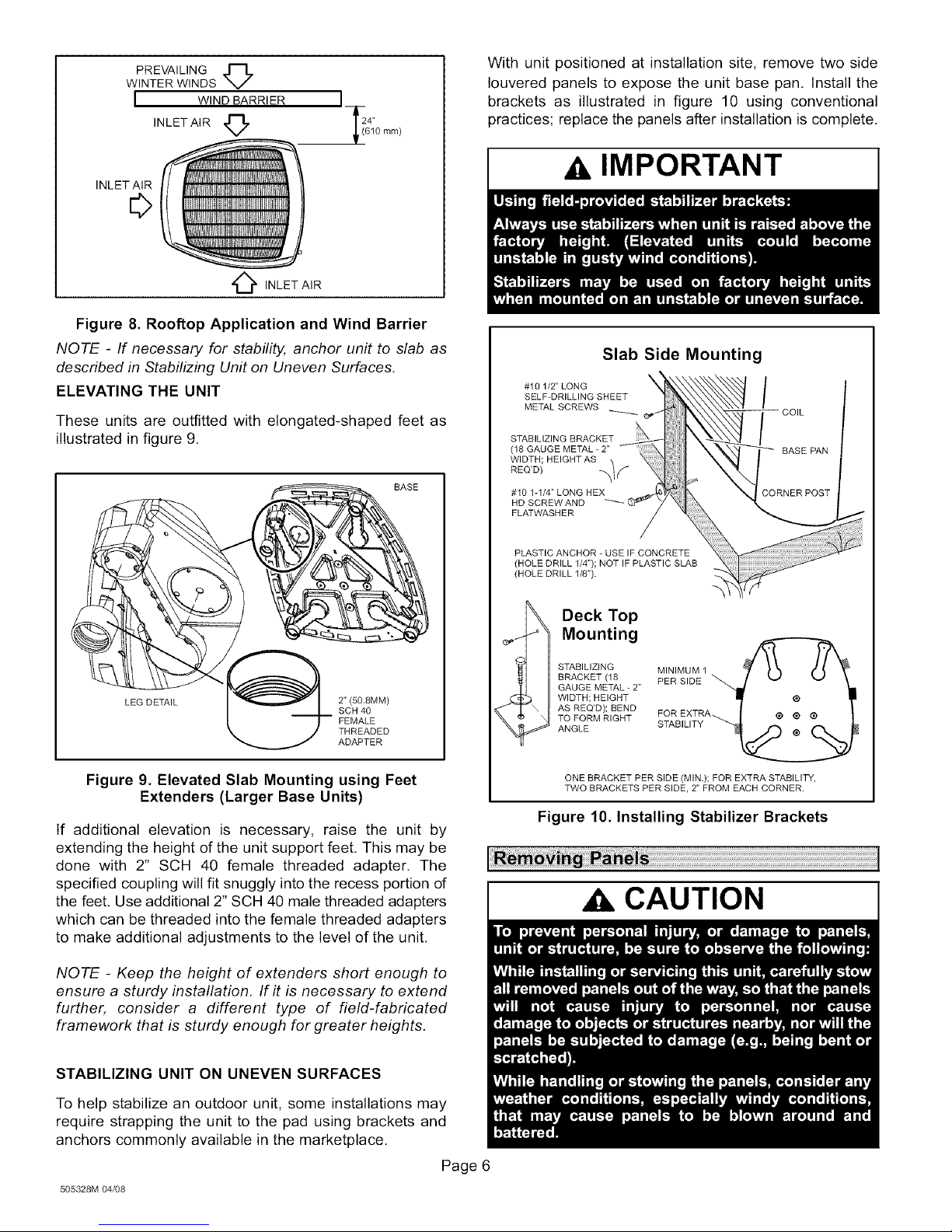

If unit coil cannot be mounted away from prevailing winter

winds, a wind barrier should be constructed as illustrated in

figure 8. Size barrier at least the same height and width as

outdoor unit, Mount barrier 24 inches (610 mm) from the

sides of the unit in the direction of prevailing winds.

Page 5

XP15 SERIES

Page 6

PREVAILING _.

WINTER WINDS

I WIND BARRIER

INLET AIR ,_

1

2_'_6" 10 ram)

With unit positioned at installation site, remove two side

Iouvered panels to expose the unit base pan. Install the

brackets as illustrated in figure 10 using conventional

practices; replace the panels after installation is complete.

INLETAIR

O INLET AIR

Figure 8. Rooftop Application and Wind Barrier

NOTE - If necessary for stability, anchor unit to slab as

described in Stabilizing Unit on Uneven Surfaces.

ELEVATING THE UNIT

These units are outfitted with elongated-shaped feet as

illustrated in figure 9.

BASE

IMPORTANT

Slab Side Mounting

#101/2" LONG

SELF-DRILLING SHEET

METAL SCREWS

STABILIZING BRACKET

(18 GAUGE METAL - 2"

RW/DTDHi HEIGHT AS _,_1 f, _

#10 1-1/4" LONG HEX

HD SCREW AND

FLATWASHER

PLASTIC ANCHOR - USE IF CONCRETE

(HOLE DRILL 1/4"); NOT IF PLASTIC SLAB

(HOLE DRILL 1/8").

/

LEG DETAIL 2"(50.8MM)

SCH 40

FEMALE

THREADED

ADAPTER

Figure 9. Elevated Slab Mounting using Feet

Extenders (Larger Base Units)

If additional elevation is necessary, raise the unit by

extending the height of the unit support feet. This may be

done with 2" SCH 40 female threaded adapter. The

specified coupling will fit snuggly into the recess portion of

the feet. Use additional 2" SCH 40 male threaded adapters

which can be threaded into the female threaded adapters

to make additional adjustments to the level of the unit.

NOTE - Keep the height of extenders short enough to

ensure a sturdy installation, If it is necessary to extend

further, consider a different type of field-fabricated

framework that is sturdy enough for greater heights.

STABILIZING UNIT ON UNEVEN SURFACES

Mounting

STABILIZING MINIMUM 1

BRACKET (18 PER SIDE

GAUGE METAL - 2"

WIDTH; HEIGHT

AS REQ'D); BEND

TO FORM RIGHT FOR EXTRA

I Deck Top

ANGLE STABILITY

ONE BRACKET PER SIDE (MIN.); FOR EXTRA STABILITY,

TWO BRACKETS PER SIDE, 2" FROM EACH CORNER.

Figure 10. Installing Stabilizer Brackets

CAUTION

To help stabilize an outdoor unit, some installations may

require strapping the unit to the pad using brackets and

anchors commonly available in the marketplace.

505328M 04/08

Page 6

Page 7

REMOVE4SCREWSTOREMOVEPANELFOR

ACCESSINGCOMPRESSORANDCONTROLS.

_ INSTALLBYPOSITIONINGPANELWITHHOLES

ALIGNED;INSTALLSCREWSANDTIGHTEN.

Figure 11. Access Panel

IMPORTANT! DO NOT ALLOW K-_

PANELS TO HANG ON UNIT BY

TOP TAB. TAB IS FOR ALIGNMENT

ANDNOTDESIGNEDTOSUPPORT

)

WE,GHTOFPANEL

PANEL SHOWN SLIGHTLY _ _

ROTATED TO ALLOW TOP TAB TO _

EXIT (OR ENTER) TOP SLOT FOR _

PANEL.

REMOVING (OR INSTALLING) _

SCREW

L. HOLES......_ _iiii_///l _

ii

Detail A

Detail B -_-_\_

ROTATE IN THIS DIRECTION;

THEN DOWN TO REMOVE PANEL

MAINTAIN MINIMUM PANEL ANGLE (AS CLOSE TO PARALLEL WITH THE UNIT

AS POSSIBLE) WHILE INSTALLING PANEL.

ANGLE MAY BE TOO THE HINGED SIDE TO MAINTAIN

EXTREME FULLY-ENGAGED TABS

PREFERRED ANGLE

FOR INSTALLATION

HOLD DOOR FIRMLY ALONG

Detail D

Figure 13. Removing/Installing Louvered Panels

(Detail D)

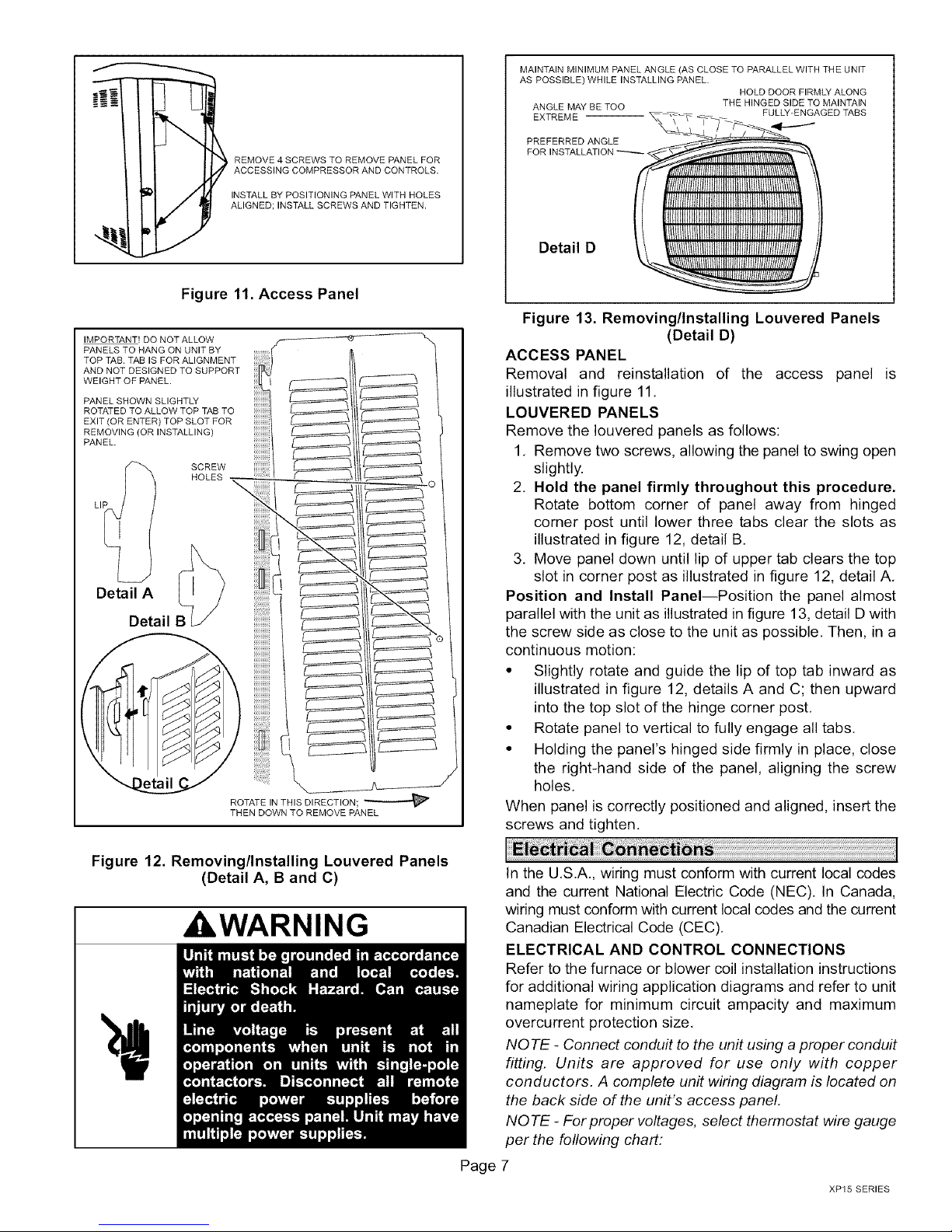

ACCESS PANEL

Removal and reinstallation of the access panel is

illustrated in figure 11,

LOUVERED PANELS

Remove the Iouvered panels as follows:

1, Remove two screws, allowing the panel to swing open

slightly.

U

2, Hold the panel firmly throughout this procedure.

Rotate bottom corner of panel away from hinged

corner post until lower three tabs clear the slots as

illustrated in figure 12, detail B.

t_

3, Move panel down until lip of upper tab clears the top

slot in corner post as illustrated in figure 12, detail A,

Position and Install Panel--Position the panel almost

parallel with the unit as illustrated in figure 13, detail D with

the screw side as close to the unit as possible. Then, in a

continuous motion:

• Slightly rotate and guide the lip of top tab inward as

illustrated in figure 12, details A and C; then upward

into the top slot of the hinge corner post.

• Rotate panel to vertical to fully engage all tabs,

• Holding the panel's hinged side firmly in place, close

the right-hand side of the panel, aligning the screw

holes.

When panel is correctly positioned and aligned, insert the

screws and tighten.

Figure 12. Removing/Installing Louvered Panels

(Detail A, B and C)

A'kWARNING

In the U,S.A., wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada,

wiring must conform with current local codes and the current

Canadian Electrical Code (CEC),

ELECTRICAL AND CONTROL CONNECTIONS

Refer to the furnace or blower coil installation instructions

for additional wiring application diagrams and refer to unit

nameplate for minimum circuit ampacity and maximum

overcurrent protection size.

NOTE - Connect conduit to the unit using a proper conduit

fitting. Units are approved for use only with copper

conductors. A complete unit wiring diagram is located on

the back side of the unit's access panel.

NOTE - For proper voltages, select thermostat wire gauge

per the following chart:

Page 7

XP15 SERIES

Page 8

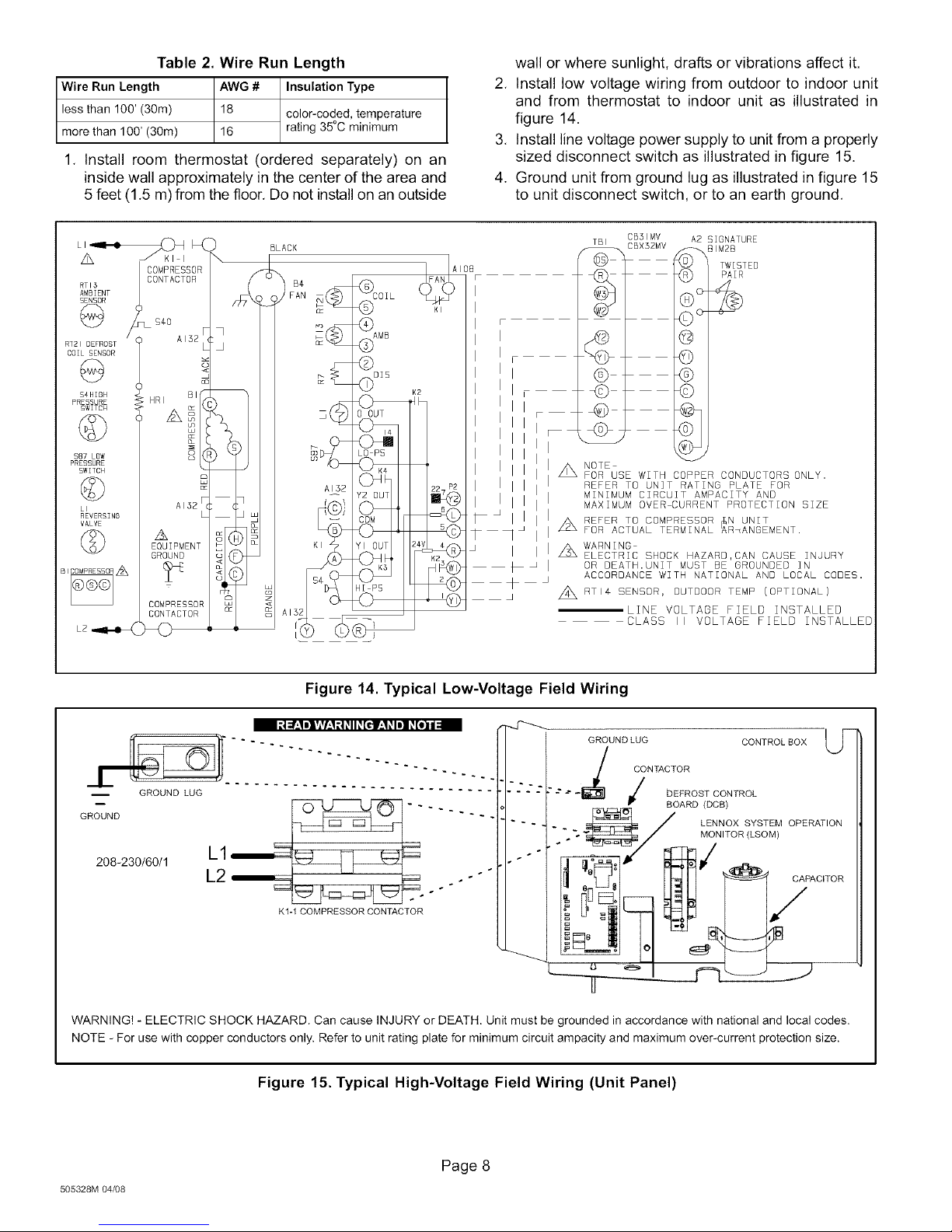

Table 2. Wire Run Length

Wire Run Length AWG # Insulation Type

less than 100' (30m) 18 color-coded, temperature

more than 100' (30m) 16 rating 35°C minimum

1. Install room thermostat (ordered separately) on an

inside wall approximately in the center of the area and

5 feet (1.5 m) from the floor. Do not installon an outside

wall or where sunlight, drafts or vibrations affect it.

2. Install low voltage wiring from outdoor to indoor unit

and from thermostat to indoor unit as illustrated in

figure 14.

3. Install line voltage power supply to unit from a properly

sized disconnect switch as illustrated in figure 15.

4. Ground unit from ground lug as illustrated in figure 15

to unit disconnect switch, or to an earth ground.

LI _._

z_

RTI$

AMBIENT

SENSOR

@

R721 DEFROST

COIL SENSOR

S4HIGH

PRESSURE

SWITCH

$87 LOW

PRESSURE

SWITCH

©

LI

REVERSING

VALVE

©

LZ_

CONTACTOR

OMPRESSOR

54O

AI32

HRI

A

AI32

A

EQUIPMENT

GROUND

COMPRESSOR

CONTACTOR

BLACK

CB31MV

TBI

CBX32MV

A2 SIGNATURE

81M2B

TWISTEO

PAIR

(W5_

(W8

"-(v _

G

BI

©

@

A NOTE

FOR USE WITH COPPER CONDUCTORS ONLY.

w

• I

REFER TO UNIT RATING PLATE FOR

MINIMUM CIRCUIT AMPACITY AND

MAXIMUM OVER CURRENT PROTECTION SIZE

A REFER TO COMPRESSOR N UNIT

FOR ACTUAL TERMINAL mRmANGEMENT.

Z_ WARNING

ELECTRIC SHOCK HAZARD,CAN CAUSE INJURY

OR DEATH.UNIT MUST BE GROUNDED IN

ACCOROANCE WITH NATIONAL AND LOCAL CODES.

A RTI4 SENSOR, OUTDOOR TEMP (OPTIONAL)

LINE VOLTAGE FIELD INSTALLED

CLASS II VOLTAGE FIELD INSTALLED

Figure 14. Typical Low-Voltage Field Wiring

GROUNDLUG

CONTACTOR

DEFROST CONTROL

GROUND

208-230/60/1 L1

L2

-''_/ L_)NNNTOoXRt LYs'<oTE_ OPERATION

"__ _[3_/ _ CAPACITOR

K1-1 COMPRESSOR CONTACTOR

BOARD (DCB)

WARNING! - ELECTRIC SHOCK HAZARD. Can cause INJURY or DEATH. Unit must be grounded in accordance with national and local codes.

NOTE - For use with copper conductors only. Refer to unit rating plate for minimum circuit ampacity and maximum over-current protection size.

CONTROLBOX _'-

Figure 15. Typical High-Voltage Field Wiring (Unit Panel)

505328M 04/08

Page 8

Page 9

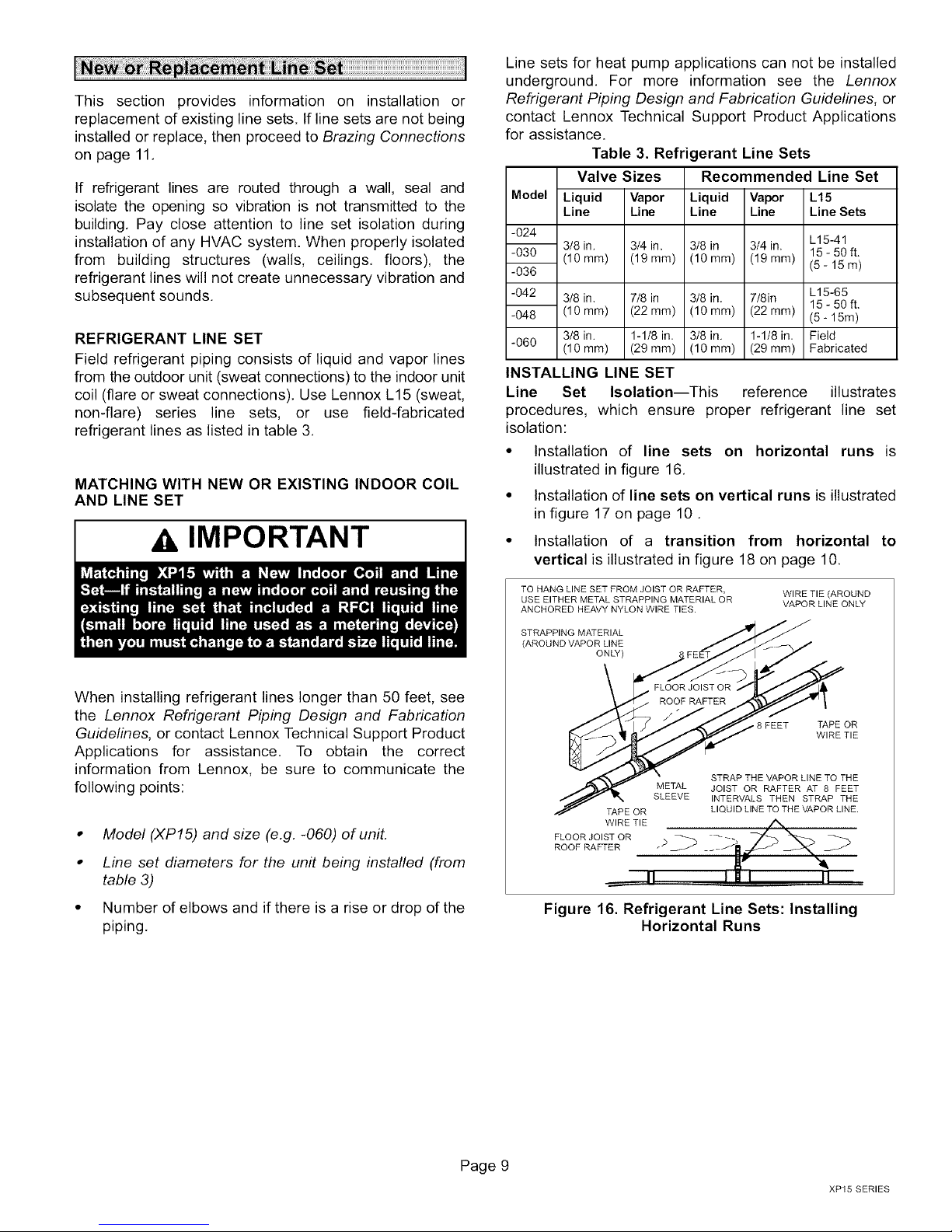

This sectionprovidesinformationon installationor

replacementofexistinglinesets.Iflinesetsarenotbeing

installedorreplace,thenproceedtoBrazing Connections

on page 11.

If refrigerant lines are routed through a wall, seal and

isolate the opening so vibration is not transmitted to the

building, Pay close attention to line set isolation during

installation of any HVAC system. When properly isolated

from building structures (walls, ceilings, floors), the

refrigerant lines will not create unnecessary vibration and

subsequent sounds.

REFRIGERANT LINE SET

Field refrigerant piping consists of liquid and vapor lines

from the outdoor unit (sweat connections) to the indoor unit

coil (flare or sweat connections). Use Lennox L15 (sweat,

non41are) series line sets, or use field-fabricated

refrigerant lines as listed in table 3.

MATCHING WITH NEW OR EXISTING INDOOR COIL

AND LINE SET

IMPORTANT

Line sets for heat pump applications can not be installed

underground. For more information see the Lennox

Refrigerant Piping Design and Fabrication Guidelines, or

contact Lennox Technical Support Product Applications

for assistance.

Table 3. Refrigerant Line Sets

Valve Sizes Recommended Line Set

Model Liquid Vapor Liquid Vapor L15

Line Line Line Line LineSets

-024

-030 (10mm) (19mm) (10mm) (19mm) 15-50ft.

-- (5 - 15 m)

-036

-042 3/8 in. 7/8 in 3/8 in. 7/Sin L15-65

-060 (10 ram) (29 ram) (10 ram) (29 ram) Fabricated

3/8 in. 3/4 in. 3/8 in 3/4 in. L15-41

15 - 50 ft.

(10mm) (22mm) (10mm) (22mm) (5-15m)

3/8 in. 1-1/8 in, 3/8 in. 1-1/8 in, Field

INSTALLING LINE SET

Line Set Isolation--This reference illustrates

procedures, which ensure proper refrigerant line set

isolation:

• Installation of line sets on horizontal runs is

illustrated in figure 16.

• Installation of line sets on vertical runs is illustrated

in figure 17 on page 10.

• Installation of a transition from horizontal to

vertical is illustrated in figure 18 on page 10.

When installing refrigerant lines longer than 50 feet, see

the Lennox Refrigerant Piping Design and Fabrication

Guidelines, or contact Lennox Technical Support Product

Applications for assistance. To obtain the correct

information from Lennox, be sure to communicate the

following points:

Model (XP15) and size (e.g. -060) of unit.

Line set diameters for the unit being installed (from

table 3)

Number of elbows and if there is a rise or drop of the

piping.

TO HANG LINE SET FROM JOIST OR RAFTER,

USE EITHER METAL STRAPPING MATERIAL OR

ANCHORED HEAVY NYLON WIRE TIES.

STRAPPING MATERIAL

(AROUND VAPOR LINE

ONLY)

METAL JOIST OR RAFTER AT 8 FEET

TAPE OR LIQUID LINE TO THE VAPOR LINE.

FLOOR JOIST OR _ _ _%

ROOF RAFTER _-

SLEEVE INTERVALS THEN STRAP THE

STRAP THE VAPOR LINE TO THE

WIRE TIE (AROUND

VAPOR LINE ONLY

8 FEET TAPE OR

_._ I1

Figure 16. Refrigerant Line Sets: Installing

Horizontal Runs

WIRE TIE

Page 9

XP15 SERIES

Page 10

OUTSIDEWALLREFRIGERANTLINESMUST

IMPORTANT-

NOTCONTACTWALL.VAPORLINELIQUIDLINE

NOTE-SIMILAR

INSTALLATION

PRACTICESSHOULDBE

USEDIFLINESETISTO

BEINSTALLEDON

EXTERIOROFOUTSIDE

WALL.

VAPORLINEWRAPPED

WITHARMAFLEX

ANCHOREDHEAVY

NYLONWIRETIE

WALL

STUD

METALSLEEVE

AUTOMOTIVE

MUFFLER-TYPEHANGER

VAPORLINE-WRAPPED

INARMAFLEX

WALL

STUD

STRAPLIQUIDLINE

TOVAPORLINE

JIDLINE

IMPORTANT!

REFRIGERANTLINES

MUSTNOTCONTACT

STRUCTURE.

PVC_ CAULK

PIPE FIBERGLASS

INSULATION

Figure 17. Refrigerant Line Sets: Installing Vertical

Runs (New Construction Shown)

1

CUT AND DEBUR

INDOOR UNIT

REMOVE CAP AND CORE FROM

BOTH LIQUID AND SUCTION

SERVICE PORTS

SERVICE PORT MUST BE

OPEN TO ALLOW EXIT

POINT FOR NITROGEN SERVICE

j SUCTION LINE _ /VALVE

_QU_DUNE SERV_CEJ

IUIDLINE

TOVAPORLINE

LIQUID

LINE

METALSLEEVE INARMAFLEX

Figure 18. Refrigerant Line Sets: Transition from

Vertical to Horizontal

VALVE

VAPORLINEWRAPPED

UNIT

outdoor

INSTALL CORE ONLY FOR

3OTH SERVICE PORTS after they

have coolED.

505328M 04/08

Figure 19. Brazing Connections

Page 10

Page 11

ISOLATION GROMMETS

Locate the provided isolation grommets Slide grommets

onto vapor and liquid lines Insert grommets into mullion to

isolate refrigerant lines from sheet metal edges

Use the following procedure to braze the line set to the new

outdoor unit Figure 19 is provided as a general guide for

preparing to braze the line sets to the outdoor unit

Before brazing, remove the access panel as illustrated in

figure 11; then remove the narrow piping panel to prevent

burning off the paint as illustrated in figure 20

REMOVE TWO SCREWS

AND REMOVE PANEL

BEFORE BRAZING

LINE SET

CONNECTION

POINTS

Figure 20. Piping Panel Removal

WARNING

underneath the valve body to protect the base paint,

Also, shield the light maroon R-410A sticker.

5. Flow regulated nitrogen (at 1 to 2 psig) through the

refrigeration gauge set into the valve stem port

connection on the liquid line service valve and out of

the valve stem port connection on the vapor service

valve. The CTXV metering device at the indoor unit

coil will allow low pressure nitrogen to flow through the

system,)

Note: Use silver alloy brazing rods with five or six percent

minimum silver alloy for copper-to-copper brazing or 45

percent silver alloy for copper-to-brass or copper-to-steel

brazing,

6. Braze the line set to the liquid line service valve. Turn

off nitrogen flow, Repeat procedure starting at

paragraph 4 for brazing the vapor line set to service

valve,

After brazing the vapor line set to the service valve,

disconnect gauge from service port, remove wrapping and

replace service port cores.

Remove the existing HCFC-22 refrigerant flow control

orifice or thermal expansion valve from the indoor coil.

Existing devices are not approved for use with HFC-410A

refrigerant and may prevent proper flushing. Use a

field-provided fitting to reconnect lines, See figure 23 on

page 13 for disassembly and typical removal instructions.

_WARNING

1. Cut ends of the refrigerant lines square (free from

nicks or dents). Debur the ends. The pipe must remain

round, do not pinch end of the line.

2. Remove service cap and core from both the vapor and

liquid line service ports.

3. Connect gauge low pressure side to liquid line service

valve,

4. To protect components during brazing, wrap a wet

cloth around the liquid line service valve body and

copper tube stub and use another wet cloth

After the line set has been connected to both the indoor

and outdoor units, check the line set connections at both

the indoor and outdoor units unit for leaks. Use the

following procedure to test for leaks:

IMPORTANT

WARNING

AWARNING

Page 11

XP15 SERIES

Page 12

WARNING I OUTOOORO.,T

1 Connect an HFC410A manifold gauge set high

pressure hose to the vapor valve service port

(Normally the high pressure hose is connected to the

liquid line port; however, connecting it to the vapor port

better protects the manifold gauge set from high

pressure damage.)

2 With both manifold valves closed connect the cylinder

of HFC410A refrigerant to the center port of the

manifold gauge set Open the valve on the HFC 410A

cylinder (vapor only)

3 Open the high pressure side of the manifold to allow

HFC 410A into the line set and indoor unit

4 Weigh in a trace amount of HFC410A [,4 trace

amount is a maximum of two ounces (57 g) refrigerant

or three pounds (31 kPa) pressure].

5, Close the valve on the HFC-410A cylinder and the

valve on the high pressure side of the manifold gauge

set.

6. Disconnect the HFC-410A cylinder,

7, Connect a cylinder of dry nitrogen with a pressure

regulating valve to the center port of the manifold

gauge set,

8, Adjust dry nitrogen pressure to 150 psig (1034 kPa),

9, Open the valve on the high side of the manifold gauge

set in order to pressurize the lineset and the indoor unit,

10, After a few minutes, open one of the service valve

ports and verify that the refrigerant added to the

system earlier is measurable with a leak detector,

11, After leak testing disconnect gauges from service

ports,

SERVICE VALVE

REMOVE SERVICE

PORT CAP

REMOVE PORT CORE

Figure 21. Typical Service Valve Port Core Removal

A IMPORTANT

A IMPORTANT

A CAUTION

A IMPORTANT

Remove both of the outdoor unit's service port cores (liquid

and vapor) as illustrated in figure 21,

505328M 04/08

If new lines are used then proceed to Installing New

Refrigerant Metering Device. Otherwise proceed with the

following procedure,

Page 12

Page 13

REQUIRED EQUIPMENT

Equipment required to flush the existing line set and indoor

unit coil:

• Two clean HCFC-22 recovery bottles,

• Oilless recovery machine with pump-down feature,

• Two gauge sets (one for HCFC-22; one for

HFC-410A),

RECOVERY MACHINE

NOTE - The inverted HCFC-22 cylinder must contain at least the same

amount of refrigerant as was recovered from the existing system.

6, Close the valve on the inverted HCFC-22 drum and

the gauge set valves. Pump the remaining refrigerant

out of the recovery machine and turn the machine off.

XP15 units are used in check thermal expansion valve

(CTXV) systems only, See the indoor unit coil installation

instructions and the Lennox Engineering Handbook for

approved CTXV match-ups and application information.

Table 3 on page 9 lists liquid and vapor line sizes and

corresponding line sets,

(Uncased Coil Shown)_ -

TWO PIECE PATCH

PLATE(UNCASED OR

COIL ONLY) ORIFICE NSION VALVE

TUBES

HOUSING

I EXPA )RI FICE _""_

I (SEE NOTE)

Figure 22. Typical Flushing Connection

PROCEDURE

1, Verify that the existing HCFC-22 refrigerant flow

control device has been removed before continuing

with flushing procedures. Existing devices are not

approved for use with HFC-410A refrigerant and may

prevent proper flushing.

2, Connect an HCFC-22 cylinder with clean refrigerant to

the vapor service valve. Connect the HCFC-22 gauge

set to the liquid line valve. Connect a recovery

machine with an empty recovery tank to the gauge set

as illustrated in figure 22.

3, Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to

allow the recovery machine to pull a vacuum on the

existing system line set and indoor unit coil.

4, Invert the cylinder of clean HCFC-22 and open its

valve to allow liquid refrigerant to flow into the system

through the vapor line valve. Allow the refrigerant to

pass from the cylinder and through the line set and the

indoor unit coil before it enters the recovery machine,

5, After all of the liquid refrigerant has been recovered,

switch the recovery machine to vapor recovery so that

all of the HCFC-22 vapor is recovered. Allow the

recovery machine to pull a vacuum on the system,

NOTE - A single system flush should remove all of the

mineral oil from the existing refrigerant lines and indoor

unit coil. A second flushing may be done (using clean

refrigerant) if insufficient amounts of mineral oil were

removed during the first flush. Each time the system is

flushed, you must allow the recovery machine to pull a

vacuum on the system at the end of the procedure.

ACCESS FITTING

(NO VALVE CORE)

On smaller vapor lines, bulb may be

mounted on top or side-mounted (prefer-

ably at 3 o'clock position).

On 518"and larger lines, mount bulb

approximately at the 4 or 8 o'clock posi-

tions; never mount on bottom of line.

o @clock

NOTE - If necessary, remove HCFC-22 flow control device (fixed

orifice/check expansion valve) from existing line set before instal-

ling HFC-410A approved expansion valve and o-ring.

Figure 23. Typical Metering Device Installation

The thermostatic expansion valve or check / thermostatic

expansion valve, can be installed internal or external to the

indoor coil. In applications where an uncased coil is being

installed in a field provided plenum, install the CTXV and

provide an access for field servicing of the CTXV. Refer to

Figure 23 for reference during installation of CTXV,

Page1

XP15 SERIES

Page 14

1, On fully cased coils, remove the coil access and

plumbing panels,

2, Remove any shipping clamps holding the liquid line

and distributor assembly,

3. Using two wrenches, disconnect liquid line from

distributor. Take care not to twist or damage distributor

tubes during this process,

4, Remove and discard RFC bullet and Teflon washer,

5. Remove and discard cap from the equalizer line port

on the vapor line. Check for valve core in port fitting

and if installed, remove from port.

6. Install one of the provided Teflon washers around the

stubbed end of the CTXV,

7. Attach the stubbed end of the kit valve to the distributor

assembly.

8. Place the remaining Teflon washer around the other

end of the CTXV.

9. Attach the liquid line to the CTXV.

10. Attach the sensing bulb of the CTXV in the proper

orientation to the vapor line using the clamp an screws

provided with the CTXV,

11. Connect the equalizer line from the CTXV to the

equalizer vapor port on the vapor line.

12. To prevent against any possibility of water damage,

properly insulate all parts of the CTXV assemble that

may sweat due to temperature differences between

the valve and its surrounding ambient temperatures.

13. The expansion/check valve can be installed internally

in coil blowers, or external or internal to indoor coil only

applications,

Expansion valves equipped with Chatleff type fittings are

available from Lennox, Refer to the Engineering

Handbook for CTXV kits for use with specific match-ups.

Table 4. Indoor CTXV Kits

Model Kit Number

XP15-024 and -036 49L24

XP15-048 and -060 91M02

A IMPORTANT

If the indoor unit being installed came with a fixed orifice

type metering device, remove that orifice and install the

CTXV as illustrated in figure 23.

Re-install both of the outdoor unit's service port cores

(liquid and vapor) as illustrated in figure 24.

LIQUID AND VAPOR

SERVICE VALVES DO NOT INSTALL

CAPS AT THIS TIME

O TOOO .

INSTALL SERVICE

PORT CORES

Figure 24. Typical Service Valve Port Core

Installation

WARNING

A IMPORTANT

Evacuating the system of non-condensables is critical for

proper operation of the unit. Non-condensables are

defined as any gas that will not condense under

temperatures and pressures present during operation of

an air conditioning system. Non-condensables and water

vapor combine with refrigerant to produce substances that

corrode copper piping and compressor parts.

1. Connect manifold gauge set to the service valve ports

as follows:

• low pressure gauge to vapor line service valve

• high pressure gauge to liquid line service valve

2. Connect micron gauge.

3. Connect the vacuum pump (with vacuum gauge) to

the center port of the manifold gauge set,

4. Open both manifold valves and start the vacuum

pump.

5. Evacuate the line set and indoor unit to an absolute

pressure of 23,000 microns (29.01 inches of

mercury).

NOTE - During the early stages of evacuation, it is

desirable to close the manifold gauge valve at least once to

determine if there is a rapid rise in sure indicates a

relatively large leak, If this occurs, repeat the leak testing

procedure.

NOTE - The term absolute pressure means the total

actual pressure within a given volume or system, above

the absolute zero of pressure. Absolute pressure in a

vacuum is equal to atmospheric pressure minus vacuum

pressure,

6. When the absolute pressure reaches 23,000 microns

(29.01 inches of mercury), close the manifold gauge

505328M 04_8

Page 14

Page 15

valves,turnoffthevacuumpumpanddisconnectthe

manifoldgaugecenterporthosefromvacuumpump.

Attachthemanifoldcenterporthosetoadrynitrogen

cylinderwithpressureregulatorsetto150psig(1034

kPa)andpurgethehose.Openthemanifoldgauge

valvestobreakthevacuuminthelinesetandindoor

unit.Closethemanifoldgaugevalves,

7, Shutoff thedry nitrogencylinderandremovethe

manifoldgaugehosefromthe cylinder.Openthe

manifoldgaugevalvestoreleasethedrynitrogenfrom

thelinesetandindoorunit,

8, Reconnectthemanifoldgaugetothevacuumpump,

turnthepumpon,andcontinuetoevacuatethelineset

andindoorunituntiltheabsolutepressuredoesnot

riseabove500microns(29.9inchesofmercury)within

a20-minuteperiodaftershuttingoffthevacuumpump

andclosingthemanifoldgaugevalves.

9,Whentheabsolutepressurerequirementabovehas

beenmet,disconnectthe manifoldhosefrom the

vacuumpumpandconnectittoanuprightcylinderof

HFC-410Arefrigerant,Openthemanifoldgaugevalve

1to2 psiginordertoreleasethevacuuminthelineset

andindoorunit,

10,Close manifoldgaugevalvesand shut off the

HFC-410Acylinderandremovethe manifoldgauge

set,

SERVICINGUNITSDELIVEREDVOIDOFCHARGE

Ifthesystemisvoidofrefrigerant,cleanthesystemusing

theproceduredescribedbelow,

1, Usenitrogentopressurizethesystemandcheckfor

leaks,Repairallleaks,

2, Evacuatethe systemto removeas muchof the

moistureaspossible,

3, Usenitrogentobreakthevacuumandinstalla new

filterdrierinthesystem.

4, Evacuatethe system again. Then, weigh the

appropriateamountofHFC-410Arefrigerantaslisted

onunitnameplateintothesystem.

5, Monitorthe systemto determinethe amountof

moistureremainingintheoil.Itmaybenecessaryto

replacethefilterdrierseveraltimesto achievethe

requireddrynesslevel.If systemdryness is not

verified,thecompressorwillfail inthefuture.

4, Replace the stem caps and tighten as specified in

Operating Service Valves on page 3.

5, Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit's

nameplate. If not, do not start the equipment until you

have consulted with the power company and the

voltage condition has been corrected,

6, Set the thermostat for a cooling demand. Turn on

power to the indoor indoor unit and close the outdoor

unit disconnect switch to start the unit.

7, Recheck voltage while the unit is running. Power must

be within range shown on the nameplate,

8, Check system for sufficient refrigerant by using the

procedures listed under Testing and Charging

System,

TESTING AND CHARGING SYSTEM

This system uses HFC-410A refrigerant which operates at

much higher pressures than HCFC-22. The pre-installed

liquid line filter drier is approved for use with HFC-410A

only, Do not replace liquid line filter drier with components

designed for use with HCFC-22,

NOTE - This unit is NOT approved for use with coils which

use capillary tubes as a refrigerant metering device,

SETTING UP TO CHECK CHARGE

1. Close manifold gauge set valves. Connect the center

manifold hose to an upright cylinder of HFC-410A.

2. Connect the manifold gauge set to the unit's service

ports as illustrated in figure 25,

• low pressure gauge to vapor service port

• high pressure gauge to liquid service port

COOLING MODE INDOOR AIRFLOW CHECK

Check airflow using the Delta-T (DT) process as illustrated

in figure 26 on page 16.

HEATING MODE INDOOR AIRFLOW CHECK

Blower airflow (CFM) may be calculated by energizing

electric heat and measuring:

• temperature rise between the return air and supply air

temperatures at the indoor coil blower unit,

• voltage supplied to the unit,

• amperage being drawn by the heat unit(s),

Then, apply the measurements taken in following formula

to determine CFM:

IMPORTANT

1. Rotate fan to check for frozen bearings or binding.

2, Inspect all factory- and field-installed wiring for loose

connections.

3, After evacuation is complete, open the liquid line and

vapor line service valves to release the refrigerant

charge (contained in outdoor unit) into the system,

Page15

CFM =

CALCULATING CHARGE

If the system is void of refrigerant, first, locate and repair

any leaks and then weigh in the refrigerant charge into the

unit, To calculate the total refrigerant charge:

Amount Adjust amount for specified per

specified variation in indoor unit

on line set length match-up Total

nameplate (table in figure 27) (tables 6 through 11) charge

Amps x Volts x 3.41

1.08 x Temperature rise (F)

Additional charge

+ + =

XP15 SERIES

Page 16

CHECK

EXPANSIONVALVE

LOW HIGH [

PRESSUREPRESSURE

_:[tGAUGEMANIFO%D1]:_

DISTRIBUTOR

DRIER OUTDOOR

MUFFLER

CO,L

OUTDOOR UNIT

REVERSING VALVE

NOTE - ARROWS INDICATE

DIRECTION OF REFRIGERANT FLOW

INDOOR UNIT

HFC-410 LINEI

ADRUM VALVE COMPRESSOF

J2

NOTE- Use gauge ports on vapor line valve and liquid valve for evacuating refrigerant

lines and indoor coil. Use vapor gauge port to measure vapor pressure during charging,

Figure 25. XP15 Cooling Cycle (Showing Gauge Manifold Connections)

Temp. l

of air I 80 24

entering,_ I 78 23

indoor _ I ==

coil °F _'?1

I

All temperatures are

expressed in °F 6

I

"- 17421

Wet-bulb °F 57

24 24 23 23 22 22 22 20 19 18 17 16 15

23 23 22 22 21 21 20 19 18 17 16 15 14

22

22 22 21 21 20 19 19 18 17 16 15 14 13

tu

21 21 20 19 19 18 17 16 16 15 14 13 12

20 19 18 17 17 161L55_15 14 13 12 11 10

72 20

70 19

19 18 18 17 17 16 15 15 14 13 12 11 10

58 59 60 61 62 63 64 65 66 67 68 69 70 I

19°

DT

n

iNDOOR WET

COiL BULB

DRY

BULB

1. Determine the desired DT--Measure entering air temper-

ature using dry bulb (A) and wet bulb (B). DT is the intersect-

ing value of A and B in the table (see triangle).

2. Find temperature drop across coil--Measure the coil's dry

bulb entering and leaving air temperatures (A and C). Tem-

perature Drop Formula: (TDrop) = A minus C.

3. Determine if fan needs adjustment--If the difference between

$

the measured TDrop and the desired DT (TDrop-DT) is within

+_3°, no adjustment is needed. See examples: Assume DT =

15 and A temp. = 72 °, these C temperatures would necessi-

LEILI9 _LaL_d EI(3LIUII_:

C° TDrop- DT = °F ACTION

53° 19 - 15 = 4 Increase the airflow

58° 14 - 15 = -1 (within +3° range) no change

62° 10 - 15 = -5 Decrease the airflow

4. Adjust the fan speed--See indoor unit instructions to in-

crease/decrease fan speed.

Changing air flow affects all temperatures; recheck tempera-

tures to confirm that the temperature drop and DT are within

+_30.

Figure 26. Checking Indoor Airflow over Evaporator Coil using Delta-T Chart

VAPOR LINE

VALVE

CHECK EXPANSION VALVE --

INDOOR

COIL

WEIGH

Refrigerant Charge per Line Set Length

Liquid Line Ounces per 5 feet (g per 1.5 m)

Set Diameter adjust from 15 feet (4.6 m) line set*

3t8" (9.5 mm) 3 ounce per 5' (85 g per 1.5 m)

NOTE - *If line length is greater than 15 ft. (4.6 m), add this

amount. If line length is less than 15 ft. (4.6 m), subtract this

amount.

505328M 04/08

L_NNOX

HIHIIIJI|I[I

@:L,

Figure 27. Using Weigh In Method

Page 16

1. Check Liquid and suction line pressures

2. Compare unit pressures with table 5,

Normal Operating Pressures,

3. Conduct leak check; evacuate as

previously outlined.

4. Weigh in the unit nameplate charge plus

any charge required for line set differences

over feet,

This nameplate is for illustration purposes

only. Go to actual nameplate on outdoor

unit for charge information.

Page 17

8UBCOOLING 1

2

3

USE COOLING

USE HEATING

%

MODE

60°F (15 °) --

MODE

4

Check the airflow as illustrated in figure 26 to be sure the indoor airflow is as

required. (Make any air flow adjustments before continuing with the following

procedure.)

Measure outdoor ambient temperature; determine whether to use cooling mode

or heating mode to check charge.

Connect gauge set.

Check Liquid and Vapor line pressures. Compare pressures with Normal

Operating Pressures table 5, (The reference table is a general guide. Expect

minor pressure variations. Significant differences may mean improper charge or

other system problem. )

Set thermostat for heat/cool demand, depending on mode being used:

Using cooling mode--When the outdoor ambient temperature is 60°F (15°C) and

above. Target subcooling values in table below are based on 70 to 80°F (21-27°C)

indoor return air temperature; if necessary, operate heating to reach that

temperature range; then set thermostat to cooling mode setpoint to 68°F (20°C).

When pressures have stabilized, continue with step 6.

SATo

LIQo -

SCo =

Using heating mode--When the outdoor ambient temperature is below 60°F (15°C).

Target subcooling values in table below are based on 65-75°F (18-24°C) indoor

return air temperature; if necessary, operate cooling to reach that temperature range;

then set thermostat to heating mode setpoint to 77°F (25°C). When pressures have

stabilized, continue with step 6.

6 Read the liquid line temperature; record in the LIQ ° space.

7 Read the liquid line pressure; then find its corresponding temperature in the

temperature/pressure chart listed in table 12 and record it in the SAT° space.

8 Subtract LIQ° temp. from SAT° temp. to determine subcooling; record it in SC° space.

9 Compare SC° results with table below, being sure to note any additional charge for

line set and/or match-up.

10 If subcooling value is greater than shown in tables 6 through 11for the applicable unit,

remove refrigerant; if less than shown, add refrigerant.

11 If refrigerant is added or removed, repeat steps 6 through 10 to verify charge.

Figure 28. Using Subcooling Method

Table 5. Normal Operating Pressure - Liquid +10 and Vapor +5 PSIG*

IMPORTANT

|lliiliTo]ilv/_-I IP.|l[[o]i[-.lllilllii['4-"[_]l)i] I[:t-$"]!ll':-.t-lliiL.]Iv|i[_ :--,).-4i[:[_rlrl_irilrlll_l_-41[-4i[_-4.111i!11i1,¢ _-"ll .F'[|[o]i[..'!ll_-'l[i-']'_ilil i,_.]i|l[ill_l[q 1['4i[_:t-11

""""'"" il"""T II

XP15-024 XP15-030 XP15-036 XP15-042 XP15-048 XP15-060

..aidI vo o. I vo o. I vo o...aidI Vo o. I Vo o. I Vo o.

HEATINGOPERATION

20 (-7.0) 315 65 308 62 284 59 293 58 312 62 349 61

30 (-1.0) 340 81 317 76 296 71 312 71 332 76 375 74

40 (4.4) 364 97 339 89 313 87 321 82 353 92 384 88

50 (10) 394 115 359 107 326 106 337 103 374 110 406 107

COOLING OPERATION

65 (18.3) 237 141 250 141 260 139 265 141 242 139 255 136

75 (23.9) 274 143 292 143 298 141 309 144 279 140 297 138

85 (29.4) 319 145 336 145 344 143 360 147 322 142 343 140

95 (35.0) 364 147 385 147 393 145 408 149 370 144 392 142

105 (40.6) 415 149 438 148 446 148 462 151 423 147 447 145

115 (49.0) 469 152 497 151 506 150 522 154 479 149 510 148

*These are most-popular-match-up pressure& Indoor match up, indoor air quality, and indoor load cause pressures to vary.

**Temperature of the air entering the outdoor coi!.

Page 17

XP15 SERIES

Page 18

Table 6. XP15-024

Target *Add

INDOOR MATCHUPS Heat Cool

CH23-51 14 6 0 14

CBX27UH-030-230 13 6 2 4

CB3OU-31 15 5 O 1

CBX32M-030 15 5 O 1

CBX32M-036 13 6 2 4

CBX32MV-024/030 15 5 O O

CBX32MV-036 13 6 2 4

CH33-42 14 6 O 14

CR33-48 38 7 3 1

CX34-31 15 5 0 1

CX34-38 SN# 6007 and after 6 6 1 15

CX34-38 before SN# 6007 13 6 1 15

Subcooling charge

(+5OF) (+1OF) Ib oz

Table 7. XP15-030

Target *Add

INDOOR MATCHUPS Heat Cool

CH23-51 13 5 0 4

CBX27UH-030-230 12 5 0 10

CBX27UH-036-230 13 5 0 8

CB30U-31 14 5 0 0

CB30U-41/46 12 5 0 10

CBX32M-030 14 5 0 0

CBX32M-036 12 5 0 10

CBX32MV-024/030 14 5 0 0

CBX32MV-036 12 5 0 10

CR33-48 31 4 0 13

CX34-38 SN# 6007 and after 5 5 0 8

CX34-38 before SN# 6007 13 5 0 8

CX34-43 9 5 1 4

CX34-49 6 5 2 0

CX34-50/60C 9 5 1 4

Subcooling charge

(+5OF) (+1OF) Ib oz

Table 8. XP15-036

Target *Add

INDOOR MATCHUPS Heat Cool

CBX27UH-036-230 13 4 0 3

CBX27UH-042-230 5 5 O 12

CB3OU-41/46 13 4 O 3

CB3OU-51 5 5 O 12

CBX32M-042 13 4 O 3

CBX32M-048 5 5 O 12

CBX32MV-036 13 4 O 3

CBX32MV-048 5 5 O 12

C33-44C 13 4 O 3

CH33-42 14 4 O 1

CH33-44/48B 9 4 O 7

CH33-48C 7 5 O 7

CH33-49C 5 5 O 12

CH33-62D 5 7 O 14

CR33-48C 37 4 O 5

CR33-50/60 32 5 O 10

CX34-31 15 4 O O

CX34-38 SN# 6007 and after 4 4 O 3

CX34-38 before SN# 6007 13 4 O 3

CX34-43 7 5 O 7

CX34-44/48 13 4 O 3

CX34-49 6 5 O 11

Subcooling charge

(+5OF) (+1OF) Ib oz

Table 9. XP15-042

Target *Add

INDOOR MATCHUPS Heat Cool

CH33-62D 7 7 0 13

CBX27UH-042-230 9 4 O 11

CBX27UH-048-230 9 4 O 11

CB3OU-51*P 9 4 O 11

CBX32M-048 9 4 O 11

CBX32MV-048 9 4 O 11

C33-44C 13 4 O O

CH33-44/48B, -48C 12 4 O 5

CH33-49C 9 4 O 12

CR33-48 35 3 O 2

CX34-38 SN# 6007 and after 4 4 O O

CX34-38 before SN# 6007 13 4 O O

CX34-43 12 4 O 5

CX34-44/48B 13 4 O O

CX34-50/60C 12 4 O 5

Subcooling charge

(+5OF) (+1OF) Ib oz

Table 10. XP1 _-048

Target *Add

INDOOR MATCHUPS Heat Cool

CH23-68 21 4 0 12

CBX27UH-048-230 22 4 O 3

CBX27UH-060-230 12 4 O 11

CB3OU-51*P 22 4 O 3

CB3OU-65*P 12 4 O 3

CBX32M-048 22 4 O 3

CBX32M-060 12 4 O 3

CBX32MV-048 22 4 O 3

CBX32MV-060 12 4 O 3

CBX32MV-068 12 4 O 7

CH33-62D 12 4 O 8

CX34-49C 13 4 O 2

CX34-6OD 14 4 O O

CX34-62D 12 4 O 5

Subcooling charge

(+5OF) (+1OF) Ib oz

Table 11. XP15-060

Target *Add

INDOOR MATCHUPS Heat Cool

CH23-68 28 6 0 0

CBX27UH-060-230 17 6 O O

CB3OU-51*R -65"P 19 6 O 2

CBX32M-O48*R -O6O*P 19 6 O 2

CBX32MV-O48*R -O6O*P 19 6 O 2

CH33-62D 18 6 O 1

*Amount of charge required in addition to charge shown on unit

nameplate. (Remember to consider lineset length difference.)

Subcooling charge

(+5OF) (+IOF) Ib oz

505328M 04_8

Page 18

Page 19

Table 12. HFC-410A Temperature (°F) -

Pressure (Psig)

°F Psig °F Psig °F Psig °F Psig

32 100.8 63 178.5 94 290.8 125 445.9

33 102.9 64 181.6 95 295.1 126 451.8

34 105.0 65 184.3 96 299.4 127 457.6

35 107.1 66 187.7 97 303.8 128 463.5

36 109.2 67 190.9 98 308.2 129 469.5

37 111.4 68 194.1 99 312.7 130 475.6

38 113.6 69 197.3 100 317.2 131 481.6

39 115.8 70 200.6 101 321.8 132 487.8

40 118.0 71 203.9 102 326.4 133 494.0

41 120.3 72 207.2 103 331.0 134 500.2

42 122.6 73 210.6 104 335.7 135 506.5

43 125.0 74 214.0 105 340.5 136 512.9

44 127.3 75 217.4 106 345.3 137 519.3

45 129.7 76 220.9 107 350.1 138 525.8

46 132.2 77 224.4 108 355.0 139 532.4

47 134.6 78 228.0 109 360.0 140 539.0

48 137.1 79 231.6 110 365.0 141 545.6

49 139.6 80 235.3 111 370.0 142 552.3

50 142.2 81 239.0 112 375.1 143 559.1

51 144.8 82 242.7 113 380.2 144 565.9

52 147.4 83 246.5 114 385.4 145 572.8

53 150.1 84 250.3 115 390.7 146 579.8

54 152.8 85 254.1 116 396.0 147 586.8

55 155.5 86 258.0 117 401.3 148 593.8

56 158.2 87 262.0 118 406.7 149 601.0

57 161.0 88 266.0 119 412.2 150 608.1

58 163.9 89 270.0 120 417.7 151 615.4

59 166.7 90 274.1 121 423.2 152 622.7

60 169.6 91 278.2 122 428.8 153 630.1

61 172.6 92 282.3 123 434.5 154 637.5

62 175.4 93 286.5 124 440.2 155 645.0

INSTALLING SERVICE VALVE CAPS

Disconnect gauge set and re-install all service valve caps.

EMERGENCY HEAT (AMBER LIGHT)

An emergency heat function is designed into some room

thermostats. This feature is applicable when isolation of the

outdoor unit is required, or when auxiliary electric heat is

staged by outdoor thermostats. When the room thermostat is

placed in the emergency heat position, the outdoor unit

control circuit is isolated from power and field-provided relays

bypass the outdoor thermostats. An amber indicating light

simultaneously comes on to remind the homeowner that the

unit is operating in the emergency heat mode.

Emergency heat is usually used during an outdoor unit

shutdown, but it should also be used following a power

outage if power has been off for over an hour and the

outdoor temperature is below 50°F (10°C), The system

should be left in the emergency heat mode at least six

hours to allow the crankcase heater sufficient time to

prevent compressor slugging.

HIGH-PRESSURE SWITCH

XP15 units are equipped with a high-pressure switch that

is located in the liquid line to the compressor. The normally

closed SPST auto-reset switch opens at 590 psi,

LOW-PRESSURE SWITCH

XP15 units are equipped with a low-pressure switch that is

located in the vapor line to the compressor. The normally

closed SPST auto-reset switch opens at 25 psi and closes

at 55 psi,

SINGLE-SPEED CONDENSER FAN MOTOR

The XP15 is equipped with a single-speed condenser fan

motor. The compressor contactor and defrost control

board (DCB) controls the operation of the motor,

FILTER DRIER

The unit is equipped with a large-capacity biflow filter drier

which keeps the system clean and dry. If replacement is

necessary, order another of like design and capacity,

Replacement filter driers must be suitable for use with

HFC-410A refrigerant,

OUTDOOR UNIT

SERVICE VALVE _ _/

Figure 29. Installing Service Valve Port Caps

The outdoor unit and indoor blower cycle on demand from

the room thermostat, When the thermostat blower switch

is in the ON position, the indoor blower operates

continuously.

THERMOSTAT OPERATION

Some indoor thermostats incorporate isolating contacts

and an emergency heat function (which includes an amber

indicating light). The thermostat is not included with the

unit and must be purchased separately,

INSTALL CAPS

The LSOM detects the most common fault conditions in

the system. When an abnormal condition is detected, the

LSOM communicates the specific condition through its

ALERT and TRIP lights, The LSOM is capable of detecting

both mechanical and electrical system problems. See

figure 30 for LSOM LED locations.

POWER LED .....

TRIP LED

ALERT LED

Figure 30. LSOM

Page 19

XP15 SERIES

Page 20

Table 13. LSOM LED Troubleshooting Codes

Status LED Status LED

Condition Description

Green Power LED ON LSOM has power

Green Power LED OFF LSOM not powering up

Red Trip LED ON

Red Trip and Yellow

Alert LEDs Flashing Simultaneous flashing,

Yellow Alert Flash

Code 1"

Yellow Alert Flash

Code 2*

Yellow Alert Flash

Code 3*

Yellow Alert Flash

Code 4*

Yellow Alert Flash

Code 5*

Yellow Alert Flash Open Start Circuit - Cur-

Code 6* rent only in run circuit

Yellow Alert Flash Open Run Circuit - Current

Code 7* only in start circuit

Yellow Alert Flash Welded Contactor -

Code 8* Compressor always runs

Yellow Alert Flash Low Voltage - Control cir-

Code 9* cuit <17VAC

*Flash code number corresponds to a number of LED flashes, followed by a pause, and then repeated. Reset ALER Tflash code by removing 24VAC power

from LSOM; last code will display for 1minute after LSOM is powered on.

Note: If the unit is equipped with a two-stagged compressor, upon Y2 signal detection and after five seconds, the LSOM will send 24 VAC to the solenoid.

Once the solenoid is fully energized, the LSOM reduces voltage to between 4 to 18 VDC .Every 15 minutes the solenoid voltage will be increase to 24 volts

for a few seconds to ensure solenoid valve is engaged until Y2 signal is no longer present.

System and compressor

check out OK

Thermostat demand signal

Y1 is present, but

compressor not running

NO TE - During 5-minute

delay in LSOM the red trip

LED will be on.

Long Run Time - Compres-

sor is running extremely

long run cycles

System Pressure Trip -

Discharge or vapor pressure

out of limits or compressor

overloaded

Short Cycling - Compres-

sor is running only briefly

Locked Rotor

Open Circuit

Status LED Troubleshooting Information

24VAC control power is present at the LSOM terminal.

Determine/verify that both R and C LSOM terminals are connected and voltage is present

at both terminals.

1Verify Y terminal is connected to 24VAC at contactor coil.

2Verify voltage at contactor coil falls below 0.5VAC when off.

3Verify 24VAC is present across Y and C when thermostat demand signal is present; if not

present, R and C wires are reversed.

1 Compressor protector is open.

2 Outdoor unit power disconnect is open.

3 Compressor circuit breaker or fuse(s) is open.

4 Broken wire or connector is not making contact.

5 Low pressure switch open if present in the system.

6 Compressor contactor has failed to close.

Indicates that the control circuit voltage is too low for operation.

1 LOW refrigerant charge.

2 Evaporator blower is not running.

3 Evaporator coil is frozen.

4 Faulty metering device.

5 Condenser coil is dirty.

6 Liquid line restriction (filter drier blocked if present).

7 Thermostat is malfunctioning.

1 Check high head pressure or discharge line sensor.

2 Condenser coil poor air circulation (dirty, blocked, damaged).

3 Condenser fan is not running.

4 Return air duct has substantial leakage.

5 If low pressure switch is present, see Flash Code 1 information.

1 Thermostat demand signal is intermittent.

2 Time delay relay or DCB is defective.

3 If high pressure switch is present, see Flash Code 2 information.

4 If low pressure switch is present, see Flash Code 2 information.

1 Run capacitor has failed.

2 Low line voltage (contact utility if voltage at disconnect is low).

3 Excessive liquid refrigerant in the compressor.

4 Compressor bearings are seized.

1 Outdoor unit power disconnect is open.

2 Unit circuit breaker or fuse(s) is open.

3 Unit contactor has failed to close.

4 High pressure switch is open and requires manual reset.

5 Open circuit in compressor supply wiring or connections.

6 Unusually long compressor protector reset time due to extreme ambient temperature.

7 Compressor windings are damaged.

1 Run capacitor has failed.

2 Open circuit in compressor start wiring or connections.

3 Compressor start winding is damaged.

1 Open circuit in compressor start wiring or connec_ons.

2 Compressor start winding is damaged.

1 Compressor contactor failed to open.

2 Thermostat demand signal not connected to LSOM.

1 Control circuit transformer is overloaded.

2 Low line voltage (contact utility if voltage at disconnect is low).

505328M 04_8

Page 20

Page 21

LSOM--LED Functions

A IMPORTANT

See table 13 on page 20 for the complete explanation of

troubleshooting codes.

LED

Color

Green Power 19-28VAC is present at LSOM con-

Yellow Alert

Red Trip the compressor is detected by the

Function Description

Indicates voltage within the range of

nection.

Communicates an abnormal system

condition through a unique flash code.

The alert LED flashes a number of

times consecutively; then pauses;

then repeats the process. This

consecutive flashing correlates to a

particular abnormal condition.

Indicates there is a demand signal

from the thermostat but no current to

LSOM.

Y terminal, If the red LED does not function as

described, refer to table 13 on page 20 to verify the

wiring,

TEST 2:

1. Disconnect power from the compressor and 24VAC

power from the LSOM

2. Remove the wire from the Y terminal of LSOM and

reapply power to the compressor, allowing the

compressor to run. The yellow alert LED will begin

flashing a code 8 indicating a welded contactor,

3. While the LSOM is off, reattach the wire to the Y

terminal,

4. Reapply power to the compressor and 24VAC power

to the LSOM; the yellow alert LED will flash the

previous code 8 for one minute and then turn off. If the

yellow LED does not function as described, refer to

table 13 on page 20 to verify the wiring,

DEFROST CONTROL BOARD (DCB) FUNCTION

The DCB measures differential temperatures to detect

when the system is performing poorly because of ice

build-up on the outdoor coil. The DCB self-calibrates when

the defrost system starts and after each system defrost

cycle. The DCB components are illustrated in figure 31.

Resetting Alert Codes

Alert codes can be reset manually or automatically:

Cycle the 24VAC power to LSOM off and on. Af-

Manual ter power up, existing code will display for one

minute and then clear.

After an alert is detected, the LSOM continues

Automatic to monitor the compressor and system. Whentif

conditions return to normal, the alert code is

turned off automatically.

LSOM--L Terminal Connection

The L connection is used to communicate alert codes to

the room thermostat. On selected Lennox SignatureStat"

thermostats, a blinking check LED will display on the room

thermostat and on select White-Rodgers room

thermostats, an icon on the display will flash. Either will

flash at the same rate as the LSOM yellow alert LED,

NOTE - ROOM THERMOSTATS WITH SERVICE OR

CHECK LIGHT FEATURE--The room thermostat may

blink the Check or Service LED or it may come on sofid,

Confirm fault by observing and interpreting the code from

the LSOM yellow alert LED at the unit,

LSOM--Installation Verification

To verify correct LSOM installation, two functional tests

can be performed.

TEST 1:

1. Disconnect power from the compressor and force a

thermostat call for cooling.

2. The red trip LED should turn on indicating a

compressor trip as long as 24VAC is measured at the

Note - Component Locations Vary by Board Manufacturer.

TEST PINS

DEFROST

TERMINATION

PIN SETTINGS

SENSOR

PLUG IN (COIL

AND AMBIENT

SENSORS)

DELAY

REVERSING

VALVE

PRESSURE

SWITCH

CIRCUIT

CONNECTIONS

rEs_ PI [_ O rAN

°

PINS

o_7 o

O wl

0-Ps

¢0_MON _2

TStPS O_ C _ 0 v_ _2

LOW

AMBIENT

THERMOSTAT

PINS

_DIAGNOSTIC

LEDS

24V TERMINAL

STRIP

CONNECTIONS

Figure 31. Defrost Control Board (DCB)

The DCB monitors ambient temperature, outdoor coil

temperature, and total run time to determine when a

defrost cycle is required. The coil temperature probe is

designed with a spring clip to allow mounting to the outside

coil tubing. The location of the coil sensor is important for

proper defrost operation.

NOTE - The DCB accurately measures the performance of

the system as frost accumulates on the outdoor coil. This

typically will translate into longer running time between

defrost cycles as more frost accumulates on the outdoor

coil before the DCB initiates defrost cycles.

Page 21

XP15 SERIES

Page 22

Pressure Switch Connections

The unit's automatic reset pressure switches (LO PS - $87

and HI PS - $4) are factory-wired into the DCB on the

LO-PS and HI-PS terminals, respectively.

Pressure Switch Event Settings

The following are the auto reset event values for low and

high pressures thresholds:

• High Pressure (auto reset) - trip at 590 psig, reset to

418 psig.

• Low Pressure (auto reset) - trip at 25 psig, reset to 55

psig.

Five-Strike Lockout Safety Function

The five-strike lockout safety function is designed to

protect the unit's compressor from damage. The DCB

monitors for an active state on the DCB's Y1 input as

referenced in figure 31 on page 21. When the Y1 input is

active the internal control logic of the DCB will do the

following:

• Count any HI-PS and LO-PS pressure switch trips

(open and close).

• If a pressure switch trips four times during the current

active state on the Y1 input, then the DCB's control

logic will reset the pressure switch trip counter to zero

at the end of currently active Y1 input state.

• If the pressure switch opens for a fifth time during the

current Y1 input state, the DCB will enter a lockout

condition.

The system will require servicing to determine the cause of

the pressure switch condition. Once the condition has

been rectified, use the following procedure to reset the

DCB.

DEFROST SYSTEM SENSORS

Sensors connect to the DCB through a field-replaceable

harness assembly that plugs into the DCB. Through the

sensors, the DCB detects outdoor ambient and coil

temperature fault conditions. As the detected temperature

changes, the resistance across the sensor changes.

Sensor resistance values can be checked by ohming

across pins shown in table 14.

NOTE - When checking the ohms across a sensor, be

aware that a sensor showing a resistance value that is not

within the range shown in table 14, may be performing as

designed. However, if a shorted or open circuit is detected,

then the sensor may be faulty and the sensor harness will

need to be replaced.

Table 14. Sensor Temperature / Resistanc4 Range

Temperature Resistance values Pins/Wire

Sensor Range °F (°C) range (ohms) Color

Outdoor -35 (-37) to 120 280,000 to 3750 3 and 4

(48) (Black)

Coil -35 (-37) to 120 280,000 to 3750 5 and 6

(48) (Brown)

Note: Sensor resistance increases as sensed temperature

decreases.

Ambient Sensor--The ambient sensor as illustrated in

figure 32 on page 24 considers outdoor temperatures

below -35°F (-37°C) or above 120°F (48°C) as a fault. Ifthe

ambient sensor is detected as being open, shorted or out

505328M 04/08

of the temperature range of the sensor, the DCB will not

perform demand defrost operation. The DCB will revert to

time/temperature defrost operation and will display the

appropriate fault code. Heating and cooling operation will

be allowed in this fault condition,

Coil Sensor--The coil temperature sensor as illustrated

in figure 32 on page 24, considers outdoor temperatures

below -35°F (-37°C) or above 120°F (48°C) as a fault. Ifthe

coil temperature sensor is detected as being open, shorted

or out of the temperature range of the sensor, the DCB will

not perform demand or time/temperature defrost

operation and will display the appropriate fault code.

Heating and cooling operation will be allowed in this fault

condition.

NOTE - Within a single room thermostat demand, if

five-strikes occur, the DCB will lock out the unit. The DCB's

24 volt power R must be cycled OFF, or the TESTpins on

DCB must be shorted between 1 to 2 seconds to reset the

DCB.

DCB OPERATIONAL MODES

The DCB has four basic operational modes which are

TEST, NORMAL CALIBRATION and DEFROST.

TEST

1. When Y1 is energized and 24V power is being applied

to the DCB, a test cycle can be initiated by: placing the

termination temperature jumper across the Test pins

(P1) for 2 to 5 seconds.

2. If the jumper remains across the Test pins longer than

five seconds, the DCB will ignore the test pins and

revert to normal operation,

3. The jumper will initiate one cycle per test.

4, Enter the TEST MODE by placing a jumper across the

TEST pins on the DCB after power-up. The TEST pins

are ignored and the test function is locked out if the

shunt is applied on the TEST pins before power-up.

5, DCB timings are reduced, the low-pressure switch is

ignored and the DCB will clear any active lock out

condition,

6, Each test pin shorting will result in one test event, For

each TEST the jumper must be removed for at least

one second and reapplied, Refer to flow chart

illustrated in figure 33 on page 24 for TEST operation,

NOTE - The Y1 input must be active (ON) and the 0 room

thermostat terminal into DCB must be inactive

NORMAL

The DCB monitors the O line, to determine the system

operating mode (heat/cool), outdoor ambient temperature,

coil temperature (outdoor coil) and compressor run time to

determine when a defrost cycle is required,

CALIBRATION

The DCB is considered uncalibrated when power is

applied to the DCB, after cool mode operation, or if the coil

temperature exceeds the termination temperature when it

is in heat mode.

DEFROST

For detail information on DEFROST MODE, see Detail

Defrost Mode Operation on page 26.

Page 22

Page 23

Table 15. Defrost Control Board (DCB) Inputs, Outputs and Configurable Settings

DCB DCB Label or

Location Description Purpose Function

P1 TEST Test Mode

P1 50, 70, 90, 100

Wl Output

C 24VAC Common

L Thermostat Service Light

P2 R 24VAC

Y2 Thermostat Input

O Thermostat Input

Y1 Thermostat Input

P3 55, 50, 45, 40 Low Ambient Thermostat Pins

DIS-YEL Coil Sensor

P4

P5

P6

DS1

DS2

FAN

O OUT

LO-PS

Y2 OUT Y2 OUT 24 VAC Output

Y1 OUT Y1 OUT 24 VAC Common Output

HS-PS HS-PS High-Pressure Switch

24V 24V 24 Volt output

AMB-BLACK Ambient Sensor

COIL-BROWN Discharge Sensor

DELAY

TST, PS DF, C, R, O, Y1, Y2

RED LED

GREEN LED

TWO CONNECTORS

O OUT

LO-PS

L Line output

Defrost Temperature Termina-

tion Shunt (Jumper) Pins

24VAC Thermostat Input /

Delay Mode

Factory Test Connectors

Diagnostic LED

Condenser Fan Operation

24 VAC output

Low-Pressure Switch

See Test Mode on page 22 for further details.

The DCB as illustrated in figure 31 on page 21 has valid selections

which are: 50, 70, 90, and 100°F (10, 21,32 and 38°C), The shunt

termination pin is factory set at 50°F (10°C). If the temperature

shunt is not installed, the default termination temperature is 90°F

(32°C).

24VAC input/output from indoor thermostat to indoor unit.

24VAC common

Thermostat service light connection,

24VAC

Controls the second stage operation of the unit,

Reversing valve solenoid.

Controls the operation of the unit,

Provides selection of the Y2 compressor lock-in temperature. Val-

id options are 40, 45, 50 and 55 degrees Fahrenheit,

(P4-5) Ground connection for outdoor coil temperature sensor.

(P4-6) Connection for outdoor coil temperature sensor.

(P4-3) Ground connection for outdoor ambient temperature sen-

sor.

(P4-4) Connection for outdoor ambient temperature sensor.

No discharge sensor is used, replaced by !OK resistor.

The DCB has a field-selectable function to reduce occasional

sounds that may occur while the unit is cycling in and out of the

defrost mode. When a jumper is installed on the DELAY pins, the

compressor will be cycled off for 30 seconds going in and out of

the defrost mode. Units are shipped with jumper installed on

DELAY pins.

NOTE - The 30 second off cycle is NOT functional when

jumperingthe TES Tpins on P1.

No field use.

Valid states for DCB's two LEDs are OFF, ON and FLASHING

which indicate diagnostics conditions that are described in table

16 on page on page 25.

These two connections provide power for the condenser fan.

24 VAC output connection for reversing valve.

When the low pressure switch trips, the DCB will cycle off the

compressor, and the strike counter in the DCB will count one

strike. The low pressure switch is ignored under the following

conditions:

• during the defrost cycle and 90 seconds after the termination

of defrost

• when the average ambient sensor temperature is below 0°F

(-18°C)

• for 90 seconds following the start up of the compressor

• during TEST mode

24 VAC output for second stage compressor solenoid.