Page 1

INSTALLATION/OPERATION

VRF

INSTRUCTIONS

©2018 Lennox Industries Inc. Dallas, Texas, USA

THIS MANUAL MUST BE LEFT WITH THE

OWNER FOR FUTURE REFERENCE

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

!

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, personal injury or loss of life.

Installation and service must be performed

by a licensed professional HVAC installer (or

equivalent) or service agency.

Failure to follow safety warnings and these

instruc tions exactly could result in property

damage, dan gerous operation, serious injury,

or death.

Any additions, changes, or conversions

required in order for the appliance to

satisfactorily meet the ap plication needs must

be made by a licensed profes sional HVAC

installer (or equivalent) using factory-specied

parts.

Do not use this system if any part has been

under water. A ood-damaged appliance is

extremely dan gerous. Immediately call a

licensed professional HVAC service technician

(or equivalent) to inspect the system and to

replace all controls and electrical parts that

have been wet, or to replace the system, if

deemed necessary.

VRB Heat Recovery

VRF SYSTEMS

OUTDOOR UNITS

507885-03

05/2019

!

WARNING

Do not change the settings of any protection

devices installed in the outdoor unit. If the

pressure switch, thermal switch, or other

protection device is shorted or forcibly

operated, re or explosion may occur.

Do not use parts other than those specied by

Lennox or re and/or explosion may occur.

CAUTION

As with any mechanical equipment, contact

with sharp sheet metal edges can result in

personal injury. Take care while handling this

equipment and wear gloves and protective

clothing.

IMPORTANT

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFC’s and HCFC’s) as of

July 1, 1992. Approved methods of recovery,

recycling or reclaiming must be followed. Fines

and/or incarceration may be levied for non-

compliance.

These units must be installed as part of a

matched system as specied in the Product

Specications (EHB) bulletin.

General

The VRB heat recovery outdoor units are matched

with up to 64 indoor units per system to create a VRF

(variable refrigerant ow) system that uses HFC-

410A refrigerant.

Refer to the Product Specication bulletin (EHB)

for the proper use of these heat recovery units with

matching indoor units, mode selection boxes, branch

pipes, line sets and controls.

Shipping and Packing List

Check the components for shipping damage. If you

nd any damage, immediately contact the last carrier. Package 1 of 1 contains the following:

1 - Assembled VRB heat recovery outdoor unit

1 - Outdoor unit installation instruction

1 - Piping accessory package

1

Page 2

Safety Requirements

!

WARNING

ELECTRICAL SHOCK, FIRE, OR EXPLOSION HAZARD.

Do not touch the unit or the controller if your hands are wet.

Do not operate appliances with an open ame near the unit.

Do not replace a fuse with a fuse of a dierent rating. Do not attempt to bypass a fuse.

Do not insert your hands, tools or any other item into the air intake or air outlet at either the indoor or outdoor

unit.

Do not allow children to operate the system.

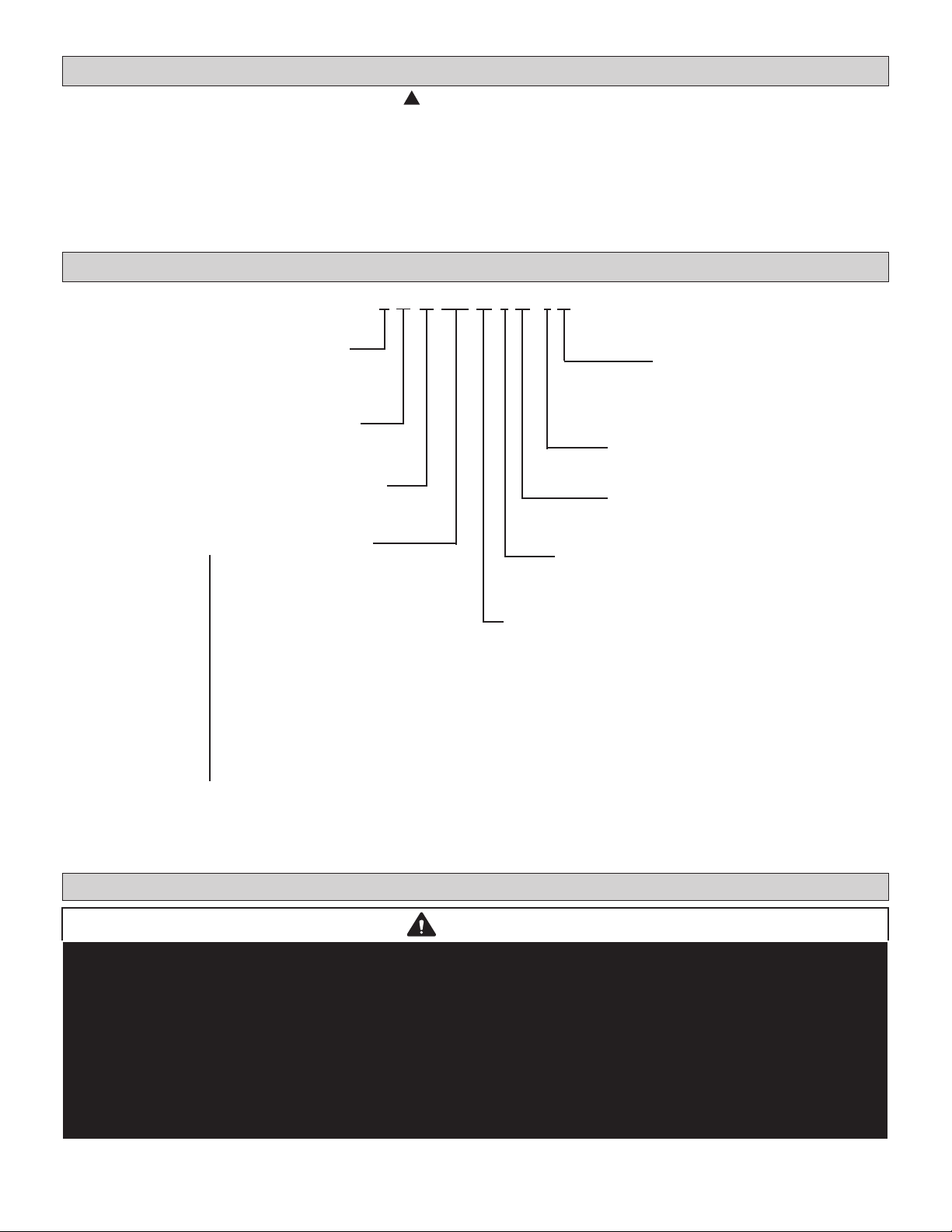

Model Number Identication

V R B 072 H 4 M -3 Y

Brand/Family

V = Variable Refrigerant Flow (VRF)

Unit Type

R = Heat Recovery Outdoor Unit

Major Design Sequence

B = 2nd Generation

Nominal Cooling Capacity - Tons

072 = 6 Tons

096 = 8 Tons

120 = 10 Tons

144 = 12 Tons

168 = 14 Tons

192 = 16 Tons

216 = 18 Tons

240 = 20 Tons

264 = 22 Tons

288 = 24 Tons

312 = 26 Tons

336 = 28 Tons

360 = 30 Tons

384 = 32 Tons

408 = 34 Tons

432 = 36 Tons

456 = 38 Tons

480 = 40 Tons

504 = 41 Tons

Voltage

Y = 208/230V-3 phase-60hz

G = 460V-3 phase-60hz

Controls Protocol

3 = Phase 3

Refrigerant Circuits

M = Multiple Circuits

Refrigerant Type

4 = R-410A

Cooling Eciency

H = High Eciency

NOTE - Lennox VRF and Lennox Mini-Split products are similar in appearance to each other. Refer to the unit’s model

number to determine if the unit is a VRF (V) or Mini-Split (M) unit. It is not possible to mix the two types of equipment

on any system.

System Piping

CAUTION

VRF system piping is customized for each installation. The Lennox VRF Selection Software (LVSS) piping report is an

engineered design that must be followed. The piping diagram or diagrams included within the LVSS report have been

prepared based on the information provided to the Lennox VRF applications department.

When the indicated lengths change from the gures stated within the report, it is imperative that prior to the commencement

of the refrigerant pipe work installation, Lennox VRF applications department are informed of these proposed changes.

Upon receipt of this new information the Lennox VRF applications department will conrm any changes that may be

applicable to this installation. If changes are required, a new piping diagram will be produced and will supersede all other

previously provided documents.

Failure to provide this information regarding changes to the original design may lead to insucient capacity, equipment

failure, warranty being made void and the refusal to commission the system.

2

Page 3

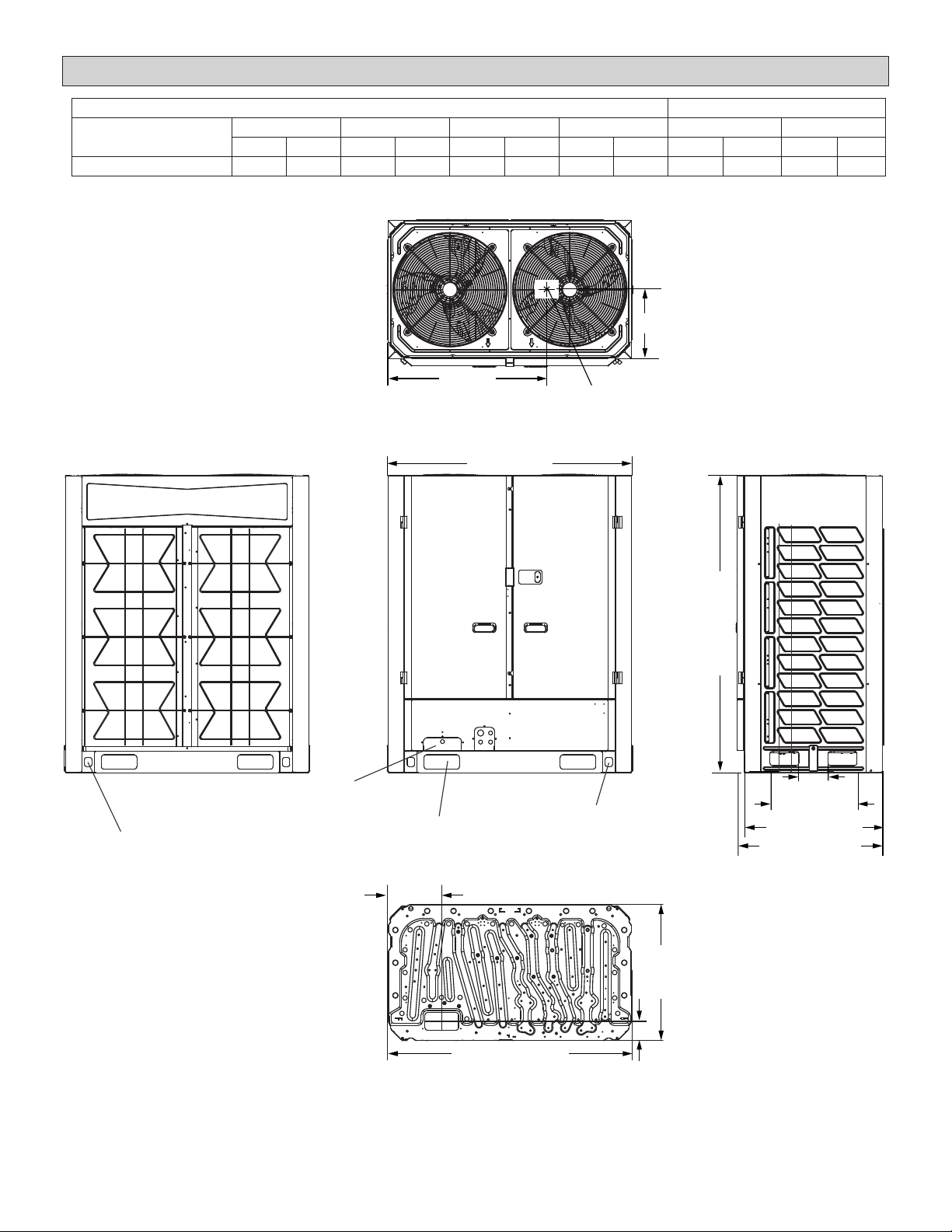

Unit Dimensions - inches (mm)

CORNER WEIGHTS CENTER OF GRAVITY

Model No. AA BB CC DD EE FF

lbs. kg lbs. kg lbs. kg lbs. kg in. mm in. mm

072, 096, 120 121 55 203 92 211 96 251 114 27-3/4 705 12-1/4 311

AA

DD

EE

TOP VIEW

52-3/4 (1340)

BB

FF

CC

CENTER OF

GRAVITY

64-3/8

(1635)

BACK VIEW

LAG BOLT DESIGNATION

(BOTH SIDES)

(TO ACCESS LAG BOLT)

PARALLEL MODULE

PIPING KNOCKOUT

FORKLIFT SLOT

REFRIGERANT LINE PATH

FRONT VIEW

(BOTH SIDES)

11-3/4 (298)

53-1/8 (1349)

BASE PAN VIEW

3

LIFTING HOLES

(BOTH SIDES)

(FOR RIGGING)

6-1/4 (159)

18-7/8 (479)

29-7/8 (759)

31-1/2 (800)

SIDE VIEW

29-1/2

(749)

4-1/8 (105)

Page 4

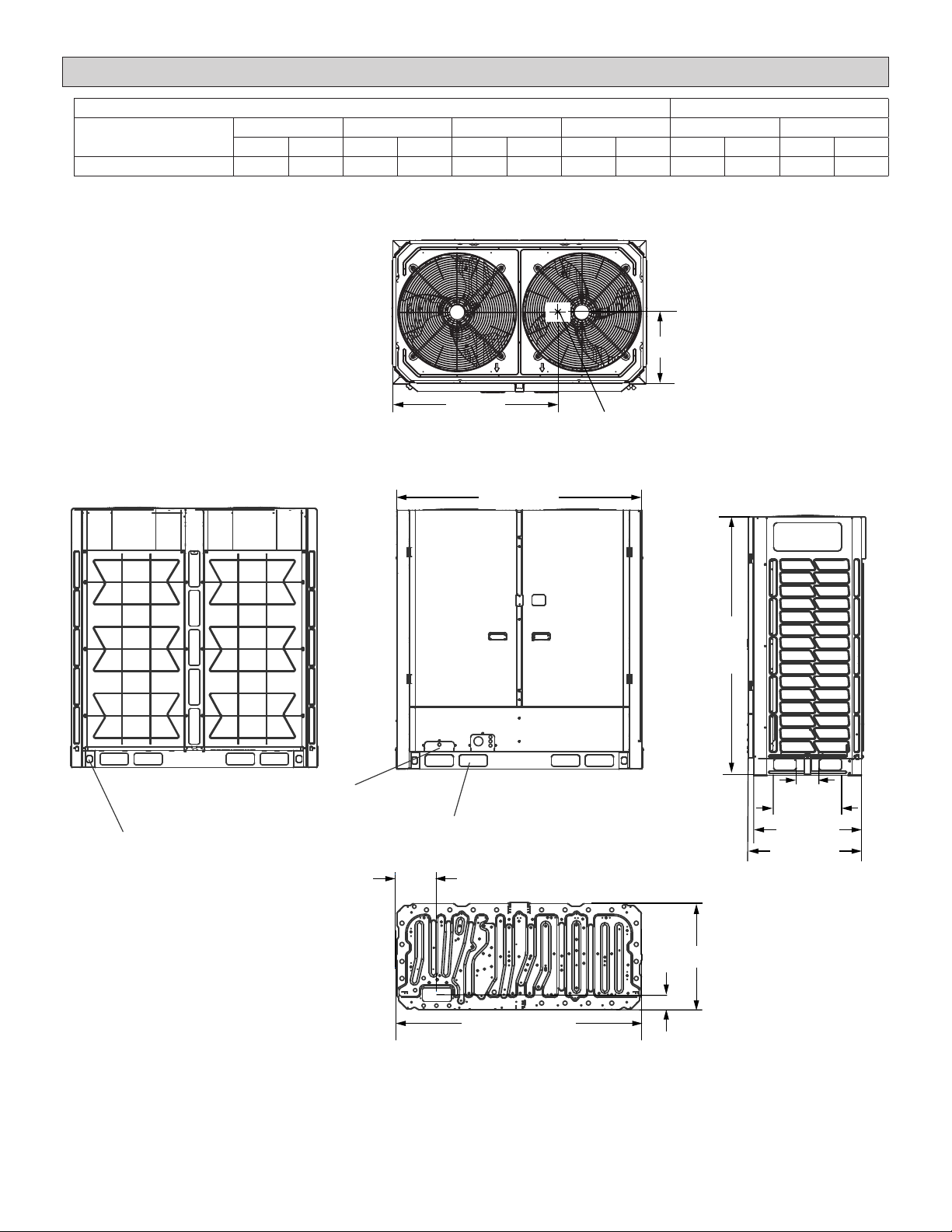

Unit Dimensions - inches (mm)

CORNER WEIGHTS CENTER OF GRAVITY

Model No. AA BB CC DD EE FF

lbs. kg lbs. kg lbs. kg lbs. kg in. mm in. mm

144, 168, 192 172 78 264 120 330 150 321 146 37-3/4 953 12 305

AA

DD

EE

TOP VIEW

68-1/2 (1740)

BB

FF

CC

CENTER OF

GRAVITY

72 (1829)

BACK VIEW

LAG BOLT DESIGNATION

(BOTH SIDES)

(TO ACCESS LAG BOLT)

PARALLEL MODULE

PIPING KNOCKOUT

REFRIGERANT LINE PATH

FRONT VIEW

FORKLIFT SLOT

(BOTH SIDES)

11-3/8 (289)

68-1/2 (1740)

BASE PAN VIEW

4

6-1/4 (159)

18-7/8 (479)

30 (762)

32-5/8 (829)

SIDE VIEW

29-3/4 (756)

4-1/8 (105)

Page 5

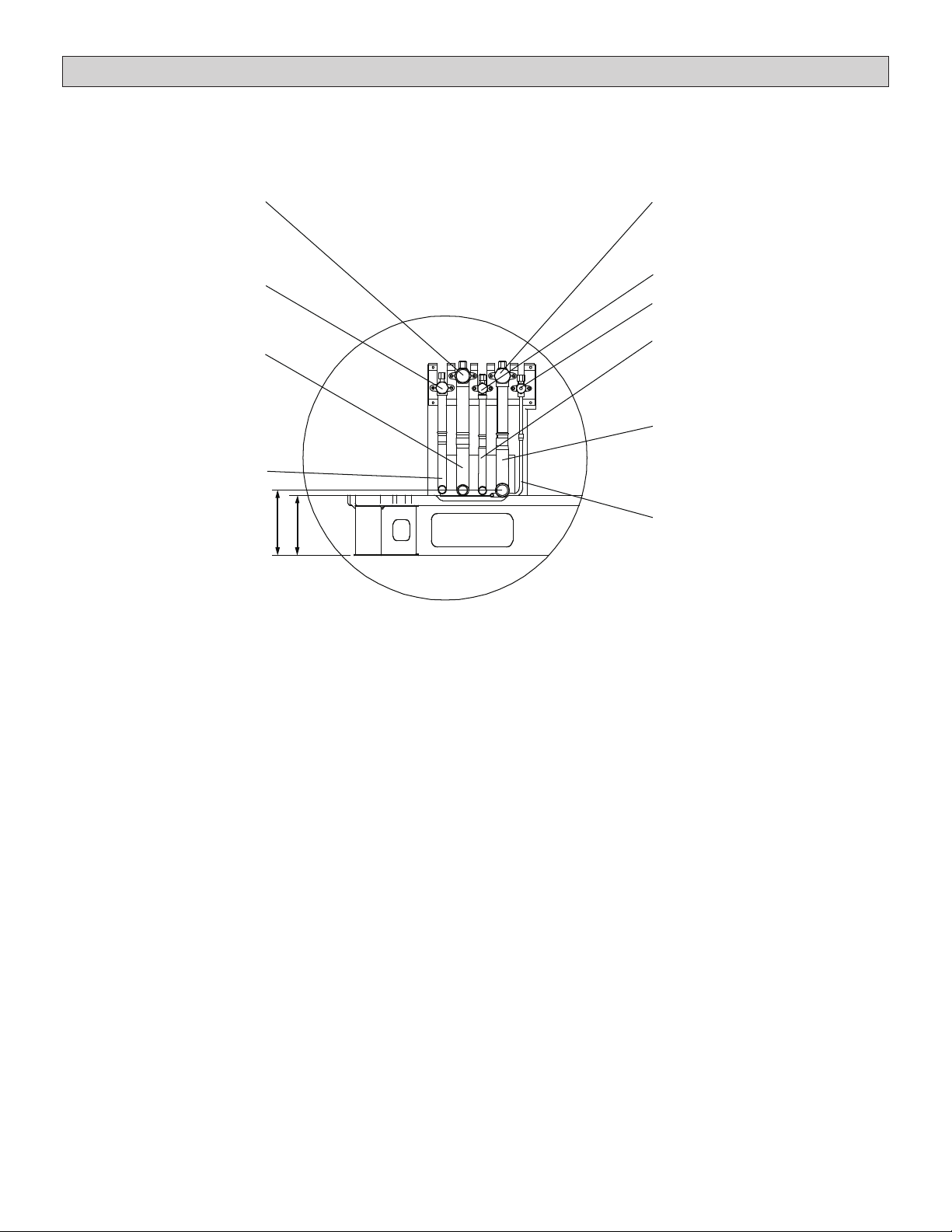

Dimensions - Piping Details - inches (mm)

Internal valve layouts are the same in both heat

recovery and heat pump units, it is their function that

is dierent. Pay close attention when making nal

piping connections.

Low pressure gas valve

High pressure

gas balance valve

Low pressure gas pipe

(1-1/8 in. diameter 072-120 sizes)

(1-3/8 in. diameter 144-192 sizes)

High pressure

gas balance pipe

(3/4 in. diameter)

6-1/4 (159)

5-5/8 (143)

Heat Recovery internal valve layouts are described

below. See the Heat Pump installation manual for

heat pump internal valve information.

High pressure gas valve

Liquid side valve

Liquid side valve

Oil balance valve

Liquid side pipe

(5/8 in. diameter 072-120 sizes)

(3/4 in. diameter 144-192 sizes)

High pressure gas pipe

(1-1/8 in. diameter 072-120 sizes)

(1-3/8 in. diameter 144-192 sizes)

Oil balance pipe

(1/4 in. diameter)

5

Page 6

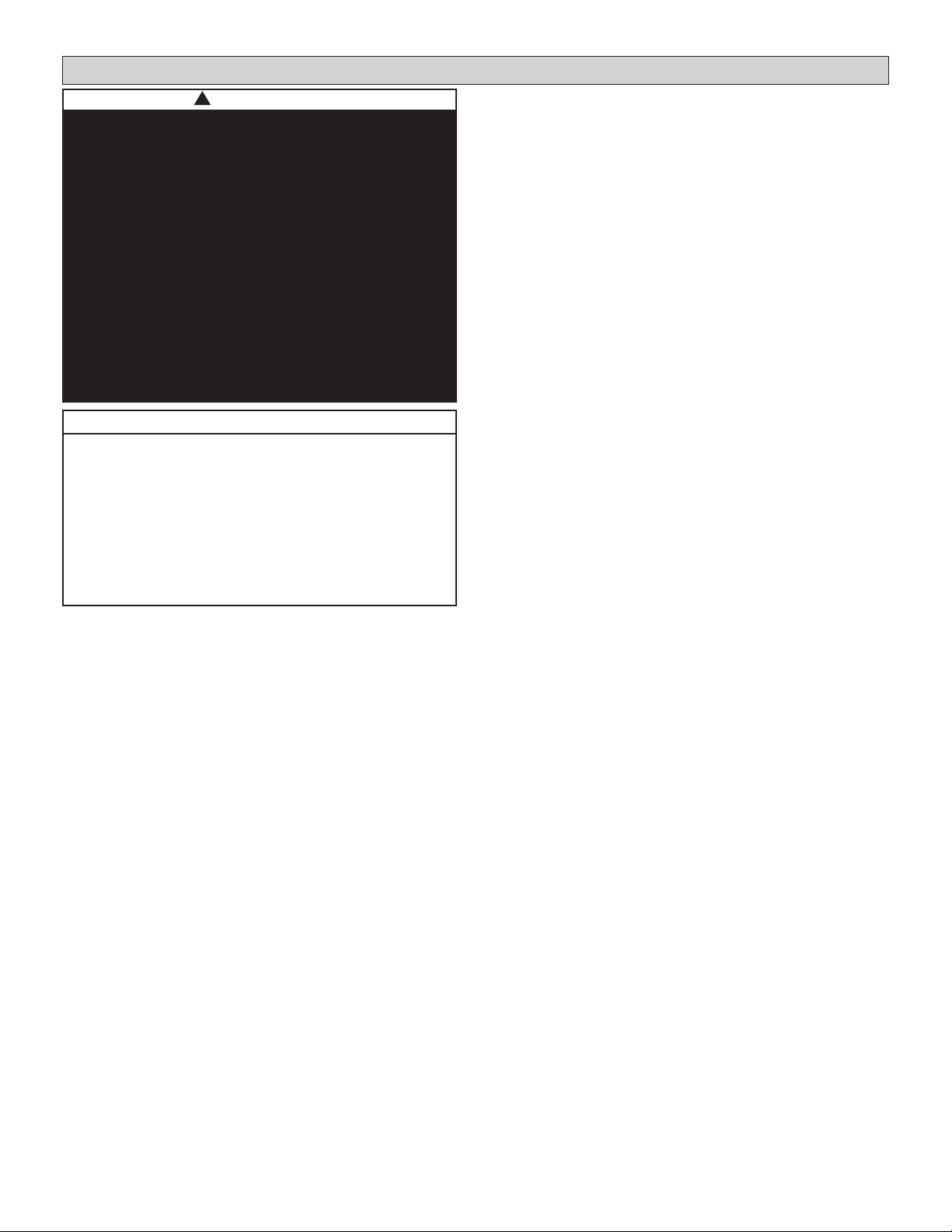

Outdoor Unit Placement Considerations

!

WARNING

Use the provided and specied components

when installing equipment. Failure to do so may

result in unit falling, water leaking or electrical

shocks, caus ing personal injury or equipment

or property dam age.

Check stability of unit support. If sup port is

not capable of carrying weight of the unit, unit

may fall causing personal injury or equipment

damage.

Safely dispose of packing materials, which

include nails, wood and other sharp objects,

as well as plastic wrapping. Children playing

with plastic wrap or bags risk the danger of

suocation.

IMPORTANT!

Exhaust vents from dryers, water heaters and

furnaces should be directed away from the

outdoor unit. Prolonged exposure to exhaust

gases and the chemicals contained within

them may cause condensation to form on the

steel cabinet and other metal components of

the outdoor unit. This will diminish unit performance and longevity.

In addition to clearances, the following items should

be considered when setting the outdoor unit:

• 2007 EPA Noise Policy. Observe local code

adoptions/enforcement as consideration should

be used when selecting an outdoor unit’s permanent placement. Sound data for each unit can be

found in the Product Specications Document.

• Glass has a very high level of sound transmission. When possible, do not install the unit directly outside a window.

• Avoid installing the unit in areas exposed to ex-

treme voltage variations (such as factories).

• Install unit level.

• Allow sucient space around unit for proper operation and maintenance.

• Install the outdoor unit a minimum of 3 ft. (1 m)

away from any antenna, power cord (line), radio,

telephone, security system, or intercom. Electri-

cal interference and radio frequencies from any

of these sources may aect operation.

• Outdoor unit shall maintain a minimum distance

of 10 ft. (3 m) from dryer exhaust vents.

• Outdoor unit shall maintain a minimum distance

of 10 ft. (3 m) from Type 1 kitchen exhaust outlets.

• Coating outdoor coils is recommended in applications installed in coastal regions less than 30

miles (48 kilometers) inland.

6

Page 7

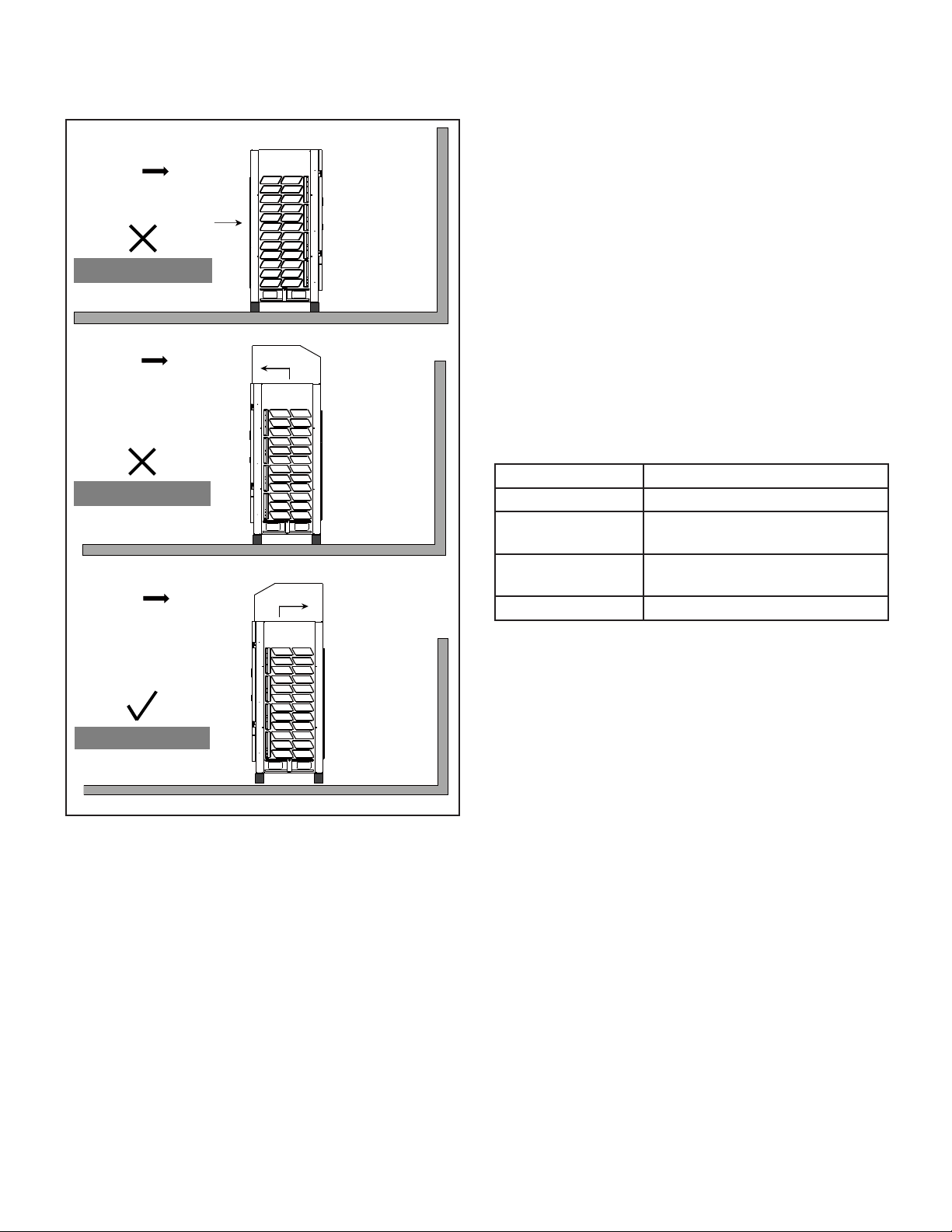

SINGLE ROW

Lifting the Unit

• Do not hold the air inlet grille while lifting the unit.

This could result in damage to the cabinet.

39 (991)

• Do not touch the fan blades with your hands or

other objects while lifting the unit.

Air Flow

Air Flow

31 (800)

39 (991)

39 (991)

Front Front

4 to 20 (102 to 508)

TWO ROWS

39 (991)

39 (991)

Front Front

39 (991)

Front Front

39 (991)

4 to 20 (102 to 508)

THREE OR MORE ROWS

FrontRear

Air Flow

Air Flow

31 (800)

39 (991)

39 (991)

39 (991)

39 (991)

39 (991)

Front Front

Air Flow

Front Front

Air Flow

31 (800)

Front Front

4 to 20 (102 to 508)

Figure 1. Installation Clearances - inches (mm)

7

Page 8

NOTICE

Drawings in this manual are for illustrative purposes

and should not be used as a template for fabricating

eld-supplied accessories or apparatuses. Consider

the environment in which this unit is being installed and

make necessary adjustments to ensure safe operation.

Local codes prevail.

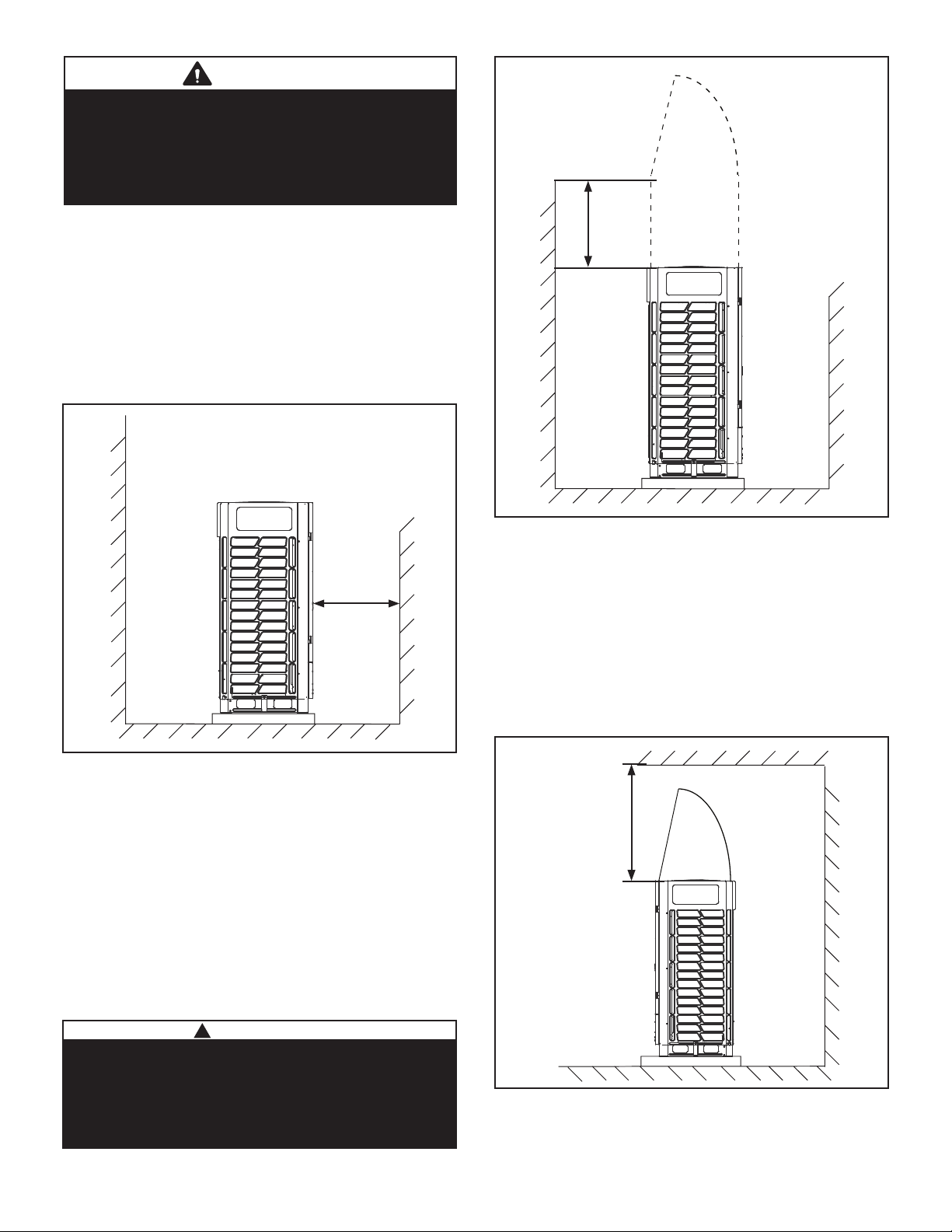

Clearances from Obstructions

• Allow adequate air ow clearance on all sides of

the unit. See Figure 1 and this section.

• Allow at least 39 in. (991 mm) clearance in front

of the unit for maintenance and service access.

The outdoor unit service access is via hinged

service doors that swing open in front of the unit.

Figure 2.

>39”

(991 mm)

Rear Side

Front Side

>32”

(813 mm)

Front SideRear Side

Figure 3. Perimeter Obstructions

• Allow at least 120 in. (3048 mm) clearance above

the unit. If an obstruction above the unit does not

allow for adequate clearance, a eld-supplied

discharge duct is required. The discharge duct

should be installed in such a way as to ensure

that discharge air goes beyond the obstruction

and does not cause recirculation of discharge air.

Ensure that the static capabilities of the outdoor

unit are not exceeded. Figure 4.

Figure 2. Maintenance & Service Clearance

• Perimeter obstructions that are 32 in. (813

mm) taller than the top of the outdoor unit

require a eld supplied air discharge duct

to avoid recirculation of discharge air.

The discharge duct should be installed to at

least the height of the surrounding obstructions

(for ex. walls) to ensure that discharge air

goes over the height of the obstruction.

Ensure that the static capabilities of the outdoor

unit are not exceeded. Figure 3.

!

CAUTION

In order to avoid injury, take proper precaution

when lifting heavy objects.

Take care when using a sling to lift the unit for

in stallation. The unit center of gravity is not at

its physical center.

>120”

(3048 mm)

Front Side Rear Side

Figure 4. Obstructions Above the Unit

8

Page 9

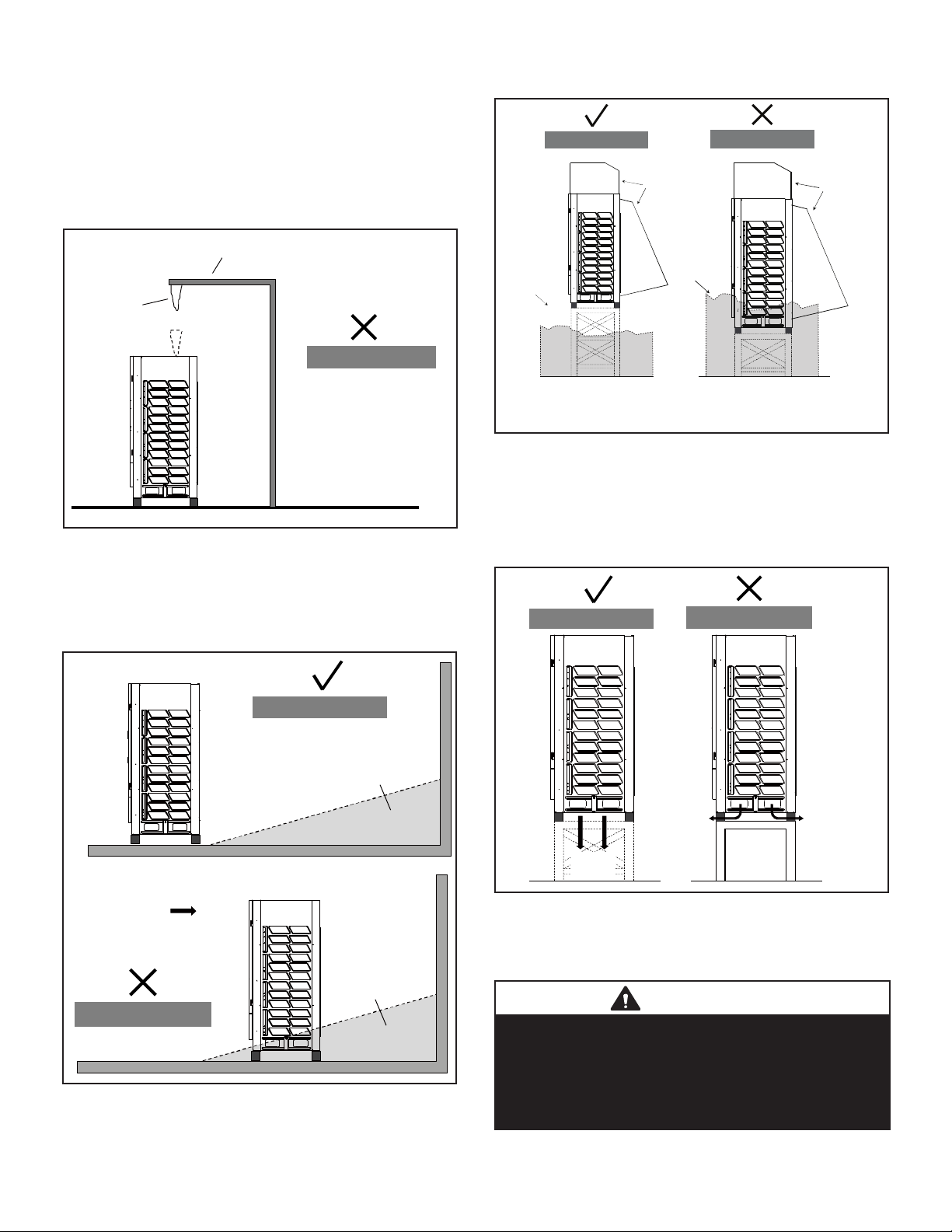

Cold Climate Considerations

Select a location where high winds and snow will not

aect the unit. In areas where typical ambient temperatures are below 50°F (10°C), the following pre-

cautions should be observed.

• Locate unit away from overhanging roof lines

which would allow water or ice to drop on, or in

front of, coil or into unit.

Eaves

Icicle

Wrong Installation

• Install snow guards to prevent snow fall from entering air inlet and outlet.

Correct Installation

Snow

Guard

Kit

Snow level

Wrong Installation

Snow

Guard

Kit

RearFrontRearFront

Snow level

RearFront

Figure 5. Do Not Locate Under Roof Overhang

• The unit base should be elevated above the

depth of average snows plus 12 in. (305 mm). In

heavy snow areas, do not locate the unit where

drifting will occur.

Correct Installation

RearFront

Snow Drifts

NOTE - Snow guards are recommended on both sides

and rear of the unit as shown in this example.

Figure 7. Elevate Above Average Snow Level

& Protect Coil

• If necessary, install the unit on a raised base

made of angle iron and that allows snow and

wind to pass through

Correct Installation

RearFront

Wrong Installation

Defrost

Water

RearFront

Defrost

Water

Wind

RearFront

Snowdrift

Wrong Installation

Figure 6. Do Not Locate Where Drifting Will Occur

Defrost

Water

Figure 8. Secure Unit to

Weather Resistant Support

IMPORTANT

These illustrations are examples of possible snow

protection options. They should not be used as a

template for fabricating the snow protection apparatuses.

Consider the environment in which this unit is being

installed and make necessary adjustments to ensure

safe operation.

9

Page 10

• When installed in areas where low ambient tem-

peratures exist, locate unit so winter prevailing

winds do not blow directly on to the outdoor unit.

Wind

Rear Front

Wind

Wind

Inlet

Outlet

RearFront

Outlet

llation

Wrong Installation

Wrong Installation

Air Discharge Duct

• Before installing the air duct, remove the two fan

guards from the top of the unit.

• Duct each outdoor unit separately. Do not use

a combined plenum as this may result in air not

being discharged directly to the outside.

• Discharge air duct shall be constructed of steel

and installed in a manner which prevents sagging

and or collapsing.

• Only one bend is allowed in the air duct.

• Duct louvers will reduce air volume, cooling and

heating capacity and eciency. Louvers are not

recommended; if they are required by the job,

the louver angle should be no larger than 15°.

• It may be necessary to install a exible connector

between the unit and the duct to reduce vibration

noise.

Table 1. Static Pressure Settings

Static Pressure Description

0 WG (0 Pa) Default

0-0.08 WG (0-20

Pa)

Above 0.08 WG

(20 Pa)

Remove fan guard, < 10 ft. (3 m)

duct length

Contact Lennox VRF Applications

Support

RearFront

Correct Installation

Figure 9. Protect Unit from Prevailing Winds

NOTE - Use dip switch S4 to change outdoor

unit static pressure settings.

10

Page 11

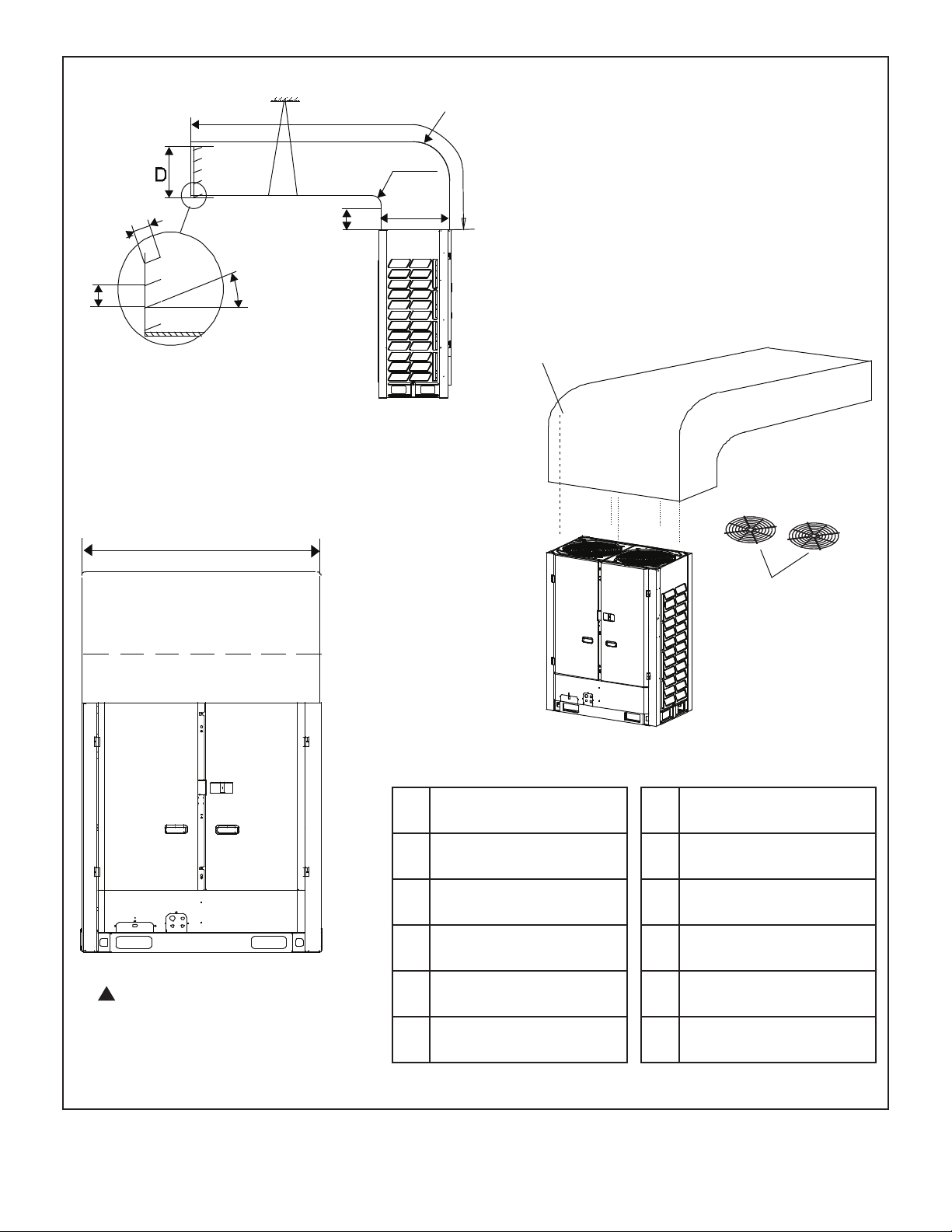

Support

C

Radius

E

A

Radius

3-1/2 in.

(89 mm)

≤ 15°

4 in. (102 mm)

Air Outlet Louver

072, 096, 120 -- 50-3/4 in. (1289 mm)

144, 168, 192 -- 65 in. (1651 mm)

B

F

8 × ST3.9

self-threading screws

Fan guards

(remove

first)

!

Contact the Lennox VRF

applications department for

assistance with ducting applications

that dier from these images.

Figure 10. Air Discharge Duct

072, 096, 120

A A ≥ 12 in.(305 mm)

B B ≥ 10 in. (254 mm)

C C ≤ 118-1/8 in. (3000 mm)

D D ≥ 24 in. (610 mm)

E E = A + 24 in. (610 mm)

F 24 in. (610 mm)

(Front or Rear Connection)

11

144, 168, 192

A A ≥ 12 in.(305 mm)

B B ≥ 10 in. (254 mm)

C C ≤ 118-1/8 in. (3000 mm)

D D ≥ 28-3/8 in. (721 mm)

E E = A + 24 in. (610 mm)

F 28-3/8 in. (721 mm)

Page 12

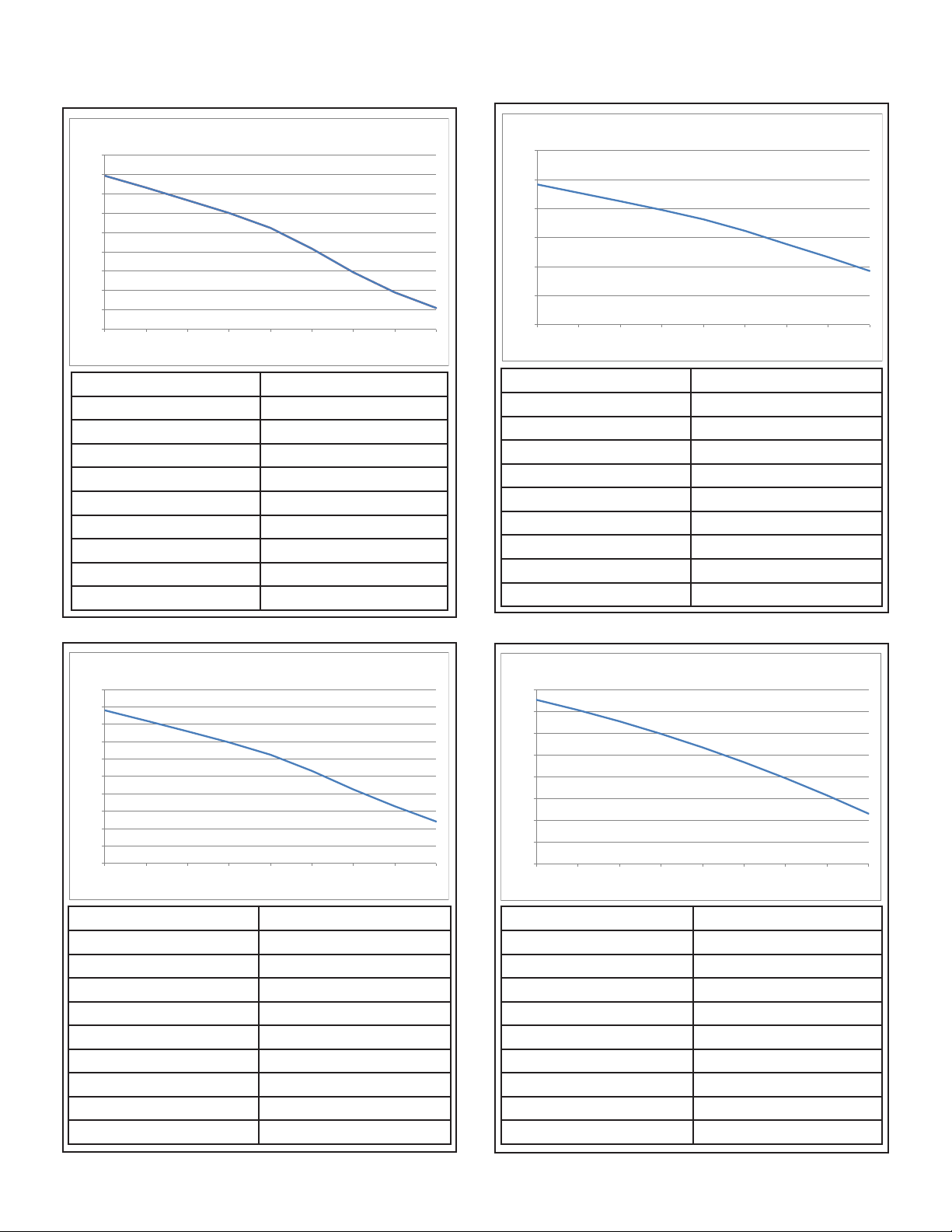

Discharge Duct Pressure Curves

VRB072

VRB120

6-ton Air Volume (CFM)

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

0 0.04 0.08 0.1 2 0.16 0.2 0.24 0.2 8 0.32

Static Pressure (in.wg.) Air Volume (CFM)

0 13934

0.04 13320

0.08 12667

0.12 12010

0.16 11236

0.2 10163

0.24 8940

0.28 7902

0.32 7094

10-ton Air Volume (CFM)

18000

16000

14000

12000

10000

8000

6000

0 0.04 0.08 0.12 0.16 0.2 0.24 0.28 0.32

Static Pressure (in.wg.) Air Volume (CFM)

0 15667

0.04 15090

0.08 14508

0.12 13907

0.16 13261

0.2 12467

0.24 11554

0.28 10655

0.32 9709

VRB096

8-ton Air Volume (CFM)

16000

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

0 0.04 0.08 0.12 0.16 0.2 0.24 0.28 0.32

Static Pressure (in.wg.) Air Volume (CFM)

0 14800

0.04 14205

0.08 13587

0.12 12958

0.16 12248

0.2 11315

0.24 10247

0.28 9279

0.32 8402

VRB144, 168, & 192

12~16-ton Air Volume (CFM)

25000

24000

23000

22000

21000

20000

19000

18000

17000

0 0.04 0.08 0.12 0.16 0.2 0.24 0.28 0.32

Static Pressure (in.wg.) Air Volume (CFM)

0 24544

0.04 24079

0.08 23559

0.12 22986

0.16 22360

0.2 21679

0.24 20945

0.28 20157

0.32 19315

12

Page 13

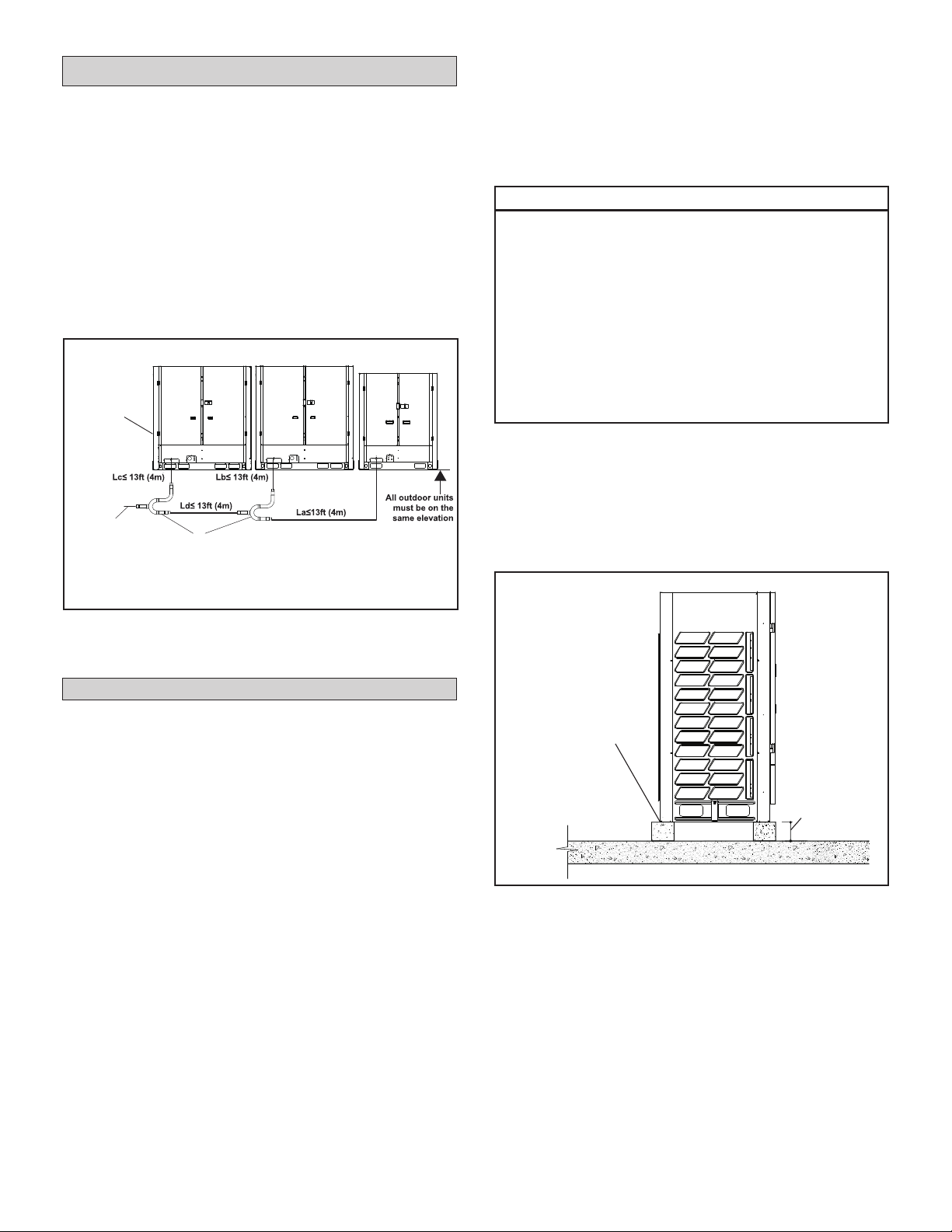

Main/Sub Outdoor Unit Placement

• A VRF system consisting of more than two

outdoor units must be placed in order from the

largest to the smallest capacity. See gure 8.

• The largest capacity outdoor unit must be

installed closest to the main pipe leading into the

building. See Figure 11.

• The largest capacity outdoor unit address is the

main unit, while the others are the sub units. See

Figure 11.

• All of the outdoor units manifolded together

should be installed at the same elevation.

Main unit

placed

closest to

main pipe

leading into

building

Main piping

to building

16-ton

Outdoor Unit

Branch Pipe Kits

14-ton 10-ton

NOTE - All of the outdoor units manifolded

together should be installed at the same elevation.

• If the unit coil cannot be installed away from

prevailing winter winds, a wind barrier should

be constructed. Size barrier at least the same

height and width as outdoor unit. Install barrier

12 inches (305 mm) minimum from the sides of

the unit in the direction of prevailing winds.

IMPORTANT!

Roof Damage!

This system contains both refrigerant and

oil. Some rubber roong material may absorb

oil. This will cause the rubber to swell when

it comes into contact with oil. The rubber will

then bubble and could cause leaks. Protect the

roof surface to avoid expo sure to refrigerant

and oil during service and instal lation. Failure

to follow this notice could result in damage to

roof surface.

Securing Outdoor Unit to Slab or Frame

Use lag bolts (min. 3/8 in.) at all four corners to

secure the unit to the eld-provided slab or frame.

Isolation material can be used to control vibration or

sound transmission. Lag bolts must extend through

material to the slab or frame. See Figure 12.

Figure 11. Main/Sub Unit Placement

(40-Ton System Example)

Installation

Slab or Roof Mounting

Install the unit a minimum of 8 inches (203 mm)

above the roof or ground surface to avoid ice buildup around the unit. Locate the unit above a loadbearing area of the roof that can adequately support

the unit. Consult local codes for rooftop applications.

• Use a eld supplied slab or suitably sized

steelwork to construct a base for locating

the condensing unit. All supporting work

should be veried by a qualied engineer.

NOTE - Prefabricated light duty equipment pads

are NOT suitable for use.

• Support the unit across the front and back of the

unit.

Use lag

bolts (4) to

secure unit

to slab or

approved frame

at each corner

8 in.

(203 mm)

Figure 12. Secure Outdoor Unit

to Approved Structure

13

Page 14

Refrigerant Piping Connections

!

WARNING

Refrigerant leaks are unlikely; however, if a

refriger ant leak occurs, open a door or windows

to dilute the refrigerant in the room. Turn o the

unit and all other appliances that may cause

a spark. Call a li censed professional HVAC

technician (or equiva lent) to repair the leak.

Use only R-410A refrigerant to charge this

system. Use of other refrigerant or gas will

damage the equipment.

Do not allow air or other contaminants to

enter sys tem during installation of refrigerant

piping. Con taminants will result in lower

system capacity and abnormally high operating

pressures and may res ult in system failure or

explosion.

Insulate all refrigerant piping.

Refrigerant pipes may be very hot during unit

opera tion. Do not allow contact between wiring

and bare copper pipes.

After refrigerant piping connections have been

completed, check the system for leaks per

commis sioning instructions.

• Both liquid and gas (vapor) lines must be indi-

vidually insulated.

• Field piping consists of three HVAC/R eld-pro-

vided copper refrigerant lines connected to the

outdoor unit. These lines carry the liquid and vapor refrigerant to and from the mode selection

box(es).

• Refrigerant piping and wiring connections can be

brought into the outdoor unit through openings

provided in the front, side(s), or underside (recommended) of the unit.

• Refrigerant piping must be connected using

mode selection boxes and individual branch pipe

kits. Six mode selection boxes are available in

varying sizes to accommodate connection of one

to 41 indoor units.

• The following restrictions apply to each VRB system:

• Total refrigerant pipe length 3280 ft. (1000 m)

• Longest pipe length actual) 574 ft. (175 m)

• Level dierence between indoor units 98 ft.

(30 m)

• Piping length from the rst branch pipe to the

farthest indoor unit 132/295 ft. (40/90 m)

• For each branch pipe, allow 20” (508 mm) of

equivalent length.

!

Contact the Lennox VRF applications department

for assistance.

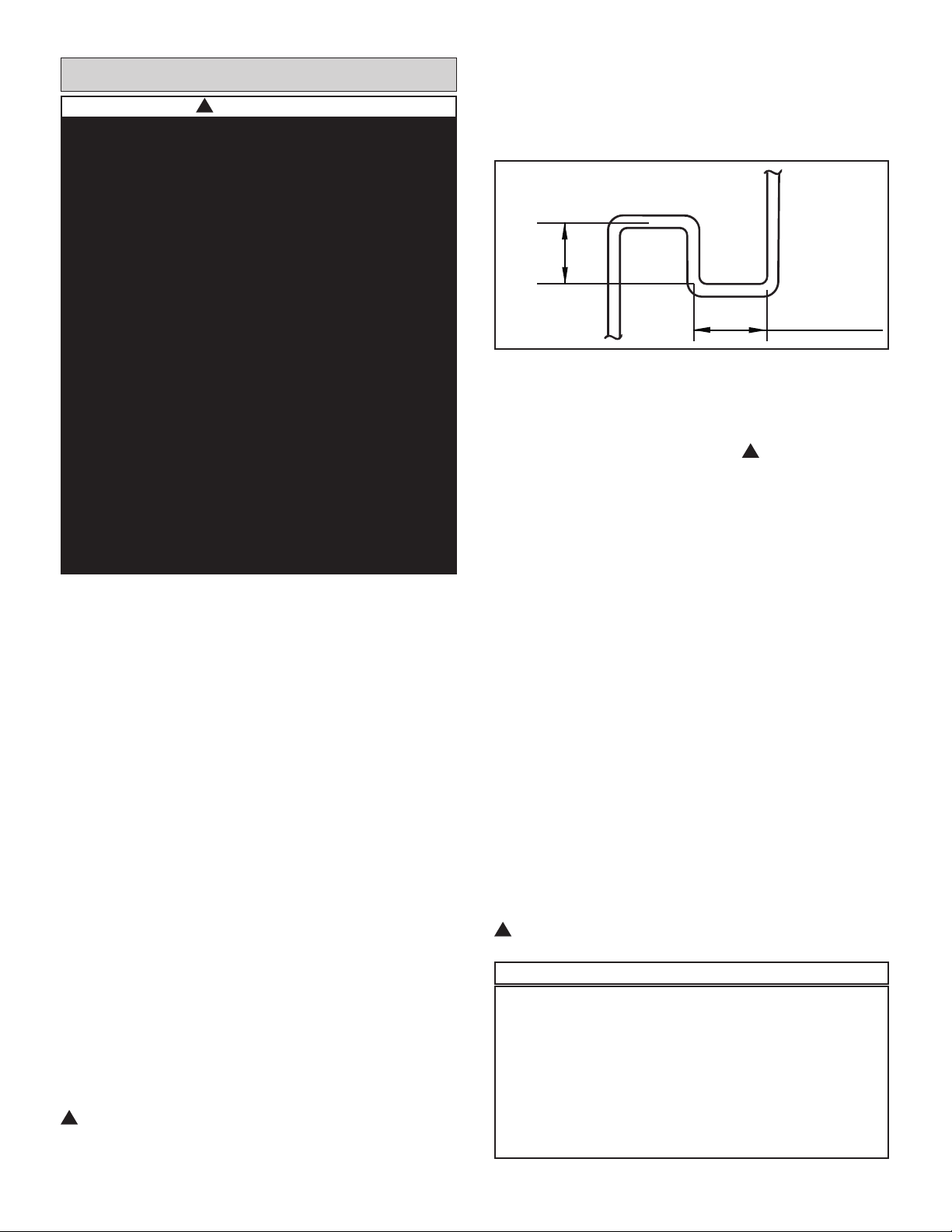

• When the outdoor unit is installed 164 feet (50

m) or more above the indoor units, install an oil

return trap every 33 feet (10 m) in the main low

pressure gas pipe. See Figure 13 for trap speci-

cations.

≥1ft

≥1ft

Figure 13. Oil Return Trap

• When the outdoor unit is 132 feet (40 m) or more

below the indoor units, increase the diameter of

the liquid line pipe from the outdoor unit to the

rst branch pipe by one size. ! Contact the Lennox VRF applications department for assistance.

• To extend the length from the rst branch pipe to

the farthest indoor unit beyond 132 ft. (40 m) and

up to 295 ft. (90 m), the following three conditions

must be met.

1. Increase diameter of the main pipe between

the rst and the last branch pipes. If the diameter of the pipe is the same as the main outdoor

pipe, then it does not need to be increased.

Ex: If 132 ft.<L1+L7+L9+L10 ≤ 295 ft., in-

crease the diameter of all the pipes by one

size.

2. The length from the indoor unit to the nearest

branch pipe must be 132 ft. (40 m) or less.

Ex: a,b,c,d,e,f,g,h,i,j,k,l,m ≤ 132 ft.

3. The dierence between [the distance from

the outdoor unit to the farthest indoor

unit] and [the distance from the outdoor

unit to the nearest indoor unit] is ≤132 ft.

Ex:(L1+L7+L9+L11+11+j+k+n)

-(L1+L7+L8+p)

≤ 132 ft.

!

Contact the Lennox VRF applications department

for assistance.

IMPORTANT!

The compressor in this unit contains PVE oil

(Polyvinylether). PVE oil is formulated for hy-

drouorocarbon (HFC) refrigerants, such as R-

410a, which this system contains. While it may

have some miscibility properties with mineral

based oil and POE oil (Polyolester), you should

not mix PVE oil with any other type of refrigerant oil.

14

Page 15

Maximum Permitted Refrigerant Pipe Length and Maximum Height Difference

OUTDOOR UNITS

(one or more outdoor units)

NOTE - Capacities are shown in parenthesis

a

b

c

MS1

L1

A

L2

L3

B

L4

C

L6

L5

MS3

MS2

INDOOR UNITS

N1

(024)

N2

(024)

d

e

The first line Branch Pipe

N4

(009)

N3

(048)

Maximum equivalent single piping length - 656 ft.(200 m)

L7

Maximum piping length from the first Branch Pipe

joint to the farthest indoor unit - 295 ft. (90 m)

LEGEND

Branch Pipe

Mode Selection

Box (MS)

Maximum level difference between

Indoor Unit

L8

D

L9

L10

E

L11

F

MS6

Indoor Unit and Outdoor Unit - 361 ft. (110 m)

MS7

f

MS4

L12

MS5

L13

Maximum piping length from MS Device

to downstream indoor unit - 131 ft. (40 m)

k

j

r

N13

(018)

q

N12

(048)

p

N11

(048)

l

N5

(048)

g

i

m n

N8

(009)

h

N9

(018)

N6

(024)

N7

(024)

N10

(018)

Maximum level difference between indoor units - 98 ft. (30 m)

Piping Length Permitted value Piping

Total piping length

Single piping length

Piping length from the rst branch joint to the

Piping

Length

farthest indoor unit

Actual length 574 ft. (175 m)

Equivalent length2 656 ft. (200 m)

Piping length from Mode Selection Box (MS) to

the downstream indoor unit of itself

Level dierence between

indoor unit and outdoor unit

Level

Level dierence between indoor units 98 ft. (30 m) - - -

Dierence

NOTES:

The rst branch in all systems must be centrally located between all Mode Selection (MS) Boxes.

1

When counting the total piping length, double the actual length of the distribution pipes between rst Branch Pipe joint and Mode Selection Box (MS): Installation.

Total piping length = L1+(L2+L3+L4+L5+L6+L7+L8+L9+L10+L11+L12+L13)×2+a+b+c+d+e+f+g+h+i+j+k+l+m+n+p+q+r ≤ 3280 ft.(1000 m).

2

Each Branch Pipe or bend is equivalent to 20 in. (508 mm).

3

The maximum allowable piping length from the rst Branch Pipe joint to the farthest indoor unit must be ≤ 132 ft. (40 m), but if the following conditions are met, the

maximum allowable length can be extended to 295 ft. (90 m):

• The piping length from each indoor unit to the nearest Branch Pipe joint or direct connected Mode Selection Box (MS) must be less than 132 ft. (40m) (b to r).

• The dierence in length between the outdoor unit to the farthest indoor unit, and the outdoor unit to the nearest indoor unit is ≤ 132 ft. (40 m).

Example: The farthest indoor unit is N10, The nearest indoor unit is N11 (L1+L7+L9+L11+j+k+n) minus (L1+L7+L8+p) ≤ 132 ft. (40 m).

• Increase the distribution pipe diameter between the rst Branch Pipe and Mode Selection Box (MS) L2-L13. If the pipe diameter is the same as the main outdoor pipe,

it does not need to be increased.

Pipe Size Allowable Increase Diameters (in.):

3/8 to 1/2 1/2 to 5/8 5/8 to 3/4 3/4 to 7/8 7/8 to 1-1/8 1-1/8 to 1-3/8 1-3/8 to 1-5/8 1-5/8 to 2-1/8

4

When the outdoor unit is higher than indoor units and the level dierence is over 164 ft. (50 m), it is required to set an oil return bend every 33 ft.(10 m) in the gas pipe of

the main pipe. Refer to Installation Instructions for additional details.

5

When the outdoor unit is lower than indoor units and the level dierence is more than 132 ft.(40 m), the main liquid pipe pipe need to increase by one size.

Outdoor unit up4 360 ft. (110 m) - - -

Outdoor unit down

1

3280 ft. (1000 m)

3

132/295 ft. (40/90 m) L7+L9+L11+j+k+n

132 ft. (40 m) j+k+n

5

230 ft. (70 m) - - -

L1+(L2+L3+L4+L5+L6+L7+L8+L9+L10+L11+L12+L1

3)×2+a+b+c+d+e+f+g+h+i+j+k+l+m+n+p+q+r

L1+L7+L9+L11+j+k+n

15

Page 16

(120)

(144)

Lead ODU

g3 g2 g1

LEGEND

Branch Pipe

Mode Selection

Box (MS)

Indoor Unit

(192)

G1

r

NOTE - Indoor and outdoor unit

capacities are shown in parenthesis.

L2

A

L1

L7

D

L9L8

L10

E

L11

MS7

N13

(018)

q

N12

(048)

p

N11

(048)

B

F

MS6

j

L3

L4

L12

L13

a

MS1

C

f

MS4

MS5

k

l

L6

b

c

MS2

L5

MS3

(009)

N5

(048)

g

i

m n

N8

(009)

N4

d

h

N9

(018)

(024)

(048)

e

N3

(048)

N6

(048)

N7

(024)

N1

N2

N10

(018)

PIPE AND COMPONENT NAMES

Name Designation

Outdoor Unit Connection Pipe g1, g2, g3, G1

Outdoor Unit Branch Pipe Assembly L, M

Main Pipe⁶ L1

Indoor Unit Main Pipe L2, L3, L4, L5, L6, L7, L8, L9, L10, L11, L12, L13

Branch Pipe Assembly between Main Pipe and Mode Selection Box (MS) A, B, C, D, E, F

Mode Selection Box (MS) MS1, MS2, MS3, etc.

Branch Pipe Assembly between Mode Selection Box (MS) and Indoor Unit I, II, III, IV

Indoor Unit auxiliary pipe between Mode Selection Box (MS) and downstream

Branch Pipe joint

Indoor Unit auxiliary pipe from Indoor Unit to the nearest Branch Pipe joint or

direct connected Mode Selection Box (MS)

Indoor Unit N1, N2, N3, etc.

⁶ When the length of main pipe L1 is larger than 230 ft. (70m), the dip switch S9-2 should be ON.

a, g, j, k

b, c, d, e, f, h, i, l, m, n, p, q, r

Figure 14. Typical Refrigerant Piping Diagram

INDOOR UNIT AUXILIARY PIPE SELECTION

(From Indoor Unit To The Nearest Branch Joint (a, b, c, d, e, f, g, h, i, j, k, l, m)

Pipe Diameter (in.)

Indoor Unit

Capacity (kBtuh)

A<18 1/2 1/4 5/8 1/4

18≤A≤54 5/8 3/8 3/4 3/8

54<A≤96 7/8 3/8 1-1/8 3/8

Pipe length less than 100 ft (30 m) Pipe length more than 100 ft (30 m)

Gas Pipe Liquid Pipe Gas Pipe Liquid Pipe

Pipe length from indoor unit to nearest branch joint

16

Page 17

OUTDOOR UNIT MAIN PIPE SELECTION (L1)

Main Pipe Diameter (in.)

Outdoor

Unit

Size

Equivalent length of all liquid pipes

is less than 295 ft. (90 m)

Low

Pressure

Gas Pipe

High

Pressure

Gas Pipe

Liquid

Pipe

First

Branch

Pipe

Assembly

Equivalent length of all liquid pipes

is more than 295 ft. (90 m)

Low

Pressure

Gas Pipe

High

Pressure

Gas Pipe

Liquid

Pipe

First

Branch

Pipe

Assembly

072 7/8 3/4 3/8 V8MSBP02 7/8 3/4 1/2 V8MSBP02

096 7/8 3/4 3/8 V8MSBP02 7/8 3/4 1/2 V8MSBP02

120 1-1/8 3/4 1/2 V8MSBP03 1-1/8 3/4 5/8 V8MSBP03

144 1-1/8 7/8 1/2 V8MSBP03 1-1/8 7/8 5/8 V8MSBP03

168-216 1-3/8 1-1/8 5/8 V8MSBP04 1-3/8 1-1/8 3/4 V8MSBP04

240 1-3/8 1-1/8 5/8 V8MSBP04 1-3/8 1-1/8 3/4 V8MSBP04

264-312 1-3/8 1-1/8 3/4 V8MSBP04 1-3/8 1-1/8 7/8 V8MSBP04

336-432 1-5/8 1-3/8 3/4 V8MSBP05 1-5/8 1-3/8 7/8 V8MSBP05

432~ 1-5/8 1-3/8 3/4 V8MSBP05 1-5/8 1-3/8 7/8 V8MSBP05

Note - The Main Pipe (L1) can be selected from the Outdoor Unit Main Pipe Selection table or the Indoor Unit Main Pipe Selection table, the larger size must be used.

INDOOR UNIT MAIN PIPE SELECTION (L1 to L13)

Indoor Unit

Total Capacity

(kBtuh)

Low Pressure

Gas Pipe

Indoor Unit Main Pipe Diameter (in.)

High Pressure

Gas Pipe

Liquid Pipe

Branch Pipe

Assembly

A < 018 1/2 3/8 1/4 V8MSBP01

018 ≤ A < 056 3/4 5/8 3/8 V8MSBP01

056 ≤ A < 078 7/8 3/4 3/8 V8MSBP02

078 ≤ A < 112 7/8 3/4 1/2 V8MSBP02

112 ≤ A < 156 1-1/8 7/8 1/2 V8MSBP03

156 ≤ A < 224 1-1/8 7/8 5/8 V8MSBP03

224 ≤ A < 314 1-3/8 1-1/8 3/4 V8MSBP04

314 ≤ A < 460 1-5/8 1-3/8 3/4 V8MSBP05

460 ≤A 1-5/8 1-3/8 7/8 V8MSBP05

OUTDOOR UNIT PIPE SELECTION (g1, g2, g3, G1)

Pipe

Outdoor Unit

Size

Low Pressure Gas Pipe High Pressure Gas Pipe Liquid Pipe

Pipe Diameter (in.)

G1 408, 432, 456, 480, 504 1-5/8 1-3/8 7/8

6 or 8-ton 7/8 3/4 1/2

g1, g2, g3

10 or 12-ton 1-1/8 7/8 5/8

14 or 16-ton 1-3/8 1-1/8 3/4

OUTDOOR UNIT BRANCH PIPE ASSEMBLY SELECTION (L, M)

Outdoor Unit Quantity Parallel Connection with Branch Pipes

2 units L use V8ODBP02HR-3

3 units L + M use V8ODBP03HR-3

INDOOR UNIT AUXILIARY PIPE SELECTION (Between Branch Box (MS) And Downstream Branch Joint) (a, g, j, k)

Indoor Unit Capacity (kBtuh)

Gas Pipe Liquid Pipe

Pipe Diameter (in.)

Available Branch Pipe

A<56 5/8 3/8 V8IDBP01

17

Page 18

Name Gas Side Joints (inch) Liquid Side Joints (inch)

Insulation

Material

(furnished)

V8IDBP01

V8IDBP02

V8IDBP03

,'

,'

,'

,'

,'

,'

,'

,'

,'

,'

,'

,'

2'

,'

,'

2'

2'

2'

2'

2'

,'

,'

,'

2'

2'

2'

,'

,'

,'

,'

,'

,'

,'

,'

,'

,'

,'

,'

,'

2'

,'

,'

,'

,'

,'

2'

2'

2'

2'

,'

2'

,'

,'

2'

2'

2'

,'

,'

,'

,'

(2 sets)

,'

(2 sets)

(2 sets)

V8IDBP04

V8IDBP05

,'

,'

,'

,'

,'

,'

2'

,'

,'

,'

2'

,'

,'

,'

2'

2'

,'

,'

,'

,'

,'

,'

,'

,'

,'

,'

,'

,'

2'

,'

2'

2'

2'

Figure 15. Indoor Unit Branch Pipe Kits

,'

,'

2'

2'

,'

,'

,'

(2 sets)

,'

(2 sets)

18

Page 19

(Liquid side used)

(Liquid side used)

Low-pressure

side used

High-pressure

side used

Liquid

side used

V8MSBP01

V8MSBP02

V8MSBP03

V8MSBP04

V8MSBP05

OD:1/2

ID:1/4

ID:3/8

OD:1/2

OD:1/2

ID:1/2

ID:3/8

ID:1/2

ID:1/4

ID:3/8

ID:5/8

OD:5/8

ID:3/4

(ID:1/2)

OD:5/8

ID:3/8

ID:5/8

(ID:1/2)

OD:5/8

ID:3/8

ID:1/4

ID:5/8

OD:5/8

ID:3/4

(ID:1/2)

OD:5/8

ID:3/8

ID:5/8

(ID:1/2)

OD:5/8

ID:3/8

ID:1/4

ID:1-3/8

ID:1-5/8

ID:1-3/8

ID:1-5/8

ID:1-5/8

ID:1-3/4

ID:1-3/4

OD:1-5/8

ID:1-1/8

ID:1-1/4

OD:1-1/8

ID:1-1/8

ID:3/4

ID:7/8

OD:1-1/8

ID:3/4

ID:7/8

OD:1-1/8

ID:5/8

ID:1-1/8

ID:1-1/4

OD:1-1/8

ID:1-1/8

ID:3/4

ID:7/8

OD:1-1/8

ID:3/4

ID:7/8

OD:1-1/8

ID:5/8

ID:5/8

(ID:3/4)

OD:7/8

ID:7/8

OD:7/8

ID:7/8

ID:1

ID:5/8

(ID:3/4)

OD:7/8

ID:1/2

ID:5/8

(ID:3/4)

OD:7/8

ID:7/8

OD:7/8

ID:7/8

ID:1

ID:5/8

(ID:3/4)

OD:7/8

ID:1/2

ID:5/8

(ID:3/4)

OD:7/8

ID:7/8

OD:7/8

ID:7/8

ID:1

ID:5/8

(ID:3/4)

OD:7/8

ID:1/2

ID:1/2

(ID:5/8)

OD:3/4

ID:3/4

OD:3/4

ID:3/4

ID:7/8

ID:1/2

(ID:5/8)

OD:3/4

ID:3/8

ID:1/2

(ID:5/8)

OD:3/4

ID:3/4

OD:3/4

ID:3/4

ID:5/8

ID:1/2

(ID:5/8)

OD:3/4

ID:1/2

(ID:5/8)

OD:3/4

ID:3/4

OD:3/4

ID:3/4

ID:5/8

ID:1/2

(ID:5/8)

OD:3/4

ID:3/4

ID:7/8

ID:1-1/8

OD:1-3/8

ID:1-3/8

OD:1-3/8

ID:1-1/2

ID:7/8

ID:1-1/8

OD:1-3/8

ID:1-3/8

ID:3/4

ID:7/8

ID:1-1/8

OD:1-3/8

ID:1-3/8

OD:1-3/8

ID:1-1/2

ID:7/8

ID:1-1/8

OD:1-3/8

ID:1-3/8

OD:1/2

ID:3/8

ID:3/8

ID:1/4

OD:3/8

ID:1/4

OD:3/8

ID:3/8

Name

Low-Pressure Gas Side Joints - Inch High-Pressure Gas Side Joints - Inch Liquid Side Joints - Inch

Insulation

Material

(furnished)

(3 sets)

(3 sets)

(3 sets)

(3 sets)

(3 sets)

Adapter Pipe - Inch

OD:5/8

ID:1/2

ID:1/2

ID:3/4

OD:7/8

ID:5/8

OD:3/4

OD:3/8

ID:1/4

ID:3/8

ID:1/2

ID:5/8

OD:3/4

Figure 16. Mode Selection Box Branch Pipe Kits

19

Page 20

Horizontal Runs

°

°

Horizontal Surface

When installed horizontally, these branch pipe kits

MUST be installed level +/- 10°.

CorrectWrong

10

10

Figure 17. Horizontal Installation

Vertical Runs

When installed vertically, mode selection branch

kits MUST be installed straight up or straight down.

Vertical Surface

Indoor unit branch kits have graduated piping diameters.

• The piping can be cut to suit the installation

needs. See figure 19.

• Use a pipe cutter designed for refrigeration tubing to cut pipe.

• Discard unused pipe.

3/4” Refrigerant Pipe

No Cut Needed

OD:1-1/8

ID:7/8

ID:3/4

7/8” Refrigerant Pipe

ID:5/8

ID:3/4

ID:7/8

OD:1-1/8

Cut Here

Be sure to maximize the total

length of the socket to ensure a

good joint

Figure 19. Vertical Installation

IMPORTANT

Locate rst branch pipe kit of the system centrally

to ensure correct distribution of refrigerant.

• Refer to the Lennox VRF Selection Software

(LVSS) pipe sizing diagram to obtain the correct

inlet and outlet sizes for the installation.

• Keep all components sealed until brazing.

ID:1-1/8

OD:1-1/8

ID:1-1/8

ID:1-1/4

1-1/8” Refrigerant Pipe

Cut Here

Be sure to maximize the total

length of the socket to ensure a

good joint

Figure 18. Cutting Branch Pipe Kits to Size Example

20

Page 21

Branch Pipe Kit Placement

Provide 24 to 36 inches of straight pipe before and

after each branch pipe kit to avoid creating refriger-

ant turbulence and ash points. Failure to follow 24

inch minimum guideline can lead to reduced capacity and equipment damage.

CONTINUE

REFRIGERANT

PIPING

24” REQUIRED

36” PREFERRED

CAUTION

24 inches (588 mm) minimum straight pipe required

before and after branch pipe kit to prevent capacity

loss, refrigerant hammering and equipment

damage.

FROM

OUTDOOR UNIT

24” REQUIRED

36” PREFERRED

FIRST ELBOW OR

BRANCH PIPE

CONNECTION

TO INDOOR UNIT OR

MS BOX

Figure 20. 24 to 36” of Straight Pipe Before and After Branch Pipe Kit

21

Page 22

12 34 5

66

• The seal on the unit refrigerant piping connections should remain in place until the last possible moment. This will prevent dust or water

from getting into the refrigerant piping before it

is connected.

• Flow the pipework with dry (oxygen-free) nitro-

gen (2.9 psig or 3 CFH) during brazing to avoid

oxidation which may block the refrigerant piping.

• Do not use ux when brazing copper-to-copper

piping. Use phosphor copper brazing ller alloy

(BCuP) which does not require ux. Flux has a

harmful eect on refrigerant pipe.

• Use a wet cloth to insulate the shut o valve dur-

ing brazing.

• Use dedicated gauges and hoses with R-410A

equipment.

IMPORTANT!

Use only oxygen-free nitrogen (OFN).

Table 2. Pressure Test Specications

1 3 bar 44 psig minimum of 10 minutes

2 15 bar 220 psig minimum of 10 minutes

3 32 bar 470 psig minimum of 10 minutes

4 45 bar 500 psig 1 hour. Stress test to

prove the integrity of the

complete installation.

5 32 bar 470 psig 24 hours. Lower system

pressure test, after

conrmation No. 4 was

successfully completed.

Pressure Test

• Follow the pressure test specications in Table 2

for proper pressure testing procedures.

• Ensure the unit service valves are fully closed

and haven’t become loose during transportation.

• Use oxygen-free nitrogen to pressure test to 650

psig and hold for 1 hour.

Evacuate System

• Follow the Lennox pressure test specications

in table 1 and the triple evacuation process described on this page to pressure test and evacuate the system.

• Use a vacuum pump capable of evacuating to

lower than 500 Microns (0.5 Torr).

• Do not open any of the outdoor unit shut-o

valves (possible max 5 valves). The outdoor unit

does not need to be evacuated.

• Evacuate the system to 500 Microns (0.5 Torr), or

below, for 4 hours.

Triple Evacuation Procedure

A Micron or Torr gauge must be used for this

procedure.

1. Discharge the oxygen-free nitrogen and evacuate

the system to a reading of 8000 Microns (8 Torr)

using all service valves.

2. Break the vacuum by allowing nitrogen into the

three inter-connecting pipework port connections

(low pressure gas pipe, high pressure gas pipe

and liquid line pipe) until a positive pressure is

achieved.

3. Evacuate the system to a reading of 5000

Microns (5 Torr).

4. Break the vacuum by allowing nitrogen into the

three inter-connecting pipework port connections

(low pressure gas pipe, high pressure gas pipe

and liquid line pipe) until a positive pressure is

achieved

5. Evacuate the system to a minimum reading of

500 Microns (0.5 Torr).

6. For a moisture free system, ensure the vacuum

is held without movement for a minimum of 4

hours.

7. If pressure loss is detected, carry out steps 2

through 6 until no pressure loss is observed.

1 - Refrigerant pipe

2 - Part to be brazed

3 - Reducer

4 - Isolation valve

5 - Pressure-regulating valve

6 - Oxygen-free nitrogen

Figure 21. Brazing Best Practices

22

Page 23

Additional Refrigerant Charge

1. Refer to the LVSS Calculation and Selection

report for proper system additional refrigerant

charge amount.

2. For manual calculations, calculate the additional

refrigerant charge using the diameter and length

of the liquid pipe (only) using Table 3.

3. Calculate the additional refrigerant charge per

outdoor unit using Table 4.

4. Calculate the additional refrigerant charge for

each liquid line branch pipe kit.

Liquid Line Length Calculation

Calculate additional refrigerant charge using the diameter and length of the liquid pipe.

Table 3. Liquid Line Calculation

Liquid Line

Additional

Refrigerant

(lbs.)

Total length (ft) of

liquid piping size

(

+

=

(

+

(

at Φ7/8

Total length (ft) of

liquid piping size

at Φ5/8

Total length (ft) of

liquid piping size

at Φ3/8

(

X 0.255 + X 0.181

(

X 0.120 + X 0.080

(

X 0.040 +

5. Calculate the additional refrigerant charge for

each Mode Selection Box using Table 5.

6. If the ratio of VMDB or V33B Indoor unit

capacity exceeds 80% of all indoor units, use

Table 6 to determine the additional refrigerant

charge to add.

7. Total all calculations.

8. Do no exceed the maximum allowed additional

refrigerant charge amount for the system. Table

7.

9. Add the calculated additional refrigerant to the

system.

Total length (ft) of

liquid piping size

(

(

(

at Φ3/4

Total length (ft) of

liquid piping size

at Φ1/2

Total length (ft) of

liquid piping size

at Φ1/4

(

(

(

X 0.015

Outdoor Unit Calculation

Calculate additional refrigerant charge per outdoor unit.

Table 4. Outdoor Unit Additional Charge

Model lb kg

6-10 Ton 6.39 2.9

12-16 Ton 15.87 7.2

Mode Selection Box Calculation

Use Table 4 to determine the amount of additional refrigerant for EACH mode selection box.

Table 5. Mode Selection Box Additional Charge

Mode Selection Box

Model

V8MSBB02-3P 2.20 1

V8MSBB04-3P 2.20 1

V8MSBB06-3P 2.20 1

V8MSBB08-3P 4.41 2

V8MSBB10-3P 4.41 2

V8MSBB12-3P 4.41 2

Amount of refrigerant

(lb/per)

Amount of refrigerant

(kg/per)

23

Page 24

Table 6. VMDB or V33B Indoor Unit Capacity Ratio over 80% of All Indoor Units

Additional Charge Amount

Pounds of additional refrigerant if ratio

Outdoor Unit

of VMDB Indoor units exceeds 80% of all

indoor units.

VRB072H4M 3.31 3.53

VRB096H4M 4.19 4.85

VRB120H4M 5.29 6.61

VRB144H4M 6.39 7.72

VRB168H4M 7.39 13.23

VRB192H4M 8.38 15.87

VRB216H4M 9.26 15.87

VRB240H4M 10.93 15.87

VRB264H4M 12.08 15.87

VRB288H4M 13.76 15.87

VRB312H4M 15.12 16.18

VRB336H4M 16.20 16.49

VRB360H4M 17.73 16.80

VRB384H4M 17.73 17.11

VRB408H4M 17.73 17.42

VRB432H4M 17.73 17.73

VRB456H4M 17.73 17.73

VRB480H4M 17.73 17.73

Pounds of additional refrigerant if ratio of

V33B indoor units exceeds 80% of all indoor

units.

Table 7. Maximum Additional Refrigerant Charge Amount

Maximum Additional

Outdoor Unit

VRB072H4M 53.07 24.07

VRB096H4M 63.58 28.84

VRB120H4M 66.01 29.94

VRB144H4M 82.03 37.21

VRB168H4M 86.99 39.46

VRB192H4M 98.83 44.83

VRB216H4M 116.25 52.73

VRB240H4M 121.06 54.91

VRB264H4M 148.17 67.21

VRB288H4M 150.18 68.12

VRB312H4M 150.18 68.12

VRB336H4M 166.21 75.39

VRB360H4M 168.23 76.31

VRB384H4M 170.26 77.23

VRB408H4M 189.71 86.05

VRB432H4M 189.71 86.05

VRB456H4M 215.15 97.60

VRB480H4M

Refrigerant Charge

lbs kg

226.19 102.60

! Contact the Lennox VRF applications department for assistance If the additional charge for the system exceeds the

amount listed in this table or for other assistance with calculating additional refrigerant charge.

24

Page 25

Branch Pipe Kit Calculation

Add 1.60 ft. (488 mm) per EACH liquid line branch pipe (incoming pipe size only) for additional charge calculation.

Example: The branch pipe kit

has an incoming pipe size of

7/8” and outgoing pipe sizes

of 3/8” and 5/8”. Use only the

incoming pipe size of 7/8”

to calculate the additional

refrigerant charge for this

branch pipe kit.

Refrigerant Charge Calculation Example

10 Ton 16 Ton

5/8 in.

7/8 in.

1-1/8 in.

10 ft.

3/4 in.

1-1/8 in.

1-3/8 in.

4 ft.

7/8 in.

1-1/8 in.

1-3/8 in.

50 ft.

5/8 in.

7/8 in.

1-1/8 in.

5/8 in.

7/8 in.

1-1/8 in.

50 ft.

40 ft.

MS06

MS08

1/4 in.

1/2 in.

1/4 in.

1/2 in.

3/8 in.

5/8 in.

3/8 in.

5/8 in.

3/8 in.

5/8 in.

1/4 in.

1/2 in.

3/8 in.

5/8 in.

3/8 in.

5/8 in.

3/8 in.

5/8 in.

Refrigerant Flow

Incoming Liquid Line Pipe

Only use this pipe size to

determine the amount of

additional refrigerant charge for

EACH liquid line branch pipe.

15 ft.

15 ft.

20 ft.

20 ft.

20 ft.

15 ft.

20 ft.

30 ft.

15 ft.

9k

15k

36k

48k

48k

12k

24k

36k

36k

3/8 in.

20 ft.

5/8 in.

48k

Refrigerant Charge Amount Calculation

1. Additional refrigerant charge amount of outdoor units = 6.39+15.87 = 22.26 lbs.

2. Additional refrigerant charge amount of MS boxes = 2.2+4.41 = 6.61 lbs.

3. Additional refrigerant charge amount of pipes = (0.12*10+0.181*4) + (0.255*(50+1.6*2)+0.12*50+0.12*40) +

[0.015*(15+15+15) + 0.04*(20+20+20+20+30+15+20)] = 32.79 lbs.

4. Additional refrigerant charge amount of indoor units = 15.12 lbs.

The total additional refrigerant charge amount = 22.26+6.61+31.95+15.12 = 76.78 lbs.

25

Page 26

Refrigerant Discharge

For systems containing more than 110 lb (50 kg)

of R-410A refrigerant, pressure-relief devices and

fusible plugs shall discharge to the atmosphere

at a location not less than 15 ft (4.57 m) above

the adjoining ground level and not less than 20 ft

(6.1 m) from any window, ventilation opening, or

exit in any building. Local codes may lower this

charge limit and shall be investigated by the design

engineer.

Atmosphere

≥20 feet (6.1 m)

Relief

valve

Figure 22. Refrigerant Discharge

26

Page 27

Connecting Manifolded Units

• See the instruction manual included with the

branch pipe kit for detailed connection information.

• Connect the branch pipes between outdoor units

so that they are horizontal level ±10°.

• Do not install outdoor unit branch pipes vertically.

• Do not allow pipe to block outdoor unit access

panels.

• Install a reverse trap if needed.

NOTE - Outdoor unit is shipped for bottom pipe

entry. For front pipe entry installation, use parts in

accessory bag.

√ Correct way

Horizontal surface

• Branch kits include pipes with graduated diameters. The piping can be cut to suit the installation needs.

• Use a pipe cutter designed for refrigeration tubing.

• Discard unused pipe.

• Refer to the Lennox VRF Selection Software

(LVSS) pipe sizing diagram to obtain the correct

inlet and outlet sizes for the installation.

• Keep all components sealed until brazing.

CorrectWrong

10°

10°

√ Correct way

X Wrong way

X Wrong way

NOTE - All the outdoor units manifolded together should be installed at the same elevation.

Figure 23. Connecting Manifolded Units

27

Page 28

High pressure

gas balance pipe

(3/4 in. diameter)

Figure 24. Heat Recovery Parallel Piping Connections

Oil balance pipe

(1/4 in. diameter)

High Pressure gas balance pipe Ø 3/4

Oil balance pipe Ø 1/4

Two-module system shown

Figure 25. Connective Piping Sizes for Manifolded Outdoor Units

Item “P” in outdoor branch

pipe kit accessory

28

Item “N” in outdoor branch

pipe kit accessory

To third outdoor unit in a

triple module configuration

Page 29

Material

Insulation

(furnished)

Joint (inch)

Oil Balance

Joint (inch)

Gas Balance

High-Pressure

Joint (inch)

Gas Balance

Low-Pressure

Refer to the pipe sizing diagram in the LVSS Calculation and Selection report to determine pipe sizes.

• Branch pipe kits are used to complete the piping

for connecting outdoor units.

(2 sets)

(4 sets)

• T-shape connectors are used for balancing

pipes only.

• U-shaped connectors are combined in the eld

ID:1/4

P

ID:3/4

N

ID: 7/8

M

to connect refrigerant piping for the structure.

See Figure 26.

Low-Pressure Gas Side Joints (inch) Liquid Side Joints (inch)

Name

8ODBP02HP-3

Triple-Module Balancing Pipes Only

8ODBP03HP-3

Figure 26. Outdoor Unit Branch Pipe Kits

29

Page 30

Connecting Mode Selection Boxes

• The Maximum No. of indoor units per port is 5

• For each mode selection box, dependant on mode selection box size, maximum possible number of

connected indoor units is 41.

• All indoor units on the same port must operate in the same mode.

• Do not install in noise sensitive areas.

• The mode selection box must be installed level horizontal.

• Main piping may be connected to either side of the mode selection box but cannot pass through to other

mode selection boxes.

• Allow at least 3 ft. (1 m) of straight pipe between the mode selection box and the branch pipes.

• There will be a 30-second auto-check function performed after the indoor and outdoor units have been

started.

• Mode selection boxes require a unique address.

• See the instruction manual included with the mode selection box for detailed installation information.

Table 8. MS Box Piping Connection Information

V8MSBB02 V8MSBB04 V8MSBB06 V8MSBB08 V8MSBB10 V8MSBB12

Indoor Unit

Pipe

Connections

(in)

Outdoor

Unit Pipe

Connections

(in)

Liquid

Gas

Liquid

H.P.

Gas

L.P.

Gas

1/4,3/8 1/4,3/8 1/4,3/8 1/4,3/8 1/4,3/8 1/4,3/8

1/2, 5/8 1/2, 5/8 1/2, 5/8 1/2, 5/8 1/2, 5/8 1/2, 5/8

7/8, 3/4, 5/8 5/8,1/2,3/8 5/8,1/2,3/8

7/8, 3/4, 5/8 1-1/8,7/8,3/4 1-1/8,7/8,3/4 1-1/8,7/8,3/4 1-1/8,7/8,3/4 1-1/8,7/8,3/4

1-1/8, 7/8, 3/4 1-3/8,1-1/8,7/8 1-3/8,1-1/8,7/8 1-3/8,1-1/8,7/8 1-3/8,1-1/8,7/8 1-3/8,1-1/8,7/8

3/4,

5/8,1/2,3/8

3/4,

5/8,1/2,3/8

3/4,

5/8,1/2,3/8

NOTE - Field piping connections for the outdoor unit gas and liquid pipes are provided on the right and left

side of the mode selection box. Only one side can be used. Piping through the box to another mode

selection box is not allowed; use the proper branch joint kit when multiple mode selection boxes are

connected. Remove charging stems and braze shut should that side of the box not be used.

30

Page 31

Green

T1C1 T2C2

T1C1

CN24

T2C2

XP2 XP1

XS2 XS1

EEVA

ON

CN18

EEVA

S1 S2

CN13

CN12

(CN12)

(CN13)

M-O M-O

Yellow

Gray

Yellow

SVP

Black

SVP

CN9

ENC1 ENC2(0)

CN14

(CN15)

M-M M-M

Gray

SV1A-1

CN15

(CN14)

SV2A-2 SV3A-3 SV4A-4

SV2B-2 SV3B-3 SV4B-4

SV1B-1

Black

Yellow

Black

Yellow

Black

SV2

SV1

CN3

CN5

CN6

DSP1

SW1 SW2

SW3 SW4

CN22 CN26

1(M-I) 2(M-I) 3(M-I) 4(M-I)

Brown

Red

White

Blue

Blue

CN34

White

CN16

POWER

CN17

CN32

TRANS IN

CN33

TRANS OUT

Blue

TRANS1

TRANSFORMER

Red

T1C1T2C2

CN24

ON

CN18

EEVA

S1 S2

CN12

CN13

(CN13)

(CN12)

M-O M-O

Yellow

Black

Yellow

SV4

SV3

CN4

DSP2

LIGHTER

Brown

Red

SVP

CN9

ENC1 ENC2(1)

CN14

(CN15)

M-M M-M

CN15

(CN14)

SV2A-6 SV3A-7 SV4A-8

SV1A-5

SV2B-6 SV3B-7 SV4B-8

SV1B-5

Yellow

Black

Yellow

Black

SV2

SV1

CN3

CN5

CN6

CN22 CN26

1(M-I) 2(M-I) 3(M-I) 4(M-I)

Brown

Red

White

Black

DSP1

SW1 SW2

SW3 SW4

Blue

SV2A-10 SV3A-11 SV4A-12

SV1A-9

SV2B-10 SV3B-11 SV4B-12

SV1B-9

Blue

CN34

LIGHTER

White

CN16

POWER

CN17

CN32

TRANS IN

CN33

TRANS OUT

Blue

TRANS2

TRANSFORMER

Red

T1C1 T2C2

CN24

SVP

ENC1 ENC2(2)

ON

CN18

EEVA

S1 S2

CN14

CN12

CN13

(CN15)

(CN13)

(CN12)

M-O M-O

CN9

M-M M-M

Black

CN6

CN15

(CN14)

Black

Yellow

SV1

CN5

CN22 CN26

1(M-I) 2(M-I) 3(M-I) 4(M-I)

Brown

Red

Yellow

Black

Yellow

Black

Yellow

SV4

SV3

SV2

CN4

CN3

DSP2

DSP1

SW1 SW2

SW3 SW4

White

Blue

Brown

Red

Yellow

Black

Yellow

SV4

SV3

CN4

DSP2

Brown

Red

CN34

LIGHTER

White

CN16

POWER

CN17

CN32

TRANS IN

CN33

TRANS OUT

Blue

TRANS3

Blue

Red

TRANSFORMER

Red

L1

The wiring picture shown is for reference only, actual product may vary.

Blue

Red

Blue

Green

X2

L2

XT1

X1

P Q

P Q

Downstream MS

Connectors

Solenoid valve

P Q P Q P Q P Q

Indoor No. 1

Indoor No. 2 Indoor No. 3 Indoor No. 4

E2

H0

E3

E4

LL

DSP1 and DSP2 display content

Communication error between MS box to master outdoor unit

Communication error between first PCB to the other PCBs

in the same MS box

Outlet of plate exchanger(subcooler) error

Inlet of plate exchanger(subcooler) error

S1/S2 setting is not consistent to communication wiring

Outdoor

/Upstream MS

To outdoor or MS units

communication bus

CODE NAME

XT1 Terminal block

XS1~XS2 Connectors

XP1~XP2

T1C1~T2C2 Temperature sensor

SV#A-X, SV#B-X

SVP

EEVA Electronic expansion valve

TRANS1~TRANS3 Transformer

Piping & Communication Cable Connection

ENC1(2)

NO.3 MS Unit

5

6

NO.2 MS Unit

5

6

NO.1 MS Unit

5

6

2 1

4

3

ENC1(1)

2 1

4

3

ENC1(0)

2 1

4

3

P Q P Q P Q P Q

Indoor No. 5

Indoor No. 6 Indoor No. 7 Indoor No. 8

To indoor units communication bus

MS PCB address

ENC2

(Factory setting, can’t be changed.

0 means the first PCB, 1 means the second

PCB, 2 means the third PCB)

● S1: 11 means synchronous control for 2 ports

S1/S2

ON

(First PCB is port 1 and 2, Second PCB is port 5 and 6, third PCB is port 9 and 10)

● S2: 11 means synchronous control for 2 ports

(00 is default)

(First PCB is port 3 and 4, Second PCB is port 7 and 8, third PCB is port 11 and 12)

Outdoor Unit

(P Q )

Guide for main control panel dial code

ENC1

MS control box address

(Field setting, the first PCB setting is required

and unique from other MS box.)

Upstream MS Downstream MS

Upstream MS Downstream MS

(P Q )

(P Q )

MS-Outdoor or MS

Outdoor

P Q P Q P Q P Q

Indoor No. 9

MS-MS

MS-MS

Downstream MS

Indoor No. 10 Indoor No. 11 Indoor No. 12

NO.3 MS Unit

Indoor

NO.1

MS-Indoor

Indoor

NO.2

NO.2 MS Unit

Indoor

Indoor

NO.1

NO.2

NO.1 MS Unit

Indoor

Indoor

NO.1

NO.2

Indoor

NO.3

MS-Indoor

Indoor

NO.3

MS-Indoor

Indoor

NO.3

Power in

Indoor

NO.4

Indoor

NO.4

Indoor

NO.4

(P Q )

Piping Line

Control Wiring

Indoor Unit

NO.1

(P Q )

Indoor Unit

NO.2

(P Q )

Indoor Unit

NO.3

(P Q )

NOTE:

Indoor control wiring must match with indoor piping connection.

Figure 27. Mode Selection Box Wiring Diagrams

31

Page 32

Wiring Connections

!

WARNING

Isolate the power supply before accessing unit

electrical terminals.

Install unit so that unit disconnect is accessible.

Follow all local and national codes, as well as

this installation instruction, during installation.

Do NOT overload electrical circuit, as this may

lead to failure and possible re.

Use specied wiring and cable to make electrical

connections. Clamp cables securely and make

sure that connections are tight to avoid strain on

wiring. Insecure wiring connections may result

in equipment failure and risk of re.

Wiring must be installed so that all cover plates

can be securely closed.

Do not attempt to repair a damaged power cord.

Do not modify the power cord in any way. Do not

attempt to extend the length of the power cord

or use an extension cord with this appliance. Do

not share the single power outlet with any other

appliances.

NOTE - Each outdoor unit requires a separate power

supply protected by a suitably sized circuit breaker.

1. Select the appropriate electrical inlet into the

outdoor unit. Local and national codes apply.

2. Locate the terminal strip in the outdoor unit

control box. Connect the power wiring (sized per

NEC/CEC and local codes) and communications

cable (2-conductor, shielded cable). Refer to unit

nameplate for rated voltage.

IMPORTANT!

DO NOT adjust DIP switch settings. Settings

may only be adjusted by a trained technician

as part of the commissioning procedures.

Take care when making nal power and control cable

connections, cross connection will result in damage

to unit’s main board.

Only apply power to the system after performing all

of the pre-commissioning steps.

!

CAUTION

This unit must be properly grounded and

protected by a circuit breaker. The ground wire

for the unit must not be connected to a gas or

water pipe, a lightning conductor or a telephone

ground wire.

Do not connect power wires to the outdoor unit

until all other wiring and piping connections

have been completed.

Install all wiring at least 3 feet away from

televisions, radios or other electronic devices

in order to avoid the possibility of interference

with the unit operation.

Separate power wiring supplies must be

provided for the outdoor unit and indoor unit(s).

Do not cross-connect refrigerant piping or

signal wires between VRF systems. Each VRF

system must be piped and wired separately.

Each indoor unit must have its own electrical

disconnect.

Do not run signal wire and power wire in the

same conduit; keep distance between the

two conduits per local codes. (Make sure to

set address of outdoor unit in case of parallel

multi-outdoor units.

Always follow NEC/CEC and Local Codes.

Power Terminal Strip

L1 L2 L3

~

208/230V 3PH

or 460V 3PH~ 60Hz

60Hz

Communication Terminal Strip

K1 K2 O A X Y P Q H1 H2

Reserved

To

kilowatthour

meter

To

centralized

controller

To MS or IDU

communication

bus

To ODU

communication

bus

NOTE - Use 18 GA 2-Conductor, Stranded,

Shielded Communication Cable

Figure 28. Wiring Terminals

32

Page 33

H-PRO

460V-3Ph-60Hz

Power in

Green

XT1

L1

L1’

L2

L2’

L3

L3’

CN12

AC filter board

CN1 CN2 CN3

CN4 CN5 CN6

U V W

CN9/CN8

N-OUT

Compressor

drive board A

Black

deR

Fan A

Fan B

U

V

w

CT2

CT3

N-in

Red

Red

Reactor A

Compressor A

IC8

Ferrite

core

N=2

L1 L2 L3

Green

Ferrite core

N=1

Ferrite core

N=2

Red

Black

AC filter

board

PCBA Layout

Compressor

drive board A

DC fan drive

board A

DC fan drive

board B

Main board

COMM.

board

Up layerDown layer

Left

Right

P-in

P-OUT

CN2

L1

L2 L3

CN15

CN10

Reserved

To

kilowatthour

meter

To

centralized

controller

CN10CN8

CN9

K1 K2 O A

X Y P Q H1 H2

Signal wire terminal block

CN11

COMM. board

CN6

CN7

Red

Black

Green

CN9

CN16

CN7

TF1

T4 T3A

T7C1

T3B

H-YL1

L-YL1

T6B

T6A

EEVA

EEVC

EEVB

Green

Green

H-PRO

TRANS2

Transformer

1

2

CN70

EEVA

CN72

EEVC

CN71

EEVB

Main board

DSP1

DSP2

CN28

O-LCD

CN87

CN25

CN10

CN20

O-O

CN22

O-C

CN1

T4 T3A

CN14

CN3

CN8

L-YL1

CN2CN5

CN4

CN7

TF1 TF2

CN9

O-DT7C2 H-YL1

CN15

CN100

CN30

CN21

CN27CN26CN16

CN17

CN18

CN19

CN23

CN91

O-C

T10

T7C1 T3B T6A O-FAN

T6B

CN29

O-LABK

CN58

CN85

ST2

CN84

HEATA

CN46

SV2

CN45

SV5

CN43

SV6B

CN40

SV8A

CN48

SV4

CN67_1

SV9

CN66_1

SV8B

CN76

HEATC1

CN75

HEATA

CN83

HEATB

CN42

ST3

CN44

ST1HEATB

CN41

SV6A

CN47

HEATC2

CN67

SV7

CN66

ALM/SV1

Blue

Blue

Blue

Blue

Blue

Blue

Blue

Blue

Brown

Brown

CN80

HEATA

HEATA

OKUPMENU

DOWN

T10

Note:

Component in dash line is optional.

The wiring picture shown is for reference only, actual product may vary.

CODE NAME

ST1,ST2,ST3 Four-way valve

XT1 Terminal block

H-PRO

TP1-PRO

High pressure ON/OFF switch

Discharge temperature

ON/OFF switch

XS1-XS2 Plug

XP1-XP2

Jack

T3A,T3B,

T6A,T6B

Condenser or evaporator

temperature sensor

Outdoor ambient

temperature sensor

T4,T10

T7C1

Discharge temperature

sensor

TF1 Heat sink temperature sensor

L-YL1

H-YL1

Low pressure sensor

High pressure sensor

CT1~3,IC8 Current sensor

SV1~SV8A Solenoid valve

HEATA Crankcase heater

L-PRO

Low pressure ON/OFF switch

HEATC1~2Chassis heater

XP1XS1

XP2 XS2

Black

CN3

P

N

DC fan drive

board A

CN2

CN3

CN4/CN1

P

N

DC fan drive

board B

CN1/CN4

CN2

Blue

Red

Blue

Red

Red

Blue

Transformer

To MS or IDU

communication

bus

To ODU

communication

bus

ST1

ST2

ST3

SV2

SV4

SV5

SV7

SV8A

HEATC1

HEATC2

Red

Black

CT1

LCD board

CN1

CN2

Low ambient

cooling kit board

EEVA~CElectronic expansion value

L-PRO

TP1-PRO

Emergency Stop Switch

CN1

CN4

CN5

CN3

CN4/CN1

CN1/CN4

Blue

Ferrite

core

N=3

Ferrite core

N=1

CEMENT RESISTOR

CN11

TRANSFORMER

Red

Red

Black

Black

Red White

Black

Red White

Black

Red

Black

Red

White

Blue

Red

White

Blue

Red White

Blue

Red

Black

Blue

Red

Black

Blue

Black

CN88/

CN88_1

CN88_1

/CN88

FUSE

Red

Red

CN3

Reactor A

CEMENT RESISTOR

Black

CN4 CN5 CN6

CN1 CN2 CN3

Black

XT1

Red

Red

Red

White

White

Red

L2’

L1’

AC filter board

L2

L1

White

Red

CT2

Red

CT1

White

Red

L1 L2 L3

208/230V-3Ph-60Hz

Power in

CN3

Compressor

CN2

CN1

drive board A

CN4

Black

Red

N-OUT

CN19

P-IN

Black

N-IN

CN21

Red

CN5

P-OUT

CN15

L1

L2 L3

White

Red

Red

Black

IC8

Blue

Ferrite core N=1

CN9/CN8

V

U

w

Black

Red

Black

Ferrite core

N=1

Blue

w

Blue

Black

U V W

Red

Compressor A

Black

Red

CN4/CN1

CN1/CN4

DC fan drive

board A

CN4/CN1

CN1/CN4

DC fan drive

board B

Brown

C_P

CN3

XP1XS1

Blue

C_N

Brown

C_P

CN3

XP2XS2

Blue

C_N

XS3

XP3

XS4

XP4

Green

Right

Fan A

Left

Fan B

AC filter

board

Compressor

drive board A

DC fan drive

board A

DC fan drive

board B

PCBA Layout

Main board

Up layerDown layer

COMM.

board

Ferrite core N=3

LCD board

HEATC2

HEATC1

SV8A

SV7

SV5

SV4

SV2

ST3

ST2

ST1

HEATA

HEATA

CN2

CODE NAME

XT1 Terminal block

XS1-XS4 Plug

Jack

XP1-XP4

High pressure ON/OFF switch

H-PRO

Low pressure ON/OFF switch

L-PRO

H-YL1

High pressure sensor

Low pressure sensor

L-YL1

Discharge temperature

TP1-PRO

ON/OFF switch

T3A,T3B,

Condenser or evaporator

T6A,T6B

temperature sensor

Outdoor ambient

T4,T10

temperature sensor

Discharge temperature

T7C1

sensor

CT1~3,IC8 Current sensor

ST1,ST2,ST3 Four-way valve

SV1~SV8A Solenoid valve

TF1 Heat sink temperature sensor

HEATA Crankcase heater

HEATC1~2Chassis heater

EEVA~CElectronic expansion value

Blue

Blue

L3’

CN7

TRANS

CN14

Transformer

CN47

L3

Black

Black

CT3

Blue

Green

Black

Green

Ferrite

core

N=1

Emergency Stop Switch

TP1-PRO

L-PRO

CN91

CN19

CN18

T7C1 T3B T6A O-FAN

CN4

T10

TF1 TF2

CN23

CN14CN3

CN7

T10

TF1

T7C1 T3B

T7C2 H-YL1

CN5

CN15

Main board

L-YL1

CN17

CN2

T4 T3A

CN1

H-YL1

T4 T3A

K1 K2 O A

DSP1

CN8

T6B

CN21

T6BT6A

L-YL1

CN100

O-C

O-C

CN22

CN9

CN6

DSP2

O-LABK

CN29

CN27CN26CN16

O-O

CN20

CN25

COMM. board

Signal wire terminal block

X Y P Q H1 H2

CN30

OKUPMENU

DOWN

EEVA

O-LCD

O-D

CN28

CN70

CN9

EEVC

EEVB

CN71

CN87

CN72

CN10

EEVB

EEVC

EEVA

CN10CN8

CN11

CN7

Black

CN58

CN88/

CN88_1

Red

HEATC2

CN76

CN85

SV9

CN75

HEATC1

CN84

SV8B

Blue

CN83

SV8A

Blue

CN46

SV7

CN42

SV6B

CN45

SV6A

Blue

CN44

SV5

Blue

CN43

SV4

Blue

CN41

SV2

CN40

Blue

ALM/SV1

CN80

ST3

Blue

CN48

ST2

Blue

CN47

ST1HEATB

CN67_1

HEATB

CN67

Brown

CN66_1

HEATA

Brown

CN66

HEATA

CN1

CN3

Low ambient

cooling kit board

Green

To

To

To MS or IDU

centralized

controller

communication

bus

To ODU

communication

bus

Note:

Component in dash line is optional.

The wiring picture shown is for reference only, actual product may vary.

Reserved

kilowatthour

meter

Figure 29. VRB072, 096, 120 - 230V

Figure 30. VRB072, 096, 120 - 460V

33

Page 34

H-PRO-1

The wiring picture shown is for reference only, actual product may vary.

Reactor A

CEMENT RESISTOR

Black

Red

L1’

CN4 CN5 CN6