Page 1

E 2010 Lennox Industries Inc.

Dallas, Texas, USA

506443−01

07/2010

SLP98UH

SERIES

VARIABLE

CAPACITY

GAS FURNACE

FIRE OR EXPLOSION HAZARD.

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

Litho U.S.A.

WARNING

WHAT TO DO IF YOU SMELL GAS:

D Do not try to light any appliance.

D Do not touch any electrical switch; do not

use any phone in your building.

D Leave the building immediately.

D Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

D If you cannot reach your gas supplier, call

the fire department.

07/10

*2P0710*

506443−01

*P506443-01*

Page 2

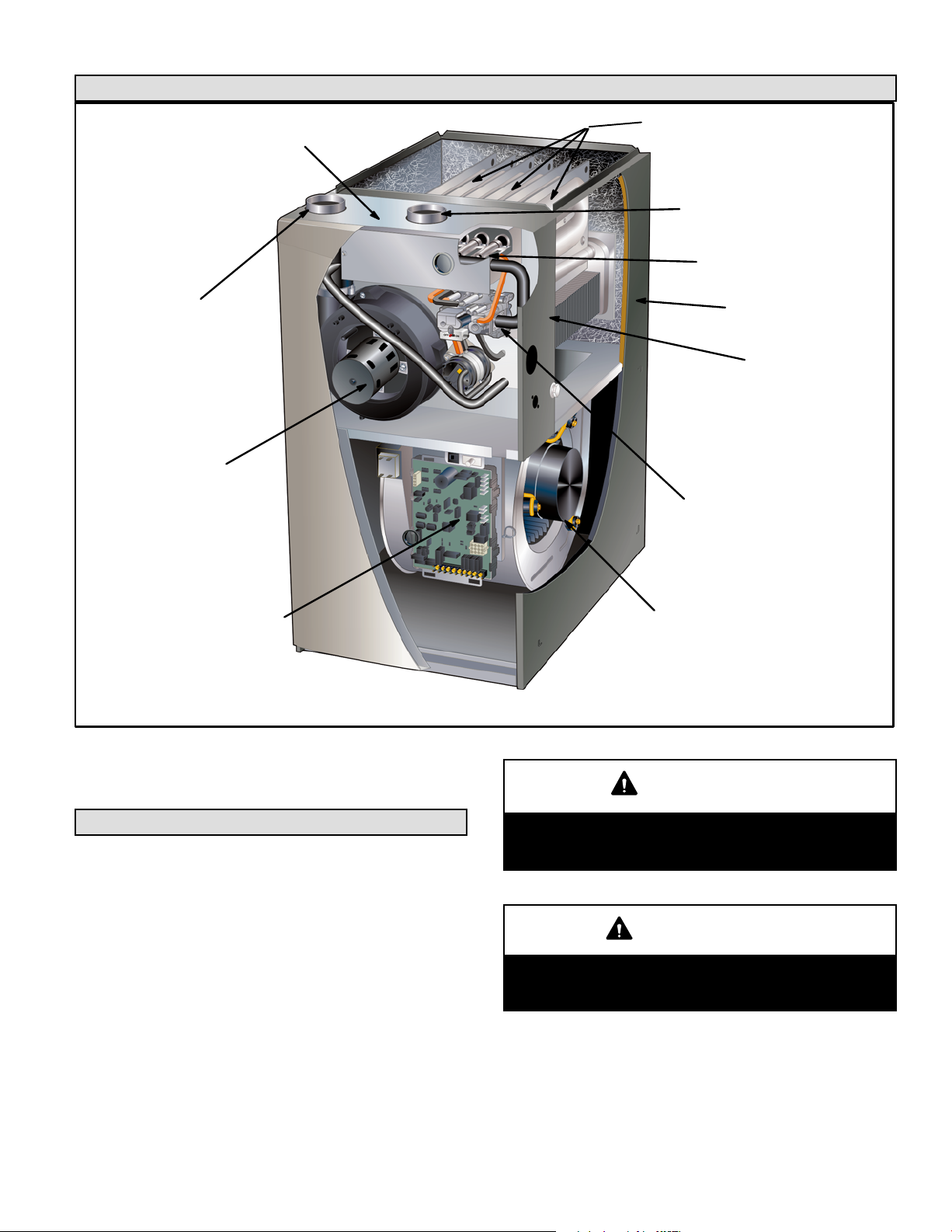

SLP98UH Parts Identification

TOP CAP

TM

DURALOK

EXCHANGER

ASSEMBLY

AIR INTAKE COLLAR

HEAT

BURNERS

FLUE

COLLAR

VARIABLE SPEED

COMBUSTION AIR

INDUCER

SURELIGHT

INTEGRATED

CONTROL

NOTE − This manual must be left with the equipment

user.

®

FIGURE 1

CABINET

PRESSURE SWITCH

ASSEMBLY

GAS VALVE

AND MANIFOLD

VARIABLE SPEED

BLOWER

MOTOR

CAUTION

Notice to Homeowner

This furnace is equipped with safety devices that protect

you and your property. If one or more of these devices is

activated, furnace operation will stop. If your home is left

unattended for an extended period of time, equipment operation must be checked periodically. If this is not possible,

the water supply to the house should be shut off and the

pipes should be drained. This will prevent problems associated with a NO HEAT condition (frozen pipes, etc.)

Page 2

As with any mechanical equipment, personal injury

can result from contact with sharp sheet metal

edges. Be careful when you handle this equipment.

WARNING

Before attempting to perform any service or maintenance, turn the electrical power to unit OFF at the

disconnect switch.

Page 3

WARNING

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you

to fiberglass wool. Breathing this may cause lung

cancer. (Fiberglass wool is known to the State of California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact your

supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

CAUTION

Do not set thermostat below 60°F (16°C) in heating

mode. Setting thermostat below 60°F (16°C) reduces

the number of heating cycles. Damage to the unit

may occur that is not covered by the warranty.

WARNING

If overheating occurs or if gas supply fails to shut off,

shut off the manual gas valve to the furnace before

shutting off electrical supply.

WARNING

Do not use this furnace if any part has been underwater. A flood−damaged furnace is extremely dangerous. Attempts to use the furnace can result in fire or

explosion. Immediately call a licensed professional

service technician (or equivalent) to inspect the furnace and to replace all gas controls, control system

parts, and electrical parts that have been wet or to replace the furnace, if deemed necessary.

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a licensed professional installer (or

equivalent), a service agency, or the gas supplier.

Safety Instructions

1 − Keep the furnace area clear and free of combustible

material, gasoline, and other flammable vapors and

liquids. If it is installed in an insulated area, the furnace

must be kept free of insulating material. Insulating material may be combustible.

2 − After any heavy snow, ice or frozen fog event, the fur-

nace vent pipes may become restricted. Always check

the vent system and remove any snow or ice that may

be obstructing the intake or exhaust plastic pipes.

3 − DO NOT obstruct air flow to unit. Unit must receive an

unobstructed flow of combustion and ventilating air.

DO NOT block or obstruct air openings on the furnace

or air openings to the area in which the furnace is

installed. Take care to maintain established clearances surrounding the furnace.

4 − DO NOT store chlorine or fluorine products near unit

or introduce these products into the combustion air.

These products can cause furnace corrosion.

5 − DO NOT draw return air from a room where this fur-

nace, or any other gas appliance (ie., a water heater), is installed. When return air is drawn from a room,

a negative pressure is created in the room. If a gas appliance is operating in a room with negative pressure,

the flue products can be pulled back down the vent

pipe and into the room. This reverse flow of the flue

gas may result in incomplete combustion and the

formation of carbon monoxide gas. This toxic gas

might then be distributed throughout the house by the

furnace duct system.

WARNING

The blower door must be securely in place when the

blower and burners are operating. Gas fumes, which

could contain carbon monoxide, can be drawn into

the living space resulting in personal injury or death.

NOTICE

Any additions, changes, or conversions required in

order for the appliance to satisfactorily meet the application needs must be made by a licensed professional installer (or equivalent) using factory−specified and approved parts.

Page 3

Your furnace is a gas appliance. It is critical that the gas

supplied to the unit be completely burned to avoid the production of carbon monoxide gas. Complete combustion of

the gas requires, but is not limited to, correct gas pressure

and gas flow rate, adequate combustion, air, and proper

venting.

Page 4

WARNING

Carbon monoxide gas is invisible, odorless and toxic.

Exposure to carbon monoxide gas can cause personal in-

jury and even death to all occupants, including pets. Any

item that is powered by or gives off heat from a combustion

process (including lawn mowers, automobiles, and fire-

places) has the potential to produce carbon monoxide gas.

Because of this, Lennox recommends the use of a car-

bon monoxide detector in your home, even if you do

not own gas appliances. Reliable detectors are available

at reasonable retail prices. Contact your Lennox dealer for

more details about this investment in your safety.

Your furnace is designed to meet standards set by national

agencies, and to operate safely when properly installed

and maintained. However, the unit’s performance can be

greatly impacted by the individual installation and the oper-

ating environment. It is your responsibility to ensure that

this appliance is maintained.

Proper maintenance is critical for your safety and the satisfactory operation of the product. Lennox strongly recom-

mends annual inspection and maintenance of this appliance. Contact your Lennox dealer for an inspection by a

licensed professional service technician.

DANGER

Danger of explosion.

There are circumstances in which odorant used with

LP/propane gas can lose its scent. In case of a leak,

LP/propane gas will settle close to the floor and may

be difficult to smell. An LP/propane leak detector

should be installed in all LP applications.

Do not attempt to bleed the gas lines of air. Call your

local gas provider.

The gas valve on the SLP98UH is equipped with a gas control switch. Use only your hand to move the control switch.

Never use tools. If the switch will not move by hand, do not

try to repair it. Call a licensed professional service technician (or equivalent). Force or attempted repair may result in

a fire or explosion.

Placing the SGLP9UH furnace into operation:

SLP98UH070 units are equipped with a SureLight

system. Do not

furnace. Each time the thermostat calls for heat, the burners will automatically light. The ignitor does not get hot

when there is no call for heat on units with SureLight® ignition system.

Operating the Gas Valve (Figure 2)

1 − STOP! Read the safety information at the beginning of

this section.

2 − Set the thermostat to the lowest setting.

3 − Turn off all electrical power to the unit.

4 − This furnace is equipped with an ignition device which

automatically lights the burners. Do not try to light the

burners by hand.

5 − Remove the outer access panel.

6 − Move the gas valve switch to the OFF position. See fig-

ure 2.

7 − Wait five minutes to clear out any gas. If you then smell

gas, STOP! Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions. If you do not smell gas go to next step.

attempt to manually light burners on this

VARIABLE CAPACITY GAS VALVE

®

ignition

Start−Up & Operation Information

WARNING

If you do not follow these instructions exactly, a fire

or explosion may result causing property damage,

personal injury or death.

BEFORE PLACING THE UNIT INTO OPERATION, smell

all around the appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than air and will

settle on the floor.

Page 4

GAS VALVE

SWITCH

GAS VALVE SHOWN IN ON POSITION

FIGURE 2

8 − Move gas valve switch to ON position. See figure 2.

9 − Replace the outer access panel.

10 − Turn on all electrical power to to the unit.

11 − Set the thermostat to desired setting.

Page 5

NOTE − When unit is initially started, steps 1 through 11

may need to be repeated to purge air from gas line.

12− If the appliance will not operate, follow the section

Turning Off Gas to the Unit" and call your service technician or gas supplier.

Turning Off Gas to the Unit

1 − Set the thermostat to the lowest setting.

2 − Turn off all electrical power to the unit if service is to be

performed.

3 − Remove the outer access panel.

4 − Move the gas valve switch to the OFF position.

5 − Replace the outer access panel.

Filters

All SLP98UH filters are installed external to the unit. Filters

should be inspected monthly. Clean or replace the filters

when necessary to ensure proper furnace operation. Replacement filters must be rated for high velocity airflow.

Table 1 lists recommended filter sizes.

A filter must be in place when the unit is operating. The filter

access panel must also be in place and properly secured

during unit operation.

TABLE 1

Furnace

Cabinet Width

17−1/2" 16 X 25 X 1 (1) 16 X 25 X 1 (1)

21−1/2" 16 X 25 X 1 (1) 16 X 25 X 1 (1)

24−1/2" 16 X 25 X 1 (1) 16 X 25 X 1 (1)

Side Return Bottom Return

Filter Size

Maintenance

A licensed professional service technician (or equivalent)

should inspect the complete system each season (heating

and cooling). The following maintenance procedures

should only be conducted by a licensed professional service technician (or equivalent). Do not attempt to service

the unit in any way.

WARNING

ELECTRICAL SHOCK, FIRE,

OR EXPLOSION HAZARD.

Failure to follow safety warnings exactly could result

in dangerous operation, serious injury, death or

property damage.

Improper servicing could result in dangerous operation, serious injury, death, or property damage.

Before servicing, disconnect all electrical power to

furnace.

When servicing controls, label all wires prior to disconnecting. Take care to reconnect wires correctly.

Verify proper operation after servicing.

Venting System

WARNING

Asphyxiation Hazard

The exhaust vent for this furnace must be leak−free

and must be securely connected to the furnace flue

collar at all times.

For your safety and to fulfill the terms of the limited

warranty, a licensed professional service technician

(or equivalent) must annually inspect this furnace

and its vent system.

Annually (before heating season) inspect furnace venting

system, vent cap, heat exchanger, and burners for corrosion, deterioration, or deposits of debris. Remove any obstructions.

Inspect the furnace for obvious signs of deterioration.

Inspect the furnace venting system to make sure it is in

place, physically sound, and without holes, corrosion, or

blockage.

Vent pipe must be clear and free of obstructions and must

slope upward away from the furnace.

Inspect the furnace return air duct connection to ensure

duct is sealed to the furnace and terminates outside the

space containing the furnace.

Inspect the physical support of the furnace to guarantee

that it is sound without sagging, cracks or gaps around

base and it maintains seal between base and support.

Inspect the condensate drain and trap for leaks and cracks.

The drain and trap must also be cleaned and the trap must

be filled with water.

During a seasonal check the service technician will conduct a combustion analysis. The technician will also inspect the indoor blower, burner flames, electrical connections and the venting system.

Blower

Check the blower wheel for debris and clean if necessary.

The blower motors are prelubricated for extended bearing

life. No further lubrication is needed.

WARNING

The blower access panel must be securely in place

when the blower and burners are operating. Gas

fumes, which could contain carbon monoxide, can

be drawn into living space resulting in personal injury or death.

Page 5

Page 6

Burner Flame

CAUTION

To ensure proper operation, a licensed professional

service technician (or equivalent) should check the

burner flame and conduct a combustion analysis

annually.

Electrical

1 − Check all wiring for loose connections.

2 − Check for the correct voltage at the furnace (furnace

operating).

3 − Check amp−draw on the blower motor.

Motor Nameplate__________Actual__________

Service Reminder

Call your Lennox service technician if the unit will not operate. Before calling, always check the following to be sure

service is required:

1 − Check that electrical disconnect switches are ON.

2 − Check room thermostat for proper setting.

3 − Replace any blown fuses or reset circuit breakers.

4 − Gas valve should be ON.

5 − Air filter should not be plugged, which will limit air flow.

6 − Is gas turned on at meter?

7 − Is manual main shut−off valve open?

Record the model and serial number of the furnace. These

numbers are on the unit nameplate, which is located on the

blower deck below the combustion air inducer.

Serial Number __________________

Model Number __________________

Safety Precautions

If you discover any of the following, shut down your

unit, and contact a Lennox dealer for an inspection by

a licensed professional service technician (or equivalent).

D If you repeatedly hear any new or unfamiliar sounds

while your unit is operating, there may be a problem. For

example, poorly performing burners can produce unfamiliar noises.

D If you smell any unusual odors, your unit may be operat-

ing improperly. For example, units can give off unfamiliar odors if components are required to operate in abnormal conditions.

D Look for visible signs of a malfunctioning unit. Examples

include unusual amounts of condensate on windows inside your house, visibly burnt components or unusual

dirt or rust accumulations on the vent pipe or in the unit.

D If you experience headache, nausea, fatigue, or dizzi-

ness, the cause could be exposure to carbon monoxide

gas. This is often misdiagnosed as the flu because

symptoms are similar. If you suffer from flu−like symptoms that are exaggerated at home, but seem to subside while you are away from the house, exposure to

carbon monoxide could be the cause.

Your vigilance may pay off in early detection of a problem

before either personal injury or property damage occurs.

Do not hesitate to contact a licensed professional service

technician (or equivalent) as an investment in your well being.

Planned Service

You should expect a service technician to check the following items during an annual inspection. Power to the unit

must be shut off for the service technician’s safety.

Fresh air grilles and louvers (on the unit and in the room

where the furnace is installed) − Must be open and unobstructed to provide combustion air.

Burners − Must be inspected for rust, dirt, or signs of water.

Vent pipe − Must be inspected for signs of water, damaged

or sagging pipe, or disconnected joints.

Unit appearance − Must be inspected for rust, dirt, signs

of water, burnt or damaged wires, or components.

Blower access door − Must be properly in place and provide a seal between the return air and the room where the

furnace is installed.

Return air duct − Must be properly attached and provide

an air seal to the unit.

Operating performance − Unit must be observed during

operation to monitor proper performance of the unit and the

vent system.

Combustion gases − Flue products must be analyzed and

compared to the unit specifications.

Problems detected during the inspection may make it necessary to temporarily shut down the furnace until the items

can be repaired or replaced.

Pay attention to your furnace. Situations can arise between annual furnace inspections that may result in unsafe

operation.

Page 6

Page 7

Repair Parts List

The following repair parts are available through Lennox dealers. When ordering parts, include the complete furnace model

number listed on the CSA International nameplate −− Example: SLP98UH070V36B. All service must be done by a li-

censed professional installer (or equivalent), a service agency, or the gas supplier.

Cabinet Parts

Outer access panel

Blower access panel

Top cap

Control Panel Parts

Transformer

SureLight

Door interlock switch

Circuit breaker

Blower Parts

Blower wheel

Motor

Blower housing cut−off plate

®

integrated control

Heating Parts

Flame Sensor

Heat exchanger assembly

Gas manifold

Combustion air inducer

Gas valve

Main burner cluster

Main burner orifices

Pressure switches

Ignitor

Primary limit control

Flame rollout switches

Page 7

Loading...

Loading...