Lennox MPA012S4S-*L, MWMB009S4-*L, MWMA009S4-*L, MPB009S4S-*L, MWMA012S4-*L Installation Instructions Manual

...Page 1

INSTALLATION

©

2017 Lennox Industries Inc.

Dallas, Texas, USA

Table of Contents

General ...........................................................................1

Included Parts.................................................................2

Model Number Identication ...........................................3

Indoor / Outdoor Unit Match-Ups....................................4

Typical System Components ..........................................5

System Dimensions ........................................................6

Outdoor Units ..............................................................6

Indoor Units .................................................................7

System Clearances ........................................................8

Outdoor Unit ................................................................8

Indoor Unit ...................................................................8

Torque Requirements for Caps and Fasteners...............9

Indoor Unit Installation ....................................................9

Unit Placement Considerations ...................................9

Determining Wall Mounting Plate Location ..................9

Installation of Wall Mounting Plate...............................9

Installation of Wall Sleeve..........................................10

Installation of Indoor Unit on Wall Mounting Plate .....10

Indoor Unit Condensate Piping Connections .............12

Outdoor Unit Installation ...............................................12

Placement Considerations .........................................12

Direct Sunlight, Rain, Snow and Ice Protection .........13

Prevailing Winds ........................................................14

Buried Refrigerant Pipe Protection ............................14

Outdoor Unit Condensate Piping ...............................14

Securing the Outdoor Unit .........................................15

Refrigerant Piping Connections ....................................15

Leak Test and Evacuation ............................................18

Leak Test ...................................................................18

Triple Evacuation Procedure......................................18

Wiring Connections ......................................................18

Outdoor Unit .............................................................18

Indoor Unit .................................................................18

Unit Start-Up .................................................................26

Adding Refrigerant for Longer Line Set ........................26

Troubleshooting ............................................................26

Test Run .......................................................................26

Pre-Checks ................................................................26

Procedure ..................................................................26

Double-Check Pipe Connections ...............................27

If Ambient Temperature is below 63°F (17°C) ...........27

Dry Mode Operation (Dehumidication) .......................27

Procedure ..................................................................27

Sequence of Operation ..............................................27

INSTRUCTIONS

MLA/MPA/MPB and

MWMA/MWMB Series

SINGLE-ZONE MINI-SPLIT SYSTEMS

(115V and 208/230V) --

Wall-Mounted Indoor Unit

507545-06

4/2017

Supersedes 10/2016

THIS MANUAL MUST BE LEFT WITH THE OWNER

FOR FUTURE REFERENCE

WARNING

Improper installation, adjustment, alteration, ser vice or

maintenance can cause property damage, personal

injury or loss of life.

Installation and service must be performed by a li censed

professional HVAC installer (or equivalent) or a service

agency.

WARNING

The clean Air Act of 1990 bans the intentional venting of

refrigerant (CFCs, HCFCs, and HFCs) as of July, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for non-compliance.

WARNING

This product contains a chemical known to the State

of California to cause cancer, birth defects, or other

reproductive harm.

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take

care while handling this equipment and wear gloves and

protective clothing.

General

These instructions are intended as a general guide and

do not supersede local or national codes in any way.

Authorities having jurisdiction should be consulted before

installation.

The MWMA and MWMB wall-mounted indoor units are

matched with an outdoor heat pump unit to create a minisplit system that uses HFC-410A refrigerant.

Page 2

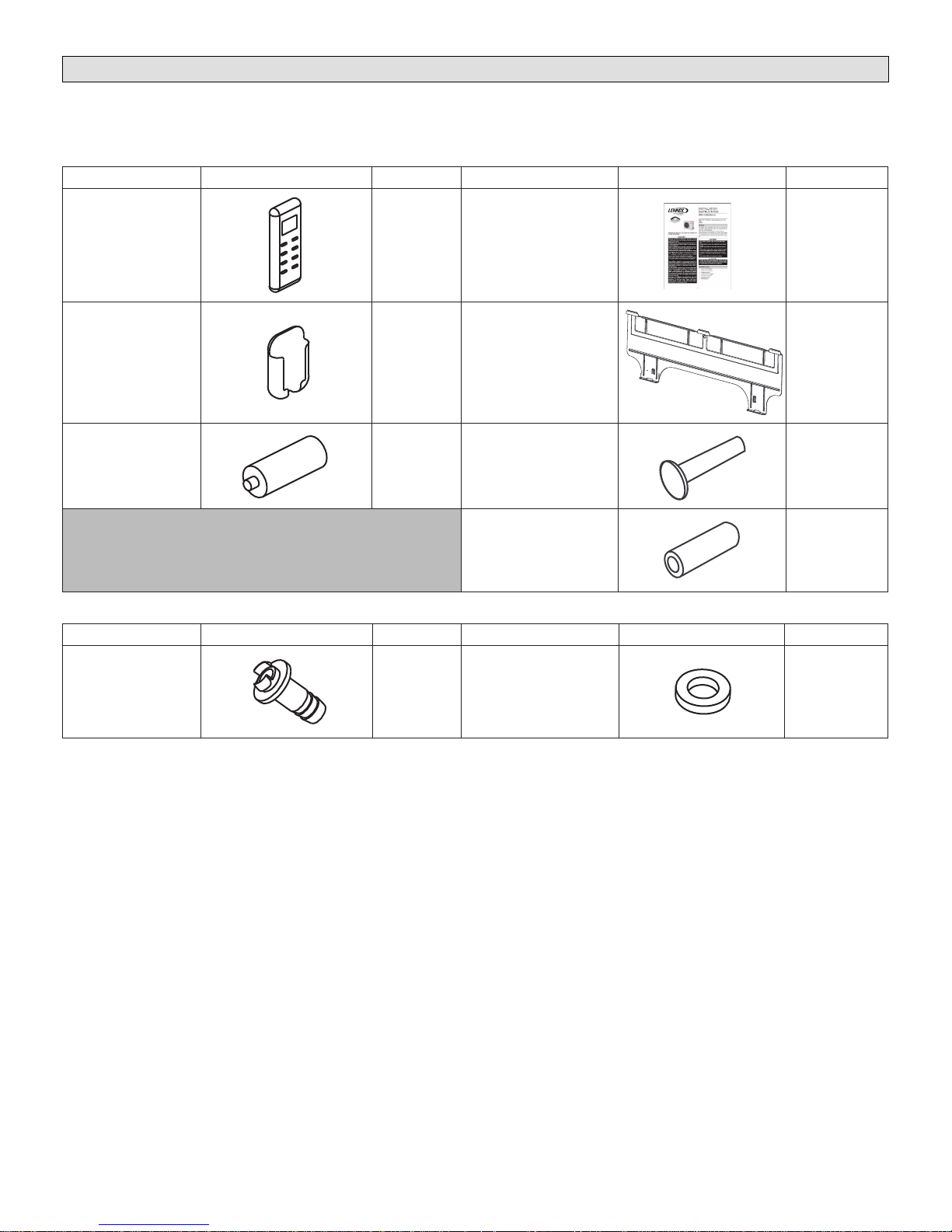

Included Parts

Package 1 of 1 contains the following:

1 - Assembled Indoor Unit

The assembled indoor unit will include the following items:

Parts Figure Quantity Parts Figure Quantity

M0STAT60Q-1

Wireless controller

Wireless control

holder with 2 mounting

screws

Batteries (AAA) 2

1

1 Mounting plate 1

Installation and owner’s

manual

Mounting plate securing

screws

Plastic screw anchors 5

1 - Assembled Outdoor Unit and the following items:

Parts Figure Quantity Parts Figure Quantity

1 ea.

5

Drain connector 1 Seal ring 1

2

Page 3

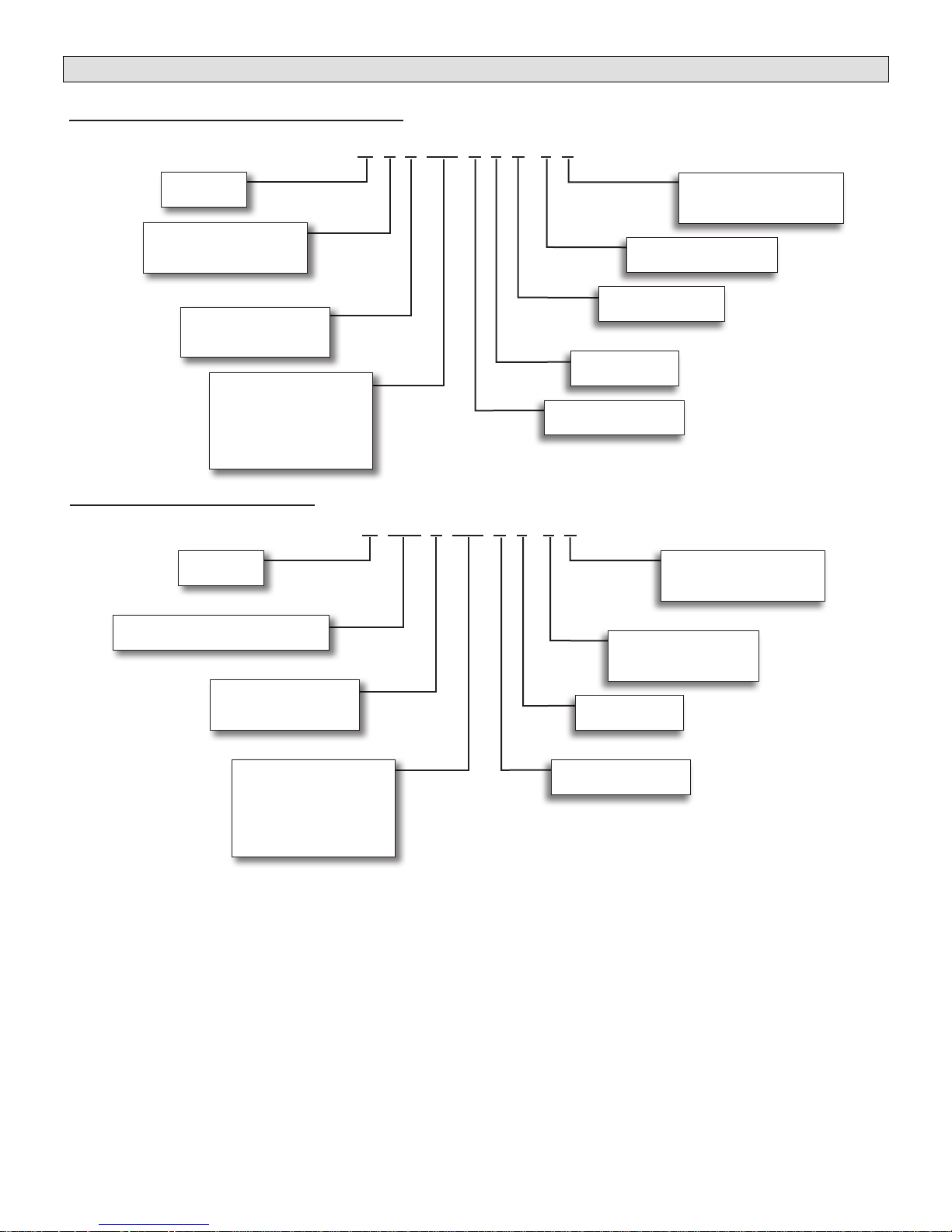

Model Number Identication

OUTDOOR SINGLE ZONE HEAT PUMP UNITS

M P A 009 S 4 S - 1 P

Series Type

M = Mini-Split

Unit Type

L = Low Ambient Heat Pump

P = Heat Pump

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Nominal Cooling Capacity

009 = 0.75 tons

012 = 1 tons

018 = 1.5 tons

024 = 2 tons

030 = 2.5 tons

WALL-MOUNTED INDOOR UNITS

Series Type

M = Mini-Split

Unit Type

WM = Wall-Mounted Non-Ducted Unit

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Voltage

L = 115V-1 phase-60hz

P = 208/230V-1 phase-60hz

Minor Design Sequence

1 = 1st Revision

Refrigerant Circuits

S = Single Circuit

Refrigerant Type

4 = HFC-410A

Cooling Efciency

S = Standard Efciency

M WM A 012 S 4 - 1 P

Voltage

L = 115V-1 phase-60hz

P = 208/230V-1 phase-60hz

Minor Design Sequence

1 = 1st Revision

2 = 2nd Revision

Refrigerant Type

4 = HFC-410A

Nominal Cooling Capacity

009 = .75 tons

018 = 1.5 tons

030 = 2.5 tons

Cooling Efciency

S = Standard Efciency

012 = 1 tons

024 = 2 tons

3

Page 4

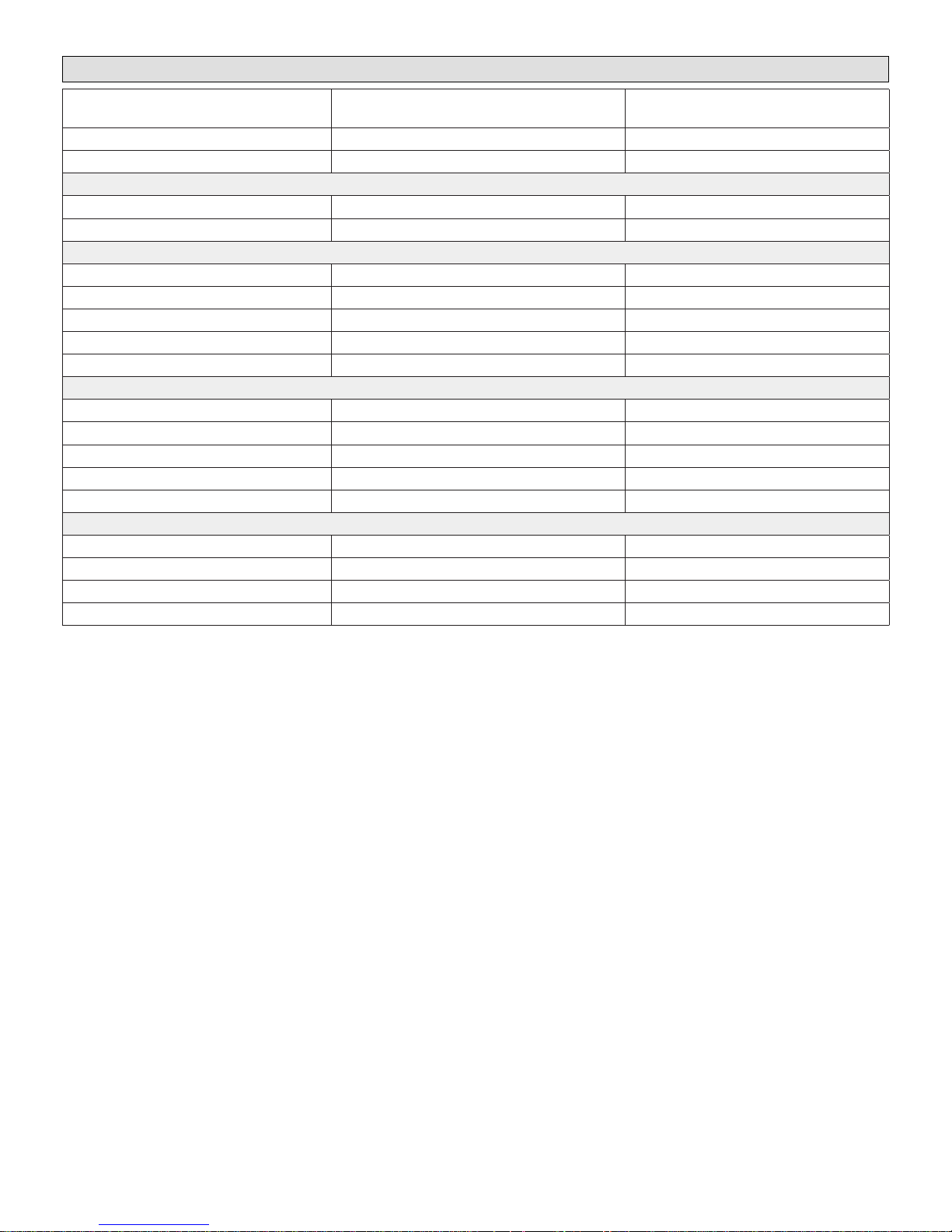

Indoor / Outdoor Unit Match-Ups

Outdoor Unit Indoor Unit Voltage

MPA009S4S-*L MWMA009S4-*L

MPA012S4S-*L MWMA012S4-*L

MPB009S4S-*L MWMB009S4-*L

MPB012S4S-*L MWMB012S4-*L

MPA009S4S-*P MWMA009S4-*P

MPA012S4S-*P MWMA012S4-*P

MPA018S4S-*P MWMA018S4-*P

MPA024S4S-*P MWMA024S4-*P

MPA030S4S-*P MWMA030S4-*P

MPB009S4S-*P MWMA009S4-*P

MPB012S4S-*P MWMA012S4-*P

MPB018S4S-*P MWMA018S4-*P

MPB024S4S-*P MWMA024S4-*P

MPB030S4S-*P MWMB030S4-*P

MLA009S4S-*P MWMA009S4-2P

MLA012S4S-*P MWMA012S4-2P

MLA018S4S-*P MWMA018S4-2P

MLA024S4S-*P MWMA024S4-2P

115V

115V

115V

115V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

4

Page 5

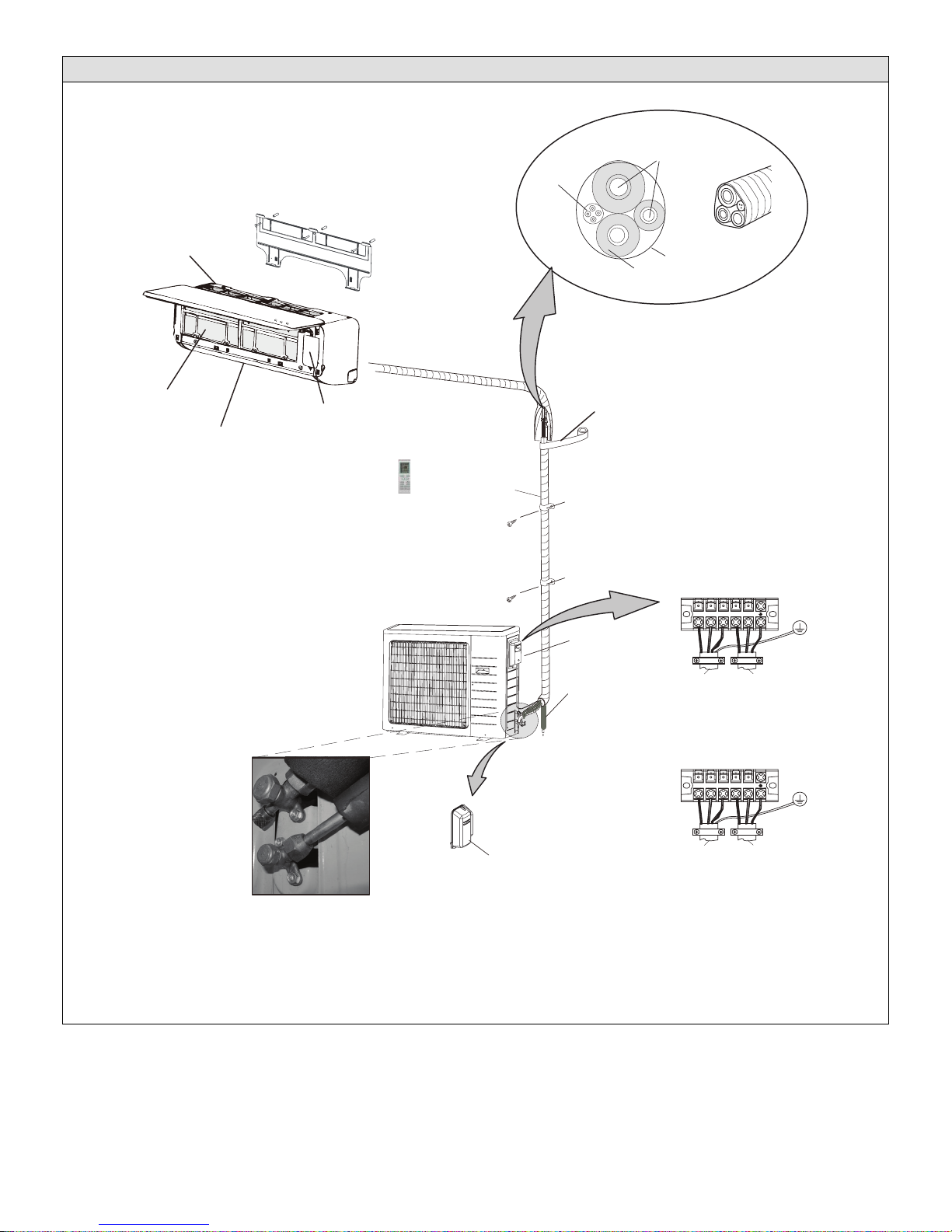

Typical System Components

IMPORTANT - Condensate drain line must always

be located at the bottom of the

bundle.)

Mounting Plate

Wiring

Line set

(wrapped in foam insulation)

Filter

Return Air

Supply Air

Indoor Unit

Indoor unit wiring connections

(under access plate)

Utility

Wireless Remote

Control

Outdoor Unit

009-030 shown

Bundle

Access cover for power

and control wiring

connections

Condensate drain line

(field-provided)

TAPE

Condensate drain line

(wrapped in foam insulation)

Refrigerant Line Set, Condensate Line

And Indoor / Outdoor Cable

(field-provided)

UV-rated tape (field-provided)

IMPORTANT - The refrigerant

metering device for this system is

located in the outdoor unit. This

makes it necessary to insulate the

refrigerant lines individually to

prevent sweating.

208/230V Outdoor Unit

Terminal Block

1 2 3 L1 L2

To Indoor

Unit

To Power

Supply

Liquid and vapor shut off valves

Figure 1. Typical System Shown

5

Access cover

for valves

115V Outdoor Unit

Terminal Block

1 2 3 L N

To Indoor

Unit

To Power

Supply

Page 6

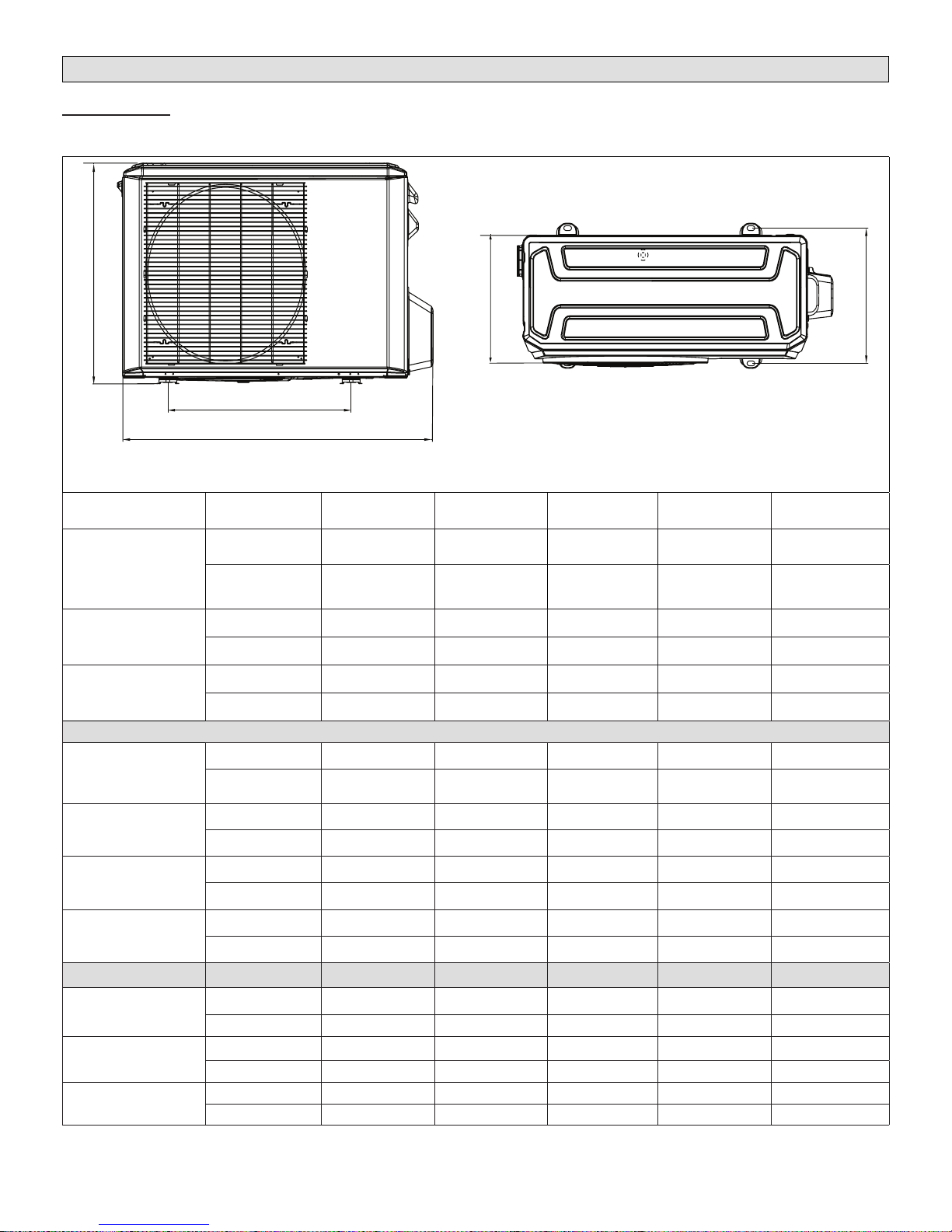

System Dimensions

A

E

D

B

C

TYPICAL APPEARANCE OF UNITS

Outdoor Units

Table 1. Outdoor Unit Dimensions - Inches (mm)

Model

MPA009S4S-*L

MPA009S4S-*P

MPA012S4S-*L

MPA012S4S-*P

MPA018S4S-*P

MPA024S4S-*P

MPA030S4S-*P

MPB009S4S-*L

MPB012S4S-*L

MPB012S4S-*P

MPB009S4S-*P

MPB018S4S-*P

MPB024S4S-*P

MPB030S4S-*P

Unit of

Measurement

inches 33-1/4 21-5/8 22 11-3/8 12-3/4

mm 845 549 559 289 324

inches 36-1/8 22 27-1/2 12-3/4 13

mm 918 559 699 324 330

inches 40-5/8 25-1/4 31-7/8 15-1/8 16

mm 1032 641 810 384 406

inches 34-1/4 20-1/4 21-7/8 13-1/8 13-3/8

mm 870 514 556 333 340

inches 33-1/8 19-1/8 21-7/8 11-7/8 11-3/4

mm 842 486 556 302 298

inches 36 21-1/4 27-5/8 14-1/4 13-3/4

mm 914 540 702 362 349

inches 37-1/4 26-1/2 31-7/8 16-3/8 15-7/8

mm 1032 673 810 416 403

A B C D E

MLA009S4S-*P

MLA012S4S-*P

MLA018S4S-*P

MLA024S4S-*P

inches 34-1/4 20-1/4 21-3/4 12-1/4 13-3/8

mm 870 514 552 311 594

inches 36 21-1/4 27-5/8 13-3/4 16

mm 914 540 702 349 406

inches 40-3/4 26-1/2 31-7/8 15-1/8 16

mm 1035 673 810 384 406

6

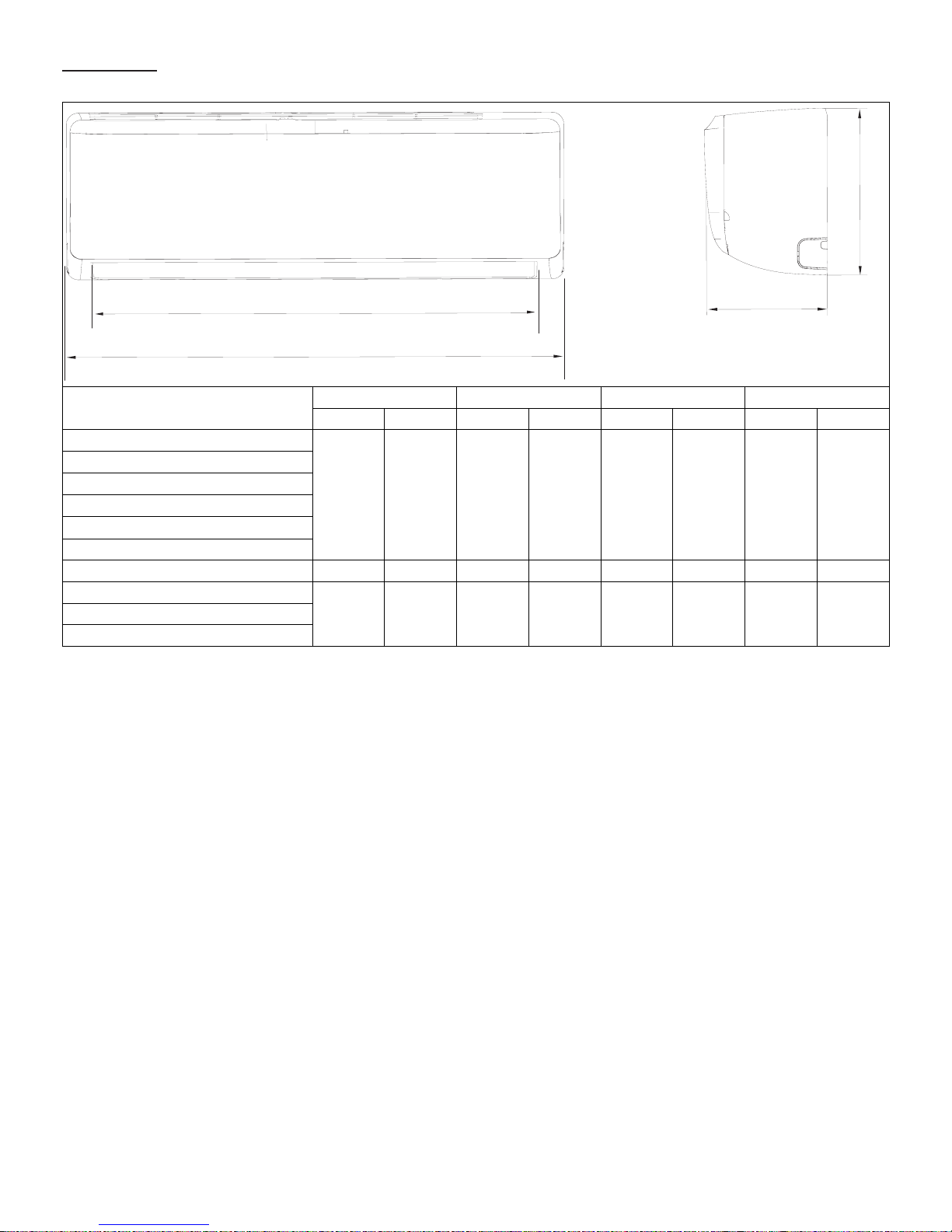

Page 7

Indoor Units

B

A

Table 2. Indoor Unit Dimensions - Inches (mm)

C

D

Size

MWMA009S4S-*L

MWMB009S4S-*L

MWMA012S4S-*L

MWMB012S4S-*L

MWMA009S4S-*P

MWMA012S4S-*P

MWMA018S4S-*P 39 991 12-3/8 314 34-3/4 883 8-5/8 210

MWMA024S4S-*P

MWMB030S4S-*P

32-7/8 835 11 279 29-1/4 743 7-7/8 200

46-3/4 1187 13-1/2 343 42-1/2 1080 10-1/4 260MWMA030S4S-*P

A B C D

in. mm in. mm in. mm in. mm

7

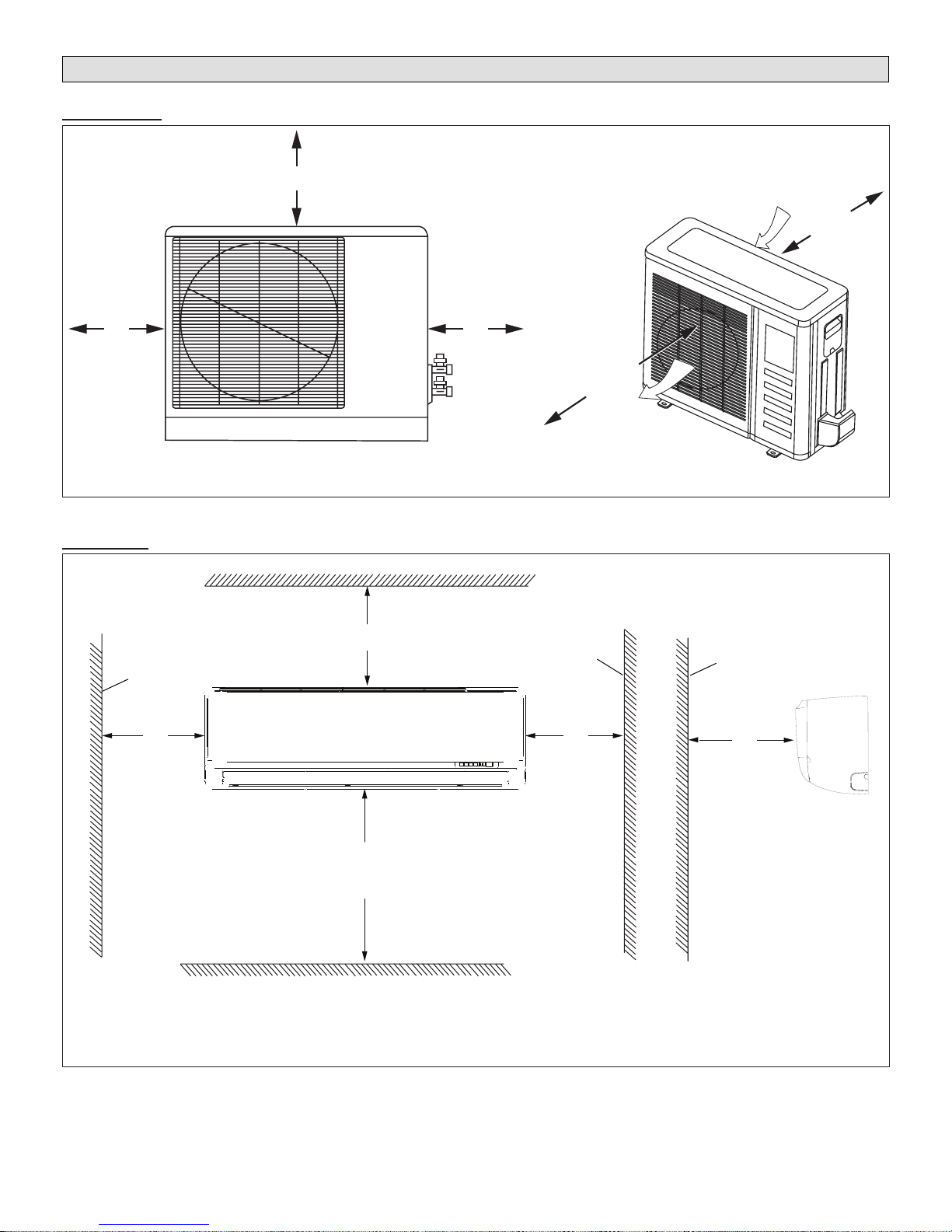

Page 8

System Clearances

Outdoor Unit

12

(305)

Indoor Unit

Wall

24 (610)

24

(610)

1

Minimum rear clearance can be 6 inches (152 mm) when mounted on brackets

and with no obstructions on the other three sides.

Figure 2. Outdoor Unit Clearances - Inches (mm)

Ceiling

6” (152 mm)

Minimum Clearance

5”

(127 mm)

Minimum

Wall

5”

(127 mm)

Minimum

79

(2007)

Air Outlet

Air Inlet

1

12

(305)

Any Object

59”

(1499 mm)

Minimum

Vertical Clearance - Clearance to Floor - 72 inches (1829 mm) Minimum

96 inches (2438 mm) Recommended

Figure 3. Indoor Unit Clearances - Inches (mm)

Floor

FRONT VIEW

SIDE VIEW

8

Page 9

Torque Requirements for Caps and

Fasteners

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened. “Table 1. Torque

Requirements” on page 9 provides torque values for

fasteners.

IMPORTANT

Only use Allen wrenches of sufcient hardness (50Rc -

Rockwell scale minimum). Fully insert the wrench into

the valve stem recess.

Service valve stems are factory-torqued from 9 ft.-lbs.

(12 N*m) for small valves, to 25 ft.-lbs. (34 N) for large

valves) to prevent refrigerant loss during shipping and

handling. Using an Allen wrench rated at less than 50Rc

risks rounding or breaking off the wrench, or stripping

the valve stem recess.

See the Lennox Service and Application Notes C-08-1

for further details and information.

Table 1. Torque Requirements

Parts

Service valve cap 8 ft.-lb. 11

Sheet metal screws 16 in.-lb. 2

Machine screws #10 27 in.-lb. 3

Compressor bolts 7 ft.-lb. 10

Gauge port seal cap 8 ft.-lb. 11

Recommended Torque

U.S. Newton-Meter- N

Indoor Unit Installation

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

Unit Placement Considerations

AVOID

Do not install the unit in the following locations:

• Areas exposed to petrochemicals or petrochemical

products

• Areas exposed to salt or other corrosive materials or

caustic gases

• Areas exposed to extreme voltage variations (such as

factories

• Tightly enclosed areas that may impede service of the

unit

• Areas exposed to fossil fuels (such as oil or gas in

kitchens)

• Areas exposed to strong electromagnetic forces

• Areas exposed to acids or alkaline detergents

DO

• Place the unit so that it is not exposed to direct sunlight

• Ensure the structural ceiling can support the weight of

the unit

• Select a location where condensate line will have the

shortest run to a suitable drain per local codes

• Allow sufcient space around unit for proper operation

and maintenance

• Install unit a minimum of 3 feet (1m) away from any

antenna, power cord (line) radio, telephone, security

system, or intercom. Electrical interference and radio

frequencies from any of these sources may affect operation

• Be sure to instruct customers how to properly operate

the unit (especially maintenance of air lter, and operation procedure) by having them carry out operations

themselves while looking at the manual provided with

the controller

Determining Wall Mounting Plate Location

Left piping

Left back piping

Right back piping

Right piping

Figure 4. Determining Exit Locations

1. Remove the wall mounting plate from the back of the

indoor unit.

2. Determine the best exit location for utility bundle (line

set, condensate line and wiring). See the following

section concerning wall sleeve installation instructions.

3. Position the wall mounting plate on the wall so that,

when installed, the unit will be at least 6 inches (152

mm) from the ceiling and 5 inches (127 mm) from the

wall on either side. The wall mounting plate must be

level side-to-side.

4. Use the wall mounting plate as a template to determine

the exit point for utility bundle. Mark the wall to facilitate

drilling hole for utility bundle.

Installation of Wall Mounting Plate

Install the wall mounting plate (see “Figure 8. Wall

Mounting Plates - Inches (mm)” on page 11) so that it is

correctly positioned horizontally and vertically. The indoor

unit must be installed level on the wall to allow proper

condensate drainage.

1. Use a carpenter’s level or measuring tape to verify the

wall mounting plate is horizontally level.

2. Secure the wall mounting plate to the wall using the

provided screws and screw anchors.

NOTE: It is important to use all screws provided to secure

the wall mounting plate to the wall. Additional holes

may be drilled through the metal wall mounting

9

Page 10

plate to better secure wall plate. Field-provided

anchors/xings may be required depending on wall

construction. Use the appropriate type of anchors

for the application.

3. The wall mounting plate must be installed ush against

the wall so that the indoor unit will be ush after

installation. Any space between the wall and unit will

cause noise and vibration.

4. The wall mounting plate must be installed horizontally

level on the wall.

Installation of Wall Sleeve

The utility bundle may be routed out of the back of the unit

or out either side. If the bundle is to be routed out the back

through an external wall, use a eld-provided wall sleeve

to protect the utility bundle.

NOTE: If the utility bundle will be routed out the side of the

indoor unit and up the wall above a false ceiling,

continue to the next section.

1. Prior to making the hole and installing the wall sleeve

for the utility bundle, check to ensure that there are

no other utilities located in the wall behind the hole

location.

2. Cut a hole in the wall using a suitable hole saw. Hole

should be at a slight downward slant - 3/16” to 3/8”

toward the outdoor side.

3. Measure the thickness of the wall from the inside edge

to the outside edge and cut the eld-provided wall

sleeve at a slight angle 1/4” (6 mm) shorter than the

thickness of the wall.

Installation of Indoor Unit on Wall Mounting Plate

1. A length of eld-provided exible condensate piping

should be connected to the drain prior to securing the

unit to the wall mounting plate.

2. If the factory-provided refrigerant piping connections

and eld-provided exible condensate piping are long

enough to enable nal eld connections after unit is

installed on wall mounting plate, use eld-provided

tape to bundle them together.

3. The utility bundle may be routed out of the back of the

unit or out either side. If the bundle is to be routed

out the back through an external wall, feed the utility

bundle through the wall sleeve. If the utility bundle is

to be routed out of the side of the indoor unit and up

an inside wall, carefully form the utility bundle so that

it makes a gentle 90° turn.

4. Align the back of the indoor unit with the hooks at the

top of the wall mounting plate. Move the unit from side

to side to make sure that it settles securely.

5. The bottom of the unit can be lifted to facilitate

refrigerant piping and condensate drain connections,

if necessary.

HOOKS AT TOP

OF MOUNTING

BRACKET

TEMPORARY

SPACER

(To facilitate

connections)

INSIDE

OUTSIDE

Typical

installation

procedure

shown.

Figure 5. Boring Hole for Wall Sleeve

USE SUITABLE TOOL TO CUT PVC FOR WALL

SLEEVE AT SLIGHT ANGLE AS SHOWN.

Figure 6. PVC Wall Sleeve Installation

NOTE: When passing bundled services through an

exterior brick or concrete wall, protect the

copper pipes and wiring from the effects of these

construction materials by using a sleeve made

of suitable material. The integrity of copper pipe

and wiring can deteriorate when exposed to these

construction materials.

Figure 7. Secure Unit to Wall Mounting Plate

10

Page 11

MWMA009S4, MWMB009S4, MWMA012S4, MWMB012S4

5-1/2 (140)

1-3/4 (44)

Left rear side

refrigerant pipe inlet

2-1/2 (64) diameter

7/8 (22)

Left rear side

refrigerant pipe inlet

2-1/2 (64) diameter

12-3/8 (314)

10-1/4 (260)

32-7/8 (835)

MWMA018SA

39 (991)

4-3/8

(111)

1-3/8

(35)

5-1/4 (133)

Indoor unit

outline

11 (279)

1-3/4 (44)

Right rear side

refrigerant pipe inlet

2-1/2 (64) diameter

Indoor unit

outline

1-3/4 (45)

Right rear side

refrigerant pipe inlet

2-1/2 (64) diameter

Left rear side

refrigerant pipe inlet

2-1/2 (64) diameter

MWMA024S4, MWMA030S4, MWMB030S4

10-1/8

(257)

46-3/4 (1187)

10-7/8

(276)

7/8 (22)

Figure 8. Wall Mounting Plates - Inches (mm)

Indoor unit

outline

13-1/2 (343)

1-3/4 (44)

Right rear side

refrigerant pipe inlet

2-1/2 (64) diameter

11

Page 12

Indoor Unit Condensate Piping Connections

e no

IMPORTANT

Make sure that drain piping is properly routed and

insulated to prevent both leaks and condensation.

1. Use a eld-provided hose clamp to secure the drain

line stub on the side of the cabinet to a eld-supplied

1-inch (25 mm) drain line.

NOTE: Take care not to over-tighten the hose clamps this

may damage the drain line stub.

NOTE: Connection between stub and drain line must be

watertight. Apply non hardening plumbing joint

compound if needed to ensure a watertight seal.

2. Conrm proper slope (not less than 1/4 inch per foot

(18 mm per m)) and routing of condensate lines to

ensure moisture is drained away from the indoor unit.

3. Drain should be as short as possible and should

not have any droops or kinks that would restrict

condensate ow and shall be approved resistant pipe.

There must be a 2-inch (51 mm) space between the

end of the condensate drain and the nal termination

point (ground, open drain, etc.) to ensure that the line

will drain freely.

4. After the system installation is complete, the

condensate drain line must be checked for leaks and

proper drainage. If a eld-provided condensate pump

has been installed, it must be checked to ensure proper

operation. This check is part of the start-up process

which must be done by the installing contractor.

IMPORTANT

Drain should have a slope of at least ¼ inch per foot and

should be approved corrosion-resistant pipe. You must

conrm operation of every drain and pump in the system

as part of the commissioning procedure.

CORRECT

Make sure there ar

kinks or dent in drain

hose to ensure proper

drainage.

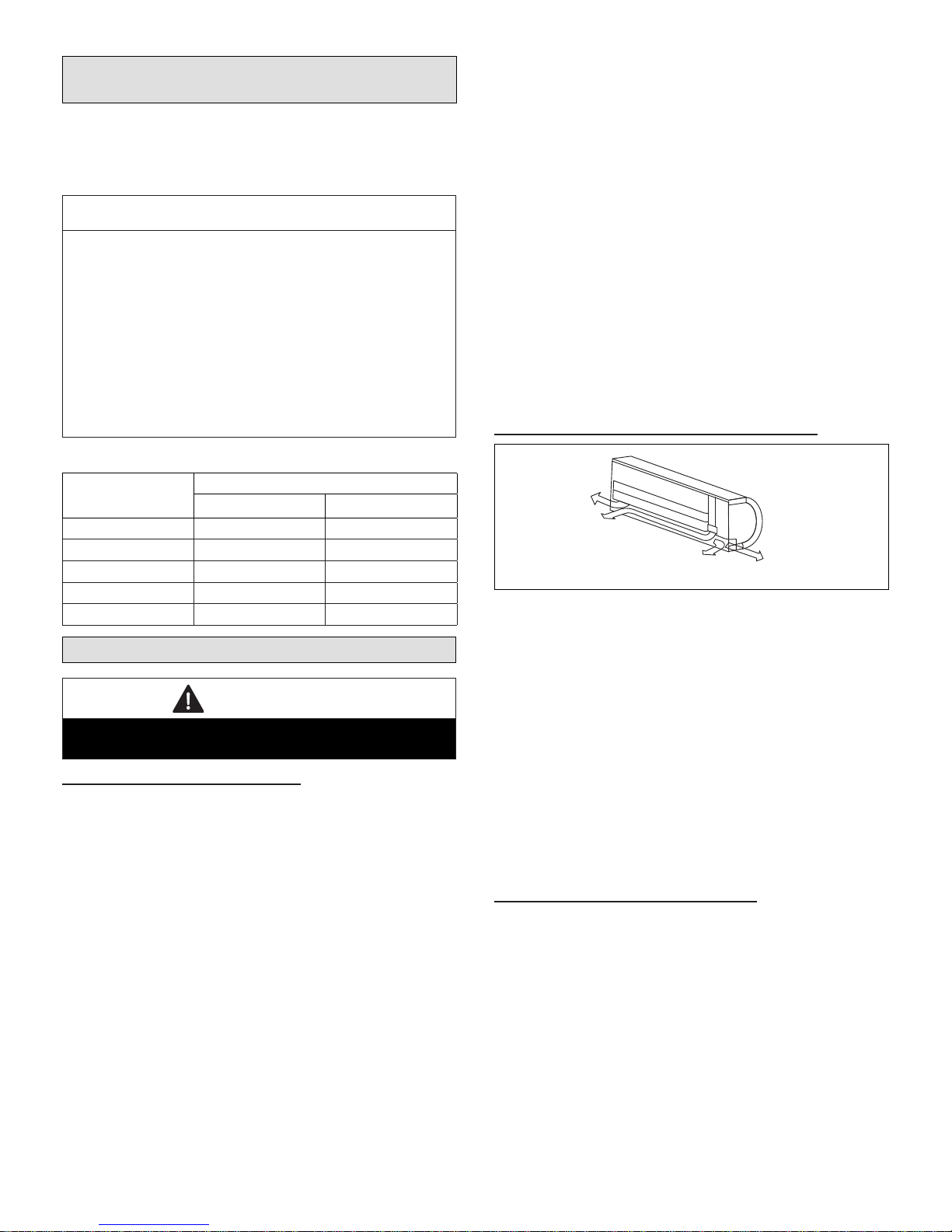

Figure 9. Condensate Line

Outdoor Unit Installation

Placement Considerations

Consider the following when positioning the unit:

• In coastal areas or other places with salty atmosphere

of sulfate gas, corrosion may shorten the life of the

unit. In coastal areas, the coil should be cleaned with

potable water several times per year to avoid corrosive

buildup (salt)

• Some localities are adopting sound ordinances based

on the unit’s sound level registered from the adjacent

property, not from the property where the unit is installed. Install the unit as far as possible from the property line

• When possible, do not install the unit directly outside

a window. Glass has a very high level of sound transmission

• Install unit level

Building Structure

Ground

Level

Figure 10. Install Unit Level

• Choose a place solid enough to bear the weight and

vibration of the unit, where the operation noise will not

be amplied

• Choose a location where the hot air discharged from

the unit or the operation noise will not be a nuisance

to neighbors

• Avoid installing the outdoor unit near a bedroom or

other places where noise may cause a problem

• There must be sufcient space to carry the unit into

and out of the site

• There must be unobstructed air ow around the air inlet and the air outlet

• The unit must not be installed in areas where a ammable gas leak may occur

• Install the outdoor unit a minimum of 3 feet (1m) away

from any antenna, power cord (line), radio, telephone,

security system, or intercom. Electrical interference

and radio frequencies from any of these sources may

affect operation

• Since water drains from the outdoor unit during various stages of operation, do not place anything which

may be damaged by moisture under the unit

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

12

Page 13

Direct Sunlight, Rain, Snow and Ice Protection

Air Inlet

Air Outlet

• If the outdoor unit is subjected to prolong exposure to

direct sunlight with temperatures over 100°F (38°C) a

canopy is recommended as illustrated in “Figure 11.

Outdoor Unit on Pedestal and Protective Canopy” or

“Figure 16. Dog House-Style Shelter” on page 14

IMPORTANT

The construction of a canopy or shade is necessary

because of an ambient limit control set to 122°F (50°C)

to protect the electronics. If the outdoor unit is placed in

direct sunlight it is possible that the limit may activate

and shut down the unit.

• Place unit away from overhanging roof lines which

would allow water or ice to drop on, or in front of, coil

or into unit. Construct a canopy as illustrated in “Figure

11. Outdoor Unit on Pedestal and Protective Canopy”

• The unit base should be elevated above the depth of

average snows as illustrated in “Figure 12. Outdoor

Unit on Brackets above Snow Line”

• In heavy snow areas, do not place the unit where drifting will occur as illustrated in “Figure 13. Outdoor Unit

Air Flow Obstructed by Snow”

• Carefully consider how to manage defrost water disposal to prevent ice from blocking walkways or creating a safety hazard near the outdoor unit as illustrated

in “Figure 14. Avoid Defrost Water Ice Hazard”

Protective canopy

Protective canopy

Figure 12. Outdoor Unit on Brackets above Snow

Line

12 in

79 in

2007 mm

Air Outlet

305 mm

Air Inlet

24 in

610 mm

12 in

305 mm

Side View

Air Inlet

Front View

Pedestal

(stand)

Pedestal

(stand)

Air Outlet

Figure 11. Outdoor Unit on Pedestal and Protective

Canopy

Figure 13. Outdoor Unit Air Flow Obstructed by

Snow

Figure 14. Avoid Defrost Water Ice Hazard

13

Page 14

Prevailing Winds

12 in

305 mm

24 in

610 mm

24 in

610 mm

12 in

305 mm

NOTE - Minimum clearances shown.

Drain

Connector

Chassis

Condensate Drain

(location varies per model)

Normally wind bafes are not required for a outdoor unit.

However, in order to maximize reliability and performance,

the following best practices should be followed.

If unit coil cannot be installed away from prevailing winter

winds, some method of protecting the coil is recommended.

However, minimum clearances as reference in “Figure 2.

Outdoor Unit Clearances - Inches (mm)” on page 8

must be observed at all times.

Common application examples are:

• When prevailing winds are from the air inlet side, then

position the wind barrier a minimum of 12 inches (305

mm) from the unit as illustrated in “Figure 15. Wind

Barrier”

• When prevailing wind is into the discharge side, then

position the wind barrier a minimum 79 inches (2007

mm) from the front of the unit as illustrated in Figure

14. Wind Barrier”

• Outdoor unit can be installed in a dog house style

shelter as illustrated in “Figure 16. Dog House-Style

Shelter”

• Outdoor unit can be installed in a alcove or under

a roof overhang as illustrated in “Figure 17. Unit Installed in Alcove”

Prevailing Winter Winds from Air Inlet Side

24 in

610 mm

12 in

305 mm

NOTE - Minimum clearances shown.

12 in

305 mm

610 mm

24 in

Figure 17. Unit Installed in Alcove

Buried Refrigerant Pipe Protection

• All refrigerant lines must be insulated regardless of if

it is buried

• In addition to insulating each line of piping, buried lines

must rest inside a sealed, watertight conduit

• The conduit must be designed so it cannot collect and

retain water

Wind Barrier

Inlet Air

Discharge Air

Wind Barrier

Prevailing Winter Winds From Air Discharge Side

12” (305mm)

Min. Distance

79” (2007mm)

Min. Distance

Figure 15. Wind Barrier

Outdoor Unit Condensate Piping

Condensate formed during the heating and defrost

processes must be drained from heat pump units. Drain

holes are provided in the base of the units to ensure proper

drainage. Heat pumps must be raised when installed on a

concrete pad or the ground to allow drainage to occur. If

the heat pump unit is installed on wall mounting bracket,

insert the provided drain connector into one of the 1

inch (25 mm) drain holes and attached a eld-provided

insulated drain hose to the connector. Use eld-provided

rubber plugs to cover any unused drain holes as illustrated

in “Figure 18. Condensate Drain”.

Figure 16. Dog House-Style Shelter

Figure 18. Condensate Drain

14

Page 15

Securing the Outdoor Unit

Slab or Roof Mounting

Install the unit a minimum of 4 inches (102 mm) above the

roof or ground surface to avoid ice build-up around the

unit. Place the unit above a load bearing wall or area of

the roof that can adequately support the unit. Consult local

codes for rooftop applications.

CAUTION

Roof Damage!

This system contains both refrigerant and oil. Some

rubber roong material may absorb oil. This will cause

the rubber to swell when it comes into contact with oil.

The rubber will then bubble and could cause leaks.

Protect the roof surface to avoid exposure to refrigerant

and oil during service and installation. Failure to follow

this notice could result in damage to roof surface.

6 in

152 mm

Air Inlet

Air Outlet

Figure 21. Securing Outdoor Unit to Brackets

Securing Outdoor Unit to Slab, Frame, or Rails

If the outdoor unit is installed on a eld-provided slab or

frame, use lag bolts or equivalent to secure the outdoor

unit to the slab or frame.

Four Field-provided Anchor Bolts

Figure 19. Securing Outdoor Unit to Slab

Four Field-Provided

Anchor Bolts

Refrigerant Piping Connections

Field piping consists of two copper lines connecting the

outdoor unit to the indoor unit. “Table 2. Refrigerant Piping

and Indoor Unit Connection Sizes” lists the connection

sizes. The connections are made using the provided brass

are nuts at the end of the refrigerant piping connections.

Both lines must be individually insulated.

1. The seal on the unit refrigerant piping connections

should remain in place until the last possible moment.

This will prevent dust or water from getting into the

refrigerant piping before it is connected.

2. CAREFULLY adjust refrigerant piping connections to

suit the application.

3. Slowly loosen one of the are nuts to release the

factory nitrogen charge from the indoor units only.

4. Remove the are nuts from the connections on the

unit and discard the seal from each of the piping

connections.

5. Slide the are nuts onto the ends of the eld-provided

refrigerant piping before using a suitable aring tool to

are the end of the copper pipe.

6. Apply recommended HFC-410A refrigerant lubricant

to the outside of the ared refrigerant lines.

Figure 20. Securing Outdoor Unit to Rails

Securing Outdoor Unit to Hanging Brackets

If the outdoor unit is installed on eld-provided wall

mounting brackets, use lag bolts or equivalent to secure

the outdoor unit to the bracket. Minimum rear clearance

can be reduced to 6 inches (152 mm) when mounted

on brackets and with no obstructions on the other three

sides. Allow for condensate disposal when placing units

above one another.

IMPORTANT

The compressor in this unit contains PVE

oil (Polyvinylether). PVE oil is formulated for

hydrouorocarbon (HFC) refrigerants, such as HFC-

410A, which this system contains. While it may have

some miscibility properties with mineral-based oil and

POE oil (Polyolester), it is not recommended to mix PVE

oil with any other type of refrigerant oil.

15

Page 16

7. Align the threaded connections with the

ared refrigerant lines. Tighten the are nuts

lightly at rst to obtain a smooth match as

illustrated in “Figure 22. Making Connections

(Male to Female Connection)”.

8. Once snug, continue another half-turn on each nut

which should create a leak-free joint. A torque wrench

may be used to tighten are nuts using “Table 3. Flare

Nut Torque Recommendations”. Do not over-tighten

a ared joint. Flared connections should always

be accessible and must be insulated to prevent

condensation.

9. After refrigerant piping has been installed and checked

for leaks, apply insulation over all ared connections.

Table 2. Refrigerant Piping and Indoor Unit

Connection Sizes

Size

(Btuh)

9000 1/4 3/8

12000 1/4 1/2

18000 1/4 1/2

24000 3/8

30000 3/8 5/8

Liquid Line

in.

Suction Line

in.

5/8

Table 3. Flare Nut Torque Recommendations

Outside

Diameter

Inches

1/4 15 ft.-lb. (20 N) 1/4 turn

3/8 26 ft.-lb. (35 N) 1/2 turn

1/2 41 ft.-lb. (56 N) 7/8 turn

5/8 48 ft.-lb. (65 N) 1 full turn

Recommended

Torque

No torque wrench available

Finger tighten and use an

appropriately sized wrench to

turn an additional:

A

CANT ON THE OUTSIDE OF

THE FLARE

MALE FLARE

CONNECTION

B

Figure 22. Making Connections

(Male to Female Connection)

IMPORTANT

Always use two wrenches when tightening are nuts to

avoid twisting refrigerant piping. DO NOT over-tighten

are nuts.

TORQUE WRENCH

TO INDOOR

UNIT

BACKUP

WRENCH

TO OUTDOOR UNIT

Figure 23. Tighten Flare Nut

16

Page 17

Table 4. Refrigerant Line Set Requirements

OUTDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

INDOOR UNIT

Maximum Line Set

Length

Maximum Line Set

Length

Maximum

Elevation -

Outdooor

Unit BELOW

Indoor Unit

Maximum

Elevation -

Outdooor

Unit ABOVE

Indoor Unit

Minimum Line Set

Length - 10 ft. (3m)

Minimum Line Set

Length - 10 ft. (3m)

Outside Unit BELOW Indoor Unit Outside Unit ABOVE Indoor Unit

Do not allow for excess length of line sets to be left rolled up as part of the

required distance, or in general. This will also cause additional performance issues.

IMPORTANT

Each system size has a line set length and vertical elevation parameters.

Line Set Diameters (in.)

System Size (KBtu)

Liquid Gas

009 1/4 3/8 40 (12) 40 (12) 82 (25)

012 1/4 1/2 40 (12) 40 (12) 82 (25)

018 1/4 1/2 66 (20) 66 (20) 98 (30)

024/030 3/8 5/8 82 (25) 82 (25) 164 (50)

Maximum Elevation

Outdoor Unit BELOW

Indoor Unit - Feet

(Meter)

Maximum Elevation

Outdoor Unit ABOVE

Indoor Unit - Feet

(Meter)

Maximum Line

Set Length - Feet

(Meters)

17

Page 18

Leak Test and Evacuation

Air and moisture remaining in the refrigerant system will

have undesirable effects as indicated below:

• Pressure in the system rises

• Operating current rises

• Cooling or heating efciency drops

• Moisture in the refrigerant circuit may freeze

• Water may lead to corrosion of parts in the refrigeration system

The line set between the indoor and outdoor units

must be leak tested and evacuated to remove any noncondensables and moisture from the system.

Leak Test

Use the following procedure to test for system leaks:

1. Connect the manifold gauge set and dry nitrogen gas

cylinder to the suction and gas service ports.

2. Open valve on nitrogen cylinder.

3. Pressurize the system per the pressure test

specications in “Table 5. Pressure Test Specications”.

4. Check that the system pressure remains stable. If

there is any movement check system for leaks.

5. After the system is found to be free of leaks:

• Close valve on nitrogen cylinder

• Relieve the nitrogen pressure by: loosening the

charge hose connector at the nitrogen cylinder

• When the system pressure is reduced to normal,

disconnect the hose from the cylinder

Table 5. Pressure Test Specications

Bar Psig kPa Duration

1 3 44 303 Minimum of 10 minutes

2 15 220 1517 Minimum of 10 minutes

3 32 470 3241 Minimum of 10 minutes

4 45 650 4482

5 32 470 3241

1 hour. Stress test to prove the

integrity of the complete installation.

24 hours. Lower system pressure

test, after conrmation No. 4 was

successfully completed.

IMPORTANT

Use only oxygen-free nitrogen (OFN).

Triple Evacuation Procedure

A Micron or Torr gauge must be used for this procedure.

1. Discharge the oxygen-free nitrogen and evacuate the

system to a reading of 8000 Microns (8 Torr) using all

service valves.

2. Break the vacuum by allowing nitrogen into the port

connections (liquid and gas line pipes) until a positive

pressure is achieved.

3. Evacuate the system to a reading of 5000 Microns (5

Torr).

4. Break the vacuum by allowing nitrogen into the port

connections (liquid and gas line pipes) until a positive

pressure is achieved

5. Evacuate the system to a minimum reading of 500

Microns (0.5 Torr).

6. For a moisture-free system, ensure the vacuum is held

without movement for a minimum of 4 hours.

7. If vacuum fails to hold, carry out steps 2 through 6 until

vacuum holds.

Wiring Connections

WARNING

Electric Shock Hazard. Can cause injury or death. Unit

must be rounded in accordance with national and local

codes.

Line voltage is present at all components when unit is

not in operation. Disconnect all remote electric power

supplies before opening access panel. Unit may have

multiple power sources.

CAUTION

All terminal connections must be made as illustrated

in the following diagrams. Improperly connected wiring

could damage unit or cause communication errors

between indoor and outdoor units.

In the U.S.A., wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada,

wiring must conform with current local codes and the

current Canadian Electrical Code (CEC).

Outdoor Unit

• Refer to unit nameplate for minimum circuit ampacity

and maximum over-current protection size

• Make all electrical power wiring connections at the outdoor unit

• Be sure to reattach all electrical box covers after connections are complete

Indoor Unit

• All indoor units are powered by the outdoor unit

• Communication Wiring (Indoor Units 30K and Below):

Use one stranded 4-conductor wire to provide power

and communication

• Communication Wiring (Indoor Units 36K and Above):

Use one stranded 3-conductor wire to provide power

and one stranded 2-conductor wire to provide communication

• Use minimum of 18 GA stranded wiring

NOTE: When installing a condensate pump the line voltage

will have to be broken by using the condensate

wiring or through the use of an external relay or

contactor

18

Page 19

208/230V Outdoor Unit

Terminal Block

208/230V Indoor Unit

Terminal Block

1 2 3 L1 L2

From Power

Supply

Outdoor Unit Indoor Unit

1 2 3

NOTE - Use minimum of 18 GA stranded wiring.

Figure 24. Single Zone Wiring

IMPORTANT

This unit must be properly grounded and protected by a

circuit breaker. The ground wire for the unit must not be

connected to a gas or water pipe, a lightning conductor

or a telephone ground wire.

Do not connect power wires to the outdoor unit until

all other wiring and piping connections have been

completed.

Do not install the unit near a lighting appliance that

includes a ballast. The ballast may affect remote control

operation.

IMPORTANT

All diagrams (Figure 25 through Figure 36) are typical

wiring diagrams. Refer to the wiring diagram on the unit

for actual wiring.

19

Page 20

M

M

5

SWING MOTOR1

NOTE: COMPONENT IN

DASH LINE IS OPTIONAL

OR FIELD WIRING

RED

B LACK

Y ELLOW

2

3

1

FOR SETTING NETADDRESS

0

1

F

2

E

3

D

4

ENC2+S 1

CODE

NETADDR ESS

C

5

B

6

A

7

9

8

0~F 0~F 0~F 0~F

0~15

U

BLUE

RED

V

W

BLACK

Y/G

CN10A

8

OPTIONAL

Wired Controller

0

ON

1

1

ON

F

2

E

3

D

4

C

5

B

6

A

7

9

2

1

8

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

2

8

0

ON

1

1

ON

F

2

E

3

D

4

C

5

B

6

A

7

9

2

1

8

5

2

16~31 32~47 48~63

CN2(CN201)

CN1(CN101)

Programmable

Wired Controller

Note: The programmable wired

controller and LVM use the same

port CN403.

Figure 25. MWMA and MWMB Unit Wiring Diagram

6

CN28

CN26

CN34

CN33

CN32

CN31

CN7

CN5

CN4

CN6

YELLOW

BLUE

BROWN

Y/G

CN15

U

V

W

RY3

L2

BLUE

4

N-A

DISPLAY BOARD

CN3(CN301)

OPTIONAL

VALVE

5

4

PAN HE ATER

CRANK CASE

HEA TER

CN501

ADAPTER BOARD

CN403

X Y E

YELLOW

BROWN

To LVM

Comm.Bus

RED

Figure 26. 115V MPA009S4S-*L and MPA012S4S-*L Outdoor Unit Wiring Diagram

L-A(CN37)

BLACK

N-B

L-B(CN36)

BLACK

CN8

RED

REACTOR

20

GND

CN10

CN9

RED

5

Y/G

N

L

POWER

SUPPLY

115V

Page 21

OR

CN9-1

WHITE

REACTOR

COMPRESSOR

BLACK

CN28

CN32-1

WHITE

RED

CN29

BLUE

CN30

CN7

3

DC-FAN

COMPRESSOR

DISCHARGE TEMP. SENSOR

CN3

CN22

Y/G

COIL TEMP. SENS

OUTDOOR

CN21

OUTDOOR TEMP. SENSOR

6

CRANKCASE

4-WAY

VALVE

BLUE

BROWN

1

HEATER

PAN

HEATER

2

YELLOW

BLUE

RED

3

L2

Y/G

CN31

CN33

CN26

CN27

CN16

CN1

CN2

Y/G

Figure 27. 208/230V MPA009S4S-*P and MPA012S4S-*P Outdoor Unit Wiring Diagram

CRANKCASE HEATER

RED

Y/G

4-WAY VALVE

BLACK

YELLOW

Y/G

RED

CN6

BLUE

CN3

CN4

CN8

CN7

CN2

CN6-1

Y/G

OUT DOOR

FAN

3

CN414

CN15

RY1

OUTDOOR

CN18

6

L-OUT

MAIN

PCB

WHITE

OUTDOOR TEMP.SENSOR

CN1

O U TD OOR COIL

TEM P.

CN14

BLACK

CN13

CN12

BLUE

RED

BLACK

CN10

COMPRESSOR

U

V

W

TEMP.SENSOR

BLUE

1

RED

2

BLACK

3

W

COMPRESSOR

BLUE

BLUE

U

V

Y/G

Figure 28. 208/230V MPA018S4S-*P Outdoor Unit Wiring Diagram

21

Page 22

Compressor

Control Board

L-OUT

COMPRESSOR DISCHARGE

TEMP.SENSOR

2

S

CN10

BLACK

RED

CODE PART NAME

COMPRESSOR

COMP

OUTDOOR DC FAN

FM1

HEAT1

CRANKCASE HEATER

HE AT 2

PA N HE ATE R

H-PRO

HIGH PRESSURE SWITCH

L-PRO

LOW PRESSURE SWITCH

PFC INDUCTOR

L

SV

4-WAY VALVE

OUTDOOR COIL

T3

TEMP.SENSOR

T4

OUTDOOR TEMP.SENSOR

Y/G

RED

PAN HEATER

Y/G

CRANK CASE HEATER

Figure 29. 208/230V MPA024S4S-*P Outdoor Unit Wiring Diagram

CN3

CN4

CN10

CN22

CN40

CN44

CN8

CN9

BLACK

CN7

3

CN33

HEAT1

HEAT2

MAIN BOARD

CN5

CN6

RED

COMP

Y/G

Compressor

Control Board

YELLOW

BLACK

W

RED

V

BLUE

U

COMPRESSOR DISCHARGE

SE NSO R

TEMP.

BLUE

SV

BLUE

BLACK

RED

BLUE

BLUE

BLUE

CN54

CN51

CN53

CN52

3

CN55

CN19

7

W

V

U

RED

BLACK

CR ANK CAS E HEA TER

PA N HEA TER

T3

T4

H-PRO

L-PRO

YELLOW

7

L

YELLOW

BLACK

V1. 0 2015/ 5/08

Y/G

FM1

3

CN12 CN11

CN2

CN1

P-1

3

YELLOW

S

BLACK

RED

Y/G

Figure 30. 208/230V MPA030S4S-*P Outdoor Unit Wiring Diagram

22

JXI

Y/G

RED

1

TO IN DOOR UNI T

BLA CK

2

3

YEL LOW

BLACK

RED

L2

L1

L1

POW ER SUP PLY

L2

Page 23

COMPRESSOR

Y/G

4-WAY VALVE

CN 50

OUTDOOR

FAN

CN 7

3

6

CN 31

PAN

HEATER

CN 15

CN 60

CRANKCASE

HEATER

CN 17

B LUE

B RO WN

BLACK

3

2

N

R E

D

B LUE

Y/G

1

Y/G

OU TD OOR

T EMP. SENS OR

C OMP R ES S OR

DISCH AR GE

T EMP. S E NSOR

CN 21

OUT DOOR C O IL

T EMP. S ENSOR

Y/G

CN 1A

Y/G

Y/G

3

CN4_1

CN4_2

CN4_3

CN4_4

REACTOR

CAPACITOR

BROWN

BROWN

BLACK

BLACK

2

2

BLACK

W

V

RED

BLUE

U

OUTDOOR

MAIN

PCB

RED

BLACK

WHTIE

Figure 31. 115V MPB009S4S-*L and MPB012S4S-*L Outdoor Unit Wiring Diagram

4-WAY VALVE

OUTDOOR

FAN

CN 7

3

6

CN 31

PAN

HEATER

CN 15

CN 60

CRANKCASE

HEATER

CN 17

BLUE

BROWN

BLACK

3

2

L2

RED

BLUE

Y/G

1

Y/G

CN 21

Y/G

CN 1A

Y/G

Y/G

COMPRESSOR

Y/G

CN 50

3

U

V

W

BLUE

RED

BLACK

EXV

OUTDOOR

MAIN

PCB

OUTDOOR

TEMP . S ENS OR

COMPRES S OR

DISCHARGE

T E MP. S E NS OR

OU TDOOR C OIL

T E MP. S E NS OR

RED

BLACK

WHTIE

Figure 32. 208/230V MPB009S4S-*P and MPB012S4S-*P Outdoor Unit Wiring Diagram

23

Page 24

Figure 33. 208/230V MPB018S4S-*P and MPB024S4S-*P Outdoor Unit Wiring Diagram

•••••

COMPONENT IN DASH

LINE IS OPTIONAL

OR FIELD WIRING.

4-WAY

VALVE

TS

EXV

Figure 34. 208/230V MPB030S4S-*P, Outdoor Unit Wiring Diagram

24

Page 25

Figure 35. 208/230V MLA009, MLA012 and 018S4S-*P Outdoor Unit Wiring Diagram

BLACK

W

COM P

YELLOW

CODE

COMP

CAP1

EEV

FM1

H-PRO

L-PRO

SV

TS

T3

T4

RED

V

BLUE

U

DRIVER BOARD

L

L

FM1

3

Y/G

3

CN5 5

CN1 9

W

BLACK

V

RED

U

BLUE

BLUE

BLUE

YELLOW

CN54

CN51

CN53

CN52

RED

BLACK

PART NAME

COMPRESSOR

FAN MOTOR CAPACITOR

ELECTRIC EXPANSION

VALVE

OUTDOOR DC FAN

HIGH PRESSURE SWITCH

PFC INDUCTOR

LOW PRESSURE SWITCH

4-WAY VALVE

DISCHARGE

TEMPERATURE SENSOR

CONDENSER

TEMPERATURE SENSOR

OUTDOOR AMBIENT

TEMPERATURE SENSOR

SV

BLUE

HEAT1

Cra nkcas e Heate r

HEAT2

Bas e Pan Hea ter

T3

T4

36K ODU

ONLY FOR

4-WAY1

H-PRO

L-PRO

BLUE

CN3

CN4

CN10

CN8

CN9

CN7

CN33

CN22

CN40

CN44

MAIN BOARD

BLACK

CN5

CN6

RED

Y/G

EEV

5(6 )

CN20

RED

BLA CK

1

TO INDOO R UNIT

2

YELLOW

L1

3

S

CN2

CN1

P-1

BLACK

RED

L2

L1

L2

POWER SUPPLY

YELLOW

BLACK

RED

Y/G

Y/G

Figure 36. 208/230V MLA024S4S-*P Outdoor Unit Wiring Diagram

25

Page 26

Unit Start-Up

Troubleshooting

IMPORTANT

Units should be energized 24 hours before unit start-up

to prevent compressor damage as a result of slugging.

1. Inspect all factory- and eld-installed wiring for loose

connections.

2. Verify that the manifold gauge set is connected.

3. Add additional refrigerant charge if required before

opening valves and while system is still under a

vacuum.

4. Open the liquid and suction line service valves to

release the refrigerant charge contained in outdoor

unit into the system.

5. Replace the stem caps and tighten to the value listed

in “Table 1. Torque Requirements” on page 9.

6. Check voltage supply at the outdoor unit terminal strip.

The voltage must be within the range listed on the

unit’s nameplate. If not, do not start the equipment

until you have consulted with the power company and

the voltage condition has been corrected.

7. Refer to the included user guide to operate the system

using the provided remote control.

8. Visually check for binding of both indoor and outdoor

fans.

Table 7. Troubleshooting Codes

Code Description

E0 Indoor unit EEPROM error

E1 Communication error between indoor unit and outdoor unit

E3 Indoor fan speed error

E4 Indoor return air temperature sensor error

E5 Indoor coil temperature sensor error

EC Low refrigerant

EE High water level alarm

F0 Outdoor current overload sensed

F1 Outdoor ambient temperature sensor error

F2 Outdoor coil temperature sensor error

F3 Compressor discharge temperature sensor error

F4 Outdoor unit EEPROM error

F5 Outdoor unit fan speed error

P0 Inverter module IPM error

P1 High or low voltage protection

P3 Outdoor unit low temperature lockout

P4 Compressor drive error

-- Mode conict

P6 Compressor high-pressure or low-pressure switch open

Test Run

Adding Refrigerant for Longer Line Set

The outdoor unit is factory-charged with refrigerant.

Calculate the additional refrigerant required according to

the diameter and the length of the liquid pipe between the

outdoor unit and indoor unit connections.

Be sure to add the proper amount of additional refrigerant.

Failure to do so may result in reduced performance.

Table 6. Additional Refrigerant Charge

System Size

(KBtu)

09 >25 (7.5) 0.161 oz/ft (15g/m)

12 >25 (7.5) 0.161 oz/ft (15g/m)

18 >25 (7.5) 0.161 oz/ft (15g/m)

24 >25 (7.5) 0.322 oz/ft (30g/m)

36 >25 (7.5) 0.322 oz/ft (30g/m)

48 >25 (7.5) 0.322 oz/ft (30g/m)

Pipe Length

(feet / meters)

Amount of Refrigerant

to add

Pre-Checks

Only perform test run after you have completed the

following steps:

• Electrical Safety Checks – Conrm that the unit’s

electrical system is safe and operating properly

• Refrigerant Leak Checks – Check all are nut connec-

tions and conrm that the system is not leaking

• Conrm that suction and liquid valves are fully open.

Procedure

You should perform the Test Run for at least 30 minutes.

1. Connect power to the unit.

2. Press the ON/OFF button on the remote controller to

turn it on.

3. Press the mode button to scroll through the following

functions, one at a time:

• COOL - Select lowest possible temperature

• HEAT - Select highest possible temperature

4. Let each function run for 5 minutes, and perform the

following checks:

26

Page 27

Table 8. Test Run Checklist

Checks Pass Fail

No electrical leakage

Unit is properly grounded

All electrical terminals

properly covered

Indoor and outdoor units are

solidly installed

All pipe connection points do

not leak

Water drains properly from

drain hose

All piping is properly

insulated

Unit performs COOL function

properly

Unit performs HEAT function

properly

Indoor unit louvers rotate

properly

Indoor unit responds to

remote controller

Double-Check Pipe Connections

During operation, the pressure of the refrigerant circuit

will increase. This may reveal leaks that were not present

during your initial leak check. Take time during the Test

Run to double-check that all refrigerant pipe connection

points do not have leaks.

1. Using remote control, return unit to the normal

operating temperature

2. Using insulation tape, wrap the indoor refrigerant pipe

connections that you left uncovered during the indoor

unit installation process

If Ambient Temperature is below 63°F (17°C)

You cannot use the remote controller to turn on the

COOL function when the ambient temperature is below

63°F (17°C). In this instance, you can use the MANUAL

CONTROL button to test the COOL function.

1. Lift the front panel of the indoor unit, and raise it until

it clicks in place

2. The MANUAL CONTROL button is located on the

right-hand side of the unit. Press it 2 times to select

the COOL function

3. Perform Test Run as normal

Manual control

button

Figure 37. Manual Control Button

Dry Mode Operation (Dehumidication)

Procedure

1. Using the provided wireless remote control, press the

MODE button and select DRY mode.

2. Press the UP/ DOWN button to select the desired

temperature. The temperature setting range is from

62°F (17°C) to 86°F (30°C) in one degree increments.

NOTE: The blower is preset at a low speed and cannot be

changed therefore it will get cold and most likely

will over shoot the temperature setting by 6-10°F

(3-5°C) depending on the room size or other

various factors. Also the Follow Me mode does

not operate in this mode.

NOTE: In addition, the indoor units do not have a humidistat

installed therefore they are unable to determine

humidity levels. This product is not recommend as

a main source for dehumidication.

Sequence of Operation

When in dry mode operation the unit is actually in cooling

mode with a low speed blower operation. Set remote temp

to a lower room temp to begin the dry mode operation.

The compressor will stop when the room temperature is

4°F (2°C) lower than the temperature setting.

However there is a temperature compensation for cooling

mode that is two degrees Celsius. So the unit will stop

when the temperature is 8°F (4°C) lower than the room

temperature settings.

27

Page 28

28

Loading...

Loading...