Page 1

E2007 Lennox Industries Inc.

Dallas, Texas, USA

3 Heat / 2 Cool Programmable

Touch Screen Thermostat

INSTALLATION

INSTRUCTIONS

WARNING

This thermostat is to be installed by a qualified service technician or

other qualified agency in accordance with the manufacturer’s instructions, all codes, and requirements of the authority having jurisdiction.

505,044M

8/2007

Page 2

Page 2

Table of Contents

General Page 2. . . . . . . . . . . . . . . . .

Shipping and Packing List Page 2.

NecessaryTools Page 2. . . . . . . . . .

Thermostat Location Page 2. . . . . .

Remove Existing Thermostat Page 3

Thermostat Installation Page 4. . . .

Wiring Connections Page 4. . . . . . .

LED Indicator Page 5. . . . . . . . . . . .

Outdoor Temp. Sensor Page 5. . . .

Field Wiring Diagrams Page 6. . . .

Install Batteries Page 8. . . . . . . . . .

Attach T’stat to Wallplate Page 8. .

Set Calendar and Clock Page 8. . .

Adv. Heat Pump Features Page 9.

Installer Set−Up Page 11. . . . . . . . . .

System Test Page 19. . . . . . . . . . . . .

Troubleshooting Page 20. . . . . . . . . .

General

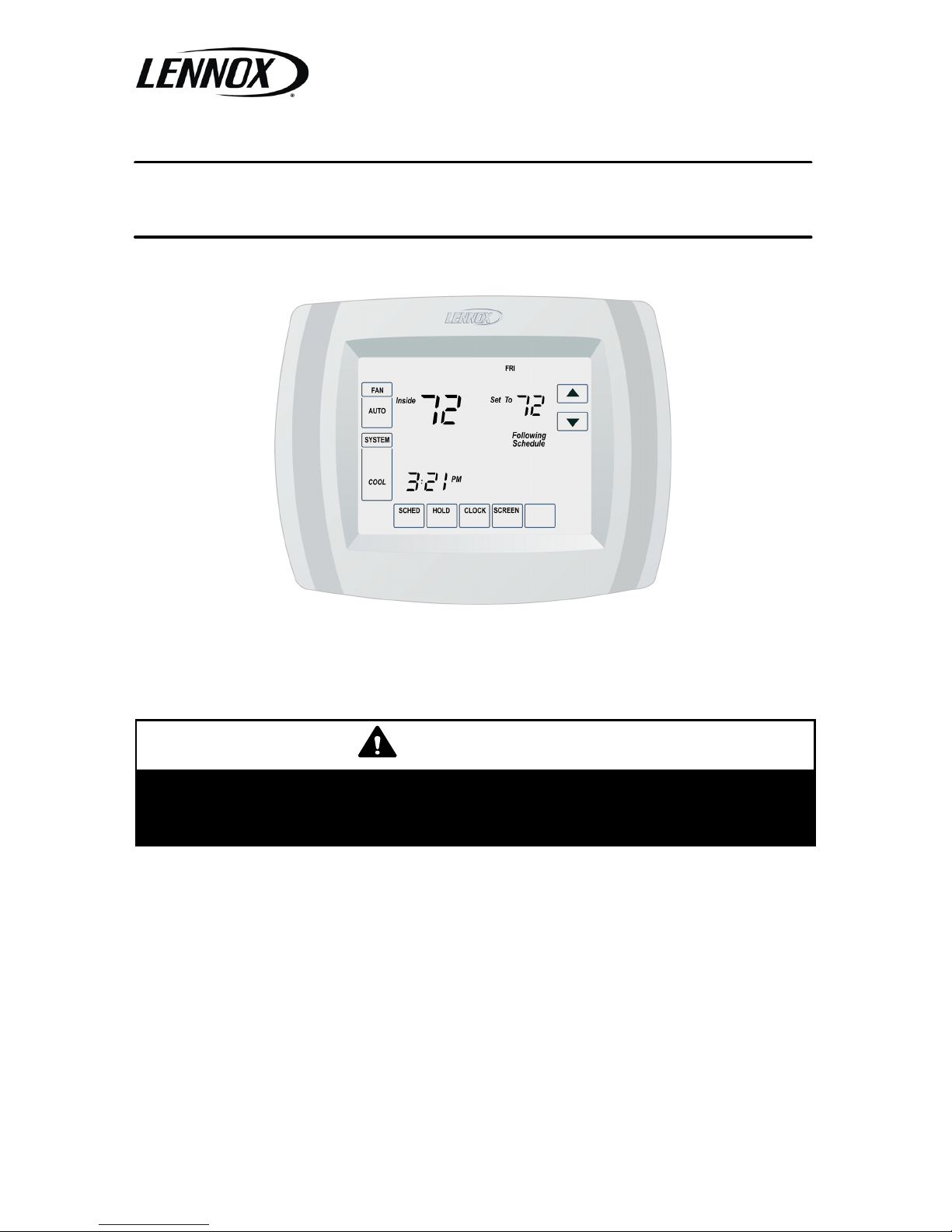

The Lennox X4147 programmable

touch-screen thermostat provides

control for up to three stages of heating

and two stages of cooling. The thermostat may be used to control either a

conventional HVAC system which includes an outdoor condensing unit and

indoor furnace or a heat pump unit and

indoor air handler. The thermostat terminal block accommodates 24V power

common from the furnace or air handler. Three AAA alkaline batteries are

provided to be used as an alternate

power source or as a back−up in case

of an interruption of power.

Shipping and Packing List

Package 1 of 1 contains

1 − Assembled thermostat (includes

wallplate and thermostat)

1− Bag assembly containing the fol-

lowing:

2 − Screws

2 − Wall anchors

3 − AAA alkaline batteries

1 − Installation instruction

1 − Owner’s guide

1 − Warranty certificate

Necessary Tools

S No. 2 Phillips screwdriver

S Standard pocket screwdriver

S Drill

S Drill bits (use 3/16" for drywall and

7/32" for plaster)

S Pencil

S Level

S Hammer

S Electrical tape

Thermostat Location

Install the thermostat about 5 feet

(1.5m) above the floor in an area with

good air circulation.

Do not install the thermostat where it

may be affected by the following:

S Drafts or dead spots behind doors

and in corners.

S Hot or cold air from ducts.

S Radiant heat from the sun or ap-

pliances.

S Concealed pipes or chimneys.

S Adjacent unconditioned areas

(outside wall behind the thermostat).

Page 3

Page 3

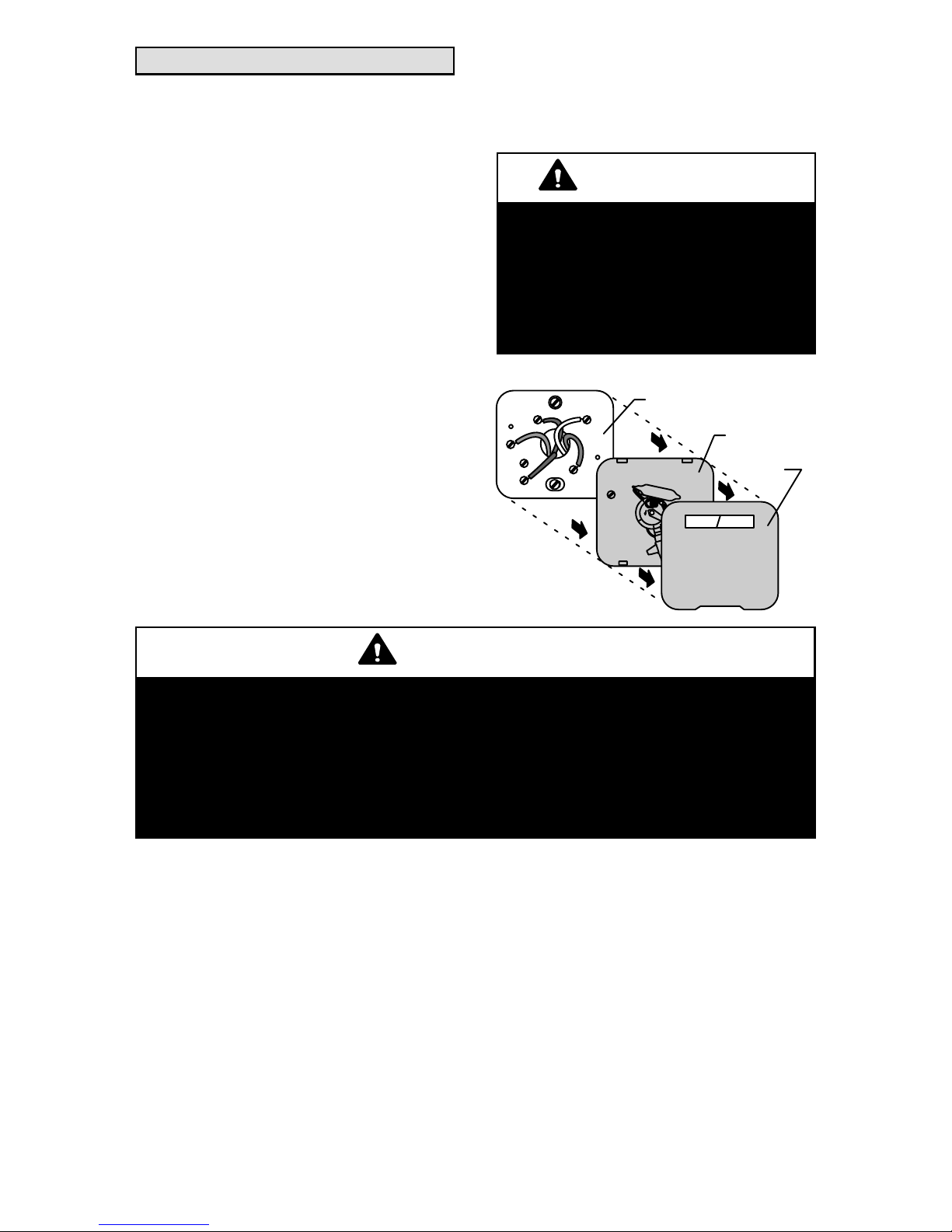

Remove Existing Thermostat

If this thermostat is being used to replace an existing thermostat, remove

the old thermostat:

1 − Turn off power at the heating and/

or cooling system or fuse/circuit

breaker panel.

2 − Remove the cover from the exist-

ing thermostat.

3 − Remove securing screws and re-

move existing thermostat from

wall or wallplate. Disconnect and

label the existing wires.

4 − Remove any remaining portion of

the existing thermostat from the

wall. Do not install the replacement thermostat faceplate on the

existing wallplate. Though the

wallplates may appear to be the

same and the faceplate may fit on

the existing wallplate, the terminal

positions may vary in important

ways. In addition, serial number

and part number information is

carried on the replacement wallplate.

Do not allow the thermostat wires

to fall behind the drywall.

WARNING

This thermostat must be

installed using the provided replacement wallplate.

Failure to do so will bypass thermostat control and activate continuous heating.

Y

G

C

R

W

OLD THERMOSTAT

.18

.

2

.

25

.

3

.

9

.

7

.

5

.

4

L

O

N

G

E

R

THERMOSTAT

COVER

WALLPLATE

WARNING

MERCURY NOTICE

If the existing thermostat includes a mercury bulb, the thermostat must

be disposed of properly.

Contact your local waste management authority for instructions regarding recycling and proper disposal of thermostats which include

mercury bulbs.

Page 4

Page 4

Thermostat Installation

The thermostat may be installed horizontally in a 4 in. X 2 in. (101.6 mm X

50.8 mm) wiring box or on the wall using the provided anchors.

1 − Separate the wallplate from the

thermostat as shown.

THERMOSTAT

WALLPLATE

WIRE HOLE

2 − Pass the labeled wires through the

hole on the wallplate.

3 − Position the wallplate on the wall

with the arrow pointing up. Level

the wallplate (for appearance

only) and use a pencil to mark the

mounting holes.

WALLPLATE

LEVEL

PLACE LEVEL ON

SUPPORT TABS

MARK

MOUNTING

HOLES (2)

4 − If anchors are used, move the

wallplate aside and drill two new

holes (3/16" for drywall; 7/32" for

plaster).

5 − Tap the provided wall anchors into

the drilled holes until the back of

the anchor head touches the wall

surface.

6 − Position the wallplate over the an-

chors and pull the thermostat

wires back through the wiring

opening.

7 − Secure the wallplate using the

provided screws.

DRILLED

HOLES (2)

WALL

ANCHORS (2)

MOUNTING

SCREWS (2)

WALLPLATE

NOTE

Thermostat heat function will

not operate if thermostat has

been stored at, or is being used

in, ambient temperatures at or

above 90°F. Heat function will be

enabled after thermostat has

been placed in ambient temperatures less than 90°F for about 30

minutes.

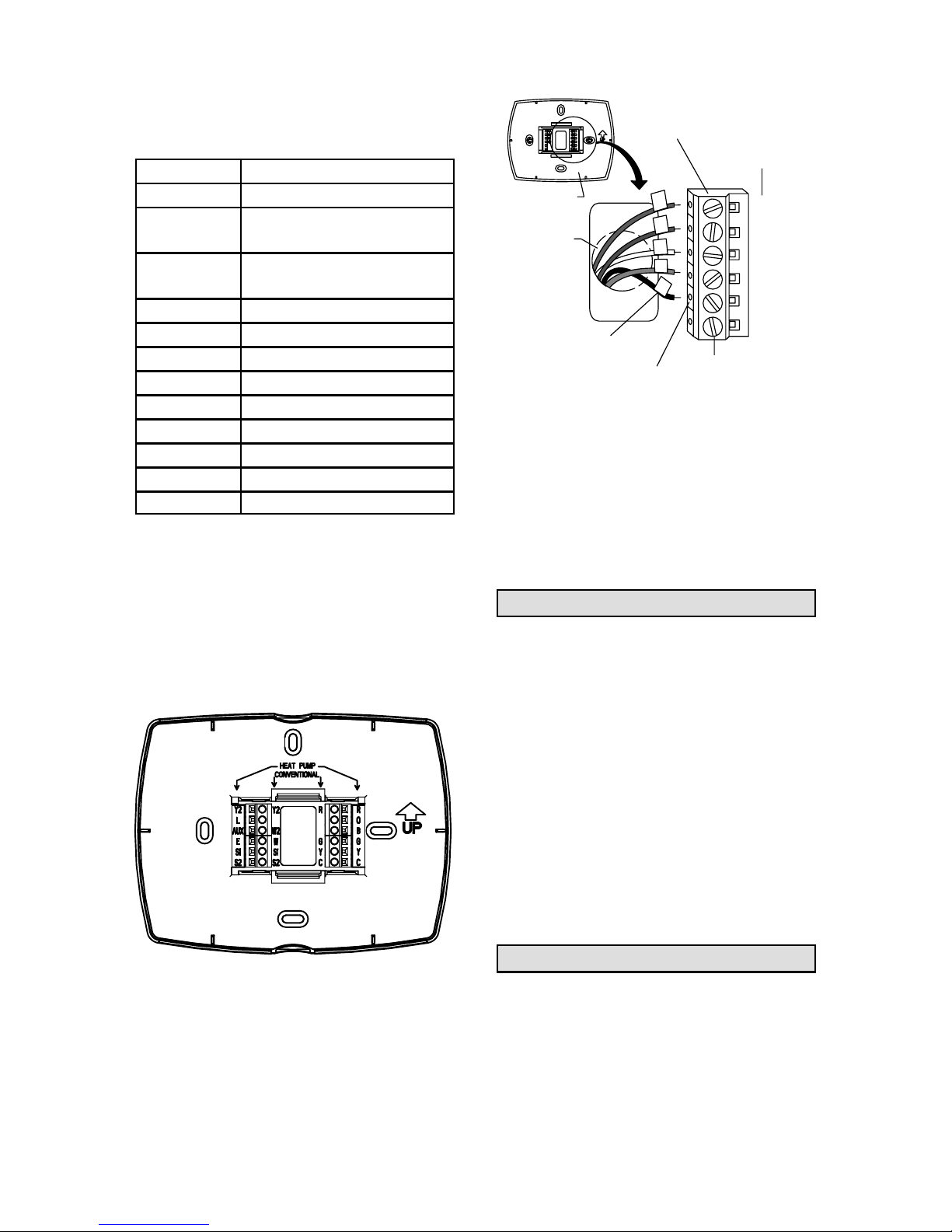

Wiring Connections

WARNING

Use minimum 18 guage wire for

all thermostat connections.

IMPORTANT

Do not connect the wires to this

thermostat based on wire color.

Improper wiring may cause

damage to the HVAC system.

Page 5

Page 5

1 − Make wiring connections per the

appropriate wiring diagram on

page 6 or 7. Refer to the table

below for terminal designations.

Terminal Description

Y2 Second−stage cooling

W2 (AUX)

Second−stage heating

(or auxiliary heating)

W (E)

First−stage heating

(or emergency heating)

S1 Remote outdoor sensor

S2 Remote outdoor sensor

R 24V power

O Reversing valve

B Reversing valve

G Fan relay

Y First−stage cooling

C 24V common

L Equipment monitor

2 − Refer to inner terminal labels

when using the thermostat with

conventional systems (gas, oil or

electric heat plus air conditioning).

Refer to outer terminal labels in

heat pump applications. See figure below.

3 − Loosen screws of terminals that

will be used. Insert appropriate

wires in the terminal block under

the loosened screws. Securely

tighten each screw.

C

Y

B

O

R

G

INSERT WIRE IN HOLE

WIRE HOLE

WALLPLATE

SCREW

TERMINALS

LETTER

DESIGNATIONS

LABELED WIRES

TERMINAL

BLOCK

4 − Connect wires to the correspond-

ing screw terminals per the appropriate diagram.

5 − Push excess wire back into the

wall.

6 − Plug hole with nonflammable in-

sulation to prevent drafts from affecting thermostat.

LED Indicator

An LED indicator is located in the upper right corner of the thermostat. It is

only visible when lit.

When an equipment monitor is connected to the thermostat L terminal,

the LED lights when the monitor sends

a check or failure message to the thermostat.

The LED requires the use of 24Vac

common power. The indicator will not

light when the thermostat is powered

by the batteries alone, or when 24Vac

power is interrupted.

Outdoor Temperature Sensor

Install the optional outdoor temperature sensor (X4148) as outlined in the

instructions provided with the sensor.

Page 6

Page 6

Field Wiring Diagrams

TYPICAL CONVENTIONAL MULTI−STAGE APPLICATION

TWO−STAGE HEAT / TWO−STAGE COOL

TYPICAL MULTI−STAGE HEAT PUMP APPLICATION

NO AUXILIARY HEAT

TYPICAL MULTI−STAGE HEAT PUMP APPLICATION

WITH AUXILIARY HEAT

Page 7

Page 7

Field Wiring Diagrams (Continued)

TYPICAL SINGLE−STAGE HEAT PUMP SYSTEM WITH AUXILIARY HEAT

TYPICAL SINGLE−STAGE HEAT PUMP SYSTEM WITHOUT AUXILIARY HEAT

Page 8

Page 8

Install Batteries

1 − Install three provided AAA alkaline

batteries in the back of the thermostat as shown.

BACK OF THERMOSTAT

BATTERIES

(3)

+

+

+

2 − Remove tab from the lower right−

hand corner of the thermostat

back to activate the real−time

clock.

REMOVE DURING

INSTALLATION

REMOVE

TAB

REMOVE DURING

INSTALLATION

Attach Thermostat to Wallplate

NOTE − The thermostat may be programmed before it is secured to the

wallplate.

1 − Align the terminal blocks on the

wallplate with the pins on the back

of thermostat.

2 − Push the thermostat straight onto

the pins until it snaps into place.

3 − Turn on power at the furnace or air

handler or at the fuse or circuit

breaker.

PINS ON

BACK OF

THERMOSTAT

WALLPLATE

TERMINAL

SCREW

BLOCK

Set Calendar and Clock

This thermostat is designed to automatically keep the current time and

date in memory for up to ten years, under normal use, once the calendar has

been set. When power is first applied to

the thermostat, the display is ready to

set the calendar.

1 − Use the arrow keys to set the year,

month and day.

2 − Press the DONE key.

DONE

USE

ARROWS

TO SET

YEAR

SET

CURRENT

DATE

SET

MONTH

MON WED THU FRI SATTUE

3 − Use the arrow keys to set the cur-

rent time.

4 − Press the DONE key.

DONE

MON WED THU FRI SAT

AM

PM

USE

ARROWS

TO SET

TIME

TUE

NOTE − Date and time may be adjusted after the initial set−up using either the installer or user set−up menu.

Page 9

Page 9

Advanced Heat Pump Features

The thermostat installer set−up may be

configured in several different ways to

ensure the desired system operation.

Heat Pump Application

Dual Fuel (Fossil Fuel) Aux. Heat

Outdoor Temperature Sensor and

Thermostat Control Aux. Heat

(No external dual fuel kit)

Installer set−up as follows:

S Installer set−up number 0170 −−

option 7, 11, or 12 −− heat pump.

S Installer set−up number 0200 −−

option 1 −− back−up heat is fossil

fuel.

S Installer set−up number 0210 −−

option 0 −− no external fossil fuel

kit.

S Installer set−up number 0340 −− not

shown −− outdoor temperature

sensor for control option chosen

by default.

S Installer set−up number 0350 −−

choose appropriate balance point

temperature.

Heating Mode Operation

Outdoor Temp. above Balance

Point

When the outdoor temperature is

above the selected balance point, the

compressor satisfies the heating demand. However, if the room thermostat

senses an indoor temperatature drop

of 2°F or more while the compressor is

operating, the heat pump operation will

stop and the furnace will satisfy the remaining heating demand.

NOTE − The balance point setting is

selected using Installer Set−Up Number 0350.

Heating Mode Operation

Outdoor Temp. below Balance Point

When the outdoor temperature is below the selected balance point, only

the furnace (fossil fuel) operates to satisfy the heating demand. The fan (G

terminal) does not energize when the

thermostat calls for heat.

Emergency Heat Operation

When the emergency heat mode of operation is selected by the thermostat,

compressor operation is locked out.

The first stage of heat becomes what is

connected to the thermostat E terminal. The second stage of heat becomes what is connected to the Aux.

terminal. In cases where there is only

one source of non−compressor heat,

the E terminal must be jumped to the

Aux. terminal.

Heat Pump Application

Dual Fuel (Fossil Fuel) Aux. Heat

Using External Dual Fuel Kit

Installer set−up as follows:

S Installer set−up number 0170 −−

option 7, 11, or 12 −− heat pump.

S Installer set−up number 0200 −−

option 1 −− back−up heat is fossil

fuel.

S Installer set−up number 0210 −−

option 1 −− external fossil fuel kit is

controlling heat pump auxiliary

heat.

S Installer set−up number 0340 −−

option 0 or 1 −− outdoor temperature sensor not used or used for

display only.

S Installer set−up number 0350 −−

choose appropriate balance point

temperature.

Heat pump operation is determined by

external fossil fuel kit.

Page 10

Page 10

Heat Pump Application

Electric Auxiliary Heat

with Outdoor Temperature Sensor

S Installer set−up number 0170 −−

heat pump.

S Installer set−up number 0200 −−

back−up heat is electric.

S Installer set−up number 0340 −−

outdoor temperature sensor for

control option chosen.

S Installer set−up number 0350 −−

choose appropriate compressor

lock−out temperature.

S Installer set−up number 0360 −−

choose appropriate auxiliary lock−

out temperature.

NOTE − There is a minimum 5°F deadband between the compressor and

auxiliary heat lock−out temperatures.

Heating Mode Operation

When the outdoor temperature is below the compressor lock−out temperature (balance point), only the auxiliary

heat operates.

When the outdoor temperature is

above the auxiliary lock−out temperature (balance point), only the compressor operates.

When the outdoor temperature is between the two temperatures, both the

compressor and auxiliary heat operate.

COMPRESSOR

LOCK−OUT

TEMPERATURE

AUXILIARY

LOCK−OUT

TEMPERATURE

COMPRESSOR ONLY

BOTH COMPRESSOR AND

AUXILIARY HEAT

AUXILIARY ONLY

50

35

OUTDOOR TEMPERATURE

Emergency Heat Operation

When the thermostat is set for the

emergency heat mode, the compressor and auxiliary lock−out features are

turned off. Compressor operation is

locked out. The first stage of heat becomes what is connected to the thermostat E terminal. The second stage of

heat becomes what is connected to the

Aux. terminal.

Page 11

Page 11

Installer Set−Up

Use the following steps and the Installer Set−Up menu to match the thermostat to the HVAC system.

1 − Press and release the SYSTEM

key.

2 − Press and hold the two blank keys

on either side of the center blank

key for approximately five seconds.

MON

CANCEL

UET WED THU FRI SATAAT SUN

PM

SS M

EMHT

Y TE

COOL

FOLLOWING

SCHEDULE

SET TO

OFF

DONE

3 − Release the two keys when the

thermostat display matches the

display below.

DONE

4 − Refer to the following figure to see

how the thermostat keys are used

to make selections from the set−up

menu.

DONE

INSTALLER

SET−UP

NUMBER

CURRENT

SETTING

ADVANCE TO NEXT

INSTALLER SET−UP

EXIT

INSTALLER

SET−UP

CHANGE THE

CURRENT

SETTING

5 − The installer set−up number is dis-

played on the left−hand side of the

screen. The current installer set−

up number is displayed on the

right−hand side of the screen. Use

the up and down arrows on the

right−hand side of the thermostat

to select the proper setting for that

particular set−up number.

6 − After the proper selection has

been made, use the up arrow in

the center of the thermostat to advance to the next set−up screen.

7 − Refer to the tables on pages 9

through 15 to make proper set−up

choices for your application.

8 − When all set−up selections have

been made, press the DONE key

to save your settings. Thermostat

display will return to the main

screen.

NOTE − Press and release the SYSTEM key, then press and hold the center blank key to access the user set−up

screens. The user set−up options are

limited to those features that would be

used by the homeowner. Press the

DONE key when finished.

Page 12

Page 12

InstallerSet−

Up No.

Installer

Set−Up

Name

Selection Description

(Factory setting in bold print)

Notes

0120

Date

(Year/

first)

Select first two digits of current calendar

year (20 for 2007, etc.)

Factory setting = 20.

0130

Date

(Year/

last)

Select last two digits of current calendar

year (07 for 2007, etc.); 01 to 99 available.

0140

Date

(Month)

Select number that represents current calendar month.

Factory setting = 8.

0150

Date

(Day)

Select number that represents current calendar date.

Factory setting = 19.

0160

Schedule

Options

0 − Non−programmable.

4 − 7−day programming. Factory setting.

0170

System

Type

1 − Single−Stage Heating and Cooling

(Conventional) −− Gas, oil or electric

heating with central air conditioning.

Factory setting.

2 − Single−Stage Heat Pump with No Back−

Up or Auxiliary Heat.

3 − Heat Only without Fan (Conventional).

4 − Heat Only with Fan (Conventional).

5 − Hot Water Heat Only (Conventional) −−

Gas or oil hot water heat. Power open/

power close hot water zone valves or normally open valves.

6 − Cooling Only (Conventional) −− Central

air conditioning only.

7 − Two Heat / One Cool Heat Pump −−

Heat pump with auxiliary or back−up heat.

8 − Two Heat / Two Cool Multi−Stage (Conventional).

9 − Two Heat / One Cool Multi−Stage (Conventional).

10 − One Heat / Two Cool Multi−Stage

(Conventional).

11 − Two Heat / Two Cool Heat Pump −− No

auxiliary heat.

12 − Three Heat / Two cool Heat Pump −−

With auxiliary heat.

Available options and defaults vary by

system type.

System type

selection automatically modifies certain default settings

and installer

set−up options.

table continued on next page

Page 13

Page 13

InstallerSet−

Up No.

Notes

Selection Description

(Factory setting in bold print)

Installer

Set−Up

Name

0180

Fan

Control

Heating

0 − Gas or Oil Heat −− Heating system

controls fan during heating demand.

Factory setting.

1 − Electric Heat −− Thermostat controls fan

during heating demand.

Available only if

conventional

system chosen.

Setting defaults

to electric heat

if heat pump is

chosen.

0200

Auxiliary

Heat

Source

0 − Electric heat is used as auxiliary

heat source in heat pump application.

Factory setting.

1 − Fossil fuel is used as auxiliary heat

source in heat pump application.

Available only if

2 ht / 1 cool or

3 ht / 2 cool

heat pump system is chosen.

0210

External

Fossil

Fuel Kit

0 − No external fossil fuel kit is controlling

heat pump auxiliary heat. Thermostat used

to control dual fuel. Must install outdoor

temperature sensor and installer set−up

number 0340 must be set to selection 2.

1 − External fossil fuel kit is controlling

heat pump auxiliary heat. Factory setting.

Shown only in

heat pump applications when

fossil fuel is

chosen as

back−up heat

source.

0220

Cycles

per Hour

(cph) 1st

Stage

Compressor

3 − Recommended setting for compressors. Factory setting.

Settings of 1 − 6 cph available.

0230

Cycles

per Hour

(cph) 2nd

Stage

Compressor

3 − Recommended setting for compressors. Factory setting.

Settings of 1 − 6 cph available.

Shown only

when two−stage

cooling is selected.

0240

Cycles

per Hour

(cph) 1st

Stage

Conventional

Heating

1 − Recommended for use with steam and

gravity.

3 − Recommended for use with hot water

heat and high−efficiency (90% or higher)

furnaces.

5 − Recommended for use with standard−efficiency (less than 90%) fossil

fuel furnaces.

9 − Recommended for use with electric furnaces.

Settings of 1 − 12 cph available.

Shown only

when conventional system is

selected.

table continued on next page

Page 14

Page 14

InstallerSet−

Up No.

Notes

Selection Description

(Factory setting in bold print)

Installer

Set−Up

Name

250

Cycles

per Hour

(cph) 2nd

Stage

Conventional

Heating

(or Auxiliary Heat

for 2

Heat / 1

Cool

Heat

Pump

Applications)

1 − Recommended for use with steam and

gravity.

3 − Recommended for use with hot water

heat and high−efficiency (90% or higher)

furnaces.

5 − Recommended for use with standard−efficiency (less than 90%) fossil

fuel furnaces. Factory setting.

9 − Recommended for use with electric furnaces or electric auxiliary heat.

Settings of 1 − 12 cph available.

Shown only

when two−stage

heating is selected.

0260

Cycles

per Hour

(cph) 3rd

Stage

Heating

1 − Recommended for use with steam and

gravity.

3 − Recommended for use with hot water

heat and high−efficiency (90% or higher)

furnaces.

5 − Recommended for use with standard−

efficiency (less than 90%) fossil fuel furnaces.

9 − Recommended for use with electric

furnaces or electric auxiliary heat. Factory setting.

Settings of 1 − 12 cph available.

Shown only in 3

heat / 2 cool

heat pump applications.

0270

Cycles

per Hour

(cph)

Emer−

gency

Heating

3 − Recommended for use with hot water

heat and high−efficiency (90% or higher)

furnaces.

5 − Recommended for use with standard−

efficiency (less than 90%) fossil fuel furnaces.

9 − Recommended for use with electric

strip heat in heat pump applications.

Factory setting.

Shown only in 2

heat/1 cool or 3

heat/2 cool heat

pump applications.

0280

Continuous

Backlight

0 − Backlight not lit continuously. Backlight comes on when key is pressed.

Factory setting.

1 − Backlight is continuously lit. (Thermostat must be powered by 24V common

wire for this feature to be allowed.)

Option always

shown; however, t’stat must

be powered by

24V common.

table continued on next page

Page 15

Page 15

InstallerSet−

Up No.

Notes

Selection Description

(Factory setting in bold print)

Installer

Set−Up

Name

0300

Changeover

0 − Manual changeover from heating

mode to cooling mode. Factory setting.

1 − Auto−changeover from heating mode to

cooling mode.

0310

Deadband

(Minimum differential

between

heating

and cooling setpoints)

2 − 2°F (1.5°C)

3 − 3°F (2°C). Factory setting.

4 − 4°F (2.5°C)

5 − 5°F (3°C)

6 − 6°F (3.5°C)

7 − 7°F (4°C)

8 − 8°F (4.5°C)

9 − 9°F (5°C)

Option shown

only when auto−

changeover has

been selected.

0320

Temperature Display

Scale

0 − Fahrenheit (factory setting).

1 − Celsius

0330

Daylight

Savings

0 − Daylight savings disabled.

1 − Daylight savings enabled using

pre−2007 calendar. Factory setting.

2 − Daylight savings enabled using 2007

DST calendar (all US; some Canada).

Set to 0 in

areas that do

not follow daylight savings.

0340

Remote

Outdoor

Temperature Sensor

0 − No remote outdoor temperature

sensor. Factory setting.

1 − Outdoor temperature sensor used for

display only.

2 − Outdoor temperature sensor used to

control heat pump lock−out settings.

Defaults and

options depend

on system type

selection.

When setting

0210 is set to 0,

setting defaults

to 2 and item is

not shown.

0350

Heat

Pump

Compressor

Lock−Out

(Balance

point)

0 − No compressor lock−out. Factory

setting.

15°F (−9.5°C).

20°F (−6.5°C).

25°F (−4°C).

30°F (−1°C).

35°F (1.5°C).

40°F (4.5°C).

45°F (7°C).

Shown only if

outdoor temperature for control

is selected. Default depends

on other selections.

table continued on next page

Page 16

Page 16

InstallerSet−

Up No.

Notes

Selection Description

(Factory setting in bold print)

Installer

Set−Up

Name

0360

Heat

Pump

Auxiliary

Heat

Lock−Out

0 − No auxiliary heat lock−out. Factory

setting.

40°F (4.5°C).

45°F (7°C)

50°F (10°C).

55°F (13°C).

60°F (15.5°C).

Shown only if

electric is selected for back−

up heat source

and outdoor

temp. sensor

for control is selected.

0500

Filter

Change

Reminder

0 − Filter change reminder off. Factory

setting.

1 − 10 run time days.

2 − 30 run time days.

3 − 60 run time days.

4 − 90 run time days.

5 − 120 run time days.

6 − 365 run time days.

Run time based

on call for fan.

0510

Humidifier Pad

Replacement

Reminder

0 − Humidifier pad replacement reminder off. Factory setting.

1 − 90 run time days.

2 − 180 run time days.

3 − 365 run time days.

0520

UV Lamp

Replacement Reminder

0 − UV lamp replacement reminder off.

Factory setting.

1 − 365 run time days.

0530

Adaptive

Intelligent

Recovery

0 − Conventional Recovery −− System

starts recovery at programmed time.

1 − Adaptive Intelligent Recovery −− System starts recovery early so that setpoint is reached by the start of the program period. Factory setting.

0540

Number

of Periods

2 − Two periods (wake and sleep) available.

4 − Four periods (wake, leave, return,

sleep) available. Factory setting.

Shown only

when programmable is chosen.

Setting applies

to all days of

the week.

0580

Minimum

Compressor−

Off Time

Settings of 0 − 5 available.

5 − Five−minute compressor−off time

setting. Factory setting.

table continued on next page

Page 17

Page 17

InstallerSet−

Up No.

Notes

Selection Description

(Factory setting in bold print)

Installer

Set−Up

Name

0600

Heat

Temperature

Range

(°F)

Settings of 40 − 90 available in 1°F increme.

Factory setting = 90.nts.

Shown in 1/2°C

increments

0610

Cool

Temperature

Range

(°F)

Settings of 50 − 99 available in 1°F increments.

Factory setting = 50.

Shown in 1/2°C

increments

0640

Clock

Format

12 − 12−hour clock. Factory setting.

24 − 24−hour clock.

0650

Heating

Mode

Extended

Fan On

Time

0 − No extended fan operation after

heating demand satisfied. Factory setting.

90 − Fan operation continues for 90 seconds after heating demand satisfied.

Not shown

when fan operation is set to

fossil fuel or in

cool only systems.

0660

Cooling

Mode

Entended

Fan On

Time

0 − No extended fan operation after

cooling demand satisfied. Factory setting.

90 − Fan operation continues for 90 seconds after cooling demand satisfied.

Not shown in

heat only systems.

0670

Keypad

Lock−Out

0 − Keypad unlocked −− all functions are

available. Factory setting.

1 − Keypad partially locked −− only temp. up

and down keys and ability to enter installer

set−up mode and modify set−up selections

are enabled.

2 − Keypad fully locked −− only ability to enter installer set−up mode and modify set−up

selections are enabled.

0680

Heating

Mode

Temperature Control

1 − Less aggressive control. Select this

setting if temperature is overshooting the

setpoint. Heating may turn off before the

setpoint is reached.

2 − Standard control. Factory setting.

3 − More aggressive control. Select this

setting if temperature is undershooting the

setpoint. Heating may remain on after the

setpoint is reached.

Applies to recovery ramp

and use of auxiliary heat during recovery.

table continued on next page

Page 18

Page 18

InstallerSet−

Up No.

Notes

Selection Description

(Factory setting in bold print)

Installer

Set−Up

Name

0690

Cooling

Mode

Temperature Control

1 − Less aggressive control. (Cooling may

turn off before setpoint reached).

2 − Standard control. Factory setting.

3 − More aggressive control. (Cooling may

remain on after setpoint reached).

Applies to recovery ramp.

0700

Temperature Display Offset

−3°F (−1.5°C).

−2°F (−1°C).

−1°F (−.5°C).

0 − No difference in displayed temperature and actual room temperature. Factory setting.

1°F (.5°C).

2°F (1.5°C).

3°F (2°C).

0710

Reset

Thermostat

0 − No thermostat reset. Factory setting.

1 − Resets all installer set−up options to

default values and resets schedule to

default setting.

Only calendar

settings and

time are retained.

Page 19

Page 19

System Test

The system test function allows the installer to check the HVAC system after

the thermostat set−up has been completed. The system test function is accessed through the installer set−up

menu.

1 − Press and release the SYSTEM

key.

2 − Press and hold the two blank keys

on either side of the center blank

key for approximately five seconds, until the screen changes.

3 − Use the down arrow in the center

of the thermostat to reach the installer test selections.

4 − The installer test number is dis-

played on the upper portion of the

screen. Press the up or down arrow next to the word test on the

screen to change the output to be

tested.

5 − Refer to the following table to se-

lect proper test options.

CAUTION

While the system is in the test

mode, the compressor minimum−off time is bypassed.

Installer Test No. Installer Set−Up Name Selection Description

Test 1 Installer Test Cool

0 − Cooling is off (factory setting).

1 − First−stage cooling is activated.

2 − Second−stage cooling is activated.

Test 2 Installer Test Fan

0 − Fan is off (factory setting).

1 − Fan is activated.

0 − Heating is off (factory setting).

1 − First−stage heat is activated.

Test 3

Install

er Test Hea

t

2 − Second−stage heat is activated.

−

−

-

3

−

Third−stage (auxiliary) heat is ac

-

tivated.

Installer Test Emergen-

0 − Emergency heat is off (factory

Test 4

Installer Test Emergen

cy Heat

setting)

.

1 − Emergency heat is activated.

Page 20

Page 20

Troubleshooting

Symptom Possible Cause Action

Display does not come

on.

Thermostat is not being

powered.

1− Check to see that there

is 24V between R and C

terminals.

2− Check to see that batteries are properly

installed.

Temperature settings do

Upper or lower temperature limits were reached.

1− Check temperature setpoints.

2− Check installer set−up

numbers 0600 and 0610.

Modify, if necessary.

not change

.

Keypad is fully locked.

Check installer set−up

number 0670 and change

keypad lock option, if necessary.

Thermostat minimum−off

time is activated.

Wait up to 5 minutes for

the system to respond.

Heating or cooling does

System selection has not

been set to heat or cool.

Select proper system

mode.

not come on.

System type selection is

incorrect.

Check installer set−up

number 0170 and make

sure proper system type

is selected.

Thermostat is calling for

heat (Heat ON) or cool

(Cool ON); but HVAC system is not operating.

Heating or cooling equipment is not operating.

1− Check wiring.

2− Check installer set−up

number 0170 and make

sure proper system type

is selected.

3− Verify operation of

equipment in system test

mode.

Thermostat does not

respond when touch

screen is pressed.

Keypad is fully locked.

Check installer set−up

number 0670 and change

keypad lock option, if necessary.

NOTE − Perform installer system tests (page 19) to verify thermostat

control of HVAC system.

Loading...

Loading...