Lennox LGH092H4B, LGH094U4E, LGH102H4B, LGH092H4M, LGH120H4B Unit Information

...

Corp. 1008-L2

Service Literature

Revised 5/2015

LGH092H through 152U

The LGH092H, 094U, 102H, 120H, 122U, 150S and

152U units are configure to order units (CTO) with a wide

selection of factory-installed options. Units are avail

able in 130,000, 180,000 Btuh or 240,000 Btuh (38.1,

52.7 or 70.3 kW) heating inputs. Gas heat sections are

designed with Lennox' aluminized steel tube heat ex

changers with stainless steel as an option.

Cooling capacities range from 7.5 to 12.5 tons (38.1 to

70.3 kW). All units are equipped with two compressors.

Ultra-high efficiency units are available with an optional di

rect drive blower or belt drive blower equipped with a sup

ply air inverter. Standard and high efficiency units are

available with a belt drive blower equipped with an option

al supply air inverter. The blower will operate at lower

speeds when demand is low and increase to higher

speeds when demand is high.

The following examples show the model numbers of tenton units with all available blower options:

LGH120H4B High Efficiency Belt Drive

LGH120H4M High Efficiency Belt Drive with Inverter

LGH122U4M Ultra High Efficiency Belt Drive with Inverter

LGH122U4E Ultra High Efficiency Direct Drive

Note - Ten-ton units are available in high and ultra high effi

ciencies only.

Standard and high efficiency units come standard with a

lightweight, all-aluminum condenser coil; optional, fin/

tube condenser coils are available. Ultra-high efficiency

units come standard with a tube/fin condenser coil.

Ultra high efficiency units come standard with two singlespeed compressors plumbed in tandem to form a single re

frigerant circuit.

Units are also designed for R410A refrigerant. See unit

nameplate. Operating pressures and pressure switch set

tings are significantly higher than R22 charged units. Ser

vice equipment must be rated for R410A.

Standard and high efficiency units offer mechanical cooling

down to 0°F when properly equipped. Ultra-high efficiency

units offer mechanical cooling down to 40°F.

All LGH units are designed to accept any of several differ

ent energy management thermostat control systems with

minimum field wiring. Factory or field provided control op

tions connect to the unit with jack plugs. When ”plugged in”

the controls become an integral part of the unit wiring.

Information contained in this manual is intended for use by

qualified service technicians only. All specifications are

subject to change. Procedures outlined in this manual are

presented as a recommendation only and do not super

sede or replace local or state codes.

LGH SERIES

7.5 to 12.5 ton

38.1 to 70.3 kW

If the unit must be lifted for service, rig unit by attaching four

cables to the holes located in the unit base rail (two holes at

each corner). Refer to the installation instructions for the

proper rigging technique.

3

3

Table of Contents

Options / Accessories Page 2.....................

Specifications Page 8............................

Blower Tables Page 14............................

Electrical Data Page 19...........................

Parts Arrangement Page 25.......................

I-Unit Components Page 28.......................

II-Placement and Installation Page 47...............

III-Charging Page 47..............................

IV-Start Up - Operation Page 55....................

V-System Service Checks Page 57................

High Altitude Page 59.........................

VI-Maintenance Page 59..........................

VII-Accessories Page 60..........................

VIII-Belt Drive Supply Air Inverter Page 67...........

IX-Direct Drive Supply Air Blower Page 70...........

X-Staged Supply Air Operation Page 71.............

XI-Wiring and Operation Sequence Page 72.........

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property va, personal in

jury or loss of life. Installation and service must be

performed by a licensed professional HVAC installer

or equivalent, service agency, or the gas supplier

CAUTION

As with any mechanical equipment, contact with

sharp sheet metal edges can result in personal in

jury. Take care while handling this equipment and

wear gloves and protective clothing.

© 2015

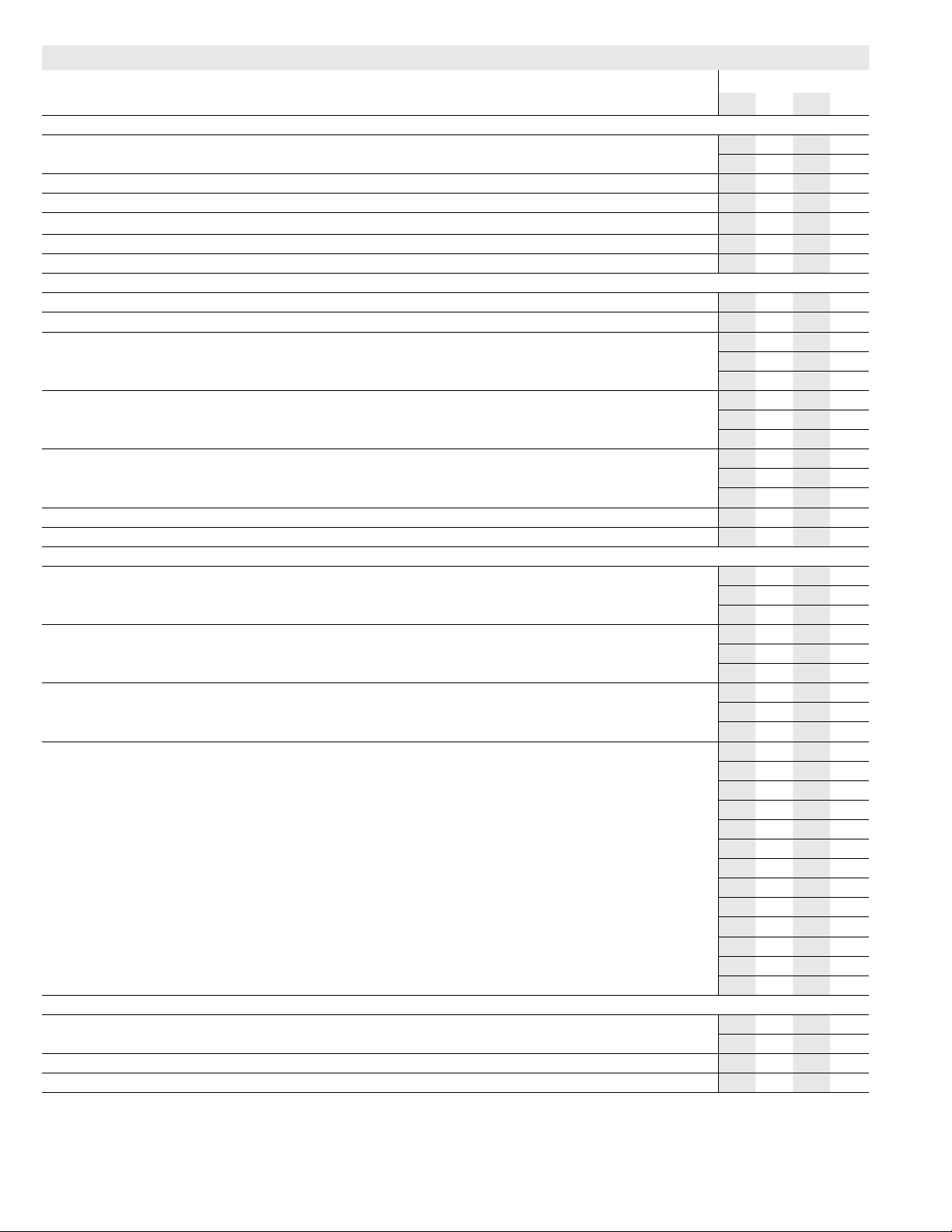

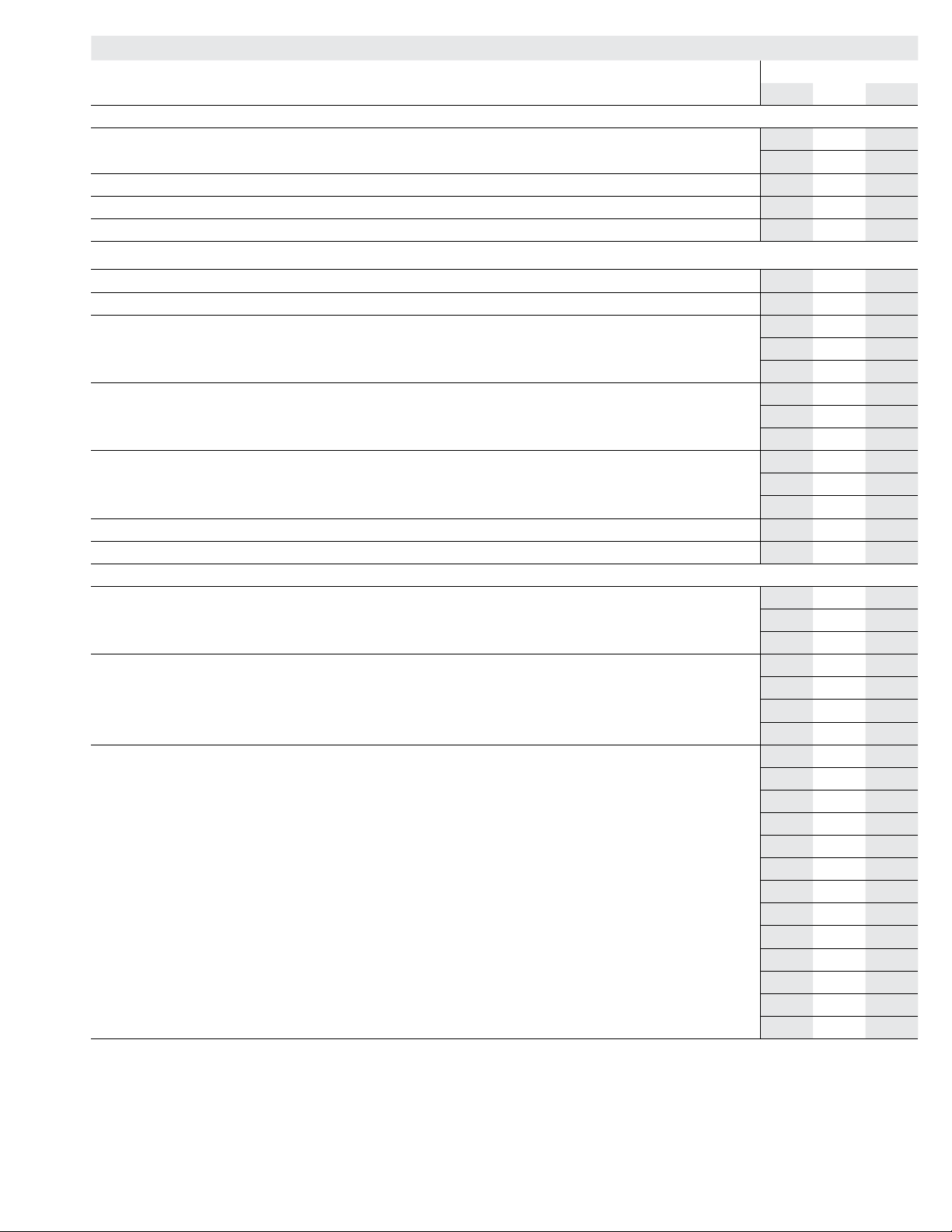

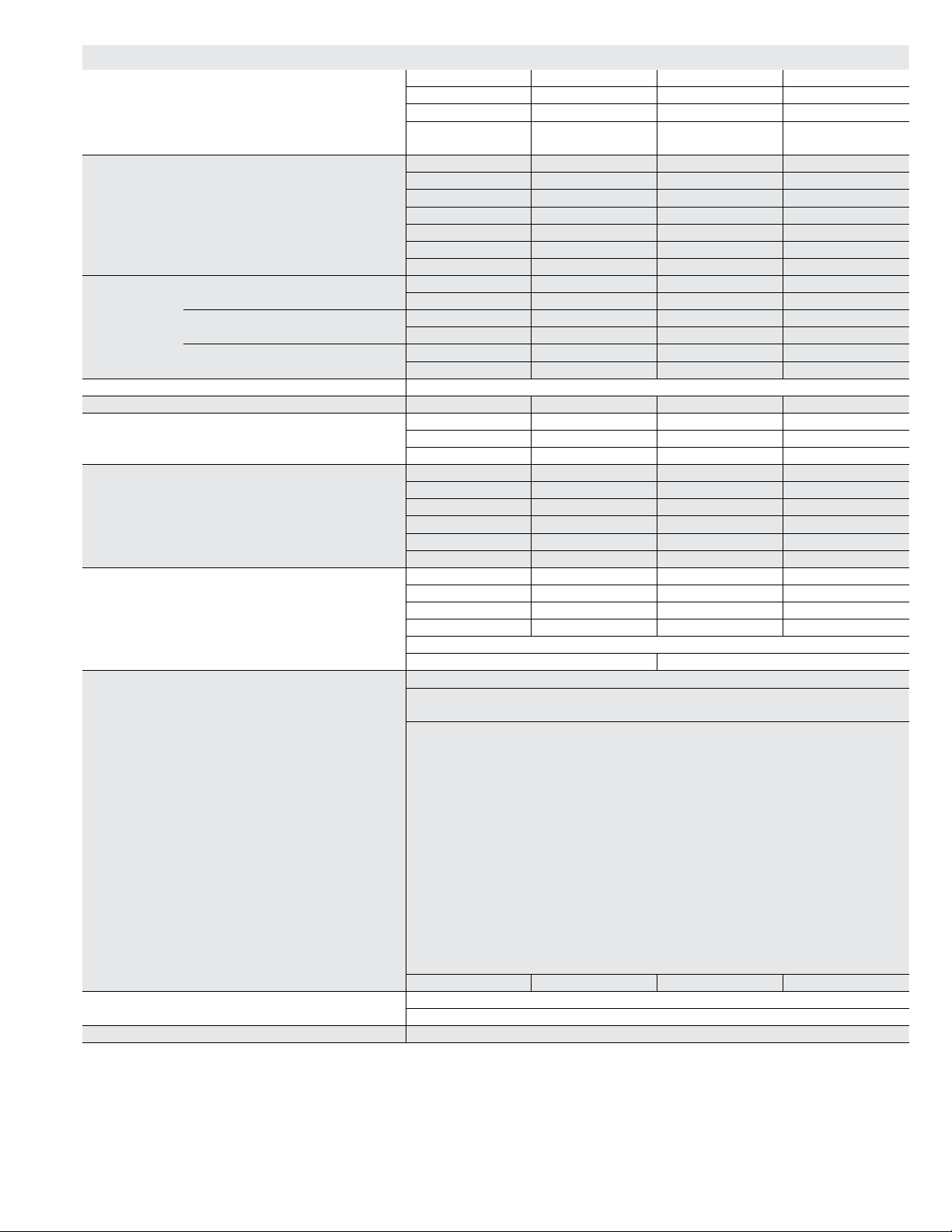

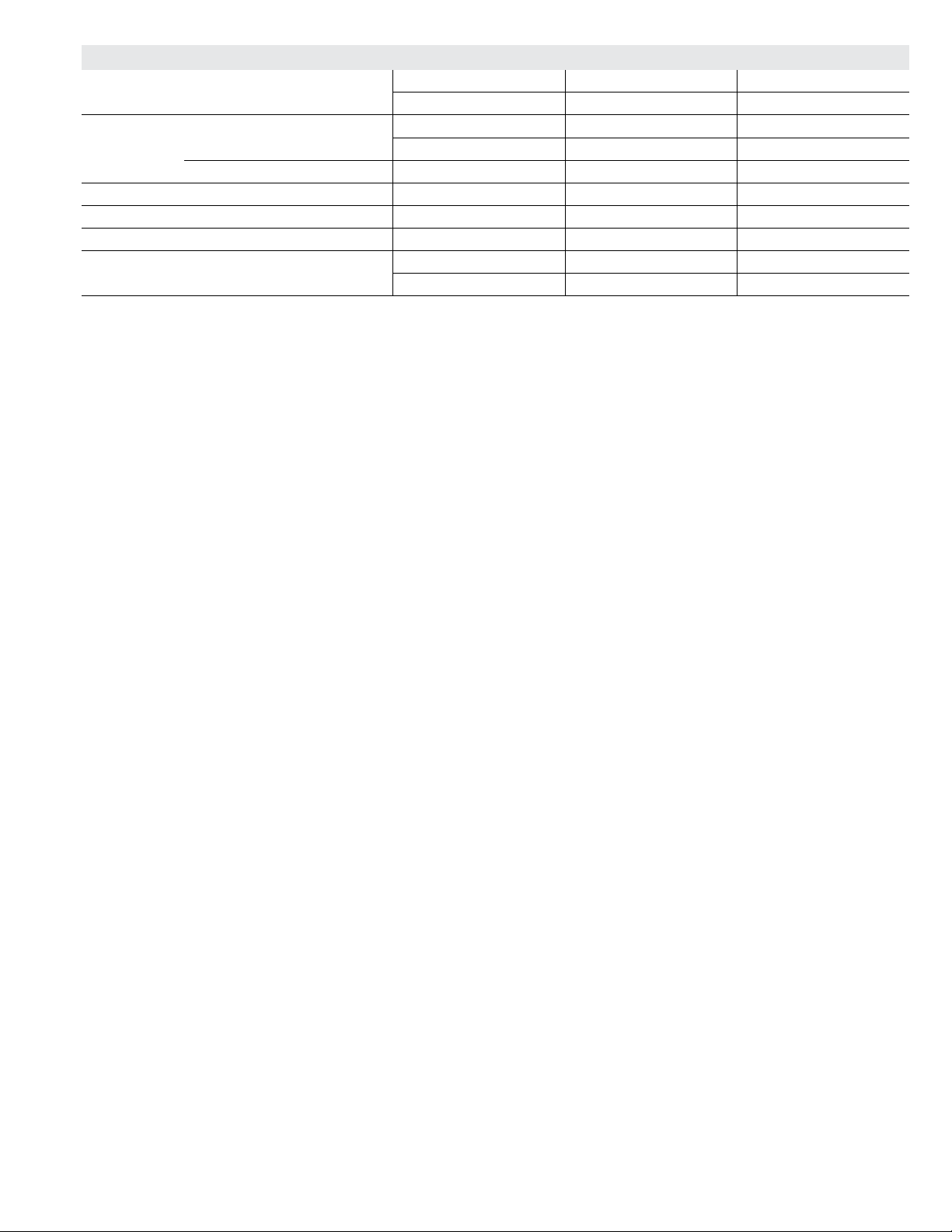

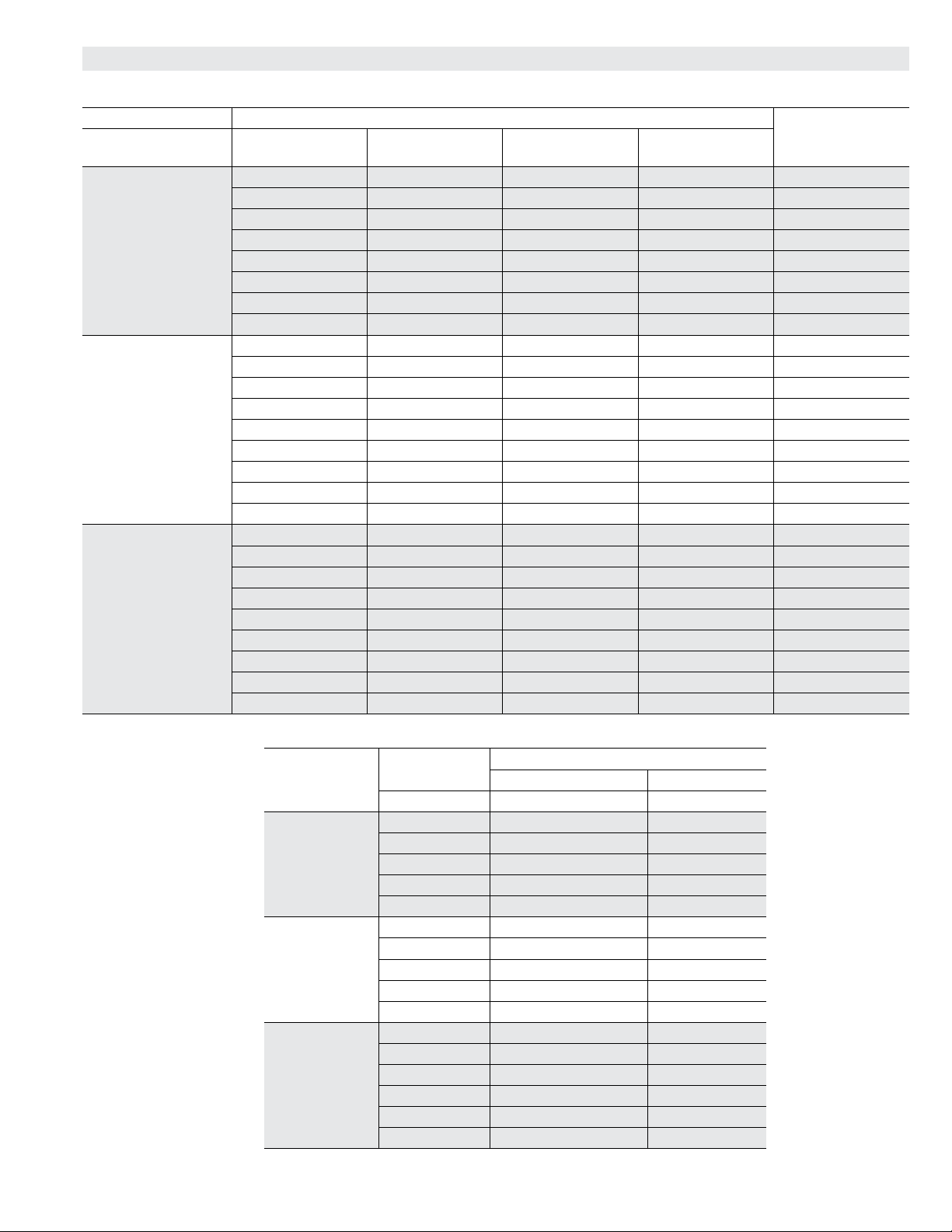

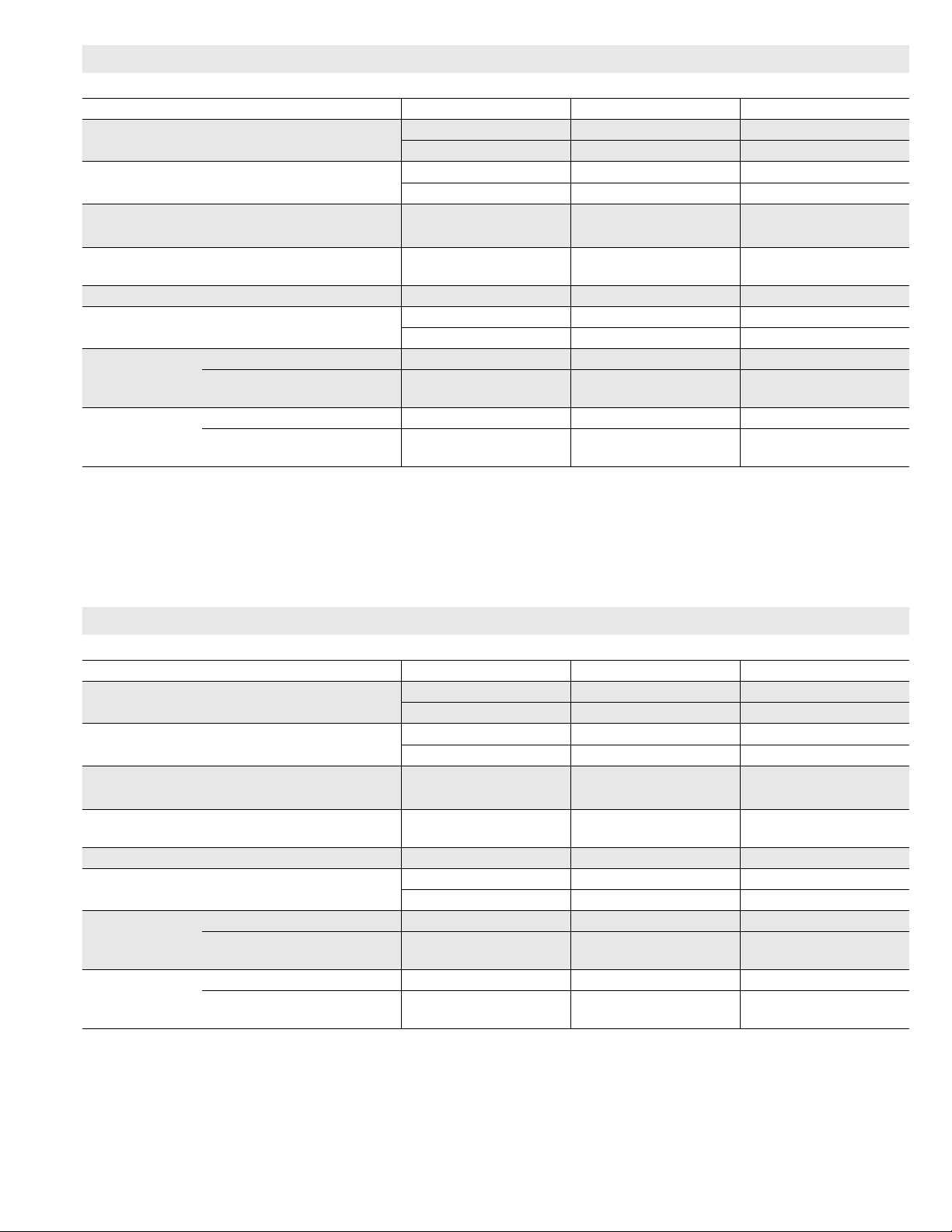

OPTIONS / ACCESSORIES - 092H, 102H, 120H, 150S

Item Description

Model

Number

Catalog

Number

COOLING SYSTEM

Condensate Drain Trap PVC - C1TRAP20AD2 76W26 OX OX OX OX

Copper - C1TRAP10AD2 76W27 OX OX OX OX

Conventional Fin/Tube Condenser Coil (replaces all-aluminum coil) Factory O O O O

Corrosion Protection Factory O O O O

Drain Pan Overow Switch E1SNSR71AD1 68W88 OX OX OX OX

Refrigerant Type R-410A O O O O

Service valves (not for all-aluminum coil equipped units) Factory O O O O

HEATING SYSTEM

Bottom Gas Piping Kit C1GPKT01B-01 54W95 OX OX OX OX

Combustion Air Intake Extensions T1EXTN10AN1 19W51 X X X X

Gas Heat Input 130,000 Btuh Factory O O O O

180,000 Btuh Factory O O O O

240,000 Btuh Factory O O O O

Low Temperature Vestibule Heater 208/230V-3ph - C1LTVH10B-1Y 55W91 OX OX OX OX

460V - C1LTVH10B-1G 55W92 OX OX OX OX

575V - C1LTVH10B-1J 55W93 OX OX OX OX

LPG/Propane Conversion Kits Standard Heat - E1LPCO10B-1 53W07 X X X X

Medium Heat - E1LPCO20B-1 53W08 X X X X

High Heat - E1LPCO30B-1 53W09 X X X X

Stainless Steel Heat Exchanger Factory O O O O

Vertical Vent Extension Kit C1EXTN2021 42W16 X X X X

BLOWER - SUPPLY AIR

Blower Option CAV (Constant Air Volume) Factory O O O O

Multi-Stage Air Volume supply air blower option (With VFD Bypass Control) Factory O O O O

Multi-Stage Air Volume supply air blower option (Without VFD Bypass Control) Factory O O O O

Motors - Constant Air

Volume (CAV)

Belt Drive (standard or high efciency) - 2 hp Factory O O O O

Belt Drive (standard or high efciency) - 3 hp Factory O O O O

Belt Drive (standard efciency) - 5 hp Factory O O O O

Motors -

Multi-Stage Air Volume

Belt Drive (standard or high efciency) - 3 hp Factory O O O O

Belt Drive (high efciency) - 2 hp Factory O O O O

Belt Drive (standard efciency) - 5 hp Factory O O O O

Drive Kits

See Blower Data Tables for selection

Kit #1 590-890 rpm Factory O O O O

Kit #2 800-1105 rpm Factory O O O O

Kit #3 795-1195 rpm Factory O O O O

Kit #4 730-970 rpm Factory O O O O

Kit #5 940-1200 rpm Factory O O O O

Kit #6 1015-1300 rpm Factory O O O O

Kit #7 730-970 rpm Factory O O O O

Kit #8 940-1200 rpm Factory O O O O

Kit #9 1015-1300 rpm Factory O O O O

Kit #10 900-1135 rpm Factory O O O O

Kit #11 1040-1315 rpm Factory O O O O

Kit #12 1125-1425 rpm Factory O O O O

Blower Belt Auto-Tensioner Factory O O O O

CABINET

Combination Coil/Hail Guards All-Aluminum Coil - E1GARD21B-1 13T05 X X X X

Conventional Fin/Tube Condenser Coil - E1GARD20B-1 13T04 X X X X

Horizontal Discharge Kit K1HECK00B-1 51W25 X X X X

Return Air Adaptor Plate (for LC/LG/LH and TC/TG/TH unit replacement) C1CONV10B-1 54W96 OX OX OX OX

NOTE - Catalog and model numbers shown are for ordering eld installed accessories.

OX - Congure To Order (Factory Installed) or Field Installed

O = Congure To Order (Factory Installed)

X = Field Installed

Unit Model No

092 102 120 150

Page 2

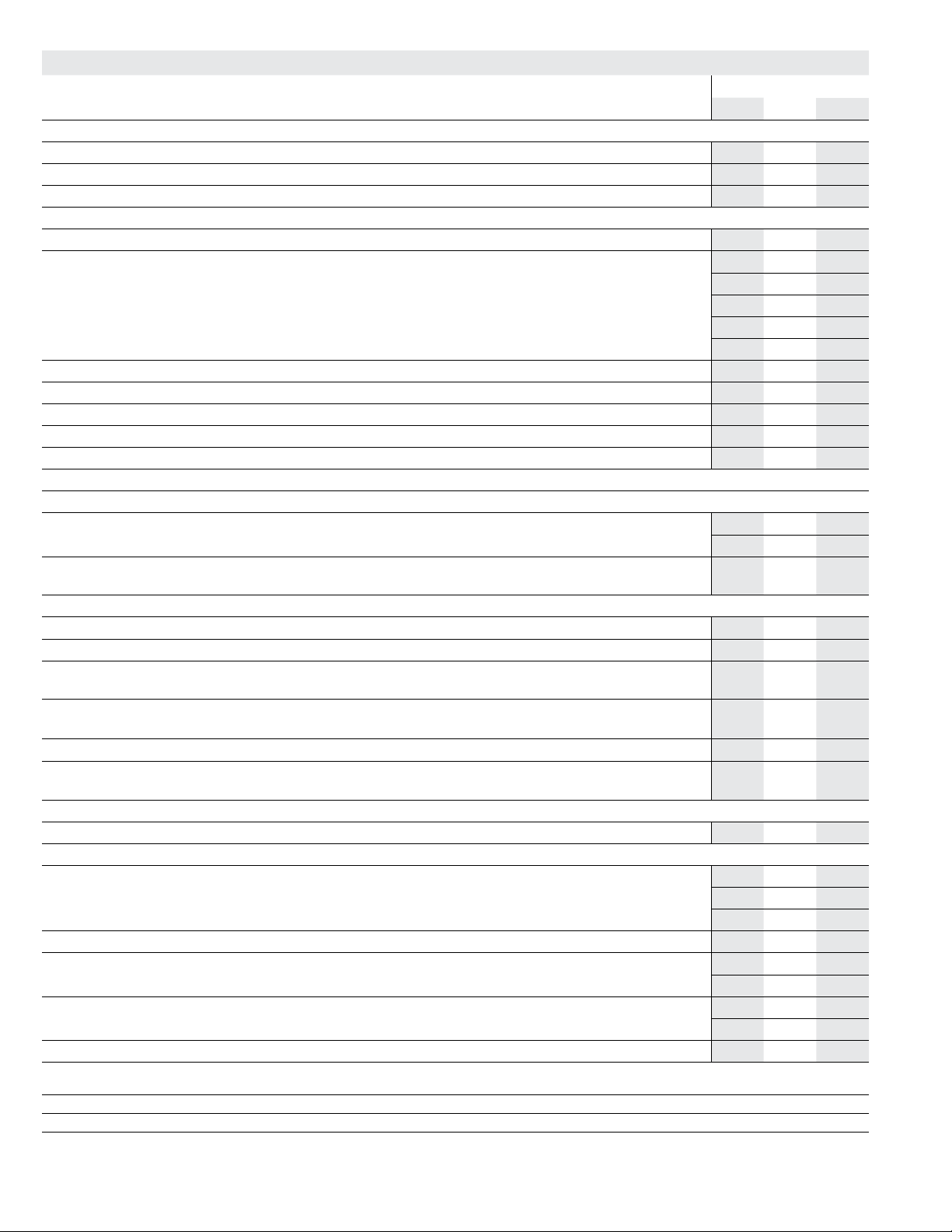

OPTIONS / ACCESSORIES - 092H, 102H, 120H, 150S

Item Description

Model

Number

Catalog

Number

CONTROLS

Blower Proving Switch C1SNSR35FF1 53W65 OX OX OX OX

Commercial Controls L Connection

Prodigy

®

Control System - BACnet® Module - C0CTRL60AE1L 59W51 OX OX OX OX

®

Prodigy

Control System - LonTalk® Module - C0CTRL65FF1 54W27 OX OX OX OX

®

Building Automation System - - - X X X X

®

ETM-2051 - E0CTRL30B1

Novar

Novar

®

LSE

64W73 OX OX OX OX

Factory O O O O

Dirty Filter Switch E1SNSR55B-1 53W67 OX OX OX OX

Fresh Air Tempering C1SNSR75AD1 58W63 OX OX OX OX

Smoke Detector - Supply or Return (Power board and one sensor) C1SNSR44B-2 11K76 OX OX OX OX

Smoke Detector - Supply and Return (Power board and two sensors) C1SNSR43B-2 11K80 OX OX OX OX

INDOOR AIR QUALITY

Air Filters

High Efciency Air Filters

20 x 25 x 2 (Order 4 per unit)

Replacement Media Filter With Metal Mesh

MERV 8 - C1FLTR15B-1 50W61 OX OX OX OX

MERV 13 - C1FLTR40B-1 52W41 OX OX OX OX

C1FLTR30B-1- Y3063 X X X X

Frame (includes non-pleated lter media)

Indoor Air Quality (CO

Sensor - Wall-mount, off-white plastic cover with LCD display C0SNSR50AE1L 77N39 X X X X

) Sensors

2

Sensor - Wall-mount, off-white plastic cover, no display C0SNSR52AE1L 87N53 X X X X

Sensor - Black plastic case with LCD display, rated for plenum

mounting

Sensor - Wall-mount, black plastic case, no display, rated for

plenum mounting

Sensor Duct Mounting Kit - for downow applications C0MISC19AE1- 85L43 X X X X

CO

2

Aspiration Box - for duct mounting non-plenum rated CO

(87N53 or 77N39)

UVC Germicidal Lamps

1

UVC Light Kit (208/230v-1ph) C1UVCL10B-1 54W62 OX OX OX OX

sensors

2

C0SNSR51AE1L 87N52 X X X X

C0MISC19AE1 87N54 X X X X

C0MISC16AE1- 90N43 X X X X

ELECTRICAL

Voltage 60 hz 208/230V - 3 phase Factory O O O O

460V - 3 phase Factory O O O O

575V - 3 phase Factory O O O O

HACR Circuit Breakers Factory O O O O

Disconnect Switch 80 amp - C1DISC080B-1 54W56 OX OX OX OX

150 amp - C1DISC150B-1 54W57 OX OX OX OX

GFI Service

Outlets

15 amp non-powered, eld-wired (208/230V, 460V only) LTAGFIK10/15 74M70 OX OX OX OX

20 amp non-powered, eld-wired (575V only) C1GFCI20FF1 67E01

Weatherproof Cover for GFI C1GFCI99FF1 10C89 X X X X

Phase/Voltage Detection (Optional for CAV options only, furnished with staged blower option) Factory O O O O

ECONOMIZER

Standard Economizer (Not for Title 24)

Standard Economizer

E1ECON15B-1 55W05 OX OX OX OX

Downow or Horizontal - Includes Outdoor Air Hood and Downow

Barometric Relief Dampers with Exhaust Hood

Order Horizontal Barometric Relief Dampers separately

High Performance Economizer (Approved for California Title 24 Building Standards)

High Performance Economizer

E1ECON17B-1 10U59 OX OX OX OX

Downow or Horizontal - Includes Outdoor Air Hood and Downow

Barometric Relief Dampers with Exhaust Hood

Order Horizontal Barometric Relief Dampers separately

Horizontal Barometric Relief Dampers

Horizontal Low Prole Barometric With Exhaust Hood LAGEDH03/15 53K04 X X X X

Economizer Controls (Not for Title 24)

Differential Enthalpy Order 2 - C1SNSR64FF1 53W64 OX OX OX OX

Sensible Control Sensor is Furnished Factory O O O O

Single Enthalpy C1SNSR64FF1 53W64 OX OX OX OX

Global Control Sensor Field Provided Factory O O O O

1

Lamps operate on 110-230V single-phase power supply. Step-down transformer may be ordered separately for 460V and 575V units. Alternately, 110V power supply

may be used to directly power the UVC ballast(s)

NOTE - Catalog and model numbers shown are for ordering eld installed accessories.

OX - Congure To Order (Factory Installed) or Field Installed

O = Congure To Order (Factory Installed)

X = Field Installed

Page 3

Unit Model No

092 102 120 150

OX OX OX OX

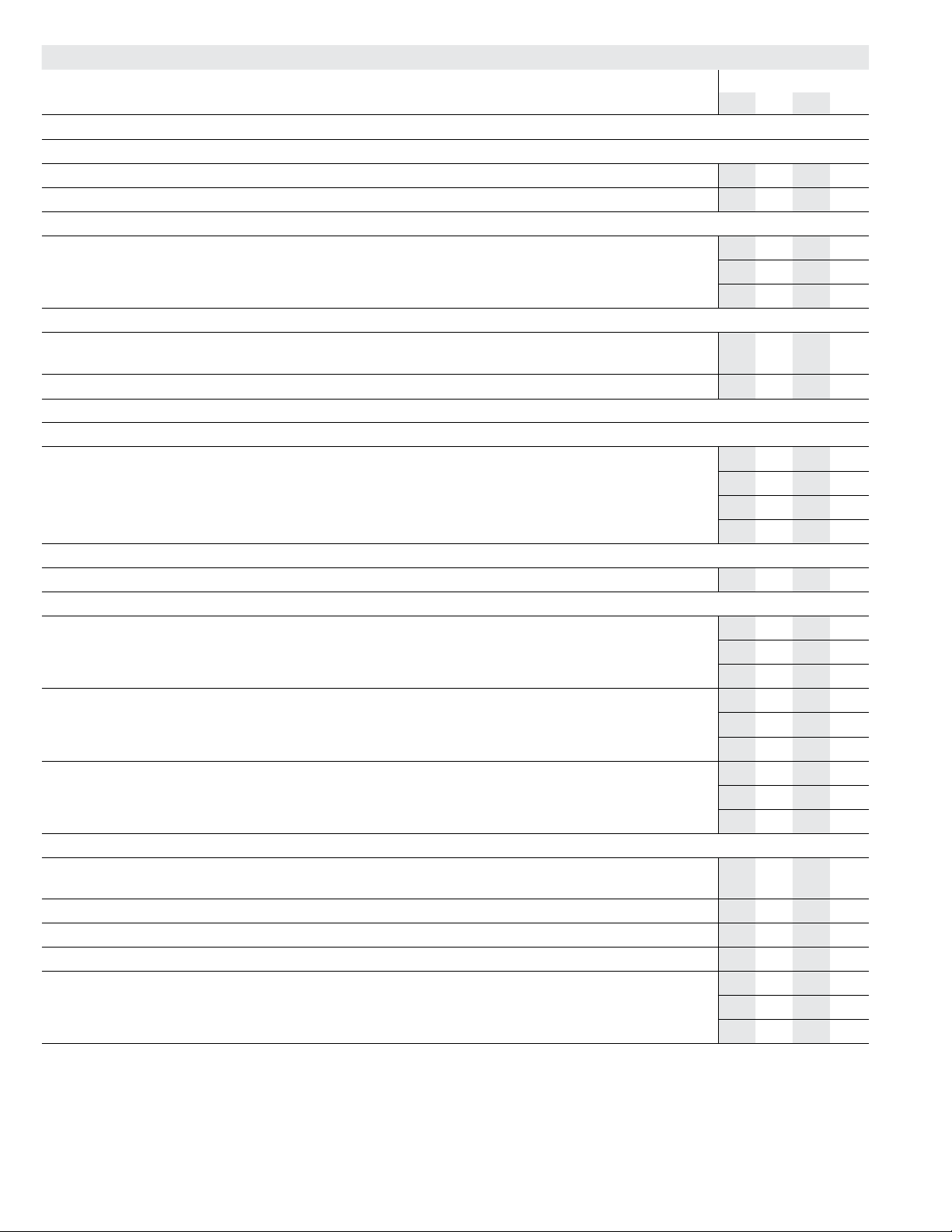

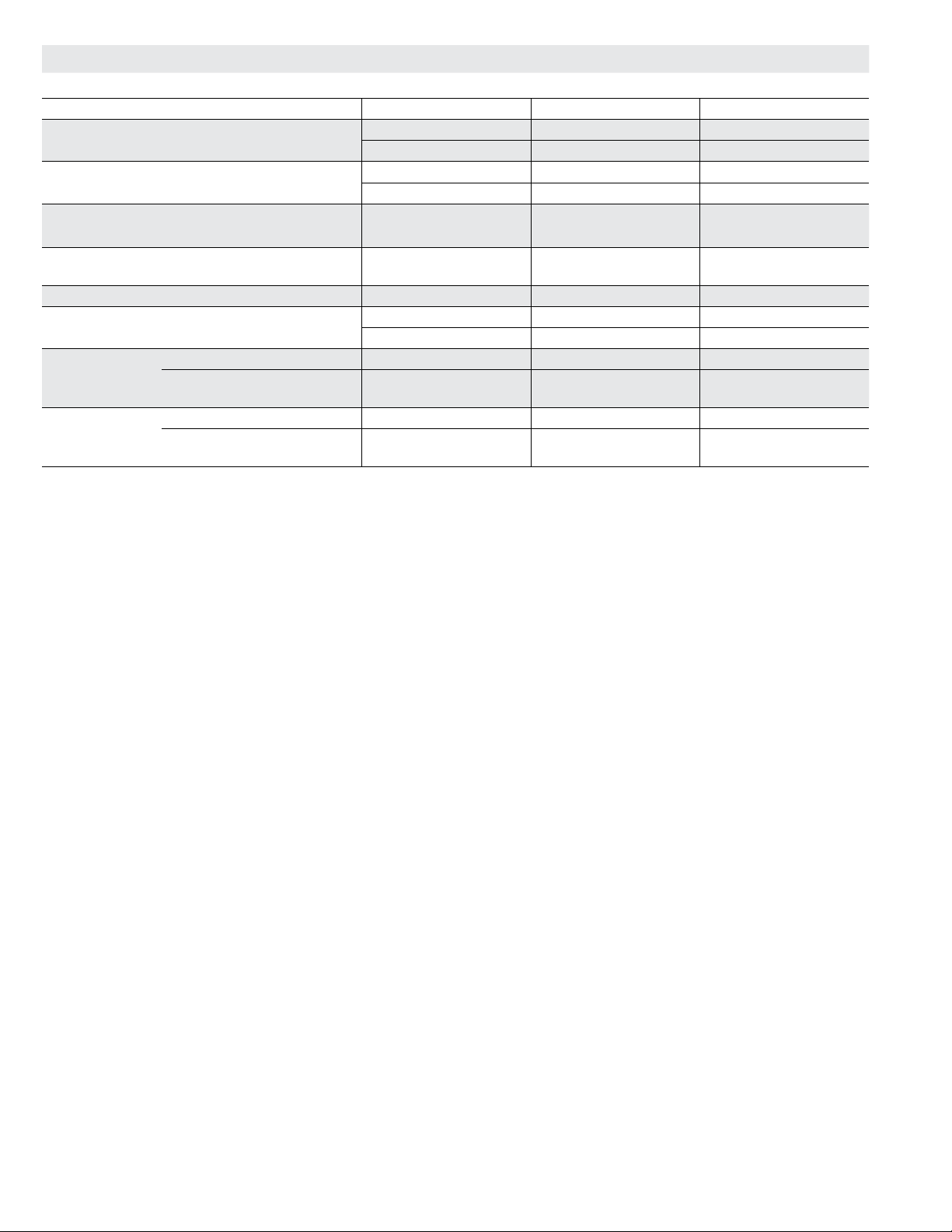

OPTIONS / ACCESSORIES - 092H, 102H, 120H, 150S

Item Description

Model

Number

Catalog

Number

OUTDOOR AIR

Outdoor Air Dampers With Outdoor Air Hood

Motorized E1DAMP20B-1 63W60 OX OX OX OX

Manual C1DAMP10B-1 53W48 OX OX OX OX

POWER EXHAUST

Standard Static 208/230V-3ph - K1PWRE10B-1Y 53W44 OX OX OX OX

460V-3ph - K1PWRE10B-1G 53W45 OX OX OX OX

575V-3ph - K1PWRE10B-1J 53W46 OX OX OX OX

®

HUMIDITROL

Humiditrol

CONDENSER REHEAT OPTION

®

Dehumidication Option (NOTE - Not available all-aluminum condenser coil.

Factory O O O O

Conventional Fin/Tube condenser coil must be ordered as a factory option)

Humidity Sensor Kit, Remote mounted (required) C0SNSR31AE-1 17M50 X X X X

ROOF CURBS

Hybrid Roof Curbs, Downow

8 in. height C1CURB70B-1 11F54 X X X X

14 in. height C1CURB71B-1 11F55 X X X X

18 in. height C1CURB72B-1 11F56 X X X X

24 in. height C1CURB73B-1 11F57 X X X X

Adjustable Pitch Curb, Downow

14 in. height C1CURB55B-1 54W50 X X X X

CEILING DIFFUSERS

Step-Down - Order one RTD11-95 29G04 X

RTD11-135 29G05 X X

RTD11-185 29G06 X

Flush - Order one FD11-95 29G08 X

FD11-135 29G09 X X

FD11-185 29G10 X

Transitions (Supply and Return) - Order one C1DIFF30B-1 12X65 X

C1DIFF31B-1 12X66 X X

C1DIFF32B-1 12X67 X

®

Sunsource

Solar Module CE

Kit

Commercial Energy System

One 285W Solar Module (silver frame), One PanelClaw Polar Bear III

Mounting System and One Enphase M250 Microinverter

10U67 X X X X

Solar Power Entry with Disconnect Factory O O O O

Enphase Envoy Communications Gateway (with Wireless Capability) 13L89 X X X X

Line Communication Filter (external) C1C400D11A 10F93 X X X X

Transformer (6 kW) E1TRFM15AD3Y (208Y to 208 VAC Delta) 11H71 X X X X

E1TRFM15AD2Y (230 VAC Delta) 11H28 X X X X

E1TRFM15AD3G (460 VAC Delta or Wye) 11H29 X X X X

NOTE - Catalog and model numbers shown are for ordering eld installed accessories.

OX - Congure To Order (Factory Installed) or Field Installed

O = Congure To Order (Factory Installed)

X = Field Installed

Unit Model No

092 102 120 150

Page 4

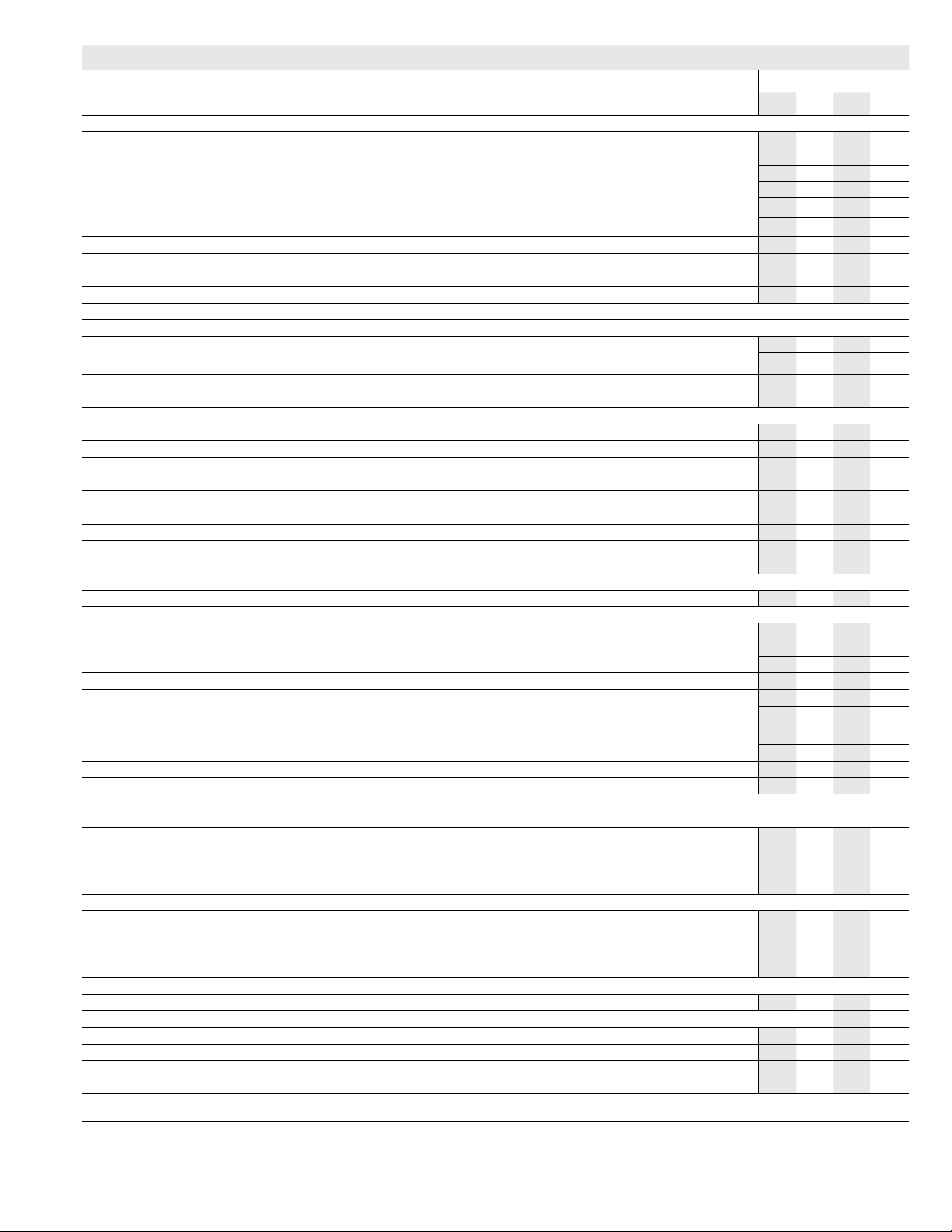

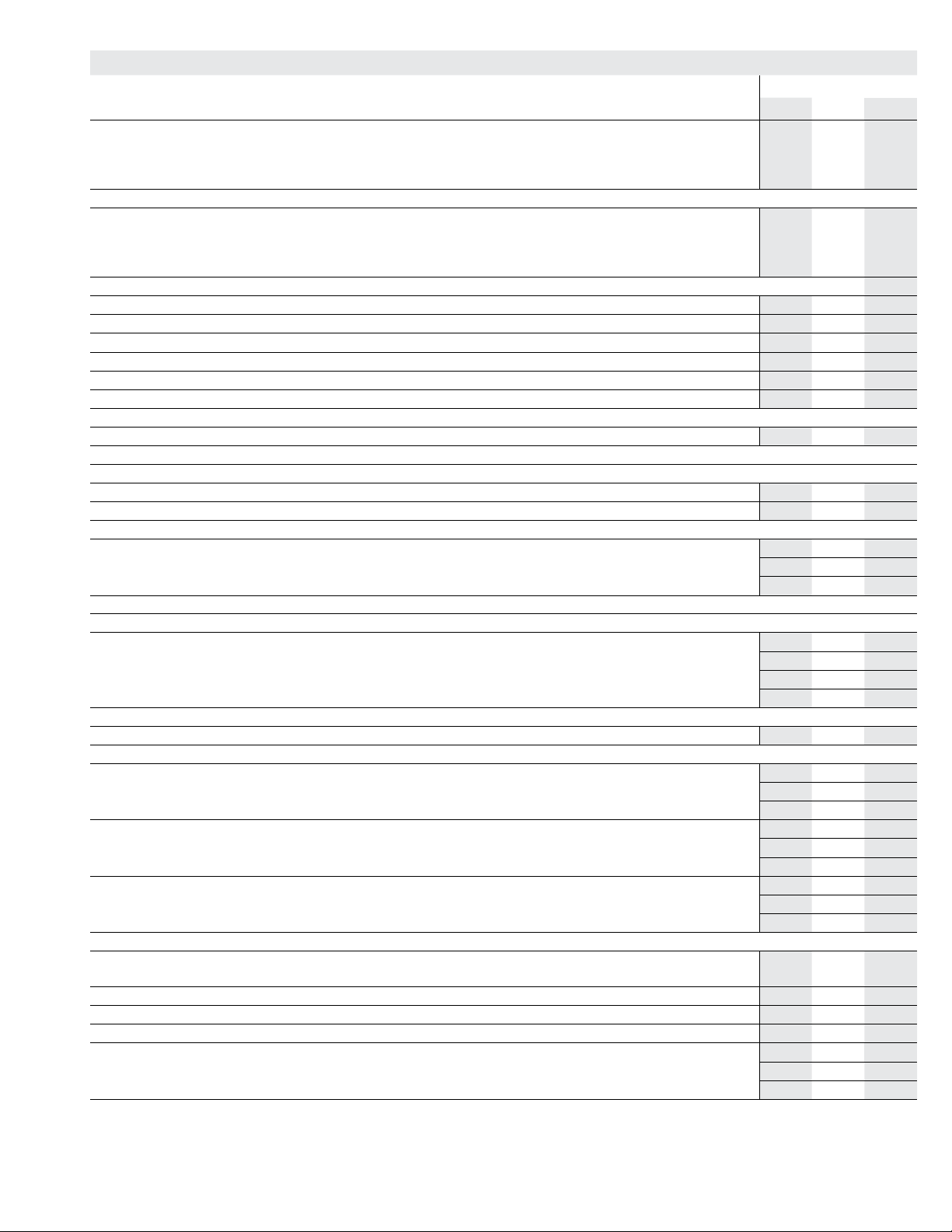

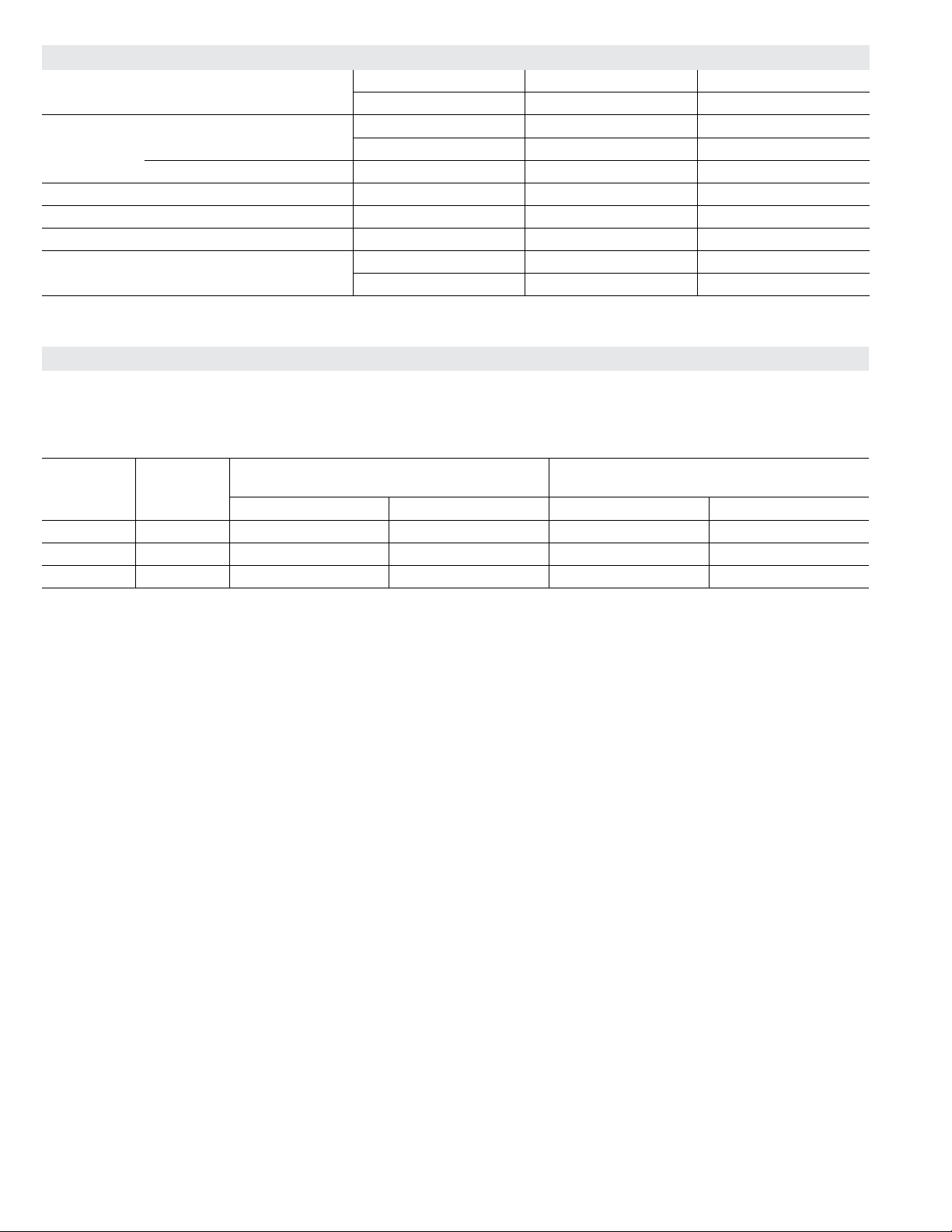

OPTIONS / ACCESSORIES - 094U, 122U, 152U

Item Description

Model

Number

Catalog

Number

COOLING SYSTEM

Condensate Drain Trap PVC - C1TRAP20AD2 76W26 OX OX OX

Copper - C1TRAP10AD2 76W27 OX OX OX

Corrosion Protection Factory O O O

Drain Pan Overow Switch E1SNSR71AD1 68W88 OX OX OX

Refrigerant Type R-410A O O O

HEATING SYSTEM

Bottom Gas Piping Kit C1GPKT01B-01 54W95 OX OX OX

Combustion Air Intake Extensions T1EXTN10AN1 19W51 X X X

Gas Heat Input 130,000 Btuh Factory O O O

180,000 Btuh Factory O O O

240,000 Btuh Factory O O O

Low Temperature Vestibule Heater 208/230V-3ph - C1LTVH10B-1Y 55W91 OX OX OX

460V - C1LTVH10B-1G 55W92 OX OX OX

575V - C1LTVH10B-1J 55W93 OX OX OX

LPG/Propane Conversion Kits Standard Heat - E1LPCO10B-1 53W07 X X X

Medium Heat - E1LPCO20B-1 53W08 X X X

High Heat - E1LPCO30B-1 53W09 X X X

Stainless Steel Heat Exchanger Factory O O O

Vertical Vent Extension Kit C1EXTN2021 42W16 X X X

BLOWER - SUPPLY AIR

Blower Direct Drive supply air blower Factory O O O

Belt Drive supply air blower (With VFD Bypass Control) Factory O O O

Belt Drive supply air blower (Without VFD Bypass Control) Factory O O O

Motors -

Multi-Stage Air Volume supply air

Direct Drive ECM 3.75 hp Factory O O O

Belt Drive (high efciency) - 2 hp Factory O O O

Belt Drive (standard or high efciency) - 3 hp Factory O O O

Belt Drive (standard efciency) - 5 hp Factory O O O

Drive Kits

See Blower Data Tables for selection

Kit #1 590-890 rpm Factory O O O

Kit #2 800-1105 rpm Factory O O O

Kit #3 795-1195 rpm Factory O O O

Kit #4 730-970 rpm Factory O O O

Kit #5 940-1200 rpm Factory O O O

Kit #6 1015-1300 rpm Factory O O O

Kit #7 730-970 rpm Factory O O O

Kit #8 940-1200 rpm Factory O O O

Kit #9 1015-1300 rpm Factory O O O

Kit #10 900-1135 rpm Factory O O O

Kit #11 1040-1315 rpm Factory O O O

Kit #12 1125-1425 rpm Factory O O O

Blower Belt Auto-Tensioner Factory O O O

NOTE - Catalog and model numbers shown are for ordering eld installed accessories.

OX - Congure To Order (Factory Installed) or Field Installed

O = Congure To Order (Factory Installed)

X = Field Installed

Unit Model No

094 122 152

Page 5

OPTIONS / ACCESSORIES - 094U, 122U, 152U

Item Description

Model

Number

Catalog

Number

CABINET

Combination Coil/Hail Guards E1GARD51BP1 13T06 X X X

Horizontal Discharge Kit K1HECK00B-1 51W25 X X X

Return Air Adaptor Plate (for LC/LG and TC/TG/TH unit replacement) C1CONV10B-1 54W96 OX OX OX

CONTROLS

Blower Proving Switch C1SNSR35FF1 53W65 OX OX OX

Commercial Controls L Connection

System - BACnet

System - LonTalk

®

Building Automation System X X X

®

Module - C0CTRL60AE1L 59W51 OX OX OX

®

Module - C0CTRL65FF1 54W27 OX OX OX

Dirty Filter Switch E1SNSR55B-1 53W67 OX OX OX

Fresh Air Tempering C1SNSR75AD1 58W63 OX OX OX

General Purpose Control Kit E1GPBK30C1 13J78 X X X

Smoke Detector - Supply or Return (Power board and one sensor) C1SNSR44B-2 11K76 OX OX OX

Smoke Detector - Supply and Return (Power board and two sensors) C1SNSR43B-2 11K80 OX OX OX

INDOOR AIR QUALITY

Air Filters

High Efciency Air Filters

20 x 25 x 2 (Order 4 per unit)

Replacement Media Filter With Metal Mesh Frame (includes non-

MERV 8 - C1FLTR15B-1 50W61 OX OX OX

MERV 13 - C1FLTR40B-1 52W41 OX OX OX

C1FLTR30B-1- Y3063 X X X

pleated lter media)

Indoor Air Quality (CO

) Sensors

2

Sensor - Wall-mount, off-white plastic cover with LCD display C0SNSR50AE1L 77N39 X X X

Sensor - Wall-mount, off-white plastic cover, no display C0SNSR52AE1L 87N53 X X X

Sensor - Black plastic case with LCD display, rated for plenum

mounting

Sensor - Wall-mount, black plastic case, no display, rated for plenum

mounting

CO

Sensor Duct Mounting Kit - for downow applications C0MISC19AE1- 85L43 X X X

2

Aspiration Box - for duct mounting non-plenum rated CO

(87N53 or 77N39)

sensors

2

C0SNSR51AE1L 87N52 X X X

C0MISC19AE1 87N54 X X X

C0MISC16AE1- 90N43 X X X

UVC Germicidal Lamps

1

UVC Light Kit (208/230v-1ph) C1UVCL10B-1 54W62 OX OX OX

ELECTRICAL

Voltage 60 hz 208/230V - 3 phase Factory O O O

460V - 3 phase Factory O O O

575V - 3 phase Factory O O O

HACR Circuit Breakers Factory O O O

Disconnect Switch 80 amp - C1DISC080B-1 54W56 OX OX OX

150 amp - C1DISC150B-1 54W57 OX OX OX

GFI Service

Outlets

15 amp non-powered, eld-wired (208/230V, 460V only) LTAGFIK10/15 74M70 OX OX OX

20 amp non-powered, eld-wired (575V only) C1GFCI20FF1 67E01 OX OX OX

Weatherproof Cover for GFI C1GFCI99FF1 10C89 X X X

1

Lamps operate on 110-230V single-phase power supply. Step-down transformer may be ordered separately for 460V and 575V units. Alternately, 110V power supply

may be used to directly power the UVC ballast(s)

ECONOMIZER

Standard Economizer (Not for Title 24)

NOTE - Catalog and model numbers shown are for ordering eld installed accessories.

OX - Congure To Order (Factory Installed) or Field Installed

O = Congure To Order (Factory Installed)

X = Field Installed

Page 6

Unit Model No

094 122 152

OX OX

OPTIONS / ACCESSORIES - 094U, 122U, 152U

Item Description

Standard Economizer

Model

Number

E1ECON15B-1 55W05 OX OX OX

Catalog

Number

Downow or Horizontal - Includes Outdoor Air Hood and Downow

Barometric Relief Dampers with Exhaust Hood

Order Horizontal Barometric Relief Dampers separately

High Performance Economizer (Approved for California Title 24 Building Standards)

High Performance Economizer

E1ECON17B-1 10U59 OX OX OX

Downow or Horizontal - Includes Outdoor Air Hood and Downow

Barometric Relief Dampers with Exhaust Hood

Order Horizontal Barometric Relief Dampers separately

Economizer Controls

Differential Enthalpy (Not for Title 24) Order 2 - C1SNSR64FF1 53W64 OX OX OX

Sensible Control Sensor is Furnished Factory O O O

Single Enthalpy (Not for Title 24) C1SNSR64FF1 53W64 OX OX OX

Global Control Sensor Field Provided Factory O O O

Building Pressure Control E1GPBK20C1 13J77 X X X

Outdoor Air CFM Control E1GPBK10C1 13J76 X X X

Horizontal Barometric Relief Dampers

Horizontal Low Prole Barometric Relief Dampers With Exhaust Hood LAGEDH03/15 53K04 X X X

OUTDOOR AIR

Outdoor Air Dampers

Motorized Dampers (Hood furnished) E1DAMP20B-1 63W60 OX OX OX

Manual Dampers (Hood furnished) C1DAMP10B-1 53W48 OX OX OX

POWER EXHAUST

Standard Static 208/230V-3ph - K1PWRE10B-1Y 53W44 OX OX OX

460V-3ph - K1PWRE10B-1G 53W45 OX OX OX

575V-3ph - K1PWRE10B-1J 53W46 OX OX OX

ROOF CURBS

Hybrid Roof Curbs, Downow

8 in. height C1CURB70B-1 11F54 X X X

14 in. height C1CURB71B-1 11F55 X X X

18 in. height C1CURB72B-1 11F56 X X X

24 in. height C1CURB73B-1 11F57 X X X

Adjustable Pitch Curb, Downow

14 in. height C1CURB55B-1 54W50 X X X

CEILING DIFFUSERS

Step-Down - Order one RTD11-95 29G04 X

RTD11-135 29G05 X

RTD11-185 29G06 X

Flush - Order one FD11-95 29G08 X

FD11-135 29G09 X

FD11-185 29G10 X

Transitions (Supply and Return) - Order one C1DIFF30B-1 12X65 X

C1DIFF31B-1 12X66 X

C1DIFF32B-1 12X67 X

Sunsource

Solar Module

CE Kit

®

Commercial Energy System

One 285W Solar Module (silver frame), One PanelClaw Polar Bear III Mounting

System and One Enphase M250 Microinverter

10U67 X X X

Solar Power Entry with Disconnect Factory O O O

Enphase Envoy Communications Gateway (with Wireless Capability) 13L89 X X X

Line Communication Filter (external) C1C400D11A 10F93 X X X

Transformer (6 kW) E1TRFM15AD3Y (208Y to 208 VAC Delta) 11H71 X X X

E1TRFM15AD2Y (230 VAC Delta) 11H28 X X X

E1TRFM15AD3G (460 VAC Delta or Wye) 11H29 X X X

NOTE - Catalog and model numbers shown are for ordering eld installed accessories.

OX - Congure To Order (Factory Installed) or Field Installed

O = Congure To Order (Factory Installed)

X = Field Installed

Unit Model No

094 122 152

Page 7

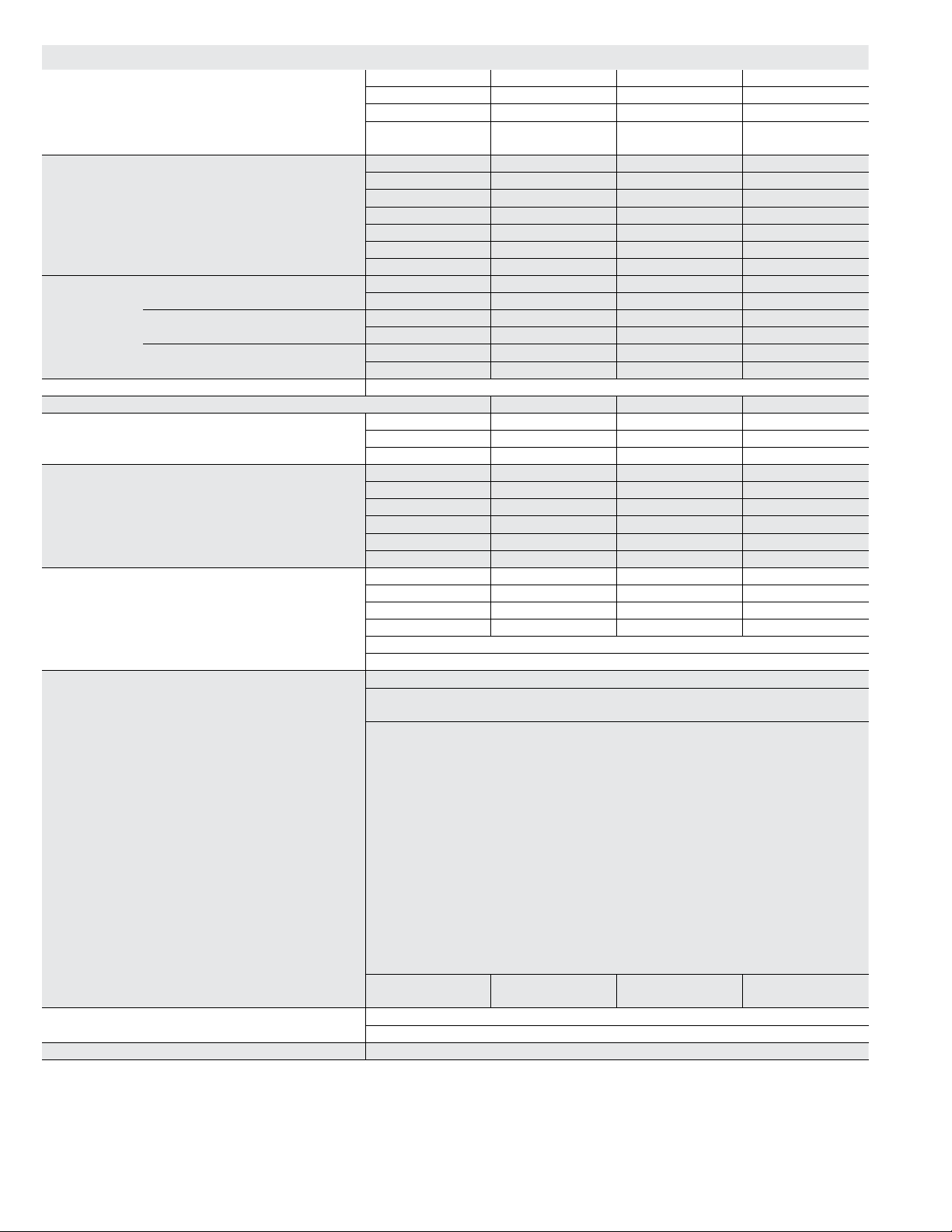

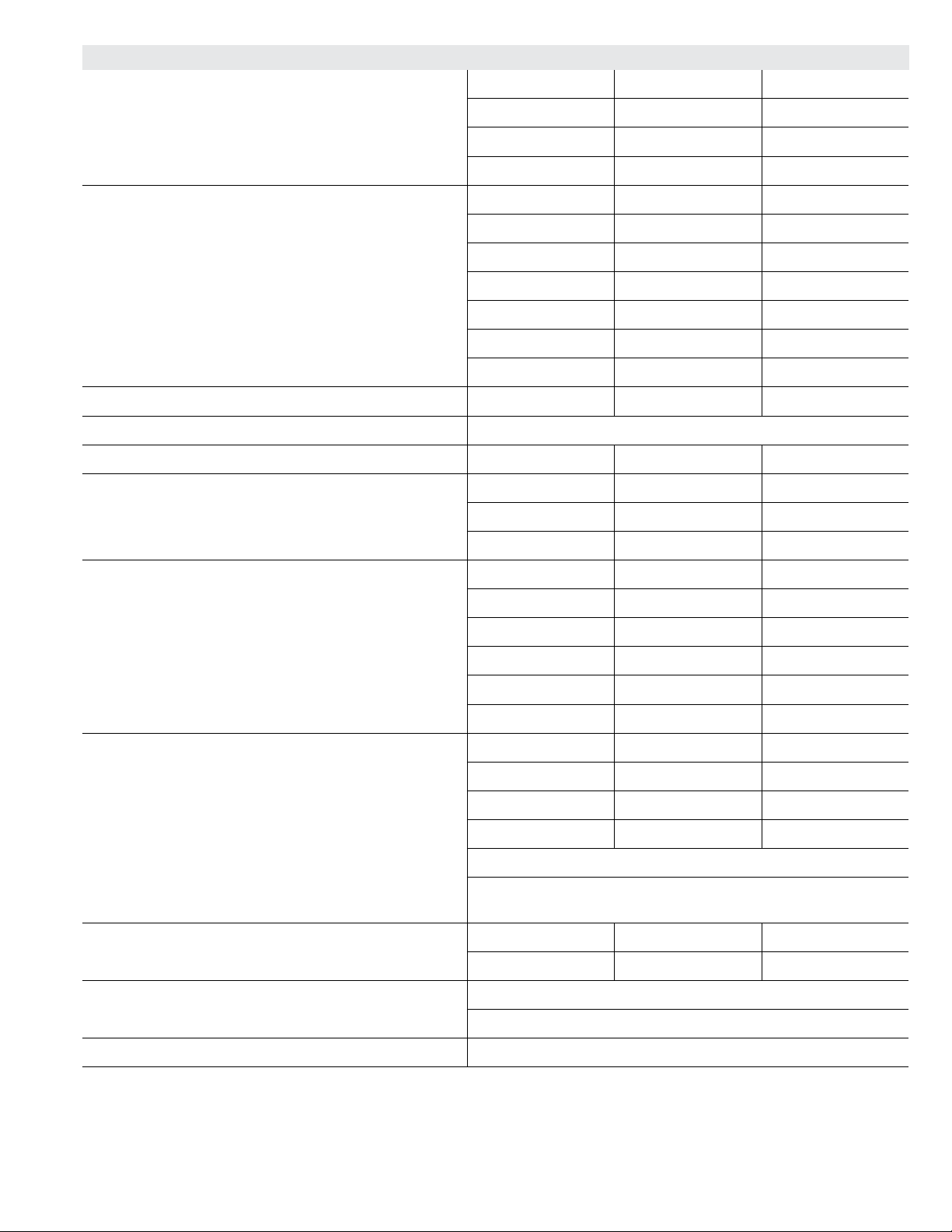

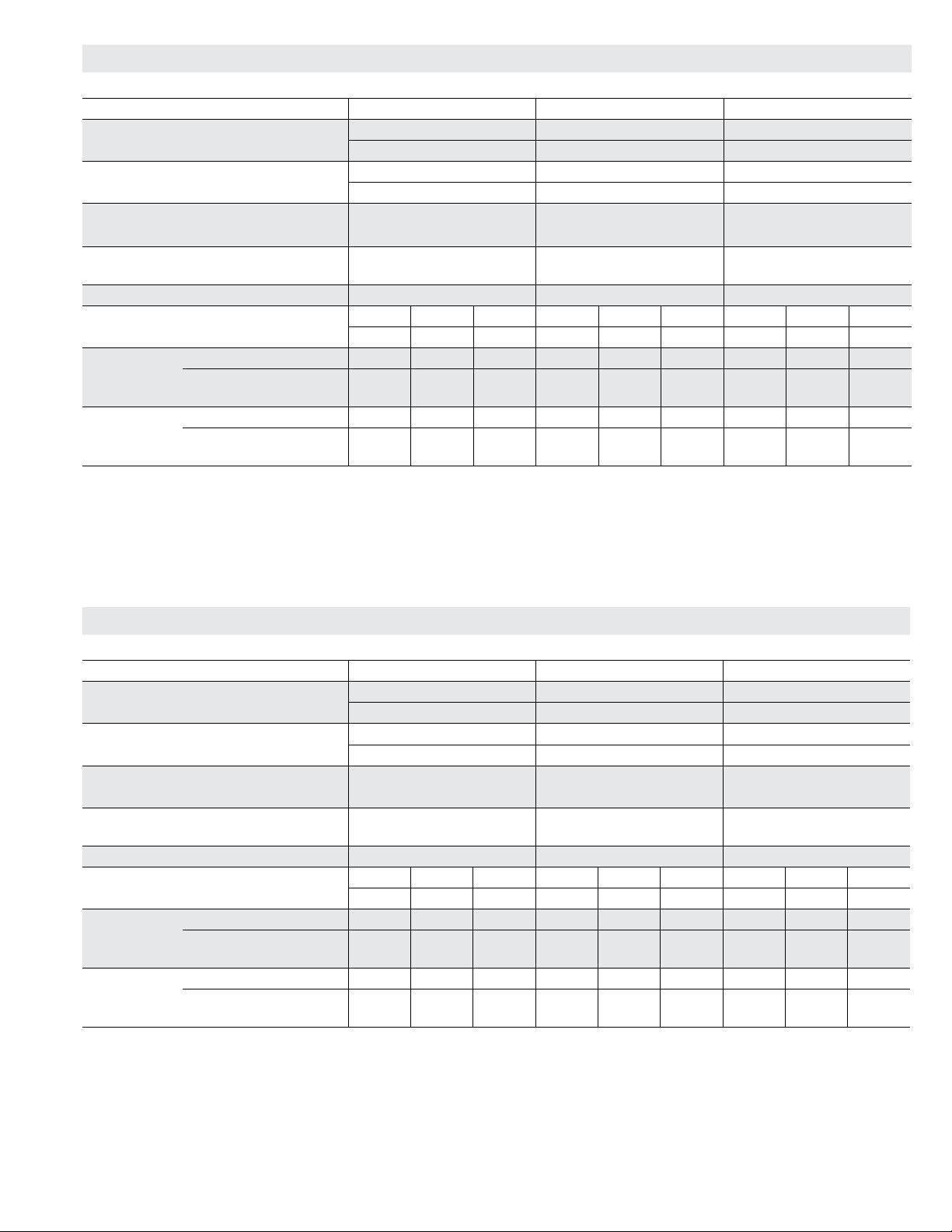

SPECIFICATIONS - 092H, 102H

General Data Nominal Tonnage 7.5 Ton 7.5 Ton 8.5 Ton 8.5 Ton

Model Number LGH092H4B LGH092H4M LGH102H4B LGH102H4M

Efciency Type High High High High

Blower Type Constant Air

Volume CAV

Cooling

Performance

Gross Cooling Capacity - Btuh 93,000 93,000 103,800 103,800

1

Net Cooling Capacity - Btuh 90,000 90,000 100,000 100,000

AHRI Rated Air Flow - cfm 3000 2800 3400 3400

Total Unit Power - kW 7.5 7.5 8.1 8.1

1

EER (Btuh/Watt) 12.5 12.5 12.2 12.2

2

IEER (Btuh/Watt) 13.0 14.0 12.9 14.0

Refrigerant Type R-410A R-410A R-410A R-410A

Refrigerant

Charge

All-Aluminum Coil

System

Conventional Fin/Tube

Coil Option

Conventional Fin/Tube

With Humiditrol

®

Circuit 1 7 lbs. 8 oz. 7 lbs. 8 oz. 7 lbs. 8 oz. 7 lbs. 8 oz.

Circuit 2 7 lbs. 8 oz. 7 lbs. 8 oz. 7 lbs. 8 oz. 7 lbs. 8 oz.

Circuit 1 13 lbs. 8 oz. 13 lbs. 8 oz. 13 lbs. 8 oz. 13 lbs. 8 oz.

Circuit 2 12 lbs. 8 oz. 12 lbs. 8 oz. 12 lbs. 8 oz. 12 lbs. 8 oz.

Circuit 1 17 lbs. 0 oz. 17 lbs. 0 oz. 17 lbs. 0 oz. 17 lbs. 0 oz.

Circuit 2 12 lbs. 8 oz. 12 lbs. 8 oz. 12 lbs. 8 oz. 12 lbs. 8 oz.

Gas Heating Options Available - See page 10 Standard (2 Stage), Medium (2 Stage), High (2 Stage)

Compressor Type (number) Scroll (2) Scroll (2) Scroll (2) Scroll (2)

Outdoor Coils

Aluminum

(Fin/Tube)

Outdoor

Coil Fans

Net face area (total) - sq. ft. 28.0 (29.33) 28.0 (29.33) 28.0 (29.33) 28.0 (29.33)

Number of rows 1 (3) 1 (3) 1 (3) 1 (3)

Fins per inch 20 (20) 20 (20) 20 (20) 20 (20)

Motor - (No.) hp (2) 1/3 (2) 1/3 (2) 1/3 (2) 1/3

Motor rpm 1075 1075 1075 1075

Total Motor watts 800 800 800 800

Diameter - (No.) in. (2) 24 (2) 24 (2) 24 (2) 24

Number of blades 3 3 3 3

Total Air volume - cfm 8800 8800 8800 8800

Indoor

Coils

Net face area (total) - sq. ft. 12.78 12.78 12.78 12.78

Tube diameter - in. 3/8 3/8 3/8 3/8

Number of rows 4 4 4 4

Fins per inch 14 14 14 14

Drain connection - Number and size (1) 1 in. NPT coupling

Expansion device type Balance port TXV, removable head

3

Indoor

Blower and

Drive

Selection

Maximum usable motor output

Blower wheel nominal diameter x

Nominal motor output 2 hp, 3 hp, 5 hp

(US Only)

Motor - Drive kit number 2 hp

(1) 15 X 15 (1) 15 X 15 (1) 15 X 15 (1) 15 X 15

width - in.

Filters Type of lter Disposable

Number and size - in. (4) 20 x 25 x 2

Electrical characteristics 208/230V, 460V or 575V - 60 hertz - 3 phase

NOTE - Net capacity includes evaporator blower motor heat deduction. Gross capacity does not include evaporator blower motor heat deduction.

1

AHRI Certied to AHRI Standard 340/360; 95°F outdoor air temperature and 80°F db/67°F wb entering evaporator air; minimum external duct static pressure.

2

Integrated Energy Efciency Ratio certied and tested according to AHRI Standard 340/360.

3

Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor output required. Maximum usable output of

motors furnished are shown. In Canada, nominal motor output is also maximum usable motor output. If motors of comparable output are used, be sure to keep within

the service factor limitations outlined on the motor nameplate.

NOTE – Units equipped with Multi-Stage Air Volume option are limited to a motor service factor of 1.0.

(Multi-Stage Air

Volume)

Constant Air

Volume CAV

2.3 hp, 3.45 hp, 5.75 hp

Kit 1 590-890 rpm (std. and high efciency)

Kit 2 800-1105 rpm (std. and high efciency)

Kit 3 795-1195 rpm (std. and high efciency)

3 hp

Kit 4 730-970 rpm (std. efciency)

Kit 5 940-1200 rpm (std. efciency)

Kit 6 1015-1300 rpm (std. efciency)

Kit 7 730-970 rpm (high efciency)

Kit 8 940-1200 rpm (high efciency)

Kit 9 1015-1300 rpm (high efciency)

5 hp

Kit 10 900-1135 rpm (std. efciency)

Kit 11 1040-1315 rpm (std. efciency)

Kit 12 1125-1425 rpm (std. efciency)

(Multi-Stage Air

Volume)

Page 8

SPECIFICATIONS - 120H, 150S

General Data Nominal Tonnage 10 Ton 10 Ton 12.5 Ton 12.5 Ton

Model Number LGH120H4B LGH120H4M LGH150S4B LGH150S4M

Efciency Type High High Standard Standard

Blower Type Constant Air

Volume CAV

Cooling

Performance

Gross Cooling Capacity - Btuh 122,000 122,000 142,600 142,600

1

Net Cooling Capacity - Btuh 118,000 118,000 138,000 138,000

AHRI Rated Air Flow - cfm 3600 3300 4300 4300

Total Unit Power - kW 9.9 9.8 12.5 12.5

1

EER (Btuh/Watt) 12 12.0 11.0 11.0

2

IEER (Btuh/Watt) 13.0 13.8 11.4 13.1

Refrigerant Type R-410A R-410A R-410A R-410A

Refrigerant

Charge

All-Aluminum Coil

System

Conventional Fin/Tube

Coil Option

Conventional Fin/Tube

With Humiditrol

®

Circuit 1 7 lbs. 4 oz. 7 lbs. 4 oz. 7 lbs. 4 oz. 7 lbs. 4 oz.

Circuit 2 7 lbs. 8 oz. 7 lbs. 8 oz. 6 lbs. 12 oz. 6 lbs. 12 oz.

Circuit 1 14 lbs. 8 oz. 14 lbs. 8 oz. 16 lbs. 8 oz. 16 lbs. 8 oz.

Circuit 2 13 lbs. 8 oz. 13 lbs. 8 oz. 14 lbs. 8 oz. 14 lbs. 8 oz.

Circuit 1 18 lbs. 0 oz. 18 lbs. 0 oz. 18 lbs. 8 oz. 18 lbs. 8 oz.

Circuit 2 13 lbs. 8 oz. 13 lbs. 8 oz. 14 lbs. 8 oz. 14 lbs. 8 oz.

Gas Heating Options Available - See page 10 Standard (2 Stage), Medium (2 Stage), High (2 Stage)

Compressor Type (number) Scroll (2) Scroll (2) Scroll (2) Scroll (2)

Outdoor Coils

Aluminum

(Fin/Tube)

Outdoor

Coil Fans

Net face area (total) - sq. ft. 28.0 (29.33) 28.0 (29.33) 28.0 (29.33) 28.0 (29.33)

Number of rows 1 (3) 1 (3) 1 (3) 1 (3)

Fins per inch 20 (20) 20 (20) 20 (20) 20 (20)

Motor - (No.) hp (2) 1/3 (2) 1/3 (2) 1/2 (2) 1/2

Motor rpm 1075 1075 1075 1075

Total Motor watts 800 800 1050 1050

Diameter - (No.) in. (2) 24 (2) 24 (2) 24 (2) 24

Number of blades 3 3 3 3

Total Air volume - cfm 8800 8800 9700 9700

Indoor

Coils

Net face area (total) - sq. ft. 13.54 13.54 13.54 13.54

Tube diameter - in. 3/8 3/8 3/8 3/8

Number of rows 4 4 4 4

Fins per inch 14 14 14 14

Drain connection - Number and size (1) 1 in. NPT coupling

Expansion device type Balance port TXV, removable head

3

Indoor

Blower and

Drive

Selection

Maximum usable motor output

Nominal motor output 2 hp, 3 hp, 5 hp

(US Only)

Motor - Drive kit number 2 hp

Blower wheel nominal diameter x width - in. (1) 15 X 15 (1) 15 X 15 (1) 15 X 15 (1) 15 X 15

Filters Type of lter Disposable

Number and size - in. (4) 20 x 25 x 2

Electrical characteristics 208/230V, 460V or 575V - 60 hertz - 3 phase

NOTE - Net capacity includes evaporator blower motor heat deduction. Gross capacity does not include evaporator blower motor heat deduction.

1

AHRI Certied to AHRI Standard 340/360; 95°F outdoor air temperature and 80°F db/67°F wb entering evaporator air; minimum external duct static pressure.

2

Integrated Energy Efciency Ratio certied and tested according to AHRI Standard 340/360.

3

Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor output required. Maximum usable output of

motors furnished are shown. In Canada, nominal motor output is also maximum usable motor output. If motors of comparable output are used, be sure to keep within

the service factor limitations outlined on the motor nameplate.

5

150 models ordered with the Humiditrol® Dehumidication option are equipped with factory installed expansion valves.

NOTE – Units equipped with Multi-Stage Air Volume option are limited to a motor service factor of 1.0.

Multi-Stage Air

Volume

Constant Air

Volume CAV

5

Refrigerant Metering Orice (RFC)

2.3 hp, 3.45 hp, 5.75 hp

Kit 1 590-890 rpm (std. and high efciency)

Kit 2 800-1105 rpm (std. and high efciency)

Kit 3 795-1195 rpm (std. and high efciency)

3 hp

Kit 4 730-970 rpm (std. efciency)

Kit 5 940-1200 rpm (std. efciency)

Kit 6 1015-1300 rpm (std. efciency)

Kit 7 730-970 rpm (high efciency)

Kit 8 940-1200 rpm (high efciency)

Kit 9 1015-1300 rpm (high efciency)

5 hp

Kit 10 900-1135 rpm (std. efciency)

Kit 11 1040-1315 rpm (std. efciency)

Kit 12 1125-1425 rpm (std. efciency)

Multi-Stage Air

Volume

Page 9

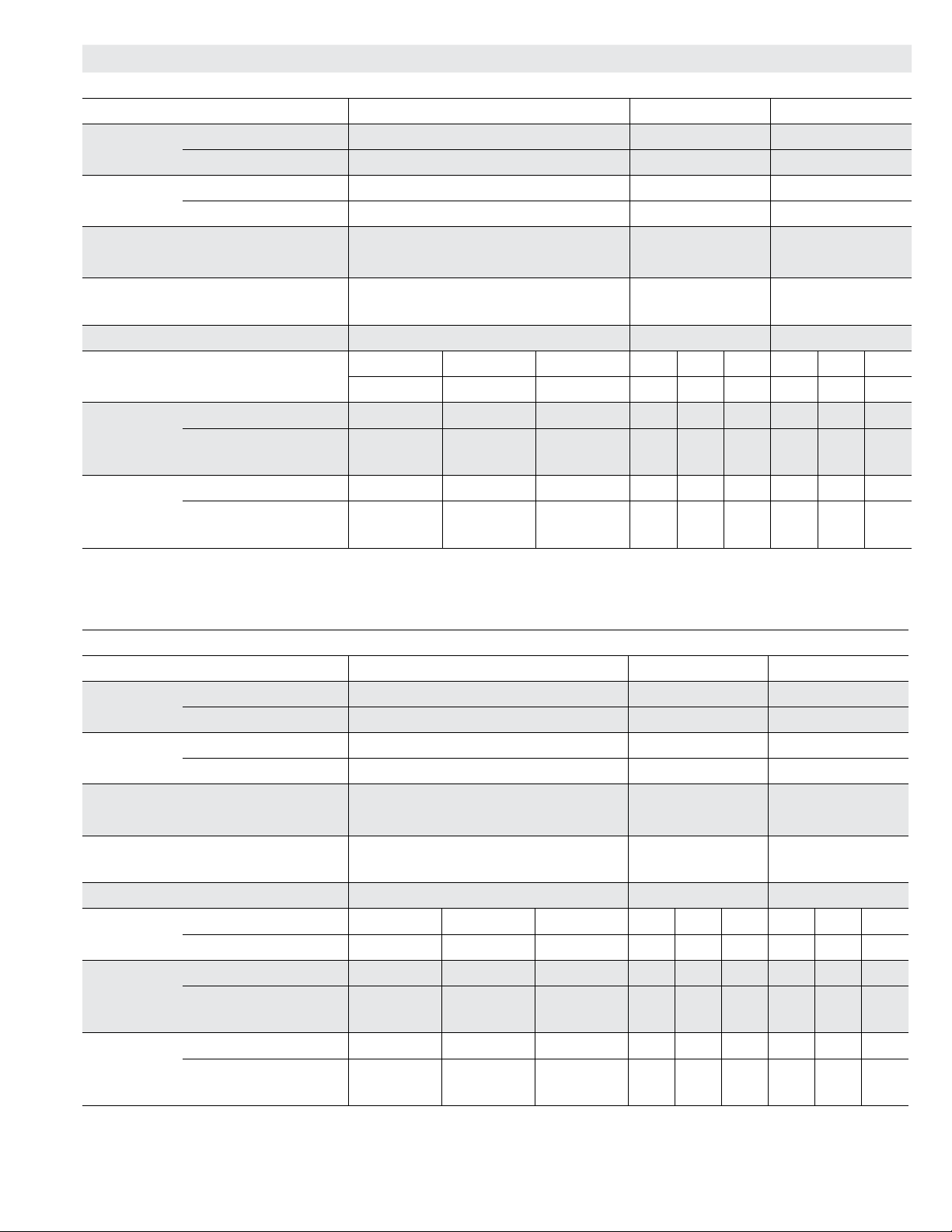

SPECIFICATIONS - GAS HEAT - 092H, 102H, 120H, 150S

Heat Input Type Standard Medium High

Number of Gas Heat Stages 2 2 2

Gas Heating

Performance

Recommended Gas Supply

Pressure - in. w.g.

Input - Btuh First Stage 84,500 117,000 156,000

Second Stage 130,000 180,000 240,000

Output - Btuh Second Stage 104,000 144,000 192,000

Temperature Rise Range - °F 15 - 45 30 - 60 40 - 70

Thermal Efciency 80% 80% 80%

Gas Supply Connections 3/4 in. npt 3/4 in. npt 3/4 in. npt.

Natural 7 in. w.c. 7 in. w.c. 7 in. w.c.

LPG/Propane 11 in. w.c. 11 in. w.c. 11 in. w.c.

HIGH ALTITUDE DERATE - 092H, 102H, 120H, 150S

Units may be installed at altitudes up to 2000 feet above sea level without any modication.

At altitudes above 2000 feet, units must be derated to match gas manifold pressures shown in table below.

At altitudes above 4500 feet unit must be derated 2% for each 1000 feet above sea level.

NOTE − This is the only permissible derate for these units.

Gas Heat

Type

Standard 2001-4500 3.4 9.6 84,500 124,000

Medium 2001-4500 3.4 9.6 117,000 172,000

High 2001-4500 3.4 9.6 156,000 230,000

Altitude

Feet

Gas Manifold Pressure

in. w.g.

Natural Gas LPG/Propane Gas First Stage Second Stage

Input Rate - Btuh

(Natural Gas or LPG/Propane)

Page 10

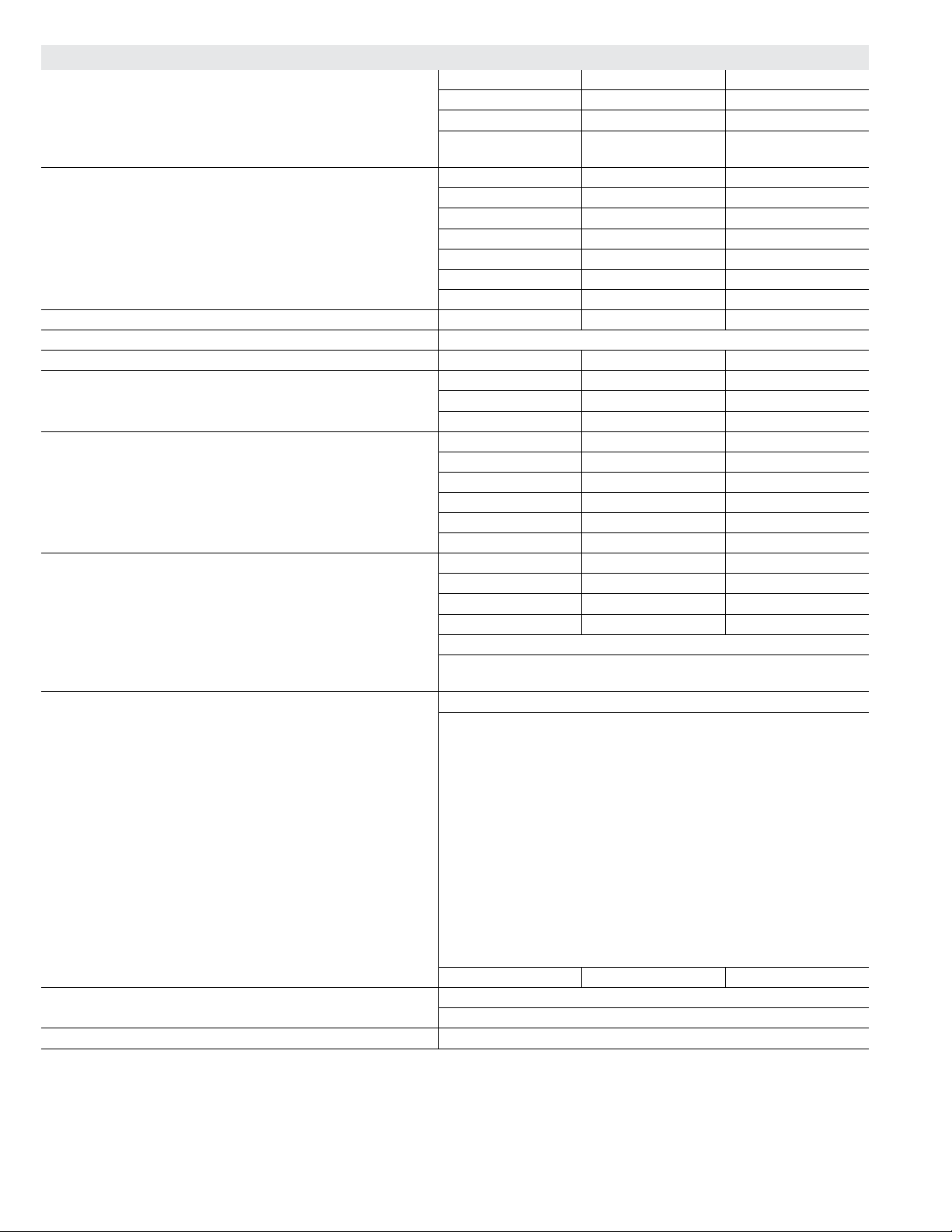

SPECIFICATIONS - DIRECT DRIVE MODELS

General Data Nominal Tonnage 7.5 Ton 10 Ton 12.5 Ton

Model Number LGH094U4E LGH122U4E LGH152U4E

Efciency Type Ultra Ultra Ultra

Blower Type Direct Drive Direct Drive Direct Drive

Cooling

Performance

Gross Cooling Capacity - Btuh 93,700 119,000 141,900

1

Net Cooling Capacity - Btuh 92,000 116,000 138,000

AHRI Rated Air Flow - cfm 2800 3600 4000

Total Unit Power - kW 6.6 8.8 11.2

1

EER (Btuh/Watt) 13.9 13.1 12.3

2

IEER (Btuh/Watt) 21.5 20.0 18.9

Refrigerant Type R-410A R-410A R-410A

Refrigerant Charge Circuit 1 29 lbs. 0 oz. 29 lbs. 0 oz. 29 lbs. 0 oz.

Gas Heating Options Available - See page 7 Standard (2 Stage), Medium (2 Stage), High (2 Stage)

Compressor Type (number) Tandem Scroll (2) Tandem Scroll (2) Tandem Scroll (2)

Outdoor Coils Net face area (total) - sq. ft. 40.8 40.8 40.8

Number of rows 2 2 2

Fins per inch 20 20 20

Outdoor

Coil Fans

Motor - (No.) hp (3) 1/3 ECM (3) 1/3 ECM (3) 1/3 ECM

Motor rpm 520 - 900 640 - 900 640 - 900

Total Motor watts 160 - 650 280 - 650 280 - 650

Diameter - (No.) in. (3) 24 (3) 24 (3) 24

Number of blades 3 3 3

Total Air volume - cfm 5160 - 10,250 7100 - 10,250 7100 - 10,250

Indoor

Coil

Net face area (total) - sq. ft. 13.54 13.54 13.54

Tube diameter - in. 3/8 3/8 3/8

Number of rows 4 4 4

Fins per inch 14 14 14

Drain connection - Number and size (1) 1 in. NPT coupling

Expansion device type Dual-Flow Thermal Expansion Valve System Dual with Flow Control

Balance port, removable head

Indoor

Blower

Blower wheel nominal diameter x width - in. (1) 22 x 9 (1) 22 x 9 (1) 22 x 9

Nominal motor output 3.75 HP (ECM) 3.75 HP (ECM) 3.75 HP (ECM)

Filters Type of lter Disposable

Number and size - in. (4) 20 x 25 x 2

Electrical characteristics 208/230V, 460V or 575V - 60 hertz - 3 phase

NOTE - Net capacity includes evaporator blower motor heat deduction. Gross capacity does not include evaporator blower motor heat deduction.

1

AHRI Certied to AHRI Standard 340/360; 95°F outdoor air temperature and 80°F db/67°F wb entering evaporator air; minimum external duct static pressure.

2

Integrated Energy Efciency Ratio certied and tested according to AHRI Standard 340/360.

Page 11

SPECIFICATIONS - BELT DRIVE MODELS - 094U, 122U, 152U

General Data Nominal Tonnage 7.5 Ton 10 Ton 12.5 Ton

Model Number LGH094U4M LGH122U4M LGH152U4M

Efciency Type Ultra Ultra Ultra

Blower Type

Belt Drive

Cooling

Performance

Gross Cooling Capacity - Btuh 93,700 119,000 141,900

1

Net Cooling Capacity - Btuh 92,000 116,000 136,000

AHRI Rated Air Flow - cfm 2800 3600 4000

Total Unit Power - kW 6.9 8.8 11.5

1

EER (Btuh/Watt) 13.4 12.6 12.0

2

IEER (Btuh/Watt) 20.7 19.2 18.1

Refrigerant Type R-410A R-410A R-410A

Refrigerant Charge Circuit 1 29 lbs. 0 oz. 29 lbs. 0 oz. 29 lbs. 0 oz.

Gas Heating Options Available - See page 7 Standard (2 Stage), Medium (2 Stage), High (2 Stage)

Compressor Type (number) Tandem Scroll (2) Tandem Scroll (2) Tandem Scroll (2)

Outdoor Coils Net face area (total) - sq. ft. 40.8 40.8 40.8

Number of rows 2 2 2

Fins per inch 20 20 20

Outdoor

Coil Fans

Motor - (No.) hp (3) 1/3 ECM (3) 1/3 ECM (3) 1/3 ECM

Motor rpm 520 - 900 640 - 900 640 - 900

Total Motor watts 160 - 650 280 - 650 280 - 650

Diameter - (No.) in. (3) 24 (3) 24 (3) 24

Number of blades 3 3 3

Total Air volume - cfm 5160 - 10,250 7100 - 10,250 7100 - 10,250

Indoor

Coil

Net face area (total) - sq. ft. 13.54 13.54 13.54

Tube diameter - in. 3/8 3/8 3/8

Number of rows 4 4 4

Fins per inch 14 14 14

Drain connection - Number and size (1) 1 in. NPT coupling

Expansion device type Dual-Flow Thermal Expansion Valve System Dual with Flow Control

Balance port, removable head

3

Indoor

Blower

and Drive

Selection

Nominal motor output 2 hp, 3 hp, 5 hp

Motor - Drive kit number 2 hp

Kit 1 590-890 rpm (std. and high efciency)

Kit 2 800-1105 rpm (std. and high efciency)

Kit 3 795-1195 rpm (std. and high efciency)

Kit 4 730-970 rpm (std. efciency)

Kit 5 940-1200 rpm (std. efciency)

Kit 6 1015-1300 rpm (std. efciency)

Kit 7 730-970 rpm (high efciency)

Kit 8 940-1200 rpm (high efciency)

Kit 9 1015-1300 rpm (high efciency)

Kit 10 900-1135 rpm (std. efciency)

Kit 11 1040-1315 rpm (std. efciency)

Kit 12 1125-1425 rpm (std. efciency)

Blower wheel nominal diameter x width - in. (1) 15 X 15 (1) 15 X 15 (1) 15 X 15

Filters Type of lter Disposable

Number and size - in. (4) 20 x 25 x 2

Electrical characteristics 208/230V, 460V or 575V - 60 hertz - 3 phase

NOTE - Net capacity includes evaporator blower motor heat deduction. Gross capacity does not include evaporator blower motor heat deduction.

1

AHRI Certied to AHRI Standard 340/360; 95°F outdoor air temperature and 80°F db/67°F wb entering evaporator air; minimum external duct static pressure.

2

Integrated Energy Efciency Ratio certied and tested according to AHRI Standard 340/360.

3

Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor output required. Maximum usable output of

motors furnished are shown. If motors of comparable output are used, be sure to keep within the service factor limitations outlined on the motor nameplate.

Belt Drive

3 hp

5 hp

Belt Drive

Page 12

SPECIFICATIONS - GAS HEAT - 094U, 122U, 152U

Heat Input Type Standard Medium High

Number of Gas Heat Stages 2 2 2

Gas Heating

Performance

Recommended Gas Supply

Pressure - in. w.g.

Input - Btuh First Stage 84,500 117,000 156,000

Second Stage 130,000 180,000 240,000

Output - Btuh Second Stage 104,000 144,000 192,000

Temperature Rise Range - °F 15 - 45 30 - 60 40 - 70

Thermal Efciency 80% 80% 80%

Gas Supply Connections 3/4 in. npt 3/4 in. npt 3/4 in. npt.

Natural 7 in. w.c. 7 in. w.c. 7 in. w.c.

LPG/Propane 11 in. w.c. 11 in. w.c. 11 in. w.c.

Page 13

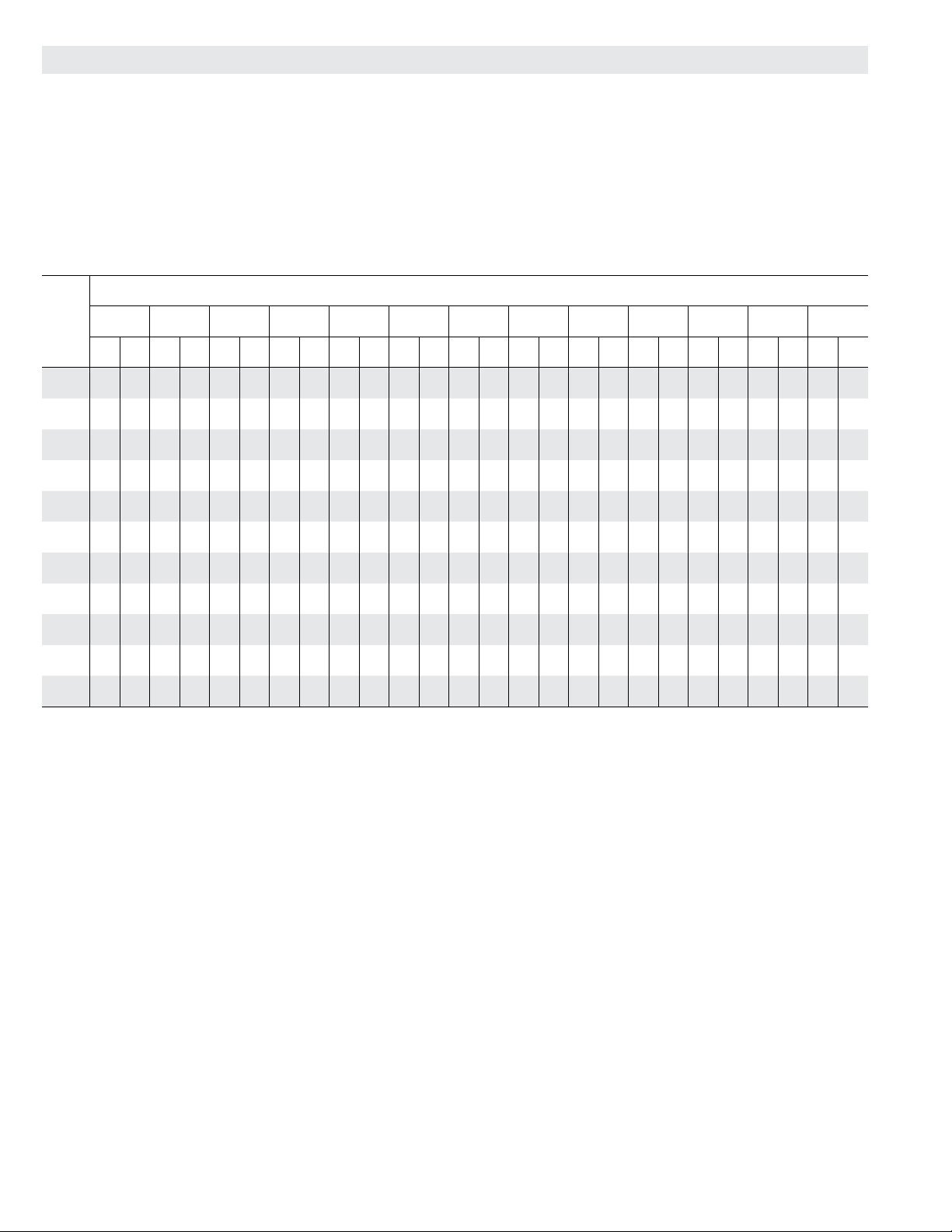

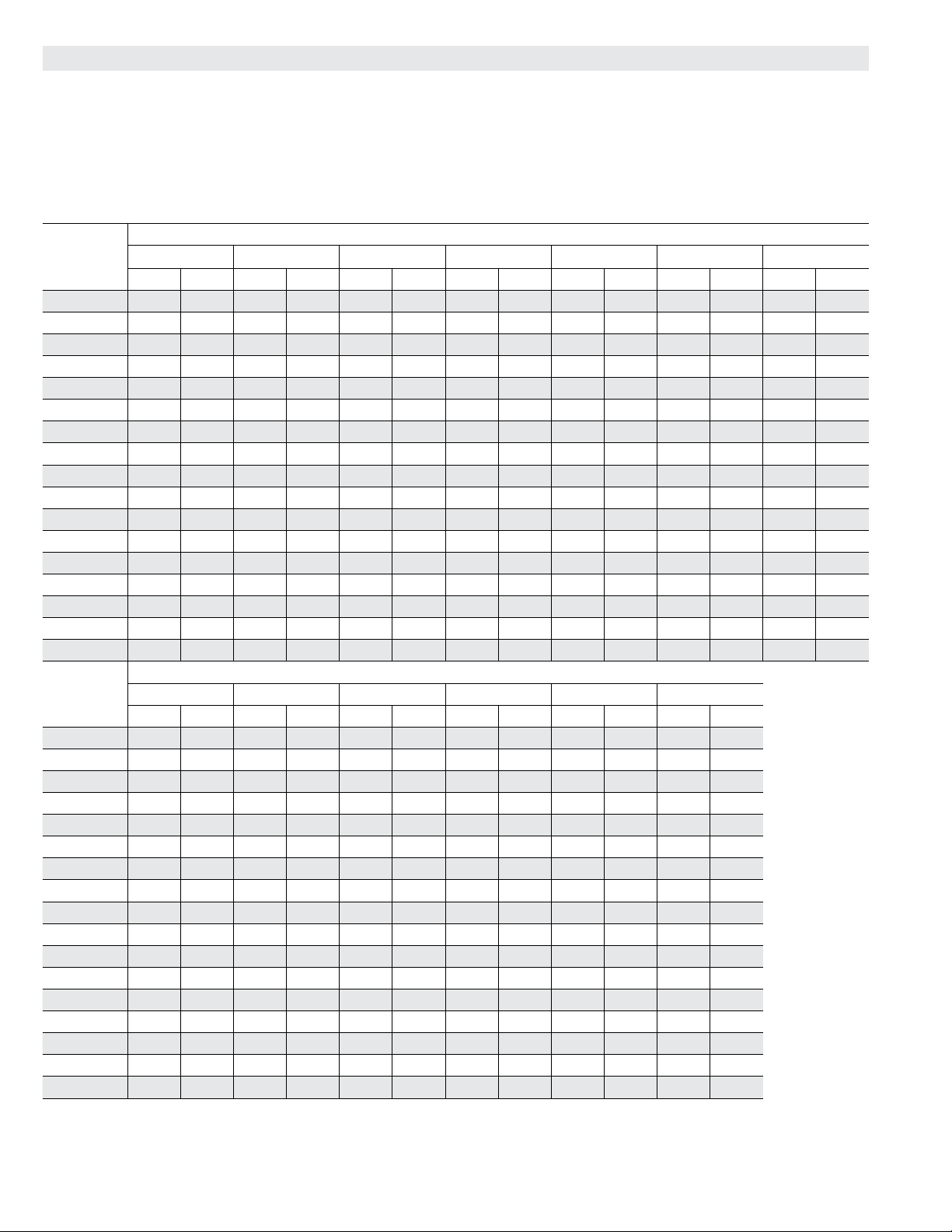

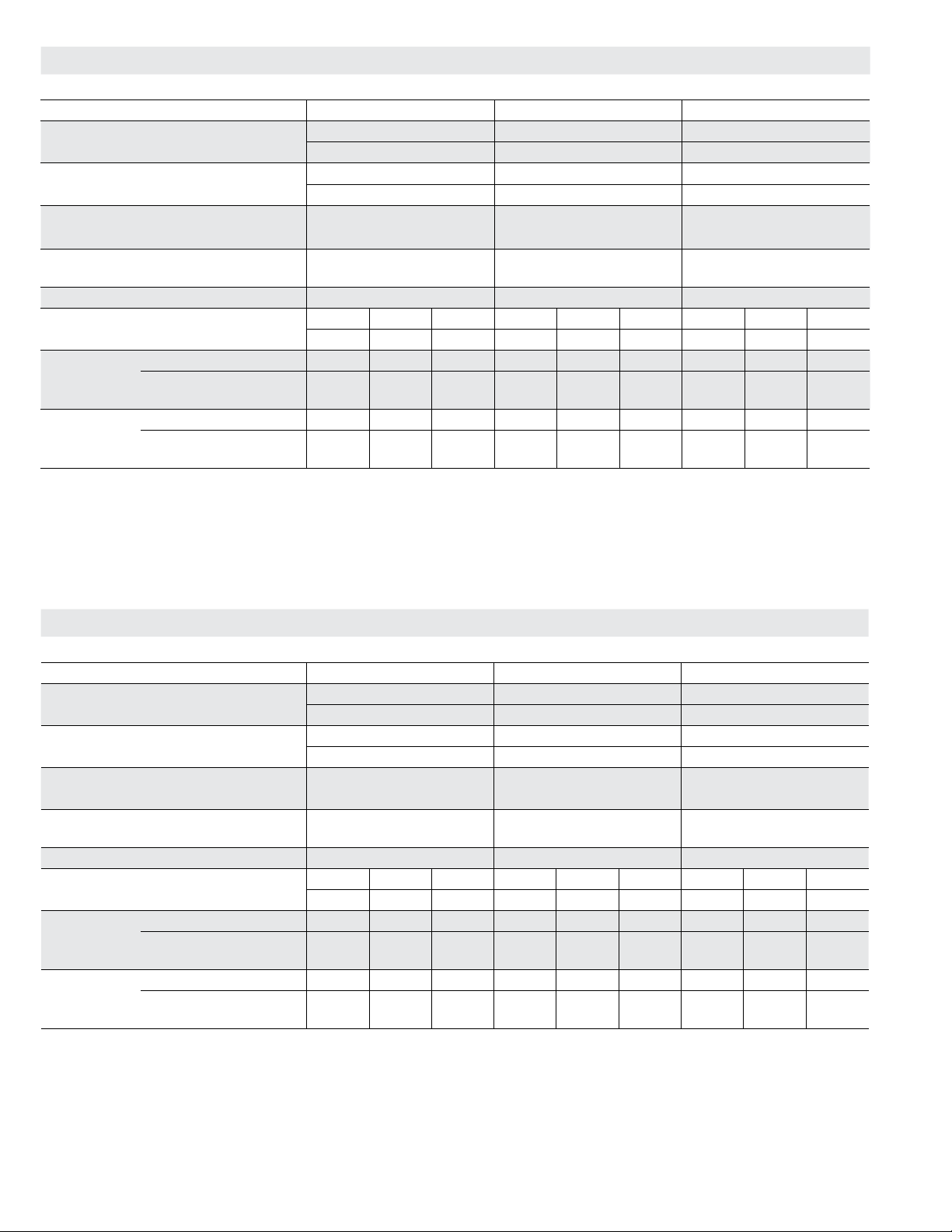

BLOWER DATA

092, 094, AND 102 BELT DRIVE BLOWER − BASE UNIT

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY (NO HEAT SECTION) WITH DRY INDOOR COIL AND AIR

FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 − Wet indoor coil air resistance of selected unit.

2 − Any factory installed options air resistance (heat section, economizer, etc.)

3 − Any eld installed accessories air resistance (duct resistance, diffuser, etc.)

Then determine from blower table blower motor output required.

See page 16 for blower motors and drives. See page 16 for wet coil and option/accessory air resistance data.

MAXIMUM STATIC PRESSURE WITH GAS HEAT - 2.0 in. w.g.

Total

Air

Volume

cfm

1750 481 0.21 549 0.4 618 0.57 688 0.7 758 0.82 824 0.93 885 1.08 941 1.23 991 1.39 1038 1.54 1082 1.68 1124 1.82 1166 1.95

2000 493 0.29 561 0.47 629 0.64 700 0.77 768 0.9 832 1.02 892 1.17 946 1.33 995 1.49 1041 1.66 1085 1.81 1126 1.97 1167 2.12

2250 507 0.37 574 0.56 643 0.72 712 0.86 779 0.99 842 1.13 900 1.28 953 1.44 1001 1.61 1045 1.78 1088 1.95 1128 2.12 1168 2.3

2500 521 0.46 588 0.64 657 0.81 727 0.95 792 1.09 853 1.24 909 1.4 960 1.57 1007 1.74 1050 1.93 1091 2.11 1130 2.29 1170 2.48

2750 537 0.56 604 0.74 674 0.91 743 1.06 806 1.21 865 1.36 920 1.53 969 1.71 1014 1.89 1055 2.08 1095 2.27 1133 2.47 1172 2.66

3000 554 0.67 622 0.86 692 1.02 760 1.18 822 1.34 878 1.5 931 1.68 979 1.86 1021 2.06 1061 2.26 1099 2.46 1136 2.65 1174 2.85

3250 572 0.78 641 0.98 712 1.15 778 1.32 838 1.49 892 1.66 943 1.84 989 2.03 1030 2.24 1068 2.45 1105 2.65 1141 2.85 1178 3.06

3500 592 0.9 663 1.12 733 1.3 798 1.47 855 1.65 907 1.83 956 2.02 1000 2.22 1039 2.44 1076 2.65 1111 2.86 1146 3.07 1183 3.27

3750 614 1.04 687 1.28 756 1.47 818 1.65 872 1.83 923 2.02 970 2.22 1011 2.43 1049 2.65 1084 2.87 1118 3.09 1152 3.29 1189 3.51

4000 639 1.22 713 1.48 780 1.66 838 1.83 890 2.02 939 2.22 984 2.44 1023 2.66 1059 2.89 1093 3.11 1126 3.33 1160 3.54 1197 3.77

4250 667 1.43 741 1.69 805 1.86 859 2.02 909 2.22 956 2.45 998 2.68 1036 2.92 1070 3.15 1103 3.37 1135 3.59 1169 3.81 1207 4.05

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Total Static Pressure − in. w.g.

Page 14

BLOWER DATA

120, 122, 150 AND 152 BELT DRIVE BLOWER − BASE UNIT

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY (NO HEAT SECTION) WITH DRY INDOOR COIL AND AIR

FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 − Wet indoor coil air resistance of selected unit.

2 − Any factory installed options air resistance (heat section, economizer, etc.)

3 − Any eld installed accessories air resistance (duct resistance, diffuser, etc.)

Then determine from blower table blower motor output required.

See page 16 for blower motors and drives. See page 16 for wet coil and option/accessory air resistance data.

MAXIMUM STATIC PRESSURE WITH GAS HEAT - 2.0 in. w.g.

Total

Air

Volume

cfm

2000 497 0.25 558 0.44 624 0.6 694 0.74 764 0.85 830 0.99 889 1.16 943 1.34 994 1.52 1045 1.71 1096 1.89 1146 2.08 1197 2.27

2250 511 0.34 573 0.52 638 0.68 708 0.82 776 0.94 839 1.09 896 1.26 948 1.45 998 1.64 1048 1.83 1098 2.01 1149 2.2 1200 2.4

2500 527 0.44 589 0.62 654 0.78 723 0.91 789 1.05 850 1.21 904 1.39 955 1.58 1003 1.77 1052 1.96 1101 2.14 1152 2.33 1203 2.53

2750 545 0.55 606 0.72 672 0.88 740 1.03 804 1.17 861 1.34 914 1.53 962 1.72 1010 1.92 1057 2.10 1105 2.29 1154 2.47 1206 2.68

3000 564 0.66 626 0.84 692 1.01 759 1.16 819 1.32 874 1.49 924 1.68 971 1.88 1017 2.08 1063 2.26 111 0 2.44 1158 2.63 1208 2.83

3250 585 0.79 648 0.98 714 1.14 778 1.31 836 1.48 887 1.66 935 1.86 981 2.06 1026 2.26 1071 2.45 111 7 2.63 1163 2.80 1213 3.00

3500 607 0.93 672 1.13 737 1.31 798 1.48 852 1.66 901 1.85 948 2.05 993 2.26 1037 2.46 1081 2.65 1125 2.83 1171 3.01 1221 3.21

3750 632 1.10 698 1.31 762 1.50 819 1.67 869 1.86 915 2.05 961 2.25 1005 2.47 1049 2.68 1092 2.88 1136 3.05 1181 3.24 1231 3.45

4000 660 1.30 726 1.52 787 1.70 838 1.87 885 2.06 930 2.26 974 2.48 1018 2.71 1062 2.93 1105 3.12 1149 3.30 1194 3.49 1245 3.72

4250 691 1.53 755 1.75 810 1.91 857 2.07 901 2.27 945 2.50 990 2.74 1034 2.98 1077 3.20 1120 3.39 1163 3.58 1210 3.79 1262 4.03

4500 724 1.78 783 1.98 831 2.12 874 2.28 917 2.50 962 2.75 1006 3.02 1051 3.27 1094 3.49 1137 3.70 1181 3.89 1228 4.11 1281 4.38

4750 757 2.05 809 2.20 851 2.33 891 2.51 935 2.76 980 3.05 1025 3.33 1070 3.59 1113 3.82 1156 4.03 1201 4.24 1249 4.47 1303 4.75

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Total Static Pressure − in. w.g.

5000 787 2.31 831 2.43 870 2.57 910 2.78 954 3.06 1000 3.38 1046 3.68 1091 3.95 1

5250 814 2.55 852 2.66 889 2.83 930 3.09 975 3.41 1023 3.76 1070 4.08 1115 4.35 1159 4.59 1203 4.81 1248 5.03 1297 5.27 1350 5.53

5500 835 2.78 871 2.91 909 3.13 952 3.44 999 3.81 1049 4.18 1096 4.51 1142 4.79 1186 5.03 1229 5.24 1275 5.46 1324 5.69 - - - - - -

5750 854 3.01 890 3.19 930 3.48 977 3.86 1027 4.27 1078 4.66 1126 4.99 1171 5.26 1214 5.49 1258 5.70 - - - - - - - - - - - - - - - - - -

6000 871 3.26 910 3.53 955 3.90 1006 4.34 1060 4.80 1111 5.19 1158 5.51 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

6250 890 3.57 934 3.94 985 4.41 1041 4.91 1096 5.38 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

135 4.19 1178 4.40 1224 4.62 1272 4.86 1325 5.13

Page 15

BLOWER DATA - 092, 094, 102, 120, 122, 150, 152

FACTORY INSTALLED BELT DRIVE KIT SPECIFICATIONS

Motor Efciency Nominal hp Maximum hp Drive Kit Number RPM Range

Standard & High 2 2.3 1 590 - 890

Standard & High 2 2.3 2 800 - 1105

Standard & High 2 2.3 3 795 - 1195

Standard 3 3.45 4 730 - 970

Standard 3 3.45 5 940 - 1200

Standard 3 3.45 6 1015 - 1300

High 3 3.45 7 730 - 970

High 3 3.45 8 940 - 1200

High 3 3.45 9 1015 - 1300

Standard 5 5.75 10 900 - 1135

Standard 5 5.75 11 1040 - 1315

Standard 5 5.75 12 1125 - 1425

NOTE - Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor output required. Maximum usable

output of motors furnished are shown. In Canada, nominal motor output is also maximum usable motor output. If motors of comparable output are used, be sure to keep

within the service factor limitations outlined on the motor nameplate.

NOTE – Units equipped with Multi-Stage Air Volume option are limited to a motor service factor of 1.0.

POWER EXHAUST FAN PERFORMANCE

Return Air System Static Pressure Air Volume Exhausted

in. w.g. cfm

0 3175

0.05 2955

0.10 2685

0.15 2410

0.20 2165

0.25 1920

0.30 1420

0.35 1200

FACTORY INSTALLED OPTIONS/FIELD INSTALLED ACCESSORY AIR RESISTANCE - in. w.g.

Air

Volume

cfm

Wet Indoor Coil

Gas Heat Exchanger

Standard

Heat

Medium

heat

High

Heat

Economizer

Humiditrol

Condenser

Reheat Coil

Filters

MERV 8 MERV 13

Return Air

Adaptor Plate

092, 102 120, 150

1750 0.04 0.04 0.06 0.02 0.02 0.05 0.02 0.01 0.03 0.00

2000 0.05 0.05 0.07 0.05 0.06 0.06 0.02 0.01 0.03 0.00

2250 0.06 0.06 0.07 0.07 0.08 0.08 0.02 0.01 0.04 0.00

2500 0.07 0.07 0.09 0.10 0.11 0.11 0.03 0.01 0.05 0.00

2750 0.08 0.08 0.09 0.11 0.12 0.12 0.03 0.02 0.05 0.00

3000 0.10 0.09 0.11 0.12 0.13 0.13 0.03 0.02 0.06 0.02

3250 0.11 0.10 0.12 0.15 0.16 0.15 0.04 0.02 0.06 0.02

3500 0.12 0.11 0.12 0.16 0.17 0.15 0.04 0.03 0.07 0.04

3750 0.14 0.13 0.14 0.19 0.20 0.15 0.05 0.03 0.08 0.07

4000 0.15 0.14 0.14 0.21 0.22 0.19 0.05 0.04 0.08 0.09

4250 0.17 0.15 0.14 0.24 0.28 0.19 0.06 0.04 0.09 0.11

4500 0.19 0.17 0.15 0.26 0.32 0.22 0.07 0.04 0.09 0.12

4750 0.20 0.18 0.16 0.29 0.37 0.25 0.07 0.05 0.10 0.16

5000 0.22 0.20 0.16 0.34 0.43 0.29 0.08 0.06 0.10 0.18

5250 0.24 0.22 0.16 0.37 0.47 0.32 0.08 0.06 0.11 0.19

5500 0.25 0.23 0.18 0.44 0.54 0.34 0.09 0.07 0.12 0.22

5750 0.27 0.25 0.19 0.49 0.59 0.45 0.10 0.07 0.12 0.25

6000 0.29 0.27 0.20 0.54 0.64 0.52 0.10 0.08 0.13 0.27

Page 16

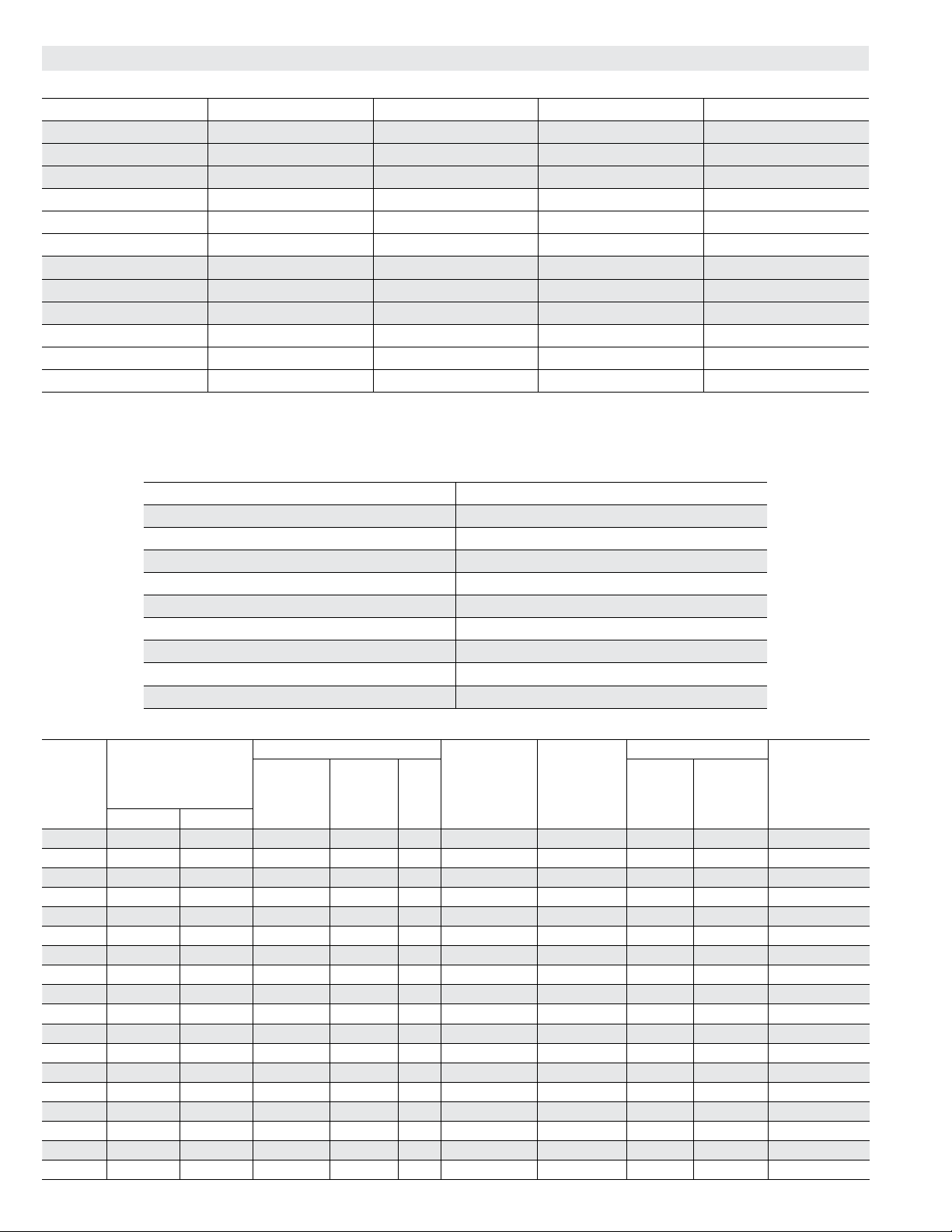

BLOWER DATA

CEILING DIFFUSERS AIR RESISTANCE - in. w.g.

Unit Size

092, 094 Models

102, 120 & 122

Models

150, 152 Models

Air Volume

cfm

2 Ends Open

2400 0.21 0.18 0.15 0.14

2600 0.24 0.21 0.18 0.17

2800 0.27 0.24 0.21 0.20

3000 0.32 0.29 0.25 0.25

3200 0.41 0.37 0.32 0.31

3400 0.50 0.45 0.39 0.37

3600 0.61 0.54 0.48 0.44

3800 0.73 0.63 0.57 0.51

3600 0.36 0.28 0.23 0.15

3800 0.40 0.32 0.26 0.18

4000 0.44 0.36 0.29 0.21

4200 0.49 0.40 0.33 0.24

4400 0.54 0.44 0.37 0.27

4600 0.60 0.49 0.42 0.31

4800 0.65 0.53 0.46 0.35

5000 0.69 0.58 0.50 0.39

5200 0.75 0.62 0.54 0.43

4200 0.22 0.19 0.16 0.10

4400 0.28 0.24 0.20 0.12

4600 0.34 0.29 0.24 0.15

4800 0.40 0.34 0.29 0.19

5000 0.46 0.39 0.34 0.23

5200 0.52 0.44 0.39 0.27

5400 0.58 0.49 0.43 0.31

5600 0.64 0.54 0.47 0.35

5800 0.70 0.59 0.51 0.39

RTD11 Step-Down Diffuser

1 Side, 2 Ends

Open

All Ends & Sides

Open

FD11 Flush

Diffuser

CEILING DIFFUSER AIR THROW DATA

1

Effective Throw Range

RTD11 Step-Down FD11 Flush

Model No.

Air Volume

cfm ft. ft.

2600 24 - 29 19 - 24

2800 25 - 30 20 - 28

092, 094

Models

3000 27 - 33 21 - 29

3200 28 - 35 22 - 29

3400 30 - 37 22 - 30

3600 25 - 33 22 - 29

3800 27 - 35 22 - 30

102, 120, 122

Models

4000 29- 37 24 - 33

4200 32 - 40 26 - 35

4400 34 - 42 28 - 37

5600 39 - 49 28 - 37

5800 42 - 51 29 - 38

150, 152

Models

6000 44 - 54 40 - 50

6200 45 - 55 42 - 51

6400 46 - 55 43 - 52

6600 47 - 56 45 - 56

1

Throw is the horizontal or vertical distance an air stream travels on leaving the outlet or diffuser

before the maximum velocity is reduced to 50 ft. per minute. Four sides open.

Page 17

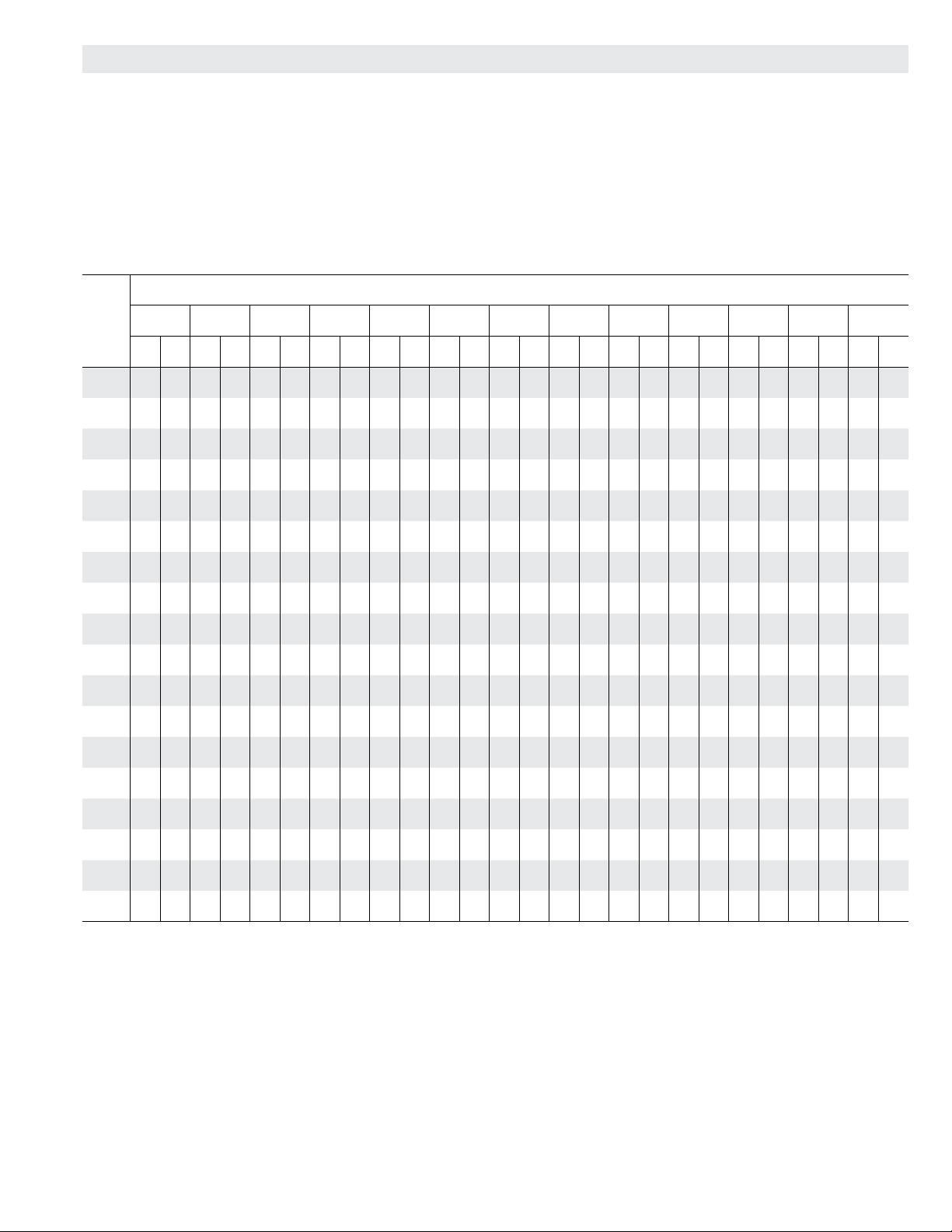

BLOWER DATA - DIRECT DRIVE - 094U, 122U, 152U

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY (NO HEAT SECTION) WITH DRY INDOOR COIL AND AIR

FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 − Wet indoor coil air resistance of selected unit.

2 − Any factory installed options air resistance (heat section, economizer, etc.)

3 − Any eld installed accessories air resistance (duct resistance, diffuser, etc.)

See page 21 for wet coil and option/accessory air resistance data.

MAXIMUM STATIC PRESSURE WITH GAS HEAT - 2.0 in. w.g.

Total

Air Volume

cfm

1750 7 11 188 771 279 836 366 905 453 975 544 1044 640 1109 737

2000 752 242 812 332 876 420 944 510 1011 606 1075 709 1138 812

2250 799 300 860 389 923 479 988 575 1052 678 1113 787 1171 896

2500 853 362 914 453 976 548 1038 650 1097 761 1154 877 1209 990

2750 914 434 974 529 1033 629 1091 739 1146 858 1199 979 1250 1098

3000 980 513 1037 614 1092 720 1146 837 1198 961 1247 1088 1295 1215

3250 1048 598 1101 705 1153 819 1203 941 1251 1071 1298 1206 1343 1343

3500 1116 693 1166 809 1214 931 1261 1060 1307 1198 1351 1341 1395 1489

3750 1185 806 1232 931 1277 1063 1322 1201 1365 1348 1407 1499 1448 1657

4000 1254 937 1299 1072 1341 1214 1383 1363 1424 1518 1464 1679 1503 1844

4250 1324 1089 1366 1234 1406 1386 1445 1545 1484 1708 1522 1876 1559 2046

4500 1395 1262 1433 1417 1471 1579 1508 1745 1544 1913 1581 2084 1616 2256

4750 1465 1455 1501 1619 1536 1787 1571 1957 1606 2128 1641 2299 1675 2470

5000 1534 1666 1568 1834 1602 2004 1635 2174 1668 2345 1701 2514 1735 2682

5250 1603 1887 1635 2055 1667 2224 1699 2392 1731 2559 1763 2724 - - - - - -

5500 1671 2110 1702 2275 1733 2441 1764 2605 - - - - - - - - - - - - - - - - - -

5750 1738 2325 1768 2488 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Total

Air Volume

cfm

1750 1172 833 1231 932 1287 1039 1340 1156 1391 1283 1442 1426

2000 1197 913 1253 1019 1306 1135 1357 1261 1407 1398 1457 1547

2250 1227 1003 1280 1117 1330 1242 1379 1378 1428 1525 1477 1680

2500 1261 1103 1311 1226 1360 1361 1407 1507 1454 1663 1501 1826

2750 1299 1219 1347 1350 1394 1494 1440 1649 1485 1813 1530 1982

3000 1342 1346 1388 1487 1432 1640 1476 1803 1520 1973 1563 2146

3250 1388 1485 1432

3500 1437 1643 1479 1805 1519 1975 1560 2148 1600 2325 1640 2502

3750 1489 1821 1528 1990 1567 2164 1605 2340 1645 2517 1685 2693

4000 1541 2014 1579 2187 1616 2364 1654 2540 1693 2715 1732 2887

4250 1596 2218 1632 2393 1668 2569 1705 2742 1743 2913 - - - - - -

4500 1652 2429 1687 2603 1722 2775 1759 2944 - - - - - - - - - - - -

4750 1709 2641 1743 281

5000 1768 2850 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

5250 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

5500 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

5750 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

0.2 0.4 0.6 0.8 1.0 1.2 1.4

RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts

1.6 1.8 2.0 2.2 2.4 2.6

RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts

1638 1475 1800 1517 1969 1558 2143 1600 2319

1 1778 2979 - - - - - - - - - - - - - - - - - -

Total Static Pressure - in. w.g.

Total Static Pressure - in. w.g.

Page 18

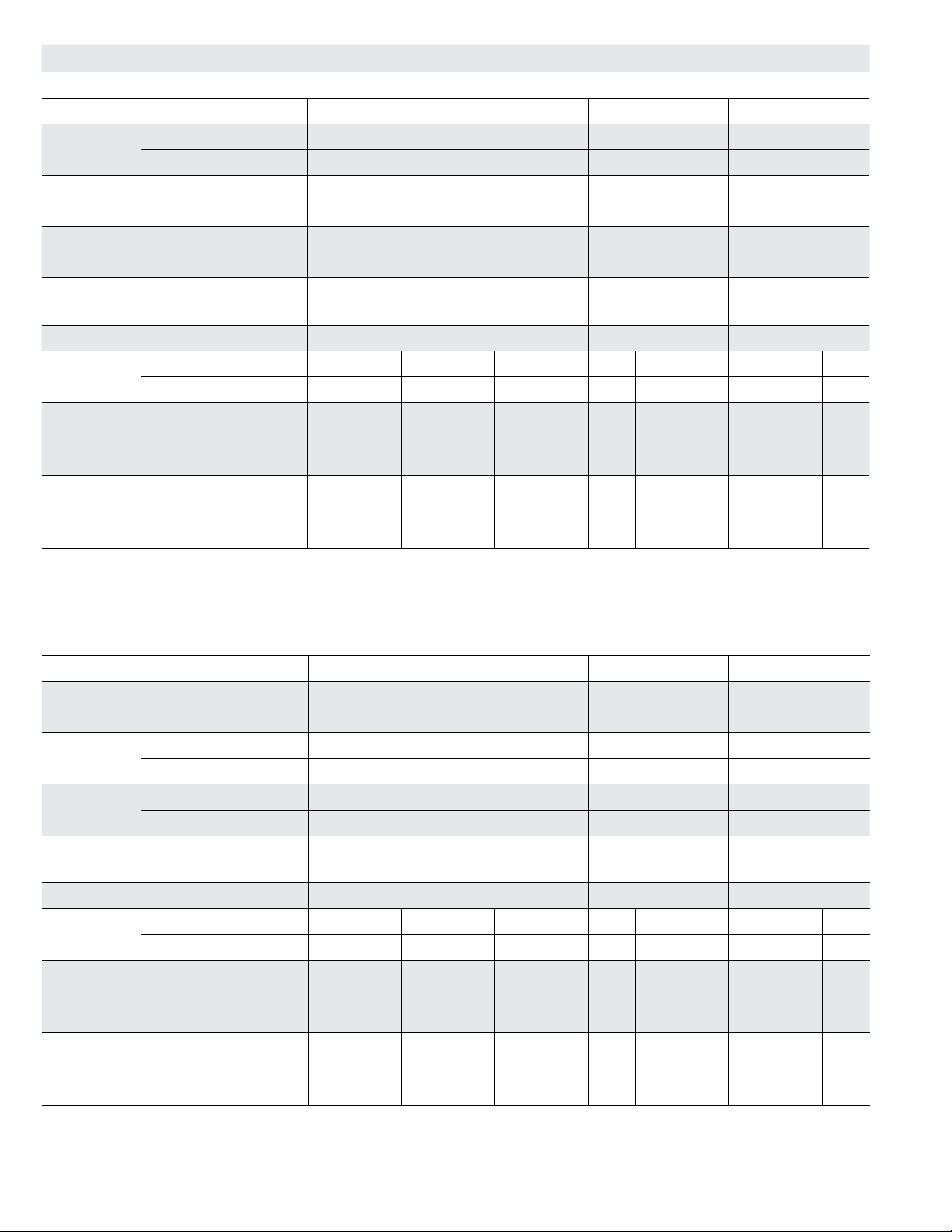

ELECTRICAL DATA

7.5 TON HIGH EFFICIENCY (R-410A) LGH092H4

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 13.1 6.1 4.4

Locked Rotor Amps 83.1 41 33

Compressor 2 Rated Load Amps 13.1 6.1 4.4

Locked Rotor Amps 83.1 41 33

Outdoor Fan

Motors (2)

Power Exhaust

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Full Load Amps 2.4 1.3 1

(total) (4.8) (2.6) (2)

Full Load Amps 2.4 1.3 1

Horsepower 2 3 5 2 3 5 2 3 5

Full Load Amps 7.5 10.6 16.7 3.4 4.8 7.6 2.7 3.9 6.1

Unit Only 50 50 60 25 25 30 15 20 20

With (1) 0.33 HP

50 60 70 25 25 30 20 20 25

Power Exhaust

Unit Only 42 45 52 20 22 25 15 16 19

With (1) 0.33 HP

45 48 55 22 23 26 16 17 20

Power Exhaust

8.5 TON HIGH EFFICIENCY (R-410A) LGH102H4

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 13.7 6.2 4.8

Locked Rotor Amps 83.1 41 33

Compressor 2 Rated Load Amps 13.7 6.2 4.8

Locked Rotor Amps 83.1 41 33

Outdoor Fan

Motors (2)

Power Exhaust

Full Load Amps 2.4 1.3 1

(total) (4.8) (2.6) (2)

Full Load Amps 2.4 1.3 1

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Horsepower 2 3 5 2 3 5 2 3 5

Full Load Amps 7.5 10.6 16.7 3.4 4.8 7.6 2.7 3.9 6.1

Unit Only 50 50 60 25 25 30 20 20 25

With (1) 0.33 HP

50 60 70 25 25 30 20 20 25

Power Exhaust

Unit Only 44 47 54 20 22 25 16 17 20

With (1) 0.33 HP

46 49 56 22 23 26 17 18 21

Power Exhaust

Page 19

ELECTRICAL DATA

10 TON HIGH EFFICIENCY (R-410A) LGH120H4

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 13.5 8 5

Locked Rotor Amps 109 59 40

Compressor 2 Rated Load Amps 13.5 8 5

Locked Rotor Amps 109 59 40

Outdoor Fan

Motors (2)

Power Exhaust

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Full Load Amps 2.4 1.3 1

(total) (4.8) (2.6) (2)

Full Load Amps 2.4 1.3 1

Horsepower 2 3 5 2 3 5 2 3 5

Full Load Amps 7.5 10.6 16.7 3.4 4.8 7.6 2.7 3.9 6.1

Unit Only 50 50 60 30 30 35 20 20 25

With (1) 0.33 HP

50 60 70 30 30 35 20 20 25

Power Exhaust

Unit Only 43 46 53 24 26 29 16 18 20

With (1) 0.33 HP

46 49 56 26 27 30 17 19 21

Power Exhaust

12.5 TON STANDARD EFFICIENCY (R-410A) LGH150S4

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 19.6 8.2 6.6

Locked Rotor Amps 136 66.1 55.3

Compressor 2 Rated Load Amps 19.6 8.2 6.6

Locked Rotor Amps 136 66.1 55.3

Outdoor Fan

Motors (2)

Power Exhaust

Full Load Amps 3 1.5 1.2

(total) (6) (3) (2.4)

Full Load Amps 2.4 1.3 1

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Horsepower 2 3 5 2 3 5 2 3 5

Full Load Amps 7.5 10.6 16.7 3.4 4.8 7.6 2.7 3.9 6.1

Unit Only 70 80 80 30 30 35 25 25 25

With (1) 0.33 HP

70 80 80 30 35 35 25 25 30

Power Exhaust

Unit Only 58 61 67 25 27 30 20 22 24

With (1) 0.33 HP

60 64 70 27 28 31 21 23 25

Power Exhaust

Page 20

ELECTRICAL DATA 7.5 TON

DIRECT DRIVE LGH094U4E

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 13.1 6.1 4.4

Locked Rotor Amps 83.1 41 33

Compressor 2 Rated Load Amps 13.1 6.1 4.4

Locked Rotor Amps 83.1 41 33

Outdoor Fan

Motors (3)

Power Exhaust

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Full Load Amps 2.8 1.4 1.1

(total) (8.4) (4.2) (3.3)

Full Load Amps 2.4 1.3 1

Horsepower 3.75 3.75 3.75

Full Load Amps 8.8 4.3 3.4

Unit Only 60 30 20

With (1) 0.33 HP

60 30 20

Power Exhaust

Unit Only 51 25 19

With (1) 0.33 HP

53 26 20

Power Exhaust

ELECTRICAL DATA 10 TON

DIRECT DRIVE LGH122U4E

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 16 7.8 5.7

Locked Rotor Amps 110 52 38.9

Compressor 2 Rated Load Amps 16 7.8 5.7

Locked Rotor Amps 110 52 38.9

Outdoor Fan

Motors (3)

Power Exhaust

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Full Load Amps 2.8 1.4 1.1

(total) (8.4) (4.2) (3.3)

Full Load Amps 2.4 1.3 1

Horsepower 3.75 3.75 3.75

Full Load Amps 8.8 4.3 3.4

Unit Only 70 35 25

With (1) 0.33 HP

70 35 25

Power Exhaust

Unit Only 58 29 22

With (1) 0.33 HP

60 30 23

Power Exhaust

Page 21

ELECTRICAL DATA 12.5 TON

DIRECT DRIVE LGH152U4E

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 19.6 8.2 6.6

Locked Rotor Amps 136 66.1 55.3

Compressor 2 Rated Load Amps 19.6 8.2 6.6

Locked Rotor Amps 136 66.1 55.3

Outdoor Fan

Motors (3)

Power Exhaust

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Full Load Amps 2.8 1.4 1.1

(total) (8.4) (4.2) (3.3)

Full Load Amps 2.4 1.3 1

Horsepower 3.75 3.75 3.75

Full Load Amps 8.8 4.3 3.4

Unit Only 80 35 30

With (1) 0.33 HP

80 35 30

Power Exhaust

Unit Only 66 30 24

With (1) 0.33 HP

68 31 25

Power Exhaust

Page 22

ELECTRICAL DATA 7.5 TON

BELT DRIVE LGH094U4M

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 13.1 6.1 4.4

Locked Rotor Amps 83.1 41 33

Compressor 2 Rated Load Amps 13.1 6.1 4.4

Locked Rotor Amps 83.1 41 33

Outdoor Fan

Motors (3)

Power Exhaust

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

4

Factory installed circuit breaker not available.

Full Load Amps 2.8 1.4 1.1

(total) (8.4) (4.2) (3.3)

Full Load Amps 2.4 1.3 1

Horsepower 2 3 5 2 3 5 2 3 5

Full Load Amps 7.5 10.6 16.7 3.4 4.8 7.6 2.7 3.9 6.1

Unit Only 60 60 70 25 30 35 20 20 25

With (1) 0.33 HP

60 60 70 30 30 35 20 20 25

Power Exhaust

Unit Only 50 53 60 24 25 28 18 19 22

With (1) 0.33 HP

52 55 62 25 27 30 19 20 23

Power Exhaust

ELECTRICAL DATA 10 TON

BELT DRIVE LGH122U4M

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 16.5 7.2 5.5

Locked Rotor Amps 110 52 38.9

Compressor 2 Rated Load Amps 16 7.8 5.7

Locked Rotor Amps 110 52 38.9

Outdoor Fan

Motors (3)

Power Exhaust

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

4

Factory installed circuit breaker not available.

5

Disconnect must be eld furnished.

Full Load Amps 2.8 1.4 1.1

(total) (8.4) (4.2) (3.3)

Full Load Amps 2.4 1.3 1

Horsepower 2 3 5 2 3 5 2 3 5

Full Load Amps 7.5 10.6 16.7 3.4 4.8 7.6 2.7 3.9 6.1

Unit Only 70 70 80 30 35 35 25 25 25

With (1) 0.33 HP

70 70 80 35 35 35 25 25 30

Power Exhaust

Unit Only 57 60 66 27 29 31 21 22 24

With (1) 0.33 HP

59 62 69 28 30 33 22 23 25

Power Exhaust

Page 23

ELECTRICAL DATA 7.5 TON

BELT DRIVE LGH094U4M

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 13.1 6.1 4.4

Locked Rotor Amps 83.1 41 33

Compressor 2 Rated Load Amps 13.1 6.1 4.4

Locked Rotor Amps 83.1 41 33

Outdoor Fan

Motors (3)

Power Exhaust

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

4

Factory installed circuit breaker not available.

Full Load Amps 2.8 1.4 1.1

(total) (8.4) (4.2) (3.3)

Full Load Amps 2.4 1.3 1

Horsepower 2 3 5 2 3 5 2 3 5

Full Load Amps 7.5 10.6 16.7 3.4 4.8 7.6 2.7 3.9 6.1

Unit Only 60 60 70 25 30 35 20 20 25

With (1) 0.33 HP

60 60 70 30 30 35 20 20 25

Power Exhaust

Unit Only 50 53 60 24 25 28 18 19 22

With (1) 0.33 HP

52 55 62 25 27 30 19 20 23

Power Exhaust

ELECTRICAL DATA 10 TON

BELT DRIVE LGH122U4M

1

Voltage - 60hz 208/230V - 3 Ph 460V - 3 Ph 575V - 3 Ph

Compressor 1 Rated Load Amps 16.5 7.2 5.5

Locked Rotor Amps 110 52 38.9

Compressor 2 Rated Load Amps 16 7.8 5.7

Locked Rotor Amps 110 52 38.9

Outdoor Fan

Motors (3)

Power Exhaust

(1) 0.33 HP

Service Outlet 115V GFI (amps) 15 15 20

Indoor Blower

Motor

2

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

NOTE - All units have a minimum Short Circuit Current Rating (SCCR) of 5000 amps.

1

Extremes of operating range are plus and minus 10% of line voltage.

2

HACR type breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

4

Factory installed circuit breaker not available.

5

Disconnect must be eld furnished.

Full Load Amps 2.8 1.4 1.1

(total) (8.4) (4.2) (3.3)

Full Load Amps 2.4 1.3 1

Horsepower 2 3 5 2 3 5 2 3 5

Full Load Amps 7.5 10.6 16.7 3.4 4.8 7.6 2.7 3.9 6.1

Unit Only 70 70 80 30 35 35 25 25 25

With (1) 0.33 HP

70 70 80 35 35 35 25 25 30

Power Exhaust

Unit Only 57 60 66 27 29 31 21 22 24

With (1) 0.33 HP

59 62 69 28 30 33 22 23 25

Power Exhaust

Page 24

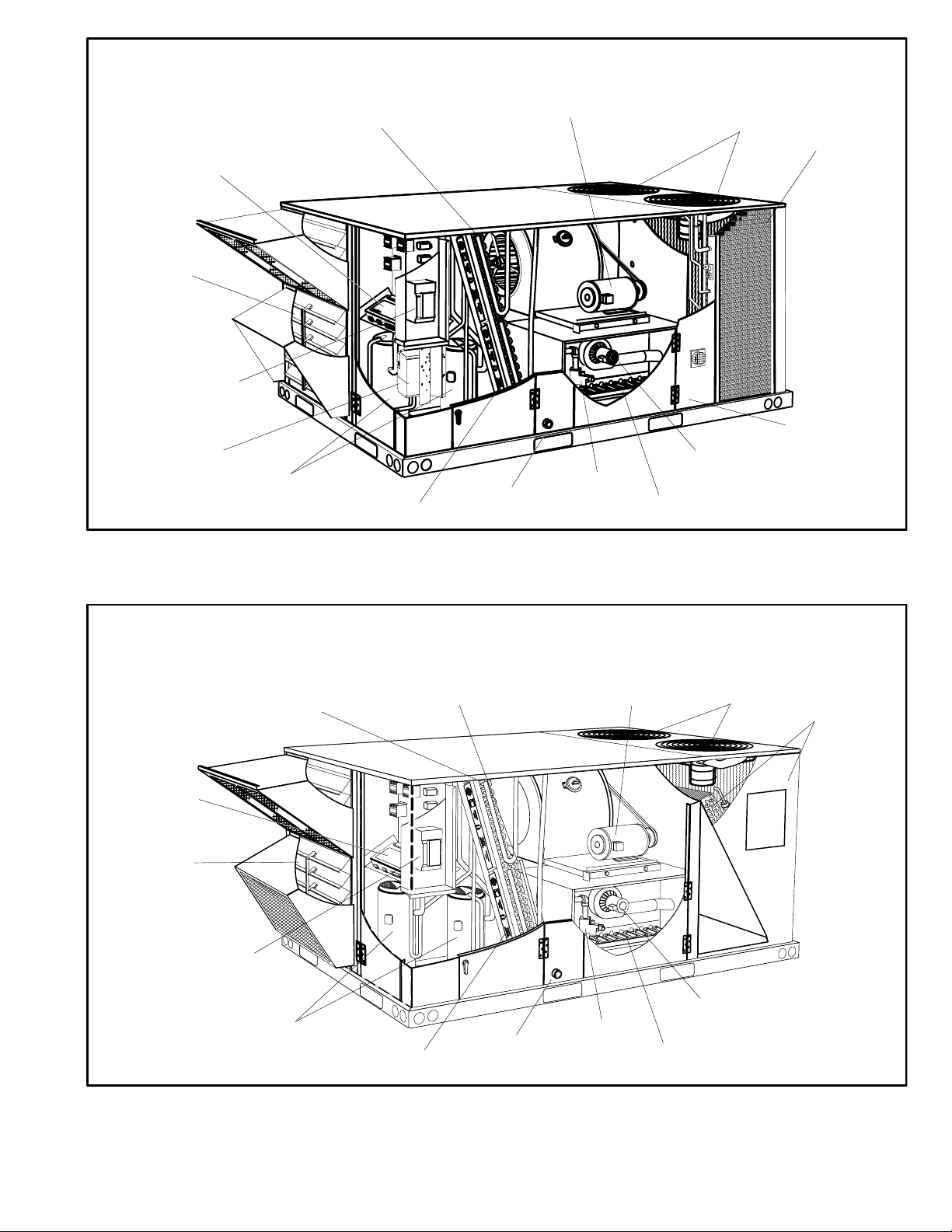

UNIT

CONTROLLER

PARTS ARRANGEMENT - 092H, 102H, 120H, 150S

ALL-ALUMINUM COIL SYSTEM

EVAPORATOR

COIL

BLOWER

MOTOR

CONDENSER

FANS

CONDENSER

COIL

ECONOMIZER

(OPTIONAL)

DISCONNECT /

CIRCUIT BREAKER

(FACTORY OR FIELD

INSTALLED OPTION)

INVERTER

(OPTIONAL)

COMPRESSORS

EVAPORATOR

COIL

3

3

BLOWER

COMBUSTION

AIR INDUCER

FILTERS

(FOUR - 20 X 25 X 2”)

CONDENSATE

DRAIN

GAS VALVE

BURNERS

PARTS ARRANGEMENT - 092H, 102H, 120H, 150S

FIN/TUBE COIL

REHEAT COIL

(Hot Gas Reheat

Units Only)

BLOWER

MOTOR

CONDENSER

FANS

HINGED

ACCESS PANEL

(OPTIONAL)

CONDENSER

COILS

UNIT

CONTROLLER

ECONOMIZER

(OPTIONAL)

DISCONNECT /

CIRCUIT BREAKER

(FACTORY OR FIELD

INSTALLED OPTION)

COMPRESSORS

FILTERS

(FOUR - 20 X 25 X 2”)

33

33

LL

LL

EE

EE

NN

NN

NN

NN

OO

OO

XX

XX

CONDENSATE

DRAIN

FIGURE 2

Page 25

BLOWER

BLOWER

GAS VALVE

COMBUSTION

AIR INDUCER

BURNERS

(FOUR - 20 X 25 X 2”)

UNIT

CONTROLLER

FILTERS

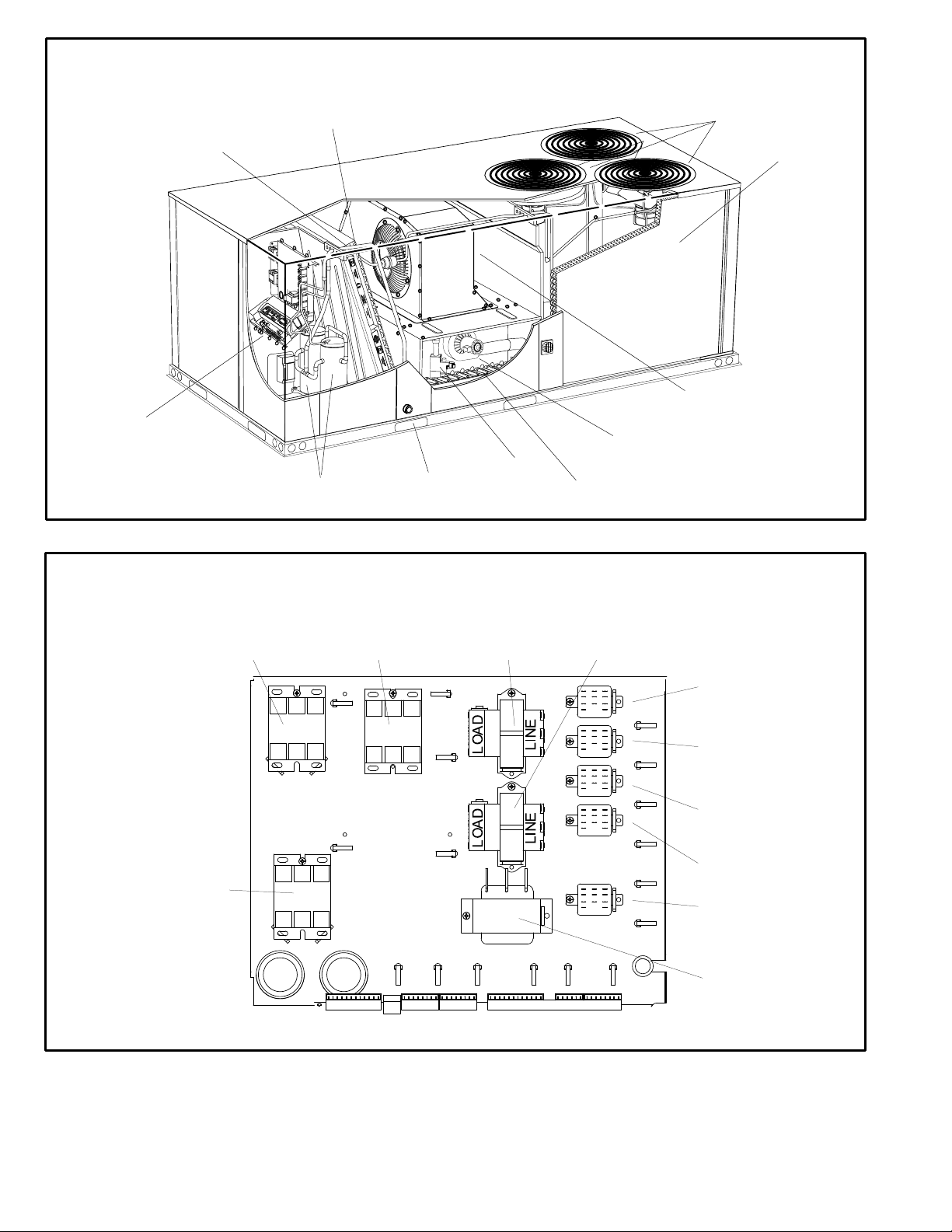

PARTS ARRANGEMENT - 094U, 122U, 152U

FIN/TUBE COIL

EVAPORATOR

COIL

BLOWER

COMBUSTION

AIR INDUCER

COMPRESSORS

CONDENSATE

DRAIN

GAS VALVE

BURNERS

CONDENSER

FANS

CONDENSER

COIL

BLOWER MOTOR THIS

SIDE OF HOUSING

(DIRECT DRIVE SHOWN)

COMPRESSOR 2

CONTACTOR

K1

COMPRESSOR 1

CONTACTOR

FIGURE 3

CONTROL BOX PARTS ARRANGEMENT -

STANDARD AND HIGH EFFICIENCY NON-CE UNITS

K2

K3

BLOWER

CONTACTOR

T1

CONTROL

TRANSFORMER

T3

T43 REHEAT

TRANSFORMER

K65

EXHAUST

FAN RELAY

K10

OUTDOOR

FAN 1 RELAY

K68

OUTDOOR

FAN 2 RELAY

K13

CAB RELAY

K125

HEAT SHUT

OFF RELAY

T3

CAB

TRANSFORMER

FIGURE 4

Page 26

Loading...

Loading...