Lennox PureAir PCO3S-14-16, PureAir PCO3S-20-16, PureAir PCO3S-16-16 Installation Instructions Manual

Page 1

AIR CLEANERS / FILTERS

©

2018 Lennox Industries Inc.

Dallas, Texas, USA

INSTALLATION INSTRUCTIONS FOR

MODELS PCO3S-14-16, PCO3S-16-16 AND PCO3S-20-16

THIS MANUAL MUST BE LEFT WITH THE OWNER FOR FUTURE REFERENCE

507785-01

2/2018

PureAir™ S

Air Purication System

CAUTION

UVA Lamp contains mercury.

Ingestion of or contact with mercury or mercury vapor is

hazardous to your health.

Take care when handling UVA lamp. If UVA lamp is broken,

avoid contact with mercury.

WARNING

Electric shock hazard.

Can cause injury or death.

Disconnect all electrical power supplies before servicing.

Access panels must be in place during appliance

operation.

Table of Contents

Shipping and Packing List ...........................................2

Models ...........................................................................2

Application ....................................................................2

Parts Identication .......................................................3

Dimensions and Specications ..................................4

Installation Examples ...................................................6

Unique Field-Supplied Installation Items .....................7

Installation .....................................................................7

Selecting Location .......................................................7

Installing Cabinet .........................................................7

Installing UVA Lamp ....................................................7

Installing UVA Lampholder ..........................................8

Installing Air Filter ........................................................8

Wiring ............................................................................9

Communication Wiring ................................................9

Communication Wiring Routing ...................................9

PureAir S Internal Factory Wiring ................................9

Communicating Control Functions ..........................10

PCO Model (H2) Jumpers .........................................10

Change Lamp Reset (SW1) ......................................10

Change Filter Reset (SW2) .......................................10

Control Manual Reset ...............................................10

Lennox S30 Thermostat Setup ..................................10

System Setup (Commissioning) ................................10

Reminders .................................................................11

Adding PureAir S to Existing System ........................11

Dealer Control Center ................................................11

Notications (Alert Codes) ........................................12

Tests and Diagnostics Function ................................12

Installation Report .....................................................12

Alert Codes .................................................................12

Soft Disable ...............................................................12

Alert Code Types .......................................................13

Operation .....................................................................14

Filter, UVA Lampholder / PCO Cartridge and

UVA Lamp Replacement ............................................15

Annual Maintenance Kits ...........................................15

Replacement Parts .....................................................15

Removing and Installing UVA Lamp,

Lampholder and Air Filter ..........................................15

Proper Clean-Up of Broken UVA Lamp .....................16

Troubleshooting Flow Chart ......................................16

Page 2

Shipping and Packing List

Assembled PureAir S air purication system which includes:

• Cabinet (1)

• UVA Lampholder / PCO cartridge (secure to interior

of cabinet) (1)

• UVA lamp in box (secure to interior of cabinet) (1)

• Healthy Climate® Carbon Clean 16® Filter (located in

interior of cabinet) (1)

• UVA lamp socket with 4-pin male connector assembly

attached to light ballast electrical connector (1)

• Lennox Communication Control interface.

• Literature bag includes power cord (120VAC)1, instal-

lation instruction, UVA Lamp Socket brass nger nuts

(2), UVA Lampholder / PCO cartridge wing nuts (2)

and warranty.

1

230VAC power cord available separately (part number

91X44).

Check equipment for shipping damage. If damage is found,

immediately contact last carrier.

Models

Table 1. Unit Catalog Numbers

Model Catalog Number

PCO3S-14-16 Y8905

PCO3S-16-16 Y8904

PCO3S-20-16 Y8903

The iComfort S30 Ultra Smart Thermostat will require

rmware version 3.4 or higher to take advantage of all of

the PureAir S features.

New features included are:

• 4-wire connection to Lennox communicating indoor

unit control

• Using sensors to:

> Automatically detect dirty air lter

> Display air lter life percentage

> Monitor UVA lamp operational state (On or Off).

> Display UVA lamp life percentage

IMPORTANT

Oil on metal ducts may cause odors.

Use a mild soap and water solution to remove oils from

transitions and duct surfaces prior to installation.

IMPORTANT

Do not use any form of silicone sealant.

Use of silicone-based products will reduce the

effectiveness of, or damage the titanium dioxide coatings

on the PCO cartridge.

IMPORTANT

Route power cord away from trafc areas where the cord

may become a safety hazard.

Application

The PureAir S air purication system uses photocatalytic

oxidation (PCO) technology to reduce levels of airborne

volatile organic compounds, cooking odors, common

household odors, airborne dust particles, mold spores and

pollen. Each unit may be connected to either 120VAC or

230VAC power supply.

Lab tests conrm a 50% reduction in total volatile organic

compounds (TVOC) within the rst 24 hours of initial

operation of the PureAir S air purication system. It may

take up to 48 hours after initial system start-up to reduce

the airborne chemicals that have built up in a home over a

long period of time.

For peak performance, unit should be installed in homes

with TVOC levels that are less than 1000 micro-gram /

cubic meter. Home source removal and ventilation may be

required to lower total volatile organic compounds to this

level.

The Healthy Climate® Carbon Clean 16® Filter combines

industry-leading MERV 16 ltration and carbon-coated ber

matrix.

For full feature benets, the PureAir S must be used with

an S30 Ultra Smart Thermostat and communicating indoor

unit.

IMPORTANT

UVA lamp life is shortened when lamp is turned off and on.

Power to unit must remain on at all times.

Do not interlock lamp operation with air handler blower

operation.

CAUTION

Ultraviolet (UVA) radiation risk.

Prolonged exposure may cause skin or eye damage.

Avoid prolonged (weeks) exposure to skin or eyes.

WARNING

Risk of carbon monoxide poisoning.

Can cause injury or death.

Do not operate system unless access panel is in place

and properly secured. Operation of this equipment without

the access panel in place may cause exhaust fumes to be

drawn into occupied spaces.

2

Page 3

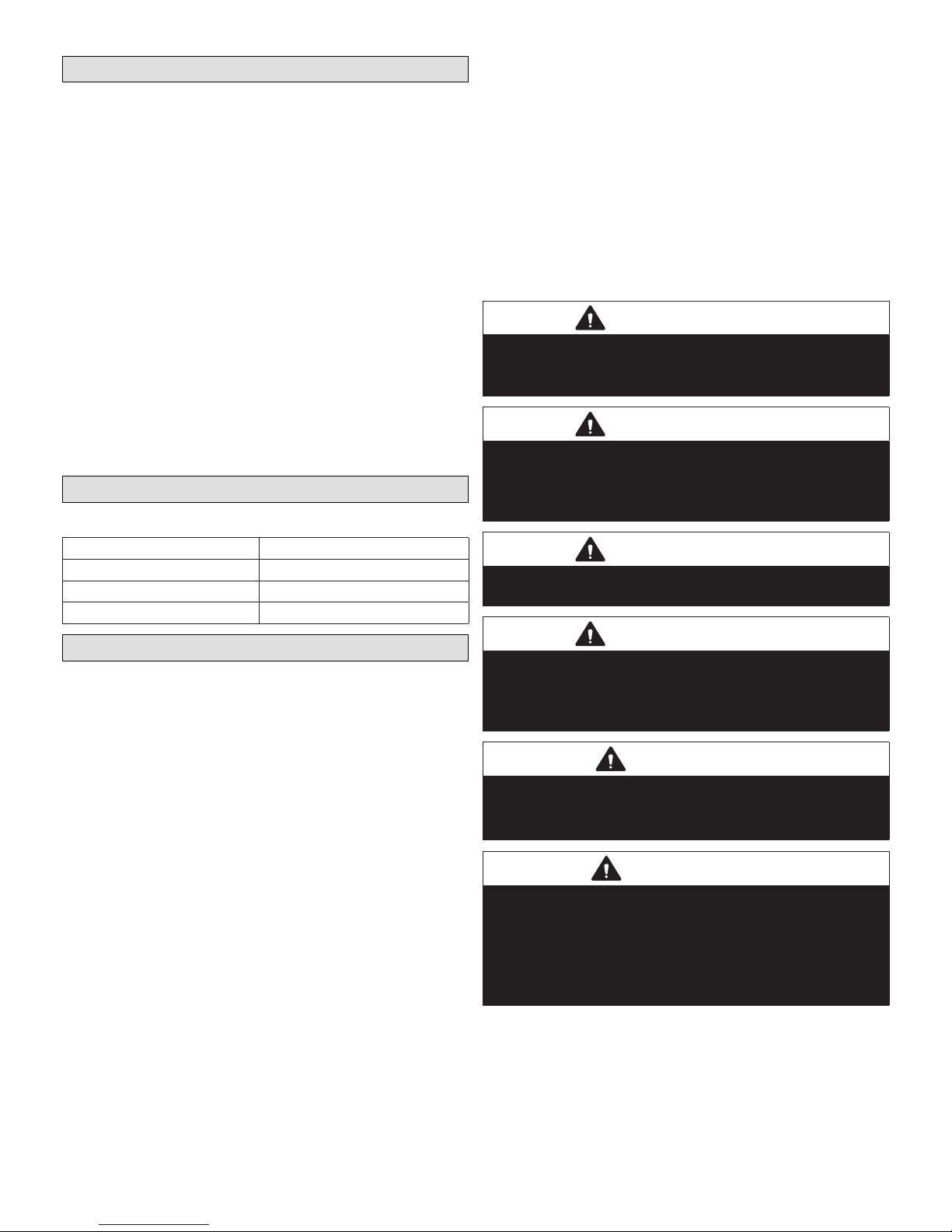

Parts Identication

Power Cord Opening

UVA Lamp Viewer

A

ccess Panel

UVA Lamp

UVA Lamp Light Sensor

UVA Lampholder /

PCO Cartridge

UVA Lampholder /

PCO Cartridge Rear

Mounting Bracket

Healthy Climate Carbon

Clean 16 Air Filter

Cabinet

Communication Control

UVA Lamp Electrical Connector

UVA Lamp Ballast

Figure 1. Parts Identication

CAUTION

Sharp edges hazard.

Sharp edges can cause injuries.

Use protective gloves when grasping equipment edges.

3

Page 4

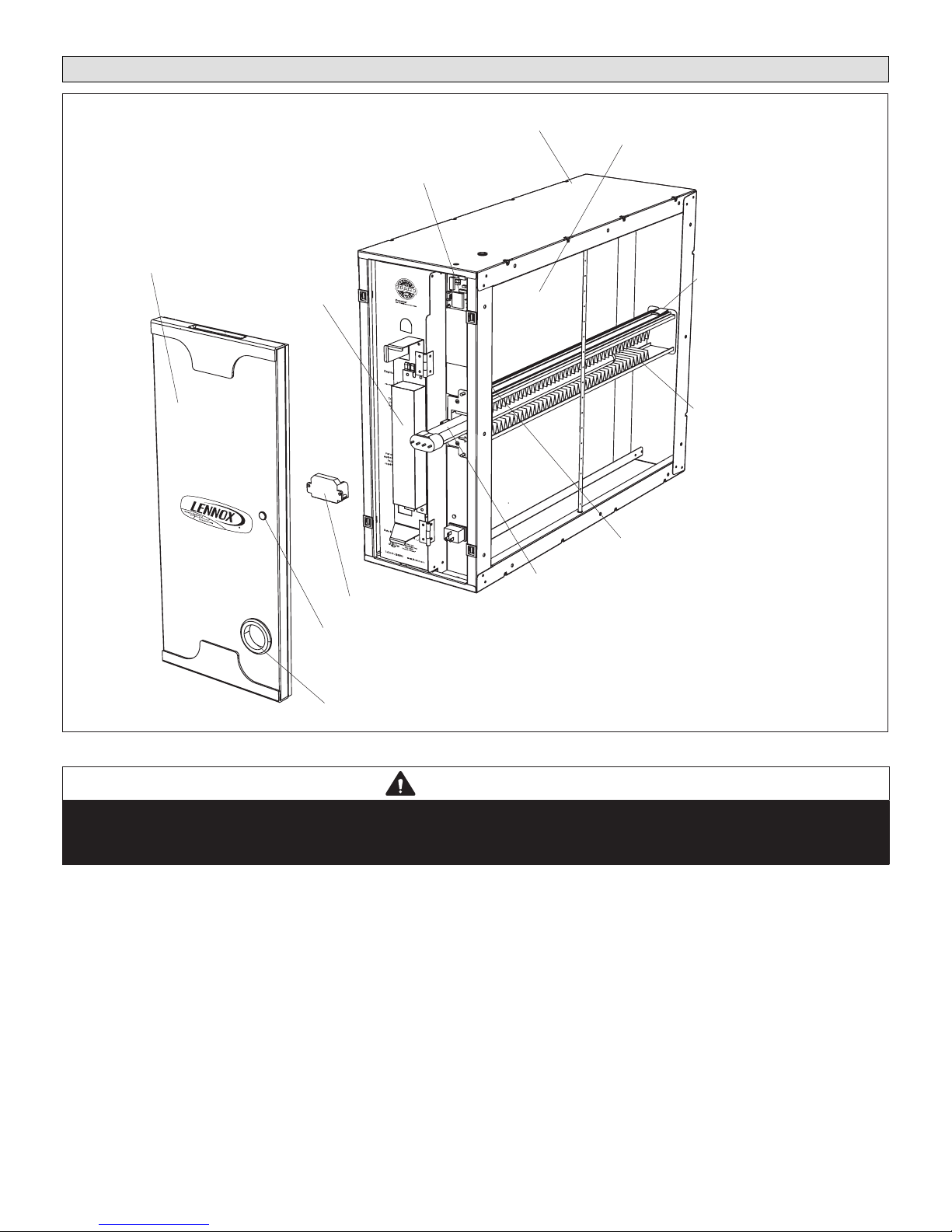

Dimensions and Specications

top for bottom.

8-3/4

(222)

11/16

(17)

1-3/4

(33)

1-3/4

(33)

1-5/16 (33)

1-5/16 (33)

INLET AND OUTLET

OPENING

SAME SIZE

A

B

C

D

1

AIR FLOW

Power

Connection

UVA Lamp

Sight Glass

1

NOTE - Airflow may be reversed by rotating the unit

E

Model No.

AB CDE

inches mm inches mm inches mm inches mm inches mm

PCO3S-14-16 23-3/4 603 23 584 20-1/4 51421-1/8537 18-1/2 470

PCO3S-16-16 26-1/2 673 25-3/4 654 23 58417-1/2445 14-5/8 371

PCO3S-20-16 26-1/2 673 25-3/4 654 23 58421-1/8537 18-1/2 470

Dimensions

specifications

Model

PCO3S-14-16 24

PCO3S-16-16 27

PCO3S-20-16 27

Weight

(lbs.)

Electrical

120V, 50/60 Hz, 0.48 Amps

-- Maximum

or

230 V, 50/60 Hz, 0.24 Amps

-- Maximum

Figure 2. Dimensions

Table 2. Specications

Power

Consumption

120VAC and

230VAC - 58

Watts Nominal

0°F to 140°F outside

10 to 60 percent relative

(Optimal performance

at 50 percent relative

Operating

Environment

of duct

humidity

humidity)

Pleated Filter

Efciency

Minimum

Efciency

Rating Value

(MERV) 16

Listings

ETL safety listing

report 3061144A.

Conforms to UL

STD 1598

Certied to CSA

STD C22.2 no.

250.0.

4

Page 5

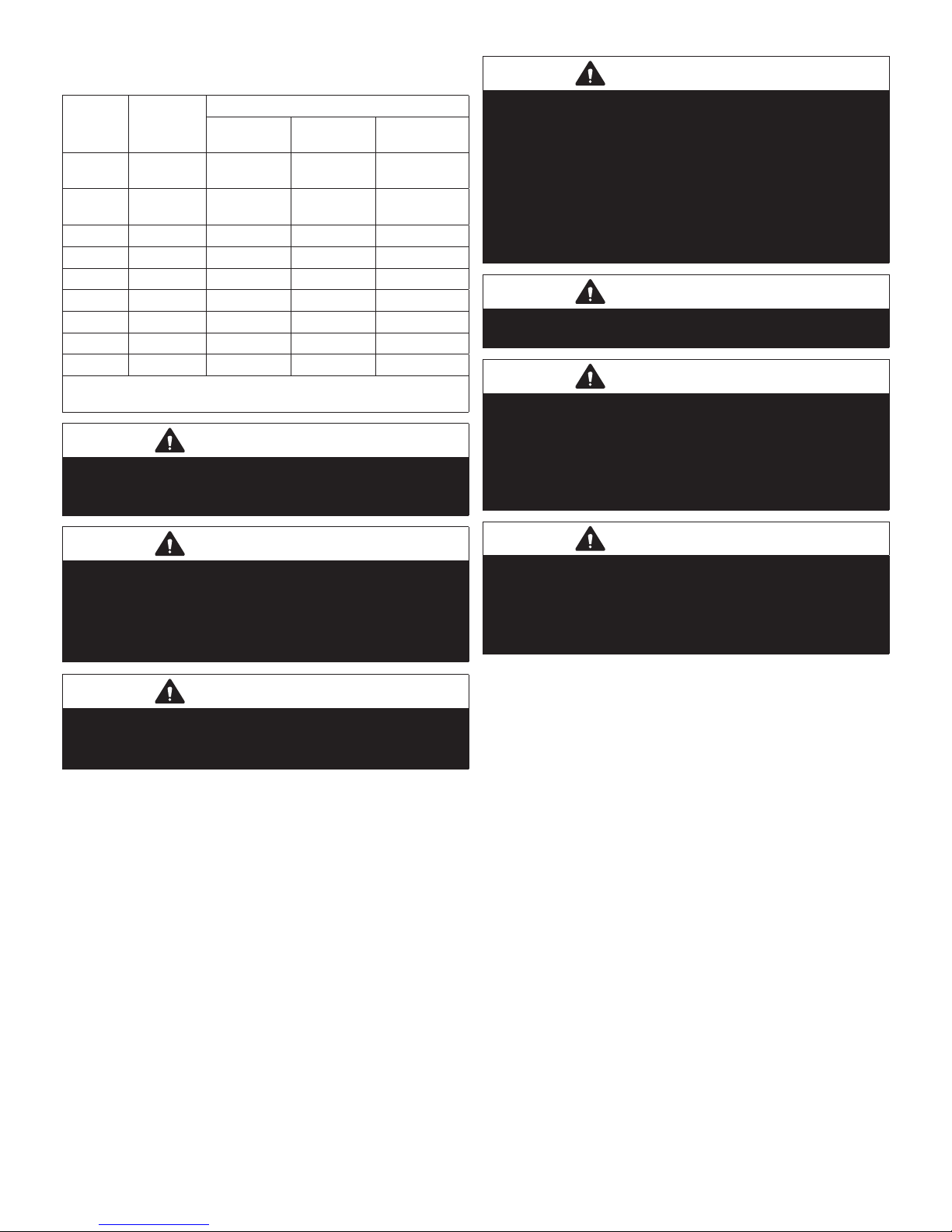

Table 3. Approximate Air Flow Resistance

(Cabinet and Filter)

Capacity

(Tons)

Low /

Variable

Low /

Variable

2.5 1000 0.15 0.15 0.11

3.5 1400 0.25 0.25 0.18

4.5 1800 * * 0.27

*Not recommended. Excessive system pressure drop can damage

HVAC system and reduce performance.

Flow Rate

(CFM)

400 0.05 0.04 0.03

600 0.07 0.07 0.06

2 800 0.11 0.11 0.08

3 1200 0.20 0.20 0.15

4 1600 * 0.31 0.22

5 2000 * * 0.31

PCO3S-14-16 PCO3S-16-16 PCO3S-20-16

Pressure Drop (in. w.g.)

IMPORTANT

Do not wash UVA Lampholder / PCO cartridge. Soap and

water will destroy the titanium dioxide catalyst that coats

the cartridge surface.

IMPORTANT

Possible odor emissions. Chemical reactions may

cause temporary odors after initial start-up or after lamp

replacement. Odor may also be present after paint,

cleaning solutions or hobby materials have been used in

the conditioned space.

Some occupants may experience irritation or discomfort

during this period. If the irritation or discomfort lasts longer

than 48 hours, the homeowner should be advised to

contact a Lennox dealer.

IMPORTANT

The cabinet should be installed so that the UVA lamp will

be in the horizontal position.

IMPORTANT

This system is NOT intended to be used for removal of

active mold growth or continuous sources of high levels of

chemicals in the air.

For existing mold growth, the mold must be properly

removed PRIOR to installation of the PureAir S air

purication system.

IMPORTANT

Unpacking required.

Remove all protective packing material from the UVA

lamp (taped to the cabinet) and the titanium dioxide PCO

cartridge.

Packing material should be disposed of properly.

IMPORTANT

Healthy Climate® Carbon Clean 16® Filter cannot tolerate

direct exposure to UVA light.

Filter is protected by PCO cartridge shield.

IMPORTANT

This appliance is intended for return air duct installation

only.

Improper installation may damage PureAir S air purication

system, HVAC system, or other equipment and may also

void warranty.

5

Page 6

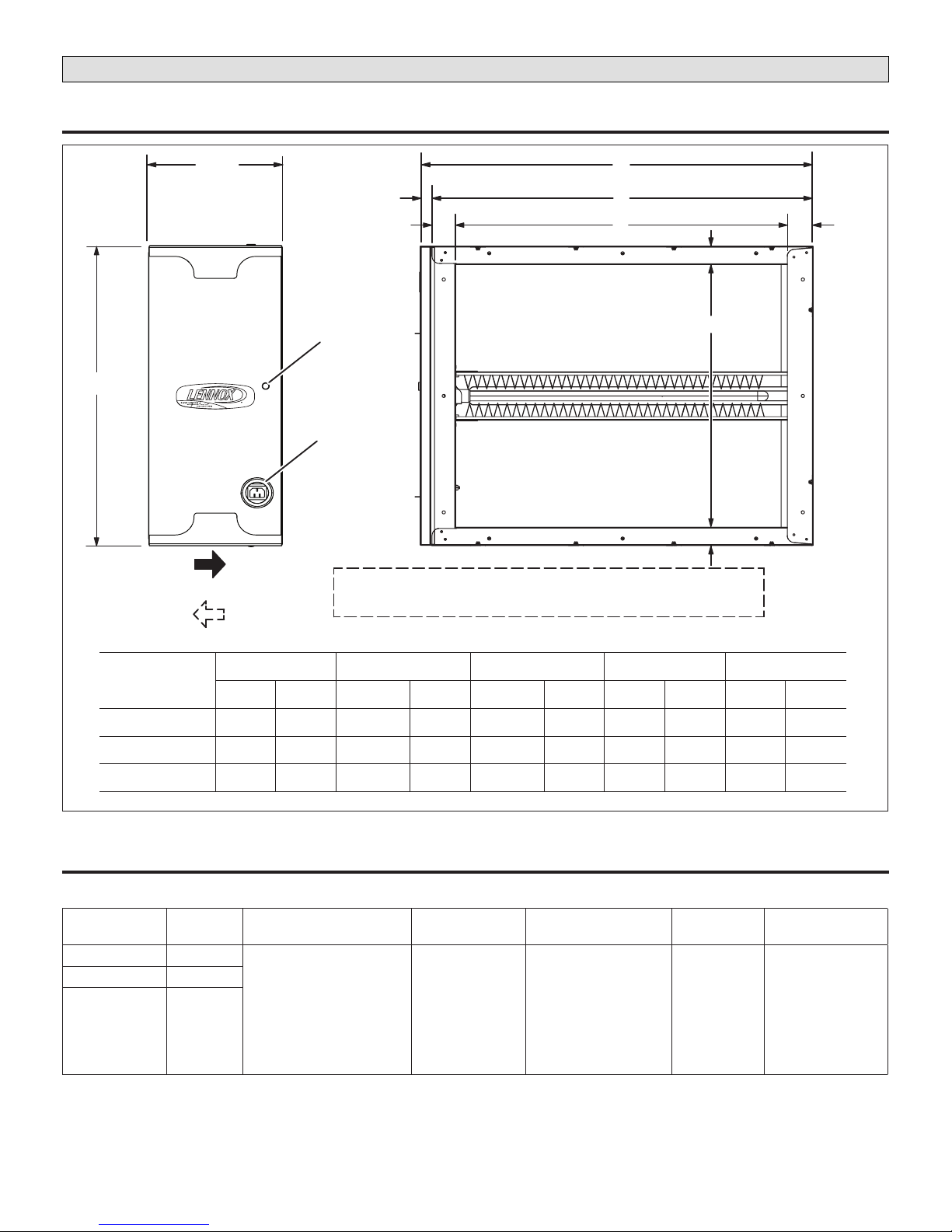

Installation Examples

UPFLOW FURNACE/AIR HANDLER

UPFLOW FURNACE

(Bottom Return Air)

SUPPLY

DUCT

RETURN

DUCT

DOWNFLOW FURNACE/AIR HANDLER

RETURN

DUCT

PCO3S

PCO3S

(Side Return Air − up to 4 ton)

RETURN

DUCT

PCO3S

UPFLOW FURNACE

(Option 1 − Side Return Air − 5 ton)

(With Optional RAB Return Air Base)

SUPPLY

DUCT

SUPPLY

DUCT

RETURN

DUCT

SUPPLY

DUCT

HORIZONTAL FURNACE/AIR HANDLER

DUCT TRANSIITON

SUPPLY DUCT

(Field Furnished)

FURNACE OR

AIR HANDLER

NOTE: Lennox badge can be rotated 180 degrees

for this application.

PCO3S

RETURN DUCT

OPTIONAL

RAB RETURN

AIR BASE

PCO3S

NOTE: Lennox badge can be rotated 180 degrees

for this application.

UPFLOW FURNACE

(Option 2 − Side Return Air − 5 ton)

(Modified Return Air Opening)

Figure 3. Installation Examples

6

Page 7

UniqUe fielD-sUpplieD installation items

Allow Approximately

30” (76cm) of Clearance

The following items are recommended to have on-hand for

installation of the unit.

• Cotton gloves and cloth (to remove nger prints from

UVA lamp)

• Aluminum foil tape or water-based mastic (NOT silicone) to be applied as a sealant.

Installation

selecting location

The unit must be installed in the return air duct upstream of

the supply blower. Allow a 30” (76cm) service clearance in

front of the access panel as shown in gure 4. The air lter

and UVA Lampholder / PCO cartridge must be removable.

5. Use eld-provided aluminum foil tape or water-based

mastic to seal all joints between the cabinet, air handler

and duct.

6. In high humidity applications, wrap cabinet with eld-

provided 2” (50mm) foil-faced insulation (foil on the

outside) to prevent condensation.

installing UVa lamp

Use cotton gloves or a cotton cloth to protect the lamp and

your hands during unpacking and installation.

1. Remove cabinet access panel.

2. The UVA Lampholder / PCO cartridge is shipped in a

protective packaging. Packaging must be removed

prior to installation. Take care to prevent damage while

removing from packaging.

3. Locate the UVA lamp box, which is taped to the inside of

cabinet and carefully remove. Set UVA lamp box aside

while preparing cabinet for UVA lamp installation.

4. Remove (slide out) Healthy Climate® Carbon Clean 16®

Filter from cabinet.

5. Disconnect the lampholder cable assembly from the

UVA lamp ballast connector.

6. Carefully remove lamp from UVA lamp box and secure

the UVA lamp electrical connector to the UVA lamp by

sliding the UVA lamp pins into the slot. Proper connection

will make a snapping sound.

Figure 4. Service Clearance

installing cabinet

The cabinet may either be installed on a level installation

deck or platform adjacent to the air handler or it may be

suspended from the rafters using metal strapping. If straps

are used, take care when attaching straps to the cabinet.

Ensure fasteners do not interfere with internal components

of the cabinet. The air lter and UVA Lampholder / PCO

cartridge must be able to slide freely into the cabinet.

1. Locate and remove the UVA Lampholder / PCO cartridge

from the cabinet.

NOTE: Oil on metal surfaces may cause odors. Use mild

soap and water solution to wash all new duct and

transition surfaces.

2. Use the air ow directional label on the inside of the UVA

Lampholder / PCO cartridge to orient the unit.

3. Properly position the cabinet next to the return air

opening of the air handling unit. Use sheet metal screws

1” (25mm) maximum length, rivets or other appropriate

fasteners to secure cabinet to the return air side of the

air handling unit.

4. Use eld-provided sheet metal screws 1” (25mm)

maximum length to fasten the return air duct to the other

side of the cabinet. Attachment holes are provided in

housing.

DEPRESS RED BUTTON

ONLY TO RELEASE UVA

LAMP FROM SOCKET.

Figure 5. Releasing UVA Lamp from Socket

7. Slide the UVA lamp into UVA Lampholder / PCO

cartridge. Verify that the UVA lamp is secure to the one

metal UVA lamp clamp located mid-way on the UVA

lamp reector.

METAL UVA LAMP

CLAMP

UVA LAMP REFLECTOR

Figure 6. UVA Lamp Metal Clamp

7

Page 8

8. Rotate the hinged control panel assembly out.

ROTATE OUT THE

CONTROL PANEL

ASSEMBLY

BRASS FINGER

NUTS

A

IRFLOW

INDICATOR

WING

NUTS

BALLAST FOUR PIN

FEMALE CONNECTOR

LAMPHOLDER

ASSEMBLY

(Y6622)

Figure 7. Rotate Out Control Panel Assembly

9. Thread the UVA Lampholder / PCO cartridge two posts

through the UVA lamp connector’s two holes.

10. Fasten the lamp socket to the UVA Lampholder / PCO

cartridge using the two-brass nger nuts located in the

literature bag.

NOTE: There is an arrow on the front of the component

indicating the correct way to install it.

3. Connect UVA lamp 4-pin male connector to ballast

female 4-pin connector.

Figure 9. Ballast 4-Pin Female Connector

4. Rotate hinged control panel assembly back into the

cabinet. Make sure no wiring is being pinched.

installing air filter

Use the following procedure to install the air lter.

1. Slide the Healthy Climate® Carbon Clean 16® Filter into

the rails on the air inlet side of the cabinet. Verify proper

airow direction.

2. Securely fasten the access panel.

3. Plug one end of the provided power cord into the

receptacle on the cabinet and the other end into a power

receptacle.

4. Look through the view port in the access panel to check

that the UVA lamp is illuminated.

NOTE: On initial start-up, the UVA lamp may not reach full

illumination for several minutes.

Figure 8. Brass Finger and Wing Nuts

installing UVa lampholDer

Use the following procedure to install the UVA Lampholder

/ PCO cartridge.

1. While aligning, slide the UVA Lampholder / PCO

cartridge into case rails and align with rear mounting

bracket.

2. Secure the UVA Lampholder / PCO cartridge to the two

frame screw posts using the provided wing nuts (2).

8

Page 9

Wiring

Unused wires

Single wire

to terminal “C”.

Indoor Unit Controller

PureAir S

KEYCOMPONENT

DS1UVA LAMP / LAMPHOLDER

P15PLUG

R15RECEP TACLE

L31BAL LAST

J12JACK

FB1FERRI TE BEAD

A17MAIN SENSOR BOARD

A18UVA SENSOR BOARD

W19INT ERCONNECT WIRE

LEGEND

Figure 10. Communicating and Low Voltage Connections

commUnication Wiring

Communicating systems requires four thermostat wires

between the PureAir S and the Lennox Communicating

Indoor Control. When a thermostat cable with more

than four wires is used, the extra wires must be properly

connected to avoid electrical noise. The wires must not be

left disconnected. See “Figure 10. Communicating and Low

Voltage Connections”.

• Use wire nuts to bundle the unused wires at each end of

the cable. A single wire should then be connected to the

indoor unit end of the wire bundle and attached to the “C”

terminals.

• Keep all communication wiring as far away from the

house electrical wiring and large electrical appliances as

possible. Recommended minimal distance is 15 feet (5

meters).

commUnication Wiring roUting

Communication wiring to the indoor unit is routed through

the opening in the top of the cabinet as illustrated below.

Route communication wiring through

grommet to indoor unit

pUreair S internal factory Wiring

The should be wired in accordance with national and local

codes.

iComfort Communicating

PCO Control

Figure 11. Routing of Communication Wiring

Figure 12. PCO Wiring Schematic

9

Page 10

Communicating Control Functions

14-16

Jumper Setting

16-16

20-16

Jumper

pco moDel (h2) JUmpers

A series of jumpers is used to select which size pure air the

control is installed.

Jumper selections are:

• Position 1 (pins 1 and 2 shorted): 14-16 (nominal airow

= 1400cfm)

• Position 2 (pins 2 and 3 shorted): 16-16 (nominal airow

= 1600cfm)

• Position 3 (pins 3 and 4 shorted): 20-16 (nominal airow

= 2000cfm)

NOTE: The correct size selection should already be set

from the factory.

Jumper Setting

Jumper Setting

Figure 13. Model Jumper Selection

change lamp reset (sW1)

After bulb replacement, press and hold for three seconds

SW1 - Change Lamp button. This resets the system.

A LED will start to ash after three seconds to indicate the

reset was successful.

change filter reset (sW2)

After air lter replacement, press and hold for three seconds

SW2 - Change Filter. This resets the system.

A LED will start to ash after three seconds to indicate the

reset was successful.

Figure 14. PureAir S Communicating Control

control manUal reset

When pressing both the SW1 and SW2 switches at the

same time for ten seconds will reset the control to factory

default.

Control can also be reset by using the S30 thermostat. Go

to menu > settings > advanced settings > view dealer

control center > equipment > reset > reset HVAC

equipment.

Lennox S30 Thermostat Setup

system setUp (commissioning)

During the initial or rerunning the commissioning of the

system using the iComfort S30 Ultra Smart thermostat, the

system will auto-detect the presence of the PureAir S unit.

Follow the instructions provided with the thermostat for the

system commissioning process. If the PureAir S component

is successfully detected, it will appear on the found

equipment screen.

welcome to iComfort

10

system

Smart Hub

Air Handler

CBX40UHV-060; 1

equipment found

non-communicating

+/-

equipment

Heat Pump

XP25-060-230

Thermostat

104553-01

previous continue

PureAir

PCO3S16-16

Mag-Mount

1045498-01

Figure 15. Equipment Found

Page 11

reminDers

disabled

Please verify or modify reminder settings.

done

PureAir maintenance

calendar time

sensor-based

run-time

aDDing pUreair S to existing system

Default setting is sensor-based. Additional options are

calendar time, run-time or disabled. On the reminder screen,

select PureAir S maintenance to change the option.

Once the PureAir S accessory has been installed and

system powered up, go to the thermostat. From the

thermostat to go to menu > settings > advanced settings

> view dealer control center > equipment and select

reset. From the reset list, select re-congure system. This

will tell the system to reboot and search for new equipment

attached to the system.

Follow the commissioning screens to the equipment

found screen, verify that the PureAir S accessory has

been detected and added to the system (see “Figure 15.

Equipment Found” on page 10).

NOTE: The Lennox S30 thermostat must have rmware

version 3.4 or later for compatibility with Lennox

Pure Air S Air Purication System.

Figure 16. PureAir S Maintenance Setting

Dealer Control Center

The Dealer Control Center menu provides access for the installer or service technician to perform various functions.

Advance equipment congurations, notications, tests, diagnostics, installation reports and general information about the

system. Go to menu > settings > advanced settings > view dealer control center.

<

“Previous Screen

<

Name”

Use to make changes to equipment settings and add or remove

non-communicating equipment or accessories. In addition the reset all

equipment option is available. This will allow the installer to reset all

To navigate back to the dealer control center,

touch on the Dave Lennox icon when available

on the top left-hand side of the screen.

To navigate back to the previous screen, touch

on the left arrow when available.

system notifications

equipment and reconfigure.

Use to display

Use to run test on

system components

notifications

tests

diagnostics

Use to run

diagnostics on

system components

dealer

control center

equipment

exit

Exit to Home

screen.

Figure 17. Dealer Control Center

installation

report

information

Used to display installation results.

NOTE: This report is not available until after

exiting the dealer control center following the

commissioning procedure. Exit and return to

the dealer control center to view the installation

report.

Use to display

system information

11

Page 12

pUreair S eqUipment parameters

The following is a complete list of all possible parameters listed under System. Parameters actually available are dependent

on the Lennox communicating equipment type detected and non-communicating equipment added.

From the Dealer Control Center Screen, go to equipment > PureAir. There you will nd the applicable parameter settings

for PureAir S.

Table 1. PureAir S Parameters

Parameter Description

Equipment PureAir Filter

Default: ON. Options are either ON or OFF. Alarms 503 and 504 will not be displayed when this parameter is set to OFF.

The diagnostics screen on the thermostat will continue to show values for both lter life and UV lamp life regardless of

the value of this parameter.

Dirty Filter and UV

Life Detection

Max Air Filtered

between Tests

UV lamp operation

detection

Filter Life Provides percentage of remaining lter life. This is for display purposes only and cannot be changed.

Last replacement

date for lter

Purier life

Last replacement date

for purier insert

• reset PureAir S will reset all PureAir S parameters back to factory defaults.

• reset purier insert will reset it to 100%. This is usually accomplished after the UVA Lamp / PCO cartridge insert has been replaced.

• reset lter will reset it to 100%. This is usually accomplished after the air lter has been replaced.

This parameter turns on and off the lter life and UV lamp life reporting. When set to off, the control will continue to

calculate the remaining lter life through continuous sampling, but will not use lter tests to determine lter life. The

control will:

• Perform a lter calibration upon indication of a lter change regardless of the value of this parameter.

• Perform a UV lamp calibration upon indication of a lamp change regardless of the value of this parameter.

• Will calculate UV lamp life remaining regardless of the value of this parameter.

Default is 100%, Range is 50% to 100% Changes can be made in increments of 10%.

This parameter modies the amount of air that is allowed to pass through the lter after a valid % life determination

before a lter test is initiated.

This parameter is expressed as a percentage of the cubic feet of air that would pass through the lter if the fan operated

at continuous fan CFM for 30 days.

Default: ON. Options are either ON or OFF.

Date last lter reset was accomplished. This is for display purposes only and cannot be changed

Provides percentage of remaining purier life. This is for display purposes only and cannot be changed

NOTE: Purier life is referring to the UVA Lamp / PCO cartridge insert.

Date last purier insert reset was accomplished. This is for display purposes only and cannot be changed

notifications (alert coDes)

The thermostat’s notication screens provide information

on active notications and previously cleared notications.

When selecting either a cleared or active notication a brief

description and alert code will be displayed. Notications are

categorized by system, indoor unit (air handler or furnace),

outdoor unit (air conditioner or heat pump), zoning control (if

installed) and thermostat.

tests anD Diagnostics fUnction

There are no installer tests or diagnostic features available

for the PureAir S accessory.

installation report

PureAir S accessory information includes equipment name,

model number, serial number and rmware version.

In addition, when selecting PureAir S, lter life, last

replacement date for lter and purier life and last

replacement date for purier information is available.

3/15/2017

3/15/2017

Overview

System

Air Conditioner

Furnace

PureAir

installation report

filter life 100%

last replacement date for filter

purifier life 100%

last replacement date for purifier 3/15/2017

Figure 18. Installation Report

Alert Codes

soft Disable

Soft disabling is when the thermostat nds an unknown

control on the system communication bus. The thermostat

sends the unknown control a message to go into soft

12

Page 13

disable mode until the component is properly congured

or removed.

The thermostat will not show any code for a soft disabled

control. When soft disabling occurs only the control that

has been disabled will display the blinking LED status.

Refer to the device’s installation and setup guide for

further guidance.

Conrm proper wiring between all devices such as

thermostat, PureAir S and Smart Hub.

Cycle power to the PureAir S.

1. Go to the menu > settings > advanced settings

> view dealer control center. Touch proceed to

continue.

2. Select equipment.

3. Touch reset.

alert coDe types

To expand a specication notication to access a more

detail description of the alert code, press the down arrow

to expand the description.

Critical alerts are displayed on Home (user) screen, in the

Homeowner alert button, and in the Installer alert button.

Critical means that a service call is needed to get the

system running.

Minor and Moderate alerts are found only in the Installer

alert button.

What does minor and moderate mean?

• Minor is information only, helps Lennox interpret

test results, understand complicated behavior.

• Moderate means that the system will likely recover

on its own, no action necessary.

• Communication System: When communication

controls are operating in a communication system,

all jumper and link setting on controls are ignored.

Jumpers and link setting are treated as defaults and

would only be active if the system was converted to

a non-communicating system.

Table 4. PureAir S Alert Codes and Troubleshooting

Initial notication of critical alerts will pop up on the home screen and will be listed under notication menu. Minor and moderate alerts are found

only under the notication menu.

Alert

Code

105 Moderate

120 Moderate

124 Critical

125 Critical

Priority

Condition

Actual

Displayed

Alert Text

Communication

Problem

Unresponsive

DEVICE2.

Active Subnet

Controller

Missing

Control

Hardware

Problem

Component or System Operational State and Troubleshooting Tip How to clear alert code

A system component has lost communication with the system. System

component (device) is unable to communicate.

This may indicate the existence of other active alert codes.

TIPS:

• In most cases errors are related to electrical noise. Verify that high voltage

power is separated from the low voltage communication wires.

• Check for incorrectly wired or loose connections between system

components (devices).

• Check for a high voltage source of noise close to the system.

There is a delay in the system component responding to the system.

TIPS:

• Typically this alert code does not cause any operational issues and will

clear on its own.

• Usually caused by a delay in the outdoor unit responding to the

thermostat.

• Check all wiring connections.

The thermostat has lost communication with a system component for more

than three minutes.

This alert code stops all associated system operations and waits for a

heartbeat message from the system component that is not communicating.

TIPS:

• Check the wiring connections.

> Ohm wires.

> Cycle power.

> Check voltage at component.

There is a hardware problem with a system component control.

TIPS:

• PCO3 jumper selector is missing.

• Replace the PCO3S control if the problem prevents operation and is

persistent.

Automatically clears

when the system detects

the issue no longer

exists.

Automatically clears after

an unresponsive system

component (device)

responds to any inquiry.

Automatically clears

after communication

is re-established with

applicable system

component (device).

Automatically clears ve

minutes after the issue

no longer exists.

13

Page 14

Table 4. PureAir S Alert Codes and Troubleshooting

Initial notication of critical alerts will pop up on the home screen and will be listed under notication menu. Minor and moderate alerts are found

only under the notication menu.

Alert

Code

131 Critical

132 Critical

500

501

502 Critical UVA Lamp Off

504 Critical Filter Life at 0%

505 Moderate

506 Critical

Priority

Condition

Minor

(Escalated

to Critical

after alarm

persists for

15 minutes)

Minor

(Escalated

to Critical

after alarm

persists for

15 minutes)

Actual

Displayed

Alert Text

Corrupted

Control

Parameters

Failed Flash

CRC Check

Diff Press

Sensor Fault

UVA Sensor

Fault

PureAir Model

Selection

Changed

UVA Lamp Life

at 0%

Component or System Operational State and Troubleshooting Tip How to clear alert code

System component control parameters are corrupted.

TIPS:

• Go to menu > advance settings > view dealer control center >

equipment and press reset all equipment. This will allow the system to

auto-detect the PCO3S control.

• Replace the PCO3S control.

PCO3S control software is corrupted.

TIPS:

• Recycle power.

• If failure re-occurs, replace the system component control.

Pressure sensor reports a fault for more than ve minutes, or does not

respond for more ve 5 minutes. Device will not perform any pressure

reading calculations until fault is recovered. Remaining lter life display will

indicate “-“ while fault exists.

TIPS:

• Verify connection of pressure sensor lines to PCO3S control.

• Replace pressure sensor.

UVA sensor reports a fault for more than ve minutes or UV sensor does not

respond for more than ve minutes.

Device will not perform any UV lamp life remaining calculations until fault has

recovered. Life remaining display shall indicate “-“ while fault exists.

TIPS:

• Verify that the wiring connections between the UV sensor control and main

PCO3S control are good.

• Replace UVA sensor control.

The light is determined to be off when the last three last light intensities

measurements are below the set threshold.

TIPS:

• Verify UVA light is installed correctly.

• Replace UVA light.

Filter life at 0%.

TIPS:

Replace air ler and reset. Go to menu > settings > advanced settings >

view dealer control center > equipment > PureAir S and select reset lter

at bottom of the screen.

Model selection jumper has changed positions while system was running.

TIPS:

Repositioned jumper back to original jumper position and cycle power to the

PCO3S and S30 system.

UV Lamp Life at 0%.

TIPS:

Replace UVA lamp and reset. Go to menu > settings > advanced settings >

view dealer control center > equipment > PureAir S and select reset puri-

er at bottom of the screen.

Will automatically clear

when system component

(device) passes memory

self-test or system

component control is

replaced.

Manual system power

reset is required to

recover from this alert

code.

Automatically clears 30

seconds after fault is

recovered.

Automatically clears 30

seconds after fault is

recovered.

Light is determined on

after single set of ve

samples are above the

set threshold.

Replace air lter and

reset to 100%.

Correct issue and cycle

power to system.

Replace UVA lamp and

reset to 100%.

Operation

1. Check to ensure that access panel is securely in place.

2. Lamp should remain illuminated continuously except

during service and maintenance.

3. For optimal odor control, air handler blower should

remain on CONTINUOUSLY (thermostat fan setting in

ON position, rather than AUTO).

NOTE: If air handler does not provide a continuous low

blower speed option, an additional blower relay

should be installed. Use Lennox part number

45H03. Contact the Lennox Application Department

at 1-800-453-6669 for wiring information.

NOTE: Continuous fan operation may result in higher

humidity. If humidity levels are uncomfortably high,

fan setting should be switched to AUTO during

cooling operation.

14

Page 15

Filter, UVA Lampholder / PCO Cartridge and

UVA Lamp Replacement

remoVing anD installing UVa lamp, lampholDer anD

air filter

IMPORTANT

Hg -- UVA Lamp contain mercury.

Manage in accord with disposal laws.

Refer to www.lamprecycle.org or call 1-800-9LENNOX.

The Healthy Climate® Carbon Clean 16® Filter, UVA

Lampholder / PCO cartridge and UVA lamp require annual

replacement. More frequent lter replacement may be

required in applications with heavier dust or dirt loads or if

you notice a reduction in odor-removal efciency. An annual

maintenance kit is available.

Annual Maintenance Kits

The annual maintenance kits include the following:

• Healthy Climate® Carbon Clean 16® Filter (1)

• PCO cartridge (1)

• UVA lamp (1)

Order using the following kit catalog numbers:

Table 5. Maintenance Kits

Part

Description

Annual

Maintenance

Kit

PCO3S-14-16 PCO3S-16-16 PCO3S-20-16

Y6616 Y6612 Y6608

Replacement Parts

Replacement parts are available through Lennox, see

“Figure 1. Parts Identication” on page 3 for parts

arrangement. Part description and catalog numbers are as

follows:

Table 6. Repair Parts

Part Description

HC Carbon Clean

16 Filter

UVA Lamp X8794

PCO cartridge

insert (Purier)

Lampholder

Assembly

Power Cord

(120VAC)

Power Cord

(230VAC)

Electrical Socket 75X77

Ballast Y6620

Probe Repair Kit 16X01 16X02 16X01

Sensor Repair Kit 16X03

PCO3S-14-16 PCO3S-16-16 PCO3S-20-16

Y6606 Y6605 Y6604

Y6621 Y6607

Catalog Numbers

Catalog Numbers

Y6622

49M48

91X44

IMPORTANT

If the system has been operated for a period of time

without the UVA lamp being illuminated, an odor may

occur when lamp is illuminated. This odor is considered

typical and should dissipate within 12 hours of full

operation. If the odor does not subside after 48 hours

of operation, instruct the homeowner to unplug the unit

and contact a Lennox dealer.

CAUTION

Personal Burn Hazard.

UVA lamp is very hot when illuminated.

Allow lamp to cool for 10 minutes before removing lamp

from socket.

Injury may result from contact with hot UVA lamp.

1. Remove power cord from 120VAC or 230VAC receptacle.

2. Remove power cord from unit.

3. Remove access panel.

4. Remove Healthy Climate® Carbon Clean 16® Filter.

5. Rotate out the hinged control panel.

6. Disconnect UVA lamp electrical connector from ballast.

7. Remove both fasteners securing the UVA Lampholder /

PCO cartridge from the chassis.

8. Slide out the UVA Lampholder / PCO cartridge from the

chassis.

9. Remove both brass nger nuts that secure the UVA

lamp elector connector to the UVA Lampholder / PCO

cartridge.

10. Slide out UVA lamp from UVA Lampholder / PCO

cartridge insert.

11. Push the red button on UVA lamp electrical connector

and gently slide off connector from UVA lamp (do not

dispose of UVA lamp electrical connector).

12. Properly dispose of UVA lamp and air lter.

13. Reinstall in reverse order starting.

15

Page 16

proper clean-Up of broken UVa lamp

START

Look through the access panel

viewing port to check lamp.

Is there power to the

PCO?

Is the lamp on?NO

Check PCO power cord for

damage and AC outlet for

power. Check breaker

panel. Repair electrical

problem and plug−in power

cord.

Is the lamp on?

Unplug power cord to

the PCO cabinet.

YES

Check lamp

electrical

connectors. Also check

electrical wiring from ballast

to lamp connector.

Any issues?

Plug power cord back

to the PCO cabinet.

N

O

Repair Issues

Is the lamp on?

Check ballast voltages (see

table below) on red and blue

wires at 4−pin connector.

Replace any burned out or

damaged components.

NO

Is the lamp on?

NO

Continue with

maintenance per unit

installation instruction.

YES

YES

YES

NO

Is PCO power cord plugged

into AC outlet? If not, plug

PCO cord into AC Outlet.

Is the lamp on?

NO

YES

NO

YES

YES

If UVA lamp is broken, it must be disposed of properly.

• Wear protective gloves, eye wear and mask.

Troubleshooting Flow Chart

• Sweep broken glass and debris into a plastic bag and

seal before disposal in accordance with instructions

provided by local waste management ofce.

• Do not use a vacuum cleaner. Do not incinerate.

BALLAST

INPUT/OUTPUT WIRE/TERM COLOR NORMAL READING (VAC)

OUTPUT

RED >60

RED >60

BLUE >200

BLUE >200

Figure 19. Troubleshooting Flowchart

SERVICE ACTION (See “Figure 12. PCO

Wiring Schematic” on page 9.)

Replace ballast if less than 60VAC.

Replace ballast if less than 200VAC.

16

Loading...

Loading...