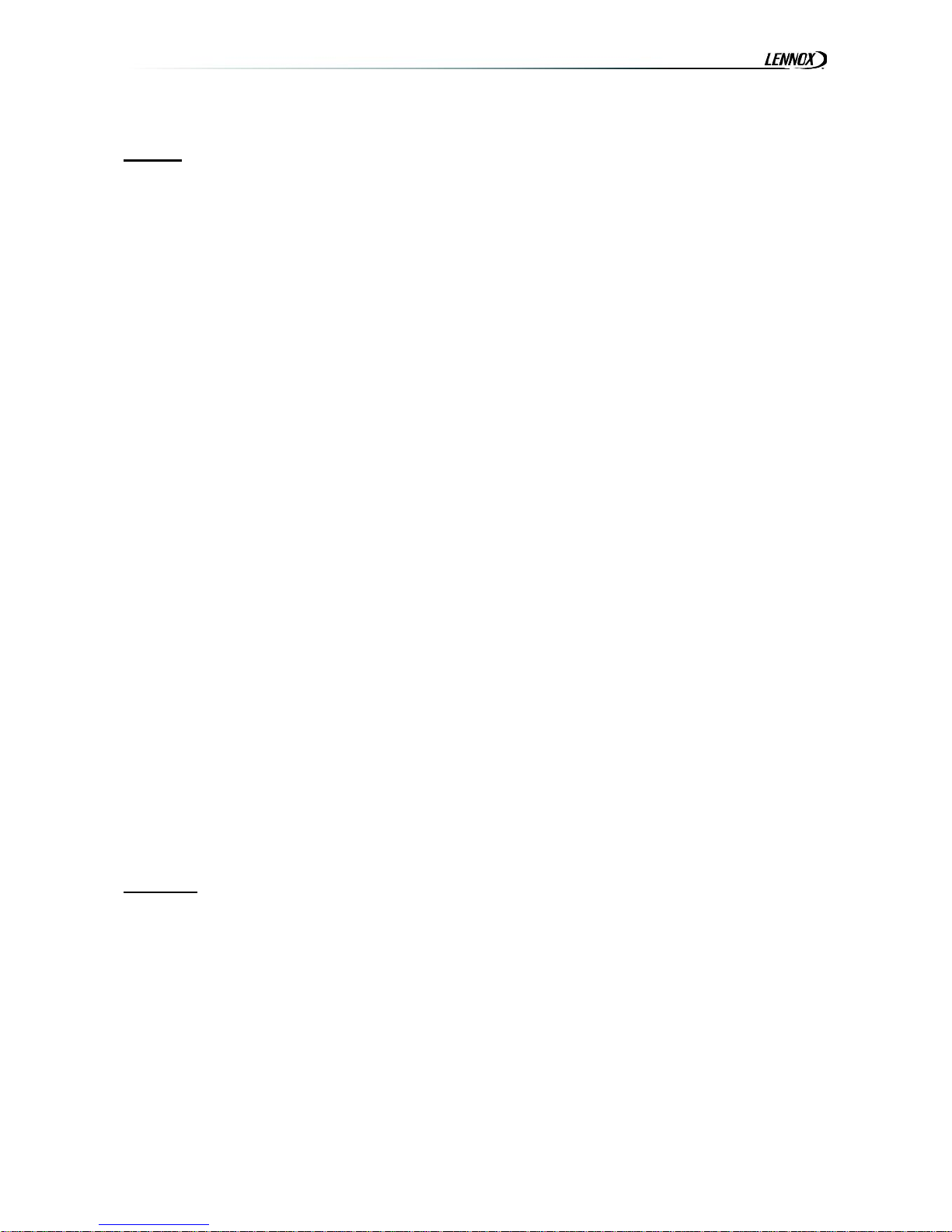

Lennox MiniAir 10, MiniAir 20, MiniAir 30, MiniAir 25, MiniAir 40 Installation, Operating And Maintenance Manual

...Page 1

Providing indoor climate comfort

MINIAIR / MINIAIR +

MINIAIR-IOM-0507-E

Installation, operating

and maintenance

Page 2

Page 3

IOM / MINIAIR-0507 1

SYMBOLOGY

ATTENTION

DANGER

a) HIGH

RISK OF ELECTRIC SHOCK

b) ATTENTION: AUTHORIZED PERSONNEL ONLY

Page 4

2 IOM / MINIAIR-0507

INDEX

MiniAir

SECTION 1 – PRESENTATION

1.1 Manual Presentation page 4

1.2 Unit Identification page 4

SECTION 2 – TECHNICAL CHARACTERISTICS

2.1 Unit dimensions page 5

2.2 Unit technical data page 6

SECTION 3 – TRANSPORTATION

3.1 Packing page 6

3.2 Transportation page 6

3.3 Checklist page 6

3.4 Storing page 6

SECTION 4 – INSTALLATION & CONNECTION

4.1 Definition page 7

4.2 Safety Regulations page 7

4.3 Preliminary operations page 8

4.4 Choosing installation position page 8

4.5 Connecting accessories page 8

4.6 MINIAIR unit positioning page 9

4.7 Duct connection page 10

4.8 Hydraulic connection page 10

4.9 Electrical connections page 11

SECTION 5 – PRE START CHECKLIST

5.1 Checks prior to initial Start-up page 12

SECTION 6 – STANDARD MAINTENANCE

6.1 Monthly maintenance page 12

6.2 Yearly maintenance page 13

SECTION 7 – TROUBLESHOOTING

7.1 Finding faults page 13

SECTION 8 – SPARE PARTS

8.1 Spare part order page 14

SECTION 9 – MATERIAL DISPOSA L

9.1 Material disposal page 14

MiniAir +

SECTION 10 – PRESENTATION

10.1 Manual presentation page 15

10.2 Machine identification page 15

SECTION 11 – TECHNICAL CHARACTERISTICS

11.1 General characteristics page 15

11.2 Accessories page 15

11.3 Packing dimensions page 16

11.4 Unit technical data page 17

11.5 Accessories technical data page 18

11.6 Possible positionin g page 19

11.7 By-pass for de-frosting or free-cooling page 21

Page 5

IOM / MINIAIR-0507 3

SECTION 12 – TRANSPORTATION

12.1 Packing page 21

12.2 Transportation page 22

12.3 Checklist page 22

12.4 Storing page 22

SECTION 13 – INSTALLATION & CONNECTION

13.1 Definition page 22

13.2 Safety regulations page 22

13.3 Preliminary operations page 23

13.4 Choosing place of installation page 23

13.5 Machine positioning page 24

13.6 Duct connection page 25

13.7 Hydraulic connection page 26

13.8 Electrical connection page 27

13.9 Installation of CVU & PCU accessories page 27

SECTION 14 – ELECTRICAL SCHEMES

14.1 MINIAIR+ 03-06 direct connection page 29

14.2 MINIAIR+ 03-06 connection with CVU speed control page 29

14.3 MINIAIR+ 03-06 connection with SKE & PCU control panel page 30

14.4 MINIAIR+ 10-14-19-25 direct conne ction page 30

14.5 MINIAIR+ 10-14-19-25 connection with CVU speed control page 31

14.6 MINIAIR+ 10-14-19-25 connection with SKE & PCU control panel page 31

14.7 MINIAIR+ 30 direct connection page 32

14.8 MINIAIR+ 30 connection with CVU speed control page 32

14.9 MINIAIR+ 30 connection with SKE & PCU control panel page 33

14.10 MINIAIR+ 40 direct connection page 33

14.11 MINIAIR+ 40 connection with CVU speed control page 34

14.12 MINIAIR+ 40 connection w ith SKE & PCU control panel page 34

SECTION 15 – PRE-START CHECKLIST

15.1 Checks prior to initial start-up page 35

SECTION 16 – STANDARD MAINTENANCE

16.1 Monthly maintenance page 35

16.2 Yearly maintenance page 36

SECTION 17 – TROUBLESHOOTING

17.1 Localisation of breakdowns page 37

SECTION 18 – MATERIAL DISPOSAL

18.1 Material disposal page 37

Page 6

4 IOM / MINIAIR-0507

MINIAIR

SECTION 1 – PRESENTATION

1.1 Manual Presentation

This instruction manual supplies the necessary information for the transportation, the installation, operation and

maintenance of the MINIAIR apparatus as supplied by the company LENNOX (from this point na med as the supplier).

It supplies the user with as much information as is normally useful for a correct and secure installation of the unit.

Lack of observation of the details found within this manual, and an inadequate installation of the MINIAIR may cause the

withdrawal of the warranty supplied with the equipment.

Furthermore, the Supplier will not respond to any eventual damage, whether direct or indirect, caused by the incorrec t

installation, or for damages caused by the installation being effectuated by inexperienced or unauthorised personnel.

Verify, upon acquisition, that the apparatus is complete and supplied as described.

Any eventual disputes must be presented in writing w ithin 8 days from the reception of the goods.

1.2 Unit Identification

The MINIAIR Unit is provided with identification plate listing the following:

- Address of Constructor;

- “CE” Mark;

- Model;

- Serial Number;

- Maximum absorbed current “A”;

- Power supp ly voltage “V”;

- Power supply frequency “Hz”;

- Number of phases “Ph”;

- Date of fabrication;

- Unit Code.

Page 7

IOM / MINIAIR-0507 5

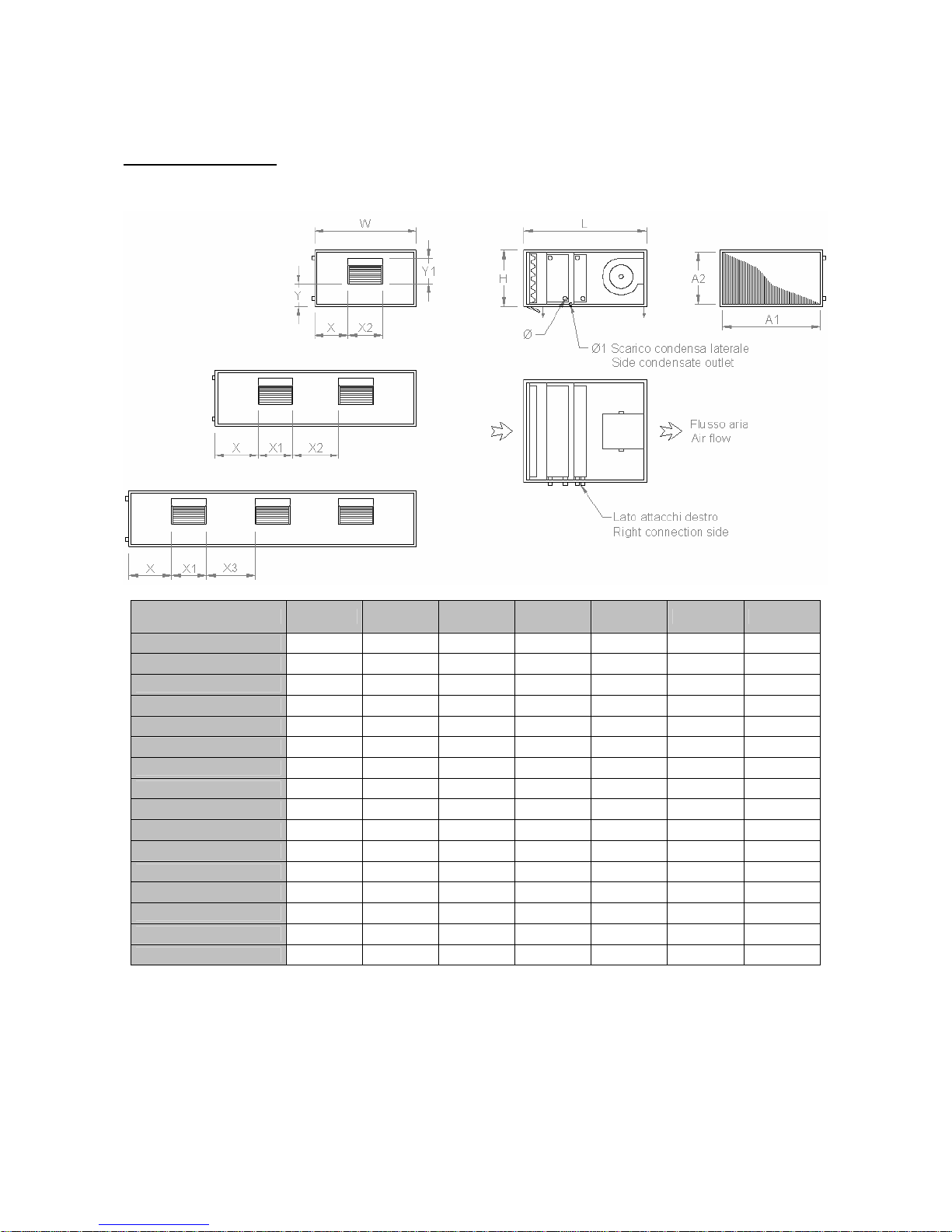

SECTION 2 – TECHNICAL FEATURES

2.1 Unit Dimensions

Model 10 20 25 30 40 50 60

2) W

710 1070 1400 1400 1680 1780 2000

L 390 390 390 390 390 480 480

H 850 850 850 850 850 960 960

2 R ¾” ¾” ¾” ¾” ¾” 1” 1”

4 R ¾” ¾” 1” 1” 1” 1 ¼” 1 ¼”

6 R ¾” 1” 1” 1” 1 ¼” 1 ¼” 1 ¼”

1 20 20 20 20 20 20 20

X1 240 306 240 240 306 306 306

3) Y1

216 270 216 270 270 270 270

X2 - - 318 318 418 435 X3 - - - - - - 285

A1 670 1030 1360 1360 1640 1720 1940

A2 350 350 350 350 350 420 420

X

235 382 301 301 325 366 256

Y

136 82 136 82 82 160 160

Weight 5260 6070 7588 7890 96110 101120 120140

Page 8

6 IOM / MINIAIR-0507

2.2 Unit technical data

Model 10 20 25 30 40 50 60

Airflow rate m3/h 1040 2150 2740 3360 3950 5070 6450

External static pressure ()

Pa 150 150 150 150 150 150 150

1 m sound pressure leve l dB (A) 52 55 55 57 58 57 59

Motor power W 147 350 2 x 350 2 x 350 2 x 350 2 x 420 3 x 420

Max. current A 1,9 3,0 2 x 3,0 2 x 3,0 2 x 3,0 2 x 3,8 3 x 3,8

Fan speeds 3 3 3 3 3 3 3

Protection grade IP 20 55 55 55 55 20 20

Isolation Class B F F F F B B

Electrical power sup ply V/ph/Hz 230 / 1 / 50

Model 10 20 25 30 40 50 60

N° G3 filter cells (356x293x48) 2 3 4 4 5 5 6

N° F6 filter cells (356x293x320) 2 3 4 4 5 5 6

() 4 row coil version at nominal airflow rate

SECTION 3 – TRANSPORTATION

3.1 Packing

The MINIAIR units and their accessories are provided with adequate packing, that must stay intac t until the moment of

installing.

The materials that are not required for technical motives are supplied in fitted packing fixed externally and internally to

the unit.

3.2 Transportation

For the lifting and transportation of the unit, use adequate equipment, according to the 89/391/CEE regulations and

successive modifications.

Each individual machine weight is listed in this manual.

Avoid any uncontrolled rotation.

3.3 Checklist

Upon reception of the apparatus, we suggest that a complete control is carried out, to verify that the unit is intact and

complete, and no damage has been sustained during transport. Any eventual damage revealed must be communicated

to the carrier, demonstrating the reserve clause within the transport documents, specifying the type of damage.

3.4 Storing

In case of long term storage, the apparatus must be kept free from dust, and away from areas susceptible to heat and

vibration.

The manufacturer declines any responsibility for any damage as a result of negligence or lack of protection from

atmospheric agents.

Page 9

IOM / MINIAIR-0507 7

SECTION 4 – INSTALLATION & CONNECTION

4.1 Definition

CLIENT– The client is the person, activity or the society, that has bought or hired the apparatus, and intends to utilise the

machinery for its intended use.

USER / OPERATOR – The User or Operator, is the actual person that has been authorised by the client to utilise the

apparatus.

TECHNICIAN – Defined as the person who has followed a relevant/specific course of study, and so is able to understand

the dangers derived from the use of the apparatus, and in turn, due to this, are capable of solving major dilemmas.

4.2 Safety Regulations

Qualified personnel must carry out the installation.

During the installation operation, use protective clothing, for example: glasses, gloves, etc. as indicated by

686/89/CEE and successive regula tions.

During the installation operate in absolute security, pollution free air and in an area free of obstructions.

Respect the regulations in force in the country in which the apparatus is being installed. Spe cifically relative to

its use, and to the disposal of packing and products used for the cleaning and maintenance of the unit. Respect

the recommendations given by the producers of such products.

Before placing in function the unit, check the perfect connection of the various components and the internal

parts of the system.

Avoid at a ll costs human contact with moving parts and contact w ith the parts themselves.

Do not commence with servicing or cleaning of the unit, before the unit has been disconnected from the

main supply.

The maintenance and the substitution of damaged or consumed parts must be carried out only by specialised

personnel, following the indications found within this manual.

The Manufacturer declines any responsibility for

failure to respect the Safety Regulations, and the

prevention as described below.

Furthermore, the manufacturer declines any

responsibility for damage caused by the improper

use of the unit and/or modifications carried out

without proper authorisation.

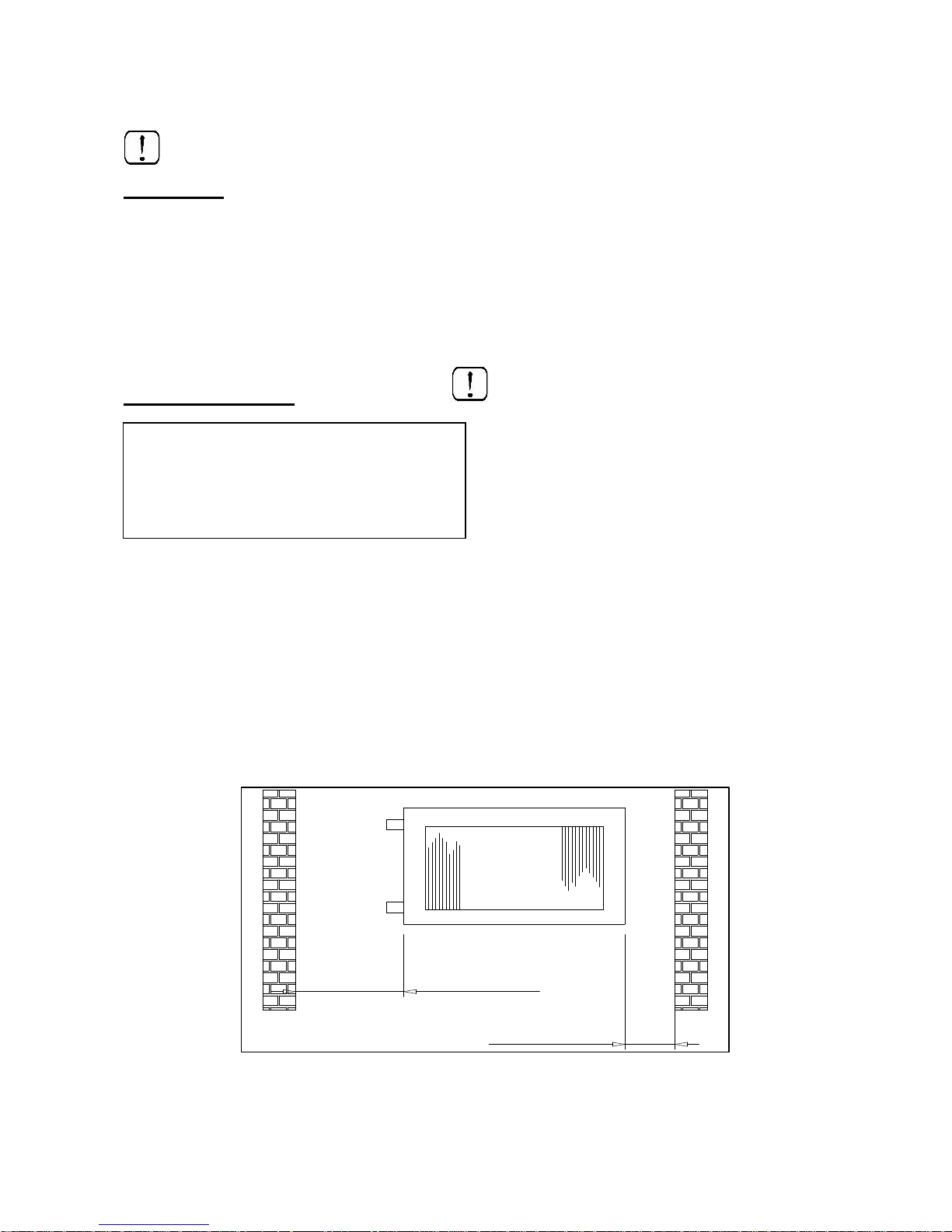

Min 400 mm

Min 100 mm

Page 10

8 IOM / MINIAIR-0507

Spare parts must correspond to the requirements specified by Manufacturer.

In case of dismantling of the unit, respect the anti-pollution regulations in force.

N.B. The installer and the user of the apparatus must take into account, and solve problems, connected with any other

type of risk that may occur to the unit. For example, risks derived from the entrance of foreign bodies, or risks due to the

presence of flammable or toxic gas.

4.3 Preliminary Operations

Check the perfect condition of the various components of the unit.

Control that contained within the packing, there are the installation accessories, and documentation.

Transport the packed section as close as is possible to the intended place of installation.

Do not place tools or weight on top of the packed unit.

4.4 Choosing installation position

Positio n the unit on a solid structure, that will not vibrate, and is capable supporting the weight of the machine.

Positio n the unit in a point where the condensation discharge may occur easily.

Do not position the unit in an area in which flammable gases, acidic or corrosive substances are present. They

may damage various components in an irreparable manner.

Allow a minimum amount of free space as indicated in the figure. This permits ease of installation and

maintenance.

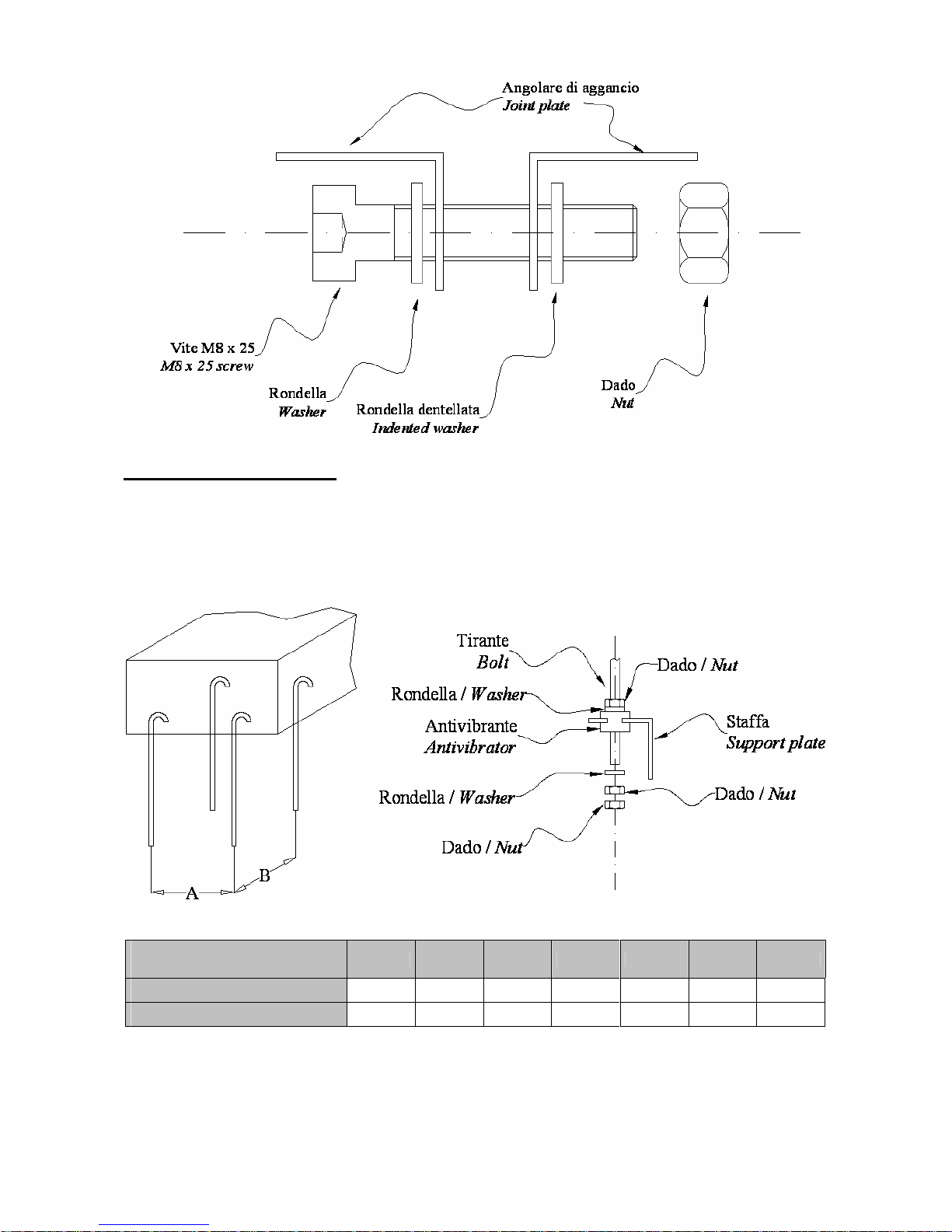

4.5 Connecting accessories

1. Fix the angular fixing clamp

2. Place together the fixing modules

3. Pass the M8 x 25 screw s through the adjacent holes and necessary washers (see diagram)

4. Screw the nut by hand

5. Tighten with an Allen key

Page 11

IOM / MINIAIR-0507 9

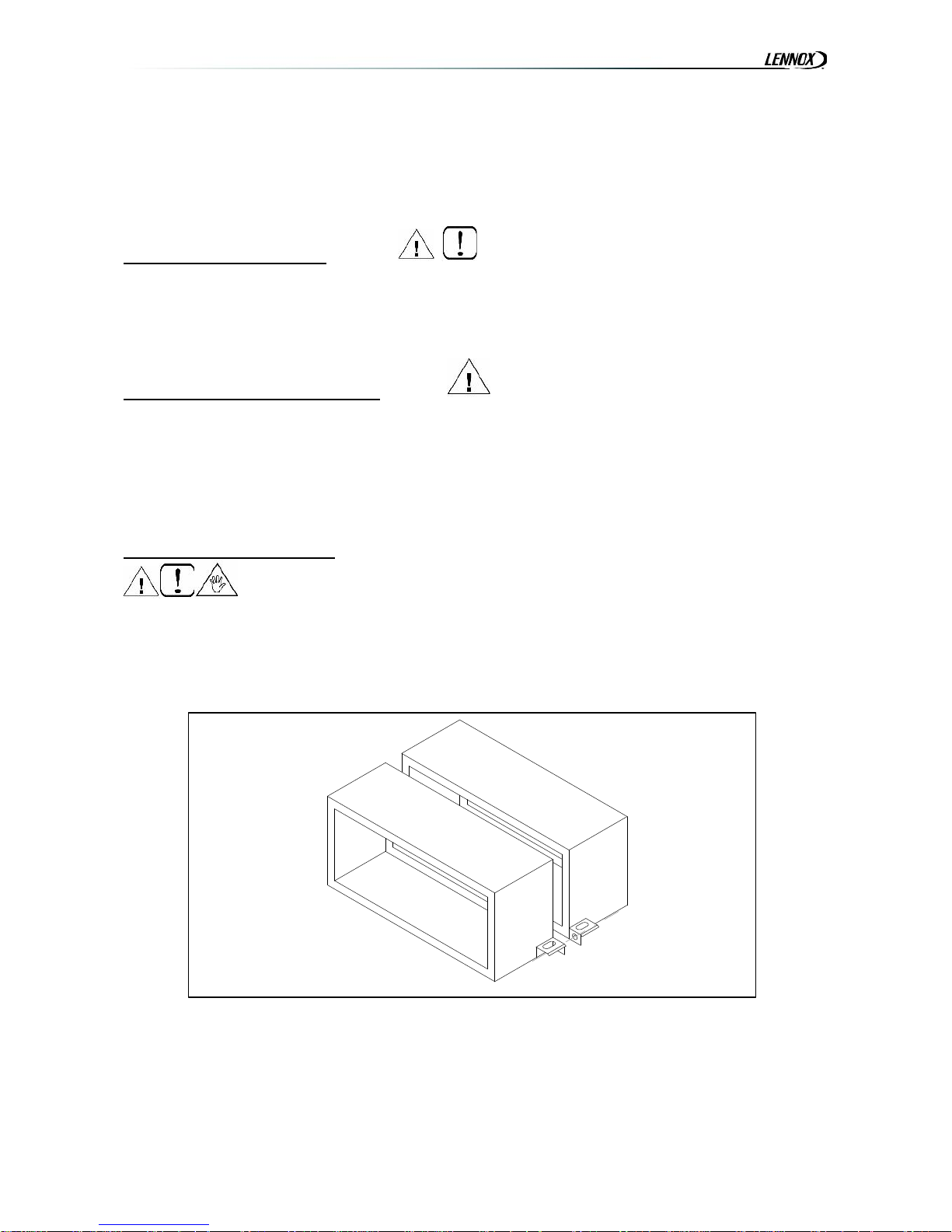

4.6 MINIAIR unit positioning

The unit is equipped with anti-vibration support plates.

As follows are indica tions the various sequence of assembly:

1. Carry out the drilling of the ceiling, and fit the four M8 threaded bolts as indicated in the diagram.

2. Position the unit on the four bolts using the supplied fixing plates.

3. Block the unit tightening the fixing bolts.

i. Dimensions

10 20 25 30 40 50 60

A

745 1105 1435 1435 1715 1820 2040

B

820 820 820 820 820 922 922

To aid the regular flow of the condensation, it is advised to install the unit with a 3mm inc lination towards the

condensation outlet.

Page 12

10 IOM / MINIAIR-0507

4.7 Duct connection

The Ducts must be the correct dimension based on the functions of syste m and the air diffusion characteristics

of the unit fans. A mistaken calculation of the ducting will cause power loss or the intervention of any eventual

devices present on the system.

To prevent the formation of condensation and cut down the sound level it is advised to use internally lined

Ducts.

To avoid the transmission of machine vibrations into the environment, it is advised to fit an anti-vibration joint

between the fans and Ducts. The electrical continuity must be guaranteed between the Ducts and the apparatus

via an earth cable.

4.8 Hydraulic connections

The installation and connecting of the piping is an operation that must be done correctly, otherwise it may

compromise the performance of the system. At worst it may cause irreversible damage to the machine. These

operations are to be effectuated by qualified personnel.

The MINIAIR units are supplied with “female” m oun ted, GAS threaded water coil s.

Extreme caution must be taken during the installation operation, to avoid damage.

The tube path must be studied in such a way to not create obstacles should an eventual extraction of unit coil or

filter be required.

Water inlet and outlet must occur allowing the thermal exchange in counterflow: follow the indications found on

the WATER INLET and WATER OUTLET plate.

Supply a lower valve for the emptying of the water contained in the coil.

Fix securely the tubes to the outside of the unit, so as to avoid offloading the weight onto the coil headers.

Once the connection has been followed, fix the external rubber seals against the panel to avoid passing of air.

The lining must just rest on the panel, to avoid the risk of burning.

Supply an interception valve to isolate the coil from the rest of the circuit in case of extraordinary maintenance.

Should the installation of the apparatus occur in areas with particula rly cold climates, empty the syste m prior to

an extended period of inutilization.

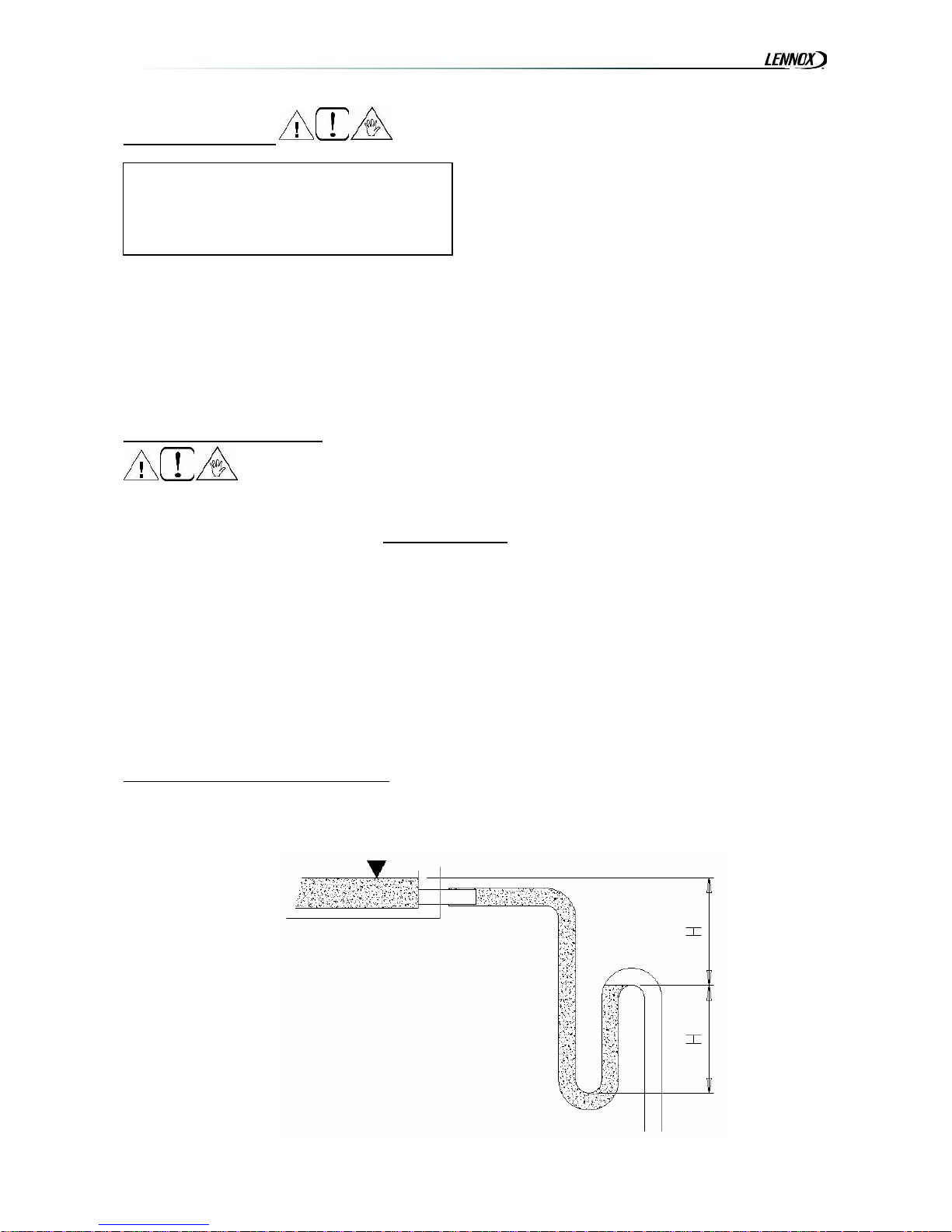

4.8.1 Condensation outlet connection

The stainless steel condensation drip tray is provided with 20 mm outlet diameter.

The system of drainage must provide an adequate trap.

The dimensions and execution of the trap must guarantee that H 50 mm.

IMPORTANT: IT IS IMPORTANT NOT TO PLACE

IN OPERATION THE UNIT IF THE FAN OUTLETS

ARE NOT DUCTED OR NOT PROTECTED BY A

SAFETY NET ADHERING WITH REGULATION

UNI 9219 OR SUCCESSIVE.

Page 13

IOM / MINIAIR-0507 11

The trap must have a tap for correct cleaning of the lower part, and must allow an easy disassembly.

The path of the condensation drainage tube must always have a gradient toward external.

Insure that the condensation run-off tube does not interfere with discharge of the unit.

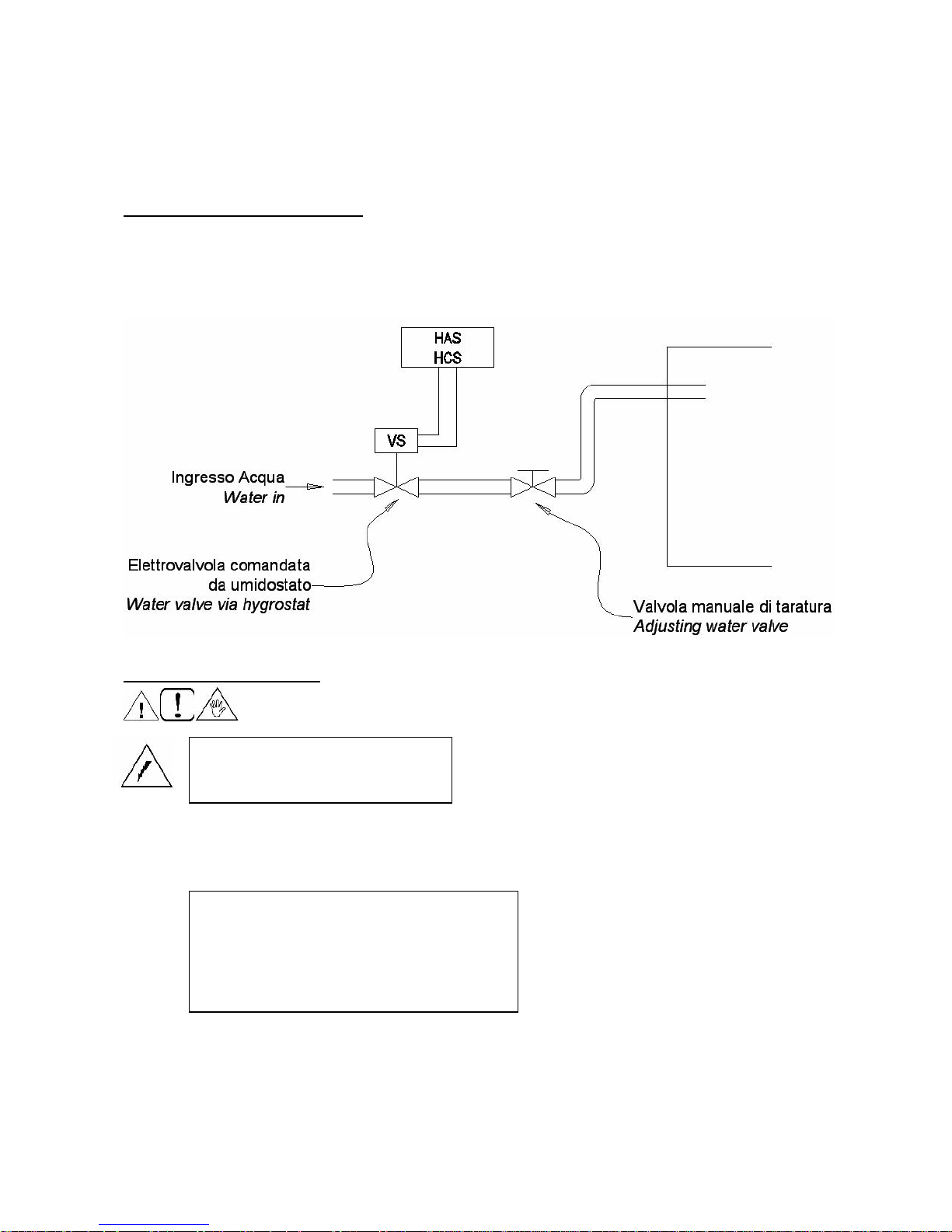

4.8.2 Water humidifier connection

The evaporative pack section is feeded by water public network (no water pump inside); the feeding system must provide

a valve (supplied by the installer) for the adjustment of the water flow; an excessive quantity may ove rflow the driptray

system present in the system.

For the drainage of the water and the realisation of the trap, see previous paragraph; furthermore it is recommended to

not reduce the diameter of the drainage tube till the sewer outlet, so as to avoid overflow and nasty odours.

4.9 Electrical connections

Qualified personnel according to the supplied schemes must carry out the electrical connections at the control

panel.

Insure that the voltage and the frequency shown on the technical plate correspond to the connecting power

supply.

For the general power supply of the unit and its accessories, the use of adapters, multiple plugs and extension

leads is to be avoided.

It is the responsibility of the installer to insure that the installation of the unit is as close as possible to

the mains power supply, or sufficiently close to protect the electrical parts.

Connect the unit to an efficient power point, using the correct screws as supplied with the unit.

Before starting any operation, insure

that the general power supply has

been switched off.

Connect the unit and its accessories using

adequate wiring for the used power while

respecting the country regulations. The

dimension of the wiring must be enough to

support a voltage drop in start up phase lower

than 3% of the nominal one.

Page 14

12 IOM / MINIAIR-0507

1 2

The electrical wiring diagrams of the ordered unit are supplied with it when delivered and they are related to the

real accessory selection.

SECTION 5 – PRE START CHECKLIST

5.1 Checks prior to Start-up

Before turning on the apparatus verify the following:

Fixing of unit to ceiling;

Connection of ducts;

Correct condensation run-off;

Connection of mains supply;

Closing of all electrical clamps.

SECTION 6 – STANDARD MAINTENANCE

It is the responsibility of the user to carry out all types of maintenance operations.

Only personnel previously trained and qualified may carry out maintenance operations.

Should the apparatus require disassembly, hand protection is required

6.1 Monthly maintenance

6.1.1 Filter section check

If the filter is dirty, open the lower panel door, remove the screws as seen in figure 1, remove filter door and remove the

filter from below (figure 2). For cleaning, utilise a vacuum cleaner or wash with normal detergent in warm water, dry well.

Remember to always fit the filter before re-starting the apparatus.

BEFORE FOLLOWING ANY TYPE OF

MAINTENANCE OPERATION, BE CERTAIN THAT

THE APPARATUS MAY NOT CASUALLY OR

ACCIDENTALLY BE CONNECTED TO THE

ELECTRICAL MAINS SUPPLY. THERFORE IT IS

NECESSARY TO SHUTDOWN THE UNIT’S

POWER SUPPLYAD PRIOR TO MAINTENANCE.

Page 15

IOM / MINIAIR-0507 13

6.1.2 Bag filter section check

The soft bag filters are high performance type and require periodical checking, as a marked deterioration may occur

during usage, especially at the point where they are attached to the main frame. This is due to the continuous

deformation, and for the weight of the dust caught.

These filters are not recyclable, and any cleaning may only be carried a few times by turning the filter upside down.

Should it become necessary to substitute the filters, verify the condition of the sealing, and proceed with the substitution.

The bags full of dust must be removed with great care, or to achieve a safer operation, cover the air inlet area. This will

avoid the over-spill of dust inside the apparatus.

6.1.3 Coil check

Check that the Coil exchanger is clean and in a perfect condition so as to guarantee correct performance.

6.1.4 Water humidifier section check

A periodical cleaning of the drip tray is recommended by using steam (high pressure or similar) or specific cleaning

products. Alternatively, replace the evaporation pack, efficient working of which is fundamental to guarantee the air

quality.

The pack must be replaced when limestone build-up is found.

The evaporative pack must be fitted in its correct position, controlling the air direction through the apparatus and the

water flow on the filter.

Always check the cleaning and the efficiency of the outlet and the inlet of the water section.

6.1.5 Power supply check

Control that the power supply voltage falls within the prescribed limits.

6.2 Yearly maintenance

Check that all the electrical equipment, in particular the fixing of the electrical connections.

Check the tightness of all nuts, bolts, flanges and hydraulic connections that the vibrations of the machine may have

loosened.

SECTION 7 – TROUBLESHOOTING

7.1 Finding faults

ANOMALY POSSIBLE CAUSE

The motor does

not run

Power supply not present

The thermostat switches are

not in their exact functioning

position

Material/foreign bodies

blocking moving parts

Loose electrical connections

Loss of

performance after

a period of

satisfactory

working

The filter and coil are dirty

The system is not correctly

balanced

Air present in hydraulic

system. Release with specific

valve.

Obstruction present in ducts

Page 16

14 IOM / MINIAIR-0507

SECTION 8 – SPARE PARTS

8.1 Spare part order

In the following table there are the codes of the unit components that might be replaced; the Customer must refer to

these codes for the possible spare part order. See 2.2 paragraph for the used quantity in the specific model.

Model

ii.

Sp

ar

e

pa

rt

10 20 25 30 40 50 60

Direct driven fan

03305021 AMF0000097 03305028 AMF0000040 AMF0000097 03305063 03305063

2-row water coil

03420192 03420193 03420105 03420105 03420106 03420199 03420202

4-row water coil

03420169 03420170 03420100 03420100 03420171 03420198 03420201

6-row water coil

03420194 03420195 03420102 03420102 03420196 03420150 03420200

G3 filter

AMF0002466

F6 bag filter

AMF0001743

SECTION 9 – MATERIAL DISPOSA L

9.1 Material disposal

At the end of the productive life cycle, the MINIAIR Unit must be dismantled and disposed of respecting the operational

regulations present in its country of installation.

The materials that the unit is constructed of are:

- Aluzink shee t metal;

- Zinc-plated sheet metal;

- Aluminium;

- Copper;

- Polye ster;

- Polye thylene ;

- Inox Stainless Steel;

- Plastic.

18.2

Page 17

IOM / MINIAIR-0507 15

MINIAIR+

SECTION 10 – PRESENTATION

10.1 Manual presentation

This instruction manual supplies the necessary information for the transportation, the installation, operation and

maintenance of the MINIAIR+ apparatus as supplied by the company LENNOX (from this point named as the supplier).

It supplies the user with as much information as is normally useful for a correct and secure installation of the unit.

Lack of observation of the details found within this manual, and an inadequate installation of the MINIAIR+ may cause

the withdrawal of the warranty supplied with the equipment.

Furthermore, the Supplier will not respond to any eventual damage, whether direct or indirect, caused by the incorrect

installation, or for damages caused by the installation being effectuated by inexperienced or unauthorised personnel.

Verify, upon acquisition, that the apparatus is complete and supplied as described.

Any eventual disputes must be presented in writing within 8 days from the reception of the goods.

10.2 Machine identification

The MINIAIR+ Unit is provided with identification plate listing the following:

- Address of Constructor

- “CE” Mark

- Model

- Serial Number

- Maximum Current absorbed in “A”

- Power supply voltage in “V”

- Power supply frequency in “Hz”

- Number of phases indicated with “Ph”

- Date of fabrication

- Gross weight in “Kg”

SECTION 11 – TECHNICAL CHARACTERISTICS

11.1 General characteristics

Completely removable aluzink plate side panels.

Panel thermal and acoustic insulation by means of polyethylene/polyester panels with a medium thickness of 20

mm.

High efficiency aluminium plate static type heat recuperators, with air flows separated by special seals.

UE3 efficiency air filters, which may be easily removed from the sides allowing their periodic cleaning.

Fan bodies mounted on anti-vibrators.

Double inlet centrifugal fans (for MINIAIR+03 single inlet fans) which may be removed from the sides for

periodic maintenance.

Multi-speed directly coupled electric motors..

To aid the electrical connections and ventilator control, a terminal block with a relay board is fitted.

Stainless steel condensation colle cting tray, with condensation drainage towards the lower part

11.2 Accessories

Electrica l reheating SKE

Water coil for reheating SKW

Regulation damper SKR

Speed selector CVU

Apparatus Control Panel PCU

Pressure operated soiled filter cut-off switch PSTD

Servomotor for damper regulations SSE

Anti-free ze thermostat TE G

Page 18

16 IOM / MINIAIR-0507

11.3 Packing dimensions

Model 03 06 10 14 19 25 30 40

A (mm) 990 990 1150 1350 1450 1700 1700 1700

B (mm) 750 750 860 900 900 1230 1230 1230

C (mm) 270 270 385 410 470 490 530 630

L (mm) 127 164 240 240 240 306 339 339

H (mm) 112 100 218 270 270 270 297 297

L1 (mm) 275 275 330 337 337 502 502 502

H1 (mm) 153 153 267 267 327 347 387 487

D (mm) - - 230 230 280 305 305 405

E (mm) 120 197 225 241 230 323 308 308

F (mm) 135 171 238 224 284 304 331 431

G (mm) 195 195 222 239 239 321 321 321

- - G ¾ G ¾ G ¾ G ¾ G ¾ G ¾

Page 19

IOM / MINIAIR-0507 17

11.4 Unit technical data

Model

MINIAIR+

03

MINIAIR+

06

MINIAIR+

10

MINIAIR+

14

MINIAIR+

19

MINIAIR+

25

MINIAIR+

30

MINIAIR+

40

Air flow m3/h 290 550 1000 1400 1900 2500 3200 4000

Available static pressure Pa 60 65 90 140 120 110 170 170

Liv. Sound pressure dB (A)

53 54 54 59.5 58 57,5 60,5 62

Fans

MINIAIR+

03

MINIAIR+

06

MINIAIR+

10

MINIAIR+

14

MINIAIR+

19

MINIAIR+

25

MINIAIR+

30

Section 1.02

INIAIR+

40

Absorbed power W 2 x 45 2 x 65 2x 147 2x 350 2x 350 2x 350 2x 550 2x 750

Poles n° 4 2 4 4 4 4 4 4

Max current A 1,32 1,6 3 5,8 6,2 6 11,4 6,2

N° fan speed 2 2 3 3 3 3 3 2

Protection 20 44 44 55 44 55 20 55

Insulation Class B F F F F F F F

Power supply

V/ph/Hz

230 / 1 / 50 400/3/50

Thermal recuperator (*)

MINIAIR+

03

MINIAIR+

06

MINIAIR+

10

MINIAIR+

14

MINIAIR+

19

MINIAIR+

25

MINIAIR+

30

MINIAIR+

40

Efficiency % 52,3 54,6 53,4 52,1 51,8 57,6 56 55,6

Capaicty recovered kW 1,34 2,57 4,6 6,2 8,4 12,3 15,3 19,4

Outlet temp °C 8,1 8,7 8,3 8,0 7,9 9,4 9,0 8,9

Filters(*)

MINIAIR+

03

MINIAIR+

06

MINIAIR+

10

MINIAIR+

14

MINIAIR+

19

MINIAIR+

25

MINIAIR+

30

MINIAIR+

40

Efficiency G3 G3 G3 G3 G3 G3 G3 G3

Frontal air speed m/s 1,7 3,6 2,9 4,1 4,5 3,8 4,3 4,3

Size mm

300

178

48

300

178

48

356

293

48

356

293

48

363

353

48

528

373

48

528

413

48

628

413

48

(*) Size valued in the following hypothesis: Ting. External =-5°C; T ambient 20°C ; nominal air flow.

Page 20

18 IOM / MINIAIR-0507

11.5 Accessories technical data

11.5.1 Water coil for reheating

Section 1.03 Coil code SKW 10 SKW 14 SKW 19 SKW 25 SKW 30 SKW 40

Geometry 25 22 25 22 25 22 25 22 25 22 25 22

Tubes per row N ° 14 14 16 17 17 21

Rows N ° 3 3 3 3 3 3

Fin pitch mm 2.5 2.5 2.5 2.5 2.5 2.5

Capacity KW 9.4 13.4 16.6 23.9 28.4 36.2

Outlet temp ° C 36 36.6 34.1 36.6 34.5 34.3

Air pressure drop Pa 65 64 85 62 85 92

Water pressure drop kPa 8 16 10 11 15 27

Size valued in the fol lowing hypothesis:

Water 70/60°C;

Air entrance temperature 8°C;

Nominal air volume.

11.5.2 Electrical reheating

Coil code SKE 03 SKE 06 SKE 10 SKE 14 SKE 19 SKE 25 SKE 30 SKE 40

Electrical coil 1 stage kW 2 4 4.5 6 9 12 12 12

Power supply V 230 230 400 400 400 400 400 400

Phases n° 1 1 3 3 3 3 3 3

Stage n° 1 1 1 1 1 1 1 1

Absorbed current A 8.7 17.4 6.5 8.7 13 17.3 17.3 17.3

Outlet Air Temp (+) °C 28.4 27.8 21.3 20.7 22 22.2 19.5 17

(+) Size valued with Ting air = 8°C and nominal air capacity.

Page 21

IOM / MINIAIR-0507 19

11.6 Possible positioning

For each size available, four possible positions for the recuperators are available. Depe nding on the ne t configuration,

and available space, one of the four possibilities below may be employed

11.6.1 Horizontal unit orientation

11.6.2 Vertical unit orientation

ESTERNO

OUTSIDE

INTERNO

Mandata

aria preriscaldata

INSIDE

Ripresa

aria ambiente

Tipo "A" - Type "A"

ESTERNO

OUTSIDE

Tipo "B" - Type "B"

INTERNO

INSIDE

Espulsione

aria viziata

Air b low-out

Aspira zione

aria di rinnovo

Air in take

renewal

ESTERNO

Aspirazione aria di rinnovo

OUTSIDE

Tipo "C" - Type "C"

INTERNO

Mandata aria preriscaldata

Ripresa aria ambiente

INSIDE

Espulsione aria viziata

INSIDE

INTERNO

ESTERNO

OUTSIDE

Tipo "D" - Type "D"

A90 R90

E90 M90

E90 M90

A90 R90

R90M90

E90 A90

E90

M90

A90

R90

Internal air

iduction

Imput pr e

heated air

Air in take

renewal

Air blow-out

Espulsione

aria viziata

Aspira zione

aria di rinnovo

Internal air

iduction

Mandata

aria preriscaldata

Imput pr e

heated air

Ripresa

aria ambiente

Imput pre heated air

Internal air duction

Air blow-out Air intake renewal

Espulsione aria viziata

Air blow-out Air intake renewal

Aspirazione aria di rinnovo

Internal air duction

Ripresa aria ambiente

Imput pre heated air

Mandata aria preriscaldata

Tipo "C" - Ty pe "C "

Tipo "D" - Type "D"

Tipo "B" - Type "B"

Tipo "A" - T ype "A "

E90

A90

M90

R90

Espulsione

aria viziata

Air blow-out

Mandata

aria preriscaldata

Imput pre

heated air

Aspirazione

aria di rinnovo

Air intake

renew al

Ripresa

aria ambiente

Internal air

iduc tion

Espulsione

aria viziata

Air blow-ou t

A90

Air intake

renewal

Aspirazione

aria di rinnovo

E90

R90

Imp ut pre

heated air

Mandata

aria preriscaldata

M90

Inte r nal air

iduction

Ripresa

aria ambiente

Espulsione

aria viziata

Air blow-out

E90

Air intake

renewal

Aspirazione

aria di rinnovo

M90

A90

Imput pre

heated air

Mandata

aria preriscaldata

R90

Internal air

iduc tion

Ripresa

aria ambiente

Mandata

aria preriscaldata

M90

Air blow-ou t

Espulsione

aria viziata

Impu t pre

heated air

E90

Ripresa

aria ambiente

R90

Aspirazione

aria di rinnovo

Air intake

renew al

Inte r nal air

iduction

A90

Page 22

20 IOM / MINIAIR-0507

Aspirazione aria di rinnovo

Tipo "A" - Type "A"

Espulsione aria viziata

R90M90

Air blow-out

Air intake renewal

Internal air duction

Ripresa aria ambiente

Imput pre heated air

Mandata aria preriscaldata

M90

Tipo "B" - Type "B"

Air intake

renewal

Aspirazione

aria di rinnovo

Espulsione

aria viziata

Air blow-out

E90

Imput pre

heated air

Ripresa

aria ambiente

Internal air

iduction

Mandata

aria preriscaldata

61,5681

61,5681

11.6.3 Vertical unit with post-heating coil

As shown in the figu re below, by simply changing the position of two panels it is possible to suck or blow out air from the

sides instead from the front of the unit

Page 23

IOM / MINIAIR-0507 21

11.7 By-pass for de-frosting or free-cooling

For MINIAIR+ 03-06-10-14-19-25-30 models the structure has a presplitting allowing defrosting by-pass or free cooling to

be carried out.

Free cooling. When the external tem perature is close to the internal temperature the recuperator may be bypassed

inserting renewal air directly in the room.

It is possible to do this by opening damper B and at the same time closing damper A.

Defrosting. In very cold periods the room delivery air could frost blocking the passage through the recuperator. Installing

an antifreeze thermostat (optional) combined with the bypass system indicated in the figure unit defrosting is obtained. In

fact opening gate A and closing gate B the recuperator is bypassed with cold air and the flow of hot air coming from the

room air delivery allows a rapid defrosting of the recuperator itself which can therefore return to operation in normal

conditions.

SECTION 12 – TRANSPORTATION

12.1 Packing

The recuperators are placed in carton boxes that must remain intact until the moment of installation.

The materials that are not required for technical motives are supplied in fitted packing fixe d externally and internally to

the unit.

ESTERNO

OUTSIDE

Espulsione

aria viziata

Air blow-out

Aspirazione

aria di rinnovo

Air intake

renewal

Imput pre

heated air

Mandata

aria preriscaldata

INTERNO

Internal air

iduction

Ripresa

aria ambiente

INSIDE

Serranda A

Serranda B

Schema 1

Air free cooling

Aspirazione

aria free cooling

INTERNO

INSIDE

Ripresa

aria ambiente

Mandata

aria preriscaldata

Internal air

iduction

Air intake

renewal

Espulsione

aria viziata

Air blow-out

ESTERNO

Aspirazione

aria di rinnovo

OUTSIDE

Imput pre

heated air

Schema 2

Serranda C

Serranda E

Serranda D

Page 24

22 IOM / MINIAIR-0507

12.2 Transportation

For the lifting and transportation of the unit, use adequate equipment, according to the 89/391/CEE regulations and

successive modifications.

Each individual machine weight is listed in this manual.

Avoid rotation without control.

12.3 Checklist

Upon reception of the apparatus, we suggest that a complete control is carried out, to verify that the unit is intact and

complete, and no damage has been sustained during transport. Any eventual damage revealed must be communicated

to the carrier, demonstrating the reserve clause within the transport documents, specifying the type of damage.

12.4 Storing

In case of long term storage, the apparatus must be kept free from dust, and away from areas susceptible to heat and

vibration.

The manufacturer declines any responsibility for any damage as a result of negligence or lack of protection from

atmospheric agents.

SECTION 13 – INSTALLATION & CONNECTION

13.1 Definition

CLIENT– The client is the person, activity or the society, that has bought or hired the apparatus, and intends to utilise the

machinery for its intended use.

USER / OPERATOR – The User or Operator, is the actual person that has been authorised by the client to utilise the

apparatus.

TECHNICIAN – Defined as the person who has followed a relevant/specific course of study, and so is able to understand

the dangers derived from the use of the apparatus, and in turn, due to this, are capable of solving major dilemmas.

13.2 Safety regulations

Qualified personnel must carry out the installation.

During the installation operation, use protective clothing, for e xample: glasses, gloves, etc. as indicated by

686/89/CEE and successive regula tions.

During the installation operate in absolute security, pollution free air and in an area free of obstructions.

Respect the regulations in force in the country in which the apparatus is being installed. Specifically relative to

its use, and to the disposal of packing and products used for the cleaning and maintenance of the unit. Respect

the recommendations given by the producers of such products.

Before placing in function the unit, check the perfect connection of the various components and the internal

parts of the system.

Avoid at a ll costs human contact with moving parts and contact w ith the parts themselves.

Do not commence with servicing or cleaning of the unit, before the unit has been disconnected from the

main supply.

The Manufacturer declines any responsibility for

failure to respect the Safety Regulations, and the

prevention as described below.

Furthermore, the manufacturer declines any

responsibility for damage caused by the improper

use of the unit and/or modifications carried out

without proper authorisation.

Page 25

IOM / MINIAIR-0507 23

The maintenance and the substitution of damaged or consumed parts must be carried out on ly by specia lise d

personnel, following the indications found within this manual.

Spare parts must correspond to the requirements specified by Manufacturer .

In case of dismantling of the unit, respect the anti-pollution regulations in force.

N.B. The installer and the user of the apparatus must take into account, and solve problems, connected with any other

type of risk that may occur to the unit. For example, risks derived from the entrance of foreign bodies, or risks due to the

presence of flammable or toxic gas.

13.3 Preliminary operations

Check the perfect condition of the various components of the unit.

Control that contained within the packing, there are the installation accessories, and documentation.

Transport the packed section as close as is possible to the intended place of installation.

Do not place tools or weight on top of the packed unit.

13.4 Choosing place of installation

Positio n the unit on a solid structure, that will not vibrate, and is capable supporting the weight of the machine.

Positio n the unit in a point where the condensation discharge may occur easily.

Do not position the unit in an area in which flammable gases, acidic or corrosive substances are present. They

may damage various components in an irreparable manner.

Allow a min imum amount of free space as indicated in the figure. This permits ease of installation and

maintenance.

Min 500

Page 26

24 IOM / MINIAIR-0507

Model 03 06 10 14 19 25 30

Section 1.04 A 300 300 350 400 400 450 450

13.5 Machine positioning

Min 500

A

Page 27

IOM / MINIAIR-0507 25

Model 03 06 10 14 19 25 30

Section 1.05 A 796 796 906 946 946 1276 1276

B 940 940 1100 1230 1380 1630 1630

C 700 700 810 830 830 1160 1160

D 1036 1036 1196 1346 1496 1746 1746

To aid the regular flow of the condensation, it is advised to install the apparatus with a 3 mm inclination towards the

condensation outlet.

13.6 Duct connection

The Ducts must be the correct dimension based on the functions of system and the air diffusion characteristics

of the unit fans. A mistaken calculation of the ducting will cause power loss or the intervention of any eventual

devices present on the system.

To prevent the formation of condensation and cut down the sound level it is advised to use internally lined

Ducts.

To avoid the transmission of machine vibrations into the environment, it is advised to fit an anti-vibration joint

between the fans and Ducts. The electrical continuity must be guaranteed between the Ducts and the apparatus

via an earth cable.

IMPORTANT: IT IS IMPORTANT N OT TO PLACE

IN OPERATION THE UNIT MINIAIR+ IF THE

MOUTHS OF THE FANS ARE NOT DUCTED OR

NOT PROTECTED BY A SAFETY NET

ADHERING WITH REGULATION UNI 9219 OR

SUCCESSIVE.

Page 28

26 IOM / MINIAIR-0507

13.7 Hydraulic connections

The installation and connecting of the piping is an operation that must be done correctly , otherwise it may compromise

the performance of the system. At worst it may cause irreversible damage to the machine. These operations are to be

effectuated by qualified personnel.

13.7.1 Condensation outlet connection

The condensation drip tray in stainless steel inox has a depth of D. 12 mm.

The system of drainage must provide an adequate trap to prevent the undesirable entrance of air into the

system in depression. The trap is also useful to avoid the infiltration of odours and insects.

The dimensions and execution of the trap must guarantee that H P, where P is expressed in mm.c.a, and is

equal to the useful static pressure of the unit installed.

The trap must have a tap for correct cleaning of the lower part, and must allow an easy disassembly.

The path of the condensation drainage tube must always have a gradient toward external.

Insure that the condensation run-off tube does not interfere with discharge of the unit.

13.7.2 Eventual connection for SKW water reheating coil

The eventual water reheating coil is supplied with “male” connections with gas threads.

The tightening must be carried out with extreme care to avoid damage to the copper collectors of the coil.

The path of the tubes must be studied in a way to avoid obstacles should it be necessary to extract the unit coil.

Inlet and outlet water must consent the thermal exchange against the current. Follow instructions found on the

WATER INLET and WATER OUTLET plate.

Provide an escape valve at the top of the unit, and a discharge valve a t the bottom.

Reinforce sufficiently the units external tubes to avoid offloading the weight onto the coil.

Once connection has been effectuated, fix the external seal flush against the control panel, in this way avoiding

the passing of air.

La insulation must not rest against the panelling, as this may provoke burning.

For control purposes, organize the interception of the tube side coil when the fan is off, to avoid internal

overheating and possible damage to internal components.

Provide an anti-freeze system.

Provide a cut out switch to isolate the coil from the rest of the circuit in case of extensive maintenance needs.

Should the unit be installed in particularly cold areas, drain completely before long periods of in-operation.

Page 29

IOM / MINIAIR-0507 27

13.8 Electrical connections

Qualified personnel according to the supplied schemes must carry out the electrical connections at the control

panel.

Insure that the voltage and the frequency shown on the technical plate correspond to the connecting power

supply.

For the general power supply of the unit, and its accessories, the use of adapters, multiple plugs and extension

leads is to be avoided.

It is the responsibility of the installer to insure that the installation of the unit is as close as possible to

the mains power supply, or sufficiently close to protect the electrical parts.

Connect the unit to an efficient power point, using the correct screws as supplied with the unit.

In the unit with rel ay board the screws of the connectors must be screwed with tork equal to 0,5 Nm

13.9 Installation of CVU & PCU accessories

13.9.1 CVU speed control

Adaptable for wall installation, allows the possibility to select one of three fan speeds.

Present on the control panel is:

- On – Off switch;

- Three speed Selector switch.

Installation and fitting

1. Loosen the central screws;

2. Remove the cap;

3. Fix the base to the wall, approximately 1,5 metres from the floor surface;

4. Carry out electrical connections;

5. Replace cap, and tighten central screws.

Before commenci

ng any operation,

insure that the general power supply

has been isolated

Follow the connection of the unit and its

accessories using adequate cabling for the

power used, and respecting the country

regulations. The dimensions of the cabling must

be sufficient to support a voltage drop in start

up phase inferior to 3% of the nominal

Page 30

28 IOM / MINIAIR-0507

Technical characteristics

Power supply: 230 +/- 10% Vac ; 50/60Hz

Control:

Manual : On / Off

Manual : Min/ Med / Max

Relay capacity: 6A with resistive load

13.9.2 PCU Control panel

Adaptable for wall installation, the PCU Control Panel allows environmental temperature control, for both summer and

winter. It also allows the possibility to select the three speed Electro-fan.

Present on the control panel is:

- On (summer -winter ) – Off switch;

- Switch for temperature regulation;

- Three speed Selector switch;

Technical characteristics

Power supply: 230 +/- 10% Vac ; 50/60Hz

Control:

Manual : On / Off

Manual : Min/ Med / Max

Relay capacity: 6A with resistive load

Page 31

IOM / MINIAIR-0507 29

SECTION 14 – ELECTRICAL SCHEMES

14.1 MINIAIR+ 03-06 direct connection

14.2 MINIAIR+ 03-06 connection with CVU speed control

MM

NELLO SCHEMA E' INDICATO IL FUNZIONAMENTO ALLA MINIMA VELOCITA'.

IL FUNZIONAMENTO ALL' ALTA VELOCITA' COLLEGARE IL NEUTRO CON IL MORSETTO 2.

POSSIBLE EXTERNAL AGREMEENT

THE DIAGRAM SHOWS OPERATION AT THE LOW SPEED.

FOR THE HIGH SPEED CONNECT THE NEUTRAL WITH CLAMP n°2.

THE CONNECTION TO BE CARRIED OUT BY THE INSTALLER ARE SHOWN BY THE DOTTER LINE.

ALL THE CONNECTIONS MUST BE PROTECTED ST THE SOURCE BY THE INSTALLER.

ALTA VELOCITA' / HIGH SPEED

BASSA VELOCITA' / LOW SPEED

COMUNE / COMMON

EVENTUALE CONSENSO ESTERNO

I COLLEGAMENTI A CURA DELL'INSTALLATORE SONO INDICATI A TRATTEGGIO.

TUTTE LE LINEE DEVONO ESSERE PROTETTE ALL'ORIGINE A CURA DELL'INSTALLATORE

NF

N

F13

RELE'

2

RELE'

V1

V2

V3

1

RELE'

N

F

BASSA VELOCITA' / LOW SPEED

ALTA VELOCITA' / HIGH SPEED

I COLLEGAMENTI A CURA D ELL'INSTAL LATORE SONO INDICATI A TRATTEGGIO.

TUTTE LE LINE E DEVON O ESSERE PROTETTE ALL'O RIGINE A CURA DEL L ' INSTALLATORE

THE CONNECTION TO BE CARRIED OUT BY THE INSTALLER ARE SHOWN BY THE DOTTER LINE.

ALL THE CONNECTIONS MUST BE PROTECTED ST THE SOURCE BY THE INSTALLER.

V2

V1

COMUNE / COMMON

V3

N

6

CVU

RELE'

1 2

1 2

3 4 5

N

F

RELE'

RELE'

F13 NF

M M

Page 32

30 IOM / MINIAIR-0507

14.3 MINIAIR+ 03-06 connection with SKE & PCU control panel

14.4 MINIAIR+ 10-14-19-25 direct connection

QUADRO COMANDO SKE SINGOLA / DOPPIA RESISTENZA

THE CONNECTION TO BE CARRIED OUT BY THE INSTALLER ARE SHOWN BY THE DOTTER LINE.

ALL THE CONNECTIONS MUST BE PROTECTED AT THE SOURCE BY THE INSTALLER.

I COLLEGAMENTI A CURA DELL'INSTALLATORE SONO INDICATI A TRATTEGGIO.

TUTTE LE LINEE DEVONO ESSERE PROTETTE ALL'ORIGINE A CURA DELL'INSTALLATOR E

SOLO CON RKE06

TSTS

SKE CONTROL CABINET

S1

N

R2

S2 R1

N

F

F

CONTROL PANEL FAN

QUADRO COMANDO VENTILATORI

ALTA VELOCITA' / HIGH SPEED

BASSA VELOCITA' / LOW SPEED

COMUNE / COMMON

3

2

M M

RELE'

1

V3

V2

V1

RELE'2RELE'

3 F1NF N

2 31 139 10 11 126 7 84 5

PCU

MM

NELLO SCHEMA E' INDICATO IL FUNZIONAMENTO ALLA MINIMA VELOCITA'.

IL FUNZIONAMENTO ALLA MEDIA VELOCITA' COLLEGARE IL NEUTRO CON IL MORSETTO 2.

IL FUNZIONAMENTO ALL'ALTA VELOCITA' COLLEGARE IL NEUTRO CON IL MORSETTO 3.

POSSIBLE EXTERNAL AGREMEENT

THE DIAGRAM SHOWS OPERATION AT THE LOW SPEED.

FOR THE MEDIUM SPEED CONNECT THE NEUTRAL WITH CLAMP n°2.

FOR THE HIGH SPEED CONNECT THE NEUTRAL WITH CLAMP n°3.

THE CONNECTION TO BE CARRIED OUT BY THE INSTALLER ARE SHOWN BY THE DOTTER LINE.

ALL THE CONNECTIONS MUST BE PROTECTED ST THE SOURCE BY THE INSTALLER.

ALTA VELOCITA' / HIGH SPEED

MEDIA VELOCITA' / MEDIUM SPEED

BASSA VELOCITA' / LOW SPEED

COMUNE / COMMON

EVENTUALE CONSENSO ESTERNO

I COLLEGAMENTI A CURA DELL'INSTALLATORE SONO INDICATI A TRATTEGGIO.

TUTTE LE LINEE DEVONO ESSERE PROTETTE ALL'ORIGINE A CURA DELL'INSTALLATORE

NF

N

F13

RELE'

2

RELE'

V1

V2

V3

1

RELE'

N

F

Page 33

IOM / MINIAIR-0507 31

14.5 MINIAIR+ 10-14-19-25 connection with CVU speed control

14.6 MINIAIR+ 10-14-19-25 connection with SKE & PCU control panel

QUADRO COMANDO SKE SINGOLA / DOPPIA RESISTENZA

THE CONNECTION TO BE CARRIED OUT BY THE INSTALLER ARE SHOWN BY THE DOTTER LINE.

ALL THE CONNECTIONS MUST BE PROTECTED AT THE SOURCE BY THE INSTALLER.

KMR2

I COLLEGAMENTI A CURA DELL'INSTALLATORE SONO INDICATI A TRATTEGGIO.

TUTTE LE LINEE DEVONO ESSERE PROTETTE ALL'ORIGINE A CURA DELL'INSTALLATORE

SKE CONTROL CABINET

TS TS

KMR1

T1

S T

S2R2 T2R1

S

N

R

T

R

S1

CONTROL PANEL FAN

QUADRO COMANDO VENTILATORI

ALTA VELOCITA' / HIGH SPEED

MEDIA VELOCITA' / MEDIUM SPEED

COMUNE / COMMON

3

2

M M

RELE'

1

V3

V2

V1

RELE'2RELE'

3 F1NF N

TS TS

1 2

PCU

643 5 7 8 9 10 11 12 13

BASSA VELOCITA' / LOW SPEED

THE CONNECTION TO BE CARRIED OUT BY THE INSTALLER ARE SHOWN BY THE DOTTER LINE.

ALL THE CONNECTIONS MUST BE PROTECTED ST THE SOURCE BY THE INSTALLER.

V3

I COLLEGAMENTI A CURA DELL'INSTALLATORE SONO INDICATI A TRATTEGGIO.

TUTTE LE LINEE DEVONO ESSERE PROTETTE ALL'ORIGINE A CURA DELL'INSTALLATORE

RELE'

RELE'

RELE'

V1

V2

CVU

1

1 2 3 F1

32 4 5 6

F

N

M M

BASSA VELOCITA' / LOW SPEED

ALTA VELOCITA' / HIGH SPEED

MEDIA VELOCITA' / MEDIUM SPEED

COMUNE / COMMON

N

F N

Page 34

32 IOM / MINIAIR-0507

14.7 MINIAIR+ 30 direct connection

14.8 MINIAIR+ 30 connection with CVU speed control

THE CONNECTION TO BE CARRIED OUT BY THE INSTALLER ARE SHOWN BY THE DOTTER LINE.

ALL THE CONNECTIONS MUST BE PROTECTED ST THE SOURCE BY THE INSTALLER.

F1

I COLLEGAMENTI A CURA DELL'INSTALLATORE SONO INDICATI A TRATTEGGIO.

TUTTE LE LINEE DEVONO ESSERE PROTETTE ALL'ORIGINE A CURA DELL'INSTALLATORE

1

RELE'

V2

EVENTUALE CONSENSO ESTERNO

POSSIBLE EXTERNAL AGREMEENT

N

F

RELE'

V1

1 2

M

RELE'

N

V3

3 F1 F N

RELE'

RELE'

V2

V1

1 2 3

F12 3 F N

M

RELE'

V3

N

F N

THE CONNECTION TO BE CARRIED OUT BY THE INSTALLER ARE SHOWN BY THE DOTTER LINE.

ALL THE CONNECTIONS MUST BE PROTECTED ST THE SOURCE BY THE INSTALLER.

I COLLEGAMENTI A CURA DELL'INSTALLATORE SONO INDICATI A TRATTEGGIO.

TUTTE LE LINEE DEVONO ESSERE PROTETTE ALL'ORIGINE A CURA DELL'INSTALLATORE

CVU

F

N

1 2 3

1

COMUNE / COMMON

BASSA VELOCITA' / LOW SPEED

MEDIA VELOCITA' / MEDIUM SPEED

F

V1

RELE'

V2

V3

RELE'

RELE'

21 F13

N

N

M

54 6

F12 3 F N

MEDIA VELOCITA' / MEDIUM SPEED

COMUNE / COMMON

V1

V2

RELE'

RELE'

V3

N

RELE'

21 3 F1 F N

M

ALTA VELOCITA' / HIGH SPEED

ALTA VELOCITA' / HIGH SPEED

BASSA VELOCITA' / LOW SPEED

Page 35

IOM / MINIAIR-0507 33

14.9 MINIAIR+ 30 connection with SKE & PCU control panel

14.10 MINIAIR+ 40 direct connection

SKE CONTROL CABINET

QUADRO COMAN DO S K E

SINGOLA / DOPPIA RESISTENZA

THE CONNECTION TO BE CARRIED OUT BY THE INSTALLER ARE SHOWN BY THE DOTTER LINE.

ALL THE CONNECTIONS MUST BE PROTECTED AT THE SOURCE BY THE INSTALLER.

T2

I COLLEGAMENTI A CURA DELL'INSTALLATORE S ONO INDICATI A TRATTEGGIO.

TUTTE LE LINEE DEVONO ESSERE PROTETTE ALL'ORIGINE A CURA DELL'INSTALLATORE

TRN

S

KMR1

S1R1 T1 S2R2

T

S

R

TS

MEDIA VELOCITA' / MEDIUM SPEED

BASSA VELOCITA' / LOW SPEED

MEDIA VELOCITA' / MEDIUM SPEED

RELE'

RELE'

RELE'

RELE'

RELE'

RELE'

CONTROL PANEL FAN

QUADRO COMAN DO VE N T ILAT OR I

COMUNE / COMMON

ALTA VELOCITA' / HIGH SPEED

V2

KMR2

V1 V3

N

COMUNE / COMMON

V3

V2V1N

TS

21

32

1

M

3 F1 F N

FF132 N

M

1 2 3 F1 F N

TS

TS

51 32 4

PCU

6 7 8 9 10 11 12 13

ALTA VELOCITA' / HIGH SPEED

BASSA VELOCITA' / LOW SPEED

Page 36

34 IOM / MINIAIR-0507

14.11 MINIAIR+ 40 connection with CVU speed control

14.12 MINIAIR+ 30 connection with SKE & PCU control panel

Page 37

IOM / MINIAIR-0507 35

SECTION 15 – PRE-START CHECKLIST

6.1 Checks prior to initial start-up

Before turning on the apparatus verify the following:

1. Fixing of unit to ceiling;

2. Connection of ducts;

3. Correct condensation run-off;

4. Connection of mains supply;

5. Closing of all electrical clamps.

SECTION 16 – STANDARD MAINTENANCE

It is the responsibility of the user to carry out all types of maintenance operations.

Only personnel previously trained and qualified may carry out maintenance operations.

Should the apparatus require disas sembly, hand protection is required

16.1 Monthly maintenance

16.1.1 Filter section checklist

Possibility for inspection to replace filters from below 1 and laterally 2

BEFORE FOLLOWING ANY TYPE OF

MAINTENANCE OPERATION, BE CERTAIN THAT

THE APPARATUS MAY NOT CASUALLY OR

ACCIDENTALLY BE CONNECTED TO THE

ELECTRICAL MAINS SUPPLY. THERFORE IT IS

NECESSARY TO SHUTDOWN THE UNIT’S

POWER SUPPLYAD PRIOR TO MAINTENANCE.

Page 38

36 IOM / MINIAIR-0507

To remove filter, dis-assemble the guides and extract filter.

For the cleaning, utilize a vacuum cleaner or wash with normal detergent and warm water, allow to dry well. Remember

to assemble the filter before operating the unit.

16.1.2 Recuperator Checklist

Verify that the plate e xchanger does not demonstrate signs of impurity, as this may lower significantly its efficiency. It is

possible to dismantle the recuperator from below, removing the condensation drip tray.

Unscrew the plugs 1, remove the tray and extract the recuperator pack

16.1.3 Condensation discharge Checklist

Remove side panel and clean, if necessary, the dirt and impurities that have formed in the condensation tray. Also check

the efficiency of the siphon.

16.1.4 Water coil Checklist

Check that the coil exchanger (optional ) is clean and in perfect state to guarantee the normal levels of performance.

16.2 Yearly maintenance

Check that all the electrical equipment, in particular the fixing of the electrical connections.

Check the tightness of all nut, bolts, flanges and hydraulic connections that the vibrations of the machine may have

loosened.

Page 39

IOM / MINIAIR-0507 37

SECTION 17 – TROUBLESHOOTING

17.1 Finding Faults

SYMPTOMS REASON

The motor does

not turn

Power supply not present

The thermostat switches are

not in their exact functioning

position

Material/foreign bodies

blocking moving parts

Loose electrical connections

Loss of

performance after

a period of

satisfactory

running

The filter and plate

exchanger are dirty

Obstruction present in ducts

SECTION 18 – MATERIAL DISPOSAL

18.1 Material Disposal

At the end of the productive life cycle, the MINIAIR+ Unit must be dismantled and disposed of respecting the operational

regulations present in its country of installation.

The materials that the unit is constructed of are:

- Aluzink shee t metal;

- Zinc-plated sheet metal;

- Aluminium;

- Copper;

- Polye ster;

- Polye thylene ;

- Inox Stainless Steel;

- Plastic.

Page 40

Page 41

Page 42

www.lennoxeurope.com

www.lennoxbelgium.com

www.lennox.cz

www.lennoxfrance.com

www.lennoxdeutschland.com

www.lennoxuk.com

www.lennoxnederland.com

www.lennoxpolska.com

www.lennoxportugal.com

www.lennoxrussia.com

www.lennoxdistribution.com

www.lennoxspain.com

www.lennoxrussia.com

www.lennoxdistribution.com

Due to Lennox’s ongoing commitment to quality,

the Specifications, Ratings and Dimensions are

subject to change without notice and without

incurring liability.

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage or personal injury.

Installation and service must be performed by a

qualified installer and servicing agency.

MINIAIR-IOM-0507-E

BELGIUM, LUXEMBOURG

CZECH REPUBLIC

FRANCE

GERMANY

GREAT BRITAIN

NETHERLANDS

POLAND

PORTUGAL

RUSSIA

SLOVAKIA

SPAIN

UKRAINE

OTHER COUNTRIES

Loading...

Loading...