Lennox Montebello MDLX40IN, Montebello MDLX45IP, Montebello MDLX40IP, Montebello MDLX45IN Installation Instructions Manual

Page 1

INSTALLATION INSTRUCTIONS

AVERTISSEMENT : Assurez-vous de bien suivre les

instructions données dans cette notice pour réduire au

minimum le risque d’incindie ou d’explosion ou pour

éviter tout dommage matériel, toute blessure ou la mort.

WARNING: If the information in these instructions

is not followed exactly, a fire or explosion may

result, causing property damage, personal injury,

or death.

WARNING /AVERTISSEMENT/AVISO

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

UNE SURFACE VITRÉE CHAUDE

PEUT CAUSER DES BRÛLURES.

LAISSER REFROIDIR LA SURFACE

VITRÉE AVANT D'Y TOUCHER.

NE PERMETTEZ JAMAIS À UN ENFANT

DE TOUCHER LA SURFACE VITRÉE.

EL VIDRIO CALIENTE

CAUSARÁ QUEMADURAS.

USTED DEBE NUNCA

TOCAR EL VIDRIO CALIENTE.

LOS NIÑOS DEBEN NUNCA

TOCAR EL VIDRIO.

- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire

department.

- Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

- Ne pas entreposer ni utilizer d’essence ni d’autres vapeurs

ou liquides inflammables dans le voisinage de cet appareil

ou de tout autre appareil.

- QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ :

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucan interrupteur. Ne pas vous servir des

téléphones se trouvant dans le bâtiment où vous trouvez.

• Appelez immédiatement votre fournisseur de gaz depuis

un voisin. Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de gaz,

appelez le service des incindies.

- L’installation et l’entretien doivent être assurés par un

installateur ou un service d’entretien qualifié ou par le

fournisseur de gaz.

Montebello® DLX

Direct Vent Gas Fireplaces

Intertek Report No.

100513650

P/N 506023-15 Rev. B 04/2013

This manual is one of a set of two supporting this product.

Refer to P/N 506025-07 for Care and Operation Instructions.

Ce manuel est disponible en francais, simplement

en faire la demande. Numéro de la pièce 506223-41.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

INSTALLATEUR : Laissez cette notice avec l'appareil.

CONSOMMATEUR : Conservez cette notice pour

consultation ultérieure.

This appliance may be installed in an aftermarket permanently located, manufactured home (USA only) or mobile

home, where not prohibited by local codes. This appliance is only for use with the type of gas indicated on the rating

plate. This appliance is not convertible for use with other gases unless a certified kit is used.

MODELS

MDLX40IN

MDLX40IP

Decorative Product: Not for use as a heating appliance.

NOTICE: Fireplace is not to be operated by a thermostat.

ELECTRONIC

MDLX45IN

MDLX45IP

Page 2

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

TABLE OF CONTENTS

Packaging ......................... 2

Introduction ........................ 2

General Information .................. 3

Massachusetts Requirements .......... 4

Cold Climate Insulation ............... 5

Manufactured Home Requirements ...... 5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Vent Termination Clearances ........... 6

Minimum Clearances to Combustibles ..... 8

Detailed Installation Steps ............. 9

Typical Installation Sequence .......... 9

Step 1. Framing .................... 9

Fireplace and Framing Specifications ...... 10

Step 2. Routing Gas Line ............. 11

Proper Sizing of Gas Line .............. 11

Step 3. Install the Vent System ........ 12

Vertical Termination Systems ........... 13

Vent Section Length Chart ............. 13

Vertical Vent Tables and Figures ......... 16

Horizontal Termination System ......... 17

Horizontal Vent Tables and Figures ...... 19

Step 4. Field Wiring ................. 21

Step 5. Removing Glass Door

Frame Assembly .................. 23

Step 6. Connecting Gas Line .......... 23

Step 7. Checking Appliance

Operation ........................ 23

Step 8. Installing Logs and Panels ...... 24

Step 9. Installing Glass Door .......... 26

Step 10. Burner Adjustments ........... 26

Finishing Requirements ............... 28

Step 11. Attaching Safety-in-

Operation Warnings ................ 29

Installation Accessories ............... 30

Gas Conversion Kits .................. 31

Please read and understand these

instructions before beginning your

installation.

PACKAGING

The assembled fireplace is packaged with the

following:

• Literature Kit (plastic bag shipped inside

rebox), containing Care and Operation

Instructions, Installation Instructions (this

manual), Safety-in-Operation Warning Labels, and Warranty.

• One (1) bag Glowing Embers

• One (1) bag Platinum Embers

• One (1) bag Volcanic Stone

• Pull Screen Kit

• Remote Control and Wall Receiver Switch

Kit

• Door Modesty Shield

• Log Grate

NOTE: For use with fireplace as shipped from fac-

tory only. Not for use with Contemporary Burner/

Floor Kit.

REQUIRED ACCESSORIES

The following accessories are required:

• One of the following Firebox Liner Kits:

a. Ceramic Firebox Liner Kit - Buff Rustic

b. Ceramic Firebox Liner Kit - Red Rustic

c. Porcelain Firebox Liner Kit - Black

d. Ceramic Firebox Liner Kit - Red Her-

ringbone

e. Ceramic Firebox Liner Kit - Buff Her-

ringbone

NOTE: Porcelain kits include side and back panels.

Optional for use with log sets. Required when

using the contemporary burner/floor kit.

• One of the following Floor Options:

a. Oak Log Set (For use with fireplace as

shipped from factory only. Not for use with

contemporary burner/floor kit.)

b. Contemporary Burner/Floor Kit

Contemporary Burner/Floor Kit requires

one of the following Media Kits:

i. Crushed Glass - Reective Black

ii. Crushed Glass - Platinum

iii. Crushed Glass - Reective Blue

iv. Crushed Glass - Goldfinger

v. Crushed Glass - Copper

NOTE

: The Contemporary Burner/Floor Kit instal-

lation and operation instructions are provided

with the kit, and are not detailed in this manual.

INTRODUCTION

The Montebello® DLX direct-vent, sealedcombustion gas fireplaces operate on natural

or propane gas. These appliances feature a

remotely controlled electronic intermittent pilot

ignition system (manual adjustment of the gas

valve settings is not possible).

The Montebello DLX is a decorative replace

and may not be installed and operated as the

primary heat source in a dwelling.

Electrical power (120 VAC line voltage) is rec-

ommended to operate the fireplace; however,

four (4) "AA" batteries can be used for full-time

operation or as a backup in case of a power

outage.

Approved Vent Components

These fireplaces are designed, tested, and

listed for operation and installation with Secure

Vent® direct vent system components (8" inner,

11" outer) manufactured by Security Chimneys

International.

These approved vent system components

are labeled for identification. USE ONLY AP-

PROVED VENT COMPONENTS. Do NOT use

any other manufacturer’s vent components

with these appliances.

Codes and Standards

These appliances comply with National Safety

Standards and are tested and listed by Intertek

(Report No. 100513650) to Z21.50 (in Canada,

CSA-2.22), and CAN/CGA-2.17-M91 in both

USA and Canada, as vented gas fireplaces.

These appliances are listed by Intertek for

installation in bedrooms and mobile homes.

Installation must conform to local codes. In

the absence of local codes, installation must

comply with the current National Fuel Gas

Code, ANSI Z223.1 (in Canada, the current

CAN/CGA-B149.1 installation code).

The appliance, when installed, must be electrically grounded in accordance with local codes

or, in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70 (latest

edition) or the Canadian Electrical Code, CSA

C22.1 (latest edition).

2

Page 3

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

WARNING

Young children should be carefully supervised when they are

in the same room as the appliance. Toddlers, young children

and others may be susceptible

to accidental contact burns. A

physical barrier is recommended

if there are at risk individuals in

the house. To restrict access to

a fireplace or stove, install an

adjustable safety gate to keep

toddlers, young children and

other at risk individuals out of

the room and away from hot

surfaces.

AVERTISSEMENT

Les jeunes enfants devraient être

surveillés étroitement lorsqu’ils

se trouvent dans la même pièce

que l’appareil. Les tout petits,

les jeunes enfants ou les adultes

peuvent subir des brûlures s’ils

viennent en contact avec la surface chaude. Il est recommandé

d’installer une barrière physique

si des personnes à risques habitent la maison. Pour empêcher

l’accès à un foyer ou à un poêle,

installez une barrière de sécurité; cette mesure empêchera les

tout petits, les jeunes enfants et

toute autre personne à risque

d’avoir accès à la pièce et aux

surfaces chaudes.

Children and adults should be alerted to the

hazards of high surface temperature and

should stay away to avoid burns or clothing

ignition.

Les enfants et les adultes devraient être

infor-més des dangers que posent les

températures de surface élevées et se

tenir à distance afin d’éviter des brûlures

ou que leurs vêtements ne s’enflamment.

DO NOT ATTEMPT TO ALTER OR MODIFY

THE CONSTRUCTION OF THE APPLIANCE OR

ITS COMPONENTS. ANY MODIFICATION OR

ALTERATION MAY VOID THE WARRANTY,

CERTIFICATION AND LISTINGS OF THIS UNIT.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause injury

or property damage. Refer to

this manual. For assistance or

additional information consult

a qualified installer, service

agency or the gas supplier.

WARNING

Failure to comply with these

installation instructions will result

in an improperly installed and

operating appliance, voiding its

warranty. Any change to this appliance and/or its operating controls

is dangerous.

WARNING

Clothing or other flammable

material should not be placed

on or near the appliance.

AVERTISSEMENT

On ne devrait pas placer de

vêtements ni d’autres matières

inflammables sur l’appareil ni à

proximité.

WARNING

Any safety screen or guard

removed for servicing the appliance must be replaced prior to

operating the appliance.

AVERTISSEMENT

Tout écran ou protecteur retiré

pour permettre l’entretien de

l’appareil doit être remis en

place avant de mettre l’appareil

en marche.

WARNING

Improper installation or use of

this appliance can cause serious

injury or death from fire, burns,

explosion or carbon monoxide

poisoning.

Installation and repair should be done by

a qualified service person. The appliance

should be inspected before use and at least

annually by a professional service person.

More frequent cleaning may be required due

to excessive lint from carpeting, bedding material, etcetera. It is imperative that control

compartments, burners and circulating air

passageways of the appliance be kept clean.

L’installation et la réparation devrait

être confiées à un technicien qualifié.

L’appareil devrait faire l’objet d’une inspection par un technicien professionnel

avant d’être utilisé et au moins une fois

l’an par la suite. Des nettoyages plus

fréquents peuvent être nécessaires si les

tapis, la literie, et cetera produisent une

quantité importante de pous-sière. Il est

essentiel que les compartiments abritant

les commandes, les brûleurs et les conduits de circulation d’air de l’appareil

soient tenus propres.

Do not use this appliance if any part has

been under water. Immediately call a

qualified service technician to inspect the

appliance and to replace any parts of the

control system and any gas control which

have been under water.

Ne pas se servir de cet appareil s'il a été

plongé dans l'eau, complètement ou en

partie. Appeler un technicien qualifié

pour inspecter l'appareil et remplacer

toute partie du système de contrôle et

toute commande qui ont été plongés

dans l'eau.

Only trim kit(s) supplied by the manufacturer

shall be used in the installation of this appliance.

Seules les trousses de garniture fournies

par le fabricant doivent être utilisées pour

l’installation de cet appareil.

Provide adequate clearances around air openings and adequate accessibility clearance for

service and proper operation. Never obstruct

the front openings of the appliance.

These appliances are designed to operate on

natural or propane gas only. The use of other

fuels or combination of fuels will degrade

the performance of this system and may be

dangerous.

These appliances must not be connected to a

chimney or flue serving a separate solid fuel

burning appliance.

3

Page 4

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

These electronic appliances are remotely

controlled and feature an electronic intermittent pilot ignition system or standing pilot.

External electrical power is required to operate

these units.

These electronic models come standard with a

remotely-modulated gas valve; flame appearance and heat output cannot be controlled at

the gas valve. The BTU Input for these appliances is shown in Table 1.

Input (BTU/HR)

Model No. Input (BTU/Hr)

Natural Gas

MDLX40IN 32,000 to 50,000

MDLX45IN 38,500 to 60,000

Propane Gas

MDLX40IP 32,000 to 50,000

MDLX45IP 38,500 to 60,000

Table 1

Gas Pressure - All Models

Appliance inlet and manifold gas pressure

requirements are listed in Tables 2 and 3.

Inlet Gas Supply Pressure

Fuel # Minimum Maximum

Natural

Gas

Propane

5.5" WC

(1.37 kPa)

11.0" WC

(2.74 kPa)

10.5" WC

(2.61 kPa)

13.0" WC

(3.23 kPa)

Table 2

Manifold Gas Supply Pressure

Fuel # Low High

Natural

Gas

Propane

1.6" WC

(.4 kPa)

6.3" WC

(1.57 kPa)

3.5" WC

(.87 kPa)

10.0" WC

(2.49 kPa)

Table 3

Orifice Sizes - Sea Level To High Altitude

(All Models)

These appliances are tested and approved

for installation at elevations of 0 - 4500 feet

(0 - 1372 meters) above sea level, using the

standard burner orifice sizes (marked with an

asterisk (*) in Table 4). For elevations above

4500 feet, contact your gas supplier or qualied

service technician.

Deration - At higher elevations, the amount

of BTU fuel value delivered must be reduced

by either:

• using gas that has been derated by the gas

company; or

• changing the burner orice to a smaller size

as regulated by the local authorities having

jurisdiction and by the (USA) National Fuel

Gas Code NFPA 54/ANSI Z223.1 - latest

edition or, in Canada, the CAN/CGA-B149.1

codes - latest edition.

Install the appliance according to the regulations

of the local authorities having jurisdiction and,

in the USA, the National Fuel Gas Code NFPA

54 / ANSI Z223.1 - latest edition or , in Canada,

the CAN/CGA-B149.1- latest edition.

NOTE: Flame appearance will diminish 4% per

thousand feet of altitude.

Burner Orifice Sizes

Elevation 0 - 4500 ft ( 0 - 1372 m)

Model Nat.Gas

drill size (inches)

MDLX40 0.1405" (#28)*

• H2286

MDLX45 0.154" (#23)*

• H8808

Table 4

* Standard size installed at factory

• Part /Cat. Number

Propane

drill size (inches)

0.086" (#44)*

• H2287

0.093" (#42)*

• H4816

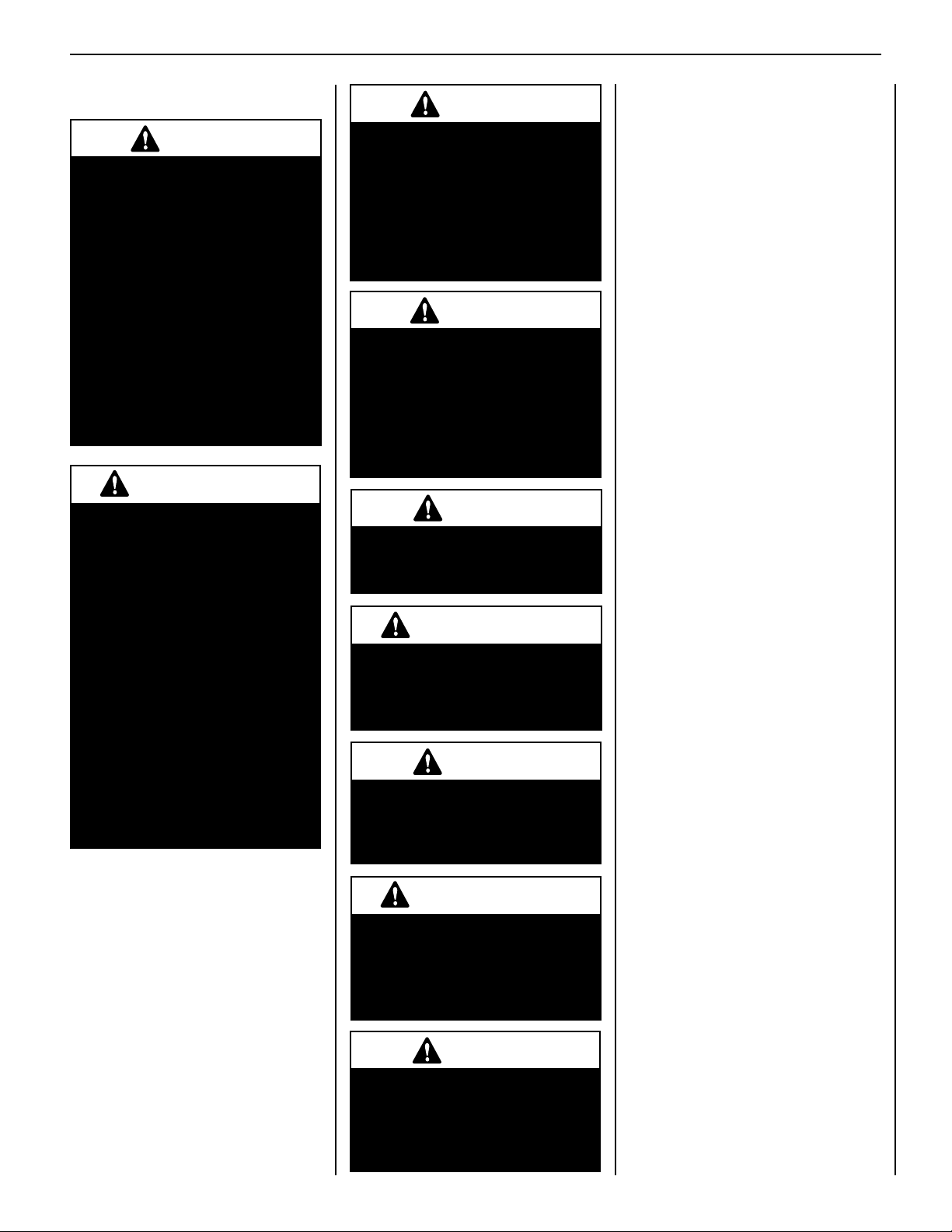

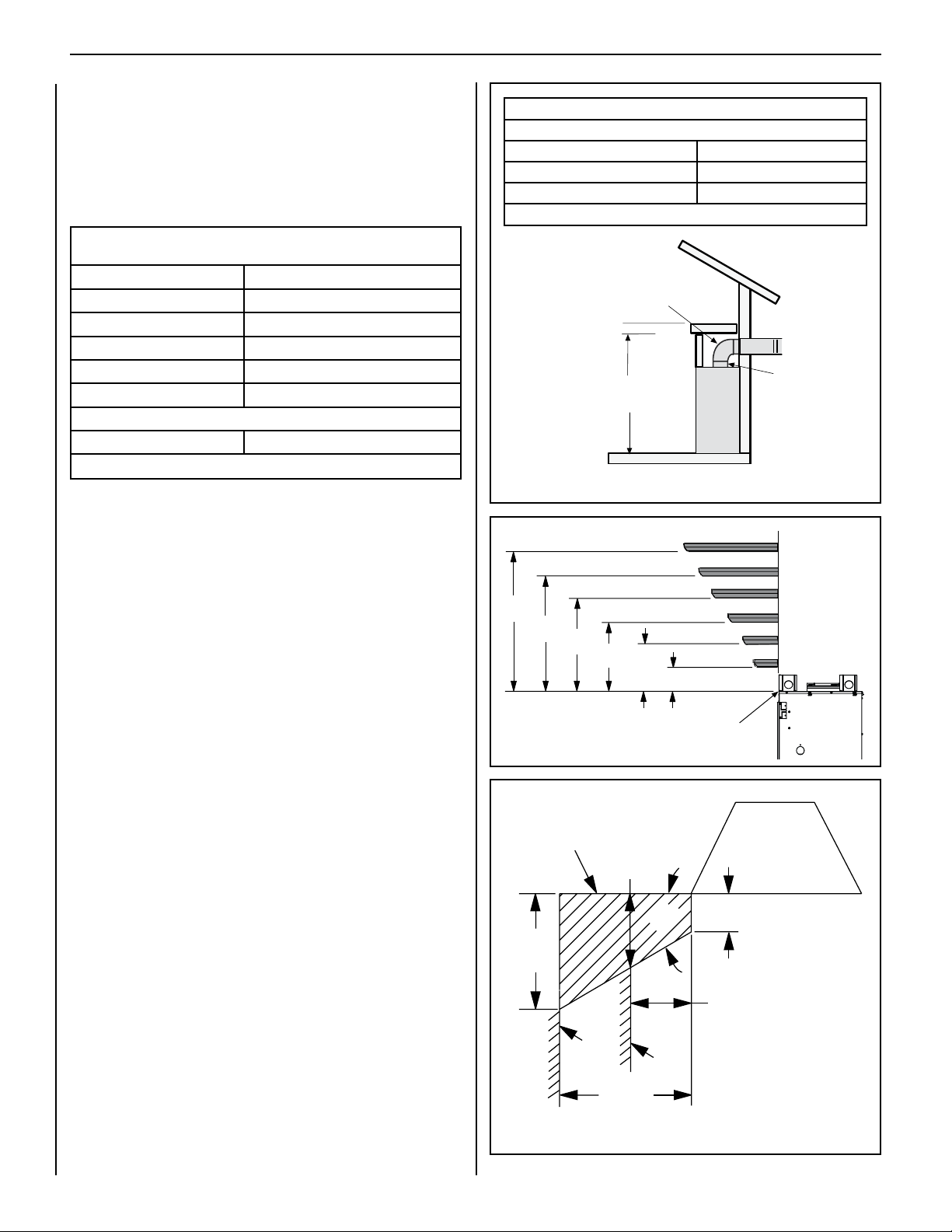

Gas Valve Diagram

The SIT Proflame gas valve is shown in Figure

1.

REQUIREMENTS FOR THE COMMONWEALTH OF MASSACHUSETTS

These fireplaces are approved for installation in

the US state of Massachusetts if the following

additional requirements are met:

• Install this appliance in accordance with

Massachusetts Rules and Regulations 248

C.M.R.

• Installation and repair must be done by a

plumber or gas fitter licensed in the Com-

monwealth of Massachusetts.

• The exible gas line connector used shall

not exceed 36 inches (92 centimeters) in

length.

• The individual manual shut-off must be a

T-handle type valve.

Massachusetts Horizontal Vent Requirements

In the Commonwealth of Massachusetts, horizontal terminations installed less than seven

(7) feet above the finished grade must comply

with the following additional requirements:

• A hard wired carbon monoxide detector

with an alarm and battery back-up must be

installed on the floor level where the gas

fireplace is installed. The carbon monoxide

detector must comply with NFPA 720, be

ANSI/UL 2034 listed and be ISA certied.

• A metal or plastic identication plate must

be permanently mounted to the exterior of

the building at a minimum height of eight (8)

feet above grade and be directly in line with

the horizontal termination. The sign must

read, in print size no less than one-half (1/2)

inch in size, GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS.

Test gauge connections are provided on the

front of the gas control valve (identified IN for

the inlet and OUT for the manifold side).

Propane tanks are at pressures that will cause

damage to valve components. Verify that the

tanks have step-down regulators to reduce the

pressure to safe levels.

The appliance and its appliance main gas

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas

supply piping system by closing its equipment

shutoff valve during any pressure testing of

the gas supply piping system at test pressures

equal to or less than 1/2 psi (3.5 kPa).

4

Green Wire

(From DFC Wire

Harness)

Manifold (Out)

Test Port

Inlet (In) Test Port

Wire

(From DFC Wire

Harness)

Main Gas Inlet

3/8" NPT

Figure 1 - SIT Proflame Valve

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Connect GTMS

Wire Harness

Pressure

Regulator

Tower

Yellow Ground Wire

(From DFC Wire

Harness)

Page 5

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

Drywall

Top Of Fireplace

Opening

Non-Combustible

HORIZONTAL VENT

VERTICAL VENT

HORIZONTAL VENT

VERTICAL VENT

COLD CLIMATE INSULATION

For cold climate installations, seal all cracks

around your appliance with noncombustible

material and wherever cold air could enter

the room. It is especially important to insulate

outside chase cavity between studs and under

floor on which appliance rests, if floor is above

ground level. Gas line holes and other openings

should be caulked or stuffed with unfaced

fiberglass insulation.

If the fireplace is being installed on a cement

slab in cold climates, a sheet of plywood or

other raised platform can be placed underneath

to prevent cold transfer to the fireplace and

into the room. It also helps to sheetrock inside

surfaces and tape for maximum air tightness

and caulk firestops.

MANUFACTURED HOME REQUIREMENTS

This appliance may be installed in an aftermarket

permanently located, manufactured home and

must be installed in accordance with the manu-

facturer's instructions and the Manufactured

Home Construction and Safety Standard, Title

24 CFR, Part 3280, in the United States, or the

Standard for Installation in Mobile Homes, CAN/

CSA Z240 MH Series, in Canada.

Cet appareil peut être installé cómme

du matéri-el d'origine dans une maison

préfabriquée (É.U. seulement) ou mobile

et doit être installé selon les instructions

du fabricant et conformément à la norme

Manufactured Home Constructions and

Safety, Title 24 CFR, Part 3200 aux Unis

ou à la norme Can/CSA-Z240 Série MM,

Maisons mobiles au Canada.

This appliance is only for use with the type of

gas indicated on the rating plate. This appliance

is not convertible for use with other gases, unless a certified kit is used.

Cet appareil doit être utilisé uniquement

avec le type de gaz indiqué sur la plaque

signalétique. Cet appareil ne peut être con-

verti à d'autres gaz, sauf si une trousse de

conversion est utilisée.

CAUTION: Ensure that the cross members

are not cut or weakened during installation. The structural integrity of the manufactured home floor, wall, and ceiling / roof

must be maintained.

When the unit is installed with one side flush with

a wall, the wall on the other side of the unit must

not extend beyond the front edge of the unit.

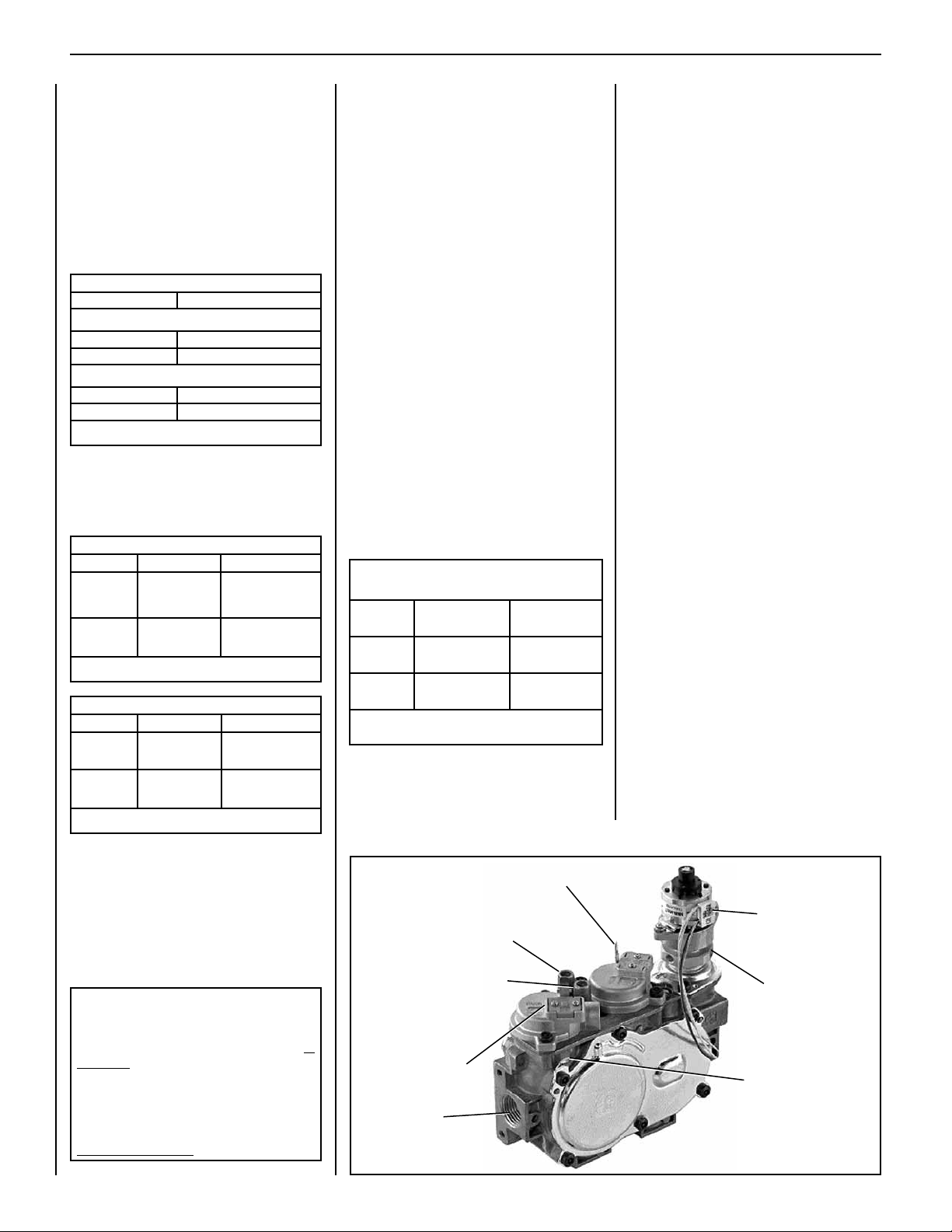

Figure 2 - Typical Installation

LOCATION

In selecting the location, the aesthetic and

functional use of the appliance are primary

concerns. However, vent system routing to

the exterior and access to the fuel supply are

also important.

Due to high temperatures, the appliance

should be located out of traffic and away from

furniture and draperies (Figure 2).

En raison des températures élevées,

l’appareil devrait être installé dans un

endroit où il y a peu de circulation et loin

du mobilier et des tentures (Figure 2).

The location should also be free of electrical,

plumbing or other heating/air conditioning

ducting.

These direct-vent appliances are uniquely

suited for installations requiring a utility shelf

positioned directly above the fireplace. Utility

shelves like these are commonly used for

locating television sets and decorative plants.

Cross Corner

Application

Room Divider

Application

Recessed

Application

Island

Application

Flat

Application

Application

Flat on Wall

Be aware that this is a heat producing appliance. Objects placed above the unit are

exposed to elevated temperatures.

Do not insulate the space between the

appliance and the area above it (see Figure

7 on Page 8).

The minimum height from the base of the

appliance to the underside of combustible

materials used to construct a utility shelf in

this fashion is shown in Figure 7 on Page 8.

The appliance must be mounted on a fully

supported base extending the full width

and depth of the unit. The appliance may be

located on or near conventional construction

materials. However, if installed on combustible

materials, such as carpeting, vinyl tile, or other

combustible material other than wood flooring,

the appliance shall be installed on a metal or

wood panel extending the full width and depth

of the appliance.

CAUTION: This appliance must be grounded to the chassis of the manufactured

home in accordance with local codes or

in the absence of local codes, with the

National Electrical Code ANSI / NFPA 70

- latest edition or the Canadian Electrical

Code CSA C22.1 - latest edition.

5

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 6

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

3"

(76 mm)

Termination Kit

Combustible Projection

greater than 2-1/2” in length

Horizontal Vent Termination Clearances

Combustible Projection

2-1/2” or less in length

24"

(610 mm)

Ventilated Or

Unventilated Soffit

12

X

Roof Pitch is X/12

2 FT

MIN.

2 FT MIN.

Lowest

Discharge

Opening

H*

*H = MINIMUM HEIGHT FROM ROOF TO

LOWEST DISCHARGE OPENING OF VENT

TERMINATION HEIGHTS FOR VENTS ABOVE

FLAT OR SLOPED ROOFS

Horizontal Overhang

Vertical

Wall

Vent

Termination

Storm Collar

Concentric

Vent Pipe

Flashing

1” (25.4 mm) Minimum

Clearance to Combustibles

VENT TERMINATION CLEARANCES

These instructions should be used as a

guideline and do not supersede local codes

in any way. Install vent according to local

codes, these instructions, the current National

Fuel Gas Code (ANSI-Z223.1) in the USA or

the current standards of CAN/CGA-B149.1 in

Canada.

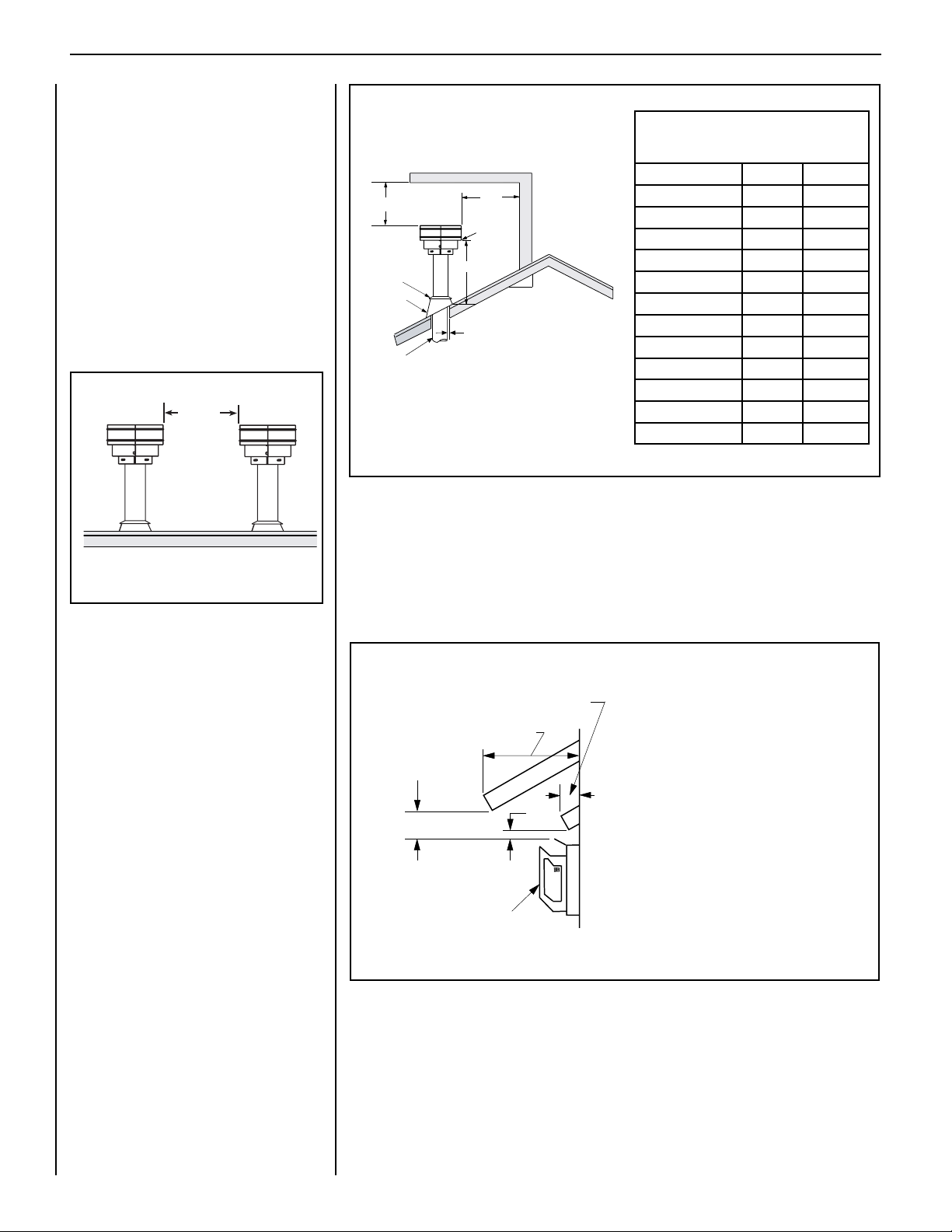

Vertical Vent Termination Clearances

Terminate multiple vent terminations according

to the installation codes listed above. Also see

Figure 3.

Terminate single vent caps relative to building

components according to Figures 3 and 4.

12”

(305mm)

Minimum

Vertical Vent Termination Clearances

The vent / air intake termination clearances

above the high side of an angled roof is as

shown in the following chart:

Figure 4

Termination Heights For Vents

Above Flat Or Sloped Roofs

Ref. NFPA 54 / ANSI Z223.1

Roof Pitch * Feet * Meters

Flat to 6/12 1.0 0.3

6/12 to 7/12 1.25 0.38

7/12 to 8/12 1.5 0.46

8/12 to 9/12 2.0 0.61

9/12 to 10/12 2.5 0.76

10/12 to 11/12 3.25 0.99

11/12 to 12/12 4.0 1.22

12/12 to 14/12 5.0 1.52

14/12 to 16/12 6.0 1.83

16/12 to 18/12 7.0 2.13

18/12 to 20/12 7.5 2.29

20/12 to 21/12 8.0 2.44

Figure 3 - Multiple Terminations

6

Horizontal Vent Termination Clearances

The horizontal vent termination must have a minimum of 3" (76 mm) clearance to any overhead

combustible projection of 2-1/2" (64 mm) or less (see Figure 5). For projections exceeding 2-1/2"

(64 mm), see Figure 5. For additional vent location restrictions refer to Figure 6 on Page 7.

See Figure 28 on Page 18 for the recess allowances, into

exterior walls, of the square horizontal terminations.

Figure 5 - Side Elevation View

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 7

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

NOTE: Local Codes Or Regulations May Require

Different Clearances.

NOTE: Location Of The Vent Termination Must Not

Interfere With Access To The Electrical Service.

3 ft.

X

A

3 ft.

Exterior Wall

Horizontal

Termination

B

V

L

X

= Air Supply Inlet

* See Item D in the Text Below.

*18”

24"

Inside Corner

Center Line

of Termination

18”

36"

DETAIL D

F

V

Ventilated Soffit

V

Fixed

Closed

Window

V

C

A

= Vent Terminal

V

Inside

Corner Detail

G

V

A

= 9" in U.S.

A

=12" in Canada

B

C

C

C

Operable

V

Window

B

B

= Area where Terminal is NOT permitted

B

A

J

Minimum Clearances Canadian Installation * US Installation **

A = Clearance above grade, veranda, porch, deck

or balcony.

B = Clearance to window or door that may be opened. 6" (15.2 cm) for appliances < 10,000 BTU/hr (3kW),

C = Clearance to permanently closed window 12" (305 mm) recommended to prevent window conden-

12" (30 cm) * 12" (30 cm) **

12" (30 cm) for appliances > 10,000 BTU/hr (3kW) and

< 100,000 BTU/hr (30kW), 36" (91 cm) for appliances >

100,000 BTU/hr (30kW)*

sation

H

E

D

M

I

X

V

K

6" (15.2 cm) for appliances < 10,000 BTU/hr (3kW),

9" (23 cm) for appliances > 10,000 BTU/hr (3kW) and

< 50,000 BTU/hr (15kW), 12" (30 cm) for appliances >

50,000 BTU/hr (15kW)*

9" (229 mm) recommended to prevent window con-

densation

V

D = Vertical clearance to ventilated soffit located

24" (61.0 cm) 24" (61.0 cm)

above the terminal within a horizontal distance of

36" (91.4cm) from the center line of the terminal

E = Clearance to unventilated soffit 24" (61.0 cm) 24" (61.0 cm)

F = Clearance to outside corner 5" (12.7 cm) 5" (12.7 cm)

G = Clearance to inside corner 36" (91.4 cm) 24" (61.0 cm)

H = Clearance to each inside of center line extended

above meter / regulator assembly

3 feet (91 cm) within a height of 15 feet above the meter /

regulator assembly *

3 feet (91 cm) within a height of 15 feet above the meter

/ regulator assembly **

I = Clearance to service regulator vent outlet 3 feet (91 cm) * 3 feet (91 cm) **

J = Clearance to non-mechanical air supply inlet

to building or the combustion air inlet to any other

appliance

6" (15.2 cm) for appliances < 10,000 BTU/hr (3kW), 12" (30

cm) for appliances > 10,000 BTU/hr (3kW) and < 100,000

BTU/hr (30kW), 36" (91 cm) for appliances > 100,000 BTU/

hr (30kW)*

6" (15.2 cm) for appliances < 10,000 BTU/hr (3kW), 9"

(23 cm) for appliances > 10,000 BTU/hr (3kW) and <

50,000 BTU/hr (15kW), 12" (30 cm) for appliances >

50,000 BTU/hr (15kW)*

K = Clearance to mechanical air supply inlet 6 feet (1.83 meters) * 3 feet (91 cm) above, if within 10 feet (3 m) horizontally**

L = Clearance above paved sidewalk or paved

7 feet (2.13 m) ‡ 7 feet (2.13 m) ‡

driveway located on public property

M = Clearance under veranda, porch, deck or

18" (46.0 cm) * ‡ 18" (46.0 cm) ** ‡

balcony

* In accordance with the current CAN/CGA-B149.1 National Gas and B149.2 Propane Installation Code - Latest Editions.

** In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Codes - Latest Edition.

‡ A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and serves both dwellings.

*‡ Only permitted if veranda, porch, deck or balcony is fully open on a minimum 2 sides beneath the oor.

Figure 6 - Exterior Horizontal Vent Termination Clearance Requirements

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

7

Page 8

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

17”

432 mm

14”

356 mm

8-1/4”

210 mm

45°

12”

305 mm

5”

127 mm

12 (305)

10 (254)

8 (203)

6 (152)

4 (102)

7

(178)

17

(432)

15

(381)

13

(330)

2 (51)

9

(229)

11

(279)

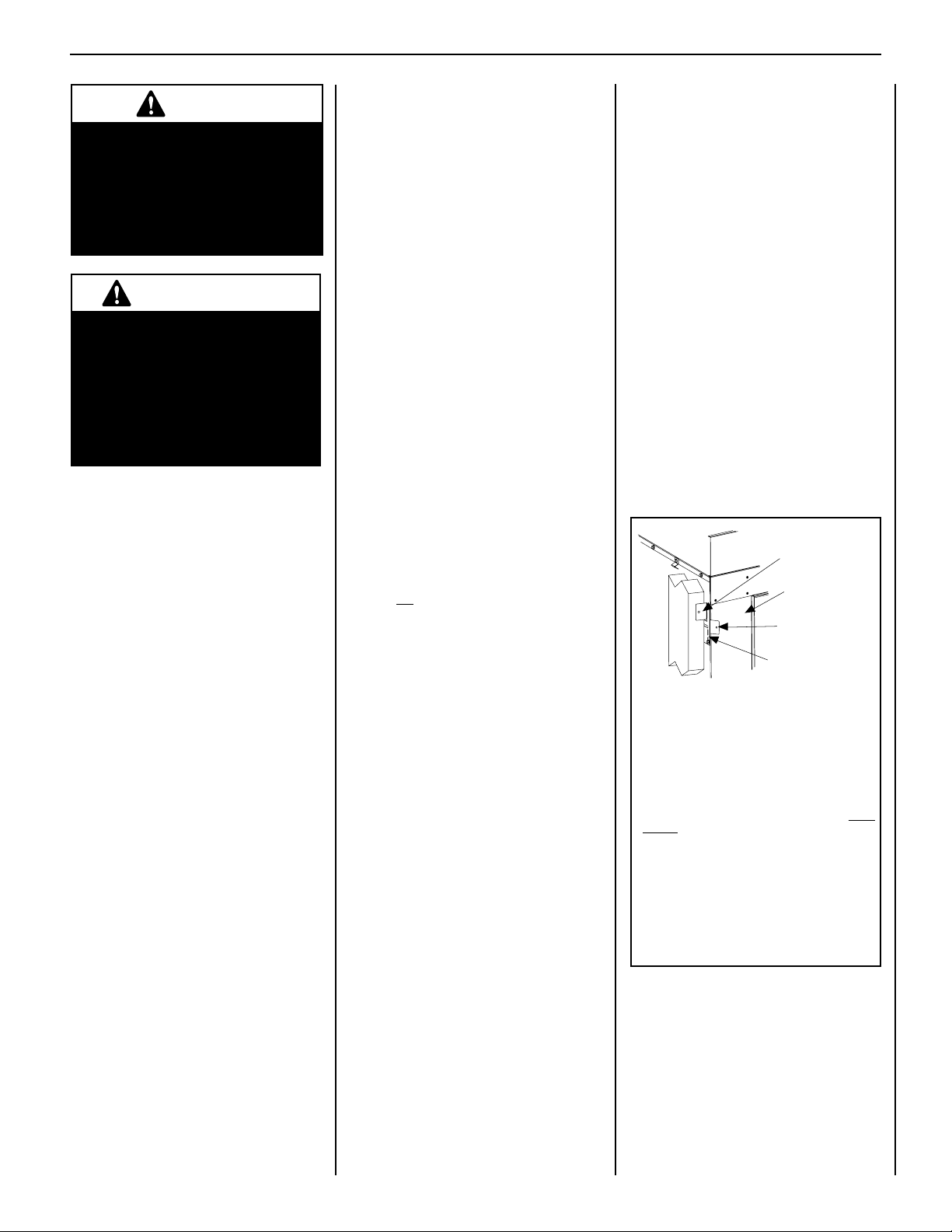

MINIMUM CLEARANCES TO COMBUSTIBLES

The appliance is approved with zero clearance to combustible materials

on all sides (as detailed in Table 5), with the following exception: When

the unit is installed with one side flush with a wall, the wall on the

other side of the unit must not extend beyond the front edge of the

unit. In addition, when the unit is recessed, the side walls surrounding

the unit must not extend beyond the front edge of the unit (see Figure 2).

APPLIANCE MINIMUM CLEARANCES*

Inches (millimeters)

Sides 1/2 (13), 0 (0) Spacers **

Top Spacers 0 (0)

Floor 0 (0)

Back 1/2 (13), 0 (0) Spacers

Bottom of Appliance To Ceiling 69 (1743)

Vent 3 (76)

Top * / 1 (25.4) Sides & Bottom

SERVICE CLEARANCES Feet (meters)

Front 3 feet (0.9 meters)

Table 5

Combustible Shelf Height -

Top Vent - with 2 Feet Vertical Vent and One 90 Degree Elbow

Model Secure Vent

MDLX40 *84-1/16 (2135)

MDLX45 *89-1/16 (2252)

* Includes 3" clearance to combustibles (required above vent components)

Do not insulate the

space between the

appliance and the

area above it.

Shelf Height

(see table)

Figure 7

Shelf Above Fireplace With Top Venting

Inches (millimeters)

®

2-1/2 ft

(to centerline)

Vertical

Vent (minimum)

*NOTE: 3" (75 mm) above any horizontal/inclined vent component.

**NOTE: See Page 9, Step 1 for clearance requirements to the nailing

flange located at each side of the unit and any screw heads adjacent

to it. See Page 28 for hearth extension requirements.

Shelf Height

To provide for the lowest possible shelf surface, the venting attached to

the top vent should be routed in a way to minimize obstructions to the

space above the appliance. Do not insulate the space between the ap-

pliance and the area above it (see Figure 7). The minimum height from

the base of the appliance to the underside of combustible materials used

to construct a utility shelf in this fashion is shown in Figure 7.

Wall Finishes / Surrounds / Mantels

NOTE: Combustible wall finish materials and/or surround materials must

not be allowed to encroach the area defined by the appliance front face

(black sheet metal). Never allow combustible materials to be positioned

in front of or overlapping the appliance face. See Figure 9 and Figure

51 on Page 28.

Non-combustible materials, such as surrounds and other appliance trim,

may be installed on the appliance front face with these exceptions: they

must not cover any portion of the removable glass panel.

Vertical installation clearances to combustible mantels vary according

to the depth of the mantel. See Figure 8. Mantels constructed of non-

combustible materials may be installed at any height above the appliance

opening. Minimum clearance requirements include any projections such

as shelves, window sills, mantels, etc. above the appliance.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

NOTE: We recommend the use of high temperature paint (rated 175° F

or higher) on the underside of the mantel.

8

Figure 8

Combustible Materials

Allowed In Shaded Area

"Safe Zone"

Side

Wall

Figure 9

Top of Appliance

Side

Wall

MANTEL

MANTEL

MANTEL

MANTEL

MANTEL

MANTEL

Top View of

Minimum Distance to

Protected Side Wall

Minimum Distance to

Unprotected Side Wall

CLEARANCES

Inches (mm)

Fireplace

(side view)

Fireplace

MANTEL

Page 9

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

WARNING

Failure to position the parts in

accordance with these diagrams

or failure to use only parts specifically approved with this appliance

may result in property damage or

personal injury.

AVERTISSEMENT

Risque de dommages ou de

blessures si les pièces ne sont

pas installées conformément à

ces schémas et ou si des pièces

autres que celles spécifiquement

approuvées avec cet appareil sont

utilisées.

DETAILED INSTALLATION STEPS

The appliance is shipped with all gas

controls and components installed and prewired.

1. Remove the shipping carton, exposing the

front glass door on the valve access side.

2. Using a Phillips screwdriver, unfasten two

(2) screws located at the top of the glass

frame (see Figure 46 on page 26). Tilt the

top of the glass frame away from the unit.

Lift it carefully off the bottom door track

and set the door aside, protecting it from

inadvertent damage.

TYPICAL INSTALLATION SEQUENCE

The typical sequence of installation is outlined

below. However, each installation is unique and

may result in variations to the steps described.

See the Page numbers references in the following steps for detailed procedures.

Step 1. (Page 9) Construct the appliance

framing. Position the appliance within

the framing and secure with nailing

brackets.

Step 2. (Page 11) Route gas supply line to the

right side.

Step 3. (Page 12) Install the vent system and

exterior termination.

Step 4. (Page 21) Connect 120 VAC electrical

power to the appliance receptacle.

Step 5. (Page 23) Remove glass door assem-

bly.

Step 6. (Page 23) Make connection to gas

supply.

Step 7. (Page 23) Verifying appliance opera-

tion.

Step 8. (Page 24) Install firebox liner panels,

logs, and glowing embers

OR

contemporary burner/floor kit, porce-

lain panels, and media.

Step 9. (Page 26) Install glass door assembly.

Step 10. (Page 26) Adjust burner to ensure

proper flame appearance.

Step 11. (Page 29) Attach safety in operation

warnings.

Step 1. FRAMING

Frame these appliances as illustrated in Figure

11 on Page 10, unless the appliance is to be

installed in a corner. See Figure 12 on Page

11 for corner framing installations. All framing

details must allow for a minimum clearance to

combustible framing members as shown in

Table 5 on Page 8.

If the appliance is to be elevated above floor

level, a solid continuous platform must be

constructed below the appliance.

Headers may be in direct contact with the

appliance top spacers but must not be supported by them or notched to fit around them.

All construction above the appliance must be

self-supporting, DO NOT use the appliance for

structural support.

The fireplace should be secured to the side

framing members using the unit's nailing

flanges - one top and bottom on each side of

the fireplace front (see Figure 10). Use 8d nails

or their equivalent.

Use Top Flange For

1/2” Thick Drywall

Front Of

Fireplace

Use Center Flange

For Flush Mount

Use Bottom Flange For

5/8” Thick Drywall

Left Side Front Corner of Fireplace Shown

(Right Side Requirements the Same)

Unit Being Secured By Its Nailing Flanges

To The Framing

NOTE: The nailing flanges, combustible members and

screw heads located in areas directly adjacent to

the nailing flanges, are EXEMPT from the 1/2” clearance to combustible requirements for the firebox

outer wrapper. Combustible framing may be in direct

contact with the nailing flanges and may be located

closer than 1/2” from screw heads and the firebox

wrapper in areas adjacent to the nailing flanges.

Frame the opening to the exact dimensions specified in the framing details of this manual.

Unit Being Secured by Its Nailing

Flanges to the Framing

Figure 10

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

9

Page 10

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

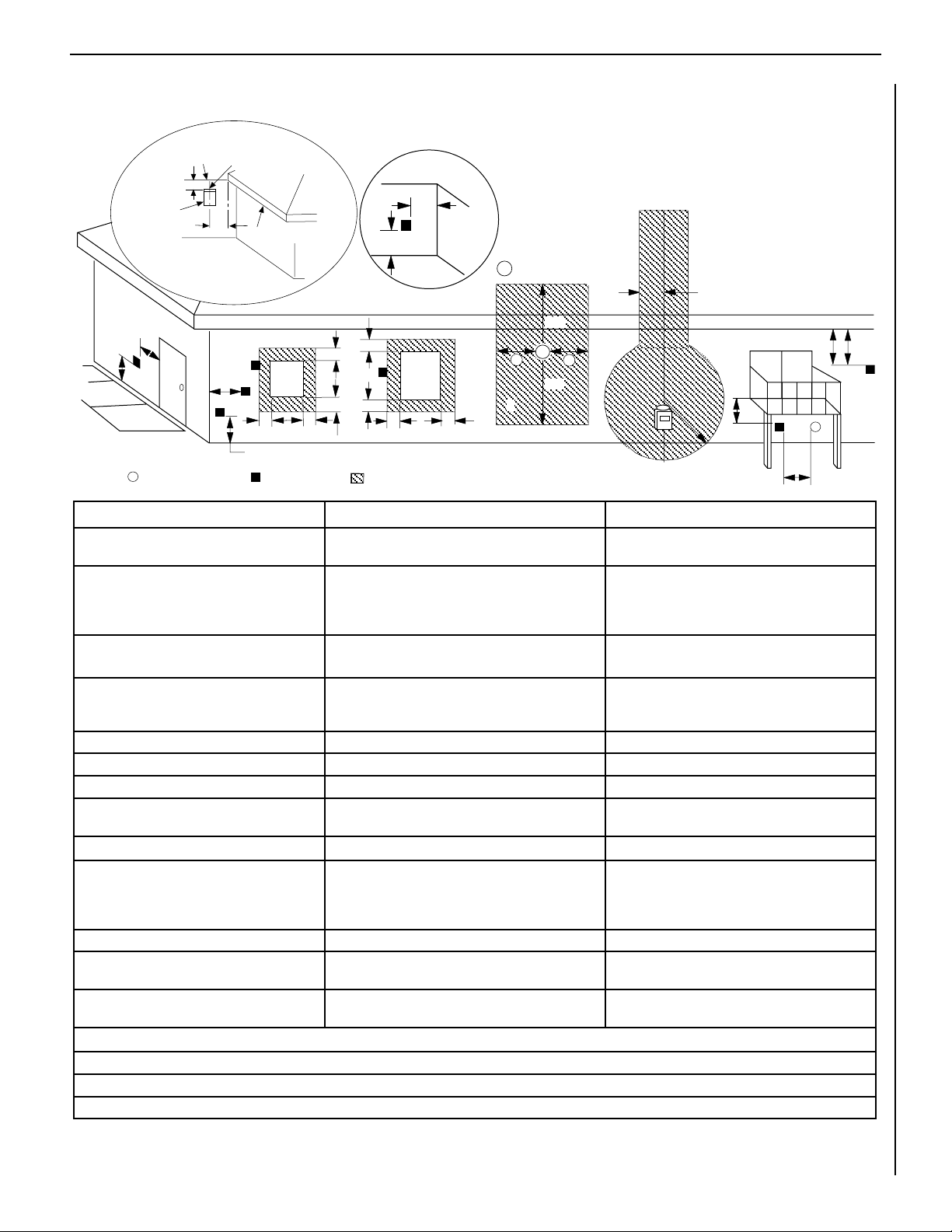

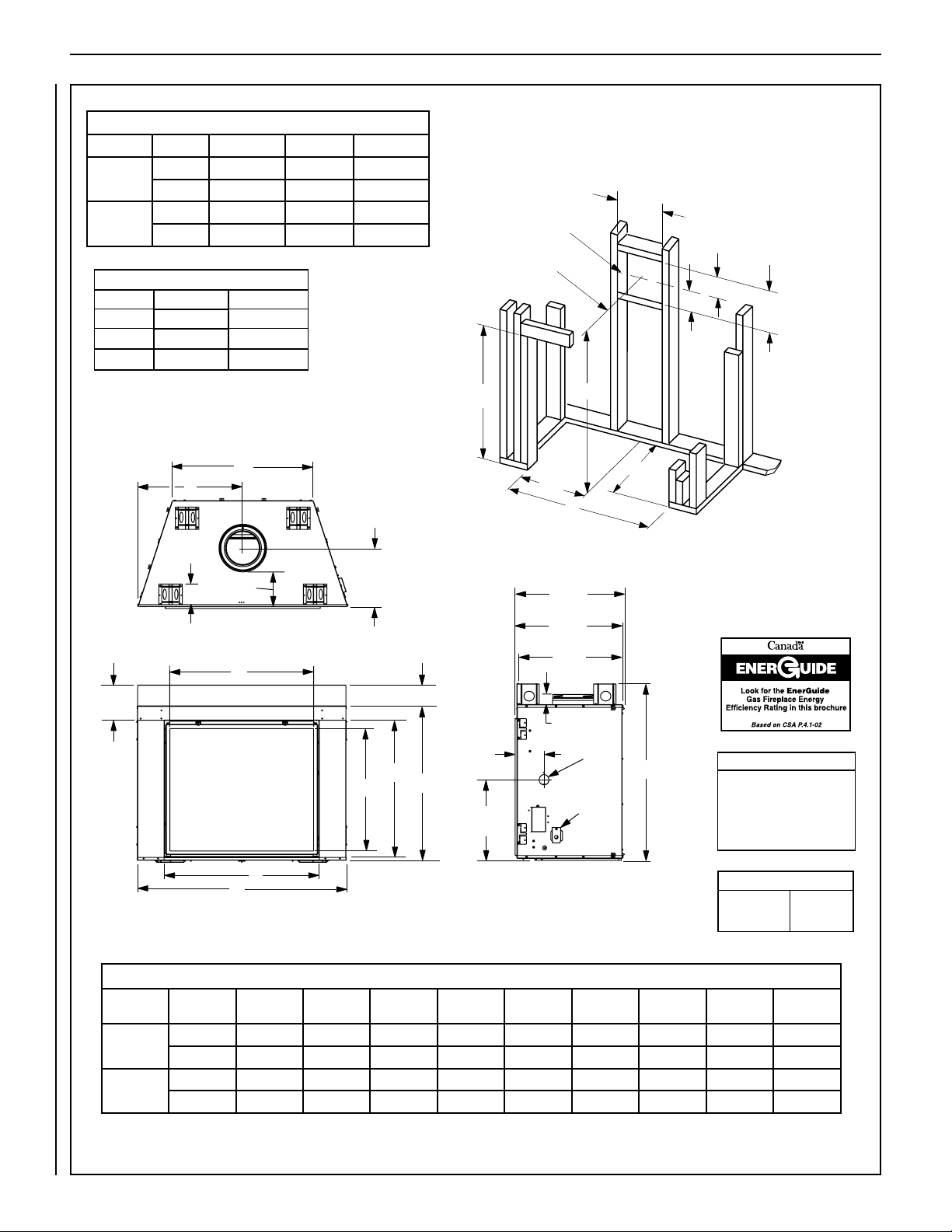

E

A

B

D

Top View

Front View

5-3/32 (129)

Right Side View

14-1/8

8-1/2”

(216)

5-1/4”

(133)

(359)

26-15/32

(672)

C

25-29/32

(658)

25-1/2

(648)

7

2-1/2 (64)

(178)

19-5/8

(498)

Gas Inlet

(This

Side

Only)

Electrical

Inlet

8-3/8

(213)

F

G

H

J

Framing should be constructed

of 2x4 or larger lumber.

A

B

C

8-1/2

(216)

13

(

330

)

VENT FRAMING

TOP VENT WITH 2 FEET

VERTICAL VENT AND

ONE 90° ELBOW

Framing should be constructed

of 2x4 or larger lumber.

Inches (mm)

(641)

25-1/4

15

(

381

)

6-1/2

(165)

1/2 A

PIPE CENTERLINE

Framing Dimensions

Models A B C

MDLX40

in. 50-3/4 43 75-1/8

mm 1289 1092 1908

MDLX45

in. 56-7/8 48 80-1/16

mm 1445 1219 2034

Thermal Efficiency (%)

Natural Gas Propane

Models P4 P4

MDLX40 35.8 TBD

MDLX45 51.2 TBD

MDLX40

MDLX45

Figure 11 - Fireplace and Framing Specifications

10

Model

No.

Notes

A B C D E F G H J

in. 50-5/8 37-1/4 42-7/8 25-5/16 34 37-5/8 33-3/32 29-9/32 34-3/4

mm 1286 946 1089 643 864 956 840 744 883

in. 56-11/16 42-1/4 47-7/8 28-3/8 40-1/8 43-5/8 38-3/32 34-1/2 40-59/64

mm 1440 1073 1216 721 1019 1108 968 876 1039

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Fireplace Dimensions

Diagrams, illustrations and photographs are not to scale - consult

installation instructions. Product

designs, materials, dimensions,

specifications, colors and prices are

subject to change or discontinuance

without notice.

Vent Size

Coaxial DV

Vent Size

8" Inner

11" Outer

Page 11

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

Right Side

Front Corner

Of Fireplace

Framing

6-1/4”

(159 mm)

19-5/8”

(498 mm)

C

Back wall of chase/enclosure

(including any finishing materials)

D

A

B

Model

No.

MDLX40

in. 50-5/8 83-5/8 59-1/8 41-7/8

A B C D

mm 1286 2124 1502 1064

MDLX45

in. 56-3/4 89-7/8 63-1/2 44-7/8

mm 1441 2283 1613 1140

Figure 12 - Corner Framing with Square Termination (SV8HTS)

Step 2. ROUTING GAS LINE

Route a 1/2" (13 mm) gas line along the inside

of the right side framing as shown in Figure

13. Gas lines must be routed, constructed and

made of materials that are in strict accordance

with local codes and regulations.

All appliances are factory-equipped with a

exible gas line connector and 1/2" shutoff

valve. (See Step 6 on Page 22).

The incoming gas line should be piped into the

valve compartment and connected in one of the

two methods as shown in Figure 36 on Page 23.

Figure 13

Proper Sizing of Gas Line

Properly size and route the gas supply line

from the supply regulator to the area where the

appliance is to be installed per requirements

outlined in the National Fuel Gas Code, NFPA

54 - latest edition (USA) or CAN/CGA-B149.1

- latest edition (Canada).

Never use galvanized or plastic pipe. Refer to

Table 6 for proper sizing of the gas supply

line, if black iron pipe is being used. Gas lines

must be routed, constructed and made of

materials that are in strict accordance with

local codes and regulations. We recommend

that a qualied individual such as a plumber

or gas fitter be hired to correctly size and route

the gas supply line to the appliance. Installing

a gas supply line from the fuel supply to the

appliance involves numerous considerations of

materials, protection, sizing, locations, controls,

pressure, sediment, and more. Certainly no one

unfamiliar and unqualied should attempt sizing

or installing gas piping.

Schedule 40 - Black Iron Pipe

Inside Diameter (Inches)

Schedule 40 Pipe

Length (feet)

0 - 10 1/2" 3/8"

10 - 40 1/2" 1/2"

40 - 100 1/2" 1/2"

100 - 150 3/4" 1/2"

150 - 200 3/4" 1/2"

Table 6

Natural

Gas

Propane

Gas

NOTES:

• All appliances are factory-equipped with a

exible gas line connector and 1/2" shutoff

valve (see Figure 36 on Page 23).

• See Massachusetts Requirements on Page

4 for additional requirements for installations

in the state of Massachusetts in the USA.

• The gas supply line should Not be connected

to the appliance until Step 6 (Page 23).

• A pipe joint compound rated for gas should be

used on the threaded joints. Ensure propane

resistant compounds are used in propane

applications. Be very careful that the pipe

compound does not get inside the pipe.

• It is recommended to install a sediment trap

in the supply line as close as possible to the

appliance (see Figure 36 on Page 23).

• Check with local building ofcial for local

code requirements.

IMPORTANT: If propane is used, be aware that

if tank size is too small (i.e. under 100 lbs, if

this is the only gas appliance in the dwelling.

Ref. NPFA 58), there may be loss of pressure,

resulting in insufficient fuel delivery (which

can result in sooting, severe delayed ignition

or other malfunctions). Any damage resulting

from an improper installation, such as this,

is not covered under the limited warranty.

11

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 12

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

RESTRICTOR

APPLIANCE VENT OUTLET

When vertically terminating the vent system above

the roof, install a vent restrictor in the top vent of

the fireplace outlet. Install the restrictor as shown

from inside the unit, in the inner fireplace collar

Step 3. INSTALL THE VENT SYSTEM

General Information

These instructions should be used as a guide-

line and do not supersede local codes in any

way. Install vent according to local codes,

these instructions, the current National Fuel

Gas Code (ANSI-Z223.1) in the USA or the

current standards of CAN/CGA-B149.1 and

-B149.2 in Canada.

Ensure clearances are in accordance with

local installation codes and the requirements

of the gas supplier.

Dégagement conforme aux codes

d'installation locaux et aux exigences du

foumisseunde gaz.

Use only approved venting components.

See Approved Vent Components on

Page 2.

These fireplaces must be vented directly

to the outside.

The vent system may not service multiple

appliances, and must never be connected to a

flue serving a separate solid fuel burning appliance. The vent pipe is tested to be run inside

an enclosing wall (such as a chase). There is

no requirement for inspection openings in the

enclosing wall at any of the joints in the vent pipe.

Installation of Vent Restrictor

A vent restrictor may be needed with this

appliance. The restrictor is installed in the

appliance top flue outlet as shown in Figure 14,

For vertical venting from 6 feet to 12 feet or

more, from the top of the fireplace to the top

of the termination, the installation of a vent

restrictor is required.

If necessary, install a vent restrictor in the

appliance flue outlet as shown in Figure 14. The

vent restrictor is held in place by friction, only.

NOTE: The restrictor is included within the

firebox.

Figure 14 - Vent Restrictor Installation

Select Venting System - Horizontal or Vertical

With the appliance secured in framing, determine vent routing and identify the exterior

termination location. The following sections

describe vertical (roof) and horizontal (exterior

wall) vent applications. Refer to the section

relating to your installation. A list of approved

venting components is shown on Page 30.

12

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 13

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

Termination

Flashing And

Storm Collar

Firestop/Spacer

SV8 6/12/24/36/48

Vent Sections

40' Max

(12.2 M)

6' Min

(1.8 M)

1" (25 mm)

Minimum

Clearance to

Combustibles

lanimoN

38

22

32

Hs

04

04

04

noitceSlanimoN

)sehcni(htgneL

621426384

T

O

T

A

L

Q

T

Y

noitceSteN

)sehcni(htgneL

2/1-42/1-012/1-222/1-432/1-64

tneVfothgieHsnoitceStneVforebmuN

sehcnitf

44121100034

0515.21010034

5.451578.21110035

5.061573.31020035

5.271573.41000505

77157.41100506

38152.51010506

6815.51000044

5.091578.51100045

5.691573.61010045

5.502521.71011507

70252.71000606

5.112526.71100607

5.712521.81010607

5.922521.91001607

5.232573.91000055

73257.91100056

5.142521.02000707

6425.02100708

25212010708

46222001708

67232000808

97252.32000066

5.082573.32100809

5.382526.32100

067

5.982521.42010067

5.103521.52001067

5.013578.52000909

5135.621009001

5.523521.72000077

0335.72100078

63382010078

54357.82000 01001

5.943521.92100 01011

27313000088

5.673573.13100089

5.973526.13000 11011

5.814578.43000099

32452.531000901

56457.8300000101

VERTICAL TERMINATION SYSTEMS (ROOF)

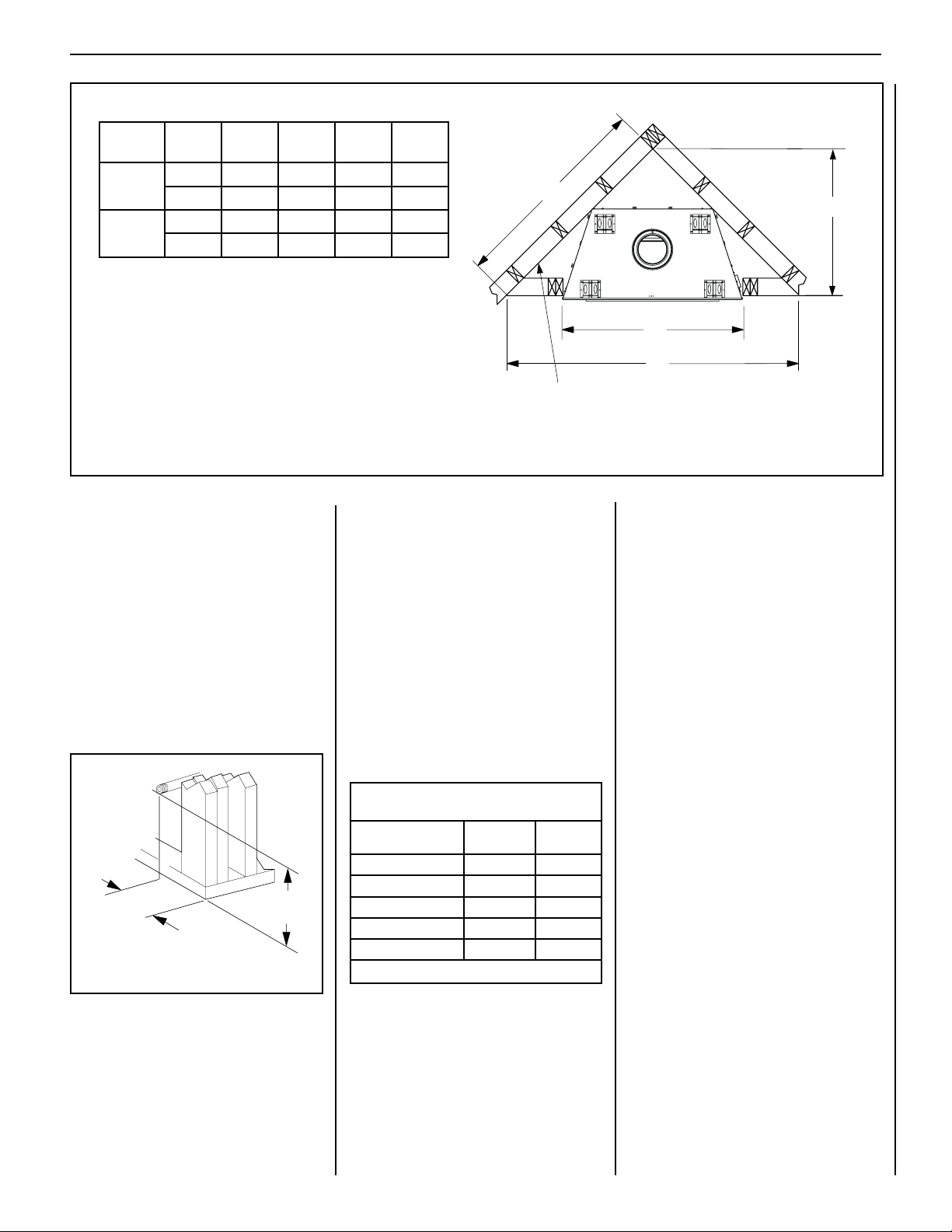

See Figure 15 and Figures 23 through 25 on

Page 16 and their associated Vertical Vent

Tables which illustrate the various vertical venting

configurations that are possible for use with these

appliances. Secure Vent

®

pipe applications

are shown in these figures. A Vertical Vent

Table summarizes each system’s minimum and

maximum vertical and horizontal length values

5.4573.0100001

957.0200002

5152.1110002

that can be used to design and install the vent

components in a variety of applications.

1257.1020002

The vertical vent system terminates through

the roof. The minimum vent height above the

roof and/or adjacent walls is specified in ANSI

Z223.1 - latest edition (In Canada, the current

CAN/CGA-B149.1 installation code) by major

building codes. Always consult your local

codes for specic requirements. A general

guide to follow is the Gas Vent Rule (refer to

Figure 4 on Page 6).

Vertical (Straight) Installation

(Figure 15)

Determine the number of straight vent sections

required. 4-1/2" (114 mm), 10-1/2" (267 mm),

22-1/2" (572 mm), 34-1/2" (876 mm) and

46-1/2" (1181 mm) net section lengths are

available (see Tables on this page and Page

30 - Vent Sections). Plan the vent lengths so

that a joint does not occur at the intersection of

ceiling or roof joists. Refer to the Vent Section

Length Chart.

Figure 15

5457.3002002

1552.4100012

7557.4001102

6652.5022004

9657.5000202

27610 30

1857.6000112

095.7021014

3957.7000022

69810 12

2015.8200024

80191003

4115.9020024

71157.9105006

6215.01001304

53152.11006006

8315.11000404

Table 7: Vent Section Length Chart

NOTE: Convert inches into metric equivalent

measurement, as follows:

Millimeters (mm) = Inches x 25.4

Centimeters (cm) = Inches x 2.54

Meters (M) = Inches x .0254

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

htgneLnoitceS

621426

)sehcni(

noitceSteN

2/1-42/1-012/1-2

)sehcni(htgneL

tneVfothgie

sehcnitf

5.01578.0010001

5.91526.12100

5.22578.1001001

5.52521.2120003

5.13526.2030003

5.43578.2000101

5.73521.3111003

5.34526.3021003

5.64578.3000011

5.94521.4102003

5.55526.4012003

5.76526.5003003

5.37521.6100203

5.97526.6010203

5.19526.7002013

5.79521.8100023

5.301526.8000303

5.811578.9110305

5.031578.01101305

5.931526.11000033

5.241578.11100405

4

/1-4

/1-64

noitceStneVforebmuN

0

T

O

T

A

L

Q

T

Y

3

Model Effective Length

SV8L6 4-1/2"

SV8L12 10-1/2"

SV8L24 22-1/2"

SV8L36 34-1/2"

SV8L48 46-1/2"

Table 8 - Effective Vent Length

13

Page 14

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

Minimum

13”

(330 mm)

Minimum

13”

(330 mm)

Vertical (Offset) Installation

Analyze the vent routing and determine the

quantities of vent sections and number of elbows

required. Refer to Vertical Vent Figures and

Tables on Page 16 to select the type of vertical

installation desired. Vent sections are available

in net lengths of 4-1/2" (114 mm), 10-1/2" (267

mm), 22-1/2" (572 mm), 34-1/2" (876 mm) and

46-1/2" (1181 mm). Refer to the Vent Section

Length Chart on Page 13 for an aid in select-

ing length combinations. Elbows are available

in 90° and 45° congurations. Refer to Figure

20 on Page 15 for the SV8 E45 and SV8 E90

elbow dimensional specifications.

Where required, a telescopic vent section

(SV8LA) may be used to provide the installer

with an option in installing in tight and confined

spaces or where the vent run made up of fixed

length pieces develops a joint in a undesirable

location, or will not build up to the required

length. The SV8LA Telescopic Vent Section has

an effective length of from 1-1/2" (38 mm) to

6-3/4" (171 mm). The SV8LA is tted with a

dimpled end (identical to a normal vent section

component) and a plain end with 3 pilot holes.

Slip the dimpled end over the locking channel

end of a standard SV8 vent component the

required distance and secure with three screws.

Maintain a minimum 1" (25 mm) clearance

to combustible materials for all vertical elements. Clearances for all horizontal elements

are 3" (76 mm) on top, 1" (25 mm) on sides

and 1" (25 mm) on the bottom.

A. Frame ceiling opening - Use a plumb line

from the ceiling above the appliance to locate

center of the vertical run. Cut and/or frame an

opening, 13" x 13" (330 mm x 330 mm) inside

dime nsions, about this center mark (Figure 16).

Roof

Framing

Ceiling

Framing

Plumb

Bob

Figure 16

B. Attach vent components to appliance Secure Vent

®

SV8 direct-vent system components are unitized concentric pipe components

featuring positive twist lock connections (see

Figure 17).

All of the appliances covered in this document

are fitted with collars having locking inclined

channels. The dimpled end of the vent components fit over the appliance collar to create the

positive twist lock connection.

Align the dimple (four places) of the

upper vent section with the opening

of the locking incline channel on the

lower vent section or appliance collar. Twist vent component clockwise

to engage and seal until arrow and

Arrow

Appliance Collar or

Vent Section

dimple align.

Dimple

Locking Incline

Channel

Connected Vent

Sections

Arrow

Figure 17

To attach a vent component to the appliance

collar, align the dimpled end over the collar,

adjusting the radial alignment until the four

locking dimples are aligned with the inlet of

the four inclined channels on the collar (refer

to Figure 17). Push the vent component against

the collar until it fully engages, then twist the

component clockwise, running the dimples

down and along the incline channels until they

seat at the end of the channels. The unitized

design of the Secure Vent components will

engage and seal both the inner and outer pipe

without the need for sealant or screws. If desired

a #6 x 1/2" screw may be used at the joint, but

it is not required as the pipe will securely lock

when twisted.

C. Attach vent components to each other - Other

vent sections may be added to the previously

installed section in accordance with the requirements of the vertical vent figures and tables.

To add another vent component to a length of

vent run, align the dimpled end over the inclined

channel end of the previously installed section,

adjusting the radial alignment until the four

locking dimples are aligned with the inlets of

the four incline channels of the previous section.

Push the vent component against the previous

section until it fully engages, then twist the

component clockwise running the dimples down

and along the incline channels until they seat at

the end of the channels. This seating position

is indicated by the alignment of the arrow and

dimple as shown in Figure 17.

D. Install firestop/spacer at ceiling - When

using Secure Vent, use SV8BF restop/spacer

at ceiling joists. If there is living space above

the ceiling level, the firestop/spacer must be

installed on the bottom side of the ceiling. If attic

space is above the ceiling, the firestop/spacer

must be installed on the top side of the joist.

Route the vent sections through the framed

opening and secure the firestop/spacer with

8d nails or other appropriate fasteners at each

corner. Remember to maintain 1" (25 mm)

clearance to combustibles, framing members,

and attic or ceiling insulation when running

vertical chimney sections. Attic insulation

shield (H3908) may be used to obtain the

required clearances indicated here. See

installation accessories on Page 30. The gap

between the vent pipe and a vertical firestop

can be sealed with non-combustible caulking.

E. Support the vertical vent run sections -

NOTE: Proper venting support is very important.

The weight of the vent must not be supported

by the fireplace in any degree.

Support the vertical portion of the venting

system every 8 feet (2.4 m) above the replace

vent outlet.

Blocking

Support Straps

(Plumber's tape)

8 feet (2.4 m)

Maximum

1" (25.4 mm)

minimum

clearance to

combustibles

Figure 18

14

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 15

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

C

D

Storm

Collar

One method of support is by utilizing field provided support straps (conventional plumber's

tape). Secure the plumber's tape to the framing

members with nails or screws. Strap the tape

around the vent, securing the ends of the tape

to the framing. If desired, sheet metal screws

#6 x 1/2" length may be used to secure the

support straps to the vent pipe. See Figure 18

on Page 14.

F. Change vent direction to horizontal/inclined

run - At transition from or to a horizontal/inclined

run, install the SV8 E45 and SV8 E90 elbows in

the same manner as the straight vent sections.

The elbows feature a twist section to allow them

to be routed about the center axis of their initial

collar section to align with the required direction of the next vent run element. Twist elbow

sections in a clockwise direction only so as

to avoid the possibility of unlocking any of

the previously connected vent sections. See

Figure 17 on Page 14 and Figure 19.

10"

(254mm)

Swivel Joint

(360° swivel)

SV8E45

(45° Elbow)

6"

(153mm)

Swivel Joint

(360° swivel)

SV8E90

(90° Elbow)

Figure 19

G. Continue installation of horizontal/inclined

sections - Continue with the installation of the

straight vent sections in horizontal/inclined run

as described in Step C. Install support straps

every 3 ft (914 mm) along horizontal/inclined

vent runs using conventional plumber’s tape.

See Page 17, Figure 26. It is very important

that the horizontal/inclined run be maintained in

a straight (no dips), slightly elevated plane. The

recommended incline is approximately 1/4" per

foot (20 mm per meter) horizontal, in a direction

away from the fireplace. The rise per foot run

ratios that are smaller are acceptable all the way

down to at or near level. Use a carpenter’s level

to measure from a constant surface and adjust

the support straps as necessary.

It is important to maintain the required clearances to combustibles: 1" (25 mm) at all sides

for all vertical runs; and 3" (76 mm) at the

top, 1" (25 mm) at sides, and 1" (25 mm) at

the bottom for all horizontal/inclined runs.

H. Frame roof opening - Identify location for

vent at the roof. Cut and/or frame opening per

Roof Framing Chart (Figure 20).

Framing Dimensions for Roof

Inches (millimeters)

Pitch C D

0/12

6/12

12/12

13"

(330 mm)

13"

(330 mm)

13"

(330 mm)

13"

(330 mm)

15-1/2"

(394 mm)

20-1/2"

(541 mm)

Figure 20 - Roof Framing

I. Install the roof flashing - Extend the vent

sections through the roof structure. Install the

roof flashing over the vent section and position such that the vent column rises vertically

(use carpenters level) (Figure 21). Nail along

perimeter to secure flashing or adjust roofing to

overlap the flashing edges at top and sides only

and trim where necessary. Seal the top and both

sides of the flashing with waterproof caulking.

J. Install the storm collar - Install the storm

collar, supplied with the flashing, over the vent/

flashing joint (see Figure 21). Loosen the storm

collar screw. Slide collar down until it meets

the top of the flashing. Tighten the adjusting

screw. Apply non-combustible caulking or

mastic around the circumference of the joint

to provide a water tight seal.

Storm

Flashing

Collar

Figure 21

K. Install the vertical termination - The final

step involves installation of the Vertical Termination. Extend the vent sections to the height as

shown in the "Vertical vent termination section"

on Page 6. The SV8VTR Vertical Termination

(Figure 22) can be installed in the exact same

fashion as any other Secure Vent® section. Align

the termination over the end of the previously

installed section, adjusting the radial alignment

until the four locking dimples of the termination

are aligned with the inlets of the four incline

channels of the last vent section. Push the termination down until it fully engages, then twist

the termination clockwise running the dimples

down and along the incline channels until they

seat at the end of the channels.

Figure 22

If the vent system extends more than 5 feet (1.5

m) above the roof ashing, stabilizers may be

necessary. Additional screws may be used at

section joints for added stability. Guide wires

may be attached to the joint for additional support on multiple joint configurations.

15

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 16

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

V

H

1

H

V

1

Ceiling

Firestop/Spacer

(SV8BF)

Wall

Firestop/Spacer

(SV8HF)

H

V

V1

Ceiling

Firestop/Spacer

(SV8BF)

40 feet (12.2 meters)

Maximum

6 feet (1.8 meters)

Minimum

Ceiling

Firestop/Spacer

(SV8BF)

VERTICAL VENT FIGURES/TABLES

Notes:

• SecureVent

the figures.

• It is very important that the horizontal/

inclined run be maintained in a straight

(no dips), slightly elevated plane. The

recommended incline is approximately

1/4" per foot (20 mm per meter) horizontal,

in a direction away from the fireplace. The

rise per foot run ratios that are smaller are

acceptable all the way down to at or near

level.

• SV8BF (Secure Vent) firestop/spacer must

be used anytime vent pipe passes through a

combustible floor or ceiling. SV8HF (Secure

Vent) firestop/spacer must be used anytime

vent pipe passes through a combustible wall.

• Two 45º elbows may be used in place of one

90º elbow. The same rise to run ratios, as

shown in the venting figures for 90º elbows,

must be followed if 45º elbows are used.

®

(rigid vent pipe) is shown in

Table A

H Maximum

feet (meter) feet (meter)

10 (3.1) 2.5 (0.762)

15 (4.65) 3.5 (1.07)

20 (6.2) 4.5 (1.37)

+ H = 40 feet (12.4 meters) Max.

V + V

V + V1 = 11 feet (3.3 meters) Minimum for MDLX40

V + V1 = 10.5 feet (3.2 meters) Minimum for MDLX45

1

Example: If 20 feet of (H) horizontal

vent run is needed, then 4-1/2 feet

minimum of (V) vertical vent will be

required.

A Vent Restrictor, as shown in

Figure 14 on Page 12, must be used

in this application.

V Minimum

A Vent Restrictor, as shown in Figure 15 on Page

12, may need to be used in this application

Figure 23 - Top Vent - Straight

Figure 24 - Top Vent - Two 90 Degree Elbows (Corner Framing with Square

Termination (SV8HTS))

Table B

H + H

Maximum

1

feet (meter) feet (meter)

10 (3.1) 2.5 (0.762)

15 (4.65) 3.5 (1.06)

20 (6.2) 4.5 (1.37)

H + H1 = 20 feet (6.2 m) Max.

V + V1 + H + H1 = 40 ft. (12.4 m) Max.

V + V1 = 11 feet (3.3 meters) Min. for MDLX40

V + V1 = 10.5 feet (3.2 meters) Min. for MDLX45

V Minimum

A Vent Restrictor, as

shown in

Figure 14 on Page 12,

must be used in this

application.

Example: If 20 feet of (H+ H

tal vent run is needed, then 4-1/2 feet

minimum of (V) vertical vent will be

required.

Figure 25 - Top Vent - Three Elbows

) horizon-

1

16

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 17

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

Support

HORIZONTAL (OUTSIDE WALL) TERMINATION

SYSTEM

See Figures 26 - 31 and their associated

Horizontal Vent tables that illustrate the various horizontal venting configurations that are

possible for use with these appliances. Secure

®

Vent

pipe applications are shown in these

Figures. A Horizontal Vent table summarizes

each system’s minimum and maximum vertical

and horizontal length values that can be used

to design and install the vent components in a

variety of applications.

The horizontal vent system terminates through

an outside wall. Building Codes limit or prohibit

terminating in specific areas. Refer to Figure 6

on Page 7 for location guidelines.

Secure Vent SV8 direct-vent system compo-

nents are unitized concentric pipe components

featuring positive twist lock connection, (refer

to Figure 17 on Page 14). All of the appliances covered in this document are fitted with

collars having locking inclined channels. The

dimpled end of the vent components fit over

the appliance collar to create the positive twist

lock connection.

A. Plan the vent run.

Analyze the vent routing and determine the

types and quantities of sections required

4-1/2" (114 mm), 10-1/2" (267 mm), 22-1/2" (572

mm), 34-1/2" (876 mm) and 46-1/2" (1181 mm) net

section lengths are available. It is recommended

that you plan the venting so that a joint does not

occur in the ceiling or roof joists. Allow for elbows

as indicated in Figure 20 on Page 15.

Maintain a minimum 1" (25 mm) clearance

to combustibles on the vertical sections.

Clearances for the horizontal runs are; 3"

(76 mm) on top, 1" (25 mm) on sides, and

1" (25 mm) at the bottom.

B. Frame exterior wall opening - Locate the

center of the vent outlet on the exterior wall

according to the dimensions shown in Figure

11 on Page 10. Cut and/or frame an opening,

15" x 13" (381 mm x 330 mm) inside dimensions, with 9" above center and 7" below center.

C. Frame ceiling opening - If the vertical

route is to penetrate a ceiling, use plumb line

to locate the center above the appliance. Cut

and/or frame an opening, 13" x 13" (330 mm x

330 mm) inside dimensions, about this center

(refer to Figure 17 on Page 14).

D. Attach vent components to appliance - To

attach a vent component to the appliance collar,

align the dimpled end over the collar, adjusting the radial alignment until the four locking

dimples are aligned with the inlets of the four

incline channels on the collar (refer to Figure

16 on Page 14).

Building

Support

Framing

SV8E90

Elbow

Vertical

Rise

Brackets

Ceiling

Firestop/Spacer

Support the vertical portion of the venting system

every 8 feet (2.4m) above the fireplace vent outlet.

Horizontal / Inclined Run

Support Bracket Spacing

Every 3 ft (914 mm)

2-1/2 Foot Vertical

Fireplace

Figure 26 - Typical Horizontal Vent Installation

Push the vent component against the collar

until it fully engages, then twist the component

clockwise, running the dimples down and along

the incline channels until they seat at the end of

the channels. The unitized design of the Secure

Vent components will engage and seal both the

inner and outer pipe elements with the same

procedure. Sealant and securing screws are

not required.

E. Attach vent components to each other - Other

vent sections may be added to the previously

installed section in accordance with the re-

quirements of the vent tables. To add another

vent component to a length of vent run, align

the dimpled end of the component over the

inclined channel end of the previously installed

section, adjusting the radial alignment until the

four locking dimples are aligned with the inlets

of the four incline channels of the previous

section. Push the vent component against the

previous section until it fully engages, then

twist the component clockwise running the

dimples down and along the incline channels

until they seat at the end of the channels. This

seating position is indicated by the alignment

of the arrow and dimple as shown in Figure

17 on Page 14.

F. Install firestop/spacer at ceiling - When

using Secure Vent, use SV8BF restop/spacer

at ceiling joists. If there is living space above

the ceiling level, the firestop/ spacer must be

installed on the bottom side of the ceiling. If

attic space is above the ceiling, the firestop/

spacer must be installed on the top side of

the joist. Route the vent sections through the

framed opening and secure the firestop/spacer

with 8d nails or other appropriate fasteners at

each corner.

Remember to maintain 1" (25 mm) clearance

to combustibles, framing members, and attic

or ceiling insulation when running vertical

chimney sections.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

SV8HTS

Termination

Shown

SV8 L6/12/24/36/48

Vent Sections

Vent (min.)

Exterior

Wall

SV8HTS

Termination

Shown

Exterior

Wall

G. Support the vertical run sections - See Step

E on Page 14.

H. Change vent direction - At transition from or

to a horizontal/inclined run, install the SV8E45

and SV8E90 elbows in the same manner as the

straight vent sections. The elbows feature a twist

section to allow them to be routed about the

center axis of their initial collar section to align

with the required direction of the next vent run

element. Twist elbow sections in a clockwise

direction only so as to avoid the possibility

of unlocking any of the previously connected

vent sections (see Figure 17 on Page 14).

I. Continue installation of horizontal/inclined

sections - Continue with the installation of the

straight vent sections in horizontal/inclined

run as described in Step E on Page 14. Install

support straps every 3 feet (1914 mm) along

horizontal/inclined vent runs using conventional

plumber’s tape.

See Figure 26, It is very important that the

horizontal/inclined run be maintained in a

straight (no dips), slightly elevated plane. The

recommended incline is approximately 1/4"

per foot (20 mm per meter) horizontal, in a

direction away from the fireplace. The rise per

foot run ratios that are smaller are acceptable

all the way down to at or near level.

It is important to maintain the required clearances to combustibles: 1" (25 mm) at all sides

for all vertical runs; and 3" (76 mm) at the

top, 1" (25 mm) at sides, and 1" (25 mm) at

the bottom for all horizontal/inclined runs.

Use a carpenter’s level to measure from a

constant surface and adjust the support straps

as necessary.

17

Page 18

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX DIRECT VENT GAS FIREPLACES (MDLX40/45) • INSTALLATION INSTRUCTIONS

Siding

Stucco

1-1/4” Maximum Recess of

Square Termination into

Exterior Finishing Material

Exterior Surface of

Framing

5” to 8-1/2”

(127 to 216 mm)

Exterior Surface of Siding

Minimum wall thickness

5” (127 mm)

Interior Surface of

Finished Wall

Maximum wall thickness

8-1/2” (216 mm)

SV8HTS

Square Termination

shown

Maximum Extent of Vent

Run Sections to Exterior

Surface of Framing

Last Vent Section. Use

Telescopic Vent Section

(SV8LA), If Necessary

Adaptor

SV8RCH

SV8HTS

Square Termination

Shown

Venting Connection and Exterior Wall Recessing

of the Horizontal Square Termination (SV8HTS).

J. Assemble vent run to exterior wall - If not

previously measured, locate the center of the

vent at the exterior wall. Prepare an opening as

described in Step B on Page 17. Assemble the

vent system to point where the terminus of the

last section is within 5" (127 mm) to 8-1/2" (216

mm) inboard of the exterior surface to which

the SV8HTS termination is to be attached, see