Page 1

Page 1

© 2004 Lennox Industries Inc.

Dallas, Texas, USA

Litho U.S.A.

504,926M

5/2004

LZP-2

ZONE CONTROL PANEL

INSTALLATION INSTRUCTIONS FOR ZONE CONTROL PANELS

USED WITH LENNOX HEATING AND COOLING EQUIPMENT

Shipping & Packing List

Package 1 of 1 contains the following:

(1) Model LZP-2 Zone Control Panel

(1) Model 88K38 Temperature Sensor

(1) Installation Instructions

(1) Owners Manual

(1) Warranty Card

Required Components (ordered separately):

24 VAC Transformer – The size of the transformer

needed is determined by the total power requirements

for the control panel, thermostats and dampers. The

control panel and thermostats together require 10VA.

The dampers require 10VA each. The size of the

transformer will depend on the greatest number of

dampers that could be energized at any given time.

NOTE – When power closed/spring open dampers

are used, at least one zone’s dampers will not be

energized during a call for heating or cooling.

Thermostats – single-stage, electronic, 24-volt

heat/cool thermostats which include a “C”

(24VAC common) terminal. Do not use mechanical

or power robbing thermostats.

Dampers – 2 or 3-wire, 24-volt dampers required.

2-wire, power closed/spring open preferred.

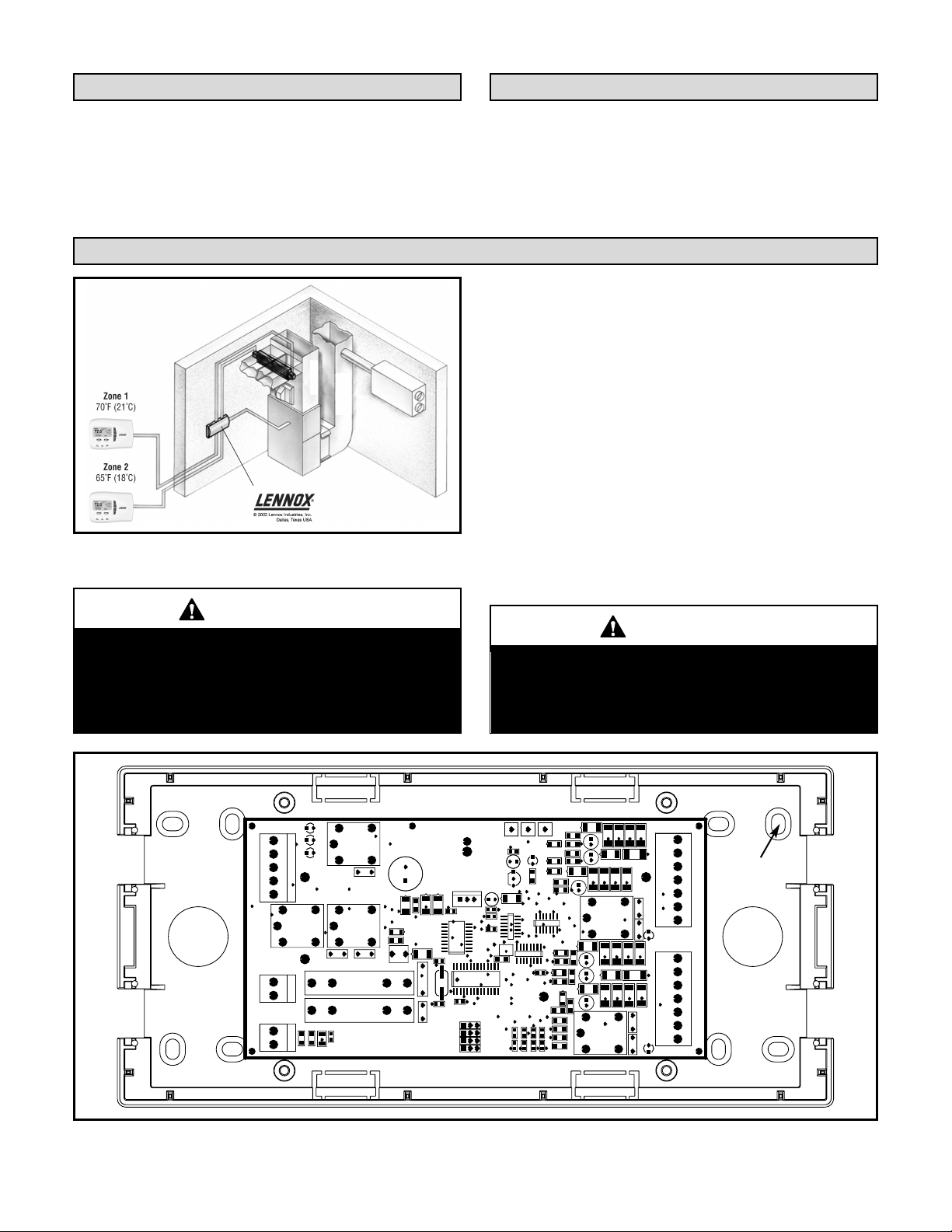

ZONING SYSTEM

TABLE 1 – TRANSFORMERS

Part Number Size Voltage Description

10P17 40VA 120/208/240V-24V

10P87 50VA 120/208/240V-24V

12P61 75VA 120/208/240V-24V

83P74 4" Square Electrical Box

FIGURE 1 – LENNOX®MODEL LZP-2 CONTROL PANEL LAYOUT

Page 2

Page 2

Application

• Two zones

• Single-stage electric or gas furnace

• Single-stage air conditioner

• Multi-stage equipment can be used provided that it

stages on it’s own internal controls

• Not applicable to heat pump systems

Installation

• Install the control panel indoors only.

• Do not install the control panel where the temperature will exceed 140°F or will drop below 32°F.

• Do not install the control panel on foundation

walls, HVAC equipment or duct system where

moisture may condense on the enclosure.

• Do not install the control panel in a room where it

will be exposed to elevated humidity levels such

as a laundry room.

1. Remove the cover. Replace the cover when

installation is complete.

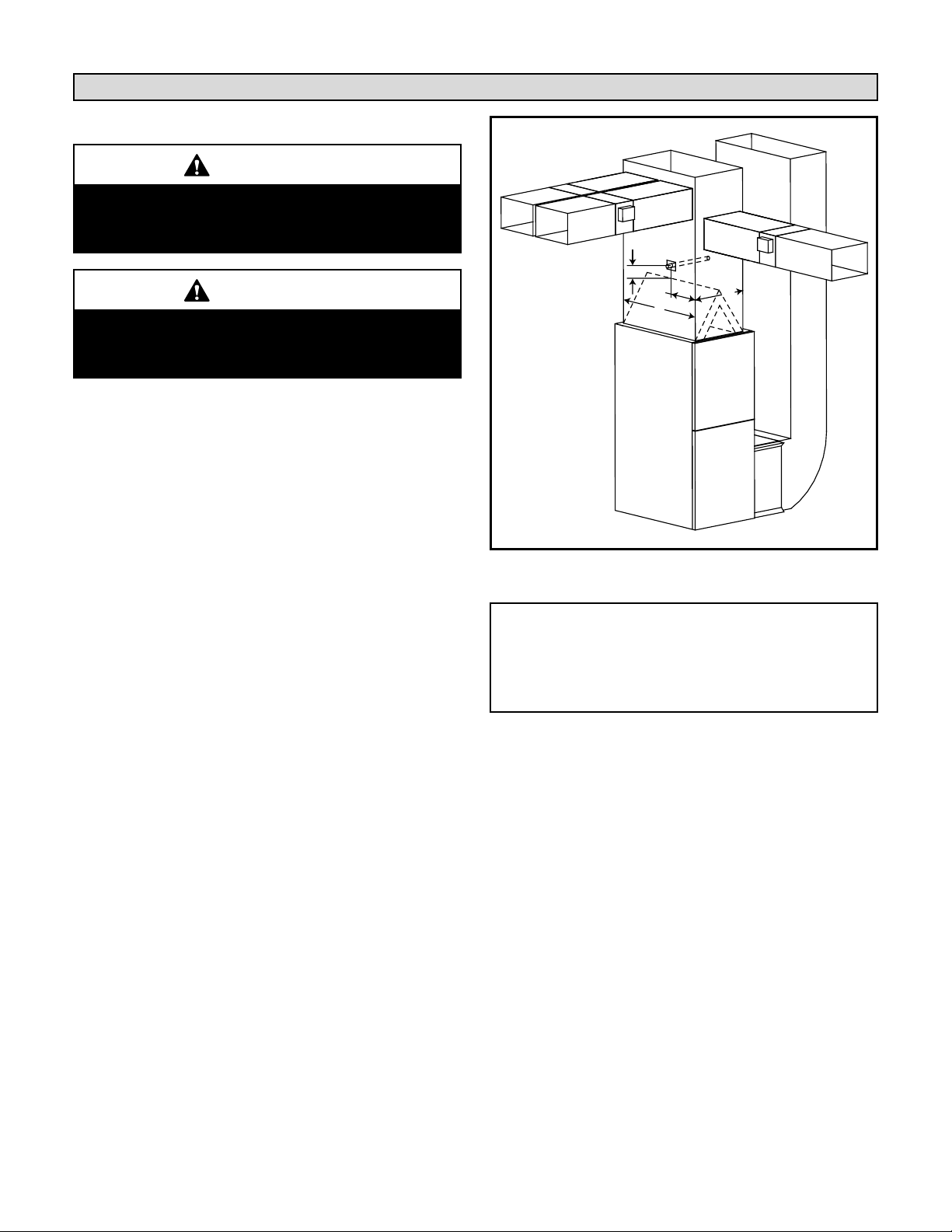

2. There are eight slots on the base of the enclosure

(see Figure 2).

3. Use #8 screws (field supplied) to install the base.

Features

• Adjustable high and low discharge air temperature limits

• ON/OFF duct air purge control

• LED indicators for outputs

• Time Delay Override

• 2 or 3-wire damper compatibility

FIGURE 2 – CONTROL PANEL AND ENCLOSURE BASE

CAUTION

Electrostatic discharge can damage the control.

Touch a grounded metal object before touching

the circuit board, and then only touch the circuit

board on the edges when handling.

(8) Mounting

Slots

The above illustration shows a typical two zone control system.

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, personal injury or loss of life. Installation

and service must be performed by a qualified

installer, service agency or the gas supplier.

D1

EQUIP.

W

G

Y

RC

RH

24VAC

R

C

DAS

W

D3

G

D5

Y

K1

J1

K4

K3

J3

J4

R43

R44

C18

R45

RV4

SPARE FUSE

MAIN FUSE

F1

F2

LENNOX

X3785 REV. 1

RV1

+

C5

RV5

LZP-2

D14

D13

D12

R17

D15

R20

D17

SW1

C10

TDO

Y1

C12

C15

RV6

PURGE

HT-160

CL-45

R4

R5

R3

D2

R2

GND

24VDC

C1

NORMAL

FLASHING

+

C3

U1

R10

C7

+

Q1

C8

U2

U6

C16

GAS

C9

R18

R19

ELECT.

NoPURGE

140

40

D11

U3

U4

TP4

R21

R39

R38

R37

C21

C19

C20

+

5VDC

R1

+

D4

R7

D8

D7

R8

D9

D10

+

R12

C6

R13

R11

K2

D19

D18

R23

U5

C13

R40

C22

+

+

R22

D20

R28

R30

D22

D23

+

R36

K5

R35

R41

R42

R47

R46

R6

C2

C4

D6

R14

ZONE 1

J2

Y

R9

R15

R16

RV2

G

R

NO

NC

C

DamperZ1

ZONE 2

J5

DamperZ2

W

Y

G

R

NO

NC

C

W

RV3

D16

C11

R25

R24

R26

R27

C14

R29

D21

C17

R34

R32

R33

R31

RV7

D24

RV8

Page 3

Page 3

Installation (continued)

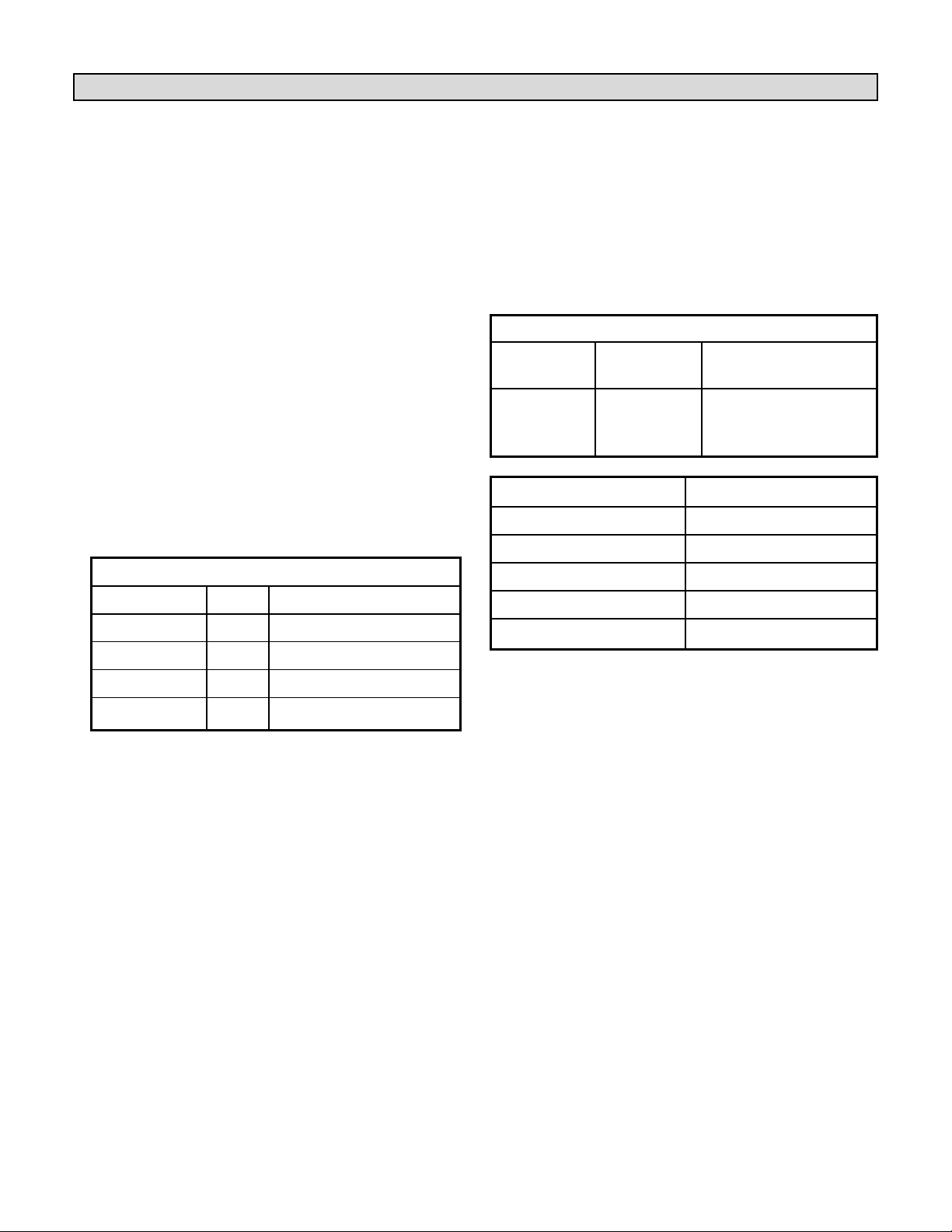

FIGURE 3 – DISCHARGE AIR SENSOR LOCATION

IMPORTANT: The discharge air sensor is required.

If a short or open circuit is detected between the

Plenum Sensor terminals, the control panel will only

respond to Zone 1 and the dampers will stay in the

open position.

4. Install and Wire the Discharge Air Temperature Sensor

The tip of the sensor must be located in a region of fully

mixed supply of air before the take-offs (not in a dead

air space) in order for the system to work correctly.

a. Wire discharge air temperature probe to control

panel using thermostat wire. Note that the

temperature sensor is not polarity sensitive.

b. Be sure that the tip of the sensor is located at

least 15 inches downstream from the leaving air

side of the evaporator in the discharge plenum,

and 1/3 of the depth (D/3) of the plenum (D) from

the front of the plenum (the front is the side with

the furnace or CB access doors), and centered

side to side. Move the adjustable bracket along

the length of the discharge air sensor to achieve

proper sensor tip location (tip of sensor to be

located at W ÷ 2). The sensor can be inserted

from any side of the plenum, as long as the tip of

the sensor is in the correct position. See Figure 3.

CAUTION

As with any mechanical equipment, personal injury

can result from contact with sharp sheet metal

edges. Be careful when you handle this equipment.

CAUTION

Before attempting to perform any service or

maintenance, turn the electrical power to unit OFF

at disconnect switch.

15"

D/3

D

W

FRONT

Page 4

Page 4

6. Install the thermostats. Refer to the instructions

provided with the thermostat.

Any 24-volt electronic thermostat with a “C” (24 VAC

common) terminal can be used. Power robbing

thermostats can cause unintended operation –

DO NOT use mechanical or power robbing

thermostats. Table 2 lists the required terminals

and recommended Lennox thermostats:

18 AWG thermostat wire minimum recommended.

TABLE 2 – THERMOSTAT REQUIREMENTS

Recommended

Type Terminals

Thermostat

HEAT/COOL R, C, W, Y, G

• SignatureStat 1H/1C

(51M26)

• Elite 1H/1C (49M55)

Thermostat Terminal Function

R 24 VAC Hot

C 24 VAC Common

W Heat

Y Cool

GFan

7. Install the dampers. Refer to the instructions provided

with the damper.

18 AWG thermostat wire minimum recommended.

Installation (continued)

5. Install the required transformer selected from Table 1

– DO NOT USE the HVAC equipment transformer to

power the control panel. Refer to the instructions

provided with the transformer.

18 AWG thermostat wire minimum recommended.

Sizing the Transformer:

The system requires approximately 10 VA for the

control panel and thermostats and 10 VA for each

damper. The size of the transformer will depend on the

greatest number of dampers that could be energized

at any given time (at least one zone’s dampers will not

be energized during a heating or cooling call when

using power close, spring open dampers). The size of

the transformer must not exceed 75VA. If the value is

greater than 75VA, some dampers will need to be

powered by a separate transformer – refer to Field

Wiring Damper Diagram 2 on page 6.

For instance, if you have 3 dampers, then you would

require 10VA for the system, 20VA (10VA X 2) for the

dampers for a total of 30VA, so catalog number 10P17

would be an adequate transformer size at 40VA.

The transformers listed in this chart include a plate

mount for a 4" square electrical box.

TABLE 1 – TRANSFORMERS

Part Number Size Voltage Description

10P17 40VA 120/208/240V-24V

10P87 50VA 120/208/240V-24V

12P61 75VA 120/208/240V-24V

83P74 4" Square Electrical Box

Page 5

Page 5

Bypass Damper Sizing

When fewer than the maximum number of zones are

calling for heating or cooling, an excess volume of air is

delivered, and because of the excess air, an excess

amount of static pressure is produced as well. Zone

systems often require a bypass duct to relieve this

pressure. A properly sized barometric bypass damper

must be installed in the bypass duct which is run

between the supply and return air duct systems (see

Figure 4). The barometric damper and the bypass duct

must be sized to accommodate the excess static

pressure from the supply duct.

The bypass tap in the return air duct must be at least

6 ft. from the furnace /air handler to ensure that the hot

or cold air coming off of the plenum has time to mix

with the return air before it passes through the air

handler again. The provided discharge air sensor will

prevent any damage to the equipment from overheating

or coil freeze-up by interrupting the HVAC equipment.

The bypass damper and duct should be sized to handle

the excess pressure created when the smallest zone is

operating alone (worst case). To size the bypass

damper, subtract the total air volume capacity of the

smallest zone from the total air volume of the system.

Example:

Total System air volume: 2000 cfm

Air volume of smallest zone: 600 cfm

Bypass requirement: 2000 - 600 = 1400 cfm

In this example, the bypass duct should be sized to

handle the 1400 cfm excess pressure created when

only the smallest zone has a demand. For bypass

damper air volume capacities, see Table 3.

Refer to the parts and supplies catalog for information

on available barometric bypass dampers.

TABLE 3

Round Rectangular

8 in. dia. – 400 cfm 12 x 8 – 1000 cfm

10 in. dia. – 750 cfm 12 x 10 – 1200 cfm

12 in. dia. – 1200 cfm 12 x 12 – 1400 cfm

14 in. dia. – 1800 cfm 20 x 8 – 1600 cfm

16 in. dia. – 2400 cfm 20 x 10 – 2000 cfm

20 x 12 – 3000 cfm

FIGURE 4 – BYPASS DAMPER INSTALLATION

ZONE 1

THERMOSTAT

ZONE

DAMPER

ZONE

DAMPER

ZONE 2

THERMOSTAT

ZONE 1

ZONE 2

BYPASS

DAMPER

SUPPLY

AIR

TRANSFORMER

FOR

DAMPERS,

PANEL AND

THERMOSTATS

HEATING/

COOLING

UNIT

DISCHARGE

AIR SENSOR

BYPASS DUCT

RETURN

AIR

6 ft. (1.8 m)

ZONE

CONTROL

PANEL

Page 6

Page 6

Field Wiring

DIAGRAM 1 – FIELD WIRING

DIAGRAM 2 – DAMPER WIRING WITH SEPARATE TRANSFORMER

Page 7

Page 7

Pin Jumper Settings (see Figure 5)

LEDs

ELECTRIC/GAS: If electric heat is to be used, move the

jumper to the “ELECT” position. This will turn on the fan

(G output terminal) with a heat call (W output terminal).

If the jumper is in the “GAS” position, it is assumed that

the heating equipment will control the fan operation.

NO PURGE / PURGE: If the NO PURGE / PURGE

jumper is moved to the “PURGE” purge position, the G

terminal will remain energized for a one minute purge

delay following the completion of a cooling call. If the

jumper is moved to the “NO PURGE” position, the G

terminal will de-energize immediately following the

completion of a cooling call. The NO PURGE setting is

designed for use with systems where the furnace or air

handler has a built in fan purge. The NO PURGE

damper hold time is longer than the PURGE setting due

to the Lennox furnaces installer settable maximum

blower off delay of 3 minutes. The following chart details

the zone panel outputs and damper hold times when a

heating or cooling call is satisfied:

DISCHARGE AIR SENSOR HT-140/160: This jumper

controls the temperature at which the heating equipment

will cut out to prevent overheating. For a high limit

temperature of 140°F, move the jumper to the “140”

position. For a high limit temperature of 160°F, leave the

jumper in the “160” position.

DISCHARGE AIR SENSOR CL-45/40: This jumper

controls the temperature at which the cooling

equipment will cut out to prevent freezing the indoor

coil. For a low limit temperature of 45°F, leave the

jumper in the “45” position. For a low limit temperature

of 40°F, move the jumper to the “40” position. To

maintain optimum operation, it is recommended to leave

this setting at “45”.

FIGURE 5 – PIN JUMPER SETTINGS

Jumper Settings Mode

Purge No Purge

Output Damper Hold Time Output Damper Hold Time

Heat/Cool

Cooling G

1

1 minute No G, 3-1/2 minutes

Gas

Heating No G 1 minute No G, 3-1/2 minutes

Heat/Cool

Cooling G

1

1 minute No G, 3-1/2 minutes

Elect.

Heating G

1

1 minute No G, 3-1/2 minutes

POWER – Blinks during normal operation. Starts to

blink approximately 6 seconds after power up.

G, Y and W – Lights when respective equipment outputs

are energized. The W LED will flash if the heating high

temperature limit has been reached. The Y LED will flash

if the cooling low temperature limit has been reached.

ZONE 1 Damper and ZONE 2 Damper – Lights when

the Normally Open (NO) damper terminal for that zone

is energized (i.e. LEDs show which zones are NOT

receiving conditioning when the HVAC equipment is

operating).

IMPORTANT: The temperature sensor is required.

If a short or open circuit is detected between the

Discharge Air Sensor (DAS) terminals, the control

panel will only respond to Zone 1 and the dampers

will not close.

1

The G terminal will remain energized for 1 minute.

Page 8

Page 8

A Time Delay Override (TDO) button is available on the

control panel to speed up the internal timer by a factor

of 60 for system checkout. One second of holding down

the button relates to one minute of speed up time in the

control.

HEATING AND COOLING EQUIPMENT OPERATION

Heating Operation

When a zone makes a call for Heat, the W output

terminal will energize. The G terminal will also energize

if the ELECTRIC/GAS jumper is in the ELECT position.

The W terminal de-energizes when (1) all zones stop

calling for Heat, (2) the call has exceeded the heat/cool

changeover time limit while a cooling call exists or (3)

the call is interrupted by the high limit setting. When the

W terminal is de-energized, a minimum off time delay of

4 minutes must elapse before it can be energized again.

Fan Purge

Time Delay

If the ELECTRIC/GAS jumper is in the ELECT

position and the PURGE/NO PURGE jumper is in the

PURGE position, the G terminal will remain energized

for one minute after the W terminal is de-energized.

The NO PURGE setting is the preferred purge control

setting for Lennox equipment. Lennox equipment

includes controls which sequence the indoor fan off

after a call for heat has been satisfied.

If the ELECTRIC/GAS jumper is set in the GAS

position, the G terminal does not turn on during purge

regardless of the position of the PURGE or NO

PURGE switch. Lennox furnaces will control the

purge though the furnace control board cool down

feature. The cool down time is often adjustable at the

furnace control board up to 3.5 minutes. NO PURGE

is the preferred method of purge when this zone

panel is applied to Lennox equipment.

Cooling Operation

When a zone makes a call for Cooling, the Y and G

terminals will energize. The Y terminal de-energizes

when (1) all zones stop calling for Cooling, (2) the call

has exceeded the heat/cool changeover time limit while

a heat call exists or (3) the call is interrupted by the low

limit temperature setting. When the Y terminal is deenergized, a minimum off time delay of 4 minutes must

elapse before it can be energized again.

Fan Purge Time Delay

If the PURGE/NO PURGE jumper is in the PURGE

position, the G terminal will remain energized for one

minute after the Y terminal is de-energized. If the

jumper is in the NO PURGE position, the G terminal

will de-energize immediately.

Heat/Cool Changeover: When a call for heating or

cooling exists and an opposing call is made from

another zone, a 20 minute timer is activated. If the

original call is not satisfied within that 20-minute time

period, the call will be interrupted, turning the equipment

off and allowing for the normal fan purge cycle and

minimum equipment off time. The opposing call will then

be answered. After 20 minutes, if the original call still

exists, the opposing call will be interrupted and the

original call can once again be recognized.

High/Low Limit Temperature: The high/low limit

temperature settings are designed to prevent the heat

exchanger from overheating or the cooling coil from

freezing. The temperature sensor in the supply duct

senses the discharge air temperature and interrupts the

heating/cooling equipment (depending on the Heat and

Cool temperatures set on the control panel) before

overheating/freezing occurs. When a heating/cooling

call is interrupted by the high/low temperature limit, the

zone control panel turns the equipment off and

energizes the G terminal (if not already energized). The

W or Y LED on the control panel will flash during a

high/low limit temperature interrupt. Once the

temperature drops/rises 10°F and the minimum off time

has expired, the equipment is turned back on if the call

for conditioning still exists. The Heating/Cooling LED will

stop flashing.

IMPORTANT: Should a short or open circuit be

detected across the DAS terminals, the zone system

will respond only to Zone 1 and the dampers will

not energize.

Sequence of Operation

Page 9

Page 9

CONTINUOUS FAN OPERATION

A call for Fan from any zone will initiate the G

equipment output terminal. The normally open (NO)

damper terminal at all zones not calling for continuous

fan will be energized.

DAMPER OPERATION

The “NO” output will be energized and the “NC” output

will be de-energized for any zone not calling for heating

or cooling while the equipment output is energized and

during the damper purge time delay. During equipment

operation or during the damper purge time delay,

should all zones stop calling for heating or cooling, the

damper terminals will remain in the position they were

in before all zones stopped calling.

Damper Purge Time Delay

When the Purge/No Purge jumper is at No Purge,

the damper purge time delay is 3.5 minutes and

begins when the equipment output(s) turn off. NO

PURGE is the preferred method of purge control for

Lennox furnaces and air conditioners. When the

jumper is at Purge, the damper purge time delay is

one (1) minute.

Sequence of Operation (continued)

Page 10

Troubleshooting

DETECTING HVAC SYSTEM PROBLEMS

Symptom Possible Solution

Pressure switch open.

Consult condensing unit manual for possible cause.

Compressor is off due to internal overload protector.

Consult condensing unit manual for possible cause.

Condenser control board anti short cycle timer is not

yet expired. Most anti short cycle timers are 5 minutes

or less, if the unit does not start after 5 minutes consult

the condensing unit manual for possible causes.

Limit on furnace open. Check position of DAS in

the plenum and move further down stream if possible.

High static condition must be corrected.

DAS limit jumper needs to be moved to a lower setting.

Trouble shoot air handler – see air handler

documentation.

Condensing unit receiving signal but will not turn on.

Air handler receiving signal but will not turn on.

Page 10

A high static condition exists. Move the sensor

further down stream to sense air that has mixed more

thoroughly. Be sure not to place the senor past

the take offs. High static pressure must be corrected.

Bypass tap is too close to inlet of air handler.

Adjust bypass tap in the return air duct so that is further

away from the furnace. This will give the air more of a

chance to be tempered with room return air before

entering the air handler again.

Furnace tripped the primary limit, but the

zone panel does not indicate that the discharge

air limit has been exceeded.

Page 11

Page 11

No power to control panel. Green “Normal Flashing”

LED should be blinking, if not apply power to

24VAC inputs of control panel. Check fuse.

Single transformer system. Install jumper between RC

and RH at HVAC Equipment outputs of control panel.

Interlock switch on furnace is open – close access doors.

Thermostat is not calling for heat. Check voltage at

the thermostat W input on the control panel.

Zone 2 calling while open or short at DAS inputs is

causing control panel to respond only to Zone 1.

Thermostat is power robbing or mechanical. Only use

line powered electronic thermostat with a C terminal.

Single transformer system. Install jumper between RC

and RH at HVAC equipment outputs of control panel.

Thermostat is not calling for cooling. Check voltage

at the thermostat Y input on the control panel.

Thermostat could be invoking a timed off delay.

Zone 2 calling while open or short at DAS inputs is

causing control panel to respond only to Zone 1.

Zone panel could be invoking a timed off delay.

Thermostat is power robbing or mechanical. Only use

line powered electronic thermostat with a C terminal.

Check if G is energized at the zone panel.

Check if G is energized at the thermostat.

Check if G is energized at the air handler.

Nothing comes on.

Heat will not come on.

Cooling will not come on.

Fan will not come on.

Troubleshooting (continued)

DETECTING HEATING, COOLING AND FAN PROBLEMS

Symptom Possible Solution

System requires the Discharge Air sensor. If DAS is not

installed, only Zone 1 calls will be recognized and dampers

will not operate. Disconnect power to the control panel,

install the DAS and restore power to the control panel.

ELECT/GAS jumper set to ELECT – change setting

to GAS.

HVAC system has built in duct purge. Set PURGE/NO

PURGE jumper on control panel to NO PURGE.

Discharge air temperature exceeds set limit.

Allow discharge air to cool 10° below set limit and

allow timed off delay to expire.

Discharge air temperature dropped below set limit.

Allow discharge air to warm 10° above set limit and

allow timed off delay to expire.

Dampers do not position on a call for heating,

cooling or fan. Heat, cooling or fan will not come on

when the Zone 2 thermostat is calling.

Fan immediately comes on with heat call.

After a cool call, the fan stops then starts right

away only to stop a short while later.

An open or short in the DAS sensor has been detected.

Install or repair the sensor.

Both the Y and W LEDs are blinking.

Fan is running but no heat, and W LED is blinking.

Fan is running but no cooling, and Y LED is blinking.

Page 12

Page 12

B2203458

10006259

Troubleshooting (continued)

CHECKING THERMOSTAT VOLTAGES

DISCHARGE AIR SENSOR CHECKOUT

Using a digital voltmeter (DVM) measure the AC voltage supplied at the R and C terminals of the Thermostat

inputs on the control panel for the zone in question. This voltage should be same as the voltage supplied to the

control panel 24VAC terminals. Make a call for heat, cooling or fan. Measure the voltage across the terminal that

should be energized (i.e. W for heat, Y for cooling, etc.) and the C terminal. This should be the same voltage as

there is between the R and C terminals. Measure the voltage across a terminal that should NOT be energized

and the C terminal; this voltage should be zero.

The discharge air sensor is a temperature dependent resistor; the higher the temperature, the lower the

resistance. In order to confirm the sensor is working, both sensor leads must be disconnected from the zone

panel board. Using a digital voltmeter (DVM) set to read resistance, touch the leads from the sensor to the

probes of the DVM. Take care not to create a parallel resistance path through your body by touching both probes

with your fingers or a faulty reading will be obtained. At 77F, the resistance of the sensor will be 10K ohm. If the

sensor is cooler than 77F, the resistance will be higher, if it is warmer, the resistance will be lower. After reading

the resistance at room temperature, warm the tip of the sensor by holding it in the palm of your hand, and take

another resistance reading. This reading should be noticeable lower than the room temperature reading.

T

emperature (°F) Resistance (ohms)

65 13476

70 11884

75 10501

80 9298

85 8249

90 7333

The zone panel is well equipped to monitor the operation of the probe and determine if a failure has occurred.

The probe should be considered an integral (but replaceable) part of the zone panel. The zone panel will indicate

if the probe is operating improperly and needs to be replaced.

DETECTING DAMPER PROBLEMS

Symptom Possible Solution

DAS shorted or open causing the panel to only respond

to zone 1 inputs while not closing any dampers.

Damper wired incorrectly. Spring open power close

dampers should be connected between NO and

C terminals.

DAS shorted or open causing the panel to only respond

to zone 1 inputs while not closing any dampers.

Damper motor faulty.

Damper opens when it should be closed.

Damper will not close.

Loading...

Loading...