Page 1

Corp. 9535−L8

Service Literature

Revised 09/2003

O23 / OHR23 / OF23 SERIES UNITS

O23 (Elite 80) series units are mid−efficiency upflow oil fur

naces manufactured with Beckett oil burners. O23 units are

available in heating capacities of 70,000 to 154,000 Btuh

(20.5 to 45.1 kW) and cooling applications from 2 through 5

tons (7.0 through 17.6 kW). Refer to Engineering Hand

book for proper sizing.

OHR23 (Elite 80) series units are mid−efficiency horizontal /

downflow oil furnaces. The OF23 (Elite 80) series units are

mid−efficiency loboy upflow oil furnaces, which come in front

(OF23) or rear (OF23R) flue openings, both with Beckett oil

burners. The OHR23 and OF23(R) units are available in heat

ing capacities of 105,000 to 154,000 Btuh (30.8 to 45.1 kW)

and cooling applications from 2 through 5 tons (7.0 through

17.6 kW). Refer to Engineering Handbook for proper siz

ing.

The drum type heat exchanger comes with strategically

placed ports allowing easy cleaning, while the oil burner

can be removed for inspection and service. The mainte

nance section gives a detailed description on how this is

done.

O23/OHR23

OF23

Information contained in this manual is intended for use by

experienced HVAC service technicians only. All specifica

tions are subject to change. Procedures outlined in this

manual are presented as a recommendation only and do

not supersede or replace local or state codes.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at discon

nect switch(es). Unit may have multiple

power supplies.

WARNING

Improper installation, adjustment, alteration, ser

vice or maintenance can cause property damage,

personal injury or loss of life. Installation and service

must be performed by a qualified installer or service

agency.

O23 SHOWN

TABLE OF CONTENTS

General 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indoor Blower Data 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Arrangement 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

I Unit Components 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II Placement and Installation 16. . . . . . . . . . . . . . . . . . . .

III Start Up 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV Heating Systems Service Checks 22. . . . . . . . . . . . .

V Disassembling Burner 24. . . . . . . . . . . . . . . . . . . . . . . .

VI Typical Operating Characteristics 26. . . . . . . . . . . . . .

VII Maintenance 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VIII Wiring Diagrams 28. . . . . . . . . . . . . . . . . . . . . . . . . .

IX Troubleshooting 31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 1

1995 Lennox Industries Inc.

Litho U.S.A.

Page 2

SPECIFICATIONS − O23

Blower wheel nominal

Fil

Model Number O23Q270 O23Q3105/120 O23Q5140/154

InputBtuh (kW) low/high 70,000 (20.5) 105,000 / 120,000(30.8 / 35.2) 140,000 / 154,000(41.0 / 45.1)

Output Btuh (kW) low/high 57,000 (16.7) 85,000 / 97,000 (24.9 / 28.4) 113,000 / 125,000 (33.1 / 36.6)

*A.F.U.E. 83.8% 82.8% (105) / 82.5% (120) 82.5% (140) / 81.4% (154)

Nozzle Rating gph (L/hr) and spray angle .50 (1.9) 80°hollow

Flue Size Diameterin. (mm) 6 (152) 6 (152) 6 (152)

Oil Burner Pump 1 Stage 1 Stage 1 Stage

Oil Burner Pump Pressure psig (Pa) 100 (690) 140 (965) 140 (965)

Blower wheel nominal

diameter x width

Blower Motor Output hp (W) 1/3 (249) 1/3 (249) 3/4 (560)

Nominal cooling that can be added

**Number and size of filtersin. (mm) (1) 16 x 25 x 1 (1) 16 x 25 x 1 (2) 16 x 25 x 1

Shipping weight lbs. (kg) 1 package 225 (102) 225 (102) 275 (125)

Electrical characteristics 115 volts 60 hertz 1 phase

Two Stage Oil Pump 65A44

Oil Filter 81P89

*Annual Fuel Utilization Efficiency based on U.S. DOE test procedures and FTC labeling regulations. Isolated combustion system rating for nonweatherized furnaces.

**Cleanable frame type filters. Furnished with unit in Side Filter Adaptor Kit for field installation external to the cabinet.

Requires return air from both sides of cabinet.

Nozzle must be field provided for field conversion to higher heating input.

in. 10 x 6 10 x 8 12 x 9

mm 254 x 152 254 x 203 305 x 229

Tons 2 thru 2.5 2 thru 3.5 3 thru 5

kW 7.0 thru 8.8 7.0 thru 12.3 10.6 thru 17.6

Optional Accessories (Must Be Ordered Extra)

.65 (2.5) 80° (105 input) solid

.75 (2.8) 80°(120 input) solid

.85 (3.2) 80° (140 input) solid

1.00 (3.8) 80° (154 input) solid

SPECIFICATIONS − OHR23

Model Number OHR23Q3105/120 OHR23Q5140/154

InputBtuh (kW) low/high 105,000 / 120,000(30.8 / 35.2) 140,000 / 154,000(41.0 / 45.1)

OutputBtuh (kW) low/high 85,000 / 97,000 (24.9 / 28.4) 113,000 / 125,000 (33.1 / 36.6)

*A.F.U.E. (low/high) 81.8% / 81.3% 81.5% / 81.7%

Nozzle RatingU.S. gph (L/hr)

and spray angle

Flue Size Diameterin. (mm) 6 (152) 6 (152)

Oil Burner Pump 1 Stage 1 Stage

Oil Burner Pump Pressure psig (Pa) 140 (965) 140 (965)

Blower wheel nominal diameter x width in. (mm) 10 x 10 (254 x 254) 12 x 9 (305 x 229)

Blower motor outputhp (W) 1/2 (373) 3/4 (560)

Nominal cooling that can be added

Shipping weightlbs. (kg) 1 package 225 (102) 265 (120)

Electrical characteristics 115 volts 60 hertz 1 phase

Two Stage Oil Pump 65A44

ter Kit

Downflo Additive Base 35K07 35K08

Horizontal Venting Kit 62J01

Burner Cover 84H26

Vestibule Cover Kit (full front cover) 37K28 37K29

Oil Filter 81P89

*Annual Fuel Utilization Efficiency based on U.S. DOE test procedures and FTC labeling regulations. Isolated combustion system rating for nonweatherized furnaces.

Nozzle must be field provided for field conversion to higher heating input.

Catalog no. 35K01 35K06

No. & size of filtersin. (mm) (2) 101/4 x 201/2 x 1 (260 x 521 x 25) (2) 113/4 x 231/2 x 1 (298 x 597 x 25)

Tons 2 to 3 3 to 5

kW 7.0 to 10.6 10.6 to 17.6

Optional Accessories (Must Be Ordered Extra)

.65 (2.5) 8 0 (105 input) solid

.75 (2.8 ) 80 (120 input) solid

.85(3.2) 8 0(140 input) solid

1.00 (3.8) 80 (154 input) solid

Page 2

Page 3

SPECIFICATIONS − OF23

Blower wheel nominal

External Static

External Static

External Static

Model Number

InputBtuh (kW) low/high 105,000 / 120,000(30.8 / 35.2) 140,000 / 154,000(41.0 / 45.1)

OutputBtuh (kW) low/high 85,000 / 97,000 (24.9 / 28.4) 113,000 / 125,000 (33.1 / 36.6)

*A.F.U.E. (low/high)

Nozzle Ratinggph (L/hr) and spray angle

Flue Size Diameterin. (mm) 6 (152) 6 (152)

Oil Burner Pump 1 Stage 1 Stage

Oil Burner Pump Pressure psig (Pa) 140 (965) 140 (965)

Optional 2 Stage Fuel Pump 65A44

Blower wheel nominal

diameter x width

Blower Motor Outputhp (W) 1/3 (249) 3/4 (560)

Nominal cooling that can be addedTons (kW) 2 thru 3 (7.0 thru 10.6) 3 thru 5 (10.6 thru 17.6)

Number and size of filters

Shipping weightlbs. (kg) 1 package 255 (116) 290 (132)

Electrical Characteristics 115 60 hertz 1 phase

Optional Accessories (Must Be Ordered Extra)

Two Stage Oil Pump 65A44

Oil Filter 91P89

*Annual Fuel Utilization Efficiency based on U.S. DOE test procedures and FTC labeling regulations. Isolated combustion system rating for nonweatherized furnaces.

Nozzle must be field provided for field conversion to higher heating input.

in. 10 x 8 12 x 9

mm 254 x 203 305 x 229

in. (1) 18 x 19 x 1 (1) 19 x 21 x 1

mm (1) 457 x 483 x 25 (1) 483 x 533 x 25

OF23Q3105/120

OF23Q3105/120R

82.4% / 81.5%

82.5% / 82.4% R Models

.65 (2.5) 80° (105 input)

.75 (2.8) 80° (120 input)

OF23Q5140/154

OF23Q5140/154R

81.8% / 81.5%

82.0% / 81.8% R Models

.85 (3.2) 80° (140 input)

1.00 (3.8) 80° (154 input)

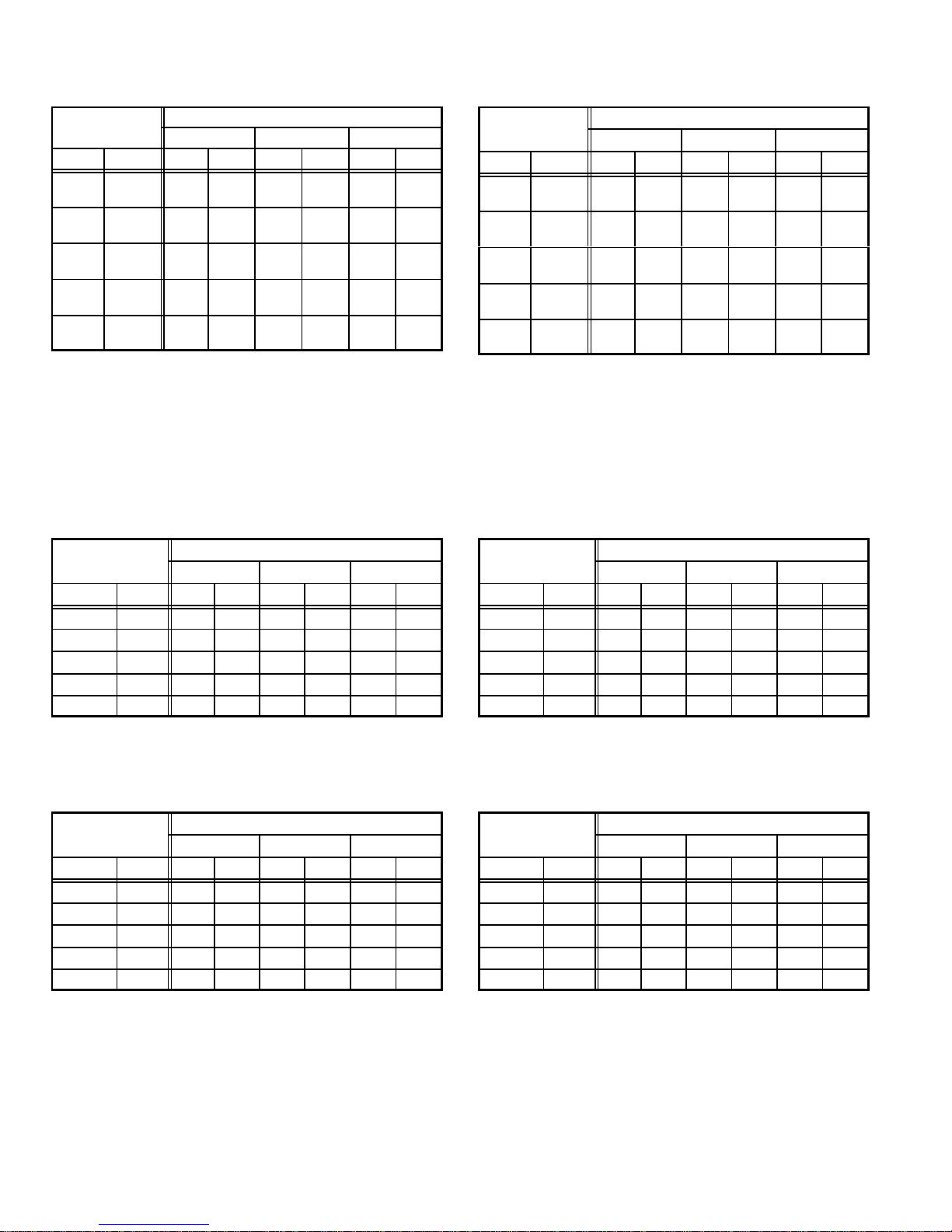

BLOWER PERFORMANCE DATA − O23

O23Q270 BLOWER PERFORMANCE

External Static

Pressure

in.w.g. Pa cfm L/s cfm L/s cfm L/s

.20 50 1260 595 870 410 520 245

.30 75 1205 570 825 390 500 235

.40 100 1135 535 780 370 480 225

.50 125 1050 495 720 340 450 210

.60 150 960 455 660 310 410 195

NOTE All air data is measured external to the unit with the air filter in place.

Air Volume at Various Blower Speeds

High Medium Low

O23Q5140/154 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

.20 50 1950 920 1620 765 1250 590

.30 75 1900 895 1590 750 1230 580

.40 100 1880 885 1560 735 1210 570

.50 125 1850 875 1540 725 1190 560

.60 150 1800 850 1490 705 1155 545

NOTE All air data is measured external to the unit with the air filter in place.

O23Q3105/120 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

.20. 50 1350 635 1215 575 1080 510

.30 75 1280 605 1180 555 1060 500

.40 100 1210 570 1140 540 1040 490

.50 125 1180 444 1085 510 1000 470

.60 150 1100 520 1025 485 950 450

NOTE All air data is measured external to the unit with the air filter in place.

Air Volume at Various Blower Speeds

High Medium Low

Air Volume at Various Blower Speeds

High Medium Low

Page 3

Page 4

BLOWER PERFORMANCE DATA − OHR23

External Static

External Static

External Static

External Static

External Static

External Static

OHR23Q3105/120 BLOWER PERFORMANCE

External Static

Pressure

in w.g. Pa cfm L/s cfm L/s cfm L/s

.20 50 1470 695 1360 640 1070 505

.30 75 1400 660 1300 615 1040 490

.40 100 1330 630 1230 580 1020 480

.50 125 1260 595 1160 545 980 460

.60 150 1180 555 1085 510 920 435

NOTE All air data is measured external to the unit with air filter in place.

Air Volume at Various Speeds

High Medium Low

BLOWER PERFORMANCE DATA − OF23

FRONT FLUE MODELS

OF23Q3105/120 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

.20 50 1490 705 1370 645 1190 560

.30 75 1430 675 1345 635 1180 555

.40 100 1375 650 1280 605 1160 545

.50 125 1300 615 1230 580 1120 530

.60 150 1230 580 1160 545 1080 510

NOTE All air data is measured external to the unit with the air filter in place.

Air Volume at Various Blower Speeds

High Medium Low

OHR23Q5140/154 BLOWER PERFORMANCE

External Static

Pressure

in w.g. Pa cfm L/s cfm L/s cfm L/s

.20 50 1950 920 1700 800 1340 630

.30 75 1920 905 1650 780 1300 615

.40 100 1900 895 1600 755 1270 600

.50 125 1870 880 1580 745 1220 575

.60 150 1780 840 1500 710 1170 550

NOTE All air data is measured external to the unit with air filter in place.

Air Volume at Various Speeds

High Medium Low

OF23Q5140/154 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

.20 50 2110 995 1850 875 1500 710

.30 75 2035 960 1810 855 1480 700

.40 100 1970 930 1750 825 1450 685

.50 125 1950 920 1690 800 1420 670

.60 150 1880 885 1620 765 1375 650

NOTE All air data is measured external to the unit with the air filter in place.

Air Volume at Various Blower Speeds

High Medium Low

OF23Q3105/120R BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

.20 50 1470 695 1330 630 1150 545

.30 75 1410 665 1295 610 1140 540

.40 100 1340 630 1250 590 1125 530

.50 125 1280 605 1190 560 1080 510

.60 150 1205 670 1130 535 1030 485

NOTE All air data is measured external to the unit with the air filter in place.

Air Volume at Various Blower Speeds

High Medium Low

REAR FLUE MODELS

OF23Q5140/154R BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

.20 50 2010 950 1765 835 1380 650

.30 75 1960 925 1720 810 1350 635

.40 100 1900 895 1660 785 1330 630

.50 125 1880 885 1600 755 1295 610

.60 150 1800 850 1560 735 1230 580

NOTE All air data is measured external to the unit with the air filter in place.

Page 4

Air Volume at Various Blower Speeds

High Medium Low

Page 5

O23 GENERAL PARTS ORIENTATION

HEAT EXCHANGER

CLEANOUT PORT

LIMIT SWITCH

CONTROL BOX

WITH FAN

CONTROL

BECKETT

AFII BURNER

INDOOR BLOWER

VENT OPENING

CLEANOUT PORT

OBSERVATION PORT

COMBUSTION AIR INTAKE

BLOWER MOTOR

CAPACITOR

FIGURE 1

LIMIT SWITCH

BECKETT

AFII BURNER

COMBUSTION

AIR INTAKE

OBSERVATION

PORT

CLEANOUT

OHR23 GENERAL PARTS ORIENTATION

CLEANOUT PORT

HEAT EXCHANGER

PORT

VENT OPENING

CONTROL BOX

WITH FAN

CONTROL

BLOWER MOTOR

INDOOR BLOWER

FIGURE 2

Page 5

Page 6

OF23 GENERAL PARTS ORIENTATION

CLEANOUT

PORT

LIMIT SWITCH

CONTROL BOX

WITH FAN

CONTROL

BECKETT

AFII BURNER

FRONT VENT

OPENING (OF23)

COMBUSTION

AIR INTAKE

FILTER

INDOOR BLOWER

REAR VENT

OPENING (OF23R)

HEAT EXCHANGER

CLEANOUT PORT

OBSERVATION PORT

FIGURE 3

NEUTRAL

TERMINALS

24VAC OUTPUT

TO BURNER

(HEAT DEMAND)

24VAC IN FROM

PRIMARY LIMIT

24VAC THERMOSTAT

DEMAND OUTPUT

BCC2 / BCC3 BLOWER CONTROL BOARD

120VAC LINE

VOLTAGE IN

THERMOSTAT TERMINAL STRIP TB1

(DETACHABLE ON EARLY −1 AND −2

MODELS ONLY)

COOLING

SPEED TAP

TERMINAL

TRANSFORMER

120VAC

COMMON

FROM TRANSFORMER

CONTINUOUS FAN

TERMINAL

BLOWER TIME

ADJUSTMENT

JUMPER

24VAC INPUT

HEATING SPEED

TAP TERMINAL

ACCESSORY

TERMINAL

To Remove Terminal Strip,

Grasp Ends of Block Between

Thumb and Forefinger. Push

Block Down and Out.

(Jack / Plug 94)

24VAC COMMON

FROM TRANSFORMER

FIGURE 4

Page 6

Page 7

I−UNIT COMPONENTS

General parts orientation for the O23, OHR23 and OF23 are

shown in figures 1, 2 and 3 respectively. The O23 and OF23

control box, burner, limit switch and cleanout ports may be ac

cessed by removing the front access panel, while the OHR23

components are exposed. The blower can be accessed in the

O23 and OF23 by removing the blower access panel, while in

the OHR23 units two 1/4" screws must be removed before the

blower access panel can be removed.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during unit instal

lation and service to protect the unit’s electronic

controls. Precautions will help to avoid control

exposure to electrostatic discharge by putting

the unit, the control and the technician at the

same electrostatic potential. Neutralize electro

static charge by touching hand and all tools on an

unpainted unit surface before performing any

service procedure.

A−Blower Control Board

BCC2 Blower Control Board (Figure 4)

−1 and −2 units

All O23, OHR23 and OF23−1 and −2 oil units utilize the BCC2

(A15) blower control manufactured by Heatcraft. The BCC2 is

a printed circuit board which controls the supply air blower and

monitors the limit controls and oil burner operation. The control

has a nonadjustable, factory preset fanon" timing. Fan off"

timing is adjustable. The board is divided into two sec

tions, 120 and 24VAC. Line voltage comes into the board

on the 120VAC side. See figure 4. See table 1 for BCC2

terminal designations.

DANGER

Shock hazard. Avoid personal injury. Make sure to

disconnect power before changing fan off" timing.

Blower Operation and Timing

Blower off" timing (time that the blower operates after the heat

demand has been satisfied) is determined by the arrange

ment of a jumper across pins on the BCC2 blower control

board. See figure 4. To adjust fan off " timing, gently discon

nect jumper and reposition across pins corresponding with

new timing. Fan on" time is factory set at 45 seconds and is

not adjustable.

NOTEIf fan off" time is set too low, residual heat in

heat exchanger may cause primary limit S10 or auxilary

limit S21 to trip resulting in frequent cycling of blower. If

this occurs, adjust blower to longer time setting.

Figure 5 shows the various fan off" timings and how

jumper should be positioned. Unit is shipped with a fac

tory fan off" setting of 150 seconds. Fan off" time will

affect comfort and efficiency and is adjustable to satisfy

individual applications. The fan off" timing is initiated

after a heating demand but not after a blower or cooling

demand (that is, when indoor thermostat switch is

changed from ON to AUTO and heating/cooling demand

is not present, the blower stops immediately).

FANOFF TIME ADJUSTMENT

TIMING

JUMPER

270

150 90

To adjust fan−off timings:

Remove jumper from BCC2

and select one of the other pin com

binations to achieve the

desired time.

Leave jumper off to achieve

210

330 second fan−off timing.

TIMING PINS (seconds)

Fanoff timing is factory

set at 150 seconds

FIGURE 5

Thermostat Connection

Thermostat wires are connected to terminal strip TB1 found

on the BCC2 control board. The terminal strip is c l early

marked with the corresponding thermostat designation.

The terminal strip (jack / plug 94) is simply removed by

grasping the ends of the block and rotating down while pull

ing away (see figure 4).

TABLE 1

BLOWER CONTROL A15 TERMINAL DESIGNATIONS

Term inal Type Function

W

R

Y

C

G

NEUTRAL 1/4" Spade 120VAC Neutral

L1 1/4" Spade 120VAC Line Voltage In

A 1/4" Spade

XFMRN 1/4" Spade 120VAC Transformer Common

CF 1/4" Spade

H 1/4" Spade

ACC 1/4" Spade

VALVE SENSE 3/16" Spade 24VAC Output To Burner

LIMIT 1/4" Spade

WI 1/4" Spade

24V 1/4" Spade

COM 1/4" Spade

Detachable

Screw Strip

Detachable

Screw Strip

Detachable

Screw Strip

Detachable

Screw Strip

Detachable

Screw Strip

Heating Demand

24VAC to Thermostat

Cooling Demand

24VAC Common

To Indoor Thermostat

Blower Demand

Switched 120VAC

to Blower Cooling Tap

Switched 120VAC to

Continuous Blower Tap

Switched 120VAC to

Blower Heating Tap

Switched 120VAC to Accessory

(Electronic Air Cleaner,

Humidifier, Etc. 1 amp rating.)

24VAC In From Primary Limit.

Limit Open: Stops Burner and Turns

On Blower

Limit Closed: Allows Burner

Operation

24VAC Thermostat

Demand Output

24VAC Input

From Transformer

24VAC Common

From Transformer

Page 7

Page 8

BCC3 Blower Control Board (Figure 4)

−3 and −4 units

All O23, OHR23 and OF23−3 and −4 oil units utilize the BCC3

(A15) blower control manufactured by Heatcraft. The BCC3 is

a printed circuit board which controls the supply air blower and

monitors the limit controls and oil burner operation. The control

has a nonadjustable, factory preset fanon" timing. Fan off"

timing is adjustable. The board is divided into two sec

tions, 120 and 24VAC. Line voltage comes into the board

on the 120VAC side. See figure 4. See table 2 for BCC3

terminal designations.

DANGER

Shock hazard. Avoid personal injury. Make sure to

disconnect power before changing fan off" timing.

Blower Operation and Timing

Blower off" timing (time that the blower operates after the heat

demand has been satisfied) is determined by the arrange

ment of a jumper across pins on the BCC3 blower control

board. See figure 4. To adjust fan off " timing, gently discon

nect jumper and reposition across pins corresponding with

new timing. Fan on" time is factory set at 45 seconds and is

not adjustable.

NOTEIf fan off" time is set too low, residual heat in

heat exchanger may cause primary limit S10 or auxilary

limit S21 to trip resulting in frequent cycling of blower. If

this occurs, adjust blower to longer time setting.

Figure 5 shows the various fan off" timings and how

jumper should be positioned. Unit is shipped with a fac

tory fan off" setting of 150 seconds. Fan off" time will

affect comfort and efficiency and is adjustable to satisfy

individual applications. The fan off" timing is initiated

after a heating demand but not after a blower or cooling

demand (that is, when indoor thermostat switch is

changed from ON to AUTO and heating/cooling demand

is not present, the blower stops immediately).

FANOFF TIME ADJUSTMENT

TIMING

JUMPER

To adjust fan−off timings:

Remove jumper from BCC2

and select one of the other pin com

binations to achieve the

desired time.

Thermostat Connection

Thermostat wires are connected to terminal strip TB1 found

on the BCC3 control board. The terminal strip is clea r ly

marked with the corresponding thermostat designation.

The terminal strip (jack / plug 94) is simply removed by

grasping the ends of the block and rotating down while pull

ing away (see figure 4).

TABLE 2

BLOWER CONTROL A15 TERMINAL DESIGNATIONS

Term inal Type Function

W

R

Y

C

G

NEUTRAL 1/4" Spade 120VAC Neutral

L1 1/4" Spade 120VAC Line Voltage In

A 1/4" Spade

XFMRN 1/4" Spade 120VAC Transformer Common

CF 1/4" Spade

H 1/4" Spade

ACC 1/4" Spade

VALVE SENSE 3/16" Spade 24VAC Output To Burner

LIMIT 1/4" Spade

WI 1/4" Spade

24V 1/4" Spade

COM 1/4" Spade

Detachable

Screw Strip

Detachable

Screw Strip

Detachable

Screw Strip

Detachable

Screw Strip

Detachable

Screw Strip

Heating Demand

24VAC to Thermostat

Cooling Demand

24VAC Common

To Indoor Thermostat

Blower Demand

Switched 120VAC

to Blower Cooling Tap

Switched 120VAC to

Continuous Blower Tap

Switched 120VAC to

Blower Heating Tap

Switched 120VAC to Accessory

(Electronic Air Cleaner,

Humidifier, Etc. 4 amp rating.)

24VAC In From Primary Limit.

Limit Open: Stops Burner and Turns

On Blower

Limit Closed: Allows Burner

Operation

24VAC Thermostat

Demand Output

24VAC Input

From Transformer

24VAC Common

From Transformer

270

150 90

Leave jumper off to achieve

210

330 second fan−off timing.

TIMING PINS (seconds)

Fanoff timing is factory

set at 150 seconds

FIGURE 6

Page 8

Page 9

ST9103A Blower Control Board (Figure 8)

−5 units

All O23, OHR23 and OF23 −5 oil units utilize the ST9103A

(A15) blower control manufactured by Honeywell. The

ST9103A is a printed circuit board which controls the supply

air blower and monitors the limit controls and oil burner opera

tion. The control has a nonadjustable, factory preset fanon"

timing. Fan off" timing is adjustable. See figure 8 and

table 3 for ST9103A terminal designations

ST9103A Blower Control Board

120V

DANGER

Shock hazard. Avoid personal injury. Make sure to

disconnect power before changing fan off" timing.

Blower Operation and Timing

The fan on time of 30 seconds is not adjustable. Fan off

time (time that the blower operates after the heat demand

has been satisfied) can be adjusted by moving the delay

switches on the fan control board. Fan off time will affect

comfort and is adjustable to satisfy individual applications.

See figure 7. Set the heat fan off delay switches to either

60, 90, 120, or 150 seconds. The factory setting is 90 sec

onds.

NOTEIf fan off" time is set too low, residual heat in

heat exchanger may cause primary limit S10 or auilary

limit S21 to trip resulting in frequent cycling of blower. If

this occurs, adjust blower to longer time setting.

Thermostat Connection

Thermostat wires are connected directly to the terminlas on

the ST9103A board. See figure 8.

Continuous Blower

If the ST9103A blower control board is wired for continuous

blower, the blower will energized on low speed and remain

energized when heat or cool demand is satisfied. Continuous

blower will also energized when indoor thermostat is left in the

OFF mode.

Fan Off Delay Switch Settings

ONON ON ON

120 sec90 sec60 sec

Figure 7

150 sec

fan off

delay switches

thermostat

terminal strip

Figure 8

TABLE 3

BLOWER CONTROL A15 TERMINAL DESIGNATIONS

J58 Pin # Function

1 Limit S10

2 L1 120V

3 T1 24V

4 L2 Common

5 Jumpered to Pin 4

6 T2 24V

7 Combustion Air Inducer

120V

8 Jumpered to Pin 7

9 Limit S21 (if used)

Thermostat Connections

G Blower Demand

W Heating Demand

R 24V

Y Cooling Demand

C Common

24 VAC CONNECTIONS

X 24V Transformer

C Common Transformer

120 VAC

S2 Line

S3 120V To Transformer

N, 2, 3, 4, 6, 7 Neutral

CONT Continuous Blower

COOL Cool Tap

HEAT Heat Tap

Page 9

Page 10

RETAINING

CLIP

HEAD

INSULATOR

−1THROUGH −4 UNIT OIL BURNER PARTS ARRANGEMENT

AIR TUBE

SCREWS

HOLE PLUG

ELECTRONIC IGNITION

TRANSFORMER

MAIN

HOUSING

ASSY

ESCUTCHEON

PLATE

CONNECTOR

TUBE

AIR TUBE

ASSY FOR

FB HEADS

FB–HEAD

NOZZLE

ADAPTER

NOZZLE LINE

ELECTRODE HEAD

FLANGE

GASKET

ASSY.

FLANGE

ELECTRODE

ASSY

REAR ACCESS

DOOR GASKET

VIEW PORT

REAR ACCESS

DOOR ASSY

OIL PUMP

SPLINED

NUT

ELECTRONIC IGNITION

TRANSFORMER

BURNER

CONTROL

RESET

BUTTON

AIR

ADJUSTMENT

0

3

4

5

6

7

8

DIAL

COUPLING

COMBUSTION AIR

MOTOR

BLOWER

FIGURE 9

Page 10

WHEEL

INLET

AIR SCOOP

Page 11

−5 UNIT BURNER PARTS ARRANGEMENT

RETAINING

CLIP

HEAD

INSULATOR

AIR TUBE

ASSY FOR

FB HEADS

1/4" HEX

HEAD SCREW

FB−HEAD

NOZZLE

ADAPTER

ELECTRODE HEAD

FLANGE

GASKET

NOZZLE LINE

ASSY.

ELECTRODE

FLANGE

ASSY

AIR TUBE

SCREWS

ELECTRONIC IGNITION

TRANSFORMER

ESCUTCHEON

CONNECTOR

PEDESTAL

PREMOUNTED PRE−PURGE VALVE

MAIN

HOUSING

ASSY

PLATE

TUBE

REAR ACCESS

DOOR ASSY

SPLINED

NUT

FUEL PUMP

COUPLING

REAR ACCESS

DOOR GASKET

MOTOR

IGNITOR

PRIMARY

CONTROL

BLOWER

WHEEL

4X4

BOX

0

3

4

5

6

7

8

AIR

ADJ.

DIAL

INLET

AIR SCOOP

FIGURE 10

Page 11

Page 12

TABLE 4

FURNACE / BURNER SPECIFICATIONS

Unit

70 35K74 AFII 85 3.0

105 35K75 AFII 85 4.0

120 35K75 AFII 85 4.5

140 35K76 AFII 150 6.0

154 35K76 AFII 150 6.5

*NOTE: The initial air dial setting is provided to get unit started. The air dial setting MUST be adjusted after startup to

achieve proper combustion.

Lennox Burner

Part Number

Burner

Model

*Initial

Air Dial

Setting

Output

57,000 BTU

(16.7 kW)

84,000 BTU

(24.6 kW)

105,000 BTU

(30.8 kW)

112,000 BTU

(32.8 kW)

125,000 BTU

(36.6 kW)

Nozzle Size

(Delevan)

0.50 X 80A

0.65 X 80B

0.75 X 80B

0.85 X 80B

1.00 X 80B

Pump

Pressure

100 psig

(689.5 kPa)

140 psig

965.3 kPa)

140 psig

965.3 kPa)

140 psig

965.3 kPa)

140 psig

965.3 kPa)

Head

FB0

FB3

FB3

FB6

FB6

B−Burner (Figures 9 & 10)

The O23, OHR23, and OF23 oil furnaces use the Beckett AFII

burner. The oil burner provides an atomized oil vapor mixed

with the correct proportion of air when it is ignited in the com

bustion chamber. Oil burner minimum and maximum ratings

are listed on the unit nameplate. Proper air adjustment for

these ratings is achieved through the air adjustment dial. Set

air dial to the initial air dial setting (see table 4). After start up

adjust air dial to achieve proper combustion. Remember to

tighten set screw on air dial.

The AFII burner is available in five sizes with either a single

or two stage pump. Table 4 identifies the burners used in

Lennox units. Figures 9 and 10 show the typical layout of the

burner assembly.

1−Combustion Air Blower / Pump Motor (B6)

The burner is activated by the primary control. A com

bustion air blower is mounted on the motor shaft. The

motor shaft also connects to the direct drive oil pump

through a coupler. The burner motor turns both the com

bustion air blower and the oil pump. The motor operates

at 3500 RPM.

Burner motors are overload protected. In the event of

excess motor temperature or current, the overload

opens to de−energize the motor. The overload automat

ically resets after temperature has returned to normal.

Keep motor clean to prevent starting switch from sticking.

All AFII motors are permanently lubricated. No further oiling is

required.

2−Combustion Air Blower / Pump Fuse (F22)

(−140 and −154 CSA units only)

In the −140 and −154 Canadian units an in line fuse (F22) is

used between the line voltage from the BCC2 blower con

trol and the blower / pump motor. The fuse is rated at 300

volts and 15 amps.

3− Pump (−1 through −4 units)

The O23, OHR23, and OF23 oil furnaces use a single

stage, 3450 RPM pump. A two stage pump is available

as an option (catalog # 65A44). The oil burner is shipped

from factory for use in a single line system. To convert the

pump to a two line system, install the bypass plug pro

vided in the attached bag according to the accompany

ing instructions.

4− Pump (−5 units only)

The O23, OHR23 and OF23−5 units all utilize the Cleancut

Fuel Unit manufactured by Becket. This pump uses a sole

noid valve to control the piston cut−on cut−off operation

instead of a cone valve and diaphram used by other con

ventional pumps. The solenoid works with the R7184B

Honeywell burner control to provide cut−on cut−off opera

tion while the burner motor is at full speed.

At startup the pump shaft is brought to full speed before the

solenoid is energized. At this time low pressure oil

(approximatley 20−25 psi) from the gearset circulates

around the pressure regulator piston which is closed and

through the open solenoid valve. The solenoid valve re

turns the oil to either the cover cavity (one pipe) or return

line (two pipe). When the solenoid vavle is energized, it

closes (and remains closed while energized) blocking the

return path to the cover cavity and return line creating pres

sure build up in the piston cavity. The piston opens and reg

ulates pressure and delivers pressurized oil to the nozzle.

At shutdown the solenoid valve will de−energize and open

before the pump shaft rotation stops. When the solenoid

valve opens the oil by−passes the cover cavity and return

line causing a pressure drop in the piston cavity. The piston

closes blocking oil to the nozzle while the burner motor is

running at full speed.

Page 12

Page 13

5−Burner Control (A3) & Transformer (T1)

−1 through −4 units

The burner control, along with the matching cad cell, proves

flame and controls the burner. After the cad cell closes a circuit

to the burner control, the burner control de−energizes the safe

ty switch heater to allow the unit to operate normally. The

burner control allows 45 seconds for the cad cell to close. If the

cad cell remains open after the 45 second time frame, the

burner control locks out. The burner control must be manually

reset by depressing the red reset button on top of the burner

control.

Transformer (T1) is part of the burner control. T1 provides

24VAC to the low voltage components in the unit and to the

thermostat.

6−Burner Control (A3) −5 units

All O 23, OHR23 and OF23 −5 units are equipped with a burn

er control R7184B manufactured by Honeywell. The burner

control, along with the matching cad cell, proves flame and

controls the burner. An LED on the control shows unit status.

See table 5 for status codes. After the cad cell closes a circuit

to the burner control, the burner control de−energizes the safe

ty switch heater to allow the unit to operate normally. When

there is a call for heat the control performs a 2 to 6 second

delay safety check. Once this is established a 15 second pre−

puge will follow. The valve then opens for a 15 second trial for

ignition. If flame is not sensed during the 15 second trial, the

control shuts down and must be manual re−set. After three

consecutive lockouts the control goes into restricted lockout.

Once flame is established after 10 seconds of run time, the ig

niiton shuts off.

If flame is lost during the heat cycle the control will shut

down the burner and begin a 60 second recycle delay. Af

ter 60 seconds the control repeats the ignition process. If

flame is lost three consecutive times during a single ther

mostat demand the control goas into restricted lockout.

Reset button

If the control lockouts three consecutive times the control

will go into restricted lockout. To reset control hold down

the reset button for 30 seconds until the LED flashes twice.

At any time the burner motor is energized, press and hold

the reset button to disable the buner. The burner will re

main disabled as long as the reset button is held and return

to operational once the button is released.

TABLE 5

LED STATUS

On Flame sensed

Off Flame not sensed

Flashing

(1/2 sec on1/2 sec off)

Flashing

(2 sec on 2 sec off)

Lockout /

Restricted Lockout

Recycle

7−Heat Shutoff Relay (K125)

−1 and −2 units only

Heat shutoff relay K125 is a SPST N.O. relay, with a 24V

coil. K125 is located on the vestibule and wired in series

with the burner. When secondary limit S21 or primary limit

S10 open, the circuit breaks opening K125 contacts which

in turn de−energizes the burner.

8−Cad Cell (R26)

Together the cad cell and the burner control prove flame.

The cad cell senses the presence of burner light (less re

sistance) to close a circuit to the burner control.

IMPORTANT−Burner should not be installed so it is ex

posed to direct sunlight or electric bulb light. If the cell

is exposed to light on start up, the burner will not oper

ate.

O23, OHR23 & OF23 −5 Units Only

Resistance for the cad cell can be checked while the burn

er is firing and after ignition is off. Press (1/2 second or

less) and release the reset button. The LED will flash 1 to 4

times depending on the cad cell resistance. The cad cell

resistance should read less than 1600 Ohms. See table 6.

O23, OHR23 & OF23 −5 UNITS

LED FLASHES RESISTANCE

1 0 − 400Ohms

2 400 − 800 Ohms

3 800 − 1600 Ohms

4

TABLE 6

1600 Ohms

Page 13

Page 14

9−Electronic Ignitor (A73)

The electronic ignitor provides the needed hot spark at the

electrodes to ignite the fuel mixture. The ignitor is a solid

state transformer . O23, OHR23 and OF23−1 through −4

units have 115V primary and 14,000V secondary wind

ings. O23, OHR23 and OF23−5 units have 120V primary

and 20,000V secondary windings. The center of the sec

ondary winding is grounded. Each secondary terminal is

7000V to ground and the total voltage between the elec

trodes is 14,000V.

NOTE−The leads for the solid state transformer are re

placeable and are available in a kit form.

NOTE−When testing the solid state transformer, do not

use a transformer tester designed for iron magnet trans

formers. Damage to the tester may result.

Testing the Ignitor

WARNING

SHOCK HAZARD

Do not touch ignitor or any metal touching ignitor

when ignitor is energized. Can result in serious per

sonal injury.

10−Gun Assembly

The gun assembly receives oil from the oil pump and feeds

it to the nozzle. The nozzle converts liquid oil into a fog−like

mist that is discharged through the flame retention head

into the combustion chamber.

11−Flame Retention Heads

The stainless steel flame retention head (see figure 11)

is used to swirl (cone) the foglike oil and air mixture as it

enters the combustion chamber. Three different heads

are used in the O23/OHR23/OF23. The firing rate dic

tates which head is used. See table 4. The greater the

FB number the larger the slots on the head. When com

bustion takes place, the flame will be cylindrical com

pact shaped as a result.

FLAME RETENTION HEAD

FB3 SHOWN

If the ignitor fails it will not produce a spark. Looking and

listening for the arc is a simple way to check. The most sure

way is to perform the screwdriver check. By placing the

blade of an insulated screwdrivere across the ignitor termi

nal leads will test for an arc. First, remove power from the

burner and disconnect the oil supply from nozzle. The cad

cell will not let the control energize the ignitor if the cad cell

senses light. Therefore remove one lead of the cad cell

from the burner control, or remove the cad cell all together

(do not forget to put back when test is complete). Place the

screwdriver blade across the terminals and slowly raise

one end of the blade off the terminal while the other re

mains in contact with the other terminal. There should be

an arc from terminal to the blade up to 3/4" away. If not re

place the ignitor. If an arc is present then place one end of

the screwdriver on one terminal and the other end with the

grounded baseplate. Raise the blade from the baseplate

and draw an arc. Repeat with the other terminal. If the arc

from the baseplate to one terminal is weaker than the arc

from the baseplate to the other terminal, replace the ignitor.

FIGURE 11

C−Primary Limit Control (S10)

The primary limit on all O23, OHR23, and OF23 units, is

located on the vestibule panel (see figures 1 through 3 for

location and figure 12 for type). When excess heat is

sensed in the heat exchanger, the limit will open. If the limit

is tripped, the blower control deenergizes the thermostat,

in turn shutting down the unit. The limit automatically re

sets when unit temperature returns to normal. The switch is

factory set and cannot be adjusted. The switch has a different

setpoint for each unit model number (see table 7). The set

point is printed on the face plate of the limit.

Page 14

Page 15

TABLE 7

PRIMARY LIMIT CONTROL (S10)

UNIT

ACTUATES

ON TEMP. RISE

O23Q2−70 210F (99C) 180F (82C)

O23Q3−105/120 220F (104C) 190F (88C)

O23Q5−140/154 210F (99C) 180F (82C)

OHR23Q3−105/120 240F (116C) 210F (99C)

OHR23Q5−140/154 190F (88C) 160F (71C)

OF23Q3−105/120

OF23Q3−105/120R

OF23Q5−140/154

OF23Q5−140/154R

SPADE CONNECTORS

240F (116C) 210F (99C)

210F (99C) 180F (82C)

LIMIT CONTROL (S10)

INSULATING COVER

ACTUATES

ON TEMP. FALL

LIMIT

1.Blower Motor (B3) and Capacitor (C4)

All O23, OHR23, and OF23 series units use single phase

direct drive blower motors. All motors used are 115V perma

nent split capacitor motors to ensure maximum efficiency.

See SPECIFICATIONS tables for horsepower and motor

nameplate for capacitor rating.The blower motor is con

nected to the blower control board via the blower motor

plug P43.

2.Secondary Limit Control (S21)

The secondary limit (S21) is used on the OHR23 series unit

only. The N.C. limit is mounted on the side and toward the

back of the blower housing. See figure 13 for location and fig

ure 14 for type. When excess heat is sensed in the blower

compartment, the limit will open. If the limit is tripped, the blow

er control deenergizes the thermostat, inturn shutting down

the unit. The limit automatically resets when unit tempera

ture returns to normal. The switch opens at 150F + 5F

(65.5C + 2.8C) on a temperature rise and resets at

140F + 5F (60.0C + 2.8C) on a temperature fall. The

switch is factory set and cannot be adjusted. The set

point is printed on the face plate of the limit.

FIGURE 12

D−Blower Compartment (Figure 13)

Blower motor (B3), capacitor (C4), and secondary limit con

trol (S21) are located in the blower compartment. The blow

er compartment can be accessed by removing the blower

access panel.

BLOWER COMPARTMENT

(OHR23 SIDE VIEW SHOWN)

SECONDARY LIMIT

CONTROL (S21)

(OHR23 ONLY)

(BACK SIDE)

BLOWER

MOTOR

CAPACITOR

(C4)

SECONDARY LIMIT CONTROL (S21)

FIGURE 14

E−Optional Accessories

Optional accessories are available from Lennox for the O23,

OHR23, and OF23 series units. Some accessories are in kit

form which come with instructions.

1.Low Speed On − Off Switch (S68)

The low speed on off switch is a kit (catalog # 67H91) which

permits continuous low speed blower operation. The switch is

a DPDT toggle switch.

FIGURE 13

BLOWER MOTOR

(B3)

2.Economizer Relay (K43)

The economizer relay (catalog # 65G40) is used to energize

the economizer if used. The relay is a 120V coil, single pole

contact which is energized by the accessory terminal of the

blower control board.

Page 15

Page 16

II−PLACEMENT AND INSTALLATION

g

Make sure unit is installed in accordance with installation in

structions and applicable codes.

A−Piping

The piping system and it’s components (oil filter, safety valves,

shutoff valves, etc.) must be designed to provide clean, air

free fuel to the burner.

An oil filter is required for all models. Use an oil filter of gener

ous capacity for all installations. Install filter inside the building

between the tank shut−off valve and the burner. Locate filter

close to burner for easy servicing. The GAR−Ber 11BV−R or

equivalent filter (with the below specifications) is recom

mended.

Fill

Pipe

Air Vent

OIL PIPING

ONEPIPE SYSTEM

Fuel

Unit

Oil

Tank

Shut−off

Valve

Aux

Filter

8 ft (2.4 m)

Maximum

One Pipe Lift

Maximum Firing Rate: 10GPH (38LPH)

Micron Removal: 10

Filtering Area: 500 in.2 (3225.8 cm2)

Working Pressure: 15 PSI (103.4 kPa)

Inlet/Outlet Dimension: 3/8" (9.5 mm) NPT

Flow Rate: 45GPH (171LPH)

Care must be taken to ensure the restriction of the piping sys

tem, plus any lift involved, does not exceed the capabili

ty of the oil pump. Each installation will be different. Use

the following guide lines when determining to use a single or

two stage pump.

When using a single pipe system with the fuel supply level

with or above the burner (see figure 15) and a vacuum of 6"

(152 mm) Hg or below, a single stage fuel unit with a supply

line and no return line should be adequate. Manual bleeding of

the fuel unit is required on initial start up. Failure to bleed air

from the pump could result in an air lock/oil starvation condi

tion.

NOTE−As an extra precaution, cycle heating on and off

ten times after bleeding air from the pump. This will elim

inate air in the gun assembly.

When using a two pipe system with the fuel supply level

below the level of the burner (see figure 16) a single

stage fuel unit should be used in lift conditions of up to

10 feet (3 m) and/or a vacuum of 10" (254 mm) Hg or be

low. A two stage fuel unit should be used when lift ex

ceeds 10 feet (3 m) and/or a vacuum of 10" (254 mm) Hg

to 15" (381 mm) Hg. Both conditions require the use of a re

turn line that purges the fuel unit of air by returning it to the fuel

tank. Use table 8 when determining the run and lift for piping.

Before converting a onepipe system to a twopipe sys

tem the pump must be converted to a twopipe system.

To convert the pump, install the bypass plug according

to the instructions. Notice in the twopipe system the re

turn line must terminate 3" (76 mm) to 4" (102 mm)

above the supply inlet. Failure to do this may introduce

air into the system and could result in loss of prime.

NOTE−If using an outside tank in cold climates a number one

fuel or an oil treatment is strongly recommended.

Page 16

FIGURE 15

OIL PIPING

TWOPIPE SYSTEM

Air Vent

Fill

Pipe

Return

Line

Oil

Tank

3"−4"

Return

Line

OUTSIDE TANK FUEL UNIT ABOVE BOTTOM OF TANK.

(76mm −102mm)

R

FIGURE 16

TABLE 8

Fuel

Unit

Aux

Filter

Inlet

H

TWO−PIPE MAXIMUM LINE LENGTH (H + R)

3450 RPM − 3 GPH (11.4 LPH)

Lift H"

Figure 15

0’

(0.0 m)

2’

(0.6 m)

4’

(1.2m)

6’

(1.8m)

8’

(2.4m)

10’

(3.0m)

12’

(3.7m)

14’

(4.3m)

16’

(4.9m)

18’

(5.5m)

3/8" (10 mm) OD

Tubing

Single

Stage

84’

(25.6 m)

73’

(22.3 m)

63’

(19.2 m)

52’

(15.8 m)

42’

(12.8 m)

31’

(9.4 m)

21’

(6.4 m)

−−−

−−−

Two

Stage

93’

(28.3 m)

85’

(25.9 m)

77’

(23.5 m)

69’

(21.0 m)

60’

(18.3 m)

52’

(15.9 m)

44’

(13.4 m)

36’

(11.0 m)

27’

(8.2 m)

−−− −−− −−−

1/2" (12 mm) OD

Tubing

Single

Stage

Stage

100’

(30.5 m)

(30.5 m)

100’

(30.5 m)

(30.5 m)

100’

(30.5 m)

(30.5 m)

100’

(30.5 m)

(30.5 m)

100’

(30.5 m)

(30.5 m)

100’

(30.5 m)

(30.5 m)

83’

(25.3 m)

(30.5 m)

41’

(12.5 m)

−−−

(30.5 m)

(30.5 m)

(23.2 m)

Two

100’

100’

100’

100’

100’

100’

100’

100’

100’

76’

Page 17

B−Venting Considerations

2− The vent connector should be as short as possible to

do the job.

WARNING

Combustion air openings in front of the furnace

must be kept free of obstructions. Any obstruction

will cause improper burner operation and may re

sult in a fire hazard or injury.

WARNING

The barometric shall be in the same atmospheric

pressure zone as the combustion air inlet to the

furnace. Deviation from this practice will cause im

proper burner operation and may result in a fire

hazard or injury.

CAUTION

Do not store combustible materials near the fur

nace or supply air ducts. The material (such as

paint, motor oil, gasoline, paint thinner, etc.) may

ignite by spontaneous combustion creating a fire

hazard.

3− The vent connector should not be smaller than the

outlet diameter of the vent outlet of the furnace.

4− Pipe should be at least 24 gauge galvanized.

5− Single wall vent pipe should not run outside or through

any unconditioned space.

6− Chimney should extend 3 feet (0.9 m) above the high

est point where the vent passes through the roof, and 2

feet (0.6 m) higher than any portion of a building within

a horizontal distance of 10 feet (3 m).

7− The vent must not pass through a floor or ceiling. Clear

ances to single wall vent pipe should be no less than 6"

(152 mm); more if local codes require it.

8− The vent may pass through a wall where provisions have

been made for a thimble as specified in the Standards of

the National Board of Fire Underwriters. See figure 17.

9− The vent pipe should slope upward toward the chim

ney on horizontal run at least 1/4 inch (6 mm) to the

foot (0.3 m) and should be supported by something

other than the furnace, such as isolation hangers. See

figure 18.

WARNING

This furnace is certified for use with type L" vent.

B" vent must not be used with oil furnaces.

NOTE−Oil burning equipment may be vented into an ap

proved masonry chimney or type L vent. (Type L vent is

similar in construction to type B gas vent except it carries a

higher temperature rating and is constructed with an inner

liner of stainless steel rather than aluminum).

Prior to installation of unit, make a thorough inspection of the

chimney to determine whether repairs are necessary. Make

sure the chimney is properly constructed and sized accord

ing to the requirements of the National Fire Protection Asso

ciation. The smallest dimensions of the chimney should be

at least equal to the diameter of the furnace vent connector.

Make sure the chimney will produce a steady draft sufficient

to remove all the products of combustion from the furnace.

A draft of at least .04" w.c. (9.9 Pa) is required during burner

operation.

1− Local building codes may have more stringent instal

lation requirements and should be consulted before

installation of unit.

10− Extend the vent pipe into the chimney so that it is flush

with the inside of the vent liner. Seal the joint between

the pipe and the liner.

11− The furnace shall be connected to a factory built

chimney or vent complying with a recognized stan

dard, or masonry or concrete chimney lined with a

lining material acceptable to the authority having

jurisdiction.

WALL THIMBLE

THIMBLE

COMBUSTIBLE

WALL

VENT PIPE

FIGURE 17

Page 17

Page 18

BAROMETRIC

CONTROL*

(IN EITHER

LOCATION)

CLEANOUT

*Barometric control may be installed in either vertical or horizontal

section of vent pipe within 18" (457 mm) of vent outlet of furnace.

LINER

CLEANOUT

MASONRY

CHIMNEY

FIGURE 18

12− When two or more appliances vent into a common vent,

the area of the common vent should not be less than the

area of the largest vent or vent connection plus 50% of

the areas of the additional vent or vent connection. Chim

ney must be able to sufficiently vent all appliances oper

ating at the same time.

13− The vent pipe shall not be connected to a chimney vent

serving a solid fuel appliance or any mechanical draft

system.

14− All unused chimney openings should be closed.

15− All vent pipe run through unconditioned areas or outside

shall be constructed of factory built chimney sections.

See figure 19.

16− Where condensation of vent gas is apparent, the vent

should be repaired or replaced. Accumulation of con

densation in the vent is unacceptable.

FACTORY−BUILT CHIMNEY

MASONRY CHIMNEY

17− Vent connectors serving this appliance shall not be

connected into any portion of mechanical draft sys

tems operating under positive pressure.

18− Keep the area around the vent terminal free of snow,

ice and debris.

NOTE−If vent pipe needs to exit from side of cabinet, use the

cross hairs (located on either side of the unit) to cut a 6" (152

mm) round hole. Attach finishing plate (provided) with four

sheet metal screws to cover rough edges.

Combustion and Ventilation Air

(Confined and Unconfined Spaces)

Until recently, there was no problem in bringing in suffi

cient amounts of outdoor air for combustion −− infiltration

provided all the air that was needed and then some. In

today’s homes built with energy conservation in mind,

tight construction practices make it necessary to bring in

air from outside for combustion. Consideration must also be

given to the use of exhaust fans, appliance vents, chimneys

and fireplaces because they force additional air that could

be used for combustion out of the house. Unless outside

air is brought into the home for combustion, negative

pressure (pressure outside is greater than inside pres

sure) will build to the point that a down draft can occur in

the furnace vent pipe or chimney. Combustion gases e n ter

the living space creating a potentially dangerous situa

tion.

The importance of the previous paragraph cannot be

overstated. Users may inadvertently block fresh air in

takes after installation.

In the absence of local codes concerning air for combus

tion and ventilation, the following section outlines guide

lines and recommends procedures for operating oil fur

naces in a manner that ensures efficient and safe

operation. Special consideration must be given to com

bustion air needs as well as requirements for exhaust vents

and oil piping.

Combustion Air Requirements

BAROMETRIC

CONTROL*

(IN EITHER

LOCATION)

*Barometric control may be installed in either vertical or horizontal

section of vent pipe within 18" (457 mm) of vent outlet of furnace.

FIGURE 19

FACTORY

BUILT

CHIMNEY

CAUTION

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. It will also

cause excess water in the heat exchanger result

ing in rusting and premature heat exchanger fail

ure. It can also cause property damage.

All oil−fired appliances require air to be used for the com

bustion process. If sufficient amounts of combustion air are not

available, the furnace or other appliance will operate in an inef

ficient and unsafe manner. Enough air must be provided to

meet the needs of all fuel−burning appliances, as well as ap

pliances such as exhaust fans which force air out of the home.

When fireplaces, exhaust fans, or clothes dryers are used at

the same time as the furnace, much more air is required

to ensure proper combustion and to prevent a down−

draft situation. Insufficient amounts of air also cause in

Page 18

Page 19

comp l ete combustion which can result in sooting. Require

ments for providing air for combustion and ventilation depend

largely on whether the furnace is installed in an uncon

fined or confined space.

Unconfined Space

CHIMNEY OR

OIL VENT

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM INSIDE

An unconfined space is an area such as a basement or

large equipment room with a volume greater than 50 cu

bic feet (1.4 cubic meters) per 1,000 Btu (293 W) per

hour of the combined input rating of all appliances

installed in that space. This space also includes adjacent

rooms which are not separated by a door. Though an area

may appear to be unconfined, it might be necessary to bring in

outdoor air for combustion if the structure does not provide

enough air by infiltration. If the furnace is located in a

building of tight construction with weather stripping and

caulking around the windows and doors, follow the proce

dures outlined for using air from the outside for combus

tion and ventilation.

Confined Space

A confined space is an area with volume less than 50 cu

bic feet (1.4 cubic meters) per 1,000 Btu (293 W) per

hour of the combined input rating of all appliances

installed in that space. This definition includes furnace closets

or small equipment rooms.

When the furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space con

taining the furnace, the return air must be handled by ducts

which are sealed to the furnace casing and which terminate

outside the space containing the furnace. This is especially

important when the furnace is mounted on a platform in a con

fined space such as a closet or small equipment room. Even a

small leak around the base of the unit at the platform or at the

return air duct connection can cause a potentially dangerous

negative pressure condition. Air for combustion and ventilation

can be brought into the confined space either from inside the

building or from outside.

Air from an Adjacent Space

If the confined space housing the furnace adjoins space

categorized as unconfined, air can be brought in by pro

viding two permanent openings between the two

spaces. Each opening must have a minimum free area

of 1 square inch (6.4 square centimeters) per 1,000 Btu

(293 W) per hour of the total input rating of all fuel−fired

equipment in the confined space. Each opening must

be at least 100 square inches (614.5 square centime

ters). One opening shall be within 12" (305 mm) of the

top of the enclosure and one opening within 12" (305

mm) of the bottom (See figure 20).

OIL

FURNACE

NOTE−Each opening shall have a free area of at least 1 square inch

(6.4 square centimeters) per 1,000 Btu (293 W) per hour of the total

input rating of all equipment in the enclosure, but not less than 100

square inches (614.5 square centimeters).

WATER

HEATER

OPENINGS

(To Adjacent Room)

FIGURE 20

Air from Outside

If air from outside is brought in for combustion and ven

tilation, the confined space shall be provided with two

permanent openings. One opening shall be within 12"

(305 mm) of the top of the enclosure and one within 12"

(305 mm) of the bottom. These openings must communicate

directly or by ducts with the outdoors or spaces (crawl or attic)

that freely communicate with the outdoors or indirectly

through vertical ducts. Each opening shall have a minimum

free area of 1 square inch (6.4 square centimeters) per 4,000

Btu (1172 W) per hour of total input rating of all equipment in

the enclosure (See figures 21 and 22). When communicating

with the outdoors through horizontal ducts, each opening

shall have a minimum free area of 1 square inch (6.4

square centimeters) per 2,000 Btu (586 W) per total input

rating of all equipment in the enclosure (See figure 23).

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

(Inlet Air from Crawl Space and

Outlet Air to Ventilated Attic)

CHIMNEY

OR OIL

VENT

VENTILATION LOUVERS

(Each end of attic)

OIL

FURNACE

VENTILATION

LOUVERS

(For unheated

crawl space)

NOTE−The inlet and outlet air openings shall each have a free area of

at least one square inch (6.4 square centimeters) per 4,000 Btu (1172

W) per hour of the total input rating of all equipment in the enclosure.

OUTLET

AIR

WATER

HEATER

INLET

AIR

FIGURE 21

Page 19

Page 20

CHIMNEY

OR OIL

VENT

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

(All Air Through Ventilated Attic)

VENTILATION LOUVERS

(Each end of attic)

OUTLET

AIR

CAUTION

Combustion air openings in the front of the furnace

must be kept free of obstructions. Any obstruction

will cause improper burner operation and may result

in a fire hazard or injury.

OIL

FURNACE

NOTE−The inlet and outlet air openings shall each have a free area of at

least one square inch (6.4 square centimeters) per 4,000 Btu (1172 W)

per hour of the total input rating of all equipment in the enclosure.

INLET AIR

(Ends 12" above

bottom)

WATER

HEATER

FIGURE 22

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

CHIMNEY

OR OIL

OIL

FURNACE

VENT

WATER

HEATER

OUTLET AIR

CAUTION

The barometric shall be in the same atmospheric

pressure zone as the combustion air inlet to the

furnace. Deviation from this practice will cause

improper burner operation and may result in a fire

hazard or injury.

Direct Connection of Outdoor Air for Combustion

The Beckett AFII burner was designed to allow for direct air

intake piping (4" [102 mm]). The maximum equivalent

length of pipe is 70 feet (21.3 m). A 90 elbow equals

6feet (1.8 m).

To convert the AFII burner from confined space to out

side combustion air, simply remove the three screws at

taching the inlet air scoop to the burner and insert 4"

(102 mm) direct air intake piping.

The use of a barometric relief placed in the intake pipe is

recommended when outdoor combustion air is directly

connected to the burner. This will allow confined space

air to be used as combustion air in the event that the

opening to the outdoor air becomes blocked. Using a

barometric relief in the intake will reduce the chance of

sooting.

INLET AIR

NOTE−Each air duct opening shall have a free area of at least one

square inch (6.4 square centimeters) per 2,000 Btu (586 W) per hour

of the total input rating of all equipment in the enclosure. If the equip

ment room is located against an outside wall and the air openings

communicate directly with the outdoors, each opening shall have a

free area of at least one square inch (6.4 square centimeters) per

4,000 Btu (1172 W) per hour of the total input rating of all other equip

ment in the enclosure.

FIGURE 23

When ducts are used, they shall be of the same cross−sec

tional area as the free area of the openings to which they

connect. The minimum dimension of rectangular air ducts

shall be no less than 3" (76 mm). In calculating free area, the

blocking effect of louvers, grilles, or screens must be con

sidered. If the design and free area of protective covering is

not known for calculating the size opening required, it may

be assumed that wood louvers will have 20 to 25 per

cent free area and metal louvers and grilles will have 60

to 75 percent free area. Louvers and grilles must be

fixed in the open position or interlocked with the equip

ment so that they are opened automatically during equip

ment operation.

CAUTION

DO NOT USE a barometric draft relief in exhaust

vent pipe if outdoor combustion air is connected

directly to the burner. The only exception are baro

metric draft reliefs as required by FIELD or TJERN

LUND power vents.

Removal of Unit from Common Venting System

In the event that an existing furnace is removed from a venting

system commonly run with separate appliances, the venting

system is likely to be too large to properly vent the remaining

attached appliances. The following test should be conducted

while each appliance is in operation and the o t her a p

pliances not in operation remain connected to the com

mon venting system. If venting system has been installed

improperly, the system must be corrected as outlined in the

previous section.

1− Seal any unused openings in the common venting sys

tem.

2− Visually inspect venting system for proper size and hori

zontal pitch and determine there is no blockage or restric

tion, leakage, corrosion or other deficiencies which could

cause an unsafe condition.

Page 20

Page 21

3− Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the com

mon venting system are located and other spaces of

the building. Turn on clothes dryers and any ap

pliances not connected to the common venting sys

tem. Turn on any exhaust fans, such as range hoods

and bathroom exhausts, so they will operate at maxi

mum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

4− Following the lighting instruction on the unit, place the

appliance being inspected in operation. Adjust thermo

stat so appliance will operate continuously.

5− Test for spillage using a draft gauge.

6− After it has been determined that each appliance re

maining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other fuel burning appliance to their previous condi

tion of use.

7− If improper venting is observed during any of the

above tests, the common venting system must be

corrected.

Horizontal Venting

(152 mm) is permissible. Calculate the equivalent vent pipe

footage from the furnace to the mechanical vent system

(Tjernlund or Field Controls) by adding the straight vent pipe

length and the equivalent elbow lengths together.

The barometric draft control must be used in horizontal (side

wall) venting system. It must be located within 18" (457 mm) of

the furnace vent outlet. See figure 24 for barometric draft con

trol location.

III−STARTUP

A−Preliminary and Seasonal Checks

1− Inspect electrical wiring, both field and factory installed

for loose connections. Tighten as required.

2− Check line voltage. Voltage must be within range

listed on the nameplate. If not, consult the power

company and have voltage condition corrected be

fore starting unit.

B−Heating StartUp

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

Do not attempt to start the burner when excess

oil has accumulated in the chamber, when the

furnace is full of vapor or when the combus

tion chamber is very hot.

HORIZONTAL VENTING

BAROMETRIC

CONTROL*

*When using indoor air,

barometric control must be

installed in the horizontal

venting system and located

within 18" (457 mm) of vent

When using direct connection,

barometric control must be

installed in the intake air pipe.

CONTROL FOR

HORIZONTAL

VENTING

outlet of furnace.

FIGURE 24

The O23 is approved for horizontal venting with the fol

lowing mechanical vent systems:

Tjernlund (sideshot) #SS1C and Field Controls #SWG−5 with

the CK−61 control kit. Refer to manufacturers’ installation

instructions for proper installation procedures and service

parts information.

Do not common vent with any other appliance when using

sidewall vent system.

Maximum permissible vent length is 70 equivalent feet (21.3

m). Minimum length is 15 equivalent feet (4.6 m). Each 90

elbow is equal to 6 feet (1.8 m) of straight pipe, each 45 el

bow is equal to 3 feet (0.9 m) of straight pipe. Minimum vent

pipe diameter is 4" (102 mm). Vent pipe of 5" (127 mm) and 6"

1− Set thermostat for heating demand.

2− Turn on electrical supply to unit and open all shutoff

valves in the oil supply line to the burner..

3− Check air adjustment dial on the right side of the burn

er (see figure 9). Set according to table 4.

4− On single line applications the oil pump must be

primed by bleeding the oil line. Open air bleed port and

start burner. A hose may be attached to direct oil into a

container. After last bubble is seen, bleed pump for 15

seconds. Hurried bleeding will impair efficient unit op

eration. Close port to stop bleeding. Single line instal

lations must be absolutely air tight to prevent leaks or

loss of prime.

5− If burner stops after flame is established, repeat the

bleeding procedure.

NOTE−Air bleeding is automatic on two line applica

tions; however, opening air bleed port will allow a faster

bleed. Run return line back to tank and terminate three to

four inches above the inlet line. Failure to bleed the sys

tem may cause air to be introduced into the system result

ing in a loss of prime.

6− If the burner does not start immediately, check the

safety switch on the burner primary control.

7− If burner fails to light again, refer to the trouble

shooting section in the back of this manual.

8− Proceed to section IV to complete start up.

C−Safety or Emergency Shutdown

Turn off unit power. Close all shutoff valves in the oil sup

ply line.

Page 21

Page 22

D−Extended Period Shutdown

Turn off thermostat or set to UNOCCUPIED" mode.

Close all shutoff valves in the oil supply line to guarantee no

oil leaks into burner. Turn off all power to unit. All access

panels, covers and vent caps must be in place and se

cured.

To check that the nozzle is approximately centered with

the head inside diameter, align the center mark of the

gauge with the center of the nozzle orifice, as shown in

figure 27, and move the gauge from side to side at sev

eral points. Be careful not to scratch the nozzle sur

face.

IV−HEATING SYSTEM SERVICE CHECKS

A−Oil Piping

All oil supply piping (factory and field) must be carefully

checked for oil leaks.

B−Electrode Adjustment

When adjusting the electrode, use the AFII multipurpose

gauge (Beckett part # T−500) packaged with each oil fur

nace, also available from Beckett.

To set the electrode tip gap spacing, position the gauge as

shown in figure 25. Align the center mark with the nozzle

and adjust the electrodes to the two outer marks (1/8"

[3mm] to 1/16" [2mm] minimum).

AFII ELECTRODE TIP

GAP

The Z" or zero dimension is important because it locates the

nozzle for the precise relationship with the combustion head.

To set the Z" dimension, position the gauge as shown in fig

ure 27 and loosen the nozzle line electrode assembly so that

it can be moved forward or backward in the air tube until the

nozzle becomes flush against the gauge. Tighten the nozzle

line escutcheon plate screw (shown in figure 9) to lock this

Z" dimension securely.

AFII NOZZLE CENTERING

FIGURE 25

To position the electrode tips beyond the face of the nozzle

and above the center line, position the gauge as shown in

figure 26. Align the center mark with the nozzle and adjust

the electrodes to the AC cross marks.

AFII ELECTRODE POSITIONING

FIGURE 26

FIGURE 27

C−Pressure Check

On −1 through −4 units use either the gauge port or

nozzle port to check operating pressure. On −5 units use

the nozzle port (−5 unit pumps are not equipped with

gauge port). The pump is factory set at 100 psig (689.5

kPa) for the O23Q2−70 and 140 psig (965.3 kPa) for all

other O23, OHR23, and OF23 units but is adjustable (see fig

ure 28). Never operate the pump in excess of 10 ps ig (6 9

kPa) above set point. Average nozzle cutoff pressure is

80 psig (551.6 kPa). To check the cutoff pressure install

a pressure gauge in nozzle port. For −5 units use the

same gauge used for operating pressure. Run the burn

Page 22

Page 23

er for a short period and then turn off. The gauge shows

cutoff pressure.

OIL PUMP PRESSURE CHECK

*PRESSURE GAUGE

**REGULATE PRESSURE

NOT SHOWN

(beside the inlet port)

PRESSURE

GAUGE

PORT (1/8" [3mm])

NOZZLE PORT

(1/8" [3mm])

INLET PORT

(1/4" [6mm])

*PRESSURE CHECKS: NORMAL OPERATING PRESSURE IS

100 PSIG (689.5 kPa) FOR THE 023Q270 AND 140 PSIG (965.3 kPa)

FOR ALL OTHER O23, OHR23, AND OF23 UNITS. NOZZLE CUTOFF

PRESSURE IS APPROXIMATELY 80 PSIG (551.6 kPa).

**TO ADJUST PRESSURE: INSERT STANDARD SCREWDRIVER.

TURN COUNTERCLOCKWISE BELOW DESIRED PRESSURE,

THEN TURN CLOCKWISE TO SET DESIRED PRESSURE.

RETURN PORT

(1/4" [6mm])

INLET PORT

SHOWN (1/4" [6mm])

BLEED PORT

1/16" (2mm) BYPASS PLUG

INSERT FOR TWOPIPE SYSTEM

(use 5/32" [4mm] allen wrench)

FIGURE 28

D−Burner Adjustment

The following instructions are essential to the proper opera

tion of O23 series oil furnaces. To prevent sooting, these in

structions must be followed in sequence:

NOTE−All w.c. measurements are below atmospheric

pressure (negative readings).

1−Draft

This test should be taken at the vent connector between

the breaching and the barometric damper. Generally a 1/4"

(6 mm) hole will need to be drilled for the draft gauge to be

inserted into the vent connector.

A minimum of 0.03" w.c. (7.5 Pa) draft must be estab

lished without the burner in operation. With the burner in

operation, the draft should be 0.04" w.c. (9.9 Pa) to 0.05"

w.c. (12.4 Pa). This is VERY critical to the flame retention

head burners.

Oil furnace installations also require careful inspection to

make sure the chimney is in good condition and can ac

commodate the products of combustion. The temperature

in unconditioned space will also affect the draft if long vent

connectors are allowed to get too cold.

2−Overfire Draft

This test should be taken with the burner in operation.

Remove the screw from the center of the center inspec

tion port. Insert your draft gauge into the hole.

A reading of the overfire draft should be 0.02" w.c. (5.0 Pa)

less than the reading found in the vent connector. If a posi

tive reading is seen at this point, the secondary heat ex

changer may be sooted or to much air may be entering

into the heat exchanger from the combustion fan. Adjust

ments to the combustion fan can be made using the air

adjustment dial.

3−Smoke Test

The smoke test should be taken at hole drilled in step 1.

Using a smoke test gun adjust the air inlet shutter so that

you will have just a trace of smoke. Somewhere be

tween a 0 and #1 smoke. This is the starting point. Do

not stop here. After the smoke test take a CO sample.

C.S.A. requires no more than 400ppm. However, a

properly installed unit under normal operating condi

tions should not read more than 50ppm.

4−CO2 Test

Again to be taken at the vent connector pipe. With the

unit firing at a trace of smoke, test for percentage of CO

in the vent gas.

From the results of this test, a window of operation" will be

determined. This window of operation establishes some tol