Page 1

E N G I N E E R I N G D A T A

H E A T P U M P O U T D O O R U N I T S

TP

T−CLASSt SPLIT SYSTEM UNITS

R−22 − 60 HZ

Bulletin No. 210438

November 2007

Supersedes October 2007

MODEL NUMBER IDENTIFICATION

TPA Y1036 S 42 n

T = T−Classt Product Line

Brand/Family

P = Heat Pump Outdoor Unit

Major Design Sequence

Nominal Cooling Capacity − Tons

Unit Type

A = 1st Generation

B = 2nd Generation

036 = 3 Tons

048 = 4 Tons

060 = 5 Tons

Cooling Efficiency

S = Standard Efficiency

SEER up to 13.0

3 to 5 Tons

Cooling Capacity − 34,000 to 57,500 Btuh

Heating Capacity − 33,600 to 55,500 Btuh

Vol ta ge

Y = 208/230V-3 phase-60hz

G = 460V-3 phase-60hz

Minor Design Sequence

1 = 1st Revision

2 = 2nd Revision

3 = 3rd Revision

Coil type

4 = Four−sided

Part Load Capability

N = No part load, single stage compressor

Refrigerant Type

2 = R−22

Page 2

FEATURES

CONTENTS

ARI Rating Tables Pages 10 − 12. . . . . . . . . . . . . . . . . . . . .

Dimensions Page 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Data Page 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features Page 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indoor Coil / Air Handler Substitutions Page 9. . . . . . . . . .

Installation Clearances Page 7. . . . . . . . . . . . . . . . . . . . . . .

Model Number Identification Page 1. . . . . . . . . . . . . . . . . .

Optional Accessories Page 6. . . . . . . . . . . . . . . . . . . . . . . .

Outdoor Sound Data Page 7. . . . . . . . . . . . . . . . . . . . . . . . .

Specifications Page 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J

B

C

I

Warranty

Compressor − limited warranty for five years.

All other covered components − one year.

Refer to Lennox Equipment Limited Warranty certificate

included with unit for specific details.

Approvals

Certified in Accordance with the USE certification

program, which is based on ARI Standard 210/240−2005.

Sound rated in Lennox reverberant sound test room in

Accordance with test conditions included in ARI Standard

270-95.

Tested in the Lennox Research Laboratory environmental

test room.

Rated According to U.S. Department of Energy (DOE)

test procedures.

Units and components within bonded for grounding to

meet safety standards for servicing required by UL, NEC

and CEC.

Units are UL and ULC listed.

ISO 9001 Registered Manufacturing Quality System.

Applications

SEER up to 13.0.

Heating COP up to 3.68.

HSPF (Region IV) up to 7.70.

3 through 5 tons.

Three−phase power supply.

Vertical air discharge allows concealment behind shrubs

at grade level or out of sight on a roof.

Designed for applications with remotely located indoor air

handler units.

See Air Handlers tab section for unit data.

Units shipped completely factory assembled, piped and

wired. Each unit is test operated at the factory insuring

proper operation.

Installer must set outdoor unit, connect refrigerant lines

and make electrical connections to complete job.

For expanded ratings, see www.lennoxdavenet.com.

H

D

E

G

F

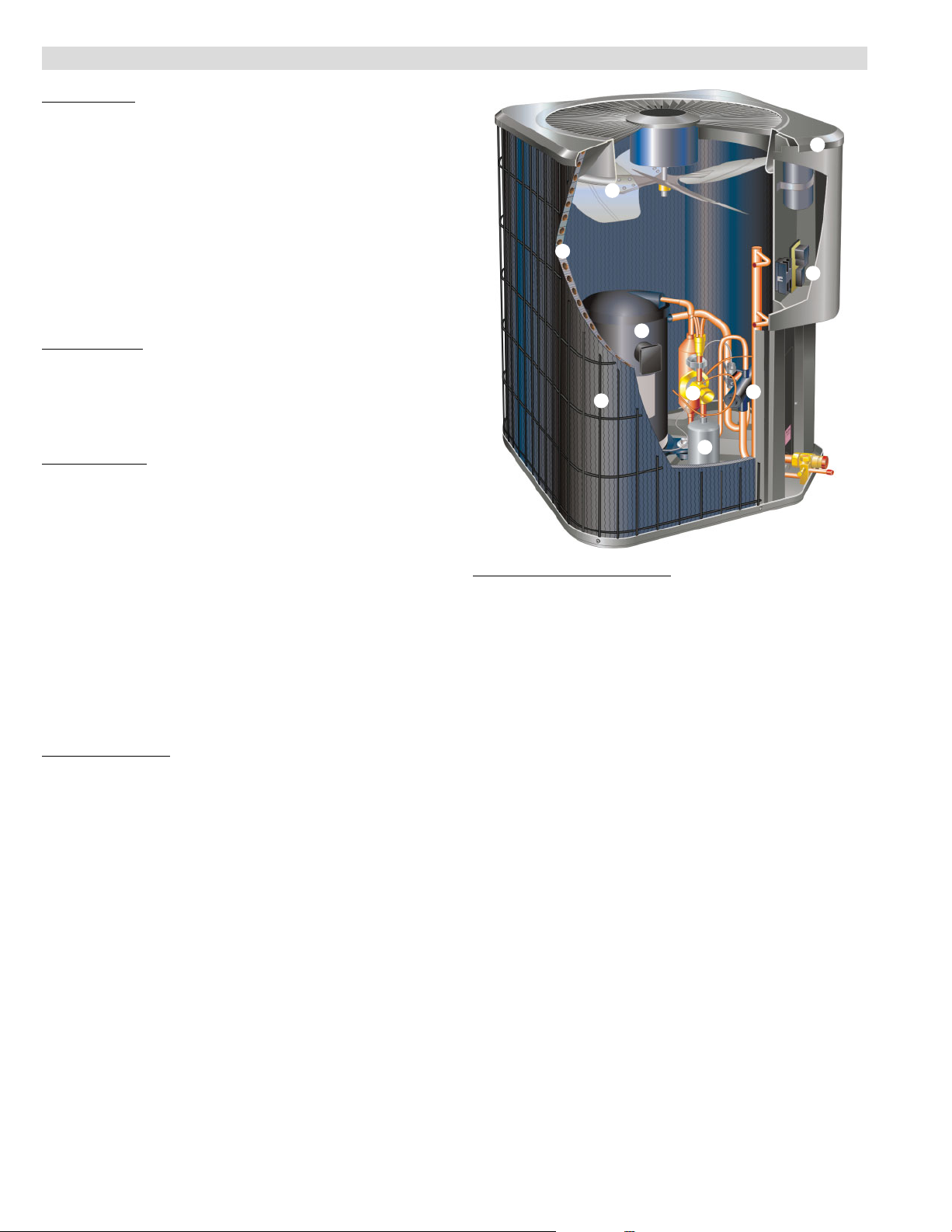

REFRIGERANT SYSTEM

Outdoor Coil Fan

B

Direct drive fan moves large air volumes uniformly

through entire outdoor coil for high refrigerant cooling and

heating capacity.

Vertical air discharge minimizes operating sounds and

eliminates damage to lawn and shrubs.

Fan motor has sleeve bearings and is inherently

protected.

Motor totally enclosed for maximum protection from

weather, dust and corrosion.

Rain shield on motor provides additional protection from

moisture.

Louvered steel top fan guard furnished as standard.

Fan service access accomplished by removal of top

panel.

Copper Tube/Enhanced Fin Coil

C

Lennox designed and fabricated coil.

Ripple-edged aluminum fins.

Copper tube construction.

Lanced fins provide maximum exposure of fin surface to

air stream resulting in excellent heat transfer.

Fin collars grip tubing for maximum contact area.

Flared shoulder tubing connections/silver soldering

construction.

Coil is factory tested under high pressure to ensure

leakproof construction.

Entire coil is accessible for cleaning.

PVC coated steel wire coil guard furnished as standard.

D

K

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 2

Page 3

FEATURES

REFRIGERANT SYSTEM (CONTINUED)

Expansion Valve − Outdoor Unit

E

Designed and sized specifically for use in heat pump

system.

Sensing bulb is located on the suction line between the

reversing valve and the compressor to sense evaporator

suction temperature in any cycle.

Factory installed and piped.

High Capacity Liquid Line Drier

F

Factory installed in the liquid line, the drier traps moisture

or dirt that could contaminate the refrigerant system.

100% molecular−sieve, bead type bi−flow drier.

Reversing Valve

G

4-way interchange reversing valve effects a rapid change

in direction of refrigerant flow resulting in quick

changeover from cooling to heating and vice versa.

Valve operates on pressure differential between outdoor

unit and indoor unit of the system. Factory installed.

OPTIONS

Check/Expansion Valve Kits

Must be ordered extra and field installed on certain indoor

units.

See ARI Ratings tables.

Chatleff−style fitting.

High Pressure Switch Kit

Protects the system from high pressure conditions that

can be a result of fan failure or a blocked/dirty coil.

Manual reset.

Loss of Charge Kit

Helps protect the compressor from damage due low

refrigerant charge conditions.

SPST, normally−closed switch, automatic reset switch

mounted on suction line.

Refrigerant Line Kits

Refrigerant lines (suction & liquid) are shipped refrigeration

clean. Lines are cleaned, dried, pressurized and sealed at

factory.

Suction line fully insulated.

Lines are stubbed at both ends.

Not available for −060 models and must be field fabricated.

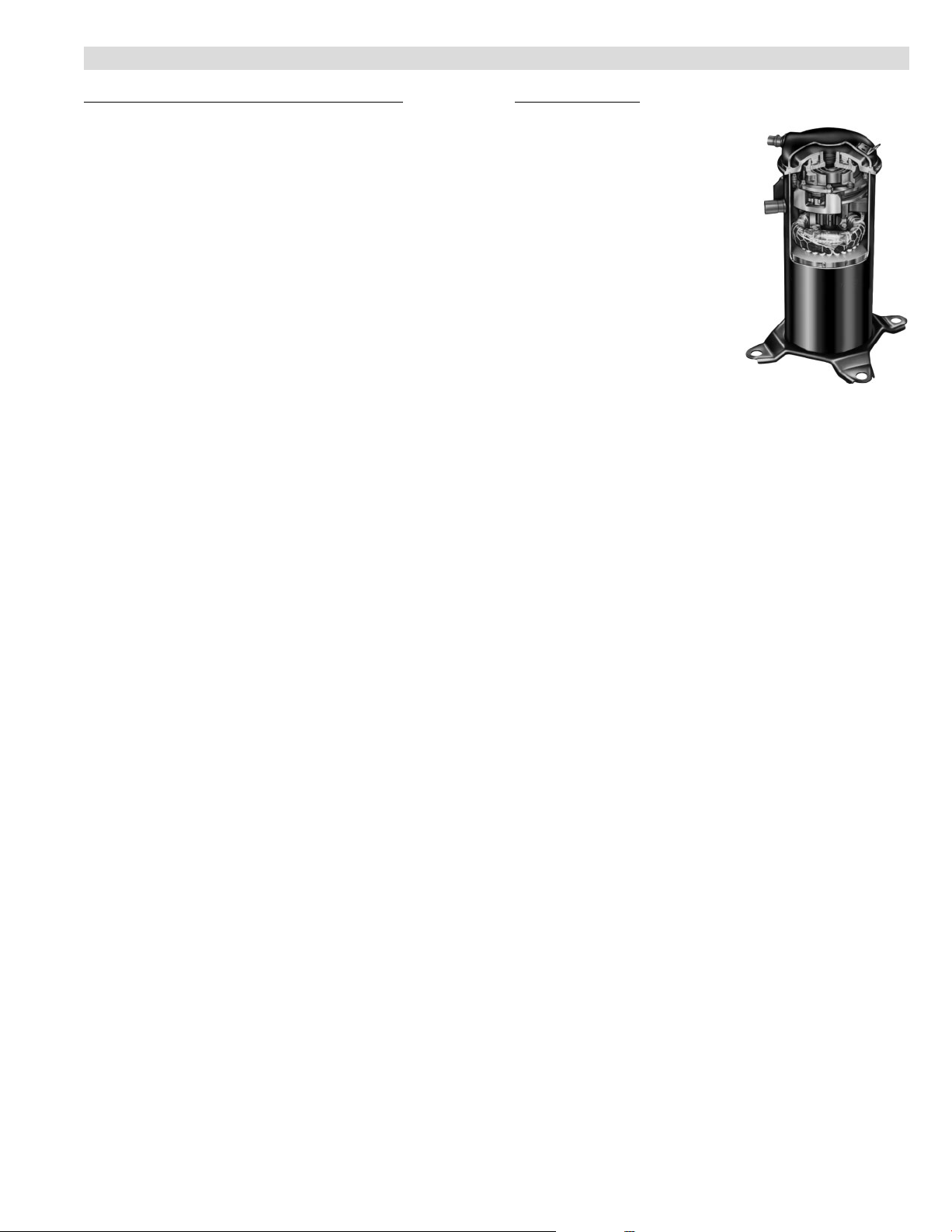

Compressor

H

Copeland Scrollt Compressor

Compressor features high

efficiency with uniform suction

flow, constant discharge flow

and high volumetric efficiency

and quiet operation.

Compressor consists of two

involute spiral scrolls matched

together to generate a series of

crescent shaped gas pockets

between them.

During compression, one scroll

remains stationary while the

other scroll orbits around it.

Gas is drawn into the outer

pocket, the pocket is sealed as

the scroll rotates.

As the spiral movement

continues, gas pockets are pushed to the center of the

scrolls. Volume between the pockets is simultaneously

reduced.

When pocket reaches the center, gas is now at high

pressure and is forced out of a port located in the center of

the fixed scrolls.

During compression, several pockets are compressed

simultaneously resulting in a smooth continuous

compression cycle.

Continuous flank contact, maintained by centrifugal force,

minimizes gas leakage and maximizes efficiency.

Scroll compressor is tolerant to the effects of slugging and

contaminants. If this occurs, scrolls separate, allowing

liquid or contaminants to to be worked toward the center

and discharged.

Low gas pulses during compression reduces operational

sound levels.

Compressor motor is internally protected from excessive

current and temperature.

Muffler in discharge line reduces operating sound levels.

Compressor is installed in the unit on resilient rubber

mounts for vibration free operation.

Compressor Crankcase Heater

Protects against refrigerant migration that can occur

during low ambient operation.

OPTIONS

Compressor Low Ambient Cut−Off

Non-adjustable switch (low ambient cut-out) prevents

compressor operation when outdoor temperature is

below 35°F.

Compressor Sound Cover

A reinforced vinyl compressor cover containing a 1−1/2

inch thick batt of fiberglass insulation.

All open edges are sealed with a one−inch wide hook and

loop fastening tape.

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 3

Page 4

FEATURES

CONTROLS

Defrost Control

I

Solid-state time/temperature defrost control is furnished

as standard equipment.

Control initiates a defrost cycle every 30, 60 or 90 minutes

of compressor on" time at outdoor coil temperatures

below 42°F (factory setting 90 minutes).

Anti−short cycle, timed−off control incorporated into the

board.

High and low pressure switch monitoring with five−trip

lockout.

Diagnostic LED’s furnished as an aid in troubleshooting.

Conveniently located in control box.

OPTIONS

Freezestat

Installs on or near the vapor line of the indoor coil or on the

suction line.

Senses suction line temperature and cycles the

compressor off when suction line temperature falls below

it’s setpoint.

Opens at 29°F and closes at 58°F.

L Connection

See L Connection Engineering Handbook Bulletin in

Controls section for details.

Low Ambient Control

Air conditioners operate satisfactorily down to 45°F

outdoor air temperature without any additional controls.

Two low ambient control options are available for field

installation.

The Low Ambient Control Kit allows unit operation down

to 30°F.

The second control option allows unit operation down to

0°F. This option requires that the outdoor fan motor and

capacitor be changed. See Low Ambient Control Option

table, page 7, for ordering information.

Freezestat should be installed on compressors equipped

with a low ambient kit.

A compressor lock−out thermostat should be added to

terminate compressor operation below recommended

operation conditions (on/off operation, 30°F or modulating

operation, 0°F).

Mild Weather Kit

Heat pump units operate satisfactorily in the heating

mode at outdoor air temperatures up to 75_F.

Mild Weather Kit can be field installed, allowing heating

operation above 75_F.

Monitor Kit − Service Light

Contains ambient compensating thermistor and service

light thermostat.

For use with thermostats requiring input for indicator lights.

Outdoor Thermostat Kit

An outdoor thermostat can be used to lock out some of the

electric heating elements on indoor units where two stage

control is applicable.

Outdoor thermostat maintains the heating load on the low

power input as long as possible before allowing the full

power load to come on the line.

Thermostat kit and mounting box must be ordered extra.

Thermostat

Thermostat not furnished with unit. See Thermostat

bulletins in Controls Section and Lennox Price Book.

®

Network

Time Delay Relay Kit

Delays the indoor blower−off time during the cooling cycle.

See ARI Rating Tables for usage.

Cabinet

J

Heavy gauge steel cabinet with five station metal wash

process.

Powder paint finish provides superior rust and corrosion

protection.

Painted base section.

Control box is conveniently located with all controls

factory wired.

Corner patch plate allows access to compressor

components.

Drainage holes are provided in base section for moisture

removal.

Refrigerant Line Connections, Electrical Inlets,

K

Service Valves

Sweat connection vapor and liquid lines are located on

corner of unit cabinet.

Fully serviceable brass service valves prevent corrosion

and provide access to refrigerant system. Vapor valve can

be fully shut off, while liquid valve may be front seated to

manage refrigerant charge while servicing system.

Refrigerant line connections and field wiring inlets are

located in one central area of cabinet for easy access. See

dimension drawing.

OPTIONS

Hail Guards

Constructed of louvered heavy gauge steel painted to

match cabinet.

Surrounds unit on all four sides to prevent damage to the

coil.

Mounting Base

Provides permanent foundation for outdoor units.

High density polyethylene structural material is

lightweight, sturdy, sound absorbing and will withstand the

rigors of the sun, heat, cold, moisture, oil and refrigerant.

Will not mildew or rot.

Can be shipped singly or in packages of 6 to a carton.

Unit Stand-Off Kit

Black high density polyethylene feet are available to raise

unit off of mounting surface away from damaging

moisture.

Four feet are furnished per order number.

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 4

Page 5

OPTIONAL CONVENTIONAL TEMPERATURE CONTROL SYSTEMS − FIElD INSTALLED

COMMERCIAL TOUCHSCREEN THERMOSTAT

Intuitive Touchscreen Interface − Two Stage Heating / Two Stage Cooling Conventional or

Heat Pump − Seven Day Programmable − Four Time Periods/Day − Economizer Output − Title 24

Compliant − E

NERGY STAR

Sensors For Touchscreen Thermostat

1

Remote non−adjustable wall mount 20k temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C0SNZN01AE1−

1

Remote non−adjustable wall mount 10k averaging temperature sensor . . . . . . . . . . . . . . . . . . . . . C0SNZN73AE1−

1

Remote non−adjustable duct mount temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C0SNDC00AE1−

Outdoor temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C0SNSR03AE1−

Accessories For Touchscreen Thermostat

Locking cover (clear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C0MISC15AE1−

1

Remote sensors for C0STAT02AE1L can be applied in the following combinations: (1)

C0SNZN01AE1−, (2) C0SNZN73AE1−, (2) C0SNZN01AE1− and (1) C0SNZN73AE1−, (4)

C0SNZN01AE1−, (3) C0SNZN01AE1− and (2) C0SNZN73AE1.

DIGITAL NON−PROGRAMMABLE THERMOSTATS

Intuitive Interface − Automatic Changeover − Simple Up and Down Temperature Control

Two−stage heating / cooling conventional systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C0STAT10AE1L

Sensor For Digital Non−Programmable Thermostats Above

®

Qualified − Backlit Display − Automatic Changeover

C0STAT02AE1L

Remote wall mounted temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C0SNZN00AE1−

Intuitive Interface − Automatic Changeover − Backlit Display − Simple Up and Down Temperature

Control

One−stage heating / cooling conventional systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C0STAT12AE1L

Sensor For Digital Non−Programmable Thermostats Above

Outdoor temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C0SNSR04AE1−

Accessories For Digital Non−Programmable Thermostats Above

Optional wall mounting plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C0MISC17AE1−

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 5

Page 6

SPECIFICATIONS

p

g

Th

t

g

General

Data

Connections

(sweat)

2

Refrigerant R−22 charge furnished 8 lbs. 10 oz.

Outdoor

Nominal Tonnage (kW) 3 (10.6)

Liquid line o.d. − in. (mm) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Vapor line o.d. − in. (mm) 7/8 (22.2)

Net face area

Coil sq. ft. (m2)

Tube diameter − in. (mm) no. of rows 5/16 (8) − 2 5/16 (8) − 2 5/16 (8) − 2

Outdoor

Diameter − in. (mm) − No. of Blades 18 (457) − 4 22 (559) − 4 26 (660) − 4

Fan

Shipping Data − lbs. (kg) 1 package 178 (81) 248 (112) 284 (129)

ELECTRICAL DATA

Line voltage data − 60 hz − 3ph 208/230V 460V 208/230V 460V 208/230V 460V

3

Maximum overcurrent protection (amps) 20 10 30 15 40 15

4

Minimum circuit ampacity 13.1 6.5 20.0 9.5 23.4 10.1

Compressor

Rated Load Amps

Locked Rotor Amps

Outdoor

Fan Motor

Locked Rotor Amps

OPTIONAL ACCESSORIES − must be ordered extra

Compressor Low Ambient Cut−Off 45F08 S S S

Compressor Sound Cover 69J03 S S S

Freezestat

Hail Guards

High Pressure Switch Kit 94J46 S S S

Loss of Charge Kit 84M23 S S S

5

Low Ambient Kit (down to 30°F) 27J00 S S S

Low Ambient Control Option (down to 0°F) See table page 7 See table page 7 See table page 7

Mild Weather Kit 33M07 S S S

Monitor Kit − Service Light 76F53 S S S

Mounting Base

Outdoor

ermosta

Kit

Refrigerant

L15−65−30, L15−65−40, or L15−65−50 S S

Line Sets

Time Delay Relay Kit 58M81 S S S

Unit Stand−Off Kit 94J45 S S S

NOTE − Extremes of operating range are plus 10% and minus 5% of line voltage.

1

Sound Rating Number rated in accordance with test conditions included in ARI Standard 270.

2

Refrigerant charge sufficient for 15 ft. length of refrigerant lines.

3

HACR type circuit breaker or fuse.

4

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

5

Freezestat is recommended with Low Ambient Kit.

3/8 in. tubing 93G35 S S S

5/8 in. tubing 50A93 S S S

Thermostat 56A87 S S S

Mounting Box 31461 S

Model No. TPA036S2 TPA048S2 TPA060S2

4 (14.1) 5 (17.6)

7/8 (22.2) 1-1/8 (28.6)

(3.91 kg)

11 lbs . 1 2 o z.

(5.33 kg)

14 lbs. 0 oz.

(6.35 kg)

Outer coil 15.21 (1.41) 21.11 (1.96) 24.94 (2.32)

Inner coil 14.50 (1.35)

20.31 (1.89) 24.13 (2.24)

Fins per inch (m) 22 (866) 22 (866) 22 (866)

Motor hp (W) 208/230V − 1/5 (149)

1/3 (249) 1/3 (249)

460V − 1/6 (124)

Cfm (L/s) 2450 (1155) 3890 (1835) 4550 (2145)

Rpm 1100 1085 830

Watts 190 375 307

9.6 4.8 14.7 7.0 17.3 6.7

Power Factor

Full Load Amps

77

.96

1.1 .55 1.7 .82 1.8 .9

1.9

35 91 50 123 49.5

.88 .96 .87 .96 .88

1.1 4.1 2.2 2.9 2.3

92M89 S

92M90 S

27W36 S

69J06 S

69J07 S S

S S

Field Fabricate

S

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 6

Page 7

LOW AMBIENT CONTROL Option (Down to 0°F)

g

Model N

Rating

Order one each: Speed Control Kit, Weatherproof Kit, Outdoor Fan Motor and Capacitor

Model No. TPA036S2

TPA048S2 TPA060S2

Speed Control Kit X5867 S S S

Weatherproof Kit 56N41 S S S

Outdoor

Fan Motor

1/2 HP − 230V 69H75 S S S

460V 69H76 S

S S

Capacitor with mounting bracket 53H06 S S S

INSTALLATION CLEARANCES − INCHES (MM)

See NOTES

See

NOTES

See NOTES

See

NOTES

CONTROL

BOX

OUTDOOR SOUND DATA

1

Unit

o.

125

TPA036S2 69.5 70.5 71.5 69.5 68.5 62.5 60.5 76

TPA048S2 75.5 74.5 75 73.5 70 66.5 63.5 80

TPA060S2 76 76.5 76.5 74.5 69.5 66 61.5 80

NOTE − the octave sound power data does not include tonal correction.

1

Tested according to ARI Standard 270 test conditions.

Octave Band Sound Power Levels dBA, re 10

250 500 1000 2000 4000 8000

NOTES:

Service clearance of 30 in. (762 mm) must be maintained on one of

the sides adjacent to the control box.

Clearance to one of the other three sides must be 36 in. (914 mm)

Clearance to one of the remaining two sides may be 12 in. (305 mm)

and the final side may be 6 in. (152 mm).

A clearance of 24 in. (610 mm) must be maintained between two units.

48 in. (1219 mm) clearance required on top of unit.

−12

Center Frequency − HZ

Watts

1

Sound

Ratin

Number (dB)

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 7

Page 8

DIMENSIONS − INCHES (MM)

Model N

INLET

AIR

INLET AIR

INLET AIR

TOP VIEW

A

INLET

AIR

LIQUID LINE

CONNECTION

(Around perimeter of base)

SUCTION LINE

CONNECTION

OPTIONAL UNIT

STAND-OFF KIT (4)

(Field Installed)

COIL DRAIN OUTLETS

OUTDOOR

COIL FAN

4-3/8

(111 )

6-3/8

(162)

4-3/8

(111 )

6-3/8

(162)

COMPRESSOR

4-3/8

(111 )

4-3/8

(111 )

TOP VIEW BASE SECTION

A

DISCHARGE AIR

4-3/8

(111)

4-3/8

(111)

COMPRESSOR

BC

VAPOR &

LIQUID LINE

CONNECTIONS

ELECTRICAL

INLETS

2-3/4 (70)

2 (51)

TPA036S2

SIDE VIEW

o.

3/4

(19)

A B C

in.

mm in. mm in. mm

24-1/4 641 33-1/4 845 32-1/2 826

OPTIONAL UNIT

STAND-OFF KIT (4)

(Field Installed)

SIDE VIEW

TPA048S2 28-1/4 718 37 940 36−1/4 921

TPA060S2 32-1/4 819 37 940 36-1/4 921

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 8

Page 9

INDOOR COIL / AIR HANDLER SUBSTITUTIONS

Substituting Coils in the ARI Tables

Most R−22 and R−410A indoor coils and air handlers are the same except for the factory installed expansion device. C33

coils can be used in place of the CX34 coils, CB26UH, CB30M and CB31MV air handlers can be used in place of the

CB26XUH, CBX32M and CBX32MV, respectively.

The expansion device is based on the size of the outdoor unit. The factory installed RFC or TXV on the

C33/CB26UH/CB31MV/CB30M must be replaced to correspond to the outdoor unit. The correct TXV’s are:

3 ton air conditioners 56J19

4−5 ton air conditioners 56J20

Example:

A four−ton air conditioner is being installed. The ARI table shows that CBX32MV−048 is a matching air handler. A

CB31MV−51 with a 56J20 TXV can be used in its place.

UP−FLOW COILS

CX34−18/24A−6F

CX34−18/24B−6F =

CX34−18/24C−6F =

CX34−44/48B−6F

CX34−44/48C−6F

R−410A R−22

=

C33−24A−2

C33−24B−2

C33−24C−2

CX34−19A−6F

CX34−25A−6F

CX34−25B−6F

CX34−30A−6F

CX34−30B−6F

CX34−30C−6F

CX34−31A−6F

CX34−31B−6F

CX34−36A−6F

CX34−36B−6F

CX34−36C−6F

CX34−38A−6F

CX34−38B−6F

CX34−42B−6F = C33−42B−2

CX34−43B−6F = C33−43B−2

CX34−43C−6F = C33−43C−2

no equivalent

CX34−49C−6F

CX34−50/60C−6F

CX34−60D−6F

CX34−62C−6F

CX34−62D−6F

=

C33−19A−2

=

C33−25A−2

=

C33−25B−2

=

C33−30A−2

=

C33−30B−2

=

C33−30C−2

=

C33−31A−2

=

C33−31B−2

=

C33−36A−2

=

C33−36B−2

=

C33−36C−2

=

C33−38A−2

=

C33−38B−2

C33−44C−2

=

C33−48B−2

=

C33−48C−2

=

C33−49C−2

=

C33−50/60C−2

=

C33−60D−2

=

C33−62C−2

=

C33−62D−2

AIR HANDLERS

R−410A R−22

CBX26UH−018

CBX26UH−024 = CB26UH−024

CBX26UH−030 = CB26UH−030

CBX26UH−036

CBX26UH−042 = CB26UH−042

CBX26UH−048 = CB26UH−048

CBX26UH−060

CBX27UH−018/024 = CB27UH−018/024

CBX27UH−030 = CB27UH−030

CBX27UH−036

CBX27UH−042 = CB27UH−042

CBX27UH−048 = CB27UH−048

CBX27UH−060

CBX32M−018/024 = CB30M−21/26

CBX32M−030 = CB30M−31

CBX32M−036

CBX32M−042 = CB30M−46

CBX32M−048 = CB30M−51

CBX32M−060

CBX32MV−018/024 no equivalent

CBX32MV−024/030 no equivalent

CBX32MV−036

CBX32MV−048 = CB31MV−51

CBX32MV−060 = CB31MV−65

CBX32MV−068

= CB26UH−018

= CB26UH−036

= CB26UH−060

= CB27UH−036

= CB27UH−060

= CB30M−41

= CB30M−65

= CB31MV−41

no equivalent

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 9

Page 10

ARI RATINGS

Expansion

Cooli

Cool

High

Low

High

Low

1

ARI Standard 210/240 Ratings

Capacity − Btuh Efficiency Tota l Wat ts COP

ng

High

Tem p.

Heating

Low

Tem p.

Heating

HSPF

SEER EER IV V

High Low High Low

Heat

Heat

Heat

Heat

TPA036S2 3 TON

Air Handlers Air Handlers

34,400 33,600 20,800 13.00 11. 00 7.70 6.75 3150 2825 2695 3.48 2.263 CB30M−41 (Multi−Position) Factory TXV

34,400 33,600 20,800 13.00 11. 00 7.70 6.70 3155 2830 2710 3.48 2.243 CB30U−41/46 (Up−Flow) Factory TXV

34,400 34,000 21,200 12.20 10.40 7.70 6.70 3245 2925 2755 3.40 2.26

34,600 33,600 20,800 13.00 11. 00 7.70 6.80 3130 2790 2670 3.52 2.283 CB30M−46 (Multi−Position) Factory TXV

34,600 34,200 21,600 12.00 10.30 7.50 6.60 3350 3045 2840 3.24 2.223 CB29M−51 (Multi−Position) Factory TXV

34,800 33,400 20,800 13.00 11. 00 7.70 6.80 3125 2765 2650 3.54 2.304 CB31MV−41 (Multi−Position) Factory TXV

34,800 33,200 20,600 13.50 11. 00 7.70 6.70 3165 2705 2570 3.60 2.34

35,200 33,800 21,000 13.00 11. 00 7.70 7.10 3165 2760 2515 3.58 2.445 CB26UH−036 (Up−Flow/Horiz.) Factory TXV

36,400 33,000 20,400 14.00 12.00 7.70 6.70 3035 2700 2505 3.58 2.38

Up−Flow Indoor Coils + Furnaces Up−Flow Coils + Furnaces

34,200 33,200 20,600 13.00 11. 00 7.70 6.80 3080 2875 2610 3.38 2.32 C33−36B

34,200 33,200 20,600 13.00 11. 00 7.70 6.75 3065 2885 2615 3.38 2.30 C33−36C

34,200 33,200 20,600 13.00 11. 00 7.70 6.80 3080 2875 2610 3.38 2.32 C33−42B

34,400 33,200 20,800 13.00 11. 00 7.70 6.80 3100 2865 2615 3.40 2.32 C33−36C

34,600 33,200 20,600 13.00 11. 00 7.70 6.85 3085 2840 2590 3.42 2.32 C33−36C

34,600 33,200 20,800 13.00 11. 00 7.70 6.80 3095 2850 2605 3.42 2.34 C33−36C

Down−Flow Indoor Coils + Furnaces Down−Flow Coils + Furnaces

34,600 33,400 20,800 13.00 11. 00 8.20 7.20 3060 2675 2425 3.66 2.52 CR33−30/36B−F4 G60DFV−36B−0902 56J19

34,600 33,400 20,800 13.00 11. 00 8.20 7.20 3075 2695 2435 3.64 2.50 CR33−30/36C−F4 G61MPV−36C−0902 56J19

34,600 33,200 20,600 13.00 11. 00 7.70 7.05 3060 2760 2495 3.52 2.42 CR33−48B−F

34,800 33,600 20,800 13.00 11. 00 8.20 7.20 3105 2680 2440 3.68 2.50 CR33−30/36C−F4 G61MPV−60C−0902 56J19

35,000 33,600 20,800 13.00 11. 00 8.20 7.25 3100 2665 2430 3.70 2.50 CR33−30/36C−F4 G61MPV−60C−1102 56J19

Horizontal Indoor Coils + Furnaces Horizontal Coils + Furnaces

34,000 33,200 20,800 13.00 11. 00 7.70 7.00 3075 2785 2510 3.50 2.42 CH23−41

34,000 33,200 20,800 13.00 11. 00 7.70 7.00 3065 2795 2510 3.48 2.42 CH23−41

34,400 33,400 20,800 13.00 11. 00 7.70 7.05 3090 2765 2505 3.54 2.44 CH23−41

34,600 33,200 20,600 13.00 11. 00 7.70 6.80 3075 2835 2625 3.44 2.30 CH33−36C−2F

34,800 33,400 20,800 13.00 11. 00 7.70 6.80 3100 2810 2625 3.48 2.32 CH33−36C−2F

35,000 33,400 20,800 13.00 11. 00 7.70 6.85 3100 2800 2615 3.50 2.32 CH33−36C−2F

NOTE − These are the only approved system match−ups. For other matches, contact the Lennox Applications Department.

NOTE − Ratings for C33 coils include all cased and uncased coils.

NOTE − When used with gas furnaces, a dual−fuel control (i.e. FM21) or a control system with dual−fuel capabilities (i.e. Harmony III, LZP−2 or LZP−4) must be used (ordered extra).

1

Certified in accordance with USE certification program which is based on ARI Standard 210/240 with 25 ft. (7.6 m) of connecting refrigerant lines;

Cooling Ratings − 95_F (35_C) outdoor air temperature and 80_F (27_C) db/67_F (19_C) wb entering indoor coil air.

High Temperature Heating Ratings − 47_F (8_C) db/43_F (6_C) wb outdoor air temperature and 70_F (21_C) db entering indoor coil air.

Low Temperature Heating Ratings − 17_F (−8.3_C) db/15_F (−9.4_C) wb outdoor air temperature and 70_F (21_C) db entering indoor coil air.

2

Factory installed expansion valve or RFC on indoor unit MUST be replaced with valve specified (if equipped).

3

Blower must be capable of time−off blower delay. Indoor Blower Off Delay Relay (58M81) is recommend for field installation.

4

Blower control must be set for a time−off blower delay.

5

Most popular air handler combination.

Indoor Unit Model No.

3,6

CB29M−46 (Multi−Position) Factory TXV

4

CB27UH−036 (Up−Flow / Horizontal) Factory TXV

4

CB27UH−042 (Up−Flow / Horizontal)

4

G60UHV−36B−0902 56J19

4

G61MPV−36C−0902 56J19

4

G60UHV−36B−0902 56J19

4

G61MPV−60C−0902 56J19

4

G60UHV−60C−1102 56J19

4

G61MPV−60C−1102 56J19

4

G60DFV−36B−0902 56J19

4

G60UHV−36B−0902 56J19

4

G61MPV−36C−0902 56J19

4

G61MPV−60C−1102 56J19

4

G61MPV−36C−0902 56J19

4

G61MPV−60C−0902 56J19

4

G61MPV−60C−1102 56J19

Device

2

56J19

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 10

Page 11

ARI RATINGS

Expansion

Cooli

Cool

High

Low

High

Low

1

ARI Standard 210/240 Ratings

Capacity − Btuh Efficiency Total Wa tts COP

ng

High

Tem p.

Heating

Low

Tem p.

Heating

HSPF

SEER EER IV V

High Low High Low

Heat

Heat

Heat

Heat

TPA048S2 4 TON

Air Handlers Air Handlers

46,000 46,000 29,800 11 .4 0 10.00 7.85 7.05 4590 4080 3620 3.30 2.42

46,500 45,500 29,600 11 .6 0 10.20 7.90 7.10 4530 4020 3560 3.32 2.443 CB29M−65 (Multi−Position) Factory TXV

49,000 47,500 30,200 13.00 11. 00 8.50 7.50 4455 3660 3420 3.80 2.58

49,500 47,500 30,200 13.00 11. 00 8.50 7.50 4500 3690 3435 3.78 2.584 CB27UH−048 (Up−Flow / Horizontal) Factory TXV

49,500 47,500 30,600 13.00 11. 00 7.70 7.40 4455 3775 3525 3.68 2.543 CB30M−51 (Multi−Position) Factory TXV

50,000 47,000 30,000 13.50 11. 50 7.70 7.50 4350 3650 3400 3.78 2.584 CB31MV−51 (Multi−Position) Factory TXV

50,500 47,500 30,600 13.00 11. 00 7.70 7.10 4520 4075 3685 3.42 2.445 CB26UH−048 (Up−Flow/Horiz.) Factory TXV

Up−Flow Indoor Coils + Furnaces Up−Flow Coils + Furnaces

49,000 47,500 30,600 13.00 11. 00 7.70 7.10 4450 4050 3675 3.44 2.44 C33−50/60C

49,500 47,500 30,600 13.00 11. 00 7.70 7.10 4470 4040 3670 3.44 2.44 C33−49C

49,500 47,500 30,600 13.00 11. 00 7.70 7.10 4465 4030 3660 3.46 2.44 C33−49C

49,500 47,500 30,400 13.00 11. 00 7.70 7.10 4455 4030 3655 3.46 2.44 C33−50/60C

50,000 47,500 30,400 13.00 11. 00 7.70 7.15 4430 3975 3620 3.50 2.46 C33−49C

50,000 47,000 30,400 13.00 11. 00 7.70 7.15 4420 3995 3620 3.44 2.46 C33−49C

50,000 47,000 30,000 13.50 11. 00 7.70 7.20 4360 3925 3535 3.50 2.48 C33−60D

50,000 47,000 30,400 13.00 11. 00 7.70 7.20 4410 3965 3585 3.48 2.48 C33−60D

51,000 47,500 30,400 13.50 11. 00 7.70 7.10 4480 4055 3640 3.44 2.44 C33−62C

51,000 47,500 30,600 13.00 11. 00 7.70 7.05 4525 4100 3685 3.40 2.44 C33−62C

51,000 47,500 30,600 13.00 11. 00 7.70 7.05 4520 4095 3680 3.40 2.44 C33−62C

51,500 47,500 30,400 13.50 11. 50 7.70 7.10 4480 4035 3625 3.46 2.46 C33−62C

Down−Flow Indoor Coils + Furnaces Down−Flow Coils + Furnaces

49,000 47,500 30,200 13.00 11. 00 7.70 7.50 4400 3685 3440 3.78 2.58 CR33−50/60C−F4 G60DFV−60C−1102 56J20

49,000 47,500 30,400 13.00 11. 00 7.70 7.40 4450 3760 3510 3.70 2.54 CR33−50/60C−F4 G61MPV−60C−1102 56J20

49,000 47,500 30,200 13.00 11. 00 7.70 7.50 4395 3680 3435 3.78 2.58 CR33−60D−F

49,000 47,500 30,400 13.00 11. 00 7.70 7.50 4395 3705 3455 3.76 2.58 CR33−60D−F

49,500 47,500 30,400 13.00 11. 00 7.70 7.50 4415 3680 3445 3.78 2.58 CR33−50/60C−F4 G60DFV−60C−0902 56J20

Horizontal Indoor Coils + Furnaces Horizontal Coils + Furnaces

50,000 47,500 30,400 13.00 11. 00 7.70 7.15 4460 4020 3625 3.46 2.46 CH33−50/60C−2F4 G60UHV−60C−1102 56J20

50,000 47,500 30,600 13.00 11. 00 7.70 7.10 4505 4065 3670 3.42 2.44 CH33−50/60C−2F4 G61MPV−60C−0902 56J20

50,000 47,500 30,600 13.00 11. 00 7.70 7.10 4505 4045 3665 3.44 2.44 CH33−50/60C−2F4 G61MPV−60C−1102 56J20

50,000 47,000 30,200 13.50 11. 00 7.70 7.20 4360 3925 3550 3.50 2.50 CH33−60D−2F

50,000 47,000 30,400 13.00 11. 00 7.70 7.15 4410 3965 3585 3.48 2.48 CH33−60D−2F

50,500 47,500 30,200 13.50 11. 50 7.70 7.65 4365 3530 3355 3.94 2.64 CH23−68

50,500 47,500 30,200 13.50 11. 00 7.70 7.60 4420 3570 3400 3.90 2.60 CH23−68

50,500 47,500 30,600 13.00 11. 00 7.70 7.15 4465 3985 3615 3.50 2.48 CH33−50/60C−2F4 G60UHV−60C−0902 56J20

NOTE − These are the only approved system match−ups. For other matches, contact the Lennox Applications Department.

NOTE − Ratings for C33 coils include all cased and uncased coils.

NOTE − When used with gas furnaces, a dual−fuel control (i.e. FM21) or a control system with dual−fuel capabilities (i.e. Harmony III, LZP−2 or LZP−4) must be used (ordered extra).

1

Certified in accordance with USE certification program which is based on ARI Standard 210/240 with 25 ft. (7.6 m) of connecting refrigerant lines;

Cooling Ratings − 95_F (35_C) outdoor air temperature and 80_F (27_C) db/67_F (19_C) wb entering indoor coil air.

High Temperature Heating Ratings − 47_F (8_C) db/43_F (6_C) wb outdoor air temperature and 70_F (21_C) db entering indoor coil air.

Low Temperature Heating Ratings − 17_F (−8.3_C) db/15_F (−9.4_C) wb outdoor air temperature and 70_F (21_C) db entering indoor coil air.

2

Factory installed expansion valve or RFC on indoor unit MUST be replaced with valve specified (if equipped).

3

Blower must be capable of time−off blower delay. Indoor Blower Off Delay Relay (58M81) is recommend for field installation.

4

Blower control must be set for a time−off blower delay.

5

Most popular air handler combination.

Indoor Unit Model No.

3,6

CB29M−51 (Multi−Position) Factory TXV

4

CB27UH−060 (Up−Flow / Horizontal) Factory TXV

4

G60UHV−60C−1102 56J20

4

G61MPV−60C−0902 56J20

4

G61MPV−60C−1102 56J20

4

G60UHV−60C−0902 56J20

4

G60UHV−60C−0902 56J20

4

G60UHV−60C−1102 56J20

4

G60UHV−60D−1352 56J20

4

G61MPV−60D−1352 56J20

4

G60UHV−60C−1102 56J20

4

G61MPV−60C−0902 56J20

4

G61MPV−60C−1102 56J20

4

G60UHV−60C−0902 56J20

4

G60DFV−60D−1352 56J20

4

G61MPV−60D−1352 56J20

4

G60UHV−60D−1352 56J20

4

G61MPV−60D−1352 56J20

4

G60UHV−60D−1352 56J20

4

G61MPV−60D−1352 56J20

Device

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 11

Page 12

ARI RATINGS

Expansion

Cooli

Cool

High

Low

High

Low

1

ARI Standard 210/240 Ratings

Capacity − Btuh Efficiency Total Wa tts COP

ng

High

Tem p.

Heating

Low

Tem p.

Heating

HSPF

SEER EER IV V

High Low High Low

Heat

Heat

Heat

Heat

TPA060S2 5 TON

Air Handlers Air Handlers

54,000 55,500 35,600 13.00 11. 00 7.70 6.70 4910 4595 4130 3.54 2.52

56,000 55,000 35,400 13.00 11. 00 7.70 6.70 5090 4660 4145 3.46 2.504 CB31MV−51 (Multi−Position) Factory TXV

57,000 55,000 35,800 13.00 11. 00 7.70 6.70 5180 4765 4240 3.42 2.483 CB30U−65 (Up−Flow) Factory TXV

57,000 55,500 35,800 13.00 11. 00 7.70 6.70 5180 4795 4265 3.40 2.46

57,000 55,500 35,800 13.00 11. 00 7.70 6.70 5180 4730 4230 3.44 2.483 CB30M−65 (Multi−Position) Factory TXV

57,500 55,000 35,400 13.00 11. 50 7.70 6.70 5000 4655 4155 3.46 2.504 CB31MV−65 (Multi−Position) Factory TXV

Up−Flow Indoor Coils + Furnaces Up−Flow Coils + Furnaces

55,000 55,000 35,600 13.00 11. 50 7.70 6.70 4785 4940 4365 3.26 2.38 C33−60D

55,500 55,000 35,600 13.00 11. 50 7.70 6.70 4825 4855 4290 3.32 2.42 C33−60D

56,000 55,500 36,000 13.00 11. 00 7.70 6.70 5090 4995 4455 3.26 2.36 C33−62C

56,000 55,000 35,600 13.00 11. 50 7.70 6.70 4870 4920 4335 3.28 2.40 C33−62D

56,500 55,500 35,800 13.00 11. 50 7.70 6.70 4915 4950 4400 3.28 2.38 C33−62C

56,500 55,000 35,600 13.50 11. 50 7.70 6.70 4915 4835 4275 3.34 2.44 C33−62D

56,500 55,500 36,000 13.00 11. 00 7.70 6.70 5135 4975 4445 3.26 2.38 C33−62C

57,000 55,500 35,800 13.00 11. 50 7.70 6.70 4955 4895 4390 3.32 2.38 C33−62C

Down−Flow Indoor Coils + Furnaces Down−Flow Coils + Furnaces

53,500 55,000 35,400 13.00 11. 00 7.70 6.70 4865 4695 4155 3.44 2.50 CR33−50/60C−F4 G60DFV−60C−0902 56J20

54,000 55,000 35,600 13.00 11. 00 7.70 6.70 4910 4670 4145 3.46 2.52 CR33−60D−F

Horizontal Indoor Coils + Furnaces Horizontal Coils + Furnaces

55,000 55,000 35,600 13.00 11. 50 7.70 6.70 4785 4990 4365 3.24 2.38 CH33−60D−2F

55,000 55,000 35,600 13.00 11. 50 7.70 6.70 4785 4935 4370 3.26 2.38 CH33−62D−2F

55,500 55,000 35,600 13.00 11. 50 7.70 6.70 4825 4895 4305 3.30 2.42 CH33−60D−2F

55,500 55,500 35,600 13.00 11. 50 7.70 6.70 4825 4540 4100 3.58 2.54 CH23−68

56,000 54,500 35,400 13.50 11. 50 7.70 6.70 4870 4895 4300 3.26 2.42 CH33−62D−2F

56,500 55,500 35,600 13.50 11. 50 7.70 6.70 4915 4470 4040 3.64 2.58 CH23−68

57,500 55,000 35,600 13.00 11. 00 7.70 6.70 5225 5000 4415 3.26 2.38 CH33−50/60C−2F4 G60UHV−60C−0902 56J20

57,500 55,000 35,800 13.00 11. 00 7.70 6.70 5225 5015 4395 3.22 2.38 CH33−50/60C−2F4 G60UHV−60C−1102 56J20

NOTE − These are the only approved system match−ups. For other matches, contact the Lennox Applications Department.

NOTE − Ratings for C33 coils include all cased and uncased coils.

NOTE − When used with gas furnaces, a dual−fuel control (i.e. FM21) or a control system with dual−fuel capabilities (i.e. Harmony III, LZP−2 or LZP−4) must be used (ordered extra).

1

Certified in accordance with USE certification program which is based on ARI Standard 210/240 with 25 ft. (7.6 m) of connecting refrigerant lines;

Cooling Ratings − 95_F (35_C) outdoor air temperature and 80_F (27_C) db/67_F (19_C) wb entering indoor coil air.

High Temperature Heating Ratings − 47_F (8_C) db/43_F (6_C) wb outdoor air temperature and 70_F (21_C) db entering indoor coil air.

Low Temperature Heating Ratings − 17_F (−8.3_C) db/15_F (−9.4_C) wb outdoor air temperature and 70_F (21_C) db entering indoor coil air.

2

Factory installed expansion valve or RFC on indoor unit MUST be replaced with valve specified (if equipped).

3

Blower must be capable of time−off blower delay. Indoor Blower Off Delay Relay (58M81) is recommend for field installation.

4

Blower control must be set for a time−off blower delay.

5

Most popular air handler combination.

Indoor Unit Model No.

4

CB27UH−060 (Up−Flow / Horizontal) Factory TXV

5

CB26UH−060−R (Up−Flow / Horizontal)2 56J20

4

G61MPV−60D−1352 56J20

4

G60UHV−60D−1352 56J20

4

G61MPV−60C−0902 56J20

4

G61MPV−60D−1352 56J20

4

G60UHV−60C−1102 56J20

4

G60UHV−60D−1352 56J20

4

G61MPV−60C−1102 56J20

4

G60UHV−60C−0902 56J20

4

G60DFV−60D−1352 56J20

4

G61MPV−60D−1352 56J20

4

G61MPV−60D−1352 56J20

4

G60UHV−60D−1352 56J20

4

G61MPV−60D−1352 56J20

4

G60UHV−60D−1352 56J20

4

G60UHV−60D−1352 56J20

Device

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 12

Page 13

Page 14

Page 15

REVISIONS

Sections Description of Change

Ratings Revised TPA060 ratings

Page 16

Visit us at www.lennox.com

For the latest technical information, www.lennoxdavenet.com

Contact us at 1−800−9−LENNOX

NOTE − Due to Lennox’ ongoing committment to quality, Specifications, Ratings and Dimensions subject to change without notice and without incurring liability.

Improper installation, adjustment, alteration, service or maintenance can cause property damage or personal injury.

Installation and service must be performed by a qualified installer and servicing agency.

©2007 Lennox Industries Inc.

Loading...

Loading...