Lennox VRB096, VRB168, VRB216, VRB192, VRB240 Installation & Operation Instructions

...

INSTALLATION/OPERATION

VRF

INSTRUCTIONS

©2018 Lennox Industries Inc. Dallas, Texas, USA

THIS MANUAL MUST BE LEFT WITH THE

OWNER FOR FUTURE REFERENCE

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

!

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, personal injury or loss of life.

Installation and service must be performed

by a licensed professional HVAC installer (or

equivalent) or service agency.

Failure to follow safety warnings and these

instruc tions exactly could result in property

damage, dan gerous operation, serious injury,

or death.

Any additions, changes, or conversions

required in order for the appliance to

satisfactorily meet the ap plication needs must

be made by a licensed profes sional HVAC

installer (or equivalent) using factory-specied

parts.

Do not use this system if any part has been

under water. A ood-damaged appliance is

extremely dan gerous. Immediately call a

licensed professional HVAC service technician

(or equivalent) to inspect the system and to

replace all controls and electrical parts that

have been wet, or to replace the system, if

deemed necessary.

VRB Heat Recovery

VRF SYSTEMS

OUTDOOR UNITS

507885-03

05/2019

!

WARNING

Do not change the settings of any protection

devices installed in the outdoor unit. If the

pressure switch, thermal switch, or other

protection device is shorted or forcibly

operated, re or explosion may occur.

Do not use parts other than those specied by

Lennox or re and/or explosion may occur.

CAUTION

As with any mechanical equipment, contact

with sharp sheet metal edges can result in

personal injury. Take care while handling this

equipment and wear gloves and protective

clothing.

IMPORTANT

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFC’s and HCFC’s) as of

July 1, 1992. Approved methods of recovery,

recycling or reclaiming must be followed. Fines

and/or incarceration may be levied for non-

compliance.

These units must be installed as part of a

matched system as specied in the Product

Specications (EHB) bulletin.

General

The VRB heat recovery outdoor units are matched

with up to 64 indoor units per system to create a VRF

(variable refrigerant ow) system that uses HFC-

410A refrigerant.

Refer to the Product Specication bulletin (EHB)

for the proper use of these heat recovery units with

matching indoor units, mode selection boxes, branch

pipes, line sets and controls.

Shipping and Packing List

Check the components for shipping damage. If you

nd any damage, immediately contact the last carrier. Package 1 of 1 contains the following:

1 - Assembled VRB heat recovery outdoor unit

1 - Outdoor unit installation instruction

1 - Piping accessory package

1

Safety Requirements

!

WARNING

ELECTRICAL SHOCK, FIRE, OR EXPLOSION HAZARD.

Do not touch the unit or the controller if your hands are wet.

Do not operate appliances with an open ame near the unit.

Do not replace a fuse with a fuse of a dierent rating. Do not attempt to bypass a fuse.

Do not insert your hands, tools or any other item into the air intake or air outlet at either the indoor or outdoor

unit.

Do not allow children to operate the system.

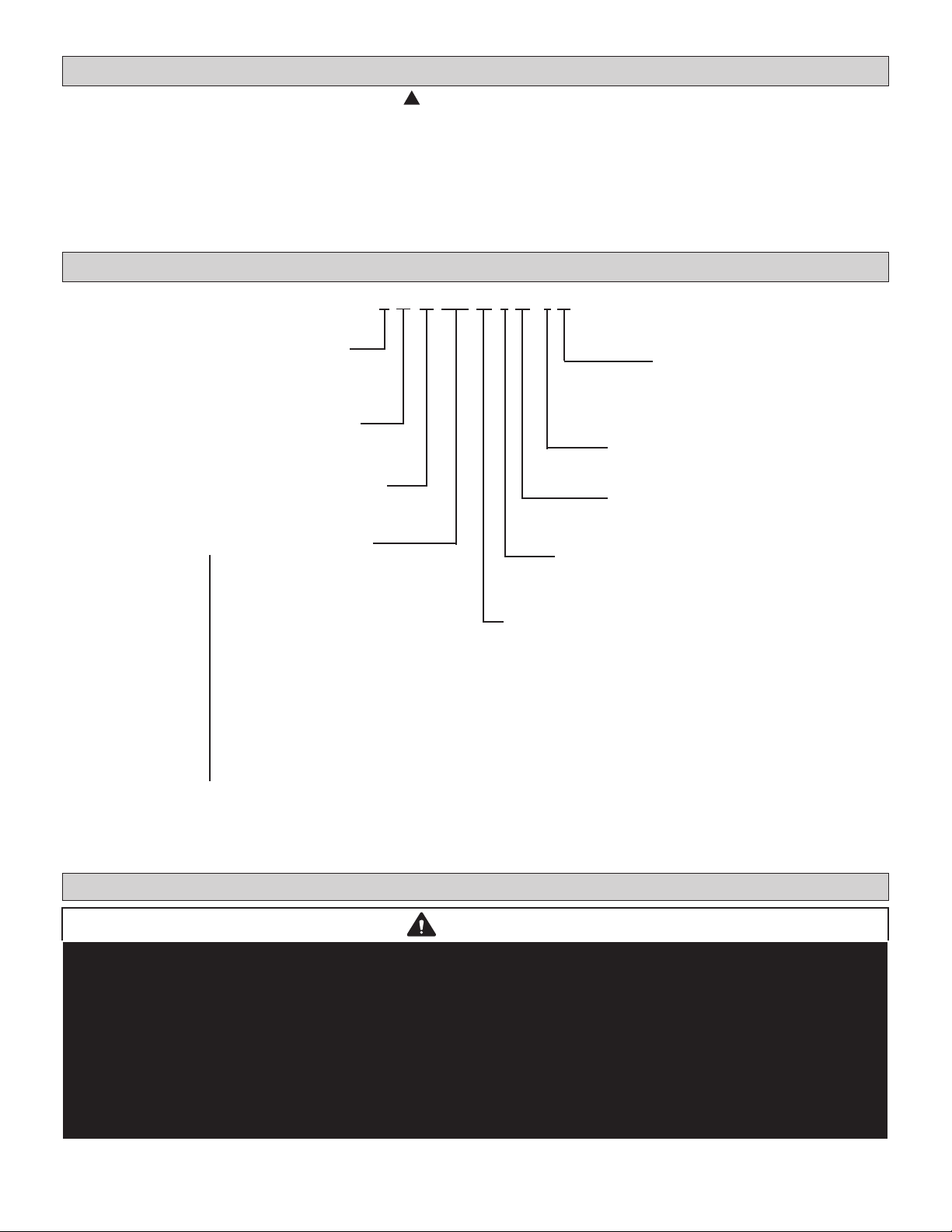

Model Number Identication

V R B 072 H 4 M -3 Y

Brand/Family

V = Variable Refrigerant Flow (VRF)

Unit Type

R = Heat Recovery Outdoor Unit

Major Design Sequence

B = 2nd Generation

Nominal Cooling Capacity - Tons

072 = 6 Tons

096 = 8 Tons

120 = 10 Tons

144 = 12 Tons

168 = 14 Tons

192 = 16 Tons

216 = 18 Tons

240 = 20 Tons

264 = 22 Tons

288 = 24 Tons

312 = 26 Tons

336 = 28 Tons

360 = 30 Tons

384 = 32 Tons

408 = 34 Tons

432 = 36 Tons

456 = 38 Tons

480 = 40 Tons

504 = 41 Tons

Voltage

Y = 208/230V-3 phase-60hz

G = 460V-3 phase-60hz

Controls Protocol

3 = Phase 3

Refrigerant Circuits

M = Multiple Circuits

Refrigerant Type

4 = R-410A

Cooling Eciency

H = High Eciency

NOTE - Lennox VRF and Lennox Mini-Split products are similar in appearance to each other. Refer to the unit’s model

number to determine if the unit is a VRF (V) or Mini-Split (M) unit. It is not possible to mix the two types of equipment

on any system.

System Piping

CAUTION

VRF system piping is customized for each installation. The Lennox VRF Selection Software (LVSS) piping report is an

engineered design that must be followed. The piping diagram or diagrams included within the LVSS report have been

prepared based on the information provided to the Lennox VRF applications department.

When the indicated lengths change from the gures stated within the report, it is imperative that prior to the commencement

of the refrigerant pipe work installation, Lennox VRF applications department are informed of these proposed changes.

Upon receipt of this new information the Lennox VRF applications department will conrm any changes that may be

applicable to this installation. If changes are required, a new piping diagram will be produced and will supersede all other

previously provided documents.

Failure to provide this information regarding changes to the original design may lead to insucient capacity, equipment

failure, warranty being made void and the refusal to commission the system.

2

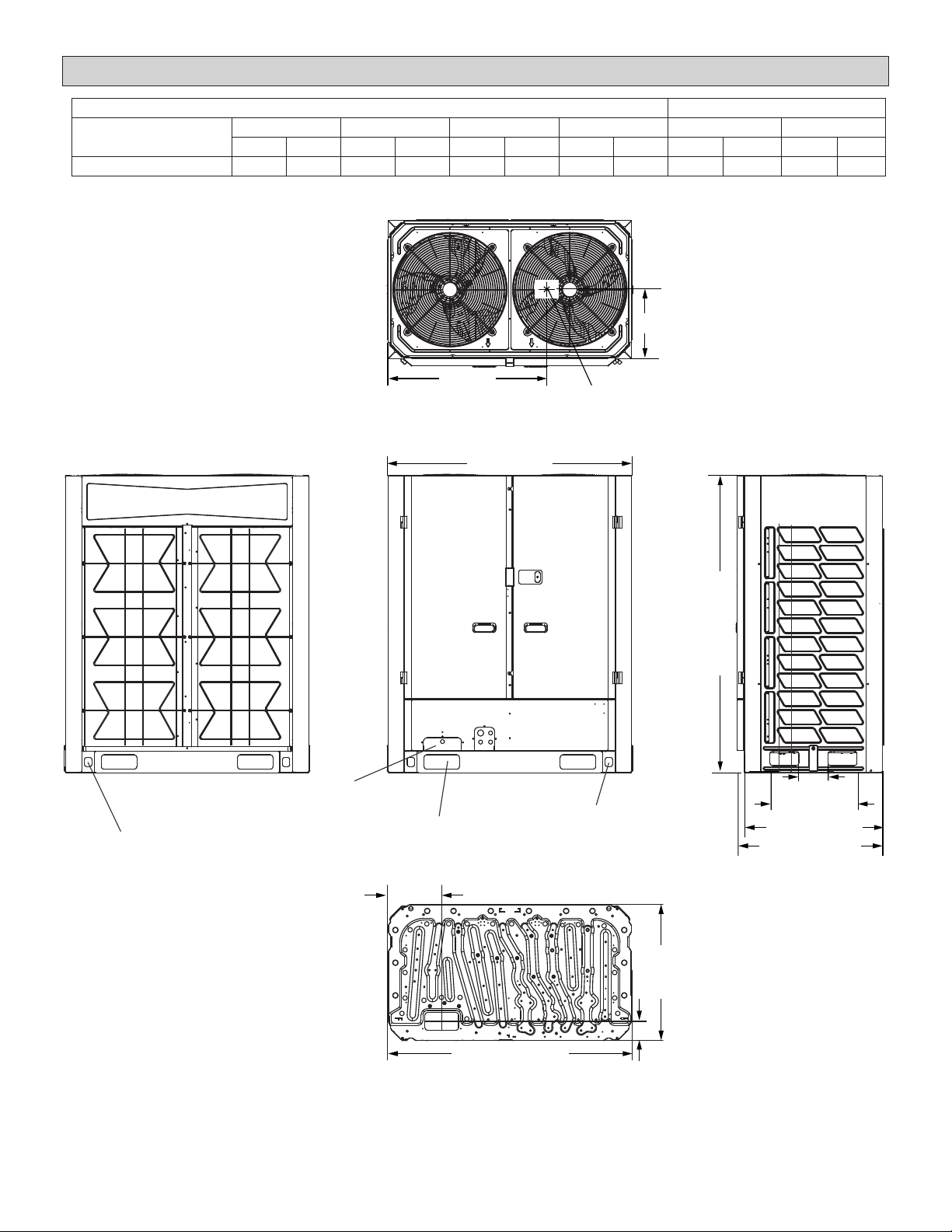

Unit Dimensions - inches (mm)

CORNER WEIGHTS CENTER OF GRAVITY

Model No. AA BB CC DD EE FF

lbs. kg lbs. kg lbs. kg lbs. kg in. mm in. mm

072, 096, 120 121 55 203 92 211 96 251 114 27-3/4 705 12-1/4 311

AA

DD

EE

TOP VIEW

52-3/4 (1340)

BB

FF

CC

CENTER OF

GRAVITY

64-3/8

(1635)

BACK VIEW

LAG BOLT DESIGNATION

(BOTH SIDES)

(TO ACCESS LAG BOLT)

PARALLEL MODULE

PIPING KNOCKOUT

FORKLIFT SLOT

REFRIGERANT LINE PATH

FRONT VIEW

(BOTH SIDES)

11-3/4 (298)

53-1/8 (1349)

BASE PAN VIEW

3

LIFTING HOLES

(BOTH SIDES)

(FOR RIGGING)

6-1/4 (159)

18-7/8 (479)

29-7/8 (759)

31-1/2 (800)

SIDE VIEW

29-1/2

(749)

4-1/8 (105)

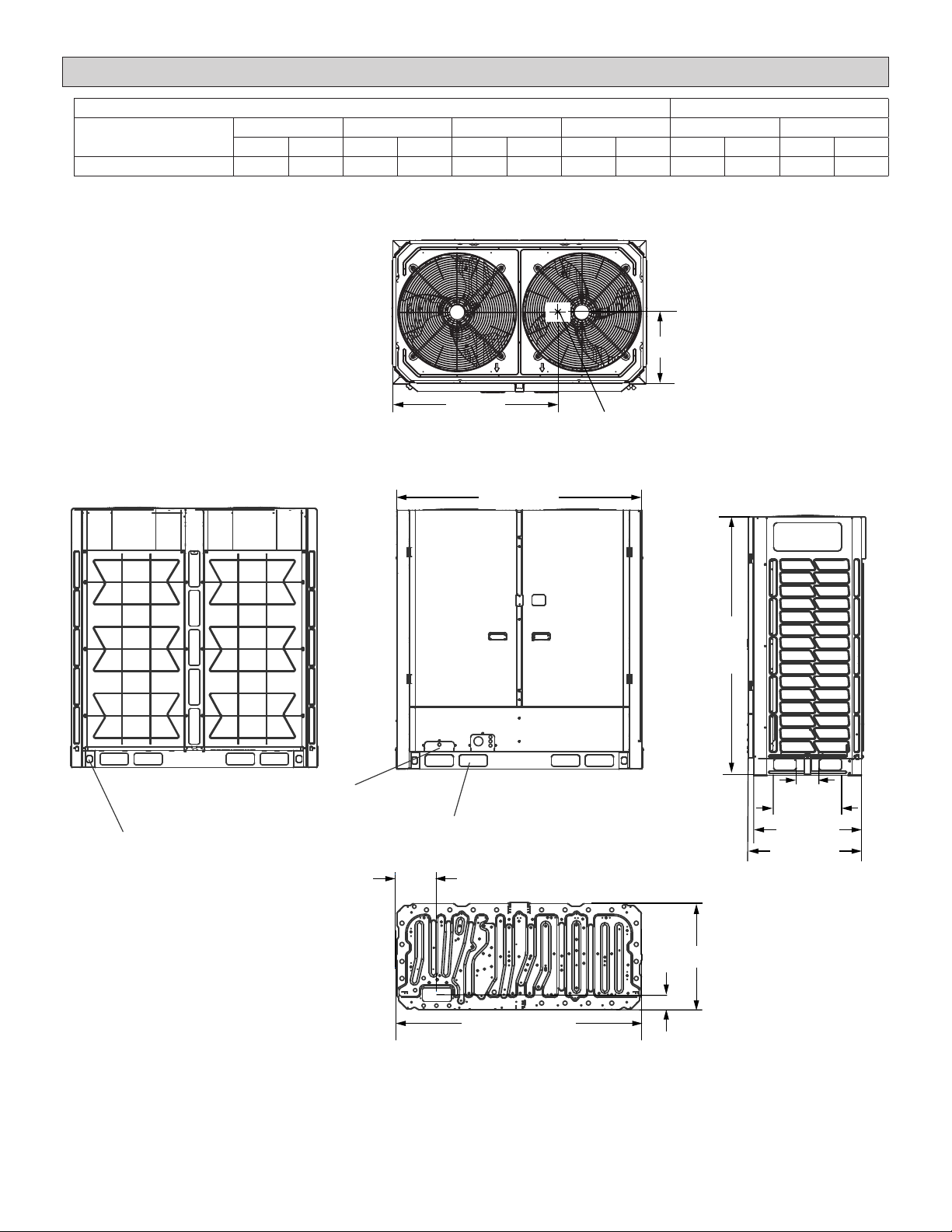

Unit Dimensions - inches (mm)

CORNER WEIGHTS CENTER OF GRAVITY

Model No. AA BB CC DD EE FF

lbs. kg lbs. kg lbs. kg lbs. kg in. mm in. mm

144, 168, 192 172 78 264 120 330 150 321 146 37-3/4 953 12 305

AA

DD

EE

TOP VIEW

68-1/2 (1740)

BB

FF

CC

CENTER OF

GRAVITY

72 (1829)

BACK VIEW

LAG BOLT DESIGNATION

(BOTH SIDES)

(TO ACCESS LAG BOLT)

PARALLEL MODULE

PIPING KNOCKOUT

REFRIGERANT LINE PATH

FRONT VIEW

FORKLIFT SLOT

(BOTH SIDES)

11-3/8 (289)

68-1/2 (1740)

BASE PAN VIEW

4

6-1/4 (159)

18-7/8 (479)

30 (762)

32-5/8 (829)

SIDE VIEW

29-3/4 (756)

4-1/8 (105)

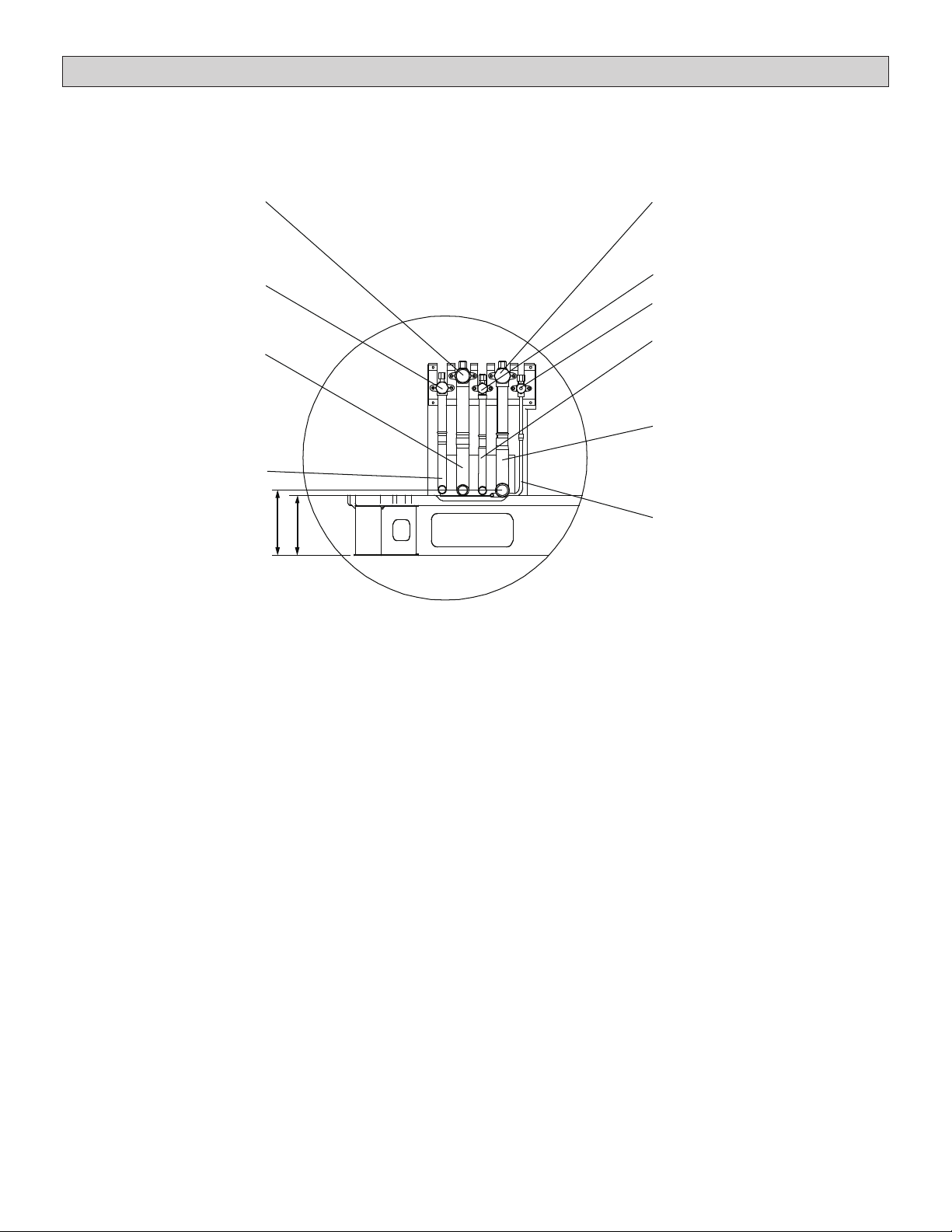

Dimensions - Piping Details - inches (mm)

Internal valve layouts are the same in both heat

recovery and heat pump units, it is their function that

is dierent. Pay close attention when making nal

piping connections.

Low pressure gas valve

High pressure

gas balance valve

Low pressure gas pipe

(1-1/8 in. diameter 072-120 sizes)

(1-3/8 in. diameter 144-192 sizes)

High pressure

gas balance pipe

(3/4 in. diameter)

6-1/4 (159)

5-5/8 (143)

Heat Recovery internal valve layouts are described

below. See the Heat Pump installation manual for

heat pump internal valve information.

High pressure gas valve

Liquid side valve

Liquid side valve

Oil balance valve

Liquid side pipe

(5/8 in. diameter 072-120 sizes)

(3/4 in. diameter 144-192 sizes)

High pressure gas pipe

(1-1/8 in. diameter 072-120 sizes)

(1-3/8 in. diameter 144-192 sizes)

Oil balance pipe

(1/4 in. diameter)

5

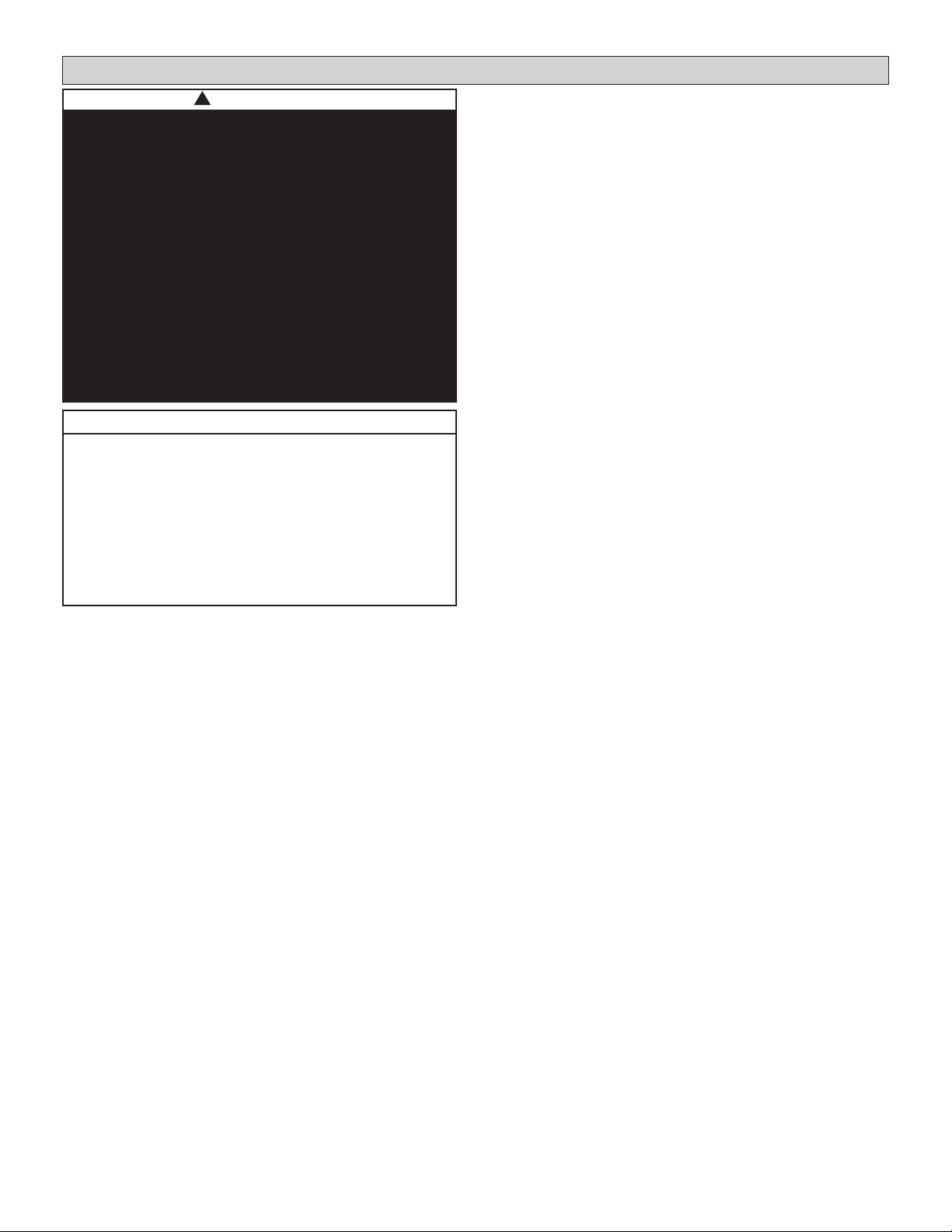

Outdoor Unit Placement Considerations

!

WARNING

Use the provided and specied components

when installing equipment. Failure to do so may

result in unit falling, water leaking or electrical

shocks, caus ing personal injury or equipment

or property dam age.

Check stability of unit support. If sup port is

not capable of carrying weight of the unit, unit

may fall causing personal injury or equipment

damage.

Safely dispose of packing materials, which

include nails, wood and other sharp objects,

as well as plastic wrapping. Children playing

with plastic wrap or bags risk the danger of

suocation.

IMPORTANT!

Exhaust vents from dryers, water heaters and

furnaces should be directed away from the

outdoor unit. Prolonged exposure to exhaust

gases and the chemicals contained within

them may cause condensation to form on the

steel cabinet and other metal components of

the outdoor unit. This will diminish unit performance and longevity.

In addition to clearances, the following items should

be considered when setting the outdoor unit:

• 2007 EPA Noise Policy. Observe local code

adoptions/enforcement as consideration should

be used when selecting an outdoor unit’s permanent placement. Sound data for each unit can be

found in the Product Specications Document.

• Glass has a very high level of sound transmission. When possible, do not install the unit directly outside a window.

• Avoid installing the unit in areas exposed to ex-

treme voltage variations (such as factories).

• Install unit level.

• Allow sucient space around unit for proper operation and maintenance.

• Install the outdoor unit a minimum of 3 ft. (1 m)

away from any antenna, power cord (line), radio,

telephone, security system, or intercom. Electri-

cal interference and radio frequencies from any

of these sources may aect operation.

• Outdoor unit shall maintain a minimum distance

of 10 ft. (3 m) from dryer exhaust vents.

• Outdoor unit shall maintain a minimum distance

of 10 ft. (3 m) from Type 1 kitchen exhaust outlets.

• Coating outdoor coils is recommended in applications installed in coastal regions less than 30

miles (48 kilometers) inland.

6

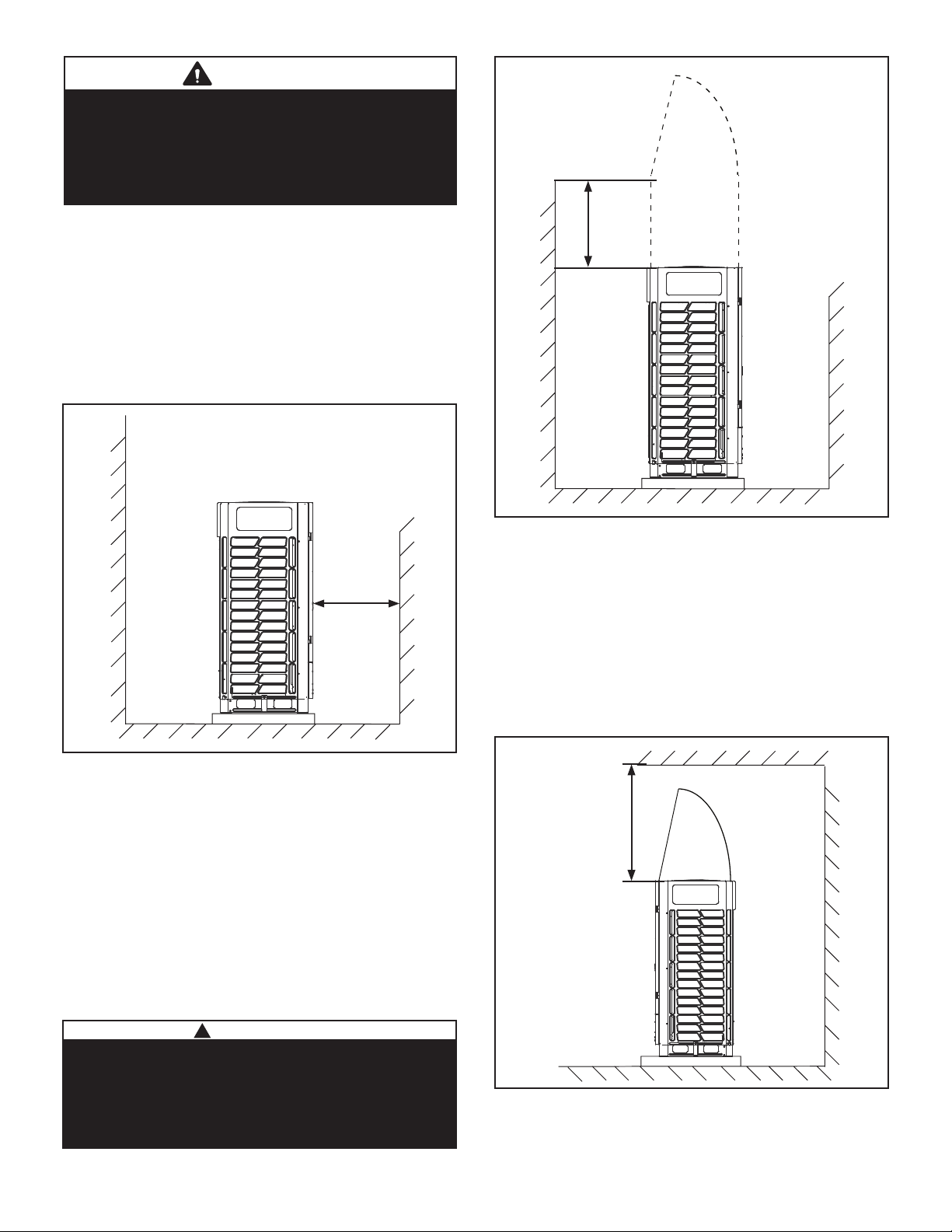

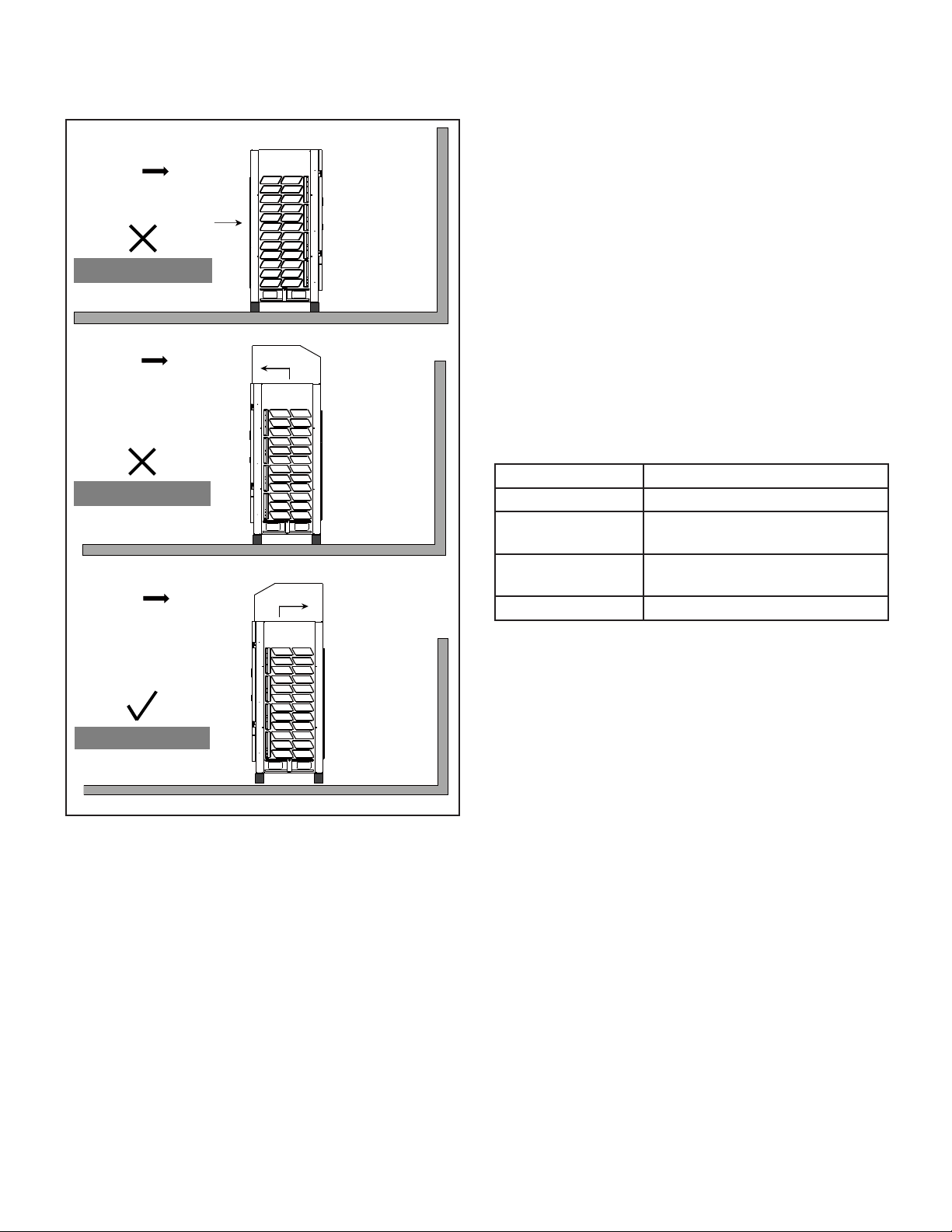

SINGLE ROW

Lifting the Unit

• Do not hold the air inlet grille while lifting the unit.

This could result in damage to the cabinet.

39 (991)

• Do not touch the fan blades with your hands or

other objects while lifting the unit.

Air Flow

Air Flow

31 (800)

39 (991)

39 (991)

Front Front

4 to 20 (102 to 508)

TWO ROWS

39 (991)

39 (991)

Front Front

39 (991)

Front Front

39 (991)

4 to 20 (102 to 508)

THREE OR MORE ROWS

FrontRear

Air Flow

Air Flow

31 (800)

39 (991)

39 (991)

39 (991)

39 (991)

39 (991)

Front Front

Air Flow

Front Front

Air Flow

31 (800)

Front Front

4 to 20 (102 to 508)

Figure 1. Installation Clearances - inches (mm)

7

NOTICE

Drawings in this manual are for illustrative purposes

and should not be used as a template for fabricating

eld-supplied accessories or apparatuses. Consider

the environment in which this unit is being installed and

make necessary adjustments to ensure safe operation.

Local codes prevail.

Clearances from Obstructions

• Allow adequate air ow clearance on all sides of

the unit. See Figure 1 and this section.

• Allow at least 39 in. (991 mm) clearance in front

of the unit for maintenance and service access.

The outdoor unit service access is via hinged

service doors that swing open in front of the unit.

Figure 2.

>39”

(991 mm)

Rear Side

Front Side

>32”

(813 mm)

Front SideRear Side

Figure 3. Perimeter Obstructions

• Allow at least 120 in. (3048 mm) clearance above

the unit. If an obstruction above the unit does not

allow for adequate clearance, a eld-supplied

discharge duct is required. The discharge duct

should be installed in such a way as to ensure

that discharge air goes beyond the obstruction

and does not cause recirculation of discharge air.

Ensure that the static capabilities of the outdoor

unit are not exceeded. Figure 4.

Figure 2. Maintenance & Service Clearance

• Perimeter obstructions that are 32 in. (813

mm) taller than the top of the outdoor unit

require a eld supplied air discharge duct

to avoid recirculation of discharge air.

The discharge duct should be installed to at

least the height of the surrounding obstructions

(for ex. walls) to ensure that discharge air

goes over the height of the obstruction.

Ensure that the static capabilities of the outdoor

unit are not exceeded. Figure 3.

!

CAUTION

In order to avoid injury, take proper precaution

when lifting heavy objects.

Take care when using a sling to lift the unit for

in stallation. The unit center of gravity is not at

its physical center.

>120”

(3048 mm)

Front Side Rear Side

Figure 4. Obstructions Above the Unit

8

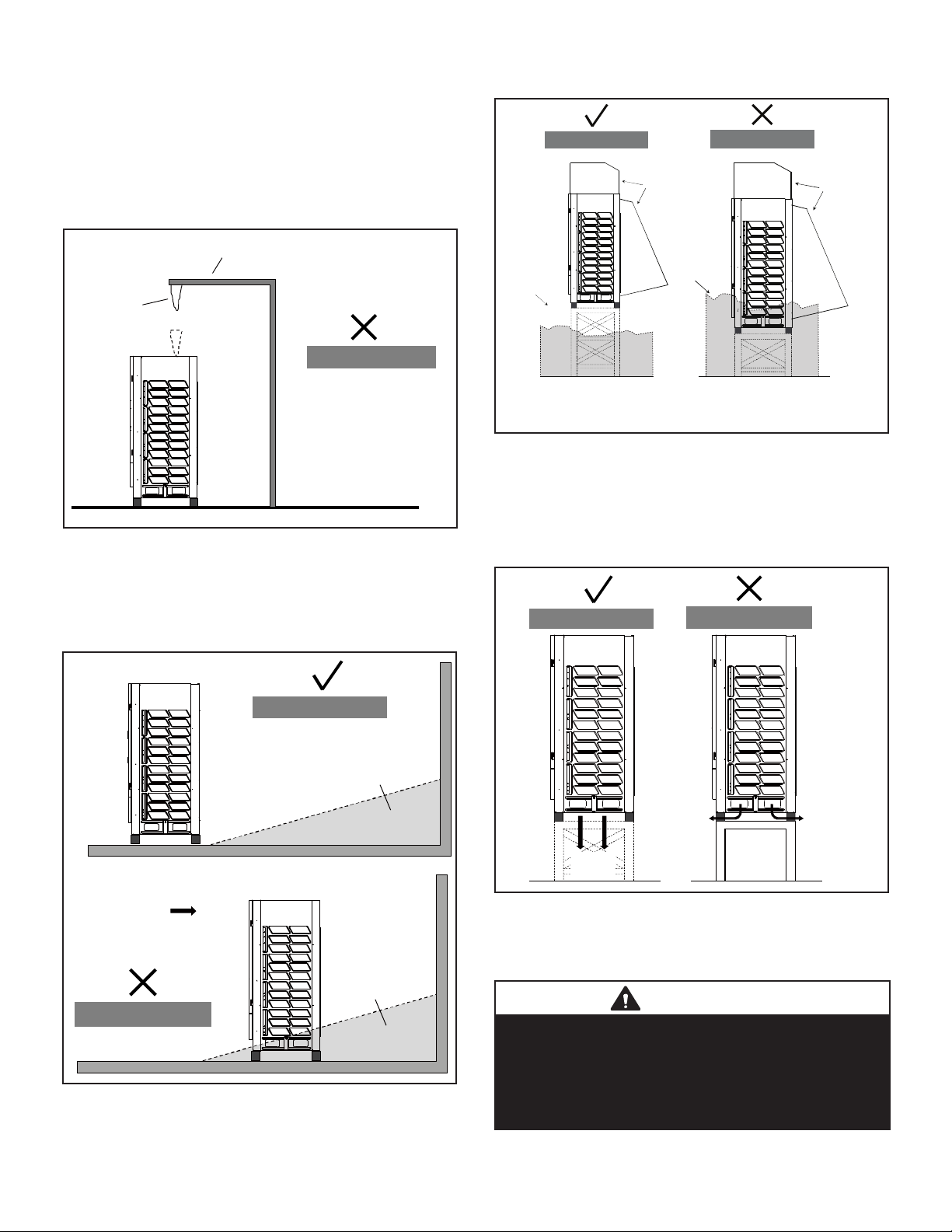

Cold Climate Considerations

Select a location where high winds and snow will not

aect the unit. In areas where typical ambient temperatures are below 50°F (10°C), the following pre-

cautions should be observed.

• Locate unit away from overhanging roof lines

which would allow water or ice to drop on, or in

front of, coil or into unit.

Eaves

Icicle

Wrong Installation

• Install snow guards to prevent snow fall from entering air inlet and outlet.

Correct Installation

Snow

Guard

Kit

Snow level

Wrong Installation

Snow

Guard

Kit

RearFrontRearFront

Snow level

RearFront

Figure 5. Do Not Locate Under Roof Overhang

• The unit base should be elevated above the

depth of average snows plus 12 in. (305 mm). In

heavy snow areas, do not locate the unit where

drifting will occur.

Correct Installation

RearFront

Snow Drifts

NOTE - Snow guards are recommended on both sides

and rear of the unit as shown in this example.

Figure 7. Elevate Above Average Snow Level

& Protect Coil

• If necessary, install the unit on a raised base

made of angle iron and that allows snow and

wind to pass through

Correct Installation

RearFront

Wrong Installation

Defrost

Water

RearFront

Defrost

Water

Wind

RearFront

Snowdrift

Wrong Installation

Figure 6. Do Not Locate Where Drifting Will Occur

Defrost

Water

Figure 8. Secure Unit to

Weather Resistant Support

IMPORTANT

These illustrations are examples of possible snow

protection options. They should not be used as a

template for fabricating the snow protection apparatuses.

Consider the environment in which this unit is being

installed and make necessary adjustments to ensure

safe operation.

9

• When installed in areas where low ambient tem-

peratures exist, locate unit so winter prevailing

winds do not blow directly on to the outdoor unit.

Wind

Rear Front

Wind

Wind

Inlet

Outlet

RearFront

Outlet

llation

Wrong Installation

Wrong Installation

Air Discharge Duct

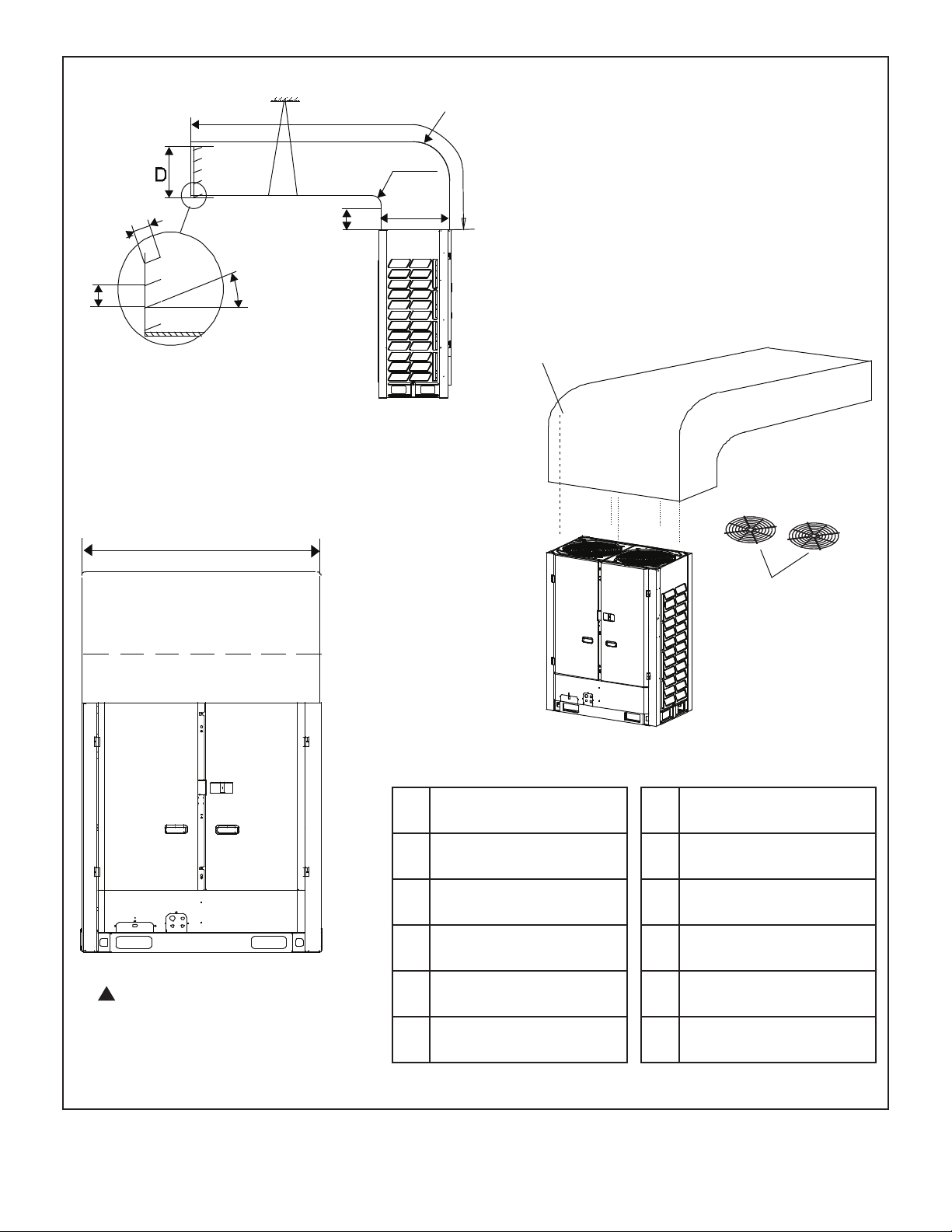

• Before installing the air duct, remove the two fan

guards from the top of the unit.

• Duct each outdoor unit separately. Do not use

a combined plenum as this may result in air not

being discharged directly to the outside.

• Discharge air duct shall be constructed of steel

and installed in a manner which prevents sagging

and or collapsing.

• Only one bend is allowed in the air duct.

• Duct louvers will reduce air volume, cooling and

heating capacity and eciency. Louvers are not

recommended; if they are required by the job,

the louver angle should be no larger than 15°.

• It may be necessary to install a exible connector

between the unit and the duct to reduce vibration

noise.

Table 1. Static Pressure Settings

Static Pressure Description

0 WG (0 Pa) Default

0-0.08 WG (0-20

Pa)

Above 0.08 WG

(20 Pa)

Remove fan guard, < 10 ft. (3 m)

duct length

Contact Lennox VRF Applications

Support

RearFront

Correct Installation

Figure 9. Protect Unit from Prevailing Winds

NOTE - Use dip switch S4 to change outdoor

unit static pressure settings.

10

Support

C

Radius

E

A

Radius

3-1/2 in.

(89 mm)

≤ 15°

4 in. (102 mm)

Air Outlet Louver

072, 096, 120 -- 50-3/4 in. (1289 mm)

144, 168, 192 -- 65 in. (1651 mm)

B

F

8 × ST3.9

self-threading screws

Fan guards

(remove

first)

!

Contact the Lennox VRF

applications department for

assistance with ducting applications

that dier from these images.

Figure 10. Air Discharge Duct

072, 096, 120

A A ≥ 12 in.(305 mm)

B B ≥ 10 in. (254 mm)

C C ≤ 118-1/8 in. (3000 mm)

D D ≥ 24 in. (610 mm)

E E = A + 24 in. (610 mm)

F 24 in. (610 mm)

(Front or Rear Connection)

11

144, 168, 192

A A ≥ 12 in.(305 mm)

B B ≥ 10 in. (254 mm)

C C ≤ 118-1/8 in. (3000 mm)

D D ≥ 28-3/8 in. (721 mm)

E E = A + 24 in. (610 mm)

F 28-3/8 in. (721 mm)

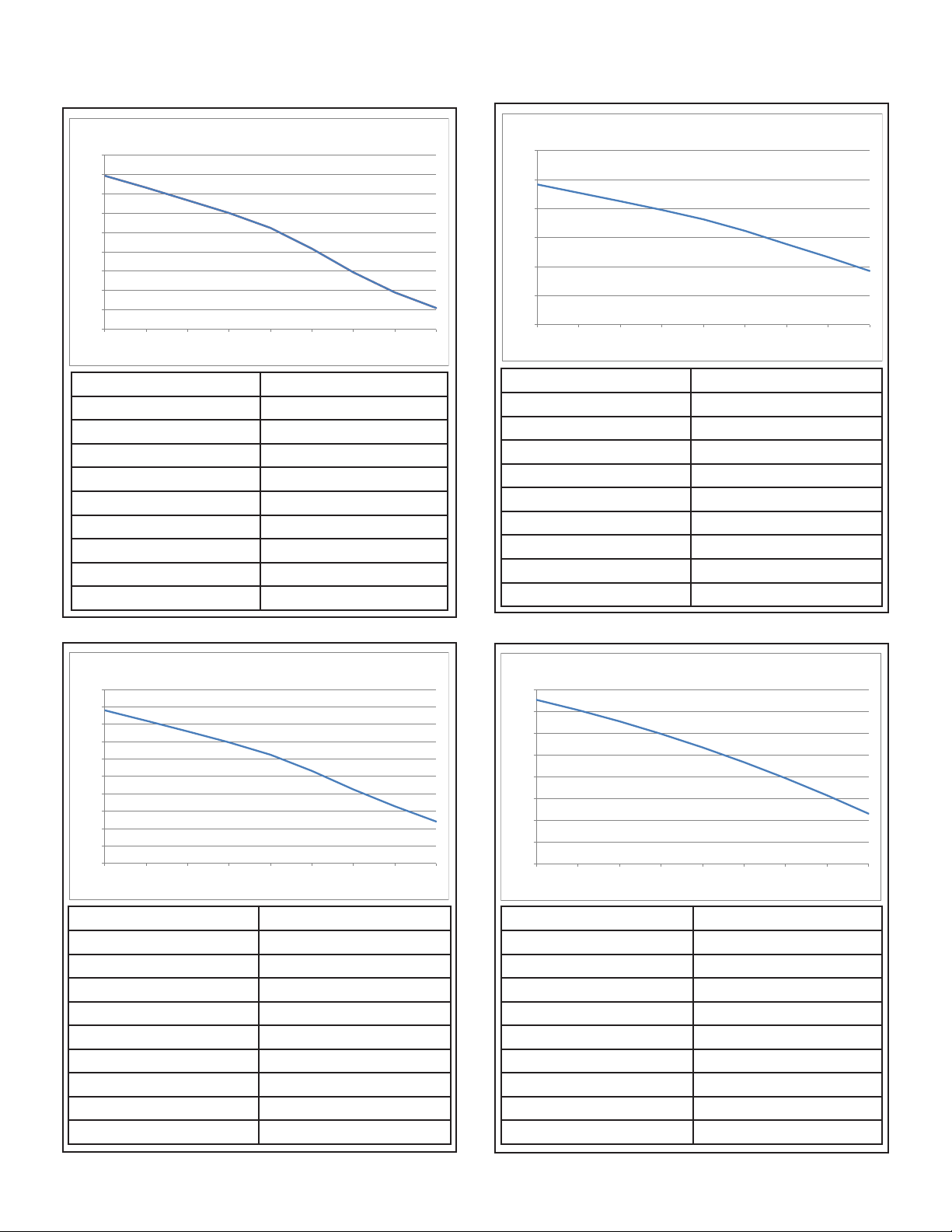

Discharge Duct Pressure Curves

VRB072

VRB120

6-ton Air Volume (CFM)

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

0 0.04 0.08 0.1 2 0.16 0.2 0.24 0.2 8 0.32

Static Pressure (in.wg.) Air Volume (CFM)

0 13934

0.04 13320

0.08 12667

0.12 12010

0.16 11236

0.2 10163

0.24 8940

0.28 7902

0.32 7094

10-ton Air Volume (CFM)

18000

16000

14000

12000

10000

8000

6000

0 0.04 0.08 0.12 0.16 0.2 0.24 0.28 0.32

Static Pressure (in.wg.) Air Volume (CFM)

0 15667

0.04 15090

0.08 14508

0.12 13907

0.16 13261

0.2 12467

0.24 11554

0.28 10655

0.32 9709

VRB096

8-ton Air Volume (CFM)

16000

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

0 0.04 0.08 0.12 0.16 0.2 0.24 0.28 0.32

Static Pressure (in.wg.) Air Volume (CFM)

0 14800

0.04 14205

0.08 13587

0.12 12958

0.16 12248

0.2 11315

0.24 10247

0.28 9279

0.32 8402

VRB144, 168, & 192

12~16-ton Air Volume (CFM)

25000

24000

23000

22000

21000

20000

19000

18000

17000

0 0.04 0.08 0.12 0.16 0.2 0.24 0.28 0.32

Static Pressure (in.wg.) Air Volume (CFM)

0 24544

0.04 24079

0.08 23559

0.12 22986

0.16 22360

0.2 21679

0.24 20945

0.28 20157

0.32 19315

12

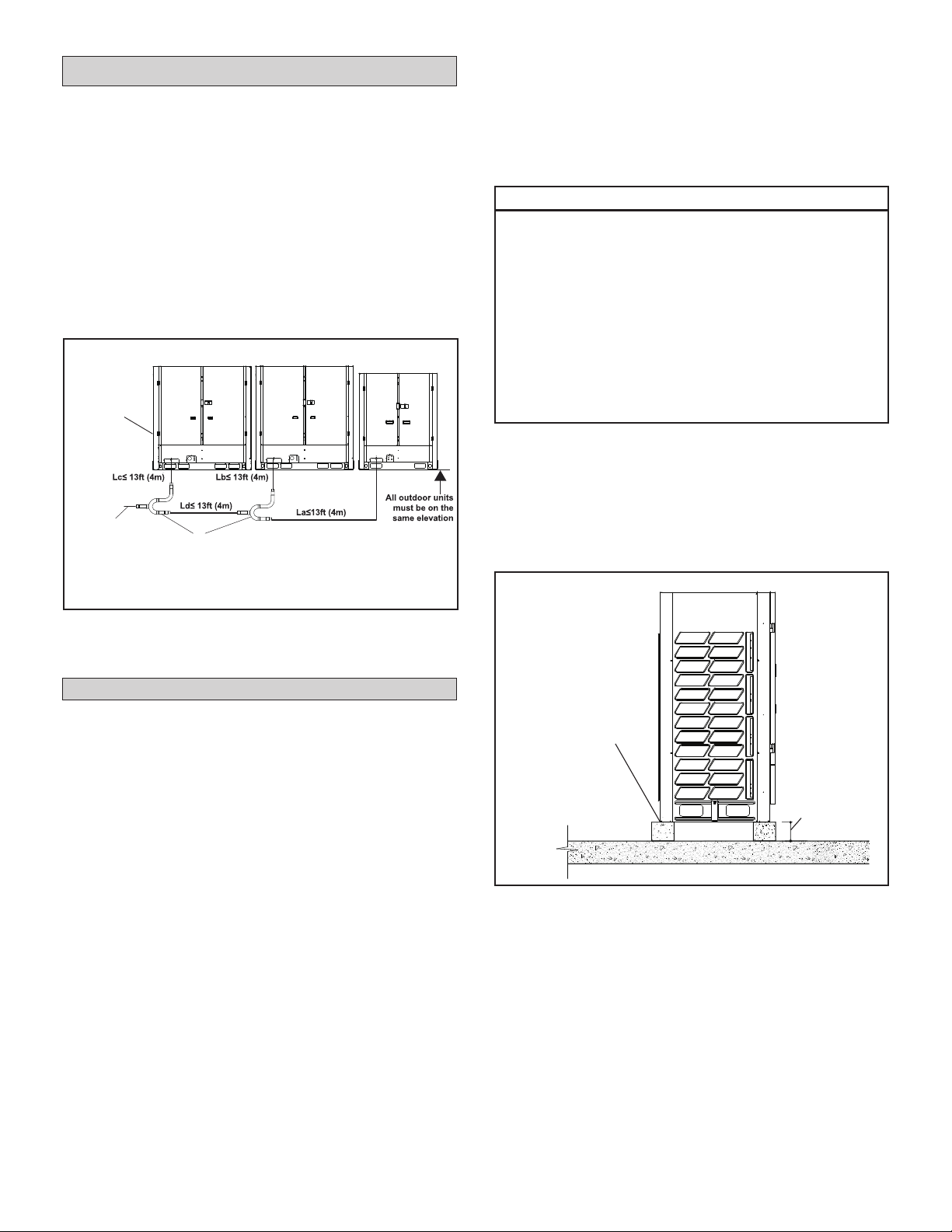

Main/Sub Outdoor Unit Placement

• A VRF system consisting of more than two

outdoor units must be placed in order from the

largest to the smallest capacity. See gure 8.

• The largest capacity outdoor unit must be

installed closest to the main pipe leading into the

building. See Figure 11.

• The largest capacity outdoor unit address is the

main unit, while the others are the sub units. See

Figure 11.

• All of the outdoor units manifolded together

should be installed at the same elevation.

Main unit

placed

closest to

main pipe

leading into

building

Main piping

to building

16-ton

Outdoor Unit

Branch Pipe Kits

14-ton 10-ton

NOTE - All of the outdoor units manifolded

together should be installed at the same elevation.

• If the unit coil cannot be installed away from

prevailing winter winds, a wind barrier should

be constructed. Size barrier at least the same

height and width as outdoor unit. Install barrier

12 inches (305 mm) minimum from the sides of

the unit in the direction of prevailing winds.

IMPORTANT!

Roof Damage!

This system contains both refrigerant and

oil. Some rubber roong material may absorb

oil. This will cause the rubber to swell when

it comes into contact with oil. The rubber will

then bubble and could cause leaks. Protect the

roof surface to avoid expo sure to refrigerant

and oil during service and instal lation. Failure

to follow this notice could result in damage to

roof surface.

Securing Outdoor Unit to Slab or Frame

Use lag bolts (min. 3/8 in.) at all four corners to

secure the unit to the eld-provided slab or frame.

Isolation material can be used to control vibration or

sound transmission. Lag bolts must extend through

material to the slab or frame. See Figure 12.

Figure 11. Main/Sub Unit Placement

(40-Ton System Example)

Installation

Slab or Roof Mounting

Install the unit a minimum of 8 inches (203 mm)

above the roof or ground surface to avoid ice buildup around the unit. Locate the unit above a loadbearing area of the roof that can adequately support

the unit. Consult local codes for rooftop applications.

• Use a eld supplied slab or suitably sized

steelwork to construct a base for locating

the condensing unit. All supporting work

should be veried by a qualied engineer.

NOTE - Prefabricated light duty equipment pads

are NOT suitable for use.

• Support the unit across the front and back of the

unit.

Use lag

bolts (4) to

secure unit

to slab or

approved frame

at each corner

8 in.

(203 mm)

Figure 12. Secure Outdoor Unit

to Approved Structure

13

Refrigerant Piping Connections

!

WARNING

Refrigerant leaks are unlikely; however, if a

refriger ant leak occurs, open a door or windows

to dilute the refrigerant in the room. Turn o the

unit and all other appliances that may cause

a spark. Call a li censed professional HVAC

technician (or equiva lent) to repair the leak.

Use only R-410A refrigerant to charge this

system. Use of other refrigerant or gas will

damage the equipment.

Do not allow air or other contaminants to

enter sys tem during installation of refrigerant

piping. Con taminants will result in lower

system capacity and abnormally high operating

pressures and may res ult in system failure or

explosion.

Insulate all refrigerant piping.

Refrigerant pipes may be very hot during unit

opera tion. Do not allow contact between wiring

and bare copper pipes.

After refrigerant piping connections have been

completed, check the system for leaks per

commis sioning instructions.

• Both liquid and gas (vapor) lines must be indi-

vidually insulated.

• Field piping consists of three HVAC/R eld-pro-

vided copper refrigerant lines connected to the

outdoor unit. These lines carry the liquid and vapor refrigerant to and from the mode selection

box(es).

• Refrigerant piping and wiring connections can be

brought into the outdoor unit through openings

provided in the front, side(s), or underside (recommended) of the unit.

• Refrigerant piping must be connected using

mode selection boxes and individual branch pipe

kits. Six mode selection boxes are available in

varying sizes to accommodate connection of one

to 41 indoor units.

• The following restrictions apply to each VRB system:

• Total refrigerant pipe length 3280 ft. (1000 m)

• Longest pipe length actual) 574 ft. (175 m)

• Level dierence between indoor units 98 ft.

(30 m)

• Piping length from the rst branch pipe to the

farthest indoor unit 132/295 ft. (40/90 m)

• For each branch pipe, allow 20” (508 mm) of

equivalent length.

!

Contact the Lennox VRF applications department

for assistance.

• When the outdoor unit is installed 164 feet (50

m) or more above the indoor units, install an oil

return trap every 33 feet (10 m) in the main low

pressure gas pipe. See Figure 13 for trap speci-

cations.

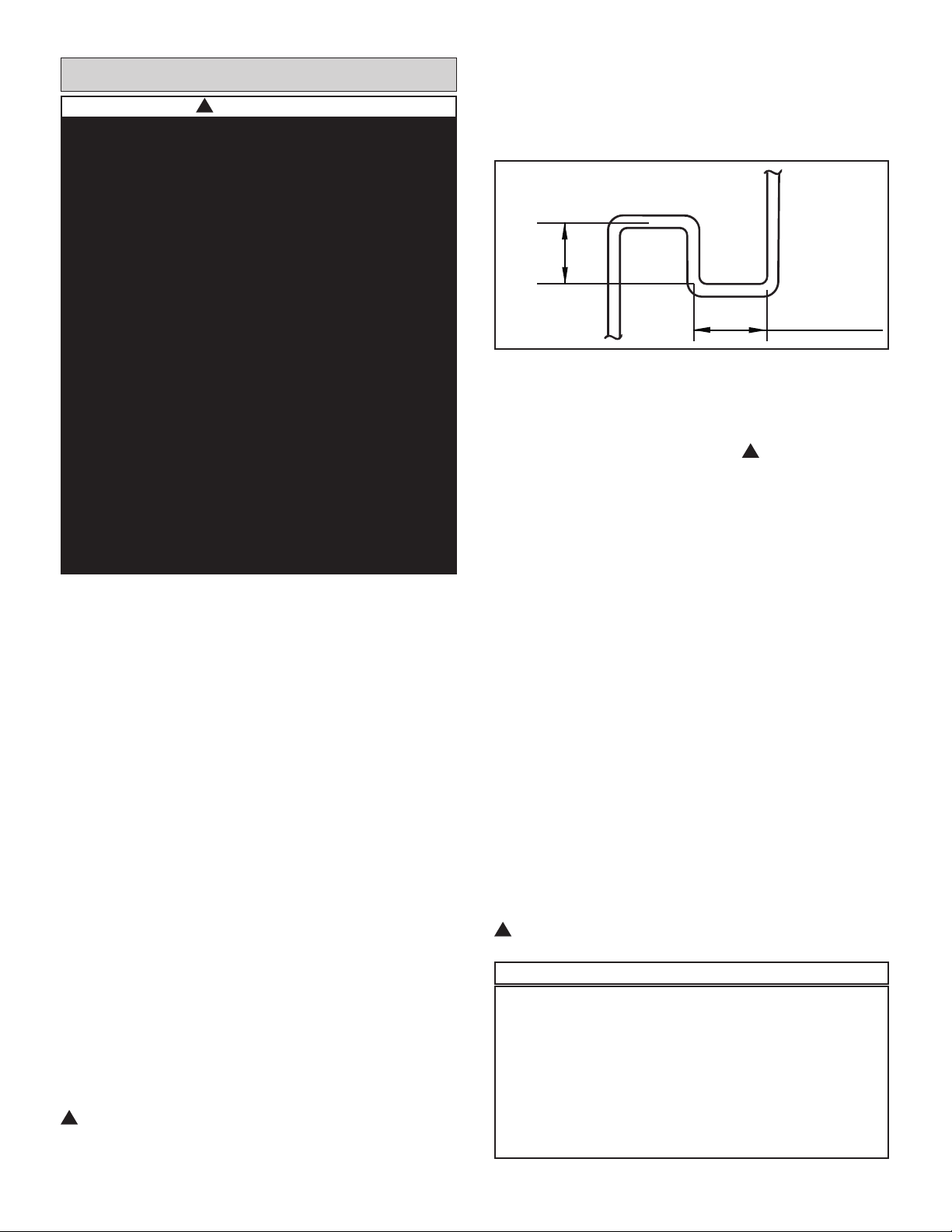

≥1ft

≥1ft

Figure 13. Oil Return Trap

• When the outdoor unit is 132 feet (40 m) or more

below the indoor units, increase the diameter of

the liquid line pipe from the outdoor unit to the

rst branch pipe by one size. ! Contact the Lennox VRF applications department for assistance.

• To extend the length from the rst branch pipe to

the farthest indoor unit beyond 132 ft. (40 m) and

up to 295 ft. (90 m), the following three conditions

must be met.

1. Increase diameter of the main pipe between

the rst and the last branch pipes. If the diameter of the pipe is the same as the main outdoor

pipe, then it does not need to be increased.

Ex: If 132 ft.<L1+L7+L9+L10 ≤ 295 ft., in-

crease the diameter of all the pipes by one

size.

2. The length from the indoor unit to the nearest

branch pipe must be 132 ft. (40 m) or less.

Ex: a,b,c,d,e,f,g,h,i,j,k,l,m ≤ 132 ft.

3. The dierence between [the distance from

the outdoor unit to the farthest indoor

unit] and [the distance from the outdoor

unit to the nearest indoor unit] is ≤132 ft.

Ex:(L1+L7+L9+L11+11+j+k+n)

-(L1+L7+L8+p)

≤ 132 ft.

!

Contact the Lennox VRF applications department

for assistance.

IMPORTANT!

The compressor in this unit contains PVE oil

(Polyvinylether). PVE oil is formulated for hy-

drouorocarbon (HFC) refrigerants, such as R-

410a, which this system contains. While it may

have some miscibility properties with mineral

based oil and POE oil (Polyolester), you should

not mix PVE oil with any other type of refrigerant oil.

14

Maximum Permitted Refrigerant Pipe Length and Maximum Height Difference

OUTDOOR UNITS

(one or more outdoor units)

NOTE - Capacities are shown in parenthesis

a

b

c

MS1

L1

A

L2

L3

B

L4

C

L6

L5

MS3

MS2

INDOOR UNITS

N1

(024)

N2

(024)

d

e

The first line Branch Pipe

N4

(009)

N3

(048)

Maximum equivalent single piping length - 656 ft.(200 m)

L7

Maximum piping length from the first Branch Pipe

joint to the farthest indoor unit - 295 ft. (90 m)

LEGEND

Branch Pipe

Mode Selection

Box (MS)

Maximum level difference between

Indoor Unit

L8

D

L9

L10

E

L11

F

MS6

Indoor Unit and Outdoor Unit - 361 ft. (110 m)

MS7

f

MS4

L12

MS5

L13

Maximum piping length from MS Device

to downstream indoor unit - 131 ft. (40 m)

k

j

r

N13

(018)

q

N12

(048)

p

N11

(048)

l

N5

(048)

g

i

m n

N8

(009)

h

N9

(018)

N6

(024)

N7

(024)

N10

(018)

Maximum level difference between indoor units - 98 ft. (30 m)

Piping Length Permitted value Piping

Total piping length

Single piping length

Piping length from the rst branch joint to the

Piping

Length

farthest indoor unit

Actual length 574 ft. (175 m)

Equivalent length2 656 ft. (200 m)

Piping length from Mode Selection Box (MS) to

the downstream indoor unit of itself

Level dierence between

indoor unit and outdoor unit

Level

Level dierence between indoor units 98 ft. (30 m) - - -

Dierence

NOTES:

The rst branch in all systems must be centrally located between all Mode Selection (MS) Boxes.

1

When counting the total piping length, double the actual length of the distribution pipes between rst Branch Pipe joint and Mode Selection Box (MS): Installation.

Total piping length = L1+(L2+L3+L4+L5+L6+L7+L8+L9+L10+L11+L12+L13)×2+a+b+c+d+e+f+g+h+i+j+k+l+m+n+p+q+r ≤ 3280 ft.(1000 m).

2

Each Branch Pipe or bend is equivalent to 20 in. (508 mm).

3

The maximum allowable piping length from the rst Branch Pipe joint to the farthest indoor unit must be ≤ 132 ft. (40 m), but if the following conditions are met, the

maximum allowable length can be extended to 295 ft. (90 m):

• The piping length from each indoor unit to the nearest Branch Pipe joint or direct connected Mode Selection Box (MS) must be less than 132 ft. (40m) (b to r).

• The dierence in length between the outdoor unit to the farthest indoor unit, and the outdoor unit to the nearest indoor unit is ≤ 132 ft. (40 m).

Example: The farthest indoor unit is N10, The nearest indoor unit is N11 (L1+L7+L9+L11+j+k+n) minus (L1+L7+L8+p) ≤ 132 ft. (40 m).

• Increase the distribution pipe diameter between the rst Branch Pipe and Mode Selection Box (MS) L2-L13. If the pipe diameter is the same as the main outdoor pipe,

it does not need to be increased.

Pipe Size Allowable Increase Diameters (in.):

3/8 to 1/2 1/2 to 5/8 5/8 to 3/4 3/4 to 7/8 7/8 to 1-1/8 1-1/8 to 1-3/8 1-3/8 to 1-5/8 1-5/8 to 2-1/8

4

When the outdoor unit is higher than indoor units and the level dierence is over 164 ft. (50 m), it is required to set an oil return bend every 33 ft.(10 m) in the gas pipe of

the main pipe. Refer to Installation Instructions for additional details.

5

When the outdoor unit is lower than indoor units and the level dierence is more than 132 ft.(40 m), the main liquid pipe pipe need to increase by one size.

Outdoor unit up4 360 ft. (110 m) - - -

Outdoor unit down

1

3280 ft. (1000 m)

3

132/295 ft. (40/90 m) L7+L9+L11+j+k+n

132 ft. (40 m) j+k+n

5

230 ft. (70 m) - - -

L1+(L2+L3+L4+L5+L6+L7+L8+L9+L10+L11+L12+L1

3)×2+a+b+c+d+e+f+g+h+i+j+k+l+m+n+p+q+r

L1+L7+L9+L11+j+k+n

15

Loading...

Loading...