Lennox 41718L098, SCU, SCU 12, SCU 13, SCU E Installation And Maintenance Instructions Manual

Page 1

INSTALLATION AND MAINTENANCE

INSTRUCTIONS

SCU Series

Split System Air Conditioner

WARNING

The equipment covered in this manual is to be installed by trained and experienced

service and installation technicians. Improper installation, modification, service or use

can cause electrical shock, fire, explosion or other conditions which may cause personal injury, death or property damage. Use appropriate safety gear including safety

glasses and gloves when installing this equipment.

WARNING

Risk of electrical shock. Disconnect all remote

power supplies before installing or servicing

any portion of the system. Failure to disconnect power supplies can result in property

damage, personal injury or death.

WARNING

Installation and servicing of air conditioning

equipment can be hazardous due to internal

refrigerant pressure and live electrical components. Only trained and qualified service

personnel should install or service this equipment. Installation and ser vice performed by

unqualified persons can result in property

damage, personal injury or death.

WARNING

Before performing maintenance operations on

system, turn off all main power switches to

indoor and outdoor units. Turn off accessory

heater power switch if applicable. Electrical

shock could cause personal injury or death.

TABLE OF CONTENTS

INSTALLATION....................................... 2

START-UP .............................................. 5

MAINTENANCE ..................................... 5

WIRING DIAGRAMS.............................. 6

WARRANTY........................................... 8

Manufactured By

A.A.C.

A Lennox International Company

421 Monroe Street

Bellevue, OH 44811

# 41718L098 Page 1

Save these instructions for future reference

Page 2

INSTALLATION

General

Read this entire instruction manual, as well as the

instructions supplied in separate equipment, bef ore

starting the installation. Observe and follow all

warnings, cautions, instructional labels and tags.

Failure to comply with these instructions could result

in an unsafe condition and/or premature component

failure.

These instructions are intended as a general guide only

for use by qualified personnel and do not supersede any

national or local codes in any way. The installation m ust

comply with all provincial, state and local codes as well as

the National Electrical Code (U.S.) or Canadian Electrical

Code (Canada). Compliance should be determined prior

to installation.

This unit has been factory charged with a quantity of

refrigerant (R22) sufficient for a matched indoor coil

and 20 feet of refrigerant tubing. If installed with other

indoor sections or with tubing sets other than 20 feet in

length, adjustments to the total system charge must be

made.

The unit has been designed to operate within the range of

indoor and outdoor temperatures as outlined in Table 1.

Following these recommendations will minimiz e component failures and maximize system perf ormance.

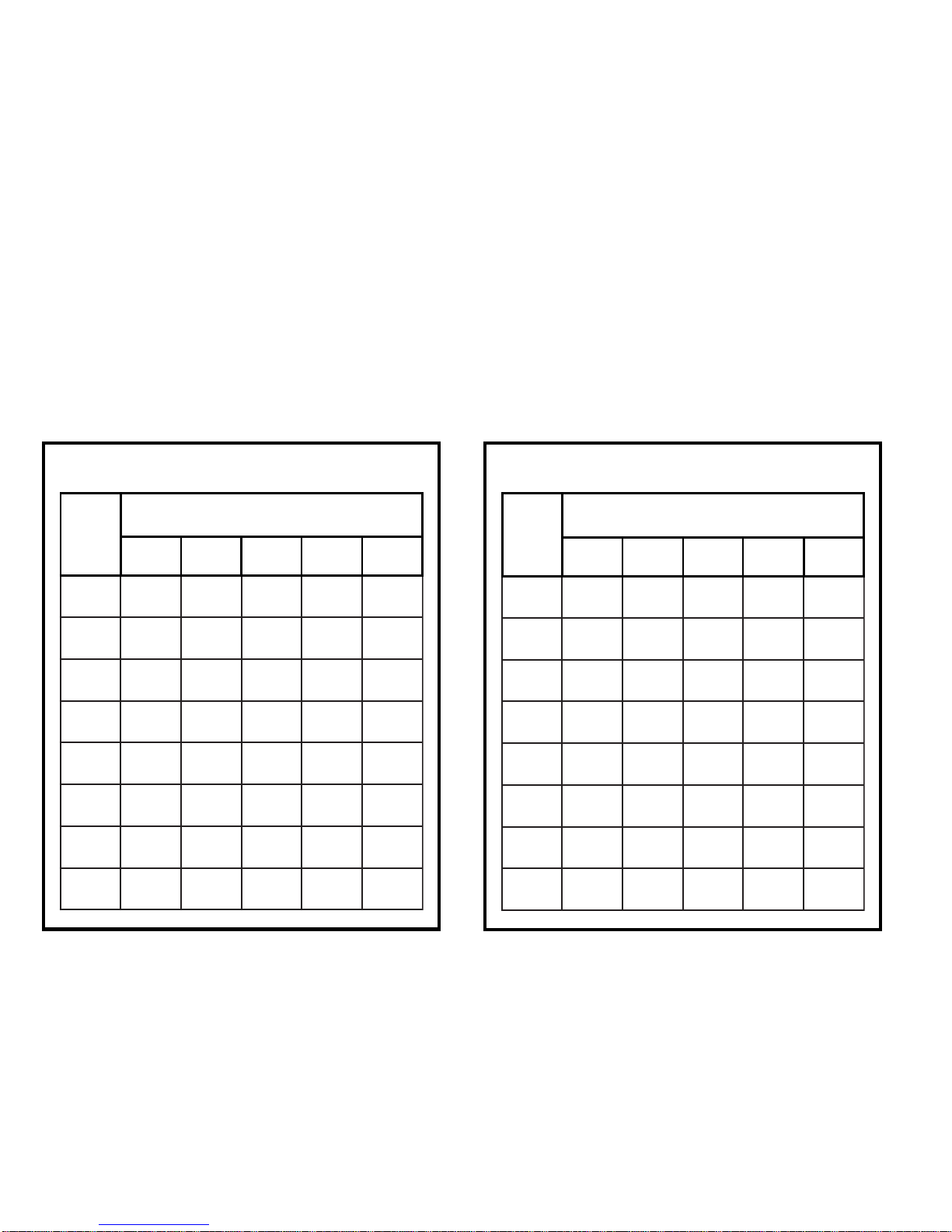

Optimum T emperature Range

roodtuO

roodnI

* If extended run times are anticipated below

outdoor temperatures of 65° F, a low ambient kit

must be installed.

ot)muminim(*F°56

)mumixam(F°511

otbwF°75/bdF°26

bwF°27/bdF°09

Table 1

Location of Unit

Install the unit on a solid, level mounting pad. To minimize

transmission of vibration, the pad should not be in direct

contact with any building walls or f oundations.

This outdoor unit has been ARI rated with sev eral Armstrong matching indoor sections for various types of

installations. To obtain optimum performance, a matched

indoor section must be installed. ARI ratings are based on

properly charged systems running at rated indoor cfm

levels . Ductwork should be specified to insure the correct

indoor airflow is obtainable.

Inspection of Shipment

Upon receipt of equipment, carefully inspect it for possible

shipping damage. If damage is f ound, it should be noted

on the carrier’s freight bill. Take special care to examine

the unit inside the carton if the carton is damaged. An y

concealed damage discovered should be reported to the

last carrier immediately , pref erab ly in writing, and should

include a request for inspection by the carrier’ s agent.

If any damages are discovered and reported to the carrier

DO NOT INSTALL THE UNIT, as c laim may be denied.

Check the unit rating plate to confirm specifications

are as ordered.

Limitations

This unit is designed and approved for outdoor use

only .

The outdoor unit must not be installed with any ductwork

in the airstream. The outdoor fan is not designed to

operate against any additional static pressure.

This unit has been designed to be located outdoors with

sufficient clearance for free entrance to the inlet and

discharge air openings. Adequate service clearance must

also be provided. Refer to Figure 1 for a detailed description of minimum clearances. Position the unit to avoid

direct contact of water , sno w or ice from a roof line

overhead.

Av oid placing the unit near quiet areas suc h as

sleeping quarters or study rooms. Normal operating

sound levels may be objectionable if the unit is placed

near certain rooms.

Electrical Wiring

All field wiring must be done in accordance with the

National Electrical Code recommendations, Canadian

Electrical Code and CSA Standards, or local codes, where

applicable. Refer to the unit rating plate for information

needed for wire sizing and branch circuit protection. An

adequately sized branch circuit disconnect should be

installed, per the NEC, within sight of and readily accessible to the unit. Route properly sized copper conductors

from the disconnect to the unit high voltage connections at

the contactor. A properly sized ground wire must be

connected to the ground screw or wire located in the

control panel. T wo low voltage thermostat wires must be

connected to the yellow wires connected to the contactor

coil. Use copper conductors only.

Page 2 # 41718L098

Page 3

12" CLEARANCE

48" OVERHEAD

CLEARANCE

Minimum Clearances

WEATHERPROOF

DISCONNECT

SWITCH

NEC CLASS 1

WIRING

TO

POWER

SUPPLY

NEC CLASS 2

WIRING

THERMOSTAT

TO

INDOOR

UNIT

TO

EVAPORATOR

COIL

NAMEPLATE

LOCATION

12" CLEARANCE

BOTH SIDES

NOTE: ALL OUTDOOR WIRING

MUST BE WEATHERPROOF

24" SERVICE

ACCESS CLEARANCE

Figure 1

Refrigerant Piping Connections

Check the indoor piston orifice to see if it matches the

required piston for the indoor and outdoor combination being installed. Refer to the refrigerant char ge

label located on the inside of the outdoor unit access

panel for the correct piston orifice size requirements.

Replace the piston orifice with the correct size if this

size is not already installed in the indoor coil.

For optimum system performance, indoor coils

should be washed with a suitable detergent to remove

any residue from the coil manufacturing processes.

Refer to the follo wing instructions when making the

refrigerant piping connections:

SEAL OPENING(S)

WITH PERMAGUM

OR EQUIVALENT

3. Route tubing to fittings on the outdoor unit vapor and

liquid service valves using properly sized refrigerant

grade tubing. Run the refrigerant tubing in as direct a

path as possible avoiding unnecessary turns and

bends.

4. Ensure that the vapor line is insulated properly and

that both vapor and liquid lines are not in direct

contact with floors, walls, ductwork, floor joists or

other piping.

5. After wrapping the service valves with a wet rag,

braze the tubing to the valve connections .

6. After brazing the tubing connections at the indoor coil,

leak test the refrigerant tubing and indoor coil.

1. The unit has been factory charged with refrigerant

(R22) suitable for a matched indoor coil and 20 f eet of

properly sized refrigerant tubing. Ref er to the unit

rating plate for the e xact amount of this f actory charge.

2. Refer to the refrigerant charge label located on the

inside surface of the outdoor unit access panel.

Locate the outdoor and indoor models being installed

and note any refrigerant adjustments that must be

made to the system. Adjustments to the system

charge must also be made if an interconnecting line

set other than 20 feet is installed.

# 41718L098 Page 3

7. Following the leak test, e vacuate the indoor coil and

line set to a minimum of 500 microns to remove

contamination and moisture.

8. After evacuation, open both the vapor and liquid

service valves fully.

Page 4

Factory charge contains refrigerant for condenser, evaporator and 20 feet of 3/8” line set. For line set other than 20

feet, adjust charge at 0.60 oz. per foot of 3/8” o.d. liquid

line and 1.2 oz. per foot of 1/2”. T o obtain optimum

performance, system charge should be weighed in

accordance to amount specified on unit rating plate and

any adjustments for additional line length o v er 20 f eet, as

stated above.

System performance may be verified by using the

refrigerant charging labels provided with each unit.

In air conditioning systems, horizontal suction lines should

be slightly sloped toward the condensing unit. Piping must

avoid dips or low spots can collect oil. To aid in the return

of oil, a trap should be installed at the bottom of any

suction riser. The top end of the riser must be pitched

toward the compressor. F or long v ertical risers, additional

traps are recommended for each additional 20 f eet of pipe

to insure proper oil movement.

A crankcase heater is recommended for applications

where additional field added charge results in a system

with a reciprocating compressor requiring more than 6 lbs.

of refrigerant or a scroll compressor requiring more than

10 lbs. of refrigerant.

Suction Line Sizes

LINE SET LENGTH AND SIZE

BTU/HR 12 FT. 25 FT. 50 FT. 75 FT. 100 FT.

000,214/34/34/34/34/3

000,814/34/34/34/34/3

000,424/34/34/34/38/7

000,034/34/34/38/78/7

000,638/78/78/78/78/11

000,248/78/78/78/118/11

000,848/78/78/78/118/11

000,068/78/78/78/118/11

Liquid Line Sizes

LINE SET LENGTH AND SIZE

BTU/HR 12 FT. 25 FT. 50 FT. 75 FT. 100 FT.

000,218/38/38/38/38/3

000,818/38/38/38/38/3

000,428/38/38/38/38/3

000,038/38/38/38/32/1

000,638/38/38/38/32/1

000,248/38/38/32/12/1

000,848/38/38/32/12/1

000,068/38/38/32/12/1

Table 2

Table 3

For installations exceeding 100 feet, contact the Armstrong Air Conditioning Inc.

Technical Services Department at (419) 483-4840.

Page 4 # 41718L098

Page 5

The procedure for start-up of the unit is as follows:

1. Operate the unit for a period of at least 15 minutes to

allow for pressures and temperatures to stabiliz e.

Unless matched with an indoor section using an

expansion valv e, the superheat method can be used

to check the system refrigerant charge. It should be

noted that this method is not accurate at low load

conditions or at outdoor ambients above 106° F.

MAINTENANCESTART-UP

WARNING

Before performing maintenance operations on

system, turn off all main power switches to

indoor and outdoor units. Turn off accessory

heater power switch if applicable. Electrical

shock could cause personal injury or death.

2. Using accurate gauges and temperature measuring

devices, determine the suction line pressure and

temperature as well as the outdoor ambient temperature.

3. Refer to the refrigerant charging instruction label

located on the inside of the outdoor unit access panel.

Locate the intersection of the measured outdoor

temperature and suction line pressure on the chart.

4. If the suction line temperature is higher than the

intersection temperature, the system is undercharged.

If the actual suction line temperature is lower than the

chart temperature, the system is overcharged.

Discharge Thermostat (if used)

Some models come equipped with a discharge thermostat

(loss of charge control) to guard against the compressor

overheating from loss of charge. The temperature cut out

for this control is set at 250°F, as determined by compressor manufacturer’ s recommendation. Discharge tem-

peratures exceeding 250°F will cause compressor oil

breakdown that will lead to premature compressor

failure. If the control trips during unit operation, a problem

exists within the system. Check for the f ollo wing as

possible causes:

Homeowner Maintenance

Leaves and other large obstructions should be carefully

removed from the outdoor coil surf aces without damaging

the fin surface of the coil.

Routinely clean or change the indoor air filter. Should the

coil become dirty, thus restricting airflow, call a qualified

service person to carefully clean the coil surface.

Dealer Maintenance

An annual inspection by a qualified service person should

be performed to ensure continued quality performance.

Outdoor coil surfaces should be cleaned, taking care not

to damage the fin surface of the coil.

Several w eep holes located in the unit base should be

inspected and cleaned, if necessary , to ensure that proper

drainage can occur.

All electrical wiring and connections should be inspected;

as should all physical connections of individual components within the units.

• Low system charge

• High discharge pressures

A thorough inspection of the system should be made to

determine the cause. The discharge gas temperature may

be verified by attaching an electronic type thermometer or

thermocouple to the discharge line near the control.

The control resets automatically. If the unit does not have

a discharge thermostat, an add-on kit is available.

# 41718L098 Page 5

Page 6

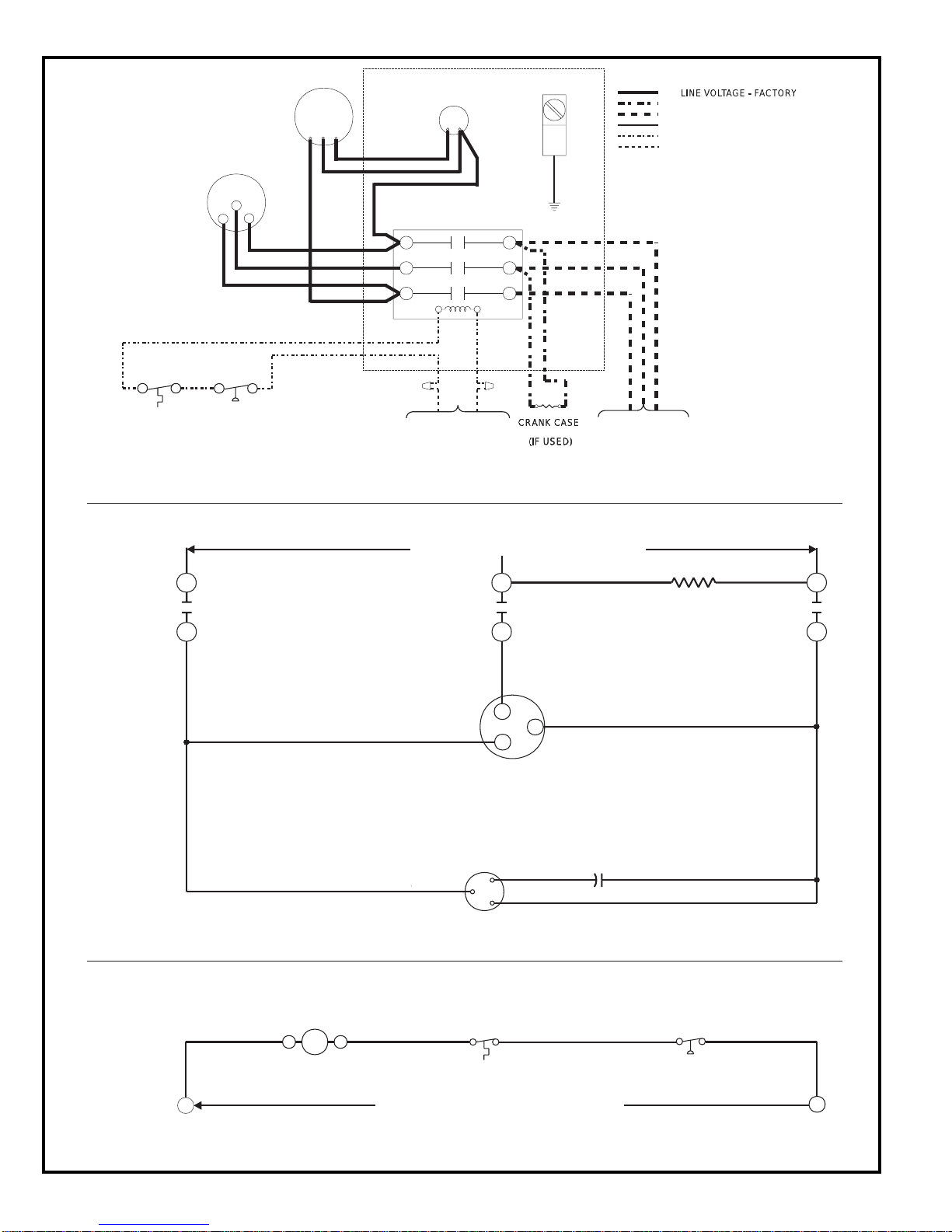

CONNECTION

DIAGRAM

COMP

T3

RED

FAN

YEL

YEL

BROWN

VIOLET

RED

T1

T2

T3

CAPACITOR

CONT ACTOR

FAN

MOTOR

BLACKBLACK

T2

T1

BRN

BLACKBLACK

EQUIPMENT GROUND

L1

L2

L3

BLK

YEL

BLK

LINEVOLTAGE - FACTORYLINE VOLTAGE - FACTORY

LINE VOLTAGE - FACTOR Y (IF USED)

LINE VOLTAGE - FIELD

LOWVOLTAGE - FACTOR Y

LOWVOLTAGE - FACTORY (IF USED)

LOWVOLTAGE - FIELD

NOTE:

REPLACEMENTWIRE MUST

BE THE SAME GAGE AND

INSULA TIONTHICKNESS,

105° APPLIANCE WIRING

MA TERIAL.

DISCHARGE

THERMOST AT

(IF USED)

SCHEMATIC

OF POWER

CIRCUIT

HIGH PRESS

SWITCH

(IF USED)

L3

COMPRESSOR

CONT ACTOR

T3

CONNECT TO“C” AND

“Y”TERMINALS OF

INDOOR CONTROL

CIRCUIT HAVING MIN.

40 VA, 24 VOLT N.E.C.40 VA, 24 VOLT N.E.C.

CLASS II TRANSFORMER.

CRANK CASECRANK CASE

OUTDOOR POWER SUPPLY

L2

T2

COMPRESSOR

MOTOR

FAN

MOTOR

T2

T3

HEATER

(IF USED)(IF USED)

T1

REFER TO RATING

PLATE FOR LINE

VOLTAGE 3 PHASE

POWER SUPPLY.USE

MINIMUM 75°C

COPPER WIRE ONLY.

CRANKCASE HEATER

(IF USED)

L1

T1

TYPICAL

SCHEMATIC

OF CONTROL

CIRCUIT

Y

Page 6 # 41718L098

R

COMPRESSOR

CONT ACTOR COIL

DISCHARGE THERMOSTAT

(IF USED)

THERMOSTAT TERMINALS

Figure 3

HIGH PRESSURE

SWITCH (IF USED)

PART NO.38942D005

C

Page 7

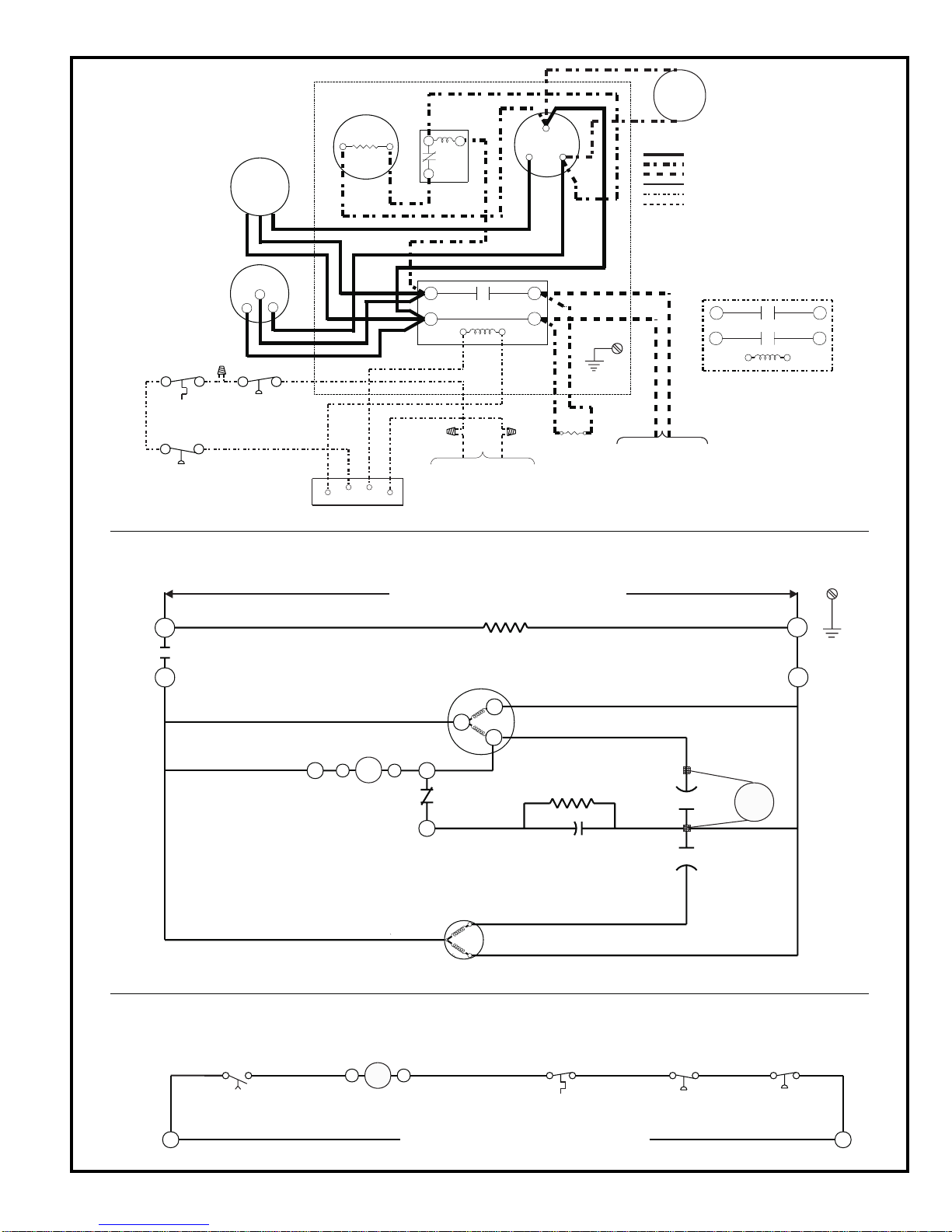

CONNECTION

DIAGRAM

DISCHARGE

THERMOSTAT

(IF USED)

LOW PRESSURE

SWITCH

(IF USED)

FAN

BROWN

BLK

VIOLET

COMP

C

S

R

R

BLK

RED

HIGH PRESSURE

SWITCH

(IF USED)

START CAP.

YEL

YEL

BLUE

LOAD

TIME DELAY RELAY

(IF USED)

RED

C

C

(IF USED)

BLUE

T'STAT

START RELAY

(IF USED)

2

5

1

RED

BLK

CONT ACTOR

T1

T2

YEL

YEL

CONNECT TO“C” AND

“Y”TERMINALS OF

INDOOR CONTROL

CIRCUIT HAVING MIN.

40 VA, 24 VOLT N.E.C.

CLASS II TRANSFORMER.

YEL

COM

HERM

FAN

COMP

RUN

CAP

L1

L2

CRANK CASE

HEATER

RED

BLK

BLK

(IF USED)

GROUND

SCREW

TO SINGLE PHASE

POWER SUPPLY PER

RATING PLATEWITH

MINIMUM 75°C COPPER

ONLY. CIRCUIT

WIRE

PROTECTION PER

RATING PLATE.

START

ASSIST

DEVICE

(IF USED)

LINE VOLTAGE - FACTORY

LINE VOLTAGE - FACTOR Y (IF USED)

LINE VOLTAGE - FIELD

LOWVOLTAGE - FACTOR Y

LOWVOLTAGE - FACTORY (IF USED)

LOWVOLTAGE - FIELD

NOTE:

IF ANY OF THE ORIGINAL

WIRE IS REPLACED,THE

SAME SIZE AND TYPEWIRE

MUST BE USED.

T1

T2

CONT ACTOR

L1

L2

ALT.

SCHEMATIC OF POWER CIRCUITSCHEMATIC OF POWER CIRCUIT

L1

COMPRESSOR

CONT A CTOR

T1

START RELAY

R

(IF USED)

OUTDOOR POWER SUPPLY

CRANKCASE HEATER

(IF USED)

R

COMPRESSOR

S

MOTOR

START CAPACITOR

(IF USED)

25

1

C

FAN

MOTOR

COMPRESSOR

RUN

CAP A CIT OR

START

ASSIST

DEVICE

(IF USED)

L2

T2

GROUND

SCREW

TYPICAL

SCHEMATIC

OF CONTROL

CIRCUIT

TDC

TIME DELAY

RELAY

(IF USED)

Y

# 41718L098 Page 7

R

COMPRESSOR

CONTACTOR COIL

DISCHARGE THERMOSTA T

(IF USED)

THERMOSTATTERMINALS

Figure 4

LOW PRESSURE

SWITCH

(IF USED)

HIGH PRESSURE

SWITCH

(IF USED)

PART NO.38602D008

C

Page 8

Limited Warranty

August 1, 1997

This warranty gives you specific legal rights and you may have other rights

which vary from state/province to state/province.

Armstrong Air Conditioning Inc. products are available under the following names: Air Ease, Armstrong Air, American Aire, Concord

Subject to the limitations stated in this warranty, we warrant to the first buyer for use the residential heating, cooling or heat pump unit,

when installed, operated and maintained as required by this warranty, to be free of defects in workmanship or material for a period of five

years (two years for commercial equipment) from the time of installation. We will replace any defective component without cost or

expense to you except for the costs of delivery and labor for removal and replacement of the defective component.

The SCU 12, 13 and E Series carry a 10 year compressor warranty. All other SCU Series air conditioners carry a 5 year compressor warranty.

The warranty period begins when the installation is complete and the product is ready to operate. You must be able to verify this date

whenever a warranty claim is made. Original bill of sale, installer’s invoice or other similar document will suffice. If the beginning date

cannot be verified, we will consider warranty coverage to begin six months after the date the product was shipped from our factory.

Implied warranties of merchantability or, to the extent applicable, fitness for a particular purpose are limited to five years, the same

duration as the basic limited written warranty provided herein. Some states/provinces do not allow limitations on how long an implied

warranty of merchantability or fitness lasts, so the above limitations or exclusions may not apply to you.

This written Limited Warranty is the only warranty made by the warrantor; this warranty is in lieu of and excludes all other warranties,

express or implied. The warrantor does not authorize any person to provide any other warranty or to assume for it any further obligation

in connection with the warranted product.

Warrantor: Armstrong Air Conditioning Inc., 421 Monroe St., Bellevue, OH 44811

Warranty Begins

Limitations on Implied Warranties

Only Warranty

What is NOT Covered

1. Cabinets or cabinet pieces.

2. Normal maintenance items such as filters, fan belts, fuses or other consumable items.

3. Damage caused by misuse, failure to maintain properly, accidents or acts of God.

4. External wiring, piping, venting or attachment of accessory products not integral to our product, including without limitation,

humidifier, air cleaner, vent damper, thermostat or other mechanical devices not manufactured by the warrantor.

5. Products that have been operated in a corrosive atmosphere where a concentration of acids, halogenated hydrocarbons or

other corrosive elements causes deterioration to metal surfaces or integral components. NOTE: Operation in a corrosive

atmosphere is considered abuse and voids this warranty.

6. Products that have NOT been installed in accordance with our published installation instructions, applicable local, state/

provincial or national codes, ACCA published standards.

7. Products that have NOT been installed by competent, qualified installers.

8. Products that have been moved from their original place of installation.

Warranty on Replacement Components

Any replacement component furnished by us will assume the remaining (unused) portion of the Limited Warranty.

Consequential Damages

The warrantor shall not be responsible for any consequential damages caused by any defect in the product. Some state/provinces do not

allow the exclusion or limitations of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

NOTE: After the first year, in the event that a gas or oil heat exchanger is no longer being manufactured by the warrantor, the warrantor

will allow a credit equal to the then current wholesale price of an equivalent heat exchanger towards the purchase of a new Armstrong gas

or oil furnace.

This product must be installed, used and cared for in accordance with the instruction manual. You are responsible for required periodic

maintenance or service, such as changing or cleaning of air filters and lubrication or cleaning of components. Failure to properly install,

operate or maintain your unit voids this warranty.

Owner Record

Model # ________________________ Serial # _________________ Installation Date __________________

INSTALLED BY:

Dealer _____________________________________________________________________________________

Address ____________________________________________________________________________________

T elephone # ____________________________ License # _______________________________

Page 8 # 41718L098

Loading...

Loading...