Lennox MPA018S4S-1P, MPA009S4S-1P, MPA024S4S-1P, MPA030S4S-1P, MPA036S4S-1P Service Manual

...Page 1

LENNOX MINI-SPLIT SYSTEMS

SERVICE MANUAL

Lennox Mini-Split Service Manual / Page 1

Page 2

Publication No. 450510

Origination date - 11/2015

©2015 Lennox Industries Inc.

Lennox Mini-Split Service Manual / Page 2

Page 3

Table of Contents

SECTION 1 - OUTDOOR UNIT DATA ..................................................................................9

SECTION 1.1 - MPA SINGLE ZONE CONDENSING UNITS ................................................10

MODEL NUMBER IDENTIFICATION ..............................................................................11

SPECIFICATIONS - 0.75 - 1 TON MPA OUTDOOR UNITS - 115V-1 PHASE ..................12

SPECIFICATIONS - 0.75 - 1.5 TON MPA OUTDOOR UNITS - 208/230V-1 PHASE ........13

SPECIFICATIONS - 2 - 4 TON MPA OUTDOOR UNITS - 208/230V-1 PHASE ................14

SECTION 1.2 - MPA MULTI-ZONE CONDENSING UNIT .....................................................15

SPECIFICATIONS - 1.5 - 2.5 TON MPA OUTDOOR UNITS ............................................16

SPECIFICATIONS - 3 - 4 TON MPA OUTDOOR UNITS ..................................................17

SECTION 2 - INDOOR UNIT DATA ......................................................................................18

SECTION 2.1 - M22A COMPACT CASSETTE UNIT ............................................................19

MODEL NUMBER IDENTIFICATION ..............................................................................20

SPECIFICATIONS - CASSETTE INDOOR UNITS - M22A009-018 ..................................21

SOUND DATA .................................................................................................................22

AIR THROW DATA..........................................................................................................23

SECTION 2.2 - M33A CASSETTE UNIT ..............................................................................24

MODEL NUMBER IDENTIFICATION ..............................................................................25

SPECIFICATIONS - CASSETTE INDOOR UNITS - M33A024-048 ..................................26

SECTION 2.3 - MMDA DUCTED UNIT .................................................................................27

MODEL NUMBER IDENTIFICATION ..............................................................................28

SPECIFICATIONS - MEDIUM STATIC DUCTED INDOOR UNITS - 009-018 ................... 29

SPECIFICATIONS - MEDIUM STATIC DUCTED INDOOR UNITS - 024-048 ................... 29

BLOWER DATA ..............................................................................................................30

SECTION 2.4 - MWMA WALL MOUNTED UNIT ..................................................................33

MODEL NUMBER IDENTIFICATION ..............................................................................34

SPECIFICATIONS - WALL-MOUNTED INDOOR UNITS - 009-012 .................................35

SPECIFICATIONS - WALL-MOUNTED INDOOR UNITS - 018-030 .................................35

SECTION 2.5 - MCFA CEILING/FLOOR UNIT ..................................................................... 36

MODEL NUMBER IDENTIFICATION ..............................................................................37

SPECIFICATIONS - CEILING/FLOOR MOUNT INDOOR UNITS - 012-024 ....................38

SPECIFICATIONS - CEILING/FLOOR MOUNT INDOOR UNITS - 036-048 ....................38

SECTION 3 - INSTALLATION DIMENSIONS OF OUTDOOR UNITS ...................................39

SECTION 3.1 - SINGLE ZONE INSTALLATION DIMENSIONS ............................................40

MPA009S4S, MPA012S4S, MPA018S4S Dimensions ...................................................41

MPA024S4S, MPA030S4S, MPA036S4S Dimensions ...................................................42

MPA048S4S Dimensions ...............................................................................................43

Lennox Mini-Split Service Manual / Page 3

Page 4

SECTION 3.2 - MULTI-ZONE INSTALLATION DIMENSIONS ..............................................44

MPA018S4M Dimensions ................................................................................................45

MPA030S4M, MPA036S4M Dimensions ............................................................................ 46

MPA048S4M Dimensions ................................................................................................47

SECTION 3.3 - MPA OUTDOOR UNIT CLEARANCES ........................................................48

Outdoor Unit Clearances ..............................................................................................49

SECTION 4 - INSTALLATION DIMENSIONS OF INDOOR UNITS .......................................50

SECTION 4.1 - M22A COMPACT CASSETTE .....................................................................51

SECTION 4.2 - M33A CASSETTE UNIT ..............................................................................54

SECTION 4.3 - MMDA DUCTED UNIT .................................................................................57

SECTION 4.4 - MWMA WALL MOUNTED UNIT ..................................................................60

SECTION 4.5 - MCFA CEILING/FLOOR UNIT ..................................................................... 63

SECTION 5 - INDOOR UNIT COMBINATIONS ....................................................................66

MULTI-ZONE SYSTEM COMBINATIONS .......................................................................67

MULTI-ZONE SYSTEM COMBINATIONS .......................................................................69

SECTION 6 - REFRIGERATION PIPE WORK ......................................................................70

SECTION 6.1 - SINGLE ZONE REFRIGERANT CYCLE DIAGRAM ....................................71

SECTION 6.2 - MULTI-ZONE REFRIGERANT CYCLE DIAGRAM .......................................73

SECTION 6.1 - REFRIGERATION PIPE WORK FOR SINGE ZONE SYSTEMS ...................78

PIPING LIMITATIONS .....................................................................................................79

SECTION 6.2 - REFRIGERATION PIPE WORK FOR MULTI-ZONE SYSTEMS ...................80

CONNECTIONS AND LINE SET USAGE ........................................................................82

CONNECTIONS AND LINE SET USAGE ........................................................................83

CONNECTIONS AND LINE SET USAGE ........................................................................84

SECTION 7 - POWER WIRING FOR OUTDOOR & INDOOR UNITS ...................................85

SECTION 8 - DATA WIRING

036 & 048 SIZES ONLY ......................................................................................................86

SECTION 9 - WIRING DIAGRAMS ......................................................................................87

SECTION 9.1 - SINGLE ZONE WIRING DIAGRAMS ...........................................................88

115V MPA009S4S-1L and MPA012S4S-1L Outdoor Unit Wiring Diagram ..................89

208/230V MPA009S4S-1P and MPA012S4S-1P Outdoor Unit Wiring Diagram ..........89

208/230

V MPA018S4S-1P Outdoor Unit Wiring Diagram ................................................................90

208/230V MPA024S4S-1P Outdoor Unit Wiring Diagram .............................................90

Lennox Mini-Split Service Manual / Page 4

Page 5

208/230V MPA030S4S-1P Outdoor Unit Wiring Diagram .............................................91

208/230V MPA036S4S-1P Outdoor Unit Wiring Diagram .............................................92

208/230V MPA048S4S-1P Outdoor Unit Wiring Diagram .............................................93

SECTION 9.1 - MULTI-ZONE WIRING DIAGRAMS .............................................................94

208/230V MPA018S4M-1P Outdoor Unit Wiring Diagram .............................................95

208/230V MPA030S4M-1P Outdoor Unit Wiring Diagram .............................................95

MPA036S4M-1P Outdoor Unit Wiring Diagram .............................................................96

MPA048S4M-1P Outdoor Unit Wiring Diagram .............................................................96

SECTION 9.1 - INDOOR UNIT WIRING DIAGRAMS ...........................................................97

MWMA Unit Wiring Diagram ..........................................................................................98

M22A009S4-1P, M22A012S4-1P, M22A018S4-1P, M33A024S4-1P Unit Wiring Diagram

99

M33A036S4-1P & M33A048S4-1P Unit Wiring Diagram ............................................... 100

MMDA024S4-1P Ducted Units Wiring Diagram ............................................................101

MMDA036S4-1P & MMDA048SA-1P Ducted Units Wiring Diagram .............................101

MMDA009S4-1P, MMDA012S4-1P, MMDAA018S4-1P Ducted Units Wiring Diagram .. 102

MCFA024S4-1P Unit Wiring Diagram ............................................................................103

MCFA036S4-1P Unit Wiring Diagram ............................................................................103

MCFA048S4-1P Unit Wiring Diagram ............................................................................104

SECTION 10 - CONDENSATE PIPE WORK INSTALLATION DATA ....................................105

SECTION 10.1 - OUTDOOR UNIT CONDENSATE PIPE ......................................................106

Condensate Piping Requirements - Outdoor Unit ....................................................... 107

SECTION 10.2 - INDOOR UNIT GRAVITY DRAIN ...............................................................108

Condensate Piping Requirements - MWMA & MCFA ...................................................109

SECTION 10.3 - INDOOR UNIT LIFT PUMP ........................................................................110

Condensate Piping Requirements - MMDA & M22A/M33A ..........................................111

MMDA .............................................................................................................................111

M22A and M33A .............................................................................................................112

SECTION 11 - CONTROLS ..................................................................................................113

SECTION 11.1 - M0STAT60Q WIRELESS CONTROLLER ..................................................114

SECTION 11.2 - M0STAT61Q-1 WIRED CONTROLLER ......................................................117

SECTION 12 - START UP ....................................................................................................119

SECTION 12.1 - GENERAL START UP INFORMATION ......................................................120

Outdoor Unit Spot Check Function ..............................................................................121

Outdoor unit’s digital display tube ...............................................................................125

Lennox Mini-Split Service Manual / Page 5

Page 6

SECTION 13 - FAULT CODES .............................................................................................126

SECTION 13.1 - QUICK REFERENCE GUIDE - FAULT CODES ........................................128

Single Zone 009/012 115VAC/208-230VAC Outdoor Units Quick Reference ...............129

Single Zone 018/030 208-230VAC Outdoor Units Quick Reference ............................130

Multi-Zone Outdoor Units Quick Reference .................................................................131

Indoor Unit Fault Code Units Quick Reference For ALL Indoor Units ........................132

SECTION 13.2 - TROUBLESHOOTING SINGLE ZONE OUTDOOR UNITS .......................133

SECTION 13.3 - TROUBLESHOOTING MULTI-ZONE OUTDOOR UNITS ...........................140

E0 Fault Code ................................................................................................................143

E0 Flow Chart ................................................................................................................144

E2 Fault Code ................................................................................................................145

E2 Flowchart ..................................................................................................................146

E3 Fault Code ................................................................................................................149

E3 Flow Chart ................................................................................................................150

E4 Fault Code ................................................................................................................152

E4 Flow Chart ................................................................................................................153

E5 Fault Code ................................................................................................................154

E5 Flow Chart ................................................................................................................155

E6 Fault Code ................................................................................................................160

E6 Flow Chart ................................................................................................................161

E8 Fault Code ................................................................................................................164

E8 Flow Chart ................................................................................................................165

F1 Fault Code ................................................................................................................168

F1 Flow Chart ................................................................................................................169

F2 Fault Code ................................................................................................................170

F2 Flow Chart ................................................................................................................171

F3 Fault Code ................................................................................................................172

F3 Flow Chart ................................................................................................................173

F4 Fault Code ................................................................................................................174

F4 Flow Chart ................................................................................................................175

F5 Fault Code ................................................................................................................176

F5 Flow Chart ................................................................................................................177

F6 Fault Code ................................................................................................................178

P1 Fault Code ................................................................................................................179

P1 Flow Chart ................................................................................................................180

P2 Fault Code ................................................................................................................182

P2 Flow Chart ................................................................................................................183

P3 Fault Code ................................................................................................................185

P3 Flow Chart ................................................................................................................186

P4 Fault Code ................................................................................................................188

P4 Flow Chart ................................................................................................................189

P5 Fault Code ................................................................................................................190

P5 Flow Chart ................................................................................................................191

P6 Fault Code ................................................................................................................192

P6 Flowchart ..................................................................................................................193

Lennox Mini-Split Service Manual / Page 6

Page 7

SECTION 13.4 - INDOOR UNIT FAULT CODES ..................................................................194

E0 Fault Code ................................................................................................................197

E0 Flowchart ..................................................................................................................198

E1 Fault Code ................................................................................................................199

E1 Flow Chart ................................................................................................................200

E3 Fault Code ................................................................................................................202

E3 Flow Chart ................................................................................................................203

E4 Fault Code ................................................................................................................204

E4 Flow Chart ................................................................................................................205

E5 Fault Code ................................................................................................................206

E5 Flow Chart ................................................................................................................207

EC Fault Code ................................................................................................................208

EC Flow Chart ................................................................................................................209

EE Fault Code ................................................................................................................210

EE Flow Chart ................................................................................................................211

F0 Fault Code ................................................................................................................212

F0 Flow Chart ................................................................................................................213

F1 Fault Code ................................................................................................................214

F1 Flow Chart ................................................................................................................215

F2 Fault Code ................................................................................................................216

F2 Flow Chart ................................................................................................................217

F3 Fault Code ................................................................................................................218

F3 Flow Chart ................................................................................................................219

F4 Fault Code ................................................................................................................220

F4 Flow Chart ................................................................................................................221

F5 Fault Code ................................................................................................................222

F5 Flow Chart ................................................................................................................223

F6 Fault Code ................................................................................................................224

F6 Flow Chart ................................................................................................................225

P0 Fault Code ................................................................................................................226

P0 Flowchart ..................................................................................................................227

P1 Fault Code ................................................................................................................228

P1 Flow Chart ................................................................................................................229

P3 Fault Code ................................................................................................................230

P3 Flow Chart ................................................................................................................231

P4 Fault Code ................................................................................................................232

P4 Flow Chart ................................................................................................................233

P5 / -- Fault Code ...........................................................................................................234

P6 Fault Code ................................................................................................................235

P6 Flow Charts ..............................................................................................................236

P7 Fault Code ................................................................................................................239

P7 Flow Chart ................................................................................................................240

Appendix 1 .....................................................................................................................241

Temperature Sensor Resistance Value Table (°C--K) ..................................................241

Appendix 2 .....................................................................................................................242

Discharge Temperature Sensor Table (°C--K) ..............................................................242

Appendix 3 .....................................................................................................................243

Celsius to Fahrenheit Conversion Table .....................................................................243

Compressor Check ........................................................................................................244

IPM Check ......................................................................................................................245

Lennox Mini-Split Service Manual / Page 7

Page 8

AC Fan Motor .................................................................................................................246

4-Way Valve ...................................................................................................................247

EXV Check ....................................................................................................................248

Low Voltage Protection .................................................................................................251

Compressor Current Limit Protection ..........................................................................251

Electronic Functions Abbreviations .............................................................................252

Electronic Control Working Environment ....................................................................252

Main Protection .............................................................................................................252

Compressor Preheating Functions ..............................................................................253

Compressor Crankcase Heater .....................................................................................253

Capacity Request Calculation ......................................................................................254

Defrost Control ..............................................................................................................256

Outdoor Fan Control .....................................................................................................257

Four-Way Valve Control ................................................................................................258

Electronic Expansion Valve (EXV) Control ..................................................................258

Lennox Mini-Split Service Manual / Page 8

Page 9

SECTION 1 - OUTDOOR UNIT DATA

Lennox Mini-Split Service Manual / Page 9

Page 10

SECTION 1.1 - MPA SINGLE ZONE

CONDENSING UNITS

Lennox Mini-Split Service Manual / Page 10

Page 11

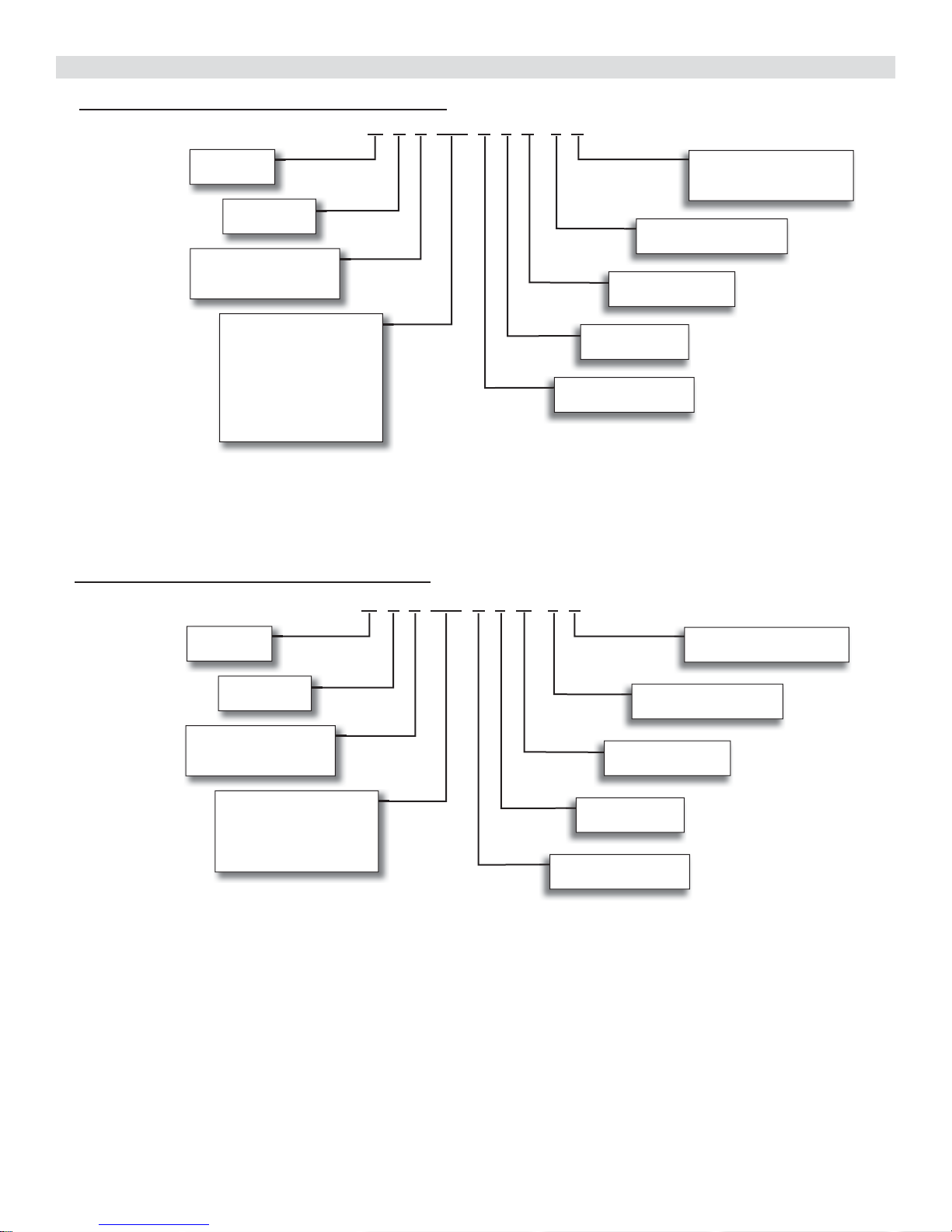

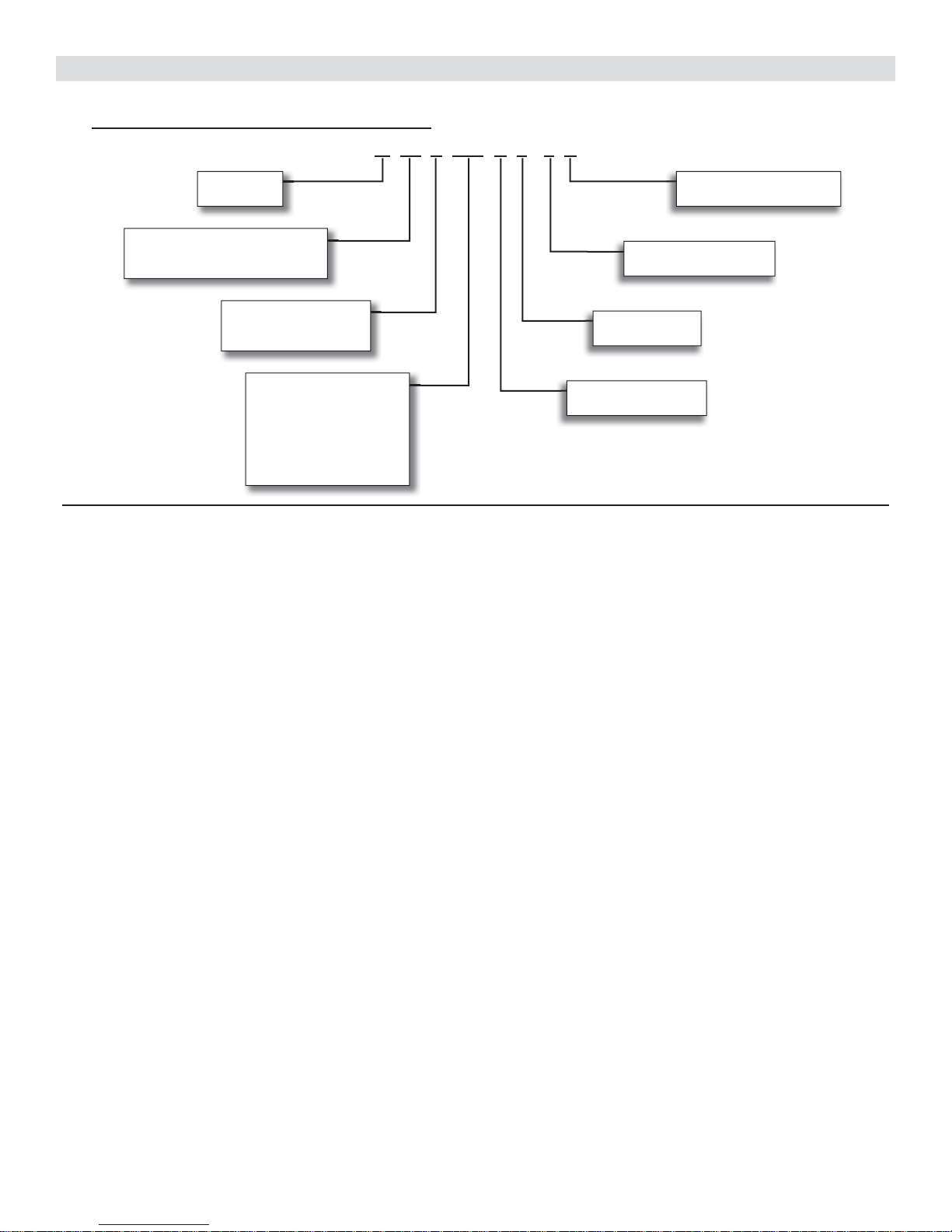

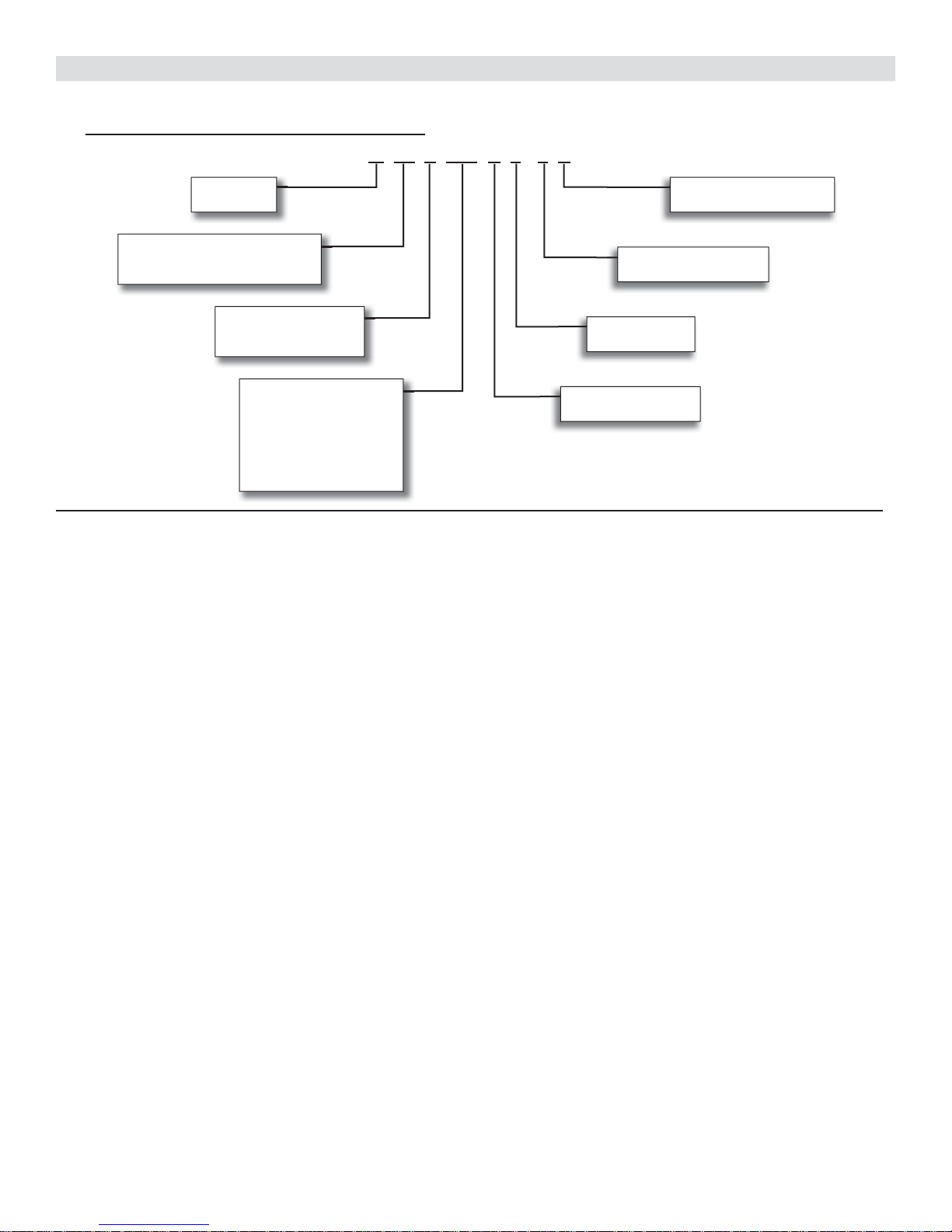

MODEL NUMBER IDENTIFICATION

OUTDOOR SINGLE ZONE HEAT PUMP UNITS

M P A 009 S 4 S - 1 P

Series Type

M = Mini-Split

Unit Type

P = Heat Pump

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Nominal Cooling Capacity

009 = 0.75 tons

012 = 1 tons

018 = 1.5 tons

024 = 2 tons

030 = 2.5 tons

036 = 3 tons

048 = 4 tons

OUTDOOR MULTI-ZONE HEAT PUMP UNITS

M P A 036 S 4 M - 1 P

Voltage

L = 115V-1 phase-60hz

P = 208/230V-1 phase-60hz

Minor Design Sequence

1 = 1st Revision

Refrigerant Circuits

S = Single Circuit

Refrigerant Type

4 = R-410A

Cooling Effi ciency

S = Standard Effi ciency

Series Type

M = Mini-Split

Unit Type

P = Heat Pump

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Nominal Cooling Capacity

018 = 1.5 tons

030 = 2.5 tons

036 = 3 tons

048 = 4 tons

Voltage

P = 208/230V-1 phase-60hz

Minor Design Sequence

1 = 1st Revision

Refrigerant Circuits

M = Multiple Circuits

Refrigerant Type

4 = R-410A

Cooling Effi ciency

S = Standard Effi ciency

Lennox Mini-Split Service Manual / Page 11

Page 12

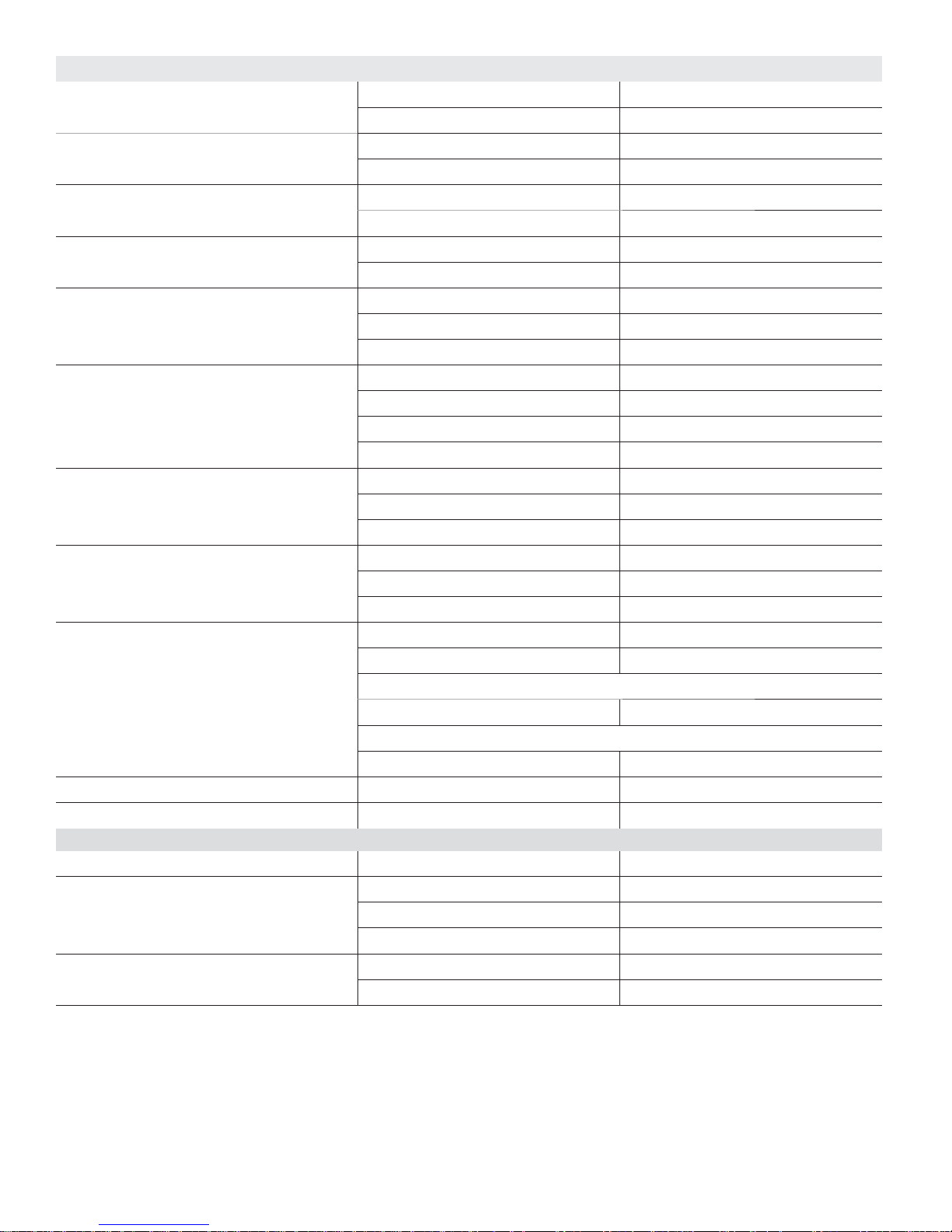

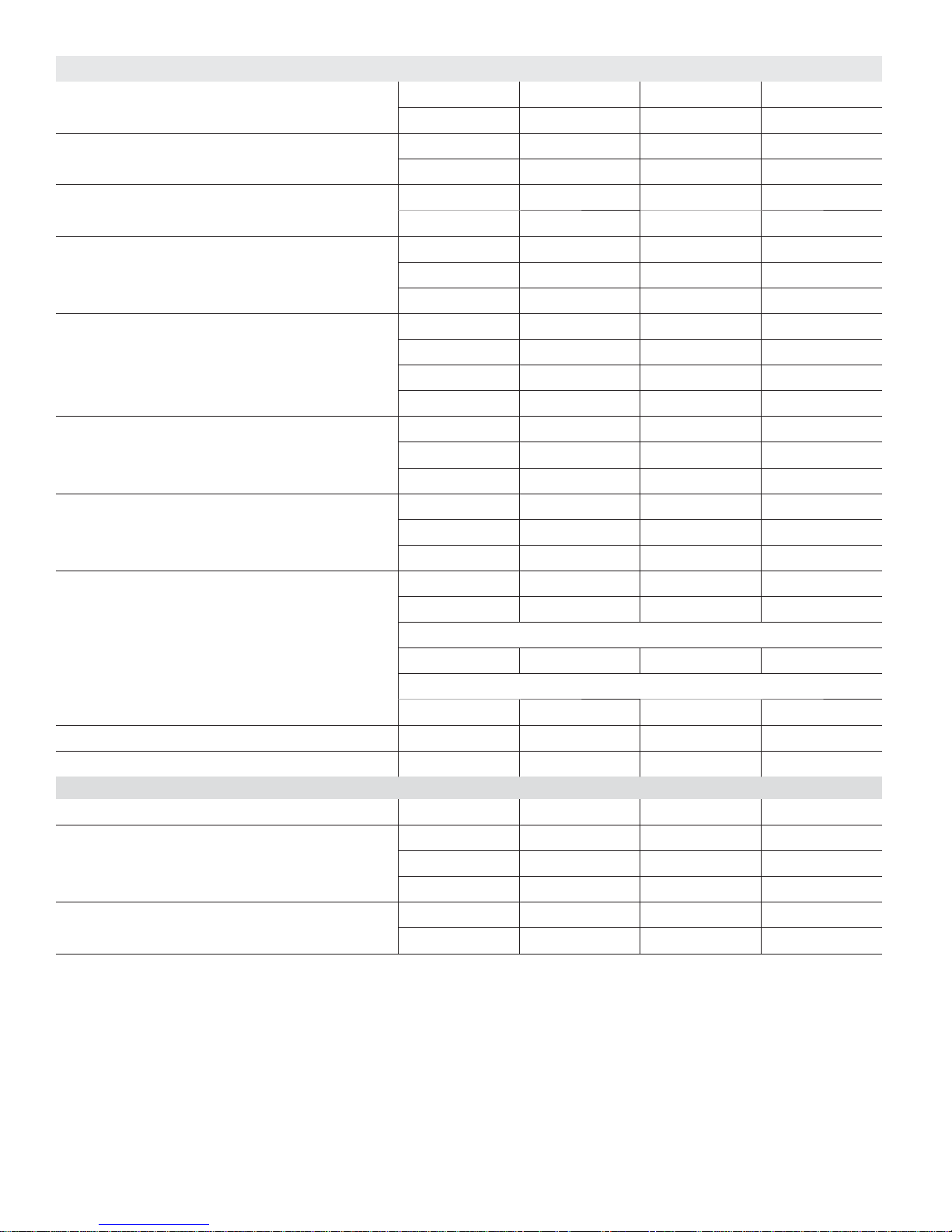

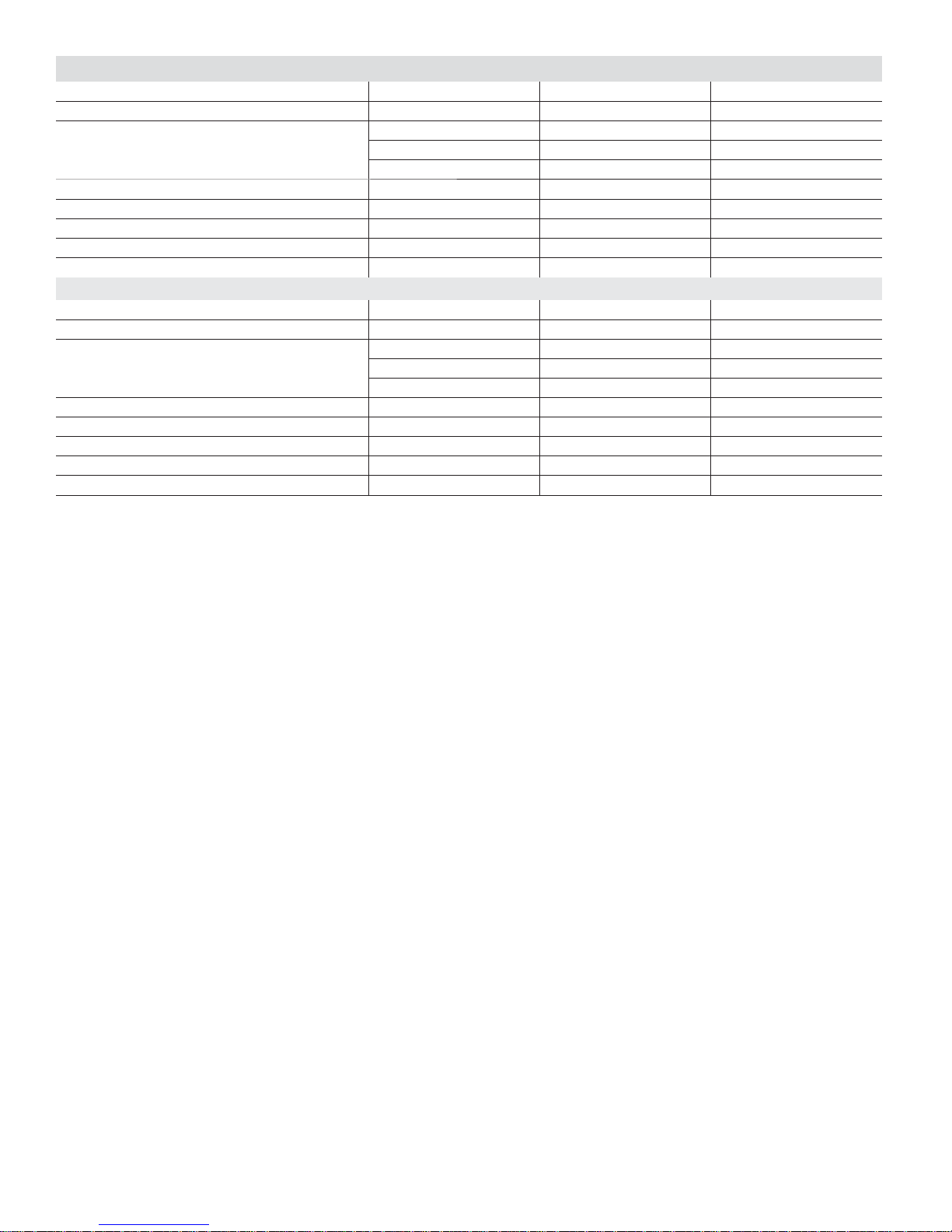

SPECIFICATIONS - 0.75 - 1 TON MPA OUTDOOR UNITS - 115V-1 PHASE

Nominal Size - Tons 0.75 1

Outdoor Unit Model No. MPA009S4S-1L MPA012S4S-1L

Input - Cooling/Heating (W) 620 / 870 888 / 1092

Rated current - Cooling/Heating (A) 5.4 / 7.6 7.7 / 9.5

Ambient Temperature

Operating Range - °F

Sound Data (dBA) Cooling 51 52

Refrigerant Charge furnished (R-410A) 2 lbs. 12 oz. 2 lbs. 12 oz.

Maximum line length with furnished charge - ft. 25 25

Additional charge required per ft. - oz. 0.16 0.16

Compressor No. and Type (1) Rotary (1) Rotary

Refrigerant oil type Ester Oil VG74 Ester Oil VG74

Refrigerant oil charge - oz. 12.5 12.5

Low ambient cut-off -13°F -13°F

Connections - in. Liquid/Gas pipe (fl are) 1/4 / 3/8 1/4 / 1/2

Maximum refrigerant pipe length - ft. 98 98

Max. difference in level of indoor unit - ft. 40 40

Outdoor

Fan

(No.) Diameter - in. (1) - 16.5 (1) - 16.5

Total air volume - cfm 1180 1180

Outdoor Coil Number of rows 2 2

Tube outside diameter - in. 1/4 1/4

Net face area - ft.

Design Pressure PSIG 550/340 550/340

Shipping Data Net/Shipping weight (lbs.) 83 / 88 83 / 88

Electrical Characteristics - 60 Hz - 1 Phase 115V 115V

1

Maximum Overcurrent Protection (amps) 20 20

2

Minimum circuit ampacity 15 15

Compressor Rated load amps 9 10

Outdoor Fan

Rated load amps 0.6 0.6

Motor

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

1

HACR type circuit breaker or fuse.

2

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Cooling 5 - 122 5 - 122

Heating –13 - 86 –13 - 86

Heating 54 54

rpm 850 850

Fins per inch 21 21

Fin type Hydrophilic aluminium

Tube type Rifl ed copper tubing

2

4.72 4.72

ELECTRICAL DATA

Output - W 40 40

Lennox Mini-Split Service Manual / Page 12

Page 13

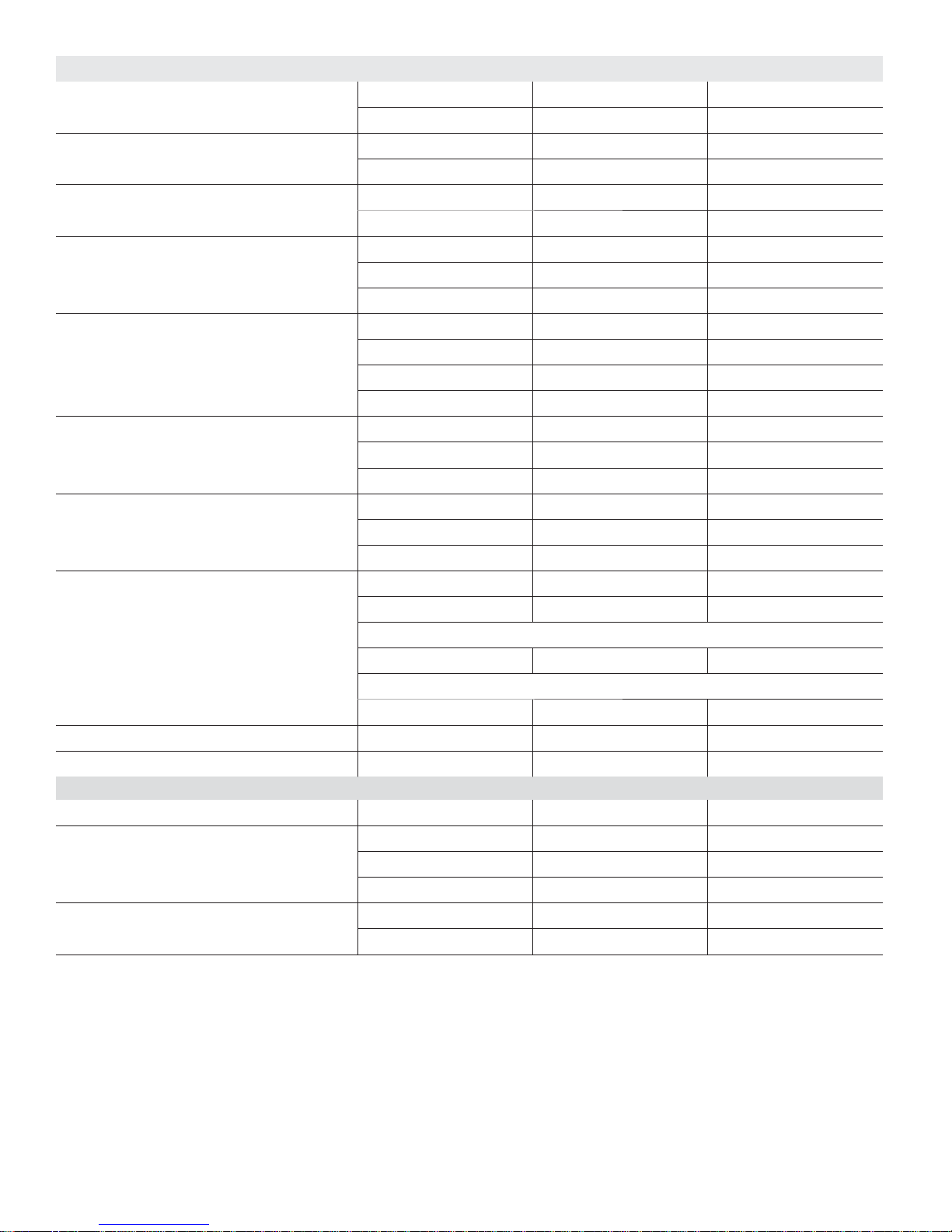

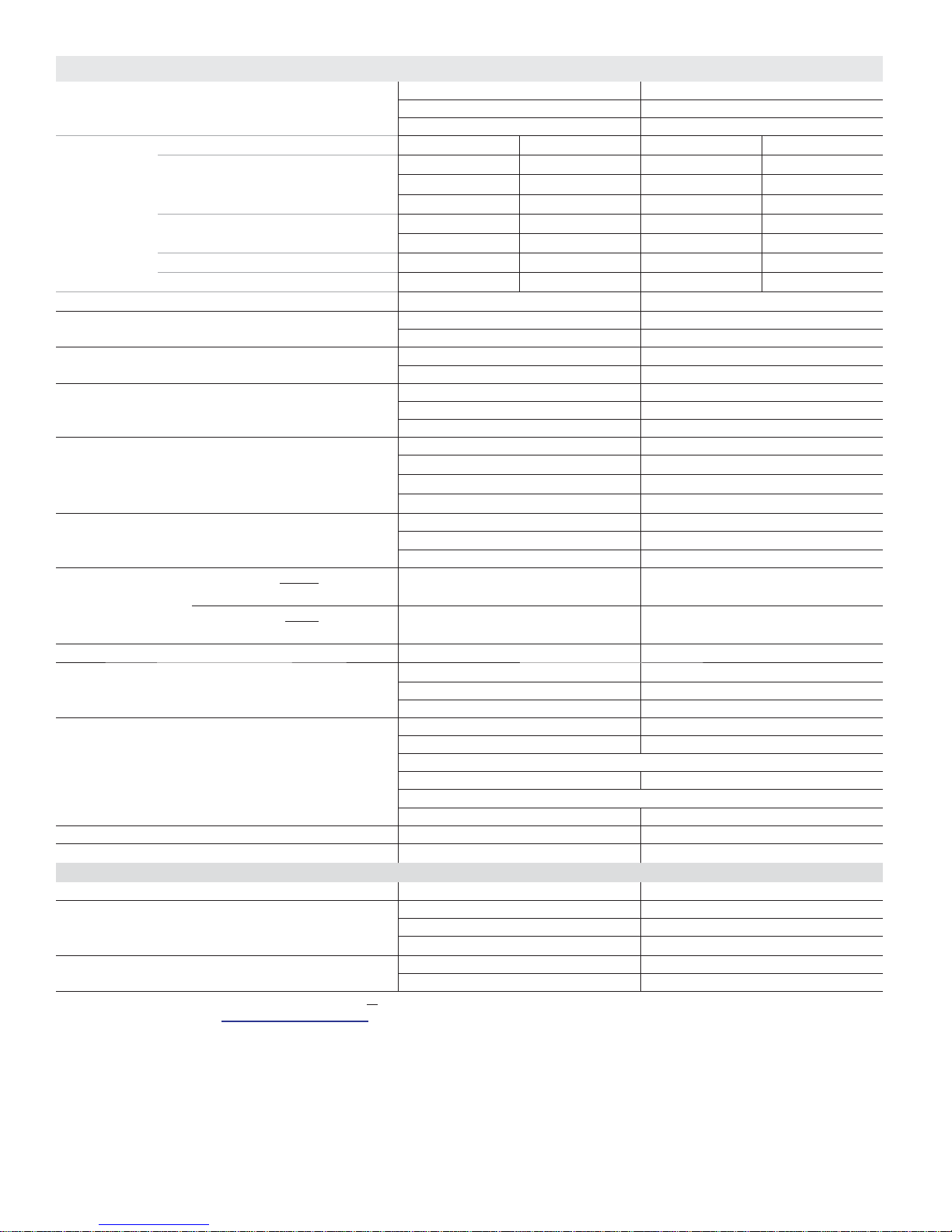

SPECIFICATIONS - 0.75 - 1.5 TON MPA OUTDOOR UNITS - 208/230V-1 PHASE

Nominal Size - Tons 0.75 1 1.5

Outdoor Unit Model No. MPA009S4S-1P MPA012S4S-1P MPA018S4S-1P

Ambient Temperature

Operating Range - °F

Sound Data (dBA) Cooling 53 54 61

Refrigerant Charge furnished (R-410A) 2 lbs. 12 oz. 2 lbs. 12 oz. 4 lbs. 3 oz.

Maximum line length with furnished charge - ft. 25 25 25

Additional charge required per ft. - oz. 0.16 0.16 0.16

Compressor No. and Type (1) Rotary (1) Rotary (1) Rotary

Refrigerant oil type Ester Oil VG74 Ester Oil VG74 Ester Oil VG74

Refrigerant oil charge - oz. 12.5 12.5 15.2

Low ambient cut-off -13°F -13°F -13°F

Connections - in. Liquid/Gas pipe (fl are) 1/4 / 3/8 1/4 / 1/2 1/4 / 1/2

Maximum refrigerant pipe length - ft. 98 98 98

Max. difference in level of indoor unit - ft. 40 40 66

Outdoor

Fan

(No.) Diameter - in. (1) - 16.5 (1) - 16.5 (1) - 18

Total air volume - cfm 1120 1180 1470

Outdoor Coil Number of rows 2 2 3

Tube outside diameter - in. 1/4 1/4 1/4

Net face area - ft.

Design Pressure PSIG 550/340 550/340 550/340

Shipping Data Net/Shipping weight (lbs.) 83 / 88 83 / 88 111 / 120

Electrical Characteristics - 60 Hz - 1 Phase 208/230V 208/230V 208/230V

1

Maximum Overcurrent Protection (amps) 15 15 20

2

Minimum circuit ampacity 15 15 13

Compressor Rated load amps 5.3 5.7 9.5

Outdoor Fan

Rated load amps 0.42 0.42 0.5

Motor

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

1

HACR type circuit breaker or fuse.

2

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Cooling 5 - 122 5 - 122 5 - 122

Heating –13 - 86 –13 - 86 –13 - 86

Heating 55 57 62

rpm 800 800 800

Fins per inch 21 21 18

Fin type Hydrophilic aluminium

Tube type Rifl ed copper tubing

2

4.72 4.72 5.42

ELECTRICAL DATA

Output - W 40 40 50

Lennox Mini-Split Service Manual / Page 13

Page 14

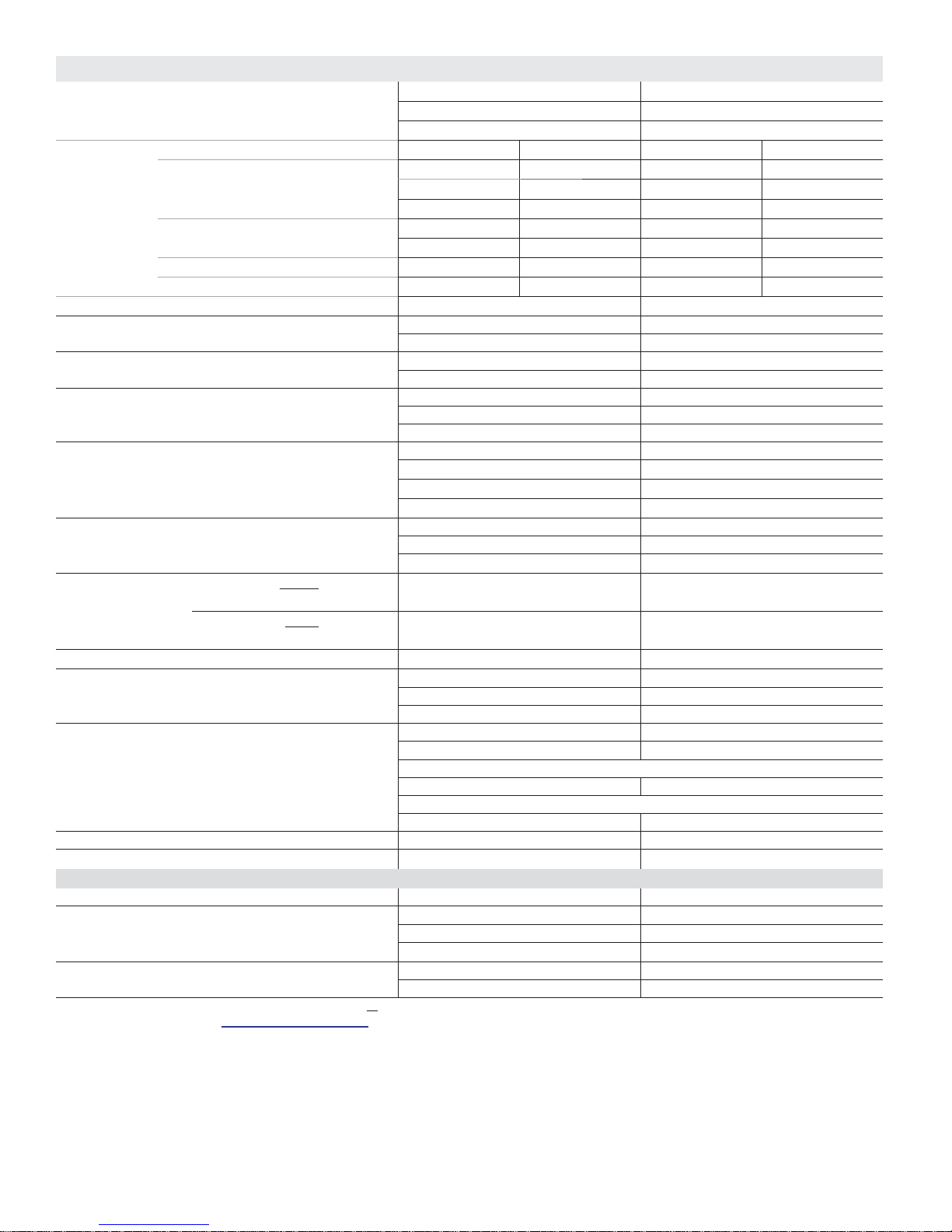

SPECIFICATIONS - 2 - 4 TON MPA OUTDOOR UNITS - 208/230V-1 PHASE

Nominal Size - Tons 2 2.5 3 4

Outdoor Unit Model No. MPA024S4S-1P MPA030S4S-1P MPA036S4S-1P MPA048S4S-1P

Ambient Temperature Operating

Range - °F

Sound Data (dBA) Cooling 59 59 62 63

Refrigerant Charge furnished (R-410A) 5 lbs. 3 oz. 6 lbs. 10 oz. 7 lbs. 13 oz. 9 lbs. 8 oz.

Maximum line length with furnished charge - ft. 25 25 25 25

Additional charge required per ft. - oz. 0.32 0.32 0.32 0.32

Compressor No. and Type Twin-Rotary Rotary Twin-Rotary Twin-Rotary

Refrigerant oil type Ester Oil VG74 FY50S FV50S FV50S

Refrigerant oil charge - oz. 27.7 36.1 36.1 47.3

Low ambient cut-off -13°F -13°F -13°F -13°F

Connections - in. Liquid/Gas pipe (fl are) 3/8 / 5/8 3/8 / 5/8 3/8 / 5/8 3/8 / 5/8

Maximum refrigerant pipe length - ft. 164 164 213 213

Max. difference in level of indoor unit - ft. 82 82 98 98

Outdoor

Fan

(No.) Diameter - in. (1) - 22 (1) - 22 (1) - 22 (2) - 20

Total air volume - cfm 2355 2530 2940 4240

Outdoor Coil Number of rows 2.6 2.6 2.6 2

Tube outside diameter - in. 1/4 1/4 3/8 5/16

Net face area - ft.

Design Pressure PSIG 550/340 550/340 550/340 550/340

Shipping Data Net/Shipping weight (lbs.) 134 / 144 158 / 170 161 / 183 220 / 251

Electrical Characteristics - 60 Hz - 1 Phase 208/230V 208/230V 208/230V 208/230V

1

Maximum Overcurrent Protection (amps) 25 30 50 60

2

Minimum circuit ampacity 15 20 30 35

Compressor Rated load amps 12 14 22 23.5

Outdoor Fan Motor Rated load amps 0.7 1.0 1.0 (2) 0.7

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

1

HACR type circuit breaker or fuse.

2

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Cooling 5 - 122 5 - 122 5 - 122 5 - 122

Heating –13 - 86 –13 - 86 –13 - 76 –13 - 76

Heating 63 61 65 65

rpm 850/750/700 950/800/750 950 860

Fins per inch 18 16 14 16

Fin type Hydrophilic aluminium

Tube type Rifl ed copper tubing

2

8.12 7.79 / 4.75 8.16 / 4.75 14.14

ELECTRICAL DATA

Output - W 120 120 120 (2) 85

Lennox Mini-Split Service Manual / Page 14

Page 15

SECTION 1.2 - MPA MULTI-ZONE

CONDENSING UNIT

Lennox Mini-Split Service Manual / Page 15

Page 16

SPECIFICATIONS - 1.5 - 2.5 TON MPA OUTDOOR UNITS

Nominal Size - Tons 1.5 2.5

Outdoor Unit Model No. MPA018S4M-1P MPA030S4M-1P

Number of Zones 2 Up to 3

1

AHRI

Ratings

High Temperature Heating - Btuh 18,000 18,500 32,000 32,000

Low Temperature Heating - Btuh 10,900 11,000 20,000 20,000

AHRI Reference Number 8129621 8129607 8129624 8129613

Energy Star Yes N o

Ambient Temperature Range - °F Cooling 5 - 122 5 - 122

Sound Data (dBA) Cooling 57 59

Refrigerant Charge furnished (R-410A) 4 lbs. 4 oz. 6 lbs. 3 oz.

Maximum line length with furnished charge (per zone) - ft. 25 25

Additional charge required per ft. - oz. 0.161 0.161

Compressor No. and Type Twin-Rotary Twin-Rotary

Refrigerant oil charge - oz. 16.9 27.7

Connections - in. Liquid+Gas pipe (fl are) (2) 1/4 + (2) 3/8 (3) 1/4 + (3) 3/8

Maximum length for all rooms - ft. 98 148

Maximum length for one indoor unit - ft. 66 82

Maximum height

Outdoor unit higher than indoor

difference between

indoor unit and

outdoor unit

Outdoor unit lower than indoor

Maximum difference in level between indoor units - ft. 33 33

Outdoor

Fan

Total air volume - cfm 1470 2060

Outdoor Coil Number of rows 2 1.6

Tube outside diameter - in. 3/8 3/8

Design Pressure PSIG 550/340 550/340

Shipping Data Net/Shipping weight (lbs.) 106 / 115 144 / 155

Electrical Characteristics - 60 Hz - 1 Phase 208/230V 208/230V

2

Maximum Overcurrent Protection (amps) 20 25

3

Minimum circuit ampacity 15 19

Compressor Rated load amps 10 12

Outdoor Fan Motor Rated load amps 0.74 0.90

NOTE - Per AHRI, the certifi ed ratings for systems are valid for all combinations of indoor units with the specifi c outdoor units listed above and in the AHRI Directory of

Certifi ed Equipment. Please visit http://www.ahridirectory.org for further details and latest updates.

1

Ratings are AHRI certifi ed to AHRI Standard 210/240-2008;

• Cooling Ratings - 80°F dry bulb/67°F wet bulb entering indoor coil air and 95°F dry bulb/75°F wet bulb outdoor air temperature.

• High Temperature Heating Ratings - 70°F dry bulb/60°F wet bulb entering indoor coil air and 47°F dry bulb/43°F wet bulb outdoor air temperature.

• Low Temperature Heating Ratings - 70°F dry bulb/60°F wet bulb entering indoor coil air and 17°F dry bulb/15°F wet bulb outdoor air temperature.

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type circuit breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE - Adaptors are furnished for the gas pipe connections:

018 - (2) 3/8 x 1/2 in.

030 - (3) 3/8 x 1/2 in.

System Type Ducted Non-Ducted Ducted Non-Ducted

Cooling - Btuh 17,000 18,000 27,000 25,000

SEER 18.00 21.00 16.50 22.00

EER 12.50 12.50 9.50 12.50

HSPF (Region IV) 8.5 9.6 8.8 9.6

Heating –13 - 76 –13 - 76

Heating 62 62

Refrigerant oil type ESTER OIL VG74 ESTER OIL VG74

Low ambient cut-off

33 33

unit - ft.

49 49

unit - ft.

(No.) Diameter - in. (1) - 18 (1) - 22

rpm 750 850

Fins per inch 14 15

Fin type Hydrophilic aluminium

Tube type Rifl ed copper tubing

Net face area - ft.

2

4.9 6.42

ELECTRICAL DATA

Output - W 50 120

Lennox Mini-Split Service Manual / Page 16

Page 17

SPECIFICATIONS - 3 - 4 TON MPA OUTDOOR UNITS

Nominal Size - Tons 3 4

Outdoor Unit Model No. MPA036S4M-1P MPA048S4M-1P

Number of Zones Up to 4 Up to 5

1

AHRI

Ratings

High Temperature Heating - Btuh 36,000 36,000 51,000 49,000

Low Temperature Heating - Btuh 24,400 23,400 31,800 31,200

AHRI Reference Number 8129615 8129614 8129617 8129616

Energy Star Yes N o

Ambient Temperature Range - °F Cooling 5 - 122 5 - 122

Sound Data (dBA) Cooling 62 58

Refrigerant Charge furnished (R-410A) 7 lbs. 15 oz. 9 lbs. 8 oz.

Maximum line length with furnished charge (per zone) - ft. 25 25

Additional charge required per ft. - oz. 0.161 0.161

Compressor No. and Type Twin-Rotary Twin-Rotary

Refrigerant oil charge - oz. 36.2 47.3

Connections - in. Liquid+Gas+Gas pipe (fl are) (4) 1/4 + (3) 3/8 + (1) 1/2 (5) 1/4 + (3) 3/8 + (2) 1/2

Maximum length for all rooms - ft. 197 246

Maximum length for one indoor unit - ft. 98 98

Maximum height

Outdoor unit higher than indoor

difference between

indoor unit and

Outdoor unit lower than indoor

outdoor unit

Maximum difference in level between indoor units - ft. 33 33

Outdoor

Fan

Total air volume - cfm 2240 (2) 4240

Outdoor Coil Number of rows 2.6 2

Tube outside diameter - in. 5/16 5/16

Design Pressure PSIG 550/340 550/340

Shipping Data Net/Shipping weight (lbs.) 162 / 174 218 / 245

Electrical Characteristics - 60 Hz - 1 Phase 208/230V 208/230V

2

Maximum Overcurrent Protection (amps) 45 50

3

Minimum circuit ampacity 27 29

Compressor Rated load amps 19.5 22

Outdoor Fan Motor Rated load amps 1.30 (2) 0.9

NOTE - Per AHRI, the certifi ed ratings for systems are valid for all combinations of indoor units with the specifi c outdoor units listed above and in the AHRI Directory of

Certifi ed Equipment. Please visit http://www.ahridirectory.org for further details and latest updates.

1

Ratings are AHRI certifi ed to AHRI Standard 210/240-2008;

• Cooling Ratings - 80°F dry bulb/67°F wet bulb entering indoor coil air and 95°F dry bulb/75°F wet bulb outdoor air temperature.

• High Temperature Heating Ratings - 70°F dry bulb/60°F wet bulb entering indoor coil air and 47°F dry bulb/43°F wet bulb outdoor air temperature.

• Low Temperature Heating Ratings - 70°F dry bulb/60°F wet bulb entering indoor coil air and 17°F dry bulb/15°F wet bulb outdoor air temperature.

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type circuit breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE - Adaptors are furnished for the gas pipe connections:

036 - (3) 3/8 x 1/2 in. and (1) 1/2 x 3/8 in.

048 - (3) 3/8 x 1/2 in., (2) 1/2 x 3/8 in., (2) 1/4 x 3/8 in. and (2) 1/2 x 5/8 in.

System Type Ducted Non-Ducted Ducted Non-Ducted

Cooling - Btuh 34,000 36,000 42,000 42,000

SEER 15.00 18.00 18.00 20.00

EER 8.20 8.80 11.00 12.50

HSPF (Region IV) 9.3 10.0 9.5 10.0

Heating –13 - 76 –13 - 76

Heating 64 62

Refrigerant oil type FV50S FV50S

Low ambient cut-off

33 33

unit - ft.

49 49

unit - ft.

(No.) Diameter - in. (1) - 22 (2) - 20

rpm 950 (2) 800

Fins per inch 15 15

Fin type Hydrophilic aluminium

Tube type Rifl ed copper tubing

Net face area - ft.

2

6.42 14.33

ELECTRICAL DATA

Output - W 120 (2) 85

Lennox Mini-Split Service Manual / Page 17

Page 18

SECTION 2 - INDOOR UNIT DATA

Lennox Mini-Split Service Manual / Page 18

Page 19

SECTION 2.1 - M22A COMPACT CASSETTE

UNIT

Lennox Mini-Split Service Manual / Page 19

Page 20

MODEL NUMBER IDENTIFICATION

CASSETTE NON-DUCTED INDOOR UNITS

M 22 A 012 S 4 - 1 P

Series Type

M = Mini-Split

Unit Type

22 = 2x2 Cassette Non-Ducted Unit

33 = 3x3 Cassette Non-Ducted Unit

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Nominal Cooling Capacity

009 = .75 tons

012 = 1 tons

018 = 1.5 tons

024 = 2 tons

036 = 3 tons

048 = 4 tons

Voltage

P = 208/230V-1 phase-60hz

Minor Design Sequence

1 = 1st Revision

Refrigerant Type

4 = R-410A

Cooling Effi ciency

S = Standard Effi ciency

Lennox Mini-Split Service Manual / Page 20

Page 21

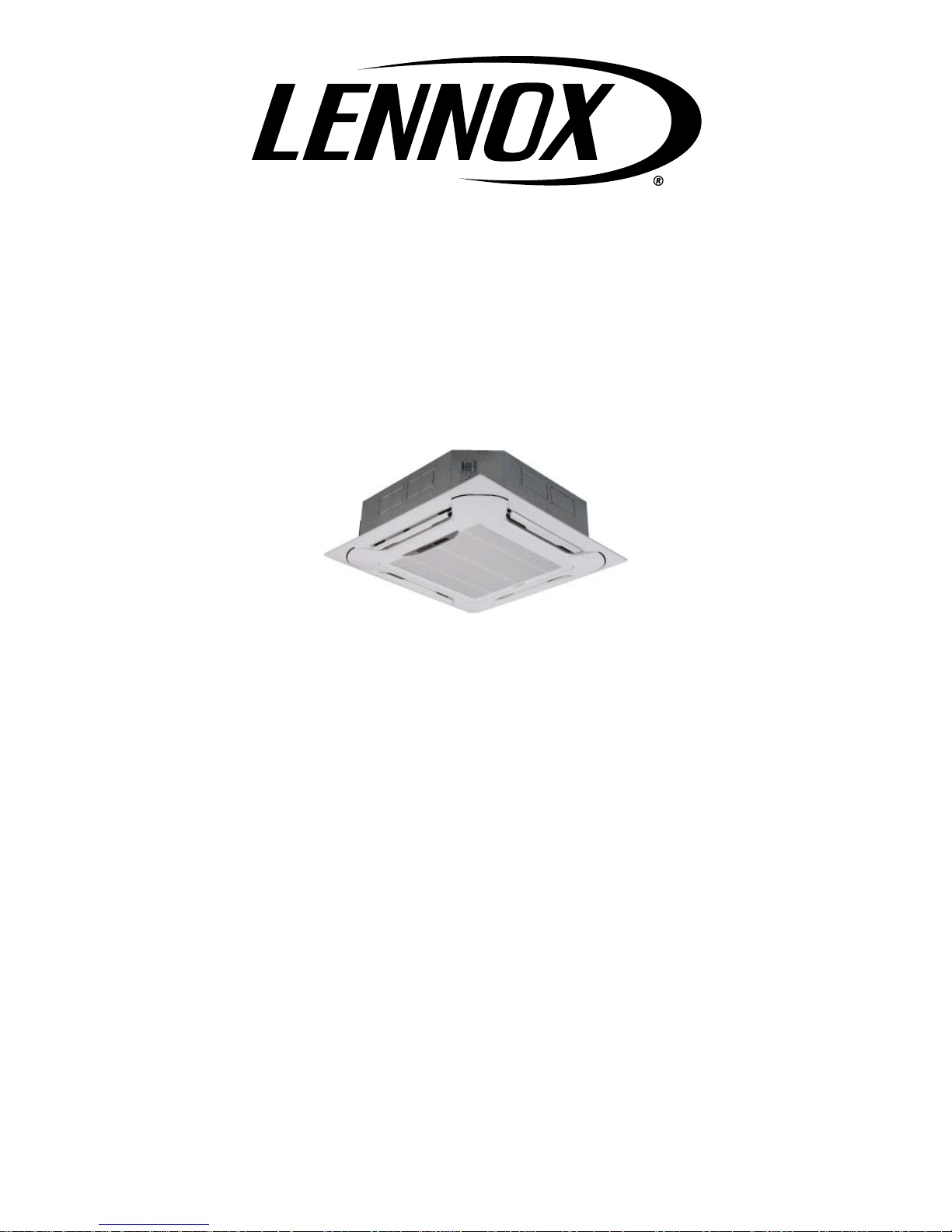

SPECIFICATIONS - CASSETTE INDOOR UNITS - M22A009-018

Model No. M22A009S4-1P M22A012S4-1P M22A018S4-1P

Nominal Tons 0.75 1 1.5

Power Supply - 60 hz - 1 phase 208/230V 208/230V 208/230V

Rated load amps 0.9 1.0 1.5

Output (W) 46 46 46

Air Volume - cfm (High/Medium/Low) 380/320/260 400/340/280 420/350/290

Sound Data (dBA) - Low/Medium/High 37/39/41 35/38/41 41/43/46

Piping Connections - Liquid/Gas - o.d. - fl are - in. 1/4 / 3/8 1/4 / 1/2 1/4 / 1/2

Drain connection o.d. - in. 1 1 1

Net/Shipping weights - lbs. Body 36 / 42 36 / 42 40 / 47

REQUIRED COMPONENTS - ORDERED SEPARATELY

Cassette Panel 13X04 (M0STAT62Q-1) 13X04 (M0STAT62Q-1) 13X04 (M0STAT62Q-1)

Net/Shipping weights - lbs. 6 / 10 6 / 10 6 / 10

Lennox Mini-Split Service Manual / Page 21

Page 22

SOUND DATA

Lennox Mini-Split Service Manual / Page 22

Page 23

AIR THROW DATA

Lennox Mini-Split Service Manual / Page 23

Page 24

SECTION 2.2 - M33A CASSETTE UNIT

Lennox Mini-Split Service Manual / Page 24

Page 25

MODEL NUMBER IDENTIFICATION

CASSETTE NON-DUCTED INDOOR UNITS

M 33 A 012 S 4 - 1 P

Series Type

M = Mini-Split

Unit Type

22 = 2x2 Cassette Non-Ducted Unit

33 = 3x3 Cassette Non-Ducted Unit

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Nominal Cooling Capacity

009 = .75 tons

012 = 1 tons

018 = 1.5 tons

024 = 2 tons

036 = 3 tons

048 = 4 tons

Voltage

P = 208/230V-1 phase-60hz

Minor Design Sequence

1 = 1st Revision

Refrigerant Type

4 = R-410A

Cooling Effi ciency

S = Standard Effi ciency

Lennox Mini-Split Service Manual / Page 25

Page 26

SPECIFICATIONS - CASSETTE INDOOR UNITS - M33A024-048

Model No. M33A024S4-1P M33A036S4-1P M33A048S4-1P

Nominal Tons 2 3 4

Power Supply - 60 hz - 1 phase 208/230V 208/230V 208/230V

Rated load amps 2 1.5 1.6

Output (W) 42 124 124

Air Volume - cfm (High/Medium/Low) 820/740/590 1060/940/820 1190/1000/850

Sound Data (dBA) - Low/Medium/High 43/47/51 44/47/52 44/48/52

Piping Connections - Liquid/Gas - o.d. - fl are - in. 3/8 / 5/8 3/8 / 5/8 3/8 / 5/8

Drain connection o.d. - in. 1-1/4 1-1/4 1-1/4

Net/Shipping weights - lbs. Body 46 / 53 56 / 63 64 / 74

REQUIRED COMPONENTS - ORDERED SEPARATELY

Cassette Panel 13X05 (M0STAT63Q-1) 13X05 (M0STAT63Q-1) 13X05 (M0STAT63Q-1)

Net/Shipping weights - lbs. 12 / 18 12 / 18 12 / 18

Lennox Mini-Split Service Manual / Page 26

Page 27

SECTION 2.3 - MMDA DUCTED UNIT

Lennox Mini-Split Service Manual / Page 27

Page 28

MODEL NUMBER IDENTIFICATION

MEDIUM STATIC DUCTED INDOOR UNITS

M MD A 012 S 4 - 1 P

Series Type

M = Mini-Split

Unit Type

MD = Medium Static Ducted Unit

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Nominal Cooling Capacity

009 = .75 tons

012 = 1 tons

018 = 1.5 tons

024 = 2 tons

036 = 3 tons

048 = 4 tons

Voltage

P = 208/230V-1 phase-60hz

Minor Design Sequence

1 = 1st Revision

Refrigerant Type

4 = R-410A

Cooling Effi ciency

S = Standard Effi ciency

Lennox Mini-Split Service Manual / Page 28

Page 29

SPECIFICATIONS - MEDIUM STATIC DUCTED INDOOR UNITS - 009-018

Model No. MMDA009S4-1P MMDA012S4-1P MMDA018S4-1P

Nominal Tons 0.75 1 1.5

Power Supply - 60 hz - 1 phase 208/230V 208/230V 208/230V

Rated load amps 0.9 1 1.5

Output (W) 55 55 90

Air Volume - cfm (High/Medium/Low) 400/330/270 400/330/270 485/380/320

Sound Data (dBA) - Low/Medium/High 31/34/37 32/36/39 31/33/35

Piping Connections - Liquid/Gas - o.d. - fl are - in. 1/4 / 3/8 1/4 / 1/2 1/4 / 1/2

Drain connection o.d. - in. 1 1 1

Net/Shipping weights - lbs. 40 / 51 40 / 51 51 / 64

SPECIFICATIONS - MEDIUM STATIC DUCTED INDOOR UNITS - 024-048

Model No. MMDA024S4-1P MMDA036S4-1P MMDA048S4-1P

Nominal Tons 2 3 4

Power Supply - 60 hz - 1 phase 208/230V 208/230V 208/230V

Rated load amps 2 1.5 1.8

Output (W) 90 150 240

Air Volume - cfm (High/Medium/Low) 800/675/585 910/800/630 1280/1100/920

Sound Data (dBA) - Low/Medium/High 45/47/50 45/49/53 41/44/47

Piping Connections - Liquid/Gas - o.d. - fl are - in. 3/8 / 5/8 3/8 / 5/8 3/8 / 5/8

Drain connection o.d. - in. 1 1 1

Net/Shipping weights - lbs. 58 / 69 78 / 93 100 / 117

Lennox Mini-Split Service Manual / Page 29

Page 30

BLOWER DATA

MMDA009S4-1P, MMDA012S4-1P

Low Speed

0.20

0.18

0.16

0.14

0.12

0.10

0.08

External Static Pressure - in. w.g.

0.06

0.04

0.02

0.00

160 260 360

Air Volume - cfm Air Volume - cfm

Medium Speed

0.20

0.15

0.10

External Static Pressure - in. w.g.

0.05

0.00

150 200 250 300 350 400

High Speed

0.30

0.25

0.20

0.15

0.10

External Static Pressure - in. w.g.

0.05

0.00

170 220 270 320 370 420 470

Air Volume - cfm

MMDA018S4-1P

Low Speed

0.16

0.14

0.12

0.10

0.08

0.06

External Static Pressure - in. w.g.

0.04

0.02

0.00

150 250 350 450

Air Volume - cfm Air Volume - cfm

Medium Speed

0.24

0.22

0.20

0.18

0.16

0.14

0.12

0.10

0.08

External Static Pressure - in. w.g.

0.06

0.04

0.02

0.00

130 230 330 430 530

High Speed

0.28

0.26

0.24

0.22

0.20

0.18

0.16

0.14

0.12

0.10

External Static Pressure - in. w.g.

0.08

0.06

0.04

0.02

0.00

150 250 350 450 550 650

Air Volume - cfm

Lennox Mini-Split Service Manual / Page 30

Page 31

MMDA024S4-1P

Low Speed

0.40

0.35

0.30

0.25

0.20

0.15

External Static Pressure - in. w.g.

0.10

0.05

0.00

260360460560660760860960

Air Volume - cfm Air Volume - cfm

Medium Speed

0.50

0.45

0.40

0.35

0.30

0.25

0.20

External Static Pressure - in. w.g.

0.15

0.10

0.05

0.00

250 450 650 850 1050

High Speed

0.45

0.40

0.35

0.30

0.25

0.20

0.15

External Static Pressure - in. w.g.

0.10

0.05

0.00

500 600 700 800 900 1000 1100 1200

Air Volume - cfm

MMDA036S4-1P

Low Speed

0.40

0.35

0.30

0.25

0.20

0.15

External Static Pressure - in. w.g.

0.10

0.05

Medium Speed

0.40

0.35

0.30

0.25

0.20

0.15

External Static Pressure - in. w.g.

0.10

0.05

High Speed

0.50

0.45

0.40

0.35

0.30

0.25

0.20

External Static Pressure - in. w.g.

0.15

0.10

0.05

0.00

400 500 600 700 800 900 1000 1100 1200

Air Volume - cfm Air Volume - cfm

0.00

600 700 800 900 1000 1100 1200 1300

0.00

400 600 800 1000 1200

Air Volume - cfm

Lennox Mini-Split Service Manual / Page 31

Page 32

MMDA048S4-1P,

Low Speed

0.40

0.35

0.30

0.25

0.20

0.15

External Static Pressure - in. w.g.

0.10

0.05

0.00

700 900 1100 1300 1500 1700

Air Volume - cfm Air Volume - cfm

Medium Speed

0.45

0.40

0.35

0.30

0.25

0.20

0.15

External Static Pressure - in. w.g.

0.10

0.05

0.00

700 900 1100 1300 1500

High Speed

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

External Static Pressure - in. w.g.

0.10

0.05

0.00

700 900 1100 1300 1500 1700

Air Volume - cfm

Lennox Mini-Split Service Manual / Page 32

Page 33

SECTION 2.4 - MWMA WALL MOUNTED UNIT

Lennox Mini-Split Service Manual / Page 33

Page 34

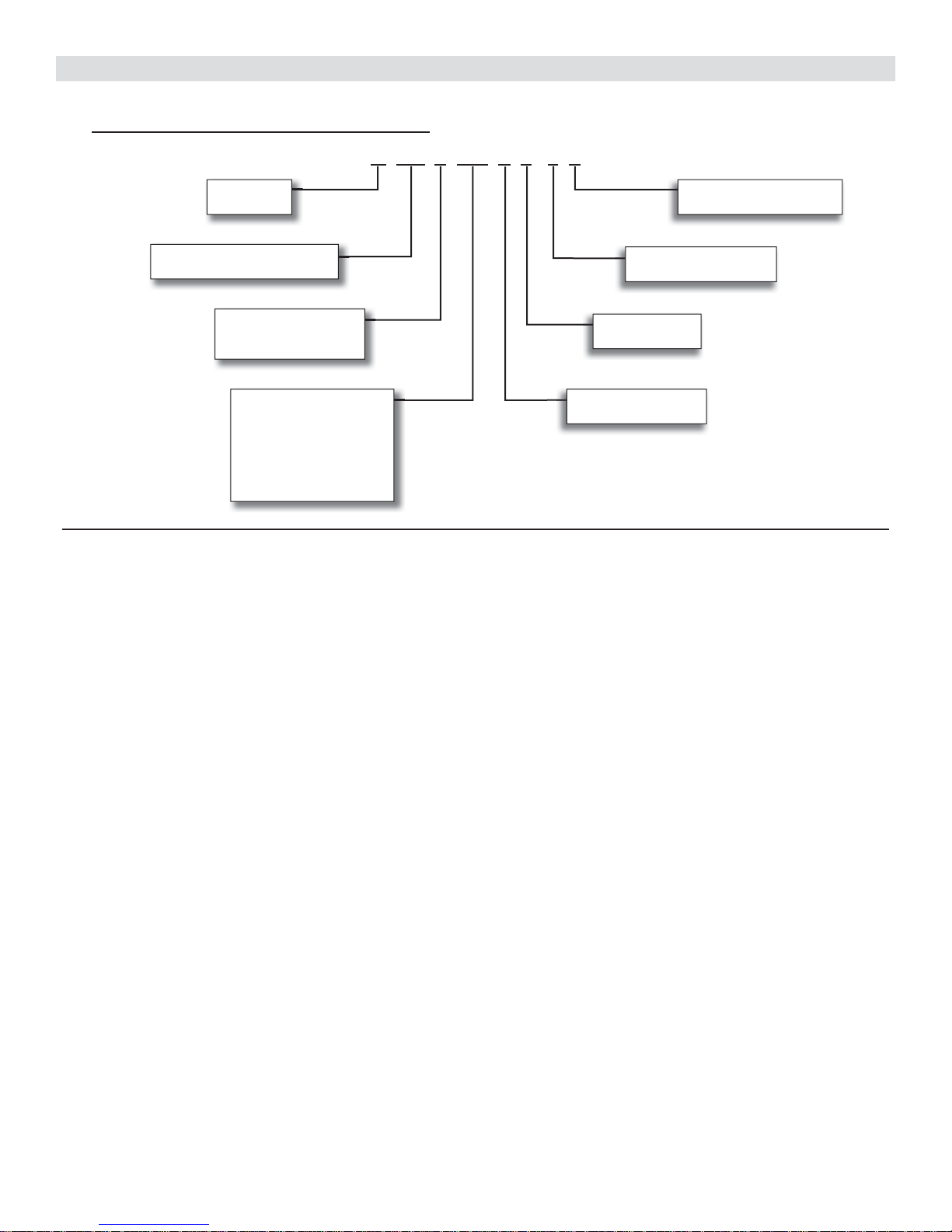

MODEL NUMBER IDENTIFICATION

WALL-MOUNTED INDOOR UNITS

M WM A 012 S 4 - 1 P

Series Type

M = Mini-Split

Unit Type

WM = Wall-Mounted Non-Ducted Unit

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Nominal Cooling Capacity

009 = .75 tons

012 = 1 tons

018 = 1.5 tons

024 = 2 tons

030 = 2.5 tons

Voltage

L = 115V-1 phase-60hz

P = 208/230V-1 phase-60hz

Minor Design Sequence

1 = 1st Revision

Refrigerant Type

4 = R-410A

Cooling Effi ciency

S = Standard Effi ciency

Lennox Mini-Split Service Manual / Page 34

Page 35

SPECIFICATIONS - WALL-MOUNTED INDOOR UNITS - 009-012

Model No. MWMA009S4-1L MWMA009S4-1P MWMA012S4-1L MWMA012S4-1P

Nominal Tons 0.75 0.75 1 1

Power Supply - 60 hz - 1 phase 115V 208/230V 115V 208/230V

Rated load amps 0.19 0.06 0.19 0.06

Output (W) 20 20 20 20

Air Volume - cfm (High/Medium/Low) 340/260/205 340/260/205 340/260/205 340/260/205

Sound Data (dBA) - Low/Medium/High 29/36.4/43.7 29.1/36.2/43.3 28.9/36.4/43.9 29.3/36.2/43

Piping Connections - Liquid/Gas - o.d. - fl are - in. 1/4 / 3/8 1/4 / 3/8 1/4 / 1/2 1/4 / 1/2

Drain connection o.d. - in. 1111

Net/Shipping weights - lbs. 20 / 26 20 / 26 20 / 26 20 / 26

SPECIFICATIONS - WALL-MOUNTED INDOOR UNITS - 018-030

Model No. MWMA018S4-1P MWMA024S4-1P MWMA030S4-1P

Nominal Tons 1.5 2 2.5

Power Supply - 60 hz - 1 phase 208/230V 208/230V 208/230V

Rated load amps 0.13 0.3 0.3

Output (W) 58 60 60

Air Volume - cfm (High/Medium/Low) 595/460/355 750/690/565 750/690/565

Sound Data (dBA) - Low/Medium/High 30.5/38.6/46.6 39.4/44.7/50 39/44.9/50.7

Piping Connections - Liquid/Gas - o.d. - fl are - in. 1/4 / 1/2 3/8 / 5/8 3/8 / 5/8

Drain connection o.d. - in. 1 1 1

Total refrigerant pipe length - ft. 98 98 164

Net/Shipping weights - lbs. 27 / 35 40 / 51 40 / 51

Lennox Mini-Split Service Manual / Page 35

Page 36

SECTION 2.5 - MCFA CEILING/FLOOR UNIT

Lennox Mini-Split Service Manual / Page 36

Page 37

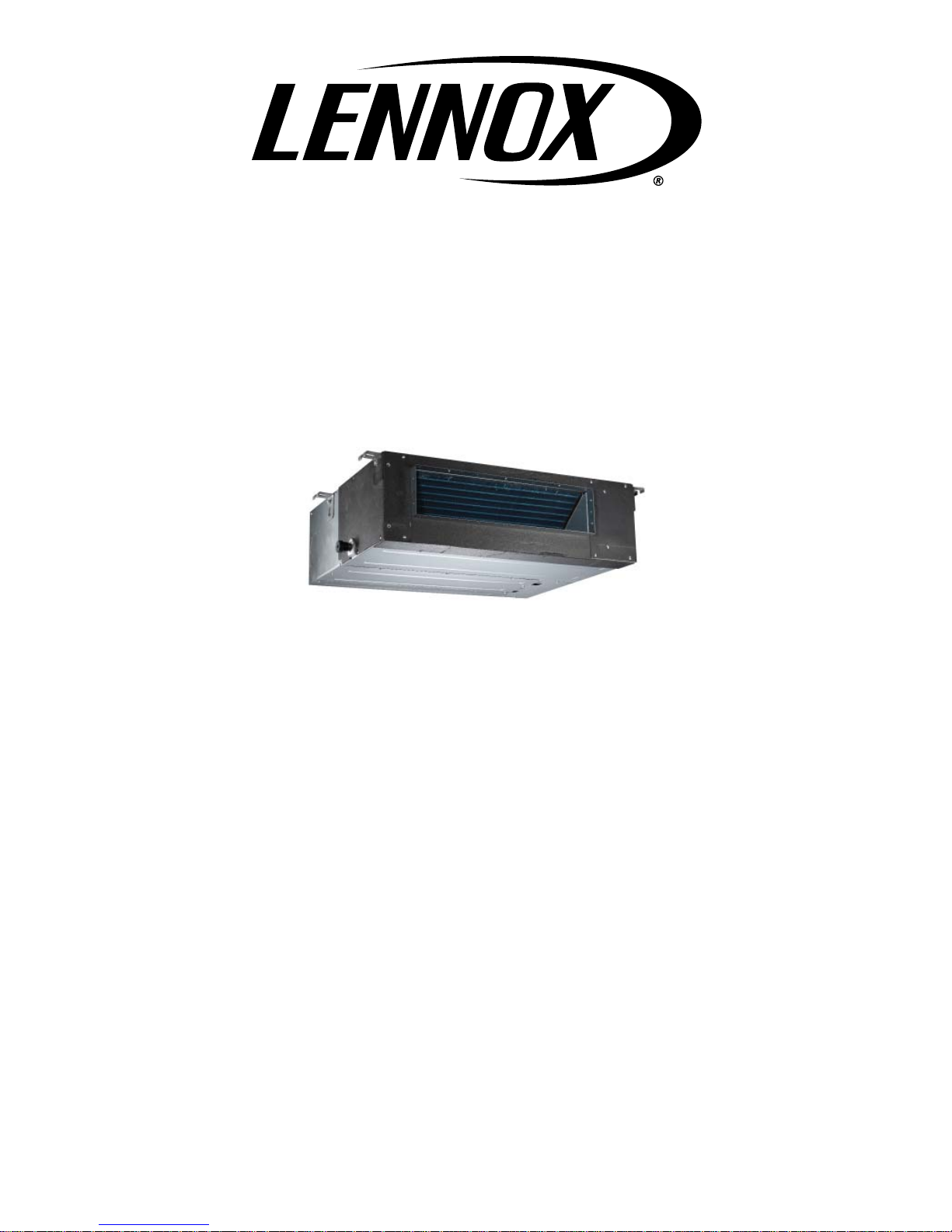

MODEL NUMBER IDENTIFICATION

CEILING/FLOOR NON-DUCTED INDOOR UNITS

M CF A 012 S 4 - 1 P

Series Type

M = Mini-Split

Unit Type

CF = Ceiling/Floor Non-Ducted

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Nominal Cooling Capacity

012 = 1 tons

018 = 1.5 tons

024 = 2 tons

036 = 3 tons

048 = 4 tons

Voltage

P = 208/230V-1 phase-60hz

Minor Design Sequence

1 = 1st Revision

Refrigerant Type

4 = R-410A

Cooling Effi ciency

S = Standard Effi ciency

Lennox Mini-Split Service Manual / Page 37

Page 38

SPECIFICATIONS - CEILING/FLOOR MOUNT INDOOR UNITS - 012-024

Model No. MCFA012S4-1P MCFA018S4-1P MCFA024S4-1P

Nominal Tons 1 1.5 2

Power Supply - 60 hz - 1 phase 208/230V 208/230V 208/230V

Rated load amps 1 1 1

Output (W) 55 55 55

Air Volume - cfm (High/Medium/Low) 470/360/290 470/360/290 880/770/650

Sound Data (dBA) - Low/Medium/High 33/38/44 34/38/46 52/55/58.5

Piping Connections - Liquid/Gas - o.d. - fl are - in. 1/4 / 1/2 1/4 / 1/2 3/8 / 5/8

Drain connection o.d. - in. 1 1 1

Net/Shipping weights - lbs. 47 / 61 53 / 67 56 / 67

SPECIFICATIONS - CEILING/FLOOR MOUNT INDOOR UNITS - 036-048

Model No. MCFA036S4-1P MCFA048S4-1P

Nominal Tons 3 4

Power Supply - 60 hz - 1 phase 208/230V 208/230V

Rated load amps 1 2

Output (W) 115 90

Air Volume - cfm (High/Medium/Low) 970/820/560 1350/1120/1000

Sound Data (dBA) - Low/Medium/High 41/48/55 52/54/57

Piping Connections - Liquid/Gas - o.d. - fl are - in. 3/8 / 5/8 3/8 / 5/8

Drain connection o.d. - in. 1 1

Net/Shipping weights - lbs. 67 / 78 84 / 97

Lennox Mini-Split Service Manual / Page 38

Page 39

SECTION 3 - INSTALLATION DIMENSIONS OF

OUTDOOR UNITS

Lennox Mini-Split Service Manual / Page 39

Page 40

SECTION 3.1 - SINGLE ZONE INSTALLATION

DIMENSIONS

Lennox Mini-Split Service Manual / Page 40

Page 41

MPA009S4S, MPA012S4S, MPA018S4S Dimensions

O

FRONT VIEW SIDE VIEW

2-1/2 (64)

31-7/8 (809)

21-5/8 (549)

22

(559)

TOP VIEW

FRONT VIEW

33-1/4 (845)

22 (559)

11-3/8 (289)

27-1/2

(699)

2-7/8 (73)

13-3/4 (349)

12-3/4 (324)

SIDE VIEW

P VIEW

T

13 (330)

12-3/4 (324)

Lennox Mini-Split Service Manual / Page 41

Page 42

MPA024S4S, MPA030S4S, MPA036S4S Dimensions

31-7/8

(810)

15-1/2

(394)

FRONT VIEW

37-1/4 (946)

25-1/4 (641)

TOP VIEW

3-3/8 (86)

16 (406)

15-1/8 (384)

17-5/8 (448)

SIDE VIEW

Lennox Mini-Split Service Manual / Page 42

Page 43

MPA048S4S Dimensions

25 (635)

15-3/8

(391)

14-1/2

(369)

36-7/8 (937)

TOP VIEW

16

(406)

3-3/8

(86)

53-3/4

(1365)

SIDE VIEW

FRONT VIEW

BOTTOM VIEW

SIDE VIEW

Lennox Mini-Split Service Manual / Page 43

Page 44

SECTION 3.2 - MULTI-ZONE INSTALLATION

DIMENSIONS

Lennox Mini-Split Service Manual / Page 44

Page 45

MPA018S4M Dimensions

MPA018S4M

12-3/4

(324)

22 (559)

TOP VIEW

12-1/4

(312)

27-3/8

(695)

13-1/8

(333)

14-1/8

(359)

33-1/8 (841) 2-3/4 (70)

FRONT VIEW SIDE VIEW

Lennox Mini-Split Service Manual / Page 45

Page 46

MPA030S4M, MPA036S4M Dimensions

31-7/8

(810)

15-1/2

(394)

FRONT VIEW

37-1/4 (946)

25-1/4 (641)

TOP VIEW

3-3/8 (86)

16 (406)

15-1/8 (384)

17-5/8 (448)

SIDE VIEW

Lennox Mini-Split Service Manual / Page 46

Page 47

MPA048S4M Dimensions

25 (635)

15-3/8

(391)

14-1/2

(369)

36-7/8 (937)

TOP VIEW

16

(406)

3-3/8

(86)

53-3/4

(1365)

SIDE VIEW

FRONT VIEW

BOTTOM VIEW

SIDE VIEW

Lennox Mini-Split Service Manual / Page 47

Page 48

SECTION 3.3 - MPA OUTDOOR UNIT

CLEARANCES

Lennox Mini-Split Service Manual / Page 48

Page 49

Outdoor Unit Clearances

A

C A

A

Air Inlet

A

B

Air Outlet

Air Inlet

A

C A

1

Dimension in. mm

1

Clearance dimensions apply to both single-fan cabinets and

double-fan cabinets.

2

Minimum rear clearance can be 6 inches (152 mm) when

mounted on brackets and with no obstructions on the other

three sides.

B

Air Outlet

A 24 610

B 79 2007

2

C 12 305

Lennox Mini-Split Service Manual / Page 49

Page 50

SECTION 4 - INSTALLATION DIMENSIONS OF

INDOOR UNITS

Lennox Mini-Split Service Manual / Page 50

Page 51

SECTION 4.1 - M22A COMPACT CASSETTE

Lennox Mini-Split Service Manual / Page 51

Page 52

M22A Indoor Cassette Units Dimensions

M22A009S4, M22A012S4, M22A018S4

DRAIN

CONNECTION

GAS

PIPE

LIQUID

PIPE

SIDE VIEW

10-3/8

(264)

5-3/4

(146)

6 in. (152 mm)

Diameter

LEFT SIDE VIEW

11-1/4

(286)

INSTALLATION

HANGERS

LEVELING

ADJUSTMENT

NUT (4)

CEILING

AIR

OUTLET

21-1/2 (546)

22-1/2 (572)

BOTTOM VIEW (Body)

DIFFUSER

PANEL

AIR

INLET

20-5/8

(524)

AIR

OUTLET

5-3/4

(146)

6 in. (152 mm)

Diameter

RIGHT SIDE VIEW

11-1/4

(286)

22-1/2

(572)

25-1/2

(648)

23-5/8 (600)

(Ceiling Opening)

SIDE VIEW

25-1/2 (648)

BOTTOM VIEW (Panel)

Lennox Mini-Split Service Manual / Page 52

Page 53

M22A Indoor Cassette Units Clearances

INSTALLATION

HANGERS

LEVELING

ADJUSTMENT

NUT (4)

CEILING

AIR

OUTLET

(914 mm)

DIFFUSER

36”

PANEL

AIR

INLET

23-5/8 (600)

(Ceiling Opening)

36”

(914 mm)

AIR

OUTLET

36”

(914 mm)

Minimum Clearance from Structural Ceiling to Drop Ceiling:

M22A009, M22A012, M22A018 -- 10-1/4” (260 mm)

Minimum Clearance to Floor - 98-1/2” (2500 mm)

36”

(914 mm)

Lennox Mini-Split Service Manual / Page 53

Page 54

SECTION 4.2 - M33A CASSETTE UNIT

Lennox Mini-Split Service Manual / Page 54

Page 55

M33A Indoor Units Dimensions

M33A024S4, M33A036S4, M33A048S4

GAS

PIPE

LIQUID

PIPE

30-3/4

(781)

A

33-1/8

(841)

DRAIN

CONNECTION

AIR

OUTLET

37-3/8

(949)

26-3/4 (679)

33-1/8 (841)

BOTTOM VIEW (Body)

DIFFUSER

PANEL

AIR

INLET

SIDE VIEW

RIGHT SIDE VIEW

AIR

OUTLET

BOTTOM VIEW (Panel)

37-3/8 (949)

Lennox Mini-Split Service Manual / Page 55

Page 56

M33A Indoor Units Clearances

INSTALLATION

HANGERS

LEVELING

ADJUSTMENT

NUT (4)

CEILING

AIR

OUTLET

DIFFUSER

PANEL

36”

(914 mm)

AIR

INLET

23-5/8 (600)

(Ceiling Opening)

36”

(914 mm)

AIR

OUTLET

36”

(914 mm)

Minimum Clearance from Structural Ceiling to Drop Ceiling:

Minimum Clearance to Floor - 98-1/2” (2500 mm)

36”

(914 mm)

M33A024 -- 10-1/4” (260 mm)

M33A036, M33A048 -- 13” (330 mm)

Lennox Mini-Split Service Manual / Page 56

Page 57

SECTION 4.3 - MMDA DUCTED UNIT

Lennox Mini-Split Service Manual / Page 57

Page 58

MMDA Indoor Units Dimensions

FRESH AIR INTAKE

3-5/8 (92) Diameter (015 thru 018)

5 (127) Diameter (024 thru 048)

SIDE VIEW

D

C

MOUNTING

LUGS (4)

MOUNTING

LUGS (4)

P

1 (25) 1 (25)

N

TOP VIEW

H

I

J

F

SUPPLY AIR

OPENING

G

A

E

FRONT VIEW

3/4 (19)3/4 (19)

ELECTRICAL

P

B

CONTROL

BOX

LIQUID

PIPE

GAS

PIPE

DRAIN

CONNECTION

OPTIONAL BOTTON

Size

RETURN AIR OPENING

M

BOTTOM VIEW

L

AIR FILTER

RETURN AIR

OPENING

K

REAR VIEW

ABCDEFGH

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm

AIR FILTER

ELECTRICAL

CONTROL

BOX

009 thru 012 27-5/8 702 8-1/4 210 25 635 22-1/2 572 31-1/8 791 2-5/8 67 19-1/2 495 1-3/8 35

018 36-1/4 921 8-1/4 210 25 635 22-1/2 572 39-3/4 1010 2-5/8 67 28 711 1-3/8 35

024 36-1/4 921 10-5/8 270 25 635 22-1/2 572 39-3/4 1010 2-5/8 67 28 711 1-3/8 35

036 44-7/8 1140 10-5/8 270 30-1/2 775 28 711 48-1/2 1232 2-5/8 67 36-3/4 933 1-3/8 35

048 47-1/4 1200 11-7/8 302 34-1/8 867 31-1/2 800 50-3/4 1289 3-1/8 79 38-1/8 968 1-1/2 38

Size

JKLMNP

in. mm in. mm in. mm in. mm in. mm in. mm

009 thru 012 4-5/8 117 23-1/2 597 7-7/8 200 3-1/8 79 29-1/8 740 13-3/4 349

018 4-5/8 117 32 813 7-7/8 200 3-1/8 79 37-3/4 959 13-3/4 349

024 7 178 32 813 10-1/4 260 3/4 19 37-3/4 959 13-3/4 349

036 7 178 40-3/4 1035 10-1/4 260 3/4 19 46-1/2 1181 19-1/4 489

048 8 203 43 1092 11-3/8 289 1-3/4 44 48-7/8 1241 19-5/8 498

Lennox Mini-Split Service Manual / Page 58

Page 59

MMDA Indoor Units Clearances

Wall

20” (508) Minimum Service Clearance

Wall

Air

DUCTED

UNIT

Flow

24” (610) Minimum Service Clearance

24” (610)

Minimum

Service

Clearance

TOP VIEW

Ceiling

1” (25 mm) Minimum Clearance

SIDE VIEW

Lennox Mini-Split Service Manual / Page 59

Page 60

SECTION 4.4 - MWMA WALL MOUNTED UNIT

Lennox Mini-Split Service Manual / Page 60

Page 61

MWMA Indoor Units Dimensions

MWMA009SA, MWMA012S4, MWMA018SA, MWMA024S4, MWMA030S4

TOP VIEW

B

Size

C

A

D

BOTTOM VIEW

ABCD

in. mm in. mm in. mm in. mm

SIDE VIEWSIDE VIEW

009, 012 32-7/8 835 11 279 29-1/4 743 7-7/8 200

018 39 991 12-3/8 314 34-3/4 883 8-5/8 219

024, 030 46-3/4 1187 13-1/2 343 42-1/2 1080 10-1/4 260

Lennox Mini-Split Service Manual / Page 61

Page 62

MWMA Indoor Units Clearances

Ceiling

6” (152 mm)

Minimum Clearance

Wall

Wall

5”

(127 mm)

Minimum

Vertical Clearance - Clearance to Floor - 72 inches (1829 mm) Minimum

96 inches (2438 mm) Recommended

Floor

FRONT VIEW

5”

(127 mm)

Minimum

Lennox Mini-Split Service Manual / Page 62

Page 63

SECTION 4.5 - MCFA CEILING/FLOOR UNIT

Lennox Mini-Split Service Manual / Page 63

Page 64

MCFA Indoor Units Dimensions

MCFA012S4, MCFA018S4

8

(203)

SIDE VIEW

Condensate Drain

Outlets (4) each corner

39 (991)

FRONT VIEW

BOTTOM VIEW

Mounting Brackets (2)

26

(660)

3/4 (19)

Refrigerant

1-5/8 (41)

Refrigerant

Piping Opening

4 x 4 (100 x 100)

(Furnished,

Field Installed)

Refrigerant

Piping

Piping

1-5/8 (41)

3/4 (19)

Refrigerant

Piping

Opening

4 x 4 (100 x 100)

35-3/4 (908)

BACK VIEW

7-7/8

(200)

7-1/8

(181)

MCFA024S4, MCFA036S4, MCFA048S4

26-5/8

(676)

9-1/4

(235)

FRONT VIEW

SIDE VIEW

Condensate Drain

Outlets (2) each side

BOTTOM VIEW

Model No.

024 42-1/8 1070 39 991

036 50-5/8 1286 47-3/8 1203

048 65 1651 61-3/4 1568

Refrigerant

Piping

2-3/8 (61)

Refrigerant

Piping Opening

3-1/2 x 7-1/4 (89 x 184)

2 (51)

Refrigerant

Piping

2-1/4 (57)

3-1/2 (89)

Refrigerant

Piping Opening

4-3/4 x 5-1/2 (121 x 140)

AB

in. mm in. mm

B

A

BACK VIEW

8-3/4

(222)

Lennox Mini-Split Service Manual / Page 64

Page 65

MCFA Indoor Units Clearances

3/4”

(19)

WALL

1”

(25.4)

WALL WALL

CEILING APPLICA TIONS

SIDE VIEW

CEILING AND FLOOR APPLICATIONS

DROP CEILING

SUPPLY

AIR

24

(610)

FRONT VIEW

24”

(610)

FLOOR APPLICA TIONS

Unit Flush with Wall

SUPPLY

AIR

24”

(610)

(Service Clearance

Front of Unit)

1”

(25.4)

SIDE VIEW

FLOOR

Lennox Mini-Split Service Manual / Page 65

Page 66

SECTION 5 - INDOOR UNIT COMBINATIONS

Lennox Mini-Split Service Manual / Page 66

Page 67

MULTI-ZONE SYSTEM COMBINATIONS

NOTE - For multi-zone systems, the total capacity of all indoor units must be 66% to 133% of the outdoor unit capacity.

Outdoor Unit

Model No.

Number

of

Zones

1

1 012 - - - - - - - - - - - - 11,977 - - - - - - - - - - - - 11,373 - - - - - - - - - - - -

Indoor Unit

Capacity

#1 #2 #3 #4 #5 #1 #2 #3 #4 #5 #1 #2 #3 #4 #5

009 009 - - - - - - - - - 9,000 9,000 - - - - - - - - - 9,250 9,250 - - - - - - - - -

MPA018S4M

2

009 012 - - - - - - - - - 8,379 10,313 - - - - - - - - - 8,538 10,508 - - - - - - - - -

012 012 - - - - - - - - - 9,450 9,450 - - - - - - - - - 9,735 9,735 - - - - - - - - -

1

1 018 - - - - - - - - - - - - 18,345 - - - - - - - - - - - - 19,730 - - - - - - - - - - - -

009 009 - - - - - - - - - 9,258 9,258 - - - - - - - - - 10,961 10,961 - - - - - - - - -

009 012 - - - - - - - - - 9,115 11,219 - - - - - - - - - 10,564 13,002 - - - - - - - - -

009 018 - - - - - - - - - 8,803 17,944 - - - - - - - - - 10,521 21,448 - - - - - - - - -

2

012 012 - - - - - - - - - 11,521 11,521 - - - - - - - - - 12,605 12,605 - - - - - - - - -

012 018 - - - - - - - - - 10,327 17,105 - - - - - - - - - 12,379 20,503 - - - - - - - - -

MPA030S4M

018 018 - - - - - - - - - 15,390 15,390 - - - - - - - - - 18,453 18,453 - - - - - - - - -

009 009 009 - - - - - - 8,915 8,915 8,915 - - - - - - 10,656 10,656 10,656 - - - - - -

009 009 012 - - - - - - 9,244 9,244 11,512 - - - - - - 10,234 10,234 12,596 - - - - - -

3

009 012 012 - - - - - - 8,681 10,684 10,684 - - - - - - 9,605 11,821 11,821 - - - - - -

009 009 018 - - - - - - 7,316 7,316 14,632 - - - - - - 8,197 8,197 16,394 - - - - - -

012 012 012 - - - - - - 9,755 9,755 9,755 - - - - - - 10,929 10,929 10,929 - - - - - -

009 018 - - - - - - - - - 8,788 17,913 - - - - - - - - - 9,540 19,447 - - - - - - - - -

012 012 - - - - - - - - - 10,287 10,287 - - - - - - - - - 11,864 11,864 - - - - - - - - -

2

012 018 - - - - - - - - - 10,052 16,649 - - - - - - - - - 10,913 18,074 - - - - - - - - -

018 018 - - - - - - - - - 17,200 17,200 - - - - - - - - - 18,240 18,240 - - - - - - - - -

009 009 009 - - - - - - 8,900 8,900 8,900 - - - - - - 9,476 9,476 9,476 - - - - - -

009 009 012 - - - - - - 8,265 8,265 10,172 - - - - - - 8,972 8,972 11,043 - - - - - -

009 009 018 - - - - - - 8,518 8,518 17,364 - - - - - - 9,033 9,033 18,414 - - - - - -

009 012 012 - - - - - - 9,228 11,357 11,357 - - - - - - 10,301 12,679 12,679 - - - - - -

009 012 018 - - - - - - 8,202 10,094 16,719 - - - - - - 8,347 10,273 17,015 - - - - - -

3

009 018 018 - - - - - - 7,640 15,575 15,575 - - - - - - 7,664 15,624 15,624 - - - - - -

MPA036S4M

012 012 012 - - - - - - 10,648 10,648 10,648 - - - - - - 11,886 11,886 11,886 - - - - - -

012 012 018 - - - - - - 9,901 9,901 16,399 - - - - - - 10,031 10,031 16,614 - - - - - -

012 018 018 - - - - - - 8,995 14,898 14,898 - - - - - - 9,175 15,197 15,197 - - - - - -

009 009 009 009 - - - 9,000 9,000 9,000 9,000 - - - 9,000 9,000 9,000 9,000 - - -

009 009 009 012 - - - 9,371 9,371 9,371 11,534 - - - 9,031 9,031 9,031 11,115 - - -

009 009 009 018 - - - 8,204 8,204 8,204 16,723 - - - 7,902 7,902 7,902 16,109 - - -

4

009 009 012 012 - - - 8,887 8,887 10,937 10,937 - - - 8,564 8,564 10,540 10,540 - - -

009 009 012 018 - - - 8,062 8,062 9,923 16,435 - - - 7,823 7,823 9,628 15,946 - - -

009 012 012 012 - - - 8,809 10,842 10,842 10,842 - - - 8,485 10,444 10,444 10,444 - - -

012 012 012 012 - - - 10,334 10,334 10,334 10,334 - - - 9,954 9,954 9,954 9,954 - - -

1

One outdoor unit may be matched with one indoor unit for single zone applications. A second indoor unit can be added at a later date for multi-zone applications.

Nominal Cooling Capacity at Rated

System Capacity (Btuh)

Nominal Heating Capacity at Rated

System Capacity (Btuh)

Lennox Mini-Split Service Manual / Page 67

Page 68

MULTI-ZONE SYSTEM COMBINATIONS

NOTE - For multi-zone systems, the total capacity of all indoor units must be 66% to 133% of the outdoor unit capacity.

Outdoor Unit

Model No.

Number

of

Zones

2

Indoor Unit

Capacity

#1 #2 #3 #4 #5 #1 #2 #3 #4 #5 #1 #2 #3 #4 #5

009 024 - - - - - - - - - 8,854 23,432 - - - - - - - - - 9,294 24,601 - - - - - - - - -

012 018 - - - - - - - - - 11,790 17,461 - - - - - - - - - 12,650 18,655 - - - - - - - - -

012 024 - - - - - - - - - 11,691 23,322 - - - - - - - - - 11,961 24,402 - - - - - - - - -

018 018 - - - - - - - - - 16,826 16,826 - - - - - - - - - 18,245 18,245 - - - - - - - - -

018 024 - - - - - - - - - 16,748 23,631 - - - - - - - - - 18,155 25,210 - - - - - - - - -

024 024 - - - - - - - - - 23,294 23,294 - - - - - - - - - 24,855 24,855 - - - - - - - - -

009 009 009 - - - - - - 9,294 9,294 9,294 - - - - - - 9,680 9,680 9,680 - - - - - -

009 009 012 - - - - - - 9,063 9,063 11,906 - - - - - - 9,565 9,565 12,750 - - - - - -

009 009 018 - - - - - - 8,952 8,952 17,965 - - - - - - 9,540 9,540 18,455 - - - - - -

009 009 024 - - - - - - 8,834 8,834 23,332 - - - - - - 9,235 9,235 24,505 - - - - - -

009 012 012 - - - - - - 9,027 12,089 12,089 - - - - - - 9,425 12,850 12,850 - - - - - -

Nominal Cooling Capacity at Rated

System Capacity (Btuh)

Nominal Heating Capacity at Rated

System Capacity (Btuh)

MPA048S4M

009 012 018 - - - - - - 9,001 11,636 17,334 - - - - - - 9,345 12,585 18,119 - - - - - -

009 012 024 - - - - - - 8,922 11,621 23,222 - - - - - - 9,330 11,950 24,395 - - - - - -

009 018 018 - - - - - - 8,844 17,193 17,193 - - - - - - 9,320 17,875 17,875 - - - - - -

009 018 024 - - - - - - 8,685 16,321 22,111 - - - - - - 9,220 16,675 22,660 - - - - - -

3

009 024 024 - - - - - - 8,421 21,121 21,121 - - - - - - 9,021 21,521 21,521 - - - - - -

012 012 012 - - - - - - 11,981 11,981 11,981 - - - - - - 12,648 12,648 12,648 - - - - - -

012 012 018 - - - - - - 11,945 11,945 17,021 - - - - - - 12,355 12,355 18,105 - - - - - -

012 018 018 - - - - - - 10,756 16,530 16,530 - - - - - - 11,550 18,035 18,035 - - - - - -

012 012 024 - - - - - - 11,583 11,583 23,111 - - - - - - 11,910 11,910 24,355 - - - - - -

012 018 024 - - - - - - 11,093 16,210 22,035 - - - - - - 11,755 16,545 22,580 - - - - - -

012 024 024 - - - - - - 9,900 20,768 20,768 - - - - - - 11,440 21,760 21,760 - - - - - -

018 018 018 - - - - - - 16,405 16,405 16,405 - - - - - - 17,170 17,170 17,170 - - - - - -

018 018 024 - - - - - - 15,383 15,383 20,270 - - - - - - 15,865 15,865 22,155 - - - - - -

1

One outdoor unit may be matched with one indoor unit for single zone applications. A second indoor unit can be added at a later date for multi-zone applications.

Lennox Mini-Split Service Manual / Page 68

Page 69

MULTI-ZONE SYSTEM COMBINATIONS

NOTE - For multi-zone systems, the total capacity of all indoor units must be 66% to 133% of the outdoor unit capacity.

Outdoor Unit

Model No.

Number

of

Zones

4

Indoor Unit

Capacity

#1 #2 #3 #4 #5 #1 #2 #3 #4 #5 #1 #2 #3 #4 #5

009 009 009 009 - - - 9,049 9,049 9,049 9,049 - - - 9,595 9,595 9,595 9,595 - - -

009 009 009 012 - - - 8,971 8,971 8,971 11,857 - - - 9,470 9,470 9,470 12,725 - - -

009 009 009 018 - - - 8,883 8,883 8,883 16,875 - - - 9,385 9,385 9,355 17,760 - - -

009 009 009 024 - - - 8,521 8,521 8,521 21,673 - - - 9,155 9,155 9,055 22,755 - - -

009 009 012 012 - - - 8,922 8,922 11,678 11,678 - - - 9,360 9,360 12,280 12,280 - - -

009 009 012 018 - - - 8,865 8,865 11,566 16,469 - - - 9,340 9,340 12,123 17,435 - - -

009 009 012 024 - - - 8,447 8,447 10,888 21,554 - - - 9,140 9,140 11,550 21,675 - - -

009 009 018 018 - - - 8,491 8,491 16,484 16,484 - - - 9,175 9,175 16,535 16,535 - - -

009 009 018 024 - - - 8,252 8,252 15,295 20,113 - - - 9,050 9,050 15,765 21,520 - - -

009 012 012 012 - - - 8,813 11,584 11,584 11,584 - - - 9,330 12,141 12,141 12,141 - - -

009 012 012 018 - - - 8,534 11,256 11,256 16,381 - - - 9,185 12,010 12,010 17,442 - - -

009 012 012 024 - - - 8,354 10,502 10,502 21,165 - - - 9,150 9,150 12,165 21,545 - - -

Nominal Cooling Capacity at Rated

System Capacity (Btuh)

Nominal Heating Capacity at Rated

System Capacity (Btuh)

009 012 018 018 - - - 8,398 10,643 16,371 16,371 - - - 9,155 11,650 16,465 16,465 - - -

MPA048S4M

012 012 012 012 - - - 11,381 11,381 11,381 11,381 - - - 12,035 12,035 12,035 12,035 - - -

012 012 012 018 - - - 10,697 10,697 10,697 16,611 - - - 11,755 11,755 11,755 16,550 - - -

012 012 012 024 - - - 10,130 10,130 10,130 20,666 - - - 11,210 11,210 11,210 20,155 - - -

012 012 018 018 - - - 10,115 10,115 15,774 15,774 - - - 11,240 11,240 16,235 16,235 - - -

009 009 009 009 009 9,000 9,000 9,000 9,000 9,000 9,800 9,800 9,800 9,800 9,800

009 009 009 009 012 8,814 8,814 8,814 8,814 11,729 9,534 9,534 9,534 9,534 12,862

009 009 009 009 018 8,672 8,672 8,672 8,672 16,753 9,355 9,355 9,355 9,355 16,825

009 009 009 009 024 8,295 8,295 8,295 8,295 19,032 9,095 9,095 9,095 9,095 19,535

009 009 009 012 012 8,687 8,687 8,687 11,079 11,079 9,305 9,305 9,335 12,325 12,325

5

009 009 009 012 018 8,486 8,486 8,486 10,849 15,598 9,105 9,105 9,105 12,025 16,325

009 009 012 012 012 8,501 8,501 11,387 11,387 11,387 9,213 9,213 11,870 11,870 11,870

009 009 012 012 018 8,457 8,457 10,815 10,815 14,253 8,933 8,933 10,967 10,967 15,870

009 012 012 012 012 8,550 10,414 10,414 10,414 10,414 8,525 11,525 11,525 11,525 11,525

012 012 012 012 012 10,306 10,306 10,306 10,306 10,306 11,055 11,055 11,055 11,055 11,055

1

One outdoor unit may be matched with one indoor unit for single zone applications. A second indoor unit can be added at a later date for multi-zone applications.

Lennox Mini-Split Service Manual / Page 69

Page 70

SECTION 6 - REFRIGERATION PIPE WORK

Lennox Mini-Split Service Manual / Page 70

Page 71

SECTION 6.1 - SINGLE ZONE REFRIGERANT

CYCLE DIAGRAM

Lennox Mini-Split Service Manual / Page 71

Page 72

Single Zone Refrigerant Cycle Diagram

ROODTUOROODNI

Indoor Coil

T2 Evaporator

temp. sensor

T1 Room temp.

sensor

LIQUID SIDE

2-WAY VALVE

GAS SIDE

3-WAY VALVE

CAPILIARY TUBE

Accumulator

Compressor

Electronic

expansion valve

T4 Ambient

temp. sensor

CAPILIARY TUBE

T3 Condenser

temp. sensor

Outdoor Coil

4-WAY VALVE

T5 Discharge

temp. sensor

COOLING

HEATING

Lennox Mini-Split Service Manual / Page 72

Page 73

SECTION 6.2 - MULTI-ZONE REFRIGERANT

CYCLE DIAGRAM

Lennox Mini-Split Service Manual / Page 73

Page 74

Two-Zone Refrigerant Cycle Diagram

temp. sensor

T3

Condenser

T4 Ambient

CHECK VALVE

CAPILIARY TUBE

Outdoor Coil

temp. sensor

4-WAY VALVE

temp. sensor

T5 Discharge

HEATING

COOLING

CAPILIARY A

EXV A

LIQUID VALVE A

CAPILIARY B

EXV B

LIQUID VALVE B

temp. sensor

T1 Room

Evaporator

temp. sensor outlet

T2B-A

T2B-B

GAS VALVE A

Compressor

Accumulator

GAS VALVE B

INDOOR OUTDOOR

Indoor Coil

temp. sensor

T2 Evaporator

middle

Lennox Mini-Split Service Manual / Page 74