Lennox XP14 Elite Series, Elite XP14-018, Elite XP14-024, Elite XP14-030, Elite XP14-036 Installation Instructions Manual

...

INSTALLATION

2010 Lennox Industries Inc.

Dallas, Texas, USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause personal injury,

loss of life, or damage to property.

Installation and service must be performed by a

qualified installer or service agency.

CAUTION

Physical contact with metal edges and corners

while applying excessive force or rapid motion can

result in personal injury. Be aware of, and use

caution when working near these areas during

installation or while servicing this equipment.

IMPORTANT

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFCs, HFCs, and HCFCs) as

of July 1, 1992. Approved methods of recovery,

recycling or reclaiming must be followed. Fines

and/or incarceration may be levied for

noncompliance.

IMPORTANT

This unit must be matched with an indoor coil as

specified in Lennox’ Engineering Handbook.

Coils previously charged with HCFC−22 must be

flushed.

INSTRUCTIONS

XP14 Elite® Series Units

HEAT PUMP UNITS

505,244M

03/10

Supersedes 10/09

Table of Contents

XP14 Outdoor Unit 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping and Packing List 1. . . . . . . . . . . . . . . . . . . . . .

Unit Dimensions and Parts Arrangement 2. . . . . . . . .

General Information 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Unit 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing Panels 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigerant Piping 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing Existing Line Set and Indoor Coil 10. . . . . . . .

Refrigerant Metering Device 11. . . . . . . . . . . . . . . . . . . .

Manifold Gauge Set 12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Valves 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leak Testing 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Evacuation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start−Up 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigerant Charge 14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Indoor Airflow before Charging 14. . . . . . . . . . . .

Setup for Checking and Adding Charge 15. . . . . . . . . .

Weigh in Charge 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subcooling Charge 15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defrost System 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Information 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-up and Performance Checklist 26. . . . . . . . . . . . . .

XP14 Outdoor Unit

The XP14 outdoor unit uses HFC−410A HFC refrigerant.

This unit must be installed with a matching indoor blower

coil and line set as outlined in the Lennox Engineering

Handbook. Elite® Series XP14 outdoor units are designed

for use in check expansion valve (CTXV) systems only and

are not to be used with other refrigerant flow control

devices. An expansion valve approved for use with

HFC−410A must be ordered separately and installed prior

to operating the unit.

Shipping and Packing List

1 − Assembled XP14 outdoor unit

Check the unit components for shipping damage. If you

find any damage, immediately contact the last carrier.

Litho U.S.A.

03/10 505,244M

*2P0310* *P505244M*

Page 1

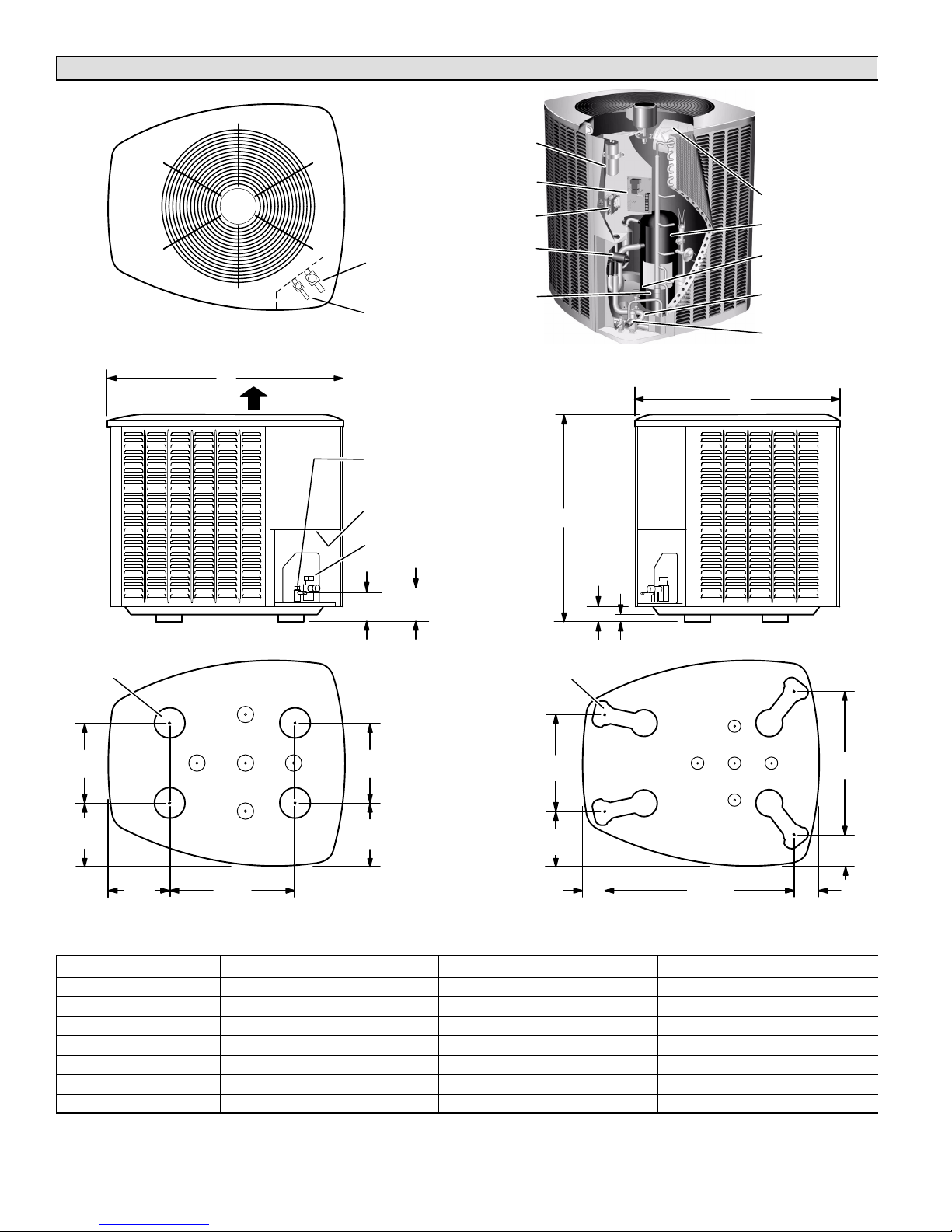

Unit Dimensions − Inches (mm) and Parts Arrangement

RUN

CAPACITOR

DEFROST

BOARD

CONTACTOR

REVERSING

VALV E

FILTER DRIER/

LIQUID LINE

CONNECTIONS

TOP VIEW

C

DISCHARGE AIR

SUCTION LINE

CONNECTION

LIQUID LINE

CONNECTION

LIQUID LINE

CONNECTION

ELECTRICAL

INLETS

VAPOR LINE

CONNECTION

108)

4−3/4

(121)

4−1/4(

PARTS ARRANGEMENT

A

2 (51)

OUTDOOR FAN

COMPRESSOR

HIGH PRESSURE

SWITCH

VAPOR LINE

VAPOR VALVE AND

GAUGE PORT/SUCTION

LINE CONNECTIONS

B

SIDE VIEW

UNIT SUPPORT

FEET

8−1/2

(216)

8−3/4

(222)

5−1/2

(140)

13−1/2

(343)

XP14−018 TO −030 BASE SECTION

9−1/2

(241)

8−1/4

(210)

UNIT SUPPORT

FEET

16−7/8

(429)

8−3/4

(222)

3−1/8

(79)

1 (25)

XP14−036 TO −060 BASE WITH

ELONGATED LEGS

Model No. A B C

XP14−018 31 (787) 27 (686) 28 (711)

XP14−024 31 (787) 27 (686) 28 (711)

XP14−030 35 (889) 27 (686) 28 (711)

XP14−036 31 (787) 35 1/2 (902) 39 1/2 (1003)

XP14−042 39 (991) 35 1/2 (902) 39 1/2 (1003)

XP14−048 39 (991) 35 1/2 (902) 39 1/2 (1003)

XP14−060 45 (1143) 35 1/2 (902) 39 1/2 (1003)

SIDE VIEW

30−3/4

(781)

26−7/8

(683)

3−3/4

(95)

4−5/8

(117)

505244M 10/09

Page 2

WARNING

Product contains fiberglass wool.

Disturbing the insulation of this product during

installation, maintenance, or repair will expose you

to fiberglass wool. Breathing this may cause lung

cancer. (Fiberglass wool is know to the State of

California to cause cancer.) Fiberglass wool may

also cause respiratory, skin and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address show below, or contact your

supervisor.

Lennox Industries Inc., PO Box 79011, Dallas, TX

75379−9011

General Information

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened. Table 1 shows

torque values for fasteners.

Table 1. Torque Requirements

Part Recommended Torque

Service valve cap 8 ft.− lb. 11 NM

Sheet metal screws 16 in.− lb. 2 NM

Machine screws #8 16 in.− lb. 2 NM

Compressor bolts 90 in.− lb. 10 NM

Gauge port seal cap 8 ft.− lb. 11 NM

4. Locate the unit so prevailing winter winds will not blow

into the coil.

5. Locate unit away from overhanging roof lines which

would allow water or ice to drop on, or in front of, coil

or into unit.

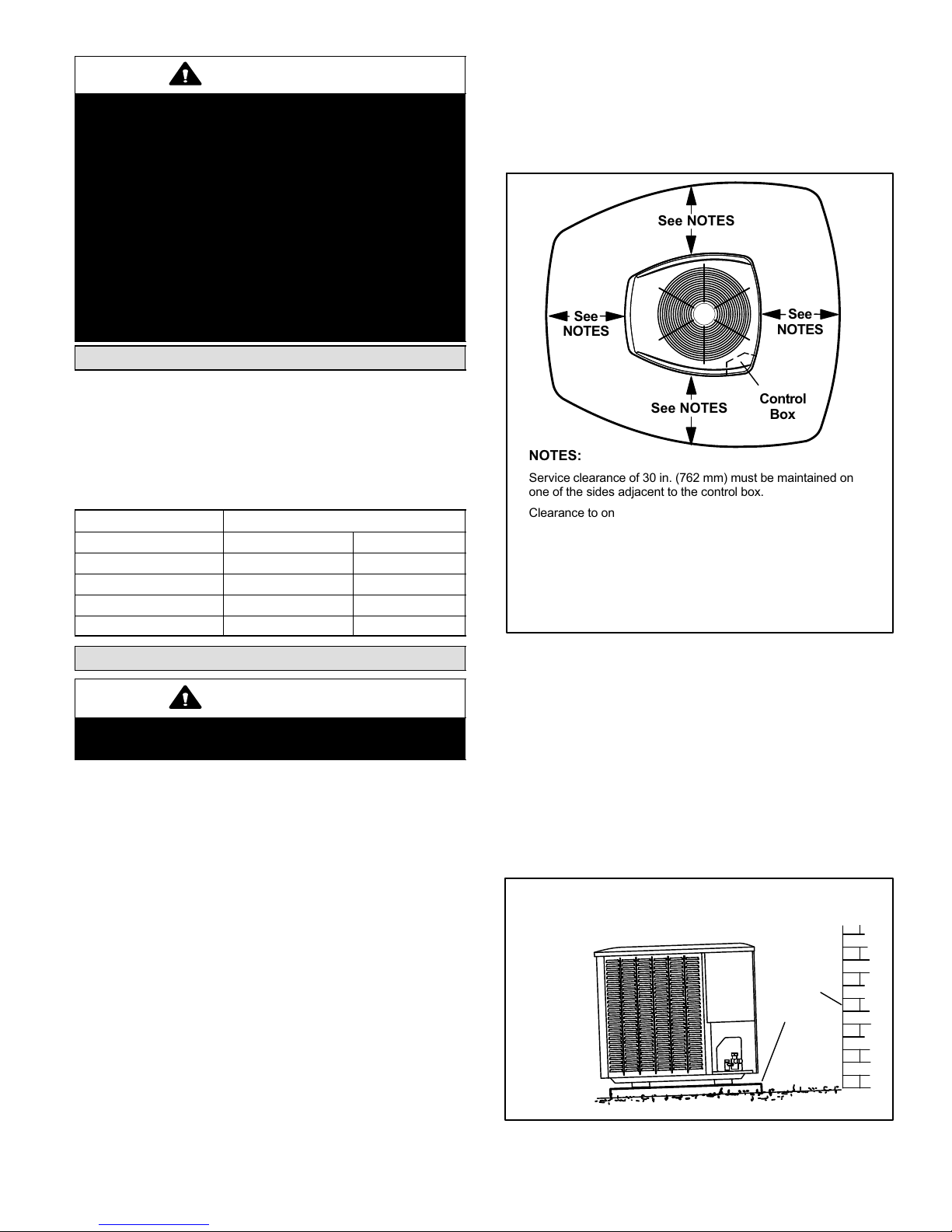

See NOTES

See

NOTES

See NOTES

NOTES:

Service clearance of 30 in. (762 mm) must be maintained on

one of the sides adjacent to the control box.

Clearance to one of the other three sides must be 36 in. (914

mm)

Clearance to one of the remaining two sides may be 12 in. (305

mm) and the final side may be 6 in. (152 mm).

A clearance of 24 in. (610 mm) must be maintained between

two units.

48 in. (1219 mm) clearance required on top of unit.

See

NOTES

Control

Box

Setting the Unit

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

Outdoor units operate under a wide range of weather

conditions; therefore, several factors must be considered

when positioning the outdoor unit.

Position the unit to allow adequate airflow and servicing

clearance. Maintain a minimum clearance of 24 inches

(610 mm) between multiple units as illustrated in figure 1

for installation clearances.

1. Place a sound-absorbing material, such as Isomode,

under the unit if it will be installed in a location or

position that will transmit sound or vibration to the

living area or adjacent buildings.

2. Install the unit high enough above ground or roof to

allow adequate drainage of defrost water and prevent

ice build-up.

3. In heavy snow areas, do not locate unit the where

snowdrifts will likely build. The unit base should be

elevated above the depth of average snows.

NOTE - Elevation of the unit may be accomplished by

constructing a frame using suitable materials. If a

support frame is constructed, it must not block drain

holes in unit base.

Figure 1. Installation Clearances

SLAB MOUNTING

When installing unit at grade level, the top of the slab

should be high enough above grade so that water from

higher ground will not collect around the unit. The slab

should have a slope tolerance away from the building of 2

degrees or 2 inches per 5 feet (50 mm per 1500 mm) to

prevent ice build-up under the unit during a defrost cycle.

NOTE − If necessary for stability, anchor unit to slab as

described in Stabilizing Unit on Uneven Surfaces on page

4.

INSTALL UNIT LEVEL OR, IF ON A SLOPE, MAINTAIN SLOPE

TOLERANCE OF 2 DEGREES (OR 2 INCHES PER 5 FEET

[50 MM PER 1.5 M]) AWAY FROM BUILDING STRUCTURE.

BUILDING

STRUCTURE

MOUNTING

SLAB

GROUND LEVEL

Figure 2. Slab Mounting Options

Page 3

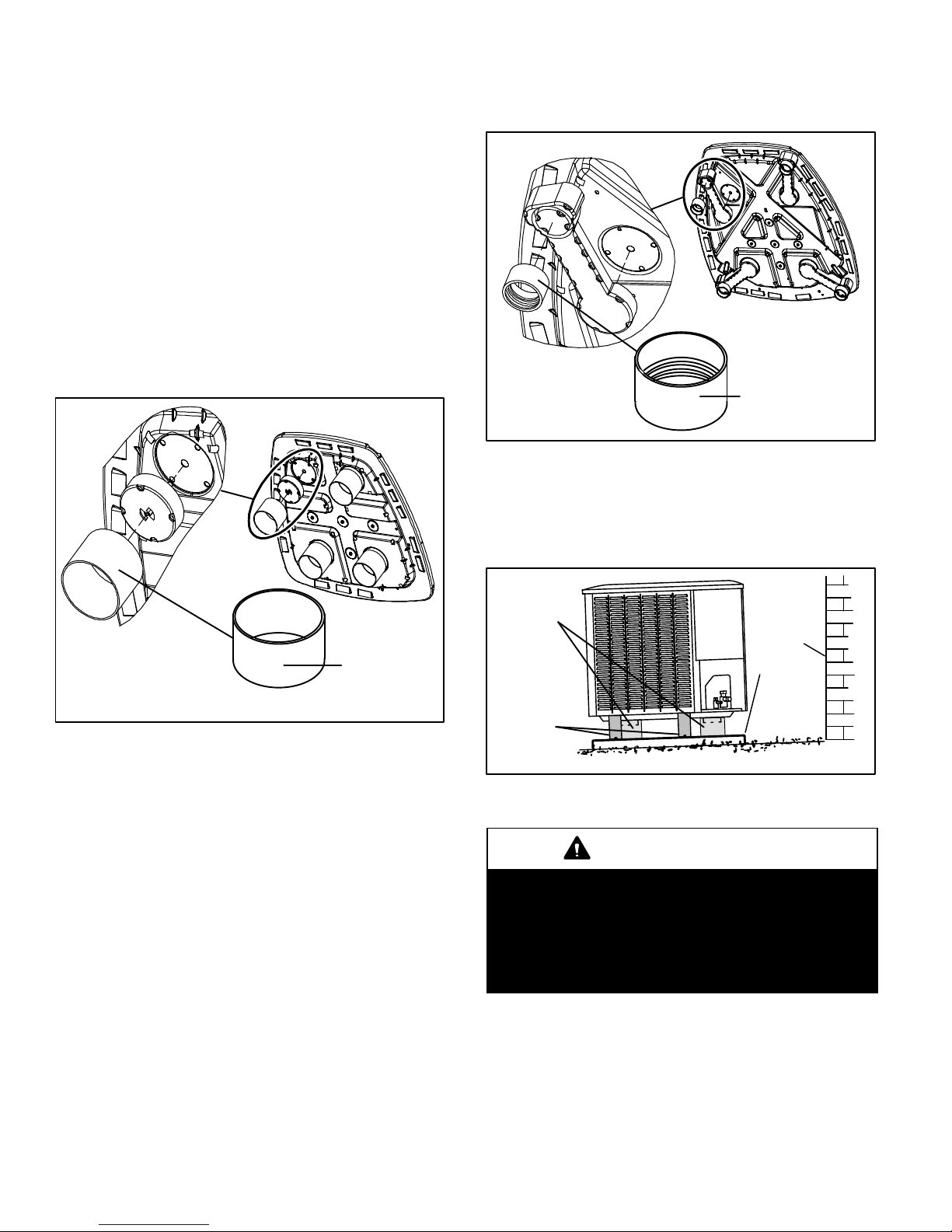

XP14 SERIES

ELEVATING THE UNIT (SMALL−BASE UNITS)

If additional elevation is necessary, raise the unit by

extending the length of the unit support feet. This may be

done by cutting four equal true−cut lengths of Schedule

(SCH) 40, 4" (101.6mm) piping to the height required as

illustrated in figure 3.

NOTE − Keep the height of extenders short enough to

ensure a sturdy installation. If it is necessary to extend

further, consider a different type of field−fabricated

framework that is sturdy enough for greater heights.

The inside diameter of the 4" (101.6mm) piping is

approximately 0.25" (6.35mm) greater than the

pre−installed feet on the unit. Devise a shim that will take up

the space and hold the extenders onto the feet during this

procedure. Small strips of 0.125" (3.175mm) thick

adhesive foam may be used. One or two small 1"

(25.4mm) square strips should be adequate to hold the

extender in place.

Base

NOTE − Keep the height of extenders short enough to

ensure a sturdy installation. If it is necessary to extend

further, consider a different type of field−fabricated

framework that is sturdy enough for greater heights.

Base

Leg Detail

2" (50.8mm)

SCH 40

Female Threaded

Adapter

Figure 4. Elevated Slab Mounting using Feet

Extenders (Larger Base Units)

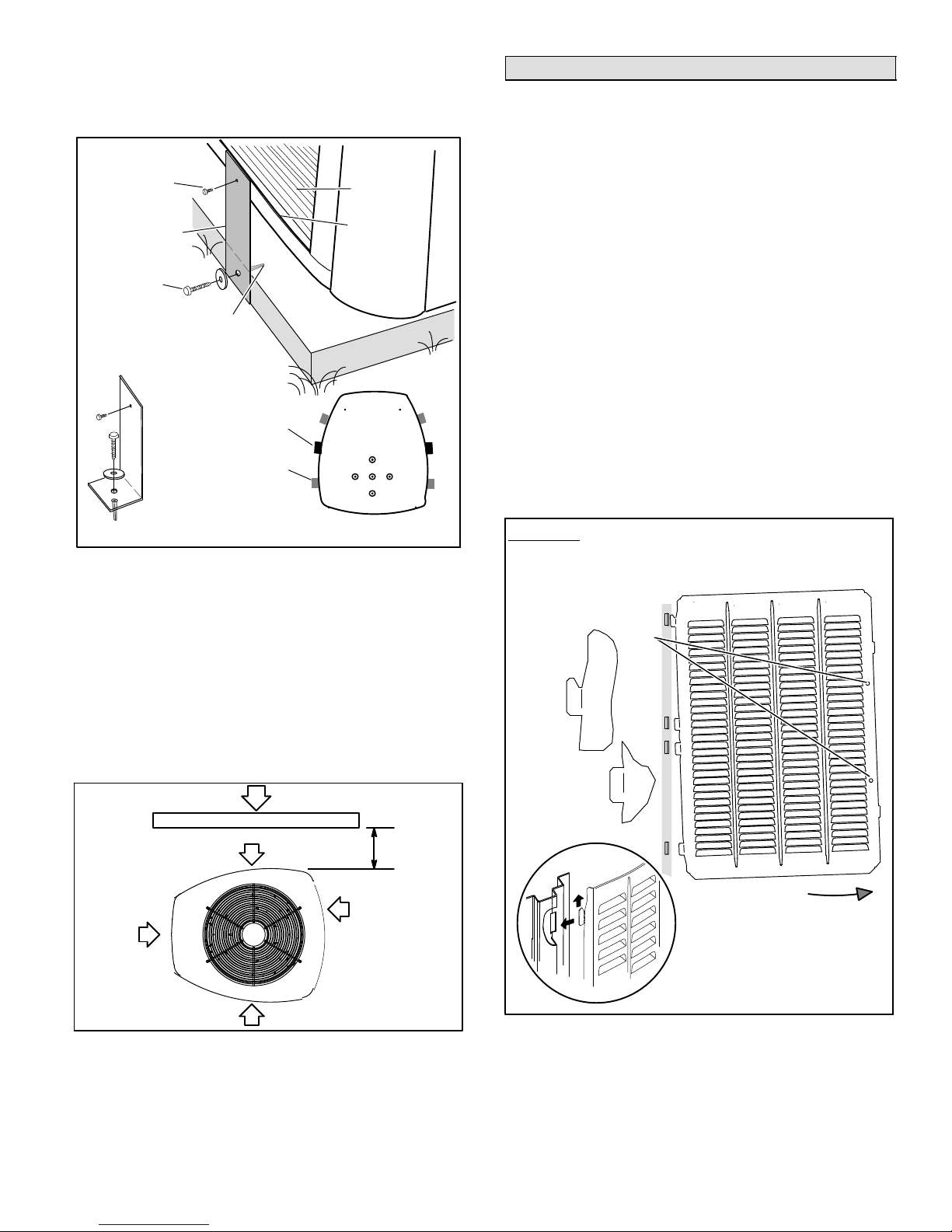

STABILIZING UNIT ON UNEVEN SURFACES

To help stabilize an outdoor unit, some installations may

require strapping the unit to the pad using brackets and

anchors commonly available in the marketplace.

Leg Detail

4" (101.6mm)

SCH 40 Piping

Figure 3. Elevated Slab Mounting using Feet

Extenders (Small Base Units)

ELEVATING THE UNIT (LARGER−BASE UNITS)

Unlike the small−base units which use round feet, the

larger−base units are outfitted with elongated feet as

illustrated in figure 4. which uses a similar method for

elevating the unit height.

If additional elevation is necessary, raise the unit by

extending the length of the unit support feet. This may be

done with 2" SCH 40 female threaded adapter. The

specified coupling will fit snuggly into the recess portion of

the feet. Use additional 2" SCH 40 male threaded adaptors

which can be threaded into the female threaded adaptors

to make additional adjustments to the level of the unit.

TYPICAL

INSTALLATION

WITH 3 TO 4 IN.

EXTENDERS

INSTALLED

IMPORTANT!

ALWAYS USE

STABILIZER

BRACKET ON

ELEVATED

INSTALLATIONS

STABILIZER

BRACKETS

GROUND LEVEL

BUILDING

STRUCTURE

MOUNTING

SLAB

Figure 5. Elevated Slab Mounting using Feet

Extenders

IMPORTANT

Unit Stabilizer Bracket Use (field−provided):

Always use stabilizers when unit is raised above the

factory height. (Elevated units could become

unstable in gusty wind conditions).

Stabilizers may be used on factory height units

when mounted on unstable or uneven surface.

505244M 10/09

Page 4

With unit positioned at installation site, remove two side

louvered panels to expose the unit base pan.

Install the

brackets as illustrated in figure 6 using conventional

practices; replace the panels after installation is complete.

#10 1/2" LONG

SELF−DRILLING SHEET

METAL SCREWS

STABILIZING BRACKET

(18 GAUGE METAL − 2"

WIDTH; HEIGHT AS

REQ’D)

#10 1−1/4" LONG HEX

HD SCREW &

FLATWASHER

PLASTIC ANCHOR − USE IF CONCRETE

(HOLE DRILL 1/4"); NOT IF PLASTIC SLAB

(HOLE DRILL 1/8").

Deck Top

Mounting

STABILIZING

BRACKET (18

GAUGE METAL − 2"

WIDTH; HEIGHT

AS REQ’D); BEND

TO FORM RIGHT

ANGLE

MINIMUM 1

PER SIDE

FOR EXTRA

STABILITY

COIL

BASE PAN

CORNER POST

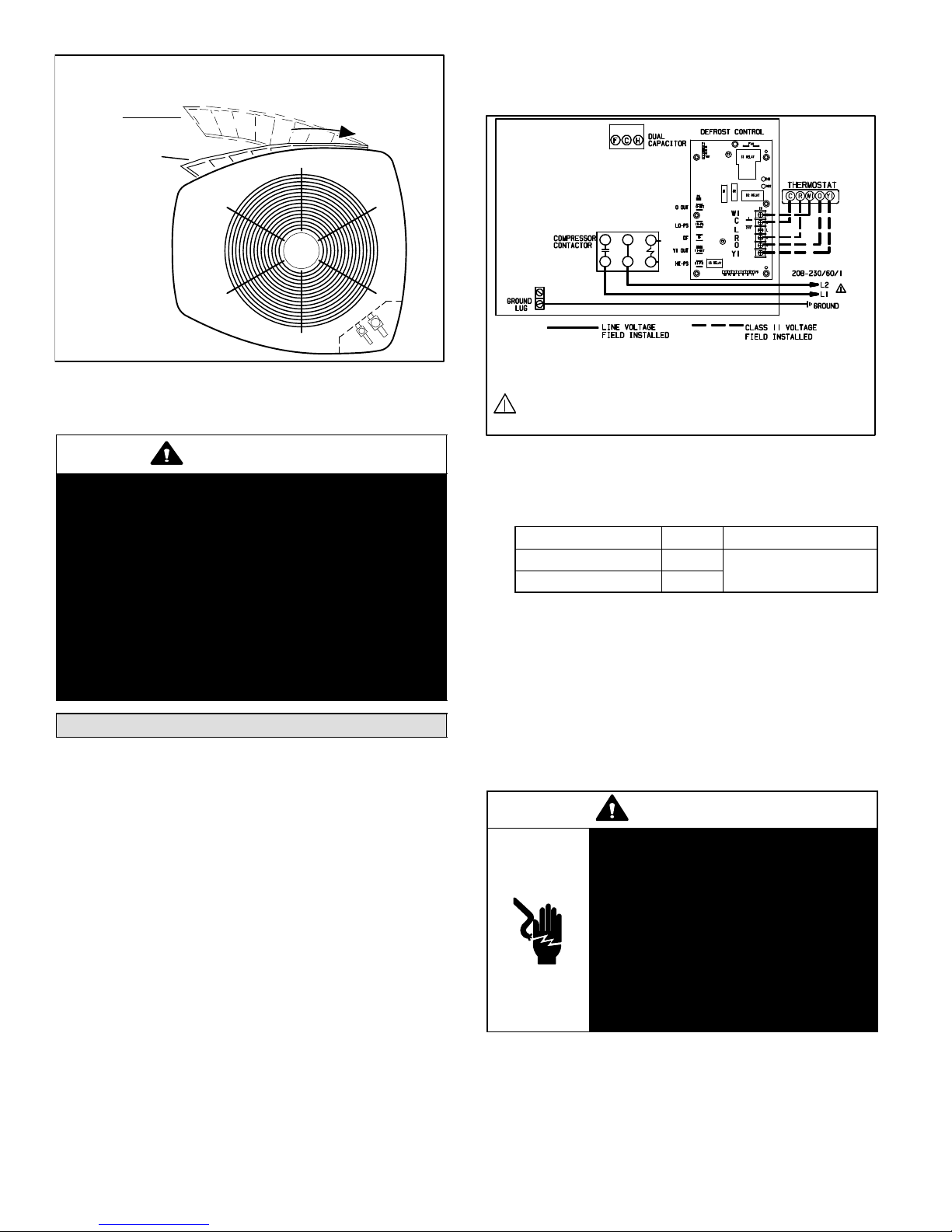

Removing Panels

Remove the louvered panels as follows:

1. Remove two screws, allowing the panel to swing open

slightly as illustrated in figure 8.

2. Hold the panel firmly throughout this procedure.

Rotate bottom corner of panel away from hinge corner

post until lower three tabs clear the slots as illustrated

figure 8, Detail B .

3. Move panel down until lip of upper tab clears the top

slot in corner post as illustrated in figure 8, Detail A.

Position and Install PanelPosition the panel almost

parallel with the unit as illustrated in figure 9, Detail D on

page 6 with the screw side as close to the unit as possible.

Then, in a continuous motion:

slightly rotate and guide the lip of top tab inward as

illustrated in figure 8, Details A and C; then upward into

the top slot of the hinge corner post.

rotate panel to vertical to fully engage all tabs.

holding the panel’s hinged side firmly in place, close

the right−hand side of the panel, aligning the screw

holes.

When panel is correctly positioned and aligned, insert the

screws and tighten.

ONE BRACKET PER SIDE (MIN.); FOR EXTRA STABILITY,

2 BRACKETS PER SIDE, 2" FROM EACH CORNER.

Figure 6. Installing Stabilizer Brackets

(Slab Side Mounting)

ROOF MOUNTING

Install unit 6" (152 mm) above the roof surface to avoid ice

build−up around the unit. Locate the unit above a load

bearing wall or area of the roof that can adequately support

the unit. Consult local codes for rooftop applications.

If unit cannot be located away from prevailing winter winds,

construct a wind barrier sized at least the same height and

width as outdoor unit. Position barrier 24" (610 mm) from

the sides of the unit in direction of prevailing winds as

illustrated in figure 7.

prevailing winter winds

wind barrier

24"

inlet air

inlet air

(610 mm)

inlet air

IMPORTANT! Do not allow panels to hang on unit by top tab. Tab

is for alignment and not designed to support weight of panel.

Panel shown slightly rotated to allow top tab to exit (or enter) top

slot for removing (or installing) panel.

SCREW

HOLES

LIP

Detail

A

Detail

B

ROTATE IN THIS DIRECTION;

THEN DOWN TO REMOVE PANEL

inlet air

Figure 7. Rooftop Application with Wind Barrier

Detail C

Figure 8. Removing/Installing Louvered Panels

(Details A, B and C)

Page 5

XP14 SERIES

MAINTAIN MINIMUM PANEL ANGLE (AS CLOSE TO PARALLEL WITH THE UNIT

AS POSSIBLE) WHILE INSTALLING PANEL.

ANGLE MAY BE TOO

EXTREME

PREFERRED ANGLE

FOR INSTALLATION

HOLD DOOR FIRMLY TO THE HINGED

SIDE TO MAINTAIN

FULLY−ENGAGED TABS

Detail D

Figure 9. Removing/Installing Louvered Panels

(Detail D)

4. Units are approved for use only with copper

conductors. (A complete unit wiring diagram is

located inside the unit control box cover.)

WARNING! − ELECTRIC SHOCK HAZARD. Can cause INJURY or DEATH. Unit must be grounded in accordance with

national and local codes.

NOTE − For use with copper conductors only. Refer to unit

rating plate for minimum circuit ampacity and maximum overcurrent protection size.

CAUTION

To prevent personal injury, or damage to panels,

unit or structure, be sure to observe the following:

While installing or servicing this unit, carefully stow

all removed panels out of the way, so that the panels

will not cause injury to personnel, nor cause

damage to objects or structures nearby, nor will the

panels be subjected to damage (e.g., being bent or

scratched).

While handling or stowing the panels, consider any

weather conditions, especially windy conditions,

that may cause panels to be blown around and

battered.

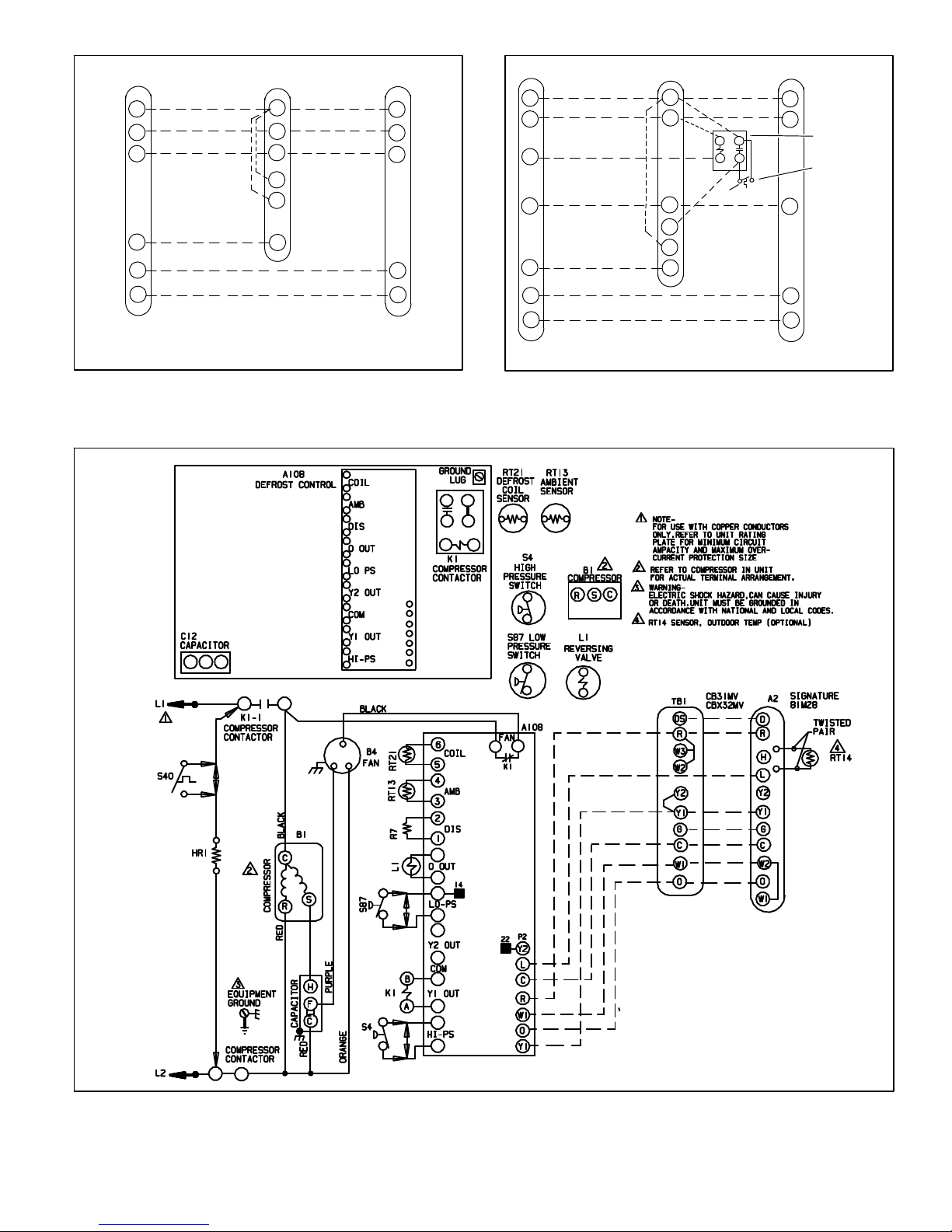

Electrical

In the U.S.A., wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada,

wiring must conform with current local codes and the current

Canadian Electrical Code (CEC).

Refer to the furnace or blower coil installation instructions

for additional wiring application diagrams and refer to unit

nameplate for minimum circuit ampacity and maximum

overcurrent protection size.

1. Install line voltage power supply to unit from a properly

sized unit disconnect switch.

2. Ground the unit at the unit disconnect switch or to

earth ground.

3. To facilitate conduit, a hole is provided in the bottom of

the control box. Connect conduit to the control box

using a proper conduit fitting.

Figure 10. Outdoor Unit Typical Field Wiring

NOTE − For proper voltages, select thermostat wire

gauge per the following chart:

Table 2. Wire Run Lengths

Wire run length AWG # Insulation type

less than 100’ (30m) 18

more than 100’ (30m) 16

color−coded, temperature

rating 35ºC minimum

5. Install room thermostat (ordered separately) on an

inside wall approximately in the center of the

conditioned area and 5 feet (1.5 m) from the floor. It

should not be installed on an outside wall or where it

can be affected by sunlight, drafts or vibrations.

6. Install low voltage wiring from outdoor to indoor unit

and from thermostat to indoor unit. See figures 11 and

12 on page 7.

NOTE − 24V, Class II circuit connections are made in the

low voltage junction box.)

WARNING

Electric Shock Hazard. Can cause

injury or death. Unit must be

grounded in accordance with national

and local codes.

Line voltage is present at all

components when unit is not in

operation on units with single-pole

contactors. Disconnect all remote

electric power supplies before

opening access panel. Unit may have

multiple power supplies.

505244M 10/09

Page 6

Thermostat Indoor Unit Outdoor Unit

24V power

R

common

C

1st-stage

W1

auxiliary heat

W3

indoor blower

G

reversing valve

O

compressor

Y1

(SOME CONNECTIONS MAY NOT APPLY. REFER TO SPECIFIC

THERMOSTAT AND INDOOR UNIT.)

W1

W2

R

C

G

24V power

common

1st-stage

auxiliary heat

R

C

W1

O

Y1

Thermostat Indoor Unit Outdoor Unit

24V power 24V power

R

common

C

emergency heat

E

1st-stage

W1

auxiliary heat

indoor blower

G

reversing valve

O

compressor

Y1

(SOME CONNECTIONS MAY NOT APPLY. REFER TO SPECIFIC

THERMOSTAT AND INDOOR UNIT.)

W1

W2

W3

R

common

C

1st-stage

auxiliary heat

G

R

C

W1

O

Y1

EMERGENCY

HEAT RELAY

OUTDOOR

THERMOSTAT

Figure 11. Outdoor Unit and Blower Unit Thermostat

Designations

Figure 12. Outdoor Unit and Blower Unit Thermostat

Designations (with Emergency Heat Relay)

Figure 13. Typical XP14 Wiring

Page 7

XP14 SERIES

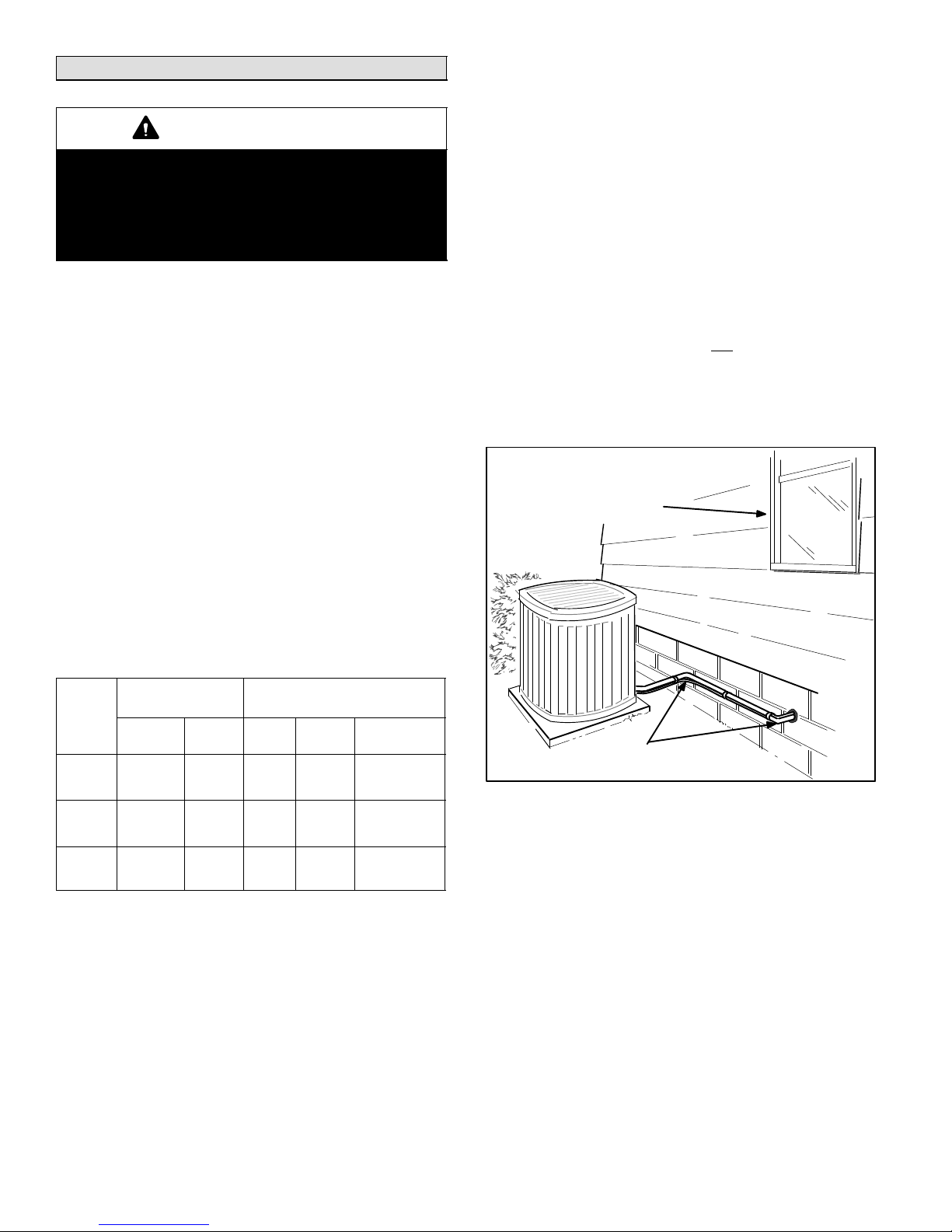

Refrigerant Piping

IMPORTANT

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFC’s, HFC’s, and HCFC’s)

as of July 1, 1992. Approved methods of recovery,

recycling or reclaiming must be followed. Fines

and/or incarceration may be levied for

noncompliance.

If the XP14 unit is being installed with a new indoor coil and

line set, the plumbing connections should be made as

outlined in this section. If an existing line set and/or indoor

coil is going to be used to complete the XP14 system, refer

to the following section that includes flushing procedures.

Field refrigerant piping consists of liquid and vapor lines

from the outdoor unit (sweat connections) to the indoor coil

(flare or sweat connections). Use Lennox L15 (sweat,

non-flare) series line sets as shown in table 3 or use

field-fabricated refrigerant lines. Refer to Refrigerant

Piping Guide (Corp. 9351−L9) for proper size, type, and

application of field−fabricated lines. Valve sizes are also

listed in table 3.

REFRIGERANT LINE CONNECTIONS − XP14

OUTDOOR UNIT MATCHED WITH NEW INDOOR

COIL AND LINE SET

If replacing an existing coil equipped with a liquid line

functioning as a metering orifice, replace the liquid line

prior to installing the XP14 unit. Line sets are described in

table 3.

Table 3. Refrigerant Line Sets

Valve Field

Model

−018

−024

−030

−036

−042

−048

−060

Connections

Liquid

Line

3/8 in.

(10 mm)

3/8 in.

(10 mm)

3/8 in.

(10 mm)

Vapor

Line

3/4 in

(19 mm)

7/8 in

(22 mm)

1−1/8 in.

(29 mm)

NOTE − When installing refrigerant lines, refer to Lennox

Refrigerant Piping Guide (Corp. 9351−L9) or Lennox

Technical Support Department Product Applications

Group for assistance. In addition, be sure to consider the

following points:

Recommended Line Set

Liquid

Line

3/8 in.

(10

mm)

3/8 in.

(10

mm)

3/8 in.

(10

mm)

Vapor

Line

3/4 in

(19 mm)

7/8 in

(22 mm)

1−1/8 in.

(29 mm)

L15

Line Sets

L15−41

15 ft. − 50 ft.

(4.6 m − 15 m)

L15−65

15 ft. − 50 ft.

(4.6 m − 15 m)

Field

Fabricated

Select line set diameters from table 3 to ensure that oil

returns to the compressor.

Units are designed for line sets of up to 50 feet (15 m);

for longer line sets, consult piping guidelines.

Size vertical vapor riser to maintain minimum velocity

at minimum capacity.

INSTALLING REFRIGERANT LINE

Pay close attention to line set isolation during installation of

any heat pump or a/c system. When properly isolated from

building structures (walls, ceilings. floors), the refrigerant

lines will not create unnecessary vibration and subsequent

noises. Also, consider the following when placing and

installing a high−efficiency outdoor unit:

1. PlacementSome localities are adopting sound

ordinances based on the unit’s noise level observed

from the adjacent property, not from the installation

property. Install the unit as far as possible from the

property line. When possible, do not install the unit

directly outside a window. Glass has a very high level

of sound transmission. Figure 14 shows how to place

the outdoor unit and line set.

Install unit

away from

windows

Two 90° elbows installed in line set

will reduce line set vibration.

Figure 14. Outside Unit Placement

2. Line Set IsolationThe following illustrations

demonstrate procedures which ensure proper

refrigerant line set isolation.

Figure 15 on page 9 shows how to install line sets

on horizontal runs.

Figure 16 on page 9 shows how to install line sets

on vertical runs.

Figure 17 on page 9 shows how to make a

transition from horizontal to vertical

505244M 10/09

Page 8

Loading...

Loading...