Page 1

lennoxemeia.com

@DNOVA

pCO1

Manuel

d’installation,

mise en service

et maintenance

Microprocesseur

INNOVA-pCO1-IOM-0907-F

Page 2

Page 3

INNOV@-pCO1-IOM-0907-E 1

Index

1 GENERAL DESCRIPTION OF THE APPLICATION ...................................................3

1.1 Program main functions............................................................................................................... 3

1.2 LCD user interface......................................................................................................................3

1.3 LAN network connections ............................................................................................................ 3

2 REGULATION LOGIC .................................................................................................4

2.1 Temperature control.................................................................................................................... 4

2.1.1 Close control units with direct expansion coil........................................................................... 4

2.1.2 Other temperature functions.................................................................................................... 5

2.1.3 Close control units with two water coils.................................................................................... 5

2.1.4 Close control units with single water coil..................................................................................6

2.2 Humidity control..........................................................................................................................6

2.2.1 Close control units with direct expansion coil...........................................................................7

2.2.2 Other humidity functions.......................................................................................................... 7

2.2.3 Close control units with water coils.......................................................................................... 8

2.3 Recovery coil..............................................................................................................................8

2.3.1 Recovery without cooling devices............................................................................................9

2.3.2 Recovery with cooling devices on close contr. units with direct expan. coil...............................9

2.3.3 Recovery with cooling devices on close control units with water coils.................................... 10

2.4 Outlet limit................................................................................................................................. 11

2.5 Condenser fans......................................................................................................................... 12

2.5.1 Single or separate coils......................................................................................................... 12

2.5.2 Condensing pressure probes ................................................................................................ 12

2.5.3 Prevent function.................................................................................................................... 13

2.5.4 Speed-up function................................................................................................................. 13

2.5.5 Pressure – temperature conversion....................................................................................... 13

2.6 Temperature set point compensation......................................................................................... 13

2.7 Compressors............................................................................................................................. 14

2.7.1 Rotation................................................................................................................................ 14

2.7.2 Timing................................................................................................................................... 14

2.7.3 Compressor alarms............................................................................................................... 14

2.8 Heaters ..................................................................................................................................... 15

2.8.1 Heater alarms .......................................................................................................................15

2.9 Modulating valves ..................................................................................................................... 15

2.9.1 Three-position valves............................................................................................................15

2.9.2 0-10Volt VALVES..................................................................................................................16

2.10 Outlet fan..................................................................................................................................16

3 THE USER INTERFACE ...........................................................................................17

3.1 Keyboard description................................................................................................................. 17

3.1.1 Switch ON/OFF of the unit..................................................................................................... 17

3.1.2 Screen loop........................................................................................................................... 17

3.2 Remote user interface............................................................................................................... 18

3.2.1 Without local display.............................................................................................................18

3.2.2 With local display..................................................................................................................18

4 BOARD CONFIGURATION AND CONNECTION .....................................................19

4.1 Address configuration................................................................................................................ 19

Page 4

2 INNOV@-pCO1-IOM-0907-E

4.1.1 Address configuration of the microprocessor (pCO1)..........................................................................19

4.1.2 Address configuration of the PGD ......................................................................................... 19

4.1.3 Address configuration of the E2V electronic expansion valve’s driver (EVD).......................... 19

4.2 Boards connection....................................................................................................................20

4.2.1 Stand alone unit.................................................................................................................... 20

4.2.2 Units connected in LAN (max. 8 units)................................................................................... 20

4.2.3 LAN status............................................................................................................................ 21

4.3 Software update........................................................................................................................ 21

4.3.1 Program download from hardware key.................................................................................. 21

4.3.2 Program download from computer.........................................................................................22

4.3.3 Restore the default parameters.............................................................................................22

4.3.4 Language selection...............................................................................................................23

5 ALARMS.................................................................................................................... 23

5.1 Table of alarms ......................................................................................................................... 23

5.2 Alarm data logging .................................................................................................................... 24

5.3 Main log ....................................................................................................................................24

6 SCREENS.................................................................................................................26

6.1 List of the screens..................................................................................................................... 26

7 LIST OF PARAMETERS AND DEFAULT VALUES...................................................28

8 ARCHITECTURE OF THE CONTROL SYSTEM ......................................................34

8.1 Microprocessor layout ............................................................................................................... 34

8.2 Configuration list ....................................................................................................................... 35

8.3 Accessories...............................................................................................................................35

8.3.1 Electronic expansion valve.................................................................................................... 35

8.3.2 Accessories ..........................................................................................................................36

8.3.3 Built-in humidifier..................................................................................................................37

9 SUPERVISION..........................................................................................................37

9.1 Supervisor and bms .................................................................................................................. 37

9.2 Gsm protocol............................................................................................................................. 39

9.3 Examples of installation............................................................................................................. 40

9.4 Shared external display............................................................................................................. 40

9.5 Automatic start and stand-by units............................................................................................. 41

9.5.1 Critical situations...................................................................................................................41

9.5.2 Forcing..................................................................................................................................41

9.5.3 Fixed-hour rotation................................................................................................................ 42

9.5.4 Fixed-day rotation .................................................................................................................42

9.5.5 Rotation based on working hours.......................................................................................... 42

9.6 Master control........................................................................................................................... 42

9.7 Technical data........................................................................................................................... 43

Page 5

INNOV@-pCO1-IOM-0907-E 3

1 GENERAL DESCRIPTION OF THE APPLIC ATION

This program manages “DX” direct expansion or “CW” water coil air-conditioning units and the main features

of the application program are described below.

1.1 Program main functions

The program main functions are:

• control of temperature and humidity inside civil or technological environments

• management of 1 to 2 hermetic compressors

• management of 1 to 2 heaters (binary logic available)

• 0-10Volt and three-position modulating heating valves

• 0-10Volt and three-position modulating cooling valves

• built-in humidifier with immersed electrodes

• on-off or modulated condensing fans, pressure-controlled

• outlet temperature control

• alarms management, alarm data logging, devices timing, warnings

• complete management of devices timing

• connection with local and BMS supervisory networks (Carel, Modbus, LonWorks, …)

1.2 LCD user interface

The LCD user interface displays the following data:

• measurement of connected probes and calibration, if required

• unit start and stop

• alarms detection

• programming of configuration and operative parameters with access protected by password

• controlled devices working hours and time bands with access protected by password

• programming of clock and time bands with access protected by password

• language selection among the available options (English, Italian, German, French)

1.3 LAN network connections

The connection with LAN network allows the program to manage the following functions as well:

• automatic time or event rotation among up to 8 units

• control of temperature and humidity of max. 8 units, taking the probes of unit no. 1 as a reference

• use of only one LCD display fo r controlling up to 8 units

Page 6

4 INNOV@-pCO1-IOM-0907-E

2 REGULATION L OGIC

2.1 Temperature control

The heating and cooling devices are managed based on the temperature value measured by the ambient (or

room temperature) probe. The measured temperature is compared to the set temperature (set point); the

devices are enabled based on the difference between the two values. The proportional band identifies the

air-conditioning unit working range and can take different values in heating and cooling mode. The dead

zone identifies the devices non-action zone round the set point. The following diagrams show the action of

the heating and cooling devices. The percentage values indicate the modulating valves opening range. The

warm and cold valves start and end opening parameters correspond to 0% and 100% respectively (default

values) and are different for the two valves; if need be, the values may be modified to delay opening start

and bring complete opening forward.

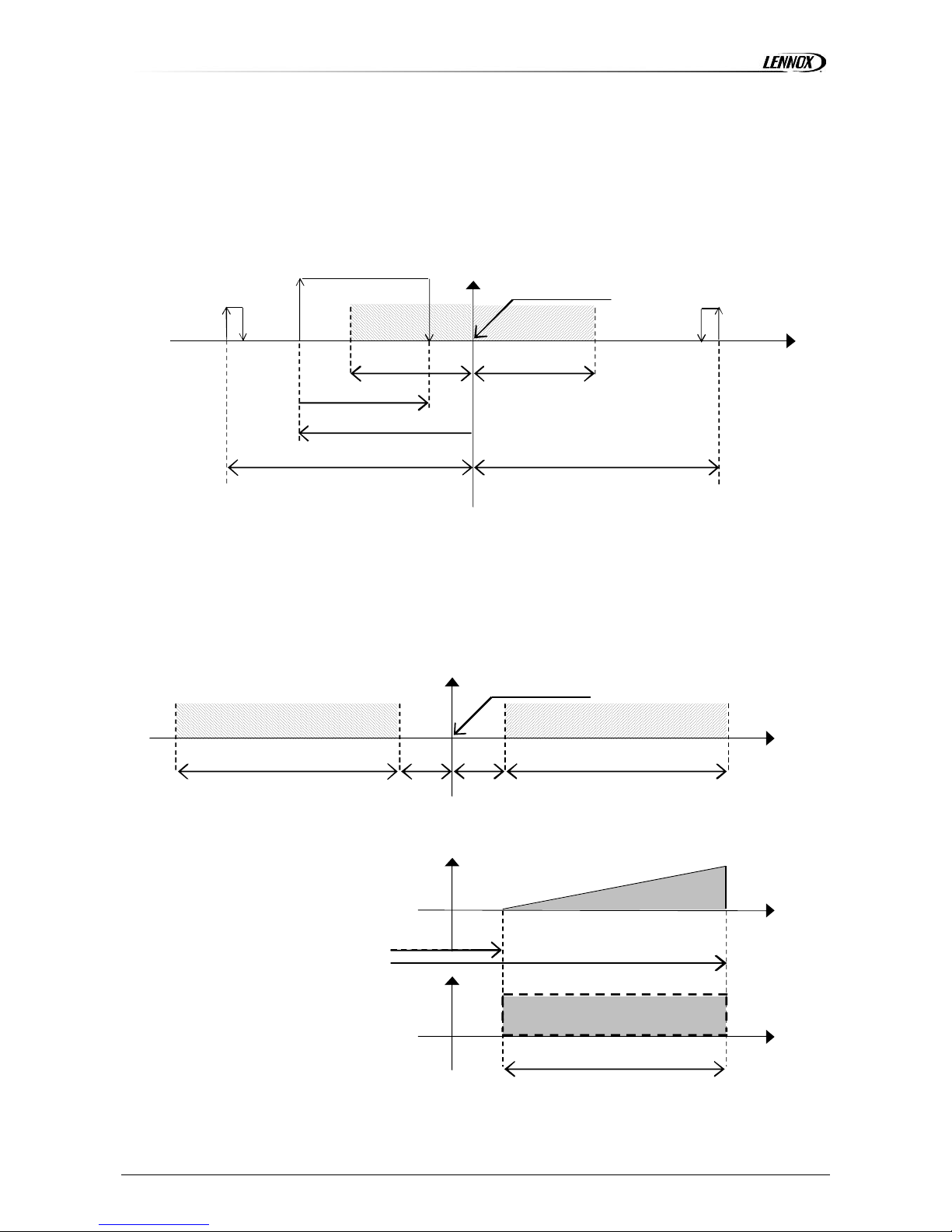

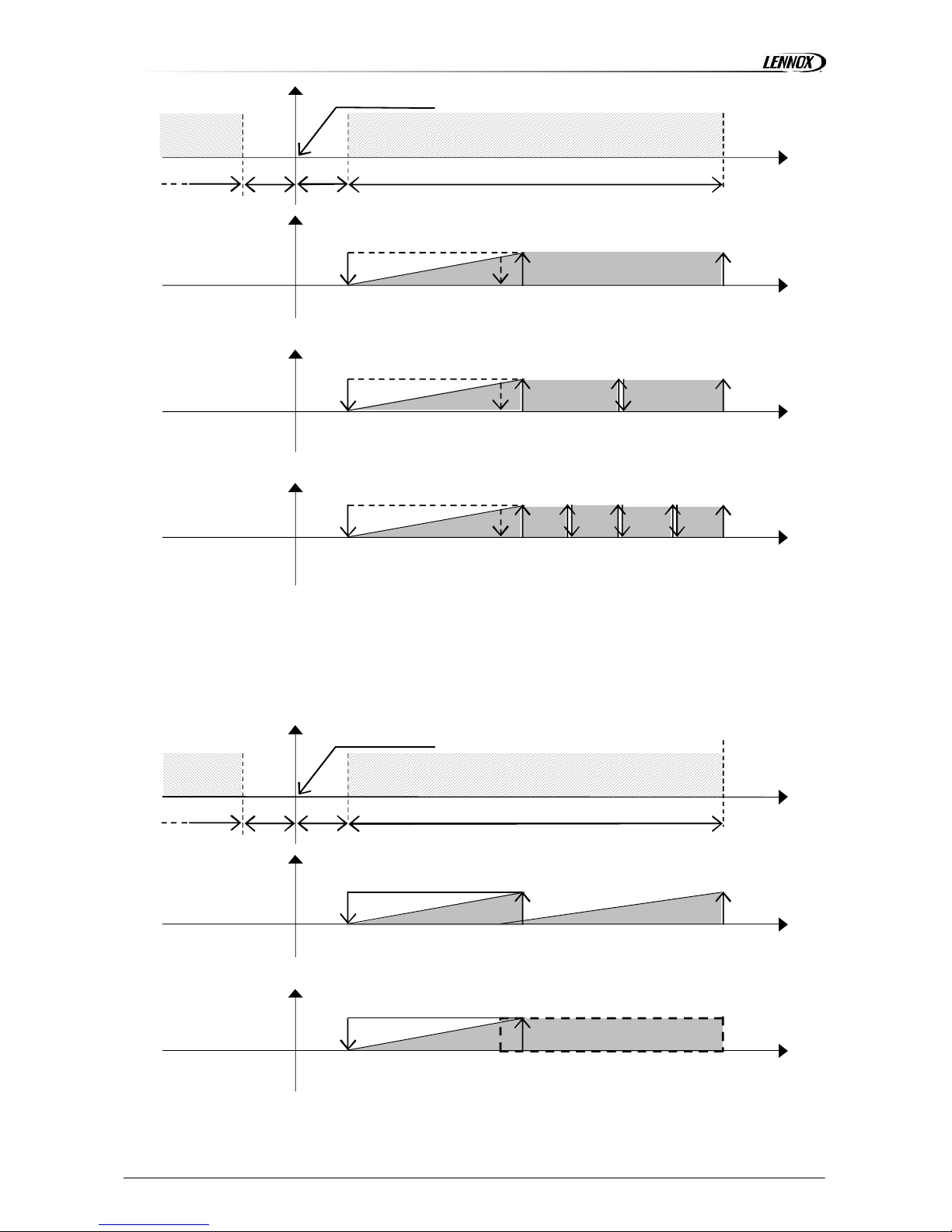

2.1.1 Close control units with direct expansion coil

Temperature set

HEATING COOLING

100% 0% 0% 100%

19.5 22.5 23.0 23.5 26.5

3°C 0.5°C 0.5°C 3°C Ambient

temp. (°C)

Warm proportional band Dead z. Dead z. Cold proportional band

1 HEATER 1 COMPRESSOR

19.5 22.5 23.0 23.5 26.5

Ambient

temp. (°C)

COMP.2/

HEATER 1 HEATER 2 COMP.1 C1 capacity control

19.5 21.5 22.5 23.0 23.5 25.0 26.5

Ambie nt

temp. (°C)

BINARY MANAGEMENT

HEATER 3 HEATER 2 HEAT ER 1 COMP.1 C1 c.c. COMP.2 C2 c.c.

19.5 20.5 21.5 22.5 23.0 23.5 24.2 25.0 25.7 26.5 Ambient

temp. (°C)

0-10 Volt WARM WATER VALVE

100%

0%

19.5 22.5 23.0 Ambient

temp. (°C)

Opening start point (0%)

Opening end point (100%)

100%

0%

19.5 22.5 23.0 Ambient

temp. (°C)

Three-position valve running time

Page 7

INNOV@-pCO1-IOM-0907-E 5

2.1.2 Other temperature functions

The high and low temperature alarms cause alarm screen signalling and have modifiable delay time.

The dehumidification stop differential establishes the minimum temperature below which dehumidification is

interrupted. Dehumidification can start again if temperature returns above the value established by the

humidification start offset; differential and offset are modifiable.

ON OFF Temperature set

Dehumidification stop

HEAT. COOL.

13.0 18.0 20.0 22.0 23.0 26.0 33.0 Ambient

3°C 3°C temp. (°C)

Warm band Cold band

4°C

Dehumid. start offset

5°C

Dehumid. stop different.

10°C 10°C

Low temperature alarm High temperature alarm

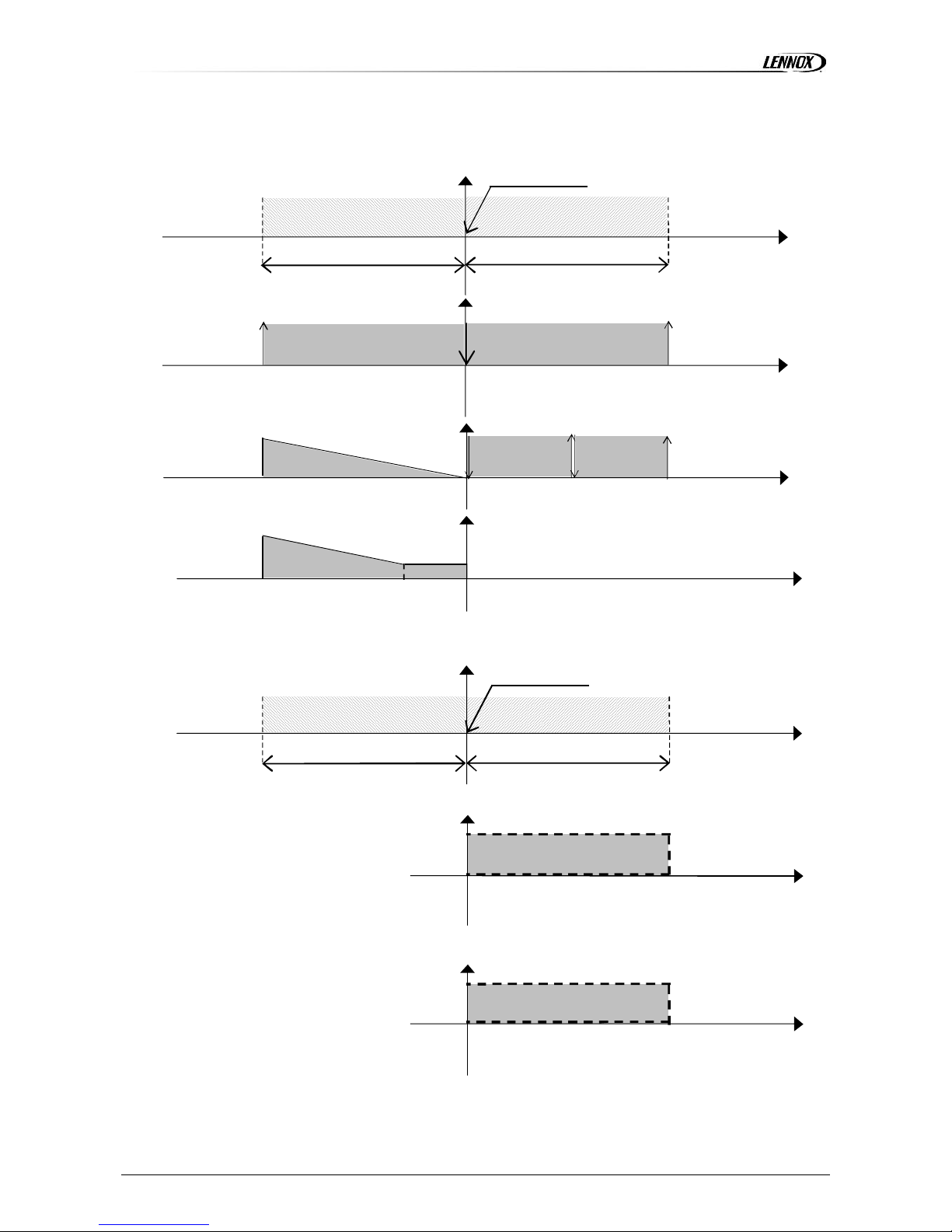

2.1.3 Close control units with two water coils

These close control units are equipped with a warm water coil and a cold water coil. In addition, heating can

also be executed by heaters. The following diagram s hows the cooling devices action, whereas the heating

devices action is dealt with in the paragraph describing the direct expansion units.

Temperature set

HEATING COOLING

100% 0% 0% 100%

19.5 22.5 23.0 23.5 26.5

3°C 0.5°C 0.5°C 3°C Ambient

temp. (°C)

Warm proportional band Dead z. Dead z. Cold proportional band

0-10 Volt WARM WATER VALVE

100%

0%

23.0 23.5 26.5 Ambient

temp. (°C)

Opening start point (0%)

Opening end point (100%)

100%

THREE-POSITION COLD WATER

0%

23.0 23.5 26.5 Am bient

temp. (°C)

Three-position valve running time

Page 8

6 INNOV@-pCO1-IOM-0907-E

2.1.4 Close control units with single water coil

In these close control units, the coil provides for both heating and coo ling, depending on the type o f water

circulating inside it. In practice, the unit works as it was equipped with two different coils. The co il o peration

depends from a Summer / Winter digital contact that “reports” whether the circulating water is warm or cold

to the board; if the “type of water” circulating inside the coil complies with the ambient request, the valve is

modulated to regulate temperature.

In addition, heating can also be executed by heaters or a warm coil. For any information about coil and

heaters operation, refer to the previous paragraphs.

2.2 Humidity control

The humidification and dehumidification devices are managed based on the humidity value measured by the

ambient (or room temperature) probe. The m easured humidity is compared to the set humidity (set point);

the devices are enabled based on the difference between the two values. The proportional band identifies

the ai r-conditioning unit working ra nge and can take different values in humidification and dehumidification

mode. The 0.2% fixed dead zone identifies the devices non-action zone round the set point.

Dehumidification enables the available cooling devices and a contact for an external dehumidifier or for

reducing the outlet fan speed.

Dehumidification can be executed as follows:

On-Off contact for an external dehumidifier or for reducing the outlet fan speed

compressors enabling (active capacity controls included, if any)

100% enabling of the 0-10Volt or three-position modulating cooling valve

The dehumidification On-Off free contact is always managed, whereas the cooling devices depend on unit

configuration and User selection. The 0-10Volt modulating output of the dehumidification outlet fan is

automatically reduced by 50% (modifiable); with On-Off fan, use the digital contact for reducing speed.

The following diagrams show the humidification and dehumidification devices action. The percentage values

indicate the modulating valves opening range.

Page 9

INNOV@-pCO1-IOM-0907-E 7

2.2.1 Close control units with direct expansion coil

Humidity set

HUMIDIFICATION DEHUMIDIFICATION

100% 0% 100%

48.0 50.0 52.0 Ambie nt

2.0% 2.0% humidity (%)

Humidification proportional band Dehumidification proportional band

1 COMPRESSOR

ON-OFF CONTACT + Capacity control, if any

48.0 50.0 52.0 Ambie nt

humidity (%)

0-10Volt MODULAT. OUTPUT

100%

COMP. 1 + COMP. 2 +

0% c.c., if any c.c., if any

48.0 50.0 51.0 52.0

Ambie nt

humidity (%)

100% INTEGRATED HUMIDIFIER

30%

48.0 49.8 50.0 Ambie nt

humidity (%)

2.2.2 Other humidity functions

Humidity set

100% 100%

48.0 50.0 52.0 Ambie nt

2.0% 2.0% humidity (%)

Humidification proportional band Dehumidification proportional band

100%

0-10V COLD WATER VALVE

0%

50.0 52.0 Ambient

humidity (%)

100%

THREE-P. COLD WATER VALVE

0%

50.0 52.0

Ambient

humidity (%)

The high and low humidity alarms cause alarm screen signalling and have modifiable delay time.

Page 10

8 INNOV@-pCO1-IOM-0907-E

2.2.3 Close control units with water coils

In these close control units, the cold water coils provide for dehumidification. For any information about their

operation, refer to the previous paragraph. The following diagrams show the dehumidification devices action.

The percentage values indicate the modulating valves opening range. Please note that the dehumidification

cold water coils are enabled at 100%, not in modulating mode, in case of both threeposition and 0-10Volt

valves.

Humidity set

40.0 48.0 50.0 52.0 60.0 Ambient

2.0% 2.0% humidity (%)

Humid. band Dehumid. band

10.0% 10.0%

Low humidity alarm High humidity alarm

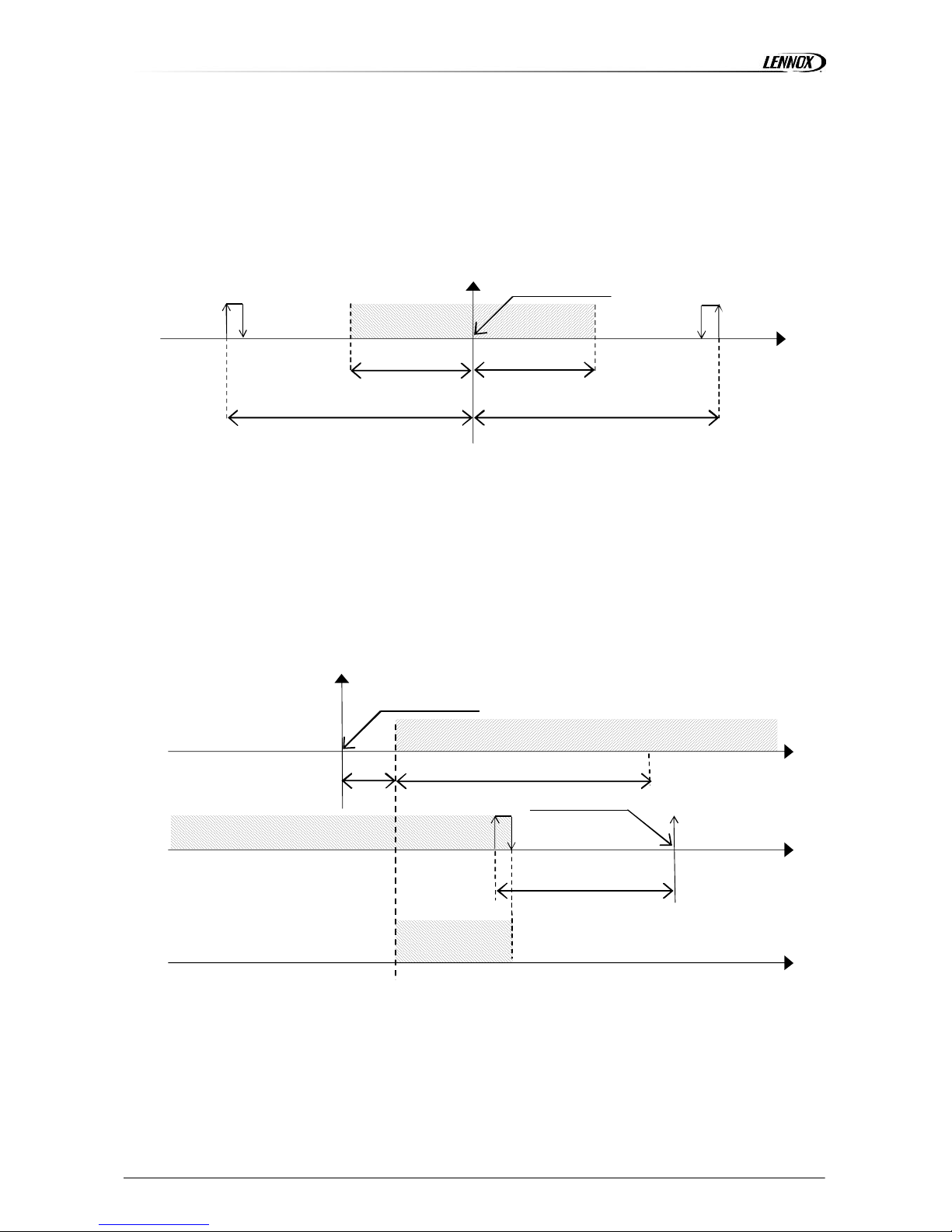

2.3 Recovery coil

Recovery is an optional function: an additional cold coil using water coming from an external source (i.e.,

evaporation tower) is enabled if the te mperature of water running inside it is quite low. This allows saving on

the system management costs. The coil is enabled by On-Off contact or 0-10Volt modulating signal.

The following diagram shows the recovery coil enabling conditions: environment cooling request and

recovery water temperature lower than recovery set – recovery differential.

Temperature set

COOLING REQUEST

0%

23.0 23.5 26.5 Ambient

0.5°C 3°C temp.(°C)

Dead z. Cold prop. band

Recovery set

RECOVERY ENABLED

10.0 12.0 Recovery

2°C temp.(°C)

Recovery differential

OFF ON OFF

Recovery

coil state

Page 11

INNOV@-pCO1-IOM-0907-E 9

2.3.1 Recovery without cooling devices

As shown in the previous diagram, the recovery coil only is enabled, whereas the conventional cooling

devices are not switched on; as it can be noted in the following diagram, the recovery coil takes up the entire

cold proportional band.

Temperature set

HEATING COOLING

100% 0% 0% 100%

19.5 22.5 23.0 23.5 26.5

3°C 0.5°C 0.5°C 3°C Ambient

temp. (°C)

Warm proportional band Dead z. Dead z. Cold proportional band

RECOVERY ON-OFF CONTACT

23.0 23.5 26.5 Ambient

temp. (°C)

0-10V RECOVERY VALVE 100%

0%

23.0 23.5 26.5 Ambient

temp. (°C)

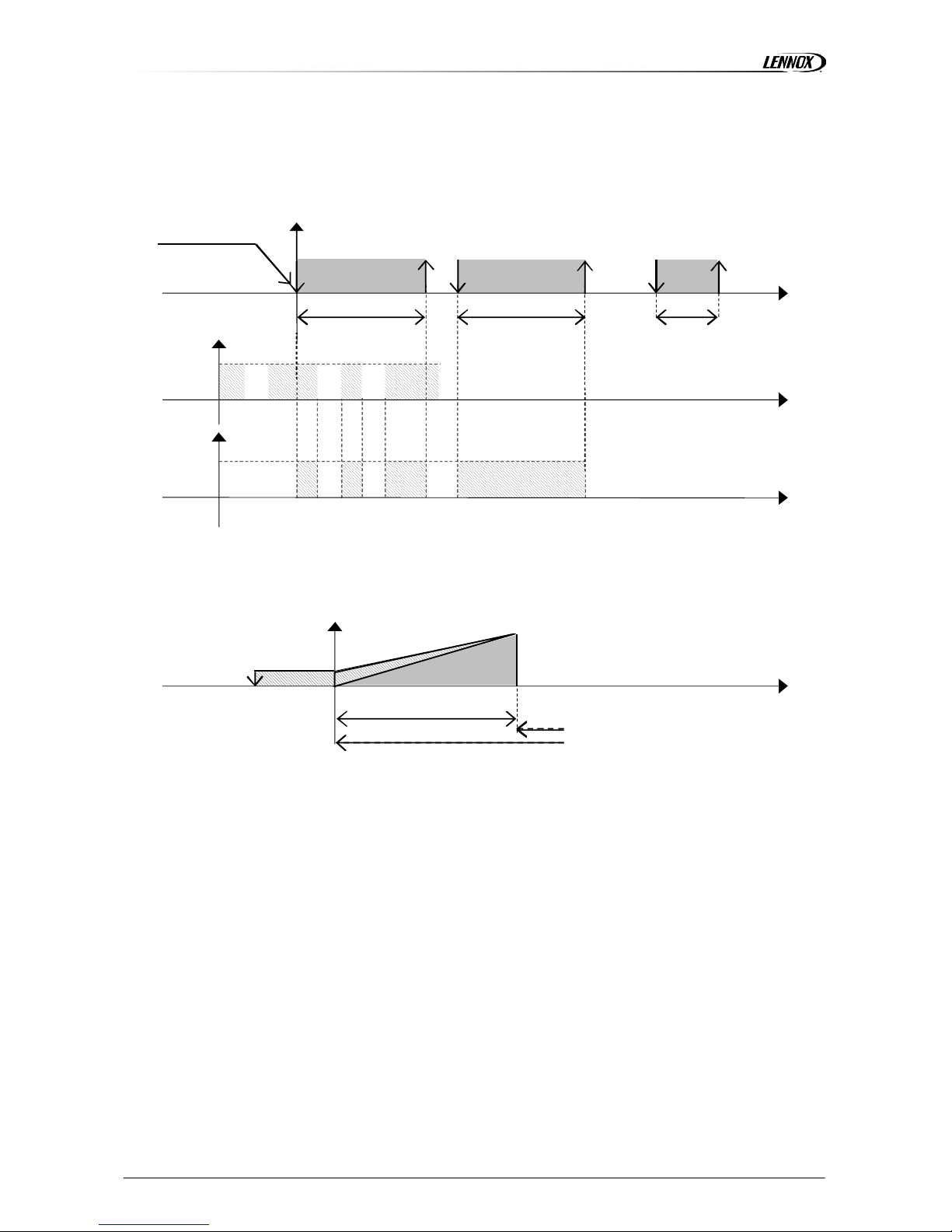

2.3.2 Recovery with cooling devices on close contr. units with direct expan.

coil

With recovery coil enabled, the conventional cooling devices a re s witched on only if ambient temperature

increases above a certain value; adding the effects of recovery coil and devices together, temperature

decreases, but before reaching the set point, the cooling devices are switched off again. In this case, the

cooling devices favour Recovery but do not substitute for it. The following diagram shows how the cooling

devices steps are offset compared to normal position to ensure energy saving.

Page 12

10 INNOV@-pCO1-IOM-0907-E

Te mpe rature set

HEAT. COOLING

0% 0% 100%

22.5 23.0 23.5 26.5

0.5°C 0.5°C 3°C Ambient

Dead z. Dead z. Cold proportional band temp. (°C)

RECOVERY COIL ON

On-Off 1 COMPRESSOR

OFF 0-10Volt

23.0 23.5 24.6 24.9 26.5

Ambie nt

temp. (°C)

RECOVERY COIL ON

On-Off COMPR. 1 COMPR. 2/

OFF 0-10Volt C1 can control

23.0 23.5 24.6 24.9 25.6 26.5

Ambie nt

temp. (°C)

RECOVERY COIL ON

On-Off C.1 C.1 C.2 C.2

OFF 0-10Volt c.c. c.c.

23.0 23.5 24.6 24.9 25.1 25.6 26.1 26.5

Ambie nt

temp. (°C)

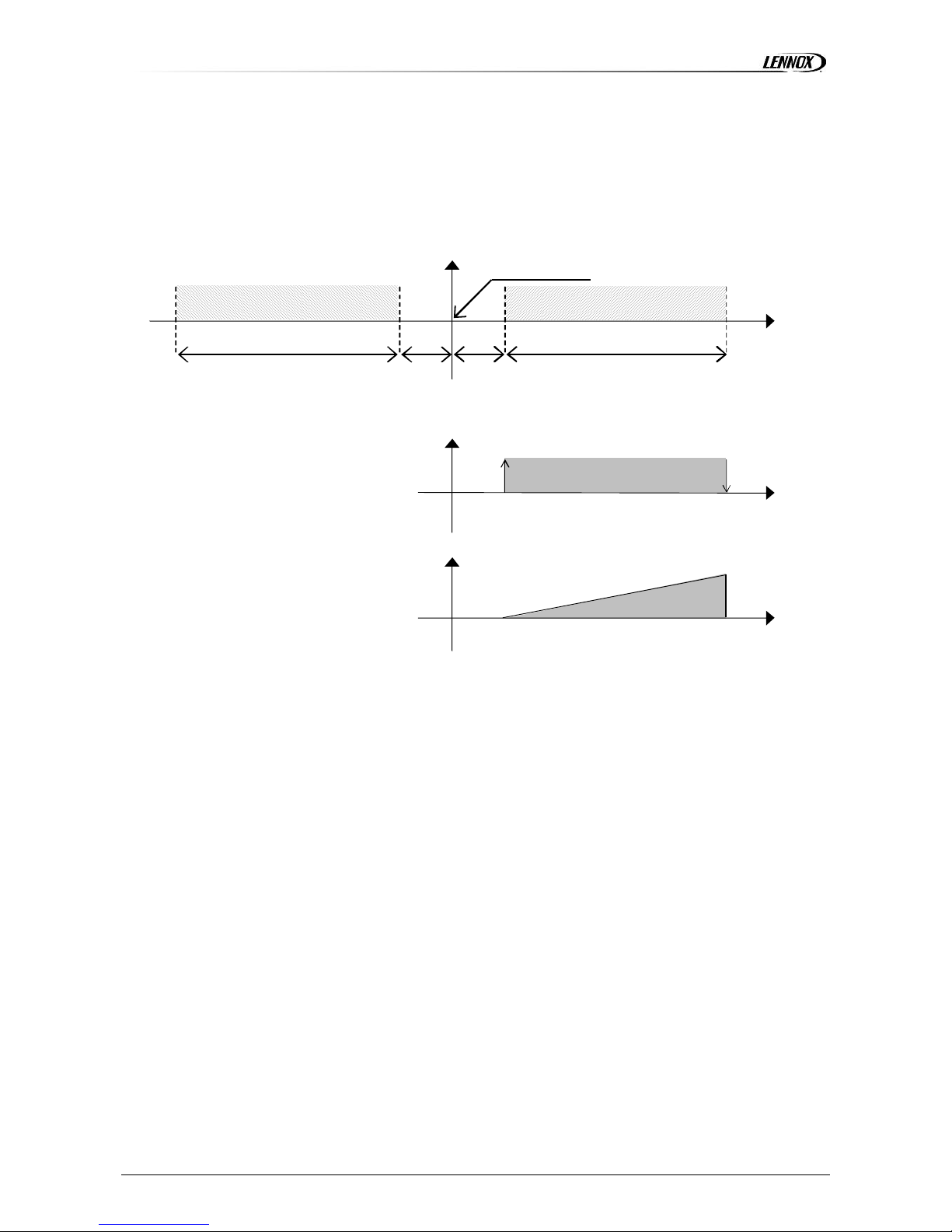

2.3.3 Recovery with cooling devices on close control units with water coils

The following diagram shows how the cold coil steps are offset compared to normal position to ensure

energy saving.

Tempe rature set

HEAT. COOLING

0% 0% 100%

22.5 23.0 23.5 26.5

0.5°C 0.5°C 3°C A mbient

Dead z. Dead z. Cold proportional band temp. (°C)

RECOVERY COIL ON 0-10V MOD. WARM VALVE

On-Off

OFF 0-10Volt

23.0 23.5 24.6 24.9 26.5

Ambie nt

temp. (°C)

RECOVERY COIL ON THREE-P- WARM VALVE

On-Off

OFF 0-10Volt

23.0 23.5 24.6 24.9 26.5

Ambie nt

temp. (°C)

Page 13

INNOV@-pCO1-IOM-0907-E 11

2.4 Outlet limit

This function prevents too cold air from circulating in the environment, thus safeguarding health of any

exposed person. A temperature probe must be positioned on the air-conditioning unit outlet and parameters

“Outlet set point” and “Outlet differential” shall be set. Such parameters identify a limiting zone, as shown in

the following diagram:

Outlet set

100% VARIABLE LIMITATION

TOTAL

LIMITATION 0%

10.0 15.0

5.0°C Ambient

Outlet differential temp. (°C)

Temperature set

1 COMPRESSOR

23.0 23.5 26.5

Ambie nt

temp. (°C)

COMPRESSOR 1 COMPRESSOR 2/

C1 can control

23.0 23.5 25.0 26.5

Ambie nt

temp. (°C)

COMP.1 C.1 c.c. COMP.2 C.1 c.c.

23.0 23.5 24.2 25.0 25.7 26.5

Ambie nt

temp. (°C)

0-10V COLD WATER VALVE

100%

0%

23.0 23.5 26.5

Ambient

temp. (°C)

THREE-POINT COLD WATER VALVE

100%

0%

23.0 23.5 26.5

Ambie nt

temp. (°C)

As shown in the diagram, if outlet temperature ranges between outlet set point and outlet differential, the

cooling devices are limited only partially; the more temperature decreases the more limitation increases.

As regards dehumidification limitation, the modulation zone is by-passed since dehumidification always

needs the cooling devices maximum capacity. In practice, the devices are switched off only if outlet

temperature is lower than differential; the devices are then switched o n a gain if outlet temperature rea ches

the outlet set point, as shown in the following diagram:

Outlet set

ON OUTLET LIMITATION

TOTAL

LIMITATION OFF LIMITATION OFF

10.0 15.0

5.0°C Outlet

Outlet differential temp. (°C)

Page 14

12 INNOV@-pCO1-IOM-0907-E

2.5 Condenser fans

Condensing pressure control is available on DX type units, in which fans are managed based on condensing

coil pressure and compressors state. Fans are enabled by 0-10V m odulating or digital outputs. Control is

based on the condensation set point and differential, as shown in the following diagram:

Condensation set

CONDENSATION HP PREVENT HP

14.0 16.0 18.0 20.0 23.5 24.5

2.0 bar 2.0 bar 1.0 bar Condensation

Condensation differential Prevent differential HP differential pressure (bar)

ON

OFF

Compressor

state

ON

OFF

Condensing

fans state

The following diagram shows fans operation with modulating outputs:

100%

13.0 0% 14.0 16.0

2.0 bar Condensation

Opening start point (100%) pressure (bar)

Opening end point (0%)

The maximum and minimum speeds of 0-10V outputs can be set; in case the set minimum speed is higher

than 0V, the fan is operated at minimum speed 1.0 bar below the condensation set point before switching off,

as indicated in the diagram above.

2.5.1 Single or separate coils

In ca s e of single coil, only one output (on-off or modulating) is enabled. In case of units with at least one

condensing probe and enabled on-off outputs, two on-off outputs may be enabled in sequence, dividing the

differential by two.

In case of separated coils, two different outputs (on-off or modulating) are enabled, one per circuit.

2.5.2 Condensing pressure probes

Foreword: besides the values read by the probes, fans enabling always considers the compressors state.

In case of single probe and separated coils, fans enabling is based on the probe value for both circuits.

In case of two probes and single coil, fans enabling is based on the highest probes value.

In case of two probes and separated coils, fans enabling is based on the probe value of the relevant circuit.

Page 15

INNOV@-pCO1-IOM-0907-E 13

In ca se no probe is present, fans are enabled simultaneously with the compressors; in case of single coil,

fans are enabled when at least o ne compressor is on; in case of separated coils, each compressor controls

the fans of its own circuit.

2.5.3 Prevent function

High pressure alarm prevention with compressors stopped. Norm ally, the condensing fans turn on only if

compressors are enabled, but in this case they are forced so as to decrease pressure and try to prevent the

high pressure alarm, which would cause unit shutdown. Pressure increase wi th compressors stopped may

be due to radiance on the coil. In case of 0-10V modulating fans, modulation is by-passed.

2.5.4 Speed-up function

To overcome inertia at high-power m odulating fans peak, they may be started at maximum speed for some

seconds, then speed decreases to the required value and modulation starts.

2.5.5 Pressure – temperature conversion

Both pressure and temperature probes can be selected. In case of pressure probes, branch I/O screens

display the temperature value corresponding to the pressure of each probe, based on the coolant type (to be

selected in the Manufacturer branch).

2.6 Temperature set point compensation

The te mperature set point can be “compensated” automatically for comfort reasons; for example, think about

a commercial concern in which people frequently enter and go out: if internal temperature is 10°C lower than

the external one, the thermal rush may annoy people and could be prejudicial to their health. The maximum

difference between internal and external temperatures should not exceed 6°C in order to obtain optimum

comfort. In this case, the compensation function increases the set point by 4°C, consequently increasing the

ambient temperature; this function prevents the difference between internal and external temperature from

exceeding 6°C.

Compensation requires a temperature probe to be installed at the exterior. The function is managed based

on the values of compensation set point, differential and offset parameters, as shown in the following

diagram:

Compensation set

2°C Compensation

offset

25.0 28.0

3°C Ex ternal

Compensation proportional band temp. (°C)

25.0°C

23.0°C

Temperat ure

set-point (°C)

Page 16

14 INNOV@-pCO1-IOM-0907-E

2.7 Compressors

Compressors are managed in ON-OFF mode. Maximum 2 compressors can be present.

2.7.1 Rotation

Compressors rotation follows the F.I.F.O. (first in, first out) logic. The first compressor turned on is the first to

turn off, the first compressor turned off is the last to turn on. This logic allows comparing the compressors

working hours and obtaining the same ageing. The rotation can be disabled.

2.7.2 Timing

START MINIMUM TIME

It represents the compressors start minimum time (in seconds) after they have been enabled. If a stop

request arises, compressors are disabled only after the established time has elapsed.

STOP MINIMUM TIME

It represents the compressors stop mini mum time (in seconds) after they have been disabled. If a start

request arises, compressors are enabled only after the established time has elapsed.

MINIMUM TIME BETWEEN DIFFERENT COMPRESSORS STARTS

It represents the mini mum time interval (in seconds) between start of a device and the following one. This

interval allows preventing contemporary peaks, which would cause a high energy absorption.

MINIMUM TIME BETWEEN COMPRESSOR STARTS

It represents the minimum time interval (in seconds) between two starts o f the same device. This parameter

allows limiting the number of starts per hour. If, for example, the maximum number of starts per hour allowed

by the default values is 10, this limit can be respected by setting a 360-second time interval.

2.7.3 Compressor alarms

Compressors alarms are distributed in two digital inputs, the alarms mean Thermal alarm / High and Low

pressure alarm.

HIGH PRESSURE – THERMAL ALARM

Immediate alarm originated by external pressure switch or compressor overload; the digital input switches

from closed to open and compressor is immediately stopped. To start the compressor again, the user has to

rearm the alarm manually by pushing the display Alarm button, provided that the pressure switch or

compressor overload have rearmed energising the digital input. After the compressor has turned off, timing is

enabled; for this reason, after alarm rearming, the compressor could not immediately turn on again.

LOW PRESSURE ALARM

Delayed alarm originated by an external pressure swit ch. When opening, the digital input enables two timers;

if, when the timers delay time (programmable by screen) elapses, the contact is open, the compressor turns

off and the alarm goes off. On the contrary, if the contact closes before delay time elapses, the alarm does

not go off and timers reset. Timers are: running compressor delay time and compressor start delay time.

Running delay is always counted, whereas compressor start delay is counted only if the input opens

immediately after compressor start and allows for fluid stabilisation. The two timers are counted in sequence.

Page 17

INNOV@-pCO1-IOM-0907-E 15

To start the compressor again, the user has to rearm the alarm manually by pushing the display Alarm

button, provided that the pressure switch has rearmed energising the digital input. After the compressor has

turned off, timing is enabled; for this reason, after alarm rearming, the compressor could not immediately turn

on again.

GENERIC ALARM

Alarm including all compressor safety devices in a single digital input, used on two-compressor small boards.

This alarm goes off immediately when opening the digital input and locks the compressor. To start the

compressor again, the user has to rearm the alarm manually by pushing t he display Alarm button, provided

that the digital input has been energised. After the compressor has turned off, timing is enabled; for this

reason, after alarm rearming, the compressor could not immediately turn on again.

2.8 Heaters

The heaters are managed as simple ON-OFF loads. Normally up to 2 heaters with the same power can be

managed, connected to the 2 outputs.

“Binary management” allows the use of three heating steps with just two outputs and 2 loads with different

power values:

The outputs with binary logic behave as follows:

2 DIFFERENT LOADS

STEP 1 Heat.1 = On / Heat.2 = Off

STEP 2 Heat.1 = Off / Heat.2 = On

STEP 3 Heat.1 = On / Heat.2 = On

The outputs are activated with a slight delay from one to the other, to avoid simultaneous peaks.

2.8.1 Heater alarms

Each heater is provided with a digital input to be connected with a compressor overload or differential for

signalling any failure.

Immediate alarm originated when the digital input switches from closed to open; the heater is immediately

disabled. To enable the heaters again, the user has to rearm the alarm manually by pushing the display

Alarm button, provided that the compressor overload or the differential have rearmed energising the digital

input.

2.9 Modulating valves

2.9.1 Three-position valves

Valves with three electrical contacts (besides supply): shared, opening and closing.

Based on the relays enabling time, the valves opening range varies from 0% to 100% taking an

opening/closing time defined as “running time” (time taken to open or close completely; it is a valves rating).

The relays must never be enabled simultaneously, thus the valve open, close or keep still.

The valves opening range is calculated based on the proportion between temperature differential and

running time. When ambient temperature corresponds to the set point, the valves keep closed; the more

temperature is o ffset compared to the set point the more the valves are opened, until they open completely

when temperature is equal or higher than set point + / - differential.

During operation, the valves are frequently subject to partial opening and closing; the program can recognise

the valves opening range at any time by adding up and subtracting all partial times executed from board

start-up.

Page 18

16 INNOV@-pCO1-IOM-0907-E

REALIGNMENT

As there is no feedback to define precisely the valves opening range, the program cannot easily manage the

three-position valves. A slight difference between the time calculated by the program and the relays enabling

time or a mechanical friction preventing the valves from moving freely may originate discrepancy between

the v a lves actual opening range and the range calculated by the program. To obviate this problem, the

following precautions are provided for:

whenever temperature control requires a valve complete opening or closing, the program increases

the opening or closing relay enabling time by 25% to ensure complete opening/closing.

whenever the board is started, the valves are completely closed during the running time; only after

time has elapsed, the valves start modulating their opening range based on the control request.

2.9.2 0-10Volt VALVES

These valves use a 0-10Volt modulating signal coming from the microprocessor to modify their opening

range from 0% to 100%.

The 0-10Volt electric s ignal is directly proportional to the temperature proportional band. Unlike the threeposition valves, these valves do not require adjustment since their opening range is directly proportional to

the analogue output value.

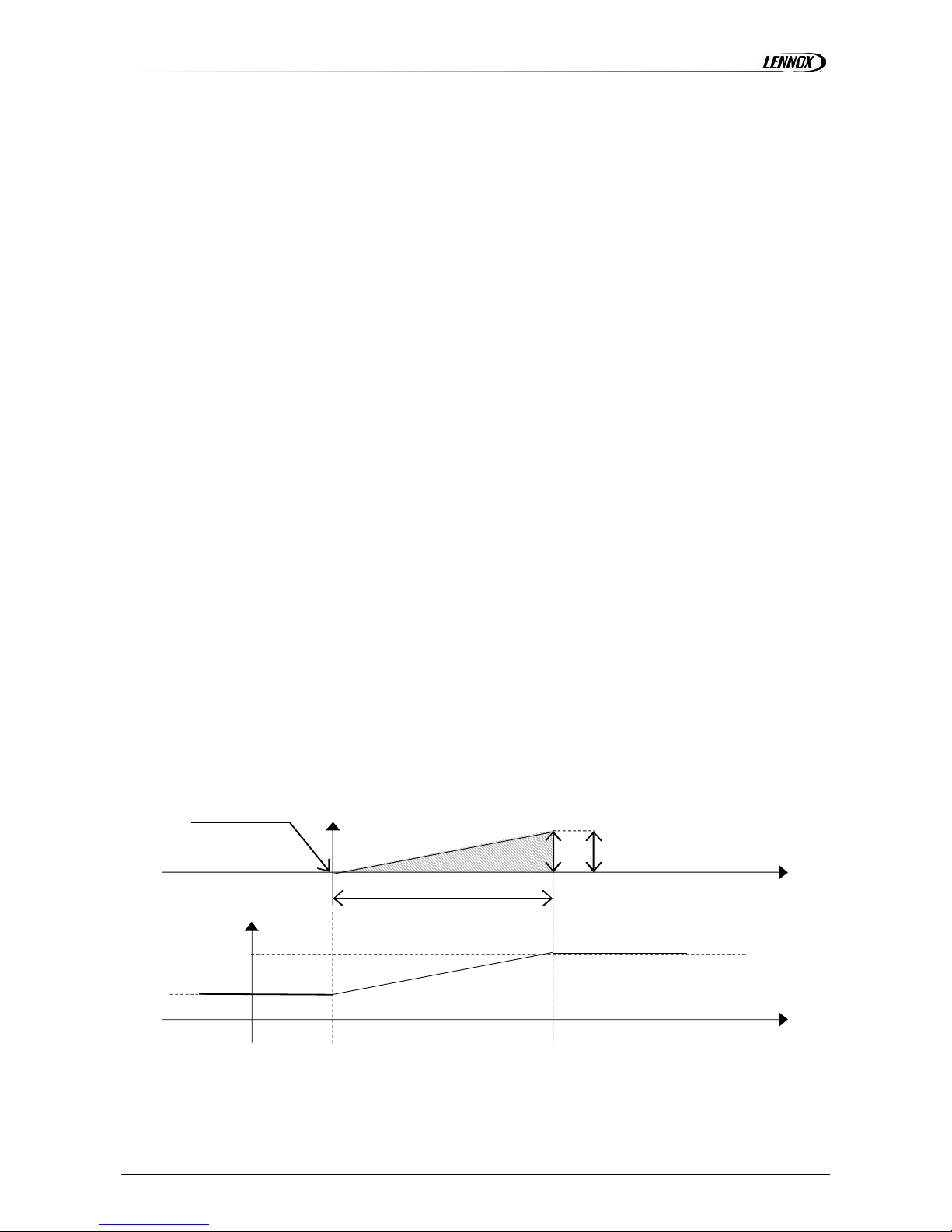

2.10 Outlet fan

With unit e nabled, the outlet fan keeps switched on. It can be managed with On–Off or modulating output.

The fan is provided with a thermal alarm and an air flow controller alarm, which lock the unit setting it to OFF

state; thermal alarm requires manual rearm, w hereas air flow controller alarm is rearmed automatically.

Description of modulating managemen t:

Temperature set

HEATING COOLING

100% 0% 0% 100%

19.5 22.5 23.0 23.5 26.5

3°C 0.5°C 0.5°C 3°C

Warm proportional band Cold proportional band

100% 100%

50%

Min speed (5.0V) Fan speed

Max speed (10.0V)

Page 19

INNOV@-pCO1-IOM-0907-E 17

3 THE USER INTERFACE

The provided user interface PGD is equipped with a LCD display (4 rows x 20 columns). and with 6 keys. It

allows carrying out all program operations. The user interface allows displaying the unit working conditions at

any time and modifying the parameters; furthermore, it may also be disconnected from the main board, as its

presence is not strictly necessary.

3.1 Keyboard description

The PGD user interface has 6 keys and their use is describe in the following table.

Keys Description

ALARM key

Press ALARM key to enter the alarm menu and to reset the alarms. When an alarm

is present the button is illuminated.

PROGRAM key

Press PROGRAM key to enter the main menu where is possible to select the items:

MAINTENANCE, PRINTER, INPUT/OUTPUT, CLOCK, SETPOINT , USER,

MANUFACTURER

ESC key Press ESC key to go out from a menu and come back into the main screen.

UP key

Press UP key to move into the next screen or to increment the value of a

parameter.

ENTER key

Press ENTER key to move into the next modifiable parameter field and confirm the

modification

DOWN key

Press DOWN key to move into the previous screen or to decrement the value of a

parameter.

PROGRAM + ESC keys

Press simultaneously PROGRAM and ESC keys to enter directly the

MANUFACTURER menu.

ESC + ENTER keys

Press simultaneously for 5 seconds, ESC and ENTER keys to enter into the screen

where you can press ENTER to switch ON/OFF the unit

3.1.1 Switch ON/OFF of the unit

The unit is switch On/Off by pressing Esc + Enter keys simultaneously for 5 seconds; after, the displayed

screen allows executing the required operation by using Enter key.

3.1.2 Screen loop

Press PROGRAM key to display the main menu; then, by using the a rrow buttons, move the cursor on the

selected item and press Enter to access it.

Page 20

18 INNOV@-pCO1-IOM-0907-E

3.2 Remote user interface

3.2.1 Without local display

3.2.2 With local display

Remote display

wall mounted Microprocessor pCO1

Unit

Remote display cable:

6 wires, with RJ11

connectors.

NOTE:

the cable is different from

the standard telephone

cable because in the

remote display cable the

connectors are reversed.

Local display

panel mounted

Remote display

wall mounted

Microprocessor pCO1

Unit

Derivator TCONN

(it is necessary only if local

and remote displays are

simultaneously present)

Remote display cable:

6 wires, with RJ11

connectors.

NOTE:

the cable is different from

the standard telephone

cable because in the

remote display cable the

connectors are reversed.

Page 21

INNOV@-pCO1-IOM-0907-E 19

4 BOARD CO NFIGURATION AND CONNECT ION

The LAN network identifies a physical connection between the microprocessor, the display and the drivers

for the electronic expansion valves. This connection allows exchanging variables from a board to another,

according to a logic established by the software, to make them work together in a functional way. The

address of the boards must be configure even in stand alone unit.

4.1 Address configuration

4.1.1 Address configuration of the microprocessor (pCO1)

For the configuration of the address of the pCO1 follow these steps:

- connected the pCO1 with a display PGD wich the address configure to 0. (See Address configuration of the

PGD)

- switch ON the power supply pressing simultaneously the ALARM and the UP keys.

- press UP or DOWN key to set the address.

- press ENTER key to save and exit from this procedure.

4.1.2 Address configuration of the PGD

For the configuration of the address of the PGD follow these steps:

- press UP+ENTER+DOWN for few seconds

- press ENTER and then press UP or DOWN key to set the address.

- press ENTER key to save and exit from this procedure.

NOTES:

- If the addresses of the microprocessor or of the PDG a re non corrected, the functioning of the unit is not

guaranteed, and the PDG can displays nothing.

- after the address configuration of the PGD, it can display the notice “NO LINK” for some seconds.

4.1.3 Address configuration of the E2V electronic expansion valve’s driver

(EVD)

For the c onfiguration o f the driver (EVD) is necessary to set

the dip-switch (using a binary logic) that are present inside of

the driver, under the frontal box.:

Address Dip-switch

Driver for circuit 1 9

Driver for circuit 2 10

Open the

frontal box to

configure the

dip-switch.

Page 22

20 INNOV@-pCO1-IOM-0907-E

4.2 Boards connection

The electrical connection among boards is executed using the following two type of cables:

Display connection

For the connection of the display is necessary to use a cable with 6 wires and RJ11 connectors; the cable is

different from the standard telephone cable because in the display cable the connectors are reversed.

LAN connection

For the LAN connection is necessary to use a cable with 2 wires plus shield, from unit to unit, by using the

terminal strip in the electrical panel (see the specific electrical diagram); the data are sent through Rs485

logic; no additional device is required.

4.2.1 Stand alone unit

4.2.2 Units connected in LAN (max. 8 units)

The units can be connected to the other units in LAN (local area network) for a maximum of 8 units. Each

unit can be connected (inside of it) to one or two drivers (EVD) for the management of the electronic valves

and to one display for user interface. In the following table are listed the addresses of the microprocessor, of

the drivers (EVD) and of the display.

List of addresses

Address of

Microproc. pCO1

Address of

EVD Driver 1

Address of

EVD Driver 2

Address of

Display

Config. by display Config. by dip-switch Config. by dip-switch Config. by display

Unit 1 1 9

10

25

Unit 2 2 11

12

26

Unit 3 3 13

14

27

Unit 4 4 15

16

28

Unit 5 5 17

18

29

LAN

cable

LAN

cable

pCO1: Address = 1

PGD: Address = 25

Driver 1:

Address = 9

Driver 2:

Address = 10

Display

cable

Page 23

INNOV@-pCO1-IOM-0907-E 21

Unit 6 6 19

20

30

Unit 7 7 21

22

31

Unit 8 8 23

24

32

The address of the microprocessor can be read from the main screen in the lower right corner.

The display with address 32 allows controlling all boards without requiring other displays or in addition to

the other displays; as a matter of fact, the program allows display with address 3 2 to access the parameters

of all connected boards, one by one. Passage among the boards can be executed by simply pushing button

ESC + DOWN.

4.2.3 LAN status

When starting the system, the LAN network could undergo some problems (failed boards and displays

displays start-up) due to improper electrical connections or to the fact that incorrect addresses have been

assigned. By means of a special screen, the LAN network state can be displayed in real time, thus

identifying which devices (boards and displays) are properly connected and addressed. To display the

special screen, push buttons Up-Down-Enter of any network display si multaneously for at least 10 sec. After

the fi rst 5 seconds, a screen is displayed; continue for another 5 seconds until the following screen is

displayed:

As it can be seen, network addresses from 1 to 32 are displayed, together with a symbol indicating if a

display (small rectangle) or a board / valve driver (big rectangle) is concerned. The dash indicates that the

board / display has incorrect address or is connected improperly. In case the symbols appear and disappear,

it means that LAN is unstable or, more probably, that repeated addresses are present. The number following

T indicates the address of the display being used. The example indicates that the network consists of one

boards or valves drivers with address 1 and of one display with address 25. After the screen is checked, if

there is some trouble cut network power off, verify connections and addresses and power the system again.

4.3 Software update

If is necessary a software update the boards shall be programmed by DOWNLOADING the application

program to the Flash buffer memory; this operation can be performed either using the hardware key or a

computer.

4.3.1 Program download from hardware key

To connect the key to the pCO1, proceed as follows:

1. Switch the pCO1 off and remove the “expansion memory” cover using a screwdriver.

2. Place the key selector on .

Page 24

22 INNOV@-pCO1-IOM-0907-E

3. Insert the key into the corresponding slot.

4. Press Up and Down together in the display and switch the board on.

5. Check that the red key LED comes on.

6. Wait until the upload request is displayed on the LCD, then release the buttons and confirm by pressing

Enter; the data transfer operation will take approximately 10 seconds.

7. Switch the pCO1 off, remove the key, place the cover in its original position and switch the board back on

again.

8. The board will now work with the program transferred from the key.

4.3.2 Program download from computer

Use the the converter (RS232/RS485) and the WinLOAD 32 program, proceeding as follows:

1. Connect the converter (RS232/RS485) to the mains using the transformer provided in the kit.

2. Connect the converter to a free serial port on the PC, using the serial cable provided in the kit.

3. Connect the converter to connector J10 on the pCO1 using a telephone cable.

4. Install Winload, if Winload is not already installed on the PC.

5. Run WinLOAD32 on the PC, with the board off.

6. Enter in the number of the PC serial port in the field “COMM” (1 for COM1, 2 for COM2).

7. Enter “0” in the field “pCO ADD.”.

8. Switch the board on.

9. Wait 30 seconds until the message “OFF LINE” becomes “ON LINE” in the WinLOAD32 program, in the

lower left, or until the yellow LED next to the dipswitch on the board s tarts flashing; now enter t he actual

board LAN address value in the field “pCO² ADD”; a blue light in the Winload program, in the bottom centre

of the window, will start flashing.

10. In WinLOAD32, select “Upload” and then “Application”.

11. Select the folder containing the application program source files.

12. Use CTRL to select a series of *.iup files, if needing to load a series of languages to the pCO1. Also

select the *.blb files (for non-LAN applications) or the flash1.bin file in the program being loaded (for LAN

applications).

13. Click “UPLOAD” to start the file download procedure, which will take approximately 1 to 5 minutes,

depending on the number of *.iup files selected and the size of the various files.

14. Wait until the message “Upload OK” appears in the progress bar.

15. Disconnect the telephone cable between the board and converter; connect the external display (if

featured), then switch the board off and on again.

NOTE: if a LAN network with a series of boards is used, the program can be installed on the other boards

without repeating the operations: after installing the program on the first board, simply repeat steps from 8 to

14, entering the new board addresses each time in the field “pCO ADD” in the WinLOAD32 program .

4.3.3 Restore the default parameters

Default parameters are the values assigned by manufacturer to the application program main operative

parameters. Parameters are assigned automatically when executing the DOWNLOAD operation as

described above. Parameters indicate timing, set points, differentials, etc… (refer to the complete list of

default values).

After installing default values, the parameters must be modified following the s pecial parameter list with the

specific parameter of the installed unit.

Operations to be carried out for default parameters manual installation:

1. Push buttons PRG + ESC keys and type the Manufacturer password, then push Enter.

2. By pushing button Down three times, move the cursor on “INITIALIZATION” (last row), then push ENTER.

3. The parameters installation screen is displayed; to install, push ENTER and type the Manufacturer

password.

4. WARNING: we recommend extreme care since this operation deletes all the installed p arameters from the

memory and replaces them by the default parameters – after this operation, parameters cannot be restored.

5. After pushing ENTER, message “PLEASE WAIT” is displayed for some seconds.

6. Switch off and then switch on the power supply.

Page 25

INNOV@-pCO1-IOM-0907-E 23

4.3.4 Language selection

English is the language automatically selected, but it can be changed into: Italian, French, German, Spanish.

To modify the language, operate as follows:

1. Press the PROGRAM key, select the MAINTENANCE item and press ENTER

2. Press ENTER in the screen A0, and UP or DOWN to modify the language

3. Press ENTER to confirm the new language.

5 ALARMS

The alarms managed by the program safeguard soundness of the connected devices and provide signals in

case the control parameters have exceeded the normal values or the board is faulty. The alarms originate

from alarm digital inputs, probes or board. Their effect ranges from the simple block signalling of one or more

devices to the air-conditioning unit stop. Many alarms are subject to programmable delay times.

When an alarm state is identified, the following signals occur:

the red LED under button ALARM turns on

abbreviation AL starts blinking on the Menu screen

Pushing button Alarm, the buzzer switches off and the alarm screen is displayed. If more alarms are active,

the s c reen of the first alarm is displayed; the other alarms can be displayed by using the arrow buttons. If

other buttons are pressed, the alarm screens are left but they keep stored and are displayed again whenever

the Alarm button is pressed.

To rearm the alarms and delete the message manually, simply move the cursor on the alarm sc reens and

push button Alarm again; if the alarm causes have disappeared (digital inputs rearmed, temperature within

the normal values, etc…), the screens disappear, the red led switches off and message “NO ALARM

ACTIVE” is displayed. If the cause of one or more alarms is still active, the disabled alarms only disappear,

whereas the other alarms keep displayed and the buzzer and the red led switch on again.

Alarms are divided into two categories: manually-rearmed alarms or automatically-rearmed alarms.

The manually-rearmed alarms require alarm screen deleting (as described above) to restart the devices or

the ai r-conditioning unit. The automatically-rearmed alarms unlock the device or restart the air-conditioning

unit after the cause has disappeared, but the alarm screen keeps stored in the memory.

5.1 Table of alarms

CODE

DESCRIPTION

DELAY

UNIT OFF

DISABLED

A01 Compressor 1 general alarm

- - Compressor 1

A02 Compressor 2 general alarm - - Compressor 2

A03 Compressor 1 low pressure

see T2 - Compressor 1

A04 Compressor 2 low pressure

see T2 - Compressor 2

A05 No air flow see T4 yes All

A06 Outlet fan thermal

- yes All

A07 Heater 1 thermal

- - Heater 1

A08 Heater 2 thermal

- - Heater 2

A09 Fire / Smoke detection

- yes All

A10 Dirty filters - - A11 High ambient temperature

see T2 - -

A12 Low ambient temperature

see T2 - A13 High ambient humidity see T2 - A14 Low ambient humidity

see T2 - A15 Compressor 1 working hours threshold reached

- - -

A16 Compressor 2 working hours threshold reached

- - -

A17 Outlet fan working hours threshold reached

- - -

A18 Ambient temperature probe faulty or disconnected 60 sec (fixed) - A19

Recovery water temperature probe faulty or

disconnected

60 sec (fixed) - -

A20 External air temperature probe faulty or disconnected 60 sec (fixed) - A21 Outlet air temperature probe faulty or disconnected

60 sec (fixed) - -

A22 Ambient humidity probe faulty or disconnected

60 sec (fixed) - -

A23 Condenser 1 pressure probe faulty or disconnected

60 sec (fixed) - -

A24 Condenser 2 pressure probe faulty or disconnected

60 sec (fixed) - A25 Condenser 1 temperature probe faulty or disconnected 60 sec (fixed) - A26 Condenser 2 temperature probe faulty or disconnected 60 sec (fixed) - A27 High humidifier current

- - Humidifier

Page 26

24 INNOV@-pCO1-IOM-0907-E

A28 No water inside humidifier cylinder

? - -

A29 No current in humidifier

? - A30 Clock card not present / faulty - - A31 Circuit 1 high pressure

- - Compressor 1

A32 Circuit 2 high pressure

- - Compressor 2

A33 Water under floor

- yes All

A34 Auxiliary alarm

- - -

A35 Compressor 1 high pressure + thermal

- - Compressor 1

A36 Humidifier working hours threshold reached

- - -

A37 Compressor 2 high pressure + thermal

- - Compressor 2

A38 Condensing fan 1 thermal - - Condensing fan 1

A39 Condensing fan 2 thermal

- - Condensing fan 2

A40 No water flow

see T4 yes All

A41 pLAN disconnected

60 sec (fixed) - -

A42 Driver 1 alarm, probes faulty or disconnected

- - Compressor 1

A43 Driver 1 EEPROM faulty or damaged

- - Compressor 1

A44 Driver 1 valve motor faulty or damaged

- - Compressor 1

A45 Driver 1 alarm, battery discharged or faulty

- - A46 Driver 1 high evaporation pressure (MOP) See Fj - A47 Driver 1 low evaporation pressure (LOP)

See Fj - -

A48 Driver 1 low superheating

See Fi - Compressor 1

A49 Driver 1 valve not closed during blackout

- - Compressor 1

A50 Driver 1 high suction pressure

See Fi - -

A51 Driver 2 alarm, probes faulty or disconnected

- - Compressor 2

A52 Driver 2 EEPROM faulty or damaged

- - Compressor 2

A53 Driver 2 valve motor faulty or damaged

- - Compressor 2

A54 Driver 2 alarm, battery discharged or faulty - - A55 Driver 2 high evaporation pressure (MOP)

See Fj - -

A56 Driver 2 low evaporation pressure (LOP)

See Fj - -

A57 Driver 2 low superheating

See Fi - Compressor 2

A58 Driver 2 valve not closed during blackout

- - Compressor 2

A59 Driver 2 high suction pressure

See Fi - -

A60

Built-in humidifier: high conductivity alarm

See threshold Gb:

delay 1h

- Humidifier

A61 Built-in humidifier: high conductivity pre alarm

See threshold Gb:

delay 1h

- -

A62 Built-in humidifier: low steam production

- Humidifier

A63 Built-in humidifier: water drain alarm

- Humidifier

A64 Built-in humidifier: cylinder full alarm

- Humidifier

A65 Built-in humidifier: cylinder being depleted signal - A66 Built-in humidifier: presence of foam

- A67 Built-in humidifier: cylinder depleted

- -

5.2 Alarm data logging

Alarms data logging allows storing the air-conditioning unit working state whenever an alarm goes off or

under particular conditions. Any storing operation becomes an event, which can be displayed as any other

event available in the memory. As it functions as a device for “taking photographs” of the system whenever

any alarm goes off, data loggi ng is extremely useful for suggesting possible c auses and s olving s ys tem

malfunctions and failures. The program is provided with a MAIN and a DEVELOPED data logging.

5.3 Main log

Events can be stored thanks to the boards very large buffer memory. The MAIN data logging can be enabled

by parameter; if the clock card (optional) is not available, neither the MAIN data logging is available. No

additional optional card is required.

The maximum number of storable events is 100; after the last space available in the memory (alarm no. 100)

is used, next alarm will be overwritten on the first alarm s tored (001), which will be automatically deleted.

This procedure applies to all following events. The user cannot delete the stored events except at the default

values installation. The MAIN data logging screen can be accessed by pushing button ALARM when screen

E4 is displayed and can be left by pushing button Esc. The screen is displayed as follows:

Page 27

INNOV@-pCO1-IOM-0907-E 25

Whenever an alarm goes off, the following air-conditioning unit data are stored for each alarm:

alarm description

time

date

event chronological number (0-100)

The event chronological number, displayed in the upper right corner, indicates the event “stay time”

compared to the 100 available memory spaces. Alarm no. 001 represents the first alarm gone off after MAIN

data logging enabling.

Moving the cursor on the chronological number and using the arrow buttons, the alarms “history” can be

scrolled from 1 to 100.

In position 001 and pushing the down arrow, the alarms cannot be scrolled.

If, for example, 15 alarms have been stored and the cursor is in position 015, pushing the up a rrow, the

alarms cannot be scrolled.

Page 28

26 INNOV@-pCO1-IOM-0907-E

6 SCREENS

The screens are divided into these categories:

MAINTENANCE: checking the devices periodically, calibrating the connected probes, modifying the working

hours and managing the devices manually. PASSWORD = 105

PRINTER: printing the list of parameter only with a special version of display. NO PASSWORD

INPUT/OUTPUT: allow to show the digital and analog input/output values. NO PASSWORD

CLOCK: allow setting and enabling the temperature and humidity time bands. PASSWORD = 108

SETPOINT: allow setting the temperature and humidity set points and regulating the clock. NO PASSWORD

USER: allow s etting the main functions (timing, sets, differentials) of the connected devices; PASSWORD =

108

MANUFACTURER: allow configuring the air-conditioning unit, enabling the main functions and selecting the

connected device. PASSWORD = available on request. This menu is divided into these categories:

CONFIGURATION, PARAM ETERS, CAREL EXV DRIVERS, TIMING AND INITIALIZATION.

6.1 List of the screens

The following list indicates the displayed screens. Columns represent the screens loops: the first screen (A0,

B0…) can be displayed by pushing the relevant button and the other screens can be scrolled by using the

arrow buttons. Codes (Ax, Bx, Cx…) are displayed in the screens upper right corner, so as to be easily

identified. The meaning of symbols “0”,”1”… is explained in the previous paragraph. Symbol PSW indicates

the screens for entering passwords.

MAIN MAINTENANC E PRINTER INPUT/OUTPUT CLOCK SETPOINT USER

M0 A0 H0 I0 K0 S0 PSW P0

M1 A1 H1 I1 PSW K1

S1 P1 M2 A2 I2 K2 P2 A3 I3 K3 P3

A4 I4 K4 P4 A5 I5 K5 P5 PSW A6

I6 K6 P6

A7 I7 K7 P7

A8 I8 K8 P8 A9 I9 K9 P9

Aa Ia Ka Pa Ab Ib Pb

Ac Ic Pc Ad Id Pd

Ae Ie Pe

Af If Pf Ag Ig Pg Ah Ih Ph

Ai Ii Pi

Aj Ij Pj Ak Ik

Al Il Am Im An In Io Ip Iq

Ir Is It Iu Iv

Page 29

INNOV@-pCO1-IOM-0907-E 27

MANUFA C T URER

PSW Z0

Gb T5 Z1 Gc T6

CONFIGURATION

C0 Gd T7 C1 Ge T8 C2 Gf

INITIALISATION

V0 C3 Gg V1

C4 Gh V2 C5 Gi C6

Gj C7

Gk C8

Gl

C9 Gm Ca

Gn Cb

Go Cc

CAREL EXV DRIVER

F0 Cd

F1 Ce

F2

Cf F3 Cg

F4

Cj F5

Ci F6 Cl F7

Cm F8 Cn

F9 Co

Fa

Cp Fb

Co Fc Cp

Fd

PARAMETERS

G0 Fe

G1 Ff G2

Fg

G3 Fh G4

Fi G5

Fj

G6

TIM

ING

T0

G7 T1 G8 T2 G9 T3 Ga T4

Page 30

28 INNOV@-pCO1-IOM-0907-E

7 LIST OF PARAMETERS AND DEFAULT VALUES

The table below lists the parameters in the program, together with the following information: screen code (the

screen code is displayed at the top right) to assist the identification of the parameter, the default value, the

minimum and maximum limits (range), and the unit of measure.

To find a specific parameter on the display, proceed as follows:

Identify the parameter in the table below and the corresponding screen code

Using the list of the screens (following paragraph) and the screen code, access the screen on the

display

PARAMETER DESCRIPTION SCREEN DEFAULT SPECIAL VALUE RANGE UOM

Maintenance Menu

Select display language A0 English En, It, Fr, De

Enter password A6 ---- 0-9999

Modify outlet fan operating hours A7 0 0-99 . 0-999 hours

Modify compressor 1 operating hours A7 0 0-99 . 0-999 hours

Modify compressor 2 operating hours A7 0 0-99 . 0-999 hours

Device operating hour threshold: main fan A8 99 0-99

hours x

1000

Device operating hour threshold: compr. circuit 1 A8 99 0-99

hours x

1000

Device operating hour threshold: compr. circuit 2 A8 99 0-99

hours x

1000

Humidity probe calibration A9 0 -9.9 – 9.9 %RH

Condenser 1 pressure probe calibration A9 0 -99.9 – 99.9 bar

Condenser 2 pressure probe calibration A9 0 -99.9 – 99.9 bar

Ambient temperature probe calibration Aa 0 -99.9 – 99.9 °C / °F

External temperature probe calibration Aa 0 -99.9 – 99.9 °C / °F

Supply temperature probe calibration Aa 0 -99.9 – 99.9 °C / °F

Recovery temperature probe calibration Ab 0 -99.9 – 99.9 °C / °F

Condenser 1 temperature probe calibration Ab 0 -99.9 – 99.9 °C / °F

Condenser 2 temperature probe calibration Ab 0 -99.9 – 99.9 °C / °F

Manual activation of digital outputs 1 – 2 – 3 Ac Off Off – On

Manual activation of digital outputs 4 – 5 – 6 Ad Off Off – On

Manual activation of digital outputs 7 – 8 – 9 Ae Off Off – On

Manual activation of digital outputs 10 – 11 – 13 Af Off Off – On

Manual activation of modulating outputs 1 – 2 Ag 0 0-10.0 Volt

Manual activation of modulating outputs 3 – 4 Ah 0 0-10.0 Volt

Manual activation of pre wash built-in humidifier Ai No No-Yes

Manual activation of total water drain built-in

humidifier

Ai No No-Yes

Hum. management: periodic drain enable Ai1 No No-Yes

Hum. management: periodic drain period Ai1 120 0-120 hours

Hum. management: stop delay Ai2 0 0-120 seconds

Hum. management: drain for inactivity period Ai2 3 1-199 hours

Hum. management: threshold running hours Ai3 4000 0 - 4000 hours

Driver 1 valve control mode Aj Automatic Auto-Man.

Driver 1 valve manual opening steps Aj 0 0-9999 Steps

Driver 2 valve control mode Ak Automatic Auto-Man.

Driver 2 valve manual opening steps Ak 0 0-9999 Steps

Driver 1 manual release on start-up Al No No-Yes

Driver 2 manual release on start-up Am No No-Yes

Enter new Maintenance password An ---- 0-9999

Printer Menu

Cyclical print interv al H1 24 0-999 hours

Send immediate print H1 No No-Yes

Clock Menu

Hour setting K0 current hour 0-23 hours

Minute setting K0 current minutes 0-59 minutes

Day setting K0 current day 1-31

Month setting K0 current month 1-12

Year setting K0 current year 0-99

Enter Clock password K1 ---- 0-9999

Page 31

INNOV@-pCO1-IOM-0907-E 29

PARAMETER DESCRIPTION SCREEN DEFAULT SPECIAL VALUE RANGE UOM

Enable temperature / humidity / On-Off time

bands

K2 No / No / No No-Yes

Start and end hour for On-Off time bands F1-1and

F1-2

K3 9 / 13 / 14 / 21 0-23 hours

Start and end minutes for On-Off time bands F1-1

and F1-2

K3 0 / 0 / 0 / 0 0-59 minutes

Start and end hour for On-Off time band F2 K4 14 / 21 0-23 hours

Start and end minutes for On-Off time band F2 K4 0 / 0 0-59 minutes

Select On-Off time bands (F1,F2,F3,F4) for each

day

K5 F3 F1-F2-F3-F4

Start hour temperature bands 1 and 2 K6 0 / 6 0-23 hours

Start minutes temperature bands 1 and 2 K6 0 / 0 0-59 minutes

Set point temperature bands 1 and 2 K6 23.0 / 23.0 see P1 ºC / ºF

Start hour temperature bands 3 and 4 K7 12 / 18 0-23 hours

Start minutes temperature bands 3 and 4 K7 0 / 0 0-59 minutes

Set point temperature bands 3 and 4 K7 23.0 / 23.0 see P1 ºC / ºF

Start hour humidity bands 1 and 2 K8 0 / 6 0-23 hours

Start minutes humidity bands 1 and 2 K8 0 / 0 0-59 minutes

Set point humidity bands 1 and 2 K8 50.0 / 50.0 see P2 %RH

Start hour humidity bands 3 and 4 K9 12 / 18 0-23 hours

Start minutes humidity bands 3 and 4 K9 0 / 0 0-59 minutes

Set point humidity bands 3 and 4 K9 50.0 / 50.0 see P2 %RH

Enter new Clock password Ka ----

Setpoint Menu

Temperature set point S1 23.0 see P1 ºC / ºF

Humidity set point S1 50.0 see P2 %RH

User Menu

Enter user password P0 ---- 0-9999

Minimum and maximum temperature set point

limits

P1 -99.9 / 99.9 -999.9-999.9 ºC / ºF

Minimum and maximum humidity set point limits P2 0.0 / 100.0 0.0-100.0 %RH

Proportional temperature bands (differential) in

Heating and cooling

P3 3.0 / 3.0 0.0-100.0 ºC / ºF

Temperature dead zone (neutral zone) P3 0,5 0.0-99.9 ºC / ºF

Proportional bands in Humidification and

Dehumidification

P4 2.0 / 2.0 0.0-99.9 %RH

Maximum production allowed, built-in humidifier P4 70.0 0% -100% % kg/h

Show language screen at start-up P5 No No-Yes

Switch unit off from button P5 Yes No-Yes

Enable remote On-Off digital input P5 Yes No-Yes

Recovery water temperature set point P6 12,0 0-99.9 ºC / ºF

Recovery air temperature set point / Differential P6 3.0 / 2.0 0-99.9 ºC / ºF

Enable compensation function P7 No No-Yes

Outside air compensation set point P7 25.0 -999.9-999.9 ºC / ºF

Outside air compensation differential band P7 3.0 -999.9-999.9 ºC / ºF

Offset maximum of compensation of the set of

temperature

P7 2.0 -999.9-999.9 ºC / ºF

High and low ambient temperature alarms offset

respect the setpoint

P8 10.0 / 10.0 -999.9-999.9 ºC / ºF

High and low ambient humidity alarms offset

respect the setpoint

P9 20.0 / 30.0 0-100,0 %RH

Enable outlet limit function Pa No No-Yes

Outlet air set point for the limitation function Pa 15.0 -999.9-999.9 ºC / ºF

Outlet air differential for the limitation function Pa 5.0 -999.9-999.9 ºC / ºF

Assign type of alarm Serious/Minor AL01-AL20 Pb All N N-Y

Assign type of alarm Serious/Minor AL21-AL40 Pc All N N-Y

Assign type of alarm Serious/Minor AL41-AL60 Pd All N N-Y

Assign type of alarm Serious/Minor AL61-AL70 Pe All N N-Y

Board identification number for supervisory

network

Pf 1 0-200

Board communication speed for supervisory

network

Pf 1200 1200-19200 Baudrate

Serial communication protocol Pf Carel

Carel, Modbus,

Lon, RS232, Gsm

Telephone numbers entered on analogue modem Pg 0 1-4

Enter telephone numbers on analogue modem Pg 0 0…9,#,*,@,ˆ

Number of rings for GSM modem Pg 0 0-9

Password to write SMS text message Pg 0 0-9999

Destination GSM telephone number Pg 0 0…9,#,*,@,ˆ

Page 32

30 INNOV@-pCO1-IOM-0907-E

PARAMETER DESCRIPTION SCREEN DEFAULT SPECIAL VALUE RANGE UOM

Number of rings for analogue modem Ph 0 0-9

Password for superv isor remote connection Ph 0 0-9999

Type of analogue modem Ph Tone Tone-Pulse

Enter new user password Pi ---- 0-9999

Manufacturer Menu

Enter manufacturer password Z0 ---- 0-9999

CONFIGURATION -->

Enable BMS C0 No No-Yes

Enable printer C0 No No-Yes

Select unit of measure for temperature probes

and parameters

C0 ºC ºC-ºF

Enable clock board C0 No No-Yes

Type of unit C1 ED ED-CW

Select refrigerant C1 R407C

R22,R134a,

R404a, R407C,

R410A

Number of compressors C2 2 1-2

Enable comp ressor capacity-control steps

(unloaders)

C2 No No-Yes

Heating mode C2 Heaters Heaters-Battery

Humber of heaters C2 2 0-1-2-Binary

Type of valve for heating battery C2 0-10Volt 0-10V / 3 points

Type of coil C3 C/H C/H-Cool

Type of valve for the coil C3 0-10Volt 0-10V/ 3 points

Heating mode C3 Heaters Heaters-Battery 2

Humber of heaters C3 2 0-1-2-Binary

Type of valve for heating coil C3 0-10Volt 0-10V/3 points

Digital input 5 configuration C4 Filter alarm

Flood alarm, Filter

alarm, Fire alarm

Digital input 12 configuration C5 Fire/smoke alarm

Fire/smoke alarm,

Water Flood alarm

Digital input 1 configuration C6 Fire/smoke alarm

Fire/smoke alarm,

Water Flood alarm

Digital output 7 configuration C7 Light alarm relay

Recovery valve,

Light alarm relay

Analog input 2 configuration C8 Pressure circ. 1

Pressure circ.1,

Temp. circ. 1,

Supply air temp.

Analog input 3 configuration C9 Pressure circ. 2

Pressure circ.2,

Temp. circ. 2,

Recovery temp.

Modulating output 1 configuration Ca Main fan damper

Recovery damper,

Main fan damper

Recovery type Ca Air Air, Water

Enable analog humidifier output Ca No No-Yes

Analog output 2 configuration Cb Recovery damper

Recovery damper,

Humidif. damper

Recovery damper enable Cc No No-Yes

Main fan damper presence Cc No No-Yes

Enable condensation function Cd No No-Yes

Type of condenser Cd Single Single-Separat.

Condensing output type Cd Inverter Inverter-Steps

Select number of condensing fans Cd 1 1-2

Maximum voltage threshold for Triac Ce 92,0 0-100 %

Minimum voltage threshold for Triac Ce 7,0 0-100 %

Duration of T riac impulse Ce 2 0-10

m

seconds

Logic of the dehumidification contact Cf NC NO-NC

Number of compressors enabled for

dehumidification

Cf 0 0-2

Enable cooling coil for dehumidification Cf No No-Yes

Enable built-in humidifier Cf No No-Yes

Type of humidifier Cg 3 Kg/h 400V 3Ph 3 Kg/h / 8 Kg/g

Maximum production Cg 70.0 0-100.0 %

Humidifier board type Cg PCOUMID000

PCOUMID200-

PCOUMID000

Enable humidity probe Ch Yes No-Yes

Type of signal from the humidity probe Ch Current

0-1V, 0-10V,

Current

Page 33

INNOV@-pCO1-IOM-0907-E 31

PARAMETER DESCRIPTION SCREEN DEFAULT SPECIAL VALUE RANGE UOM

Minimum and maximum value measured by the

humidity probe

Ch 0.0 / 100.0 0-100.0 %RH

Enable pressure probe 1

Ci

No No-Yes

Type of signal pressure probe 1 Ci Current

0-1V, 0-10V,

Current

Minimum and maximum value pressure probe 1 Ci 0.0 / 30.0 -20.0 - 50.0 Bar

Enable pressure probe 2 Cj No No-Yes

Type of signal pressure probe 2 Cj Current

0-1V, 0-10V,

Current

Minimum and maximum value pressure probe 2 Cj 0.0 / 30.0 -20.0 - 50.0 Bar

Room temperature probe type Ck NTC NTC-PT1000

Enable supply air probe Ck Yes No-Yes

Supply air temperature probe type Ck NTC NT C-PT1000

Enable external temperature probe Cl No No-Yes

External temperature probe type Cl NTC NTC-PT1000

Enable recovery temp erature probe Cl No No-Yes

Recovery temperature probe type Cl NTC NTC-PT1000

Enable condenser 1 temperature probe Cm No No-Yes

Condenser 1 temperature probe type Cm NTC NTC-PT1000

Enable condenser 2 temperature probe Cm No No-Yes

Condenser 2 temperature probe type Cm NTC NTC-PT1000

LAN unit configuration Unit 1 (U1) Cn Present/No rotat.

Present/Rotation

Present/No rotat.

Not present

LAN unit configuration Unit 2-3 (U2-U3) Cn Not present

Present/Rotation

Present/No rotat.

Not present

LAN unit configuration Unit 4-5-6 (U4-U5-U6) Co Not present

Present/Rotation

Present/No rotat.

Not present

LAN unit configuration Unit 7-8 (U7-U8) Cp Not present

Present/Rotation

Present/No rotat.

Not present

Enable analog fan on analog out 2 Cq Yes No-Yes

Enable ex pansion card Cr Off Off-On

Enable ex pansion card alarm Cr Off Off-On

Expansion card alarm delay Cr 120 0-999 seconds

Reheating system Cs No Reheating

No Reheating,

Elect. Heaters, Hot

gas On/Off, Hot

gas modulat.

PARAMETERS -->

Enable comp ressors/cooling battery together with

recovery valve

G0 No No-Yes

Enable FIFO compressor rotation G1 Yes No-Yes

Temperature regulation type G1 Prop. Prop.-P+I

Logic of the capacity-control contact G1 NC NC-NO

Starting point to open modulating valve in cooling

(or single valve) with recovery (see G0)

G2 50.0 0.0-100.0 %

Starting and end point to open modulating valve in

cooling (or single valve)

G2 0.0 / 100.0 0.0-100.0 %

Starting point to open 3 position valve in cooling

(or single valve) with recovery (see G0)

G3 50,0 0.0-100.0 %

Starting and end point to open 3 position valve in

cooling (or single valve)

G3 0.0 / 100.0 0.0-100.0 %

Starting and end point to open modulating valve in

heating

G4 0.0 / 100.0 0.0-100.0 %

Starting and end point to open 3 position valve in

heating

G5 0.0 / 100.0 0.0-100.0 %

Starting and end point to open modulating valve in

recovery

G6 0.0 / 100.0 0.0-100.0 %