Litho U.S.A.

2015

INSTALLATION

INSTRUCTIONS

WARNING

Improper installation, adjustment, alteration, ser

vice or maintenance can cause property damage,

personal injury or loss of life. Installation and ser

vice must be performed by a licensed professional

HVAC installer or equivalent, service agency, or the

gas supplier

CAUTION

Danger of sharp metallic edges. Can cause injury.

Take care and wear protective clothing when

servicing unit to avoid accidental contact with

sharp edges.

Table Of Contents

Dimensions Page 2.................................

Parts Arrangements Page 4.........................

Shipping and Packing List Page 5....................

General Page 5....................................

Safety Page 5.....................................

Unit Support Page 6................................

Duct Connection Page 7............................

Rigging Unit For Lifting Page 7.......................

Condensate Drains Page 7..........................

Gas Piping Page 9.................................

Pressure Test Gas Piping Page 10.....................

High Altitude Derate Page 11.........................

Electrical Connections Page 11.......................

Blower Operation and Adjustments Page 14............

LGH092H, LCH092H

LGH094U, LCH094U

LGH102H, LCH102H

LGH120H, LCH120H

LGH122U, LCH122U

LGH150S, LCH150S

LGH152U, LCH152U

PACKAGED UNITS

507245-02

9/2015

Supersedes 507245-01

Cooling Start-Up Page 22............................

Gas Heat Start-Up Page 34...........................

Heating Operation and Adjustments Page 35............

Electric Heat Start-Up Page 35........................

Supply Air Inverter Start-Up Page 36...................

Supply Air Inverter and Direct Drive Operation Page 38...

Direct Drive Start-Up Page 38.........................

Hot Gas Reheat Operation and Start-Up Page 40........

Service Page 41....................................

Unit Controller Parameter Settings Page 45.............

(7.5 Ton)

(7.5 Ton)

(8.5 Ton)

(10 Ton)

(10 Ton)

(12.5 Ton)

(12.5 Ton)

RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

3

3

LGH SHOWN

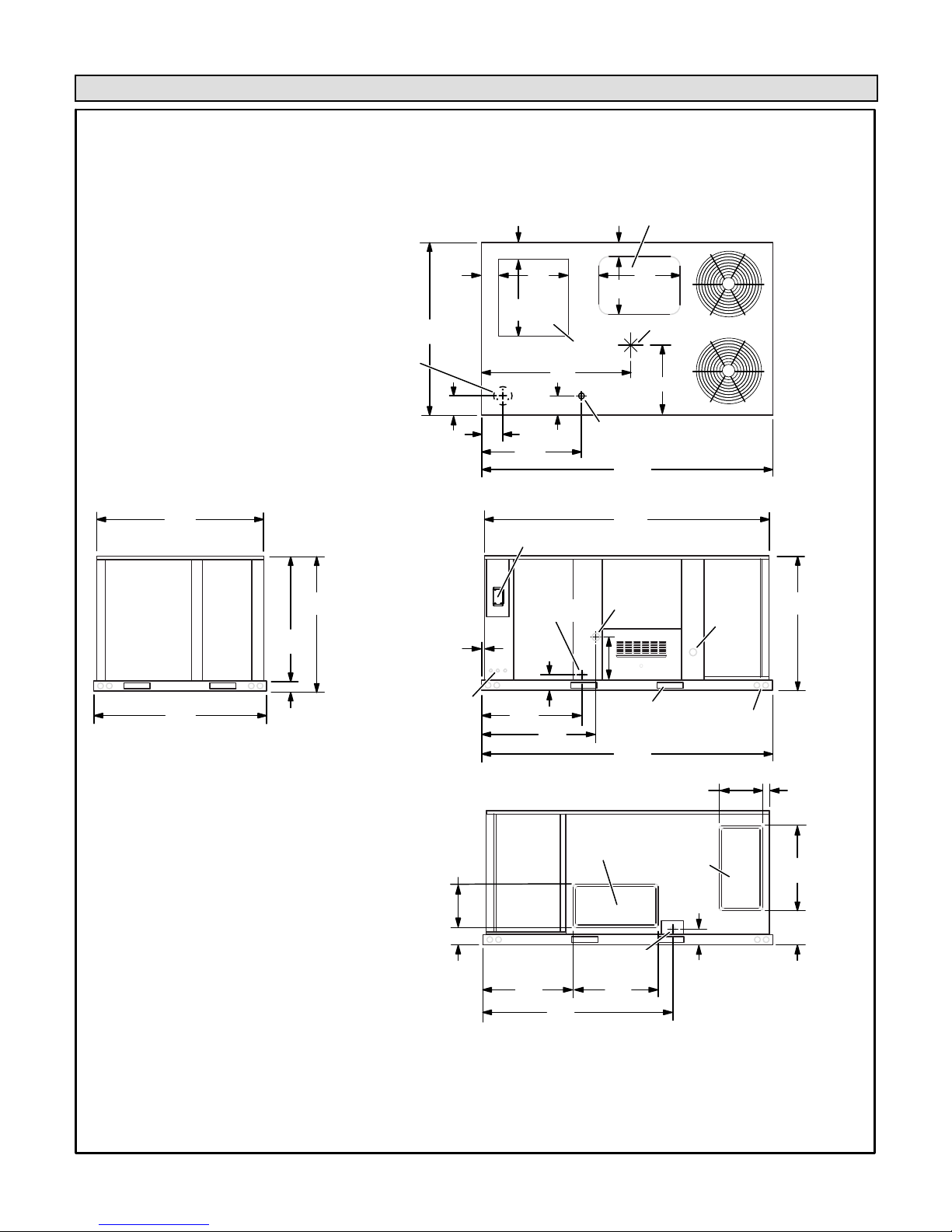

LGH/LCH092, 102, 120, & 150 DIMENSIONS - GAS HEAT SECTION SHOWN

58-1/8

(1476)

43-3/8

(1102)

46-7/8

(1191)

60-1/8 (1527)

BOTTOM

POWER ENTRY

5-1/2 (140) Dia.

BASE

AA

6-1/8

(156)

7 (178)

1

(25)

6-1/8

(156)

(610)

27

(686)

BOTTOM RETURN

6-5/8

(168)

DD

7 (178)

34-7/8

(886)

OPTIONAL DISCONNECT

(FACTORY INSTALLED)

CONDENSATE

DRAIN (FRONT)

24

10-3/4

(273)

AIR OPENING

EE

5-3/8

(137)

5-5/8

(143)

28

(711)

20

(508)

BOTTOM

CONDENSATE

101-1/4

(2572)

TOP VIEW

99-1/4

(2521)

GAS SUPPLY

INLET

18-1/2

(470)

BOTTOM SUPPLY

AIR OPENING

CENTER OF

GRAVITY

FF

BASE

OUTLET

FLUE

BB

CC

46-7/8

(1191)

60-1/8

(1527)

END VIEW

3-1/2

(89)

ELECTRIC

INLETS

15-1/2

(394)

6-1/8

(156)

34-7/8

(886)

31-1/2

(800)

FORKLIFT SLOTS

39-7/8

(1013)

(BOTH SIDES)

101-1/4

(2572)

SIDE VIEW

HORIZONTAL

SUPPLY AIR

OPENING

CONDENSATE

DRAIN (BACK)

30

66-3/8

(1686)

(762)

SIDE VIEW

(Horizontal Openings)

LIFTING HOLES

(FOR RIGGING)

15-1/2

(394)

HORIZONTAL

RETURN AIR

OPENING

5-3/8

(137)

1-5/8

(41)

30

(762)

12-1/8

(308)

Page 2

LGH/LCH094, 122, & 152 DIMENSIONS - GAS HEAT SECTION SHOWN

58-1/8

(1476)

43-3/8

(1102)

BOTTOM

POWER ENTRY

5-1/2 (140)

Diameter

46-7/8

(1191)

6-1/8

(156)

60-1/8 (1527)

BASE

7 (178)

6-1/8

(156)

AA

24

(610)

27

(686)

BOTTOM RETURN

AIR OPENING

6-5/8

(168)

5/8

(16)

DD

7 (178)

34-7/8

(886)

OPTIONAL DISCONNECT

(FACTORY OR FIELD INSTALLED)

CONDENSATE

DRAIN (FRONT)

5-3/8

(137)

10-3/4

(273)

CENTER OF

GRAVITY

EE

5-5/8

(143)

28

(711)

20

(508)

BOTTOM

CONDENSATE

TOP VIEW

GAS SUPPLY

INLET

18-1/2

(470)

BOTTOM SUPPLY

AIR OPENING

FF

BASE

124-3/8

(3159)

123-1/8

(3127)

FLUE

OUTLET

BB

CC

46-7/8

(1191)

60-1/8

(1527)

END VIEW

3-1/2

(89)

ELECTRIC

INLETS

34-7/8

(886)

39-7/8

(1013)

54-5/8

(1387)

124-3/8

(3159)

SIDE VIEW

HORIZONTAL

SUPPLY AIR

89-1/2

(2273)

OPENING

CONDENSATE

DRAIN (BACK)

15-1/2

(394)

6-1/8

(156)

SIDE VIEW

(Horizontal Openings)

FORKLIFT SLOTS

(BOTH SIDES)

HORIZONTAL

RETURN AIR

OPENING

30

(762)

LIFTING HOLES

(FOR RIGGING)

15-1/2

(394)

5-3/8

(137)

1-5/8

(41)

30

(762)

12-1/8

(308)

Page 3

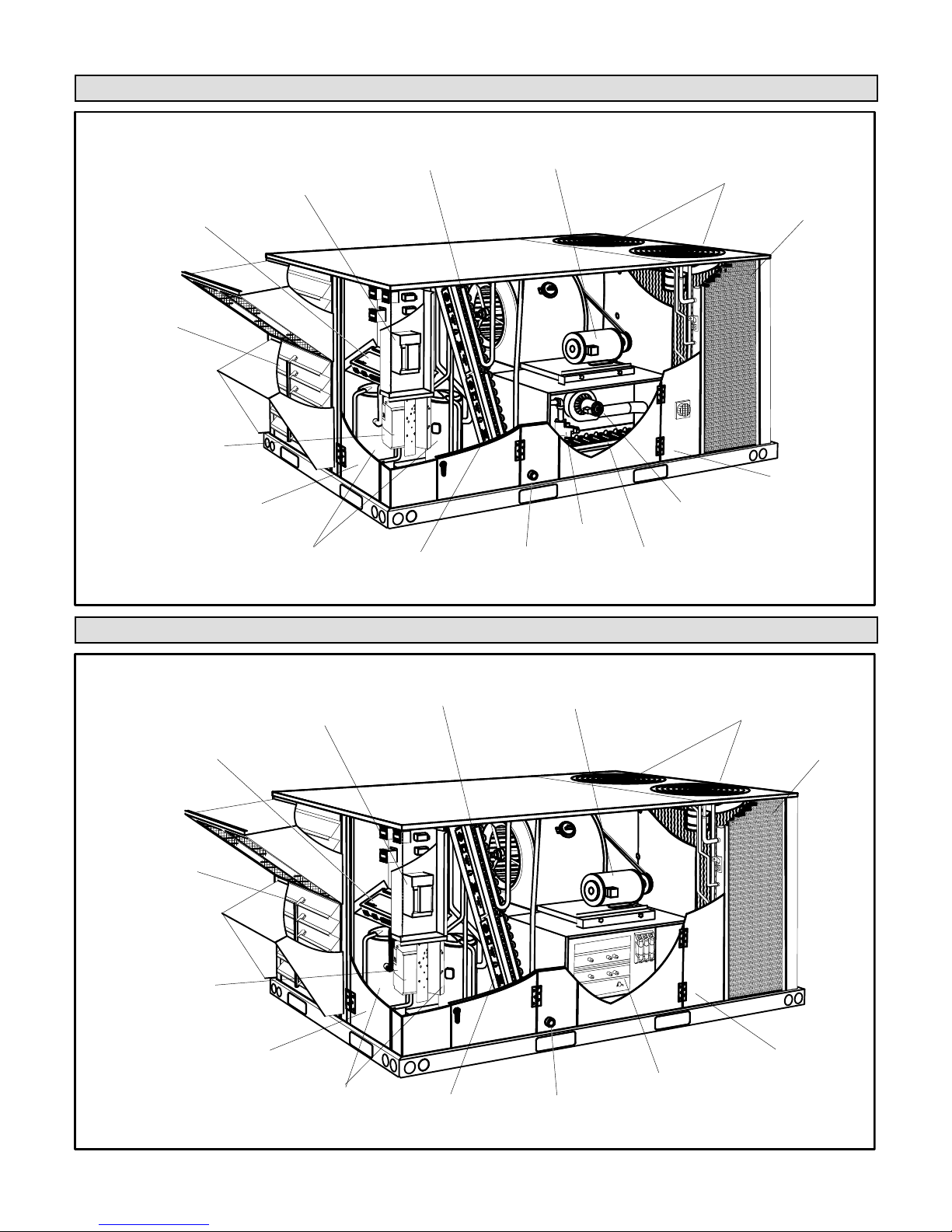

LGH092, 094, 102, 120, 122, 150 & 152 PARTS ARRANGEMENT

UNIT

CONTROLLER

ECONOMIZER

(OPTIONAL)

INVERTER (OPTIONAL)

OR INDOOR BLOWER

TRANSFORMER (575V

UNITS WITH DIRECT

DRIVE BLOWER)

OUTDOOR FAN

TRANSFORMER (094, 122,

152 460V OR 570V UNITS)

DISCONNECT /

CIRCUIT BREAKER

(FACTORY OR FIELD

INSTALLED OPTION)

COMPRESSORS

(FOUR - 20 X 25 X 2”)

EVAPORATOR

COIL

3

FILTERS

BLOWER MOTOR

(BELT DRIVE

SHOWN)

BLOWER

3

GAS VALVE

CONDENSATE

DRAIN

CONDENSER FANS

(2 FANS ON 092, 102, 120,

150 UNITS; 3 FANS ON

094, 122, 152 UNITS)

CONDENSER

COIL

HINGED

ACCESS PANEL

(OPTIONAL)

COMBUSTION

AIR INDUCER

BURNERS

LCH092, 094, 102, 120, 122, 150 & 152 PARTS ARRANGEMENT

BLOWER MOTOR

(BELT DRIVE

SHOWN)

BLOWER

3

ELECTRIC HEAT

CONDENSATE

DRAIN

UNIT

CONTROLLER

ECONOMIZER

(OPTIONAL)

INVERTER (OPTIONAL)

OR INDOOR BLOWER

TRANSFORMER (575V

UNITS WITH DIRECT

DRIVE BLOWER)

OUTDOOR FAN

TRANSFORMER (094, 122,

152 460V OR 570V UNITS)

DISCONNECT /

CIRCUIT BREAKER

(FACTORY OR FIELD

INSTALLED OPTION)

COMPRESSORS

EVAPORATOR

COIL

3

FILTERS

(FOUR - 20 X 25 X 2”)

CONDENSER FANS

(2 FANS ON 092, 102, 120,

150 UNITS; 3 FANS ON

094, 122, 152 UNITS)

CONDENSER

COIL

HINGED

ACCESS PANEL

(OPTIONAL)

(Optional)

Page 4

Shipping and Packing List

Safety

Package 1 of 1 contains:

1- Assembled unit

IMPORTANT - Hot gas reheat units require a specific

field-provided and installed humidity sensor.

Check unit for shipping damage. Receiving party should

contact last carrier immediately if shipping damage is found.

General

These instructions are intended as a general guide

and do not supersede local codes in any way.

Authorities having jurisdiction should be consulted

before installation.

The LGH092, 094, 102, 120, 122, 150 & 152

gas/electric packaged rooftop unit is available in

130,000, 180,000, or 240,000 Btuh heating inputs.

The LCH092, 094, 102, 120, 122, 150 & 152 cooling

packaged rooftop unit is the same basic design as the

LGH unit except for the heating section. Optional

electric heat is factory- or field-installed in LCH units.

Ultra high efficiency units have a tandem refrigerant

circuit. High and standard efficiency units have two

typical circuits.

High and standard efficiency units are equipped with a

lightweight, all-aluminum condenser coil; an optional,

traditional fin/tube condenser coil is available. Ultra

high efficiency units are equipped with a traditional

fin/tube condenser coil.

High and standard efficiency units are available with an

optional hot gas reheat coil which provides a

dehumidifying mode of operation. Refer to Reheat

Operation section.

Ultra high efficiency units are available with an optional

direct drive blower or belt drive blower equipped with an

optional supply air inverter. Standard and high efficiency

units are available with a belt drive blower equipped with

an optional supply air inverter. The blower will operate at

lower speeds when demand is low and increase to higher

speeds when demand is high. Refer to Inverter and Direct

Drive Start−Up section.

The following examples show the model numbers of ten

ton units with blower options.

LGH/LCH120H4B Belt drive

LGH/LCH120H4M Belt drive with inverter

LGH/LCH122U4M Belt drive with inverter

LGH/LCH122U4E Direct drive

All units are available using R410A, an ozone-friendly HFC

refrigerant. Refer to the Cooling Start-Up section for

precautions when installing unit.

Page 5

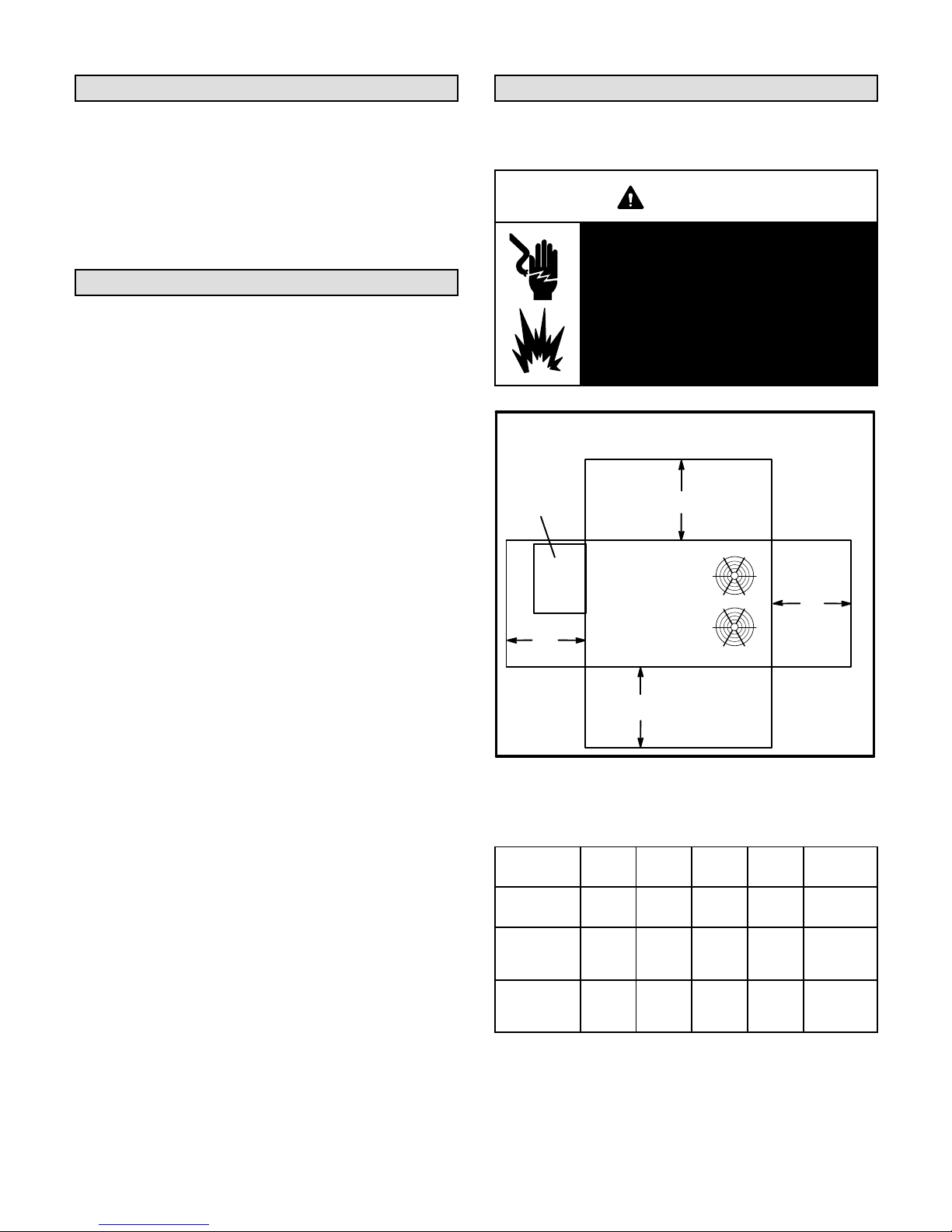

See table 1 for unit clearances.

WARNING

Electric shock hazard and danger of

explosion. Can cause injury, death or

product or property damage. Turn off

gas and electrical power to unit before

performing any maintenance or

servicing operations on the unit. Follow

lighting instructions attached to unit

when putting unit back into operation

and after service or maintenance.

UNIT CLEARANCES

Optional

Outdoor

Air Hood

D

UNIT CLEARANCES

1

Unit

Clearance

Service

Clearance60(1524)36(914)36(914)60(1524)

Clearance to

Combus

tibles

Minimum

Operation

Clearance

Note - Entire perimeter of unit base requires support when elevated above

mounting surface.

1

Service Clearance - Required for removal of serviceable parts.

Clearance to Combustibles - Required clearance to combustible material

(gas units).

Minimum Operation Clearance - Required clearance for proper unit operation.

A

in.(mm)Bin.(mm)Cin.(mm)Din.(mm)

36

(914)

36

(914)36(914)36(914)36(914)

C

A

FIGURE 1

TABLE 1

1 (25) 1 (25) 1 (25)

B

To p

Clearance

Unob

structed

Unob

structed

Unob

structed

NOTICE

Roof Damage!

This system contains both refrigerant and oil.

Some rubber roofing material may absorb oil,

causing the rubber to swell. Bubbles in the rubber

roofing material can cause leaks. Protect the roof

surface to avoid exposure to refrigerant and oil

during service and installation. Failure to follow

this notice could result in damage to roof surface.

IMPORTANT

The Clean Air Act of 1990 bans the intentional vent

ing of refrigerant (CFC's and HCFC's) as of July 1,

1992. Approved methods of recovery, recycling or

reclaiming must be followed. Fines and/or incar

ceration may be levied for non-compliance.

Use of this unit as a construction heater or air conditioner

is not recommended during any phase of construction.

Very low return air temperatures, harmful vapors and

operation of the unit with clogged or misplaced filters will

damage the unit.

Unit Support

In downflow discharge installations, install the unit on a

non-combustible surface only. Unit may be installed on

combustible surfaces when used in horizontal discharge

applications or in downflow discharge applications when

installed on an C1CURB7*B roof mounting frame.

NOTE - Securely fasten roof frame to roof per local codes.

CAUTION

To reduce the likelihood of supply / return air by

pass and promote a proper seal with the RTU, duct

work / duct drops / diffuser assemblies must be

supported independently to the building structure.

A-Downflow Discharge Application

Roof Mounting with C1CURB7*B

1- The C1CURB7*B roof mounting frame must be

installed, flashed and sealed in accordance with the

instructions provided with the frame.

2- The C1CURB7*B roof mounting frame should be

square and level to 1/16” per linear foot (5mm per

linear meter) in any direction.

If this unit has been used for heating or cooling of

buildings or structures under construction, the following

conditions must be met or the warranty will be void:

A room thermostat must control the unit. The use of

fixed jumpers that will provide continuous heating or

cooling is not allowed.

A pre-filter must be installed at the entry to the return

air duct.

The return air duct must be provided and sealed to

the unit.

Return air temperature range between 55°F (13°C)

and 80°F (27°C) must be maintained.

Air filters must be replaced and pre-filters must be

removed upon construction completion.

The input rate and temperature rise must be set per

the unit rating plate.

The heat exchanger, components, duct system, air

filters and evaporator coil must be thoroughly

cleaned following final construction clean-up.

The unit operating conditions (including airflow,

cooling operation, ignition, input rate, temperature

rise and venting) must be verified according to these

installation instructions.

Page 6

3- Duct must be attached to the roof mounting frame

and not to the unit; supply and return plenums must

be installed before setting the unit.

Installer's Roof Mounting Frame

Many types of roof frames can be used to install the unit

depending upon different roof structures. Items to keep

in mind when using the building frame or supports are:

1- The base is fully enclosed and insulated, so an

enclosed frame is not required.

2- The frames or supports must be constructed with

non-combustible materials and should be square and

level to 1/16” per linear foot (5mm per linear meter)

in any direction.

3- Frame or supports must be high enough to prevent

any form of moisture from entering unit.

Recommended minimum frame height is 14”

(356mm).

4- Duct must be attached to the roof mounting frame

and not to the unit. Supply and return plenums must

be installed before setting the unit.

5- Units require support along all four sides of unit base.

Supports must be constructed of steel or suitably

treated wood materials.

NOTE-When installing a unit on a combustible surface for

downflow discharge applications, an C1CURB7*B roof

mounting frame is required.

B-Horizontal Discharge Applications

1- Units installed in horizontal airflow applications must

use a horizontal conversion kit K1HECK00.

2- Specified installation clearances must be maintained

when installing units. Refer to figure 1.

3- Top of support slab should be approximately 4”

(102mm) above the finished grade and located so no

run-off water from higher ground can collect around

the unit.

4- Units require support along all four sides of unit base.

Supports must be constructed of steel or suitably

treated wood materials.

Duct Connection

All exterior ducts, joints and openings in roof or building

walls must be insulated and weather-proofed with

flashing and sealing compounds in accordance with

applicable codes. Any duct passing through an

unconditioned space must be insulated.

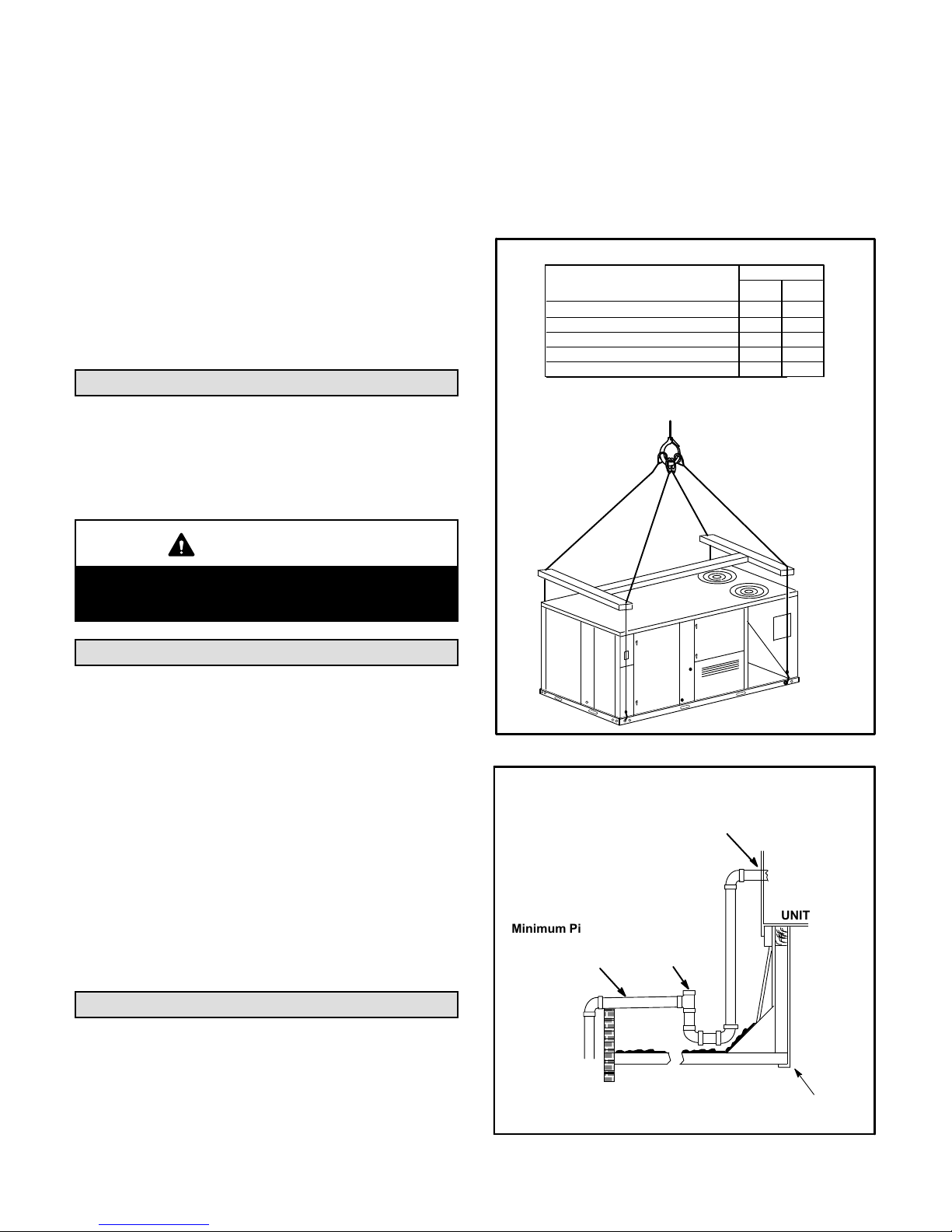

A trap must be installed between drain connection and an

open vent for proper condensate removal. See figure 3 or

4. It is sometimes acceptable to drain condensate onto

the roof or grade; however, a tee should be fitted to the

trap to direct condensate downward. The condensate line

must be vented. Check local codes concerning

condensate disposal. Refer to pages 1 and 2 for

condensate drain location.

RIGGING

Unit

Gas Packaged (2 O.D. Fans)

Cooling Packaged (2 O.D. Fans)

Heat Pump Packaged

Gas Packaged (3 O.D. fans)

Cooling Packaged (3 O.D. Fans)

*Maximum weight with all available

factory-installed accessories.

CAUTION - Do not

walk on unit.

*Weight

Lbs. Kg.

1401

1366

1514

1551

1516

IMPORTANT - ALL

PANELS MUST BE IN

PLACE FOR RIGGING.

LIFTING POINT SHOULD

BE DIRECTLY ABOVE

CENTER OF GRAVITY

636

620

687

704

688

CAUTION

In downflow applications, do not drill or punch

holes in base of unit. Leaking in roof may occur if

unit base is punctured.

Rigging Unit For Lifting

Rig unit for lifting by attaching four cables to holes in unit

base rail. See figure 2.

1- Detach wooden base protection before rigging.

Note - Remove all 7 (5 brackets on units with three

outdoor fans) base protection brackets before

setting unit.

2- Connect rigging to the unit base using both holes in

each corner.

3- All panels must be in place for rigging.

4- Place field‐provided H‐style pick in place just above

top edge of unit. Frame must be of adequate

strength and length. (H-style pick prevents damage

to unit.)

FIGURE 2

CONDENSATE SIDE DRAIN CONNECTION

CAULK AROUND CONDENSATE COUPLING

NOTE - Allow clearance to

open doors when installing

condensate piping.

Minimum Pitch

1” (25 mm) per

10' (3 m) of line

OPEN VENT

UNIT

Condensate Drains

Make drain connection to the 1” N.P.T. drain coupling

provided on unit.

Note - The drain pan is made with a glass reinforced

engineered plastic capable of withstanding typical joint

torque but can be damaged with excessive force. Tighten

pipe nipple hand tight and turn an additional quarter turn.

MOUNTING

FRAME

FIGURE 3

Page 7

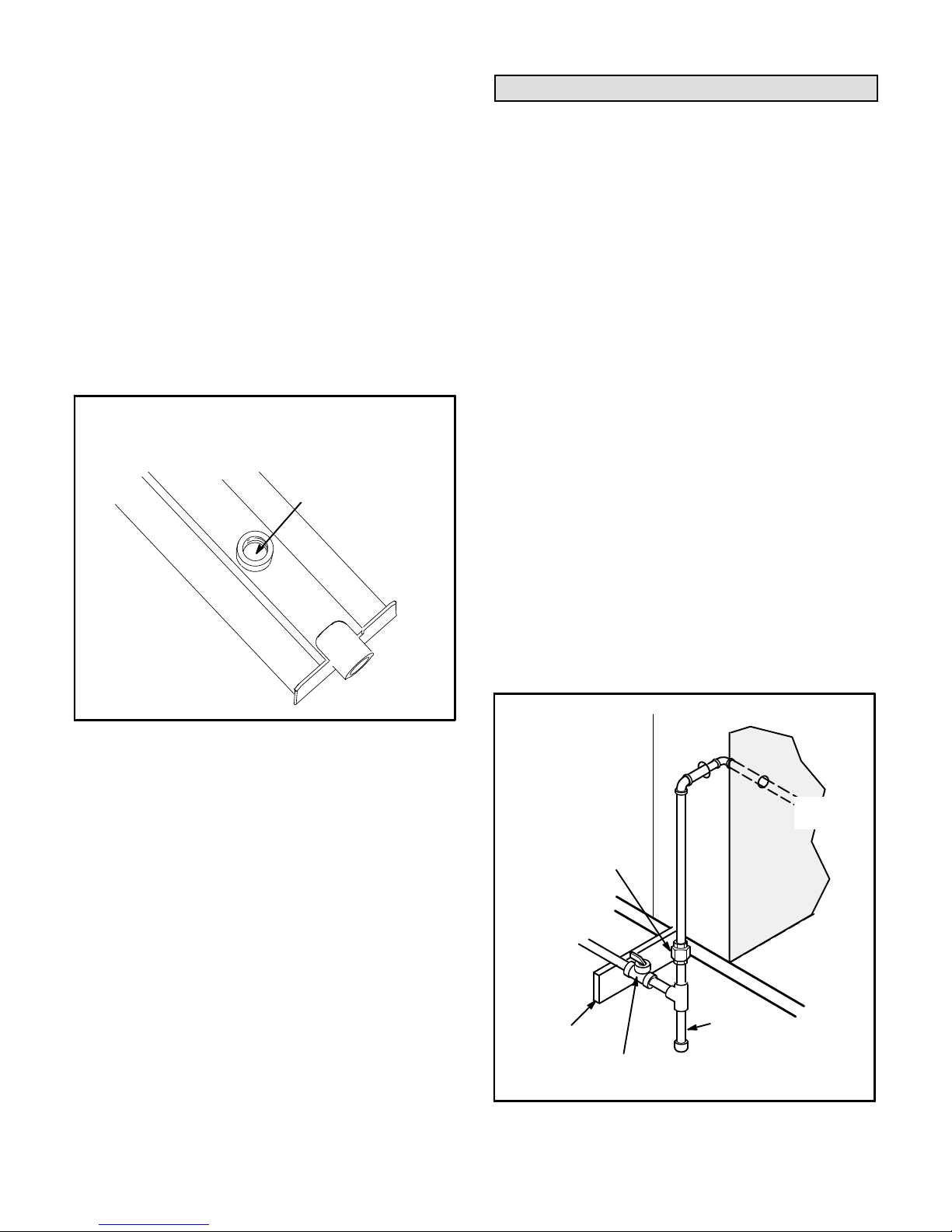

CONDENSATE BOTTOM DRAIN CONNECTION

UNIT

2- Remove six screws from filter access door. Refer to

figure 6.

UNITS WITH HINGED PANELS

FILTER DOOR

DRAIN PAN

CAULK AROUND

CONDENSATE COUPLING

OPEN VENT

MOUNTING

FRAME

Minimum Pitch

1” (25 mm) per 10'

(3 m) of line

FIGURE 4

Units are shipped with the drain coupling facing the front

of the unit. Condensate can be drained from the back or

bottom of the unit with the following modifications. The

unit can be installed in either downflow or horizontal air

discharge regardless of condensate drain location.

Rear Drain Connection

1- Open blower and heat access doors. See figure 5.

CONDENSATE

DRAIN MULLION

REMOVE

THREE

SCREWS

(PER HINGE)

FIGURE 6

3- Open filter access door hinges and carefully remove

door.

4- Remove eight screws holding condensate drain

mullion and remove mullion.

5- Lift front edge of the drain pan (to clear bottom drain

plug) and slide drain pan out of unit. See figure 7.

FILTER

ACCESS DOOR

BLOWER

ACCESS DOOR

CONDENSATE

DRAIN MULLION

FIGURE 5

HEAT

ACCESS DOOR

DRAIN PAN

FIGURE 7

6- Make sure the cap over the unit bottom drain hole is

secure.

7- Rotate the drain pan until the downward slope is

toward the back of the unit. Slide the drain pan back

into the unit. Be careful not to dislodge the cap over

the bottom drain hole.

8- From the back side of the unit, pull the drain pan

coupling through the rear condensate opening.

9- Replace the condensate drain mullion and reinstall

eight screws.

10- Reinstall filter door on hinges.

Page 8

Bottom Drain Connection

1- Open blower and heat access doors. See figure 5.

2- Remove six screws from filter access door. Refer to

figure 6.

3- Open filter access door hinges and carefully remove

door.

4- Remove eight screws holding condensate drain

mullion and remove mullion.

5- Lift front edge of the drain pan (to clear bottom drain

plug) and slide drain pan out of unit. See figure 7.

6- Turn the drain pan upside down and drill a pilot hole

through the bottom of the drain pan in the center of

the coupling. See figure 8.

BOTTOM CONDENSATE DRAIN

CAUTION: Be careful not to

damage the coupling threads

when drilling the hole.

DRILL A PILOT

HOLE IN CENTER

OF COUPLING

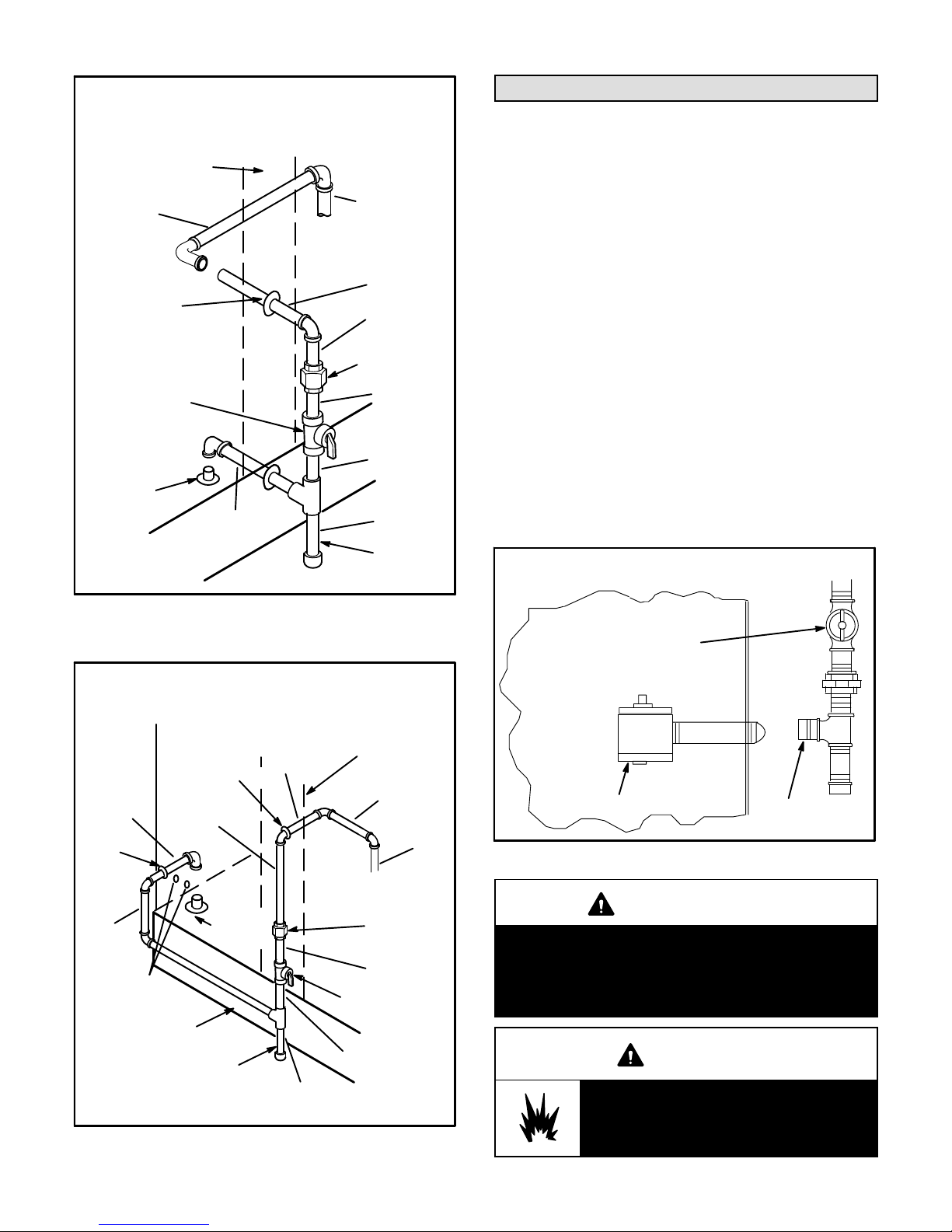

Connect Gas Piping (Gas Units)

Before connecting piping, check with gas company or

authorities having jurisdiction for local code

requirements. When installing gas supply piping, length

of run from gas meter must be considered in determining

pipe size for 0.5” w.c. (.12kPa) maximum pressure drop.

Do not use supply pipe smaller than unit gas connection.

For natural gas units, operating pressure at the unit gas

connection must be a minimum of 4.7” w.c. (1.17kPa)

and a maximum of 10.5” (2.60kPa) w.c. For LP/propane

gas units, operating pressure at the unit gas connection

must be a minimum of 10.5” w.c. (2.61kPa) and a

maximum of 13.0” w.c. (3.23kPa).

When making piping connections a drip leg should be

installed on vertical pipe runs to serve as a trap for

sediment or condensate. A 1/8” N.P.T. plugged tap is

located on gas valve for test gauge connection. Refer to

Heating Start-Up section for tap location. Install a ground

joint union between the gas control manifold and the main

manual shut-off valve. See figure 9 for gas supply piping

entering outside the unit. Figure 10 shows bottom gas

entry piping through the curb. Figure 11 shows bottom

gas entry piping through the unit.

After drilling the pilot

hole, drill a 7/8” hole from

the inside of the pan.

FIGURE 8

7- From the inside of the pan, use a Vari-Bit® bit to

enlarge the hole to 7/8”. Do not damage coupling

threads.

8- Remove the cap over the unit bottom drain hole.

9- Slide the drain pan back into the unit.

10- From the back side of the unit, pull the drain pan

coupling through the rear condensate opening.

11- From the front side of the unit, move the drain pan

until the bottom coupling settles into the unit bottom

drain opening. Once in place, check to make sure the

coupling is still positioned through the rear

condensate drain hole.

12- Use a field-provided 1” plug to seal side drain

connection.

13- Replace the condensate drain mullion and reinstall

eight screws.

14- Reinstall filter door on hinges.

Page 9

Compounds used on threaded joints of gas piping shall be

resistant to the action of liquified petroleum gases.

OUTSIDE OF UNIT GAS PIPE CONNECTION

TO GAS

VALV E

GROUND

JOINT UNION

TO GAS

SUPPLY

GAS PIPING

SUPPORT

MANUAL MAIN

SHUT-OFF VALVE

DRIP LEG

(REFER TO

LOCAL CODES)

FIGURE 9

BOTTOM ENTRY GAS PIPING

THROUGH THE CURB

MULLION BETWEEN

HEAT AND COMPRES

SOR SECTIONS

4” NIPPLE

GROMMET

ALL ELBOWS ARE 3/4”

MANUAL MAIN

SHUT-OFF VALVE

TO GAS

VALV E

4” NIPPLE

5” NIPPLE

7-1/2” NIPPLE

GROUND

JOINT UNION

4” NIPPLE

Pressure Test Gas Piping (Gas Units)

When pressure testing gas lines, the gas valve must

be disconnected and isolated. Gas valves can be

damaged if subjected to more than 0.5 psig (3.48kPa).

See figure 12.

NOTE-Codes may require that manual main shut-off

valve and union (furnished by installer) be installed in

gas line external to unit. Union must be of the ground

joint type.

After all connections have been made, check all piping

connections for gas leaks. Also check existing unit gas

connections up to the gas valve; loosening may occur

during installation. Use a leak detection solution or other

preferred means. Do not use matches candles or other

sources of ignition to check for gas leaks.

TO GAS

SUPPLY

ROOF

MOUNTING

FRAME

ALL ELBOWS ARE 3/4”

10” NIPPLE

GROMMET

7”

NIPPLE

ALTERNATE

KNOCKOUTS

ROOF MOUNTING

FRAME

7-1/2” NIPPLE

10” NIPPLE

FIGURE 10

BOTTOM GAS ENTRY

THROUGH THE UNIT

MULLION BETWEEN

HEAT AND COMPRES

GROMMET

TO GAS

SUPPLY

DRIP LEG

5” NIPPLE

3” NIPPLE

FIGURE 11

3-1/2” NIPPLE

3” NIPPLE

DRIP LEG

SOR SECTIONS

4” NIPPLE

4” NIPPLE

TO GAS

VALV E

GROUND

JOINT UNION

4” NIPPLE

MANUAL MAIN

SHUT-OFF VALVE

3-1/2” NIPPLE

NOTE-In case emergency shut down is required, turn off

the main manual shut-off valve and disconnect main

power to unit. These devices should be properly labeled

by the installer.

PRESSURE TEST GAS LINE

MANUAL MAIN

SHUT-OFF VALVE

GAS VALVE

CAP

FIGURE 12

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or othe sources of ignition

to check for gas leaks.

WARNING

Danger of explosion. Can cause injury

or product or property damage. Do not

use matches, candles, flame or other

sources of ignition to check for leaks.

Page 10

High Altitude Derate

CONTROL WIRING

Locate the high altitude conversion sticker in the unit

literature bag. Fill out the conversion sticker and affix next

to the unit nameplate.

Refer to table 2 for high altitude adjustments.

TABLE 2

HIGH ALTITUDE DERATE

Altitude Ft.* Gas Manifold Pressure

2000-4500 See Unit Nameplate

4500 And Above Derate 2% / 1000 Ft. Above Sea Level

*Units installed at 0-2000 feet do not need to be modified.

NOTE ‐ This is the only permissible derate for these units.

Electrical Connections

POWER SUPPLY

Do not apply power or close disconnect switch until

installation is complete. Refer to start-up directions.

Refer closely to unit wiring diagram.

Refer to unit nameplate for minimum circuit ampacity

and maximum fuse size.

1- 230/460/575 volt units are factory wired. For 208V

supply, disconnect the orange wire (230V) at all

control power transformer(s). Reconnect the red

wire (208V). Tape the exposed end of the 230V

orange wire.

2- Route power through the bottom power entry area.

On gas units or units with electric heat, connect

power wiring to TB2. On cooling only units,

connect power to F4. If unit contains an optional

factory-installed circuit breaker or disconnect

switch, connect line voltage to CB10 or S48. See

unit wiring diagram.

3- Connect separate 120v wiring to optional GFCI

outlet.

CAUTION

Electrostatic discharge can affect electronic com

ponents. Take precautions during unit installation

and service to protect the electronic controls. Pre

cautions will help to avoid control exposure to elec

trostatic discharge by putting the unit, the control

and the technician at the same electrostatic poten

tial. Neutralize electrostatic charge by touching

hands and all tools on an unpainted unit surface,

such as the gas valve or blower deck, before per

forming any service procedure.

A-Thermostat Location

Room thermostat mounts vertically on a standard 2” X 4”

handy box or on any non-conductive flat surface.

Locate thermostat approximately 5 feet (1524mm)

above the floor in an area with good air circulation at

average temperature. Avoid locating the room

thermostat where it might be affected by:

-drafts or dead spots behind doors and in corners

-hot or cold air from ducts

-radiant heat from sun or appliances

-concealed pipes and chimneys

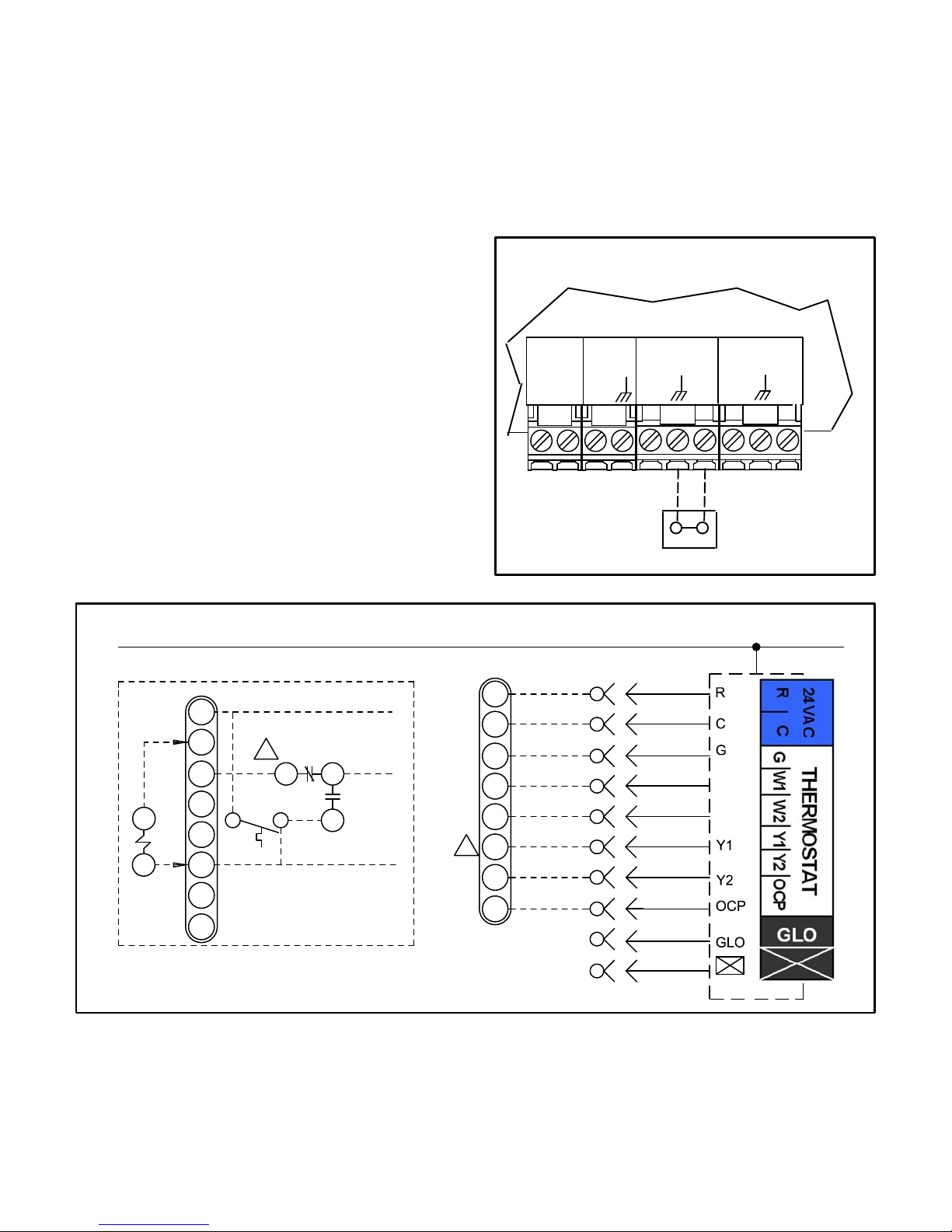

B-Control Wiring

The Unit Controller will operate the unit from a

thermostat or room sensor based on the System

Mode. The default System Mode is the thermostat

mode. Refer to the Unit Controller Installation and

Setup Guide to change the System Mode. Use the

menu navigation arrows and select button; SETTINGS

> CONTROL. Options are: “WIRED THERMOSTAT”

and “NETWORK”.

Thermostat Mode

1- Route thermostat cable or wires from subbase to

control area above compressor (refer to unit

dimensions to locate bottom and side power entry).

IMPORTANT - Unless field thermostat wires are rated

for maximum unit voltage, they must be routed away

from line voltage wiring. Use wire ties located on the front

border of the control panel to secure thermostat cable.

Use18 AWG wire for all applications using remotely

installed electro-mechanical and electronic

thermostats.

Page 11

2- Install thermostat assembly in accordance with

instructions provided with thermostat.

3- Connect thermostat wiring to the bottom of the Unit

Controller.

4- Wire as shown in figure 14 for electro-mechanical

and electronic thermostats. If using other

temperature control devices or energy management

systems see instructions and wiring diagram

provided by manufacturer.

IMPORTANT-Terminal connections at the Unit Controller

must be made securely. Loose control wire connections

may allow unit to operate but not with proper response to

room demand.

Room Sensor Mode

The Unit Controller will operate heating and cooling

based on the Unit Controller internal setpoints and the

temperature from the A2 room sensor. An optional

Network Control Panel (NCP) can also be used to provide

setpoints. A thermostat or return air sensor can be used

as a back-up mode. Make room sensor wiring

connections as shown in figure 13.

be used to initiate dehumidification instead of a

sensor.

2- Make wiring connections as shown in figure 14 for

thermostat mode or figure 13 for room sensor

mode. In addition, connect either a humidity

sensor or a dehumidification input. See figure 15

or 16 for humidity sensor wiring or figure 17 for

dehumidification input wiring.

FIELD WIRING IN ROOM SENSOR MODE

(Room Sensor Mode)

UNIT CONTROLLER

24VAC

RC

SENSOR

IAQ

AI1

SENSOR

HUM

TMP

OUTPUTS

D01

D02

J298

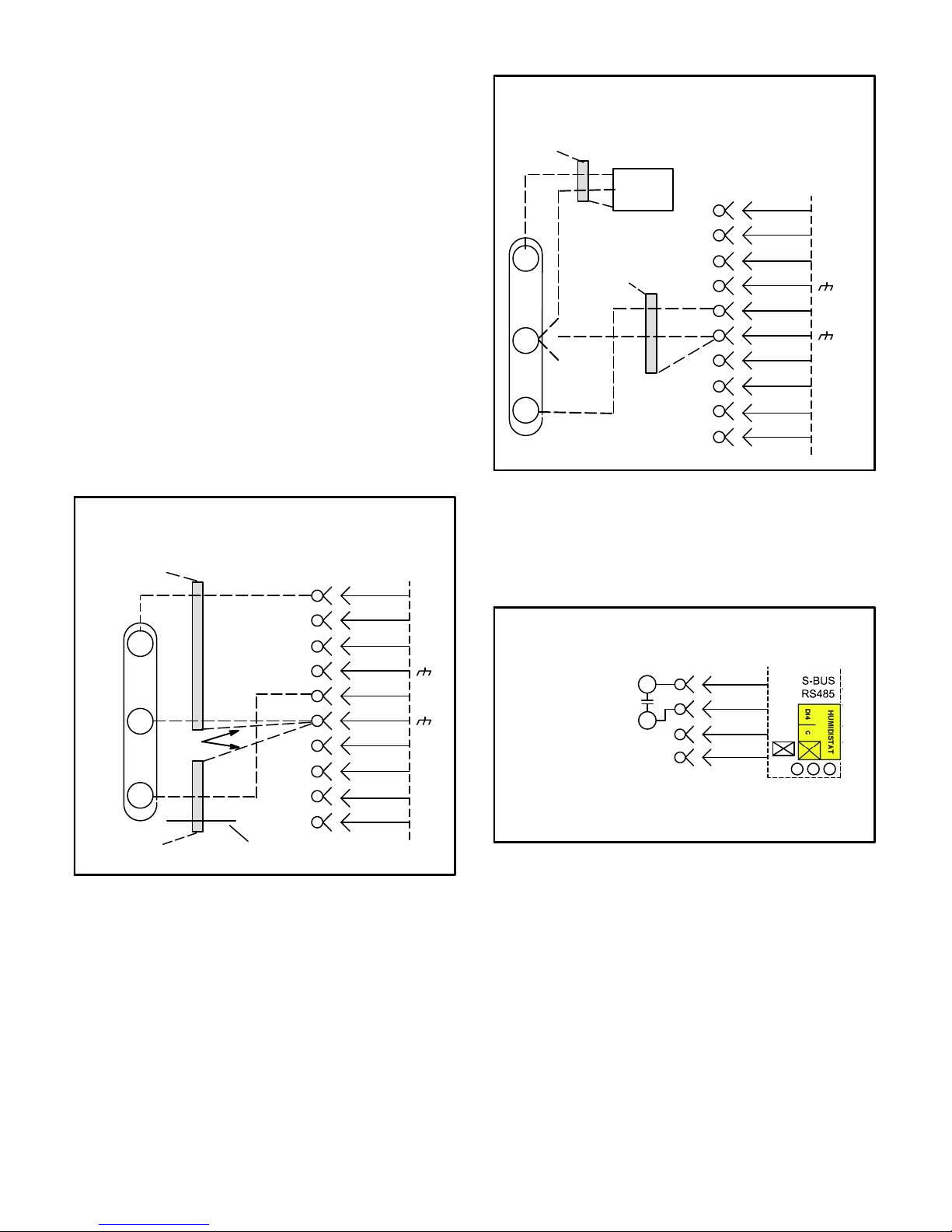

C-Hot Gas Reheat Units Only -

1- Install humidity sensor in accordance with

instructions provided with sensor. A DDC input may

24 VOLT FIELD WIRING IN THERMOSTAT MODE

24 V POWER

TO UNIT CONTROLLER

R

C

G

B

K55

A

TO PROVIDE SUPERMARKET REHEAT SCHEME

USE S86 DEHUMIDISTAT AND K55.

W1

W2

Y1

Y2

OCP

THERMOSTAT INPUTS

TO R

2

2

7

K55−1

TO G

S86

5

TO Y1

ALL OTHER THERMOSTAT

SIGNALS REMAIN CONNECTED

AS SHOWN ON THE RIGHT.

A2 SENSOR

FIGURE 13

J297A

R

C

G

W1

W2

Y1

2

Y2

OCP

P297

1

A55

P262

10

J262C

2

B

11

3

4

5

W1

W2

12

6

7

8

C

9

10

FIGURE 14

Page 12

Humidity Sensor Cable Applications:

Wire runs of 50 feet (mm) or less:

Use two separate shielded cables containing 20AWG

minimum, twisted pair conductors with overall shield.

Belden type 8762 or 88760 (plenum) or equivalent.

Connect both cable shield drain wires to the Unit

Controller as shown in figure 15.

Wire runs of 150 feet (mm) or less:

Use two separate shielded cables containing 18AWG

minimum, twisted pair conductors with overall shield.

Belden type 8760 or 88760 (plenum) or equivalent.

Connect both cable shield drain wires to the Unit

Controller as shown in figure 15.

Wire runs over 150 feet (mm):

Use a local, isolated 24VAC transformer such as Lennox

cat #18M13 (20VA minimum) to supply power to RH

sensor as shown in figure 16. Use two shielded cables

containing 20AWG minimum, twisted pair conductors

with overall shield. Belden type 8762 or 88760 (plenum)

or equivalent.

FIELD WIRING HOT GAS REHEAT UNITS (Using A

Humidity Sensor With Less Than 150 Ft. Wire Runs)

NOT

CONNECTED

A91

VIN

GND

VO

NOT

CONNECTED

DRAIN

J298A

UNUSED

WIRE

1

2

B

3

4

C

5

6

7

D

8

9

10

A55 UNIT

CONTROLLER

P298

R

C

AI-1

HUM

TMP

DO-1

C

DO-2

DI-1

FIGURE 15

FIELD WIRING HOT GAS REHEAT UNITS (Using A

Humidity Sensor With More than 150Ft. Wire Runs)

NOT

CONNECTED

A91

VIN

GND

ISOLATED 24V

TRANSFORMER

DRAIN

NOT

CONNECTED

J298A

A55 UNIT

CONTROLLER

P298

1

2

B

3

4

C

5

R

C

AI-1

HUM

6

7

TMP

D

VO

8

9

10

DO-1

C

DO-2

DI-1

FIGURE 16

FIELD WIRING HOT GAS REHEAT UNITS

(Using A Dehumidification Switch)

J299

R

DI−4

C

DEHUMIDIFICATION

SWITCH

Use 24 VAC (R) from any terminal

available on J299−2, −5, or −7.

7

8

9

10

FIGURE 17

Page 13

Blower Operation and Adjustments

Belt Drive With Supply Air Inverter or Direct Drive

Units - The blower rotation will always be correct on units

equipped with an inverter or a direct drive blower.

Checking blower rotation is not a valid method of

determining voltage phasing for incoming power.

IMPORTANT

Three Phase Scroll Compressor Voltage Phasing

Three phase scroll compressors must be phased se

quentially to ensure correct compressor and blower*

rotation and operation. Compressor and blower are

wired in phase at the factory. Power wires are colorcoded as follows: line 1-red, line 2-yellow, line 3-blue.

1-Observe suction and discharge pressures and blow

er* rotation on unit start-up.

2-Suction pressure must drop, discharge pressure must

rise and blower* rotation must match rotation marking.

If pressure differential is not observed or blower* rota

tion is not correct:

3-Disconnect all remote electrical power supplies.

4-Reverse any two field-installed wires connected to

the line side of S48 disconnect or TB13 terminal strip.

Do not reverse wires at blower contactor.

5-Make sure the connections are tight.

Discharge and suction pressures should operate at

their normal start‐up ranges.

*Supply air inverter driven motors should rotate in the

correct direction; verify scroll compressor rotation

separately. Contact technical support if the blower is

rotating incorrectly.

Units Equipped With Belt Drive Blowers Controlled

by an Inverter OR Direct Drive Blowers Equipped

With Optional Voltage or Phase Detection - The Unit

Controller checks the incoming power during start-up. If

the voltage or phase is incorrect, the Unit Controller will

display an alarm and the unit will not start.

A-Blower Operation

Note - On units with staged blowers, use the Unit

Controller to start the blower. Refer to the appropriate

start-up section.

Initiate blower only (G) demand at thermostat according

to instructions provided with thermostat. Unit will cycle on

thermostat demand. The following steps apply to

applications using a typical electro-mechanical

thermostat.

1- Blower operation is manually set at the thermostat

subbase fan switch. With fan switch in ON position,

blowers will operate continuously.

2- With fan switch in AUTO position, the blowers will

cycle with demand. Blowers and entire unit will be off

when system switch is in OFF position.

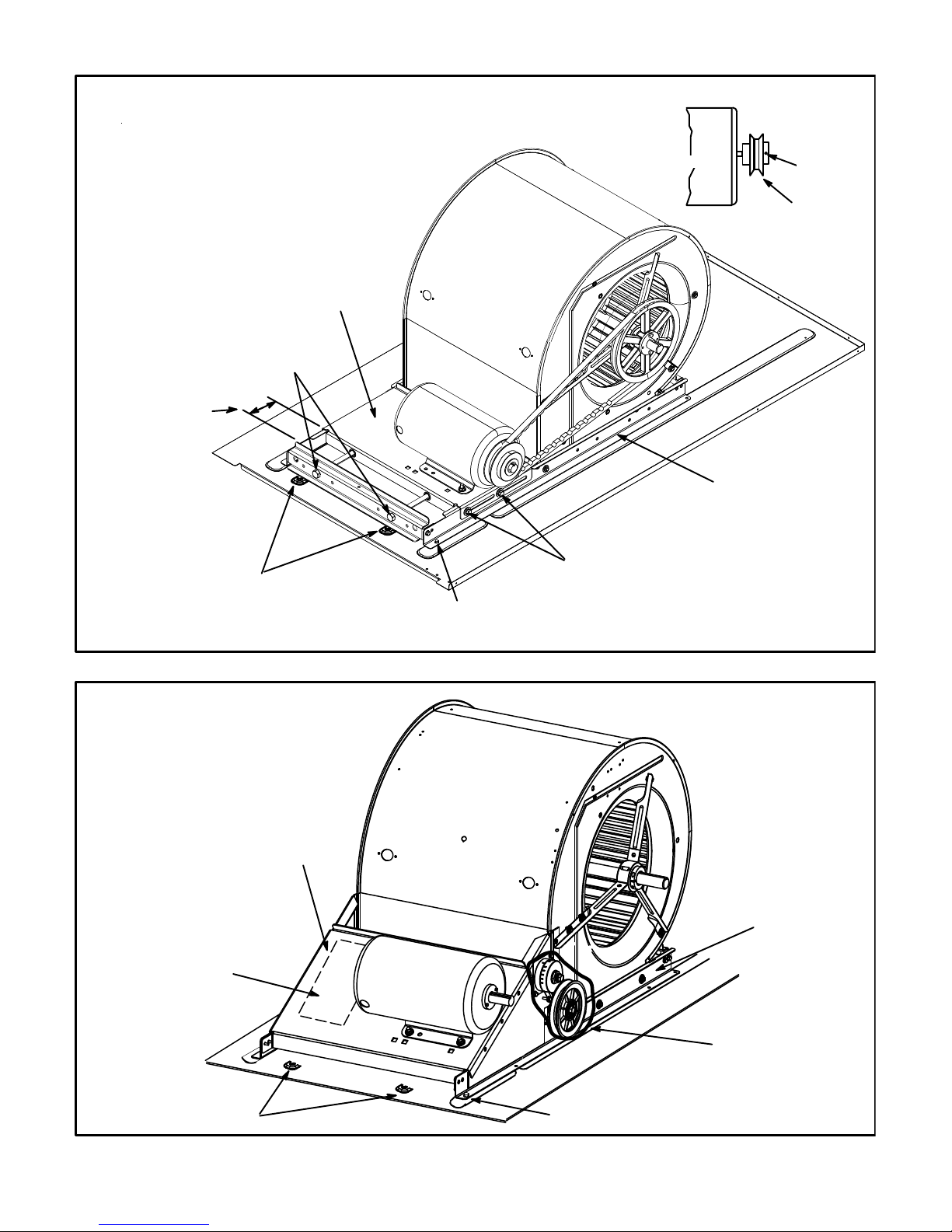

B-Blower Access

The blower assembly is secured to a sliding frame which

allows the blower motor assembly to be pulled out of the

unit. See figure 18, 19 or 20.

Belt Drive Blowers

1- Loosen the reusable wire tie which secures the

blower wiring to the blower motor mounting plate.

2- Remove and retain screws on either side of sliding

frame. Pull frame toward outside of unit.

3- Slide frame back into original position when finished

servicing. Reattach the blower wiring in the previous

location on the blower motor base using the wire tie.

4- Replace retained screws on either side of the sliding

frame.

Direct Drive Blowers

1- Loosen the reusable wire tie which secures the

controls and high voltage blower wiring to the blower

housing.

2- Remove and retain screws in front and on either side

of blower housing. Pull frame toward outside of unit.

3- Slide frame back into original position when finished

servicing. Reattach the blower wiring in the previous

location on the blower motor base using the wire tie.

4- Replace retained screws in front and on either side of

the blower housing.

Page 14

TO INCREASE BELT TENSION

1- Loosen four bolts securing motor mounting base

to frame.

2- Turn adjusting bolt to the right, or clockwise, to

move the motor away from the blower housing.

IMPORTANT - Gap between end of frame and motor

mounting base should be equal at both ends, i.e. par

allel along gap.

3- Tighten four bolts securing motor mounting base

to frame.

4- Relieve tension on two adjusting bolts.

MOTOR MOUNTING

BASE

BELT ADJUSTING BOLTS

- TURN CLOCKWISE

TO TIGHTEN BELT

GAP BETWEEN

EDGES SHOULD BE

PARALLEL ON BOTH

ENDS BEFORE

TIGHTENING MOTOR

MOUNTING BASE IN

PLACE

BELT DRIVE BLOWER ASSEMBLY

BLOWER

HOUSING

MOTOR

SIDE VIEW

MOTOR

BLOWER

FRAME

ALLEN

SCREW

PULLEY

REMOVE TWO SCREWS

TO COMPLETELY SLIDE

BLOWER OUT OF UNIT

BELT DRIVE BLOWER ASSEMBLY WITH TENSIONER (VIEW SHOWN WITHOUT BELT)

TO INCREASE OR

DECREASE BELT

TENSION, REFER TO

INSTALLATION LABEL

LOOSEN BEFORE

ADJUSTING BELT TENSION

(TWO EACH SIDE)

REMOVE TWO SCREWS ON EACH

SIDE TO SLIDE FRAME PARTIALLY

OUT OF UNIT FOR SERVICE ACCESS

FIGURE 18

BLOWER

HOUSING

MOTOR

MOUNTING

BASE

BLOWER

FRAME

MOTOR

TO COMPLETELY REMOVE

BLOWER ASSEMBLY FROM

UNIT, TWO ADDITIONAL

SCREWS MUST BE REMOVED

TENSIONER

REMOVE TWO SCREWS ON EACH

SIDE TO SLIDE FRAME PARTIALLY

OUT OF UNIT FOR SERVICE ACCESS

FIGURE 19

Page 15

Loading...

Loading...