Lennox PureAir PCO-12C-2, PureAirPCO-20C-2 Installation And Maintenance Instructions Manual

Page 1

AIR CLEANERS/

FILTERS

HEALTHY CLIMATE

®

©2003 Lennox Industries, Inc.

Dallas, Texas USA

504,745M

08/2003

PUREAIR™ AIR PURIFICATION SYSTEM

PHOTOCATALYTIC OXIDATION TECHNOLOGY(PCO)

INSTALLATION AND MAINTENANCE INSTRUCTIONS FOR CASED PUREAIR™ MODELS PCO-12C-2, PCO-20C-2

General

The PureAir™ air purification system helps to significantly reduce levels of airborne volatile organic

compounds, cooking odors, common household

odors, airborne dust particles, mold spores, and

pollen in residential spaces. The PureAir™ air purification system (cased model) includes a MERV 9

pleated filter, UVA lamps, and a metal insert that is

coated with a titanium dioxide catalyst. As air enters

the system, a percentage of airborne particles and

bioaerosols, such as mold and bacteria, ranging in

size down to .3 microns, are captured by the pleated filter. The smaller airborne particles, odors, and

chemicals continue through the system. The UVA

lamp activates the catalyst on the metal insert. The

catalyst combines with water vapor in the air to form

hydroxyl radicals that destroy a percentage of the

remaining odors and chemicals.

In laboratory & field tests, we found greater than

(TVOC) within 24 hours of initial installation and

operation of the PureAir™ air purification system.

When the system is first started, it may take up to 48

hours to reduce the airborne chemicals that have

built up in your home over a long period of time.

After that period, there will be a balance between

chemicals emitted inside your home and chemicals

removed by your PureAir™ air purification system.

Please refer to the included Homeowners IAQ guide

for other measures to improve indoor air quality.

The PureAir™ air purification system is NOT intended to be used for

removal of active mold growth or continuous source of high levels

of chemicals in the air. For existing mold growth, the mold must be

appropriately removed PRIOR to installation of your PureAir™ air

purification system.

Shipping and Packing List

Package 1 of 1 contains:

1 - PureAir™ air purification system c/w:

1 - Metal cabinet, including insulated door

1 - One piece slide-in assembly (Metal Frame and

ballasts, with associated wiring.)

1 - MERV 9, 4" pleated filter

4 - Installed UVA lamps (PCO-12C)

6 - Installed UVA lamps (PCO-20C)

1 - Separately wrapped titanium dioxide metal insert

1 - Power cord

1 - Installation and maintenance instructions

1 - Homeowners IAQ Guide

1 - Warranty certificate

1 - Registration card

Unique Supplies

• Cotton gloves and cloth (to remove finger prints

from lamps.)

• Sealant: Aluminum foil duct tape or water based

mastic. (NOT silicone)

NOTICE

Possible odor emissions.

Odors may be present temporarily after initial startup, painting, cleaning, remodeling, hobby activities or

after lamp replacement.

Some occupants may notice irritation or discomfort

during this period.

WARNING

Electric shock hazard.

Can cause injury or death.

Disconnect all remote electrical

power supplies before servicing.

Access panels must be in place during the appliance operation.

If irritation or discomfort persists longer than 48

hours, unplug the PCO device and contact your

Lennox authorized dealer.

WARNING

Risk of property damage, injury, or death.

Installation, adjustments, alterations, service and

maintenance must be performed by a qualified

service technician.

212361-03 Rev. 1B 8/03

Page 2

Dimensions/Specifications

DIMENSIONS:

Model PCO-12C: 29" L x 11

(737mm x 295mm x 495mm)

Model PCO-20C: 29" L x 11

(737mm x 295mm x 606mm)

5

/8" W x 19 1/2" H

5

/8" W x 237/8" H

WEIGHT:

Model PCO-12C: 54 lbs.(24 kg.) Installed

67 lbs.(30 kg.) Shipping

Model PCO-20C: 62 lbs.(28 kg.) Installed

76 lbs.(34 kg.) Shipping

ELECTRICAL:

Model PCO-12C: 120V, 1.6 Amps, 60Hz

Model PCO-20C: 120V, 2.4 Amps, 60Hz

Line Voltage: 108V-132V (If unit operates above

128V, a reduction in lamp life on the order of 10 -

15 may occur.)

POWER CONSUMPTION:

Model PCO-12C: 192 Watts

Model PCO-20C: 288 Watts

Model PCO-12C

115/8"

191/2"

Model PCO-20C

115/8"

237/

8"

29"

29"

OPERATING ENVIRONMENT:

0°F - 140°F (-18°C - 60°C) Outside of duct.

10 -60 relative humidity. (PCO has optimal performance at 50 relative humidity.)

PLEATED FILTER EFFICIENCY:

Minimum Efficiency Rating Value - MERV 9. Tested

to ASHRAE Standard 52.2.

LISTINGS:

ETL Safety Listing Report #J99*9379-001,

Conforms to UL STD 1598, Certified to CSA STD

C22.2 NO.250.0

Specifications subject to change without notice.

Approximate Air Flow Resistance

Capacity Flow Rate Pressure Drop (inches w.g.)

(Tons)

(CFM)

PCO-12C PCO-20C

2 800 .08 .07

2.5 1000 .12 .09

3 1200 .16 .12

3.5 1400 * .15

4 1600 * .18

4.5 1800 * .21

5 2000 * .24

*Not Recommended. Excessive system pressure drop can

damage your HVAC system and reduce its performance.

2

Page 3

Installation

UNPACKING THE PCO-12C/20C (Fig. 1)

The MERV 9 pleated filter has been vapor barrier

packaged. The metal insert has been vacuum

packaged. All protective wrapping MUST BE

removed prior to installation and operation of

system.

Remove carbon

pouch inside metal

insert packaging.

Fig. 1 Remove and discard all wrapping and packaging

material prior to installation and operation of PCO-12C/20C.

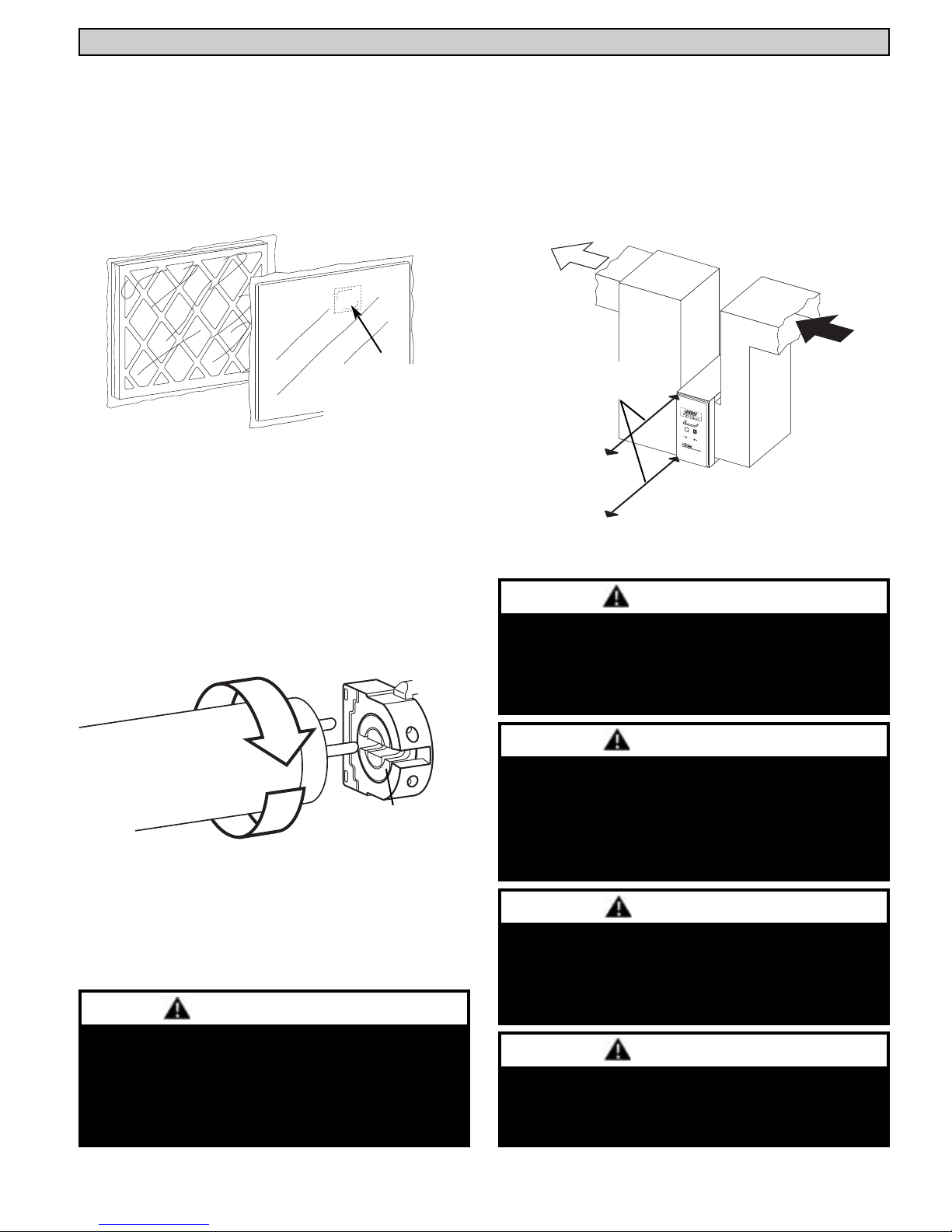

SELECTING A LOCATION(Fig. 3)

Install the PCO-12C/20C ONLY in the return air

duct upstream of the supply blower. Allow approximately 30" of clearance in front of access door to

slide out the PCO-12C/20C assembly. This provides easier access to change the pleated filter,

metal insert, and UVA lamps.

Allow approximately

30" of clearance.

CHECKING THE LAMPS (Fig. 2)

Lamps are factory installed as shown below. Make

sure that the lamps have not become disengaged

during shipping. Use cotton gloves or cloth to

avoid fingerprints on the lamp.

Excessive force

may damage

plastic socket.

Fig.2 Verify proper installation of lamps.

CAUTION

Fig.3 Install PCO-12C/20C in the return air duct.

CAUTION

Sharp edges hazard.

Equipment sharp edges can cause injuries.

Use protective gloves when grasping equipment edges.

NOTICE

Unpacking required.

Remove all protective packing material from the

pleated filter and the titanium dioxide metal insert.

All packing material should be discarded properly

in refuse containers.

NOTICE

Clean lamps prior to installation using a cotton

cloth to remove dirt and fingerprints.

Failure to clean lamps could reduce the system's

efficiency

Lamps contain Mercury.

Ingestion or contact with mercury or mercury vapor

is hazardous to your health.

Take care when handling lamps. If lamp is broken,

avoid contact with mercury.

NOTICE

Intended for return air duct installation only.

Improper installation can damage HVAC system,

PureAir™ or other equipment and may void warranty.

3

Page 4

Installation

INSTALLATION EXAMPLES

Up-Flow

(Side Installation)

Note - At sharp turns,

turning vanes should be

installed before the PCO12C/20C.

Up-Flow

Down-Flow: Note - Due to flue

location on some down-flow furnaces,

the front of PCO-12C/20C must be

installed to side or rear of furnace cabinet. If installed in a confined space,

service clearance may be restricted.

Typical Transition: If furnace opening

does not match up to the PCO opening, a sheet

metal transition should be used. Transition

must be planned for each job. Reduction

should not be more than 4 inches per linear

foot, approximately 20 angular degrees.

Horizontal

INSTALLING THE CABINET (Cont'd)

High Humidity Environments: Wrapping cabinet with

2" foil faced insulation (foil on the outside) around the

case (excluding the insulated door) will prevent condensation on the sides of the PureAir™ case.

INSTALLING THE ASSEMBLY (Fig. 4)

1. Check lamps for proper seating in sockets.

2. Slide the PCO-12C/20C assembly into cabinet,

using the cabinet rails as a guide.

3. Slide the pleated filter into the rails on the air

inlet side of the PCO-12C/20C assembly. Verify

proper air flow direction through pleated filter.

4. Slide metal insert into rails downstream of UVA

lamps so that 1/2” flange is toward back of cabinet.

5. Install access door using provided screws. Be

sure unused plug opening is covered with black

hole plug.

6. Plug one end of provided power cord into

receptacle on PCO-12C/20C and the other end

into a 120V power receptacle.

IMPORTANT: Route power cord away from

traffic areas where the cord may become a

safety hazard.

7. Verify that the lamps are illuminated.

INSTALLING THE CABINET

Oil on metal ducts can cause odors. Wash all new

transitions and duct surfaces with mild soap and

water to remove oils prior to installation. Connect the

PCO-12C/20C cabinet to the return air side of the air

handling unit with field provided sheet metal screws,

rivets, or appropriate method. Be sure to orient cabinet to airflow direction as indicated on label inside

cabinet. Fasten return air duct to other side of PCO12C/20C cabinet. Seal all joints between the cabinet,

air handling unit, and ducting with aluminum foil

tape or water based mastic. Ducts and air handler(s)

should be sealed to prevent contamination from

unconditioned spaces (such as basements,

garages, or attics).

Optionally, the cabinet can be strap-mounted from the

ceiling. When drilling screw holes in the cabinet for

straps, be sure to locate them where they do not interfere with the insertion of the PCO-12C/20C assembly.

CAUTION

Airflow

direction.

Fig. 4 Slide PCO-12C/20C assembly with provided pleated

filter and metal insert into the PCO-12C/20C cabinet.

NOTICE

Do not use any form of silicone sealant.

Use of silicone-based products will reduce the effectiveness or damage the titanium dioxide coatings.

NOTICE

Ultraviolet (UV-A) radiation risk.

Prolonged exposure may cause skin or eye damage.

Avoid prolonged (weeks) exposure to skin or eyes.

Oil on metal ducts can cause odors

Wash all new transitions and duct surfaces with mild soap

and water to remove oils prior to installation.

4

Page 5

Installation

Operation

WIRING INSTRUCTIONS (See wiring diagrams)

The PCO-12C/20C must be wired in accordance

with national and local codes.

IMPORTANT: To ensure UVA lamps life, power

MUST remain on to PCO-12C/20C at all times. Do

not interlock with air handler blower.

MODEL PCO-12C WIRING DIAGRAM

1. Door on unit must be secured in place prior to

operation.

2. Lamps to remain illuminated continuously except

during service and maintenance.

3. For optimal odor control, fan should remain on

continuously (i.e. run with thermostat fan setting in

the “ON” position, not the “Auto” position.)

Running fan continuously during cooling operation may result in higher humidity. If this occurs,

set thermostat in the “Auto” position during cooling operation.

4. For those air handlers that do not have a continu-

ous "Low Fan Speed " mode, an additional blower

relay will need to be installed. Use Lennox blower

relay part number 45H03. Lennox utilizing the

Lennox Surelight™ heating control do not require

the use of an additional blower relay.

MODEL PCO-20C WIRING DIAGRAM

WARNING

Electric shock hazard.

Can cause injury or death.

Disconnect all remote electrical

power supplies before servicing.

Access panels must be in place during the appliance operation.

WARNING

Risk of Carbon Monoxide poisoning.

Can cause injury or death.

Do not operate without access panel in

place. Operation of this equipment

without the access panel in place may

cause gas fumes from the heating system to be drawn into occupied spaces.

5

Page 6

Maintenance

The PCO-12C/20C has three components that will

require maintenance: MERV 9 pleated filter, metal

insert, and UVA lamps.(For replacement part numbers refer to Replacement Parts section in these

instructions. PCO-12C/20C performance will be

dramatically reduced if the required maintenance

is not performed on these three components.)

MERV 9 PLEATED FILTER

The pleated filter should be replaced every 12

months. More frequent filter changes may be

required in situations with high dust or dirt loads.

1. Unplug the power cord and remove the access

door.

2. Partially slide out the PCO-12C/20C assembly.

3. Remove the pleated filter and replace with the

same MERV 9 filter. (Performance of PCO12C/20C will be dramatically affected if improper

filter is installed.)

4. Slide assembly back into cabinet and install access

door.

5. Reconnect power cord.

METAL INSERT/LAMP REPLACEMENT(Cont'd)

6. Install new metal insert.

7. Slide assembly back into cabinet and install

access door.

8. Reconnect power cord.

9. Verify that the lamps are illuminated.

Note: DO NOT WASH metal insert. Washing will

destroy the titanium dioxide catalyst that coats the

insert surface.

Note: If the system has been operated for a period

of time without the lamp(s) being illuminated (such

as at startup or with a failed lamp), an odor may

occur when lamps are (re)started. This symptom is

considered to be typical and should only be temporary. In the event that an odor does occur, it

should subside and dissipate within 12 hours of

full operation. If this odor persists longer than 48

hours, you should unplug the PCO and contact

your Lennox authorized dealer.

6. Verify that the lamps are illuminated.

METAL INSERT & LAMP REPLACEMENT

Replace metal insert and lamps* every 24 months.

Replace insert more frequently if you notice a significant drop in odor removal efficiency.

If you find that you need to replace the insert more

frequently than every 24 months, consider source

reduction and/or ventilation to reduce the levels of

contaminants in your home (see Homeowners IAQ

Guide for additional recommendations).

* Lamps will continue to glow at the end of the 24

months. However, their output efficiency will have

degraded to the point that they must be replaced to

assure effective performance of your PureAir™ unit.

1. Unplug the power cord and remove the access

door.

2. Slide out PCO-12C/20C assembly.

3. Remove metal insert.

4. Twist/rotate each lamp approximately 1/4 turn to

remove from sockets.

5. Install new lamps making sure to snap them

completely into the sockets and twist/rotate

lamp approximately 1/4 turn. Use gloves or cloth

to avoid fingerprints on lamps. (See page 3.)

CAUTION

Ultraviolet (UV-A) radiation risk.

Prolonged exposure may cause skin or eye damage.

Avoid prolonged (weeks) exposure to skin or eyes.

NOTICE

Clean lamps prior to installation using a cotton

cloth to remove dirt and fingerprints.

Failure to clean lamps could reduce the system's

efficiency.

CAUTION

Lamps contain Mercury.

Ingestion or contact with mercury or mercury vapor

is hazardous to your health.

Take care when handling lamps. If lamp breaks,

avoid contact with mercury.

6

Page 7

Replacement PartsMaintenance

LAMP CHECKOUT (Does not illuminate.)

1. Check power cord for 120V power.

2. Unplug power cord and remove access door.

3. Slide out assembly and remove pleated filter or

metal insert.

4. Check lamps for proper connection in sockets.

5. Exchange non-working lamp with one of the

working lamps. If the new lamp operates normally, replace defective lamp.

6. If steps 1 through 5 pass inspection then the ballast

may be at fault. Ballast must be replaced with an

approved ballast by a qualified service technician.

LAMP DISPOSAL

Hg-LAMP CONTAINS MERCURY.

Manage in accord with disposal laws.

Refer to www.lamprecycle.org or call 1-800-9-LENNOX.

CAUTION

Lamps contain Mercury.

Ingestion or contact with mercury or mercury vapor

is hazardous to your health.

Take care when handling lamps. If lamp breaks,

avoid contact with mercury.

No. Description PCO-12C-2 PCO-20C-2

Complete PureAir™ System 75X69 75X61

1 Cabinet 75X72 75X65

2 Assembly 75X70 75X62

3 Access Door 93X39 75X64

4 Electrical Socket 75X77 75X77

5 UVA Lamp 10M35(4) 10M35(6)

6 Lamp Socket 49M00 49M00

7 Ballast 56M12 56M12

8 Titanium dioxide coated metal insert 75X73 75X66

9 MERV 9 pleated filter 75X74 75X67

Power Cord (Not Shown) 49M48 49M48

Contact your local Lennox dealer to order replacement parts.

For the Lennox dealer nearest you, dial 1-800-9-LENNOX.

Visit us at http://www.Lennox.com

PROPER CLEAN-UP TECHNIQUE IN CASE OF

LAMP BREAKAGE

●

Wear protective gloves, eyewear and mask.

●

Sweep the broken glass and debris into a plastic bag,

seal the bag, and dispose of properly. Contact your

local waste management office for proper disposal.

●

Do not use a vacuum cleaner. Do not incinerate

.

Model PCO-12C Exploded View

Model PCO-20C Exploded View

1

2

3

4

5

6

7

8

9

7

Page 8

Troubleshooting

Service Flow Chart PCO-C

Start

Check inspection port

to see if lamps are lit

Are

Are

Lamps

Lamps

Lite?

Lit?

Yes

Continue with

maintenance per unit

instruction manual

End

No

Do you have

120V to

PCO?

Yes

Unplug PCO power

and immediately

plug back in

Did

Lamps

Light?

No

Check all electrical

connections, bulbs, and ballast.

Replace any burned out or

damaged components and plug

unit in.

No

Yes

Check power supply.

(Breakers, Plug, Electrical

wiring) Repair electrical and

plug unit in.

Continue with

maintenance per unit

instruction manual

Yes

Are

Lamps

Lit?

No

End

Are

Lamps

Lit?

NO

Replace

Assembly

End

Yes

Continue with

maintenance per unit

instruction manual

8

End

Loading...

Loading...