Page 1

INSTALLATION

E 2002 Lennox Industries Inc.

Dallas, Texas, USA

INSTRUCTIONS

O23 SERIES UNITS

OIL UNITS

504,626M

38152A059

01/04

Supersedes 04/02

Table of Contents

General 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping & Packing 1. . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O23 Unit Dimensions 2. . . . . . . . . . . . . . . . . . . . . . . . . . .

O23 Start−Up & Performance Check List 2. . . . . . . . .

O23 Unit Parts Arrangement 3. . . . . . . . . . . . . . . . . . . . .

O23 Oil Burner Parts Arrangement 3. . . . . . . . . . . . . . . .

Locate & Level the Unit 5. . . . . . . . . . . . . . . . . . . . . . . .

Setting the Unit 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Adjustments 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Venting 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flue Connections 10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply & Return Air Plenums 11. . . . . . . . . . . . . . . . .

Oil Supply Line & Filter Connections 12. . . . . . . . . . .

Leak Check 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Wiring 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Start-Up & Adjustments 15. . . . . . . . . . . . . . . . . .

Service 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litho U.S.A.

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNING

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service, or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information, consult a qualified installer

or service agency.

CAUTION

When venting this appliance, keep vent terminal free

of snow, ice and debris.

General

These instructions are intended as a general guide and do

not supersede local codes in any way. Only qualified technicians can install and service the Lennox Elite® Series

O23 oil furnaces. In Canada, refer to CSA B139 for recommended installation procedures. Consult authorities who

have jurisdiction before installation.

CAUTION

Never burn garbage or paper in the heating system.

Never leave papers near or around the unit.

Shipping & Packing List

1− Assembled oil furnace

1− Barometric draft control

1− Side exhaust pipe collar

1− Direct intake collar (AFII burner units only)

Check the components for shipping damage. If you find any

damage, immediately contact the last carrier.

01/04

*2P0104*

Page 1

504,626M

*P504626M*

Page 2

O23 Unit Dimensions − Inches (mm)

O23Q2/3-70/90

3/4

(19)

3/4

(19)

C

D

SUPPLY

AIR

OPENING

TOP FLUE

OUTLET

FLUE OUTLET

CENTERING HOLE

(Field Fabricate

ELECTRICAL INLET

(Right Side Only)

OIL PIPING INLET

(Left Side Only)

OPT. OUTDOOR

COMBUSTION

CENTERING HOLE

(Field Fabricate

1-1/2

Right Side only)

(38)

1-1/4

(32)

Model No. A B C D E

O23Q2/3-70/90

O23Q3/4-105/120

O23Q5-140/154

TOP VIEW

SIDE

Either Side)

FLUE

CONNECTION

(On Heat

Exchanger)

AB

54

(1372)

AIR FLOW

AIR INLET

1-1/2

(38)

22

14

(356)

(559)

RETURN AIR

OPENING

(Either Side)

23-1/2

(597)

2 (51)

22

(559)

RETURN AIR

E

RETURN AIR

SIDE VIEW FRONT VIEW

in. 19-1/2 30-5/8 18 19-5/8 16

mm 495 778 457 498 406

in. 22-1/2 33-1/8 21 22-1/8 18

mm 572 841 533 562 457

O23 Start−Up & Performance Check List

Job Name

Job Location

Installer

Unit Model No.

HEATING SECTION

Electrical Connections Tight?

Supply Voltage

Blower Motor H.P.

Blower Motor Lubrication O.K.?

Piping Connections Tight?

Burner Model No.

Oil Pump Pressure [recommended min. 100 psig for −70;

min. 140 psig for all other units )]

Blower Motor Amps

All Valves Open?

Serial Number

Job No.

Serial No.

Page 2

Date

City

City

State

State

Serviceman

PROPER DRAFT

Draft Reading (recommended .03−.04 inches w.c.)

% CO2 (recommended 12%)

Flue Connections Tight?

Fan Control Setting (maximum 130_ F)

(55_C)

Temperature RiseFan Control Cutout

Filter Clean & Secure?

Vent Clear?

THERMOSTAT

Calibrated? Heat Anticipator Properly Set? Level?

Page 3

O23 Unit Parts Arrangement

clean-out port

limit switch

control box

with fan control board

Beckettr

AFII burner

heat exchanger

flue opening

clean−out port

observation

port

combustion air intake

blower motor

indoor blower

O23 Oil Burner Parts Arrangement

RETAINING

CLIP

HEAD SCREW

HEAD

INSULATOR

FLANGE

GASKET

AIR TUBE

ASSY FOR

FB HEADS

1/4" HEX

FB−HEAD

NOZZLE

ADAPTER

NOZZLE LINE

ELECTRODE HEAD

ASSY.

FLANGE

ELECTRODE

ASSY

AIR TUBE

SCREWS

PREMOUNTED OIL−DELAY VALVE

PEDESTAL

Figure 1

ELECTRONIC IGNITION

TRANSFORMER

REAR ACCESS

DOOR GASKET

REAR ACCESS

DOOR ASSY

MAIN

HOUSING

ASSY

SPLINED

NUT

ESCUTCHEON

PLATE

CONNECTOR

TUBE

FUEL PUMP

COUPLING

Figure 2

capacitor

IGNITOR

MOTOR

PRIMARY

CONTROL

BLOWER

WHEEL

4X4

BOX

0

3

4

5

6

7

8

AIR

ADJ.

DIAL

INLET

AIR SCOOP

Page 3

Page 4

Requirements

IMPORTANT

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you

to fiberglass wool dust. Breathing this may cause

lung cancer. (Fiberglass wool is known to the State

of California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact your

supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a qualified installer or service

agency.

Installation of Lennox oil−fired furnaces must conform with

the National Fire Protection Association Standard for the

Installation of Oil Burning Equipment, NFPA No. 31, the

National Electrical Code, ANSI/NFPA No.70 (in the

U.S.A.), CSA Standard CAN/CSA−B139 (in Canada),

Installation Code for Oil Burning Equipment, the Canadian

Electrical Code Part1, CSA 22.1 (Canada), the recommendations of the National Environmental Systems Contractors Association and any state or provincial laws or local ordinances. Authorities having jurisdiction should be

consulted before installation. Such applicable regulations

or requirements take precedence over general instructions

in this manual.

Chimneys and chimney connectors must be of the type and

construction outlined in section 160 of NFPA No. 31.

Air for combustion and ventilation must conform to standards outlined in section 140 of NFPA No. 31 or, in Canada,

CSA Standard B139. When installing O23 units in confined

spaces such as utility rooms, two combustion air openings

are required. Dimensions of combustion air openings are

shown in table 1. One opening shall be below burner level

and the other opening shall be no more than 6"(152 mm)

from the room’s ceiling.

An opening to the outside for combustion air is

strongly recommended, especially in new homes.

Refer to table 2 or the unit rating plate for specific

combustion air opening dimensions.

The combustion air opening should provide a minimum

free area one-half square inch per 1,000 Btu per hour input.

This combustion air should be brought into the area containing the furnace below the level of the furnace burner.

Table 1

Combustion Air Opening Dimensions

Model No.

O23−70/105/120 10" X 20" (254 mm X 508 mm)

O23−140/154 11" X 22" (279 mm X 559 mm)

This unit is approved for use on combustible flooring and

for clearances to combustible material as listed on unit rating plate and in table 2. Unit service and accessibility clearances take precedence over fire protection clearances.

Installation Clearances inches (mm)

Clearances 70/105/120 140/154

top of plenum and duct 2 (51) 2 (51)

plenum sides 3 (76) 3 (76)

sides 0 (0) 0 (0)

rear 0 (0) 0 (0)

front 4 (120) 4 (120)

flue pipe measured from

above

flue pipe measured vertical 6 (152) 6 (152)

NOTE − Service access clearance must be maintained.

*Minimum clearance shown for flue pipe may be reduced by using special

protection as provided by local building codes and the National Fire

Protection Association Standards.

Unit must be adjusted to obtain a temperature rise in the

range listed in table 6 in the Start-Up section of this manual.

When installed, furnace must be electrically grounded in

accordance with local codes or, in the absence of local

codes, with the current National Electric Code, ANSI/NFPA

No. 70, or Canadian Electric Code (CEC) if an external

electrical source is utilized.

Field wiring connection with unit must meet or exceed

specifications of type T wire and withstand a 63_F (17_C)

temperature rise.

Combustion Air Opening

Dimensions (2 required)

Table 2

6 (152) 6 (152)

Page 4

Page 5

When furnace is used in conjunction with cooling units, it shall

be installed in parallel with, or on the upstream side of, cooling

units to avoid condensation in the heating element. With a

parallel flow arrangement, a damper (or other means to control the flow of air) shall be adequate to prevent chilled air from

entering the furnace and, if manually operated, must be

equipped with means to prevent operation of either unit, unless damper is in the full heat" or cool" position.

Locate & Level the Unit

1− Set the unit in desired location keeping in mind the clear-

ances listed in table 2. Also keep in mind oil supply connections, electrical supply, flue connections and sufficient clearance for installing and servicing unit.

2− Level the unit from side to side and from front to rear. If

the furnace is not level, place fireproof wedges or

shims between the low side of the furnace and the

floor. Make sure the weight of the furnace is distributed

evenly on all four corners. Strain on sides of cabinet

causing cracking and popping noises may occur if

weight of furnace is not evenly distributed.

Unit Adjustments

Neither the nozzle setting nor the air adjustments are factory set. The furnace is fire tested and the limit control is

checked to make sure it functions properly; no factory settings are made. During installation, the furnace must be

set up." The installing dealer/contractor must have and

use proper test equipment in order to correctly set up the oil

furnace. Proper testing equipment is required to ensure

correct operation of the unit. The use of test equipment is

now more critical than ever due to tighter tolerances needed to keep the furnace operating efficiently.

Among the test equipment for an oil furnace, the proper

combustion test kit should contain the following:

D Draft gauge

D CO

or O2 analyzer

2

D Smoke tester

D Pressure gauge

D High temperature thermometer

D Beckett T−500 gauge

D Oil vacuum gauge

D Knowledge of proper test equipment operation

CAUTION

Improper nozzle and/or air adjustment of this unit

may result in sooting problems. Refer to the following section for correct adjustment procedures.

Adjusting the Nozzle

Proper adjustment of the nozzle assembly is critical because alignment may have changed during shipping. Before the furnace and oil lines are installed, the nozzle assembly must be checked. To check the nozzle assembly, remove

the entire burner assembly (not just the nozzle) from the furnace. The lower firing nozzle is factory installed. This should

be verified by the installer. Inspect the spark transformer

leads also to ensure they are still attached to the electrodes.

The burner assembly is attached to the vestibule panel by

three nuts. Slots are provided in the mounting flange for removing the burner assembly from the vestibule. By loosening the nuts and by turning the whole burner assembly

counterclockwise (figure 3), the entire burner assembly will

come out of the furnace. There is adequate wire to remove

the burner without disconnecting wires. Once removed,

turn the burner around in the vest panel area.

O23 Series Burner Removal

Loosen three nuts which at-

tach burner to vest panel.

To correctly adjust the nozzle, use a Beckett #T−500 gauge

Insert the small end of the gauge into the end of the cone

and measure from the flat of the end cone to the tip of the

nozzle. When nozzle depth is correct, the tip of the nozzle

should just touch the end of the gauge. Refer to the illustration sheet provided with the gauge. Note that the scale side

of the gauge is not used for this purpose. Make corrections

by sliding the nozzle assembly forward or backward within

the blast tube (figure 4). At the same time, check the nozzle

alignment.

Rotate burner counterclockwise on

slots then pull toward you.

Figure 3

Page 5

Page 6

To check nozzle alignment, again insert the small end into

the end cone and measure the nozzle and electrode alignment against the center lines marked on the gauge (again

refer to enclosed illustration sheet). If the nozzle is not centered, but found to be too far left or right, a new nozzle assembly will need to be ordered. Do not attempt to adjust by

bending the 90 degree elbow in the oil line.

Beckett Oil Burner Nozzle Adjustment

Burner must be removed from

furnace for this procedure.

2

GAUGE

TO ADJUST NOZZLE:

1−Loosen screw.

2−Slide entire nozzle/electrode assembly back and forth until

nozzle just touches gauge.

Figure 4

1

Venting

WARNING

Combustion air openings in front of the furnace must

be kept free of obstructions. Any obstruction will

cause improper burner operation and may result in

a fire hazard.

WARNING

The barometric damper shall be in the same atmospheric pressure zone as the combustion air inlet to

the furnace. Deviation from this practice will cause

improper burner operation and may result in a fire

hazard.

higher temperature rating and is constructed with an inner

liner of stainless steel rather than aluminum).

Prior to installation of unit, make a thorough inspection of

the chimney to determine whether repairs are necessary.

Make sure the chimney is properly constructed and sized

according to the requirements of the National Fire Protection Association. The smallest dimensions of the chimney

should be at least equal to the diameter of the furnace vent

connector. Make sure the chimney will produce a steady

draft sufficient to remove all the products of combustion

from the furnace. A draft of at least .04" w.c. (9.9 Pa) is required during burner operation.

1 − Local building codes may have more stringent installa-

tion requirements and should be consulted before

installation of unit.

2 − The vent connector should be as short as possible to

do the job.

3 − The vent connector should not be smaller than the out-

let diameter of the vent outlet of the furnace.

4 − Pipe should be at least 24 gauge galvanized.

5 − Single wall vent pipe should not run outside or through

any unconditioned space.

6 − Chimney should extend 3 feet (0.9 m) above highest

point where the vent passes through the roof, and 2

feet (0.6 m) higher than any portion of a building within

a horizontal distance of 10 feet (3 m).

7 − The vent must not pass through a floor or ceiling.

Clearances to single wall vent pipe should be no less

than 6" (152 mm); more if local codes require it.

8 − The vent may pass through a wall where provisions

have been made for a thimble as specified in the Standards of the National Board of Fire Underwriters. See

figure 5.

WALL THIMBLE

THIMBLE

CAUTION

Do not store combustible materials near the furnace

or supply air ducts. The material (such as paint, motor oil, gasoline, paint thinner, etc.) may ignite by

spontaneous combustion creating a fire hazard.

WARNING

This furnace is certified for use with type L" vent.

B" vent must not be used with oil furnaces.

NOTE − Oil burning equipment may be vented into an approved masonry chimney or type L vent. (Type L vent is

similar in construction to type B gas vent except it carries a

COMBUSTIBLE

WALL

FIGURE 5

9 − The vent pipe should slope upward toward the chim-

ney on horizontal run at least 1/4 inch (6 mm) to the

foot (0.3 m) and should be supported by something

other than the furnace, such as isolation hangers. See

figure 6.

Page 6

VENT PIPE

Page 7

BAROMETRIC

CONTROL*

(IN EITHER

LOCATION)

MASONRY CHIMNEY

LINER

NOTE − If vent pipe needs to exit from side of cabinet,

use the pilot hole (located on either side of the unit) to

cut a 6" (152 mm) round hole. Attach finishing plate

(provided) with four sheet metal screws to cover rough

edges.

FACTORY−BUILT CHIMNEY

CLEAN OUT

MASONRY

CHIMNEY

CLEAN OUT

*Barometric control may be installed in either vertical or horizontal section of flue pipe within 18" of flue outlet of furnace.

Figure 6

10− Extend the vent pipe into the chimney so that it is flush

with the inside of the vent liner. Seal the joint between

the pipe and the liner.

11− The furnace shall be connected to a factory built chim-

ney or vent complying with a recognized standard, or

masonry or concrete chimney lined with a lining material acceptable to the authority having jurisdiction.

12− When two or more appliances vent into a common

vent, the area of the common vent should not be less

than the area of the largest vent or vent connection

plus 50% of the area of the additional vent or vent connection. Chimney must be able to sufficiently vent all

appliances operating at the same time.

13− The vent pipe shall not be connected to a chimney

vent serving a solid fuel appliance or any mechanical

draft system.

14− All unused chimney openings should be closed.

15− All vent pipe run through unconditioned areas or out-

side shall be constructed of factory built chimney sections. See figure 7.

16− Where condensation of vent gas is apparent, the vent

should be repaired or replaced. Accumulation of condensation in the vent is unacceptable.

17− Vent connectors serving this appliance shall not be

connected into any portion of mechanical draft systems operating under positive pressure.

18− Keep the area around the vent terminal free of snow,

ice and debris.

BAROMETRIC

CONTROL*

(IN EITHER

LOCATION)

*Barometric control may be installed in either vertical or horizontal section of flue pipe within 18" of flue outlet of furnace.

FACTORY

BUILT

CHIMNEY

DRAIN FOR

CONDENSATE

Figure 7

Combustion and Ventilation Air

(Confined and Unconfined Spaces)

In the past, there was no problem in bringing in sufficient

amounts of outdoor air for combustion − infiltration provided

all the air that was needed and then some. In today’s

homes built with energy conservation in mind, tight

construction practices make it necessary to bring in air

from outside for combustion. Consideration must also be

given to the use of exhaust fans, appliance vents, chimneys and fireplaces because they force additional air that

could be used for combustion out of the house. Unless outside air is brought into the home for combustion, negative

pressure (pressure outside is greater than inside pressure)

will build to the point that a down draft can occur in the furnace vent pipe or chimney. Combustion gases enter the living space creating a potentially dangerous situation.

The importance of the previous paragraph cannot be overstated. Users may inadvertently block fresh air intakes after

installation.

In the absence of local codes concerning air for combustion and ventilation, the following section outlines guidelines and recommends procedures for operating oil furnaces in a manner that ensures efficient and safe

operation. Special consideration must be given to combustion air needs as well as requirements for exhaust vents

and oil piping.

Page 7

Page 8

Combustion Air Requirements

CAUTION

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. It will also cause

excess water in the heat exchanger resulting in rusting and premature heat exchanger failure. It can also

cause property damage.

All oil-fired appliances require air to be used for the combustion process. If sufficient amounts of combustion air are

not available, the furnace or other appliance will operate in

an inefficient and unsafe manner. Enough air must be provided to meet the needs of all fuel-burning appliances, as

well as appliances such as exhaust fans which force air out

of the home. When fireplaces, exhaust fans, or clothes dryers are used at the same time as the furnace, much more

air is required to ensure proper combustion and to prevent

a down-draft situation. Insufficient amounts of air also

cause incomplete combustion which can result in sooting.

Requirements for providing air for combustion and ventilation depend largely on whether the furnace is installed in an

unconfined or confined space.

Unconfined Space

An unconfined space is an area such as a basement or

large equipment room with a volume greater than 50 cubic

feet (1.4 cubic meters) per 1,000 Btu (293 W) per hour of

the combined input rating of all appliances installed in that

space. This space also includes adjacent rooms which are

not separated by a door. Though an area may appear to be

unconfined, it might be necessary to bring in outdoor air for

combustion if the structure does not provide enough air by

infiltration. If the furnace is located in a building of tight

construction with weather stripping and caulking around

the windows and doors, follow the procedures outlined for

using air from the outside for combustion and ventilation.

Confined Space

A confined space is an area with volume less than 50 cubic

feet (1.4 cubic meters) per 1,000 Btu (293 W) per hour of

the combined input rating of all appliances installed in that

space. This definition includes furnace closets or small

equipment rooms.

When the furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containing the furnace, the return air must be handled by ducts

which are sealed to the furnace casing and which terminate

outside the space containing the furnace. This is especially

important when the furnace is mounted on a platform in a

confined space such as a closet or small equipment room.

Even a small leak around the base of the unit at the platform

or at the return air duct connection can cause a potentially

dangerous negative pressure condition. Air for combustion

and ventilation can be brought into the confined space either from inside the building or from outside.

Air from an Adjacent Space

If the confined space housing the furnace adjoins space

categorized as unconfined, air can be brought in by providing two permanent openings between the two spaces.

Each opening must have a minimum free area of 1 square

inch (6.4 square centimeters) per 1,000 Btu (293 W) per

hour of the total input rating of all fuel-fired equipment in the

confined space. Each opening must be at least 100 square

inches (614.5 square centimeters). One opening shall be

within 12" (305 mm) of the top of the enclosure and one

opening within 12" (305 mm) of the bottom (See figure 8).

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM INSIDE

CHIMNEY OR

OIL VENT

OIL

FURNACE

NOTE−Each opening shall have a free area of at least 1 square inch

(6.4 square centimeters) per 1,000 Btu (293 W) per hour of the total

input rating of all equipment in the enclosure, but not less than 100

square inches (614.5 square centimeters).

WATER

HEATER

OPENINGS

(To Adjacent Room)

FIGURE 8

Air from Outside

If air from outside is brought in for combustion and ventilation, the confined space shall be provided with two permanent openings. One opening shall be within 12" (305 mm)

of the top of the enclosure and one within 12" (305 mm) of

the bottom. These openings must communicate directly or

by ducts with the outdoors or spaces (crawl or attic) that

freely communicate with the outdoors or indirectly through

vertical ducts. Each opening shall have a minimum free

area of 1 square inch (6.4 square centimeters) per 4,000

Btu (1172 W) per hour of total input rating of all equipment

in the enclosure (See figures 9 and 11). When communicat-

Page 8

Page 9

ing with the outdoors through horizontal ducts, each opening shall have a minimum free area of 1 square inch (6.4

square centimeters) per 2,000 Btu (586 W) per total input

rating of all equipment in the enclosure (See figure 11).

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

(Inlet Air from Crawl Space and

Outlet Air to Ventilated Attic)

CHIMNEY

OR OIL

VENT

VENTILATION LOUVERS

(Each end of attic)

OIL

FURNACE

VENTILATION

LOUVERS

(For unheated

crawl space)

OUTLET

AIR

WATER

HEATER

INLET

AIR

NOTE − The inlet and outlet air openings shall each have a free area of

at least one square inch (6.4 square centimeters) per 4,000 Btu (1172

W) per hour of the total input rating of all equipment in the enclosure.

FIGURE 9

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

(All Air Through Ventilated Attic)

CHIMNEY

OR OIL

VENT

OIL

FURNACE

OUTLET

AIR

VENTILATION LOUVERS

(Each end of attic)

INLET AIR

(Ends 12" above

bottom)

WATER

HEATER

NOTE−The inlet and outlet air openings shall each have a free area of at

least one square inch (6.4 square centimeters) per 4,000 Btu (1172 W)

per hour of the total input rating of all equipment in the enclosure.

FIGURE 10

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

CHIMNEY

OR OIL

VENT

OIL

FURNACE

NOTE − Each air duct opening shall have a free area of at least one

square inch (6.4 square centimeters) per 2,000 Btu (586 W) per hour

of the total input rating of all equipment in the enclosure. If the equipment room is located against an outside wall and the air openings

communicate directly with the outdoors, each opening shall have a

free area of at least one square inch (6.4 square centimeters) per

4,000 Btu (1172 W) per hour of the total input rating of all other equip-

WATER

HEATER

OUTLET AIR

INLET AIR

ment in the enclosure.

FIGURE 11

When ducts are used, they shall be of the same cross−sectional area as the free area of the openings to which they

connect. The minimum dimension of rectangular air ducts

shall be no less than 3" (76 mm). In calculating free area,

the blocking effect of louvers, grilles, or screens must be

considered. If the design and free area of protective covering is not known for calculating the size opening required, it

may be assumed that wood louvers will have 20 to 25 percent free area and metal louvers and grilles will have 60 to

75 percent free area. Louvers and grilles must be fixed in

the open position or interlocked with the equipment so that

they are opened automatically during equipment operation.

Direct Connection of Outdoor Air for Combustion

The Beckett AFII burner was designed to allow for direct air

intake piping (4" [102 mm]). The maximum equivalent

length of pipe is 70 feet (21.3 m). A 90_ elbow equals

6feet (1.8 m). The enclosed intake pipe ring may be used

to facilitate direct air intake to the burner through the right

side of the cabinet. The AFG burner requires a special kit

for direct air intake. Refer to kit instructions.

To convert the AFII burner from confined space to outside

combustion air, simply remove the three screws attaching

the inlet air scoop to the burner and insert 4" (102 mm) direct air intake piping.

The use of a barometric relief placed in the intake pipe is

recommended when outdoor combustion air is directly

connected to the burner. This will allow confined space air

to be used as combustion air in the event that the opening

to the outdoor air becomes blocked. Using a barometric relief in the intake will reduce the chance of sooting.

Page 9

Page 10

CAUTION

DO NOT USE a barometric draft relief in exhaust vent

pipe if outdoor combustion air is connected directly

to the burner.

Removal of Unit from Common Venting System

In the event that an existing furnace is removed from a

venting system commonly run with separate appliances,

the venting system is likely to be too large to properly vent

the remaining attached appliances. The following test

should be conducted while each appliance is in operation

and the other appliances not in operation remain connected to the common venting system. If venting system

has been installed improperly, the system must be corrected as outlined in the previous section.

1 − Seal any unused openings in the common venting sys-

tem.

2 − Visually inspect venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion or other deficiencies

which could cause an unsafe condition.

3 − Insofar as is practical, close all building doors and win-

dows and all doors between the space in which the appliances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryers and any appliances not connected to the common venting system. Turn on any

exhaust fans, such as range hoods and bathroom exhausts, so they will operate at maximum speed. Do not

operate a summer exhaust fan. Close fireplace dampers.

4 − Following the lighting instruction on the unit, place the

appliance being inspected in operation. Adjust thermostat so appliance will operate continuously.

5 − Test for spillage using a draft gauge.

6 − After it has been determined that each appliance re-

maining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other fuel burning appliance to their previous condition of use.

7− If improper venting is observed during any of the

above tests, the common venting system must be corrected.

Horizontal Venting

The O23 is approved for horizontal venting with the following mechanical vent systems:

Tjernlund (sideshot) #SS1C (Cat. #35E08) or Field Controls #SWG−5 (Cat. #35P08) with the CK−61 (Cat. #18N28)

control kit. Refer to the manufacturers’ installation instructions for proper installation procedures and service parts

information.

Do not use the same vent with any other appliance

when using a sidewall vent system.

Maximum permissible vent length is 70 equivalent feet.

Minimum length is 15 equivalent feet. Calculate the equivalent vent pipe footage from the furnace to the mechanical

vent system (Tjernlund or Field Controls) by adding the

straight vent pipe length and the equivalent elbow lengths

together.

Locate the barometric draft control within 18 inches of the

furnace flue outlet. See figure 12 for barometric draft control location.

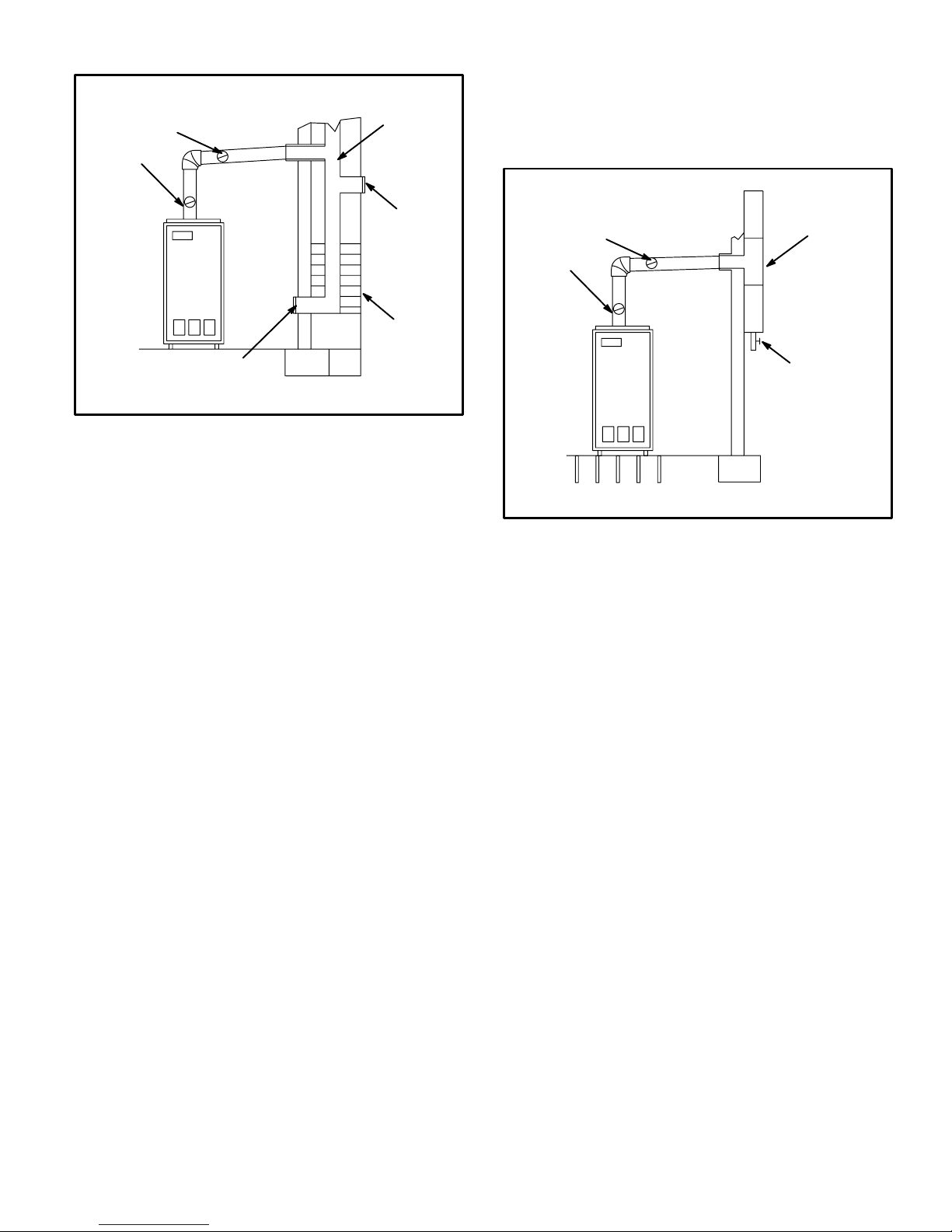

HORIZONTAL VENTING

barometric

control*

horizontal venting

control

*Barometric control must

be installed in the hori-

zontal venting system and

located within 18" of flue

outlet of furnace.

Figure 12

Flue Connections

IMPORTANT

When flue pipe is installed at less than minimum

clearance listed in table 2, radiation shields must be

installed. See figure 13.

Page 10

Page 11

combustible

material

unit

cabinet

noncombustible

spacers

Radiation Shield Installation

O23 unit

(top)

radiation

shields

A

See note 2

radiation shields

(see note 1)

flue

pipe

A

See note 3

1"

(25 mm)

min

(305 mm)

(178 mm)

B

12"

min

7"

min

est flue or vent connector, plus 50% of the area of any additional flues or vent connectors. Install a barometric draft

control (provided) and flue pipe according to instructions

packed with control.

Inspect flue pipe annually. Clean soot or ash from flue pipe,

if necessary. If pipe is rusted, replace.

Install draft control at least 12 inches beyond the furnace. If

there is no space to install the draft control in the flue pipe it

may be installed in the vent above the flue pipe. Follow the

instructions packed with the draft control.

Alternate Side Flue Connections

The vent pipe may exit the top or sides of the cabinet. A

hole is provided in the top cap for top exit. For side exit, locate the center hole punched in the side of the cabinet. See

unit dimensions on page 2. Using it as the center point, cut

a 6 inch (152 mm) round hole in the cabinet’s side. Install

the barometric draft control within 18 inches of the furnace

flue outlet.

Attach the provided finishing plate to cover rough edges.

O23 UNIT

(front)

NOTE 1−Radiation shields must be constructed of 24 gauge sheet

metal minimum.

NOTE 2−Radiation shields required when A is less than 9" (229 mm).

NOTE 3−Radiation shields should extend from the top of the unit to

the top of the flue pipe.

Figure 13

Use 24 gauge or heavier galvanized smoke pipe and fittings to connect the furnace to the vent. Connect flue pipe

to chimney using the least number of elbows and angles

possible. Flue pipe or vent connector must be inserted into

but not beyond the outside wall of the chimney flue. No reduction in diameter of flue pipe is acceptable. It is best to

have flue pipe as short and direct as possible. Where two or

more appliances vent into a common flue, the area of the

common flue should be at least equal to the area of the larg-

Supply & Return Air Plenums

Secure return air plenum to unit using sheet metal screws.

NOTE − The following are suggested procedures that should

be followed when installing the supply air plenum.

1− Use sealing strips of fiberglass.

2− In all cases, the plenum should be secured to furnace or

evaporator cabinet with sheet metal screws.

3− Install supply and return air ducts as desired.

Oil Supply Lines Sizing

Ensure that the restrictions of the piping system, plus any

lift involved, do not exceed the capability of the oil pump.

Use the following guidelines when determining whether to

use a single−or two−stage oil pump.

One−Pipe System

When using a one−pipe system even with the oil tank that is

above the burner and a vacuum of 6" (152 mm) Hg or less,

a single−stage fuel pump with a supply line and no return

line should be adequate. See figure 14.

Page 11

Page 12

Manual bleeding of the fuel pump is required on initial start

up. Failure to bleed air from the oil pump could result in an

air lock/oil starvation condition.

NOTE − As an extra precaution, cycle heating on and off ten

times after bleeding air from the oil pump. This will eliminate air in the gun assembly.

Fill

Pipe

Air Vent

Oil Piping

Two-Pipe System

Return

pipe

fuel

pump

Aux

Filter

Inlet

Oil Piping

air vent

fill

pipe

To determine the correct tubing size for piping, refer to table 3 .

Line Length Pipe Diameter (OD Tubing)

0−50’ (15 m) 3/8" (10 mm)

51−100’ (15 m) 1/2" (12 mm)

When using a two−pipe system with the oil tank below the

level of the burner, use a single−stage fuel pump in lift conditions of up to 10 feet (3 m) and/or a vacuum of 10" (254

mm) Hg or less. See figure 15. Use a two−stage fuel pump

when lift exceeds 10 feet (3 m) and/or a vacuum of 10" (254

mm) Hg to 15" (381 mm) Hg. Both conditions require that

you use of a two−pipe system, which consists of a return

line that purges the fuel pump of air by returning it to the

tank. To determine the run and lift for piping, refer to table 4 .

Use continuous lengths of heavy wall copper tubing or

steel pipe for oil supply pipe. Install oil supply pipe under

floor or near walls to protect it from damage. Avoid running

pipes along joists or reverberating surfaces. Always use

flare fittings. All fittings must be accessible. Do not use

compression fittings.

One-Pipe System

Oil

Tank

Shut−off

Valve

Figure 14

Table 3

One−Pipe Oil Sizing

Two−Pipe System

fuel

pump

Aux

Filter

8 ft (2.4 m)

Maximum

One Pipe Lift

IMPORTANT

Both oil supply and return pipes must be submerged

in oil in the supply tank.

Oil

Tank

Return

pipe

3"−4"

(76 mm −102 mm)

R

outside tank fuel pump above bottom of tank.

H

Figure 15

Table 4

Two−Pipe Maximum Pipe Length (H + R)

3450 RPM − 3 GPH (11.4 LPH)

Lift H"

0’

(0.0 m)

2’

(0.6 m)

4’

(1.2 m)

6 ’

(1.8m)

8’

(2.4 m)

10’

(3.0 m)

12’

(3.7 m)

14’

(4.3 m)

16’

(4.9 m)

18’

(5.5 m)

3/8" (10 mm) OD

Tubing

Single

Stage

84’

(25.6 m)

73’

(22.3 m)

63’

(19.2 m)

52’

(15.8 m)

42’

(12.8 m)

31’

(9.4 m)

21’

(6.4 m)

−−−

−−−

Two

Stage

93’

(28.3 m)

85’

(25.9 m)

77’

(23.5 m)

69’

(21.0 m)

60’

(18.3 m)

52’

(15.9 m)

44’

(13.4 m)

36’

(11.0 m)

27’

(8.2 m)

−−− −−− −−−

1/2" (12 mm) OD

Tubing

Single

Stage

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

83’

(25.3 m)

41’

(12.5 m)

−−−

Two

Stage

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

100’

(30.5 m)

(23.2 m)

76’

Oil Supply Line & Filter Connections

One−Pipe Systems

CAUTION

Do not install the bypass plug into the pump on one−

pipe systems.

The burner is shipped with fuel pump set for one−pipe operation. For one−pipe systems, the oil supply pipe is connected to the inlet tap on the pump. A one−pipe system

should only be used where there is gravity oil flow to the

pump and the pipe is not run at any point above the oil level

in the tank.

Page 12

Page 13

1 − Connect the inlet pipe to the pump inlet. Start the burner.

2 − Arrange the primary burner control for continuous op-

eration during purging. See figure 14.

3 − Turn the bleed valve one turn counterclockwise to

open.

4 − Bleed the unit until all air bubbles disappear.

NOTE − Hurried bleeding will prevent the unit from operating properly.

5 − Tighten the bleed valve securely.

Two−Pipe Systems

If the installation requires a two−pipe operation, install the

bypass plug included in the bag which is attached to the

pump. To convert the pump, install the bypass plug according to the provided pump instructions. Notice in the twopipe system the return pipe must terminate in the tank 3"

(76 mm) to 4" (102 mm) above the supply inlet. Ensure the

return pipe terminates at the correct measurement or air

may escape into the system. This could result in loss of

prime.

NOTE− If using an outside tank in cold climates a number

one fuel or an oil treatment is strongly recommended.

1 − Remove 1/4" plug from return port.

2 − Insert bypass plug and tighten it. See figure NO TAG.

3 − Attach the return and inlet pipes. Start the burner. Air

bleeding is automatic.

NOTE − If a faster bleed is necessary, open the bleed

valve.

4 − The return pipe must terminate 3" to 4" above the sup-

ply pipe inlet. See figure NO TAG.

NOTE − If the return pipe does not terminate where it

should, air may enter the system, and prime may be

lost.

An oil filter is required for all models. Install filter inside

the building between the tank shut-off valve and the burner.

Locate filter close to burner for easy maintenance. Table 5

lists the filters for the O23 furnace.

Table 5

Installation Clearances inches (mm)

Oil Filters

Cat.

Number

Consult burner manufacturer’s instructions packaged with

unit for further details concerning oil supply pipe connections.

Leak Check

After oil piping is completed, carefully check all piping connections (factory and field) for oil leaks.

Oil Pipe Heater (Optional)

A heater for the oil pipe is available for applications that are

located in cold climates. The heater warms the oil pipe to

assist the initial start−up.

Electrical Wiring

All wiring must conform to the National Electric Code

(NEC), or Canadian Electric Code (CEC) and any local

codes. Refer to figure 16 for the terminal designations on

the fan control board.

1− Refer to the appliance rating plate for proper fuse size.

2− Install the room thermostat and make wire connections

to the fan control board. Avoid installing thermostat on

an outside wall or where it can be affected by radiant

heat. Set the adjustable heat anticipator on thermostat

according to the wiring diagram sticker provided on

unit.

3− Install a separate fused disconnect switch near unit so

power can be shut off for servicing.

4− Complete line voltage wiring from disconnect switch

near unit to make-up box.

NOTE − An equipment ground screw is provided. Refer

to unit wiring diagram and figure 16 for O23 series

units. Ground unit using a suitable ground wire.

5− Any accessory rated up to 1 amp can be connected to

the accessory terminal. The accessory terminal is energized when the blower is operating.

10 micron filter (no mounting bracket) 81P89

10 micron filter (mounting bracket) 53P92

10 micron replacement cartridge for filter, 45 gph 53P93

Filter restriction indicator gauge 53P90

IMPORTANT

When an accessory is being used in a continuous fan

application which does not include the S68 ON/OFF

switch, the accessory must be wired between L1 and

N on the fan control board to ensure proper voltage.

Page 13

Page 14

Fan Control Board

thermostat

terminal strip

Figure 16

Typical O23 Wiring Diagram

fan off

delay switches

Figure 17

Page 14

Page 15

Typical O23 Wiring Diagram

Figure 18

Page 15

Page 16

Unit Start−Up & Adjustments

Before starting unit, make sure the oil tank is adequately

filled with clean No. 1 or No. 2 furnace oil.

NOTE − Water, rust or other contaminants in oil supply system will cause malfunction and failure of the internal parts

of the fuel pump.

CAUTION

Never burn garbage or paper in the heating system.

Never leave papers near or around the unit.

CAUTION

Blower door must be in place before start−up.

readings, subtract the readings. The difference in temperatures in the supply and return air plenums should approximate the temperature rise range listed in table 6 and the appliance rating plate. If not, adjust the blower motor pulley to

adjust the blower speed.

Table 6

O23

nozzle size,

Unit

−70 .50GPH−80° A 100 70,000 57,000 FB0 60−70

−105 .65GPH−80° B 140 105,000 84,000 FB3 65−75

−120 .75GPH−80° B 140 119,000 105,000 FB3 70−80

−140 .85GPH−80° B 140 140,000 112,000 FB6 65−75

−154 1.0GPH−80° B 140 154,000 125,000 FB6 70−80

spray

angle,

& pattern

pump

PSIG

input

rating

BTU/HR

output

rating

BTU/HR

head temp

rise

F°

1− Set thermostat for heating demand and turn on electri-

cal supply to unit.

2− Check initial air adjustment. All units are equipped with

an air adjustment dial on the right side of the burner.

See burner parts arrangement illustration.

3− Turn unit on. Place a can or container under the bleed

port located on the fuel pump. Loosen nut on bleed port

to release air and oil mixture from fuel line. Allow mixture to escape until a steady stream of oil is emitted

from the port. Drain at least 1/2 pint of oil from the

pump. Retighten the nut on bleed port. If lockout occurs, press reset button and continue with bleed procedure.

NOTE − A two−pipe fuel system will normally bleed itself

by forcing air back to the tank through the return line.

This type of bleeding procedure is not necessary.

4− If burner fails to start, push reset button on primary

safety control and the burner motor reset button. See

part arrangement illustration.

CAUTION

Do not push the reset button on the primary control

more than one time.

5− If the burner fails to light again, refer to the trouble-

shooting section in this manual.

A − Fuel Pump Pressure

Measure fuel pump pressure with unit off. Attach pressure

gauge to pump outlet. Turn unit on and check pressure and

compare to table 6. Adjust if necessary.

B − Temperature Rise

To measure temperature rise, place plenum thermometers

in warm air and return air plenums. Locate thermometer in

warm air plenum where thermometer will not see" the heat

exchanger to prevent it from picking up radiant heat. Set

thermostat to its highest setting to start unit. After plenum

thermometers have reached their highest and steadiest

C − Limit Control

Limit Control − Do not adjust it from factory setting.

D − Fan Control

The fan on time of 30 seconds is not adjustable. Fan off

time (time that the blower operates after the heat demand

has been satisfied) can be adjusted by moving the delay

switches on the fan control board. Fan off time will affect

comfort and is adjustable to satisfy individual applications.

See figure 19. Set the heat fan off delay switches to either

60, 90, 120, or 150 seconds. The factory setting is 90 seconds.

Fan Off Delay Switch Settings

120 sec90 sec60 sec

Figure 19

150 sec

E − Burner Adjustment

The following instructions are essential to the proper operation of O23 series oil furnaces. To prevent sooting,

these instructions must be followed in sequence:

1 − Draft

This test should be taken at the breach between the outlet

of the vent connector and the barometric draft control. Generally a 1/4" hole will need to be drilled for the draft gauge to

be inserted into the vent connector.

A minimum of 0.03 draft must be established without the

burner in operation. With the burner in operation, the draft

should be 0.04 to 0.05. This is VERY critical to the flame

retention head burners.

Oil furnace installations also require careful inspection to

make sure the chimney is in good shape and can accommodate the products of combustion. The temperature in

the unconditioned space will also affect the draft if long vent

connectors are allowed to get too cold.

Page 16

Page 17

2 − Overfire Draft

This test should be taken with the burner in operation. Remove the screw from the center of the inspection port. Insert your draft gauge into the hole.

A reading of the overfire draft should be 0.02 less than the

reading found in the vent connector. If a positive reading is

seen at this point, the combustion fan is pumping too much

air into the heat exchanger. Make the necessary adjustments at the air adjustment dial.

3 − Smoke Test

The smoke test should be taken at the hole drilled in step 1.

Using a smoke test gun adjust the air inlet shutter so that

you will have just a trace of smoke. Somewhere between a

0 and #1 smoke. This is the starting point. Do not stop here.

4 − CO2 Test

Again, take this sample at the vent pipe. With the unit firing

at a trace of smoke, take a sample of the CO2.

From the results of this test, a window of operation" will be

determined. This window of operation establishes some

tolerance. The tolerance the installer builds in provides

room within the set-up for those things which might affect

combustion. Those things which might affect combustion

can then do so without causing the unit to start sooting/

smoking. Things which might affect combustion include a

nozzle going bad, draft that changes during different climatic conditions, dirty oil, dirt obstructing the air inlet, etc.

To build in a window of operation," set up the burner to be

2% less in CO2. For example, if you find a reading of 12%

CO2, adjust the air inlet shutter to increase the air and drop

the CO2 to 10%.

5 − Retest the Smoke

With a drop in the CO2 and increase in the air you should

see that the smoke has returned to 0.

6 − Retest the Overfire Draft

Service

CAUTION

Do not tamper with unit controls. Call your qualified

service technician.

A − Servicing Filter

NOTE − Under no circumstances should the access panels

to the blower compartment be left off or left partially open.

Throw-Away Type Filters Check filters monthly and re-

place when necessary to assure proper furnace operation.

Replace filters with like kind and size filters.

Reusable Type Filters Filters should be checked monthly and cleaned when necessary to assure proper furnace

operation.

B − Blower

Blower motor is prelubricated and sealed for extended operation. No further lubrication is required. Disconnect power to unit before cleaning blower wheel for debris.

C − Flue Pipe Inspection

The flue pipe should be inspected annually by a qualified

service technician. Remove and clean any soot or ash

found in the flue pipe. Inspect pipe for holes or rusted

areas. If replacement is necessary, replace with the same

size and type as required by code. Inspect the flue draft

control device and replace if found defective.

D − Cleaning the Heat Exchanger

1− Remove the vent pipe from the furnace.

2− Remove the locking screws and the caps from the

clean out tubes. Remove flue access elbow.

3− Using a long spiral wire brush, sweep down the outer

drum of the heat exchanger. Then using the hose attachment, vacuum out loose debris.

4− Remove the locking screw and cap from the observa-

tion tube and with the spiral wire brush, reach upward

toward the rear of the heat exchanger to clean out the

crossover tube.

This test serves to confirm that you have not increased the

air too much. Again you do not want a positive pressure at

the test port. It should still be 0.02 less than the draft pressure reading taken at the breach. You may need to increase the stack draft by adjusting the barometric draft control.

7 − Stack Temperature

Take a stack temperature reading in the vent pipe. Subtract

the room air temperature from the stack temperature. This

will give you the net stack temperature. Use the efficiency

charts provided in most CO2 analyzers to determine furnace efficiency.

CAUTION

Do not attempt to clean the combustion chamber. It

can be easily damaged.

5− Replace the clean out caps and flue access elbow.

Make sure locking screws are secure.

6− Brush out and vacuum the vent outlet area of the outer

drum and replace vent pipe.

7− Clean around the burner, blower deck and vestibule

area.

NOTE − A heat exchanger clean-out kit ABRSH380

(35K09) is available from Lennox.

Page 17

Page 18

Troubleshooting

Burner failure or improper operation can result from a number of different causes.

Often the cause can be pinpointed by observing the different types of failure or by the process of elimination. The fol-

Troubleshooting: Fan board operating sequence

Action System Response

lowing troubleshooting charts list some failures, causes

and a sequence of steps to isolate the point of failure.

Check the simplest and most obvious items before progressing to other items.

Thermostat calls for heat.

(W terminal is energized.)

Thermostat ends call for heat.

(W terminal is de−energized.)

Burner fails to light. Oil primary control locks out within lockout timing (timing depends on oil primary control).

Established flame fails. Burner motor is de−energized and oil primary control goes into recycle mode.

Thermostat begins call for cool.

(G and Y terminals are energized.)

Thermostat ends call for cool.

(G and Y terminals are de−energized.)

Thermostat begins call for fan.

(G terminal is energized.)

Thermostat ends call for fan.

(G terminal is de−energized.)

Limit switch string opens. Oil primary control shut off the burner.

ST9103A closes oil primary control T−T connections.

Ignition system and oil primary control start the furnace. Oil flows as long as oil primary

control senses flame.

Burner motor is energized and heat fan on delay timing begins. When timing is complete,

the circulating fan is energized at heat speed and warm air is delivered to the controlled

space.

Oil primary control is de−energized, terminating the burner cycle.

Heat fan off delay timing begins. When timing is complete, the circulating fan is de−energized.

ST9103A returns to standby mode (oil primary control and circulating fan are off).

Burner motor is de−energized.

If heat fan has started, it continues through the selected delay off period.

If selected heat fan off delay is longer than the recycle delay timing, the heat fan continues to run through the next trial for ignition.

Circulating fan is energized at the cool speed.

Cooling compressor turns on immediately.

Circulating fan and cooling compressor turn off immediately.

Circulating fan is energized immediately at cool speed.

ST9103A may be factory−configured to operate heat speed in this mode.

Circulating fan is de−energized.

Circulating fan is energized immediately at heat speed.

ST9103A opens oil primary control T−T connections.

Circulating fan runs as long as limit string stays open.

If there is a call for cooling or fan, the circulating fan switches from heat speed to cool

speed.

Limit switch string closes. ST9103A begins heat fan off delay sequence.

Continuous circulating fan is connected.

(Optional connectors are available for separate circulating fan speed tap.)

Electronic air cleaner is connected.

(Optional connectors are available for 120 Vac electronic air cleaner.)

Humidity control is connected.

(Optional connectors are available for 120 Vac humidifier.)

Circulating fan turns off after the selected heat fan off delay timing.

ST9103A closes oil primary control T−T connections.

Oil primary control is energized, initiating burner light off.

Circulating fan is energized at low speed when there is no call for heat, cool or fan.

If fan operation is required by a call for heat, cool, or fan, the ST9103A switches off the

continuous fan speed tap before energizing the other fan speed.

Electronic air cleaner (EAC) connections are energized when the heat or cool speed of

the circulating fan is energized. EAC connections are not energized when the optional

continuous fan terminal is energized.

Humidifier connections are energized when the burner motor is energized.

Page 18

Page 19

Troubleshooting: Burner fails to start.

Check f

t

Thermostat

mostat terminals on primary

fault is in the thermostat circuit

,

the burner starts, fault is in the

Pri

ili

l

indicat

black

hite leads to th

p

blower wheel by hand. If seized

power to the motor and burner

Source Procedure Causes Correction

Thermostat in OFF or COOL Switch to HEAT.

Thermostat Check thermostat settings.

Thermostat is set too low

Burner motor overload tripped Push reset button pump motor.

Turn thermostat to higher temperature.

Safety Overloads

Power

CAD Cell

Primary Control

Burner

Check burner motor, primary

safety control, & auxiliary limit

switch.

urnace disconnec

switch & main disconnect.

Touch jumper wire across thermostat terminals on primary

control. If burner starts, then

Disconnect the flame detector

wires at the primary control. If

the burner starts

detector circuit. short circuit in the flame detec-

Place trouble light between the

black and white leads. No light

es that no power is going

to the control.

Place trouble light between the

orange and white leads. No light

indicates faulty control.

Place the trouble light between

the black and white leads to the

burner motor. No light indicates

that no power is getting to the

motor.

Place trouble light between the

and w

blower motor. Light indicates

ower to the motor and burner

fault.

fault is in the

e

Primary control tripped on safety

Auxiliary limit switch tripped on

safety

Open switch Close switch.

Blown fuse or tripped circuit

breaker

Broken or loose thermostat

wires

Loose thermostat screw connection

Dirty thermostat contacts Clean contacts.

.

Thermostat not level Level thermostat.

Faulty thermostat Replace thermostat.

Flame detector leads are

shorted

Flame detector exposed to light Seal off false source of light.

tor

mary or aux

switch is open

Open circuit between disconnect switch and limit control

Low line voltage or power failure

Defective internal control circuit Replace the control.

Blown fuse Replace the fuse.

Binding burner blower wheel

Sized fuel pump

Defective burner motor Replace the motor.

ary contro

Reset primary control.

Reset auxiliary limit.

Replace fuse or reset circuit

breaker.

Repair or replace wires.

Tighten connection.

Separate leads.

Replace detector.

Check adjustment. Set the

maximum setting.

Jumper terminals; if burner

starts, switch is faulty, replace

control.

Trace wiring and repair or replace it.

Call the power company.

Turn off power and rotate the

blower wheel by hand. If seized,

free the wheel or replace the

fuel pump.

,

Page 19

Page 20

Troubleshooting: Burner starts, but no flame is established.

Start the b

ilk

Air leak i

pggpp

pray (g

serve the oil spray (gun assem

Repl

Inspect the nozzle for plugged

type

Cl

gap

the gap to 5/32 inches and cor

g

p

to transformer primary

pp

ing or excessive drag

Source Procedure Causes Correction

Oil Supply

Oil Filters & Oil Line

Oil Pump

Nozzle

Check tank gauge or use dip

stick.

Coat dip stick with litmus paste

and insert into bottom of tank.

Listen for pump whine. Tank shut−off valve closed Open valve.

Listen for pump whine.

Open bleed valve or gauge port.

urner. No oil or m

oil indicates loss or prime.

Install pressure gauge on pump

and read pressure. Should not

be less than 140 psi.

Disconnect ignition leads. Observe the oil s

bly must be removed from unit).

Inspect the nozzle for plugged

orifice or carbon build−up around

orifice.

un assem-

No oil in tank Fill tank.

Water in oil tank

Oil line filter is plugged Replace filter cartridges.

Kinks or restriction in oil line Repair or replace oil line.

Plugged fuel pump strainer Clean strainer or replace pump.

y

Pump is partially or completely

frozen. No pressure and the

motor locks out on overload.

Coupling disengaged or broken

− no pressure

Fuel pressure too low Adjust to 100 psi.

Nozzle orifice plugged

Nozzle strainer plugged

Poor or off center spray

Fouled or shorted electrodes

Dirty electrodes and leads

n oil supply line

If water depth exceeds 1 inch,

pump or drain water.

Locate and correct leak.

Tighten all connections.

Replace pump.

Re−engage or replace coupling.

ace nozzle with the same

size, spray angle, and spray

.

ean electrode leads.

Ignition Electrodes

Ignition

Transformer

Burner Motor

Remove gun assembly and inspect electrodes and leads.

Connect ignition leads to the

transformer. Start burner and observe spark. Check line voltage

rimary.

to transformer

Motor does not come up to

speed and trips out on overload.

Turn off power and rotate blower

wheel by hand to check for bind-

.

.

Eroded electrode tips

Improper electrode gap spacing

Improper position of electrode

tips

Bad buss bar connection Retension and realign.

Cracked or chipped insulators Replace electrode.

Cracked or burned lead insulators

Low line voltage

Burned out transformer windings.

No spark or weak spark

Low line voltage

Pump or blower overloading

motor

Faulty motor Replace motor.

Clean electrode tips and reset

the

rectly position tips.

Replace electrode leads.

Check voltage at power source.

Correct cause of voltage drop

or call the power company.

Replace the transformer.

Properly ground the transformer

case.

Check voltage at power source.

Correct cause of voltage drop

or the call power company.

Correct cause of overloading.

to 5/32 inches and cor-

Page 20

Page 21

Troubleshooting: Burner starts and fires, but lock out on safety.

p

due to poor

ately jumper

y

If fire is good

mary control

(d

k

If fire is good

Fl

across flame

in the fuel sys

Source Procedure Causes Correction

Unbalanced fire Replace nozzle

Reduce combustion air − check

combustion.

Increase combustion air − check

combustion.

Adjust barometric damper for

correct draft.

Correct draft or remove restriction.

Replace cad cell.

Secure connections or replace

cad cell holder and wire leads.

Poor Fire

Flame Detector

Primary Control

After burner

fires, immedi-

across flame

detector terminals at the primar

control.

.

If burner continues to run,

this may be

due to

fire. Inspect

fire.

fault is in the

flame detector.

Check detector circuit.

If burner locks

out on safety,

fault is in the

primary control.

oor

Too much air − −lean short fire

Too little air − − long dirty fire

Excessive draft

Too little draft or restriction

Dirty cad cell face Clean cad cell face.

,

Faulty cad cell − exceeds 15000

hms

Loose or defective cad cell

wires

Primary control circuit defective Replace primary control.

Troubleshooting: Burner Starts and Fires, but Loses Flame and Lock Out on Safety

Source Procedure Causes Correction

Unbalanced fire Replace nozzle

Too much air − − lean short fire Reduce combustion air − check

combustion.

combustion.

Adjust barometric damper for

correct draft.

Correct draft or remove restriction.

Replace CAD cell.

Secure connections or replace

cad cell holder and wire leads.

Check supply line for loose connections and tighten fittings.

inch) pump or drain out water.

Replace nozzle.

Poor Fire If burner con-

tinues to run

oes not loc

out of safety),

fault may be

After burner

ame Detector

Oil Supply

fires, immediately jumper

across flame

detector terminals at the primary control.

fault is in the

flame detector.

Check detector circuit.

If burner loses

flame (does

not lock out on

safety), fault is

in the fuel system.

Too little air − − long dirty fire Increase combustion air − check

Excessive draft

Too little draft or restriction

Dirty CAD cell face Clean CAD cell face.

,

Faulty CAD cell − − exceeds

15000 hms

Loose or defective cad cell

wires

Pump loses prime − air slug Prime pump at bleed port

Pump loses prime − air leak in

supply line

Water slug in line Check oil tank for water (over 1

Partially plugged nozzle or

nozzle strainer

Restriction in oil line Clear restriction.

Listen for pump whine

Plugged fuel pump strainer Clean strainer or replace pump.

Cold oil − outdoor tank Change to number 1 oil.

Page 21

Page 22

Troubleshooting: Burner starts and fires, but short cycles (too little heat)

Thermostat

Check thermostat

(

Limit Control

control (black & white leads). If

P

If burner turns

Thermostat

p

circuit.

wires at the pri

Source Procedure Causes Correction

Heat anticipator set too low Correct heat anticipator setting.

Thermostat Check thermostat.

Connect voltmeter between line

Limit Control

ower power source. Recheck voltage

voltage connections to primary

control

burner cycles due to power interruption, it is cycling on limit.

If voltage fluctuates, fault is in the

at the power source.

black & white leads). If

.

Vibration at thermostat Correct source of vibration.

Thermostat in the path of a

warm air draft

Dirty furnace air filters Clean or replace filter.

Burner running too slow

Blower motor seized or burned

out

Blower bearings seized Replace bearings and shaft.

Blower wheel dirty Clean blower wheel.

Blower wheel in backward Reverse blower wheel.

Wrong motor rotation

Restrictions in return or supply

air system

Adjustable limit control set too

low

Loose wiring connection Locate and secure connection.

Low or fluctuating line voltage Call power company.

Shield thermostat from draft or

relocate.

Increase blower speed to maintain proper temp. rise.

Replace motor.

Replace with properly rotating

wheel.

Correct cause of restriction.

Reset limit to maximum stop

setting.

Troubleshooting: Burner runs continuously (too much heat).

Source Procedure Causes Correction

Thermostat

Primary control

Disconnect

thermostat

wires at the

mary control.

If burner turns

off, fault is in

the thermostat

circuit.

ri-

-

If burner does

not turn off,

fault is in the

primary control.

Shorted or welded thermostat

contacts

Stuck thermostat bimetal

Thermostat not level Level thermostat.

Shorted thermostat wires Repair short or replace wires.

Thermostat out of calibration Replace thermostat.

Thermostat in cold draft

Defective primary control

Repair or replace the thermostat.

Clear obstruction or replace

thermostat.

Correct draft or relocate the

thermostat.

Replace the defective primary

control.

Page 22

Page 23

Troubleshooting: Burner runs continuously (too little heat).

L

CO

l

Dirt

g

Check b

reading more

CO2, stack tem

smoke

High stack tem

550 F Net.

Oil P

Inspect fire and check

Source Procedure Causes Correction

Too much combustion air Reduce combustion air.

Combustion

ressure

urner

combustion for

CO2, stack temperature, and

Inspect fire and check

oil pressure.

ow

ess

2

than 10%.

High smoke

readin

more

than a trace.

High stack temperature is

more than

_F Net.

550

Air leaks into heat exchanger

around inspection door, etc.

Excessive draft

Incorrect burner head adjustment

Correct cause of air leak.

Adjust barometric draft control for correct draft.

Correct burner head setting.

Clean heat exchanger.

y or plugged heat exchanger

Readjust burner.

Insufficient draft Increase draft.

Incorrect burner head adjustment

Correct burner setting.

Too little combustion air Increase combustion air.

Too little blower air

Blower belt too loose (if

equipped)

-

Increase blower speed to

maintain proper temp. rise.

Tighten blower belt.

Dirty or plugged heat exchanger Clean heat exchanger.

Dirty blower wheel Clean blower wheel.

Dirty furnace air filters Clean or replace filter.

Restricted or closed registers or

dampers

Partially plugged or defective

nozzle

Oil pressure is too low: less

than 100 psi.

Readjust registers or dampers.

Replace nozzle.

Increase oil pressure top

100psi.

Page 23

Loading...

Loading...