Page 1

HEAT PUMP KITS AND ACCESSORIES

Litho U,S,A.

©1993 LennoxIndustries Inc.

Dallas,Texas 9/93

502,673M

Supersedes 3/92

SOLID STATE DEFROST

REPLACEMENT BOARD

INSTALLATION INSTRUCTIONS FOR SOLID STATE DEFROST REPLACEMENT BOARD

LB-83114C (61H42) USED ON HP7-1, -2, HP8, CliP9 AND CliP10 SERIES UNITS

,/SHIPPINGANDPACKING _ : : :: : ]

Package 1 of 1 contains:

1- Control board on mounting bracket

1- Defrost thermostat

1- Outdoor fan/defrost relay

8- Wires with 3/16" terminals

1- Screw

2- Wire nuts

/tNSTA_TiON: :

1- Turn off power supply to unit.

2- Remove compressor access panel and control

box cover.

A- Defrost Thermostat

3- Disconnect coil thermistor from coil return bend

and air thermistor from fan section. Replace coil

thermistor with provided defrost thermostat.

Secure to liquid line as close as possible to the

outdoor coil.

NOTE-/t may be necessary to remove the front corner

panel for access to coil thermistor,

B-Defrost Board

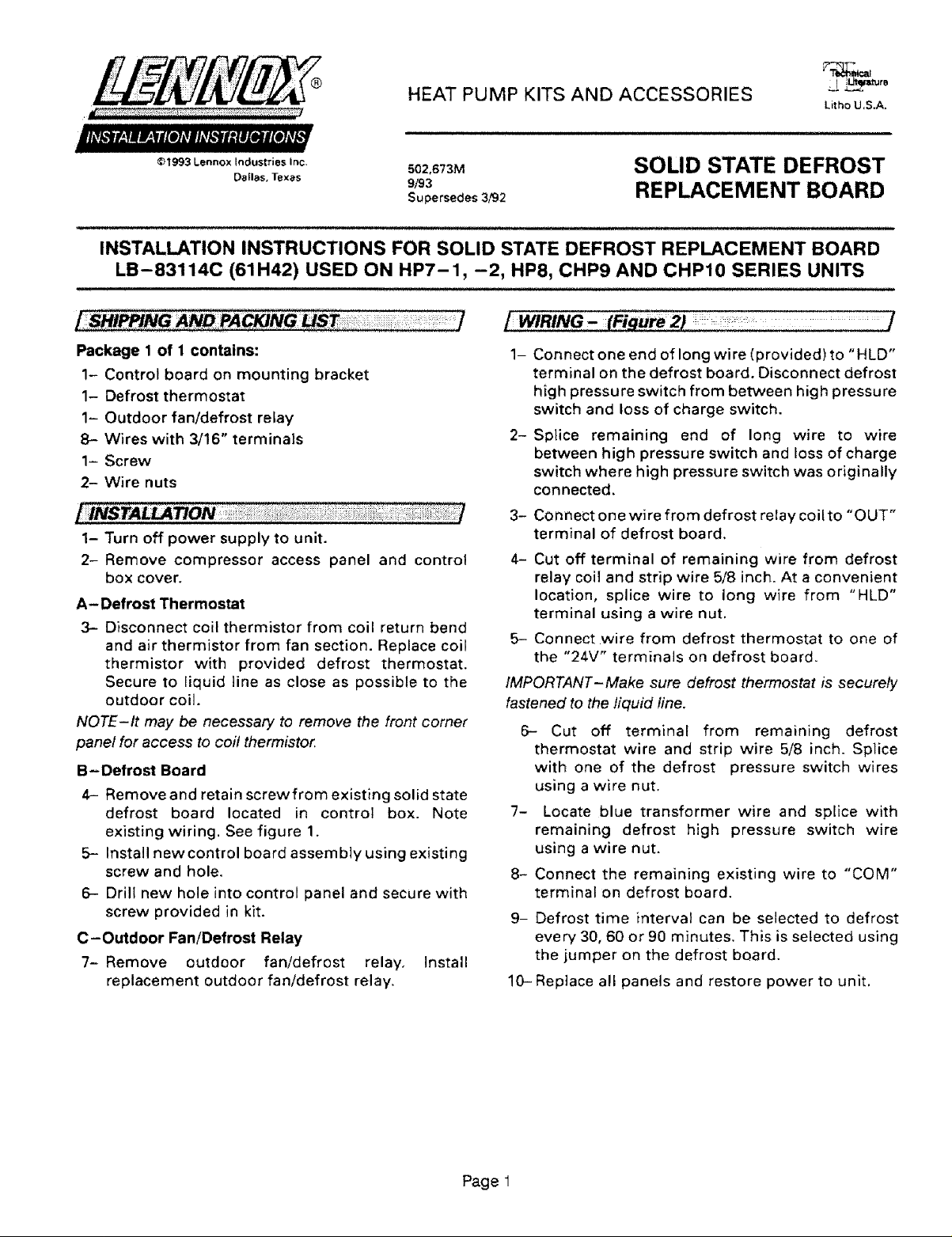

4- Remove and retain screwfrom existing solid state

defrost board located in control box. Note

existing wiring. See figure 1.

5- Install newcontrol board assembly using existing

screw and hole.

6- Drill new hole into control panel and secure with

screw provided in kit.

C-Outdoor Fan/Defrost Relay

7- Remove outdoor fan/defrost relay. Install

replacement outdoor fan/defrost relay.

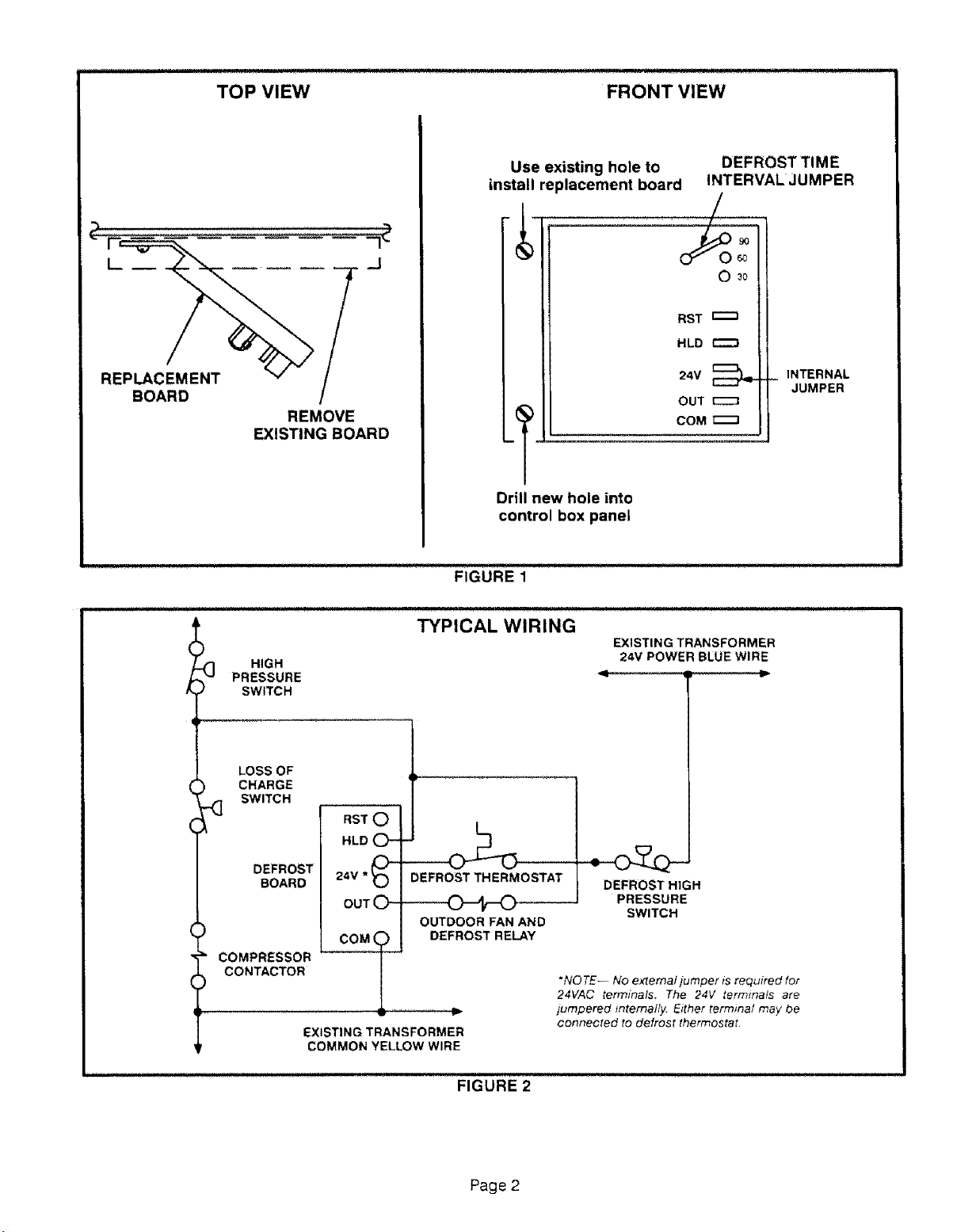

1- Connect one end of long wire (provided) to "HLD"

terminal on the defrost board. Disconnect defrost

high pressure switch from between high pressure

switch and loss of charge switch.

2-Splice remaining end of long wire to wire

between high pressure switch and toss of charge

switch where high pressure switch was originally

connected.

3- Connect onewire from defrost relaycoitto "OUT"

terminal of defrost board.

4- Cut off terminal of remaining wire from defrost

relay coil and strip wire 5/8 inch. At a convenient

location, splice wire to long wire from "HLD"

terminal using a wire nut.

5- Connect wire from defrost thermostat to one of

the "24V" terminals on defrost board.

IMPORTANT-Make sure defrost thermostat is securely

fastened to the fiquid line.

6- Cut off terminal from remaining defrost

thermostat wire and strip wire 5/8 inch. Splice

with one of the defrost pressure switch wires

using a wire nut.

7- Locate blue transformer wire and splice with

remaining defrost high pressure switch wire

using a wire nut.

8- Connect the remaining existing wire to "COM"

terminal on defrost board.

9- Defrost time interval can be selected to defrost

every 30, 60 or 90 minutes. This is selected using

the jumper on the defrost board.

10-Replace all panels and restore power to unit.

Page 1

Page 2

TOP VIEW FRONT VIEW

REPLACEMENT

BOARD

_J

f

REMOVE

EXISTING BOARD

Use existing hole to

install replacement board

I

®1

Drill new hole into

control box panel

FIGURE 1

DEFROST TIME

INTERVAL JUMPER

9O

6O

0 _o

RST

HLD

24V

OUT

COM

_ INTERNAL

JUMPER

_] HIGH

PRESSURE

SWITCH

LOSS OF

, CHARGE

._ SWITCH

DEFROST

BOARD

COMPRESSOR

CONTACTOR

TYPICAL WIRING

RST 0

HLD

24V * _)-

OUT (_

tOM9

EXISTING TRANSFORMER

COMMON YELLOW WIRE

DEFROST THERMOSTAT

OUTDOOR FAN AND

DEFROST RELAY

EXISTING TRANSFORMER

24V POWER BLUE WIRE

DEFROST HIGH

PRESSURE

SWITCH

*NO TE-- No external/umper tsrequtred for

24VAC terminals. The 2,4V terminals are

jumpered lnternal/}z Either termina/ may be

connected to defrost thermostat•

Page 2

Page 3

The defrost control is a solid state control

manufacturedby HamiltonStandard.The control

providesautomaticswitchingfrom normalheating

operationto defrostmode and back.The defrost

controlcontainsasolidstatetimerwhichswitchesan

externa] defrost relay through 1/4" male spades

mountedonthecontrol'scircuitboard.Thecontrol

energizesthedefrostrelayat regular timed intervals.

On some units, anormally open defrost switch placed

in series between the defrost relay and the control

initiates defrost only when needed at the end of the

timed intervals. On other units, the control initiates

defrost on demand from the defrost thermostat,

Defrost Control Components:

1- 24V Terminal

Terminat 24V receives 24VAC from the control

transformer. This terminal powers the control's

internal timer and relays. Terminal 24V must be

powered at all times to provide HOLD between

thermostat demands.

2 COM Terminal

Terminal COM provides 24VAC common.

3- HLD Terminal

Terminal HLD hold the internal timer in place

between thermostat demands and altows the unit

to continue timing upon resumption of

thermostat demand, tn most units, terminal HLD

is connected directly to thermostat demand.

4- OUT Terminal

Terminal OUT controls unit defrost when

connected to one side of the defrost relay coil. An

internal relay connected to terminal OUT closes

to allow external defrost relay to energize and

initiate defrost. At the end of the defrost period,

the internal relay connected to terminal OUT

opens to de-energize the external defrost relay.

5- RST Terminal

This terminal is not functional for the specified

application.

6- Timing Pins (T1,T2,T3)

Each of these pins provides a different timed

interval between defrosts (30, 60 or 90 seconds).

A jumper connects the pins to circuit board

terminal Wl. To change the interval between

defrosts, remove the jumper from the pin it is

connected to and reconnect the jumper to one of

the other available pins.

7- Timing Jumper

A factory installed jumper on the circuit board

connects terminal Wl on the circuit board to one

of the three timing pins.

8- TST Pins

Each board is equipped with a test pins for use in

troubleshooting the unit. When jumpered

together, these pins reduce the control timing to

about 1/256 original time.

A CAUTION

To Place Control in Test Mode:

1- Turn off all power to avoid damaging the circuit

board.

2- Make sure all control terminats are connected as

shown on unit wiring diagram before attempting

to place control in test mode.

IMPORTANT

3- Connect jumper to "TST" pins,

4- Turn indoor thermostat to heat mode and adjust

to highest temperature setting.

5- See table 1 for control timings in "TST" mode,

6- Turn on power to unit and re-adjust thermostat.

Be sure to remove jumper when test is complete.

TABLE 1

TEST MODE CONTROL TIMINGS

NORMAL !_ 30+3 60±6 : 90_9 _ 14+1,4

OPERATION MIN MIN i MIN. MIN.

"TST" PINS

JUMPERED SEC. i SEC i SEC* i SEC

TOGETHER !

1!7+0r7 14+1A i 21_+21 3-3_0.3

Page 3

Page 4

DEFROST CONTROL TROUBLESHOOTING FLOWCHART

START HERE

I

Check control transformer primary

and secondary voltages. Repair or

replace as necessary.

I

Turn off power to unit.

I

Check defrost sensor. Is sensor

temperature or pressure acti-

vated? For help in determining, re-

fer to operation of control in unit

installation instructions and unit

wiring diagram.

I

I I

Pressure Temperatu re

Is sensor making good

Yes _ No

Check all electrical connections

at the defrost control. Defrost

sensor and defrost relay.

I

Connect a jumper across

the defrost relay.

I

Connect a jumper across the two

"TST" pins on the delrost Control,

I

Turn indoor thermostat to

heat mode and adjust to high-

est temperature setting.

1

Turn on power to unit.

I

Check voltage across "HLD"

terminal and "COM" termi-

nal, Is voltage 24 + 6VAC?

1

ls solenoid engaging?

Yes _t No

i 1

Replace reversing Replace solenoid.

valve. Repeat Repeat troubleshoot-

troubleshooting ing procedure,

procedure.

I

contact with coil?

Repair or

replace sensor

bracket.

I

............i .... 1 .o___1

Is defrost control set for Is compressor contactor

30, 60 or 90 minute de = energized?

frost intervals?

i---No ................I Yes

Check thermostat and

thermostat widng. Repair

or replace as necessary

I

Repeat troubleshooting

procedure.

Does un_ go into defrost

within appropriate time? I

Yes No _ procedure.

Check circuit from "HLD"

terminal back to thermo-

stat, Repair or replace as

necessary.

t

|

Repeat troubleshooting

i ]

Unit is operating properly. Check voltage across "OUT"

Turn off power to unit, terminal and "COM" terminal.

Remove all test jumpers. Is voltage 24 ± 6VAC?

I

Yes

Check and repair circuit

through defrost relay to

Repeat troubleshooting

Reassemble unit.

Connect a jumper between "OUT" terminal

and "COM" terminal. CAUTION-Be careful

not to short "OUT" terminal to "24v" terminal,

Permanent controt damage could result.

Does unit go immediately into defrost?

Yes t

I

Turn off power to unit.

Remove all test jumpers.

Replace defrost control with new

control board,

Repeat troubleshooting procedure.

Check voltage across re=

versing valve coil. Is volt-

age 24 ÷ 6VAC?

I

I

No

I

Turn off power to unit.

from reversing valve

control transformer.

procedure.

Yes

I

I

["-_ Yes _ No

Is defrost relay

energized?

Yes

Turn off power to unit.

Check circuit from defrost

switch back to control

transformer. Repair of re-

place as necessary,

Repeat troubleshooting

procedure,

I No

Check voltage across "24Y"

terminal and "COM" terminal. Is

NO ,,,, ,,,,,,

I

No

Check voltage across de-

frost relay coil. Is voltage

24 ± 6VAC?

I

voltage 24 ± 6VAC?

I

_ ..... Yes

I

Turn off power to unit.

Replace defrost relay,

Repeat troubleshooting

procedure.

Page 4

Loading...

Loading...