Page 1

©2019 Lennox Industries Inc. Dallas, Texas, USA

VRF

!

WARNING

Improper installation, adjustment,

alteration, service or maintenance can

cause property damage, personal injury

or loss of life.

Installation and service must be

performed by a licensed professional

HVAC installer (or equivalent) or service

agency.

CAUTION

To ensure proper system performance and

reliability, Lennox does not recommend

operation of VRF systems during any phase

of construction. Construction debris, low

temperatures, harmful vapors, and operation

of the unit with misplaced lters can damage

the units. Failure to follow these guidelines

will result in the warranty being voided.

IMPORTANT

Frequent changes to operating mode

may cause system malfunction. Allow at

least one minute between mode changes

to allow the system to stabilize.

This manual must be left with the

owner for future reference.

INSTALLATION/

OPERATION

INSTRUCTIONS

V0STAT51P-3 Touch Screen

Programmable Local Controller

CONTROLS

507900-01

03/2019

General

The V0STAT51P-3 is a wired touch screen

programmable local controller for VRF Heat

Recovery and Heat Pump indoor units with

convenient timed schedules for daily operation.

These instructions are intended as a general

guide and do not supersede local codes in any

way. Consult authorities having jurisdiction before installation.

Requirements

Be sure that power supply has been turned

o before beginning installation. This controller should be used only as described in this

manual.

Shipping and Packing List

Package 1 of 1 contains;

1 – Wired Controller

1 – CR2032 Lithium battery

2 – Phillips screws

2 – Plastic spacers

2 – 1/8” polymer toggle anchors

1 – Installation and operation manual

Tools Needed

#2 Phillips screwdriver

Slotted precision screwdriver

Level

1/8” wall anchor tools

Controller Placement

Avoid installing local controller in high load

or heat loss areas such as exterior walls or

walls that are against unconditioned spaces,

near entry doors and windows, or where direct sunlight may be present.

1

Page 2

Contents

General ........................................................................................................................................1

Requirements ..............................................................................................................................1

Shipping and Packing List ..........................................................................................................1

Tools Needed...............................................................................................................................1

Controller Placement ..................................................................................................................1

Installation ...................................................................................................................................4

Connecting to One Indoor Unit ............................................................................................5

Connecting to Multiple Indoor Units ....................................................................................6

Mounting the Controller .......................................................................................................7

Home Screen Display ................................................................................................................10

Operation ...................................................................................................................................14

ON/OFF .............................................................................................................................14

Error Code Display ............................................................................................................15

Mode Settings............................................................................................................................16

Cooling Mode Operation ...................................................................................................16

Heating Mode Operation ..................................................................................................17

Auto Mode Operation ........................................................................................................18

Dry Mode Operation ..........................................................................................................20

Fan-Only Operation ...........................................................................................................21

Temperature Setpoint .......................................................................................................22

Space Temperature and Space Humidity Display ............................................................23

Temperature Unit Switching (ºF/ºC) ...................................................................................24

Fan Speed .........................................................................................................................25

Swing .................................................................................................................................26

Weekly Schedule Settings Quick Access ..........................................................................27

Override Settings ...............................................................................................................28

Schedule Management..............................................................................................................29

Setup Schedule Templates ................................................................................................31

Paste a Schedule ..............................................................................................................32

Copy and Paste a Schedule Template ..............................................................................32

Copy a Schedule ..............................................................................................................32

Rename a Schedule Template ..........................................................................................34

Delete a Schedule Template .............................................................................................35

Add a Daily Schedule Action .............................................................................................36

Delete a Daily Schedule Action .........................................................................................37

Rename a Daily Schedule Action ......................................................................................37

Edit a Daily Schedule Action .............................................................................................38

Setup a Weekly Schedule .................................................................................................39

Tap the Add button. ...........................................................................................................40

Rename a Weekly Schedule .............................................................................................41

Delete a Weekly Schedule ................................................................................................42

Modify a Weekly Schedule ................................................................................................43

Select the Weekly Schedule to Use ..................................................................................44

Setup Holiday and Special Day Schedules .......................................................................45

Add a Holiday and Special Day Schedule .........................................................................46

Rename a Holiday and Special Day Schedules ................................................................47

Modify a Holiday and Special Day Schedules ...................................................................48

Delete a Holiday and Special Day Schedules ...................................................................49

Override Scheduled Settings .............................................................................................50

General Settings Conguration .................................................................................................52

Time Format Settings ........................................................................................................53

Time Settings .....................................................................................................................53

Theme Settings .................................................................................................................54

2

Page 3

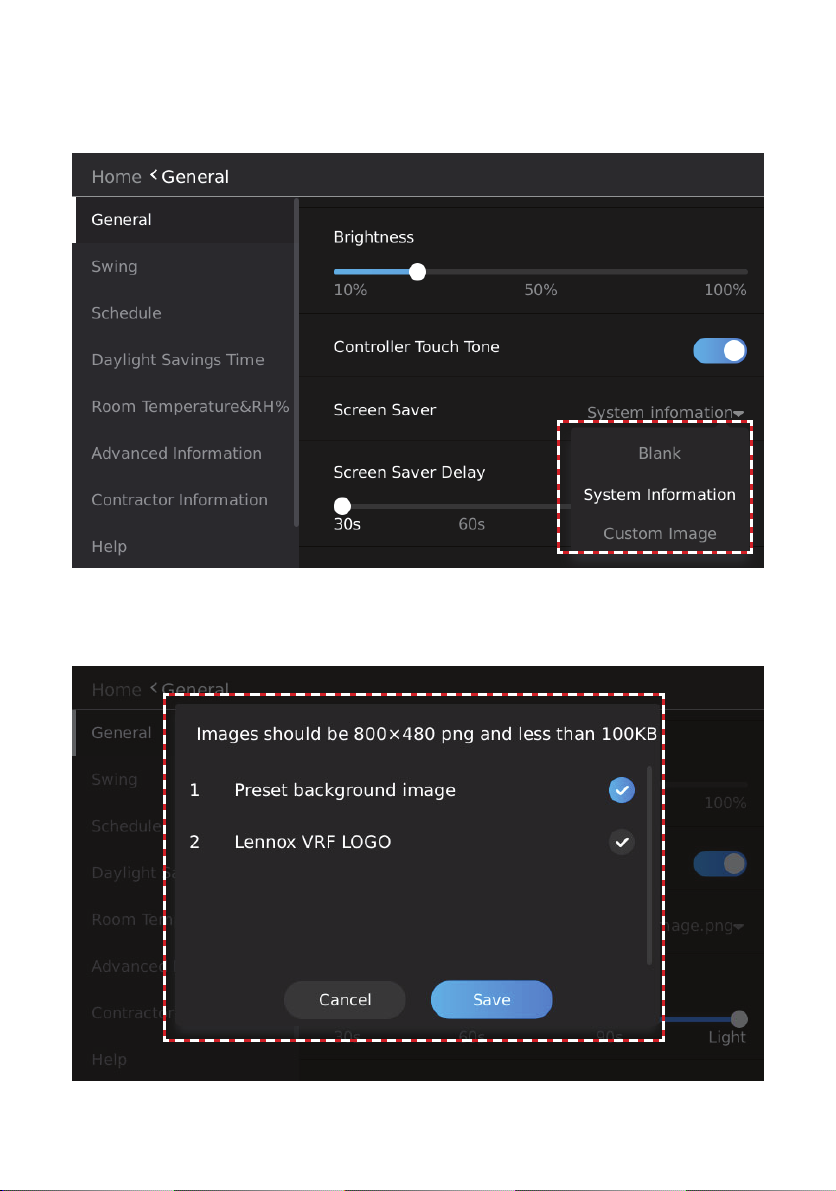

Brightness Settings ...........................................................................................................54

Controller Touch Tone (Sound) Settings ............................................................................ 55

Standby Interface (Screen Saver) Settings .......................................................................56

Standby (Screen Saver) Duration Settings .......................................................................57

Swing Angle Settings ................................................................................................................. 58

Daylight Savings Time Settings .................................................................................................58

Room Temperature and Humidity Display Settings ...................................................................61

Contractor Information Input ......................................................................................................62

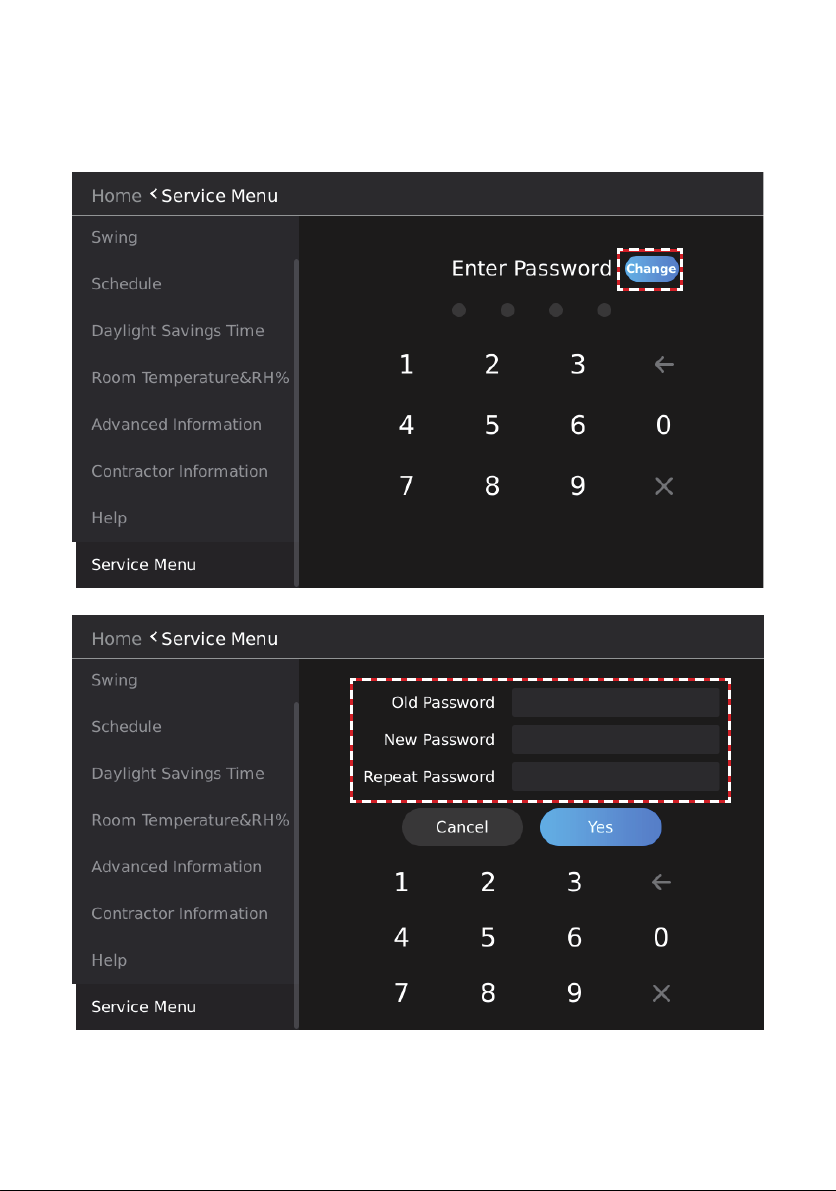

Service Menu.............................................................................................................................63

Access Service Menu ........................................................................................................63

Change Password .............................................................................................................64

Master / Sub Wired Controller Settings .....................................................................................65

Master / Sub Wired Controller Operation ..................................................................................66

Indoor Unit Address Settings .....................................................................................................68

Indoor Unit Display Board & Buzzer (Sound) Settings ..............................................................69

Room Temperature Sensor Settings .........................................................................................70

Auto Mode Settings ...................................................................................................................72

Draft (Cold Blow) Prevention Settings .......................................................................................74

Stand-by Fan Speed Settings....................................................................................................75

Indoor Unit Static Pressure Settings..........................................................................................76

Occupancy Sensor Function Settings .......................................................................................77

Dry Mode Settings .....................................................................................................................78

Auxiliary / Alternate Heat Settings .............................................................................................79

Setpoint Limit Settings ...............................................................................................................81

Locking Function Settings .........................................................................................................82

Advanced Information................................................................................................................83

Device Operation Information Query .................................................................................84

Device Operation Error History Query ...............................................................................86

HHE Dry Contact Relay Interface Status Query ................................................................90

Controller Information ........................................................................................................91

Firmware and Setting Information .............................................................................................92

Software Version ...............................................................................................................93

Controller Software Update ...............................................................................................94

Indoor Unit Software Update .............................................................................................96

Setting Parameters Backup ...............................................................................................99

Setting Parameters Import ..............................................................................................100

Reset Settings .................................................................................................................101

Help .........................................................................................................................................102

Get On-screen Help ........................................................................................................102

3

Page 4

Installation

!

WARNING

Be sure that power supply has been

turned o before beginning installation.

Do not operate controller with wet hands.

!

CAUTION

Do not install controller in areas where

harmful gases containing sulfur or

other damaging agents may exist or the

controller may be damaged.

Clean controller using a clean, damp

cloth. Do not spray cleanser on or around

controller.

IMPORTANT

Electrostatic discharge can aect electronic

components. Take precautions to neutralize

electrostatic charge by touching your hand

and tools to metal prior to handling the control.

IMPORTANT

Read all of the information in this manual

before using this controller. All wiring must

conform to local and national building and

electrical codes and ordinances. This is a

12 VDC controller. Do not install on voltages

higher than 12 VDC.

• This manual provides the installation

instructions for this controller. Refer to the

included wiring diagrams to connect the

controller to the indoor unit.

• The controller uses low voltage. Keep a

minimum distance of 12” (305 mm) between

low voltage control wire and high voltage

power wires.

Power wiring between controller and rst

indoor unit:

• Minimum 18 AWG stranded, shielded cable

up to 164 feet (50 m).

• Ensure there are no gaps between the controller back cover and the mounting surface.

• Fill any holes in the wall behind the control-

ler to avoid false readings from inltration.

• Ground the shielded control wiring.

• Do not use a megger to test insulation.

Communication wiring between indoor

units:

• Minimum 18 AWG stranded, shielded cable.

4

Page 5

Connecting to One Indoor Unit

Connect the controller to one indoor unit main control board using 4-conductor shielded 18 GA

cable. Connect to terminals 12V,COM,HA,HB. See Figure 1.

HB

HB

HA

NOTE - 1. Connect up to 16 indoor units

2. Ground cable shielding at indoor unit

3. All wiring is polarity sensitive

Figure 1. Connect Controller to Single Indoor Unit Wiring Connections

COM

12V

HA

COM

12V

5

Page 6

Connecting to Multiple Indoor Units

Connect the controller to multiple indoor units, up to 16. Use 4-conductor shielded cable to connect

to the rst indoor unit, then daisy chain control wiring to each indoor unit using the HA/HB terminals

in the electrical control box of the indoor unit. Do not daisy chain 12V power cable. See Figure 2.

NOTE – All of the indoor units connected to the controller must be on the same refrigerant circuit,

connected to the same outdoor unit.

HB

HA

HB

HA

COM

COM

12V

12V

NOTES - 1. Connect “+12V” on the controller to terminal “+12V” on the first indoor

unit only. 12V connection provides power to controller; connection to

multiple indoor units will damage controller and indoor unit boards.

2. Ground cable shielding at each indoor unit.

4. Use stranded, shielded, 18 GA cable.

5. Connect up to 16 indoor units.

HB

HA

COM

12V

Figure 2. Connect Controller to Multiple Indoor Units Wiring Connections

CAUTION

Connect “12V” on the controller to

terminal “12V” on the rst indoor unit

only. 12V connection provides power to

controller; connection to multiple indoor

units will damage controller and indoor

unit boards.

HB

HA

COM

12V

6

Page 7

Mounting the Controller

1. Remove the back cover from the controller. See Figure 3.

Figure 3. Remove Back Cover from Controller

2. Attach the back cover to the wall using screws. See Figure 4.

Figure 4. Attach Back Cover to Wall

7

Page 8

3. Connect the controller to one indoor unit main control board using 4-conductor shielded 18 GA

cable. Connect to terminals 12V,COM,HA,HB on the back of the controller.

HA HB

12V COM

HB

HA

COM

P12V Q

Figure 5. Connect Cabling

4. Insert the controller into the bottom snap joints of the back cover at an angle. See Figure 6.

Figure 6. Insert Controller into Back Cover

8

Page 9

5. Push the controller back toward the wall until it “snaps” into place. See Figure 7.

Figure 7. Snap Controller Into Place

9

Page 10

Home Screen Display

3

4

7

5

8

2

10

6

9

1

Figure 8. Home Screen Display 1

15

11

14

13

12

Figure 9. Home Screen Display 2

10

16

17

18

Page 11

Table 1. Home Screen Display

Number Display Item Description

1 ON/OFF button Tap to turn the indoor unit on or o.

2 Settings button Tap to access the menu screen.

3 Time Display Displays the current system time.

Select Auto mode when the indoor unit is ON, and then

4 Auto Mode Settings

the indoor unit will run in Auto mode (the icon illuminates

after selection).

Select Cooling mode when the indoor unit is ON, and

5 Cooling Mode Settings

then the indoor unit will run in Cooling mode (the icon

illuminates after selection).

Select Heating mode when the indoor unit is ON, and

6 Heating Mode Settings

then the indoor unit will run in Heating mode (the icon

illuminates after selection).

Select Dry mode when the indoor unit is ON, and then the

7 Dry Mode Settings

indoor unit will run in Dry mode (the icon illuminates after

selection).

Select Fan mode when the indoor unit is ON, and then the

8 Fan Mode Settings

indoor unit will run in Fan mode (the icon illuminates after

selection).

9

Temperature Unit Settings

Switch the temperature unit: display in

Fahrenheit/Celsius temperature.

10 Operation Mode Displays the mode of operation of the indoor unit.

11

12

Fan Speed Control

Button

Indoor Temperature

and Humidity Display

Select fan speed, and tap “Auto”, “High”, “Med”, or “Low”

to conrm the selection.

Display the temperature and humidity of the room in

which the indoor unit is located.

13 Setpoint Displays the setpoint.

14

15

16

17

18

Setpoint Adjustment

Slider

Vertical Swing Angle

Display

Horizontal Swing Position Display

Weekly Schedule

Display

Override Status

Display

Adjust the setpoint by pressing and sliding.

Displays the vertical swing angle of the indoor unit; tap to

access the vertical swing angle settings.

Display the horizontal swing angle of the indoor unit; tap

to enter the horizontal swing angle settings.

Display the setting status of the weekly schedule status,

and tap to access the weekly.

Display the Override status and tap here to set the

Override settings.

11

Page 12

Table 2. Special Status Symbol Displays

No. Icon Name Description

1 Fan

2 Cool

3 Heat

4 Dry

5 Cooling operation in Auto mode

6 Heating operation in Auto mode

7 Centralized controller lock

8 Group control

9 Occupancy sensor

Displays when the indoor unit is in Fan

mode.

Displays when the indoor unit is in

Cooling mode.

Displays when the indoor unit is in

Heating mode.

Displays when the indoor unit is in Dry

mode.

Displays when the indoor unit is in Auto

mode providing cooling operation.

Displays when the indoor unit is in Auto

mode providing heating operation.

Displays when some functionality is

locked by a centralized controller.

Displays when more than one indoor

unit is connected to the controller.

Displays when an occupancy sensor

is active.

10 Help Tap to see the Help screens.

Displays when the indoor unit is in

11 Mode conict prompt

mode conict with the outdoor unit

(heat pump systems)

12 Auto Dry function Displays when auto dry function is ON.

13 Master controller Displays if the controller is a master.

14 Master controller Displays if the controller is a sub.

15 Outside air ducted indoor unit

16 ON/OFF lock

Displays if the connected indoor unit is

providing outside air.

Displays when some functionality is

locked by settings on this controller.

17 Mode lock Displays when Mode is locked.

12

Page 13

No. Icon Name Description

18 Setpoint lock Displays when Setpoint is locked.

19 Schedule lock Displays when Schedule is locked.

20 Defrosting or oil return

20 Cold air prevention

Displays when the outdoor unit is in

defrost or oil return operation.

Displays during period of time before

the coil warms to the determined cold

air prevention temperature. The fan

will not run during this time period.

13

Page 14

Operation

NOTE - Indoor units connected to a local controller may also be controlled by a centralized controller. Indoor units respond to the last command sent. It is recommended that indoor units be controlled from a single source of control, either local controller or centralized controller but not both,

to avoid conicts in commands.

ON/OFF

Tap the On/O button to turn the indoor unit on or o.

Figure 10. ON/OFF Operation

14

Page 15

Error Code Display

When the connected indoor units or outdoor unit has an error, the original set temperature interface will display the error code.

Tap the error display area and to open the error code description interface.

Figure 11. Error Code Display

15

Page 16

Mode Settings

Cooling Mode Operation

When the indoor unit is powered on, tap COOLING in the operating mode selection interface.

The selected icon will illuminate when the indoor unit runs in Cooling mode. The Cooling icon is

displayed in the upper right corner of the home page.

To adjust the setpoint, tap the setpoint slider and drag the slider to the new setpoint temperature.

The default setpoint range is 62°F to 86°F (17°C to 30°C).

Figure 12. Cooling Mode Operation

16

Page 17

Heating Mode Operation

When the indoor unit is powered on, tap HEATING in the operating mode selection interface. The

selected icon will illuminate when the indoor unit runs in Heating mode. The Heating icon is displayed in the upper right corner of the home page.

To adjust the setpoint, tap the setpoint slider and drag the slider to the new setpoint temperature.

The default setpoint range is 62°F to 86°F (17°C to 30°C).

Figure 13. Heating Mode Operation

17

Page 18

Auto Mode Operation

When the indoor unit is powered on, tap AUTO in the operating mode selection interface. The selected icon will illuminate when the indoor unit runs in Auto mode. The Auto icon or the Cooling icon

is displayed in the upper right corner of the home page.

NOTE - During Auto mode, both operation mode (cooling or heating) setpoints display on the Home

screen. The current operation mode setpoint displays larger than the non-current operation

mode.

In Auto mode the Cooling setpoint range is 68°F to 86°F (20°C to 30°C), the Heating setpoint range

is 62°F to 81°F (17°C to 27°C).

To adjust the setpoint of either cooling or heating while in Auto mode, tap the appropriate setpoint,

either cooling or heating. That setpoint will display as the larger number. Drag the temperature

slider to the new setpoint temperature. If the setpoint you adjusted is not the current operation

mode, after 10 seconds, the current operation mode setpoint will display as the larger number.

NOTE - The setpoint deadband between cooling and heating setpoints is setup in the Settings

menu.

Figure 14. Auto Mode Operation

18

Page 19

Figure 15. Auto Mode Setpoints

19

Page 20

Dry Mode Operation

When the indoor unit is powered on, tap DRY in the operating mode selection interface. The selected icon will illuminate when the indoor unit runs in Dry mode. The Dry icon is displayed in the

upper right corner of the home page.

Fan speed cannot be adjusted during Dry mode.

Figure 16. Dry Mode Operation

20

Page 21

Fan-Only Operation

When the indoor unit is powered on, tap FAN in the operating mode selection interface. The selected icon will illuminate when the indoor unit runs in Fan mode. The Fan icon is displayed in the

upper right corner of the home page.

The indoor unit fan operates without heating or cooling.

Figure 17. Fan-Only Mode Operation

21

Page 22

Temperature Setpoint

To adjust the setpoint, tap the setpoint slider and drag the slider to the new setpoint temperature.

The default setpoint range is 62°F to 86°F (17°C to 30°C). The setpoint range can be adjusted using the Setpoint Limit screen in the Service menu.

Figure 18. Temperature Setpoint

22

Page 23

Space Temperature and Space Humidity Display

On the main screen of the controller, you can view the current setpoint, space temperature and

space humidity.

When the master wired controller chooses the Follow function, the Space Temp will display the

temperature and corrected value detected by the temperature sensor of the master wired controller

itself.

When the master and Sub wired controllers do not choose the Follow function, their Space Temp

will display the temperature detected by their own temperature sensors (without a corrected value).

The temperature sampling range is -16°F to 156°F (-9°C to 70°C). The humidity sampling range

is 0% to 100%.

Figure 19. Setpoint, Space Temperature & Space Humidity Display

23

Page 24

Temperature Unit Switching (ºF/ºC)

Tap TEMPERATURE UNIT SETTING at the lower right corner to switch the temperature display

unit between Fahrenheit and Celsius.

Figure 20. Fahrenheit or Celsius Temperature Display

24

Page 25

Fan Speed

Tap Auto, High, Med, or Low to change the fan speed. The corresponding icon illuminates after

selection.

Figure 21. Fan Speed Operation

25

Page 26

Swing

Tap the Vertical Swing Angle Settings icon and the Horizontal Swing Angle Settings icon to enter

the swing angle settings interface.

Figure 22. Swing Settings

26

Page 27

Weekly Schedule Settings Quick Access

Tap the Weekly Schedule Settings icon to enter the weekly schedule settings interface.

Figure 23. Quick Access to Weekly Schedule Settings

27

Page 28

Override Settings

Tap the Override icon and the Override delay time selection box displays.

Figure 24. Override Settings

28

Page 29

Schedule Management

NOTE – If schedules are used and a centralized controller is installed on the system, controller

functions should not be locked from the centralized controller.

Tap the Schedule button to access the schedule management settings interface.

Set by week, and run dierent set statuses at dierent times of the day.

Before setting Schedule Templates, Schedule Setup, and Holiday and Special Day Schedule, you

must rst complete the date and time settings.

Figure 25. Tap Schedule Button to access Schedule Settings

29

Page 30

If the system time is detected to be earlier than 01:00 AM Dec 30, 2017 (the factory default time is

2017-12-30), the setting date and time box will display.

Tap “YES” to open to the date and time settings screen, or tap “NO” to return to the previous

page.

Figure 26. Set System Date & time

30

Page 31

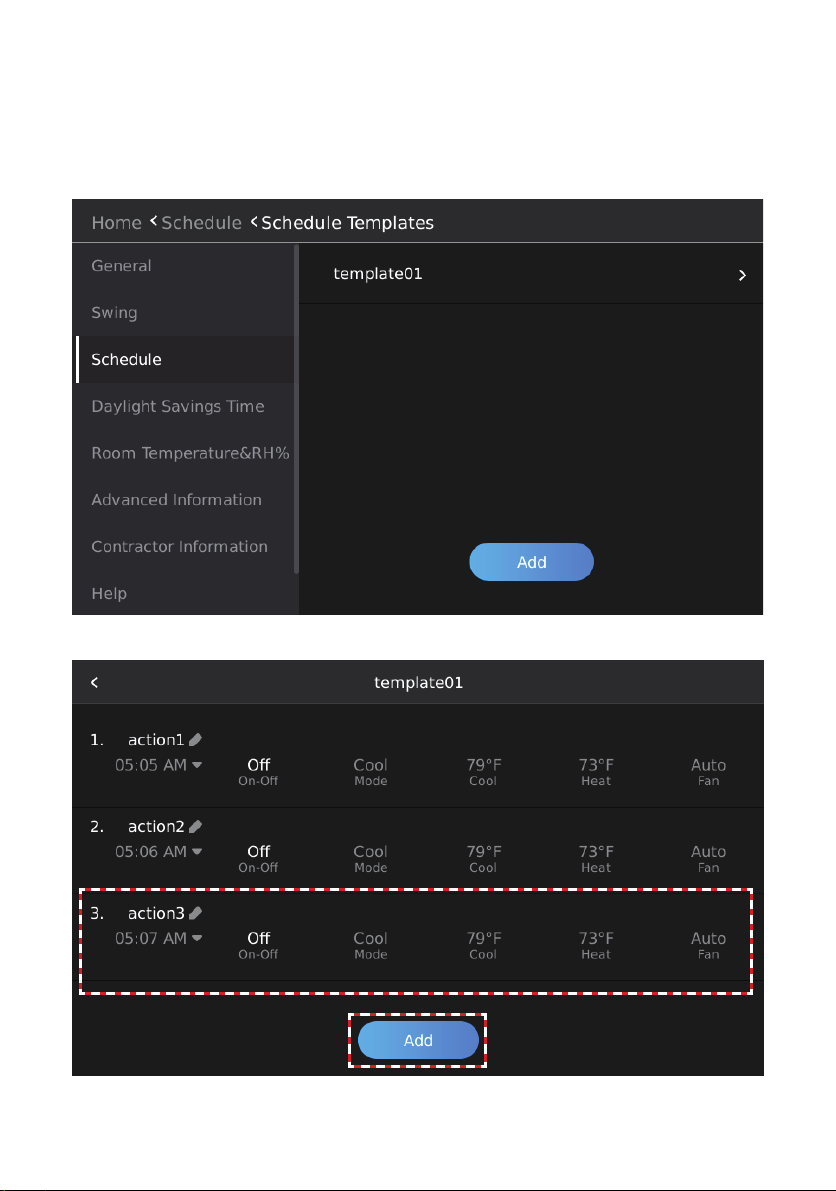

Setup Schedule Templates

Create a scheduled day’s events. Tap the Schedule Templates button to access the daily schedule template settings interface.

Figure 27. Tap Schedule Templates Button

Tap the Add button to add a daily schedule template. Up to 10 templates.

Figure 28. Add Daily Template

31

Page 32

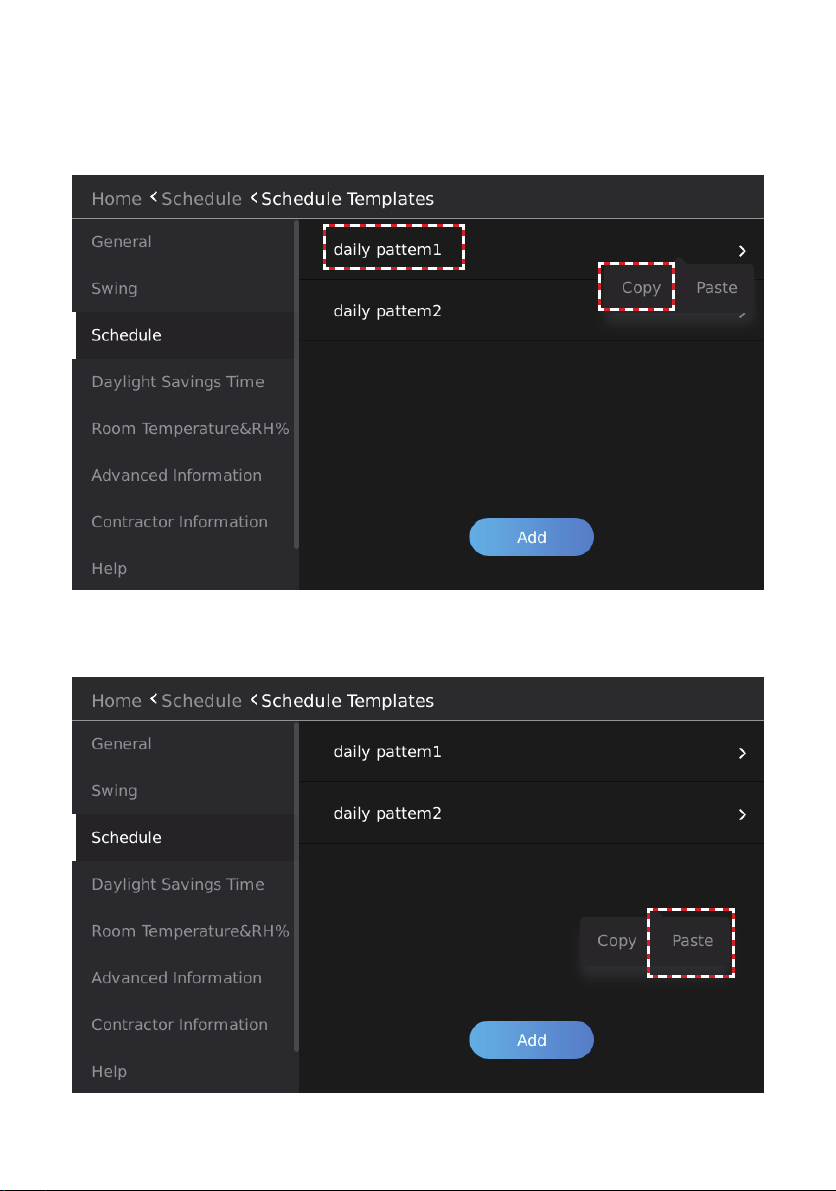

Copy and Paste a Schedule Template

Use the Copy and Paste buttons to copy a template and use it to create a new daily template.

Copy a Schedule

Press and hold the schedule template you want to copy. The Copy and Paste buttons will display.

Tap the Copy button.

Figure 24. Copy or Paste a Daily Schedule Template

Figure 29. Copy a Schedule Template

Paste a Schedule

After copying a scheduled template, tap the Paste button.

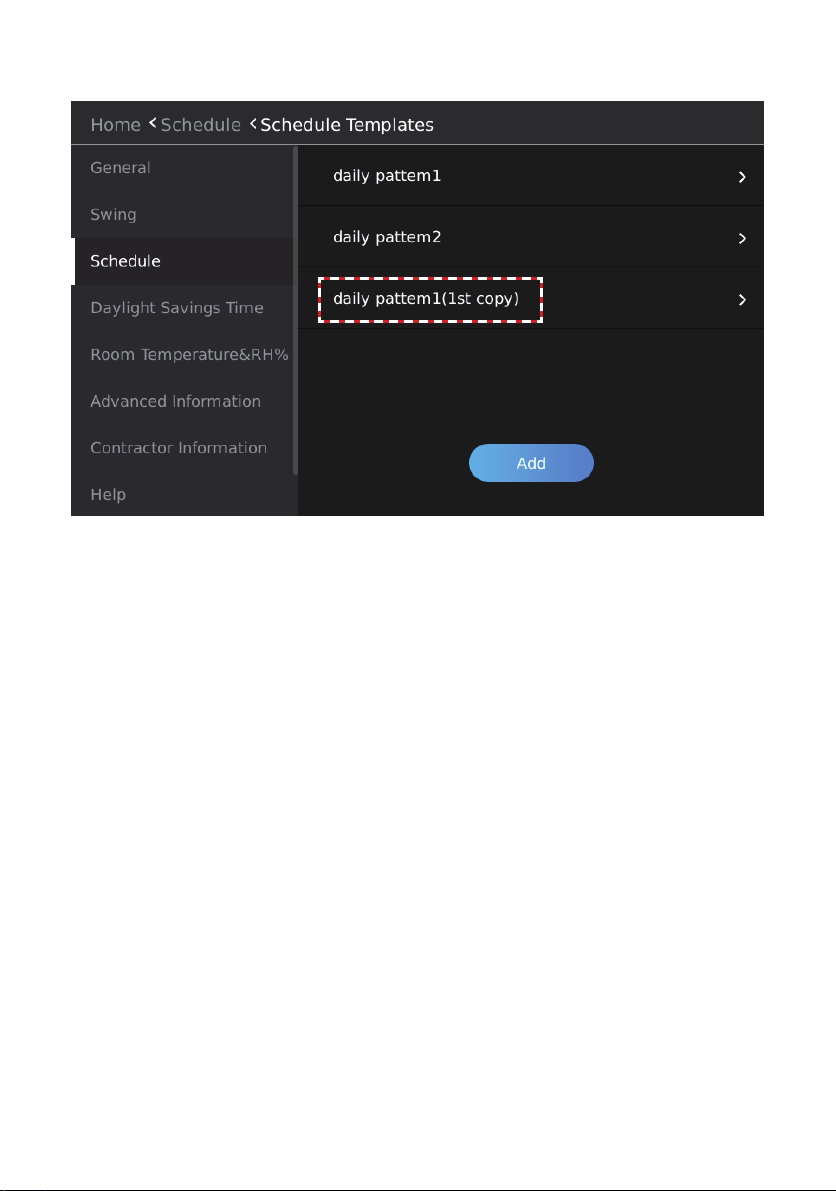

Figure 30. Paste to Create a New Schedule Template

32

Page 33

The new schedule template will display. Rename the template as needed.

Figure 31. New Schedule Template

33

Page 34

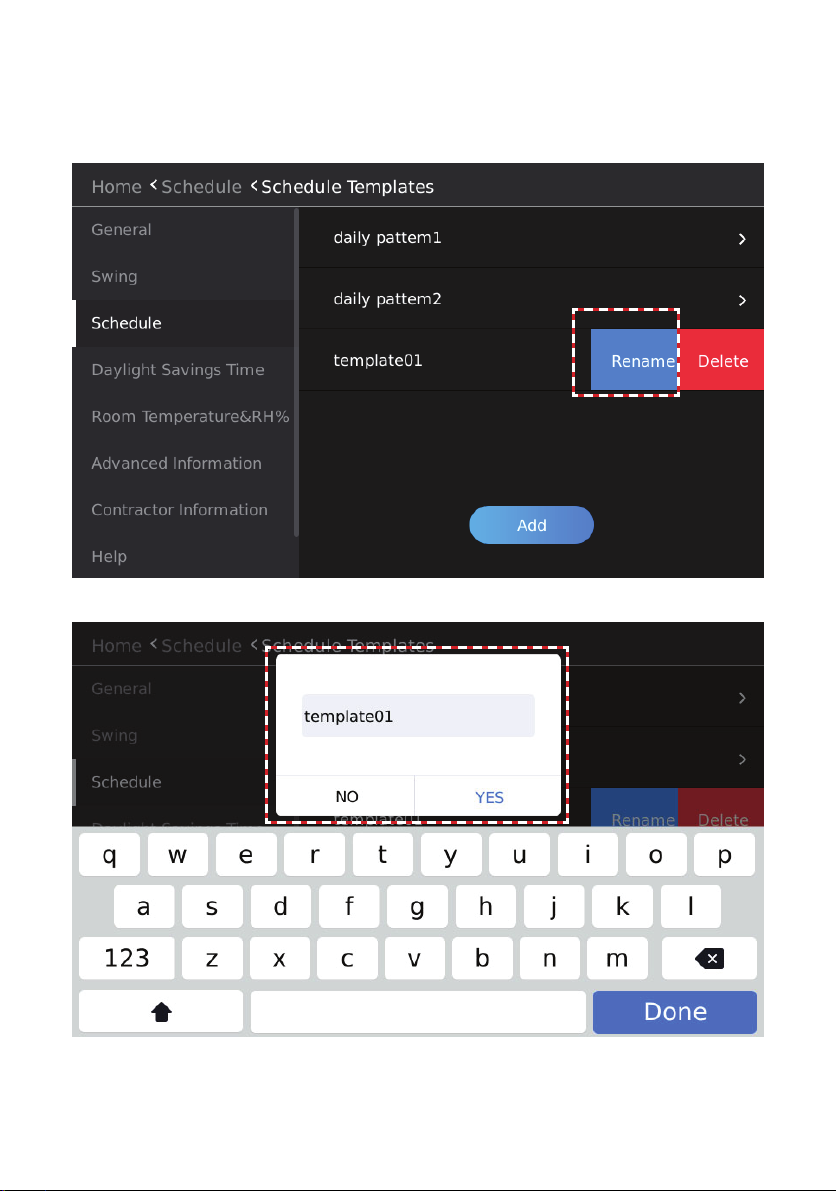

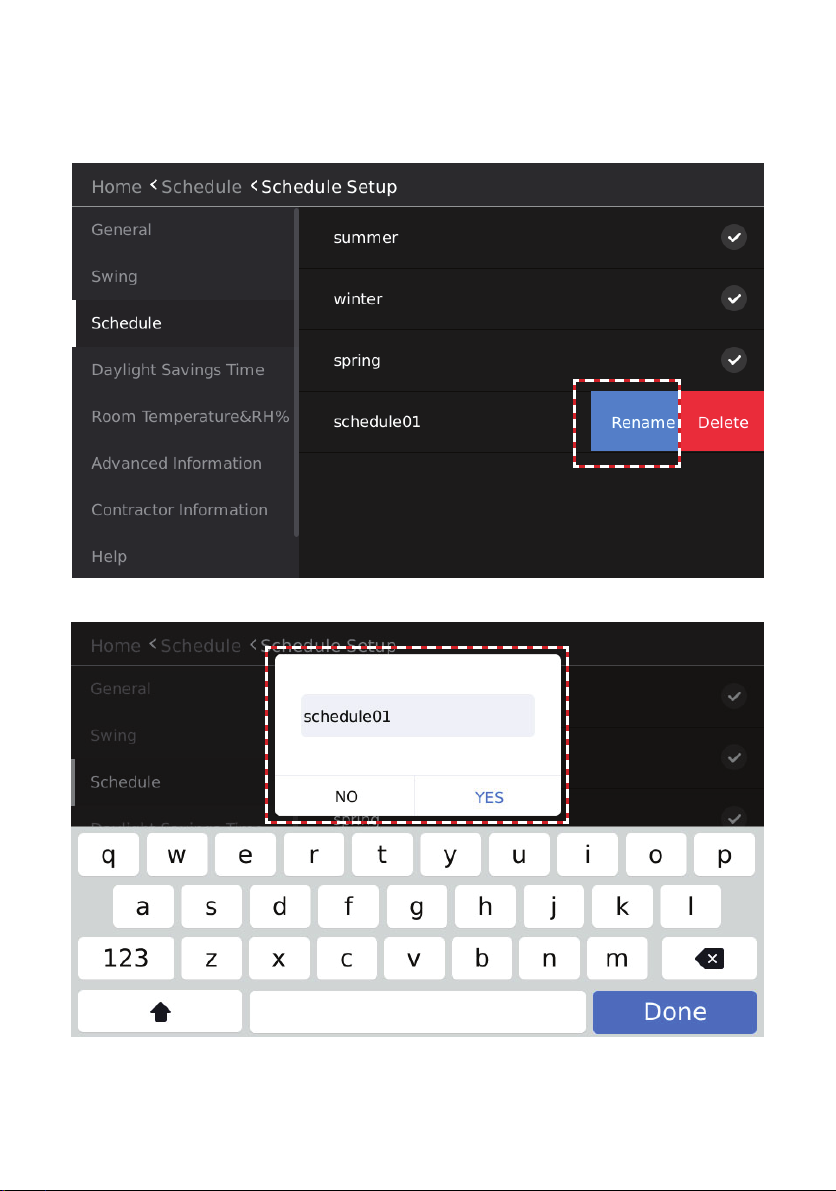

Rename a Schedule Template

Slide the daily schedule template to be deleted from the right to left, and “Rename” and “Delete”

boxes will display. Tap Rename and enter the new name in the Edit box. Tap Yes to conrm. Tap

Cancel to return to the previous screen.

Figure 32. Rename a Schedule Template

Figure 33. Enter Schedule Template Name

34

Page 35

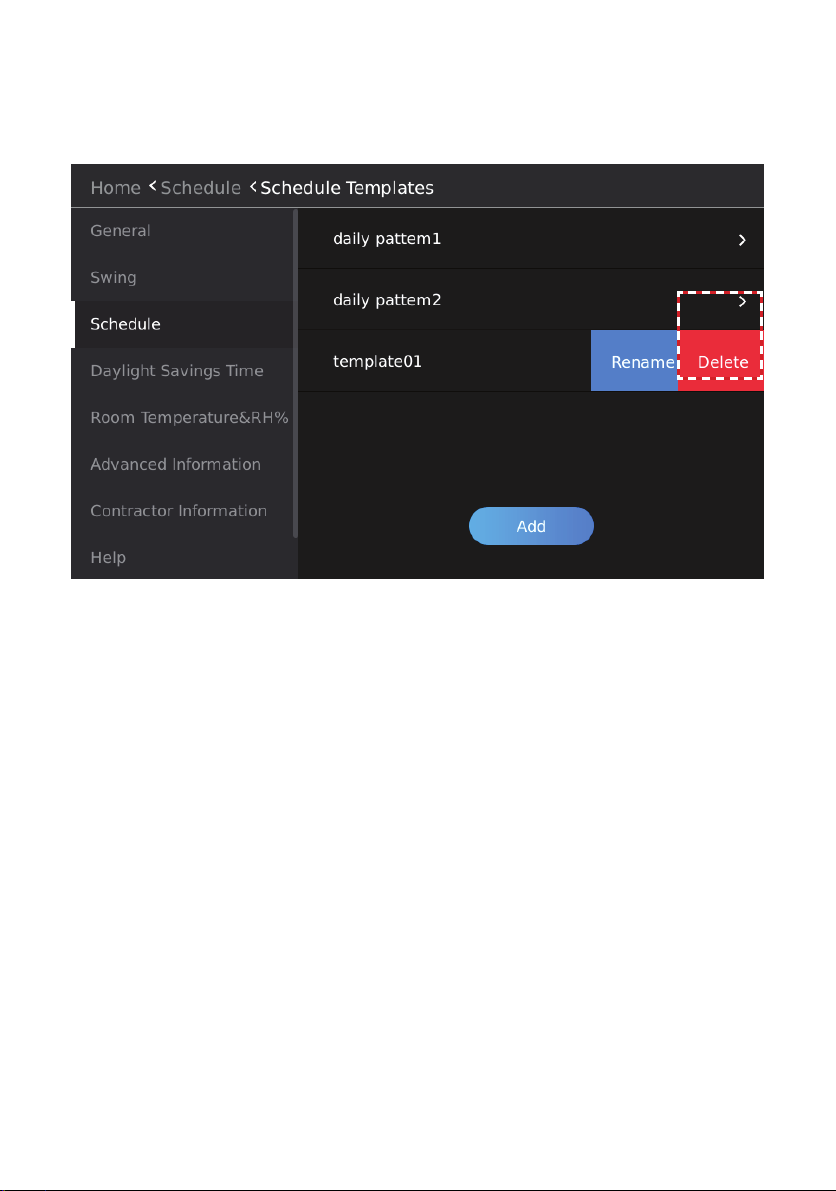

Delete a Schedule Template

Slide the daily schedule template to be deleted from the right to left, and “Rename” and “Delete”

boxes will display. Tap Delete and Tap Yes when prompted. Tap Cancel to return to the previous

screen.

Figure 34. Delete a Schedule Template

35

Page 36

Add a Daily Schedule Action

Tap the template to add the action to. Maximum of 8 actions per daily schedule template.

The Action setup screen will display. Select the Action’s Start Time, ON/OFF status, Operation

Mode, Cooling Setpoint, Heating Setpoint and Fan speed. Each action will end at the Start time of

the next action.

Figure 35. Add a Daily Schedule Action

Figure 36. Setup Daily Schedule Action

36

Page 37

Delete a Daily Schedule Action

Slide the daily schedule action that needs to be deleted from right to left, and the Delete box will

display.

Tap Delete to delete the daily schedule action.

Figure 37. Delete Daily Schedule Action

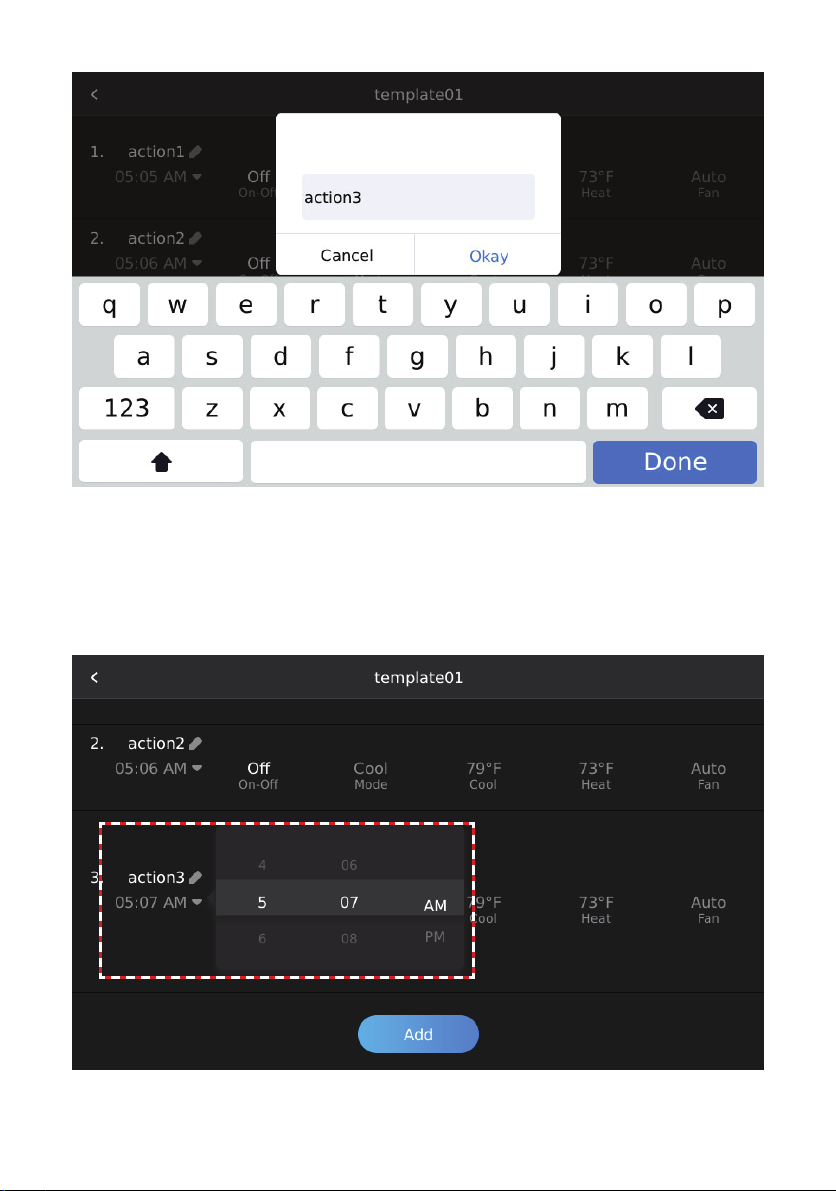

Rename a Daily Schedule Action

Tap the Edit button on the right of the action to rename the event.

Figure 38. Rename a Daily Schedule Action

37

Page 38

Figure 39. Rename a Daily Schedule Action Edit Box

Edit a Daily Schedule Action

Tap the daily schedule action content (e.g., time) that needs to be modied, and enter the daily

schedule action content editing mode.

Slide up/down to increase/decrease the value and modify the daily schedule action content.

The highlighted value in the middle is the currently set parameter.

Figure 40. Modify a Daily Schedule Action

38

Page 39

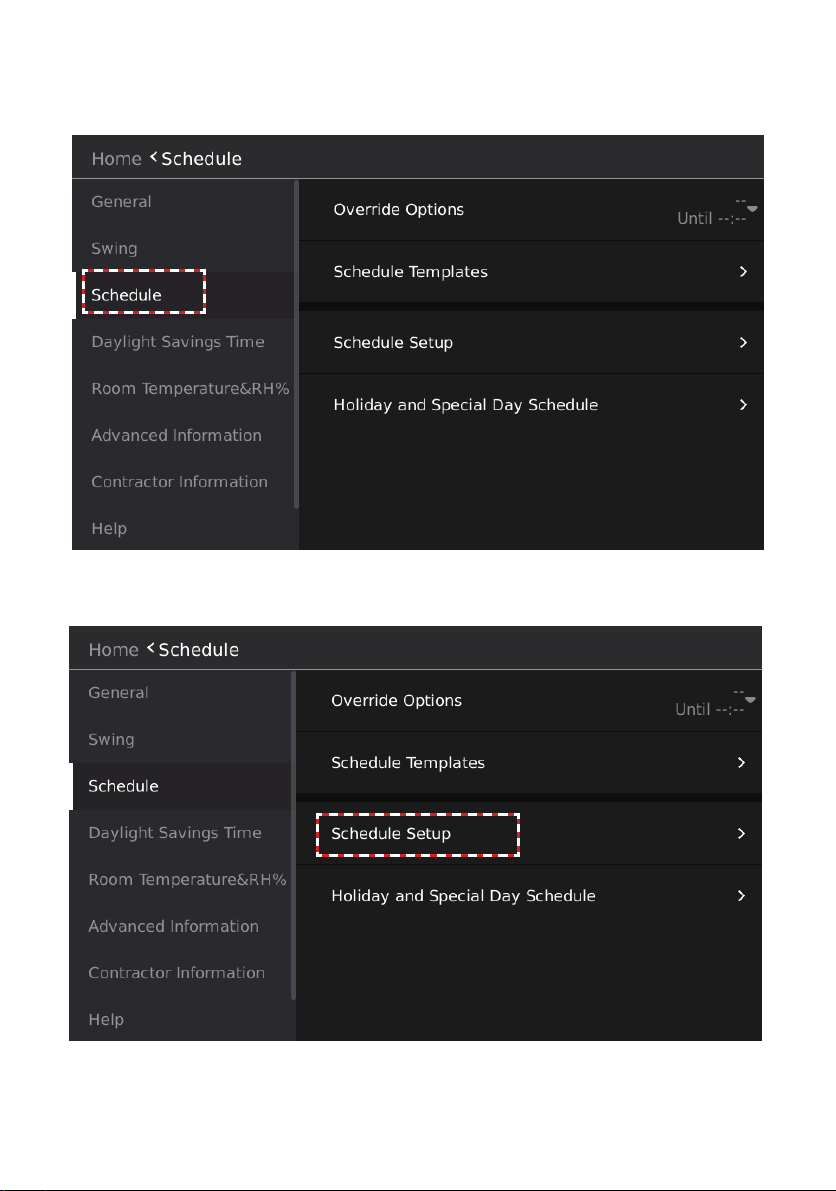

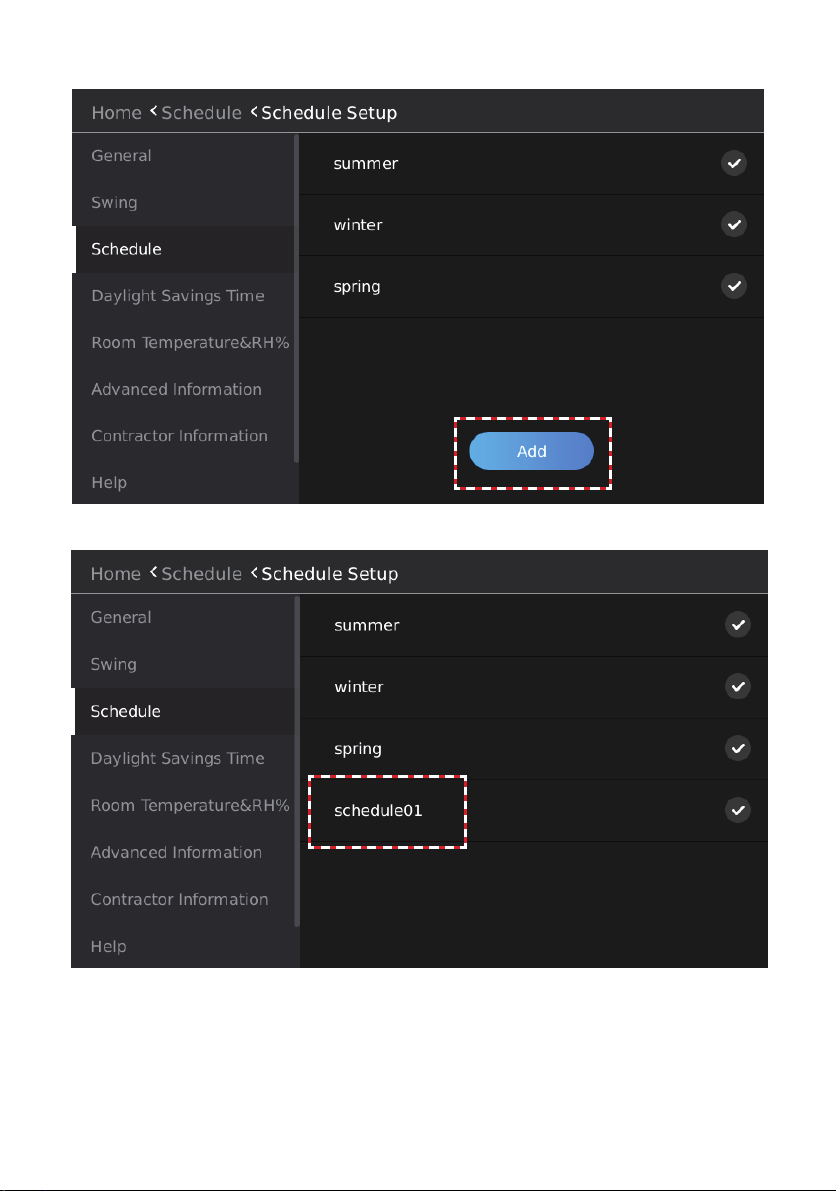

Setup a Weekly Schedule

Create a Weekly Schedule. Tap the Schedule button to access the schedule management settings

interface.

Figure 41. Tap Schedule Button to Access Schedule Settings

Tap the Schedule Setup button. The Schedule Setup screen will display.

Figure 42. Tap Schedule Setup Button

39

Page 40

Tap the Add button.

Figure43. Add a New Weekly Schedule

Figure 44. New Weekly Schedule

40

Page 41

Rename a Weekly Schedule

Slide the weekly schedule to be deleted from the right to left, and “Rename” and “Delete” boxes

will display. Tap Rename and enter the new name in the Edit box. Tap Yes to conrm. Tap Cancel

to return to the previous screen.

Figure 45. Rename a Weekly Schedule

Figure 46. Enter Weekly Schedule Name

41

Page 42

Delete a Weekly Schedule

Slide the weekly schedule to be deleted from the right to left, and “Rename” and “Delete” boxes

will display. Tap Delete and Tap Yes when prompted. Tap Cancel to return to the previous screen.

Figure 47. Delete a Schedule Template

Figure 47. Conrm Deletion

42

Page 43

Modify a Weekly Schedule

Enter the weekly schedule template content editing interface.

Tap the drop-down button on the right of “Everyday” and select the weekly schedule combination

mode.

Figure 49. Modify a Weekly Schedule

Table 3. Schedule Options

Schedule Description

Everyday

Set the schedule independently for each

day of the week.

Set the schedule uniformly for Monday

5+1+1

through Friday and independently for Saturday and Sunday.

Set the schedule uniformly for Monday

5+2

through Friday and uniformly for Saturday

and Sunday.

7

Set the schedule uniformly for each day of

the week.

43

Page 44

Tap the “daily pattern2” drop-down button to import the desired daily schedule template.

Figure 50. Select Daily Schedule Templates to Include in the Weekly Schedule

Select the Weekly Schedule to Use

Tap the button on the right of the weekly schedule template you want to select to complete the

weekly schedule selection. The selected icon is highlighted after selection.

44

Page 45

Setup Holiday and Special Day Schedules

Create a special schedule for holidays. Tap the Schedule button to access the schedule management settings interface.

Figure 51. Tap Schedule Button to Access Schedule Settings

Tap the Holiday and Special Day Schedule button. The Holiday and Special Day Schedule screen

will display.

Figure 52. Tap Schedule Setup Button

45

Page 46

Figure 53. Holiday & Special Day Schedule Screen

Add a Holiday and Special Day Schedule

Tap the Add button to create a new holiday schedule. The new schedule displays at the end of the

list.

Figure 54. New Holiday & Special Day Schedule

46

Page 47

Rename a Holiday and Special Day Schedules

Tap the name of the holiday schedule that you want to modify, enter the rename edit interface, and

type the name of the holiday.

Tap YES to nish naming and modifying the holiday schedule, or tap NO to return to the previous

page.

Figure 55. New Holiday & Special Day Schedule

Figure 56. Rename Holiday & Special Day Schedule

47

Page 48

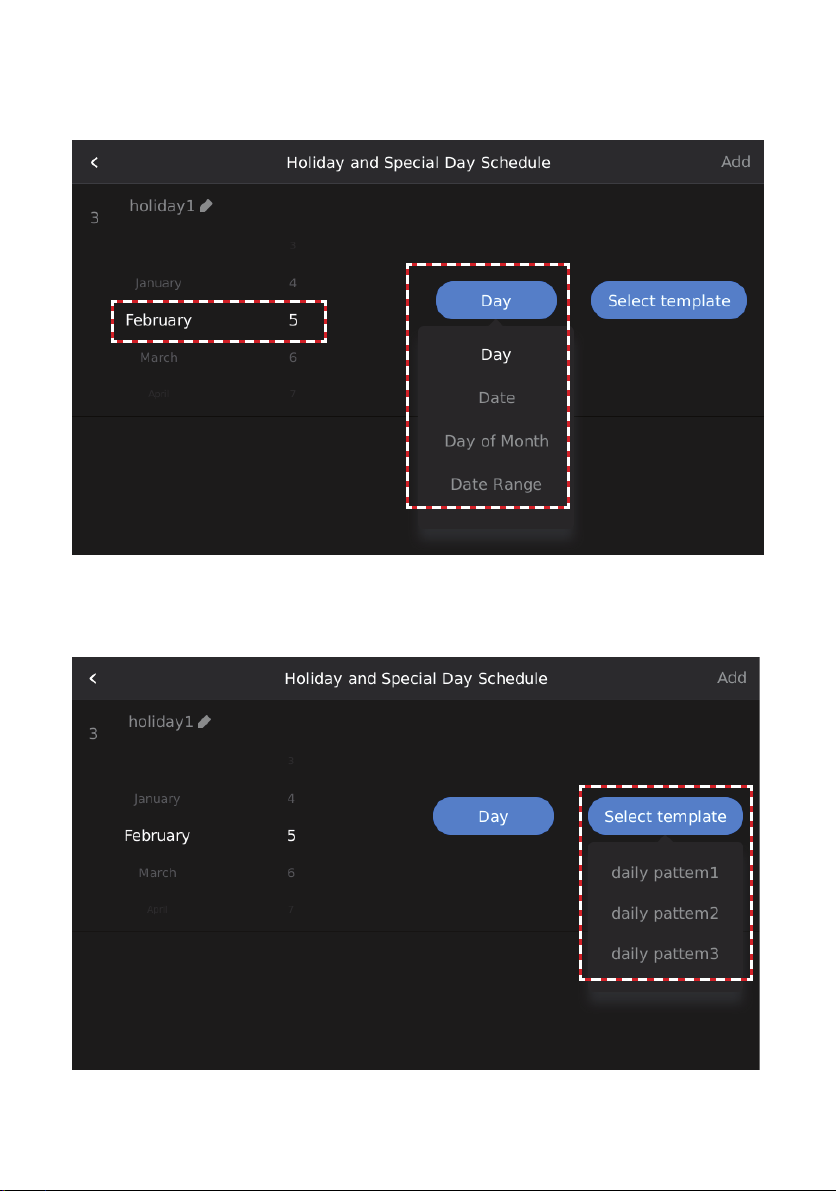

Modify a Holiday and Special Day Schedules

Tap the Day button of the holiday schedule that needs to be edited, select the type of holiday schedule date setting and set the date.

Figure 57 Select the Type of Holiday & Special Day Schedule

Tap the Select template button for the holiday schedule to be edited and select the daily schedule

template for the holiday.

Figure 58. Select the Daily Schedule Template for the Holiday Schedule

48

Page 49

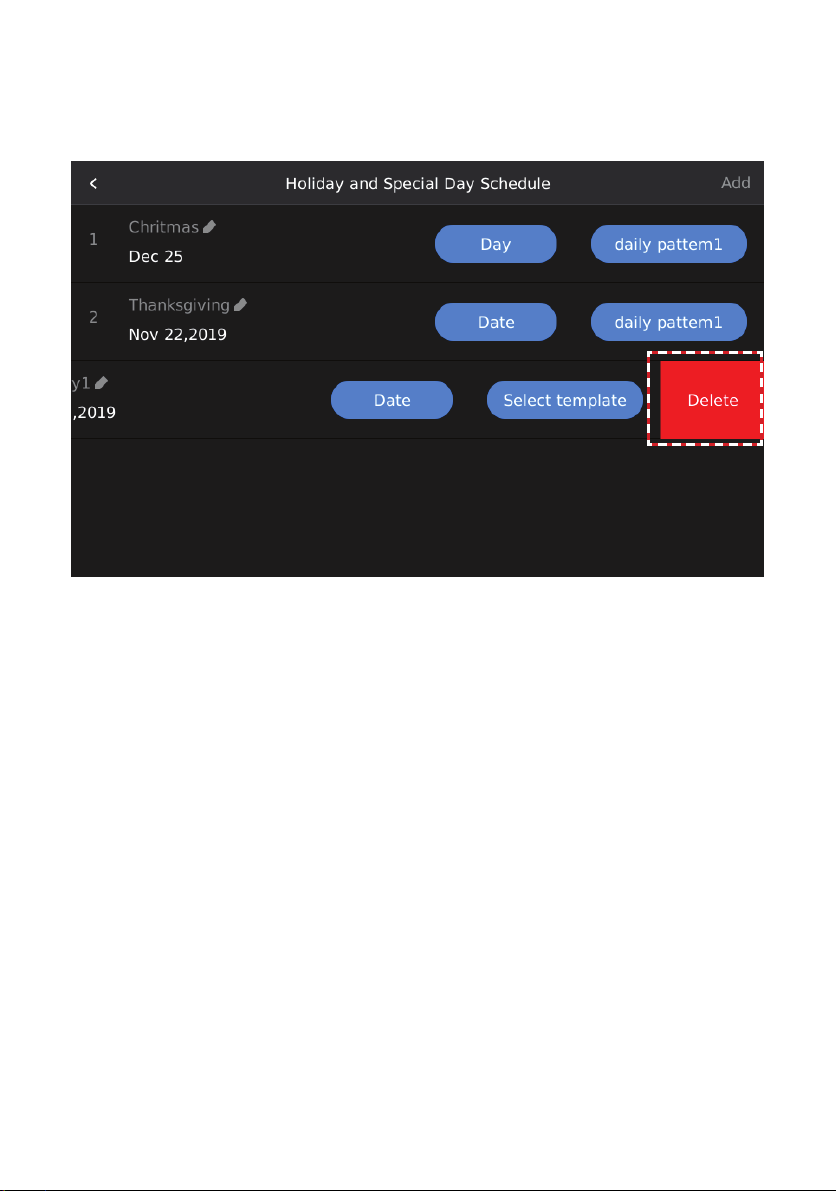

Delete a Holiday and Special Day Schedules

Slide the holiday schedule (e.g., holiday1) that needs to be deleted from right to left, and then a

Delete box will display.

Tap the Delete button to delete the selected holiday schedule.

Figure 59. Delete Holiday & Special Day Schedule

49

Page 50

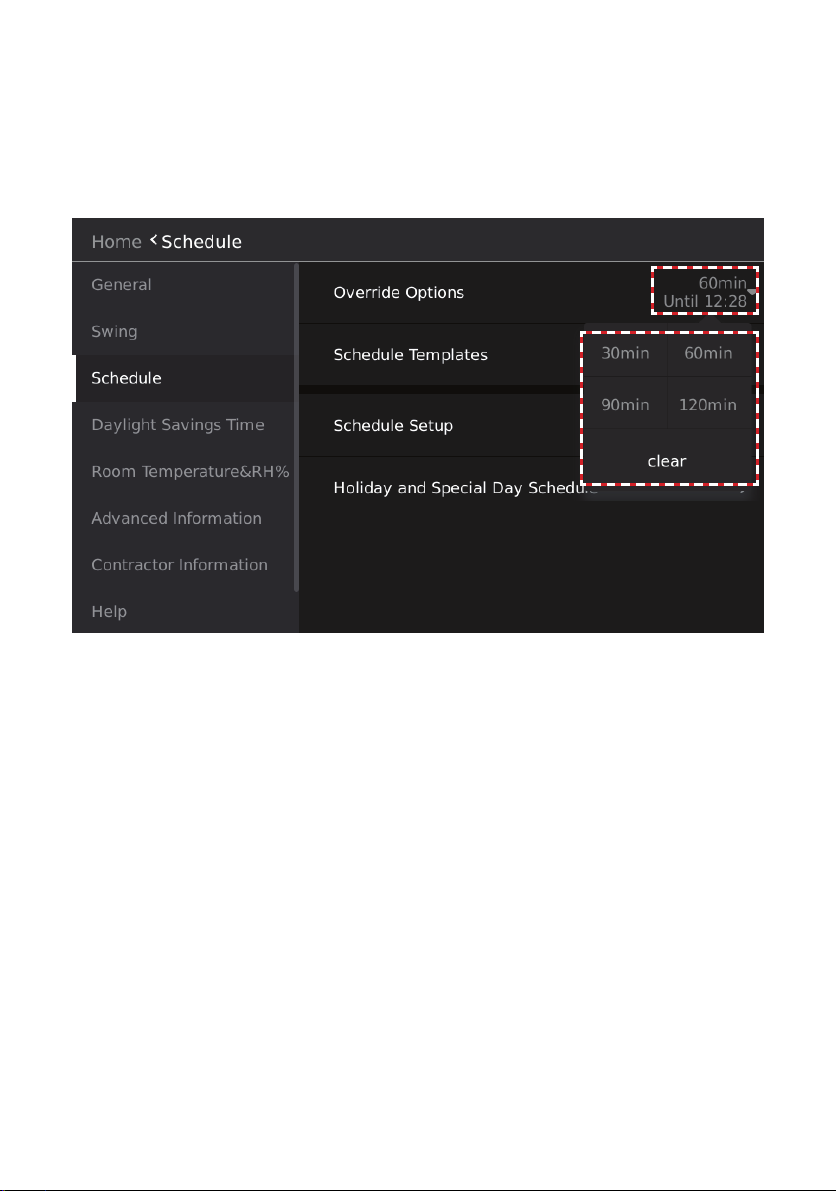

Override Scheduled Settings

Set the system to operate according to the current settings rather than the weekly schedule settings

for a period of time.

Tap the drop-down button on the right of Override Options to set the Override delay time. The Override time can be set to 30, 60, 90, or 120 minutes.

Clear will clear the set time.

After setting, the currently selected delay time is displayed to the right of Override Options.

Figure 60. Override Scheduled Settings

50

Page 51

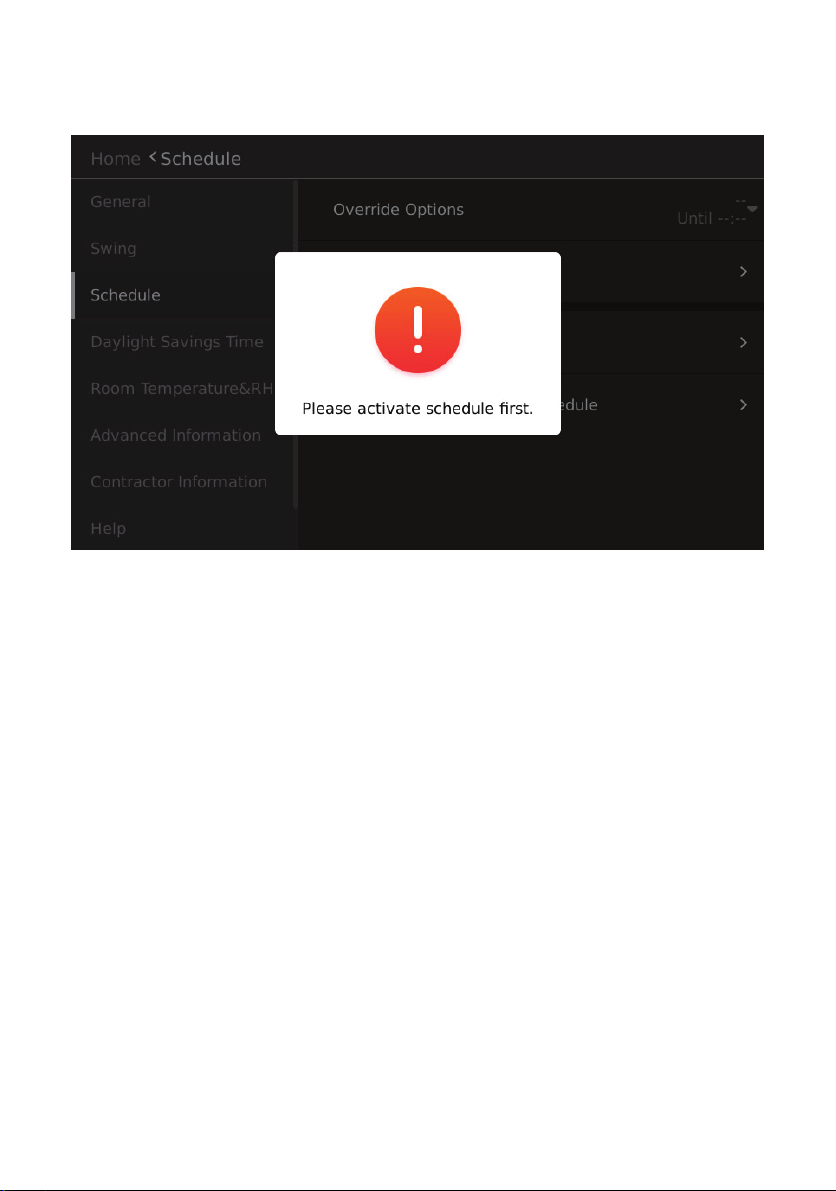

The Override function is only active when the weekly schedule function is enabled. If the weekly

schedule is inactive and the Override time is selected, the prompt box “Please activate schedule

rst” will display.

Figure 61. Activate Schedule Before Overriding Scheduled Settings

51

Page 52

General Settings Conguration

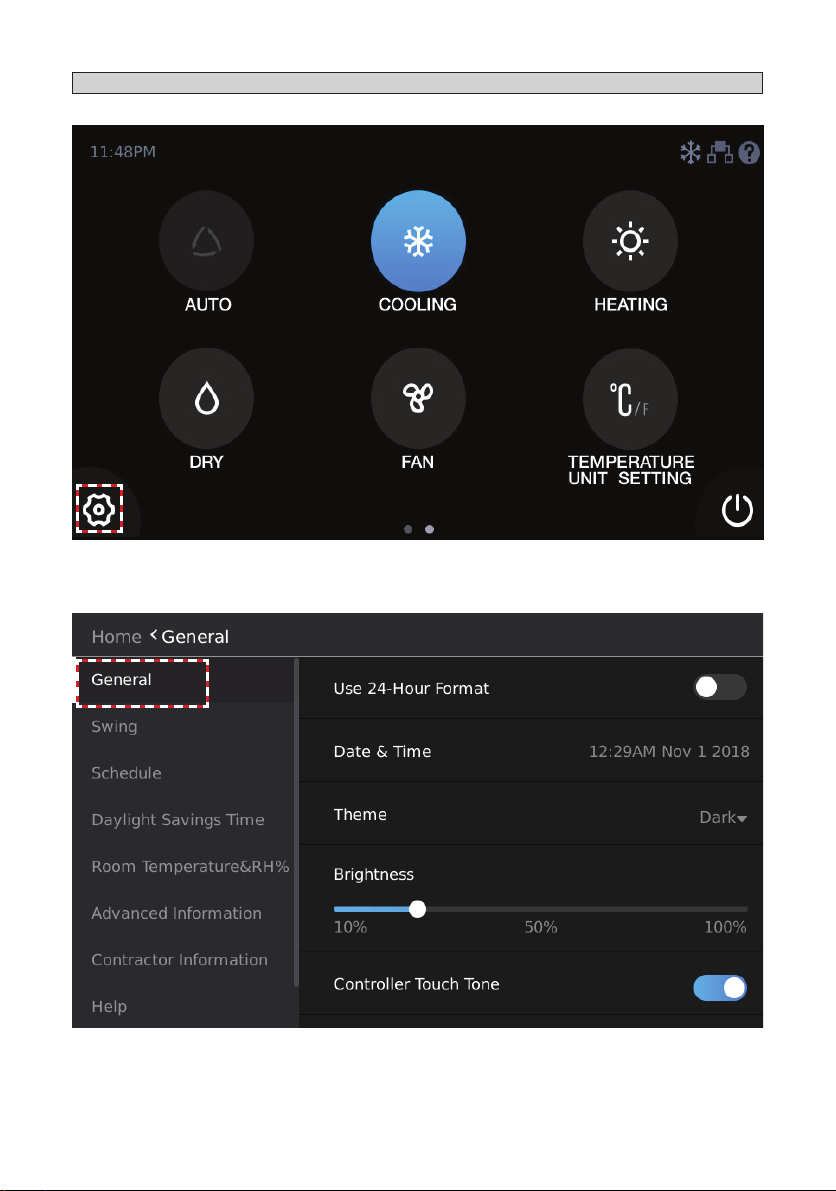

Tap the Settings icon on the main interface to enter the Settings interface.

Figure 62. Access the Settings Interface

Tap the General button to enter the wired controller settings interface.

Figure 63. General Settings Screen

52

Page 53

Time Format Settings

Slide or tap the button on the right of Use-24-Hour Format to switch between 12 hour and 24 hour

clock display.

Figure 64. Time Format Settings

Time Settings

Tap the area to the right of Data & Time, and the time settings box will display. Slide up/down in the

corresponding position to increase/decrease the value and change the time. The highlighted value

in the middle is the currently set parameter.

Figure 65. Time Settings

53

Page 54

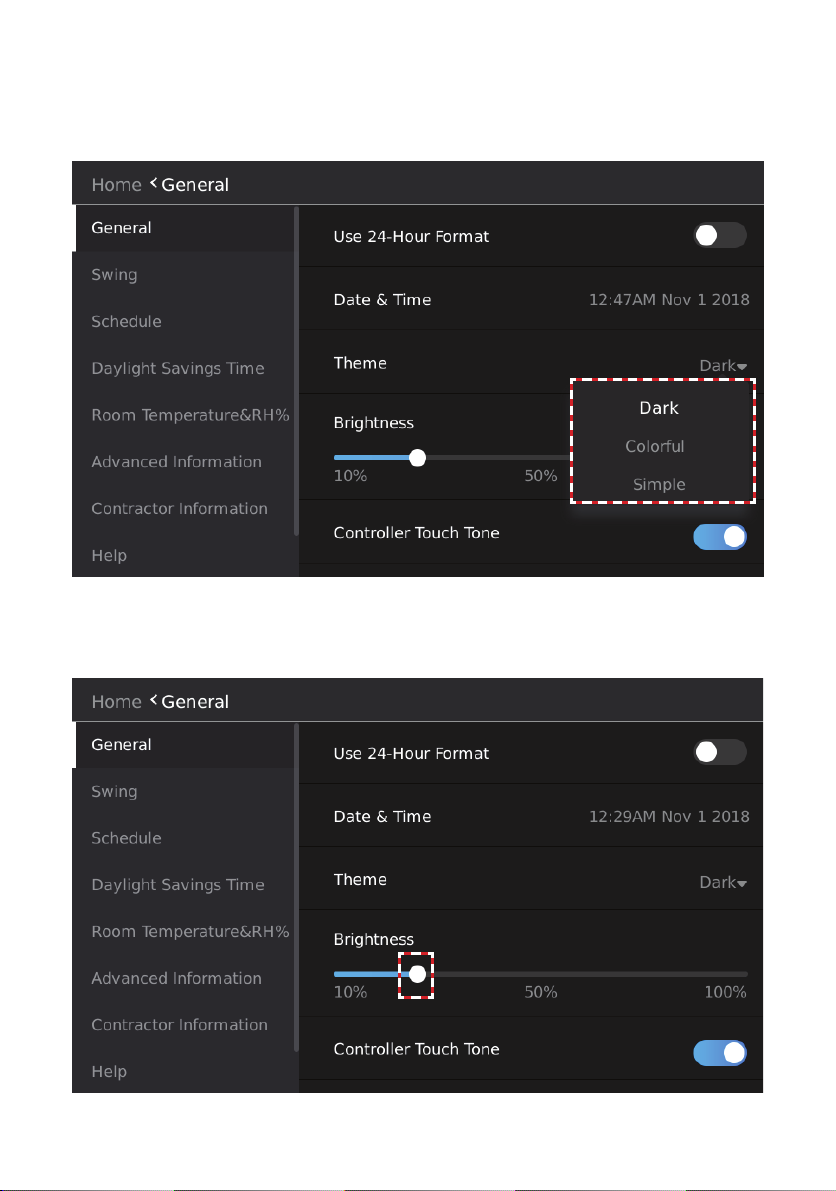

Theme Settings

Tap the drop-down symbol on the right of Theme and select a theme from the selection box that

displays.

There are three themes: Dark, Colorful and Simple.

Figure 66. Theme Settings

Brightness Settings

Slide the button below Brightness to complete the brightness modication.

The brightness range is 10%-100%.

Figure 67. Brightness Settings

54

Page 55

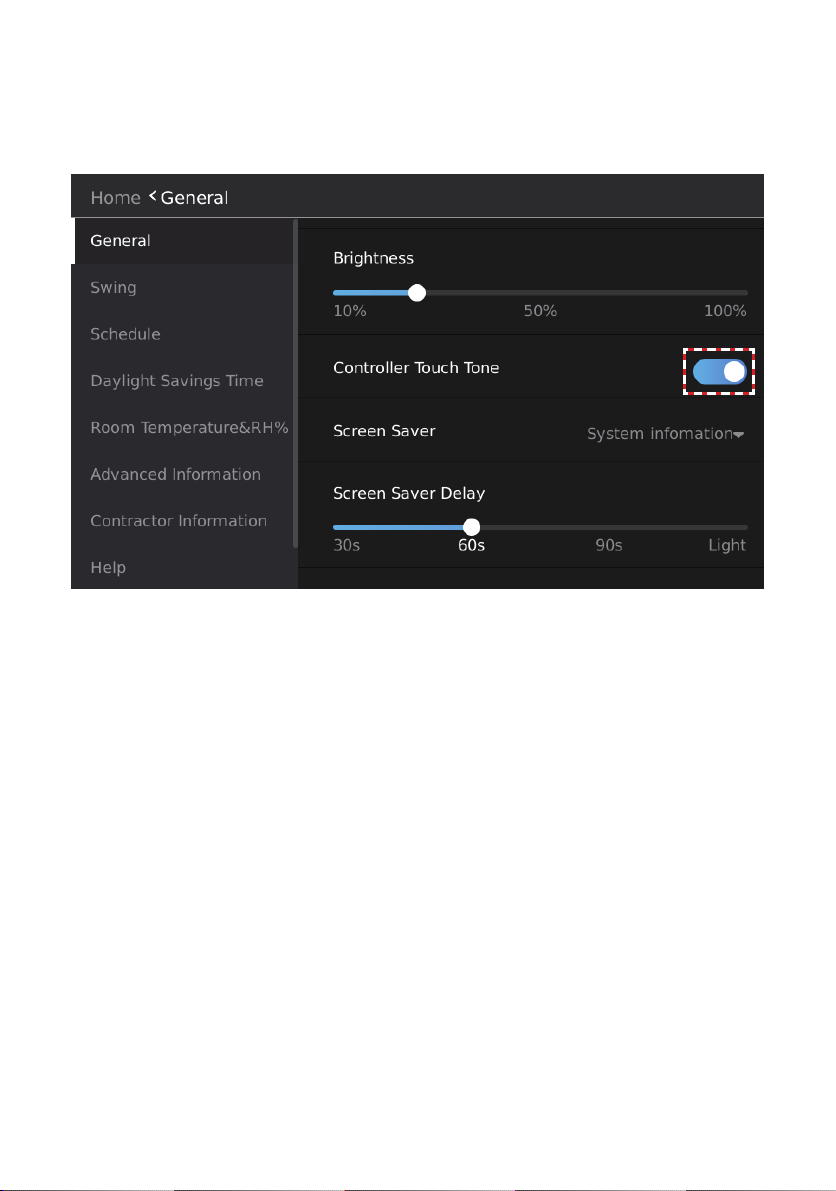

Controller Touch Tone (Sound) Settings

Slide or tap the button on the right of Controller Touch Tone to select whether the controller touch

tone is active.

When the touch tone is inactive, neither the controller nor the indoor unit will beep when a command is sent to the indoor unit.

Figure 68. Touch Tone (Sound) Settings

55

Page 56

Standby Interface (Screen Saver) Settings

Tap the drop-down symbol on the right of Screen Saver and select a standby screen in the selection box that appears.

The standby screen can be set to Blank, System Information, or Custom Image.

Figure 69. Standby Interface (Screen Saver) Settings

When you select the Custom Image theme, the box for selection of pictures on the USB will

display. You can then select the custom picture to use.

Tap Save to save the theme settings, or tap Cancel to return to the previous interface.

Figure 70. Select Custom Image

56

Page 57

NOTE - Custom image resolution is 800*480, in .png format, and the size must not exceed 100

KB.

Standby (Screen Saver) Duration Settings

Slide the button below Screen Saver Delay and select a time period after which the system enters

the standby interface when no operation is made.

Figure 71. Standby (Screen Saver) Duration

57

Page 58

Swing Angle Settings

Tap the Swing button to enter the swing angle settings interface.

Slide the Vertical button and select the angle of vertical swing.

Click the Horizontal button to select whether to enable horizontal swing.

Figure 72. Swing Settings

Daylight Savings Time Settings

Tap the Daylight Savings Time button to enter the daylight savings time setting interface.

Figure 73. Daylight Savings Time Settings

58

Page 59

Slide or tap the button on the right of Daylight Savings Time and select ON or OFF for daylight

savings time.

Tap the time zone on the right of Start and select the starting time of the daylight savings time.

Figure 74. Select Start Date and Time

Slide the date that needs to be modied up or down. The highlighted value in the middle is the

currently set parameter.

Figure 75. Select Start Date and Time

59

Page 60

Tap the time zone on the right of End and select the ending time of the daylight savings time.

Figure 76. Select Daylight Savings Time Start Date and Time

Slide the date that needs to be modied up or down. The highlighted value in the middle is the

currently set parameter.

Figure 77. Select Daylight Savings Time End Date and Time

60

Page 61

Room Temperature and Humidity Display Settings

Tap the Room Temperature&RH% button to enter the temperature and humidity display settings

interface.

Figure 78. Room Temperature & Relative Humidity (RH) % Settings

Tap the ºC/ºF button on the right of Temperature Unit to switch the temperature units.

Tap or slide the button on the right of Display Space Temperature On Homepage to choose

whether the main interface displays the temperature value.

Tap or slide the button on the right of Display RH% On Homepage to select whether the home

page displays the humidity value.

Figure 79. Room Temperature & Relative Humidity (RH) % Settings

61

Page 62

Contractor Information Input

Tap the Contractor Information button to enter the contractor information input interface.

Figure 80. Contractor Information

Type the information you want to display using the input information interface.

Tap YES to nish information input, or tap NO to return to the previous page.

Figure 81. Enter Contractor Information

62

Page 63

Service Menu

Access Service Menu

• Tap the Service Menu button to enter the password entry interface.

• Tap the corresponding number buttons to enter the correct service password.

• During password entry, tap the backspace key “←” to delete information.

• Tap X to clear all input information.

• The user password can be changed on the Lock screen within the Service Conguration Op-

tions. The default password is 0000.

Figure 82. Access Service Menu

63

Page 64

Change Password

1. Tap the Change button to enter the password modication interface. Tap the corresponding

number buttons and enter the old password once, and the new password twice.

2. Tap YES to conrm the password modication, or tap Cancel to exit the password modica-

tion interface.

Figure 83. Change Password

Figure 84. Enter New Password

64

Page 65

Master / Sub Wired Controller Settings

1. Tap the Master/Sub button to enter the Master / Sub wired controller setting screen.

2. Tap the Master or Sub button to identify the wired controller as a master/Sub controller.

3. Tap the Change button, and then the Restart the system to implement the change box will

display. Tap “ok”. The settings will be applied and the wired controller will restart automatically.

NOTE - Only one master controller is allowed in each group of indoor units.

Figure 85. Identify Controller as Master or Sub

65

Page 66

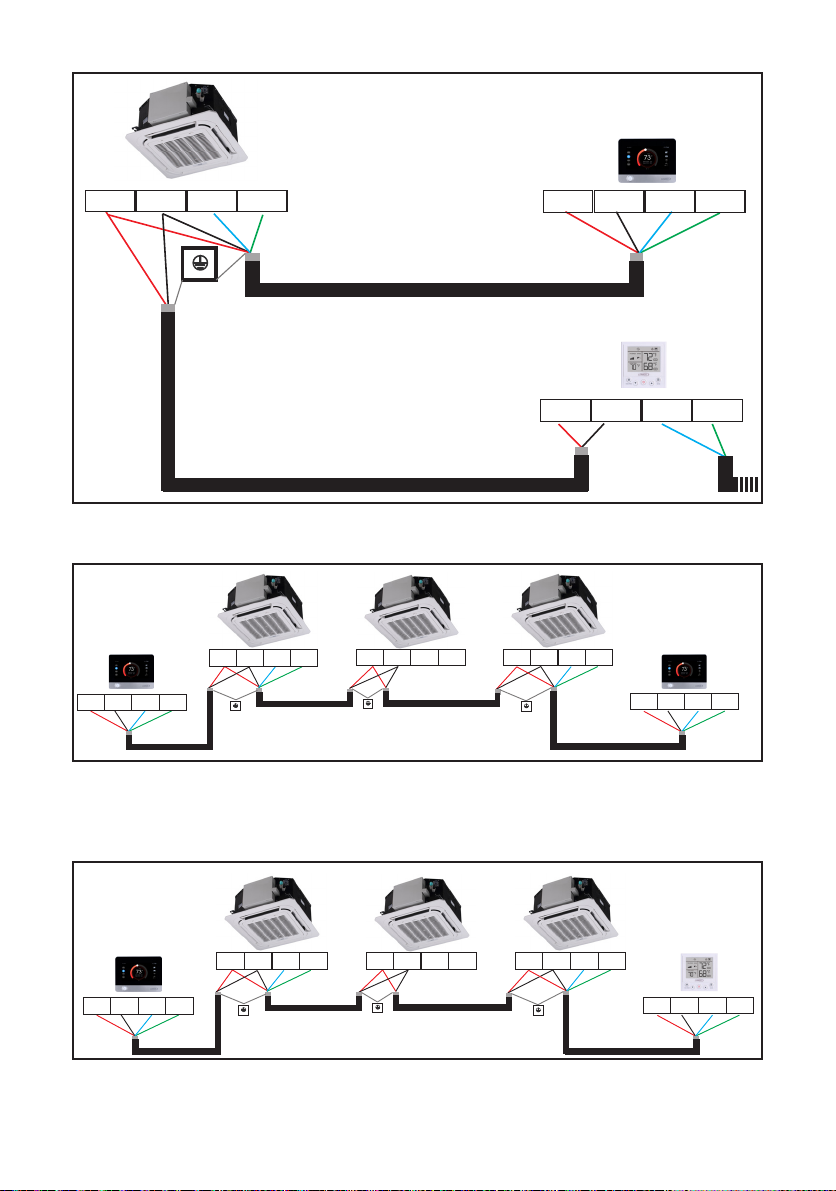

Master / Sub Wired Controller Operation

Up to two controllers can be connected to an indoor unit or group of indoor units. When two controllers are connected, one controller is the master controller and one is the sub controller for that

indoor unit or group of indoor units.

Both the master and sub controller can change the indoor unit’s operation. Other functionality is

limited to the master controller.

Table 4. Master/Sub Controller Operation of Indoor Unit

Function

ON/OFF Yes Yes Yes

Mode(Auto/Cooling/

Heating/Dry/Fan

Fan Speed Yes Yes Yes

Setpoint Yes Yes Yes

Swing Ye s Ye s Ye s

Schedule (including

holidays)

Override Yes No No

Temperature Unit Display Setting (°F/°C)

Setpoint Limit Yes No No

Master Controller

Available

Yes Yes Yes

Yes No No

Yes No No

Sub Controller

Available

Synchronize

Controller Display

HA

HB

COM

12V

HA

HA

Figure 86. Master/Sub Conguration: V0STAT51 Master & V0STAT51 Sub

66

HB

HB

COM

COM

12V

12V

Page 67

HA

HB

COM

12V

HA

HA

Figure 87. Master/Sub Conguration: V0STAT51 Master & V0STAT54 Sub

HB

HB

COM

COM

12V

12V

12V

HB

HA

COM

HA

12V

COM

HB

HA

12V

COM

HB

HA

12V

COM

HB

HA

12V

COM

HB

Figure 88. Master/Sub Conguration: Multiple Indoor Units Connected

V0STAT51 Master & V0STAT54 Sub

12V

HB

HA

COM

HA

12V

COM

HB

HA

12V

COM

HB

HA

12V

COM

HB

HA

12V

COM

HB

Figure 89. Master/Sub Conguration: Multiple Indoor Units Connected

V0STAT51 Master & V0STAT54 Sub

67

Page 68

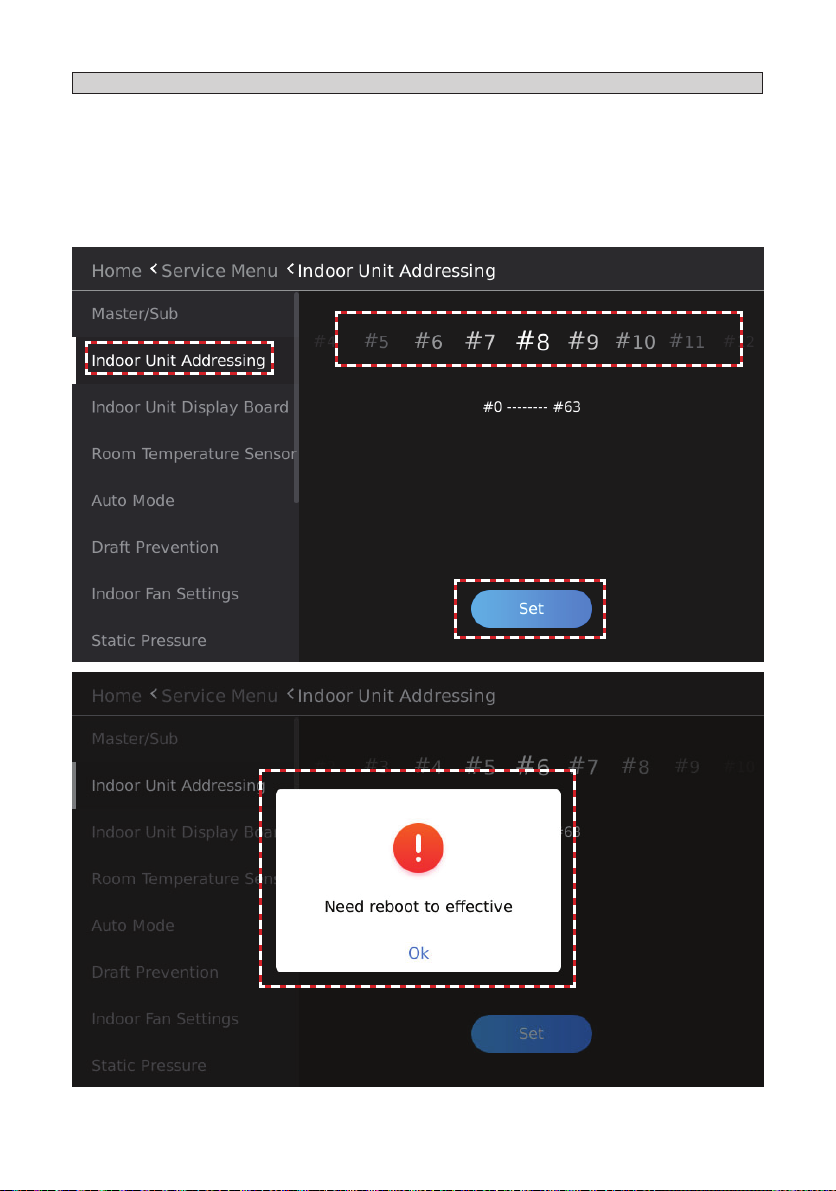

Indoor Unit Address Settings

1. Tap the Indoor Unit Addressing button on the screen to enter the Indoor unit address settings

screen.

2. Slide the number left and right, and select the address value that you want to assign to the

connected indoor unit.

3. Tap the Set button, and then the Need reboot to eective dialog will display.

4. Tap Ok. The settings will take eect and the wired controller will restart automatically.

NOTE - Requires a one-to-one connection to the indoor unit.

Figure 90. Assign Indoor Unit Address

68

Page 69

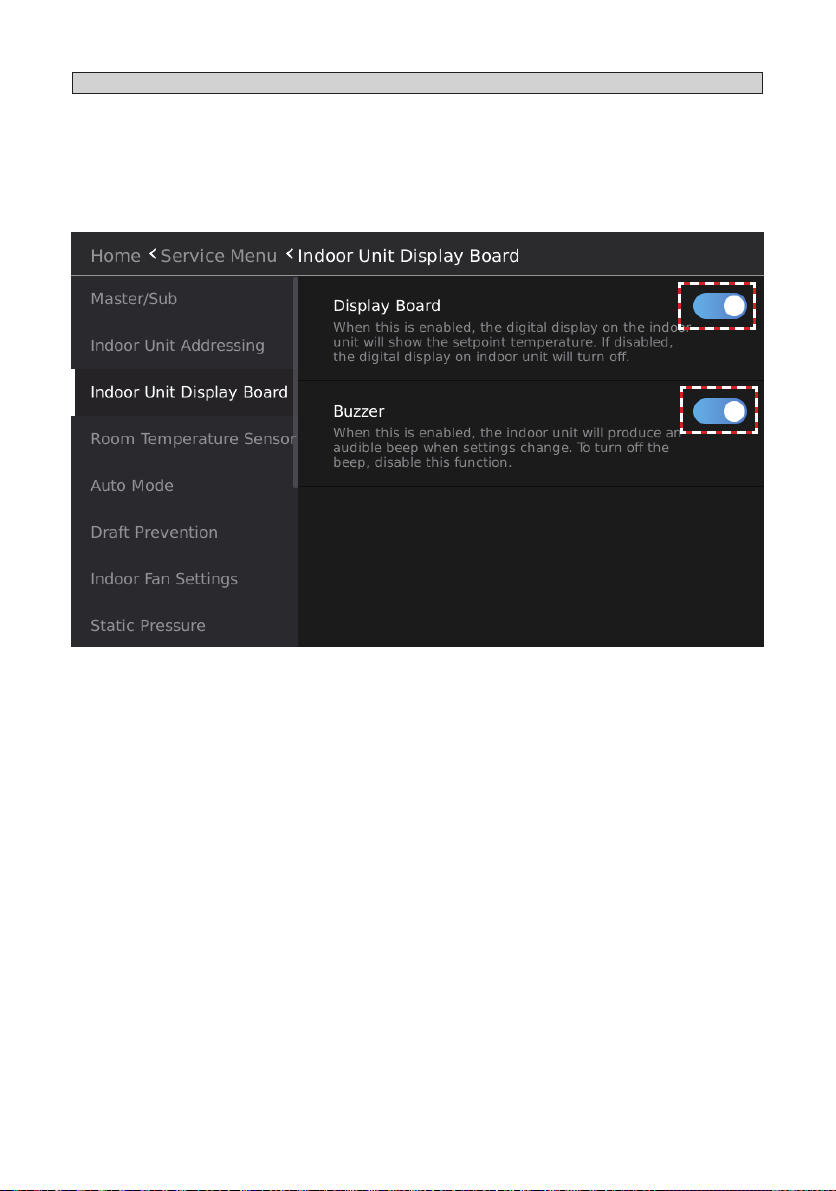

Indoor Unit Display Board & Buzzer (Sound) Settings

1. Tap the Indoor Unit Display Board button to access the Indoor unit display board and buzzer

settings screen.

2. Slide or tap the button on the right of Display Board to select whether to enable the display

function of the indoor unit display board.

3. Slide or tap the button on the right of Buzzer to select whether to enable the buzzer (sound)

function of the indoor unit display board.

Figure 91. Indoor Unit Display & Buzzer (Sound) Settings

69

Page 70

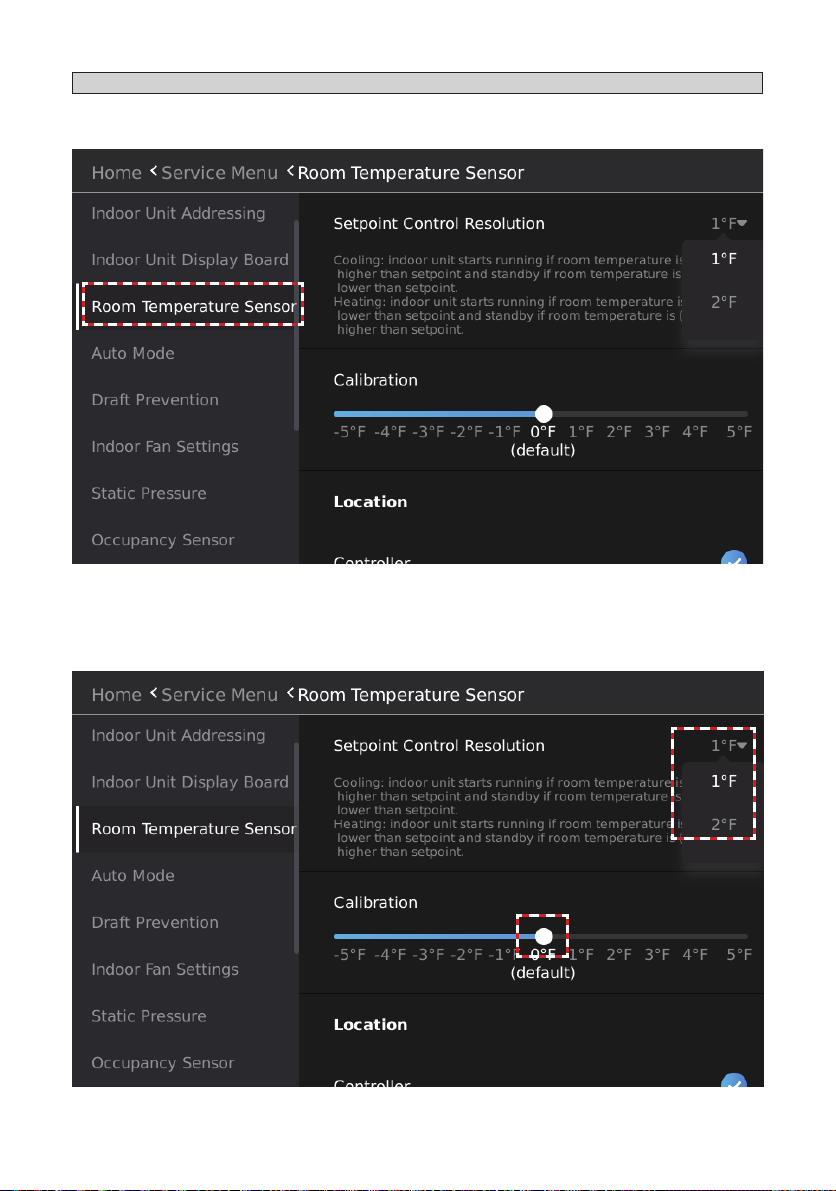

Room Temperature Sensor Settings

1. Tap the Room Temperature Sensor button to access the room temperature sensor settings

screen.

Figure 92. Room Temperature Sensor Settings

2. Tap the drop-down button on the right of Setpoint Control Resolution and select the return

dierence temperature.

3. Slide the Calibration button and select the room temperature calibration value.

Figure 93. Room Temperature Control Resolution & Calibration

70

Page 71

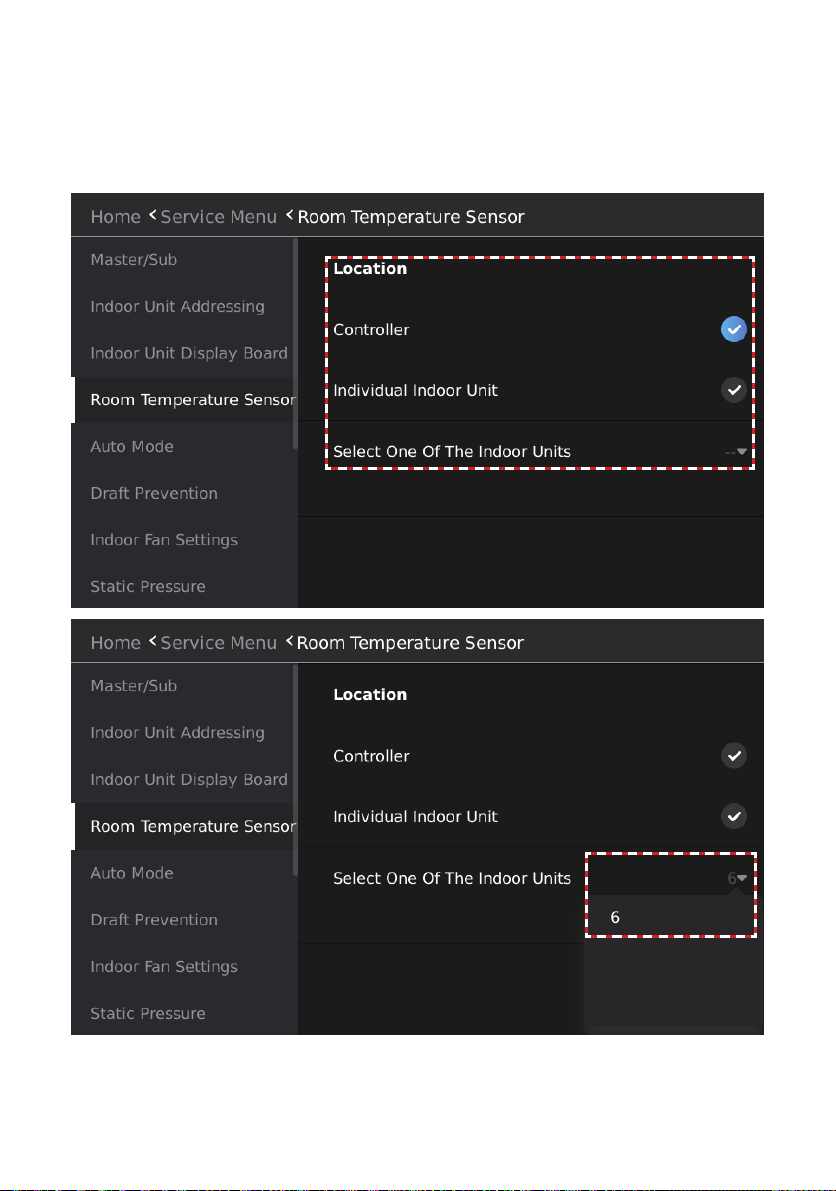

Tap the button below Location and select the Return Air (T1) temperature sensor location.

Controller. Use the controller’s T1 (return air) sensor for all connected indoor units.

Individual Indoor Unit. All connected indoor units will use their own T1 (return air) sensor.

Select One Of The Indoor Units. All connected indoor units will use the T1 (return air) sen-

sor of the selected indoor unit. Tap the drop-down button on the right and select the address

of indoor unit.

Figure 94. Select Return Air Sensor Location

71

Page 72

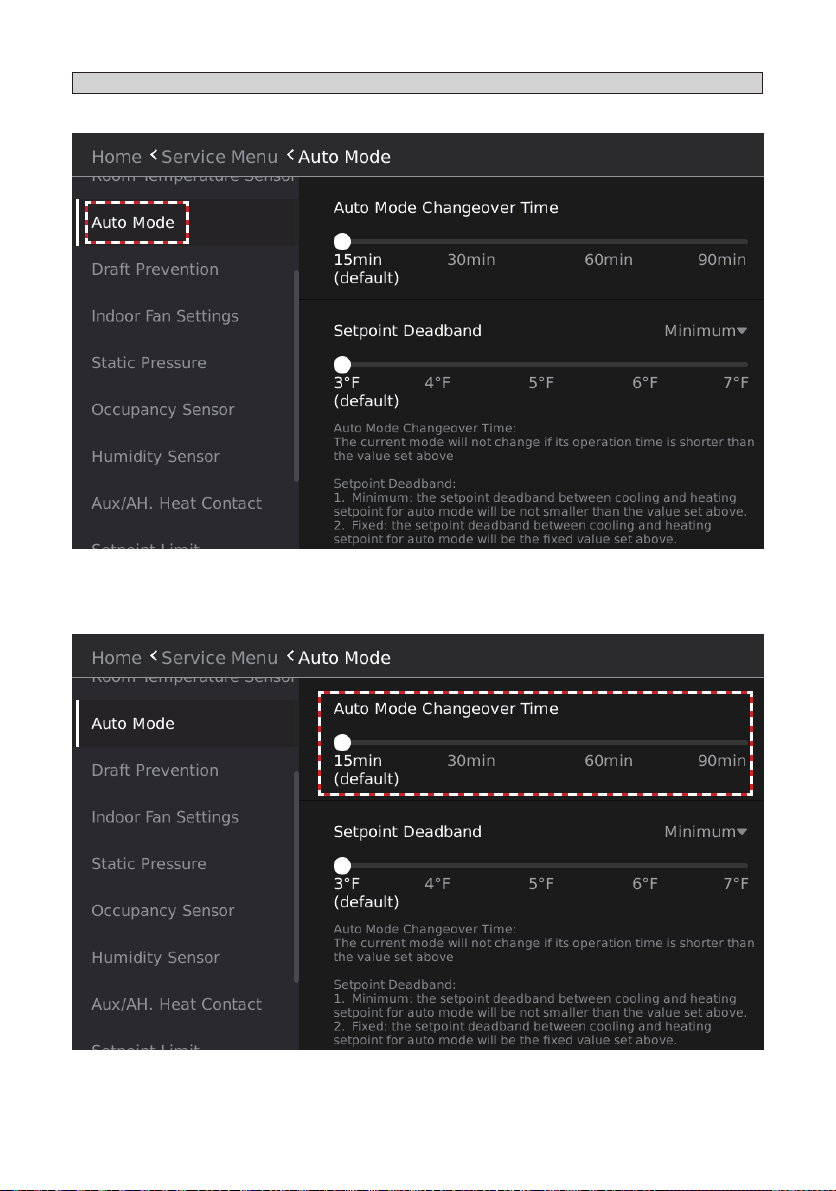

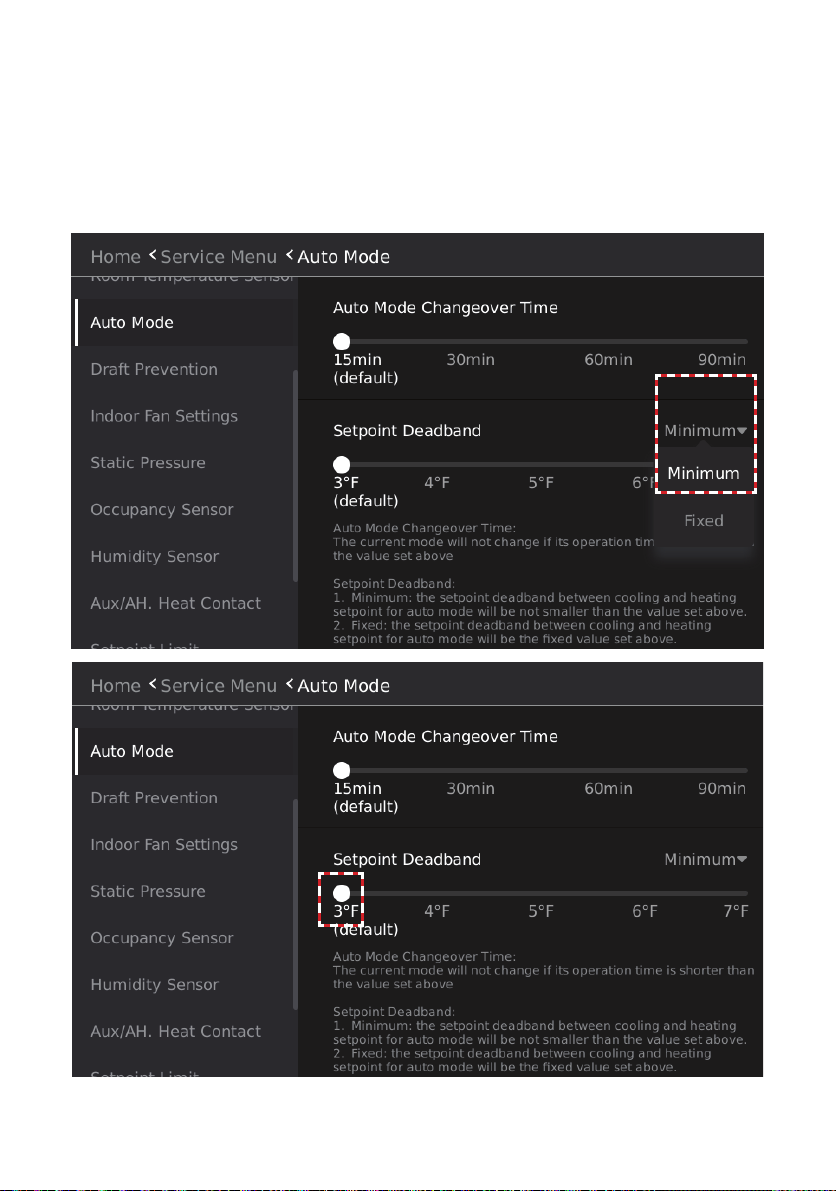

Auto Mode Settings

• Tap the Auto Mode button to access the room auto mode settings screen.

Figure 95. Auto Mode Settings

• Slide the button below Auto Mode Changeover Time and select the auto mode changeover

time.

Figure 96. Auto Mode Changeover Time

72

Page 73

• Tap the drop-down button on the right of Setpoint Deadband and select the method for setting

the temperature dierence between the cooling setpoint and heating setpoint in Auto mode.

• When the Setpoint Deadband in Auto mode is set to Minimum, the temperature dierence

between the cooling setpoint and the heating setpoint is set to a minimum value.

• When the Setpoint Deadband in Auto mode is set to Fixed, the temperature dierence be-

tween the cooling setpoint and the heating setpoint is set to a xed value.

• Slide the button below Setpoint Deadband and select the dierence between the setpoint for

auto mode in cooling and the setpoint for auto mode in heating.

Figure 97. Auto Mode Setpoint Deadband

73

Page 74

Draft (Cold Blow) Prevention Settings

Set the temperature the coil must reach before the fan engages to prevent cold air from being

distributed from the indoor unit.

1. Tap the Draft Prevention button to enter the cold air prevention temperature settings page.

2. Slide the temperature selection button and select the cold air prevention temperature set

value.

Figure 98. Draft (Cold Blow) Prevention

74

Page 75

Stand-by Fan Speed Settings

Set the indoor unit fan operation when the indoor unit setpoint is satised.

1. Tap the Indoor Fan Settings button to enter the stand-by fan speed settings interface.

2. Slide the button below Cooling and select the fan status setting when the cooling setpoint is

satised.

3. Slide the button below Heating and select the fan status setting when the heating setpoint is

satised.

Figure 99. Indoor Fan Settings

75

Page 76

Indoor Unit Static Pressure Settings

Set the indoor unit static pressure. Ducted units only.

1. Tap the Static Pressure button to enter the static pressure settings screen.

2. Slide the static pressure selection button and select the static pressure setting.

NOTE - Requires a one-to-one connection to the indoor unit.

Figure 100. Static Pressure Settings

76

Page 77

Occupancy Sensor Function Settings

Setup the controller’s occupancy sensor.

1. Tap the Occupancy Sensor button to access the occupancy sensor function settings screen.

2. Slide the button on the right of Occupancy Sensor to select whether to enable the occu-

pancy sensor function.

3. Slide the button below Delay to select the duration of the detection of the unoccupied status.

4. Slide the button below Unoccupied Setpoint Oset and select the temperature change value

when unoccupied status is detected.

5. Tap the drop-down button on the right of Heating Set Back and select the temperature limit

to enter the set back operation period.

Figure 101. Occupancy Sensor Function Settings

77

Page 78

Dry Mode Settings

Setup humidity sensing from the controller.

1. Tap the Humidity Sensor button to enter the auto dry mode settings screen.

2. Slide the button on the right of Auto Dry and choose whether to enable the Auto Dry function.

3. Slide the slider on the right of Dehumidier Contact and select whether to install the dehu-

midier in the indoor unit.

4. Slide the value below Target RH% to set the indoor target humidity. The highlighted value in

the middle is the current set parameter.

5. Slide the number below Cuto to set the limit when the Cuto dehumidication operation

temperature is lower than the set temperature. The highlighted value in the middle is the

currently set parameter.

Figure 102. Occupancy Sensor Function Settings

78

Page 79

Auxiliary / Alternate Heat Settings

Setup auxiliary and alternate heat source activation from the controller.

1. Tap the Aux/AH. Heat Contact button to access the auxiliary heat source function settings

page.

2. Select the button on the right of No Auxiliary/Alternative Heat Installed, Aux/Alt Heat Installed

at IDU or in Duct or Other Aux/Alt Heat Installation and conrm the installation method of the

auxiliary heat source.

Figure 103. Auxiliary / Alternate Heat Settings

79

Page 80

3. Slide the Heat On temperature value below Auxiliary heat. The highlighted value in the

middle is the currently selected parameter. This means that when the indoor ambient tem-

perature is Δt1 lower than the set temperature, the external heat source is turned on.

4. Slide the Heat O temperature value below Auxiliary heat. The highlighted value in the

middle is the currently selected parameter. This means that when when the indoor ambient

temperature is Δt2 higher than the set temperature, the auxiliary heat source is turned o.

Figure 104. Auxiliary / Alternate Heat ON and OFF Settings

80

Page 81

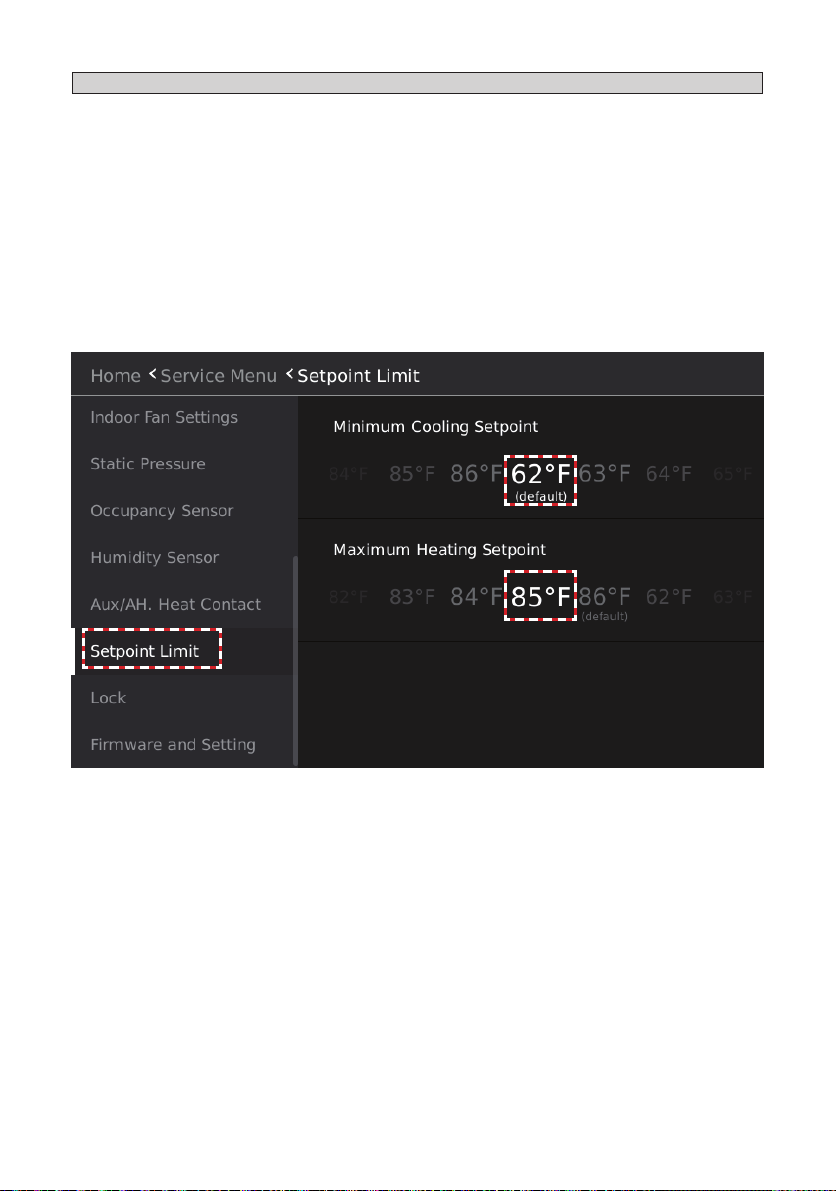

Setpoint Limit Settings

Setup auxiliary and alternate heat source activation from the controller.

1. Tap the Setpoint Limit button to enter the setpoint limit screen.

2. Slide the temperature value below Minimum Cooling Setpoint and select the minimum cool-

ing setpoint. The highlighted value in the middle is the currently selected parameter. After

setting the minimum cooling setpoint, the user will be unable to set a value lower than this

set value when adjusting the setpoint in Cooling mode and Dry mode, or the cooling setpoint

in Auto mode.

3. Slide the temperature value below Maximum Heating Setpoint and select the maximum of

the heating setpoint. The highlighted value in the middle is the currently selected parameter.

After setting the maximum heating setpoint, the user will be unable to set a value higher

than this set value when adjusting the setpoint in Heating mode, or the heating setpoint in

Auto mode.

Figure 105. Setpoint Limit Settings

81

Page 82

Locking Function Settings

Lock the button operation of the controller to prevent the user from adjusting the controller.

1. Tap the Lock button to access the locking function settings screen.

2. Slide the button on the right of ON/OFF, Mode, Temperature Setpoint, Schedule, Horizontal

Louver or Vertical Louver to select whether to lock the parameter.

NOTE - When functionality is locked, the Lock icon will display on the Home screen.

Figure 106. Locking Function Settings

Table 5. Lock Functions

Locking Type Description

ON/OFF Lock the ON/OFF button operation of the wired controller.

Mode Lock the operation mode button operation of the wired controller.

Temperature

Setpoint

Lock the set temperature adjustment button operation of the wired controller.

Schedule Lock the weekly schedule operation parameter.

Horizontal Louver Lock the vertical swing button operation of the wired controller.

Vertical Louver Lock the horizontal swing button operation of the wired controller.

82

Page 83

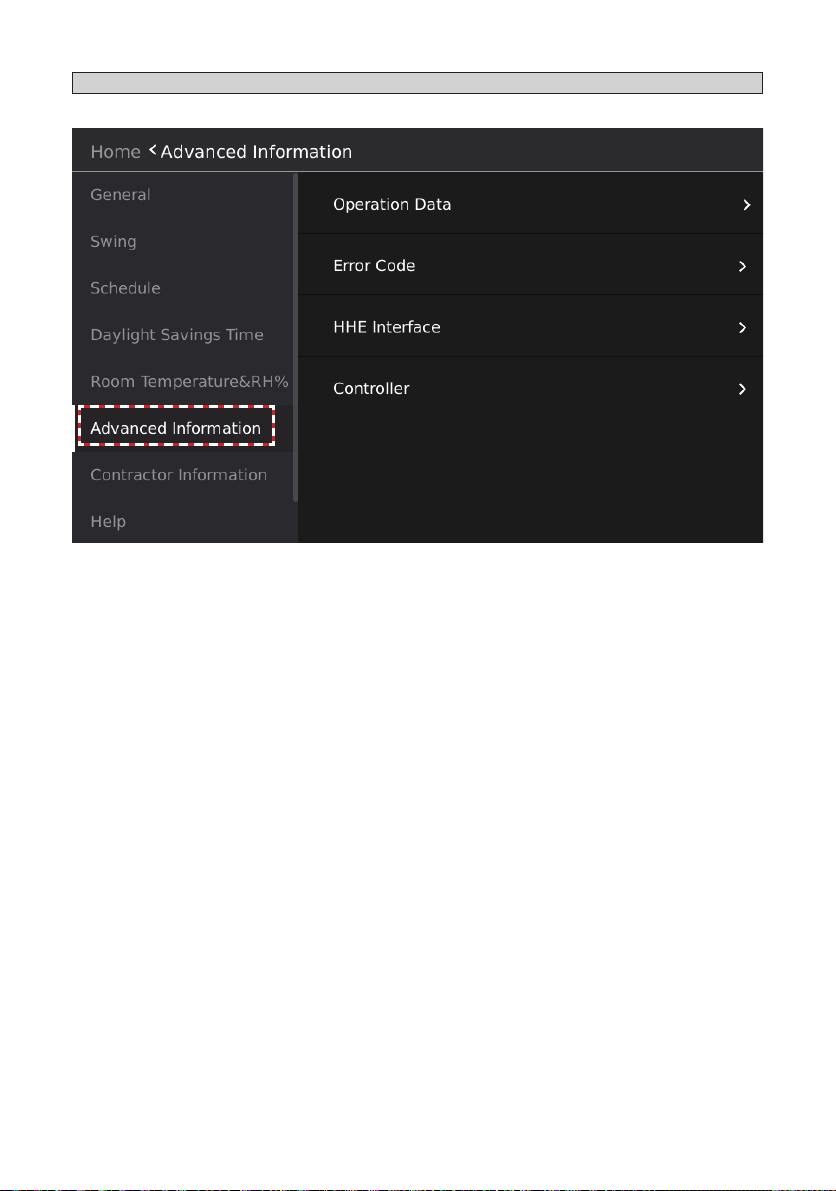

Advanced Information

Tap the Advanced Information button to access the indoor unit information query interface.

Figure 107. Advanced Information

83

Page 84

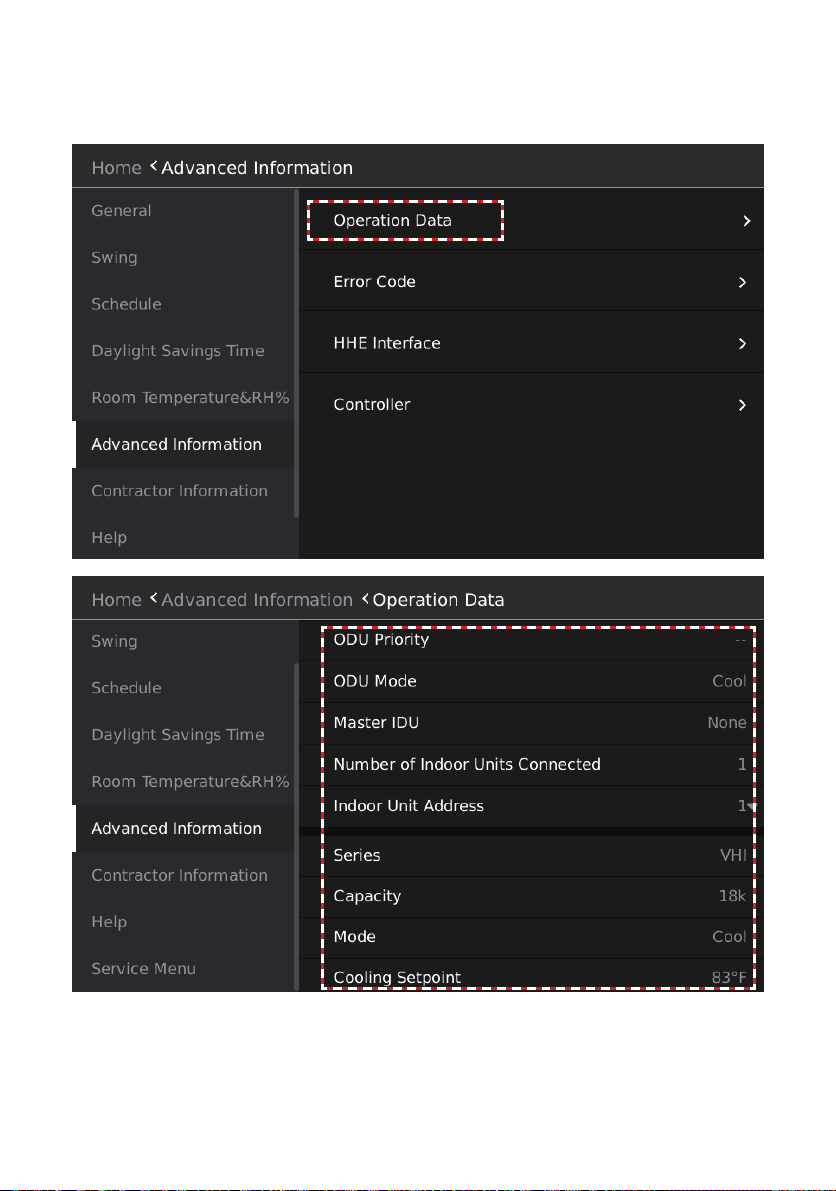

Device Operation Information Query

Tap the Operation Data button on the screen to enter the system operation information query

interface.

Figure 108. Operation Data Query

84

Page 85

Table 6. System Operation Information Queries

Item Description

ODU Priority Auto/Cool/Heat/VIP/Heat Only/Cool Only

ODU Mode Cool/Heat/Fan/Force Cool/OFF

Master IDU Show VIP indoor unit address; "None" is displayed when there is no VIP

Indoor unit.

Indoor quantity Show the number of connected Indoor Units

Address Indoor unit address (can be selected if there are multiple indoor unit)

Series Indoor unit type

Capacity Indoor unit capacity

Mode Indoor unit (operation) mode

Cooling setpoint The cooling setpoint

Heating setpoint The heating setpoint

T1-In Use Indoor temperature used by the system

T1-IDU Temperature value collected by the Indoor Unit’s own sensor

T2 Evaporator middle temperature

T2A Evaporator inlet temperature

T2B Evaporator outlet temperature

EEV EXV opening

Fan speed Fan (operating fan speed) speed

Software version Indoor Unit software version number.

Table 7. Indoor Unit Types

Indoor Unit Type Model Number

360° Cassette V33

Wall-Mounted VWM

Medium Static Concealed Ducted VMD

Vertical Air Handler VVC

High Static Concealed Ducted VHI

Compact 360° Cassette V22

Ceiling Floor Convertible VCF

85

Page 86

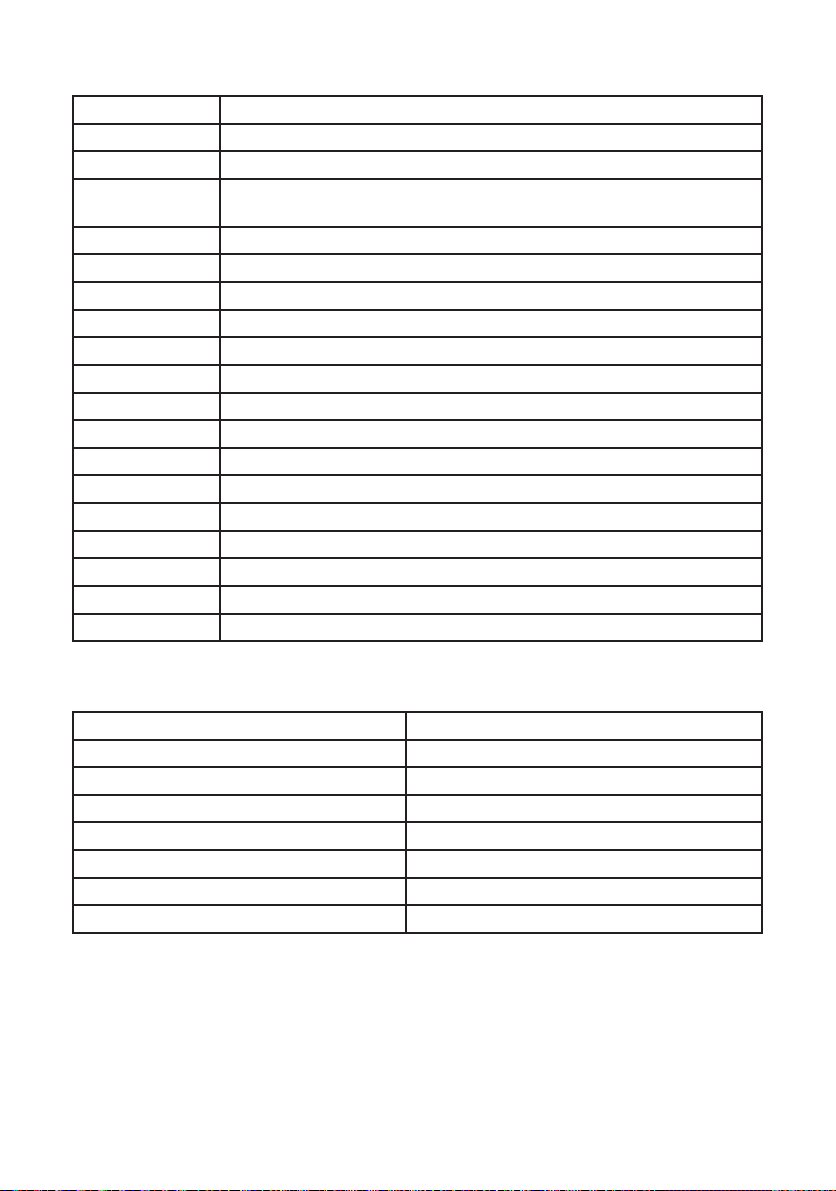

Device Operation Error History Query

Check the error information of the system to which the wired controller is connected.

Tap the Error Code button to enter the system error information query interface.

Figure 109. Error Code History Query

86

Page 87

Table 8. Error Code Information

Indoor Unit Type Model Number

No. Serial number.

IDU# Address of the faulty indoor unit. If the error is related to the outdoor unit,

MS box or controller “- -“ is displayed.

Error Error code number. Use this number to look up the error in the VRF app.

Type IDU - Indoor unit, ODU - Outdoor unit, CTRL - Controller. Identies what

equipment type is faulty.

Time Date and time of the error.

87

Page 88

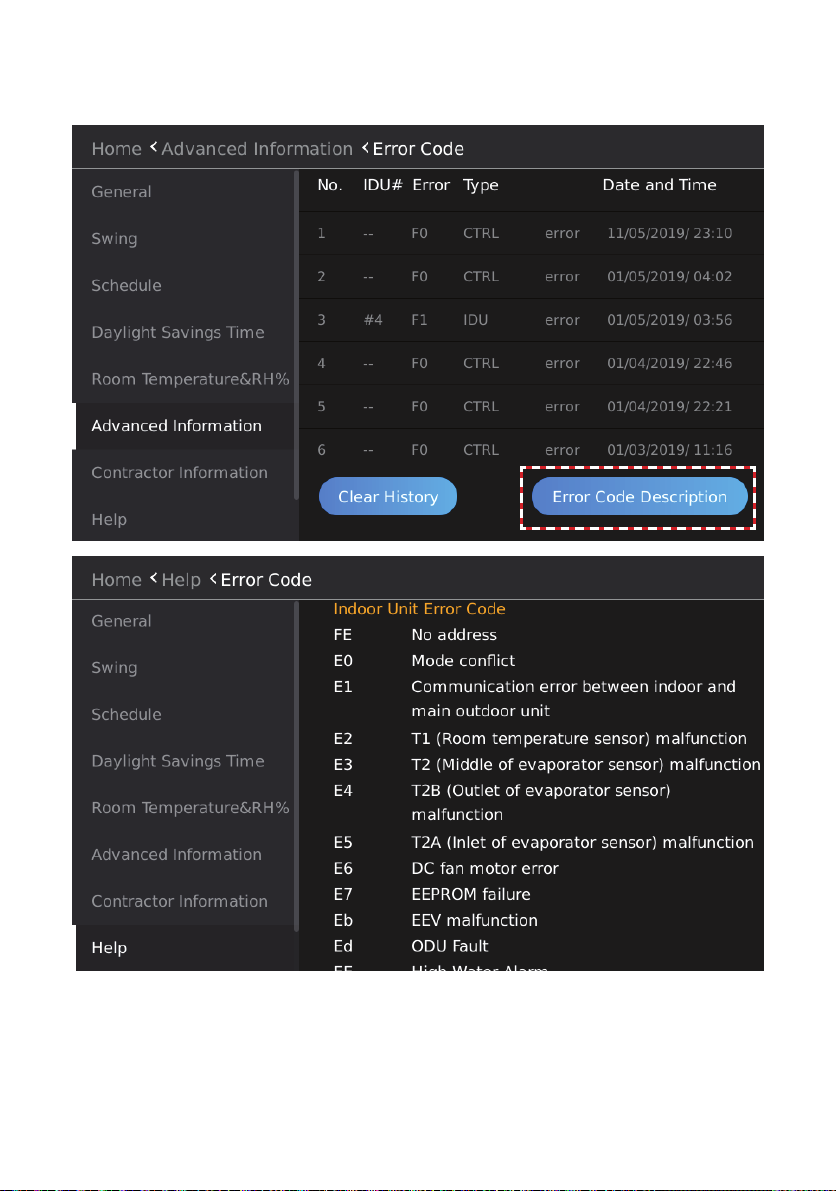

Tap the Error Code Description button to enter the error code details screen.

Detailed error code analysis and fault nding information is available in the Lennox VRF app.

Figure 110. Error Code Descriptions

88

Page 89

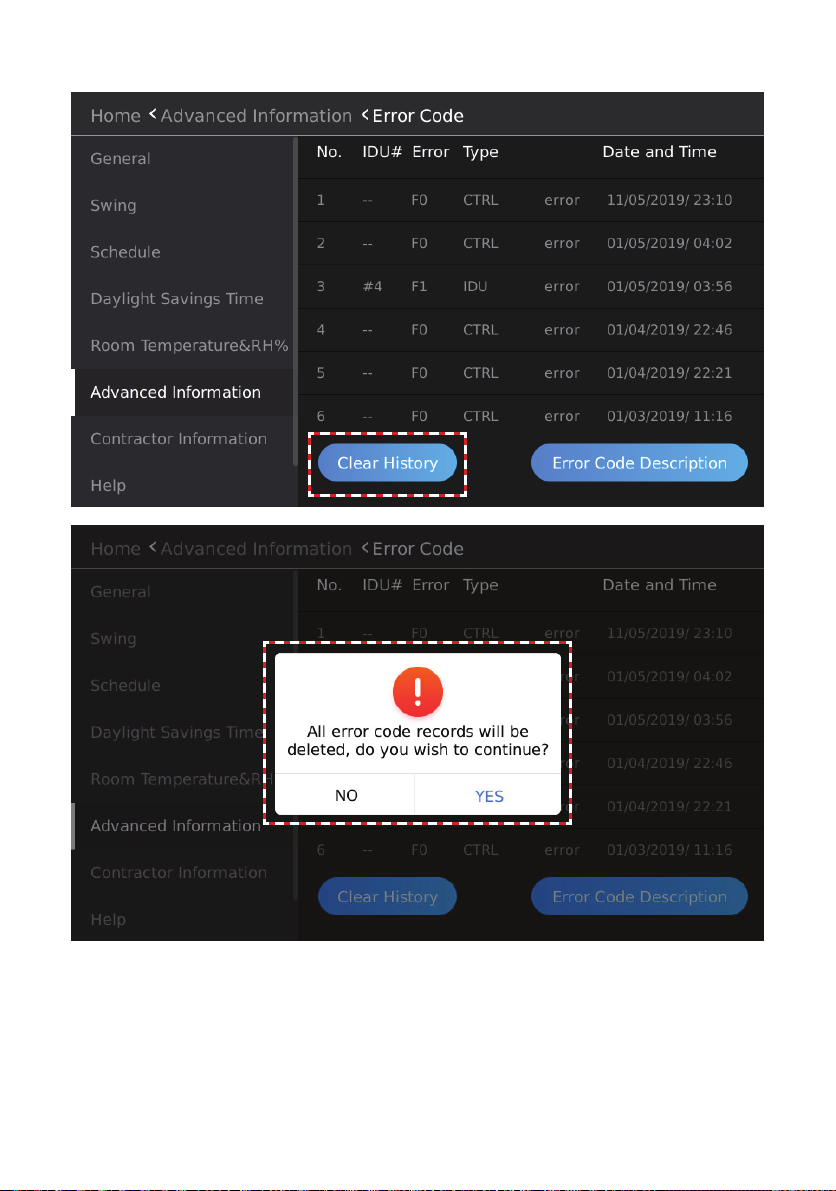

Tap the Clear History button to delete the error code history from the controller.

Figure 111. Clear Error Code History

89

Page 90

HHE Dry Contact Relay Interface Status Query

Tap the HHE Interface button to access the HHE relay query interface.

Figure ##. Access HHE Dry Contact Relay Interface

Tap the drop-down button on the right of the Indoor Unit Address, and select an indoor unit address

to query the status of dry contacts.

Figure 112. View HHE Dry Contact Relay Information

90

Page 91

Controller Information

Tap the Controller button to access the controller information interface.

Figure 113. Controller Information

91

Page 92

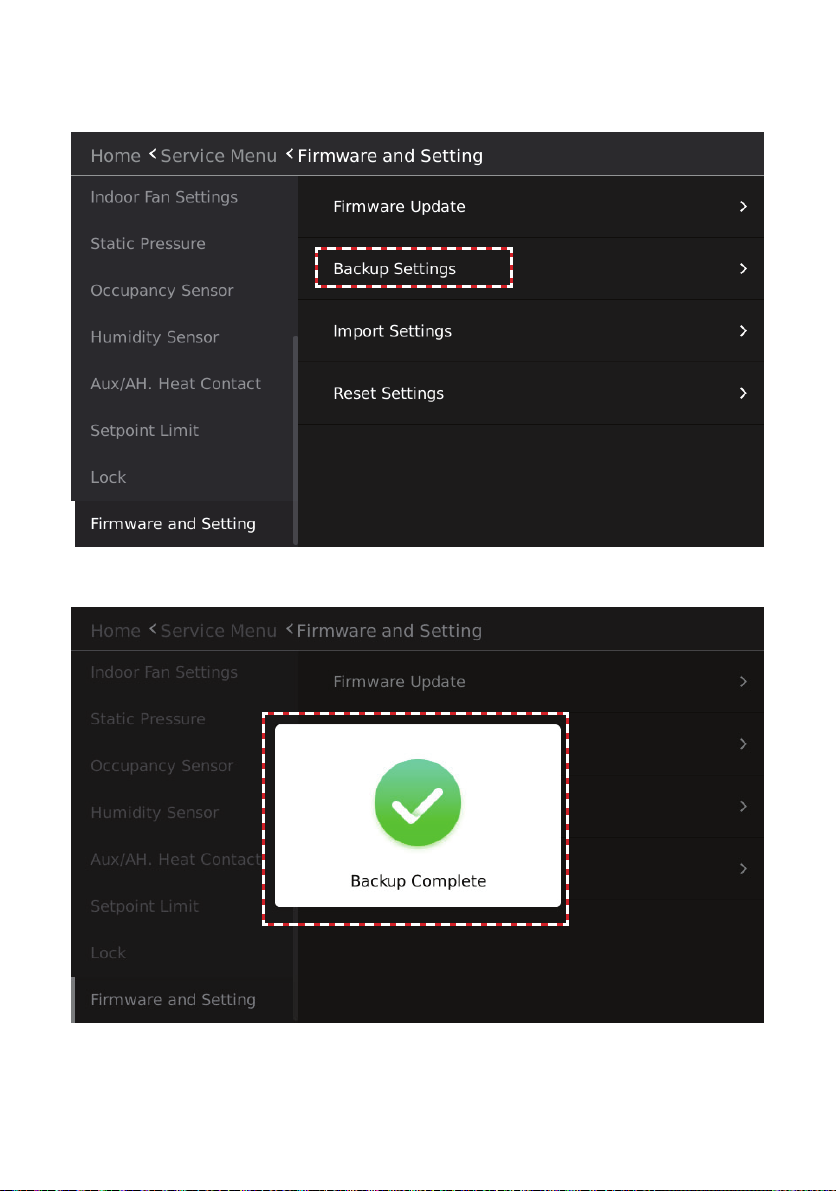

Firmware and Setting Information

Tap the Firmware and Setting button to access the Software Update and Firmware screen.

Figure 114. Access Firmware and Settings

CAUTION

DO NOT turn o power to the indoor

unit or the controller during the software

update process. Damage to indoor unit and

controller boards may occur.

IMPORTANT

After initial setup, make a back up copy

of the controller settings by following the

instructions on page 97. Store the copy on

a large capacity ash drive for permanent

storage. This ensures the controller can be

reset to initial settings if needed.

92

Page 93

Software Version

Tap the Firmware and Setting button to access the software update screen.

Figure 115. Access Software Update & Version Information

The software update screen displays the current version of the wired controller software.

Figure 116. Software Version

93

Page 94

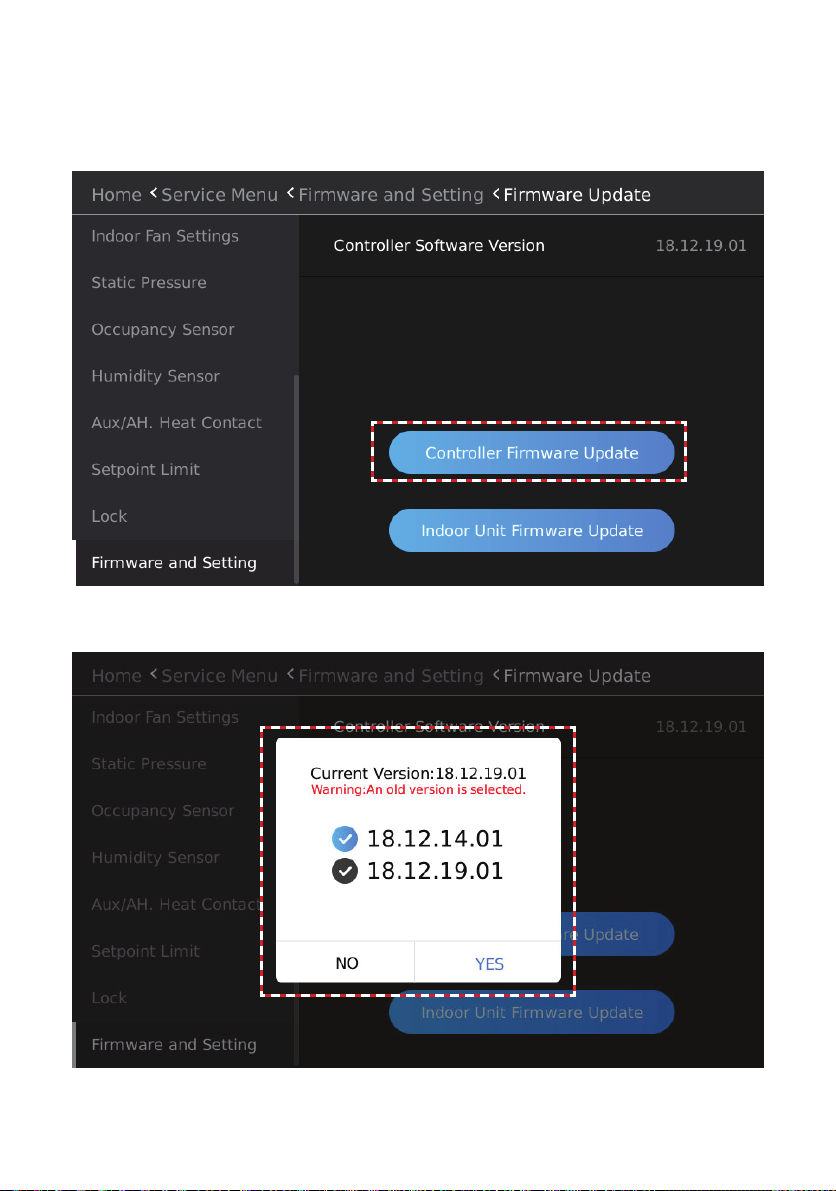

Controller Software Update

1. Insert the USB containing the software update les into the USB port on the bottom of the

controller.

2. Tap the Controller Firmware Update button, and a list of software installed in the USB device

will display.

Figure 117. Controller Software Update

3. Select the controller software version number to upgrade.

Figure 118. Available Controller Software Update Files

94

Page 95

4. Tap YES to upgrade the controller software. Wait for about 10 seconds. Then the Update

success pop-up window will display. Or, tap NO to return to the previous screen.

Figure 119. Controller Software Update Success!

5. After the controller software upgrade, the Reboot the system to nish the update prompt box

will display. Tap YES to restart the system, or tap NO to return to the previous interface.

Figure 120. Reboot After Controller Software Update

95

Page 96

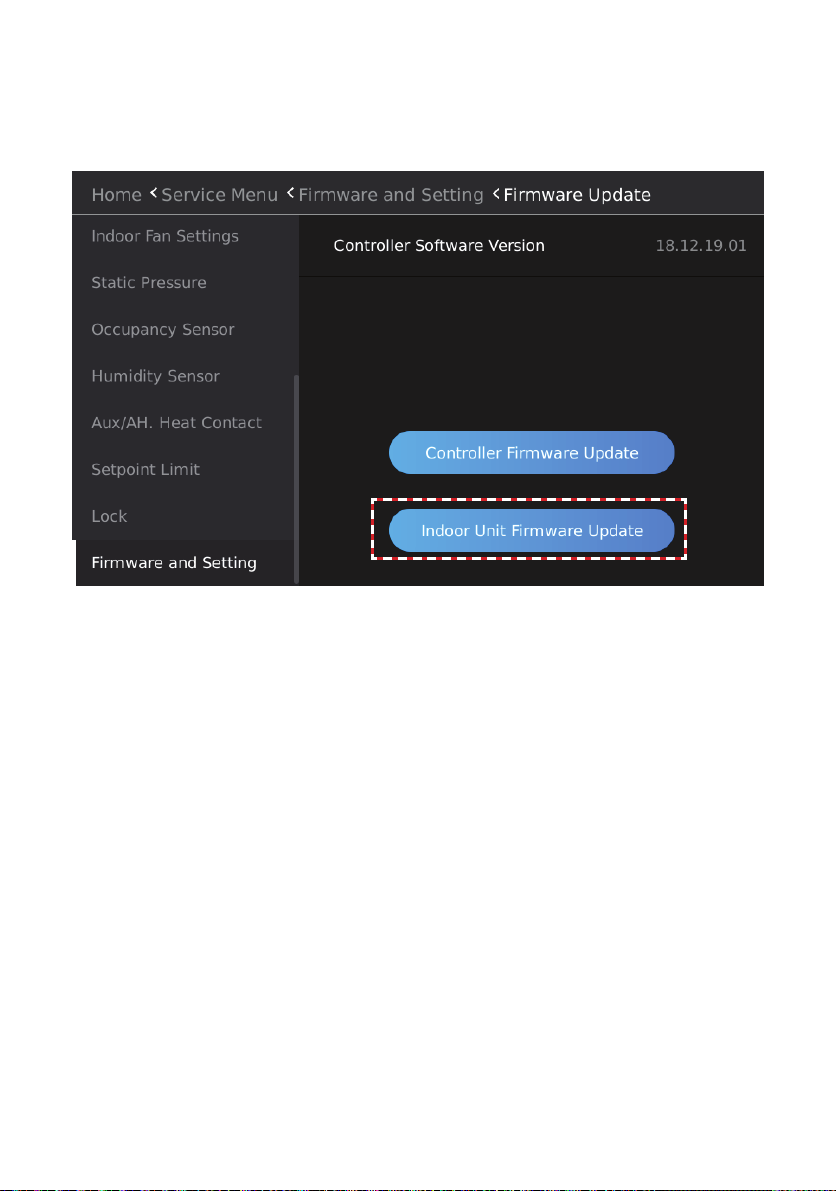

Indoor Unit Software Update

Update the connected indoor unit software; requires one-to-one connection between indoor unit

and controller.

1. Insert the USB containing the software update les into the USB port on the bottom of the

controller.

Figure 121. Indoor Unit Software Update

96

Page 97

2. Tap the Indoor Unit Firmware Update button, and a list of software installed in the USB

device will display.

3. Select the indoor unit software version number to upgrade.

Figure 122. Indoor Unit Software Update File Selection

97

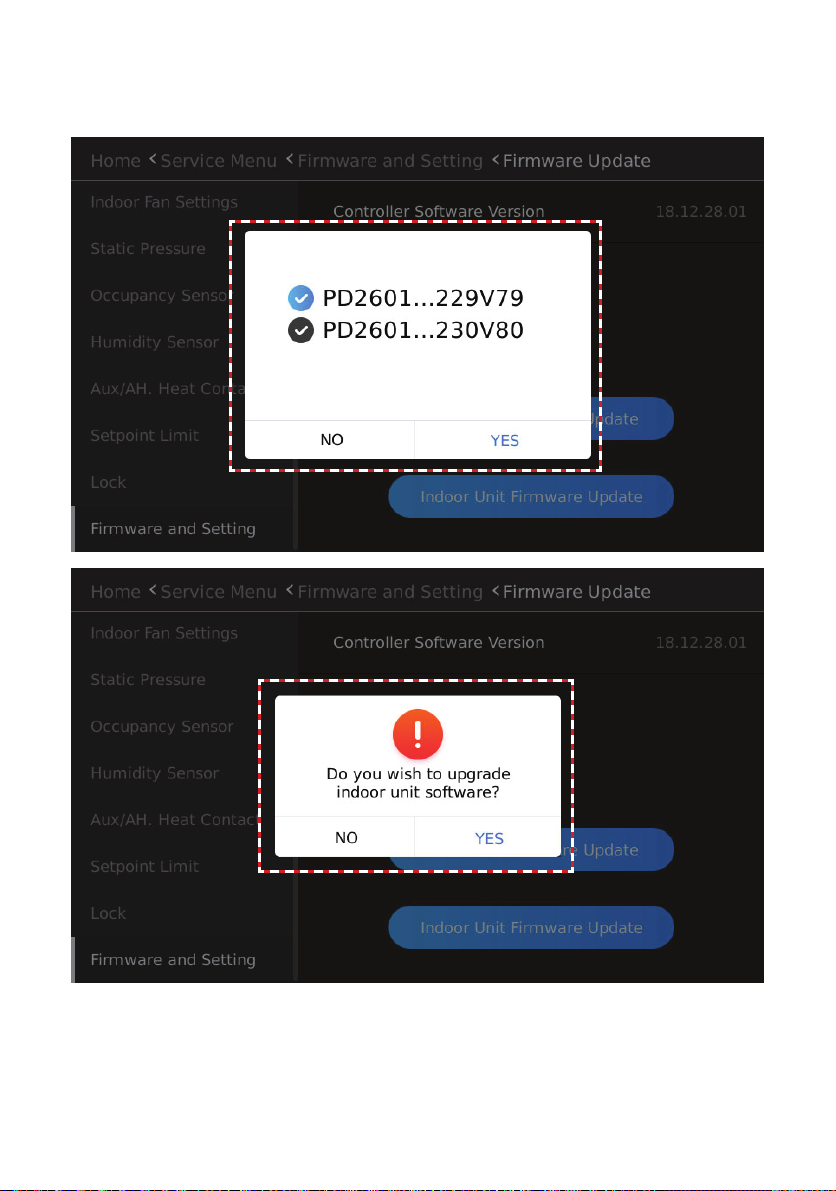

Page 98

4. Tap YES, and then the Do you wish to upgrade indoor unit software? pop-up window will

display. Or, tap NO to return to the previous screen.

5. The Upgrading software notication will display until the update is complete.

Figure 123. Indoor Unit Software Update In Progress

If the software upgrade is unsuccessful, the notication Indoor unit software upgrade failed. will

display.

Figure 124. Indoor Unit Software Update Failure

98

Page 99

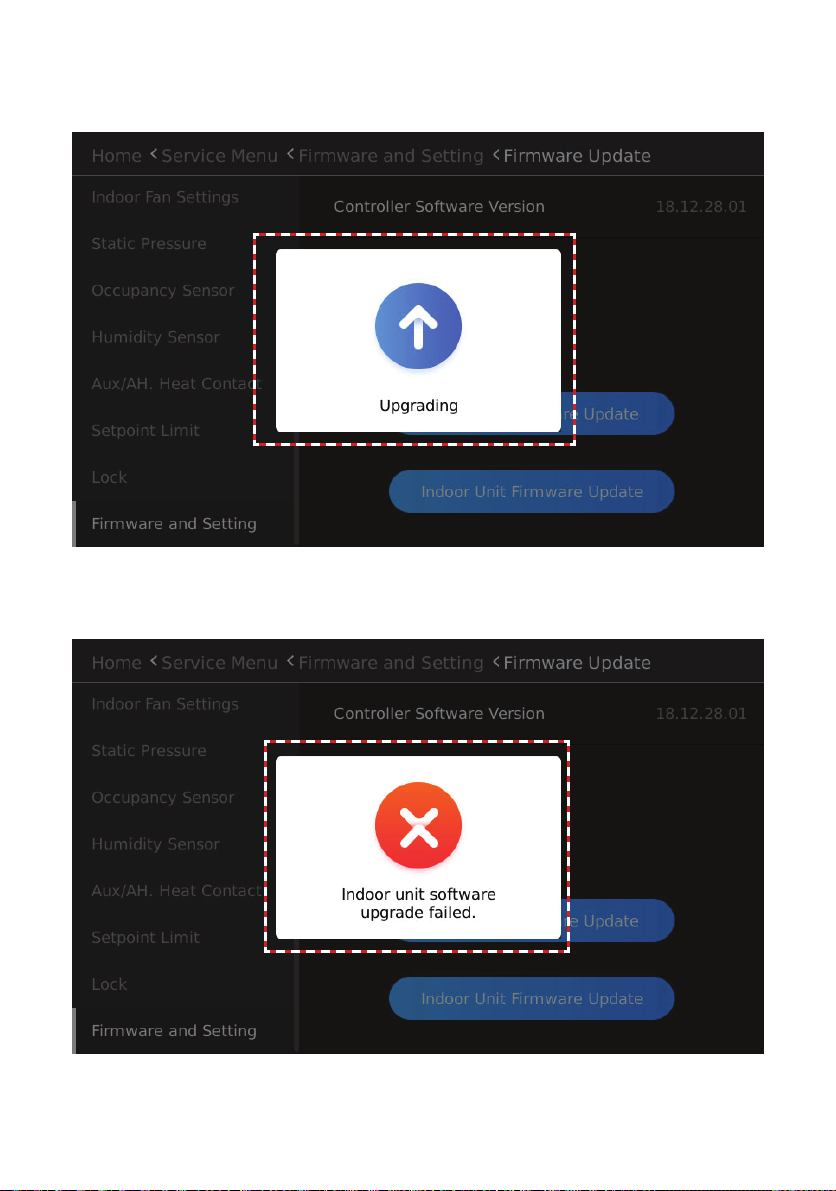

Setting Parameters Backup

Tap the Backup Settings button to export parameters for the general function settings and advanced settings of the wired controller to the connected USB device.

Figure 125. Backup Controller Settings

The Backup Complete pop-up window displays after the setting parameters have been exported.

Figure 126. Backup Complete Notication

99

Page 100

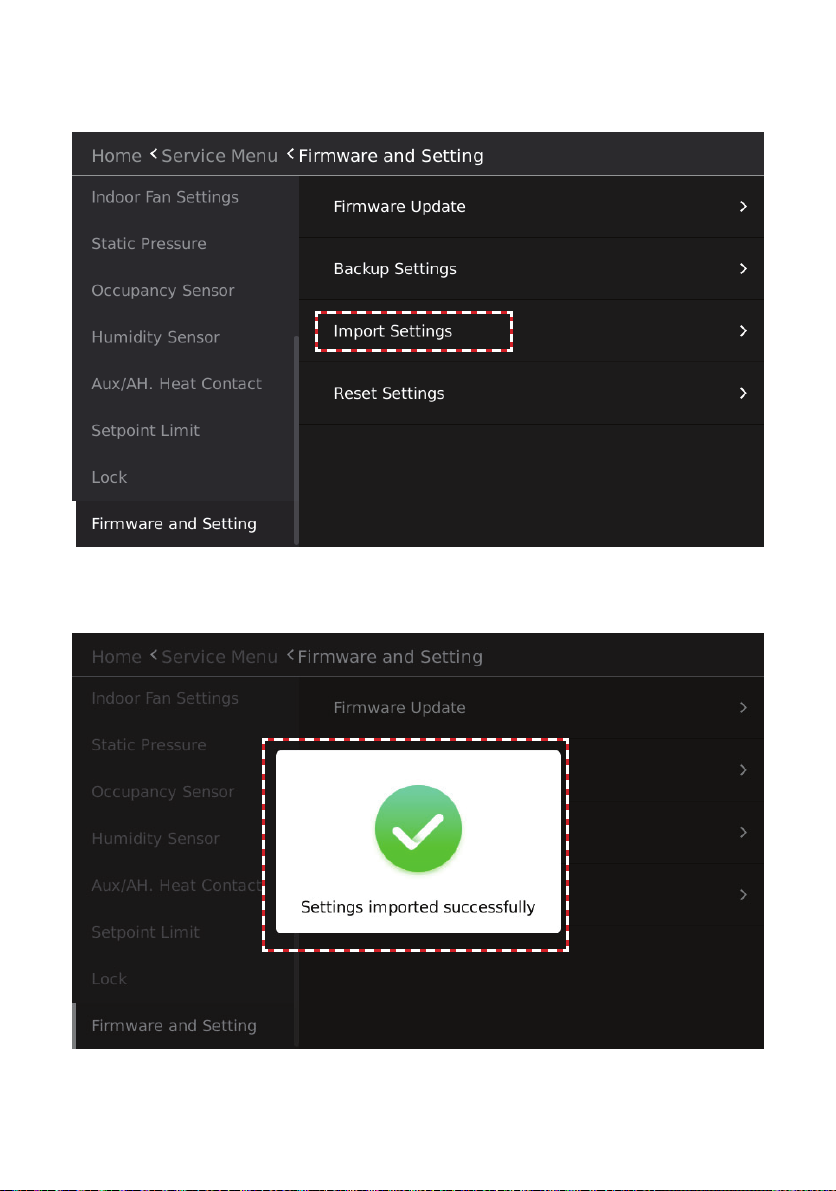

Setting Parameters Import

Tap the Import Settings button to import parameters for the general function settings and advanced settings of the wired controller from the connected USB device.

Figure 127. Import Controller Settings

The Settings imported successfully pop-up window displays after the setting parameters have

been exported.

Figure 128. Import Successful Notication

100

Loading...

Loading...