Page 1

Service Manual

Lennox Electric Fireplaces

Merit Series

MPE36

MPE33

Page 2

Contents

• Removal Log Grate page 3

• Removal of Logs/Ember page 3

• Changing ember bul bs page 4

• Removal of glass panel page 5

• Component identification page 7

• Confirm power supply page 8

• Transformer testing page 9

• Flame panel removal page 11

• Flame cylinder bulb replacement page 12

• Lights: Flame and Ember page 13

• Electrical junction box access page 15

• Opti onal wall thermostat page 16

• Opti onal wall switch page 17

• Control board page 18

• Remote control sensor page 23

• Remote control feature page 24

• Heater thermostat operation page 24

• Flame cylinder motor replacement page 25

• Control panel sw itches page 29

• Remote control does not function page 31

• Heater sensor page 32

• Heater access page 33

• Testing the heater/blower page 34

• Junction box w iring page 42

• Parts List page 45

• Read this first

• This manual is provided as a

tool to assist professional

service personnel working on

Lennox Electric Fireplaces.

• Do not attempt to service this

electrical appliance if:

– You have not been trained

how to safely service

electrical appliances.

– You are not familiar w ith the

use of electrical diagnostic

tools.

• Disconnect the power supply

prior to attempting any service.

• Electrical Shock Hazard

• Read this manual and the

installation and operation

instructions for this appliance

before attempting any service.

• If you have any questions

regarding this appliance

contact Lennox Technical

Service at: (800) 655-2008

Page 3

Remove Grate and Log

Set

• The grate must be removed

before removing the log set.

• Remove the two screws that

secure the grate in place

and remove the grate.

• Place your thumbs on the

front edge of the ember

base approximately 1/3 of

the way in from the ends of

the log set.

• Push towards the back

causing the ember base to

flex. As you push gently lift

the front edge of the ember

base. The log set and

ember base may be lifted up

and out of place.

Page 4

Changing ember bulbs

• Remove logs and grate

(see page 3)

• On MPE36R

replacement bulbs will be

found in a pocket in the

log set

• Lift at the front of the

plastic ember bed to

“pop” it up and release it.

• Remove ember bed.

• Remove spring retainer

from bulb.

• Remove defective bulb.

• Using plastic gloves or a

small plastic bag to

prevent oils from your

hands from coating the

bulbs, insert the

replacement bulb in the

socket and replace the

retaining spring.

• Replace ember bed

• Replace logs and grate.

Page 5

Removal of rear glass

panel

• Remove logs and grate

• Remove ember bed

• Remove screws from

right and left retaining

brackets

• Remove screws from top

retaining bracket

Caution: wear protective gloves

when removing or handling the

glass panel.

Gloves will help prevent cuts

and will also prevent the oils

from your hands from staining

the surface of the glass panel

Page 6

Removal of rear glass

panel (continued)

• Grasp glass panel at top

and tip forward.

• With panel loose, grasp

on top and bottom edges

to remove from fireplace.

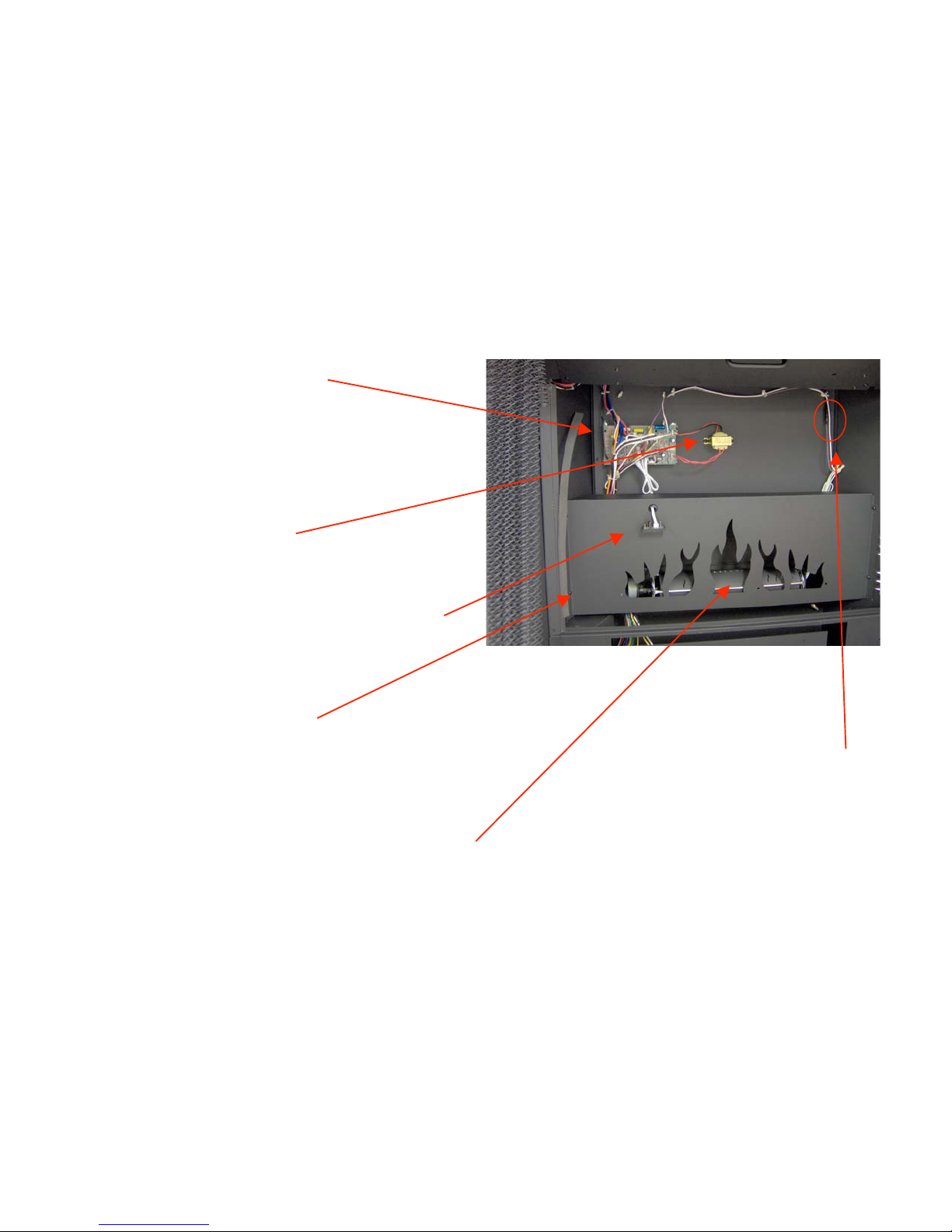

Page 7

Components

• Control board

• Transformer

• Remote control receiver

• Flame cover panel

• Motor and Flame cylinder

Fuse location

Page 8

Power supply

• When the electric fireplace

is initially connected to a

power supply:

– By plugging in the power

cord to a receptacle

– By turning on the circuit

breaker (hard wired

connection at the junction

box)

• The control board will emit two

loud “beeps” to confirm

“power up”.

• If you do not hear these

‘beeps”:

– Confirm that the circuit

breaker is “on”

– Confirm power to the

receptacle.

– Is an external switch

controlling the power to the

fireplace? If so it must be on.

• If power is available to the

fireplace and the two “beeps”

are not sounded at”power up”,

look for:

– Transformer failure (page 9)

– Control board failure

Control Board- beeps twice

to confirm “power up”

Page 9

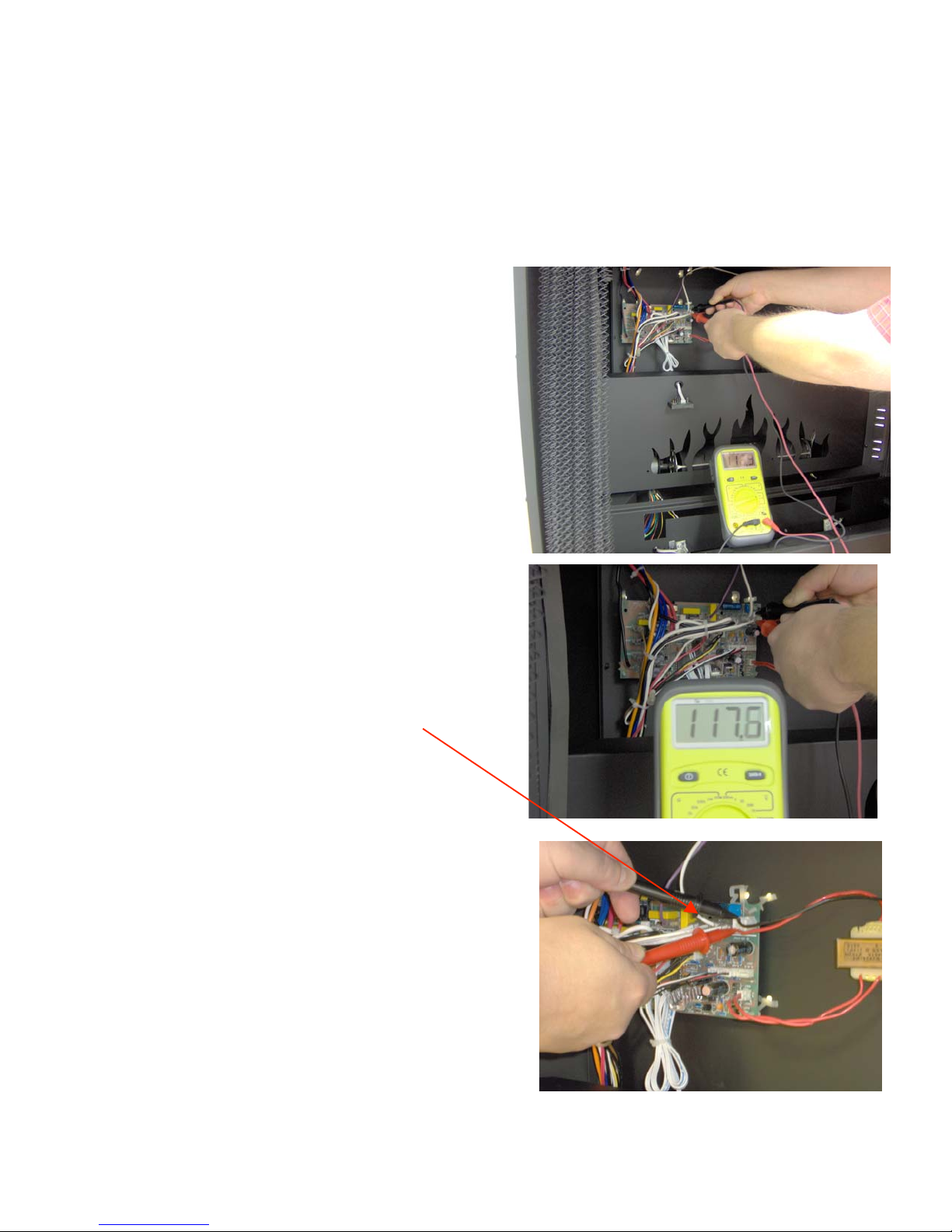

Testing Transformer

• Caution:

electrical

shock hazard!

• This tests confirms that

line voltage 120 VAC is

available to power the

transformer.

• Place multimeter leads

on control board

terminals as shown.

• Line voltage should be

between 105 VAC – 127

VAC.

Page 10

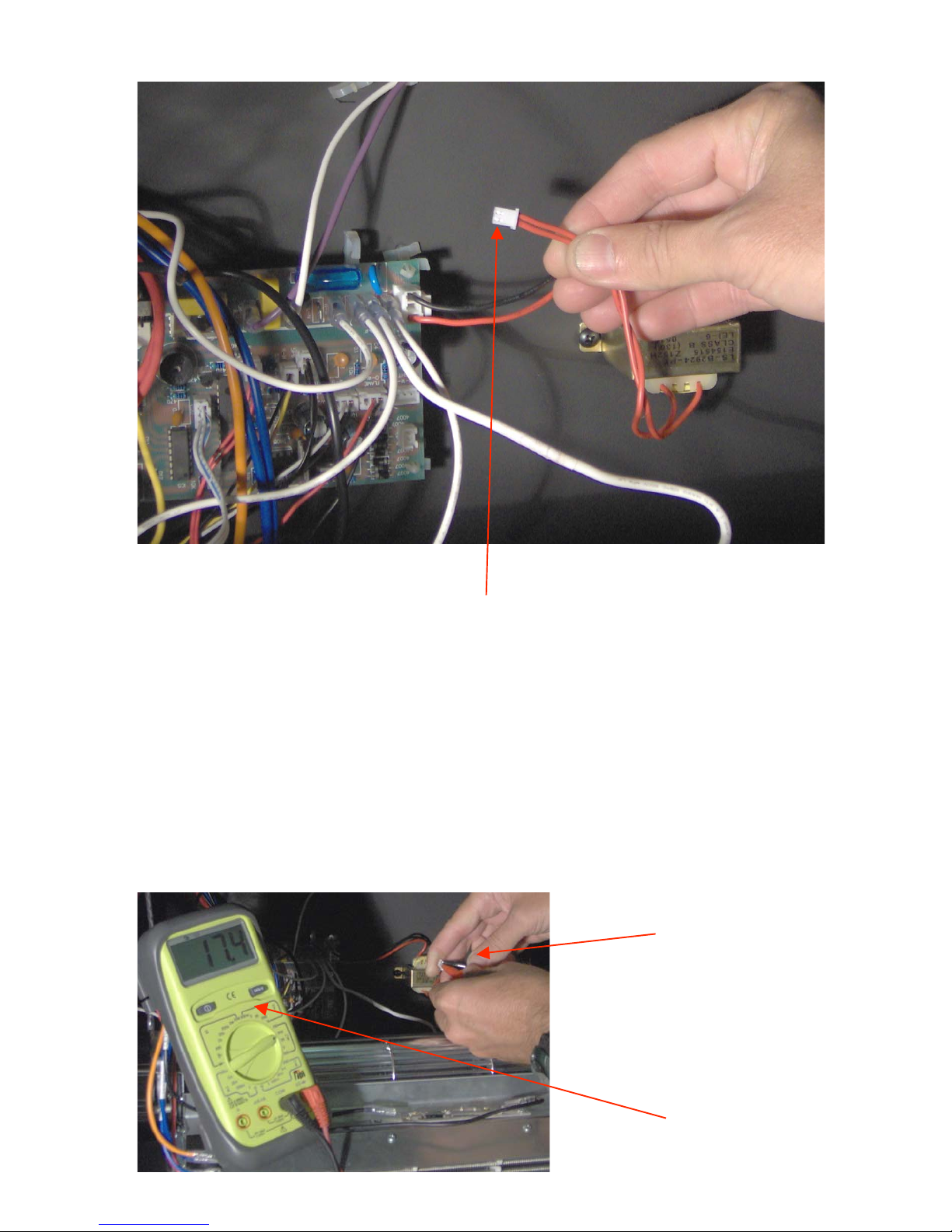

To test the transformer:

•Remove the low voltage connector (two red wires) from the control board as

shown. On the side of the connector two silver terminals will be visible.

•Set your Multimeter to test AC voltage. Touch the probes to the two silver

connectors on the transformer wires. Voltage should between 16 – 18 VAC

•When the transformer is reconnected to the board there should be two

“beeps” should be heard confirming “power up” of the control board.

Probes connected to

transform wire terminals

16-18 VAC

Page 11

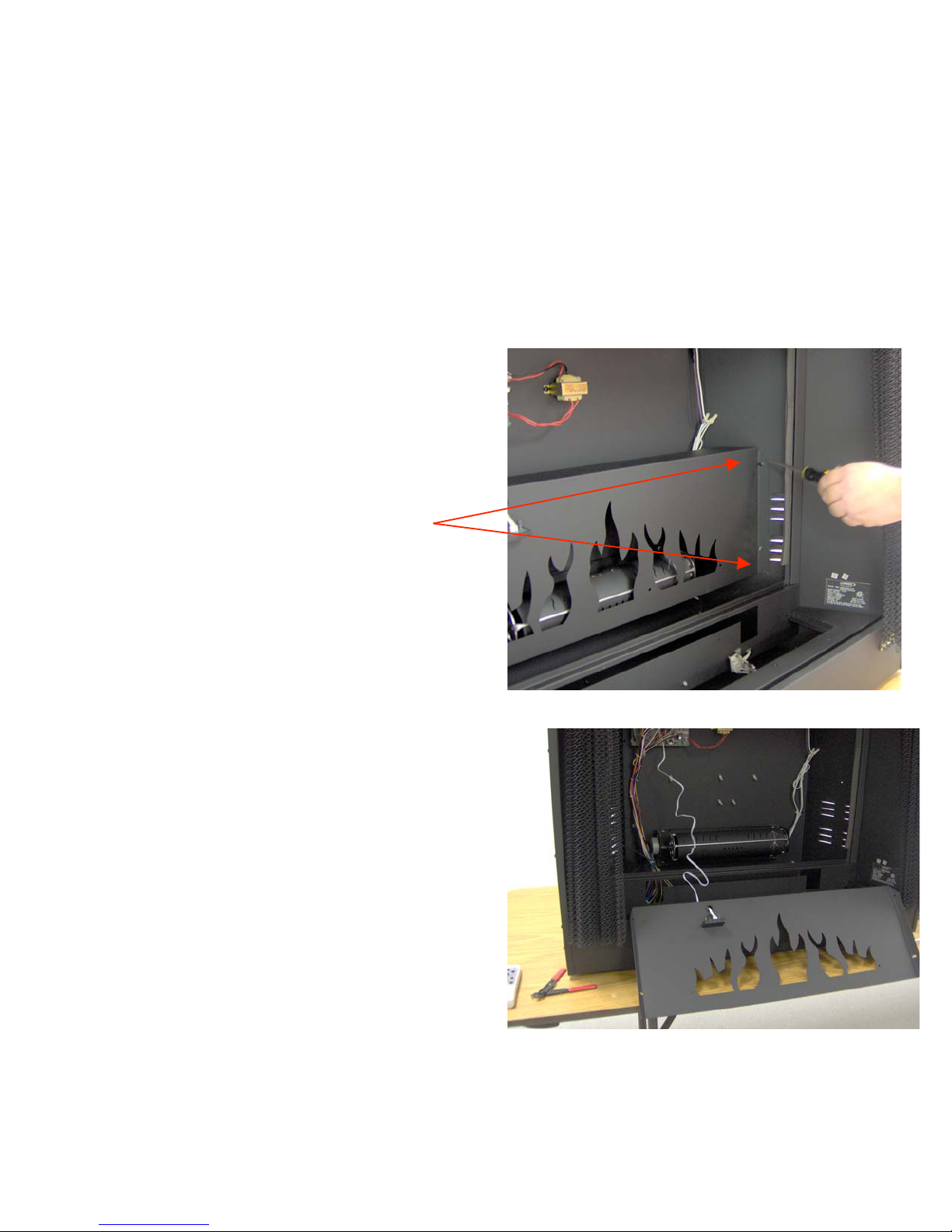

Removal of flame panel

• Use wire cutters to clip

the plastic wire tie

binding the remote

control receiver wire.

• Use a screwdriver to

remove the screws on

the right and left edges

of the flame cover panel.

• The panel may be placed

upon the floor in front of

the fireplace during

service

Page 12

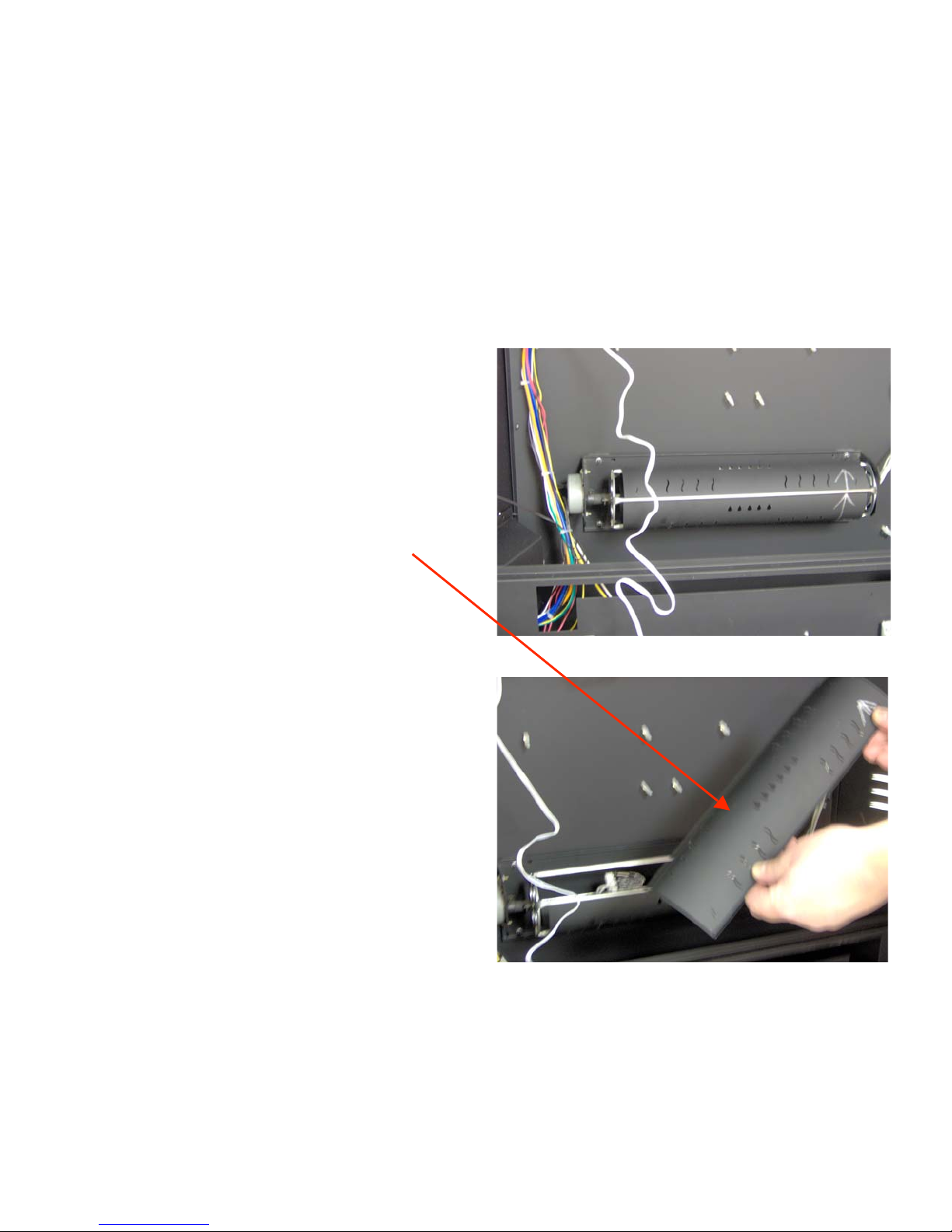

Changing bulbs in flame

cylinder

• Grasp the top of the

flame cylinder and

squeeze gently

disengaging the flame

cylinder cover.

• Lift the cover off to

expose the two flame

bulbs.

Caution: The edges of the flame

cylinder may be sharp! Wear

protective gloves to prevent

injury

Page 13

Lights: Flame and Ember

• With the flame cylinder

cover removed, the two

bulbs are visible.

• When the flame switch is

activated the bulbs

should light and the

flame wheel should turn.

• Use the remote control to

brighten and to dim the

flame bulbs and the

ember bed bulbs.

• When testing voltage to

the ember and flame

lights:

– If the lights are

activated by the control

panel switch voltage

will be approximately

114VAC

– If the lights are

activated by the remote

control the dimmer

function will vary the

voltage from

approximately 4 VAC

(low) to 114 VAC at the

high setting.

Page 14

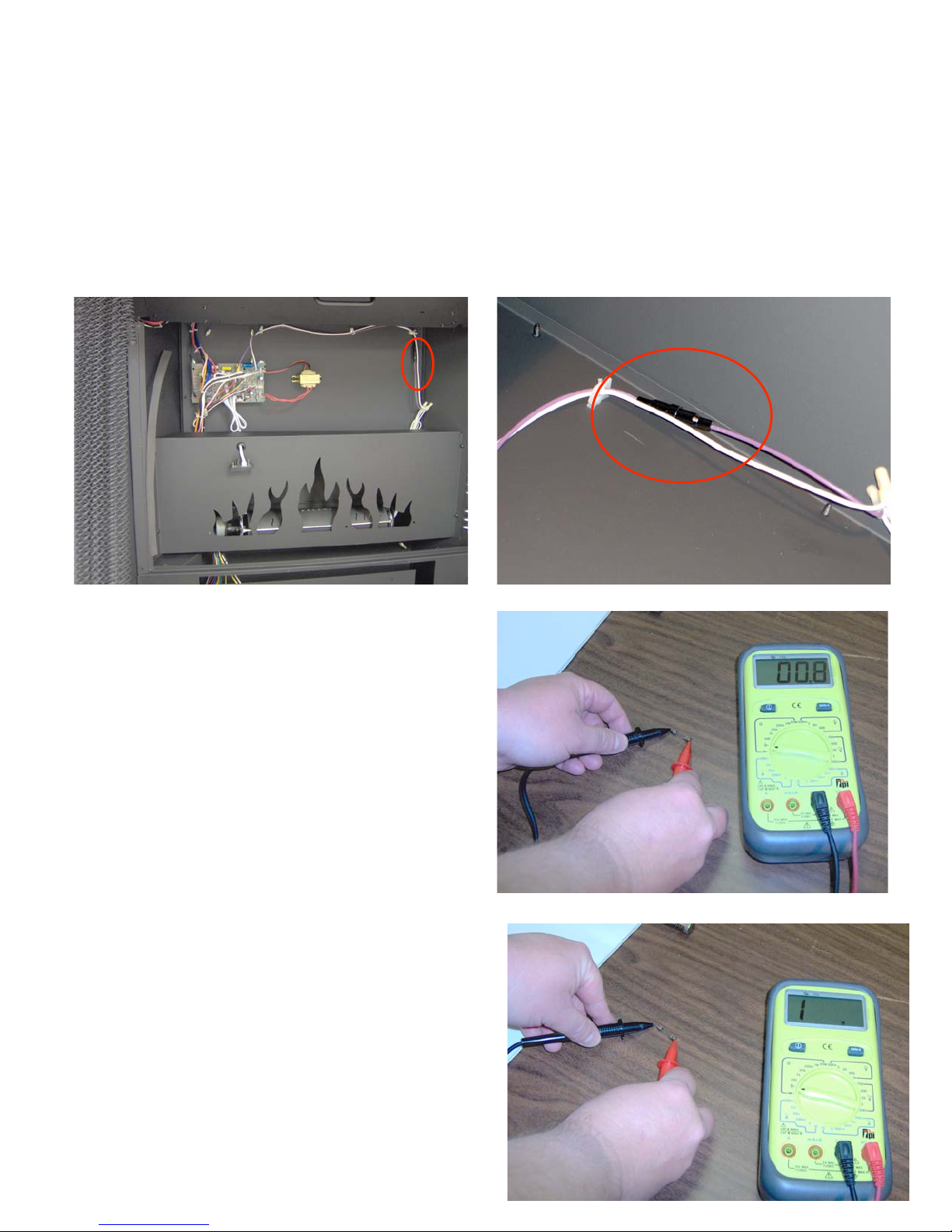

If ember and flame lights

fail to operate

•Check the in-line fuse located to the

right of the control board.

•Perform a continuity test on the fuse. If

the multimeter displays “1” the fuse has

blown and must be replaced.

•If the bulbs and fuse test “OK” , check

the continuity of the control panel switch

(power On/Off) and (lights On/Off)

•If switches test OK then test control

board.

•L- Light to N-Light =114VAC

•L-Flame to N-Flame = 114VAC

Page 15

Access to electrical

junction box

• Turn off power to the fireplace by

either unplugging the power cord or

setting the circuit breaker in the

home’s electrical panel to the “off”

position.

• Remove screws in junction box

cover.

Wire connections to a) factory supplied

power cord or b) Romex power

supply should be as follows:

120VAC linefireplace

black black

white blue N1

blue N2

white

green green/yellow

For 240 VAC wiring see page 42

Page 16

Wires for optional

controls

• The junction box

contains two wires that

may be used for an

optional wall switch to

control the flame

and/or an optional

thermostat to control

the heater.

• A length of black and

white wire is provided for

the connection of an

optional wall mounted

thermostat kit.

Page 17

Electrical junction box

• A length of red

wire may be

bundled in the

bottom of the

junction box.

• This allows

operation of the

fireplace from

an optional wall

mounted switch.

• See the

drawing for

proper wiring

• Note: to

operate the

fireplace from

the wall switch

the unit

mounted power

switch must be

in the ‘off’

position.

Page 18

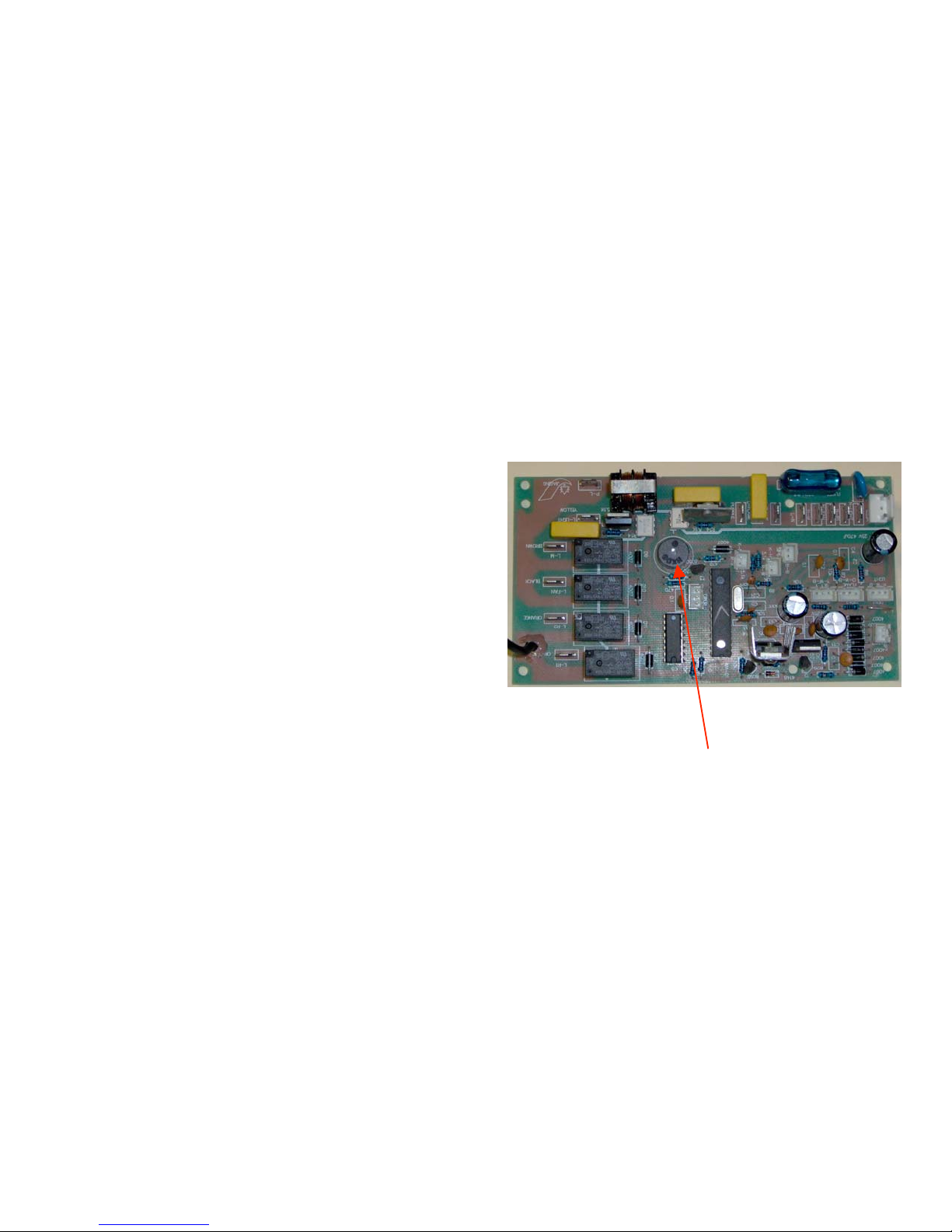

Control board

• Replacement part # H1625

– Contains:

– Control Board

– Remote Receiver

Procedure for replacing control board:

• Disconnect Power Supply by

unplugging power cord or

turning off circuit breaker.

• Orient replacement board to match

defective board.

• Hold replacement board directly

below defective board.

• Remove one wire at a time from

the defective board and connect it

to the replacement board.

• Repeat until all wires have been

transferred.

• Use needle nose pliers to squeeze

the plastic corner fasteners to

release the defective board.

Remove defective board

• Place replacement board over

corner fasteners and push to lock

in place.

• Confirm all connections with the

wiring diagram.

• Restore power and test fireplace

functions.

Page 19

Control board wiring

120 VAC to transformer

Line voltage to

Heater Elements

Red

Control Panel Switch

Main Power on/off

(also to optional wall

switch)

Red/Red

Temperature

sensor-heater

Black/Black

24 VAC from

transformer to board

Flame/Ember on/off

switch

Red/Black

Page 20

Control Board Wiring (Hot)

L-FAN: Black wire

(hot) to fan motor

L-M: Brown wire

(hot) to flame motor

P-L: Black wire (hot) from junction box- to board- to

fusible link

L-Light: Yellow wire

(hot) to ember lights

L-R1 & L-R2: Red wires

(hot) to heater element

Black wire from board to

fusible link

L-Flame: Purple

wire(hot) to flame

wheel lights

Page 21

Control board wiring

(neutral)

L-N: Not used

N-Flame: White (neutral)

from flame wheel lights

N-M: White wire (neutral) from

flame wheel motor

N-Fan: White wire(neutral)

from fan motor

N-Power: White wire(neutral) from

junction box to control board

N-Light: white wire (neutral) from

ember lights

Page 22

Sensors/ Switches

Heater switch

black/yellow

Main power switch red/red

Transformer/

Temperature sensor

black/black

120 VAC to transformer

black/red

Wire for optional wall thermostat

black/white (stored in junction box)

Remote control sensor

white

Not used

Flame/Embers on-off switch

red/black

24 VAC from

transformer red/red

Page 23

Remote control sensor

Page 24

Page 25

Replacement of flame

cylinder motor

• Use wire cutter to

remove plastic wire ties

as shown

• Expose two crimp on

wire nuts (white to black)

and (brown to black)

leading to the motor

Page 26

Motor removal

• Cut crimped on wire nuts

to allow removal of the

motor,

• Use a small Phillips head

screw driver to loosen

the linkage clamp.

• Use needle-nose pliers

to loosen the nuts

securing the motor to its

mounting bracket

Page 27

Motor removal

• Remove the defective

motor.

Page 28

Replacement motor

• Slide the replacement

motor into the rubber

linkage and tighten.

• Reinstall motor mounting

screws and tighten the

two hex nuts

• With wire strippers strip

the ends of the

replacement motor wires

and also of the brown

and white wires as

shown.

• Using wire nuts secure

the connections. Use

wire ties to re-bundle the

wires. Tuck wires into

plastic retainers

Page 29

Control switches

• Top photo: Main power

switch (note 4 red wires

are connected to this

switch to allow for the

use of an optional wall

switch)

• Middle photo: Heater

switch (Black and yellow

wires)

• Lower photo: Flame

switch (Red and black

wires)

• Perform a continuity test

to confirm that switches

are functioning properly.

Disconnect one wire

from each switch before

conducting the test.

Page 30

Continuity test: control

panel switches

• Earlier production models of the

MPE-36R have switches that

were soldered to their wires

rather than the push on

connector that are used on later

models.

• To test these soldered switches:

– See page 21 of the manual for the

location of the switch connector at

the control board.

– Remove the connector from the

control board.

– Set your multimeter to Ohms and

conduct a continuity test of the

wires and sw itch.

– When the sw itch is “off”/open the

multimeter w ill display “1” .

– When the sw itch is “on”/closed the

multimeter should display a

measure of resistance (0.1

approx.)

• If the multimeter displays “1” with

the switch in the “on” setting, the

switch is defective and must be

replaced.

• If you suspect a defective

switch, test the switch 6 – 10

times to confirm proper

operation and reliability.

Page 31

Remote control does not

function

• Power switches must be correctly set to allow remote control

operation.

• When the switches are correctly set, a “beep” will be heard

whenever a button on the remote control is depressed.

• If no sound is heard test in this order:

– Check switch settings

– Check batteries in remote control

– Test operation with another remote control transmitter

– Test operation with a replacement remote receiver connected to the board

– Replace control board

Page 32

Heater sensor

• The heater sensor

measures the air

temperature and turns

the heater and blower on

and off based upon the

setting of the remote

control.

• If the heater does not

turn on, the remote may

have been set to a

temperature lower than

the current room

temperature.

• Set the remote to “high”

if the room temperature

is lower than 86 degrees,

the heater should turn on.

Page 33

Heater Access

• Remove screws to release heater panel

• Grasp handle and lower heater to the service position.

• The heater will be suspended by two wire cables

Page 34

Testing the heater

• Testing the fuse plate

assembly

• Unplug the fireplace or

turn off the power at the

circuit breaker.

• Remove one black wire

lead to the fuse plate

assembly as shown

• Perform a continuity test

with the multimeter set to

Ohms. (picture to the

right indicates a good

fuse plate assembly)

Page 35

Testing the heater

(continued)

• Continuity test Fuse

Plate Assembly

• Remove one black lead

as shown.

• Set multimeter to “Ohms”

to measure resistance.

• Touch probes to spade

connectors on fuse plate

assembly as shown.

• If multimeter displays “1”

the fuse plate assembly

has failed and must be

replaced.

• Failure of the fuse plate

assembly may indicate

incorrect wiring in the

junction box or of the

heater element, or the

possibility of a short

circuit .

• Check and confirm all

wiring before

reactivating power

supply.

Page 36

To replace “fuse plate

screw

assembly”

screw

• Disconnect wires as shown above.

• Remove screws from end of fuse plate assembly

• Replace with part # H5043

Page 37

Orange

Blue

Red

Heater element wiring

• Heating element wiring:

• Orange : Top center

terminal

• Blue wires N1 & N2:

Middle terminals

• Red wires (from control

board): lower terminals

Page 38

Blower wiring 120VAC

From Left:

Black

White

Orange

Blue

Blue

• Note: 120 VAC operation:

• Blue wires N1 & N2 run directly from electrical

junction box to the heater element.

• Orange wire (dummy wire in 120 VAC installation)

also runs directly from the electrical junction box to

the heater element. Orange wire must be capped in

the junction box.

• Black (hot) wire runs from junction box to the control

board and then to the fusible link for the heater

• White (neutral wire) runs from the junction box to the

control board,

Page 39

Blower wiring 240 volt

From left:

Black

White

Orange

Blue

Blue

• Note: 240 VAC operation:

• Blue wires N1 & N2 run directly from electrical junction box

to the heater element. (Blue wires are not used in 240VAC

and must not be connected to a power source in the

junction box. Blue wires should be capped with wire

nuts to prevent accidental contact with power supply)

• Orange (hot) wire also runs directly from the electrical

junction box to the heater element. Orange wire is connected

to Hot (Red or Black power supply in the junction box)

• Black (hot) wire runs from junction box to the control board

and then to the fuse plate assembly for the heater Black wire

is connect to Hot (Red or Black power supply in the junction

box)

• White (neutral wire) runs from the junction box to the control

board.

Page 40

Orange

Blue

Red

Heater element wiring

• To test the heater element:

• Turn off all power at the circuit breaker or unplug the power

cord (120VAC)

• Remove orange wire, both blue wires, and both red wires from

the heater element.

• With the multimeter set to Ohms: touch the probes to the

terminals from which the red wires were removed.

• If the multimeter displays “1” the heating element has failed and

must be replaced.

• Normal Ohm readings for the heater coil (red to red) is between

65 Ohms and 90 Ohms.

• Be careful to replace all wires as shown in this picture.

Page 41

Electrical grounding

• For safe operation the fireplace must be grounded.

• In electrical junction box the green ground wire from the power

supply must be firmly connected to the green and yellow wire

shown here. Confirm that the ground wire is properly and securely

fastened to the ground screw located to the left of the flame wheel

motor.

• Inspect the power cord to make certain that the ground plug is in

place and has not been removed.

• Using a multimeter confirm that the electrical outlet has proper

polarity and is properly grounded.

Page 42

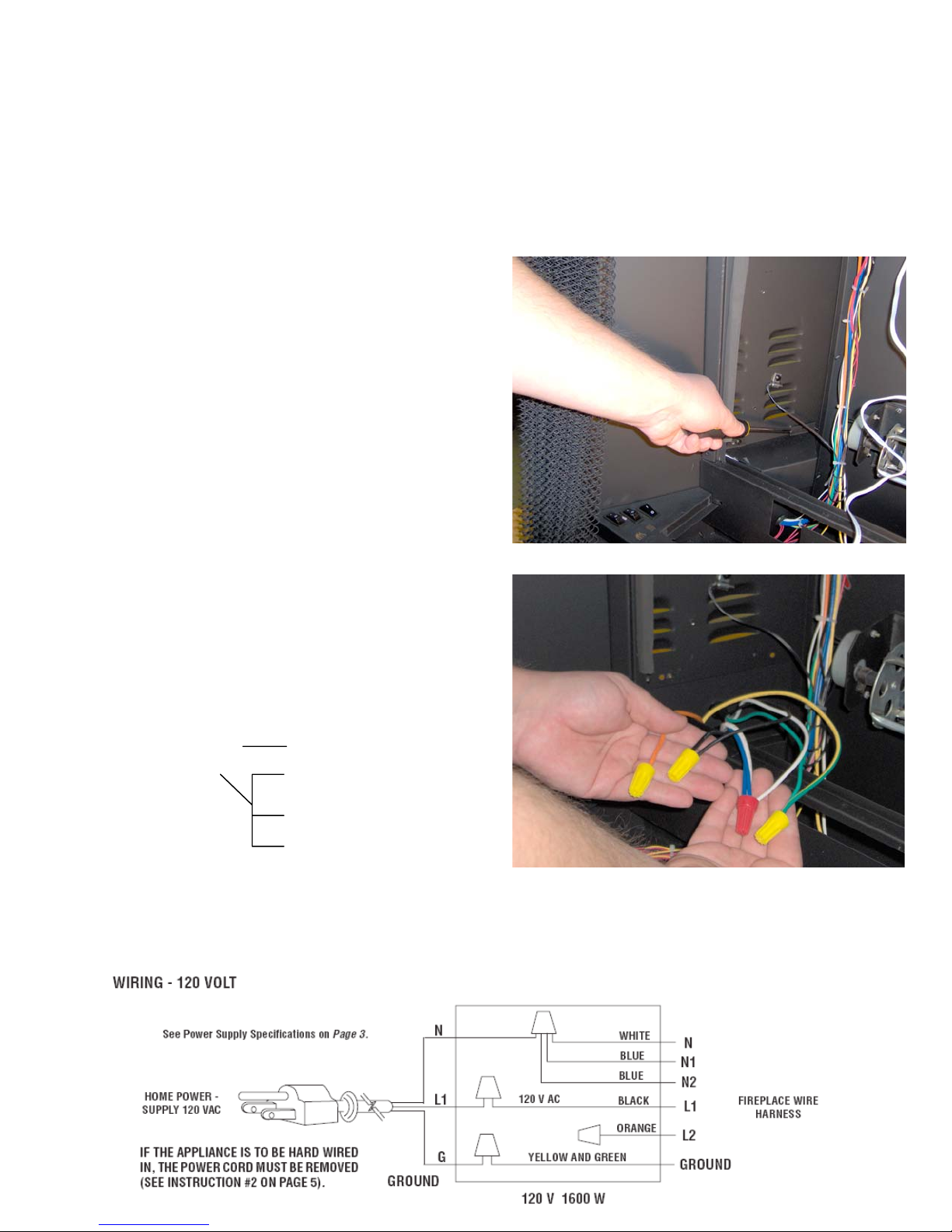

Junction box wiring

Page 43

Wiring diagram 120 Volt

Page 44

Wiring diagram 240 Volt

Page 45

MPE-33R

Page 46

Page 47

MPE-36R

Page 48

Loading...

Loading...