Page 1

DON’T

THROW

IT AWAY !

This manual contains

important operating

and safety

information.

Wait...

CARE AND OPERATION INSTRUCTIONS

▪

F

▪

R

▪

E

▪

E

▪

▪

See Page 2 For Details

▪

SAFETY

GUA RD

PROTECTS AGAINST BURNS

AVERTISSEMENT : Assurez-vous de bien suivre les

instructions données dans cette notice pour réduire au

minimum le risque d’incindie ou d’explosion ou pour

éviter tout dommage matériel, toute blessure ou la mort.

- Ne pas entreposer ni utilizer d’essence ni d’autres vapeurs

ou liquides inflammables dans le voisinage de cet appareil

ou de tout autre appareil.

- QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ :

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucan interrupteur. Ne pas vous servir des

téléphones se trouvant dans le bâtiment où vous trouvez.

• Appelez immédiatement votre fournisseur de gaz depuis

un voisin. Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de gaz,

appelez le service des incindies.

- L’installation et l’entretien doivent être assurés par un

installateur ou un service d’entretien qualifié ou par le

fournisseur de gaz.

WARNING: If the information in these instructions

is not followed exactly, a fire or explosion may

result, causing property damage, personal injury,

or death.

-

vapors and liquids in the vicinity of this or any other

appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

•

department.

- Installation and service must be performed by a

WARNING /AVERTISSEMENT / AVISO

• HOT GLASS WILL CAUSE

BURNS.

• DO NOT TOUCH GLASS

UNTIL COOLED.

• NEVER ALLOW CHILDREN

TO TOUCH GLASS.

• UNE SURFACE VITRÉE CHAUDE

PEUT CAUSER DES BRÛLURES.

• LAISSER REFROIDIR LA SURFACE

VITRÉE AVANT D'Y TOUCHER.

• NE PERMETTEZ JAMAIS À UN ENFANT

DE TOUCHER LA SURFACE VITRÉE.

• EL VIDRIO CALIENTE

CAUSARÁ QUEMADURAS.

• USTED DEBE NUNCA

TOCAR EL VIDRIO CALIENTE.

• LOS NIÑOS DEBEN NUNCA

TOCAR EL VIDRIO.

US

Portland

MPB35ST B-Vent See-Through

Gas Fireplaces

P/N 875024M Rev. D 01/2011

This manual is part of a set of two supporting this product.

Refer to P/N 850023M for Installation Instructions.

Ce manuel est disponible en francais, simplement

en faire la demande. Numéro de la pièce 875024CF.

WHAT'S INSIDE

Table of Contents .................................... 2

Safety and Your Fireplace............................. 2

FREE Safety Guard Offer

Important Safety Information .......................... 4

Attaching the Safety-in-Operation Warnings .............. 5

[EN FRANÇAIS] L’information de sûreté importante ............ 3–4

Apposition des mises en garde relatives à la sécurité d’utilisation ... 5

[EN ESPAÑOL] Información importante de seguridad............ 3–4

Colocación de advertencias de seguridad en operación .......... 5

(Protects Against Burns) ............. 2

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

INSTALLATEUR : Laissez cette notice avec l'appareil.

CONSOMMATEUR : Conservez cette notice pour consultation ultérieure.

MODELS

MILLIVOLT:

MPB35ST-NM-B

MPB35ST-PM-B

OTL Report No. 116-F-27-5

ELECTRONIC:

MPB35ST-NE-B

Page 2

Thank you for your purchase. We appreciate your business!

Please carefully read and follow all instructions in this manual.

Pay special attention to all warnings and safety information.

Following these safety, care, and operation instructions will help

ensure many years of dependable and enjoyable service from

your fireplace.

•

FREE

severe burns and injuries by preventing direct contact

To receive your FREE SAFETY GUARD, call 1-800-786-7976

or visit www.lennox.com

Table of Contents

Safety and Your Fireplace................................. 2

Important Safety Information .............................. 4

Attaching the Safety-in-Operation Warnings .................. 5

General Information ...................................... 6

Operation/Care of Your Appliance ..............................8

Gas Controls/Control Compartment, Access ......................8

Variable Flame Adjustment ....................................9

Venting Operation / Spill Switch ................................9

Outside Combustion Air Control ..............................10

Maintenance ..............................................11

Front Glass Enclosure Panel, Removal and Installation .............12

Logs, Vermiculite & Ember Placement ...........................12

Burner Adjustments ........................................15

Millivolt Appliance Checkout .................................16

Electronic Appliance Checkout ................................16

Warranty ................................................17

Replacement Parts ........................................17

Product Reference Information ...............................17

Wiring Diagrams ..........................................17

Accessory Components .....................................18

Lighting Instructions – Millivolt ...............................22

Lighting Instructions – Electronic .............................24

Maintenance Schedule ......................................26

Troubleshooting Guide – Millivolt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Troubleshooting Guide – Electronic ............................27

Replacement Parts List .....................................29

2

SAFETY GUARD

The Lennox® SAFETY GUARD protects against

with the front glass surface of your fireplace.

(Lennox Hearth Products / Owner Resources)

OFFER

Safety and

Your Fireplace

All parts of your Lennox

•

Hearth Products fireplace

get EXTREMELY HOT!

To prevent severe burns and injuries, install

a screen or physical barrier to prevent direct

contact with the glass.

To order a FREE Lennox® SAFETY GUARD

for your fireplace, see details at left.

Follow the safety instructions below

and be sure everyone in your household

understands this burn hazard:

The surfaces on your fireplace get •

EXTREMELY HOT!

The glass on the front •

of the fireplace reaches

EXTREMELY HIGH

temperatures and can

cause severe burns if touched.

Keep children away from an operating •

fireplace. Closely supervise children in

any room where a fireplace is operating

to prevent contact with glass.

Keep clothing, furniture, •

gasoline, and other

flammable liquids away

from the fireplace.

Even after the gas is turned off, fireplace •

surfaces remain extremely hot.

Be sure to attach the enclosed Safety-in-

Operation Warnings where you turn on your

fireplace, to help remind everyone of the

dangers associated with high temperatures

(see page 5).

Read Important Safety Information on

page 4.

Page 3

[FRENCH] [SPANISH]

La sécurité et

votre foyer

Toutes les parties de votre foyer

Lennox Hearth Products deviennent

EXTRÊMEMENT CHAUDES !

Afin d'éviter de vous brûler gravement ou de

vous blesser, installez une grille ou une barrière

physique pour empêcher tout contact direct

avec la vitre.

Pour commander un PANNEAU DE PROTECTION

Lennox® GRATUIT pour votre foyer, consultez

les détails dans la partie gauche.

Suivez les instructions de sécurité ci-dessous

et veillez à ce que tous les membres de votre

famille soient conscients du danger de brûlure

encouru :

Les surfaces de votre foyer deviennent •

EXTRÊMEMENT CHAUDES !

La vitre située à l'avant du foyer •

atteint des températures

EXTRÊMEMENT ÉLEVÉES et peut causer

de graves blessures en cas de contact.

Tenez les enfants à l'écart du foyer lorsqu'il •

fonctionne. Surveillez attentivement

les enfants dans les pièces où un foyer

est utilisé afin d'éviter qu'ils ne soient

en contact avec la vitre.

Tenez tous les vêtements, les •

meubles, l'essence et tout autre

liquide inflammable à l'écart du foyer.

Même après fermeture du gaz, les surfaces •

du foyer restent extrêmement chaudes.

Seguridad y

su chimenea

¡Todas las partes de la chimenea

Lennox Hearth Products se ponen

MUY CALIENTES!

Instale una malla o barrera física para evitar

el contacto directo con el vidrio y prevenir

las quemaduras y lesiones graves.

Ver los detalles a la izquierda para ordenar

un Lennox® SAFETY GUARD GRATIS

para su chimenea.

Siga las instrucciones de seguridad a

continuación y asegúrese de que todos

en su hogar sepan acerca de este peligro

de quemadura:

¡Las superficies de la chimenea se ponen •

MUY CALIENTES!

El vidrio delante de la chimenea alcanza •

temperaturas EXTREMADAMENTE ALTAS y

puede causar quemaduras graves si se toca.

Mantenga a los niños alejados de la •

chimenea en funcionamiento. Supervise

en forma cercana a los niños en cualquier

cuarto donde haya una chimenea

funcionando para impedir el contacto

con el vidrio.

Mantenga la ropa, mobiliario, gasolina •

y otros líquidos inflamables alejados

de la chimenea.

Aún después de haber apagado el gas, •

las superficies de la chimenea permanecen

extremadamente calientes.

Veillez à coller les Étiquettes de mise en garde

relatives à la sécurité d'utilisation à l'endroit

où vous utilisez le foyer, pour rappeler à tous les

utilisateurs les dangers liés aux températures

élevées (voir page 5).

Lisez la section Informations importantes

relatives à la sécurité, page 4.

Asegúrese de colocar las Etiquetas de

advertencia de seguridad de operación en

el lugar donde enciende la chimenea, para

que todos recuerden los peligros asociados

con las altas temperaturas (ver la página 5).

Lea la Información importante de seguridad

en la página 4.

3

Page 4

Important Safety Information

L'information de sûreté importante

WARNING: Do not operate appliance with the glass front 1.

removed, cracked or broken. Replacement of the glass

should be done by a licensed or qualified service person .

Do not use this appliance if any part has been under water. 2.

Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system

and any gas control which has been under water.

Due to 3. high temperatures, the appliance should be located

out of traffic and away from furniture and draperies.

Children and adults should be alerted to the hazards of 4.

high surface temperature and should stay away to avoid

burns or clothing ignition.

Clothing or other flammable material should not be placed 5.

on or near the appliance.

Young children should be carefully supervised when they 6.

are in the same room as the appliance. Toddlers, young

children, and others may be susceptible to accidental

contact burns. A physical barrier is recommended if there

are at-risk individuals in the house. To restrict access to a

fireplace or stove, install an adjustable safety gate to keep

toddlers, young children, and other at-risk individuals out

of the room and away from hot surfaces.

Any safety screen or guard removed for servicing an 7.

appliance must be replaced prior to operating the

appliance.

Installation and repair should be done by a qualified 8.

service person. The appliance should be inspected

before use and at least annually by a professional service

person. More frequent cleaning may be required due to

excessive lint from carpeting, bedding material, et cetera.

It is imperative that control compartments, burners, and

circulating air passageways of the appliance be kept

clean. See maintenance instructions on page 11.

AVERTISSEMENT. Ne pas utiliser l’appareil si le panneau frontal 1.

en verre n’est pas en place, est craqué ou brisé. Confiez le

remplacement du panneau à un technicien agréé

Ne pas utiliser cet appareil s’il a été plongé, même partiellement, 2.

dans l’eau. Appeler un technicien qualifié pour inspecter

l’appareil et remplacer toute partie du système de commande

et toute commande qui a été plongée dans l’eau.

En raison des températures élevées, l’appareil devrait être 3.

installé dans un endroit où il y a peu de circulation et loin du

mobilier et des tentures.

Les enfants et les adultes devraient être informés des dangers 4.

que posent les températures de surface élevées et se tenir à

distance afin d’éviter des brûlures ou que leurs vêtements ne

s’enflamment.

On ne devrait pas placer de vêtements ni d’autres matières 5.

inflammables sur l’appareil ni à proximité.

Les jeunes enfants devraient être surveillés étroitement lorsqu’ils 6.

se trouvent dans la même pièce que l’appareil. Les tout petits,

les jeunes enfants ou les adultes peuvent subir des brûlures s’ils

viennent en contact avec la surface chaude. Il est recommandé

d’installer une barrière physique si des personnes à risques

habitent la maison. Pour empêcher l’accès à un foyer ou à un

poêle, installez une barrière de sécurité ; cette mesure empêchera

les tout petits, les jeunes enfants et toute autre personne à risque

d’avoir accès à la pièce et aux surfaces chaudes.

Tout écran ou protecteur retiré pour permettre l’entretien de 7.

l’appareil doit être remis en place avant de mettre l’appareil en

marche.

L’installation et la réparation devrait être confiées à un technicien 8.

qualifié. L’appareil devrait faire l’objet d’une inspection par un

technicien professionnel avant d’être utilisé et au moins une

fois l’an par la suite. Des nettoyages plus fréquents peuvent

être nécessaires si les tapis, la literie, et cetera produisent

une quantité importante de poussière. Il est essentiel que les

compartiments abritant les commandes, les brûleurs et les

conduits de circulation d’air de l’appareil soient tenus propres.

Voyez les instructions d’entretien à la page 11.

[SPANISH]

Información importante de seguridad

ADVERTENCIA: No opere el artefacto con el frente de vidrio quitado, 1.

agrietado o roto. Un técnico de servicio licenciado o capacitado

debe reemplazar el vidrio.

No use este artefacto si alguna de sus partes ha estado bajo agua. 2.

Llame de inmediato a un técnico de servicio calificado para que

inspeccione el artefacto y reemplace cualquier parte del sistema

de control y cualquier control de gas que haya estado bajo agua.

Debido a las altas temperaturas, el artefacto debe situarse fuera 3.

de las áreas de tráfico y lejos del mobiliario y cortinas.

Se debe alertar a los niños y adultos sobre los peligros de 4.

las altas temperaturas en la superficie y que se mantengan

alejados para evitar quemaduras o ignición de la ropa.

No debe colocarse ropa u otros materiales inflamables 5.

4

sobre y cerca del artefacto.

Se debe supervisar de cerca a los niños cuando estén en el mismo 6.

cuarto que el artefacto. Los niños pequeños, los jóvenes y otras

personas pueden ser susceptibles a quemaduras por contacto

accidental. Se recomienda instalar una barrera física si hay

personas en riesgo en la casa. Para restringir el acceso a una

chimenea o estufa, instale una puerta de seguridad ajustable

para mantener a los niños pequeños, jóvenes y otras personas

en riesgo fuera del cuarto y lejos de las superficies calientes.

Cualquier malla o resguardo de seguridad quitado para dar servicio 7.

a un artefacto, debe reinstalarse antes de operar el artefacto.

Una persona de servicio competente debe realizar la instalación y 8.

reparación. Una persona de servicio profesional debe inspeccionar

el artefacto antes de usar al menos una vez por año. Se puede

requerir limpieza más frecuente debido a la pelusa excesiva

del alfombrado, del material de cobijas, etc. Es imprescindible

mantener limpios los compartimientos de control, los quemadores

y los pasajes de circulación del aire del artefacto. Ver las

instrucciones de mantenimiento en la página 11.

Page 5

HOMEOWNER’S INSTRUCTIONS - ATTACHING SAFETY-IN-OPERATION WARNINGS

ATTACHING SAFETY-IN-OPERATION

WARNINGS

Your fireplace has been furnished with safety instruction labels that are to be affixed to the operation and

control point of the fireplace. A safety instruction

label should be affixed to the wall switch plate where

the fireplace is turned on and off (See Figure A) and

if used on the remote control handheld transmitter

(Figure B). The warnings should already have been

put in place when the fireplace initial set-up was

completed. If they are not affixed at these spots,

locate the multi-lingual adhesive labels provided with

these instructions and proceed as follows:

1. Locate the wall switch that controls the fireplace

(verify the switch operates the fireplace by turning it on and off). Clean the wall switch plate

thoroughly to remove any dust and oils. Affix the

label to the surface of the plate of the wall switch

that controls the fireplace (Figure A). Choose

the language primarily spoken in the home.

2. If a remote control is used to control the fireplace,

locate the transmitter and clean it thoroughly

to remove any dust and oils. Affix the label to

the surface of handheld transmitter (Figure B).

Choose the language primarily spoken in the

home.

3. If you are unable to locate the labels, please call

Lennox Hearth Products or your nearest Lennox

Hearth Products dealer to receive additional

safety instruction labels free of charge.

Cat. No. H8024 Replacement Label Kit

LENNOX HEARTH PRODUCTS

1-800-9-LENNOX

Note: English is red text on clear label. French and

Spanish are white text on black label.

APPOSITION DES MISES EN GARDE RELATIVES

À LA SÉCURITÉ D’UTILISATION

Votre foyer a été livré avec des étiquettes de sécurité qui

doivent être collées à côté des dispositifs de contrôle

du foyer. Une étiquette de sécurité devrait être collée

sur la plaque de l’interrupteur contrôlant l’allumage du

foyer (voir Figure A) et, le cas échéant, sur le boîtier

de la télécommande (Figure B). Les mises en garde

auraient dû être collées au moment de l’installation

initiale du foyer. Si ce n’est pas le cas, prenez les

étiquettes adhésives multilingues fournies avec ces

instructions et procédez comme suit:

1. Repérez l’interrupteur qui contrôle le foyer (vérifiez

que l’interrupteur contrôle le fonctionnement du

foyer en le faisant basculer de Marche à Arrêt, et

vice-versa). Nettoyez soigneusement la plaque

murale de l’interrupteur pour éliminer la poussière

et les traces de graisse ou d’huile. Collez l’étiquette

sur la surface de la plaque de l’interrupteur mural

qui contrôle le foyer (Figure A). Choisissez la langue

qui est principalement parlée dans la résidence

du propriétaire.

2. Si une télécommande est utilisée pour contrôler

le foyer, nettoyez la soigneusement pour éliminer

la poussière et les traces de graisse ou d’huile.

Collez l’étiquette sur le boîtier de la télécommande

(Figure B). Choisissez la langue qui est principalement parlée dans la résidence du propriétaire.

3. Si vous ne trouvez pas les étiquettes, veuillez

appeler Lennox Hearth Products ou votre distributeur Lennox Hearth Products local pour recevoir

gratuitement des étiquettes supplémentaires.

Étiquettes de remplacement, n° cat. H8024

LENNOX HEARTH PRODUCTS

1-800-9-LENNOX

Remarque : Le texte anglais est rouge sur un support

transparent. Le texte français et espagnol est blanc

sur un support noir.

COLOCACIÓN DE ADVERTENCIAS DE

SEGURIDAD EN OPERACIÓN

Su chimenea incluye etiquetas de instrucciones de

seguridad que deben colocarse en el punto de operación

y control de la chimenea. Se debe colocar una etiqueta

de instrucciones de seguridad en la placa del interruptor

de pared desde el cual se enciende y se apaga la

chimenea (ver la Figura A) y en el transmisor de control

remoto (Figura B) si se usa. Las advertencias ya deben

haberse colocado cuando se completó la instalación

inicial de la chimenea. Si no están colocadas en estos

lugares, encuentre las etiquetas adhesivas multilingües

proporcionadas con estas instrucciones y prosiga de

la siguiente manera:

1. Identifique el interruptor de pared que controla

la chimenea (verifique que el interruptor opera la

chimenea encendiéndola y apagándola). Limpie

bien la placa del interruptor de pared para quitar el

polvo y aceite. Pegue la etiqueta en la superficie de

la placa del interruptor que controla la chimenea

(Figura A). Seleccione el idioma que más se habla

en la casa.

2. Si se usa un control remoto para controlar la

chimenea, encuentre el transmisor y límpielo bien

para quitar el polvo y aceite. Pegue la etiqueta en la

superficie del transmisor (Figura B). Seleccione el

idioma que más se habla en la casa.

3. Si no puede encontrar las etiquetas, sírvase llamar

a Lennox Hearth Products o al distribuidor de

Lennox Hearth Products más cercano para recibir

etiquetas de instrucciones de seguridad adicionales

gratuitas.

Juego de etiquetas de repuesto - Nº de cat. H8024

LENNOX HEARTH PRODUCTS

1-800-9-LENNOX

Nota: La etiqueta en inglés es transparente con texto

rojo. Las etiquetas en francés y español son negras

con texto blanco.

SAFETY LABEL

DIAGRAMS

Figure A

DIAGRAMMES DES ÉTIQUETTES

DE SÉCURITÉ

Figure B

DIAGRAMAS DE ETIQUETAS

DE SEGURIDAD

5

Page 6

General Information

The Millivolt appliances have a millivolt gas

control valve with piezo ignition system.

The Electronic appliances have an electronic

intermittent pilot ignition system. External

electrical power is required to operate these

units.

These appliances comply with National Safety

Standards and are tested and listed by OmniTest Laboratories (Report No. 116-F-27-5) to

ANSI Z21.500 (in Canada, CSA 2.22), and CAN/

CGA-2.17-M91 in both USA and Canada, as

vented gas fireplaces.

The Installation must conform to local codes

or, in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1/NFPA

54-latest edition, or the Natural Gas and Propane

Installation Code, CAN/CSA B149.1-latest edition. The appliance, when installed, must be

electrically grounded in accordance with local

codes or, in the absence of local codes, the

latest edition of the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22.1 - latest editions.

INSTALLATION, SERVICE,

AND MAINTENANCE

IMPORTANT: Improper installation,

adjustment, alteration, service, or

maintenance can cause injury or

property damage. Refer to this manual.

For assistance or additional information,

consult a qualified installer, service

agency or the gas supplier.

Only trim kit(s) supplied by the

manufacturer shall be used in the

installation of this appliance.

Draft relief openings must not be

covered or blocked.

These appliances must not be

connected to a chimney or flue serving a

separate solid fuel burning appliance.

Any change to this appliance and/or

its operating controls is dangerous.

Improper installation or use of this

appliance can cause serious injury or

death from fire, burns, explosion or

carbon monoxide poisoning.

These appliances are designed to

operate on natural gas or propane

gas only. The use of other fuels or

combinations of fuels will degrade the

performance of this system and may be

dangerous.

Provide adequate clearances around

air openings and adequate accessibility

clearance for service and proper

operation. Never obstruct the front

openings of the appliance.

Do not use this appliance if any part has

been under water. Immediately call a

qualified service technician to inspect the

appliance and to replace any part of the

control system and any gas control that

has been under water.

WARRANTY

Failure to comply with the installation

and operating instructions provided

will result in an improperly installed

and operating appliance, voiding its

warranty.

WARNING

B-Vent appliances are not

designed to operate in negatively

pressured environments (pressure within the home is less than

pressures outside). Significant

negatively pressured environments caused by weather, home

design, or other devices may

impact the operation of these

appliances. Negative pressures may result in poor flame

appearance, sooting, damage to

property and/or severe personal

injury. Do not operate these

appliances in negatively pressured environments.

These fireplaces are designed as supplemental heaters. Therefore, it is advisable

to have an alternate primary heat source

when installed in a dwelling.

These appliances must not be connected to

a chimney or flue serving a separate solid

fuel burning appliance.

Carbon Monoxide Poisoning: Early

signs of carbon monoxide poisoning

are similar to the flu with headaches,

dizziness and/or nausea. If you

have these signs, obtain fresh air

immediately. Turn off the gas supply to

the appliance and have it serviced by

a qualified professional, as it may not

be operating correctly. Some people

are more affected by carbon monoxide

than others, including pregnant women,

people with heart or lung disease or

anemia, those under the influence of

alcohol, and those at high altitudes.

Turn off gas and electrical power to the

fireplace and allow it to cool before

cleaning or servicing the appliance.

OPERATION

Do not operate appliance with the glass

front removed, cracked, or broken.

These fireplaces are vented gas

appliances. Do not burn wood or other

material in these appliances.

This appliance is only for use with the

type of gas indicated on rating plate.

This appliance is not convertible for use

with other gases, unless a certified kit is

used.

Do not attempt to alter or modify the

construction of the appliance or its

components. Any modification or

alteration may void the warranty,

certification, and listings of this unit.

6

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 7

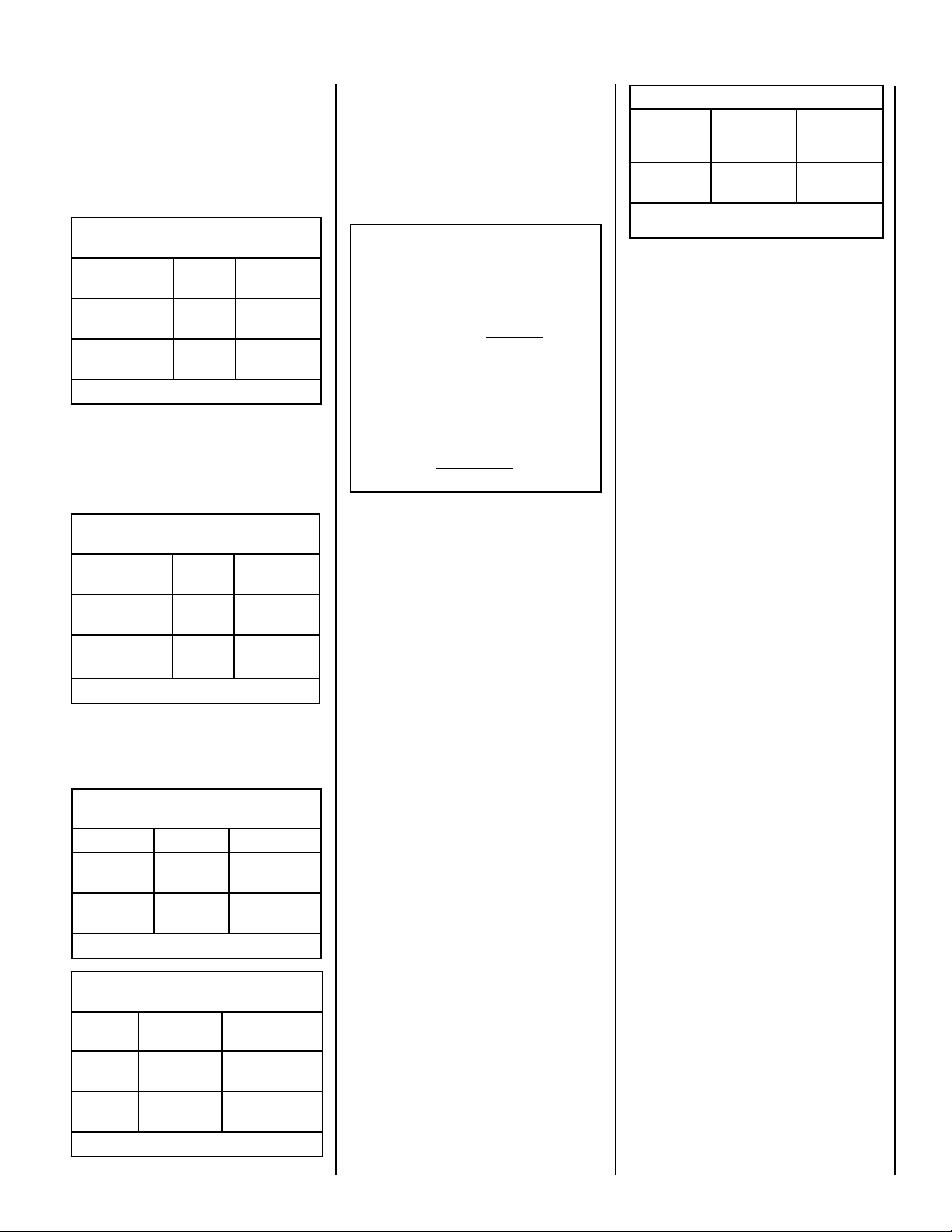

Millivolt Models - BTU Input

Millivolt models come standard with the

manually-modulated gas valve; flame appearance and heat output can be controlled at the

gas valve. Input of for these models is shown

in Table 1.

Input (BTU) Manually-Modulated Gas

Valves (millivolt models)

Models Fuel

Type

MPB35ST-NM-B Nat. Gas

MPB35ST-PM-B Propane

Input Rate

(BTU / HR)

30,000 high

23,000 low

28,000 high

22,000 low

Table 1

Electronic Models -

Electronic models have a fixed rate gas valve.

Input of electronic models is shown in Table

2.

Test gauge connections are provided on the front

of the millivolt gas control valve, identified IN

for the inlet and OUT for the manifold side (see

Figure 2 on Page 9). A 1/8" NPT Test gauge con-

nection is provided at the inlet and outlet side of

the electronic gas control valve (see Figure 3

on Page 9).

These appliances must be isolated

from the gas supply piping system (by

closing their individual manual shut-off

valve) during any pressure testing of

the gas supply piping system at test

pressures equal to or less than 1/2 psig

(3.5 kPa).

These appliances and their individual

shut-off valves must be disconnected

from the gas supply piping system during any pressure testing of that system

at pressures greater than 1/2 psig (3.5

kPa).

Burner Orifice Sizes (all models)

Elevation

Feet (meters)

0-4500

(0-1372)

Table 5

Natural

Gas

drill size (inches)

#37 (.104")

24M10•

* Standard size installed at factory

• Part /Cat. Number

*

Propane

Gas

drill size (inches)

1.55

mm

(.061")

42M79•

*

Burn-in Period

During the first few fires of this appliance there

will be some odor due to the curing of the

paint and burning off of lubricants used in the

manufacturing process. Depending on your

use, the burn-in period may take a few hours

or a few days.

KEEP YOUR HOUSE WELL VENTILATED

DURING THE CURING PROCESS. THE ODOR

AND HAZE EMITTED DURING THE CURING

PROCESS CAN BE QUITE NOTICEABLE AND

MAY SET OFF A SMOKE DETECTOR.

Input (BTU) - Fixed Rate

(electronic models)

Models Fuel

Type

Input Rate

(BTU / HR)

MPB35ST-NE-B Nat. Gas 30,000

MPB35ST-PE-B

(if field converted)

Pro. Gas 28,000

Table 2

Gas Pressure -

Tables 3 and 4 show the appliances' gas

pressure requirements.

Inlet Gas Supply Pressure

(all models)

Fuel # Minimum Maximum

Natural Gas

Propane

5.0" WC

(1.24 kPa)

11.0" WC

(2.74 kPa)

10.5" WC

(2.61 kPa)

13.0" WC

(3.23 kPa)

Table 3

Manifold Gas Supply Pressure

(all models)

Fuel # Low

(millivolt only)

Natural

Gas

Propane

(Lo) 2.2" WC

(.55 kPa)

(Lo) 6.3" WC

(1.57 kPa)

High

(Hi) 3.5" WC

(.87 kPa)

(Hi) 10.0" WC

(2.49 kPa)

Table 4

Orifice Sizes - Sea Level to High Altitude

(All Models)

These appliances are tested and approved for

installation at elevations of 0-4500 feet (0-1372

meters) above sea level using the standard

burner orifice sizes (marked with an "*" in Table

5). For elevations above 4500 feet, contact your

gas supplier or qualified service technician.

Deration - At higher elevations, the amount

of BTU fuel value delivered must be reduced

by either:

• Using gas that has been derated by the gas

company.

• Changing the burner orice to a smaller size

as regulated by the local authorities having

jurisdiction and by the (USA) National Fuel

Gas Code NFPA 54/ANSI Z223.1 - latest

edition or, in Canada, the CAN/CSA-B149.1

codes - latest edition.

Install the appliance according to the regulations

of the local authorities having jurisdiction and,

in the USA, the National Fuel Gas Code NFPA

54 / ANSI Z223.1 - latest edition or, in Canada,

the CAN/CSA-B149.1 - latest edition.

NOTE: Flame appearance will diminish 4% per

thousand feet.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

A white film may develop on the glass front

during the first few fires as part of the curing

process. The glass should be kept clean during

the first two weeks of use to prevent the film from

baking on (making it very difficult to remove).

See Cleaning Glass on Page 11.

7

Page 8

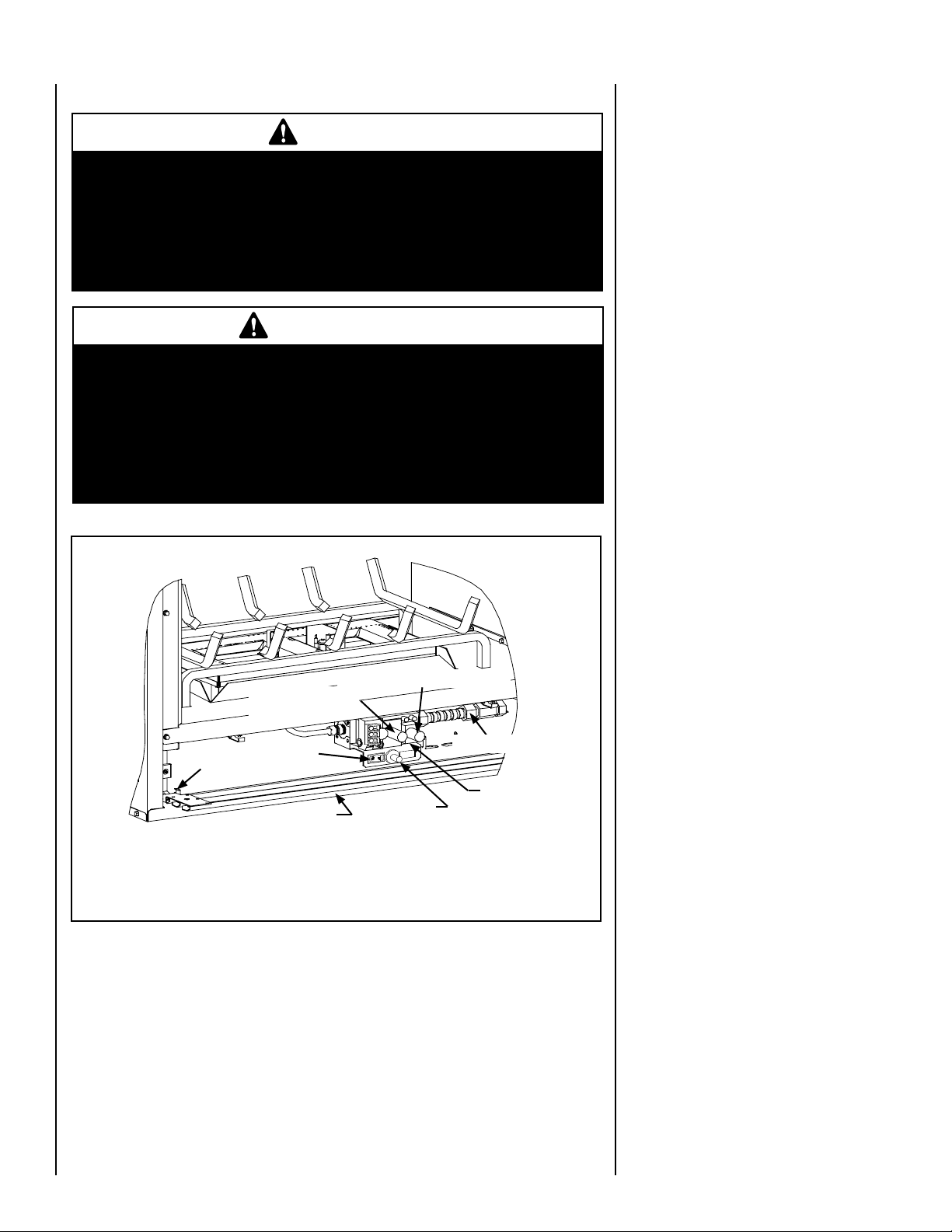

OPERATION AND CARE OF YOUR APPLIANCE

WARNING

Young children should be carefully supervised when they are in the

same room as the appliance. Toddlers, young children and others

may be susceptible to accidental contact burns. A physical barrier is

recommended if there are at risk individuals in the house. To restrict

access to a fireplace or stove, install an adjustable safety gate to keep

toddlers, young children and other at risk individuals out of the room

and away from hot surfaces.

On millivolt systems, the piezo igniter, HI/LO

flame adjustment knob, and pilot and main

gas OFF/ON control knob are located below

the glass panel enclosure. The gas valve for

electronic systems is also located below the

glass enclosure panel. See Figure 1.

Operation of millivolt and electronic gas control systems are different. Before lighting and

operating your appliance determine if you have

a millivolt or electronic appliance. Familiarize

yourself with the gas control valve that your

appliance uses. Refer to Figure 1 for access

to the gas control valve.

AVERTISSEMENT

Les jeunes enfants devraient être surveillés étroitement lorsqu’ils se trouvent dans la même pièce que l’appareil. Les tout petits, les jeunes enfants

ou les adultes peuvent subir des brûlures s’ils viennent en contact avec

la surface chaude. Il est recommandé d’installer une barrière physique

si des personnes à risques habitent la maison. Pour empêcher l’accès

à un foyer ou à un poêle, installez une barrière de sécurité; cette mesure

empêchera les tout petits, les jeunes enfants et toute autre personne à

risque d’avoir accès à la pièce et aux surfaces chaudes.

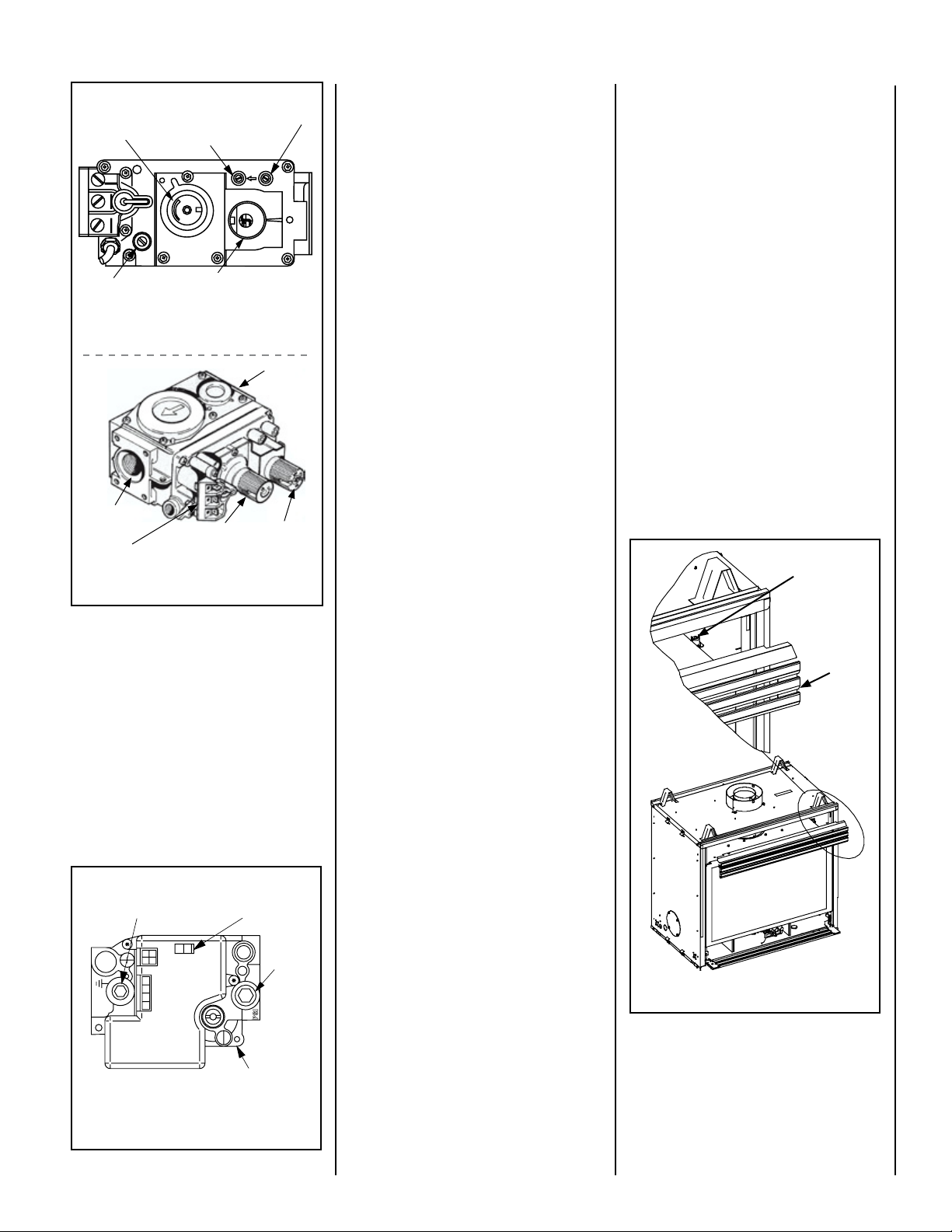

OFF/PILOT/ON (gas control knob)

HI/LO (flame height

control knob)

OFF/ON Switch

Hinge Pin

Control

Compartment Access panel

Note: The gas supply line must be installed in accordance with building codes by a qualified

installer approved and/or licensed as required by the locality. In the Commonwealth of Massachusetts, installation must be performed by a licensed plumber or gas fitter.

Piezo Igniter

Figure 1 - Gas Control Compartment Access

Gas Flex Line

Gas Valve

Millivolt Appliances - Appliances with

Millivolt systems will be fitted with the gas

control valve shown in Figure 2.

Electronic Appliances - Appliances with

electronic systems will be fitted with the

electronic valve shown in Figure 3.

Millivolt Appliances -

To light millivolt appliances refer to Figure

1. Detailed lighting instructions are found on

Pages 22 and 23. Millivolt appliance lighting

instructions may also be found on the pull out

lighting instruction labels attached to the gas

control valve.

Once the pilot is lit, the main burner may be

turned ON and OFF using a wall switch, remote

control, unit-mounted rocker switch, or wall

thermostat. To operate: Toggle the switch

between its ON and OFF positions.

If your millivolt appliance is equipped with an

optional remote switch kit (wall switch or remote

control) and the pilot is lit, the appliance main

burner may be turned on and off using the

optional switch. When using an optional remote

switch, turn off the standard OFF/ON switch.

Note: To prevent excessive resistance in burner

circuit (which can cause burner operation

problems), only one burner control switch

should be wired to valve.

Gas Controls/Control Compartment Access

The standard controls for appliance operation are located behind the hinged drop-down panel

below the appliance front glass enclosure panel (see Figure 1). Optional control switches are also

available (see Page 18 - Remote Wall Switch or Remote Control).

To open the control compartment access panel, actuate the spring-loaded magnetic catches securing the panel. First, depress the outer top right corner of the panel until the catch "pops" the door

free. Then, gently pull the door forward until the left top corner "pops" free, allowing the panel to

swing out and down to open.

To ease door closure, depress the catches to place them in their retracted position, then close

the door.

8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 9

H

I

L

O

W

HTPTHTPT

P

I

L

O

T

P

I

L

O

T

O

N

it

O

F

F

IN

OUT

HI/LO Variable

FFO

NI

P

S

I

NO

LORTNOC

GI N TI ER

Flame Height

Adjustment

Pilot Adjustment

Screw

Manifold Pressure Tap

Inlet Pressure Tap

Main Gas Control Knob

OFF/PILOT/ON

Note: The piezo igniter is located below

the valve (see Figure 1).

Gas

Inlet

TPTH TP TH

Gas

Outlet

Main Gas

Control Knob

OFF/PILOT/ON

Terminals

TPTH,TP & TH

HI/LO Variable

Flame Height

Adjustment

Figure 2 - SIT Millivolt Gas Valve

Electronic Appliances -

To light electronic appliances refer to the detailed

lighting instructions found on Pages 24 and

25 of these instructions. Electronic appliance

lighting instructions may also be found on the

pull out lighting instruction labels attached to

the gas control valve.

If your electronic appliance is equipped with an

optional remote wall switch or remote control kit

the appliance main burner may be turned on and

off with the wall switch or remote control.

Manifold

Pressure

Port

ON / OFF Switch

Inlet

Pressure

Port

Variable Flame Height Adjustment

(Millivolt Appliances only)

All Millivolt appliances are equipped with a

variable gas control valve. Flame height for

these models may be adjusted through a range

between fixed low and high settings while the

appliance is in operation. Adjust the flame

height as desired after lighting the appliance

by rotating the variable adjustment control

knob (HI/LO) located on the front of the valve

(refer to Figure 2).

VENT OPERATION TEST

A vent operation test is required as part of the

installation to verify that proper venting conditions exist and should be done periodically to

ensure nothing has changed that would affect

proper venting of the appliance.

Procedure:

1. ENSURE APPLIANCE IS OFF (PILOT ONLY)

AND COOL.

2. Open both latches on one of the glass

enclosure doors and slightly prop it open at

the bottom (approx. 1/4” gap). See Figure

6 on Page 12.

3. Turn on all the exhaust fans in the dwelling

(and any other appliances which remove

air from the dwelling, such as a furnace or

clothes dryer, etc.).

4. Ensure that all the doors and windows in

the room where the fireplace is located are

closed.

5. Light the appliance (see Lighting Instruc-

tions, Pages 22 to 25). Adjust flame height to

highest setting and operate for approximately

5-10 minutes. Do not leave appliance unattended.

6. Take a smoke producing device and move it

along the bottom edge of the glass door (where

it is cracked open). If smoke is drawn into the

firebox, the vent operation is adequate.

IF THE SMOKE IS NOT DRAWN INTO

THE FIREBOX, TURN THE APPLIANCE

OFF AND CALL A QUALIFIED SERVICE

TECHNICIAN.

SPILL SWITCH OPERATION

Manual-Reset (safety limit) Spill Switch

This appliance is equipped with a (safety limit)

spill switch that is designed to "trip" and discon-

nect the burner circuit if flue spillage occurs

(because of improper venting of combustion

products or vent blockage). If, during appliance

operation, the burner flame goes out (independently of the burner OFF/ON wall switch), it may

be due to the operation of this (safety limit) spill

switch. If this switch "trips" it will need to be

manually reset by pressing the reset button on

switch (see Figure 4).

Procedure to Reset (safety limit) Spill Switch

ALLOW APPLIANCE TO COOL COMPLETELY

BEFORE ACCESSING AND RESETTING

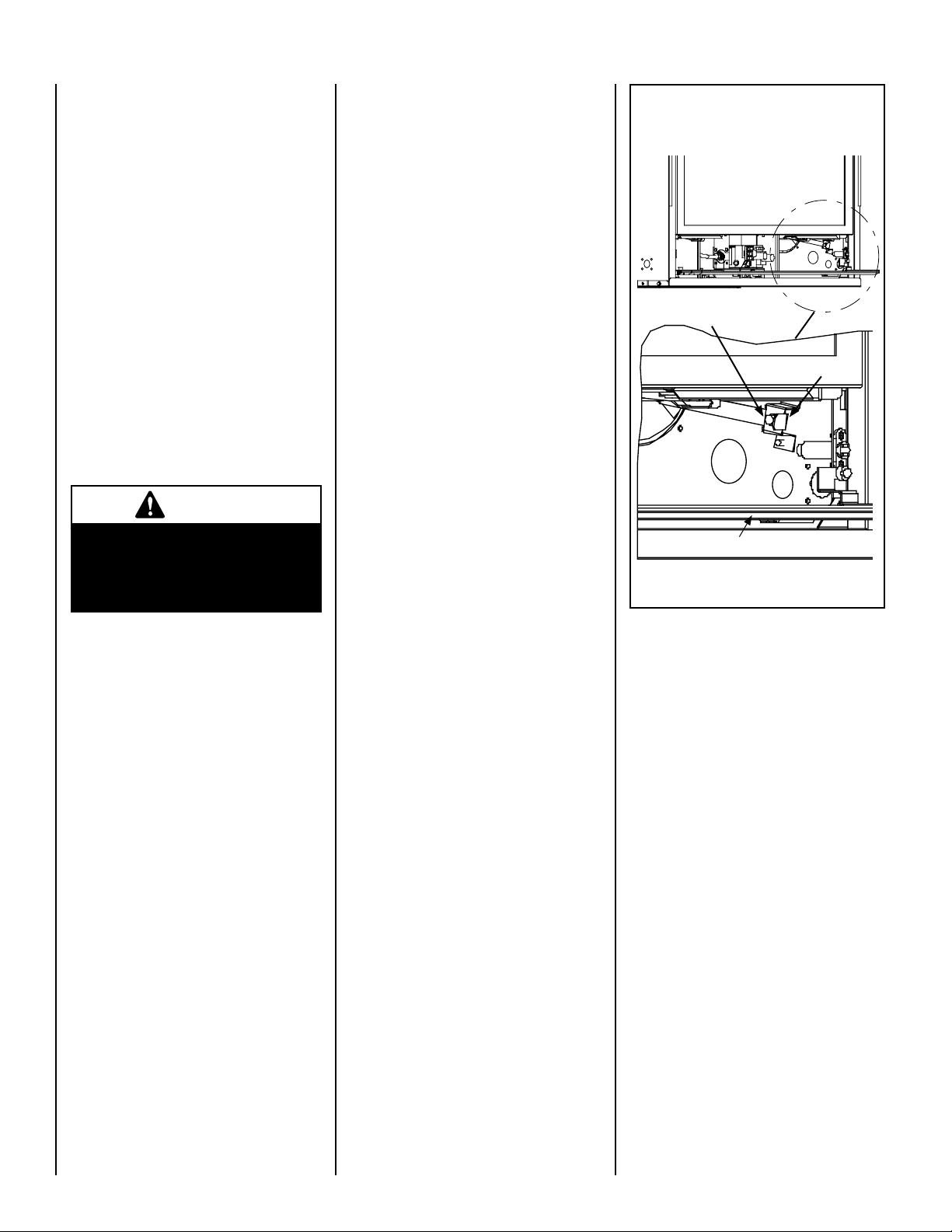

To access the spill switch:

1. Pull off the top louvered panel.

2. Locate and press the red reset button on

the switch (it will click & lock in).

The appliance should then relight and remain

lit. If this does not occur, turn off the appliance

and call a qualified service technician.

Press Reset Button on

Spill Switch

Remove Top

Louvered

Panel (or

optional

radiant panel,

if applicable)

Figure 4 - Spill Switch

Electronic Gas

Control Valve

Figure 3 - Honeywell Electronic Gas Valve

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

9

Page 10

Outside Combustion Air Controls

Many appliances are equipped, when installed,

with an outside (make-up air) vent system

that is designed to provide the appliance with

outside make-up air for combustion when in

operation.

The outside air control lever for the outside

air system is standard on all appliances but

should not be operated if the complete system

is not installed. Refer to Figure 5. When the

complete outside air vent system is installed,

the installer will remove the securing screw

from the combustion air control lever located

on the right side of the fireplace opening.

If the securing screw has not been removed

and you have reason to believe that you have

a complete outside air system, contact your

distributor to have your appliance inspected for

the presence of the complete system. DO NOT

assume that you have this system in place.

WARNING

Do not operate the shutoff lever

unless a complete outside combustion air system has been

installed with your appliance.

To open the outside air shutter, open the bottom

control access panel, and pull the outside air

control lever all the way out. The outside air

shutter should be fully open when the fireplace

is in use and completely closed when the fireplace is not being used. Closing it when not in

use will prevent outside cold air from entering

the dwelling.

The hand operated outside air control lever is

located on the right side of the fireplace opening. See Figure 5.

To open the outside air , open the bottom control access panel, reach into the gap between

the firebox bottom and pull the outside air

control lever all the way out.

The outside air shutter should be fully open when

the fireplace is in use and completely closed

when the fireplace is not being used. Closing

it when not in use will prevent outside cold air

from entering the dwelling.

Operate the actuator through several cycles

including the closed position. Ensuring proper

operation and freedom of movement. Return

the actuator arm to the closed position.

Outside Air Control Lever

and Securing Screw Location

Glass Front

Outside Air Control Lever

with Stop Behind

Securing Screw

Control Compartment Access Panel

Figure 5

10

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 11

MAINTENANCE

(See Maintenance Schedule, Page 26)

Refer to the maintenance schedule for maintenance tasks, procedures, frequency and

by whom they should be performed. Always

verify proper operation of the appliance after

servicing.

WARNING

Turn off gas and electrical power

to the fireplace and allow it to

cool before cleaning or servicing

the appliance.

CAUTION: Wear gloves and safety

glasses for protection while doing

required maintenance.

Verify proper operation after servicing.

S'assurer que l'appareil fonctionne adéquatement une fois l'entretien terminé.

Always turn off gas to the pilot (millivolt

appliances) before cleaning. Before relighting, refer to the lighting instructions

in this manual. Instructions are also found

on a pull-out panel located in the control

compartment.

Inspect Venting System

The appliance and venting system should be

thoroughly inspected before initial use and at

least annually by a qualified service technician

(inspection should include ensuring that exhaust

passage is unobstructed and vent components

are properly assembled and not damaged).

Homeowner must contact a qualified service

technician at once if any abnormal condition

is observed.

If the venting system is disassembled for any

reason, a qualified service technician should

follow vent installation instructions for proper

reassembly and proper sealing of the venting

system components. However, more frequent

periodic inspections and cleanings should be

performed by the homeowner.

Cleaning Glass

(see Front Glass Enclosure Panel, Removal and

Installation on Page 10)

Note: Clean glass after first two weeks of operation (after Burn-In period is over) and then only

when necessary and when the fireplace is cool.

Wipe surface with clean, dampened, soft cloth.

Follow with a dry, soft towel as desired. Take

care not to scratch the glass surface.

IMPORTANT: Do not use abrasive cleaners on glass. Never clean the glass when

it is hot.

The viewing glass should be cleaned periodically to remove any build-up caused from the

following:

• During start-up, it is normal for condensation to form on the inside of the glass (this

condensation and fog will usually disappear

in a few minutes). The moisture can cause

lint, dust and other airborne particles to cling

to the glass surface.

• Initial curing of the high temperature paint

and burning off of lubricants used in the

manufacturing process may result in a film

on the glass.

• A white coating may form on the glass as

a result of impurities and minerals in the

fuel.

It is recommended that the glass be cleaned

two or three times during each heating season,

depending on the circumstances present. The

following cleaning solutions are approved for

use to clean glass:

• Non-ammonia based household cleaner

• 50%-50% mix of white vinegar and water

• Gas replace/stove glass cleaner

Inspect Glass Gasket - Visually inspect the

gasket on the backside of the glass enclosure

panels. The gasket surface must be clean, free

of irregularities and seated firmly.

Clean Control Compartment

Keep control compartment clean by vacuuming

or brushing at least twice a year. More frequent

cleaning may be required due to excessive lint

from carpeting, bedding materials, etc. It is

important that control compartments, burners

and circulating air passageways of the appliance

be kept clean.

Clean Logs And Burner

Carefully remove the logs (use care when handling the fiber logs, as they become quite fragile

after curing). Vacuum out any foreign matter

(lint, carbon, etc.) on the burner. Ensure the

burner ports are “open.” Remove any carbon

deposits from the under side of the logs using

a vacuum cleaner, or a soft bristled brush (i.e.

paint brush).

Note: Improper positioning of logs can create

carbon build-up and will alter the performance

of the appliance.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Replacing Logs

If the logs become damaged by accident or

improper handling and need replacement,

use only the proper replacement logs from

manufacturer (see Page 29 for ordering

information).

Re-Install Embers, Logs and Vermiculite

Carefully follow placement instructions on

Pages 12 to 15). All logs should fit onto corresponding pins and/or log stoppers. This will

ensure a proper flame and safe combustion.

Inspect Wiring

Refer to wiring diagrams on Page 17.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous

operation. Verify proper operation after

servicing.

ATTENTION: Au moment de l'entretien

des commandes, étiquetez tous les fils

avant de les débrancher. Des erreurs

de cáblage peuvent entraîner un fonctionnement inadéquat et dangereux.

Inspect and clean all wire connections. Ensure

that there is no melting or damage. Inspection

should include:

• Terminals at the Valve

• OFF/ON Switch

• (Optional Control Switch) Remote Control

or Remote Wall Switch Kit

Inspect Burner Flame Appearance

Ensure that the burner flame appearance

resembles the flame shown in Figure 15 and

as described in Flame Appearance and Sooting

on Page 15. The Homeowner must contact

a qualified service technician at once if any

abnormal condition is observed.

Small Area Paint Touch-up

Only use a factory supplied paint kit for touchups. Paint is available at your local authorized

Lennox Hearth Products dealer. Never attempt

to paint a hot fireplace.

If the surface later becomes stained or marred,

it may be lightly sanded and touched up with

spray paint.

11

Page 12

Front Glass Enclosure Panel, Removal

and Installation

WARNING

• Do not attempt to substitute the

materials used on this door,

or replace cracked or broken

glass.

• Handle this glass with extreme

care! Glass is susceptible to

damage – Do not scratch or

handle roughly while reinstalling the glass door frame.

• The glass door(s) of this appli-

ance must only be replaced as

a complete unit as provided

by the manufacturer. Do not

attempt to replace broken,

cracked or chipped glass separately.

• Do not attempt to touch the

front enclosure glass with your

hands while the fireplace is in

use.

WARNING

Do not operate appliance with

the glass front removed, cracked

or broken.

AVERTISSEMENT

Ne pas utiliser l'appareil si le

panneau frontal en verre n'est

pas en place, est craqué ou

brisé.

WARNING

Any safety screen or guard

removed for servicing the appliance must be replaced prior to

operating the appliance.

AVERTISSEMENT

Tout écran ou protecteur retiré

pour permettre l’entretien de

l’appareil doit être remis en

place avant de mettre l’appareil

en marche.

12

Only doors certified with the appliance

shall be used.

Seules des portes certifiées pour cet

appareil doivent être utilisées.

CAUTION: DO NOT abuse glass door by

striking or slamming shut.

These fireplaces are designed to operate only

with the glass enclosure panels properly

installed. Generally the glass enclosure panels

should not be removed except to gain access

to the components within the firebox, and the

appliance may only be operated without the

front glass enclosure panel in place for very

brief periods of time during initial appliance

checkout and adjustment.

Removing Glass Enclosure Panels

(see Figure 6)

1. Remove the top louver assembly or radiant

panel by pulling it out and off.

2. Open the control compartment access panel

by actuating the spring-loaded magnetic

catches securing the panel (gently depress

the outer top corners of the louvered or

radiant panel until the catches "pop" the door

free, allowing it to swing out and down to

the open position).

3. Locate the two (2) latches at the top of the

control compartment. To disengage the two

latches from the bottom vee-flange of the

glass enclosure panel, reach for the handles

located towards the back of the latches and

pull the handles down toward the front of

the appliance.

4. Swing the bottom of the door out and raise

it slightly to lift the top flange of the door

frame away from the appliance.

Installing Glass Enclosure Panels

(see Figure 6)

1. Visually inspect the gasket on the backside of

the panels. The gasket surface must be clean,

free of irregularities and seated firmly.

2. Position the glass enclosure panel in front of

the firebox opening at a 45 degree angle and

engage the top flange over the lip at the top

of the firebox opening. See Figure 6.

3. Swing the glass enclosure panel down and

back. Ensure the gasket seats evenly as the

panel draws shut. Engage the Vee-flange at

the bottom of the panel with the latches and

close the latches to secure the panel.

4. Close the bottom control compartment

access panel.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Lower Compartment

Door & Hinge

Bottom Vee-flange

Glass Door

Glass Door Latch

Note: When installing the glass door, ensure the

spacing on both sides are equal.

Figure 6

Installing Grate, Vermiculite, Glowing

Embers And Logs

Top Flange

Glass Door

Glass Door

(Enclosure Panel)

Firebox Floor

WARNINGS

•DONOTattempttoinstallthe

logs until the appliance installation has been completed, the

gas line connected and tested

for leaks and the initial burner

operation has been checked

out.

•Thesizeandpositionofthelog

set was engineered to give the

appliance a safe, reliable and

attractive flame pattern. Any

attempt to use a different log

set in the fireplace will void

the warranty and will result in

incomplete combustion, sooting, and poor flame quality.

•Logs get very hot and will

remain hot up to one hour after

gas supply is turned off. Handle

only when logs are cool. Turn

off all electricity to the appliance before you install grate,

volcanic stone, vermiculite,

embers and logs.

Page 13

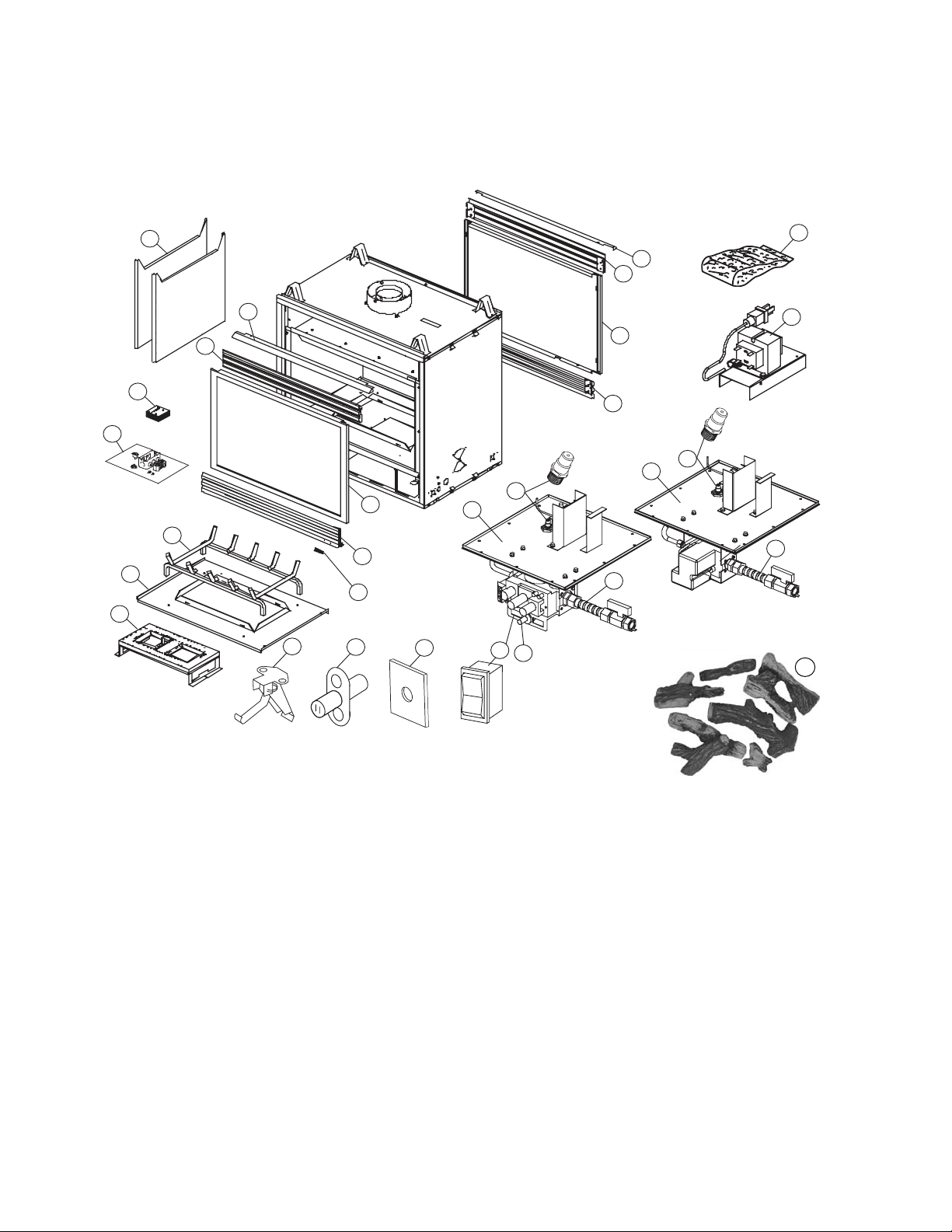

LOG SET - IDENTIFICATION

LOG SET

Catalog Number

* Item

A

B

C

D

E

F

* Item "letters" above correspond to photos on right

H3210

Description

Log, Center

Log, Left Rear

Log, Left Front

Log, Right Rear

Log, Top Center

Log, Front Center

Bottom View of Logs (in packaging)

C

A

B

F

REFERENCE

Firebox Accessories / Parts

Cat. No. Model No. Description

88L53 FGE Bag of Glowing Embers

H6319

(1 oz. rockwool)

Vermiculite, Bag (2 liters)

WARNING

• This appliance is not designed

to burn wood. Any attempt to

do so could cause irreparable

damage to appliance and prove

hazardous to your safety.

• If logs are not installed accord-

ing to the log installation

instructions, flame impingement and improper combustion

could occur and result in soot

and/or excessive production of

carbon monoxide (CO), a colorless, odorless, toxic gas.

Glowing Embers

D

E

Top View of Logs

B

E

D

A

C

F

Top View of Logs - Installed

B

Figure 7

Separate into Quarter

Size (separate) Pieces

Bag of Glowing

Embers (rockwool)

C

(Valve Access Side)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

D

E

F

A

13

Page 14

READ LOG WARNINGS ON PAGE 12 BEFORE PROCEEDING

8. Place Log (B) as shown in Figure 10.

1. Remove front glass enclosure panel from appliance.

a. Open Control Compartment Access Panel (see Control Compart-

ment Access Instructions on Page 8.

b. Remove the glass panel enclosure (see Removing Glass Enclosure

Panel instructions on Page 12).

2. Remove the following from firebox; log set, embers (rockwool) and

vermiculite. Handle logs carefully to prevent breakage.

3. Ensure the Grate is properly installed in the firebox with the 4 legs

of the grate fitting into the 4 dimples on the firebox floor.

4. Install Vermiculite - Place some vermiculite on the firebox floor around

the grate (the entire bag of vermiculite will NOT be used). See Figure 15

on Page 15. DO NOT PLACE ANY VERMICULITE ON THE BURNER.

6. Placement of Glowing Embers -

Separate the Embers (rockwool) into pieces about the size of a quarter

(see Figure 7). Keep the pieces fluffed up, not matted. Distribute these

pieces over the surface of the burner, as shown in Figure 8. Do not

use more than is necessary. Ensure that the main burner ports remain

uncovered by the ember material.

Note: This appliance is provided with enough Glowing Embers for

several applications, do not use all that is in a new bag at one time. For

best glowing effect, replace the ember material annually. Replacement

Glowing Embers are available (order Catalog Number 88L53).

Place Embers on burner as shown.

Position Log (B) Against The Back Of

The Grate Here

B

Position Groove at The Bottom Of Log (B) Over The Grate

Here And Slide It Against The Back Of The Grate

Figure 10

9. Place Log (C) as shown in Figure 11.

(Valve Access Side)

Log (C) Lays Over Logs (A) and (B)

Figure 8

DO NOT PLACE EMBERS OVER

GAS PORTS / AREAS CIRCLED

7. Place Log (A) on the grate as shown in Figure 9

A

B

C

Position The Groove in The Back of Log (C)

Figure 11

Against The Grate

10. Place Log (D) as shown in Figure 12.

Position And Slide Log (D) Against The

The Grate

Back Of

A

A

(Valve Access Side)

14

Position Groove At The Bottom Of

Log (A) Over The Log Support Here

Figure 9

Position The Groove At The Bottom Of

Log (A) Over The Grate And Slide It

Forward Against The Grate Here

(Valve Access Side)

(Valve Access Side)

Figure 12

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

D

Place Log (D) Over The

Flat Spot On Log (A)

Here

Page 15

10. Place Log (E) as shown in Figure 13.

Position round end of log (E) against the notch of log

(D) here. Two charred spots face the front

BURNER ADJUSTMENTS

(QUALIFIED TECHNICIANS ONLY)

Flame Appearance and Sooting

Proper flame appearance is a flame which is

E

D

blue at the base and becomes yellowish-orange

in the body of the flame. When the appliance

is first lit, the entire flame may be blue and will

gradually turn yellowish-orange during the first

15 minutes of operation. After 15 minutes of

operation, if the flame is blue, or if the flame is

orange with evidence of sooting (black tip), the

air shutter opening may need to be adjusted.

C

Position Small End of Log (E)

on The Notch of Log (C) Here

Figure 13

11. Place Log (F) as shown in Figure 14.

Log (F) sits in front of the grate

(Valve Access Side)

Figure 14

(Valve Access Side)

F

If the air shutter opening is closed too far, sooting

may develop. Sooting is indicated by black puffs

developing at the tips of very long orange flames.

Sooting results in black deposits forming on the

logs, appliance inside surfaces and on exterior

surfaces adjacent to the vent termination.

Sooting is caused by incomplete combustion in

the flames and lack of combustion air entering

the air shutter opening. To achieve a warm

yellowish-orange flame with an orange body

that does not soot, the shutter opening must be

adjusted between these two extremes.

Air Shutter Adjustment Guidelines

• If there is smoke or soot present, rst

check the log set positioning to ensure that

the flames are not impinging on any of the

logs. If the log set is properly positioned

and a sooting condition still exists, then the

air shutter opening should be increased.

• If there are offsets in the vent system, the air

shutter opening may need to be increased.

• An appliance operated with the air shutter

opened too far, may have flames that appear

blue and transparent. These weak, blue and

transparent flames are termed anemic.

Vermiculite

Figure 15 - Burner Flame Appearance

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

• Propane models may exhibit flames which

candle or appear stringy. If this is present and

persists, adjust the air shutter to a more open

position, then operate the appliance for a few

more minutes to ensure that the flame normalizes and the flames do not appear sooty.

The following chart is provided to aid you in

achieving the correct air shutter adjustment

for your installation.

Air Shutter Adjustment Guidelines:

Amount of

Primary Air

If air shutter is

closed too far

If air shutter is

open too far

Flame

Color

Flame will

be orange

Flame will

be blue

Air Shutter

Adjustment

Air shutter

gap should be

increased

Air shutter

gap should be

decreased

15

Page 16

Burner Air Shutter Adjustment Procedure

WARNINGS

• Air shutter adjustment should

only be performed by a qualified professional service

technician.

• Ensure front glass panel are

in place and sealed during

adjustment.

CAUTIONS

• Soot will be produced if the

air shutter is closed too much.

Any damage due to carboning

resulting from improperly

setting the air shutter is not

covered under the warranty.

• The air shutter door and nearby

appliance surfaces are hot.

Exercise caution to avoid

injury while adjusting flame

appearance.

1. Locate adjustment rod and adjust air shutter

to the standard setting as shown in Figure

16 (adjustment rod is located in the lower

control area). Note: Rotating the adjustment

rod counterclockwise decreases air and

clockwise increases air.

2. Light appliance (follow lighting procedure on

lighting label in control compartment or see

care and operation instructions manual).

3. Allow the burner to operate for at least 15 min-

utes while observing the flame continuously

to ensure that the proper flame appearance

has been achieved (see Figure 15). If the

following conditions are present, adjust

accordingly.

• If ame appears weak or sooty, adjust

the air shutter, incrementally, to a more

open position until the proper flame

appearance is achieved.

• If ame stays lowered blue, adjust the

air shutter, incrementally, to a more

closed position until the proper flame

appearance is achieved.

4. Leave the control knob (off/pilot/on) in the

ON position and the burner OFF/ON switch

OFF (and remote switches, if applicable).

5. When satisfied that the burner flame appear-

ance is normal, close the lower control

compartment door.

Main Burner Factory Air Shutter

Opening Setting - All Models

Model Natural

MPB35ST

Ref. Air shutter Patent:

U.S. Pat. 5,553,603

3.2mm

Adjustment Rod Positions

(when viewed from above)

Gas

1/8”

Propane

Gas

1/4”

6.4mm

Figure 16

Millivolt Appliance Checkout

The pilot flame should be steady, not lifting

or floating. Flame should be blue in color with

traces of orange at the outer edge.

The top 3/8" (10 mm) at the pilot generator

(thermopile) and the top 1/8" min (tip) of the

quick drop out thermocouple should be engulfed

in the pilot flame. The flame should project 1"

(25 mm) beyond the hood at all three ports.

See Figure 17.

To light the burner, refer to the lighting instructions on Page 22.

Proper Pilot Flame

Appearance

Thermocouple

Pilot

Nozzels

Thermopile

Hood

Igniter Rod

3/8" Min.

(9 mm)

Figure 17 - Millivolt Pilot Assembly

Decrease Shutter Opening

In This Direction

Air Shutter

Adjusting

Rod

Electronic Appliance Checkout

To light the burner, refer to the lighting instructions on Page 24. Ensure the igniter lights the

pilot. The pilot flame should engulf the flame

sensor as shown in Figure 18.

Pilot

Nozzels

Increase Shutter Opening

In This Direction

Proper Pilot Flame Appearance

Proper Flame

Adjustment

Note - Burners are

omitted in this

view for clarity.

Orifice

3/8" to 1/2"

(9 -13 mm)

Ground

Electrode

Flame Rod

Hot Surface

Igniter

Figure 18 - Electronic Pilot Assembly

16

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 17

WARRANTY

Thermopile

TH

TP

TH

TP

White

White

Black

Spill Switch

1. If any of the original wire as supplied must be replaced,

1. it must be replaced with Type AWM 105°C – 18 GA.

wire.

2. 120V, 60Hz – Less than 3 amps.

BK

Junction Box

Transf.

120 V.

24 V

BL

Electronic Wiring Diagram (Honeywell)

R

WT

BL

G

W

120

VAC.

BK

W

Gas Valve

B

R

IGNITER

PILOT

ASSEMBLY

BK

G

Outlet Box Green

Ground Screw

Hot side of Outlet

*ON/OFF Switch (Integral

with Gas Valve)

White Wire

To Opposite

Side

*Leave the ON/OFF switch, which is integral

with the gas valve, in the ON position.

SPILL SWITCH

(high limit disc)

WT

G

Your gas appliance is covered by a limited twenty

year warranty. You will find a copy of the warranty accompanying this manual. Please read

the warranty to be familiar with its coverage.

Retain this manual. File it with your other documents for future reference.

REPLACEMENT PARTS

A complete parts list is found at the end of

this manual. Use only parts supplied from the

manufacturer.

With proper care and maintenance, your appliance will provide many years of enjoyment. If

you should experience any problem, first refer

to the troubleshooting guide in this manual. If

problem persists, contact your Lennox Hearth

Products dealer or distributor.

Normally, all parts should be ordered through

your Lennox Hearth Products distributor or

dealer. Parts will be shipped at prevailing prices

at time of order.

When ordering repair parts, always give the

following information:

1. The model number of the appliance.

LENNOX HEARTH PRODUCTS

1508 Elm Hill Pike, Suite 108

Nashville, TN 37210

visit us at www.Lennox.com

1-800-9-LENNOX

PRODUCT REFERENCE INFORMATION

2. The serial number of the appliance.

3. The part number.

4. The description of the part.

5. The quantity required.

6. The installation date of the appliance.

If you encounter any problems or have any

questions concerning the installation or ap-

We recommend that you record the following

important information about your fireplace.

Please call Lennox Hearth Products for the

phone number of your nearest Lennox Hearth

Products dealer who will answer your questions

or address your concerns.

plication of this system, please contact your

dealer or distributor.

Your Fireplace's Model Number ___________________________________________

Your Fireplace's Serial Number ___________________________________________

The Date On Which Your Fireplace Was Installed ______________________________

The Type of Gas Your Fireplace Uses _______________________________________

Your Dealer's Name ___________________________________________________

WIRING DIAGRAMS

Wiring diagrams are provided here for reference

purposes only. This information is also provided

on schematics attached directly to the appliance

on a pullout panel located within the control

compartment.

CAUTION: LABEL ALL WIRES

PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS. WIRING

ERRORS CAN CAUSE IMPROPER

AND DANGEROUS APPLIANCE

OPERATION.

ATTENTION : AU MOMENT DE

L'ENTRETIEN DES COMMANDES,

ÉTIQUETEZ TOUS LES FILS AVANT

DE LES DÉBRANCHER. DES

ERREURS DE CÁBLAGE PEU-VENT

ENTRAÎNER UN FONCTIONNEMENT

INADÉQUAT ET DANGEREUX.

* Optional Control Switches - OFF/ON wall

switch or remote control receiver.

Schematic Representation Only

Figure 19

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Field Wired

Factory

Wired

Millivolt Wiring Diagram

Schematic

Representation Only

Field Wired

Factory

* Optional

Control Switch

Appliance mounted

OFF / ON Switch

Wired

If any of the original wire as supplied must

be replaced, it must be replaced with Type

AWM105 C - 18 gage wire.

* Optional Control Switches - OFF/ON wall switch

or remote control receiver.

Note: Turn the appliance-mounted OFF/ON burner

control switch to the OFF position if an optional

control switch is installed.

Figure 20

17

Page 18

ACCESSORY COMPONENTS

P

A

I

N

T

Product Reference Information

Cat.

No.

H7808 MPB35ST-NM-B 220 lbs 46W x 26D x 43H

H7809 MPB35ST-PM-B 220 lbs 46W x 26D x 43H

H7810 MPB35ST-NE-B 220 lbs 46W x 26D x 43H

Model Ship.

Weight

Ship.

Volume

(30 cu.ft.)

(30 cu.ft.)

(30 cu.ft.)

Bag of Glowing Embers

Bag of Volcanic Stone

Replacement ember materials or volcanic stone

are available for use with these appliances.

Order kits as part of the periodic maintenance

of the appliance.

3 Piece Finished Trim Kit

Cat. No. Model No. Description

96K21 TK35PB3 35”, Polished Brass

H4821 TK35C3 35”, Black

(ref. Form # 750,147M)

Polished Brass 3-Piece Trim Kit

Remote Control Kit, Standard

Cat. No. Model No. Description

H0249 RCL Remote Control System

(Standard)

(ref. Form # 750,127M)

Standard Remote Control System

The Model RCL (Standard) Remote Control

System, features a simplistic OFF/ON control

function for the fireplace. This model includes

a hand-held transmitter, a remote receiver

with wall-mount cover plate and all hardware

required to install the unit. The remote receiver

can be wall or hearth mounted.

The transmitter has ON and OFF functions that

are activated by pressing either button on the

face of the transmitter. When a button on the

transmitter is pressed, a signal light illuminates

briefly to verify that a signal has been sent.

The Model RCL is designed to operate with all

millivolt ignition systems, as well as electronic

ignition systems. It may be installed with use

for either natural or propane gas appliances.

The RCL offers ease of installation and allows

you to execute on-off commands to the fireplace

effortlessly with one simple motion.

The Model RCL comes complete with detailed

operating instructions.

Decorative Firebox Accessories

Cat. No. Model No. Description

88L53 FGE Bag of Glowing Embers

80L42 FDVS

(FDVS ref. Form #750,010M)

Cat. No. Model No. Description

85L87 FWSK OFF/ON Wall Switch Kit

(1 oz. rockwool)

Bag of Decorative

Volcanic Stone

White Wall Switch Kit

OFF/ON Wall Switch Kit

The OFF/ON wall switch kit may be used to

control the operation of the fireplace burner.

Install the OFF/ON wall switch in a convenient

location near the fireplace.

This kit contains brass trim pieces used to

finish the gaps between the wall board and

the fireplace, providing the appliance a brass

perimeter highlight. This kit contains the trim

pieces and these instructions.

4 Piece Trim Kit

Cat. No. Model No. Description

96K17 TK35PB4 35” 4 Piece Finish Trim Kit,

Polished Brass

(ref. Form # 750,147M)

Touch-Up Paint Kits

Cat. No. Model No. Description

90L73 FTPK-B Touch-Up Paint (Black)

(TPK-C ref. Form # 504,216M)

Touch-Up Paint Kit

Repair of minor scratches and discoloration of

the appliance black painted surfaces may be

accomplished with the touch-up paint kit.

18

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 19

ACCESSORY COMPONENTS

Arch Pane

Design

Arch

Design

Square

Design

Decorative Arch Screen Panel Kit

This easy to install optional screen installs over the

standard glass enclosure panel to provide protection

from direct contact with the hot glass surface. These

screen panels cannot be used in conjunction with

the arch door kits or door frame kits.

35" Screen Heat Guard Kit

Cat. No. Model No. Description

26M48 HG35M 35" Screen Heat Guard Kit

(ref. Form # 750,101M)

Square

Pane

Design

Style View Screen Doors -

These Style View screen doors come in 4 beautiful

styles. They are easy to install and will not require

hardware to attach them to the standard glass door

frame. The screens prevent direct contact with the

hot glass surface. The door includes heavy duty

magnet door latches and functional twin-pane

screen doors.

Arch Pane Design Kits

H0930 APD35C 35” Arch Pane Doors, Black

H0931 APD35TI 35” Arch Pane Doors, Text. Iron

H0932 APD35SP 35” Arch Pane Doors, Satin Pew.

H0933 APD35AB 35” Arch Pane Doors, Ant. Brass

Arch Design Kits

Cat. No. Model Description

H0858 AD35C 35” Arch Doors, Black

H0859 AD35TI 35” Arch Doors, Textured Iron

H0860 AD35SP 35” Arch Doors, Satin Pewter

H0861 AD35AB 35” Arch Doors, Antique Brass

Square Design Kits

Cat. No. Model Description

H0946 SD35C 35” Sq. Doors, Black

H0947 SD35TI 35” Sq. Doors, Textured Iron

H0948 SD35SP 35” Sq. Doors, Satin Pewter

H0949 SD35AB 35” Sq. Doors, Antique Brass

Square Pane Design Kits

H0962 SPD35C 35” Sq. Pane Doors, Black

H0963 SPD35TI 35” Sq. Pane Doors, Text. Iron

H0964 SPD35SP 35” Sq. Pane Doors, Satin Pew.

H0965 SPD35AB 35” Sq. Pane Doors, Ant. Brass

(ref. Form # 775,169M)

Decorative Arch Screen Panel Kit

Cat. No. Model Model

H3593 DASPK35TI 35” Dec. Arch Screen Panel

(ref. Form # 750,199M)

Tall Style View Doors

These decorative screen doors are offered in four

attractive finishes and fit on the face of the appliance

over the glass doorframe and prevent direct contact

with the hot glass surface. These doors replace

the bottom louver assembly and cover the control

compartment which elongates the appearance of the

height of the fireplace face.

Style View Tall Arch 35" Pane Screen Door Kits

Cat. No. Model Description

H3525 TAPD35C Arch Pane, Black

H3527 TAPD35SP Arch Pane, Satin Pewter

(ref. Form # 750,200M)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Screen Heat Guard Kit

This easy to install optional screen heat guard