Lennox ML180DF045P36A, ML180DF070P36A, ML180DF090P48B, ML180DF090XP48B, ML180DF110P60C Unit Information

...Page 1

Corp. 1219-L4

Service Literature

ML180DF series units are mid-efficiency gas furnaces

used for downflow applications only, manufactured with

Lennox Duralokt heat exchangers formed of aluminized

steel. ML180DF units are available in heating capacities of

44,000 to 110,000 Btuh and cooling applications 1.5 to 5

tons. Refer to Product Specifications bulletin for proper siz

ing.

Units are factory equipped for use with natural gas. Kits are

available for conversion to LP/Propane operation.

ML180DF model units are equipped with a hot surface igni

tion system. All units use a redundant gas valve to assure

safety shut-off as required by C.S.A.

All specifications in this manual are subject to change. Pro

cedures outlined in this manual are presented as a recom

mendation only and do not supersede or replace local or

state codes. In the absence of local or state codes, the

guidelines and procedures outlined in this manual (except

where noted) are recommended only and do not constitute

code.

TABLE OF CONTENTS

Specifications Page 2.............................

Blower Data Page 4..............................

Parts Identification Page 5.........................

I Unit Components Page 6........................

II Installation Page 14.............................

III Start Up Page 14..............................

IV Heating System Service Checks Page 14.........

Revised 02/2013

ML180DF(X)

IMPORTANT

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, person

al injury or loss of life. Installation and service must

be performed by a qualified installer, service agency

or the gas supplier.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at discon

nect switch(es). Unit may have multiple

power supplies.

V Typical Operating Characteristics Page 19.........

VI Maintenance Page 19..........................

VII Wiring and Sequence of Operation Page 22......

VIII Twinning Page 27.............................

Page 1

WARNING

Sharp edges.

Be careful when servicing unit to avoid sharp edges

which may result in personal injury.

© 2013 Lennox Industries Inc.

Page 2

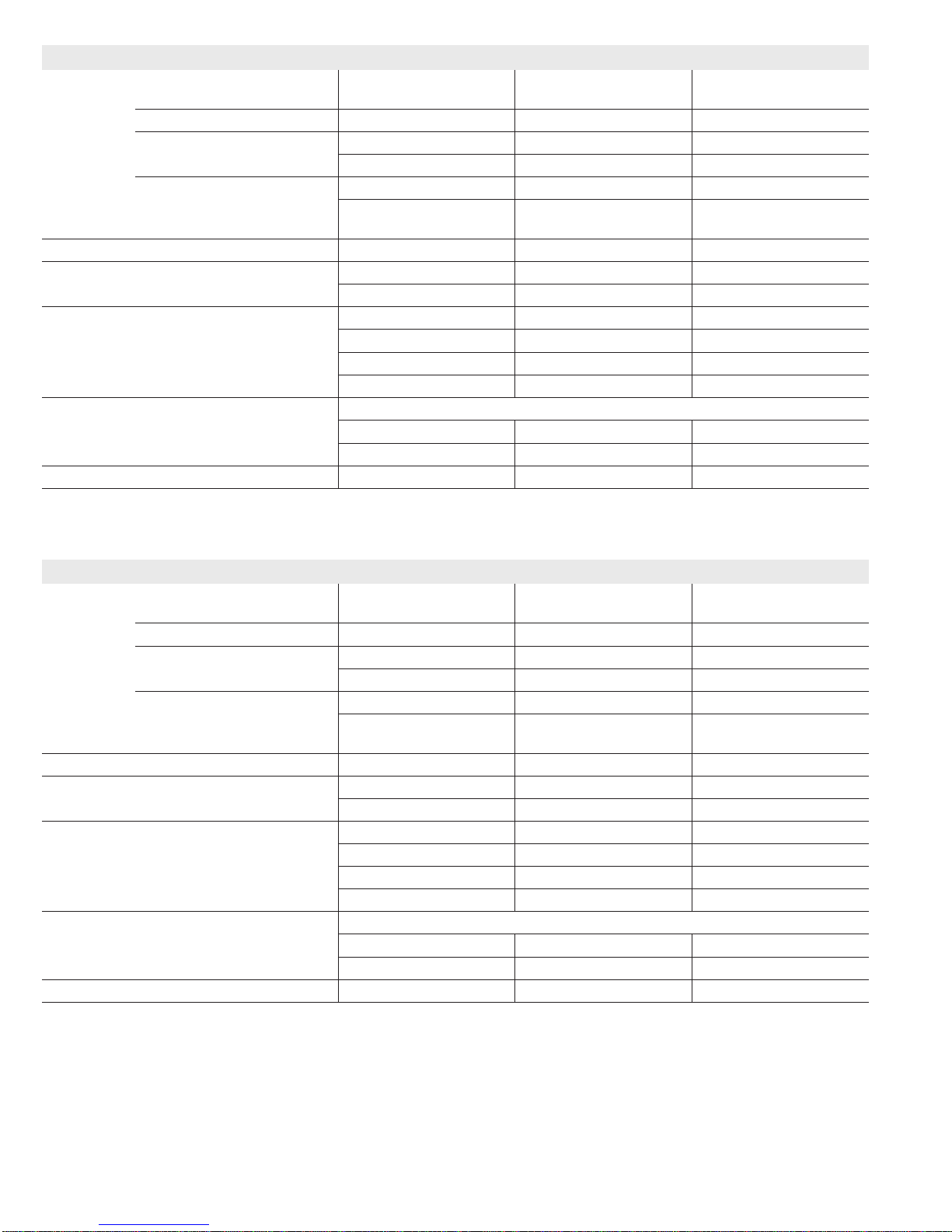

SPECIFICATIONS

Gas

Heating

Model No. - Low NO

Performance

Temperature rise range - °F 25 - 55 15 - 45 25 - 55

Gas Manifold Pressure (in. w.g.)

Nat. Gas / LPG/Propane

High Static - in. w.g. 0.50 0.50 0.50

Connections

Flue connection - in. round 4 4 4

in.

Indoor

Wheel nom. dia. x width - in. 10 x 7 10 x 8 10 x 8

Blower

Tons of add-on cooling 1.5 - 2 2 - 3 2 - 3

Air Volume Range - cfm 401 - 1157 739 - 1524 717 - 1562

Electrical

Data

Blower motor full load amps 3.1 6.1 6.1

Maximum overcurrent protection 15 15 15

Shipping Data lbs. - 1 package 105 113 128

NOTE - Filters and provisions for mounting are not furnished and must be eld provided.

1

Annual Fuel Utilization Efciency based on DOE test procedures and according to FTC labeling regulations. Isolated combustion system rating for non-weatherized furnaces.

Model No.

1

AFUE 80% 80% 80%

ML180DF045P24A

x

- - -

ML180DF045P36A

- - -

ML180DF070P36A

ML180DF070XP36A

Input - Btuh 44,000 44,000 66,000

Output - Btuh 35,000 36,000 53,000

3.5 / 10.0 3.5 / 10.0 3.5 / 10.0

Gas pipe size IPS 1/2 1/2 1/2

Motor output - hp 1/5 1/3 1/3

Voltage 120 volts - 60 hertz - 1 phase

SPECIFICATIONS

Gas

Heating

Model No. - Low NO

Performance

Temperature rise range - °F 35 - 65 25 - 55 30 - 60

Gas Manifold Pressure (in. w.g.)

Nat. Gas / LPG/Propane

High Static - in. w.g. 0.50 0.50 0.50

Connections

Flue connection - in. round 4 4 4

in.

Indoor

Wheel nom. dia. x width - in. 10 x 9 10 x 10 11-1/2 x 10

Blower

Tons of add-on cooling 2 - 3 3 - 4 4 - 5

Air Volume Range - cfm 743 -1695 917 - 1929 1517 - 2760

Electrical

Data

Blower motor full load amps 6.1 8.2 10.0

Maximum overcurrent protection 15 15 15

Shipping Data lbs. - 1 package 131 140 160

NOTE - Filters and provisions for mounting are not furnished and must be eld provided.

1

Annual Fuel Utilization Efciency based on DOE test procedures and according to FTC labeling regulations. Isolated combustion system rating for non-weatherized furnaces.

Model No.

1

AFUE 80% 80% 80%

ML180DF090P36B

x

- - -

ML180DF090P48B

ML180DF090XP48B

ML180DF110P60C

ML180DF110XP60C

Input - Btuh 88,000 88,000 110,000

Output - Btuh 71,000 71,000 89,000

3.5 / 10.0 3.5 / 10.0 3.5 / 10.0

Gas pipe size IPS 1/2 1/2 1/2

Motor output - hp 1/3 1/2 1

Voltage 120 volts - 60 hertz - 1 phase

Page 2

Page 3

OPTIONAL ACCESSORIES - ORDER SEPARATELY

“A” Width

Models

CABINET ACCESSORIES

Downow Combustible Flooring Base 11M59 11M60 11M61

CONTROLS

Twinning Kit 15L38 15L38 15L38

FILTERS

1

Downow Filter Cabinet 51W06 51W07 51W08

No. and Size of lter - in. (1) 20 x 20 x 1 (2) 20 x 16 x 1 (2) 20 x 16 x 1

service kits

Night Service Kit 51W03 51W03 51W03

Universal Service Kit - Switches 89W19 89W19 89W19

1

Cleanable polyurethane, frame-type lter.

“B” Width

Models

“C” Width

Models

GAS HEAT ACCESSORIES

Natural Gas

High Altitude

Orice Kit

Input

High Altitude

Pressure Switch Kit

Natural Gas to

LPG/Propane Kit

LPG/Propane

to Natural Gas Kit

0 - 4500 ft. 4501 - 7500 ft. 7501 - 10,000 ft. 0 - 7500 ft. 7501 - 10,000 ft. 0 - 7500 ft. 7501 - 10,000 ft.

045 No Change No Change 80W51 70W89 76W15 73W81 73W37

070 No Change 80W52 80W51 70W89 76W15 73W81 73W37

090 No Change No Change 80W51 70W89 76W15 73W81 73W37

110 No Change 80W52 80W51 70W89 76W15 73W81 73W37

HIGH ALTITUDE DERATE

NOTE - Units may be installed at altitudes up to 4500 ft. above sea level without any modications.

At altitudes above 4500 ft. units must be derated to match information in the shaded areas shown below.

NOTE - This is the only permissible derate for these units.

Gas Manifold Pressure (Outlet) in. w.g. Line Pressure - in. w.g.

Input

0 - 4500 Feet 4501 - 7500 Feet 7501 - 10,000 ft. Minimum

1

Natural

Gas

LPG/

Propane

Natural

Gas

LPG/

Propane

Natural

Gas

LPG/

Propane

Natural

Gas

LPG/

Propane

045 3.5 10 3.5 10 3.5 10 4.5 11 13

070 3.5 10 3.3 10 3.5 10 4.5 11 13

090 3.5 10 3.3 10 3.5 10 4.5 11 13

110 3.5 10 3.3 10 3.5 10 4.5 11 13

1

Natural Gas High Alitude Orice Kit required.

INSTALLATION CLEARANCES

Vent Type Type B1 Type C

Sides 0 in. (0 mm)

1

in. (0 mm)

Rear 0 in. (0 mm) 0 in. (0 mm)

Top 1 in. (25 mm) 1 in. (25 mm)

Front 2-1/4 in. (57 mm) 2-1/4 in. (57 mm)

Front (service/alcove) 24 in. (610 mm) 24 in. (610 mm)

Floor

2

Combustible

2

Combustible

Flue 1 in. (25 mm) 6 in. (152 mm)

NOTE − Air for combustion must conform to the methods outlined in the

National Fuel Gas Code (NFPA 54/ANSI-Z223.1).

NOTE − In the U.S. ue sizing must conform to the methods outlined in the

current National Fuel Gas Code (NFPA 54/ANSI-Z223.1) or applicable

provisions of local building codes.

1

Left side requires 4 in. if single wall vent is used on 14-1/2 in. “A” width

cabinets, 2 in. on 17-1/2 in. “B” width cabinets.

2

Clearance for installation on combustible oor if Optional Downow

Combustible Flooring Base is installed between furnace and combustible oor.

Not required in add-on cooling applications if installed in accordance with local

codes, National Fuel Gas Code ANSI-Z223.1 or National Standard of Canada

CAN/CSA-B149.1 and CAN/CSA-B149.2 Installation Code for Gas Burning

Appliances”. Do not install the furnace directly on carpeting, tile, or other

combustible materials other than wood ooring.

Maximum

Page 3

Page 4

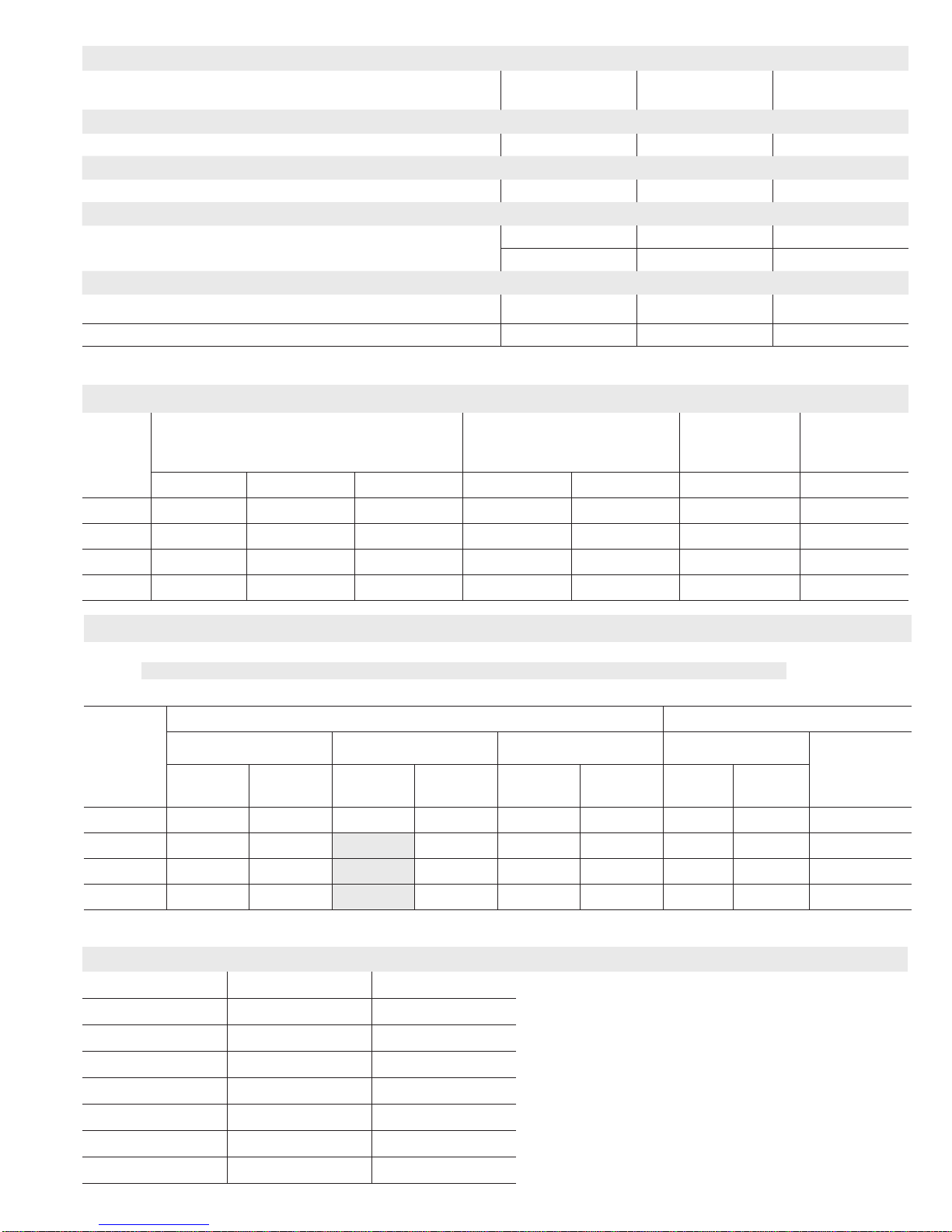

BLOWER DATA

ML180DF045P24A PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.10 1157 399 938 333 764 273 699 243

0.20 1120 381 924 322 745 264 677 237

0.30 1084 362 890 311 723 258 650 230

0.40 1027 349 864 298 695 250 633 224

0.50 975 334 814 283 674 238 605 215

0.60 902 322 764 268 623 225 564 203

0.70 831 305 682 248 549 208 477 186

0.80 713 280 576 228 470 192 401 171

ML180DF070P36A PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.10 1562 591 1386 539 1159 436 956 374

0.20 1506 553 1355 504 1149 418 953 361

0.30 1459 528 1314 473 1119 392 941 343

0.40 1390 500 1264 442 1082 374 915 323

0.50 1306 477 1200 415 1048 352 904 305

0.60 1213 441 1129 391 987 332 849 288

0.70 1140 417 1066 361 901 304 798 270

0.80 1038 395 975 342 836 283 717 244

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Medium-

High

Medium-

High

Medium-

Low

Medium-

Low

Low

Low

ML180DF045P36A PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.10 1524 567 1385 528 1144 431 947 366

0.20 1465 542 1351 490 1129 407 943 354

0.30 1414 517 1293 463 1111 393 950 341

0.40 1343 489 1236 436 1083 371 945 329

0.50 1255 464 1190 409 1038 356 897 311

0.60 1205 443 1106 380 999 333 870 292

0.70 1140 421 1059 366 943 317 816 275

0.80 1031 388 962 335 870 297 739 252

ML180DF090P36B PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.10 1695 647 1431 546 1180 468 973 379

0.20 1641 611 1405 516 1162 443 967 368

0.30 1595 589 1384 492 1146 420 958 349

0.40 1525 548 1344 472 1136 399 954 337

0.50 1438 515 1271 432 1110 374 929 319

0.60 1370 489 1197 400 1057 352 886 299

0.70 1260 451 1119 374 983 328 823 273

0.80 1164 425 1020 344 900 300 743 249

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Medium-

High

Medium-

High

Medium-

Low

Medium-

Low

Low

Low

ML180DF090P48B PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.10 1929 755 1794 668 1585 572 1332 489

0.20 1864 717 1745 623 1544 540 1321 463

0.30 1779 683 1676 588 1496 510 1296 440

0.40 1694 647 1600 558 1443 473 1265 417

0.50 1596 607 1502 511 1363 440 1212 393

0.60 1483 577 1413 485 1258 406 1148 370

0.70 1340 544 1273 449 1148 374 1042 339

0.80 1221 505 1138 416 1018 350 917 307

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Medium-

High

Medium-

Low

Low

ML180DF110P60C PERFORMANCE (Less Filter)

External

Static

Pressure

in. w.g.

0.10 2760 1401 2325 1045 1888 871 1531 686

0.20 2670 1362 2319 1003 1937 847 1565 679

0.30 2557 1292 2257 964 1945 832 1605 674

0.40 2536 1287 2220 949 1935 812 1622 661

0.50 2384 1230 2152 9 11 1918 782 1626 644

0.60 2273 1191 2063 884 1884 762 1617 630

0.70 2197 1151 2021 875 1822 737 1574 610

0.80 2115 1140 1950 854 1749 708 1517 579

Air Volume / Watts at Various Blower Speeds

High

cfm Watts cfm Watts cfm Watts cfm Watts

Medium-

High

Medium-

Low

Low

Page 4

Page 5

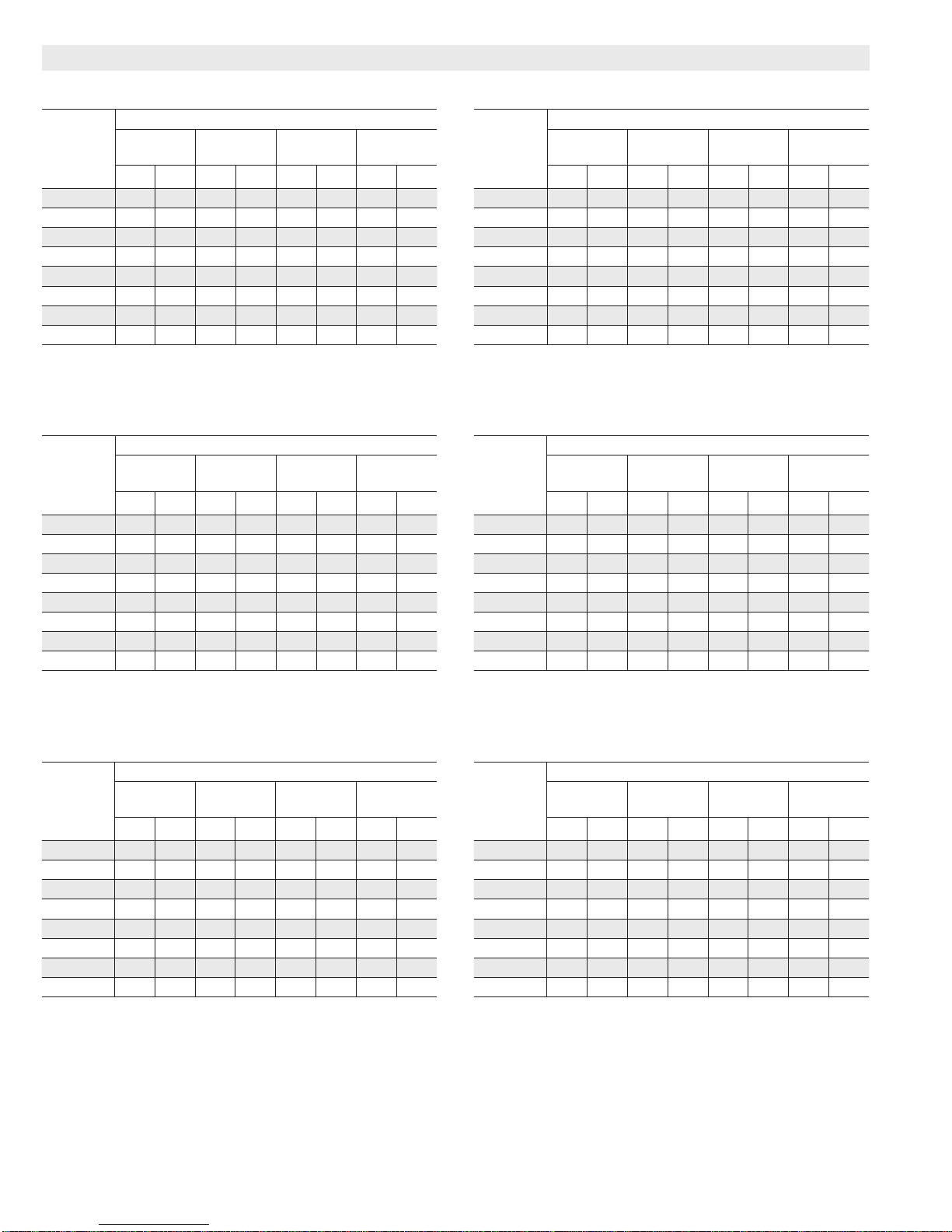

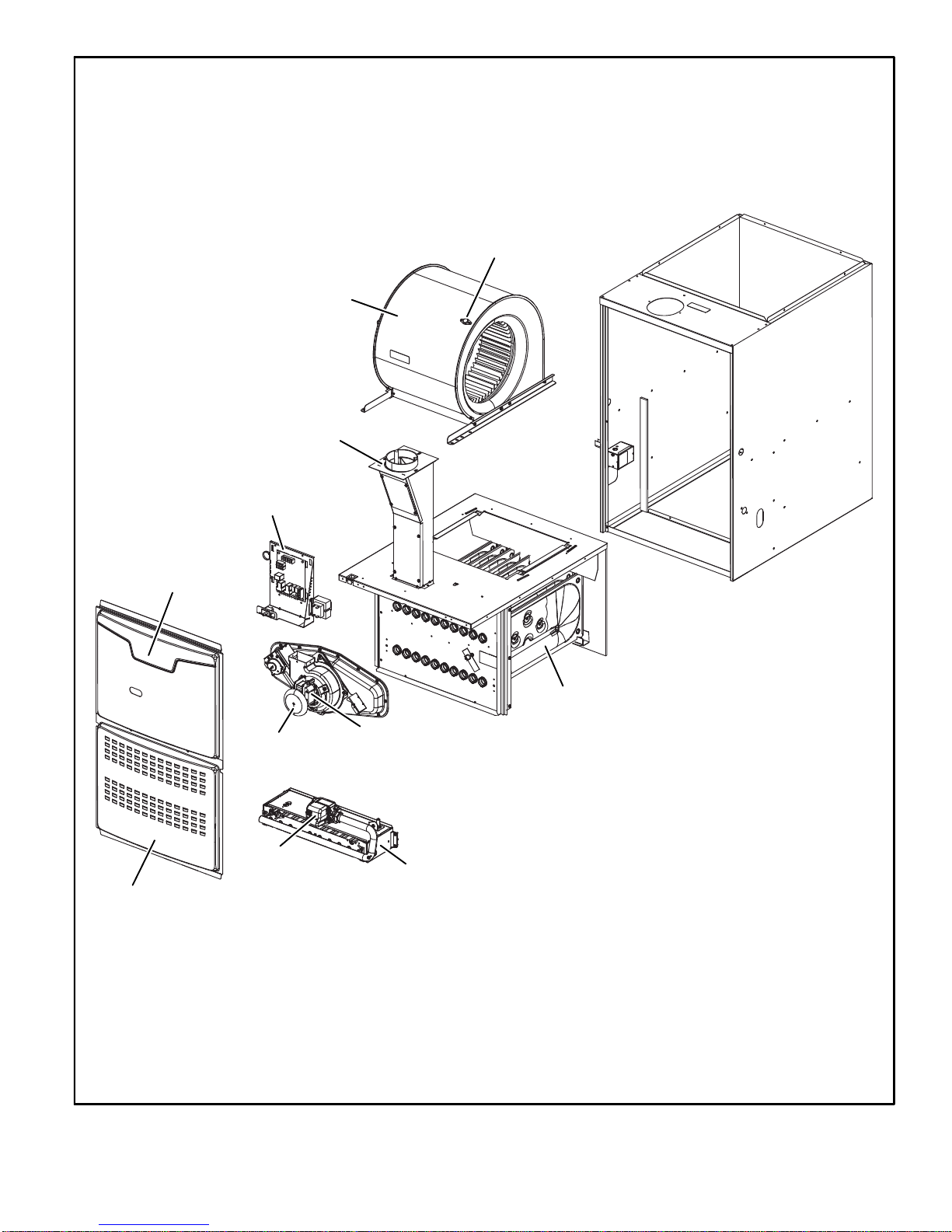

Blower Assembly

Flue Chase

Control Box

(includes integrated control,

interlock switch and transformer)

ML180DF PARTS ARRANGEMENT

Secondary Limit

Blower Access Panel

Heating Compartment

Access Panel

Primary Limit

(under combustion

air inducer)

Gas Valve

Heat Exchanger

Combustion

Air Inducer

Burner Box

(includes sensor, ignitor

and rollout switches)

FIGURE 1

Page 5

Page 6

I-UNIT COMPONENTS

ML180DF unit components are shown in figure 1.The gas

valve, combustion air inducer and burners can be ac

cessed by removing the heating compartment access pan

el. Electrical components are in the control box (figure 2)

found in the blower section.

CAUTION

Electrostatic discharge can affect elec

tronic components. Take precautions

to neutralize electrostatic charge by

touching your hand and tools to metal

prior to handling the control.

1. Control Transformer (T1)

A transformer located in the control box provides power to

the low voltage section of the unit. Transformers on all

models are rated 40VA with a 120V primary and a 24V sec

ondary.

2. Door Interlock Switch (S51)

A door interlock switch rated 14A at 125VAC is wired in se

ries with line voltage. When the blower door is removed the

unit will shut down.

CONTROL BOX ML180DF

Integrated Control

Door

Interlock

Switch

FIGURE 2

Transformer

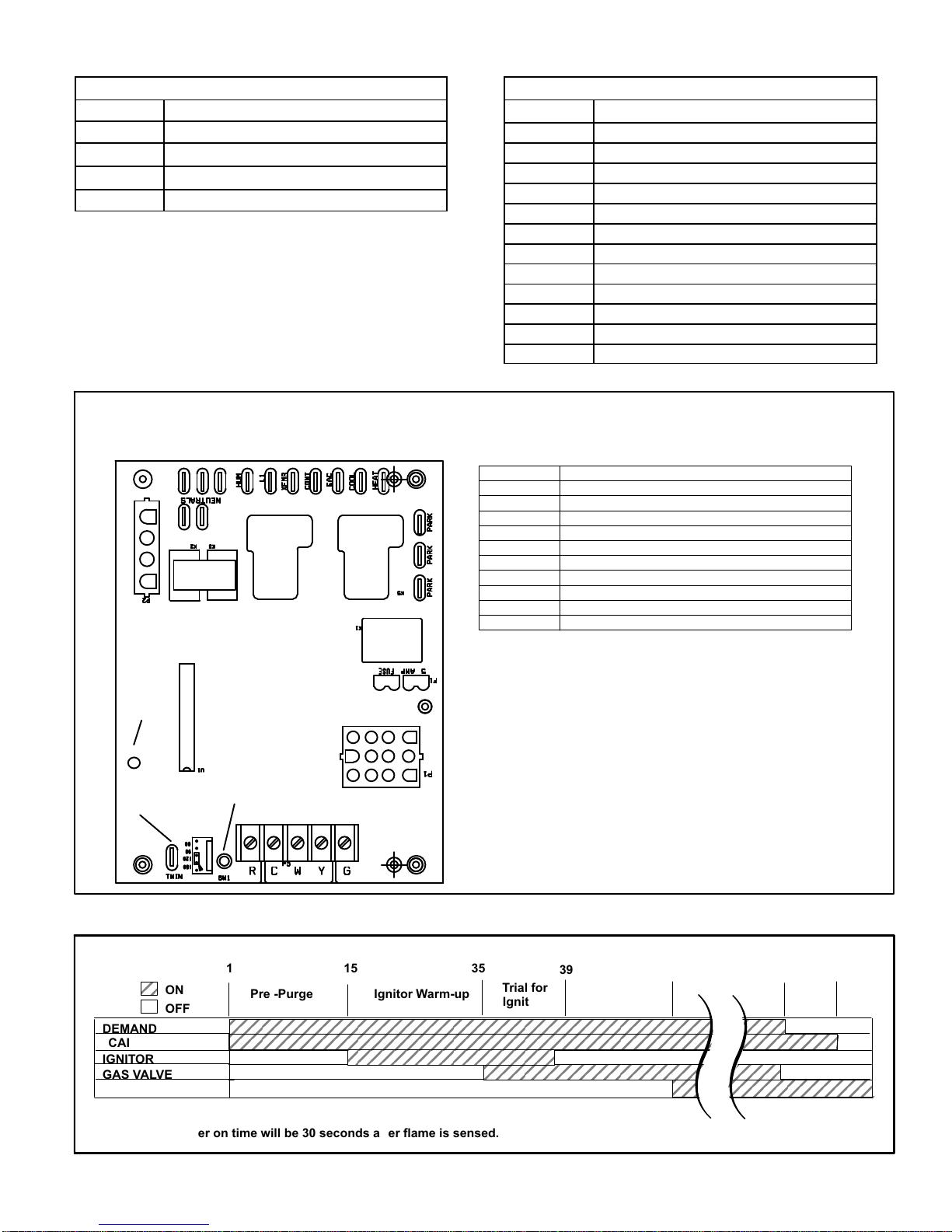

3. Integrated Control (A92)

WARNING

Shock hazard.

Disconnect power before servicing. Control is not

field repairable. If control is inoperable, simply re

place entire control.

Can cause injury or death. Unsafe operation will re

sult if repair is attempted.

The hot surface ignition control system consisting of an in

tegrated control (figure 3 with control terminal designa

tions in tables 1 and 2), flame sensor and ignitor (figure 6).

The integrated control and ignitor work in combination to

ensure furnace ignition and ignitor durability. The inte

grated control, controls all major furnace operations. The

integrated control also features a RED LED for trouble

shooting and two accessory terminals rated at (1) one

amp. See table 3 for troubleshooting diagnostic codes.

The 120 volt ignitor is made from a high strength, silicon

nitride material that provides long life and trouble free

maintenance.

Electronic Ignition (Figure 4)

On a call for heat the integrated control monitors the com

bustion air inducer pressure switch. The control will not be

gin the heating cycle if the pressure switch is closed (bypassed). Once the pressure switch is determined to be

open, the combustion air inducer is energized. When the

differential in the pressure switch is great enough, the pres

sure switch closes and a 15-second pre-purge begins. If

the pressure switch is not proven within 2-1/2 minutes, the

integrated control goes into Watchguard-Pressure Switch

mode for a 5-minute re-set period.

After the 15-second pre-purge period, the ignitor warms up

for 20 seconds after which the gas valve opens for a 4-sec

ond trial for ignition. The ignitor remains energized for the

first 3 seconds of trial for ignition. If ignition is not proved

during the trial for ignition, the integrated control will try four

more times with an inter purge and warm-up time between

trials of 30 seconds. After a total of five trials for ignition (in

cluding the initial trial), the integrated control goes into

Watchguard-Flame Failure mode. After a 60-minute reset

period, the integrated control will begin the ignition se

quence again.

Page 6

Page 7

TABLE 1

4-Pin Terminal Designation

PIN # FUNCTION

1 Combustion Air Inducer Line

2

3

4

Ignitor Line

Combustion Air Inducer Neutral

Ignitor Neutral

12-Pin Terminal Designations

PIN # FUNCTION

1 High Limit Output

2 Sensor

3 24V Line

4 Not Used

5 Rollout Switch Out

6 24V Neutral

7 High Limit Input

8 Ground

9 Gas Valve Common

10 Pressure Switch In

11 Rollout Switch In

12 Gas Valve Out

INTEGRATED CONTROL

(Automatic Hot Surface Ignition System)

TERMINAL DESIGNATIONS

HUM

LINE

XFMR

EAC

COOL

HEAT

PARK

CONT

NEUTRALS

TWIN

Humidifier (120VAC)

Input (120VAC)

Transformer (120VAC)

Indoor Air Qality Accessory Air Cleaner (120VAC)

Blower - Cooling Speed (120VAC)

Blower - Heating Speed (120VAC)

Dead terminals to park alternate spd taps

Continuous blower

Neutral terminals (120VAC)

Twinning Terminal (24VAC)

TABLE 2

LED

TWIN

ON

OFF

DEMAND

CAI

IGNITOR

GAS VALVE

INDOOR BLOWER

*Blower on time will be 30 seconds after flame is sensed. Blower off time will depend on “OFF TIME” Setting.

PUSH BUTTON

1

Pre -Purge Ignitor Warm-up

15

FIGURE 3

ELECTRONIC IGNITION

35

Trial for

Ignition

39

Blower “On”*

Delay

5 SEC69

Post

Purge

FIGURE 4

Page 7

Page 8

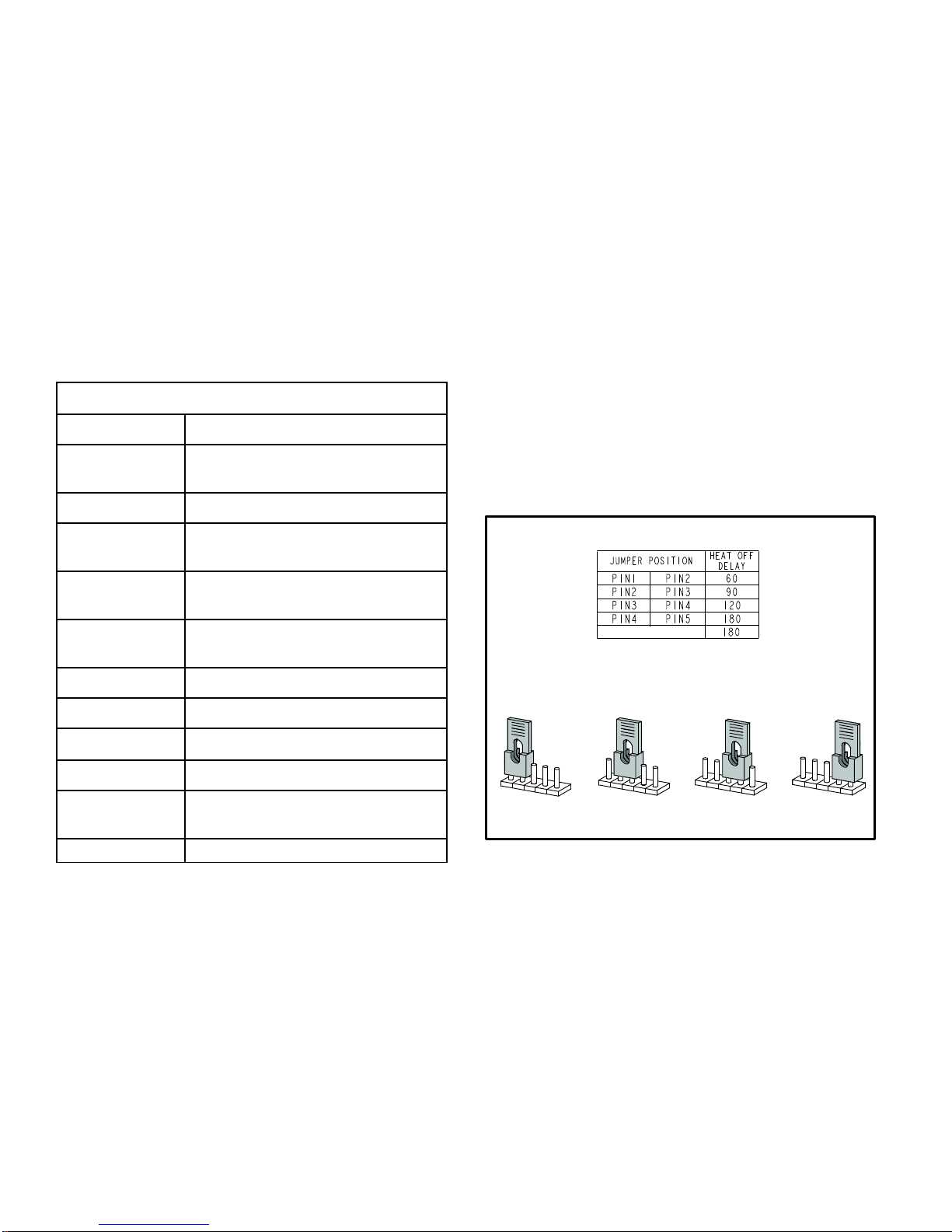

TABLE 3

Note - This control is equipped with a push button switch for

diagnostic code recall. The control stores the last 5 fault

codes in non-volatile memory. The most recent fault code is

flashed first, the oldest fault code is flashed last. There is a

2 second pause between codes. When the push button

switch is pressed for less than 5 seconds, the control will

flash the stored fault codes when the switch is released.

The fault code history may be cleared by pressing the push

button switch for more than 5 seconds.

Integrated Control Diagnostic Codes

DIAGNOSTIC CODES

LED Status DESCRIPTION

LED Off

LED On Normal operation.

No power to control or control harware

fault detected.

Fan Time Control

Heating Fan On Time

The fan on time of 30 seconds is not adjustable.

Heating Fan Off Time

Fan off time (time that the blower operates after the heat

demand has been satisfied) can be adjusted by moving the

jumper to a different setting. The unit is shipped with a fac

tory fan off setting of 120 seconds. For customized comfort,

monitor the supply air temperature once the heat demand

is satisfied. Note the supply air temperature at the instant

the blower is de-energized.

Adjust the fan-off delay to achieve a supply air temperature

between 90° - 110° at the instant the blower is de-ener

gized. (Longer delay times allow for lower air temperature,

shorter delay times allow for higher air temperature). See

figure 5.

Cooling Fan On Time

The fan on time is 2 seconds and is not adjustable.

Cooling Fan Off Time

The control has a 60 second fan off delay after cooling de

mand has been met. This delay is factory set and not ad

justable.

1 Flash

2 Flashes

3 Flashes

4 Flashes Primary limit switch open.

5 Flashes Rollout switch open.

6 Flashes Pressure switch cycle lockout.

7 Flashes Lockout, burners fail to light.

8 Flashes

Flame present with gas vavle

de-energized.

Pressure switch closed with combustion

air inducer de-energized.

Pressure switch open with combus

tion air inducer energized.

Lockout, buners lost flame too many

times.

9 Flashes Line voltage polarity incorrect.

HEAT FAN‐OFF TIME IN SECONDS

NO JUMPER

To adjust fan-off timing, reposition jumper across pins to

60 Second

off Time

60

90

120

180

achieve desired setting.

90 Second

off Time

60

90

120

180

120 Second

off Time

60

90

120

180

FIGURE 5

180 Second

off Time

60

90

120

180

Page 8

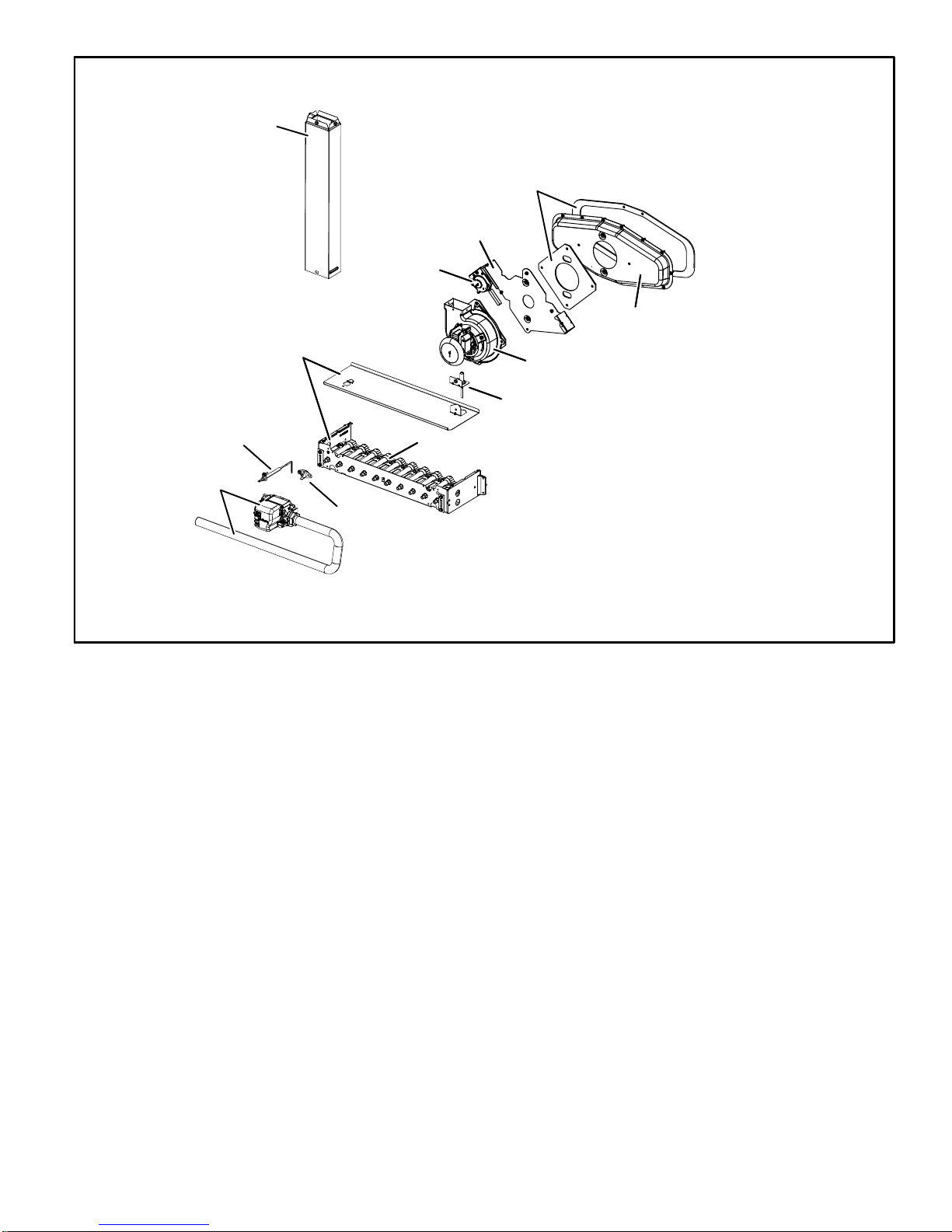

Page 9

Internal flue pipe

Burner box

assembly

ML180DF HEATING COMPONENTS

Gasket

Orifice plate

Pressure switch

Collector box

Combustion air inducer

Ignitor

Rollout

switch

Burners

Manifold and

Gas valve

Sensor

FIGURE 6

4. Flame Rollout Switch (Figure 6)

Flame rollout switch (S47) is a high temperature limit. The

limit is a N.C. SPST manual‐reset limit connected in series

with the integrated control A92. When S47 senses rollout,

the integrated control immediately stops ignition and

closes the gas valve. If unit is running and flame rollout is

detected, the gas valve will close and integrated control will

be disabled. Rollout can be caused by a blocked heat ex

changer, blocked flue or lack of combustion air. The switch

has a factory setpoint of 210°F and cannot be adjusted. To

manually reset a tripped switch, push the reset button located

on the control.

5. Primary Limit Control

The primary limit on ML180DF units is located in the heating

vestibule panel under the combustion air inducer. When ex

cess heat is sensed in the heat exchanger, the limit will open. If

the limit is open, the integrated control energizes the supply air

blower and closes the gas valve. The limit automatically resets

when unit temperature returns to normal. The switch must re

set within three minutes or the control will go into Watchguard

for one hour. The switch is factory set and cannot be ad

justed. The switch may have a different setpoint for each unit

model number. If limit switch must be replaced, refer to Len

nox ProductZone repair parts list on Lennox DaveNet®.

6. Flame Sensor (Figure 6)

A flame sensor is located on the left side of the burner sup

port. The sensor is mounted on the flame rollout plate and

the tip protrudes into the flame envelope of the left-most

burner. The sensor can be removed for service (clean us

ing steel wool) without removing any part of the burners.

During operation, flame is sensed by current passed

through the flame and sensing electrode. The integrated

control allows the gas valve to remain open as long as

flame signal is sensed.

A microamp DC meter is needed to check the flame signal

on the integrated control.

Flame (microamp) signal is an electrical current which passes

from the integrated control to the sensor during unit operation.

Current passes from the sensor through the flame to ground to

complete a safety circuit.

Page 9

Page 10

To Measure Flame Signal - Integrated Control:

Use a digital readout meter capable of reading DC micro

amps. See figure 7 and table 4 for flame signal check.

1 - Set the meter to the DC amps scale.

2 - Turn off supply voltage to control.

3 - Remove sensor wire from integrated control.

4 - Connect (-) lead to flame sensor wire.

5 - Connect (+) lead to Terminal FS on integrated control.

Measuring Flame Signal

(upflow furnace shown)

6 - Turn supply voltage on and close thermostat contacts to

cycle system.

7 - When main burners are in operation for two minutes, take

reading.

TABLE 4

Flame Signal in Microamps

Normal Low Drop Out

1.5

0.5 - 1.4

0.4

Flame

Sensor

Flame Sensor

Wire

Integrated

Control

(+)

Flame Sensor

Terminal

(+) To Control

Sensor

Terminal

Remove Sensor Wire from

Integrated Control and

Connect Alligator Clip (−)

to Flame Sensor Lead

DIGITAL METER

Set dial to measure dc microamps

Red Collar

Indicates

Positive Lead

(+)

(-) To

flame

sensor

Remove Sensor Wire from

Integrated Control and

Connect Alligator Clip (+)

to Terminal on Control

FIGURE 7

Page 10

Page 11

7. Ignitor (Figure 6)

The nitride ignitor used on ML180DF units is made from a

proprietary ceramic material. To check ignitor, measure its

resistance and voltage. A value of 39 to 70 ohms indicates

a good ignitor. Voltage to the ignitor should be 120VAC.

See figure 8 for resistance, and voltage check.

NOTE - The ML180DF furnace contains electronic

components that are polarity sensitive. Make sure that

the furnace is wired correctly and is properly grounded.

Check ignitor circuit for correct resistance.

Test 1

Remove 4-pin plug from control.

Check ohms reading across terminals 2 and 4.

If value is correct (39 to 70 ohms), this is the only test

needed.If the reading on the meter is not correct,

(0 or infinity) then a second test is needed.

Test 2

Check ignitor for correct resistance.

Seperate the 2-pin jack-plug near the manifold and check

resistance of ignitor at the plug. Reading should be

between 39 and 70 ohms. If the reading is correct, then

the problem is with the wiring between the jack-plug and

the control. If reading is not correct, the issue is the ignitor.

Test 2

Test 1

Integrated Control Board

Detail

Insert meter probes into terminals 2 and 4 (use small

Check ignitor for correct voltage

diameter probes in order not to damage plug).

Check voltage during 20 second ignitor warm up period.

Voltage should read 120 volts +

these values, check for correct supply voltage to furnace.

Test 3

10%. If voltage reads below

Integrated Control Board

Detail

Test 3

Integrated Control Board

Detail

FIGURE 8

Page 11

Page 12

8. Gas Valve (Figure 6)

The ML180DF uses internally redundant gas valve to as

sure safety shut-off. If the gas valve must be replaced, the

same type valve must be used.

24VAC terminals and valve switch are located on the valve. All

terminals on the gas valve are connected to wires from the in

tegrated control. 24V applied to the terminals energizes the

valve.

Inlet and outlet pressure taps are located on the valve. A regu

lator adjustment screw is located on the valve.

LPG changeover kits are available from Lennox. Kits include

burner orifices and a gas valve regulator spring.

9. Combustion Air Inducer (B6)

All ML180DF units use a combustion air inducer to move air

through the burners and heat exchanger during heating op

eration. The blower uses a 120VAC motor. The motor oper

ates during all heating operation and is controlled by inte

grated control A92. The inducer also operates for 15 sec

onds before burner ignition (pre‐purge) and for 5 seconds

after the gas valve closes (post‐purge).

A pressure switch mounted on the combustion air inducer ori

fice plate is used to prove inducer operation. The combustion

air inducer orifice will be different for each model. See table 5

for orifice sizes. The switch monitors air pressure in the induc

er housing. During normal operation, the pressure in the

housing is negative. If pressure becomes less negative (sig

nifying any obstruction in the flue) the pressure switch opens.

When the proving switch opens, the integrated control (A92)

immediately de-energizes the gas valve to prevent burner

operation.

TABLE 5

ML180DF Unit

C.A.I. Orifice Size

045P24A 1.094

045P36A 1.063

070(X)P36A 1.344

090P36B 1.531

090(X)P48B 1.531

110(X)P60C 1.718

10. Combustion Air Inducer

Pressure Switch (S18)

ML180DF series units are equipped with a combustion air

pressure switch located on the combustion air inducer ori

fice bracket. The switch is connected to the combustion air

inducer housing by means of a flexible silicone hose. It mon

itors negative air pressure in the combustion air inducer

housing.

The switch is a SPST Normally open proving switch electri

cally connected to the furnace control. The purpose of the

switch is to prevent burner operation if the combustion air in

ducer is not operating or if the flue becomes obstructed.

On start‐up, the switch senses that the combustion air in

ducer is operating. It closes a circuit to the integrated con

trol when pressure inside the combustion air inducer de

creases to a certain set point. Set points vary depending on

unit size. See table 6. The pressure sensed by the switch is

negative relative to atmospheric pressure. If the flue be

comes obstructed during operation, the switch senses a

loss of negative pressure (pressure becomes more equal

with atmospheric pressure) and opens the circuit to the in

tegrated control and gas valve. A bleed port on the switch

allows relatively dry air in the vestibule to purge switch tub

ing, to prevent condensate build up.

TABLE 6

ML180DF Set Point inches w.c.

045P24A 0.60

045P36A 0.60

070(X)P36A 0.65

090P36B 0.60

090(X)P48B 0.60

110(X)P60C 0.65

110P60C 0.69

The switch is factory set and is not field adjustable. It is a

safety shut‐down control in the furnace and must not be bypassed for any reason. If switch is closed or by-passed, the

integrated control will not initiate ignition at start up.

Troubleshooting

See figure 9 for measuring operating pressure and check

ing resistance in the pressure switch.

Page 12

Page 13

MULTI−METER

SET TO MEASURE OHMS

Pressure Switch

FIGURE 9

Remove tubing from CAI and

insert “Tee” and additional tubing.

To

Field Provided

Tubing To CAI Port

High

or

Low

11. Blower Motors and Capacitors

All ML180DF units use direct drive blower motors. All motors

are 120V permanent split capacitor motors to ensure maxi

mum efficiency. See Specifications section at the front of this

manual for motor specifications. Ratings for capacitors will

be on motor nameplate.

12. Secondary Limit Control

The secondary limit is located in the blower compartment on

the back side of the blower housing. See figure 10. When ex

cess heat is sensed in the blower compartment, the limit will

open. If the limit is open, the furnace control energizes the sup

ply air blower and closes the gas valve. The limit automatically

resets when unit temperature returns to normal. The secon

dary limit cannot be adjusted.

Supply Air Blower

To Remove Blower From Unit:

1. Disconnect Power, 2. Remove internal flue pipe and chase

3. Remove Control Box 4. Remove Bolts. 5. Unplug Motor

Wires From Control Board. Then Slide Out Front of Unit.

FIGURE 10

Page 13

Page 14

II- PLACEMENT AND INSTALLATION

Make sure unit is installed in accordance with installation

instructions and applicable codes.

III- START‐UP

A- Heating Start‐Up

WARNING

Shock and burn hazard.

ML180DF units are equipped with a hot surface igni

tion system. Do not attempt to light manually.

Gas Valve Operation

MANIFOLD

PRESSURE

ADJUSTMENT

SCREW

INLET

PRESSURE

PORT

1 - STOP! Read the safety information at the beginning of

this section.

2 - Set the thermostat to the lowest setting.

3 - Turn off all electrical power to the unit.

4 - This furnace is equipped with an ignition device which

automatically lights the burners. Do not try to light the

burners by hand.

5 - Remove the heating compartment access panel.

6 - Move gas valve switch to OFF position. Do not

force. See figure 11.

7 - Wait five minutes to clear out any gas. If you then smell

gas, STOP! Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's instruc

tions. If you do not smell gas go to next step.

8 - Move gas valve switch to ON position. Do not force.

See figure 11.

9 - Replace the heating compartment access panel.

10- Turn on all electrical power to to the unit.

11- Set the thermostat to desired setting.

NOTE - When unit is initially started, steps 1 through 11

may need to be repeated to purge air from gas line.

12- If the appliance will not operate, follow the instructions

“Turning Off Gas to Unit” and call the gas supplier.

Turning Off Gas to Unit

1 - Set the thermostat to the lowest setting.

GAS VALVE SHOWN IN ON POSITION

FIGURE 11

MANIFOLD

PRESSURE

OUTLET

PORT

2 - Turn off all electrical power to the unit if service is to be

performed.

3 - Remove the heating compartment access panel.

4 - Move gas valve switch to OFF position. Do not

force. See figure 11.

5 - Replace the heating compartment access panel.

B- Safety or Emergency Shutdown

Disconnect main power to unit. Close manual and main gas

valves.

C- Extended Period Shutdown

Turn off thermostat or set to “UNOCCUPIED” mode. Close

all gas valves (both internal and external to unit) to guaran

tee no gas leaks into combustion chamber. Turn off power

to unit. All access panels and covers must be in place and

secured.

IV-HEATING SYSTEM SERVICE CHECKS

A- C.S.A. Certification

All units are C.S.A. design certified without modifications.

Refer to the ML180DF Installation Instruction.

B- Gas Piping

Gas supply piping should not allow more than 0.5”W.C. drop

in pressure between gas meter and unit. Supply gas pipe

must not be smaller than unit gas connection.

Compounds used on gas piping threaded joints should be

resistant to action of liquefied petroleum gases.

C- Testing Gas Piping

CAUTION

If a flexible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe

shall be installed at the gas valve and extend outside

the furnace cabinet.

IMPORTANT

In case emergency shutdown is required, turn off

the main shut‐off valve and disconnect the main

power to unit. These controls should be properly

labeled by the installer.

WARNING

Do not exceed 600 in-lbs (50 ft-lbs) torque when at

taching the gas piping to the gas valve.

When pressure testing gas lines, the gas valve must be dis

connected and isolated. Gas valves can be damaged if

subjected to more than 0.5 psig (14” W.C.). See figure 12. If

the pressure is equal to or greater than 0.5 psig (14”W.C.),

close the manual shut-off valve before pressure testing to

isolate furnace from gas supply.

Page 14

Page 15

GAS PIPING TEST PROCEDURE

MANUAL MAIN SHUT-OFF VALVE

WILL NOT HOLD TEST PRESSURE

IN EXCESS OF 0.5 PSIG (14”W.C.)

CAP

GAS VALVE

FIELD PROVIDED

LINE PRESSURE TAP

FIGURE 12

When checking piping connections for gas leaks, use pre

ferred means. Kitchen detergents can cause harmful corro

sion on various metals used in gas piping. Use of a specialty

Gas Leak Detector is strongly recommended. It is available

through Lennox under part number 31B2001. See Corp.

8411-L10, for further details.

Do not use matches, candles, flame or any other source of

ignition to check for gas leaks.

D- Gas Pressure Adjustment

Gas Flow (Approximate)

TABLE 7

GAS METER CLOCKING CHART

Seconds for One Revolution

ML180DF

Unit

Natural LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

DIAL

-045 80 160 200 400

-070 55 110 136 272

-090 41 82 102 204

-110 33 66 82 164

-135 27 54 68 136

Natural-1000 btu/cu ft LP-2500 btu/cu ft

Furnace should operate at least 5 minutes before check

ing gas flow. Determine time in seconds for two revolu

tions of gas through the meter. (Two revolutions assures a

more accurate time.) Divide by two and compare to time

in table 7. If manifold pressure matches table 9 and rate is

incorrect, check gas orifices for proper size and restric

tion. Remove temporary gas meter if installed.

NOTE - To obtain accurate reading, shut off all other gas

appliances connected to meter.

E- Supply and Manifold Pressure

Supply Pressure Measurement

1 - Remove the threaded plug from the inlet side of the

gas valve and install a field-provided barbed fitting.

Connect to a test gauge to measure supply pressure.

2 - Start unit and allow 5 minutes for unit to reach steady

state.

3 - After allowing unit to stabilize for 5 minutes, record

supply pressure and compare to value given in table 9.

Manifold Pressure Measurement

1 - Remove the threaded plug from the outlet side of the

gas valve and install a field-provided barbed fitting.

Connect to a test gauge to measure manifold pres

sure.

2 - Start unit and allow 5 minutes for unit to reach steady

state.

3 - While waiting for the unit to stabilize, observe the

flame. Flame should be stable and should not lift from

burner. Natural gas should burn blue.

4 - After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in table

9.

NOTE - Shut unit off and remove manometer as soon as an

accurate reading has been obtained. Take care to remove

barbed fitting and replace threaded plug.

F- Proper Combustion

Furnace should operate a minimum 15 minutes with cor

rect manifold pressure and gas flow rate before checking

combustion. Take combustion sample beyond the flue out

let and compare to the tables below. The maximum carbon

monoxide reading should not exceed 50 ppm.

TABLE 8

ML180DF Unit

CO2%

Nat

For

CO2%

L.P.

For

-045

-070

-090

6.0 - 7.5 6.9 - 8.5

-110

G- High Altitude

The manifold pressure may require adjustment and com

bustion air pressure switch may need replacing to ensure

proper combustion at higher altitudes. Refer to table 9 for

manifold pressure and table 10 for pressure switch change

and gas conversion kits.

IMPORTANT

For safety, shut unit off and remove manometer as

soon as an accurate reading has been obtained.

Take care to replace pressure tap plug.

Page 15

Page 16

TABLE 9

Manifold Pressure Settings at all Altitudes

Model

Input Size

045

070

090

110

Model

Input Size

045

070 80W52

090 No Change

090(X)

110

High Altitude Pressure Switch Kit

0-4500 ft 4501-7500 ft 7501 - 10,000 ft 7501 - 10,000 ft 0 - 7500 ft 7501 - 10,000 ft 0 - 7500 ft

No Change

LP/propane 10.0 10.0 10.0 11.0 13.0

LP/propane 10.0 10.0 10.0 11.0 13.0

LP/propane 10.0 10.0 10.0 11.0 13.0

LP/propane 10.0 10.0 10.0 11.0 13.0

No Change

Supply Pressure

Gas 0-4500 ft 4501-7500 ft 7501 - 10,000 ft

Nat 3.5 3.5 3.5 4.5 13.0

Nat 3.5 3.3 3.5 4.5 13.0

Nat 3.5 3.3 3.5 4.5 13.0

Nat 3.5 3.3 3.5 4.5 13.0

in.wg.

Min Max

TABLE 10

Pressure Switch and Gas Conversion Kits at all Altitudes

80W52

High Altitude

Natural Gas Burner

Orifice Kit

80W51 73W37 70W89 76W15 73W81

Natural Gas to LP/Propane

Gas Change Over Kit

LP/Propane to

Natural Gas

Change Over Kit

NOTE - A natural to L.P. propane gas changeover kit is necessary to convert this unit. Refer to the changeover kit installation instruction for the conversion

procedure.

Page 16

Page 17

H- Proper Ground and Voltage

A poorly grounded furnace can contribute to premature ig

nitor failure. Use the following procedure to check for

ground and voltage to the integrated control.

1 - Measure the AC voltage between Line Neutral (spade

terminals) and “C” terminal (low voltage terminal

block) on the integrated control. See figure 13. A wide

variation in the voltage between Line Neutral and “C”

as a function of load indicates a poor or partial ground.

Compare the readings to the table below. If the read

ings exceed the maximum shown in table 1, make re

pairs before operating the furnace.

2 - In addition, measure the AC voltage from Line Hot to

Line Neutral (spade terminals) on the integrated con

trol. See figure 14. This voltage should be in the range

of 97 to 132 Vac

TABLE 11

Furnace Status

Power On Furnace Idle 0.3 2

CAI / Ignitor Energized 0.75 5

Indoor Blower Energized Less than 2 10

Measurement VAC

Expected Maximum

CHECK VOLTAGE BETWEEN LINE NEUTRAL

AND LOW VOLTAGE “C” TERMINAL

CHECK VOLTAGE BETWEEN LINE HOT

AND LINE NEUTRAL

FIGURE 13

FIGURE 14

Page 17

Page 18

V-TYPICAL OPERATING CHARACTERISTICS

A-Blower Operation and Adjustment

NOTE- The following is a generalized procedure and

does not apply to all thermostat controls.

1 - Blower operation is dependent on thermostat control

system.

2 - Generally, blower operation is set at thermostat sub

base fan switch. With fan switch in ON position, blower

operates continuously. With fan switch in AUTO position,

blower cycles with demand or runs continuously while

heating or cooling circuit cycles.

3 - Depending on the type of indoor thermostat, blower

and entire unit will be off when the system switch is in

OFF position.

B-Temperature Rise (Figure 15)

Temperature rise for ML180DF units depends on unit input,

blower speed, blower horsepower and static pressure as

marked on the unit rating plate. The blower speed must be

set for unit operation within the range of “TEMP. RISE °F”

listed on the unit rating plate.

C-External Static Pressure

1 - Tap locations shown in figure 16 .

2 - Punch a 1/4” diameter hole in supply and return air ple

nums. Insert manometer hose flush with inside edge of

hole or insulation. Seal around the hose with perma

gum. Connect the zero end of the manometer to the

discharge (supply) side of the system. On ducted sys

tems, connect the other end of manometer to the return

duct as above.

3 - With only the blower motor running and the evaporator

coil dry, observe the manometer reading. Adjust blow

er motor speed to deliver the air desired according to

the job requirements. For heating speed external static

pressure drop must not be more than 0.5” W.C. For

cooling speed external static pressure drop must not

be more than 0.8” W.C.

4 - Seal the hole when the check is complete.

EXTERNAL STATIC PRESSURE

Supply Duct Static

Return Duct Static +

Total Duct Static =

(dry coil)

Upflow Furnace Shown

TEMPERATURE RISE

Supply Duct Temperature _____

Return Duct Temperature - ____

Temperature Rise = _________

Upflow Furnace Shown

Supply Air

Return Air

FIGURE 15

Supply Air

High

Low

or

+

Return Air

-

FIGURE 16

D-Blower Speed Taps

Blower speed tap changes are made on the integrated con

trol. See figure 3. The heating tap is connected to the

“HEAT” terminal and the cooling tap is connected to the

“COOL” terminal. The continuous blower tap is connected

to the “CONT” terminal. Unused taps must be secured on

dummy terminals labeled ”PARK. To change out existing

speed tap, turn off power and switch out speed tap with tap

connected to “PARK”. See blower speed tap table on unit

diagram for motor tap colors for each speed.

Page 18

Page 19

VI-MAINTENANCE

A-Preliminary and Seasonal Checks

1 - Inspect electrical wiring, both field and factory installed

for loose connections. Tighten as required.

2 - Check voltage at disconnect switch. Voltage must be

within range listed on the nameplate. If not, consult the

power company and have voltage condition corrected

before starting unit.

At the beginning of each heating season, the system

should be checked as follows:

B-Filters

Filters should be inspected monthly. Clean or replace the

filters when necessary to ensure that the furnace operates

properly. Replacement filters must be rated for high veloc

ity airflow. See table 12.

IMPORTANT

If a highefficiency filter is being installed as part of

this system to ensure better indoor air quality, the fil

ter must be properly sized. Highefficiency filters

have a higher static pressure drop than standardef

ficiency glass/foam filters. If the pressure drop is too

great, system capacity and performance may be re

duced. The pressure drop may also cause the limit to

trip more frequently during the winter and the indoor

coil to freeze in the summer, resulting in an increase

in the number of service calls.

Before using any filter with this system, check the

specifications provided by the filter manufacturer

against the data given in the appropriate Lennox

Product Specifications bulletin. Additional informa

tion is provided in Service and Application Note

ACC002 (August 2000).

TABLE 12

Cabinet Width Return Air Filter Size (inches)

A (14-1/2”) 14 x 25 x 1 (1)

B (17-1/2”) 16 x 25 x 1 (1)

C (21”) 20 x 25 x 1 (1)

Cleaning the Heat Exchanger and Burners

NOTE - Use papers or protective covering in front of the fur

nace during cleaning.

1 - Turn off both electrical and gas power supplies to fur

nace.

2 - Remove flue pipe, top cap, flue chase and internal flue

pipe assembly from the unit.

3 - Label the wires from gas valve, rollout switches, prima

ry limit switch and make-up box then disconnect them.

4 - Remove the screws that secure the combustion air in

ducer/pressure switch assembly to the collector box.

Carefully remove the combustion air inducer to avoid

damaging blower gasket. If gasket is damaged, it must

be replaced to prevent leakage.

5 - Remove the collector box located behind the combus

tion air inducer. Be careful with the collector box gas

ket. If the gasket is damaged, it must be replaced to

prevent leakage.

6 - Disconnect gas supply piping. Remove the four screws

securing the burner manifold assembly to the vestibule

panel and remove the assembly from the unit.

7 - NOX units only - Remove screw securing NOX insert.

Remove NOX insert.

8 - Remove screws from both sides, top and bottom of

vestibule panel.

9 - Remove heat exchanger. It may be necessary to

spread cabinet side to allow more room. If so, remove

five screws from the left side or right side of cabinet.

See figure 18.

10- Back wash using steam. Begin from the burner opening

on each clam. Steam must not exceed 275°F.

11- To clean burners, run a vacuum cleaner with a soft brush

attachment over the face of burners. Visually inspect in

side the burners and crossovers for any blockage

caused by foreign matter. Remove any blockage. Figure

17 shows burner detail.

12- To clean the combustion air inducer visually inspect and

using a wire brush clean where necessary. Use com

pressed air to clean off debris and any rust.

13- Reinstall heat exchanger in vestibule. (Replace the

five screws in the cabinet from step 10 if removed).

14- NOX units only - replace NOX inserst.

15- Reinstall collector box, combustion air assembly, inter

nal flue pipe and flue chase. Seal with high tempera

ture RTV. Reinstall all screws to the collector box and

combustion air inducer. Failure to replace all screws

may cause leaks. Inspect gaskets for any damage and

replace if necessary.

Page 19

Page 20

Gasket

ML180DF BURNER, COMBUSTION AIR INDUCER ASSEMBLY &

HEAT EXCHANGER REMOVAL

Internal flue pipe

Gasket

Combustion air inducer

Ignitor

Manifold and

Gas valve

Glue chase

Burner box

assembly

Sensor

Pressure switch

Burners

Rollout

switch

Orifice plate

FIGURE 17

16- Reinstall burner box, manifold assembly and burner box

cover.

17- Reconnect all wires.

Collector box

Heat exchanger

Nox insert

(if applicable)

Retention rings

Cross over

Remove five screws if necessary

(either side of cabinet)

18- Reconnect top cap and vent pipe to combustion air in

ducer outlet.

19- Reconnect gas supply piping.

20- Turn on power and gas supply to unit.

21- Set thermostat and check for proper operation.

22- Check all piping connections, factory and field, for gas

leaks. Use a leak detecting solution or other preferred

means.

CAUTION

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly af

ter leak test has been completed. Do not use

matches, candles, flame or other sources of ignition

to check for gas leaks.

23- If a leak is detected, shut gas and electricity off and

repair leak.

24- Repeat steps 22 and 23 until no leaks are detected.

25- Replace access panel.

4

3

5

2

1

FIGURE 18

Page 20

Page 21

C-Supply Air Blower

1 - Check and clean blower wheel.

2 - Motors used on the Lennox ML180DF series units

are permanently lubricated and need no further lu

brication.

D-Flue and Chimney

Flue must conform to local codes. In the absence of local

codes, flue must meet the National Fuel Gas Code

ANSI-Z223.1 venting requirements. Flue pipe deteriorates

from the inside out and must be disconnected in order to

check thoroughly. Check flue pipe, chimney and all con

nections for tightness and to make sure there is no block

age or leaks.

E-Electrical

1 - Check all wiring for loose connections.

2 - Check for the correct voltage at the furnace (furnace

operating). Correct voltage is 120VAC +

10%

3 - Check amp-draw using a true RMS meter on the blow

er motor with blower access panel in place. See figure

19.

Furnace Nameplate__________Actual__________

Check Motor AMP Draw

(upflow furnace shown)

OFF

P

−

EX

MR

W

3

2

1

kWh

kVAr

COMMV3V1

V2

True RMS Meter

FIGURE 19

Page 21

Page 22

VII- WIRING AND SEQUENCE OF OPERATION

ML180DF Schematic Wiring Diagram and Sequence of Operation

3

10

1

4

5

5

1

1 - Line voltage is applied to L1 and N. the T1 low voltage transformer is energized, and line voltage is applied to B3 indoor blower.

2 - S47 rollout switch must be closed in order for 24V from transformer to be output on integrated control ”R” to power thermostat.

3 - When there is a call for heat, W1 of the thermostat energizes W of the furnace control with 24VAC.

4 - A92 integrated control runs a self-check. S10 primary limit and S21 secondary limit contacts are found to be closed. Call for heat can continue.

5 - A92 integrated control energizes B6 combustion air inducer. S18 combustion air pressure switch closes . Once S18 closes, a 15-second

pre-purge follows.

6 - A92 integrated control energizes R33 ignitor. A 20-second warm-up period begins.

7 - GV1 gas valve opens for a 4-second trial for ignition

8 - Flame is sensed, gas valve remains open for the heat call.

9 - After 30-second delay (from flame sensed), A92 integrated control applies 24VAC to Heat speed of B3 indoor blower.

10 - When heat demand is satisfied, W1 of the indoor thermostat de-energizes W of A92ignition control which de-energizes GV1 gas valve.

B6 combustion air inducer continues a 5-second post-purge period, and B3 indoor blower completes a selected OFF time delay.

6

8

9

2

7

Page 22

Page 23

Troubleshooting: Heating Sequence of Operation

HEATING SEQUENCE OF OPERATION

NORMAL HEATING MODE

POWER ON

CONTROL SELF-CHECK OKAY?

YES

IS POLARITY CORRECT?

YES

IS THERE A PROPER GROUND?

YES

IS VOLTAGE

ABOVE 90 VOLTS?

YES

ROLLOUT SWITCH CLOSED?

YES

NO

NO

NO

ABNORMAL HEATING MODE

GAS VALVE OFF. COMBUSTION AIR INDUCER OFF.

NO

NO

CONTROL WILL NOT RESPOND TO CALL FOR HEAT

IGNITOR WILL GLOW DIMLY BUT WILL NOT LIGHT

GAS VALVE OFF. COMBUSTION AIR INDUCER ON.

SEQUENCE HOLDS UNTIL ROLLOUT SWITCH CLOSES

AND POWER IS RESET OR T'STAT IS INTERRUPTED

INDOOR BLOWER DELAY OFF.

LED: OFF

POLARITY REVERSED.

LED: 9 FLASHES

IMPROPER GROUND.

LED: OFF

UNTIL PROPER GROUND.

LED: ON STEADY

INDOOR BLOWER ON.

LED: 5 FLASHES

FOR MINIMUM OF 1 SECOND.

NO

BURNER OFF?

(Contiuous Flame Check)

YES

NORMAL OPERATION:

LED: STEADY ON

YES

THERMOSTAT CALLS FOR HEAT:

LED: STEADY ON

YES

PRIMARY AND SECONDARY LIMIT SWITCH.

CLOSED?

YES

IS COMBUSTION AIR

PRESSURE SWITCH OPEN?

YES

IS COMBUSTION AIR INDUCER

ENERGIZED?

YES

HAS COMBUSTION AIR PRESSURE

SWITCH CLOSED IN 2.5 MINUTES?

YES

CONTINUED NEXT PAGE

NO

NO

GAS VALVE OFF. COMBUSTION AIR INDUCER ON.

INDOOR BLOWER ON HEATING SPEED.

COMBUSTION AIR INDUCER OFF.

NO

NO

PRESSURE SWITCH IS IN WATCHGUARD MODE.

GAS VALVE OFF. COMBUSTION AIR INDUCER OFF.

INDOOR BLOWER OFF WITH DELAY.

IS 5‐MINUTE RESET PERIOD COMPLETE?

LED: 1 FLASH

INDOOR BLOWER ON

LED: 4 FLASHES

GAS VALVE OFF.

COMBUSTION AIR INDUCER OFF.

INDOOR BLOWER OFF WITH DELAY.

LED: 2 FLASHES

(Sequence holds until pressure switch

opens or thermostat resets control.)

LED: 3 FLASHES

YES

Page 23

Page 24

Troubleshooting: Heating Sequence of Operation (Continued)

HEATING SEQUENCE CONTINUED

NORMAL HEATING MODE ABNORMAL HEATING MODE

15‐SECOND COMBUSTION AIR INDUCER PREPURGE

INITIATED BY CLOSED PRESSURE SWITCH.

YES

IGNITOR WARM‐UP -- 20 SECONDS.

YES

4‐SECOND TRIAL FOR IGNITION.

GAS VALVE OPENS.

YES

FLAME STABILIZATION PERIOD.

4 SECONDS

FLAME RECTIFICATION CURRENT

CHECK. CAN FLAME BE PROVEN WITHIN

4 SECONDS AFTER GAS VALVE OPENS?

YES

FLAME PRESENT?

NO

IS VOLTAGE ABOVE 90 VOLTS?

YES

GAS VALVE OFF. COMBUSTION AIR INDUCER ON.

NO

HAS CONTROL FAILED TO SENSE FLAME FOR

FIVE CONSECUTIVE TRIES DURING A SINGLE

WATCHGUARD MODE. GAS VALVE OFF.

LED: 7 FLASHES WATCHGUARD FAILURE CODE.

IS 60‐MINUTE RESET PERIOD COMPLETE?

NO

INDOOR BLOWER OFF.

HEAT DEMAND?

COMBUSTION AIR INDUCER OFF.

INDOOR BLOWER OFF WITH DELAY

HAS CONTROL RESET IGNITION

SEQUENCE FOUR TIMES?

NO

LED: ON STEADY

UNTIL VOLTAGE IS

ABOVE 95 VOLTS,

THEN RESTARTS

HEATING

SEQUENCE.

NO

YES

YES

NO

YES

FLAME SIGNAL 1.5 MICROAMPS OR GREATER?

YES

INDOOR BLOWER ON

AFTER 30-SECOND DELAY

YES

PRIMARY AND SECONDARY LIMIT

SWITCHES CLOSED?

YES

ROLLOUT SWITCH CLOSED?

YES

COMBUSTION AIR PRESSURE

SWITCH CLOSED?

YES

THERMOSTAT DEMAND SATISFIED.

YES

LED: ON STEADY

YES

COMB. AIR INDUCER CONTINUES 15‐SECOND

POST PURGE AFTER T'STAT DEMAND IS SATISFIED.

INDOOR AIR BLOWER COMPLETES SELECTED “OFF”

DELAY BEFORE SHUTTING OFF.

NO

COMBUSTION AIR INDUCER DE-ENERGIZED.

INDOOR BLOWER ON UNTIL SWITCH CLOSES.

NO

NO

NO

NO

LOW FLAME SIGNAL

(Does not affect operation of control)

LED: ON STEADY

GAS VALVE DE-ENERGIZED.

LED: 4 FLASHES

IS LIMIT SWITCH CLOSED?

NO

5 MINUTE WATCHGUARD MODE.

HAS LIMIT SWITCHED CLOSED

AFTER 5 MINUTES?

GAS VALVE POWER OFF.

COMBUSTION AIR INDUCER POWER ON AFTER 15

SECOND DELAY. INDOOR BLOWER ON

LED: 5 FLASHES

SEQUENCE HOLDS UNTIL ROLLOUT SWITCH IS RESET

AND MAIN POWER IS INTERRUPTED OR

THERMOSTAT IS CYCLED OFF/ON FOR 1 SEC. MINIMUM.

HAS PRESSURE SWITCH OPENED 5

TIMES IN THE SAME HEAT DEMAND?

NO

GAS VALVE DE-ENERGIZED.

COMBUSTION AIR INDUCER ON.

INDOOR BLOWER OFF WITH DELAY

LED: 6 FLASHES 5 MINUTE PRESSURE

SWITCH WATCHGUARD MODE.

YES

YES

YES

WATCHGUARD

1 HR

PRESSURE

SWITCH

MODE

Page 24

Page 25

Troubleshooting: Cooling Sequence of Operation

COOLING SEQUENCE OF OPERATION

NORMAL COOLING MODE ABNORMAL COOLING MODE

POWER ON

IGNITION CONTROL MAIN POWER ON. LED: ON STEADY

CONTROL SELF DIAGNOSTIC CHECK.

IS CONTROL OPERATING NORMALLY?

YES

IS THERE A PROPER GROUND?

YES

IS POLARITY CORRECT?

YES

IS VOLTAGE

ABOVE 90 VOLTS?

YES

NO

NO

NO

NO

GAS VALVE OFF. COMBUSTION AIR INDUCER OFF.

INDOOR BLOWER OFF WITH NORMAL DELAY.

LED: OFF

INTERRUPT MAIN POWER TO RESET CONTROL.

LED: ON STEADY

CONTROL WILL CONTINUE TO CALL FOR COOLING

IN THIS CONDITION.

LED: 9 FLASHES

CONTROL WILL CONTINUE TO CALL FOR COOLING

IN THIS CONDITION.

LED: ON STEADY.

CONTROL WILL CONTINUE TO CALL FOR

COOLING IN THIS CONDITION.

REMAINS UNCHANGED THROUGHOUT COOLING CYCLE.

THERMOSTAT CALLS FOR COOLING.

COMPRESSOR CONTACTOR AND SYSTEM FAN

ENERGIZED WITH 2‐SECOND DELAY

(COOLING SPEED). EAC TERM. ENERGIZED.

SYSTEM FAN AND EAC TERM. OFF

LED: ON STEADY.

THERMOSTAT OPENS.

COMPRESSOR OFF.

WITH 60‐SECOND DELAY.

Page 25

Page 26

Troubleshooting: Continuous Fan Sequence of Operation

CONTINUOUS FAN SEQUENCE OF OPERATION

MANUAL FAN SELECTION MADE AT THERMOSTAT.

CONTROL (G) ENERGIZES SYSTEM FAN ON CONTINUOUS

BLOWER SPEED. EAC TERMINAL IS ENERGIZED.

THERMOSTAT CALLS FOR HEAT (W).

NO

THERMOSTAT CALLS FOR COOLING.

YES

SYSTEM FAN SWITCHED TO COOL SPEED.

EAC TERM. REMAINS ON.

THERMOSTAT OPENS.

MANUAL FAN SELECTION MADE AT THERMOSTAT.

CONTROL (G) ENERGIZES SYSTEM FAN ON

CONTINUOUS BLOWER SPEED.

LED: ON STEADY

NO

HUM TERM. ENERGIZES

WITH COMB. AIR INDUCER.

YES

SYSTEM FAN SWITCHES TO

HEATING SPEED.

THERMOSTAT OPENS.

HUM TERM. DE-ENERGIZES

WITH COMB. AIR INDUCER

SYSTEM FAN SWITCHES TO

CONTINUOUS BLOWER SPEED

.

Page 26

Page 27

VIII- TWINNING

Twinning 2 ML180DF Furnaces

The control board in this furnace is equipped with a provi

sion to ”twin” (interconnect) two(2) adjacent furnaces with a

common plenum such that they operate as one (1) large

unit.

When twinned, the circulating blower speeds are synchro

nized between the furnaces. If either furnace has a need to

run the blower, both furnaces will run the blower on the

same speed. The cooling speed has highest priority, fol

lowed by heating speed and fan speed.

Field installation of twinning consists of connecting wires

FIELD WIRING FOR TWINNING THE ML180DF

between the ”C” and ”Twin” terminals of the two controls.

The 24 VAC secondary of the two systems must be in

phase. All thermostat connections are made to one control

only. Figure 20 show wiring for two-stage and single stage

thermostats.

The twinned furnace without thermostat connections is to

have the call for heat supplied by an external 24VAC isola

tion relay to prevent its rollout switch from being bypassed

by the other twinned furnace. The coil of the isolation relay

connects from the thermostat ”W” to 24 VAC common. The

contacts of the relay connect ”R” to ”W” on the non-thermo

stat twin.

TWO-STAGE THERMOSTAT

R

Call For Cool

Call For Fan

Call For 1st

Stage Heat

Call For 2nd

StageHeat

Y

G

W1

W2

ISOLATION

RELAY

TWIN

TWIN

SINGLE STAGE THERMOSTAT

R

TWIN 1

Y

G

W

C

R

TWIN 2

Y

G

W

Call For Cool

Call For Fan

Call For Heat

R

Y

G

W

ISOLATION

RELAY

TWIN

TWIN

R

TWIN 1

Y

G

W

C

R

TWIN 2

Y

G

W

C

C

FIGURE 20

Page 27

Loading...

Loading...