Page 1

2017

INSTALLATION

WARNING

Improper installation, adjustment, alteration, ser

vice or maintenance can cause property damage,

personal injury or loss of life. Installation and ser

vice must be performed by a licensed professional

HVAC installer or equivalent or service agency.

CAUTION

As with any mechanical equipment, contact with

sharp sheet metal edges can result in personal in

jury. Take care while handling this equipment and

wear gloves and protective clothing.

Table Of Contents

Dimensions Page 2.................................

Shipping and Packing List Page 3....................

General Page 3....................................

Requirements Page 3...............................

Unit Support Page 4................................

Duct Connection Page 5............................

RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

INSTRUCTIONS

KDB024 (2 TON)

KDB036 (3 TON)

KDB048 (4 TON)

KDB060 (5 TON)

ROOFTOP PACKAGED UNITS

507626-01

04/2017

Supersedes 8/2016

Rigging Unit For Lifting Page 5.......................

Condensate Drains Page 6..........................

Electrical Connections Page 9.......................

Unit Power-Up Page 9..............................

Blower Operation and Adjustments Page 10............

Defrost Control Board Page 30........................

Service Page 33....................................

KDB024, 036, 048, 060 PARTS ARRANGEMENT

ECONOMIZER

(OPTIONAL)

INDOOR

TXV

CONDENSATE

DRAIN

FILTERS

COMBUSTION

AIR INDUCER

BURNERS

TB1 LOW VOLTAGE

TERMINAL BLOCK

EVAPORATOR

COIL

GAS VALVE

BLOWER

REVERSING

VALV E

CONDENSER

FAN

OUTDOOR

TXV

CONDENSER

COIL

COMPRESSOR

Page 2

KDB024, 030, 036, 048, 060 DIMENSIONS

Model

KDB024, 036

KDB048, 060

2-1/4

(57)

(Overall dimensions

same as end view

without economizer)

No.

7/8

(22)

A

30-7/16

(773)

7/8

UNIT RETURN AIR DUCT

(22)

OPENING WITH HORIZONTAL

ECONOMIZER INSTALLED

END VIEW

A

in. mm

18-3/4 476

22-1/2 572

2-1/4

(57)

5-5/8

(143)

7 (178)

(737)

47 (1192)

BASE

3-1/2 (89)

LIFTING HOLES

(For rigging)

16-1/4

(413)

11

AA

29

DD CC

(279)

26-1/2

(673)

6-5/8

(168)

BOTTOM

RETURN

AIR

OPENING

BOTTOM

SUPPLY

AIR

OPENING

18

(457)

5 (127)

20

(508)

BOTTOM

CONDENSATE

OUTLET

CENTER

OF

GRAVITY

FF

BOTTOM POWER ENTRY

3 X 8 (76 X 203)

25-3/4 (654)

024 thru 074

38-3/4 (984) 090

9-1/2

(241)

EE

TOP VIEW (Base)

83-1/4 (2115) 024, 036

96-1/4 (2445) 048, 060

ELECTRICAL

INLET

GAS

INLET

15

(381)

(686)

27

CONDENSATE

OUTLET

(EITHER SIDE)

43-3/8 (1102) KDB048, 060

35-3/8 (899) KDB024, 036

26-1/2

(673)

FLUE/VENT

OUTLET

5-1/2

(140)

85-1/4 (2165) 024 thru 036 BASE

98-1/4 (2496) 060 BASE

SIDE VIEW

BB

1 (25)

45

(1143)

1 (25)

47 (1194)

BASE

(Without Economizer)

END VIEW

38-7/8 (987) KDB024, 036

46-7/8 (1191) KDB048, 060

Page 2

FORKLIFT SLOTS

(Front, Back and

Blower End)

BACK VIEW

20

(508)

5-1/2

(140)

19-1/2

(495)

18-3/8

HORIZONTAL

SUPPLY AIR

OPENING

11

(467)

(279)

HORIZONTAL

RETURN AIR

OPENING

(Without Economizer)

2 (51)

29

(737)

5-1/2

(140)

Page 3

Shipping and Packing List

Package 1 of 1 contains:

1- Assembled unit

Check unit for shipping damage. Receiving party should

contact last carrier immediately if shipping damage is

found.

General

These instructions are intended as a general guide and

do not supersede local codes in any way. Authorities

having jurisdiction should be consulted before

installation.

KDB units have 2, 3, 4, and 5-ton cooling capacities.

Units are available in three gas heating inputs.

KDB036, 048, and 060 3-phase units are equipped with

two-speed, belt or direct drive supply air blowers.

KDB024, 036, 048 and 060 1-phase units are equipped

with variable speed, direct drive blowers. These units will

provide supply air at lower speeds when cooling demand

is low and increase to higher speeds when cooling

demand is high. Refer to Blower Operation section.

Availability of units and options varies by brand.

Requirements

The KDB unit is ETL/CSA certified for outdoor

installations only at the clearances to combustible

materials listed on unit nameplate and in figure 1.

Installation of KDB dual fuel heat pumps must conform

with standards in National Fire Protection Association

(NFPA) “Standard for Installation of Air Conditioning

and Ventilating Systems NFPA No. 90A,” “Standard for

Installation of Residence Type Warm Air Heating and

Air conditioning Systems NFPA No. 90B,” local

municipal building codes and manufacturer's

installation instructions.

NOTICE

Roof Damage!

This system contains both refrigerant and oil.

Some rubber roofing material may absorb oil,

causing the rubber to swell. Bubbles in the rubber

roofing material can cause leaks. Protect the roof

surface to avoid exposure to refrigerant and oil

during service and installation. Failure to follow

this notice could result in damage to roof surface.

The National Electric Code (ANSI/NFPA No. 70-1984) is

available from:

National Fire Protection Association

1 Batterymarch Park

PO Box 9101

Quincy, MA 02269-9101

UNIT CLEARANCES

C

D

A

FIGURE 1

1

Unit

Clearance

Service

Clearance

Clearance to

Combustibles36(914)1(25)1(25)1(25)

Minimum Opera

tion Clearance36(914)36(914)36(914)36(914)

Note - Entire perimeter of unit base requires support when elevated above

mounting surface.

1

Service Clearance - Required for removal of serviceable parts.

Clearance to Combustibles - Required clearance to combustible

material.

Minimum Operation Clearance - Required clearance for proper unit operation.

A

in.(mm)Bin.(mm)Cin.(mm)Din.(mm)

36

(1524)36(914)36(914)36(914)

WARNING

Electric shock hazard and danger of

explosion. Can cause injury, death or

product or property damage. Turn off

gas and electrical power to unit before

performing any maintenance or

servicing operations on the unit. Follow

lighting instructions attached to unit

when putting unit back into operation

and after service or maintenance.

The KDB unit is ETL/CSA certified as a dual fuel heat

pump with cooling and auxiliary gas heat for

non-residential use only at the clearances to combustible

materials as listed on the unit nameplate and in figure 1.

Installation of ETL/CSA certified units must conform with

current standard C273.5 “Installation Requirements for

Heat Pumps” and applicable local codes. Authorities

having jurisdiction should be consulted before

installation.

Page 3

B

To p

Clearance

Unob

structed

Unob

structed

Unob

structed

Page 4

Use of this unit as a construction heater or air conditioner

is not recommended during any phase of construction.

Very low return air temperatures, harmful vapors and

operation of the unit with clogged or misplaced filters will

damage the unit.

If this unit has been used for heating or cooling of

buildings or structures under construction, the following

conditions must be met or the warranty will be void:

A room thermostat must control the unit. The use of

fixed jumpers that will provide continuous heating or

cooling is not allowed.

A pre-filter must be installed at the entry to the return

air duct.

The return air duct must be provided and sealed to

the unit.

Return air temperature range between 55°F (13°C)

and 80°F (27°C) must be maintained.

Air filters must be replaced and pre-filter must be

removed upon construction completion.

The unit components, duct system, air filters and

evaporator coil must be thoroughly cleaned following

final construction clean-up.

The unit operating conditions (including airflow,

cooling operation, and heating operation) must be

verified according to these installation instructions.

WARNING

Electric shock hazard and danger of

explosion. Can cause injury, death or

product or property damage. Turn off

electrical power to unit before

performing any maintenance or

servicing operations on the unit.

IMPORTANT

The Clean Air Act of 1990 bans the intentional vent

ing of refrigerant (CFC's and HCFC's) as of July 1,

1992. Approved methods of recovery, recycling or

reclaiming must be followed. Fines and/or incar

ceration may be levied for non-compliance.

Unit Support

NOTE - Securely fasten roof frame to roof per local codes.

CAUTION

To reduce the likelihood of supply / return air by

pass and promote a proper seal with the RTU, duct

work / duct drops / diffuser assemblies must be

supported independently to the building structure.

A-Downflow Discharge Application

Roof Mounting with C1CURB

1- The C1CURB roof mounting frame must be installed,

flashed and sealed in accordance with the

instructions provided with the frame.

2- The C1CURB roof mounting frame should be square

and level to 1/16” per linear foot (5mm per linear

meter) in any direction.

3- Duct must be attached to the roof mounting frame

and not to the unit; supply and return plenums must

be installed before setting the unit.

Installer's Roof Mounting Frame

Many types of roof frames can be used to install the unit,

depending upon different roof structures. Items to keep

in mind when using the building frame or supports are:

1- The unit base is fully enclosed and insulated, so an

enclosed frame is not required.

2- The frames or supports must be constructed with

non-combustible materials and should be square and

level to 1/16” per linear foot (5mm per linear meter)

in any direction.

3- Frame or supports must be high enough to prevent

any form of moisture from entering unit.

Recommended minimum frame height is 14”

(356mm).

4- Duct must be attached to the roof mounting frame

and not to the unit. Supply and return plenums must

be installed before setting the unit.

5- Units require support along all four sides of unit base.

Supports must be constructed of steel or suitably

treated wood materials.

NOTE-When installing unit on a combustible surface for

downflow discharge applications, the C1CURB roof

mounting frame is required.

B-Horizontal Discharge Applications

1- Units which are equipped with an optional

economizer and installed in horizontal airflow

applications must use a horizontal conversion kit.

2- Specified installation clearances must be maintained

when installing units. Refer to figure 1.

Page 4

Page 5

3- Top of support slab should be at least 4” (102mm)

above the finished grade and located so no run-off

water from higher ground can collect around the unit.

4- Units require support along all four sides of unit base.

Supports must be constructed of steel or suitably

treated wood materials.

Duct Connection

All exterior ducts, joints, and openings in roof or building

walls must be insulated and weatherproofed with flashing

and sealing compounds in accordance with applicable

codes. Any duct passing through an unconditioned space

must be insulated.

!

CAUTION

In downflow applications, do not drill or punch

holes in base of unit. Leaking in roof may occur if

unit base is punctured.

Rigging Unit For Lifting

1- Detach wooden base protection before rigging.

2- Connect rigging to the unit base using both holes in

each corner. See figure 2.

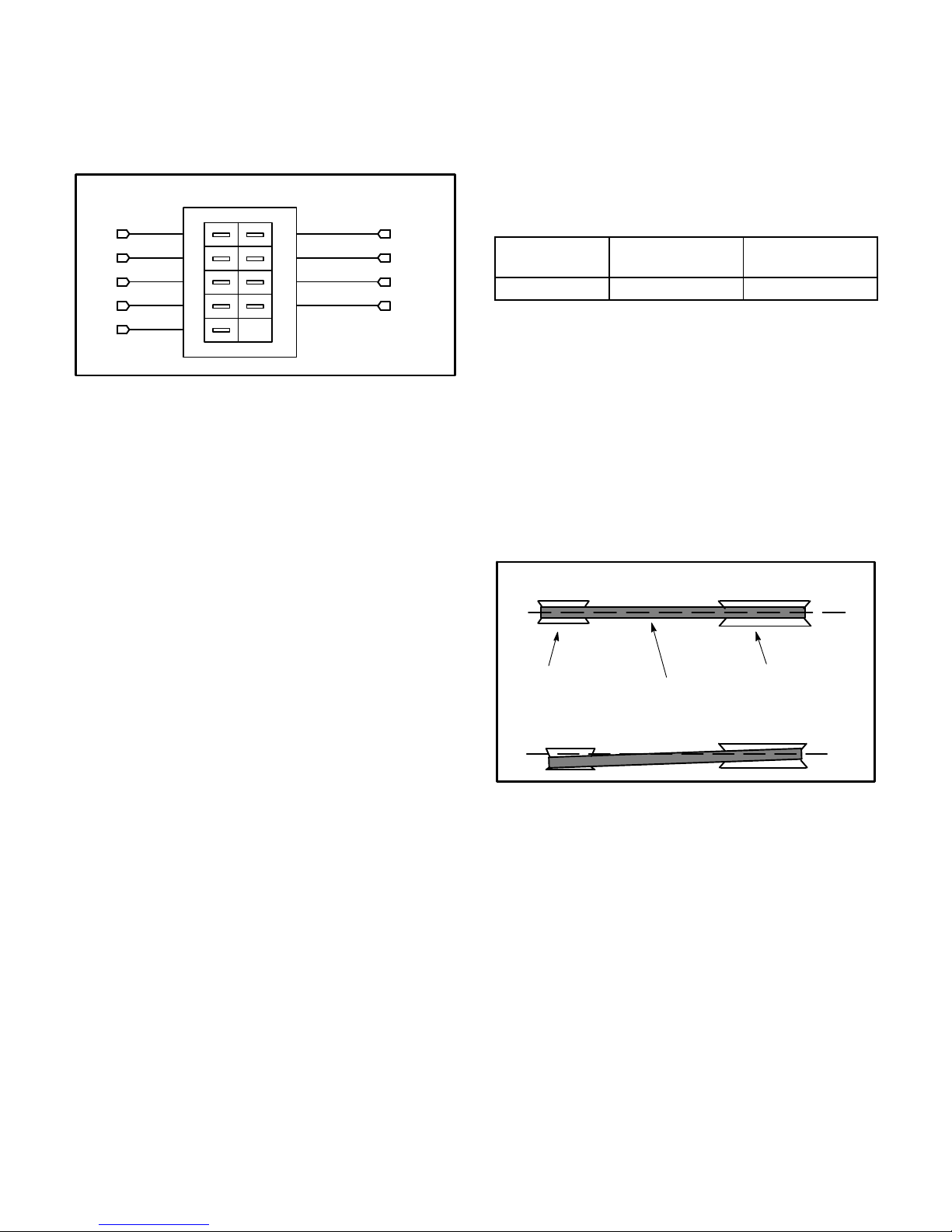

Horizontal Air Discharge

Unit is shipped with panels covering the horizontal supply

and return air openings. Remove horizontal covers and

place over downflow openings for horizontal air discharge.

See figure 3. Secure in place with sheet metal screws.

Units Equipped With An Optional Economizer

1- Remove the horizontal supply air cover and position

over the downflow supply air opening. Secure with

sheet metal screws.

2- Leave the horizontal return air cover in place.

3- Locate the separately ordered horizontal air

discharge kit. Place the kit panel over the downflow

return air opening.

4- Remove and retain the barometric relief dampers and

lower hood.

5- Install return air duct beneath outdoor air intake. See

figure 4. Install barometric relief damper in lower

hood and install in ductwork as shown in figure 4.

UNIT SUPPLY AND RETURN AIR OPENINGS

HORIZONTAL

HORIZONTAL

RETURN AIR

OPENING

SUPPLY AIR

OPENING

3- All panels must be in place for rigging.

4- Place field‐provided H‐style pick in place just above

top edge of unit. Frame must be of adequate

strength and length. (H-style pick prevents damage

to unit.)

Unit

All

*Maximum weight with all avail

able installed accessories.

CAUTION: DO NOT

WALK ON UNIT.

Weight*

Lbs. Kg.

894 406

Lifting Point Should

Be Directly Above

Center Of Gravity.

DOWNFLOW

RETURN AIR

OPENING

DOWNFLOW

SUPPLY AIR

OPENING

FIGURE 3

HORIZONTAL RETURN AIR DUCTWORK

WITH ECONOMIZER

HORIZONTAL

RETURN AIR

DUCT

UNITUNIT

FIGURE 2

INSTALL BAROMETRIC RELIEF DAMPERS

AND HOOD IN RETURN AIR DUCT

FIGURE 4

Page 5

Page 6

Condensate Drains

Make drain connection to the 1” N.P.T. drain coupling

provided on unit.

Note - The drain pan is made with a glass reinforced

engineered plastic capable of withstanding typical joint

torque but can be damaged with excessive force. Tighten

pipe nipple hand tight and turn an additional quarter turn.

Units are shipped with the drain coupling facing the front

of the unit. Condensate can be drained from the back or

bottom of the unit with the following modifications. The

unit can be installed in either downflow or horizontal air

discharge regardless of condensate drain location.

Rear Drain Connection

A trap must be installed between drain connection and an

open vent for proper condensate removal. See figure 5 or

6. It is sometimes acceptable to drain condensate onto

the roof or grade; however, a tee should be fitted to the

trap to direct condensate downward. The condensate line

must be vented. Check local codes concerning

condensate disposal. Refer to pages 2 for condensate

drain location.

CONDENSATE SIDE DRAIN CONNECTION

CAULK AROUND CONDENSATE COUPLING

NOTE - Allow clearance to

open doors when installing

condensate piping.

Minimum Pitch

1” (25 mm) per

10' (3 m) of line

OPEN VENT

UNIT

MOUNTING

FRAME

1- Remove the condensate drain mullion. See figure 7.

Remove the two panels on each side of the mullion.

If the unit has hinged panels, two hinge screws must

be removed in addition to the mullion screws. See

figure 8.

CONDENSATE

DRAIN MULLION

FIGURE 7

FIGURE 5

CONDENSATE BOTTOM DRAIN CONNECTION

UNIT

DRAIN PAN

CAULK AROUND

CONDENSATE COUPLING

OPEN VENT

MOUNTING

FRAME

Minimum Pitch

1” (25 mm) per 10'

(3 m) of line

FIGURE 6

2- Lift the front edge of the drain pan and slide pan out

of unit. See figure 9.

3- Make sure the cap over the unit bottom drain hole is

secure.

UNITS WITH HINGED PANELS

CONDENSATE

DRAIN MULLION

REMOVE

TWO

SCREWS

FIGURE 8

Page 6

Page 7

REMOVE DRAIN PAN

DRAIN PAN

BOTTOM CONDENSATE DRAIN

CAUTION: Be careful not to

damage the coupling threads

when drilling the hole.

DRILL A PILOT

HOLE IN CENTER

OF COUPLING

FIGURE 9

4- Rotate the drain pan until the downward slope is

toward the back of the unit. Slide the drain pan back

into the unit. Be careful not to dislodge the cap over

the bottom drain hole.

5- From the back side of the unit, pull the drain pan

coupling through the rear condensate opening.

6- Replace the condensate drain mullion and reinstall

screws.

7- Reinstall access doors.

Bottom Drain Connection

1- Remove the condensate drain mullion. See figure 7.

If the unit has hinged panels, two hinge screws must

be removed in addition to the mullion screws. See

figure 8.

2- Lift the front edge of the drain pan and slide pan out

of unit. See figure 9.

3- Turn the drain pan upside down and drill a pilot hole

through the bottom of the drain pan in the center of

the coupling. See figure 10.

4- From the inside of the pan, use a Vari-Bit

®

bit to

enlarge the hole to 7/8”. Do not damage coupling

threads.

5- Remove the cap over the unit bottom drain hole.

6- Slide the drain pan back into the unit.

7- From the back side of the unit, pull the drain pan

coupling through the rear condensate opening.

8- From the front side of the unit, move the drain pan

until the bottom coupling settles into the unit bottom

drain opening. Once in place, check to make sure the

coupling is still positioned through the rear

condensate drain hole.

After drilling the pilot

hole, drill a 7/8” hole from

the inside of the pan.

FIGURE 10

9- Use a field-provided 1” plug to seal side drain

connection.

10- Replace the condensate drain mullion and reinstall

screws.

11- Reinstall access doors.

Connect Gas Piping

Before connecting field-provided piping, check with gas

company or authorities having jurisdiction for local code

requirements. When installing gas supply piping, length

of run from gas meter must be considered in determining

pipe size for 0.5” w.c. (.12kPa) maximum pressure drop.

Do not use supply pipe smaller than unit gas connection.

For natural gas units, operating pressure at the unit gas

connection must be a minimum of 4.5” w.c. (1.12kPa)

and a maximum of 10.5” (2.60kPa) w.c. For LP/propane

gas units, operating pressure at the unit gas connection

must be a minimum of 11” w.c. (2.74kPa) and a maximum

of 13.0” w.c. (3.23kPa).

When making piping connections a drip leg should be

installed on vertical pipe runs to serve as a trap for

sediment or condensate. A 1/8” N.P.T. plugged tap is

located on gas valve for test gauge connection. Refer to

Heating Start-Up section for tap location. Install a ground

joint union between the gas control manifold and the main

manual shut-off valve. See figure 11 for gas supply piping

entering outside the unit. Figure 12 shows bottom gas

entry piping through the unit.

Compounds used on threaded joints of gas piping shall be

resistant to the action of liquified petroleum gases.

Page 7

Page 8

OUTSIDE OF UNIT GAS PIPE CONNECTION

TO GAS

VALV E

GROUND

JOINT UNION

TO GAS

SUPPLY

After all connections have been made, check all piping

connections for gas leaks. Also check existing unit gas

connections up to the gas valve; loosening may occur

during installation. Use a leak detection solution or other

preferred means. Do not use matches candles or other

sources of ignition to check for gas leaks.

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or othe sources of ignition

to check for gas leaks.

WARNING

GAS PIPING

SUPPORT

MANUAL MAIN

SHUT-OFF VALVE

DRIP LEG

(REFER TO

LOCAL CODES)

FIGURE 11

BOTTOM ENTRY GAS PIPING COMPLETED

GROUND

JOINT UNION

STREET

ELBOW

7” NIPPLE

2-1/2” NIPPLE

DRIP LEG

Grommets for both gas pipe openings are field provided.

TO GAS

VALV E

TO GAS

SUPPLY

MANUAL MAIN

SHUT-OFF VALVE

FIGURE 12

Pressure Test Gas Piping

When pressure testing gas lines, the gas valve must

be disconnected and isolated. Gas valves can be

damaged if subjected to more than 0.5 psig (3.48kPa).

See figure 13.

NOTE-Codes may require that manual main shut-off

valve and union (furnished by installer) be installed in

gas line external to unit. Union must be of the ground

joint type.

Danger of explosion. Can cause injury

or product or property damage. Do not

use matches, candles, flame or other

sources of ignition to check for leaks.

NOTE-In case emergency shut down is required, turn off

the main manual shut-off valve and disconnect main

power to unit. These devices should be properly labeled

by the installer.

PRESSURE TEST GAS LINE

MANUAL MAIN

SHUT-OFF VALVE

GAS VALVE

CAP

FIGURE 13

High Altitude Derate

Locate the high altitude conversion sticker in the unit

literature bag. Fill out the conversion sticker and affix next

to the unit nameplate.

Refer to table 1 for high altitude adjustments.

TABLE 1

HIGH ALTITUDE DERATE

Altitude Ft.* Gas Manifold Pressure

2000-4500 See Unit Nameplate

4500 And Above Derate 2% / 1000 Ft. Above Sea Level

*Units installed at 0-2000 feet do not need to be modified.

NOTE ‐ This is the only permissible derate for these units.

Page 8

Page 9

Electrical Connections

POWER SUPPLY

Do not apply power or close disconnect switch until

installation is complete. Refer to start-up directions.

Refer to unit nameplate for minimum circuit ampacity

and maximum fuse size.

1- 230,460,575 volt units are factory wired. For 208V

supply, disconnect the pink wire (230V) at all control

power transformer(s). insulated terminal cover from

the 208V terminal on the control transformer. Move

the wire from the transformer 240V terminal to the

208V terminal. Place the insulated terminal cover on

the unused 240V terminal.

2- Route power through the bottom power entry area

and connect to the top of K1 compressor contactor

or factory-installed disconnect or circuit breaker.

Secure power wiring with factory-installed wire

ties provided in control box. See unit wiring

diagram.

CONTROL WIRING

A-Thermostat Location

Room thermostat mounts vertically on a standard 2” X 4”

handy box or on any non-conductive flat surface.

Locate thermostat approximately 5 feet (1524 mm)

above the floor in an area with good air circulation at

average temperature. Avoid locating the room

thermostat where it might be affected by:

-drafts or dead spots behind doors and in corners

-hot or cold air from ducts

-radiant heat from sun or appliances

-concealed pipes and chimneys

IMPORTANT - Unless field thermostat wires are rated

for maximum unit voltage, they must be routed away

from line voltage wiring.

B-Control Wiring

1- Route thermostat cable or wires from subbase to

unit control box (refer to unit dimensions to locate

bottom and side power entry).

IMPORTANT - Unless field thermostat wires are rated

for maximum unit voltage, they must be routed away

from line voltage wiring. Use wire ties located near the

front of the control section to secure thermostat cable.

Use18 AWG wire for all applications using remotely

installed electro-mechanical and electronic

thermostats.

2- Install thermostat assembly in accordance with

instructions provided with thermostat.

3- Connect thermostat wiring to TB1 terminal board on

the lower side of the controls hat section. Wire as

shown in figure 14 for electro-mechanical and

electronic thermostats. If using other temperature

control devices or energy management systems see

instructions and wiring diagram provided by

manufacturer.

24 VOLT FIELD WIRING WITH ELECTRONIC AND

ELECTRO-MECHANICAL THERMOSTATS

TB1

NOT ALL TERMINALS

ARE FOUND ON ALL

THERMOSTATS

Jumper terminals R and

OC when thermostat has

no night setback terminals

A2 THERMOSTAT

Note - On electro-mechanical thermo

stats set anticipator at 0.1 amps.

on units equipped with an

economizer.

FIGURE 14

IMPORTANT-Terminal connections at the wall plate or

subbase must be made securely. Loose control wire

connections may allow unit to operate but not with proper

response to room demand.

Unit Power-Up

A-General

1- Make sure that unit is installed in accordance with the

installation instructions and applicable codes.

2- Inspect all electrical wiring, both field and factory

installed, for loose connections. Tighten as required.

3- Check to ensure that refrigerant lines do not rub against

the cabinet or against other refrigerant lines.

4- Check voltage at main unit power connection.

Voltage must be within range listed on nameplate. If

not, consult power company and have voltage

condition corrected before starting unit.

5- Make sure filters are in place before start‐up.

6- Make sure there is no heating, cooling, or blower

demand from thermostat. Apply power to unit.

Page 9

Page 10

Blower Operation and Adjustments

KD 024 units are equipped with multi-tap ECM, direct

drive blowers only.

KD 036, 048 and 060 units are equipped with either

multi-tap ECM, direct drive or two-stage belt drive

blowers.

The blower will operate at high speed with Y2 thermostat

demand and low speed with a Y1 thermostat demand.

Low speed operation delivers approximately 2/3 of air

volume of high speed. Two-speed blower operation

results in lower energy consumption.

IMPORTANT

Three phase scroll compressors must be phased

sequentially for correct compressor and blower

rotation. Follow “COOLING START-UP” section of

installation instructions to ensure proper compres

sor and blower operation.

A-Blower Operation

Initiate blower demand at thermostat according to

instructions provided with thermostat. Unit will cycle on

thermostat demand. The following steps apply to

applications using a typical electro-mechanical thermostat.

1- Blower operation is manually set at the thermostat

subbase fan switch. With fan switch in ON position,

blowers will operate continuously.

2- With fan switch in AUTO position, the blowers will

cycle with demand. Blowers and entire unit will be off

when system switch is in OFF position.

Belt Drive Blowers

2- Remove and retain screws on either side of sliding

frame. Pull frame toward outside of unit.

3- Slide frame back into original position when finished

servicing. Reattach the blower wiring in the previous

location on the blower motor base using the wire tie.

4- Replace retained screws on either side of the

sliding frame.

Direct Drive Blowers

1- Loosen the reusable wire tie which secures the

controls and high voltage blower wiring to the blower

housing.

2- Remove and retain screws in front and on either side

of blower housing. Pull frame toward outside of unit.

3- Slide frame back into original position when finished

servicing. Reattach the blower wiring in the previous

location on the blower motor base using the wire tie.

4- Replace retained screws in front and on either side of

the blower housing.

B-Determining Unit CFM - Direct Drive Blowers

1- The following measurements must be made with air

filters in place.

2- With all access panels in place, measure static

pressure external to unit (from supply to return). Add

any additional air resistance for options and

accessories shown in accessory air resistance tables.

Blower performance data is based on static pressure

readings taken in locations shown in figure 15.

Note - Static pressure readings can vary if not taken

where shown.

1- Loosen the reusable wire tie which secures the

blower wiring to the blower motor mounting plate.

LOCATION OF STATIC PRESSURE READINGS

INSTALLATIONS WITH DUCTWORK

ROOFTOP UNIT

RETURN AIR

READING LOCATION

SUPPLY

MAIN

DUCT RUN

RE

TURN

FIRST BRANCH

OFF OF MAIN RUN

SUPPLY AIR

READING

LOCATION

FIGURE 15

SUPPLY AIR

Page 10

3- Use figure 16 to determine the factory-set blower

speed.

INSTALLATIONS WITH CEILING DIFFUSERS

ROOFTOP UNIT

RETURN AIR

READING

RE

TURN

LOCATION

READING

SUPPLY

DIFFUSER

LOCATION

Page 11

4- Use direct drive blower tables, the measured static

pressure and the factory-set blower speed to

determine CFM. If CFM is lower or higher than the

design specified CFM, move the leads as shown in

figure 16.

BLOWER SPEED FACTORY SETTINGS

Gray

C

Pink

Green/Yellow

Yellow

N

Common

L1

GND

L2

High

Green

White

Brown

1

2

3

4

5

4- The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley

clockwise to increase CFM. Turn counterclockwise to

decrease CFM. See figure 18. Do not exceed

minimum and maximum number of pulley turns as

shown in table 2.

TABLE 2

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt

A Section 0 5

*No minimum number of turns open when B belt is used on

pulleys 6” O.D. or larger.

Minimum

Turns Open

Maximum

Turns Open

D-Blower Belt Adjustment

FIGURE 16

C-Determining Unit CFM - Belt Drive Blowers

IMPORTANT - Direct drive multi-tap ECM blower unit

CFM is determined by the blower motor speed tap. Refer

to the Direct Drive Variable Speed Start-Up section.

1- The following measurements must be made with a

dry indoor coil. Run blower without a cooling demand.

Measure the indoor blower shaft RPM. Air filters must

be in place when measurements are taken.

2- With all access panels in place, measure static

pressure external to unit (from supply to return).

Blower performance data is based on static pressure

readings taken in locations shown in figure 15.

Note - Static pressure readings can vary if not taken

where shown.

3- Referring to pages 17 to 22, use static pressure and

RPM readings to determine unit CFM. Use page 23

when installing units with any of the optional

accessories listed.

Maximum life and wear can be obtained from belts only

if proper pulley alignment and belt tension are

maintained. Tension new belts after a 24-48 hour

period of operation. This will allow belt to stretch and

seat in the pulley grooves. Make sure blower and motor

pulleys are aligned as shown in figure 17.

1- Loosen four bolts securing motor base to mounting

frame. See figure 18.

PULLEY ALIGNMENT

ALIGNED

MOTOR

PULLEY

BELT

NOT ALIGNED

BLOWER

PULLEY

FIGURE 17

Page 11

Page 12

BLOWER ASSEMBLY

TO INCREASE CFM

LOOSEN ALLEN SCREW &

TURN PULLEY CLOCKWISE

SIDE VIEW

MOTOR

TO INCREASE BELT TENSION

1-Loosen four bolts securing motor base to mounting

frame.

2-Slide the motor downward to tighten the belt.

3-Tighten four bolts on motor base.

TO DECREASE CFM

TURN PULLEY

COUNTERCLOCKWISE

ALLEN

SCREW

PULLEY

2- To increase belt tension -

Slide blower motor downward to tighten the belt. This

increases the distance between the blower motor and

the blower housing.

To loosen belt tension -

Slide blower motor upward to loosen the belt. This

decreases the distance between the blower motor

and the blower housing.

LOOSEN ALLEN

SCREW TO

ADJUST CFM

LOOSEN FOUR BOLTS AND

SLIDE BLOWER MOTOR

DOWNWARD TO TIGHTEN BELT

FIGURE 18

(35-48kPa). For a new 5hp belt, the deflection force

should be 7-10lbs. (48-69kPa).

A force below these values indicates an

undertensioned belt. A force above these values

indicates an overtensioned belt.

MEASURE BELT TENSION

3- Tighten four bolts securing motor base to the

mounting frame.

E-Check Belt Tension

Overtensioning belts shortens belt and bearing life.

Check belt tension as follows:

1- Measure span length X. See figure 19.

2- Apply perpendicular force to center of span (X) with

enough pressure to deflect belt 1/64” for every inch

of span length or 1.5mm per 100mm of span length.

Example: Deflection distance of a 40” span would be

40/64” or 5/8”.

Example: Deflection distance of a 400mm span

would be 6mm.

3- Measure belt deflection force. For a new 2 and 3hp

belt, the deflection force should be 5.0-7.0 lbs.

FORCE

DEFLECTION 1/64” PER INCH OF SPAN

OR 1.5mm PER 100mm OF SPAN

FIGURE 19

F-Field-Furnished Blower Drives

For field-furnished blower drives, use pages to

determine BHP and RPM required. Reference pages

17 to 23 to determine the drive number. Reference table

3 for drive component manufacturer's numbers.

Page 12

Page 13

BLOWER DATA - DIRECT DRIVE - HIGH EFFICIENCY 2 TON

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (economizer, wet coil, etc.) See page 23.

2 - Any eld installed accessories air resistance (electric heat, duct resistance, diffuser, etc.) See page 23.

External Static

Pressure in. w.g.

DOWNFLOW KDB024H4E

0.0 635 825 918 1121 1336

0.1 547 763 861 1071 1290

0.2 433 699 806 1031 1253

0.3 371 636 749 986 1212

0.4 280 559 677 927 1166

0.5 217 481 605 868 1120

0.6 - - - - - - 548 819 1071

0.7 - - - - - - 491 773 1029

0.8 - - - - - - 442 714 983

0.9 - - - - - - 393 653 929

1.0 - - - - - - - - - 604 879

HORIZONTAL KDB024H4E

0.0 602 815 908 1096 1302

0.1 509 750 852 1057 1263

0.2 413 689 793 1007 1227

0.3 340 625 736 964 1189

0.4 266 561 679 918 1142

0.5 220 501 620 864 1100

0.6 - - - - - - 560 809 1061

0.7

0.8 - - - - - - 444 706 964

0.9 - - - - - - 390 661 913

1.0 - - - - - - 352 612 872

Tap 1 Tap 2 Tap 3 Tap 4 Tap 5

- - - - - - 500 752 1015

Air Volume at Specic Blower Taps (cfm)

Page 13

Page 14

BLOWER DATA - DIRECT DRIVE - HIGH EFFICIENCY 3 TON

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (economizer, wet coil, etc.) See page 23.

2 - Any eld installed accessories air resistance (electric heat, duct resistance, diffuser, etc.) See page 23.

External Static

Pressure in. w.g.

DOWNFLOW KDB036H4E

0.0 893 1035 1375 1600 1840

0.1 838 965 1330 1574 1780

0.2 768 895 1277 1543 1748

0.3 705 800 1253 1505 1712

0.4 645 750 1200 1473 1677

0.5 575 690 1150 1435 1638

0.6 - - - - - - 1095 1390 1608

0.7 - - - - - - 1052 1345 1577

0.8 - - - - - - 1004 1302 1528

0.9 - - - - - - 950 1260 1491

1.0 - - - - - - 900 1218 1455

HORIZONTAL KDB036H4E

0.0 900 1045 1379 1599 1810

0.1 828 970 1305 1549 1749

0.2 777 900 1264 1504 1718

0.3 702 800 1216 1479 1677

0.4 635 750 1173 1434 1649

0.5 553 685 1131 1399 1622

0.6 - - - - - - 1078 1359 1577

0.7

0.8 - - - - - - 986 1280 1509

0.9 - - - - - - 933 1236 1471

1.0 - - - - - - 885 1196 1438

Tap 1 Tap 2 Tap 3 Tap 4 Tap 5

- - - - - - 1038 1315 1544

Air Volume at Specic Blower Taps (cfm)

Page 14

Page 15

BLOWER DATA - DIRECT DRIVE - HIGH EFFICIENCY 4 TON

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (economizer, wet coil, etc.) See page 23.

2 - Any eld installed accessories air resistance (electric heat, duct resistance, diffuser, etc.) See page 23.

External Static

Pressure in. w.g.

DOWNFLOW KDB048H4E

0.0 1225 1310 1561 2015 2168

0.1 1167 1254 1514 1995 2143

0.2 1112 1203 1473 1977 2126

0.3 1052 1145 1424 1942 2097

0.4 1000 1098 1387 1917 2078

0.5 939 1040 1343 1888 2049

0.6 894 996 1300 1854 2020

0.7 840 941 1250 1819 1991

0.8 780 883 1201 1787 1952

0.9 734 839 1159 1749 1914

1.0 681 784 1115 1704 1856

HORIZONTAL KDB048H4E

0.0 1185 1265 1504 1983 2120

0.1 1130 1213 1467 1957 2098

0.2 1085 1171 1432 1932 2077

0.3 1035 1125 1395 1906 2054

0.4 978 1069 1347 1870 2023

0.5 929 1023 1304 1841 1992

0.6 880 977 1267 1811 1962

0.7

0.8 764 863 1175 1740 1900

0.9 718 820 1133 1710 1869

1.0 549 712 1096 1652 1772

Tap 1 Tap 2 Tap 3 Tap 4 Tap 5

822 920 1224 1776 1931

Air Volume at Specic Blower Taps (cfm)

Page 15

Page 16

BLOWER DATA - DIRECT DRIVE - HIGH EFFICIENCY 5 TON

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (economizer, wet coil, etc.) See page 23.

2 - Any eld installed accessories air resistance (electric heat, duct resistance, diffuser, etc.) See page 23.

External Static

Pressure in. w.g.

DOWNFLOW KDB060H4E

0.0 1351 1405 1801 1982 2339

0.1 1303 1359 1769 1956 2310

0.2 1254 1314 1736 1928 2281

0.3 1206 1268 1703 1900 2253

0.4 1158 1222 1669 1870 2224

0.5 1109 1177 1634 1838 2195

0.6 1061 1131 1598 1806 2166

0.7 1012 1085 1561 1772 2137

0.8 964 1040 1524 1736 2108

0.9 915 994 1486 1700 2080

1.0 867 949 1446 1662 2051

HORIZONTAL KDB60H4E

0.0 1329 1353 1728 1886 2206

0.1 1284 1320 1708 1872 2189

0.2 1239 1285 1685 1859 2174

0.3 1193 1258 1661 1832 2157

0.4 1147 1218 1636 1814 2135

0.5 1100 1178 1608 1796 2118

0.6 1052 1125 1579 1770 2102

0.7

0.8 955 1044 1516 1716 2058

0.9 906 991 1481 1689 2036

1.0 856 938 1445 1654 2020

Tap 1 Tap 2 Tap 3 Tap 4 Tap 5

1004 1085 1548 1743 2080

Air Volume at Specic Blower Taps (cfm)

Page 16

Page 17

BLOWER DATA - BELT DRIVE 3 TON

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (larger gas heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 23 for blower motors and drives and wet coil and options/accessory air resistance data.

DOWNFLOW KDB036H4T

Air

Volume

cfm

700 447 0.09 517 0.12 589 0.15 663 0.17 739 0.19 815 0.20 883 0.23 938 0.25

800 465 0.10 534 0.14 605 0.17 678 0.19 753 0.21 825 0.23 890 0.25 946 0.27

900 486 0.12 554 0.16 623 0.20 695 0.22 767 0.23 836 0.25 897 0.28 953 0.30

1000 508 0.15 576 0.19 643 0.22 713 0.24 783 0.26 848 0.28 907 0.30 961 0.33

1100 533 0.18 599 0.22 665 0.25 733 0.27 800 0.28 863 0.31 919 0.34 971 0.36

1200 560 0.21 625 0.25 689

1300 591 0.24 654 0.28 716 0.31 779 0.33 841 0.35 897 0.38 948 0.41 996 0.44

1400 631 0.26 690 0.30 748 0.34 807 0.36 864 0.39 916 0.42 964 0.46 1011 0.49

1500 676 0.28 729 0.33 782 0.36 835 0.40 887 0.43 935 0.47 981 0.50 1028 0.54

Air

Volume

cfm

700 988 0.27 1039 0.29 1088 0.31 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

800 996 0.30 1047 0.32 1098 0.34 1144 0.36 1185 0.39 1224 0.42 - - - - - - - - - - - -

900 1004 0.33 1055 0.35 1106 0.37 1152 0.40

1000 1011 0.36 1062 0.38 1111 0.41 1157 0.43 1199 0.47 1238 0.50 1276 0.53 1311 0.56

1100 1020 0.39 1070 0.41 1118 0.44 1163 0.47 1206 0.51 1245 0.54 1282 0.58 1318 0.61

1200 1031 0.43 1079 0.45 1127 0.48 1171 0.52 1213 0.55 1252 0.59 1289 0.62 1324 0.66

1300 1044 0.47 1091 0.49 1137 0.53 1181 0.56 1221 0.60 1259 0.64 1296 0.68 1330 0.71

1400 1058 0.51 1105 0.54 1150 0.57 1191 0.61 1231 0.65 1268 0.69 1303 0.73 1337 0.77

1500 1074 0.56 1120 0.59 1163 0.63 1203 0.67 1241 0.71 1277 0.75 1312 0.79 1345 0.82

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.28 755 0.30 820 0.32 879 0.34 932 0.37 983 0.40

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

External Static - in. w.g.

External Static - in. w.g.

1193 0.43 1232 0.46 1269 0.49 1305 0.52

Page 17

Page 18

BLOWER DATA - BELT DRIVE 3 TON

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (larger gas heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 23 for blower motors and drives and wet coil and options/accessory air resistance data.

HORIZONTAL KDB036H4T

Air

Volume

cfm

700 445 0.08 516 0.11 591 0.13 670 0.15 753 0.16 820 0.19 870 0.22 918 0.24

800 463 0.09 534 0.12 608 0.14 685 0.16 766 0.18 830 0.21 878 0.24 926 0.27

900 485 0.11 554 0.14 627 0.16 703 0.18 780 0.21 841 0.23 888 0.27 935 0.30

1000 509 0.13 578 0.16 649 0.19 722 0.21 796 0.23 854 0.26 900 0.29 947 0.33

1100 537 0.16 605 0.19 674 0.21 744 0.24 813 0.26 868 0.29 913 0.33 959 0.36

1200 567 0.19 633 0.22 700

1300 599 0.22 664 0.25 729 0.28 793 0.30 853 0.33 902 0.37 945 0.41 990 0.44

1400 634 0.26 697 0.29 758 0.31 819 0.34 875 0.38 921 0.42 964 0.46 1008 0.49

1500 669 0.30 730 0.33 789 0.36 846 0.39 897 0.42 941 0.47 983 0.51 1028 0.54

Air

Volume

cfm

700 969 0.27 1021 0.29 1071 0.32 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

800 977 0.29 1030 0.32 1082 0.34 1128 0.37 1169 0.40 1205 0.42 - - - - - - - - - - - -

900 986 0.32 1039 0.35 1090 0.37 1137 0.40

1000 997 0.35 1048 0.38 1098 0.41 114 0.44 1184 0.47 1221 0.50 1255 0.53 1287 0.56

1100 1008 0.39 1059 0.41 1107 0.44 1150 0.47 1191 0.51 1228 0.54 1263 0.57 1295 0.60

1200 1022 0.43 1071 0.45 1117 0.48 1160 0.52 1200 0.55 1237 0.59 1271 0.62 1303 0.66

1300 1037 0.47 1058 0.50 1130 0.53 1171 0.57 1210 0.60 1246 0.64 1280 0.68 1312 0.71

1400 1054 0.52 1100 0.54 1144 0.58 1183 0.62 1221 0.66 1256 0.70 1290 0.73 1321 0.77

1500 1073 0.57 1117 0.60 1159 0.64 1197 0.67 1234 0.71 1268 0.75 1301 0.79 1332 0.83

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.24 768 0.27 833 0.30 884 0.33 928 0.37 974 0.40

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

External Static - in. w.g.

External Static - in. w.g.

1177 0.43 1214 0.46 1248 0.49 1280 0.51

Page 18

Page 19

BLOWER DATA - BELT DRIVE 4 TON

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (larger gas heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 23 for blower motors and drives and page 30 for wet coil and options/accessory air resistance data.

DOWNFLOW KDB048H4T

Air

Volume

cfm

900 466 0.10 525 0.14 586 0.17 646 0.20 729 0.20 821 0.19 899 0.20 953 0.23

1000 484 0.12 543 0.16 603 0.19 664 0.22 745 0.23 834 0.23 908 0.24 959 0.26

1100 505 0.15 563 0.18 622 0.22 682 0.25 762 0.26 847 0.26 917 0.27 966 0.30

1200 527 0.18 584 0.21 643 0.25 702 0.28 779 0.30 860 0.30 927 0.31 973 0.34

1300 550 0.21 607 0.25 664 0.29 722 0.32 797 0.33 875 0.34 937 0.35 981 0.38

1400 574 0.25 630

1500 603 0.28 659 0.32 714 0.36 770 0.39 839 0.41 907 0.42 962 0.44 1002 0.47

1600 651 0.29 703 0.33 754 0.37 806 0.41 867 0.43 927 0.45 976 0.48 1014 0.51

1700 708 0.30 754 0.34 800 0.38 846 0.42 898 0.46 949 0.49 992 0.53 1028 0.57

1800 764 0.31 804 0.36 844 0.40 884 0.45 927 0.49 970 0.54 1008 0.58 1044 0.63

1900 812 0.34 847 0.39 881 0.44 916 0.49 953 0.54 990 0.59 1025 0.64 1061 0.69

2000 857 0.42 889 0.47 920 0.52 952 0.57 986 0.62 1020 0.68 1055 0.73 1091 0.77

Air

Volume

cfm

900 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

1000 996 0.31 1034 0.35 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

1100 1001 0.34 1040 0.38 1083 0.42 1128 0.46 1176 0.49 - - - - - - - - - - - - - - - - - -

1200 1008 0.38 1047 0.42 1089 0.46 1133 0.49 1180 0.53 1224 0.56 1261 0.60 - - - - - -

1300 1017 0.42 1055 0.46 1097 0.50 1139 0.53 1184 0.57 1228 0.60 1264 0.63 1295 0.67

1400 1026 0.46 1065 0.50 1106 0.54 1147 0.57 1191 0.61 1233 0.64 1269 0.68 1300 0.71

1500 1038 0.51 1076 0.55 1117 0.59 1157 0.62 1199 0.65 1240 0.69 1275 0.72 1305 0.76

1600 1050 0.56 1089 0.60

1700 1065 0.61 1103 0.65 1142 0.69 1181 0.73 1221 0.76 1259 0.80 1292 0.83 1320 0.88

1800 1081 0.67 1118 0.71 1156 0.75 1194 0.79 1234 0.82 1271 0.86 1302 0.90 1330 0.94

1900 1098 0.73 1135 0.77 1172 0.81 1209 0.85 1248 0.88 1284 0.92 1314 0.97 1341 1.01

2000 1128 0.82 1164 0.86 1201 0.89 1239 0.93 1276 0.97 1310 1.01 1336 1.06 1362 1.10

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.29 687 0.32 744 0.35 817 0.37 890 0.38 949 0.39 991 0.42

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP

1129 0.64 1168 0.67 1209 0.71 1249 0.74 1282 0.78 1312 0.82

External Static - in. w.g.

External Static - in. w.g.

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Page 19

Page 20

BLOWER DATA - BELT DRIVE 4 TON

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (larger gas heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 23 for blower motors and drives and wet coil and options/accessory air resistance data.

HORIZONTAL KDB048H4T

Air

Volume

cfm

900 464 0.10 514 0.13 576 0.15 644 0.17 728 0.18 817 0.19 893 0.21 951 0.24

1000 482 0.12 533 0.15 595 0.17 662 0.19 744 0.21 829 0.22 902 0.24 957 0.27

1100 504 0.14 556 0.17 617 0.20 683 0.22 762 0.24 843 0.25 912 0.28 965 0.31

1200 528 0.17 581 0.20 641 0.23 706 0.25 782 0.27 859 0.29 924 0.31 974 0.34

1300 556 0.21 609 0.24 669 0.26 731 0.29 804 0.31 877 0.33 938 0.35 985 0.38

1400 592 0.24 645 0.27 702

1500 641 0.26 692 0.29 746 0.33 801 0.36 862 0.38 921 0.41 970 0.44 1011 0.48

1600 696 0.28 743 0.32 792 0.35 842 0.39 894 0.42 945 0.45 988 0.49 1027 0.53

1700 750 0.31 792 0.35 836 0.39 880 0.43 924 0.47 968 0.51 1007 0.55 1043 0.59

1800 799 0.35 837 0.39 875 0.43 913 0.48 952 0.52 990 0.56 1026 0.61 1061 0.65

1900 840 0.40 873 0.45 907 0.49 941 0.54 976 0.58 1011 0.63 1045 0.67 1080 0.72

2000 883 0.48 913 0.53 944 0.57 976 0.62 1009 0.67 1043 0.71 1078 0.76 1112 0.8

Air

Volume

cfm

900 995 0.28 1034 0.31 1077 0.35 1121 0.38 - - - - - - - - - - - - - - - - - - - - - - - -

1000 999 0.31 1038 0.34 1081 0.38 1124 0.41 1168 0.44 1211 0.47 - - - - - - - - - - - -

1100 1006 0.34 1044 0.38 1086 0.41 1129 0.44 1171 0.47 1213 0.50 1253 0.53 1293 0.56

1200 1014 0.38 1052 0.42 1093 0.45 1135 0.48 1176 0.51 1217 0.54 1257 0.58 1296 0.61

1300 1023 0.42 1061 0.46 1102 0.50 1143 0.53 1184 0.56 1224 0.59 1263 0.62 1302 0.66

1400 1035 0.47 1073 0.51 1112 0.54 1153 0.57 1193 0.61 1232 0.64 1271 0.67 1309 0.71

1500 1048 0.52 1086 0.56 1125 0.59 1164 0.63 1204 0.66 1243 0.69 1280 0.73 1317 0.77

1600 1063 0.57 1100 0.61 1139 0.65

1700 1079 0.63 1116 0.67 1154 0.71 1192 0.74 1230 0.78 1267 0.81 1302 0.85 1337 0.89

1800 1097 0.69 1133 0.73 1171 0.77 1209 0.80 1246 0.84 1281 0.88 1315 0.92 1349 0.96

1900 1116 0.76 1152 0.80 1189 0.84 1226 0.87 1262 0.91 1296 0.95 1329 0.99 1361 1.03

2000 1148 0.84 1183 0.88 1220 0.92 1257 0.96 1291 1.00 1323 1.04 1354 1.08 1385 1.12

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.30 763 0.32 830 0.35 898 0.37 953 0.39 997 0.43

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP

External Static - in. w.g.

External Static - in. w.g.

RPM BHP RPM BHP RPM BHP RPM BHP

1178 0.68 1216 0.71 1254 0.75 1291 0.79 1326 0.83

Page 20

Page 21

BLOWER DATA - BELT DRIVE 5 TON

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (larger gas heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 23 for blower motors and drives and wet coil and options/accessory air resistance data.

DOWNFLOW KDB060H4T

Air

Volume

cfm

1100 512 0.15 571 0.19 630 0.23 690 0.26 770 0.26 854 0.26 922 0.27 970 0.30

1200 535 0.18 593 0.22 651 0.26 710 0.30 788 0.30 868 0.30 933 0.31 978 0.34

1300 559 0.22 616 0.26 674 0.29 732 0.34 807 0.34 883 0.34 944 0.35 987 0.38

1400 584 0.26 641 0.29 698 0.33 755 0.37 827 0.37 899 0.38 956 0.40 997 0.43

1500 615 0.29 671 0.33 726 0.36 782 0.41 850 0.41 917 0.42 970 0.44 1009 0.47

1600 665 0.30 716 0.34 768

1700 723 0.31 768 0.35 814 0.39 860 0.47 910 0.47 959 0.50 1001 0.54 1037 0.58

1800 779 0.32 818 0.37 857 0.41 897 0.50 939 0.50 980 0.55 1018 0.59 1054 0.64

1900 826 0.36 859 0.41 894 0.45 928 0.56 964 0.56 1000 0.61 1036 0.66 1072 0.70

2000 857 0.42 889 0.47 920 0.52 952 0.62 986 0.62 1020 0.68 1055 0.73 1091 0.77

2100 878 0.49 909 0.54 940 0.59 973 0.70 1006 0.70 1041 0.75 1076 0.80 1112 0.85

2200 897 0.55 929 0.61 961 0.66 994 0.78 1028 0.78 1063 0.83 1099 0.89 1134 0.93

2300 918 0.62 950 0.68 983 0.74 1017 0.86 1052 0.86 1087 0.92 1122 0.97 1157 1.02

2400 941 0.70 974

Air

Volume

cfm

1100 1006 0.35 1045 0.39 1089 0.43 1134 0.46 - - - - - - - - - - - - - - - - - - - - - - - -

1200 1013 0.38 1053 0.42 1095 0.46 1139 0.50 1186 0.53 1230 0.57 1266 0.60 - - - - - -

1300 1022 0.42 1062 0.46 1104 0.50 1146 0.54 1192 0.57 1234 0.60 1269 0.64 1301 0.68

1400 1033 0.47 1072 0.51 1114 0.55 1155 0.58 1199 0.61 1240 0.65 1275 0.68 1305 0.72

1500 1045 0.52 1085 0.56 1125 0.60 1165 0.63 1208 0.66 1248 0.69 1281 0.73 1311 0.77

1600 1059 0.57 1098 0.61 1138 0.65

1700 1074 0.62 1113 0.66 1152 0.70 1190 0.74 1231 0.77 1268 0.80 1299 0.84 1328 0.89

1800 1091 0.68 1129 0.72 1167 0.76 1205 0.80 1244 0.83 1280 0.87 1310 0.91 1338 0.95

1900 1109 0.75 1146 0.79 1183 0.82 1221 0.86 1260 0.90 1294 0.94 1323 0.98 1349 1.02

2000 1128 0.82 1164 0.86 1201 0.89 1239 0.93 1276 0.97 1310 1.01 1336 1.06 1362 1.10

2100 1148 0.89 1185 0.93 1221 0.97 1258 1.01 1294 1.05 1325 1.09 1351 1.14 1376 1.19

2200 1170 0.97 1206 1.01 1242 1.05 1277 1.09 1311 1.14 1341 1.18 1365 1.23 1390 1.28

2300 1193 1.06 1228 1.09 1262 1.14 1295 1.19 1327 1.24 1355 1.29 1380 1.33 1406 1.37

2400 1216 1.15 1250 1.19

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.38 819 0.44 879 0.44 937 0.46 985 0.49 1022 0.52

0.77 1008 0.83 1042 0.96 1077 0.96 1111 1.01 1146 1.06 1181 1.11

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1282 1.24 1313 1.30 1343 1.36 1371 1.40 1396 1.44 1423 1.48

External Static - in. w.g.

External Static - in. w.g.

1177 0.68 1218 0.71 1257 0.75 1290 0.79 1319 0.83

Page 21

Page 22

BLOWER DATA - BELT DRIVE 5 TON

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL AND AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Any factory installed options air resistance (larger gas heat section, economizer, wet coil, etc.).

2 - Any eld installed accessories air resistance (duct resistance, diffuser, etc.).

See page 23 for blower motors and drives and wet coil and options/accessory air resistance data.

HORIZONTAL KDB060H4T

Air

Volume

cfm

1100 509 0.15 562 0.18 624 0.20 691 0.22 771 0.24 852 0.25 919 0.28 970 0.31

1200 535 0.18 589 0.21 650 0.23 715 0.25 792 0.27 869 0.29 932 0.32 980 0.35

1300 564 0.21 618 0.24 678 0.27 741 0.29 815 0.31 887 0.33 946 0.36 991 0.39

1400 604 0.24 657 0.27 715 0.30 775 0.33 842 0.35 908 0.37 962 0.40 1004 0.43

1500 656 0.26 706 0.30 760 0.33 814 0.36 874 0.39 931 0.41 979 0.45 1019 0.48

1600 712 0.29 758 0.32 807

1700 766 0.32 808 0.36 850 0.40 892 0.44 936 0.47 978 0.51 1016 0.56 1052 0.60

1800 814 0.36 851 0.40 888 0.44 925 0.49 963 0.53 1000 0.57 1035 0.62 1071 0.66

1900 853 0.41 886 0.46 919 0.50 952 0.55 986 0.60 1021 0.64 1056 0.69 1091 0.73

2000 883 0.48 913 0.53 944 0.57 976 0.62 1009 0.67 1043 0.71 1078 0.76 1112 0.80

2100 906 0.56 936 0.60 967 0.65 999 0.70 1033 0.75 1067 0.79 1101 0.84 1135 0.88

2200 930 0.64 960 0.68 991 0.73 1024 0.78 1058 0.83 1092 0.88 1126 0.92 1160 0.96

2300 954 0.72 985 0.77 1017 0.82 1051 0.87 1085 0.92 1119 0.96 1152 1.00 1186 1.04

2400 981 0.81 1013

Air

Volume

cfm

1100 1010 35.00 1049 0.38 1091 0.42 1134 0.45 1176 0.78 1218 0.51 1258 0.54 1297 0.57

1200 1019 0.38 1058 0.42 1099 0.46 1141 0.49 1182 0.52 1223 0.55 1263 0.58 1302 0.61

1300 1030 0.43 1068 0.47 1108 0.50 1149 0.53 1190 0.56 1230 0.59 1270 0.63 1308 0.66

1400 1042 0.47 1080 0.51 1120 0.55 1160 0.58 1200 0.61 1240 0.65 1278 0.68 1315 0.72

1500 1056 0.53 1094 0.57 1133 0.60 1172 0.63 1212 0.67 250 0.70 1288 0.74 1324 0.77

1600 1071 0.58 1109 0.62 1147 0.66

1700 1088 0.64 1126 0.68 1164 0.72 1202 0.75 1240 0.78 1276 0.82 1311 0.86 1345 0.90

1800 1107 0.70 1143 0.74 1181 0.78 1219 0.81 1256 0.85 1290 0.89 1324 0.93 1357 0.97

1900 1126 0.77 1163 0.81 1200 0.85 1237 0.88 1273 0.92 1306 0.96 1339 1.00 1371 1.04

2000 1148 0.84 1183 0.88 1220 0.92 1257 0.96 1291 1.00 1323 1.04 1354 1.08 1385 1.12

2100 1170 0.92 1206 0.96 1242 1.00 1277 1.04 1310 1.08 1340 1.13 1370 1.17 1401 1.21

2200 1195 1.00 1230 1.04 1265 1.08 1299 1.13 1330 1.18 1359 1.23 1388 1.27 1418 1.31

2300 1220 1.08 1254 1.13 1288 1.17 1320 1.23 1350 1.28 1378 1.34 1406 1.38 1435 1.42

2400 1245 1.18 1278 1.22

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.36 855 0.39 906 0.43 955 0.46 997 0.50 1035 0.54

0.86 1046 0.91 1079 0.96 1113 1.00 1180 1.05 1180 1.09 1213 1.13

0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1311 1.28 1341 1.33 1370 1.40 1397 1.45 1425 1.50 1454 1.54

External Static - in. w.g.

External Static - in. w.g.

1186 0.69 1225 0.72 1263 0.76 1299 0.80 1334 0.83

Page 22

Page 23

BLOWER DATA

BELT DRIVE KIT SPECIFICATIONS

Model

No.

036 0.75 0.86 2 low 449-673

048 0.75 0.86 2 - - - low 497-673

060 1 1.15 2 low 555-833

NOTE - Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor hp required. Maximum usable hp of

motors furnished are shown. In Canada, nominal motor hp is also maximum usable motor hp. If motors of comparable hp are used, be sure to keep within the service

factor limitations outlined on the motor nameplate.

OPTIONS / ACCESSORIES AIR RESISTANCE - in. w.g.

Air Volume

cfm

800 0.01 0.01 0.02 0.02 0.04 0.04 0.05

1000 0.02 0.01 0.02 0.02 0.04 0.04 0.07

1200 0.02 0.01 0.02 0.02 0.04 0.04 0.07

1400 0.03 0.02 0.02 0.03 0.04 0.04 0.07

1600 0.04 0.03 0.03 0.04 0.04 0.04 0.07

1800 0.05 0.04 0.03 0.05 0.05 0.05 0.07

2000 0.06 0.05 0.04 0.06 0.05 0.05 0.08

2200 0.08 0.06 0.04 0.07 0.05 0.05 0.08

2400 0.09 0.07 0.05 0.08 0.05 0.05 0.08

2600 0.10 0.08 0.05 0.09 0.06 0.05 0.08

2800 0.11 0.09 0.06 0.10 0.06 0.05 0.08

3000 0.13 0.10 0.07 0.11 0.06 0.05 0.08

Motor HP No. of

Nominal Maximum A01 A02 A03 A05 A06 A07

Speeds

Drive Kits and RPM Range

- - - - - - - - - - - - - - -

high 673-1010

1 1.15 2 - - - - - - - - - low 598-897

- - - - - -

high 897-1346

- - - - - - - - - - - -

high 745-1117

2 2.3 2 - - - - - - - - - - - - low 714-953

- - -

high 1071-1429

high 833-1250

2 2.3 2 low 808-1032

high 1212-1548

Wet Indoor Coil Gas Heat

024 036, 048 060 Medium Input High Input MERV 8 MERV 13

Economizer

Filters

CEILING DIFFUSERS AIR RESISTANCE (in. w.g.)

Air Volume

cfm

2 Ends

Open

RTD9-65S Step–Down Diffuser FD9-65S Flush

1 Side &

All Ends & Sides Open

2 Ends Open

800 0.15 0.13 0.11 0.11

1000 0.19 0.16 0.14 0.14

1200 0.25 0.20 0.17 0.17

1400 0.33 0.26 0.20 0.20

1600 0.43 0.32 0.20 0.24

1800 0.56 0.40 0.30 0.30

2000 0.73 0.50 0.36 0.36

2200 0.95 0.63 0.44 0.44

Page 23

Diffuser

Page 24

MANUFACTURER'S NUMBERS

TABLE 3

DRIVE COMPONENTS

MOTOR PULLEY BLOWER PULLEY BELTS

Drive No.

A01 1VP34 X 3/8 31K6901 AK54 X 1 100244-19 A40 100245-17

A02 1VP34 X 3/8 31K6901 AK49 X 1 100244-18 A39 100245-16

A03 1VP34 X 3/8 31K6901 AK44X 1 100244-16 A39 100245-16

A04 1VP40 X 3/8 79J0301 AK49 X 1 100244-18 A41 100245-18

A05 1VP34 X 3/8 31K6901 AK41 X 1 100244-15 A38 100245-15

A06 1VP44 X 3/8 P-8-1488 AK51 X 1 18L2201 A41 100245-18

A07 1VP50 X 3/8 53J1501 AK54 X 1 100244-19 AX43 73K8201

A08 1VP44 X 3/8 P-8-1488 AK46 X 1 100244-17 A40 100245-17

Browning No. OEM Part No. Browning No. OEM Part No. Browning No. OEM Part No.

Start-Up

IMPORTANT

If unit is equipped with a crankcase heater. Make

sure heater is energized 24 hours before unit startup to prevent compressor damage as a result of

slugging.

A-Start-Up

Heating

1- Set thermostat or temperature control device to

initiate a first-stage heating demand.

2- A first-stage heating demand (W1) will energize

compressors 1 and the outdoor fan.

Note - L1 reversing valve is de-energized in the

heating mode.

Cooling

1- Initiate first and second stage cooling demands

according to instructions provided with thermostat.

See table 4 for operation.

2- Units contain one refrigerant circuit or stage.

Note - Units are equipped with two-stage compressors.

3- Unit is charged with R-410A refrigerant. See unit

rating plate for correct amount of charge.

4- Refer to Refrigerant Charge and Check section for

proper method to check refrigerant charge.

TABLE 4

COOLING OPERATION

T'Stat

Demand

No Economizer or Outdoor Air Unsuitable

Y1 Compressor Low Speed* OD Fan Low Sp.

Y2 Compressor High Speed** OD Fan High Sp.

Unit Equipped With An Economizer

Y1 Economizer na

Y2

Economizer + Compressor

Low Speed*

Energized

OD Fan Low Sp.

*67% of full capacity

**100% of full capacity

Note - The reversing valve is energized at the same time

as the compressor.

Page 24

Page 25

B-Three Phase Scroll Compressor Voltage Phasing

Three phase scroll compressors must be phased

sequentially to ensure correct compressor and blower

rotation and operation. Compressor and blower are

wired in phase at the factory. Power wires are

color-coded as follows: line 1-red, line 2-yellow, line

3-blue.

1- Observe suction and discharge pressures and

blower rotation on unit start-up.

2- Suction pressure must drop, discharge pressure

must rise, and blower rotation must match rotation

marking.

If pressure differential is not observed or blower rotation is

not correct:

3- Disconnect all remote electrical power supplies.

4- Reverse any two field-installed wires connected to

the line side of K1 contactor. Do not reverse wires at

blower contactor.

Make sure the connections are tight.

Discharge and suction pressures should operate at

their normal start‐up ranges.

C-Refrigerant Charge and Check

WARNING-Do not exceed nameplate charge under

any condition.

This unit is factory charged and should require no further

adjustment. If the system requires additional refrigerant,

reclaim the charge,

evacuate the system, and add

required nameplate charge.

NOTE - System charging is not recommended below

60F (15C). In temperatures below 60F (15C), the

charge must be weighed into the system.

If weighing facilities are not available, or to check the

charge, use the following procedure:

IMPORTANT - Charge unit in standard cooling mode.

1- Make sure outdoor coil is clean. Attach gauge

manifolds and operate unit at full CFM in cooling mode

with economizer disabled until system stabilizes

(approximately five minutes). Make sure all outdoor air

dampers are closed.

2- Compare the normal operating pressures (see table

5 through 8) to the pressures obtained from the

gauges. Check unit components if there are

significant differences.

3- Measure the outdoor ambient temperature and the

suction pressure. Refer to the appropriate circuit

charging curve to determine a target liquid

temperature.

Note - Pressures are listed for sea level applications.

4- Use the same thermometer to accurately measure the

liquid temperature (in the outdoor section).

If measured liquid temperature is higher than

the target liquid temperature, add refrigerant to

the system.

If measured liquid temperature is lower than

the target liquid temperature, recover some

refrigerant from the system.

5- Add or remove charge in increments. Allow the

system to stabilize each time refrigerant is added or

removed.

6- Continue the process until measured liquid

temperature agrees with the target liquid

temperature. Do not go below the target liquid

temperature when adjusting charge. Note that

suction pressure can change as charge is adjusted.

7- Example KDB024: At 95°F outdoor ambient and a

measured suction pressure of 130psig, the target

liquid temperature is 102°F. For a measured liquid

temperature of 112°F, add charge in increments

until measured liquid temperature agrees with the

target liquid temperature.

Page 25

Page 26

TABLE 5

KDB024H Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

113 217 114 254 11 7 295 119 342 121 395 124 455

120 222 125 259 123 304 128 349 130 401 133 459

141 226 143 262 142 303 145 353 148 404 154 465

154 233 162 270 167 312 170 358 171 410 175 466

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

TABLE 6

KDB036H Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

113 230 115 268 11 7 310 119 358 121 412 121 471

121 233 123 273 125 314 128 364 130 417 130 476

142 240 142 278 144 321 146 370 149 425 151 483

157 247 163 286 165 330 168 378 170 431 173 491

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

TABLE 7

KDB048H Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

107 234 109 272 11 0 314 112 363 116 409 11 7 462

115 242 117 279 11 9 321 121 366 123 415 123 470

129 247 134 284 137 328 140 375 143 425 144 480

134 251 145 292 154 335 159 382 162 432 164 489

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

TABLE 8

KDB060H Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

105 236 106 274 109 317 11 2 365 115 419 11 9 474

115 243 119 280 11 9 324 122 372 124 422 129 480

135 251 137 289 139 332 142 381 146 432 148 489

152 261 157 300 160 344 163 392 166 443 170 500

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Page 26

Page 27

130

120

110

100

90

KDB 024H Charging Curves

Outdoor Temperature (°F)

115°

105°

95°

85°

Liquid Temperature (° F)

80

70

65°

60

110 120 130 140 150 160 170

Suction Pressure (psig)

KDB 036H Charging Curves

Outdoor Temperature (°F)

130

120

110

100

75°

180

115°

105°

95°

90

Liquid Temperature (° F)

80

70

60

110 120 130 140 150 160 170

85°

75°

65°

180

Suction Pressure (psig)

Page 27

Page 28

Liquid Temperature (° F)

130

120

110

100

90

80

KDB 048H Charging Curves

Outdoor Temperature (°F)

115°

105°

95°

85°

75°

65°

Liquid Temperature (° F)

70

130

120

110

100

90

100

110 120 130 140 150 160 170

Suction Pressure (psig)

KDB 060H Charging Curves

Outdoor Temperature (°F)

115°

105°

95°

85°

75°

80

70

100

110 120 130 140 150 160 170

65°

Suction Pressure (psig)

Page 28

Page 29

D - Compressor Controls

See unit wiring diagram to determine which controls are

used in each unit. Optional controls are identified on

wiring diagrams by arrows at junction points.

1- Freezestat (S49)

Switch de-energizes compressor when indoor coil

temperature falls below 29F (-2C) to prevent coil

freeze-up. Switch resets when indoor coil

temperature reaches 58F (15C).

2- High Pressure Switch (S4)

Auto-reset switch is located on the discharge line.

Switch opens at 640 psig and closes at 475 psig.

Switch is wired directly into the defrost control

(CMC1), which provides a 5 strike lockout feature.

3- Defrost Switch (S6)

100269 Series Only

Defrost switch closes to initiate defrost when liquid

line temperature falls to 42° F (5.6°C). Defrost switch

opens when liquid line temperature reaches 70°F

(21°C) to terminate defrost. If the liquid line

temperature does not rise above 70°F (21°C), the

CMC1 will terminate defrost after 14 minutes. The

defrost switch is located on the liquid line between the

outdoor expansion valve and the distributor

a defrost cycle begins and operates for 14 minutes.

The defrost switch can terminate the defrost cycle

before the 14 minutes elapses if liquid line

temperature reaches 70°F (21°C).

Note - The defrost control will not energize a defrost cycle

unless the unit has been operating in heating mode for an

accumulated 90 minutes (default) on 100269 series

boards. The run time interval can be changed by moving

the jumper on the CMC board timing pins. See figure 20.

The defrost interval can be adjusted to 30, 60, or 90

minutes. If the timing selector jumper is not in place, the

control defaults to a 90-minute defrost interval.

DEFROST CONTROL BOARD CMC1

TIMING JUMPER:

100269 SERIES: 90 MINUTES

DIAGNOSTIC

LEDS

4- Ambient and Coil Temperature Sensors (RT13, RT21)

100135 Series Only

Both sensors provide input to the defrost control

which cycles defrost. The ambient sensor is located

on the inside of the corner mullion on the back of the

outdoor coil section. The coil sensor is located on a

return bend on the front of the outdoor coil.

5- Defrost Controls (CMC1)

Gas heat is energized during defrost to maintain

discharge air temperature.

100269 Series Time/Temperature

When the liquid line temperature drops below 42°F

(5.6°C), the defrost switch closes and signals the

defrost control that a defrost cycle is needed. If the

defrost switch is still closed after 90 minutes (default),

100269 SERIES:REMOVED

AT THE FACTORY TO DIS

ABLE COMPRESSOR DELAY

FIGURE 20

Page 29

Page 30

DEFROST CONTROL BOARD CMC1

DEFROST TEMPERATURE

TERMINATION JUMPER:

100135-06: 50

5F(105C)

DIAGNOSTIC

LEDS

Defrost Control Board

The defrost control ensures that the heat pump outdoor

coil does not ice excessively during the heating mode.

The defrost control uses input from a defrost switch on

100269 series defrost control boards. The defrost control

uses input from a coil and an ambient temperature sensor

on 100135 series defrost control boards.

Defrost Test Option

COIL AND AMBI

ENT SENSOR

CONNECTIONS

DELAY PINS

REVERSING

VALV E

PRESSURE

SWITCH CIRCUIT

CONNECTIONS

24V TERMINAL

STRIP

CONNECTIONS

FIGURE 21

5- Defrost Controls (CMC1) - Continued

100135 Series Demand Defrost Control

After 34 minutes of heating mode operation, if the

difference between the ambient temperature

(RT13) and the coil temperature (RT21) is higher

than the maximum difference allowed by the

control, the defrost control will initiate defrost. The

defrost control will also initiate defrost after 6

hours of heating mode operation when coil

temperatures remain below 35°F (2°C). The

defrost cycle ends when the coil temperature is

higher than the termination temperature (50°F

default) or after 14 minutes of operation. If the

defrost is terminated by the 14-minute timer,

another defrost cycle will be initiated after 34

minutes of run time.

Note - The defrost termination temperature can be

adjusted to 50, 70, 90 or 1005F. The jumper termination

pin is factory-set at 505F (105 C). If the temperature

jumper is not installed, the default termination

temperature is 905F (325C). See figure 21.

A TEST option is provided for troubleshooting. The TEST

mode may be started any time the unit is in the heating

mode and the defrost thermostat is closed or jumpered. If

the timing jumper is in the TEST position at power‐up, the

defrost control will ignore the test pins. When the jumper

is placed across the TEST pins for two seconds, the

control will enter the defrost mode. If the jumper is

removed before an additional 5-second period has

elapsed (7 seconds total), the unit will remain in defrost

mode until the defrost pressure switch opens or 14

minutes have passed. If the jumper is not removed until

after the additional 5-second period has elapsed, the

defrost will terminate and the test option will not function

again until the jumper is removed and re-applied.

Diagnostic LEDs

The defrost board uses two LEDs for diagnostics. The

LEDs flash a sequence according to the condition.

TABLE 9

Defrost Control Board Diagnostic LED

Mode

No power to control OFF OFF

Normal operation /

power to control

Anti‐short cycle

lockout

Low pressure switch,

freezestat fault

Low pressure switch,

freezestat lockout

High pressure switch

fault

High pressure switch

lockout

*Ambient sensor fault Simultaneous FAST flash

*Coil sensor fault Alternating FAST flash

Green LED

(DS2)

Simultaneous Slow FLASH

Alternating Slow FLASH

OFF Slow FLASH

OFF ON

Slow FLASH OFF

ON OFF

Red LED (DS1)

*100135-06 board only

Page 30

Page 31

Gas Heat Start-Up

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

Electric shock hazard. Can cause injury

or death. Do not use this unit if any part

has been under water. Immediately call

a qualified service technician to inspect

the unit and to replace any part of the

control system and any gas control

which has been under water.

This unit is equipped with an automatic spark ignition

system. There is no pilot. In case of a safety shutdown,

move thermostat switch to OFF and return the thermostat

switch to HEAT to reset ignition control.

A-Placing Unit In Operation

WARNING

Danger of explosion and fire. Can cause

injury or product or property damage.

You must follow these instructions

exactly.

WARNING

Danger of explosion. Can cause injury

or product or property damage. If over

heating occurs or if gas supply fails to

shut off, shut off the manual gas valve

to the appliance before shutting off

electrical supply.

WARNING

Electric shock hazard. Can cause

injury or death. Before attempting to

perform any service or maintenance,

turn the electrical power to unit OFF at

disconnect switch(es). Unit may have