Page 1

APPLICATION

GUIDE

ErP

DIRECTIVE

2009/125/EC

ECODESIGN

&

LABELLING

NEOSYS

NAC - NAH

AIR COOLED CHILLER & HEAT PUMP

200 - 1000 kW

LENNOX participates in the ECP

Check ongoing validity of certifi cate :

programme for LCP-HP.

www.eurovent-certifi cation.com

www.lennoxemea.com

NEOSYS-AGU-1801-E

Page 2

Page 3

NEOSYS

APPLICATION GUIDE

GENERAL

1.

Model number description

Key customer benefi ts

Features and benefi ts

Technical description

Options and accessories

GENERAL DATA

2.

General data

Pressure drops

Hydraulic data

- eDrive

- Partial heat recovery

- Total heat recovery

- Free-cooling

Acoustic data

Operating limits

Ref : NEOSYS-AGU-1801-E

2

3

4

6

8

10

17

19

23

27

28

30

32

33

ELECTRICAL DATA

4.

Electrical tables

PERFORMANCES

5.

NAC 37

NAH 50

DIMENSIONAL DATA

6.

Dimensional data

Weight data

Product designed and manufactured

under quality management systems

certifi ed ISO 9001 and ISO 14001.

www.eurovent-certifi cation.com

www.certifl ash.com

Our company’s products comply

with European standards.

34

52

62

All the technical and technological information contained in this manual, including any drawing and technical descriptions

provided by us, remain the property of Lennox and must not be utilised (except in operation of this product), reproduced, issued to

or made available to third parties without the prior written agreement of Lennox.

Application Guide /NEOSYS-AGU-1801-E

• 1 •

Page 4

MODEL NUMBER DESCRIPTION

EXAMPLE :

N

A

C

200

D

N

M

5

M

NAC 200D N M5 M

NEOSYS

Air cooled

C = Cooling mode

H = Heat pump mode

Cooling capacity in kW

Number of circuits :

S = 1 circuit

D = 2 circuits

T = 3 circuits

F = 4 circuits

Non ducted

R410 A refrigerant

Revision number

400V/3/50 Hz

• 2 •

Application Guide / NEOSYS-AGU-1801-E

Page 5

KEY CUSTOMER BENEFITS

Air-cooled Liquid Chiller for outdoor installation (NAC)

Air-to-water Heat Pump for outdoor installation (NAH)

Nominal cooling capacity :

200 ► 1000 kW (NAC)

200 ► 450 kW (NAH)

Nominal heating capacity :

200 ► 500 kW (NAH)

Sustainable Performance

- Extended qualifi cation tests (vibration tests, run tests, fi eld

tests) to ensure superior reliability.

- High effi ciency aluminium micro channel heat exchanger

(MCHX) with improved corrosion resistance for moderate

marine or urban applications (Cooling only version). 3-year

warranty*.

- Specifi c MCHX coil design with high mechanical fi n resistance

that offers easy cleaning with high pressure air or water washers

for extended life cycle.

- V-coil design, compressor and hydraulic enclosure to protect

the unit against climatic conditions (e.g. sun rays, UV light, hail).

- Exclusive Compliant Scroll® compressor design with both

axial and radial compliance to increase compressor operation

tolerance of liquid refrigerant or debris, substantially improving

durability and reliability.

- Exclusive fan design with SKF hybrid Ceramic bearings

to double (treble in some cases) the service life of the motors

and to reduce noise level. With these sealed hybrid ceramic

bearings, our customer can expect little or no maintenance of

the motor throughout its life.

Quiet performance

3-year warranty*.

3-year warranty*.

Y

*

Y

E

T

N

3

A

R

A

R

Energy performance

-

High Energy Performance (ESEER above 4; EER up to 2.9 ;

COP up to 3,2) for improved energy consumption all around the

year.

- Aluminium micro channel heat exchanger that offers +10%

outstanding system effi ciency (cooling only version).

- R410A refrigerant for optimized system performance.

- Energy savings due to lower system minimum water content

reducing the time to reach setpoint. This can also eliminate the

need for a buffer tank.

Architectural integration

- State of the art design with hidden compressors, fans and

pump for perfect architectural integration.

- Flat top, aesthetic grilles, very low unit height (< 2 m) for

discrete installation on a roof reducing the requirement of costly

cladding solutions around the unit.

A

W

R

- Unique design with compressor, pump(s) and fan acoustic

enclosure to reduce radiated noise emissions.

- Inverter fans using external rotor technology associated with

high performance aluminium fan blades of the latest generation

(Owlet™ design).

- Elimination of intrusive fan start/stop noise that is irritating

to the human ear.

- Active Acoustic Attenuation System™ to meet changing

building load requirements while automatically adjusting the

air fl ow to meet night and day sound level constraints (Time

schedule with 4 time zones per day).

Quick performance and service

- Complete hydraulic module with single or twin, low or high

pressure pump (options) that includes all necessary equipment

for quick connection: pump(s), regulating valve, expansion tank

vessel with pressure gauge, pressure tapping points, water

fi lter, air vent, pressure relief valve and Victaulic connections.

- 400V, 50 Hz, 3 phase power supply (without neutral) with a

single point of power connection. Main on/off switch included

in as standard.

- Air spring powered Butterfl y electrical panel with jacks top

opening providing protection to service engineers against rain

or snow during commissioning and maintenance operations.

* This warranty covers parts only. The above warranty is liable if

the start-up and periodic maintenance agreement is contracted

by a LENNOX company or any company accredited by LENNOX.

Refer to LENNOX 3 year warranty conditions.

Application Guide /NEOSYS-AGU-1801-E

• 3 •

Page 6

FEATURES AND BENEFITS

Flat top and low profi le for best architectural

integration

The NEOSYS design is minded to be perfectly integrated into

urban or residential environments. The state of the art design of

NEOSYS includes a painted casing, a fl at top that hides the fans

and aesthetic protection grilles.

The very low unit height less than two meters makes easier for

architects and design engineers to integrate the unit on a roof.

Many interviewed customers confi rm that the state of the art

design of NEOSYS will replace any requirement of costly cladding

solutions around the unit.

ACTIVE ACOUSTIC ATTENUATION SYSTEM™

SELECT YOU MODE PER TIME ZONE

Performance Mode

Sound (dBA)

Compressor unloading

Max (dBA)

HP

Auto Quiet Mode

Sound (dBA)

Smarts acoustics with inverter fans

No more need to make a choice between a high effi ciency version,

a low noise or an ultra low noise version. NEOSYS can adapt all

situations with only one version. NEOSYS is fi tted in standard

with the Active Acoustic Attenuation System™ that is using an

electronic control associated with inverter fans. NEOSYS can

change automatically the speed of all the fans – from 0% to 100%

of the nominal air fl ow – to meet the building load requirements

while respecting maximum authorised noise level in the time zone.

NEOSYS is surely achieving the best acoustic signature of the

market thanks to the latest generation of Owlet™ high performance

aluminium fan blades and noiseless ceramic bearings.

Max (dBA)

Customer (dBA)

Sound (dBA)

Max (dBA)

Customer (dBA)

Compressor

unloading

Fan speed override

HP

Quiet Mode

Compressor

unloading

• 4 •

HP

Application Guide / NEOSYS-AGU-1801-E

Page 7

FEATURES AND BENEFITS

A high energy performance

4,60

4,40

4,20

4,00

ESEER

3,80

3,60

3,40

270 300 340 370 420 480 540 600

Screw R134A units

By using R410A refrigerant associated with high effi ciency micro

channel coils and variable speed fans NEOSYS is contributing to

a very low energy consumption all year around with an average

energy effi ciency ratio (ESEER)* in cooling mode above 4.0.

NEOSYS Heat-pumps are also achieving very high performances

in cooling and heating mode (COP* up to 3.2).

Furthermore NEOSYS advanced control allows energy savings

all year around by using smart control functions:

- Low water system quantity to reduce the time to reach the setpoint.

- Dynamic defrost (patented) to limit the number of defrost cycles.

- Set-point reset based on outside air temperature to relax the

chilled water set-point.

NEOSYS

kW

Scroll R410A units

Floating high pressure

LENNOX optimizes the performance of the NEOSYS chillers with

electronic expansion valve (as an option) and variable speed

ventilation (as standard) to achieve maximum energy savings.

We defi ne a condensation temperature depending on the outside

air temperature at an optimum value to obtain the lowest power

inputs of couples, compressors and condenser fan motors.

*ESEER : European Seasonal Energy Effi ciency Ratio in cooling mode.

COP : Coeffi cient of Performance in heating mode.

R410A Micro channel heat exchanger

With the use of fully

aluminium coils already

used in the automotive

industry, NEOSYS offers

many customer benefi ts:

- Up to 40% less refrigerant

charge that contributes to

reduce the total amount

of refrigerant used in the

system.

- A more effi cient system

(EER + 10%).

- An air heat exchanger

with signifi cantly impro-

ved corrosion resistance

results (x 2) from the

same aluminium alloy (no galvanic action) vs. the traditional

copper tube/aluminium fi n coils. By using this type of coil, units

can be used in light corrosive or seacoast environments without

any need for additional, and expensive, pre-treated fi ns or coil

coating.

- High mechanical resistance eases the cleaning with high pressure

air or water washers without any risk of damaging the fi ns.

Available in cooling only version, this technology will surely be

enlarged shortly to reversible applications.

Application Guide /NEOSYS-AGU-1801-E

• 5 •

Page 8

TECHNICAL DESCRIPTION

GENERAL CHARACTERISTICS OF THE UNIT

The NEOSYS unit is designed to be integrated into urban or

residential environments.

As main characteristics the NEOSYS unit offers state of the

art design to match architectural constraints and adjustable

sound level performances during day and night to satisfy local

environmental constraints.

CASING/CHASSIS

- Casing made of galvanised steel sheet metal painted with a white

powdered polyester paint and a red stripe.

- Fully grey colour painted chassis protecting against corrosion.

- State of the art design with hidden compressors, fans and pump

for perfect architectural integration.

- Flat top, aesthetic grilles, very low unit height (2 meters) for

discrete installation on a roof reducing the requirement of costly

cladding solutions around the unit

- Aesthetic side anti-intrusion grilles as standard to protect the

unit during transportation and against human aggressions.

COMPRESSOR

- Exclusive Compliant Scroll® design with both axial and radial

compliance to increase compressor operation tolerance to liquid

refrigerant, substantially improving durability and reliability. 3-year

warranty*.

- Motor cooled by suction gas.

- Electronic control of the compressor discharge temperature.

- Motor protection device against high temperature or over current

situations.

- Discharge non-return valve.

- Low noise scroll compressors mounted in a sound-proofed technical

cabinet to reduce noise emissions.

- Compressors assembly installed on an independent chassis

supported by anti-vibration mountings.

WATER HEAT EXCHANGER

- True dual circuit plate heat exchanger

- Copper brazed Stainless steel plate heat exchanger.

- 13 mm thermal insulation foam.

- Water heat exchanger located in a technical cabinet protecting

the insulation against climatic conditions (UV light, rain).

3-year warranty*

AIR HEAT EXCHANGER

- High effi ciency aluminium Micro Channel heat exchangers (MCHX)

with improved corrosion resistance in moderate marine or urban

environment (cooling only version). 3-year warranty*.

- Standard copper tubes/aluminium fi ns heat exchanger (heat pump

version).

- V-coil design to protect the unit against climatic conditions (e.g.

hail).

FANS

- Inverter fans (0 to 900 rpm operating range).

- Active Acoustic Attenuation System™ to meet changing building

load requirements while automatically adjusting the air fl ow to

respect night and day sound level constraints (adjustable setting

over time schedule with 4 time zones per day).

- Elimination of intrusive start/stop noise that is irritating to the

human ear.

- Fan-motor assembly using external rotor technology associated

with owlet high performance aluminium fan blades of the latest

generation.

- IP 54 electrical motor, class F protected against high temperature

with an internal sensor.

- Exclusive fan design with hybrid Ceramic bearings to extend the

service life of motors and to reduce noise level. With these sealed

hybrid ceramic bearings, our customer can expect little or no

maintenance of the motor throughout its life. 3-year warranty*.

- Extremely rigid fan assembly via the integration of the fans mounted

within a pre-formed bell mouth roof panel, thus improving rigidity

while reducing vibrations.

- Rounded top acoterion panels to hide the fans and reduce noise

emissions for quieter operation.

REFRIGERANT CIRCUIT

NEOSYS uses R410A refrigerant in 2 independent circuits

(minimum). Each circuit includes:

- A refrigerant charge reduced by 30% due to the use of R410A

combined with micro channel heat exchanger (NAC/Cooling only

version).

- Suction piping with thermal insulation.

- Filter drier with removable cartridge fi lter.

- Thermostatic or electronic expansion valve (Electronic device only

when "winter operation" option selected).

- Temperature sensors and pressure transducers.

- Four-way valve and liquid receiver (heat pump units only).

- Leak-tight refrigerant circuit with brazing carried out under nitrogen

by certifi ed engineers.

- Each refrigerant circuit is pressure and leak tested with a Hydrogen/

Nitrogen mixture, and vacuumed before being charged with

refrigerant. All units are then subjected to a complete functional

and operational run test to guarantee perfect sealing before

leaving the factory.

* Warranty under conditions - See page 3

• 6 •

Application Guide / NEOSYS-AGU-1801-E

Page 9

TECHNICAL DESCRIPTION

ELECTRICAL BOX

- Unit electrical cabinet, components and wiring in compliance with

EN 60204-1 electrical directive.

- 400V, 50 Hz, 3 phase power supply (without neutral) with a single

point of power connection (except sizes 680 to 1080).

- Bottom entry (through the base) for electrical power.

- IP54 protection class.

- Air spring powered Butterfl y electrical panel with top opening

providing protection to the service engineers against rain or snow

during commissioning and maintenance operations.

- Recognized brand electrical components (Schneider) for ease of

maintenance.

- Main on/off switch mounted on the front panel.

- DC60 advanced user interface mounted on the front panel.

- Main disconnect switch with high trip capacity allowing optimized

sizing of the customer power supply.

- 400/24 V transformer to supply the control circuit.

- Numbered electrical wires to facilitate maintenance and diagnostic.

- Variable Frequency Drives (VFD) to control the fan speed.

CONTROL

CLIMATIC microprocessor based control is providing the following

functions:

- 4 scheduling time zones per day over 7 days to allow energy

consumption and sound level management according to the

building use and environmental constraints.

- PI control of the water temperature with operating time equalisation

of the compressors.

- Water set-point offset based on outdoor air temperature.

- Active variable speed control of all fans to optimize the unit

condensing pressure and energy performances at full- and partload while meeting authorized maximum noise level in the time

zone (Active Acoustic Attenuation System™ control patented).

- Intelligent advanced control algorithm to protect the compressors

against excessive short-cycling and to allow operation of the unit

without buffer tank in most comfort air conditioning applications

(e.g. unit with fan-coils). Refer to minimum installation water loop

volume recommendations.

- Dynamic defrost to limit the number and the duration of the

defrost cycles in winter for high performance of the unit (Dynamic

Defrost patented).

- Automatic compressor unloading in case of excessive condensing

pressure allowing the operation of the machine at high outdoor

air temperature (operation extended up to 46°C ambient).

- Water pump control with operating time equalization and automatic

change-over in case of a pump fault (Twin pump only).

- Master/slave or cascade control of two chillers operating in parallel

with operating time equalization and automatic change-over in

case of a unit fault.

COMMUNICATION

The control board is equipped with a RS485 serial communication

port to allow remote management through communication bus.

According to the wished communication protocol, our control board

can be fi tted with ModBUS®, BacNET® (RS485 or TCP/IP) or

LonWorks® communication interface (options).

The main control board has free dry contacts that allow remote

control of the unit by wired cable:

- Remote on/off of the unit.

- Remote alarm reset to re-start the unit.

- Alarm or alert indications.

- Free customer contact.

With the optional extension board BE60, it is possible to get

additional customized digital or analog inputs / outputs for remote

control of the unit:

- Fault fans or pumps (dry contact).

- Operation indication at 100% on circuit 1 or 2 (dry contact).

- Dual water set-point management (dry contact).

- Force heating or cooling mode (24V AC input).

- Power limitation by disabling circuit 1 or 2 (24V AC input).

- Force unoccupied mode (24V AC input).

- Water set-point offset based on a 4-20mA signal. Note: non

available with heat-pump units.

DIRECTIVES

The unit is built to meet European norms and standards & Eurovent

certifi cation performance standards.

• DI 97/23/CE Pressure Equipment Directive.

• DI 98/37/CE Machinery Directive.

• DI 73/23/CE Low Voltage Directive.

• DI 89/336/CE Electro Magnetic Compatibility Directive

• EN 378-2 Safety and Environmental Directive.

• The European Restriction of the Use of Certain Hazardous

Substances (RoHS).

CLIMATIC is pre-factory confi gured with default settings allowing

a fast commissioning on site. The DC60 advanced user interface

with graphical display is easy to use, intuitive. Main customer

parameters can be read or modifi ed without main power shut-off

(Entering/leaving water temperatures, outdoor air temperature, alarm

history, scheduling of the different time zone, water and noise level

set-points, high and low pressure reading).

The DS60 service display (optional) is a “plug and play" controller

that allows service people to read and modify all unit parameters

(Unit settings, operating time and number of compressor starts,

low and high pressure reading, read the history of last 32 faults...).

Application Guide /NEOSYS-AGU-1801-E

• 7 •

Page 10

OPTIONS AND ACCESSORIES

OPTIONS DESCRIPTION ADVANTAGES MODELS

Low-pressure single-pump

hydraulic module

High-pressure single-pump

hydraulic module

Low-pressure twin-pump

hydraulic module

High-pressure twin-pump

hydraulic module

Partial heat recovery

Total heat recovery (Free

hot water : 100% heat

recovery)

Low-pressure single pump, regulating valve,

Victaulic couplings, fi lter and all necessary

hydraulic devices. Refer to specifi c chapter.

High-pressure single pump, regulating valve,

Victaulic couplings, fi lter and all necessary

hydraulic devices. Refer to specifi c chapter.

Low-pressure twin pumps, regulating valve,

Victaulic couplings, fi lter and all necessary

hydraulic devices. Refer to specifi c chapter.

High-pressure twin pumps, regulating valve,

Victaulic couplings, fi lter and all necessary

hydraulic devices. Refer to specifi c chapter.

Plate heat exchanger on each compressor

circuit allowing recovery of 20% of the rejected

heat

Recovery brazed plates heat exchanger dualcircuit mounted in parallel to the air condensers

allow 100% heat recovery in all outdoor air

conditions.

Quick start-up on job site. Available

pressure around 150 kPa.

Quick start-up on job site. Available

pressure around 250 kPa.

Quick start-up on job site. Available

pressure around 150 kPa.

Quick start-up on job site. Available

pressure around 250 kPa.

Allow free hot water production

simultaneously with unit operation

Production of free hot water at the

same time of the production of chilled

water.

NAC 200 ► 640

NAH 200 ► 480

NAC 200 ► 640

NAH 200 ► 480

NAC 200 ► 640

NAH 200 ► 480

NAC 200 ► 640

NAH 200 ► 480

NAC 200 ► 640

NAH 200 ► 300

NAC 200 ► 640

Free cooling

Winter operation (from +6°C

down to -20°C) – Cooling

only units

Brine operation (From +5°C

down to -10°C)

Anti-freeze protection (down

to -20°C)

Anti-freeze protection

of Total Heat Recovery

exchanger

Additional free cooling coils (one “V” or two “V”

depending on needed capacity) with inverter

fans and motorised valves.

Unit fi tted with electronic expansion valve and

variable frequency driven fans. Select “antifreeze protection” option if no glycol water

Unit fi tted with electronic expansion valve,

variable frequency driven fans and reinforced

evaporator and piping thermal insulation.

Resistance heaters on the evaporator,

hydraulic module and partial heat recovery if

selected. To be selected if no glycol water.

Resistance heater and insulation of the

recovery exchanger, to be selected if no glycol

water.

Allow the chilled water to run through

the free-cooling system, which uses

less power and utilises the lower

ambient air to cool the water.

Increased operating range in

cooling down to -20°C ambient

temperature. (Standard on sizes

540/600/640/1080).

Increased operating range in

cooling down to -10°C water leaving

temperature for thermal storage or

process cooling.

Evaporator and hydraulic module

frost protection down to -20°C

ambient temperature

The recovery exchanger have frost

protection down to -20°C ambient

temperature.

NAC 200 ► 540

NAC 200 ► 480

NAC 680 ► 960

NAC 200 ► 1080

NAC 200 ► 1080

NAH 200 ► 480

NAC 200 ► 640

Heavy anti-corrosion coil

treatment

Rear protection grille Metallic grille fi tted at the back of the unit

• 8 •

Application of LenGuard treatment on the

entire coil surface.

High corrosion resistance for

severe industrial, marine and dirty

environments.

Prevents the rear V-coil against

possible damage

Application Guide / NEOSYS-AGU-1801-E

NAC 200 ► 1080

NAH 200 ► 480

NAC 200 ► 640

NAH 200 ► 480

Page 11

OPTIONS AND ACCESSORIES

OPTIONS DESCRIPTION ADVANTAGES MODELS

Soft starter

Power Factor correction Capacitors fi tted into the unit

Electric meter

Single main power

connection

BE60 extension board for

additional inputs/outputs

Modbus communication

interface

Electronic soft starter fi tted into the electrical

cabinet

Active energy total counter, power factor,

operating time counter, max. active power

demand, ModBus.

Electrical cabinet equipped with one single

point of connection and power cut-off for the

complete unit.

Electronic extension board with additional

analog inputs (4), digital inputs (4) and digital

outputs (4). See control manual.

Communication card using ModBus/JBus

protocol with RS485 or TCP/IP connection.

Start-up current reduced by 15 % up

to 30 %.

Cos phi correction up to 0.95

to reduce current and energy

consumption.

This device allows monitoring of the

unit electric power consumption on

the unit and from a BMS

Allow easy electrical connection

with one single cable instead of two

cables

Relay card for remote control and

alarm report using dry contacts, 24

Vac or 4-20 mA signals.

Communication interface with a

building management system.

NAC 200 ► 1080*

NAH 200 ► 480

NAC 200 ► 1080

NAH 200 ► 480

NAC 200 ► 1080

NAH 200 ► 480

NAC 680 ► 1080

NAC 200 ► 1080

NAH 200 ► 480

NAC 200 ► 1080

NAH 200 ► 480

LonWorks® communication

interface

BACnet® communication

interface

Communication card using LonTalk® protocol

with FTT-10A connection.

Communication card using Bacnet® protocol

with RS485 or TCP/IP connection.

Communication interface with a

building management system.

Communication interface with a

building management system.

*except in case of main power connection option

NAC 200 ► 1080

NAH 200 ► 480

NAC 200 ► 1080

NAH 200 ► 480

ACCESSORIES DESCRIPTION ADVANTAGES MODELS

This protection must be fi tted in

Water fi lter

Flange connection

Anti-vibration mounts

DC60 remote comfort

display

1000 microns water Y fi lter delivered with

piping and fl ange connections.

Two connections sleeves with victaulic groove

and fl ange on opposite side.

Rubber anti-vibration mounts to be mounted

under the unit.

Customer display located at 600 meters

maximum from the unit.

the customer water supply piping

to protect the evaporator from any

possible impurities.

Allow easy connection with fl anges

on customer side.

Reduction of the transmission of

vibration to the ground and the

general level.

Remote customer parameter reading

and modifi cation.

NAC 200 ► 1080

NAH 200 ► 480

NAC 200 ► 1080

NAH 200 ► 480

NAC 200 ► 1080

NAH 200 ► 480

NAC 200 ► 1080

NAH 200 ► 480

Plug and play display delivered with 1 meter

DS60 service display

Adalink™ supervision

Application Guide /NEOSYS-AGU-1801-E

cable and connector for quick connection on

Climatic controller.

Electronic board with RS485 cables, RJ11

phone cable, Ethernet cable and power supply

cable.

Display for service technicians only.

Remote supervision of the unit via an

intuitive web page.

NAC 200 ► 1080

NAH 200 ► 480

NAC 200 ► 1080

NAH 200 ► 480

• 9 •

Page 12

GENERAL DATA

COOLING ONLY

410AR

NAC

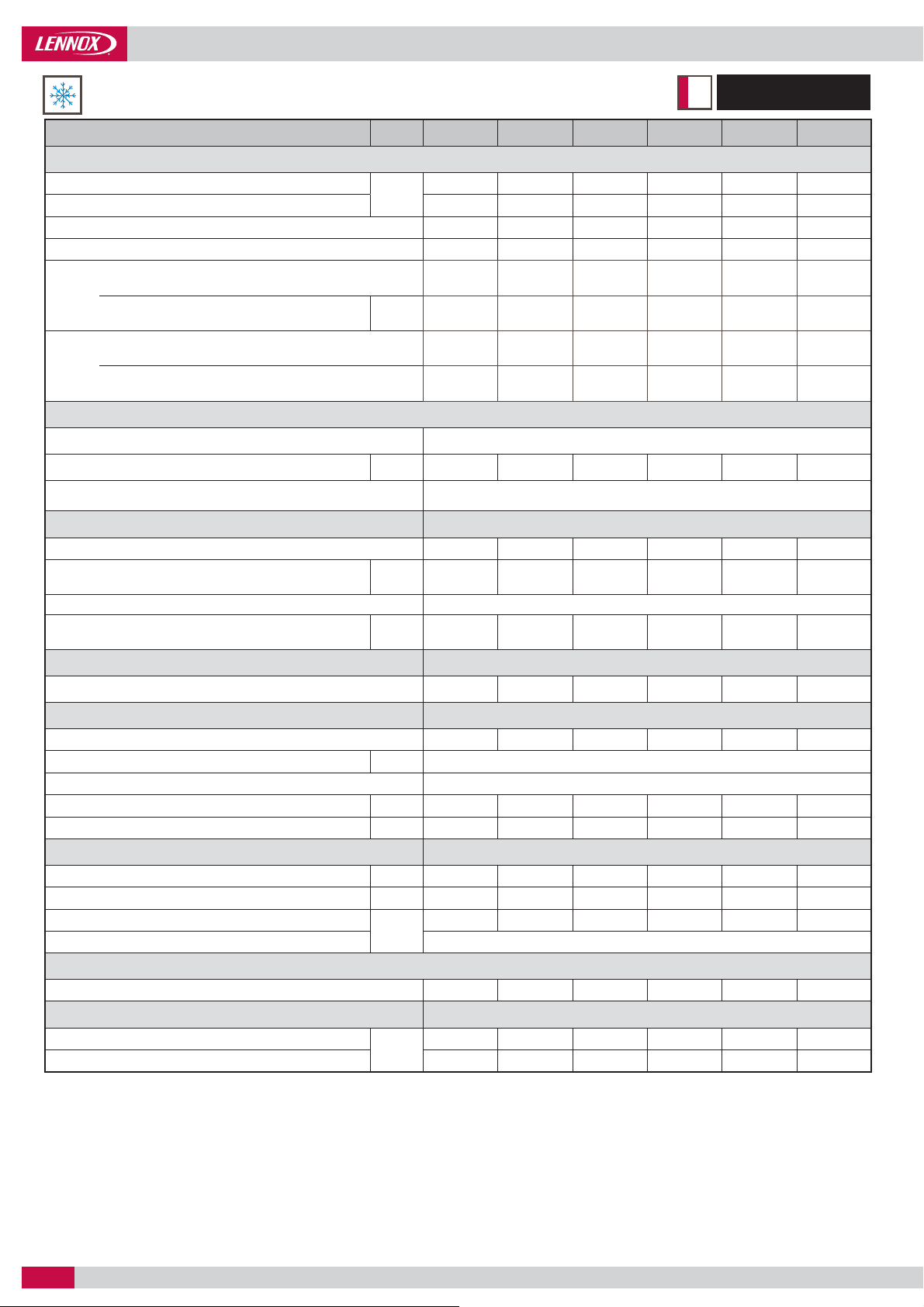

NEOSYS NAC 200 230 270 300 340 380

Cooling mode

Cooling capacity

Total absorbed power

(1)

EER

(2)

ESEER

Comfort

applications

tions

Process

applica-

Refrigeration circuit

Number of circuit

Refrigerant load per circuit (R410A)

Type of expansion valve Thermostatic expansion valve

Compressors Scroll - Hermetic

Number of compressors

Capacity steps

Oil type MOBIL EAL Arctic 22CC or ICI EMKARATE RL32CF

Oil load per compressor l

(1)

(1)

Seasonal Energy Effi ciency Ratio

(3)

SEER

Seasonal energy efficiency

(4)

ɳs,c

Seasonal Energy Performance Ratio

SEPR - High temperature (7°C)

Seasonal Energy Performance Ratio

SEPR - Medium temperature (-8°C)

208,2 235,7 272,8 307,6 351,3 387,3

kW

72,1 85,7 106,7 106,9 125,6 149,1

2,89 2,75 2,56 2,88 2,80 2,60

4,24 4,03 3,99 4,04 4,15 3,90

3,83 3,85 3,82 3,89 3,89 3,99

% 150 151 150 153 153 157

(5)

(6)

4,88 4,93 5,01 4,95 4,98 5,01

3,20 3,26 3,50 3,30 3,40 3,50

2

kg 12,4/13 12,3/13 14,1/15 18,2/19,1 22,4/19,3 22,4/19,4

444455

%

+ (3,2+6,8)

31-62-81-

100

(3,2+6,8)

34-68-84-

100

(3,2+6,3)

+ (3,2+6,3)

28-57-78-

100

(6,8+6,3)

+ (6,8+6,3)

27-53-73-

100

(6,3x2)

+ (6,8+6,3)

18-41-59-

82-100

(6,8x3)

+ (6,3x2)

20-40-60-

80-100

(6,3x3)

+ (6,3x2)

Condenser Microchannel Aluminium Tube and fi ns

Number of condenser

444666

Fan & Motor Variable speed fans

Number of fans

Diameter

mm 800

444666

Maximum speed Variable speed - 900 rpm maximum

3

m

Nominal air fl ow (100%)

Total motor power input (900 rpm)

/h 87 200 87 200 87 200 130 800 130 800 130 800

kW 6,4 6,4 6,4 9,6 9,6 9,6

Evaporator AISI 304 stainless steel plate brazed with copper heat exchanger

Water fl ow rate

(1)

Water volume l

Pressure drop

(1)

Water operating pressure

m3/h 35,8 40,6 46,9 52,9 60,4 66,6

13 13 16 24 35 35

kPa

43,0 54,1 55,9 48,1 34,7 41,6

600

Hydraulic connections Victaulic

Water inlet/outlet

Electrical data

Start-up intensity

Maximum current

(1) EUROVENT certifi ed data, in accordance

with standard EN14511 :

Water inlet/outlet temperature = 12°C / 7°C

Outdoor air temperature = 35°C.

(2) ESEER following Eurovent calculation

method, in accordance with standard

EN14511

(3) SEER in accordance with standard

EN14825.

(4) Following ecodesign regulation nr

EU 2016/2281 on space cooling,

normalized leaving water temperature

at 7°C, in accordance with standard

EN14825.

(5) Following ecodesign regulation nr

EU 2016/2281 on process cooling units,

normalized leaving water temperature

at 7°C, in accordance with standard

EN14825.

4" 4" 4" 4" 5" 5"

400V / III / 50 Hz

393,9 446,5 475,7 498,0 527,9 572,0

A

166,5 195,8 225,0 247,3 277,2 321,3

(6) Following ecodesign regulation nr

EU 2015/1095 on process cooling chillers,

normalized leaving water temperature

at -8°C, in accordance with standard

EN14825.

• 10 •

Application Guide / NEOSYS-AGU-1801-E

Page 13

GENERAL DATA

COOLING ONLY

410AR

NAC

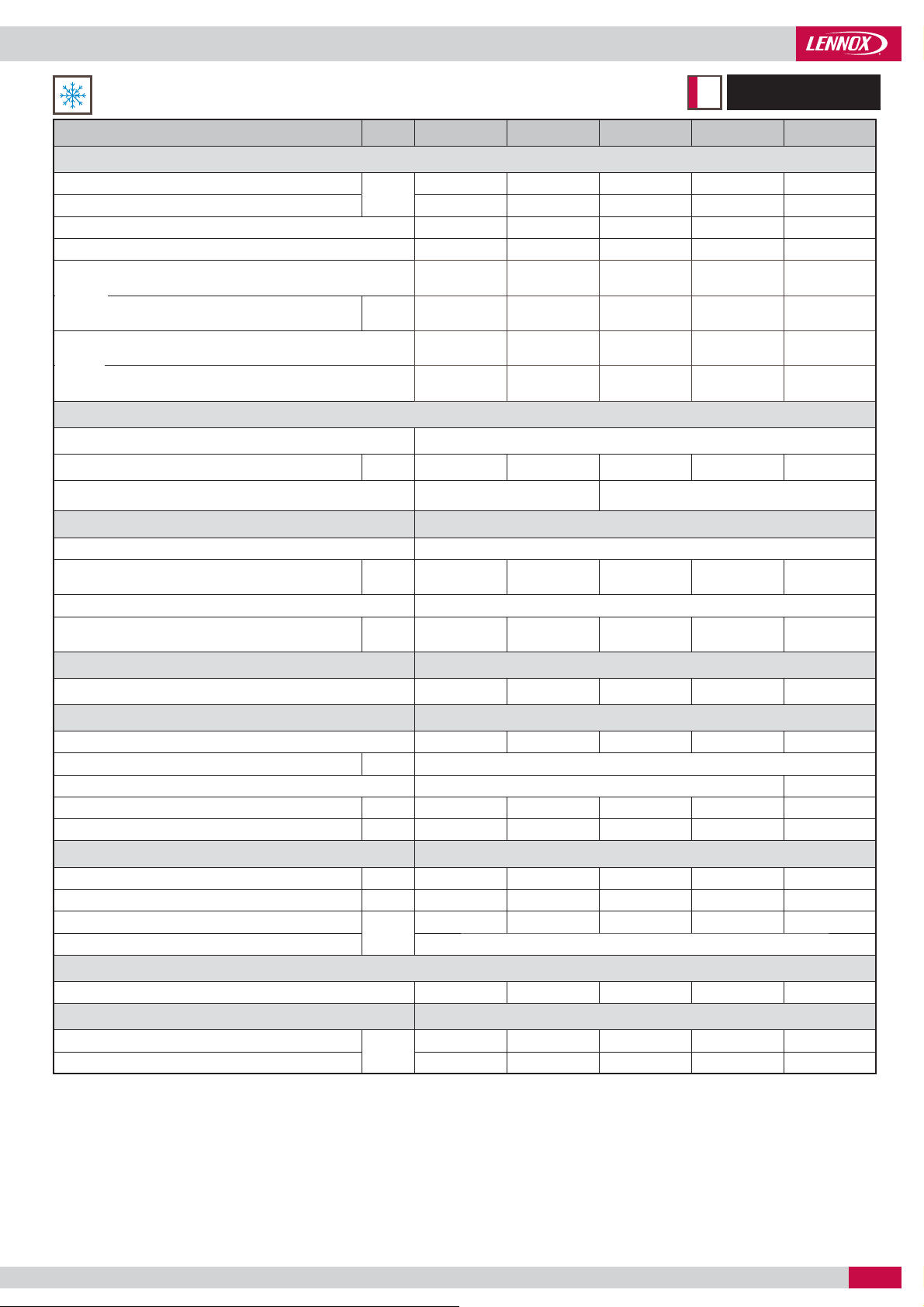

NEOSYS NAC 420 480 540 600 640

Cooling mode

Cooling capacity

Total absorbed power

(2)

EER

(3)

ESEER

Comfort

applications

tions

Process

applica-

Refrigeration circuit

Number of circuit

Refrigerant load per circuit (R410A)

Type of expansion valve Thermostatic expansion valve Electronic expansion valve

Compressors Scroll - Hermetic

Number of compressors

Capacity steps

Oil type MOBIL EAL Arctic 22CC or ICI EMKARATE RL32CF

Oil load per compressor

(1)

(1)

Seasonal Energy Effi ciency Ratio

(3)

SEER

Seasonal energy efficiency

(4)

ɳs,c

Seasonal Energy Performance Ratio

SEPR - High temperature (7°C)

Seasonal Energy Performance Ratio

SEPR - Medium temperature (-8°C)

kW

429,6 489,9 530,9 605,0 626,9

152,3 174,3 201,9 219,1 226,1

2,82 2,81 2,63 2,76 2,77

4,19 4,01 4,0 4,15 4,17

4,12 4,11 4,17 4,15 4,17

% 162 161 164 163 164

(5)

(6)

5,02 5,04 5,02 5,01 5,01

3,50 3,60 3,60 3,70 3,70

2

kg 34 34 34 42,5 42,5

6

14-33-48-67-81-

%

(6,3x3)

+ (6,8x3)

100

17-33-50-67-

83-100

(6,3x3)

+ (6,3x3)

18-33-51-67-

85-100

(6,3x3)

+ (6,3x3)

17-33-50-67-

83-100

(6,3x3)

+ (6,3x3)

17-33-50-67-

83-100

(6,3x3)

+ (6,3x3)

Condenser Microchannel aluminium tube and fi ns - Air cooled

Number of condenser

8 8 8 10 10

Fan & Motor Variable speed fans

Number of fans

Diameter

mm 800

8 8 8 10 10

Maximum speed Variable speed - 900 rpm maximum

Nominal air fl ow (100%)

Total motor power input (900 rpm)

3

m

/h 174 400 174 400 174 400 218 000 218 000

kW 12,8 12,8 12,8 16 16

Evaporator AISI 304 stainless steel plate brazed with copper heat exchanger

Water fl ow rate

(1)

Water volume

Pressure drop

(1)

Water operating pressure

3

m

/h 73,9 84,3 91,3 104,1 107,9

35 43 43 52 56

kPa

50,3 48,8 56,7 59,0 58,4

600

Hydraulic connections Victaulic

Water inlet/outlet

Electrical data

Start-up intensity

Maximum current

(1) EUROVENT certifi ed data, in accordance

with standard EN14511 :

Water inlet/outlet temperature = 12°C / 7°C

Outdoor air temperature = 35°C.

(2) ESEER following Eurovent calculation

method, in accordance with standard

EN14511

(3) SEER in accordance with standard

EN14825.

A

(4) Following ecodesign regulation nr

EU 2016/2281 on space cooling,

normalized leaving water temperature

at 7°C, in accordance with standard

EN14825.

(5) Following ecodesign regulation nr

EU 2016/2281 on process cooling units,

normalized leaving water temperature

at 7°C, in accordance with standard

EN14825.

5" 5" 6" 6" 6"

400V / III / 50 Hz

594,8 638,9 765,9 817,0 817,0

344,1 388,2 431,7 482,8 482,8

(6) Following ecodesign regulation nr

EU 2015/1095 on process cooling chillers,

normalized leaving water temperature

at -8°C, in accordance with standard

EN14825.

Application Guide /NEOSYS-AGU-1801-E

• 11 •

Page 14

GENERAL DATA

COOLING ONLY

410AR

NAC

NEOSYS NAC 680 760 840 960 1080

Cooling mode

Cooling capacity

Power input

(2)

EER

(3)

ESEER

Comfort

applications

tions

Process

applica-

Refrigeration circuit

Number of circuit

Refrigerant load per circuit (R410A)

Type of expansion valve Thermostatic expansion valve

Compressors

Number of compressors

Type of compressor Scroll - Hermetic

Capacity steps

Oil type MOBIL EAL Arctic 22CC or ICI EMKARATE RL32CF

Oil load per compressor l

Condenser Microchannel aluminium tube and fi ns

Number of condenser

Fan & Motor Variable speed fans

Number of fans

Diameter

Maximum speed Variable speed - 900 rpm maximum

Nominal air fl ow (100%)

Total motor power input (900 rpm)

Evaporator AISI 304 stainless steel plate brazed with copper heat exchanger

Water fl ow rate

Water volume l

Pressure drop

Water operating pressure

Hydraulic connections Victaulic

Water inlet/outlet

Electrical data

Start-up intensity

Maximum current

(1)

(1)

Seasonal Energy Effi ciency Ratio

(3)

SEER

Seasonal energy efficiency

(4)

ɳs,c

Seasonal Energy Performance Ratio

SEPR - High temperature (7°C)

Seasonal Energy Performance Ratio

SEPR - Medium temperature (-8°C)

(1)

(1)

kW

702,6 774,7 859,1 979,8 1061,9

251,3 298,2 304,6 348,7 403,8

2,80 2,60 2,82 2,81 2,63

4,15 3,91 4,21 4,01 4,0

4,14 4,14 4,22 4,11 4,11

% 163 163 166 162 162

(5)

(6)

5,05 5,03 5,01 5,04 5,01

3,60 3,50 3,50 3,60 3,60

4

kg

22,4/19,3/

22,4/19,3

22,4/19,4/

22,4/19,4

34 34 34

Electronic expan-

sion valve

10 10 12 12 12

9-18-30-41-

%

50-59-70-82-

[(6,8x3) +

(6,3x2)] x 2

91-100

10-20-30-4050-60-70-80-

90-100

[(6,3x3) +

(6,3x2)] x 2

8-15-24-33-

41-48-58-67-

74-82-91-100

[(6,3x3) +

(6,8x3)] x 2

8-17-25-33-

42-50-58-67-

75-83-92-100

[(6,3x3) + (6,3x3)] x 2

8-15-24-33-41-48-

58-67-74-82-91-

100

12 12 16 16 16

12 12 16 16 16

mm 800

3

m

/h 261 600 261 600 348 800 348 800 348 800

kW 19,2 19,2 25,6 25,6 25,6

3

m

/h 120,9 133,3 147,8 168,6 182,7

275 290 300 335 345

kPa

57,0 51,3 56,0 66,0 71,0

600 600 600 600 600

8"

400V / III / 50 Hz

805,2 893,3 939,0 1027,1 1197,6

A

554,5 642,6 688,3 776,4 863,4

(1) EUROVENT certifi ed data, in accordance

with standard EN14511 :

Water inlet/outlet temperature = 12°C / 7°C

Outdoor air temperature = 35°C.

(2) ESEER following Eurovent calculation

method, in accordance with standard

EN14511

(3) SEER in accordance with standard

EN14825.

• 12 •

(4) Following ecodesign regulation nr

EU 2016/2281 on space cooling,

normalized leaving water temperature

at 7°C, in accordance with standard

EN14825.

(5) Following ecodesign regulation nr

EU 2016/2281 on process cooling units,

normalized leaving water temperature

at 7°C, in accordance with standard

EN14825.

(6) Following ecodesign regulation nr

EU 2015/1095 on process cooling chillers,

normalized leaving water temperature

at -8°C, in accordance with standard

EN14825.

Application Guide / NEOSYS-AGU-1801-E

Page 15

GENERAL DATA

COOLING ONLY

410AR

NAC

Acoustic data

NEOSYS NAC 200 230 270 300 340 380

Active Acoustic Attenuation System™

Global sound power level

Sound pressure level 10 meters from the unit

Minimum global sound power level with A

Minimum sound pressure level with A3 system

10 meters from the unit

NEOSYS NAC 420 480 540 600 640

Global sound power level

Sound pressure level 10 meters from the unit

Minimum global sound power level with A

Minimum sound pressure level with A3 system

10 meters from the unit

NEOSYS NAC 680 760 840 960 1080

Global sound power level

Sound pressure level 10 meters from the unit

Minimum global sound power level with A

Minimum sound pressure level with A3 system

meters from the unit

(1) All data are at Eurovent condition,

(1)

89,2 89,3 89,7 91,2 91,3 91,4

57 57 58 59 59 59

3

system

(3)

(3)

dB(A)

82,2 82,8 84,4 85,0 85,5 85,9

51 52 54 54 55 55

Active Acoustic Attenuation System™

(1)

92,5 92,6 93,0 94,0 94,0

61 61 61 62 62

3

system

(3)

(3)

dB(A)

86,5 86,8 88,2 89,3 89,3

56 56 57 59 59

Active Acoustic Attenuation System™

(1)

94,3 94,4 95,5 95,6 96,0

62 62 64 64 64

3

system

(3)

(3)

- 10

dB(A)

88,5 88,9 89,5 89,8 91,2

58 58 59 59 60

Gross cooling capacity with 12/7°C water temperature and 35°C air ambient.

Gross heating capacity with 7°C air inlet temperature and 40/45°C water temperature.

EER and COP according to EN14511 Eurovent calculation method

Dimensional data

NEOSYS NAC 200 230 270 300 340 380 420 480 540 600 640

Dimensions

Length

mmWidth

Height

Footprint m²

Operating weight

kg

Shipping weight

NEOSYS NAC 680 760 840 960 1080

Dimensions

Length

mmWidth

Height

Footprint m²

Operating weight

kg

Shipping weight

3590 4620 5650 6680

2280 2280 2280 2280

2025 2025 2025 2025

8,2 10,5 12,9 15,2

1983 2011 2278 2676 3003 3045 3580 3661 3712 4152 4175

1961 1989 2253 2643 2955 2997 3532 3604 3655 4086 4105

9040 11100

2280 2280

1964 1964

20,6 25,3

6770 6854 7981 8141 8229

6495 6564 7681 7806 7884

Application Guide /NEOSYS-AGU-1801-E

• 13 •

Page 16

GENERAL DATA

HEAT PUMP

410AR

NAH

NEOSYS NAH 200 230 270 300

Cooling mode

Cooling capacity

Total absorbed power

Full load amps

(1)

EER

(2)

ESEER

tions

applica-

Comfort

tions

Process

applica-

Heating mode

Heating capacity

Power input

Full load amps

(3)

COP

Comfort

applications

Compressors Scroll - Hermetic

Number of compressors

Capacity steps

Oil type MOBIL EAL Arctic 22CC or ICI EMKARATE RL32CF

Oil load per compressor

Refrigeration circuit

Number of circuit

Refrigerant load per circuit (R410A)

Type of expansion valve Thermostatic expansion valve

Condenser Copper tube - Aluminium fi n - Air-cooled

Number of condenser

Fan & Motor Variable speed fans

Number of fans

Diameter

Maximum speed Variable speed - 900 rpm maximum

Nominal air fl ow (100%)

Total motor power input

Evaporator AISI 304 stainless steel plate brazed with copper heat exchanger

Water fl ow

Water volume

Pressure drop

Water operating pressure

Hydraulic connections Victaulic

Water inlet/outlet

Electrical data

Starting current

Maximum current

(1) EUROVENT certifi ed data, in accordance with

standard EN14511 :

Water inlet / outlet temperature = 12 °C / 7 °C

Outdoor air temperature = 35 °C.

(2) ESEER following Eurovent calculation method,

in accordance with standard EN14511

(3) Following ecodesign regulation nr

EU 2016/2281 on space cooling, normalized

leaving water temperature at 7 °C, in

accordance with standard EN14825.

(1)

(1)

(1)

Seasonal Energy Effi ciency Ratio

SEER

Seasonal energy effi ciency

(3)

ɳs,c

Seasonal Energy Performance Ratio

SEPR - High temperature (7°C)

Seasonal Energy Performance Ratio

SEPR - Medium temperature (-8°C)

(1)

(1)

(1)

Seasonal energy effi ciency

(8)

SCOP

Seasonal energy effi ciency

(7)

ɳs,h

Seasonal energy effi ciency class

(1)

(1)

(9)

kW

A 127,9 150,7 185,6 203,5

(4)

% 154 154 154 157

(5)

(6)

kW

A 125,9 145,3 172,8 192,5

% 134 130 132 135

%

kg 28 28 40 42

mm 800

3

/h 76 000 76 000 114 000 114 000

m

kW 6,4 6,4 9,6 9,6

3

m

/h 32,9 37,3 46,6 50,8

kPa

A

(4) SEER in accordance with standard

EN14825.

(5) Following ecodesign regulation nr

EU 2016/2281 on process cooling units,

normalized leaving water temperature at 7°C,

in accordance with standard EN14825.

(6) Following ecodesign regulation nr

EU 2015/1095 on process cooling chillers,

normalized leaving water temperature at

-8°C, in accordance with standard EN14825

191 217 271 295

73,5 86,7 106,7 117,0

2,60 2,50 2,54 2,52

4,00 3,76 3,99 3,94

3,93 3,91 3,92 4,00

5,20 5,04 5,06 5,01

3,15 3,20 3,02 3,09

219 235 291 339

71,7 84,0 104,3 112,7

3,05 2,80 2,78 3,01

3,44 3,32 3,39 3,45

A+

4

31 - 62 81 - 100

(3,2+6,8)

+ (3,2+6,8)

34 - 68 84 - 100

(3,2+6,3)

+ (3,2+6,3)

28 - 57 78 - 100

(6,8+6,3)

+ (6,8+6,3)

25 - 50 75 - 100

(6,3x2)

+ (6,3x2)

2

4466

4466

20 20 23,2 23,2

36,7 46,4 55,2 44,7

600

4"

400V / III / 50 Hz

393,9 446,5 483,3 512,7

166,5 195,8 232,6 262,0

(7) SCOP in accordance with standard

EN14825. Heating mode performance is

defi ned for average climate.

(8) Following ecodesign regulation nr

EU 813/2013 on space heaters, normalized

leaving water temperature at 7°C, in

accordance with standard EN14825, average

climate.

(9) Following energy labelling regulation nr

EU 811/2013 on space heaters.

• 14 •

Application Guide / NEOSYS-AGU-1801-E

Page 17

GENERAL DATA

HEAT PUMP

410AR

NAH

NEOSYS NAH 340 380 420 480

Cooling mode

Cooling capacity

Total absorbed power

Full load amps

(1)

EER

(2)

ESEER

tions

applica-

Comfort

tions

Process

applica-

Heating mode

Heating capacity

Power input

Full load amps

(3)

COP

Comfort

applications

Compressors Scroll - Hermetic

Number of compressors

Capacity steps

Oil type MOBIL EAL Arctic 22CC or ICI EMKARATE RL32CF

Oil load per compressor l

Refrigeration circuit

Number of circuit

Refrigerant load per circuit (R410A)

Type of expansion valve Thermostatic expansion valve

Condenser Copper tube - Aluminium fi n - Air-cooled

Number of condenser

Fan & Motor Variable speed fans

Number of fans

Diameter

Maximum speed Variable speed - 900 rpm maximum

Nominal air fl ow (100%)

Total motor power input

Evaporator AISI 304 stainless steel plate brazed with copper heat exchanger

Water fl ow

Water volume l

Pressure drop

Water operating pressure

Hydraulic connections Victaulic

Water inlet/outlet Inches

Electrical data

Starting current

Maximum current

(1) EUROVENT certifi ed data, in accordance with

standard EN14511 :

Water inlet / outlet temperature = 12 °C / 7 °C

Outdoor air temperature = 35 °C.

(2) ESEER following Eurovent calculation method,

in accordance with standard EN14511

(3) Following ecodesign regulation nr

EU 2016/2281 on space cooling, normalized

leaving water temperature at 7 °C, in

accordance with standard EN14825.

(1)

(1)

(1)

Seasonal Energy Effi ciency Ratio

SEER

Seasonal energy effi ciency

(3)

ɳs,h

Seasonal Energy Performance Ratio

SEPR - High temperature (7°C)

Seasonal Energy Performance Ratio

SEPR - Medium temperature (-8°C)

(1)

(1)

(1)

Seasonal energy effi ciency

(8)

SCOP

Seasonal energy effi ciency

(7)

ɳs,h

Seasonal energy effi ciency class

(1)

(1)

kW

A 223,3 231,4 269,7 311,9

(4)

% 166 165 162 163

(5)

(6)

kW

A 125,9 145,3 172,8 192,5

% 136 132 130 131

(9)

%

kg 42 50 52 52

mm 800

3

/h 114 000 152 000 152 000 152 000

m

kW 9,6 12,8 12,8 12,8

3

/h 55,7 62,1 68,4 78,1

m

kPa

A

(4) SEER in accordance with standard

EN14825.

(5) Following ecodesign regulation nr

EU 2016/2281 on process cooling units,

normalized leaving water temperature at 7°C,

in accordance with standard EN14825.

(6) Following ecodesign regulation nr

EU 2015/1095 on process cooling chillers,

normalized leaving water temperature at

-8°C, in accordance with standard EN14825

324 361 397 454

128,4 133,1 155,1 179,4

2,52 2,71 2,56 2,53

4,01 4,08 3,86 4,14

4,23 4,20 4,12 4,16

5,21 5,25 5,11 5,12

3,23 3,09 3,11 3,19

363 404 452 499

121,3 132,9 151,7 169,5

3,00 3,04 2,98 2,95

3,47 3,39 3,33 3.35

A+

5666

18 - 41 - 59 -

82 - 100

(6,8 x 3)

+ (6,3 x 2)

17 - 33 - 50 - 67

- 83 - 100

(6,8 x 3)

+ (6,8 x 3)

14 - 33 - 48 - 67

- 81 - 100

(6,3 x 3)

+ (6,8 x 3)

17 - 33 - 50 - 67

- 83 - 100

(6,3 x 3)

+ (6,3 x 3)

2

6888

6888

34,6 34,6 34,6 42,7

29,8 36,5 43,6 42,3

600

5"

400V / III / 50 Hz

527,9 579,6 594,8 638,9

277,2 328,9 344,1 388,2

(7) SCOP in accordance with standard

EN14825. Heating mode performance is

defi ned for average climate.

(8) Following ecodesign regulation nr

EU 813/2013 on space heaters, normalized

leaving water temperature at 7°C, in

accordance with standard EN14825, average

climate.

(9) Following energy labelling regulation nr

EU 811/2013 on space heaters.

Application Guide /NEOSYS-AGU-1801-E

• 15 •

Page 18

GENERAL DATA

HEAT PUMP

410AR

NAH

Acoustic data

NEOSYS NAH 200 230 270 300 340 380 420 480

Active Acoustic Attenuation System™

Global sound power level

Sound pressure level

10 meters from the unit

Minimum global sound power level with A

Minimum sound pressure level with A3 system

10 meters from the unit

(1) All data are at Eurovent condition,

(1)

dB(A)

3

system

(3)

(3)

89,2 89,3 91,1 91,2 91,3 92,4 91,5 91,6

57 57 59 59 59 61 61 61

82,2 82,8 84,9 85,0 85,5 86,1 86,2 86,5

51 52 54 54 55 56 56 56

Gross cooling capacity with 12/7°C water temperature and 35°C air ambient.

Gross heating capacity with 7°C air inlet temperature and 40/45°C water temperature.

EER and COP according to EN14511 Eurovent calculation method

Dimensional data

NEOSYS NAH 200 230 270 300 340 380 420 480

Dimensions

Length

mmWidth

Height

Footprint m²

Operating weight

kg

Shipping weight

3590 4620 5650

2280 2280 2280

2025 2025 2025

8,2 10,5 12,9

2176 2175 2906 3380 3349 4020 4066 4148

2154 2153 2881 3347 3301 3972 4020 4091

• 16 •

Application Guide / NEOSYS-AGU-1801-E

Page 19

PRESSURE DROPS

EVAPORATOR AND CONDENSER CURVES

Curves

100

NAC/NAH

NAC

200

230

270

300

340

380

420

480

540

600

640

680

760

840

960

1080

Evaporator

ABB

ACC

BCC

CCD

DCD

DCE

DCE

EGG

EJJ

FJJ

GJ J

H-

H-

H-

I-

I-

AB C

Evaporator pressure drop in units with

total heat recovery option

200

Condenser

D

Pressure Drop (kPa)

10

20 30 50 80

Flow rate (m3/h)

b

NEOSYS

200/230

270

300

340/380/420

480/540

600

640

540/600/640

ΔP = a X

ab

0,057 1,8516

0,0419 1,8695

0,0333 1,8333

0,0175 1,8509

0,0124 1,8669

0,009 1,892

0,0082 1,8953

0,0072 1,9104

100

E

F

100

H

I

G

J

Pressure Drop (kPa)

10

50 70 100 200

Flow rate (m3/h)

b

NEOSYS

680

760

840

960

1080

ΔP = a X

ab

0,0056 1,8666

0,0056 1,8666

0,0056 1,8666

0,0042 1,886

0,0042 1,886

Pressure drops are given for information only. A tolerance of +/- 20 kPa must be considered when selecting water pumps.

Application Guide /NEOSYS-AGU-1801-E

• 17 •

Page 20

PRESSURE DROPS

FILTER CURVE

NAC/NAH NAC

200

230 600

270 640

300 680

340

380 840

420 960

480 1080

Curve Curve

540

L

760

M

10

1

L

N

O

MN

O

0,1

Pressure drop (kPa)

0,01

1 4 10 50 100 200

Flow rate (m3/h)

Size of the fi lter mesh: 1 mm

NEOSYS

200/230/270/300

340/380/420/480

540/600/640

680/760/840/960/1080

ab

0,00332 1,7409

0,0000011 3,1026

8,00E-09 4,023

0,0000000005 4,2717

ΔP = a X

b

• 18 •

Pressure drops are given for information only. A tolerance of +/- 20 kPa must be considered when selecting water pumps.

Application Guide / NEOSYS-AGU-1801-E

Page 21

0

HYDRAULIC DATA

NAC

NAH ---

Nominal water fl ow m3/h

200 230 270 300 340 380 420 480

35,8 40,5 46,9 52,9 60,4 66,6 73,9 84,3 91,3 104,0 107,8

540 600 640

Single pump

Available static pressure

(1)

kPa

101 119 89 127 125 144 125 107 146 133 130

Double pump

Available static pressure

(1)

kPa

80 92 82 119 116 136 115 95 133 115 110

Single pump HP

Available static pressure

(1)

kPa

191 218 201 207 215 202 214 192 230 215 212

Double pump HP

Available static pressure

(1)

kPa

171 204 203 206 213 198 202 171 213 191 186

Expansion vessel

Volume l

Maximum pressure kPa

Gross Weight kg

50

400

12,2

(1) : Pump external static pressure - Evaporator pressure drop

PUMP PRESSURE CURVES

Low pressure

Single pump

240,0

220,0

200,0

180,0

160,0

140,0

120,0

100,0

80,0

60,0

40,0

Pressure drop (kPa)

20,0

0,0

0 20 40 60 80 100 120 140

B

A

E

D

C

Flow rate (m3/h)

360,0

330,0

300,0

F

270,0

240,0

210,0

180,0

150,0

120,0

90,0

Pressure drop (kPa)

60,0

30,0

0,0

0102030405060708090100110

High pressure

Single pump

A

Flow rate (m3/h)

C

E

B

D

F

Low pressure

Double pump

240,0

220,0

200,0

180,0

160,0

140,0

120,0

100,0

80,0

60,0

40,0

Pressure drop (kPa)

20,0

0,0

0 20 40 60 80 100 120 14

B

A

E

D

C

Flow rate (m3/h)

A NAC/NAH 200 D NAC/NAH 300/340

B NAC/NAH 230 E NAC/NAH 380/420/480

C NAC/NAH 270 F NAC 540/600/640

Application Guide /NEOSYS-AGU-1801-E

High pressure

Double pump

330,0

300,0

270,0

240,0

F

210,0

180,0

150,0

120,0

90,0

60,0

Pressure drop (kPa)

30,0

0,0

0 102030405060708090100110

C

B

A

E

D

F

Flow rate (m3/h)

A NAC/NAH 200 D NAC/NAH 300/340/380

B NAC/NAH 230 E NAC/NAH 420/480

C NAC/NAH 270 F NAC 540/600/640

• 19 •

Page 22

HYDRAULIC DATA

UNIT WITH HYDRAULIC MODULE

NAC/NAH

200 - 230 - 270 - 300

05

04

02

01

IN

01 07

02 08

03 09

04 10

05 11

06 12

03

03

09

12

OUT

10

Water fi lter (item supplied loose) Electronic fl ow switch

Air purge Plate heat exchanger

Pressure tap Setting valve

Pump Pressure tap and drain valve

Safety valve with manometer Return temperature sensor

Expansion vessel Supply temperature sensor

07

11

08

06

NAC 340 - 380 - 420 - 480 - 540 - 600 - 640

NAH 340 - 380 - 420 - 480

06

05

1111

0202

1212

0303

0707

0404

0303

0101

08

09

10

MINIMUM WATER CONTENT OF AN INSTALLATION

Thanks to multi step capacity control and smart anti-short compressor cycling, NEOSYS can work with minimum water loop volume

as defi ned here below. This can eliminate the need for a buffer tank in most of air-conditioning applications (e.g. NEOSYS application

with fan-coil units).

Vmini = 86 x Q / (Nstages x Dt)

V

Q

Where :

Nstage Number of control steps available in the unit

Dt

Important note: In case NEOSYS is used in air-conditioning applications with a short water system (e.g. NEOSYS application with air

handling units) or in case NEOSYS is used for industrial process cooling, it is mandatory to use a buffer tank.

Minimum water content of the installation

Cooling capacityof the chiller

Maximum acceptable temperature rise (Dt = 6°c for an air conditioning application)

• 20 •

Application Guide / NEOSYS-AGU-1801-E

Page 23

HYDRAULIC DATA

MINIMUM WATER CONTENT OF AN INSTALLATION

Unit Size

NAC

200

230

270

300

340

380

420

480

540

600

640

680

760

840

960

1080

Number of stages

4 717

4 824

4 968

4 1075

5 975

5 1089

6 1003

6 1147

6 1290

6 1433

6 1529

10 975

10 1089

12 1003

12 1147

12 1290

Mini water volume

(l)

Unit Size

NAH

200

230

270

300

340

380

420

480

Number of stages

4 717

4 824

4 968

4 1075

5 975

6 908

6 1003

6 1147

Mini water volume

(l)

MAXIMUM WATER CONTENT OF AN INSTALLATION

The maximum water content of the installation is determined by the capacity of the expansion vessel.

On units fi tted with a standard Hydraulic Module it is possible to determine the maximum water content of the installation.

Max. volume clear water (l) Max. volume Glycol water (l)

Unit Size

200-230-270

300-340-380

420-480

540

600-640

Expansion

vessel

volume

50 l 1,5 Bar 5 230 l 4 180 l 4 020 l 3 210 l

Pressure in

the expansion

vessel

Static pressure Static pressure

5 m 10 m 5 m 10 m

GLYCOL CORRECTION FACTOR

Minimum ambient temperature or water

outlet temperature

+ 5°C ► 0°C 10% 1,05 1,02 0,99 0,994

Ethylene

glycol

Pressure

drop

Water

fl ow

CAPACITIES

Cooling Heating

0°C ► -5°C 20% 1,10 1,05 0,98 0,993

- 5°C ► -10°C 30% 1,15 1,08 0,97 0,99

- 10°C ► -15°C 35% 1,18 1,10 0,96 0,987

Example : 10% glycol

Minimum fl ow : 1,19 m3/h x 1,02

Pressure drop x 1,07

System capacity x 0,99

Application Guide /NEOSYS-AGU-1801-E

• 21 •

Page 24

HYDRAULIC DATA

MINIMUM WATER FLOW THROUGH THE EVAPORATOR

In case of installation with fi xed speed pump, to prevent from freezing risk, the fl ow rate through the evaporator must be higher than

the minimum fl ow given in the table below.

In case of variable primary fl ow, the pump speed must be controlled through the CLIMATIC control. Additionally, the hydraulic system

must be properly designed and balanced to ensure a right water fl ow distribution through the chiller evaporator and the terminal units.

This is especially important when the system is designed with fan coils equipped with two-way valves. When the two-way valves are

closing in response to building load change, it is important that the system is designed to ensure a minimum evaporator fl ow that is

always minimum 60% of the chiller’s design fl ow rate. This can be done with a bypass from chilled water supply to chilled water return

opened via a signal from a fl ow meter.

Additionnaly, some terminals can be fi tted with three way control valves in order to ensure the fl ow will not drop below the minimum

value at any load condition as indicated in the table below.

Water fl ow rate (m³/h)

Models Capacity (kW)

200

230

270

300

340

380

420

480

540

600

640

680

760

840

960

1080

208 21,5 35,8 57,9

236 24,4 40,6 57,9

273 28,1 46,9 57,9

308 31,7 52,9 126,4

351 36,2 60,4 126,4

387 40,0 66,6 126,4

430 44,3 73,9 126,4

490 50,6 84,3 126,4

531 54,8 91,3 126,4

605 62,5 104,1 126,4

627 64,7 107,9 126,4

702 72,6 121,0 252,9

774 80,1 133,4 252,9

860 88,8 148,0 252,9

980 101,3 168,8 252,9

1062 109,7 182,9 252,9

Minimum

(with fi xed and eDrive™

variable speed pump)

Nominal Maximum

Important note : The water fl ow must not vary by more than 10% per minute. If the fl ow rate changes more rapidly, the system should

contain a minimum of 6,5 litres of water per kW instead of 3 l/kW.

• 22 •

Application Guide / NEOSYS-AGU-1801-E

Page 25

HYDRAULIC EQUIPMENT

eDrive™ TECHNOLOGY, THE RIGHT CHOICE TO SAVE 75% OF PUMP ENERGY COSTS.

LENNOX offers the eDrive, a variable speed drive pump option (with single or double pump) which modulates the water fl ow through

the evaporator and reduces energy costs. This option is available on chillers and heat pumps from 20 to 1000 kW.

In a water system, one major contributor to annual energy consumption is the pump motor. Pumping energy cost can represent 20%

of the total cost of owning a chiller. This ratio can be even bigger for a heat-pump.

eDrive™ variable speed driven pump is contributing to continuous Lennox efforts to save energy while exploring possibilities

to reduce installation cost.

eDrive™ variable speed driven pump benefi ts:

• Cost savings on the energy consumption especially at part-load conditions and during off period.

75% of this energy could be saved !

• Cost savings on the initial system cost. Fewer pumps and piping connections than primary–secondary systems, terminal units

equipped with two-way control valves instead of three-way valves, elimination of water fl ow set valve.

• Flexibility and accuracy in the pump operation control (smooth start and stop, gradual change of speed, accuracy and stability of

control)

• Reduction of the repeated stress on the pump and piping resulting in longer equipment life time (elimination of the «hammer blow»

in pipes).

• Elimination of the start-up current thanks to variable frenquency drive that controls a gradual pump motor supply.

Designing a VWF chilled water plant that performs reliably at all load conditions requires careful attention to chiller design. Thanks

to the newest generation of chiller controllers and intensive testing, NEOSYS can now reliably maintain the desired chilled water

temperature with a fl ow range from 60% to 100% that gives up to 75% annual energy savings.

LENNOX eDrive™ Technology modulates the Water Flow especially in Part-Load Conditions through a Specifi c Algorithm and a

Variable Frequency Driver.

Typical cost split in a chiller through 15-year lifespan

Chiller with fixed speed pump Chiller with variable speed pump

20 %

10 %

22 %

Energy savings

15 %

47 %

10 %

23 %

5 %

47 %

Cooling energy cost Maintenance cost

Equipment cost Pump energy cost

Application Guide /NEOSYS-AGU-1801-E

• 23 •

Page 26

0

10

20

30

40

50

60

70

80

90

100

0

10

20

30

40

50

60

70

80

90

100

HYDRAULIC EQUIPMENT

eDrive™ VARIABLE WATER FLOW SAVES YOUR MONEY IN THE ENERGY COST

• Through the elimination of the energy normally lost in the water fl ow control valve during unit full-load operation (Variable water

fl ow = perfect pump curve adjustment to the required nominal water fl ow and delta P)

• Through pump rotation speed reduction during unit part-load operation.

• Thanks to pump running at minimum speed during Chiller “off” period (night, unoccupied)

Pump energy consumption

Fan coil with 3 way valves and constant T

PUMP AFFINITY LAWS

“The power required for pumps varies as the

Energy

20% water fl ow reduction = 50% energy reduction.

40% water fl ow reduction = 80% energy reduction.

cube of the fl ow rate.”

100% load 75% load 50% load 25% load Off

Chiller load

Fixed speed pump Variable speed pump

eDrive™ VARIABLE WATER FLOW MAY SAVE MONEY IN THE SYSTEM DESIGN COST

Variable speed

drive

Terminal unit

1

Terminal unit

2

Terminal unit

...

Control

valve

Water pressure

transducer

Pump

Balancing

valve

PP

By-pass valve

Variable primary fl ow system with constant pressure

A variable primary fl ow design uses fewer components than primary–secondary systems as the pumps of the secondary distribution

loop and the mixing tank are eliminated.

When compared with constant primary fl ow systems, terminal units can equipped with two-way control valves instead of three-way valves

often used in constant volume systems. Using two-way valves instead of three-way valve on fan coils represent a budget reduction

that pays for the variable frequency driver cost. On top of that, the water fl ow set valve is eliminated as the pump adjustment to real

installation needs can be done electronically. These factors may reduce the initial cost of the chilled water system

• 24 •

Application Guide / NEOSYS-AGU-1801-E

Page 27

HYDRAULIC EQUIPMENT

eDrive™ VARIABLE WATER FLOW BY LENNOX

3 control modes available :

Constant speed

• Interest to set the right installation design fl ow (avoid setting valve).

Constant Delta P (setting to declare the required working pressure)

• Implementation and management adapted to systems with two-way valves and bypass of the installation to ensure a minimum

water fl ow back into the evaporator.

Constant Delta T (Setting to declare the required delta T)

• Need a good installation with well balanced circuits to ensure good fl ow distribution when the fl ow is reduced.

• Installation with terminal units fi tted with 3-way valves.

Operation for each mode:

• Constant speed : eDrive pilots the pump to the water fl ow desired when the compressors are in operation. When the compressors

are stopped (dead zone), control will automatically reduce the speed of the pump to the minimum water fl ow This minimum fl ow

is also adjustable within minimum 30Hz (60% fl ow).

• Constant delta P : the eDrive™ regulation is managing the pump to maintain the required delta P in order to keep constant the

customer available static pressure. When the terminals control valves close in response to decreased building loads, the pump

controller slows the pump speed to maintain the target delta P. In this mode the pump does not detect terminal capacity reduction

(fan speed staging)

• Constant Delta T : the eDrive™ regulation is managing the pump to maintain the required Delta T. When the Delta T is increasing

in response to the number of compressors running, the pump controller increases the speed of the pump. Conversely, when the

compressors are stopping in response to decreased building loads, the pump controller slows the pump speed to maintain the

target Delta T.

Safety parameters:

• If the evaporating pressure reaches the low limit (risk of evaporator frosting), the fl ow is increased.

• If the outlet evaporator temperature reaches the low limit, the fl ow is set to the maximum.

• When the pump speed varies and the fl ow switch trips, the fl ow is automatically increased.

• During defrost procedure (HP), the fl ow is set to the maximum.

• Pump motor supply range from 30 Hz minimum to 50Hz maximum. Minimum pump motor frequency set at 30 Hz. Below this value,

risk of pump motor failure due to overheat.

• For safe operation of the chiller, the unit is protected by the fl ow switch.

• Minimum and maximum admissible water fl ow per unit size: with constant delta T, the fl ow may vary from 60% to 100% of the

selected pump nominal fl ow.

• Maximum change in fl ow rate through the evaporator: a 10% per minute change in fl ow rate is admissible in most of air conditioning

applications.

Application Guide /NEOSYS-AGU-1801-E

• 25 •

Page 28

HYDRAULIC EQUIPMENT

Installation instructions to respect in case of variable primary fl ow:

• The hydraulic system will have to be properly designed and balanced to ensure a right water fl ow distribution through the chiller

evaporator and the terminal units.

• The hydraulic system will have to be properly designed to respect minimum and maximum water fl ow through each chiller following

the values given by the manufacturer.

Case of constant Delta P mode :

• In case of system designed with terminal units equipped with 2 way valves, the hydraulic system will need to have a bypass fl ow

to ensure a minimum water fl ow through the chiller evaporator.

Méthode de by-pass :

• Bypass adequate water fl ow can be achieved with a slow modulating opening as soon as the water fl ow rate is near the mini-

mum. When the water fl ow rises according to predefi ned setting, this valve closes. This bypass modulating valve provided by

LENNOX (contact customer service) is controlled by our Climatic control. The bypass should be positioned at the beginning of

the installation near the unit and allows signifi cant energy savings and cost as opposed to a location at the end of the system.

• An alternative is to install some 3-way valves at different points of the terminal units. This approach allows constant minimum

fl ow in the chiller or heat pump and ensures a cheaper system.

• The minimum water fl ow through the chiller evaporator will need to respect a minimum value that is 60% of the nominal chiller

water fl ow.

• The fl ow bypass from chilled water supply to chilled water return can be done with a motorized bypass valve opened via a signal

from a fl ow meter.

• For safe operation some terminals can be equipped with three way control valves in order to ensure the fl ow will not drop below

the minimum value at any load condition.

• The water fl ow must not vary by more than 10% per minute. If the fl ow rate changes more rapidly, the system should contain a

minimum of 6,5 liters of water per kW instead of 3 liters/kW.

• Check the control valve authority in low load periods, especially in case of long pipe hydraulic systems.

• 26 •

Application Guide / NEOSYS-AGU-1801-E

Page 29

PARTIAL HEAT RECOVERY

Compared with the basic confi guration, this option features an additional refrigerant/water

heat exchanger on the compressor discharge line, allowing recovery of 15% of the rejected

heat. This heat exchanger is large enough to recover heat for the production of free hot

water simultaneously with chilled water production. The heating capacity of the heat recovery

circuit is approximately equal to the power input of the compressor.

Typical heat recovery applications can be facilities with high domestic hot water usage,

such as health care, hotels, etc.

Notes:

This option is available on cooling only and heat-pump versions.

Heat recovery can only occur when the unit is running either in cooling or heating mode.

Partial heat recovery

Free hot water up to 70°C

Air cooled condenser

Desuperheater

Electronic expansion valve

Partial heat recovery

Scroll compressor

Evaporator

Water in/out: 50/55 °C Water in/out: 55/60 °C Water in/out: 50/60 °C

Recovery

(kW)

NAC/NAH 200

NAC/NAH 230

NAC/NAH 270

NAC/NAH 300

NAC 340

NAC 380

NAC 420

NAC 480

NAC 540

NAC 600

NAC 640

Wf : Dp :

Water fl ow in m3 per hour Water pressure drop in KPa

41 7,18 6,00 32 5,62 4 37 3,26 2

52 9,11 9,00 43 7,55 6 48 4,22 2

56 9,81 7,00 44 7,73 5 50 4,40 2

65 11,39 9,17 52 9,13 6 59 5,19 2

79 13,84 9,80 64 11,24 6 72 6,34 2

101 17,69 14,28 83 14,58 10 93 8,18 3

91 15,94 9,17 73 12,82 6 82 7,22 2

106 18,57 12,00 86 15,11 8 96 8,45 3

143 25,05 15,00 118 20,73 11 129 11,35 4

150 26,28 13,00 122 21,43 9 136 11,97 3

154 27,07 13,33 125 22,07 9 139 12,33 3

Wf

3

(m

/h)Dp(kPa)

Recovery

(kW)

Wf

(m3/h)Dp(kPa)

Recovery

(kW)

Wf

(m3/h)Dp(kPa)

Application Guide /NEOSYS-AGU-1801-E

• 27 •

Page 30

TOTAL HEAT RECOVERY

Heat recovery is one of our solutions to decrease and offset energy

bills continually on the rise.

NEOSYS with Heat Recovery option operate as a standard chiller

as long as heat is not required or simultaneously produce chilled

and hot water which can be used for applications like preheating

of a boiler, heating or domestic hot water.

Heating or preheating in series with a boiler, the heat recovery

option enables to reduce :

- Purchase and installation cost : boiler is undersized.

- Operating cost : free hot water when unit produce chilled

water.

In series with an auxiliary heater , this option can also replace the

heater in low temperature heating systems.

A heat recovery chiller is suitable for all industrial process requiring

both chilled and hot water.

The LENNOX total heat recovery system on NEOSYS :

- Parallel assembly, stainless steel brazed plate heat exchanger

mounted in parallel to the air condensers maintain maximum

performance and effi ciency whatever the conditions : 100%

heat recovery in opposite of series assembly.

- Free hot water from 25 to 55°C

- Very Low refrigerant charge, no additional refrigerant charge

thanks to braze plate heat exchanger.

- High Total Energy Ratio values : TER (*)

- Standard Features factory mounted and tested:

• Stainless steel heat exchanger with control

• Paddle water fl ow switch

• Temperature hydraulic sensors

• Victaulic coupling

• 3 way valve ( 0-10V) for cold start

• On/Off pump control

• Antifreeze protection + insulation (in option)

(*) TER: Total Effi ciency Ratio is the total energy effi ciency of the units

when there is a production of chilled water and hot water simultaneously.

Cold water and hot water are valuated to the total power consumption

of the unit: TER = (cooling capacity + recovered heating capacity) / total

power consumption.

Control principle:

The unit switches to recovery mode using a dry contact supplied

by the user and connected to the CLIMATIC. CLIMATIC controller

regulates the water leaving temperature of the recovery exchanger

using temperature probes included at inlet and outlet of the

exchanger. It offers the possibility of programming schedule one

or more setpoints.