Page 1

HOMEOWNER'S CARE AND

OPERATION INSTRUCTIONS

DIRECT VENT MERIT®

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNINGS

• Hot! Do not touch! The glass and

surfaces of this appliance will be hot

during operation and will retain heat

for a while after shutting off the appliance. Severe burns may result.

Carefully supervise children in the

•

same room as appliance.

•

If small children are present in the home, it is

recommended that this appliance be fi tted with

a screen door or screen panel kit. See Pages

14 & 15 for ordering information.

WARNING: IF THE INFORMATION IN THIS MANUAL

IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

FOR YOUR SAFETY: Do not store or use gasoline

or other fl ammables or liquids in the vicinity of

this or any other appliance.

FOR YOUR SAFETY: What to do if you smell gas:

LMDV-33/35/40 SERIES

DIRECT-VENT GAS FIREPLACE HEATERS

P/N 875,028M REV. D 05/2006

MODELS

Millivolt Models Electronic Models

LMDVT-3328CNM

LMDVT-3328CPM

LMDVR-3328CNM

LMDVR-3328CPM

A French manual is available upon request. Order P/N 875,028CF

Ce manuel d’installation est disponible en francais, simplement en

faire la demande. Numéro de la pièce 875,028CF

AVERTISSEMENT: ASSUREZ-VOUS DE BIEN

SUIVRE LES INSTRUCTIONS DONNÉ DANS CETTE

NOTICE POUR RÉDUIRE AU MINIMUM LE RISQUE

D'INCENDIE OU POUR ÉVITER TOUT DOMMAGE

MATÉRIEL, TOUTE BLESSURE OU LA MORT.

POUR VOTRE SÉCURITÉ: Ne pas entreposer ni

utiliser d'essence ni d'autre vapeurs ou liquides

infl ammables dans le voisinage de cet appareil ou

de tout autre appareil.

LMDV-3530CNM

LMDV-3530CPM

LMDV-4035CNM

LMDV-4035CPM

LMDVT-3328CNE

LMDVR-3328CNE

LMDV-3530CNE

LMDV-4035CNE

• DO NOT light any appliance.

• DO NOT touch any electrical switches.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow your gas suppliers

instructions.

• If your gas supplier cannot be reached, call

the fi re department.

Installation and service must be performed by

a qualifi ed installer, service agency or the gas

supplier.

OTL Report No. 116-F-31-5

POUR VOTRE SÉCURITÉ: Que faire si vous sentez

une odeur de gaz:

• Ne pas tenter d'allumer d'appareil.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones se trouvant dans le batiment où vous vous trouvez.

• Evacuez la piéce, le bâtiment ou la zone.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le service dos incendies.

L'installation et service doit être exécuté par un

qualifi é installeur, agence de service ou le fournisseur de gaz.

Page 2

SAFETY & WARNIING

INFORMATION

IMPORTANT: PLEASE READ THIS

MANUAL IN ITS ENTIRETY AND

UNDERSTAND THESE RULES TO

FOLLOW FOR SAFETY.

WARNING

If the information in this

manual is not followed

exactly, a fi re or explosion may result causing property damage,

personal injury or loss

of life.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause injury

or property damage. Refer to

this manual. For assistance or

additional information consult

a qualified installer, service

agency or the gas supplier.

WARNING

Children and adults should be

alerted to the hazards of high

surface temperatures. Use

caution around the appliance

to avoid burns or clothing ignition. Young children should be

carefully supervised when they

are in the same room as the

appliance.

Note: An Optional Screen Panel

for the glass is available (see

Pages 14 & 15 for ordering

information).

WARNING

Do not place clothing or other

fl ammable materials on or near

this appliance.

AVERTISSEMENT

Surveiller les enfants. Garder les

vêtements, les meubles, l'essence

ou autres liquides à vapeur infl ammables à cote de l'appareil.

WARNING

Do not use these appliances if

any part has been under water.

Immediately call a qualifi ed,

professional service technician

to inspect the appliances and to

replace any parts of the control

system and any gas controls

which have been under water.

AVERTISSEMENT

Ne pas se servir de cet appareil

s'il a été plongé dans l'eau,

complètement ou en partie.

Appeler un technicien qualifi é

pour inspecter l'appareil et remplacer toute partie du système de

contrôle et toute commande qui

ont été plongés dans l'eau.

WARNING

Do not attempt to alter or modify

the construction of the appliance

or its components. Any modifi cation or alteration may void

the warranty, certifi cation and

listings of this unit.

WARNING

Failure to comply with the installation and operating instructions

provided in this document will

result in an improperly installed

and operating appliance, voiding

its warranty. Any change to this

appliance and/or its operating

controls is dangerous. Improper

installation or use of this appliance can cause serious injury or

death from fi re, burns, explosion

or carbon monoxide poisoning.

IMPORTANT

These appliances must not be

connected to a chimney or fl ue

serving a separate Solid-Fuel

burning appliance.

2

WARNING

Carbon monoxide poisoning:

early signs of carbon monoxide

poisoning are similar to the fl u

with headaches, dizziness and/or

nausea. If you have these signs,

obtain fresh air immediately.

Turn off the gas supply to the

appliance and have it serviced

by a qualifi ed professional, as it

may not be operating correctly.

WARNING

Any safety guard or screen

removed for servicing the appliance must be replaced prior to

operating the appliance.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

WARNING

This appliance is only for use with

the type of gas indicated on rating

plate. This appliance is not convertible for use with other gases,

unless a certifi ed kit is used.

AVERTISSEMENT

Cet appareil doit être utilisé

uniquement avec les types de

gaz indiqués sur la plaque signalétique. Ne pas l'utiliser avec

d'autres gaz sauf si un kit de

conversion certifi é est installé.

WARNING

These fi replaces are vented heaters. Do not burn wood or other

material in these appliances.

Page 3

CONGRATULATIONS!

In selecting this LENNOX Direct-Vent Gas Appliance you have chosen the fi nest and most

dependable fi replace to be found anywhere. Its a beautiful, prestigious alternative to a

wood burning fi replace. Welcome to a Family of tens of thousands of satisfi ed LENNOX

Fireplace Owners.

Please carefully read and follow all of the instructions found in this manual. Please pay

special attention to the safety instructions provided in this manual. The Homeowner's

Care and Operation Instructions included here will assure that you have many years of

dependable and enjoyable service from your LENNOX product.

TABLE OF CONTENTS

Safety & Warning Information ..........Page 2

Introduction ......................................Page 3

General Information ..........................Page 3

Gas Controls Access .........................Page 4

Operation/Care of Your Appliance .....Page 4

Variable Flame Adjustment ................Page 5

Maintenance ......................................Page 6

Front Glass Enclosure Panel,

Removal and Installation .................Page 6

Install Vermiculite, Volcanic Stone,

Embers & Logs .................................Page 8

Burner Flame Appearance & Sooting Page 11

Burner Flame Adjustments ................Page 12

Millivolt Appliance Checkout .............Page 12

Electronic Appliance Checkout ..........Page 12

Wiring Diagrams ...............................Page 13

Warranty ...........................................Page 13

Product Reference Information .........Page 13

Accessory Components ....................Page 14

Lighting Instructions – Millivolt ........Page 18

Lighting Instructions – Electronic .....Page 20

Maintenance Schedule ......................Page 22

Troubleshooting Guide – Millivolt .....Page 23

Troubleshooting Guide – Electronic ..Page 23

Replacement Parts List .....................Page 25

INTRODUCTION

The Fireplace models covered in this manual

are Direct-Vent sealed combustion gas fi replace

heaters designed for residential application.

Direct-Vent appliances operate with the combustion chamber completely isolated from the

indoor environment. All air for combustion is

brought in from the outside and exhaust gases

are vented through the same direct vent, co-axial

(intake/exhaust) vent system.

The Millivolt appliances have a millivolt gas

control valve with piezo ignition system provides

safe, effi cient operation. If any optional accessories which require electrical power are being

installed, the electrical power must be provided

at the time of appliance installation.

The Electronic appliances have an electronic

intermittent pilot system provides safe, effi cient

operation. External electrical power is required

to operate these appliances.

These appliances comply with National Safety

Standards and are tested and listed by OmniTest Laboratories (Report No. 116-F-31-5) to

ANSI ZZ21.88b-2003 (in Canada, CSA-2.33b-

2003), and CAN/CGA-2.17-M91 in both USA and

Canada, as vented gas fi replace heaters.

The Installation must conform to local codes

or, in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1/NFPA

54-latest edition, or the Natural Gas and

Propane Installation Code, CSA B149.1-latest

edition. The appliance, when installed, must

be electrically grounded in accordance with

local codes or, in the absence of local codes,

the latest edition of the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22.1 - latest editions.

GENERAL INFORMATION

Note: Installation and repair should be performed by a qualifi ed service person. The

appliance should be inspected annually by a

qualifi ed professional service technician. More

frequent inspections and cleanings may be

required due to excessive lint from carpeting,

bedding material, etc.

It is imperative that the control compartment,

burners and circulating air passage ways of

appliance be kept clean. See Maintenance

instructions on Page 6.

S'assurer que le brùleur et le compartiment des

commandes sont propres. Voir les instructions

d'installation et d'utilisation qui accompagnent

l'appareil.

Provide adequate clearances around air openings and adequate accessibility clearance for

service and proper operation. Never obstruct

the front openings of the appliance.

Due to high temperatures the appliance should

be located out of traffi c and away from furniture

and draperies. Locate furniture and window

coverings accordingly.

These fi replaces are designed as supplemental heaters. Therefore, it is advisable to have

an alternate heat source when installed in a

dwelling.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

These appliances are designed to operate on natural

gas or propane gas only. The use of other fuels or

combination of fuels will degrade the performance

of this system and may be dangerous.

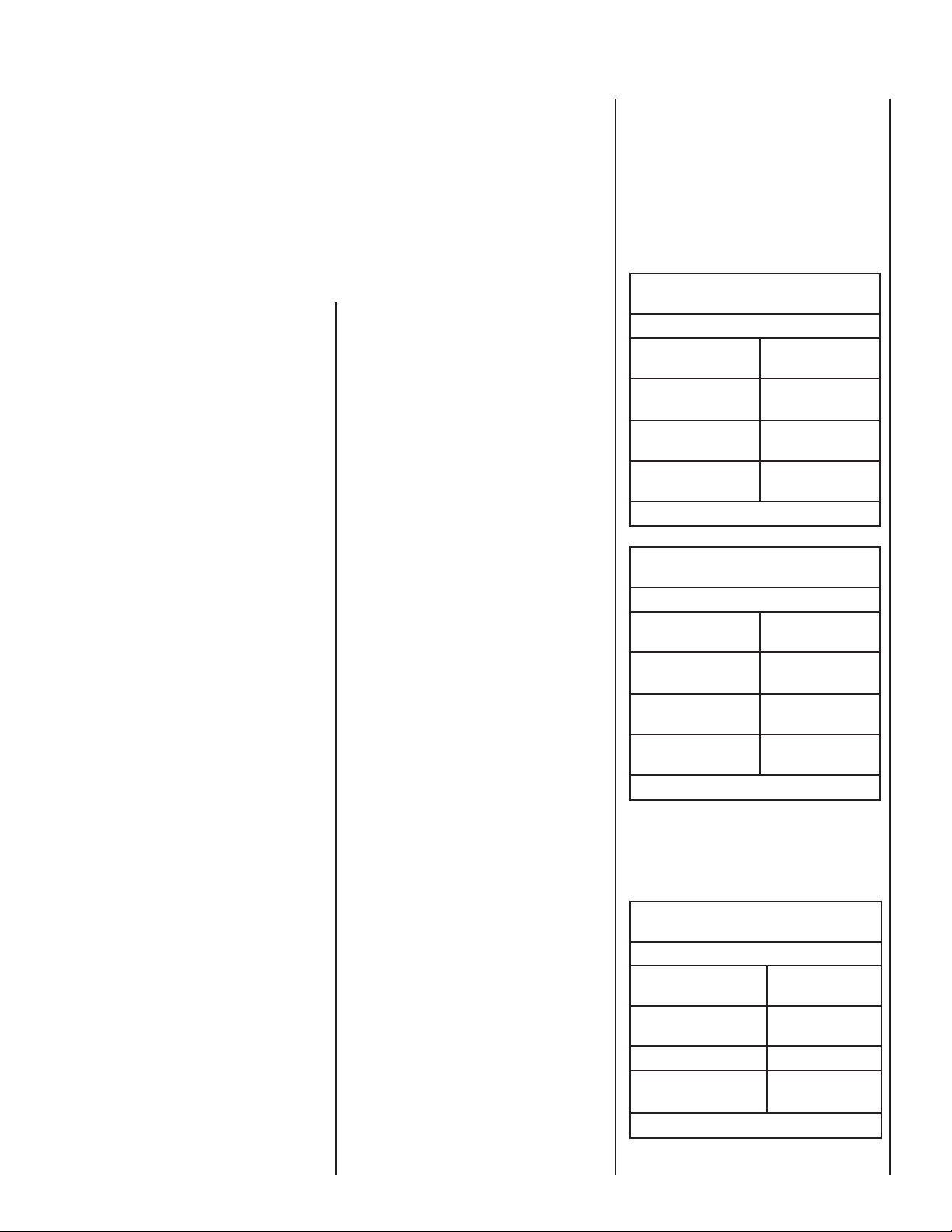

Millivolt Models - BTU Input

Millivolt models come standard with the mAnnually-modulated gas valve; fl ame appearance and

heat output can be controlled at the gas valve.

The BTU Input for millivolt models is shown in

Tables 1 & 2:

Input (BTU) MAnnually-Modulated Gas

Valves (millivolt models)

NATURAL GAS

Models Input Rate

(BTU/HR)

LMDVT-3328CNM

LMDVR-3328CNM

LMDV-3530CNM

LMDV-4035CNM

17,500 high

11,700 low

20,000 high

12,800 low

27,000 high

18,500 low

Table 1

Input (BTU) MAnnually-Modulated Gas

Valves (millivolt models)

PROPANE GAS

Models Input Rate

(BTU/HR)

LMDVT-3328CPM

LMDVR-3328CPM

LMDV-3530CPM

LMDV-4035CPM

17,500 high

14,000 low

20,000 high

15,200 low

27,000 high

21,500 low

Table 2

Electronic Models -

Electronic models have a fi xed rate gas valve.

The BTU Input for electronic models is shown

in Table 3:

Input (BTU) - Fixed Rate

(electronic models)

NATURAL GAS & PROPANE GAS

Models Input Rate

(BTU/HR)

LMDVT-3328CNE

LMDVR-3328CNE

LMDV-3530CNE 20,000

LMDV-4035CNM

LMDV-4035CPM

17,500

28,000

Table 3

3

Page 4

Gas Pressure -

Tables 4, 5 and 6 show the appliances' gas

pressure requirements.

Inlet Gas Supply Pressure

(all models)

Fuel # Minimum Maximum

Natural Gas

Propane

5.0" WC

(1.24 kPa)

11.0" WC

(2.74 kPa)

10.5" WC

(2.61 kPa)

13.0" WC

(3.23 kPa)

Table 4

Manifold Gas Supply Pressure

(millivolt models)

Fuel # Low High

Natural

Gas

Propane

(Lo) 2.2" WC

(.55 kPa)

(Lo) 6.3" WC

(1.57 kPa)

(Hi) 3.5" WC

(.87 kPa)

(Hi) 10.0" WC

(2.49 kPa)

Table 5

Manifold Gas Supply Pressure

(electronic models)

Fuel # Fixed

Natural Gas

Propane

3.5" WC

(.87 kPa)

10.0" WC

(2.49 kPa)

Table 6

Test gauge connections are provided on the

front of the millivolt gas control valve, identifi ed

IN for the inlet and OUT for the manifold side

(see Figures 4 or 5 on Page 5). A 1/8" NPT

Test gauge connection is provided at the inlet

and outlet (manifold) ports on the electronic gas

control valve (see Figure 3 on Page 5).

These appliances must be isolated from the

gas supply piping system (by closing their

individual manual shut-off valve) during any

pressure testing of the gas supply piping

system at test pressures equal to or less than

1/2 psig (3.5 kPa).

These appliances and their individual shut-off

valves must be disconnected from the gas

supply piping system during any pressure

testing of that system at pressures greater

than 1/2 psig (3.5 kPa).

Orifi ce Sizes - Sea Level to High Altitude

(All Models): These appliances are tested and

approved for installations at elevations of 0-4500

feet (0-1372 meters) above sea level using the

standard burner orifice sizes (marked with an

"*" in Table 7).

4

At the time of installation, it must be determined

if the appliance needs to be derated. Contact

your local gas supplier for deration requirements

for your area.

Deration - At higher elevations, the amount of

BTU fuel value delivered must be reduced by

either using gas that has been derated by the gas

company or by changing the burner orifi ce to a

smaller size as regulated by the local authorities

having jurisdiction and by the (USA) National

Fuel Gas Code NFPA 54/ANSI Z223.1 - latest

edition or, in Canada, the CAN1-B149.1 and .2

codes - latest edition.

Burner Orifi ce Sizes

Elevation 0-4500 feet ( 0-1372 meters)

Model

Series

LMDVT-3328

LMDVR-3328

LMDV-3530

LMDV-4035

* Standard size installed at factory

• Part /Cat. Number

Natural

Gas

drill size

(inches)

#45 (.082")

39L66 •

#44 (.086")

60J80 •

#37 (.104")

24M10 •

*

*

*

Propane

Gas

drill size (inches)

1.2 mm (.048")

99K78 •

#55 (.052")

19L52 •

1/16" (.0625")

21L01 •

*

*

*

Table 7

Burn-in Period

During the fi rst few fi res of this appliance there

will be some odor due to the curing of the

paint and burning off of lubricants used in the

manufacturing process.

Depending on your use, the burn-in period may

take a few hours or a few days.

KEEP YOUR HOUSE WELL VENTILATED

DURING THE CURING PROCESS. THE ODOR

AND HAZE EMITTED DURING THE CURING

PROCESS CAN BE QUITE NOTICEABLE AND

MAY SET OFF A SMOKE DETECTOR.

If an optional blower is installed, Do not turn it

on during the Burn-In period.

A white fi lm may develop on the glass front

during the fi rst few fi res as part of the curing

process. The glass should be kept clean during

the fi rst two weeks of use to prevent the fi lm from

baking on (making it very diffi cult to remove).

See Cleaning Glass on Page 6.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

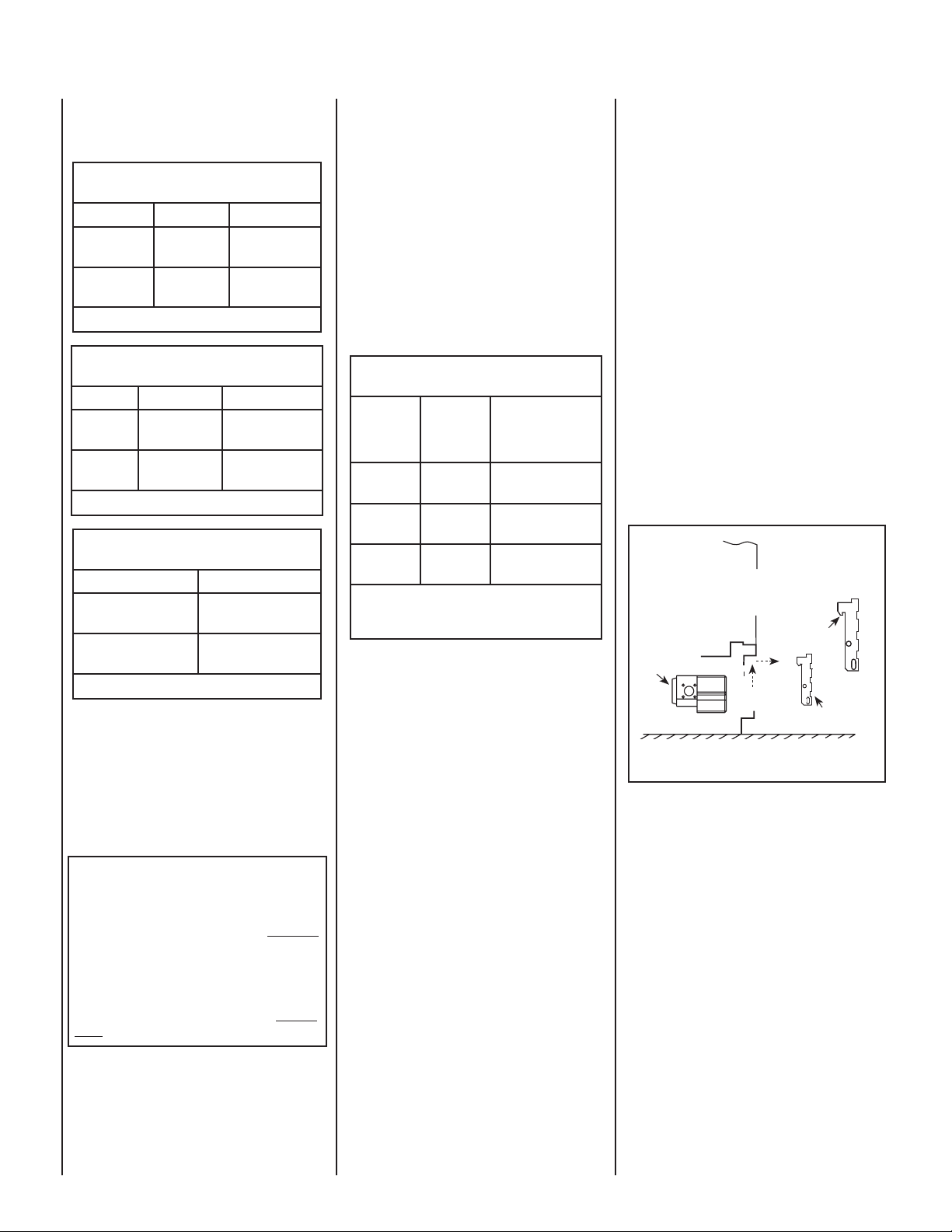

Gas Controls/Control Compartment

Access

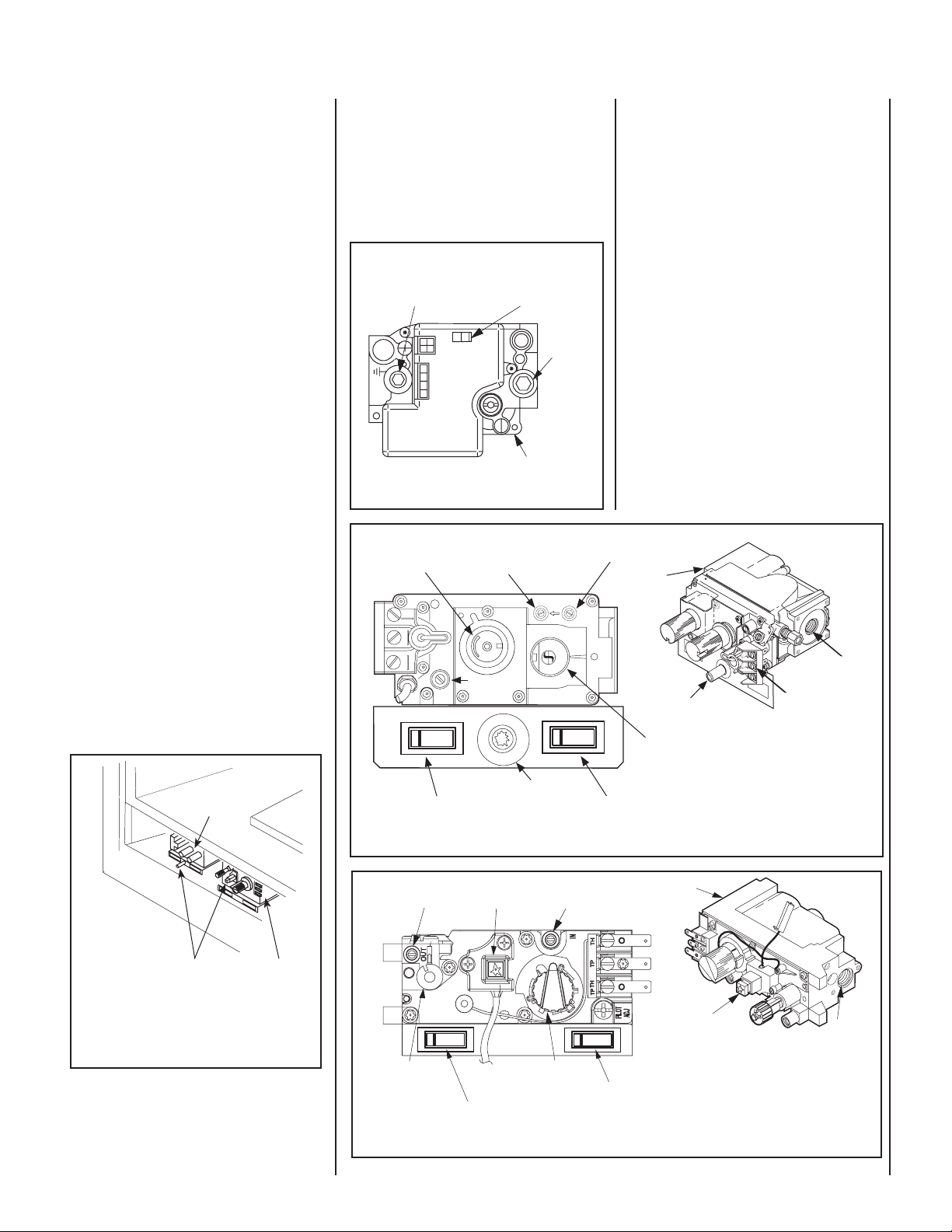

The gas controls can be found behind the control

compartment access door.

Removing Control Compartment Door:

Open the door by gently liftint it upward until the

hook catches on boths sides clear the locating

slots. Then pull door out to remove.

On millivolt systems, the piezo igniter, HI/LO

fl ame adjustment knob, and pilot and main

gas OFF/ON control knob are located below

the glass panel enclosure. The gas valve for

electronic systems is also located below the

glass enclosure panel. See Figure 1.

Reinstalling Control Compartment Door:

To reinstall, insert the hook catches on each side

of the door into the corresponding slots in the

control compartment opening, then gently push

forward and slide down until it locks in place.

Lift the Lower Control

OPENING CONTROL

COMPARTMENT DOOR

Control Valve

Compartment Door

up and pull out to

remove.

Hook Catch

Out

Up

Lower Control

Compartment Door

Figure 1

OPERATION AND CARE OF YOUR

APPLIANCE

The standard controls for appliance operation

are located behind the panel below the appliance front glass enclosure panel (see Figure

1). Optional control switches are also available

(see Page 14 - Remote Wall Switch, Remote

Control or Wall Thermostat).

Operation of millivolt and electronic gas control systems are different. Before lighting and

operating your appliance determine if you have

a millivolt or electronic appliance. Familiarize

yourself with the gas control valve that your

appliance uses. Refer to Figure 1 for access

to the gas control valve.

Page 5

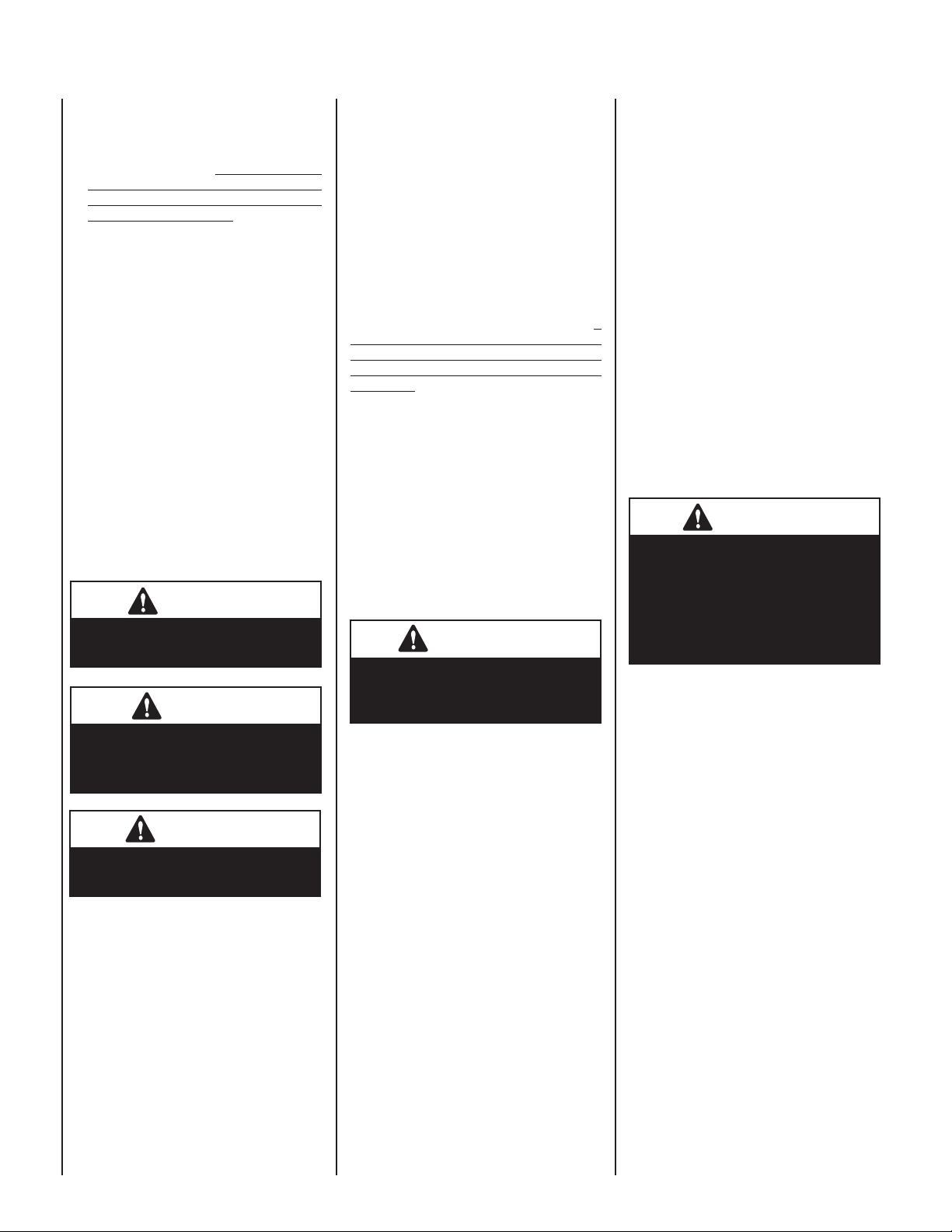

Millivolt Appliances - Appliances with

Millivolt systems will be fi tted with the gas

control valve shown in Figures 4 or 5.

Electronic Appliances - Appliances with

electronic systems will be fi tted with the

electronic valve shown in Figure 3.

Millivolt Appliances - To light millivolt appliances refer to the detailed lighting instructions

found on Pages 18 & 19 . Millivolt appliance

lighting instructions may also be found on the

pull out lighting instruction labels attached to

the gas control valve.

Millivolt appliances are fi tted with an OFF/ON

Rocker Switch located behind the control

compartment access door, below the appliance front glass enclosure panel (see Figure 2

for location). Once the pilot is lit, the OFF/ON

rocker switch will control the appliance OFF/ON

burner operation. To operate: Toggle the switch

between its ON and OFF positions.

If your millivolt appliance is equipped with an

optional remote switch kit (wall switch, remote

control or wall thermostat) and the pilot is lit,

the appliance main burner may be turned on

and off using the optional switch. When using

an optional remote switch, turn off the standard

OFF/ON switch.

Note: To prevent excessive resistance in burner

circuit (which can cause burner operation problems), only one burner control switch should be

wired to valve. Therefore, if an optional control

switch is installed, the standard Off/On switch

and wires should be removed.

SIT Gas Valve

Electronic Appliances -

To light electronic appliances refer to the detailed

lighting instructions found on Pages 20 & 21

of these instructions. Electronic appliance

lighting instructions may also be found on the

pull out lighting instruction labels attached to

the gas control valve.

Honeywell Electronic Gas Valve

Manifold Pressure

Port

I

G

N

I

T

ER

Figure 3

HI/LO Variable

Flame Height

Adjustment

T

P

T

H

T

P

T

H

OFF

Optional Burner OFF/ON

Rocker Switch

Figure 4

ON/OFF Switch

C

O

N

T

R

NO

O

FFO

L

Electronic Gas

Control Valve

Manifold Pressure Tap

I

H

L

W

O

Pilot Adjustment

P

I

L

O

Screw

T

ON

Piezo Igniter

Inlet

Pressure

Port

NI

PSI

OUT

F

F

O

P

I

L

O

ti

T

O

N

OFF

Inlet Pressure Tap

IN

ON

Optional Blower OFF/ON

Rocker Switch

If your electronic appliance is equipped with an

optional remote wall switch or remote control kit

the appliance main burner may be turned on and

off with the wall switch or remote control.

If your electronic appliance is not equipped

with a wall switch or remote control, the main

burner must be turned off and on with the gas

control switch. Toggle the switch from ON to

OFF to operate the main burner .

Variable Flame Height Adjustment

(Millivolt Appliances only)

1. All Millivolt appliances are equipped with a

variable gas control valve. Flame height for

these models may be adjusted through a

range between fi xed low and high settings

while the appliance is in operation. Adjust

the fl ame height as desired after lighting the

appliance by rotating the variable adjustment

control knob (HI/LO) located on the front of

the valve (refer to Figures 4 & 5).

2. During the fi rst initial burns of these appli-

ances, there will be some odor emitted (see

Burn-In Period on Page 4).

Gas

Inlet

Gas

Outlet

Piezo Igniter

Main Gas

Control Knob

OFF/PILOT/ON

Terminals

TPTH,TP & TH

SIT Millivolt Gas Valve

Shown with control

compartment door

removed

Piezo Igniter

Honeywell

Gas Valve

Sit and Honeywell Millivolt Gas Valve

Showing Piezo Igniter Location (Each Unit is

Equipped with Only One of these Gas Valves)

Figure 2

Manifold Pressure

Piezo Igniter

Tap

H

I

O

L

ON

OFF

HI/LO Variable

Flame Height

Adjustment

Optional Burner OFF/ON

Rocker Switch

Figure 5

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Inlet Pressure Tap

F

F

T

O

O

L

I

P

N

O

Main Gas

Control Knob

OFF/PILOT/ON

Gas

Outlet

ON

OFF

Optional Blower OFF/ON

Rocker Switch

Piezo Igniter

Gas

Inlet

Honeywell Millivolt Gas Valve

5

Page 6

3. Keep the lower control compartment clean

by vacuuming or brushing at least twice a

year. More frequent cleaning may be required

due to excessive lint from carpeting, bedding

materials, pet hair, etc. It is very important

that the control compartments, burners

and circulating air passageways of the

appliance are kept clean.

4. Always turn off gas to the pilot (millivolt

appliances) and let the appliance cool down

before cleaning. Before re-lighting, refer

to the lighting instructions in this manual.

Lighting instructions may also be found

on the pull out lighting instruction labels

attached to the gas control valve.

5. Always keep the appliance area clear and

free from combustible materials, gasoline

and other fl ammable liquids.

6. Remember, Millivolt appliances have a continu-

ous burning pilot fl ame. Exercise caution when

using products with combustible vapors.

MAINTENANCE

(See Maintenance Schedule, Page 22)

Refer to the maintenance schedule for maintenance

tasks, procedures, periodicity and by whom they

should be performed. Always verify proper operation of the appliance after servicing.

WARNING

Turn off gas and electrical power

before servicing the appliance.

CAUTION

Wear gloves and safety Glasses

for protection while doing

required maintenance

.

IMPORTANT

Always verify proper operation

after servicing.

Before re-lighting the fi replace, refer to the

lighting instructions in this manual. Instructions are also found on pull-out panels

located below the glass door in the control

compartment.

Inspect Venting System

The appliance and venting system should be

thoroughly inspected before initial use and

at least annually by a qualifi ed service technician (inspection should include ensuring that

exhaust or intake passages are unobstructed

and vent components are properly assembled

and not damaged).

If the venting system is disassembled for any

reason, a qualifi ed service technician should

follow vent installation instructions for proper

reassembly and proper sealing of the venting

system components. However, more frequent

periodic inspections and cleanings should be

performed by the homeowner.

Clean Lower Control Compartment

Keep lower control compartment clean by

vacuuming or brushing it out at least twice a

year (also clean the air venturi with a brush or

wire). More frequent cleaning may be required

due to accumulation of lint from carpeting,

bedding materials, pet hair, spider webs, etc. It

is very important that control compartments,

burners, circulating air passageways and air

venturi on the appliance are NOT obstructed

in any way.

Cleaning Glass

(see Front Glass Enclosure Panel, Removal and

Installation on Page 7)

Note: Clean glass after fi rst two weeks of operation (after Burn-In period is over) and then only

when necessary and when the fi replace is cool.

Wipe surface with clean, dampened, soft cloth.

Follow with dry, soft towel as desired. Take care

not to scratch the glass surface.

The viewing glass should be cleaned periodically to remove any build-up caused from the

following:

IMPORTANT

Do not use abrasive cleaners

on glass. Never clean the glass

when it is hot.

• During start-up, it is normal for condensation to form on the inside of the glass (this

condensation and fog will usually disappear

in a few minutes). The moisture can cause

lint, dust and other airborne particles to cling

to the glass surface.

• Initial curing of the high temperature paint

and burning off of lubricants used in the

manufacturing process may result in a fi lm

on the glass.

• A white coating may form on the glass as a

result of impurities and minerals in the fuel.

It is recommended that the glass be cleaned

two or three times during each heating season,

depending on the circumstances present. The

following cleaning solutions are approved for use

to clean glass:

• Non-ammonia based household cleaner

• 50%-50% mix of white vinegar & water

• Gas fi replace/stove glass cleaner

Inspect Glass Gasket - Visually inspect the

gasket on the backside of the glass enclosure

panels. The gasket surface must be clean, free

of irregularities and seated fi rmly.

Clean Logs And Burner

Carefully remove the logs (use care when handling the fi ber logs, as they become quite fragile

after curing). Vacuum out any foreign matter

(lint, carbon, etc). on the burner. Ensure the

burner ports are “open.” Remove any carbon

deposits from the under side of the logs using

a vacuum cleaner, or a soft bristled brush (i.e.

paint brush). Note: Improper positioning of

logs can create carbon build-up and will alter

the performance of the appliance.Replacing

Logs -

If the logs become damaged by accident or improper handling and need replacement, use only

the proper replacement logs from manufacturer

(see Pages 25 & 26 for ordering information).

Re-Install Embers, Logs and Vermiculite

- Carefully follow placement instructions on

Pages 8 to 10). All logs should fi t onto corresponding pins and/or log stoppers. This will

ensure a proper fl ame and safe combustion.

Inspect Wiring

Refer to wiring diagrams on Page 13.

WARNING

Label all wires prior to disconnection when servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper operation

after servicing.

Inspect and clean all wire connections. Ensure

that there is no melting or damage. Inspection

should include:

• Terminals at the Valve

• OFF/ON Switch

• (Optional Control Switch) Wall Thermostat,

Remote Control or Remote Wall Switch Kit

Inspect Burner Flame Appearance

Ensure that the burner flame appearance

resembles the fl ame shown in Figures 10 &

11 and as described in Flame Appearance and

Sooting on Page 11. The Homeowner must

contact a qualifi ed service technician at once

if any abnormal condition is observed.

Small Area Paint Touch-up

The fi nish of the appliance is a high-quality powdercoat. Only use factory supplied

powdercoat paint kit for touch-ups. Paint is

available at your local authorized Lennox Hearth

Products dealer, cat. no. 90L74. Never attempt

to paint a hot fi replace.

Do not attempt to repaint the appliance until the

fi nish is completely cured (see Burn-In Period

on Page 4). If the surface later becomes stained

or marred, it may be lightly sanded and touched

up with spray paint.

6

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 7

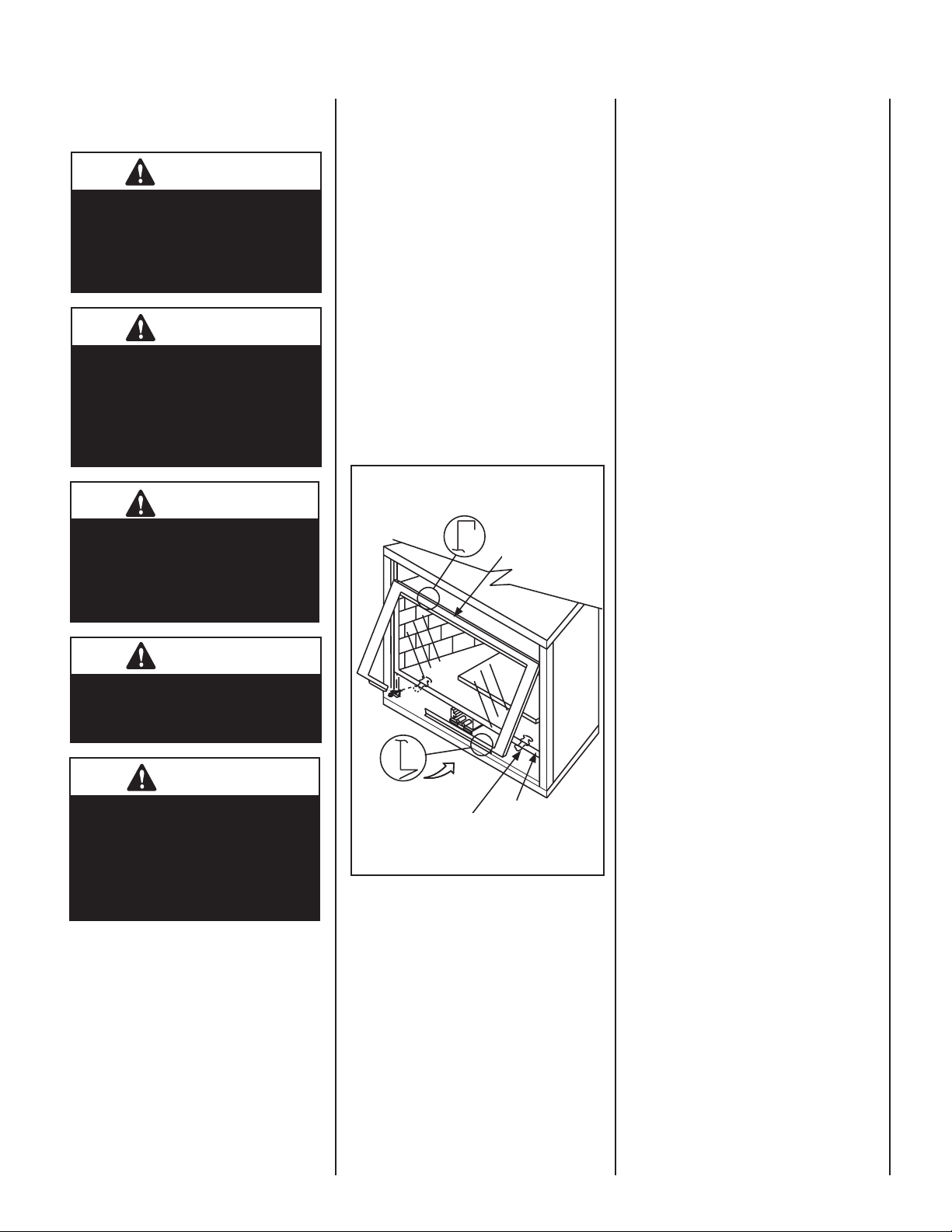

Front Glass Enclosure Panel, Removal

and Installation

WARNING

Do not operate appliance with the

glass front removed, cracked or

broken. Replacement of the glass

should be done by a licensed or

qualifi ed service technician.

WARNING

Do not attempt to substitute the

materials used on this door, or

replace cracked or broken glass

with any materials other than

those provided by the appliance

manufacturer.

WARNING

These are direct-vent appliances. They are

designed to operate only when the front glass

enclosure panel is installed. Generally the front

glass enclosure panel should not be removed

except to gain access to the components within

the fi rebox, and the appliance may only be operated without the front glass enclosure panel

in place for very brief periods of time during

appliance checkout and adjustment. Note: The

fl ame appearance will be diminished while the

front glass enclosure panel is removed.

During this appliance checkout and adjustment period, a potential safety hazard exists

- EXERCISE EXTREME CAUTION to prevent

the occurrence of any burn injuries from the

exposed fl ames or hot surfaces. Also note, that

while the front glass enclosure panel (or any of

the panels) is removed, the fl ame appearance

will appear to be smaller than normal.

Top Flange on

Glass Door

Removing Glass Enclosure Panels

(see Figure 6)

1. Remove the top louver assembly by pulling

it up and out.

2. Remove the control compartment access

door (see removal instructions on Page 4

- Removing Control Compartment Door).

3. Locate the two (2) latches at the top of the

control compartment. To disengage the two

latches from the bottom vee-fl ange of the

glass enclosure panel, reach for the handles

located towards the back of the latches and

pull the handles down toward the front of

the appliance.

4. Swing the bottom of the door out and raise

it slightly to lift the top fl ange of the door

frame away from the appliance.

Installing Glass Enclosure Panels

(see Figure 6)

Handle this glass with extreme

care! Tempered glass is susceptible to damage – do not scratch

or handle roughly while reinstalling the glass door frame.

WARNING

Do not attempt to touch the front

enclosure glass with your hands

while the fi replace is in use.

WARNING

The glass door of this appliance must only be replaced as a

complete unit as provided by the

manufacturer. Do not attempt to

replace broken, cracked or chipped

glass separately.

Glass Door

Bottom Vee-fl ange

Glass Door

Glass Door Latch

Firebox Floor

Figure 6 - INSTALLING GLASS DOOR

1. Visually inspect the gasket on the backside

of the glass panel. The gasket surface must

be clean, free of irregularities and seated

fi rmly.

2. Position the glass enclosure panel in front of

the fi rebox opening at a 45 degree angle and

engage the top fl ange over the lip at the top

of the fi rebox opening. See Figure 6.

3. Swing the glass enclosure panel down and

back. Ensure the gasket seats evenly as the

panel draws shut. Engage the Vee-fl ange at

the bottom of the panel with the latches and

close the latches to secure the panel.

4. Reinstall the control compartment door

see installation instructions on Page 4 ,

Reinstalling Control Compartment Door).

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

7

Page 8

INSTALL VERMICULITE, VOLCANIC

STONE, GLOWING EMBERS AND LOGS

1. Remove the front glass enclosure panel

(see Removing Glass Enclosure Panels on

this page).

2. Carefully remove the old logs, embers

volcanic stone and vermiculite from the

fi rebox. Handle logs carefully to prevent

breakage.

3. Install Vermiculite - Place some vermiculite

on the fi rebox fl oor around the burner (the

entire bag of vermiculite will NOT be used).

See Figures 8 & 9. DO NOT PLACE ANY

VERMICULITE ON THE BURNER. Mound

up a portion of the vermiculite in front of the

burner.

4. Install decorative volcanic stone - Sprinkle

the decorative volcanic stone (dark colored)

on top of the vermiculite (light colored) in a

pleasing pattern (see Figures 8 & 9).

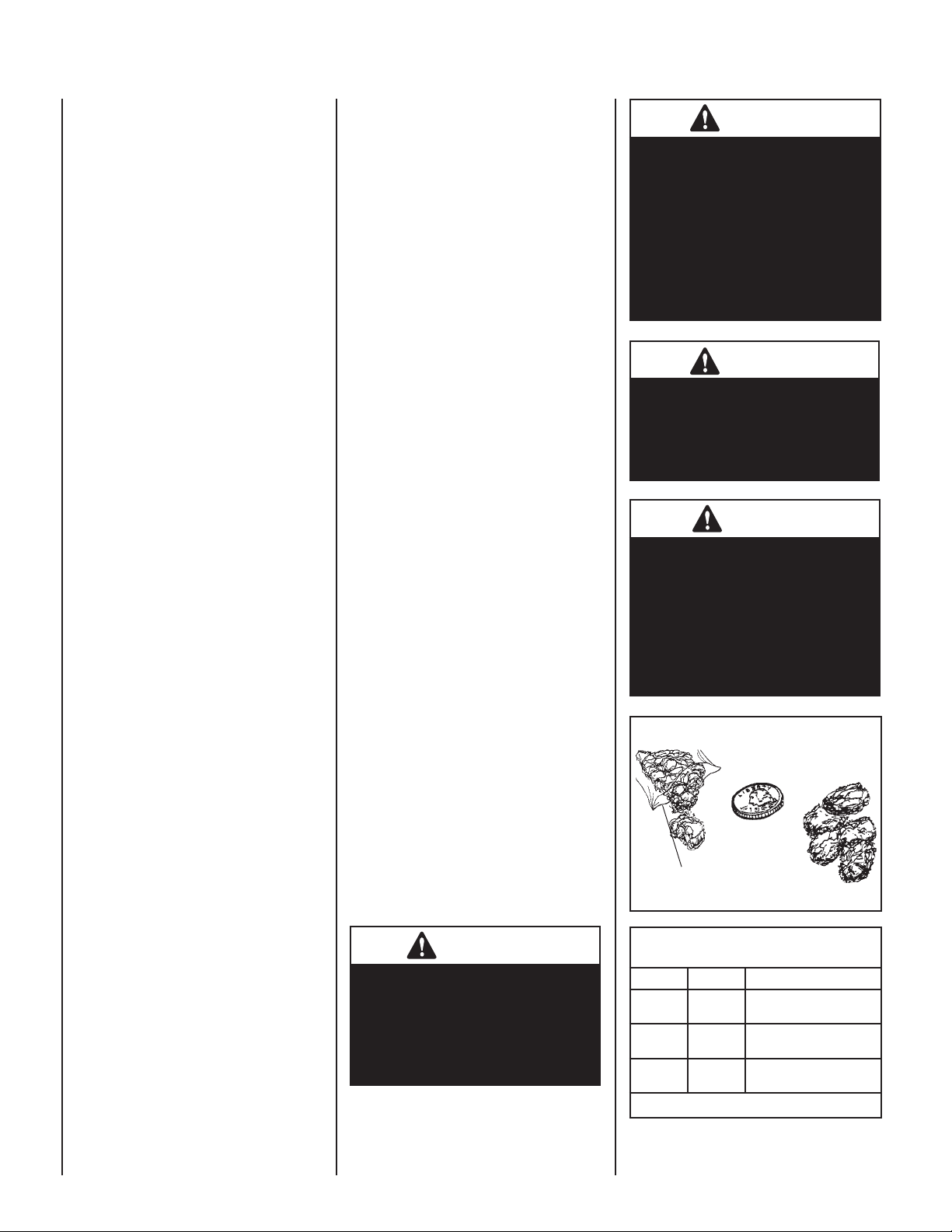

5. Placement of Glowing Embers -

Separate the Embers (rockwool) into pieces

about the size of a quarter (see Figure 7).

Keep the pieces fl uffed up, not matted.

Distribute these pieces over the surface of

the burner, as shown in Figures 8 & 9. Do

not use more than is necessary. Ensure that

the main burner slots remain uncovered by

the ember material.

Note: This appliance is provided with enough

Glowing Embers for several applications, do

not use all that is in a new bag at one time. For

best glowing effect, replace the ember material

annually.

6. Placement of Logs and Twigs -

All logs that have locating notches or slots to

help ensure that they are properly positioned.

All top logs that rest on lower logs, do so

over notches, indents or pins. Proper twig

placement is critical to prevent sooting. Twigs

should be placed in the gaps between the fl ame

peaks and should be positioned so they do not

impinge the fl ames.

LMDV-3328 & LMDV-3530 - Install as Follows

Carefully position the ceramic fi ber logs and twigs

over the burner as shown in Figure 8. Logs

should be placed in the order shown and per the

following instructions.

1. Place the rear log (A) as shown. Position the

2 notches on the bottom of the log over the

2 corresponding locating brackets against

the back wall of fi rebox.

2. Place the left log (B) as shown. The notch

on the bottom of the log should fi t over the

corresponding locating bracket.

3. Place the right log (E) as shown. The hole

on the back of the log should fi t over the

corresponding pin on the rear log (A). Make

sure that the log is positioned so it aligns

to the sides of the gas ports on the corner

of the burner.

4. Place the left center log (C) as shown.

The forked end of the log fi ts into the corresponding notch on rear log (A). The slot

on the other end (bottom) of log fi ts over

the corresponding locating bracket on the

sub-fl oor.

5. Place the right center log (D) as shown. One

end of the log fi ts into the corresponding

indent on the right log (E). The slot on

the other end (bottom) of log fi ts over the

corresponding locating bracket on the subfl oor.

LMDV-4035 - Install as Follows

Carefully position the ceramic fi ber logs and twigs

over the burner as shown in Figure 9. Logs

should be placed in the order shown and per the

following instructions.

1. Position the center log (C) onto the 2 cor-

responding location pins on the burner.

2. Place the rear log (A) as shown. Position the

2 notches on the bottom of the log over the

2 corresponding locating brackets against

the back wall of fi rebox.

3. Place the left log (B) as shown. The notch

on the bottom of the log should fi t over the

corresponding locating bracket.

4. Place the right log (E) as shown. The notch

on the bottom of the log should fi t over the

corresponding locating bracket. Make sure

that the log is positioned so it aligns to the

sides of the gas ports on the corner of the

burner.

5. Place the center front log (D) as shown.

The slot in the bottom of the log fi ts over

the corresponding location bracket on the

sub-fl oor.

WARNING

DO NOT attempt to install the logs

until the appliance installation

has been completed, the gas line

connected and tested for leaks

and the initial burner operation

has been checked out.

WARNING

The size and position of the log

set was engineered to give the

appliance a safe, reliable and

attractive fl ame pattern. Any

attempt to use a different log

set in the fi replace will void

the warranty and will result in

incomplete combustion, sooting, and poor fl ame quality.

WARNING

This appliance is not designed

to burn wood. Any attempt to

do so could cause irreparable

damage to appliance and prove

hazardous to your safety.

WARNING

If logs are not installed according

to the log installation instructions, fl ame impingement and

improper combustion could

occur and result in soot and/or

excessive production of carbon

monoxide (CO), a colorless,

odorless, toxic gas.

Glowing Embers

Separate into Quarter

Size (separate) Pieces

Bag of Glowing

Embers (rockwool)

Figure 7

REFERENCE

Firebox Accessories/Parts

Cat. No. Model No. Description

88L53 FGE Bag of Glowing Embers

H3696

80L42 FDVS

Table 8

(1 oz. rockwool)

Vermiculite, Bag (2 liters)

Bag of Decorative

Volcanic Stone

8

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 9

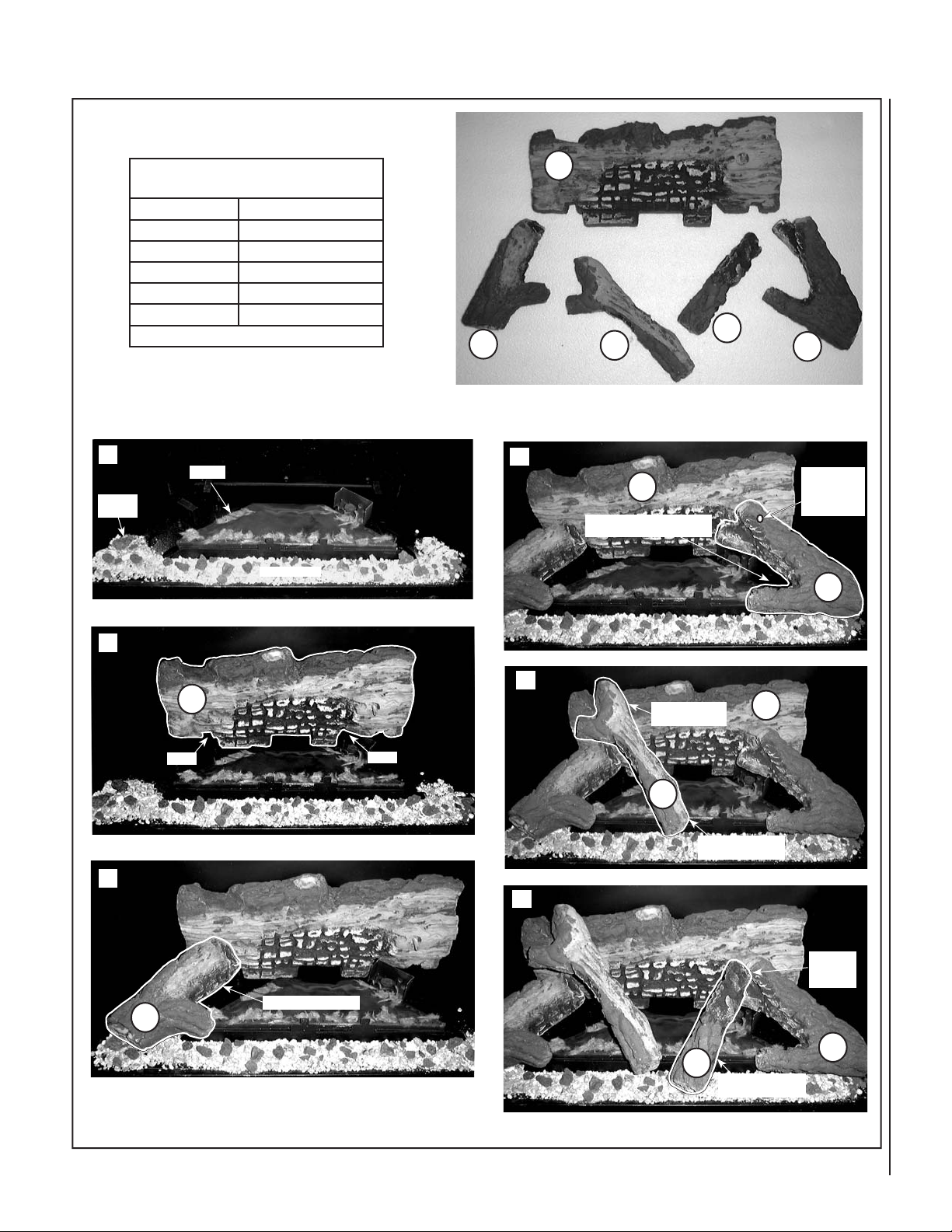

MODEL LMDV-3328 & LMDV-3530

Log Placement Instructions

LOG SET

Catalog Number

* Item

A

B

C

D

E

* Item "letters" above correspond to photos

Install the Embers, Vermiculite, Volcanic Stone and Logs in the order

shown here (1 through 6) and per the instructions on Page 8.

H3366

Description

Log, Rear

Log, Left

Log, Left Center

Log, Right Center

Log, Right

A

D

B

C

E

1

Volcanic

Stone

2

3

DO NOT PLACE EMBERS OVER GAS SLOTS

Embers

Vermiculite

The 2 notches on log bottom rest on locating brackets

A

Notch

Notch

4

Hole on bot-

A

V-Shape area of log (E) should

align to sides of burner ports

tom of log (E)

fi ts over pin

on log (A).

E

5

Log (C) fi ts into

indent in Log (A)

A

C

Slot on bottom of Log

(C) fi ts over bracket

6

Figure 8

Log (D) fi ts

into indent

on Log (E)

Slot fi ts over bracket.

B

E

D

Slot on bottom of Log

(D) fi ts over bracket

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

9

Page 10

MODEL LMDV-4035

Log Placement Instructions

LOG SET

Catalog Number

* Item

A

B

C

D

E

* Item "letters" above correspond to photos

Install the Embers, Vermiculite, Volcanic Stone and Logs in the order

shown here (1 through 6) and per the instructions on Page 8.

1

Volcanic

Stone

2

DO NOT PLACE EMBERS OVER GAS SLOTS

Place log over pins

H3365

Description

Log, Rear

Log, Left

Log, Center

Log, Center Front

Log, Right

Embers

Vermiculite

A

C

B

E

D

4

B

Notch on log bottom

fi ts over bracket

3

Figure 9

Notch

C

5

Pin

Pin

E

The 2 notches

A

on log bottom

rest on locating

brackets

Notch

Notch on log bottom

fi ts over bracket

6

D

Slot on bottom of Log

(D) fi ts over bracket

10

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 11

BURNER ADJUSTMENTS

(QUALIFIED TECHNICIANS ONLY)

Flame Appearance and sooting

Proper fl ame appearance is a fl ame which is

blue at the base and becomes yellowish-orange

in the body of the fl ame. When the appliance

is fi rst lit, the entire fl ame may be blue and will

gradually turn yellowish-orange during the fi rst

15 minutes of operation. If after a short period

the fl ame stays lowered blue, or if the fl ame is

orange with evidence of sooting (black tip), the

air shutter opening may need to be adjusted.

If the air shutter openings closed too far, sooting

may develop. Sooting is indicated by black puffs

developing at the tips of very long orange fl ames.

Sooting results in black deposits forming on the

logs, appliance inside surfaces and on exterior

surfaces adjacent to the vent termination. Sooting is caused by incomplete combustion in the

fl ames and lack of combustion air entering the

air shutter opening. To achieve a warm yellowish-orange fl ame with an orange body that does

not soot, the shutter opening must be adjusted

between these two extremes.

Air Shutter Adjustment Guidelines

• If there is smoke or soot present, fi rst check

the log set positioning to ensure that the

fl ames are not impinging on any of the logs.

If the log set is properly positioned and a

sooting condition still exists, then the air

shutter opening should be increased.

• The more offsets in the vent system, the larger

the air shutter opening will need to be.

• An appliance operated with the air shutter

opened too far, may have fl ames that appear

blue and transparent. These weak, blue and

transparent fl ames are termed anemic.

• Propane models may exhibit fl ames which

candle or appear stringy. If this is present

and persists, adjust the air shutter to a more

open position, then operate the appliance for

a few more minutes to ensure that the fl ame

normalizes and the fl ames do not appear

sooty.

Figure 10 - Burner Flame Appearance Model LMDV-3328 & LMDV-3530

The following chart is provided to aid you in

achieving the correct air shutter adjustment

for your installation.

Air Shutter Adjustment Guidelines:

Amount of

Primary Air

If air shutter is

closed too far

If air shutter is

open too far

Flame

Color

Flame will

be orange

Flame will

be blue

Air Shutter

Adjustment

Air shutter

gap should be

increased

Air shutter

gap should be

decreased

Figure 11 - Burner Flame Appearance Model LMDV-4035

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

11

Page 12

Burner Air Shutter Adjustment Procedure

1. Locate adjustment rod and adjust air shutter

to the standard setting as shown in Figure

12 (adjustment rod is located in the lower

control compartment). Note: Rotating the

adjustment rod clockwise decreases air and

counterclockwise increases air.

2. Light appliance (follow lighting procedure on

lighting label in control compartment or see

homeowners manual).

3. Allow the burner to operate for at least 15 minutes while observing the fl ame continuously

to ensure that the proper fl ame appearance

has been achieved (see Figure 10 or 11). If

the following conditions are present, adjust

accordingly.

• If flame appears weak or sooty, adjust

the air shutter, incrementally, to a more

open position until the proper fl ame

appearance is achieved.

• If fl ame stays lowered blue, adjust the

air shutter, incrementally, to a more

closed position until the proper fl ame

appearance is achieved.

4. Leave the control knob (off/pilot/on) in the

ON position and the burner OFF/ON switch

OFF (& remote switches, if applicable).

5. When satisfi ed that the burner fl ame ap-

pearance is normal, close the lower control

compartment door.

WARNING

Air shutter adjustment should

only be performed by a qualifi ed

professional service technician.

WARNING

Ensure front glass panel is in place

and sealed during adjustment.

CAUTION

The air shutter door and nearby

appliance surfaces are hot. Exercise caution to avoid injury while

adjusting fl ame appearance.

CAUTION

Carbon will be produced if the air

shutter is closed too much. Any

damage due to carboning resulting from improperly setting the

air shutter is not covered under

the warranty.

Burner Air Shutter Adjustment

Adjustment Set-Screw

Adjustment Rod Up

(Fully Open Position)

Burner Tube

Air Shutter

Adjustment Rod Down

(minimum air opening

position)

Main Burner Factory Air Shutter

Opening Setting - Inches (millimeter)

Model Natural

LMDVT-3328

LMDVR-3328

LMDV-3530

LMDV-4035

Figure 12

Millivolt Appliance Checkout

The pilot fl ame should be steady, not lifting

or fl oating. Flame should be blue in color with

traces of orange at the outer edge.

The top 3/8" (10 mm) at the pilot generator

(thermopile) and the top 1/8" minimum (tip)

of the quick drop out thermocouple should be

engulfed in the pilot fl ame. The fl ame should

project 1" (25 mm) beyond the hood at all three

ports. See Figures 13 or 14.

To light the burner, refer to the lighting instructions on Pages 18 & 19.

(1.58 mm)

(1.58 mm)

(1.58 mm)

(3.18mm)

Gas

1/16"

1/16"

1/16"

1/8"

Ref. Air shutter Patent:

U.S. Pat. 5,553,603

Propane

Gas

1/4"

(6.35 mm)

1/4"

(6.35 mm)

5/16"

(7.94 mm)

3/8"

(9.53 mm)

SIT MILLIVOLT PILOT ASSEMBLY

Proper Pilot Flame Appearance

Hood

Thermocouple

Pilot

Nozzels

Figure 13

HONEYWELL MILLIVOLT PILOT ASSEMBLY

1/8" Min.

(3 mm)

Pilot

Nozzels

Thermopile

Proper Pilot Flame Appearance

Thermocouple

Igniter Rod

Figure 14

Electronic Appliance Checkout

To light the burner, refer to the lighting instructions on Pages 19 & 20. Ensure the igniter

lights the pilot. The pilot fl ame should engulf

the fl ame sensor as shown in Figure 15.

ELECTRONIC PILOT ASSEMBLY

Proper Pilot Flame Appearance

Proper Flame

Adjustment

Pilot

Nozzels

Figure 15

Igniter Rod

3/8" Min.

(9 mm)

Hood

3/8" Min.

(9 mm)

Thermopile

3/8" to 1/2"

(9 -13 mm)

Ground

Electrode

Flame Rod

Hot Surface

Igniter

12

With proper care and maintenance, your appliance will provide many years of enjoyment. If

you should experience any problem, fi rst refer

to the troubleshooting guide in this manual.

If problem persists, contact your Lennox

distributor.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 13

WIRING DIAGRAMS

Wiring diagrams are provided here for reference purposes only. This information is also

provided on schematics attached directly to the

appliance on a pullout panel located within the

control compartment.

CAUTION

Label all wires prior to disconnection when servicing controls. Wiring errors can cause

improper and dangerous appliance operation.

Millivolt Wiring Diagram

Schematic Representation Only

If any of the original wire as supplied must

be replaced, it must be replaced with Type

AWM 105

Standard OFF/ON Switch

* Optional Kits Installed - OFF/ON wall switch,

wall thermostat or remote control receiver.

Note: Turn the appliance-mounted OFF/ON

burner control switch to the OFF position if

any of these kits are installed.

Figure 16

o

C - 18 gage wire.

Thermopile

*Optional Switch

TP

TH

TP

TH

Field Wired

Factory

Wired

Electronic Wiring Diagram (Honeywell) Showing Blower Wiring for Optional FBK-100, FBK-200 & FBK-250 Kits

Schematic Representation Only

Wall Mounted Blower Speed Control Switch or

Auxiliary View A

J-Box Wiring when

using unit mounted

relay module.

BK

W

G

Junction Box

Pilot Burner

Assembly

BL

BL

BK

Optional Control Switch

C

AV

02

1

Igniter

Connector

Relay Module C/W FBK-250 only. Plug blower

into J-Box receptacle for FBK-100 or FBK-200

application. View A for J-Box wiring.

Optional Blower

*OFF/ON Switch

(Integral with

Gas Valve)

Honeywell

Electronic

Gas

Valve

24 V

Secondary

GROUND

Field Wired

Factory

Wired

Transformer

BL

R

BK

BK = BLACK BL = BLUE

BK

R = RED W = WHITE

W

G = GREEN

ON/OFF Switch for Blower Kit (optional)

Outlet Box Green

Ground Screw

Break off Tab

Hot side

of Outlet

* Leave the OFF/ON switch, which is

integral with the gas valve, in the ON

position.

** Optional Control Switches: Wall

Switch, Wall Thermostat or Remote

120 VAC

Primary

Control Receiver.

Notes:

1. If any of the original wire as supplied

must be replaced, use Type AWM 105°C

- 18 gage wire ONLY.

2. 120 VAC, 60 Hz - Less than 3 Amps.

Caution: label all wires prior to

disconnection when servicing controls.

Wiring errors can cause improper and

dangerous operation.

120

VAC

Junction

Box

BK

W

G

G

BK

R

White Wire

to Opposite

Side (neutral)

Figure 17

WARRANTY

Your gas appliance is covered by a limited

twenty year warranty. You will fi nd a copy

of the warranty accompanying this manual.

Please read the warranty to be familiar with

its coverage.

Retain this manual. File it with your other

documents for future reference.

PRODUCT REFERENCE INFORMATION

We recommend that you record the following

important information about your fi replace.

Please contact your Lennox dealer for any

questions or concerns. For the number of

your nearest Lennox dealer, please call 1-8009-LENNOX.

REPLACEMENT PARTS

A complete parts list is found at the end of

this manual. Use only parts supplied from the

manufacturer.

Normally, all parts should be ordered through

your Lennox distributor or dealer. Parts will be

shipped at prevailing prices at time of order.

When ordering repair parts, always give the

following information:

1. The model number of the appliance.

2. The serial number of the appliance.

3. The part number.

4. The description of the part.

5. The quantity required.

6. The installation date of the appliance.

Visit us at www.Lennox.com

Your Fireplace's Model Number ________________________________________

Your Fireplace's Serial Number ________________________________________

The Date On Which Your Fireplace Was Installed ___________________________

The Type of Gas Your Fireplace Uses ____________________________________

Your Dealer's Name ________________________________________________

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

If you encounter any problems or have any questions concerning the installation or application

of this system, please contact your distributor,

or Lennox directly:

LENNOX HEARTH PRODUCTS

1110 West Taft Avenue

Orange, CA 92865

13

Page 14

ACCESSORY COMPONENTS

Product Reference Information

Cat.

No.

H3313 LMDVT-3328CNM 95 lb. 13.08 cu. ft.

H3314 LMDVT-3328CPM 9 5 lb. 13.08 cu. ft.

H3315 LMDVR-3328CNM 95 lb. 13.08 cu. ft.

H3316 LMDVR-3328CPM 95 lb. 13.08 cu. ft.

H3317 LMDVT-3328CNE 95 lb. 13.08 cu. ft.

H3318 LMDVR-3328CNE 95 lb. 13.08 cu. ft.

H3319 LMDV-3530CNM 113 lb. 15.75 cu. ft.

H3320 LMDV-3530CPM 113 lb. 15.75 cu. ft.

H3321 LMDV-3530CNE 113 lb. 15.75 cu. ft.

H3322 LMDV-4035CNM 147 lb. 20.18 cu. ft.

H3323 LMDV-4035CPM 147 lb. 20.18 cu. ft.

H3324 LMDV-4035CNE 147 lb. 20.18 cu. ft.

Wall Thermostat

The wall thermostat kit provides temperature control

for optimum comfort.

Model Ship.

Weight

Ship.

Volumn

Standard Remote Control System

The Model RCL (Standard) Remote Control System,

features a simplistic OFF/ON control function for the

fi replace. This model includes a hand-held transmitter,

a remote receiver with wall-mount cover plate and

all hardware required to install the unit. The remote

receiver can be wall or hearth mounted.

The transmitter has ON and OFF functions that are

activated by pressing either button on the face of

the transmitter. When a button on the transmitter

is pressed, a signal light illuminates briefl y to verify

that a signal has been sent.

The Model RCL is designed to operate with all millivolt ignition systems, as well as electronic ignition

systems. It may be installed with use for either

natural gas or propane gas appliances. The RCL

offers ease of installation and allows you to execute

on-off commands to the fi replace effortlessly with

one simple motion.

The Model RCL comes complete with detailed operating instructions.

Deluxe Remote Control System

The Model RCL-T (Deluxe) Remote Control System

has all of the features of the standard system along

with an added easy to read LCD screen which presents

access to many enhancements, including; battery

power level indicator, timer, mode of operation,

thermostatic display including room temperature in

either metric of English units, fl ame indicator and

clock. Fully programmable, the Model RCL-T allows

for virtual command over nearly all operational and

temperature variables, using the hand held remote

control transmitter.

The Model RCL-T (Deluxe) remote control system

is installed in the same manner as the standard

system, may be operated with electronic and millivolt systems with either natural gas or propane gas.

The RCL-T comes complete with detailed operating

instructions.

Wall Thermostat, Millivolt

Cat. No. Model No. Description

89L36 WTK Wall Thermostat Kit,

White

Unit-Mountable Rocker Switch

This rocker switch kit can be installed directly in

the gas valve mounting bracket (millivolt gas valve

equipped fi replaces) to provide On/Off operation in

lieu of a wall switch.

Rocker Switch Kit

Cat. No. Model No. Description

80L41 FRS Rocker Switch Kit

(ref. Form # 750,037M)

14

Remote Control Kit, Standard

Cat. No. Model No. Description

H0249 RCL Remote Control System

(Standard)

(ref. Form # 750,127M)

Arch Door Kits

The arch door kits are easy to install and do not require hardware to attach them to the standard door

frame. The decorative arch kits can not be used in

conjunction with the screen panel kit.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Remote Control Kit, Deluxe

Cat. No. Model No. Description

H0251 RCL-STAT Remote Control System

(ref. Form # 750,129M)

Arch Door Kit - Polished Brass

Cat. No. Model Fireplace Model

98L05 ADK33CPB

26M43 ADK35CMPB LMDV-3530

81L35 ADK40CPB LMDV-4035

Arch Door Kit - Brushed Stainless Steel

Cat. No. Model Fireplace Model

98L62 ADK33CBS

26M44 ADK35CMBS LMDV-3530

98L69 ADK40CBS LMDV-4035

(ref. Form # 750,021M)

(Deluxe)

LMDVT-3328,

LMDVR-3328

LMDVT-3328,

LMDVR-3328

Page 15

ACCESSORY COMPONENTS

Screen Panel Kit

This easy to install optional screen installs over the

standard glass enclosure panel to provide protection

from direct contact with the hot glass surface. These

screen panels cannot be used in conjunction with

the arch door kits or door frame kits.

Screen Panel Kits

Cat. No. Model No. Models Where Used

98L04 HG33

26M48 HG35M LMDV-3530

26M49 HG40M LMDV-4035

(ref. Form # 750,101M)

LMDVT-3328

LMDVR-3328

Style View Doors - Arch Design Kits

Cat. No. Model Model Model

H0858 AD35C 35” Arch Doors, Charcoal

H0859 AD35TI 35” Arch Doors, Textured Iron

H0860 AD35SP 35” Arch Doors, Satin Pewter

H0861 AD35AB 35” Arch Doors, Antique Brass

H0862 AD40C 40” Arch Doors, Charcoal

H0863 AD40TI 40” Arch Doors, Textured Iron

H0864 AD40SP 40” Arch Doors, Satin Pewter

H0865 AD40AB 40” Arch Doors, Antique Brass

Series

LMDV-3530

LMDV-4035

Style View Doors - Arch Pane Design Kits

H0930 APD35C 35” Arch Pane Doors, Charcoal

H0931 APD35TI 35” Arch Pane Doors, Textured Iron

H0932 APD35SP 35” Arch Pane Doors, Satin Pewter

H0933 APD35AB 35” Arch Pane Doors, Antique Brass

H0934 APD40C 40” Arch Pane Doors, Charcoal

H0935 APD40TI 40” Arch Pane Doors, Textured Iron

H0936 APD40SP 40” Arch Pane Doors, Satin Pewter

H0937 APD40AB 40” Arch Pane Doors, Antique Brass

LMDV-3530

LMDV-4035

Style View Doors - Square Design Kits

H0946 SD35C 35” Sq. Doors, Charcoal

H0947 SD35TI 35” Sq. Doors, Textured Iron

H0948 SD35SP 35” Sq. Doors, Satin Pewter

H0949 SD35AB 35” Sq. Doors, Antique Brass

H0950 SD40C 40” Sq. Doors, Charcoal

H0951 SD40TI 40” Sq. Doors, Textured Iron

H0952 SD40SP 40” Sq. Doors, Satin Pewter

H0953 SD40AB 40” Sq. Doors, Antique Brass

LMDV-3530

LMDV-4035

Arch Design

Arch Pane Design

Square Design

Style View Doors - Square Pane Design Kits

H0962 SPD35C 35” Sq. Pane Doors, Charcoal

H0963 SPD35TI 35” Sq. Pane Doors, Textured Iron

H0964 SPD35SP 35” Sq. Pane Doors, Satin Pewter

H0965 SPD35AB 35” Sq. Pane Doors, Antique Brass

H0966 SPD40C 40” Sq. Pane Doors, Charcoal

Decorative Arch Screen Panel Kit

This easy to install optional screen installs over the

standard glass enclosure panel to provide protection

from direct contact with the hot glass surface. These

screen panels cannot be used in conjunction with

the arch door kits or door frame kits.

H0967 SPD40TI 40” Sq. Pane Doors, Textured Iron

H0968 SPD40SP 40” Sq. Pane Doors, Satin Pewter

H0969 SPD40AB 40” Sq. Pane Doors, Antique Brass

(ref. Form # 775,169M)

Style View Screen Doors -

These Style View screen doors come in 4 beautiful styles. They are easy to install and will not require hardware

to attach them to the standard glass door frame. The screens prevent direct contact with the hot glass surface.

The door includes heavy duty magnet door latches and functional twin-pane screen doors.

Decorative Arch Screen Panel Kit

Cat. No. Model Model Model Series

H3592 DASPK33TI 33” Decorative Arch Screen Panel LMDVT-3328 & LMDVR-3328

H3593 DASPK35TI 35” Decorative Arch Screen Panel LMDV-3530

H3594 DASPK40TI 40” Decorative Arch Screen Panel LMDV-4035

(ref. Form # 750,199M)

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Square Pane Design

LMDV-3530

LMDV-4035

15

Page 16

ACCESSORY COMPONENTS

Forced Air Blower Kits

Cat.

Model No. Description

No.

80L84 FBK-100 Blower, Standard

80L85 FBK-200 Blower, Variable Speed

80L86 FBK-250 Blower, Variable Speed

94L89 FBK-100-36 Blower, Standard, 36 Pack

94L90 FBK-200-36 Blower Kit - Variable Speed

H0543 FBK-250-36 Blower Kit - Variable Speed

(ref. Form # 750,028M & 750,029M)

(single speed)

(w/wall-mounted switch)

(w/unit-mounted switch)

with Wall Switch 36 Pack

with Thermo Snap Switch

36 Pack

White Wall Switch Kit

Cat. No. Model No. Description

85L87 FWSK OFF/ON Wall Switch Kit

OFF/ON Wall Switch Kit

The OFF/ON wall switch kit may be used to control

the operation of the fi replace burner. Install the

OFF/ON wall switch in a convenient location near

the fi replace.

4 Piece Trim Kit

Cat. No. Model No. Description

96K17 TK35PB4

96K18 TK40PB4

(ref. Form # ii-9299)

35” 4 Piece Finish Trim Kit,

Polished Brass, LMDV-3530

40” 4 Piece Finish Trim Kit,

Polished Brass, LMDV-4035

Polished Brass 4-Piece Trim Kit

This kit contains brass trim pieces used to fi nish the

gaps between the wall board and the fi replace, providing the appliance a brass perimeter highlight. This kit

contains the trim pieces and these instructions

Forced Air Kit

The FBK-100 blower provides constant velocity forced

air circulation. The FBK-200 assembly with variable

speed, wall-mountable switch provides variable speed

forced air circulation. The FBK-250 assembly with

variable speed unit-mountable switch, also provides

variable speed forced air circulation.

Variable Speed Wall Switch

Cat. No. Model No. Description

045571H VSWS Rocker Switch Kit

Variable Speed Wall Switch

Provides variable speed control if optional blower

kit is purchased.

3 Piece Trim Kit

Cat. No. Model No. Description

H0453 TK33PB3

96K21 TK35PB3

96K22 TK40PB3

H1813 TK33BS3

H1815 TK35BS3

H1816

TK40BS3

H4820 TK33C3

H4821 TK35C3

H4823 TK40C3

(ref. Form # 750,147M)

33” Polished Brass,

LMDVT-3328, LMDVR-3328

35” Polished Brass,

LMDV-3530

40" Polished Brass,

LMDV-4035

33” Brushed Stainless,

LMDVT-3328, LMDVR-3328

35” Brushed Stainless,

LMDV-3530

40", Brushed Stainless,

LMDV-4035

33” Charcoal,

LMDVT-3328, LMDVR-3328

35” Charcoal,

LMDV-3530

40" Charcoal,

LMDV-4035

Polished Brass 3-Piece Trim Kit

This kit contains brass trim pieces used to fi nish the

gaps between the wall board and the fi replace, providing the appliance a brass perimeter highlight. This kit

contains the trim pieces and these instructions

Brickaded Wall Liner Kits

Cat. No. Model No. Description

H0912 MBLK-33T

H0918 MBLK-33R

H0913 MBLK-35

H0914 MBLK-40

(ref. Form # 750,160M)

Brick Liner Kit, Top Vent,

LMDVT-3328

Brick Liner Kit, Rear Vent,

LMDVR-3328

Brick Liner Kit, Top/Rear,

LMDV-3530

Brick Liner Kit, Top/Rear,

LMDV-4035

Brickaded Panel Liner Kit

The brickaded liner kits include ceramic panels as

shown here. The panels have brick-like features in relief.

16

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 17

ACCESSORY COMPONENTS

P

T

A

N

I

Touch-Up Paint Kit

Repair of minor scratches and discoloration of the

appliance charcoal painted surfaces may be accomplished with the touch-up paint kit.

Touch-Up Paint Kits

(all models)

Cat. No. Model No. Description

90L74 TPK-C Touch-Up Paint (Charcoal)

(TPK-C ref. Form # 504,216M)

* Assembled 8-Piece Louver Kits

Polished Brass Brushed Stainless Models

Where Used

Cat. # Model Cat. # Model

H1522 LK-400B H1523 LK-400BS

H1524 LK-500B H1525 LK-500BS

H1526 LK-600B H1527 LK-600BS

(ref. Form # 750,166M)

LMDVT-3328

LMDVR-3328

LMDV-3530

LMDV-4035

* Lennox Nameplate Logo, 12L15, is sold separately.

Polished Brass & Brushed Stainless Louvers Kits

These kits include a top 4-louver assembly and a bottom 4-louver assembly. They provide a touch of elegance.

These kits can be retrofi tted to previously installed appliances.

2- Piece Door Frame Kits

Polished Brass Brushed Stainless

Cat. # Model Cat. # Model

98L18 2DFK33PB 98L19 2DFK33BS

26M88 2DFK35PB 26M91 2DFK35BS LMDV-4035

26M89 2DFK40PB 26M92 2DFK40BS LMDV-4035

(ref. Form # 750,098M)

Models

Where Used

LMDVT-3328

LMDVR-3328

Polished Brass & Brushed Stainless 2-Piece Door Frame Kits

These kits are designed to attach directly to the front face of the appliance at the glass enclosure panel's top

and bottom edges.

Decorative Firebox Accessories

(all models)

Cat. No. Model No. Description

88L53 FGE

80L42 FDVS

(FDVS ref. Form #750,010M)

Bag of Glowing Embers

(1 oz. rockwool)

Bag of Decorative

Volcanic Stone

Bag of Glowing Embers

Bag of Volcanic Stone

Replacement ember materials or volcanic stone are

available for use with these appliances. Order kits as

part of the periodic maintenance of the appliance.

4 Piece Door Trim Kits

Polished Brass Brushed Stainless Models

Cat. # Model Cat. # Model

98L22 4DFK33PB 98L23 4DFK33BS

26M82 4DFK35PB 26M85 4DFK35BS LMDV-3530

26M83 4DFK40PB 26M86 4DFK40BS LMDV-4035

Where Used

LMDVT-3328

LMDVR-3328

(ref. Form # 750,098M)

Door Frame Kits

A decorative door frame kit is available for use with these appliances. It is designed to attach directly to the front face

of the appliance at the four edges of the glass enclosure panel resulting in the appearance of a picture frame.

Eyebrow Hood Kits

Polished Brass Brushed Stainless Models

Where Used

Cat. # Model Cat. # Model

98L10 EB33PB 98L11 EB33BS

96K67 EB35PB 88L49 EB35BS LMDV-4035

96K68 EB40PB 88L50 EB40BS LMDV-4035

* These hood kits replace the standard hood that comes with

these fi replaces.

(ref. Form #504,142M)

LMDVT-3328

LMDVR-3328

Polished Brass & Brushed Stainless Hood Kits

Attractive hoods are available in two styles. These hoods are designed to be fi tted to the glass viewing sides

of the appliance. In addition to providing an aesthetically pleasing appearance to your appliance installation,

the hood reduces heat effects to decorative mantles and fi nish materials located above the fi replace opening.

The hood kit replaces the standard hood that comes with these appliances and snaps into place. These kits

can be retrofi tted to previously installed appliances.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

17

Page 18

LIGHTING INSTRUCTIONS – HONEYWELL AND SIT MILLIVOLT GAS VALVE

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION

MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

A. This appliance has a pilot which must be lighted with a piezo

igniter. When lighting the pilot, follow these instructions

exactly.

B. BEFORE OPERATING smell all around the appliance area for

gas. Be sure to smell next to the fl oor because some gas is

heavier than air and will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS

• Extinguish any open fl ame.

• Open windows.

• Do not light any appliance.

• Do not touch any electrical switches.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above on this Page.

2. Access the lower control compartment.

3. Turn remote wall switch to “OFF.”

4. Verify main line shut-off valve is open.

5. Push in gas control knob slightly and turn clockwise

to “OFF.”

IGNITER

F

T

F

O

O

L

H

I

O

L

I

P

N

O

HONEYWELL

MILLIVOLT

GAS VALVE

IN

T

P

HT

T

TP

H

L

P

I

L

O

T

OUT

I

H

F

F

O

P

I

L

O

ti

W

O

T

O

N

SIT

MILLIVOLT

GAS VALVE

6. Wait fi ve (5) minutes to clear out any gas. If you then smell gas,

7. Push in gas control knob slightly and turn counterclockwise

8. Push in control knob all the way and hold in.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone.

• If your gas supplier cannot be reached, call the fi re department.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

do not try to repair it, call a qualifi ed service technician. Force

or attempted repair may result in a fi re or an explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualifi ed service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

STOP! Follow “B” in the safety information above on this Page. If you

do not smell gas, go to the next step.

to “PILOT.”

HONEYWELL

MILLIVOLT PILOT

Immediately light the pilot by triggering the

spark igniter (pushing the button) until pilot

lights. Continue to hold the control knob in

for about 1 minutes after the pilot is lit.

Release knob and it will pop back up. Pilot

should remain lit. If it goes out, repeat steps 5

through 8.

• If knob does not pop up when released,

stop and immediately call your service

technician or gas supplier.

SIT

MILLIVOLT PILOT

• If pilot will not stay lit after several tries,

turn the control knob to “OFF” and call

your service technician or gas supplier.

IGNITER

Note: Knob cannot be turned from “PILOT” to “OFF”

unless the knob is pushed in slightly. Do not force.

1. Turn remote wall switch “OFF.” The pilot will remain lit for

normal service.

2. For complete shutdown, turn remote wall switch to “OFF.”

3. Access the lower control compartment.

18

9. Turn gas control knob counterclockwise

to “ON.”

10. Close lower control compartment.

TO TURN OFF GAS TO APPLIANCE

4. Depress gas control knob slightly and turn clockwise

to “OFF.” Do not force.

5. Close lower control compartment.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 19

INSTRUCTIONS D’ALLUMAGE – VANNE GAZ MILLIVOLT HONEYWELL ET SIT

POUR VOTRE SÉCURITÉ, LISEZ CES INSTRUCTIONS AVANT L’ALLUMAGE

AVERTISSEMENT : SI VOUS NE SUIVEZ PAS CES INSTRUCTIONS À LA LETTRE, IL POURRAIT S’EN SUIVRE UN INCENDIE OU UNE

EXPLOSION CAUSANT DES DOMMAGES MATÉRIELS, DES BLESSURES CORPORELLES OU MÊME DES PERTES DE VIE.

A. Cet appareil est muni d’une veilleuse qui doit être allumée avec un

allumeur piézo-électrique. Lorsque vous allumez la veilleuse, suivre

exactement ces instructions.

B. AVANT L’ALLUMAGE: Assurez-vous que vous ne détectez aucune

odeur de gaz autour de l’apareil ainsi que près du sol; certains gaz, étant

plus lourds que l’air, descendent au niveau du sol.

VOICI CE QUE VOUS DEVEZ FAIRE SI VOUS DÉCELEZ UNE ODEUR

DE GAZ:

• Éteignez toute flamme visible.

• Ouvrez les fenêtres.

• N’allumez aucun appareil.

• Ne touchez à aucun commutateur électrique.

• Ne vous servez d’aucun téléphone dans votre édifice.

INSTRUCTIONS D'ALLUMAGE

1. ARRÊTEZ! Lisez les consignes de sécurité au verso de cette plaque.

2. Ouvrez le compartiment de contrôle du bas.

3. Tournez l’interrupteur mural à la position d’arrêt “OFF”.

4. Assurez-vous que la soupape d’arrêt de la canalisation principale est

ouverte.

5. Enfoncez légèrement le bouton de réglage du gaz et tournez-le dans

le sens des aiguilles d’une montre jusqu’à la position

d’arrêt “OFF”.

F

T

F

O

O

L

N

O

PIEZO-ELECTRIQUE

I

H

L

W

O

I

P

IN

OUT

F

F

O

P

I

L

i

O

t

T

O

N

H

I

O

L

T

P

T

H

TPT

H

P

I

L

O

T

VANNE GAZ

MILLIVOLT

HONEYWELL

VANNE GAZ

MILLIVOLT SIT

• Appelez immédiatement votre compagnie de gaz en utilisant le téléphone

du voisin.

• S’il vous est impossible de contacter votre compagnie de gaz, appelez

le service des incendies.

C. N’utilisez que votre main pour manipuler le bouton de réglage du gaz.

N’utilisez jamais d’outils. Si le bouton refuse de tourner ou de bouger,

n’essayez pas de le réparer. Communiquez immédiatement avec un

technicien de service qualifié. Toute tentative pour le forcer ou le

réparer, risquerait de provoquer un incendie ou une explosion.

D. Ne vous servez pas de cet appareil si l’un de ses éléments a été

immergé dans l’eau. Appelez immédiatement un technicien compétent

pour faire inspecter l’appareil et remplacer toute pièce du système de

réglage ou commande du gaz qui a été sous l’eau.

8. Enfoncez le bouton de réglage jusqu’au fond et gardez-le enfoncé.

Allumez immédiatement la veilleuse en déclenchant l’allume-gaz à

étincelle (en poussant le bouton) jusqu’à ce que la veilleuse