2017

INSTALLATION

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a licensed professional HVAC installer

or equivalent, service agency, or the gas supplier

Table of Contents

Dimensions Page 2.................................

Parts Arrangements Page 4.........................

Shipping and Packing List Page 5....................

General Page 5....................................

Unit Support Page 5................................

Duct Connection Page 6............................

Rigging Unit For Lifting Page 7.......................

Shipping Blocks Page 7.............................

Reverse Condensate Drains Page 10..................

Condensate Drains Page 11..........................

Connect Gas Piping Page 11.........................

Pressure Test Gas Piping Page 11.....................

Flue and Intake Hoods Page 12.......................

High Altitude Derate Page 12.........................

Electrical Connections Page 13.......................

Multi-Staged Air Volume Start-Up Page 16..............

Variable Air Volume Start-Up Page 18..................

Blower Operation and Adjustments Page 19............

Cooling Start-Up Page 32............................

Gas HeatStart-Up Page 36...........................

Gas Heat Operation and Adjustment Page 37...........

Electric Heat Start-Up Page 37........................

INSTRUCTIONS

LGH420, 480, 540, 600

LCH420, 480, 540, 600

(35, 40, 45, & 50 Ton)

GAS AND COOLING PACKAGED UNITS

507232-04

7/2017

Supersedes 507232-03

IMPORTANT

Supply air VFD motor rotation is controlled indepen

dently from scroll compressor rotation. See Cooling

Start-Up section for correct compressor rotation.

Compressor damage due to improper rotation is the

responsibility of the installer.

Options

Economizer Start-Up Page 38...................

Power Exhaust Page 50........................

Barometric Relief Dampers Page 51..............

Outdoor Air Dampers Page 51...................

Outdoor Air Hoods Page 51.....................

Hot Gas

Modulating Gas Valves Page 56.................

Hot Gas Bypass Page 57.......................

Outdoor Air CFM Control Page 58................

Energy Recovery Wheels Page 59...............

Service Page 60....................................

Reheat Page 53........................

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

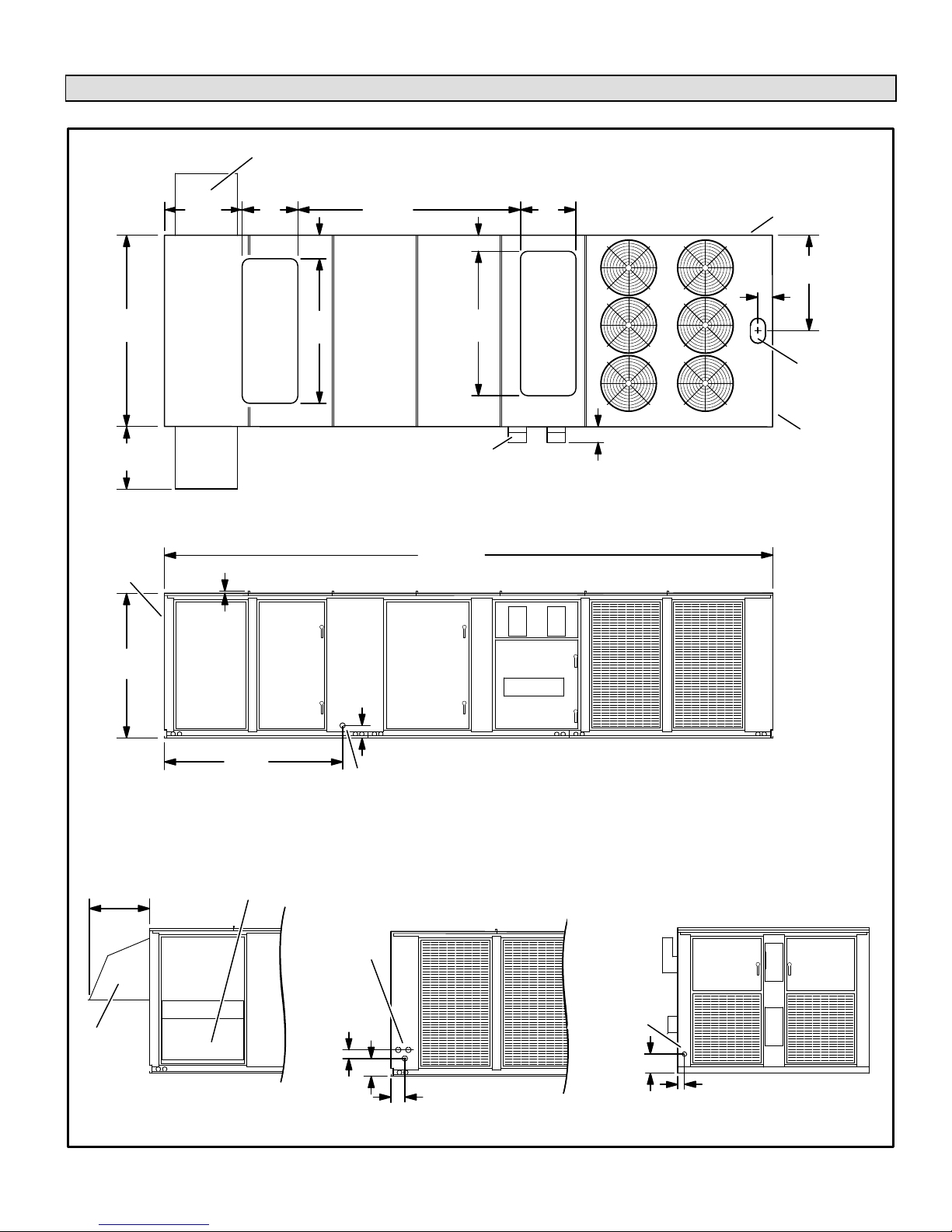

LGH/LCH 420, 480, 540, 600 Unit Dimensions Vertical Airflow - Inches (mm) - Gas Heat Shown

Optional Barometric Relief Hoods (one or two, each side).

NOTE - If only one hood is used it is located on this side of unit.

90

(2286)

28-3/4

(730)

See Optional

Outdoor Air

Hood Detail

36-3/4

(933)

26

(660)

11 (279)

Return

Air

Opening

1 in. (25 mm) Typ.

68

(1727)

104-3/4

(2661)

7-1/2

68

(1727)

Flue Outlets

TOP VIEW - Base Section

286 (7264)

26

(660)

Supply

Air

Opening

6 (152)

6

(152)

See Electrical

Inlet Detail

45

(1143)

5 x 8 in.

(127 x 203 mm)

Bottom

Wiring Inlet

See Gas

Inlet Detail

68

(1727)

28-3/4

(730)

Outdoor

Air Hood

Optional Barometric Relief Hoods (one or two, each side).

NOTE - If only one hood is used it is located on the opposite side.

OPTIONAL OUTDOOR

AIR HOOD DETAIL

82-7/8

(2105)

5-1/2

(140)

Condensate Drain

Electric

Inlet

8-7/8

(225)

3-3/8

(86)

(Either Side)

SIDE VIEW

ELECTRICAL

INLET DETAIL

Gas

Supply

Inlet

13-1/4 (337)

4-7/8

(124)

GAS INLET

DETAIL

Page 2

LGH/LCH420, 480, 540, 600

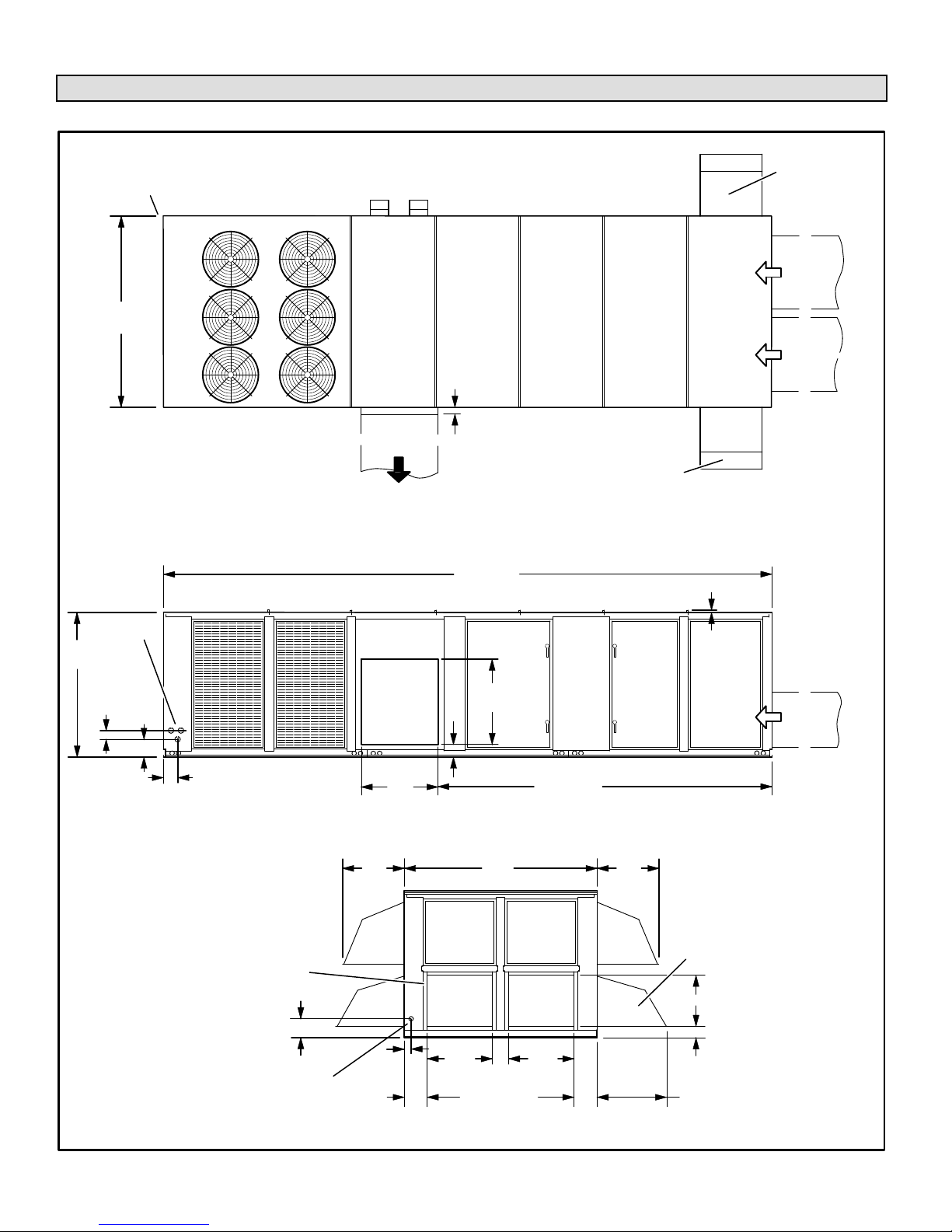

LGH/LCH420, 480, 540, 600 Unit Dimensions Horizontal Airflow - In. (mm) - Gas Heat Shown

Optional

See End View for gas

supply inlet detail

90

(2286)

1-1/2 (38)

(all 4 sides of supply

air opening)

TOP VIEW

Optional Barometric

Relief Hoods

(one or two, each side).

NOTE - If only one hood

is used it is located on

the same side of unit as

the Supply Air Opening.

Outdoor Air

Hoods (2)

Return

Opening

Return

Opening

Air

Air

68

(1727)

Electric

3-3/8

(86)

Inlet

8-7/8

(225)

5-5/8

(143)

1-3/8 in. (35 mm) wide

gasketed seal

recessed 1-1/8 in. (29 mm)

(all 4 sides of each

return air opening)

13-1/4 (337)

Gas

Supply

Inlet

Opening

26-1/4

(667)

4-7/8

(124)

Supply

Air

36

(914)

10-3/8

(264)

286 (7264)

(1016)

6 (152)

SIDE VIEW

(2286)

Return

Air

Opening

31-1/4

(794)

69-1/4 (1759)

END VIEW

40

90

6-3/4

(171)

157 (3988)

Return

Air

Opening

31-1/4

(794)

10-3/8

(264)

26-1/4

(667)

1 in. (25 mm) Typ.

Return

Air

Opening

Optional Barometric

Relief Hoods

(one or two, each side).

NOTE - If only one hood

is used it is located on

the same side of unit as

the Supply Air Opening.

23-3/4 (603)

6-1/4

(159)

28-3/4

(730)

507232-04 7/2017

Page 3

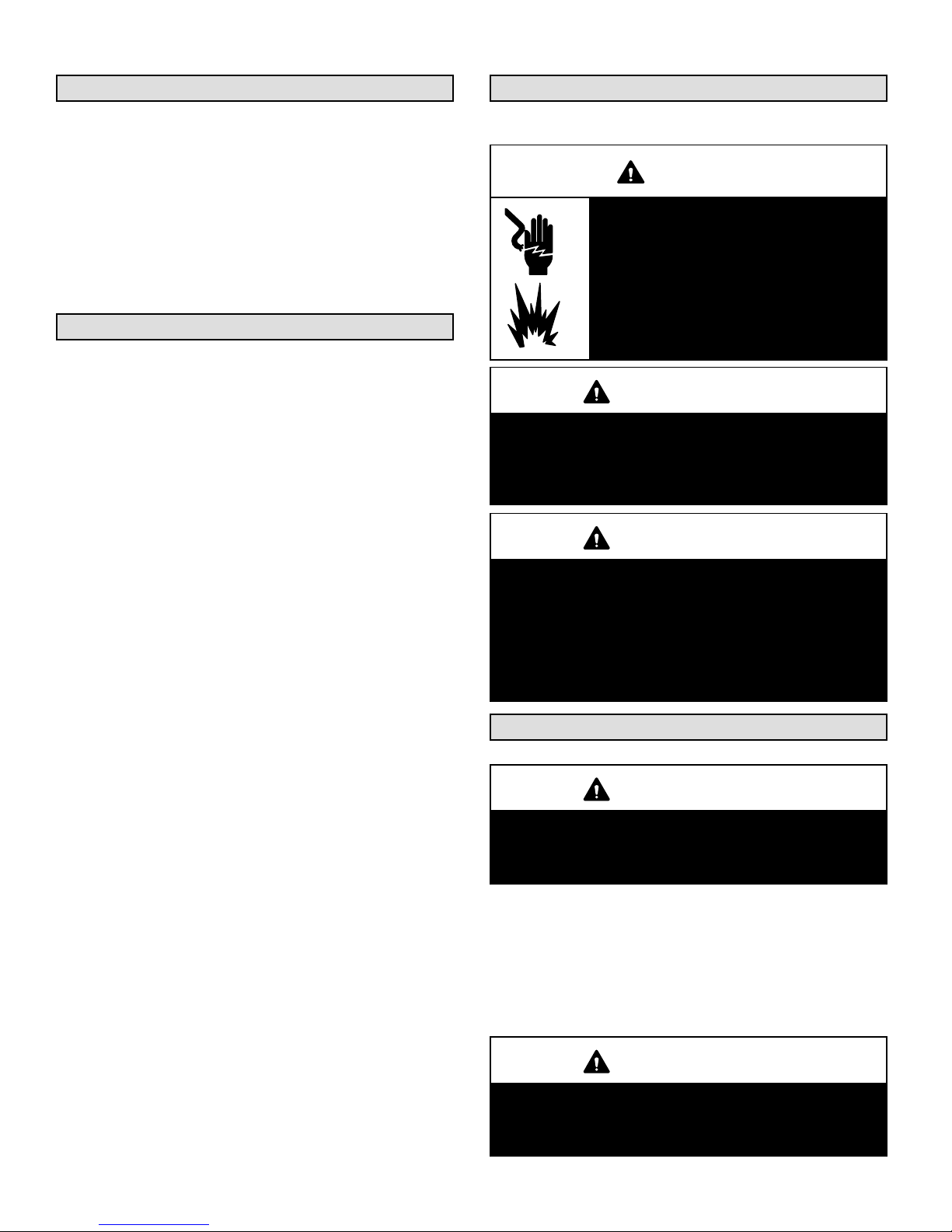

CONTROL

FANS (6)

CONDENSER

BOX

COMPRESSORS (4)

FILTERS

ELEVEN - 16 x 25 x 2”

(406 x 635 x 51mm)

OR

16 X 25 X 4”

(OPTIONAL)

ECONOMIZER

LGH420, 480, 540, 600 PARTS ARRANGEMENT

WHEEL (OPTIONAL)

ENERGY RECOVERY

BLOWERS

(406 X 635 X 102mm)

FILTER

HOT GAS

(OPTIONAL)

REHEAT COILS

BURNERS

DRIERS

GAS VALVES (2)

LOUVERS

(OPTIONAL)

COILS (4)

CONDENSER

Page 4

COILS

EVAPORATOR

(OPTIONAL)

DISCHARGE

POWER EXHAUST

DRAIN

CONDENSATE

LGH/LCH420, 480, 540, 600

Shipping and Packing List

Requirements

Package 1 of 1 contains:

1- Assembled unit

Check unit for shipping damage. Receiving party should

contact last carrier immediately if shipping damage is found.

IMPORTANT - Hot gas reheat units require a specific

field-provided and installed humidity sensor or digital

input. Refer to control wiring section.

General

These instructions are intended as a general guide and do

not supersede local codes in any way. Authorities having

jurisdiction should be consulted before installation.

Use of this unit as a construction heater or air conditioner is

not recommended during any phase of construction. Very

low return air temperatures, harmful vapors and operation

of the unit with clogged or misplaced filters will damage the

unit.

If this unit has been used for heating or cooling of buildings

or structures under construction, the following conditions

must be met or the warranty will be void:

The vent hood must be installed per these installation

instructions.

A room thermostat must control the unit. The use of

fixed jumpers that will provide continuous heating or

cooling is not allowed.

A pre-filter must be installed at the entry to the return air

duct.

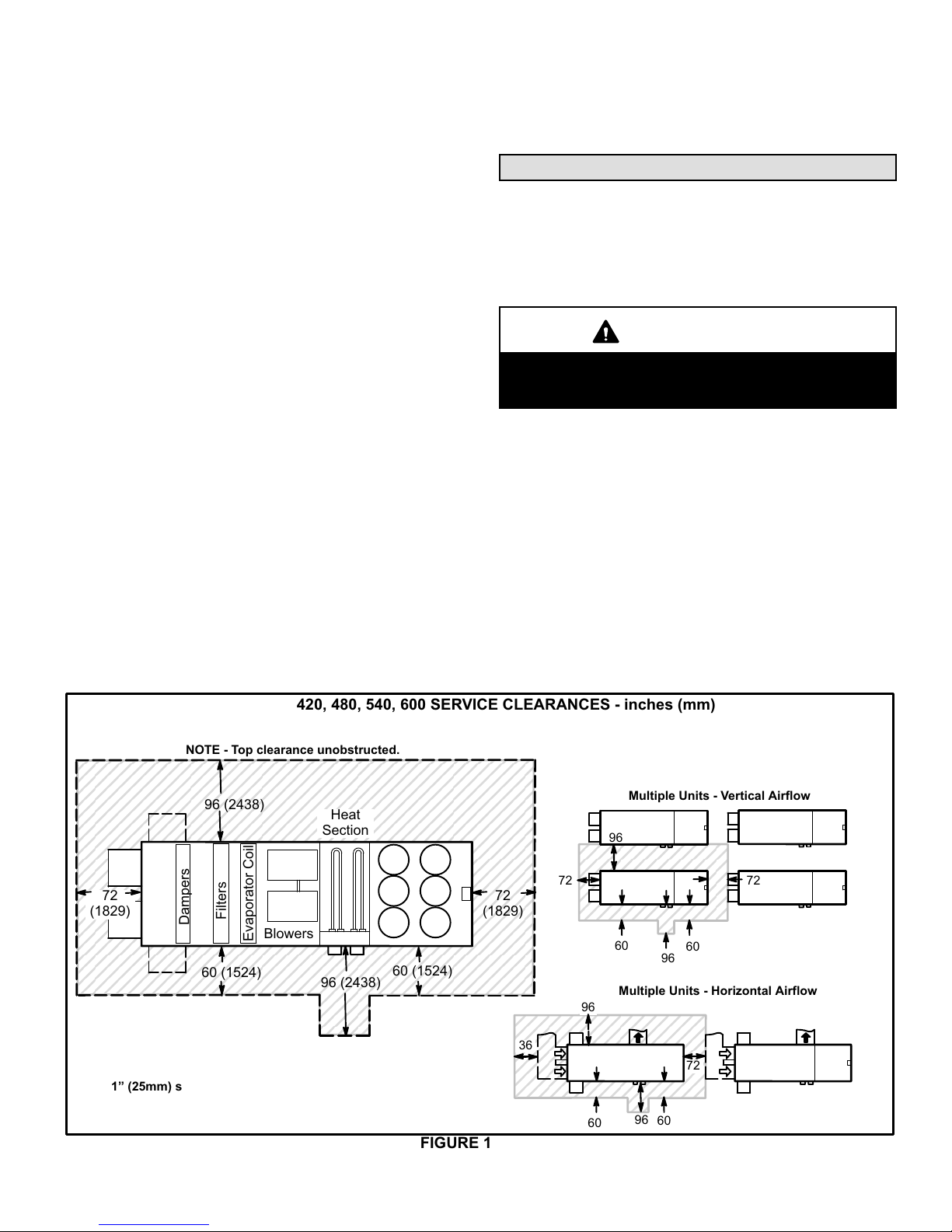

See figure 1 for unit clearances.

WARNING

Electric shock hazard and danger of

explosion. Can cause injury, death or

product or property damage. Turn off

gas and electrical power to unit before

performing any maintenance or

servicing operations on the unit. Follow

lighting instructions attached to unit

when putting unit back into operation

and after service or maintenance.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting

of refrigerant (CFC's and HCFC's) as of July 1, 1992.

Approved methods of recovery, recycling or reclaim

ing must be followed. Fines and/or incarceration may

be levied for non-compliance.

NOTICE

Roof Damage!

This system contains both refrigerant and oil. Some

rubber roofing material may absorb oil, causing the

rubber to swell. Bubbles in the rubber roofing

material can cause leaks. Protect the roof surface to

avoid exposure to refrigerant and oil during service

and installation. Failure to follow this notice could

result in damage to roof surface.

Unit Support

The return air duct must be provided and sealed to the

unit.

Return air temperature range between 55°F (13°C) and

80°F (27°C) must be maintained.

Air filters must be replaced and pre-filters must be

removed upon construction completion.

The input rate and temperature rise must be set per the

unit rating plate.

The heat exchanger, components, duct system, air

filters and evaporator coil must be thoroughly cleaned

following final construction clean-up.

The unit operating conditions (including airflow, cooling

operation, ignition, input rate, temperature rise and

venting) must be verified according to these installation

instructions.

507232-04 7/2017

CAUTION

As with any mechanical equipment, contact with

sharp sheet metal edges can result in personal injury.

Take care while handling this equipment and wear

gloves and protective clothing.

In downflow discharge installations, install the unit on a

non-combustible surface only. Unit may be installed on

combustible surfaces when used in downflow discharge

applications when installed on an S1CURB10E-1 roof

mounting frame.

NOTE - Securely fasten roof frame to roof per local codes.

CAUTION

To reduce the likelihood of supply / return air bypass

and promote a proper seal with the RTU, duct work /

duct drops / diffuser assemblies must be supported

independently to the building structure.

Page 5

A-Downflow Discharge Application

Roof Mounting with S1CURB10E-1

1- The S1CURB10E-1 roof mounting frame must be

installed, flashed and sealed in accordance with the

instructions provided with the frame.

5- Units require support along all four sides of unit base.

Supports must be constructed of steel or suitably

treated wood materials.

Duct Connection

2- The S1CURB10E-1 roof mounting frame should be

square and level to 1/16” per linear foot (1.6mm per 305

linear mm) in any direction.

3- Duct must be attached to the roof mounting frame and

not to the unit; supply and return plenums must be

installed before setting the unit.

Installer's Roof Mounting Frame

Many types of roof frames can be used to install the unit

depending upon different roof structures. Items to keep in

mind when using the building frame or supports are:

1- The base is fully enclosed and insulated, so an

enclosed frame is not required.

2- The frames or supports must be constructed with

non-combustible materials and should be square and

level to 1/16” per linear foot (1.6mm per 305 linear mm)

in any direction.

3- Frame or supports must be high enough to prevent any

form of moisture from entering unit. Recommended

minimum frame height is 14” (356mm).

4- Duct must be attached to the roof mounting frame and

not to the unit. Supply and return plenums must be

installed before setting the unit.

All exterior ducts, joints and openings in roof or building

walls must be insulated and weather-proofed with flashing

and sealing compounds in accordance with applicable

codes. Any duct passing through an unconditioned space

must be insulated.

CAUTION

In downflow applications, do not drill or punch holes

in base of unit. Leaking in roof may occur if unit base

is punctured.

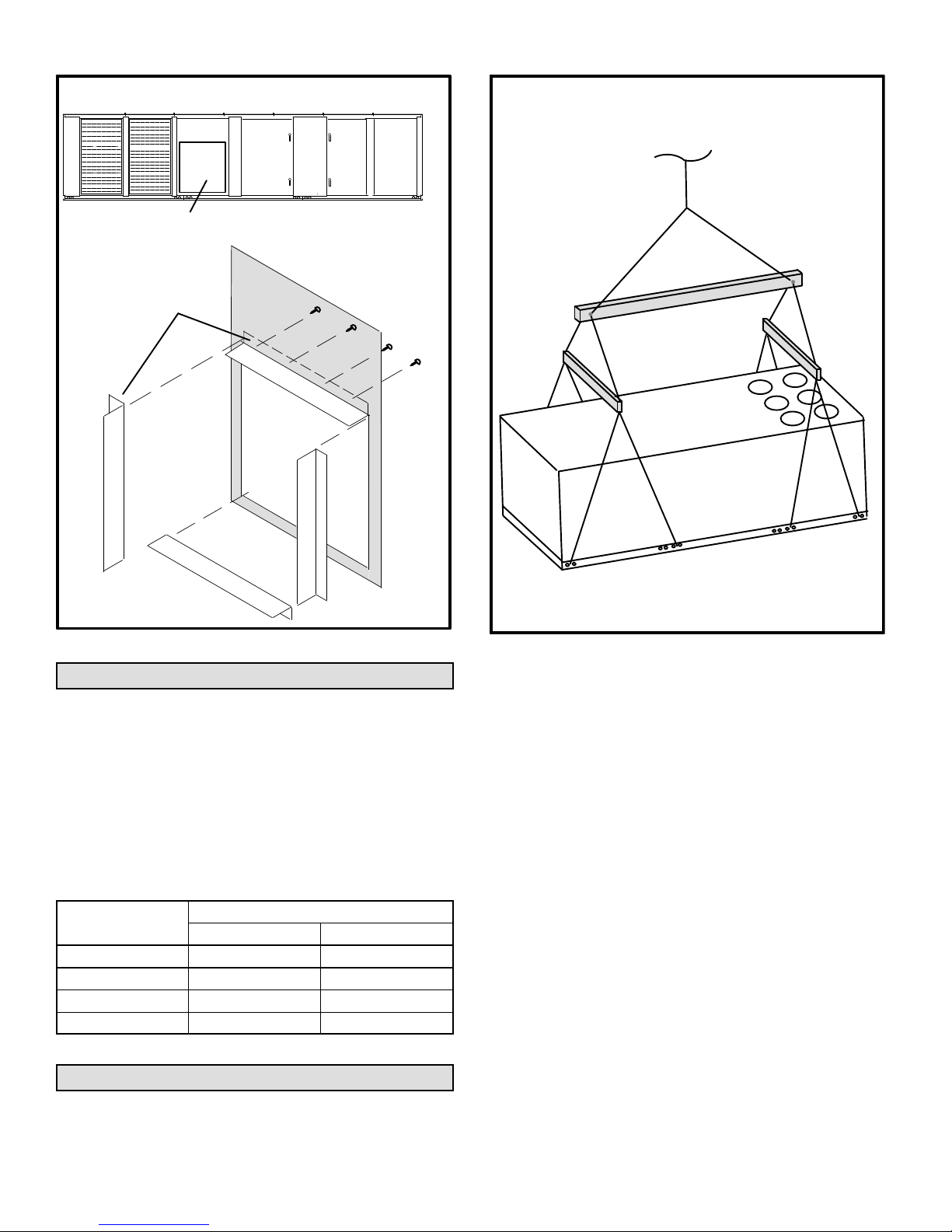

Horizontal Supply Air

1- Locate horizontal discharge air flanges in blower

section.

2- Remove and discard horizontal supply air shipping

cover from supply air panel on back side of unit. See

figure 2.

3- Position flanges as shown in figure 2. Make sure the

narrow side of the flange is positioned on the inside of the

unit panel. Secure with screws from the inside of the unit.

4- Secure ductwork to flanges per applicable codes.

420, 480, 540, 600 SERVICE CLEARANCES - inches (mm)

NOTE - Top clearance unobstructed.

96 (2438)

72

(1829)

1” (25mm) supply duct clearance for a distance of 3' (914m)

is required on LC units equipped with electric heat.

Filters

Dampers

60 (1524)

Blowers

Evaporator Coil

Heat

Section

96 (2438)

60 (1524)

FIGURE 1

72

(1829)

36

72

Multiple Units - Vertical Airflow

96

60

Multiple Units - Horizontal Airflow

96

60

96

60

96

60

72

72

Page 6

LGH/LCH420, 480, 540, 600

HORIZONTAL SUPPLY AIR

BACK OF UNIT

RIGGING UNIT

LIFTING POINT SHOULD BE DIRECTLY

ABOVE CENTER OF UNIT

HORIZONTAL SUPPLY AIR

SHIPPING COVER

INSTALL NARROW

SIDE OF FLANGE

ON THE INSIDE

OF PANEL

FIGURE 2

SECURE FLANGES

WITH SCREWS FROM

INSIDE OF UNIT

CAUTION - Do not

walk on unit.

ALL 8 POINTS MUST BE

USED FOR HOISTING

IMPORTANT - All panel must be in place for rigging.

FIGURE 3

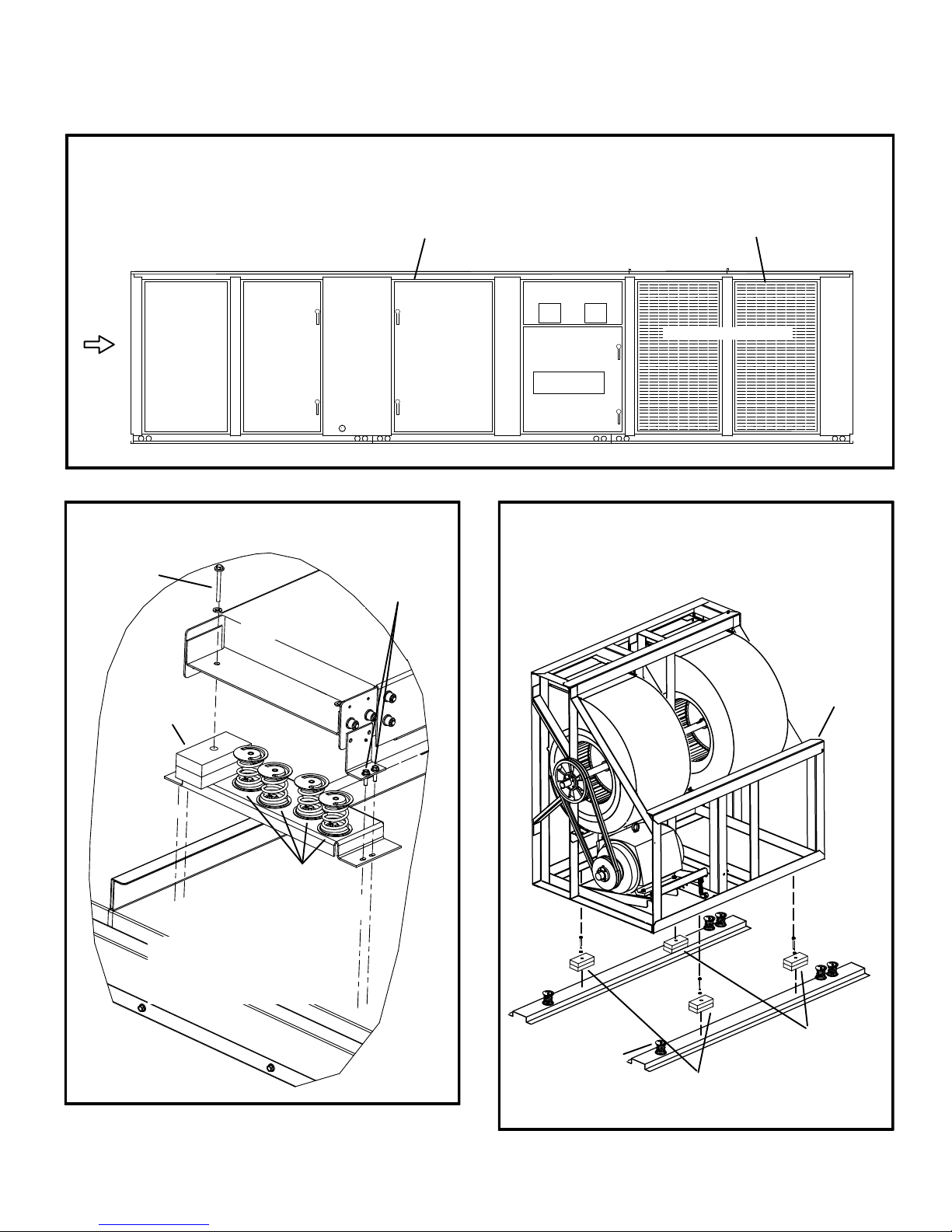

Rigging Unit For Lifting

1- Connect rigging to the unit base rail using holes in each

corner and unit sides. ALL 8 POINTS MUST BE USED

FOR HOISTING. See figure 3.

2- All panels must be secured in place before lifting.

3- Three field-provided spreader bars must be used.

THE LENGTHWISE SPREADER BAR MUST BE AT

LEAST 16 FEET (5 METERS) LONG. The horizontal

spreader bars must be at least 90 inches (2.3m) long

to prevent unit damage.

Maximum Weight*

Unit

420 8545 3875

480 8575 3889

540 8585 3893

600 8600 3900

*Maximum weight with all available factory-installed accessories.

Lbs. Kgs.

Shipping Blocks

Note - Wooden shipping blocks are installed only in

units equipped with optional factory-installed spring

mounts.

Page 7

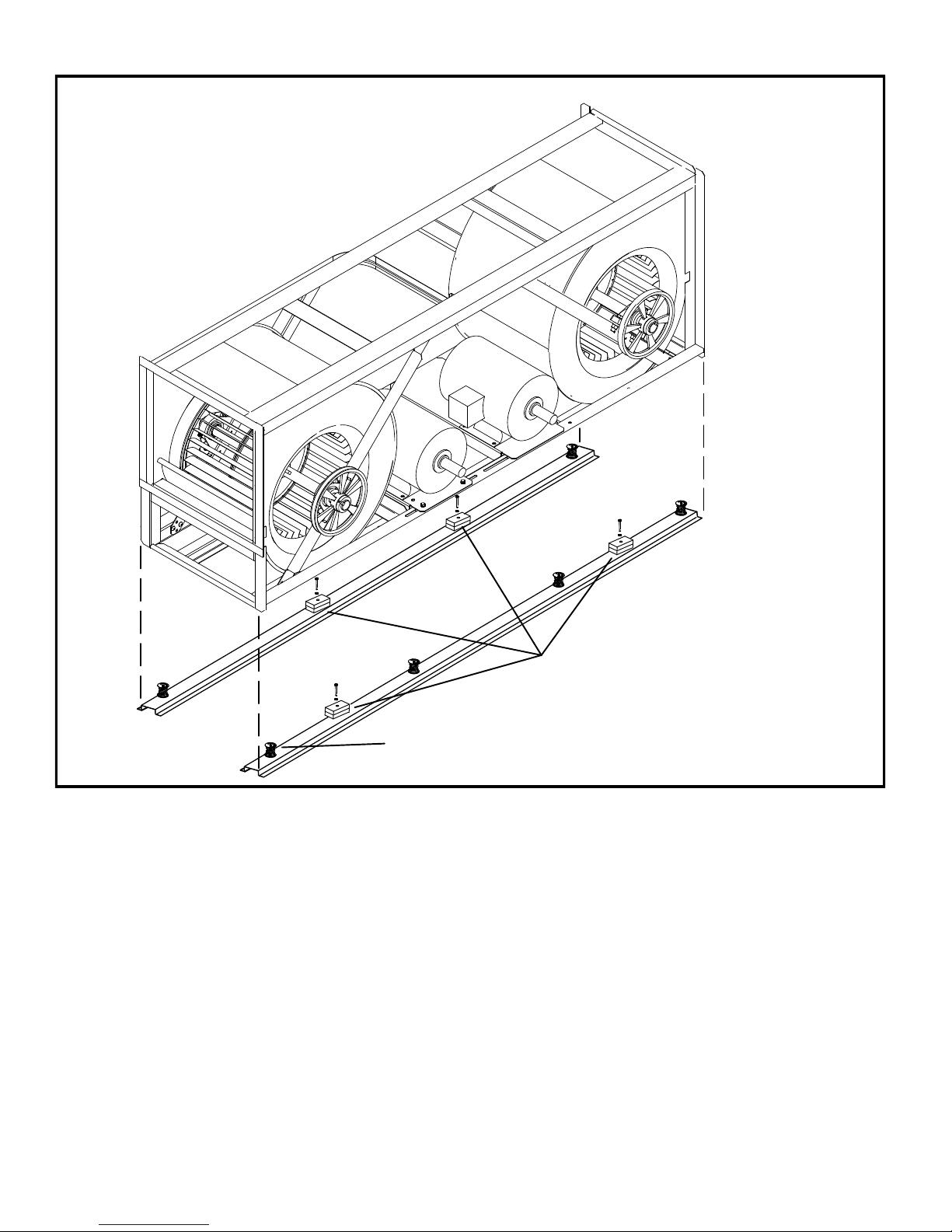

Compressor Hat Section Shipping Blocks

1- Remove screws and open front and back hinged

condenser access panels. See figure 4 for panel

location.

2- Remove two shipping blocks beneath the compressor

hat section. Access one shipping block from the front

side of the unit as shown in figure 5. The other shipping

block is located in the same place on the back side of

the unit.

3- Remove shipping screws. See figure 5.

Indoor Blower Shipping Blocks

1- Open front and back blower access panels. See figure

4 for panel location.

2- Remove four shipping blocks and screws located

beneath the indoor blower frame. Access two shipping

blocks from the back side of the unit as shown in figure

6. Access the other two shipping blocks from the same

place on the front side of the unit.

507232-04 7/2017

Power Exhaust Shipping Blocks

1- Open access panels on return end end of unit. See

figure 4.

ACCESS TO COMPRESSOR HAT SECTION AND INDOOR BLOWER SHIPPING BLOCKS

FRONT SIDE OF UNIT SHOWN

2- Remove four shipping blocks and screws beneath the

power exhaust assembly frame as shown in figure 7.

INDOOR BLOWER

SHIPPING BLOCK ACCESS

(BOTH SIDES)

RETURN

AIR END

OF UNIT

Economizer

Section

Blower Motor

Access

Opposite

FIGURE 4

COMPRESSOR HAT SECTION SHIPPING BLOCKS

(FRONT SIDE SHOWN)

REMOVE

SHIPPING

SCREW

REMOVE

SHIPPING

SCREWS

COMPRESSOR

HAT SECTION

Side

COMPRESSOR HAT SECTION

SHIPPING BLOCK ACCESS

(BOTH SIDES)

Heat

Section

Condenser Section

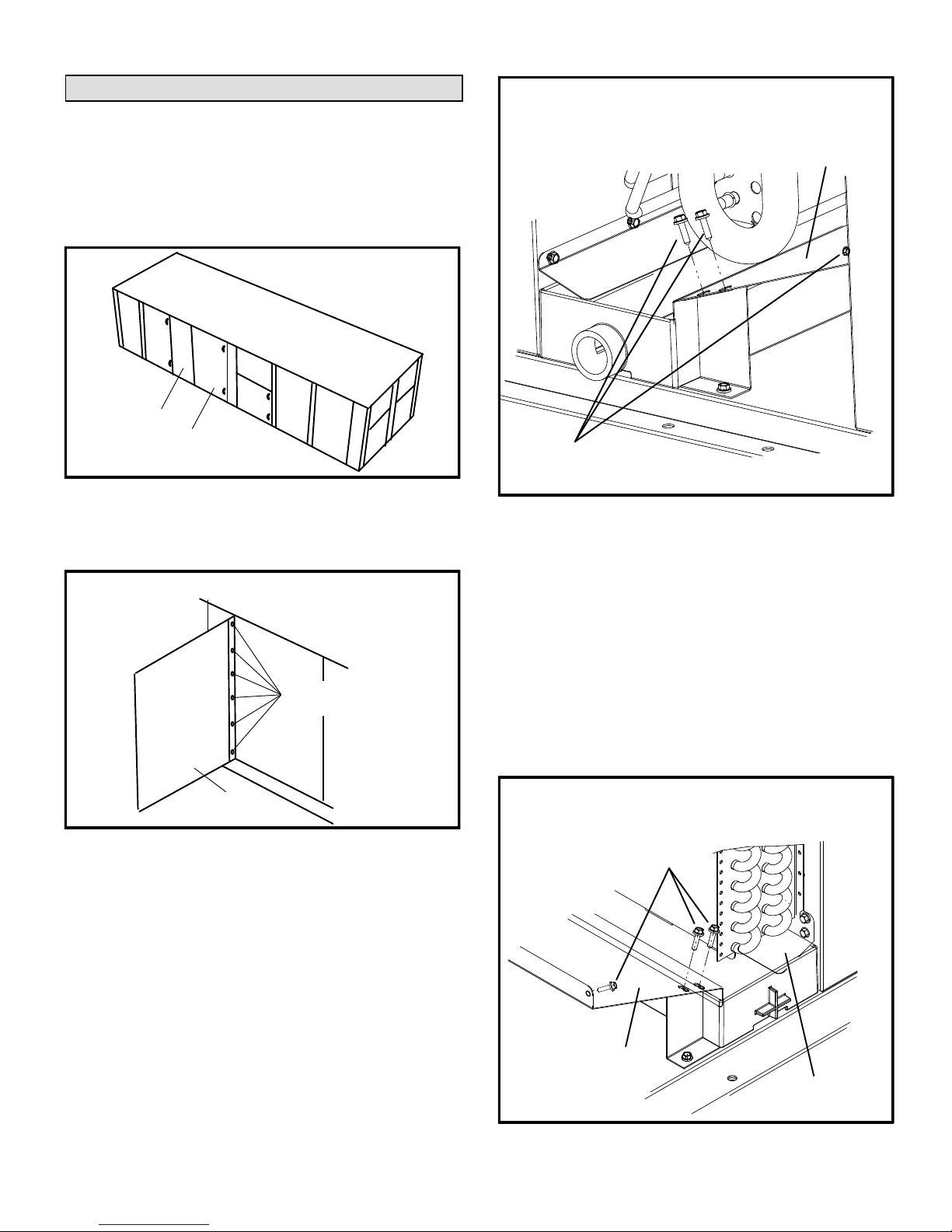

INDOOR BLOWER SHIPPING BLOCKS

(BACK VIEW SHOWN)

Note - Shipping blocks

are only present when

optional spring

mounts are installed.

REMOVE

SHIPPING

BLOCK

Note - Shipping blocks

are only present when

optional spring mounts

are installed.

FIGURE 5

OPTIONAL

SPRING

MOUNTS

OPTIONAL

SPRING MOUNT

(TYPICAL)

BLOCKS AND SCREWS

REMOVE SHIPPING

(BACK SIDE)

FIGURE 6

INDOOR

BLOWER

FRAME

REMOVE SHIP

PING BLOCKS

AND SCREWS

(FRONT SIDE)

Page 8

LGH/LCH420, 480, 540, 600

POWER EXHAUST SHIPPING BLOCKS

Note - Shipping blocks are

only present when optional

spring mounts are installed.

OPTIONAL SPRING

MOUNT (TYPICAL)

FIGURE 7

REMOVE SHIPPING

BLOCKS AND SCREWS

507232-04 7/2017

Page 9

Reverse Condensate Drain Pan

Unit is shipped from the factory with the condensate drain

facing the front of the unit. Reverse drain pan when needed

as follows:

1- Remove blower door on front of unit. See figure 8 and 9.

FRONT MULLION

BLOWER DOOR

FIGURE 8

REMOVE SCREWS SECURING DRIP SHIELD

AND DRAIN PAN

LONG DRIP

SHIELD

REMOVE

SCREWS

FIGURE 10

REMOVE BLOWER DOOR

REMOVE

SCREWS

BLOWER

DOOR

2- Remove and retain the patch plate on the front mullion.

3- Remove front mullion.

4- Remove and retain three screws securing drip shield.

See figure 10.

5- Locate the patch plate on the back mullion. Remove the

patch plate and install on the front mullion.

8- Remove and retain three screws securing drip shields

on back side of unit. See figure 11. Remove long drip

shield.

9- Push the drain pan downward and remove from unit.

10- Rotate the drain pan and reinstall.

11- Reinstall long drip shield with retained screws.

12- Replace mullions and blower door.

REMOVE SCREWS SECURING DRIP SHIELD

AND DRAIN PAN

REMOVE

SCREWS

6- Remove back mullion.

7- Install patch plate from the front mullion on the back

mullion. Position the patch plate in the same location as

the previous patch plate.

LONG DRIP

SHIELD

BACK DRIP

SHIELD

FIGURE 11

Page 10

LGH/LCH420, 480, 540, 600

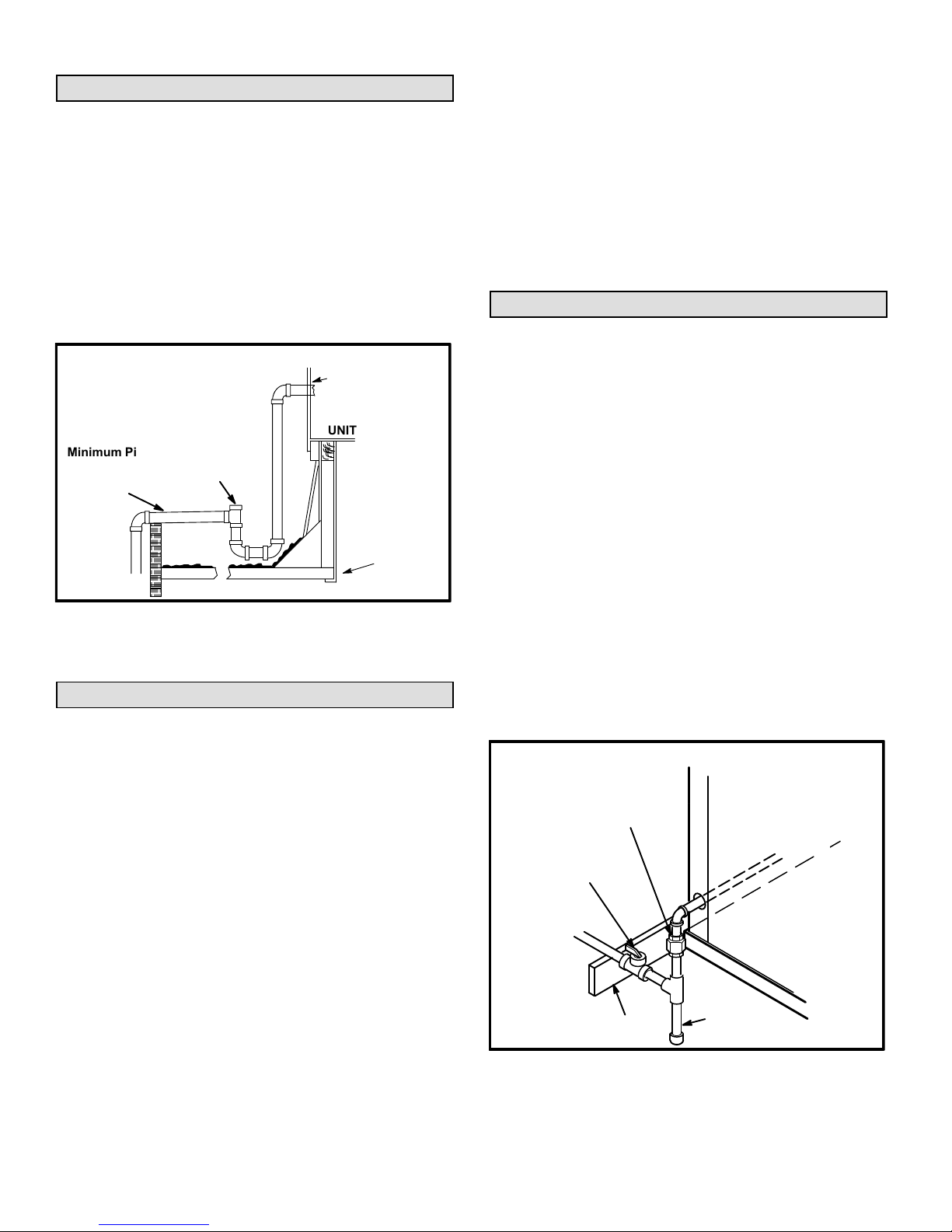

Condensate Drain

Make drain connection to the 1” N.P.T. drain coupling

provided on unit. A trap must be installed between drain

connection and an open vent for proper condensate

removal. See figure 12. It is sometimes acceptable to drain

condensate onto the roof or grade; however, a tee should

be fitted to the trap to direct condensate downward. The

condensate line must be vented. Check local codes

concerning condensate disposal. Refer to pages 1 and 2

for condensate drain location.

CONDENSATE DRAIN CONNECTION

NOTE - Allow clearance to

open doors when installing

condensate piping.

Minimum Pitch

1” (25 mm) per

10' (3 m) of line

OPEN VENT

FIGURE 12

CAULK AROUND

CONDENSATE

COUPLING

UNIT

MOUNTING

FRAME

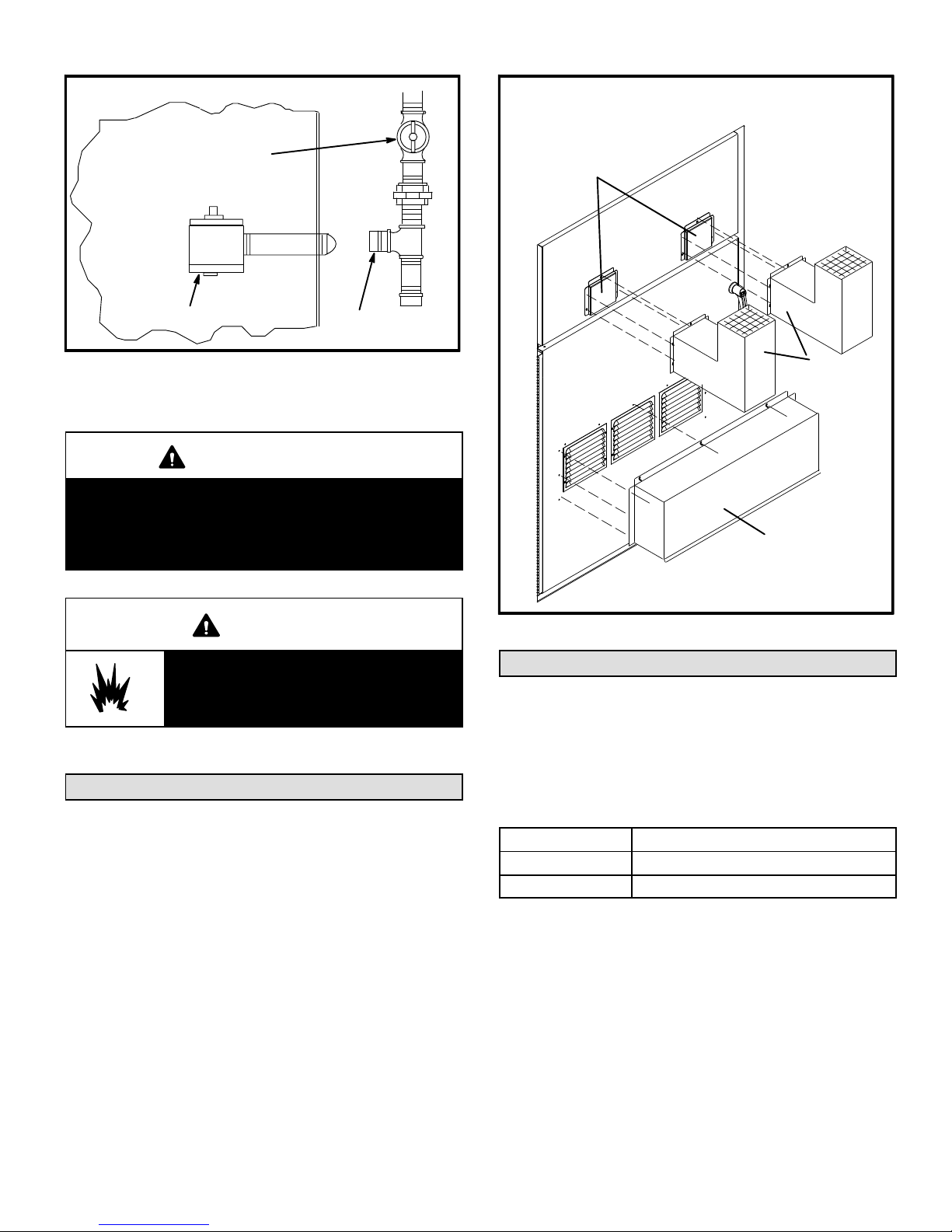

When making piping connections a drip leg should be

installed on vertical pipe runs to serve as a trap for

sediment or condensate. A 1/8” N.P.T. plugged tap is

located on gas valve for test gauge connection. Refer to

Heating Start-Up section for tap location. Install a ground

joint union between the gas control manifold and the main

manual shut-off valve. See figure 13 for side entry gas

supply piping.

Compounds used on threaded joints of gas piping shall be

resistant to the action of liquified petroleum gases.

Pressure Test Gas Piping

When pressure testing gas lines, the gas valve must be

disconnected and isolated. Gas valves can be

damaged if subjected to more than 0.5 psig (3.5kPa).

See figure 14.

NOTE-Codes may require that manual main shut-off

valve and union (furnished by installer) be installed in gas

line external to unit. Union must be of the ground joint

type.

After all connections have been made, check all piping

connections for gas leaks. Also check existing gas

connections up to the gas valve; loosening may occur during

installation. Use a leak detection solution or other preferred

means. Do not use matches candles or other sources of

ignition to check for gas leaks.

Connect Gas Piping

Two grommets are packaged with the flue exhaust and air

intake hoods located in the gas heat section. Grommets are

installed in the unit entry and gas heat division panel

knockouts. An additional grommet is required when routing

gas piping through the bottom of the unit.

Before connecting piping, check with gas company or

authorities having jurisdiction for local code requirements.

When installing gas supply piping, length of run from gas

meter must be considered in determining pipe size for 0.5”

w.c. (.12kPa) maximum pressure drop. Do not use supply

pipe smaller than unit gas connection. For natural gas

units, operating pressure at the unit gas connection must

be a minimum of 6.0” w.c. (1.5kPa) and a maximum of 14”

(3.50kPa) w.c. For LP/propane gas units, operating

pressure at the unit gas connection must be a minimum of

11” w.c. (2.74kPa) and a maximum of 13.5” w.c. (3.36kPa).

NOTE-In case emergency shut down is required, turn off

the main manual shut-off valve and disconnect main power

to unit. These devices should be properly labeled by the

installer.

SIDE ENTRY OF GAS SUPPLY PIPING

(REFER TO

GROUND

JOINT UNION

MANUAL MAIN

SHUT-OFF VALVE

TO GAS

SUPPLY

GAS PIPING

SUPPORT

LOCAL CODES)

TO GAS

VALV E

DRIP LEG

FIGURE 13

507232-04 7/2017

Page 11

PRESSURE TEST GAS LINE

MANUAL MAIN

SHUT-OFF VALVE

INSTALL EXHAUST AND INTAKE HOODS

REMOVE AND DISCARD

SHIPPING COVERS OVER

EXHAUST OPENINGS

GAS VALVE

FIGURE 14

CAP

CAUTION

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or othe sources of ignition

to check for gas leaks.

WARNING

Danger of explosion. Can cause injury

or product or property damage. Do not

use matches, candles, flame or other

sources of ignition to check for leaks.

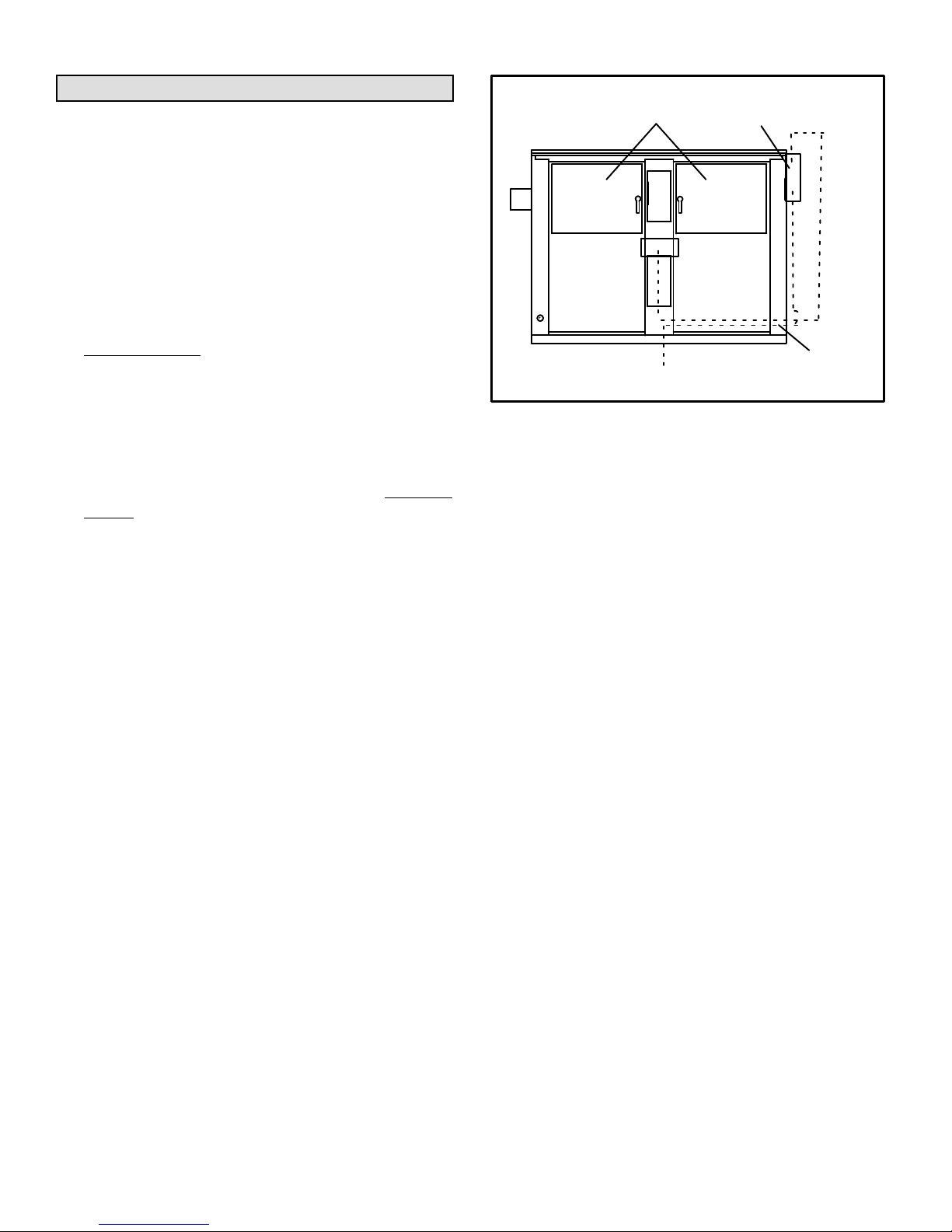

Flue and Intake Hoods

Hoods are shipped in the gas heat section. Install as shown

in figure 15. Secure with screws provided.

Two grommets are also shipped with the hood assemblies

for gas piping knockouts. Install one grommet in the gas

piping entry knockout. Install the other grommet in the heat

section division panel knockout.

EXHAUST

HOODS

INTAKE

HOOD

FIGURE 15

High Altitude Derate

Locate the high altitude conversion sticker in the unit

literature bag. Fill out the conversion sticker and affix next to

the unit nameplate.

Refer to table 1 for high altitude adjustments.

TABLE 1

HIGH ALTITUDE DERATE

Altitude Ft.* Gas Manifold Pressure

2000-4500 See Unit Nameplate

4500 And Above Derate 4% / 1000 Ft. Above Sea Level

*Units installed at 0-2000 feet do not need to be modified.

NOTE ‐ This is the only permissible derate for these units.

Page 12

LGH/LCH420, 480, 540, 600

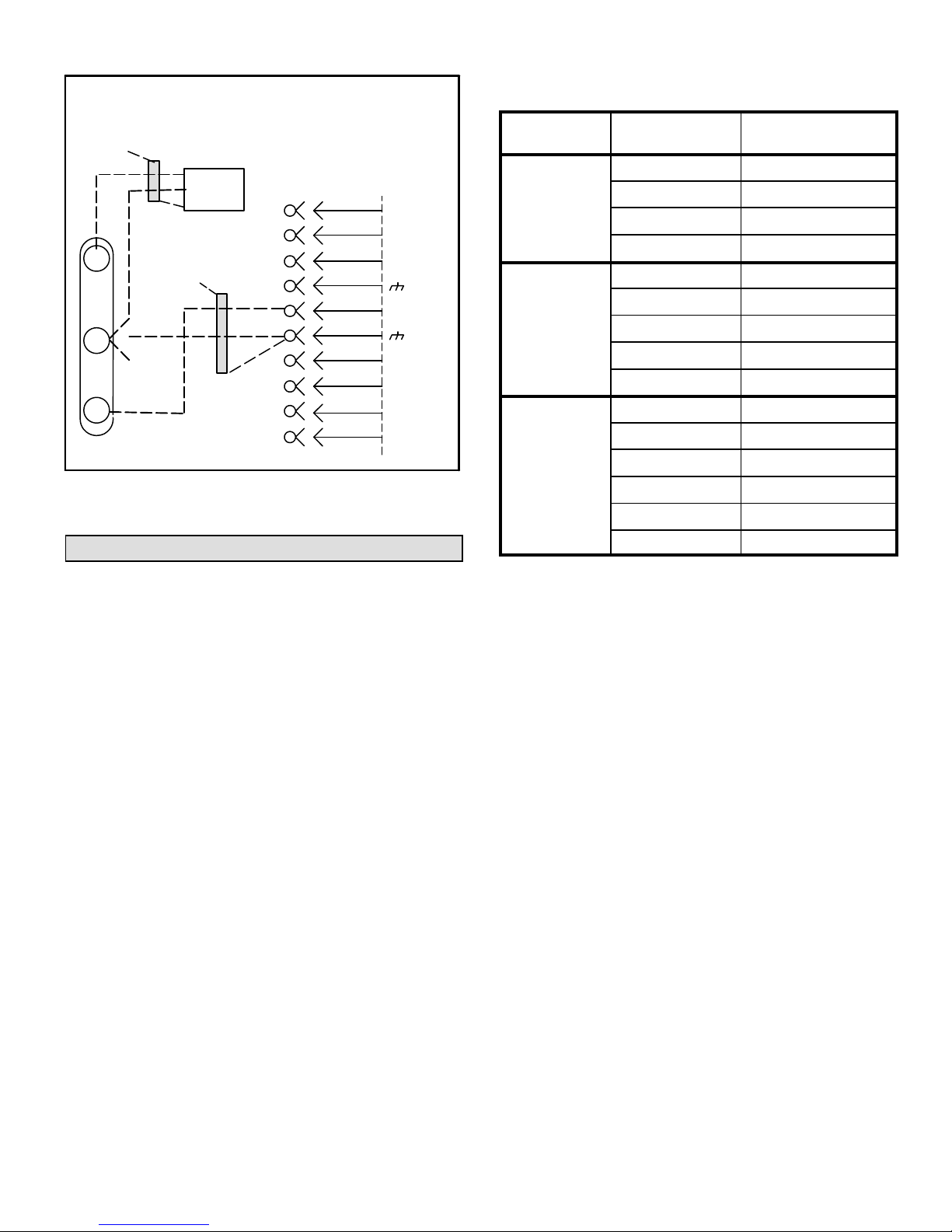

Electrical Connections

POWER SUPPLY

Do not apply power or close disconnect switch until

installation is complete. Refer to start-up directions in

Cooling Start-Up section. Refer closely to unit wiring

diagram.

Control Box

2nd Disconnect

Mounting Location

(Dual Power Supply)

Refer to unit nameplate for minimum circuit ampacity and

maximum fuse size.

1-T1 Control Transformer -

Units are factory-wired for 240/460/575 volt supply.

For 208V supply,

remove the insulated terminal cover

from the 208V terminal on the control transformer.

Move the wire from the transformer 240V terminal to

the 208V terminal. Place the insulated terminal cover

on the unused 240V terminal.

2- T18 Contactor Transformer -

230/460/575 volt units are factory wired. For 208V

supply, disconnect the orange wire (230V) at control

power transformer(s). Reconnect the red wire

(208V). Tape the exposed end of the 230V orange

wire.

3- Route electrical supply through the bottom or rear

electric entry area and connect to line side of TB2.

See unit dimensions in the front of this manual. If unit

has optional disconnect or circuit breaker, connect

power wiring to disconnect or circuit breaker. See

unit wiring diagram.

If unit is equipped with optional electric heat and dual

power supply is specified, refer to electric heat wiring

diagram on inside unit panels. See figure 16.

3- Units With Optional Field-Wired 120v GFCI Outlet -

Route and connect separate 120v wiring to GFCI outlets

which do not have factory-installed wiring.

CONTROL WIRING

A-Thermostat Location

Locate thermostat approximately 5 feet (1524mm) above

the floor in an area with good air circulation at average

temperature. Avoid locating the room thermostat where it

might be affected by:

-drafts or dead spots behind doors and in corners

-hot or cold air from ducts

-radiant heat from sun or appliances

-concealed pipes and chimneys

Page 13

TB2

Knockout

Bottom Power Entry

(conduit)

FIGURE 16

B-Wire Routing

Route thermostat cable or wires from subbase through

knockout or bottom power entry area provided in unit. Use

18 AWG wire for all applications using remotely installed

electro-mechanical and electronic thermostats.

IMPORTANT - Unless field thermostat wires are rated for

maximum unit voltage, they must be routed away from line

voltage wiring.

On hot gas reheat units, route wires from RH sensor or

remote switch through knockout or bottom power entry

area. For sensor installations, use 22AWG stranded, two

twisted pairs, individually shielded, 100% aluminum shield

with drain wire and Teflon jacket.

C-Wiring Connections

This unit is equipped with a Unit Controller which controls

unit function. Refer to the Unit Controller manual provided

with each unit.

The Unit Controller will operate the unit from a thermostat,

zone sensor, or zoning system based on the System Mode.

The default System Mode is the thermostat mode. Refer to

the Unit Controller Installation and Setup Guide to change

the System Mode. Use the menu navigation arrows and

select button; see SETTINGS>CONTROL.

1- Default Thermostat Mode -

The Unit Controller will operate two stages of heating

and cooling based on thermostat demands. Install

thermostat assembly in accordance with instructions

provided with thermostat. See figure 17 and wiring

diagrams on unit for field wiring.

IMPORTANT-Terminal connections at the wall plate or

subbase must be made securely. Loose control wire

connections may result in intermittent operation.

507232-04 7/2017

24 VOLT FIELD WIRING IN THERMOSTAT MODE

(Unit Controller in default T'Stat System Mode 6.01 Option 0)

2A2 (2HT/2C)

THERMOSTAT

R

C

G

W1

W2

Y1

Y2

O

UNIT CONTROLLER

24

THERMOSTAT

VAC

G

W1 W2 Y1 Y2

C

R

G

L

O

CP

O

NOTE - ON ELECTRO-ME

CHANICAL THERMOSTATS SET

ANTICIPATOR AT 0.1 AMPS.

Not all terminals

are provided on

all thermostats.

FIGURE 17

UNIT CONTROLLER

24VAC

DI1

RRC R

INPUTSSMOKE

DI2 DI3

Install optional A42

Phase Monitor and/or

S149 Overflow Control

HUMIDISTAT

DI4

C

2- Zone Sensor Mode -

The Unit Controller will operate up to four stages of

heating and cooling based on the Unit Controller

internal setpoints and the temperature from the A2

zone sensor. An optional Network Control Panel (NCP)

24 VOLT FIELD WIRING IN ZONE SENSOR MODE

(Unit Controller in Zone Sensor Mode)

24VAC

RC

SENSOR

AI1

Note - Install sensor and make communication wiring

connections as shown in literature provided with sensor.

UNIT CONTROLLER

IAQ

SENSOR

HUM

TMP

can also be used to provide setpoints. A thermostat or

return air sensor can be used as a back-up mode. See

figure 18 for field wiring.

OUTPUTS

D01

D02

A2 SENSOR

FIGURE 18

Page 14

LGH/LCH420, 480, 540, 600

3- Third-Party Zoning -

The Unit Controller will operate up to four stages of

heating and cooling based on a third-party zoning

system. Only 4 digital inputs are required to control

the rooftop unit: G (blower enable), OCP (occupied),

Y1 (enables discharge cooling) and W1 (enables

discharge heating). Make wiring connections as

shown in figure 19.

24 VOLT FIELD WIRING

FOR UNITS WITH SUPPLY AIR VFD

RTU w/Unit

Controller

G

O

Y1

W1

TB18

3rd Party

Zoning

Control

System

24VAC Digital Signals

Ventilation Demand

Occupied Demand

Cooling Demand

Heating Demand

D-Hot Gas Reheat Units Only -

Install humidity sensor in accordance with instructions

provided with sensor. A DDC input may be used to initiate

dehumidification instead of a sensor. Make wiring

connections as shown in figure 17 for Thermostat Mode

and figure 18 for Zone Sensor Mode. In addition, connect

either a zone sensor or a dehumidification input as shown

in figure 20.

Humidity Sensor Cable Applications:

Wire runs of 50 feet (mm) or less:

Use two separate shielded cables containing 20AWG

minimum, twisted pair conductors with overall shield.

Belden type 8762 or 88760 (plenum) or equivalent.

Connect both cable shield drain wires to TB1-7 as shown in

figure 20.

Wire runs of 150 feet (mm) or less:

Use two separate shielded cables containing 18AWG

minimum, twisted pair conductors with overall shield.

Belden type 8760 or 88760 (plenum) or equivalent.

Connect both cable shield drain wires to TB1-7 as shown in

figure 20.

Supply Static Pr.

Sensor (A30)

R C

CCC

Optional Building Static Pressure

Switch(s) (S37,S39) or Sensor (A34)

FIGURE 19

24 VOLT FIELD WIRING HOT GAS REHEAT UNITS

(Using A Humidity Sensor With Less Than 150 Ft. Wire Runs)

UNIT CONTROLLER

THERMOSTAT

W1

G

G24VAC

L

O

P

Y2

O

Y1

W2

24VAC

A91

HUMIDITY

SENSOR

VIN

IAQ

CR AI1 HUM

TMP

DRAIN

OUTPUTSSENSOR

D01

Wire runs over 150 feet (mm):

Use a local, isolated 24VAC transformer such as Lennox cat

#18M13 (20VA minimum) to supply power to RH sensor as

shown in figure 21. Use two shielded cables containing

20AWG minimum, twisted pair conductors with overall

shield. Belden type 8762 or 88760 (plenum) or equivalent.

HUMIDISTAT

DI4

DI3

C

D02

UNUSED

WIRE

TWISTED

PAIR

INPUTSSMOKE

24VAC

DI1

DI2

RRC R

ENERGY MANAGEMENT SYSTEM

DEHUMIDIFICATION SWITCH

507232-04 7/2017

GND

VOUT

NOT CONNECTED

Install optional A42

Phase Monitor and/or

S149 Overflow Control

FIGURE 20

Page 15

FIELD WIRING HOT GAS REHEAT UNITS

(Using A Humidity Sensor With More

NOT

CONNECTED

A91

VIN

GND

VO

Than 150 Ft. Wire Runs)

ISOLATED 24V

TRANSFORMER

J298A

DRAIN

NOT

CONNECTED

1

2

B

3

4

C

5

6

7

D

8

9

10

FIGURE 21

A55 UNIT

CONTROLLER

P298

R

C

AI-1

HUM

TMP

DO-1

C

DO-2

DI-1

Blower CFM Design Specifications

No. Stages /

Control Type

2 Stages /

Thermostat

3 Stages /

Thermostat

4 Stages /

Room Sensor

OR

Discharge Air

Control

Blower Speed

Htg.

Clg. High

Clg. Low

Ventilation

Htg.

Clg. High

Clg. Med.

2

Clg. Low

Ventilation

Htg.

Clg. High

Clg. Med. High

Clg. Med. Low

Clg. Low

TABLE 2

1

Design

Specified CFM

Multi-Staged Air Volume Start-Up

A-Design Specifications

Use table 2 to fill in field-provided, design specified blower

CFM for appropriate unit.

If only high and low cooling design specifications are

provided, set the medium cooling CFM at the high or low

cooling design spec or any CFM between.

B-Set Maximum CFM

Use table 2 to determine highest blower CFM for

appropriate unit. Adjust the blower pulley to deliver that

amount of CFM with only the blower operating. See

Determining Unit CFM in the Blower Operation and

Adjustment section.

C-Set Blower Speeds

1-Use the following menu to enter the blower design

specified CFM into the Unit Controller. Make sure

blower CFM is within limitations shown in table 3. Refer

to the Unit Controller manual provided with unit.

SETUP > TEST & BALANCE > BLOWER >

2-Enter the following design specifications as shown in

table 2.

Blower / Heat CFM

Cooling High CFM

Cooling Low CFM

Vent CFM

1

1

Page 16

Ventilation

1

Available blower speeds vary by unit and thermostat stages.

2

Requires a transfer relay (K27) and three-stage thermostat.

3-Adjust the blower RPM to deliver the target CFM based

on the measured static pressure using the blower table.

4-Measure the static pressure again and apply the static

pressure and RPM to the blower tables to determine

adjusted CFM.

5-Repeat adjustments until design CFM is reached.

1

The Unit Controller will prompt when more cooling stages

are available depending on the number of compressors and

the control mode.

2

Requires a transfer relay (K27) and three-stage thermostat.

D-Set Damper Minimum Position

To maintain required minimum ventilation air volumes when

the unit is in the occupied mode, two minimum damper

positions must be set. The Unit Controller will open the

dampers to “Min OCP Blwr Low” when blower CFM is

BELOW a “midpoint” CFM. The Unit Controller will open the

damper to “Min OCP Blwr High” when blower CFM is at or

ABOVE the “midpoint” CFM.

The Unit Controller will calculate the “midpoint” CFM.

Set Minimum Position 1

Use the following menu in the Unit Controller to set “Min

OCP Blwr Low” for the blower CFM below the “midpoint”

CFM. When navigating into this menu, the Unit Controller

will bring on the corresponding blower speed and allow

damper position adjustment.

LGH/LCH420, 480, 540, 600

SETTINGS > RTU OPTIONS > EDIT PARAMETER >

ENTER DATA ID - 9 > MIN DAMPER LOW BLOWER =

X.X%

Measure the intake air CFM. If the CFM is lower than the

design specified CFM for ventilation air, use the Unit

Controller to increase the damper percent open. If the

CFM is higher than specified, decrease the damper

percent open.

Note - Intake air CFM can also be determined using the

outdoor air temperature, return air temperature and mixed

air temperature. Refer to the economizer or outdoor air

damper installation instructions.

Set Minimum Position 2

Use the same menu in the Unit Controller to set “Min OCP

Blwr High” for the blower CFM above the “midpoint” CFM.

When navigating into this menu, the Unit Controller will

bring on the corresponding blower speed and allow damper

position adjustment.

SETTINGS > RTU OPTIONS > DAMPER > MIN

DAMPER POSITION BLOWR ON HIGH = X.X%

Measure the intake air CFM. If the CFM is lower than the

design specified CFM for ventilation air, use the Unit

Controller to increase the damper percent open. If the CFM

is higher than specified, decrease the damper percent

open.

Note - Intake air CFM can also be determined using the

outdoor air temperature, return air temperature and mixed

air temperature. Refer to the economizer or outdoor air

damper installation instructions.

E-Inverter Bypass Option

The supply air inverter is factory-set to by-pass the inverter

manually. To by-pass the inverter and operate the blower in

the constant air volume mode, use the following Unit

Controller menu and set to “engaged”:

SETTINGS > RTU OPTIONS > BLOWER > VFD

BYPASS

To configure the unit to by-pass the inverter automatically,

use the following Unit Controller menu.

SETUP > INSTALL

Press SAVE until the menu reads:

CONFIGURATION ID 1

Change the 6

th

character position to A for automatic bypass

option.

Press SAVE

Caution - Units not equipped with an inverter will have the

th

6

character set to N, indicating the inverter is not

bypassed. The blower motor could be damaged and/or

result in product or property damage if the setting is

changed to automatic or manual.

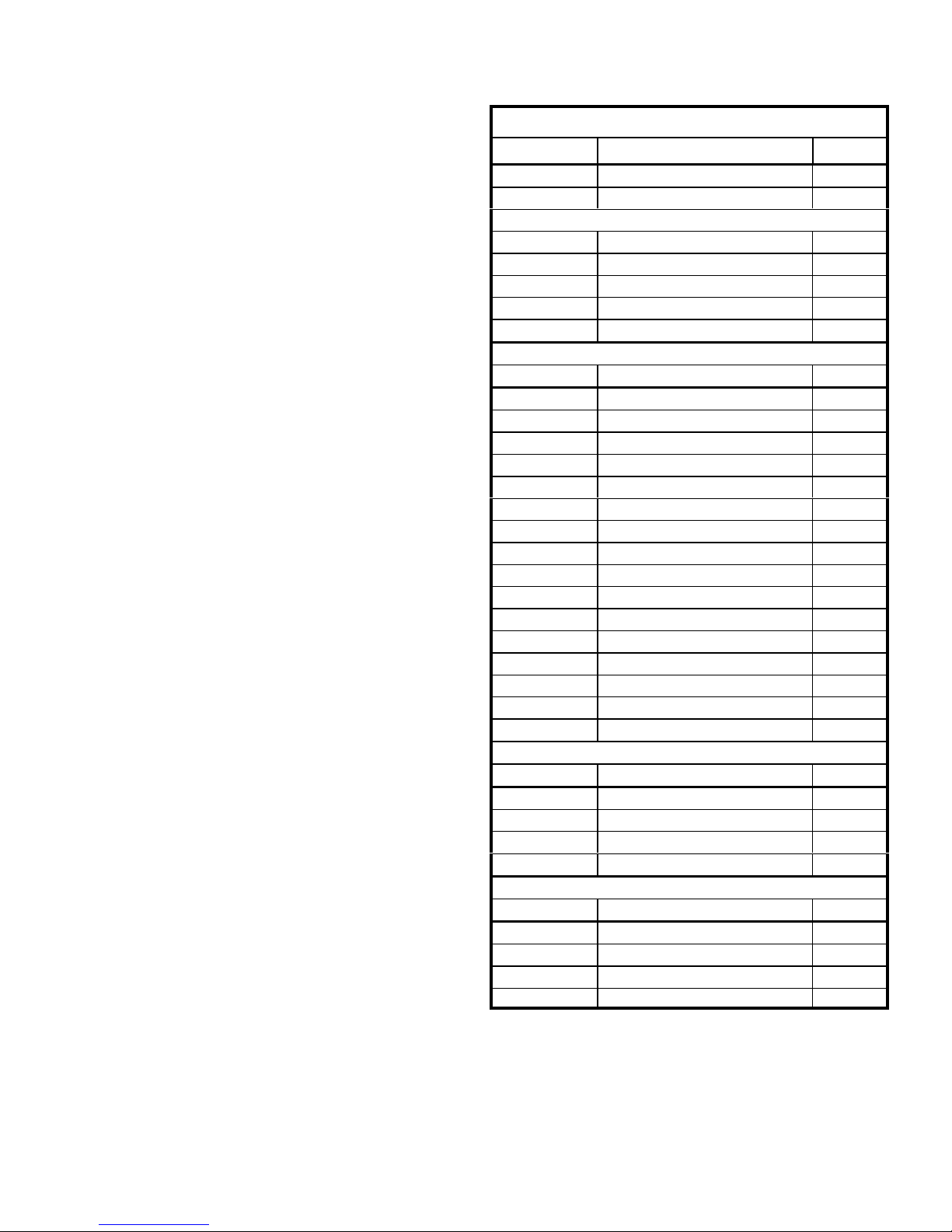

MINIMUM AND MAXIMUM CFM - STAGED BLOWERS

TABLE 3

Gas Heat Minimum CFM

Unit Gas Heat Size Airflow CFM

LGH420-600 Std, Std Mod 9300

LGH420-600 High, High Mod 10800

Electric Heat Minimum CFM

Unit Heat Size (kw) Airflow CFM

LCH420 All 9800

LCH480 All 11200

LCH540 All 12600

LCH600 All 14000

Cooling minimum CFM

Unit Blower Speed Airflow CFM

LGH/LCH420 Cool 1; Clg. Low 5600

Cool 2; Clg. Med. Low 5600

Cool 3; Clg. Med. High 5600

Cool 4; Clg. High 9800

LGH/LCH480 Cool 1; Clg. Low 6400

Cool 2; Clg. Med. Low 6400

Cool 3; Clg. Med. High 6400

Cool 4; Clg. High 11200

LGH/LCH540 Cool 1; Clg. Low 7200

Cool 2; Clg. Med. Low 7200

Cool 3; Clg. Med. High 7200

Cool 4; Clg. High 12600

LGH/LCH600 Cool 1; Clg. Low 8000

Cool 2; Clg. Med. Low 8000

Cool 3; Clg. Med. High 8000

Cool 4; Clg. High 14000

Smoke and Ventilation Minimum CFM

Unit Not Applicable Airflow CFM

LGH/LCH420 NA 5250

LGH/LCH480 NA 6000

LGH/LCH540 NA 6750

LGH/LCH600 NA 7500

Heating and Cooling Maximum CFM

Unit Blower Speed Airflow CFM

LGH/LCH420 High 16800

LGH/LCH480 High 19200

LGH/LCH540 High 21600

LGH/LCH600 High 24000

507232-04 7/2017

Page 17

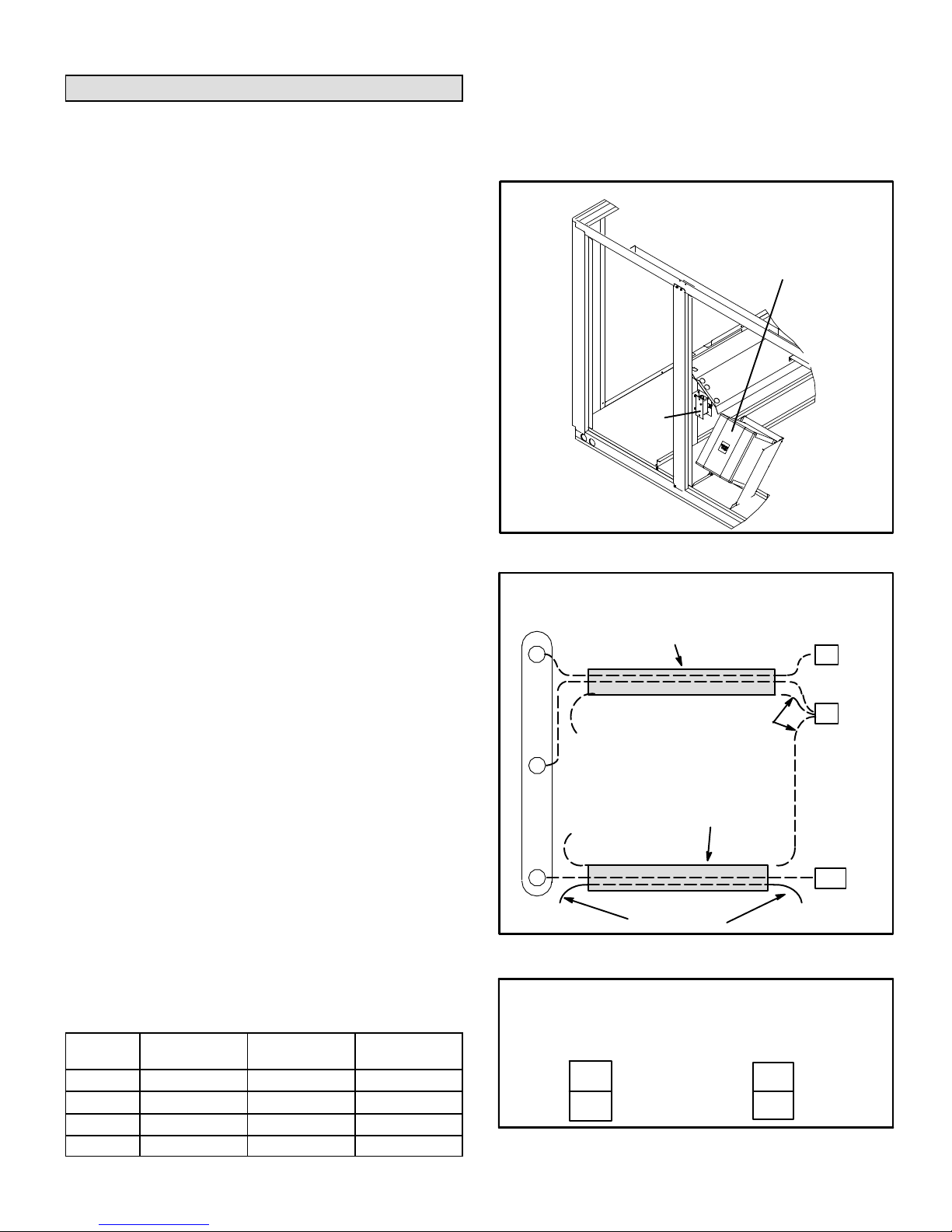

Variable Air Volume Start-Up

Units may contain an optional supply air blower equipped

with a variable frequency drive A96 (VFD) which varies

supply air CFM.

The supply air VFD (A96) is located near the compressors.

See figure 22.

A-Start-Up

1- A pressure transducer (A30) is shipped in a box in the

blower compartment. Install the transducer according

to manufacturer's instructions.

Note - Make sure the transducer is installed in the main duct

at least 2/3 of the distance away from the unit.

2- Two twisted pairs of shielded cable must be used to

connect the pressure transducer. See figure 23.

3- Open all zone dampers and/or boxes.

4- Locate the A55 Unit Controller in the control box.

5- Use the Unit Controller to calibrate the blower CFM.

Select the SETUP->TEST & BALANCE->BLOWER

menu to start the blower. The Unit Controller will

display the percent of blower speed. Adjust blower

speed percentage to meet design airflow

specifications. Allow blower speed to stabilize.

6- Press SAVE to display the current static pressure. If

the static pressure meets the design specification,

press SAVE again to set the setpoint. If the static

pressure does not meet the design specification,

adjust the pressure and press SAVE to set the

setpoint.

7- Record new setpoints in table 4.

Note - The Unit Controller will lock-out the unit for 5

minutes if static pressure exceeds 2.0”w.c. for 20

seconds. The Unit Controller will permanently shut down

the unit after three occurrences. See Unit Controller

parameters 110, 42, and 43 to adjust default values.

8- If the desired CFM cannot be met with current pulley

setup, refer to the Blower Operation and Adjustments

section to adjust CFM.

B-Unit Operation

Use the Unit Controller to check unit mechanical operation.

See the Service - Test section of the Unit Controller manual.

C-Supply Air VFD By-Pass Plug (Optional)

IMPORTANT - All dampers must be open to prevent

damage to duct work and dampers.

TABLE 4

RECORD ADJUSTED SETPOINTS

Parameter

386 Smoke

387 Ventilation

388 Heating

389 Cooling

Setpoint

Description

Setpoint

“w.c.

Display

Setting

Page 18

The supply air VFD may be by-passed using jack/plug

connections. Locate J/P198 connectors in control box

area under the relays. Disconnect J198 from P198 and

connect J204 to P198. See figure 24. Blower will operate in

constant air volume mode.

SUPPLY AIR VARIABLE FREQUENCY DRIVE

SUPPLY AIR

VFD (A96)

OUTDOOR

AIR

SECTION

OPTIONAL

A34

VIEW SHOWN

FROM FRONT

SIDE OF UNIT

FIGURE 22

PRESSURE TRANSDUCER WIRING

UNIT

DRAIN

CONTROLLER

TB18

6

9

TB24

26

A30

+

_

CONNECTED

+

NOT

CONNECTED

NOT

UNUSED WIRE

TWISTED

PAIR

TWISTED

PAIR

FIGURE 23

SUPPLY AIR VFD BY-PASS CONNECTOR

CONNECTORS USED

FOR SUPPLY AIR

VFD OPERATION

J198

P198

CONNECTORS USED TO BY-PASS

VFD AND OPERATE SUPPLY AIR

BLOWER AT MAXIMUM SPEED

J204

P198

FIGURE 24

LGH/LCH420, 480, 540, 600

BLOWER ASSEMBLY

UPPER

ADJUSTMENT

NUT

LOCKWASHER

LOWER

ADJUSTMENT

NUT

BLOWER

MOTOR

PULLEY

MOTOR

SUPPORT

PLATE

BELT TENSION

ADJUSTMENT

BOLTS

FIGURE 25

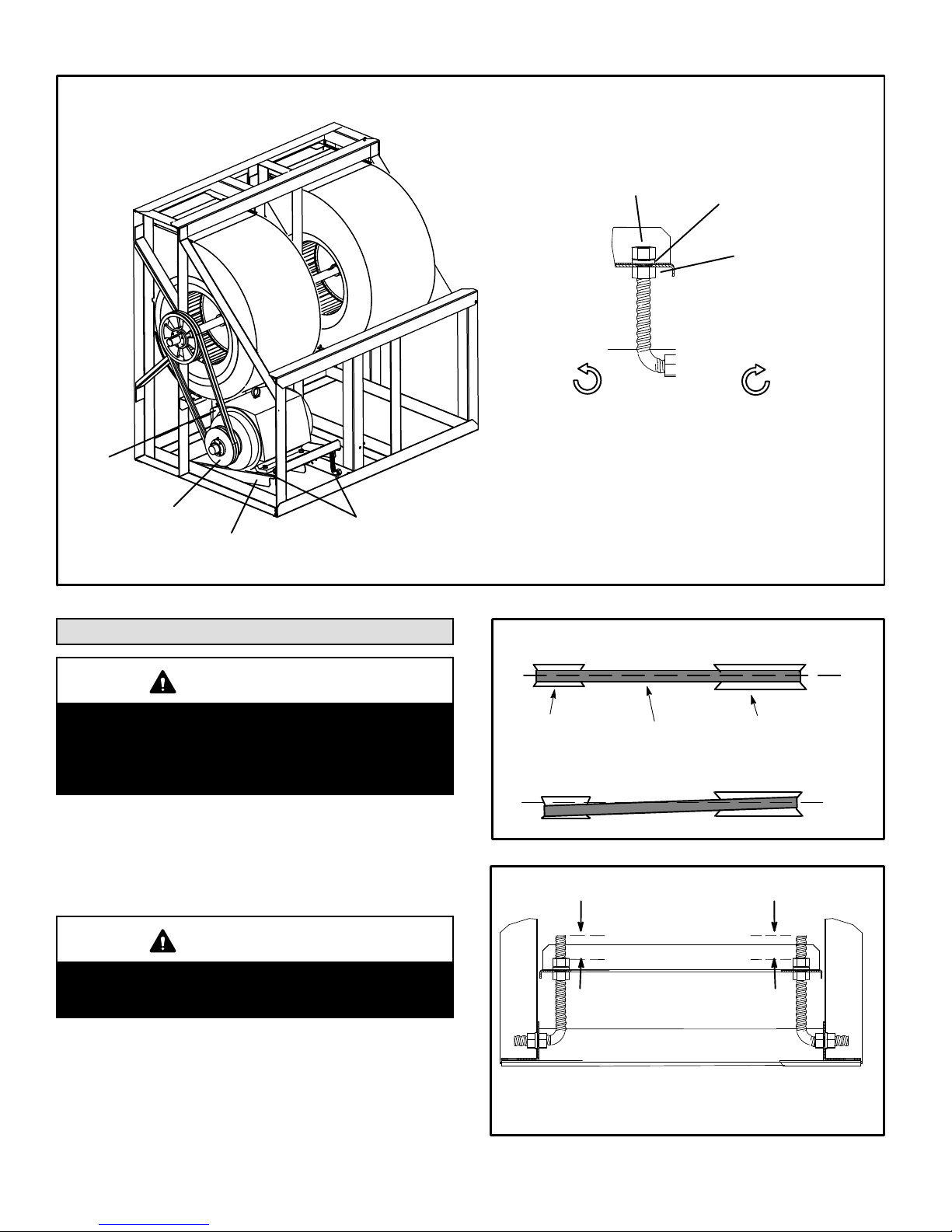

Blower Operation and Adjustments

IMPORTANT

Three phase scroll compressors must be phased se

quentially for correct compressor and blower rota

tion. Follow “COOLING START-UP” section of instal

lation instructions to ensure proper compressor and

blower operation.

A-Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are maintained.

Tighten belt as shown in figure 25.

TO LOOSEN BELT

Turn upper nut on both ad

justment bolts counter

clockwise. Secure support

plate with lower nuts.

TO TIGHTEN BELT

Turn lower nuts on both

adjustment bolts clock

wise. Secure support

plate with upper nuts.

PULLEY ALIGNMENT

ALIGNED

BLOWER

PULLEY

BELT

NOT ALIGNED

FIGURE 26

BLOWER MOTOR SUPPORT PLATE

MOTOR

PULLEY

IMPORTANT

After a 24-48 hour period of operation, tighten new

belts again. This will allow belt to stretch and seat

into grooves.

Make sure blower and motor pulley are aligned as shown in

figure 26. Also make sure motor support plate is level. See

figure 27.

507232-04 7/2017

Measure the position of the nuts on the adjusting

screw to make sure the support plate is level.

Tighten upper and lower adjustment nuts.

FIGURE 27

Page 19

Loading...

Loading...