Lennox Merit Series 13HPX Units Installation Instructions Manual

INSTALLATION

©2014 Lennox Industries Inc.

Dallas, Texas, USA

THIS MANUAL MUST BE LEFT WITH THE

HOMEOWNER FOR FUTURE REFERENCE

WARNING

The State of California has determined that this product

may contain or produce a chemical or chemicals, in very

low doses, which may cause serious illness or death. It

may also cause cancer, birth defects, or reproductive

harm.

NOTICE !

For more in-depth information, consult the Installa

tion and Service Procedures manual, available as

Corp. 0619-L4 on DaveNet or through the Technical

Support department at 800-453-6669.

INSTRUCTIONS

Merit® Series 13HPX Units

HEAT PUMP

506727-01

3/2014

Supersedes 6/2013

GENERAL

This 13HPX outdoor heat pump is designed for use with

HFC-410A refrigerant only. This unit must be installed with

an approved indoor air handler or coil. See the Lennox

13HPX Product Specifications bulletin for approved indoor

component match ups.

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause personal injury, loss of life, or

damage to property.

Installation and service must be performed by a licensed

HVAC professional installer (or equivalent) or a service

agency.

Litho U.S.A.

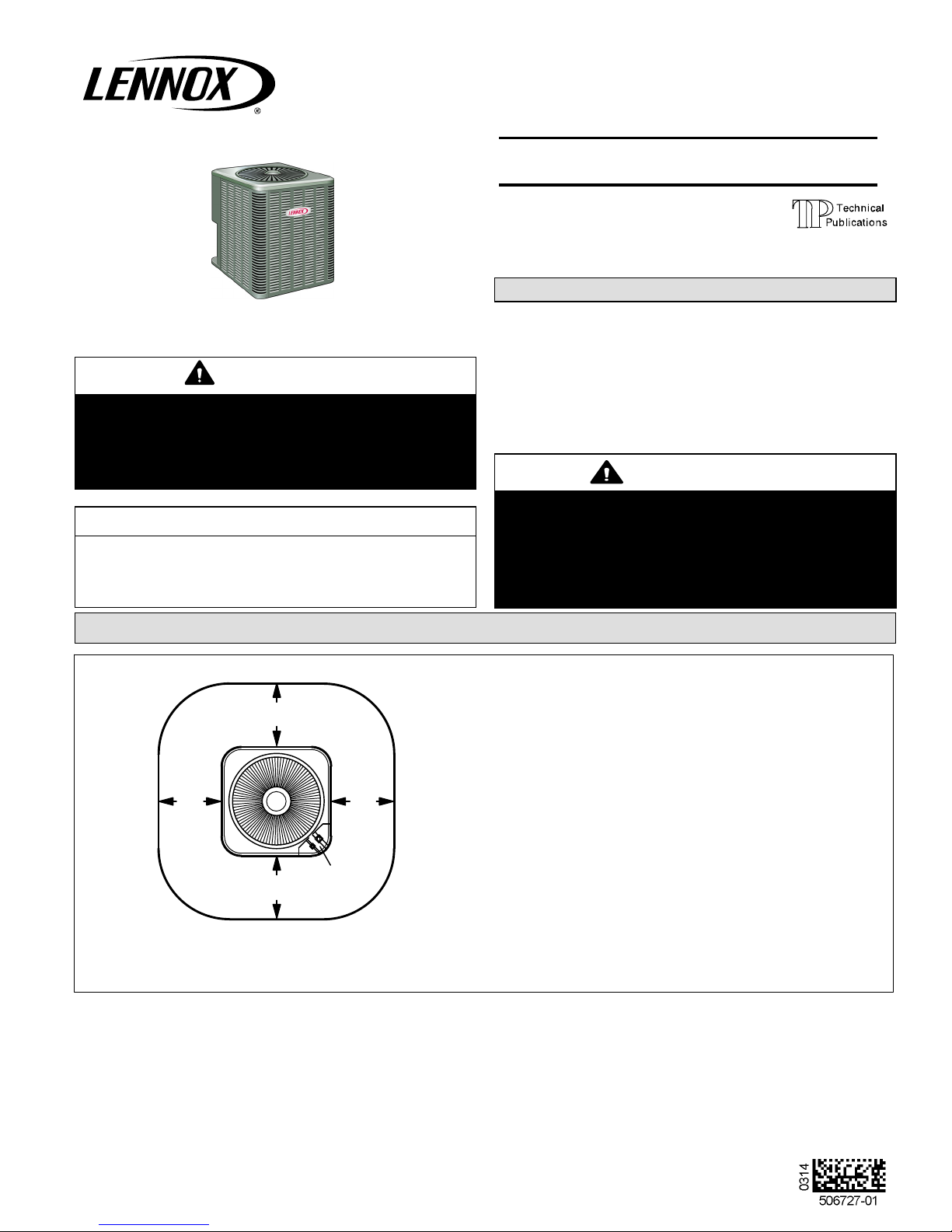

STEP 1 -- SETTING THE UNIT -- CLEARANCES

NOTES:

See

NOTES

See NOTES

See NOTES

See

NOTES

CONTROL

BOX

Service clearance of 30 in. (762 mm) must be maintained on

one of the sides adjacent to the control box.

Clearance to one of the other three sides must be 36 in. (914

mm)

Clearance to one of the remaining two sides may be 12 in.

(305 mm) and the final side may be 6 in. (152 mm).

A clearance of 24 in. must be maintained between two units.

48 in. (1219 mm) clearance required on top of unit.

FIGURE 1

Page 1

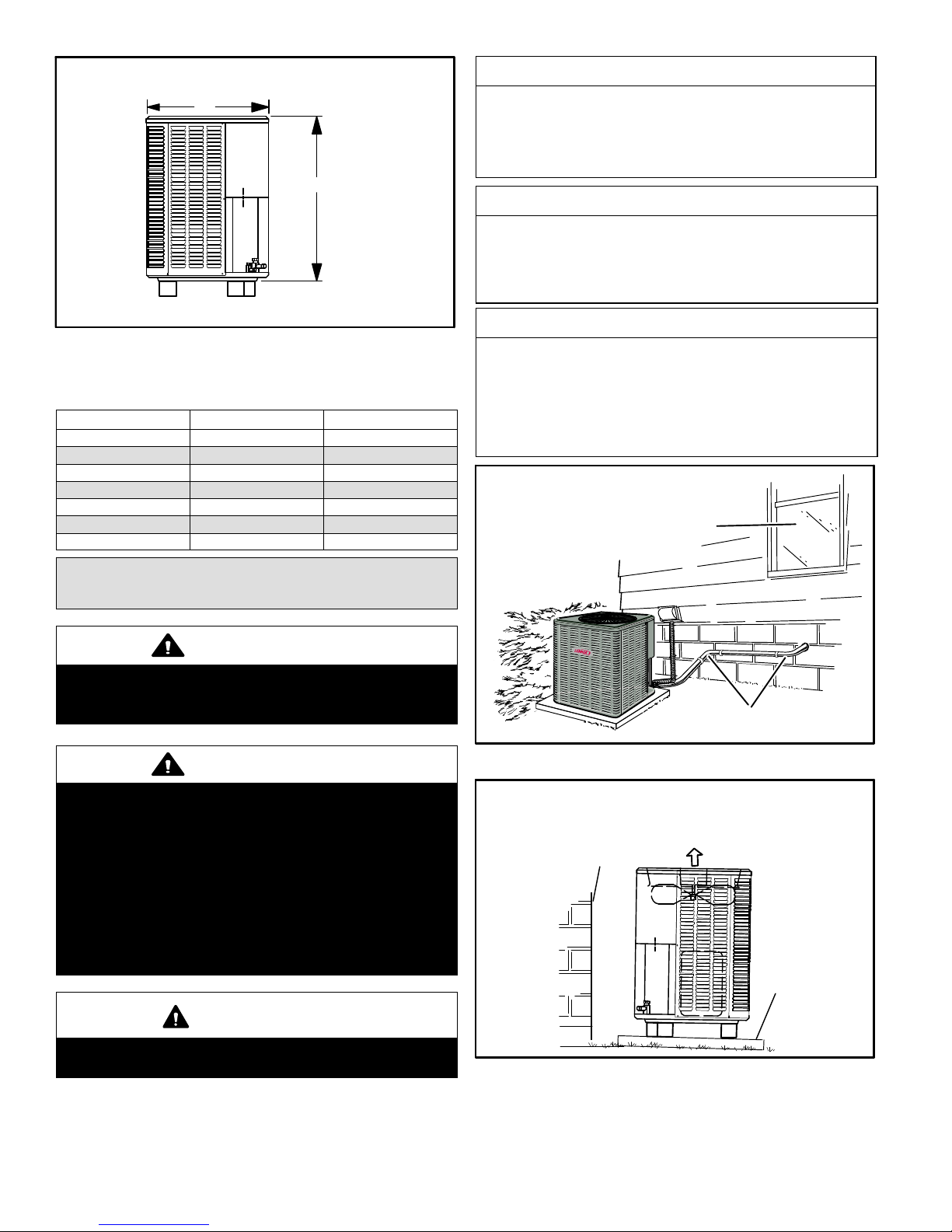

UNIT DIMENSIONS - INCHES (MM)

A

B

SIDE

VIEW

FIGURE 2

TABLE 1

UNIT DIMENSIONS

Model No. A B

13HPX-018-230 24-1/4 (616) 33-1/4 (845)

13HPX-024-230 24-1/4 (616) 33-1/4 (845)

13HPX-030-230 28-1/4 (718) 29-1/4 (743)

13HPX-036-230 28-1/4 (718) 37-1/4 (946)

13HPX-042-230 28-1/4 (718) 43-1/4 (1099)

13HPX-048-230 28‐1/4 (718) 33-1/4 (845)

13HPX-060-230 28‐1/4 (718) 37-1/4 (946)

NOTICE !

Roof Damage!

This system contains both refrigerant and oil. Some

rubber roofing material may absorb oil, causing the

rubber to degrade. Failure to follow this notice could

result in damage to roof surface.

IMPORTANT !

This model is designed for use in check / expansion

valve systems only. An indoor expansion valve ap

proved for use with HFC-410A refrigerant must be or

dered separately and installed prior to operating the

system.

IMPORTANT !

Exhaust vents from dryers, water heaters and furnaces

should be directed away from the outdoor unit. Pro

longed exposure to exhaust gases and the chemicals

contained within them may cause condensation to

form on the steel cabinet and other metal components

of the outdoor unit. This will diminish unit performance

and longevity.

PLACEMENT

INSTALL UNIT AWAY

FROM WINDOWS

STEP 1 -- SETTING THE UNIT

(CONTINUED) -- Unit Placement

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take care

while handling this equipment.

WARNING

To prevent personal injury, as well as damage to panels,

unit or structure, observe the following:

While installing or servicing this unit, carefully stow all

removed panels so that the panels will not cause injury to

personnel, objects or nearby structures. Also, take care to

store panels where they will not be subject to damage

(e.g., being bent or scratched).

While handling or stowing the panels, consider any

weather conditions (especially wind) that may cause

panels to be blown around and damaged.

CAUTION

Before attempting to perform any service or maintenance,

turn the electrical power to unit OFF at disconnect switch.

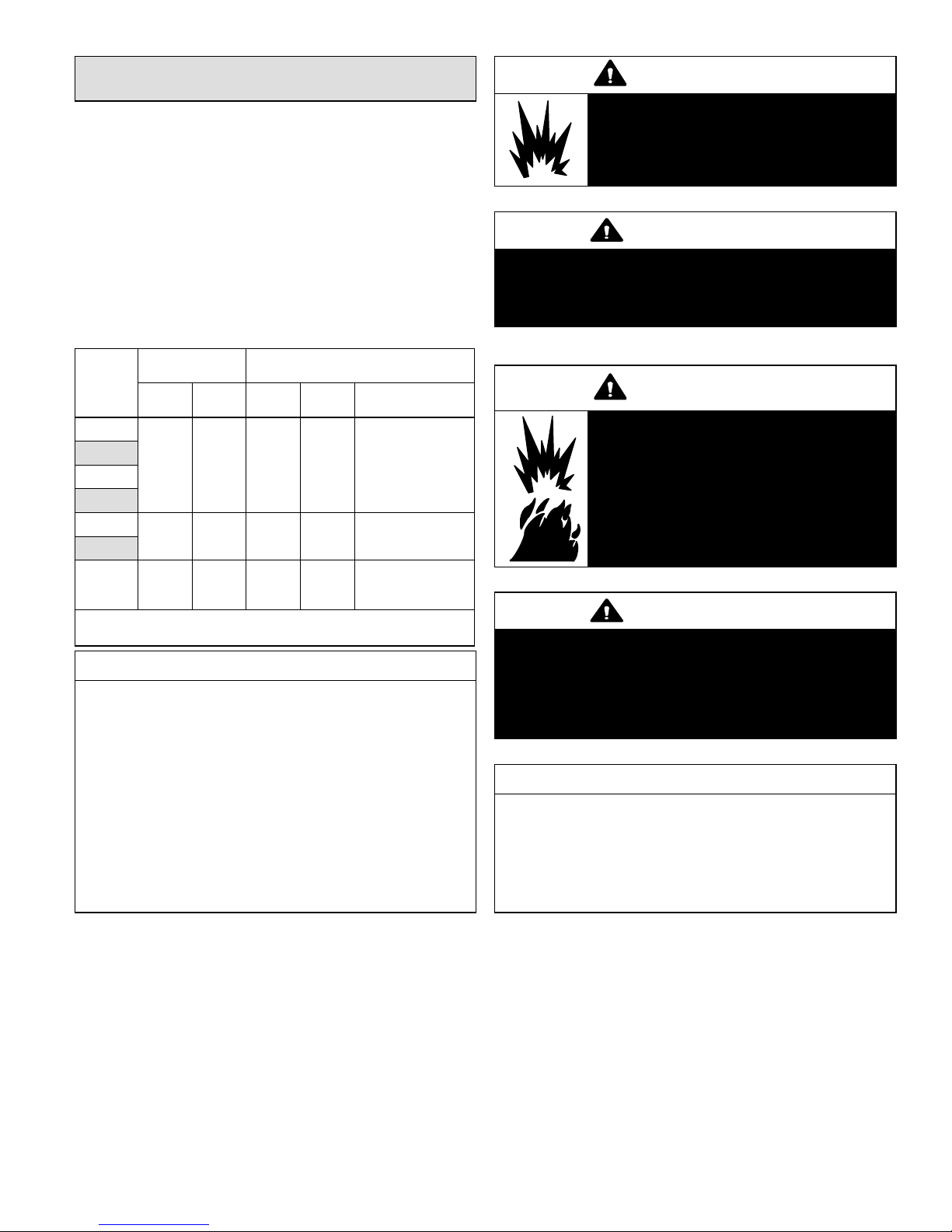

TWO 90_ ELBOWS INSTALLED IN LINE SET

WILL REDUCE LINE SET VIBRATION

FIGURE 3

SLAB MOUNTING

Install unit level or, if on a slope, maintain slope tolerance of 2 degrees

(or 2 inches per 5 feet [50 mm per 1.5 m]) away from building structure.

BUILDING

STRUCTURE

DISCHARGE AIR

MOUNTING

SLAB

GROUND LEVEL

FIGURE 4

Page 2

STEP 2 -- REFRIGERANT PIPING -- Flush

ing Existing Line Set and Indoor Coil

Flush the existing line set per the following

instructions. For more information, refer to the

Installation and Service Procedures manual available

on DaveNet. CAUTION - DO NOT attempt to flush and

re-use existing line sets or indoor coil when the system

contains contaminants (i.e., compressor burn out).

NOTE - When installing refrigerant lines longer than 50 feet,

refer to the Refrigerant Piping Design and Fabrication

Guidelines manual available on DaveNet (Corp. 9351-L9),

or contact the Technical Support Department Product

Application group for assistance.

TABLE 2

REFRIGERANT LINE SET — INCHES (MM)

Field

Model

-018

-024

-030

-036

-042

-048

-060

NOTE — Some applications may required a field provided 7/8” to 1-1/8”

adapter

Connections

Liquid

Line

3/8 in.

(10

mm)

3/8 in.

(10

mm)

3/8 in.

(10

mm)

Vapor

Line

3/4 in.

(19

mm)

7/8 in.

(22

mm)

1-1/8

in. (29

mm)

Recommended Line Set

Liquid

Line

3/8 in.

(10

mm)

3/8 in.

(10

mm)

3/8 in.

(10

mm)

Vapor

Line

3/4 in.

(19

mm)

7/8 in.

(22

mm)

1-1/8

in. (29

mm)

L15 Line Sets

L15-41 — 15 ft. 50 ft. (4.6 m - 15

m)

L15-65 — 15 ft. 50 ft. (4.6 m - 15

m)

Field Fabricated

IMPORTANT !

If this unit is being matched with an approved line set

or indoor unit coil that was previously charged with

mineral oil, or if it is being matched with a coil which

was manufactured before January of 1999, the coil

and line set must be flushed prior to installation. Take

care to empty all existing traps. Polyol ester (POE)

oils are used in Lennox units charged with HFC-410A

refrigerant. Residual mineral oil can act as an insula

tor, preventing proper heat transfer. It can also clog

the expansion device and reduce system perfor

mance and capacity.

Failure to properly flush the system per this instruc

tion and the detailed Installation and Service Proce

dures manual will void the warranty.

WARNING

When using a high pressure gas such as

nitrogen to pressurize a refrigeration or air

conditioning system, use a regulator that

can control the pressure down to 1 or 2 psig

(6.9 to 13.8 kPa).

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in personal injury

or death.

WARNING

Fire, Explosion and Personal Safety Haz

ard. Failure to follow this warning could re

sult in damage, personal injury or death.

Never use oxygen to pressurize or purge re

frigeration lines. Oxygen, when exposed to

a spark or open flame, can cause fire and/or

an explosion, that could result in property

damage, personal injury or death.

WARNING

Polyol ester (POE) oils used with HFC-410A

refrigerant absorb moisture very quickly. It is very

important that the refrigerant system be kept closed as

much as possible. DO NOT remove line set caps or

service valve stub caps until you are ready to make

connections.

IMPORTANT !

Some scroll compressors have an internal vacuum

protector that will unload scrolls when suction pres

sure goes below 20 psig. A hissing sound will be

heard when the compressor is running unloaded.

Protector will reset when low pressure in system is

raised above 40 psig. DO NOT REPLACE COMPRES

SOR.

Page 3

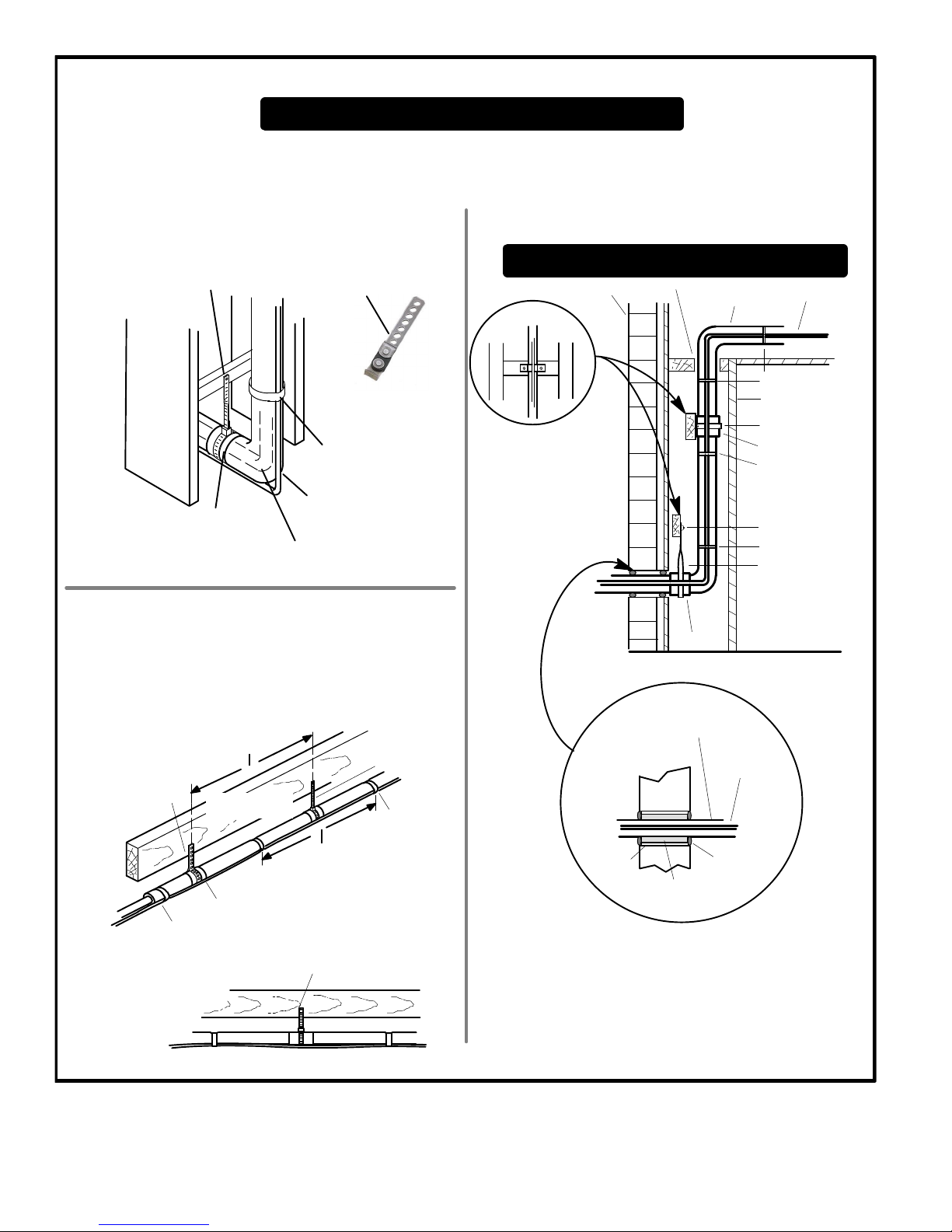

13HPX SERIES

LINE SET INSTALLATION

IMPORTANT — Refrigerant lines must not contact structure.

Line Set Isolation — The following illustrations are

examples of proper refrigerant line set isolation:

REFRIGERANT LINE SET — TRANSITION

FROM VERTICAL TO HORIZONTAL

ANCHORED HEAVY NYLON

WIRE TIE OR AUTOMOTIVE

MUFFLER‐TYPE HANGER

WALL

STUD

NON-CORROSIVE

METAL SLEEVE

AUTOMOTIVE

MUFFLER‐TYPE HANGER

STRAP LIQUID LINE TO

VAPOR LINE

LIQUID LINE

VAPOR LINE - WRAPPED

IN ARMAFLEX

REFRIGERANT LINE SET — INSTALLING

VERTICAL RUNS (NEW CONSTRUCTION SHOWN)

NOTE — Insulate liquid line when it is routed through areas where the

surrounding ambient temperature could become higher than the

temperature of the liquid line or when pressure drop is equal to or greater

than 20 psig.

IMPORTANT — Refrigerant lines must not contact wall

OUTSIDE WALL

WOOD BLOCK

BETWEEN STUDS

VAPOR LINE

LIQUID LINE

WIRE TIE

INSIDE WALL

STRAP

NON-CORROSIVE

METAL SLEEVE

WIRE TIE

WOOD BLOCK

WIRE TIE

STRAP

REFRIGERANT LINE SET — INSTALLING

HORIZONTAL RUNS

To hang line set from joist or rafter, use either metal strapping material

or anchored heavy nylon wire ties.

WIRE TIE (AROUND

VAPOR LINE ONLY)

8 FEET (2.43 METERS)

STRAPPING

MATERIAL (AROUND

VAPOR LINE ONLY)

FLOOR JOIST OR

ROOF RAFTER

TAPE OR

WIRE TIE

FLOOR JOIST OR

ROOF RAFTER

8 FEET (2.43 METERS)

NON-CORROSIVE

METAL SLEEVE

STRAP THE VAPOR LINE TO THE JOIST

OR RAFTER AT 8 FEET (2.43 METERS)

INTERVALS THEN STRAP THE LIQUID

LINE TO THE VAPOR LINE.

TAPE OR

WIRE TIE

SLEEVE

VAPOR LINE WRAPPED

WITH ARMAFLEX

OUTSIDE

PVC

PIPE

WALL

FIBERGLASS

INSULATION

CAULK

LIQUID

LINE

NOTE — Similar installation practices should be used if line set is

to be installed on exterior of outside wall.

FIGURE 5

Page 4

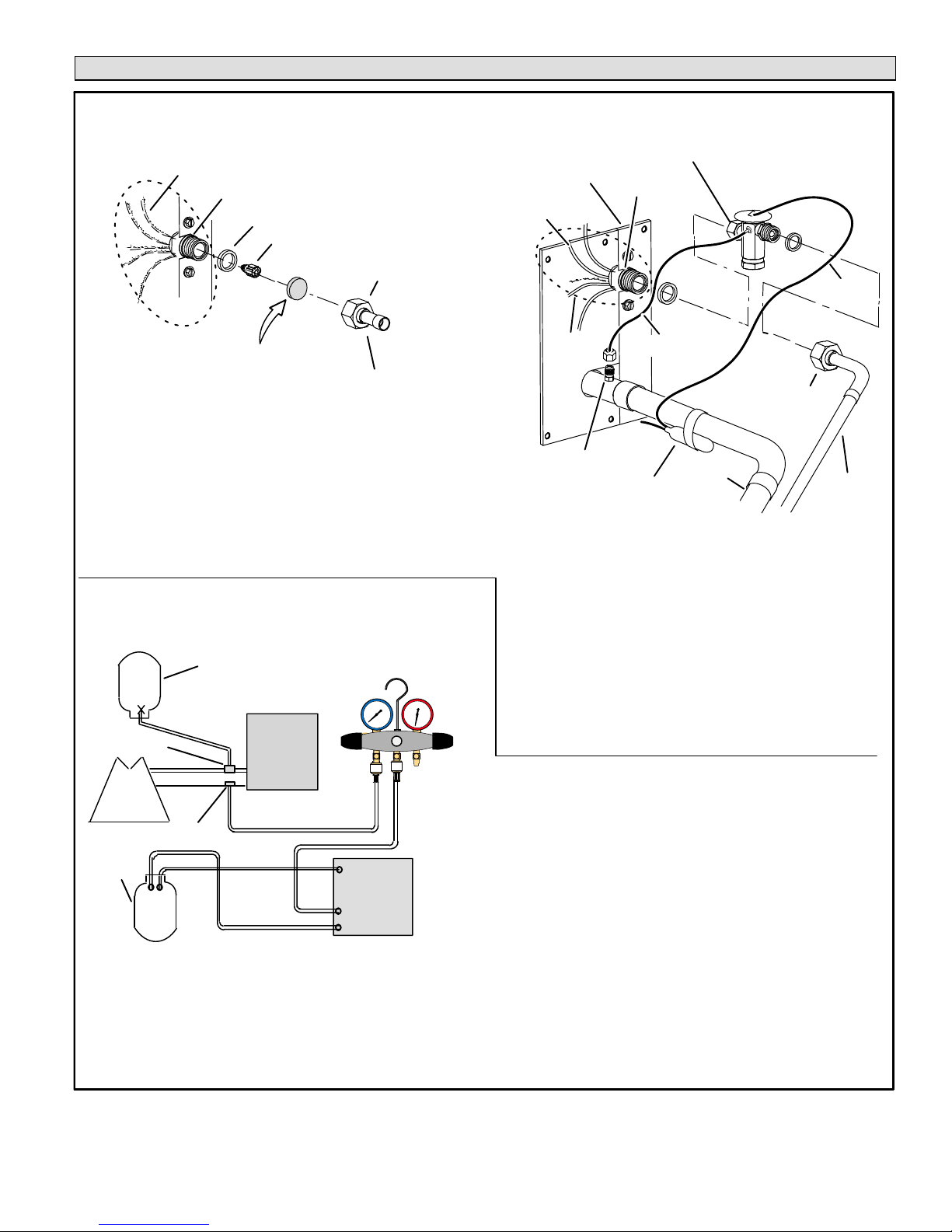

STEP 2 -- REFRIGERANT PIPING -- Removing Existing Indoor Metering Device

TYPICAL EXISTING FIXED ORIFICE

1A

DISTRIBUTOR

ASSEMBLY

A. On fully cased coils, remove the coil access and plumbing panels.

B. Remove any shipping clamps from the liquid line and distributor as

sembly.

C. Using two wrenches, disconnect liquid line from liquid line orifice hous

ing. Take care not to twist or damage distributor tubes during this pro

cess.

D. Remove and discard fixed orifice, valve stem assembly (if present)

and Teflon® washer as illustrated above.

E. Use a field-provided fitting to temporarily reconnect the liquid line to the

indoor unit's liquid line orifice housing.

(UNCASED COIL SHOWN)

DISTRIBUTOR TUBES

LIQUID LINE ORIFICE HOUSING

TEFLON® RING

FIXED ORIFICE

REMOVE AND DISCARD

WHITE TEFLON

(IF PRESENT)

®

SEAL

LIQUID LINE ASSEMBLY

(INCLUDES STRAINER)

REMOVAL PROCEDURE

OR

BRASS NUT

1B

TWO-PIECE PATCH PLATE

CONNECT GAUGES AND EQUIPMENT FOR

FLUSHING PROCEDURE

2

CYLINDER CONTAINING

CLEAN HCFC-22 TO BE

USED FOR FLUSHING

(Positioned to deliver liquid

A

refrigerant)

1

VAPOR LINE

SERVICE VALVE

EXISTING

INDOOR

UNIT

LIQUID LINE SERVICE

VALV E

RECOVERY

CYLINDER

VAPOR

LIQUID

OUTDOOR

B

NEW

UNIT

OPENED

C

D

RECOVERY MACHINE

A. HCFC-22 cylinder with clean refrigerant (positioned to deliver liquid

refrigerant) to the vapor service valve.

B. HCFC-22 gauge set (low side) to the liquid line valve.

C. HCFC-22 gauge set center port to inlet on the recovery machine with an

empty recovery tank connected to the gauge set.

D. Connect recovery tank to recovery machine per machine instructions.

GAUGE

MANIFOLD

LOW HIGH

CLOSED

TANK

RETURN

INLET

DISCHARGE

TYPICAL EXISTING EXPANSION VALVE REMOVAL

PROCEDURE (UNCASED COIL SHOWN)

ORIFICE

HOUSING

EQUALIZER

LINE

STUB END

TEFLON

RING

VAPOR

CHECK

EXPANSION

VALV E

®

LIQUID LINE

ASSEMBLY WITH

BRASS NUT

LINE

TEFLON

(UNCASED COIL ONLY)

DISTRIBUTOR

TUBES

DISTRIBUTOR

ASSEMBLY

MALE EQUALIZER

LINE FITTING

A. On fully cased coils, remove the coil access and plumbing panels.

B. Remove any shipping clamps from the liquid line and distributor

assembly.

C. Disconnect the equalizer line from the check expansion valve

equalizer line fitting on the vapor line.

D. Remove the vapor line sensing bulb.

E. Disconnect the liquid line from the check expansion valve at the

liquid line assembly.

F. Disconnect the check expansion valve from the liquid line orifice

housing. Take care not to twist or damage distributor tubes during

this process.

G. Remove and discard check expansion valve and the two Teflon

rings.

H. Use a field-provided fitting to temporarily reconnect the liquid line

to the indoor unit's liquid line orifice housing.

LIQUID LINE

SENSING BULB

FLUSHING LINE SET

The line set and indoor unit coil must be flushed with at least the same

3

amount of clean refrigerant that previously charged the system. Check

the charge in the flushing cylinder before proceeding.

A. Set the recovery machine for liquid recovery and start the

recovery machine. Open the gauge set valves to allow the

recovery machine to pull a vacuum on the existing system line

B

set and indoor unit coil.

B. Position the cylinder of clean HCFC-22 for delivery of liquid

refrigerant and open its valve to allow liquid refrigerant to flow

into the system through the vapor line valve. Allow the refrigerant

to pass from the cylinder and through the line set and the indoor

unit coil before it enters the recovery machine.

C. After all of the liquid refrigerant has been recovered, switch the

recovery machine to vapor recovery so that all of the HCFC-22

vapor is recovered. Allow the recovery machine to pull the

system down to 0.

D. Close the valve on the inverted HCFC-22 drum and the gauge

set valves. Pump the remaining refrigerant out of the recovery

machine and turn the machine off.

RING

®

SENSING

LINE

LIQUID

LINE

®

FIGURE 6

Page 5

13HPX SERIES

Loading...

Loading...