Page 1

INSTALLATION AND OPERATION MANUAL

US

Free-Standing

EPA Certied

Wood-Burning Stoves

Retain These Instructions

For Future Reference

P/N 775,214M, Rev. B, 09/2007

Striker™ S160

A French manual is available upon request. Order P/N 775,214CF.

Ce manuel d’installation est disponible en francais, simplement en faire la demande. Numéro de la

pièce 775,214CF.

These appliances must be properly installed and operated in order to prevent the

possibility of a house re. Please read this entire installation and operation

manual before installing and using your wood stove. Failure to follow

these instructions could result in property damage, bodily injury or

even death. Contact your local building or re ofcials to obtain

a permit and information on any installation requirements

Report # 050-S-03b-2

and inspection requirements in your area.

Striker SA160

Wood Stoves

Model Striker™ S160

WARNINGS

• Hot! Do not touch! The glass and surfaces of this appliance will

be hot during operation and will retain heat for a while after

shutting off the appliance. Severe burns may result.

• Carefully supervise children in the same room as appliance.

Page 2

TesTing informaTion

This manual describes the installation and operation of the

Striker™ S160 non-catalytic wood heaters. These heaters

meet the U.S. Environmental Protection Agency’s emissions

limits for wood heaters sold on or after July 1, 1990. This

heater has been developed, tested, and constructed in accordance with the requirements of UL 1482, ULC S627-and

HUD standards and is listed by OMNI Test Laboratories,

Beaverton, OR. It has been approved for residential, mobile

home, and alcove installations.

general safeTy PrecauTions

1. When this room heater is not properly installed, a

house fire may result. To reduce the risk of fire, follow

the installation instructions. Contact local building

or fire officials about restrictions and installation

inspection requirements in your area.

6. While burning, fuel utilizes oxygen from the air in the

room. Be sure to allow an adequate amount of fresh

air into the room where the stove is burning.

7. The outside surface of the stove will be hot while

burning properly and can set items like clothing

and curtains on fire. Keep furnishings and other

combustible materials away from the stove. Using

the heat from the stove to dry wet clothing can be

hazardous if clothes are placed too near the surface

of the stove.

8. Do not allow children to play near the stove without

close supervision. Do not touch the stove while it

is burning. Use extreme caution while the unit is

in use. Surface temperatures become dangerously

hot and can cause serious burns.

9. Do not allow anyone to operate the stove who is

not familiar with the operating instructions.

2. Wear gloves during installation to avoid injury from

sharp edges on the stove and/or its parts.

3. This unit is designed and engineered to burn only

dry, well-seasoned wood. Burning wet wood will

greatly reduce the Stove’s efficiency, produce excessive amounts of smoke, and can cause dangerous

chimney fires due to creosote build-up.

4. Before opening the door, the

draft control must be

fully open to avoid possible combustion flash (igni-

tion of hot volatile gases as the door is opened).

5. Do not use gasoline, gasoline-type lantern fuel,

kerosene, charcoal lighter fluid, or similar liquids

to start or “freshen up” a fire in this stove. Keep all

flammable liquids and combustible materials 36”

from any point of the stove when it is in use.

10. Attempts to achieve heat output rates that exceed

stove design specifications can result in permanent

damage to the stove. Never leave your stove unattended on high burn rates. This may cause overfiring.

Overfiring the stove may cause a house fire. If the

stove glows, you are overfiring.

11. Use smoke detectors near your stove as well as in

sleeping areas. Keep a water hose or hand-operated

fire extinguisher close for safety.

12. Inspect your chimney at least once a month during

the burning season to check for soot and creosote

accumulations. Any accumulations over 1/4” thick

should be removed by a professional chimney

sweep. Do not attempt to burn out heavy creosote

accumulations with a hot fire. If large accumulations

are occurring, review your burning procedures.

2

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 3

TABLE OF CONTENTS

TesTing informaTion .........................................................................................2

general safeTy PrecauTions ................................................................................2

n

egaTive Pressure Warning ...........................................................................4

creosoTe .....................................................................................................4

ash DisPosal ................................................................................................4

DrafTing .....................................................................................................4

fuel ..........................................................................................................5

Break-in PerioD .............................................................................................5

PainT curing .................................................................................................5

clearances To comBusTiBles ................................................................................6

insTallaTion ..................................................................................................7

moBile home insTallaTions .................................................................................7

leg anD heaTshielD insTallaTion .............................................................................7

ouTsiDe air kiT insTallaTion ................................................................................8

sTove insTallaTion ...........................................................................................9

PeDesTal insTallaTion ...................................................................................... 10

PosT insTallaTion checks .................................................................................. 11

Brick insTallaTion ......................................................................................... 11

oPTional BloWer insTallaTion ............................................................................ 13

oPeraTing hinTs ........................................................................................... 13

sTarTing anD mainTaining a fire .......................................................................... 14

clean glass ............................................................................................... 15

oPeraTing Techniques anD hinTs .......................................................................... 15

geTTing The mosT ouT of your sTove .................................................................... 15

maximizing your sTove’s overall efficiency ............................................................. 16

achieving clean, long Burns ............................................................................. 16

mainTenance ............................................................................................... 17

TrouBleshooTing ........................................................................................... 18

Do’s anD Don’Ts ........................................................................................... 19

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

3

Page 4

13. If a creosote fire should develop, the fire department

should be called immediately, and then attempts

should be made to control the fire until assistance

arrives. If a “runaway” fire should develop causing

over-heating of the stove, the door and draft regulators should be closed immediately. The fire should

die down once deprived of oxygen. After a severe

chimney fire, the complete chimney system should

be checked before further use.

14. Do not operate with a grate or with an elevated

fire. Always build the fire on the surface of the

firebrick.

15. Please read this entire manual before you install

and use your new room heater. Failure to follow

instructions may result in property damage, bodily

injury, or even death.

negaTive Pressure Warning

This appliance is not designed to be operated in a negative

pressure. Very airtight homes with large kitchen exhaust

fans, or homes with furnace cold air returns located in close

proximity to the wood stove or fireplace insert may create

negative pressure in the same room as the heating appliance. This can create dangerous back drafting of the stove

and chimney joints, drawing combustion by-products into

the home. Be sure your home has adequate makeup air to

eliminate negative pressures caused by the above-mentioned

sources. Outside air connected to the appliance probably

will not resolve such a problem as the stove or fireplace

insert is not the source of negative pressure. Lennox Hearth

Products accepts no liability for damages resulting from

negative pressures described above.

DrafTing

Your wood stove is dependent upon a properly functioning

chimney for optimum performance. It is a high efficiency

appliance that loses much less heat up the chimney than

older appliances and fireplaces. For this reason it is important

to match the stove to the chimney. The chimney has two

functions: 1) It draws combustion air into the appliance

(without air, no fuel will burn) and 2) It exhausts combustion

by-products. Your new Country™ Collection stove is what is

known as a “natural draft” appliance. The appliance depends

solely on the natural draft of the chimney system to draw

combustion air into the unit. Draft is the force that moves air

from the appliance up into the chimney. The amount of draft

in your chimney depends on the length of the chimney, local

geography, nearby obstructions, and other factors. Too much

draft may cause excessive temperatures in the appliance. Slow

or inadequate draft equals poor combustion and possible

smoking problems. The two main culprits of poor chimney

draft are: 1) A chimney too large for your appliance and 2)

A chimney with not enough height to produce adequate draft

for your particular stove model. Your Lennox Hearth Products dealer will be able to advise you on matching a proper

system for your new stove. Inadequate draft will cause the

appliance to leak smoke into the room through the stove

and the chimney connector joints. An uncontrollable burn

or a glowing red stove or chimney part indicates excessive

draft. Also see Troubleshooting on page 18.

creosoTe

Creosote---Formation and Need for Removal---When wood

is burned slowly, it produces tar and other organic vapors,

which combine with expelled moisture to form creosote. The

creosote vapors condense in the relatively cool chimney flue

of a slow-burning fire. As a result, creosote residue accumulates on the flue lining. When ignited, this creosote makes

an extremely hot fire. The chimney and chimney connector

should be inspected at least once every two months during

the heating season to determine if a creosote build-up has

occurred. If creosote has accumulated, it should be removed

to reduce the risk of a chimney fire.

ash DisPosal

Ashes should be scooped out of a cool stove with a small

metal shovel. Ashes should be placed in a metal container

with a tight fitting lid. The closed container of ashes should

be placed on a non-combustible floor or on the ground, well

away from all combustible materials, pending final disposal. If

the ashes are disposed of by burial in soil or otherwise locally

dispersed, they should be retained in the closed container

until all the cinders have thoroughly cooled. Ashes can ignite

up to 72 hours after removal from the stove.

4

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 5

fuel

This unit is designed and engineered to burn, dry, wellseasoned wood only. Dry, seasoned wood is that which

has been cut, split, and allowed to dry under a covered area

where air is free to flow and circulate under and around the

wood (not under a tarp or plastic). Make sure wood is not

stacked directly on the ground, it may absorb moisture from

the ground. It should be allowed to dry in these conditions

for a minimum of six months, preferably one year or more.

IT MUST BE UNDERSTOOD THAT WOOD CANNOT BE

LEFT IN ANY KIND OF WET OR DAMP AREA OR IT WILL

NEVER BECOME COMPLETELY SEASONED. Your stove will

not operate at the level that it is meant to unless you use

seasoned, dry wood. Do not burn driftwood or wood that

has been in salt water, doing so will void your warranty. Do

not burn treated wood, coal, garbage, cardboard, solvents,

or colored paper. Burning treated wood, garbage, solvents,

or colored paper may result in the release of toxic fumes.

This type of burning will also void your warranty.

Break-in PerioD

If your stove has a Gold or Nickel-Plated Door, be sure

to clean it with Windex brand glass cleaner and a very

soft cloth to remove any fingerprints and residues prior

to the first fire and before any fire if the gold has been

handled or soiled. Do not close the door tightly during

the “Break-in Period.” Also, open the door frequently

(every 5-10 minutes) to keep the gasket from adhering to

the curing paint. Ventilate the house well during these first

firings as the paint gives off carbon dioxide and unpleasant odors. It is recommended that persons sensitive to an

imbalance in the indoor air quality avoid the stove during

the curing process.

Please be patient with the heat output of your stove for the

first few weeks. The steel will go through a curing process that

eliminates moisture, which is deep in the steel and firebrick.

This moisture will reduce initial heat output of your stove

and may make it difficult to start. After you have broken in

the paint on the stove it will be necessary to build hot fires

to thoroughly remove the moisture from the appliance. Running the stove with the draft fully open for 1 to 1-1/2 hours

after starting and adding generous amounts of fuel during

the first week or two should complete the curing process.

We recommend the use of a thermometer attached to the

stovetop or chimney. Temperatures on the connector pipe

should run in the 250-600 degree range. (DO NOT OVERFIRE

THE STOVE DURING THIS PROCESS. IF THE STOVE OR

CHIMNEY BECOMES RED, REDUCE THE AMOUNT OF AIR

ENTERING THE STOVE IMMEDIATELY).

PainT curing

Your new Striker™ S160 is painted with Forest High Temperature Paint that cures during the first few firings. We

recommend that you put your stove through a regimen of

three burns. The first two should last for 20 minutes each at

250 degrees (the stove should be allowed to cool completely

between each burn). The third should be a burn of at least

450 degrees F. for 45-60 minutes. The paint will become

soft, gummy, and emit non-toxic smoke during these burns.

After the stove cools down for the third time, the paint will

harden. DO NOT BUILD A LARGE ROARING FIRE UNTIL

THIS CURING EFFECT IS COMPLETE OR YOU MAY DAMAGE THE FINISH OF YOUR STOVE. Spray can touch-ups

should be done only with Forest brand paint, available from

all Lennox Hearth Products dealers.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

5

Page 6

clearances To comBusTiBles

Mobile Home Installations

WARNING: BE ABSOLUTELY SURE THE DISTANCE BETWEEN

THE HEATER AND THE SURFACE OF ANY COMBUSTIBLE

CONSTRUCTION IS NOT LESS THAN SHOWN.

Floor Protection

USA - The floor in front and under the heater must be pro-

tected with a minimum of 3/8” thick noncombustible material.

The covering must extend 16” in front of the door opening

of the heater and 8” to either side of the door opening and

5-1/2” to the rear or to the wall, whichever is smaller. In all

installations a 16” minimum hearth extension (in front of

the stove) is required as measured from the door opening

of the unit.

Canada - The floor in front and under the heater must be

protected with a minimum of 3/8” thick noncombustible

material. The covering must extend 457 mm in front of the

door opening of the heater and 200mm to either side of the

stove body and 200 mm to the rear or to the wall, whichever

is smaller. In all installations a 457mm minimum hearth

extension (in front of the stove) is required as measured

from the door opening of the unit.

Reduced Clearances

All mobile home installations require an outside air kit (part #

71111 or 71112). The stove must be bolted to the floor and

grounded to the chassis of the mobile home.

WARNING: DO NOT INSTALL IN SLEEPING ROOM OF A

MOBILE HOME.

CAUTION: THE STRUCTURAL INTEGRITY OF THE MOBILE

HOME FLOOR, WALL, AND CEILING/ROOF MUST BE

MAINTAINED.

Approved Chimney* - Your stove is approved for use with

Class A, UL 103HT Chimney and double wall connector pipe

from Security™ Chimneys.

Clearances to connector pipe shall be measured from the

flue collar of the stove.

Chimney & Connector

Minimum 6" diameter, minimum 24 MSG black steel connector pipe with listed factory-built chimney suitable for use

with solid fuels or masonry chimney. Horizontal connection

not tested, refer to local building codes for installation. Restrictions apply! Read instructions before installing.

Clearances to combustible surfaces can be reduced with the

use of listed double wall connector pipe. See the clearances

with double wall pipe on the following page.

Alcove Clearances

Single Wall Pipe - Minimum 48"(1219mm) width, maxi-

mum 48" (1219mm) depth. Minimum ceiling height is 72”

(1829m).

Double Wall Pipe - Minimum 44"(1117mm) width, maximum 48" (1219mm) depth. Minimum ceiling height is 72”

(1829m).

Clearance dimensions are to 6” (152mm) flue collar. If a

single wall connector pipe with shield is used, a 1 inch air

space is needed between pipe and shield. Shield attaches

to rear of stove pipe and must run from stove top to ceiling.

Pipe shield shall be UL listed.

Residential chimney systems must be from the same brands

as listed for mobile homes but connector pipe may be double

wall, single wall or single wall with shield as listed above.

Connector pipe and chimney must be of the same brand.

Components Required For Installation

Legs AND Bottom Heat Shield or Pedestal Base.

If optional blower is NOT used, Rear Heat Shield Block Off

Plate shall be installed.

* Other approved chimney brands are Projet, Jakes Evans/GSW, Dura-vent,

6

Metal Fab, Ameri-Tec, Metalbestos and Industrial Chimney (ICC).

Page 7

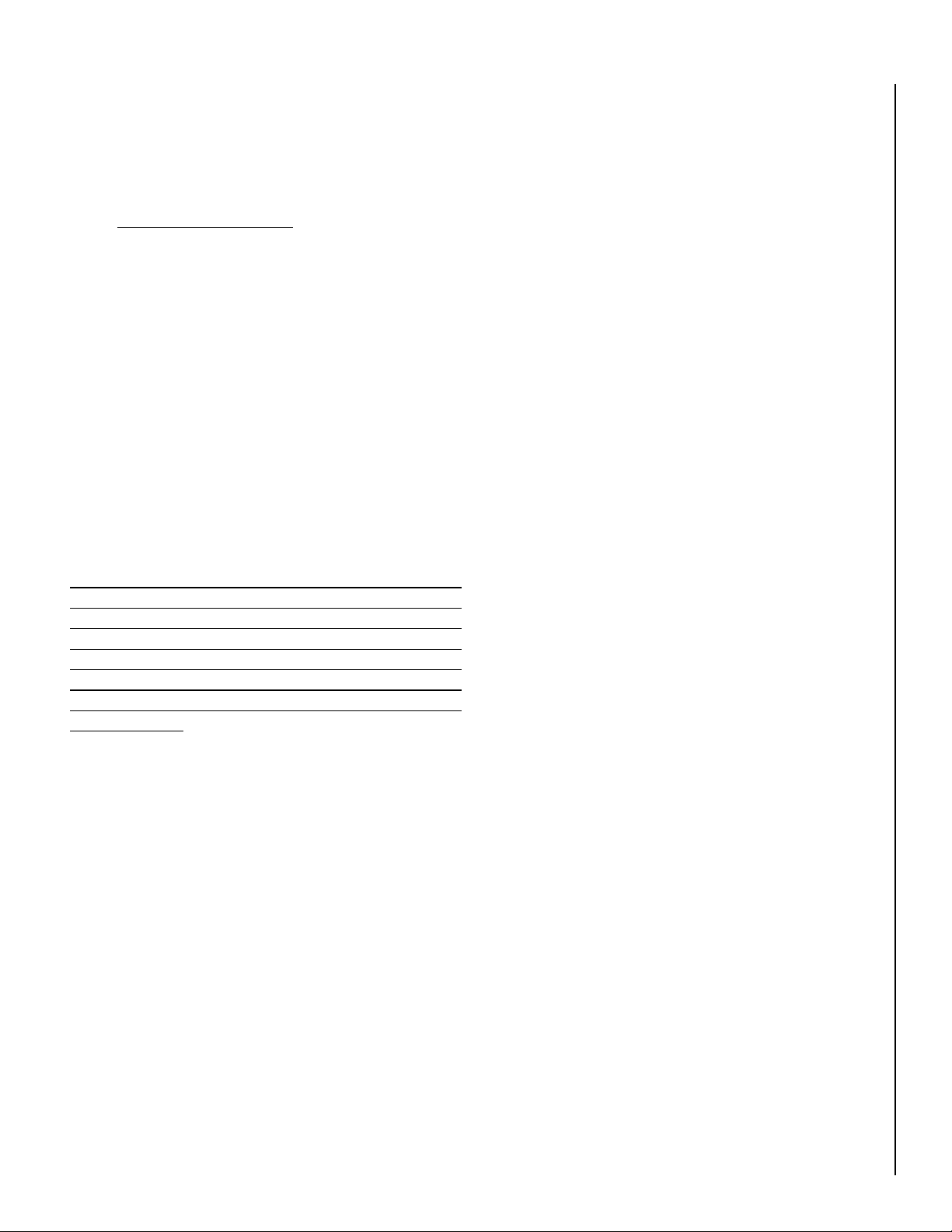

Diagram B: Side View-Alcove & Parallel Installation

Diagram A: Top View-Parallel Installation

K

B

A

E

C

D

*L

K

Floor Protection

Floor Protection

Floor Protection

G G

F F

72" Min.

H

I

M

J

I

J

H

†

E

†

E

L

48”

Maximum

Depth

Diagram C: Top

View-Corner

Installation

N

P

T

insTallaTion clearances - refer To Diagrams a, B & c

PIPE INSTALLATION A

6” Single

Wall

6” Single w/

Pipe Shield

6” Double

Wall

Residential or

Alcove

Residential or

Alcove

Residential or

Alcove or Mobile

USA-16”

CAN-483mm

USA-10”

CAN-330mm8”200mm

USA-10”

CAN-330mm

Home*

PIPE INSTALLATION

Single Wall Residential or

Alcove

Single w/

Pipe Shield

Double Wall

Air-Cooled

Residential or

Alcove

Residential or

Alcove or Mo-

H (2) I (6) J (2) K L (5)

USA-33-3/4”

CAN-1111mm

USA-33-3/4”

CAN-1111mm

USA-33-3/4”

CAN-1111mm

bile Home*

PIPE INSTALLATION Nu Pu

Single Wall Residential or

Alcove

Single w/

Pipe Shield

Double Wall

Air-Cooled

Residential or

Alcove

Residential or

Alcove or Mo-

30"

762mm

30"

762mm

30"

762mm

bile Home*

B (1)

14”

356mm

8”

200mm

USA-47-3/4”

CAN-1340mm

USA-41-3/4”

CAN-1188mm

USA-41-3/4”

CAN-1188mm

36"

914mm

36"

914mm

36"

914mm

C

USA-21”

CAN-610mm

USA-18”

CAN-533mm

USA-18”

CAN-533mm

USA-33-1/2”

CAN-1003mm

USA-33-1/2”

CAN-1003mm

USA-33-1/2”

CAN-1003mm

T (6)

USA-58-1/2”

CAN-1645mm

USA-52”

CAN-1686mm

USA-52”

CAN-1686mm

D (1)

12-1/2”

318mm

E†

8”

200mm

9-1/2”

241mm8”200mm

9-1/2”

241mm8”200mm

USA-16”

CAN-450mm

USA-16”

CAN-450mm

USA-16”

CAN-450mm

† USA=8" (200mm) from door opening,

Canada=8" (200mm) from sides and back

of unit

u

Dimensions to Stove Body

* Mobile Home - USA only

F (1,4)

9-3/4”

248mm

5-1/2”

140mm

5-1/2”

140mm

USA 0"

CAN-200mm

USA 0"

CAN-200mm

USA 0"

CAN-200mm

G (4)

USA-18”

CAN-533mm

USA-13-1/2”

CAN-419mm

USA-13-1/2

CAN-419mm

M

84”

2134mm

84”

2134mm

72”

1829mm

”

Diagram C: Top View Corner Clearance,

Stove & Flue to Wall

Footnotes:

1- These dimensions to the stove body are for reference only. Actual

distances should be measured from the stove’s flue collar.

2- Minimum noncombustible hearth pad dimensions.

3- Shield shall be attached to the rear of the stove pipe with a 1” air

space and must run from the top of the stove to the ceiling.

4- Not applicable to alcove installations.

5- In corner applications, when installed at minimum back wall clear-

ances, the required floor protection is dimensioned off the back

plane of the stove, therefore the floor protection required off the

back corners (at a 45 degree angle) only needs to extend to the

wall. This situation will only occur in CANADA installations.

6- Reference dimension only, to assist in planning the installation.

Clearances to connector pipe shall be measured from the flue

collar of the stove.

7

Page 8

leg anD heaTshielD insTallaTion

Clip

1/4” Bolt

Note: The threaded rods used to bolt the legs to the stove

are packaged with the heatshield, as a heatshield is required

when a stove is installed on legs.

Residential and Mobile Homes

(Bolting down and grounding of stove are required only

in mobile homes).

Open all cartons, if any, and remove the contents upon receipt and check for any damaged or missing parts. If there

is hidden damage, notify your freight company or Lennox

Hearth Products dealer immediately.

Heatshield

Mounting

Holes

Leg Installation

1. Carefully place stove on its back. Be careful not to

scratch the stove, use a piece of cardboard or carpet

to protect the back of the stove.

2. Mount all four legs as shown in Figure 1 below.

3. First, screw the threaded rods into the holes at the

four corners on the bottom of the stove. Screw the

threaded rods into the firebox three full rotations or

3/16 to 1/4” (if the rear rods are screwed in too far

they will lift the bricks off the bottom of the stove).

Use a washer and nut to secure the leg. Be sure the

legs are mounted squarely on the firebox bottom.

Tighten nuts securely.

4. Use the two bolts and washers provided with the

heatshield kit to mount the heatshield as shown in

Figure 2 below.

5. Do not over tighten the heatshield mounting bolts as

it may bend the heatshield.

Figure 2

Front

Air Channel

ouTsiDe air kiT insTallaTion

To install the “Outside Air Kit,” position the clip so that the

nut is directly above the hole punched in the back of the

heatshield (See Figure 3). Install the outside air adapter

box on the stove by sliding it into the air channel located

between the bottom heatshield and the stove bottom until

the oblong ring is approximately 1/4” from the rear edge

of the lower heatshield. Make sure the ring is facing down.

Thread the 1/4” bolt up through the nut in the clip until snug

against the adapter box.

Expanded View of Clip

Line up the hole in the clip with the hole in

the rear center of the bottom heatshield

Figure 3

Figure 1

To locate the hole in the hearth for outside air, mark a 4”

circle on the hearth. The circle’s center should be 2-3/4”

8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

directly back from the center of the flue outlet and 5/8” to

the left side.

Page 9

sTove insTallaTion

1. If not previously installed, install floor protection and

move the heater into the desired location.

2. Position the stove on your floor protection in the exact

location where it is to be located, making sure all

minimum clearances are met.

3. If you are installing outside air on your stove, mark a 4”

circle on the floor protection just below the oblong ring.

When cut out, this hole will accommodate the flexible

outside air tube.

4. If the stove is to be fastened to the floor, locate the hold

down brackets inside the leg box and mark the floor

protection below the holes in the brackets.

5. If you are installing outside air on your stove, remove

the stove and cut the floor protection and the floor

where the 4” air tube circle had been previously drawn.

If the stove is to be fastened to the floor, drill ½” holes

through the floor protection only, at the marks that were

for fastening the stove to the floor if so desired. Slip the

flexible outside air tube through the hole in the floor,

leaving 1” of tube above the floor protector surface,

using tape to hold it in place.

6. Place the stove on the floor protection so that the

previously cut or drilled holes line up. Attach the stove

to the floor with the lag bolts if so desired.

7. If you are installing outside air on your stove place the

hose clamp over the flexible air tube and slide the tube

up over the 4” ring on the outside air adaptor box and

tighten the hose clamp. Push the outside air adaptor

forward 1/4” until full contact is made with the lower

heatshield. Tighten the 1/4” bolt until the adaptor box is

held firmly in place. Use silicone sealant to create a seal

between the flexible air tube and your floor protection.

8. If it is necessary to level, secure or ground your

stove, use the holes in the bottom of the leg for those

applications. To level the stove on Olympic cast legs,

locate the front leg that is not touching the hearth pad.

Insert the allen head screw through the slotted washer

(supplied with the legs) and into the threaded hole in the

bottom of the leg. See the drawing to the right. Push the

slotted washer down until it touches the hearth pad and

then tighten the screw into the leg. Should any other leg

not be resting on the hearth pad, install a washer and

screw in that leg as well.

9. Install bricks and baffle as per instructions on page 11.

It is highly recommended that the baffle be assembled

before the chimney is installed so that the insulating

fiber blankets can be adjusted into place through the

flue collar.

10. If installed into a mobile home, the stove shall be

grounded to the mobile home chassis with a #8 AGW

copper wire or equivalent.

11. For residential installations, install the first section of

stove pipe with the crimped end going down inside

the flue collar on the heater. Continue with your stove

pipe, installing each section-crimped end down. Make

the final connection to your chimney. Your dealer

carries the necessary pipe and fittings to connect to the

various listed factory-built chimneys. YOUR CHIMNEY

INSTALLATION MUST COMPLY WITH LOCAL BUILDING

AND FIRE CODES.

12. Be sure to fasten each stove pipe connection with at

least 3 sheet metal screws.

13. Install chimney as per manufacturer’s instructions.

Some brands of pipe may require removal of the spacer

ring in the flue collar.

14. All horizontal runs of pipe should be as short as possible

and are required by NFPA No. 211 to have an upward

pitch or rise in the same direction the smoke travels of

no less than 1/4” to the linear foot. The connector pipe

must meet minimum clearances in any direction to walls

or other combustible materials. It must attach to a listed

double wall metal chimney

at least 6” in diameter or to

a masonry chimney with a

flue passage of at least 48

square inches.

15. It is required that a chimney

connector pipe not extend

further than the inner wall of

the flue when it is connected

to a masonry chimney, and

that it either be cemented to

the masonry or be installed

without cement in a thimble

connected to the masonry

wall. When the connector

is inserted into a thimble,

the joint must be tight

enough so that it will not be

dislodged in normal use.

Install connector at no

less than the minimum

clearances from the ceiling

when using a 90-degree

elbow to pass through combustible constructions.

16. Chimney connector pipes should never pass through

a floor, ceiling, fire wall, partition, or combustible

construction of any type unless certain precautions are

taken. The best method is to use a listed thimble and a listed

chimney in accordance with the manufactures directions.

NFPA No. 211 gives approved methods for passing a

flue pipe through combustible constructions.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

9

Page 10

PeDesTal insTallaTion

(For ash drawer pedestal see instructions included with

pedestal).

Residential and Mobile Homes

(Bolting down and grounding are required only in mobile

homes).

Caution: Wear gloves during installation in case of sharp

edges on the stove.

7. Make four 1-1/2” cuts in one end of the corrugated

tube and fold the flaps back. Cut a 4’ hole through

the floor protection and the floor, and insert the corrugated tube into the hole. Cover it with the supplied

screen and fasten it to the floor protector.

8. Locate the 11-1/2”x 14” metal plate and paint to

match the stove if necessary. Position this piece so

that the 14” dimension evenly overlaps the lips on the

back of the pedestal (see drawing above). Attach this

plate to the back of the pedestal with the self-tapping

screws supplied.

1. Remove the heater from the carton, if packaged,

upon receipt and check for any damaged or missing

parts.

2. Carefully put the stove on pedestal with the open end

of the pedestal facing the rear. DO NOT LEAVE THE

STOVE UNATTENDED UNTIL IT IS BOLTED SECURELY

TO THE PEDESTAL.

3. Line up the holes in the brackets on the pedestal with

the threaded holes in the bottom of the stove. Use

the two 1/2” long bolts and 3/8” standard washers

to bolt the stove to the pedestal. Be sure to see that

the stove is mounted squarely on the pedestal before

tightening the two bolts securely.

4. When installing a pedestal on this stove you

MUST

plug the four leg mounting bolt holes, located on the

bottom of the stove in the four corners, with the bolts

that were used to mount the shipping legs. The two

rear bolts should not be installed more than two full

rotations to prevent lifting the bricks off the bottom of

the stove. FAILURE TO INSTALL THESE FOUR BOLTS

PROPERLY WILL RESULT IN REDUCED CONTROL

OF THE STOVE’S COMBUSTION SYSTEM!

9. If the stove is to be fastened to the floor, attach the

stove with the supplied lag bolts, through the pedestal

base on opposite sides, attaching them into the floor

beneath the floor protection. Seal any irregularities

with silicone sealer.

Block Off Plate is

Required When

Installing Outside

Air Into Unit (Plate

is Included With

Kit # OAK-P)

10. If installed in a mobile home, the heater shall be

grounded to the chassis with a #8 AGW copper wire

or equivalent.

10

5. If required, install the Outside Air Kit (71112) as per

the following instructions. To locate the hole in the

hearth for outside air mark and cut a 4” hole in the

hearth. The hole’s center should be 3” directly forward

from the center of the flue outlet or locate as per the

instructions below.

6. Position the stove on your floor protection in the

exact location where it is to be located, making sure

all minimum clearances are met. Mark the floor

protection where the pedestal will be located, then

remove the stove.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

11. Install bricks as per instructions on pages 11 and 12.

It is highly recommended that the baffle be assembled

before the chimney is installed so that the ceramic

fiber blankets can be adjusted into place from the

flue outlet.

12. Install chimney as per manufacturer’s instructions.

Page 11

PosT insTallaTion checks

Brick insTallaTion

1. Check that all chimney pipe joints are securely fastened.

2. Check that the heater is securely fastened to the floor

(if applicable).

3. Make sure the intake vent has clear access to outside

air (if applicable).

4. Make sure the outside air vent has been sealed

properly to keep rodents out (if applicable).

5. Be sure all roof flashings are watertight.

6. Be sure the stove is properly grounded (if appli

cable).

FOR YOUR OWN PROTECTION AND INSURANCE

PURPOSES, HAVE YOUR CHIMNEY AND CONNECTOR

PIPE INSTALLATION INSPECTED BY YOUR LOCAL

BUILDING CODE AUTHORITY OR FIRE MARSHAL

BEFORE STARTING A FIRE IN YOUR STOVE. NOTIFY

YOUR INSURANCE COMPANY.

CAUTION: Wear gloves during brick installation in

case of sharp edges inside the stove.

Note: Installation of the baffle bricks and insulating blanket

is easier when you can still access the flue outlet, (before

connecting the flue pipe). Be sure the insulating blanket is

placed flat on the bricks so as not to block the flue. Use a

ruler or a piece of kindling to reach over the blanket to be

sure it is completely flat on top of the baffle bricks.

Measure bricks before installing, as per list of dimensions

on next page, to be sure the correct bricks are installed in

the correct location.

-

1. Install bricks #1-18 in the numbered sequence shown

in Figure 6 on the next page.

2. Next, install bricks #19 & 20 into the rear stainless

steel baffle support (see Figures. 7 & 8 on the next

page).

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

11

Page 12

3. Next, install baffle bricks #21-24 by sliding the back

of each brick over the center tube and support until

the front of the brick clears the front tube and support. Then lift the front of the brick above the front

support and tube and slide it forward as far as it can

go (very important), it will hit the front of the stainless support when it is fully forward. The rear of the

bricks sit on top of bricks #19-20 (Figures. 7 & 8).

Figure 6

4. Carefully slip the ceramic blanket up over the front

of the front stainless support and bricks #21-24.

Grasp the edge of the blanket and slide it back until

the front of the blanket is flush to the front of bricks

#21-24 (Figure 7). Shake the blanket gently from

side to side to get it to lay flat. Be sure the ceramic

blanket is directly on top of the baffle bricks and that

it does not hang out past the front of the baffle as

shown in Figure 7, also see note above.

Brick Sizes

A = 4-1/4”x 9”

B = 2-1/4”x 8-7/8”

C = 3-1/2”x 9”

D = 2-1/4”x 9”

E = 1-1/2”x 8-7/8”

F = Full Brick (4-1/2”x 9”)

G = 1-1/2”x 9”

H = 3-1/2”x 8-7/8”

12

Figure 7

Ceramic Fiber

Blanket

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Figure 8

Baffle Bricks Top View

Page 13

oPTional BloWer insTallaTion

A blower, part# 71000, can be installed on the stove

to improve hot air distribution throughout the room.

To install the blower:

1. Remove all the contents from the blower box. Included

with the blower should be a blower speed control.

2. Remove the screws in the round knock-out plate on

the back of the stove. Bend the knock-out plate back

and forth until it can be removed.

3. Mount the blower as shown below. Make sure the cord

is at the bottom when mounted and that it does not

touch the stove anywhere. Remove the four screws

from the back of the stove. Use one of the four screws

with a washer on it and attach the blower through

one of the four mounting legs on the blower housing.

Check to make sure that the fan blade does not touch

the large hole in the rear heatshield. (Spin it to check

all directions). Finish attaching the blower with the

other three screws. Tighten the screws moderately

tight but do not over tighten as you may strip the

holes out.

4. Plug in the fan speed control into the nearest outlet,

then plug the blower cord into the speed control. Do

not route the fan power cord under the stove or allow

it to come in contact with any surface of the stove.

Read the section Starting and Maintaining a Fire for

proper fan operating instructions on page 15.

WARNING: In the event that you remove the blower

for any reason, make sure a cover plate available

from Lennox Hearth Products is reinstalled before

using the heater. Excessive rear wall temperatures

will result if the stove is burned without the cover

plate.

oPeraTing hinTs

1. Burn only dry, well-seasoned wood for maximum heat

output. In some states it is illegal to burn wet wood

or anything other than clean, dry wood products.

2. Your stove is designed to operate with the door closed!

Operate only with the door shut tightly at all times

except when loading wood.

DO NOT hit or move the baffle brick while loading

3.

wood. Occasionally check the baffle. Make sure the

insulating blanket is always flush with the front of the

baffle brick. Loading oversized logs may dislodge the

baffle bricks.

CAUTION: THE DRAFT CONTROL MUST BE FULLY

4.

OPEN BEFORE OPENING THE DOOR TO AVOID POSSIBLE COMBUSTION FLASH!! (Ignition of hot volatile

gases as the door is opened).

5. Feeding excessive amounts of fuel to the stove should

be avoided. It is important to supply it with sufficient

draft and fuel to maintain a moderately hot fire. If,

during overnight burns, heavy creosote deposits

develop inside your stove and on the door, the draft

is set too low - review your burning habits!

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

13

Page 14

sTarTing anD mainTaining a fire

Be sure to clean the Nickel or Gold Plated door with

Windex brand cleaner and a very soft cloth to remove

any fingerprints and residues prior to the first fire.

4. Light the paper and allow sufficient time for the

kindling to become fully engulfed in flames. Close

the door. Your door may or may not need to be left

slightly open during this process, depending on your

stove model and chimney draft. Once the kindling is

burning well, larger pieces of wood may be added.

1. NEVER USE FLAMMABLE LIQUIDS TO START OR

REKINDLE A SOLID FUEL FIRE!!

2. Fully open the primary draft control by pulling the 1”

plastic knob out on the left side (lower front corner)

until it stops (away from the stove). This control

determines the amount of air entering the stove.

Pushing it toward the stove reduces the burn rate

in the firebox. For your convenience, the rod on this

control is marked with four grooves to assist you in

obtaining repeatable burn rates.

3. Place a small amount of crumpled paper in front of the

firebox and cover it with a few pieces of kindling.

5. For best results, use smaller pieces of wood to get

stove temperature very high before loading larger

wood for sustained burns. If necessary, crack the

door to allow ignition of the fuel charge. Now you can

add larger pieces of wood and after several minutes

of high burn, set the left control for the desired heat

output. Check the exhaust in about 15 to 20 minutes.

Large amounts of smoke indicate an improper burn

setting (either too high or too low). Adjust and recheck

in 5 to 10 minutes.

6. After your stove has been thoroughly preheated, your

blower can be switched on. When refueling your

stove, turn the blower off for the first 30 minutes. On

low and medium-low burns run the blower on low.

These burn rates would be achieved by operating

the stove with the draft rod fully pushed in to up to

3/4” open (out). To do this, turn on the blower at the

speed control and rotate the control all the way to

the right. On medium-high and high burns you may

run the blower on high. These burn rates would be

achieved by opening the draft rod further than stated

previously. To do this, turn on the blower with the

speed control and do not rotate the switch after it

clicks on.

14

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 15

clean glass

SEE MAINTENANCE ON PAGE 17 FOR GLASS CLEANING

TIPS

The operator plays an important part in keeping the glass

clean and free of build-ups. The first and most important part

the operator plays is making sure to burn only well-seasoned

firewood. Wet wood = Dirty glass. Keeping your glass door

clean is partly accomplished by the air wash system of the

stove, which sends clean, fresh air for combustion, over

the window before it enters the fire. The high temperatures

inside the firebox also keep the glass clean. No stove door

stays perfectly clean. The following are methods for keeping build-up on your glass to a minimum. When properly

installed and operated by a knowledgeable operator, your

glass door should require very little maintenance. Do not

expect to get extremely long burn times and keep the window perfectly clean. Cool temperatures cause condensation

of unburned volatiles on the glass. If your glass gets very

dirty during overnight burning, try preheating the stove a

little longer before damping it down for an overnight burn.

Also, don’t damper your stove down as low because you’ll

get more heat for your money by burning a little hotter for

a slightly shorter time.

The air wash system will perform at its best at medium burn

rates. Some stove models will self clean by burning very hot

fires but be sure not to over-fire the stove. If it glows red it

is over-fired. Over-firing a stove also causes the window to

soot up. Extremely hot fires with fresh wood may cause the

flow rate to exceed one foot per second, which is as fast as

a flame can burn. This is why a candle goes out when you

blow on it. Blow on it gently and it burns brightly. Blow on

it hard and it goes out. This will cause excessive exhaust

emissions and your window to soot up, as the stove is unable to burn the gases emitted from the wood. Try slowing

the stove down a little by closing the damper somewhat as

it warms up.

Keeping freshly loaded wood away from the window will also

help. Load fresh logs in the rear of the firebox. Build-up tends

to occur first on the right side of the window. This is caused

by the swirling motion of the exhaust gases similar to water

running down a drain. Keep fresh logs further back on the

right side of the firebox to help prevent this problem.

Understanding how your Country™ Collection stove works

should help you keep your glass door very clean, but as

stated: no glass door stays perfectly clean. We hope this

information is helpful in keeping your glass door clean so

that you may enjoy many hours viewing your high efficiency

stove. For more information, contact your Lennox Hearth

Products dealer.

oPeraTing Techniques anD hinTs

Recent developments in wood-burning technology have

made wood-burning a cleaner and more convenient way to

heat your home. Overall efficiency in a wood-burning appliance is a combination of combustion efficiency and heat

transfer efficiency. Whether heating your entire home, or just

a room or two, your understanding of how to best operate

your stove or insert will enhance its overall efficiency and

performance. What this can mean to you is longer, cleaner

burns, less wood use, and more heat.

geTTing The mosT ouT of your sTove

The following sections will outline techniques you can

use to “get the most out of your stove.” Please read them

carefully.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

15

Page 16

maximizing your sTove’s overall efficiency

It is important to know that for high, combustion efficient,

clean burns, you will need to have sufficient temperatures

inside the firebox for thorough combustion. The best method

for determining if you have sufficient temperatures is to

watch the brick lining in your firebox. When you first light

your stove, the bricks will turn a dark brown or black. After

20 to 30 minutes of a hot fire, most of the bricks should

return to near their original light brown or yellow color. This

means the bricks have reached a high enough temperature

for your stove to achieve high combustion efficiency.

Second, and just as important, is achieving a high level

of heat transfer efficiency. Slowing the rate of flow through

the stove or insert enhances heat transfer, thus allowing

more time for heat to be transferred into your home. To

do this, be sure to thoroughly preheat your stove and then

reduce the amount of primary air by closing the draft control (lower left) to about 1/2 to 3/4 open. This will decrease

the excess oxygen in your flue, which carries heat up your

chimney, but should still be enough air to allow the stove to

produce its maximum heat output. (More air may produce

a lightly greater amount of heat, but will greatly increase

wood consumption). When the area being heated reaches

a comfortable temperature, slow the burn rate by closing

the control to further improve heat transfer.

To get the most out of your Country™ Collection stove,

you will need to combine good combustion efficiency with

good heat transfer practices. The following are some tips

on how to operate your stove to achieve the highest overall

efficiency.

1. Thoroughly preheat your stove before slowing the

burn rate by closing the draft control.

2. Measure the stove temperature at the hottest point on

the stove top or face. Use this information to repeat

burn rates.

3. Once preheated, add wood (if needed) and partially

close the draft control (lower left).

4. Operate your stove as much as possible in the low to

medium burn ranges.

5. Do not lower the draft setting so low as to completely

extinguish the flames in the firebox. Check for at least

some small flames 20 minutes after setting the draft

control.

6. Do not continually operate your stove in the high

(wide open) setting. This wastes wood by carrying

a great deal of heat up the chimney and can damage

your stove and chimney.

7. Go outside and check your chimney. More than a

very small amount of smoke indicates wasted heat,

creosote build-up, and pollution.

achieving clean, long Burns

To achieve long burn times, after having thoroughly preheated the stove, let the stove top cool down to 275 to 400

degrees (on Elites, locate thermometer on the face of the

insert just above the door). Now load the firebox and set the

draft control. At this point, you may need to burn the stove

with the draft open for a few minutes to ignite the wood. All

Country Collection stoves are EPA tested for emissions at low

burn with the air control completely closed. Whether or not

you should burn your stove with the air control completely

closed will depend on the following factors.

16

* How you load your wood.

* Your chimney type, height, and draft.

* Your wood type and its moisture content.

* The temperature of the stove.

* Which model Stove or insert you have.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 17

Experiment with different loading configurations to achieve

longer burns. Try loading the wood from side to side and

nesting it in the ashes to prevent airflow under and around

the wood. Fresh wood should be loaded to the back of the

firebox or to the sides. Hot coals or half burned wood should

be brought towards the front of the firebox. The way you load

your wood can seriously affect burn times. If the new load

does not ignite within a few minutes, try crisscrossing the

load to allow more airflow around the fire, or try a slightly

hotter stove temperature.

Do not reload the stove for long burns when the stainless

secondary tubes or baffle supports are glowing red, or when

the stove is uncomfortably hot to load. This indicates the

stove is too hot to load for a long burn. Also, do not load

wood for a long burn on a deep bed of hot coals. Try stirring

the coals a few minutes before loading the stove for a low

burn to allow some of the unburned coals time to burn.

mainTenance

Determining the lowest setting for efficient low burns. This

will require some experimentation on your part. Try closing

the air control all the way with the stove temperature at 325

to 350 degrees. If the flames are completely extinguished,

open the air control halfway and then slowly close it until

there is only a small amount of flame. It is important to

check the stove about 20 minutes after setting the draft

control as it takes this long for the stove temperature to

stabilize. There should still be some small flames on or

above the wood load.

Use 325 degrees as a starting point

. You can try starting

temperatures 25 degrees higher or lower to achieve desired

burn times, start 25 degrees lower if the stove burns the

wood too quickly or 25 degrees higher if there are no flames

in the firebox for more than a few minutes after loading the

wood. You may or may not need to burn the stove with the

air control open for a few minutes prior to setting the draft

for a low burn, this will depend on the factors mentioned

above. Be sure not to smolder a fire overnight. Check your

chimney for large amounts of smoke as this indicates very

poor combustion.

It is important to realize that stove technology has changed.

Stoves have changed a great deal in the last few years. This

has led to substantial changes in the methods of operation in

new stoves as compared to older stoves. In old stoves without

full brick linings and ceramic insulation, the rule was “get

the stove as hot as possible before setting the draft on low

for overnight burns.” On newer, high technology Country™

Collection stoves, this is not necessary. Although it is still

important to have the stove hot enough to burn efficiently,

it will require less preheating. Once you have determined

your optimum operating temperatures for various burn rates,

we believe you will find your stove an extremely convenient

way to achieve your heating needs.

DOOR HINGES: If door hinges need lubricating, use an antiseize compound (never use oil) available from your Lennox

Hearth Products dealer.

DOOR LATCH:

If your door latch fails to latch tightly and the

gasket is in good condition, place a length of pipe (cheater

bar) over the inside portion of the door handle and bend

slightly toward the door until the proper

adjustment is obtained. If the door handle does not close

easily, apply high temperature anti-seize to the striker.

DOOR GASKET:

Periodically check gasket to make sure it is

not over-compressed. If compressed, replace with a special

woven Door Rope. (Don’t try substituting rope, only use

special Lennox Hearth Products Door Rope).

GOLD OR NICKEL PLATED DOOR:

Clean only with WINDEX brand glass cleaner and a very soft cotton cloth. Other

products may damage brass, paint, and gaskets.

INSULATING BLANKETS: Your insulating blanket should be

inspected during every chimney cleaning. If the blanket is

compressed or heavily stained, it should be replaced. Heavy

creosote stains or matting is an indication of improper use

and your burning habits should be reviewed.

GLASS CLEANING:

Only clean glass with products specifically made to use on wood stoves. Other products could

damage gaskets and paint. Never scrape glass with a razor

blade. This can pit the glass and make it impossible to clean

in the future.

WINDOW GASKET: The window gasket can be checked by

running the flame of a match near the gasket and

around the door. If the flame is drawn in around the window,

the gasket should be replaced.

DOOR HANDLE: Door handle may become tight as you

use the stove. Free the handle up by using dry graphite

supplied with the stove. The directions are included with

the graphite.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

17

Page 18

TrouBleshooTing

ProBlem soluTion

POOR DRAFT: Extend chimney in length or have the chimney realigned to the proper size flue. Oversized

chimneys normally have poor drafts. Remember, the stoves’ draft depend solely on the natural

draft of the chimney (See Drafting section on page 4). If your stove is not drafting properly,

your chimney is the problem. All stoves are thoroughly tested to ensure proper draft with the

correct size chimney flue.

EXCESSIVE DRAFT: With better chimneys being more common, excessive draft can be an issue. Alleviate excessive

draft by slowing the burn rate of the stove once it has reached proper operating temperature

(See Maximizing Your Stoves Overall Efficiency on page 16).

DIRTY GLASS: 1) Burn smaller, hotter fires and check to make sure you are not setting the draft down too far

with the draft control.

2) Make sure your wood is well-seasoned and dry (not open to rain - see Creosote and Fuel

sections on page 3).

3) See Poor Draft section (above) and Clean Glass on page 15 .

SMOKES WHEN 1) If smoke is entering the room, check to make sure your baffle bricks are properly installed

DOOR IS OPEN: and that the insulating blanket is pushed back flush with the front of the baffle brick.

2) Check the chimney for blockage due to creosote (see Chimney & Creosote sections on

pages 3 and 4).

3) Check draft (See POOR DRAFT section above).

WOOD BURNS 1) The draft control must be closed further.

TOO FAST: 2) Add fuel at lower firebox temperatures.

3) Load wood side to side and reduce the flow of air under wood.

4) The door seal may need replacing, check for leakage.

5) See “Excessive Draft.”

POOR HEAT 1) Check your wood. Wet, moist, unseasoned wood will not produce heat.

OUTPUT: 2) Your stove needs to be seasoned (moisture removed from the steel and brick). Continue

to burn a fire. It normally takes from one to three weeks of burning to season your stove (See

Break-in Procedures on page 5).

3) See Excessive Draft section above.

PAINT GIVES OFF Paint is tempering-in. Burn only moderately hot for the first few days until paint is fully cured.

ODOR (smoke):

Then burn a very hot fire to cure any paint that may not easily cure. Open windows or door to

ventilate (See Break-in Procedures on page 5).

18

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 19

Do’s anD Don’Ts

DO NOT: Install or operate this stove before reading this manual.

DO NOT: Close the draft beyond the point at which the flames are completely extinguished.

DO NOT: Open the stove door without fully opening the draft first.

DO NOT: Burn driftwood or wood that has been in salt water. This includes some mill ends and scrap lumber that

has been floated in salt water on the way to the mill. (This will void your warranty).

DO NOT: Handle the Nickel or Gold faceplate unnecessarily. Use the door handle only.

DO NOT: Force oversized logs into the firebox as this may dislodge the baffle assembly.

DO NOT: Close the door tightly during break-in period.

DO: Be sure to clean any fingerprints from the Gold or Nickel faceplate before burning the stove. Clean the

Gold or Nickel door only with Windex and a very soft cloth.

DO: Consult local building department if other than recommended clearances are desired.

DO: Read instructions for the brick baffles occasionally to ensure you have not bumped or moved them out

of place when loading wood.

DO: Check the chimney and baffle a minimum of every 3 months to make sure they are clean.

DO: Burn seasoned, dry wood only! (RAIN = WET WOOD)

DO: Complete and return your warranty card.

DO: Open the door frequently during break-in period to keep gasket from adhering to the curing paint.

DO: Enjoy the warm feeling of your new Country™ Collection stove.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

19

Page 20

The manufacturer reserves the right to make changes at any time, without notice, in design,

materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local distributor for fireplace code information.

Printed in U.S.A. © 2007 by Lennox Hearth Products

P/N 775,214M REV. B 09/2007

1110 West Taft Avenue • Orange, CA 92865

Loading...

Loading...