Page 1

OPERATION

MANUAL

www.lennoxcommercial.com

1

Page 2

2

Page 3

The Prodigy® control system is the latest example of Lennox’ commitment

to advanced HVAC technology. Standard on every Strategos

®

rooftop unit,

the Prodigy control system makes setup, troubleshooting and servicing

easier than ever.

The Prodigy control system includes:

• Prodigy unit controller

• SmartWire™ system

• Optional Prodigy BACnet module (BTL certified)

®

• Optional Prodigy LonTalk

module (LonTalk certified)

www.lennoxcommercial.com

3

3

Page 4

NAVIGATION

www.lennoxcommercial.com

415

Page 5

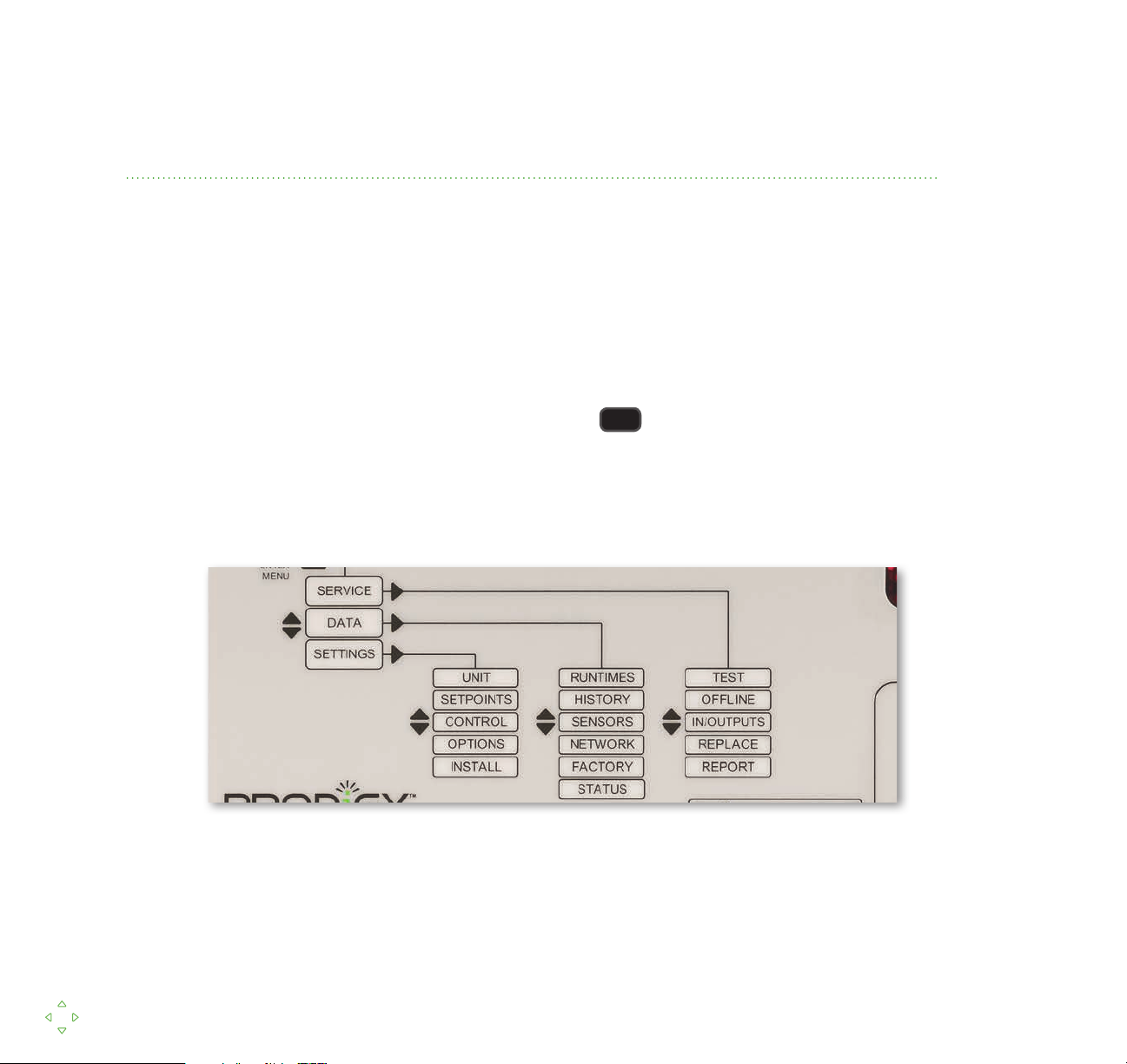

1. Navigation is performed by using the arrowed keys and the

enter button

• To reset the Prodigy® unit controller, press the left arrow and

hold for 5 seconds

— You will now be at the beginning of the menu structure

• Press the enter or right arrow to go into the sub menus:

Navigation

Display Service Data Settings

SERVICE

UNIT

SETPOINTS

CONTROLS

OPTIONS

INSTALL

• Press the down arrow until you see

RUNTIMES

HISTORY

SENSORS

NETWORK

FACTORY

STATUS

TEST

OFFLINE

IN/OUTPUTS

REPLACE

REPORT

DATA

• To exit the menu structure, press the left arrow

— Press the left arrow again to return to the Display mode.

www.lennoxcommercial.com

SmartWire

System

5

5

™

Page 6

DISPLAY

• Display shows the controller’s current state

— It will show either the current mode of operation or an alarm/

• To exit the display mode, press enter

• You are now in the menu structure

• Notice that the first level of the menu structure is located on the controller

status message

English, French or Spanish language can be selected.

www.lennoxcommercial.com

6

Page 7

ALARMS

The Prodigy® unit controller displays alarms in descriptive, actionable text.

• To simulate an alarm, press the left arrow until you are in the

display mode

• Flip down the switch to the right of the controller labeled Compressor

1HP (s4). It is located on the green trainer board next to the lower right

corner of the gray M2

Navigation Display Service Data Settings

• This will show the alarm for a high-pressure switch trip for Compressor 1

• To silence the alarm, press enter

• To turn off the alarm, simply flip the switch (S4) back to the up position

SmartWire

System

www.lennoxcommercial.com

7

7

™

Page 8

USB SERVICE REPORTS

www.lennoxcommercial.com

819

Page 9

1. The Prodigy® controller’s USB port can download service reports

• To generate a report, insert a USB memory stick into the USB port

then press enter

Navigation Display Service Data Settings

• With displayed, press enter to write

REPORT

the report

• The display will show it is writing the report and then indicate when

it is complete

• The report will be saved to the memory stick with a file name

based on the unit’s serial number

• This report can be transferred to any computer via the

memory stick

www.lennoxcommercial.com

SmartWire

System

9

™

Page 10

=========================================================================================

USB SERVICE REPORT

=========================================================================================

Service Date

Service Time

Serial No. 5609K00002

M2 Version 7.06.00

DB1 Version

Unit No.

Sbus Address

BACnet Address

CAT No.

MODEL NO.

COOLING

Status

=========================================================================================

Runtime Data

Total Power On

Before Install

Filter

Belt

Blower

Compressor 1

7/4/2010

3:15:00

1.06.00

2

2

2

36L87

Compressor 2

Compressor 3

Compressor 4

Outdoor Fan 1

Outdoor Fan 2

Outdoor Fan 3

Outdoor Fan 4

Outdoor Fan 5

Outdoor Fan 6

Heat Stage 1

=========================================================================================

Sensor Data

LGH036H4ES1Y

79 CYCLES

1832 HRS

2040 HRS

1063 HRS

1162 HRS

46 HRS

0 HRS

0 HRS

0 HRS

14 HRS

0 HRS

0 HRS

0 HRS

0 HRS

0 HRS

5 HRS

0 HRS

15 HRS

0 HRS

MENU TO CLEAR LOCKOUTS.

CHARGE, FILTERS, AIR FLOW. COIL

ALARM(5) FILTER S27 REPLACE FILTER OR CHECK FILTER

SWITCH S27

286 HRS

Heat Stage 2

Reheat

Free Cooling

UV Lamp

=========================================================================================

Alarm/Status Log

2 HRS

OAT : 100 degF

RAT : 85 degF

DAT : 86 degF

ZAT : 83 degF

RH : 60 %

CO2 : 415 ppm

23 ALARM(23) STRIKE 3 ON COMP 1 S87 COMP LOCKOUT.

CHECK CHECK CHARGE, FILTER, AIR FLOW, COIL, USE SERVICE

( 23) 7.04.2010 1:05:00

22 ALARM(22) COMP 1 LOW PRESS S87 COMP OFF. CHECK

( 22) 7.04.2010 1:00:00

( 5) 6.30.2010 21:05:00

=========================================================================================

END OF REPORT

---------

---------

---------

131 CYCLES

66 CYCLES

--------0 CYCLES

0 CYCLES

32 CYCLES

2 CYCLES

0 CYCLES

0 CYCLES

0 CYCLES

0 CYCLES

17 CYCLES

16 CYCLES

13 CYCLES

1608 CYCLES

---------

=========================================================================================

Sensor Data

=========================================================================================

Alarm/Status Log

( 22) 7.04.2010 1:00:00

( 5) 6.30.2010 21:05:00

=========================================================================================

END OF REPORT

1

=========================================================================================

USB SERVICE REPORT

=========================================================================================

Service Date

Service Time

Serial No.

M2 Version

DB1 Version

Unit No.

Sbus Address

BACnet Address

CAT No.

MODEL NO.

Status COOLING

=========================================================================================

Runtime Data

Outdoor Fan 2 0 HRS 2 CYCLES

Outdoor Fan 3 0 HRS 0 CYCLES

Outdoor Fan 4 0 HRS 0 CYCLES

Outdoor Fan 5 0 HRS 0 CYCLES

Outdoor Fan 6 0 HRS 0 CYCLES

Heat Stage 1

Heat Stage 2

Reheat 2 HRS 13 CYCLES

Free Cooling

UV Lamp

OAT : 100 degF

RAT : 76 degF

DAT : 57 degF

ZAT : 77 degF

RH : 50 %

CO2 : 415 ppm

( 23) 7.04.2010 1:05:00

4:23:00

5609K00002

Total Power On 1832 HRS 80 CYCLES

Before Install 286 HRS --------Filter 0 HRS ---------

Belt 1063 HRS ---------

Blower 1162 HRS 131 CYCLES

Compressor 1

Compressor 2

Compressor 3

Compressor 4

Outdoor Fan 1 14 HRS 32 CYCLES

0 HRS 0 CYCLES

0 HRS --------0 HRS 0 CYCLES

0 HRS 0 CYCLES

5 HRS 17 CYCLES

0 HRS 16 CYCLES

15 HRS 1608 CYCLES

0 HRS ---------

23 ALARM(23) STRIKE 3 ON COMP 1 S87 COMP LOCKOUT.

CHECK CHECK CHARGE, FILTER, AIR FLOW, COIL, USE SERVICE

MENU TO CLEAR LOCKOUTS.

22 ALARM(22) COMP 1 LOW PRESS S87 COMP OFF. CHECK

CHARGE, FILTERS, AIR FLOW. COIL

ALARM(5) FILTER S27 REPLACE FILTER OR CHECK FILTER

SWITCH S27

2

www.lennoxcommercial.com

10

Page 11

USB SERVICE REPORTS

The reports at left are an example of a service call.

1. The first report shows the status of a unit with a faulty compressor and

dirty filter

• The sensor data illustrates the issue

2. The second report shows the same unit with a new compressor

and filter

Navigation Display Service Data Settings

• Notice the new sensor readings and the reset runtime information

SmartWire

System

www.lennoxcommercial.com

11

11

™

Page 12

USB PROFILES

www.lennoxcommercial.com

12

Page 13

You can also save a unit profile which can be uploaded to another similar unit.

• To save or upload a unit profile, insert a USB memory stick in the

USB port

Navigation Display Service Data Settings

• Press enter when the screen reads then scroll

down to and press enter

PROFILES

USB

• The controller will automatically check to see if there is a profile that

matches the unit

• If there is a profile saved to the memory stick with a matching cat

number, the controller will ask to upload it

• This will instantly upload all setpoints to the unit that are saved to

the profile

• If there is no profile saved, the controller will ask if you want to save

the unit’s profile

SmartWire

System

www.lennoxcommercial.com

13

13

™

Page 14

SELF-TEST

The Prodigy® unit controller features a self-test function. This allows the user to

individually test critical component operation.

• First, navigate to the menu and press enter

• Then, press enter again to access the menu

• Press the down arrow to find and press enter

• Then select either an individual compressor or stage (L or H)

• The controller will turn on just that compressor (stage)

• It will then return the RAT and DAT as a check of correct operation

SERVICE

TEST

COOL

www.lennoxcommercial.com

14

Page 15

REPLACE

The replace function is used to reset component runtime information. To

demonstrate, we will use a filter replacement.

Navigation Display Service Data Settings

• First, navigate to the menu and press enter

• Press the down arrow to scroll to and

press enter

• Press enter on which should be the first category

• To reset the filter runtime, press enter

• This resets the filter runtime, which should be done after every

filter change

SERVICE

REPLACE

FILTER

SmartWire

System

www.lennoxcommercial.com

15

15

™

Page 16

RUNTIMES

www.lennoxcommercial.com

16

Page 17

The Prodigy® unit controller contains runtime information on all key components.

Navigation Display Service Data Settings

• Navigate to the menu and press enter

• Press enter again on to access the menu

DATA

RUNTIMES

• You can scroll through all the runtimes using the up and

down arrows

• Press the left button twice to return to the menu

DATA

SmartWire

System

www.lennoxcommercial.com

17

17

™

Page 18

HISTORY

You can also view the history of alarm and status messages.

• From the screen, press enter and scroll

to and press enter

HISTORY

• Press enter on the screen

• The Prodigy® unit controller will display the last five alarms

• Press the left button three times to return to

the screen

DATA

DATA

ALARMS

www.lennoxcommercial.com

18

Page 19

SENSOR DATA

The Prodigy® unit controller can also display important sensor data.

Navigation Display Service Data Settings

• Once on the screen, press enter and scroll

to then press enter

• You can scroll through all the sensors and their current readings

• This data can be critical in diagnosing a problem

• Press the left button twice to return to the menu

SENSORS

DATA

DATA

SmartWire

System

www.lennoxcommercial.com

19

19

™

Page 20

SETPOINTS

www.lennoxcommercial.com

20

Page 21

Changing setpoints on the Prodigy® unit controller is quick and easy.

Navigation Display Service Data Settings

• First, navigate to the menu and press enter

• Press the down arrow to scroll to the menu

SETTINGS

SETPOINTS

and press enter

• Press enter to view the setpoints

• Press enter to change the cooling setpoint

COOLING

OCCUPIED

• Use the up and down arrows change the setpoint

• Press enter to set the value

SmartWire

System

www.lennoxcommercial.com

21

21

™

Page 22

SMARTWIRE™ SYSTEM

1

www.lennoxcommercial.com

22

Page 23

The SmartWire™ system is designed to simplify field wiring and sensor

installation.

1. Advanced connectors are color-coded, labeled and keyed to prevent

miswiring and ensure units are installed and set up correctly

• The wire-coloring scheme is standard across all units

• Each connection is intuitively labeled to simplify troubleshooting

Navigation Display Service Data Settings

SmartWire

System

www.lennoxcommercial.com

23

™

Page 24

SOLUTIONS FOR CUSTOMIZED COMFORT

Don’t just choose a Lennox® product…choose a Lennox Commercial Comfort System. These complete

packages of HVAC solutions provide tools to create a healthy and comfortable environment.

Packaged Units

• Strategos® Rooftop Units

•

Energence® Rooftop Units

•

Landmark® Rooftop Units

Split Systems

• S-Class™ Air Conditioners/

Heat Pumps

•

T-Class™ Air Conditioners/

Heat Pumps

• Air Handlers

• Indoor Coils

(64W34)-01/18

For a complete list of the registered and common law trademarks owned by Lennox Industries Inc., please visit www.lennox.com.

Heating

• T-Class Unit Heaters

• Unit Heaters

• Duct Furnaces

• Furnaces

Commercial Controls

• Prodigy® Control System

•

L Connection® Network

•

Systems Integration Solutions

• Commercial Thermostats

© 2018 Lennox Industries Inc.

Visit us at www.lennox.com, or contact us at 1-877-726-0024

Indoor Air Quality

• Humiditrol®

Dehumidification System

•

Demand Control Ventilation

• Energy Recovery Systems

• Air Filters

• UVC Germicidal Lights

Litho U.S.A.

PC67865

Loading...

Loading...