Lennox XC20-036-230-01, XC20-060-230-01, XC20-024-230-01, XC20-048-230-01 Installation And Service Procedure

Page 1

INSTALLATION AND SERVICE

PROCEDURE

Service Literature

Elite Series

Corp. 1407-L10

August 25, 2015

IMPORTANT

XC20 units have refrigerant piping requirements that are

unique to this unit. Size and install the refrigerant piping

per table 2 (page 14) to ensure proper unit operation.

IMPORTANT:

Before applying any power (main or low voltage) to the outdoor

unit, confirm that the iComfort Wi-Fi® or iComfort® S30

thermostat has software Version 2.1 or higher installed.

(Reference the iComfort Wi-Fi® or iComfort® S30 thermostat

manual.)

This unit is an integral component of a system that requires an

iComfort Wi-Fi

iComfort

XC20

®

®

or iComfort® S30 thermostat and

-enabled air handler or furnace.

iComfort Wi-Fi

thermostat

iComfort

®

thermostat

S30

iComfort

air handler or

furnace

®

®

-enabled

XC20

®

XC20 Units

TABLE OF CONTENTS

I. OVERVIEW

Model Number Identification 2....................

Typical Serial Number Identification 2..............

Specifications 2.................................

Electrical Data 3................................

Unit Dimensions 4..............................

Typical Unit Parts Arrangement 5.................

Operating Service Valves 7.......................

General 7.....................................

II. INSTALLATION

Unit Placement 9...............................

Removing and Installing Panels 12.................

New or Replacement Line Set 13..................

Brazing Connections 16...........................

Flushing the System 19...........................

Leak Testing the System 21.......................

Evacuating the System 21.........................

Electrical 24.....................................

Servicing Unit Delivered Void of Charge 29..........

Unit Start-Up 29.................................

III. SYSTEM OPERATION AND SERVICE

7-Segment Alert and System Status Codes 30.......

Outdoor Control Push-Button Operation 38..........

Configuring Unit 42...............................

Reconfiguring Outdoor Control using iComfort Wi-Fi

iComfort

System Overview 43.............................

Maintenance 44..................................

Unit Wiring Diagrams 45..........................

Factory Wiring Diagrams 48.......................

Unit Sequence of Operations 50...................

Component Testing 53............................

System Refrigerant 75............................

Appendix - Charging Sticker ....................

®

S30 Thermostat 43.....................

®

or

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause personal injury, loss of life, or

damage to property. Installation and service must be

performed by a licensed professional installer (or

equivalent) or a service agency.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of

refrigerant (CFCs, HCFCs AND HFCs) as of July 1, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for noncompliance.

1

2015 Lennox Industries Inc.

Page 2

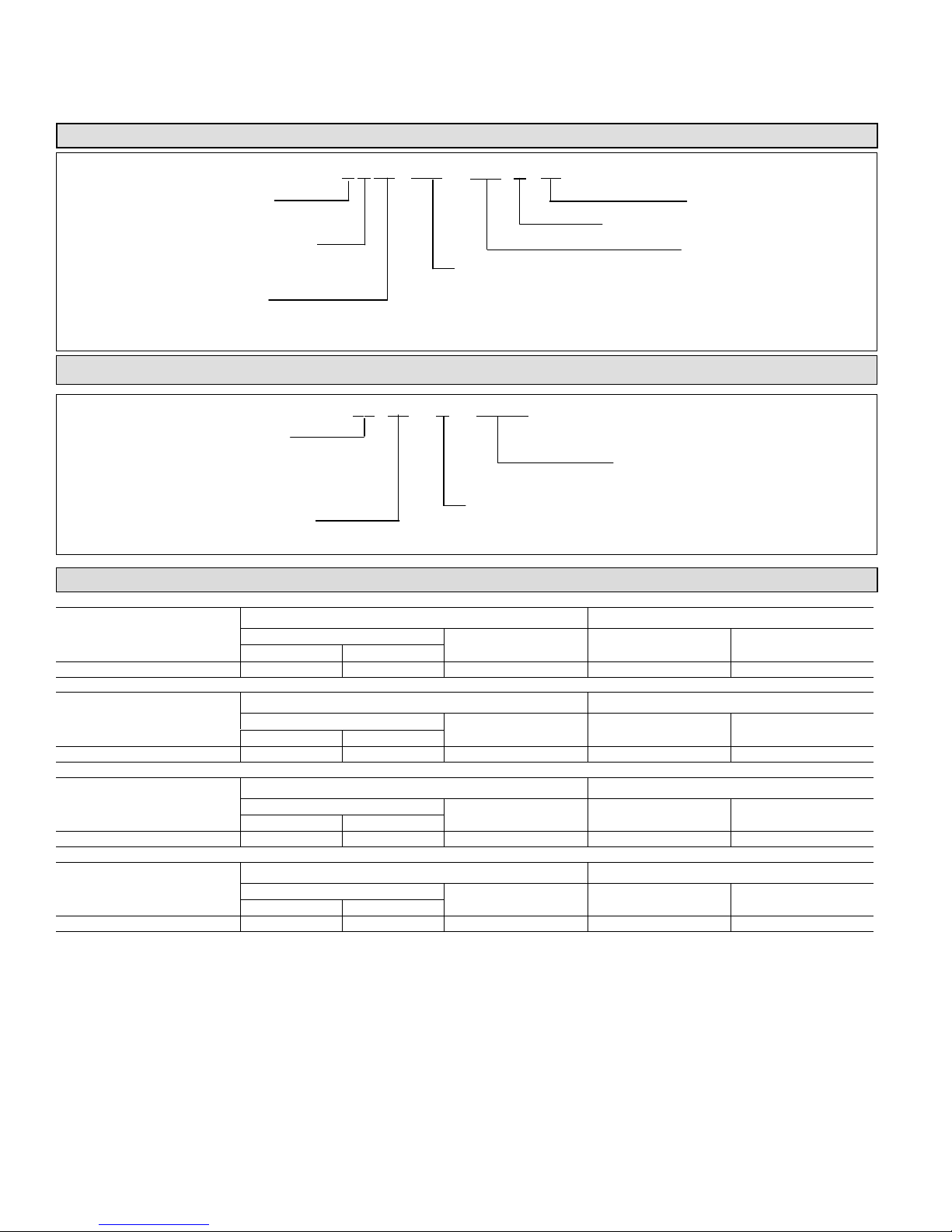

Model Number Identification

I. OVERVIEW

Refrigerant Type

X = R-410A

Unit Type

C = AIR CONDITIONER

C 20 036

X

− −

230

Nominal Cooling Capacity

A

-02

Minor Revision Number

Ratings Revision Level

Voltage

230 = 208/230V-1ph-60hz

024 = 2 tons

Series

036 = 3 tons

048 = 4 tons

060 = 5 tons

Typical Serial Number Identification

Location Code

19 = Saltillo, Mexico

58 = Marshalltown, IA

Year Code

08 = 2008

09 = 2009

10 = 2010

8 09 C

5

05716

5 (or 6) Digit Unique Number

Month Code

A = January

B = February

C = March

Specifications

Unit Outdoor Fan

Model Number

XC20-024-230-01 72 65 7 lbs, 5 oz 4 22

Sound Rating Number (dB)

Maximum Minimum

1

Factory Refrigerant

Charge

2

Number of Blades Diameter - inches.

Unit Outdoor Fan

Model Number

XC20-036-230-01 75 67 8 lbs, 6 oz 4 22

Model Number

XC20-048-230-01 77 68 10 lbs, 7 oz 4 22

Model Number

XC20-060-230-01 77 69 12 lbs, 1 oz 3 26

1

Tested according to AHRI Standard 270-2008 test conditions.

2

Factory refrigerant charge is sufficient for refrigerant line lengths up to 15 feet.

Sound Rating Number (dB)

Maximum Minimum

Sound Rating Number (dB)

Maximum Minimum

Sound Rating Number (dB)

Maximum Minimum

1

Unit Outdoor Fan

1

Unit Outdoor Fan

1

Factory Refrigerant

Factory Refrigerant

Factory Refrigerant

Charge

Charge

Charge

2

2

2

Number of Blades Diameter - inches.

Number of Blades Diameter - inches.

Number of Blades Diameter - inches.

XC20

2

Page 3

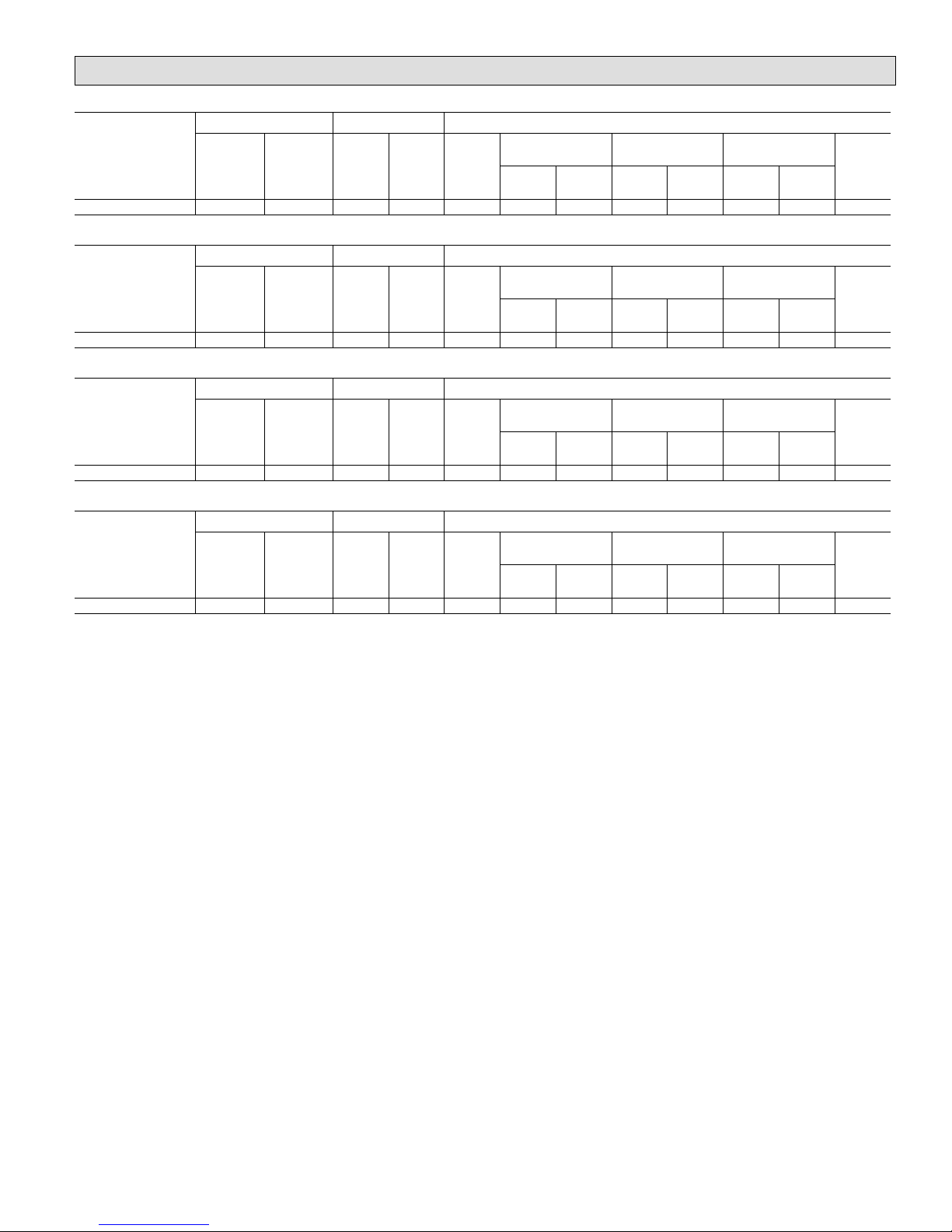

Electrical Data

208/230V-60 Hz-1 Ph

Unit Compressor Outdoor Fan (RPM varies with compressor RPM)

Model Number

Maximum

Over-

current

Protection

(amps)

1

Minimum

Circuity

Ampacity

XC20-024-230-01 30 19.1 13.0 13.0 1/6 2600 1500 700 400 60 25 2.8

Unit Compressor Outdoor Fan (RPM varies with compressor RPM)

Model Number

Maximum

Over-

current

Protection

(amps)

1

Minimum

Circuity

Ampacity

XC20-036-230-01 30 20.6 14.2 13.0 1/4 3600 3100 700 600 115 80 2.8

Unit Compressor Outdoor Fan (RPM varies with compressor RPM)

Model Number

Maximum

Over-

current

Protection

(amps)

1

Minimum

Circuity

Ampacity

XC20-048-230-01 50 29.1 21.0 20.0 1/3 4000 3000 800 600 160 70 2.8

Unit Compressor Outdoor Fan (RPM varies with compressor RPM)

Model Number

Maximum

Over-

current

Protection

(amps)

1

Minimum

Circuity

Ampacity

XC20-060-230-01 50 29.3 21.2 20.0 1/3 4325 2900 865 600 195 80 2.8

1

HACR type circuit breaker or fuse.

2

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Rated

Load

Amps

2

(RLA)

Locked

Rotor

Amps

(LRA)

Motor

HP

CFM RPM WATTS

MAX MIN MAX MIN MAX MIN

Load

Amps

(FLA)

208/230V-60 Hz-1 Ph

Rated

Load

Amps

2

(RLA)

Locked

Rotor

Amps

(LRA)

Motor

HP

CFM RPM WATTS

MAX MIN MAX MIN MAX MIN

Load

Amps

(FLA)

208/230V-60 Hz-1 Ph

Rated

Load

Amps

2

(RLA)

Locked

Rotor

Amps

(LRA)

Motor

HP

CFM RPM WATTS

MAX MIN MAX MIN MAX MIN

Load

Amps

(FLA)

208/230V-60 Hz-1 Ph

Rated

Load

Amps

2

(RLA)

Locked

Rotor

Amps

(LRA)

Motor

HP

CFM RPM WATTS

MAX MIN MAX MIN MAX MIN

Load

Amps

(FLA)

Full

Full

Full

Full

XC20

3

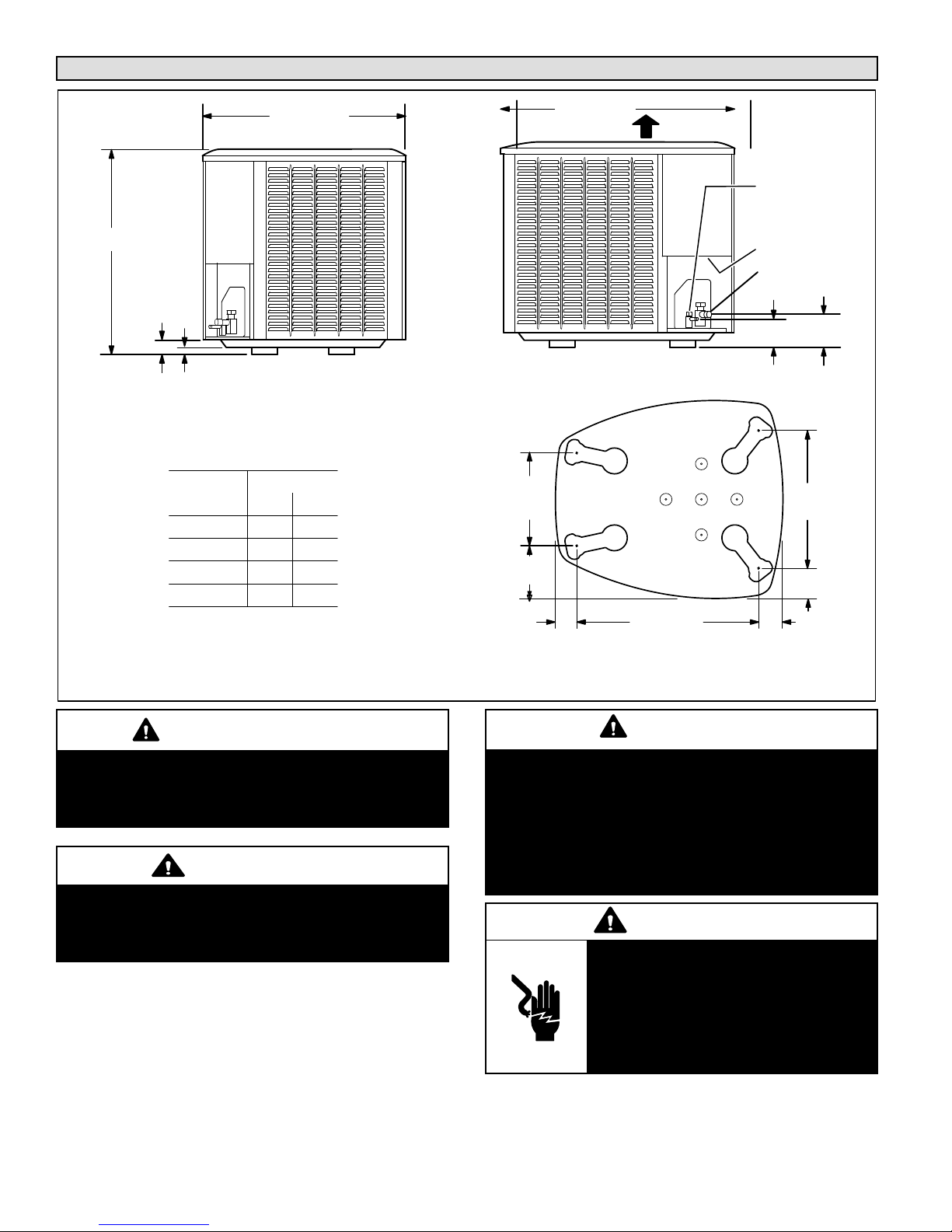

Page 4

Unit Dimensions -- Inches (mm)

35−1/2 (902)

A

2 (51)

39−3/8 (1000)

DISCHARGE AIR

LIQUID LINE

CONNECTION

ELECTRICAL

INLETS

SUCTION LINE

CONNECTION

4−1/4(108)

4−3/4

(121)

SIDE VIEW

1 (25)

Model No.

XC20−024 39 991

XC20−036 39 991

XC20−048 45 1143

XC20−060 45 1143

END VIEW

in. mm

UNIT SUPPORT

FEET

A

16−7/8

(429)

8−3/4

(222)

3−1/8

(79)

26−7/8

(683)

)3−3/4 (95

30−3/4 (781)

4−5/8

(117)

IMPORTANT

This unit must be matched with an indoor coil as

specified in Lennox Product Specification bulletin.

Coils previously charged with HCFC-22 must be

flushed.

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take care

while handling this equipment and use protective

clothing.

BASE WITH ELONGATED LEGS

WARNING

Electric Shock Hazard. Can cause injury or death. Unit

must be grounded in accordance with national and local

codes.

Line voltage is present at all components when unit is not

in operation on units with single‐pole contactors.

Disconnect all remote electric power supplies before

opening access panel. Unit may have multiple power

supplies.

WARNING

Electrical Hazard

High Voltage

Wait 5 Minutes

Electrical components may hold charge. Do

not remove this panel or service this area for

5 minutes after the power has been

removed.

XC20

4

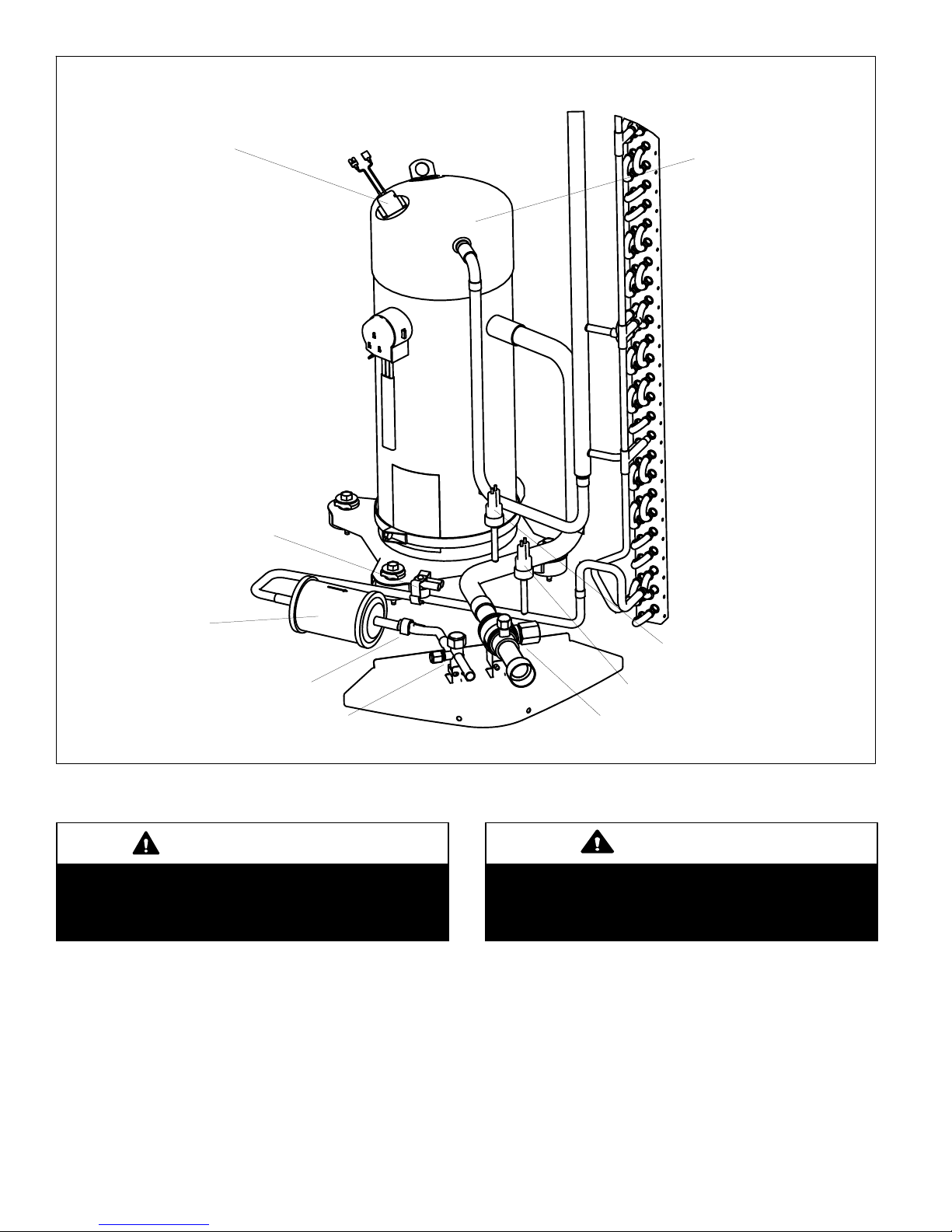

Page 5

Typical Unit Parts Arrangement

OUTDOOR

CONTROL

INVERTER REACTOR

CONTROL PANEL FOR

XC20-024 AND -036

DC INVERTER

CONTROL

GROUND LUG

CONTACTOR-SPST

OUTDOOR CONTROL

INVERTER REACTOR

CONTROL PANEL FOR

XC20-048 AND -060

DC INVERTER

CONTROL

INVERTER NOISE FILTER

GROUND LUG

CONTACTOR-SPST

Figure 1. Control Panel Components

XC20

5

Page 6

COMPRESSOR TOP CAP

SWITCH (THERMAL)

Typical Plumbing Components

COMPRESSOR

CRANKCASE HEATER THERMOSTAT

(S40) OPENS AT 70ºF, CLOSES AT 50ºF

(ONE WAY - HFC-410A)

DRIER

LIQUID LINE SENSOR

SERVICE VALVE

Figure 2. Plumbing Component Locations

IMPORTANT

This unit must be matched with an indoor coil as

specified in Lennox Product Specification bulletin.

Coils previously charged with HCFC-22 must be

flushed.

LOW PRESSURE

SWITCH

HIGH PRESSURE

SERVICE VALVE

SWITCH

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take care

while handling this equipment and use protective

clothing.

XC20

6

Page 7

WARNING

Electric Shock Hazard. Can cause injury

or death. Unit must be grounded in

accordance with national and local

codes.

Line voltage is present at all components

when unit is not in operation on units with

single‐pole contactors. Disconnect all

remote electric power supplies before

opening access panel. Unit may have

multiple power supplies.

General

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

The XC20 is a high-efficiency residential split-system air

conditioner, which features a variable-capacity scroll com

pressor and uses HFC-410A refrigerant. Units are

available in 2, 3, 4 and 5-ton sizes. The series is designed

for use with an expansion valve (approved for use with

HFC-410A) in the indoor unit only.

USING MANIFOLD GAUGE SET

When checking the system charge, only use a manifold

gauge set that features low loss anti-blow back fittings.

Manifold gauge set used with HFC-410A refrigerant sys

tems must be capable of handling higher system operating

pressures. The gauges should be rated for use with pres

sures of 0 - 800 psig on the high side and a low side of 30”

vacuum to 250 psig, with dampened speed to 500 psi.

Gauge hoses must be rated for use at or up to 800 psig of

pressure with a 4000 psig burst rating.

Table 1. Torque Requirements

Parts Recommended Torque

Service valve cap 8 ft.- lb. 11 NM

Sheet metal screws 16 in.- lb. 2 NM

Machine screws #10 28 in.- lb. 3 NM

Compressor bolts 90 in.- lb. 10 NM

Gauge port seal cap 8 ft.- lb. 11 NM

TORQUE REQUIREMENTS

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened. Table 1 lists

torque values for fasteners.

Operating Service Valves

The liquid and vapor line service valves are used for re

moving refrigerant, flushing, leak testing, evacuating,

checking charge and charging.

Each valve is equipped with a service port which has a fac

tory-installed valve stem. Figure 3 provides information on

how to access and operating both angle and ball service

valves.

IMPORTANT

Only use hex wrenches of sufficient hardness (50Rc Rockwell Harness Scale minimum). Fully insert the

wrench into the valve stem recess.

Service valve stems are factory-torqued (from 9 ft-lbs for

small valves, to 25 ft-lbs for large valves) to prevent

refrigerant loss during shipping and handling. Using a

hex wrench rated at less than 50Rc risks rounding or

breaking off the wrench, or stripping the valve stem

recess.

See the Lennox Service and Application Note #C-08-1

for further details and information.

WARNING

The State of California has determined that this product

may contain or produce a chemical or chemicals, in very

low doses, which may cause serious illness or death. It

may also cause cancer, birth defects, or reproductive

harm.

IMPORTANT

To prevent stripping of the various caps used, the

appropriately sized wrench should be used and fitted

snugly over the cap before tightening.

XC20

7

Page 8

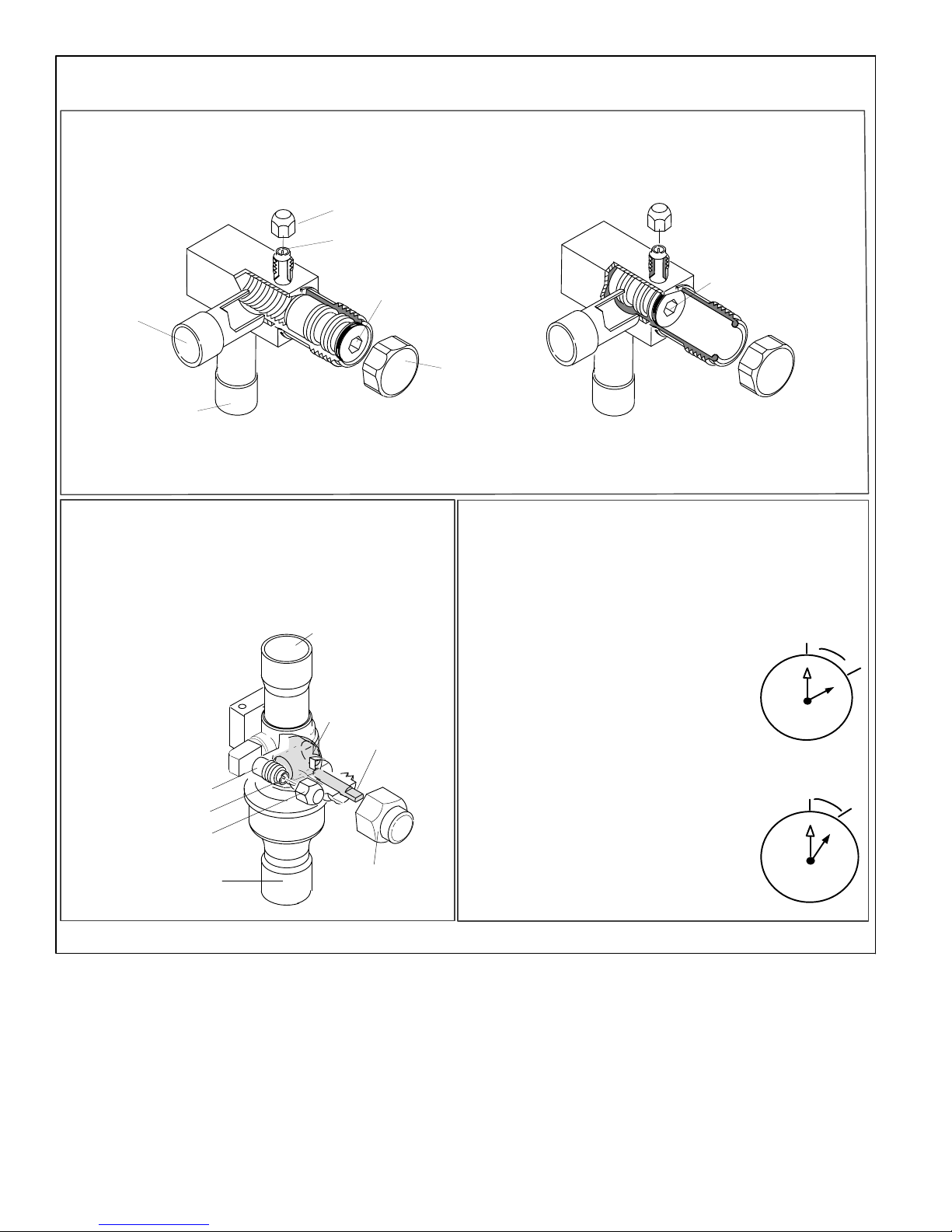

SERVICE VALVES

ANGLE AND BALL

Operating Angle–Type Service Valve:

1. Remove stem cap with an appropriately sized wrench.

2. Use a service wrench with a hex-head extension (3/16” for liquid line valve sizes and 5/16” for vapor line valve sizes) to back

the stem out counterclockwise as far as it will go.

SERVICE PORT CAP

SERVICE PORT CORE

(VALVE STEM SHOWN

CLOSED) INSERT HEX

WRENCH HERE

TO INDOOR

UNIT

(VALVE STEM SHOWN OPEN)

INSERT HEX WRENCH HERE

STEM CAP

TO OUTDOOR UNIT

ANGLE-TYPE SERVICE VALVE

(BACK-SEATED OPENED)

When service valve is OPEN, the service port is

open to line set, indoor and outdoor unit.

Operating Ball Type Service Valve:

1. Remove stem cap with an appropriately sized wrench.

2. Use an appropriately sized wrenched to open. To open valve,

rotate stem counterclockwise 90°. To close, rotate stem

clockwise 90°.

TO INDOOR UNIT

TO OPEN ROTATE STEM

COUNTERCLOCKWISE 90°.

TO CLOSE ROTATE STEM

CLOCKWISE 90°.

SERVICE PORT

SERVICE PORT

SERVICE PORT

CORE

CAP

TO OUTDOOR

UNIT

BALL (SHOWN

CLOSED)

VALV E

STEM

STEM CAP

ANGLE-TYPE SERVICE VALVE

(FRONT-SEATED CLOSED)

When service valve is CLOSED, the service port is open

to the line set and indoor unit.

To Access Service Port:

A service port cap protects the service port core from contamination and

serves as the primary leak seal.

1. Remove service port cap with an appropriately sized wrench.

2. Connect gauge set to service port.

3. When testing is completed, replace service port cap and tighten as

follows:

D With torque wrench: Finger tighten and

torque cap per table 1.

D Without torque wrench: Finger tighten and

use an appropriately sized wrench to turn

an additional 1/6 turn clockwise.

10

9

8

Reinstall Stem Cap:

Stem cap protects the valve stem from damage and serves as the

primary seal. Replace the stem cap and tighten as follows:

D With Torque Wrench: Finger tighten and then

torque cap per table 1.

D Without Torque Wrench: Finger tighten and

use an appropriately sized wrench to turn an

additional 1/12 turn clockwise.

10

9

8

11

11

7

7

12

6

12

6

1/6 TURN

1

2

4

5

1/12 TURN

1

4

5

3

2

3

NOTE - A label with specific torque requirements may be affixed to the stem cap. If the label is present, use the specified torque.

Figure 3. Angle and Ball-Type Service Valves

XC20

8

Page 9

II. INSTALLATION

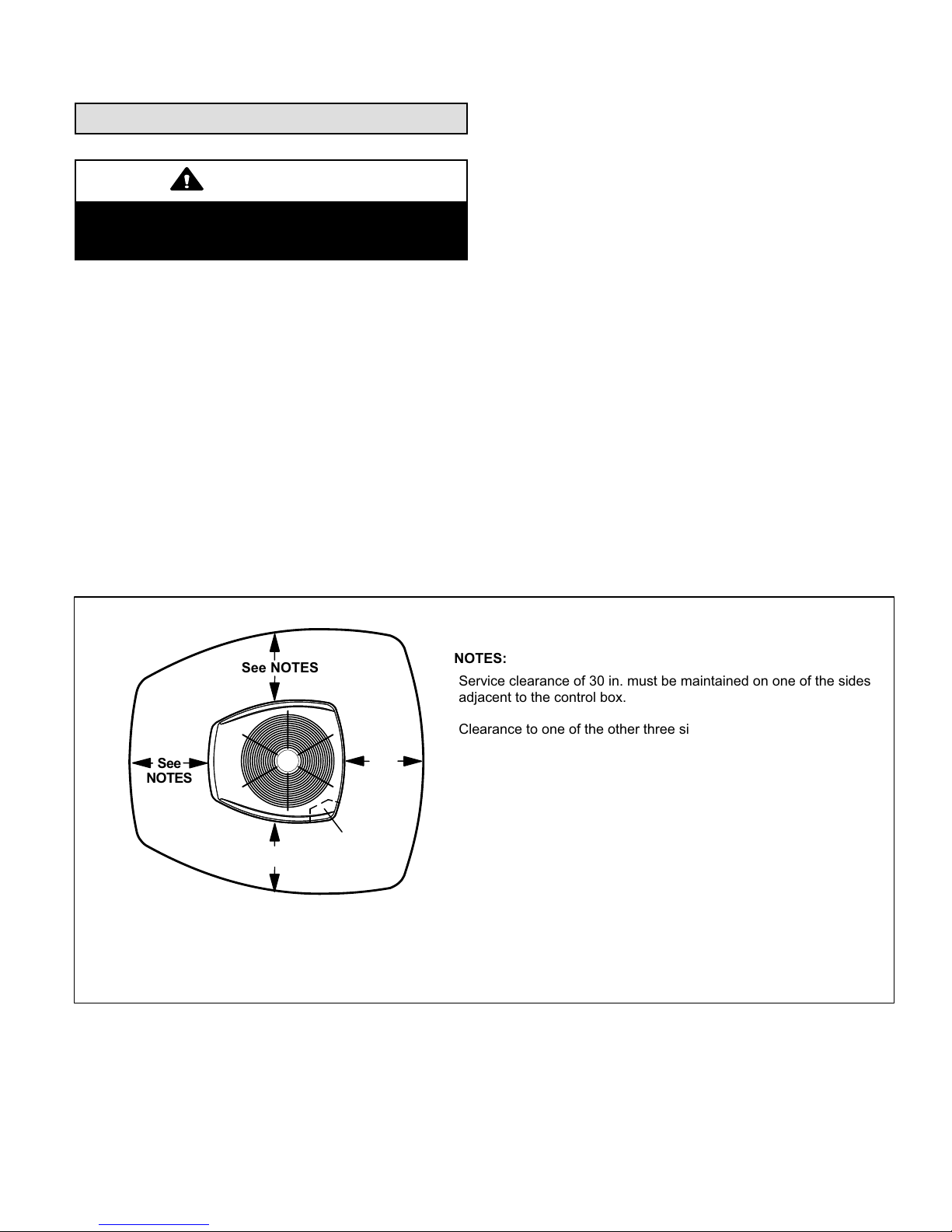

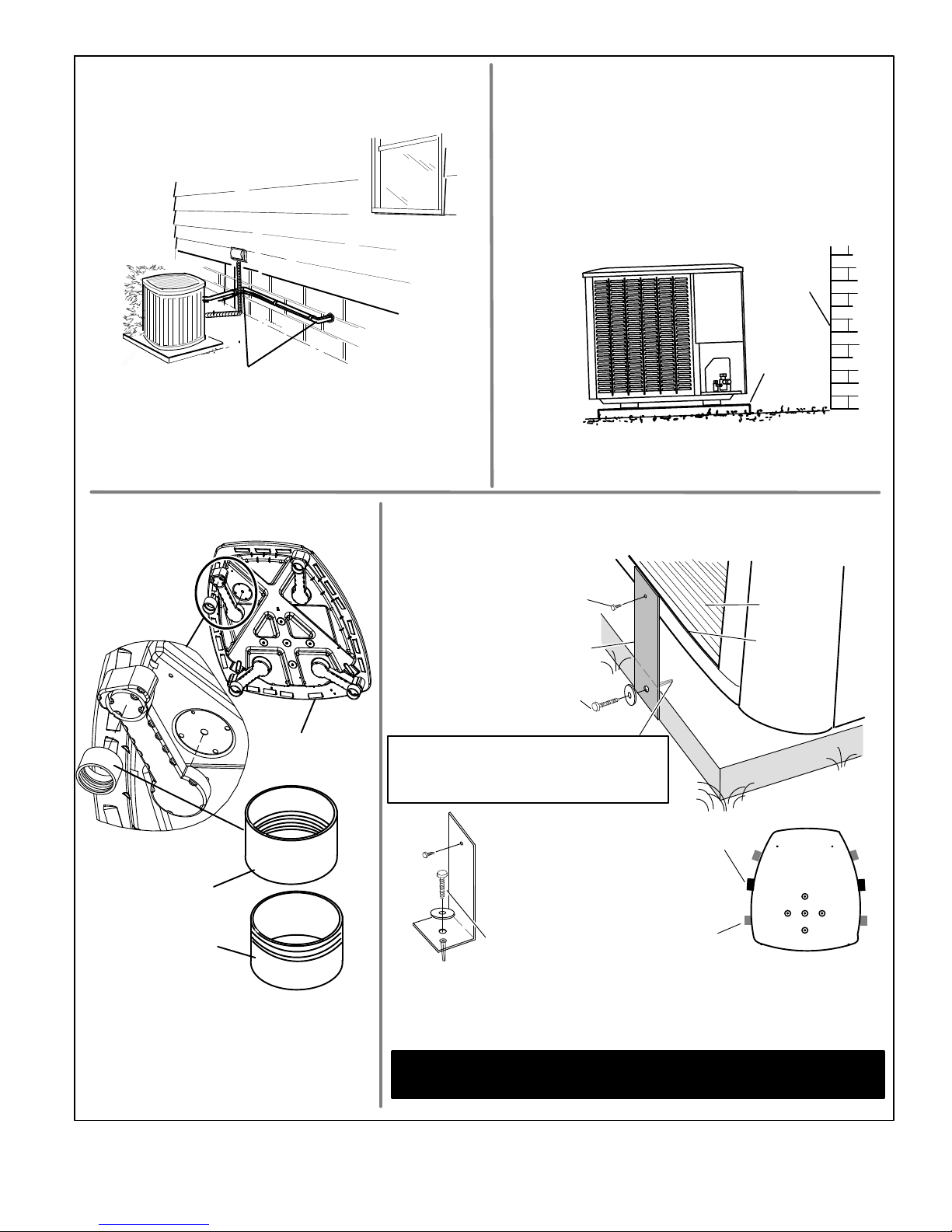

Unit Placement

CAUTION

This unit may weigh up to 320 lbs. It could take more than

two people to lift this product. Take proper precautions

when lifting heavy objects.

See Unit Dimensions on page 4 for sizing mounting slab,

platforms or supports. Refer to figure 4 for mandatory

installation clearance requirements.

POSITIONING CONSIDERATIONS

Consider the following when positioning the unit:

D Some localities are adopting sound ordinances based

on the unit sound level registered from the adjacent

property, not from the installation property. Install the

unit as far as possible from the property line.

D When possible, do not install the unit directly outside

a window. Glass has a very high level of sound trans

mission. For proper placement of unit in relation to a

window see figure 5, detail A.

PLACING UNIT ON SLAB

When installing unit at grade level, the top of the slab

should be high enough above grade so that water from

higher ground will not collect around the unit. The slab

should have a slope tolerance as described in figure 5, de

tail B.

NOTE - If necessary for stability, anchor unit to slab as de

scribed in figure 5, detail D.

ELEVATING THE UNIT

Units are outfitted with elongated support feet as illustrated

in figure 5, detail C.

If additional elevation is necessary, raise the unit by ex

tending the height of the unit support feet. Use a 2-inch

(50.8mm) Schedule 40 female threaded adapter to raise

the height of the unit.

The specified coupling will fit snugly into the recessed por

tion of the feet. Use additional 2-inch (50.8mm) Schedule

40 male threaded adaptors which can be threaded into the

female threaded adaptors to make additional adjustments

to the level of the unit.

NOTE - Keep the height of extenders short enough to en

sure a sturdy installation. If it is necessary to extend the

height further than what is stable, consider a different type

of field-fabricated framework that is sturdy enough for

greater heights.

NOTES:

Service clearance of 30 in. must be maintained on one of the sides

adjacent to the control box.

Clearance to one of the other three sides must be 36 in.

Clearance to one of the remaining two sides may be 12 in. and the

final side may be 6 in.

A clearance of 24 in. must be maintained between two units.

48 in. clearance required on top of unit.

See

NOTES

See NOTES

See NOTES

See

NOTES

Control

Box

NOTICE: Specific applications may require adjustment of the listed installation clearances to provide protection for

the unit from physical damage or to avoid conditions which limit operating efficiency. (Example: Clearances may

have to be increased to prevent snow or ice from falling on the top of the unit. Additional clearances may also be

required to prevent air recirculation when the unit is installed under a deck or in another tight space.)

Figure 4. Installation Clearances

XC20

9

Page 10

STABILIZING UNIT ON UNEVEN SURFACES

IMPORTANT

Unit Stabilizer Bracket Use (field-provided):

Always use stabilizers when unit is raised above the

factory height. (Elevated units could become unstable in

gusty wind conditions.)

Stabilizers may be used on factory height units when

mounted on unstable an uneven surface.

1. Remove the louvered panel from each side to expose

the unit base.

2. Install the brackets as illustrated in figure 5, detail D us

ing conventional practices.

3. Replace the panels after installation is complete.

ROOF MOUNTING

Locate the unit above a load-bearing wall or area of the roof

that can adequately support the unit. Consult local codes

for rooftop applications.

NOTICE

Roof Damage!

This system contains both refrigerant and oil. Some

rubber roofing material may absorb oil and cause the

rubber to swell when it comes into contact with oil. The

rubber will then bubble and could cause leaks. Protect

the roof surface to avoid exposure to refrigerant and oil

during service and installation. Failure to follow this

notice could result in damage to roof surface.

XC20

10

Page 11

DETAIL A DETAIL B

INSTALL UNIT LEVEL OR, IF ON A SLOPE, MAINTAIN SLOPE

TOLERANCE OF 2 DEGREES (OR 2 INCHES PER 5 FEET [50 MM PER 1.5

M]) AWAY FROM BUILDING STRUCTURE.

Install unit away from windows.

TWO 90° ELBOWS INSTALLED IN LINE SET

WILL REDUCE LINE SET VIBRATION.

GROUND LEVEL

Slab Mounting at Ground Level

Outside Unit Placement

BUILDING

STRUCTURE

MOUNTING

SLAB

DETAIL C

BASE

LEG DETAIL

2” (50.8MM) SCH 40

FEMALE THREADED

USE ADDITIONAL 2” SCH 40 MALE THREADED ADAPT

ERS WHICH CAN BE THREADED INTO THE FEMALE

THREADED ADAPTERS TO MAKE ADDITIONAL AD

JUSTMENTS TO THE LEVEL OF THE UNIT.

Elevated Slab Mounting using Feet

ADAPTER

2” (50.8MM) SCH 40

MALE THREADED

ADAPTER

Extenders

DETAIL D

Slab Side Mounting

#10 1/2” LONG SELF-DRILLING

SHEET METAL SCREWS

STABILIZING BRACKET (18 GAUGE

METAL — 2” WIDTH; HEIGHT AS

#10 1-1/4” LONG HEX HEAD

SCREW AND FLAT WASHER

CONCRETE SLAB — USE TWO PLASTIC

ANCHORS (HOLE DRILL 1/4”)

WOOD OR PLASTIC SLAB — NO PLASTIC ANCHOR

(HOLE DRILL 1/8”)

REQUIRED)

CORNER POST

MINIMUM ONE

Deck Top Mounting

STABILIZING BRACKET (18 GAUGE METAL

— 2” (50.8MM) WIDTH; HEIGHT AS

REQUIRED); BEND TO FORM RIGHT ANGLE

SAME FASTENERS AS

SLAB SIDE MOUNTING.

ONE BRACKET PER SIDE (MIN.); FOR EXTRA STABILITY, TWO

BRACKETS PER SIDE, 2” (50.8MM) FROM EACH CORNER.

PER SIDE

FOR EXTRA

STABILITY

Stabilizing Unit on Uneven Surfaces

IMPORTANT - To help stabilize an outdoor unit, some installations may require strap

ping the unit to the pad using brackets and anchors commonly available in the

marketplace.

COIL

BASE PAN

Figure 5. Placement and Slab Mounting

XC20

11

Page 12

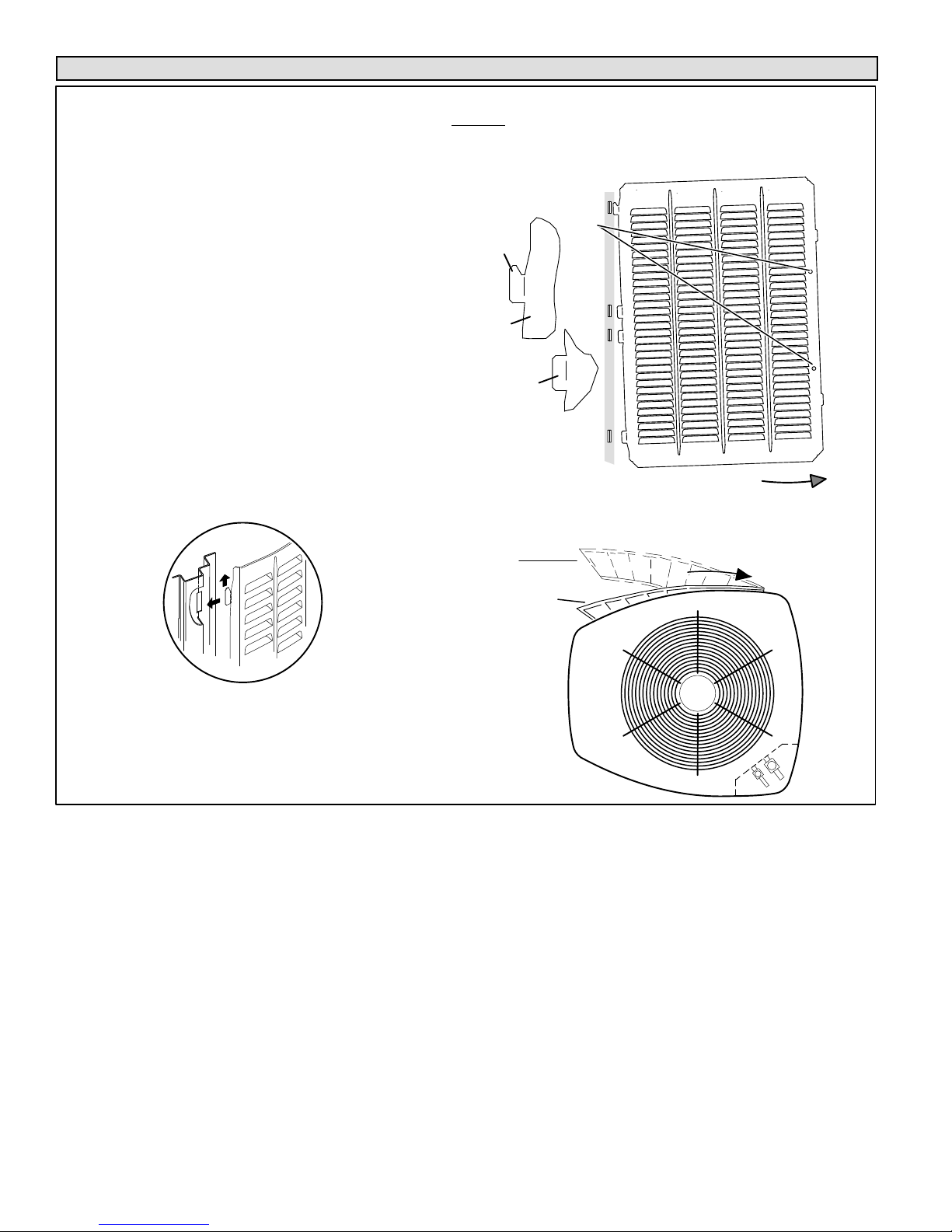

Removing and Installing Panels

LOUVERED PANEL REMOVAL

Remove the louvered panels as follows:

1. Remove two screws, allowing the panel to swing open slight

ly.

2. Hold the panel firmly throughout this procedure. Rotate bot

tom corner of panel away from hinged corner post until lower

three tabs clear the slots as illustrated in Detail B.

3. Move panel down until lip of upper tab clears the top slot in

corner post as illustrated in Detail A.

LOUVERED PANEL INSTALLATION

Position the panel almost parallel with the unit as illustrated in

Detail D with the screw side as close to the unit as possible.

Then, in a continuous motion:

1. Slightly rotate and guide the lip of the top tab inward as

illustrated in Detail A and C; then upward into the top slot

of the hinge corner post.

2. Rotate the panel until it is completely vertical to fully en

gage all of the tabs.

3. Holding the panel's hinged side firmly in place, close the

right-hand side of the panel, aligning the screw holes.

4. When panel is correctly positioned and aligned, insert the

screws and tighten.

IMPORTANT

ALIGNMENT AND NOT DESIGNED TO SUPPORT WEIGHT OF PANEL.

PANEL SHOWN SLIGHTLY ROTATED TO ALLOW TOP TAB TO EXIT (OR

ENTER) TOP SLOT FOR REMOVING (OR INSTALLING) PANEL.

! DO NOT ALLOW PANELS TO HANG ON UNIT BY TOP TAB. TAB IS FOR

SCREW

LIP

HOLES

Detail A

Detail B

ROTATE IN THIS DIRECTION;

ANGLE MAY BE TOO

EXTREME

THEN DOWN TO REMOVE

SIDE TO MAINTAIN FULLY-ENGAGED TABS

PANEL

HOLD DOOR FIRMLY TO THE HINGED

Detail C

MAINTAIN MINIMUM PANEL ANGLE (AS CLOSE TO PARALLEL

WITH THE UNIT AS POSSIBLE) WHILE INSTALLING PANEL.

Figure 6. Removing and Installing Panels

PREFERRED ANGLE

FOR INSTALLATION

XC20

12

Page 13

New or Replacement Line Set

REFRIGERANT LINE SET

This section provides information on installation or replace

ment of existing line set. If new or replacement line set is

not being installed then proceed to Brazing Connections on

page 16.

IMPORTANT

Lennox highly recommends changing line set when

converting the existing system from HCFC-22 to

HFC-410A If that is not possible and the line set is the

proper size as referenced in table 2, use the procedure

outlined under Flushing the System on page 19.

If refrigerant lines are routed through a wall, seal and isolate

the opening so vibration is not transmitted to the building.

Pay close attention to line set isolation during installation of

any HVAC system. When properly isolated from building

structures (walls, ceilings, floors), the refrigerant lines will

not create unnecessary vibration and subsequent sounds.

See figure 7 for recommended installation practices. Also,

consider the following when placing and installing a high-

efficiency outdoor unit.

Liquid lines that meter the refrigerant, such as RFC1 liquid

lines, must not be used in this application. Existing line set

of proper size may be reused. If system was previously

charged with HCFC-22 refrigerant, then existing line set

must be flushed (see Flushing the System on page 19).

IMPORTANT

Mineral oils are not compatible with HFC-410A. If oil

must be added, it must be a Polyol ester oil.

IMPORTANT !

If this unit is being matched with an approved line set

or indoor unit coil that was previously charged with

mineral oil, or if it is being matched with a coil which

was manufactured before January of 1999, the coil

and line set must be flushed prior to installation.

Take care to empty all existing traps. Polyol ester

(POE) oils are used in Lennox units charged with

HFC-410A refrigerant. Residual mineral oil can act as

an insulator, preventing proper heat transfer. It can

also clog the expansion device and reduce system

performance and capacity.

Failure to properly flush the system per the XC20

Installation and Service Procedures will void the

warranty.

WARNING

Refrigerant can be harmful if it is inhaled.

Refrigerant must be used and recovered

responsibly.

Failure to follow this warning may result in personal

injury or death.

WARNING

Fire, Explosion and Personal Safety

Hazard. Failure to follow this warning

could result in damage, personal inju

ry or death.

Never use oxygen to pressurize or

purge refrigeration lines. Oxygen,

when exposed to a spark or open

flame, can cause fire and/or an ex

plosion, that could result in property

damage, personal injury or death.

WARNING

When using a high pressure gas such

as nitrogen to pressurize a

refrigeration or air conditioning

system, use a regulator that can

control the pressure down to 1 or 2

psig (6.9 to 13.8 kPa).

Recommended POE oils are Mobil EAL ARCTIC 22 CC or

ICI EMKARATEt RL32CF.

WARNING

Danger of fire. Bleeding the refrigerant

charge from only the high side may

result in the low side shell and suction

tubing being pressurized. Application

of a brazing torch while pressurized

may result in ignition of the refrigerant

and oil mixture - check the high and

low pressures before unbrazing.

IMPORTANT !

Some scroll compressors have an internal vacuum

protector that will unload scrolls when suction pres

sure goes below 20 psig. A hissing sound will be

heard when the compressor is running unloaded.

Protector will reset when low pressure in system is

raised above 40 psig. DO NOT REPLACE COMPRES

SOR.

The XC20 is a variable-capacity cooling system utilizing

variable-speed compressor technology. With the variablespeed compressor and variable pumping capacity,

additional consideration must be given to refrigerant piping

sizing and application. The following guidelines are to be

used exclusively for the XC20 systems.

XC20

13

Page 14

COOLING SYSTEM (HFC410A)

D Total equivalent length equals 180 feet (all piping and

fittings included).

NOTE - This is a general guide. Lengths may be more or

less, depending on remaining system design factors.

D Maximum linear (actual) length = 150 feet.

D Maximum linear liquid lift = 60 feet.

NOTE - Maximum lifts are dependent on total length, num

ber of elbows, and other factors that contribute to total

pressure drop.

D Maximum linear length of vapor riser = 60 feet.

D Size vertical vapor riser per table 2.

D Line set lengths up to 50 linear feet: Use rated line

sizes listed in table 2.

D Line set lengths between 51 and 150 linear feet:

Crankcase heater and nonbleed port TXV factory-in

stalled. No additional components required. Vertical

vapor riser must be sized to the vapor riser listed in

table 3 on systems with line sets longer than 51 feet.

Use tables 3 and 4 to determine the correct liquid and

vapor line sizes.

D Line set lengths over 150 linear feet: Not recom

mended.

D Additional oil is not required for systems with line

lengths up to 150 feet.

NOTE - Recommended POE oils are Mobil EAL ARCTIC

22 CC or ICI EMKARATEt RL32CF.

SUCTION TRAPS

In systems with the outdoor unit 5 to 60 feet above the in

door unit, one trap must be installed at the bottom of the

suction riser.

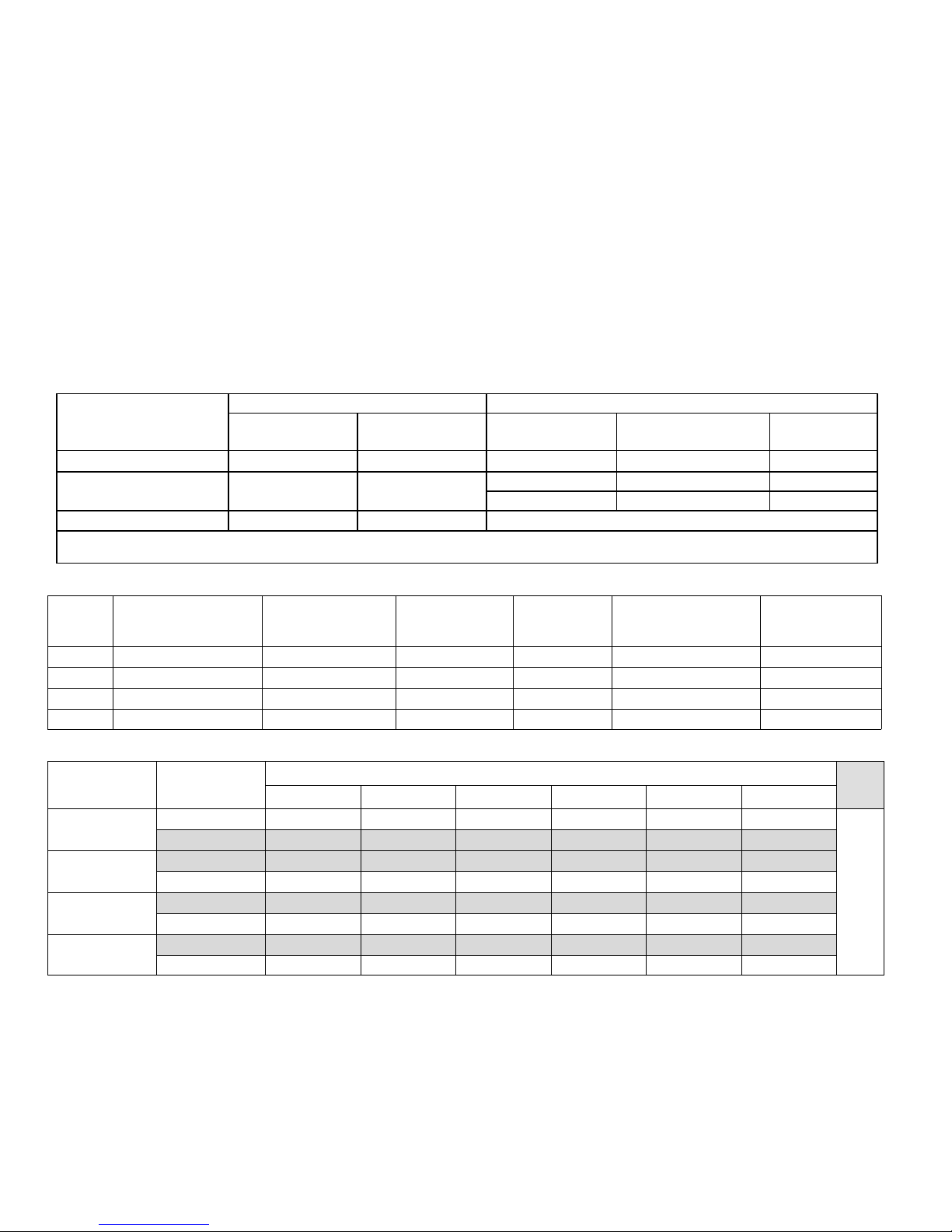

Table 2. Standard Refrigerant Line Set — Up to 50 Linear Feet

Valve Size Connections Recommended Line Sets

Model Number (-xx*)

XC20-024-230-XX 3/8” (10 mm) 3/4” (19 mm) L15-41-30 30 feet (9.1 m) 89J60

XC20-036-230-XX

XC20-048-230-XX

XC20-060-230-XX 3/8” (10 mm) 1-1/8” (29 mm) ** Field-fabricated

* Applicable to all minor revision numbers unless otherwise specified.

** Some applications may require a field-provided 1-1/8” to 7/8” adapter.

Liquid Line Suction Line

3/8” (10 mm) 7/8” (22 mm)

L15 Line Set

Model

L15-65-40 40 feet (12.2 m) 89J61

L15-65-50 50 feet (15.2 m) 89J62

Line Set Length

Catalog

Number

Table 3. XC20 Line Set Guidelines — 51 to 150 Linear Feet in Length

Model

024 180 150 60 60 3/4” 5/8”

036 180 150 60 60 7/8” 3/4”

048 180 150 60 60 7/8” 7/8”

060 180 150 60 60 7/8” 7/8”

Maximum Total

Equivalent Length (ft)

Maximum Linear

(actual) Length (ft)

Maximum Vapor

Riser (ft)

Maximum

Linear Liquid

Lift (ft)

Preferred Vapor Line

Sizes for Horizontal

Runs

Required Vapor

Riser Size

Table 4. Liquid Line Diameter Selection Table

Total Linear Length (feet)

Unit

024

036

048

060

Line Size

5/16” 25 50 55 48 40 33

3/8” 25 50 60 60 60 60

3/8” 25 50 60 56 51 45

1/2” 25 50 60 60 60 60

3/8” 25 50 50 41 31 22

1/2” 25 50 60 60 60 60

3/8” 25 50 36 22 8 NR

1/2”

25 50 75 100 125 150

25

50 60 60 60 59

Note Shaded rows indicate rated liquid line size.

1. Find your unit on the left side of the table.

2. Start with the rated liquid line size (shaded row) for the outdoor unit.

3. Select the actual total linear length of your system shown at the top of the table.

4. The elevation listed in the table is the maximum allowed for the liquid line listed.

5. Consider the larger liquid line size shown in the table if the elevation does not meet your requirements.

Max. Elevation

(ft)

XC20

14

Page 15

LINE SET

INSTALLATION

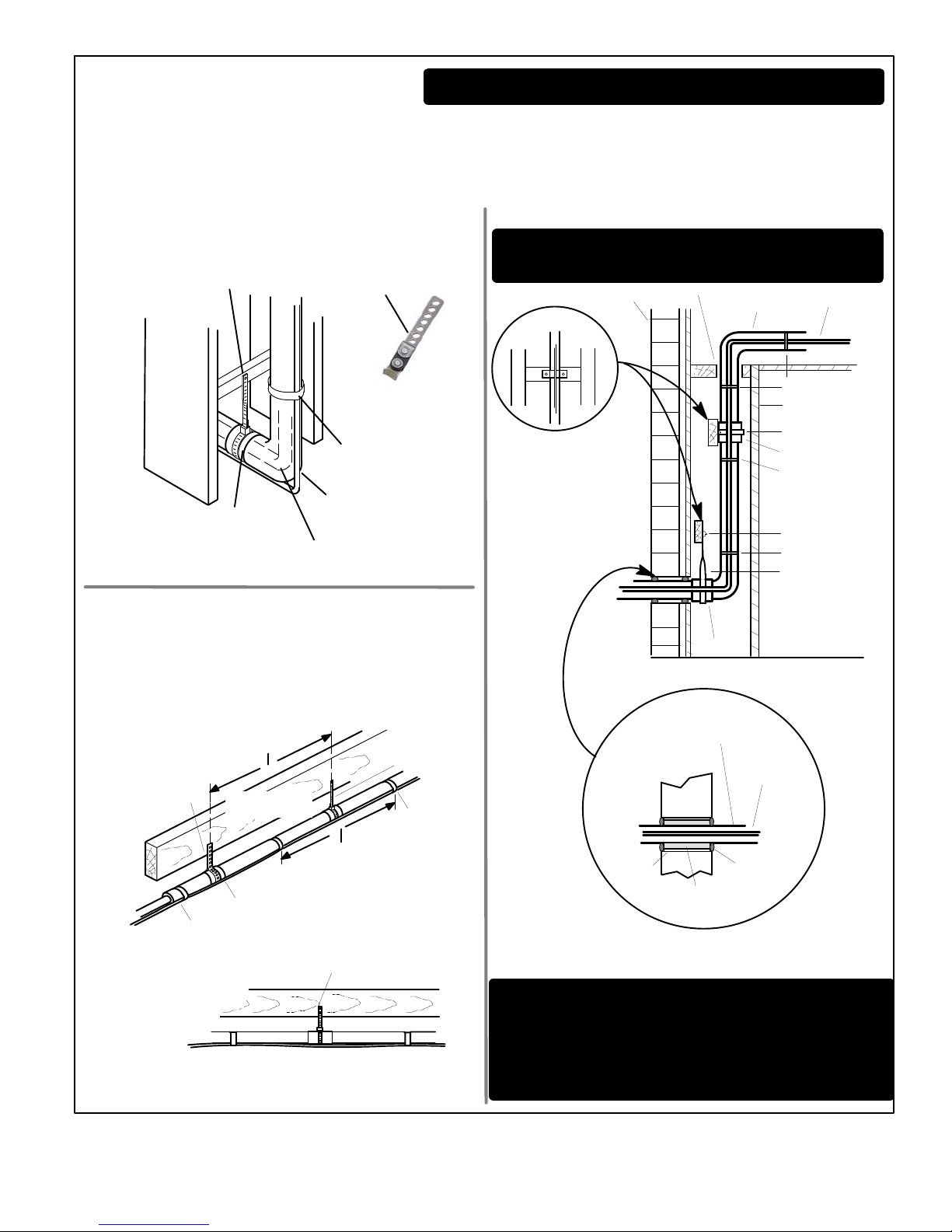

LINE SET ISOLATION — THE FOLLOWING ILLUSTRATIONS ARE EXAM

PLES OF PROPER REFRIGERANT LINE SET ISOLATION:

REFRIGERANT LINE SET — TRANSITION

FROM VERTICAL TO HORIZONTAL

ANCHORED HEAVY NYLON

WIRE TIE OR AUTOMOTIVE

MUFFLER‐TYPE HANGER

AUTOMOTIVE

MUFFLER‐TYPE HANGER

IMPORTANT - Refrigerant lines must not contact structure.

REFRIGERANT LINE SET — INSTALLING

VERTICAL RUNS (NEW CONSTRUCTION SHOWN)

NOTE - INSULATE LIQUID LINE WHEN IT IS ROUTED THROUGH AREAS

WHERE THE SURROUNDING AMBIENT TEMPERATURE COULD BECOME

HIGHER THAN THE TEMPERATURE OF THE LIQUID LINE OR WHEN

PRESSURE DROP IS EQUAL TO OR GREATER THAN 20 PSIG.

IMPORTANT - Refrigerant lines must not contact

wall

OUTSIDE WALL

VAPOR LINE

LIQUID LINE

WALL

STUD

STRAP LIQUID LINE TO

VAPOR LINE

LIQUID LINE

NON-CORROSIVE

METAL SLEEVE

VAPOR LINE - WRAPPED

IN ARMAFLEX

REFRIGERANT LINE SET — INSTALLING

HORIZONTAL RUNS

TO HANG LINE SET FROM JOIST OR RAFTER, USE EITHER METAL

STRAPPING MATERIAL OR ANCHORED HEAVY NYLON WIRE TIES.

WIRE TIE (AROUND

VAPOR LINE ONLY)

8 FEET (2.43 METERS)

STRAPPING

MATERIAL (AROUND

VAPOR LINE ONLY)

TAPE OR

WIRE TIE

FLOOR JOIST OR

ROOF RAFTER

8 FEET (2.43 METERS)

NON-CORROSIVE

METAL SLEEVE

STRAP THE VAPOR LINE TO THE

JOIST OR RAFTER AT 8 FEET (2.43

METERS) INTERVALS THEN STRAP

THE LIQUID LINE TO THE VAPOR LINE.

TAPE OR

WIRE TIE

WIRE TIE

INSIDE WALL

WOOD BLOCK

BETWEEN

STUDS

SLEEVE

VAPOR LINE WRAPPED

WITH ARMAFLEX

OUTSIDE

WALL

PVC

PIPE

FIBERGLASS

INSULATION

NOTE - SIMILAR INSTALLATION PRACTICES SHOULD BE USED IF

LINE SET IS TO BE INSTALLED ON EXTERIOR OF OUTSIDE WALL.

CAULK

STRAP

NON-CORROSIVE

METAL SLEEVE

WIRE TIE

WOOD BLOCK

WIRE TIE

STRAP

LIQUID

LINE

FLOOR JOIST OR

ROOF RAFTER

WARNING - Polyol ester (POE) oils used with

HFC-410A refrigerant absorb moisture very quickly.

It is very important that the refrigerant system be kept

closed as much as possible. DO NOT remove line set

caps or service valve stub caps until you are ready to

make connections.

Figure 7. Line Set Installation

XC20

15

Page 16

Brazing Connections

Use the procedures outlined in figures 8 and 9 for brazing

line set connections to service valves.

WARNING

IMPORTANT

Allow braze joint to cool before removing the wet rag

from the service valve. Temperatures above 250ºF can

damage valve seals.

Danger of fire. Bleeding the refrigerant

charge from only the high side may result

in pressurization of the low side shell and

suction tubing. Application of a brazing

torch to a pressurized system may result

in ignition of the refrigerant and oil mixture

- Check the high and low pressures

before applying heat.

CAUTION

Brazing alloys and flux contain materials which are

hazardous to your health.

Avoid breathing vapors or fumes from brazing

operations. Perform operations only in well-ventilated

areas.

Wear gloves and protective goggles or face shield to

protect against burns.

Wash hands with soap and water after handling brazing

alloys and flux.

WARNING

Fire, Explosion and Personal Safety

Hazard.

Failure to follow this warning could re

sult in damage, personal injury or death.

Never use oxygen to pressurize or

purge refrigeration lines. Oxygen, when

exposed to a spark or open flame, can

cause a fire and/or an explosion, that

could result in property damage, per

sonal injury or death.

XC20

16

Page 17

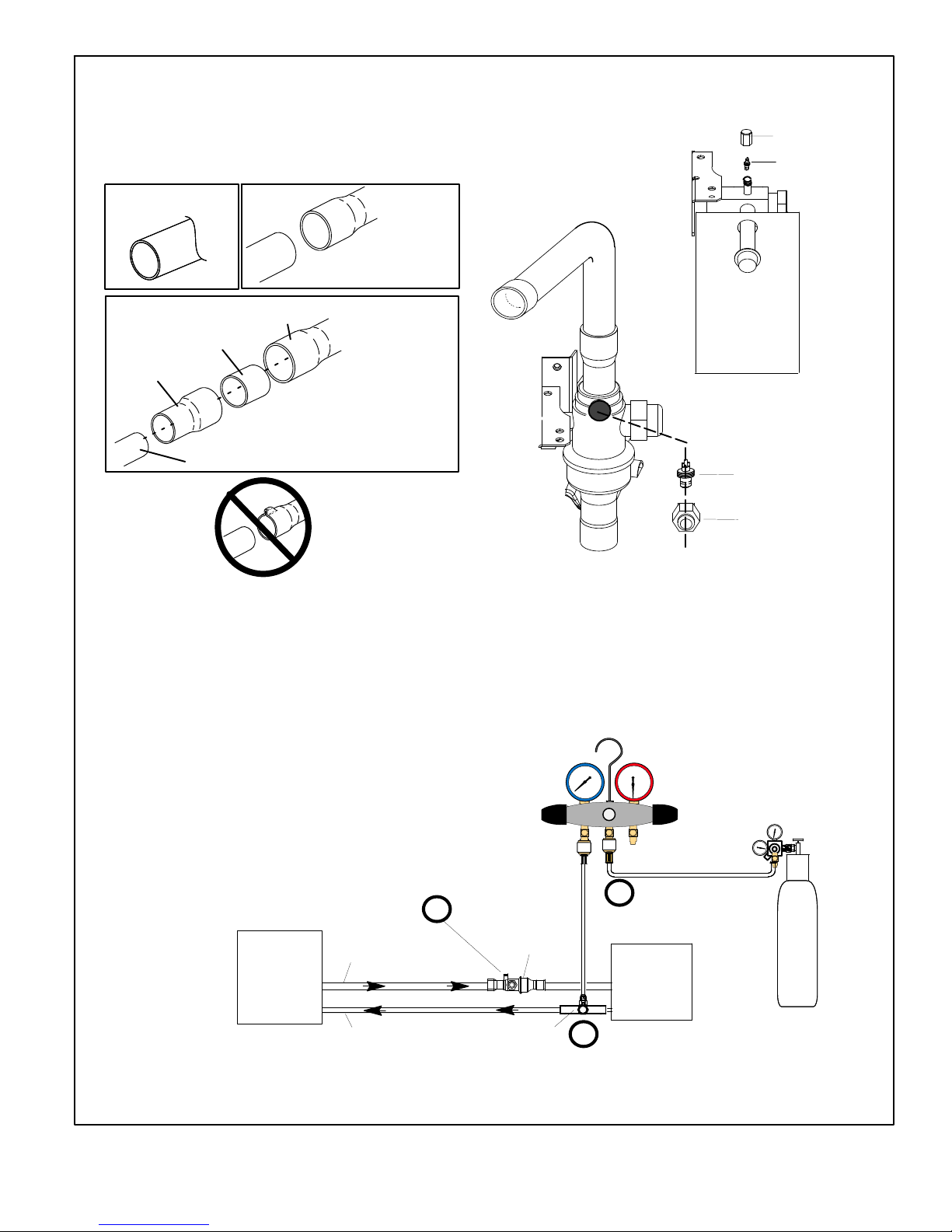

PIPING PANEL REMOVAL AND LINE SET

PREPARATION

1

Remove piping panel for easier access to service valves. Cut ends

of the refrigerant lines square (free from nicks or dents) and debur

the ends. The pipe must remain round. Do not crimp end of the line.

CUT AND DEBUR

LINE SET SIZE MATCHES

SERVICE VALVE CONNECTION

SERVICE VALVE

COPPER TUBE

REDUCER

STUB

CONNECTION

LINE SET SIZE IS SMALLER

THAN CONNECTION

CAP AND CORE REMOVAL

Remove service cap and core from both the suction and liquid line

2

service ports.

SERVICE PORT CAP

SERVICE PORT

CORE

LIQUID LINE SERVICE VALVE

REFRIGERANT LINE

DO NOT CRIMP SERVICE

VALVE CONNECTOR WHEN

PIPE IS SMALLER THAN

CONNECTION

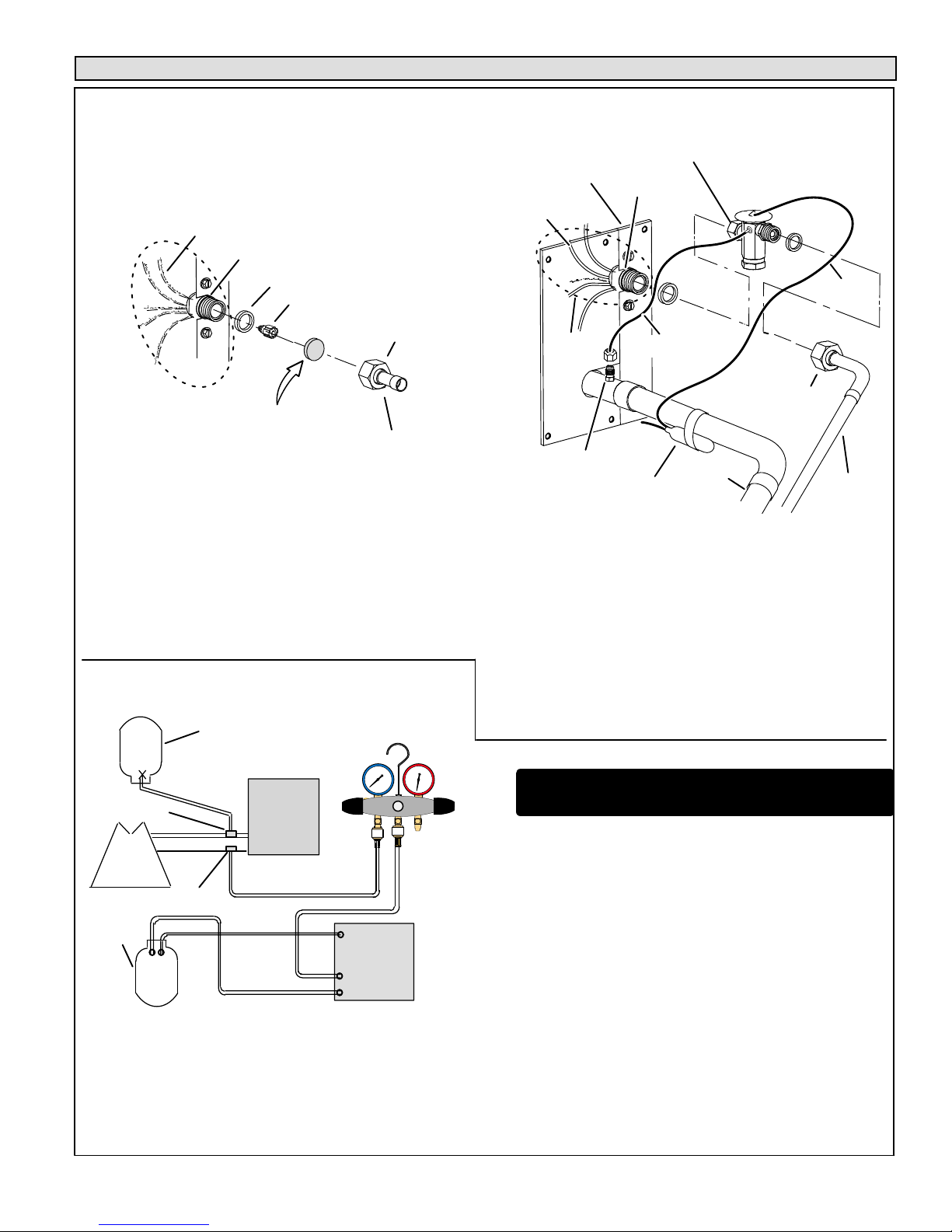

ATTACH THE MANIFOLD GAUGE SET FOR BRAZING

LIQUID AND SUCTION LINE SERVICE VALVES

3

A. Connect gauge set low pressure side to liquid line

service valve (service port).

B. Connect gauge set center port to bottle of nitrogen

with regulator.

C. With valve core removed from the suction line service

port, nitrogen flow will have an exit point.

SUCTION SERVICE PORT MUST BE OPEN AND

SERVICE PORT CORE REMOVED TO ALLOW

EXIT POINT FOR NITROGEN FLOW

SUCTION LINE

INDOOR

UNIT

C

SUCTION LINE

SERVICE VALVE

SUCTION LINE SERVICE

VALV E

LOW

ATTACH

GAUGES

B

OUTDOOR

UNIT

HIGH

SERVICE PORT

CORE

SERVICE

PORT CAP

LIQUID LINE

LIQUID LINE SERVICE

VALV E

A

Figure 8. Brazing Procedures

17

NITROGEN

XC20

Page 18

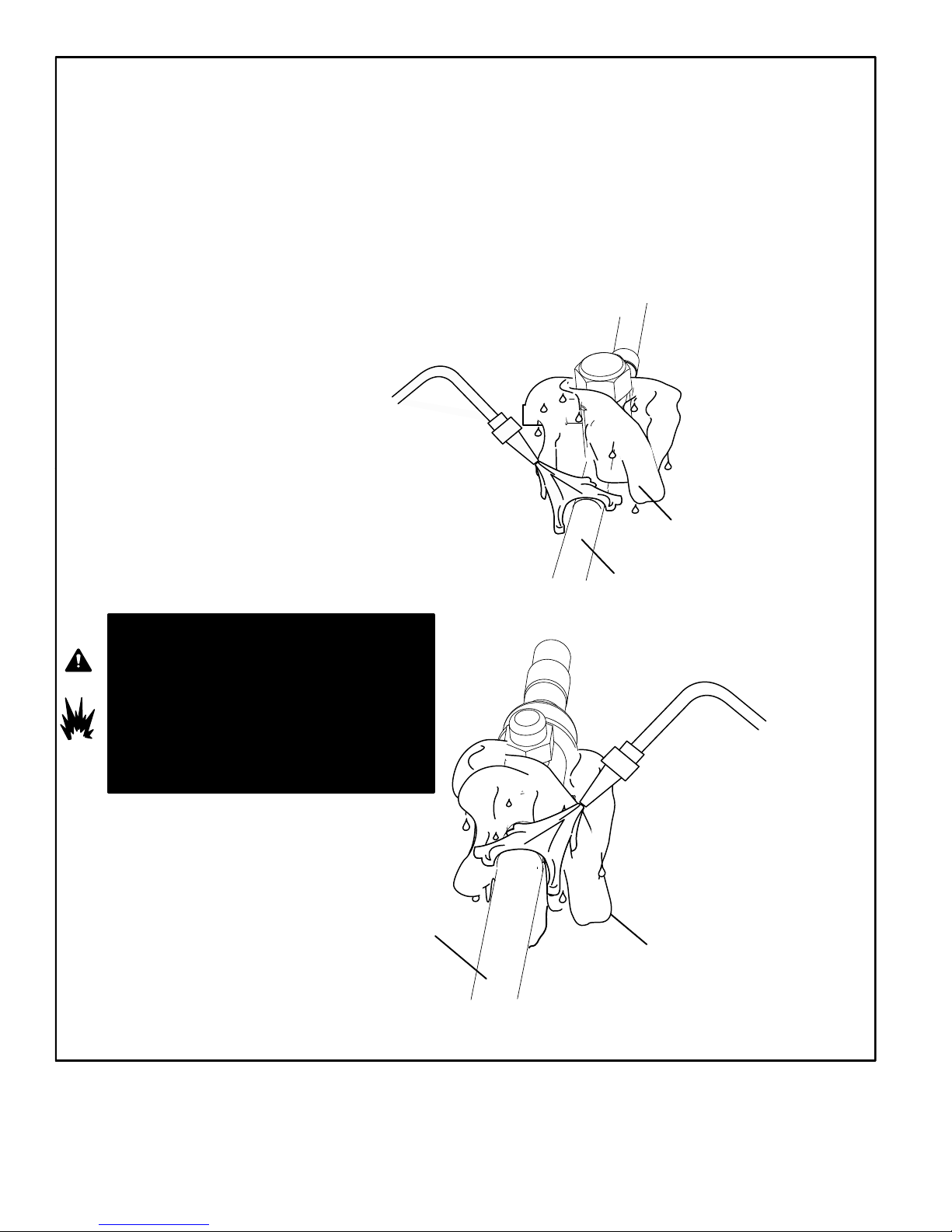

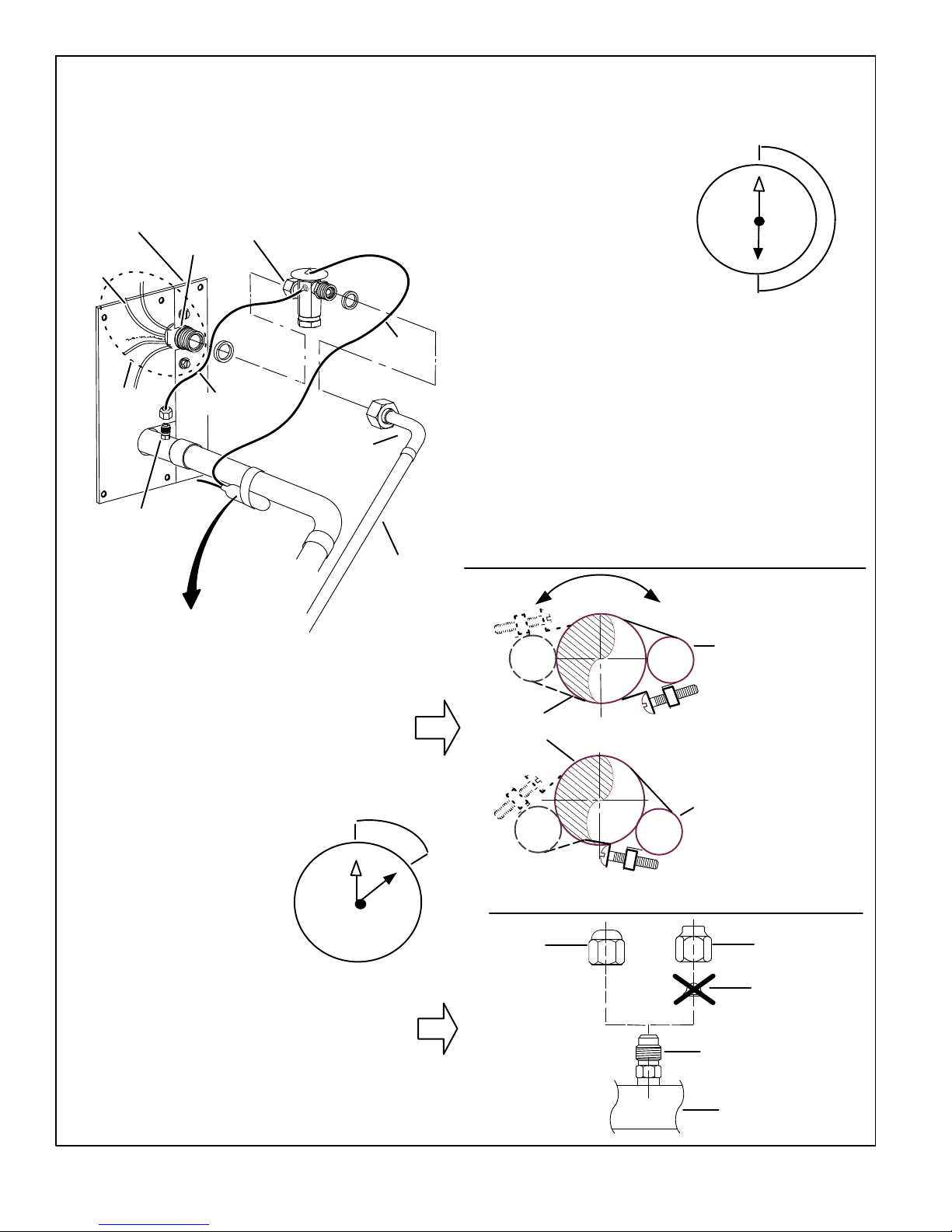

WRAP SERVICE VALVES

To help protect service valve seals during brazing, wrap water-saturated cloths around service valve bodies and copper tube stubs. Use

4

additional water-saturated cloths underneath the valve body to protect the base paint.

FLOW NITROGEN

Flow regulated nitrogen (at 1 to 2 psig) through the refrigeration gauge set into the valve stem port connection on the liquid service valve

5

and out of the suction / vapor valve stem port. See steps 3A, 3B and 3C on manifold gauge set connections.

BRAZE LINE SET

Wrap both service valves with water-saturated cloths as illustrated here and as mentioned in step 4, before brazing to line set. Cloths

6

must remain water-saturated throughout the brazing and cool-down process.

LIQUID LINE SERVICE VALVE

WHEN BRAZING LINE SET TO

SERVICE VALVES, POINT FLAME

AWAY FROM SERVICE VALVE.

IMPORTANT - Allow braze joint to cool. Apply additional

water-saturated cloths to help cool brazed joint. Do not

remove water-saturated cloths until piping has cooled.

Temperatures above 250ºF will damage valve seals.

LIQUID LINE

WATER-SATURATED

CLOTH

WARNING

FIRE, PERSONAL INJURY, OR PROPERTY DAMAGE

may result if you do not wrap a water-saturated cloth

around both liquid and suction line service valve bodies

and copper tube stub while brazing the line set! The braze,

when complete, must be quenched with water to absorb

any residual heat.

Do not open service valves until refrigerant lines and

indoor coil have been leak-tested and evacuated.

Refer to Installation and Service Procedures manual

found on DAVENET.

SUCTION LINE

PREPARATION FOR NEXT STEP

Disconnect manifold gauge set from service ports after all connections have been brazed. Apply additional water-saturated cloths to both

7

service valves to cool piping. Once piping is cool, remove all water-saturated cloths.

SUCTION LINE SERVICE

VALV E

SERVICE VALVES, POINT FLAME

WATER-SATURATED

CLOTH

WHEN BRAZING LINE SET TO

AWAY FROM SERVICE VALVE.

Figure 9. Brazing Procedures (Continued)

XC20

18

Page 19

Flushing the System

LINE SET AND INDOOR COIL (1 OF 2)

TYPICAL EXISTING EXPANSION VALVE

REMOVAL PROCEDURE (UNCASED COIL

1B

TWO PIECE PATCH PLATE

TYPICAL EXISTING FIXED ORIFICE

REMOVAL PROCEDURE (UNCASED COIL

1A

DISTRIBUTOR

ASSEMBLY

A. ON FULLY CASED COILS, REMOVE THE COIL ACCESS AND PLUMBING

PANELS.

B. REMOVE ANY SHIPPING CLAMPS HOLDING THE LIQUID LINE AND DIS

TRIBUTOR ASSEMBLY.

C. USING TWO WRENCHES, DISCONNECT LIQUID LINE FROM LIQUID LINE

ORIFICE HOUSING. TAKE CARE NOT TO TWIST OR DAMAGE DISTRIBU

TOR TUBES DURING THIS PROCESS.

D. REMOVE AND DISCARD FIXED ORIFICE, VALVE STEM ASSEMBLY (IF

PRESENT) AND TEFLON

E. USE A FIELD-PROVIDED FITTING TO TEMPORARILY RECONNECT THE

LIQUID LINE TO THE INDOOR UNIT'S LIQUID LINE ORIFICE HOUSING.

SHOWN)

DISTRIBUTOR TUBES

REMOVE AND DISCARD

WHITE TEFLON

LIQUID LINE ORIFICE HOUSING

TEFLON® RING

FIXED ORIFICE

BRASS NUT

®

(IF PRESENT)

®

WASHER AS ILLUSTRATED ABOVE.

SEAL

LIQUID LINE ASSEMBLY

(INCLUDES STRAINER)

CONNECT GAUGES AND EQUIPMENT FOR

FLUSHING PROCEDURE

2

INV ERT ED HCFC-22

CYLINDER CONTAINS

CLE AN HCFC-22* TO BE

USED FOR FLUSHING.

A

1

VAPOR LINE

SERVICE VALVE

EXISTING

INDOOR

UNIT

LIQUID LINE SERVICE

RECOVERY

CYLINDER

VALV E

VAPOR

LIQUID

NEW

OUTDOOR

UNIT

B

OPENED

C

D

A. INVERTED HCFC-22 CYLINDER WITH CLEAN REFRIGERANT* TO THE

VAPOR SERVICE VALVE.

B. HCFC-22 GAUGE SET (LOW SIDE) TO THE LIQUID LINE VALVE.

C. HCFC-22 GAUGE SET CENTER PORT TO INLET ON THE RECOVERY

MACHINE WITH AN EMPTY RECOVERY TANK TO THE GAUGE SET.

D. CONNECT RECOVERY TANK TO RECOVERY MACHINE PER MACHINE

INSTRUCTIONS.

*IMPORTANT - Clean refrigerant is any refrigerant in a system that has not had compressor burn out. If the system

has experienced burn out, it is recommended that the existing line set and indoor coil be replaced.

RECOVERY MACHINE

MANIFOLD

LOW

TANK

RETURN

INLET

DISCHARGE

GAUGE

CLOSED

(UNCASED COIL ONLY)

OR

HIGH

SHOWN)

LIQUID LINE

DISTRIBUTOR

TUBES

DISTRIBUTOR

ASSEMBLY

MALE EQUALIZER

LINE FITTING

SENSING BULB

A. ON FULLY CASED COILS, REMOVE THE COIL ACCESS AND PLUMBING

PANELS.

B. REMOVE ANY SHIPPING CLAMPS HOLDING THE LIQUID LINE AND DIS

TRIBUTOR ASSEMBLY.

C. DISCONNECT THE EQUALIZER LINE FROM THE CHECK EXPANSION

VALVE EQUALIZER LINE FITTING ON THE VAPOR LINE.

D. REMOVE THE VAPOR LINE SENSING BULB.

E. DISCONNECT THE LIQUID LINE FROM THE CHECK EXPANSION VALVE

AT THE LIQUID LINE ASSEMBLY.

F. DISCONNECT THE CHECK EXPANSION VALVE FROM THE LIQUID LINE

ORIFICE HOUSING. DO NOT TO TWIST OR DAMAGE DISTRIBUTOR

TUBES DURING THIS PROCESS.

G. REMOVE AND DISCARD CHECK EXPANSION VALVE AND THE TWO TEF

H. USE A FIELD-PROVIDED FITTING TO TEMPORARILY RECONNECT THE

®

RINGS.

LON

LIQUID LINE TO THE INDOOR UNIT'S LIQUID LINE ORIFICE HOUSING.

ORIFICE

HOUSING

EQUALIZER

LINE

STUB END

TEFLON

RING

VAPOR

CHECK

EXPANSION

VALV E

®

LIQUID LINE

ASSEMBLY WITH

BRASS NUT

LINE

TEFLON

RING

FLUSHING LINE SET

3

CAUTION -This procedure should not be performed on systems

which contain contaminants (Example, compressor burn out).

THE LINE SET AND INDOOR UNIT COIL MUST BE FLUSHED WITH AT

LEAST THE SAME AMOUNT OF CLEAN REFRIGERANT* THAT PRE

VIOUSLY CHARGED THE SYSTEM. CHECK THE CHARGE IN THE

FLUSHING CYLINDER BEFORE PROCEEDING.

B

A. SET THE RECOVERY MACHINE FOR LIQUID RECOVERY AND

START THE RECOVERY MACHINE. OPEN THE GAUGE SET

VALVES TO ALLOW THE RECOVERY MACHINE TO PULL A VACU

UM ON THE EXISTING SYSTEM LINE SET AND INDOOR UNIT COIL.

B. INVERT THE CYLINDER OF CLEAN HCFC-22* AND OPEN ITS

VALVE TO ALLOW LIQUID REFRIGERANT TO FLOW INTO THE SYS

TEM THROUGH THE VAPOR LINE VALVE. ALLOW THE REFRIGER

ANT TO PASS FROM THE CYLINDER AND THROUGH THE LINE SET

AND THE INDOOR UNIT COIL BEFORE IT ENTERS THE RECOVERY

MACHINE.

C. AFTER ALL OF THE LIQUID REFRIGERANT HAS BEEN RECOV

ERED, SWITCH THE RECOVERY MACHINE TO VAPOR RECOVERY

SO THAT ALL OF THE HCFC-22 VAPOR IS RECOVERED. ALLOW

THE RECOVERY MACHINE TO PULL SYSTEM DOWN TO 0.

D. CLOSE THE VALVE ON THE INVERTED HCFC-22 DRUM AND THE

GAUGE SET VALVES. PUMP THE REMAINING REFRIGERANT OUT

OF THE RECOVERY MACHINE AND TURN OFF THE MACHINE.

®

SENSING

LINE

LIQUID

LINE

XC20

19

Page 20

FLUSHING LINE SET AND INDOOR COIL (2 OF 2)

TYPICAL NEW CHECK EXPANSION VALVE INSTALLATION PROCEDURE

THIS OUTDOOR UNIT IS DESIGNED FOR USE IN SYSTEMS THAT USE A CHECK EXPANSION VALVE METERING DEVICE. SEE LENNOX XC20

PRODUCT SPECIFICATIONS FOR APPROVED EXPANSION VALVE KIT MATCH-UPS AND APPLICATION INFORMATION.

4

THE EXPANSION VALVE UNIT CAN BE INSTALLED INTERNAL OR

EXTERNAL TO THE INDOOR COIL. IN APPLICATIONS WHERE AN

TWO PIECE

PATCH PLATE

(UNCASED

COIL ONLY)

DISTRIBUTOR

TUBES

DISTRIBUTOR

ASSEMBLY

MALE EQUALIZER LINE

FITTING (SEE

EQUALIZER LINE

INSTALLATION FOR

FURTHER DETAILS)

SENSING BULB INSULATION IS REQUIRED

IF MOUNTED EXTERNAL TO THE COIL

CASING. SEE SENSING BULB

INSTALLATION FOR BULB POSITIONING.

(Uncased Coil Shown)

LIQUID LINE

ORIFICE

HOUSING

STUB

END

TEFLON

RING

EQUALIZER

LINE

EXPANSION

VALV E

®

LIQUID LINE

ASSEMBLY WITH

BRASS NUT

VAPOR

LINE

UNCASED COIL IS BEING INSTALLED IN A FIELD-PROVIDED

PLENUM, INSTALL THE CHECK EXPANSION VALVE IN A MANNER

THAT WILL PROVIDE ACCESS FOR FIELD SERVICING OF THE

EXPANSION VALVE. REFER TO BELOW ILLUSTRATION FOR

REFERENCE DURING INSTALLATION OF EXPANSION VALVE

UNIT.

®

TEFLON

RING

A. REMOVE THE FIELD-PROVIDED FITTING THAT TEMPORARILY RECON

NECTED THE LIQUID LINE TO THE INDOOR UNIT'S DISTRIBUTOR AS

SENSING

LINE

LIQUID LINE

SEMBLY.

B. INSTALL ONE OF THE PROVIDED TEFLON

STUBBED END OF THE EXPANSION VALVE AND LIGHTLY LUBRICATE

THE CONNECTOR THREADS AND EXPOSE SURFACE OF THE TEFLON

RING WITH REFRIGERANT OIL.

C. ATTACH THE STUBBED END OF THE EXPANSION VALVE TO THE LIQUID

LINE ORIFICE HOUSING. FINGER TIGHTEN AND USE AN APPROPRIATELY

SIZED WRENCH TO TURN AN ADDITIONAL 1/2 TURN CLOCKWISE AS IL

LUSTRATED IN THE FIGURE ABOVE, OR 20 FT-LB.

D. PLACE THE REMAINING TEFLON

OF THE EXPANSION VALVE. LIGHTLY LUBRICATE CONNECTOR

THREADS AND EXPOSE SURFACE OF THE TEFLON

FRIGERANT OIL.

E. ATTACH THE LIQUID LINE ASSEMBLY TO THE EXPANSION VALVE. FIN

GER TIGHTEN AND USE AN APPROPRIATELY SIZED WRENCH TO TURN

AN ADDITIONAL 1/2 TURN CLOCKWISE AS ILLUSTRATED IN THE FIGURE

ABOVE OR 20 FT-LB.

9 O'CLOCK TO

3 O'CLOCK

BULB

12

®

BULB

9

WASHER AROUND THE OTHER END

12

11

10

8

7

6

®

RINGS AROUND THE

®

ON LINES SMALLER THAN

7/8”, MOUNT SENSING

BULB BETWEEN THE 9

AND 3 O'CLOCK

POSITIONS.

SENSING BULB INSTALLATION

VAPOR LINE

A. ATTACH THE VAPOR LINE SENSING BULB IN THE PROPER

ORIENTATION AS ILLUSTRATED TO THE RIGHT USING THE

CLAMP AND SCREWS PROVIDED.

NOTE - CONFIRM PROPER THERMAL CONTACT BETWEEN

VAPOR LINE AND CHECK EXPANSION BULB BEFORE INSU

LATING THE SENSING BULB ONCE INSTALLED.

B. CONNECT THE EQUALIZER LINE

FROM THE EXPANSION VALVE TO

THE EQUALIZER VAPOR PORT ON

THE VAPOR LINE. FINGER

TIGHTEN THE FLARE NUT PLUS

1/8 TURN (7 FT-LBS) AS ILLUS

TRATED BELOW.

9

10

11

12

1

8

7

5

6

1/8 TURN

2

3

4

VAPOR LINE

BULB

FLARE SEAL CAP

ON 7/8” AND LARGER LINES,

MOUNT SENSING BULB AT

EITHER THE 4 OR 8 O'CLOCK

POSITION. NEVER MOUNT

12

BULB

NOTE - NEVER MOUNT THE SENSING BULB ON

BOTTOM OF LINE.

THE SENSING BULB ON

BOTTOM OF LINE.

FLARE NUT

1/2 TURN

1

2

3

4

5

®

RING WITH RE

EQUALIZER LINE INSTALLATION

REMOVE AND DISCARD EITHER THE FLARE SEAL CAP OR FLARE

NUT WITH COPPER FLARE SEAL BONNET FROM THE EQUALIZER

LINE PORT ON THE VAPOR LINE AS ILLUSTRATED IN THE FIGURE

TO THE RIGHT.

XC20

20

OR

COPPER FLARE

SEAL BONNET

MALE BRASS EQUALIZER

LINE FITTING

VAPOR LINE

Page 21

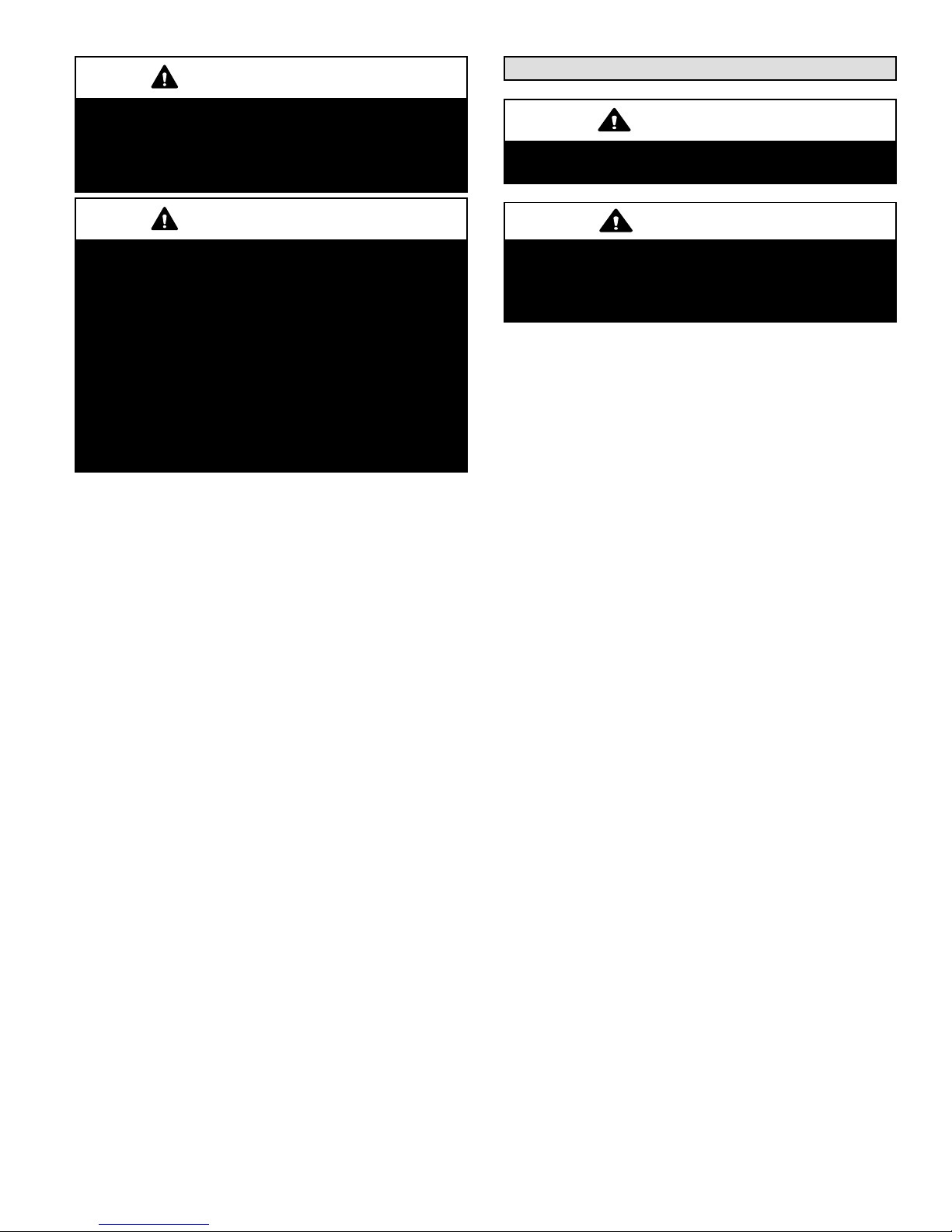

IMPORTANT

Leak Testing the System

The Environmental Protection Agency (EPA) prohibits

the intentional venting of HFC refrigerants during

maintenance, service, repair and disposal of appliance.

Approved methods of recovery, recycling or reclaiming

must be followed.

IMPORTANT

If this unit is being matched with an approved line set

or indoor unit coil which was previously charged with

mineral oil, or if it is being matched with a coil which was

manufactured before January of 1999, the coil and line

set must be flushed prior to installation. Take care to

empty all existing traps. Polyol ester (POE) oils are

used in Lennox units charged with HFC-410A

refrigerant. Residual mineral oil can act as an insulator,

preventing proper heat transfer. It can also clog the

expansion device, and reduce the system

performance and capacity.

Failure to properly flush the system per the instructions

below will void the warranty.

IMPORTANT

Leak detector must be capable of sensing HFC

refrigerant.

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in personal injury

or death.

XC20

21

Page 22

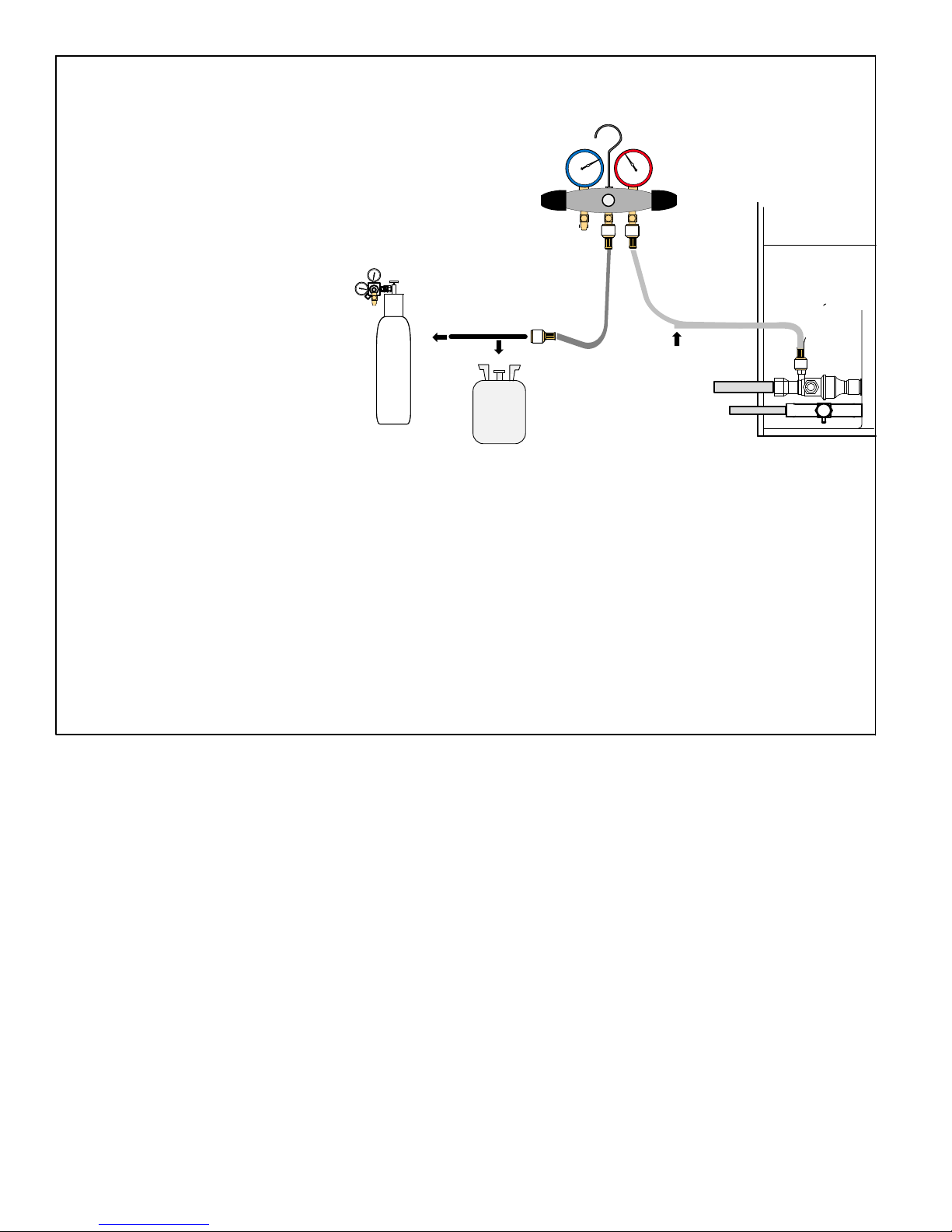

LEAK TEST

LINE SET AND INDOOR COIL

NOTE - NORMALLY, THE HIGH PRESSURE HOSE IS CONNECTED TO THE LIQUID LINE

PORT. HOWEVER, CONNECTING IT TO THE VAPOR PORT BETTER PROTECTS THE

MANIFOLD GAUGE SET FROM HIGH PRESSURE DAMAGE.

LOW

HIGH

CONNECT GAUGE SET

A. CONNECT AN HFC-410A MANIFOLD GAUGE SET HIGH PRESSURE

1

2

HOSE TO THE VAPOR VALVE SERVICE PORT.

B. WITH BOTH MANIFOLD VALVES CLOSED, CONNECT THE CYLINDER

OF HFC-410A REFRIGERANT TO THE CENTER PORT OF THE

MANIFOLD GAUGE SET.

NOTE - LATER IN THE PROCEDURE,

THE HFC-410A CONTAINER WILL BE

REPLACED BY THE NITROGEN

CONTAINER.

NITROGEN

TEST FOR LEAKS

AFTER THE LINE SET HAS BEEN CONNECTED TO THE INDOOR AND OUTDOOR UNITS, CHECK THE LINE SET CON

NECTIONS AND INDOOR UNIT FOR LEAKS. USE THE FOLLOWING PROCEDURE TO TEST FOR LEAKS:

A. WITH BOTH MANIFOLD VALVES CLOSED, CONNECT THE CYLINDER OF HFC-410A REFRIGERANT TO THE CENTER PORT OF THE

MANIFOLD GAUGE SET. OPEN THE VALVE ON THE HFC-410A CYLINDER (VAPOR ONLY).

B. OPEN THE HIGH PRESSURE SIDE OF THE MANIFOLD TO ALLOW HFC-410A INTO THE LINE SET AND INDOOR UNIT. WEIGH IN A TRACE

AMOUNT OF HFC-410A [A TRACE AMOUNT IS A MAXIMUM OF TWO OUNCES (57 G) REFRIGERANT OR THREE POUNDS (31 KPA) PRES

SURE]. CLOSE THE VALVE ON THE HFC-410A CYLINDER AND THE VALVE ON THE HIGH PRESSURE SIDE OF THE MANIFOLD GAUGE

SET. DISCONNECT THE HFC-410A CYLINDER.

C. CONNECT A CYLINDER OF DRY NITROGEN WITH A PRESSURE REGULATING VALVE TO THE CENTER PORT OF THE MANIFOLD

GAUGE SET.

D. ADJUST DRY NITROGEN PRESSURE TO 150 PSIG (1034 KPA). OPEN THE VALVE ON THE HIGH SIDE OF THE MANIFOLD GAUGE SET IN

ORDER TO PRESSURIZE THE LINE SET AND THE INDOOR UNIT.

E. AFTER A FEW MINUTES, OPEN ONE OF THE SERVICE VALVE PORTS AND VERIFY THAT THE REFRIGERANT ADDED TO THE SYSTEM

EARLIER IS MEASURABLE WITH A LEAK DETECTOR.

F. AFTER LEAK TESTING, DISCONNECT GAUGES FROM SERVICE PORTS.

HFC-410A

B

MANIFOLD GAUGE SET

TO VAPOR

SERVICE VALVE

OUTDOOR UNIT

A

XC20

Figure 10. System Leak Test

22

Page 23

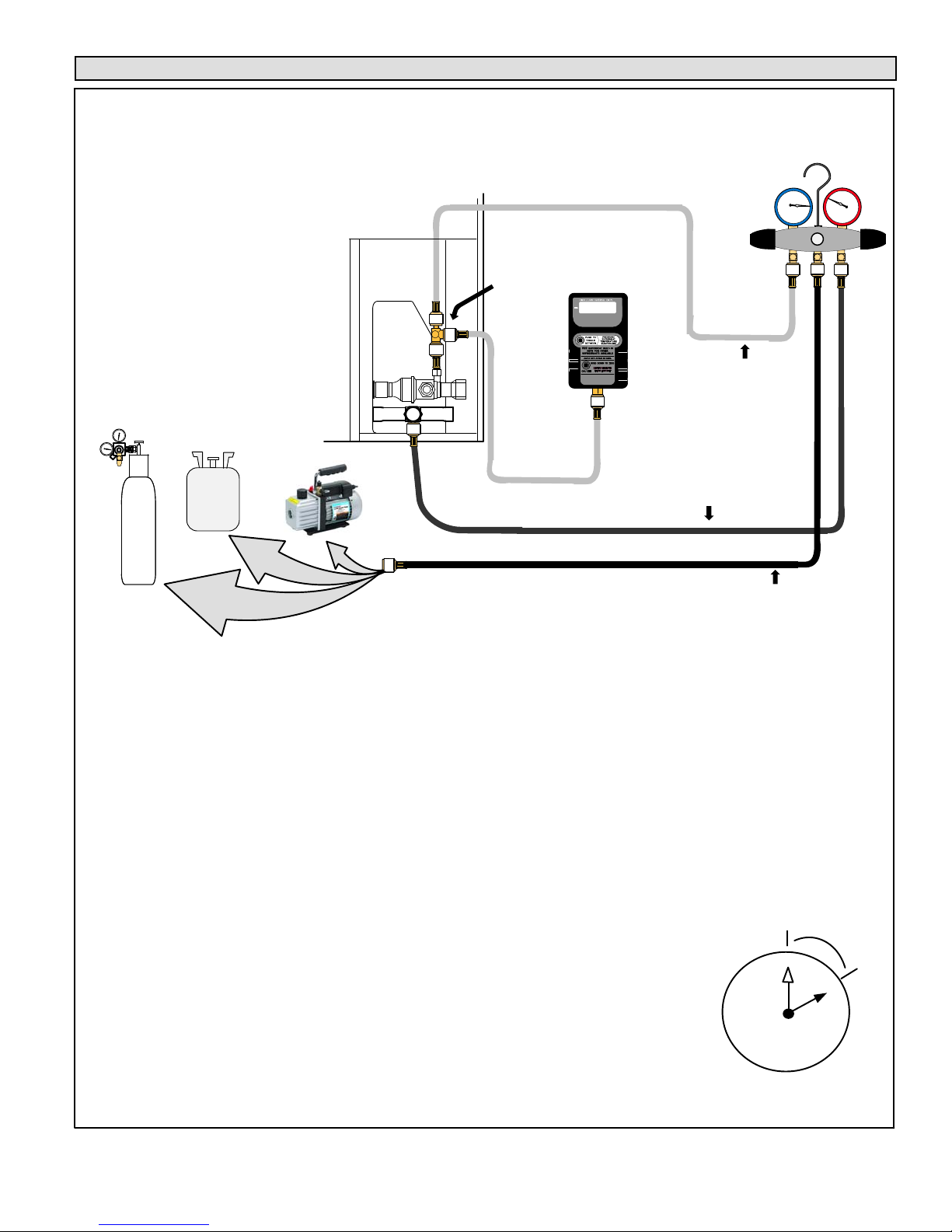

Evacuating the System

LINE SET AND INDOOR COIL

CONNECT GAUGE SET

1

NOTE - REMOVE CORES FROM SERVICE VALVES (IF

NOT ALREADY DONE).

A. CONNECT LOW SIDE OF MANIFOLD

GAUGE SET WITH 1/4 SAE IN-LINE TEE TO

VAPOR LINE SERVICE VALVE.

B. CONNECT HIGH SIDE OF MANIFOLD

GAUGE SET TO LIQUID LINE SERVICE

VALVE.

C. CONNECT MICRON GAUGE TO AN

AVAILABLE CONNECTOR ON THE 1/4 SAE

IN-LINE TEE.

D. CONNECT THE VACUUM PUMP (WITH

VACUUM GAUGE) TO THE CENTER PORT

OF THE MANIFOLD GAUGE SET. THE

CENTER PORT LINE IS USED LATER FOR

BOTH THE AND NITROGEN

CONTAINERS.

OUTDOOR

UNIT

A

A34000 1/4 SAE TEE WITH

SWIVEL COUPLER

500

C

MICRON

GAUGE

LOW

TO VAPOR

SERVICE VALVE

MANIFOLD

GAUGE SET

HIGH

HFC-410A

VACUUM PUMP

B

TO LIQUID LINE

SERVICE VALVE

D

NITROGEN

EVACUATE THE SYSTEM

A. OPEN BOTH MANIFOLD VALVES AND START THE VACUUM PUMP.

2

B. EVACUATE THE LINE SET AND INDOOR UNIT TO AN ABSOLUTE PRESSURE OF 23,000 MICRONS (29.01 INCHES OF MERCURY).

NOTE - DURING THE EARLY STAGES OF EVACUATION, IT IS DESIRABLE TO CLOSE THE MANIFOLD GAUGE VALVE AT LEAST ONCE. A

RAPID RISE IN PRESSURE INDICATES A RELATIVELY LARGE LEAK. IF THIS OCCURS, REPEAT THE LEAK TESTING PROCEDURE.

NOTE - THE TERM ABSOLUTE PRESSURE REFERS TO THE TOTAL ACTUAL PRESSURE (ABOVE ABSOLUTE ZERO) WITHIN A GIVEN

VOLUME OR SYSTEM. ABSOLUTE PRESSURE IN A VACUUM IS EQUAL TO ATMOSPHERIC PRESSURE MINUS VACUUM PRESSURE.

C. WHEN THE ABSOLUTE PRESSURE REACHES 23,000 MICRONS (29.01 INCHES OF MERCURY), CLOSE THE MANIFOLD GAUGE VALVES, TURN

OFF THE VACUUM PUMP AND DISCONNECT THE MANIFOLD GAUGE CENTER PORT HOSE FROM VACUUM PUMP. ATTACH THE MANIFOLD

CENTER PORT HOSE TO A DRY NITROGEN CYLINDER WITH PRESSURE REGULATOR SET TO 150 PSIG (1034 KPA) AND PURGE THE HOSE.

OPEN THE MANIFOLD GAUGE VALVES TO BREAK THE VACUUM IN THE LINE SET AND INDOOR UNIT. CLOSE THE MANIFOLD GAUGE VALVES.

D. SHUT OFF THE DRY NITROGEN CYLINDER AND REMOVE THE MANIFOLD GAUGE HOSE FROM THE CYLINDER. OPEN THE MANIFOLD

GAUGE VALVES TO RELEASE THE DRY NITROGEN FROM THE LINE SET AND INDOOR UNIT.

E. RECONNECT THE MANIFOLD GAUGE TO THE VACUUM PUMP, TURN THE PUMP ON, AND CONTINUE TO EVACUATE THE LINE SET AND IN

DOOR UNIT UNTIL THE ABSOLUTE PRESSURE DOES NOT RISE ABOVE 500 MICRONS (29.9 INCHES OF MERCURY) WITHIN A 20-MINUTE

PERIOD AFTER SHUTTING OFF THE VACUUM PUMP AND CLOSING THE MANIFOLD GAUGE VALVES.

F. WHEN THE ABSOLUTE PRESSURE REQUIREMENT ABOVE HAS BEEN MET, DISCONNECT THE MANIFOLD HOSE FROM THE VACUUM PUMP

AND CONNECT IT TO AN UPRIGHT CYLINDER OF HFC-410A REFRIGERANT. OPEN THE MANIFOLD GAUGE VALVE 1 TO 2 PSIG IN ORDER TO

RELEASE THE VACUUM IN THE LINE SET AND INDOOR UNIT.

G. PERFORM THE FOLLOWING:

1. Close manifold gauge valves.

2

. Shut off HFC-410A cylinder.

. Reinstall service valve cores by removing manifold hose from service valve. Quickly install cores with core

3

tool while maintaining a positive system pressure.

. Replace the stem caps and secure finger tight, then tighten an additional one-sixth (1/6) of a turn as illus

4

trated.

RECOMMEND

MINIMUM 3/8” HOSE

11

10

9

8

7

12

6

1/6 TURN

1

2

3

4

5

Figure 11. Evacuating System

XC20

23

Page 24

IMPORTANT

Load Shedding

Use a thermocouple or thermistor electronic vacuum

gauge that is calibrated in microns. Use an instrument

capable of accurately measuring down to 50 microns.

WARNING

Danger of Equipment Damage. Avoid deep vacuum

operation. Do not use compressors to evacuate a

system. Extremely low vacuums can cause internal

arcing and compressor failure. Damage caused by

deep vacuum operation will void warranty.

Evacuating the system of non-condensables is critical for

proper operation of the unit. Non-condensables are

defined as any gas that will not condense under temperat

ures and pressures present during operation of an air

conditioning system. Non-condensables combine with re

frigerant to produce substances that corrode copper piping

and compressor parts.

Electrical

In the U.S.A., wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada,

wiring must conform with current local codes and the current

Canadian Electrical Code (CEC).

Refer to the furnace or air handler installation instructions

for additional wiring application diagrams. Refer to unit

nameplate for minimum circuit ampacity and maximum

over-current protection size.

24VAC TRANSFORMER

Use the transformer provided with the furnace or air hand

ler for low‐voltage control power (24VAC - 40 VA

minimum).

Utility Load Shedding Mode ACTIVATED

(Utility Cycled Unit OFF) – The normally closed set of

contacts in the utility load shedding control receiver OPEN.

This removes 24VAC from the coil of the field-provided re

lay (catalog # 69J79). The relay contacts close (terminal 7

to terminal 2), completing the circuit between terminals R

and L on the outdoor control. The 24VAC input to terminal L

activates the load-shedding mode in the outdoor control,

cycling the outdoor unit OFF. The 7-Segment display on

the outdoor control displays a load shedding alert code

(E600) and an alert appears on the display of the iComfort

®

thermostat. The customer receives email notifica

Wi-Fi

tions when the alert occurs, if the option to receive

notifications is selected.

Utility Load-Shedding Mode DEACTIVATED

(Normal Equipment Operation) – When load shedding

mode is not required, the contacts in the utility load control

receiver are closed. This provides 24VAC to the coil of the

field-provided relay (catalog # 69J79).The relay contacts

OPEN (terminal 7 to terminal 2) removing 24VAC from the

L terminal on the outdoor control. This deactivates the

load-shedding mode in the outdoor control. The outdoor

unit returns to normal operation and alert code clears once

load-shedding mode is deactivated.

For more information, see the Load-Shedding Feature Wir

ing Diagram on page 47.

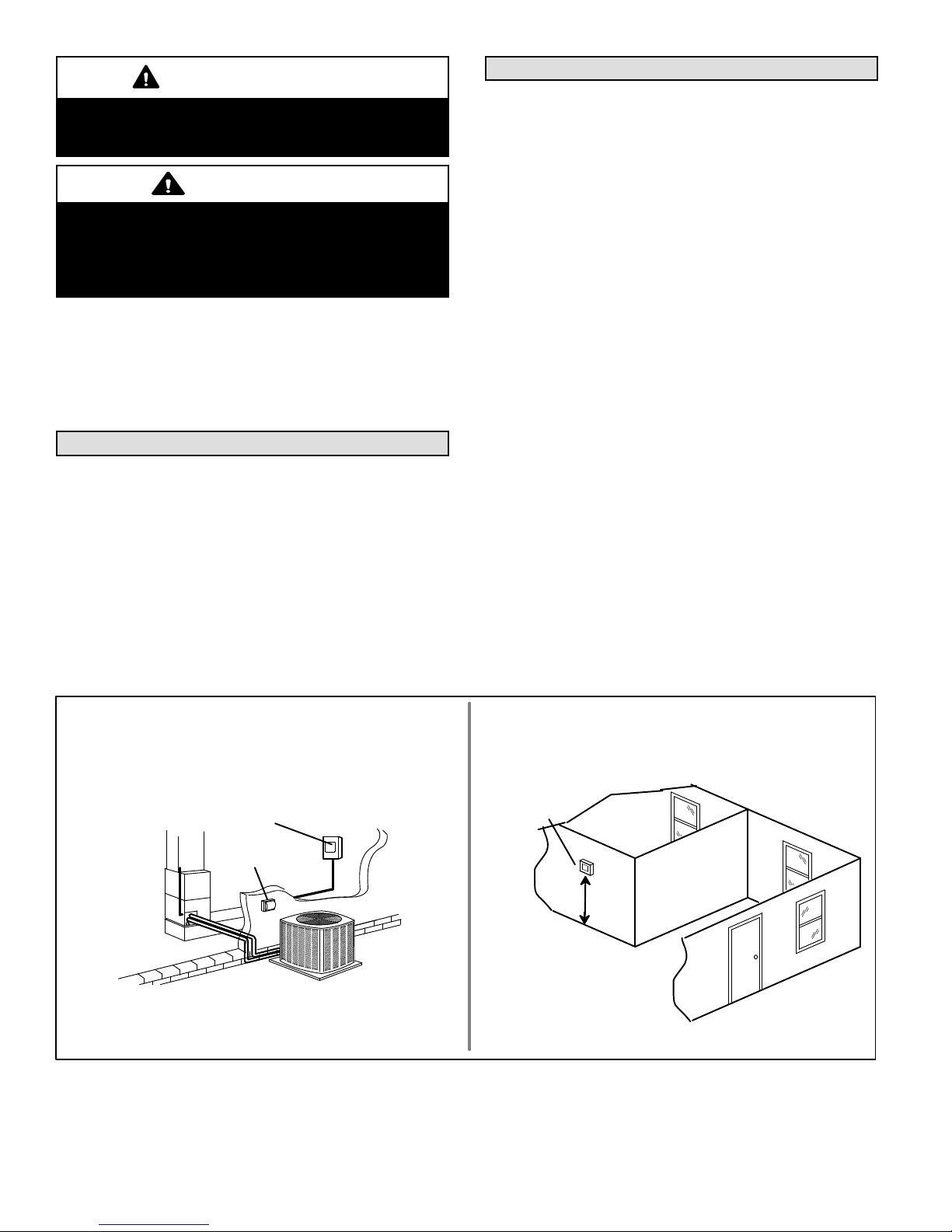

SIZE CIRCUIT AND INSTALL DISCONNECT

SWITCH

1

REFER TO THE UNIT NAMEPLATE FOR MINIMUM CIRCUIT AMPACITY,

AND MAXIMUM FUSE OR CIRCUIT BREAKER (HACR PER NEC).

INSTALL POWER WIRING AND PROPERLY SIZED DISCONNECT

SWITCH.

MAIN FUSE BOX/

BREAKER PANEL

DISCONNECT

SWITCH

NOTE - UNITS ARE APPROVED FOR USE ONLY WITH COPPER

CONDUCTORS. GROUND UNIT AT DISCONNECT SWITCH OR TO AN

EARTH GROUND.

Figure 12. Electrical Installation

INSTALL THERMOSTAT

INSTALL ROOM THERMOSTAT (ORDERED SEPARATELY) ON AN

INSIDE WALL, APPROXIMATELY IN THE CENTER OF THE

2

CONDITIONED AREA AND 5 FEET (1.5M) FROM THE FLOOR. IT

SHOULD NOT BE INSTALLED ON AN OUTSIDE WALL OR WHERE IT

CAN BE AFFECTED BY SUNLIGHT OR DRAFTS.

THERMOSTAT

5 FEET

(1.5M)

NOTE - 24VAC, CLASS II CIRCUIT CONNECTIONS ARE MADE IN THE CON

TROL BOX.

XC20

24

Page 25

ROUTE CONTROL WIRES

Maximum length of wiring (18 gauge) for all connections on the RSBus is 1500 feet (457 meters). Wires should be color-coded, with

3

a temperature rating of 95

field-provided field-installed grommet installed in electrical inlet.

The iComfort Wi-Fi

iComfort® control and four wires between the outdoor unit and the furnace/air handler iComfort® control. When a thermostat cable

with more than four wires is used, the extra wires must be properly connected to avoid electrical noise (see below).

Use a wire nut to bundle the four unused wires at each end of the cable. Each bundle should also include an additional wire that should

be connected on each end to the C terminal as shown in the figure below.

º

F (35ºC) minimum, and solid-core (Class II Rated Wiring). All low voltage wiring must enter unit through

®

or iComf ort® S30 thermostats require four thermostat wires between the thermostat and the furnace / air handler

OUTDOOR UNIT

PROVIDED RAST

6-PIN CONNECTOR

CONNECTS TO

RAST 6-PIN

CONNECTOR

ROUTE CONTROL

WIRING THROUGH

GROMMET AND

SECURE WITH

CABLE TIE

Single Wire To

C Terminal

Unused Wires

GROMMET AND

CABLE TIE.

INDOOR CONTROL

Indoor Control

CONNECT CONDUIT

TO CUTOUT AND

ROUTE HIGH

VOLTAGE WIRING

USE WATERTIGHT

CONDUIT FOR HIGH

VOLTAGE

Single Wire To C Terminal

Unused Wires

ROUTE HIGH VOLTAGE AND GROUND WIRES

Any excess high voltage field wiring should be trimmed and secured away from any low voltage field wiring. To facilitate a conduit, a

4

cutout is located on the bottom of the control box. Connect conduit to the control box using a proper conduit fitting.

Figure 13. Electrical Installation (Continued)

XC20

25

Page 26

CAUTION

Electrostatic discharge can affect electronic components. Take precautions

ELECTROSTATIC DISCHARGE

(ESD)

Precautions and Procedures

STEP 3 -- ELECTRICAL (Continued) -- Outdoor Control Unit

during unit installation and service to protect the unit's electronic controls.

Precautions will help to avoid control exposure to electrostatic discharge by

putting the unit, the control and the technician at the same electrostatic potential.

Neutralize electrostatic charge by touching hand and all tools on an unpainted

unit surface before performing any service procedure.

NOTE - The green LED located on the outdoor control flashes

when communication occurs between the outdoor control and

either the thermostat or the inverter.

XC20

WHEN THE UNIT IS IN PUMP-DOWN MODE, IS SHOWN ON

TO ACTIVATE PUMP-DOWN MODE, REFER TO PUMP-DOWN

Figure 14. Outdoor Unit Control

26

7-SEGMENT

PUSH

BUTTON

THE 7-SEGMENT DISPLAY.

CYCLE SEQUENCE ON PAGE 39.

DISPLAY

Page 27

TABLE 5

Outdoor Control Terminal Designations and Input /Outputs (see figure 14 for terminal locations)

Designator Description Input Output Common

O

O OUT

LO PS Low pressure switch N/A 5ma @18VAC N/A

LO PS Low pressure switch sensing connection 5ma @18VAC N/A N/A

Hi PS High pressure switch N/A 24VAC nominal N/A

Hi PS High pressure switch sensing connection 24VAC nominal N/A N/A

TP

TP Top cap thermostat switch sensing connection 24VAC nominal N/A N/A

Cntctr

Cntctr Contactor common N/A 24VAC common

Fan PWM PWM fan output N/A

COM PWM fan common connection N/A N/A

Fan Park

Unused on XC20, for heat pump applications

only.

Unused on XC20, for heat pump applications

only.

Top cap thermostat switch (in series with the HI

PS)

Control (inverter power) contactor switched out

put (in series with the HI PS and TC)

PWM fan parking spot for unused terminal, not

connected.

N/A

N/A N/A 24VAC common

N/A 24VAC nominal N/A

N/A

N/A N/A N/A

Switched 24VAC

nominal

Switched 24VAC

Nominal

1097% duty cycle,

1923 VDC peak

N/A

N/A

N/A

Fan PWM com

mon

P2 Terminal Designations

O

Y1 Y1 emergency input

C 24VAC nominal power return. N/A N/A 24VAC common

i Low data line. Data Data N/A

i+ High data line. Data Data N/A

R 24VAC nominal power input.

DF OEM test N/A N/A N/A

TOUT

TST

Unused on XC20, for heat pump applications

only.

26Vdc transistor output to Lennox factory OEM

tester

OEM test pin.

In each terminal box:

P2 Terminal 1 TEST

P2 Terminal 2 TOUT

P2 Terminal 3 DF

P2 Terminal 4 R

24VAC nominal from ther

mostat and loaded to draw

17ma at 30VAC

24VAC nominal from ther

mostat and loaded to draw

17ma at 30VAC

24VAC nominal board main

power input.

N/A N/A N/A

24VAC nominal 17ma @

30VAC

N/A N/A

N/A N/A

N/A N/A

N/A N/A

XC20

27

Page 28

Table 5 continued.

Outdoor Control Terminal Designations and Input /Outputs

WARNING - Electric Shock Hazard. Can cause injury or death. Unit must be grounded in accordance with national and

local codes. The 4 pins in P6 have the potential of transferring up to 250 volts to the unit cabinet ground.

Designator Description Input Output Common

Outdoor control

communication

transmit pin.

Inverter common.

P6 - Pin 1 Tx

P6 - Pin 2

Inverter

Common

Transmit data to inverter, connects to

Rx of inverter.

Inverter common

NOTE - This is a signal reference point

and not an earth ground.

Outdoor control

communication

receive pin.

P6 - Pin 3 Rx

Receive data from the inverter.

Connects to Tx of inverter.

P6 - Pin 4 Inv 5V Inverter 5VDC volts. Inverter 5VDC volts

LIQ

Liquid line temperature sensor sup

ply.

N/A N/A N/A

• Pin 1 to pin 2 should read 4.5 to 5.5

VDC when not communicating.

• Pin 3 to pin 2 should read 4.5 to 5.5

VDC when not communicating.

• Pin 4 to pin 2 should read 4.5 to 5.5

VDC.

NOTE - Communication signals switch off

and on rapidly. This may cause volt meter

readings to fluctuate. This is normal.

Communication signals will switch

between this 5V and common (Pin 2).

LIQ Liquid line temperature sensor return. N/A N/A N/A

AMB

AMB

COIL

COIL

Pump Down

Outdoor ambient temperature sensor

supply.

Outdoor ambient temperature sensor

return.

Outdoor coil temperature sensor sup

ply.

Outdoor coil temperature sensor re

turn.

To initiate pump-down function, place jumper in

the ON position. (See PUMP-DOWN MODE

OPERATION on page 37.)

1. Place the jumper in the ON position to

activate pump-down mode.

2. Place the jumper in the OFF position to

deactivate pump-down mode.

NOTE -If the pump-down jumper is in the ON

position during power-up, it is ignored.

NOTE - The outdoor control stays in pump-down

mode for five minutes, after which the outdoor

control initiates a compressor shutdown

sequence.

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

PUMP

DOWN

ON

OFF

PUMP

DOWN

ON

OFF

24VAC input to L en

L Load-shedding input

ergizes load shed

N/A N/A

ding feature.

Load-shedding input reference. Refer

C

to wiring of load-shedding terminals

N/A N/A

located on page 47.

24VAC

common

XC20

28

Page 29

Servicing Units Delivered Void of Charge

If the outdoor unit is void of refrigerant, clean the system us

ing the procedure described below.

1. Leak test the system using the procedure outlined on

page 22.

2. Evacuate the system using procedure outlined on

page 23.

3. Use nitrogen to break the vacuum and install a new fil

ter drier in the system.

4. Evacuate the system again using procedure outlined

on page 23.

5. Weigh in refrigerant using procedure outlined in figure

56.

6. Monitor the system to determine the amount of mois

ture remaining in the oil. It may be necessary to replace

the filter drier several times to achieve the required dry

ness level. If system dryness is not verified, the

compressor will fail in the future.

Unit Start-Up

IMPORTANT

1. Rotate fan to check for binding.

2. Inspect all factory- and field-installed wiring for loose

connections.

3. After evacuation is complete, open both the liquid and

vapor line service valves to release the refrigerant

charge contained in outdoor unit into the system.

4. Replace the stem caps and tighten to the value listed

in table 1.

5. Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit's

nameplate. If not, do not start the equipment until you

have consulted with the power company and the

voltage condition has been corrected.

6. Set the thermostat for a cooling demand. Turn on

power to the indoor unit and close the outdoor unit dis

connect switch to start the unit.

7. Recheck voltage while the unit is running. Power must

be within range shown on the nameplate.

If unit is equipped with a crankcase heater, it should be

energized 24 hours before unit start-up to prevent

compressor damage as a result of slugging.

8. Check system for sufficient refrigerant by using the

procedures listed in the System Refrigerant section on

page 75.

XC20

29

Page 30

III. SYSTEM OPERATION AND SERVICE

7-Segment Alert and System Status Codes

Alert codes are displayed using the 7-segment display loc

ated on the outdoor control.

NOTE - System fault and lockout codes take precedence

over system status codes (cooling, heating operating per

centages or defrost/dehumidification).

The 7-segment will display an abnormal condition (error

code) when detected in the system. A list of the codes are

shown in table 6.

RESETTING ALERT CODES

Alert codes can be reset manually or automatically:

1. Manual Reset

Manual reset can be achieved by one of the following

methods:

Table 6. Outdoor Control 7-Segment Display Alert Codes and Inverter LED Flash Codes

NOTE - System fault and lockout codes take precedence over system status codes (cooling, heating operating percentages or defrost/dehumidification).

Only the latest active fault or lockout codes are displayed (if present). If no fault or lockout codes are active, then system status codes are displayed. Alert

codes are also displayed on the iComfort Wi-Fi

Inverter LED Flash

Alert

Codes

N/A N/A ON OFF N/A XC/XP 20-024 and -036 only: Indicates inverter is operating normally.

N/A N/A ON ON N/A XC/XP 20-048 and -060 only: Indicates inverter is operating normally.

N/A N/A OFF OFF N/A Indicates inverter is NOT energized.

E 105 N/A N/A N/A Moderate

E 120 N/A N/A N/A Moderate

E 124 N/A N/A N/A Critical

E 125 N/A N/A N/A Critical

E 131 N/A N/A N/A Critical

E 132 N/A N/A N/A Critical Internal software error. Replace outdoor control.

E 180 N/A N/A N/A Critical

Inverter

Code

Code (number of

flashes)

Red LED Green LED

XC20

®

or iComfort

Priority Alarm Description Possible Causes and Clearing Alarm

®

S30 thermostat.

The outdoor control has

lost communication with

either the thermostat or in

door unit.

There is a delay in the out

door unit responding to the

system.

The iComfort WiFi® or

iComfort

has lost communication

with the outdoor unit for

more than 3 minutes.

There is a hardware prob

lem with the outdoor con

trol.

The outdoor unit control

parameters are corrupted.

The outdoor unit ambient

temperature sensor has

malfunctioned. As a result

the outdoor unit control will

not perform low ambient

cooling.

®

S30 thermostat

• Disconnecting R wire from the outdoor control R

terminal.

• Turning the indoor unit off and back on again

After power up, all currently displayed codes are

cleared.

2. Automatic Reset

After an alert is detected, the outdoor control continues

to monitor the unit's system and compressor opera

tions. When/if conditions return to normal, the alert

code is turned off automatically.

NOTE - Error codes can be recalled by following in

formation shown in the table on page 37.

Equipment is unable to communicate. Indicates nu

merous message errors. In most cases errors are re

lated to electrical noise. Make sure high voltage power

is separated from RSBus. Check for miswired and/or

loose connections between the stat, indoor unit and

outdoor unit. Check for a high voltage source of noise

close to the system. Fault clears after communication

is restored.

Typically, this alarm/code does not cause any issues

and clears on its own. The alarm/code is usually

caused by a delay in the outdoor unit responding to the

thermostat. Check all wiring connections. Cleared

after unresponsive device responds to any inquiry.

Equipment lost communication with the thermostat.

Check the wiring connections and resistance, then

cycle the system power. This alarm stops all associ

ated HVAC operations and waits for a signal from the

non-communicating unit. The alarm / fault clears after

communication is reestablished.

There is a control hardware problem. Replace the out

door control if the problem prevents operation and is

persistent. The alarm / fault is cleared 300 seconds after

the fault recovers.

Reconfigure the system. Replace the control if heating or

cooling is not available.

Valid temperature reading is lost during normal opera

tion and after outdoor control recognized sensors.

Compare outdoor sensor resistance to temperature/

resistance charts in unit installation instructions. Re

place sensor pack if necessary. At the beginning of

(any) configuration, furnace or airhandler control de

tects the presence of the sensor(s). If detected (reading

in range), appropriate feature is shown in the iComfort

®

WiFi

or iComfort® S30 thermostat About screen. The

alarm / fault clears upon configuration, or when normal

values are sensed.

30

Page 31

Table 6. Outdoor Control 7-Segment Display Alert Codes and Inverter LED Flash Codes

NOTE - System fault and lockout codes take precedence over system status codes (cooling, heating operating percentages or defrost/dehumidification).

Only the latest active fault or lockout codes are displayed (if present). If no fault or lockout codes are active, then system status codes are displayed. Alert

codes are also displayed on the iComfort Wi-Fi

Inverter LED Flash

Alert

Codes

Inverter

Code

Code (number of

flashes)

Red LED Green LED

E 345 N/A N/A N/A Critical

E 409 N/A N/A N/A Moderate

E 410 N/A N/A N/A Moderate

E 411 N/A N/A N/A Critical

E 412 N/A N/A N/A Moderate

E 413 N/A N/A N/A Critical

E 416 N/A N/A N/A

®

thermostat.