Lennox 2PGE13 series, 2, PGE15 series, 4PGE15 series, 4PGE13 series Installation Instructions Manual

...

INSTALLAT I STRUCTIO

Gas

(2,4)PG E/SG(13/15)

Heatin ectric Coolin

SAFETY ................................................. 2

INSTALLATION ....................................... 2

START-UP ............................................ 10

OPERATION ........................................ 11

MAINTENANCE ................................... 13

Series

Package Unit

TABLE OF CONTENTS

CONTROL SYSTEM DIAGNOSTICS .. 14

WIRING DIAGRAMS ............................ 15

Manufactured By

A.A.C.

A Lennox International Inc. Company

421 Monroe Street

Bellevue, OH 44811

6AS-HREB

II!il!iilIIIllUI!11II o

I A CAUTION1

The installation of the furnace, wiring, warm air ducts, venting, etc. must conform to the requirements of the

National Fire Protection Association; the National Fuel Gas Code, ANSI Z223.1 (latest edition) and the

National Electrical Code, ANSl/NFPA No. 70 (latest edition) in the United States; the Canadian Installation

Codes CAN/CGA-B149.1 & .2 (latest edition) and the Canadian Electrical Code Part 1, CSA 22.1 (latest

edition) in Canada; and any state or provincial laws, local ordinances, or local gas utility requirements. Local

authorities having jurisdiction should be consulted before installation is made. Such applicable regulations

or requirements take precedence over the general instructions in this manual.

# 48111B005 Save these instructionsfor future reference Page 1

SAFETY INSTALLATION

The following is a list of safety rules and precautions that

must be followed when installing this furnace.

1. Use only with the type of gas approved for this

furnace. Refer to the furnace rating plate.

2. Install this furnace only in a location and position as

specified in the Location section on page 3 of these

instructions.

3. Adequate clearance must be provided around the vent

hood as specified in the Clearances section on page 4

of these instructions.

4.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifi-

cally for the detection of leaks to check all connec-

tions, as specified in Gas Supply and Piping

beginning on page 6 of these instructions.

Always install furnace to operate within the furnace's

intended temperature-rise range with a duct system

which has an external static pressure within the allowable

range, as specified in Temperature Rise on page 11 of

these instructions. See furnace rating plate.

These instructions must be hung on or near the

furnace in a conspicuous place.

These units are single package air conditioners with gas

heat designed for outdoor installation on a rooftop or a slab.

The units are completely assembled. All piping, refrigerant

charge, and electrical wiring are factory installed and

tested. The units require only electric power, gas piping,

condensate drain, and duct connections, plus assembly of

the heating vent hood at the point of installation.

If components are to be added to a unit to meet local

codes, they are to be installed at the dealer's and/or

customer's expense.

The size of unit for the proposed installation should be based

on heat loss/heat gain calculation made according to the

methods of Air Conditioning Contractors of America (ACCA).

These installation instructions are intended as a

general guide only, for use by an experienced, quali-

fied contractor.

These units are listed by UL:

6.

The furnace is not recommended for use for temporary

heating of buildings or structures under construction

unless certain installationand operating conditions are

adhered to, as specified in the Location section on

page 3 of these instructions.

• For use as a forced air furnace with cooling unit.

For outdoor installation only.

For installation on combustible material.

For use with natural gas or propane gas.

(Conversion kit required for propane gas application.)

These units are not suitable for use with conventional

venting systems.

IMPORTANT: This product has been designed and manu-

factured to meet ENERGY STAR criteria for energy effi-

ciency. However, proper refrigerant charge and proper air

flow are critical to achieve rated capacity and efficiency.

Installation of this product should follow the manufacturer's

refrigerant charging and airflow instructions. Failure to

confirm proper charge and airflow may reduce energy

efficiency and shorten equipment life.

inspection

As soon as the unit is received, it should be inspected for

possible damage during transit. Ifdamage is evident, the

extent of the damage should be noted on the carrier's

freight bill. A separate request for inspection by the

carrier's agent should be made in writing.

Page 2 # 48111 B005

Location • Air filters must be replaced upon construction completion.

Use the following guidelines to select a suitable location

for the unit.

1. Unit is designed for outdoor installation only. Unit must

be installed so all electrical components are protected

from water.

2. Condenser coils must have an unlimited supply of air.

3. For ground level installation, use a level prefabricated

pad or use a level concrete slab. Do not tie the slab to

the building foundation.

4. Maintain level within a tolerance of 1/4" maximum

across the entire length or width of the unit.

5. Do not locate the unit where the combustion air supply

will be exposed to any of the following substances:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine-based swimming pool chemicals

Water softening chemicals

Deicing salts or chemicals

Carbon tetrachloride

Halogen-type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

Chlorinated laundry products

Hydrochloric acid

The input rate and temperature rise must be set per

the unit rating plate.

100% outdoor air must be provided for combustion air

requirements during construction, installation of this unit

in its intended outdoor location will accomplish this.

The heat exchanger, components, duct system, air

filter(s), and evaporator coil must be thoroughly

cleaned following final construction cleanup.

Following the final cleaning, all furnace operating

conditions (including ignition, input rate, temperature

rise, and venting) must be verified according to these

instructions.

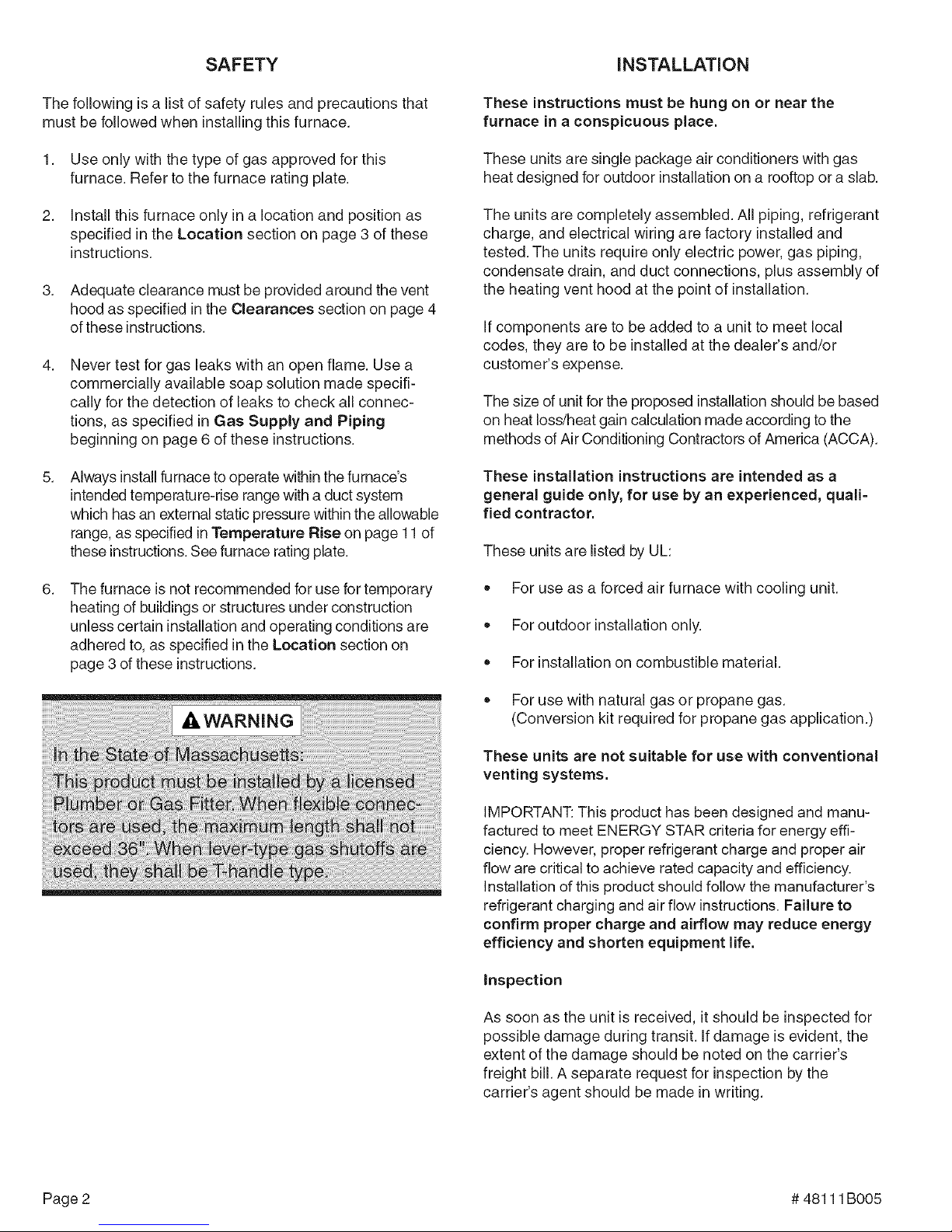

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. An

accessory lift kit can be purchased to aid in rigging (see

Figure 1). Spreaders whose length exceed the largest

dimension across the unit must be used across the top

of the unit. Recommended spreader length: 3 ton and

smaller package units- 44", 3.5 ton and larger units - 54".

Units may also be moved or lifted with a forklift while still in

the factory-supplied packaging. The lengths of the forks

of the forklift must be a minimum of 42".

Use of unit as a construction heater during any phase of

construction is not recommended. Very low return air

temperatures, harmful vapors, and operation of the unit

with clogged or misplaced filters will damage the unit.

However, if the installation and operating conditions

specified below are followed, use of this unit for heating of

buildings or structures under construction is permissible:

The vent hood must be installed per these installation

instructions.

A room thermostat must control the furnace. The use

of fixed jumpers that will provide continuous heating is

not allowed.

The return air duct must be provided and sealed to

the unit.

Return air temperature must be maintained between

60°F (16°0) and 80°F (27°0).

Air filters must be installed in the system and must be

maintained during construction.

# 48111 BOO5 Page 3

Using Accessory Lift Kit

Spreaders

(Field Supplied)

To avoid possible

damage to unit

panels from lifting

clevis, place

packing material

between clevis

and panels before

lifting unit.

Figure 1

Roof Curb Installation

If a roof curb is used, follow the manufacturer's installation

instructions and be sure that all required clearances are

observed (see following Clearances section).

Roof Curb Assembly

Figure 2

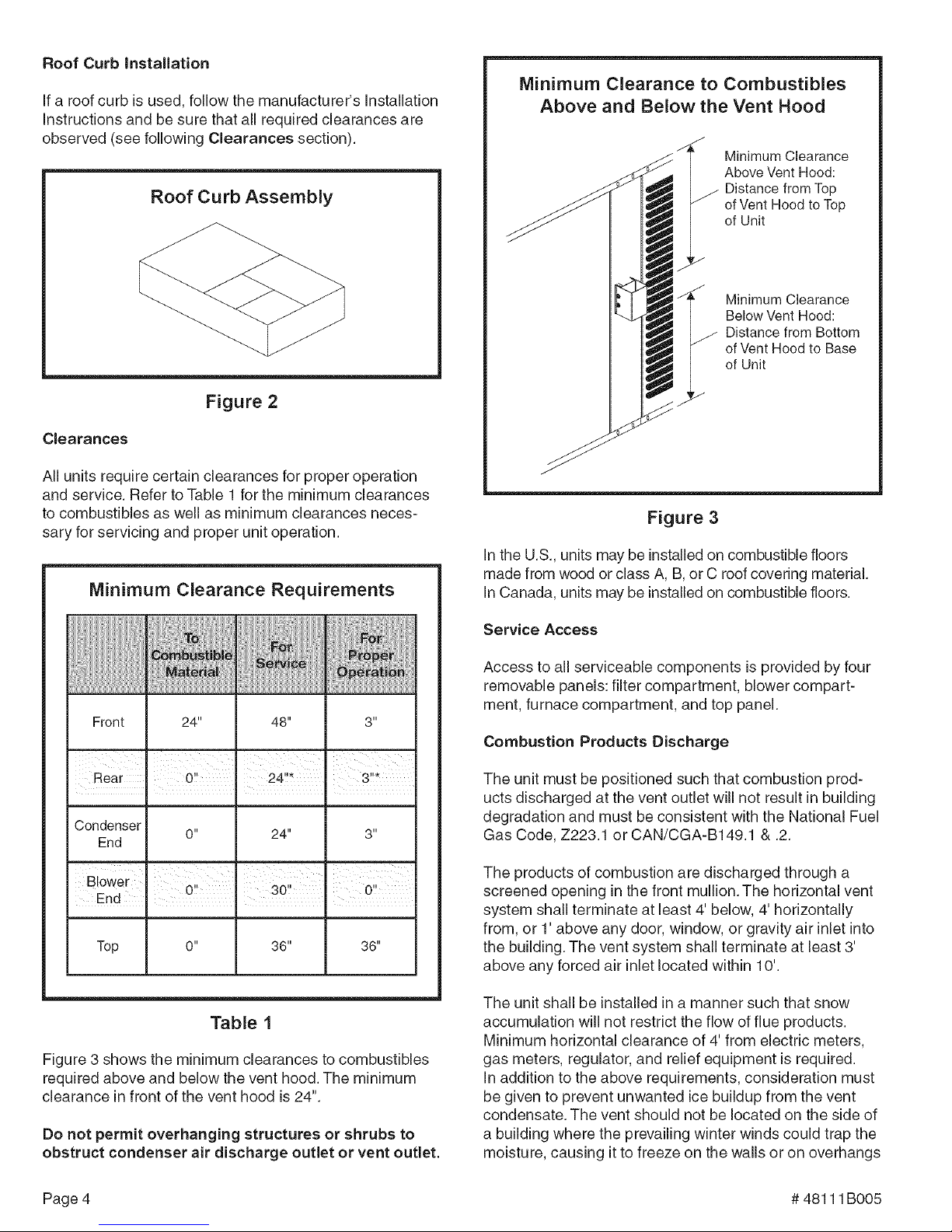

Clearances

All units require certain clearances for proper operation

and service. Refer to Table 1 for the minimum clearances

to combustibles as well as minimum clearances neces-

sary for servicing and proper unit operation.

Minimum Clearance Requirements

Minimum Clearance to Combustibles

Above and Below the Vent Hood

Minimum Clearance

Above Vent Hood:

Distance from Top

of Vent Hood to Top

of Unit

Minimum Clearance

Below Vent Hood:

Distance from Bottom

of Vent Hood to Base

of Unit

Figure 3

In the U.S., units may be installed on combustible floors

made from wood or class A, B, or C roof covering material.

In Canada, units may be installed on combustible floors.

Front 24" 48" 3"

Rear 0!! 24!!* 3!!_

Condenser

End

Blower , '

End . . ,

Top 0" 36" 36"

0" 24" 3"

0!' 30" 0!!

n n

Table 1

Figure 3 shows the minimum clearances to combustibles

required above and below the vent hood. The minimum

clearance in front of the vent hood is 24".

Do not permit overhanging structures or shrubs to

obstruct condenser air discharge outlet or vent outlet.

Service Access

Access to all serviceable components is provided by four

removable panels: filter compartment, blower compart-

ment, furnace compartment, and top panel.

Combustion Products Discharge

The unit must be positioned such that combustion prod-

ucts discharged at the vent outlet will not result in building

degradation and must be consistent with the National Fuel

Gas Code, Z223.1 or CAN/CGA-B149.1 & .2.

The products of combustion are discharged through a

screened opening in the front mullion. The horizontal vent

system shall terminate at least 4' below, 4' horizontally

from, or 1' above any door, window, or gravity air inlet into

the building. The vent system shall terminate at least 3'

above any forced air inlet located within 10'.

The unit shall be installed in a manner such that snow

accumulation will not restrict the flow of flue products.

Minimum horizontal clearance of 4' from electric meters,

gas meters, regulator, and relief equipment is required.

In addition to the above requirements, consideration must

be given to prevent unwanted ice buildup from the vent

condensate. The vent should not be located on the side of

a building where the prevailing winter winds could trap the

moisture, causing it to freeze on the walls or on overhangs

Page 4 # 48111 B005

(undereaves).Theventlocationshouldnotdischarge

overasidewalk,patio,orotherwalkwaywherethecon-

densatecouldcausethesurfacetobecomeslippery.

kWARNING

The products of combustion must not be allowed to

accumulate within a confined space and recirculate.

Vent Hood

The unit is shipped with the vent hood, screen, and sheet

metal screws packed in the plastic bag containing the

Installation Instructions.

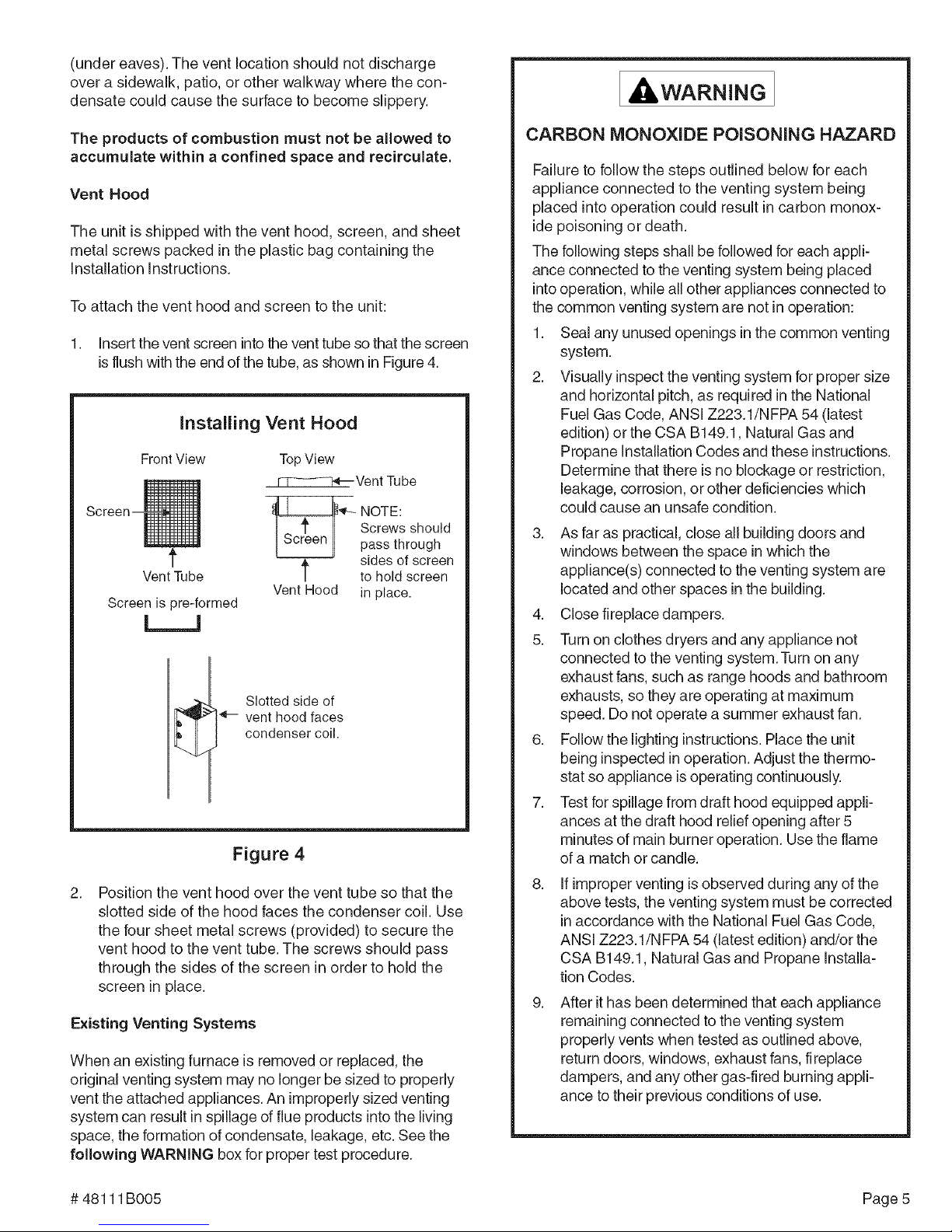

To attach the vent hood and screen to the unit:

1. Insert the vent screen into the vent tube so that the screen

is flush with the end of the tube, as shown in Figure 4.

Installing Vent Hood

FrontView TopView

_Vent Tube

'_-- OTE:

Screws should

pass through

sides of screen

VentTube

Screen is lore-formed

t to hold screen

Vent Hood in place.

L__J

_-- vent hood faces

condenser coil.

Slotted side of

Figure 4

2. Position the vent hood over the vent tube so that the

slotted side of the hood faces the condenser coil. Use

the four sheet metal screws (provided) to secure the

vent hood to the vent tube. The screws should pass

through the sides of the screen in order to hold the

screen in place.

Existing Venting Systems

When an existing furnace is removed or replaced, the

original venting system may no longer be sized to properly

vent the attached appliances. An improperly sized venting

system can result in spillage of flue products into the living

space, the formation of condensate, leakage, etc. See the

following WARNING box for proper test procedure.

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being

placed into operation could result in carbon monox-

ide poisoning or death.

The following steps shall be followed for each appli-

ance connected to the venting system being placed

into operation, while all other appliances connected to

the common venting system are not in operation:

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch, as required in the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 (latest

edition) orthe CSA B149.1, Natural Gas and

Propane Installation Codes and these instructions.

Determine that there is no blockage or restriction,

leakage, corrosion, or other deficiencies which

could cause an unsafe condition.

3. As far as practical, close all building doors and

windows between the space in which the

appliance(s) connected to the venting system are

located and other spaces inthe building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not

connected to the venting system. Turn on any

exhaust fans, such as range hoods and bathroom

exhausts, so they are operating at maximum

speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the unit

being inspected in operation. Adjust the thermo-

stat so appliance is operating continuously.

7. Test for spillage from draft hood equipped appli-

ances at the draft hood relief opening after 5

minutes of main burner operation. Use the flame

of a match or candle.

8.

If improper venting is observed during any of the

above tests, the venting system must be corrected

in accordance with the National Fuel Gas Code,

ANSI Z223.1/N FPA 54 (latest edition) and/or the

CSA B149.1, Natural Gas and Propane installa-

tion Codes.

9.

After it has been determined that each appliance

remaining connected to the venting system

properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers, and any other gas-fired burning appli-

ance to their previous conditions of use.

# 48111B005 Page 5

Loading...

Loading...