Lennox MPA036S4M-*P, MLA018S4M-*P, MLA030S4M-*P, MPB030S4M-*P, MPA048S4M-*P Installation Instructions Manual

...Page 1

INSTALLATION

©

2017 Lennox Industries Inc.

Dallas, Texas, USA

Table of Contents

General ...........................................................................1

Included Parts.................................................................2

Compatible Indoor Units .................................................2

Model Number Identication ...........................................2

Typical Multi-Zone System Components ........................3

Outdoor Unit Dimensions ...............................................4

Outdoor Unit Clearances ................................................4

Torque Requirements for Caps and Fasteners...............5

Outdoor Unit Installation .................................................5

Placement Considerations ..........................................5

Direct Sunlight, Rain, Snow and Ice Protection ..........5

Prevailing Winds .........................................................6

Buried Refrigerant Pipe Protection .............................7

Outdoor Unit Condensate Piping ................................7

Securing the Outdoor Unit ..........................................7

Refrigerant Piping Connections ......................................8

Indoor Unit Installation ....................................................9

Connecting Multiple Capacity Indoor Units .................9

Indoor / Outdoor Unit Match-Ups ..............................11

Leak Test and Evacuation ............................................16

Leak Test ..................................................................16

Triple Evacuation Procedure .....................................16

Wiring Connections ......................................................16

Outdoor Unit .............................................................17

Indoor Units...............................................................17

Unit Start-Up .................................................................24

Refrigerant Charge .......................................................24

WARNING

This product contains a chemical known to the State

of California to cause cancer, birth defects, or other

reproductive harm.

INSTRUCTIONS

MPA, MPB and MLA

MULTI-ZONE OUTDOOR

UNITS

MULTI-ZONE MINI-SPLIT OUTDOOR UNITS

(208/230V) --

507549-05

3/2017

Supersedes 10/2016

THIS MANUAL MUST BE LEFT WITH THE OWNER

FOR FUTURE REFERENCE

WARNING

Improper installation, adjustment, alteration, ser vice or

maintenance can cause property damage, personal

injury or loss of life.

Installation and service must be performed by a li censed

professional HVAC installer (or equivalent) or a service

agency.

WARNING

The clean Air Act of 1990 bans the intentional venting of

refrigerant (CFCs, HCFCs, and HFCs) as of July, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for non-compliance.

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take

care while handling this equipment and wear gloves and

protective clothing.

General

Refer to the Product Specications bulletin (EHB) for more

product information.

These instructions are intended as a general guide and

do not supersede local or national codes in any way.

Authorities having jurisdiction should be consulted before

installation.

The MWMA, MWMB, M22A, M33A, M33B, MMDA, MCFA

and MCFB indoor units are matched with a two to ve port

multi-zone outdoor heat pump unit to create a mini-split

system that uses HFC-410A refrigerant.

Page 2

Included Parts

Check the components for shipping damage. If you nd any damage, immediately contact the last carrier.

Package contains the following:

1 - Assembled Indoor Unit (The assembled indoor unit will include accessories specic to the unit, see each indoor unit’s

section within this manual for accessories included with that unit.)

1 - Assembled Outdoor Unit and the following items:

Parts Figure Qty Parts Figure Qty Parts Figure Qty

Drain connector 1

Installation and

owner’s manual

1 ea. Seal Ring 1

Line Set Adapters

MPA018S4M-*P

MPB018S4M-*P

MLA018S4M-*P

2 adapt. – 3/8” to 1/2”

MPA030S4M-*P

MPB030S4M-*P

MLA030S4M-*P

3 adapt. – 3/8” to 1/2”

MPA036S4M-*P

MPB036S4M-*P

MLA036S4M-*P

3 adapt. – 3/8” to 1/2”

1 adapt. – 1/2” to 3/8”

MPA048S4M-*P

MPB048S4M-*P

3 adapt. – 3/8” to 1/2”

2 adapt. – 1/2” to 3/8”

Compatible Indoor Units

Indoor Unit Voltage Indoor Unit Voltage

MWMA009S4-*P

MWMA012S4-*P

MWMA018S4-*P

MWMA024S4-*P

M22A009S4-*P

M22A012S4-*P

M22A018S4-*P

1

The 24,000 Btu indoor unit is only allowed to be connected to MPA048S4M, MPB048S4M and MLA036S4M multi-zone outdoor units.

Only second generation (-2P) indoor units will work with MLA multi-zone outdoor units.

1

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

M33A024S4-*P

MMDA009S4-*P

MMDA012S4-*P

MMDA018S4-*P

MMDA024S4-*P

MCFB018S4-*P

MCFA024S4-*P

1

1

1

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

208/230V

Model Number Identication

Series Type

M = Mini-Split

Unit Type

L = Low Ambient Heat Pump

P = Heat Pump

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Nominal Cooling Capacity

018 = 1.5 ton

030 = 2.5 tons

036 = 3 tons

048 = 4 tons

M P A 018 S 4 M - 1 P

Voltage

P = 208/230V-1 phase-60hz

Minor Design Sequence

1 = 1st Revision

Refrigerant Circuits

M = Multiple Circuits

Refrigerant Type

4 = HFC-410A

Cooling Efciency

S = Standard Efciency

2

Page 3

Typical Multi-Zone System Components

Filter

MPA018S4M Shown

Outdoor Unit Appearance May Vary by Capacity

Utility Bundle

One per

indoor unit

Return Air

Supply Air

Indoor unit wiring connections

(under access plate)

IMPORTANT - The refrigerant

metering device for this system is

located in the outdoor unit. This

makes it necessary to insulate the

refrigerant lines individually to

prevent sweating.

UV-rated tape (field-provided)

Access cover for power

and control wiring

connections

Condensate drain line

(field-provided, one per

indoor unit)

Liquid line shut off valve

Gas line shut off valve

Port B

Liquid line shut off valve

Gas line shut off valve

Port A

Wiring

Condensate drain line

(wrapped in foam insulation)

Refrigerant Line Set, Condensate Line

And Indoor / Outdoor Cable

(field-provided)

TAPE

Line set

(wrapped in foam

insulation)

See Outdoor Unit wiring

diagram for individual system

wiring.

Access cover for

service valves

Liquid line shut off valve

Gas line shut off valve

Port C

Liquid line shut off valve

Gas line shut off valve

Port E

Liquid line shut off valve

Gas line shut off valve

Port D

Up to 5 ports depending on outdoor unit model

MWMA009 Shown

Up to 5 ports depending on outdoor unit model

Indoor unit type may vary

L2L1

208/230V Outdoor Unit

Terminal Block

MPA048S4M shown

Liquid and vapor line service

and shut off valves

I

MPORTANT - Condensate drain line must always

be located at the bottom of the

bundle.)

Figure 1. Typical System Shown

3

Page 4

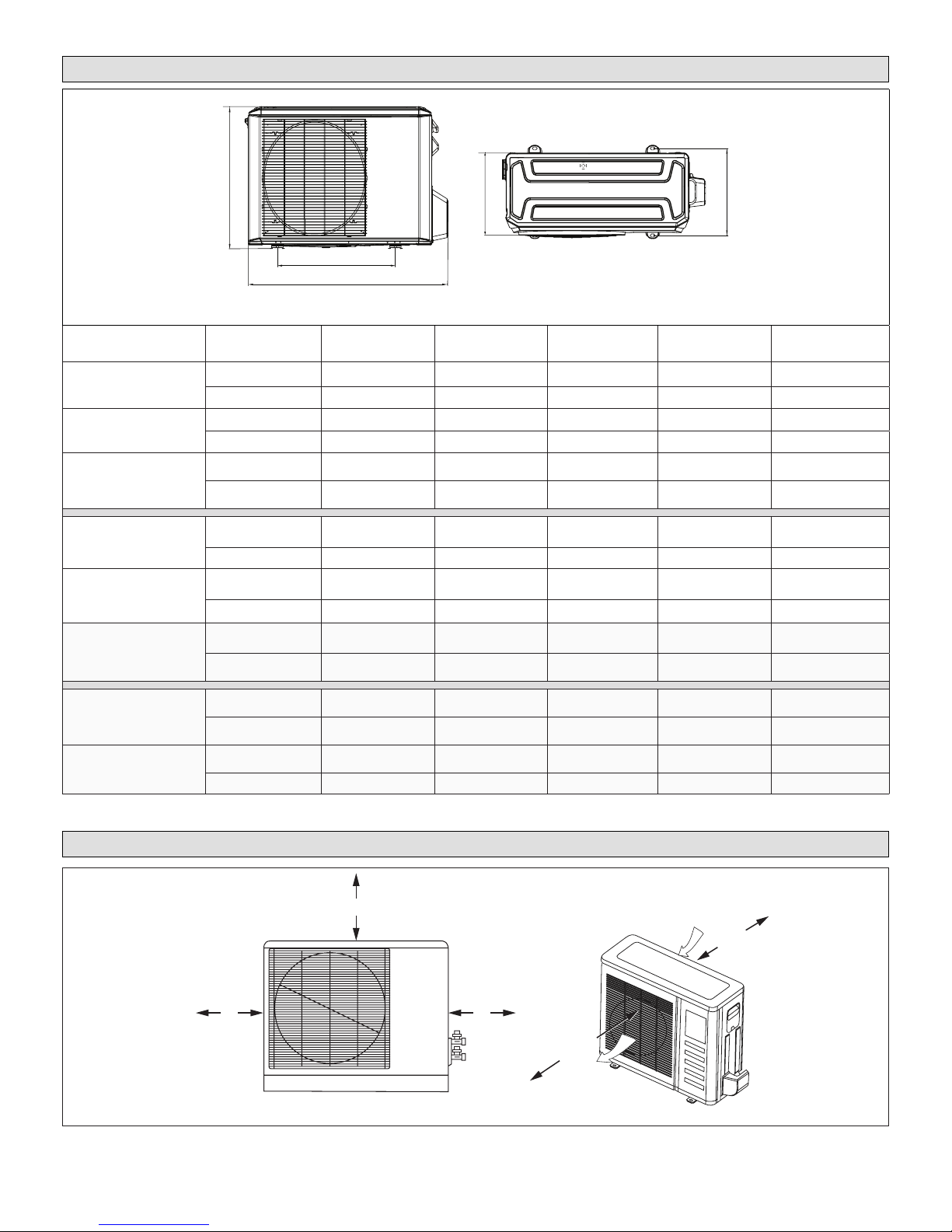

Outdoor Unit Dimensions

A

E

D

B

C

TYPICAL APPEARANCE OF UNITS

Model

MPA018S4M-*P

MPA030S4M-*P

MPA036S4M-*P

MPA048S4M-*P

MPB018S4M-*P

MPB030S4M-*P

MPB036S4M-*P

MPB048S4M-*P

MLA018S4M-*P

MLA030S4M-*P

MLA036S4M-*P

Unit of

Measurement

A B C D E

inches 35-3/4 22 27-3/8 12-3/4 13-1/8

mm 911 559 695 324 333

inches 37-1/4 25-1/4 31-7/8 15-1/2 16

mm 946 641 810 394 406

inches 36-7/8 32-7/8 54-1/2 15-3/8 16

mm 937 835 1385 391 408

inches 36 21-1/4 27-5/8 13-1/4 13-3/4

mm 914 540 702 335 350

inches 40-3/4 26-1/2 31-7/8 15-1/8 15-7/8

mm 1035 673 810 386 403

inches 41-3/4 25 52-1/2 16-3/8 15-7/8

mm 1060 634 1333 415 404

inches 40-5/8 26-1/2 31-7/8 16-5/8 15-7/8

mm 1032 673 810 422 403

inches 41-1/8 25 52-1/2 15-3/8 15-7/8

mm 1045 635 1334 391 403

Figure 2. Outdoor Unit Dimensions - Inches (mm)

Outdoor Unit Clearances

12

(305)

1

Minimum rear clearance can be 6 inches (152 mm) when mounted on brackets

and with no obstructions on the other three sides.

Figure 3. Outdoor Unit Clearances - Inches (mm)

24 (610)

24

(610)

4

79

(2007)

Air Outlet

Air Inlet

1

12

(305)

Page 5

Torque Requirements for Caps and

Fasteners

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened. “Table 1. Torque

Requirements” provides torque values for fasteners.

IMPORTANT

Only use Allen wrenches of sufcient hardness (50Rc -

Rockwell scale minimum). Fully insert the wrench into

the valve stem recess.

Service valve stems are factory-torqued from 9 ft.-lbs.

(12 N*m) for small valves, to 25 ft.-lbs. (34 N*m) for large

valves) to prevent refrigerant loss during shipping and

handling. Using an Allen wrench rated at less than 50Rc

risks rounding or breaking off the wrench, or stripping

the valve stem recess.

See the Lennox Service and Application Notes C-08-1

for further details and information.

Table 1. Torque Requirements

Parts

Service valve cap 8 ft.-lb. 11

Sheet metal screws 16 in.-lb. 2

Machine screws #10 27 in.-lb. 3

Compressor bolts 7 ft.-lb. 10

Gauge port seal cap 8 ft.-lb. 11

Recommended Torque

U.S. Newton-Meter- N

Outdoor Unit Installation

Placement Considerations

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

Consider the following when positioning the unit:

• In coastal areas or other places with salty atmosphere

of sulfate gas, corrosion may shorten the life of the

unit. In coastal areas, the coil should be cleaned with

potable water several times per year to avoid corrosive

buildup (salt)

• Some localities are adopting sound ordinances based

on the unit’s sound level registered from the adjacent

property, not from the property where the unit is installed. Install the unit as far as possible from the property line

• When possible, do not install the unit directly outside

a window. Glass has a very high level of sound transmission

• Install unit level

Building Structure

Ground

Level

Figure 4. Install Unit Level

• Choose a place solid enough to bear the weight and

vibration of the unit, where the operation noise will not

be amplied

• Choose a location where the hot air discharged from

the unit or the operation noise will not be a nuisance

to neighbors

• Avoid installing the outdoor unit near a bedroom or

other places where noise may cause a problem

• There must be sufcient space to carry the unit into

and out of the site

• There must be unobstructed air ow around the air inlet and the air outlet

• The unit must not be installed in areas where a ammable gas leak may occur

• Install the outdoor unit a minimum of 3 feet (1m) away

from any antenna, power cord (line), radio, telephone,

security system, or intercom. Electrical interference

and radio frequencies from any of these sources may

affect operation

• Since water drains from the outdoor unit during various stages of operation, do not place anything which

may be damaged by moisture under the unit

Direct Sunlight, Rain, Snow and Ice Protection

• If the outdoor unit is subjected to prolonged exposure

to direct sunlight with temperatures over 100°F (38°C)

a canopy is recommended as illustrated in “Figure 5.

Outdoor Unit on Pedestal (Stand) and Protective Can-

opy” on page 6 or “Figure 10. Dog House-Style

Shelter” on page 7

IMPORTANT

The construction of a canopy or shade is necessary

because of an ambient limit control set to 122°F (50°C)

to protect the electronics. If the outdoor unit is placed in

direct sunlight it is possible that the limit may activate

and shut down the unit.

• Place unit away from overhanging roof lines which

would allow water or ice to drop on, or in front of, coil or

into unit. Construct a canopy as illustrated in “Figure 5.

Outdoor Unit on Pedestal (Stand) and Protective Can-

opy” on page 6

5

Page 6

• The unit base should be elevated above the depth of

Protective canopy

Air Inlet

Air Outlet

Air Outlet

Air Inlet

12 in

305 mm

79 in

2007 mm

average snows as illustrated in “Figure 6. Outdoor Unit

on Brackets above Snow Line” on page 6

• In heavy snow areas, do not place the unit where drifting will occur as illustrated in “Figure 7. Outdoor Unit

Air Flow Obstructed by Snow” on page 6

• Carefully consider how to manage defrost water disposal to prevent ice from blocking walkways or creating a safety hazard near the outdoor unit as illustrated

in “Figure 8. Avoid Defrost Water Ice Hazard” on page

6

Protective canopy

24 in

610 mm

12 in

305 mm

Air Inlet

Air Outlet

Figure 7. Outdoor Unit Air Flow Obstructed by

Snow

Pedestal

(stand)

Side View

Front View

Pedestal

(stand)

Figure 5. Outdoor Unit on Pedestal (Stand) and

Protective Canopy

Figure 6. Outdoor Unit on Brackets above Snow

Line

Figure 8. Avoid Defrost Water Ice Hazard

Prevailing Winds

Normally wind bafes are not required for a outdoor unit.

However, in order to maximize reliability and performance,

the following best practices should be followed.

If unit coil cannot be installed away from prevailing winter

winds, some method of protecting the coil is recommended.

However, minimum clearances as reference in “Figure 3.

Outdoor Unit Clearances - Inches (mm)” on page 4

must be observed at all times.

Common application examples are:

• When prevailing winds are from the air inlet side, then

position the wind barrier a minimum of 12 inches (305

mm) from the unit as illustrated in “Figure 9. Wind Barrier”

• When prevailing wind is into the discharge side, then

position the wind barrier a minimum 79 inches (2007

mm) from the front of the unit as illustrated in “Figure

9. Wind Barrier”

• Outdoor unit can be installed in a dog house style shel-

ter as illustrated in”Figure 10. Dog House-Style Shelter”

• Outdoor unit can be installed in a alcove or under a

roof overhang as illustrated in “Figure 11. Unit installed

in Alcove”

6

Page 7

Prevailing Winter Winds from Air Inlet Side

Wind Barrier

Inlet Air

Discharge Air

Wind Barrier

Prevailing Winter Winds From Air Discharge Side

12” (305mm)

Min. Distance

79” (2007mm)

Min. Distance

Figure 9. Wind Barrier

Buried Refrigerant Pipe Protection

• All refrigerant lines must be insulated regardless of if

it is buried

• In addition to insulating each line of piping, buried lines

must rest inside a sealed, watertight conduit

• The conduit must be designed so it cannot collect and

retain water

Outdoor Unit Condensate Piping

Condensate formed during the heating and defrost

processes must be drained from heat pump units. Drain

holes are provided in the base of the units to ensure proper

drainage. Heat pumps must be raised when installed on a

concrete pad or the ground to allow drainage to occur. If

the heat pump unit is installed on wall mounting bracket,

insert the provided drain connector into one of the 1

inch (25 mm) drain holes and attached a eld-provided

insulated drain hose to the connector. Use eld-provided

rubber plugs to cover any unused drain holes.

24 in

12 in

305 mm

610 mm

NOTE - Minimum clearances shown.

24 in

610 mm

Figure 10. Dog House-Style Shelter

24 in

610 mm

12 in

305 mm

NOTE - Minimum clearances shown.

12 in

305 mm

610 mm

24 in

12 in

305 mm

Drain

Connector

Chassis

Condensate Drain

(location varies per model)

Figure 12. Condensate Drain

Securing the Outdoor Unit

Slab or Roof Mounting

Install the unit a minimum of 4 inches (102 mm) above the

roof or ground surface to avoid ice build-up around the

unit. Place the unit above a load bearing wall or area of

the roof that can adequately support the unit. Consult local

codes for rooftop applications.

CAUTION

Roof Damage!

This system contains both refrigerant and oil. Some

rubber roong material may absorb oil. This will cause

the rubber to swell when it comes into contact with oil.

The rubber will then bubble and could cause leaks.

Protect the roof surface to avoid exposure to refrigerant

and oil during service and installation. Failure to follow

this notice could result in damage to roof surface.

Figure 11. Unit installed in Alcove

7

Page 8

Securing Outdoor Unit to Slab, Frame, or Rails

If the outdoor unit is installed on a eld-provided slab or

frame, use lag bolts or equivalent to secure the outdoor

unit to the slab or frame.

Four Field-provided Anchor Bolts

Figure 13. Securing Outdoor Unit to Slab

Four Field-Provided

Anchor Bolts

Figure 14. Securing Outdoor Unit to Rails

Securing Outdoor Unit To Hanging Brackets

If the outdoor unit is installed on eld-provided wall

mounting brackets, use lag bolts or equivalent to secure

the outdoor unit to the bracket. Minimum rear clearance

can be reduced to 6 inches (152 mm) when mounted

on brackets and with no obstructions on the other three

sides. Allow for condensate disposal when placing units

above one another.

6 in

152 mm

Air Inlet

Air Outlet

Figure 15. Securing Outdoor Unit to Brackets

Both lines must be individually insulated.

1. The seal on the unit refrigerant piping connections

should remain in place until the last possible moment.

This will prevent dust or water from getting into the

refrigerant piping before it is connected.

2. CAREFULLY adjust refrigerant piping connections to

suit the application.

3. Slowly loosen one of the are nuts to release the

factory nitrogen charge from the indoor units only.

4. Remove the are nuts from the connections on the

unit and discard the seal from each of the piping

connections.

5. Slide the are nuts onto the ends of the eld-provided

refrigerant piping before using a suitable aring tool to

are the end of the copper pipe.

6. Apply recommended HFC-410A refrigerant lubricant

to the outside of the ared refrigerant lines.

IMPORTANT

The compressor in this unit contains PVE

oil (Polyvinylether). PVE oil is formulated for

hydrouorocarbon (HFC) refrigerants, such as HFC-

410A, which this system contains. While it may have

some miscibility properties with mineral-based oil and

POE oil (Polyolester), it is not recommended to mix PVE

oil with any other type of refrigerant oil.

7. Align the threaded connections with the

ared refrigerant lines. Tighten the are nuts

lightly at rst to obtain a smooth match as

illustrated in “Figure 16. Making Connections

(Male to Female Connection)” on page 9.

8. Once snug, continue another half-turn on each nut

which should create a leak-free joint. A torque wrench

may be used to tighten are nuts using “Table 3.

Flare Nut Torque Recommendations” on page 9

recommendations. Do not over-tighten a ared joint.

Flared connections should always be accessible

and must be insulated to prevent condensation.

9. After refrigerant piping has been installed and checked

for leaks, apply insulation over all ared connections.

Table 2. Refrigerant Piping and Indoor Unit

Connection Sizes

Size

(Btuh)

9000 1/4 3/8

12000 1/4 1/2

18000 1/4 1/2

24000 3/8

Liquid Line

in.

Gas Line

in.

5/8

Refrigerant Piping Connections

Field piping consists of two copper lines connecting

the outdoor unit to the indoor unit. “Table 1. Torque

Requirements” lists the connection sizes. The connections

are made using the provided brass are nuts at the end of

the refrigerant piping connections.

8

Page 9

A

B

CANT ON THE OUTSIDE OF

THE FLARE

Figure 16. Making Connections

(Male to Female Connection)

MALE FLARE

CONNECTION

• The largest cpacity indoor unit must be connected to

the lowest rerigerant connection ports on the outdoor

unit.

• The 24,000 Btu indoor unit is only allowed to be

connected to MPA048S4M, MPB048S4M and

MLA036S4M outdoor units.

NOTE: Each indoor unit must be piped AND wired to

the correct zone piping connections and wiring

terminals. Make sure that indoor unit A is wired

to the zone A terminal block and connected to the

appropriate refrigerant pipe connections.

outdoor

wire

C

A

B

D

indoor

IMPORTANT

Always use two wrenches when tightening are nuts to

avoid twisting refrigerant piping. DO NOT over-tighten

are nuts.

TORQUE WRENCH

TO INDOOR

UNIT

TO OUTDOOR UNIT

Figure 17. Tighten Flare Nut

Table 3. Flare Nut Torque Recommendations

Outside

Diameter

Inches

1/4 15 ft.-lb. (20 N) 1/4 turn

3/8 26 ft.-lb. (35 N) 1/2 turn

1/2 41 ft.-lb. (56 N) 7/8 turn

5/8 48 ft.-lb. (65 N) 1 full turn

Recommended

Torque

No torque wrench available

Finger tighten and use an

appropriately sized wrench to

turn an additional:

BACKUP

WRENCH

pipe

Unit D

Unit C

Unit B

Unit A

L4(ft)

L3(ft)

L2(ft)

L1(ft)

Unit D

Unit C

Unit B

Unit A

Figure 18. Pipe and Wire Each Zone Separately

C(1/4in)

C(3/8in)

B(1/4in)

B(3/8in)

A(1/4in)

A(1/2in)

Indoor Unit Installation

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

Please refer to the installation instruction included with the

indoor unit for setup.

IMPORTANT

Pipe and wire to each zone separately.

Test each indoor unit separately to ensure proper

operation.

Connecting Multiple Capacity Indoor Units

Figure 19. Connecting Multiple Capacity Indoor

Units

9

Page 10

INDOOR UNIT

INDOOR UNIT

NOTE - Minimum Line Set

Length - 10 ft. (3 m) per

Indoor Unit

INDOOR UNIT

Maximum

Elevation -

Outdoor Unit

BELOW

Indoor Units

49 ft.

(15 m)

NOTE - Maximum Line Set

Length Includes ALL

piping in measurement

NOTE - Maximum Difference

in Elevation Between

Indoor Units - 33 ft. (10 m).

Maximum Line Set

Furthest Indoor Unit

OUTDOOR UNIT

33 ft. (10 m) for MPA

INDOOR UNIT

ABOVE Indoor Unit

INDOOR UNIT

Outdoor Unit Model No.

Maximum Number of

Indoor Units

Indoor Unit Connections Liquid / Gas

MPA018S4M-*P

MPB018S4M-*P

MLA018S4M-*P

Two Three Four Five

(2) 1/4 / 3/8 (3) 1/4 / 3/8

MPA030S4M-*P

MPB030S4M-*P

MLA030S4M-*P

Total Length of All Piping 98 ft. (30 m) 148 ft. (45 m) 197 ft. (60 m) 246 (75 m)

Maximum Line Set

Length - Furthest Indoor

66 ft. (20 m) 82 ft. (25 m) 98 ft. (30 m) 98 ft. (30 m)

Unit

49 ft. (15 m) for MLA and MPB

Maximum

Elevation -

Outdoor Unit

MPA036S4M-*P

MPB036S4M-*P

MLA036S4M-*P

(3) 1/4 / 3/8

(1)1/4 / 1/2

MPA048S4M-*P

MPB048S4M-*P

(3) 1/4 / 3/8

(2) 1/4 / 1/2

Figure 20. Multi-Zone Systems with All Indoor Unit Models

10

Page 11

Indoor / Outdoor Unit Match-Ups

Each system is formed of one outdoor unit and a selection

of indoor units as referenced in the Product Specications

(EHB). Only these combinations are allowed.

NOTE: Each indoor unit must be piped AND wired to

the correct zone piping connections and wiring

terminals. Make sure that indoor unit A is wired

to the zone A terminal block and connected to the

appropriate refrigerant pipe connections.

Table 4. Match-Ups

Outdoor

Model

MPA018S4M

MPB018S4M

Indoor Unit A

1/4” liq + 3/8” gas

Indoor Unit B

1/4” liq + 3/8” gas

MPA030S4M

MPB030S4M

Indoor Unit A

1/4” liq + 3/8” gas

Indoor Unit B

1/4” liq + 3/8” gas

Indoor Unit C

1/4” liq + 3/8” gas

No. of

Zones

Indoor Unit

Capacity

(Unit No.)

1 012 (A)1 1/4 in. x 1/2 in.

2

2

2

009 (A) 1/4 in. x 3/8 in.

009 (B) 1/4 in. x 3/8 in.

009 (B) 1/4 in. x 3/8 in.

012 (A)1 1/4 in. x 1/2 in.

012 (A)1 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

1 018 (A)1 1/4 in. x 1/2 in.

2

2

2

2

2

2

009 (A) 1/4 in. x 3/8 in.

009 (B) 1/4 in. x 3/8 in.

009 (B) 1/4 in. x 3/8 in.

012 (A)1 1/4 in. x 1/2 in.

009 (B) 1/4 in. x 3/8 in.

018 (A)1 1/4 in. x 1/2 in.

012 (A)1 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

018 (A)1 1/4 in. x 1/2 in.

018 (A)1 1/4 in. x 1/2 in.

018 (B)1 1/4 in. x 1/2 in.

009 (A) 1/4 in. x 3/8 in.

3

009 (B) 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (B) 1/4 in. x 3/8 in.

3

009 (C) 1/4 in. x 3/8 in.

012 (A)1 1/4 in. x 1/2 in.

Line Set

Required

(Liquid x Gas)

Outdoor

Model

MPA030S4M

MPB030S4M

Indoor Unit A

1/4” liq + 3/8” gas

Indoor Unit B

1/4” liq + 3/8” gas

Indoor Unit C

1/4” liq + 3/8” gas

MPA036S4M

MPB036S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 3/8” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

Table 4. Match-Ups

No. of

Zones

2

2

Indoor Unit

Capacity

(Unit No.)

009 (C) 1/4 in. x 3/8 in.

3

012 (A)

012 (B)

009 (B) 1/4 in. x 3/8 in.

3

009 (C) 1/4 in. x 3/8 in.

018 (A)

012 (A)

3

012 (B)

012 (C)1 1/4 in. x 1/2 in.

2

4

009 (B) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

009 (B) 1/4 in. x 3/8 in.

024 (A)

2

4

012 (A) 1/4 in. x 1/2 in.

012 (B)

012 (B)

024 (A)

2

012 (B)

018 (A) 1/4 in. x 1/2 in.

2 018 (A) 1/4 in. x 1/2 in.

018 (B)

009 (B) 1/4 in. x 3/8 in.

3

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

009 (B) 1/4 in. x 3/8 in.

3

009 (C) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

009 (B) 1/4 in. x 3/8 in.

3

009 (C) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

3

012 (A) 1/4 in. x 1/2 in.

012 (B)

Line Set

Required

(Liquid x Gas)

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

2,3

3/8 in. x 5/8 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

2,3

3/8 in. x 5/8 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

11

Page 12

Outdoor

Model

MPA036S4M

MPB036S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 3/8” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

Table 4. Match-Ups

3

3

3

3

3

4

4

4

4

4

4

4

Indoor Unit

Capacity

(Unit No.)

009 (C) 1/4 in. x 3/8 in.

012 (B)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

018 (B)1 1/4 in. x 1/2 in.

012 (A) 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

018 (B)1 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

024 (A)

009 (B) 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

009 (A)1 1/4 in. x 3/8 in.

009 (B) 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

009 (B) 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (B)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

009 (D) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

No. of

Zones

3

Line Set

Required

(Liquid x Gas)

2,3

3/8 in. x 5/8 in.

Outdoor

Model

MPA048S4M

MPB048S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 1/2” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

Indoor Unit E

1/4” liq + 3/8” gas

Table 4. Match-Ups

4

2

2

2

2

2

2

3

3

3

3

3

3

Indoor Unit

Capacity

(Unit No.)

012 (A) 1/4 in. x 1/2 in.

012 (B)

012 (C)1 1/4 in. x 1/2 in.

012 (D)1 1/4 in. x 1/2 in.

009 (B)

024 (A)

012 (B) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

024 (A)

018 (A) 1/4 in. x 1/2 in.

018 (B) 1/4 in. x 1/2 in.

018 (B) 1/4 in. x 1/2 in.

024 (A)

024 (A)

024 (B)

009 (A)

009 (B)

009 (C) 1/4 in. x 3/8 in.

009 (B)

009 (C) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

009 (B)

009 (C) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

009 (B)

009 (C) 1/4 in. x 3/8 in.

024 (A)

009 (C) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

012 (B) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

No. of

Zones

Line Set

Required

(Liquid x Gas)

1

1/4 in. x 1/2 in.

1

1/4 in. x 3/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

1

1/4 in. x 3/8 in.

1

1/4 in. x 3/8 in.

1

1/4 in. x 3/8 in.

1

1/4 in. x 3/8 in.

1

1/4 in. x 3/8 in.

2, 3

3/8 in. x 5/8 in.

12

Page 13

Outdoor

Model

MPA048S4M

MPB048S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 1/2” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

Indoor Unit E

1/4” liq + 3/8” gas

Table 4. Match-Ups

3

3

3

3

3

3

3

3

3

3

3

3

4

4

Indoor Unit

Capacity

(Unit No.)

009 (C) 1/4 in. x 3/8 in.

012 (B) 1/4 in. x 1/2 in.

024 (A)

009 (C) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

018 (B) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

018 (B) 1/4 in. x 1/2 in.

024 (A)

009 (C) 1/4 in. x 3/8 in.

024 (A)

024 (B)

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

012 (C) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

018 (B)1 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

024 (A)

012 (B) 1/4 in. x 1/2 in.

018 (C)1 1/4 in. x 1/2 in.

024 (A)

012 (C)1 1/4 in. x 1/2 in.

024 (A)

024 (B)

018 (A) 1/4 in. x 1/2 in.

018 (B) 1/4 in. x 1/2 in.

018 (C)1 1/4 in. x 1/2 in.

018 (B) 1/4 in. x 1/2 in.

018 (C)

024 (A)

009 (A)1 1/4 in. x 3/8 in.

009 (B)1 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

009 (B)1 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

No. of

Zones

Line Set

Required

(Liquid x Gas)

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

1

1/4 in. x 1/2 in.

2, 3

3/8 in. x 5/8 in.

Outdoor

Model

MPA048S4M

MPB048S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 1/2” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

Indoor Unit E

1/4” liq + 3/8” gas

Table 4. Match-Ups

4

4

4

4

4

4

4

Indoor Unit

Capacity

(Unit No.)

009 (B)

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

009 (B)

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

024 (A)

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (B) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

018 (B) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

018 (B) 1/4 in. x 1/2 in.

024 (A)

009 (D) 1/4 in. x 3/8 in.

012 (A)

012 (B)

012 (C) 1/4 in. x 1/2 in.

No. of

Zones

Line Set

Required

(Liquid x Gas)

1

1/4 in. x 3/8 in.

1

1/4 in. x 3/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

13

Page 14

Outdoor

Model

MPA048S4M

MPB048S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 1/2” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

Indoor Unit E

1/4” liq + 3/8” gas

Table 4. Match-Ups

4

4

4

4

5

5

5

5

5

5

Indoor Unit

Capacity

(Unit No.)

009 (D) 1/4 in. x 3/8 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

009 (D) 1/4 in. x 3/8 in.

012 (C)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

018 (B) 1/4 in. x 1/2 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

012 (D)1 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

012 (D)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

009 (A)1 1/4 in. x 3/8 in.

009 (B)1 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

009 (E) 1/4 in. x 3/8 in.

009 (B)1 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

009 (E) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

009 (B)1 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

009 (E) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

009 (B)1 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

009 (E) 1/4 in. x 3/8 in.

024 (A)

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

009 (E) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

009 (E) 1/4 in. x 3/8 in.

012 (B) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

No. of

Zones

Line Set

Required

(Liquid x Gas)

2, 3

3/8 in. x 5/8 in.

Outdoor

Model

MPA048S4M

MPB048S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 1/2” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

Indoor Unit E

1/4” liq + 3/8” gas

MLA018S4M

Indoor Unit A

1/4” liq + 3/8” gas

Indoor Unit B

1/4” liq + 3/8” gas

MLA030S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 3/8” gas

Indoor Unit C

1/4” liq + 3/8” gas

Table 4. Match-Ups

5

5

5

5

2

2

2

2

2

2

2

2

2

2

2

2

3

Indoor Unit

Capacity

(Unit No.)

009 (D) 1/4 in. x 3/8 in.

009 (E) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

009 (D) 1/4 in. x 3/8 in.

009 (E) 1/4 in. x 3/8 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

009 (E) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

012 (D)1 1/4 in. x 1/2 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

012 (D)1 1/4 in. x 1/2 in.

012 (E)

009 (A) 1/4 in. x 3/8 in.

009 (B) 1/4 in. x 3/8 in.

012 (A)

009 (B) 1/4 in. x 3/8 in.

009 (B) 1/4 in. x 3/8 in.

018 (A)

012 (A)

012 (B)

009 (A)

009 (B) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

009 (B) 1/4 in. x 3/8 in.

009 (B) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

009 (B) 1/4 in. x 3/8 in.

024 (A)

012 (A) 1/4 in. x 1/2 in.

012 (B)

012 (B)

018 (A) 1/4 in. x 1/2 in.

024 (A)

012 (B)

018 (A) 1/4 in. x 1/2 in.

018 (B)

009 (A)

009 (B) 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

No. of

Zones

Line Set

Required

(Liquid x Gas)

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 3/8 in.

2, 3

3/8 in. x 5/8 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

2, 3

3/8 in. x 5/8 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 1/2 in.

1

1/4 in. x 3/8 in.

14

Page 15

Outdoor

Model

MLA030S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 3/8” gas

Indoor Unit C

1/4” liq + 3/8” gas

MLA036S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 1/2” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

Table 4. Match-Ups

3

3

3

3

3

2

2

2

2

2

2

2

2

3

3

Indoor Unit

Capacity

(Unit No.)

009 (B) 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

009 (B) 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B)1 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

009 (B)1 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

009 (B)1 1/4 in. x 3/8 in.

024 (A)

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

024 (A)

018 (B) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

018 (B) 1/4 in. x 1/2 in.

024 (A)

024 (B)

024 (A)

009 (A)1 1/4 in. x 3/8 in.

009 (B)1 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (B)1 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

No. of

Zones

Line Set

Required

(Liquid x Gas)

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

Outdoor

Model

MLA036S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 1/2” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

Table 4. Match-Ups

3

3

3

3

3

3

3

3

3

3

4

4

Indoor Unit

Capacity

(Unit No.)

009 (B)

009 (C) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

009 (B) 1 1/4 in. x 1/2 in.

024 (A)

009 (C) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

012 (B) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

024 (A)

012 (B) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

018 (B) 1/4 in. x 1/2 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

024 (A)

012 (C)1 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

018 (B) 1/4 in. x 1/2 in.

009 (B)

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

009 (A)

009 (B)

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

No. of

Zones

Line Set

Required

(Liquid x Gas)

1

1/4 in. x 3/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

2, 3

3/8 in. x 5/8 in.

1

1/4 in. x 3/8 in.

1

1/4 in. x 3/8 in.

1

1/4 in. x 3/8 in.

15

Page 16

Table 4. Match-Ups

4

4

4

4

4

Indoor Unit

Capacity

(Unit No.)

009 (B)1 1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (B) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

009 (D) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)1 1/4 in. x 1/2 in.

012 (D)1 1/4 in. x 1/2 in.

Outdoor

Model

MLA036S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 1/2” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

1

3/8 x 1/2 in. gas pipe adaptor is required for line set connection to outdoor unit

(furnished with outdoor unit).

2

1/4 x 3/8 in. liquid pipe adaptor is required for line set connection to the 048

outdoor unit (furnished with outdoor unit).

3

1/2 x 5/8 in. gas pipe adaptor is required for line set connection to the 048

outdoor unit (furnished with outdoor unit).

4

Not a valid combination when using the MPA036S4M.

No. of

Zones

Line Set

Required

(Liquid x Gas)

Leak Test and Evacuation

Air and moisture remaining in the refrigerant system will

have undesirable effects as indicated below:

• Pressure in the system rises

• Operating current rises

• Cooling or heating efciency drops

• Moisture in the refrigerant circuit may freeze

• Water may lead to corrosion of parts in the refrigeration system

The line set between the indoor and outdoor units

must be leak tested and evacuated to remove any noncondensables and moisture from the system.

there is any movement check system for leaks.

5. After the system is found to be free of leaks:

• Close valve on nitrogen cylinder.

• Relieve the nitrogen pressure by: loosening the

charge hose connector at the nitrogen cylinder.

• When the system pressure is reduced to normal,

disconnect the hose from the cylinder.

IMPORTANT

Use only oxygen-free nitrogen (OFN).

Triple Evacuation Procedure

A Micron or Torr gauge must be used for this procedure.

1. Discharge the oxygen-free nitrogen and evacuate the

system to a reading of 8000 Microns (8 Torr) using all

service valves.

2. Break the vacuum by allowing nitrogen into the port

connections (liquid and gas line pipes) until a positive

pressure is achieved.

3. Evacuate the system to a reading of 5000 Microns (5

Torr).

4. Break the vacuum by allowing nitrogen into the port

connections (liquid and gas line pipes) until a positive

pressure is achieved

5. Evacuate the system to a minimum reading of 500

Microns (0.5 Torr).

6. For a moisture-free system, ensure the vacuum is held

without movement for a minimum of 4 hours.

7. If vacuum fails to hold, carry out steps 2 through 6 until

vacuum holds.

Table 5. Pressure Test Specications

1 3 bar 44 psig Minimum of 10 minutes

2 15 bar 220 psig Minimum of 10 minutes

3 32 bar 470 psig Minimum of 10 minutes

4 45 bar 650 psig 1 hour. Stress test to prove the

integrity of the complete installation.

5 32 bar 470 psig 24 hours. Lower system pressure

test, after conrmation No. 4 was

successfully completed.

Leak Test

Use the following procedure to test for system leaks:

1. Connect the manifold gauge set and dry nitrogen gas

cylinder to the liquid and gas service ports.

2. Open valve on nitrogen cylinder.

3. Pressurize the system per the pressure test

specications in “Table 5. Pressure Test Specications”.

4. Check that the system pressure remains stable. If

16

Page 17

Wiring Connections

IMPORTANT

Install unit so that unit disconnect is accessible.

Use specied wiring and cable to make electrical

connections. Clamp cables securely and make sure that

connections are tight to avoid strain on wiring. Insecure

wiring connections may result in equipment failure and

risk of re.

Wiring must be installed so that all cover plates can be

securely closed.

WARNING

Electric Shock Hazard. Can cause injury or death. Unit

must be rounded in accordance with national and local

codes.

Line voltage is present at all components when unit is

not in operation. Disconnect all remote electric power

supplies before opening access panel. Unit may have

multiple power sources.

CAUTION

All terminal connections must be made as illustrated

in the following diagrams. Improperly connected wiring

could damage unit or cause communication errors

between indoor and outdoor units.

In the U.S.A., wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada,

wiring must conform with current local codes and the

current Canadian Electrical Code (CEC).

Outdoor Unit

• Refer to unit nameplate for minimum circuit ampacity

and maximum over-current protection size

• Make all electrical power wiring connections at the outdoor unit

• Be sure to reattach all electrical box covers after connections are complete

Indoor Units

Refer to the installation instruction included with the indoor

unit for further details.

17

Page 18

IMPORTANT

All diagrams (Figure 23 through Figure 33) are typical wiring diagrams. Refer to the wiring diagram on the unit for actual

wiring.

From Power

Supply

208/230V Outdoor Unit

Terminal Block

2(A)

1(A)

L2

3(A)

Outdoor Unit

Figure 21. Connection Diagram - Systems 30k and Below

1(B)

2(B)

3(B)

208/230V Indoor Unit B

Terminal Block

1 2 3

Indoor Unit B

208/230V Indoor Unit A

Terminal Block

1 2 3

Indoor Unit A

From Power

Supply

L2

To Indoor Unit A

208/230V Outdoor Unit

Terminal Block

1(A)

3(A)

2(A)

1(B)

3(B)

2(B)

To Indoor Unit B

Outdoor Unit

Figure 22. Connection Diagram - Systems 36k and Above

1(C)

2(C)

To Indoor Unit C

1(E)

3(E)

1(D)

3(C)

2(E)

3(D)

2(D)

208/230V Indoor Unit

Terminal Block

1 2 3

208/230V Indoor Unit

Terminal Block

1 2 3

Indoor Unit E

Indoor Unit D

18

Page 19

CN6

INDOOR COIL OUTLET

TEMP.SENSOR

OUTDOOR

T4

TEMP. SENSOR

OUTDOOR

T3

L-OUT

2

CN38

COIL TEMP. SENSOR

T5

COMPRESSOR

DISCHARGE TEMP.

CN11

CN12

RED

BLUE

CN39

BLACK

RED

L2

L1

BLUE

BROWN

2(A)

1(A)

BLACK

BLUE

BROWN

BLACK

1(B)

3(B)3(A)

2(B)

4 WAY

VALVE

PAN

HEATER

CRANKCASE

HEATER

B

A

Figure 23. MPA018S4M-*P Outdoor Unit Wiring Diagram

L-PRO

LOW PRESSURE SWITCH

2

H-PRO

HIGH PRESSURE SWITCH

INDOOR COIL OUTLET

TEMP.SENSOR

RED

YELLOW

4

C

CN11

CN12

RED

BLUE

B

A

ELECTRONIC

EXPANSION

VALVE

OUTDOOR

T4

TEMP. SENSOR

OUTDOOR

T3

COIL TEMP. SENSOR

T5

COMPRESSOR

DISCHARGE TEMP.

CN38

6

ELECTRONIC

6

EXPANSION

VALVE

6

Figure 24. MPA030S4M-*P Outdoor Unit Wiring Diagram

BLACK

RED

BLUE

BLACK

BROWN

3(A)

1(A)

L2

2(A)

BROWN

1(B)

BLACK

BLUE

2(B)

3(B) 3(C)

BLUE

BLACK

BROWN

1(C)

2(C)

PAN

HEATER

CRANKCASE

HEATER

4 WAY

VALVE

19

Page 20

BLACK

W

RED

COMP

V

BLUE

Y/G

U

DRIVER BOARD

YELLOW

L

CODE PART NAME

COMP

H-PRO

EEV

FM1

HEAT_Y

HEAT_D

COMPRESSOR

HIGH PRESSURE SWITCH

ELECTRIC EXPANSIVE

VALVE

OUTDOOR DC FAN

CRANKCASE HEATER

PAN HEATER

BLACK

RED

BLUE

BLUE

BLUE

YELLOW

CN54

CN51

CN53

CN52

CN7

W

V

U

L-PRO

CN5 5

RED

BLACK

L

T5

SV

T3

T4

7

4-WAY1

SV

BLUE

BLUE

HEAT_Y

HEAT_D

T3

T4

H-PRO

L-PRO

PART NAMECODE

PFC INDUCTOR

LOW PRESSURE SWITCH

COMPRESSOR

DISCHARGE TEMP.

4-WAY VALVE

CONDENSER

TEMPERATURE SENSOR

OUTDOOR AMBIENT

TEMPERATURE SENSOR

TP

FM1

CN12 CN11

6

CN20

CN3

ORANGE

CN4

CN10

ORANGE

ORANGE

ORANGE

CN8

CN9

7

CN7

CN33

CN22

CN40

CN44

MAIN BOARD

BLACK

CN5

RED

CN6

P-1

Y/G

CN1

CN2

RED

BLACK

A

CN21

B

CN17

C

CN18

D

CN2 9

CN30

CN2 7

CN2 8

M

6

M

6

M

EEV

6

M

indoor coil

outlet temp.

sensor

BLACK

BLUE

Y/G

W

V

RED

V

U

COMP

IPM & PFC BOARD

CN15

U

CN55

W

CN14

RED

BLUE

CN39

DCFAN2

Figure 25. MPA036S4M-*P Outdoor Unit Wiring Diagram

YELLOW

YELLOW

CN2

CN5

CN6

MAIN BOARD

D C

CN30

CN26

6

6

ELECTRONIC

EXPANSION

VALVE C

L

B

CN23

6

ELECTRONIC

EXPANSION

VALVE B

A

CN15

6

ELECTRONIC

EXPANSION

VALVE A

P-6

T2B-A B C D E

E D B A

INDOOR COIL

OUTLET TEMP.

SENSOR

CN13

C

P-4

P-5

CN13

CN16

CN21

CN29

CN37

BLACK

CN3

CN1

BLACK

E

3

D

3

C

3

B

3

A

3

9NC

YELLOW

01NC

RED

CN8

T5

CN9

Ferrite bead

CH3

D

BLACK

12

4

RED

CH2

CN8

CN6

CN3

Ferrite bead

7

CN7

5

CN11

5

BLACK

RED

3

5

BLACK

CH1

5

Ferrite bead

CT1

CN39

CN4

DCFAN1

BLUE

C N1 7

C N1 8

BLUE

C N2 4

C N2 5

C N1 9

C N2 0

E

CN33

6

ELECTRONIC

ELECTRONIC

EXPANSION

EXPANSION

VALVE E

VALVE D

HEA T_Y

HEA T_D

4-W AY

SV

WHITE

T4

T3

Y/G

BLACK

BLUE

BROWN

BLACK

BLUE

BROWN

BLACK

BLUE

BROWN

BLACK

BLUE

BROWN

BLACK

BLUE

BROWN

H-PRO

L-PRO

XT3

XT2

XT1

CODE

LPPUS REWOP Y

COMP

2L

1L

3(E)

2(E)

TO E

1(E)

3(D)

2(D)

TO D

1(D)

3(C)

2(C)

TO C

1(C)

3(B)

2(B)

TO B

1(B)

3(A)

2(A)

TO A

1(A)

CT1

D

DCFAN1,DCFAN2

HEAT_Y

HEAT_D

H-PRO

L

L-PRO

SV

T5

T3

T4

PART NAME

COMPRESSOR

AC CURRENT DETECTOR

DIODE MODULE

OUTDOOR DC FAN

CRANKCASE HEATER

PAN HEATER

HIGH PRESSURE SWITCH

PFC INDUCTOR

LOW PRESSURE SWITCH

4-WAY VALVE

DISCHARGE

TEMP. SENSOR

OUTDOOR COIL

TEMP. SENSOR

OUTDOOR TEMP. SENSOR

Figure 26. MPA048S4M-*P Outdoor Unit Wiring Diagram

20

Page 21

INDO OR COI L OUTL ET

TEMP. SENSOR

BR OW N

BL UE

HE AT 1

HE AT 2

RE AC TO R

BL UE

BL UE

OUTDOOR

TEMPERATURE SE NSOR

OUTDOOR COIL

TEMPERATURE SENSOR

REACT0R2 R05094A

WHITE

WHITE

6

3

3

6

1(A)

3(A)

L2

2(A)

L1

BLACK

BLUE

BROWN

BLACK

BLUE

BROWN

BLACK

RED

1(B)

2(B)

3(B)

COMPRE SSOR DI SCHARG E

TEMPER ATURE SENSOR

Figure 27. MPB018S4M-*P Outdoor Unit Wiring Diagram

HEAT1

SV

HEAT2

WHITE

WHITE

6

BLACK

BLUE

BROWN

BLACK

RED

L2

BROWN

BROWN

BLUE

BLUE

BLACK

BLACK

1(A)

3(A)

2(A)

1(B)

3(B)

2(B)

1(C)

2(C)

3(C)

3

3

6

6

CRANKCASE

HEATER

PAN

HEATER

Figure 28. MPB030S4M-*P Outdoor Unit Wiring Diagram

21

Page 22

CO MP

FM 1

MAIN B OA RD

RED

BL ACK

U

V

W

Y/G

Y/G

L

L-PRO

T3

T4

H-PRO

Y/G

TP

V

U

CN19

CN51

CN55

W

EXV

BLACK

DRIVER BOARD

RED

7

7

YELLOW

BLUE

P-1

CN53

CN3

CN4

CN10

CN40

CN22

CN44

C N8

C N9

CN7

C N2

C N1

CN5

CN54

CN52

CN33

CN6

SV

4-WAY

VALVE

BLUE

BLUE

HEAT_2

HEAT_1

BLACK

RED

BLUE

BLUE

BLUE

YELLOW

RED

BLACK

RED

BLACK

CN20

M

6

A

CN21

M

6

B

CN17

M

6

C

CN18

M

6

D

CN30

C N2 9

C N2 8

C N2

7

CODE PART NAME

COMPRESSOR

HEAT _2

4-WAY VALVE

COMP

EXV

ELECTRIC EXPANSIO N

VALVE

H-PRO

L-PRO

LOW PRE SSURE SWITCH

HIGH PRESSURE SWIT CH

T3

T4

OUTDOOR COIL

TEMPERATU RE SENSOR

OUTDOOR

TEMPERAT URE SENSOR

PAN HEAT ER

SV

L

PFC INDUCTOR

T2B

INDOOR COIL OUTLET

TEMPERAT URE SENSOR

TP

COMPRESSOR D ISCHARGE

TEMPERAT URE SENSOR

FM1

OUTDOOR DC FAN

PART NAMECODE

BLUE

BLUE

RDE

BLACK

BLACK

RDE

EXV

EXV

EXV

HEAT _1

CRANKCAS E HEAT ER

Figure 29. MPB036S4M-*P Outdoor Unit Wiring Diagram

DR IV ER B OA RD

CODE

PART NAME

COMPRESSOR

D

HEAT _1

CT1

AC CURRENT DETECTOR

4-WAY VALVE

COMP

EXV

ELECTRIC EXPANSIO N

VALVE

H-PRO

L-PRO

LOW PRESSURE SWITCH

HIGH PRESSURE SWITCH

T3

T4

OUTDOOR COIL

TEMPERATU RE SENSOR

OUTDOOR

TEMPERAT URE SENSOR

CRANKCAS E HEATER

DIODE MODULE

SV

L

PFC INDUCTOR

TP

COMPRESSOR DISCHA RGE

TEMP ERATURE SENS OR

MAIN BOARD

FM1, FM2

OUTDOOR DC FAN

L2

L1

XT 1

D

12

3

4

5

P5

CN37

FAN1

RED

CN4

CN2

CN3

CN1

CO MP

U

V

W

Y/G

CN6

CN9

10

3

CN1

CN2

L

YELLOW

YELLOW

U

V

W

BLUE

BLACK

RED

Y/G

XT 2

XT 3

PO WE R S U PP LY

CN29

CN21

CN16

CN13

RED

BLACK

BLACK

RED

BLACK

P9

CH1

CT1

FM 2

FM 1

Y/G

Y/G

DC MOT OR

DR IV ER B OA RD

CON1

FAN1

CN1

FAN2

3

3

P6

2

CN6

CN3

CN19

CN20

CN24

CN25

CN17

CN18

HEAT_2

HEAT_1

SV

4-WAY

VALVE

BLUE

BLUE

ORAN GE

ORA NGE

RED

BLACK

CH2

CH2

CH2

~

~

~

Y/G

Y/G

HEAT_2

PAN HEATER

T2B

INDOOR COIL

TEMPER ATUR E SENSOR

XT

TERMINAL STRIP

Figure 30. MPB048S4M-*P Outdoor Unit Wiring Diagram

22

Page 23

INDUCTOR

1R25027

D R IV E R B O A R D

INDOOR COIL OUTLET TEMP SENSOR

OUTDOOR TEMP SENSOR

OUTDOOR TEMP SENSOR

COMPRESSOR DISCHARGE

TEMP SENSOR

E X V

E X V

GN D

P-1

SV

HE A T _1

4 WAY

CR A N K C AS E

VALVE

HE A T ER

INDUCTOR 2R0509A

Figure 31. MLA018S4M-*P Outdoor Unit Wiring Diagram

HE A T _1

HE A T _2

HE A T _2

PAN

HE A T ER

TE M P. S EN S O R

IN D O O R C O IL O U T L ET

HEAT_1

CRANKCASE HEATER

HEAT_2

Figure 32. MLA030S4M-*P Outdoor Unit Wiring Diagram

COMPRESSOR DISCHARGE

TEMP. SENSOR

OUTDOOR COIL

TEMP. SENSOR

OUTDOOR

TEMP. SENSOR

INDOOR COIL OUTLET

TEMP. SENSOR

23

GN D

P-1

Page 24

HE A T _2

HE A T _1

IND O O R C OIL

OU T L ET

TE M P. S EN SO R

Figure 33. MLA036S4M-*P Outdoor Unit Wiring Diagram

HE A T _1

HE A T _2

AC CURRENT DETECTOR

PAN HEATER

COMPRESSOR DISCHARGE

TEMP. SENSOR

OUTDOOR COIL

TEMP. SENSOR

OUTDOOR

TEMP. SENSOR

INDOOR COIL OUTLET

TEMP. SENSOR

Unit Start-Up

IMPORTANT

Units should be energized 24 hours before unit

start-up to prevent compressor damage as a result

of slugging.

1. Inspect all factory-installed and eld-installed wiring

for loose connections.

2. Verify that the manifold gauge set is connected.

3. Add additional refrigerant charge if required before

opening valves and while system is still under a

vacuum.

4. Open the liquid and gas line master valves and each

individual port’s service valve to release the refrigerant

charge contained in outdoor unit into the system.

5. Replace the stem caps and tighten to the value listed

in “Table 1. Torque Requirements” on page 5.

6. Check voltage supply at the outdoor unit terminal strip.

The voltage must be within the range listed on the

unit’s nameplate. If not, do not start the equipment

until you have consulted with the power company and

the voltage condition has been corrected.

7. Refer to the included user guide to operate the system

using the provided remote control.

8. Visually check for binding of both indoor and outdoor

fans.

Refrigerant Charge

The outdoor unit is factory-charged with refrigerant.

Calculate the additional refrigerant required according to

the length of the liquid pipe (one way) between the outdoor

unit and indoor unit connections.

Be sure to add the proper amount of additional refrigerant.

Failure to do so may result in reduced performance.

Table 6. Refrigerant Charge

System

Two-port 50 ft. (15 m)

Threeport

Four-port 100 ft. (30 m)

Five-port 125 ft. (38 m)

Pre-charge

Pipe Length

75 ft. (23 m)

Amount of Refrigerant to add

0.16 oz ((L1 ft + L2 ft) - 50 ft)

0.005 kg ((L1 m + L2 m) - 15 m)

0.16 oz ((L1 ft + L2 ft + L3 ft) - 75 ft)

0.005 kg ((L1 m + L2 m + L3 m) - 23

m)

0.16 oz ((L1 ft + L2 ft + L3 ft + L4 ft)

- 100 ft)

0.005 kg ((L1 m + L2 m + L3 m + L4

m) - 30 m)

0.16 oz ((L1 ft + L2 ft + L3 ft + L4 ft +

L5 ft) - 125 ft)

0.005 kg ((L1 m + L2 m + L3 m + L4

m + L5 m) - 38 m)

24

Loading...

Loading...