Lennox XC15, XC15-024, XC15-030, XC15-036, XC15-042 Installation Instructions Manual

...

INSTALLATION

E2008 Lennox Industries Inc.

Dallas, Texas, USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause personal injury,

loss of life, or damage to property.

Installation and service must be performed by a

licensed professional installer (or equivalent) or a

service agency.

CAUTION

Physical contact with metal edges and corners

while applying excessive force or rapid motion can

result in personal injury. Be aware of, and use

caution when working near these areas during

installation or while servicing this equipment.

INSTRUCTIONS

Dave Lennox Signature

Collection XC15 Units

AIR CONDITIONER

506044−01

06/08

Supersedes 04/08

Table of Contents

Shipping and Packing List 1. . . . . . . . . . . . . . . . . . . . . .

XC15 Outdoor Unit 3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Dimensions and Parts Arrangement 2. . . . . . . . .

General Information 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Recovering Refrigerant from Existing System 5. . . . .

Removing Existing Outdoor Unit 5. . . . . . . . . . . . . . . . .

Positioning New Outdoor Unit 5. . . . . . . . . . . . . . . . . . .

Removing and Installing Panels 7. . . . . . . . . . . . . . . . .

New or Replacement Line Set 8. . . . . . . . . . . . . . . . . . .

Brazing Line Set Connections 9. . . . . . . . . . . . . . . . . . .

Removing Indoor Unit Metering Device 11. . . . . . . . . . .

Flushing System 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing New Indoor Unit Metering Device 13. . . . . . . .

Testing for Leaks 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Evacuating the System 15. . . . . . . . . . . . . . . . . . . . . . . . .

Servicing Unit Delivered Void of Charge 15. . . . . . . . . . .

Electrical Connection 15. . . . . . . . . . . . . . . . . . . . . . . . . .

Start−Up and Charging Procedures 16. . . . . . . . . . . . . . .

System Operation 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lennox System Operation Monitor (LSOM) 20. . . . . . .

Maintenance 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound Reduction Cover and Assembly Procedure 23. .

Homeowner Information 23. . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 24. . . . . . . . . . . . . . . . . . . . . . . . . .

Start−Up and Performance Checklist 24. . . . . . . . . . . . .

Shipping and Packing List

®

Litho U.S.A.

This unit must be matched with an indoor coil as

specified in Lennox Engineering Handbook. Coils

previously charged with HCFC−22 must be

flushed.

IMPORTANT

IMPORTANT

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFCs, HCFCs AND HFCs) as

of July 1, 1992. Approved methods of recovery,

recycling or reclaiming must be followed. Fines

and/or incarceration may be levied for

noncompliance.

06/08 506044−01

*2P0608* *P506044-01*

Check the unit for shipping damage and listed times below

are intact. If damaged, or if parts are missing, immediately

contact the last shipping carrier.

1 Assembled outdoor unit.

1 Bag Assembly

S 1 Bushing (for low voltage wiring

S 2 Isolation grommets for liquid and suction

lines.

ISOLATION GROMMETS (2)

Figure 1. Bag Assembly (Parts)

Page 1

BUSHING (1)

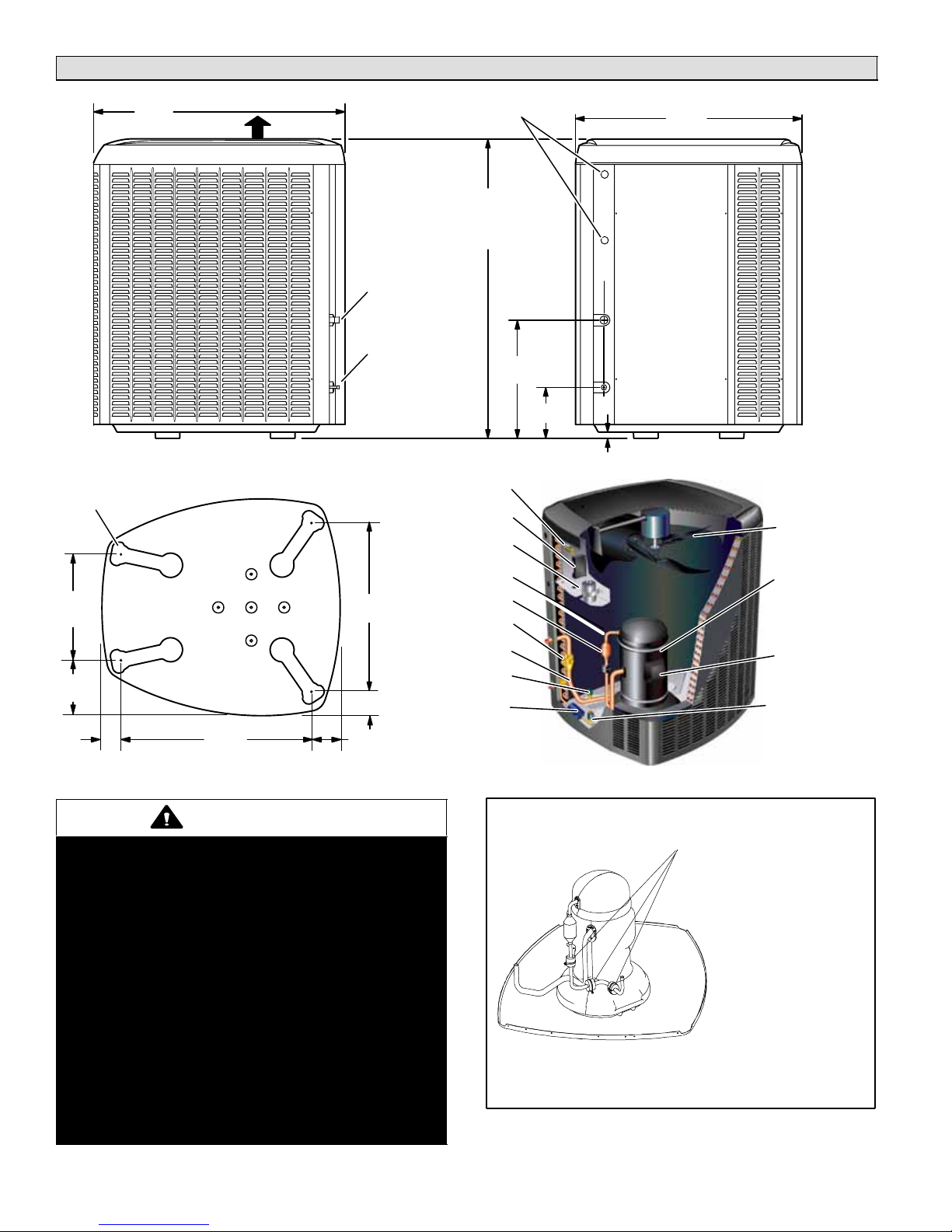

Unit Dimensions − Inches (mm) and Parts Arrangement

39.40"

(1003)

UNIT SUPPORT FEET

16−7/8

(429)

8−3/4

(222)

3−1/8

(79)

DISCHARGE AIR

SIDE VIEW

30−3/4

(781)

SUCTION LINE

INLET

LIQUID LINE

INLET

26−7/8

(683)

3−3/4 (95)

4−5/8

(117)

ELECTRICAL

INLETS

[−024] 41 (1040)

[−030 THROUGH −060]

47 (1194)

CONTACTOR

SYSTEM OPERATION

SUCTION VALVE AND

MONITOR

RUN CAPACITOR

DISCHARGE LINE

MUFFLER

GAUGE PORT

SUCTION LINE

LOW PRESSURE

SWITCH

FILTER DRIER

18.60"

(470)

8.00"

(203)

1 (25)

35.50"

(902)

ACCESS VIEW

OUTDOOR FAN

COMPRESSOR

AND SOUND

REDUCTION

COVER

COMPRESSOR

TERMINAL PLUG

HIGH PRESSURE

SWITCH

BASE WITH ELONGATED LEGS

WARNING

This product and/or the indoor unit it is matched

with may contain fiberglass wool.

Disturbing the insulation during installation,

maintenance, or repair will expose you to fiberglass

wool dust. Breathing this may cause lung cancer.

(Fiberglass wool is known to the State of California

to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

506044−01 06/08

Page 2

XC15 PARTS ARRANGEMENT

VIBRATION ISOLATOR SLEEVE

LOCATIONS ON −024, −030 AND

−036.

NOTE: ON THE −042, ALL THREE

VIBRATION ISOLATOR

SLEEVES ARE LOCATED ON

THE HORIZONTAL SECTION OF

THE DISCHARGE LINE.

DO NOT REMOVED THE THREE VIBRATION ISOLATOR SLEEVES (IF

PRESENT) FROM THE COMPRESSOR DISCHARGE LINE

Figure 1. Discharge Line Vibration Isolators

XC15 Outdoor Unit

The XC15 Air Conditioners, which will also be referred to in

this instruction as the outdoor unit, uses HFC−410A

refrigerant. This outdoor unit must be installed with a

matching indoor unit and line set as outlined in the Lennox

XC15 Engineering Handbook.

This outdoor unit is designed for use in systems that use

thermal expansion valve (TXV) refrigerant metering

devices.

General Information

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

When servicing or repairing HVAC components, ensure

caps and fasteners are appropriately tightened. Table 1

lists torque values for typical service and repair items.

Table 1. Torque Requirements

Part Recommended Torque

Service valve cap 8 ft.− lb. 11 NM

Sheet metal screws 16 in.− lb. 2 NM

Machine screws #10 28 in.− lb. 3 NM

Compressor bolts 90 in.− lb. 10 NM

Gauge port seal cap 8 ft.− lb. 11 NM

USING MANIFOLD GAUGE SETS

When checking the system charge, only use a manifold

gauge set that features low−loss anti−blow back fittings.

See figure 4 for a typical manifold gauge connection setup.

Manifold gauge sets used with HFC−410A refrigerant

systems must be capable of handling the higher system

operating pressures. The gauges should be rated for use

with pressures of 0 − 800 on the high side and a low side of

30" vacuum to 250 psi with dampened speed to 500 psi.

Gauge hoses must be rated for use at up to 800 psi of

pressure with a 4000 psi burst rating.

OPERATING SERVICE VALVES

The liquid and suction line service valves are used for

removing refrigerant, flushing, leak testing, evacuating,

checking charge and charging.

Each service valve is equipped with a service port which

has a factory−installed valve stem.

IMPORTANT

Only use Allen wrenches of sufficient hardness

(50Rc − Rockwell Harness Scale minimum). Fully

insert the wrench into the valve stem recess.

Service valve stems are factory−torqued (from 9

ft−lbs for small valves, to 25 ft−lbs for large valves) to

prevent refrigerant loss during shipping and

handling. Using an Allen wrench rated at less than

50Rc risks rounding or breaking off the wrench, or

stripping the valve stem recess.

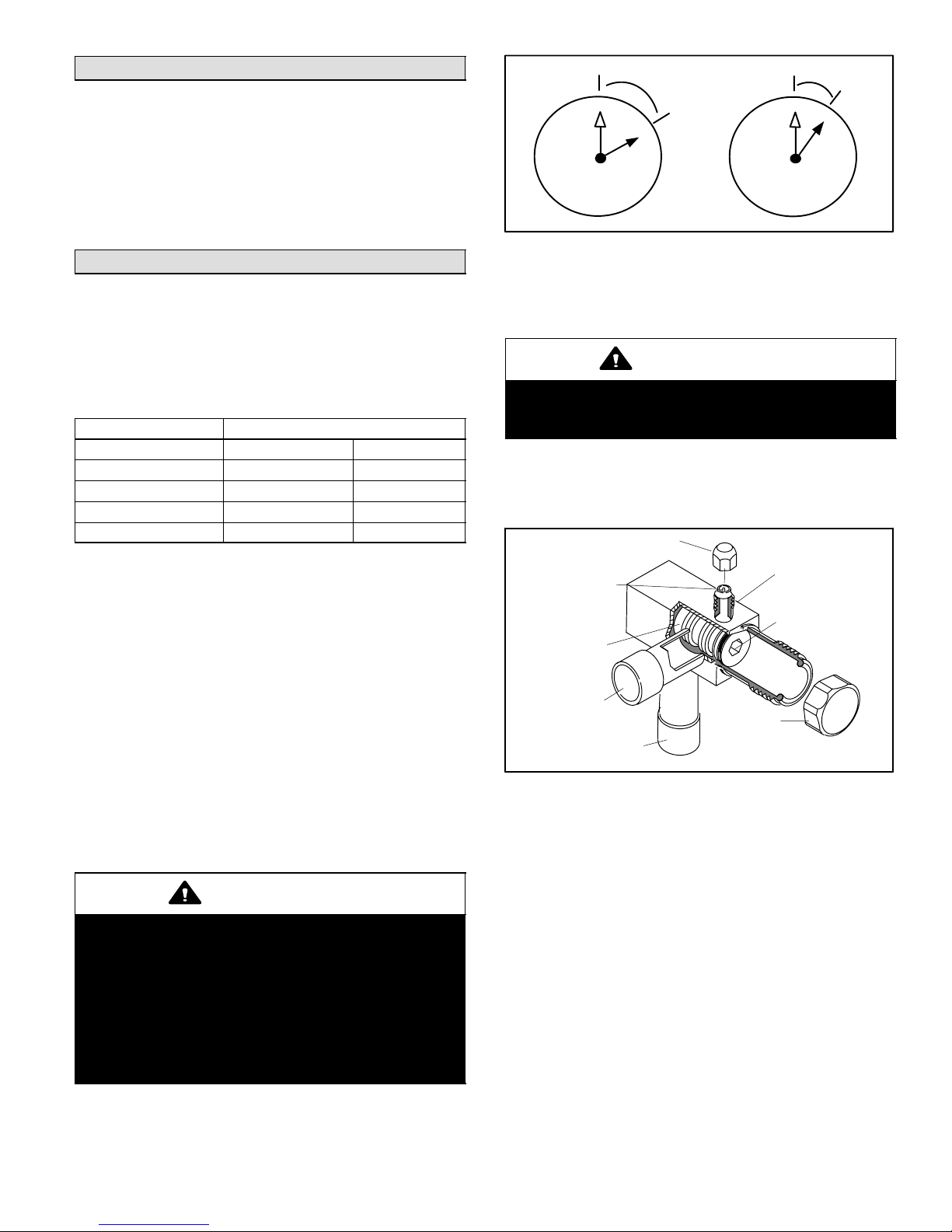

1/12 TURN

12

1

2

3

4

7

5

6

9

10

8

11

1/6 TURN

12

1

2

3

4

7

5

6

11

10

9

8

Figure 2. Cap Tightening Distances

NOTE − A label with specific torque requirements may be

affixed to the stem cap. If the label is present, use the

specified torque.

IMPORTANT

To prevent stripping of the various caps used, the

appropriately sized wrench should be used and

fitted snugly over the cap before tightening.

To Access Angle−Type Service Port:

A service port cap protects the service port core from

contamination and serves as the primary leak seal.

SERVICE PORT CAP

STEM CAP

SERVICE PORT

(VALVE STEM SHOWN

CLOSED) INSERT HEX

WRENCH HERE

SERVICE PORT

CLOSED TO BOTH

INDOOR AND

OUTDOOR UNITS

FRONT-SEATED

CORE

VALVE STEM

TO INDOOR

UNIT

TO OUTDOOR UNIT

Figure 3. Angle−Type Service Valve

(Font−Seated Closed)

1. Remove service port cap with an appropriately sized

wrench.

2. Connect gauge to the service port.

3. When testing is completed, replace service port cap and

tighten as follows:

S With Torque Wrench: Finger tighten and then

tighten per table 1.

S Without Torque Wrench: Finger tighten and use an

appropriately sized wrench to turn an additional

1/6 turn clockwise as illustrated in figure 2.

To Open and Close Angle−Type Service Valve:

A valve stem cap protects the valve stem from

contamination and assures a leak−free seal.

Page 3

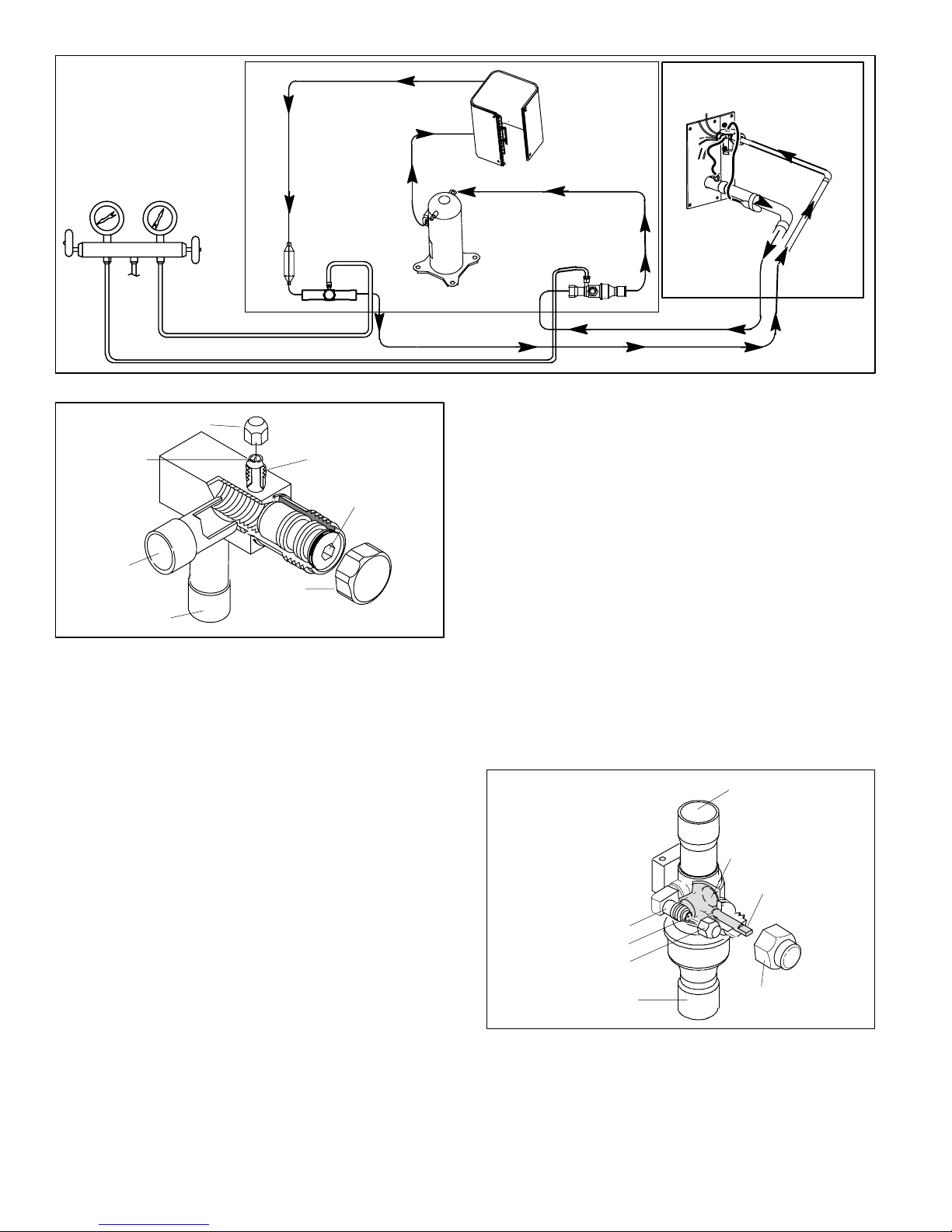

XC15 SERIES

OUTDOOR UNIT

(Uncased Coil Shown)

LOW

PRESSURE

GAUGE MANIFOLD

PRESSURE

TO

HFC−410A

DRUM

HIGH

FILTER

DRIER

LIQUID LINE

SERVICE VALVE

COMPRESSOR

Figure 4. Typical Manifold Gauge Connection Setup

SERVICE PORT CAP

SERVICE PORT

CORE

OPEN TO BOTH

INDOOR AND

OUTDOOR UNITS

TO INDOOR

UNIT

TO OUTDOOR UNIT

STEM CAP

SERVICE PORT

(VALVE STEM SHOWN OPEN)

INSERT HEX WRENCH HERE

Figure 5. Angle−Type Service Valve

(Back−Seated Opened)

1. Remove stem cap with a wrench.

2. Use a service wrench with a hex−head extension

(3/16" for liquid-line valve sizes and 5/16" for

suction-line valve sizes) to back the stem out

counterclockwise as far as it will go.

3. Replace the stem cap and tighten as follows:

S With Torque Wrench: Tighten finger tight and then

tighten per table 1.

S Without Torque Wrench: Finger tighten and use an

appropriately sized wrench to turn an additional

1/12 turn clockwise as illustrated in figure 2.

To Access Ball−Type Service Port:

A service port cap protects the service port core from

contamination and serves as the primary leak seal.

1. Remove service port cap with an appropriately sized

wrench.

2. Connect gauge to the service port.

3. When testing is completed, replace service port cap and

tighten as follows:

OUTDOOR

COIL

SUCTION LINE

SERVICE VALVE

TXV

S With Torque Wrench: Finger tighten and then

tighten per table 1.

S Without Torque Wrench: Finger tighten and use an

appropriately sized wrench to turn an additional

1/6 turn clockwise as illustrated in figure 2.

To Open and Close Ball−Type Service Valve:

A valve stem cap protects the valve stem from

contamination and assures a leak−free seal.

1. Remove stem cap with a wrench.

2. Use an appropriately sized wrench to open. To open

valve, rotate stem counterclockwise 90°. To close

rotate stem clockwise 90°.

3. Replace the stem cap and tighten as follows:

S With Torque Wrench: Finger tighten and then

tighten per table 1.

S Without Torque Wrench: Finger tighten and use an

appropriately sized to wrench turn an additional

1/12 turn clockwise as illustrated in figure 2.

OPEN TO LINE SET WHEN VALVE IS

CLOSED, TO BOTH LINE SET AND

UNIT WHEN VALVE IS OPEN.

TO OPEN ROTATE STEM

COUNTERCLOCKWISE

90°.

TO CLOSE ROTATE

STEM CLOCKWISE 90°.

SERVICE

PORT

SERVICE

PORT CORE

SERVICE PORT

TO OUTDOOR UNIT

CAP

Figure 6. Ball−Type Service Valve

TO INDOOR UNIT

BALL

(SHOWN

CLOSED)

VALV E

STEM

STEM

CAP

506044−01 06/08

Page 4

Recovering Refrigerant from Existing

System

Remove existing HCFC−22 refrigerant using one of the

following methods:

METHOD 1:

Use this method if the existing outdoor unit is not equipped

with manual shut−off valves, and plan on using existing

HCFC−22 refrigerant to flush the system.

NOTE − Use recovery machine instructions for specific

setup requirements.

Perform the following task:

1. Disconnect all power to the existing outdoor unit.

2. Connect to the existing unit a gauge set, clean

recovery cylinder and a recovery machine. Use the

instructions provided with the recover machine on how

to setup the connections.

3. Remove all HCFC−22 refrigerant from the existing

system. Check gauges after shutdown to confirm that

the entire system is completely void of refrigerant.

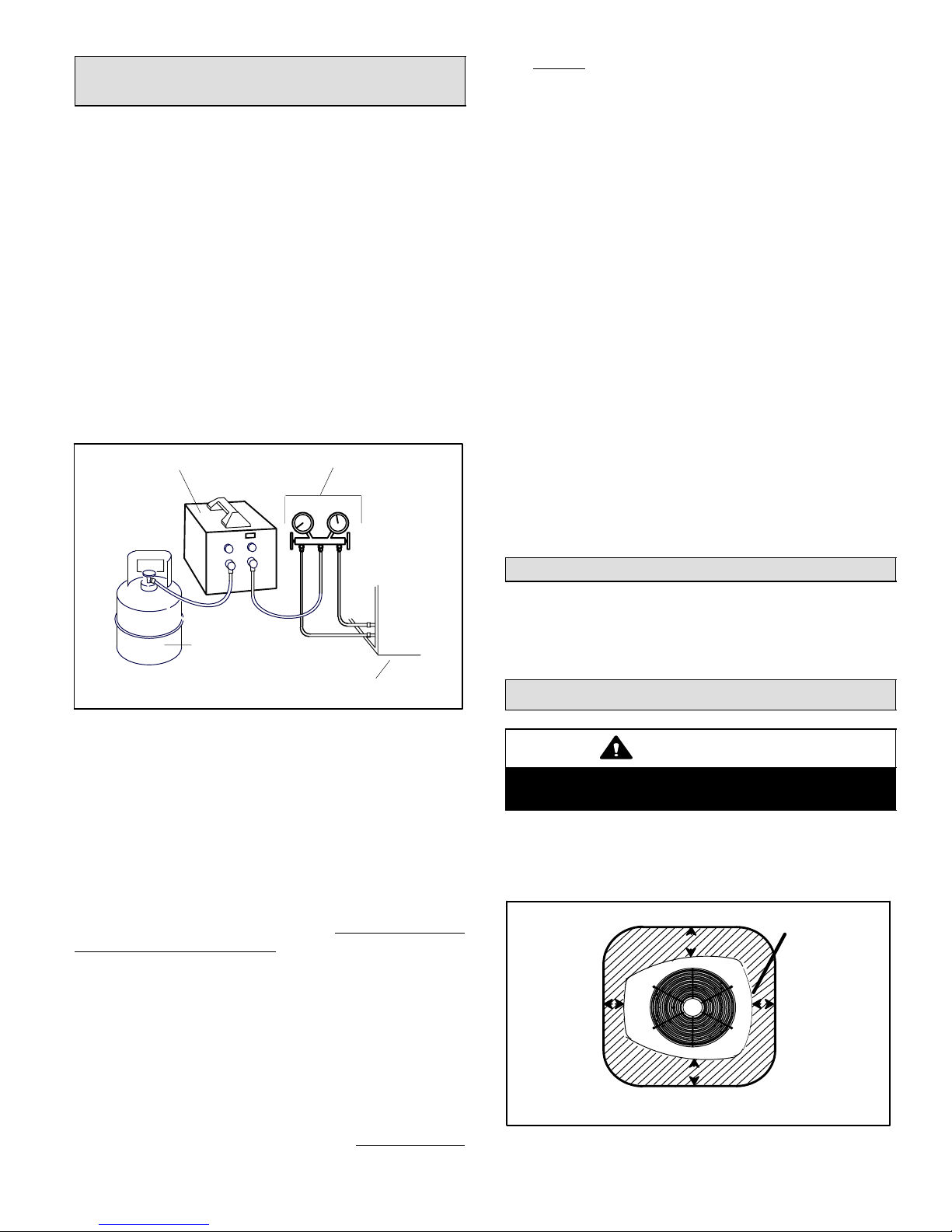

RECOVERY MACHINE

MANIFOLD GAUGES

allowed to go into a vacuum. Prolonged operation at

low suction pressures will result in overheating of the

scrolls and permanent damage to the scroll tips, drive

bearings and internal seals).

Once the compressor can not pump down to a lower

pressure due to one of the above system conditions, shut

off the suction valve. Turn OFF the main power to unit and

use a recovery machine to recover any refrigerant left in

the indoor coil and line set.

Perform the following task:

1. Start the existing HCFC−22 system in the cooling

mode and close the liquid line valve.

2. Pump as much of the existing HCFC−22 refrigerant

with the compressor back into the outdoor unit until

you have reached the limitations of the outdoor

system. Turn the outdoor unit main power OFF and

use a recovery machine to remove the remaining

refrigerant in the system.

NOTE − It may be necessary to bypass the low pressure

switches if equipped to ensure complete refrigerant

evacuation.

3. When the low side system pressures reach 0 psig,

close the suction line valve.

4. Check gauges after shutdown to confirm that the

valves are not allowing refrigerant to flow back into the

low side of the system.

CLEAN RECOVERY

CYLINDER

OUTDOOR UNIT

Figure 7. Typical Refrigerant Recovery

(Method 1)

METHOD 2:

Use this method if the existing outdoor unit is equipped

with manual shut−off valves, and plan on using new

HCFC−22 refrigerant to flush the system.

IMPORTANT: Some system configurations may contain

higher than normal refrigerant charge due to either large

internal coil volumes, and/or long line sets. The following

conditions may cause the compressor to stop functioning:

The following devices could prevent full system charge

recovery into the outdoor unit:

S Outdoor unit’s high or low−pressure switches (if

applicable) when tripped can cycled the compressor

OFF.

S Compressor can stop pumping due to tripped internal

pressure relief valve.

S Compressor has internal vacuum protection that is

designed to unload the scrolls (compressor stops

pumping) when the pressure ratio meets a certain

value or when the suction pressure is as high as 20

psig. (Compressor suction pressures should never be

Removing Existing Outdoor Unit

Perform the following task at the existing outdoor unit:

S Disconnect line set at the service valves.

S Disconnect electrical service at the disconnect switch.

S Remove old outdoor unit.

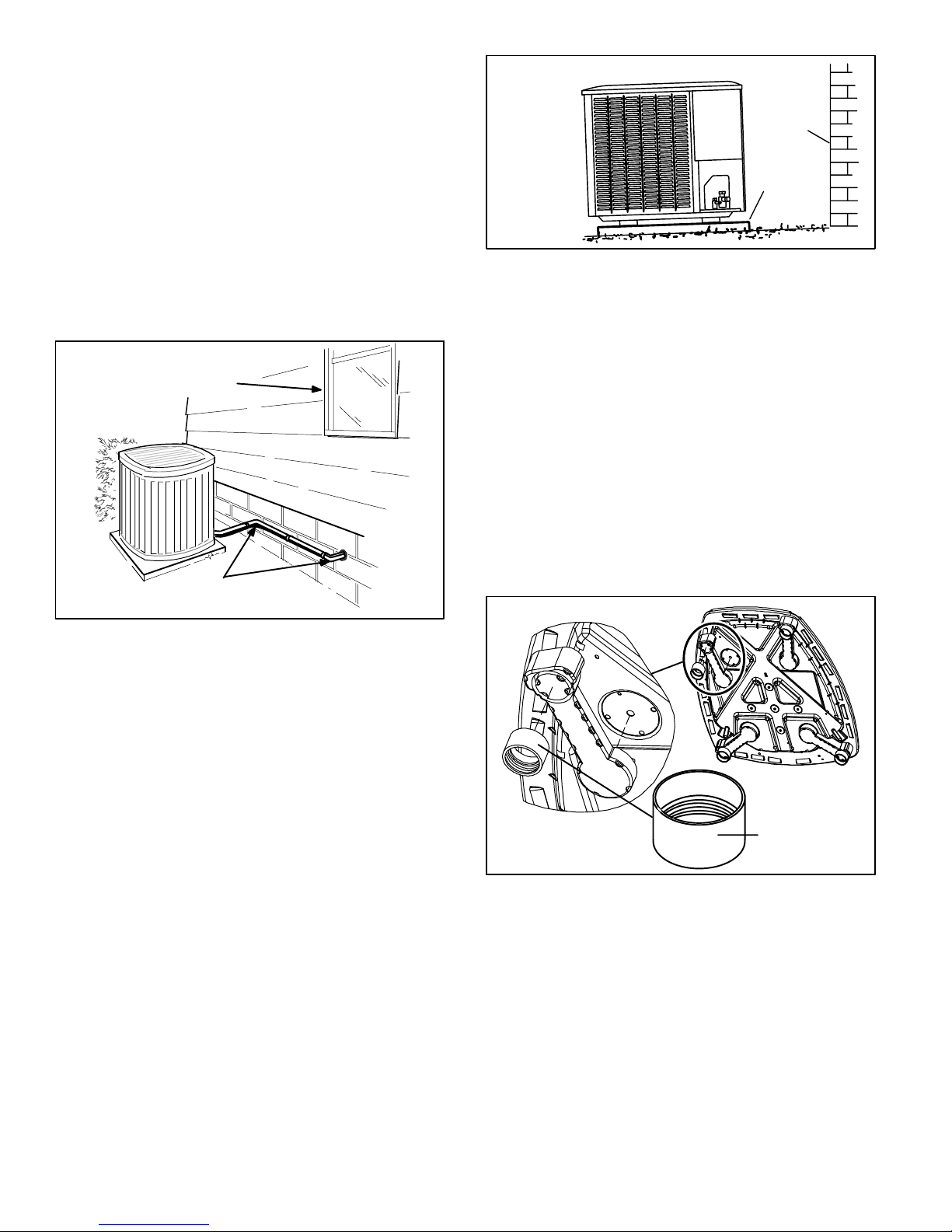

Positioning New Outdoor Unit

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

See Unit Dimensions on page 2 for sizing mounting slab,

platforms or supports. Refer to figure 8 for mandatory

installation clearance requirements.

CONTROL PANEL

ACCESS LOCATION

*

Page 5

*

*

* SEE NOTES ON NEXT PAGE FOR FURTHER DETAILS.

Figure 8. Installation Clearances

*

XC15 SERIES

NOTES:

S Service clearance of 30 in. (762 mm) must be

maintained on one of the sides adjacent to the control

box.

S Clearance to one of the other three sides must be 36

in. (914 mm)

.

S Clearance to one of the remaining two sides may be

12 in. (305 mm) and the final side may be 6 in. (152

.

mm)

S 48 in. (1219 mm) clearance required on top of unit.

S A clearance of 24 in. (610 mm) must be maintained

between two units.

POSITIONING CONSIDERATIONS

Consider the following when positioning the unit:

BUILDING

STRUCTURE

MOUNTING

SLAB

GROUND LEVEL

Figure 10. Slab Mounting at Ground Level

NOTE − If necessary for stability, anchor unit to slab as

described in Stabilizing Unit on Uneven Surfaces on page

7.

INSTALL UNIT

AWAY FROM

WINDOWS

TWO 90° ELBOWS INSTALLED IN

LINE SET WILL REDUCE LINE SET

VIBRATION.

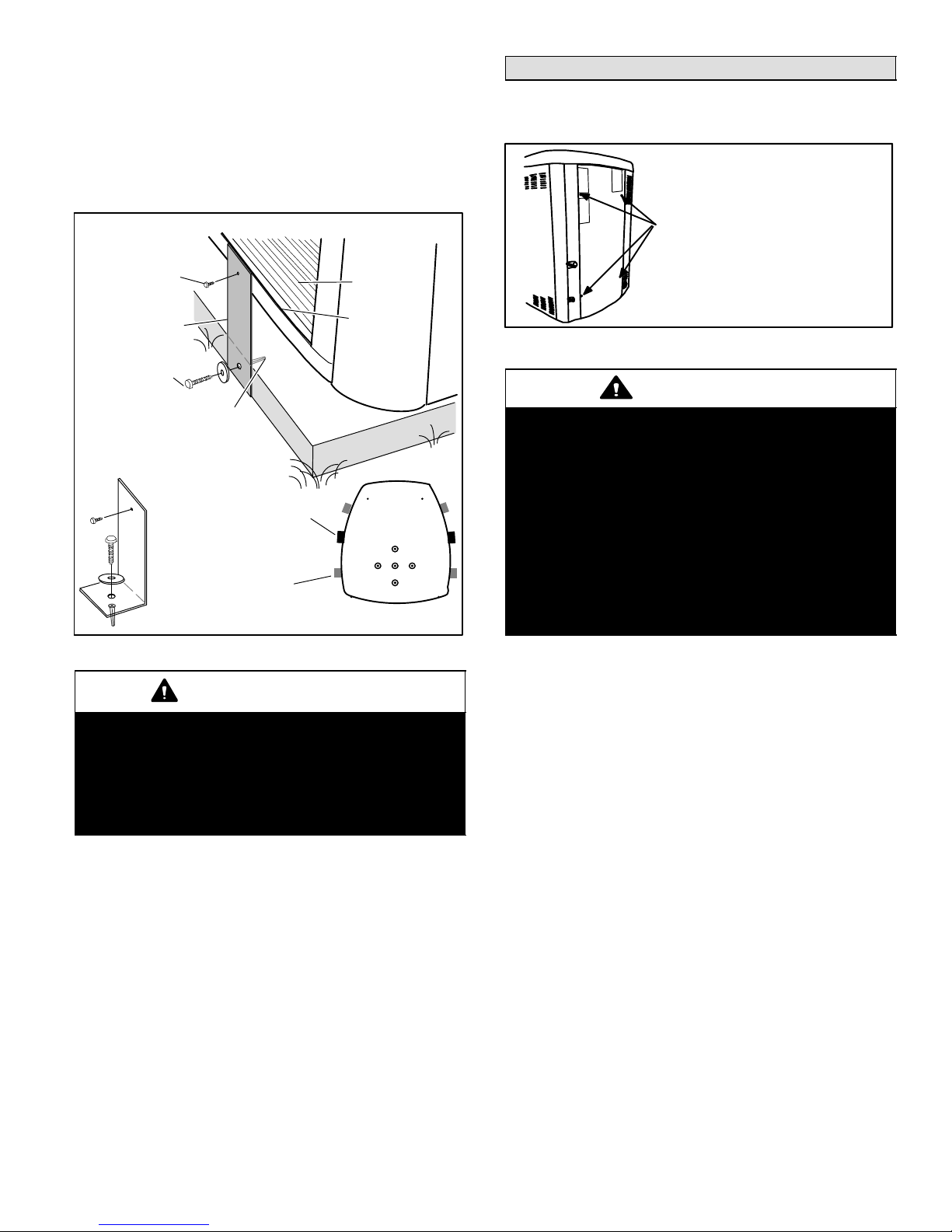

Figure 9. Outside Unit Placement

S Some localities are adopting sound ordinances based

on the unit’s sound level registered from the adjacent

property, not from the installation property. Install the

unit as far as possible from the property line.

S When possible, do not install the unit directly outside

a window. Glass has a very high level of sound

transmission. For proper placement of unit in relation

to a window see the provided illustration in figure 9.

PLACING OUTDOOR UNIT ON SLAB

When installing unit at grade level, the top of the slab

should be high enough above grade so that water from

higher ground will not collect around the unit. The slab

should have a slope tolerance as described in figure 10.

NOTE − Install unit level or, if on a slope, maintain slope

tolerance of 2 degrees (or 2 inches per 5 feet [50 mm per

1.5 m]) away from building structure.

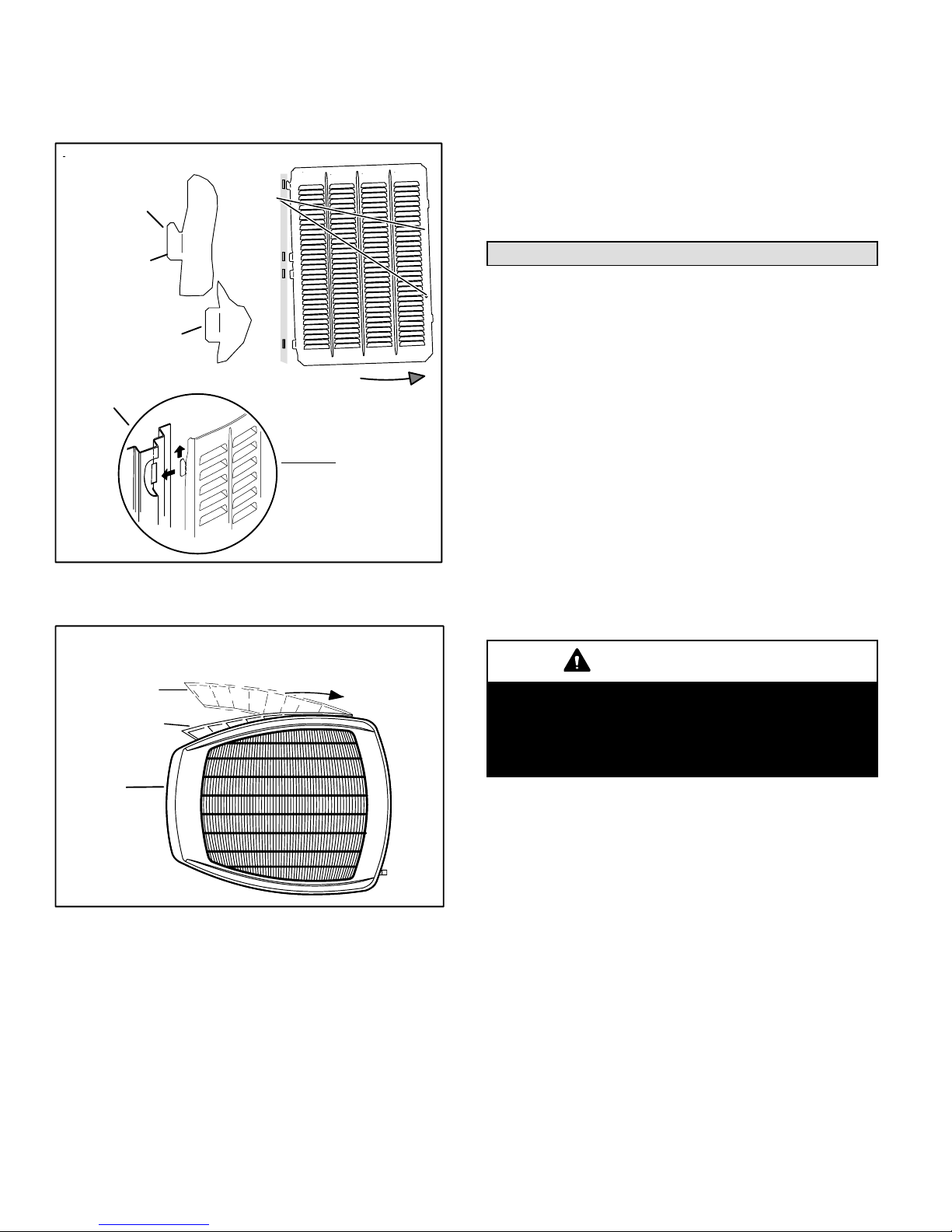

ELEVATING THE UNIT

Unlike the small−base units which use round support feet,

the larger−base units are outfitted with elongated support

feet as illustrated in figure 11 which uses a similar method

for elevating the unit.

If additional elevation is necessary, raise the unit by

extending the length of the unit support feet. This may be

achieved by using a 2" SCH 40 female threaded adapter.

The specified coupling will fit snuggly into the recessed

portion of the feet. Use additional 2" SCH 40 male threaded

adaptors which can be threaded into the female threaded

adaptors to make additional adjustments to the level of the

unit.

BASE

LEG DETAIL

2" (50.8MM) SCH 40

FEMALE THREADED

ADAPTER

Figure 11. Elevated Slab Mounting using

Feet Extenders (Larger Base Units)

NOTE − Keep the height of extenders short enough to

ensure a sturdy installation. If it is necessary to extend

further, consider a different type of field−fabricated

framework that is sturdy enough for greater heights.

506044−01 06/08

Page 6

STABILIZING UNIT ON UNEVEN SURFACES

To help stabilize an outdoor unit, some installations may

require strapping the unit to the pad using brackets and

anchors commonly available in the marketplace.

With unit positioned at installation site, remove two side

louvered panels to expose the unit base pan. Install the

brackets as illustrated in figure 12 using conventional

practices; replace the panels after installation is complete.

Slab Side Mounting

#10 1/2" LONG SELF−

DRILLING SHEET

METAL SCREWS

STABILIZING

BRACKET (18 GAUGE

METAL − 2" WIDTH;

HEIGHT AS REQ’D)

#10 1−1/4" LONG

HEX HD SCREW

AND FLATWASHER

COIL

BASE PAN

CORNER POST

Removing and Installing Panels

ACCESS PANEL

Remove and reinstall access panel as shown in figure 13.

REMOVE 4 SCREWS TO REMOVE PANEL

FOR ACCESSING COMPRESSOR AND

CONTROLS.

INSTALL BY POSITIONING PANEL WITH

HOLES ALIGNED; INSTALL SCREWS AND

TIGHTEN.

Figure 13. Access Panel

CAUTION

CONCRETE SLAB − USE PLASTIC

PLASTIC ANCHOR (HOLE DRILL

1/4")PLASTIC SLAB − NO PLASTIC

ANCHOR (HOLE DRILL 1/8")

STABILITY

MINIMUM 1

PER SIDE

Deck Top

Mounting

STABILIZING BRACKET

(18 GAUGE METAL − 2"

WIDTH; HEIGHT AS

REQ’D); BEND TO FORM

RIGHT ANGLE

ONE BRACKET PER SIDE (MIN.); FOR EXTRA STABILITY,

2 BRACKETS PER SIDE, 2" FROM EACH CORNER.

FOR EXTRA

Figure 12. Installing Stabilizer Brackets

IMPORTANT

Unit Stabilizer Bracket Use (field−provided):

Always use stabilizers when unit is raised above the

factory height. (Elevated units could become

unstable in gusty wind conditions).

Stabilizers may be used on factory height units

when mounted on unstable an uneven surface.

ROOF MOUNTING

Install unit at a minimum of four inches above the surface

of the roof. Care must be taken to ensure weight of unit is

properly distributed over roof joists and rafters. Either

redwood or steel supports are recommended.

To prevent personal injury, or damage to panels,

unit or structure, be sure to observe the following:

While installing or servicing this unit, carefully stow

all removed panels out of the way, so that the panels

will not cause injury to personnel, nor cause

damage to objects or structures nearby, nor will the

panels be subjected to damage (e.g., being bent or

scratched).

While handling or stowing the panels, consider any

weather conditions, especially windy conditions,

that may cause panels to be blown around and

battered.

INSTALLING ISOLATION GROMMETS

Locate the isolation grommets (provided). Slide grommets

onto suction and liquid lines. Insert grommets into mullion

to isolate refrigerant lines from sheet metal edges.

REMOVING PANELS

Remove the louvered panels as follows:

1. Remove two screws, allowing the panel to swing open

slightly as illustrated in figure 14.

NOTE − Hold the panel firmly throughout this procedure

2. Rotate bottom corner of panel away from hinge corner

post until lower three tabs clear the slots as illustrated

in figure 14, detail B.

3. Move panel down until lip of upper tab clears the top

slot in corner post as illustrated in figure 14, detail A.

Page 7

XC15 SERIES

INSTALLING PANEL

Install unit at a minimum of four inches above the surface

of the roof. Care must be taken to ensure weight of unit is

properly distributed over roof joists and rafters.

IPANEL SHOWN SLIGHTLY ROTATED TO ALLOW TOP TAB TO EXIT (OR ENTER) TOP

SLOT FOR REMOVING (OR INSTALLING) PANEL.

SCREW

LIP

HOLES

2. With a continuous motion slightly rotate and guide the

lip of top tab inward as illustrated in figure 14, details

A and C, then upward into the top slot of the hinge

corner post.

3. Rotate panel to vertical to fully engage all tabs.

4. Holding the panel’s hinged side firmly in place, close

the right−hand side of the panel, aligning the screw

holes.

5. When panel is correctly positioned and aligned, insert

the screws and tighten.

DETAIL A

DETAIL B

ROTATE IN THIS DIRECTION; THEN DOWN TO REMOVE PANEL

DETAIL C

IMPORTANT! DO NOT ALLOW

PANELS TO HANG ON UNIT BY TOP

TAB. TAB IS FOR ALIGNMENT AND

NOT DESIGNED TO SUPPORT

WEIGHT OF PANEL.

Figure 14. Removing/Installing Louvered

Panels (Details A, B and C)

MAINTAIN MINIMUM PANEL ANGLE (AS CLOSE TO PARALLEL WITH THE UNIT

AS POSSIBLE) WHILE INSTALLING PANEL.

ANGLE MAY BE

TOO EXTREME

PREFERRED ANGLE

FOR INSTALLATION

DETAIL D

HOLD DOOR FIRMLY TO THE

HINGED B SIDE TO MAINTAIN

FULLY−ENGAGED TABS

Figure 15. Removing/Installing Louvered

Panels (Detail D)

New or Replacement Line Set

This section provides information on installation or

replacement of existing line set. If line set are not being

installed then proceed to Brazing Connections on page 9.

If refrigerant lines are routed through a wall, seal and

isolate the opening so vibration is not transmitted to the

building. Pay close attention to line set isolation during

installation of any HVAC system. When properly isolated

from building structures (walls, ceilings. floors), the

refrigerant lines will not create unnecessary vibration and

subsequent sounds.

REFRIGERANT LINE SET

Field refrigerant piping consists of liquid and suction lines

from the outdoor unit (braze connections) to the indoor unit

coil (flare or sweat connections). Use Lennox L15 (sweat,

non−flare) series line set, or use field−fabricated refrigerant

lines as listed in table 2.

MATCHING WITH NEW OR EXISTING INDOOR COIL

AND LINE SET

IMPORTANT

Matching XC15 with a New Indoor Coil and Line

SetIf installing a new indoor coil and reusing the

existing line set that included a RFCI liquid line

(small bore liquid line used as a metering device)

then you must change to a standard size liquid line.

NOTE − When installing refrigerant lines longer than 50

feet, see the Lennox Refrigerant Piping Design and

Fabrication Guidelines, or contact Lennox Technical

Support Product Applications for assistance. To obtain the

correct information from Lennox, be sure to communicate

the following points:

S Model (XC15) and size of unit (e.g. −060).

Install the louvered panels as follows:

1. Position the panel almost parallel with the unit as

illustrated in figure 15, detail D with the screw side as

close to the unit as possible.

506044−01 06/08

S Line set diameters for the unit being installed as listed

in table 2 and total length of installation.

S Number of elbows and if there is a rise or drop of the

piping.

Page 8

Loading...

Loading...