Lennox Merit 13CHP-24, Merit 13CHP-36, Merit 13CHP-30, Merit 13CHP-42, Merit 13CHP-60 Installation Instructions Manual

...Page 1

INSTALLATION

,t,: 2006 Lennox Industries inc,

DaIias, Texas, USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

INSTRUCTIONS

13CliP SERIES UNITS

PACKAGED HEAT PUMPS (2-5 TONS)

505,175M (38152A074)

02/06

1 - Assembled packaged heat pump unit

As soon as the unit is received, it should be inspected for

possible damage during transit. If you find any damage,

immediately contact the last carrier.

Ak WARNING

Ak WARNING

_j_p Technical

ublications

Litho U.S.A.

Shipping & Packing List ......................... 1

Unit Dimensions ............................... 2

Parts Arrangement ............................. 3

General ....................................... 3

Requirements .................................. 4

Location Selection .............................. 4

Rigging & Setting Unit .......................... 4

Clearances .................................... 4

Existing Common Vent Systems .................. 5

Condensate Drain .............................. 6

Filters ......................................... 6

Supply & Return Connections .................... 6

Compressors .................................. 7

Electrical ...................................... 7

Defrost System ............................... 10

Unit Start-Up and Operation .................... 11

Condenser Fan Clearances ..................... 12

Maintenance .................................. 12

_kCAUTION

,&,WARNING

02/06

IIIIIIIIIIIIIIIIIIIIIIIIIIIIHIlllllll

Page 1

505,175M

IIIllllllllllllllllllllllllllllllHlllllllll

Page 2

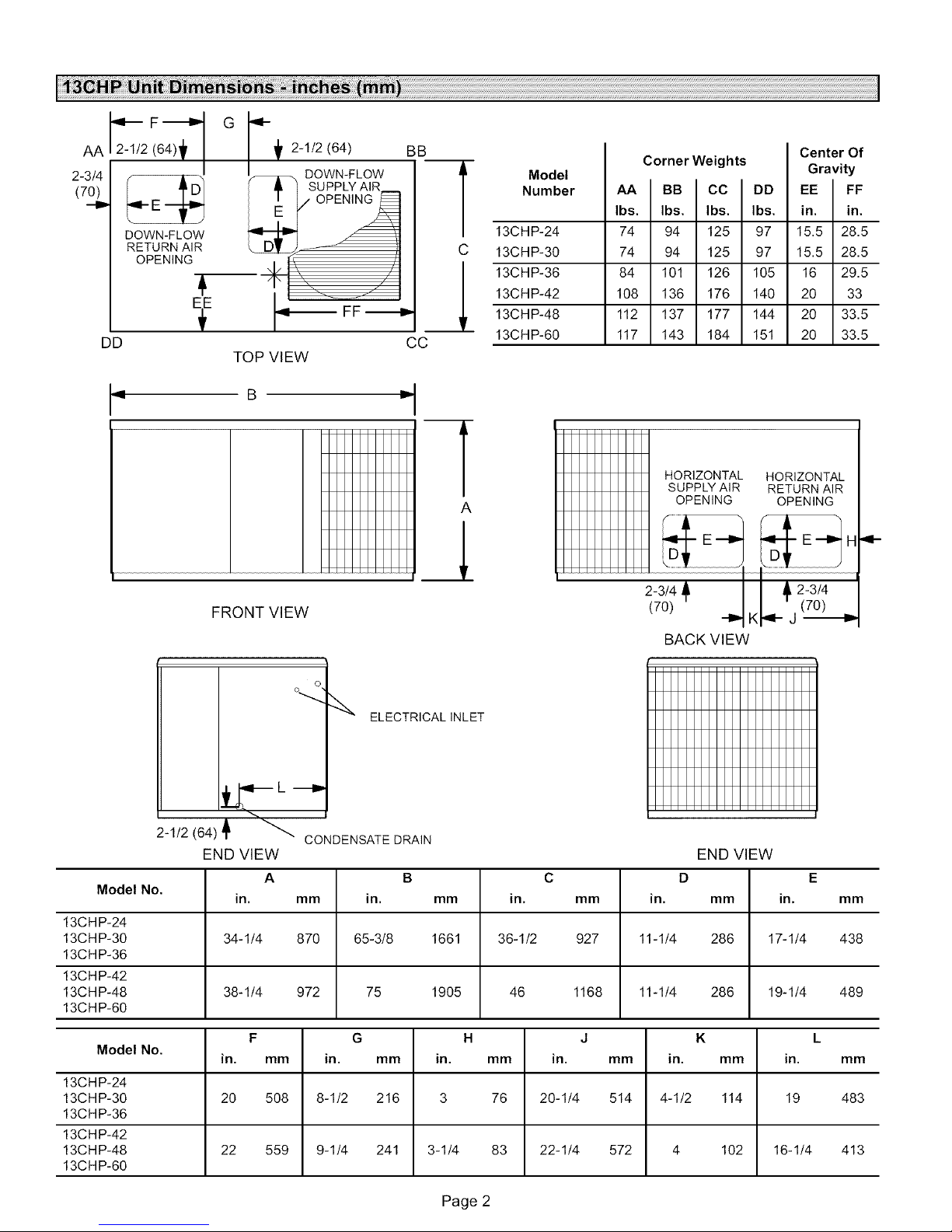

G

AA

21,%

2-3/4

(7O)

DOWN-FLOW

RETURNAIR

OPENING

DD

,9 B

f 2-1/2 (64)

TOP VIEW

DOWN-FLOW

SUPPLYAIR

BB

CC

f

C

Model

Number

13CHP-24

13CHP-30

13CHP-36

13CHP-42

13CHP-48

13CHP-60

Corner Weights

74

94

74

94

84

101

108

136

112

137

117

143

HORIZONTAL HORIZONTAL

SUPPLY AIR RETURN AIR

Center Of

Gravity

125 97 15.5

125 97 15.5

126 105 16

176 140 20

177 144 20

184 151 20

FF

in.

28.5

28.5

29.5

33

33.5

33.5

FRONT VIEW

BACK VIEW

o

ELECTRICALINLET

--..,

2-1/2 (64) '_ _ CONDENSATEDRAIN

END VIEW END VIEW

Model No.

13CHP-24

13CHP-30 34-1/4 870 65-3/8 1661 36-1/2 927 11-1/4 286 17-1/4 438

13CHP-36

13CHP-42

13CHP-48 38-1/4 972 75 1905 46 1168 11-1/4 286 19-1/4 489

13CHP-60

Model No.

13CHP-24

13CHP-30 20 598 8-1/2 216 3 78 29-1/4 514 4-1/2 114 19 483

13CHP-36

13CHP-42

13CHP-48 22 559 9-1/4 241 3-1/4 83 22-1/4 572 4 102 16-1/4 413

13CHP-60

A B C D E

in. mm in. mm in. mm in. mm in. mm

F G H J K L

in. mm in. mm in. mm in. mm in. mm in. mm

Page 2

Page 3

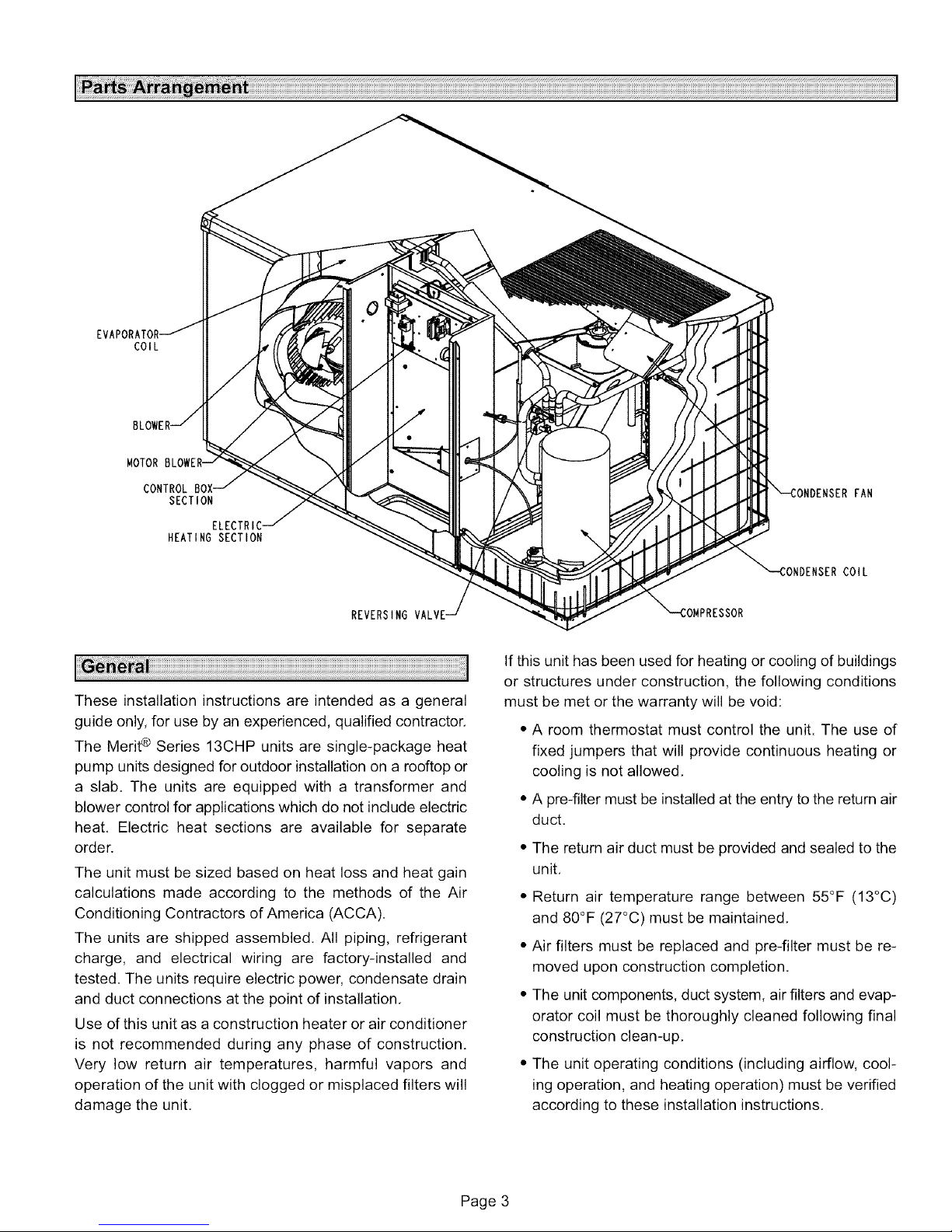

COIL

MOTOR

CONTROL B(

SECTION

HEATING SECTION

REVERSING

These installation instructions are intended as a general

guide only, for use by an experienced, qualified contractor.

The Merit® Series 13CliP units are single-package heat

pump units designed for outdoor installation on a rooftop or

a slab. The units are equipped with a transformer and

blower control for applications which do not include electric

heat. Electric heat sections are available for separate

order.

The unit must be sized based on heat loss and heat gain

calculations made according to the methods of the Air

Conditioning Contractors of America (ACCA).

The units are shipped assembled. All piping, refrigerant

charge, and electrical wiring are factory-installed and

tested. The units require electric power, condensate drain

and duct connections at the point of installation.

Use of this unit as a construction heater or air conditioner

is not recommended during any phase of construction.

Very low return air temperatures, harmful vapors and

operation of the unit with clogged or misplaced filters will

damage the unit.

FAN

COIL

If this unit has been used for heating or cooling of buildings

or structures under construction, the following conditions

must be met or the warranty will be void:

• A room thermostat must control the unit. The use of

fixed jumpers that will provide continuous heating or

cooling is not allowed,

• A pre-filter must be installed at the entry to the return air

duct,

• The return air duct must be provided and sealed to the

unit,

• Return air temperature range between 55°F (13°C)

and 80°F (27°C) must be maintained,

• Air filters must be replaced and pre-filter must be re-

moved upon construction completion,

• The unit components, duct system, air filters and evap-

orator coil must be thoroughly cleaned following final

construction clean-up.

• The unit operating conditions (including airflow, cool-

ing operation, and heating operation) must be verified

according to these installation instructions.

Page 3

Page 4

Theseunitsmustbe installedin accordancewith all

applicablenationalandlocalsafetycodes,

Theseinstructionsareintendedasageneralguideanddo

notsupersedelocalcodesinanyway,Consultauthorities

havingjurisdictionbeforeinstallation.

Ifcomponentsaretobeaddedtoaunittomeetlocalcodes,

theyaretobeinstalledatthedealer'sand/orcustomer's

expense.

Theseunitsaredesignlistedby ULin boththeUnited

StatesandCanadaasfollows:

• Foruseasaheatpump,

• Foroutdoorinstallationonly.

• Forinstallationoncombustiblematerial.

5 - The unit foundation should be raised a minimum of 3"

above finish grade, In areas which have prologed pe-

riods of temperature below freezing and snowfall,

elevate the unit above the average snow line. Take

care to allow free drainage of condensate from de-

frost cycles to prevent ice accumulation. Do not lo-

cate the unit near walkways to prevent the possible

icing of surfaces due to defrost condensate.

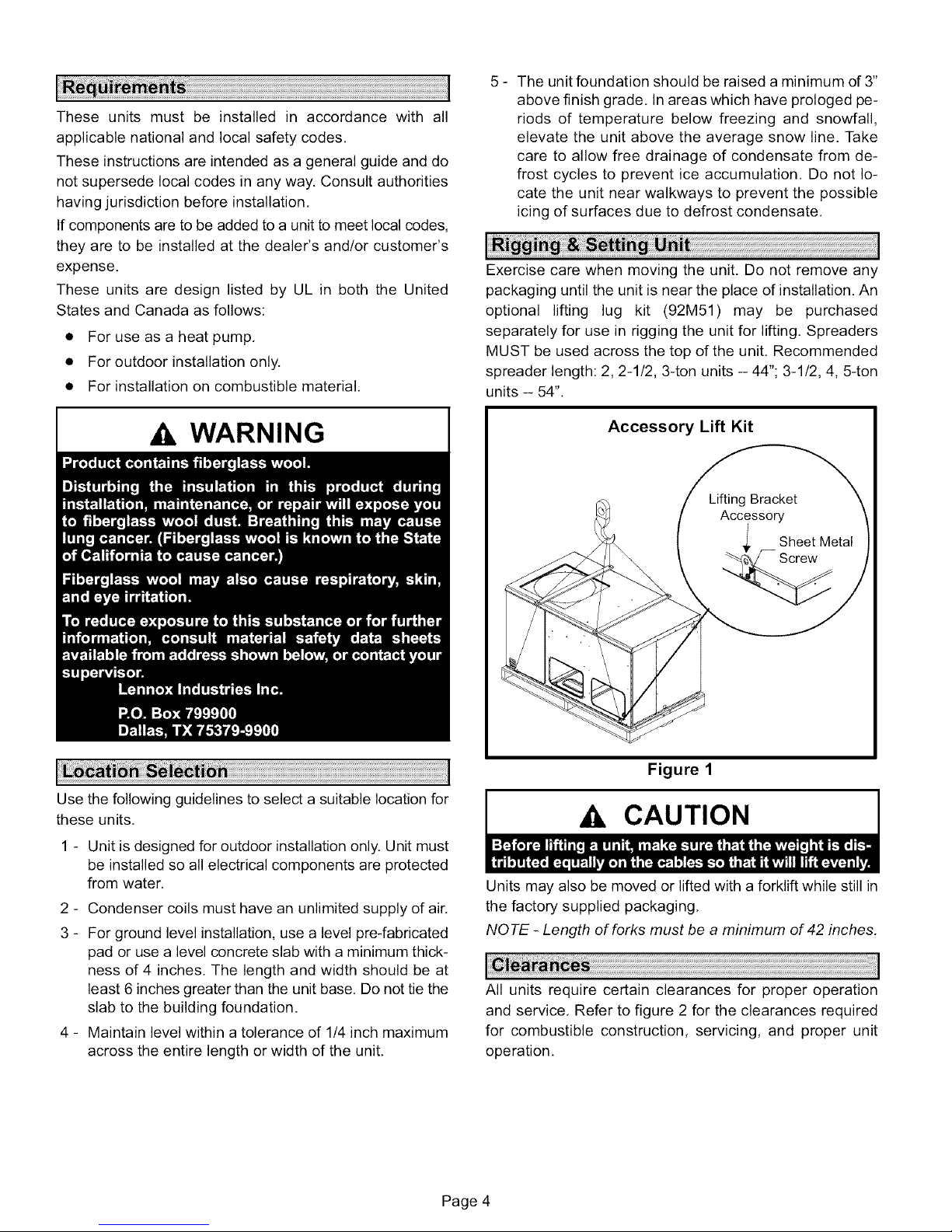

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. An

optional lifting lug kit (92M51) may be purchased

separately for use in rigging the unit for lifting. Spreaders

MUST be used across the top of the unit. Recommended

spreader length: 2, 2-1/2, 3-ton units -- 44"; 3-1/2, 4, 5-ton

units -- 54".

WARNING

Use the following guidelines to select a suitable location for

these units.

1 - Unit is designed for outdoor installation only. Unit must

be installed so all electrical components are protected

from water,

2 - Condenser coils must have an unlimited supply of air.

3 - For ground level installation, use a level pre-fabricated

pad or use a level concrete slab with a minimum thick-

ness of 4 inches. The length and width should be at

least 6 inches greater than the unit base. Do not tie the

slab to the building foundation.

4 - Maintain level within a tolerance of 1/4 inch maximum

across the entire length or width of the unit.

Accessory Lift Kit

Figure 1

CAUTION

Units may also be moved or lifted with a forklift while still in

the factory supplied packaging,

NOTE - Length of forks must be a minimum of 42 inches,

All units require certain clearances for proper operation

and service, Refer to figure 2 for the clearances required

for combustible construction, servicing, and proper unit

operation.

Page 4

Page 5

Service Clearances

3 (76)*

REAR

FRONT

48 (1219)

*Rear clearance is 18"(457)when required for

accessory maintenance.

NOTE- TopClearance - 36 in. (914 mm)

NOTE- Entire perimeter of unit base requires

support when elevated above mounting surface.

Figure 2

NOTE - Do not permit overhanging structures or shrubs to

obstruct condenser air discharge outlet.

In the U.S. units may be installed on combustible floors

made from wood or class A, B, or C roof covering material.

In Canada, units may be installed on combustible floors.

Install the unit so that snow accumulation will not restrict

the airflow. Allow a required minimum horizontal clearance

of 4 feet from electric meters, gas meters, regulators and

relief equipment. In addtion to the above requirements,

ensure that unwanted ice caused by condensate is not

allowed to accumulate around the unit. Do not locate the

unit on the side of the building where the prevailing winter

winds could trap moisture, causing it to freeze on the walls

or on overhangs (under eaves).

The 13CHP packaged heat pump may replace an existing

furnace which is being removed from a venting system

commonly run with separate gas appliances. In this case,

the existing vent system is likely to be too large to properly

vent the remaining attached appliances.

Conduct the following test while each appliance is operat-

ing and the other appliances (which are not operating) re-

main connected to the common venting system. If the

venting system has been installed improperly, you must

correct the system as indicated in the general venting re-

quirements section.

1 - Seal any unused openings in the common venting sys-

tem.

2 - Inspect the venting system for proper size and horizontal

pitch. Determine that there is no blockage, restriction,

leakage, corrosion, or other deficiencies which could

cause an unsafe condition.

3 - Close all building doors and windows and all doors be-

tween the space in which the appliances remaining

connected to the common venting system are located

and other spaces of the building. Turn on clothes dry-

ers and any appliances not connected to the common

venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they will oper-

ate at maximum speed. Do not operate a summer ex-

haust fan. Close fireplace dampers.

4 - Follow the lighting instructions. Turn on the appliance

that is being inspected. Adjust the thermostat so that

the appliance operates continuously.

5 - After the main burner has operated for 5 minutes, test

for leaks of flue gases at the draft hood relief opening.

Use the flame of a match or candle, or smoke from a

cigarette, cigar, or pipe.

6 - After determining that each appliance connected to the

common venting system is venting properly, (step 3)

return all doors, windows, exhaust fans, fireplace

dampers, and any other gas-burning appliances to

their previous mode of operation.

7 - If a venting problem is found during any of the preced-

ing tests, the common venting system must be modi-

fied to correct the problem.

Resize the common venting system to the minimum

vent pipe size determined by using the appropriate

tables in Appendix G. (These are in the current stan-

dards of the National Fuel Gas Code

ANSI-Z223.1/NFPA 54 in the USA, and the appropri-

ate Category 1 Natural Gas and Propane appliances

venting sizing tables in the current standards of the

CSA B149 Natural Gas and Propane Installation

Codes in Canada.)

Page 5

Page 6

The13CliPunitisequippedwitha3/4inchFPTcoupling

forcondensatelineconnection,Plumbingmustconformto

localcodes,Usea sealingcompoundon malepipe

threads,

Thedrainlinemustbeproperlytrappedandroutedto a

suitabledrain.Seefigure3forproperdrainarrangement,

Thedrainlinemustpitchto an opendrainor pumpa

minimumof1inchper10feettopreventcloggingofthe

line,Sealarounddrainconnectionwithsuitablematerialto

preventairleakageintoreturnairsystem.

Drainpipingshouldnotbesmallerthandrainconnectionat

coil.Anopenventindrainlinewillsometimesberequired

dueto linelength,frictionandstaticpressure.Drains

shouldbeconstructedinamannertofacilitatefutureclean-

ing,

NOTE - The condensate drain fine MUST be trapped to

provide proper drainage,

CAUTION

Typical Condensate Drain

accommodate the use of 1". 2" or 4" filters. If the optional

filter kit is not used, a filter must be field-installed,

Filters must always be installed ahead of evaporator coil

and must be kept clean or replaced, Dirty filters will reduce

the airflow of the unit, Filter sizes are shown in table 1.

Table 1

Unit Filter Size

UnitModel Filter Size Filter Quantity

-24, -30, -36 20 in. X 25 in. 1

-42, -48, -60 16 in. X 25 in. 2

The duct system should be designed and sized according

to the methods in Manual Q of the Air Conditioning

Contractors of America (ACCA).

A closed return duct system shall be used. This shall not

preclude use of economizers or outdoor fresh air intake, It

is recommended that supply and return duct connections

at the unit be made with flexible joints,

The supply and return air duct systems should be

designed for the CFM and static requirements of the job,

They should NOT be sized by simply matching the

dimensions of the duct connections on the unit.

Ducting installed outdoors MUST be insulated and

waterproofed.

1 in. (25 ram) per

10' (3 m) of line

Minimum Pitch

open

ve;tII

Trap must be deep enough to offset maximum mounting

static difference(Generally,3 inches minimum), frame

Figure 3

Filters are not factory-supplied with the unit; however,

optional internally installed filter kits are available. Filter kit

92M54 is used with 2, 2-1/2 and 34on units. Filter kit 92M55

is used with 3-1/2, 4 and 5-ton units. The filter kits

CAUTION

The 13CHP unit is shipped ready for horizontal air

discharge (side duct connections). If bottom air discharge

is desired, the covers must be removed from the supply

and return air openings on the bottom of the unit and

re-installed to cover the side openings.

Removing Supply and Return

Air Opening Covers

®

®

1. Remove screw and lift.

2. Slide cover to free back pin.

Figure 4

Base-_ d

Page 6

Page 7

Units are shippedwith the compressormountings

factory-adjustedandreadyforoperation,

All wiring should be done in accordance with the

current National Electric Code ANSI/NFPA No. 70 in the

United States. In Canada, wiring must be done in

accordance with the current CSA C22.2 Part 1. Local

codes may take precedence.

Use wiring with a temperature limitation of 75_C min.; run

the 208 or 230 volt, 60 hertz electric power supply through a

fused disconnect switch to control box of unit and connect

as shown in the wiring diagram located on the inside of the

control access panel. Refer to figure 5 for electrical access.

Electrical Access

CONDUCTORS ONLY. Each unit must be wired with a

separate branch circuit and be properly fused.

WARNING

CAUTION

WARNING

Thermostat _

Entry / •

Line Voltage

Entry

Figure 5

Unit must be electrically grounded in accordance with local

codes or in the absence of local codes with the National

Electric Code, ANSI/NFPA No, 70 (latest edition) or CSA

C22.2 Part 1 (latest edition).

Power supply to the unit must comply with all applicable

codes and NEC or CEC. A fused disconnect switch should

be field provided for the unit. The switch must be separate

from all other circuits. If any of the wire supplied with the

unit must be replaced, replacement wire must be of the

type shown on the wiring diagram,

Electrical wiring must be sized to carry minimum circuit

ampacity marked on the unit, USE COPPER

See figure 7 for typical field wiring connections and figure 8

for typical unit wiring diagram.

Optional Electric Heat

Optional electric heat is available and must be purchased

separately. Install the electric heat section as outlined in the

installation instructions packaged with the electric heat

section,

Thermostat

The room thermostat should be located on an inside wall

where it will not be subject to drafts, sun exposure or heat

from electrical fixtures or appliances. Follow

manufacturer's instructions enclosed with thermostat for

general installation procedure, Color coded insulated wires

(# 18 AWG) should be used to connect thermostat to unit,

Six wires are required for heat pump operation (including a

common wire, if required by the thermostat).

Blower Control Board

The circulating air blower is controlled by a blower control

board located in the unit control box. Blower operation is

NOT delayed after a call for either heating or cooling, A

blower "off" delay of 90 seconds begins when the

thermostat demand is satisfied. These delays are not

adjustable. See figure 6.

Page 7

Page 8

Blower Drive Control

RiO

R7

@ R6

i)°<_>

QI R4 @

RS @

R1

RII

Figure 6

C2 _ D3 3 _N_X

Z1 _ D1

dl]d3 IdS

R5 0

D5 OWl C3_ _/ _:X

Z2

@

1005 83 175 x

HSC]

3

Typical Single-Phase Unit Wiring Connections

THE_X_T_

[]

_N_LLED

®

[]

-JJ_

_D_JMD

Figure 7

Page 8

Page 9

r_

C.D

GO

SLQ!fl[R SPEED CHART

UNIT F.IEIOI Y _IIIPI_I) _q*ll_

CO01.I _ I IIPUT (DtX)

24 LOg

30 MUD

36 HiGH

42 LOg

48 MUD

60 HiGH

MOTOR

_PEED TAPe/

LI (_ KH

COMPRESSOR

"_ CONTACTOR

?O8/RSOV-l-6O

81

BLN

r

COMPRESSOR

L2

13CHP Series Packaged Heat Pump Units

Typical Wiring Diagram

_A(_OST/CD_W.AY

NoPo_r to Control

MorMt _wrotieo I Po_r to

Coltrol

A_ti-Sbort Cycle Lockout

LowPressure Switch Fault

LowPros=Ire _itch Locko=t

High Pro#lure Switch Fault

High Pressure Switch Lochemt

P-I

< _------

SEE CHART--_

UNCl FOR WIRIRG_

DEFROST

DUAL CONTROL

CAPACITOR

CI2[--.-.-.-.-.-..¢%-3BAS

t j PUN

CONDENSER

:AN MOTOR

KI'?

OFF OFF

SimettoneousSlowFloss

bib€riots Slow Flash

OFF Stowt'to_h

OFF ON

StowFto#h OFF

ON OFf

i

P-D

BLO_ER

CONTROL

l

CAPAOITOB

P-2

<<

INDOOR

BLOWER

MOTOR

Note: Secol=e the Pre_l_e SlitChll ere monitored omly then "Yl' (Imp=It il o(til+_ the €Ode

for pressure +witch opel will not be seenwhen+Yt" is oft. lanced, the "Morro<ItOporotio," or

"Aett Short Cycle" codewill be #wen,

Also. wheno pressure =lilts opeR_andcou_edo short cycle lockout, the pressure _litoh+epe,

code wilt be seen until it €loven. then the short cycle Iockolt codewill tlo_h nloss it So=already

expired.

) >

All

WI & WE CA# BE USED TO STAGE

ELECTRIC HEAT ACCESSORY ON

IS & EOKW MODELS

5+ 7,G & IO_W HEATER ACCESSC431US

FUNCTION 01oF II ONLY+

THERMOSTAT

CONTACTOR

YEL

+ REV.VALVE

K

PRESSU_ L I_]-'_io_

_I _w,+c, S79_

(IF +SES)

l I T'STAT_ /Oi-i

_OL

11

P_4

FAN

O_OUT

_PS+

Z4V

+Tl OUT Y

'_- Ps,'_

CMCI

_FRD_TCOnTrOL

NOTE:

IF ANT OF THE ORiGiNAL

GRN

P+6

P-5

RED

ORN

LINE VOLTAGE FIELD INSTALLED

WIRE 1S REPLACED THE

SAME SIZE AND TYPE WIRE

MUST BE USED+

USE COPPER CONDUCTOR

ONLY, MIN TS"C WIRE

z_CONNECTION MUST BE JUMPEREDWHEN PRESSURE SWITCH iS NOT USED.

WARNING-

ELECTRIC SHOCK HAZARD_ UNIT

MUST BE GROUNDED IN ACCORDANCE

WiTH NATIONAL AND LOCAL CODES,

Page 10

13CHP units are equipped with a defrost control board that

includes the combined functions of time/temperature de-

frost control, defrost relay, diagnostic LEDs and a low volt-

age terminal strip. See figure 9.

The control provides automatic switching from normal

heating operation to defrost mode and back. During the

compressor cycle (call for defrost), the control accumu-

lates compressor run time at 30, 60 or 90-minute field-ad-

justable intervals. If the defrost thermostat is closed when

the selected compressor run time interval ends, the defrost

relay is energized and the defrost begins.

The defrost timing jumper is factory-installed to provide a

60-minute defrost interval. If the timing selector jumper is

not in place, the control defaults to a 90-minute defrost in-

terval. The maximum defrost period is 14 minutes and is

not adjustable. See figure 9 for the location of the defrost

interval timing pins.

A test option is provided for troubleshooting. The test

mode may be started any time the unit is in the heating

mode and the defrost thermostat is closed or jumpered. If

the jumper is in the TEST position at power up, the control

will ignore the test pins. When the jumper is placed across

the TEST pins for 2 seconds, the control will enter the de-

frost mode. If the jumper is removed before an additional

5-second period has elapsed (7 seconds total), the unit

will remain in defrost mode until the defrost thermostat

opens or 14 minutes have passed. If the jumper is not re-

moved until after the additional 5-second period has

elapsed, the defrost will terminate and the test option will

not function again until the jumper is removed and reap-

plied.

The defrost control board includes a compressor delay

function which cycles the compressor off for 30 seconds

while going into and coming out of the defrost cycle. This

function is activated when the jumper is removed from the

compressor delay pins.

NO TE -- The 30-second compressor delay is not function-

al when the TEST pins are jumpered.

Defrost Control Board

Defrost Interval

Timing Pins

Test Pins

Compressor

Delay Pins

Reversing Valve -

Low Pressure/

Loss of Charge --

Switch

Defrost T'stat j

High Pressure i

Switch

PI (_ FAll

- LO*PS

_Diagnostic

LEDs

24V Terminal

Strip

Connections

Figure 9

The defrost thermostat is located on the liquid line be-

tween the check/expansion valve and the distributor.

When the defrost thermostat senses a liquid line tempera-

ture of 42°F or cooler, the thermostat contacts close and

send a signal to the defrost control board to begin the de-

frost timing. The defrost thermostat also terminates the

defrost when the liquid line temperature warms to 70°F.

The defrost control board includes HI-PS and LO-PS ter-

minals to receive signals from the optional high pressure

switch and loss of charge switch. These optional switches

must be ordered separately and field-installed,

During a single demand cycle, the defrost control locks

out compressor operation after the fifth time that the cir-

cuit is interrupted by any pressure switch wired to the con-

trol board. In addition, the diagnostic LEDs indicate a

locked-out pressure switch after the fifth open pressure

switch occurrence, Compressor operation remains

locked out until power to the board is interrupted, then re-

established, or until the jumper is applied to the TEST pins

for 0,5 seconds,

NOTE -- The defrost control board ignores input from the

optional loss of charge switch terminals as follows:

During the test mode;

During the defrost cycle;

During the 90-second start-up period;

During the first 90 seconds following

a reversing valve switch between the

heating and cooling modes.

The defrost control board includes two diagnostic

LEDs. LED codes indicate operating status. The diag-

nostics codes are given in table 2.

Table 2

Defrost Control Board Diagnostic LEDs

Mode Green LED Red LED

(DS2) (DS1)

No power to OFF OFF

board

Normal

Operation / Simultaneous Slow Flash

Power to Board

Anti-Short Cycle Alternating Slow Flash

Lockout

Loss of Charge

Pressure Switch OFF Slow Flash

Fault*

Loss of Charge

Pressure Switch OFF ON

Lockout*

High Pressure Slow Flash OFF

Switch Fault*

High Pressure ON OFF

Switch Lockout*

* These fault codes require installation of optional loss

of charge and high pressure switches.

Page 10

Page 11

Each13CHPpackagedheatpumpisfactory-chargedwith

R-22refrigerant.Thecompressorishermeticallysealed,

internallysprungandbase-mountedwithrubber-insulated

hold-downbolts,

Pre-Start Check List:

1 - Make sure refrigerant lines do not rub against the cabi-

net or each other.

2- Inspect all electrical wiring, both factory- and field-

installed, for loose connections.

3 - Check voltage at the disconnect switch. Voltage must

be within the range listed on the unit nameplate. If not,

consult power company and have voltage condition

corrected before starting unit.

4 - Recheck voltage with unit running. If power is not with-

in the range listed on the unit nameplate, stop the unit

and consult the power company. Check unit amper-

age. Refer to unit nameplate for correct running amps.

5 - Make sure filter is in place before unit start-up.

6 - Before placing the unit into full operation, energize the

unit for three false starts. Energize the compressor

just long enough for it to make a few revolutions, wait

five to seven minutes before repeating a second and

third time.

Cooling Sequence of Operation

When the thermostat calls for cooling, the "O" circuit is

energized to activate the reversing valve, The "R" to "Y"

circuit is closed to energize the compressor contactor. The

contactor brings on both the compressor and outdoor fan,

The thermostat also closes the "R" to "G" circuit to energize

the circulating air blower, When the cooling demand is

satisfied, the thermostat opens the circuits, as well as the

compressor contactor. The compressor and outdoor fan

immediately stop. The circulating air blower continues

operating through a 90-second delay,

Unit compressors have internal protection. If there is an

abnormal rise in the compressor temperature, the

protector will open and the compressor will stop.

Heating Sequence of Operation

When the thermostat calls for heating, the "R" to "Y" circuit

is closed to energize the compressor contactor. The

contactor brings on both the compressor and outdoor fan.

The reversing valve is not energized in the heating mode.

The thermostat also closes the "R" to "G" circuit to energize

the circulating air blower. When the heating demand is

satisfied, the thermostat opens these circuits, as well as

the compressor contactor. The compressor and outdoor

fan immediately stop. The circulating air blower continues

operating through a 90-second delay.

System Performance

System subcooling values are given in table 3.

Table 3

Subcooling Values

Cooling Mode Heating Mode

Unit Model No. Subcooling Value Subcooling Value

13CHP-24 10"F 20"F

13CHP-30 10_'F 15°F

13CHP-36 20_'F 15°F

13CHP-42 7°F 30°F

13CH P-48 7 _'F 25 ° F

13CH P-60 7 _'F 25 ° F

Verify system performance using table 4 and table 5 as a

general guide. Minor variations in these pressures may be

expected due to differences in installations. Significant dif-

ferences could mean that the system is not properly

charged or that a problem exists with some component in

the system.

Used carefully, these tables could serve as a useful service

guide. Data is based on 80°F dry bulb / 67°F wet bulb return

air. Allow unit operation to stabilize before taking pressure

readings.

Page 11

Page 12

Table 4

Cooling Mode -- Normal Operating Pressures

80°F db/67°F wb RETURN AIR Air Temperature Entering Outdoor Coil(°F)

UNIT PRESSURE 65 70 75 80 82 85 90 95 100 105 110 115

13CHP-24 70 73 75 78 79 80 82 86 86 88 90 93

13CHP-30 76 77 78 79 79 80 80 81 82 83 84 85

13CHP-36 88 88 88 89 89 89 89 90 88 88 88 88

13CHP-42 85 85 85 85 85 85 84 85 83 83 82 82

13CHP-48 79 80 81 82 82 82 83 84 84 84 85 85

13CHP-60 81 82 83 84 84 84 85 86 86 86 87 87

13CHP-24 138 152 166 179 185 193 207 221 235 246 263 277

13CHP-30 141 156 171 187 193 203 219 233 251 264 283 300

13CHP-36 141 158 176 193 200 211 230 245 267 282 304 323

13CHP-42 Liquid 135 150 165 179 185 194 219 223 238 250 268 283

13CHP-48 139 154 169 184 190 200 214 229 247 260 279 295

13CHP-60 146 162 179 195 202 213 230 245 266 280 301 319

Suction

Table 5

Heating Mode -- Normal Operating Pressures

70°F RETURN AIR

UNIT

13CHP-24

13CHP-30

13CHP-36

13CHP-42

13CHP-48

13CHP-60

13CHP-24

13CHP-30

13CHP-36

13CHP-42

13CHP-48

13CHP-60

PRESSURE 0 5 10 17 20 25 30 35 40 45 50 55 60

18 22 27 33 36 40 45 49 54 106 110 118 125

14 19 23 30 33 37 42 47 51 104 109 116 124

Suction

Liquid 135 146 158 174 181 192 204 215 227 243 250 261 273

5 11 17 25 29 34 40 46 52 101 105 113 120

15 19 24 31 34 39 44 48 53 107 112 120 127

16 20 24 30 33 37 41 45 49 102 107 114 122

5 10 15 22 25 30 35 40 45 97 101 108 116

157 164 170 180 184 191 198 205 211 221 225 232 239

146 152 158 167 171 177 183 189 195 204 208 214 220

153 159 164 171 174 179 184 190 195 202 205 210 215

128 142 156 175 183 197 211 225 239 258 266 2860 294

160 165 170 177 180 185 190 195 200 207 210 215 220

Air Temperature Entering Outdoor Coil (°F)

Motors

Indoor, outdoor fan and vent motors are permanently

The top of the condenser fan should be 1-1/2 inchs from the

bottom of the top grille. This dimension should be checked

and the fan should be adjusted accordingly any time servic-

ing of the outdoor fan system is required.

lubricated and require no further lubrication. Motors

should be cleaned yearly to prevent the accumulation of

dust and dirt on the windings or motor exterior.

Coil

Dirt and debris should not be allowed to accumulate on the

coil surfaces or other parts in the air conditioning circuit.

Cleaning should be performed as often as necessary. Use

Periodic inspection and maintenance normally consists of

changing or cleaning filters and (under some conditions)

cleaning the main burners.

Filters

Not supplied. Inspect once a month. Replace disposable or

clean permanent type as necessary. DO NOT replace per-

manent type with disposable.

a brush, vacuum cleaner attachment, or other suitable

means. If water is used to clean the coil, be sure the power

to unit is shut off prior to cleaning.

NOTE - Care should be used when cleaning the coil so that

the coil fins are not damaged.

Do not permit the hot condenser air discharge to be ob-

structed by overhanging structures or shrubs.

Filter Kit (2-ton to 3-ton capacity units)

Filter Kit (3-1/2-ton to 5-ton capacity units)

Description

Accessories

LENNOX Cat.

Number

92M54

92M55

Page 12

Loading...

Loading...