Lennox ML193UH045P36B, ML193UH090P36C, ML193UH070P36B, ML193UH110P48C, ML193UH110P60C Unit Information

...Page 1

Corp. 1025−L5

Service Literature

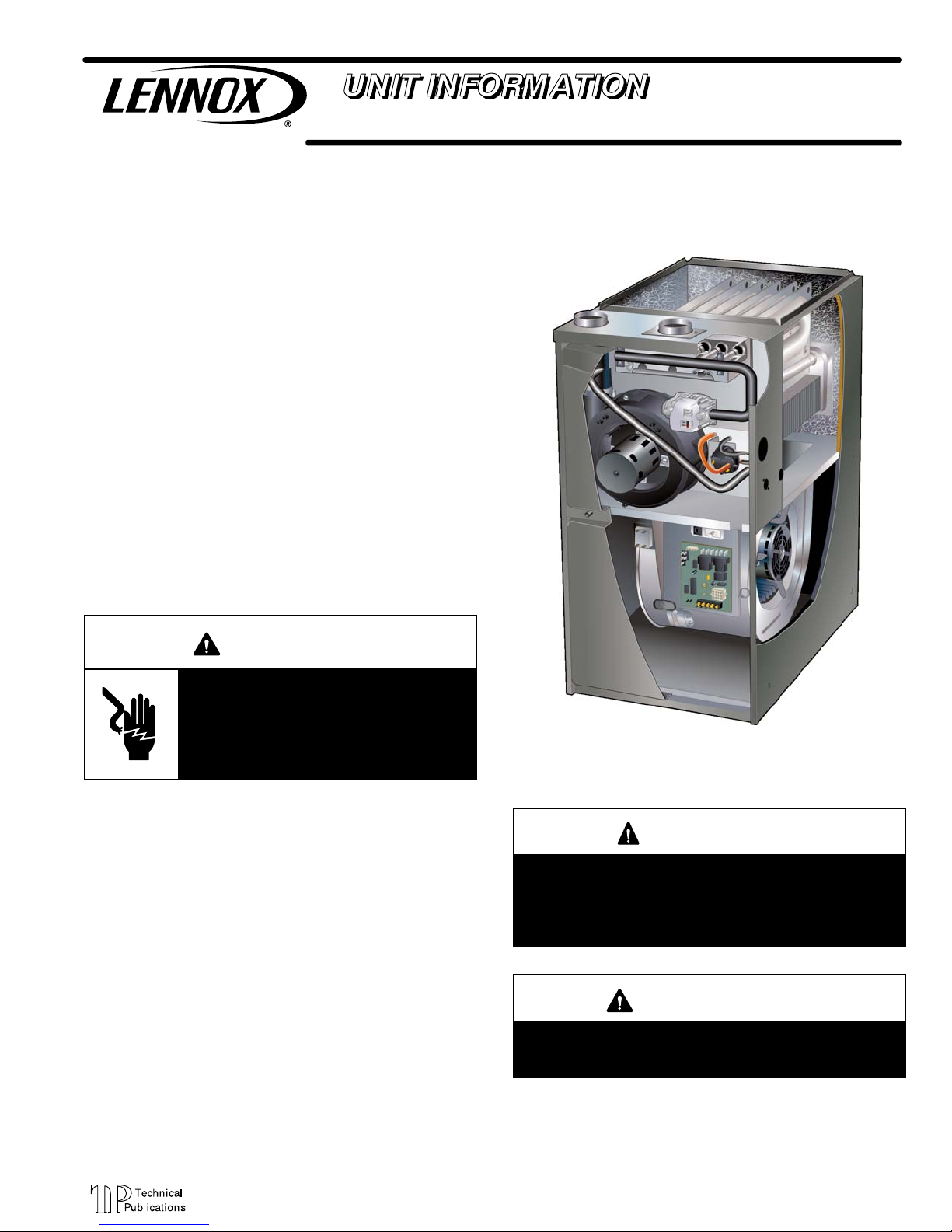

ML193UH SERIES UNITS

ML193UH series units are high−efficiency gas furnaces

manufactured with Lennox DuralokPlust aluminized

steel clamshell−type heat exchangers, with a stainless steel

condensing coil. ML193UH units are available in heating

input capacities of 44,000 to 132,000 Btuh (13 to 38.6 kW)

and cooling applications from 2 through 5 tons (7.0 through

17.6 kW). Refer to Engineering Handbook for proper sizing.

Units are factory equipped for use with natural gas. A kit is

available for conversion to LPG operation. All ML193UH

units are equipped with a hot surface ignition system. The

gas valve is redundant to assure safety shut−off as required by C.S.A.

The heat exchanger, burners and manifold assembly can be

removed for inspection and service. The maintenance section

gives a detailed description on how this is done.

All specifications are subject to change. Procedures outlined

in this manual are presented as a recommendation only

and do not supersede or replace local or state codes.

ML193UH

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect switch(es). Unit may have multiple

power supplies.

Table of Contents

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 3. . . . . . . . . . . . . . . . . . . . . . . . . .

Blower Performance Data 4. . . . . . . . . . . . . . . . . . . . . .

I−Unit Components 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II Placement and Installation 14. . . . . . . . . . . . . . . . . . . .

III−Start−Up 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV−Heating System Service Checks 36. . . . . . . . . . . . . .

V−Typical Operating Conditions 38. . . . . . . . . . . . . . . . . .

VI−Maintenance 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VII−Sequence of Operation and Flow Charts 41. . . . . . .

VIII−Integrated Control Troubleshooting 46. . . . . . . . . . .

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a licensed professional installer (or

equivalent), service agency or the gas supplier.

WARNING

Sharp edges.

Be careful when servicing unit to avoid sharp edges

which may result in personal injury.

Page 1

© 2010 Lennox Industries Inc.

Litho U.S.A.

Page 2

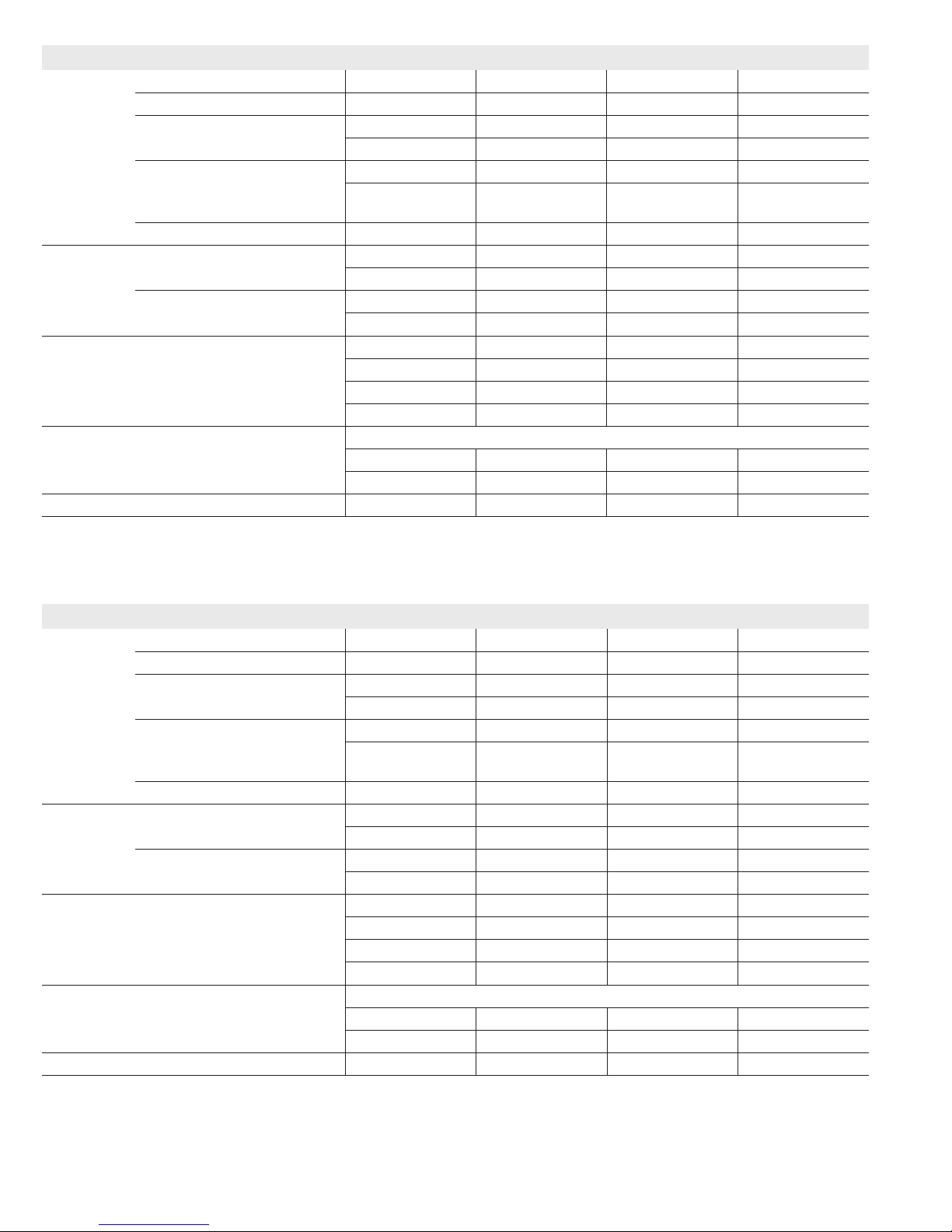

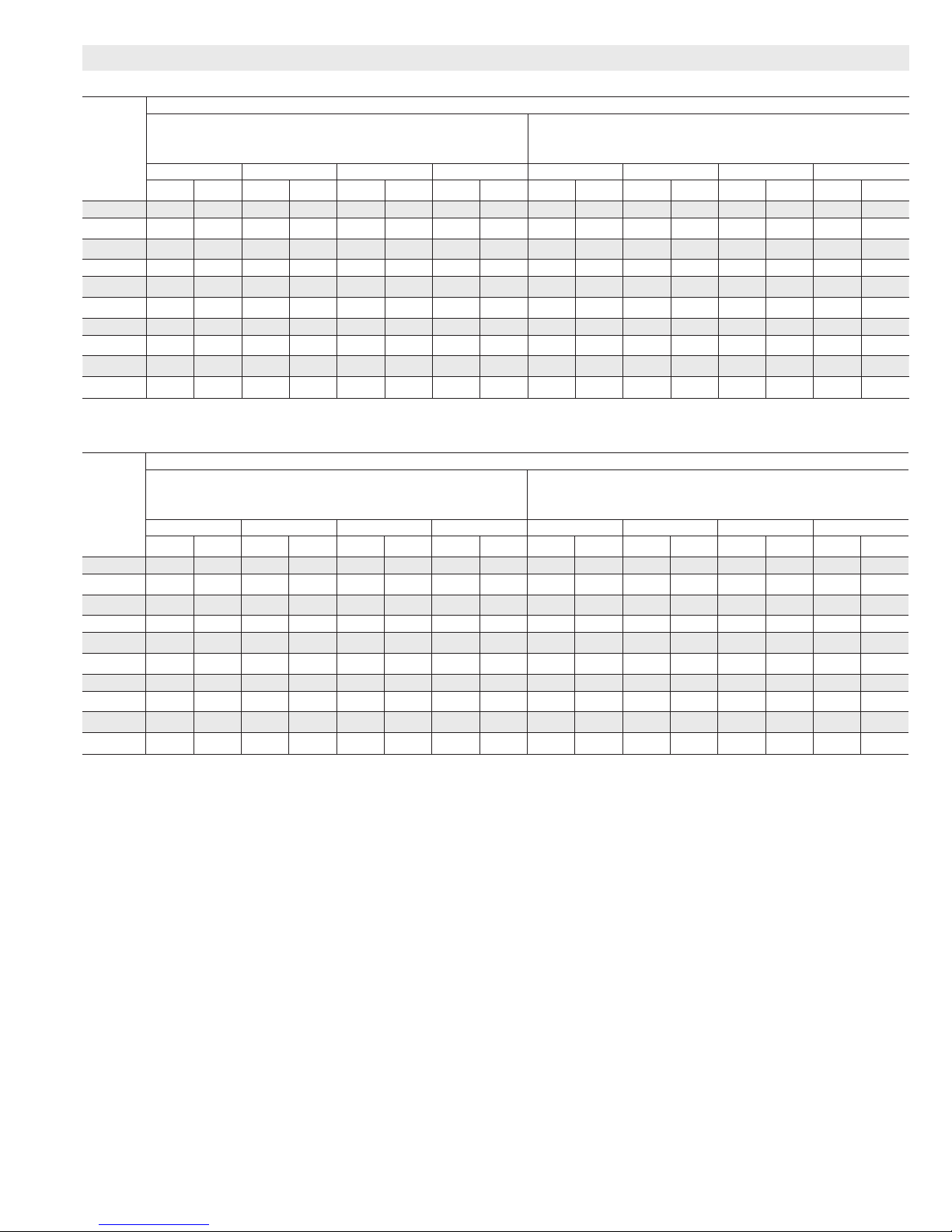

SPECIFICATIONS

Gas

Heating

Performance

Temperature rise range - °F 25 - 55 50 - 80 40 - 70 50 - 80

Gas Manifold Pressure (in. w.g.)

Nat. Gas / LPG/Propane

High static - in. w.g. 0.50 0.50 0.50 0.50

Connections

Intake / Exhaust Pipe (PVC) 2 / 2 2 / 2 2 / 2 2 / 2

in.

Condensate Drain Trap (PVC pipe) - i.d. 1/2 1/2 1/2 1/2

with eld supplied (PVC coupling) - o.d. 3/4 3/4 3/4 3/4

Indoor

Wheel nom. dia. x width - in. 10 x 8 10 x 8 10 x 8 10 x 8

Blower

Tons of add-on cooling 2.5 - 3 1.5 - 2 2.5 - 3 2 - 3

Air Volume Range - cfm 700 - 1600 390 - 1140 660 - 1615 695 - 1620

Electrical

Data

Blower motor full load amps 6.1 3.1 6.1 6.1

Maximum overcurrent protection 15 15 15 15

Shipping Data lbs. - 1 package 122 125 127 143

NOTE - Filters and provisions for mounting are not furnished and must be eld provided.

1

Annual Fuel Utilization Efciency based on DOE test procedures and according to FTC labeling regulations. Isolated combustion system rating for non-weatherized

furnaces.

Model No. ML193UH045P36B ML193UH070P24B ML193UH070P36B ML193UH090P36C

1

AFUE 93% 93% 93% 93%

Input - Btuh 44,000 66,000 66,000 88,000

Output - Btuh 42,000 62,000 62,000 83,000

3.5 / 10.0 3.5 / 10.0 3.5 / 10.0 3.5 / 10.0

Gas pipe size IPS 1/2 1/2 1/2 1/2

Motor output - hp 1/3 1/5 1/3 1/3

Voltage 120 volts - 60 hertz - 1 phase

SPECIFICATIONS

Gas

Heating

Performance

Temperature rise range - °F 40 - 70 50 - 80 40 - 70 45 - 75

Gas Manifold Pressure (in. w.g.)

Nat. Gas / LPG/Propane

High static - in. w.g. 0.50 0.50 0.50 0.50

Connections

Intake / Exhaust Pipe (PVC) 2 / 2 2 / 2 2 / 2 2 / 2

in.

Condensate Drain Trap (PVC pipe) - i.d. 1/2 1/2 1/2 1/2

with eld supplied (PVC coupling) - o.d. 3/4 3/4 3/4 3/4

Indoor

Wheel nom. dia. x width - in. 10 x 10 10 x 10 11 ½ x 10 11 ½ x 10

Blower

Tons of add-on cooling 3 - 4 3 - 4 4 - 5 4 - 5

Air Volume Range - cfm 900 - 2025 850 - 2030 1210 - 2525 1340 - 2800

Electrical

Data

Blower motor full load amps 8.2 8.2 11.5 11.5

Maximum overcurrent protection 15 15 15 15

Shipping Data lbs. - 1 package 146 155 161 178

NOTE - Filters and provisions for mounting are not furnished and must be eld provided.

1

Annual Fuel Utilization Efciency based on DOE test procedures and according to FTC labeling regulations. Isolated combustion system rating for non-weatherized

furnaces.

Model No. ML193UH090P48C ML193UH110P48C ML193UH110P60C ML193UH135P60D

1

AFUE 93% 93% 93% 93%

Input - Btuh 88,000 110,000 110,000 132,000

Output - Btuh 83,000 103,000 103,000 123,000

3.5 / 10.0 3.5 / 10.0 3.5 / 10.0 3.5 / 10.0

Gas pipe size IPS 1/2 1/2 1/2 1/2

Motor output - hp 1/2 1/2 1 1

Voltage 120 volts - 60 hertz - 1 phase

Page 2

Page 3

OPTIONAL ACCESSORIES - MUST BE ORDERED EXTRA

“B” Width

Models

CABINET ACCESSORIES

Horizontal Suspension Kit - Horizontal only 51W10 51W10 51W10

Return Air Base - Upow only 50W98 50W99 51W00

CONDENSATE DRAIN KITS

Condensate Drain Heat Cable 6 ft. 26K68 26K68 26K68

24 ft. 26K69 26K69 26K69

50 ft. 26K70 26K70 26K70

Heat Cable Tape Fiberglass - 1/2 in. x 66 ft. 36G53 36G53 36G53

Aluminum foil - 2 in. x 60 ft. 16P89 16P89 16P89

Crawl Space Vent Drain Kit 51W18 51W18 51W18

CONTROLS

Twinning Kit 65W80 65W80 65W80

FILTER KITS

1

Air Filter and

Rack Kit

Horizontal (end) Size of lter - in. 87L96 - 18 x 25 x 1 87L97 - 20 x 25 x 1 87L98 - 25 x 25 x 1

Side Return Single 44J22 44J22 44J22

Ten Pack 66K63 66K63 66K63

Size of lter - in. 16 x 25 x 1 16 x 25 x 1 16 x 25 x 1

NIGHT SERVICE KITS

Night Service Kit 51W03 51W03 51W03

TERMINATION KITS

See Installation Instructions for specic venting information.

Termination Kits Direct Vent

Applications Only

Termination Kits Direct or NonDirect vent

Roof Termination Flashing Kit - Direct or

Non-Direct Vent (2 ashings)

1

Cleanable polyurethane frame type lter.

2

Kits contain enough parts for two, non−direct vent installations.

3

Non−direct vent only.

NOTE - Termination Kits 44W92, 44W93, 30G28, 81J20 are certied to ULC S636 standard for use in Canada only.

Concentric US - 2 in. 71M80 69M29 - - -

3 in. - - - 60L46 60L46

Canada - 2 in. 44W92 44W92 - - -

3 in. - - - 44W93 44W93

Flush-Mount 2, 2-1/2 or 3 in. 51W11 51W11 51W11

Wall - Close

Couple

Wall - Close

Couple WTK

US - 2 in. 22G44 - - - - - -

3 in. 44J40 44J40 44J40

Canada - 2 in. 30G28 - - - - - -

3 in. 81J20 81J20 81J20

Roof 2 in. 15F75 15F75 - - -

Wall Ring Kit 2 in. 15F74

2 in. 44J41 44J41 44J41

“C” Width

“D” Width

Models

3

15F74 - - -

Models

High Altitude

Input

Pressure Switch Kit

4501 - 7500 ft. 7501 - 10,000 ft. 0 - 7500 ft. 0 - 7500 ft. 7501- 10,000 ft.

all models 74W90 74W91 69W73 73W81 73W37

INSTALLATION CLEARANCES - INCHES (MM)

Top/Plenum 1 inch (25 mm)

Front (service/alcove) 24 inches (610 mm)

NOTE − Air for combustion must conform to the methods outlined in the National Fuel Gas Code (NFPA 54/ANSI−Z223.1)

or the National Standard of Canada CAN/CSA−B149.1 Natural Gas and Propane Installation Code”.

NOTE − In the U.S. ue sizing must conform to the methods outlined in the current National Fuel Gas Code (NFPA 54/

ANSI−Z223.1) or applicable provisions of local building codes. In Canada ue sizing must conform to the methods

outlined in National Standard of Canada CAN/CSA−B149.1.

1

Allow proper clearances to accommodate condensate trap and vent pipe installation.

2

Do not install the furnace directly on carpeting, tile, or other combustible materials other than wood ooring.

GAS HEAT ACCESSORIES

Natural Gas to

LPG/Propane Kit

Sides

1

0 inches (0 mm)

Rear 0 inches (0 mm)

Front 0 inches (0 mm)

2

Floor

Combustible

Page 3

LPG/Propane

to Natural Gas Kit

Natural Gas

High Altitude

Orice Kit

Page 4

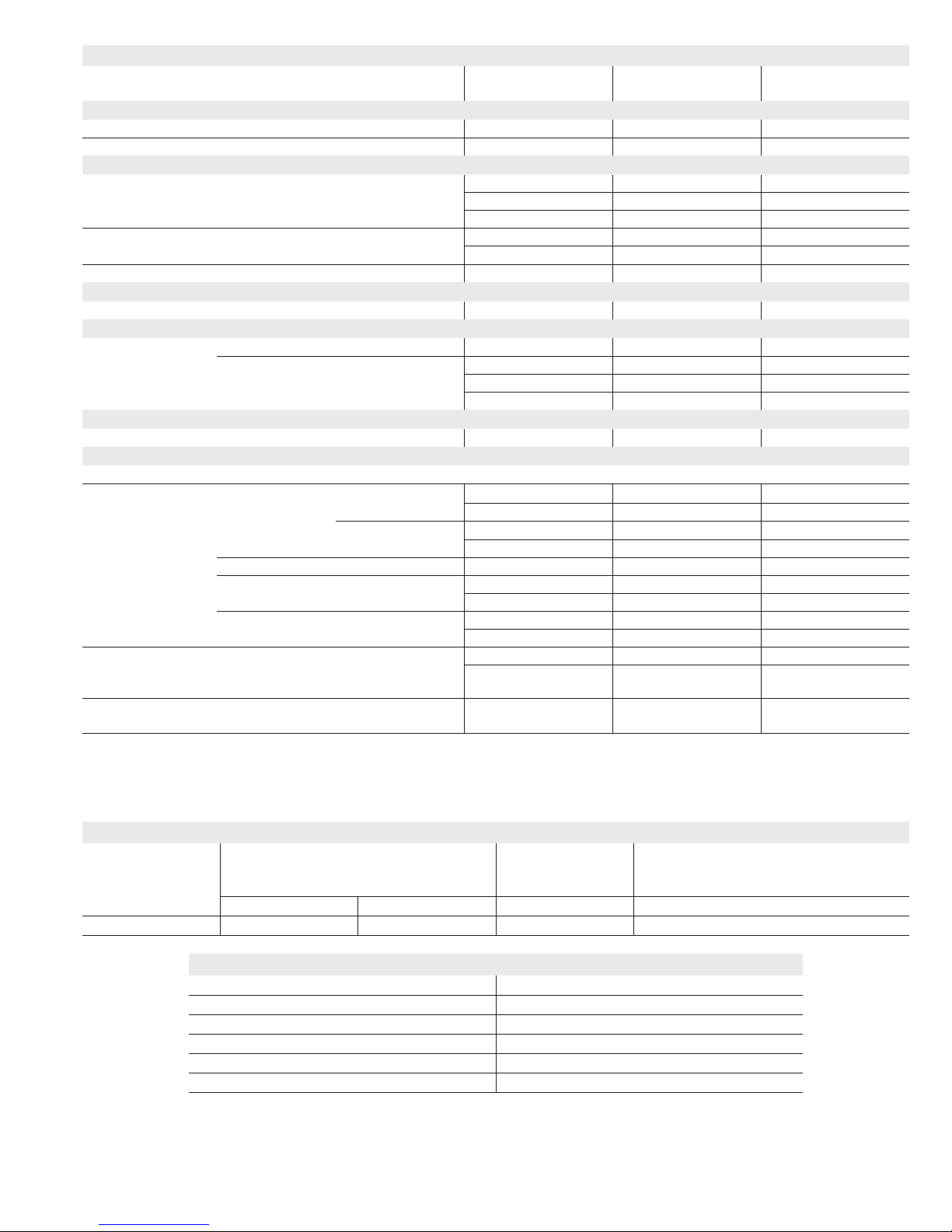

BLOWER DATA

ML193UH045P36B PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.00 1600 700 1370 590 1160 475 1005 400

0.10 1600 685 1355 565 1155 465 1015 390

0.20 1550 650 1330 540 1150 445 1000 380

0.30 1480 625 1295 515 1140 430 975 365

0.40 1425 590 1280 490 1105 415 975 350

0.50 1355 565 1190 460 1085 395 940 335

0.60 1320 545 1165 435 1030 375 900 315

0.70 1225 500 111 0 425 975 355 855 310

0.80 1135 480 1050 395 920 330 780 280

0.90 1025 445 950 360 800 295 700 255

ML193UH070P24B PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.00 1140 455 920 365 765 295 710 265

0.10 1135 445 900 360 765 290 690 255

0.20 1125 430 895 350 755 285 680 255

0.30 1090 415 870 340 725 280 660 250

0.40 1065 405 870 325 715 270 635 245

0.50 1020 390 825 315 675 260 605 235

0.60 945 365 780 300 640 250 555 225

0.70 910 350 740 295 585 240 505 220

0.80 790 325 670 275 510 225 455 205

0.90 735 310 575 255 460 220 390 195

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Medium-

High

Medium-

High

Medium-

Low

Medium-

Low

Low

Low

ML193UH090P36C PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.00 1620 745 1340 620 1130 500 965 405

0.10 1610 720 1335 595 1135 490 975 395

0.20 1565 695 1335 565 1145 465 970 385

0.30 1525 665 1300 555 1135 455 970 370

0.40 1485 635 1295 520 1110 435 960 355

0.50 1431 600 1260 495 1090 405 940 345

0.60 1365 570 1210 475 1035 390 900 330

0.70 1295 535 1155 445 995 365 860 305

0.80 1200 505 1065 415 930 340 745 270

0.90 1060 460 955 375 820 305 695 260

ML193UH090P48C PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.00 2025 900 1690 780 1395 645 1200 540

0.10 1995 880 1705 760 1390 635 1205 525

0.20 1925 835 1675 715 1405 605 1205 505

0.30 1850 795 1640 680 1400 580 1170 490

0.40 1790 760 1575 645 1395 560 1170 475

0.50 1700 725 1540 625 1350 535 1140 450

0.60 1610 690 1455 580 1295 505 1100 430

0.70 1540 645 1365 550 1225 480 1030 405

0.80 1415 615 1265 510 1125 445 980 385

0.90 1270 565 1165 470 1060 420 900 350

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Medium-

High

Medium-

High

Medium-

Low

Medium-

Low

Low

Low

ML193UH070P36B PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.00 1615 680 1355 570 1140 480 1030 400

0.10 1565 660 1365 545 1150 465 1020 385

0.20 1535 630 1340 525 1150 440 1025 375

0.30 1440 600 1300 500 1110 420 1000 350

0.40 1405 570 1255 470 1075 400 975 345

0.50 1340 535 1200 445 1045 380 945 330

0.60 1255 500 1125 420 995 355 875 310

0.70 1165 475 1080 395 935 335 820 290

0.80 1060 455 990 365 870 315 750 265

0.90 955 425 895 345 750 285 660 245

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Medium-

High

Medium-

Low

Low

ML193UH110P48C PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.00 2030 905 1750 805 1425 665 1225 530

0.10 1950 865 1755 770 1430 630 1215 515

0.20 1935 840 1675 735 1455 610 1230 505

0.30 1885 810 1660 685 1410 585 1200 485

0.40 1830 780 1585 645 1385 570 1190 470

0.50 1750 740 1565 630 1320 535 1165 455

0.60 1660 695 1485 585 1280 505 1105 425

0.70 1540 665 1380 555 1230 485 1060 405

0.80 1420 615 1290 520 1140 445 945 375

0.90 1290 575 1175 470 1045 410 850 350

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Medium-

High

Page 4

Medium-

Low

Low

Page 5

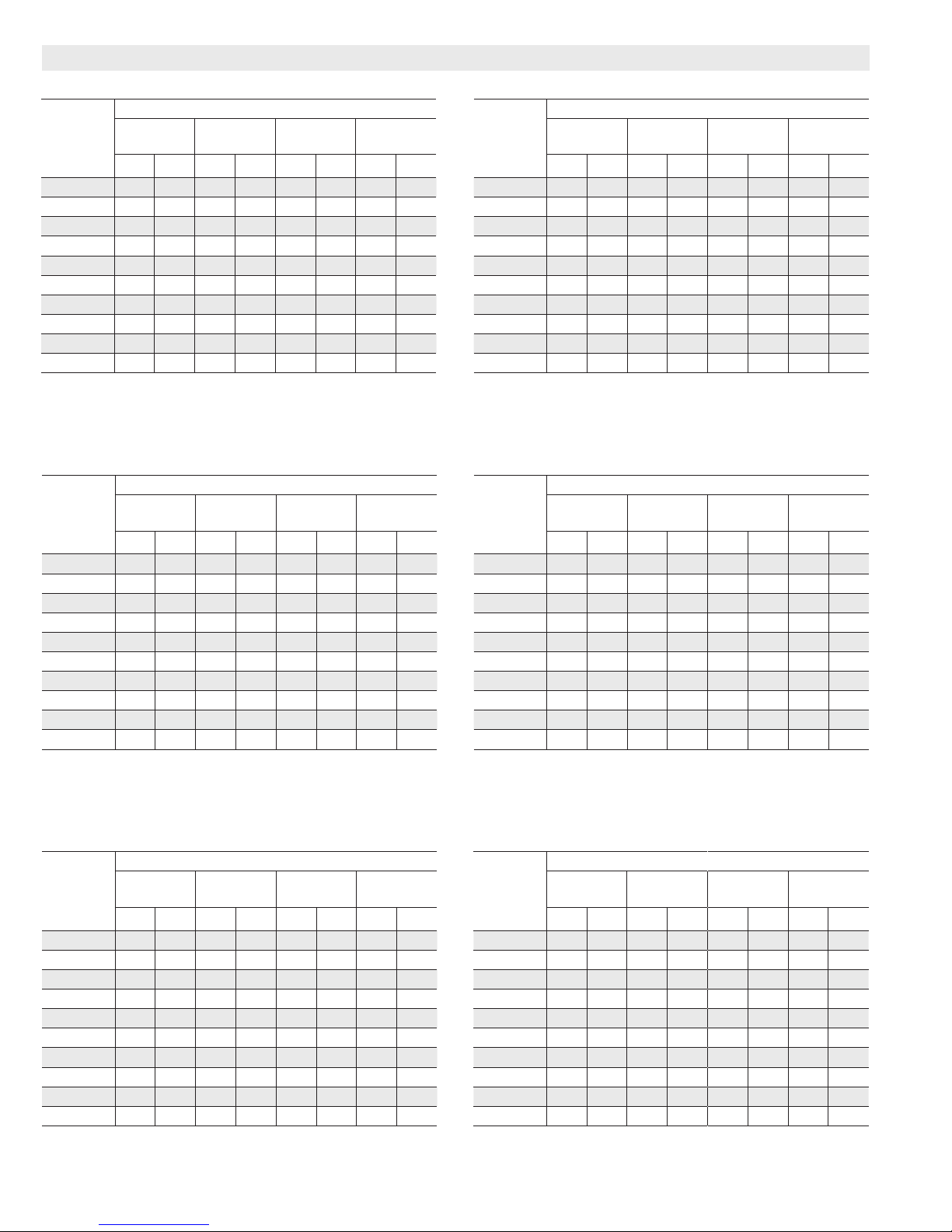

BLOWER DATA

ML193UH110P60C PERFORMANCE (Less Filter)

Air Volume / Watts at Different Blower Speeds

External

Static

Pressure

in. w.g.

0.00 2525 1560 2175 1165 1820 905 1465 725 2520 1545 2135 1150 1750 905 1445 720

0.10 2585 1545 2200 1135 1860 900 1475 710 2555 1545 2135 1115 1775 890 1470 715

0.20 2515 1505 2150 1110 1840 890 1490 705 2465 1480 2105 1085 1775 875 1465 705

0.30 2445 1445 2135 1065 1790 870 1500 690 2370 1430 2045 1055 1750 855 1460 690

0.40 2340 1385 2065 1035 1770 845 1500 675 2275 1375 1990 1010 1730 830 1460 680

0.50 2230 1350 1985 985 1755 810

0.60 2130 1295 1920 950 1685 785 1425 640 2060 1290 1850 935 1650 780 1420 635

0.70 2030 1250 1815 905 1640 760 1405 625 1930 1230 1760 900 1580 750 1355 610

0.80 1920 1190 1735 865 1560 725 1350 605 1825 1180 1660 855 1505 710 1290 585

0.90 1735 1135 1620 830 1450 685 1270 575 1665 1130 1520 810 1415 675 1210 560

ML193UH135P60D PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.00 2800 1715 2155 1160 1730 900 1375 695 2720 1685 2110 1135 1670 905 1355 705

0.10 2770 1665 2170 1145 1740 895 1415 700 2660 1650 2110 1115 1725 895 1390 700

0.20 2690 1635 2150 1110 1770 890 1450 700 2600 1585 2125 1090 1750 885 1450 695

0.30 2590 1560 2140 1080 1785 870 1455 695 2535 1525 2075 1065 1750 865 1465 685

0.40 2500 1535 2105 1055 1785 855 1475 690 2400 1490 2055 1030 1715 845 1460 680

0.50 2420 1465 2050 1025 1770 835

0.60 2330 1410 2015 995 1720 810 1460 655 2270 1385 1950 970 1720 800 1445 650

0.70 2225 1370 1965 960 1690 785 1450 650 2175 1335 1895 950 1665 780 1430 635

0.80 2150 1335 1875 925 1655 755 1435 630 2075 1295 1840 910 1605 745 1400 620

0.90 2025 1290 1830 890 1575 720 1375 605 1975 1255 1755 875 1540 725 1340 590

Bottom Return Air, Side Return Air with Optional Return

Air Base, Return Air from Both Sides or Return Air from

Bottom and One Side.

High Medium-High Medium-Low Low High Medium-High Medium-Low Low

cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts

1470 665 2185 1345 1930 970 1690 800 1460 655

Air Volume / Watts at Different Blower Speeds

Bottom Return Air, Side Return Air with Optional Return

Air Base, Return Air from Both Sides or Return Air from

Bottom and One Side.

High Medium-High Medium-Low Low High Medium-High Medium-Low Low

cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts

1465 665 2335 1420 2000 1005 1725 825 1455 660

Single Side Return Air − Air volumes in bold require eld

fabricated transition to accommodate 20 x 25 x 1 in. air lter

in order to maintain proper air velocity.

Single Side Return Air − Air volumes in bold require eld

fabricated transition to accommodate 20 x 25 x 1 in. air lter

in order to maintain proper air velocity.

Page 5

Page 6

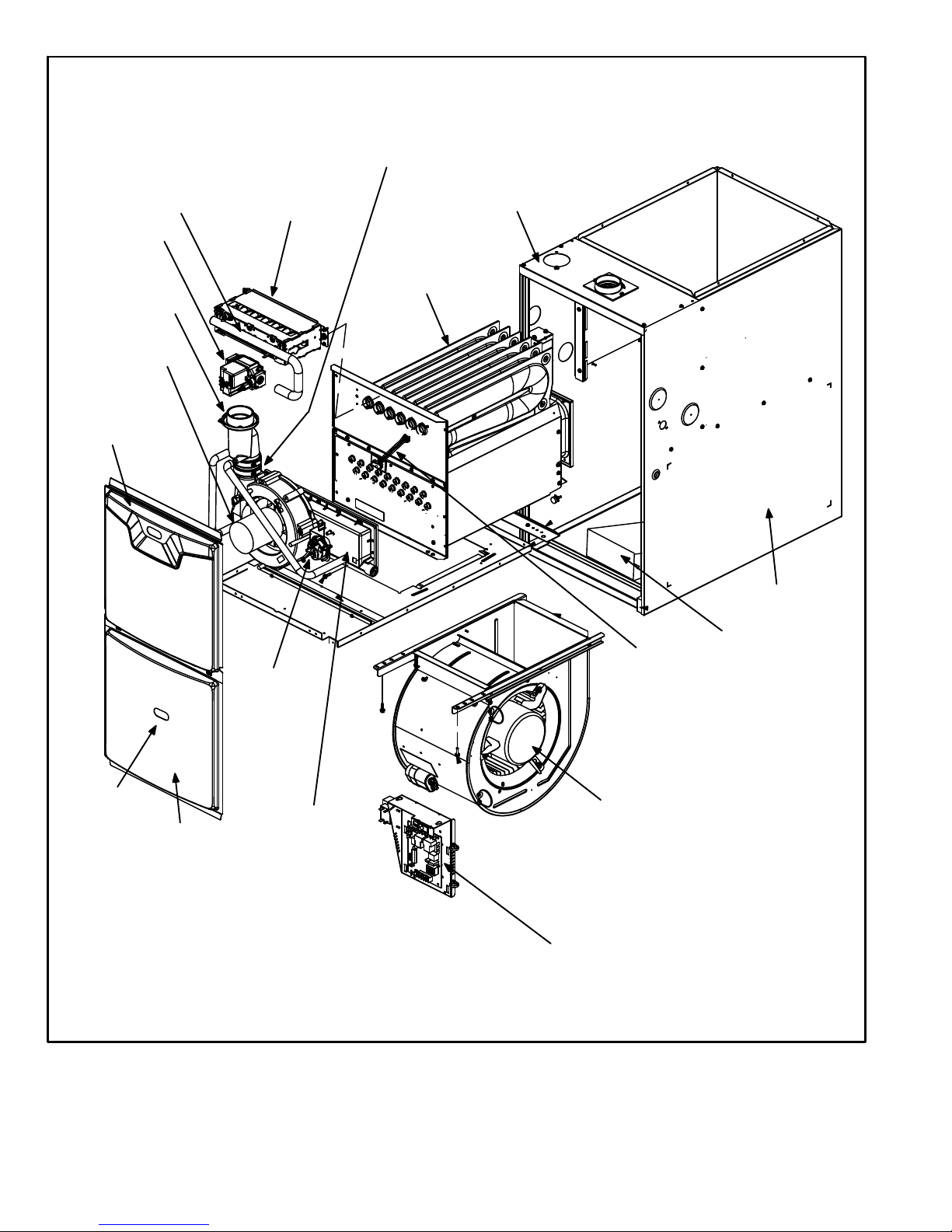

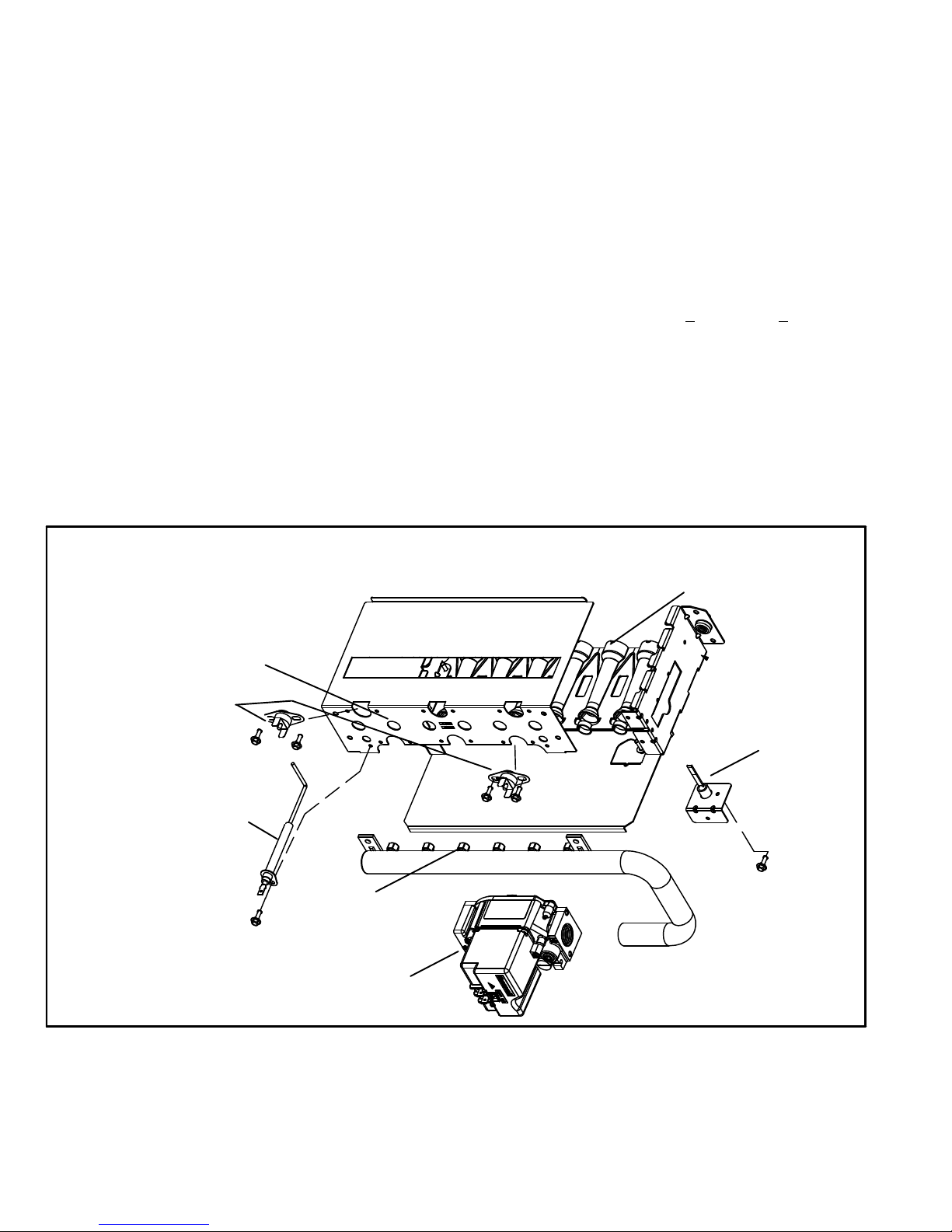

ML193UH PARTS IDENTIFICATION

FLEXIBLE NO−HUB

EXHAUST COLLAR

MANIFOLD

GAS VALVE

FLUE COLLAR

COMBUSTION AIR

INDUCER

BURNER

ACCESS

PANEL

BURNER BOX

ASSEMBLY

COMBUSTION

AIR PRESSURE

SWITCH

DuralokPlus

HEAT EXCHANGER

ASSEMBLY

TM

TOP CAP

PRIMARY LIMIT

CABINET

BAG ASSEMBLIES

(shipping location)

SIGHT

GLASS

BLOWER

ACCESS

DOOR

COLD END

HEADER BOX

BLOWER

ASSEMBLY

CONTROL BOX

(includes integrated itegrated control, transformer and interlock switch)

FIGURE 1

Page 6

Page 7

I−UNIT COMPONENTS

ML193UH unit components are shown in figure 1. The

combustion air inducer, gas valve and burners can be accessed by removing the burner access panel. The blower

and control box can be accessed by removing the blower access door.

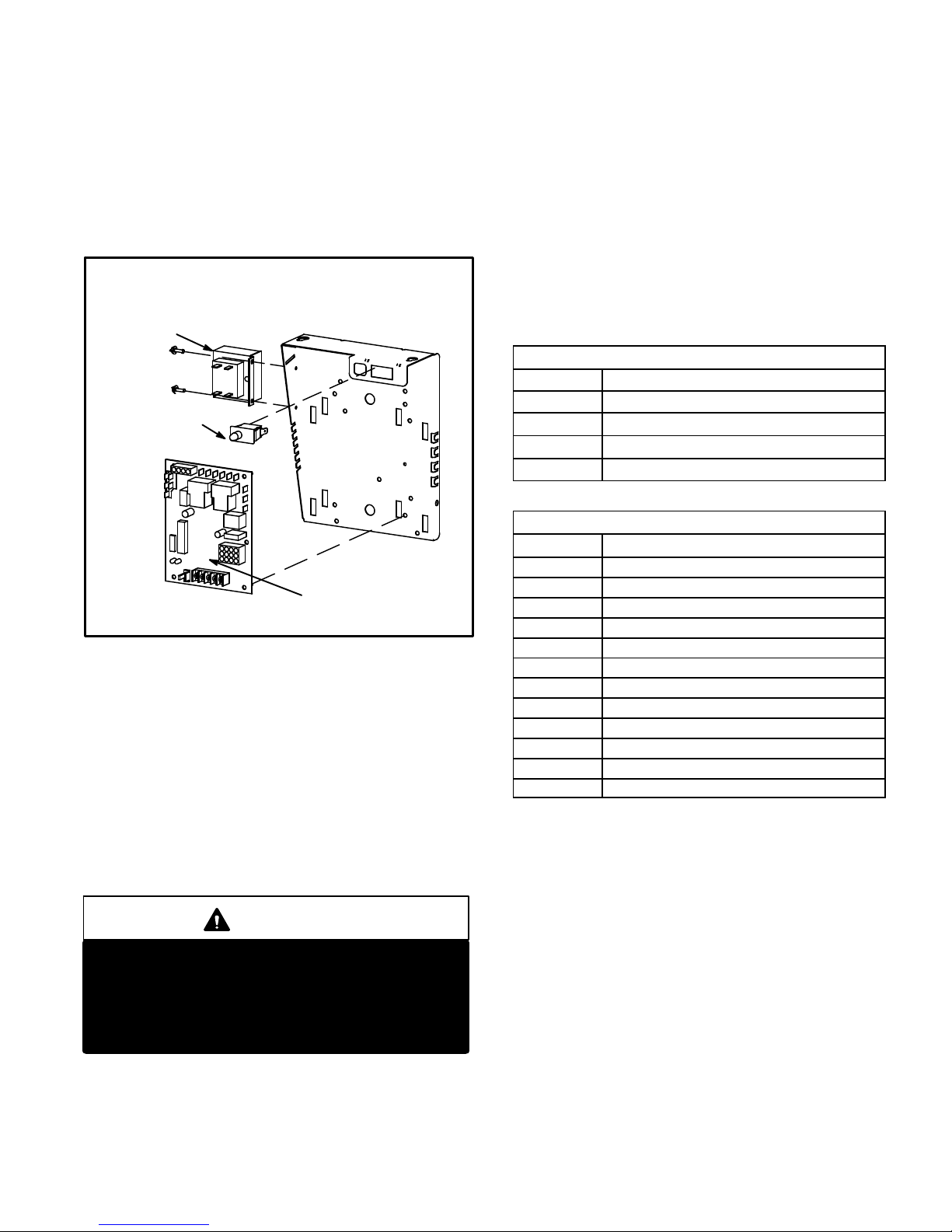

A−Control Box Components (Figure 2)

Unit transformer (T1) and integrated ignition control (A92)

are located in the control box. In addition, a door interlock

switch (S51) is located in the control box.

ML193UH Control Box

TRANSFORMER

(T1)

DOOR INTERLOCK

SWITCH (S51)

INTEGRATED IGNITION

CONTROL

(A92)

FIGURE 2

1. Transformer (T1)

A transformer located in the control box provides power to

the low voltage section of the unit. The transformers on all

models are rated at 40VA with a 120V primary and 24V

secondary.

2. Door Interlock Switch (S51)

A door interlock switch rated 14A at 120VAC is located on

the control box. The switch is wired in series with line voltage. When the blower door is removed the unit will shut

down.

3. Integrated Ignition Control (A92)

WARNING

Shock hazard.

Disconnect power before servicing. Control is not

field repairable. If control is inoperable, simply replace entire control.

Can cause injury or death. Unsafe operation will

result if repair is attempted.

integrated control also features two LED lights (DS1 red

and DS2 green) for troubleshooting and two accessory

terminals rated at (1) one amp. The integrated control also

features a (3) amp fuse for overcurrent protection. Tables 1

and 2 show jack plug terminal designations. See table 3 for

troubleshooting diagnostic codes. The mini−nitride ignitor

is made from a non−porous, high strength proprietary ceramic material that provides long life and trouble free

maintenance. The integrated control continuously monitors line voltage and maintains the ignitor power at a consistent level to provide proper lighting and maximum ignitor life.

TABLE 1

4−Pin Terminal Designation

PIN # FUNCTION

1 Combustion Air Inducer Line

2

3

4

Ignitor Line

Combustion Air Inducer Neutral

Ignitor Neutral

TABLE 2

12−Pin Terminal Designations

PIN # FUNCTION

1 High Limit Output

2 Not Used

3 24V Line

4 Not Used

5 Rollout Switch Out

6 24V Neutral

7 High Limit Input

8 Ground

9 Gas Valve Common

10 Pressure Switch In

11 Rollout Switch In

12 Gas Valve Out

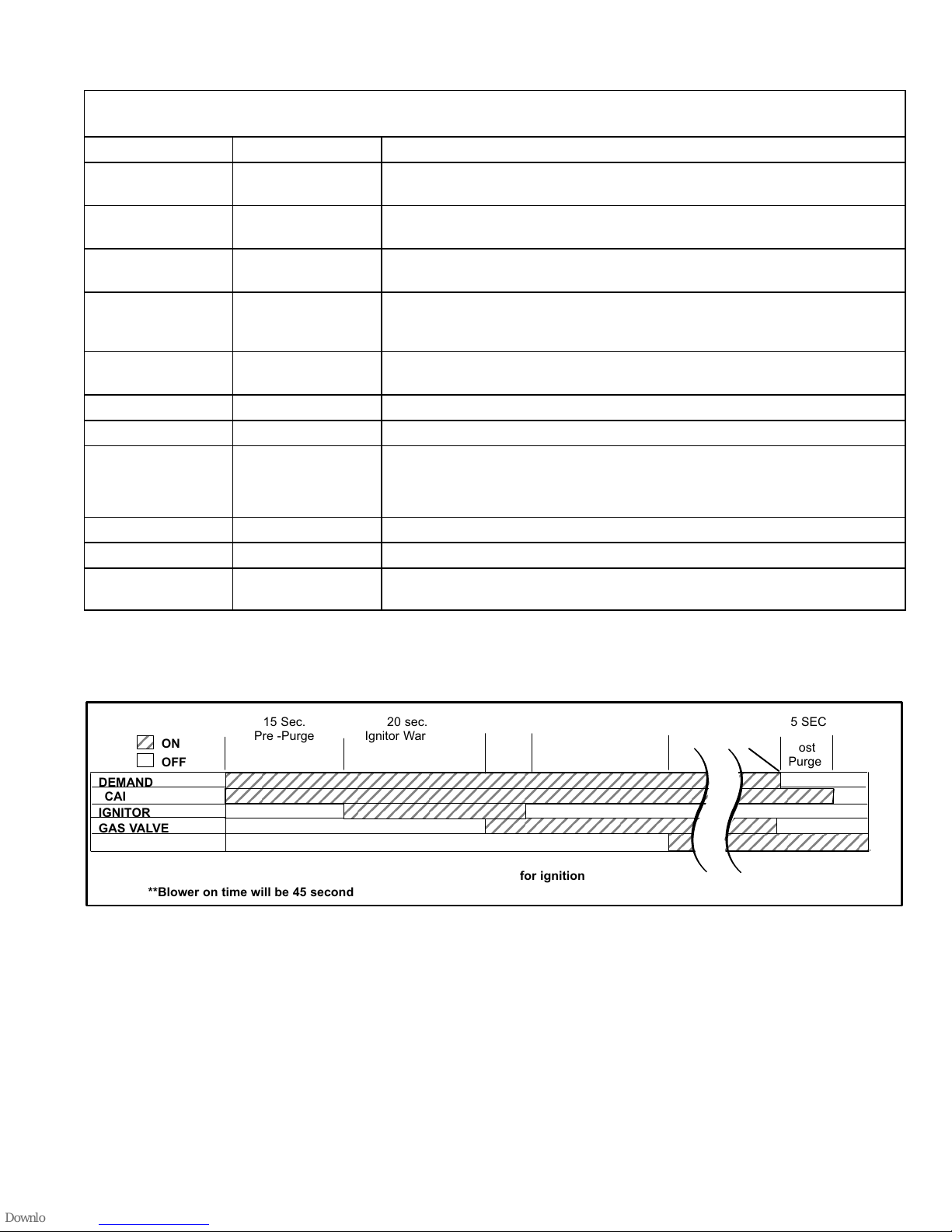

Electronic Ignition (See Figure 5)

On a call for heat the integrated control monitors the combustion air inducer prove switch. The integrated control will

not begin the heating cycle if the prove switch is closed (by−

passed). Once the prove switch is determined to be open,

the combustion air inducer is energized. When the differential in the prove switch is great enough, the prove switch

closes and a 15−second pre−purge begins. If the prove

switch is not proven within 2−1/2 minutes, the integrated

control goes into Watchguard−Pressure Switch mode for a

5−minute re−set period.

The ignition control system consists of an integrated control (figure 4) ignitor (figure 6) and flame sensor (figure 6).

The integrated control and ignitor work in combination to

ensure furnace ignition and ignitor durability. The integrated control, controls all major furnace operations. The

Page 7

Page 8

After the 15−second pre−purge period, the ignitor warms up

for 20 seconds during which the gas valve opens at 19 seconds for a 4−second trial for ignition. The ignitor remains

energized for the first 3 seconds during the 4 second trial. If

ignition is not proved during the 4−second period, the integrated control will try four more times with an inter purge

and warm−up time between trials of 35 seconds. After a total of five trials for ignition (including the initial trial), the integrated control goes into Watchguard−Flame Failure mode.

After a 60−minute reset period, the integrated control will

begin the ignition sequence again.

The integrated control has an added feature of ignitor power regulation to maintain consistent lighting and longer ignitor life under all line voltage conditions.

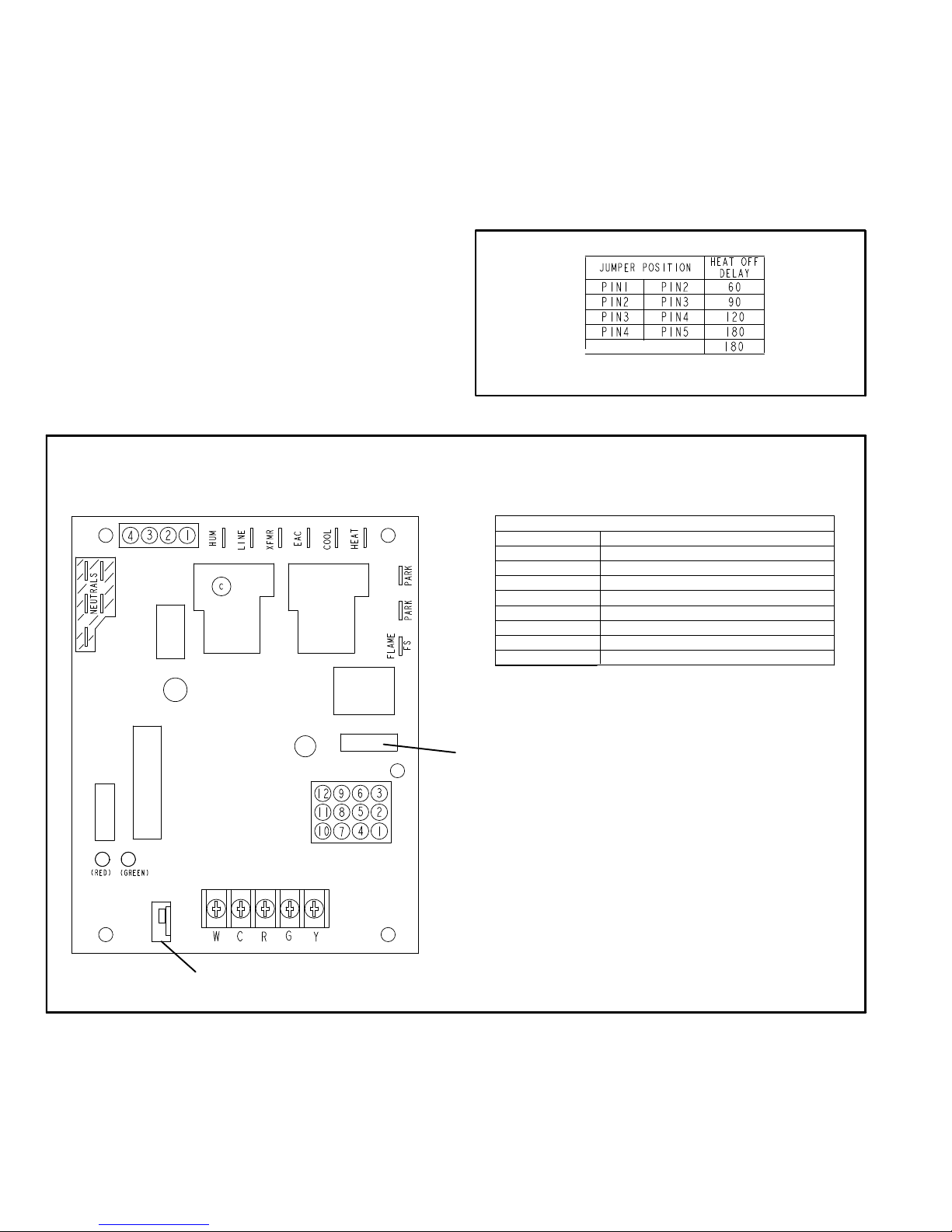

Fan Control

The fan on time of 30 seconds is not adjustable. The fan off

delay (amount of time that the blower operates after the

heat demand has been satisfied) may be adjusted by

INTEGRATED CONTROL

(Automatic Hot Surface Ignition System)

changing the jumper position across the five pins on the

integrated control. The unit is shipped with a factory fan off

setting of 90 seconds. The fan off delay affects comfort and

is adjustable to satisfy individual applications. Adjust the

fan off delay to achieve a supply air temperature between

90° and 110°F at the moment that the blower is de−energized. Longer off delay settings provide lower return air

temperatures; shorter settings provide higher return air

temperatures. See figure 3.

FAN-OFF TIME IN SECONDS

NO JUMPER

To adjust fan−off timing, reposition jumper across pins

to achieve desired setting.

FIGURE 3

LED 1

LED 2

HUM

LINE

XFMR

EAC

COOL

HEAT

PARK

FLAME

NEUTRALS

3 AMP, 32 VAC FUSE

TERMINAL DESIGNATIONS

Humidifier (120VAC)

Input (120VAC)

Transformer (120VAC)

Electronic Air Cleaner (120VAC)

Blower − Cooling Speed (120VAC)

Blower − Heating Speed (120VAC)

Dead terminals to park alternate spd taps

Flame sensor

Neutral terminals (120VAC)

BLOWER OFF

DELAY JUMPER

FIGURE 4

Page 8

Page 9

The integrated control is equipped with two LED lights for troubleshooting. The diagnostic codes are listed below in table 3.

ЙЙЙЙЙЙЙЙЙ

TABLE 3

DIAGNOSTIC CODES

Make sure to Identify LED’S Correctly.

LED #1 (Red) LED #2 (Green) DESCRIPTION

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS

FAST FLASH

SLOW FLASH ON

OFF SLOW FLASH

ALTERNATING

SLOW FLASH

SLOW FLASH OFF Flame sensed without gas valve energized.

ON SLOW FLASH Rollout switch open. OR: 12-pin connector improperly attached.

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS

FAST FLASH

ALTERNATING

SLOW FLASH

Power on − Normal operation.

Also signaled during cooling and continuous fan.

Normal operation − signaled when heating demand initiated at thermostat.

Primary or secondary limit switch open. Limit must close within 3 minutes or unit

goes into 1 hour Watchguard.

Pressure prove switch open.

OR: Blocked inlet/exhaust vent;

OR: Pressure switch closed prior to activation of combustion air inducer.

Watchguard 1 hour −− burners failed to ignite or lost flame 5 times during single

heating demand.

ON

ON

OFF

ON

OFF

ON

Circuit board failure or control wired incorrectly.

FAST FLASH SLOW FLASH Main power polarity reversed. Switch line and neutral.

SLOW FLASH FAST FLASH Low flame signal. Measures below 1.5 microamps. Replace flame sense rod.

ALTERNATING

FAST FLASH

ALTERNATING

FAST FLASH

Improper main ground.

OR: Line voltage below 90 volts.

NOTE − Slow flash rate equals 1 Hz (one flash per second). Fast flash rate equals 3 Hz (three flashes per second).

Minimum flame sense current = 0.5 microAmps.

*4

Sec.Trial

for Ign.

**Blower On"

Delay

End of

Heat Demand

5 SEC

Post

Purge

Blower

Off

Time

ON

OFF

DEMAND

CAI

IGNITOR

GAS VALVE

INDOOR BLOWER

*Ignitor will energize the first 3 seconds of the 4 second trial for ignition

**Blower on time will be 45 seconds after gas valve is energized. Blower off time will depend on OFF TIME" Setting.

15 Sec.

Pre −Purge

20 sec.

Ignitor Warmup

FIGURE 5

Page 9

Page 10

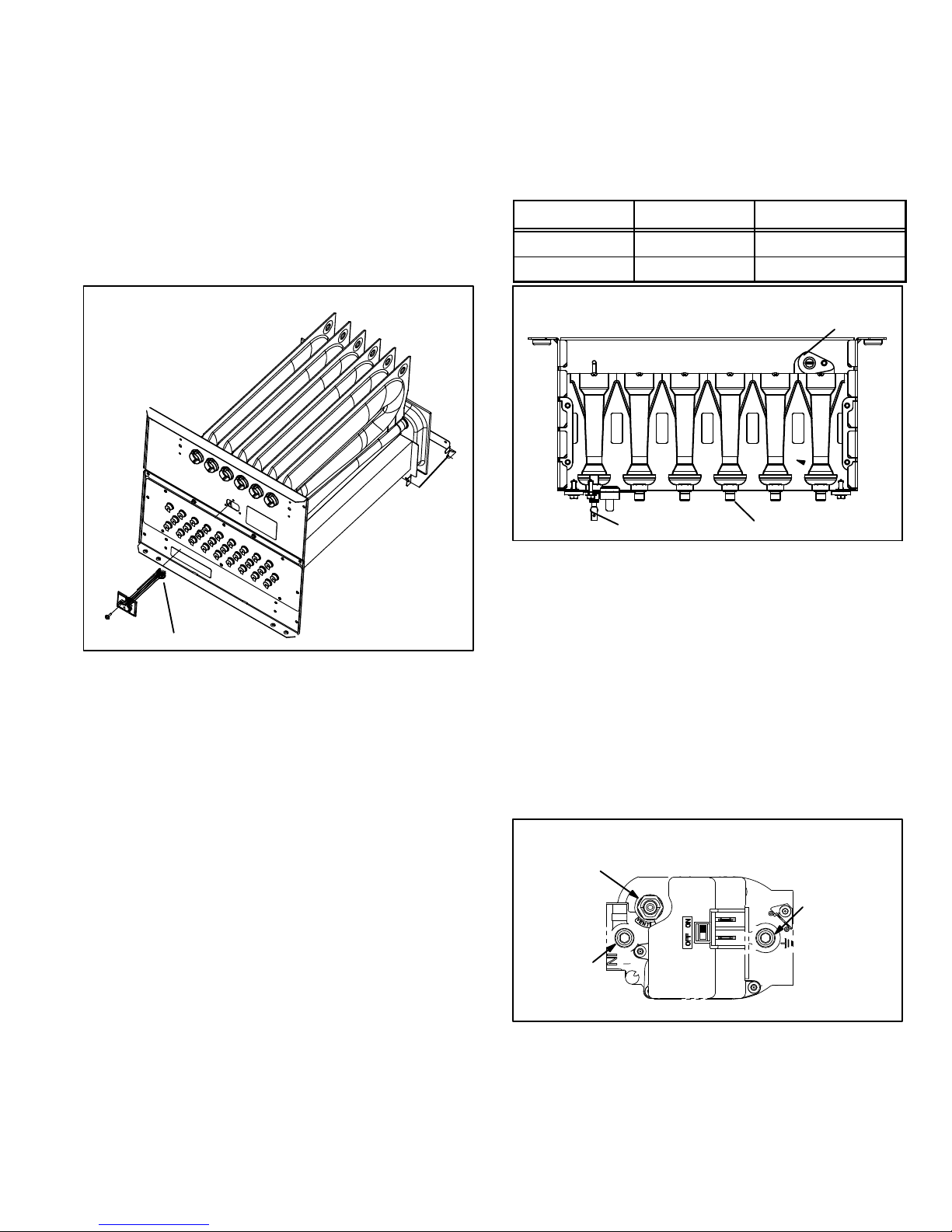

B−Heating Components

Combustion air inducer (B6), primary limit control (S10),

SureLight ignitor, burners, flame rollout switch (S47), gas

valve (GV1), combustion air prove switch (S18), and clamshell heat exchangers are located in the heating compartment. The heating compartment can be accessed by removing the burner access panel.

1. Ignitor (Figure 6)

ML193UH units use a mini−nitride ignitor made from a proprietary ceramic material. Ignitor longevity is enhanced by

controlling the voltage to the ignitor. Due to this feature of

the integrated control, voltage cannot be measured. To

check ignitor, measure its resistance. A value of 50 to 450

ohms indicates a good ignitor.

2. Flame Sensor (Figure 6)

A flame sensor is located on the left side of the burner support. The sensor is mounted on the front burner box plate

and the tip protrudes into the flame envelope of the left−

most burner. The sensor can be removed for service without removing any part of the burners. During operation,

flame is sensed by current passed through the flame and

sensing electrode. The ignition control allows the gas valve

to remain open as long as flame signal is sensed.

NOTE − The ML193UH furnace contains electronic

components that are polarity sensitive. Make sure that

the furnace is wired correctly and is properly grounded.

3. Flame Rollout Switches (Figure 6)

Flame rollout switches S47 are SPST N.C. high temperature

limits located on the top left and bottom right of the front buner

box plate. S47 is wired to the burner ignition control A92.

When either of the switches sense flame rollout (indicating a blockage in the combustion passages), the flame

rollout switch trips, and the ignition control immediately

closes the gas valve. Switch S47 in all ML193UH units is

factory preset to open at 210_F + 12_F (99_C + 6.7_C) on a

temperature rise. All flame rollout switches are manual reset.

FRONT BURNER BOX PLATE

ROLLOUT SWITCHES

FLAME SENSOR

ML193UH Burner Box Assembly

BURNERS

IGNITOR

ORIFICES

GAS VALVE

FIGURE 6

Page 10

Page 11

4. Primary Limit Control (Figure 7)

Primary limit (S10) used on ML193UH units is located in the

heating vestibule panel. When excess heat is sensed in the

heat exchanger, the limit will open. Once the limit opens, the

furnace control energizes the supply air blower and de−energizes the gas valve. The limit automatically resets when

unit temperature returns to normal. The switch is factory

set and cannot be adjusted. For limit replacement remove

wires from limit terminals, remove mounting screws, rotate

limit switch 90 degrees and slowly remove from the vestibule panel. Install replacement limit with same care.

an orifice which is precisely matched to the burner input.

See table 4 for orifice size. The burner is supported by the

orifice and will easily slide off for service. A flame retention

ring in the end of each burner maintains correct flame length

and shape and keeps the flame from lifting off the burner head.

TABLE 4

Gas Orifice Size

Unit Fuel Orifice Size

All Natural 0.0625

All L.P./Propane 0.0340

Primary Limit Location and Heat Exchanger

Install limit face down

FIGURE 7

5. Heat Exchanger (Figure 7)

ML193UH units use an aluminized steel primary and

stainless steel secondary heat exchanger assembly.

Heat is transferred to the air stream from all surfaces of

the heat exchanger. The shape of the heat exchanger ensures maximum efficiency.

The combustion air inducer pulls fresh air through the burner box. This air is mixed with gas in the burners. The gas /

air mixture is then burned at the entrance of each clamshe ll. Combustion gases are then pulled through the primary

and secondary heat exchangers and exhausted out the exhaust vent pipe.

6. Burners (Figure 8)

All units use inshot burners. Burners are factory set and do not

require adjustment. Burners can be removed as an assembly

for service. Burner maintenance and service is detailed in the

MAINTENANCE section of this manual. Each burner uses

Burner Detail Top View

IGNITOR

FLAME SENSOR

ORIFICES

FIGURE 8

7. Gas Valve (GV1)

The ML193UH uses an internally redundant valve to assure

safety shut-off. If the gas valve must be replaced, the same

type valve must be used.

24VAC terminals and gas control switch are located on

top of the valve. All terminals on the gas valve are connected to wires from the ignition control. 24V applied to the

terminals opens the valve.

Inlet and outlet pressure taps are located on the valve. A

manifold adjustment screw is also located on the valve. An

LPG changeover kit is available.

MANIFOLD

PRESSURE

ADJUSTMENT

SCREW

INLET

PRESSURE

PORT

Gas Valve

MANIFOLD

PRESSURE

OUTLET

PORT

FIGURE 9

Page 11

Page 12

8. Combustion Air Inducer (B6)

& Cold End Header Box

All ML193UH units use a combustion air inducer to move

air through the burners and heat exchanger during heating operation. The blower uses a shaded pole 120VAC

motor. The motor operates during all heating operation and

is controlled by integrated control A3. Blower operates continuously while there is a call for heat. The integrated control will not proceed with the ignition sequence until combustion air inducer operation is sensed by the proving switches.

The combustion air inducer is installed on the cold end

header box. The cold end header box is a single piece

made of hard plastic. The box has an internal channel

where the combustion air inducer creates negative pressure at unit start up. The channel contains an orifice used

to regulate flow created by the combustion air inducer.

The box has pressure taps for the combustion air inducer

pressure switch hoses. The pressure switch measures

the pressure across the combustion air inducer orifice or

difference in the channel and the box. If replacement is

necessary the gaskets used to seal the box to the

vestibule panel and the combustion air inducer to the

box, must also be replaced.

TABLE 5

ML193UH Unit Combustion Air Inducer

Orifice Size

−045 0.563

−070 0.844

−090 1.00

−110 1.22

−135 1.30

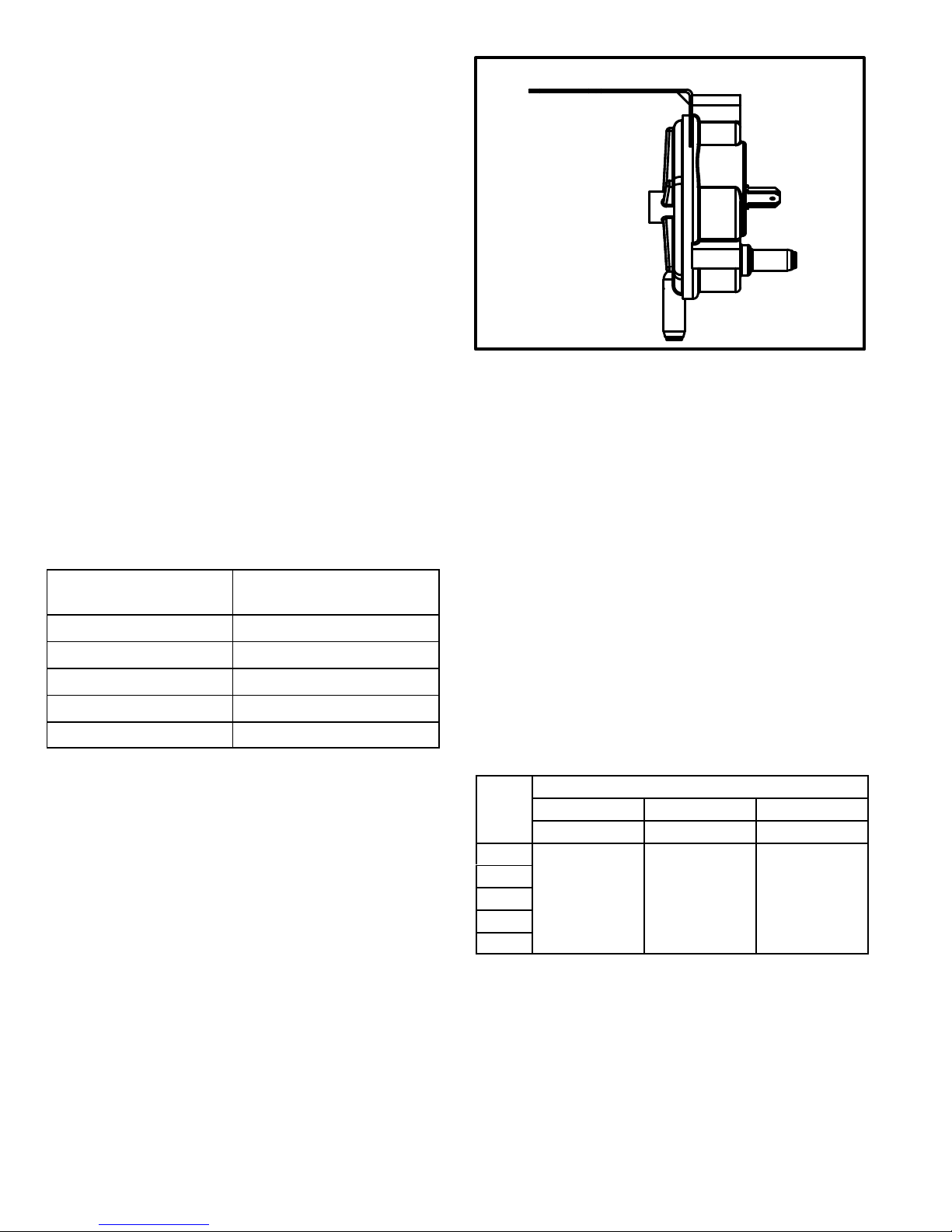

9. Combustion Air Pressure Switch

(Figure 10)

ML193UH series units are equipped with a differential

pressure switch located on the cold end header box. The

switch monitors across the combustion air inducer orifice to insure proper flow through the heat exchanger.

The switch is a SPST N.O. prove switch electrically connected to the integrated control. The purpose of the switch is

to prevent burner operation if the combustion air inducer is not

moving enough air for proper combustion.

Pressure Switch

FIGURE 10

On start-up, the switch monitors whether the combustion air

inducer is operating. It closes a circuit to the integrated

control when the difference in pressure across the combustion air inducer orifice exceeds a non−adjustable factory

setting. If the switch does not successfully sense the required differential, the switch cannot close and the furnace cannot operate. If the flue or air inlet become obstructed during operation, the switch senses a loss of

pressure differential and opens the circuit to the integrated

control. If the condensate line is blocked, water will back up

into the header box and reduce the pressure differential

across the switch. The prove switch opens if the differential

drops below the set point. See table 6.

Checks of pressure differential can aid in troubleshooting.

When measuring the pressure differential, readings should be

taken at the pressure switch. See figure 11. Lack of differential

usually indicates problems in the intake or exhaust piping, but

may indicate problems in the heat exchanger, condensing coil, header boxes, combustion inducer or other

components.

TABLE 6

Altitude ft.

Unit

−045

−070

−090

−110

−135

*Set point is factory set and non−adjustable

0 − 4500 4501 − 7500 7501 − 10000

Set Point w.c. Set Point w.c Set Point w.c.

−0.65 −0.60 −0.055

Page 12

Page 13

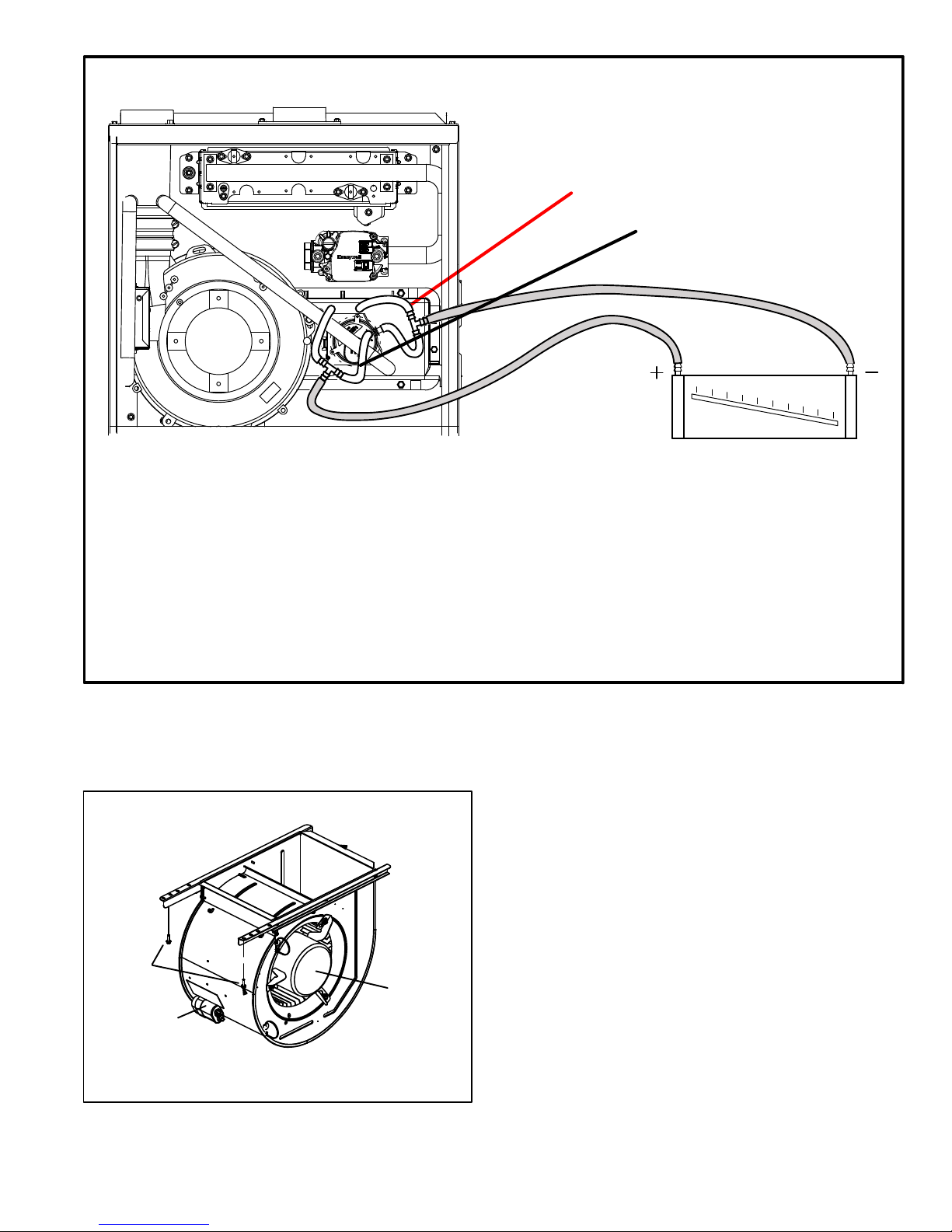

Measuring Pressure Differential

RED TUBING

NEGATIVE

BLACK TUBING

POSITIVE

1 − Remove thermostat demand and allow unit to

cycle off.

2 − Install a tee in the negative (−) line (red tubing) and a

tee in the positive (+) line (black tubing) running from

the pressure switch to the cold end header box.

3 − Install a manometer with hose from the negative (−)

side of the manometer to the tee installed in the

negative (−) line and with hose from the positive (+)

side of the manometer to the tee in the positive (+)

line.

NOTE − Both sides of the cold end header box are negative. However the (+) port reads less negative pressure

than the (−) port.

FIGURE 11

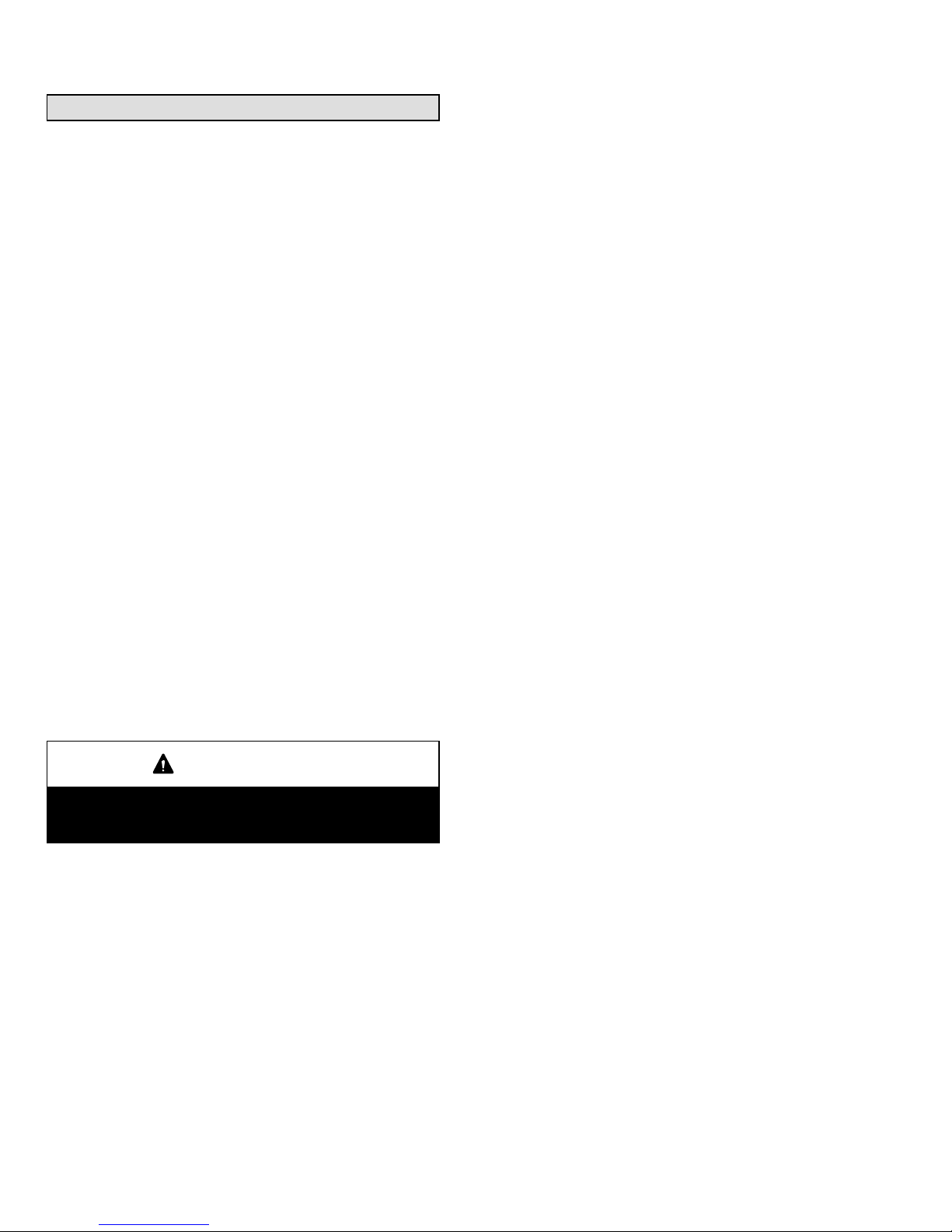

C− Blower Compartment

Blower motor (B3) and capacitor (C4), are located in the

blower compartment. The blower compartment can be accessed by removing the blower access panel.

Blower Motor Housing

4 − Operate unit and observe manometer reading.

Readings will change as heat exchanger warms.

a. Take one reading immediately after start-up.

b. Take a second reading after unit has reached

steady state (approximately 5 minutes). This will be

the pressure differential.

The pressure differential should be greater

than those listed in table 6.

5 − Remove thermostat demand and allow to cycle off.

6 − Remove manometer and tee’s. Reinstall combustion

air sensing hoses to the pressure switch.

1. Blower Motor (B3) and Capacitor (C4)

All ML193UH units use single−phase direct−drive blower motors. All motors are 120V permanent split capacitor motors

to ensure maximum efficiency. See SPECIFICATIONS table

at the front of this manual for more detail. See motor nameplate for capacitor ratings.

BOLTS

CAPACITOR

To Remove Blower From Unit: Disconnect Power, Remove Control

Box, Remove Bolts and Unplug Motor Wires From Control. Then

Slide Out Front of Unit.

FIGURE 12

MOTOR

Page 13

Page 14

II−PLACEMENT AND INSTALLATION

Combustion, Dilution & Ventilation Air

If the ML193UH is installed as a Non−Direct Vent Furnace, follow the guidelines in this section.

NOTE − In Non−Direct Vent installations, combustion air

is taken from indoors and flue gases are discharged out−

doors.

In the past, there was no problem in bringing in sufficient

outdoor air for combustion. Infiltration provided all the air

that was needed. In today’s homes, tight construction

practices make it necessary to bring in air from outside

for combustion. Take into account that exhaust fans, appliance vents, chimneys, and fireplaces force additional

air that could be used for combustion out of the house.

Unless outside air is brought into the house for combustion, negative pressure (outside pressure is greater than

inside pressure) will build to the point that a downdraft

can occur in the furnace vent pipe or chimney. As a result,

combustion gases enter the living space creating a potentially dangerous situation.

In the absence of local codes concerning air for combus−

tion and ventilation, use the guidelines and procedures in

this section to install ML193UH furnaces to ensure efficient and safe operation. You must consider combustion

air needs and requirements for exhaust vents and gas

piping. A portion of this information has been reprinted

with permission from the National Fuel Gas Code (ANSI−

Z223.1/NFPA 54). This reprinted material is not the complete and official position of the ANSI on the referenced

subject, which is represented only by the standard in its

entirety.

In Canada, refer to the CSA B149 installation codes.

CAUTION

Do not install the furnace in a corrosive or contaminated atmosphere. Meet all combustion and ventilation air requirements, as well as all local codes.

All gas-fired appliances require air for the combustion process. If sufficient combustion air is not available, the furnace or other appliance will operate inefficiently and unsafely. Enough air must be provided to meet the needs of all

fuel−burning appliances and appliances such as exhaust

fans which force air out of the house. When fireplaces, exhaust fans, or clothes dryers are used at the same time as

the furnace, much more air is required to ensure proper

combustion and to prevent a downdraft. Insufficient air

causes incomplete combustion which can result in carbon

monoxide.

In addition to providing combustion air, fresh outdoor air dilutes contaminants in the indoor air. These contaminants

may include bleaches, adhesives, detergents, solvents

and other contaminants which can corrode furnace components.

The requirements for providing air for combustion and ventilation depend largely on whether the furnace is installed in

an unconfined or a confined space.

Unconfined Space

An unconfined space is an area such as a basement or

large equipment room with a volume greater than 50 cubic

feet (1.42 m3) per 1,000 Btu (.29 kW) per hour of the combined input rating of all appliances installed in that space.

This space also includes adjacent rooms which are not

separated by a door. Though an area may appear to be unconfined, it might be necessary to bring in outdoor air for

combustion if the structure does not provide enough air by

infiltration. If the furnace is located in a building of tight

construction with weather stripping and caulking around

the windows and doors, follow the procedures in the Air

from Outside section.

Confined Space

A confined space is an area with a volume less than 50 cubic

feet (1.42 m3) per 1,000 Btu (.29 kW) per hour of the com−

bined input rating of all appliances installed in that space. This

definition includes furnace closets or small equipment rooms.

When the furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containing the furnace, the return air must be handled by ducts

which are sealed to the furnace casing and which terminate

outside the space containing the furnace. This is especially

important when the furnace is mounted on a platform in a

confined space such as a closet or small equipment room.

Even a small leak around the base of the unit at the platform

or at the return air duct connection can cause a potentially

dangerous negative pressure condition. Air for combustion

and ventilation can be brought into the confined space either from inside the building or from outside.

Air from Inside

If the confined space that houses the furnace adjoins a

space categorized as unconfined, air can be brought in by

providing two permanent openings between the two

spaces. Each opening must have a minimum free area of 1

square inch (645 mm2) per 1,000 Btu (.29 kW) per hour of

total input rating of all gas−fired equipment in the confined

space. Each opening must be at least 100 square inches

(64516 mm2). One opening shall be within 12 inches (305

mm) of the top of the enclosure and one opening within 12

inches (305 mm) of the bottom. See figure 13.

Page 14

Page 15

EQUIPMENT IN CONFINED SPACE − ALL AIR FROM INSIDE

ROOF TERMINATED

EXHAUST PIPE

OPENINGS

SIDE WALL

TERMINATED

EXHAUST PIPE

(ALTERNATE

LOCATION)

NOTE − Each opening shall have a free area of at least one square inch

per 1,000 Btu (645mm

all equipment in the enclosure, but not less than 100 square inches

(64516mm.

2).

ML193UH

2

per .29kW) per hour of the total input rating of

(To Adjacent

Unconfined

Space)

FIGURE 13

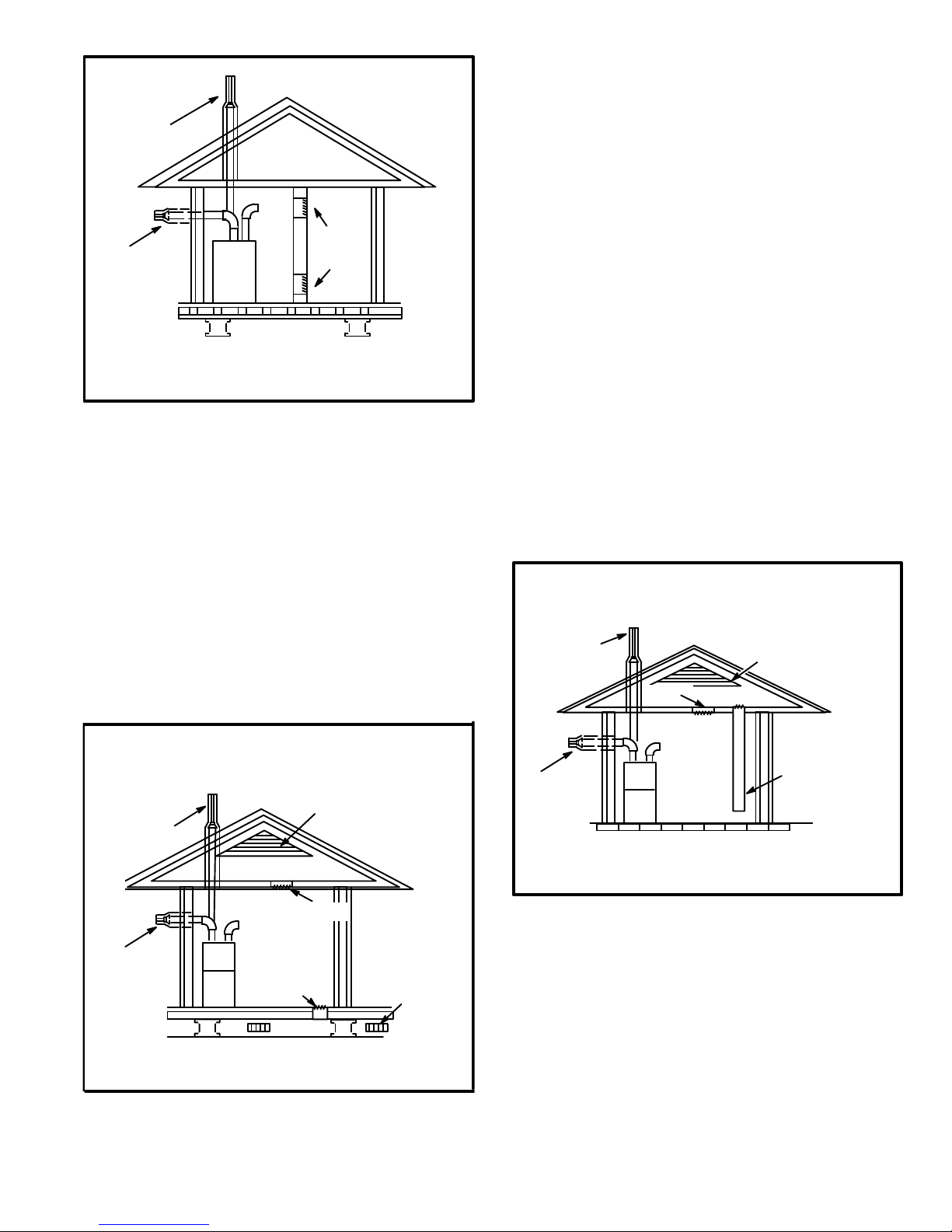

Air from Outside

If air from outside is brought in for combustion and ventilation, the confined space shall be provided with two permanent openings. One opening shall be within 12" (305mm)

of the top of the enclosure and one within 12" (305mm) of

the bottom. These openings must communicate directly

or by ducts with the outdoors or spaces (crawl or attic) that

freely communicate with the outdoors or indirectly

through vertical ducts. Each opening shall have a minimum free area of 1 square inch per 4,000 Btu (645mm

per 1.17kW) per hour of total input rating of all equipment

in the enclosure. When communicating with the outdoors

through horizontal ducts, each opening shall have a minimum free area of 1 square inch per 2,000 Btu (645mm

per .59kW) per total input rating of all equipment in the enclosure (See figure 14).

If air from outside is brought in for combustion and ventilation, the confined space must have two permanent openings. One opening shall be within 12 inches (305 mm) of

the top of the enclosure and one opening within 12 inches

(305 mm) of the bottom. These openings must communicate directly or by ducts with the outdoors or spaces (crawl

or attic) that freely communicate with the outdoors or indirectly through vertical ducts. Each opening shall have a

minimum free area of 1 square inch (645 mm2) per 4,000

Btu (1.17 kW) per hour of total input rating of all equipment

in the enclosure. See figures 14 and 15. When

communicating with the outdoors through horizontal

ducts, each opening shall have a minimum free area of 1

square inch (645 mm2) per 2,000 Btu (.56 kW) per total input rating of all equipment in the enclosure. See figure 16.

When ducts are used, they shall be of the same cross−sectional area as the free area of the openings to which they

connect. The minimum dimension of rectangular air ducts

shall be no less than 3 inches (75 mm). In calculating free

area, the blocking effect of louvers, grilles, or screens

must be considered. If the design and free area of protective covering is not known for calculating the size opening

required, it may be assumed that wood louvers will have

20 to 25 percent free area and metal louvers and grilles

will have 60 to 75 percent free area. Louvers and grilles

must be fixed in the open position or interlocked with the

equipment so that they are opened automatically during

equipment operation.

2

2

EQUIPMENT IN CONFINED SPACE − ALL AIR FROM OUTSIDE

(All Air Through Ventilated Attic)

ROOF TERMINATED

EXHAUST PIPE

OUTLET

AIR

VENTILATION LOUVERS

(Each end of attic)

EQUIPMENT IN CONFINED SPACE − ALL AIR FROM OUTSIDE

(Inlet Air from Crawl Space and Outlet Air to Ventilated Attic)

ROOF TERMINATED

EXHAUST PIPE

OUTLET

AIR

SIDE WALL

TERMINATED

EXHAUST PIPE

(ALTERNATE

LOCATION)

FURNACE

INLET

AIR

NOTE−The inlet and outlet air openings shall each have a free area

of at least one square inch per 4,000 Btu (645mm

hour of the total input rating of all equipment in the enclosure.

FIGURE 14

VENTILATION LOUVERS

(Each end of attic)

VENTILATION

LOUVERS

(For unheated

crawl space)

2

per 1.17kW) per

Page 15

SIDE WALL

TERMINATED

EXHAUST PIPE

(ALTERNATE

LOCATION)

FURNACE

NOTE−The inlet and outlet air openings shall each have a free area of

at least one square inch per 4,000 Btu (645mm

INLET AIR

(Ends 12" above

bottom)

2

per 1.17kW) per hour

of the total input rating of all equipment in the enclosure.

FIGURE 15

Page 16

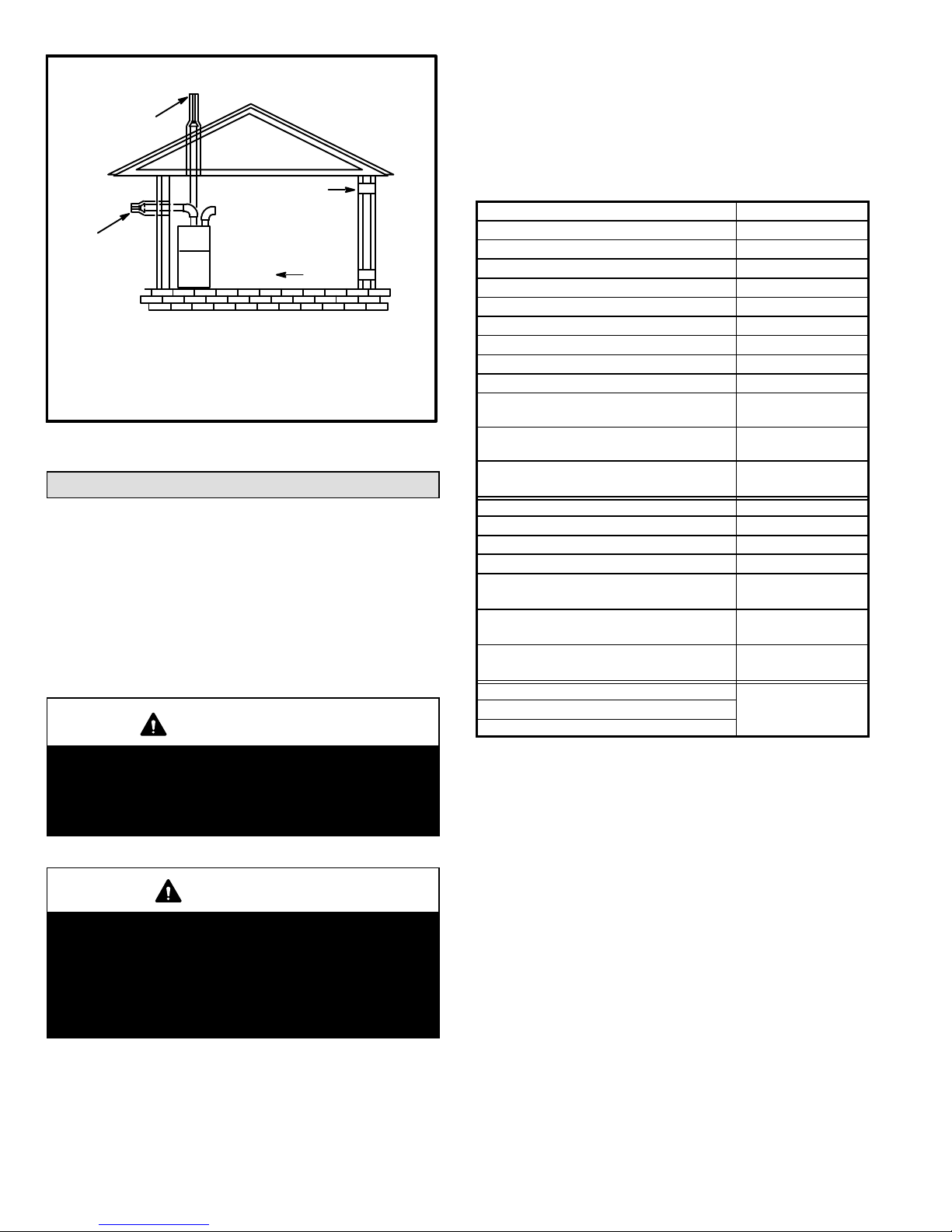

EQUIPMENT IN CONFINED SPACE −

ALL AIR FROM OUTSIDE

ROOF TERMINATED

EXHAUST PIPE

OUTLET AIR

SIDE WALL

TERMINATED

EXHAUST PIPE

(ALTERNATE

LOCATION)

NOTE−Each air duct opening shall have a free area of at least one

square inch per 2,000 Btu (645mm

input rating of all equipment in the enclosure. If the equipment room

is located against an outside wall and the air openings communicate directly with the outdoors, each opening shall have a free area

of at least 1 square inch per 4,000 Btu (645mm

hour of the total input rating of all other equipment in the enclosure.

FURNACE

INLET AIR

2

per .59kW) per hour of the total

2

per 1.17kW) per

FIGURE 16

Pipe & Fittings Specifications

All pipe, fittings, primer and solvent cement must conform

with American National Standard Institute and the American Society for Testing and Materials (ANSI/ASTM) standards. The solvent shall be free flowing and contain no

lumps, undissolved particles or any foreign matter that adversely affects the joint strength or chemical resistance of

the cement. The cement shall show no gelation, stratification, or separation that cannot be removed by stirring. Refer to the table 7 below for approved piping and fitting materials.

IMPORTANT

ML193UH exhaust and intake connections are made

of PVC. Use PVC primer and solvent cement when

using PVC vent pipe. When using ABS vent pipe, use

transitional solvent cement to make connections to

the PVC fittings in the unit.

CAUTION

Solvent cements for plastic pipe are flammable liquids and should be kept away from all sources of

ignition. Do not use excessive amounts of solvent

cement when making joints. Good ventilation should

be maintained to reduce fire hazard and to minimize

breathing of solvent vapors. Avoid contact of cement

with skin and eyes.

Use PVC primer and solvent cement or ABS solvent cement

meeting ASTM specifications, refer to Table 7. As an alternate, use all purpose cement, to bond ABS, PVC, or CPVC

pipe when using fittings and pipe made of the same materials. Use transition solvent cement when bonding ABS to either PVC or CPVC.

TABLE 7

PIPING AND FITTINGS SPECIFICATIONS

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (Cellular Core Pipe) F891

Schedule 40 PVC (Fittings) D2466

Schedule 40 CPVC (Pipe) F441

Schedule 40 CPVC (Fittings) F438

SDR−21 PVC or SDR−26 PVC (Pipe) D2241

SDR−21 CPVC or SDR−26 CPVC (Pipe) F442

Schedule 40 ABS Cellular Core DWV (Pipe) F628

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

ABS−DWV (Drain Waste & Vent)

(Pipe & Fittings)

PVC−DWV (Drain Waste & Vent)

Pipe & Fittings)

PRIMER & SOLVENT CEMENT

PVC & CPVC Primer F656

PVC Solvent Cement D2564

CPVC Solvent Cement F493

ABS Solvent Cement D2235

PVC/CPVC/ABS All Purpose Cement For

Fittings & Pipe of the same material

ABS to PVC or CPVC Transition Solvent

Cement

CANADA PIPE & FITTING & SOLVENT

CEMENT

PVC & CPVC Pipe and Fittings

PVC & CPVC Solvent Cement

ABS to PVC or CPVC Transition Cement

D2661

D2665

ASTM

SPECIFICATION

D2564, D2235, F493

D3138

MARKING

ULCS636

Low temperature solvent cement is recommended during

cooler weather. Metal or plastic strapping may be used for

vent pipe hangers. Uniformly apply a liberal coat of PVC

primer for PVC or use a clean dry cloth for ABS to clean inside socket surface of fitting and male end of pipe to depth

of fitting socket.

Canadian Applications Only − Pipe, fittings, primer

and solvent cement used to vent (exhaust) this appliance must be certified to ULC S636 and supplied by a

single manufacturer as part of an approved vent (exhaust) system. When bonding the vent system to the furnace, use ULC S636 approved One−Step Transition Cement to bond the pipe to the flue collar, or to bond the 90°

elbow or reducing 90° elbow to the flue collar. In addition, the first three feet of vent pipe from the furnace flue

collar must be accessible for inspection.

Page 16

Page 17

ML193

UNIT

OUTDOOR TERMINATION KITS USAGE

TABLE 8

STANDARD CONCENTRIC

Outdoor Ex-

VENT

PIPE

DIA.

haust Accel-

erator

(Dia. X

(in.)

2 YES YES YES* YES YES YES

Length)

1−1/2" X 12" 2" X 12"

Outdoor Exhaust Accel-

erator

(Dia. X

Length)

2" Wall Plate

Kit

22G44

or 30G28

3" Wall Plate

Kit

44J40

or 81J20

2" Wall

Ring Kit

15F74 51W11**

FlushMount

Kit

Concentric

44W92

1−1/2"

Kit

71M80

or

2" Con-

centric Kit

69M29

or

44W92

3" Con-

centric Kit

60L46

or 44W93

045

070

090

110

135 3 YES YES YES

*Requires field−provided and installed 1−1/2" exhaust accelerator.

** Kit 51W11 is provided with a 1−1/2" accelerator which must be used for all ML193UH−045, −070 and −090 installations.

Termination kits 44W92, 44W93, 30G28 and 81J20 approved for use in Canadian installations to meet CSAB149.

The 44W92 Concentric kit is provided with a 1−1/2" accelerator which must be installed on the exhaust outlet when this kit is used with the ML193UH045P36B,

ML193UH070P24B and ML193UH070P36B

2−1/2 YES YES YES* YES YES YES

3 YES YES YES* YES YES YES

2 YES YES YES* YES YES YES

2−1/2 YES YES YES* YES YES YES

3 YES YES YES* YES YES YES

2 YES YES YES YES YES YES

2−1/2 YES YES YES YES YES YES

3 YES YES YES YES YES YES

2 YES YES YES YES YES YES

2−1/2 YES YES YES YES YES YES

3 YES YES YES YES YES YES

furnaces.

5 − Uniformly apply a liberal coat of PVC primer for PVC or

Joint Cementing Procedure

All cementing of joints should be done according to the

specifications outlined in ASTM D 2855.

use a clean dry cloth for ABS to clean inside socket

surface of fitting and male end of pipe to depth of fitting

socket.

NOTE − Time is critical at this stage. Do not allow primer to dry before applying cement.

DANGER

6 − Promptly apply solvent cement to end of pipe and in-

side socket surface of fitting. Cement should be ap-

DANGER OF EXPLOSION!

Fumes from PVC glue may ignite during system

check. Allow fumes to dissipate for at least 5 minutes

before placing unit into operation.

plied lightly but uniformly to inside of socket. Take

care to keep excess cement out of socket. Apply second coat to end of pipe.

7 − Immediately after applying last coat of cement to pipe,

and while both inside socket surface and end of pipe

1 − Measure and cut vent pipe to desired length.

2 − Debur and chamfer end of pipe, removing any ridges

or rough edges. If end is not chamfered, edge of pipe

may remove cement from fitting socket and result in a

leaking joint.

3 − Clean and dry surfaces to be joined.

4 − Test fit joint and mark depth of fitting on outside of pipe.

are wet with cement, forcefully insert end of pipe into

socket until it bottoms out. Turn PVC pipe 1/4 turn during assembly (but not after pipe is fully inserted) to distribute cement evenly. DO NOT turn ABS or cellular

core pipe.

NOTE − Assembly should be completed within 20 seconds after last application of cement. Hammer blows

should not be used when inserting pipe.

Page 17

Page 18

8 − After assembly, wipe excess cement from pipe at end

of fitting socket. A properly made joint will show a

bead around its entire perimeter. Any gaps may indicate an improper assembly due to insufficient solvent.

9 − Handle joints carefully until completely set.

Venting Practices

CHIMNEY

OR GAS

VENT

(Check sizing

for water

heater only)

FURNACE

(Replaced

by ML193)

REPLACING FURNACE THAT WAS

PART OF A COMMON VENT SYSTEM

WATER

HEATER

Piping Suspension Guidelines

SCHEDULE 40

PVC − 5’

all other pipe* − 3’

* See table 7 for allowable pipe.

NOTE − Isolate piping at the point where it exits the outside wall or

roof in order to prevent transmission of vibration to the structure.

Wall Thickness Guidelines

24" maximum

3/4" minimum

inside outside

Wall

insulation

(if required)

FIGURE 17

1 In areas where piping penetrates joists or interior

walls, hole must be large enough to allow clearance on

all sides of pipe through center of hole using a hanger.

2. When furnace is installed in a residence where unit is

shut down for an extended period of time, such as a

vacation home, make provisions for draining condensate collection trap and lines.

OPENINGS

(To Adjacent

Room)

If an ML193UH furnace replaces a furnace which

was commonly vented with another gas appliance,

the size of the existing vent pipe for that gas appliance must be checked. Without the heat of the

original furnace flue products, the existing vent pipe

is probably oversized for the single water heater or

other appliance. The vent should be checked for

proper draw with the remaining appliance.

FIGURE 18

Exhaust Piping (Figures 21 and 22)

Route piping to outside of structure. Continue with installation following instructions given in piping termination section.

CAUTION

Do not discharge exhaust into an existing stack or

stack that also serves another gas appliance. If vertical discharge through an existing unused stack is required, insert PVC pipe inside the stack until the end

is even with the top or outlet end of the metal stack.

CAUTION

The exhaust vent pipe operates under positive pressure and must be completely sealed to prevent leakage of combustion products into the living space.

Page 18

Page 19

Vent Piping Guidelines

The ML193UH can be installed as either a Non−Direct

Vent or a Direct Vent gas central furnace.

NOTE − In Non-Direct Vent installations, combustion air is

taken from indoors and flue gases are discharged outdoors.

In Direct Vent installations, combustion air is taken from outdoors and flue gases are discharged outdoors.

Intake and exhaust pipe sizing −− Size pipe according to

tables 9 and 10. Table 9 lists the minimum vent pipe lengths

permitted. Table 10 lists the maximum pipe lengths permitted.

Regardless of the diameter of pipe used, the standard roof

and wall terminations described in section Exhaust Piping

Terminations should be used. Exhaust vent termination

pipe is sized to optimize the velocity of the exhaust gas as

it exits the termination. Refer to table 11.

In some applications which permit the use of several different sizes of vent pipe, a combination vent pipe may be

used. Contact Lennox’ Application Department for assistance in sizing vent pipe in these applications.

NOTE − The exhaust collar on all models is sized to accommodate 2" Schedule 40 vent pipe. When vent pipe

which is larger than 2" must be used in an upflow application, a transition must be applied at the exhaust collar in

order to properly step to the larger diameter vent pipe.

Contact the Application Department for more information

concerning sizing of vent systems which include multiple

pipe sizes.

Use the following steps to correctly size vent pipe diameter.

1

Furnace capacity?

Which termination?

2

3

4

Which needs

most elbows?

How many?

045, 070,

090, 110

or 135 btuh

Standard or

Concentric?

See table 8

Intake or

exhaust

Exhaust Pipe

12" Min.

12" max

of straight pipe

Horizontal Application

NOTE − All horizontal runs of exhaust pipe must slope back toward unit. A minimum of 1/4" (6mm) drop for each 12" (305mm)

of horizontal run is mandatory for drainage.

NOTE − Exhaust pipe MUST be glued to furnace exhaust fittings.

NOTE − Exhaust piping should be checked carefully to make

sure there are no sags or low spots.

FIGURE 19

TABLE 9

MINIMUM VENT PIPE LENGTHS

ML193UH

MODEL

045, 070, 090, 110

135**

*Any approved termination may be added to the minimum length listed.

**ML193UH135P60D must have 3" to 2" reducing ell (supplied or field replacement Canadian kit) installed directly into unit flue collar.

MIN. VENT LENGTH*

15 ft. or

5 ft plus 2 elbows or

10 ft plus 1 elbow

Desired pipe size?

5

6

What is the altitude?

Use table 5 to find

7

max. pipe length.

2", 2 1/2", 3"

FIGURE 20

IMPORTANT

Do not use screens or perforated metal in exhaust or

intake terminations. Doing so will cause freeze−ups

and may block the terminations.

Page 19

Page 20

Number

Of 90°

Ebows

Used

Number

Of 90°

Ebows

Used

Maximum Allowable Vent Length in Feet

TABLE 10

Standard Termination at Elevation 0 − 10,000 ft.

Pipe

Size

Model 045 070 090 110 135 045 070 090 110 135 045 070 090 110 135

1 81 66 44 24

2 76 61 39 19 11 0 95 63 38 132 132 113 113 109

3 71 56 34 14 105 90 58 33 127 127 108 108 104

4 66 51 29

5 61 46 24 95 80 48 23 11 7 11 7 98 98 94

6 56 41 19 90 75 43 18 11 2 11 2 93 93 89

7 51 36 14 85 70 38 13 107 107 88 88 84

8 46 31

9 41 26 75 60 28 97 97 78 78 74

10 36 21 70 55 23 92 92 73 73 69

Pipe

Size

Model 045 070 090 110 135 045 070 090 110 135 045 070 090 110 135

1 73 58 42 22

2 68 53 37 17 100 85 59 34 116 116 109 109 100

3 63 48 32 12 95 80 54 29 111 111 104 104 95

4 58 43 27

5 53 38 22 85 70 44 19 101 101 94 94 85

6 48 33 17 80 65 39 14 96 96 89 89 80

7 43 28 12 75 60 34

8 38 23

9 33 18 65 50 24 81 81 74 74 65

10 28 13 60 45 19 76 76 69 69 60

2" 2−1/2" 3"

115 100 68 43

100 85 53 28 122 122 103 103 99

n/a

n/a

80 65 33

n/a

Concentric Termination Elevation 0 − 10,000 ft.

2" 2−1/2" 3"

105 90 64 39

90 75 49 24 106 106 99 99 90

n/a

n/a

70 55 29 86 86 79 79 70

n/a

n/a

n/a

137 137 118 118 114

n/a

102 102 83 83 79

121 121 114 114 105

n/a

91 91 84 84 75

Page 20

Page 21

TYPICAL EXHAUST PIPE CONNECTIONS AND CONDENSATE TRAP INSTALLATION

IN UPFLOW DIRECT OR NON−DIRECT VENT APPLICATIONS

Pipe size determined in table 10

3”

TRANSITION

2”

TRAP

Use only the

factory−supplied trap.

Trap can be installed

on either side of

cabinet within 5 ft. of

the furnace.

TYPICAL EXHAUST PIPE CONNECTIONS AND CONDENSATE TRAP INSTALLATION

2”

EXHAUST

2”

2”

2”

or

2”

DO NOT transition

from smaller to larger

pipe in horizontal runs

of exhaust pipe.

FIGURE 21

IN HORIZONTAL DIRECT OR NON−DIRECT VENT APPLICATIONS

(RIGHT HAND DISCHARGE SHOWN)

12" max.

2”

EXHAUST

Use only the factory−supplied

trap. Trap can be installed

within 5 ft. of the furnace and

MUST be installed on left side

for left−hand discharge.

2”

or

2”

2”

FIGURE 22

45°

MAX

3”

2”

2”

TRANSITION

2”

SIDE VIEW

45°

MAX

DO NOT transition

from smaller to larger

pipe in horizontal runs

of exhaust pipe.

Page 21

Page 22

3”

TRANSITION

TYPICAL AIR INTAKE PIPE CONNECTIONS IN UPFLOW

DIRECT VENT APPLICATIONS

Pipe size determined in table 10

2”

AIR INTAKE

TRAP

*2”

2”

Use only the factory−supplied

trap. Trap can be installed on

either side of cabinet within 5

ft. of the furnace.

2”

2”

or

2”

FIGURE 23

TYPICAL AIR INTAKE PIPE CONNECTIONS IN HORIZONTAL DIRECT VENT APPLICATIONS

(RIGHT HAND DISCHARGE SHOWN)

2”

AIR INTAKE

Use only the factory−supplied trap.

Trap can be installed within 5 ft. of the

furnace and MUST be installed on left

side for left−hand discharge.

2”

or

2”

2”

FIGURE 24

3”

2”

2”

TRANSITION

2”

Page 22

Page 23

Intake Piping

The ML193UH furnace may be installed in either direct

vent or non−direct vent applications. In non−direct vent

applications, when intake air will be drawn into the furnace

from the surrounding space, the indoor air quality must be

considered and guidelines listed in Combustion, Dilution

and Ventilation Air section must be followed.

Follow the next two steps when installing the unit in Direct

Vent applications, where combustion air is taken from

outdoors and flue gases are discharged outdoors. The

provided air intake screen must not be used in direct

vent applications (outdoors).

1 − Use transition solvent cement or a sheet metal screw

to secure the intake pipe to the inlet air connector.

2 − Route piping to outside of structure. Continue with

installation following instructions given in general

guide lines for piping terminations and intake and exhaust piping terminations for direct vent sections. Refer to table 10 for pipe sizes.

TYPICAL AIR INTAKE PIPE CONNECTIONS

UPFLOW NON−DIRECT

VENT APPLICATIONS

INTAKE

DEBRIS

SCREEN

(Provided)

TYPICAL AIR INTAKE PIPE CONNECTIONS

HORIZONTAL NON−DIRECT VENT APPLICATIONS

(Horizontal Right−Hand Air Discharge Application Shown)

PVC pipe

coupling

OR

INTAKE

DEBRIS

SCREEN

(Provided)

NOTE − Debris screen may be positioned straight out

(preferred) or with an elbow rotated to face down.

FIGURE 26

Follow the next two steps when installing the unit in NonDirect Vent applications where combustion air is taken

from indoors and flue gases are discharged outdoors.

1 − Use field−provided materials and the factory−provided

air intake screen to route the intake piping as shown in

figure 25 or 26. Maintain a minimum clearance of 3"

(76mm) around the air intake opening. The air intake

opening (with the protective screen) should always be

directed forward or to either side in the upflow position,

and either straight out or downward in the horizontal

position.

The air intake piping must not terminate too close

to the flooring or a platform. Ensure that the intake

air inlet will not be obstructed by loose insulation

or other items that may clog the debris screen.

2 − Use a sheet metal screw to secure the intake pipe to

the connector, if desired.

NOTE − Debris screen and elbow may be rotated, so that

screen may be positioned to face forward or to either side.

FIGURE 25

Page 23

Page 24

General Guidelines for Vent Terminations

In Non-Direct Vent applications, combustion air is taken

from indoors and the flue gases are discharged to the outdoors. The ML193UH is then classified as a non-direct

vent, Category IV gas furnace.

In Direct Vent applications, combustion air is taken from

outdoors and the flue gases are discharged to the outdoors. The ML193UH is then classified as a direct vent,

Category IV gas furnace.

In both Non-Direct Vent and Direct Vent applications, the

vent termination is limited by local building codes. In the

absence of local codes, refer to the current National Fuel

Gas Code ANSI Z223−1/NFPA 54 in U.S.A., and current

CSA−B149 Natural Gas and Propane Installation Codes in

Canada for details.

Position termination according to location given in figure 27

or 28. In addition, position termination so it is free from any

obstructions and 12" above the average snow accumulation.

At vent termination, care must be taken to maintain

protective coatings over building materials (prolonged

exposure to exhaust condensate can destroy protective

coatings). It is recommended that the exhaust outlet not be

located within 6 feet (1.8m) of a condensing unit because

the condensate can damage the painted coating.

NOTE − If winter design temperature is below 32°F (0°C),

exhaust piping should be insulated with 1/2" (13mm), Armaflex or equivalent when run through unheated space.

Do not leave any surface area of exhaust pipe open to outside air; exterior exhaust pipe should be insulated with

1/2" (13mm) Armaflex or equivalent. In extreme cold climate areas, 3/4" (19mm) Armaflex or equivalent may be

necessary. Insulation on outside runs of exhaust pipe

must be painted or wrapped to protect insulation from deterioration. Exhaust pipe insulation may not be necessary

in some specific applications.

NOTE − During extremely cold temperatures, below

approximately 20°F (6.7°C), units with long runs of vent

pipe through unconditioned space, even when insulated,

may form ice in the exhaust termination that prevents the

unit from operating properly. Longer run times of at least 5

minutes will alleviate most icing problems. Also, a heating

cable may be installed on exhaust piping and termination

to prevent freeze−ups. Heating cable installation kit is

available from Lennox. See Condensate Piping section

for part numbers.

IMPORTANT

Do not use screens or perforated metal in exhaust

terminations. Doing so will cause freeze−ups and

may block the terminations.

IMPORTANT

For Canadian Installations Only:

In accordance to CSA International B149 installation

codes, the minimum allowed distance between the

combustion air intake inlet and the exhaust outlet of

other appliances shall not be less than 12 inches

(305mm).

Page 24

Page 25

VENT TERMINATION CLEARANCES

FOR NON−DIRECT VENT INSTALLATIONS IN THE USA AND CANADA

INSIDE CORNER

DETAIL

G

D

A

E

B

L

C

Fixed

F

Closed

Operable

B

B

B

VENT TERMINAL

AIR SUPPLY INLET

US Installations

A =

B =

C =

Clearance above grade, veranda,

porch, deck or balcony

Clearance to window or

door that may be opened

Clearance to permanently

12 inches (305mm) or 12 in. 305mm)

above average snow accumulation.

4 feet (1.2 m) below or to side of opening;

1 foot (30 cm) above opening

closed window

D =

Vertical clearance to ventilated soffit

located above the terminal within a

* Equal to or greater than soffit depth.

horizontal distance of 2 feet (mm)

from the center line of the terminal

E =

F =

G =

H =

I =

J =

Clearance to unventilated soffit

Clearance to outside corner

Clearance to inside corner

Clearance to each side of center line ex-

tended above meter / regulator assembly

Clearance to service regulator

vent outlet

Clearance to non−mechanical air

supply inlet to building or the com-

bustion air inlet to any other ap-

* Equal to or greater than soffit depth.

* No minimum to outside corner * No minimum to outside corner

* 3 feet (.9m) * 3 feet (.9m)

3 feet (.9m) within a height 15 feet (4.5m)

*

above the meter / regulator assembly

* 3 feet (.9m)

4 feet (1.2 m) below or to side of opening;

1 foot (30 cm) above opening

pliance

K =

L =

Clearance to mechanical air sup-

ply inlet

Clearance above paved sidewalk or

3 feet (.9m) above if within 10 feet

(3m) horizontally

7 feet (2.1m)

paved driveway located on public property

M =

1

2

A vent shall not terminate directly above a sidewalk or paved driveway that is located

between two single family dwellings and serves both dwellings.

Permitted only if veranda, porch, deck or balcony is fully open on a minimum of two

sides beneath the floor. Lennox recommends avoiding this location if possible.

Clearance under veranda, porch,

deck or balcony

In accordance with the current ANSI Z223.1/NFPA 54 Natural Fuel Gas Code

In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code

*12 inches (305mm)

FIGURE 27

H

Operable

A

Fixed

Closed

J

B

I

M

AREA WHERE TERMINAL

IS NOT PERMITTED

1

Canadian Installations

12 inches (305mm) or 12 in. 305mm)

above average snow accumulation.

6 inches (152mm) for appliances <10,000

Btuh (3kw), 12 inches (305mm) for

appliances > 10,000 Btuh (3kw) and

<100,000 Btuh (30kw), 36 inches (.9m)

for appliances > 100,000 Btuh (30kw)

* 12"

* 12"

* Equal to or greater than soffit depth.

* Equal to or greater than soffit depth.

3 feet (.9m) within a height 15 feet (4.5m)

above the meter / regulator assembly

3 feet (.9m)

6 inches (152mm) for appliances <10,000

Btuh (3kw), 12 inches (305mm) for

appliances > 10,000 Btuh (3kw) and

<100,000 Btuh (30kw), 36 inches (.9m)

for appliances > 100,000 Btuh (30kw)

6 feet (1.8m)

7 feet (2.1m)

12 inches (305mm)

*For clearances not specified in ANSI Z223.1/NFPA 54 or CSA B149.1,

clearance will be in accordance with local installation codes and the requirements of the gas supplier and these installation instructions."

K

2

Page 25

Page 26

VENT TERMINATION CLEARANCES

FOR DIRECT VENT INSTALLATIONS IN THE USA AND CANADA

INSIDE CORNER

DETAIL

G

D

A

E

B

L

C

Fixed

F

Closed

Operable

B

B

B

VENT TERMINAL

AIR SUPPLY INLET

US Installations

A =

B =

Clearance above grade, veranda,

porch, deck or balcony

Clearance to window or

door that may be opened

12 inches (305mm) or 12 in. 305mm)

above average snow accumulation.

6 inches (152mm) for appliances <10,000

Btuh (3kw), 9 inches (mm) for appliances

> 10,000 Btuh (3kw) and <50,000 Btuh

(15 kw), 12 inches (305mm) for ap-

pliances > 50,000 Btuh (15kw)

C =

Clearance to permanently

closed window

D =

Vertical clearance to ventilated soffit

located above the terminal within a

* Equal to or greater than soffit depth

horizontal distance of 2 feet (mm)

from the center line of the terminal

E =

F =

G =

H =

Clearance to unventilated soffit

Clearance to outside corner

Clearance to inside corner

Clearance to each side of center line ex-

tended above meter / regulator assembly

I =

Clearance to service regulator

vent outlet

J =

Clearance to non−mechanical air

supply inlet to building or the com-

bustion air inlet to any other ap-

pliance

* Equal to or greater than soffit depth * Equal to or greater than soffit depth

* No minimum to outside corner

* 3 feet (.9m)

3 feet (.9m) within a height 15 feet (4.5m)

above the meter / regulator assembly

*

3 feet (.9m)

6 inches (152mm) for appliances <10,000

Btuh (3kw), 9 inches (mm) for appliances

> 10,000 Btuh (3kw) and <50,000 Btuh

(15 kw), 12 inches (305mm) for ap-

pliances > 50,000 Btuh (15kw)

K =

L =

M =

1

2

A vent shall not terminate directly above a sidewalk or paved driveway that is located

between two single family dwellings and serves both dwellings.

Permitted only if veranda, porch, deck or balcony is fully open on a minimum of two

sides beneath the floor. Lennox recommends avoiding this location if possible.

Clearance to mechanical air sup-

ply inlet

Clearance above paved sidewalk or

paved driveway located on public property

Clearance under veranda, porch,

deck or balcony

In accordance with the current ANSI Z223.1/NFPA 54 Natural Fuel Gas Code

In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code

3 feet (.9m) above if within 10 feet

(3m) horizontally

* 7 feet (2.1m)

*12 inches (305mm)

FIGURE 28

H

Operable

A

Fixed

Closed

J

B

I

M

AREA WHERE TERMINAL

IS NOT PERMITTED

1

Canadian Installations

12 inches (305mm) or 12 in. 305mm)

above average snow accumulation.

6 inches (152mm) for appliances <10,000

Btuh (3kw), 12 inches (305mm) for

appliances > 10,000 Btuh (3kw) and

<100,000 Btuh (30kw), 36 inches (.9m)

for appliances > 100,000 Btuh (30kw)

* 12"

* 12"

* Equal to or greater than soffit depth* Equal to or greater than soffit depth

* No minimum to outside corner

* 3 feet (.9m)

3 feet (.9m) within a height 15 feet (4.5m)

above the meter / regulator assembly

3 feet (.9m)

6 inches (152mm) for appliances <10,000

Btuh (3kw), 12 inches (305mm) for

appliances > 10,000 Btuh (3kw) and

<100,000 Btuh (30kw), 36 inches (.9m)

for appliances > 100,000 Btuh (30kw)

6 feet (1.8m)

7 feet (2.1m)

12 inches (305mm)

*For clearances not specified in ANSI Z223.1/NFPA 54 or CSA B149.1, clearance will be in accordance with local installation codes and the requirements

of the gas supplier and these installation instructions."

K

2

Page 26

Page 27

Details of Intake and Exhaust Piping Terminations for

Direct Vent Installations

NOTE − In Direct Vent installations, combustion air is taken from outdoors and flue gases are discharged to outdoors.

Intake and exhaust pipes may be routed either horizontally

through an outside wall or vertically through the roof. In attic

or closet installations, vertical termination through the roof

is preferred. Figures 29 through 40 show typical terminations.

1. Exhaust and intake exits must be in same pressure

zone. Do not exit one through the roof and one on the

side. Also, do not exit the intake on one side and the

exhaust on another side of the house or structure.

2. Intake and exhaust pipes should be placed as close

together as possible at termination end (refer to illustrations). Maximum separation is 3" (76mm) on roof

terminations and 6" (152mm) on side wall terminations.

3. On roof terminations, the intake piping should terminate straight down using two 90° elbows (See figure

29).