Page 1

HOMEOWNER'S CARE AND

OPERATION INSTRUCTIONS

OASIS SERIES

43" Wood Burning Outdoor Fireplaces

P/N 875,019M REV. B 03/2007

MODELS

LSO-43 LSO-43-H

The information contained in this manual applies to all model fireplaces

identified on this page. This information will help you obtain safe and

dependable service from your Lennox fireplace system. Keep this document in a safe place for future reference.

Before you start your first fire, read this Care and Operations Manual

carefully to be sure you understand your fireplace system completely.

Failure to follow these suggestions could result in hazardous operation or

fireplace malfunction, creating a serious potential for personal injury and/

or property damage.

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

If you have any questions regarding the safe use or operation of your

fireplace, contact your local Lennox Dealer or your contractor/builder.

WARNING: EXERCISE CAUTION WHEN OPERATING YOUR

OUTDOOR FIREPLACE. DO NOT BURN LARGE FIRES.

ATMOSPHERIC CHANGES MAY CAUSE UNEXPECTED

GUSTS OF WIND. FLAMES AND ASHES MAY BE BLOWN

OUT OF THE FIREPLACE. KEEP THE SCREEN CURTAINS

CLOSED AT ALL TIMES.

OTL Report No. 116-F-01-2

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

1

Page 2

TABLE OF CONTENTS

General Safety Precautions................ page 2

General Information........................... page 2

Fuels .................................................. page 2

Gas Logs ........................................... page 2

Disposal of Ashes .............................. page 3

Softwood vs Hardwood ..................... page 3

Starting a Fire .................................... page 4

Damper.............................................. page 4

Glass Door Operating Safety

Precautions and Instructions ........... page 4

Air Inlet .............................................. page 4

Refractories ....................................... page 5

Maintenance Guidelines..................... page 5

Twice a Year Check-Up ...................... page 6

Cleanout Panel................................... page 6

Creosote Formation and Removal...... page 6

Troubleshooting ................................ page 6

Warranty............................................ page 7

Product Reference Information ......... page 7

Replacement Parts ............................ page 7

Accessory Components ..................... page 7

Replacement Parts List...................... page 8

GENERAL SAFETY PRECAUTIONS

IMPORTANT! READ AND UNDERSTAND BEFORE YOUR FIRST FIRE.

1. Use SOLID WOOD only for fuel. It is best to

use dry and well seasoned hardwood. Soft

woods tend to burn very quickly. Solid scrap

construction lumber produces excessive

sparks. DO NOT use treated wood, artificial

wax based logs, charcoal, coal, trash, driftwood or woods that have been dipped in tar,

pitch, pine tar, creosote, etc. Wood products

made with synthetic binders, such as plywood, produce abnormally high temperatures

and sputtering, smoking fires.

2. NEVER use gasoline, gasoline-type lantern

fuel, kerosene, charcoal lighter fluid, or similar

liquids to start or “freshen up” a fire in this

fireplace. Keep any flammable liquids a safe

distance from the fireplace.

3. NEVER leave children unattended when

there is a fire burning in the fireplace.

4. Always ensure that the air inlet to the

fireplace is free from debris and any other

obstructions that can block the entrance of air.

5. With the fire burning, close the protective

mesh screens to keep sparks and embers INSIDE the firebox.

6. Keep any combustible furniture or decorative objects at least 60" (1524 mm) from the

fireplace opening.

7. Never leave your fireplace unattended while

it is burning.

8. Be careful adding wood fuel to the fire or

handling fireplace tools such as shovels, tongs

or pokers.

9. Never modify or alter your fireplace system

in any way. To do so may create a potential fire

hazard and void the Limited Warranty.

10. The bottom refractory can be cracked by

excessive abuse such as tossing heavy logs

onto the grate or gouging with fireplace tools.

Exercise caution when adding wood to your

fireplace.

11. DO NOT use a fireplace insert or any other

product not specified by the manufacturer for

use with this fireplace.

12. Neither the manufacturer nor the seller

warrants "smoke free" operation nor are they

responsible for inadequate system draft caused

by mechanical systems, general construction

conditions, inadequate chimney heights, adverse wind conditions and/or unusual

environmental factors or conditions beyond

our control.

WARNING: TO AVOID THE RISK OF

DAMAGING FIREPLACE MATERIALS

AND INCREASING THE RISK OF FIRE,

DO NOT USE THE FIREPLACE TO COOK

OR WARM FOOD.

GENERAL INFORMATION

1. The all-steel, multi-wall firebox is the heat

center of the system. It is constructed for safe

clearance to combustibles.

2. The hearth floor and sidewalls of the

firebox are lined with a brick pattern reinforced refractory for the look of authenticity

and to provide safety.

3. The metal chimney sections extending from

the firebox top to beyond your roof are two

walled and air-cooled. The inner passage, or

flue, provides the exit for smoke and gases.

4. This fireplace does not have a damper.

There is a flue strainer provided at the flue

entrance to keep debris from entering the

chimney. Before you start a fire, the strainer

must be checked to ensure that it is free of

obstructions.

5. Closed screens prevent fire, sparks and

embers from popping out of the firebox while

a fire is burning. Pull screens back when

adding wood to the firebox.

6. Why use a fuel grate? Besides positioning

the firebed properly, it protects the refractory

floor, back and sides of the fireplace. Further,

it ensures a proper flow of combustion air into

and around the firebed. The grate must be

used at all times when burning. Your warranty

may be voided without the use of this grate.

7. This fireplace is not a heater. It is designed

to ensure homeowner comfort by providing

supplemental heat to its immediate area.

FUELS

Never Use Coal in Your Fireplace

Your fireplace system is not designed to be

used with coal derivative products. The combustion process of certain types of coal can

deposit corrosive materials in the fireplace and

chimney system which can lead to premature

product failure. Never use coal as a fuel in this

fireplace system.

Gas Logs

If your fireplace system was installed with a

gas line, you may wish to install one of two

types of gas log sets.

This fireplace has been tested and approved

for use with a decorative gas appliance incorporating an automatic shut-off device and

complying with the Standard for Decorative

Gas Appliances for installation in vented fireplaces, ANSI Z21.60 (1991). Decorative gas

appliances may be installed in these fireplaces.

Installation must be in accordance with the

national Fuel Gas Code, ANSI Z223.1 for compliance with the revised U.L. 127 Standard.

2

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 3

WARNING: THIS FIREPLACE HAS NOT

BEEN TESTED WITH AN UNVENTED GAS

LOG SET. TO REDUCE THE RISK OF

FIRE OR INJURY, DO NOT INSTALL AN

UNVENTED GAS LOG SET INTO THIS

FIREPLACE.

Prior to installing any gas log set, refer to the

fireplace installation instructions for verification of mantle heights and placement of

combustible materials around the firebox opening. Vented gas log sets do not have restrictions

placed upon their BTU rating.

Wood Fuel Pointers

SOFTWOOD VS HARDWOOD

Softwoods contain about 15 percent highly

flammable resin which generates creosote soot

in the chimney flue. Burning softwood exclusively may not be as desirable nor as safe as

burning denser hardwoods. Many experienced

fire-builders use small amounts of softwood

kindling and newspaper in conjunction with

starting a fire with split hardwood logs. Here are

some guidelines to remember:

1. Softwoods produce fast warming and shorter

fires. Hardwoods burn less vigorously, have

shorter flames and produce steady, glowing

coals.

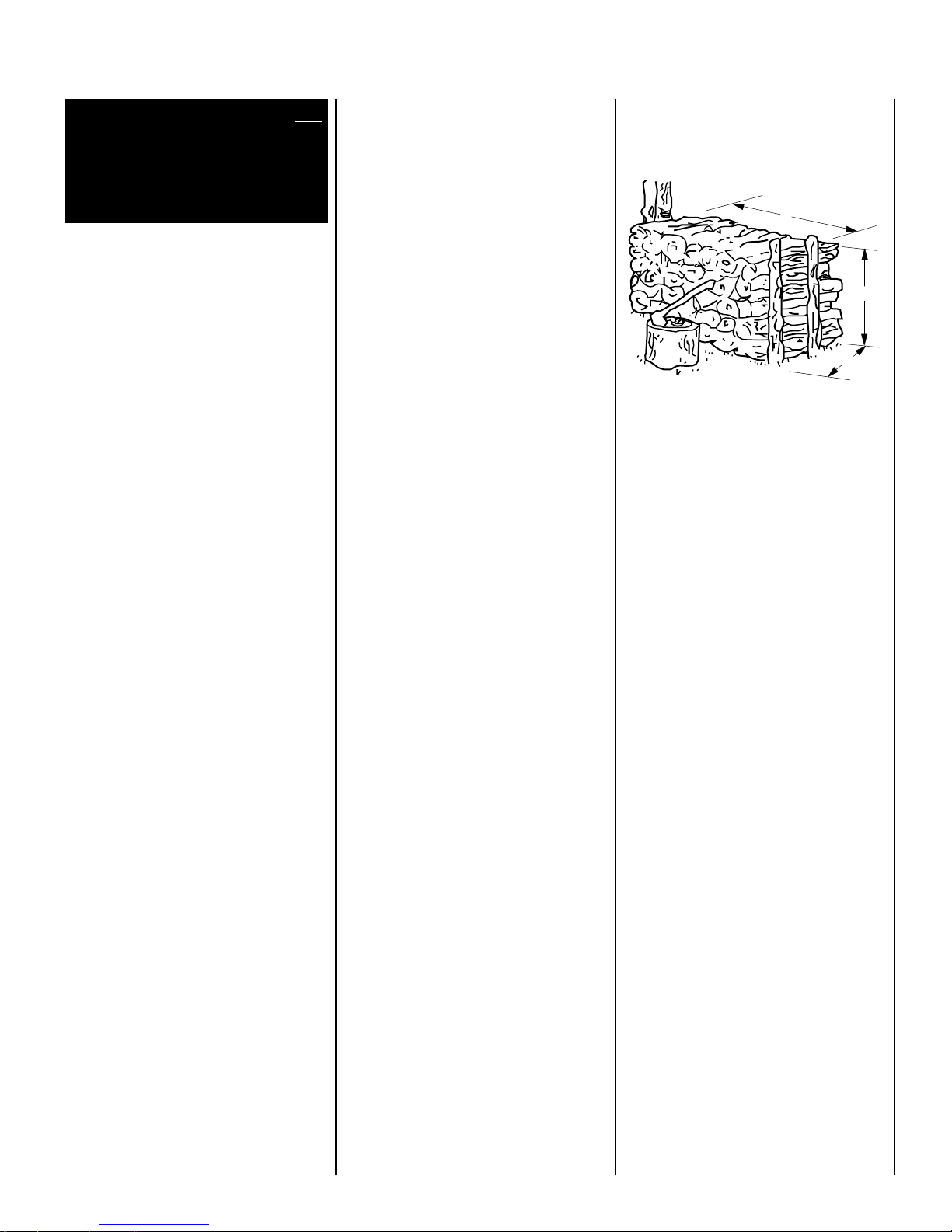

8. Be a knowledgeable wood buyer. There is a

difference in cord sizes. A standard cord stack

of logs is 4 ft. high by 8 ft. long by 4 ft. deep or

the equivalent of this cubic footage, (

Figure 1

Standard

Cord of

8'

Wood

4'

4'

).

Wood is a wonderful renewable fuel source.

Normally it burns clean, leaving only a minimum of waste ash, provides comforting heat

and can provide a variety of aromas and visual

images.

You will want to know which woods are best for

use. Sometimes you may want a quick, short

fire to offset a morning chill. Soft woods are

preferable in this case. Other times you would

want more slow burning and a uniform heat

output. Hardwoods are preferable for this use.

The amount of heat available from the logs will

be about equal on a weight basis. However,

logs are generally not weighed so the amount

of heat will depend on:

1. The type of wood used.

2. How dry it is.

3. How many logs you put in.

4. The size of the logs.

The last statement means that one big log

weighing 10 pounds has as much heating potential as 10 pounds of twigs. However, air

cannot get at the solid log to feed the fire so the

solid log will burn slowly. While you would get

the same amount of heat out of either fire, the

smaller the pieces of wood and the more air

space around them, the faster the fire will burn.

DISPOSAL OF ASHES

Ashes should be placed in a metal container

with a tight fitting lid. The closed container of

ashes should be placed on a noncombustible

floor or on the ground, well away from all

combustible materials, pending final disposal.

If the ashes are to be disposed of by burial in

soil or other wise locally dispersed, they should

be retained in the closed container until all

cinders have thoroughly cooled.

2. As a general rule, denser woods contain

more potential heat per pound. Most softwoods

offer moderate heat value per pound.

3. Different woods vary widely in flame heights,

flame intensities, smoke characteristics and in

sparking. Most hardwoods do not spark.

4. Most freshly cut “green” wood will not burn

well and will smoke. Green wood can be from

10 to 40 percent less efficient than air-dried

seasoned wood.

5. Moisture and resin found inside unseasoned

wood cells will build up pressure under heat

and explode as sparks.

6. Most wood needs to be seasoned 9 to 12

months to reduce the moisture content and

produce good steady fires. When moisture

content is reduced from 60 to 20%, the gain in

heat potential is nearly 7%.

7. Proper storage of wood, especially during

seasoning, is essential. We recommend that

you:

a. Never store wood on the ground. This will

cause rotting and insect infiltration. Raise wood

on flat rock or scrap wood.

b. Stack wood loosely to allow air circulation.

c. Store wood where it will not be excessively

exposed to weather, such as under a tarp or

under a roof.

d. Do not stack wood directly against the walls

of your home.

Figure 1

A face cord is the same height and length as a

standard cord but the depth is only the length

of the logs (12, 18 or 24 inches). A face cord

can contain as little as 25% of the wood found

in a standard cord.

If you buy by the ton, remember that wood

becomes lighter as it dries. When buying green

or wet wood, ask for some extra poundage to

allow for the extra water you will be getting.

9. When comparing woods of the same moisture content and same species, we find most

woods have approximately the same heating

potential per pound.

However, most wood is sold by volume, not by

weight. To determine the best heating source,

look at the density of various wood types.

(Density is the weight for a given size.) The

higher the density, the more potential heat

output. A standard cord has a volume of 128

cubic feet. This figure also includes the air

space between and around the wood. The actual volume in a standard cord is between 60

and 100 cubic feet; depending on how tightly

the wood is packed.

Assuming that you are comparing two standard

cords of different species but the same volume

and moisture content, the denser species will

provide more BTU’s. The table of wood species/

densities reveals more helpful guidelines.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

3

Page 4

HARDWOODS DENSITY

Alser, Red .41

Ash .49-.60

Aspen .38-.39

Basswood, American .37

Beech, American .64

Birch .55-.65

Butternut .38

Cherry, Black .50

Chestnut, American .43

Cottonwood .34-.40

Elm .60.63

Hackberry .53

Hickory, Pecan .60.66

Hickory, True .69-.75

Honey locust .66 (est.)

Locust, Black .69

Magnolia .48-.50

Maple .48-.63

Oak, Red .59-.67

Oak, White .64-.88

Poplar .42

Sassafras .42

Sweet gum .52

Sycamore, American .49

Tanoak .64 (est.)

Tupelo .50

Walnut, Black .55

Willow, Black .39

SOFTWOODS DENSITY

Bald cypress .46

Cedar .31-.47

Douglas Fir .46-.50

Fir .32-.43

Hemlock .40-.45

Larch, Western .52

Pine .39-.59

Redwood .35-.40

Spruce .35-.41

Tamarack .53

DAMPER

Note: This appliance does not have a damper.

A flue strainer has been provided to prevent

any debris from entering into the chimney.

FLUE STRAINER

The flue strainer is a wire cloth attached to the

flue entrance to prevent debris from entering

the chimney.

Periodical inspection and cleaning may be

required. See

Figure 2

and follow the instruc-

tions below for removal and installation:

1. With a flat screw driver, press on the retainer bracket and pull the strainer downwards

to release.

2. Clean or discard the strainer if damaged.

3. Reinstall or replace the flue strainer.

Flue Strainer

Retainer Bracket

Figure 2

REINSTALLING OR REPLACING THE FLUE

STRAINER (P/N LB-101309)

1. Hang the retaining brackets on the outer-

most screws inside the firebox at the back,

near the flue inlet.

2. Place one side of the flue strainer, wedged

between the front screws and the top, inside

the firebox.

3. With the aid of a flat screw driver, push

upwards on the opposite end of the flue strainer

against the retainer brackets, (one at a time)

until it snaps to its locking position.

AIR INLET

This appliance requires the installation of an

air inlet for proper operation.

The fireplace draws air into the chimney and

firebox chambers through the air inlet to cool

the firebox during operation.

It is important to inspect the air inlet and free

it from any obstruction before operating the

fireplace (

see Figure 3

).

WARNING: DO NOT OPERATE THE FIREPLACE UNLESS A COMPLETE AIR INLET

SYSTEM HAS BEEN INSTALLED.

Fireplace Air Inlet

Must Be Free Of

Any Obstructions

Figure 3

REFRACTORIES

All fireboxes contain a furnace refractory floor,

sides and back. These refractories are reinforced with steel, but can be broken by improper

use. Dropping logs on the bottom refractory

and building fires directly against the refractories can cause premature burnout of these

components. It may easily be repaired or replaced at costs far below repair and maintenance

for masonry fireplaces.

Proper care and “burn-in” of the firebox will

prolong the period of enjoyment without extensive maintenance. For the first few uses, build

small fires – not roaring infernos. The materials

used in the refractories contain and absorb moisture. It is important to “cure” the refractories by

building only modest fires. Under normal usage,

it is expected that hairline cracks will appear in the

refractory surface. These hairline cracks do not

affect the safe operation of the fireplace.

STARTING A FIRE

Note: Caution must be observed when operat-

ing this fireplace under windy conditions. Do

Not burn large fires, as flames may be drawn

out of the firebox. If this occurs, close the glass

doors immediately. If not equipped with doors,

extinguish the fire or keep it to a minimum if

safe. The screens must be closed at all times

while in operation, except when feeding the fire.

1. To start a fire in the fireplace properly, first

check that the flue strainer is clear and the air

inlet is unobstructed.

4

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 5

2. The grate in the firebox should be centered

on or over the bottom hearth so your fire can

breath properly. Crumble and twist plenty of

newspapers UNDER the grate and criss-cross

some small dry kindling sticks on top of the

paper or on the bottom of the grate.

3. Build a pyramid of three split logs (split will

start much faster). Arrange the uneven wood to

provide plenty of air space between.

4. When lighting your fire, a little smoke may

escape – more likely if the chimney is cold. To

correct this, hold a lighted newspaper up inside

the firebox near the chimney opening. This will

turn around any downdraft and clear the flue of

cold air. As your log fire burns below, the

updraft will improve as the chimney heats up.

5. Now, light the paper at both sides of the

firebox.

6. Close the screens to prevent the escape of

sparks and embers.

GLASS DOOR OPERATING SAFETY

PRECAUTIONS AND INSTRUCTIONS

These fireplaces may be equipped with glass

doors. Refer to the end of this document for a

listing of the glass doors approved for use with

these fireplaces.

WARNING: IF YOUR FIREPLACE IS

EQUIPPED WITH GLASS DOORS, IT

SHOULD BE OPERATED WITH THE DOORS

FULLY OPEN OR FULLY CLOSED. IF THE

DOORS ARE LEFT PARTIALLY OPEN, GAS

AND FLAMES MAY BE DRAWN OUT OF

THE OPENING, CREATING RISKS OF BOTH

FIRE AND SMOKE. SEE

FIGURE 4

FOR

PROPER OPERATING CONDITIONS.

Glass Doors

Fully Open or

Fully Closed

(Bi-Fold Doors)

Figure 4

CAUTION: IF A SMOKING CONDITION EXISTS, GLASS DOORS SHOULD BE CLOSED

DURING FIREPLACE OPERATION.

Care and Cleaning of Your Glass Doors

Never clean the glass when the doors are hot.

Do not use ammonia or ammonia based glass

or household cleaner to clean the glass or the

door frame. An ammonia based cleaner will

damage the finish of the glass door.

Clean the glass doors by wiping with a damp towel

followed by a clean dry towel to remove streaks.

Remove stubborn stains from the glass with a

mild soap solution and a towel dampened with

clean water. Dry with a clean dry towel.

• The fire must always be confined within the

boundaries of the fuel grate.

• The fireplace screens must always be closed

whenever the fireplace is being used.

• Never slam the glass door since it could cause

the glass to break.

• Do not build excessively large or hot fires —

scorching or discoloring of the plated brass

trim may occur.

• Extreme temperature changes can cause glass

breakage — do not build a hot fire and close the

glass doors if the doors are cold.

• If the tempered glass pane becomes scratched

or chipped, it creates a weakness in the glass

which can cause the glass to break when heated.

Replace the pane of glass by contacting your

nearest dealer.

CAUTION: GLASS AND METAL FRAMES

GET HOT — ALWAYS USE HANDLES TO

OPEN AND CLOSE THE DOORS.

WARNING: BE AWARE THAT SAFETY

GLASS IS UNPREDICTABLE WHEN HOT

AND MAY BREAK, EXPELLING HOT GLASS

INTO THE ROOM. ADVISE ALL FAMILY

MEMBERS TO REMAIN WELL AWAY

FROM THE FIREPLACE WHEN OPERATING WITH DOORS CLOSED TO AVOID

ANY POSSIBLE PERSONAL INJURY.

IMPORTANT: Plated polished brass glass

doors may have a plastic covering over all

brass pieces for protection during shipping

and handling. The plastic covering should be

removed before installation of the glass doors.

Under the plastic covering is a protective

lacquer coating which should not be removed.

In some instances, if it is removed, irreversible damage to the brass finish could occur.

Refer to the following for specific information

on plated polished brass.

IMPORTANT: The lacquer coating on the polished brass glass doors and trim pieces can

be damaged or removed causing corrosion

and/or tarnish. Do not remove the protective

lacquer coating from plated polished doors

and trim. To help protect the finish; use a

non-acidic wax and avoid the over-spray of

acidic/alkali based glass cleaners on the

brass pieces. Please understand that the

heat of the fire will cause the protective

lacquer finish to slightly change to a light

caramel color. Do not be alarmed as this is

a normal occurrence.

MAINTENANCE GUIDELINES

Your fireplace is designed to operate troublefree with minimum maintenance. However, like

any fine appliance, it deserves and requires

some housekeeping attention.

Your fireplace will perform better – and certainly look more attractive to family and friends

– if it is cleaned before each use. Before the first

seasonal use in Autumn and after the last fire in

Spring, it is important to inspect the fireplace

system carefully. We recommend at least two

complete fireplace inspections a year.

Before Each Use

1. Clean the firebox of excessive ashes. Some

owners prefer to leave a small layer to insulate

the cold refractory below the grate which helps

fire starting.

This fireplace has a factory supplied grate attached, it is permissible to remove the grate for

cleaning; however, the grate must be re-attached to the fireplace before the next burn.

2. Keep the fireplace screens clean so combustion air flows freely.

3. Spot check the brick-like refractory for small

cracks. Heat from the fire expands it slightly.

When it cools, it contracts.

Refractories should be replaced when:

1. The crack opens more than ¹⁄₄" (19 mm).

2. Pitting in the surface is extensive and pits

become deeper than ³⁄₁₆" (4.76 mm).

3. Any piece of refractory larger than 2" (51 mm)

in radius and ³⁄₁₆" deep becomes dislodged.

If conditions 1, 2 or 3 occur, the refractory

should be replaced.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

5

Page 6

TWICE A YEAR CHECK-UP

Normally, twice a year, you should inspect

your fireplace following this list:

1. Inspect the opening in your chimney top

and remove any debris that could clog it. The

cap is usually held in place by four (4) screws,

which remove easily for checking or cleaning

the full length of the flue from above. Remove

the chimney top while wearing gloves to guard

against any sharp metal edges.

2. Inspect the entire flue from the top down for

obstructions such as birds nests, leaves, etc.

This may be done by using a flexible handled

chimney cleaning brush. If the chimney contains offset/return elbows; a soft brush cleaning

from the top down to any elbow and then from

the firebox up to the offset/return section is the

proper method. The beam from a powerful

flashlight will help in this inspection, (removal

of the flue strainer may be needed).

3. Look up from inside the fireplace to see if

any obstructions are in the lower flue area. If

present, shut the glass doors (if installed) to

seal the firebox and contain any soot that

might fall.

If your fireplace does not have glass doors

installed, a damp sheet covering the fireplace

opening and sealed with masking tape will do.

Then clean the flue from the top down (if an

offset system, clean per Step 2) using a proper

size chimney brush with flexible pole sections.

Don’t open the doors or remove the sheet until

all soot has settled. Vacuum, don’t sweep.

Note: Removal of the flue strainer may be

required to clear any obstructions inside the flue.

4. Check the metal flashing and seals around

your chimney. Seal any cracks or loose nailhead openings to prevent roof leaks.

5. Clean the firebox thoroughly by using a soft

brush or equivalent.

6. Check outside air inlet and free from any

obstructions.

7. Exposed stainless steel face may be cleaned

with a solution of baking soda and water:

Mix a tablespoon of baking soda in a cup of

water and spray on the exposed stainless steel

face. Wipe with a clean cloth.

CLEANOUT PANEL (DOOR SUPPORT

FRAME)

The Cleanout Panel provides an outlet for

water that may enter the fireplace during raining or melting snow. Therefore it is important

to keep it clear from ashes and debris.

Remove the Cleanout Panel by removing the

screw at each end and lift (

Check inside and clean if necessary.

Make sure the area is free of any debris and

reattach the panel with the screws previously

removed.

see Figure 5

).

Note: The hearth area can be vacuum cleaned.

Larger debris must be removed manually. It is

recommended to clean the hearth area while

the cleanout panel is removed to make sure

that no ashes will fill the cleanout panel area

upon reattachment.

Screw

Screw

Cleanout Panel

Figure 5

Stainless Steel Outdoor Weather Cover

(P/N H0321)

An optional Stainless Steel Outdoor Weather

Cover can be purchased to provide additional

protection against leaves and other objects

that wind can carry which can accumulate

inside your fireplace or damage your fireplace

Glass Doors. Complete instructions for use

are provided with the cover.

WARNING: CONTINUED OVERFIRING

CAN PERMANENTLY DAMAGE YOUR

FIREPLACE SYSTEM. SOME EXAMPLES

OF OVERFIRING ARE:

• BURNING QUANTITIES OF SCRAP

LUMBER, PINE BRANCHES, PAPER OR

CARDBOARD BOXES WHICH EXCEED

THE VOLUME OF THE NORMAL LOG FIRE.

• USE OF ARTIFICIAL WAX BASE LOGS,

TRASH OR OTHER CHEMICALS OR

CHEMICALLY TREATED COMBUSTIBLES.

CREOSOTE FORMATION AND REMOVAL

When wood is burned slowly, it produces tar

and other organic vapors, which combine with

expelled moisture to form creosote. The creosote vapors condense in the relatively cool

chimney flue of a slow-burning fire. As a

result, creosote residue accumulates on the

flue lining. When ignited, this creosote makes

an extremely hot fire.

The chimney should be inspected at least

twice yearly during the heating season to determine if a creosote build-up has occurred.

If creosote has accumulated, it should be

removed to reduce the risk of a chimney fire.

If creosote build-up is found, do not use chemical chimney cleaners that are poured on a hot

fire. The chemical cleaners can be dangerous

and generally only work on the flue section

nearest the fire, leaving the rest of the flue

unaffected. It is best to take the time to clean

the flue as previously described or have the

chimney professionally cleaned by a qualified

chimney sweep.

TROUBLESHOOTING

Note: "Smoke Free" operation is not warranted

nor are we responsible for inadequate system

draft, general construction conditions, inadequate chimney heights, adverse wind conditions and/or unusual environmental factors or

conditions beyond our control.

If you do experience a problem, here are several things to check:

1. Remember – always check to ensure that

the flue strainer and air inlet are clear from

obstructions before lighting a fire!

2. Is your fire too far forward? Move it toward

the back with your poker. Keep the fire well

within the confines of your fuel grate.

3. Keep your fire up on the grate and the refractory below free of excessive ashes. The fire

needs plenty of air movement around the logs.

4. Is a breeze or wind blowing? This can cause

negative pressure and an unwanted downdraft

– and smoking.

5. Is your wood fuel too wet or unseasoned?

Or does it contain some chemical substance

that causes sputtering, smoking and toxic

fumes?

6

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 7

6.

Figure 6

illustrates the correct height of

your chimney top. It is unlikely that your installation does not adhere to the installation

instructions. However, if not correct, you

could experience an unusual downdraft. Usually, the best solution is to increase the chimney

height. This may also be necessary if nearby

trees, adjoining roof lines or a hill is causing a

downdraft condition.

7. Remember, your fireplace has been designed as a decorative, supplemental heating

device only, it is not intended for heating

purposes.

ACCESSORY COMPONENTS

3'

(914mm)

Min.

Less than

10' (3m) To

Roof Peak

2' (610mm)

Min.

10' (3m)

2' (610mm)

Min.

FTF10-CT1

3'

(914mm)

Min.

Figure 6

WARRANTY

This fireplace is covered by a limited warranty detailed separately from this document.

Retain this manual. File it with your other documents for future reference.

PRODUCT REFERENCE INFORMATION

We recommend that you record the following important information about your fireplace. Please

contact your Lennox dealer for any questions or concerns. For the number of your nearest Lennox

dealer, please call 1-800-9-LENNOX

Bi-Fold Doors H0329 43LBFOD-BS

Bi-Fold Doors

Your fireplace can be fitted with beautiful bifold doors. These doors are easily fitted to the

fireplace opening. Model LBFOD-BS doors

have the striking look of brushed steel.

To ensure warranty and to prevent a potential

fire hazard, do not use any other doors on

these appliances.

Your Fireplace's Model Number _______________________________________

Your Fireplace's Serial Number ________________________________________

The Date On Which Your Fireplace Was Installed __________________________

Your Dealer's Name_________________________________________________

REPLACEMENT PARTS

A complete parts list is found at the end of this

manual. Use only parts supplied from the

manufacturer.

Normally, all parts should be ordered through

your Lennox dealer. Parts will be shipped at

prevailing prices at time of order.

When ordering repair parts, always give the

following information:

1. The model number of the appliance.

2. The serial number of the appliance.

3. The part number.

4. The description of the part.

5. The quantity required.

6. The installation date of the appliance.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Outdoor Weather Cover H0321 43L-ODC

Stainless Steel Outdoor Weather Cover

Your fireplace can be fitted with an attractive

Stainless Steel Outdoor Weather Cover. This

cover is easily fitted to the fireplace opening.

7

Page 8

REPLACEMENT PARTS

LSO-43 LSO-43H

No. DESCRIPTION Part No. Qty. Part No. Qty.

Fireplace Assembly H0303 1 H0304 1

1. Firescreen 35M0901 2 35M0901 2

2. Rod, Screen LB-101301 2 LB-101301 2

3. Refractory, Side, Right (Traditional) 16M31 1 – –

Refractory, Side, Right (Herringbone) – – 16M39 1

4. Refractory, Side, Left (Traditional) 16M31 1 – –

Refractory, Side, Left (Herringbone) – – 16M40 1

5. Refractory, Rear (Traditional) 16M34 1 – –

Refractory, Rear (Herringbone) – – 16M42 1

6. Refractory Base 16M36 1 16M44 1

7. Grate LB-97144 1 LB-97144 1

8. Frame, Front Lower LB-97044 1 LB-97044 1

9. Frame, Side L.H. LB-97045A 1 LB-9704A 1

10. Frame, Side R.H. LB-97045B 1 LB97045B 1

11. Frame, Door Support (Cleanout Panel) LB-97037 1 LB-97037 1

12. Frame, Top LB-97046 1 LB-97046 1

13. Flue Strainer LB-101309 1 LB-101309 1

14. Retainer Bracket (Flue Strainer) LB-101340 2 LB-101340 2

4

7

Lennox reserves the right to make changes at any time, without notice, in design,

materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local distributor for fireplace code information.

5

6

13

3

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

14

9

1

2

12

10

8

11

Printed in U.S.A. © 2002 by LENNOX

P/N 875,019M REV. B 03/2007

1110 West Taft Avenue

Orange, CA 92865

Loading...

Loading...