Page 1

©2018 Lennox Industries Inc.

Dallas, Texas, USA

V8MSBB04 Shown

THIS MANUAL MUST BE LEFT WITH THE

OWNER FOR FUTURE REFERENCE

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

personal injury or loss of life.

Installation and service must be performed by a licensed professional HVAC installer, service agency

or the gas supplier.

Failure to follow safety warnings and these instructions exactly could result in property damage, dangerous operation, serious injury, or death.

Any additions, changes, or conversions required in

order for the appliance to satisfactorily meet the application needs must be made by a licensed professional HVAC installer (or equivalent) using factoryspecifi ed parts.

Do not use this system if any part has been under

water. A fl ood-damaged appliance is extremely dan-

gerous. Immediately call a licensed professional

HVAC service technician (or equivalent) to inspect

the system and to replace all controls and electrical

parts that have been wet, or to replace the system, if

deemed necessary.

WARNING

The Mode Selection Box is factory fi tted with Black

plastic caps over the fl are connection points. These

must be replaced with the supplied brass fl are nuts.

Under no circumstances can the plastic caps be used

as a permanent seal even when not all ports are used.

A suitable blanking device must be fi tted on all unused

ports.

INSTALLATION

INSTRUCTIONS

Mode Selection Box

VRF SYSTEMS

507453-05

05/2018

Shipping and Packing List

Check the components for shipping damage. If you fi nd

any damage, immediately contact the last carrier.

Package 1 of 1 contains the following:

1 - Assembled mode selection box

3 - Insulation sleeves for piping from outdoor unit

1 - 1” X ¾” condensate drain adaptor

1 to 6* - ⅜” to ¼” adaptors

1 to 6* - ⅝” to ½” adaptors

1 to 6* - ¼” brass fl are nuts

1 to 6* - ½” brass fl are nuts

1 to 6* - Gas pipe insulation sleeve(s)

1 to 6* - Liquid pipe insulation sleeves

*Quantity of these items depends on number of refrigerant

piping connection pairs.

Installation

Mode selection boxes V8MSBB01, V8MSBB02, V8MSBB03 and V8MSBB04 are used with VRA heat recovery

outdoor units to allow simultaneous heating and cooling in

multiple zones. Mode selection boxes are designed for indoor installation only.

Mode selection boxes include solenoid valves which control

refrigerant fl ow through the individual indoor units so that

unit operation (heating or cooling) matches the comfort requirements being sent by the occupant.

Mode selection boxes are sized to accommodate up to 24

indoor units. See Table 1.

Mode selection boxes are equipped with fl ared fi ttings for

indoor unit refrigerant piping connections and braze fi ttings

for outdoor unit connections.

Refer to the Product Specifi cation bulletin (EHB) for the

proper use of mode selection boxes with matching VRA

heat recovery units, indoor units, branch pipes, line sets

and controls.

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take

care while handling this equipment and wear gloves and

protective clothing.

1

Page 2

CAUTION

To ensure proper system performance and reliability, Lennox does not recommend operation of VRF systems during any phase of construction. Construction debris, low

temperatures, harmful vapors, and operation of the unit

with misplaced fi lters can damage the units. Failure to

follow these guidelines will result in the warranty being

voided.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting

of refrigerant (CFC’s and HCFC’s) as of July 1, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for non-compliance.

System Piping

CAUTION

VRF system piping is customized for each installation.

The LVSS (Lennox VRF Selection Software) piping report

is an engineered design that must be followed. The piping

diagram or diagrams included within the LVSS report have

been prepared based on the information provided to the

Lennox VRF applications department.

When the indicated lengths change from the fi gures

stated within the report, it is imperative that prior to the

commencement of the refrigerant pipe work installation,

Lennox VRF applications department are informed of

these proposed changes.

Upon receipt of this new information the Lennox VRF

applications department will confi rm any changes that

may be applicable to this installation. If changes are

required, a new piping diagram will be produced and will

supersede all other previously provided documents.

Failure to provide this information regarding changes

to the original design may lead to insuffi cient capacity,

equipment failure, warranty being made void and the

refusal to commission the system.

2

Page 3

Unit Dimensions - inches (mm)

V8MSBB01, V8MSBB02, V8MSBB03, V8MSBB04

9

(229)

MOUNTING

LUGS (4)

11- 3/4

(298)

23-5/8

(600)

CONNECTIONS TO INDOOR UNITS

OUTDOOR UNIT

CONNECTIONS TO

CONDENSATE

DRAIN 1 (25) dia.

LOW

PRESSURE

GAS PIPE

TO OUTDOOR

UNIT

HIGH

PRESSURE

GAS PIPE

TO OUTDOOR

UNIT

LIQUID PIPE

TO OUTDOOR

UNIT

GAS

PIPE

LIQUID

PIPE

B

A

AB

Model No.

in. mm in. mm

V8MSBB01 24-3/4 629 19-1/4 489

V8MSBB02 24-3/4 629 19-1/4 489

V8MSBB03 37-3/4 959 32-1/4 819

V8MSBB04 37-3/4 959 32-1/4 819

Pipe Diameter - in.

Model No.

Low Pressure

Gas Pipe

Connections to Outdoor Unit Connections to Indoor Unit

High Pressure

Gas Pipe

Liquid

Pipe

1

Liquid Pipe

2

Gas Pipe

V8MSBB01 7/8 3/4 1/2 3/8 5/8

V8MSBB02 7/8 3/4 1/2 3/8 5/8

V8MSBB03 1-1/8 7/8 5/8 3/8 5/8

V8MSBB04 1-1/8 7/8 5/8 3/8 5/8

1

3/8 x 1/4 in. adaptor furnished for liquid pipe connection to outdoor unit (if required).

2

5/8 x 1/2 in. adaptor furnished for gas pipe connection to outdoor unit (if required).

3

Page 4

Installation Clearances - inches (mm)

CONCRETE CEILING

Minimum

11-7/8 (300) Minimum

2 (51)

SUSPENDED CEILING

Required! Suitably sized access

panel required to provide full

access to electrical panel

24

(610)

REFRIGERANT

PIPE

59 (1500)

Maximum

PIPE

HANGER

59 (1500)

Maximum

15-3/4

(400)

CONNECTIONS TO INDOOR UNITS

36

(914)

Minumum

Suitably sized access panel for gaining access to flare nuts or isolating

ball valves if mounted above a solid ceiling

OUTDOOR UNIT

CONNECTIONS TO

36

(914)

Minimum

Access panels are a requirement for system commissioning and future

preventative maintenance.

4

Page 5

Table 1. Mode Selection Boxes

Model No. Application

V8MSBB01* 1 group, 1 indoor unit maximum

V8MSBB02

V8MSBB03

V8MSBB04

*Use with VHIA072 and VHIA096 only.

2 groups, 4 indoor units maximum per group,

8 indoor units maximum

4 groups, 4 indoor units maximum per group,

16 indoor units maximum

6 groups, 4 indoor units maximum per group

24 indoor units maximum

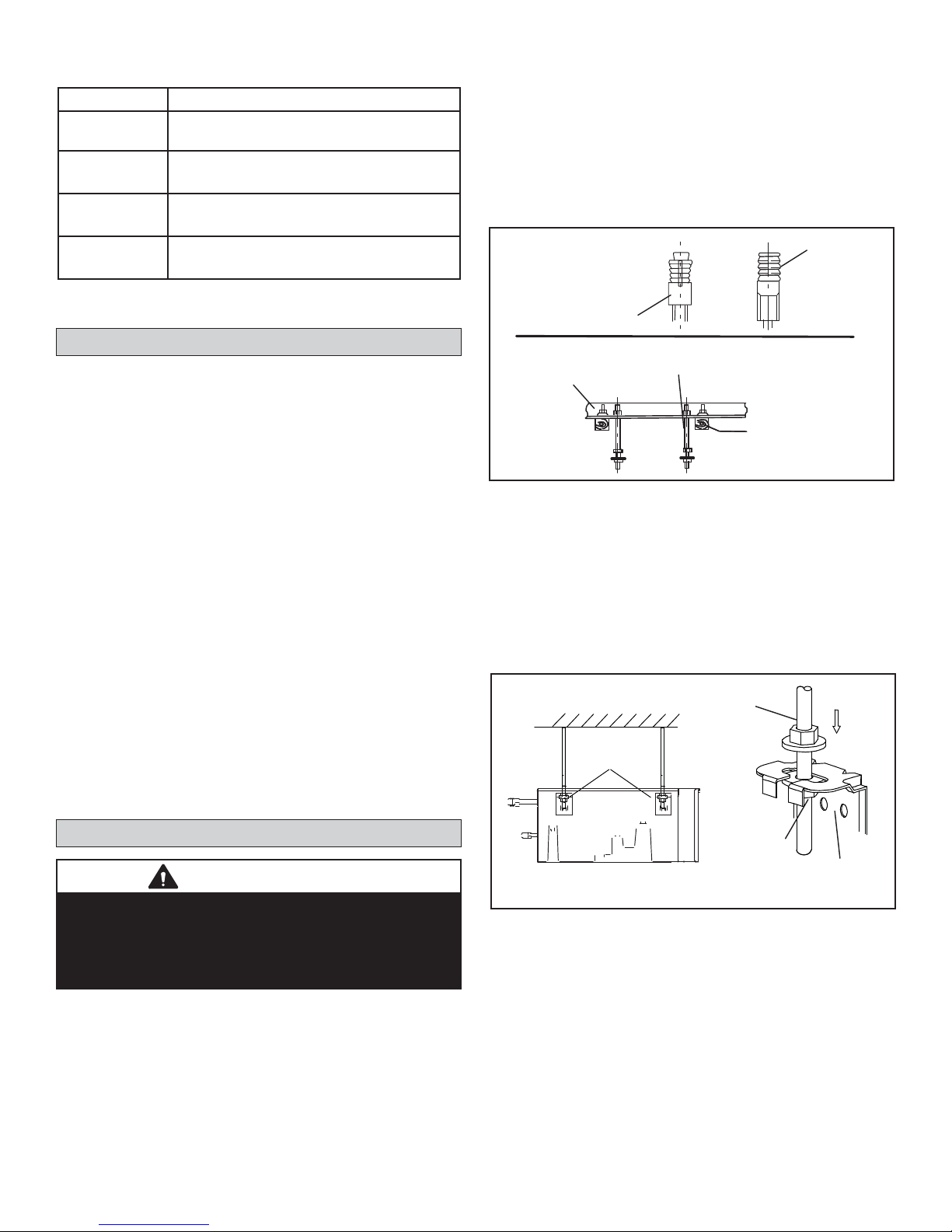

1. Make sure that the structural ceiling is able to support

the weight of the mode selection box(es). It may be

necessary to add extra support. If the structural ceiling

is constructed of concrete, install anchors to accept

four ⅜ inch threaded rods to suspend the mode

selection box. If the structural ceiling includes wooden

joists, use angle iron or a Unistrut channel fi xed

securely in place to accept the ⅜ inch threaded rods.

See Figure 1.

Ǫ´7+5($'(D

CONCRETE CEILING

USING ANCHORS

$1&+25

ROD

Mode Selection Box Location

Consider the following items when positioning the mode

selection box for installation:

• Sounds are made by refrigerant as solenoid valves

open and close inside the mode selection box. Do not

install the mode selection box where these sounds

may disturb building occupants.

• The mode selection box must be sloped 1/8” toward

condensate drain outlet.

• Provide suffi cient clearance around mode selection

box to allow 3 feet of straight pipe before the fi rst

elbow or branch pipe is installed. See Figure 3.

• If the unit is being installed in an application that

includes a sheet rock (plasterboard) ceiling, it is

required that an access panel be installed in a

suitable location. This will also allow access for

future maintenance (requirement of Lennox warranty

program).

Access is required during the commissioning process

to check the internal components, solenoid valves and

associated fl are nuts (See page 3), and to check the

local disconnect.

ANGLE IRON

BOLTED IN PLACE

ACROSS WOODEN JOISTS

Ǫ´7+5($'(D

ROD

ANGLE IRON

ACROSS

WOODEN JOISTS

WOODEN JOIST

Figure 1. Suspending Methods

NOTE - Threaded rod (requirement of Lennox

warranty program) is the ONLY acceptable method of

suspending the unit; do not use chains or straps.

2. Slide one nut and one washer onto each threaded rod.

Use electrical tape to keep the washer from failing off.

Position the nuts slightly above the fi nal resting place

of the four suspension brackets.

Ǫ´7+5($'('

STRUCTURAL CEILING

SUSPENSION

BRACKETS

52'

Mode Selection Box Installation

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting

of refrigerant (CFC’s and HCFC’s) as of July 1, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for non-compliance.

Use the provided suspension brackets to suspend the

mode selection box(es) between the outdoor and indoor

units. The mode selection box location must be able to

accommodate the size of the box, as well as the required

3 feet of straight pipe length between the box and the fi rst

elbow or branch pipe. Refer to the dimension drawing on

Page 3 and Figure 3.

LEVELING NUT

72:$5'&21'(16$7('5$,1&211(&7,21

%2;08676/23(´

SUSPENSION

BRACKET

Figure 2. Suspension Hardware

3. Raise the mode selection box and insert the threaded

rods into the suspension brackets. Slide a washer

and then a nut onto each rod below each suspension

bracket. Use the leveling nut (beneath suspension

bracket) to adjust the mode selection box. Remove

the electrical tape holding the upper washers and nuts

in place and tighten each of the four nuts above the

brackets down onto the brackets. The mode selection

box must be sloped 1/8” toward condensate drain

outlet.

4. Continue with refrigerant piping connections.

5

Page 6

Refrigerant Piping Connections

WARNING

Refrigerant leaks are unlikely; however, if a refrigerant

leak occurs, open a door or windows to dilute the

refrigerant in the room. Turn off the unit and all other

appliances that may cause a spark. Call a licensed

professional HVAC technician (or equivalent) to repair

the leak.

Use only R410A refrigerant to charge this system. Use of

other refrigerant or gas will damage the equipment.

Do not allow air or other contaminants to enter system

during installation of refrigerant piping. Contaminants

will result in lower system capacity and abnormally high

operating pressures and may result in system failure or

explosion.

Insulate all refrigerant piping.

Refrigerant pipes may be very hot during unit operation.

Do not allow contact between wiring and bare copper

pipes.

After refrigerant piping connections have been

completed, check the system for leaks per

commissioning instructions.

WARNING

The Mode Selection Box is factory fi tted with Black

plastic caps over the fl are connection points. These

must be replaced with the supplied brass fl are nuts.

Under no circumstances can the plastic caps be used

as a permanent seal even when not all ports are used.

A suitable blanking device must be fi tted on all unused

ports.

IMPORTANT

Do not remove seals from refrigerant piping stubs until

connections are being made. This will prevent dust or

water from getting into the refrigerant piping before it is

connected.

From

Outdoor

Unit

To

Indoor

Unit

First Elbow or

Branch Pipe

Conection

>36”

>36”

MS

Box

Figure 3. Mode Selection Box Piping

6

Page 7

• Refrigerant piping connections from outdoor unit(s)

are made with fi eld-brazed connections. Field piping

connections for the outdoor unit gas pipes and liquid

pipe are provided on the right side of the mode

selection box.

• The four available mode selection boxes can

accommodate varying numbers of indoor units. See

Table 1 and Figure 4.

Outgoing gas and liquid connections for the indoor

units are on the front of the box. Connections to the

indoor units are made using the provided brass fl are

nuts. Adaptors are provided with the mode selection

box to accommodate the use of different pipe sizes.

Refer to the LVSS (Lennox VRF Selection Software)

piping report for pipe sizes.

• Refer to the VRA heat recovery unit installation

instructions and product specifi cations (EHB) bulletin

for more detailed information on refrigerant piping

connections.

Gas pipe O.D. (5/8” O.D.1)

• Field refrigerant piping for the VRA heat recovery units

includes a variety of branch pipe kits, mode selection

boxes and fi eld-provided piping.

Outdoor unit branch pipe kits are used to join multiple

outdoor units to reach the required system capacity.

Mode selection box branch pipe kits are available

to evenly split system capacity among the varying

numbers of mode selection boxes.

Indoor unit branch pipe kits split the system capacity

among up to four indoor units per connection from

each mode selection box. See mode selection box

branch pipe kits in Figure 8 and a typical VRA system

piping schematic in Figure 9.

• Allow a minimum of 3 feet between the mode selection

box and the fi rst elbow or branch pipe in refrigerant

piping. See Figure 3.

• After refrigerant piping has been installed and checked

for leaks, apply the provided insulation sleeves over all

connections.

Low-pressure gas pipe (7/8” O.D.)

Liquid pipe O.D. (3/8” O.D.

2

)

High-pressure gas pipe (3/4” O.D.)

Liquid pipe O.D. (1/2” O.D.)

Drain connection (1” O.D.3)

V8MSBB01*

V8MSBB02

* Use with VHIA072 and 096 only. Connective branch pipe kit included with indoor unit.

Gas pipe O.D. (5/8” O.D.1)

Liquid pipe O.D. (3/8” O.D.

2

)

Low-pressure gas pipe (1-1/8” O.D.)

High-pressure gas pipe (7/8” O.D.)

Liquid pipe (5/8” O.D.)

Drain connection (1” O.D.

V8MSBB03

Gas pipe O.D. (5/8” O.D.1)

Liquid pipe O.D. (3/8” O.D.

2

)

Low-pressure gas pipe (1-1/8” O.D.)

High-pressure gas pipe (7/8” O.D.)

Liquid pipe (5/8” O.D.)

Drain connection (1” O.D.3)

V8MSBB04

3

)

1

3/8 x 1/4 in. adaptor furnished for liquid pipe connection to indoor unit (if required).

2

5/8 x 1/2 in. adaptor furnished for gas pipe connection to indoor unit (if required).

3

1 inch x 3/4 in. condensate drain adaptor furnished for fi eld installation (if required).

Figure 4. Mode Selection Box Piping Connection Details

7

Page 8

All lines must be individually insulated.

1. The seal on the mode selection box refrigerant piping

connections should remain in place until the last

possible moment. This will prevent dust or water from

getting into the refrigerant piping before it is connected.

2. Remove the black plastic caps from the mode selection

box connections and discard.

3. Slide the fl are nuts onto the ends of the fi eld-provided

refrigerant piping before using a suitable fl aring tool to

fl are the end of the copper pipe.

4. Apply recommended R-410A refrigerant lubricant to the

outside of the fl ared refrigerant lines (Figure 5-A).

5. Align the threaded connections with the fl ared refrigerant

lines. Tighten the fl are nuts lightly at fi rst to obtain a

smooth match (Figure 5-B).

Table 2. Refrigerant Piping Connections

(Up to a maximum of 32 ft. only)

Size

(Btuh)

7000

12000

15000

18000

24000

30000

36000

48000

Liquid Line

in.

1/4 1/2

3/8 5/8

Vapor Line

in.

Always refer to the provided piping diagram for correct piping sizes. Contact Lennox VRF Application support for assistance with piping sizing or an updated piping diagram.

NOTE - 5/8” and 3/8” fl are nuts are part of the reducing

adapters. Cut the reducing adapters to release the 5/8”

and 3/8” fl are nuts.

A

CANT ON THE OUTSIDE OF

THE FLARE

MALE FLARE

CONNECTION

B

Figure 5. Making Connections

(Male to Female Connection)

6. Then, use two wrenches to continue to tighten the nuts

without twisting the pipes. Once snug, continue another

half-turn on each nut which should create a leak-free

joint. A torque wrench may be used to tighten fl are

nuts using table 3 recommendations. See Figure 6. Do

not over-tighten a fl ared joint. Flared connections

should always be accessible and must be insulated

to prevent condensation.

7. After refrigerant piping has been installed and checked

for leaks, apply insulation over the piping and all fl are

connections.

IMPORTANT

Always use two wrenches when tightening fl are nuts to

avoid twisting refrigerant piping. DO NOT over-tighten

fl are nuts.

Torque

To

Mode

Selection

Box

Wrench

Backup

Wrench

To Indoor Unit

Figure 6. Tighten Flare Nut

8

Page 9

Table 3. Flare Nut Torque Recommendations

Outside

Diameter

Inches U.S.

1/4” 15 ft.-lb. 1/4 turn

3/8” 26 ft.-lb. 1/2 turn

1/2” 41 ft.-lb. 7/8 turn

5/8” 48 ft.-lb. 1 full turn

Flare nuts may need further tightening. Check ALL system

fl are nut connections during pressure testing process.

Recommended

Torque

No torque wrench

available

Finger tighten and

use an appropriately

sized wrench to turn an

additional:

Table 4. Piping Connection Information

IMPORTANT!

Flared connections should always be accessible and must be insulated to prevent condensation. See Figure 7.

Insulate ALL flared connections

to prevent condensation.

MS Box

Figure 7. Insulate Flared Connections

Indoor Unit

Indoor Unit

Capacity BTUs

7,000 1/2 x 1/4 1/2 x 1/4

9,000 1/2 x 1/4 1/2 x 1/4

12,000 1/2 x 1/4 1/2 x 1/4

15,000 1/2 x 1/4 1/2 x 1/4

18,000 5/8 x 3/8 5/8 x 3/8 No 3/4 x 1/2

24,000 5/8 x 3/8 5/8 x 3/8 No 3/4 x 1/2

30,000 5/8 x 3/8 5/8 x 3/8 No 3/4 x 1/2

36,000 5/8 x 3/8 5/8 x 3/8 No 3/4 x 1/2

48,000 5/8 x 3/8 5/8 x 3/8 No 3/4 x 1/2

54,000 5/8 x 3/8 5/8 x 3/8 No 3/4 x 1/2

NOTE - For VHIA072/096 indoor units, refer to the VHIA

installation manual and system piping diagram for correct

pipe sizes.

NOTE - All VVCA units have brazed connections. Piping

length rules still apply.

Factory Flare

Connection

Sizes Gas/Liquid

Piping Length

From MS Box

to Indoor Unit Is

equal to or less

than 32 ft.

Adaptor

Required for

Connection to

MS Box

Yes -Factory

Supplied

Yes -Factory

Supplied

Yes -Factory

Supplied

Yes -Factory

Supplied

It is imperative that the system piping is installed per the

LVSS (Lennox VRF Selection Software) piping report! If

the measurements on the Lennox VRF piping diagram

do not match the anticipated fi eld measurements, contact

Lennox VRF Application Support before beginning piping

installation.

Piping Length

from MS Box to

Indoor Unit is

greater than 32

ft.

5/8 x 3/8 No

5/8 x 3/8 No

5/8 x 3/8 No

5/8 x 3/8 No

Required for

Connection to

IMPORTANT

Adaptor

MS Box

Yes -Field

Supplied

Yes -Field

Supplied

Yes -Field

Supplied

Yes -Field

Supplied

Yes -Field

Supplied

Yes -Field

Supplied

9

Page 10

Material

Insulation

(furnished)

ID:1/4

OD:3/8

ID:3/8

ID:1/2

ID:5/8

Adapter Pipe - Inch

ID:1/2

OD:5/8

ID:3/8

OD:1/2

OD:3/4

(3 sets)

Liquid

side used

side used

High-pressure

side used

Low-pressure

ID:3/8

ID:1/2

OD:1/2

(3 sets)

ID:1/2

ID:5/8

ID:3/4

ID:5/8

OD:5/8

OD:3/4

(3 sets)

(Liquid side used)

ID:7/8

ID:3/4

OD:3/4

(3 sets)

ID:3/4

(3 sets)

OD:7/8

(Liquid side used)

ID:1

ID:7/8

OD:7/8

ID:3/8

OD:3/8

ID:1/4

ID:5/8

OD:5/8

(ID:1/2)

ID:3/8

ID:3/4

ID:5/8

OD:5/8

ID:5/8

ID:3/4

OD:3/4

OD:3/8

ID:3/8

ID:1/4

OD:5/8

(ID:1/2)

ID:3/8

ID:1/4

ID:3/4

OD:3/4

(ID:5/8)

ID:1/2

ID:1/2

OD:1/2

ID:3/8

ID:1/4

ID:5/8

ID:3/4

OD:3/4

ID:1

ID:7/8

OD:7/8

OD:1/2

ID:3/8

ID:1/4

OD:3/4

ID:1/2

(ID:5/8)

ID:5/8

OD:5/8

(ID:1/2)

ID:3/8

ID:7/8

OD:7/8

(ID:3/4)

ID:5/8

ID:1

ID:7/8

OD:7/8

ID:1-1/4

ID:1-1/8

OD:1-1/8

OD:5/8

ID:3/8

ID:1/4

OD:7/8

ID:5/8

ID:1/2

(ID:1/2)

(ID:3/4)

ID:3/4

OD:3/4

(ID:5/8)

ID:1/2

ID:1-1/8

OD:1-1/8

ID:7/8

ID:3/4

ID:1-1/4

ID:1-1/8

OD:1-1/8

ID:1-1/2

ID:1-3/8

OD:1-3/8

OD:3/4

(ID:5/8)

ID:1/2

ID:3/8

OD:1-1/8

ID:7/8

ID:3/4

ID:5/8

ID:7/8

OD:7/8

(ID:3/4)

ID:5/8

ID:1-3/8

OD:1-3/8

ID:1-1/8

ID:7/8

OD:7/8

(ID:3/4)

ID:5/8

ID:1/2

ID:1-1/2

ID:1-3/8

OD:1-3/8

OD:1-3/8

ID:1-1/8

ID:7/8

ID:3/4

ID:1-3/4

ID:1-5/8

OD:1-5/8

ID:3/4

OD:3/4

(ID:5/8)

ID:1/2

OD:3/4

(ID:5/8)

ID:1/2

Low-Pressure Gas Side Joints - Inch High-Pressure Gas Side Joints - Inch Liquid Side Joints - Inch

Name

V8MSBP01

Locate fi rst branch pipe kit of system centrally to ensure

even distribution of refrigerant.

Figure 8. Mode Selection Box Branch Pipe Kits

OD:7/8

(ID:3/4)

ID:5/8

ID:1/2

ID:1-1/8

OD:1-1/8

ID:7/8

ID:3/4

ID:7/8

OD:7/8

(ID:3/4)

ID:5/8

V8MSBP02

IMPORTANT

10

OD:1-1/8

ID:7/8

ID:3/4

ID:5/8

V8MSBP03

ID:1-3/8

OD:1-3/8

ID:1-1/8

ID:7/8

OD:1-3/8

ID:1-1/8

ID:7/8

ID:3/4

V8MSBP04

ID:1-3/4

ID:1-5/8

ID:1-3/8

ID:1-5/8

ID:1-3/8

V8MSBP05

Page 11

(96) (120) (120)

g3 g2 g1

0

LEGEND

Branch Pipe

Mode Selection

Box (MS)

Indoor Unit

G1

NOTE - Indoor and outdoor unit

capacities are shown in parenthesis

L2

/

L1

A

b

a

Ė

c

MS1

L3

B

L4

C

L6

L5

MS3

MS2

d

N1

(024)

N2

(024)

e

L7

N4

(009)

N3

(048)

D

g

Ę

N8

(009)

N5

(048)

h

ė

i

mn

(018)

L9L8

f

MS4

L10

E

L11

MS7

r

N13

(018)

q

N12

(048)

p

N11

(048)

F

MS6

j

L12

L13

ę

MS5

k

l

N9

N6

(024)

N7

(024)

N10

(018)

PIPE AND COMPONENT NAMES

Name Designation

Outdoor Unit Connection Pipe g1, g2, g3, G1

Outdoor Unit Branch Pipe Assembly L, M

Main Pipe L1

Indoor Unit Main Pipe L2, L3, L4, L5, L6, L7, L8, L9, L10, L11, L12, L13

Branch Pipe Assembly between Main Pipe and Mode Selection Box (MS) A, B, C, D, E, F

Mode Selection Box (MS) MS1, MS2, MS3, etc.

Branch Pipe Assembly between Mode Selection Box (MS) and Indoor Unit I, II, III, IV

Indoor Unit auxiliary pipe between Mode Selection Box (MS) and downstream

Branch Pipe joint

Indoor Unit auxiliary pipe from Indoor Unit to the nearest Branch Pipe joint or

direct connected Mode Selection Box (MS)

Indoor Unit N1, N2, N3, etc.

a, g, j, k

b, c, d, e, f, h, i, l, m, n, p, q, r

Figure 9. Typical Piping Diagram

11

Page 12

Branch Pipe Kit Placement

Provide 24 inches to 36 inches of straight pipe before

and after each branch pipe kit to avoid creating refrigerant turbulence and fl ash points. Failure to follow 24

inch minimum guideline can lead to reduced capacity

and equipment damage. See Figure 7.

To Indoor Unit

CAUTION

24 inches minimum straight pipe required before and after

branch pipe kit to prevent capacity loss and equipment

damage.

From MS Box or

Previous Indoor

Unit

24” REQUIRED

36” PREFERRED

FIRST ELBOW OR

BRANCH PIPE

24” REQUIRED

CONNECTION

36” PREFERRED

To Indoor Unit

Top View

Branch pipe kits MUST be installed horizontal +/- 10°

NOTE - A maximum of four indoor units can be connected to one port on the Mode Selection Box. The combined maximum capacity of all indoor units connected to one port on a Mode Selection Box must not exceed 54,000 BTUs.

Insulation

Name Gas Side Joints (inch) Liquid Side Joints (inch)

,'

,'

2'

,'

2'

,'

,'

,'

2'

,'

V8IDBP01

,'

,'

2'

,'

2'

,'

2'

,'

Material

(furnished)

(2 sets)

OPERATION NOTE — All indoor units within a group

(units connected to a single piping connector on the mode

selection box) must operate in the same mode at all times.

Figure 10. Inches of Straight Pipe Before and After Branch Pipe Kit

IMPORTANT

12

Page 13

Condensate Drain Connection

A 1 inch OD condensate drain connection is provided

on the mode selection box. Route condensate piping to

a suitable drain per best practices, taking care to slope

the drain properly to ensure drainage. A 1 inch to ¾ inch

adaptor is provided if ¾ inch condensate pipe is preferred.

Mode Selection Box Wiring Connections

WARNING

Isolate the power supply before accessing unit electrical

terminals.

Install unit so that unit disconnect is accessible.

Follow all local and national codes, as well as this

installation instruction, during installation. Do NOT

overload electrical circuit, as this may lead to failure and

possible fi re.

Use specifi ed wiring and cable to make electrical

connections. Clamp cables securely and make sure that

connections are tight to avoid strain on wiring. Insecure

wiring connections may result in equipment failure and

risk of fi re.

Wiring must be installed so that all cover plates can be

securely closed.

This unit must be properly grounded and protected by a

circuit breaker. The ground wire for the unit must not be

connected to a gas or water pipe, a lightning conductor or

a telephone ground wire.

Do not connect power wires to the outdoor unit until all

other wiring and piping connections have been completed.

The mode selection box must be sloped 1/8” toward drain

outlet.

In the U.S.A., wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada,

wiring must conform with current local codes and the current

Canadian Electrical Code (CEC).

Refer to unit nameplate for minimum circuit ampacity and

maximum overcurrent protection size.

NOTE - Three-conductor shielded cable must be used for

the communication wiring. This is necessary to ensure

proper system communication and operation.

Remove the cover panel from the mode selection box and

locate the terminal strip.

Connect properly sized power wiring and three-conductor

shielded cable as shown.

Indoor units and mode selection boxes on the same

refrigeration circuit should have a common power supply

but must have an independent disconnect switch installed

adjacent to the mode selection box for servicing and

maintenance purposes. Indoor unit and mode selection

box power supply MUST not be taken from the outdoor

unit. Always follow NEC/CEC and Local Codes.

13

Page 14

Power DistribuƟon Box

L1/L2

L1/L2

L1/L2

MS

Box

L1/L2/L3

PQE

PQE

PQE

PQE

PQE

PQE

L1/L2/L3

L1/L2/L3

L1/L2

L1/L2

PQE

L1/L2

L1/L2

L1/L2

L1/L2

PQE

MS

PQE

L1/L2

Box

L1/L2

PQE

L1/L2

PQE

Legend

PQE CommunicaƟon wiring

L1/L2 Single-Phase power wiring

L1/L2/L3 Three-Phase power wiring

Electrical disconnect switch

Figure 11. Typical Power Wiring Diagram (VRF Heat Recovery System Shown)

14

Page 15

NOTE - Each communication wire from the mode selection box should follow the refrigerant piping for that port.

Figure 12. Typical Communication Wiring Diagram (VRF Heat Recovery System)

15

Page 16

TRANS

EXVA

L1 L2

208-230V

M-O

CN10

Y/G

T2C1 T2C2

YEIIOW

TO OUTDOOR

To other MS boxes on

same refrigeration circuit.

GRAY

M-I

CN13

RED

BLACK

PQEPQE

TO INDOOR

BROWN

BLACK

2# MS UNIT

1# MS UNIT

S1

O N

1 2

REFRIGERANT PIPING

COMMUNICATIONS CABLE

Figure 13. V8MSBB01 Connections

VHIA072 and VHIA096 Only

OUTDOOR

UNIT

(P Q E)

INDOOR

UNIT

(P Q E)

NOTE - Use 3-conductor, shielded cable

for communication wiring.

NOTE - Indoor c

ommunications cable

must match indoor piping connections.

1# MS UNIT

gnituoR elbaC snoitacinummoC dna gnipiPsnoitcennoC gniriW

TRANS

EXVA

L2

L1

208-230V

2# MS UNIT

2

1

1# MS UNIT

2

1

M-O

M-I

CN13

Y/G

T2C1 T2C2

BLUE

WHITE

PQE PQE PQE

BLACK

ORANGE

YELLOW

BLACK

YEIIOW

BLACK

GRAY

INDOOR UNIT

INDOOR UNIT

(P Q E)

(P Q E)

(P Q E)

OUTDOOR UNIT

1# MS UNIT

06í,1'22R

NO.2 NO.1

MSíOUTDOOR

NOTE - Use 3-conductor, shielded cable

for communication wiring.

NOTE - Indoor c

ommunications cable

must match indoor piping connections.

gnituoR elbaC snoitacinummoC dna gnipiPsnoitcennoC gniriW

To other

MS boxes

on same

REFRIGERANT PIPING

COMMUNICATIONS CABLE

refrigeration

circuit.

Figure 14. V8MSBB02 Connections

16

Page 17

TRANS1

Wiring Connections

TRANS2

L2

L1

POWER IN

208-230V

RED

Y/G

2# MS UNIT

123456

1# MS UNIT

1234 56

BLUE

BLUE

WHITE

M-I(5, 6)

BLACK

YEIIOW

BLACK

ORANGE

T4C T4C1

PURPLE

GRAY

BLACK

ORANGE

GREEN

M-I(1~4)

BLACK

PQEPQE PQEPQE

TO INDOOR 6

TO INDOOR 5

TO INDOOR 4

TO INDOOR 3

Piping and Communications Cable Routing

(P Q E)

OUTDOOR

UNIT

NO.6

NO.5

M-O

BLUE

WHITE

BLACK

RED

BROWN

BLACK

PQE PQE

TO INDOOR 2

NO.4

TO INDOOR 1

1# MS UNIT

MS-INDOOR MS-OUTDOOR

NO.3 NO.2 NO.1

EXVA

YEIIOW

GRAY

BLACK

PQE

TO OUTDOOR

To other MS boxes on

same refrigeration circuit.

INDOOR UNIT

INDOOR UNIT

(P Q E)

REFRIGERANT PIPING

COMMUNICATIONS CABLE

Figure 15. V8MSBB03 and V8MSBB04 Connections

Network Address and Commissioning

After the system has been installed, use the system

remote control to assign a separate address for each of

the indoor units as part of the commissioning procedure.

INDOOR UNIT

(P Q E)

(P Q E)

INDOOR UNIT

(P Q E)

INDOOR UNIT

(P Q E)

INDOOR UNIT

(P Q E)

NOTE - Use 3-conductor, shielded cable for communication wiring.

NOTE - Indoor c

ommunications cable must match indoor piping connections.

Mode selection boxes do not require an address; however,

each indoor unit connected to the mode selection box

must be assigned an individual address.

17

Page 18

V8MBB01 Piping and Wiring Connection to VHIA072 or 096

Refrigerant Piping

• Use the provided branch pipe kit to connect both sets

of refrigerant line connections.

• Locate branch pipes no more than 32 feet from indoor

unit.

See piping report

for pipe sizes

• Piping between branch pipe and indoor unit: liquid line

= 3/8” and gas line = 5/8“.

• Consult LVSS piping report diagram for all other piping

sizes.

VHIA072/096V8MBB01

Gas branch pipe

(Provided with Mode

Selection Box)

Gas branch pipe

(Provided with VHIA unit)

5/8”

3/8”

Liquid branch pipe

(Provided with Mode

Selection Box)

Liquid branch pipe

(Provided with VHIA unit)

32’ maximum distance

between branch pipes and indoor unit

Top view of piping. Branch pipe kits MUST be installed level +/- 10°.

Figure 16. Piping for VHIA072 or 096 when V8MSBB01 is Greater Than 15 ft. (4.5 m) Away - VRA Heat Recovery

V8MBB01

VHIA072/096

Figure 17. Piping for VHIA072 or 096 when V8MSBB01 is Equal To or Less Than 15 ft. (4.5 m) Away - VRA Heat

5/8”

3/8”

Recovery

18

Page 19

Connect these

two pipes as

shown in “A”

below.

A

Incoming

liquid line

connection

Incoming

suction line

connection

Incoming

suction line

connection

Incoming

liquid line

connection

Connect these two

pipes as shown in

“A” left.

Figure 18. VHIA072 and 096 Refrigerant Connections

System Communication Wiring

• Connect PQE wiring to Board A of the VHIA072 or 096

Indoor unit.

Terminal Block A

PQE

Figure 19. VHIA072 and 096 Communication Terminal Block

Terminal Block B

PQE

19

Page 20

Troubleshooting

LED Lamp Defi nitions

LED Lamp Normally ON Slow Flash Flash

LED 1 Outdoor unit ON Outdoor unit standby Outdoor unit communication error

LED 2 Indoor unit ON of this MS Indoor unit OFF this MS Indoor unit communication error

Operation Mode References

0 OFF

2 COOLING MODE

3 HEATING MODE

4 FORCED COOLING MODE

5 MAIN COOLING MODE

6 MAIN HEATING MODE

20

Page 21

Spot Check

No. Description

1 Indoor unit quantity under the port

2 Operation mode under the port

3 Subcool inlet temperature

4 Superheated outlet temperature

T2 average of the system if operation mode is heating under

5

the port.

T2B average of the system if operation mode is cooling under

the port

T2 average of indoor units under the port if operation mode is

6

heating under the port.

T2B average of indoor units under the port if operation mode is

cooling under the port

7

Indoor unit quantity in the system which operate the same

mode as the port.

8 System operation mode

9 Sub cool EXV Pulse Position

10 Indoor unit quantity under the port which are ON.

11 Software version

12 End

Notes

When actual temp. ≤-9°, show -9; When indoor unit is OFF or operating Fan mode, show

-9 (means invalid value)

Figure 16. Spot Check

LED display (all ports)

Port 1

Port 2Port 3Port 4Port 5Port 6

Spot check

button

(one per port)

21

Page 22

Technical Support

1-844-GET-VRF1

(1-844-438-8731)

vrftechsupport@lennoxind.com

www.LennoxVRF.com

Download the app

from the Apple App Store or the Google Play store.

22

Loading...

Loading...