Page 1

INSTALLATION AND OPERATION MANUAL

US

TM

Direct-Vent Gas

Fireplace Heater Inserts

The Shoreline™ replace insert is factory equipped for 40,000 BTU

input and can be converted to 33,000 using the smaller orice provided.

Retain These Instructions For Future Reference

P/N 850,050M Rev. C, 01/2008

A French manual is available upon request. Order P/N 850,050CF. Ce manuel d’installation

est disponible en francais, simplement en faire la demande. Numéro de la pièce 850,050CF.

In the Commonwealth of Massachusetts:

• Installation must be performed by a licensed plumber or gas tter

• See Table of Contents for location of additional Commonwealth of

Massachusetts requirements

• Hot! Do not touch! The glass and surfaces of this appliance will be hot during operation and will

retain heat for a while after shutting off the appliance. Severe burns may result.

Carefully supervise children in the same room as appliance.

•

• If small children are present in the home, it is recommended that this appliance be fitted with a

screen door or screen panel kit. See Page 33 for ordering information.

Report No. 050-F-22-5

WARNINGS

Shoreline™ 33/40 DV INS

• Suitable for installation into masonry or factory built fireplaces. These appliances may be installed in an aftermarket permanently located, manufactured (mobile) home (USA only), where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate.

• This appliance is not convertible for use with other gases unless a certified kit is used.

• Lennox™ gas-burning appliances are designed for use as a supplemental heater. They are not intended for

continuous use as a primary heat source.

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result

causing property damage, personal injury or loss

of life.

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

appliance.

AVERTISSEMENT: Assurez-vous de bien suivre les

instructions donné dans cette notice pour réduire au

minimum le risque d’incendie ou pour éviter tout dommage matériel, toute blessure ou la mort.

POUR VOTRE SÉCURITÉ: Ne pas entreposer ni utiliser

d’essence ni d’autre vapeurs ou liquides inflammables dans

le voisinage de cet appareil ou de tout autre appareil.

POUR VOTRE SÉCURITÉ: Que faire si vous sentez une odeur

WHAT TO DO IF YOU SMELL GAS:

• Do not light any appliance.

• Do not touch any electrical switch; do not

Use any phone in your building.

•

Immediately call your gas supplier from a

neighbor’s phone. Follow your gas supplier's

instructions.

• If your gas supplier cannot be reached, call

the fire department.

de gaz:

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones se trouvant dans le batiment où vous

vous trouvez.

• Evacuez la piéce, le bâtiment ou la zone.

• Appelez immédiatement votre fournisseur de gaz depuis

un voisin. Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de gaz,

appelez le service dos incendies.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

L’installation et service doit être exécuté par un qualifié instal-

leur, agence de service ou le fournisseur de gaz.

Page 2

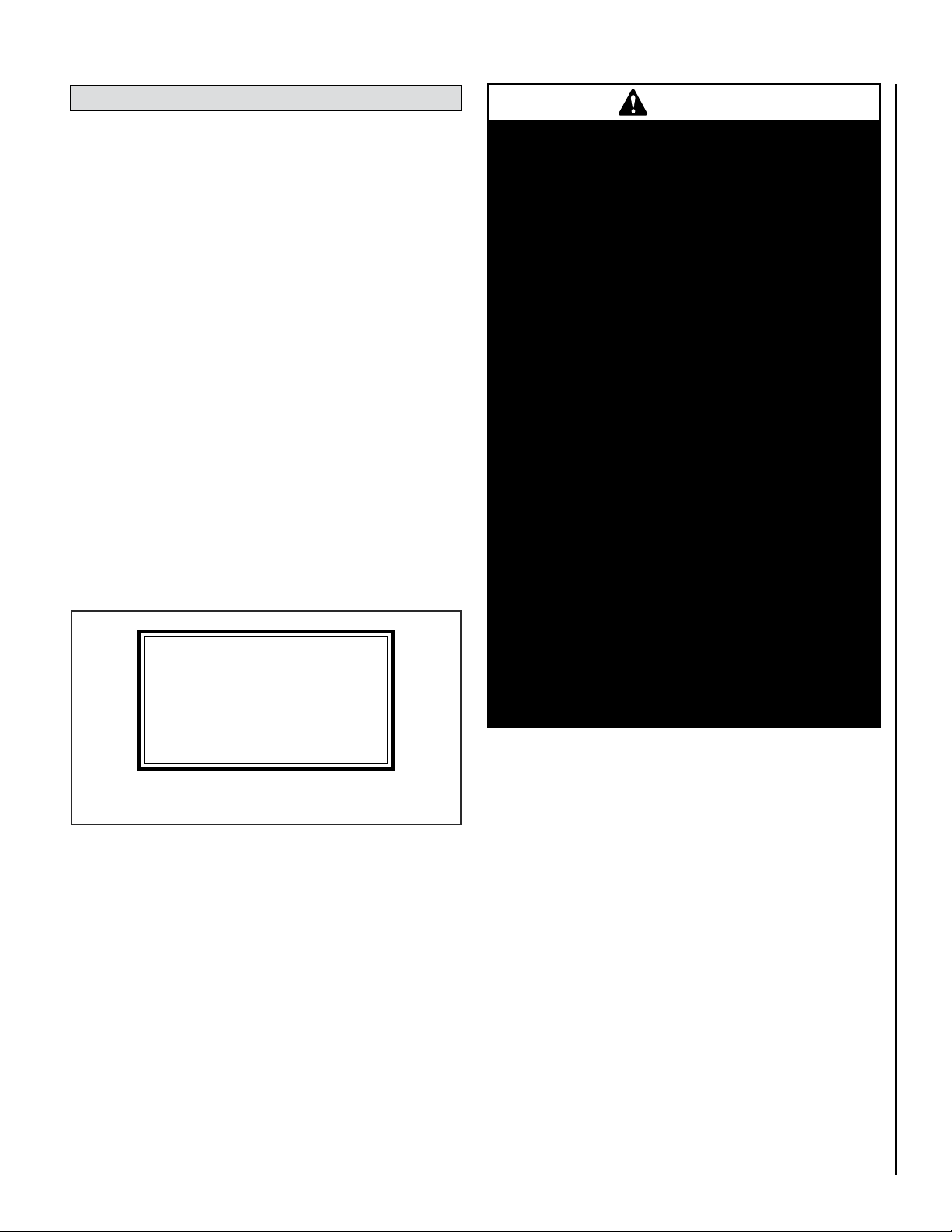

IMPORTANT SAFETY AND WARNING

INFORMATION

READ THIS MANUAL IN ITS ENTIRETY AND UNDERSTAND THESE RULES TO FOLLOW FOR SAFETY

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information consult a qualified installer,

service agency or the gas supplier.

WARNING

Do not attempt to alter or modify the construction of

the appliance or its components. Any modification

or alteration may void the warranty, certification

and listings of this unit.

WARNING

Failure to comply with the installation and operating

instructions provided in this document will result in

an improperly installed and operating appliance,

voiding its warranty. Any change to this appliance

and/or its operating controls is dangerous. Improper

installation or use of this appliance can cause serious injury or death from fire, burns, explosion or

carbon monoxide poisoning.

1. FOR YOUR SAFETY do not install or operate your fireplace

insert without first reading and understanding this manual.

Any installation or operation of the appliance deviating from

that which is stated in this manual WILL void the warranty

and may be hazardous.

2. INSTALLATION AND REPAIR SHOULD ONLY BE DONE BY A

QUALIFIED SERVICE TECHNICIAN. DO NOT ATTEMPT TO

SERVICE THE APPLIANCE YOURSELF.

3. The insert should be inspected and cleaned before use and

at least annually by a qualified service technician. More

frequent cleaning may be required due to excessive lint from

bedding material, carpeting, etc.

4. It is imperative that control compartments, burners, and

circulating air passageways of the room heater be kept

clean. S'assurer que le brùleur et le compartiment des commandes sont propres. Voir les instructions d'installation et

d'utilisation qui accompagnent l'appareil.

5. Adequate clearances around the combustion chamber and

accessibility clearances for servicing and proper operation

must be maintained.

6. Turn off the gas before servicing this appliance. It is recommended that a qualified service technician perform an appliance check-up at the beginning of each heating season.

7. All installations must conform with all local, state, and

national codes. In the absence of local codes, the installation must conform with National Fuel Gas Code ANSI

Z223.1-latest edition, also known as NFPA 54 (In Canada,

2

the current CAN/CSA B149.1 installation code).

Refer to the National Fuel Gas Code and local zoning and

code authorities for details on installation requirements. Your

fireplace insert must be vented to the outside in accordance

with the latest edition of the National Fuel Gas Code.

8. This gas insert MUST be vented directly to the outside and

.

MUST NEVER be attached to a chimney serving a separate

solid fuel burning appliance. Each gas appliance MUST USE

a separate vent system. Common vent systems are PROHIBITED.

9. Manufactured (mobile) home installations must conform with

the Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280 (in Canada CAN/CSA Z240 MH) (in

Canada CAN/CSA Z240 MH), or, when such a standard is not

applicable, the Standard for Manufactured Home Installations, ANSI A225.1.

10. The appliance, when installed, must be electrically grounded

in accordance with local codes or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70 latest edition. In Canada, the current CSA C22-1 Canadian

Electrical Code - latest edition.

11.Your Shoreline™ gas insert must be equipped for the proper

fuel type and altitude at which it will be operated. Any operation outside the parameters outlined in this manual may result

in a hazardous condition and will void the warranty. Please

carefully read the sections pertaining to these subjects and/or

be sure your appliance is properly equipped.

12.Do not use this insert if any part has been under water.

Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system

and any gas control which has been under water.

Ne pas se servir de cet appareil s'il a été plongé dans l'eau,

complètement ou en partie. Appeler un technicien qualifié pour

inspecter l'appareil et remplacer toute partie du système de

contrôle et toute commande qui ont été plongés dans l'lau.

13.Due to high temperatures, the fireplace insert should be located

out of traffic areas and away from furniture and draperies. The

recommended clearance zone from the front of the appliance

to combustibles is 36 inches (914 mm).

14. Children and adults should be alerted to the hazards of

high surface temperature and should stay away to avoid

burns or clothing ignition. Young children should be carefully supervised when they are in the same room as the gas

insert. Clothing or any other flammable material should not

be placed on or near the appliance.

Surveiller les enfants. Garder les vêtements, les meubles,

l'essence ou autres liquides à vapeur inflammables lin de

l'appareil.

15. Never use solid fuels such as wood, paper, cardboard, coal,

or any flammable liquids, etc., in this appliance.

16. Any grill, panel, or glass removed for service MUST be

replaced prior to operating the fireplace insert. Do not operate

appliance with the glass front removed, cracked or broken.

Replacement of the glass should be done by a qualified

service technician.

17. DO NOT USE abrasive cleaner on the glass door assembly.

DO NOT ATTEMPT to clean the glass door when it is hot.

18. Gold and nickel plated surfaces must be cleaned with glass

cleaner and a clean soft cloth before firing the first time or

fingerprints will remain permanently. NEVER use brass polish

to clean gold or nickel, this will remove the plating!!!

19. When opening the access door (right side surround panel)

be very careful because the door is hot during operation.

20. Lennox Hearth Products, its employees, or any of its representatives assume no responsibility for any damages caused

by an inoperable, inadequate, or unsafe condition as a result

of any improper operation, service or installation procedures,

whether direct or indirect.

Page 3

CONGRATULATIONS ON THE PURCHASE OF YOUR NEW

GAS APPLIANCE MANUFACTURED BY LENNOX HEARTH

PRODUCTS.

When you purchased your new gas-fired heater, you joined the ranks

of thousands of individuals whose answer to their home heating needs

reflects their concern for efficiency and our environment. We extend our

continued support to help you achieve the maximum benefit and enjoy

ment available from your new gas-fired heater. It is our goal at Lennox

Hearth Products to provide you, our valued customer, with an appliance

that will ensure years of trouble-free warmth and pleasure.

Thank you for selecting a Lennox Hearth Products gas-fired heater as

the answer to your home heating needs.

Sincerely, All of us at Lennox Hearth Products

TABLE OF CONTENTS

Important Safety and Warning Information ..................... Page 2

Packaging List ..............................................................

Introduction ................................................................. Page 3

General Information .....................................................

Codes and Approvals ...................................................

New York City MEA Approval .......................................

Requirements for the

Commonwealth of Massachusetts ..........................

Specifications - Insert Dimensions ..............................

Clearances to Combustibles .........................................

Installation ................................................................... Page 9

Fireplace Requirements

........................................... Page 9

Venting Requirements .............................................

Insert Leveling ........................................................

Door Assembly Installation

or Removal Instructions

...................................... Page 12

Refractory Brick Panel Installation Instructions ......

Log Set Installation Instructions .............................

Surround Installation Instructions ..........................

Gas Line Installation .....................................................

Gas Pressure Requirements

.................................... Page 18

LP and Natural Gas Supplies ...................................

Operating Instructions .................................................

Pre-Lighting Checklist .............................................

Lighting Instructions ...............................................

To Turn Gas Off to Appliance ...................................

Shutdown Procedure ..............................................

Flame Appearance and Sooting ...............................

Air Shutter Adjustment ...........................................

Burn-In Period ........................................................

Quiet Operation .......................................................

Blower Operation and Wiring Diagram ....................

Shoreline™ Main Burner Operation .........................

Millivolt Control System and Wiring Diagram .........

Maintenance and Servicing ..........................................

Maintenance Checklist ............................................

Glass Maintenance ..................................................

Door Removal .........................................................

Blower Removal ......................................................

Paint Touch-Up .......................................................

Inspecting Wiring ....................................................

Fuel Conversion Kits ...............................................

Maintenance Schedule ............................................

Troubleshooting ........................................................... Page 26

Replacement Parts List. ...............................................

Part Identification .........................................................

Optional Accessories ....................................................

Safety / Listing Label ....................................................

Lighting Instructions Label ..........................................

Warranty and Product Reference Information ..............

Page 3

Page 4

Page 4

Page 6

Page 6

Page 7

Page 8

Page 10-11

Page 11

Page 13

Page 14-15

Page 16

Page 18

Page 18

Page 18-22

Page 18

Page 19

Page 19

Page 19

Page 20

Page 20

Page 21

Page 21

Page 21

Page 22

Page 22

Page 23-25

Page 23

Page 23-24

Page 24

Page 24

Page 24

Page 24

Page 24

Page 25

Page 27

Page 28-32

Page 33-35

Page 36

Page 37

Page 38

This installation manual will help you obtain a safe, efficient, dependable installation for your appliance and vent system.

PLEASE READ AND UNDERSTAND THESE INSTRUCTIONS

BEFORE BEGINNING YOUR INSTALLATION

-

PACKAGING LIST

To install a Shoreline insert, an insert body, refractory brick panel set

and surround kit are required (each sold separately. See

ordering information).

Fireplace Insert Body Packaging List

Model: Shoreline 33/40 DV INS

1) Fireplace Insert Body ...................... 1) 150 cfm Blower

with Burner Cassette

1) Gas pipe (3/8” x 8”)

1) Installation and Operation Manual

1) Bag of Glowing Ember Material

1) Front Leveling Leg Kit

Refractory Brick Panel Sets - 6 pieces:

Standard

Red

Architectural Stone

......................1) 5-Piece Log Set

........................ 1) Optional Shoreline #33 orifice

.. 1) Bag of Decorative Lava Rock

...... 1) Fireplace Warning Label

Surround Kits:

Small 3-sided - 36-5/8” Wide x 25-7/8” High (930 mm x 657 mm)

Large 3-sided - 41” Wide x 28” High (1041 mm x 711 mm)

Small 4-sided - 36-5/8” Wide x 29-3/16” High (930 mm x 741 mm)

Large 4-sided - 41” Wide x 33-1/2” High (1041 mm x 851 mm)

INTRODUCTION

The Insert models covered in this manual are direct-vent sealed combustion gas heaters designed for residential application for installation

into an existing masonry or factory built solid fuel burning fireplace. The

required liners for the air intake and exhaust are as follows:

•

Air Intake: Use 3” diameter UL 181 or UL 1777 listed liner only.

• Exhaust: Use 3” diameter UL 1777 listed gas vent liner only. DO

NOT USE UL 181 LISTED LINER.

These vent systems must be routed through the existing fireplace flue

system to the vent termination.

Installation Options

• . Residential • Manufactured (mobile) home

• . Bedrooms • Commercial

Your direct vent Insert is designed to be vented vertically with a minimum

height of 10 feet and maximum of 35 feet from top of the flue collar using

natural gas or propane gas (LP).

This appliance is only for use with the type of gas indicated on the

rating plate. This appliance is not convertible for use with other gases,

unless a certified kit is used.

Cet appareil doit être utilisé uniquement avec les types de gaz indiqués

sur la plaque signalétique. Ne pas l'utiliser avec d'autres gaz sauf si

un kit de conversion certifié est installé.

These appliances comply with National Safety Standards and are tested

and listed by OMNI-Test Laboratories Inc.; Beaverton, Oregon (Report No.

050-F-22-5) to ANSI Z21.88-2005/CSA 2.33-2005, and CGA 2.17-M91 in

both USA and Canada, as Vented Gas Fireplace Heaters and are approved

for installation in bedrooms and manufactured (mobile) homes.

Page 34 for

3

Page 4

GENERAL INFORMATION

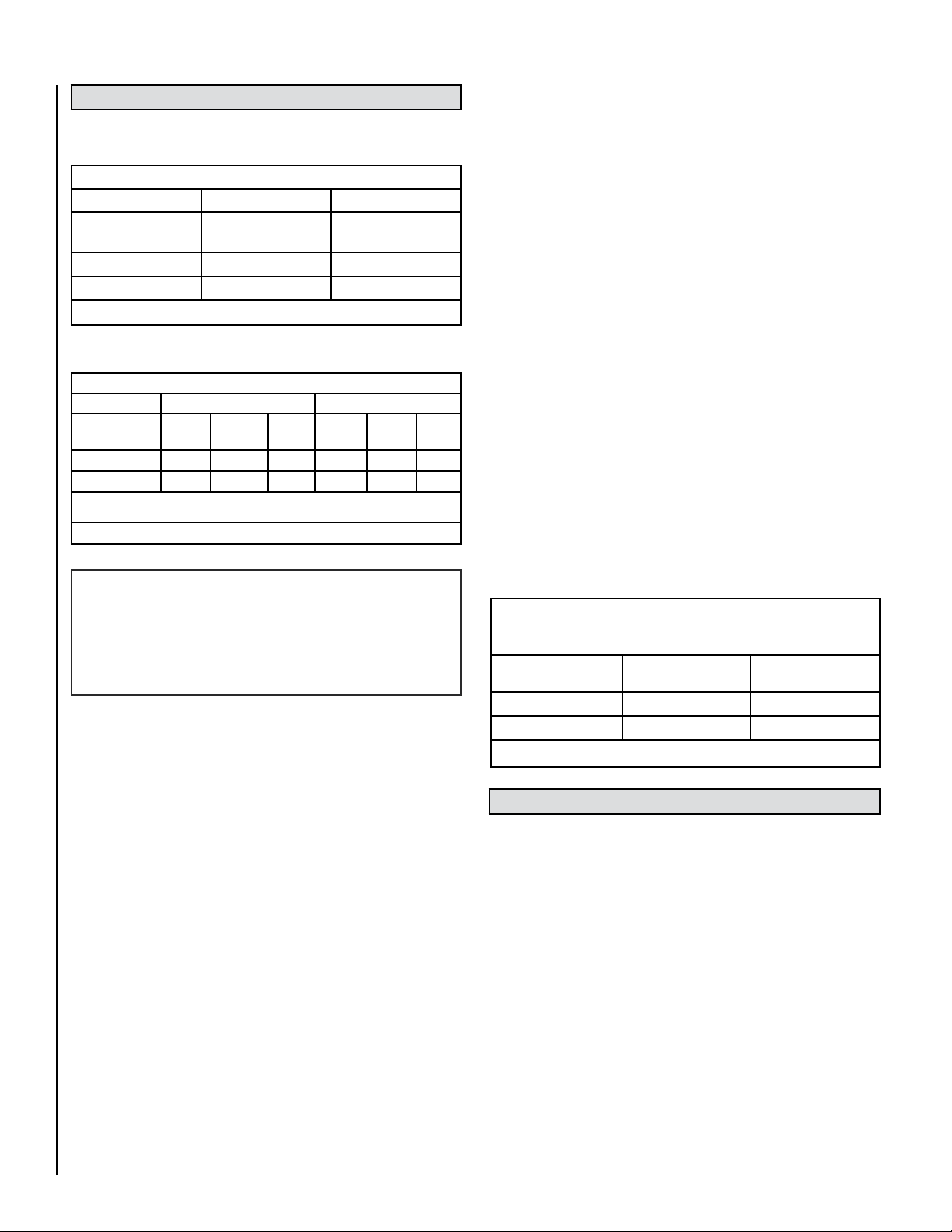

Table 1 shows the BTU input for each model:

Millivolt Models with Manually-Modulated Gas Valves

Natural Gas Propane (LP) Gas

Model Input Rate

(BTU/HR)

Input Rate

(BTU/HR)

SHR33 19,500 to 33,000 19,500 to 33,000

SHR40 24,000-40,000 21,500 to 37,500

Table 1

Table 2 shows efficiencies for the Shoreline™.

Efficiencies %

Natural Gas Propane

Models P4** Steady

State*

AFUE P4** Steady

State*

AFUE

SHR33 60.91 83 60 64.35 83 65

SHR40 62.70

* The Steady State Efficiency numbers based on maximum vent configuration.

** Tested to CSA P.4.1-02 “Testing Method for Measuring Annual Fireplace Efficiency.

83

63 65.98

83

67

Table 2

These appliances may be installed in an aftermarket permanently

located, manufactured home (USA only) or mobile home, where not

prohibited by local codes.

Cet appareil peut être installé dans un maison préfabriquée (É.-U.

seulement) ou mobile déjà installée à demeure si les réglements

locaux le permettent.

Note: These appliances are designed as supplemental heaters. Therefore, it is advisable to have an alternate heat source when installed in a

dwelling.

Fuel

This insert comes from the factory equipped to burn natural gas from 0

to 2,000 feet (610 M) of elevation in the USA and 0 - 4,500 feet (1372

M) in Canada. The insert can be converted to burn LP (liquid propane)

by installing a conversion kit. Only Lennox Hearth Products conversion

kits can be used to convert from NG to LP or LP to NG. Contact your

Lennox Hearth Products dealer for details. An orifice is also supplied to

change the unit from 40,000 BTU’s (NG) or 37,500 BTU’s (LP) to 33,000

BTU’s. This must be done by a qualified service technician if you decide

to change orifices.

The use of other fuels or combination of fuels will degrade the performance

of this system and may be dangerous.

Orifice Size/Altitude Adjustment

These appliances are tested and approved for installations at elevations

of 0 to 2,000 feet (610 M) in the USA and 0 to 4,500 feet (0-1372 M) in

Canada using the factory installed orifice shown in Table 3. At higher

elevations the BTU input must be de-rated by 4% for every 1,000 feet

(305 M) to maintain the proper ratio of gas to air. Contact your local gas

supplier for deration requirements for your area.

Deration - At higher elevations, the amount of BTU fuel value delivered

must be reduced by either using gas that has been derated by the gas

company or by changing the burner orifice to a smaller size as regulated

by the local authorities having jurisdiction and by the (USA) National

Fuel Gas Code NFPA 54 / ANSI Z223.1 - latest edition or, in Canada,

the CAN/CSA B149.1 - latest edition. If it is determined that a smaller

burner orifice is needed, contact your Lennox Hearth Products dealer to

purchase the orifice.

Burner Orifice Sizes

USA - Elevation 0-2000 feet ( 0-610 meters)

Canada - Elevation 0-4500 feet ( 0-1372 meters)

Model

Natural Gas

drill size (inches) *

SHR33 #36 (0.1065”) #51 (0.067”)

SHR40 1/8” (0.125”) #49 (.073”)

Table 3

* Standard size installed at factory

Propane

drill size (inches) *

Millivolt Valve & Electrical

These appliances use a millivolt type control system consisting of a gas

control valve with regulator (control to adjust for flame appearance and heat

output), a standing pilot burner assembly, a thermopile, thermocouple, a

piezo igniter, and ON/OFF switch.

APPLIANCES DO NOT REQUIRE 120 VOLT POWER TO OPERATE. Because

this fireplace insert is operated with a millivolt valve it will burn even

during a power outage.

The Shoreline features a spark igniter (piezo) that allows the appliance's

pilot gas to be lit without the use of matches or batteries. However, the heat

circulation blower motor requires 120 Volts AC (the appliance can be safely

used with the blower turned off). The blower operation is controlled by a

variable speed rheostat.

4

THE GAS BURNER SYSTEM ON THESE

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

CODES AND APPROVALS

Listing and Safety Standards - Gas appliances must be tested and certi-

fied by a nationally recognized testing and certification laboratory to ANSI

(American National Standard Institute) gas appliance safety standards.

This insert has been tested and certified by OMNI -Test Laboratories to

ANSI Z21.88-2005/CSA 2.33-2005 “Vented Gas Fireplace Heaters and

CGA 2.17-M91 “Gas-Fired Appliances for Use at High Altitudes” and UL

307B Gas Burning Heating Appliances for Manufactured (Mobile) Homes

in both USA and Canada. These appliances have been certified for use

with either natural gas or propane and are approved for installation in

sitting rooms and/or bedrooms.

type of gas indicated on the rating plate (and is not for use with solid

fuels). This appliance is not convertible for use with other gases,

unless a certified kit is used.

Cet appareil doit être utilisé uniquement avec les types de gaz indiqués

sur la plaque signalétique. Ne pas l'utiliser avec d'autres gaz sauf si

un kit de conversion certifié est installé.

This appliance is only for use with the

Page 5

Manufactured Home Installations - These appliances must conform

to the Manufactured Home Construction and Safety Standard, Title 24

CFR, Part 3280 (in Canada CAN/CSA Z240 MH) (in Canada CAN/CSA

Z240 MH), or when such a standard is not applicable, the Standard

for Manufactured Home Installations, ANSI A225.1 - latest edition for

manufactured (mobile) home installations and the current Standard for

Fire Safety Criteria for Manufactured Home Installations, Sites and Com

munities, ANSI/NFPA 501A.

Local, State and National Codes - These appliances must conform with

all local, state, and national installation codes. In the absence of local

and state codes, installation must comply with the current National Fuel

Gas Code, ANSI Z223.1, also known as NFPA 54 (In Canada, the current

CAN/CSA B149.1 installation code). Electrical wiring must comply with

the National Electrical Code ANSI/ NFPA 70 - latest edition. In Canada, the

current CSA C22-1 Canadian Electrical Code - latest edition. Refer to the

National Fuel Gas Code and local zoning and code authorities for details

on installation requirements. These appliances must be vented directly

to the outside in accordance with the current edition of the National Fuel

Gas Code (NFPA 54 in U.S.A and CAN/CSA B149.1 in Canada) and must

never be attached to a chimney serving a separate solid fuel burning

appliance.

Fireplace Standards - These heaters are designed to be installed into

an existing masonry fireplace (built to UBC 37 or ULC S628 standards)

or factory built solid fuel, wood, burning fireplace (listed to UL 127 or

ULC S610) only. All exhaust gases must be vented outside the structure.

Combustion air is drawn from outside the structure.

Questions To Ask Local Building Official

These appliances must be installed per manufacturers’ instructions.

Installations must conform to appropriate local codes and applicable

state and federal requirements. Familiarity with these requirements

before installation is essential. Some important considerations to

-

discuss with local building officials include:

1. Applicable codes (i.e. Uniform Mechanical Code, State or Regional

Gas Codes, National Fuel Gas Code).

2. Local amendments

3. Recognized testing lab: OMNI-Test Laboratories Inc.; Beaverton,

Oregon

4. Is a permit required - cost?

5. In some states or municipalities, a licensed gas fitter or plumber may

be required to install these appliances. Check with your local building official for requirements in your area (i.e. Is a license required for

installation of gas supply line)?

6. Maximum amount of gas pipe without a pressure test - type of test

required?

7. Are below grade penetrations of the gas line allowed?

8. Is concealed gas piping allowed?

9. Specific requirements of concealed fittings?

10. Is rigid pipe to appliance required?

11. Allowed piping materials?

12. Shut-off valve required within 4 feet of the firebox?

13. May the shut-off valve be concealed?

14. Rooms where the installation is not allowed?

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

5

Page 6

NEW YORK CITY, NEW YORK (MEA)

Installation of these fireplaces are approved for installation in New York

City in the US state of New York (MEA#: 138-07-E).

Inspection

The state or local gas inspector of the side wall horizontally vented gas

fueled equipment shall not approve the installation unless, upon inspection,

the inspector observes carbon monoxide detectors and signage installed

in accordance with the provisions of 248 CMR 5.08(2)(a)1 through 4.

COMMONWEALTH OF MASSACHUSETTS REQUIREMENTS

Note: The following requirements reference various Massachusetts

and national codes not contained in this document.

For all side wall horizontally vented gas fueled equipment installed in every

dwelling, building or structure used in whole or in part for residential

purposes, including those owned or operated by the Commonwealth and

where the side wall exhaust vent termination is less than seven (7) feet

above finished grade in the area of the venting, including but not limited

to decks and porches, the following requirements shall be satisfied:

Installation Of Carbon Monoxide Detectors

At the time of installation of the side wall horizontal vented gas fueled

equipment, the installing plumber or gas-fitter shall observe that a hard

wired carbon monoxide detector with an alarm and battery back-up is

installed on the floor level where the gas equipment is to be installed.

In addition, the installing plumber or gas-fitter shall observe that a battery operated or hard wired carbon monoxide detector with an alarm is

installed on each additional level of the dwelling, building or structure

served by the side wall horizontal vented gas fueled equipment. It shall

be the responsibility of the property owner to secure the services of

qualified licensed professionals for the installation of hard wired carbon

monoxide detectors.

In the event that the side wall horizontally vented gas fueled equipment

is installed in a crawl space or an attic, the hard wired carbon monoxide

detector with alarm and battery back-up may be installed on the next

adjacent floor level.

In the event that the requirements of this subdivision can not be met

at the time of completion of installation, the owner shall have a period

of thirty (30) days to comply with the above requirements; provided,

however, that during said thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

Exemptions

The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

• The equipment listed in Chapter 10 entitled “Equipment Not Required

To Be Vented” in the most current edition of ANSI Z233.1 / NFPA 54

(In Canada CAN/CSA B149.1 - current edition) as adopted by the

Board; and

• Product Approved side wall horizontally vented gas fueled equipment

installed in a room or structure separate from the dwelling, building

or structure used in whole or in part for residential purposes.

MANUFACTURER REQUIREMENTS

Gas Equipment Venting System Provided

When the manufacturer of Product Approved side wall horizontally vented

gas equipment provides a venting system design or venting system com

ponents with the equipment, the instructions provided by the manufacturer

for installation of the equipment and the venting system shall include:

• Detailed instructions for the installation of the venting system design

or the venting system components; and

• A complete parts list for the venting system design or venting

system.

Gas Equipment Venting System NOT Provided

When the manufacturer of a Product Approved side wall horizontally

vented gas fueled equipment does not provide the parts for venting the

flue gases, but identifies “special venting systems”, the following require

ments shall be satisfied by the manufacturer:

• The referenced “special venting system” instructions shall be included

with the appliance or equipment installation instructions; and

-

-

Approved Carbon Monoxide Detectors

Each carbon monoxide detector as required in accordance with the

above provisions shall comply with NFPA 720 and be ANSI/UL 2034

listed and IAS certified.

Signage

A metal or plastic identification plate shall be permanently mounted to

the exterior of the building at a minimum height of eight (8) feet above

grade directly in line with the exhaust vent terminal for the horizontally

vented gas fueled heating appliance or equipment. The sign shall read, in

print size no less than one-half (1/2) inch in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS.”

6

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

• The “special venting systems” shall be Product Approved by the

Board, and the instructions for that system shall include a parts list

and detailed installation instructions.

A copy of all installation instructions for all Product Approved side wall

horizontally vented gas fueled equipment, all venting instructions, all

parts lists for venting instructions, and/or all venting design instructions

shall remain with the appliance or equipment at the completion of the

installation.

• Installation and repair must be done by a plumber or gas fitter licensed

in the Commonwealth of Massachusetts.

• The flexible gas line connector used shall not exceed 36 inches (92

centimeters) in length.

• The individual manual shut-off must be a T-handle type valve.

Page 7

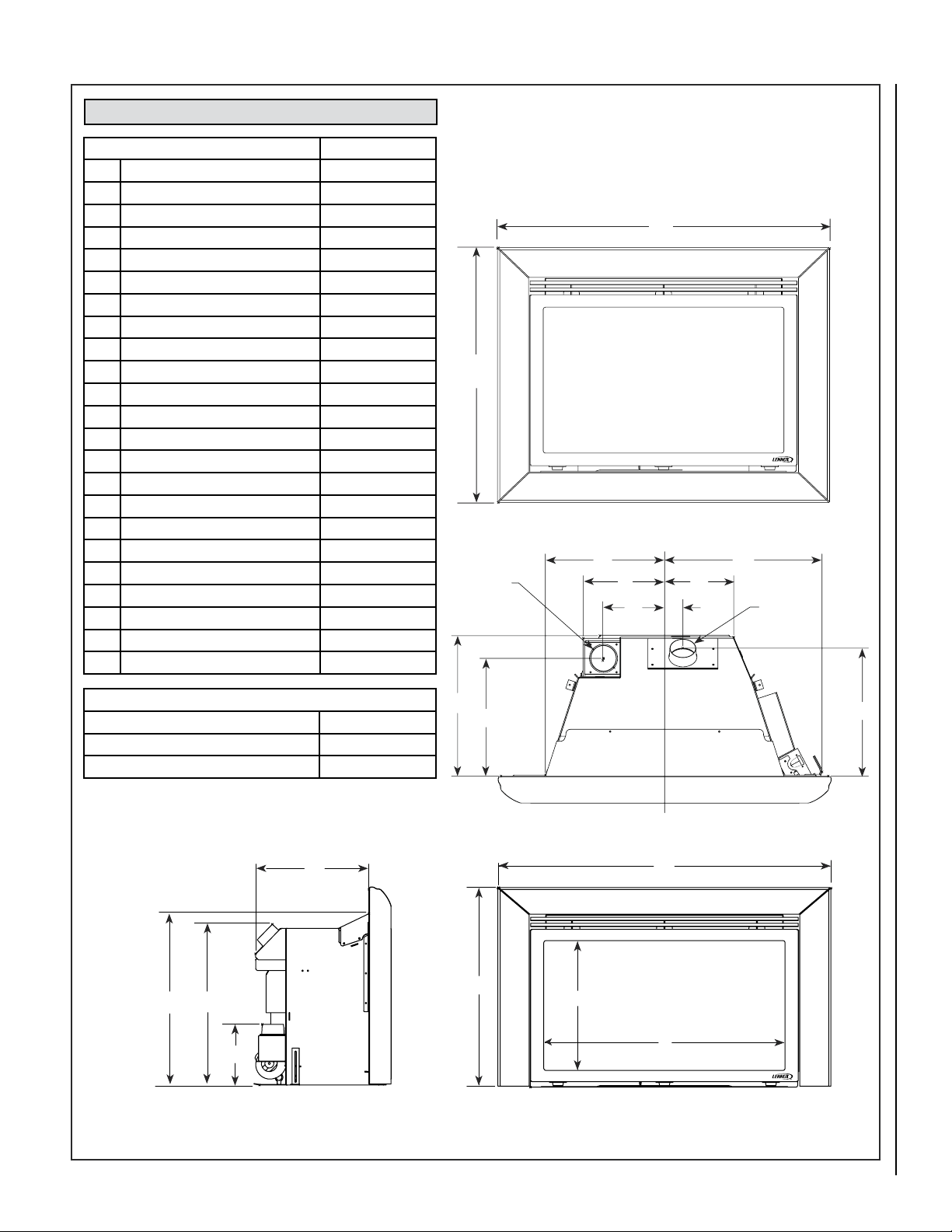

Center

A

B

C

D

E

F

G

H

I

K

L

M

J

N

R

S

O

P

Q

3-Sided Surround Kit

4-Sided Surround Kit

FLUE

Ø 2-7/8

AIR INTAKE

Ø 2-7/8

SPECIFICATIONS: Shoreline™

Insert Dimensions Inches (millimeters)

A

Left front of unit to center line 13-1/8 (333)

B

Right front of unit to center line 17-1/4 (438)

C

Left rear of unit to center line 9 (229)

D

Right Rear Of Unit To Center Line 7-5/8 (194)

E

Center Of Air Intake To Center Line 6-3/4 (172)

F

Center Of Flue To Center Line 2 (51)

G

Insert Depth Into Fireplace 15-3/8 (391)

H

Air Intake Center From Front 12-7/8 (327)

I

Flue Center From Front Of Unit 14 (356)

J

Front Of Unit To Back Of Flue Collar 15-1/8 (384)

K

Unit Height At Front 22-3/8 (568)

L

Base Of Unit To Top Of Flue Collar 21 (533)

M

Base Of Unit To Intake Collar 7-7/8 (200)

N

O.D. Width, Small, 3-pc Flange 36-5/8 (930)

N

O.D. Width, Large, 3-pc Flange 41 (1041)

O

O.D. Height, Small, 3-pc Flange 25-7/8 (657)

O

O.D. Height, Large, 3-pc Flange 28 (711)

P

O.D. Width, Small, 4-pc Flange 36-5/8 (930)

P

O.D. Width, Large, 4-pc Flange 41 (1041)

Q

O.D. Height, Small, 4-pc Flange 29-3/16 (741)

Q

O.D. Height, Large, 4-pc Flange 33-1/2 (851)

R Glass Viewing Height 16-7/8 (429)

S Glass Viewing Width 26-5/8 (676)

Rear Insert Dimensions - Inches (millimeters)

Rear width of unit 16-5/8 (422)

Front Width of unit 30-3/8 (772)

Depth of unit (excluding Surround Kit) 15-3/8 (391)

Note: Due to Lennox’ ongoing commitment to quality , all specifications,

ratings and dimensions are subject to change without notice.

Front View

Side View

Top View

Front View

Figure 1

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

7

Page 8

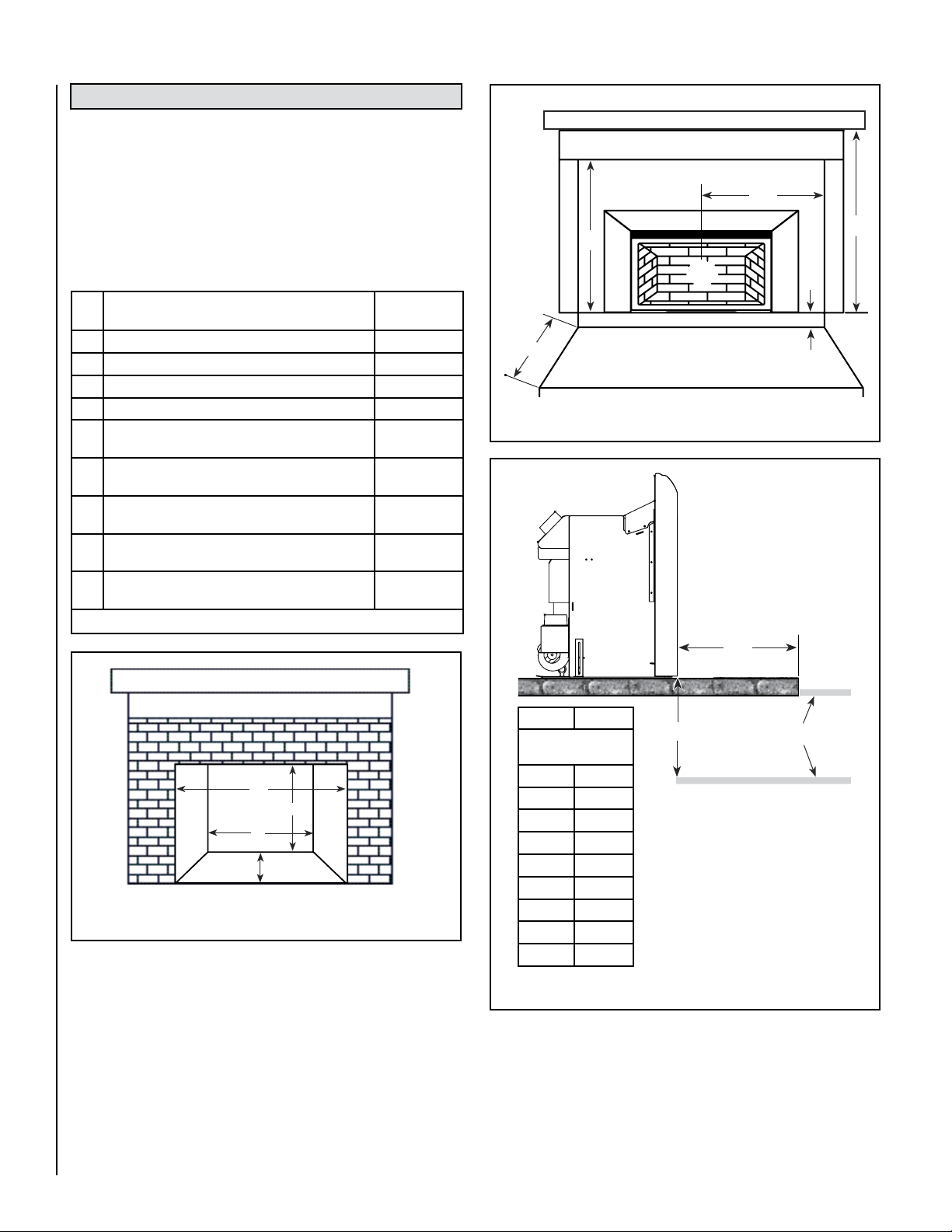

A

B

C

D

E

F

G

H

I

C

L

MINIMUM CLEARANCES TO COMBUSTIBLES

These appliances can be installed in most fireplace configurations. If

installed close to an adjacent wall, ensure that the minimum clearances

to combustible surfaces are maintained. A local building inspector

should review your plans prior to installation.

Refer to Figures 2 through 4 for clearances to combustibles. Minimum

clearances

spacers/standoffs or surfaces to combustible construction

include any projections such as shelves, window sills, mantels,

etc. above the

appliance. Paint or lacquer used to finish the mantel must be heat resistant

in order to avoid discoloration.

Mantel - 12” Depth

Combustibles Trim or Mantel Depth of 8” or Less

Minimum Fireplace Dimensions

and Minimum Clearances

A Minimum front opening required 36 (914)

B Minimum height required 21-1/2 (546)

C Minimum rear width required 19-1/2 (495)

D Minimum fireplace depth required 16 (406)

E Clearance needed from bottom of insert to com-

bustibles or 8” mantel

F Clearance required from center of glass to com-

bustible material

G Minimum inches of hearth protection needed from

front of unit

H Vertical clearance needed under the bottom of the

insert for NO hearth protection

I Clearance needed from bottom of insert to 12”

mantel

Table 4

Refer to Figures 2 through 4

Refer to Table 4

Figure 2 - Existing Fireplace Minimum Dimensions

Hearth / Floor Protection Requirements

The hearth and/or floor protection must be a thermally rated hearth/floor

protector meeting or exceeding a thermal rating of k = .84 (or lower) or

r= 1.19 (or higher) with a listed thickness of 1" minimum. If an hearth

extension is used, check with the manufacturer for the listed thermal rating

of the hearth extension to ensure it meets the thermal requirements of k

= .84, r= 1.19, listed thickness 1". If a custom hearth or floor protection

is planned, see NFI (National Fireplace Institute) certification manuals

showing methods for calculating minimum thicknesses and approved

fireplace hearth/floor protection materials.

8

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

Inches

(millimeters)

35 (889)

30 (762)

12 (305)

8 (203)

38 (965)

Hearth Protection

Figure 3 - Minimum Clearances

Fireplace Firebox

Insert

G H

H dimension deter-

mines G minimum

0” 8”

1-1/2”

3” 6”

4-1/2”

6” 4”

7-1/2”

9” 2”

10-1/2”

12”

7”

5”

3”

1”

0”

H

Examples:

Hearths that are level with the base

of the insert require 12” minimum of

forward hearth protection.

Hearths that are elevated 8” minimum

above combustible floor require 0” of

forward hearth protection.

Figure 4 - Hearth Protection

Refer to Table 4

Hearth Protection

G

Combustible Floor

Page 9

INSTALLATION

CAUTIONS

Fireplace Requirements

These heaters are designed to be installed into an existing masonry

fireplace (built to UBC 37 or ULC S628 standards) or factory built solid

fuel, wood burning fireplace (listed to UL 127 or ULC S610) only. All

exhaust gases must be vented outside the structure. Combustion air

is drawn from outside the structure. When installing in a factory built

fireplace, the fireplace grate must be removed and the damper must be

removed or secured open.

The insert is designed to fit into a fireplace with a minimum firebox

height of 21-1/2 inches (546 mm). To facilitate this the hood will need to

be removed and discarded

insert body). The air intake on the Shoreline™ is removable for easier

installation.

If the factory-built fireplace has no gas access hole(s) provided, an access

hole of 1-1/2 inches (38 mm) or less may be drilled through the lower

sides or bottom of the firebox in a proper workmanship like manner. This

access hole must be plugged with a non-combustible insulation after the

gas supply line has been installed. The installer must mechanically attach

the marking supplied with the gas fireplace insert to the inside of the firebox

of the fireplace into which the gas fireplace insert is installed.

IMPORTANT: When installing these appliances into a factory built fireplace

or heat-form, the air flow within and around the fireplace shall not be

altered by the installation of the insert (i.e. DO NOT BLOCK louvers or

cooling air inlet or outlet ports, circulating air chambers in a steel fireplace

liner or metal heat circulator).

(Note: the screws should be replaced in the

WARNING

THIS FIREPLACE HAS BEEN ALTERED TO

ACCOMMODATE A FIREPLACE INSERT AND

SHOULD BE INSPECTED BY A QUALIFIED

PERSON PRIOR TO RE-USE AS A

CONVENTIONAL FIREPLACE.

• The fireplace in which this gas insert is to be

installed must be thoroughly cleaned if it has

been used to burn wood or synthetic logs. Have

the chimney and all inside surfaces of the fireplace brushed and vacuumed so that no soot,

embers, or loose combustion deposits can be

drawn into the heat circulation blower and blown

into the living area.

• If any portion of the chimney system shows signs

of structural or mechanical weaknesses, such

as: cracks, leaky joints, corroded or warped

surfaces, the faulty portion must be repaired

or replaced prior to installing this appliance.

• The factory built firebox must accept the insert

without modification other than removing bolted

or screwed together pieces such as baffles /

smoke shelf / deflectors, ash lips, glass door,

screen or door tracks, log grates, refractory or

masonry lining and damper assemblies. Any

fireplace component, which is removed, must be

retained so they can be reinstalled to restore the

fireplace to its original operating condition. The

removal of any part must not alter the integrity

of the outer shell of the pre-engineered fireplace

cabinet in any way. Any parts removed must be

replaceable. If any components are removed

from (or altered) from the existing fireplace, a

Warning Label (see Figure 5) must be affixed

inside the fireplace firebox, so that it shall be

visible upon removal of the fireplace insert. Note:

RTV high temperature silicone is an approved

adhesive to affix the label.

Figure 5 - Fireplace Warning Label

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

9

Page 10

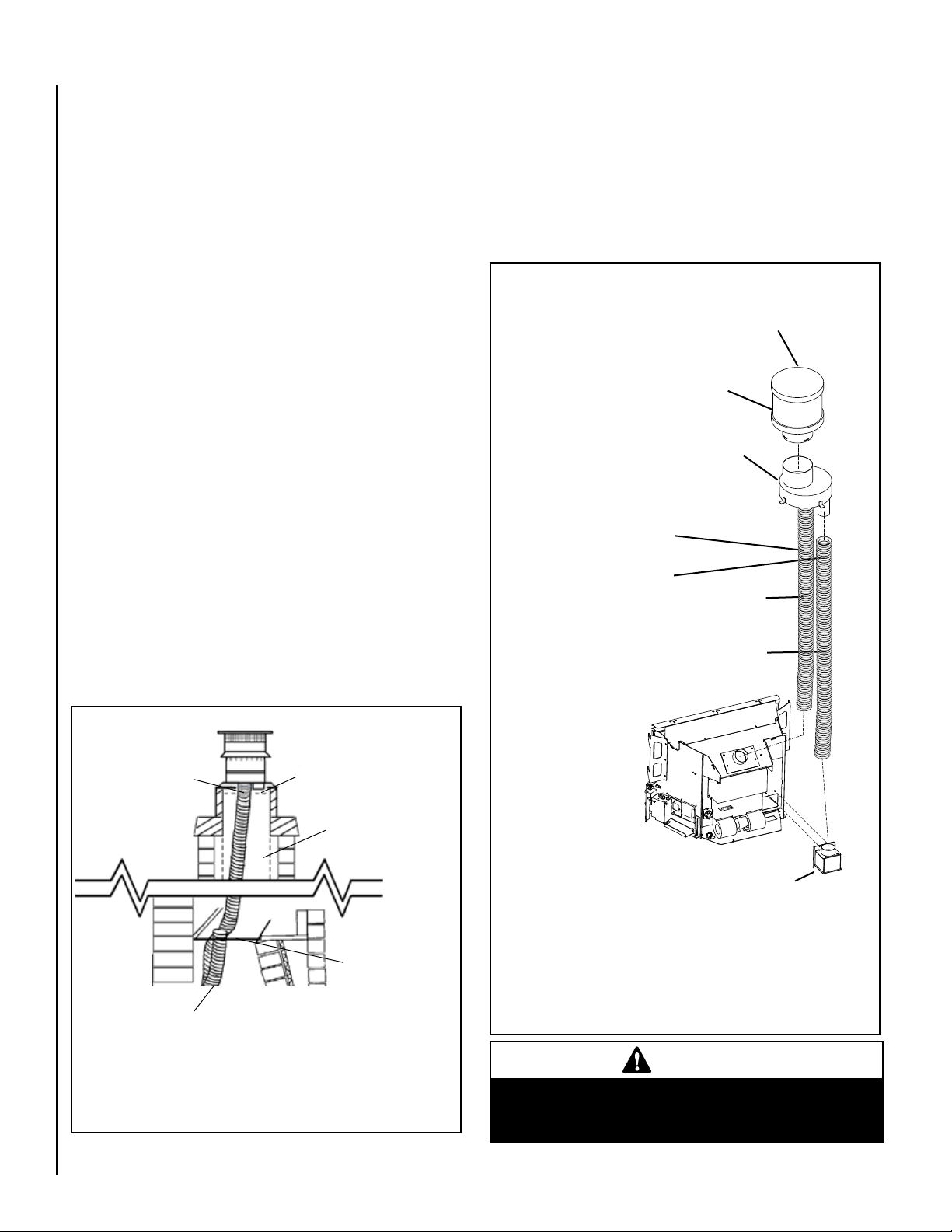

Venting Requirements

Approved Vent Systems:

Lennox Hearth Products Co-linear Chimney Liner Kit Recommended:

• The Flex Kit, Cat. No. H0909 includes one 35 feet flex liner and four

gear clamps.

• The Termination Kit, Cat. No. TKDVI includes the termination cap with two

co-linear collars for 3 inches (76 mm) flex attachments and flashing.

Secure Vent™ Co-Linear Chimney Liner Kit Recommended:

• Direct Vent Vertical Termination Kit (includes Vertical Termination

Cap gas/Connector, Flashing, Qty 2 of 25 feet (7.6 M) length of 3 inches

(76 mm) Aluminum Flex, Clamps and Sealant) #DV3FK25

• Direct Vent Vertical Termination Kit (includes Vertical Termination Cap/

Connector, Flashing, Qty 2 of 35 feet length of 3 inches Aluminum

Flex, Clamps and Sealant) #DV3FK35

Standard Simpson Dura-vent Co-linear Chimney Liner Kit recommended:

• Direct Vent Vertical Termination Cap #991

• Liner Termination Kit

(includes termination connector and flashing) #923GK

• 3" x 35 feet (76 mm x .91 M) Alum Flex #2280

Selkirk/Metalbestos Direct-Temp Co-Linear Chimney Liner Kit recom

mended

• Direct Vent Vertical Termination Cap #4DT-VC

• Liner Termination Kit

(includes termination connector and flashing) #4DT-CTB

• 3” x 35’ (76 mm x .91 M) Aluminum Flex #AF3-35L

Amerivent Direct Co-Linear Chimney Liner Kit recommended

• Direct Vent Vertical Termination Cap #4DVC

• Co-Linear Adaptor #4DCAT33

• Flashing #4DF or #5DF

• 3” x 35’ Aluminum Flex #3AFL-35

-

Positive Flue Connection (acceptable methods for sealing chimney throat)

Masonry and Factory Built Fireplaces

A qualified installer should evaluate the existing fireplace to determine the

best method for achieving a positive flue connection between the vent and

intake liners and the chimney. One method is to secure a noncombus

tible seal-off plate (i.e. 22-gage sheet steel) in the fireplace throat using

masonry screws. Other acceptable methods include packing unfaced

fiberglass insulation around the liners. Whichever “seal off” method is

used must effectively seal the area to prevent room air passage to the

chimney of the fireplace.

The existing fireplace chimneys may take

various contours which the flexible liners will

accommodate. However, keep the flexible liner

as STRAIGHT as possible, avoid unnecessary

bending.

Vertical Cap

Termination

Connector

The standard cap

in Termination Kit,

TKDVI, is a high

wind cap

Liner Requirements:

Use 3" (76 mm) diameter listed gas

vent liner (UL1777 ONLY) for the

EXHAUST

Use 3" (76 mm) diameter listed

liner (UL 181 or UL1777) for the

AIR INTAKE.

Vertical Height Min. = 10 ft. (3.05 M)

Vertical height Max. = 35 ft. (10.67 M)

Exhaust

Intake

-

Exhaust 3" (75mm) UL

1777. A full length liner

is required from the

exhaust outlet on appliance to center collar of

termination cap.

Exhaust

Air Inlet

Air Inlet Liner (for combustion air) When

terminating the air inlet liner at this point, a

positive flue connection is required (to ensure

combustion air is drawn down the chimney

only).

The outside air inlet does not

require a full reline (if intake

liner is terminated in chimney

and a positive flue connection

is achieved as specified).

Air Inlet

Masonry and Factory Built Fireplaces

Figure 6a - Terminating Air Inlet in Chimney

Existing Fireplace Flue

(chimney)

Positive Flue Connection (sealing

fireplace throat

using a noncombustible seal-off plate

or insulation).

The flexible vent pipe

must NOT be allowed to

sag behind insert or in

fireplace flue.

Combustion Air Intake

Make sure that both liners will pass through existing damper area. Remove

or lock damper to allow the passage of the flexible liners. If the damper

will not allow the passage of both liners, DO NOT PROCEED FURTHER.

(If fireplace is masonry) Consult a local mason for removal of the damper

without risk of structural damage or leakage (if the fireplace is factory

built) The appliance may NOT be installed into the fireplace.

Figure 6b

WARNING

Do not substitute the heat-rated flex liner (UL1777) for the

exhaust with any other type liner or a fire may result causing property damage, personal injury or loss of life.

10

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

Page 11

Vertical Venting

DETAIL B

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

The vent pipes must be connected to the proper collars on the unit and

the exhaust vent pipe must be connected to the termination cap or the

unit will not operate. The combustion air vent pipe can be connected to

the termination cap (see

(see

Figure 6a). The bottom opening of the chimney must be sealed

Figure 6b) or it can terminate inside the chimney

around the vent pipes if the combustion air vent is not connected to the

termination cap. Use unfaced fiberglass insulation to seal around the vent

pipes or a positive flue connection using a seal-off plate. The insulation

may give off an odor during the first hour of operation.

NOTES:

The minimum vertical rise (exhaust vent) is 10 feet (3.05 M) and the

maximum vertical rise is 35 feet (10.67 M). These dimensions are

measured from the flue collar of the unit to the end of the vent pipe,

The fireplace and fireplace chimney must be clean and in good working

order and constructed of non-combustible materials. Inspect chimney

clean-outs for proper fit and seal.

See Table 5 for the minimum vertical termination height requirements.

Vertical Termination Height Minimum

(Factory Built and Masonry Fireplaces)

The vent/air intake termination clearances above the high side of an

angled roof is as follows:

Feet (meters)

8 (2.4)

7 (2.1)

6 (1.8)

5 (1.5)

4 (1.2)

3 (0.9)

2 (0.6)

1 (0.3)

0 (0.0)

FRONT

LEVELING

LEGS

Figure 7

Front leveling legs

See

Detail B

DETAIL B

Right front leveling leg

Use open end 9/16”

wrench to adjust height

up or down

6/12

Roof Pitch

8/12

10/12

Table 5

2/12

4/12

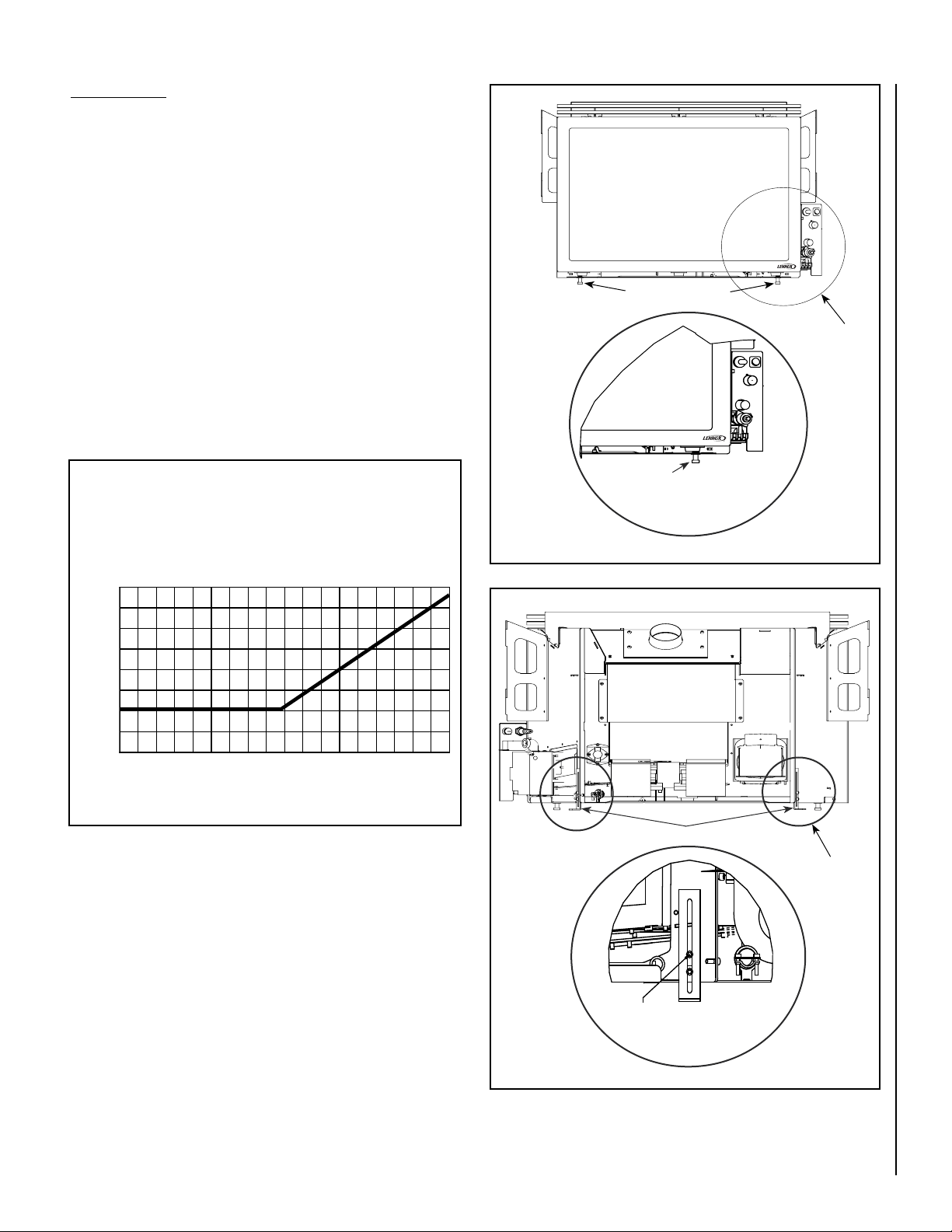

Insert Leveling

At each front and rear corner of the insert is an adjustable leg provided

to level the insert should the hearth of the fireplace be uneven. To adjust

the legs in the rear, loosen the two 5/32” allen head screws, move the leg

to the desired height, and then tighten the screws. Repeat these steps

for each adjusting leg. To adjust the legs in the front use a 9/16” open

end wrench. See

Figures 7 and 8.

14/12

12/12

16/12

REAR

LEVELING

LEGS

Figure 8

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

Rear leveling legs

See

Detail C

DETAIL C

Use 5/32 allen wrench to loosen

and adjust bracket up or down,

tighten when at right height

11

Page 12

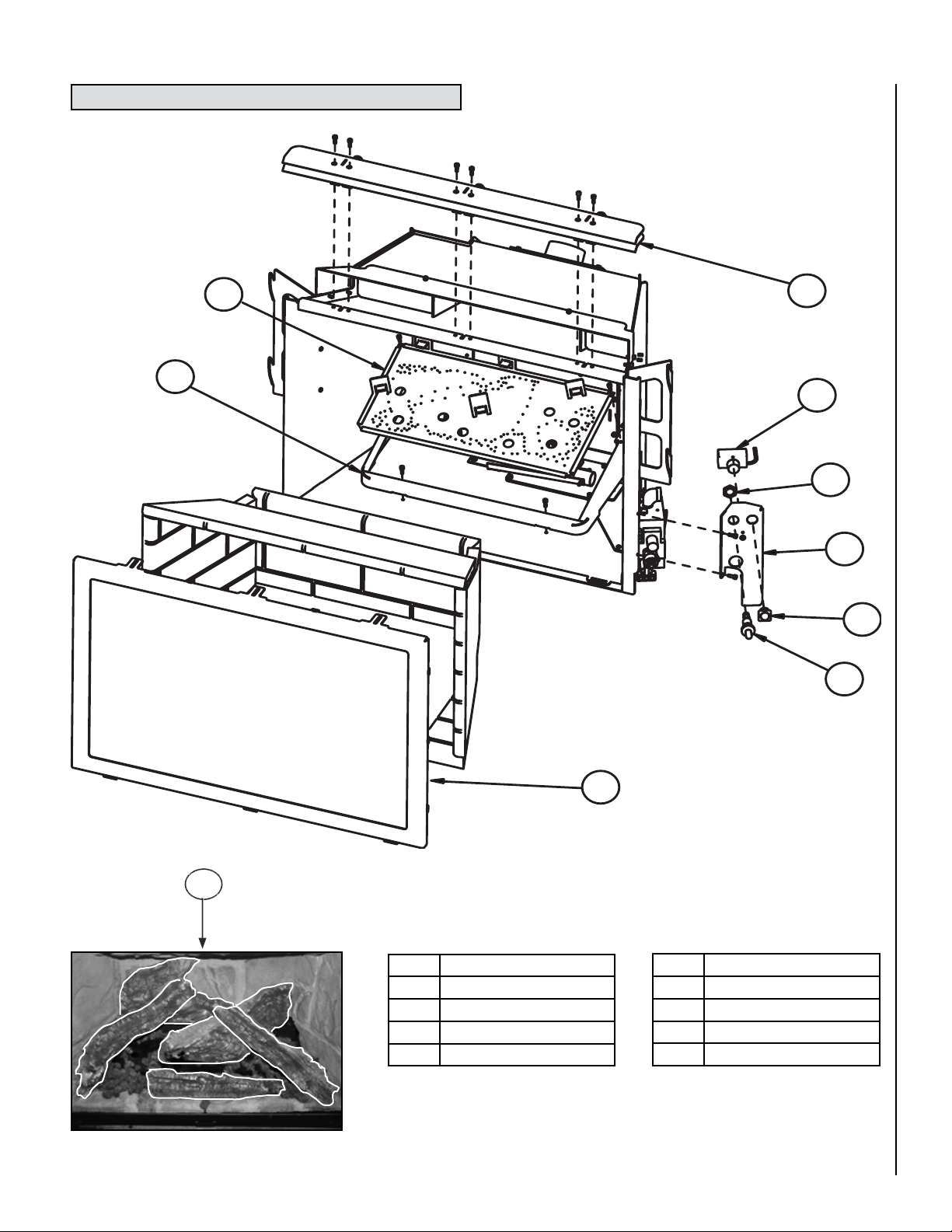

SHORELINE™ DOOR ASSEMBLY INSTALLATION OR REMOVAL

INSTRUCTIONS

Tools Needed: No tools are needed

Cat. No. Description

H5746 Shoreline Door Assembly

Shoreline Door Kit - Packaging List

Models SHR33 & SHR40

Quantity Description

1

Table 6 - (refer to Figure 9)

Shoreline Door Assembly

(Figure 9)

Note: The Shoreline insert comes with the door already on the

unit. Just reverse the steps here to remove the door to access

the burner area.

Figure 11

3. Pull the louvers out to the farthest point and then lift up. Push door

against the face of the insert. Drop the louvers down and let the

springs pull the three latches into the three slots located on the top

of the insert. See

Figure 12.

Figure 9

1. Locate three tabs on the bottom of the door. These tabs will go into

the tab slots along the bottom of insert. See Figure 10.

Tab

Figure 10

2. Drop the door into the three tab slots on the bottom of the insert as

shown in Figure 11. The door should be at a 25 degree angle to the

front of the insert to be able to place the door correctly.

Figure 12

4. Figure 13 shows the insert with the door in place.

Figure 13

12

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

Page 13

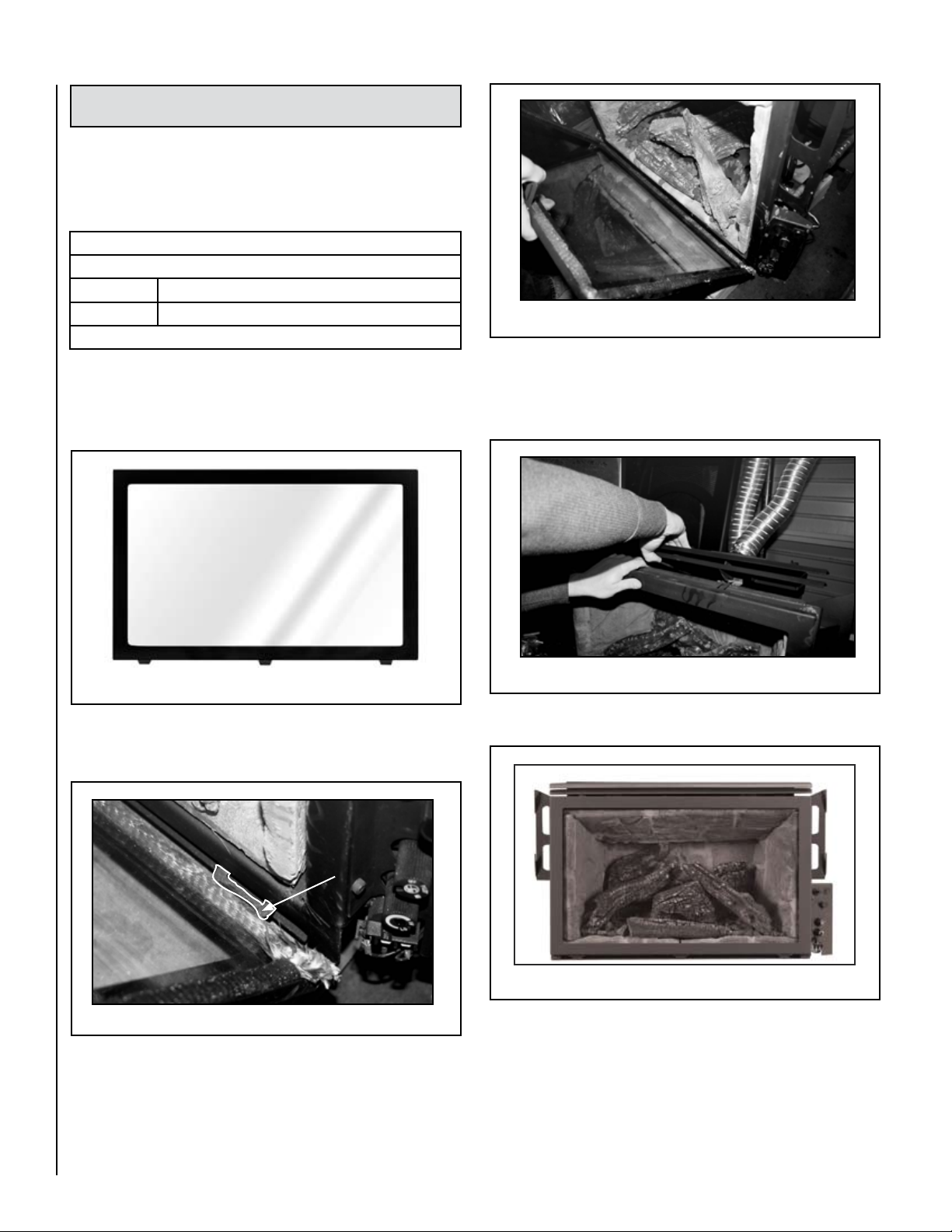

SHORELINE™ REFRACTORY BRICK INSTALLATION INSTRUCTIONS

Tools Needed: No tools are needed

Cat. No. Model Description

75383 SHR-BRICK-STD Brick Panel Set, Standard

75384 SHR-BRICK-RED Brick Panel Set, Red

75391 SHR-BRICK-ARCHSTONE Brick Panel Set, Architectural (shown)

Refractory Brick Panel Kits - Packaging List

Models SHR33 & SHR40

Quantity Description

2 Front Bottom Panels - Left ( A ), Right ( B )

1 Rear Panel (C)

1 Left Side Panel (D)

1 Right Side Panel (E)

1 Top Panel (F )

Table 7 - (refer to Figure 14)

IMPORTANT NOTE: A refractory brick panel kit is required for proper

operation (sold separately). Never operate this appliance without

all the refractory brick panels properly installed.

Figure 14

C

2. Next place the rear panel (C). It will set on the bracket mounted to the

blower mounting plate on the back of the firebox. See Figure 16.

C

Figure 16

3. Position and slide the side panels against the rear panel. Make sure

panels are behind brackets to hold them in at the top. The side panels

will hold the rear brick panel against the back of the firebox. See Figure

17.

DE

F

A

B

CAUTION

Before you install the refractory brick panels and log

set, the insert should be installed in the fireplace, the

venting attached, the gas line connected and tested

for leaks and the initial burner operation checked.

To Install Panels:

1. Start with the front bottom panels (A and B). Set them in place with

detail side up as shown. See Figure 15.

D E

Figure 17

4. Slide the top panel in place with the detailed side down. Make sure

panel is positioned all way back and resting on side panels. Top panel

should be flush in front with the side panels. See Figure 18.

F

Figure 15

A

B

Figure 18

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

13

Page 14

SHORELINE™ LOG SET INSTALLATION INSTRUCTIONS

CAUTIONS

Tools Needed: No tools are needed

Cat. No. Description

H5747 5-Piece Ceramic Log Set

Log Set - Packaging List

Models SHR33 & SHR40

Quantity Description

1 Rear Log (A)

1 Center Log (B)

1 Left Log (C)

1 Right Log (D)

1 Front Log (E)

1 Bag of Glowing Embers (F)

1 Bag of Decorative Lava Rock (G)

Table 8 - (refer to Figure 19)

G

A

• If logs are not installed according to the log

installation instructions, flame impingement

and improper combustion could occur and result

in soot and/or excessive production of carbon

monoxide (CO), a colorless, orderless, toxic

gas.

• The size and position of the log set is critical

to achieve a safe, reliable and attractive flame

pattern. Any attempt to use a different log set

in the fireplace will void the warranty and will

result in incomplete combustion, sooting, and

poor flame quality.

To Install Log Set:

1. Open the box and carefully remove and identify the different items.

Start with the rear log (A). Set it down on the log supports located

on the left rear of firebox. See

Log supports

Figure 21.

F

Figure 19

B

C

A

D

E

Figure 21

A

C

B

D

E

14

Figure 20

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

Page 15

2. Separate the glowing embers (F) into quarter size pieces and place

along ports on burner pan. DO NOT cover burner secondary holes

on burner pan. The pattern for the glowing embers should be similar

to what is shown in Figure 22.

F

Glowing Embers

Separate into Quarter

Size (separate) Pieces

4. Place left log (C) on pin in back. Push log against left side of refractory

in front. See

Figure 24.

pin

C

Figure 24

5. Locate groove in center log (B), and place the top of the right log

(D) in groove with the bottom end of the log resting against the right

refractory panel. See Figure 25.

Groove for log (D)

Bag of Glowing

Embers (rockwool)

Figure 22

3. Place center log (B) on supports towards bottom left and top right of

log (B). See Figure 23.

B

Figure 23

D

Figure 25

6. Place the front log (E) as shown in

ports are covered. Place the decorative lava rock around logs as

desired, again making sure there are no ports or holes covered.

Figure 26, making sure no burner

Figure 26

7. Figure 26 shows the complete set of ceramic logs in the correct locations.

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

E

15

Page 16

SHORELINE™ SURROUND ASSEMBLY INSTALLATION

Tools Needed: No tools are needed

One of the following surround kits is required (Purchased separately).

Surround Kits

Models SHR33 & SHR40

Part/Cat. # Description Dimensions

75387 Small 3-sided Flange 36-5/8”W x 25-7/8”H

75385 Small 4-sided Flange 36-5/8”W x 29-3/16”H

75388 Large 3-sided Flange 41”W x 28”H

75386 Large 4-sided Flange 41”W x 33-1/2”H

Table 9

Note: Install surround with insert positioned in the fireplace, but a

few inches in front of its final location.

Hook A

Figure 29

2 Slide the insert into its final location in the fireplace. In case of uneven

wall surface open the right surround access door and make any

adjustments needed to ensure there is enough clearance to open the

access door (see

Page 17).

Figure 27

To Install Surround Panels:

1. Hang the surround on hooks attached to insert (labeled A and B).

Make sure the surround is seated firmly on the hooks. See Figures

28 and 29.

Hook A

Hook B

Figure 28

Figure 30

Important Note: The trim panels or surrounds must not seal ventilation

openings on the appliance.

16

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

Page 17

SURROUND BALL SCREW MOUNT ADJUSTMENT

Tools Needed:

7/16” wrench

Flat End Screwdriver

Adjustment Procedure:

C

Step 1 Open the surround access door. Inspect the tension or lack of

tension while opening the door to determine if it should open

easier or tighter.

Step 2 With the access door open you will see the ball screw latch as

shown in Pictures A and B. Using a 7/16” wrench, loosen the

jam nut on the ball screw assembly as shown in Picture F.

Step 3 Once this jam nut is loose you can then adjust the ball screw for

more or less tension using your hand

a screwdriver as seen in

clockwise, as you are looking at it, will give you more tension

and turning the screw clockwise will give you less tension.

Step 4 You can then test close the surround access door to ensure it

has proper tension. Readjust if needed.

Step 5 Once proper tension is achieved, hold the ball screw with either

your hand or a flat screwdriver, then using a 7/16” wrench

tighten the jam, counter-clockwise (SNUG ONLY, DO NOT

OVERTIGHTEN).

Picture D. Turning the screw counter-

Picture E or the flat end of

A

Ball Screw

Latch

Ball Screw

Latch

Ball Screw

Jam Nut

D

E

Jam Nut

B

Ball Screw

Latch

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

Jam Nut

F

17

Page 18

GAS LINE INSTALLATION

We recommend that a qualified individual such as a plumber or gas fitter be

used to correctly size and route the gas supply line to the appliance. Installing

a gas supply line from the fuel supply to the appliance involves numerous

considerations of materials, protection, sizing, locations, controls, pressure,

sediment, and more. Certainly no one unfamiliar and unqualified should attempt

sizing or installing gas piping. Never use galvanized or plastic pipe.

The gas supply line should be plumbed from the fuel source to the area

where the appliance is to be installed per requirements outlined in NFPA

54 - latest edition (USA) or CAN/CSA B149.1 - latest edition (Canada)

and per local codes.

The insert comes with an 8 inch (203 mm) nipple attached to the supply

side of the gas valve. After connecting the gas line, all joints in the line

and connections at the valve should be checked for leaks using a gas

leak test solution before final positioning of the unit.

Gas Pressure Requirements

It is important to check the gas pressure during the initial installation

of the insert and ensure there are no operating problems. This insert

will not function properly unless the required gas pressure is supplied.

Tables 10 and 11 show the units' gas pressure requirements for

these appliances.

Inlet Gas Supply Pressure

Fuel # Minimum Maximum Desired

Natural

Gas

Propane

5" WC/po. C.E

(1.25 kPa)

10.5" WC/po. C.E

(2.61 kPa)

10.5" WC/po. C.E

(2.61 kPa)

13.0" WC/po. C.E

(3.23 kPa)

7" WC/po. C.E

(1.74 kPa)

11" WC/po. C.E

(2.74 kPa)

Table 10

Manifold Gas Supply Pressure

Fuel # Low High

Natural Gas

Propane

(Lo) 1.3" WC/po. C.E

(.32 kPa)

(Lo) 5.4" WC/po. C.E

(1.35 kPa)

(Hi) 3.5" WC/po. C.E

(.87 kPa)

(Hi) 10.0" WC/po. C.E

(2.49 kPa)

Table 11

Two pressure taps are provided on the insert's valve to check gas pres

sures (see

on/off/pilot knob. The top tap is the inlet (supply) pressure side. To check

inlet pressure (with the fireplace insert burning), insert a small regular

screwdriver into the tap and turn a half turn counterclockwise. Cover the

tap with the line from a manometer and check the pressure. Close the tap

gently but securely after completing the check. The manifold (outlet) tap

is below the inlet tap. To check manifold pressure (with the insert burning

at the high burn setting) insert a small phillips screwdriver into the tap

and turn a half turn counterclockwise. Cover the tap with the line from

the manometer and check the pressure. Again, close the tap gently but

securely after completing the check. Check the taps for gas leaks with a

gas leak test solution and retighten if necessary.

If the pressure is too low, make sure the gas supply line is large enough,

the supply regulator is properly adjusted, and the total gas load for the

residence does not exceed the amount supplied.

IMPORTANT NOTE: If propane is used, be aware that if the tank size is too

small (i.e. under 100-lbs, if this is the only gas appliance in the dwelling.

Ref. NPFA 58), there may be loss of pressure, resulting in insufficient fuel

delivery (which can result in sooting or other malfunctions). Any damage

resulting from an improper installation, such as this, is not covered under

the limited warranty.

Figure 37 on Page 22). The taps are located to the left of the

These appliances and their individual shut-off valves must be discon-

nected from the gas supply piping system during any pressure testing

of that system at pressures

greater than 1/2 psig (3.5 kPa).

These appliances must be isolated from the gas supply piping system

(by closing their individual manual shut-off valve) during any pressure

testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig (3.5 kPa).

-

LP and Natural Gas Supplies

Your Shoreline™ can be operated with either natural gas or liquid

propane (LP). It is shipped from the factory for use with only natural

gas. The fireplace insert must always be operated with the same gas as

specified on the label unless converted by a qualified service technician

as per this manual.

Also check the orifice size on the label located below the Shoreline insert.

It must be the correct size for the fuel and altitude.

OPERATING INSTRUCTIONS

Pre-Lighting Checklist

Be sure to check these items before the initial lighting of the insert:

_____ The insert gas label corresponds to the gas supply available

- that is "natural gas" for natural gas or "LP gas" for LP gas.

_____ Gas pressure has been checked carefully.

_____ All gas fittings have been checked for leaks.

_____ All clearances to combustibles have been met.

_____ All combustible materials have been removed from the area

_____ All vented areas of the insert face are unobstructed.

_____ House is ventilated to clear initial curing odor.

_____ All packaging materials have been removed from the fire

_____ While insert is cool, fingerprints or other marks should be

_____ Brick panels and log set have been installed.

_____ The glass door is in place and is properly sealed.

in front of the insert.

box.

cleaned from any surfaces with a soft cloth. Marks left on these

surfaces may become etched into the finish if not removed

prior to burning the unit.

-

18

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

Page 19

CAUTION

Your Shoreline™ gas appliance must always be

operated with glass door in place.

Lighting Instructions

STOP! Read the safety information on the front cover of the manual

before proceeding.

1. Open the right side access door. Ensure the gas supply shut-off cocks are

open and ON/OFF Rocker Switch is “OFF”. If equipped with a thermostat,

set it to the lowest setting.

2. Turn off all electrical power to the appliance.

3. Push in the gas control knob slightly and turn clockwise to “OFF”.

NOTE: The knob cannot be turned from “PILOT” to “OFF” unless the knob

is pushed in slightly. Do not force.

4. Wait five (5) minutes to clear out any gas. If you smell gas, STOP! Follow

instructions on the front cover of this manual. If you do not smell gas

continue.

5. Locate the pilot assembly by looking at the rear center of the burner,

behind the large center log. A blue flame will be seen when the pilot is

lit.

6. Turn the gas control knob counterclockwise to the “PILOT” posi

tion.

7. Push the knob all the way in and hold in that position. Immediately light

the pilot by pressing the igniter button several times until pilot is lit.

Continue to hold the knob in for about 30 seconds after the pilot is lit.

Release knob and it will pop back out. Pilot should remain lit. If it goes

out, repeat steps 4-8 holding knob in an additional 15 seconds after pilot

is lit.

• If knob does not pop out when released, stop and immediately call

your service technician or gas supplier.

• If the pilot will not stay lit after several tries, turn the gas control knob

to “OFF” and call your service technician or your gas supplier.

8. After pilot is lit, turn gas control counterclockwise to “ON”. Knob

can only be turned “ON” if the knob has popped out.

9. To turn burner on, turn “ON/OFF” rocker switch to “ON” or set the ther

mostat to the desired temperature above room temperature.

10. Adjust the flame height (and heat output) by turning the flame height

knob clockwise for reduced flame and counterclockwise

for full flame.

11. Set the blower to the desired air flow after it turns on when the appliance

reaches operating temperature.

Piezo Igniter

Blower Speed

Control (rheostat)

Figure 31 - Gas Controls

ON/OFF

Switch

Gas Control Knob

(Pilot / On / Off)

Flame Height

Control Knob

(Hi/Lo)

Pilot Hood

Thermopile

Figure 32 - Pilot Assembly

Igniter (electrode)

Thermocouple

Pilot Assembly

To Turn Off Gas To Appliance

1. Turn off the “ON/OFF” rocker switch and/or thermostat (if installed).

2. Turn off electric power to the appliance if service is to be performed.

3. Turn gas control knob clockwise to “OFF”. Do not force.

This appliance needs fresh air for safe operation and must be installed

so there are provisions for adequate combustion and ventilation air. See

-

Installation and Operation Manual accompanying appliance.

Operation of this appliance when not connected to a properly installed and

maintained venting system can result in carbon monoxide (CO) poisoning and

possible death.

Shutdown Procedure

1. To turn off the burner, switch the rocker switch to “OFF” or adjust the

thermostat to a setting below room temperature (if installed). The

pilot will remain lit for future burner ignition.

For complete shutdown: See “To Turn Off Gas To Appliance” above.

-

WARNINGS

• Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage. For assistance or additional

information, consult a qualified installer, service

agency or your gas supplier.

• Operation of this appliance when not connected

to a properly installed and maintained venting

system can result in carbon monoxide (CO)

poisoning and possible death.

• Carbon monoxide poisoning – early signs of

carbon monoxide poisoning resemble the flu

with headaches, dizziness, or nausea. If you

have these signs, get fresh air at once! Have the

heater inspected by a qualified service technician. Some people are more affected by carbon

monoxide than others. These include pregnant

women, people with heart or lung disease or

anemia, those under the influence of alcohol,

and those at high altitudes.

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

19

Page 20

Flame Appearance and Sooting

Your Shoreline™ fireplace insert is designed for maximum heating

efficiency. Therefore, upon lighting of the main burner the flames will be

semi-transparent or “bluish.” After 10-20 minutes of operation the logs

will heat up and the flames will become a yellow/orange color. If after

20 minutes the flame stays lowered blue, or if the flame is orange with

evidence of sooting (black tip), the air shutter may require adjustment.

Adjusting the insert to cause the flames to turn orange sooner may result

in poor combustion, sooting, and a hazardous situation. See

and 34 showing proper flame appearance.

Sooting is indicated by black puffs developing at the tips of very long

orange flames. Sooting results in black deposits forming on the logs,

appliance inside surfaces and on exterior surfaces adjacent to the vent

termination. Sooting is caused by incomplete combustion in the flames

and lack of combustion air entering the air shutter opening. To achieve

a warm yellow to orange flame that does not soot, the shutter opening

must be adjusted between these two extremes.

Soot at

Flame Tip

Dark Orange

Flame

No Blue Flame

Center

Soot above

Flame Tip

Ports on Pan

Burner Assembly

No Soot at

Flame Tip

Semi-Transparent

Yellow Flame

Blue Flame

Center

Figures 33

CAUTIONS

• Carbon will be produced if the air shutter is

closed too much. Any damage due to carboning

resulting from improperly setting the air shutter

is not covered under the warranty.

• The air shutter control arm and nearby appliance surfaces are hot. Exercise caution to avoid

injury while adjusting flame appearance.

• The air shutter should never be set so as to make

the tips of the flames sooty or create sooting on

the viewing glass, logs, or heat exchanger. If

soot begins to form after burning, the air shutter

should be opened gradually until the sooting

condition stops. Gas quality and gas pressure

may vary, which can affect the burning characteristics of the insert.

IMPROPERLY

BURNING FLAME

Figure 33 - Burner Flame Appearance

Figure 34 - Proper Burner Flame Appearance

PROPERLY

BURNING FLAME

Air Shutter Adjustment

The Shoreline has an air shutter control lever located below the front

door, left of the center point of the gas insert. The lever is linked to the

primary air shutter on the main burner. The air shutter regulates the

amount of primary air the burner receives and therefore how clean the

insert burns. The air shutter should only be adjusted by a qualified gas

technician. The insert should burn for about 15 minutes with the logs

installed before adjusting the air shutter. More air will result in shorter

flames and less color, less air will result in bigger flames and more color.

To adjust the air shutter, move the slide adjustment from side to side

(see

Figure 35). Moving the air shutter lever to the right opens the air

shutter (more air). Moving the air shutter lever to the left closes the air

shutter (less primary air).

Shutter Adjuster

See DETAIL A

Moving bracket to the right will open shutter, to the left will close shutter.

CLOSE

Shutter Adjuster

DETAIL A

Figure 35 - Air Shutter Adjustment

OPEN

20

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

Page 21

Burn-In Period

This Shoreline™ insert has been painted with a high temperature metallic black stove paint. It leaves the factory dry to the touch, but finishes

curing as the fireplace insert is used. Fire the fireplace insert four suc

cessive times for ten minutes each time with a five minute cool down

between each firing to cure the paint and burn off lubricants used in the

manufacturing process. Ventilate the house during these first firings as

the paint gives off an unpleasant odor. It is recommended that persons

sensitive to an imbalance in the indoor air quality avoid the area where

the fireplace insert is located during the curing process.

blower during Burn-In period.

Do not turn on

WARNING

The power cord must be plugged directly into a prop-

-

erly grounded, 120 Volt, 60 Hz, 3-prong receptacle

electrical outlet. Do not cut or remove the grounding prong from this plug. It must be routed to avoid

contact. Do not route power cord under or in front

of appliance.

IMPORTANT

Keep your house well ventilated during the curing

process. The odor and haze emitted by the curing

process can be quite noticeable and may set off a

smoke detector.

Quiet Operation

As the Shoreline is burning, a number of normal operational sounds may

be heard. The flow of gas through the gas valve and orifice may make a

rushing or whistling noise. If this noise is objectionable, it can be reduced

by turning down the flame. Turning down the flame can reduce total heat

output by more than 30%. When the blower turns on, the sound of rushing

air may be heard. The blower sounds may be reduced by adjusting the

speed control rheostat (see

be heard as the gas valve or blower switch turn on and off.

Electrical Requirements

This gas insert operates without an outside power source, however the

blower requires a 120-Volt electrical service outlet. This appliance, when

installed, must be electrically grounded in accordance with local codes,

or in the absence of local codes, the National Electrical Code ANSI/NFPA

70 - latest edition. In Canada, the current CSA C22-1 Canadian Electrical Code - latest edition. (

thermostat and ON/OFF switch information).

Figure 31). Also, a slight clicking sound may

See Shoreline Main Burner Operation for

CAUTION

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper

and dangerous appliance operation. See Figures

36 and 37.

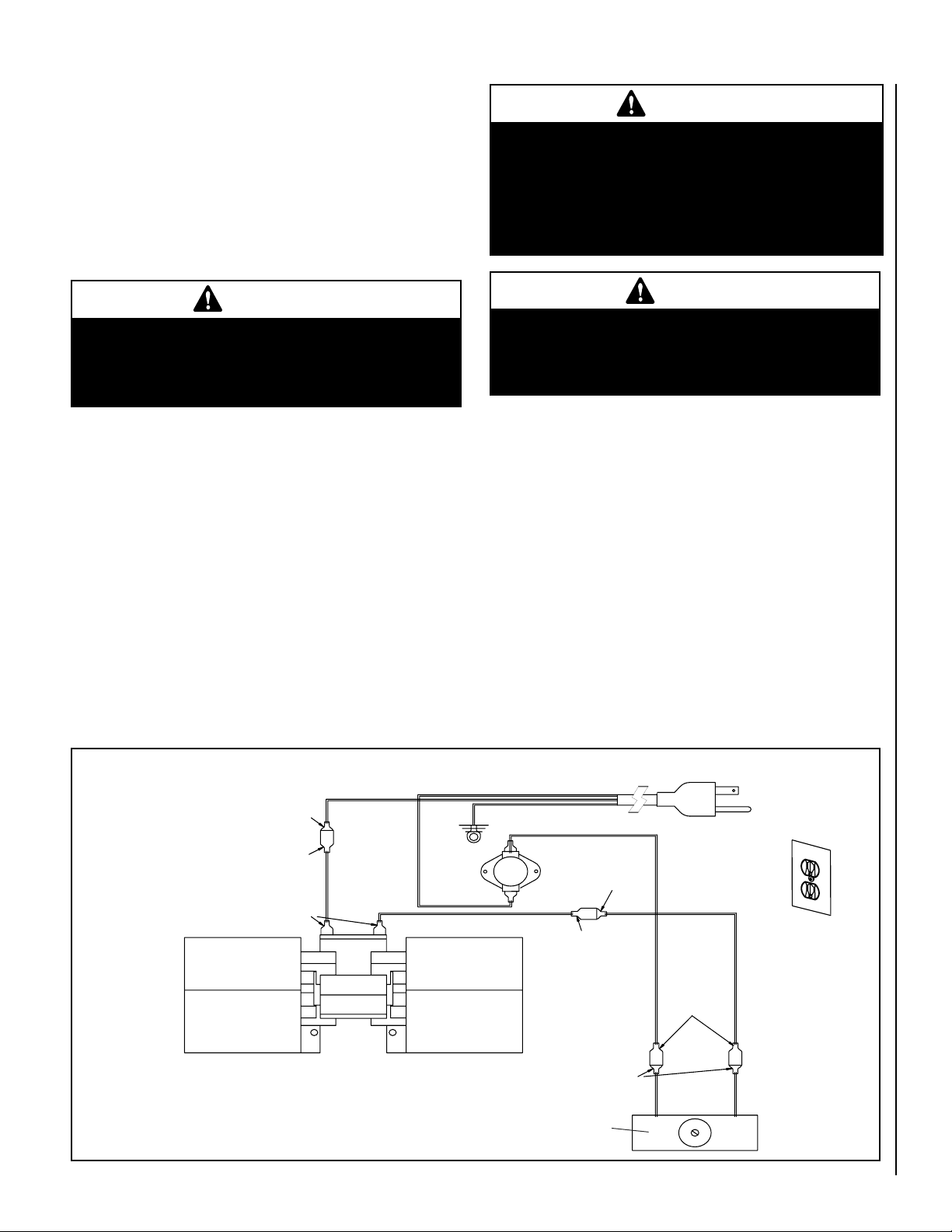

Blower Operation

Your Shoreline gas insert comes equipped with a 150 CFM blower with

a variable speed control and an automatic temperature activated On/Off

snap switch.

1. Plug the blower power cord into a grounded (three-prong) outlet.

Read Warning above.

2. After the fireplace insert warms up, the blower will turn on if the speed

control (located at the right below the firebox) is left in the "ON" posi

tion. The blower will not operate until the fireplace insert is warm.

3. Once the blower turns on, turn the knob to the desired speed. No

further adjustment is necessary.

4. If you do not wish to have the blower on, turn the knob counterclock

wise until it clicks into the "OFF" position.

-

-

FEMALE SPADE 1/4”

MALE SPADE 1/4”

FEMALE SPADE 1/4”

Figure 36 - Blower Wiring Diagram

BLACK

WHITE

BLACK

WHITE

BLACK

BLOWER

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

GREEN/GROUND

BLOWER SNAP DISC

FEMALE SPADE 1/4”

MALE SPADE 1-4”

FEMALE

SPADE 1/4”

BLOWER RHEOSTAT

POWER CORD

WHITE

BLACK

MALE SPADE

1/4”

WHITE

PLUG INTO 120 VAC

60 HZ GROUNDED

OUTLET

BLACK

21

Page 22

Shoreline™ Main Burner Operation

PILOT

OFF

ON

HI

LO

PILOT

PILOT

OFF

ON

HI

LO

PILOT

TPTH

TP TH

1

2

3

Your Shoreline fireplace insert comes with an “ON/OFF” rocker switch

used to turn the burner on and off while the pilot is on. The rocker switch

is located in the control panel above the blower rheostat switch and to the

left of the igniter. This is all located behind the right side surround.

A wall-mounted switch, a millivolt wall thermostat, or a remote control,

can be used to supplement the rocker switch. The gas valve is powered

by millivolts generated by the pilot assembly. This millivolt system is very

sensitive to electrical resistance, therefore, make sure all connections are

tight, clean, and free from corrosion. Do not splice any millivolt wires.

Table 12 to determine the proper gage of wire for the thermostat

Consult

or wall switch connections. This chart refers to the total length of the wire

(out to the switch and back). The thermostat must be a millivolt type.