Page 1

E N G I N E E R I N G D A TA

A I R C O N D T I O N E R S

XC16

ELITE® Series

R-410A - Two-Stage Compressor - SilentComfort™ Technology

Bulletin No. 210465

October 2009

Supersedes March 2009

MODEL NUMBER IDENTIFICATION

X C 16 - 036 - 230 - 2

Refrigerant Type

X = R-410A

Unit Type

C = Air Conditioner

Series

SEER up to 17.20

2 to 5 Tons

Cooling Capacity - 24,600 to 60,000 Btuh

Minor Revision Number

Voltage

230 = 208/230V-1phase-60hz

Nominal Cooling Capacity

024 = 2 tons

036 = 3 tons

048 = 4 tons

060 = 5 tons

Page 2

FEATURES

Contents

AHRI System Matches..................................................8

Dimensions ..................................................................7

Electrical Data ..............................................................5

Features........................................................................2

Field Wiring ..................................................................6

Installation Clearances ................................................6

Model Number Identication .........................................1

Optional Accessories ...................................................5

Outdoor Sound Data ....................................................6

Specications ...............................................................5

H

B

G

Equipment Warranty

Compressor - limited warranty for ten years in

residential installations and ve years in non-residential

installations.

All other covered components - ve years in

residential installations and one year in non-residential

installations.

Refer to Lennox Equipment Limited Warranty certicate

included with unit for specic details.

ApplicationS

SEER up to 17.20.

2 through 5 ton.

Single phase power supply.

Sound levels as low as 74 dB.

Vertical air discharge allows concealment behind shrubs

at grade level or out of sight on a roof.

Matching add-on furnace indoor coils or air handlers

provide a wide range of cooling capacities and

applications. See AHRI System Matches.

See Indoor Coils and Air Handlers tab sections for data.

Units shipped completely factory assembled, piped, and

wired. Each unit is test operated at the factory insuring

proper operation.

Installer must set air conditioner, connect refrigerant

lines, and make electrical connections to complete job.

Approvals

Certied in accordance with USE certication program

which is based on AHRI Standard 210/240-2008.

Sound rated in Lennox reverberant sound test room

in accordance with test conditions included in AHRI

Standard 270-2008.

Tested in the Lennox Research Laboratory

environmental test room.

Rated according to U.S. Department of Energy (DOE)

test procedures.

Air conditioners and components within bonded for

grounding to meet safety standards for servicing

required by UL and CEC.

Units are UL and ULC listed.

ISO 9001 Registered Manufacturing Quality System.

EnErgy Star® certied units are designed to use less

energy, help save money on utility bills, and help protect

the environment.

For expanded ratings, see www.lennoxdavenet.com.

XC16 - 2 to 5 Ton Heat Pump / Page 2

C

D

F

E

J

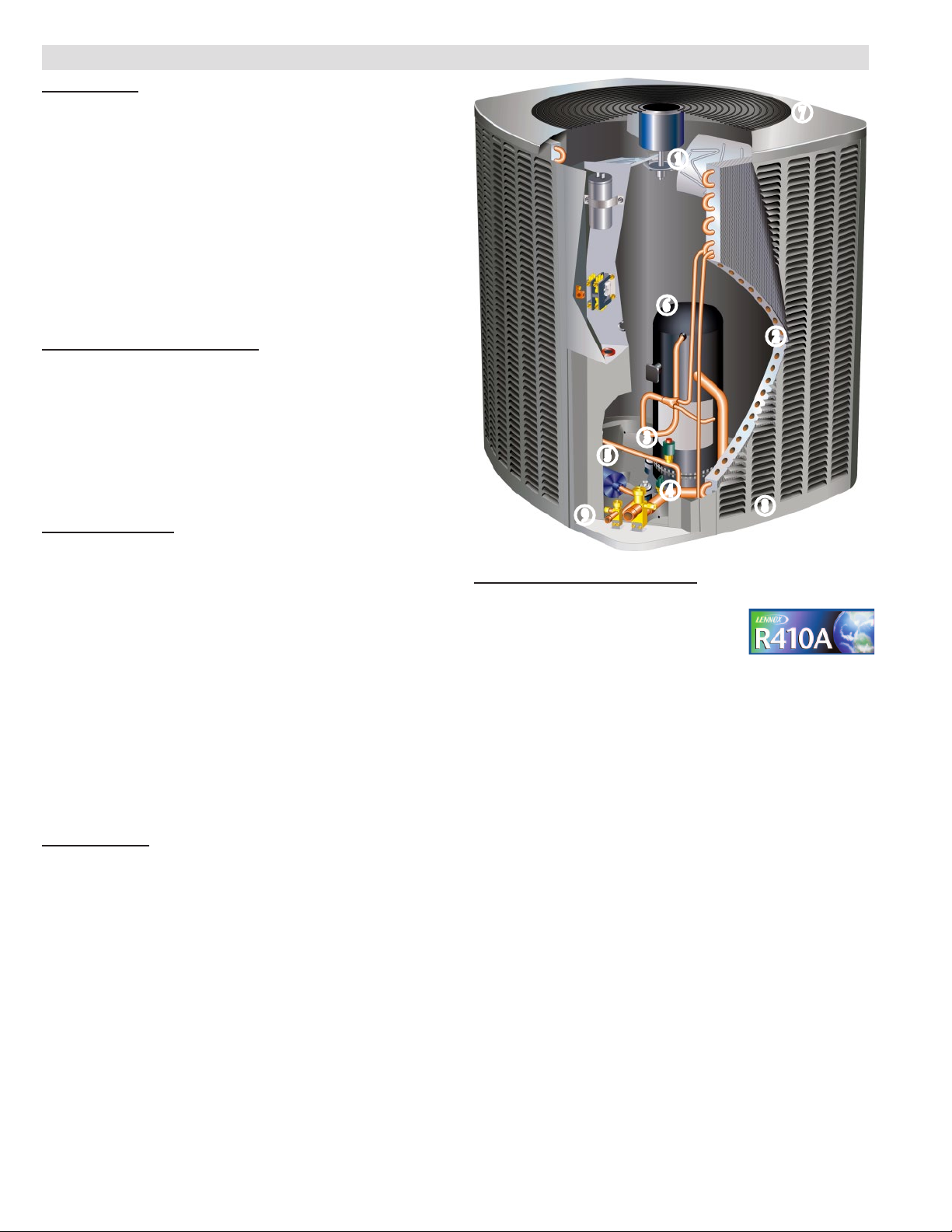

REFRIGERATION SYSTEM

R-410A Refrigerant

Non-chlorine, ozone friendly, R-410A.

Unit pre-charged with refrigerant.

See Specication table.

Outdoor Coil Fan

B

Direct drive fan moves large air volumes uniformly

through entire condenser coil for high refrigerant cooling

capacity.

Vertical air discharge minimizes operating sounds and

eliminates damage to lawn and shrubs.

Fan motor has sleeve bearings and is inherently

protected.

Motor totally enclosed for maximum protection from

weather, dust and corrosion

Fan guard constructed of corrosion-resistant PVC

(polyvinyl chloride) coated steel.

Fan service access accomplished by removal of fan

guard.

Copper Tube/Enhanced Fin Coil

C

Lennox designed and fabricated coil.

Ripple-edged aluminum ns.

Copper tube construction.

Lanced ns provide maximum exposure of n surface to

air stream resulting in excellent heat transfer.

Fin collars grip tubing for maximum contact area.

Flared shoulder tubing connections/silver soldering

construction.

Coil is factory tested under high pressure to insure

leakproof construction.

Entire coil is accessible for cleaning.

I

A

Page 3

FEATURES

REFRIGERATION SYSTEM (CONTINUED)

High Pressure Switch

D

Shuts off unit if abnormal operating conditions cause the

discharge pressure to rise above setting.

Protects compressor from excessive condensing

pressure.

Manual reset.

Low Pressure Switch

E

Shuts off unit if suction pressure falls below setting.

Provides loss of charge and freeze-up protection.

Automatic reset.

Hi-Capacity Liquid Line Drier

F

Factory installed in the liquid line, the drier traps

moisture or dirt that could contaminate the refrigerant

system.

100% molecular-sieve bead type drier.

OPTIONS

Expansion Valve Kits

Must be ordered extra and eld installed on certain

indoor units. See Specication table and TXV

Substitution table.

Chatleff style tting.

Freezestat

Installs on or near the discharge line of the indoor coil or

on the suction line.

Senses suction line temperature and cycles the

compressor off when suction line temperature falls

below it’s setpoint.

Opens at 29°F and closes at 58°F.

Refrigerant Line Kits

Refrigerant lines (suction & liquid) are shipped

refrigeration clean. Lines are cleaned, dried,

pressurized, and sealed at factory.

Suction line fully insulated.

L15 lines are stubbed at both ends.

See Specications table for selection.

Not available for -060 model and must be eld

fabricated.

COMPRESSOR

Copeland Scroll Ultra Tech™ Two-Stage Compressor

G

Compressor features high

efciency with uniform

suction ow, constant

discharge ow and high

volumetric efciency and

quiet operation.

Compressor consists

of two involute spiral

scrolls matched together

to generate a series of

crescent shaped gas

pockets between them.

During compression, one

scroll remains stationary

while the other scroll

orbits around it.

Gas is drawn into the

outer pocket, the pocket

is sealed as the scroll

rotates.

As the spiral movement continues, gas pockets are

pushed to the center of the scrolls. Volume between the

pockets is simultaneously reduced.

When pocket reaches the center, gas is now at high

pressure and is forced out of a port located in the

center of the xed scrolls. During compression, several

pockets are compressed simultaneously resulting in a

smooth continuous compression cycle.

Continuous ank contact, maintained by centrifugal

force, minimizes gas leakage and maximizes efciency.

Scroll compressor is tolerant to the effects of slugging

and contaminants. If this occurs, scrolls separate,

allowing liquid or contaminants to be worked toward the

center and discharged.

On the xed scroll there

are two bypass ports in

the rst suction pocket. On

the outside of the xed

scroll there is a “slider

ring” that is controlled by

an internal solenoid that

will rotate and cover the

bypass ports. When the

thermostat calls for

rst-stage cooling, the

bypass ports are open and

the compressor operates

at 67% capacity, creating more cost-effective and

efcient compressor operation. The bypassed

refrigerant is returned to the compressor housing

through the bypass ports. When the thermostat calls for

second-stage cooling, the internal solenoid is energized,

the slider ring rotates and covers the bypass ports, and

the compressor operates at full capacity.

Low gas pulses during compression reduces

operational sound levels.

XC16 - 2 to 5 Ton Heat Pump / Page 3

Page 4

FEATURES

COMPRESSOR (CONTINUED)

Compressor motor is internally protected from

excessive current and temperature.

Compressor is installed in the unit on specially

formulated, resilient rubber mounts for better sound

dampening and vibration free operation.

Crankcase Heater

Crankcase heater prevents migration of liquid

refrigerant into compressor and ensures proper

compressor lubrication.

OPTIONS

Compressor Hard Start Kit

Single-phase units are equipped with a PSC

compressor motor.

This type of motor normally does not need a potential

relay and start capacitor.

In conditions such as low voltage, kit may be required to

increase the compressor starting torque.

Hard start kit is required in applications where the

supply voltage is less than 230V.

CONTROLS

OPTIONS

ComfortSense® 7000

Touchscreen Thermostat

Electronic 7-day, universal,

multi-stage, programmable,

touchscreen thermostat.

HOME SCHEDULE OPTIONS

MODE

AUTO

ON

SCHED

INDOOR RH 26%

WED AN 21 12:35AM

SETAT

HEAT

SETAT

COOL

4 Heat/2 Cool.

Auto-changeover.

Controls humidity during

cooling mode.

Offers enhanced capabilities including humidication /

dehumidication / dewpoint measurement and control,

Humiditrol® control, and equipment maintenance

reminders.

Easy-to-use, menu driven thermostat with a back-lit,

LCD touchscreen.

Remote outdoor temperature sensor (optional) allows

the thermostat to display outdoor temperature. Required

in dual fuel and Humiditrol® applications.

See the ComfortSense 7000 Engineering Handbook

bulletin in the Controls section for more information.

Indoor Blower Off Delay Relay

Delays the indoor blower-off time during the cooling

cycle.

See AHRI System Matches for usage.

Indoor Blower Speed Relay

Relay kit provides optimum humidity control conditions

by automatically reducing indoor blower speed during

continuous fan or rst-stage compressor operation.

Low Ambient Kit

Air conditioner will operate satisfactorily down to 45°F

outdoor air temperature without any additional controls.

Kit can be added in the eld enabling unit to operate

properly down to 30°F.

A Freezestat should be installed on compressors

equipped with a low ambient kit.

A Compressor Low Ambient Cut-Off should be added to

terminate compressor operation below recommended

operation conditions.

Thermostat

Thermostat not furnished with unit. See Thermostat

bulletins in Controls Section and Lennox Price Book.

CAbinet

Heavy-gauge steel construction

H

Pre-painted cabinet nish.

Painted base section.

Control box is conveniently located with all controls

factory wired.

Large removable panel provides service access.

Drainage holes are provided in base section for

moisture removal.

High density polyethylene unit support feet raise the

unit off of the mounting surface, away from damaging

moisture.

SmartHinge™ Louvered Coil Protection

I

Steel louvered panels

provides complete coil

protection.

Panels are hinged to allow

easy cleaning and servicing

of coils.

Panels may be completely

removed.

Interlocking tabs and slots

assure tight t on cabinet.

Refrigerant Line Connections, Electrical Inlets and

J

Service Valves

Suction and liquid lines are located on corner of unit

cabinet and are made with sweat connections. See

dimension drawing.

Fully serviceable brass service valves prevent corrosion

and provide access to refrigerant system. Suction valve

can be fully shut off, while liquid valve may be front

seated to manage refrigerant charge while servicing

system.

Refrigerant line connections and eld wiring inlets

are located in one central area of the cabinet. See

dimension drawing.

XC16 - 2 to 5 Ton Heat Pump / Page 4

Page 5

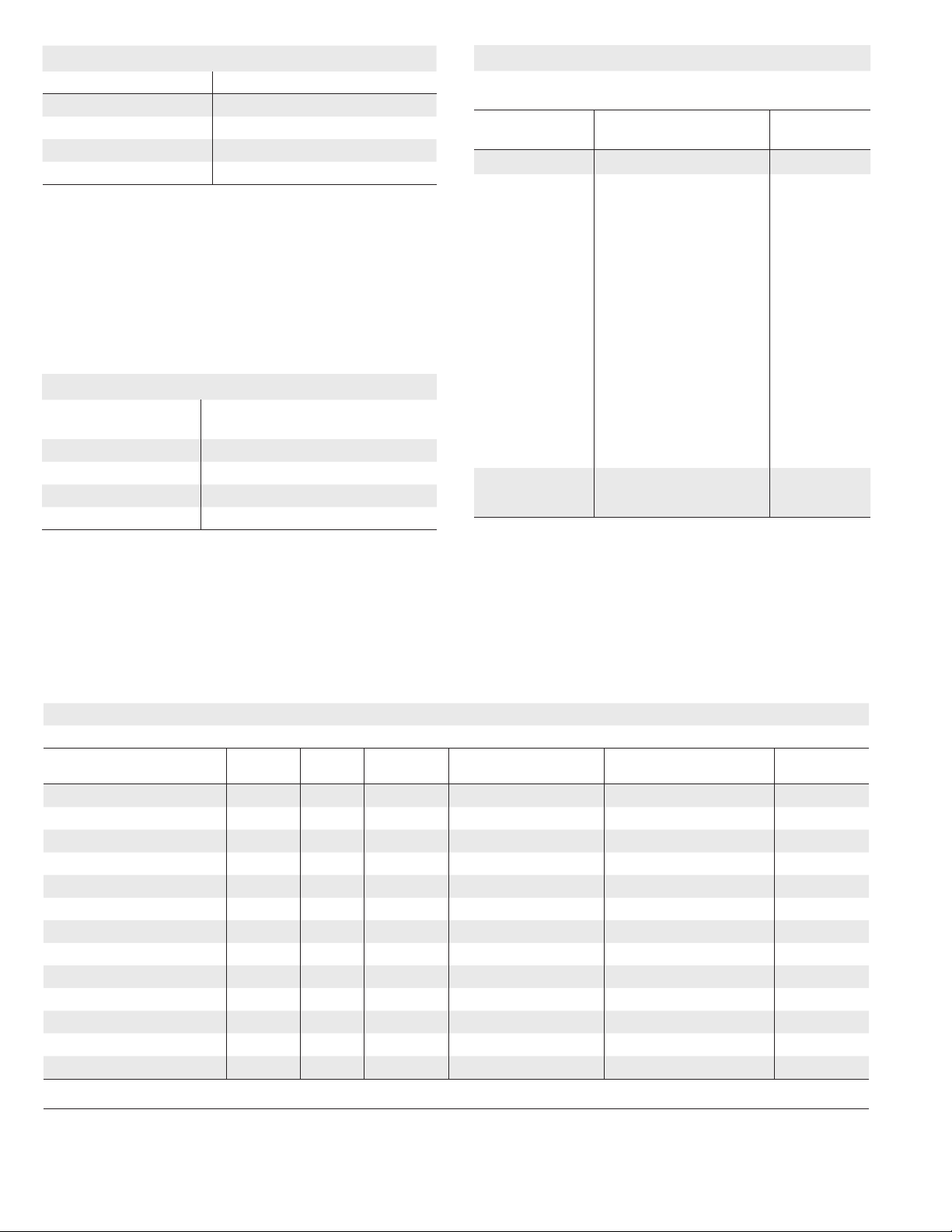

SPECIFICATIONS

General

Data

Connections

(sweat)

Refrigerant

Outdoor

Net face area - sq. ft. Outer coil 21.00 24.5 21.00 24.93

Liquid line (o.d.) - in. 3/8 3/8 3/8 3/8

Suction line (o.d.) - in. 3/4 7/8 7/8 1-1/8

1

R-410A charge furnished 7 lbs. 6 oz. 8 lbs. 8 oz. 11 lbs. 4 oz. 14 lbs. 2 oz.

Coil

Tube diameter - in. 5/16 5/16 5/16 5/16

Outdoor

Fan

Shipping Data - lbs. 1 pkg. 230 249 268 323

ELECTRICAL DATA

Line voltage data - 60hz

2

Maximum overcurrent protection (amps) 20 35 45 60

3

Minimum circuit ampacity 13.6 22.0 28.2 33.9

Compressor Rated load amps 10.3 16.7 21.2 25.9

Locked rotor amps 52 82 96 118

Outdoor Fan

Motor

Locked Rotor amps 2.1 2.1 3.1 2.9

OPTIONAL ACCESSORIES - must be ordered extra

®

ComfortSense

7000 Thermostat Y2081

Outdoor Temperature Sensor - for

ComfortSense 7000 Thermostat

Compressor Hard Start Kit - Required in

applications with less than 230V

Compressor Low Ambient Cut-Off 45F08

Compressor Time-Off Control 47J27

Freezestat 3/8 in. tubing 93G35

5/8 in. tubing 50A93

Indoor Blower Off Delay Relay 58M81

Indoor Blower Speed Relay 40K58

Low Ambient Kit 34M72

Refrigerant

Line Sets

L15-41-20 L15-41-40

L15-41-30 L15-41-50

L15-65-30 L15-65-40

NOTE - Extremes of operating range are plus 10% and minus 5% of line voltage.

1

Refrigerant charge sufcient for 15 ft. length of refrigerant lines.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

4

Hard start kit is required in applications where the supply voltage is less than 230V.

Model No. XC16-024 XC16-036 XC16-048 XC16-060

Nominal Tonnage 2 3 4 5

Inner coil - - - - - - 20.27 24.14

No. of rows 1 1 2 2

Fins per inch 26 26 22 22

Diameter - in. 22 22 22 26

No. of blades 4 4 4 3

Motor hp 1/6 1/6 1/4 1/3

Cfm 3230 3260 3955 4380

Rpm 840 840 835 850

Watts 215 220 320 280

4

230V-1ph

4

230V-1ph

4

230V-1ph

4

230V-1ph

Power factor 0.98 0.99 0.99 0.99

Full load amps 1.1 1.1 1.7 1.8

X2658

10J42

81J69

L15-65-50

Field Fabricate

XC16 - 2 to 5 Ton Heat Pump / Page 5

Page 6

OUTDOOR SOUND DATA

Octave Band Sound Power Levels dBA, re 10-

1

Unit

Model No.

XC16-024

XC16-036

XC16-048

XC16-060

NOTE - the octave sound power data does not include tonal correction.

1

Tested according to AHRI Standard 270-2008 test conditions.

63 125 250 500 1000 2000 4000 8000

50 55 62 67 68.5 65.5 63 58.5 74

50.5 54.5 61 68 67 63 63 59.5 76

81.5 72 72 72.5 68.5 64.5 59.5 56.5 76

79 71 70.5 76.5 71 65 61.5 57.5 78

FIELD WIRING

Center Frequency - HZ

12

Watts

1

Sound

Rating

Number

(dB)

DISCONNECT

SWITCH

(By Others)

B

THERMOSTAT

(Optional)

D

C

LENNOX

AIR

CONDITIONER

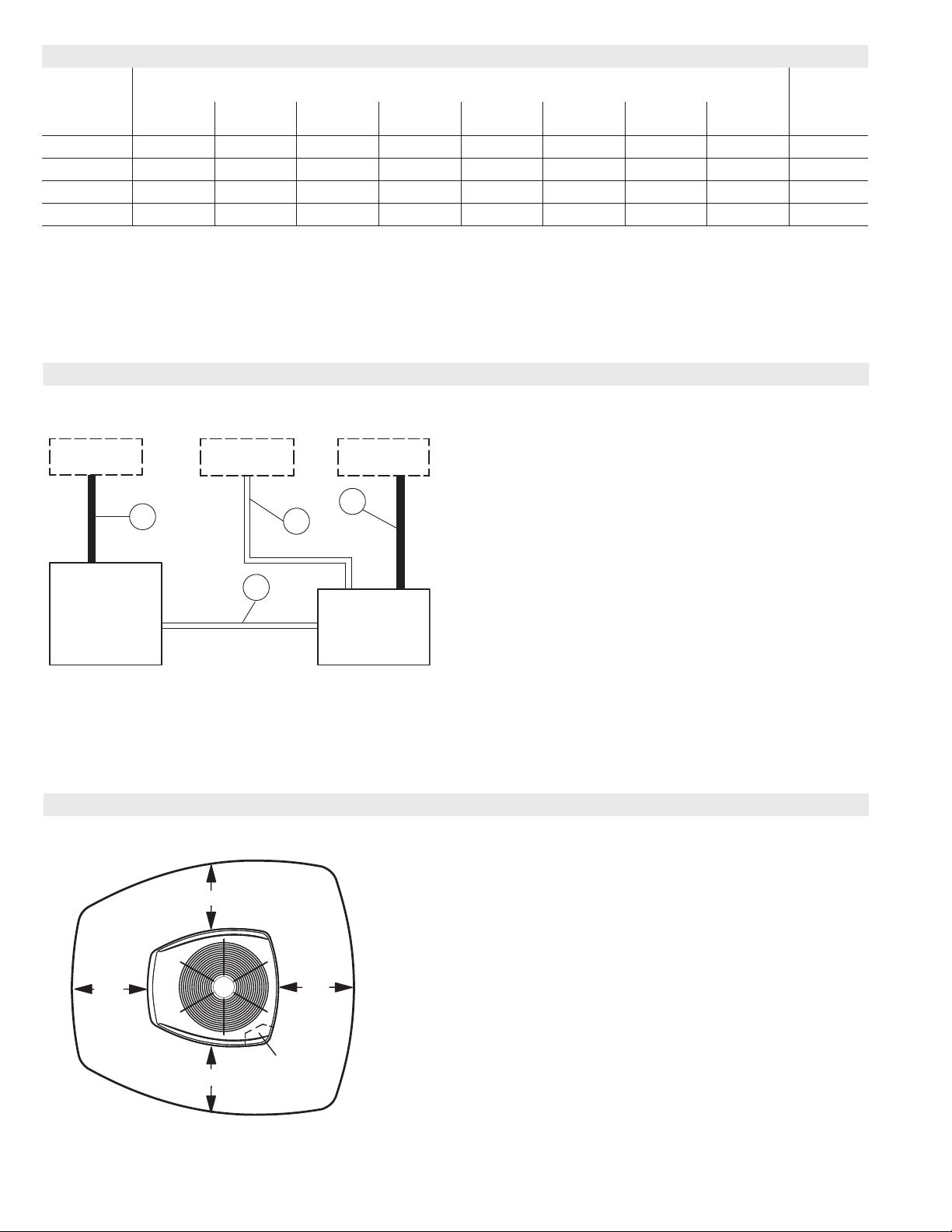

INSTALLATION CLEARANCES

See NOTES

DISCONNECT

SWITCH

(By Others)

A

LENNOX

HEATING UNIT

OR

AIR HANDLER

UNIT

A - Two Wire Power (not furnished)

B - Two Power (not furnished). See Electrical Data

C - Four Wire Low Voltage (not furnished). 18 ga. minimum

D - Six Wire Low Voltage (not furnished). 18 ga. minimum

All wiring must conform to NEC or CEC and local electrical codes.

NOTES:

Service clearance of 30 in. (762 mm) must be maintained on one

of the sides adjacent to the control box.

See

NOTES

See NOTES

XC16 - 2 to 5 Ton Heat Pump / Page 6

See

NOTES

Control

Box

Clearance to one of the other three sides must be 36 in. (914 mm)

Clearance to one of the remaining two sides may be 12 in. (305

mm) and the final side may be 6 in. (152 mm).

A clearance of 24 in. (610 mm) must be maintained between two

units.

48 in. (1219 mm) clearance required on top of unit.

Page 7

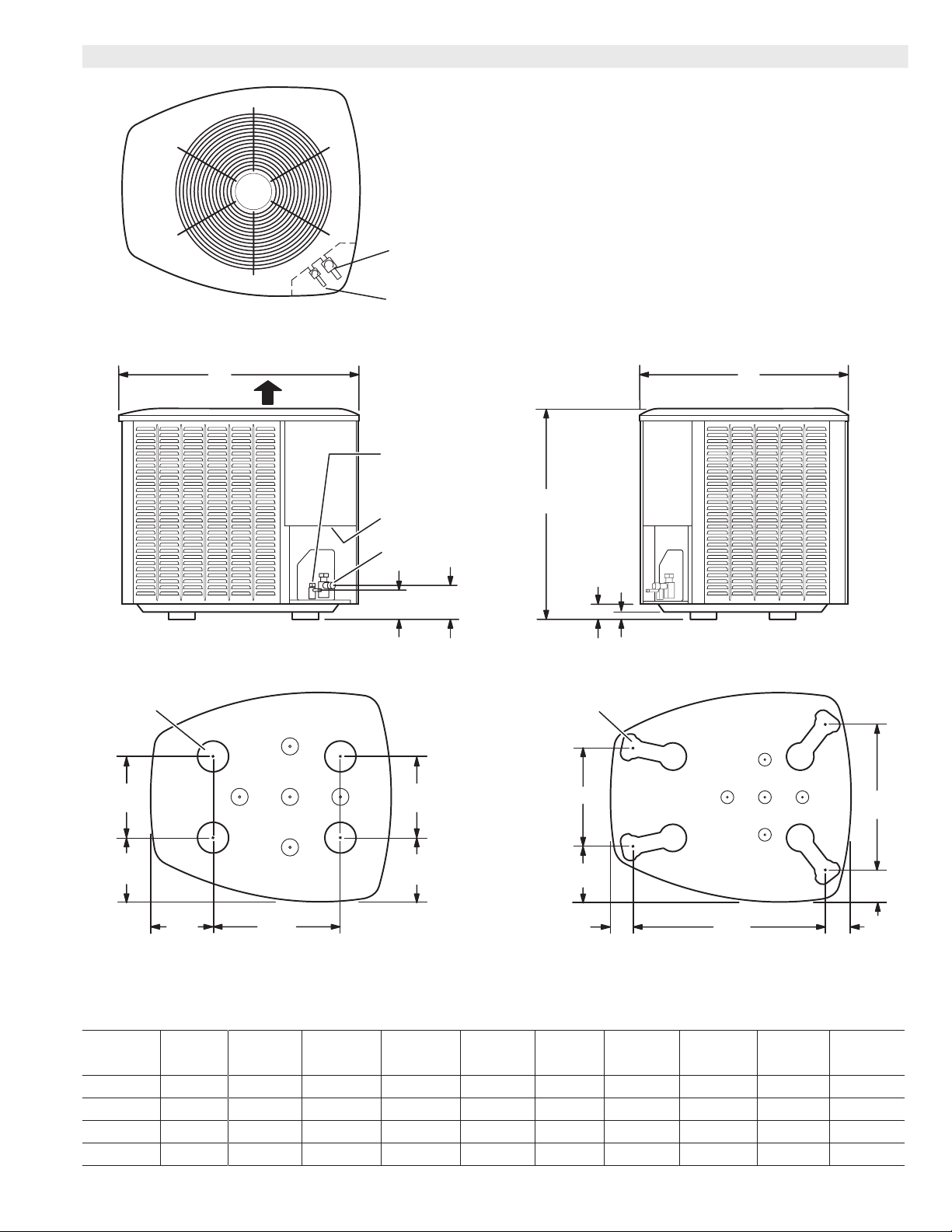

DIMENSIONS - INCHES (MM)

(216)

TOP VIEW

DISCHARGE AIR

SUCTION LINE

CONNECTION

LIQUID LINE

CONNECTION

BC

LIQUID LINE

CONNECTION

UNIT SUPPORT

FEET

8−1/2

8−3/4

(222)

5−1/2

(140)

4−1/4(108)

SIDE VIEW

13−1/2

(343)

XC16-024 BASE SECTION

ELECTRICAL

INLETS

SUCTION LINE

CONNECTION

4−3/4

(121)

9−1/2

(241)

8−1/4

(210)

A

2 (51)

UNIT SUPPORT

FEET

D

E

1 (25)

F

END VIEW

G

H

XC16-036 TO -060 BASE SECTION

K

J

Model No.

A B C D E F G H J K

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm

XC16-024 39 991 30-1/2 775 35 889 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

XC16-036 45 1143 30-1/2 775 35 889 13-7/8 352 7-3/4 197 3-1/4 83 27-1/8 689 3-5/8 92 4-1/2 114 20-5/8 524

XC16-048 39 991 30-1/2 775 35 889 13-7/8 352 7-3/4 197 3-1/4 83 27-1/8 689 3-5/8 92 4-1/2 114 20-5/8 524

XC16-060 39 991 35-1/2 902 39-1/2 1003 16-7/8 429 8-3/4 222 3-1/8 79 30-3/4 781 4-5/8 117 3-3/4 95 26-7/8 683

XC16 - 2 to 5 Ton Heat Pump / Page 7

Page 8

THERMAL EXPANSION VALVES (TXV)

Model No. Order No.

XC16-024 37L51

XC16-036 37L51

XC16-048 91M02

XC16-060 91M02

CX34 upow coils and all Lennox air handlers (except CB26UH “R”) are

shipped with a factory installed TXV. In most cases, no change out of the valve

is needed.

If a change out is required it will be listed in the “TXV SUBSTITUTIONS” table.

The correct TXV must be ordered and eld installed. C33 coils and all horizontal

and downow coils are shipped without a TXV. The TXV must be ordered and

eld installed.

MOST POPULAR MATCHES

Outdoor Unit

Model No.

XC16-024 CX34-36B with G60UHV-36B-040

XC16-036 CX34-43C with G60UHV-60C-110

XC16-048 CX34-62C with G60UHV-60C-090

XC16-060 CX34-62C with G60UHV-60C-090

Indoor Unit

Model No

*tXV SUBSTITUTIONS

Indoor Coils/Air Handlers with factory installed expansion

valves that require eld replacement

Model No.

XC16-024 CBX26UH-024 37L51

XC16-036 CX34-42 37L51

XC16-036 CX34-43 37L51

XC16-036 CX34-44/48 37L51

XC16-036 CX34-49 37L51

XC16-036 CBX26UH-030 37L51

XC16-036 CBX27UH-072 37L51

XC16-036 CBX32M-042 37L51

XC16-036 CBX32MV-024/030 37L51

XC16-036 CBX32MV-048 37L51

XC16-036 CBX40UHV-030 37L51

XC16-036 CBX40UHV-042 37L51

XC16-036 CBX40UHV-048 37L51

XC16-048 CX34-44/48 91M02

XC16-048 CBX26UH-042 91M02

*CX34 coils and all air handlers (except CB26UH “R”) - the factory installed

expansion valve must be replaced with the expansion valve listed (ordered

separately). If the combination is not listed above, the factory installed TXV is

used.

C33 and CH33 coils and CB26UH “R” air handlers - use the RFC shipped with

the outdoor unit or replace the factory installed RFC with the expansion valve

listed in the Thermal Expansion Valves Table.

CR33 and CH23 - use the RFC shipped with the outdoor unit or use the expansion valve listed in the Thermal Expansion Valves Table.

Indoor Coil or Air

Handler

Order No.

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-024-230 + TXV 25,200 15.70 12.70 C33-19 CBWMV-24B-040 3496089

XC16-024-230 + TXV 25,400 16.50 12.70 C33-19 G60UHV-36A-070 3069061

XC16-024-230 + TXV 24,800 14.20 11.50 C33-19 3069056

XC16-024-230 + TXV 25,800 16.50 13.00 C33-25 G60UHV-36A-070 3069062

XC16-024-230 + TXV 26,000 16.70 13.20 C33-25 G60UHV-36B-090 3069063

XC16-024-230 + TXV 26,000 16.50 13.00 C33-25 G61MPV-36B-045 3069064

XC16-024-230 + TXV 25,800 16.50 13.00 C33-25 G61MPV-36B-070 3069065

XC16-024-230 + TXV 25,800 16.50 13.00 C33-25 G71MPP-36B-070 3069066

XC16-024-230 + TXV 25,200 14.20 11.70 C33-25 3069057

XC16-024-230 + TXV 25,200 16.00 12.70 C33-30 G60UHV-36A-070 3069067

XC16-024-230 + TXV 25,200 16.00 12.70 C33-30 G60UHV-36B-090 3069068

XC16-024-230 + TXV 25,200 15.70 12.50 C33-30 G61MPV-36B-045 3069069

XC16-024-230 + TXV 25,200 15.70 12.70 C33-30 G61MPV-36B-070 3069070

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 8

Page 9

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-024-230 + TXV 25,200 16.00 12.50 C33-30 G61MPV-36B-071 3069072

XC16-024-230 + TXV 25,000 16.00 12.70 C33-30 G61MPV-36C-090 3069163

XC16-024-230 + TXV 25,200 15.70 12.70 C33-30 G71MPP-36B-070 3069071

XC16-024-230 + TXV 25,000 16.00 12.70 C33-30 G71MPP-36C-090 3069164

XC16-024-230 + TXV 26,200 16.70 13.20 C33-31 G60UHV-36A-070 3069073

XC16-024-230 + TXV 26,400 17.00 13.50 C33-31 G60UHV-36B-090 3069074

XC16-024-230 + TXV 26,400 16.70 13.20 C33-31 G61MPV-36B-045 3069075

XC16-024-230 + TXV 26,200 16.70 13.20 C33-31 G61MPV-36B-070 3069076

XC16-024-230 + TXV 26,400 16.70 13.20 C33-31 G61MPV-36B-071 3069078

XC16-024-230 + TXV 26,200 16.70 13.20 C33-31 G71MPP-36B-070 3069077

XC16-024-230 + TXV 25,600 14.50 12.00 C33-31 3069058

XC16-024-230 + TXV 25,200 15.50 12.70 C33-36 CBWMV-24B-040 3493246

XC16-024-230 + TXV 25,800 16.50 13.00 C33-36 G60UHV-36A-070 3069079

XC16-024-230 + TXV 25,400 16.00 12.70 C33-36 G60UHV-36B-090 3068760

XC16-024-230 + TXV 25,800 16.50 13.00 C33-36 G61MPV-36B-045 3069080

XC16-024-230 + TXV 25,800 16.50 13.00 C33-36 G61MPV-36B-070 3069081

XC16-024-230 + TXV 25,800 16.50 13.00 C33-36 G61MPV-36B-071 3069083

XC16-024-230 + TXV 25,600 16.50 13.20 C33-36 G61MPV-36C-090 3069084

XC16-024-230 + TXV 25,800 16.50 13.00 C33-36 G71MPP-36B-070 3069082

XC16-024-230 + TXV 25,600 16.50 13.20 C33-36 G71MPP-36C-090 3069085

XC16-024-230 + TXV 24,600 13.70 11.50 C33-36 3069059

XC16-024-230 + TXV 26,400 17.00 13.20 C33-38 G60UHV-36A-070 3069086

XC16-024-230 + TXV 26,600 17.00 13.50 C33-38 G60UHV-36B-090 3069087

XC16-024-230 + TXV 26,600 16.70 13.20 C33-38 G61MPV-36B-045 3069088

XC16-024-230 + TXV 26,400 17.00 13.20 C33-38 G61MPV-36B-070 3069089

XC16-024-230 + TXV 26,600 17.00 13.20 C33-38 G61MPV-36B-071 3069091

XC16-024-230 + TXV 26,400 17.00 13.20 C33-38 G71MPP-36B-070 3069090

XC16-024-230 + TXV 25,400 14.20 11.70 C33-38 3069060

XC16-024-230 + TXV 26,000 15.20 12.50 CB26UH-024 3069092

XC16-024-230 + TXV 26,000 16.20 13.20 CB27UH-024-230 3069094

XC16-024-230 + TXV 26,200 17.00 13.50 CB27UH-030-230 3069095

XC16-024-230 + TXV 25,400 14.50 12.00 CB30M-21/26P 3069093

XC16-024-230 + TXV 26,000 15.20 12.50 CBX26UH-024 3068837

XC16-024-230 + TXV 26,000 16.20 13.20 CBX27UH-024-230 3068841

XC16-024-230 + TXV 26,200 17.00 13.50 CBX27UH-030-230 3068842

XC16-024-230 + TXV 25,400 14.50 12.00 CBX32M-018/024 3068838

XC16-024-230 + TXV 25,400 15.50 12.20 CBX32MV-018/024 3068839

XC16-024-230 + TXV 25,600 15.50 12.50 CBX32MV-024/030 3068840

XC16-024-230 + TXV 25,400 15.50 12.20 CBX40UHV-024 3291609

XC16-024-230 + TXV 25,600 15.50 12.50 CBX40UHV-030 3291634

XC16-024-230 + TXV 24,600 16.00 12.70 CH23-31 G61MPV-36B-070 3068814

XC16-024-230 + TXV 24,600 16.00 12.70 CH23-31 G71MPP-36B-070 3068815

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 9

Page 10

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-024-230 + TXV 24,000 13.50 11.00 CH23-31 3068767

XC16-024-230 + TXV 25,800 16.50 13.00 CH23-41 G60UHV-36A-070 3068816

XC16-024-230 + TXV 25,200 14.20 11.70 CH23-41 3068768

XC16-024-230 + TXV 25,400 16.20 12.70 CH33-19 G60UHV-36A-070 3068817

XC16-024-230 + TXV 24,800 14.00 11.50 CH33-19 3068769

XC16-024-230 + TXV 25,200 16.00 12.70 CH33-24/30 G60UHV-36A-070 3068818

XC16-024-230 + TXV 24,600 14.00 11.50 CH33-24/30 3068843

XC16-024-230 + TXV 26,000 16.50 13.00 CH33-25A G60UHV-36A-070 3068819

XC16-024-230 + TXV 25,400 14.50 11.70 CH33-25A 3068772

XC16-024-230 + TXV 25,800 16.70 13.20 CH33-25B G60UHV-36B-090 3068820

XC16-024-230 + TXV 25,800 16.50 13.00 CH33-25B G61MPV-36B-045 3068821

XC16-024-230 + TXV 25,800 16.50 13.00 CH33-25B G61MPV-36B-070 3068822

XC16-024-230 + TXV 26,000 16.50 13.00 CH33-25B G61MPV-36B-071 3068824

XC16-024-230 + TXV 25,800 16.50 13.00 CH33-25B G71MPP-36B-070 3068823

XC16-024-230 + TXV 25,200 14.20 11.70 CH33-25B 3068773

XC16-024-230 + TXV 26,400 16.70 13.20 CH33-31A G60UHV-36A-070 3068825

XC16-024-230 + TXV 25,800 14.70 12.00 CH33-31A 3068774

XC16-024-230 + TXV 26,600 17.00 13.50 CH33-31B G60UHV-36B-090 3068826

XC16-024-230 + TXV 26,400 16.70 13.20 CH33-31B G61MPV-36B-045 3068827

XC16-024-230 + TXV 26,400 16.70 13.20 CH33-31B G61MPV-36B-070 3068828

XC16-024-230 + TXV 26,600 17.00 13.20 CH33-31B G61MPV-36B-071 3068830

XC16-024-230 + TXV 26,400 16.70 13.20 CH33-31B G71MPP-36B-070 3068829

XC16-024-230 + TXV 25,800 14.50 12.00 CH33-31B 3068775

XC16-024-230 + TXV 25,600 16.20 12.70 CH33-36A G60UHV-36A-070 3068831

XC16-024-230 + TXV 25,200 14.20 11.70 CH33-36A 3068770

XC16-024-230 + TXV 25,800 16.70 13.20 CH33-36B G60UHV-36B-090 3068832

XC16-024-230 + TXV 25,800 16.20 13.00 CH33-36B G61MPV-36B-045 3068833

XC16-024-230 + TXV 25,800 16.50 13.00 CH33-36B G61MPV-36B-070 3068834

XC16-024-230 + TXV 25,800 16.50 13.00 CH33-36B G61MPV-36B-071 3068836

XC16-024-230 + TXV 25,800 16.50 13.00 CH33-36B G71MPP-36B-070 3068835

XC16-024-230 + TXV 25,000 14.20 11.70 CH33-36B 3068771

XC16-024-230 + TXV 26,200 16.70 13.00 CR33-30/36 G60DFV-36A-070 3068808

XC16-024-230 + TXV 26,600 17.20 13.50 CR33-30/36 G60DFV-36B-090 3068809

XC16-024-230 + TXV 26,200 16.70 13.20 CR33-30/36 G61MPV-36B-045 3068810

XC16-024-230 + TXV 26,200 16.70 13.20 CR33-30/36 G61MPV-36B-070 3068811

XC16-024-230 + TXV 26,200 16.70 13.20 CR33-30/36 G61MPV-36B-071 3068813

XC16-024-230 + TXV 26,200 16.70 13.20 CR33-30/36 G71MPP-36B-070 3068812

XC16-024-230 + TXV 25,400 14.50 11.70 CR33-30/36 3068766

XC16-024-230 + TXV 25,200 15.70 12.70 CX34-18/24 CBWMV-24B-040 3496087

XC16-024-230 + TXV 25,400 16.50 12.70 CX34-18/24 G60UHV-36A-070 3493257

XC16-024-230 + TXV 24,800 14.20 11.50 CX34-18/24 3493256

XC16-024-230 + TXV 25,400 16.50 12.70 CX34-19 G60UHV-36A-070 3068776

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 10

Page 11

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-024-230 + TXV 24,800 14.20 11.50 CX34-19 3068761

XC16-024-230 + TXV 25,800 16.50 13.00 CX34-25 G60UHV-36A-070 3068777

XC16-024-230 + TXV 26,000 16.70 13.20 CX34-25 G60UHV-36B-090 3068778

XC16-024-230 + TXV 26,000 16.50 13.00 CX34-25 G61MPV-36B-045 3068779

XC16-024-230 + TXV 25,800 16.50 13.00 CX34-25 G61MPV-36B-070 3068780

XC16-024-230 + TXV 25,800 16.50 13.00 CX34-25 G71MPP-36B-070 3068781

XC16-024-230 + TXV 25,200 14.20 11.70 CX34-25 3068762

XC16-024-230 + TXV 25,200 16.00 12.70 CX34-30 G60UHV-36A-070 3068782

XC16-024-230 + TXV 25,200 16.00 12.70 CX34-30 G60UHV-36B-090 3068783

XC16-024-230 + TXV 25,200 15.70 12.50 CX34-30 G61MPV-36B-045 3068784

XC16-024-230 + TXV 25,200 15.70 12.70 CX34-30 G61MPV-36B-070 3068785

XC16-024-230 + TXV 25,200 16.00 12.50 CX34-30 G61MPV-36B-071 3068787

XC16-024-230 + TXV 25,000 16.00 12.70 CX34-30 G61MPV-36C-090 3068844

XC16-024-230 + TXV 25,200 15.70 12.70 CX34-30 G71MPP-36B-070 3068786

XC16-024-230 + TXV 25,000 16.00 12.70 CX34-30 G71MPP-36C-090 3068845

XC16-024-230 + TXV 26,200 16.70 13.20 CX34-31 G60UHV-36A-070 3068788

XC16-024-230 + TXV 26,400 17.00 13.50 CX34-31 G60UHV-36B-090 3068789

XC16-024-230 + TXV 26,400 16.70 13.20 CX34-31 G61MPV-36B-045 3068790

XC16-024-230 + TXV 26,200 16.70 13.20 CX34-31 G61MPV-36B-070 3068791

XC16-024-230 + TXV 26,400 16.70 13.20 CX34-31 G61MPV-36B-071 3068793

XC16-024-230 + TXV 26,200 16.70 13.20 CX34-31 G71MPP-36B-070 3068792

XC16-024-230 + TXV 25,600 14.50 12.00 CX34-31 3068763

XC16-024-230 + TXV 25,200 15.50 12.70 CX34-36 CBWMV-24B-040 3493247

XC16-024-230 + TXV 25,800 16.50 13.00 CX34-36 G60UHV-36A-070 3068794

XC16-024-230 + TXV 25,800 16.70 13.20 CX34-36 G60UHV-36B-090 3068795

XC16-024-230 + TXV 25,800 16.50 13.00 CX34-36 G61MPV-36B-045 3068796

XC16-024-230 + TXV 25,800 16.50 13.00 CX34-36 G61MPV-36B-070 3068797

XC16-024-230 + TXV 25,800 16.50 13.00 CX34-36 G61MPV-36B-071 3068799

XC16-024-230 + TXV 25,600 16.50 13.20 CX34-36 G61MPV-36C-090 3068800

XC16-024-230 + TXV 25,800 16.50 13.00 CX34-36 G71MPP-36B-070 3068798

XC16-024-230 + TXV 25,600 16.50 13.20 CX34-36 G71MPP-36C-090 3068801

XC16-024-230 + TXV 24,600 13.70 11.50 CX34-36 3068764

XC16-024-230 + TXV 26,400 17.00 13.20 CX34-38 G60UHV-36A-070 3068802

XC16-024-230 + TXV 26,600 17.00 13.50 CX34-38 G60UHV-36B-090 3068803

XC16-024-230 + TXV 26,600 16.70 13.20 CX34-38 G61MPV-36B-045 3068804

XC16-024-230 + TXV 26,400 17.00 13.20 CX34-38 G61MPV-36B-070 3068805

XC16-024-230 + TXV 26,600 17.00 13.20 CX34-38 G61MPV-36B-071 3068807

XC16-024-230 + TXV 26,400 17.00 13.20 CX34-38 G71MPP-36B-070 3068806

XC16-024-230 + TXV 25,400 14.20 11.70 CX34-38 3068765

XC16-036-230 + TXV 34,400 15.50 11.20 C33-36 CBWMV-36C-090 3184066

XC16-036-230 + TXV 34,200 15.00 11.00 C33-36 G60UHV-36A-070 3069103

XC16-036-230 + TXV 34,600 15.70 11.50 C33-36 G60UHV-36B-090 3069104

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 11

Page 12

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-036-230 + TXV 35,000 16.00 11.50 C33-36 G60UHV-60C-090 3069105

XC16-036-230 + TXV 34,800 15.70 11.50 C33-36 G60UHV-60C-110 3069106

XC16-036-230 + TXV 34,200 15.20 11.00 C33-36 G61MPV-36B-045 3069107

XC16-036-230 + TXV 34,400 15.50 11.00 C33-36 G61MPV-36B-070 3069108

XC16-036-230 + TXV 34,200 15.20 11.00 C33-36 G61MPV-36B-071 3069110

XC16-036-230 + TXV 34,200 15.50 11.50 C33-36 G61MPV-36C-090 3069111

XC16-036-230 + TXV 34,400 15.50 11.00 C33-36 G71MPP-36B-070 3069109

XC16-036-230 + TXV 34,200 15.50 11.50 C33-36 G71MPP-36C-090 3069112

XC16-036-230 + TXV 33,800 13.70 10.70 C33-36 3069097

XC16-036-230 + TXV 35,600 15.70 11.50 C33-38 G60UHV-36A-070 3069113

XC16-036-230 + TXV 35,800 16.20 11.70 C33-38 G60UHV-36B-090 3069114

XC16-036-230 + TXV 35,600 16.00 11.20 C33-38 G61MPV-36B-045 3069115

XC16-036-230 + TXV 35,400 16.00 11.50 C33-38 G61MPV-36B-070 3069116

XC16-036-230 + TXV 35,400 16.00 11.50 C33-38 G61MPV-36B-071 3069118

XC16-036-230 + TXV 35,400 16.00 11.50 C33-38 G71MPP-36B-070 3069117

XC16-036-230 + TXV 34,600 14.00 10.90 C33-38 3069098

XC16-036-230 + TXV 34,400 15.70 11.50 C33-42 G60UHV-36B-090 3069119

XC16-036-230 + TXV 34,200 15.20 11.00 C33-42 G61MPV-36B-045 3069120

XC16-036-230 + TXV 34,000 15.20 11.00 C33-42 G61MPV-36B-070 3069121

XC16-036-230 + TXV 34,000 15.20 11.00 C33-42 G61MPV-36B-071 3069123

XC16-036-230 + TXV 34,000 15.20 11.00 C33-42 G71MPP-36B-070 3069122

XC16-036-230 + TXV 33,800 13.70 10.70 C33-42 3069099

XC16-036-230 + TXV 35,800 16.00 11.70 C33-43 CBWMV-36C-090 3184068

XC16-036-230 + TXV 36,000 16.20 12.00 C33-43 G60UHV-36B-090 3069124

XC16-036-230 + TXV 36,600 16.50 12.00 C33-43 G60UHV-60C-090 3069125

XC16-036-230 + TXV 36,000 16.50 12.00 C33-43 G60UHV-60C-110 3069096

XC16-036-230 + TXV 35,600 16.00 11.50 C33-43 G61MPV-36B-045 3069126

XC16-036-230 + TXV 35,400 16.00 11.50 C33-43 G61MPV-36B-070 3069127

XC16-036-230 + TXV 35,400 16.20 12.00 C33-43 G61MPV-36C-090 3069129

XC16-036-230 + TXV 36,200 16.20 12.00 C33-43 G61MPV-60C-090 3069131

XC16-036-230 + TXV 36,200 16.20 11.70 C33-43 G61MPV-60C-091 3069133

XC16-036-230 + TXV 36,200 16.00 12.00 C33-43 G61MPV-60C-110 3069134

XC16-036-230 + TXV 36,200 16.20 12.00 C33-43 G61MPV-60C-111 3069136

XC16-036-230 + TXV 35,400 16.00 11.50 C33-43 G71MPP-36B-070 3069128

XC16-036-230 + TXV 35,400 16.20 12.00 C33-43 G71MPP-36C-090 3069130

XC16-036-230 + TXV 36,200 16.20 12.00 C33-43 G71MPP-60C-090 3069132

XC16-036-230 + TXV 36,200 16.00 12.00 C33-43 G71MPP-60C-110 3069135

XC16-036-230 + TXV 35,200 14.20 11.00 C33-43 3069100

XC16-036-230 + TXV 36,000 16.20 12.00 C33-44C G60UHV-60C-090 3068758

XC16-036-230 + TXV 35,800 16.20 11.70 C33-44C G60UHV-60C-110 3068697

XC16-036-230 + TXV 35,200 16.00 11.70 C33-44C G61MPV-36C-090 3068698

XC16-036-230 + TXV 35,600 16.20 11.70 C33-44C G61MPV-60C-090 3068700

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 12

Page 13

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-036-230 + TXV 35,800 16.00 11.50 C33-44C G61MPV-60C-091 3068702

XC16-036-230 + TXV 35,600 15.70 11.70 C33-44C G61MPV-60C-110 3068703

XC16-036-230 + TXV 35,600 16.20 11.70 C33-44C G61MPV-60C-111 3068705

XC16-036-230 + TXV 35,200 16.00 11.70 C33-44C G71MPP-36C-090 3068699

XC16-036-230 + TXV 35,600 16.20 11.70 C33-44C G71MPP-60C-090 3068701

XC16-036-230 + TXV 35,600 15.70 11.70 C33-44C G71MPP-60C-110 3068704

XC16-036-230 + TXV 35,400 16.20 11.70 C33-48 G60UHV-36B-090 3069137

XC16-036-230 + TXV 36,000 16.20 11.70 C33-48 G60UHV-60C-090 3069138

XC16-036-230 + TXV 35,800 16.20 11.70 C33-48 G60UHV-60C-110 3069139

XC16-036-230 + TXV 35,200 15.70 11.20 C33-48 G61MPV-36B-045 3069140

XC16-036-230 + TXV 35,000 15.70 11.50 C33-48 G61MPV-36B-070 3069141

XC16-036-230 + TXV 35,200 15.70 11.20 C33-48 G61MPV-36B-071 3069143

XC16-036-230 + TXV 35,200 16.00 11.70 C33-48 G61MPV-36C-090 3069144

XC16-036-230 + TXV 35,600 16.00 11.70 C33-48 G61MPV-60C-090 3069146

XC16-036-230 + TXV 35,800 16.00 11.50 C33-48 G61MPV-60C-091 3069148

XC16-036-230 + TXV 35,600 15.70 11.70 C33-48 G61MPV-60C-110 3069149

XC16-036-230 + TXV 35,600 16.00 11.70 C33-48 G61MPV-60C-111 3069151

XC16-036-230 + TXV 35,000 15.70 11.50 C33-48 G71MPP-36B-070 3069142

XC16-036-230 + TXV 35,200 16.00 11.70 C33-48 G71MPP-36C-090 3069145

XC16-036-230 + TXV 35,600 16.00 11.70 C33-48 G71MPP-60C-090 3069147

XC16-036-230 + TXV 35,600 15.70 11.70 C33-48 G71MPP-60C-110 3069150

XC16-036-230 + TXV 34,800 14.20 10.90 C33-48 3069101

XC16-036-230 + TXV 35,600 14.50 11.00 C33-49 3069102

XC16-036-230 + TXV 34,800 14.70 11.20 CB26UH-030 3069152

XC16-036-230 + TXV 35,200 14.70 11.20 CB26UH-036 3069153

XC16-036-230 + TXV 35,000 15.70 11.70 CB27UH-036-230 3069157

XC16-036-230 + TXV 36,000 16.50 12.00 CB27UH-042-230 3069158

XC16-036-230 + TXV 34,200 15.00 11.00 CB30M-31P 3069154

XC16-036-230 + TXV 34,400 14.70 11.00 CB30M-41P 3069155

XC16-036-230 + TXV 34,600 14.70 11.20 CB30M-46P 3069156

XC16-036-230 + TXV 34,800 14.70 11.20 CBX26UH-030 3068746

XC16-036-230 + TXV 35,200 14.70 11.20 CBX26UH-036 3068747

XC16-036-230 + TXV 35,000 15.70 11.70 CBX27UH-036-230 3068754

XC16-036-230 + TXV 36,000 16.50 12.00 CBX27UH-042-230 3068755

XC16-036-230 + TXV 34,200 15.00 11.00 CBX32M-030 3068748

XC16-036-230 + TXV 34,400 14.70 11.00 CBX32M-036 3068749

XC16-036-230 + TXV 34,600 14.70 11.20 CBX32M-042 3068750

XC16-036-230 + TXV 34,400 15.50 11.20 CBX32MV-024/030 3068751

XC16-036-230 + TXV 35,000 16.00 11.50 CBX32MV-036 3068752

XC16-036-230 + TXV 36,000 16.50 12.00 CBX32MV-048 3068753

XC16-036-230 + TXV 34,400 15.50 11.20 CBX40UHV-030 3291635

XC16-036-230 + TXV 35,000 16.00 11.50 CBX40UHV-036 3291687

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 13

Page 14

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-036-230 + TXV 36,000 16.50 12.00 CBX40UHV-042 3291711

XC16-036-230 + TXV 36,000 16.50 12.00 CBX40UHV-048 3291797

XC16-036-230 + TXV 34,400 15.50 11.50 CH23-41 G61MPV-36B-070 3068714

XC16-036-230 + TXV 34,200 13.70 10.80 CH23-41 3068640

XC16-036-230 + TXV 34,600 14.00 10.90 CH23-65 3068641

XC16-036-230 + TXV 33,800 15.00 11.00 CH33-36A G60UHV-36A-070 3068715

XC16-036-230 + TXV 32,600 13.00 10.30 CH33-36A 3068642

XC16-036-230 + TXV 34,000 15.70 11.50 CH33-36B G60UHV-36B-090 3068716

XC16-036-230 + TXV 33,800 15.20 11.00 CH33-36B G61MPV-36B-045 3068717

XC16-036-230 + TXV 33,800 15.20 11.20 CH33-36B G61MPV-36B-070 3068718

XC16-036-230 + TXV 33,800 15.20 11.20 CH33-36B G61MPV-36B-071 3068720

XC16-036-230 + TXV 33,800 15.20 11.20 CH33-36B G71MPP-36B-070 3068719

XC16-036-230 + TXV 33,800 13.70 10.70 CH33-36B 3068643

XC16-036-230 + TXV 35,400 16.20 11.70 CH33-36C G60UHV-60C-090 3068759

XC16-036-230 + TXV 35,200 16.00 11.70 CH33-36C G60UHV-60C-110 3068721

XC16-036-230 + TXV 35,000 15.70 11.50 CH33-36C G61MPV-36C-090 3068722

XC16-036-230 + TXV 35,000 15.70 11.50 CH33-36C G71MPP-36C-090 3068723

XC16-036-230 + TXV 34,200 14.00 10.80 CH33-36C 3068644

XC16-036-230 + TXV 35,400 16.00 11.50 CH33-42 G60UHV-36B-090 3068724

XC16-036-230 + TXV 34,800 15.50 11.20 CH33-42 G61MPV-36B-045 3068725

XC16-036-230 + TXV 34,800 15.50 11.20 CH33-42 G61MPV-36B-070 3068726

XC16-036-230 + TXV 34,800 15.50 11.20 CH33-42 G61MPV-36B-071 3068728

XC16-036-230 + TXV 34,800 15.50 11.20 CH33-42 G71MPP-36B-070 3068727

XC16-036-230 + TXV 34,600 14.20 10.90 CH33-42 3068645

XC16-036-230 + TXV 36,200 16.20 12.00 CH33-43B G60UHV-36B-090 3068729

XC16-036-230 + TXV 35,800 16.00 11.50 CH33-43B G61MPV-36B-045 3068730

XC16-036-230 + TXV 36,200 16.00 11.50 CH33-43B G61MPV-36B-070 3068731

XC16-036-230 + TXV 36,000 16.00 11.50 CH33-43B G61MPV-36B-071 3068733

XC16-036-230 + TXV 36,200 16.00 11.50 CH33-43B G71MPP-36B-070 3068732

XC16-036-230 + TXV 35,800 14.50 11.00 CH33-43B 3068646

XC16-036-230 + TXV 36,600 16.50 12.00 CH33-43C G60UHV-60C-090 3068734

XC16-036-230 + TXV 36,400 16.50 12.00 CH33-43C G60UHV-60C-110 3068735

XC16-036-230 + TXV 35,400 16.20 12.00 CH33-43C G61MPV-36C-090 3068736

XC16-036-230 + TXV 35,400 14.50 11.00 CH33-43C 3068647

XC16-036-230 + TXV 35,400 16.00 11.70 CH33-44/48 G60UHV-36B-090 3068737

XC16-036-230 + TXV 35,200 15.70 11.50 CH33-44/48 G61MPV-36B-045 3068738

XC16-036-230 + TXV 35,200 15.70 11.50 CH33-44/48 G61MPV-36B-070 3068739

XC16-036-230 + TXV 35,200 15.70 11.50 CH33-44/48 G61MPV-36B-071 3068741

XC16-036-230 + TXV 35,200 15.70 11.50 CH33-44/48 G71MPP-36B-070 3068740

XC16-036-230 + TXV 35,200 14.20 11.00 CH33-44/48 3068648

XC16-036-230 + TXV 35,200 14.20 11.00 CH33-48 3068649

XC16-036-230 + TXV 36,400 16.50 12.00 CH33-48C G60UHV-60C-090 3068742

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 14

Page 15

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-036-230 + TXV 36,200 16.50 12.00 CH33-48C G60UHV-60C-110 3068743

XC16-036-230 + TXV 35,600 16.20 11.70 CH33-48C G61MPV-36C-090 3068744

XC16-036-230 + TXV 35,600 16.20 11.70 CH33-48C G71MPP-36C-090 3068745

XC16-036-230 + TXV 34,600 15.20 11.00 CR33-30/36 G60DFV-36A-070 3068706

XC16-036-230 + TXV 34,600 15.70 11.50 CR33-30/36 G60DFV-36B-090 3068707

XC16-036-230 + TXV 34,400 15.20 11.00 CR33-30/36 G61MPV-36B-045 3068708

XC16-036-230 + TXV 34,400 15.50 11.20 CR33-30/36 G61MPV-36B-070 3068709

XC16-036-230 + TXV 34,200 15.50 11.00 CR33-30/36 G61MPV-36B-071 3068711

XC16-036-230 + TXV 34,600 15.50 11.50 CR33-30/36 G61MPV-36C-090 3068712

XC16-036-230 + TXV 34,400 15.50 11.20 CR33-30/36 G71MPP-36B-070 3068710

XC16-036-230 + TXV 34,600 15.50 11.50 CR33-30/36 G71MPP-36C-090 3068713

XC16-036-230 + TXV 34,200 14.00 10.70 CR33-30/36 3068638

XC16-036-230 + TXV 34,000 13.70 10.70 CR33-48 3068639

XC16-036-230 + TXV 34,400 15.50 11.20 CX34-36 CBWMV-36C-090 3184067

XC16-036-230 + TXV 34,200 15.00 11.00 CX34-36 G60UHV-36A-070 3068650

XC16-036-230 + TXV 34,600 15.70 11.50 CX34-36 G60UHV-36B-090 3068651

XC16-036-230 + TXV 35,000 16.00 11.50 CX34-36 G60UHV-60C-090 3068756

XC16-036-230 + TXV 34,800 15.70 11.50 CX34-36 G60UHV-60C-110 3068652

XC16-036-230 + TXV 34,200 15.20 11.00 CX34-36 G61MPV-36B-045 3068653

XC16-036-230 + TXV 34,400 15.50 11.00 CX34-36 G61MPV-36B-070 3068654

XC16-036-230 + TXV 34,200 15.20 11.00 CX34-36 G61MPV-36B-071 3068656

XC16-036-230 + TXV 34,200 15.50 11.50 CX34-36 G61MPV-36C-090 3068657

XC16-036-230 + TXV 34,400 15.50 11.00 CX34-36 G71MPP-36B-070 3068655

XC16-036-230 + TXV 34,200 15.50 11.50 CX34-36 G71MPP-36C-090 3068658

XC16-036-230 + TXV 33,800 13.70 10.70 CX34-36 3068632

XC16-036-230 + TXV 35,600 15.70 11.50 CX34-38 G60UHV-36A-070 3068659

XC16-036-230 + TXV 35,800 16.20 11.70 CX34-38 G60UHV-36B-090 3068660

XC16-036-230 + TXV 35,600 16.00 11.20 CX34-38 G61MPV-36B-045 3068661

XC16-036-230 + TXV 35,400 16.00 11.50 CX34-38 G61MPV-36B-070 3068662

XC16-036-230 + TXV 35,400 16.00 11.50 CX34-38 G61MPV-36B-071 3068664

XC16-036-230 + TXV 35,400 16.00 11.50 CX34-38 G71MPP-36B-070 3068663

XC16-036-230 + TXV 34,600 14.00 10.90 CX34-38 3068633

XC16-036-230 + TXV 34,400 15.70 11.50 CX34-42 G60UHV-36B-090 3068665

XC16-036-230 + TXV 34,200 15.20 11.00 CX34-42 G61MPV-36B-045 3068666

XC16-036-230 + TXV 34,000 15.20 11.00 CX34-42 G61MPV-36B-070 3068667

XC16-036-230 + TXV 34,000 15.20 11.00 CX34-42 G61MPV-36B-071 3068669

XC16-036-230 + TXV 34,000 15.20 11.00 CX34-42 G71MPP-36B-070 3068668

XC16-036-230 + TXV 33,800 13.70 10.70 CX34-42 3068634

XC16-036-230 + TXV 35,800 16.00 11.70 CX34-43 CBWMV-36C-090 3184069

XC16-036-230 + TXV 36,000 16.20 12.00 CX34-43 G60UHV-36B-090 3068670

XC16-036-230 + TXV 36,600 16.50 12.00 CX34-43 G60UHV-60C-090 3068671

XC16-036-230 + TXV 36,000 16.50 12.00 CX34-43 G60UHV-60C-110 3068631

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 15

Page 16

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-036-230 + TXV 35,600 16.00 11.50 CX34-43 G61MPV-36B-045 3068672

XC16-036-230 + TXV 35,400 16.00 11.50 CX34-43 G61MPV-36B-070 3068673

XC16-036-230 + TXV 35,400 16.20 12.00 CX34-43 G61MPV-36C-090 3068675

XC16-036-230 + TXV 36,200 16.20 12.00 CX34-43 G61MPV-60C-090 3068677

XC16-036-230 + TXV 36,200 16.20 11.70 CX34-43 G61MPV-60C-091 3068679

XC16-036-230 + TXV 36,200 16.00 12.00 CX34-43 G61MPV-60C-110 3068680

XC16-036-230 + TXV 36,200 16.20 12.00 CX34-43 G61MPV-60C-111 3068682

XC16-036-230 + TXV 35,400 16.00 11.50 CX34-43 G71MPP-36B-070 3068674

XC16-036-230 + TXV 35,400 16.20 12.00 CX34-43 G71MPP-36C-090 3068676

XC16-036-230 + TXV 36,200 16.20 12.00 CX34-43 G71MPP-60C-090 3068678

XC16-036-230 + TXV 36,200 16.00 12.00 CX34-43 G71MPP-60C-110 3068681

XC16-036-230 + TXV 35,200 14.20 11.00 CX34-43 3068635

XC16-036-230 + TXV 35,400 16.20 11.70 CX34-44/48 G60UHV-36B-090 3068683

XC16-036-230 + TXV 36,000 16.20 11.70 CX34-44/48 G60UHV-60C-090 3068757

XC16-036-230 + TXV 35,800 16.20 11.70 CX34-44/48 G60UHV-60C-110 3068684

XC16-036-230 + TXV 35,200 15.70 11.20 CX34-44/48 G61MPV-36B-045 3068685

XC16-036-230 + TXV 35,000 15.70 11.50 CX34-44/48 G61MPV-36B-070 3068686

XC16-036-230 + TXV 35,200 15.70 11.20 CX34-44/48 G61MPV-36B-071 3068688

XC16-036-230 + TXV 35,200 16.00 11.70 CX34-44/48 G61MPV-36C-090 3068689

XC16-036-230 + TXV 35,600 16.00 11.70 CX34-44/48 G61MPV-60C-090 3068691

XC16-036-230 + TXV 35,800 16.00 11.50 CX34-44/48 G61MPV-60C-091 3068693

XC16-036-230 + TXV 35,600 15.70 11.70 CX34-44/48 G61MPV-60C-110 3068694

XC16-036-230 + TXV 35,600 16.00 11.70 CX34-44/48 G61MPV-60C-111 3068696

XC16-036-230 + TXV 35,000 15.70 11.50 CX34-44/48 G71MPP-36B-070 3068687

XC16-036-230 + TXV 35,200 16.00 11.70 CX34-44/48 G71MPP-36C-090 3068690

XC16-036-230 + TXV 35,600 16.00 11.70 CX34-44/48 G71MPP-60C-090 3068692

XC16-036-230 + TXV 35,600 15.70 11.70 CX34-44/48 G71MPP-60C-110 3068695

XC16-036-230 + TXV 34,800 14.20 10.90 CX34-44/48 3068636

XC16-036-230 + TXV 35,600 14.50 11.00 CX34-49 3068637

XC16-048-230 + TXV 45,500 15.00 11.70 C33-44C G60UHV-60C-090 1003984

XC16-048-230 + TXV 45,500 14.70 11.50 C33-44C G61MPV-60C-090 1003983

XC16-048-230 + TXV 45,500 14.50 11.50 C33-44C G61MPV-60C-110 1003988

XC16-048-230 + TXV 45,500 14.70 11.20 C33-44C G61MPV-60C-091 1046650

XC16-048-230 + TXV 45,500 14.50 11.50 C33-44C G61MPV-60C-111 1046651

XC16-048-230 + TXV 45,500 14.50 11.50 C33-44C G71MPP-60C-110 1488411

XC16-048-230 + TXV 46,000 15.00 11.70 C33-48 G60UHV-60C-090 1003987

XC16-048-230 + TXV 45,500 15.00 11.70 C33-48 G60UHV-60C-110 1003990

XC16-048-230 + TXV 45,500 14.50 11.50 C33-48 G61MPV-60C-110 1003986

XC16-048-230 + TXV 45,000 14.20 11.20 C33-48 O23V5-140/154 1038249

XC16-048-230 + TXV 45,500 13.70 11.20 C33-48 1003999

XC16-048-230 + TXV 45,500 14.70 11.20 C33-48 G61MPV-60C-091 1046652

XC16-048-230 + TXV 45,500 14.50 11.50 C33-48 G61MPV-60C-111 1046653

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 16

Page 17

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-048-230 + TXV 45,500 14.70 11.50 C33-48 G71MPP-60C-090 3145298

XC16-048-230 + TXV 45,500 14.50 11.50 C33-48 G71MPP-60C-110 1488410

XC16-048-230 + TXV 47,500 15.50 12.20 C33-49 G60UHV-60C-090 1003772

XC16-048-230 + TXV 47,500 15.50 12.20 C33-49 G60UHV-60C-110 1003773

XC16-048-230 + TXV 47,500 15.20 12.00 C33-49 G61MPV-60C-090 1003774

XC16-048-230 + TXV 47,500 15.00 12.00 C33-49 G61MPV-60C-110 1003775

XC16-048-230 + TXV 46,500 14.70 11.70 C33-49 O23V5-140/154 1038250

XC16-048-230 + TXV 47,000 14.20 11.70 C33-49 1003730

XC16-048-230 + TXV 47,500 15.00 11.70 C33-49 G61MPV-60C-091 1046654

XC16-048-230 + TXV 47,000 15.00 11.70 C33-49 G61MPV-60C-111 1046655

XC16-048-230 + TXV 47,500 15.20 12.00 C33-49 G71MPP-60C-090 3145301

XC16-048-230 + TXV 47,500 15.00 12.00 C33-49 G71MPP-60C-110 1488403

XC16-048-230 + TXV 46,500 15.20 11.70 C33-50/60C G60UHV-60C-090 1003769

XC16-048-230 + TXV 46,500 15.00 11.70 C33-50/60C G60UHV-60C-110 1003759

XC16-048-230 + TXV 46,000 15.00 11.70 C33-50/60C G61MPV-60C-090 1003766

XC16-048-230 + TXV 46,000 14.70 11.70 C33-50/60C G61MPV-60C-110 1003768

XC16-048-230 + TXV 46,000 14.50 11.20 C33-50/60C O23V5-140/154 1038251

XC16-048-230 + TXV 46,500 13.70 11.20 C33-50/60C 1003726

XC16-048-230 + TXV 46,000 15.20 11.20 C33-50/60C CBWMV-60C-100 1088641

XC16-048-230 + TXV 46,000 14.70 11.50 C33-50/60C G61MPV-60C-091 1046656

XC16-048-230 + TXV 46,000 14.70 11.70 C33-50/60C G61MPV-60C-111 1046657

XC16-048-230 + TXV 46,000 15.00 11.70 C33-50/60C G71MPP-60C-090 3145296

XC16-048-230 + TXV 46,000 14.70 11.70 C33-50/60C G71MPP-60C-110 1488402

XC16-048-230 + TXV 47,000 15.70 12.20 C33-60D G60UHV-60D-135 1003982

XC16-048-230 + TXV 46,500 15.00 11.50 C33-60D O23V5-140/154 1003981

XC16-048-230 + TXV 46,500 14.00 11.50 C33-60D 1004000

XC16-048-230 + TXV 47,000 15.50 12.20 C33-60D G61MPV-60D-135 3133211

XC16-048-230 + TXV 48,000 15.70 12.30 C33-62C G60UHV-60C-090 1003980

XC16-048-230 + TXV 48,000 15.70 12.20 C33-62C G60UHV-60C-110 1003979

XC16-048-230 + TXV 48,000 15.70 12.20 C33-62C G61MPV-60C-090 1003978

XC16-048-230 + TXV 47,500 15.20 12.00 C33-62C O23V5-140/154 1003977

XC16-048-230 + TXV 47,500 14.20 11.70 C33-62C 1003996

XC16-048-230 + TXV 48,000 15.50 12.00 C33-62C G61MPV-60C-091 1046658

XC16-048-230 + TXV 48,000 15.50 12.30 C33-62C G61MPV-60C-111 1046659

XC16-048-230 + TXV 48,000 15.50 12.30 C33-62C G71MPP-60C-090 3145297

XC16-048-230 + TXV 47,500 15.70 12.50 C33-62D G60UHV-60D-135 1003976

XC16-048-230 + TXV 47,000 15.20 12.00 C33-62D O23V5-140/154 1003975

XC16-048-230 + TXV 47,000 14.20 11.50 C33-62D 1003997

XC16-048-230 + TXV 48,000 14.70 11.70 CB26UH-042 1003995

XC16-048-230 + TXV 48,000 14.70 11.70 CB26UH-042-R 1186491

XC16-048-230 + TXV 48,000 14.70 12.00 CB26UH-048 1003952

XC16-048-230 + TXV 48,000 14.70 12.00 CB26UH-048-R 1186489

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 17

Page 18

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-048-230 + TXV 47,000 15.70 12.20 CB27UH-048-230 1348995

XC16-048-230 + TXV 46,500 15.50 12.20 CB27UH-060-230 1348996

XC16-048-230 + TXV 47,000 14.70 12.00 CB30M-51P 1003794

XC16-048-230 + TXV 47,500 14.50 11.70 CB30M-65P 1003793

XC16-048-230 + TXV 48,000 14.70 11.70 CBX26UH-042 1003953

XC16-048-230 + TXV 48,000 14.70 12.00 CBX26UH-048 1003954

XC16-048-230 + TXV 47,000 15.70 12.20 CBX27UH-048-230 1145118

XC16-048-230 + TXV 46,500 15.50 12.20 CBX27UH-060-230 1145119

XC16-048-230 + TXV 47,000 14.70 12.00 CBX32M-048 1003958

XC16-048-230 + TXV 47,500 14.50 11.70 CBX32M-060 1003957

XC16-048-230 + TXV 47,000 15.70 12.20 CBX32MV-048 1003956

XC16-048-230 + TXV 47,500 15.70 12.20 CBX32MV-060 1003955

XC16-048-230 + TXV 47,500 15.70 12.50 CBX32MV-068 1003963

XC16-048-230 + TXV 47,000 15.70 12.20 CBX40UHV-048 3291798

XC16-048-230 + TXV 47,500 15.70 12.20 CBX40UHV-060 3291847

XC16-048-230 + TXV 45,000 15.20 11.70 CH23-51 G60UHV-60C-090 1038817

XC16-048-230 + TXV 45,000 13.50 11.20 CH23-51 1003722

XC16-048-230 + TXV 56,000 14.50 11.00 CH23-65 G60UHV-60C-090 1038818

XC16-048-230 + TXV 45,500 13.70 11.20 CH23-65 1003998

XC16-048-230 + TXV 47,000 14.20 11.70 CH23-68 1003723

XC16-048-230 + TXV 46,500 15.20 11.70 CH33-48 G60UHV-60C-090 1003971

XC16-048-230 + TXV 46,500 15.20 11.70 CH33-48 G60UHV-60C-110 1003973

XC16-048-230 + TXV 46,500 15.00 11.70 CH33-48 G61MPV-60C-090 1003972

XC16-048-230 + TXV 46,500 15.00 11.70 CH33-48 G61MPV-60C-091 1046660

XC16-048-230 + TXV 46,500 14.70 11.70 CH33-48 G61MPV-60C-111 1046661

XC16-048-230 + TXV 46,500 15.00 11.70 CH33-48 G71MPP-60C-090 3094645

XC16-048-230 + TXV 46,000 14.00 11.20 CH33-48C 1003724

XC16-048-230 + TXV 47,500 15.50 12.20 CH33-49 G60UHV-60C-090 1132856

XC16-048-230 + TXV 47,500 15.50 12.20 CH33-49 G60UHV-60C-110 1132857

XC16-048-230 + TXV 47,500 15.20 12.00 CH33-49 G61MPV-60C-090 1132858

XC16-048-230 + TXV 47,500 15.00 11.50 CH33-49 G61MPV-60C-091 1132859

XC16-048-230 + TXV 47,500 15.00 12.00 CH33-49 G61MPV-60C-110 1132860

XC16-048-230 + TXV 47,500 15.00 11.70 CH33-49 G61MPV-60C-111 1132861

XC16-048-230 + TXV 47,500 15.20 12.00 CH33-49 G71MPP-60C-090 3094646

XC16-048-230 + TXV 47,500 15.00 12.00 CH33-49 G71MPP-60C-110 1488548

XC16-048-230 + TXV 47,000 14.20 11.70 CH33-49 1132855

XC16-048-230 + TXV 47,500 15.50 12.20 CH33-50/60C G60UHV-60C-090 1003970

XC16-048-230 + TXV 47,000 15.20 12.00 CH33-50/60C G60UHV-60C-110 1003969

XC16-048-230 + TXV 47,000 15.00 11.70 CH33-50/60C G61MPV-60C-110 1003968

XC16-048-230 + TXV 47,000 15.50 12.00 CH33-50/60C CBWMV-60C-100 1088639

XC16-048-230 + TXV 47,000 15.20 11.70 CH33-50/60C G61MPV-60C-090 3094647

XC16-048-230 + TXV 47,000 15.20 11.70 CH33-50/60C G61MPV-60C-091 1046662

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 18

Page 19

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-048-230 + TXV 47,000 15.00 11.70 CH33-50/60C G61MPV-60C-111 1046663

XC16-048-230 + TXV 47,000 15.20 11.70 CH33-50/60C G71MPP-60C-090 3094648

XC16-048-230 + TXV 47,000 15.00 11.70 CH33-50/60C G71MPP-60C-110 1488409

XC16-048-230 + TXV 47,000 14.20 11.70 CH33-50/60C 1050279

XC16-048-230 + TXV 47,000 15.50 12.20 CH33-60D G60UHV-60D-135 1003994

XC16-048-230 + TXV 47,000 15.50 12.20 CH33-60D G61MPV-60D-135 1003993

XC16-048-230 + TXV 46,500 14.00 11.50 CH33-60D 1003992

XC16-048-230 + TXV 47,000 15.50 12.20 CH33-60D G71MPP-60D-135 1489284

XC16-048-230 + TXV 47,000 15.50 12.20 CH33-62D G60UHV-60D-135 1003757

XC16-048-230 + TXV 47,500 15.50 12.20 CH33-62D G61MPV-60D-135 1003758

XC16-048-230 + TXV 47,000 14.00 11.50 CH33-62D 1003725

XC16-048-230 + TXV 47,500 15.50 12.20 CH33-62D G71MPP-60D-135 1489277

XC16-048-230 + TXV 44,500 14.70 11.70 CR33-48 G60DFV-60C-090 1003756

XC16-048-230 + TXV 45,000 14.70 11.50 CR33-48 G60DFV-60C-110 1003755

XC16-048-230 + TXV 44,500 14.20 11.20 CR33-48 G61MPV-60C-110 1003754

XC16-048-230 + TXV 44,500 13.20 11.00 CR33-48 1003771

XC16-048-230 + TXV 44,500 14.20 11.20 CR33-48 G61MPV-60C-091 1046664

XC16-048-230 + TXV 44,500 14.20 11.20 CR33-48 G61MPV-60C-111 1046665

XC16-048-230 + TXV 44,500 14.20 11.20 CR33-48 G71MPP-60C-110 1488401

XC16-048-230 + TXV 47,000 15.20 12.20 CR33-50/60 G60DFV-60C-090 1003763

XC16-048-230 + TXV 46,500 15.20 12.00 CR33-50/60 G60DFV-60C-110 1003764

XC16-048-230 + TXV 46,000 15.20 11.70 CR33-50/60 G61MPV-60C-090 1003762

XC16-048-230 + TXV 46,000 13.70 11.20 CR33-50/60 1003770

XC16-048-230 + TXV 46,000 14.70 11.50 CR33-50/60 G61MPV-60C-091 1046666

XC16-048-230 + TXV 46,000 15.00 11.70 CR33-50/60 G61MPV-60C-111 1046667

XC16-048-230 + TXV 46,500 15.50 12.00 CR33-60 G60UHV-60D-135 1003760

XC16-048-230 + TXV 46,000 13.70 11.20 CR33-60 1005092

XC16-048-230 + TXV 46,000 15.00 11.70 CX34-44/48 G60UHV-60C-090 1003959

XC16-048-230 + TXV 45,500 15.00 11.70 CX34-44/48 G60UHV-60C-110 1003960

XC16-048-230 + TXV 45,500 14.70 11.50 CX34-44/48 G61MPV-60C-090 1003961

XC16-048-230 + TXV 45,500 14.70 11.70 CX34-44/48 CBWMV-60C-100 3060548

XC16-048-230 + TXV 45,500 14.70 11.20 CX34-44/48 G61MPV-60C-091 1046668

XC16-048-230 + TXV 45,500 14.50 11.50 CX34-44/48 G61MPV-60C-111 1046669

XC16-048-230 + TXV 45,500 14.70 11.50 CX34-44/48 G71MPP-60C-090 3145299

XC16-048-230 + TXV 45,500 13.70 11.20 CX34-44/48 3024355

XC16-048-230 + TXV 47,500 15.50 12.20 CX34-49 G60UHV-60C-090 1003911

XC16-048-230 + TXV 47,500 15.50 12.20 CX34-49 G60UHV-60C-110 1003912

XC16-048-230 + TXV 47,500 15.00 12.00 CX34-49 G61MPV-60C-110 1003910

XC16-048-230 + TXV 46,500 14.70 11.70 CX34-49 O23V5-140/154 1003909

XC16-048-230 + TXV 47,500 15.20 12.00 CX34-49 G61MPV-60C-090 3490811

XC16-048-230 + TXV 47,500 15.00 11.70 CX34-49 G61MPV-60C-091 1046670

XC16-048-230 + TXV 47,000 15.00 11.70 CX34-49 G61MPV-60C-111 1046671

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 19

Page 20

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-048-230 + TXV 47,500 15.20 12.00 CX34-49 G71MPP-60C-090 3145300

XC16-048-230 + TXV 47,500 15.00 12.00 CX34-49 G71MPP-60C-110 3094644

XC16-048-230 + TXV 47,000 14.20 11.70 CX34-49 1050269

XC16-048-230 + TXV 46,500 15.20 11.70 CX34-50/60C G60UHV-60C-090 1003786

XC16-048-230 + TXV 46,500 15.00 11.70 CX34-50/60C G60UHV-60C-110 1003787

XC16-048-230 + TXV 46,000 15.00 11.70 CX34-50/60C G61MPV-60C-090 1003788

XC16-048-230 + TXV 46,000 14.50 11.20 CX34-50/60C O23V5-140/154 1003785

XC16-048-230 + TXV 46,000 15.20 11.20 CX34-50/60C CBWMV-60C-100 1088640

XC16-048-230 + TXV 46,000 14.70 11.50 CX34-50/60C G61MPV-60C-091 1046672

XC16-048-230 + TXV 46,000 14.70 11.70 CX34-50/60C G61MPV-60C-111 1046673

XC16-048-230 + TXV 46,000 15.00 11.70 CX34-50/60C G71MPP-60C-090 3076771

XC16-048-230 + TXV 46,500 13.70 11.20 CX34-50/60C 1050270

XC16-048-230 + TXV 47,000 15.50 12.20 CX34-60D G61MPV-60D-135 1003906

XC16-048-230 + TXV 46,500 15.00 11.50 CX34-60D O23V5-140/154 1003905

XC16-048-230 + TXV 46,500 14.00 11.50 CX34-60D 1050271

XC16-048-230 + TXV 47,000 15.50 12.20 CX34-60D G71MPP-60D-135 1489281

XC16-048-230 + TXV 48,000 15.70 12.30 CX34-62C G60UHV-60C-090 1003907

XC16-048-230 + TXV 48,000 15.70 12.20 CX34-62C G60UHV-60C-110 1003908

XC16-048-230 + TXV 48,000 15.50 12.20 CX34-62C G61MPV-60C-110 1003904

XC16-048-230 + TXV 47,500 15.20 12.00 CX34-62C O23V5-140/154 1003903

XC16-048-230 + TXV 48,000 15.50 12.00 CX34-62C G61MPV-60C-091 1046674

XC16-048-230 + TXV 48,000 15.50 12.00 CX34-62C G61MPV-60C-111 1046675

XC16-048-230 + TXV 48,000 15.50 12.30 CX34-62C G71MPP-60C-090 3076772

XC16-048-230 + TXV 47,500 14.20 11.70 CX34-62C 1050272

XC16-048-230 + TXV 48,000 15.50 12.30 CX34-62C G71MPP-60C-110 1488407

XC16-048-230 + TXV 47,500 15.50 12.20 CX34-62D G61MPV-60D-135 1003902

XC16-048-230 + TXV 47,000 15.20 12.00 CX34-62D O23V5-140/154 1003901

XC16-048-230 + TXV 47,000 14.20 11.50 CX34-62D 1050273

XC16-048-230 + TXV 47,500 15.50 12.30 CX34-62D G71MPP-60D-135 1489280

XC16-060-230 + TXV 59,000 15.20 11.70 C33-49 G60UHV-60C-110 1003777

XC16-060-230 + TXV 58,500 15.20 11.70 C33-49 G61MPV-60C-090 1003778

XC16-060-230 + TXV 59,000 15.00 11.70 C33-49 G61MPV-60C-110 1003779

XC16-060-230 + TXV 58,500 15.00 11.20 C33-49 O23V5-140/154 1003776

XC16-060-230 + TXV 59,000 14.50 11.50 C33-49 1003784

XC16-060-230 + TXV 58,500 15.00 11.20 C33-49 G61MPV-60C-091 1046676

XC16-060-230 + TXV 59,000 15.20 11.70 C33-49 G61MPV-60C-111 1046677

XC16-060-230 + TXV 59,000 15.00 11.70 C33-49 G71MPP-60C-110 1488404

XC16-060-230 + TXV 57,500 15.00 11.50 C33-50/60C G60UHV-60C-110 1003809

XC16-060-230 + TXV 57,500 14.70 11.20 C33-50/60C G61MPV-60C-090 1003810

XC16-060-230 + TXV 57,500 14.70 11.20 C33-50/60C G61MPV-60C-110 1003808

XC16-060-230 + TXV 57,500 14.50 11.20 C33-50/60C O23V5-140/154 1003780

XC16-060-230 + TXV 57,500 14.20 11.20 C33-50/60C 1003795

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 20

Page 21

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-060-230 + TXV 57,500 14.70 11.20 C33-50/60C CBWMV-60C-120 3184074

XC16-060-230 + TXV 57,500 14.70 11.20 C33-50/60C G61MPV-60C-091 1046678

XC16-060-230 + TXV 57,500 14.70 11.20 C33-50/60C G61MPV-60C-111 1046679

XC16-060-230 + TXV 57,500 14.70 11.20 C33-50/60C G71MPP-60C-110 1488406

XC16-060-230 + TXV 59,500 15.70 12.00 C33-60D G60UHV-60D-135 1003934

XC16-060-230 + TXV 58,500 15.00 11.50 C33-60D O23V5-140/154 1003930

XC16-060-230 + TXV 58,500 14.20 11.50 C33-60D 1003951

XC16-060-230 + TXV 58,500 15.50 11.40 C33-60D G61MPV-60D-135 3133210

XC16-060-230 + TXV 60,000 15.70 12.00 C33-62C G60UHV-60C-090 1003929

XC16-060-230 + TXV 60,000 15.70 12.00 C33-62C G60UHV-60C-110 1003928

XC16-060-230 + TXV 60,000 15.20 11.70 C33-62C G61MPV-60C-110 1004033

XC16-060-230 + TXV 59,500 15.20 11.50 C33-62C O23V5-140/154 1003927

XC16-060-230 + TXV 60,000 14.70 11.70 C33-62C 1003950

XC16-060-230 + TXV 59,500 15.50 11.50 C33-62C G61MPV-60C-091 1046680

XC16-060-230 + TXV 60,000 15.50 11.70 C33-62C G61MPV-60C-111 1046681

XC16-060-230 + TXV 60,000 15.20 11.70 C33-62C G71MPP-60C-110 1488412

XC16-060-230 + TXV 59,000 15.20 11.50 C33-62D O23V5-140/154 1003932

XC16-060-230 + TXV 59,000 14.50 11.50 C33-62D 1003965

XC16-060-230 + TXV 59,500 15.70 12.00 C33-62D G61MPV-60D-135 3281425

XC16-060-230 + TXV 60,000 15.20 11.70 CB26UH-060 1003943

XC16-060-230 + TXV 60,000 15.20 11.70 CB26UH-060-R 1186490

XC16-060-230 + TXV 58,500 15.50 11.70 CB27UH-060-230 1348997

XC16-060-230 + TXV 59,000 14.70 11.70 CB30M-65P 1003802

XC16-060-230 + TXV 60,000 15.20 11.70 CBX26UH-060 1003948

XC16-060-230 + TXV 58,500 15.50 11.70 CBX27UH-060-230 1145120

XC16-060-230 + TXV 59,000 14.70 11.70 CBX32M-060 1003949

XC16-060-230 + TXV 58,500 15.70 11.70 CBX32MV-048 1003947

XC16-060-230 + TXV 59,000 15.70 11.70 CBX32MV-060 1003946

XC16-060-230 + TXV 59,000 15.70 12.00 CBX32MV-068 1003945

XC16-060-230 + TXV 58,500 15.70 11.70 CBX40UHV-048 3291799

XC16-060-230 + TXV 59,000 15.70 11.70 CBX40UHV-060 3291848

XC16-060-230 + TXV 56,500 14.00 11.20 CH23-65 1003966

XC16-060-230 + TXV 57,000 15.20 11.50 CH23-65 G60UHV-60C-090 1232764

XC16-060-230 + TXV 60,000 14.50 11.70 CH23-68 1003783

XC16-060-230 + TXV 59,500 15.70 12.00 CH23-68 G60UHV-60C-090 1232765

XC16-060-230 + TXV 58,500 15.20 11.70 CH33-50/60C G60UHV-60C-110 1003939

XC16-060-230 + TXV 58,500 15.20 11.50 CH33-50/60C G61MPV-60C-090 1003938

XC16-060-230 + TXV 58,500 15.00 11.50 CH33-50/60C G61MPV-60C-110 1003942

XC16-060-230 + TXV 58,500 14.50 11.50 CH33-50/60C 1003967

XC16-060-230 + TXV 58,500 14.20 11.50 CH33-50/60C CBWMV-60C-120 1260281

XC16-060-230 + TXV 58,500 15.20 11.70 CH33-50/60C G60UHV-60C-090 3069475

XC16-060-230 + TXV 58,500 14.70 11.20 CH33-50/60C G61MPV-60C-091 1046682

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 21

Page 22

AHRI SYSTEM MATCHES

NOTE - For the latest up-to-date system matches please visit the AHRI web site at http://www.ahridirectory.org

Model

No.

Capacity SEER EER

XC16-060-230 + TXV 58,500 15.20 11.50 CH33-50/60C G61MPV-60C-111 1046683

XC16-060-230 + TXV 58,500 15.20 11.50 CH33-50/60C G71MPP-60C-090 3094655

XC16-060-230 + TXV 58,500 15.00 11.50 CH33-50/60C G71MPP-60C-110 1488408

XC16-060-230 + TXV 59,000 15.70 12.00 CH33-60D G60UHV-60D-135 1003940

XC16-060-230 + TXV 58,000 14.20 11.50 CH33-60D 1003964

XC16-060-230 + TXV 58,500 15.20 11.70 CH33-60D CBWMV-60C-100 1086362

XC16-060-230 + TXV 58,500 15.50 11.70 CH33-60D G61MPV-60D-135 3069477

XC16-060-230 + TXV 59,500 15.70 12.00 CH33-62D G60UHV-60D-135 1003805

XC16-060-230 + TXV 58,500 15.50 11.70 CH33-62D G61MPV-60D-135 1003806

XC16-060-230 + TXV 58,500 14.20 11.50 CH33-62D 1003782

XC16-060-230 + TXV 58,500 15.50 11.70 CH33-62D G60UHV-60C-090 1132862

XC16-060-230 + TXV 58,500 15.50 11.70 CH33-62D G60UHV-60C-110 1132863

XC16-060-230 + TXV 58,500 15.20 11.70 CH33-62D G61MPV-60C-090 1132864

XC16-060-230 + TXV 58,500 15.20 11.50 CH33-62D G61MPV-60C-091 1132865

XC16-060-230 + TXV 58,500 15.00 11.70 CH33-62D G61MPV-60C-110 1132866

XC16-060-230 + TXV 58,500 15.20 11.70 CH33-62D G61MPV-60C-111 1132867

XC16-060-230 + TXV 58,500 15.00 11.70 CH33-62D G71MPP-60C-110 1488549

XC16-060-230 + TXV 58,500 15.50 11.70 CH33-62D G71MPP-60D-135 1489279

XC16-060-230 + TXV 58,000 15.20 11.70 CR33-60 G60DFV-60D-135 1003807

XC16-060-230 + TXV 57,500 15.20 11.50 CR33-60 G61MPV-60D-135 1003801

XC16-060-230 + TXV 57,500 14.20 11.20 CR33-60 1003781

XC16-060-230 + TXV 57,500 15.20 11.50 CR33-60 G71MPP-60D-135 1489278

XC16-060-230 + TXV 59,000 15.50 11.70 CX34-49 G60UHV-60C-090 1003921

XC16-060-230 + TXV 58,500 15.20 11.70 CX34-49 G61MPV-60C-090 1003919

XC16-060-230 + TXV 58,500 15.00 11.20 CX34-49 O23V5-140/154 1003916

XC16-060-230 + TXV 59,000 15.20 11.70 CX34-49 G60UHV-60C-110 3069476

XC16-060-230 + TXV 58,500 15.00 11.20 CX34-49 G61MPV-60C-091 1046684

XC16-060-230 + TXV 59,000 15.00 11.70 CX34-49 G61MPV-60C-110 3094650

XC16-060-230 + TXV 59,000 15.20 11.70 CX34-49 G61MPV-60C-111 1046685

XC16-060-230 + TXV 58,500 15.20 11.70 CX34-49 G71MPP-60C-090 3094649

XC16-060-230 + TXV 59,000 15.00 11.70 CX34-49 G71MPP-60C-110 3094651

XC16-060-230 + TXV 59,000 14.50 11.50 CX34-49 1050274

XC16-060-230 + TXV 57,500 15.20 11.50 CX34-50/60C G60UHV-60C-090 1003800

XC16-060-230 + TXV 57,500 14.70 11.20 CX34-50/60C G61MPV-60C-090 1003797

XC16-060-230 + TXV 57,500 14.70 11.20 CX34-50/60C G61MPV-60C-110 1003798

XC16-060-230 + TXV 57,500 14.50 11.20 CX34-50/60C O23V5-140/154 1003796

XC16-060-230 + TXV 57,500 14.70 11.20 CX34-50/60C CBWMV-60C-120 3184076

XC16-060-230 + TXV 57,500 15.00 11.50 CX34-50/60C G60UHV-60C-110 3069480

XC16-060-230 + TXV 57,500 14.70 11.20 CX34-50/60C G61MPV-60C-091 1046686

XC16-060-230 + TXV 57,500 14.70 11.20 CX34-50/60C G61MPV-60C-111 1046687

XC16-060-230 + TXV 57,500 14.70 11.20 CX34-50/60C G71MPP-60C-090 3094652

XC16-060-230 + TXV 57,500 14.20 11.20 CX34-50/60C 1050275

NOTES:

+ TXV = Matched with Thermostatic Expansion Valve.

Ratings are certied in accordance with USE certication program which is based on AHRI Standard 210/240; 95°F outdoor air temperature, 80°F db / 67°F wb entering

evaporator air with 25 ft. of connecting refrigerant lines.

All ratings include the use of a blower time delay relay (TDR). All Lennox variable-speed furnaces and Air Handlers have time delay capabilities. Other Furnaces and Air

Handlers may require an optional time delay relay (58M81) for eld installation. See furnace or air handler specications to determine if relay is needed.

Also see TXV Substitutions Table.

Coil or

Air Handler

Furnace

AHRI

Reference

XC16 - 2 to 5 Ton Heat Pump / Page 22

Page 23

AHRI SYSTEM MATCHES