Lennox LT-B3661CL, LT-B3621CL, LT-B3021HL, LT-B3621HW, LT-B3621CW Installation Operating & Maintenance Manual

...

INSTALLATION

OPERATING &

MAINTENANCE MANUAL

SPLIT CASSETTE

English

June 2002

REFERENCE EQUIVALENCE :

LENNOX REFERENCE FACTORY NUMBER

DHA 28 LT-B2861HL

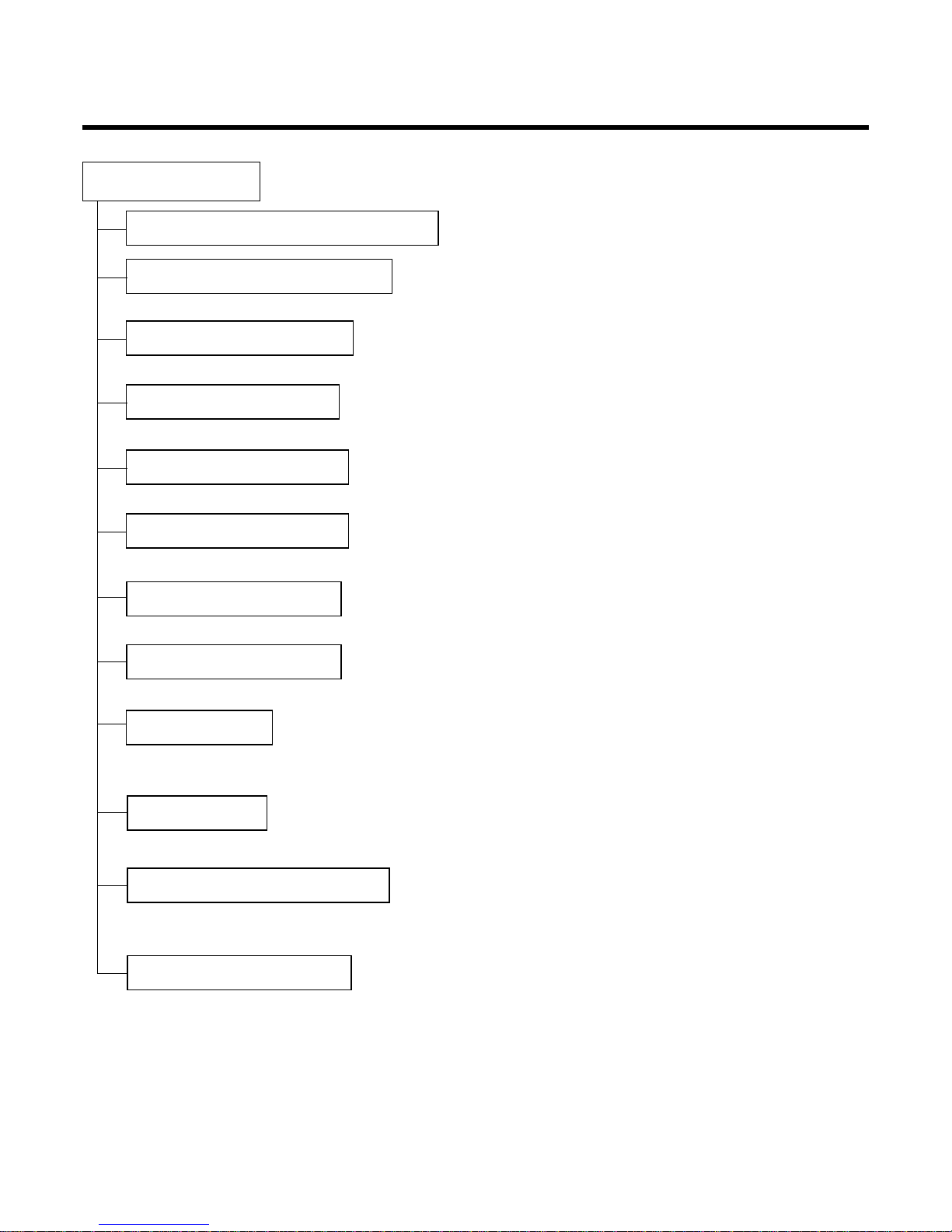

Contents

Functions................................................................................................................................ 3

Product Specifications (Cooling & Heating)........................................................................ 5

Dimensions............................................................................................................................. 8

Refrigeration Cycle Diagram............................................................................................... 11

Wiring Diagram..................................................................................................................... 13

Operation Details ................................................................................................................. 19

Installation of Indoor, Outdoor Unit.................................................................................... 22

Test Running ........................................................................................................................ 34

Cycle...................................................................................................................................... 36

Cycle Troubleshooting Guide.............................................................................................. 39

Electronic Parts Troubleshooting Guide............................................................................ 40

Electronic Control Device.................................................................................................... 44

Schematic Diagram.............................................................................................................. 45

Exploded View and Replacement Parts List...................................................................... 47

–2–

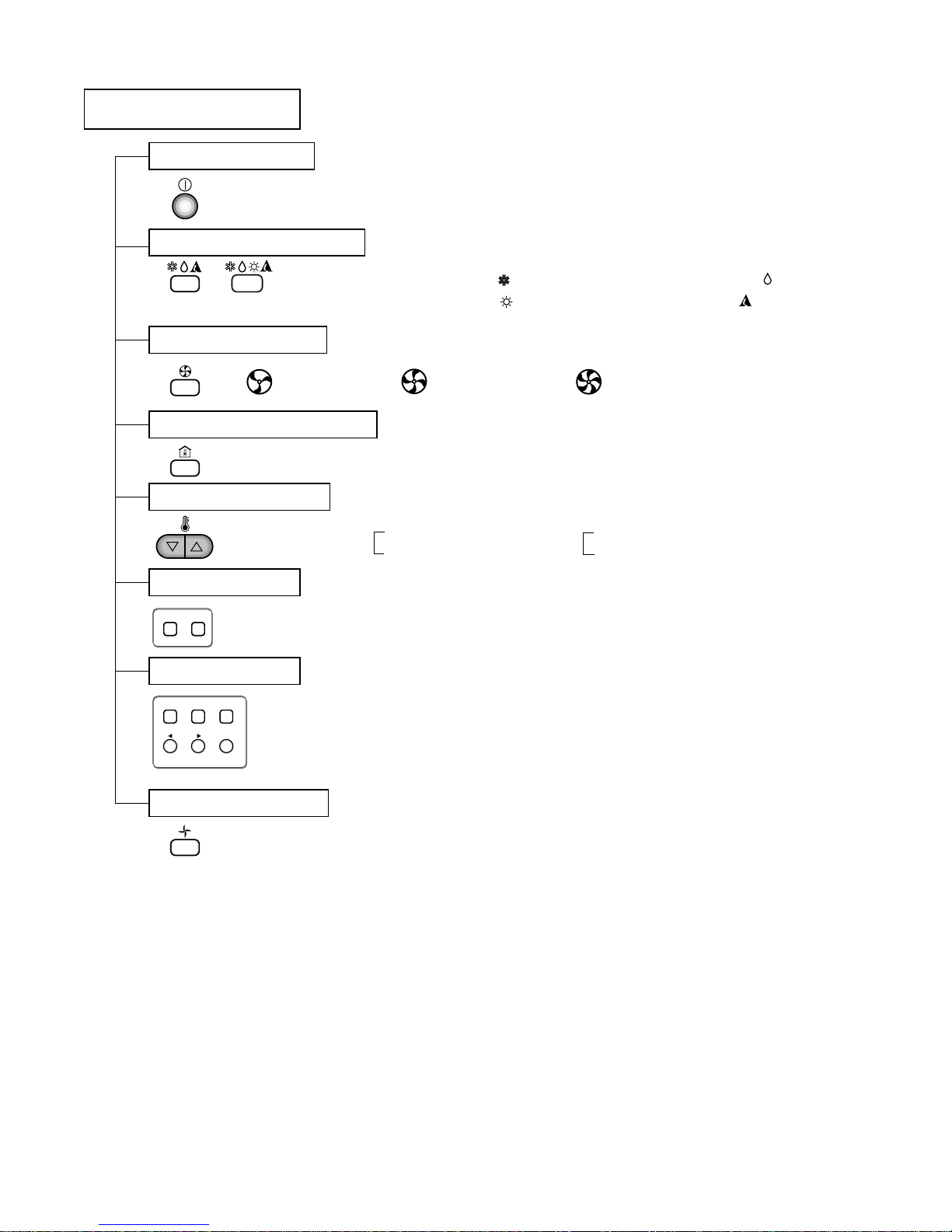

Functions

• Room temperature sensor. (Thermistor)

• Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low

• Intermittent operation of fan at low speed.

• The louver can be set at swing up and down automatically.

• Although the air-conditioner is turned off by a power failure, it is restarted automatically previous operation

mode after power supply.

• The setting temperature and desired operation mode are automatically set by fuzzy rule.

• Both the indoor and outdoor fan stops during defrosting.

• Hot start after defrost ends.

• The indoor fan stops until the evaporator piping temperature will be reached at 28°C.

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Soft Dry Operation Mode

Airflow Direction Control

Auto Operation

Deice (Defrost) control (Heating)

Hot-start Control (Heating)

Auto Restart

–3–

–4–

Remote Controller

Operation ON/OFF

Operation Mode Selection

Fan Speed Selection

Room Temperature Display

Temperature Setting

Setting the Timer

Weekly Timer

(Cooling

model only)

(Heating

model only)

(Low) (Med) (High)

Cooling Operation Mode ( )

Heating Operation Mode ( ) Auto Operation Mode ( )

Soft Dry Operation Mode ( )

Fan Operation Mode

HIMEDLO

Program Holiday

SET/CLR

MinHour

Week

Timer CancelTimer Cancel

: High:39°C ↔ LOW:11°C

: Fan Operates without cooling & heating

Cooling

Heating

Down to 18°C

Up to 30°C

Down to 16°C

Up to 30°C

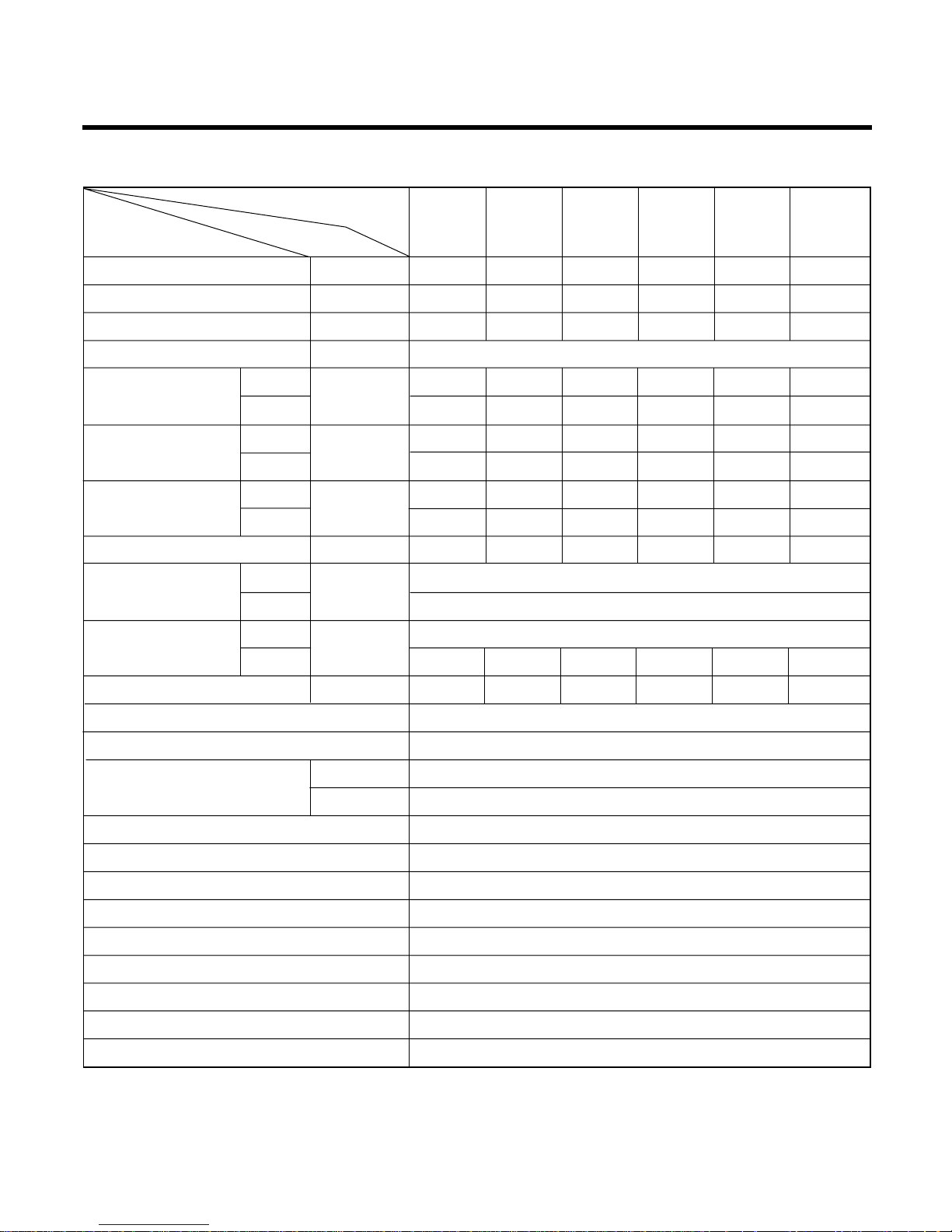

Product Specifications (Cooling & Heating)

1. 60Hz

Model Name

Item Unit

Cooling Capacity Btu/h(kcal/h)

Heating Capacity Btu/h(kcal/h)

Moisture Removal l/h

Power Source Ø, V, Hz

Indoor

Outdoor

Input

Cooling

Heating

Running Current

Cooling

Heating

E.E.R. Btu/h-W

Indoor

Outdoor

Net Weight

Indoor

kg

Outdoor

Refrigerant (R-22) g

Airflow Direction Control (Up & Down)

Remocon Type

Liquid

Gas

Drain Hose

Connecting Wire

Main Power Cable

Time Delay Safety Function

Air Circulation

Soft Dry

Fan Speed (Indoor)

Timer

Self-Diagnosis

Air Circulation

m3/min

Dimensions

(W×H×D)

mm

W

A

LT-

B2421CL

24,000(6,048)

–

3.5

17

50

2,700

–

12.5

–

8.89

60

2,000

24,000(6,048)

24,000(6,048)

3.5

17

50

2,700

2,400

12.5

10.5

8.89

61

1,870

28,000(7,056)

–

4.0

19

52

2,850

–

12.8

–

9.82

60

2,150

30,000(7,560)

–

4.3

19

52

2,850

–

12.8

–

10.53

60

2,150

30,000(7,560)

30,000(7,560)

4.3

19

52

2,850

2,750

12.8

12.3

10.53

65

2,400

28,000(7,056)

28,000(7,056)

4.0

19

52

2,850

2,750

12.8

12.3

9.82

65

2,400

LT-

B2421HL

LT-

B2821CL

LT-

B3021CL/CW

LT-

B2821HL

LT-

B3021HL/HW

–5–

Service Valve &

Connecting Tube

870 x 800 x 320

800 x 800 x 298(910 x 910 x 30)

35(30+5)

1Ø, 220V, 60Hz

870 x 655 x 320

O

Wired Remocon, Wireless Remocon(Optional)

3/8"(9.52)

5/8"(15.88)

O

0.75mm2↑

2.5mm2↑

O

O

O

3(Hi, Med, Low)

24Hrs

O

–6–

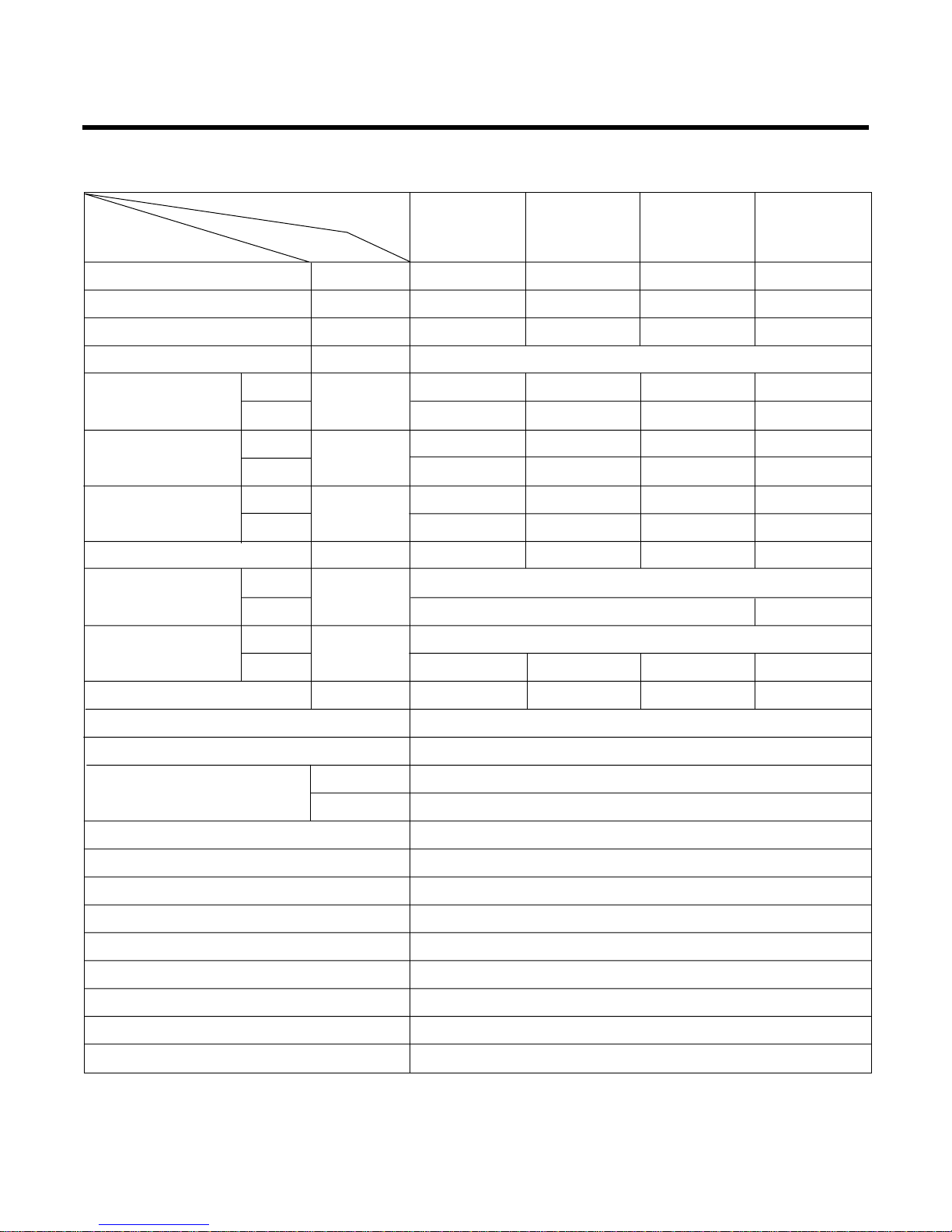

Model Name

Item Unit

Cooling Capacity Btu/h(kcal/h)

Heating Capacity Btu/h(kcal/h)

Moisture Removal ℓ/h

Power Source , V, Hz

Indoor

Outdoor

Input Cooling

Heating

Running Current Cooling

Heating

E.E.R. Btu/h-W

Indoor

Outdoor

Net Weight

Indoor

kg

Outdoor

Refrigerant (R-22) g

Airflow Direction Control (Up & Down)

Remocon Type

Liquid

Gas

Drain Hose

Connecting Wire

Main Power Cable

Time Delay Safety Function

Air Circulation

Soft Dry

Fan Speed (Indoor)

Timer

Self-Diagnosis

Air Circulation

m

3

/min

Dimensions

(W×H×D)

mm

W

A

LT-B2461CL LT-B2461HL LT-B2861CL LT-B2861HL

24,000(6,048)

–

3.5

17

50

2,800

–

13.5

–

8.57

60

1,900

24,000(6,048)

24,000(6,048)

3.5

17

50

2,800

2,500

14

13

8.57

61

1,870

28,000(7,056)

–

4.0

19

52

2,850

–

13.4

–

9.82

60

2,100

28,000(7,056)

28,000(7,056)

4.0

19

52

2,850

2,650

13.4

12.6

9.82

65

2,400

Service Valve &

Connecting Tube

800 x 800 x 298(910 x 910 x 30)

1Ø, 220V~240V, 50Hz

35(30+5)

870 x 800 x 320

870 x 655 x 320

O

Wired Remocon, Wireless Remocon(Optional)

3/8"(9.52)

5/8"(15.88)

O

0.75mm2↑

2.5mm2↑

O

O

O

3(Hi, Med, Low)

24Hrs

O

2. 50Hz

–7–

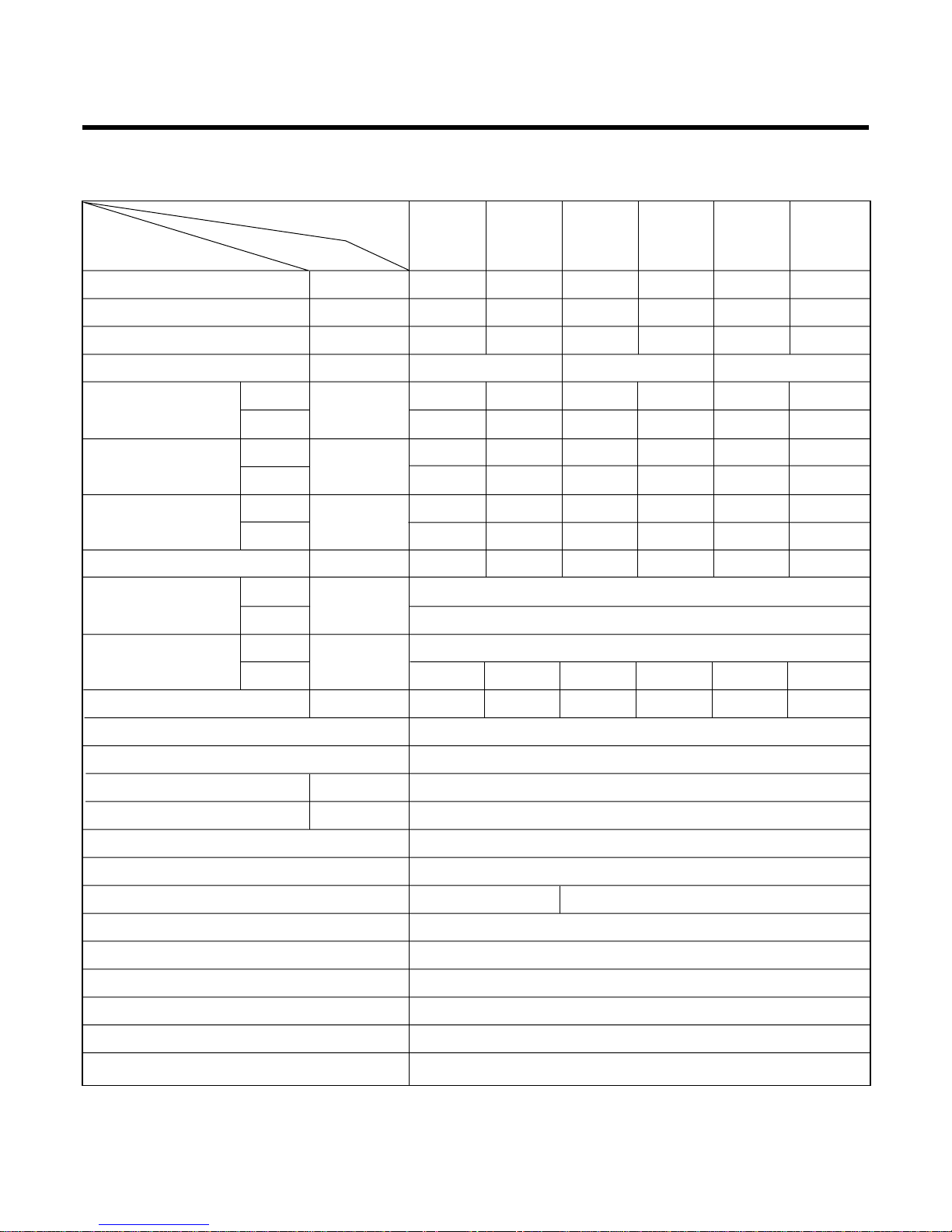

Model Name

Item Unit

Cooling Capacity Btu/h(kcal/h)

Heating Capacity Btu/h(kcal/h)

Moisture Removal l/h

Power Source Ø, V, Hz

Indoor

Outdoor

Input Cooling

Heating

Running Current Cooling

Heating

E.E.R. Btu/h-W

Indoor

Outdoor

Net Weight

Indoor

kg

Outdoor

Refrigerant (R-22) g

Airflow Direction Control (Up & Down)

Remocon Type

Liquid

Gas

Drain Hose

Connecting Wire

Main Power Cable

Time Delay Safety Function

Air Circulation

Soft Dry

Fan Speed (Indoor)

Timer

Self-Diagnosis

Air Circulation

m3/min

Dimensions

(W×H×D)

mm

W

A

LT-

B3681CL

36,000(9,072)

–

5.0

22

58

4,300

–

7.5

–

–

80

3,150

36,000(9,072)

36,000(9,072)

5.0

22

58

4,300

4,100

7.5

7.0

–

81

3,150

36,000(9,072)

–

5.0

22

58

4,400

–

22

–

–

80

3,150

36,000(9,072)

36,000(9,072)

5.0

22

58

4,400

4,100

22

21

–

81

3,150

36,000(9,072)

36,000(9,072)

5.0

22

58

4,000

3,800

18

17

–

81

3,000

36,000(9,072)

–

5.0

22

58

4,000

–

18

–

–

80

3,150

LT-

B3681HL

LT-

B3661CL

LT-

B3661HL

LT-

B3621CL/CW

LT-

B3621HL/HW

Service Valve &

Connecting Tube

800 x 800 x 298(910 x 910 x 30)

35(30+5)

3Ø, 380-415V, 50Hz

1Ø, 220-240V, 50Hz

1Ø, 220V, 60Hz

790 x 965 x 320

O

Wired Remocon, Wireless Remocon(Optional)

3/8"(9.52)

3/4"(19.05)

O

0.75mm2↑

2.5mm2↑ 3.5mm2↑

O

O

O

3(Hi, Med, Low)

24Hrs

O

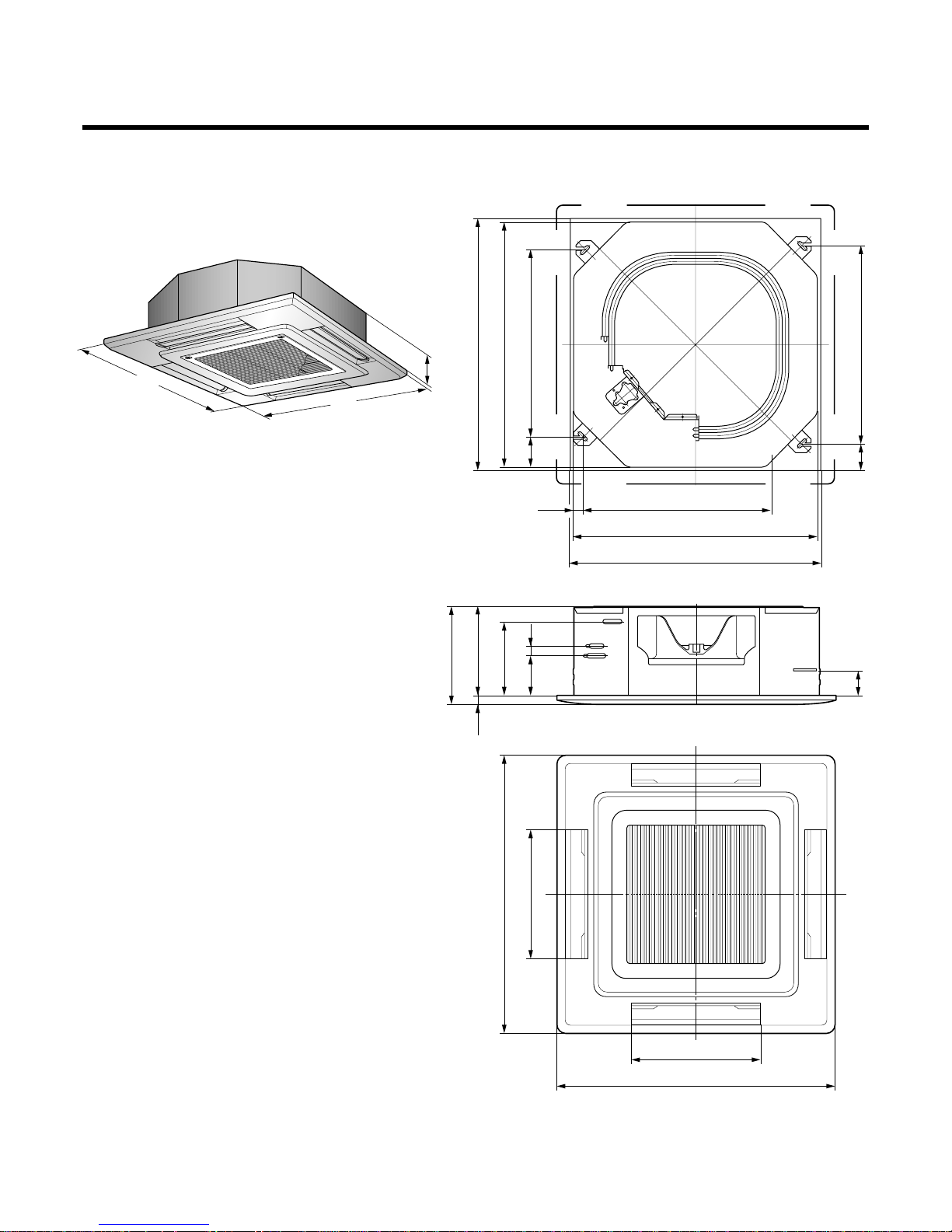

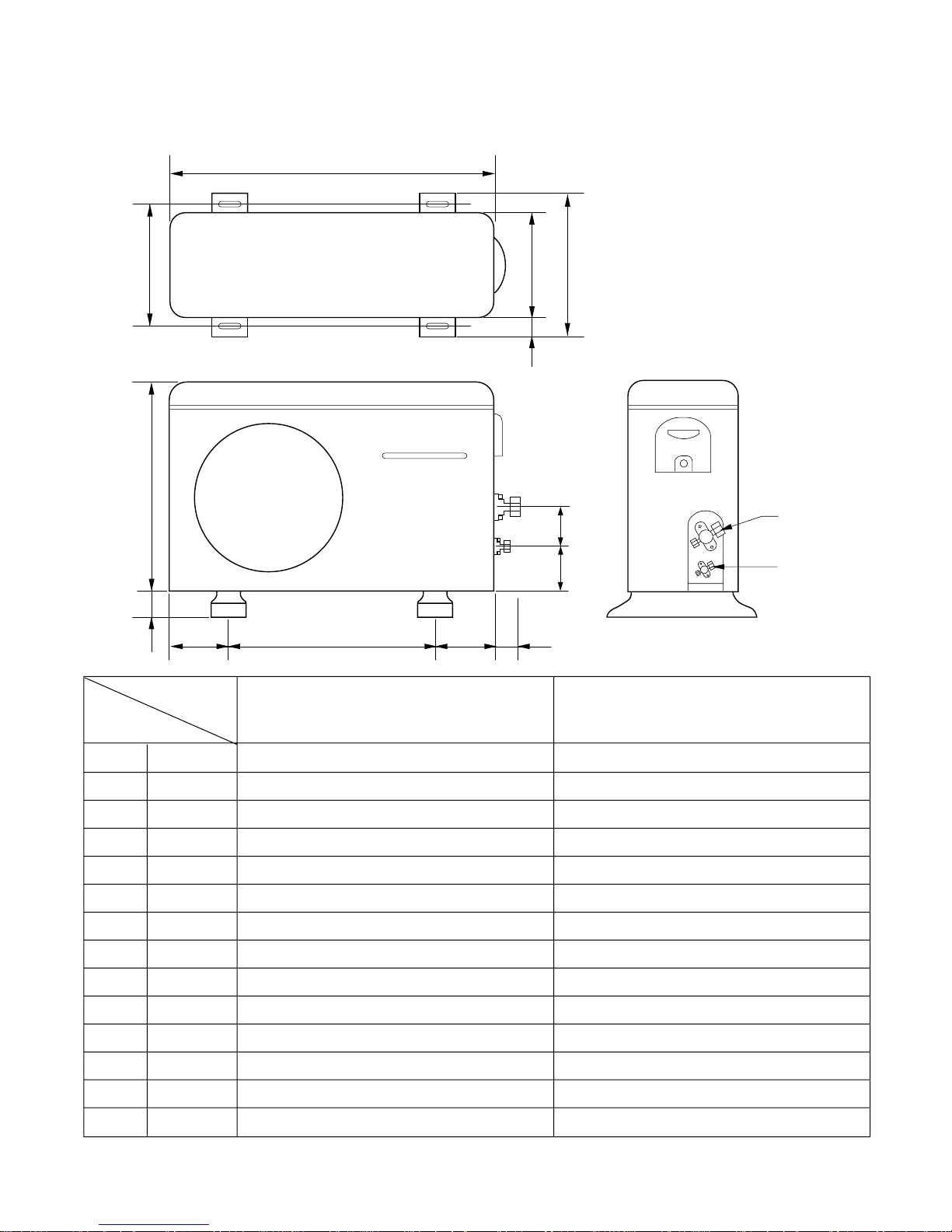

Dimensions

Indoor Unit

910

910

298

707

800

600113

65075

100

145423

910 255

29830

(328)

30

800

840

840

423

910

–8–

–9–

Outdoor Unit

Gas side

3-way valve

Liquid side

3-way valve

W

L6L7 L8 L9

L4

L11

L10

D

L1

L2

L5

L3

MODEL

DIM

W mm 870 870

H mm 655 800

D mm 320 320

L1 mm 370 370

L2 mm 25 25

L3 mm 340 340

L4 mm 630 775

L5 mm 25 25

L6 mm 546 546

L7 mm 162 162

L8 mm 162 162

L9 mm 54 54

L10 mm 74.5 74.5

L11 mm 79 79

LT-B2421CL/HL, LT-B2461CL/HL

LT-B2861CL, LT-B2821CL, LT-B3021CL/CW

LT-B2861HL, LT-B2821HL, LTB3021HL/HW

–10–

Outdoor Unit(LT-B3621CL/CW/HL/HW, B3661CL/HL, B3681CL/HL)

320

790

385

72

482

4-ø12Hole

249

71

145

500

145

10

334

354

10

265

440

925

965

130

40

80

292.5

5

3

1

2

4

(Air intake vent)

(Air intake vent)

(Air intake vent)

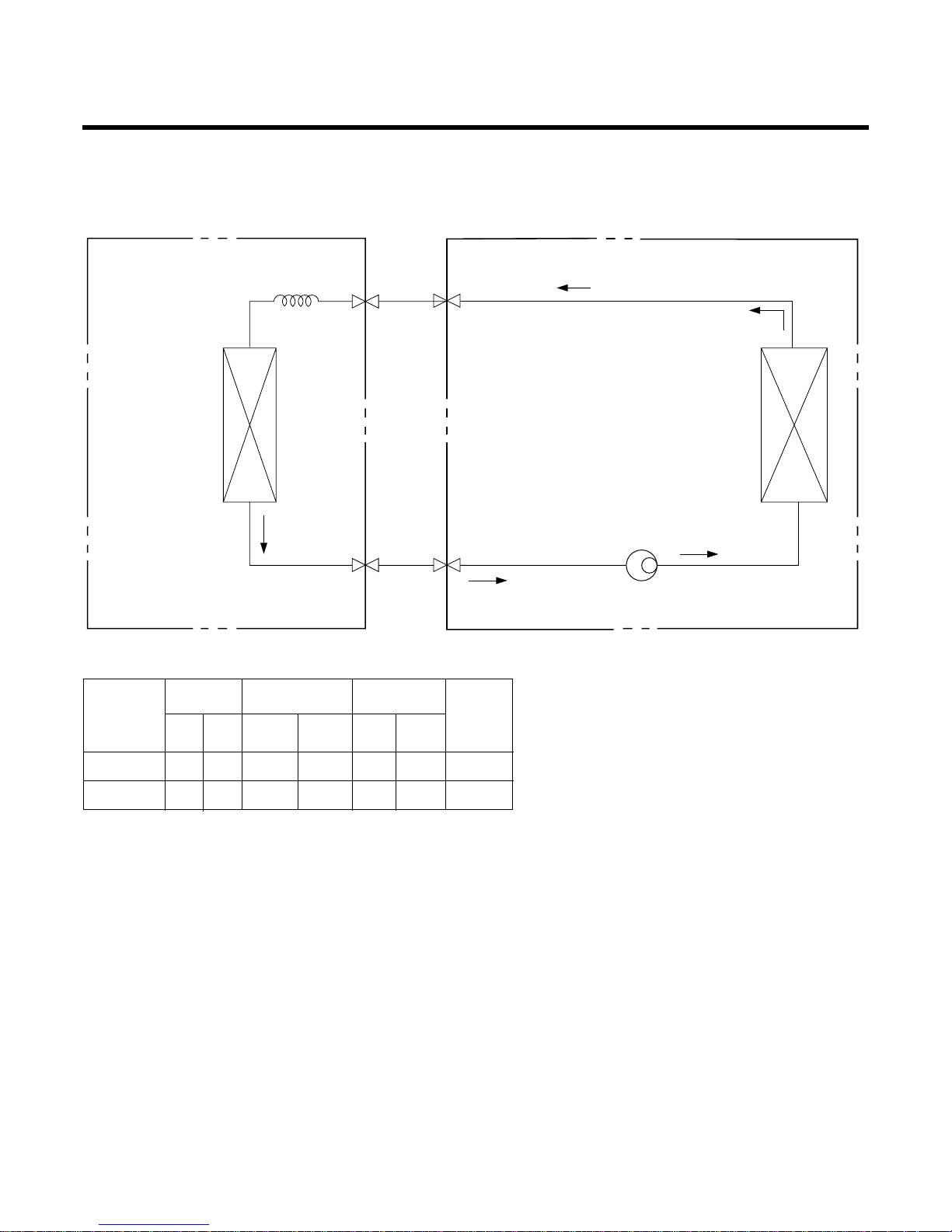

Refrigeration Cycle Diagram

• COOLING ONLY

• Rated performance for refrigerant line length of: 5m

• If 24K or 28K Model is installed at a distance of 15m, 500g of refrigerant

should be added ....................................................(15-5)x50g

MODEL

24K, 28K, 30K BTU

5/8" 3/8" 5 20

36

K BTU

3/4" 3/8" 5 25

GAS LIQUID

515 50

520 70

Elevation B(m)

Length A(m)

* Additional

refrigerant

(g/m)

Pipe Size

Rated Rated

Max. Max.

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGER

(EVAPORATOR)

HEAT

EXCHANGER

(CONDENSER)

COMPRESSOR

GAS SIDE

LIQUID SIDE

CAPILLARY TUBE

–11–

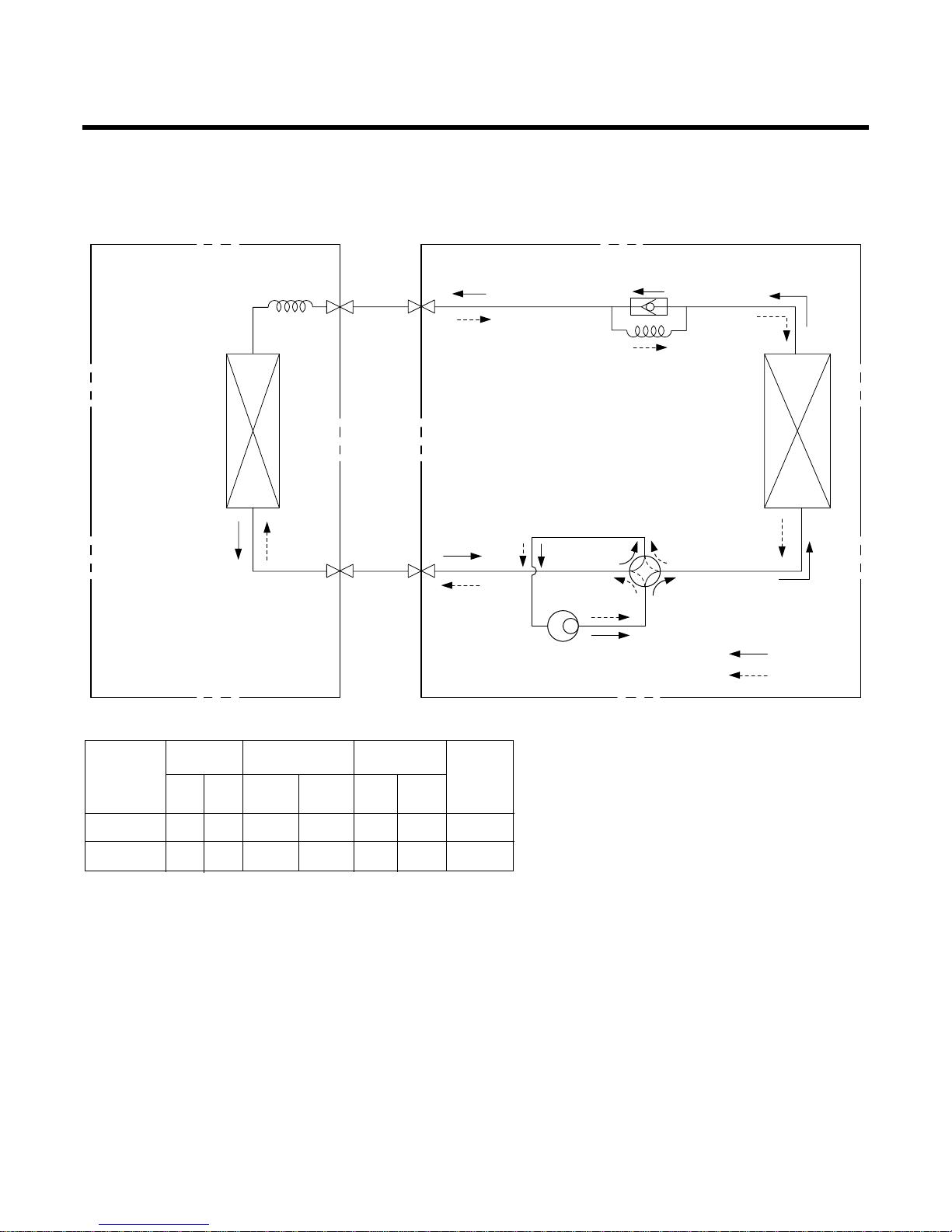

• HEAT PUMP

–12–

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGER

HEAT

EXCHANGER

COMPRESSOR

GAS SIDE

LIQUID SIDE

COOLING

HEATING

REVERSING

VALVE

CHECK VALVE

CAPILLARY TUBE

CAPILLARY TUBE

• Rated performance for refrigerant line length of: 5m

• If 24K or 28K Model is installed at a distance of 15m, 500g of refrigerant

should be added ....................................................(15-5)x50g

MODEL

24K, 28K, 30K BTU

5/8" 3/8" 5 20

36

K BTU

3/4" 3/8" 5 25

GAS LIQUID

515 50

520 70

Elevation B(m)

Length A(m)

* Additional

refrigerant

(g/m)

Pipe Size

Rated Rated

Max. Max.

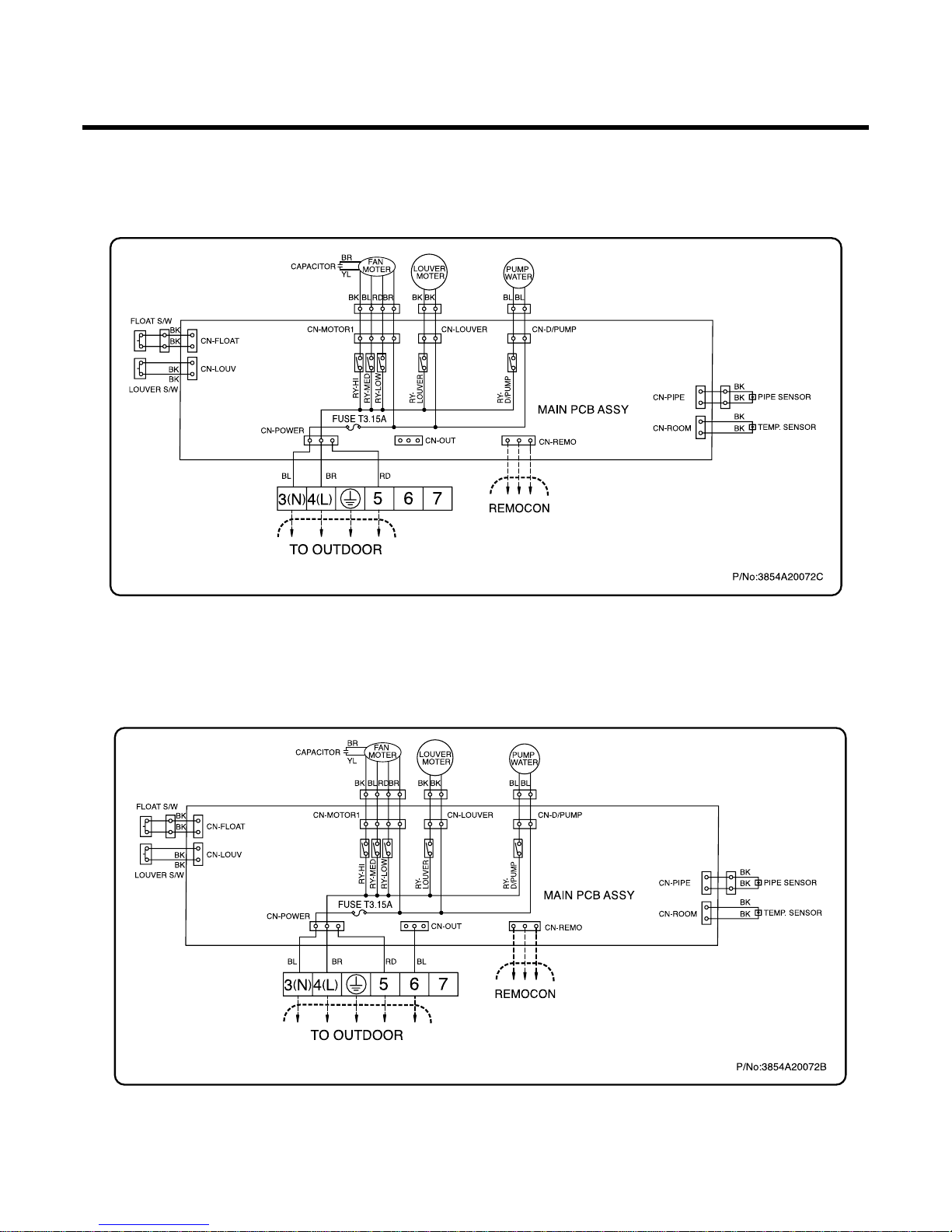

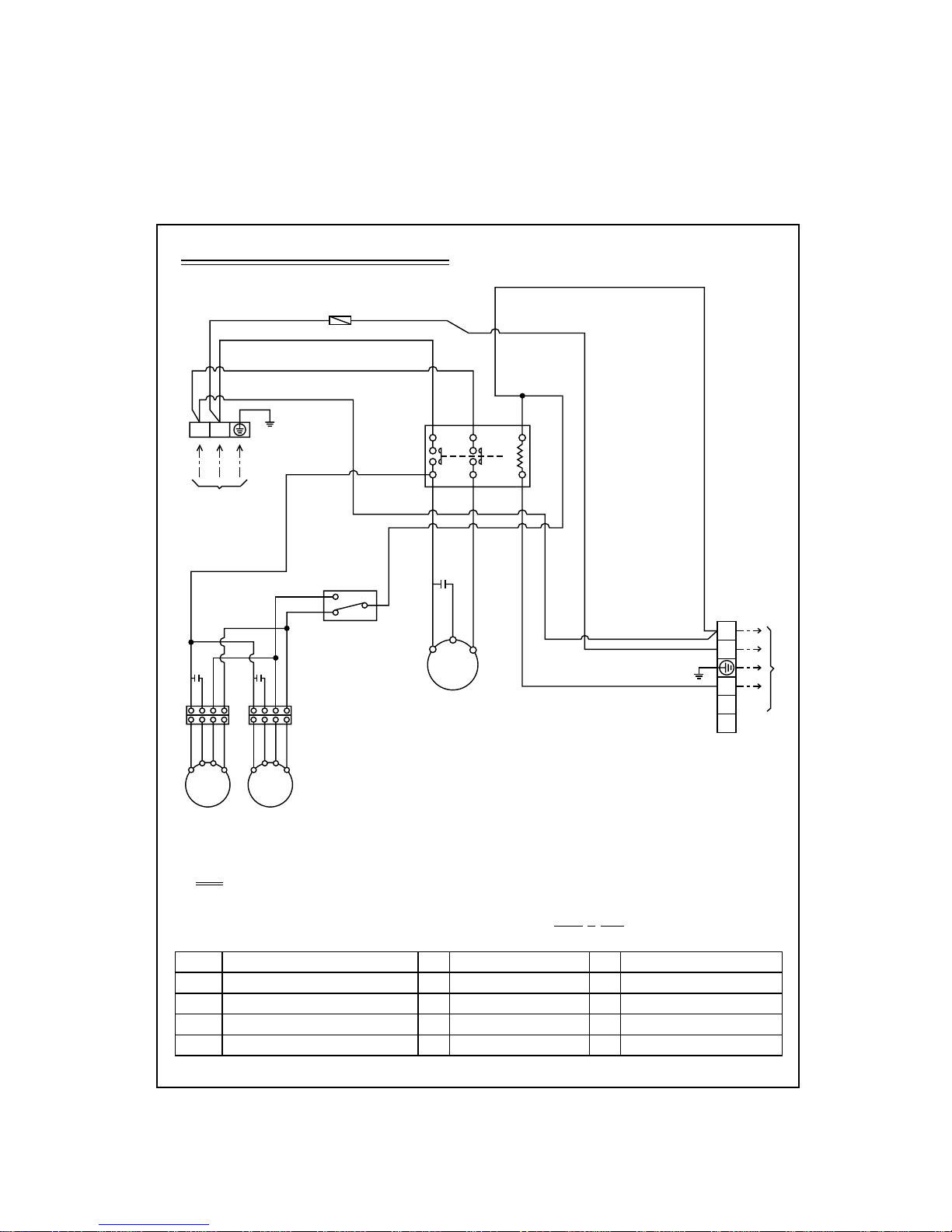

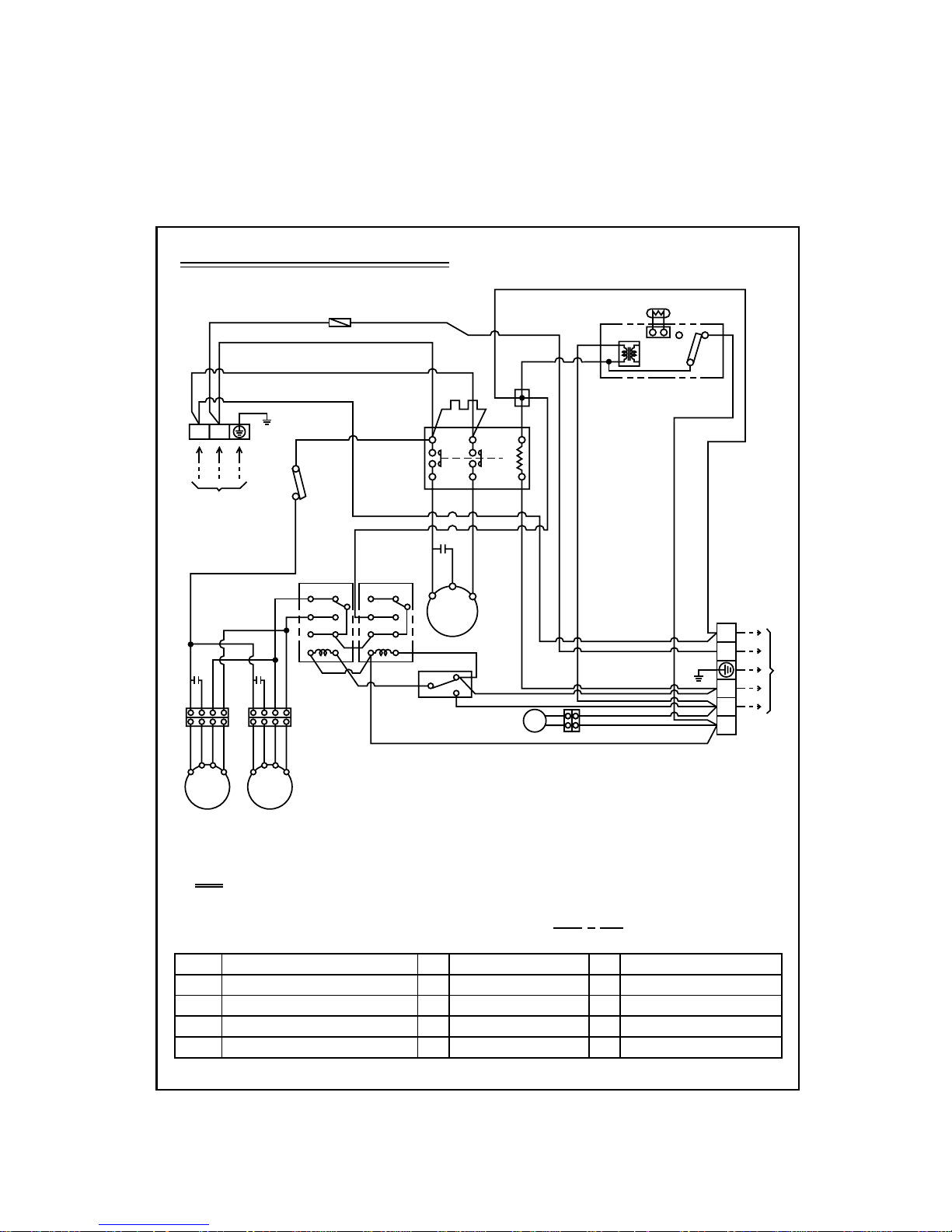

Wiring Diagram

(1) Indoor Unit

1. COOLING ONLY

2. HEAT PUMP

–13–

–14–

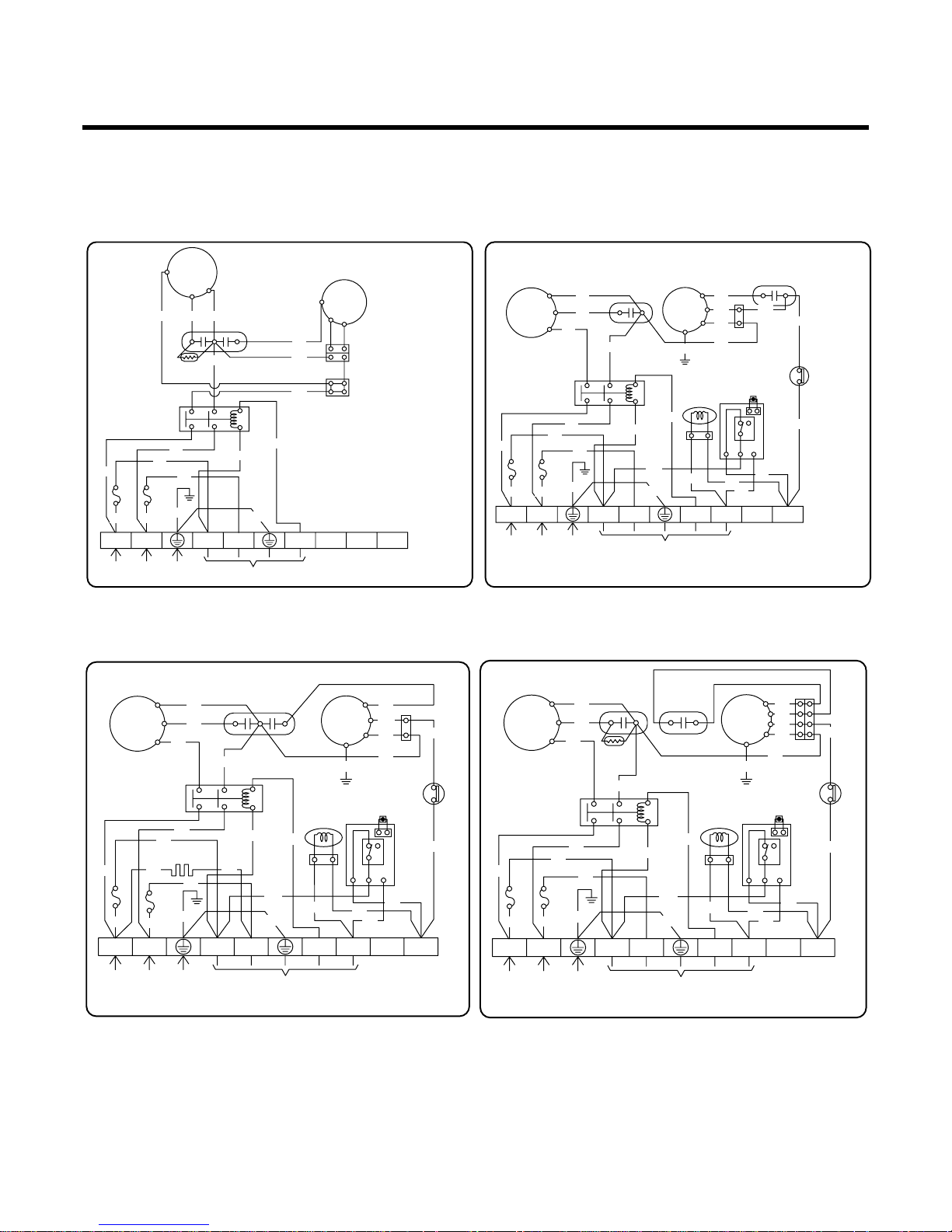

(2) Outdoor Unit

1. LT-B2461CL/B2861CL/B2421CL

B2821CL/B3021CL/B3021CW

2. LT-B2461HL/B2421HL

3. LT-B2861HL 4. LT-B2821HL/B3021HL/B3021HW

COMP.

MOTOR

R

S

C

RD

BL

BL

P.T.C

(OPTION)

BR

BR

BRBL

BL

BL

FUSE(5A)

FUSE(5A)

BL

YL

RD

POWER

RELAY

841

620

CAPACITOR

GN/YL

TO INDOOR

POWER INPUT

1(N)2(L

)

3(N)4(L

)

5678

TERMINAL

BLOCK

GN/YL

OR

BR

BK

BR

COMP.

MOTOR

R

S

C

BL

BR

BR

BR

BR

BL

BL

BKBK

WH

BL

CRANK CASE

HEATER

FUSE(5A)

FUSE(5A)

BL

RD

YL

BK

OR

OR

BK

BK

RD

REVERSING

COIL

BK

BK

YL

BL

POWER

RELAY

841

620

Capacitor

HIGH PRESSURE S/W

GN/YL

L1L2L3

GN/YL

TO INDOOR

POWER INPUT

1(N)2(L

)

3(N)4(L

)

5678

TERMINAL

BLOCK

3854A90002G

GN/YL

BK

COMP.

MOTOR

R

S

C

BL

BR

BR

BR

BRBL

BL

WH

BL

FUSE(5A)

FUSE(5A)

BL

RD

P.T.C

(OPTION)

BR

YL

OR

BK

BK

BK

BK

RD

REVERSING

COIL

BK

BK

YL

BL

POWER

RELAY

841

620

Capacitor

Capacitor

HIGH PRESSURE S/W

GN/YL

L1L2L3

GN/YL

TO INDOOR

POWER INPUT

1(N)2(L

)

3(N)4(L

)

5678

TERMINAL

BLOCK

3854A90002N

GN/YL

BK

COMP.

MOTOR

R

S

C

BL

BR

BR

BR

BRBL

BL

WH

BL

FUSE(5A)

FUSE(5A)

BL

RD

YL

OR

BK

BK

BK

BK

RD

REVERSING

COIL

BK

BK

YL

OR

BL

POWER

RELAY

841

620

Capacitor

Capacitor

HIGH PRESSURE S/W

GN/YL

L1L2L3

GN/YL

TO INDOOR

POWER INPUT

1(N)2(L

)

3(N)4(L

)

5678

TERMINAL

BLOCK

GN/YL

BK

–15–

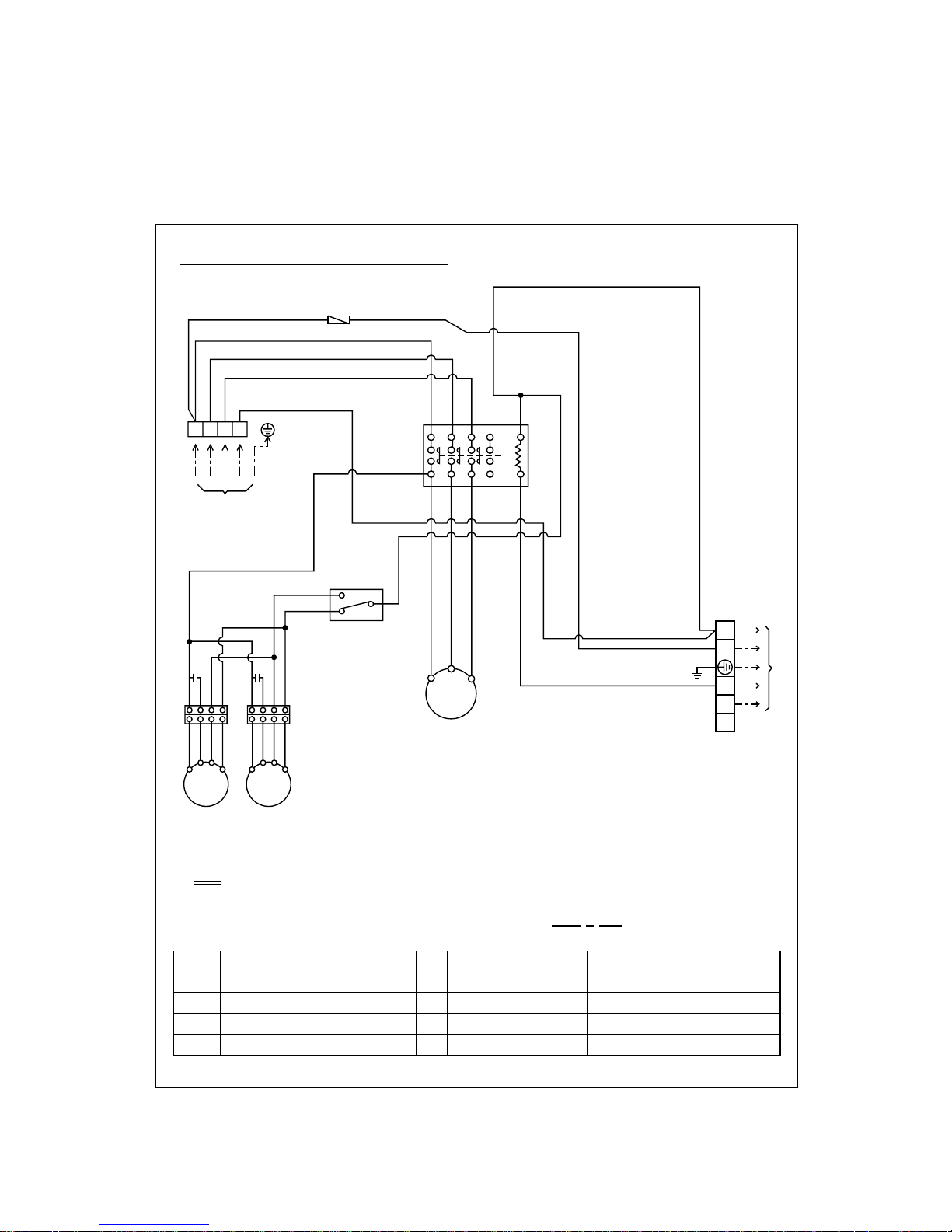

5. LT-B3681CL

THMO

C

H

L

TO INDOOR

Outdoor Unit Wiring Diagram

NOTE

BL : BLUE

BK : BLACK

BR : BROWN

OR : ORANGE GN/YL : GREEN/YELLOW

63H2

TMo

Co

HIGH PRESSURE SWITCH FOR HEATING

TERMINAL BLOCK

RUN CAPACITOR FOR FMo

TMCMMAIN TERMINAL BLOCK

COMPRESSOR

F1

FMo

FUSE (250V, 5A)

OUTDOOR FAN MOTOR

P/NO : 3854A30042P

RD : RED

WH : WHITE

YL : YELLOW

WIRING OF FIELD

(CONNECTING WIRE)

TM

3Ø, 380-415V

POWER SUPPLY

BK

52C

13531

24632

B

A

BK

WH

BK

WH

RD

BK

BK

RD

BL BK

WH

T1

T3

T2

CM

WH

WH

BL

BK

RSTN

Co

OR YLBLBK OR YLBLBK

Co

FMo1 FMo2

GN/YL

3(N)

4(L)

5

6

7

F1

–16–

6. LT-B3681HL

Outdoor Unit Wiring Diagram

NOTE

BL : BLUE

BK : BLACK

BR : BROWN

OR : ORANGE GN/YL : GREEN/YELLOW

63H2

C TH

20SV

52C

TMo

HIGH PRESSURE SWITCH FOR HEATING

THERMISTOR FOR PIPE TEMP.

REVERSING COIL

MAGNECTIC CONTACTOR

TERMINAL BLOCK

TM

52F1

CM

Co

FMo

MAIN TERMINAL BLOCK

RELAY FOR FMo

COMPRESSOR

RUN CAPACITOR FOR FMo

OUTDOOR FAN MOTOR

F1

DP

CH1

THMO

52F2

FUSE (250V, 5A)

DEICER PCB

CRANK CASE HEATER FOR CM

THEMOSTAT FOR COOLING

RELAY FOR FMO CONTROL.

P/NO : 3854A30042H

RD : RED

WH : WHITE

YL : YELLOW

WIRING OF FIELD

(CONNECTING WIRE)

TM

3Ø, 380-415V

POWER SUPPLY

BK

63H2

52C

13531

24632

B

A

BK

WH

BK

TNS

NO

C TH

NC

D.P

WH

T/B1

BK

WH

WH

RD

BK

WH

BK

BK

RD

BL BK BK

WH

T1

T3

T2

CH1

CM

YL WH

WH

BL

BK

RSTN

Co

OR YLBLBK OR YLBLBK

Co

FMo1 FMo2

20SV

BKBKBK

BK

WH

YL

WH

YL

BL

BL

THMO

C

L

H

GN/YL

TOO INDOOR

3(N)

4(L)

5

6

7

78

52F2

12

34

56

78

52F1

12

34

56

F1

–17–

7. LT-B3621CL/B3621CW/B3661CL

Outdoor Unit Wiring Diagram

NOTE

BL : BLUE

BK : BLACK

BR : BROWN

OR : ORANGE GN/YL : GREEN/YELLOW

52C

TMo

Co

MAGNETIC CONTACTOR

TERMINAL BLOCK

RUN CAPACITOR FOR FMo

TM

CM

CR

MAIN TERMINAL BLOCK

COMPRESSOR

RUN CAPACITOR FOR CM

F1

FMo

FUSE (250V, 5A)

OUTDOOR FAN MOTOR

P/NO : 3854A30042N

RD : RED

WH : WHITE

YL : YELLOW

WIRING OF FIELD

(CONNECTING WIRE)

TM

POWER SUPPLY

BK

Cr

52C

BK

BK

L1T1L2T2B

A

WH

BK

WH

BK

WH

BL BK BK

RD

R

C

S

CM

WH

WH

GN/YL

WH

BL

BK

1(N)2(L

)

Co

OR YLBLBK OR YLBLBK

Co

FMo1 FMo2

THMO

C

H

L

GN/YL

TO INDOOR

3(N)

4(L)

5

6

7

F1

–18–

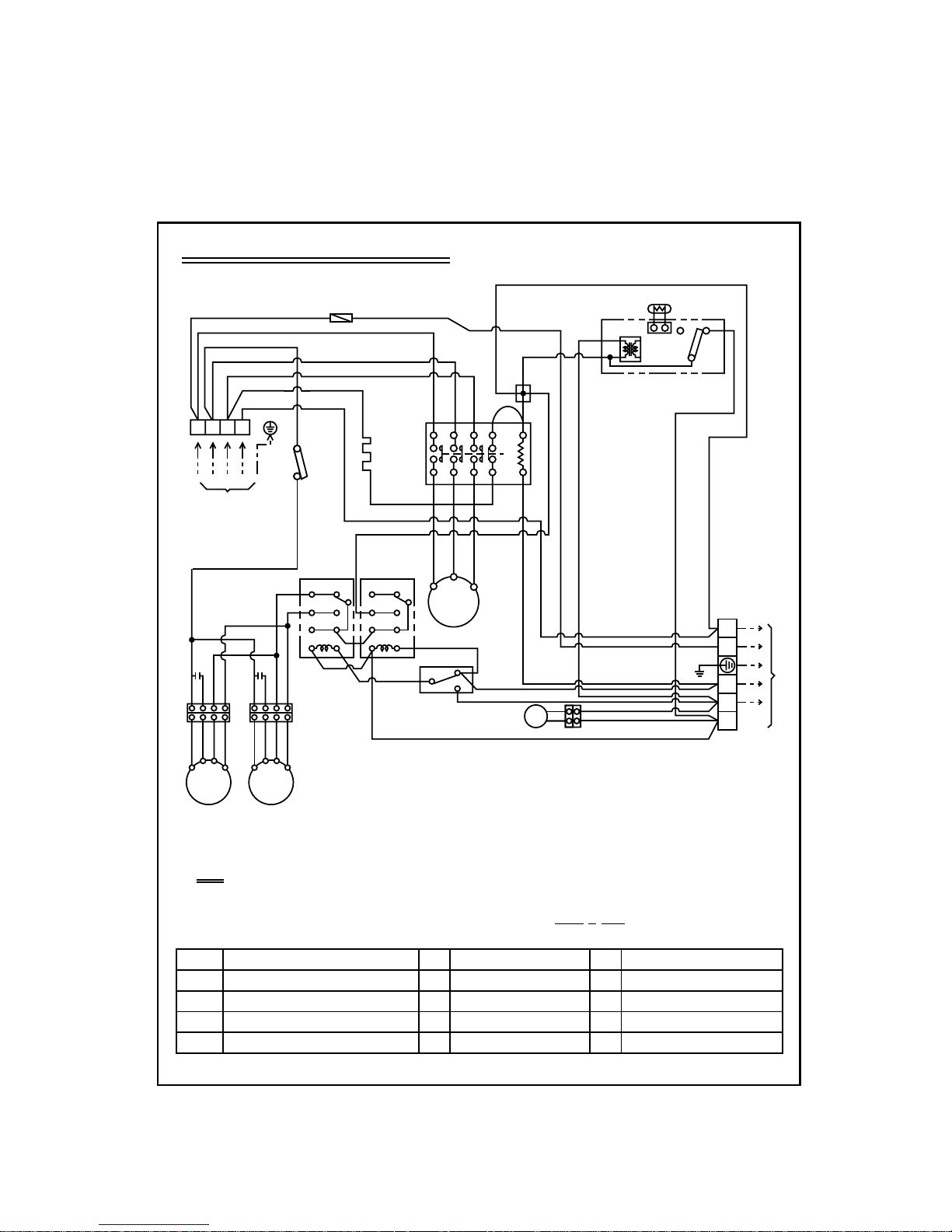

8. LT-B3621HL/B3621HW/B3661HL

Outdoor Unit Wiring Diagram

NOTE

BL : BLUE

BK : BLACK

BR : BROWN

OR : ORANGE GN/YL : GREEN/YELLOW

63H2

C TH

20SV

52C

Cr

HIGH PRESSURE SWITCH FOR HEATING

THERMISTOR FOR PIPE TEMP.

REVERSING COIL

MAGNECTIC CONTACTOR

RUN CAPACITOR FOR CM

TM

52F1

CM

Co

FMo

MAIN TERMINAL BLOCK

RELAY FOR FMo

COMPRESSOR

RUN CAPACITOR FOR FMo

OUTDOOR FAN MOTOR

F1

DP

CH1

THMO

52F2

FUSE (250V, 5A)

DEICER PCB

CRANK CASE HEATER FOR CM

THEMOSTAT FOR COOLING

RELAY FOR FMO CONTROL.

P/NO : 3854A30042L

RD : RED

WH : WHITE

YL : YELLOW

WIRING OF FIELD

(CONNECTING WIRE)

TM

POWER SUPPLY

BK

63H2

Cr

52C

CH1

BK

BK BK

BK

L1T1L2T2B

A

WH

BK

TNS

NO

C TH

NC

D.P

WH

T/B1

BK

WH

WH

BK

WH

BL BK BK

RD

R

C

S

CM

YL WH

WH

GN/YL

WH

BL

BK

1(N)2(L

)

Co

OR YLBLBK OR YLBLBK

Co

FMo1 FMo2

20SV

BKBKBK

BK

WH

YL

WH

YL

BL

BL

THMO

C

L

H

GN/YL

TO INDOOR

3(N)

4(L)

5

6

7

78

52F2

12

34

56

78

52F1

12

34

56

F1

–19–

Operation Details

(1) The function of main control

1. Time Delay Safety Control

• 3min The compressor is ceased for 3minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

• 5sec

Vertical louvers are delayed for 5 secs to be opened to prevent the frictional sound between louver and air flow.

• 30sec The 4-way valve is ceased for 30sec. to prevent abnormal noise when the Heating operation is OFF or

switched to the other operation mode while compress is off.

While compressor is running, it takes 3~5 seconds to switch.

2. Auto Swing Control

• This function is to swing the louver up and down automatically.

3. Air-Filter Checking Control

• 'Filter' sign will appear on the remote controller display and main body display when an air-filter is polluted. Then

clean the air-filter referring to Owners Manual.

4. Soft-Dry Operation

• The indoor fan speed is automatically set to the low, and fan speed control is not available because of already

being set to the best speed for Dry Operation by Micom Control.

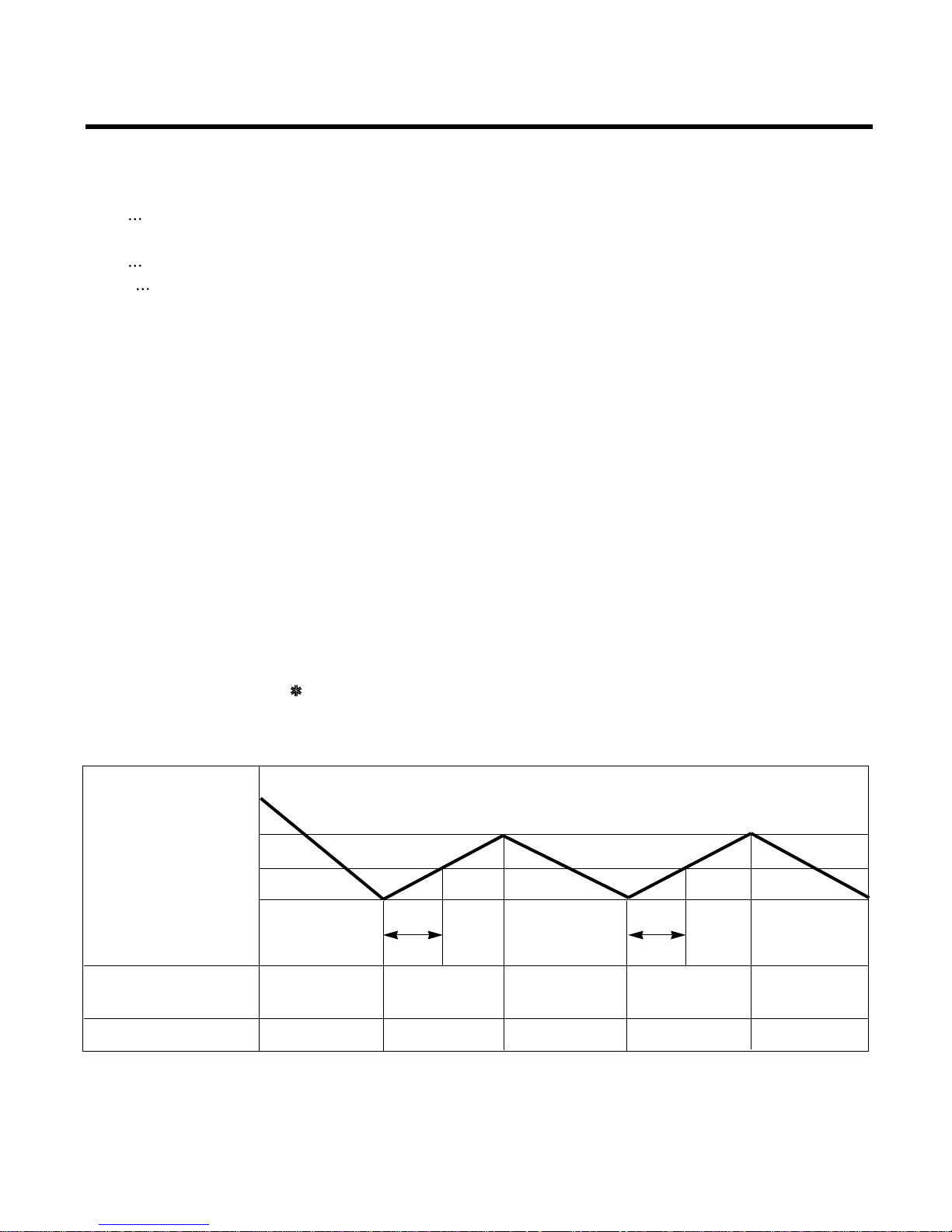

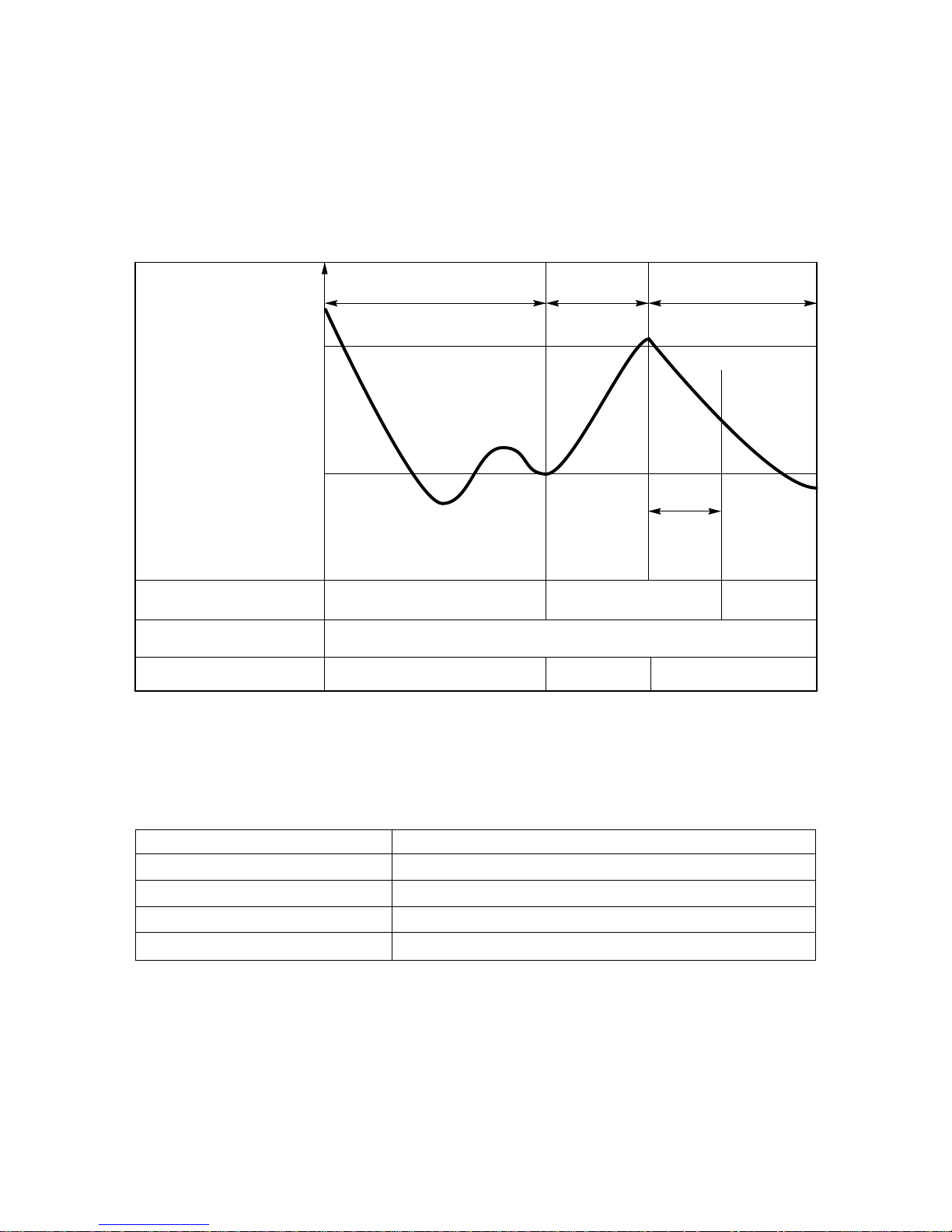

5. Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote con-

troller and the operation diagram is as follows.

Intake Air temp.

SET TEMP.+0.5°C

(COMP. ON)

SET TEMP

SET TEMP. -0.5°C

(COMP. OFF)

Selected Selected Selected

fan speed fan speed fan speed

COMPRESSOR ON OFF ON OFF ON

INDOOR FAN Low Low

More than

3 minutes

More than

3 minutes

–20–

Intake Air temp.

Setting temp.+3°C

(Compressor OFF)

Setting temp.

(Compressor ON)

INDOOR FAN

COMPRESSOR ON OFF ON OFF

A point; While the indoor Heat-Exchanger temperature is higher than 40°C fan operates at low speed, when

it becomes lower than 40˚C fan stops.

B point; When the indoor Heat-Exchanger temperature is higher than 42°C, fan operates at selected fan

speed, when it becomes lower than 39°C, the fan operates at low speed.

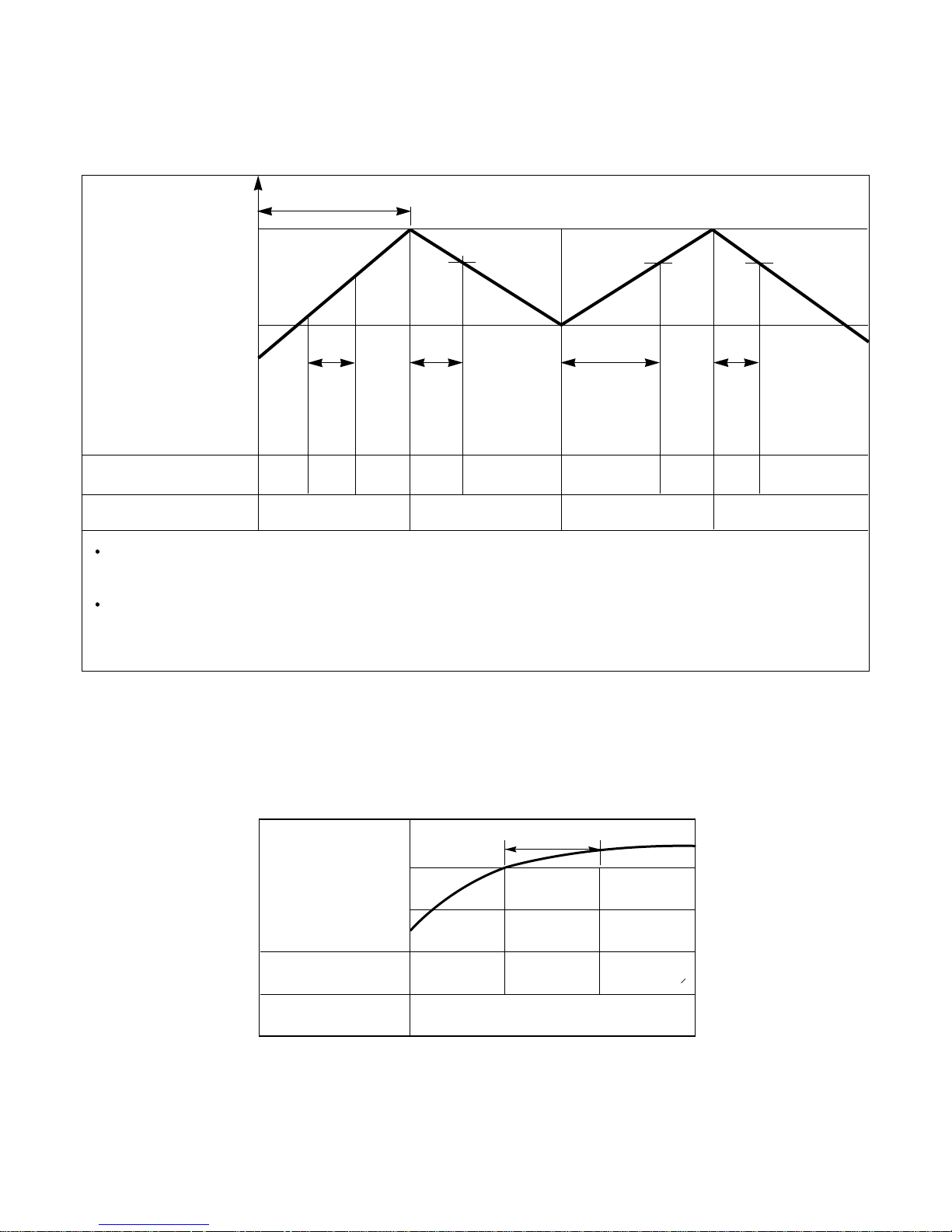

6. Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as follows.

(Hot Start)

Low

OFF

Selected

Fan Speed

minimum 3min

Selecting fan

speed

LowLowLow OFF

OFF

minimum

10sec.

1min

A

A

minimum

1min.

minimum

10sec.

B

7. Hot-Start Control

• The indoor fan stops until the evaporator piping temperature reaches to 25°C.

• If the evaporator piping temperature drops below 22°C, indoor fan stops again.

• The operation diagram is as follows.

PIPING

TEMPERATURE

1min

COMPRESSOR

INDOOR FAN

ON

OFF LOW

Selected

fan speed

22°C

25°C

–21–

8. Defrost Control

• Defrost control is available 45 minutes later since heating mode operation started, and it will not prolong over

10 minutes.

• Defrost control is carried out when the outdoor pipe temp. falls below -6°C for more than 3 minutes after 45

minutes passed from starting of heating operation.

• Defrost ends after 10 minutes passed from starting of defrost operation or when the outdoor pipe temp. rises

over 12°C after 5 minutes passed from starting of defrost.

9. Self-Diagnosis Function

• 'CH' will flash in the remote controller display when a problem occurs.

• Correct the 'FAULT MESSAGES' as shown in the table below before restarting operation.

• During the normal operation 'CH' won't be displayed in the remote controller.

Remote controller LCD FAULT MESSAGES

CH 01 Indoor temperature thermistor error

CH 02 Indoor piping thermistor error

CH 03 Indoor/Outdoor unit communication error

CH 04 Water level float switch error

More than 45 minutes

of heating operation

Within

9min. 45sec.

ON OFF

ON

ON

ON OFF

COMPRESSOR

4-WAY VALVE

INDOOR FAN

-6°C ON

12°C OFF

The outdoor

piping Temp.

More than 10 min.

running of compressor

More than 45 minutes

of heating operation

HOT-

START

ON

–22–

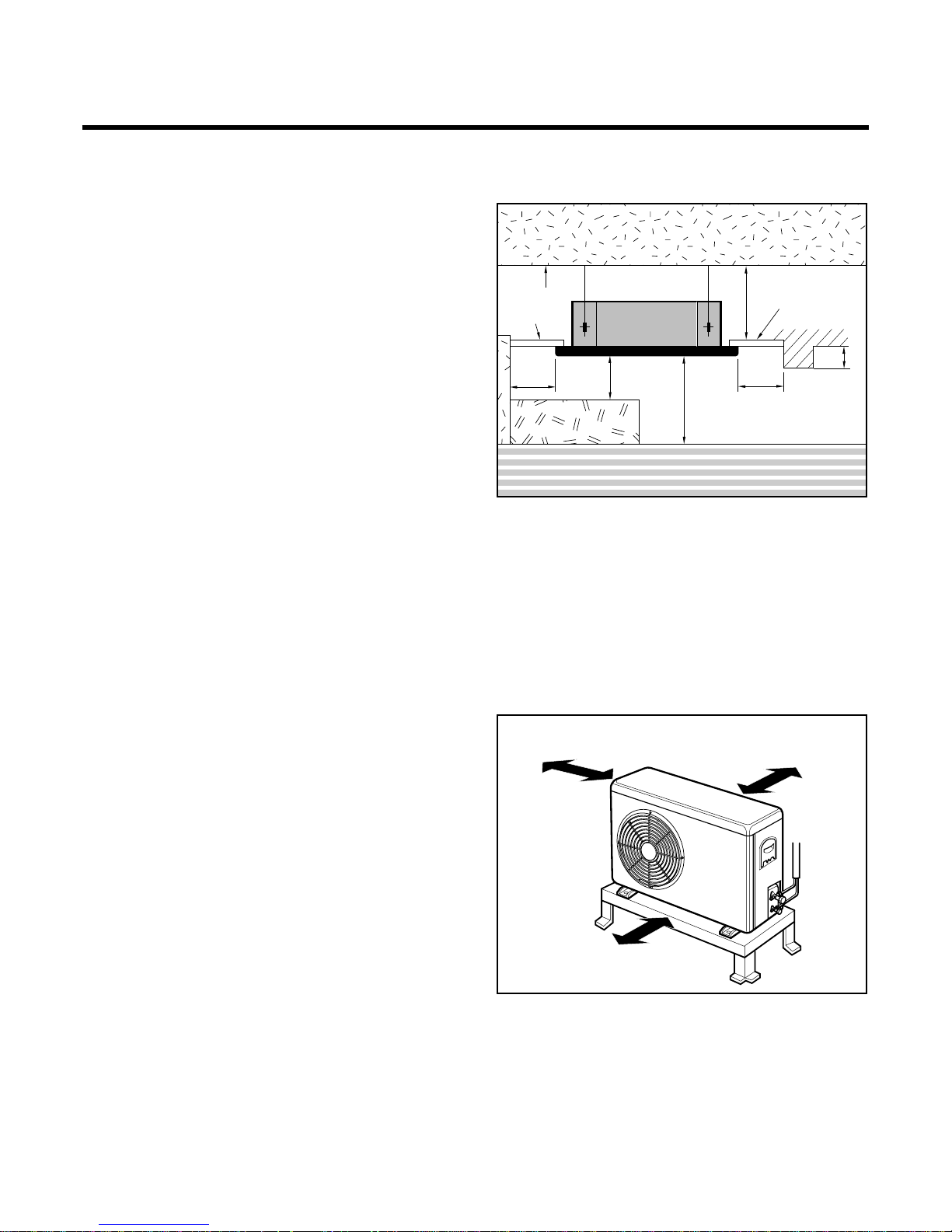

Installation of Indoor, Outdoor Unit

1. Selection of the best location

1) Indoor unit

• There should not be any heat source or steam

near the unit.

• There should not be any obstacles to the air circulation.

• A place where air circulation in the room will be

good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into con-

sideration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from the

wall, ceiling, or other obstacles.

• The indoor unit must have the maintenance

space around.

2) Outdoor unit

• If an awning is built over the unit to prevent direct

sunlight or rain exposure, be careful that heat

radiation from the condenser is not restricted.

• There should not be any animals or plants which

could be affected by hot air discharged.

• Ensure the spaces indicated by arrows from the

wall, ceiling, fence or other obstacles.

More than 10cm

More than 10cm

More than 70cm

Unit:cm

Ceiling

Ceiling Board

Ceiling Board

30 or more

Above 250

300 or less

100

or more

50 or

more

50 or

more

30 or less

Floor

–23–

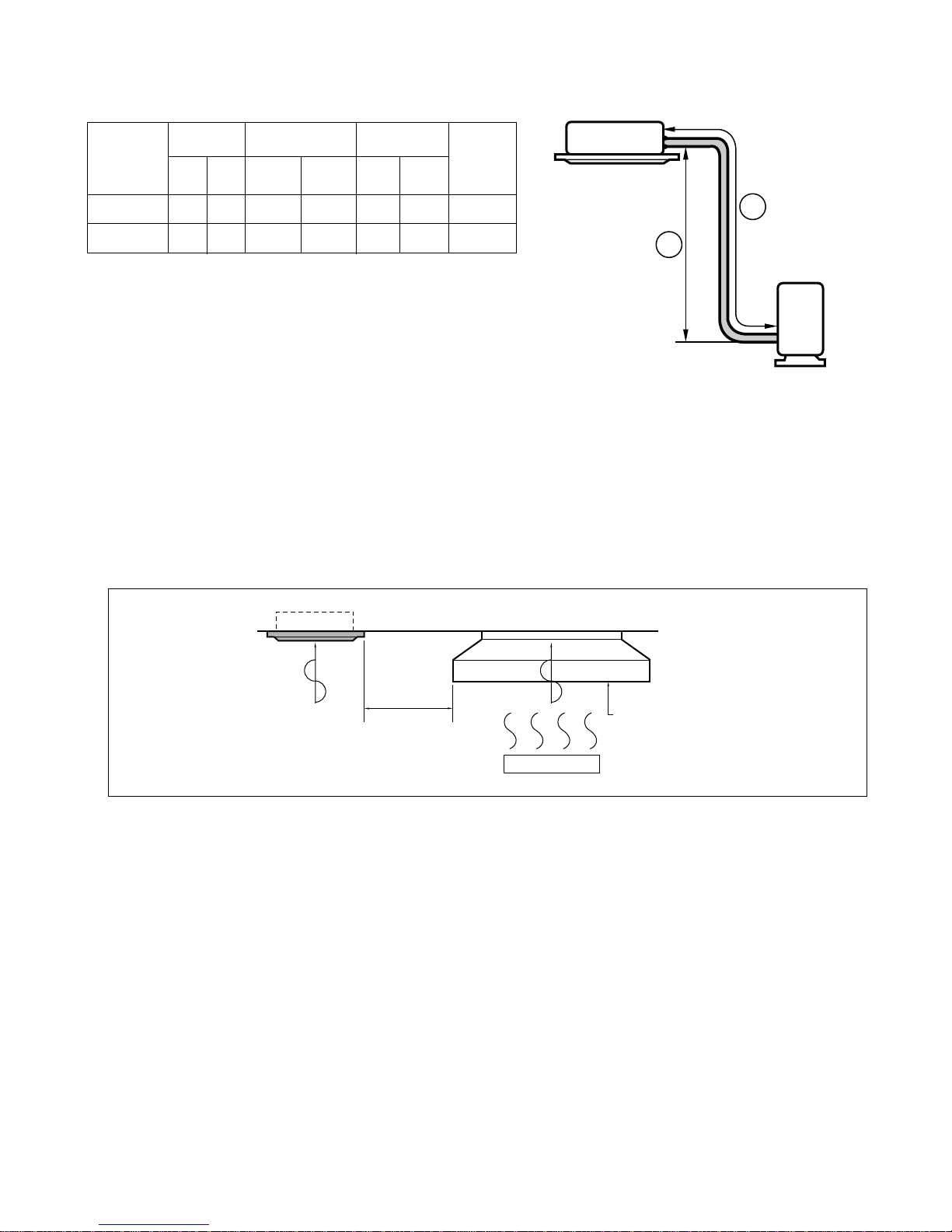

Indoor unit

Outdoor unit

B

A

• Rated performance for refrigerant line length of: 5m

• If 24K or 28K Model is installed at a distance of 15m, 500g of refrigerant

should be added ....................................................(15-5)x50g

3) Piping length and the elevation

MODEL

24K, 28K, 30K BTU

5/8" 3/8" 5 20

36

K BTU

3/4" 3/8" 5 25

GAS LIQUID

515 50

520 70

Elevation B(m)

Length A(m)

* Additional

refrigerant

(g/m)

Pipe Size

Rated Rated

Max. Max.

NOTE:

• Avoid the following installation location.

1. Such places as restaurants and kitchen where considerable amount of oil steam and flour is generated.

These may cause heat exchange efficiency reduction, or water drops, drain pump mal-function.

In these cases, take the following actions;

• Make sure that ventilation fan is enough to cover all noxious gases from this place.

• Ensure enough distance from the cooking room to install the air conditioner in such a place where it may

not suck oily steam.

2. Avoid installng air conditioner in such places where cooking oil or iron powder is generated.

3. Avoid places where inflammable gas is generated.

4. Avoid place where noxious gas is generated.

5. Avoid places near high frequency generators.

Use the ventilation fan

for smoke-collecting

hood with sufficient

capacity.

Cooking table

Air conditioner

Take enough

distance

–24–

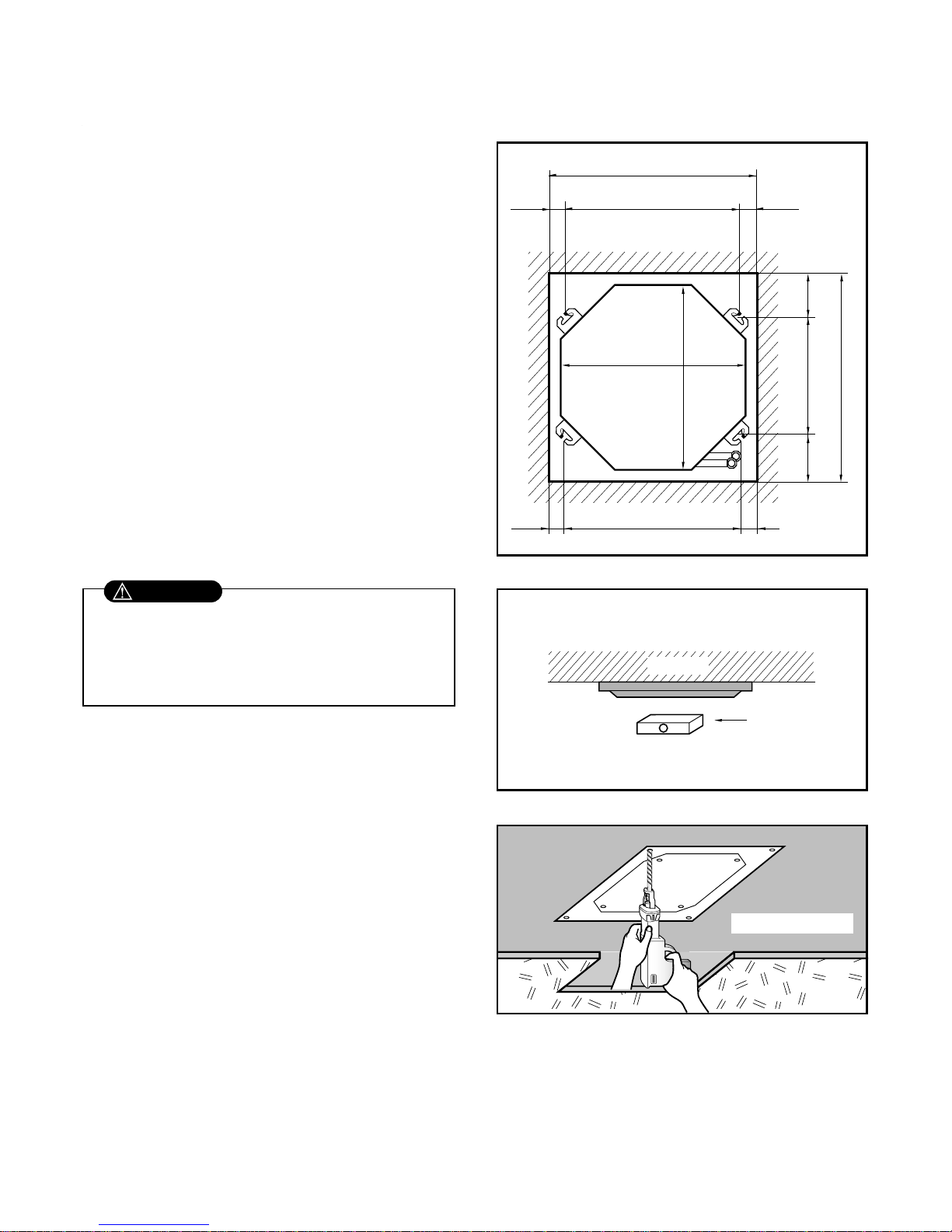

• The dimensions of the paper model for installing are

the same as those of the ceiling opening dimensions.

• Select and mark the position for fixing bolts and piping hole.

• Decide the position for fixing bolts slightly tilted to

the drain direction after considering the direction of

drain hose.

• Drill the hole for anchor bolt on the wall.

Level gauge

Unit:mm

Ceiling

800 Unit size

800 Unit size

720 (Hanging bolt)

6060

840 (Ceiling opening)

840 (Ceiling opening)

624(Hanging bolt)

108

108

600

120

120

Ceiling board

• This air-conditioner uses a drain pump.

• Install the unit horizontly using a level gauge.

• During the installation, care must be taken not to

damage electric wires.

CAUTION

2. Ceiling opening dimensions and hanging bolt location

Loading...

Loading...