Page 1

APPLICATION

GUIDE

Water cooled chillers

Heat pumps

MWC

MWR

180 720 kW

MCW-AGU-0410-E

lennoxemeia.com

Page 2

Page 3

TABLE OF CONTENTS

APPLICATION GUIDE

1.

GENERAL

Features and benefi ts

Options and accessories

Model number description

2.

GENERAL DATA

General data

Pressure drops

Hydraulic data

Acoustic data

Operating limits

Ref : MWC-AGU-0410-E

2

4

5

6

10

11

12

13

ELECTRICAL DATA

4.

Electrical tables

PERFORMANCES

5.

MWC - Cooling mode

MRC - Cooling mode

MWC - Heating mode

DIMENSIONAL DATA

6.

Dimensional data

14

15

16

17

18

Our company is member of the Eurovent certifi cation program.

The MWC™ Lennox chillers are tested and rated in accordance with Eurovent certifi cation program.

Our products comply with the European standards.

Product designed and manufactured under a quality management system certifi ed ISO 9001.

All the technical and technological information contained in this manual, including any drawing and technical descriptions provided

by us, remain the property of Lennox and must not be utilised (except in operation of this product), reproduced, issued to or made

available to third parties without the prior written agreement of Lennox.

Application Guide • MWC-0410-E • 1 •

Page 4

FEATURES AND BENEFITS

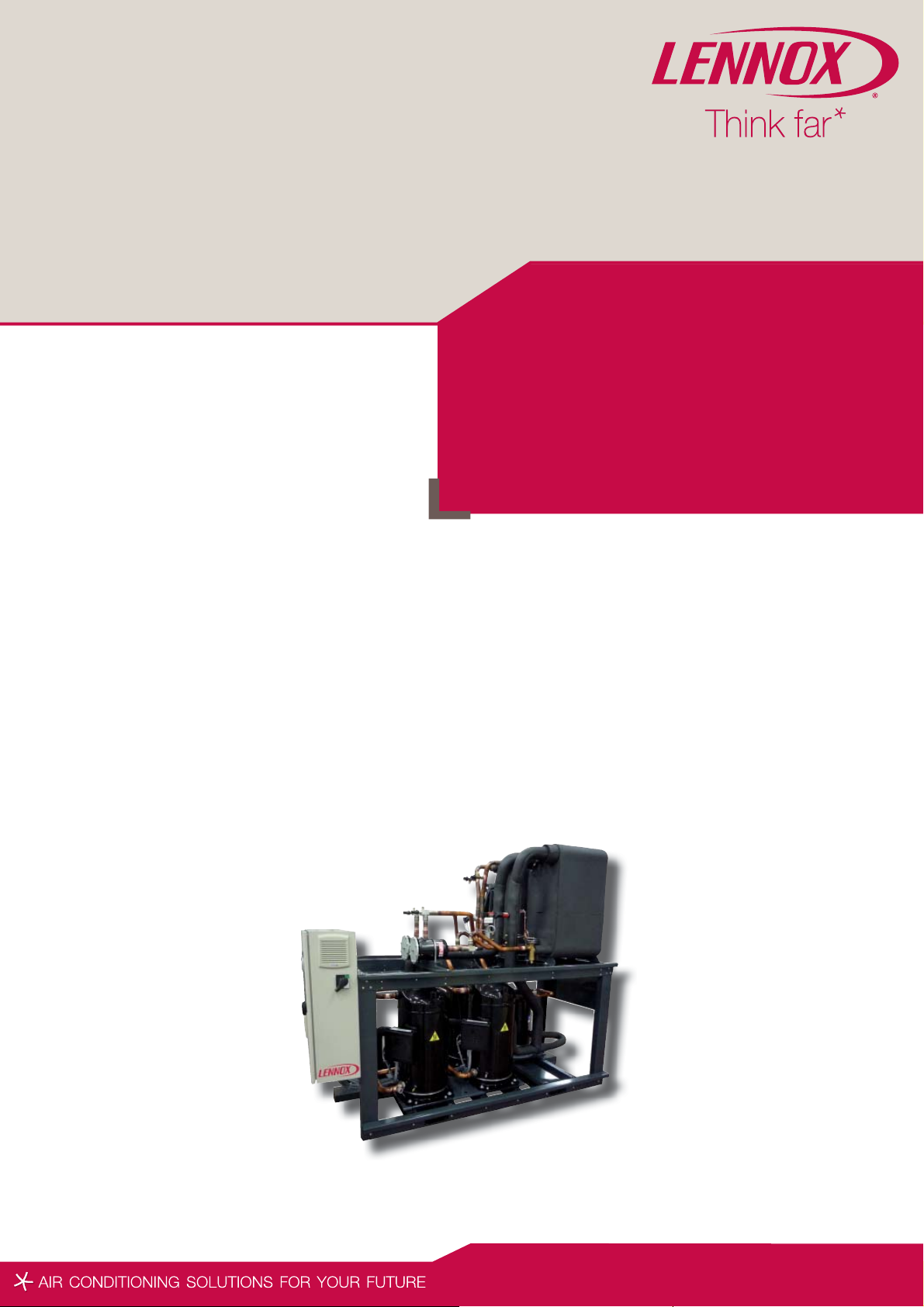

Water cooled liquid chiller for indoor installation

GENERAL CHARACTERISTICS OF THE UNIT

The MWC unit is designed for industrial and commercial

applications where customers require reduced total cost of

ownership for new air conditioning equipment.

As main characteristics the MWC unit offers multi scroll

R410A compressors with two circuits for safety operation and

oversized heat exchangers for high full and part load energy

performances (Class B effi ciency / ESEER > 6.0).

The MWC is the solution for indoor installation. Thanks to

very compact dimensions and limited footprint MWC can be

installed easily into any technical room.

The MWC is available in 2 main versions to meet all customer

requirements and applications :

- MWC version is the water-cooled chiller. This version can

be used for air conditioning applications in association with

a separate dry-cooler or using ground water. The MWC version can also be used for heating applications. With the “hot

water set point control” option the MWC range can supply

hot water up to +50°C.

- MRC version is the split version without condenser. This

version can be used for air conditioning applications in association with a remote air-cooled condenser

COMPRESSOR

MWC is using R410A vibration-free compliant® scroll compressors

to guarantee a low operating sound level, a high durability and

reliability and no maintenance.

- Exclusive Compliant® Scroll design with both axial and radial

compliance to increase compressor operation tolerance to

liquid refrigerant, substantially improving durability and reliability.

- Motor cooled by suction gas.

- Electronic control of the compressor discharge temperature.

- Motor protection device against high temperature or over

current situations.

- Discharge non-return valve.

- Compressors assembly installed on an independent chassis

supported by anti-vibration mountings.

- Optional sound-proofed panel enclosures to reduce noise

emissions.

WATER HEAT EXCHANGER (EVAPORATOR

AND CONDENSER)

MWC is using stainless steel brazed plate heat exchangers with

true dual circuit.

REFRIGERANT CIRCUIT

MWC is using R410A refrigerant in 2 independent circuits that

allows operation at 50% of the capacity in case of issue on one

circuit.

Each circuit includes:

- A refrigerant charge reduced by 30% thanks to the use of

R410A combined with plate heat exchanger

- Suction piping with thermal insulation.

- Moisture sight glass on the MRC version

- Filter drier with removable cartridge fi lter.

- Thermostatic valve or electronic expansion valve (optional

from size 180 to 570, standard on size 650 & 720).

- Temperature sensors and pressure transducers.

- Leak-tight refrigerant circuit with brazing carried out under

nitrogen by certifi ed technicians.

- Each refrigerant circuit is pressure and leak tested with a

Hydrogen/Nitrogen mixture, and vacuumed before being

charged with refrigerant. All units are then subjected to a

complete functional and operational run test to guarantee

perfect sealing before leaving the factory.

- Copper brazed stainless steel plate heat exchanger.

- 13 mm closed cell thermal foam insulation.

- Evaporator protected against freezing risks thanks to an

electronic water fl ow switch

- Condenser protected against low condensing temperature

thanks to a 0-10 V output signal available from the controller

to control a condenser water inlet valve (Not from Lennox

supply).

CASING/CHASSIS

- Chassis made of galvanised steel sheet metal painted with

a RAL 7016 (grey) powdered polyester paint.

- Optional casing with removable panels made of galvanised

steel sheet metal painted with a RAL 7016 (grey) powdered

polyester paint.

• 2 • Application Guide • MWC-0410-E

Page 5

FEATURES AND BENEFITS

ELECTRICAL BOX

The MWC is designed for 400V/3/50Hz supply.

- Unit electrical cabinet, components and wiring in compliance

with EN 60204-1 electrical directive.

- 400V/3/50Hz power supply (without neutral) with a single

point of power connection.

- IP24 protection class.

- Recognized brand electrical components for ease of maintenance.

- Main on/off switch mounted on the front panel.

- DC50 user interface mounted on the front panel.

- 400/24 V transformer to supply the control circuit.

- Labelled electrical wires to facilitate maintenance and diagnostic.

- Optional power and control circuit for the pumps.

CONTROL

CLIMATIC™ microprocessor based control is providing the

following functions:

- 4 scheduling time zones per day over 7 days to allow energy

consumption management according to the building use and

environmental constraints.

- PI control of the water temperature with operating time

equalisation of the compressors.

- Intelligent advanced control algorithm to protect the compressors against excessive short-cycling and to allow operation

of the unit without buffer tank in most comfort air conditioning

applications (e.g. unit with fan-coils). Refer to minimum installation water loop volume recommendations.

- Water pump control with operating time equalization and

automatic change-over in case of a pump fault (Twin pump

only).

- Master/slave or cascade control of two chillers operating

in parallel with operating time equalization and automatic

change-over in case of a unit fault.

CLIMATIC™ is pre-factory confi gured with default settings

allowing a fast commissioning on site. The DC50™ user interface

with graphical display is easy to use, intuitive. Main customer

parameters can be read or modifi ed without main power shut-off

(Entering/leaving water temperatures, alarms, water set-points,

high and low pressure readings).

The DS50™ service display (optional) is a .plug and play"

controller that allows service people to read and modify all

unit parameters (Unit settings, operating time and number of

compressor starts, low and high pressure reading, read the

history of last 32 faults...).

COMMUNICATION

The control board is equipped with a RS485 serial communication

port to allow remote management through communication

bus.

According to the wished communication protocol, our control

board can be fi tted with ModBUS®, LonWorks® or BacNET®

communication interface (options).

The main control board has free dry contacts that allow remote

control of the unit by wired cable:

- Remote on/off of the unit.

- Remote alarm reset to re-start the unit.

- Alarm or alert indications.

- Free customer contact.

With the optional extension board BE50, it is possible to get

additional customized digital or analog inputs/outputs for remote

control of the unit:

- Fault pumps (dry contact).

- Operation indication at 100% on circuit 1 or 2 (dry

contact).

- Dual water set-point management (dry contact).

- Force heating or cooling mode (24V AC input).

- Power limitation by disabling circuit 1 or 2 (24V AC input).

- Force unoccupied mode (24V AC input).

- Water set-point offset based on a 4-20mA signal.

DIRECTIVES

The unit is built to meet European norms and standards &

Eurovent certiFIcation performance standards.

. DI 97/23/CE Pressure Equipment Directive.

. DI 98/37/CE Machinery Directive.

. DI 73/23/CE Low Voltage Directive.

. DI 89/336/CE Electro Magnetic Compatibility Directive

. EN 378-2 Safety and Environmental Directive.

. The European Restriction of the Use of Certain Hazardous-

Substances (RoHS).

Application Guide • MWC-0410-E • 3 •

Page 6

OPTIONS AND ACCESSORIES

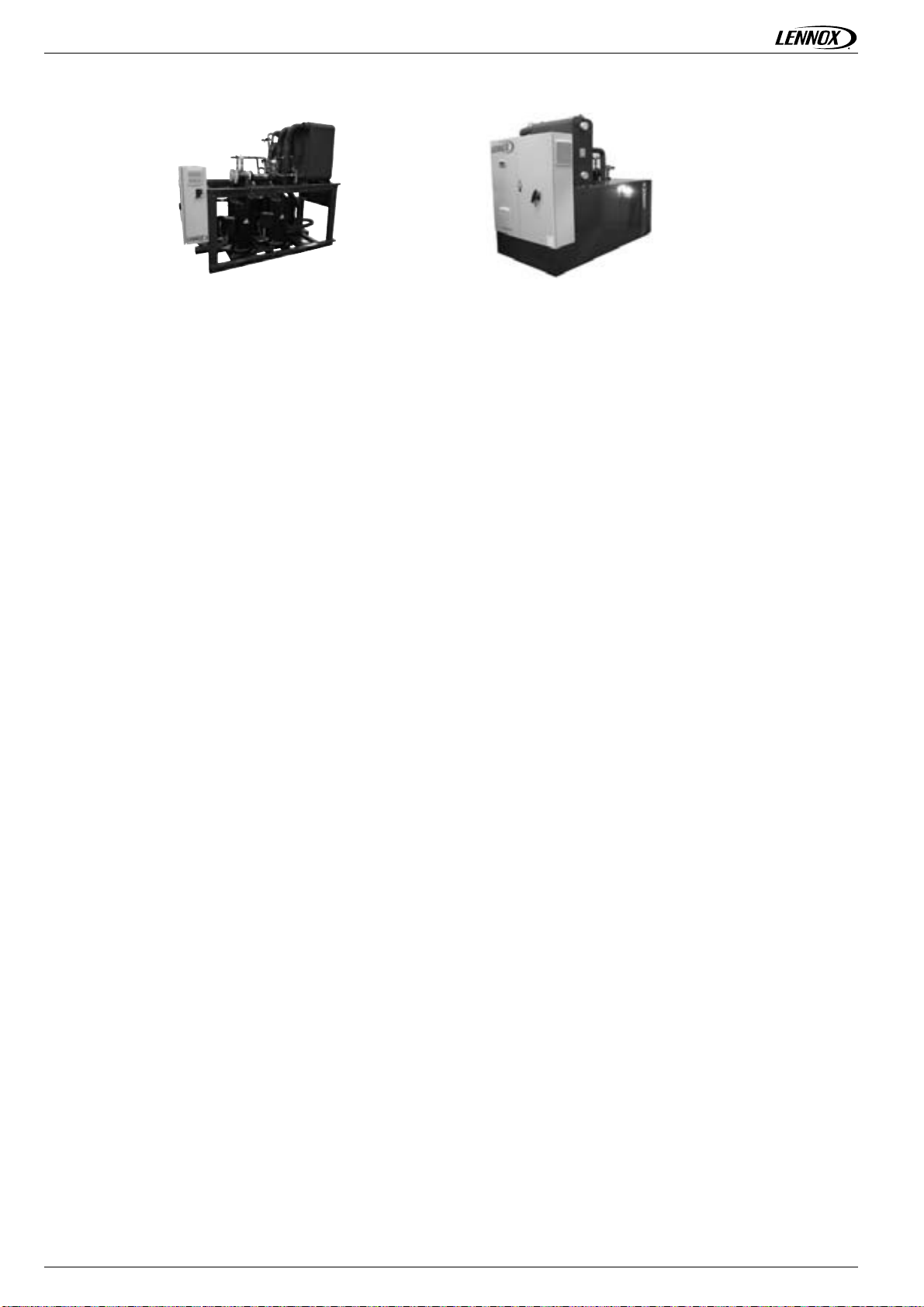

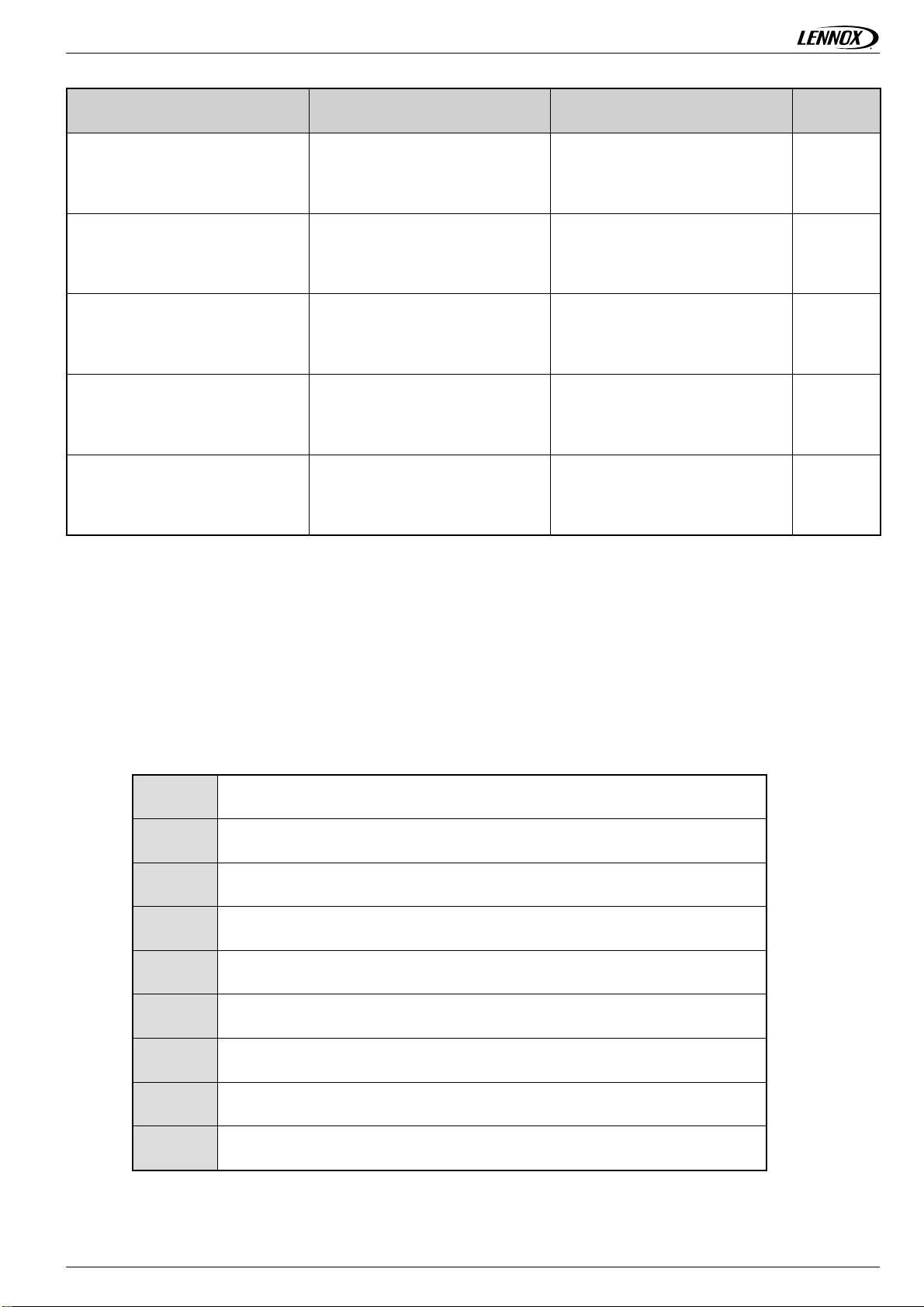

OPTIONS DESCRIPTION ADVANTAGES MODELS

Control/Power electrical equipment of

single evaporator pump

Control/Power electrical equipment of

dual evaporator pump

Control/Power electrical equipment of

single condenser pump

Control/Power electrical equipment of

dual condenser pump

Electronic expansion valve

Evaporator fi lter (supplied loose)

Unit equipped with electrical power

and control circuit for one single

speed pump

Unit equipped with electrical power

and control circuit for dual single

speed pumps.

Unit equipped with electrical power

and control circuit for one single

speed pump

Unit equipped with electrical power

and control circuit for dual single

speed pumps.

Unit equipped with an electronic

expansion valve for smooth operation

in every temperature conditions

1000 microns water fi lter delivered

with piping and Victaulic connections.

Quick start-up on job site.

Quick start-up on job site.

Quick start-up on job site.

Quick start-up on job site.

Allows applications with changing

temperature conditions.

This protection must be fi tted to

protect the evaporator from any

possible impurities.

MWC/MRC

180 ► 720

MWC/MRC

180 ► 720

MWC

180 ► 720

MWC

180 ► 720

MWC

180 ► 570

MWC/MRC

180 ►720

Condenser fi lter (supplied loose)

Evaporator fl ange connections

(supplied loose)

Condenser fl ange connections

(supplied loose)

Hot water set-point control (Heat

pump mode)

DC50™ remote comfort display

(supply loose)

DS50™ service display (supply

loose)

1000 microns water fi lter delivered

with piping and Victaulic connections.

Two connection sleeves with Victaulic

groove and fl ange on opposite side.

Two connection sleeves with Victaulic

groove and fl ange on opposite side

Unit equipped with insulated heat

exchanger and hot water sensor on

condenser side for heating purpose.

Customer display located at 600

meters maximum from the unit.

Plug and play display delivered with 1

meter cable and connector for quick

connection on Climatic controller.

This protection must be fi tted to

protect the condenser from any

possible impurities.

Allow easy connection with fl anges

on customer side.

Allow easy connection with fl anges

on customer side.

Allow heat pump operation.

Remote customer parameter reading

and modifi cation.

Display for service technicians only.

MWC

180 ►720

MWC/MRC

180 ►720

MWC

180 ► 720

MWC

180 ►720

MWC/MRC

180 ►720

MWC/MRC

180 ►720

Communication card using ModBus/

Modbus communication interface

LonWorks® communication interface

• 4 • Application Guide • MWC-0410-E

.

JBus protocol

Communication card using LonTalk®

protocol.

Communication interface with a

building management system.

Communication interface with a

building management system.

MWC/MRC

180 ►720

MWC/MRC

180 ►720

Page 7

OPTIONS AND ACCESSORIES

OPTIONS DESCRIPTION ADVANTAGES MODELS

BACnet® communication interface

Adalink™ supervision (Customer

friendly web based supervision)

BE50™ extension board for

additional inputs/outputs

Anti-vibration mounts (supplied

loose)

Panel enclosure (compressors)

Communication card using Bacnet®

protocol.

Electronic board with RS485 cables,

RJ11 phone cable, Ethernet cable

and power supply cable.

Electronic extension board with

additional analog inputs (4), digital

inputs (4) and digital outputs (4). See

control manual.

Rubber anti-vibration mounts to be

mounted under the unit.

Unit equipped with removable panels

around the compressors to reduce

sound level.

Communication interface with a

building management system.

Remote supervision of the unit via an

intuitive web page.

Relay card for remote control and

alarm report using dry contacts, 24

Vac or 4-20 mA signals.

Reduction of the transmission of

vibration to the ground.

Reduction of the unit sound power

level.

MWC/MRC

180 ►720

MWC/MRC

180 ►720

MWC/MRC

180 ►720

MWC/MRC

180 ►720

MWC/MRC

180 ►720

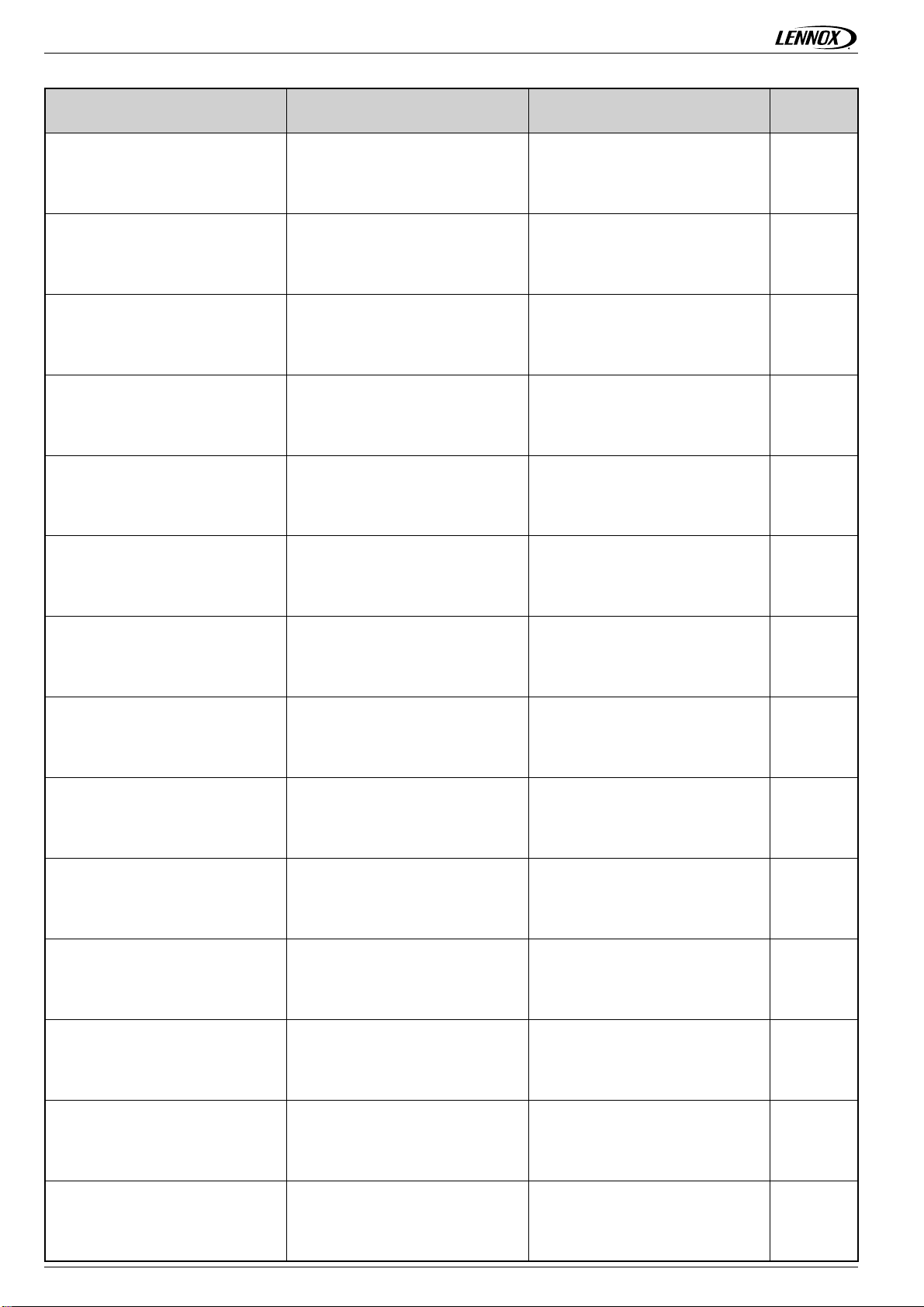

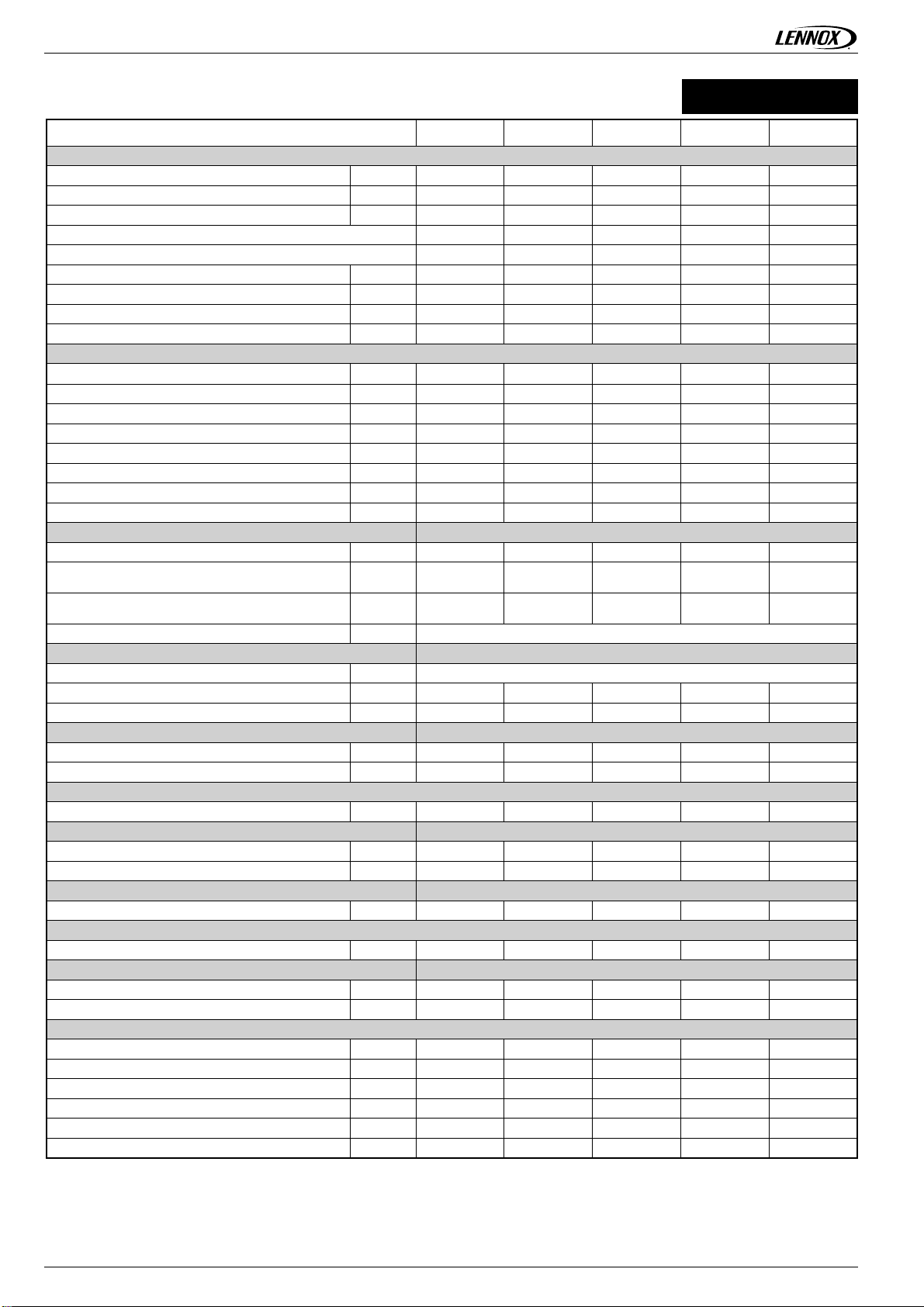

MODEL NUMBER DESCRIPTION

EXAMPLE : MWC 200D

M

W

C

200

D

N

M

1

Medium

W = Water cooled

R = Remote condenser

C = Cooling mode

Cooling capacity in kW

Number of circuits :

D = 2 circuits

Non ducted

R410 A refrigerant

Revision number

M

Application Guide • MWC-0410-E • 5 •

400V/3/50 Hz

Page 8

GENERAL DATA

COOLING ONLY

MWC

MWC™ 180 230 280 330 380

Cooling mode

Cooling capacity

Power input

Full load amps

EER 4,74 4,66 4,70 4,70 4,70

(2)

ESEER

Evaporator water fl ow

Evaporator pressure drop

Condenser water fl ow

Condenser pressure drop

Heating mode

Heating capacity

Power input

Full load amps

COP

Condenser water fl ow

Condenser pressure drop

Evaporator water fl ow

Evaporator pressure drop

Compressor Scroll - Hermetic

Number of compressor nr

Capacity steps

Oil charge per compressor

Oil type type MOBIL EAL Arctic 22CC or ICI EMKARATE RL32CF

Refrigerant

Expansion type Thermostatic expansion valve

Number of circuit nr

Charge per circuit

Condenser (Heating mode) AISI 316 stainless steel plate brazed with copper heat exchanger

Water volume

Water operating pressure

Hydraulic connections Victaulic

Water inlet/outlet Inches

Evaporator (Cooling mode) AISI 316 stainless steel plate brazed with copper heat exchanger

Water volume

Water operating pressure

Hydraulic connections Victaulic

Water inlet/outlet Inches

Acoustic

Global sound power level

Electrical data

Start-up intensity

Maximum current

Dimensions

Length

Width

Height

Footprint

Operating weight

Shipping weight

(1)

(1)

(1)

kW

186,1 232,8 280,7 333,6 380,4

kW 39,3 49,9 59,7 70,9 81,0

A 70,6 86,6 101,1 118,1 133,2

6,74 6,31 6,38 6,25 6,03

(1)

(1)

(1)

(1)

(3)

(3)

(3)

m3/h 32,0 40,1 48,3 57,4 65,4

kPa 34,9 28,9 40,7 31,5 40,2

m3/h 37,2 46,7 56,2 66,8 76,2

kPa 46,2 38,3 30,3 41,8 40,5

kW

196,5 246,4 296,9 351,9 401,7

kW 48,5 61,5 73,1 86,9 99,1

A 86,6 110,0 130,7 155,3 177,1

4,05 4,00 4,06 4,05 4,05

(3)

(3)

(3)

(3)

3

/h 33,8 42,4 51,1 60,5 69,1

m

kPa 38,6 32,1 25,4 34,8 33,7

m3/h 32,0 40,1 48,3 57,4 65,4

kPa 34,9 28,9 40,7 31,5 40,2

44444

%

l

20-50-75-

100%

(2 x 3,2)

+ (2 x 3,2)

21-43-62-83-

100%

(3,2+6,3)

+ (2 x 3,2)

21-36-53-71-

85-100%

(3,2+6,3)

+ (3,2+6,3)

15-46-61-87-

100%

(2 x 6,3)

+ (3,2+6,3)

25-50-75-

100%

(2 x 6,3)

+ (2 x 6,3)

R410A

22222

kg8 12141422

l 13 24 35 35 43

kPa 600 600 600 600 600

4" 4" 4" 4" 4"

l 13 24 24 35 35

kPa 600 600 600 600 600

4" 4" 4" 4" 4"

(1)

dB(A) 81 87 89 90 92

400V / III / 50 Hz

A 266,9 402,9 431,7 460,1 488,3

A 123,8 152,2 181,0 209,4 237,6

mm 2150 2150 2150 2150 2150

mm 820 820 820 820 820

mm 1645 1870 1870 1870 1870

m² 1,8 1,8 1,8 1,8 1,8

kg 756 974 1158 1328 1534

kg 736 914 1088 1248 1444

All data are at Eurovent conditions :

(1) Gross cooling capacity with 12/7°C evaporator water temperature and

30/35°C condenser water temperature.

(*) Except for MWC 720 :13/7°C evaporator water temperature.

(2) ESEER according to EN14511 Eurovent calculation method.

(3) Gross heating capacity with 40/45°C condenser water temperature and 10°C

evaporator water inlet, with the same evaporator water fl ow as in cooling

mode.

OPERATING LIMITS on page 13

• 6 • Application Guide • MWC-0410-E

Page 9

GENERAL DATA

COOLING ONLY

MWC

MWC™ 450 510 570 650 720 (*)

Cooling mode

Cooling capacity

Power input

Full load amps

EER 4,66 4,59 4,66 4,57 4,44

(2)

ESEER

Evaporator water fl ow

Evaporator pressure drop

Condenser water fl ow

Condenser pressure drop

Heating mode

Heating capacity

Power input

Full load amps

COP

Condenser water fl ow

Condenser pressure drop

Evaporator water fl ow

Evaporator pressure drop

Compressor Scroll - Hermetic

Number of compressor nr

Capacity steps

Oil charge per compressor

Oil type type MOBIL EAL Arctic 22CC or ICI EMKARATE RL32CF

Refrigerant

Expansion type Thermostatic expansion valve

Number of circuit nr

Charge per circuit

Condenser (Heating mode) AISI 316 stainless steel plate brazed with copper heat exchanger

Water volume

Water operating pressure

Hydraulic connections Victaulic

Water inlet/outlet Inches

Evaporator (Cooling mode) AISI 316 stainless steel plate brazed with copper heat exchanger

Water fl ow

Water volume

Hydraulic connections Victaulic

Water inlet/outlet Inches

Acoustic

Global sound power level

Electrical data

Start-up intensity

Maximum current

Dimensions

Length

Width

Height

Footprint

Operating weight

Shipping weight

All data are at Eurovent conditions :

(1) Gross cooling capacity with 12/7°C evaporator water temperature and

30/35°C condenser water temperature.

(*) Except for MWC 720 :13/7°C evaporator water temperature.

(2) ESEER according to EN14511 Eurovent calculation method.

(1)

(1)

(1)

kW

442,9 499,0 570,3 642,3 715,5

kW 95,0 108,7 122,3 140,6 161,1

A 154,0 177,6 201,0 230,9 264,5

6,04 6,04 6,09 5,97 5,67

(1)

(1)

(1)

(1)

(3)

(3)

(3)

m3/h 76,2 85,9 98,1 110,5 102,6

kPa 40,4 50,5 46,0 57,7 50,0

m3/h 88,7 100,4 114,4 129,3 143,7

kPa 43,6 51,0 61,6 34,0 41,5

kW

468,3 530,4 602,6 682,1 750,6

kW 116,3 133,0 149,7 169,9 192,8

A 207,9 237,8 267,5 303,8 344,6

4,03 3,99 4,03 4,01 3,89

3

m

/h 80,6 91,2 103,7 117,4 129,1

kPa 36,4 42,6 51,1 28,4 34,0

m3/h 76,2 85,9 98,1 110,5 102,6

kPa 40,4 50,5 46,0 57,7 50,0

66666

18-36-53-70-

%

85-100%

(3 x 6,8)

l

+ (3 x 6,8)

16-37-51-70-

83-100%

(3 x 6,8)

+ (3 x 6,3)

18-36-53-70-

85-100%

(3 x 6,3)

+ (3 x 6,3)

16-37-52-70-

83-100%

(3 x 6,3)

+ (3 x 6,3)

18-37-53-70-

85-100%

(3 x 6,3)

+ (3 x 6,3)

R410A

Electronic

expansion valve

22222

kg 27 29 31 30 30

l 52 56 61 77 77

kPa 600 600 600 600 600

5" 5" 5" 5" 5"

(1)

43 43 61 61 61

600 600 600 600 600

5" 5" 5" 5" 5"

(1)

dB(A) 92 93 93 96 97

400V / III / 50 Hz

A 495,9 563,1 606,9 734,3 778,4

A 268,6 312,4 356,2 400,3 444,4

mm 2200 2200 2200 2200 2200

mm 1200 1200 1200 1200 1200

mm 1870 1870 1870 1870 1870

m² 2,6 2.6 2.6 2.6 2.6

kg 1984 2100 2240 2440 2480

kg 1894 1990 2110 2270 2310

(3) Gross heating capacity with 40/45°C condenser water temperature and 10°C

evaporator water inlet, with the same evaporator water fl ow as in cooling

mode.

OPERATING LIMITS on page 13

Application Guide • MWC-0410-E • 7 •

Page 10

GENERAL DATA

COOLING ONLY

MRC

MRC™ 180 230 280 330 380

Cooling mode

Cooling capacity

Power input

Full load amps

EER 3.24 3.21 3.18 3.23 3.20

Evaporator water fl ow

Evaporator pressure drop

Compressor Scroll - Hermetic

Number of compressor nr

Capacity steps

Oil charge per compressor

Oil type type MOBIL EAL Arctic 22CC or ICI EMKARATE RL32CF

Refrigerant

Expansion type Thermostatic expansion valve

Number of circuit nr

Capacity per circuit C1/C2

Refrigerant connections

Liquid line Inches

Discharge line Inches

Evaporator AISI 316 stainless steel plate brazed with copper heat exchanger

Water volume

Water operating pressure

Hydraulic connections Victaulic

Water inlet/outlet Inches

Acoustic

Global sound power level

Electrical data

Start-up intensity

Maximum current

Dimensions

Length

Width

Height

Footprint

Operating weight

Shipping weight

(1)

(1)

(1)

(1)

(1)

kW

161.1 202.0 241.9 288.7 328.5

kW 49.7 63.0 76.2 89.4 102.5

A 89.3 109.3 129.0 148.9 168.5

m3/h 26.8 22.3 31.0 24.1 30.6

kPa 148.3 186.3 223.3 266.4 303.3

44444

%

l

25-50-75-

100%

(2 x 3,2)

+ (2 x 3,2)

21-43-62-83-

100%

(3,2 + 6,3)

+ (2 x 3,2)

21-36-53-71-

85-100%

(3,2 + 6,3)

+ (3,2 + 6,3)

15-46-61-87-

100%

(2 x 6,3)

+ (3,2 + 6,3)

25-50-75-

100%

(2 x 6,3)

+ (2 x 6,3)

R410A

22222

% 50-50% 60-40% 50-50% 57-43% 50-50%

7/8" 1" 1/8 - 7/8" 2 x 1" 1/8 2 x 1" 1/8 2 x 1"1/8

1" 1/8 1" 3/8 - 1" 1/8 2 x 1" 3/8 2 x 1" 3/8 2 x 1" 3/8

l1324243535

kPa 600 600 600 600 600

4" 4" 4" 4" 4"

(1)

dB(A) 81 87 89 90 92

400V / III / 50Hz

A 266.9 402.9 431.7 460.1 488.3

A 123.8 152.2 181.0 209.4 237.6

mm 2150 2150 2150 2150 2150

mm 820 820 820 820 820

mm 1645 1870 1870 1870 1870

m² 1.8 1.8 1.8 1.8 1.8

kg 650 810 950 1120 1290

kg 620 770 910 1080 1240

All data are at Eurovent conditions :

(1) Gross cooling capacity with 12/7°C water temperature

(*) Except for MWC 720 :13/7°C evaporator water temperature.

OPERATING LIMITS on page 13

• 8 • Application Guide • MWC-0410-E

Page 11

GENERAL DATA

COOLING ONLY

MRC

MRC™ 450 510 570 650 720 (*)

Cooling mode

Cooling capacity

Power input

Full load amps

EER 3,18 3.16 3.21 3.15 3.10

Evaporator water fl ow

Evaporator pressure drop

Compressor Scroll - Hermetic

Number of compressor nr

Capacity steps

Oil charge per compressor

Oil type type MOBIL EAL Arctic 22CC or ICI EMKARATE RL32CF

Refrigerant

Expansion type Thermostatic expansion valve

Number of circuit nr

Capacity per circuit C1/C2

Refrigerant connections

Liquid line Inches

Discharge line Inches

Evaporator AISI 316 stainless steel plate brazed with copper heat exchanger

Water volume

Water operating pressure

Hydraulic connections Victaulic

Water inlet/outlet Inches

Acoustic

Global sound power level

Electrical data

Start-up intensity

Maximum current

Dimensions

Length

Width

Height

Footprint

Operating weight

Shipping weight

(1)

(1)

(1)

(1)

(1)

kW

382,0 432,8 494,3 554,8 615,4

kW 120,3 137.0 153.8 176.2 198.6

A 194,9 223.8 252.8 289.4 326.0

m3/h 30,7 31.3 35.0 43.6 53.2

kPa 352,6 399.9 456.5 512.2 568.0

66666

18-36-53-70-

%

85-100%

(3 x 6,8)

l

+ (3 x 6,8)

16-37-51-70-

83-100%

(3 x 6,8)

+ (3 x 6,3)

18/36-53-70-

85-100%

(3 x 6,3)

+ (3 x 6,3)

16-37-52-70-

83-100%

(3 x 6,3)

+ (3 x 6,3)

18-37-53-70-

85-100%

(3 x 6,3)

+ (3 x 6,3)

R410A

22222

% 50-50% 56-44% 50-50% 55-45% 50-50%

2 x 1" 3/8" 2 x 1" 3/8" 2 x 1" 3/8" 1" 5/8 - 1" 3/8 2 x 1" 5/8"

2 x 1" 5/8 2 x 1" 5/8 2 x 1" 5/8 2" 1/8 - 1" 5/8 2 x 2" 1/8

l4343616161

kPa 600 600 600 600 600

5" 5" 5" 5" 5"

(1)

dB(A) 92 93 93 96 97

400V / III / 50Hz

A 495,9 563,1 606,9 734,3 778,4

A 268,6 312,4 356,2 400,3 444,4

mm 2200 2200 2200 2200 2200

mm 1200 1200 1200 1200 1200

mm 1870 1870 1870 1870 1870

m² 2,6 2,6 2,6 2,6 2,6

kg 1660 1740 1870 1980 2020

kg 1620 1690 1790 1890 1930

All data are at Eurovent conditions :

(1) Gross cooling capacity with 12/7°C water temperature

(*) Except for MWC 720 :13/7°C evaporator water temperature.

OPERATING LIMITS on page 13

Application Guide • MWC-0410-E • 9 •

Page 12

PRESSURE DROPS

EVAPORATORS CURVE

100

Pressure Drop (kPa)

10

10 20 30 40 50 60 70 80 90 100

Flow rate (m3/h)

CONDENSER CURVE

100

AB

AB

C

D

E

C

Pressure Drop (kPa)

10

10 20 30 40 50 60 70 80 90

Flow rate (m3/h)

FILTER CURVE

10

MWC

DN 100

1

DN 125

180 A A DN100

230 B B DN100

Evaporator Condenser Filter

Curves

D

E

F

G

H

Pressure drops are given for information only, A tolerance of +/- 20kPa must be considered when selecting water pumps,

100

280 B C DN100

330 C C DN100

380 C D DN100

0,1

Pressure Drop (kPa)

0,01

10

• 10 • Application Guide • MWC-0410-E

Water fl ow rate (m3/h)

100

450 D E DN125

510 D F DN125

570 E G DN125

650 E H DN125

720 E H DN125

Page 13

HYDRAULIC DATA

MINIMUM WATER CONTENT OF AN INSTALLATION

Thanks to multi step capacity control and smart anti-short compressor cycling, MWC™ can work with minimum water loop volume

as defi ned here below. This can eliminate the need for a buffer tank in most of air-conditioning applications (e.g. MWC™ application

with fan-coil units). :

Vmini = 86 x Q / (Nstages x Dt)

V

Q

Where :

Nstage Number of control steps available in the unit

Dt

Important note: In case MWC™ is used in air-conditioning applications with a short water system (e.g. MWC™ application with air

handling units) or in case MWC™ is used for industrial process cooling, it is mandatory to use a buffer tank.

Minimum water content of the installation

Cooling capacity of the chiller

Maximum acceptable temperature rise (Dt = 6°c for an air conditioning application)

MINIMUM WATER CONTENT OF AN INSTALLATION

Unit Size

MWC

180 4 645

230 5 659

280 6 669

Number of stages Mini water volume (l)

330 5 946

380 4 1362

450 6 1075

510 6 1218

570 6 1362

650 6 1553

720 6 1720

Note : The volume of the condenser water loop has no impact on the chiller operation. In heat pump operation (with hot water set point control option)

the minimum volume of the condenser water loop must be calculated based on the heating capacity using the same formula.

GLYCOL CORRECTION FACTOR

Minimum ambient temperature or water

outlet temperature

+ 5°C ► 0°C 10% 1,05 1,02 0,99 0,994

0°C ► -5°C 20% 1,10 1,05 0,98 0,993

Ethylene

glycol

Pressure

drop

Water

fl ow

CAPACITIES

Cooling Heating

- 5°C ► -10°C 30% 1,15 1,08 0,97 0,99

- 10°C ► -15°C 35% 1,18 1,10 0,96 0,987

Example : 10% glycol

Minimum fl ow : 1,19 m3/h x 1,02

Pressure drop x 1,07

System capacity x 0,99

Application Guide • MWC-0410-E • 11 •

Page 14

ACOUSTIC DATA

STANDARD UNIT

Spectrum per octave band dB(A)

125Hz250Hz500Hz1000Hz2000Hz4000Hz8000

MWC

180 38 57 70 78 78 70 65

230 44 67 74 82 84 77 69

280 46 70 76 84 87 80 71

330 48 71 78 85 88 81 73

380 49 72 79 86 89 82 74

450 50 73 79 87 90 83 75

510 50 74 80 88 91 84 75

570 51 74 80 88 91 84 76

650 55 73 81 91 94 86 76

720 57 71 81 93 95 87 75

Hz

Global sound

power

EUROVENT

Lwa dB(A)

81

87

89

90

92

92

93

93

96

97

Sound pressure at

10 m.

Semi-spheric

(1)

Lp dB(A)

54 50

59 56

61 58

63 60

64 61

65 62

65 62

66 63

68 65

70 66

MWC

Sound pressure

envelopping

surface at 10 m.

(2)

Lp dB(A)

UNIT WITH PANEL ENCLOSURE (OPTION)

Spectrum per octave band dB(A)

125Hz250Hz500Hz1000Hz2000Hz4000Hz8000

MWC

180 39 53 65 67 66 58 53

230 44 69 71 72 74 67 57

280 46 72 74 75 77 70 59

330 47 74 75 76 78 71 61

380 48 75 76 77 79 73 62

450 49 76 77 78 80 73 63

510 50 76 78 79 81 74 63

570 50 77 78 79 81 74 64

650 54 75 78 82 84 76 63

720 56 73 78 84 85 78 63

(1) : For information only: data calculated by semi spheric method in free open fi el.

(2) : For information only : data calculated by envelopping surface method in free open fi eld.

Hz

Enveloping Surface

Global sound

power

EUROVENT

Lwa dB(A)

71

78

80

82

83

84

85

85

87

88

Sound pressure at

10 m

Semi-spheric

(1)

Lp dB(A)

43 40

50 47

53 50

55 51

56 52

56 53

57 54

57 54

59 56

60 57

Semi spheric

Sound pressure

envelopping

surface at 10 m.

(2)

Lp dB(A)

h+d

d

L+ 2d

A = 2(L+2d)(h+d)+2(l+2d)(h+d)+(L+2d)(l+2d)

• 12 • Application Guide • MWC-0410-E

d

l+ 2d

Lp = Lw - 10 log 2π d²

Page 15

OPERATING LIMITS

COOLING ONLY

MWC

MWC 180 230 280 330 380 450 510 570 650 720

Min. evaporator outlet water temperature

Max. evaporator outlet water temperature

Min. difference water inlet/outlet

Max. difference water inlet/outlet

Min. condenser outlet water temperature

Maximum condenser outlet water temperature :

Full capacity operation

Evaporator and condenser water Delta T = 5°C

REMOTE CONDENSER

°C 5

°C 20

°C 3

°C 8

°C 20

°C 56

MRC

MRC 180 230 280 330 380 450 510 570 650 720

Min. evaporator outlet water temperature

Max. evaporator outlet water temperature

Min. difference water inlet/outlet

Max. difference water inlet/outlet

Minimum discharge temperature

Maximum discharge temperature :

Full capacity operation

Evaporator water Delta T = 5°C

MWC

Operating limits

60

50

40

30

20

temperature (°C)

10

Condenser outlet water

0

-15 -10 -5 0 5 10 15 20 25

GLYCOL

Evaporator outlet water temperature

°C 5

°C 20

°C 3

°C 8

°C 25

°C 62

MRC

Operating limits

70

60

50

40

30

20

10

Condensing temperature (°C)

0

-15 -10 -5 0 5 10 15 20 25

GLYCOL

Evaporator outlet water temperature

Application Guide • MWC-0410-E • 13 •

Page 16

ELECTRICAL DATA

UNITS

MWC/MRC

MWC™ 180 230 280 330 380

Minimum and maximum voltage

Maximum power

Maximum current

Maximum current (with cos phi 0,95 option)

Start-up intensity

Start-up intensity

(with sofstarter option)

Start-up intensity

(with cos phi 0,95 option)

Maximum connectable power section

kW

mm²

V

380 V / 420 V

68,9 87,8 106,8 125,7 144,5

A

123,8 152,2 181,0 209,4 237,6

A

104,8 133,5 162,6 191,3 219,8

A

266,9 402,9 431,7 460,1 488,3

A

197,3 278,9 307,7 336,1 364,3

A

183,0 264,6 293,7 322,4 350,9

185 185 185 185 185

MWC™ 450 510 570 650 720

Minimum and maximum voltage

Maximum power

Maximum current

Maximum current (with cos phi 0,95 option)

Start-up intensity

Start-up intensity

(with sofstarter option)

Start-up intensity

(with cos phi 0,95 option)

Maximum connectable power section

kW

mm²

V

380 V / 420 V

165,8 191,3 216,7 243,7 270,8

A

268,6 312,4 356,2 400,3 444,4

A

252,0 290,7 329,5 370,5 411,5

A

495,9 563,1 606,9 734,3 778,4

A

387,1 439,1 482,9 571,1 615,2

A

373,2 421,9 460,6 546,8 587,8

300 300 300 300 300

• 14 • Application Guide • MWC-0410-E

Page 17

PERFORMANCES

COOLING MODE

Condenser water oulet temperature

MWC

Pf Pe

kW kW m3/h kPa kW kW m3/h kPa kW kW m3/h kPa kW kW m3/h kPa

183,6 35,0 31,6 34,1 174,8 39,2 30,1 31,1 164,8 43,6 28,4 27,9 153,8 48,4 26,5 24,5

180

229,9 44,6 39,6 28,2 218,5 49,7 37,6 25,7 205,9 55,3 35,4 23,1 192,1 61,4 33,0 20,3

230

276,7 53,6 47,6 39,6 263,2 59,3 45,3 36,2 248,4 65,7 42,7 32,5 232,4 73,0 40,0 28,8

280

329,6 63,7 56,7 30,8 312,8 70,4 53,8 28,0 294,6 78,0 50,7 25,0 275,1 86,7 47,3 22,1

330

375,6 72,9 64,6 39,2 356,5 80,3 61,3 35,6 336,0 89,0 57,8 31,9 314,1 98,9 54,0 28,2

380

437,0 85,5 75,2 39,4 415,5 94,3 71,5 35,9 392,0 104,4 67,4 32,2 366,4 115,9 63,0 28,4

450

5 °C

492,4 97,8 84,7 49,3 467,9 107,8 80,5 44,8 441,4 119,5 75,9 40,2 412,7 132,8 71,0 35,5

510

563,2 110,1 96,9 44,9 534,5 121,2 92,0 40,6 503,6 134,3 86,6 36,2 470,5 149,4 80,9 31,8

570

633,5 127,2 109,0 56,2 602,7 139,4 103,7 51,1 569,0 153,5 97,9 45,8 532,3 169,7 91,6 40,3

650

705,6 146,3 101,2 48,7 672,1 159,8 96,4 44,4 634,9 175,3 91,0 39,8 594,0 192,9 85,2 35,1

720*

195,6 34,9 33,7 38,3 186,1 39,3 32,0 34,9 175,5 43,9 30,2 31,3 163,8 48,7 28,2 27,6

180

245,1 44,8 42,2 31,7 232,8 49,9 40,1 28,9 219,3 55,6 37,7 25,9 204,7 61,9 35,2 22,8

230

295,3 53,9 50,8 44,6 280,7 59,7 48,3 40,7 264,8 66,2 45,6 36,6 247,8 73,5 42,6 32,4

280

351,7 64,3 60,5 34,8 333,6 70,9 57,4 31,5 314,2 78,6 54,1 28,2 293,4 87,4 50,5 24,9

330

400,9 73,6 69,0 44,3 380,4 81,0 65,4 40,2 358,5 89,7 61,7 36,0 335,0 99,6 57,6 31,8

380

466,1 86,3 80,2 44,5 442,9 95,0 76,2 40,4 417,8 105,1 71,9 36,3 390,7 116,6 67,2 32,0

450

7 °C

525,4 98,7 90,4 55,6 499,0 108,7 85,9 50,5 470,6 120,4 81,0 45,3 440,1 133,7 75,7 40,0

510

601,1 111,2 103,4 50,8 570,3 122,3 98,1 46,0 537,2 135,4 92,4 41,0 501,9 150,5 86,3 36,0

570

675,5 128,5 116,2 63,5 642,3 140,6 110,5 57,7 606,3 154,7 104,3 51,7 567,3 170,8 97,6 45,5

650

751,5 147,8 107,7 55,0 715,5 161,1 102,6 50,0 675,8 176,6 96,9 44,9 632,4 194,1 90,7 39,5

720*

201,8 34,9 34,7 40,6 192,0 39,3 33,0 37,0 181,0 44,0 31,1 33,2 169,0 48,9 29,1 29,2

180

252,9 44,8 43,5 33,6 240,2 50,0 41,3 30,6 226,3 55,8 38,9 27,4 211,2 62,1 36,3 24,2

230

304,8 54,0 52,4 47,3 289,7 59,9 49,8 43,1 273,3 66,4 47,0 38,8 255,8 73,8 44,0 34,3

280

363,1 64,6 62,5 36,9 344,4 71,2 59,3 33,4 324,3 79,0 55,8 29,9 302,9 87,7 52,1 26,4

330

414,0 74,0 71,2 47,0 392,8 81,4 67,6 42,6 370,1 90,1 63,7 38,2 345,9 100,0 59,5 33,7

380

481,1 86,7 82,8 47,2 457,1 95,4 78,6 42,9 431,2 105,5 74,2 38,5 403,3 116,9 69,4 33,9

450

8 °C

542,3 99,2 93,3 59,0 515,1 109,2 88,6 53,6 485,8 120,8 83,6 48,1 454,4 134,1 78,2 42,4

510

620,7 111,8 106,8 54,0 588,7 122,9 101,3 48,8 554,5 136,0 95,4 43,6 518,1 151,1 89,1 38,3

570

697,2 129,1 119,9 67,5 662,8 141,2 114,0 61,2 625,5 155,3 107,6 54,8 585,4 171,4 100,7 48,3

650

775,2 148,5 111,1 58,3 737,9 161,8 105,8 53,1 696,9 177,2 99,9 47,6 652,2 194,7 93,5 41,9

720*

214,7 34,8 36,9 45,5 204,2 39,3 35,1 41,5 192,5 44,1 33,1 37,2 179,8 49,2 30,9 32,8

180

269,0 45,0 46,3 37,6 255,5 50,3 44,0 34,2 240,7 56,1 41,4 30,7 224,7 62,5 38,7 27,1

230

324,4 54,4 55,8 53,1 308,3 60,3 53,0 48,3 290,9 66,9 50,0 43,4 272,3 74,3 46,9 38,5

280

386,7 65,1 66,5 41,4 366,7 71,9 63,1 37,5 345,3 79,6 59,4 33,6 322,7 88,4 55,5 29,6

330

440,9 74,8 75,9 52,8 418,2 82,2 72,0 47,9 394,1 90,9 67,8 42,9 368,5 100,8 63,4 37,9

380

512,0 87,5 88,1 53,0 486,5 96,2 83,7 48,2 458,9 106,3 79,0 43,2 429,4 117,7 73,9 38,2

450

10 °C

Evaporator water outlet temperature

12 °C

14 °C

Pf : Pe : Wf : Dp :

Net cooling capacity in kW Effective absorbed power in cooling

Application Guide • MWC-0410-E • 15 •

577,3 100,2 99,3 66,3 548,2 110,2 94,3 60,2 517,0 121,8 89,0 54,0 483,8 135,1 83,2 47,7

510

660,9 113,0 113,7 60,9 626,8 124,1 107,8 55,0 590,4 137,2 101,6 49,1 551,8 152,3 94,9 43,2

570

741,7 130,4 127,6 75,9 705,0 142,5 121,3 68,9 665,4 156,5 114,5 61,7 622,8 172,5 107,2 54,4

650

823,8 150,0 118,1 65,5 784,0 163,2 112,4 59,6 740,5 178,5 106,2 53,4 693,3 195,8 99,4 47,1

720*

228,1 34,7 39,2 50,9 216,9 39,4 37,3 46,4 204,6 44,3 35,2 41,6 191,1 49,5 32,9 36,7

180

285,8 45,1 49,2 42,1 271,4 50,5 46,7 38,3 255,8 56,5 44,0 34,3 238,9 63,0 41,1 30,3

230

344,8 54,7 59,3 59,3 327,6 60,7 56,4 54,0 309,2 67,4 53,2 48,6 289,6 74,8 49,8 43,1

280

411,2 65,7 70,7 46,4 389,9 72,5 67,1 42,1 367,3 80,3 63,2 37,7 343,3 89,1 59,1 33,2

330

468,9 75,6 80,7 59,2 444,7 83,0 76,5 53,7 419,1 91,7 72,1 48,1 392,1 101,6 67,5 42,5

380

544,2 88,3 93,6 59,4 517,1 97,0 89,0 54,0 488,0 107,0 84,0 48,5 456,9 118,4 78,6 42,9

450

613,6 101,3 105,6 74,3 582,7 111,2 100,2 67,5 549,6 122,8 94,6 60,5 514,6 136,1 88,5 53,5

510

702,7 114,2 120,9 68,5 666,4 125,4 114,6 61,9 627,8 138,5 108,0 55,2 587,1 153,6 101,0 48,6

570

787,9 131,7 135,6 85,2 748,8 143,7 128,8 77,3 706,9 157,7 121,6 69,3 662,0 173,7 113,9 61,1

650

874,2 151,4 125,3 73,4 831,9 164,5 119,3 66,7 785,9 179,7 112,7 59,9 736,2 197,0 105,5 52,8

720*

242,0 34,5 41,6 56,8 230,1 39,4 39,6 51,8 217,1 44,5 37,4 46,5 203,0 49,8 34,9 41,0

180

303,3 45,3 52,2 46,9 288,0 50,8 49,5 42,7 271,5 56,8 46,7 38,3 253,8 63,4 43,7 33,8

230

366,0 55,1 63,0 66,2 347,7 61,1 59,8 60,3 328,3 67,9 56,5 54,2 307,6 75,4 52,9 48,1

280

436,6 66,4 75,1 51,9 414,1 73,2 71,2 47,0 390,2 81,0 67,1 42,1 365,0 89,8 62,8 37,2

330

497,9 76,5 85,7 66,1 472,3 83,9 81,3 60,0 445,2 92,5 76,6 53,8 416,7 102,5 71,7 47,6

380

577,7 89,2 99,4 66,4 549,0 97,8 94,4 60,4 518,3 107,8 89,2 54,2 485,6 119,2 83,5 48,0

450

651,3 102,3 112,0 83,1 618,5 112,3 106,4 75,4 583,6 123,9 100,4 67,7 546,7 137,1 94,1 59,9

510

746,1 115,5 128,4 76,8 707,6 126,7 121,7 69,4 666,8 139,8 114,7 62,0 623,9 154,9 107,3 54,6

570

835,9 133,1 143,8 95,4 794,4 145,0 136,7 86,6 750,1 159,0 129,0 77,6 702,8 174,9 120,9 68,5

650

926,4 152,8 132,8 82,0 881,5 165,8 126,4 74,5 833,0 180,9 119,4 66,9 780,8 198,1 111,9 59,1

720*

30 35 40 45

Wf

Dp Pf Pe

mode

Wf

Dp Pf Pe

Water fl ow in m3 per hour Water pressure drop in KPa

Wf

Dp Pf Pe

Wf

Dp

Page 18

PERFORMANCES

COOLING MODE

Saturated discharge temperature

MRC

5 °C

7 °C

8 °C

10 °C

Evaporator water outlet temperature

12 °C

14 °C

Pf : Pe : Wf : Dp :

Net cooling capacity in kW Effective absorbed power in cooling

• 16 • Application Guide • MWC-0410-E

Pf Pe Wf Dp Pf Pe Wf Dp Pf Pe Wf Dp Pf Pe Wf Dp Pf Pe Wf Dp

kW kW

172,1 40,3 29,6 30,2 162,0 44,7 27,9 27,0 150,9 49,4 26,0 23,7 138,7 54,2 23,9 20,3 125,6 59,3 21,6 16,9

180

215,6 50,9 37,1 25,1 202,9 56,6 34,9 22,4 189,1 62,8 32,5 19,7 174,2 69,5 30,0 17,0 158,2 76,8 27,2 14,2

230

257,8 61,5 44,4 34,8 242,6 68,3 41,7 31,2 226,3 75,9 38,9 27,4 208,7 84,3 35,9 23,6 190,0 93,5 32,7 19,9

280

308,2 72,2 53,0 27,2 289,8 80,1 49,8 24,3 270,0 89,1 46,5 21,3 249,0 99,2 42,8 18,3 226,6 110,3 39,0 15,4

330

350,3 82,8 60,3 34,5 329,4 91,8 56,7 30,8 307,1 102,2 52,8 27,0 283,4 113,9 48,8 23,3 258,3 126,9 44,4 19,6

380

407,2 97,5 70,1 34,6 383,3 108,1 65,9 30,9 357,4 120,0 61,5 27,1 329,6 133,4 56,7 23,3 299,9 148,1 51,6 19,5

450

460,9 110,7 79,3 35,3 433,9 122,8 74,7 31,5 404,9 136,6 69,7 27,6 373,8 152,1 64,3 23,7 340,7 169,2 58,6 19,9

510

527,1 124,2 90,7 39,5 495,7 137,8 85,3 35,2 462,2 153,3 79,5 30,8 426,6 170,9 73,4 26,4 388,8 190,4 66,9 22,1

570

591,5 143,8 101,8 49,3 556,9 158,7 95,8 43,9 519,5 175,7 89,4 38,4 479,1 194,8 82,4 33,0 436,0 215,9 75,0 27,5

650

655,9 163,6 112,8 60,0 618,1 179,7 106,3 53,6 576,7 198,1 99,2 46,9 531,7 218,7 91,5 40,2 483,1 241,4 83,1 33,5

720*

183,6 40,3 31,6 34,1 172,9 44,9 29,7 30,5 161,1 49,7 27,7 26,8 148,3 54,7 25,5 23,0 134,5 59,9 23,1 19,2

180

230,2 51,0 39,6 28,3 216,7 56,8 37,3 25,3 202,0 63,0 34,8 22,3 186,3 69,8 32,0 19,2 169,5 77,1 29,2 16,1

230

275,4 61,7 47,4 39,3 259,2 68,5 44,6 35,2 241,9 76,2 41,6 31,0 223,3 84,6 38,4 26,7 203,5 93,8 35,0 22,6

280

329,4 72,5 56,7 30,8 309,7 80,5 53,3 27,5 288,7 89,4 49,7 24,1 266,4 99,5 45,8 20,8 242,8 110,6 41,8 17,5

330

374,5 83,2 64,4 39,0 352,2 92,2 60,6 34,8 328,5 102,5 56,5 30,6 303,3 114,2 52,2 26,4 276,8 127,2 47,6 22,3

380

435,0 97,9 74,8 39,1 409,4 108,4 70,4 34,9 382,0 120,3 65,7 30,7 352,6 133,5 60,7 26,4 321,3 148,2 55,3 22,2

450

492,5 111,2 84,7 40,0 463,7 123,3 79,8 35,7 432,8 137,0 74,5 31,3 399,9 152,4 68,8 27,0 365,0 169,4 62,8 22,7

510

563,5 124,8 96,9 44,9 530,0 138,3 91,2 39,9 494,3 153,8 85,0 35,0 456,5 171,3 78,5 30,0 416,6 190,8 71,7 25,2

570

631,5 144,6 108,6 55,8 594,6 159,4 102,3 49,8 554,8 176,2 95,5 43,6 512,2 195,2 88,1 37,4 466,8 216,2 80,3 31,3

650

699,5 164,4 120,3 67,9 659,2 180,4 113,4 60,6 615,4 198,6 105,9 53,2 568,0 219,0 97,7 45,6 517,0 241,5 88,9 38,1

720*

189,6 40,3 32,6 36,2 178,6 45,0 30,7 32,4 166,5 49,8 28,6 28,4 153,4 54,9 26,4 24,4 139,2 60,2 24,0 20,4

180

237,8 51,0 40,9 30,0 223,8 56,8 38,5 26,9 208,8 63,1 35,9 23,6 192,6 70,0 33,1 20,4 175,4 77,3 30,2 17,2

230

284,5 61,8 49,0 41,7 267,8 68,7 46,1 37,3 250,0 76,3 43,0 32,9 230,9 84,7 39,7 28,4 210,6 94,0 36,2 24,0

280

340,4 72,7 58,6 32,7 320,1 80,6 55,1 29,2 298,4 89,6 51,3 25,6 275,5 99,6 47,4 22,1 251,3 110,7 43,2 18,7

330

387,1 83,4 66,6 41,5 364,0 92,4 62,6 37,0 339,6 102,7 58,4 32,6 313,7 114,4 54,0 28,1 286,4 127,3 49,3 23,8

380

449,3 98,1 77,3 41,5 423,0 108,6 72,8 37,1 394,8 120,4 67,9 32,6 364,6 133,6 62,7 28,1 332,6 148,2 57,2 23,7

450

508,9 111,5 87,5 42,6 479,1 123,5 82,4 38,0 447,3 137,2 77,0 33,3 413,5 152,5 71,1 28,7 377,7 169,6 65,0 24,2

510

582,4 125,1 100,2 47,8 547,7 138,7 94,2 42,5 511,0 154,1 87,9 37,3 472,1 171,6 81,2 32,0 431,1 191,0 74,2 26,9

570

652,2 145,0 112,2 59,4 614,1 159,7 105,7 52,9 573,2 176,5 98,6 46,4 529,5 195,4 91,1 39,9 482,9 216,3 83,1 33,4

650

722,0 164,8 124,2 72,1 680,6 180,7 117,1 64,4 635,5 198,8 109,3 56,5 586,9 219,1 101,0 48,5 534,6 241,6 92,0 40,6

720*

202,0 40,3 34,8 40,7 190,3 45,0 32,7 36,4 177,6 50,0 30,6 32,0 163,8 55,3 28,2 27,6 149,1 60,7 25,6 23,2

180

253,4 51,1 43,6 33,7 238,6 57,0 41,1 30,2 222,8 63,3 38,3 26,6 205,8 70,2 35,4 23,0 187,7 77,7 32,3 19,5

230

303,4 62,0 52,2 46,9 285,7 68,9 49,1 42,0 266,8 76,6 45,9 37,1 246,7 85,0 42,4 32,1 225,4 94,3 38,8 27,2

280

363,2 73,1 62,5 36,9 341,6 81,0 58,8 32,9 318,7 89,9 54,8 29,0 294,5 100,0 50,7 25,0 269,1 111,0 46,3 21,2

330

413,0 83,9 71,1 46,8 388,5 92,9 66,8 41,8 362,7 103,1 62,4 36,8 335,4 114,7 57,7 31,8 306,6 127,7 52,8 27,0

380

479,1 98,6 82,4 46,8 451,2 109,0 77,6 41,9 421,5 120,7 72,5 36,9 389,7 133,9 67,1 31,9 356,1 148,4 61,3 26,9

450

542,7 112,1 93,4 48,1 511,1 124,0 87,9 42,9 477,5 137,6 82,2 37,7 441,9 152,9 76,0 32,6 404,3 169,9 69,6 27,5

510

621,4 125,9 106,9 54,1 584,6 139,3 100,6 48,2 545,7 154,7 93,9 42,2 504,6 172,1 86,8 36,4 461,5 191,5 79,4 30,7

570

695,0 145,7 119,6 67,0 654,6 160,3 112,6 59,8 611,4 177,0 105,2 52,5 565,4 195,8 97,3 45,2 516,5 216,6 88,9 38,0

650

768,6 165,6 132,2 81,3 724,7 181,4 124,7 72,6 677,2 199,3 116,5 63,8 626,1 219,4 107,7 54,9 571,4 241,7 98,3 46,1

720*

215,1 40,2 37,0 45,7 202,7 45,1 34,9 40,9 189,3 50,2 32,6 36,1 174,9 55,6 30,1 31,1 159,5 61,2 27,4 26,2

180

269,8 51,1 46,4 37,8 254,2 57,1 43,7 33,9 237,5 63,5 40,9 29,9 219,7 70,5 37,8 26,0 200,8 78,0 34,5 22,0

230

323,0 62,2 55,6 52,6 304,3 69,1 52,4 47,2 284,4 76,8 48,9 41,7 263,3 85,3 45,3 36,2 241,0 94,6 41,5 30,8

280

387,0 73,4 66,6 41,5 364,2 81,3 62,7 37,1 340,0 90,3 58,5 32,7 314,6 100,3 54,1 28,3 287,9 111,4 49,5 24,0

330

440,1 84,4 75,7 52,6 414,2 93,3 71,3 47,0 386,9 103,6 66,6 41,5 358,2 115,1 61,6 35,9 328,0 128,0 56,4 30,5

380

510,3 99,0 87,8 52,7 480,9 109,4 82,7 47,2 449,5 121,1 77,3 41,6 416,3 134,1 71,6 36,0 381,1 148,6 65,6 30,5

450

578,0 112,7 99,4 54,2 544,6 124,6 93,7 48,4 509,2 138,1 87,6 42,6 471,8 153,3 81,2 36,9 432,3 170,2 74,4 31,3

510

662,1 126,7 113,9 61,1 623,2 140,1 107,2 54,4 582,1 155,4 100,1 47,8 538,9 172,7 92,7 41,2 493,6 192,1 84,9 34,9

570

739,6 146,6 127,2 75,5 697,0 161,0 119,9 67,4 651,5 177,6 112,1 59,3 603,1 196,2 103,8 51,1 552,0 217,0 95,0 43,2

650

817,1 166,4 140,6 91,3 770,8 182,0 132,6 81,7 720,9 199,8 124,0 71,9 667,3 219,7 114,8 62,0 610,2 241,9 105,0 52,3

720*

228,7 40,0 39,3 51,1 215,7 45,1 37,1 45,9 201,6 50,4 34,7 40,5 186,6 55,9 32,1 35,1 170,5 61,6 29,3 29,7

180

286,9 51,2 49,4 42,3 270,4 57,2 46,5 38,0 252,9 63,7 43,5 33,6 234,3 70,8 40,3 29,2 214,6 78,4 36,9 24,9

230

343,5 62,5 59,1 58,9 323,8 69,4 55,7 52,9 302,9 77,1 52,1 46,8 280,7 85,7 48,3 40,7 257,4 95,0 44,3 34,7

280

411,9 73,8 70,9 46,6 387,8 81,7 66,7 41,6 362,4 90,7 62,4 36,7 335,7 100,7 57,8 31,9 307,8 111,8 52,9 27,1

330

468,3 85,0 80,6 59,0 441,0 93,9 75,9 52,8 412,3 104,1 70,9 46,6 382,1 115,6 65,7 40,5 350,5 128,4 60,3 34,5

380

542,9 99,5 93,4 59,1 511,9 109,8 88,1 53,0 479,0 121,4 82,4 46,8 444,2 134,4 76,4 40,7 407,4 148,8 70,1 34,6

450

614,9 113,4 105,8 60,9 579,7 125,2 99,7 54,5 542,4 138,6 93,3 48,0 503,2 153,8 86,6 41,7 461,9 170,6 79,5 35,4

510

704,6 127,5 121,2 68,8 663,5 140,8 114,2 61,4 620,3 156,1 106,7 54,0 575,0 173,4 98,9 46,7 527,5 192,7 90,8 39,6

570

786,1 147,4 135,2 84,8 741,2 161,7 127,5 75,8 693,4 178,2 119,3 66,8 642,8 196,7 110,6 57,8 589,3 217,3 101,4 48,9

650

867,6 167,2 149,3 102,4 818,9 182,6 140,9 91,7 766,5 200,2 131,9 80,8 710,5 220,0 122,2 69,9 650,9 242,0 112,0 59,2

720*

40 45 50 55 60

m3/h kPa

mode

kW kW

m3/h kPa

kW kW

m3/h kPa

Water fl ow in m3 per hour Water pressure drop in KPa

kW kW

m3/h kPa

kW kW

m3/h kPa

Page 19

PERFORMANCES

HEATING MODE

Outdoor air temperature

MWC

Ph Pe

kW kW m3/h kPa kW kW m3/h kPa kW kW m3/h kPa kW kW m3/h kPa

200,1 43,6 34,4 40,0 194,1 48,4 33,4 37,8 187,2 53,4 32,2 35,3 179,5 58,6 30,9 32,7

180

250,7 55,3 43,1 33,1 243,4 61,4 41,9 31,3 235,4 68,1 40,5 29,5 226,7 75,4 39,0 27,5

230

301,6 65,7 51,9 26,1 293,2 73,0 50,4 24,8 284,3 80,9 48,9 23,4 275,1 89,7 47,3 22,0

280

357,7 78,0 61,5 35,9 347,4 86,7 59,8 34,0 336,7 96,4 57,9 32,1 325,8 107,2 56,0 30,2

330

408,0 89,0 70,2 34,7 396,5 98,9 68,2 32,9 384,8 110,2 66,2 31,1 372,9 122,7 64,2 29,3

380

475,9 104,7 81,9 37,5 462,5 116,2 79,6 35,5 448,5 129,0 77,2 33,5 433,9 143,2 74,6 31,5

450

5 °C

538,4 119,5 92,6 43,8 523,7 132,8 90,1 41,6 508,6 147,8 87,5 39,3 493,1 164,4 84,8 37,1

510

612,4 134,3 105,4 52,7 595,1 149,4 102,4 49,9 577,5 166,4 99,4 47,1 559,7 185,3 96,3 44,3

570

693,6 153,5 119,3 29,3 673,9 169,7 115,9 27,7 653,4 187,8 112,4 26,2 632,0 208,0 108,7 24,6

650

771,9 175,1 132,8 35,8 749,9 192,7 129,0 33,9 726,3 212,5 125,0 31,9 701,2 234,3 120,6 29,9

720*

210,6 43,9 36,2 43,9 204,0 48,7 35,1 41,4 196,6 53,9 33,8 38,7 188,4 59,3 32,4 35,7

180

264,0 55,6 45,4 36,4 255,9 61,9 44,0 34,3 247,1 68,7 42,5 32,2 237,8 76,0 40,9 30,0

230

317,8 66,2 54,7 28,8 308,5 73,5 53,1 27,3 298,7 81,5 51,4 25,7 288,5 90,3 49,6 24,1

280

377,1 78,6 64,9 39,5 365,6 87,4 62,9 37,3 353,7 97,1 60,9 35,1 341,6 107,9 58,8 32,9

330

430,2 89,7 74,0 38,3 417,3 99,6 71,8 36,2 404,2 110,9 69,5 34,1 390,9 123,4 67,3 32,0

380

501,3 105,4 86,3 41,4 486,4 116,8 83,7 39,1 470,8 129,7 81,0 36,7 454,6 143,8 78,2 34,4

450

7 °C

567,4 120,4 97,6 48,4 550,9 133,7 94,8 45,7 534,0 148,6 91,9 43,1 516,6 165,2 88,9 40,5

510

645,7 135,4 111,1 58,3 626,3 150,5 107,7 55,0 606,6 167,5 104,4 51,7 586,7 186,4 100,9 48,5

570

730,5 154,7 125,7 32,3 708,5 170,8 121,9 30,5 685,7 188,9 118,0 28,7 662,0 209,0 113,9 26,8

650

812,1 176,4 139,7 39,4 787,5 193,9 135,5 37,2 761,4 213,6 131,0 34,9 733,8 235,3 126,3 32,6

720*

216,0 44,0 37,2 46,0 209,2 48,9 36,0 43,4 201,5 54,1 34,7 40,5 193,0 59,6 33,2 37,4

180

270,8 55,8 46,6 38,1 262,4 62,1 45,1 35,9 253,3 69,0 43,6 33,7 243,5 76,4 41,9 31,4

230

326,2 66,4 56,1 30,2 316,4 73,8 54,4 28,6 306,1 81,8 52,7 26,9 295,5 90,6 50,8 25,2

280

387,2 79,0 66,6 41,5 375,0 87,7 64,5 39,1 362,6 97,5 62,4 36,8 349,8 108,3 60,2 34,4

330

441,7 90,1 76,0 40,2 428,1 100,0 73,7 38,0 414,3 111,3 71,3 35,7 400,4 123,8 68,9 33,5

380

514,5 105,7 88,5 43,5 498,8 117,2 85,8 41,0 482,4 130,0 83,0 38,5 465,5 144,1 80,1 36,0

450

8 °C

582,3 120,8 100,2 50,8 564,9 134,1 97,2 48,0 547,1 149,1 94,1 45,1 528,9 165,6 91,0 42,3

510

662,9 136,0 114,1 61,3 642,4 151,1 110,5 57,7 621,7 168,1 107,0 54,2 600,7 187,0 103,4 50,8

570

749,6 155,3 129,0 33,9 726,5 171,4 125,0 31,9 702,5 189,4 120,9 30,0 677,7 209,5 116,6 28,0

650

832,8 177,0 143,3 41,3 807,0 194,5 138,8 38,9 779,6 214,1 134,1 36,5 750,8 235,8 129,2 34,0

720*

227,2 44,1 39,1 50,6 219,8 49,2 37,8 47,6 211,7 54,6 36,4 44,3 202,7 60,2 34,9 40,9

180

285,0 56,1 49,0 41,8 275,8 62,5 47,4 39,4 266,0 69,5 45,8 36,9 255,5 77,0 44,0 34,2

230

343,5 66,9 59,1 33,3 332,8 74,3 57,2 31,4 321,6 82,4 55,3 29,4 310,0 91,3 53,3 27,5

280

407,9 79,6 70,2 45,7 394,6 88,4 67,9 43,0 381,0 98,2 65,5 40,3 367,0 109,0 63,1 37,6

330

465,5 90,9 80,1 44,4 450,5 100,8 77,5 41,8 435,3 112,1 74,9 39,2 420,0 124,6 72,3 36,6

380

541,8 106,5 93,2 47,9 524,5 117,9 90,2 45,1 506,6 130,7 87,2 42,2 488,1 144,8 84,0 39,3

450

10 °C

Evaporator water outlet temperature

12 °C

14 °C

Ph : Pe : Wf : Dp :

Net heating capacity in kW Effective absorbed power in cooling

613,3 121,8 105,5 56,0 594,1 135,1 102,2 52,8 574,5 150,0 98,8 49,5 554,5 166,6 95,4 46,3

510

698,5 137,2 120,2 67,7 676,0 152,3 116,3 63,6 653,1 169,3 112,4 59,6 630,1 188,3 108,4 55,6

570

789,0 156,5 135,7 37,3 763,6 172,5 131,4 35,1 737,3 190,6 126,8 32,8 710,1 210,6 122,2 30,6

650

875,4 178,3 150,6 45,3 847,1 195,7 145,7 42,6 817,3 215,2 140,6 39,8 786,0 236,8 135,2 37,0

720*

238,9 44,3 41,1 55,5 231,0 49,5 39,7 52,1 222,3 55,0 38,2 48,6 212,8 60,8 36,6 44,8

180

299,8 56,5 51,6 45,9 289,9 63,0 49,9 43,2 279,3 70,0 48,0 40,3 268,1 77,7 46,1 37,4

230

361,5 67,4 62,2 36,6 349,9 74,8 60,2 34,4 337,8 83,1 58,1 32,2 325,2 92,0 55,9 30,1

280

429,7 80,3 73,9 50,3 415,1 89,1 71,4 47,2 400,3 98,9 68,9 44,2 385,2 109,8 66,3 41,1

330

490,4 91,7 84,4 48,9 474,0 101,6 81,5 45,9 457,4 112,9 78,7 42,9 440,6 125,4 75,8 40,1

380

570,4 107,3 98,1 52,8 551,5 118,7 94,9 49,6 532,1 131,4 91,5 46,3 512,0 145,5 88,1 43,1

450

645,6 122,8 111,1 61,8 624,6 136,1 107,5 58,0 603,2 151,0 103,8 54,3 581,4 167,5 100,0 50,7

510

735,7 138,5 126,6 74,8 711,0 153,6 122,3 70,0 686,1 170,6 118,0 65,4 661,0 189,5 113,7 60,9

570

830,0 157,7 142,8 41,0 802,3 173,7 138,0 38,5 773,7 191,7 133,1 35,9 744,2 211,7 128,0 33,4

650

919,8 179,5 158,2 49,7 889,0 196,8 152,9 46,6 856,7 216,2 147,4 43,5 822,8 237,7 141,6 40,3

720*

251,1 44,5 43,2 60,8 242,7 49,8 41,8 57,1 233,5 55,5 40,2 53,2 223,5 61,4 38,4 49,0

180

315,2 56,8 54,2 50,3 304,5 63,4 52,4 47,2 293,2 70,6 50,4 44,1 281,3 78,3 48,4 40,8

230

380,3 67,9 65,4 40,2 367,7 75,4 63,3 37,7 354,7 83,7 61,0 35,3 341,2 92,7 58,7 32,9

280

452,3 81,0 77,8 55,4 436,6 89,8 75,1 51,9 420,5 99,7 72,4 48,4 404,2 110,6 69,5 45,0

330

516,3 92,5 88,8 53,8 498,5 102,5 85,8 50,4 480,5 113,7 82,7 47,1 462,3 126,3 79,5 43,8

380

600,2 108,1 103,3 58,2 579,8 119,4 99,7 54,5 558,8 132,2 96,1 50,8 537,1 146,2 92,4 47,1

450

679,2 123,9 116,9 68,0 656,4 137,1 112,9 63,8 633,3 152,0 108,9 59,6 609,7 168,5 104,9 55,4

510

774,4 139,8 133,2 82,4 747,7 154,9 128,6 77,1 720,7 171,9 124,0 71,9 693,4 190,9 119,3 66,8

570

872,7 159,0 150,1 45,0 842,6 174,9 145,0 42,2 811,7 192,9 139,7 39,3 780,0 212,8 134,2 36,5

650

965,9 180,7 166,2 54,5 932,6 197,9 160,4 51,0 897,7 217,2 154,4 47,5 861,4 238,7 148,2 43,9

720*

40 45 50 55

Wf

Dp Ph Pe

mode

Wf

Dp Ph Pe

Water fl ow in m3 per hour Water pressure drop in KPa

Wf

Dp Ph Pe

Wf

Dp

Application Guide • MWC-0410-E • 17 •

Page 20

DIMENSIONAL DATA

355±5233±5

MWC 180

648±5

820±5

D1/D2G1/G2

Fixing detail view

4 x n20

30

60

369±5119 7±1 5

Fixing detail view

1000 Mini

In1

Out2

110

In2

Out1

1645 ± 15

D1/G1 D2/G2

1600±5150±5

1900±5

2149±15

In/Out = Ø 4" Victaulic

In2

Out2

In1

Out1

MWC 180 MRC 180

Evaporator

In1 4" 4"

Out1 4" 4"

Water inlet

Water outlet

Condenser

In2 4" -

Out2 4" -

Liquid line

Discharge line

Water inlet

Water outlet

- 7/8"

- 1" 1/8

LOAD DITRIBUTION

(Kg - Operating weights)

D1

D2

G1

MWC 180 MRC 180

162 160

162 150

162 140

G2

Lennox recommend load distribution as detailed above

• 18 • Application Guide • MWC-0410-E

262 200

Page 21

DIMENSIONAL DATA

355±5233±5

568±5117 2±15

MWC 230 Î 380

In1

Out2

1000 Mini

101±5

In2

Out1

1871 ± 15

648±5

820±5

D1/D2G1/G2

Fixing detail view

D1/G1 D2/G2

1600±5150±5

1900±5

2150±15

Fixing detail view

304 x n20

60

MWC

230 Î 380

230 280 330 380

MRC

Evaporator

In1 4" 4"

Out1 4" 4"

Water inlet

Water outlet

Condenser

In2 4" -

Out2 4" -

Liquid line

Discharge line

Water inlet

Water outlet

-

-

1" 1/8

7/8"

1" 3/8

1" 1/8

2 x 1"1/8 2 x 1"1/8 2 x 1" 1/8

2 x 1"3/8 2 x 1"3/8 2 x 1" 3/8

In/Out = Ø 4" Victaulic

In2

Out2

In1

Out1

LOAD DITRIBUTION

(Kg - Operating weights)

D1

D2

G1

G2

Lennox recommend load distribution as detailed above

Application Guide • MWC-0410-E • 19 •

MWC

230

MWC

280

MWC

330

MWC

380

MRC

230

MRC

280

MRC

330

MRC

204 237 277 311 200 230 270 270

214 257 387 441 190 220 350 300

204 247 277 321 170 210 240 310

344 417 387 461 250 290 260 410

380

Page 22

DIMENSIONAL DATA

MWC 450 Î 570

1000 Mini

150±5

2200±5

1438±5

1600±5

1900±5

231±5

568±51172±5

D1/G1 D2/G2D1/D2G1/G2

Fixing detail view

1008±5

1200±5

21

In1

Out2

In2

Out1

1871±15

Fixing detail view

4 x n20

In1

Out1

Out2

In2

MWC

450 Î 570

MRC

450 Î 570

Evaporator

In1 5" 5"

Out1 5" 5"

Water inlet

Water outlet

Condenser

In2 5" -

Out2 5" -

Liquid line

Discharge line

LOAD DITRIBUTION

(Kg - Operating weights)

Water inlet

Water outlet

MWC

450

MWC

510

- 2 x 1" 3/8

- 2 x 1" 5/8

MWC

570

MRC

450

30

60

MRC

510

In/Out = Ø 5" Victaulic

MRC

570

D1

D2

G1

G2

• 20 • Application Guide • MWC-0410-E

553 575 645 540 560 630

543 585 605 350 370 380

453 475 515 440 460 500

433 465 475 330 350 360

Page 23

DIMENSIONAL DATA

MWC 650 Î 720

1000 Mini

719±5 719±5 231±5

D1/D2G1/G2 D1/G1 D2/G2

1600±5150±5

1900±5

2200 ± 15

568±51168 ± 15

1871 ± 15

22

1008±5

1200±5

Fixing detail view

In1

Out2

In2

Out1

Fixing detail view

30

60

In/Out = Ø 5" Victaulic

Out1

In1

Out2

In2

Out2

In2

MWC

650 Î 720

4 x n20

MRC 650 MRC 720

Evaporator

In1 5" 5" 5"

Out1 5" 5" 5"

Water inlet

Water outlet

Condenser

In2 5" - -

Out2 5" -

Liquid line C1 & C2

Discharge line C1 & C2

LOAD DITRIBUTION

(Kg - Operating weights)

Water inlet

Water outlet

MWC

650

MWC

720

-

-

MRC

650

1" 5/8

1" 3/8

2" 1/8

1" 5/8

MRC

720

2 x 1" 5/8

2 x 2" 1/8

D1

D2

G1

G2

Application Guide • MWC-0410-E • 21 •

775 785 660 670

655 665 410 420

545 555 530 540

465 475 380 390

Page 24

SALES OFFICES :

lennoxemeia.com

BELGIUM AND LUXEMBOURG

+ 32 3 633 3045

FRANCE

+33 1 64 76 23 23

GERMANY

+49 (0) 40 589 6235 0

ITALY

+ 39 02 495 26 200

NETHERLANDS

+ 31 332 471 800

POLAND

+48 22 58 48 610

RUSSIA

+7 495 626 56 53

SPAIN

+34 902 533 920

UKRAINE

+38 044 585 59 10

UNITED KINGDOM AND IRELAND

+44 1604 669 100

OTHER COUNTRIES :

PORTUGAL

+351 229 066 050

MCW-AGU-0410-E

LENNOX DISTRIBUTION

+33 4 72 23 20 00

Due to Lennox’s ongoing commitment to quality, the specifi cations,

ratings and dimensions are subject to change without notice and

without incurring liability.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage or personal injury.

Installation and service must be performed by a qualifi ed installer

and servicing agency

Loading...

Loading...