Page 1

INSTALLATION AND OPERATION MANUAL

US

Portland

Pellet-Fired

Fireplace Insert

Save These Instructions

For Future Reference

P/N 775,229M, Rev. B, 08/2008

Pellet Insert

Model Winslow™ (PI40)

A French manual is available upon request. Order P/N 775,229CF.

Ce manuel d’installation est disponible en francais, simplement en faire la demande. Numéro de la pièce

775,229CF.

Report No. 050-S-14b-2

These appliances must be properly installed and operated in order to prevent the possibility

of a house re. Please read this entire manual before installation and use of this pellet

fuel-burning room heater. Failure to follow these instructions could result in property

damage, bodily injury or even death. Contact your local building or re ofcials

to obtain a permit and information on any installation requirements and

inspection requirements in your area.

WARNINGS

• Hot! Do not touch! The glass and surfaces of this appliance will be

hot during operation and will retain heat for a while after shutting off

the appliance. Severe burns may result.

• Carefully supervise children in the same room as appliance.

• Lennox™ pellet-burning appliances are designed for use as a supplemental heater. They are not intended for continuous use as a primary

heat source.

Page 2

IMPORTANT SAFETY AND WARNIING

INFORMATION

READ THIS MANUAL IN ITS ENTIRETY AND UNDERSTAND THESE RULES TO FOLLOW FOR SAFETY.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information consult a qualified installer,

service agency or the gas supplier.

WARNING

Do not attempt to alter or modify the construction of

the appliance or its components. Any modification

or alteration may void the warranty, certification

and listings of this unit.

1. DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING

ANOTHER APPLIANCE.

2. Do not connect this appliance to air ducts or any air distribution system.

3. DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING

SYSTEM OF THIS UNIT.

4. Do not use class B venting intended for gas appliances as a

chimney or connector pipe on a pellet-fired appliance.

5. The minimum clearances must be maintained for all combustible surfaces and materials including; furniture, carpet,

drapes, clothing, wood, papers, etc. Do not store combustibles

within this clearance space (see Clearances on Page 7).

6. INSTALLATION DISCLAIMER - It is imperative that the exhaust

venting system be installed correctly and sealed gas-tight

(not allowing exhaust to leak). Follow the vent manufacturer's

instructions for proper installation. Since Lennox Hearth

Products has no control over the installation of your fireplace insert, Lennox Hearth Products grants no warranty,

implied or stated for the installation or maintenance of your

insert, and assumes no responsibility for any consequential

damage(s).

7. Burning any kind of fuel consumes oxygen. If outside air is

not ducted to the appliance, ensure that there is an adequate

source of fresh air available to the room where the appliance

is installed.

8. The appliance will not operate using natural draft, nor without

a power source for the blower and fuel feeding systems.

9. Never use gasoline, gasoline-type lantern fuel, kerosene,

charcoal lighter fluid, or similar liquids to start or “freshen up”

a fire in this heater. Keep all such liquids well away from the

heater while it is in use.

10. The authority having jurisdiction such as municipal building department, fire department, fire prevention bureau, etc

should be consulted before installation to determine the need

to obtain a permit.

2

10. APPROVED FUEL: This appliance is designed specifically for

use only with pelletized wood fuels only. This appliance is

designed and approved for the burning of wood residue pellets

with up to 3% ash content. This appliance is NOT approved to

burn cardboard, nut hulls, cherry pits, corn, etc. regardless

if it is in pellet form. Failure to comply with this restriction

will void all warranties and the safety listing of the fireplace

insert. Consult with your Lennox Hearth Products dealer for

more information on approved pellet fuels.

11. These appliances are designed as supplemental heaters.

Therefore, it is advisable to have an alternate heat source

when installed in a dwelling.

12. CONTINUOUS OPERATION: When operated correctly, this

appliance cannot be overfired. Continuous operation at a

maximum burn can, however, shorten the life of the electrical components (blowers, motors, and electronic controls),

and is not recommended. Typical approved operation would

include running at the low to mid range setting with occasional

running on the maximum setting during the coldest periods

of the winter.

instructions regarding the proper use of this insert.

13. CAUTION: NEVER PUT FINGERS NEAR AUGER. Pellet fuel is

fed to the UltraGrate™ by a screw auger. This auger is driven

by a high torque motor. The auger is capable of doing serious harm to fingers. Keep pellets in the hopper at all times

and keep fingers away from auger. The auger can start and

stop automatically at any time while the insert is running.

14.CAUTION: NEVER PUT FINGERS NEAR AUGER. Pellet fuel is

fed to the UltraGrate™ by a screw auger. This auger is driven

by a high torque motor. The auger is capable of doing serious

harm to fingers. Keep pellets in the hopper at all times and

keep fingers away from auger. The auger can start and stop

automatically at any time while the insert is running.

15. FLY ASH BUILD-UP: For all wood pellet fuel-burning heaters,

the combustion gases will contain small particles of fly-ash.

This will vary due to the ash content of the fuel being burned.

Over time, the fly-ash will collect in the exhaust venting

system and restrict the flow of the flue gases. The exhaust

venting system should be inspected regularly and cleaned

as necessary.

16. SOOT FORMATION: Incomplete combustion, such as occurs

during startup, shutdown, or incorrect operation of the room

heater will lead to some soot formation which will collect in

the exhaust venting system. A precautionary inspection on

a regular basis is advisable to determine the necessity of

cleaning. The exhaust venting system should be inspected

regularly and cleaned as necessary.

17. DISPOSING OF ASHES: Any ashes removed from the pellet

fireplace insert must be deposited in a metal container with

a tight-fitting lid. The closed container of ashes should be

placed on a noncombustible floor or on the ground, well

away from all combustible materials, outside of the dwelling pending final disposal. If the ashes are disposed of by

burial in soil or otherwise locally dispersed, they should be

retained in the closed container until all cinders have been

thoroughly cooled.

19. The instructions must be strictly adhered to. Do not use

makeshift methods or compromise in the installation.

20.

Do not abuse the door glass by striking, slamming or similar

trauma. Do not operate the insert with the glass removed,

cracked or broken.

18. SAVE THESE INSTRUCTIONS.

19. See the listing label on the appliance.

DO NOT OVER-FIRE THIS INSERT. Follow all

Page 3

CONGRATULATIONS!

When you purchased your new pellet stove, you joined the ranks of

thousands of individuals whose answer to their home heating needs,

aesthetics, efficiency and our environment. We extend our continued

support to help you achieve the maximum benefit and enjoyment available from your new pellet stove.

It is our goal at Lennox Hearth Products to provide you, our valued

customer, with an appliance that will ensure you years of trouble free

warmth and pleasure.

Thank you for selecting a Lennox Hearth Products stove as the answer

to your home supplemental heating needs.

TABLE OF CONTENTS

Important Safety Warnings ................................................... Page.2

Using this Manual ................................................................. Page 3

Planning Your Installation ..................................................... Page 4

Selecting a Location .............................................................. Page 4

Features and Specifications .................................................. Page.5

Insert Dimensions ................................................................. Page.6

Minimum Fireplace Size ........................................................ Page.6

Clearances to Combustibles .................................................. Page.7

Hearth Protection .................................................................. Page.7

Installation ....................................................................... Page.8-17

Control Board Installation.......................................... Page.8

Venting ...................................................................... Page.8

Vent Termination Requirements ................................ Page.8

Vent Termination Locations .......................................

Insert Leveling......................................................... Page.10

Surround Installation............................................... Page.10

Mobile Home Installations ....................................... Page.11

Outside Air Installations .......................................... Page.12

Thermostat installation ............................................ Page.12

Door Trim Installation Instructions .........................

Door Grill Installation Instructions .........................

Brick Panel Installation Instructions ........................

Log Set Installation Instructions ............................ Page.17

Operation ....................................................................... Page.14-19

Control Board .......................................................... Page.18

Filling the Hopper .................................................... Page.18

Lighting ................................................................... Page.18

Manual Operation .................................................... Page.18

Thermostat Operation ............................................. Page.18

Shut Down .............................................................. Page.19

Paint Curing ............................................................ Page.19

Convection Blower Operation .................................. Page.19

Operating Sounds ................................................... Page.19

Page 9

Page.12

Page.14

Page.15

Pellet Fuel ................................................................ Page.19

Corn Fuel ................................................................. Page.19

Cautions .................................................................. Page.19

Cleaning and Maintenance ............................................. Page.20-23

Burn Pot Cleaning ................................................... Page.20

Cleaning Glass......................................................... Page.20

Cleaning Heat Exchanger ......................................... Page.20

Cleaning Flue Gas Passageways .............................. Page.20

Cleaning Combustion Blower .................................. Page.21

Cleaning Vent Pipe .................................................. Page.21

Removing Ash from the Firebox .............................. Page.21

Cleaning Convection Blower .................................... Page.22

Adjustable Hopper ................................................... Page.22

Cleaning “Proof of Fire” Switch ...............................

Page 22

Front Door Opening and Removal ........................... Page.23

Side Door Removal ................................................. Page.23

Component Location and Functions ............................... Page.24-25

Igniter...................................................................... Page.24

Vacuum Switch ....................................................... Page.24

Auger and Auger Motor .......................................... Page.24

Over Temperature Snap Switch ............................... Page.24

Proof of Fire Snap Switch........................................ Page.24

Convection Blower Snap Switch .............................. Page.24

Draft Adjuster .......................................................... Page.25

Wiring Diagram ....................................................... Page.25

Diagnostic Codes ................................................................ Page.26

Troubleshooting .................................................................. Page.26

Replacement Parts .............................................................. Page.27

Accessories ......................................................................... Page.28

Heat Kit Instructions .......................................................... Page.29

Pellet Insert ZC Kit Assembly Instructions .......................... Page 30

ZC Framing Dimensions for

Combustible Hearth /Floor ........................................... Page.33

ZC Framing Dimensions for Non-

Combustible Hearth /Floor ........................................... Page.34

Product Reference Information ........................................... Page.36

USING THIS MANUAL

Please read and carefully follow all of the instructions found in this

manual. Please pay special attention to the safety instructions provided

in this manual.

PRODUCT IS SUBJECT TO CHANGE WITHOUT NOTICE

3

Page 4

PLANNING YOUR INSTALLATION

Questions To Ask Local Building Official

A correct installation is critical and imperative for reducing fire hazards and

perilous conditions that can arise when wood pellet burning appliances

are improperly installed. The installer must follow all of the manufacturers’ instructions.

WARNING

Check all local building and safety codes before

installation. The installation instructions and appropriate code requirements must be followed exactly

and without compromise. Alterations to the stove are

not allowed. Do not connect the stove to a chimney

system serving another stove, appliance, or any air

distribution duct. Failure to follow these instructions

will void the manufacturers warranty.

Surge Protectors - A surge protector is recommended to ensure the

stove’s electrical components are not damaged due to a surge in the

electrical supply. Only high quality protectors should be used - cheap

ones do not provide the protection needed.

Smoke Detectors - Since there are always several potential sources of

fire in any home, we recommend installing smoke detectors. If possible,

install the smoke detector in a hallway adjacent to the room (to reduce

the possibility of occasional false activation from the heat produced

by these appliances). If your local code requires a smoke detector be

installed within the same room, you must follow the requirements of

your local code. Check with your local building department for requirements in your area.

Installation / Maintenance Standards - National Fire Protection Association – The primary NFPA standard that refers to installation and maintenance of pellet appliances and venting is NFPA 211 – Latest Edition:

Chimneys, Fireplaces, Vents, and Solid Fuel appliances.

SELECTING A LOCATION

The installation of this appliance must conform to local codes and applicable state and federal requirements. Familiarity with these requirements

before installation is essential. Important considerations to discuss with

local building officials include:

Applicable codes (i.e. Uniform Mechanical Code, State or Regional

1.

Codes).

Electrical codes:

In USA, NEC, ANSI/NFPA 70 – Latest Edition

In Canada, CSA C22.1 – Latest Edition

Power Supply Requirements

The power cord must be plugged into a standard, 120 volt, 60 Hz grounded

electrical outlet. The power supply cord must be routed to avoid contact

with any of the hot or sharp exterior surface areas of the stove. When

installed in a manufactured home, the appliance must be electrically

grounded to the steel chassis (see Mobile Home Installations on Page

11, for additional requirements). These requirements must be met unless

otherwise specified by state or local authorities.

Electrical

• The fireplace insert requires 120 volts AC for operation.

• Maximum wattage is 700.

• Igniter wattage is 400.

• Normal operating wattage is 300.

Electrical Generator Operation

Your Winslow™ PI40 insert can be powered with a gas driven electrical

gererator. However, the generator’s electrical regulator may not be compatible with the insert’s electronics. The higher the quality of the gererator,

the greater the chance that it is compatible with the insert.

WARNING

Electrical grounding instructions: This appliance is

equipped with a three-prong (grounding) plug for

your protection against shock hazard and should

be plugged directly into a properly grounded threeprong receptacle. Do not cut or remove the grounding prong from this plug. Do not route power cord

under or in front of appliance.

2. Local amendments

3. Is a permit required - cost. You may wish to contact your insurance

company to ask if they require this.

4. If outside combustion air is required

5. Rooms where the installation is not allowed

4

The design of your home and where you place your stove will determine

its value as a source of heat. This type of appliance depends primarily on

air circulation (convection) to disperse its heat, and therefore, a central

location is often best. There are other practical considerations, which

must be considered before a final selection of locations is made.

• Existing Chimneys

• Pellet Fuel Storage

• Aesthetic Considerations

• Roof Design (rafter locations & roof pitch)

• Room Traffic

• Proximity to Combustibles

• Electrical Wiring

CAUTION

The body of these appliances are very heavy. The

use of a heavy duty escalara (stair step hand truck)

is recommended for lifting the appliance body.

NEGATIVE PRESSURE WARNING

This appliance is not designed to be operated in a negative pressure. Very

airtight homes with large kitchen exhaust fans, or homes with furnace

cold air returns located in close proximity to the stove may create negative pressure in the same room as the heating appliance. This can create

dangerous condition, drawing combustion by-products into the home. Be

sure your home has adequate makeup air to eliminate negative pressures

caused by the above-mentioned sources. Outside air connected to the

appliance probably will not resolve such a problem as the stove is not the

source of negative pressure. Lennox Hearth Products accepts no liability

for damages resulting from negative pressures described here.

Ventilation Requirements - Provide adequate air for combustion. The

fresh air requirements of this appliance must be met within the space where

it will be installed. Ventilation is essential when using a solid-fuel-burning

heater. In well insulated and weather tight homes, it may inhibit the rate

the exhaust flows through the venting system (caused by a shortage of

air in the home). The lack of air is caused by many common household

appliances which exhaust air from the home (such as a furnace, heat

pump, air conditioner, clothes dryer, exhaust fans, fireplaces, and other

fuel burning appliances). Also, the combustion process of this heater

uses oxygen from inside the dwelling. If the available fresh air delivery

in the dwelling is insufficient to support the demands of these appliances, problems can result (i.e. excessive negative pressure will result

in performance problems. To correct this problem it may help to open

a window (preferably on the windward side of the house) or install an

outside combustion air duct to the appliance.

Page 5

FEATURES AND SPECIFICATIONS

Installation Options

• Residential

• Vented vertical and horizontal (see venting instructions)

• Manufactured home and mobile home

• Thermostat or manual operation

• Bedrooms

Heating

• Max. feed rate is 4.5 pounds/hour or 37,500 BTU/hour

• Min. feed rate is 1.8 pounds/hour or 15,120 BTU/hour

• BTU CONTENT: There are a number of variations in pellet fuels that are

not included in PFI standards. For example, BTU (heat value) content

may range from just under 8,000 to almost 9,000 Btu, depending

upon species and region of the country and other variables.

Corn Specifications: Use only clean-shelled corn with a moisture content

less than 15% and approximate fuel value of 7000 BTU/lb (16,200 kJ/kg).

Do not attempt to burn corn with higher moisture content or burn lesser

grade fuels. Do not burn other types of agricultural pellets or by-products

(alfalfa, cherry pits, olive pits, nut shells, etc.) as they are not permitted

to be burned in these appliances.

Weight - 270 pounds

Venting

This appliance is approved for venting with Type L and Type PL pellet vent

pipe. The flue collar on the fireplace insert accepts 3” diameter pipe. The

vent pipe can be installed vertically or horizontally (see Venting section

for recommended installations).

The combustion air for this fireplace insert is drawn through a pipe at

the lower rear of the fireplace insert. For mobile home installations a 2”

ID flex line or pipe can be attached to the fireplace insert’s air intake to

draw air from outside the house.

Thermostat

This fireplace insert can be operated manually or with a thermostat.

Lighting

This fireplace insert is equipped with an electric self ignitor for ease of

ignition.

Fuel Specifications

This insert is designed to burn wood pellet fuel. In addition, a corn/wood

pellet mixture, with a maximum of 50 percent corn can be burned. Burning

any other fuel that is not approved for use with this appliance will void the

appliance warranty. IMPORTANT: The corn/wood mix needs to be mixed

evenly before being put in the Winslow™ pellet insert hopper.

Wood Pellet Specifications: This appliance has been designed to burn

wood residue pellets with up to 3% ash content. Dirty fuel will adversely

affect the performance of the insert. Any questions regarding pellet fuel

can be answered at the Pellet Fuels Institute (PFI), www.pelletheat.org.

CAUTION

THE USE OF UNAPPROVED, DIRTY, WET AND/OR

HIGH SALT CONTENT FUEL WILL VOID THE WARRANTY!

Wood pellets manufactured to the pellet fuels institute (P.F.I.) certification

standard are available in two grades, Standard and Premium. The primary

difference between the two is the ash content of the pellets.

The P.F.I. specification for standard grade and premium grade residential

pellet fuel is as follows:

• CHLORIDES (Salt): Less than 300 p.p.m. to avoid insert and vent

rusting.

• BULK DENSITY: 40 lb. / Cu. Ft. minimum

• MOISTURE CONTENT: 8% maximum

• ASH CONTENT: < 3% maximum (standard grade) < 1% maximum

(premium grade)

• FINES: 0.5% maximum through a 1/8” screen

Hopper Capacity

55 pounds (adjustable down to 40 pounds to fit into small fireplaces)

Listing Information

The Winslow™ PI40 insert is safety listed with the following agencies:

• OMNI-Test Laboratories, Inc., Portland Oregon to ASTM E 1509

• US EPA List of Exempt Wood Heating Appliances

• Colorado Approved Pellet Stoves

Appearance Options

The Winslow PI40 insert can be ordered with the following door trims, grills,

surround (flange) assemblies, log set and brick panel options :

Door Trim Kits Grill Kits

Black 79038 Black 79000

Gold 79034 Gold 79001

Nickel 79037 Nickel 79002

Brush Nickel 79035 Brush Nickel 79022

Black Nickel 79036 Black Nickel 79039

Surround Kits

29” Ht. x 41” Wd. Black Trim 79004

29” Ht. x 48” Wd. Black Trim 79005

33” Ht. x 41” Wd. Black Trim 79006

33” Ht. x 48” Wd. Black Trim 79007

32” ZC Surround Kit *

29” Ht. x 41” Wd. x 3” Deep 79032

* This black surround kit positions the insert 3” forward so that it will

allow the insert to fit into a fireplace with a narrower width in the front

(32” min.). Note: No trim kits are available for this kit at this time.

Surround Trim Kits

Trim/Black 29” Ht. x 41” Wd. H5143

Trim/Black 29” Ht. x 48” Wd. H5145

Trim/Black 33” Ht. x 41” Wd. H5144

Trim/Black 33” Ht. x 48” Wd. H5146

Trim/Gold 29” Ht. x 41” Wd. 75036

Trim/Gold 29” Ht. x 48” Wd. 75038

Trim/Gold 33” Ht. x 41” Wd. 75040

Trim/Gold 33” Ht. x 48” Wd. 75042

Trim/Nickel 29” Ht. x 41” Wd. 75037

Trim/Nickel 29” Ht. x 48” Wd. 75039

Trim/Nickel 33” Ht. x 41” Wd. 75041

Trim/Nickel 33” Ht. x 48” Wd. 75043

Log Set

Brick Panel Kit - Required

H5142

79030

5

Page 6

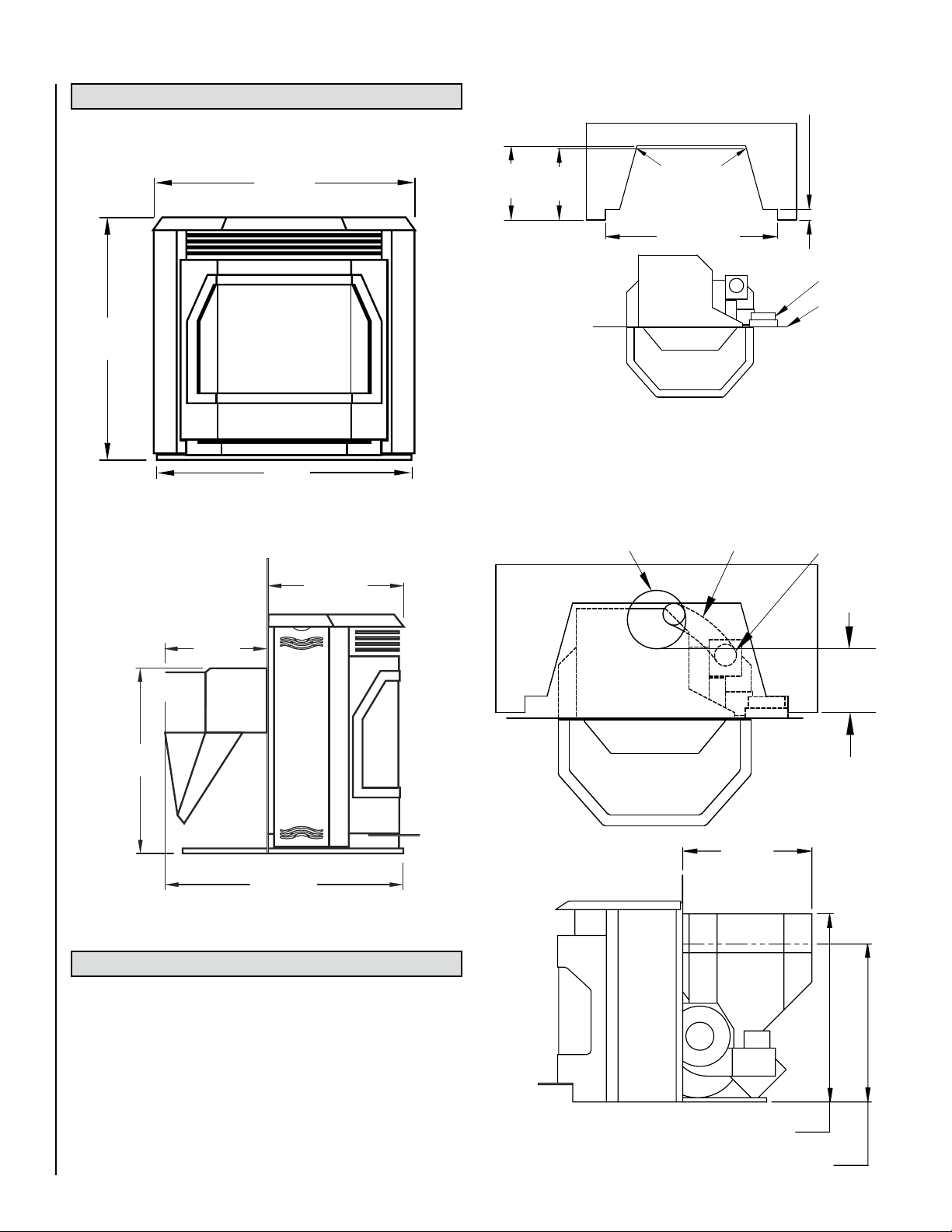

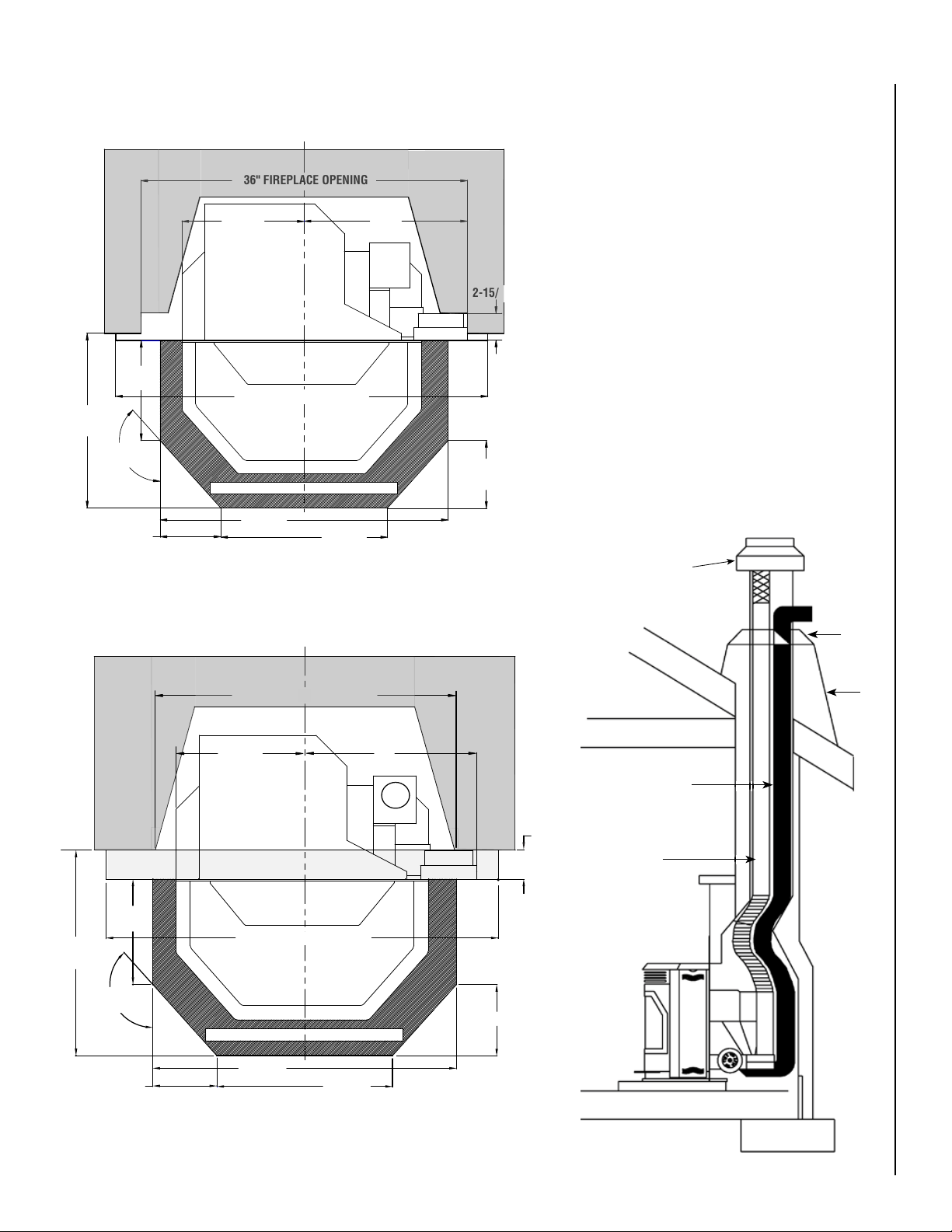

INSERT DIMENSIONS

2-1/2” Minimum Screen Pocket is Needed for the Control

Board (not applicable if P/N 79032 ZC Surround Kit is used*)

Front View

23-3/8”

(594mm)

Figure 1

26-1/4”

(667mm)

26”

(660mm)

Side View

14-3/8”

(365mm)

15-1/2”

(394mm)

* This fireplace insert can fit into a fireplace with a narrower width in the front

(32” min. instead of 36” min.) when the 3” Deep ZC Surround Kit is used (P/N

79032). See Figure 11C on Page 11 for more information. Please take note

that because the appliance will be positioned in a more forward position on

the existing hearth, additional floor protection may need to be added to the

front of the appliance (see Figure 7).

15”

(381mm)

23” (584mm)

Minimum

36” (914mm)

Minimum*

Control

Board

Side

Surround

Panel

Figure 3

Existing 8” Flue

Flex Pipe

Exhaust Collar

15-1/4”

(387mm)

19”

(483mm)

29-3/4”

(756mm)

Figure 2

MINIMUM FIREPLACE SIZE

Figures 3 and 5

Winslow™ PI40 insert when any of the four non-extended surround

sizes are used.

With the hopper at its largest size (as shipped from the factory), the

fireplace needs to be a minimum of 22-1/2” (572 mm) high. When the

hopper is adjusted to its smallest size (see “Adjustable Hopper”), the

fireplace needs to be a minimum of 19” (483 mm) high.

shows the minimum sized fireplace required for the

8-3/4”

(222mm)

Min.

Figure 4

15”

(381mm)

W/Hopper Extension 21-13/16” (554mm)

6

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Figure 5

W/O Hopper Extension 18-5/16” (465mm)

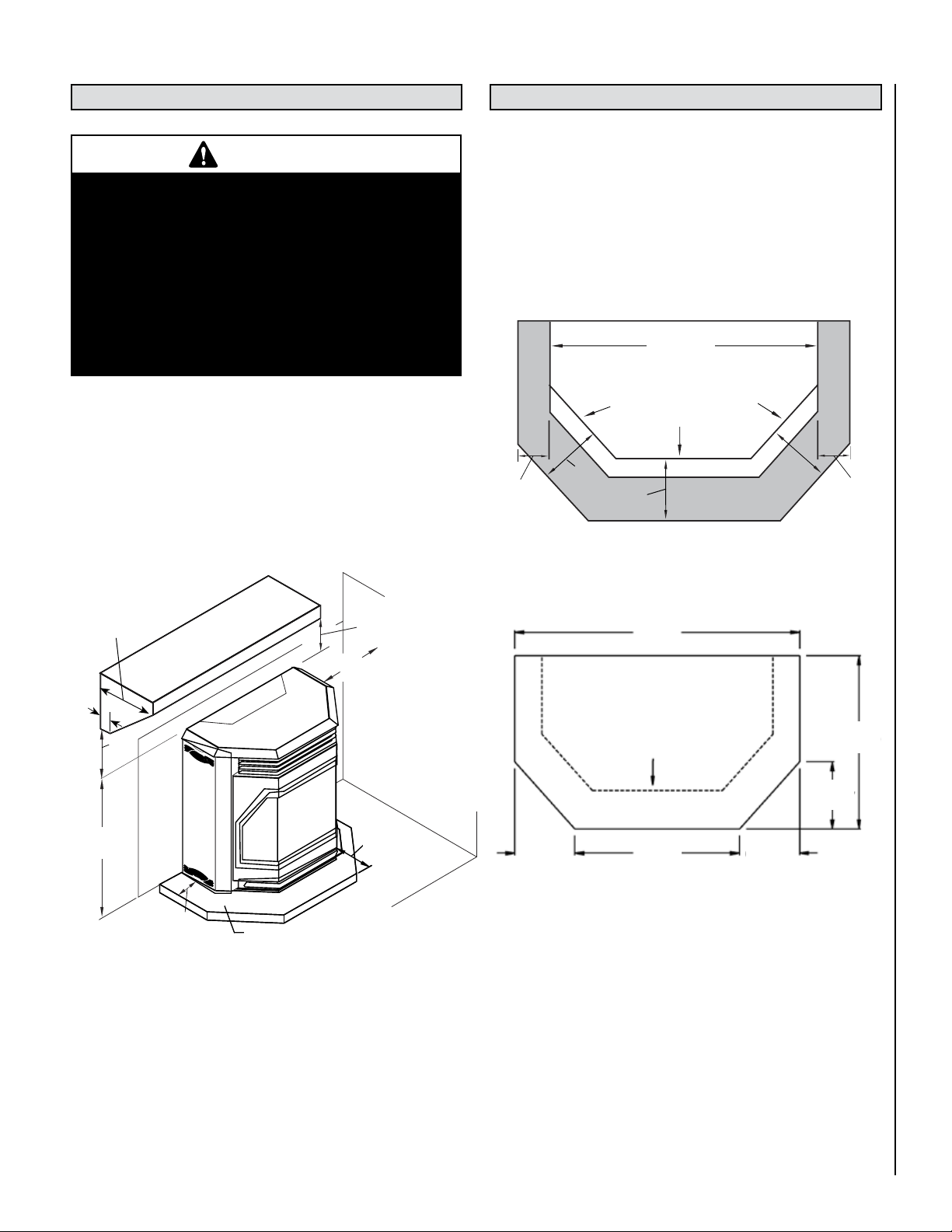

Page 7

Mantel

Floor Protection

Combustible

W

all

CLEARANCES TO COMBUSTIBLES

IMPORTANT

• Minimum clearances specified may not allow

for ease of operation and maintenance (please

take this in to account when planning the instal

lation).

• Recommended clearance zone from the front

of the appliance to combustibles is 4 feet mini

mum.

• Clearances to combustibles for the appliance

can only be reduced by means approved by the

regulatory authority.

HEARTH PROTECTION

The floor protector must be a non-combustible material extending

beneath the insert from the surround panels forward and to the front

and sides as shown in Figure 7. Important, if anything other than a

masonry hearth is used in the installation you must use the Heat Kit

(Cat. No. 79024).

-

Hearth Protection

-

(shaded gray)

Insert Base

INSTALL VENT AT CLEARANCES SPECIFIED BY THE VENT

MANUFACTURER.

Important: The control board attaches to the back of the right

side surround panel. Therefore, the width of the fireplace firebox

needs to be 36” (914 mm) wide at the front if the insert with control

board is to slide into the firebox. Extended surround panels are

available to accommodate narrower fireboxes.

10”

1-1/2”

(38mm)

(594mm)

(254mm)

Max.

6”

(152mm)

23-3/8”

9-1/2”

(241mm)

7-1/2”

(191mm)

6”

(152mm)

3”

(76mm)

Figure 7

6-11/16”

(170mm)

Figure 8

Firebox Front Edge

6”

(152mm)

6”

(152mm)

Minimum Size Floor Protection

(807mm)

Outline of Insert Base

(467mm)

Floor Protection

31-3/4”

18-3/8”

(152mm)

6-11/16”

(170mm)

6”

3”

(76mm)

19-1/4”

(489mm)

7-7/16”

(189mm)

Figure 6

3”

(76mm)

Zero Clearance Kit and Heat Kit Installation

The Winslow™ PI40 insert has a Zero Clearance Kit (Cat. No. 79025) and

a Heat Kit (Cat. No. 79024) approved for new construction or remodel

installations. See Zero Clearance and Heat kit installation instructions at

the back of this manual for requirements. Both kits have been tested and

approved through OMNI Testing Laboratories Inc.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

7

Page 8

INSTALLATION

Vent Termination Requirements:

If the insert is not vented vertically, the following apply:

Control Board Installation

The Winslow PI40 insert is shipped with the control board wrapped and

placed behind the firebox. To install the control board, unwrap it and

the right side surround panel found in the surround kit. There are four

prongs protruding from the surround. Place the two slots in the bottom

and the two holes in the top of the control board over the four prongs

on the surround panel. Install the surround panels following the instructions on Page 10.

Venting

Pellet pipe type PL, L, or listed pellet flex liner must be used to vent the

Winslow™ PI40 insert. The insert’s flue collar is 3” in diameter. The insert’s

combustion blower pressurizes and pushes flue gases out the pellet pipe.

All pipe joints should be locked together or screwed with three screws if

the pipe does not have a locking system. The pipe joints can be sealed

with high temperature silicone if there is a possibility of flue gases leaking

into the living area. The pipe should be fastened with three screws to the

insert’s flue collar. The longer the run of pipe and the more elbows used,

the greater the resistance to the flow of flue gases. Four inch diameter

pellet pipe is recommended for pipe runs greater than 15 feet or when a

number of elbows are used. A 3-4” increaser can be used to connect the

4” pipe to the 3” flue collar. The outside air pipe may run up the chimney,

horizontally, or down provided the structural integrity of the fireplace and

chimney system are maintained. DO NOT INSTALL A FLUE DAMPER IN

THE EXHAUST VENTING SYSTEM OF THIS UNIT. DO NOT CONNECT THIS

UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

1. Do not terminate the vent in any enclosed or semi-enclosed areas

such as a carport, garage, attic, crawlspace, narrow walkway, closely

fenced area, under a sundeck or porch, or any location that can build

up a concentration of fumes such as stairwells, covered breezeway,

etc.

2. Vent surfaces can become hot enough to cause burns if touched.

Non-combustible shielding or guards may be required.

3. Termination must exhaust above the inlet elevation. It is recommended

that at least five feet of vertical pipe be installed outside when the

insert is vented directly through a wall. This will create a natural draft

to prevent the possibility of smoke or odor during appliance shut

down or power failure and avoid exposing people or shrubs to high

temperatures.

4. The vent should terminate no less than four feet below, no less than

four feet horizontally from, and no less than one foot above doors

and windows, or gravity/ventilation air inlets into the building.

5. The distance between the bottom of termination and grade should be

12” minimum. The distance between the bottom of the termination

and a public walkway should be a minimum of seven feet.

6. Locate the vent termination at least two feet away from combustible

materials such as shrubs, plants, grass, fences, roof overhangs, and

adjacent buildings.

8

Page 9

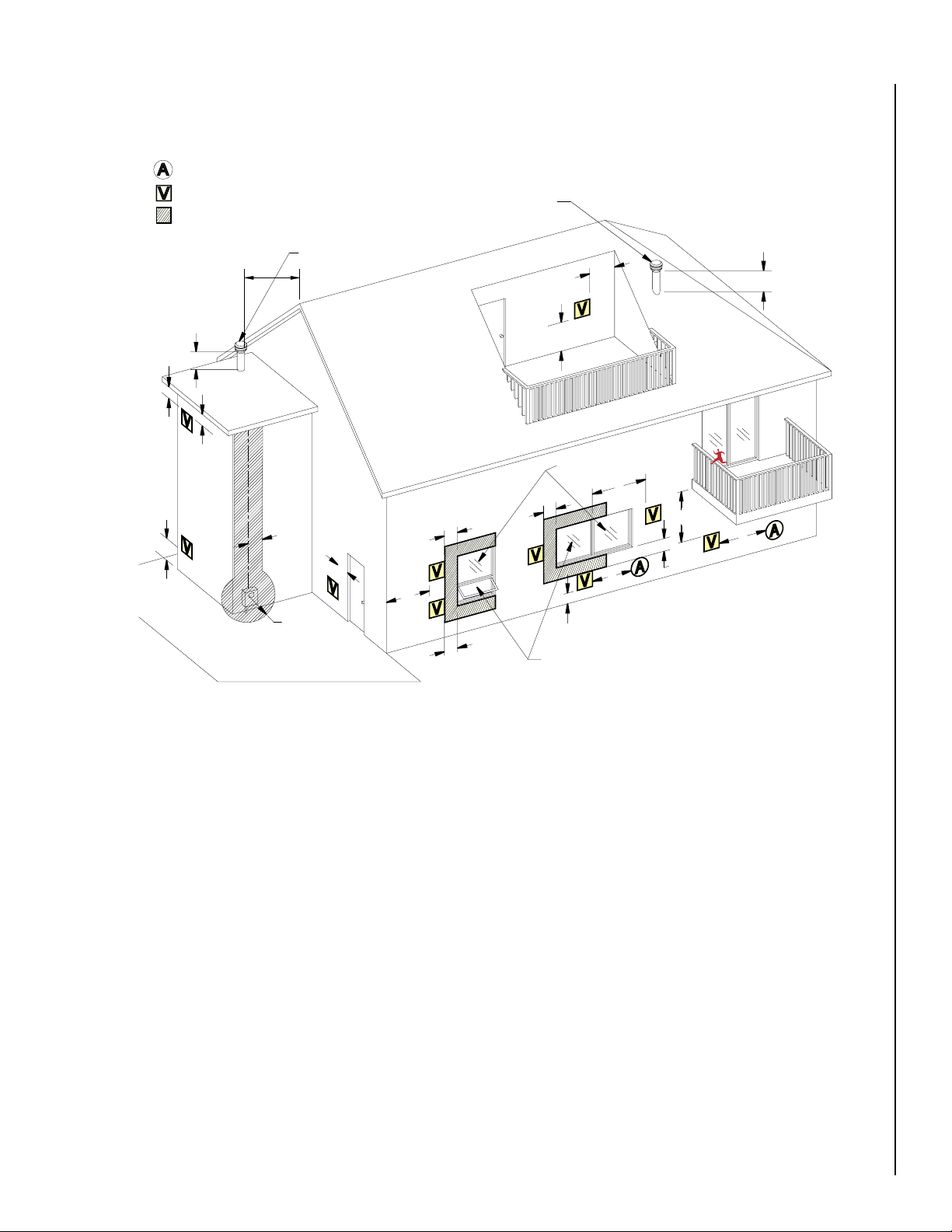

Vent Terminal

Area Where Terminal Is Not Permitted

(From Eave)

Vertical Terminal

Vertical Terminal

Fixed Closed

Able To Open

A

A

B

B

B

B

C

D

E

F

G

H

J

K

L

M

N

24”

(610mm)

B

Air Supply Inlet

24”

(610mm)

Vent Termination Locations

A = Clearance above grade, veranda, porch, deck, or balcony (min.

12”/30cm)

B = Clearance to window or door that may be opened (min. 12”/30cm

above - 48”/1.2m below and to the side)

C = Clearance to permanently closed window *(min. 12”/30cm)

D = Vertical clearance to ventilated soffit located above the terminal

within a horizontal distance of *(min. 24”/60cm) from the center-

line of the terminal (min. 22”/55cm) check with local code.

E = Clearance to unventilated soffit *(min. 12”/30cm)

F = Clearance to outside corner *(min. 12”/30cm)

G = Clearance to inside corner *(min. 12”/30cm)

H = Not to be installed above a meter/regulator assembly within *(min.

36”/90cm) horizontally from the centerline of the regulator.

J = Clearance to service regulator vent outlet *(min. 72”/1.8m)

K = Clearance to non-mechanical air supply inlet to building or the

combustion air inlet to any other appliance *(min. 48”/1.2m)

Figure 9

L = Clearance to a mechanical air supply inlet *(min. 120”/3.1m)

M = **Clearance above paved sidewalk or a paved driveway located on

public property *(min. 84”/2.1m)

N = ***Clearance under veranda, porch, deck, or balcony (min.

12”/30cm)

Note:

* Local codes or regulations may require different clearances.

** A vent shall not terminate directly above a sidewalk or paved

driveway which is located between two single family dwellings

and serves both dwellings.

*** Only permitted if veranda, porch, deck, or balcony is fully open on

a minimum of two sides beneath the floor.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

9

Page 10

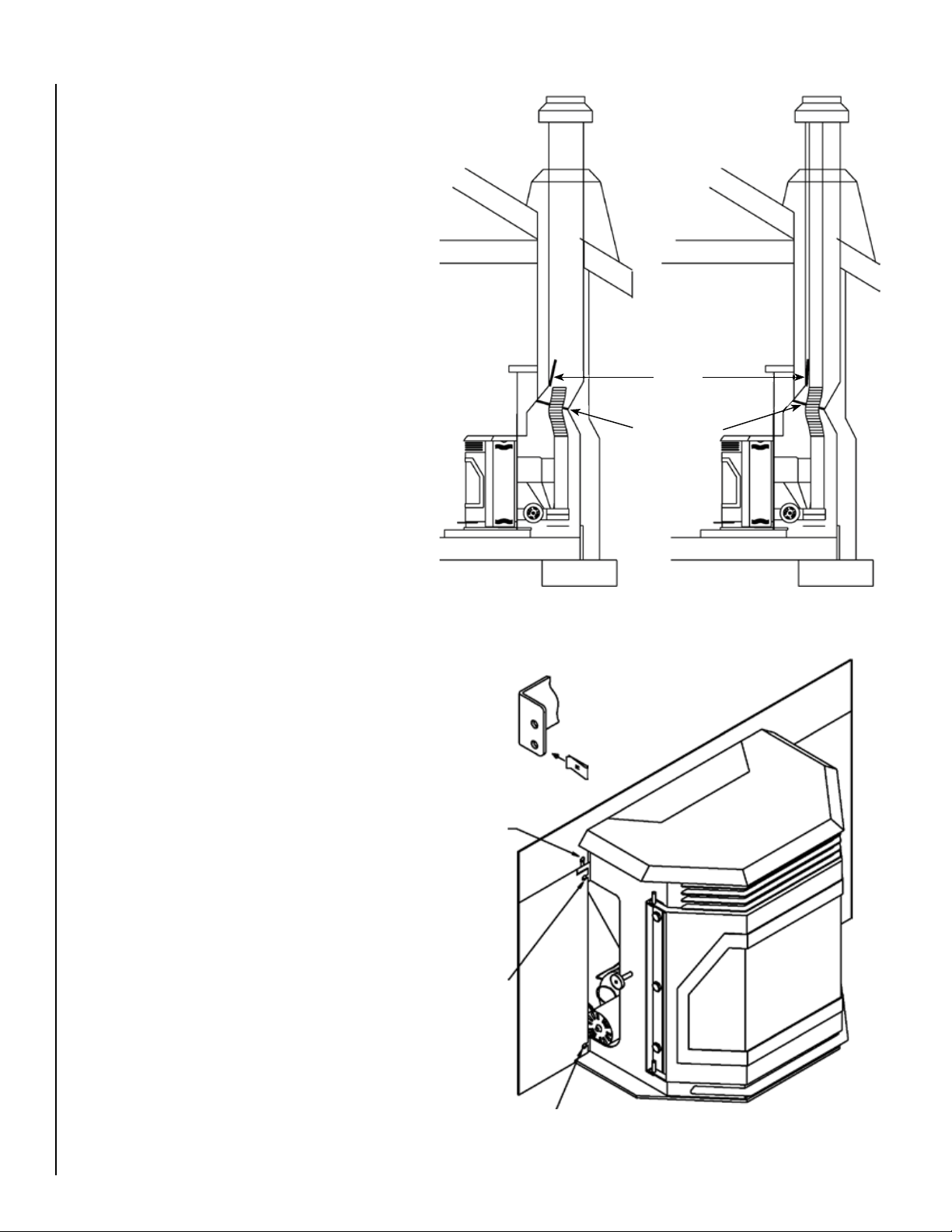

The recommended pipe installation is running the pellet pipe

from the insert all the way to the top of the chimney. However,

the pipe may terminate inside the chimney above the damper if

the chimney is sealed below the pellet pipe termination with a

block off panel (see Figure 10). The insert can also be vented

horizontally out the back of the fireplace, but a listed pellet pipe

thimble must be used if the pipe goes through a combustible wall

and the structural integrity of the fireplace and chimney system

must be maintained.

Insert Leveling

Inside the firebox is a bag of hardware with four 4”x 3/8” carriage

bolts. If the insert needs to be leveled, install one of these bolts

(from the bottom side) in the nuts at the left and right rear of the

base of the insert. Open the front door and remove the bolts screwed

into the nuts at the left and right front of the firebox floor.

From the bottom outside of the insert, install the remaining two

carriage bolts in the nuts from which the bolts were just removed.

A zero clearance front support is available to fill the space between

the insert and hearth.

Surround (Flange) Installation

To install the surround panels:

1. Remove the side doors (see Page 23

mounting brackets. Remove the speed nuts from the parts bag

found in the firebox. Install the six speed nuts (with the flat

surface forward) on the six surround mounting bracket holes,

three on each side of the insert. A flat-bladed screwdriver may

help in installing the nuts. See the expanded view in Figure

11A.

2. Screw the six 1/4” truss head screws partially into the speed

nuts (see A in Figure 11A).

3. The side surround panel with the small access door for the

control board goes on the right side of the insert (see Figures

11B and 11C

). Slide the slots in the side surround panels and

top surround panels behind the heads of the truss screws.

Tighten all six truss screws after shifting surround panels to

eliminate space between the side and top surround panels.

4. Install two spring clips approximately five inches from each

end of each of the three trim pieces. The spring clips should be

installed in the channel of the trim with the curved portion of

the clip to the front toward the rounded surface of the trim.

5. Place the longest trim piece with the rounded surface out along

the edge of the top surround panel with the spring clips slightly

behind the surround panel. Pull the trim forward, compressing

the spring clips, and slide the trim down onto the surround.

6. Insert the elbowed retainer in the mitred end of the side trim

pieces and fasten with flat screwdriver. Insert the other end

of the retainer in the end of the already installed top surround

trim and slide side trim onto the edge of the side surround

compressing the spring clips in the process. Repeat the same

steps for the other side trim. Fasten the elbowed retainer

securely in the top surround making a nice mitred corner.

) to access the surround

*The block off panel should be

air tight to ensure smoke does

not enter the house and to help

establish chimney draft when the

pipe does not terminate at the top

of the chimney.

Damper

Block Off Panel*

Figure 10

Speed Nut

Expanded View

A

A

10

Figure 11A

A

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 11

Cap

Flashing

Outside Air Pipe

Listed Pellet Pipe or

Flex Liner

Storm Collar

CONTROL BOARD

36" FIREPLACE OPENING

18"

13-1/2"

FIREPLACE OPENING C/L

19-1/4"

18-3/8"

HEARTH / FLOOR PROTECTION

31-3/4"

11"

7-7/16"

6-11/16"

138°

41" SURROUND WIDTH

2-15/16"

CONTROL

BOARD

18"

13-1/2"

FIREPLACE OPENING C/L

21-1/2"

18-3/8"

HEARTH/FLOOR PROTECTION

31-3/4"

11"

7-7/16"

6-11/16"

138°

3"

41" SURROUND WIDTH

32" FIREPLACE OPENING

DEEP

SURROUND

Fireplace Installation Using Standard Surround Kits

(P/N 79004, 79005, 79006 and 79007)

Mobile Home Installations

The following steps are required for installation of the Winslow™

PI40 insert in mobile homes. See Figure 12.

1. Connecting the Winslow PI40 insert to outside combustion

air is optional, except in mobile home installations and when

required by local building codes. The insert’s air intake will

accept 2” ID pipe to accommodate outside air installations.

The air intake on the exterior of the home should always

be located substantially below the flue termination and

terminate with a cover to keep out weather and pests.

2. The insert must be fastened to the hearth/floor using lag

screws. The screws can be inserted through the holes in

the base located behind the side doors. If the hearth is

concrete or masonry, use proper lag bolts and methods

designed for anchoring to masonry or concrete.

3. The insert must be grounded with a #8 or larger copper

wire.

WARNING: DO NOT INSTALL THIS INSERT IN A SLEEPING ROOM IN A MANUFACTURED HOME.

CAUTION: THE STRUCTURAL INTEGRITY OF THE

MANUFACTURED HOME FLOOR, WALL, AND CEILING/ROOF MUST BE MAINTAINED.

Figure 11B

Fireplace Installation Using 3 Inch Deep ZC Surround Kit

(P/N 79032 *)

Termination Cap

* This black surround kit positions the insert 3” forward so that it will allow the insert to fit

into a fireplace with a narrower width in the front (32” min.). Note: No trim kits are available for this kit at this time. See instruction sheet P/N 506033-05 for more information.

Figure 11C

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Figure 12

11

Page 12

Wiring Block

Rear View of Control Board

Pellet Stove Door

Trim Pieces

Outside Air Installations

Door Trim Installation Instructions

Connecting the Winslow PI40 insert to outside combustion air is optional,

except in mobile home installations and when required by local building

codes. The fireplace insert’s air intake will accept 2” ID pipe to accommodate

outside air installations. The air intake on the exterior of the home should

always be located substantially below the flue termination and terminate

with a cover to keep out weather and pests. The outside air pipe may run

up the chimney, horizontally, or down provided the structural integrity of

the fireplace and chimney system are maintained.

Thermostat installation

The Winslow PI40 insert can be operated manually or by thermostat.

The insert comes from the factory wired to operate manually, see control

board operation on Page 18. A low voltage thermostat can be installed

on the insert. To install the thermostat:

1. Unplug the insert from the electrical outlet. Open the right side door

and lift out the control board from its retaining brackets. Locate the

light green wiring block at the bottom back of the board (see Figure

13), loosen the two screws B at the back of the block, and remove

the U shaped jumper wire A protruding from the block.

2. Insert a wire from the thermostat into one of the slots from which the

jumper wire was removed. Repeat this process for the other thermostat

wire.

Retain the jumper wire for future reinstallation. See Page 18 for thermostat operation instructions.

IMPORTANT NOTE: Install the thermostat per the manufacturers

instructions, provided with the thermostat. Failure to follow

manufacturers instructions could result in a malfunction. Pay

special attention to the thermostat location requirements. If the

location requirements are not adhered to the appliance, erratic

operation or failure may occur.

Parts List (A)

Qty

(2) Trim Pieces (Gold, Nickel, Brushed Nickel or Black Nickel)

(6) #10 nuts

(6) #10 washers

Tools Needed

Qty

(1) 3/8” nut driver or socket wrench

CAUTION: Always ensure that plated surfaces are clean and

free of fingerprints before lighting the insert. Fingerprints

will leave permanent blemishes if left on plated surface when

lit. When installation is complete, the trim should be gently

cleaned with soft cloth and either alcohol or glass cleaner. Do

not overtighten nuts, overtightening can create visible dimples

on the plated surface.

To Install Door Trim:

1. Remove the trim pieces and hardware from its packaging and ensure

that all pieces are present before beginning installation. Take care not to

scratch finished surfaces.

2. Open right and left side door. The side doors swivel open towards the

back of the insert. See Figure 16.

3. Open front door. Put trim in place by inserting trim studs into the cor-

responding holes in the door (Figures 14 and 15). The top piece of

trim will only fit in one direction, but the bottom piece can be installed

incorrectly. When placing the bottom piece of trim, make sure there

is a 9/16” gap between the top of the trim piece and the glass in the

door. See Figure 18.

Do not mount the thermostat where it may be affected by:

• Radiant heat from the insert, fireplaces, sun or other heat

sources.

• Drafts or dead spots behind doors or in corners.

• Hot or cold air from ducts.

Figure 13

12

Rear View of Control Board

A = Jumper Wire

B = Screws

Wiring Block

A

Pellet Insert Door

Trim Pieces

Figure 14

B

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 13

A

Figure 15

Trim Pieces

Trim Nuts

Holes for trim studs

#10 washers

4. Place one washer on each stud. Using a 3/8” nut driver, snug up the

nuts on each piece of trim. Do not finish tightening the nuts yet. See

Figure 19

.

5. There should be approximately a 7/8” (22 mm) gap between the top

edge of the upper trim and the top edge of the door and a 1-1/2” (38

mm) gap between the bottom trim to the bottom of the door. Visually

inspect the alignment of the trim and adjust if necessary. See Figure

20.

6. Finish tightening nuts.

CAUTION - DO NOT OVER-TIGHTEN NUTS,

DIMPLING OF THE TRIM WILL OCCUR!!!

Figure 16

Figure 17

Door Handle

Figure 19

Trim stud

Top of Trim

Figure 18

Figure 20

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

13

Page 14

Door Grill Installation Instructions

Parts Needed

Qty

(4) Button Head Screws (already in place in insert)

3. Rotate the grill back to the horizontal position and re-install the four

button head screws through the two holes at each end of the grill and

into the insert body. See Figures 23 and 24.

Tools Required:

1/8” allen wrench

To install the Grill:

1. Remove the four button head screws from body of the insert with a

1/8” allen wrench. See Figure 21.

Button Head Screw

Figure 21

2. Pull the scraper rod out, rotate the grill vertically, (with the notch to

the left) and slide the grill over the scraper rod (slide the rod between

the third and fourth bar). See Figure 22.

Rotate Grill Back To Horizontal Position

Figure 23

Re-install Button Head Screws

14

Figure 22

Notch

Slider Rod

Between 3rd & 4th Bar

Figure 24

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 15

Brick Panel Installation

A

B

Option: Part #79030

Kit Contents

Brick Panel (A)

4 Tap Tights (B)

Tools Required

Drill (90° drill recommended)

#18 drill bit

5/32 allen wrench

Figure 25

2. Remove all pellets and ash from the firebox to ensure a proper fit for

the brick panel.

3. Insert the brick panel, top first, as shown in Figure 27

out corners should be at the bottom.

. The two cut

Figure 27

Note: The brick panel comes pre-painted with Metallic Black paint. The

brick panel may be painted with any color of high-temp paint (paint

may discolor with use).

1. Remove the front door of the pellet insert. To remove the front door,

open the two side panels, swing open the front door, and lift it up and

off of its hinges. Remove the optional log set, if present, and the burn

pot.

4. Make sure that the brick panel is centered, with equal space on either

side of the auger tube. While holding the panel in place, use the drill

with a #18 drill bit to drill out the four holes in the back of the firebox,

as shown in Figure 28.

Figure 28

Figure 26

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

15

Page 16

5. Screw in the four tap tights, included with this kit, using a 5/32 allen

wrench.

Figure 29

6. Replace the burn pot and check that it is firmly in place (if you can

rotate the burn pot it is not installed correctly). If present, install

the optional log set according to the log set installation instructions

(included with your log set).

7. Re-hang the door by reversing the instructions in step 1.

16

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 17

Log Set Installation Instructions

Kit Contents

(refer to Figure 30)

Cat. No. #H5142

Qty

(1) left log (B)

(1) right log (C)

(1) front log (D)

(2) log support brackets (E)

cut lines

B

D

E

C

Figure 30

Tools Required

None

CAUTION: The logs can be damaged if they are not handled

with care!

Figure 31

Figure 32

Bracket correctly placed

E

B

C

To Install the log set:

1. Remove the two log support brackets from the box and bend the ends

of the brackets 90 degrees at the cut lines. See Figure 31.

2. One bracket goes into the left corner and the other into the right corner

of the firebox. Rotate the brackets so they are placed as shown in

Figure 32

. The bracket fits between the back of the firebox and the

air wash at the front of the insert.

3. Remove the ceramic logs from the box and carefully unwrap them.

Position each back log (Figure 33, B, C) in their proper place, one

on each side against the back of the firebox.

4. The front log should face the front of the firebox with the wood grain

showing. It should rest on the other two back logs. See Figure 33

for assembled log set.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

D

Figure 33

17

Page 18

OPERATION

Heat Selector

Knob

Igniting Ready Feeding

Start

Control Fuse

Igniter Fuse

Off

High

1

2

3

4

Control Board

The control board regulates all functions of the insert. The following is

a list of the board’s components:

2. Push the start button and the ignite and feeding lights will come on

and the lighting sequence will begin. For about the next 15 minutes the

insert will feed pellets cyclically into the burn pot, the combustion fan

will come on, and the igniter will heat up. During this sequence, some

smoke in the firebox is to be expected. After the igniting sequence is

complete, the insert will begin burning at the level indicated by the

heat selector knob.

•

Feeding light - lights up when the auger is feeding pellets into the

burn pot.

Ready Light - lights up when insert is ready to operate.

•

Igniting Light - lights up when the insert is in the ignition sequence.

Start Button - is pushed to start the ignition sequence after the heat

•

selector knob is turned from off.

Heat Selector Knob - is turned to off to shut the insert off or turned

to a setting from 1 to high to regulate the burn

rate.

Igniter Fuse - six amp fuse to protect igniter heating element.

•

Control Fuse - three amp fuse to protect the control board.

•

Note: Upon the insert’s initial light up, or if the insert has previously run

out of pellets, the auger feed tube may not contain a sufficient number of

pellets to allow the insert to continue burning after the ignition sequence.

It may be necessary to push the start button a second time to run the start

sequence again. It is important to always empty (when cool) the burn pot

of pellets before pushing the start button a second time.

WARNINGS

• Never empty pellets from the Burn-Pot into the hopper.

Pellets that may appear to be cool may retain enough

heat to ignite other pellets resulting in smoke or fire

damage.

• DO NOT OVERFIRE THIS STOVE. This may cause

serious damage to your stove and void your warranty.

It also may create a fire hazard in your home. IF ANY

EXTERNAL PART OF THE UNIT BEGINS TO GLOW, YOU

ARE OVERFIRING. Immediately slide the knob to the

"OFF" position on the control board.

Manual Operation

After the insert is burning (see Lighting on this page), the heat selector

knob controls the pellet burn rate and the insert’s heat output. Turning the

knob to setting 1 allows the insert to burn about 1.8 pounds of pellets per

hour - about 8,500 BTUs per hour. Turning the knob to high allows the

insert to burn 4.7 pounds of pellets per hour - about 39,000 BTUs per hour.

Once set, the insert will continue to burn at this rate until shut off.

Figure 34

Filling the Hopper

The hopper can be accessed by lifting the lid at the rear of the top of the

insert. The hopper will hold 60 pounds of pellets. Remove any contents

from the hopper and fill with pellets.

Lighting

1. Turn the heat selector knob (see Figure 34) to the heat level desired

- 1 through high - and the ready light will turn green.

18

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Thermostat Operation

This insert will operate with a low voltage thermostat. See Page 12 for

instructions on installing the thermostat. Once installed, the thermostat

will control the operation of the insert. Important: When connected to a

thermostat, it is necessary to push the ignite button for the initial burn,

when the electrical flow to the insert is interrupted, if the selector knob

is turned to off (and then back on), or if the insert runs out of pellets and

therefore shuts off. After the initial ignition sequence, when the thermostat

calls for heat (the room temperature is less than the temperature set on

the thermostat) and the heat selector knob is not in the off position, the

insert will burn at the heat selector knob setting. The higher the setting,

the quicker the room will heat up. Once the thermostat no longer calls for

heat (the room is up to the desired temperature), the insert will continue

to burn for one additional hour at the lowest setting. If the thermostat

does not call for heat again during that hour, the insert will shut off. During that hour, if the thermostat calls for heat again, the insert will again

burn at the heat selector knob setting until the thermostat no longer

calls for heat. If the insert shuts off after that hour it will relight when

the thermostat calls for heat.

Page 19

Shut Down

Normal - To turn the insert off, turn the heat selector knob to off. The

fans will continue to operate until the control board completes the shut

down cycle.

Once you find a pellet brand that burns well, continue using this brand.

High ash fuel increases the frequency of insert cleaning. Fuel with an

excessive moisture content may jam the auger assembly.

Corn Fuel

Power Outage - If the insert loses electrical power for less than 10 seconds

it will continue to operate. If the power loss is greater than 10 seconds,

the insert will go into the ignition sequence and normal operation when

the power is restored. If the insert is connected to a thermostat, the insert

will not start the ignition sequence until the thermostat calls for heat.

Paint Curing

This insert has been painted with a high temperature metallic paint. It

leaves the factory dry to the touch, but completes the curing process as

the insert is used. The paint will cure during the first few times the insert

is burned. Also some parts of the appliance may be lightly coated with

machining oil. Ventilate the house during these first firings as the paint

and oil give off carbon dioxide and unpleasant odors. It is recommended

that persons sensitive to an imbalance in the indoor air quality avoid the

insert during the curing process.

Convection Blower Operation

Your Winslow™ PI40 insert comes equipped with a temperature activated

convection blower that extracts heat from the insert. After the insert

warms up, a heat activated switch will turn the fan on. The speed of the

fan varies with the burn rate of the insert. The fan will continue to extract

heat after the insert shuts off and until it is cooled down.

Operating Sounds

As the Winslow PI40 insert is burning, a number of normal operational

sounds may be heard. Pellets can be heard sliding down the auger tube

and into the burn pot. Also, the motor powering the auger can be heard

as the control board calls for pellets. Occasionally a loud noise can be

heard as the auger cuts a pellet in half. When the blowers come on, the

sound of rushing air may be heard. The lower the burn rate the slower

the fan operates. Hourly, the combustion fan will blow at a high speed

to clean ash from the burn pot.

Pellet Fuel

Pellet fuel is made from sawdust and scrap wood from many different

species of wood. Pellets are either 1/4” or 5/16” in diameter and vary

in length (see Fuel Specifications on Page 5). The Winslow PI40 insert

will burn either diameter pellets. Pellets made from hardwoods contain

more ash than those made from softwoods. Minerals from ash and sand

in the pellets form clinkers under the extreme temperatures in the burn

pot. Try burning various brands of pellets until you find one that burns

with minimum ash and clinkers.

Shelled corn can be burned in the Winslow PI40 insert when it is mixed

with wood pellet fuel (see Fuel Specifications on Page 5). The mixture

can contain a maximum of 50 percent corn. Burning corn may create

more ash than wood pellets and may necessitate the need to clean the

burn pot and glass more frequently.

CAUTIONS

INSTALLATION AND REPAIR SHOULD ONLY BE PERFORMED

BY A QUALIFIED SERVICE TECHNICIAN. DO NOT ATTEMPT TO

SERVICE THE APPLIANCE YOURSELF.

Avoid overfiring the insert - do not hand feed pellets to the

appliance.

Never use gasoline, gasoline-type lantern fuel, kerosene,

charcoal lighter fluid, or similar liquids to start or fresh up a

fire in this heater. Keep all such liquids well away from the

heater while it is in use.

For your safety, do not install or operate your Winslow PI40

insert without first reading and understanding this manual.

Any installation or operation of the appliance deviating from

that which is stated in this instruction manual WILL void the

warranty and may be hazardous.

Due to high temperatures, the insert should be located out of

traffic areas and away from furniture and draperies. Children

and adults should be alerted to the hazards of high surface

temperature and should stay away to avoid burns or clothing

ignition. Young children should be carefully supervised when

they are in the same room as the Winslow PI40 insert. Clothing

or any other flammable material should not be placed on or near

the insert. Any grill, panel, or glass removed for service MUST

be replaced prior to operating the insert.

Do not operate appliance with the glass front removed, cracked,

or broken. Replacement of the glass should be done by a qualified service technician.

Lennox Hearth Products, its employees, or any of its representatives assume no responsibility for any damages caused by

an inoperable, inadequate, or unsafe condition as a result of

any improper operation, service, or installation procedures,

whether direct or indirect.

The appliance, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes, with

the National Electrical Code, ANSI/NFPA 70-latest edition.

19

Page 20

A

CLEANING AND MAINTENANCE

Unplug and let the Winslow™ PI40 insert cool before performing any

maintenance or cleaning. Some brands of pellets produce more ash and

clinkers than others. Therefore the frequency of performing the following cleaning procedures depends to a great degree on the quality of the

pellets burned. Not cleaning this unit will cause it to burn poorly and

will void your insert’s warranty.

Burn Pot Cleaning

The combustion fan comes on at high speed once an hour to blow the

byproducts of combustion out of the burn pot. However, the burn pot

should be cleaned more thoroughly after burning about 10 bags of pellets. The burn pot has a number of holes in the bottom and sides that

provide combustion air to the pellets. The extreme temperatures in the

burn pot can cause the impurities in the pellets to form ash and clinkers.

When the insert is cool, open the front door and lift out the cast iron burn

pot. Scrape the inner bottom and sides of the pot with a screwdriver to

remove all ash and clinkers from these surfaces. Make sure all the holes

in the pot are open. Place the burn pot in the hole from which it was

removed. Make sure the high side of the pot is rotated toward the front

of the insert (see Figure 35). Push the burn pot down so surface A is

tight against the steel supporting the pot. Do not substitute any other

grate or pot for use in this insert.

Reinstall the ash drawer by inserting the drawer in the insert and refastening the left and right latches securely. Note that if the ash drawer

does not seal tightly to the insert, the control board may detect a leak

and shut the insert down.

High Side Of Burn Pot Goes

Toward Front Of Insert

A

Figure 35

Cleaning Glass

CAUTION: Do not open the front door when the fireplace insert

is hot. To open the door, follow the first two steps listed in Front

Door Removal on Page 23. Clean the glass using a soft cloth

or paper towel and a household glass cleaner or gas stove

window cleaner. A damp cloth with a small amount of ash from

the firebox can also be used to clean the glass.

Cleaning the Heat Exchanger

CAUTION: Do not operate the heat exchange scraper when the

insert is hot. Located at the center of the Grill on the top front of

the insert is a bent rod that is attached to a scraper on the heat

exchange tubes. To remove ash build-up and maintain efficient

heat extraction from the insert, this rod should be pulled in and

out at least weekly.

Cleaning the Flue Gas Passageways

Cleaning the flue gas passageways should be done at least once a year.

Burning high ash pellets may require this cleaning to be done more often.

Clean these passageways only when the insert and ash are cold, do not

start a fire in the vacuum cleaner by vacuuming up hot ash.

B

On each side of the insert there are two access covers (see B and C in

Figure 36

screws. Insert a cleaning brush in the openings to loosen any ash buildup and use a vacuum cleaner to remove the loosened ash. Reinstall the

covers when cleaning is complete.

20

) that can be removed by unscrewing the two 5/32” allen head

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

C

Figure 36

Page 21

Cleaning the Combustion Blower

Removing the Ash from the Firebox

To clean the combustion blower, unplug the insert from the power source

and remove the six nuts labeled A in the drawing to the right with an

11/32” wrench. After removing these nuts, the motor with fan attached

can be pulled from the fan housing. The fan blades and the fan housing

can be vacuumed once the motor is removed. When reinstalling the motor, a new gasket may need to be installed between the motor and the fan

housing. To complete the reinstallation, place the motor back on the fan

housing and reinstall the six nuts. Make sure the motor’s green ground

wire is secured under one of the nuts.

Cleaning the Vent Pipe

Soot and Flyash: Formation and Need for Removal

The products of combustion will contain small particles of flyash. The

flyash will collect in the exhaust venting system and restrict the flow of

the flue gases. Incomplete combustion, such as occurs during start-up,

shutdown, or incorrect operation of the room heater will lead to some soot

formation which will collect in the exhaust venting system. The exhaust

venting system should be inspected at least once every year to determine

if cleaning is necessary. Sweep the pipe as needed.

The insert has a clean-out box to which the flue pipe or flex pipe is attached. To access the clean-out box, remove the right side surround panel

and right door. Figure 37 shows the box in the upright position attached

to the flue fan. Figure 38 shows the box from the bottom, revealing the

latch securing the box door. Pull the latch down to open the box. When

the ash is cold, use a vacuum cleaner to remove the ash from the box.

Refasten the box door by rotating the latch handle up.

CAUTION: Do not remove the ash when the insert or ash is hot.

To remove the ash, swing open the left and right side doors and

open the front door. Vacuum or scoop out the ash on the bottom

and side of the firebox.

CAUTION: Disposal of ashes should be placed in a metal container with a tight fitting lid. The closed container should be

placed on a non-combustible floor or the ground, well away from

all combustibles materials, pending final disposal. If the ashes

are disposed of by burial in soil or otherwise locally dispersed,

they should be retained in the closed container until all cinders

have been thoroughly cooled.

A

Required Cleaning Schedule After Number Of Bags Burned:

Burn Pot = 10 bags

Ash Drawer = 50 bags

Traps = 50 bags

Flue Fan = 100 bags

Blower = 100 bags

Cleaning schedule will vary depending on quality of pellets used.

Note:

Burning high ash pellets will require more frequent cleaning.

Figure 37

Top

Rotate

Latch

Handle

Bottom

Figure 38

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

21

Page 22

Cleaning the Convection Blower

To clean the convection blower, remove the left side door (see the following

page). Disconnect the insert power cord from the electrical outlet. Loosen

the two screws (A in Figure 39) securing the blower to the blower duct.

Slide the blower toward the outside of the insert - disengaging it from the

blower duct. A vacuum can be used to remove any dust accumulation on

the blower’s blades or inside the blower duct. Caution should be used not

to damage the blower’s blades during cleaning. To reinstall the blower,

slide the blower back into the retaining lip B and retighten screws A.

Adjustable Hopper

The Winslow™ PI40 insert is shipped with the 55 pound hopper. With

the larger hopper installed, that part of the insert that slides into the

fireplace is 22-1/2” (572 mm) high. For installations in smaller fireboxes,

the hopper is adjustable down to a height of 19” (483 mm). To adjust the

hopper to its lowest height of 19” (483 mm), remove screws C around

the hopper lid and lift the lid off. Next, remove the screws D around the

hopper extension and remove the extension. Place the lid back over the

hopper and reinstall the screws securing the lid.

To adjust the hopper height between the maximum and the minimum,

remove screws D and slide the hopper extension (with lid attached) down

around the hopper bottom to the height desired. The extension can be

lowered at most 2-1/2” (64 mm). Reinstall the self-tapping screws through

the holes in the extension (creating new holes in the hopper bottom).

Slide to the side to

remove.

Blower Duct

Figure 39

B

A

Proof of Fire Switch

This switch needs to be removed and cleaned after every

100 bags of fuel burned.

Cleaning Procedure:

1. UNPLUG STOVE!

2. Locate the switch on the combustion blower (see Figure

43).

3. Using a flat-head screwdriver, remove the 2 screws which

secures the switch to the blower housing.

4. Using a dry cloth, wipe off any flyash build-up on the

sensor portion of the switch.

5. Reinstall switch. Ensure wires are properly connected

to the switch and the connectors are not making contact

with the blower housing. Close side panel.

Note: Failure to clean the proof of fire switch when

needed may result in nuisance shut-downs because the

fly-ash build-up insulates heat from reaching the switch.

(Recommended Frequency of 1 year or after every 100

bags of fuel used)

Hopper Extension

D

Hopper Lid

C

22

Figure 40

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 23

Front Door Opening and Removal

CAUTION: Do not open the front door when the insert is hot.

To remove the door, swing the left and right side doors A open. Pull

the front door handle B to the front and swing the front door open. Lift

the front door up and off the hinges as shown in Figure 41 (see C). To

reinstall the door repeat the steps in reverse order.

Side Door Removal

To remove the door,

1. Swing the door open

2. Lift the door up, and

3. Pull the bottom of the door out and down - pulling the top hinge pin

out of the retaining hole in the top hinge bracket.

To reinstall the door, slide the pin on the top of the door up and into the

hole in the upper hinge bracket. Slide the pin on the bottom of the door

into the hole in the pedestal base and rotate the door closed.

C

A

Front Door

B

Figure 41

2

Side

Door

1

3

Figure 42

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

23

Page 24

COMPONENT INFORMATION

The following is a list of components and their functions.

Igniter

The Winslow™ PI40 insert comes equipped with an automatic igniter

for lighting the fuel when the insert is in the lighting mode. The igniter

superheats air that is pulled through the burn pot by the combustion

blower to light the fuel. The igniter remains energized for the first seven

minutes of the lighting sequence.

Vacuum Switch

The Winslow PI40 insert has a vacuum switch located behind the left door,

fastened to the base (see A in Figure 44). If there is a leak in the firebox

created by the front door being ajar or a blocked flue, the vacuum switch

will sense it and cause the insert to go into a shutdown mode.

Auger and Auger Motor

The 1.25 RPM auger motor (B in Figure 22) turns the auger lifting pellets

up the auger tube. The pellets are then dropped down a tube and into the

firepot. The auger is controlled by the control board.

Over Temperature Snap Switch

(Opens at 225F) This switch is installed on the convection blower (see C in

Figure 44

) and shuts the insert down if it senses excessive temperatures.

This snap switch has a reset button on it and will not allow the insert to

start up until the reset button has been pushed.

Proof of Fire Snap Switch

(Closes at 140° F) This switch is installed on the combustion blower and

shuts the insert down if it does not detect fire in the burn pot.

Convection Blower Snap Switch

(Closes at 120° F) This switch is installed on the right rear of the

firebox and turns the convection blower on when the insert gets up to

temperature.

Combustion

Blower

Figure 43

24

B

Figure 44

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

C

A

Room Air

(Convection) Blower

Page 25

A

Draft Adjuster

Draft Adjuster

Molex 10 Pin Connector

10

YEL

9

RED

8

WHT

7

GRY

6

BRWN

5

ORNG

4

BLK

3

GRN

2

BLU

1

VIOL

YELLOW

PROOF OF

FIRE SNAP

SWITCH

IGNITER

VACUUM

SWITCH

COMBUSTION

BLOWER

ORANGE

BROWN

GREEN

GROUND

BROWN

BLACK

GREEN

GRAY

BLUE

VIOLET

OVER TEMP

SNAP SWITCH

BLOWER

SNAP SWITCH

RED

VIOLET

ORANGE

BROWNBROWN

YELLOW

GREEN

BLUE

GRAY

WHITE

BLACK

RED

WHITE

WHITE

WHITE

WHITE

AUGER

MOTOR

ROOM AIR

(CONVECTION) BLOWER

WHITE

BLACK

WHITE

BUS

WHITE

The Winslow™ PI40 insert has a draft adjuster located at the right side

of the insert directly in front of the combustion blower. Should the insert

installation require long runs of vent pipe, a situation may be created

where excessive combustion air is flowing through the firebox and causing the fuel to burn faster than it can be delivered to the burn pot. Should

this happen, the draft can be slowed down by the adjuster. The insert

is shipped with the adjuster in the fully open position. To slow the draft

down, loosen the 5/32” allen head screw (A in Figure 45) and move the

adjuster handle toward the center of the insert. Retighten the screw when

the desired adjustment is reached.

Wiring Diagram

A

Draft Adjuster

Figure 45

Figure 46

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

25

Page 26

DIAGNOSTIC CODES

If the insert operates abnormally, the ready light on the control board will signal the nature of the abnormal operation. The following is a list of possible signals or codes:

Ready light is constant red Ignition Failure

Ready light flashes red 1 short and 1 long blink Vacuum Switch Open

Ready light flashes red 2 short blinks Proof of Fire Snap Switch Open

Ready light flashes red 2 long blinks Over Temperature Snap Switch Open

Troubleshooting

Ignition Failure - Code - Ready light is constant red and ignite light flashes two short blinks

Possible Problem Solution

Hopper is out of pellets Fill the hopper with pellets

Auger tube was not full of pellets when start button was pushed When cool, empty pellets in burn pot and push start button again

Burn pot dirty - holes plugged Clean the burn pot

Igniter not functioning Replace the igniter

Igniter fuse blown Replace 6 amp fuse located on front of the control board

Control Board has no Power - When selector knob is turned no lights light up

Possible Problem Solution

Power cord is not plugged in Plug in power cord

Board fuse blown Replace 3 amp fuse located on front of control board

Wall outlet not energized Check circuit breaker panel

Board broken, damaged, or defective Replace the control board

Vacuum Switch Shuts Insert Down - Code - Ready light flashes red 1 short and 1 long blink

Possible Problem Solution

Front door is not sealing Latch or adjust the front door or replace door gasket

Ash drawer is not sealing Close latches, adjust latches, or replace drawer gaskets

Flue gas passageways restricted

Vent pipe restricted

Clean the passageways (see Page 20)

Clean the vent pipe (see Page 21)

Vacuum hose plugged Clean or replace the vacuum hose

Vacuum switch defective Replace the vacuum switch

Proof of Fire Snap Switch Shuts Insert Down - Code - Ready light flashes red 2 short blinks

Possible Problem Solution

Hopper is out of pellets Fill the hopper with pellets

Auger tube was not full of pellets when start button was pushed When cool, empty pellets in burn pot and push start button again

Snap switch* defective Replace the snap switch

“Proof of fire” switch is dirty

Clean switch per instructions on Page 22

26

Page 27

Over Temperature Snap Switch Shuts Insert Down - Code - Ready light flashes red 2 long blinks

Possible Problem Solution

Convection blower not running Blower dirty, blower snap switch bad, or blower broken