Page 1

APPLICATION

GUIDE

WING

Page 2

Page 3

Congratulations you have made a wise choice with the purchase of your Lennox

air conditioning unit.

This product has been designed, assembled and supplied in one of our world class manufacturing facilities

and we feel sure that it will meet your expectations.

Lennox an international organisation with world wide distribution takes pride in supplying you with this

product.

CONTENTS

CONTENTS

. PRODUCT RANGE

. SYSTEM CONFIGURATION

. GENERAL DESCRIPTION

. SPECIFICATIONS

. ELECTRICAL DATA

. ELECTRICAL CONNECTIONS

. INDOOR MOTOR FAN CHARACTERISTICS

. OPERATING LIMITS

. REFRIGERANT CONNECTIONS

. DIMENSIONS AND SETTING UP TEMPLATES OUTDOOR UNIT

. DESCRIPTION OUTDOOR UNIT

. ENTRANCE STANDARD/ OPTIONAL OUTDOOR UNIT

. DIMENSIONS AND SETTING UP TEMPLATES INDOOR UNIT

. INSTALATION AND MOUNTING

. OPTIONS

MAINTENANCE

. POINTS TO KEEP IN MIND

PÁGE

2-3

4

5

6-9

10-11

12-14

15

16

17-19

20

21-22

23

24

25

26-27

28

29

1

Page 4

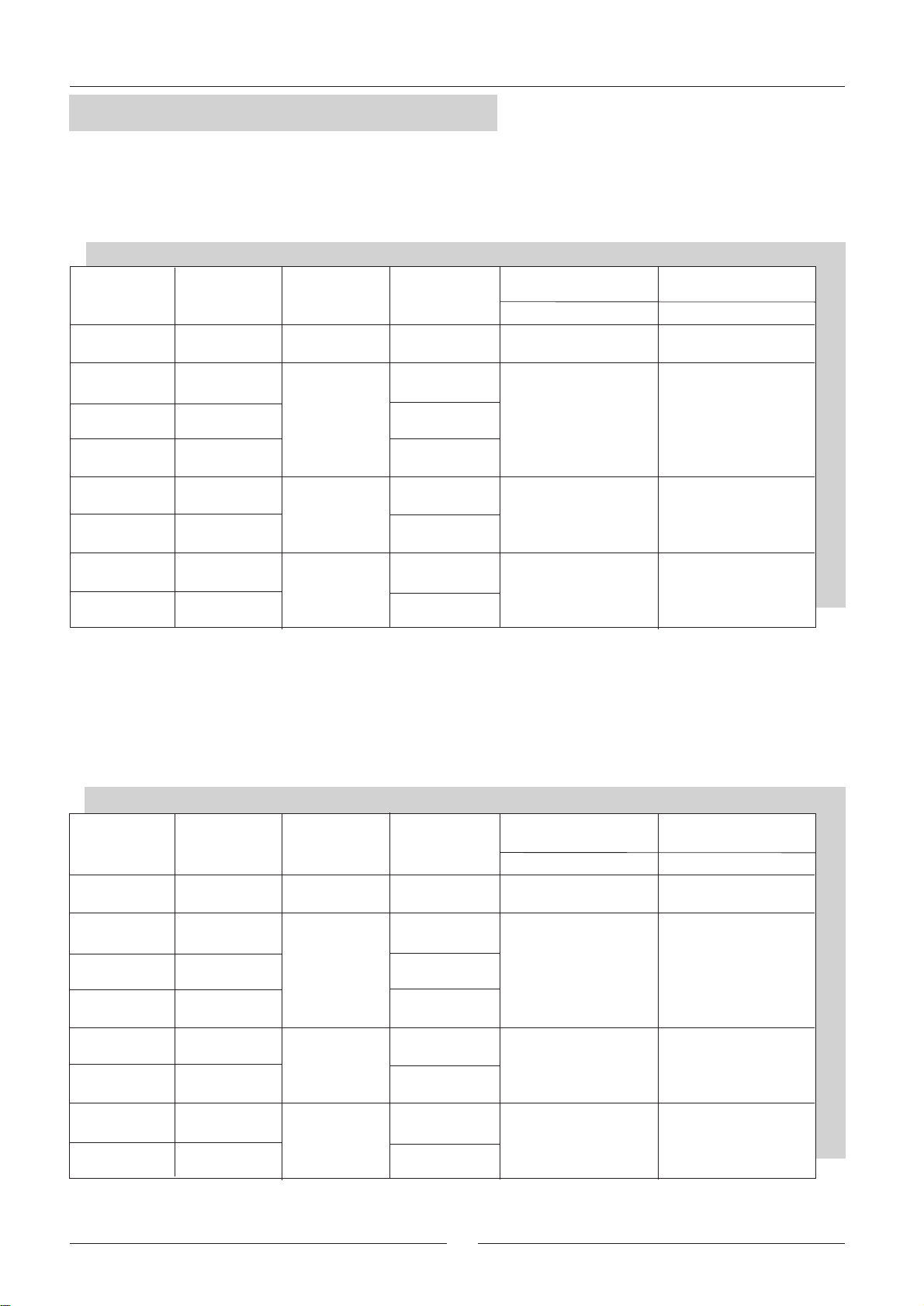

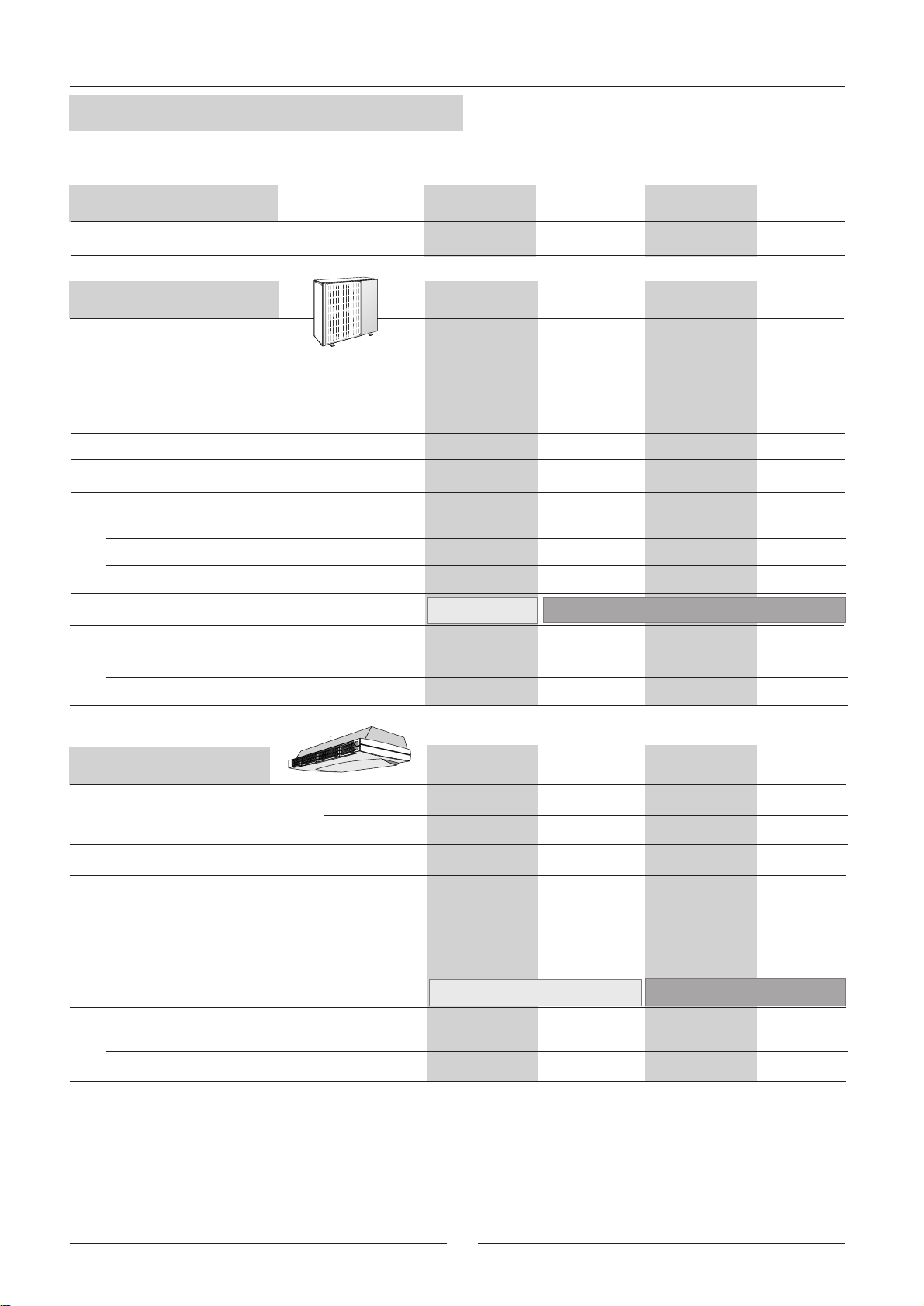

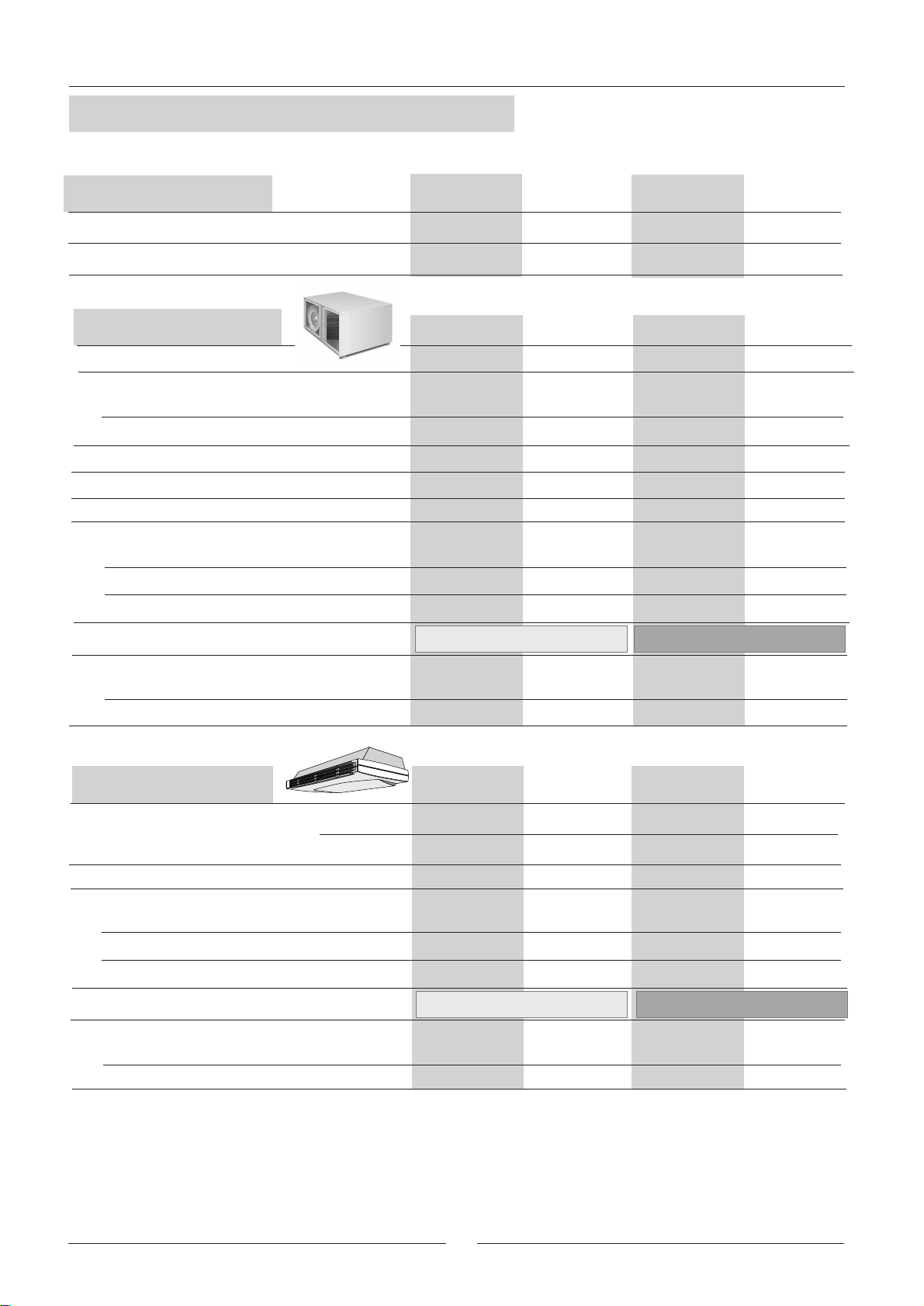

PRODUCT RANGE

COOLING ONLY R-407C

LTX INDOOR UNIT IN COMBINATION, WITH AXIAL FAN OUTDOOR UNIT

MODEL

WING 3TFK

WING 3TFK

WING 3TFK

WING 4TFK

WING 4TFK

WING 5TFK

WING 5TFK

OUTDOOR

UNIT

KJF 3K

KJF 3K

KJF 3K

KJF 4K

KJF 4K

KJF 5K

KJF 5K

INDOOR

UNIT

LTX 3

LTX 5

LTX 5

V / Ph / 50 Hz

230V-1Ph 7.350 3,06WING 2,8TFK KJF 2,8K LTX 3

230V -1Ph

230 V - 3Ph

400 V - 3Ph

230 V - 3Ph

400 V - 3Ph

230 V - 3Ph

400 V - 3Ph

NOMINAL

CAPACITY W

COOLING ONLY

9.500

11.600

13.500

NOMINAL

CAPACITY KW

COOLING ONLY

3,85

4,70

5,60

LTX INDOOR UNIT IN COMBINATION, WITH CENTRIFUGAL FAN OUTDOOR UNIT

MODEL

WING 3CFK

WING 3CFK

WING 3CFK

WING 4CFK

WING 4CFK

WING 5CFK

WING 5CFK

OUTDOOR

UNIT

KCF 3K

KCF 3K

KCF 3K

KCF 4K

KCF 4K

KCF 5K

KCF 5K

INDOOR

UNIT

LTX 3

LTX 5

LTX 5

V / Ph / 50 Hz

230V-1Ph 7.130 3,07WING 2,8CFK KCF 2,8K LTX 3

230V -1Ph

230 V - 3Ph

400 V - 3Ph

230 V - 3Ph

400 V - 3Ph

230 V - 3Ph

400 V - 3Ph

NOMINAL

CAPACITY W

COOLING ONLY

9.100

12.100

14.000

NOMINAL

CAPACITY KW

COOLING ONLY

3,86

5,17

7,00

2

Page 5

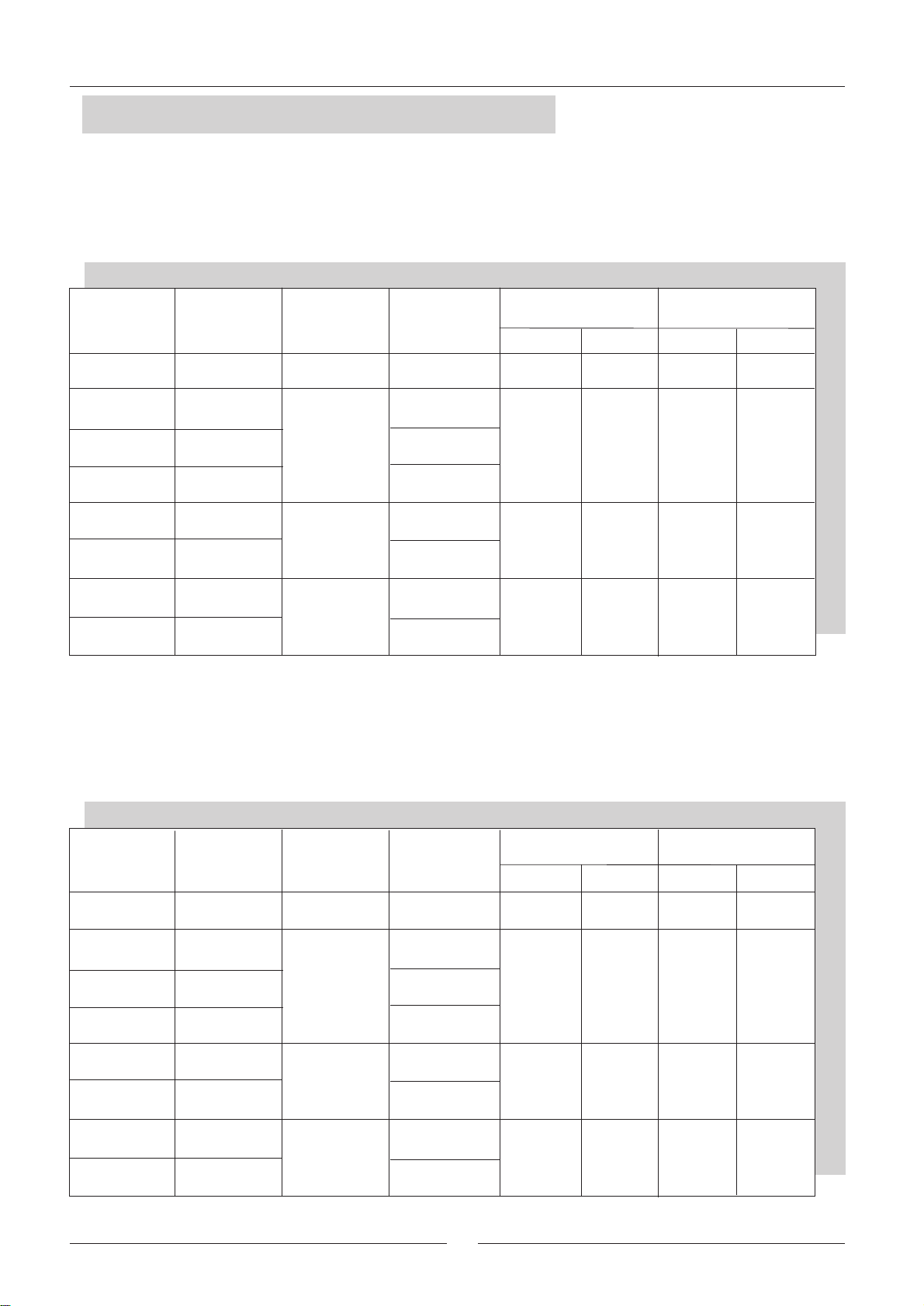

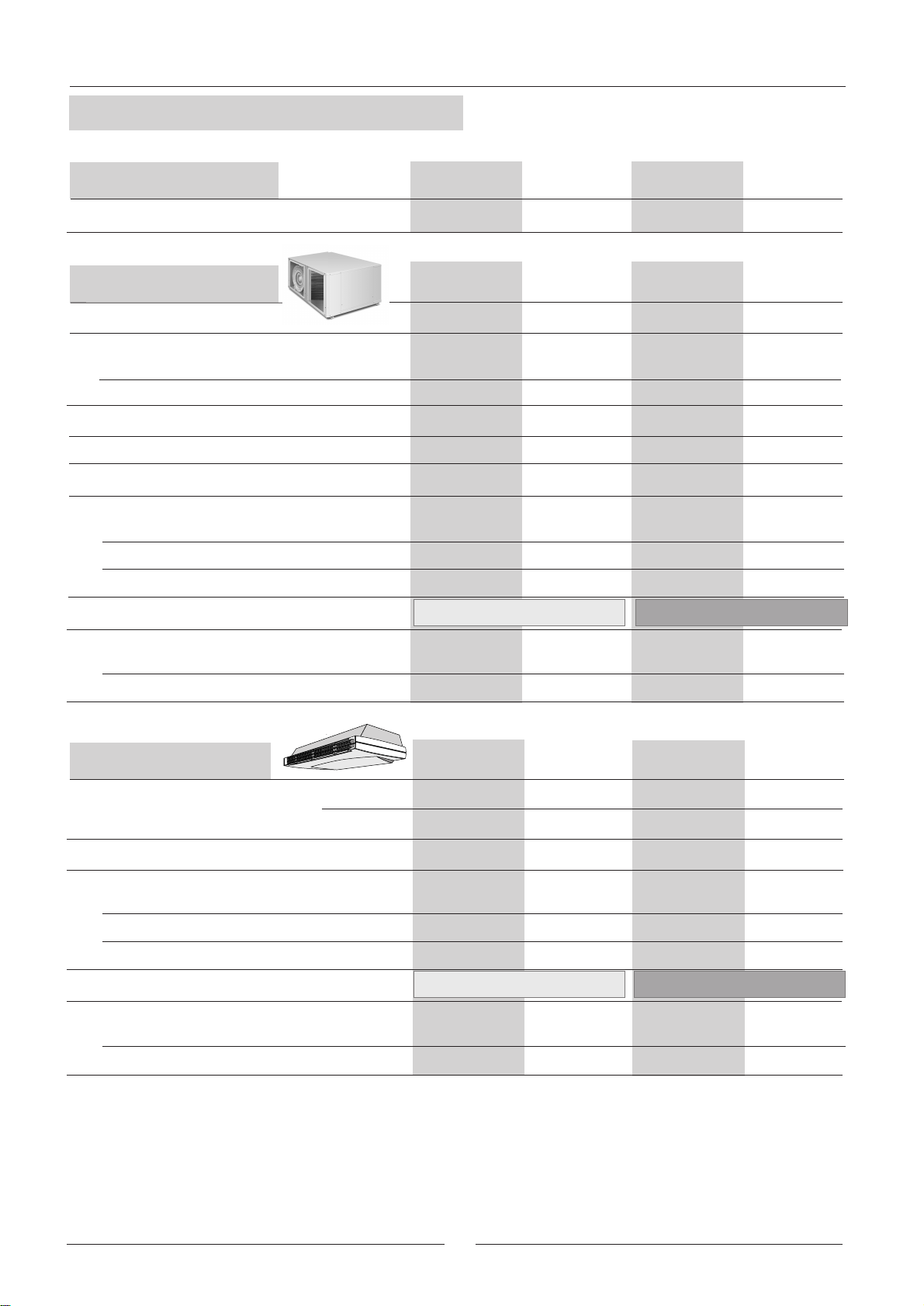

PRODUCT RANGE HEAT PUMP

LTX INDOOR UNIT IN COMBINATION, WITH AXIAL FAN OUTDOOR UNIT

HEAT PUMP R-22C

MODEL

OUTDOOR

UNIT

INDOOR

UNIT

WING 2,8TB LTX 3

WING 3TB

WING 3TB

WING 3TB

WING 4TB

KJB 3

KJB 3

KJB 3

KJB 4

LTX 3

LTX 5

WING 4TB

WING 5TB

KJB 4

KJB 5

LTX 5

WING 5TB

KJB 5

V / Ph / 50 Hz

230V-1Ph 7.800 2,607.350 3,06KJB 2,8

230V -1Ph

230 V - 3Ph

400 V - 3Ph

230 V - 3Ph

400 V - 3Ph

230 V - 3Ph

400 V - 3Ph

NOMINAL

CAPACITY W

COOLING

ONLY

9.250

11.600

13.700

HEAT

PUMP

9.000

12.100

14.600

NOMINAL

CAPACITY KW

COOLING

ONLY

3,70

4,70

5,90

HEAT

PUMP

3,00

3,90

5,00

LTX INDOOR UNIT IN COMBINATION, WITH CENTRIFUGAL FAN OUTDOOR UNIT

MODEL

OUTDOOR

UNIT

INDOOR

UNIT

WING 2,8CB LTX 3

WING 3CB

WING 3CB

WING 3CB

WING 4CB

KCB 3S

KCB 3S

KCB 3S

KCB 4S

LTX 3

LTX 5

WING 4CB

WING 5CB

KCB 4S

KCB 5S

LTX 5

WING 5CB

KCB 5S

V / Ph / 50 Hz

230V-1Ph 8.150 2,777.130 3,07KCB 2,8S

230V -1Ph

230 V - 3Ph

400 V - 3Ph

230 V - 3Ph

400 V - 3Ph

230 V - 3Ph

400 V - 3Ph

NOMINAL

CAPACITY W

COOLING

ONLY

9.100

12.100

14.000

HEAT

PUMP

10.220

13.500

17.400

NOMINAL

CAPACITY KW

COOLING

ONLY

3,86

5,17

7,00

HEAT

PUMP

3,40

4,33

6,40

3

Page 6

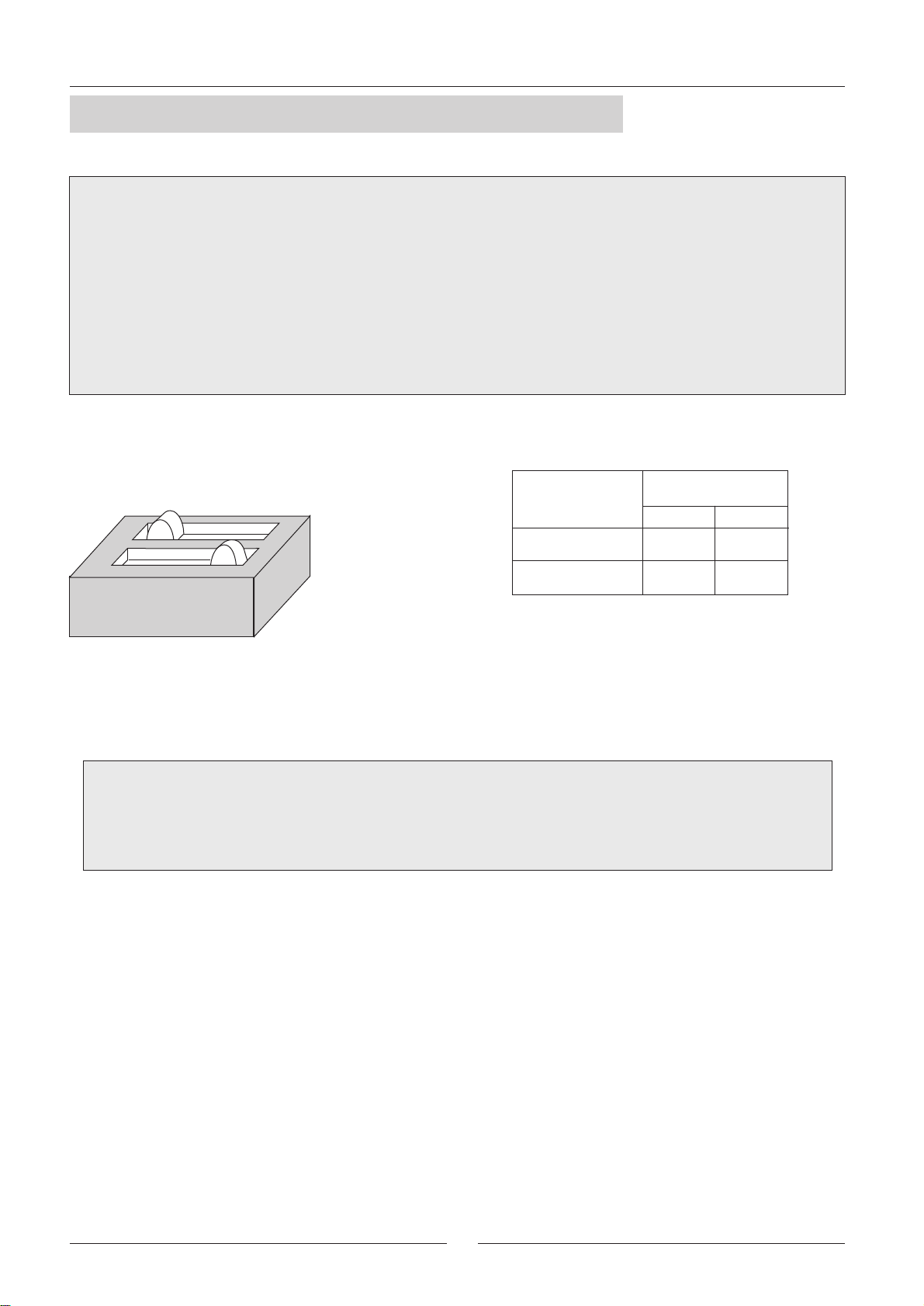

SYSTEM CONFIGURATION (INDOOR UNIT)

IMPORTANT

Prior of making the electrical connections,

set the switch for heat pump unit or for cooling only unit.

This unit is valid for operating as a cold only or heat pump application.

The unit should be configured prior to making the electrical connections, by setting the configuration

switch as follows:

SWITCH

MODEL

COOLING ONLY

(*)

HEAT PUMP

1 2

ONOFF

ON ON

Switch 2

Switch 1

(*) Configuration from factory..

ON OFF

Check page 8 for more information about the situation of this switch.

NOTE:

If errors are made during the configuration of the system, switch off the main power supply, set

configuration switch in the correct position and then switch the power on.

4

Page 7

GENERAL DESCRIPTION

INDOOR

UNIT LTX

OUTDOOR UNIT

KJF/KJB

OUTDOOR UNIT

KCF/KCB

CABINE

The outdoor unit is made on electrozinced steel with

epoxy painted finish, able to work outdoors under

the worst conditions. its dimensions and features

allow the unit to be positioned in almost any location.

It incorporate thermal acoustic insulation. The indoor

unit is finished in a decorative plastic with thermal

acoustic insulation.

HEAT EXCHANGER

Made of cooper tubes and aluminium fins. Coils have

been designed and manufactured to ensure maximum

efficiency. The L shaped outside unit heat exchanger

makes this unit compact an highly efficiency.

The ceiling air conditioner SPLIT, on version cooling only and

heat pump, are units air condensed. The indoor unit with direct

air supply, realise function of cooling , heating dehumidification,

cleaning air of the sites. Also the option to incorporate with

maximum facilities a heating resistance on units cooling only

and also on heat pump units.

The indoor unit can be combine with outdoor units provide with

axial fan (KJF/ KJB) for outside installation or with outdoor unit

provide with centrifugal fan (KCF/ KCB) for installation inside

buildings.

AIR SWEEP

The indoor unit (LTX) have an automatic dispositive

to distribute horizontal air flow.

COOLING CIRCUIT

Made of welded dehydrated copper pipe with service

port on the suction and liquid lines. Coupling valves

on outdoor unit and flare connexion on indoor unit

to facilitate the refrigerant connexion. A muffler in

the compressor discharge line eliminates noise and

pulsation of the discharge line. The unit includes

filter dryer and expansion system. It has unidirectional

and reversing valves of 4 pipes for unit in heat pump.

COMPRESSOR

An hermetically sealed compressor, with internal

thermal protection. It is mounted on vibration

absorbent blocks both on the inside and outside,

statically an dynamically balanced. In all cases the

compressors are acoustically isolated, resulting in

low noise.

FANS

The indoor units includes centrifugal motor fan of

three speed, with exceptional features on noise level

Depending on outdoor type, it includes one or two

axial motor fan (units KJF/KJB), or one centrifugal

fan (units KCF/ KCB),with exceptional features in

noise level and flow .

ELECTRIC CIRCUIT

The indoor unit electrical panel includes a printed

board, which control the operating of the unit,

defrosting timer thermostat and system of reversing

on heat pump cycle. The unit is controlled from an

infrared remote controller.

OPTIONS

OUTDOOR UNIT

• Heating electrical heater.

OUTDOOR UNIT TYPE KJF/KJB

• Supporting with braxkets( depends on units)

• Winter control.

OUTDOOR UNIT TYPE KCF/KCB

• Winter control

• Main switch (depends on models)

• Grille external air

5

Page 8

SPECIFICATIONS COOLING ONLY

OUTDOOR UNIT WITH AXIAL FAN

MODEL

Cooling capacity

(*)

OUTDOOR UNIT

COMPRESSOR

FAN

Air flow outdoor unit

REFRIGERANT

EXPANSIÓN

WEIGHT

DIMENSIONS

Height

Width

Depth

PACKING DIMENSIONS

Nª / Type

Type / R-407C

W

m3/h.

gr.

Kg

mm.

mm.

mm.

mm.

(1)

WING

2,8TFK

7.350

KJF 2,8K

1 / ALT.

3.100

1650

Capillary

78

781

973

333

WING

3TFK

9.500

KJF 3K

1 / ALT.

5.100

2500

Capillary

85

1035

973

333

WING

4TFK

11.600

KJF 4K

1 / ALT.

5.400

2600

Capillary Capillary

96

1035

973

333

845 x 1060 x 385 1085 x 1275 x 385

R-407C

WING

5TFK

13.500

KJF 5K

1 / ALT.

5.400

2600

98

1035

973

333

REFRIGERANT COUPLING

Liquid pipe

Gas pipe

INDOOR UNIT

FAN

Air flow indoor unit

WEIGHT

DIMENSIONS

Height

Width

Depth

PACKING DIMENSIONS

REFRIGERANT COUPLING

Liquid pipe

Gas pipe

m3/h.

Max.

Min.

Kg

mm.

mm.

mm.

mm.

3/8"

5/8"

LTX 3

1.300

1.100

40

267

1.409

656

310 x 1430 x 680

3/8"

3/4"

3/8"

3/4"

LTX 3

1.300

1.100

40

267

1.409

656

3/8"

3/4"

(2)

3/8"

3/4"

LTX 5

2.100

1.800

57

312

1.719

756

352 x 1749 x 776

1/2"

(2)

3/4"

1/2"

3/4"

LTX 5

2.100

1.800

57

312

1.719

756

1/2"

3/4"

(*) Air entry temperature into the indoor unit 27°C DB/19 °C WB

(*) Air entry temperature into the outdoor unit 35ºC DB

(1) Charge of refrigerant, factory charged on outdoor unit. See page 22, to calculate model refrigerant charge.

(2) Use the coupling fittings included in indoor unit for refrigerant connection with outdoor unit.

DB.- Dry Bulb

WB.- Wet Bulb

6

Page 9

SPECIFICATIONS COOLING ONLY

OUTDOOR UNIT WITH CENTRIFUGAL FAN

R-407C

MODEL

Cooling capacity

OUTDOOR UNIT

COMPRESSOR

FAN

Air flow outdoor unit

Available pressure

REFRIGERANT

EXPANSIÓN

WEIGHT

DIMENSIONS

Height

Width

Depth

PACKING DIMENSIONS

Nª / Type

Type / R-407C

(*)

m3/h.

Pa

gr.

Kg

mm.

mm.

mm.

mm.

(1)

W

WING

2,8CFK

7.180

KCF 2,8K

1 / ALT.

2.500

40

2255

Capillary

89

505

1050

750

630 x 1140 x 850

WING

3CFK

9.100

KCF 3K

1 / ALT.

2.500

40

2350

Capillary

91

505

1050

750

WING

4CFK

12.100

KCF 4K

1 / ALT.

3.400

50

3070

Capillary Capillary

125

525

1300

855

WING

5CFK

14.000

KCF 5K

1 / ALT.

5.000

50

4950

140

575

1300

855

775 x 1330 x 865

REFRIGERANT COUPLING

Líquid pipe

Gas pipe

INDOOR UNIT

FAN

Air flow indoor unit

WEIGHT

DIMENSIONS

Height

Width

Depth

PACKING DIMENSIONS

REFRIGERANT COUPLING

Líquid pipe

Gas pipe

m3/h.

Max.

Min.

Kg

mm.

mm.

mm.

mm.

3/8"

5/8"

LTX 3

1.300

1.100

40

267

1.409

656

310 x 1430 x 680

3/8"

3/4"

(2)

3/8"

3/4"

LTX 3

1.300

1.100

40

267

1.409

656

3/8"

3/4"

3/8"

3/4"

LTX 5

2.100

1.800

57

312

1.719

756

352 x 1749 x 776

1/2"

(2)

3/4"

1/2"

3/4"

LTX 5

2.100

1.800

57

312

1.719

756

1/2"

3/4"

(*) Air entry temperature into the indoor unit 27°C DB/19 °C WB

(*) Air entry temperature into the outdoor unit 35ºC DB

(1) Charge of refrigerant, factory charged on outdoor unit. See page 22, to calculate model refrigerant charge.

(2) Use the coupling fittings included in indoor unit for refrigerant connection with outdoor unit.

DB.- Dry Bulb

WB.- Wet Bulb

7

Page 10

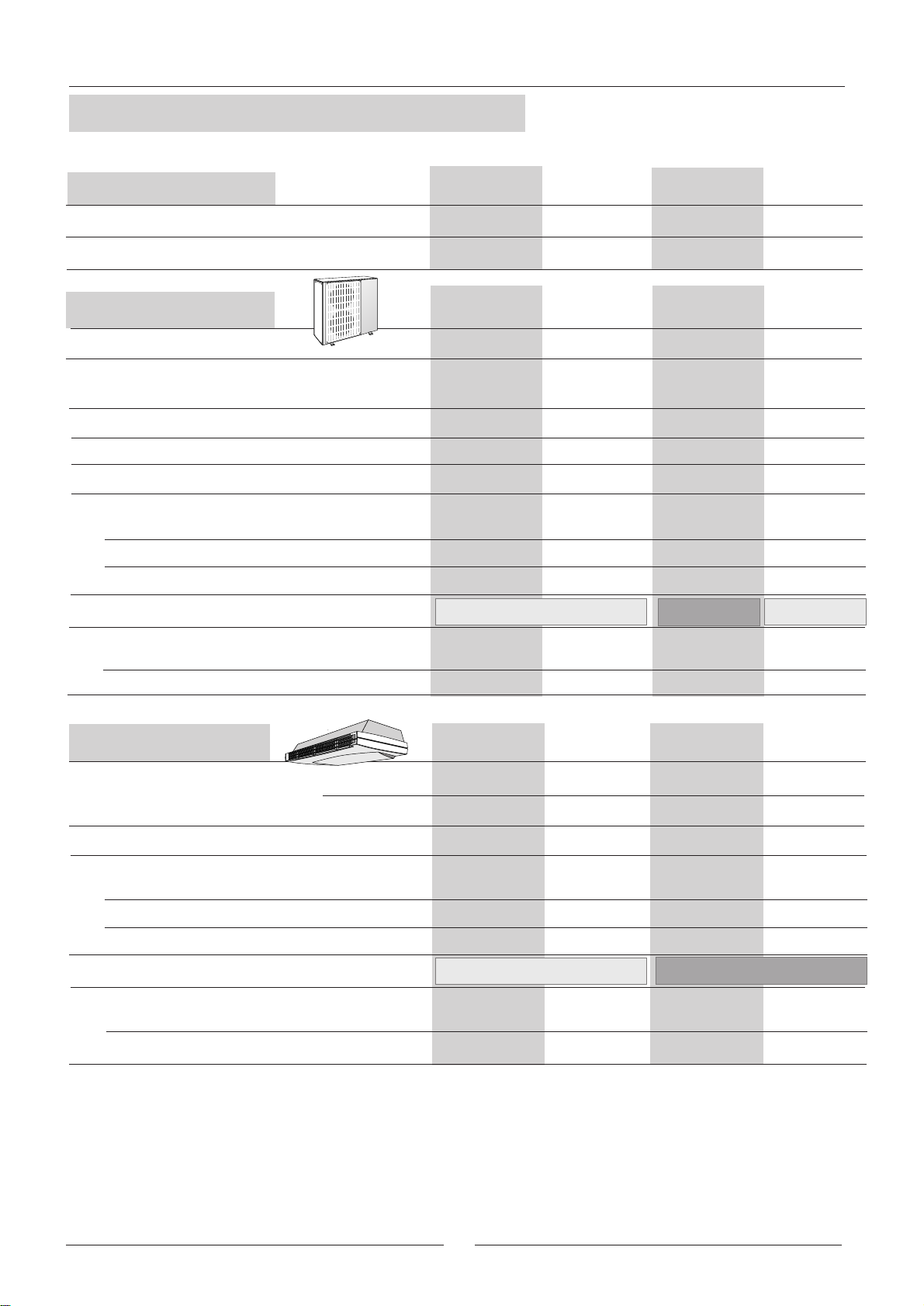

SPECIFICATIONS HEAT PUMP

OUTDOOR UNIT WITH AXIAL FAN

MODEL

Cooling capacity

Heating capacity

(*)

(**)

OUTDOOR UNIT

COMPRESSOR

FAN

Air flow outdoor unit

REFRIGERANT

EXPANSIÓN

WEIGHT

DIMENSIONS

Height

Width

Depth

PACKING DIMENSIONS

REFRIGERANT COUPLING

Líquid pipe

Gas pipe

Nª / Type

Type / R-22

m3/h.

gr.

Kg

mm.

mm.

mm.

mm.

W

W

WING

2,8TB

7.350

7.800

KJB 2,8

1 / ALT.

3.100

1775

Capillary

81

781

973

333

845 x 1060 x 385

3/8"

5/8"

WING

3TB

9.250

9.000

KJB 3

1 / ALT.

3.100

2500

Capillary

83

781

973

333

3/8"

3/4"

WING

4TB

11.600

12.100

KJB 4

1 / ALT.

5.400

2800

Capillary

99

1035

973

333

1085 x 1275

x 385

3/8"

3/4"

R-22

WING

5TB

13.700

14.600

KJB 5

1 / ALT.

5.600

3500

Restrictor

129

1330

1005

386

1495 x 1057

x 430

1/2"

3/4"

INDOOR UNIT

FAN

Air flow indoor unit

WEIGHT

m3/h.

Max.

Min.

Kg

LTX 3

1.300

1.100

40

LTX 3

1.300

1.100

40

LTX 5

2.100

1.800

57

LTX 5

2.100

1.800

DIMENSIONS

Height

Width

Depth

PACKING DIMENSIONS

mm.

mm.

mm.

mm.

267

1.409

656

310 x 1430 x 680

267

1.409

656

312

1.719

756

352 x 1749 x 776

REFRIGERANT COUPLING

Líquid pipe

Gas pipe

3/8"

3/4"

(2)

3/8"

3/4"

1/2"

3/4"

(2)

DB.- Dry Bulb

(*) Air entry temperature into the indoor unit 27°C DB/19 °C WB

WB.- Wet Bulb

(*) Air entry temperature into the outdoor unit 35ºC DB

(**) Air entry temperature into the indoor unit 20°C DB/12 °C WB

(**) Air entry temperature into the outdoor unit 7ºC DB/6ºCWB

(1) Charge of refrigerant, factory charged on outdoor unit. See page 22, to calculate model refrigerant charge

(2) Use the coupling fittings included in indoor unit for refrigerant connection with outdoor unit..

57

312

1.719

756

1/2"

3/4"

8

Page 11

SPECIFICATIONS HEAT PUMP

OUTDOOR UNIT WITH CENTRIFUGAL FAN

R-22

MODEL

Cooling capacity

Heating capacity

(*)

(**)

OUTDOOR UNIT

COMPRESSOR

FAN

Air flow outdoor unit

Available pressure

REFRIGERANT

EXPANSIÓN

WEIGHT

DIMENSIONS

Height

Width

Depth

PACKING DIMENSIONS

REFRIGERANT COUPLING

Líquid pipe

Gas pipe

Nª / Type

Type / R-22

m3/h.

Pa

gr.

Kg

mm.

mm.

mm.

mm.

(1)

W

W

WING

2,8CB

7.180

8.150

KCB 2,8S

1 / ALT.

2.500

40

2425

Capillary

92

505

1050

750

WING

3CB

9.100

10.220

KCB 3S

1 / ALT.

2.500

40

2525

Capillary

94

505

1050

750

WING

4CB

12.100

13.500

KCB 4S

1 / ALT.

3.400

50

3400

Capillary Capillary

135

525

1300

855

630 x 1140 x 850 775 x 1330 x 865

3/8"

5/8"

3/8"

3/4"

3/8"

3/4"

WING

5CB

14.000

17.400

KCB 5S

1 / ALT.

5.000

50

5300

150

575

1300

855

1/2"

3/4"

INDOOR UNIT

FAN

Air flow indoor unit

WEIGHT

m3/h.

Max.

Min.

Kg

LTX 3

1.300

1.100

40

LTX 3

1.300

1.100

40

LTX 5

2.100

1.800

57

LTX 5

2.100

1.800

57

DIMENSIONS

Height

Width

Depth

PACKING DIMENSIONS

mm.

mm.

mm.

mm.

267

1.409

656

310 x 1430 x 680

267

1.409

656

312

1.719

756

312

1.719

756

352 x 1749 x 776

REFRIGERANT COUPLING

Líquid pipe

Gas pipe

3/8"

3/4"

(2)

3/8"

3/4"

1/2"

3/4"

(2)

1/2"

3/4"

DB.- Dry Bulb

(*) Air entry temperature into the indoor unit 27°C DB/19 °C WB

WB.- Wet Bulb

(*) Air entry temperature into the outdoor unit 35ºC DB

(**) Air entry temperature into the indoor unit 20°C DB/12 °C WB

(**) Air entry temperature into the outdoor unit 7ºC DB/6ºCWB

(1) Charge of refrigerant, factory charged on outdoor unit. See page 22, to calculate model refrigerant charge

(2) Use the coupling fittings included in indoor unit for refrigerant connection with outdoor unit..

9

Page 12

SPECIFICATIONS

SET WITH AXIAL FAN OUTDOOR UNIT

SOUND LEVEL

Sound

pressure

level

(Lp)

Indoor unit

Outdoor unit

(1)

(2)

dBA

dBA

WING 2,8TFK

WING 2TB

41/46 (*)

52

WING 3TFK

41/46 (*)

55

WING 3TB

41/46 (*)

53

WING 4TFK

WING 4TB

43/48 (*)

56

WING 5TFK

WING 5TB

43/48 (*)

56

(1) Sound level measured to a distance of 2m from the unit, normal absorption, room size according to unit capacity.

(2) Sound level measured to a distance of 5 m, free space.

(*) High speed / Low speed

ELECTRICAL DATA

Voltage

Nominal total input power

cooling capacity

Nominal total input power

heat pump

Rated current

Current max.

V/f (50 Hz)

Kw

Kw

A

A

WING 2,8TFK

WING 2TB

3,06

2,60

14,87

17,9

WING 3TFK

230V / 1 Ph

3,85

----

19,3

13,4/8,0

24,4

17,3/10,7

WING 3TB WING 5TB

3,70

3,00

18,3

12,8/7,7

23,4

16,5/10,2

WING 4TFK

WING 4TB

230V-400V / 3 Ph

4,70

3,90

18,3/9,1

21,3/12,1

WING 5TFK

5,60

---

20,4/10,2

23,1/11,9

5,90

5,00

21,5/11,3

24,4/13,2

Starting current max.

OUTDOOR UNIT

Voltage

Nominal total input power

cooling capacity

Nominal total input power

heat pump

Rated current

Current max.

Starting current max.

INDOOR UNIT

Voltage

Nominal total input power

cooling capacity

Nominal total input power

heat pump

Rated current

Starting current max.

A

V/f (50 Hz)

Kw

Kw

A

A

A

V/f (50 Hz)

Kw

Kw

A

A

91

KJF 2,8K

KJB 2,8

2,88

2,42

14,05

17,12

91

LTX 3

0,18

0,18

0,82

2,46

90

78 / 39

KJF 3K

230V / 1 Ph

3,67

---

18,48

13,2/7,1

23,58

16,4/9,8

90

78 / 39

LTX 3

0,18

---

0,82

2,46

90

78 / 39

KJB 3

3,52

2,82

17,48

12,0/6,9

22,60

15,7/9,4

90

78 / 39

LTX 3

0,18

0,18

0,82

2,46

106 / 53

KJF 4K

KJB 4

230V-400V / 3 Ph

4,45

3,65

17,2/8,0

20,2/11,0

106 / 53

LTX 5

230V / 1 Ph

0,25

0,25

1,14

3,42

124 / 62

KJF 5K

5,35

----

19,2/9,0

22,1/10,9

124 / 62

LTX 5

0,25

---

1,14

3,42

124 / 62

KJB 5

5,65

4,75

20,4/10,2

23,3/12,1

124 / 62

LTX 5

0,25

0,25

1,14

3,42

10

Page 13

SPECIFICATIONS

SET WITH CENTRIFUGAL FAN OUTDOOR UNIT

SOUND LEVEL

Sound

pressure

level

(Lp)

Indoor unit

Outdoor unit

(1)

(2)

dBA

dBA

WING 2,8CFK

WING 2CB

41/46 (*)

57

WING 3CFK

WING 3CB

41/46 (*)

58

WING 4CFK

WING 4CB

43/48 (*)

60

WING 5CFK

WING 5CB

43/48 (*)

62

(1) Sound level measured to a distance of 2m from the unit, normal absorption, duct size and installation according

to unit capacity.

(2)

Sound level measured to a distance of 5 m, normal absorption, duct size and installation according to unit

capacity.

(*) High speed / Low speed

ELECTRICAL DATA

Voltage

Nominal total input power

cooling capacity

Nominal total input power

heat pump

Rated current

Current max.

V/f (50 Hz)

Kw

Kw

A

A

WING 2,8CFK

WING 2CB

3,07

2,77

14,92

19,82

WING 3CFK

WING 3CB

230V / 1 Ph

3,86

3,40

18,3

11,7/5,4

23,4

16,5/10,2

WING 4CFK

WING 4CB

230V-400V / 3 Ph

5,17

4,33

16,6/10,0

21,9/12,7

WING 5CFK

WING 5CB

7,00

6,40

22,3/13,3

24,5/16,7

Starting current max.

OUTDOOR UNIT

Voltage

Nominal total input power

cooling capacity

Nominal total input power

heat pump

Rated current

Current max.

Starting current max.

INDOOR UNIT

Voltage

Nominal total input power

cooling capacity

Nominal total input power

heat pump

Rated current

Starting current max.

A

V/f (50 Hz)

Kw

Kw

A

A

A

V/f (50 Hz)

Kw

Kw

A

A

91

KCF 2,8K

KCB 2,8S

2,89

2,59

14,10

19,00

91

LTX 3

0,18

0,18

0,82

2,46

78 / 39

KCF 3K

KCB 3S

230V / 1 Ph

3,68

3,22

17,77

10,8/4,5

22,65

15,7/9,4

78 / 39

LTX 3

0,18

0,18

0,82

2,46

90

90

230V / 1 Ph

106 / 53

KCF 4K

KCB 4S

230V-400V / 3 Ph

4,92

4,08

15,5/8,9

20,8/11,60

106 / 53

LTX 5

0,25

0,25

1,14

3,42

124 / 62

KCF 5K

KCB 5S

6,75

6,15

21,2/12,2

23,4/15,56

124 / 62

LTX 5

0,25

0,25

1,14

3,42

11

Page 14

ELECTRICAL CONNECTIONS

OUTDOOR

UNIT

ELECTRIC

WIRING DIAGRAM

For electrical connection refer to wiring diagram

in the unit

MODELS 2,8-3-4-5

1

2

3

1

Power supply

2

Connection indoor unit with outdoor unit

3

Sensor connection

MODEL

VOLTAGE

230 V / 1Ph

2.8

400 V / 3Ph

230 V / 1Ph

3

230 V / 3Ph

400 V / 3Ph

4

230 V / 3Ph

400 V / 3Ph

230 V / 3Ph

5

400 V / 3Ph

1º Remove the front details at the corners and unit cover

panel.

2º Remove the filters

See picture

NUMBER OF WIRES X SECTION

COOLING ONLY HEAT PUMP

21 21

3x4mm

5x2,5mm

3x4mm

4x4mm

5x2,5mm

4x4mm

5x2,5mm

4x6mm

5x4mm

2

2

2

2

2

2

2

2

2

4x1,5mm

4x1,5mm

4x1,5mm

4x1,5mm

4x1,5mm

4x1,5mm

4x1,5mm

4x1,5mm

4x1,5mm

2

2

2

2

2

2

2

2

2

5x2,5mm

3x4mm

4x4mm

5x2,5mm

4x4mm

5x2,5mm

4x6mm

5x4mm

3x4mm

2

2

2

2

2

2

2

2

2

6x1,5mm

6x1,5mm

6x1,5mm

6x1,5mm

6x1,5mm

6x1,5mm

6x1,5mm

6x1,5mm

6x1,5mm

3

2

2x1,5mm

2

2x1,5mm

2

2x1,5mm

2

2

2

2

2

2

2x1,5mm

2x1,5mm

2x1,5mm

2x1,5mm

2x1,5mm

2x1,5mm

2

2

2

2

2

2

2

2

2

NOTE: The sections has been calculated to a distance no superior o 50m and a low supply of 10V

12

Page 15

ELECTRICAL CONNECTIONS AND SYSTEM CONFIGURATION

IMPORTANT

Prior of making the electrical connections, set the switch for heat pump unit or for cooling only

unit.

This unit is valid for operating as a cold only or heat pump application. The unit should be configured

prior to making the electrical connections, by setting the configuration switch as follows:

1

3

Remove the front details at the corners and unit cover panel.

Rolling side

2

DETALLE A

Remove the filters

Sides and carcass

Filters

P.C.B(1)

PCB

NOTE: THE UNIT LEAVES FACTORY

CONFIGURATED ON COOLING MODE

SWICHT

SWICHT CONFIGURATION

CONFIGURATION

MODEL

1 2

COOLING ONLY

(*)

HEAT PUMP

ON ON

(*) Configuration from factory.

ONOFF

SWICHT CONFIGURATION

Switch 2

Switch 1

ON OFF

NOTE:

If errors are made during the configuration of the system, switch off the main power supply, set configuration switch

in the correct position and then switch the power on.

CONNECTIONS OF OUTDOOR UNITS

-FOR HEAT PUMP UNITS, remove the resistor form the terminal

plate and connect the sensor outdoor unit

-FOR COOLING ONLY UNITS, keep connected the resistor.

DON´T TOUCH.

DETAIL B

5

4

COOLING ONLY

5

4

HEAT PUMP

SENSOR OUTDOOR

UNIT

13

DETAIL B

Regleta de terminales, y

conexión de la sonda exterior

Page 16

ELECTRICAL CONNECTIONS

COOLING ONLY

PE L N 1 2 3

PE L1 N 1 2N 3L2 L3

L3

400V/50HZ 3Ph + N

LTX 3-5

5

4

OUTDOOR

UNIT

PE L N 1 2 3

N

PE L

1 2 43

230V/50HZ 1Ph + N

HEAT PUMP

CONTROL

SENSOR

4 5

PE L N 1 2 3

LTX 3

5

OUTDOOR

UNIT

PE L N 1 2 3

PE L1 N 1 2N 3L2 L3

L3

230V/50HZ 3Ph

LTX 3

LTX 3-5

5

4

OUTDOOR

UNIT

Wire overwhelm

CONTROL

SENSOR

4 5

4 5

CONTROL

SENSOR

4 5

4 5

PE L N 1 2 3

PE

L2

L1

L3

230V/50HZ 3Ph

PE L1 PE N 1L 2L2 L3

N

230V/50HZ 3Ph

N 1 2

N

PE L N 1 2 3

3

4 5

PE L N 1 2

LTX 3

OUTDOOR

UNIT

LTX 5

3

OUTDOOR

UNIT

N

230V/50HZ 1Ph + N

3

CONTROL

SENSOR

4 5

4 5

CONTROL

SENSOR

4 5

4 5

OUTDOOR

UNIT

PE L N 1 2 3

PE

L2

L1

L3

400V/50HZ 3Ph + N

PE L1 PE N 1L 2L2 L3

N

400V/50HZ 3Ph + N

N 1 2

N

PE L N 1 2 3

3

LTX 3

OUTDOOR

UNIT

LTX 5

OUTDOOR

3

UNIT

14

Page 17

OUTDOOR UNIT MOTOR-FAN CHARACTERISTICS

OUTDOOR UNIT WITH CENTRIFUGAL FAN

AIR FLOW

AIR FLOW

3

m /h

3

m /h

KCF2,8K / KCB 2,8S

STATIC PRESSUERE AVIALABLE

110 75

40

0

1500 1700 2500 2900

KCF 4K / KCB 4S KCF 5K / KCB 5S

STATIC PRESSUERE AVIALABLE

110 80 50

2800 3100 3400

0

3800

Pa.

Pa.

KCF 3K / KCB 3S

STATIC PRESSUERE AVIALABLE

100 70 54

1500 1650 2500

0

2900

STATIC PRESSUERE AVIALABLE

150 110 50

4250 4650 5050

0

5400

Pa.

Pa.

AIR FLOW

15

Page 18

OPERATING LIMITS

Supply air temperature into the

*

outdoor unit ºC

Supply air temperature into the

**

indoor unit ºC

OPERATING LIMITS COOLING ONLY UNITS

46° DB

STANDARD

*

19° DB

-10° DB

L.A.C. ON/OFF

L.A.C. PROPROC

DB.- Dry Bulb

WB.- Wet Bulb

THE ON/OFF LOW AMBIENT CONTROL IS STANDARD

THE PROPORTIONAL LOW AMBIENT CONTROL IS OPTIONAL

OPERATING LIMITS HEAT PUMP UNITS

COOL CYCLE

Supply air temperature into the

*

outdoor unit ºC

Supply air temperature into the

**

indoor unit ºC

DB.- Dry Bulb

WB.- Wet Bulb

46° DB

*

19° DB

STANDARD

21°/15º

DB/WB

21°/15º

DB/WB

**

32°/23º

DB/WB

**

32°/23º

DB/WB

24°/18º

DB/WB

*

-8°/-9º

DB/WB

HEAT CICLE

15°

DB

**

27°

DB

16

Page 19

REFRIGERANT CONNECTIONS

Flared nuts

INDOOR

UNIT

Service valve

Coupling

OUTDOOR

UNIT

Protective hoods

Insulation

REFRIGERANT CONECTION FOR UNITS WITH COUPLINGS AND SERVICE VALVES

NOTE: THE REFRIGERANT LINES GAS AND LIQUID, MUST BE INSULATED

Make the refrigerant connections between the outdoor and indoor unit, as follows:

-With the valves closed on outdoor unit, unscrew the flare nuts, removing all the protective hoods.

-Unscrew the flare nuts and the coupling on indoor unit, removing the protecting hoods.

-Introduce the flare nuts in the corresponding union tubes, previously isolated.

-Make the thread union of the tubes in valves and coupling using the keys, as shown in the picture.

-To do vacuum, first close the valves on outdoor unit, second connect the plug of the vacuum pump to the

suction valves service port 1/4”, do vacuum to get an absolute pressure of 0.5 mm Hg. This way the vacuum will

be created in indoor unit and union pipes.

-Remove the plugs and open the valves of outdoor unit.

-Verify leakage in couplings.

-Insulate pipes and service ports.

Pipe cutter

CUT THE PIPE PROPERLY

YES

90°

Bent

Unpolished

MAKE A CORRECT FLARE

FAULTY

NO

AVOID FROM METALIC DUST ENTERING INTO THE PIPE

CLEAN THE BURRS

Apply the tightening torque shown in the table.

Insufficient tightening torque could cause

excessive tightening torque will damage pipe

TIGHTENING TORQUE

refrigerant leak,

flare.

PIPE DIAMETER

3/8''

Service port

TIGHTENING TORQUE

31-35 Nm

1/2'' 50-55 Nm

3/4''

65-70 Nm

Bent

Damaged surface Flawed Irregular

0-0.5 m.m.

Copper pipe

Gas line

Liquid line

Wrench

17

Page 20

REFRIGERANT CONNECTIONS

To locate the outdoor and the indoor units, refer to the

following information.

L : Distance length between both units.

1 = Refrigerant vapour line.

2 = Liquid aspiration line.

OUTDOOR U.

2

1

L

DISTANCES BETWEEN UNITS

OUTDOOR U.

INDOOR U.

2

L

1

INDOOR UNIT

OUTDOOR U.

1

INDOOR U.

2

L

MODEL

Tube size

Refrigerant lines sizes

Refrigerant lines sizes L

Max. number of bends

Liquid

Vapour

Máx.Vertical

Total vertical

+

Horizontal

2,8

3/8"

5/8"(1)

15

20

8

3

3/8"

3/4"

15

25

12

4

3/8"(1)

3/4"

15

20

8

5

1/2"

3/4"

15

20

8

If the height length is greater than 5 meters, a siphon suction must be installed on the suction line every 5 meters

to ensure that oil return to the compressor.

(1) Use the coupling fittings included in indoor unit for refrigerant connection with outdoor unit..

NOTE: THE REFRIGERANT LINES GAS AND LIQUID, MUST BE INSULATED

For other positions and longer lengths, consult the Lennox Technical Support Department for application

assistance.

The following data will be obtained from that estimation:

Pipe dimensions, Siphon suction, Insulation, Refrigerant charge

18

Page 21

REFRIGERANT CONNECTIONS

REFRIGERANT CHARGE

OUTDOOR UNITS TYPE KJF-K/ KJB

MODEL

COOLING

ONLY

HEAT

PUMP

(gr.) (*)

(gr.) (**)

(gr.) (***)

(gr.) (*)

(gr.) (**)

(gr.) (***)

2,8

1.650

30

1.775

45 45 45

OUTDOOR UNITS TIPO KCF-K/ KCB

MODEL

COOLING

ONLY

HEAT

PUMP

(gr.) (*)

(gr.) (**)

(gr.) (***)

(gr.) (*)

(gr.) (**)

(gr.) (***)

2,8

2.255

5

30

2.425 2.525 3.400

5

45 45 45

3

2.500

30

2.500 2.800

2.600

3

2.350

0

30

0/5

3.070304.950

5

30

54

2.600

5555

55

3.500

5555

105

54

55

55

5.300

5/0

105

(*) Refrigerant charge R-22 precharge from factory on the outdoor unit.

(**) Meter of installation line where outdoor unit is precharged+charge also to the group

(***) If line is different to meters indicated on table put more or less charge of refrigerant per meter indicated.

EXAMPLE:

If you need to install a group WING 5CFK, with distance of line between indoor and outdoor unit of 6 meter. The

refrigerant charge R-407C needed in the installation is:

Charge precharge on outdoor unit

Charge per line 55gr/m x (6-5)m==

T otal charge of the installation = 5355

19

5300

55

gr

Page 22

DIMENSIONS OF OUTDOOR UNIT WITH CENTRIFUGAL FAN (mm.)

MAXIMUM DIMENSIONS

A

A

MODELS

KCF-K / KCB-S 2,8-3

B

A

SETTING UP

TEMPLATE (mm)

UNITS 2-2,5-2,8-3

C

B

C

MODELS

KCF-K / KCB-S- 4-5

KCF-K

KCB-S

A

B

C

A

B

B

C

C

AIR OUT

STANDARD

2,8-3

490

1050

750

505

1100

841

AIR IN

STANDARD

4 5

525

1300

830

525

1300

890

575

1300

830

575

1300

890

A

AIR OUT

OPTIONAL

KCF / KCB-S- 2,8 - 3

B

Use 4 rod of a diameter of 10mm if the unit is fixed in

the roof , or screw M.10 if the unit is fixed on the ground.

Dimensions recommended on

point A and B are refered to the

A

1064

B

660

20

hole of support of the unit.

OPTIONAL

B

AIR IN

A

B

Page 23

DESCRIPTION OUTDOOR UNIT KCF-K / KCB 2,8-3

13

1514

14

2

10

4

5

12

1

FAN

2

EXCHANGER

3

COMPRESSOR

4

CONNETION PIPE

5

ACCESS PANEL TO COMPRESSOR AND PIPES COMPONENTS

6

ELECTRICAL BOX

7

ACCESS PANEL TO ELECTRICAL BOX

MAIN SWITCH (OPTIONAL)

8

ELECTRICAL SUPPLY ENTRY ELECTRICAL SUPPLY

9

1

AIR IN

STANDARD

3

3

15

6

7

10

DRAINGE ( O 16 EXTERNAL)

11

REARM ON ON HIGH PRESSOSTAT

INTAKE PRESSURE (MOD.2,8-3)

12

CONDENSATE PUMP

13

14

AIR OUT

POSICIÓN STANDARD

POSICIÓN OPCIONAL

15

AIR IN

POSITION STANDARD

POSTION OPTIONAL

8

4

12

10

ACCESS TO ELECTRICAL BOX

In the electrical box is included the mechanism of high

pressostat rearm.

21

11

6

8

3

9

Page 24

DESCRIPTION OUTDOOR UNIT KCF / KCB-S 4 - 5

8

6

2

3

3

5

6

8

1

FAN

2

EXCHANGER

3

COMPRESSOR

4

ELECTRICAL BOX

5

CONNETION PIPE

6

ACCESS PANEL TO COMPRESSOR AND PIPES COMPONENTS

7

ACCESS PANEL TO ELECTRICAL BOX

10

1

9

4

7

9

11

12

AIR OUT

8

POSICIÓN STANDARD

POSICIÓN OPCIONAL

AIR IN

9

POSITION STANDARD

POSTION OPTIONAL

10

DRAINGE ( O 16 EXTERNAL)

11

ELECTRICAL SUPPLY ENTRY ELECTRICAL SUPPLY

12

MAIN SWITCH (OPTIONAL)

5

8

6

9

10

11

22

12

Page 25

ENTRANCE STANDARD/ OPTIONAL OUTDOOR UNIT KCF-K / KCB

ENTRANCE STANDARD

E

E

SUPPLY AIR

B

H

25

RETURN AIR

F

D

A

G

C

ENTRANCE OPTIONAL (TO BE REALISE BY THE INSTALLATOR

E

D

M

RETURN AIR

A

L

D

F

SUPPLY AIR

B

L

ENTRANCE STANDARD

E

K

E

F

K

RETURN AIR

STANDARD

J

RETURN AIR

OPTIONAL

E

F

K

RETURN AIR

OPTIONAL

MODELS 2,8-3

SUPPLY AIR

STANDARD

MODELS 4-5

SUPPLY AIR

OPTIONAL

F

D

RETURN AIR

G

A

SUPPLY AIR

B

C

ENTRANCE OPTIONAL (TO BE REALISE BY THE INSTALLATOR)

E

D

RETURN AIR

M

A

L

D

F

N

H

SUPPLY AIR

L

RETURN AIR

STANDARD

B

SUPPLY AIR

STANDARD

N

J

K

SUPPLY AIR

OPTIONAL

T o change entrances from standard position to optional position, you must sustitute the entrance panel correspondent,

and refixe using the same fixation screw.

KCF-K / KCB 3S

KCF-K / KCB 4S

KCF-K / KCB 5S

A

350

B

470

C D

1050 490

E

36,5

400

500 375 1300 525 36 432 195 110 65 35,3 830 50

G

F

45.5

H

35,5

147

K

J

53,5

L M

750 332,5

N

---

293,4

500 375 1300 575 36 432 195 110 65 35,3 830 50 293,4

23

Page 26

DIMENSIONS AND SETTIING UP TEMPLATES OF OUTDOOR UNIT WITH AXIAL FAN

FLOOR MOUNTED

Min. 150 (**)

Min. 300 (**)

Min. 300 (**)

E

FF

D

E

G

KJF-K

B

KJB

KJF-2.8K

KJB-2.8

A

B

C

D

E

F

G

973

781

333

620 620

176,4 176,4 176,4 176,4

10 10 1010

(**)

C

ALWAYS KEEP

A

FREE

DIMENSIONS AND SETTING TEMPLATES OF INDOOR UNIT LTX

Min. 1

0

0 (**)

KJF-K

Ø 12

KJB

OUTDOOR UNIT

KJF-3K KJF-4K

KJB-4

973 973 973 1.005

1.035

333

973

781

333

620

176,4

343,5

1.035 1.035 1.330

333

620

10

343,5343,5343,5

FLOOR MOUNTED

KJF-5K

333 386

620 602

10

343,5

KJB-5KJB-3

198

410

J

K

J

B

H

78

C

D

LTX 5

LTX 3

F

G

F F

G

E

D

E

F

A

LTX 3 LTX 5

A

B

C

D

E

F

G

H

I

J

K

L

M

N

1.409

223

656

1.104

1.076

14

359,5

267,5

177,5

52

460 508

653

162,5

131 157

1.719

268

756

1.330

807

261,5

383

312,5

177,5

753

213

I

N

L

M

N

L

M

24

Page 27

INSTALLATION INDOOR UNIT

INSTALLATION UNIT

Install the unit in a way that the discharge air would not be direct to persons, differences of temperature can create

disturbs.

Keep in mind in the installation of the unit, some ambient can supply electromagnetic radiation that can affect the

good function of the unit, follow then the following instruction recommended in this document.

Rolling sides

A

A

To remove the casing, slide them over the rolling

sides and remove horizontally (See picture A).

B

Remove the AIR VANES by moving them in the

opposite direction of the air sweep motor until

they come out, then release the central fixing

clip, so that the AIR SWEEP is removed giving

better access to the top of the unit (See picture

B).

C

Install the unit with the M-8 screws, always use

washers. Fix the screws following the pattern

on page 26.

Check the strength of the screws to avoid

movement of the indoor unit when removing the

side and cover panel.. See picture C

D

Sides and carcass

AIR-SWEEP

Filters

B

C

Min. 100 mm.

D

Always install the filters. If the unit operates

without filters there is a risk of damage in the

indoor unit from dust..

OPENING IN FLASE CEILING

LTX 3

X

Y

1.321 mm

562 mm

LTX 5

1.630 mm

670 mm

25

X

Y

Page 28

INDOOR UNIT OPTIONALS

ELECTRICAL HEATER

BEFORE ATTEMPTING TO PERFORM ANY SERVICE OR MAINTENANCE, TURN OFF

THE ELECTRICAL POWER, AND CHECK THAT THE FAN HAS STOPPED

1

To remove the casing, slide them over the rolling sides and remove horizontally

2

Remove the filters.

3

Remove drain pan.

4

Introduce the electrical heater kit rods in the holes of one side of the coil and fix with screws on the other.

5

Fix the contactor to the fan deck.

Rolling side

Sides and carcass

Electric heat

Fan

LTX 3

Filters

Contactor

Drain pan

FIG 1

Contactor

Contactor

Fan

LTX 5

NOTE: The safety thermostat must always be at the top of the heater.

26

Electric Heat

Electric Heat

Page 29

OUTDOOR UNIT OPTIONALS

MAIN SWITCH

The main swicth is located on the access panel to the electrical box, in such a way that the unit is disconnected

when the panel is opened, for the models KCF and KCB.

(Refer to the size diagram on pages 25 to 30, to see the position of the electrical box access panel)

WINTER CONTROL

The low ambient kit should be fitted to the cooling units, when the outdoor temperature is lower then 19 ºC. in

cooling cycle.Keeps condensing temperature constant aprosimatelly 40ºC.

KIT GRID OF TAKES OF FOREIGN AIR

Field assembly.

This kit is comprised of an air filter and grille for outdoor air intake which should be installed on the suction side

of the outdoor unit.

27

Page 30

MAINTENANCE OF THE UNIT

POSSIBLE PROBLEMS

PROBLEM SOLUTION

1.- Unit do not work.

2.- The fan of the unit

works quicker without any

3.- Noise on pipe system.

NOTE: Some noises are

normal when unit stop and

4.- Excess of condensation

5.- The indoor battery

freeze continuously.

• Check electrical supply of the unit.

• Check electrical connexion.

• Check the remote controller and parameter works correctly.

• Check that the filter of the unit is clean.

• Check electrical connexion.

• If the problem persist, check the function of the motor.

• Check refrigerant charge is correct.

• Was the vacuum done correctly?

• Check internal temperature, could be quite low.

• Check possible obstructions in the condensate pan, and also out of the pan.

• Check correct level of the unit.

• Check drainage pipe.

• Check the air filter of the indoor unit.

• Check the level of refrigerant.

• Check strangulation air flow or recirculation.

• If the freeze persist the expansion can be obstructed.

• ¿Is the temperature below 21 º C?

• Check indoor temperature sensor.

6.- Unit work perfectly on

cooling mode, but do not

produce heat on mode heat

7.-External fan stop

8.-Excessive pressure of

condensation (Working

cooling cycle)

9.-Low pressure

condensation.

(Working on cooling

cycle)

10.-Excessive pressure

on return air (Working

on heat pump)

11.-Low pressure on

return air. (working

on heat pump)

• Check if you have configurate correctly the function mode of the unit.

• Check inverter valve of the outdoor unit.

• Check the plate PCB to the solenoid inverted valve.

• Check that terminal connexion are slack.

• Check the motor.

• Check the condenser situation.

• Check that that the rele of defrost is not activited

(Units heat pump).

• Check that the external exchanger is not dirty and obstructed.

• Check that there is no condensable gas and air in the refrigerant circuit.

• Check that the external fan works correctly.

• Check that the refrigerant charge is correct

• Check that the refrigerant charge is correct

• Check possible obstruction on the expansion system of the outdoor unit, liquid

• Check that air filter is not dirty or wrong function of indoor fan.

• Check that the refrigerant charge is correct

• Check the situation of inverter valve.

• Check retention valve situation.

• Check that the refrigerant charge is correct

• Check possible obstruction on the expansion system of the outdoor unit

• Check that the external fan works correctly.

• Check the correct function of the defrost thermostat .

28

Page 31

POINTS TO KEEP IN MIND

Abrasive

surfaces

WARNING

Electric shock hazard can cause injury

or death. Before attempting to perform

any service or maintenance on the

unit, turn OFF the electrical power,

and check that the fan has stopped.

FILTER CLEANING

Check the air filter and make

sure it is not blocked with dust

or dirt.

Low

temperatures

High

temperatures

Standard Guidelines to Lennox Refac equipment

Risk of injury with

moving objects

The air filter cleaning operations do not

require technical service; however when

an electrical or mechanical operation

is required call an Engineer.

If the filter is dirty, wash it in a bowl with neutral

soap and water, drying it in the shade before

inserting it in the unit.

Electrical

voltage

Risk of injury with

rotating objects

All technical data contained in these operating instructions including the diagrams and technical description

remains the property of Lennox Refac and may not be used (except for the purpose of familiarising the user

with the equipment), reproduced, photocopied, transferred or transmitted to third parties without prior written

authorisation from Lennox Refac.

The data published in the operating instructions is based on the latest information available. We reserve the

right to make modifications without notice.

We reserve the right to modify our products without notice without obligation to modify previously supplied

goods.

These operating instructions contain useful and important information for the smooth operation and maintenance

of your equipment.

The instructions also include guidelines on how to avoid accidents and serious damage before commissioning

the equipment and during its operation and how to ensure smooth and fault-free operation. Read the operating

instructions carefully before starting the equipment, familiarise yourself with the equipment and handling of

the installation and carefully follow the instructions. It is very important to be properly trained in handling the

equipment. These operating instructions must be kept in a safe place near the equipment.

Like most equipment, the unit requires regular maintenance. This section concerns the maintenance personnel

and management.

If you have any queries or would like to receive further information on any aspect relating to your equipment,

do not hesitate to contact us.

29

Page 32

30

Page 33

Page 34

BELGIUM :

LENNOX BENELUX N.V./S.A.

tél. : + 32 3 633 30 45

fax : + 32 3 633 00 89

e-mail : info.be@lennoxbenelux.com

CZECH REPUBLIC :

FRANCE :

GERMANY :

MIDDLE EAST :

NETHERLANDS :

POLAND :

LENNOX JANKA

tél. : + 420 2 510 88 111

fax : + 420 2 579 10 393

e-mail : janka@janka.cz

LENNOX FRANCE

tél. : + 33 4 72 23 20 20

fax : + 33 4 78 20 07 76

e-mail : accueil@lennoxfrance.com

LENNOX DEUTSCHLAND GmbH

tél. : + 49 69 42 09 79 0

fax : + 49 69 42 09 79 40

e-mail : info.de@lennoxdeutschland.com

LENNOX DISTRIBUTION

tél. : + 971 4 262 9309

fax : + 971 4 266 7082

e-fax : + 1 240 368 73 62

Mobile : 971 50 4510669

e-mail : mmrifal@emirates.net.ae

LENNOX BENELUX B.V.

tél. : + 31 33 2471 800

fax : + 31 33 2459 220

e-mail : info@lennoxbenelux.com

LENNOX POLSKA Sp. z o. o.

tél. : + 48 22 832 26 61

fax : + 48 22 832 26 62

info@lennoxpolska.pl

e-mail :

PORTUGAL :

RUSSIA :

SLOVAKIA :

SPAIN :

UKRAINE :

UNITED KINGDOM :

LENNOX CLIMATIZAÇAO LDA.

tél. : +351 22 999 84 60

fax : +351 22 999 84 68

e-mail : info@lennoxportugal.com

LENNOX DISTRIBUTION MOSCOW

tél. : + 7 095 246 07 46

fax : + 7 502 933 29 55

e-mail : lennox.dist.moscow@mtu-net.ru

LENNOX SLOVAKIA

tél. : + 421 2 44 87 19 27

fax : + 421 2 44 88 64 72

LENNOX REFAC S.A.

tél. : + 34 915 40 18 10

fax : + 34 915 42 84 04

e-mail : marketing@lennox-refac.com

LENNOX DISTRIBUTION KIEV

tél. : + 380 44 213 14 21

fax : + 380 44 213 14 21

e-mail : jankauk@uct.kiev.ua

LENNOX INDUSTRIES LTD

tél. : + 44 1604 599400

fax : + 44 1604 594200

e-mail : marketing@lennoxind.com

OTHER EUROPEAN

COUNTRIES, AFRICA,

LENNOX DISTRIBUTION :

MIL55S-101 05-2001

tél. : + 33 4 72 23 20 14

fax : + 33 4 72 23 20 28

e-mail : marketing@lennoxdist.com

www.Lennoxeurope.com

Loading...

Loading...